Page 1

XR-C2MD

MD/CD COMPONENT SYSTEM

X-MDX707

XR-C2MD

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

LBWXJ AC110V

NLWXJ/HK AC220V

¶ X-MDX707 is combination of the following components.

¶ For speaker system S-C2-LR, refer to the service manual RRV2156.

STEREO MD/CD CASSETTE DECK RECEIVER XR-C2MD RRV2165 This manual.

SPEAKER SYSTEM S-C2-LR RRV2156

Model

XR-C2MD

Component

Power Requirement Remarks

Model

X-MDX707

Service manual Remarks

ORDER NO.

RRV2165

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

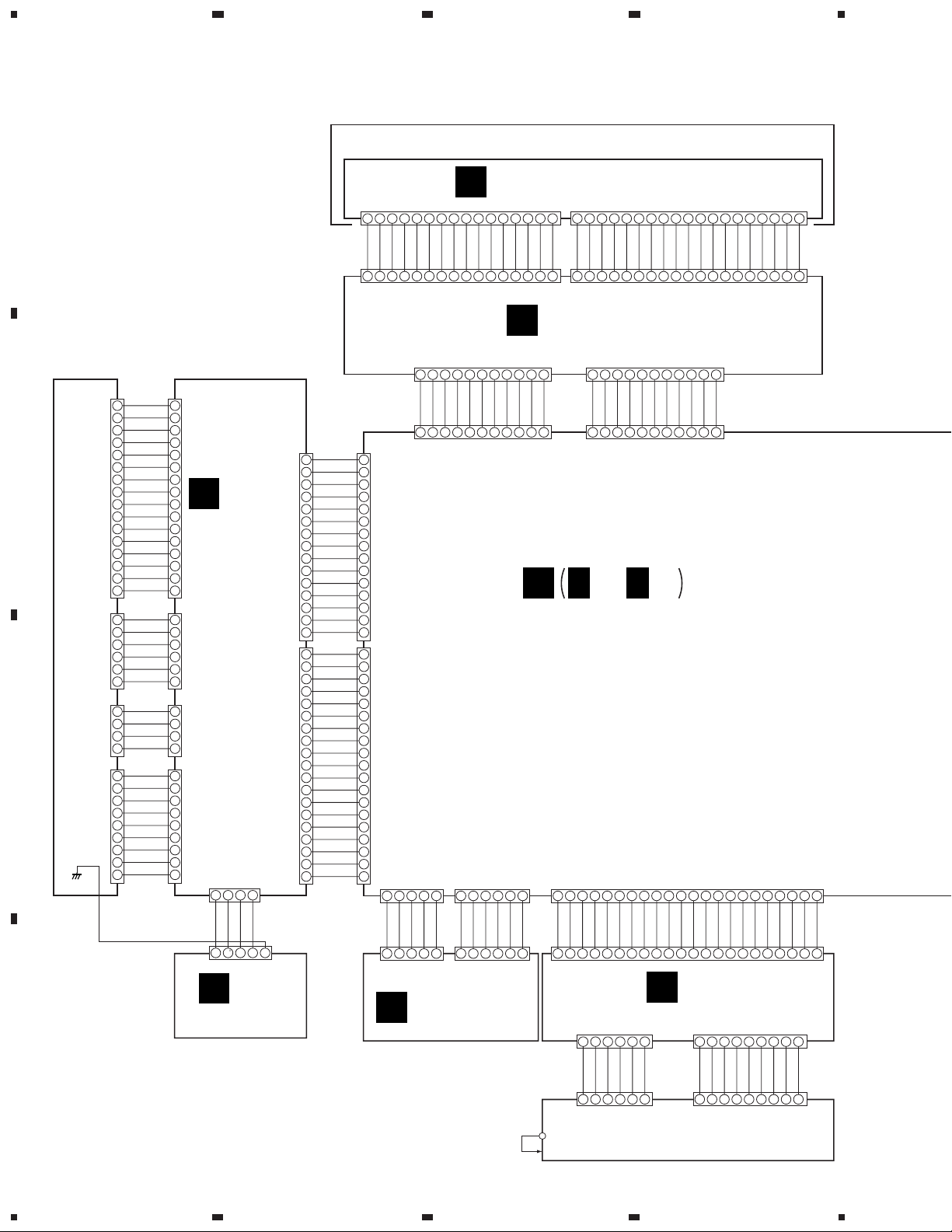

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 1999

...............................................

....................................................

......................................

...............

...

.........................

18

40

54

60

2

3

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 TROUBLESHOOTING

7.1.2 DISASSEMBLY/ASSEMBLY

7.2 PARTS

7.2.1 IC

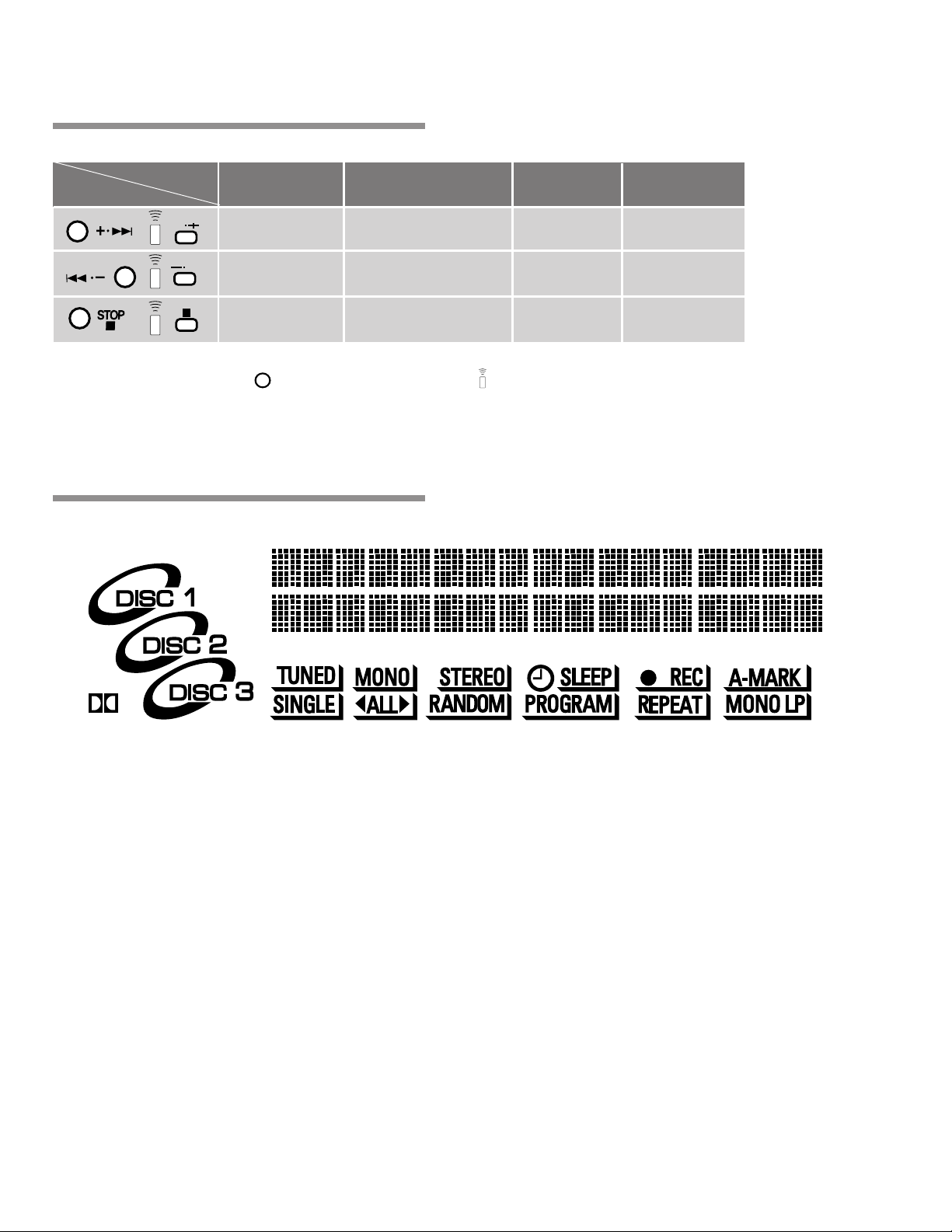

7.2.2 DISPLAY

8. PANEL FACILITIES AND SPECIFICATIONS

..................................................

..........................................................

............................................................

.................................................

................................

...........................

..................

T – ZZK AUG. 1999 Printed in Japan

.......

68

68

68

78

86

86

90

93

Page 2

X-MDX707, XR-C2MD

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

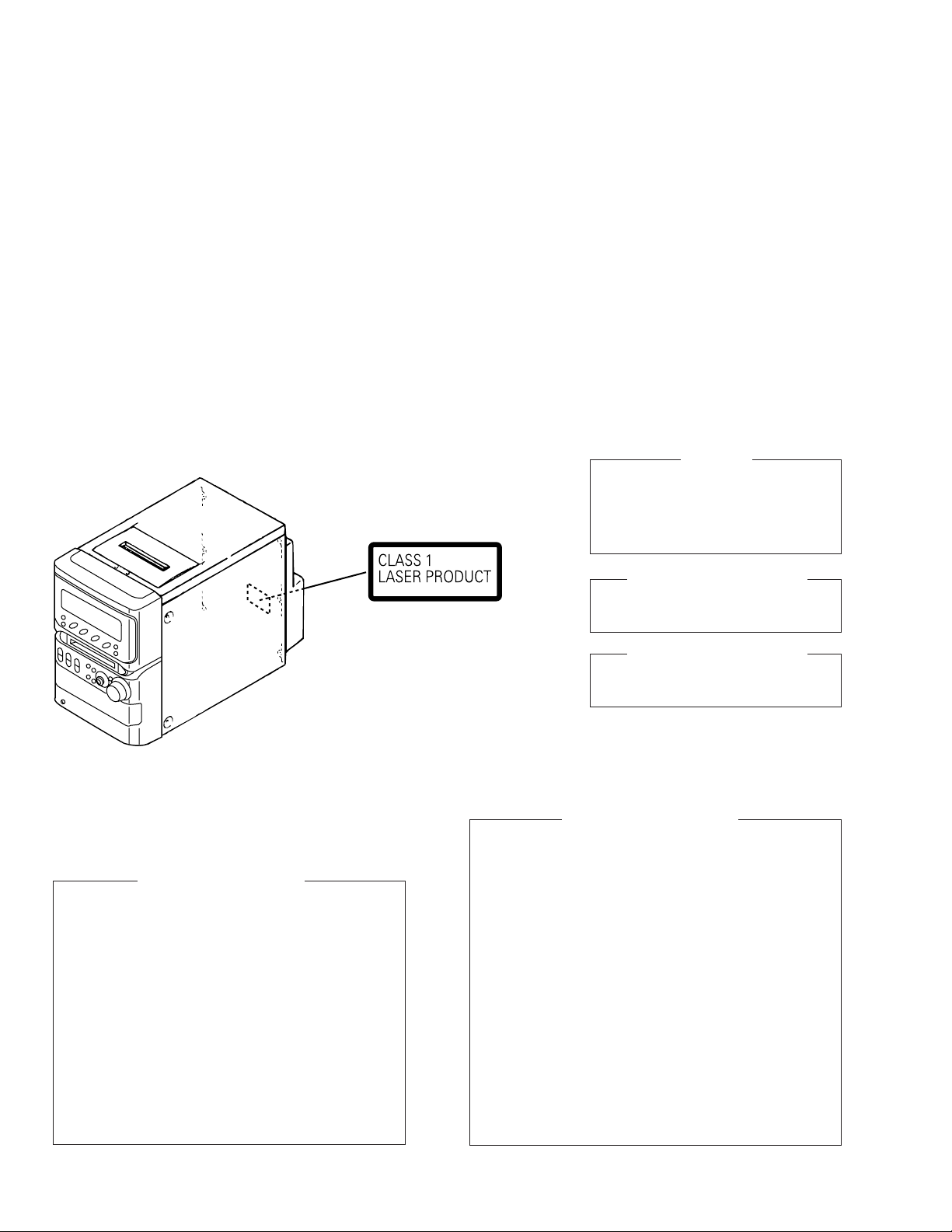

LABEL CHECK

Additional Laser Caution

of CD PLAYER

1.Laser Interlock Mechanism

The position of the switch for detecting loading state is

detected by the system microprocessor, and the design

prevents laser diode oscillation when the switch is

pressed physically.

Thus, the interlock will no longer function if the switch is

released physically and deliberatery.

Laser diode oscillation will continue, if pin 33 of

CXA1782BQ (IC803) on the CD UNIT is connected to

GND, or else the terminals of Q802 are shorted to each

other (fault condition).

2.When the cover is opened, close viewing of the

objective lens with the naked eye will cause exposure

to a Class 1 laser beam.

THIS PIONEER APPARATUS CONTAINS

IMPORTANT

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

OF CD PLAYER

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 760 - 800 nm

LASER DIODE CHARACTERISTICS

OF MD RECORDER

MAXIMUM OUTPUT POWER: 40 mW

WAVELENGTH: 775 - 800 nm

Additional Laser Caution

of MD RECORDER

Control method of the current through a laser diode.

The resistor R166 on the MD MOUNT ASSY (For MD mechanism

assembly) are for the limiting of current through a laser diode.

Control method of the laser output power

The laser pick-up assembly provide the photo-diodes and APC

(Auto Power Control) circuit.

The photo-diode detect output of the laser diode then IC201 control

the APC circuit according to the signal voltage of the photo-diode via

IC101.

Laser Interlock Switch

The loading position detect switch is set to “ LOAD ON ” position,

IC201 get the “ LOAD ” signal, and hand the laser “ LDON ” signal to

APC (Auto Power Control) circuit of the Laser pick-up assembly.

Then a laser diode can be lighted when the “ LOAD ”signal is “

LOAD ON ” position.

2

Page 3

S-C2-LR

5

XR-C2MD

3

4

10

11

13

16

2

1

12

14

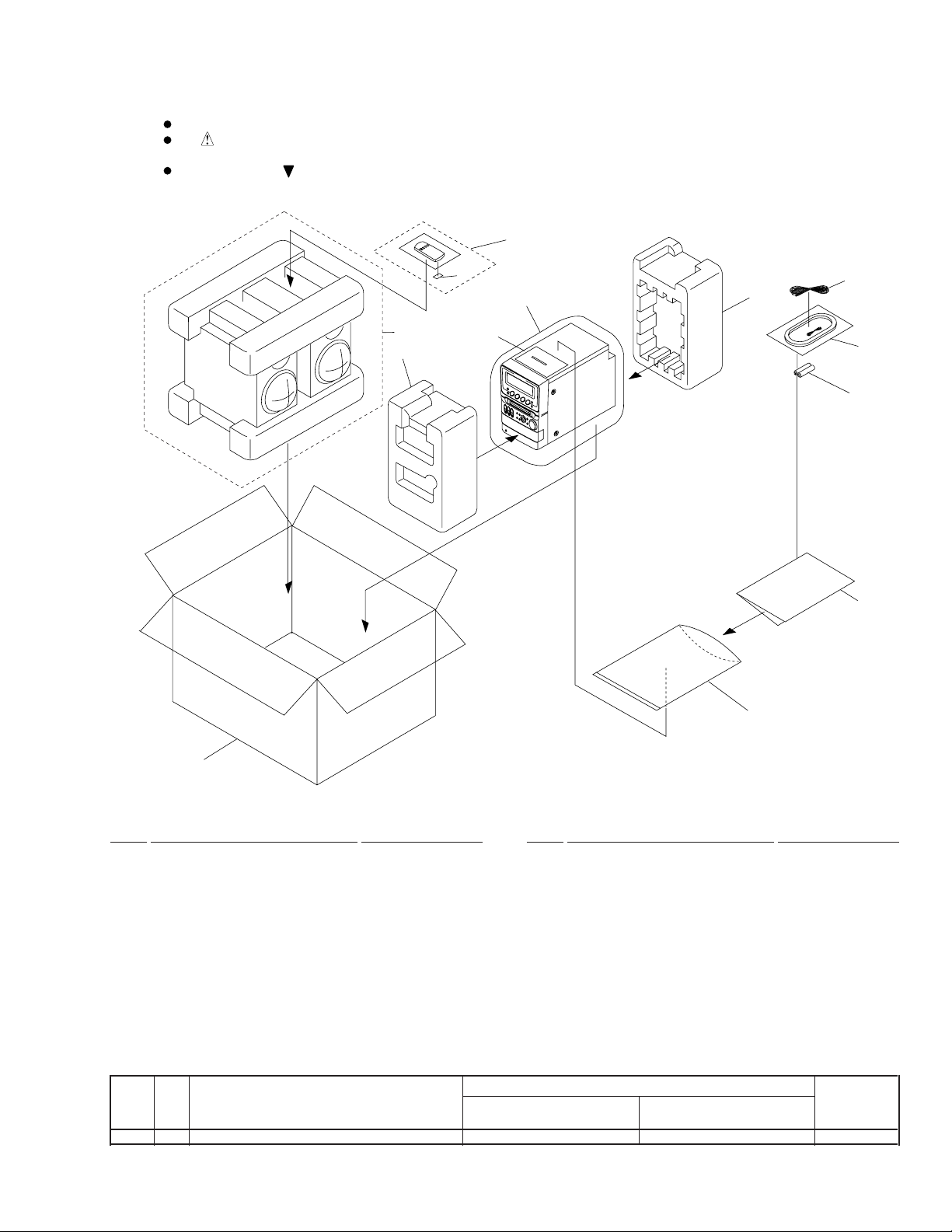

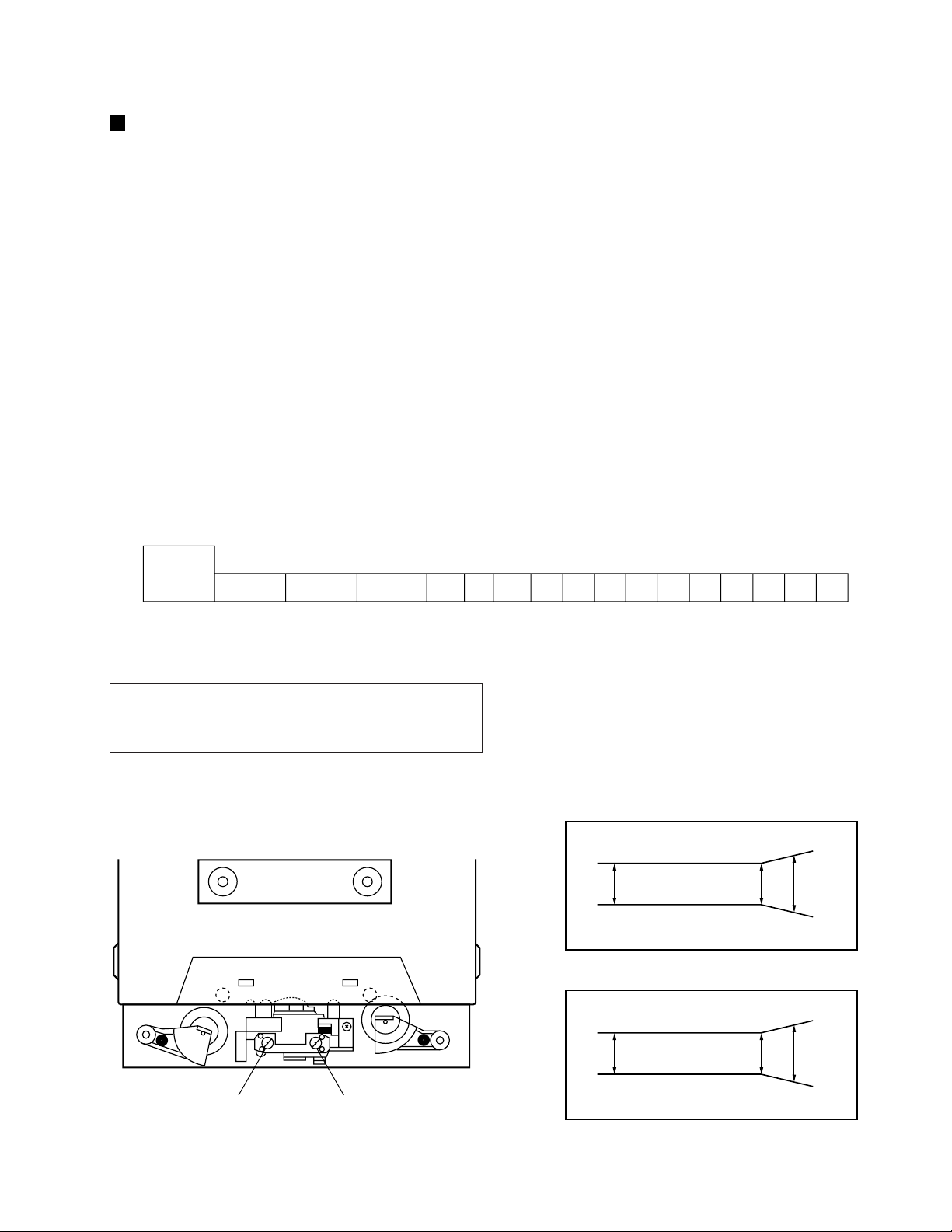

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

2.1 PACKING

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

X-MDX707, XR-C2MD

(1) PACKING PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Styloform F 4707900000

2 Styloform R 4707901000

3 Gift box See Contrast table (2)

4 Operating Instructions 4707920003

(English/Chinese)

5 Mirror Mat 4700915000

6 • • • • •

7 • • • • •

8 • • • • •

9 • • • • •

NSP 10 AA batteries (R6P) VEM-013

11 AM loop antenna 004690500013

12 Remote control unit

(CU-XR043) 0088041001

13 FM T-type antenna 004783500013

NSP 14 Polyethylene Bag AHG7030

15 • • • • •

16 Battery Cover AZA7331

(2) CONTRAST TABLE

X-MDX707/LBWXJ and NLWXJ/HK are constructed the same except for the following :

Part No.

Mark No. Symbol and Description X-MDX707 X-MDX707 Remarks

/LBWXJ /NLWXJ/HK

3 Gift box 4707911003 4707911002

3

Page 4

X-MDX707, XR-C2MD

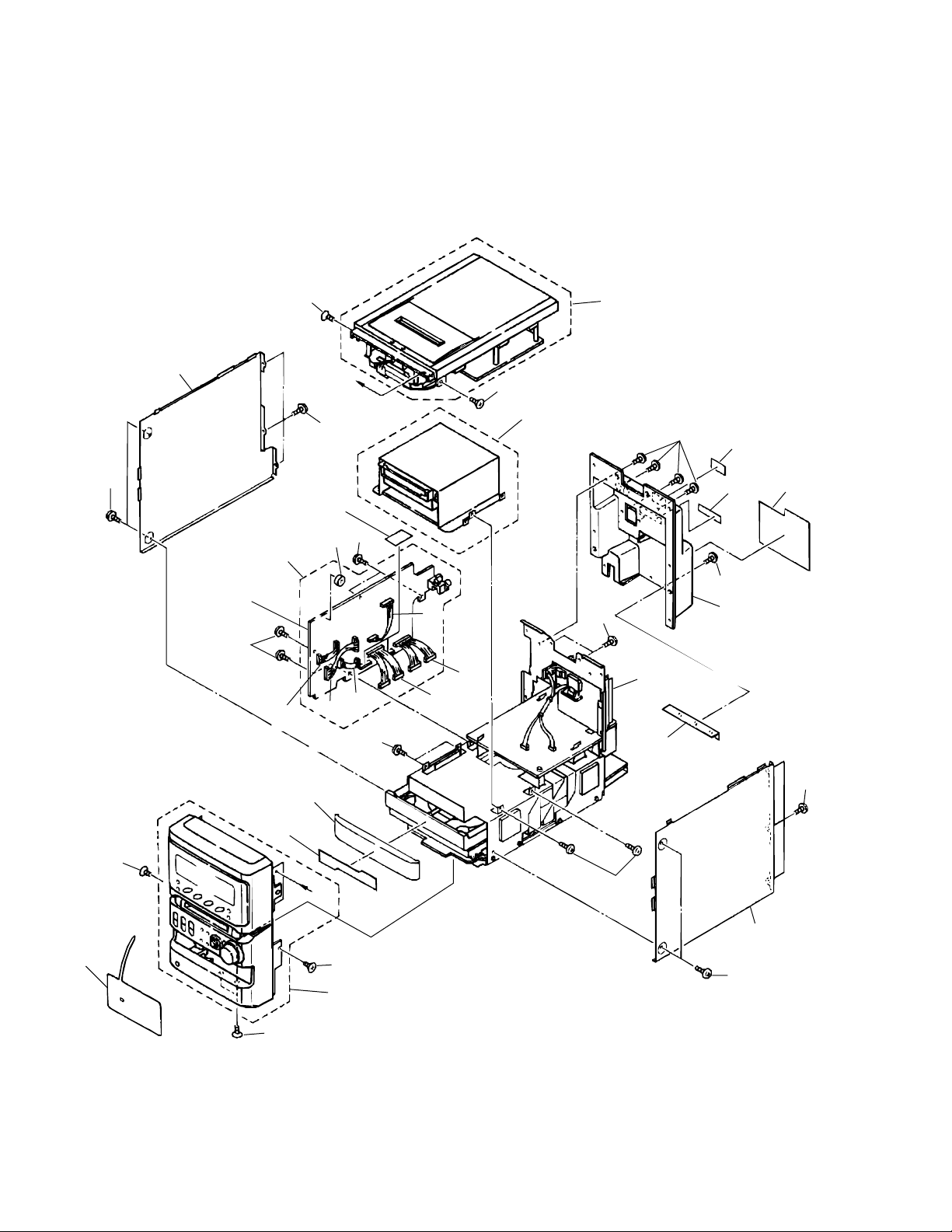

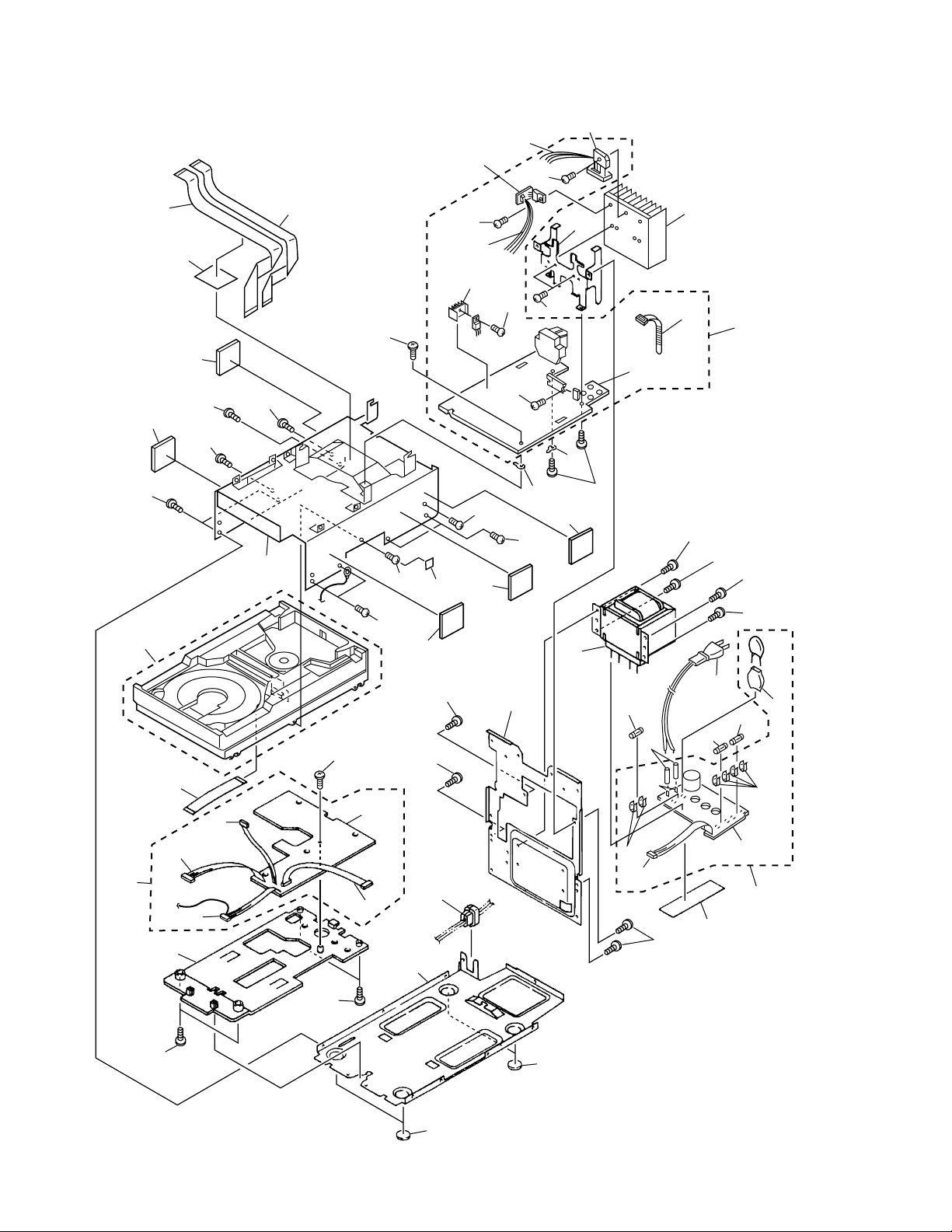

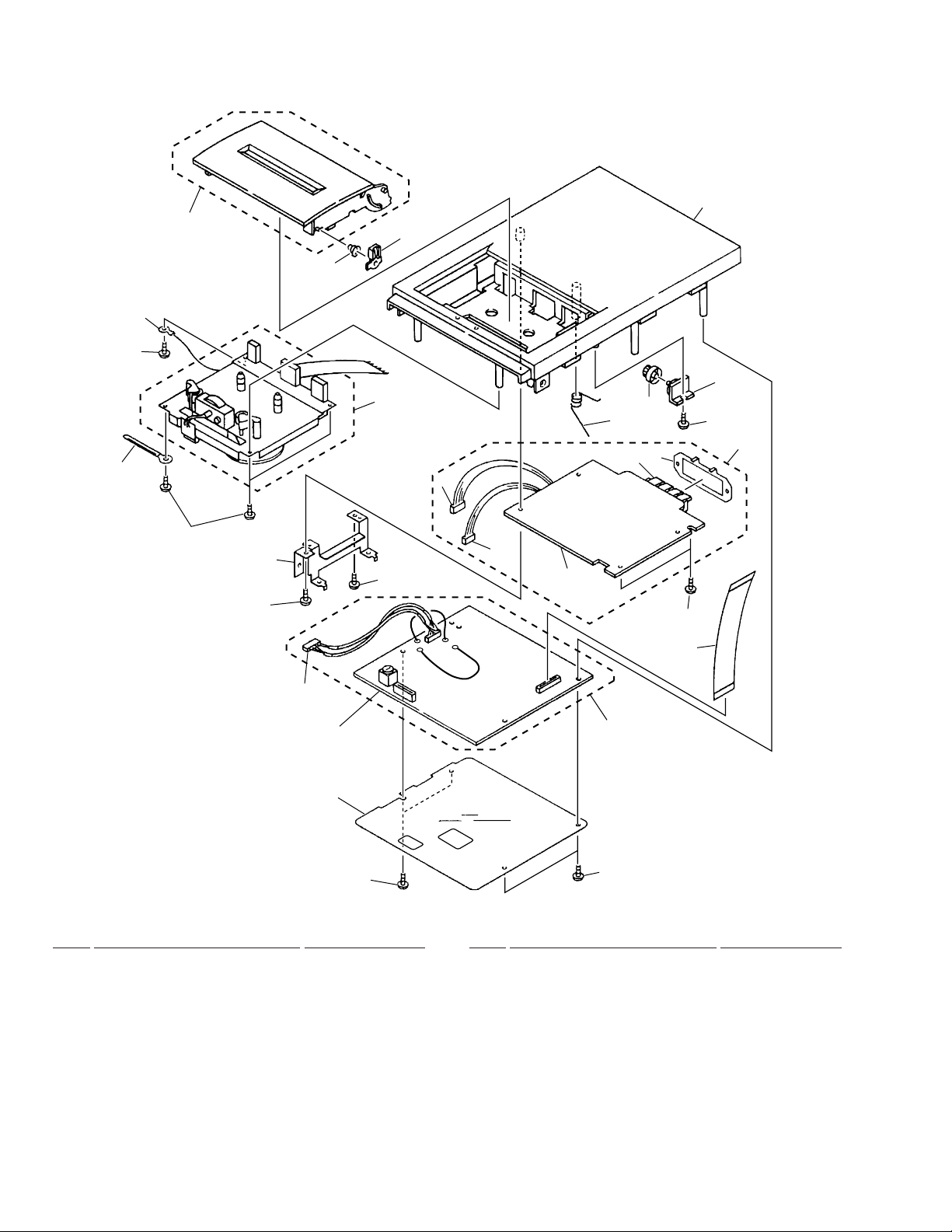

2.2 UNIT ASSY (1/2)

1

4

8

9

CONTROL

PCB

2

15

8

Insulation

Plate

10

10P

7P

16

4P

A

2

15P

14

14P

12

7P

13

2

1

Refer to "2.5 MD UNIT".

11

Refer to "2.4 TOP PANEL ASSY".

2

2

Refer to "2.2 UNIT ASSY (2/2)".

20

18

19

2

3

7

8

17

6

POP Label

1

A

1

Refer to "2.3 FRONT UNIT".

1

2

5

8

4

Page 5

(1) UNIT ASSY (1/2) PARTS LIST

Mark No. Description Part No.

1 Screw CCZ30P060FMC

2 Screw BBZ30P080FZK

3 Rear Panel 4707810001

4 Side Panel L 4707814001

5 Side Panel R 4707815001

X-MDX707, XR-C2MD

NSP 7 Rear Label See Contrast table (2)

6 Tray Panel 4707807001

8 Screw BBT30P080FNI

9 CONTROL Unit 4707006000

10 Speaker Piezo CB13PA 002384700013

11 Wire Connector 14P (CN454) 4707561000

12 Wire Connector 15P (CN455) 4707562000

13 Flat Cable 4P 4707571000

14 Flat Cable 7P 4707573000

15 Wire Connector 7P 4707572000

16 Wire Connector 10P 4707574000

17 CD Label 4701855002

18 ANT Caution Label 4707854002

19 SP Caution Label 4707855002

20 Spacer 4707882000

(2) CONTRAST TABLE

XR-C2MD/LBWXJ and NLWXJ/HK are constructed the same except for the following :

Part No.

Mark No. Symbol and Description XR-C2MD XR-C2MD Remarks

/LBWXJ /NLWXJ/HK

NSP 7 Rear Label 4707850003 4707850002

5

Page 6

X-MDX707, XR-C2MD

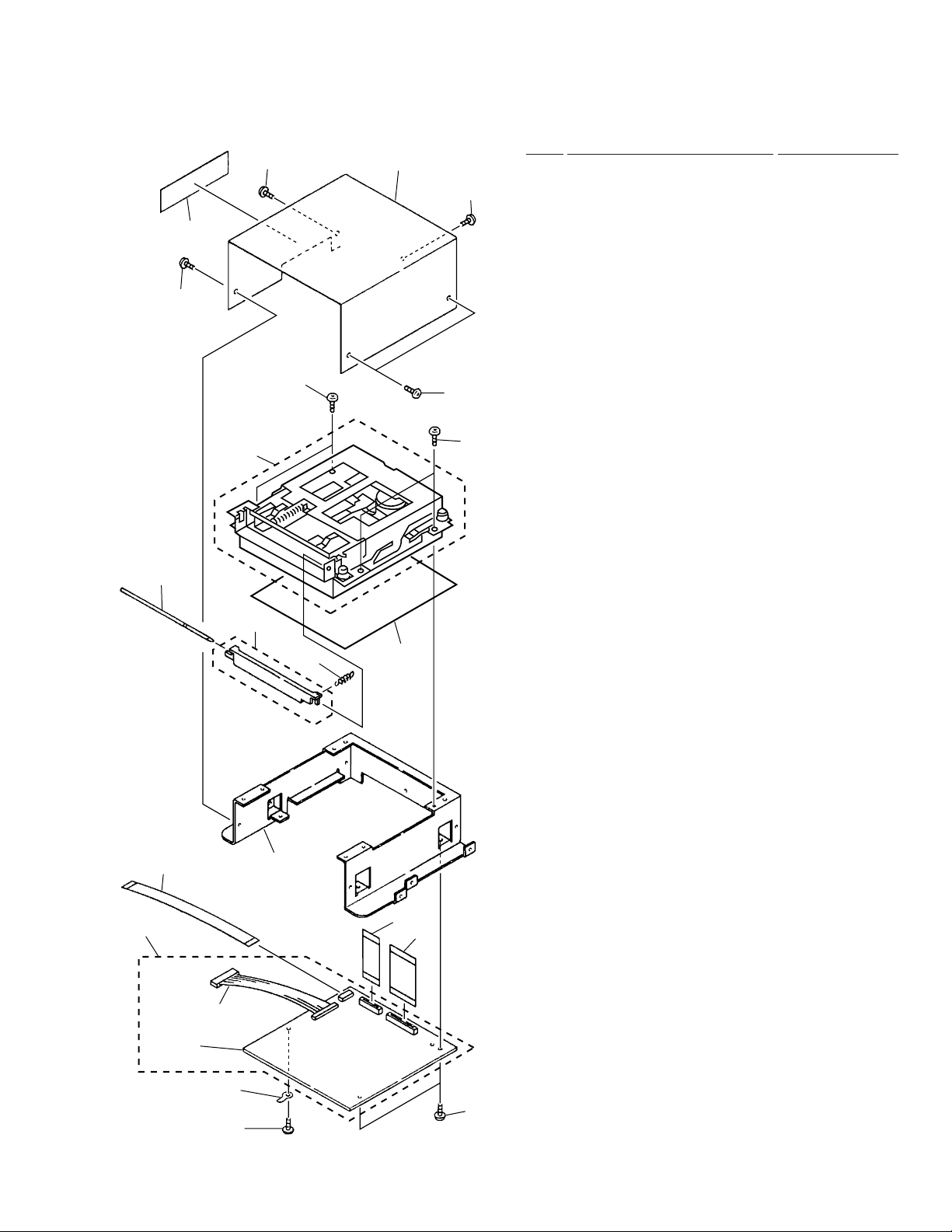

2.3 UNIT ASSY (2/2)

40

19P

Double Face

43

42

43

28

42

Refer to "2.10

CD MECHA".

30

15P

36

28

39

2

42

28

43

38

IC PCB

6

13

5

28

Double

Face

48

14

DI PCB

4P

6

4P

11

10

7

49

4

AMP PCB

6

8

8

7

43

42

21

24

21

24

47

26

29

31

37

33

34

16P

32

2

23

44

20

27

2

16

CD

PCB

4P

35

6P

1

9P

5P

5P

17

22

18

19

46

45

17

PS PCB

15

25

2

41

29

3

3

6

Page 7

X-MDX707, XR-C2MD

(1) UNIT ASSY (2/2) PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Cord Bushing 0064695000

2 Screw BBZ30P080FZK

3 Rubber Foot 4701881000

4 AMP Unit 4707001000

5 Heat Sink 4707720000

26 CD Unit 4707030000

27 PT Screw P2006SK 0972920065

28 Screw BPZ26P100FMC

29 Screw BPZ30P120FMC

30 CD Mecha,CMCF0210 4707150000

6 Screw IPZ30P120FMC

7 Screw BBZ30P080FZK

8 WL030140040B1 0987100600

9 • • • • •

10 H.S Bracket 4701273100

11 Heat Sink 4701720100

12 • • • • •

13 Wire Connector 4P (WC401) 4701576000

14 Wire Connector 4P (WC403) 4701576000

15 PS Unit See Contrast table (2)

16 Pin Terminal 0034473000

17 Fuse Holder,TP00351- 0045522000

18 AC Cord With Plug See Contrast table (2)

19 Cover,Spark Killer 0064644000

20 PT6AWG03T20 0950103020

21 Screw BSZ40P060FMC

22 Wire Connector 5P 4701565000

23 Rear Chassis 4701817000

24 Screw FBT40P060FZK

25 Himelon 4701898100

44 Fuse (F601) See Contrast table (2)

45 Fuse (F602/T5A) 0045049041

46 Fuse (F603/T2.5A) 0045023041

47 Power Trans (T601) See Contrast table (2)

NSP 49 Binder (BK-1) ZCA-BK1

31 CD Mecha Chassis 4701270000

32 Wire Connector 4P (CN805) 4707563000

33 Wire Connector 9P (CN806) 4707564000

34 Wire Connector 5P (CN807) 4701568000

35 Wire Connector 6P (CN804) 4701571000

36 CD Mecha Cover 4701819100

37 FFC 16P (CD-CD Mecha) 4701553000

38 Himelon 4701895000

39 FFC 15P (CD-CONT) 4701552000

40 FFC 19P (CD-CONTROL) 4701554000

41 Bottom Chassis 4701814000

42 ST Screw B2605SBK 0972726053

43 Cushion 4701897000

48 Screw BBZ30P080FNC

50 Fuse Label See Contrast table (2)

51 Fuse Label (T2.5A/L250V) 0074005174

52 Fuse Label (T5A/L250V) 0074005175

(2) CONTRAST TABLE

XR-C2MD/LBWXJ and NLWXJ/HK are constructed the same except for the following :

Part No.

Mark No. Symbol and Description XR-C2MD XR-C2MD Remarks

/LBWXJ /NLWXJ/HK

15 PS Unit 4707014000 4707012000

18 AC Cord With Plug 004701800005 004744300003

44 Fuse (F601/T1.6A) 0045017041 Not used

44 Fuse (F601/T800mA) Not used 0045013041

47 Power Trans (T601) (110V) 001950000005 Not used

47 Power Trans (T601) (220V) Not used 001947100005

50 Fuse Label (T1.6A/L250V) 0074005165 Not used

50 Fuse Label (T800mA/L250V) Not used 0074005176

7

Page 8

X-MDX707, XR-C2MD

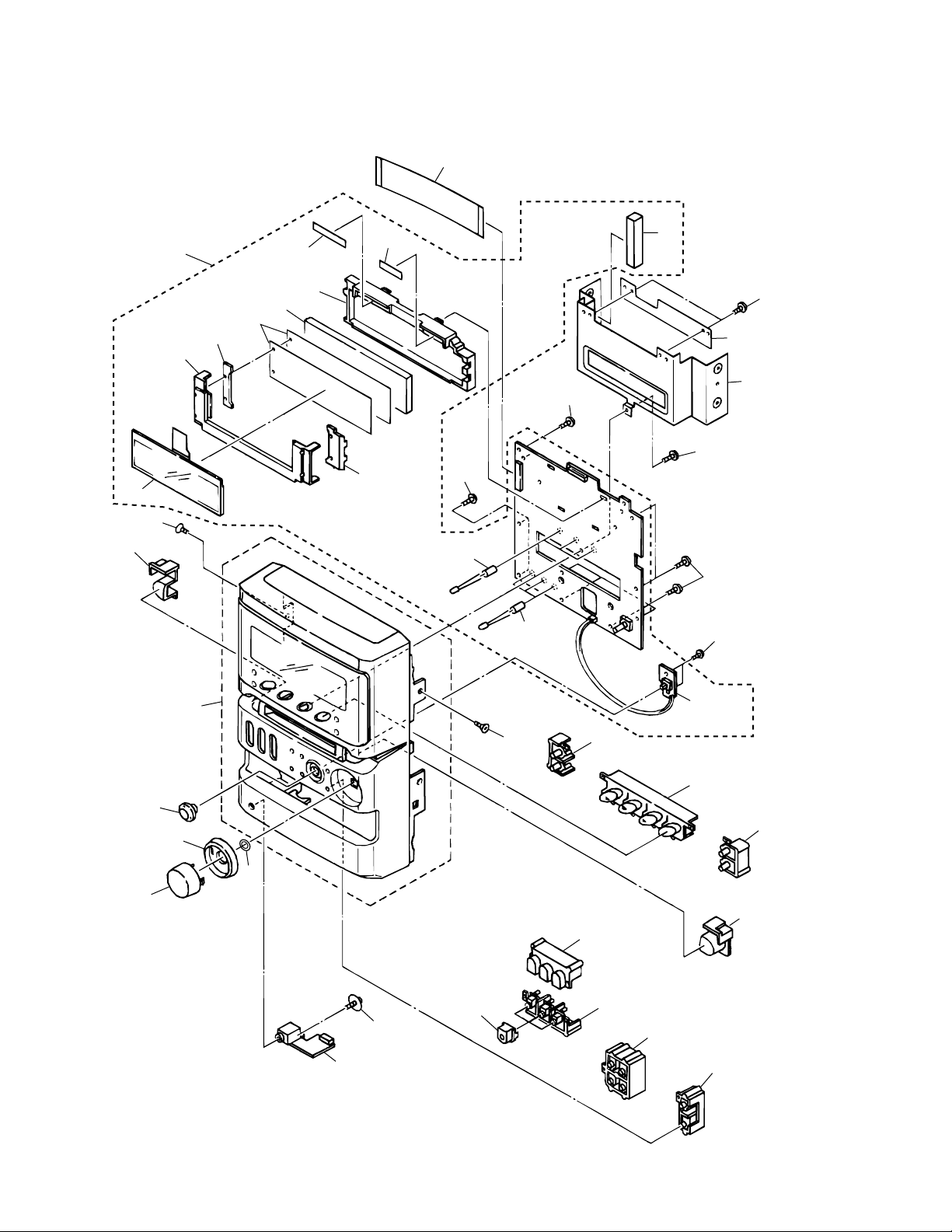

2.4 FRONT UNIT

1

30P

21

38

35

33

10

4

5

12

7

6

11

36

8

36

9

9

23

36

24

34

36

36

37

20

14

26

13

39

25

SW PCB

35

31

3

17

15

16

22

18

19

27

28

8

Page 9

X-MDX707, XR-C2MD

• FRONT UNIT PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 FFC 30P (FRONT-CONT) 4707550000

2 • • • • •

3 Screw 0979914200

4 LCD Holder 4707270000

5 Diffusion Plate 4707274000

NSP 25 HP PCB

21 Power Knob 4707863001

22 MD Eject Knob 4707864001

23 Cushion 4701896000

24 Shield Plate 4707816000

6 LCD Lens 4707271000

7 Reflector L 4707877000

8 Reflector R 4707878000

9 LED Spacer 4707880000

NSP 10 Double Face A 4701887000

NSP 11 Double Face B 4701888000

12 Diffusion Sheet 4707890000

13 Front Panel Set 4707800001

14 Enter Knob 4707879001

15 Function Knob Set 4707859001

16 Stop Knob 4707862001

17 AUX Knob 4707861001

18 CD Eject Knob 4707868001

19 CD Select Knob 4707869001

20 Volume Knob 4707865001

26 Volume Knob Ring 4707876001

27 Tact Knob A 4707866001

28 Tact Knob B 4707867001

29 • • • • •

30 • • • • •

31 Knob Cover 4707870001

32 • • • • •

33 FRONT Unit 4707035000

34 Front Chassis 4707812000

35 Screw CCZ30P060FMC

36 Screw BPZ26P100FMC

37 Screw TP2x6-SBK-C BPZ20P060FZK

38 LCD PANEL LMG172C1-F 004044100021

39 Stop Ring 4707401000

9

Page 10

X-MDX707, XR-C2MD

2.5 TOP PANEL ASSY

19

15

18

14

16

10

9

10

20

10

9P

6P

8

DECK PCB

21

13

Refer to "2.6 DECK

MECHA (1/2) FRONT"

AND

"2.7 DECK

MECHA

(2/2) REAR".

10

6

12

11

17

6P

5P

5

TUNER

PCB

422

7

10

10

3

2

22P

1

1

• TOP PANEL ASSY PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Screw BBZ30P080FZK

2 FFC 22P (DECK-CONT) 4701556000

3 TUNER Unit 4707021000

4 Connector Plate SP 1600779000

5 Wire Connector 5P 4701569000

6 Wire Connector 6P 4701570000

7 DECK Unit 4707015000

8 Wire Connector 6P 4701563000

9 Lead Wire Clamper 0065375000

10 Screw BPZ30P120FMC

10

11 Gear 2401872000

12 Gear Holder 2401873000

13 Mecha Set,CRH34-07 4700100000

14 Lock Lever 4700281000

15 Lug Washer W/Wire 4701561000

16 COM Spring 4700400000

17 Up Case Spring 4701401000

18 Top Panel 4707803001

19 Up Case Set 4707804001

20 Deck Bracket 4701818000

21 Insulation Sheet 4701891000

22 Antenna Terminal 4P 003402900013

Page 11

X-MDX707, XR-C2MD

2.6 MD UNIT

Himelon

1

Refer to

"2.8 MD MECHA (1/2)

LOADING ASSY".

• MD UNIT PARTS LIST

1

1

2

4

1

1

1

Mark No. Description Part No.

1 ST Screw B2605SBK 0972726053

2 MD Mecha,KMK-260AAB GXX1155

3 MD Mecha Chassis 4707813000

4 MD Mecha Chassis 4701827000

5 MD Door Set 4750308004

6 Shaft 4750306000

7 EXT Spring 4750307000

8 WL030140040B1 0987100600

9 Wire Connector 11P 4701572000

10 FFC 11P (MD-CONT) 4701551000

11 FFC 19P (MD-MD Mecha) 4701555000

12 FFC 19P (MD-MD Mecha) 4701559000

13 Shield Plate 4750735000

14 MD Unit 4707025000

* GXX1155 is MD mechanism for service by which resistance

(R123, R213, R142) is removed from KMK-260AAB.

14

6

10

11P

5

7

3

15P

11P

9

13

12

11

19P

MD PCB

8

1

1

11

Page 12

X-MDX707, XR-C2MD

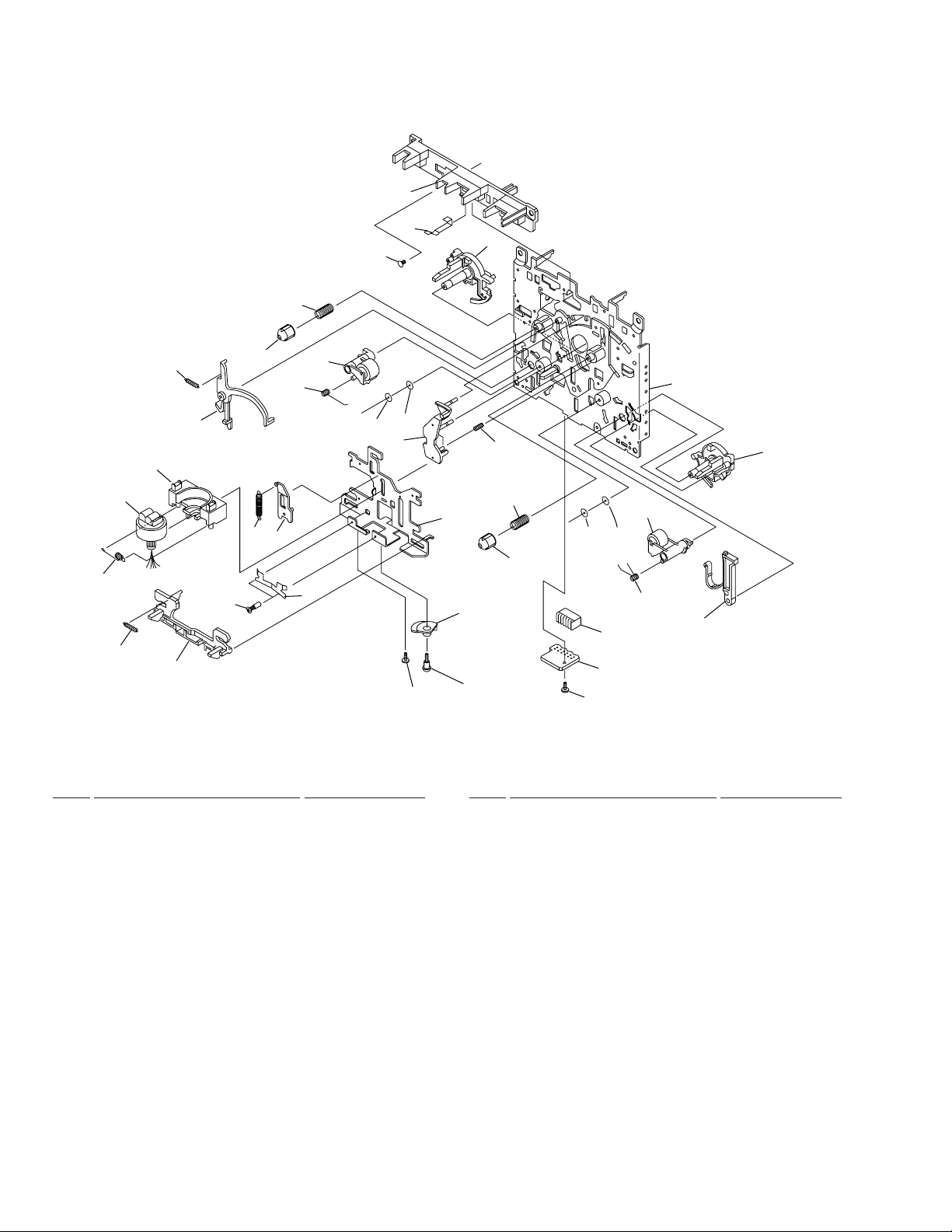

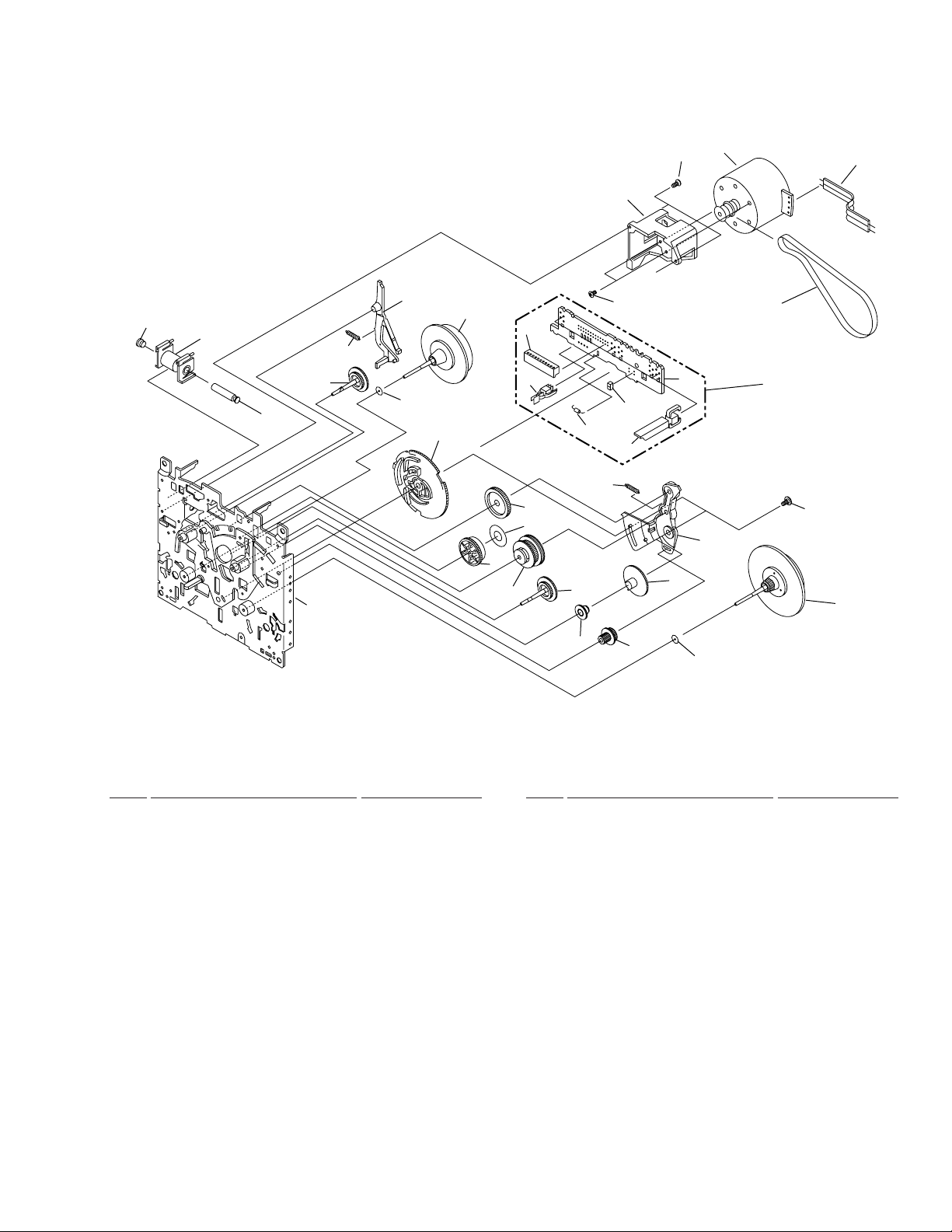

2.7 DECK MECHA (1/2) FRONT

18

21

27

17

34

23

24

13

2

1

3

10

25

30

12

29

36

38

11

5

4

31

16

15

22

26

7

37

10

6

32

33

9

35

28

8

20

19

14

• DECK MECHA (1/2) FRONT PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

12

1 Assy Holder Head 330934098

2 Frame Head 332193023

3 Lever Head 332593015

4 Spring Azimuth 161604032

5 Assy Lever Assist 330934055

6 Gear Arm Head 222394020

7 Chassis Head B 331123030

8 Eject Lock 332394024

9 Assy Arm Pinch R 330934060

10 Cap Reel 182283231

11 Arm UD 332393012

12 Assy Arm Pinch L 330934059

13 Arm Brake 332393014

14 Frame B 332113019

15 Assy Chassis 330933056

16 Frame C 332112020

17 Spring Cassette 331604031

18 Frame D 332112021

19 P.C.B Head 330704061

20 Housing S5BEH

NSP 31 Screw GSL20A2008

21 Spring 010804535

22 Spring 010814483

23 Spring 010814493

24 Spring 010804482

25 Spring 010804489

26 Spring 010814492

27 Spring 010804479

28 Spring 010824485

29 Spring 010824486

30 Screw 033004056

32 Screw 033004043

33 Screw GSE10A2004

34 Screw GSD20A2005

35 Washer GWN13X050040

36 Washer GWN13X060040

37 Washer GWN16X040050

38 Washer GWN15S040050

Page 13

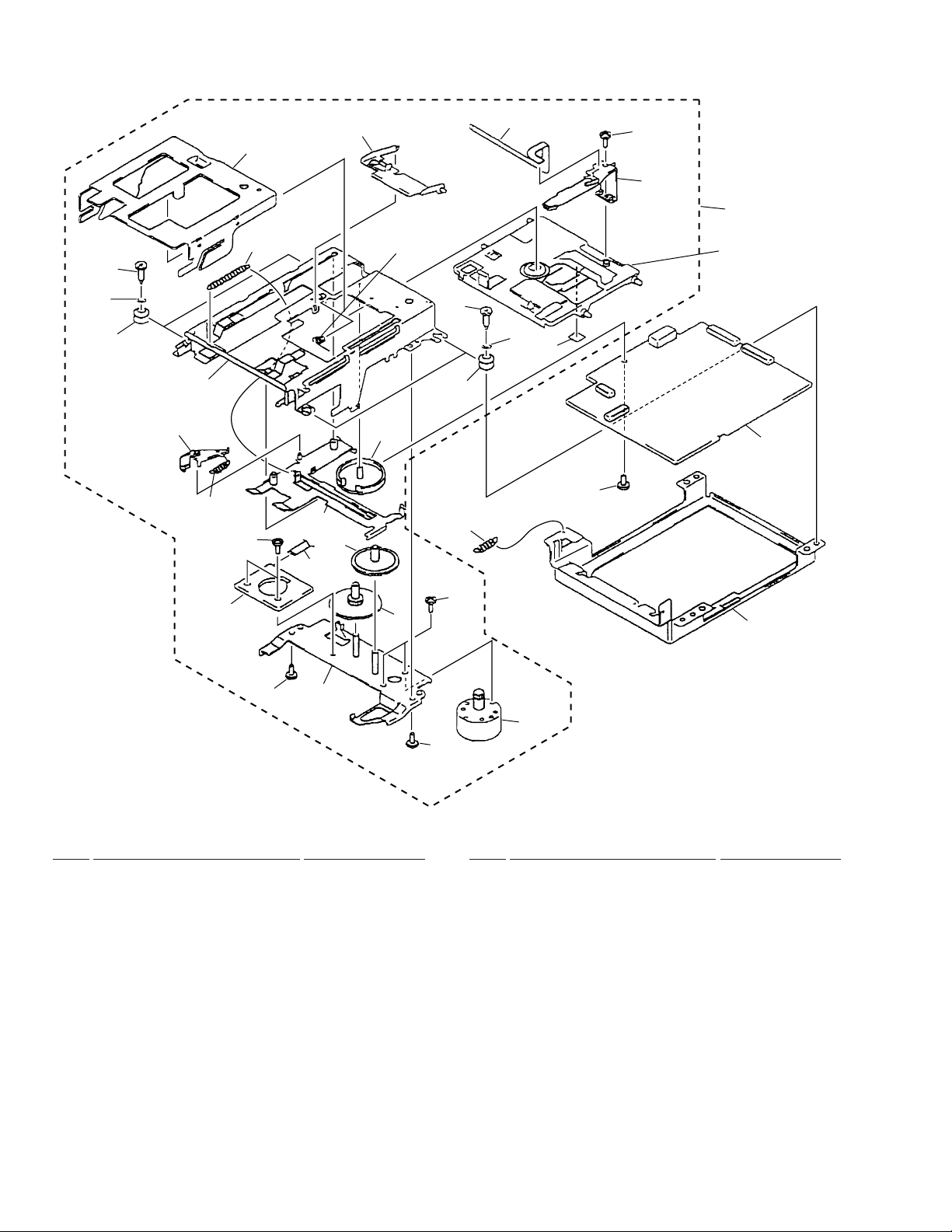

2.8 DECK MECHA (2/2) REAR

17

X-MDX707, XR-C2MD

18

30

19

5

1

2

28

4

33

3

ASSY CHASSIS

6

22

26

7

8

27

9

10

11

32

21

24

25

23

29

14

12

13

33

4

16

20

31

15

• DECK MECHA (2/2) REAR PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 K Plunger 033194259

2 Assy Coil 330934051

3 Plunger 033004338

4 Gear Reel 332224009

5 Arm Trigger 332683013

6 Assy Flywheel L 330934050

7 Gear Cam 332212010

8 Gear IDL 332224008

9 Gear REF 332224164

10 Assy Clutch 330933045

11 Gear P 332224002

12 Gear A 332224001

13 Gear FR 332224003

14 Arm FR 332393011

15 Assy Flywheel R 330934048

16 Belt 020844146

17 Bracket MM 332193025

18 Assy Motor 330934104

19 Wire 160724055

20 Assy P.C.B 330933147

NSP 22 9P Housing HBRK9R - 2

21 P.C.Board 330703035

23 Switch (Leaf) MTS10041MVLO

24 Photo Sensor SG105BC

25 Resistor ERDS2TJ681

26 Mode Switch MSW1722NCV

27 Refrector 330004140

28 Spring 010804480

29 Spring 010804543

30 Screw GSD20A2005

31 Screw 033004344

32 Screw GSP11A2605

33 Washer GWP18X060050

13

Page 14

X-MDX707, XR-C2MD

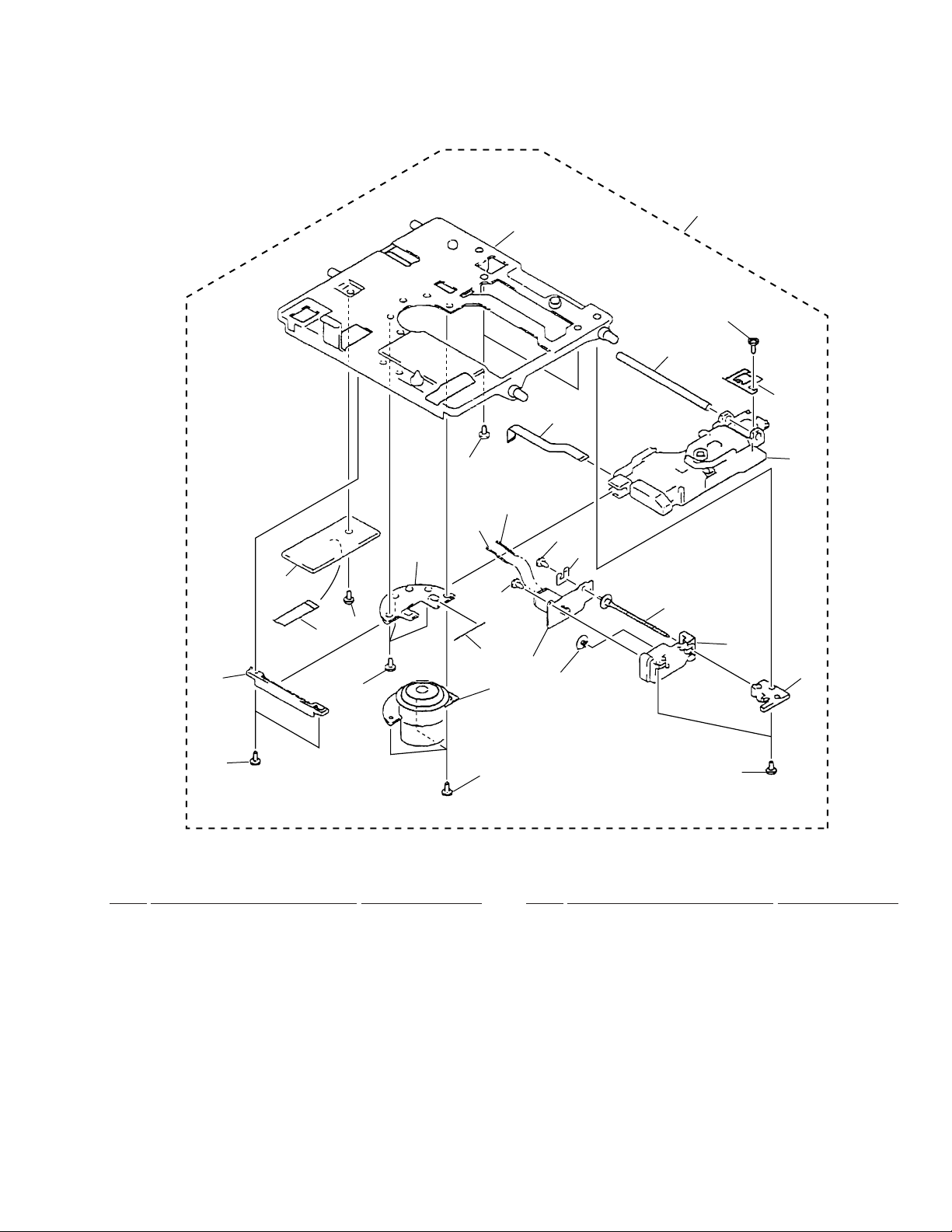

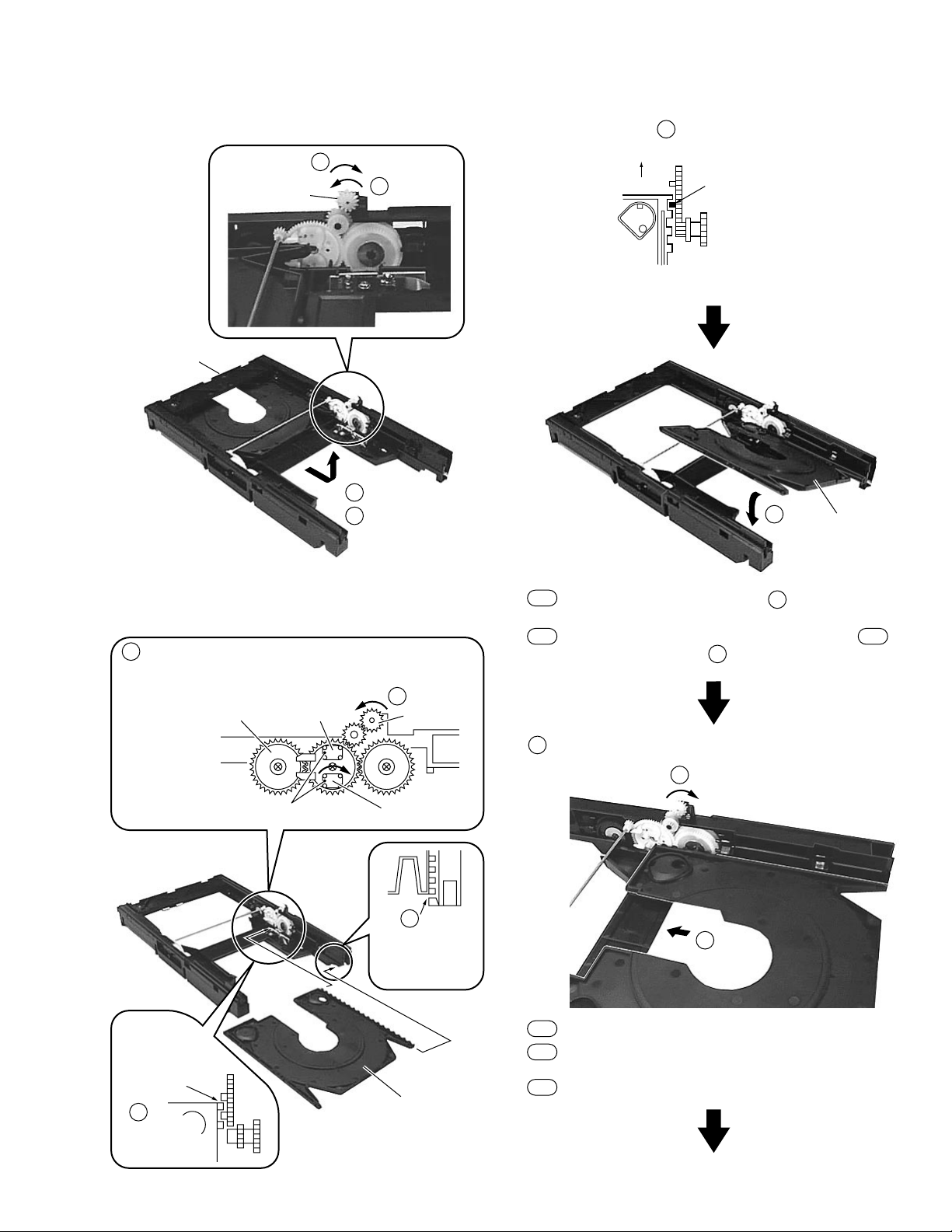

2.10 MD MECHA (1/2) LOADING ASSY

12

13

11

14

16

10

9

8

32

15

17

13

11

18

7

6

4

26

19

12

22

24

20

21

33

Refer to

"2.9 MD MECHA

(2/2) DECK

MECHA ASSY".

23

3

2

1

5

31

27

30

2

• MD MECHA (1/2) LOADING ASSY PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 Motor Plate Assy X-2646-247-1

2 Screw +P2.6×4.5 TYPE3 7-627-854-28

3 L-SW Mount Board 1-668-261-11

4 Wire Flat Type (6p) 1-783-386-11

5 Gear (Relay B) 2-646-555-02

6 Gear (Relay A) 2-646-554-01

7 Slot Frame Assy X-2646-249-2

8 Spring (Slot Arm) 2-646-563-01

9 Arm Slot 2-646-556-01

NSP 10 Road Frame Assy X-2646-248-2

11 Insulator 2-646-548-01

12 Screw 7-688-002-11

13 Screw Step 4-628-167-01

NSP 14 Frame Slide 2-646-557-01

15 Arm Head 2-646-559-01

NSP 22 Sheet Double-Fase 2-646-549-02

NSP 23 MD MOUNT A-4917-020-A

NSP 27 Flame Main 2-646-547-02

NSP 33 Loading Assy A-4912-117-A

19 PWB Head Flexible 1-669-181-11

20 Grip +P1.7×2.5TYPE2 2-627-529-01

21 Over Write Head 1-550-518-12

24 Screw Toothed Lock 2-643-228-01

25 • • • • •

26 Spring (Door Arm) Tension 2-646-545-01

28 • • • • •

29 • • • • •

30 Loading Motor Assy X-2626-328-1

31 Screw +P1.7×1.8TYP.3 7-627-852-38

32 Screw +P2×3 TYP.3 7-627-553-37

14

16 Spring Tension Coil 2-646-562-01

(Slot Frame)

17 Spring SP Tension 2-646-561-01

(Arm Head)

18 Cam Mode 2-646-560-01

Page 15

2.11 MD MECHA (2/2) DECK MECHA ASSY

6

X-MDX707, XR-C2MD

23

12

11

13

8

1

9

10

7

5

4

3

2

1

4

15

25

19

18

15

14

20

21

16

17

1

24

22

• MD MECHA (2/2) DECK MECHA ASSY PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Grip +P1.4×3.5TYPE3 2-627-404-01

2 Guide Sub 2-646-453-01

3 Wire Flat Type (7P) 1-783-387-11

4 Screw+P1.4×1.8TYPE3 7-627-850-79

5 D-SW MOUNT BOARD 1-668-262-11

16 SL Motor Assy X-2626-329-1

17 Gear (MD) 2-646-571-01

18 Screw +P1.7×4 TYPE3 7-627-852-18

19 SP Motor Assy X-2626-327-1

20 Lead Screw Assy X-2626-330-1

NSP 6 Shassis Mechanical 2-646-575-01

7 Bracket SP Motor 2-646-566-01

8 PWB OP Flexible 1-669-180-11

NSP 9 Wire SL Motor Lead 1-783-318-11

NSP 10 Wire SL Motor Lead 1-783-318-21

11 Shaft Guide 2-646-452-01

12 Grip +P1.4×1.4TYPE2 2-627-530-01

13 Rack (Inserter) 4-963-914-02

14 Plate Pre Road 2-646-567-01

15 Screw (1.2×3.3) 2-627-431-01

21 Lead Holder Assy X-2626-331-1

22 Holder (B) Lead 2-646-573-01

NSP 23 Deck Mecha Assy A-4912-118-A

24 Devise, Mini Disc KMS-260A

25 Spring SP Tension 2-646-564-01

15

Page 16

X-MDX707, XR-C2MD

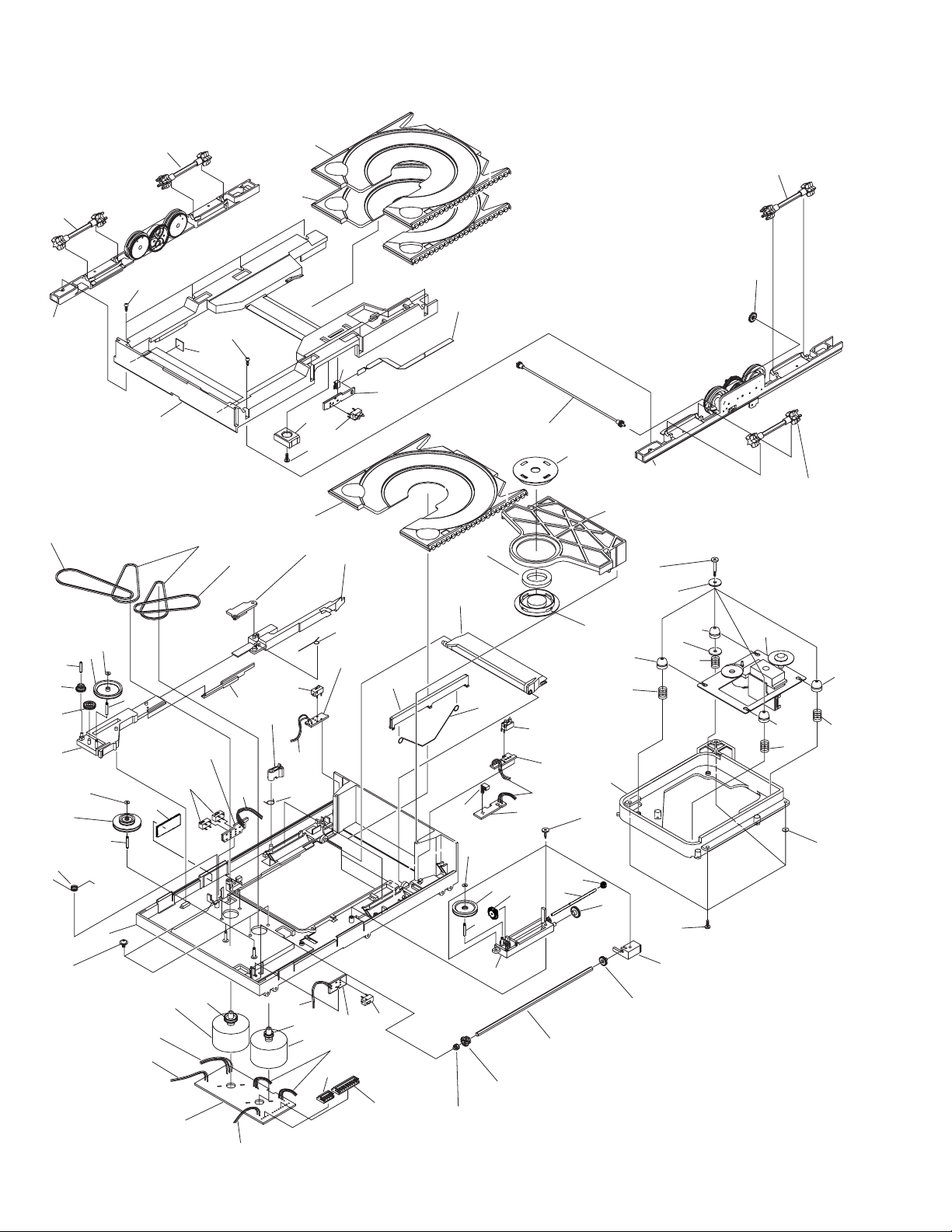

2.12 CD MECHA

9

9

6

9

47

39

25

26

22

3

69

67

18

71

33

71

66

73

57

73

41

2

40

39

61

53

23

58

37

66

53

65

1

49

52(3/7)

48

24

50

80

51

54

21

38

52(2/7)

52(1/7)

29

55

27

71

31

66

36

17

52(6/7)

16

5

54

52(7/7)

59

68

32

15

72

28

30

42

14

45

43

75

4

74

43

79

46

78

8

9

44

43

43

46

45

70

16

77

58

61

63

52(5/7)

35

60

60

34

63

59

56

52(4/7)

62

53

11

20

19

12

10

13

Page 17

X-MDX707, XR-C2MD

• CD MECHA PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Chassis 45-210-2317

2 Drawer 45-264-2004

3 Assy Holder L 45-093-4088

4 Assy Holder R3 45-264-3278

5 Assy Gear Drive 45-093-4075

41 Cushion 45-063-4136

42 Frame S 45-211-3072

43 Rubber Cushion SO 45-063-4072

44 Pick-up Unit KSM213CCM

45 Spring 01-081-4561

6 Assy Carriage 100 45-093-4189

7 • • • • •

8 Bevel Gear 4 45-222-4214

9 Assy Gear Star 45-093-4084

10 Shaft 45-300-4018

11 Cap 45-262-4019

12 Gear Spring 45-222-4021

13 Bevel Gear 1 45-222-4059

14 Gear Idler 1 45-222-4026

15 Gear Idler 3 45-222-4067

16 Bevel Gear 3 45-222-4061

17 Pulley C 45-222-4058

18 Pulley B 45-229-4053

19 Holder 2 45-219-4062

20 Holder 1 45-219-3055

21 Slider 1 45-259-2031

22 Slider 2 45-259-3066

23 Arm Stopper A2 45-239-4279

24 Arm Stopper B 45-239-4065

25 Gear Idler A 45-222-4049

26 Gear Idler C 45-222-4051

27 Lever 45-259-3008

28 Clamper A 45-229-3024

29 Lifter 45-259-3025

30 Arm 45-239-1037

31 Magnet 36-067-4928

32 Clamper B 45-229-3069

33 Pulley A 45-222-4052

34 Pulley Motor 23-226-4031

35 Pulley Motor 23-226-4096

46 Spring 01-081-4562

47 Assy Carriage 200 45-093-4190

48 Assy Carriage 300 45-093-4191

49 Plate E 45-219-4107

50 Spacer SW 45-219-4127

51 Connector 04FM-1.0SP

52 PC Board 45-070-3074

53 Switch MPU10101MMB0

54 Switch MPU20273BLB0

55 Connector 04FM-1.0ST

56 Connector S4BEH

57 Card Wire 45-072-4077

58 Wire 45-070-4080

59 Wire 45-072-4078

60 Wire 45-070-4081

61 Wire 45-072-4079

62 Connector S9BEH

63 Motor RF500TB14415

64 • • • • •

65 Rubber Cushion 45-063-4115

66 Shaft 03-300-4404

67 Shaft 03-300-4403

68 Shaft 03-300-4409

69 Spring 01-082-4577

70 Washer GWP23X055025

71 Washer GWP15X045025S

72 Screw GSL20A2010

73 Screw GSL10B2006

74 Washer GSN31X120050

75 Screw 03-300-4366

36 Spring 01-000-4541

37 Spring 01-082-4558

38 Spring 01-082-4559

39 Belt 02-083-4157

40 Belt 02-083-4152

76 • • • • •

77 Screw GSP14A2604

78 Screw GSL20A2610

79 Washer 03-000-4427

80 Screw GSL15A2005

17

Page 18

1

23

X-MDX707, XR-C2MD

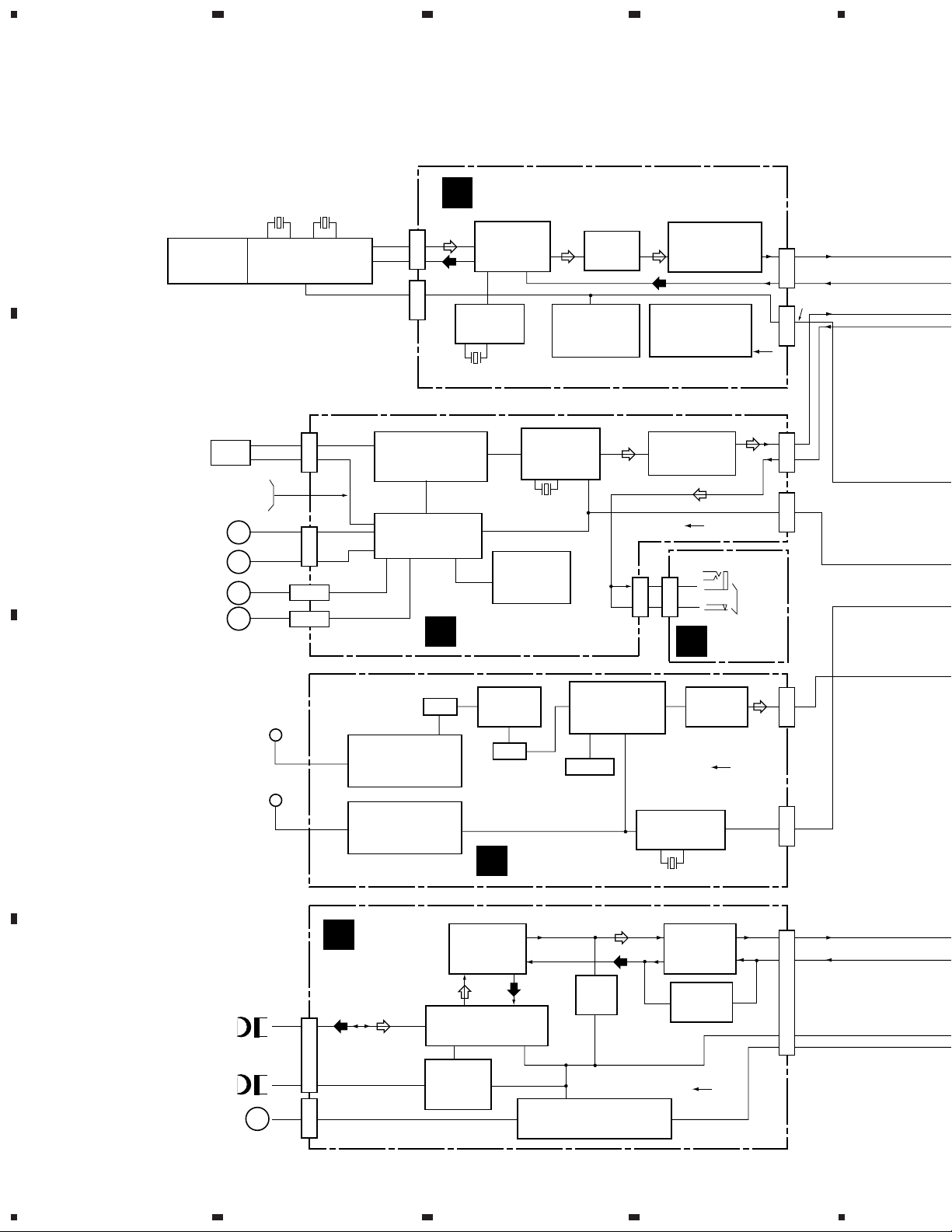

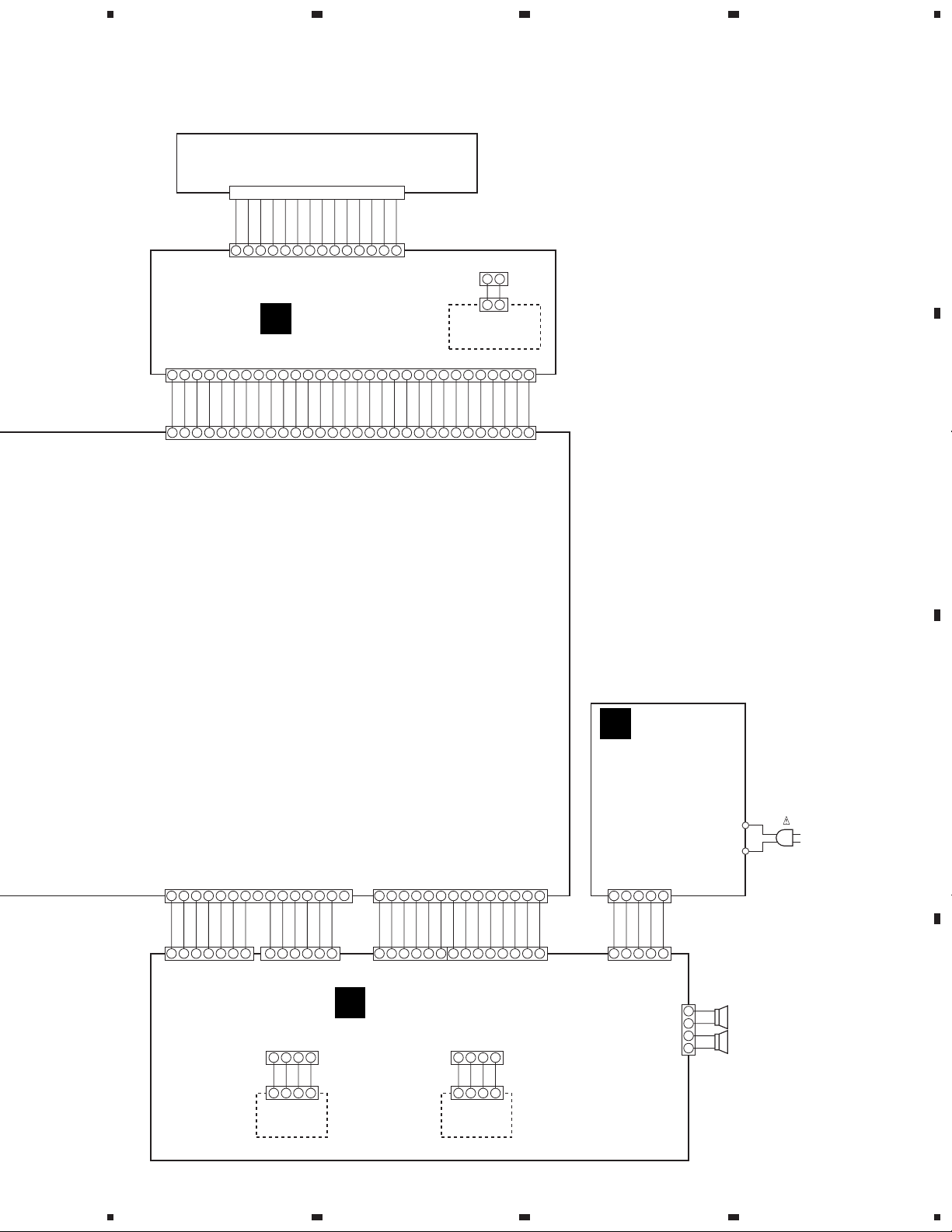

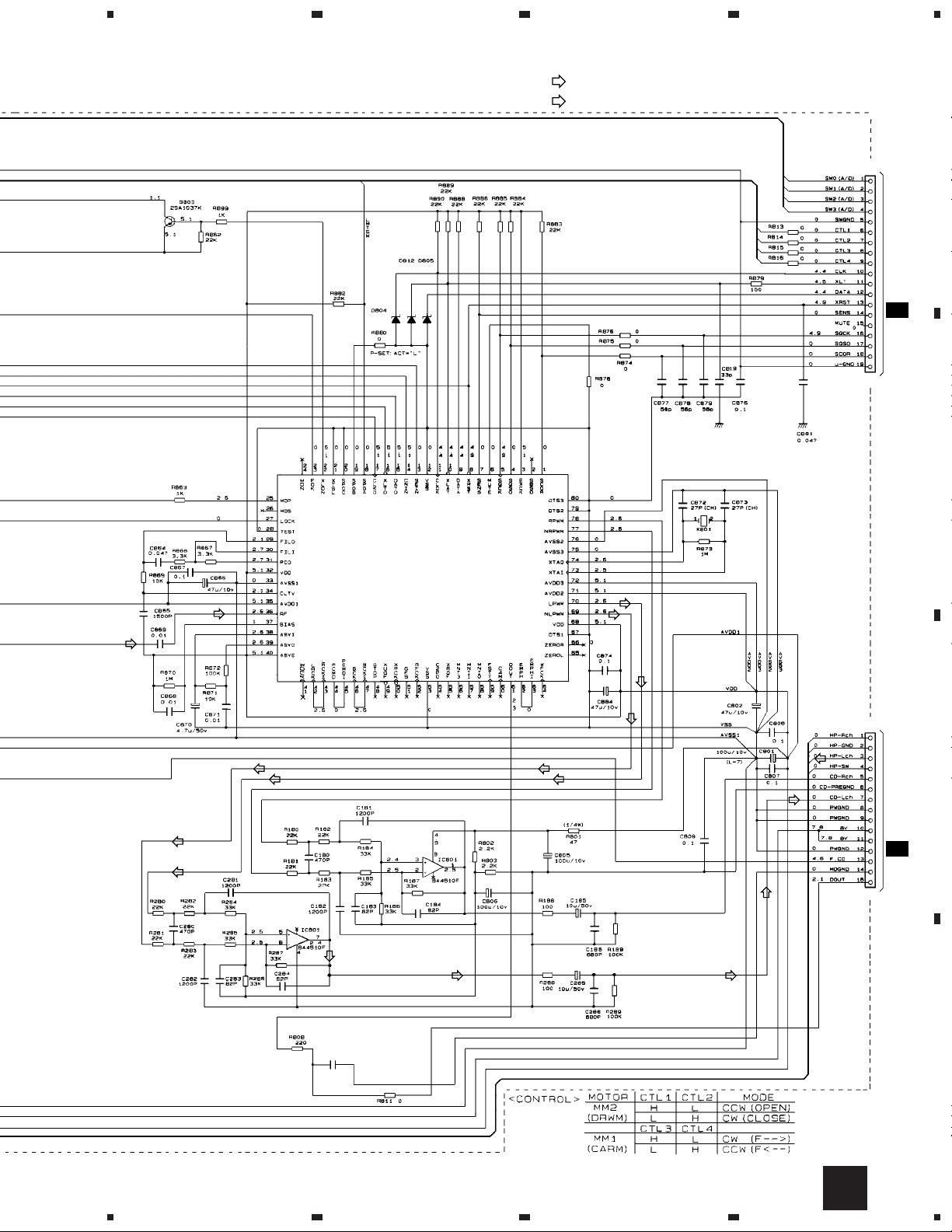

3.BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

4

• MD MECHA

MD MECHA

GXX1155

20MHz 32kHz

MD CONTROL MICON

8-759-533-77

(RU8X12MF-0030)

5

1

CN502CN501

MD UNIT

D

AD/DA

15

0911505000

12

(PCM3003)

XTAL OSC

IC502

TC7WU04FU

X501

22.5792MHz

IC503

19

6

TEMP-SENSOR

0911110000

(BA10358)

FILTER

IC504

BA4510F

IC505

MUTE

Q502 DTA114EK

76

Q503,Q504

DTC114TK

+3.3V REG.

IC501

0911209300

(S-81340HG-KJ-X)

11

Vcc3

3

P.B

REC

CN503CN504CN801

CONT

• CD MECHA

FOCUS/TRACKING

B

PIC

TRACKING

FOCUS

SPINDLE

MOTOR

SLED

MOTOR

CARRIAGE

MOTOR

DRAWER

MOTOR

M

M

M

M

CN803

CN804

CN805

CN805

1,2

3,4

1,2

3,4

1,2

3,4

SERVO

IC803 0911168502

(CXA1782BQ)

POWER DRIVER

IC802 0911209400

(BA5936S)

14,15

30,31

CD UNIT

C

31

1-CHIP

36

PROCESSOR

IC804

CXD2508AQ

X801

16.1344MHz

CD +5V REG.

Q801

0906209425

(2SA966Y)

5,

69,

70

LOW-PASS

6

FILTER

IC801 BA4510F

3

42

CN807

3

CN750

B

Vcc2

J700

PHONES

HP PCB

77

3

CN802WC1WC2CN302

5

FM: IF/DET/MPX

24

AM: RF/IF/DET

IC1 0911209800

(TA2099N)

AM OSC

TPSS

IC302

BA335

13

20

PLL

IC2 0911177300

(TC9216P)

4.5MHz

14

DOLBY-B

99

0911200400

(CXA1552P)

BA15218N

19kHz BP

Q7,Q8

2SC1740S

X1

IC304

ALC

IC305

Vcc4

Vcc1

11

16

1

8

6

19

IF AMP

CF-1

FM ANT

C

AM LOOP

ANT

RF1

FM TUNER MODULE

8

0039654000

(TFF-J2-J-559A)

RF2

AM RF TUNING UNIT

12,13

0039640000

(RBW07VB)

E

• DECK MECHA

REC/P.B

HEAD

D

ERASE

HEAD

MOTOR

M

DECK UNIT

1

CN301CN303

5

1

P.B-REC AMP

P.B

P.B/R.P SWITCH

Q101,Q102,Q201,Q202

BIAS

Q306,Q311

0906202003

(2SD467)

Q1

2SC1740S

CF-3

8

A

IC301

0911166600

(TA8142P)

8

11

2SJ103

TUNER UNIT

REC

C-MECHA GAVANA REG.

Q319 0900008725 (2SA1359)

Q320,Q322,Q325 DTC114TS

18

1234

Page 19

5

678

X-MDX707, XR-C2MD

3

11

CN452CN450CN460CN459CN451 CN458

9

13

5

Q450 DTA114TK

Q451 2SC2412K

Q650,Q750 0906505419

Q651,Q751 2SD1302

15

17

CN453

: PB SIGNAL

: REC SIGNAL

F

CONTROL UNIT

FUNCTION/

16

SOUND/VOLUME

17

19

21

REC AMP

IC452

BA15218N

MD INTERFACE

TC74HCT08AF

MICROCOMPUTER

(CXP740096-109Q)

BUZZER DRIVER

Q459 0906505419

(2SD1757K)

TAPE/LINE SW

19

LINE IN

IC450

LC75394NED

(REC)

31

IC901

X901

X900

16MHz

32kHz

IC900

0037502200

BUZZER

BU450

58

PS DET 0

Q911,Q913

2SC2412K

IC903 0911186600

(S-81350HG)

Q903 2SC2412K

Q904 2SA1037K

CN461

CN700

KEY LED

DISC LED DRIVER

Q700 – Q702

2SC2412K

KEY

VR

JOG

13

11

7

Vcc4

PS DET 1

Q912,Q914

2SC2412K

RESET

IC902

0911851600

(S-80727AN)

REG. +5V

LED DRIVER

Q456 0900008725

(2SA1359Y)

Q457 2SC2412K

LED FILTER

Q905-Q907,

Q915-Q917

0906505419

(2SD1757K)

Q908-Q910

2SC2412K

BACK-LIGHT LED

DRIVER

Q703 – Q708

0906505319

(2SD1963-S)

REMOCON REC

RM700

0039648000

(SPS-444-1)

CN454CN455

DISC-LED

1–3

G

AMP UNIT

2

4

CN406 CN405 CN401

CN400

BACKLIGHT

LED

JW700

Q152,Q252

2SD1302

2

Vcc1

Vcc4

LD700

4-DIRECTION

TACT SW

JW701

I

FRONT UNIT

MUTE

S-MUTE

Q150,Q250

2SD1302

TUNER +5V

Q400

0906202003

(2SD467)

Q403,Q407,Q415 2SC2412K

Q406 0900008725(2SA1359)

H.P. AMP

1

IC400

BA15218N

2

POWER AMP

2

IC401

0911209600

(LA4663)

POWER-AMP CONT.

(ST-BY) AND (MUTE)

Q416,Q417 2SC2412K

Q418 DTA114TK

TUNER +9V

Q401

0906209425

(2SA966)

Vcc2

Vcc3

AUDIO REG. (+8V)

CD +7.8V

IC402

0911209700

(PQ20RX11)

MD +5V

IC403

0911209700

(PQ20RX11)

H

PS UNIT

LC700

LCD PANEL

004044100021

S723

14

CN403

WC601

POWER

TRANSFORMER

LBWXJ TYPE

: 001950000005

NLWXJ/HK TYPE

: 001947100005

D423

0913013600

(KBU603)

16V

D424–D427

2626323000

(1N5401TM)

11V

T601

SPEAKER

TARMINAL

SPEAKER

6Ω

(15W)

AC IN

A

B

C

D

19

5

6

7

8

Page 20

1

23

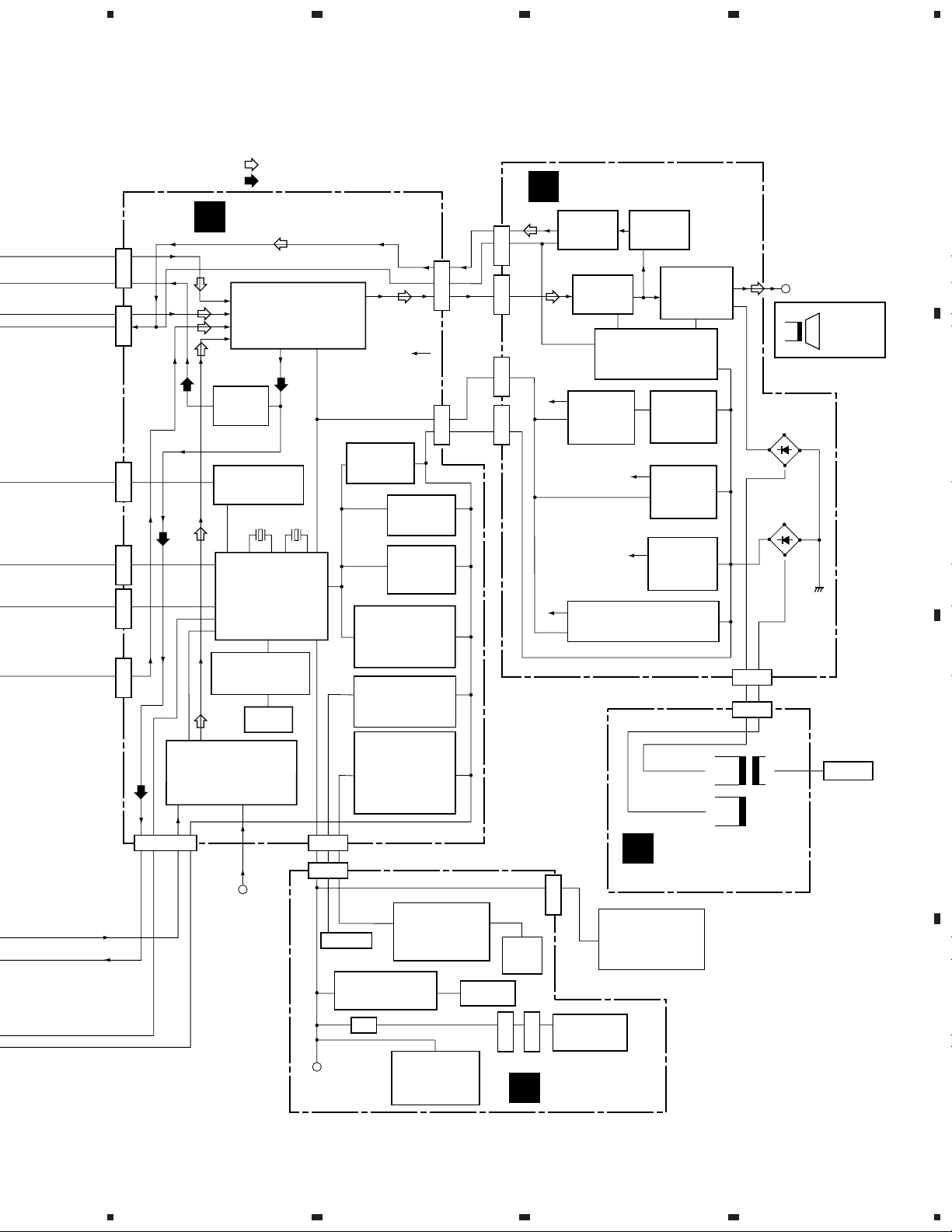

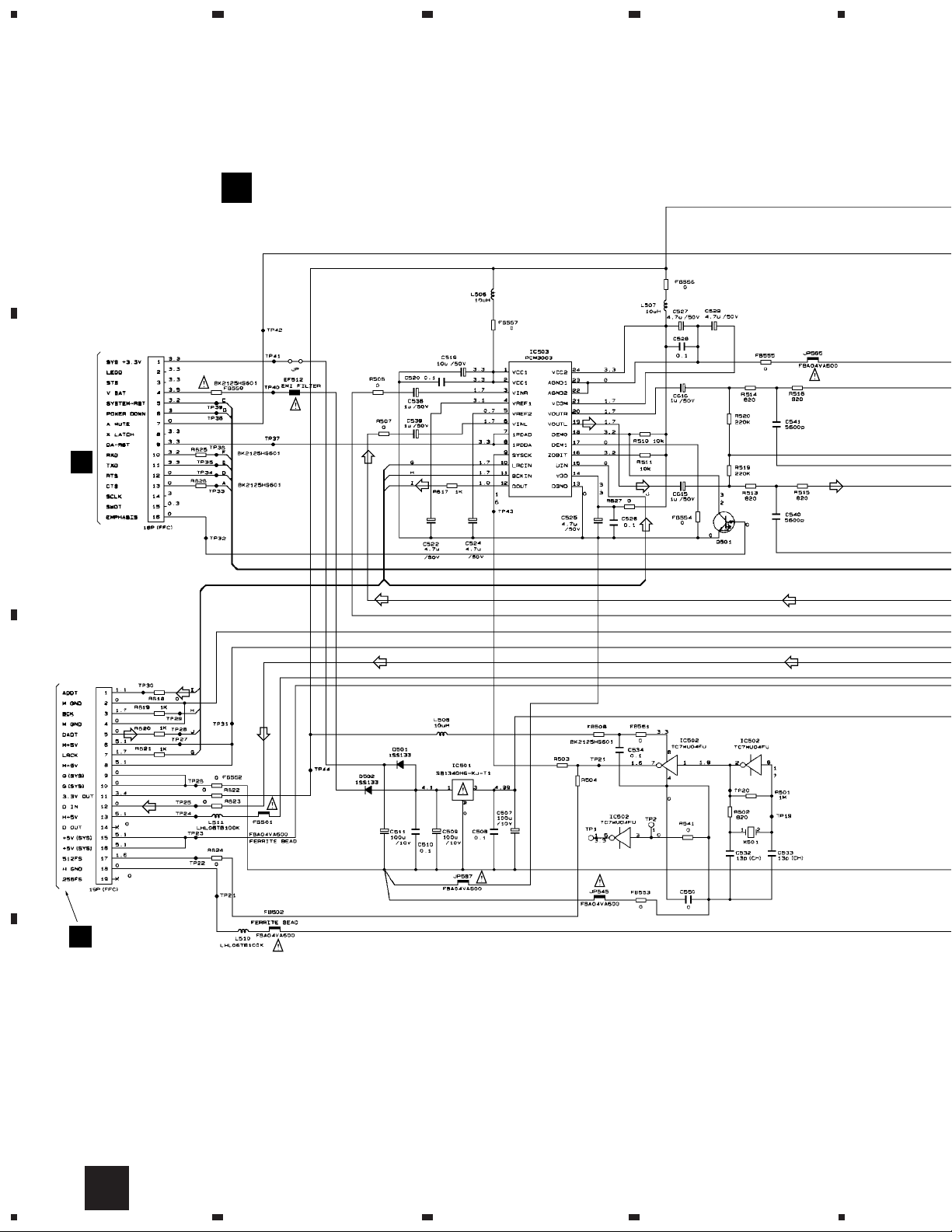

X-MDX707, XR-C2MD

3.2 OVERALL CONNECTION DIAGRAM

A

MD MECHANISM (GXX1155)

MD MOUNT (A-4917-020-A)

CN103 CN102

123456789

J

10111213141516

123456789

4

10111213141516

171819

STB

VBAT

LEDO

SYS+3.3V

123456789

AMUTE

P DOWN

SYS RST

TXD

RXD

DARST

XLATCH

10111213141516

RTS

CTS

SCLK

ADDT

SWDT

EMPHASIS

123456789

BCK

MGND

DADT

MGND

M+5V

M+5V

LRCK

DIN

H+5V

GSYS

GSYS

3.3VOUT

10111213141516

DOUT

+5VSYS

512FS

+5VSYS

171819

HGND

256FS

CN501 CN502

MD UNIT

D

(4707025000)

CN504 CN503

123456789

VC

1

+5V

2

3

4

B

C

Chassis

5

6

7

8

GND

9

LD

10

VR

11

PD

12

F+

13

T+

14

15

16

SP+

1

SP–

2

SL+

3

SL–

4

LIMIT

5

GND

(4707150000)

6

CD MECHANISM

1

2

3

4

1

2

3

4

5

6

7

8

9

CARR–

CARR+

DRAW–

DRAW+

SW8

SW7

SW6

SW5

SW4

SW3

SW2

SW1

SWGND

CN803

1

2

E

3

D

4

A

5

B

6

C

7

F

8

C

9

10

CD UNIT

11

12

(4707030000)

13

14

T–

15

F–

16

CN804

1

2

3

4

5

6

CN805

1

2

3

4

CN806

1

2

3

4

5

6

7

8

9

123

CN801

CN802

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

HP Rch

HP GND

HP Lch

HP SW

CD Rch

PRIGND

CD Lch

GND

GND

+7V

+7V

GND

FCD

GND

DIN

SW0

SW1

SW2

SW3

SWGND

CTL1

CTL2

CTL3

CTL4

CLK

XLT

DATA

XRST

SENS

NC

SQCK

SQSO

SCOR

GND

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

CN450

CN459

CN451CN807

123451

RTS

GND

TEMP

DOUT

D GND

123456789

P DOWN

CN460 CN452

CN458 CN453

12345

10

11

TXD

CTS

RXD

RESET

MDREC

10

11

F

CONTROL UNIT

(4707006000)

6

123456789

MD+5V

Lch OUT

Rch OUT

F F

1/2, 2/2

22212019181716151413121110

MDH+5V

MDM+5V

MDA GND

123456789

MDH GND

MDM GND

Rch REC

REC GND

10

11

Lch REC

10

11

987

654

321

Lch

SW

Rch

GND

GND

12345

B

HP PCB

D

+9V

+5V

L ch

R ch

GND

5

PERIOD

234

WC1 WC2

TUNER UNIT

A

(4707021000)

TDATA

CLOCK

TUNING

12345

GND

STEREO

6

+11V

A +8V

A GND

PRIGND

123456789

LchREC

RchREC

LchPB

RchPB

CN302CN750

E

CN301 CN303

HEAD.

GND

12345

Lch

Rch

12345

6

GND

GND

COM.

E HEAD

6

DECK MECHANISM

TPSS

DOLBY

BEAT CUT

REC/PLAY

REC/MUTE

DECK SW3

10111213141516

DECK UNIT

(4707015000)

123456789

HALF

REC F

REC R

123456789

DECK SW2

DECK SW1

DECK SW0

171819

NC

PHOTO

SOLENOIDO

PHOTO

MOTOR

REPEAT

SOLENOIDO

202122

VCC

MODE

P GND

CONT.

BIAS

(4700100000)

20

1234

Page 21

5

678

X-MDX707, XR-C2MD

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST"

LC700 LCD PANEL

(004044100021)

E

RS

RW

DB0

DB1

DB3

DB2

DB4

DB5

DB6

VSOUT

LCDVCC

LCDGND

123456789

LD700

FRONT UNIT

I

(4707035000)

CN700

302928272625242322212019181716151413121110

VCC

GND

KEY1

KEY0

KEY2

DISC3

DISC2

DISC1

VJOG0

REMOCON

PWP-KEY

123456789

VJOG1

KEY3

LEDVCC

1011121314151617181920212223242526

LEDGND

CN461

DB7

1011121314

BLCONT B

BLCONT R

BLCONT G

LCDGND

RS

98765

E

RW

DB0

JW700

1

1

JW701

KEY PCB

DB1

DB2

DB3

DB4

27 4

2

2

DB5

28 3

DB6

29 2

A

DB7

30 1

B

PS UNIT

H

(LBWXJ TYPE

: 4707014000)

(NLWXJ/HK TYPE

: 4707012000)

CN455 CN454

13

14

151

MDS GND

MDH GND

MDM GND

23456

10

11

12

MD+5V

MDH+5V

MDA GND

NC

MDM+5V

TUNERGND

7

TUNER+5V

TUNER+9V

CDPRIGND

12345

123456789

NC

CDGND

CD+8V/+7V

6

10

11

12

13

141

L ch

R ch

ACDET

PSCONT

GND

HP SW

HP Lch

HP Rch

HP GND

FTUNER

2345612345678

A GND

S MUTE

+11V

A +8V

123456789

CN400 CN406 CN401 CN405 CN403

AMP UNIT

G

(4707001000)

WC401

123

123

WC404

IC PCB

4

4

WC403

123

123

WC406

DI PCB

4

4

WC601

12345

GND

AC16V2

AC16V1

12345

AC11V2

AC11V1

CN402

Lch 1

Lch 2

Rch 1

Rch 2

NEUTRAL

1

2

3

4

LIVE

SPEAKER

LBWXJ

AC110V

NLWXJ/HK

AC220V

AC POWER CORD

LBWXJ

: 004701800005

NLWXJ/HK

: 004744300003

C

D

21

5

6

7

8

Page 22

1

X-MDX707, XR-C2MD

23

4

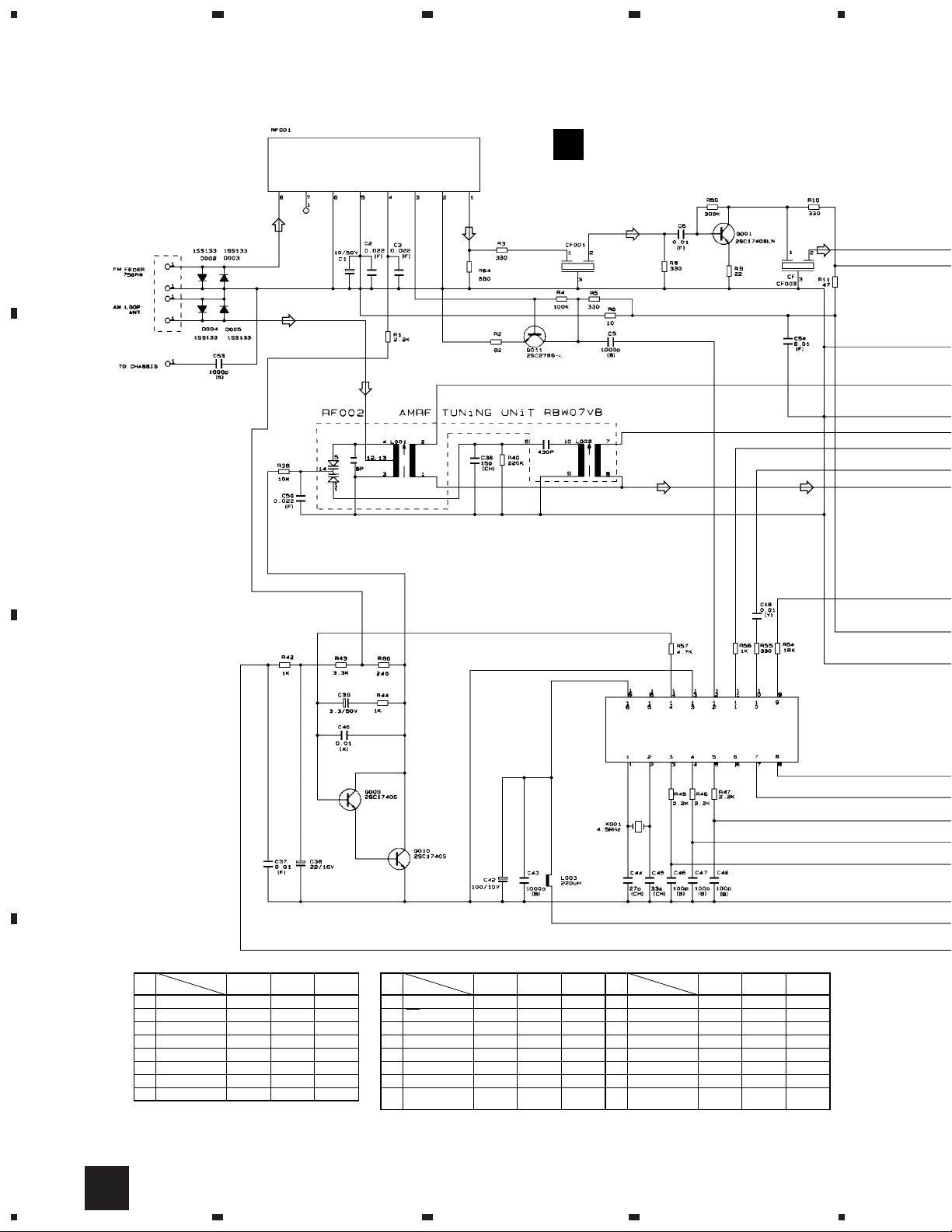

3.3 TUNER UNIT

A

B

003402900013

AT1

0039655000

(FM)

(AM)

RF MODULE

0039640000

(AM)

(FM)

TUNER UNIT (4707021000)

A

0039067000

(FM)

(AM)

(FM)

0039067000

(AM)

IC002 0911177300

(TC9216P)

C

0038168000

RF001

Pin

No.

D

Condition

Pin Nane

1

20GND 0 0

3 1.1F OUT 1.1 0

4 1.1VT ––– 7.1

5 7.6VCC 7.6 0

60GND 0 0

70ANT 0 0

8 –––––––– ––– –––

FM NO

Signal

0IF OUT

FM ST

00

AM NO

Signal

(V)

IC002

Pin

No.

Condition

Pin Nane

1

2 2.4XT 2.4 2.4

3 4.6DATA 4.6 4.6

4 4.6CLOCK 4.6 4.6

5 4.6PERIOD 4.6 4.6

6 000

7 4.8AM/FM (H-FM) 4.8 0

FM ST. VCO

8 4.8

STOP (H-ST)

FM NO

Signal

2.3XT

FM ST

AM NO

Signal

2.3 2.3

4.8 0

Pin

No.

Condition

Pin Nane

9

10 2.5IF IN 2.5 2.5

11 0AM IN 0 2.5

12 2.2FM IN 2.2 0

13 0GND 0 0

14 1.1DO1 1.1 1.1

15 0DO2 0 4.9

16 4.9VCC 4.9 4.9

FM NO

Signal

0IF CONT

AM NO

FM ST

Signal

00

(V)

22

A

1234

Page 23

(AM)

(AM)

(FM)

0012340000

5

678

X-MDX707, XR-C2MD

(T)

: TUNER AUDIO SIGNAL ROUTE

(FM)

(AM)

0039155000

IC001 0911209800

(TA2099N)

(T) (T)

: FM SIGNAL ROUTE

(AM)

: AM SIGNAL ROUTE

(T)

(T)

L4,L5 :

0039876000

A

B

0906222500

2/2

F

CN451

WC1

4701569000

4701570000

WC2

1/2

F

CN458

IC001

Pin

No.

Condition

Pin Nane

1

2 3.2FM BW 2.4 1.9

30FM VL SENS 0 0

4 2.0AM OSC 2.0 2.0

5 1.3FM IF SENS 1.3 1.6

6 5.0VCC 5.0 5.0

7 1.3AGC 1.5 1.2

80GND 0 0

9 1.6IF OUT/CONT 1.6 1.6

10 5.0TUN IND. 0 5.0

11 5.0ST. IND. 0 5.0

12 1.0Rch OUT 1.0 1.0

13 1.0Lch OUT 1.0 1.0

14 0.6VCO 0.7 0

LPF2

15 3.4

(GND-MONO)

LPF1

16 3.0

(GND-AM)

17 1.2MPX IN 1.2 1.2

18 1.1AM DET OUT 1.3 1.3

19 2.3FM DET OUT 1.6 1.9

20 1.8FM QUAD 1.8 2.1

21 2.0AM IF IN 2.0 2.0

22 2.0V stb 2.0 2.0

23 5.0AM MIX OUT 5.0 5.0

24 2.0FM IF IN 2.0 2.0

FM NO

Signal

2.0AM RF

FM ST

2.0 2.0

3.4 0.5

3.0 0.6

AM NO

Signal

(V)

C

D

A

5

6

7

8

23

Page 24

1

X-MDX707, XR-C2MD

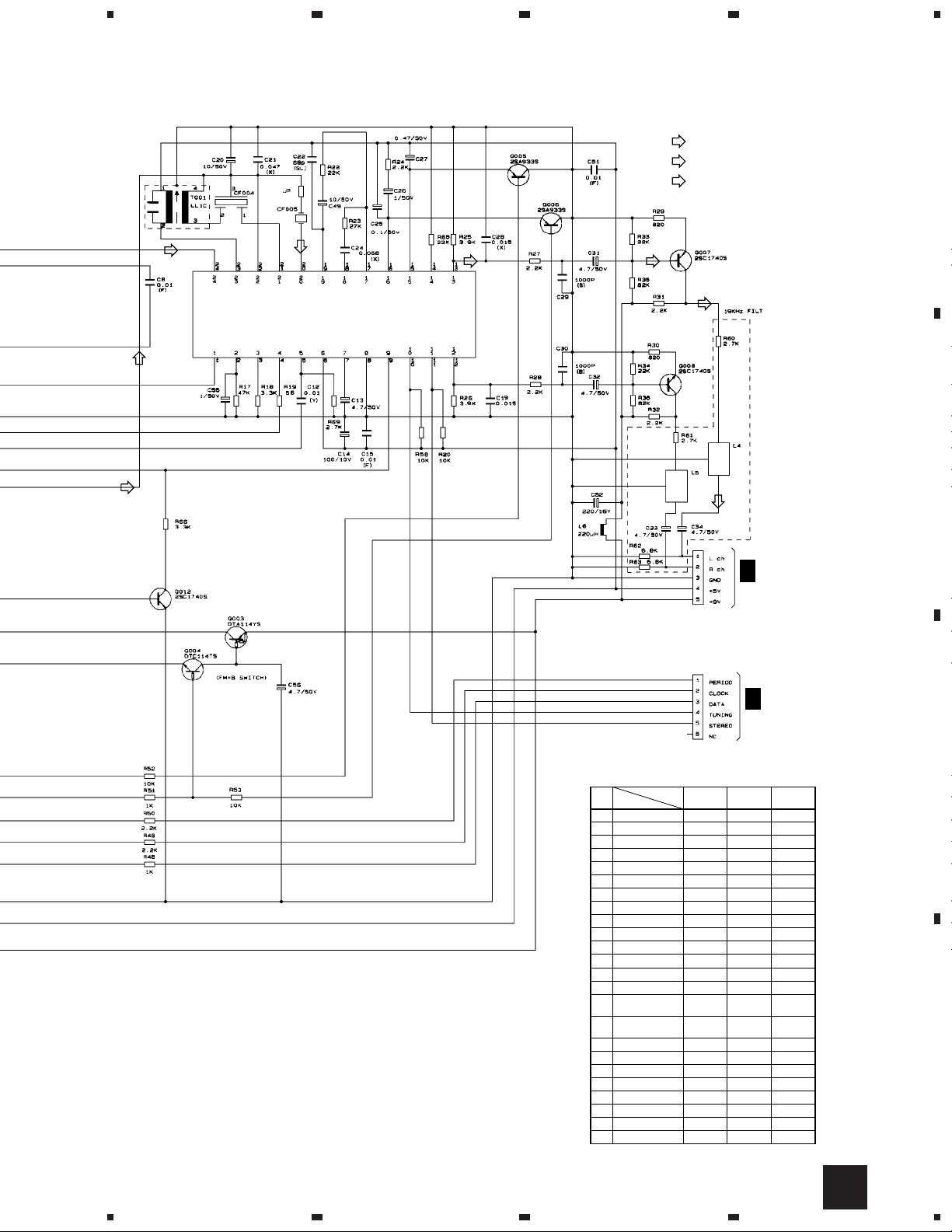

3.4 HP PCB, CD UNIT

23

A/D

(V) SW0

0.00~2.00 : (ACCIDENT)

2.01~2.78 :

2.79~3.36 :

3.37~4.00 :

4.01~5.00 : C.EXT/C.HOM C.No1/C.No.2

D.OPN/D.CLSE

D.OPN SW

D.CLS SW

SW1

C.HOME SW

C.EXT SW

(NO USE)

SW2

C.No1 SW

C.No2 SW

SW3

S.FWD/S.REV

S.FWD SW

S.REV SW

CD UNIT

C

(4707030000)

4

SW1 : COMMON

SW1 : DRAWER OPEN DETECT SW

SW2 : CARRIAGE EXTRA POSITION SW

SW3 : CARRIAGE HOME POSITION SW

SW4 : CARRIAGE NUMBER SW

SW5 : CARRIAGE NUMBER SW

SW6 : DRAWER CLOSE DETECT SW

SW7 : SLIDER FORWARD POSITION SW

SW8 : SLIDER REVERSE POSITION SW

A

(CD)

4707564000

CN806

CN803

(CD)

(CD)

(CD)

(CD)

(CD)

(CD)

CD MECHANISMCD MECHANISM

0034887016

B

TP5

TO

TP4

FO

TRACKING

BALANCE

TP3

TEO

0031781503

0031781203

FOCUS

OFFSET

(CD)

(CD)

TP1

VC

(CD)

IC803

0911168502

(CXA1782BQ)

(CD)

(CD)

(CD)

TRACKING

GAIN

0031781203

0

0031781103

FOCUS

GAIN

180k

TP2

RFO

(CD)

C

CN804

15k

4701571000

0911209400

CN805

4707563000

HP PCB

B

003352100001

D

PHONES

0034751005

(HP)

FB750

D750,D751 : 1SS133

CN750

CN807

(HP)

4701568000

Q801 : 0906209425

24

B

C

1234

Page 25

5

678

X-MDX707, XR-C2MD

(CD)

: CD AUDIO SIGNAL ROUTE

(HP)

: HP AUDIO SIGNAL ROUTE

(CD)

(CD)

D804,D805,D812

: MTZJ5.1B

IC804

CXD2508AQ

(CD)

(CD)

X801 : 16.1344MHz

0038136000

CN802

0034887019

A

CN459

1/2

F

B

(CD)

(CD)

(CD)

(CD)

(2/2)

C800

4P

(CD)

(CD)

(CD)

(CD)

(CD)

(1/2)

(CD) (CD)

(CD)

(CD)

(HP)

CN801

C

CN450

2/2

F

0034887015

D

C

5

6

7

8

25

Page 26

1

X-MDX707, XR-C2MD

3.5 MD UNIT

A

23

MD UNIT (4707025000)

D

4

EF512:

0011612203

DTF1067

CN103

B

C

J

(MD)

CN501

0034688016

(MD REC)

(MD DI)

(MD REC)

(MD DI)

(MD REC)

(MD DI)

(MD

REC)

0911209300

0911505000

DTF1067

DTF1067

(MD)

DTF1067

(3/3)

(MD)

0011813000

(MD)

(MD)

DTC114EK

(MD REC)

(MD DI)

(1/3) (2/3)

DTF1067

X501 : 22.5792MHz

0038204000

J

CN502

0034688019

CN102

L510,L511 :

0991401005

FB501,FB502 :

0011813000

JP545, JP587: 0011813000

D

26

D

1234

Page 27

5

678

X-MDX707, XR-C2MD

A

(MD)

(MD REC)

DTA114EK

DTC114TK

(1/2)

: MD AUDIO SIGNAL ROUTE

: MD REC ANALOG AUDIO SIGNAL ROUTE

(MD DI)

: MD REC FROM CD DIGITAL AUDIO SIGNAL ROUTE

EF501-EF511:

0011612203

(MD)

SHIELD PLATE

47050735000

(MD)

(2/2)

(MD REC) (MD REC)

(MD DI)

R650

10(1/4W)

DTC114TK

(MD)

(MD)

(1/2)

0911110000

(MD DI)

R530

4.7k

R529

2.7k

(MD REC)

CN503

4701572000

CN504

0034887011

2/2

F

CN452

1/2

F

CN460

B

C

0918004400

0911110000

(2/2)

D

D

5

6

7

8

27

Page 28

1

X-MDX707, XR-C2MD

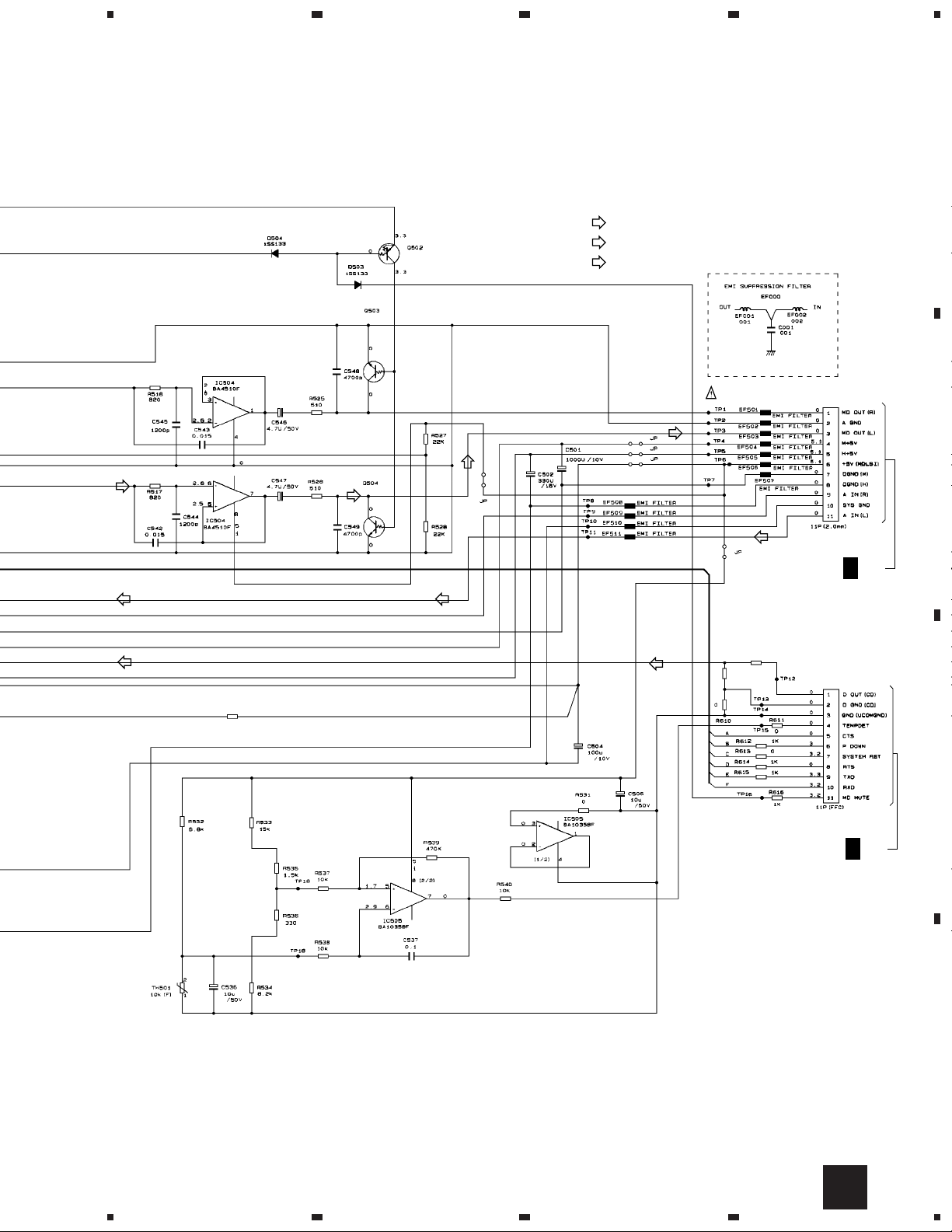

3.6 DECK UNIT

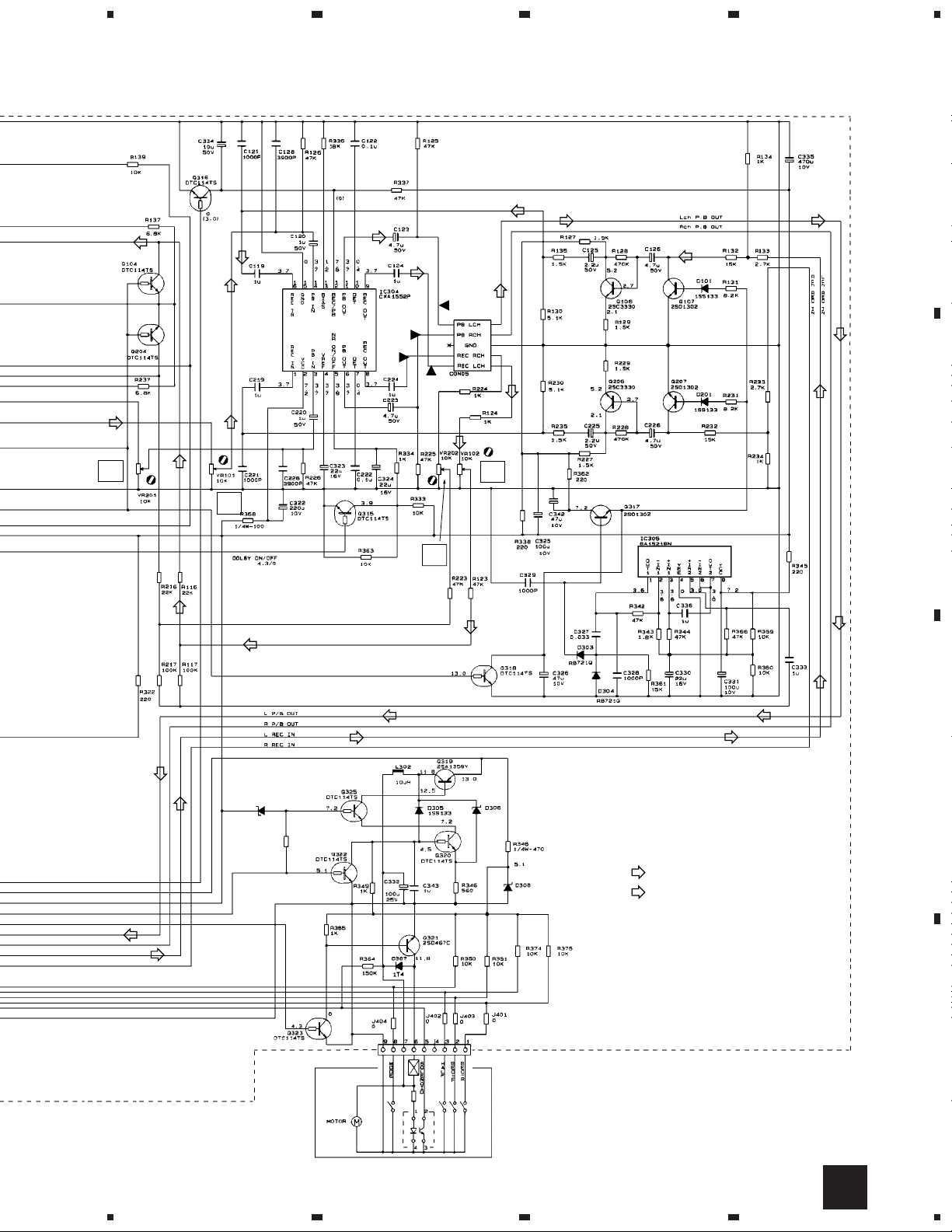

23

4

A

DECK

MECHANISM

B

CN301

4701563000

(PB)

(PB)

(REC) (REC)

(PB)

0906222500

(REC) (REC)

(PB)

(PB)

(PB)

(PB)

0911166600

0990415624

(REC)

0990415624

(PB)

0906202003

0015083000

REC

BIAS

0031781103

0906202003

0906222500

C

CN305

0034210003

Normal condition PLAY MODE.

( ) : Condition REC MODE.

DECK UNIT (4707015000)

E

(PB)

(REC)

(PB)

(REC)

D

0034688022

CN302

CN453

2/2

F

28

E

1234

Page 29

(REC)

5

678

X-MDX707, XR-C2MD

A

(REC)

(PB) (PB)

(PB)

(REC)

(REC)

(REC)

(PB)

Rch

(PB)

(PB)

PB

(REC)

PB

Lch

VR101,VR102,VR201,VR202 :

0031781103

(REC)

(REC)

(REC)

(PB)

D309

MTZJ5.1B

(REC)

R377

2.2k

0991401005

0911200400

(PB)

REC

Rch

0900008725

CN304

0034209005

(REC)

(REC)

(PB)

REC

Lch

D303,D304 :

0915037750

(REC)

MTZJ7.5B

MTZJ5.1B

(REC)

(PB)

: DECK PB AUDIO SIGNAL ROUTE

(REC)

: DECK REC AUDIO SIGNAL ROUTE

(PB)

(REC)

B

(PB)

(REC)

(PB)

C

(REC)

(PB)

5

D307 :

0915033250

CN303

Q321 :

0906202003

0034208009

DECK

D

MECHANISM

E

6

7

8

29

Page 30

1

X-MDX707, XR-C2MD

3.7 CONTROL UNIT (1/2)

23

4

A

CN458

PERIOD

CLOCK

T-DATA

A

TUNING

STEREO

WC2

C

CN802

B

SW0

SW1

SW2

SW3

SWGND

CTL1

CTL2

CTL3

CTL4

DATA

XRST

SENS

SQCK

SQSO

SCOR

GND

NC

CN459

CLK

XLT

NC

0034203019

1

2

3

4

5

6

CON6

0034750006

0011813000

FB901

FBA04VA600

(P=10.0)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

CON19

F

1/2

FB917 FBA04VA600

FB915 HS601

FB916 HS601

JP

FB915,FB916: DTF1067

FB917: 0011813000

C905 100p

C906 100p

JP

JP

JP

JP

JP

JP

C913

100p

CONTROL UNIT (4707006000)

C907 100p

C908 100p

R905 4.7k

R906 4.7k

R907 4.7k

R908 4.7k

R909 4.7k

L905 10µH

L906 10µH

R929 1k

R930 1k

R931 1k

R932 1k

L909 10µH

R934 1k

R935 1k

R937 1k

R938 1k

R939 1k

D901

D902

R913 100k

D901-D903:

MTZJ5.1B

D903

R914 100k

R915 100k

R916 100k

R943

100k

R917 100k

R918 100k

R919 100k

TU1

TU2

TU3

TU4

TU5

R920 100k

CD1

CD2

CD3

CD4

CD5

CD6

CD7

CD8

CD9

CD10

CD11

CD12

CD13

CD14

CD15

CD16

CD17

AM10

AM11

AM12

AM6

AM5

AM4

AM8

X901: 0038202000

C933

15p

C934

X901

15p

16MHz

R949 1k

R950 1k

R951 1k

JP

R953 1k

R955 1k

R957 1k

JP

R970

1M

R958 10k

R959 10k

R960 10k

R961 1k

R962 10k

R963 100k

A

D

R964 10k

R967 1k

R971 1kC

R974 10k

R972 1k

R965 100k

R966 100k

R973

100k

R532

10k

FR7

C995 100p

C996 100p

C997 100p

C998 100p

IC901

TC74HCT08AF

1

14

2

13

3

12

4

C

DOUT

DGND

GND

TEMP

D

CN504

RTS

PDOWN

RESET

CTS

RXD

TXD

MD REC

CN460

1

2

3

4

5

6

7

8

9

10

11

CON11

0034221011

FB907,FB908:

DTF1067

FB907 HS601

FB908 HS601

JP

11

5

10

6

9

7

8

C987

47/16V

R539

R557

6.8k

R554

6.8k

6.8k

JP

JP

JP

JP

C993

1

C962

L903 10µH

R558

R559

3.3k

R553

1k

MD1

MD2

MD3

MD4

MD5

1k

MD6

MD7

0.1

R540

6.8k

R545 1k

R546 3.3k

R547 3.3k

R548 3.3k

R549 3.3k

R550 1k

R555

6.8k

D

30

1/2

F

1234

Page 31

5

678

X-MDX707, XR-C2MD

TU4

TU5

TU2

TU3

TU1

BEATCUT

DOLBY

MOTOR

PSCONT30

29

31

SOUND CE

32

SOUND DI

33

SOUND CL

34

S MUTE

35

F CD

36

F MD

37

F TUNER

38

F TAPE

39

F AUX

40

RST

41

VSS

42

XTAL

43

EXTAL

44

CLKSFT

45

PSDET1

46

NC

47

BEEP

48

PSDET0

49

TSEL

50

VJOG1

VJOG051AVSS52AVREF53AVDD54KEY355KEY256KEY157KEY058TRAYSW359TRAYSW260TRAYSW161TRAYSW062CD MUTE63TEMP64MD CTS65MD REC66MD RST67MS RTS68MDRXD69MD TXD70CD CTL471CD CTL372CD CTL273CD CTL174CD XLT75CD CLK76CD SENS77CD SCLK

R598 10k

R533

C994

10k

1

FR6

21

22

23

24

25

262728

D MUTE

REPEAT

DECKSW0

REC/PLAY

SOLENOID

(CXP740096-109Q)

CD4

FB914

0011813000

R534 1k

R535 1k

R536 1k

R537 1k

17

18

19

20

PHOTO

DECKSW3

DECKSW2

DECKSW1

IC900

0037502200

CD3

CD2

CD1

CD14

16

TPSS

REC BIAS

14

15

PERIOD

REC MUTE

12

13

T DATA

10

11

TUNING

STEREO

T CLOCK

8

9

BLCONT1

BLCONT0

CD8

CD7

7

CD6

TP4

1

5NC6

BLCONT2

DISCSEL1

CD5

CD10

3

4

DISCSEL3

DISCSEL2

PWR KEY

78

CD9

CD13

CD17

R596

100k

1

2

RW

LCD

LCD RS

LCD E

ELECONT

LCD DB0

LCD DB1

LCD DB2

LCD DB3

LCD DB4

LCD DB5

LCD DB6

LCD DB7

NC

VDD

VSS

TX

TEX

REMOTE

ADJ

CD XRST

CD

SQCK

CD SQSO79CD DATA

80

CD16

CD11

R985 1k

R986 1k

R987 1k

R988 1k

R989 1k

R990 1k

R991 1k

R992 1k

R993 1k

R994 1k

R995 1k

R996 1k

R997 1k

R998 1k

R595 1k

R508 1k

R509 1k

R510 1k

R511 1k

R512 1k

R513 1k

R514 1k

R515 4.7k

R516 4.7k

100

R517 4.7k

99

R518 4.7k

98

R519 4.7k

97

R520 4.7k

96

R521 4.7k

95

R522 4.7k

94

93

R523 4.7k

R524 4.7k

92

R525 4.7k

91

90

89

88

87

86

R527 1k

85

R528 1k

84

1

83

82

CD12

81

CD15

L902

10µH

R

G

B

FR3

FR4

FR5

FR13

X900:

0038201000

FR12

FR14

FR15

FR16

FR17

FR18

FR19

FR20

FR21

FR22

FR1

FB501

FR2

0011813000

(S-80727AN-DQ-T1)

R538

1k

AM3

AM24

AM14

AM18

AM9

AM15

AM23

AM26

AM22

AM21

AM20

AM19

AM25

AM17

AM13

AM16

AM7

C964

R526

0.22F/5.5V

47

C964:

0939932500

X900

32.769kHz

IC902

0911851600

13

D904

1SS355

C965

C966

C977

/6.3V

Q903

220

C978

220

/6.3V

R5291kR530

Q904

2SA1037K

L901

10µH

2SC2412K

27p

27p

JP

2

C999

1

C500

1

JP

FB906:

DTF1067

FB906 HS601

C518

C961

1000/6.3V

1

TP3

FB501

JP

IC903(S-81350HG-KD-T1)

D905

09111866600

1SS355

13

C981

0.1

R531

C979

12k

1

D906

1SS355

C980

C984

1

1

100k

2

R597

2k

C985

47/16V

C982

1000p

C963

1

D908 (DRA-1T4)

0915033250

D909 (DRA-1T4)

0915033250

D910 (DRA-1T4)

0915033250

D911 (DRA-1T4)

0915033250

D912 (DRA-1T4)

0915033250

A

B

FR11

FR10

FR9

L904 10µH

C502

1

FR7

FR6

FR1

FR2

FR3

FR4

FR5

123456789

DISC3

DISC2

DISC1

VJOG0

VJOG1

PWP KEY

REMOCON

FR8

MD6

MD1

MD6

MD2

MD3

MD5

MD4

Q905

R563

2SD1757K

10k

C504

R562

22

100k

R561

/16V

47k

Q906

R570

2SD1757K

10k

C509

R569

22

100k

R568

/16V

47k

1

KEY3

I

LEDVCC

LEDGND

Q907

2SD1757K

R575

47k

JP

FR12

RS

LCDGND

BLCONT B

BLCONT R

BLCONT G

CN700

R577

10k

C510

R576

22

100k

/16V

Q905-Q907,Q915-Q917:

0906505419

FR13

FR14

FR15

FR16

E

RW

DB0

DB1

FB910 0011813000

C503

FB911 F0011813000

FR8

FR9

FR10

FR11

101112131415161718192021222324252627282930

VCC

GND

KEY0

KEY1

KEY2

F900:

004560704102

AM1

AM2

ACDET

AM3

R500

R501

R564

10k

10k

C505

C506

1

1

R503

R571

10k

10k

C508

C507

1

1

R505

R578

10k

10k

C511

C512

1

1

FR17

FR18

FR19

FR20

FR21

FR22

CON30

CN461

0034203030

DB2

DB3

DB4

DB5

DB6

DB7

10k

R585

Q915

2SD1757K

R502

10k

R572

Q916

2SD1757K

R504

10k

R579

Q917

2SD1757K

R566

22k

1k

Q908

R567

2SC2412K

1k

R

R573

22k

1k

Q909

R574

2SC2412K

1k

G

AM1

R580

22k

1k

Q910

R581

2SC2412K

1k

AM2

B

R583

R582

100k

R584

100k

C514

100p

C515

100p

R585

100k

1k

Q911

2SC2412K

Q912

2SC2412K

R586

R587

10k

10k

R589

100k

Q913

2SC2412K

Q914

2SC2412K

R590

100k

R594

10k

R599

3.9k

R591

10k

C519

A

D

C

F900

250mA:

125V

1

D914

R592

R593

12k

82k

D914

MTZJ5.1B

AM4

AM5

BEEP

AM6

+11V

AM7

DOUT

DGND

AM8

AM9

AM10

AM11

AM12

VSS

AM13

AM14

AM15

AM16

AM17

AM18

AM19

AM20

AM21

AM22

AM23

AM24

AM25

AM26

EL +

EL –

ACDET

PSCONT

FTUNER

FCD

BEEP

SMUTE

+11V

ELCONT

DIN

DGND

FAUX

DECKMUTE

CE

DI

CL

VSS

BIAS

DOLBY

RECPLAY

RECMUTE

TPSS

BEATCUT

DECKSW3

DECKSW2

DECKSW1

DECKSW0

SOLENOID

MOTOR

PHOTO

REPEAT

C

2/2

F

D

1/2

F

5

6

7

8

31

Page 32

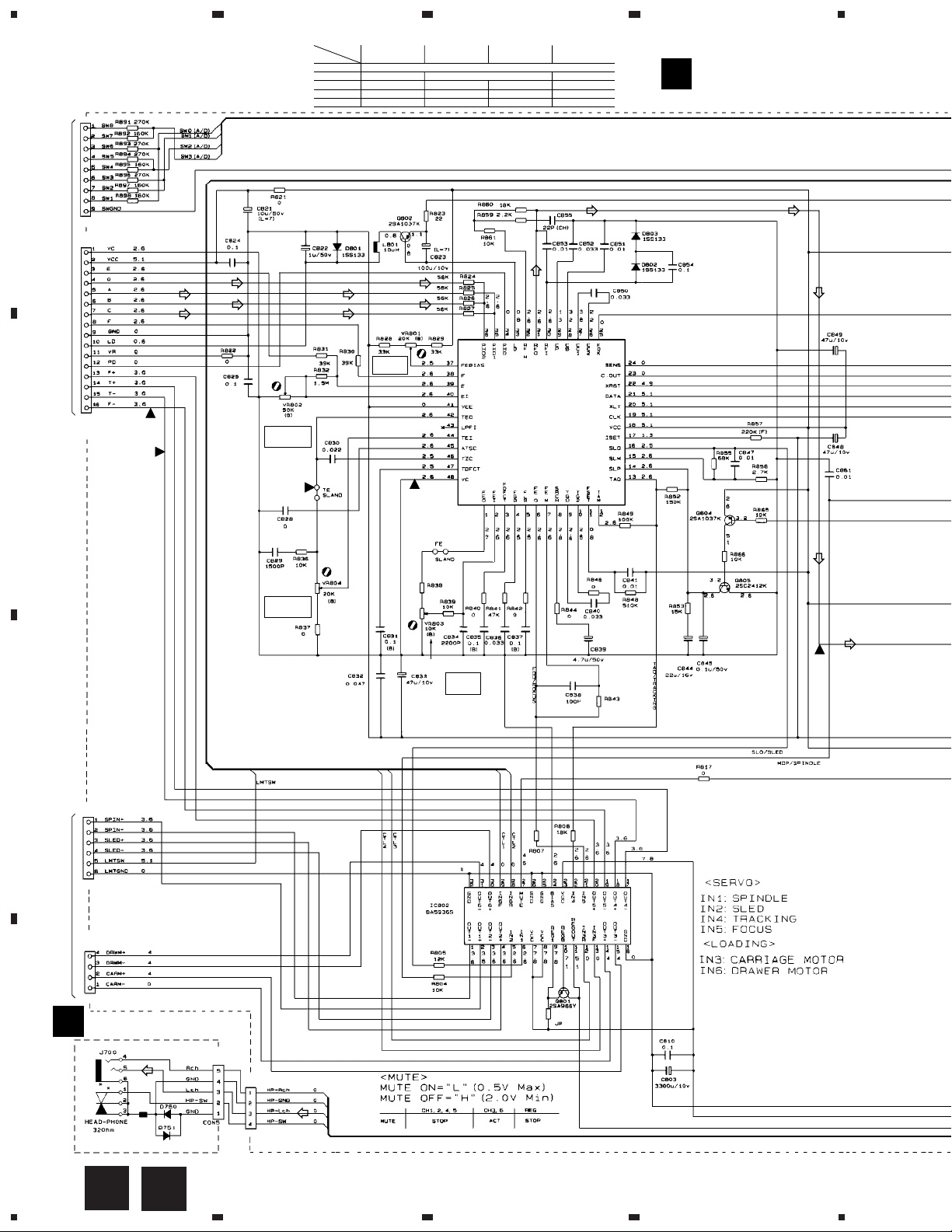

1

X-MDX707, XR-C2MD

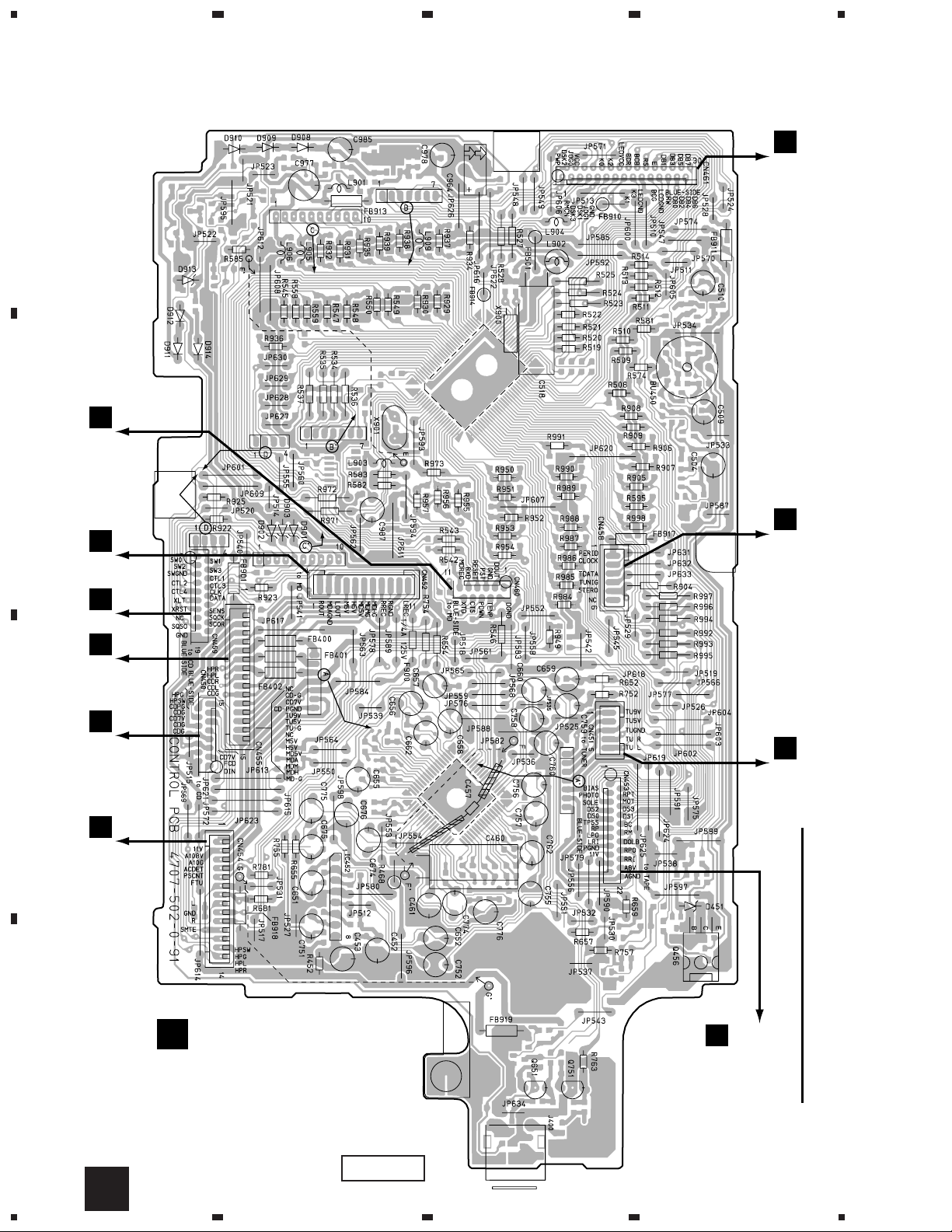

3.8 CONTROL UNIT (2/2)

A

F

23

2/2

CONTROL UNIT (4707006000)

4

CN450

CN801

C

0034221015

(CD)

(HP)

R650

10k

R750 10k

R651

2.2k

R751

2.2k

(CD)

(MD)

(CD)

(T)

(PB)

(T)

(MD)(MD)

(PB)

IC450

LC75394NED

B

0034750005

CN451

WC1

A

CN452

CN503

D

0034750011

(MD)

(T)

JP

FB400

0011813000

R752 10k

R652 10k

R754

12k

R654

12k

R755

2.2k

R683

4.7k

R753

4.7k

R783

4.7k

(T)

R653

4.7k

C755

4.7/50

C455

1000p

(MD REC)

R659

4.7k

(PB)

R759 4.7k

R662

27k

R664

68k

R764

68k

R762

27k

R663

4.7k

CN453

1

2

3

4

C

5

6

7

8

9

10

11

12

CN302

13

14

E

15

16

17

18

19

20

21

22

0034203022

J400:

003402700013

D

Q650,Q750:

0906505419

(PB)

(REC)

R655

2.2k

R763

4.7k

R657

8.2k

(PB)

R757 8.2k

R660 27k

R760 27k

(PB)

FB919

1SS355

IC452

BA15218N

32

2/2

F

1234

Page 33

5

678

X-MDX707, XR-C2MD

0011813000

002384700013

0906505419

D451:

MTZJ5.6B

FB918

0900008725

R464

1M

1SS355

R781

1.3k

R681

1.3k

1SS355

1SS355

(HP)

4707561000

4707562000

EL+

EL–

ACDET

PSCONT

FTUNER

FCD

BEEP

SMUTE

+11V

ELCONT

DIN

DGND

FAUX

DECKMUTE

CE

DI

CL

VSS

BIAS

DOLBY

RECPLAY

RECMUTE

TPSS

BEATCUT

DECKSW3

DECKSW2

DECKSW1

DECKSW0

SOLENOID

MOTOR

PHOTO

REPEAT

CN454

CN455

10

11

12

13

14

15

1/2

F

A

1

2

3

4

5

G

G

CN405

CN401

6

7

8

9

10

11

12

13

14

B

1

2

3

4

5

G

G

CN406

CN400

6

7

8

9

C

D

: AUDIO SIGNAL ROUTE

(T)

: TUNER AUDIO SIGNAL ROUTE

(CD)

: CD AUDIO SIGNAL ROUTE

(MD)

: MD AUDIO SIGNAL ROUTE

5

(PB)

: DECK PB AUDIO SIGNAL ROUTE

(REC)

: DECK REC AUDIO SIGNAL ROUTE

6

(MD REC)

(HP)

7

: MD REC ANALOG AUDIO SIGNAL ROUTE

: HP AUDIO SIGNAL ROUTE

2/2

F

8

33

Page 34

1

X-MDX707, XR-C2MD

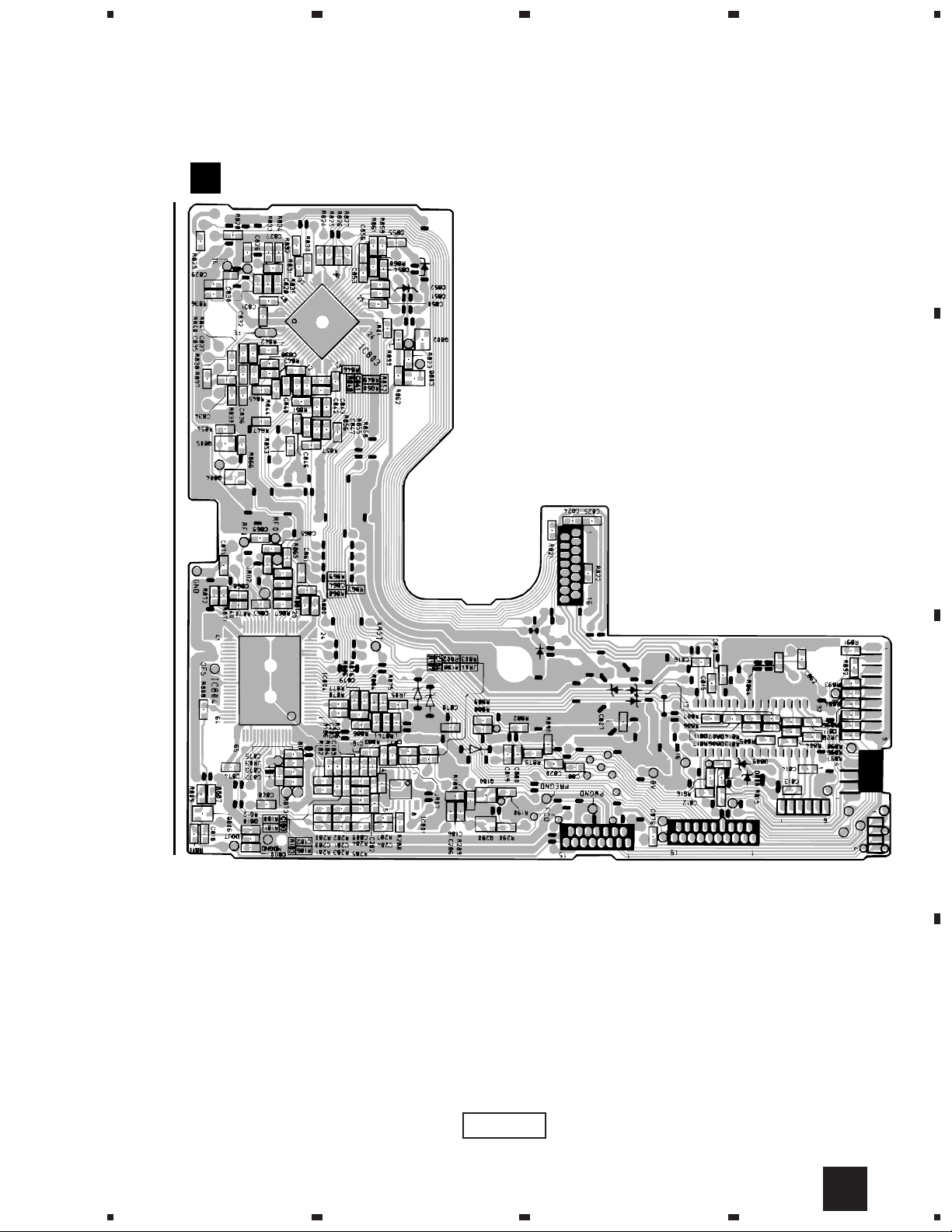

3.9 AMP, PS UNIT

A

23

4

POWER TRANS

H

WC601

4701565000

PS UNIT

(0045023041)

T2.5A/L250V

(0045049041)

T5A/L250V

LBWXJ :

001950000005

NLWXJ/HK :

001947100005

0013914000

(LBWXJ TYPE : 4707014000)

LBWXJ :

(0045017041)

T1.6A/L250V

NLWXJ/HK :

(0045013041)

T800mA/L250V

003994600011

LBWXJ

AC110V

NLWXJ/HK

AC220V

AC POWER CORD

LBWXJ :

004701800005

NLWXJ/HK :

004744300003

(NLWXJ/HK TYPE : 4707012000)

B

CN406

2/2

F

CN455

CN400

C

AMP UNIT (4707001000)

G

0034751006

0915033200

0034751007

0906202003

MTZJ5.6B

0906209425

D402:

MTZJ5.6B

0911209700

WC404

WC401

4701576000

0900008725

IC403

0911209700 (PQ20RX11)

MTZJ6.8B

R417

R432

2k

C417

47u

16V

2.2k

C438

1u

C412

220u

16V

C419

1u

D

34

G

H

1234

Page 35

5

678

X-MDX707, XR-C2MD

A

0034751008

CN405

R168

47k

R268

47k

C440

1u/50V

R437

47k

Q150

2SD1302

Q250

2SD1302

R253

4.7k

R267

4.7k

R167

4.7k

R153

4.7k

(HP)

MTZJ4.7B

(HP)

0911209600

(HP)

(HP)

CN401

0034751006

003402600013

CN402

2/2

F

CN454

SPEAKER

B

R420

470

D423:

0913013600

C428

4700u

16V

MTZJ5.1B

C432,C433,C436,C437:

0939934300

D422:

0915033250

D424–D427:

2626323000

WC406

WC403

4701576000

0034888005

CN403

: AUDIO SIGNAL ROUTE

(HP)

: HP AUDIO SIGNAL ROUTE

G

5

6

7

8

35

C

D

Page 36

1

X-MDX707, XR-C2MD

3.10 FRONT UNIT

23

4

A

0034887030

CN700

B

0039648000

FRONT UNIT (4707035000)

I

CN461

1/2

F

NSTM515S NSTM515S

D712-D717:

C

0034689014

UDZS5.1B

LD701,LD702:

0916038600

LCD PANEL

D

Q703-Q708: 0906505319

FB701,FB702:

DTF1067

36

I

1234

Page 37

5

D701-D706: 0916038600

678

X-MDX707, XR-C2MD

A

0031936000

B

S700-S719,S721,S722: 0028650000

S700 : STANDBY/ON

S701 : OPEN/CLOSE ( 1 )

S702 : OPEN/CLOSE ( 2 )

S703 : OPEN/CLOSE ( 3 )

S704 : CD SELECT ( 1 )

S705 : CD SELECT ( 2 )

S706 : CD SELECT ( 3 )

S707 : STOP ( )

S708 : TUNER FM/AM

S709 : CD ( )

S710 : MD ( )

S711 : TAPE ( )

S712 : AUX

S713 : • –

S714 : MD EJECT ( )

S715 : REC MODE

S716 : COLOR/CLOCK

S717 : TIMER

S718 : DOLBY NR

S719 : + •

S721 : EDIT

S722 : DEL/DISP

S723 : ENTER JOG

JW700 JW701

JW700: 4707570000

KEY PCB

C

002871200001

D

37

I

5

6

7

8

Page 38

1

X-MDX707, XR-C2MD

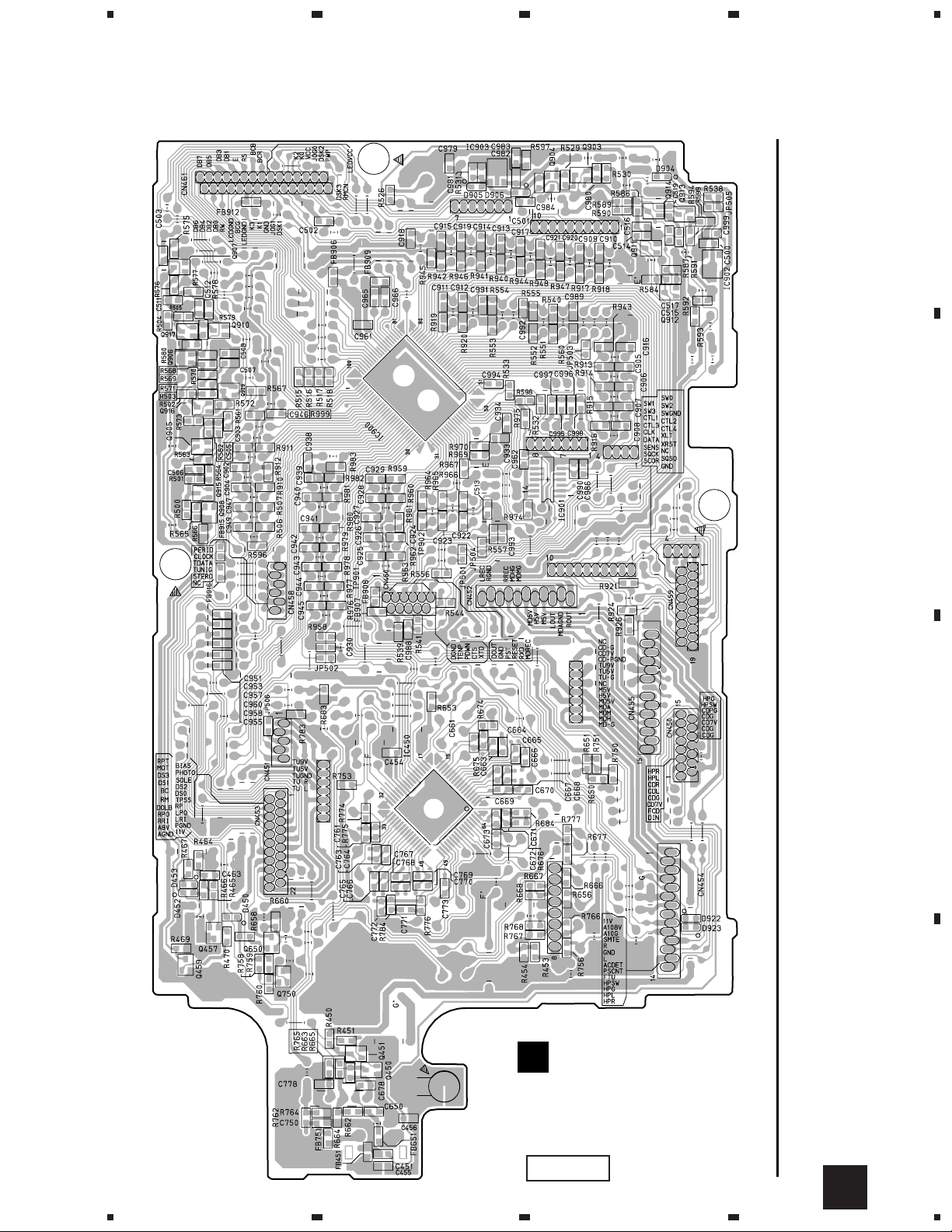

3.11 MD MOUNT

23

4

A

MD MOUNT

J

(A-4917-020-A)

OWH2

CN104

TO OWH

TP26 TP27

IC103: 8-729-903-10

4P

TO OP

KMS-260A/J1N

B

C

(FOR CHECK)

VEE

VCC

LD GND

ILCC

MOD

FCS+

FCS–

TRK+

TRK–

I+3V

CN101

G

21

E

20

E

D

19

D

C

F

I

VC

A

B

J

VR

PD

K

IOP

TE

VC

RF

C

18

F

17

16

15

14

13

12

11

10

I

VC

A

B

J

VCC

LG

IL

9

MOD

8

VR

7

PD

6

K

5

F+

4

F-

3

T+

2

T-

1

L101-L103:

21P

F.B

AGND

FSC–

TRK–

FSC+

TRK+

RF

TP160

VC

TP161

TE

TP162

IOP

TP163

I+3V

TP164

5P

5

4

3

2

1

C118

1

PD

A+3V

LD GND

ILCC

FSC+

TRK+

FSC–

TRK–

C107

0.1/25

F

VC

CN110

TO D-SW PWB

SLED–

SLED+

SPDL–

SPDL+

PROTECT

GND

REFLECT

CN105

7

6

5

4

3

2

1

7P

OWH1

DTC114EK

WRPWR

LDON

OWH1

Q102

IC103

2SA1037K

FMW1

2

3

1k

4

R103

5

1

R115

1k

Q103

I

J

VC

A

B

C

D

E

F

Q101

DTA144EK

R117

470k

R105

C105

4.7k

0.01

/50 B

C1621C167

0.1

/25 F

Q162

2SB798-T1

AZQ7132

IC152

BH6511FS-E2

8-759-430-26

ROHM DRIVER

R106 3.3M

D181,D183:

8-719-046-87

R182

S

L108

47k

Q181

2SJ278MYTR

8-729-018-75

C184

22

Q182

2SK1764KYR

8-729-017-65

C185

0.001

/500

WSR

R112

47k

R113

1k

Q104

DTC114EK

C109

0.022

/25 B

R163

R169

1 1/4W

R166

1/2W

S

R186

1

R110

10k

VC

AGND

C120

1

R107

470k

2.2k

C114

1

DAN202K

A+3V

AGND

Q163

DTA144EK

C168

0.1

/25 F

2.2

R165

100k

R167

4.7k

LD GND LD GND

C153

0.01

XRST

/50 B

CAPA-

CAPA+

GNDVGIN4R

C156

0.1

/25 F

XRST

TRK–

TRK+

0

L109

D181

0

F1J6

D183

F1J6

R183

47k

R187

1

R180

10k

C117

0.1

/25 B

4748 46 45 44 43 42 41 40 39 38 37

I

1

MORFI

MORFO

J

2

VC

3

A

4

B

5

C

6

D

7

E

8

F

9

PD

10

APCREF

APC

11

12

GND

TEMPI

13 14 15 16 17 18 19 20 21 22 23 24

C106

0.001

/50 CH

D101:

R104

10k

LDON

R164

680

VM2

IN2F

IN2R

VM12

OUT2F

OUT2R

PGND2

IN4F

VM4

OUT4F

PGND4

OUT4R

VM34

987654321

RFO

TEMPR

OUT1R

OUT3R

R109

0

R111

0

HGND

R184

10k

C116

C188

0.022

0.01/50 B

/50 B

OPN

OPO

ADDC

COMPP

RF AMP

IC101

CXA2523AR

8-752-080-95

SWDT

SCLK

XLAT

XSTBY

D101

R158

100k

C158

0.0068/50

VREF

VM1

IN1F

OUT1F

PGND1

PGND3

OUT3F

VM3

IN3F

11 12 13 14 15 1610

HARD DRIVE

8-759-523-48

(TC74ACT02)

8

9

10

11

12

13

14

C802

10/10

C115

0.22/16 B

RF

AGC1

RFAGC

COMPO

ADAGC

CSLED

WBLADJ

FOCNT

VREF

EOADJ

3TADJ

3.3k

R175

10k

R189

B

C1021C189

LD+3V

XRST

MOD

LDON

WRPWR

TE

171819202122232428 27 26 2529303132

VDD

IN1R

IN3R

PSB

IC181

IC181

PEAK

BOTM

ABCD

AUX

ADFG

ADIN

ADFM

VCC

C197

/25 F

FE

SE

TE

R177

R188

0.1

VCVC

36

35

34

33

32

31

30

29

28

27

26

25

3.3k

R159

10k

100k

0.033/25 B

C164

0.01

/50 B

C182

1

7

6

5

4

3

2

1

R162

2.2k

C163

0.01

/50 B

ABCD

FE

FE

C112

0.0047

/50 B

R179

R185

R190

10k

R161

DGND

DGND

MGND

REFLECT

VC

VC

AUX

C113

1/16

B

C111

0.068/25 B

47k

10k

AGND

2.2k

C152

0.1

/25 F

MGND

M+5V

SE

XLRF

DTRF

TC7S08F

5 4

C151

100

/6.3

PROTECT

H+5V

PEAK

BOTM

ABCD

VC

TE

FOCNT

IC122

MGND

M+5V

RF

FE

TE

CKRF

321

D+3V

A+3V

HGND

H+5V

TRDR

TFDR

EFMO

TP3

TP1

TE

SRDR

SFDR

FFDR

FRDR

SPRD

SPFD

H+5V

H+5V

C803

10

/10

HGND

R146 330

R148

680

ADFG

FOCNT

XLRF

CKRF

DTRF

APCREF

SRDR

SFDR

APCREF

FFDR

FRDR

R147

100

TRDR

TFDR

R141

SPRD

SPFD

L122

0

A2 GND

C134

0.1/25

F

A2+3V

A2+3V

HGND

A2 GND

SCTX

DCH GND

H+5V

D+3V

DGND

D+3V

DGND

DCH GND

A2+3V

A2 GND

A2+3V

A+3V

AGND

LD+3V

LD GND

C146

0.1/25

F

D

38

J

1234

Page 39

5

678

X-MDX707, XR-C2MD

VC

SE

TE

DCHG

76

APC

77

ADFG

78

FOCNT

79

XLRF

80

CKRF

81

DTRF

82

APCREF

83

LDDR

84

TRDR

85

TFDR

86

DVDD

87

FFDR

88

FRDR

89

FS4

90

SRDR

91

SFDR

92

SPRD

93

SPFD

94

FGIN

95

TEST1

96

TEST2

97

TEST3

98

DVSS

99

EFMO

100

C142,C143:

C136

100/6.3

100p/50

CH

MSM51V4400-70TS-K

C135

0.1/25

F

TE

SE

AVSS

ADRB

AUX2

MNT0(FOK)

MNT1(SHCK)

MNT2(XBUSY)

MNT3(SLOC)

SWDT

M0

M3

M2

C142

M1 TP153

IC125

8-759-498-44

A2+3V

A2 GND

R137

100

RF RF1

VC

ADIO

AUX1

ADRT

AVDD

DSSP & DSP

CXD2652AR

8-752-384-47

SCLK

XLAT

SRDT

SENS

XRST

11 12 13 14 15 16 17 18 19 2010

987654321

C143

R143 10k

C144 0.1/50

C133

0.0047

/50 B

FE

PEAK

ABCD

BOTM

IC121

SQSY

DQSY

RECP

XINTTXOSC1

C122 0.01/50 B

D3

D2

D3

VSS

D0D1WE

D0D1XWEA9A0A1A2

C130

100p/50

C131

0.015

/50 B

R140

150

C132

0.47

/16 B

R136

1k

R134 1k

FILI

PCO

FILO

CLTV

OSC0

XISL

R121 100k

DCH GND

A2 GND

A+3V

LD+3V

XOE

XCAS

D2

CAS

RASA9A0A1A2

XRAS

CH

3.3k

R135

PDO

AVSS

RVDD

RVSS

21 22 23 24

C110

0.1/25 F

A8A7A6A5A4

A8A7A6A5A4

OE

R133 680k

RF1

BIAS

AVDD

DIN

DOUT

ADDT

315

7

4268

R123 470

11121314151617181920

A3

VCC

10

987654321

A3

C127

0.1/25 F

0.1/25 F

C129

0.47

/16 B

C128

0.01

/50 B

R132 100k

R131

10k

515253545556575859606171 6272 6373 6474 6575 6667686970

ASYI

MVC1

ASYO

XWE

XRAS

A09

XCAS

XOE

DVSS

A11

A08

A07

A06

A05

A04

A10

A00

A01

A02

A03

DVDD

LRCK

256FS

XBCK

DADT

25

C124

D3

D2

D0

D1

RB120

Not

used

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

100

D+3V

DGND

DGND

XRAS

XCAS

0.1/25

D+3V

DGND

A2+3V

A2+3V

AGND

LD GND

XWE

XOE

C123

M+5V

IC202

LB1638MTE-L

8-759-823-87

C213

0.1

/25 F

MGND

X202:

XINT

SQSY

DQSY

C207

100p

SENS

MNT1

C208

100p

R203

10k

D3

D2

MNT2

D0

MNT3

D1

A9

C209

A8

0.1

A7

/25

A6

A5

A4

A0

A1

A2

A3

R213

100

F

Not used

L121

C191

0.1/25

F

31

32

33

34

35

36

3

4

37

1

2

38

6

5

39

8

7

40

41

42

RB204

43

100k

44

45

46

47

48

49

50

F

32.768kHz

C204

0.1

3

0.1

GND

SDA

SDA

SCL

Q05

2SD999

XIN

SCL

D102

12

XOUT

C205 15p

GND

X202

XIN-1

R122

15p

C206

XOUT-1

RXD

150

C192

1

C203

C202 0.001

2122232428 27 26 252930

VBAT

+3.3V

(TEST)

SYSTEM RST

RU8X12MF-0030

TXD

RTS

CTS

TP201

8-759-533-77

X201

12MHz

R218

1M

SENS

SHOCK

STB

REC P