Page 1

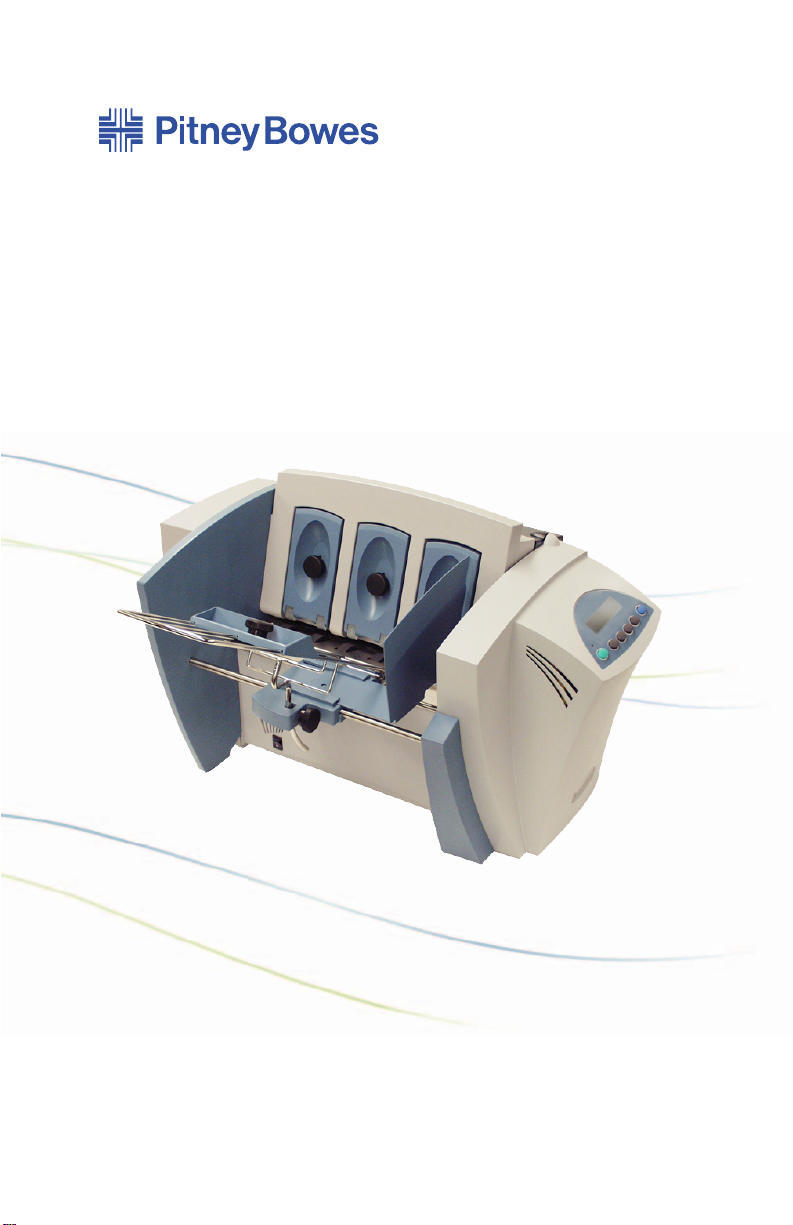

AddressRight™DA Series Printer

DA50S, DA55S

Operator Guide

US/International English Version

Page 2

NOTICE

The use of this information by the recipient or others for purposes

other than the repair, adjustment or operation of Pitney Bowes

equipment may constitute an infringement of patent and/or other

intellectual property rights of Pitney Bowes or others. Pitney Bowes

assumes no responsibility for any such use of the information.

Except as provided in writing, duly signed by an officer of Pitney

Bowes, no license, either express or implied, under any Pitney

Bowes or any third party’s patent, copyright, or other intellectual

property rights is granted by providing this information.

SV61663 Rev. D

Fourth Edition, December, 2006.

©2006 Pitney Bowes Inc. All rights reserved.

This book may not be reproduced in whole or in part in any fashion

or stored in a retrieval system of any type or transmitted by any

means, electronically or mechanically, without the express written

permission of Pitney Bowes.

We have made every reasonable effort to assure the accuracy and

usefulness of this manual, however we can not assume responsibility

for errors or omissions or liability for the misuse or misapplication of

our products.

Envelope Designer and SmartMailer are registered trademarks

of Pitney Bowes, Inc. Microsoft and Windows are trademarks or

registered trademarks of Microsoft Corporation.

NOTE: DA50S/DA55S

The similarity of the DA50S and DA55S printers allows their features

and operation to be documented together. The principle difference

in these printers is that the DA55S is a color printer that uses both

a black and color ink cartridge. The DA50S only uses a black ink

cartridge.

The photos and illustrations in this document are of the DA55S

printer, but representative of each printer.

IMPORTANT: Model and feature availability varies by country.

Contact your machine supplier for more information. This guide

covers all models and features. Inclusion within this guide does not

guarantee availability of a particular model or feature within your

country.

Page 3

Conforms to the Following:

FCC Rules

NOTE: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause interference to radio

communications. Operation of this equipment in a residential area is

likely to cause interference in which case the user will be required to

correct the interference at his own expense.

CAUTION: Changes or modifications to this equipment not

expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Shielded USB cables must be used with this equipment to ensure

compliance with the limits. Use of unshielded USB cables is

prohibited.

WARNING! This is a Class A product. In a domestic environment

this product may cause radio interference in which case the user

may be required to take adequate measures.

EMC Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

Tested for compliance by TUV Rheinland Product Safety to meet

regulatory requirements in USA, Canada, and Europe.

Also Conforms to:

Directive 2002/96/EC (OJ:L37/24/2003) on waste electrical and

electronic equipment (The WEEE Directive)

Directive 2002/95/EC of the European Parliament and of the Council

of 27 January 2003 on the restriction of the use of certain hazardous

substances in electrical and electronic equipment.

Page 4

Table of Contents

Contact Information List

USA Contacts .......................................................................iii

Canada Contacts ..................................................................iii

Other Country Contacts ....................................................... iv

Chapter 1 - Introduction

Welcome to the DA50S/DA55S Ink Jet Printer ..................1-2

Using This Guide ...............................................................1-2

System Requirements .......................................................1-2

Getting Help .......................................................................1-3

Online Help ................................................................ 1-3

Printer Options ...................................................................1-3

Important Safety Notes ......................................................1-4

Other Informational Cautions .....................................1-5

Important Safety Notes for the EU Only ..................... 1-6

Printer Parts and Locations ...............................................1-7

Chapter 2 - Printer Basics

Printer Features Overview .................................................2-2

Setting Up a Job ................................................................2-3

1. Setting the Separator Gap ................................... 2-3

2. Centering the Input Guide under the Material .....2-5

3. Setting the Feed Angle ........................................ 2-5

4. Positioning the Side Guide .................................. 2-6

5. Loading Material .................................................. 2-7

6. Adjusting the Position of the Feed Ramp ............ 2-8

7. Adjusting the Media Thickness Lever .................. 2-9

8. Adjusting the Upper Exit Rollers ........................ 2-10

9. Printing a Test Piece ...........................................2-11

Printer Driver Software ....................................................2-11

Selecting Printer Properties ......................................2-11

Using the Control Panel ...................................................2-12

Using the Menus ..............................................................2-13

Using the Main Menu ............................................... 2-14

Using the Setup Menu ............................................. 2-15

iSV61663 Rev. D

Page 5

Table of Contents

Chapter 3 - Printer Maintenance

Preventive Maintenance ....................................................3-2

Print Quality Problems .......................................................3-2

Cleaning the Exit Rollers ...................................................3-3

Cleaning the Sensor ..........................................................3-3

Cleaning the Floor Assembly and Top Cover ....................3-3

Purging the Printhead ........................................................3-3

Installing and Removing the Ink Jet Cartridges .................3-4

Installing the Ink Jet Cartridges (Color & Black) ........ 3-4

Removing the Ink Jet Cartridges ................................ 3-6

CMYK Printing Alignment (DA55S ONLY) .........................3-7

Chapter 4 - Troubleshooting

Problems and Solutions .....................................................4-2

Feed Problems ..................................................................4-2

Print Quality Problems .......................................................4-3

Interface Problems ............................................................4-4

Motor Problems .................................................................4-4

Barcode Problems .............................................................4-4

Other Problems .................................................................4-5

Appendix A - Specifications

Equipment Specifications ................................................. A-2

Material Specifications ......................................................A-8

Appendix B - Glossary

Glossary ........................................................................... B-1

Index

Index ...................................................................................I-1

ii SV61663 Rev. D

Page 6

Contact Information List

USA Contacts

Product Name - DA50S or DA55S

• For frequently asked questions, go to: www.pb.com and click on

Customer Support.

• To place requests for service or training, go to: www.pb.com and

click on My Account.

• To order supplies and accessories, call the Supply Line™ at:

1.800.243.7824 or go to: www.pb.com and click on Online

Store.

• To view and pay invoices online, go to: www.pb.com and click

on My Account.

• To view inventory, go to: www.pb.com and click on My Account.

• For direct questions, call: 1.800.522.0020. Customer Service

Representatives are available Monday through Friday, 8:00 AM

- 8:00 PM ET.

Canada Contacts

Product Name - DA50S or DA55S

• For frequently asked questions or to order supplies, go to:

www.pitneybowes.ca

• For direct questions, call: 1.800.672.6937. Customer Service

Representatives are available Monday through Friday, 8:30 AM

- 4:00 PM ET.

iiiSV61663 Rev. D

Page 7

Contact Information List

Other Country Contacts

Contact information is given in a separate publication supplied with

the product.

iv SV61663 Rev. D

Page 8

1 • Introduction

The DA50S/DA55S is a versatile, easy-to-use desktop printer

designed for addressing applications. This chapter explains

what's in this guide, and tells you how to order supplies and

where to get more information about using your printer.

Welcome to the DA50S/DA55S Ink Jet Printer ...................1-2

Using This Guide ................................................................1-2

System Requirements ........................................................1-2

Getting Help........................................................................1-3

Online Help ..................................................................1-3

Printer Options....................................................................1-3

Important Safety Notes .......................................................1-4

Other Informational Cautions .......................................1-5

Important Safety Notes for the EU Only .......................1-6

Printer Parts and Locations ................................................1-7

1-1SV61663 Rev. D

Page 9

1 • Introduction

Welcome to the DA50S/DA55S Ink Jet Printer

The DA50S/DA55S ink jet printer is a desktop printer used to

print addresses, graphics and other information, in color (DA55S),

on a wide range of material of various sizes, construction and

composition. You can define the font, placement, print quality and bar

code characteristics for your addresses.

Using This Guide

Refer to this guide for information about printer setup, operation and

troubleshooting. It is divided into the following chapters:

Chapter 1, Introduction - Contains an overview of the Operator

Guide, Help resources, safety information, as well as printer parts

and locations.

Chapter 2, Printer Basics - Explains how to set up your printer to

run a job.

Chapter 3, Printer Maintenance - Describes how to keep the printer

clean and functioning properly.

Chapter 4, Troubleshooting - Contains a list of possible problems

and their solutions.

Appendix A, Specifications - Provides hardware and material

specifications. Your printer will run at its best when your material

conforms to our specifications.

Appendix B, Glossary - Explains the meanings of common terms

used with address printing equipment.

System Requirements

In order to operate the printer with your computer, your system must

meet the following requirements:

CPU: Pentium III 500MHz. or greater, 500MB RAM or more

preferred.

Operating System: Windows 2000/2003 Server/XP

USB Cable or Ethernet Cable: A USB cable is supplied with your

printer. If you choose to use another cable, make sure it isn't any

longer than 16 feet (5m).

1-2 SV61663 Rev. D

Page 10

Introduction • 1

Getting Help

As you use your printer, there may be times when you need help

to solve a specific application problem, or you may want additional

information about printer operation.

Refer to the Contact Information List at the front of this guide for

more information or in the separate contact sheet supplied with your

machine.

Online Help

The Print Driver for your printer has a built-in help system. To get to

the driver, click on Properties from Windows print dialog box. Rightclick on items in question for the "What's This" Help button.

If you're using programs such as Envelope Designer™ or

SmartMailer™, press the F1 key while you're using the program

to display information about the open screen. Select the Help

menu to display a list of topics or search for a term. Refer to the

documentation supplied with these programs for more information.

NOTE: The availability of software varies by country. Refer to your

machine supplier for details of software available to you.

Printer Options

There are several options available for your addressing printer, such

as ink drying equipment which may reduce smudging on glossy

stock, stackers, and envelope designing software.

NOTE: The availability of software and product varies by country.

Refer to your machine supplier for availability details in your

country.

1-3SV61663 Rev. D

Page 11

1 • Introduction

Important Safety Notes

Follow the normal safety precautions for all office equipment:

• It is recommended that you use only Pitney Bowes approved

supplies, in particular aerosol dusters. Improper storage and

use of aerosol dusters or flammable aerosol dusters, can cause

an explosive-like condition that could result in a personal injury

and/or property damage. Never use aerosol dusters labeled

flammable and always read instructions and safety precautions

on the duster container label.

• To obtain supplies, please contact our Supply Line™ to place

orders. Material Safety Data Sheets can be obtained on the web

or from our Supply Line™. Refer to the Contact Information List

for more information.

• Use the power cord supplied with the machine and plug it into

a properly grounded wall outlet located near the machine and

easily accessible. Failure to properly ground the machine can

result in severe personal injury and/or fire.

• Avoid touching moving parts or materials while the machine is in

use. Keep hands, loose clothing, jewelry and long hair away from

all moving parts.

• Do not remove covers or defeat safety interlock switches. Covers

enclose hazardous parts that should only be accessed by

properly trained service personnel. Immediately report to service

any damaged or non-functioning components that renders the

unit unsafe.

• Place the unit in an accessible location to allow for proper

venting of the equipment and to facilitate servicing.

• The power cord wall plug is the primary means of disconnecting

the machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet.

• Do not remove the ground pin from the line cord.

• Do not route the power cord over sharp edges or trap between

furniture.

• Ensure there is no strain on the power cord and that it does not

become jammed between the equipment, walls or furniture.

1-4 SV61663 Rev. D

Page 12

Introduction • 1

• Be certain the area in front of the wall receptacle into which the

machine is plugged is free from obstruction.

• Before clearing a jam, be sure machine mechanisms come to a

stop.

• When removing jammed material, avoid using too much force to

protect against minor personal injury and damaging equipment.

• To prevent overheating, do not cover the vent openings.

• Operation of this equipment without periodic maintenance will

inhibit optimum operating performance and could cause the

equipment to malfunction. Contact your machine supplier for

required service schedule.

• Read all instructions before attempting to operate the equipment.

• Use this equipment only for its intended purpose.

Other Informational Cautions

NOTES:

• In case of an ink spill, leaking ink, or excessive ink

accumulation, immediately disconnect the power cord plug

from the wall outlet and call your machine supplier for a

cleaning.

• Always follow the specific occupational safety and health

standards for your workplace.

• Avoid using wall outlets that are controlled by wall switches,

or shared with other equipment. If a wall outlet controlled by

a wall switch is used, mail could be interrupted if the printer is

plugged in when the wall switch is used to turn power off.

1-5SV61663 Rev. D

Page 13

1 • Introduction

Important Safety Notes for the EU Only

In some countries the equipment is supplied with a moulded mains

lead and plug. In other countries, or if the supplied lead is not used,

the following information applies:

1. An approved mains lead for the country concerned must be

used.

2. As the colours of the wires in the mains lead of this equipment

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

- The wire which is coloured green and yellow must be

connected to the terminal in the plug which is marked with

the letter “E” or by the earth symbol (

or green and yellow.

- The wire which is coloured blue must be connected to the

terminal which is marked with the letter “N” or coloured

black.

- The wire which is coloured brown must be connected to the

terminal which is marked with the letter “L” or coloured red.

3. The wires in the supplied mains lead are coloured in accordance

with the following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

) or coloured green

WARNING! THIS EQUIPMENT MUST BE

EARTHED. The socket outlet should be near to the

equipment and should be easily accessible.

1-6 SV61663 Rev. D

Page 14

Introduction • 1

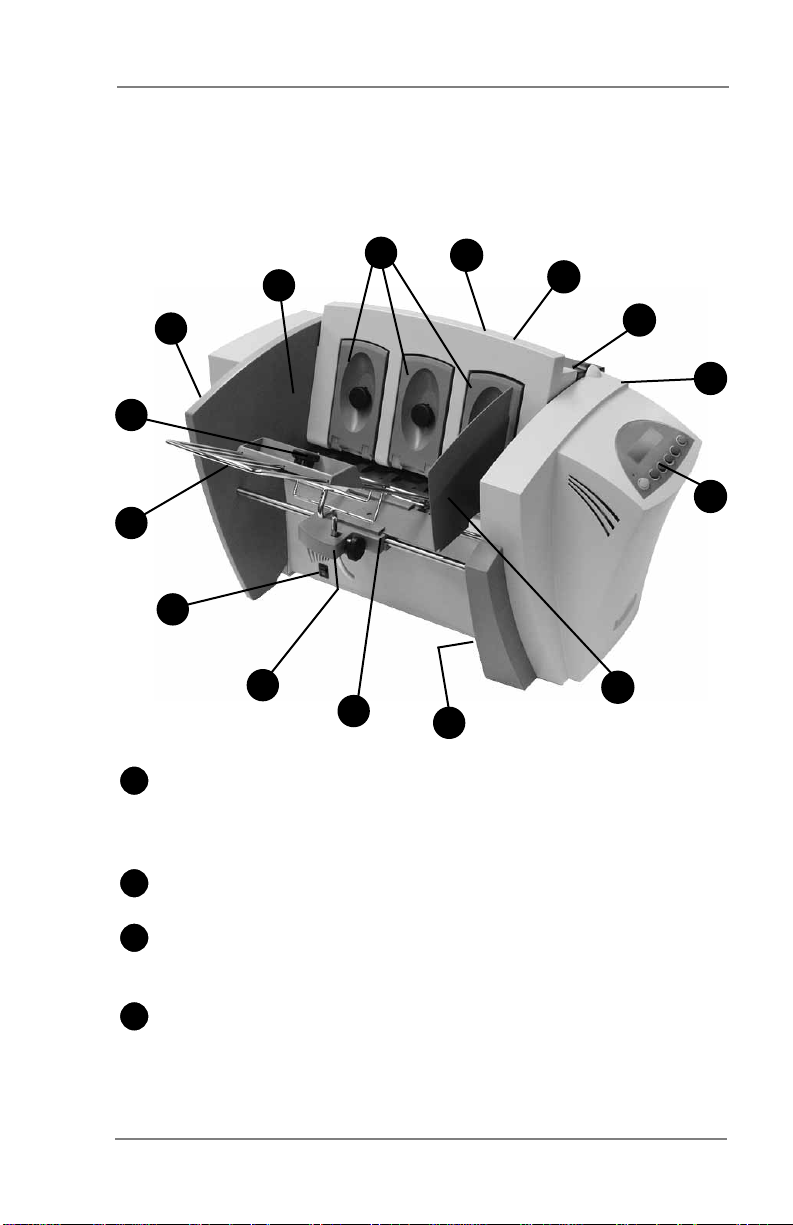

Printer Parts and Locations

The figure below calls out key machine components, each of which

is briefly described in the text that follows. Refer to the figure below

for component location.

1

2

3

4

5

6

7

8

H-Block Separators - Adjust to the thickness of your material.

1

15

14

13

10

9

The gap between the H-Block separator fingers and the feed

rollers should be just enough to allow a single piece to feed

through the printer.

Input Area - Where you stack material for printing. You'll make

2

most setup adjustments in this general area.

Interface Panel (Not Shown) - Located on the lower part of

3

the rear cover, the panel has the power cord receptacle. See

figure on page 1-9.

Feed Ramp and Lock Knob - The feed ramp adds a gentle

4

slope to the stack to help feeding. Lower the feed ramp until

the top of the bottom piece in the stack reaches the middle of

the feed ram. Secure the feed ramp with the lock knob.

12

11

1-7SV61663 Rev. D

Page 15

1 • Introduction

Input Guide - Supports the material stack. Adjust the feed

5

angle to accommodate the weight of the material you're

running. Adjust its side-to-side position so it's centered under

the stack.

6

ON/OFF Switch - Powers the printer on and off.

Input Guide Slide Block - Slides the input guide side to side.

7

Lock in position with the lock lever (Item 8).

Input Guide Slide Lock Lever (Not Shown) - Locks the input

8

guide slide in position.

USB and Ethernet Cable Connectors (Not Shown) - Used

9

to connect the printer to a PC. See figure on page 1-9.

Side Guide - Helps confine the stack. Adjust to the width of

10

your material plus 1/16" (2mm) clearance.

Control Panel - Use the control panel buttons to access

11

printer menus, define print options, run the print job, position

the print carriage and turn the printer on and off line. If you

have the print driver loaded on your computer, you can easily

perform these functions from within your application.

Output Stacker Tray (Not Shown) - Printed material is

12

deposited in the stacker (catch) tray. The tray holds about 5"

(130mm) of material.

Transport Door (Not Shown) - Open to gain access to the

13

print cartridge and exit rollers. See figure on page 1-9.

Exit Rollers (Not Shown) - Guides the printed material as it

14

exits the printer. Adjust so that each roller overlaps the edge of

the material by 1/4" (6mm). See figure on page 1-9.

Output Area - Where printed material is ejected from the

15

printer.

1-8 SV61663 Rev. D

Page 16

Power Receptacle

Printer Interface Panel

Introduction • 1

USB

Cable

connects

here

USB/Ethernet Connectors

Exit Rollers

Transport Door (Open) and Exit Rollers

Ethernet

Cable

connects

here

1-9SV61663 Rev. D

Page 17

1 • Introduction

This page is intentionally blank.

1-10 SV61663 Rev. D

Page 18

2 • Printer Basics

In this chapter you'll learn about key printer features and how

to adjust it to meet the requirements of your print jobs.

Printer Features Overview ..................................................2-2

Setting Up a Job .................................................................2-3

1. Setting the Separator Gap .....................................2-3

2. Centering the Input Guide under the Material .......2-5

3. Setting the Feed Angle ..........................................2-5

4. Positioning the Side Guide ....................................2-6

5. Loading Material ....................................................2-7

6. Adjusting the Position of the Feed Ramp ..............2-8

7. Adjusting the Media Thickness Lever ....................2-9

8. Adjusting the Upper Exit Rollers ..........................2-10

9. Printing a Test Piece ............................................2-11

Printer Driver Software .....................................................2-11

Selecting Printer Properties .......................................2-11

Using the Control Panel....................................................2-12

Using the Menus...............................................................2-13

Using the Main Menu .................................................2-14

Using the Setup Menu ...............................................2-15

2-1SV61663 Rev. D

Page 19

2 • Printer Basics

Printer Features Overview

This section provides a brief overview of the printer features. Refer to

Appendix A, Specifications, for detailed specifications for the printer,

including specific requirements for using each type of material.

Speed (pieces per hour)

Printer speed refers to the number of pieces of mail that can be

processed in an hour. The printer can process up to 10,000 #10

or DL envelopes per hour, depending on the address content and

configuration. Printer speed depends on the number of characters

per line, the number of lines, character size, font, interface, barcode,

material size and graphics.

Print Qualities

Draft, Letter, Executive with optional Light Mode.

Internal Fonts

13 (14 including Code 3 of 9 Barcode).

Font Size

Font size refers to the size of each typeface. The printer uses from 4

to 144 point size for internal or downloaded fonts.

Media Size

The printer can print on the following range of material sizes.

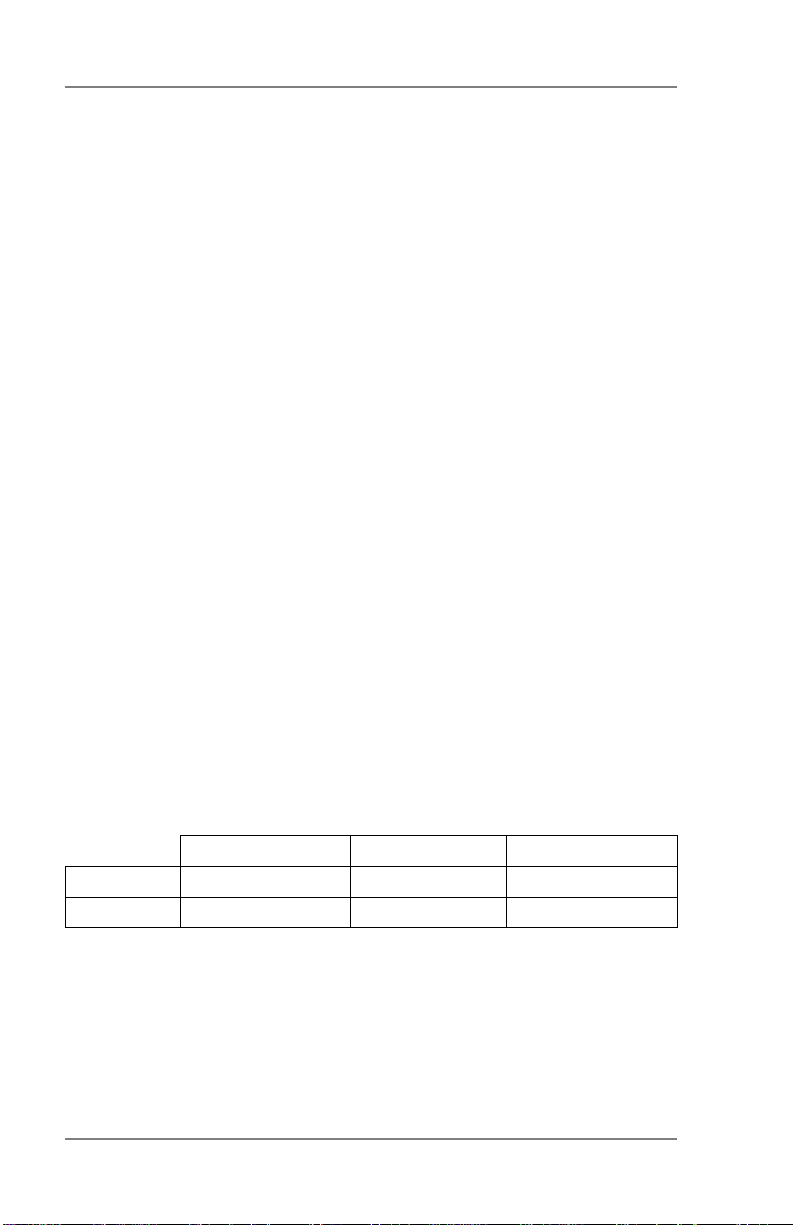

Width Height Thickness

Minimum 4.5" (114 mm) 3.5" (89 mm) .003" (.08 mm)

Maximum 12.75" (324 mm) 13.5" (343 mm) .125" (3.175 mm)

Approved Media Types

The printer can be used with envelopes, booklets, catalog envelopes,

postcards, self mailers, and paper. All envelopes must be without

windows, empty and unsealed. Any folded material needs to be

tabbed.

2-2 SV61663 Rev. D

Page 20

Printer Basics • 2

Setting Up a Job

Setting up a print job means adjusting the printer to accommodate

the width, height, thickness and weight of your material.

There are two things that determine how reliably your printer feeds:

the setup adjustments and the quality of your material. A good setup

minimizes misfeeds and jams. And your printer will perform at its best

when you run material that falls within our published specifications.

Please see Appendix A, Specifications for complete material

specifications.

1. Setting the Separator Gap

Switching from one material type to another requires setting the

gap between the separators and the feed roller before printing

begins. To find the correct spacing, refer to the figure on the next

page and follow the instructions below:

A. Loosen the lock knobs to unlock all three H-Blocks.

B. Lift all three H-Blocks to their highest position and lock in

place.

C. Place a sample piece of material into the input area. Align

the sample with the left wall of the input area, then place it

between the separator fingers (the lower section of the HBlocks) and the feed roller.

D. Lower only the H-Blocks that come in direct contact with

the sample material. Make sure the material is between the

separator fingers and the feed rollers, and that the separator

fingers do not directly contact the feed rollers.

E. Lock each separator in place.

NOTE: If the separator gap is not set properly, the printer

will misfeed or jam. If the gap is too big, the printer will feed

doubles (two or more pieces at the same time). If the gap is

too small, material will jam at the feed roller entrance. If you're

running post cards and have feeding problems, set a smaller

gap between the H-Block separators and feed rollers, or use

thinner media.

2-3SV61663 Rev. D

Page 21

2 • Printer Basics

Setup Example Using #10 or DL Envelopes

Perform preceding steps A-E for setting the feed gap using #10

or DL envelopes. Notice that only two of the H-Block Assemblies

completely rest on the envelope. The third H-Block has one

separator finger on the envelope and one on the feed roller.

A. Take Side Guide off and remove out of the way.

B. Fit a second envelope between the other half of the H-Block

Assembly and the Feed Roller.

C. Loosen the H Block

Knob to let the HBlock Assembly

fall freely onto the

envelope. Verify

envelopes are

between all the

Separator Fingers

and the Feed Rollers.

D. Lock in Place by

tightening the H Block

Separator

Finger

Feed Roller

Knob.

E. Remove the second envelope from under the third H-Block

Assembly.

F. Replace the Side Guide and proceed to the instructions in

sections:

• 2. Centering the Input Guide under the Material

• 3. Setting the Feed Angle

• 4. Positioning the Side Guide

G. The Input Bin can now be filled with # 10 envelopes for

printing. The stack of envelopes should be “shingled” or

layered with the piece on top partially covering the piece

below it like shingles on a roof. Load into the input bin

with flap away from the feed roller and facing downward.

Start with just a few envelopes to start the stack and get

the angled contour of the bin area, then add several more

pieces, Then add the remainder of the stack.

H-Block Lock Knob

2-4 SV61663 Rev. D

Page 22

Printer Basics • 2

2. Centering the Input Guide under the Material

A. Place a sample piece of material in the feed area, up against

the support plate.

B. Push down on the input guide lock lever to free the input

guide slide.

C. Center the input guide under your sample piece of material.

D. Pull up on the lock lever to secure the input guide in position.

3. Setting the Feed Angle

The feed angle of the input guide depends on the type of

material you're running:

• Heavy material: adjust to a low angle.

• Standard material: adjust to the center (45 degree Angle).

• Light material: adjust to a high angle.

To make the adjustment:

A. Loosen the lock knob on the input guide slide.

B. Move the input guide up or down as required.

C. Tighten the lock knob to secure the input guide.

Input Guide

Lock Knob

2-5SV61663 Rev. D

Page 23

2 • Printer Basics

4. Positioning the Side Guide

Your printer comes with two side guides—a long one and a short

one. Use the long side guide for #10 or DL envelopes and larger

materials. Use the short side guide for materials smaller than a

#10 or DL envelope.

It is important that the side guide not be adjusted tight against

the media.

To position the fence:

A. Place a sample piece or trial stack of material in the input

area.

B. Slide the side guide until it almost touches the stack of

material.

C. Check that there's about 1/16" (2mm) clearance (the

thickness of a dime) between the side guide and the stack.

NOTE: Proper clearance is important. If you push the side

guide tight up against the stack, it could impede feeding

and cause jams. If the clearance is too great, pieces could

skew as they feed into the printer.

Side Guide

2-6 SV61663 Rev. D

Page 24

Printer Basics • 2

5. Loading Material

Once your printer is set up, you can load material and make a

test print. Avoid misfeeds by following these precautions:

A. Make sure the input area is free of dust and other matter.

B. Take a manageable amount of material and while holding

it as shown, fan all sides of the material to separate each

piece. This step helps keep misfeeds to a minimum.

C. Tamp the material on a flat surface, making sure that the

stack is square.

D. Shingle the stack as you load it into the input area. Load

envelopes so the side to be printed faces up. Flaps should

be down and oriented away from the feed roller (flaps

trailing).

E. Position the right edge of the envelopes flush against the

support plate. Begin with just a few envelopes to start the

stack and get the proper contour, then add several more

pieces. Then, add the remainder of the stack.

NOTE: Envelope feeding is generally more reliable if there

are more than just a couple of envelopes in the input bin.

F. Adjust the position of the feed ramp as described on the next

page.

2-7SV61663 Rev. D

Page 25

2 • Printer Basics

6. Adjusting the Position of the Feed Ramp

With a stack of material loaded:

A. Loosen the lock knob that holds the feed ramp in position.

B. Lower the feed ramp until the top of the bottom piece of the

stack reaches the middle of the feed ramp.

C. Tighten the feed ramp's lock knob to hold it in position.

Feed Ramp

At this point, it's a good idea to recheck your setup adjustments:

• Is the separator gap adjustment correct?

• Is the input guide centered under the material?

• Is the feed angle okay?

• Is there a slight clearance between the side guide and the

edge of the stack?

2-8 SV61663 Rev. D

Page 26

Printer Basics • 2

7. Adjusting the Media Thickness Lever

The media thickness lever sets the distance between the

printhead and the material. Use it to compensate for different

material thicknesses. The lever is located inside the printer under

the transport door, as shown below.

Media Thickness

Lever

1. Set for approximate material thickness:

• Up position for thicker material (.118" or 2mm).

• Down position for paper or card stock (.010" or 0.25mm).

2. Print a test piece with the lever in the middle position. If the

address appears blurred or too light, lower the lever; if the

address appears smeared, raise the lever.

A NOTE ABOUT PRINT QUALITY: The printer is designed to

feed and print on a range of materials with various finishes and

coatings. However, the sharpness of the print may vary with

different materials, depending on how absorbent the surface is,

as well as other qualities.

You'll get best results using white wove bonded stock. Printing

is less sharp on Tyvek, recycled and glossy material. It is also

possible that ink may not dry thoroughly on certain very glossy

materials. Always test high gloss materials for their drying

qualities before you buy them in quantity and attempt to run a

print job.

2-9SV61663 Rev. D

Page 27

2 • Printer Basics

8. Adjusting the Upper Exit Rollers

Adjust the upper exit rollers so the outside edge of the rollers

overlap the left and right edges of the material by 1/4" (6mm).

Slide the rollers from side to side to make the adjustment.

IMPORTANT: Make sure the rollers do not touch any printed

area of the material. If this happens, the rollers will act like a

printing press and imprint a faint impression at incremental

distances on the material. If this happens, move the roller or

rollers toward the nearest clear zone, that is, an area free of

printing.

Exit Rollers

Output Stack Height

The output stacker holds up to five inches of material before

it becomes necessary to remove the stack from the bin. The

optional power stacker increases capacity to 300 #10 or DL

envelopes.

NOTE: As the stack approaches the 5" (130mm) limit, there is

a potential for stacking misfeed (pieces not neatly stacked one

on top of the other). This can cause envelopes to stack out of

printed sequence.

2-10 SV61663 Rev. D

Page 28

Printer Basics • 2

9. Printing a Test Piece

Print a test piece to ensure the material is loaded properly.

(Or you can use a single test piece if you'd like to check your

setup adjustments.) Use the Control Panel keys to print a test

piece. Refer to Using the Control Panel in this chapter for more

information.

Check the print quality. If it's not what you want, adjust the media

thickness lever as required and run another test piece. When

you're satisfied with the setup adjustments, you're ready to run

the job.

Printer Driver Software

Before you can use your printer with your computer, you must install

a printer driver. The driver gives your computer information about the

printer you're using, and tells the printer about the settings you want

to use in your print job.

If you have not previously installed the printer driver on your

computer, refer to the installation instructions furnished with it.

The printer drivers are contained on a CD that comes with your

printer. To set up, follow the instructions as shown in the installer.

Selecting Printer Properties

This section describes printer properties and use of the windows

for selecting the available options. To access the main properties

window, follow these steps:

1. Click the Start button in the task bar, then select Settings.

2. Click Printers. The Printer window displays.

3. Right click the Pitney Bowes printer icon, then left click the

Properties option.

The Properties window opens and displays seven tabs, each of

which allows access to different printer options. An explanation of the

items on each tab is available by doing the following:

• Right click an item to display the "What's This" button.

• Right or left click this button to display the information about the

selected item.

Options may differ depending on which software drivers are used.

2-11SV61663 Rev. D

Page 29

2 • Printer Basics

Using the Control Panel

Use the buttons on the control panel to get to the printer menus,

define the print options, run a print job, position the print carriage

and turn the printer ON LINE and OFF LINE. You’ll normally perform

these actions from within the application you’re using to set up your

envelope layout.

NOTE: You also have a PC Control Panel which allows you similar

functionality to the LCD menus. The Control Panel also has online

help.

On Line Eject/- Menu Enter Cartridge/+ Test Env.

The buttons on the control panel perform the following functions:

This Button... Does This...

ON LINE

Eject/- (minus)

Menu

2-12 SV61663 Rev. D

Toggles (switches) between ON LINE

(communicates with host) and OFF LINE

(no communications with host). Note that

the functions of two buttons, Eject/- and

Cartridge/+, vary, depending on whether

the printer is ON LINE or OFF LINE .

When printer is OFF LINE, press to eject

the last printed piece from the printer.

When printer is OFF LINE, press to scroll

through menu items from bottom to top

printer.

Displays the options on the Main Menu and

the Setup Menu. The printer must be OFF

LINE to access the menus.

Page 30

This Button... Does This...

Enter

Press to select the currently displayed

menu option.

Printer Basics • 2

Cartridge/+(plus)

Test Env. With the printer OFF LINE, press to print a

With the printer OFF LINE, press to move

the ink cartridge holder to the center of the

printer. This makes it easy to remove the

cartridge. With the printer OFF LINE, press

to scroll forward through the menu options.

test envelope.

Using the Menus

The printer has two menus, both displayed on the LCD:

• Use the Main Menu to control how your printed material looks.

• Use the Setup Menu to configure your printer so it will function

correctly with your computer.

NOTE: The printer must be OFF LINE to access the menu

options.

To select an option:

1. Press the ON LINE button until the LCD message displays OFF

LINE.

2. To access the MAIN MENU, press the Menu button.

3. To access the SETUP MENU, press and hold the Menu button

for four (4) seconds.

4. Press the plus (+) or minus (-) buttons to move through the list

of menu options.

5. When the appropriate menu option appears, press the Enter

button to display the choices associated with that option.

6. Press + or - to scroll through the choices. When an option has an

asterisk (*) in front of it, means that option is presently selected.

(Upon receipt from the factory, the asterisk is typically the default

setting.) When you press the Enter button to define a new

option, an asterisk will appear before the selected option.

7. Press the Menu button several times to back out of the Menu

until the printer displays OFF LINE. Then press the ON LINE

button to print

2-13SV61663 Rev. D

Page 31

2 • Printer Basics

Using the Main Menu

The Main Menu options are:

MAIN MENU MENU OPTIONS

1. ADDRESS LAYOUT A. DISTANCE TO RIGHT

B. DISTANCE TO BOTTOM

C. LINE SPACING

D. INVERTED PRINTING

E. ORIENTATION

F. ORIENTATION CONTROL

2. PRINT QUALITY A. QUALITY

B. LIGHT MODE

3. FONT A. NAME

B. SIZE

C. BOLD

D. ITALIC

4. BARCODE (U.S. Only) A. LOCATION

B. 9 DIGIT ON/OFF

C. BAR WIDTH

5. ADDRESS RECOVERY A. GET ADDRESS (BATCH)

B. GET ADDRESS (INTER)

C. CLEAR MEMORY

6. CLEAR COUNTER

7. IMAGE OVERLAY A. CAPTURE OVERLAY

B. CLEAR OVERLAY

C. PRINT OVERLAY

NOTE: The settings you defi ne in a software application such

as SmartMailer™ override any settings you choose in the printer

menus.

2-14 SV61663 Rev. D

Page 32

Printer Basics • 2

Using the Setup Menu

The Setup Menu Options are:

SETUP MENU MENU OPTIONS

1. HEAVY MEDIA MODE

2. TEST PRINT HEAD

3. PURGE PRINT HEAD

4. LINES PER ADDRESS

5. COMMUNICATIONS A. TCP/IP

B. LINE TERMINATION

6. HEX DUMP MODE

7. LANGUAGE A. SYMBOL SET

B. INCH/MILLIMETER

C. MENU LANGUAGE

8. ENVELOPE FEED DELAY

9. ENVELOPE AUTO EJECT A. AUTO EJECT MODE

B. DELAY

10. ROM REVISION #

11. PRINT HEAD MAINT A. HEAD MAINTENANCE

B. MAINT. CYCLE TIME

12. BUNDLE BREAK

13. TRAY BREAK

14. LOW INK WARNING A. DISPLAY WARNING

15. LOGGING SETTINGS A. ENABLE LOGGING

A. ENABLE/DISABLE

B. BREAK CHARACTER

C. BREAK CHARACTER COUNT

D. CHAR. ORIENTATION

E. BREAK LOCATION

F. PRINT BRK CHARS

G. BRK PAUSE TIME

B. WARNING THRESHOLD

C. STOP WHEN EMPTY

B. LOGGING LEVEL

C. PRINT LOG

NOTE: To print a list of the Main Menu and Setup Menu settings,

press the Test button when ROM REV is displayed.

2-15SV61663 Rev. D

Page 33

2 • Printer Basics

This page is intentionally blank.

2-16 SV61663 Rev. D

Page 34

3 • Printer Maintenance

This chapter describes the maintenance procedures you

should perform on a regular basis to keep your printer running

trouble-free.

Preventive Maintenance .....................................................3-2

Print Quality Problems ........................................................3-2

Cleaning the Exit Rollers ....................................................3-3

Cleaning the Sensor ...........................................................3-3

Cleaning the Floor Assembly and Top Cover .....................3-3

Purging the Printhead .........................................................3-3

Installing and Removing the Ink Jet Cartridges ..................3-4

Installing the Ink Jet Cartridges (Color & Black) ..........3-4

Removing the Ink Jet Cartridges ..................................3-6

CMYK Printing Alignment (DA55S ONLY) ..........................3-7

3-1SV61663 Rev. D

Page 35

3 • Printer Maintenance

Preventive Maintenance

The printer is designed for trouble-free service with a minimal

amount of care. You should schedule regular cleaning of the Feed

Rollers, Exit Rollers and Lower Guide.

CAUTION:

• Clean print head, cartridge, ink surfaces and

covers with plain water only. (Water works best!)

• Clean all rubber rollers with isopropyl, denatured

and rubbing alcohol only.

• Use of any other cleaning solvents will void all

warranties.

• Keep petroleum based cleaning solvents away

from rubber or plastic parts. Anything but alcohol

will cause premature breakdown of the rubber

compound.

Print Quality Problems

The print head performs a self cleaning cycle periodically. If print

quality is unacceptable, try the following:

• Adjust the media thickness lever to see if print quality improves.

• Clean the print head cartridge: dampen a soft cotton cloth with

water and wipe the nozzles clean.

Correct Incorrect

• From the Setup Menu, select 3. Purge Printhead. The purging

process clears any clogged ink on the print nozzle. Often this

returns the print quality to a normal level. See Purging the

Printhead in this chapter for more information.

• Install a new ink cartridge. See Installing and Removing Ink Jet

Cartridges in this chapter.

3-2 SV61663 Rev. D

Page 36

Printer Maintenance • 3

Cleaning the Exit Rollers

If the right and left exit rollers are misaligned, that is, contact printed

surfaces, they can become contaminated with ink. Use water to

dampen a soft cloth and remove the ink from the rollers.

Cleaning the Sensor

A film and/or dust can build up on the sensors and cause misfeeds of

the material. Lift the transport door and use compressed air to blow

dust from the sensors. Cans of compressed air are available from

many computer supply houses.

Sensor Location

Cleaning the Floor Assembly and Top Cover

Periodically wipe the cover and floor assembly (feed deck) with a soft

cotton cloth, dampened with water only.

Purging the Printhead

1. To access the SETUP MENU, press and hold the Menu button

for four (4) seconds.

2. Press the + or - buttons to scroll through the SETUP MENU

options until 3. PURGE PRINT HEAD appears on the LCD

panel.

3. Press the Enter button to select this option.

4. To select Purge Printhead cycle, press Enter when the "Purge

Printhead?" message displays.

5. Press the + button (YES) to enable this option. The printer will

display "Please wait...print head being purged".

6. Press the Menu button to back out of the menu until printer

displays "OFF LINE". Then press the ON LINE button to enable

the printer.

3-3SV61663 Rev. D

Page 37

3 • Printer Maintenance

Installing and Removing the Ink Jet Cartridges

Installing the Ink Jet Cartridges (Color & Black)

The printer uses Ink Jet Cartridges for printing. You must install

a black only cartridge (DA50S), or a black and a color cartridge

(DA55S), before you can print. To begin:

1. With the printer on, press the ON LINE button until the printer

displays "OFF LINE".

2. Open the Transport Door of the printer.

3. Press the Cartridge/+ key on the control panel to move the

carriage to the middle of the printer.

4. Remove the color (DA55S only) or black cartridge (both models)

from its shipping container by peeling the top cover off. Be

careful not to touch the copper ribbon.

WARNING! The ink in the cartridge may be

harmful if swallowed. Keep new and used

cartridges out of reach of children. Discard empty

cartridges immediately.

5. Gently remove the tape covering the ink nozzles on the print

cartridge. Be careful not to touch the copper nozzles.

6. Gently insert the cartridge (color to the right, black to the left) into

the carriage at approximately a 20 degree angle with copper strip

to the bottom and in first.

7. Press down on the cartridge until it is seated.

NOTE:

The print

cartridge

photos in

this section

are of the

DA55S

printer. The

DA50S has

only one

cartridge.

3-4 SV61663 Rev. D

Page 38

Printer Maintenance • 3

8. Push the cartridge forward (away from you) until it snaps in

place.

9. Close the Transport Door.

10. The prompt asks about resetting the ink level. Select "YES" if

you have installed a new cartridge. Otherwise, select "NO".

11. Press Enter. The display returns to the "OFF LINE" screen.

IMPORTANT: When installing cartridges on the DA55S,

please immediately perform the CMYK Printing Alignment

procedure in this chapter.

3-5SV61663 Rev. D

Page 39

3 • Printer Maintenance

Removing the Ink Jet Cartridges

To remove or replace the ink jet cartridges, follow these steps:

1. With the printer on, press the ON LINE button until the printer

displays "OFF LINE".

2. Open the Transport Door of the printer.

3. Press the Cartridge/+ key on the control panel. This moves the

carriage to the middle of the printer.

4. To remove the ink jet cartridge (color or black), place your thumb

on the grooved surface and press down until it pops loose.

5. Lift the print cartridge out of the cradle.

3-6 SV61663 Rev. D

Page 40

Printer Maintenance • 3

CMYK Printing Alignment (DA55S ONLY)

Your DA55S printer allows black (K) to print with color (CMY) at the

same time (known as CMYK printing). To ensure proper printing, the

black (K) and color cartridges (CMY) need to be correctly aligned.

The alignment procedure should be done whenever you replace any

of your cartridges. Follow this procedure to align the cartridges:

1. Turn ON the DA55S. When the startup completes, the "ON

LINE" screen displays.

2. Press the Cartridge/+ button.

3. Replace the ink print cartridge (if you haven't done so already).

The "Press a key when print heads replaced" prompt displays.

Press any key to continue.

4. When the "Reset color (or black) Ink..." prompts displays, press

Cartridge/+ to reset the ink if you have just installed a new

cartridge; otherwise, press Eject/- if all you need to do is the

alignment procedure.

5. When the "ALIGN INK CARTRIDGES" prompt displays, press

(+):

6. When the "--COLOR ALIGNMENT--" prompt displays, insert an

envelope into the printer and press Enter.

7. The "Horiz adjust" prompt displays and the sample shown below

prints on the envelope.

Color

Cartridge

Line on

Top

Select number with best matched lines

123456789

Not Aligned Aligned Not Aligned

10 11 12 13 14 15

Black

Cartridge

Line on

Bottom

3-7SV61663 Rev. D

Page 41

3 • Printer Maintenance

8. Press the (+) or (-) buttons to scroll through the selections and

choose the number that represents the best horizontal alignment

of the upper and lower lines (for the color and black cartridges,

respectively).

9. Insert an envelope into the printer and press Enter. The

horizontal adjustment prompt displays and the sample shown

below prints on the envelope.

NOTE: The number you selected is highlighted (underlined)

and all lines on the envelope should now be aligned.

Number

Selected

When correct pattern isis sselected

all lines should be strtraight

Highlighted

123456789

Both Black and Color

Cartridge Lines Together

Aligned Aligned

10 11 12 13 14 15

10. Press MENU to return to the alignment choice window

11. Press (+) or (-) to move to the vertical alignment screen.

12. Insert an envelope into the printer and press Enter. The vertical

adjustment prompt displays and the sample shown on the next

page prints on the envelope.

3-8 SV61663 Rev. D

Page 42

Printer Maintenance • 3

123456789

Color Cartridge

Line on Top

Black Cartridge

Line on Bottom

Not Aligned Not AlignedAligned

10 11 12 13 14 15

Black Cartridge

Line on Top

Color Cartridge

Line on Bottom

13. Press (+) or (-) to scroll through the selections and choose the

number that represents the best vertical alignment of the upper

and lower lines (for the color and black cartridges, respectively).

14. Insert an envelope into the printer and press Enter. The vertical

adjustment prompt displays and the sample shown on the next

page prints on the envelope.

NOTE: The number you selected will be highlighted and all

lines on the envelope should now be aligned.

3-9SV61663 Rev. D

Page 43

3 • Printer Maintenance

When correct pattern isis sselected

all lines should be strtraight

Number

Selected

Highlighted

123456789

Both Black and Color

Cartridge Lines Together

Aligned Aligned

10 11 12 13 14 15

15. Press Menu twice to return to the normal ON LINE screen.

3-10 SV61663 Rev. D

Page 44

4 • Troubleshootin

g

This chapter lists some common printer problems and offers

suggestions on how to fix them.

Problems and Solutions......................................................4-2

Feed Problems ...................................................................4-2

Print Quality Problems ........................................................4-3

Interface Problems .............................................................4-4

Motor Problems ..................................................................4-4

Barcode Problems ..............................................................4-4

Other Problems ..................................................................4-5

4-1SV61663 Rev. D

Page 45

4 • Troubleshooting

Problems and Solutions

Before calling for service, look for your problem below. If you can

solve the problem yourself, you will be able to resume printing

sooner.

Feed Problems

Problem Reason Solution

Intermittent

Feed

Multifeeds

(Feeds

Doubles) or

Skewing

Feed Ramp not used. The feed ramp adds a gentle

slope to the stack and helps

feeding. If you're using the

ramp, check the H-Block gap for

proper separation. Also make

sure the input guide is centered

under the ma te ri al.

See Chapter 2, Printer Basics

for more information.

Dirty feed rollers. Clean the feed roller with

alcohol. DO NOT use any other

solvents or detergents. They

could damage the feed rollers.

Paper dust present

(yellow or white

residue), blocking

feed sensor.

Separators (H-blocks)

not set correctly.

Side guide set

incorrectly.

Clean sensor with compressed

air.

See Chapter 3, Printer

Maintenance for more

information.

Adjust H-Blocks to thickness of

material.

Check side guide position.

See Chapter 2, Printer Basics

for more information.

4-2 SV61663 Rev. D

Page 46

Troubleshooting • 4

Print Quality Problems

Problem Reason Solution

No Print Ink cartridge

problem.

Grey or Light

Print–Black Ink

Off Color

or Low Ink

Intensity

- Color Ink

DA55S Only

Address

Smudging

Address

Printing is not

Sharp

Unwanted

Bolding

Addresses

"Walking"

Ink supply is low. Check adjustment of the media

Incorrect media

thickness lever

setting.

Ink may not dry

on very high gloss

ma te ri al.

Incorrect media

thickness lever

setting. Also,

un suit able material

Escape sequence

turning on bold

or bold se lec tion

in printer's menu

options is set to bold.

Incorrect address

setup.

Purge ink cartridge. See

Chapter 5, Printer Maintenance

for more information.

Clean cartridge jets with soft

cotton cloth and water.

Change to a new cartridge(s)

thick ness lever.

If this fails to correct the

prob lem, replace ink

car tridge. See Chapter 3,

Printer Maintenance for more

information.

Check whether media thickness

lever is adjusted too low.

Try using less glossy material.

Check exit idler rollers.

Check whether media thickness

lever is adjusted too high. Print

quality is less sharp when using

Tyvek®, recycled or glossy

media.

Turn off bolding in software

and/or turn bold selection in

printer menu OFF. Refer to help

system provided with printer for

more information. If prob lem still

exists, call for service.

Count carriage returns and

line feeds and adjust Lines Per

Address to the same number.

Also check line termination:

Typical, CR=CR; LF=LF.

Other choices, (CR=CR+LF;

LF=LF), CR=CR; LF=CR+LF),

(CR=CR+LF; LF=CR+LF),

double spacing.

4-3SV61663 Rev. D

Page 47

4 • Troubleshooting

Interface Problems

Problem Reason Solution

Printer Not

Responding

Motor Problems

Problem Reason Solution

Motor Turning

but No

Feed Roller

Movement

Barcode Problems

Problem Reason Solution

Barcode (Lower

Right) is not

Printing (U.S.

Only)

Address too

High

Incorrect printer

driver, bad USB or

Ethernet connection,

bad printer controller

board.

Mechanical problem. Call for service.

Barcode not enabled. Turn barcode ON using

Missing ZIP Code. Insert ZIP Code.

Invalid ZIP Code

format.

Address too low. Verify the bottom of the last line

Address field is

within 1/10” (2.5mm)

of the top edge of the

media.

Use appropriate printer driver;

replace USB or Ethernet cable.

Make sure cable connections

are tight. If the problem still

persists, call for service.

Clear memory.

Cycle power (turn printer off,

then on).

Envelope Designer™ Plus, the

appropriate print driver or the

printer’s control panel menus.

Check ZIP Code for invalid

character. Example: Zero (0)

can only be the number, not

the letter (O). Verify that there

is a dash inserted between the

5 + 4 ZIP Code per local postal

specifications.

of the address field is not less

than 5/8” (16mm) from bottom

edge of the media.

Move address field down

to within local postal

specifications.

4-4 SV61663 Rev. D

Page 48

Troubleshooting • 4

Other Problems

Problem Reason Solution

Paper Out or

Paper Jam

Shuttle Jam Media thickness

Out of Memory The printer can run

Input area is empty. Refill the input area.

H-Block separators

not adjusted

correctly.

Paper jam

obstructing paper

path.

Dirty paper feed

sensor.

lever is set too low

for material.

Lower rail shaft dirty Wipe lower rail shaft clean.

out of memory when

downloading fonts or

graphics.

Adjust the H-Blocks to the

thickness of the material you’re

running.

See page Chapter 2, Printer

Basics for more information.

Clear obstructed paper path.

Clean sensor with compressed

air.

See page Chapter 2, Printer

Basics for more information.

Open the transport door and

adjust the media thickness

lever.

See page Chapter 2, Printer

Basics for more information.

This generally means you’re

trying to use a graphic (artwork)

that’s too big or you have too

many fonts or too large a font

size. If the out-of-memory

message appears, try reducing

the size of your art and limiting

the number and size of your

fonts. Then shut the printer

OFF, then ON and retry.

4-5SV61663 Rev. D

Page 49

4 • Troubleshooting

This page is intentionally blank.

4-6 SV61663 Rev. D

Page 50

Appendix A •

Specifications

This Appendix contains detailed hardware and material

specifications for the printer.

Equipment Specifications ..................................................A-2

Material Specifications.......................................................A-8

A-1SV61663 Rev. D

Page 51

Appendix A • Specifications

Equipment Specifications

Physical Dimensions

14.7” (37.3 cm) high; 16.2” (41.2 cm) wide; 21.7” (55.1 cm) deep

(without input guide).

Weight

44.11 lbs. (20 kg), including print cartridges (B & C) and catch bin.

Electrical

100-240 Vac, 50/60 Hz., 5.0 A

Agency Approvals

cTUVus/TUV Rheinland-GS - Refer to the FCC and CE statements

at the front of this guide for more information.

Interface

USB, Ethernet

Control Language

PCL5, modified

Address Recovery

Memory buffer holds a maximum of 99 addresses

Print Modes (Print Resolution)

The printer has three print resolutions. These resolutions are

Executive (600), Letter (300), and Draft (150), which represent the

horizontal density. Additionally, there are two Light Mode settings

(ON and OFF), which represent the vertical density. When Light

Mode is "ON", the vertical density setting is 300 DPI; when Light

Mode is "OFF" the vertical density setting is 600 DPI. Refer to the

table on the next page for the print mode options.

A-2 SV61663 Rev. D

Page 52

Specifications • Appendix A

Print Quality: With Light Mode

set to "ON":

Executive 600 x 300 DPI 600 x 600 DPI

Letter 300 x 300 DPI 300 x 600 DPI

Draft 150 x 300 DPI 150 x 600 DPI

Fonts

Resident Fonts

Arial, Comic Sans MS, Courier New, Georgia, Impact, Kino, MSLogo,

Symbol, Tahoma, Times New Roman, Trebuchet MS, Verdana,

Webdings, Wingding, an OCR-A font and a Code 39 font. All fonts

are scalable from 4 to 144 point size.

Resident Font Enhancements

Bold, Italic

Downloadable Fonts

Supports bitmapped, downloadable fonts.

Cartridge Fonts

Not Required. Fonts are downloaded with addresses.

With Light Mode

set to "OFF":

User-Definable Parameters

• Font Characteristics

• Address Placement

• Barcode Characteristics

• Print Quality

A-3SV61663 Rev. D

Page 53

Appendix A • Specifications

Barcode Printing Position

The printer can print a barcode in one of three positions:

• lower right of the envelope

• above the address block

• below the address block.

Barcode Printing Types

The printer can print the following barcodes:

1-Dimensional

• The printer is capable of printing a USPS Certified POSTNET

barcode. All types of barcodes can be printable including FIM, 3

of 9, 4 state barcode (UK, Canadian, Euro, Australia, etc.) and

others.

• The printer is capable of printing 5-, 9-, or 11- digit POSTNET

barcodes. 5-digit barcode printing may be disabled through

menu selection.

• Delivery point barcode is generated by transmitting the three

digits.

• The printer is capable of printing planet barcode used for delivery

confirmation services. The printer is also capable of printing any

barcode rendered by a Windows

®

true type font.

2-Dimensional

The printer is capable of printing an USPS Certified IBIP barcode

as well as all types of 2-D barcodes defined for the countries (UK,

Canadian, Euro, Australia etc.) and others to the defined standards.

Reference applicable Postal Standards.

A-4 SV61663 Rev. D

Page 54

Specifications • Appendix A

Special Note on FIM Barcode (U.S. Only)

FIM (Face Identifi cation Marking) barcode was developed by the

USPS as part of their POSTNET barcoding system. It is normally

used by high-volume mailers to put on return envelopes for their

customers’ invoices.

When the invoices are mailed back in their return envelope, the

USPS sorts and processes this mail according to what version of

FIM barcode is used on the envelope: FIM A (Postage required,

POSTNET bar code included), FIM C (Postage prepaid, POSTNET

bar code included), and FIM D (Postage required, POSTNET bar

code not included).

One of the requirements of the FIM barcode is that it needs to be

printed on the edge of the envelope (typically printed in the top right

corner). This is diffi cult to support by our printers, especially on on

the trail edge. Inverted mode may supply a better print for the FIM,

but any attempt to print to the exact edge of the envelope is liable to

"miss" the edge occasionally. Because of these issues, we cannot

guarantee full USPS compliance.

Throughput

10,000 letters per hour (lph)

Based on:

• Print quality - Draft mode

• 3-line destination address

• 18 characters per line

• 12-point character size

• Time New Roman font

• Bidirectional printing of text

NOTE: Adding graphics and/or printing at a higher resolution (e.g.,

Letter or Executive mode) will decrease throughput.

Stacker Capacity

Input Stacker: 200 #10 or DL Envelopes

Output Stacker: 150 #10 or DL Envelopes

A-5SV61663 Rev. D

Page 55

Appendix A • Specifications

Effective Print Area

The printable width is 9.4" (24cm) measured from the right side of

the piece of mail. The printable height is 15" (38cm) measured from

the bottom edge of the piece of mail. See the figure below.

Flap on

Opposite

Trailing Edge (Top)

Feed Direction

Side

Left

Leading Edge (Bottom)

Right

NOTES:

• All edges are viewed from the front surface of the material.

• Two clear zones, each 0.3" (7.6mm) wide, are required on the

piece of mail to allow clearance for the exit rollers.

• Printing is allowed to the top edge of the media, however print

quality will be degraded.

• The lower 5/8" (16mm) of the material is reserved for the lower

right barcode when it is used.

Ordering Supplies - Printhead/InkJet Cartridges (U.S. Only)

The following supplies are available for your printer:

• Single Black Ink Cartridge (order number 711-1)

• Single Color Ink Cartridge (DA55S only) (order number 660-5)

• 4 Pack of Black Ink Cartridges (order number 660-9)

Refer to the Contact Information List at the front of this guide for

ordering information.

A-6 SV61663 Rev. D

Page 56

Specifications • Appendix A

Print Position Accuracy

For a #10 or DL envelope (Acclaim #10 WW Commercial,Regular):

• Horizontal: within +/- 1.5 mm

• Vertical: within +/- 1.5 mm

• Skew: within +/- 1 degree

For other media:

• Horizontal: within +/- 3.0 mm

• Vertical: within +/- 3.0 mm

• Skew: within +/- 2-1/2 degrees

Environmental Limits

Operating Conditions

• Temperature: 55 to 95°F (12 to 35°C)

• Humidity: 8 to 80%

• Maximum Wet Bulb Temperature: 80°F (27°C)

Storage Conditions

• Temperature (Printer): 42 to 100°F (5 to 40°C)

• Humidity (Supplies): 10 to 90%

• Maximum Wet Bulb Temperature: 85°F (29°C)

Shipment Conditions

• Temperature (Printer): -40 to 140°F

• Humidity (Supplies): 5 to 100%

• Maximum Wet Bulb Temperature: 85°F (29°C)

Noise Level

The sound pressure level at the operator’s position for this

equipment as measured in any mode using ANSI and ISO Standards

is less than 68 dB(A).

A-7SV61663 Rev. D

Page 57

Appendix A • Specifications

Recommended Usage

This printer has been tested under many different conditions. We

recommend that you do not exceed the usage levels specified below:

• Monthly usage is 77,000 pieces

NOTE: Usage beyond these recommended cycles is not

covered under your Equipment Maintenance Agreement.

• Product life is 5 years or 4,620,000 cycles (whichever comes

first)

Material Specifications

For envelope addressing purposes, the printer is compatible with any

word processor or database application that can print a mailing label.

Approved Media

The paper types listed below are approved for use with the printer.

Please note that the dimensional limits above apply in all cases, and

that all media (flats, envelopes, postcards, catalog envelopes, etc.)

must be without windows, unstuffed and unsealed.

• White Wove

• Bond paper

• Recycled paper

• Coated paper

• Card stock

• Brown kraft

• Manila

• Perforations

NOTE: Refer to the Media Size table in Chapter 2, Printer Basics

for specifi c media sizes.

A-8 SV61663 Rev. D

Page 58

Specifications • Appendix A

Material Notes

• Envelopes have a flap along the long edge and are processed

by the printer non-flap edge first. Envelopes may have either a

diagonal or straight edge along the envelope flap.

• Booklets are defined as media having physical dimensions 6 x 9”

(15.25 x 23cm) or larger. Booklets have an opening along their

long edge which is covered by a flap with an adhesive seal.

• Catalog envelopes have an opening along their short edge which

is closed by a flap with an adhesive seal.

• Postcards have no folds or bends. The printable side may have a

higher surface roughness than the non-printable side.

• Self-mailers may be of “C,” “Z,” or half-folded construction. They

may not exceed the maximum allowable thickness as specified

on the previous page and must be tabbed per postal regulations.

• A catalog may consist of multiple pages bound by adhesive or

tabs on the feed edge or at 90 degrees with respect to the feed

edge.

2

• Sheet stock may consist of 16 to 28 lb. (60 to 105g/m

well as 60 to 80 lb. (220 to 300g/m2) coated stock. The size and

thickness constraints specified above apply.

) bond as

A-9SV61663 Rev. D

Page 59

Appendix A • Specifications

Envelope Sizes

Paper Name Displayed in List Size

(Width)

US/Canada Envelope/Paper Sizes

ENV_9 Envelope #9 8⅞"3⅞"

ENV_10 Envelope #10 9½" 4⅛"

ENV_11 Envelope #11 10⅜" 4½"

ENV_12 Envelope #12 11" 4¾"

PPR_Booklet_9_12 Booklet 9 x 12 12" 9"

ENV_MONARCH Envelope Monarch 7½" 3⅞"

PPR_Card_4_6 Card 6 x 4 6" 4"

PPR_Card_5_7 Card 7 x 5 7" 5"

LETTER Letter 8½" 11"

LEGAL Legal 8½" 14"

EXECUTIVE Executive 7¼" 10½ in

European Envelope/Paper Sizes

ENV_B4 Envelope B4 353mm 250mm

ENV_B5 Envelope B5 250mm 176mm

ENV_B6 Envelope B6 176mm 125mm

ENV_C4 Envelope C4 324mm 229mm

ENV_C5 Envelope C5 229mm 162mm

ENV_C6 Envelope C6 162mm 114mm

ENV_C65 Envelope C65 229mm 114mm

PG_ENV_C76 Envelope C76 162mm 81mm

PG_ENV_C7 Envelope C7 114mm 81mm

ENV_DL Envelope DL 220mm 110mm

ENV_DLX Envelope DLX 235mm 120mm

ENV_DLE Envelope DLE 225mm 114mm

A4 A4 210mm 297mm

A5 A5 148mm 210mm

Size

(Height)

A-10 SV61663 Rev. D

Page 60

Specifications • Appendix A

Paper Name Displayed in List Size

(Width)

Asian Envelope/Paper Sizes

Envelope 12JE 140mm 265mm

Envelope 9JE 190mm 265mm

Envelope 6JE 215mm 305mm

Envelope ZL

[China]

Chou #3 Yoko 120mm 235mm

Chou #4 Tate 90mm 205mm

Hagaki 100mm 148mm

Postcard #3 165mm 102mm

Postcard #4 183mm 100mm

Maximum Paper Size 9.4" 15"

230mm 120mm

Size

(Height)

A-11SV61663 Rev. D

Page 61

Appendix A • Specifications

This page is intentionally blank.

A-12 SV61663 Rev. D

Page 62

Appendix B • Glossary

This Appendix contains a glossary of terms related to your

Address Printer and Computer.

B-1SV61663 Rev. D

Page 63

Appendix B • Glossary

Cable

Wires that carry the information between the computer and the

printer.

Character

A printable letter or symbol.

Character height

The height of a uppercase letter. A character height is measured

in points.

Characters per inch

The number of characters printed in a horizontal inch. Also called

pitch.

Character set

The set of characters or symbols that make up a language.

Clean print cartridge

Describes the process of removing dried ink from the nozzles of

the ink jet cartridge.

Configuration

The settings used by the printer to communicate with the

computer. Also the internal settings in the printer that control the

print job.

Control code

The instructions sent to the printer to describe how to perform

the print job.

Control panel

The buttons and display that are used to manually change the

printer’s settings.

CPI

See characters per inch.

Data communications

The sending of data from the computer to a peripheral device,

i.e., the printer.

Dots per inch

The number of ink dots printed in one horizontal inch. The larger

the number the better the resolution of print.

B-2 SV61663 Rev. D

Page 64

Glossary • Appendix B

Double feeding

A condition in which two or more pieces of media feed at the

same time or without separation.

DPI

See dots per inch.

Draft quality

A lower print resolution which saves ink and allows faster printing

of a document.

Drivers

A file used by the computer’s software to communicate

commands and information that the printer needs to layout and

print a document.

Embedded printer commands

Commands sent in a record or document to instruct the printer to

change printing options.

Escape character

A special non-printable character used to instruct the printer to

change printing options.

Escape sequence

Commands sent beginning with the escape character that

instruct the printer to change printing options: fonts, page

orientation, etc.

Feed gap

Adjustable opening between the ends of the H-Block Assembly

fingers and the Feed Rollers so the media is fed one at a time.

Font

A set of printable characters with consistent style and

characteristics.

Grounded

A electrical circuit that has a voltage of zero.

Handshaking

A method for the computer to communicate with peripheral

devices to ensure complete transfer of information.

B-3SV61663 Rev. D

Page 65

Appendix B • Glossary

Hex dump

A printer option that allows all the information and commands

sent to the printer as base 16 digits.

Internal test address message

The preprogrammed Address that is printed when the Test button

is pressed.

Interface cable

The cable that connects the printer or other device to the

computer.

Interface connector

The connectors on both ends of the interface cable that insert

into the interface ports.

Internal fonts

Resident or built-in fonts supplied with a printer.

Jam

See Paper Jam.

Letter quality

Print resolution which saves ink and still provides a high quality

document.

Lines per inch

The number of lines printed in one vertical inch.

Menu directories

The list of available printer controls that appear on the bottom of

the LCD display. A directory can contain other directories called

"sub-directories."

Off Line

A condition in which the printer will not respond to information

sent from the computer.

On line

A condition in which the printer will accept and respond to

information sent from the computer.

Outline fonts

Scaleable printer fonts.

Paper jam

A condition in which media is stuck in the printer.

B-4 SV61663 Rev. D

Page 66

Glossary • Appendix B

Parity

An error checking method used when communicating between

the computer and a peripheral device.

PCL commands

A standard printer language of commands to access printer

features or options.

Point size

A measurement standard for the height of a printed character.

One point equals one seventy-second of an inch.

Postal regulations

Rules and guidelines set up by the Postal Authority for mail.

Power socket

The socket on the back of the printer where the line cord is

connected.

Print cartridge

A removable container that holds ink for printing.

Print quality

Refers to the resolution or level of sharpness of the printed

image.

Printer driver

See Drivers.

Record

A collection of related fields that make up the name and address

of an individual in a mailing list file.

Sans serif

A font typeface that contains no serifs or finishing strokes on the

top or bottom of the characters. Helvetica and Arial are examples