Pioneer PD-S507 Service Manual

COMPACT DISC PLAYER

PD-S507

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

MYXK ‡ AC220–230V

MVXK ‡ AC220–230V

Model

PD-S507

Power Requirement

Remarks

ORDER NO.

RRV2034

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............3

3. SCHEMATIC DIAGRAM................................... 10

4. PCB CONNECTION DIAGRAM .......................17

5. PCB PARTS LIST.............................................24

6. ADJUSTMENT.................................................. 27

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

PIONEER ELECTRONIC CORPORATION 1998

7. GENERAL INFORMATION .............................. 35

7.1 IC................................................................ 35

7.2 DISPLAY ....................................................36

7.3 BLOCK DIAGRAM .....................................37

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................................38

T–ZZR OCT. 1998 Printed in Japan

PD-S507

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

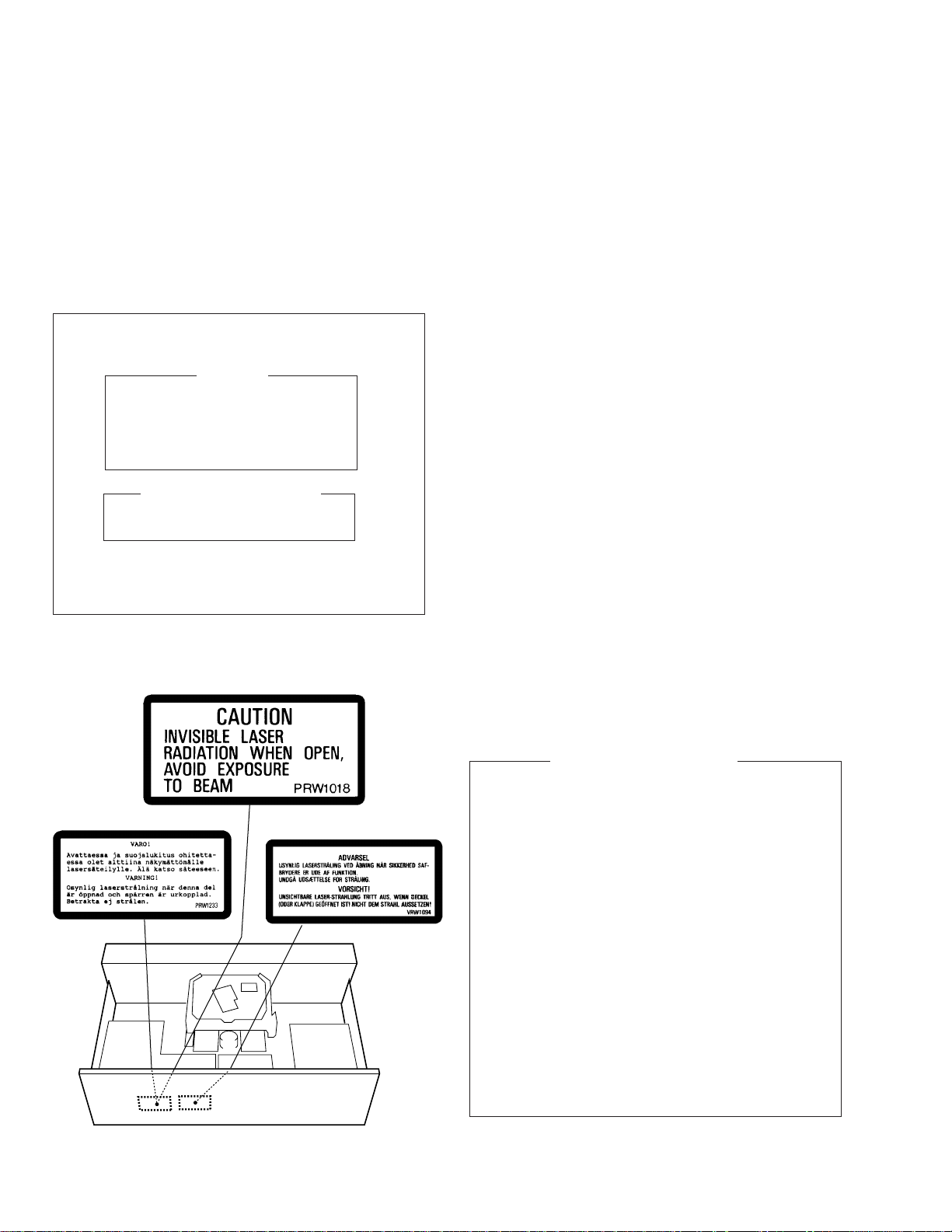

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mw

WAVELENGTH: 780 – 785 nm

LABEL CHECK

MVXK type

MYXK type

IMPORTANT

MYXK type

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S601) for detecting loading

state is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch

(S601) is not on CLMP terminal side (CLMP signal is OFF

or high level.). Thus, the interlock will no longer function if

the switch (S601) is deliberately set to CLMP terminal

side (low level).

The interlock also does not function in the test mode∗.

Laser diode oscillation will continue, if pin 33 of

CXA1782CQ (IC151) on the MAIN BOARD ASSY is

connected to GND, or pin 22 of IC301(LDON) is

connected to low level (ON), or else the terminals of Q151

are shorted to each other (fault condition).

2. When the cover is opened with the servo mechanism

block removed and turned over, close viewing of the

objective lens with the naked eye will cause exposure to a

REAR

Class 1 laser beam.

∗ Refer to page 28.

2

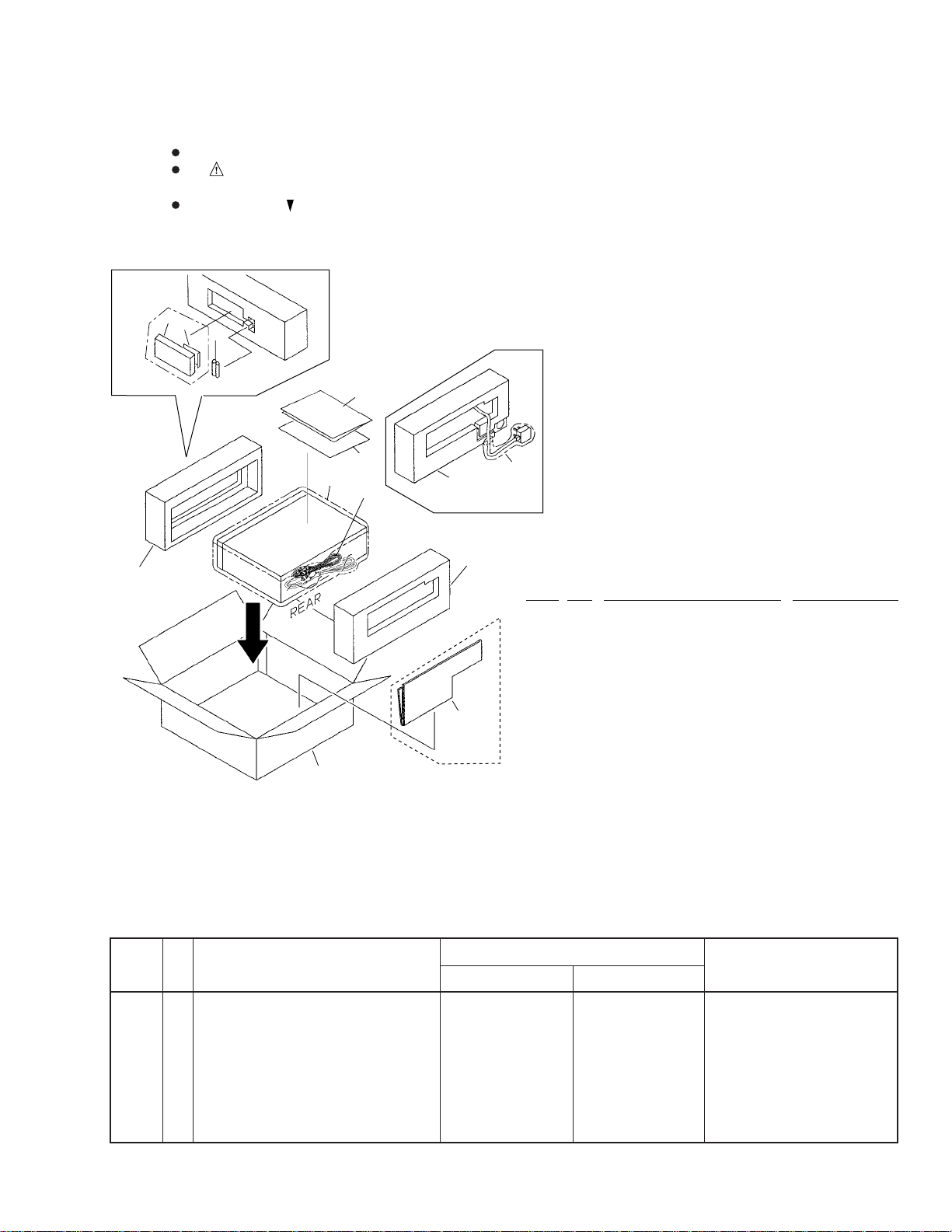

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

2.1 PACKING

8

9

7

6

For MVXK

PD-S507

12

4

5

1

2

11

2

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 Protector F PHA1329

2 Protector R

3 Packing Case

4 Packing Sheet Z23–007

(750 × 600 × 0.5)

5 Output Cable (L=1.2m) PDE1248

10

NSP 7 Batteris (R03, AAA) VEM–022

3

MVXK Only

NSP 12 Warranty Card ARY7022

6 Operating Instructions

8 Remote Control Unit(CU-PD096) XWW1001

9 Battery Cover XZN1001

10 Spacer

11 Polyethylene Bag

(115 × 270 × 0.05)

(2) CONTRAST TABLE

PD-S507/MYXK and MVXK are constructed the same except for the following:

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

Mark

Part No.

MYXK type MVXK type

2 Protector R PHA1331 PHA1332

3 Packing Case PHG2314 PHG2330

6 Operating Instructions PRE1270 Not used

(English/ French/ German/Italian/

Dutch/ Swedish/Spanish/Portuguese)

6 Operating Instructions (English) Not used PRB1274

10 Spacer Not used PHC1078

11 Polyethylene Bag (115 × 270 × 0.05) Not used Z21–013

RemarksSymbol and DescriptionNo.

3

PD-S507

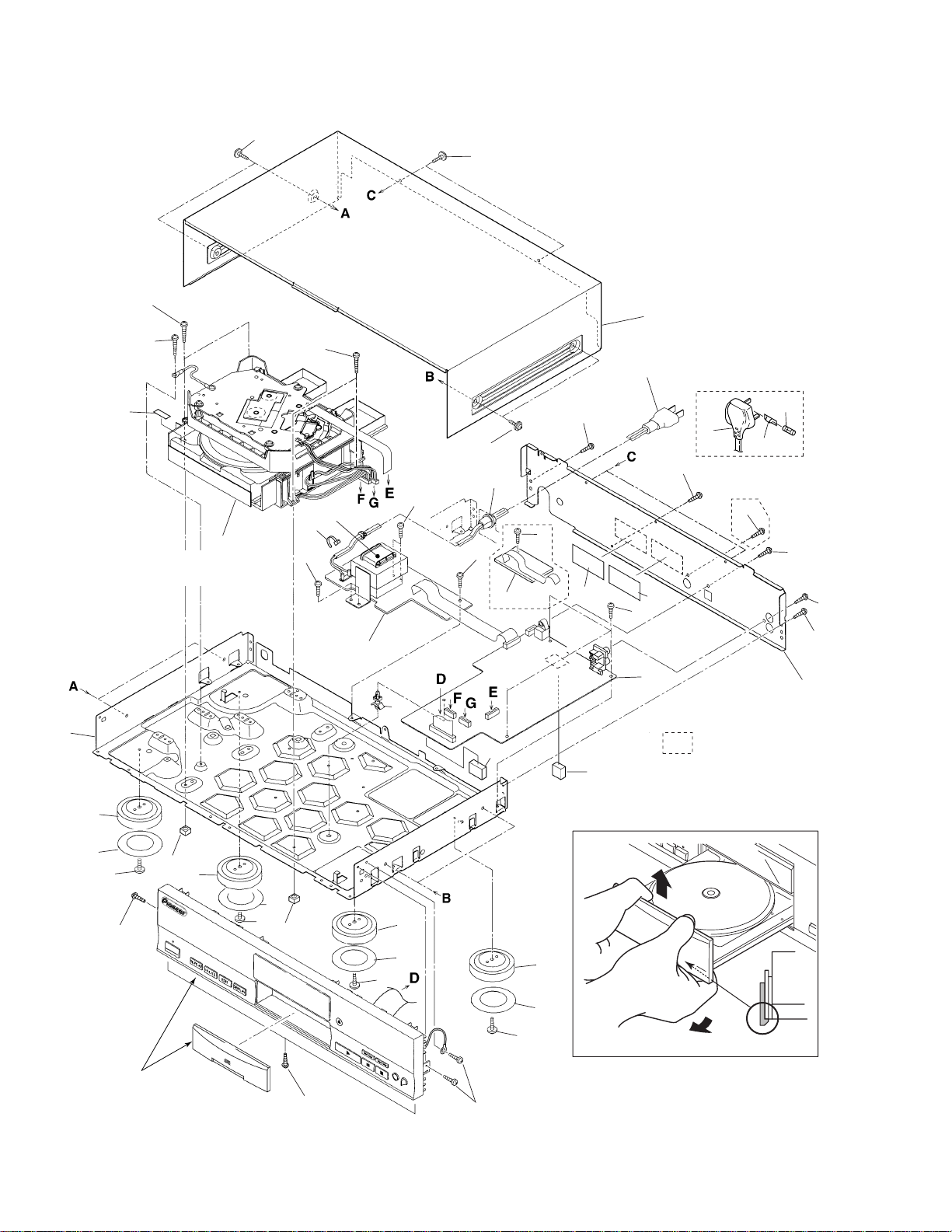

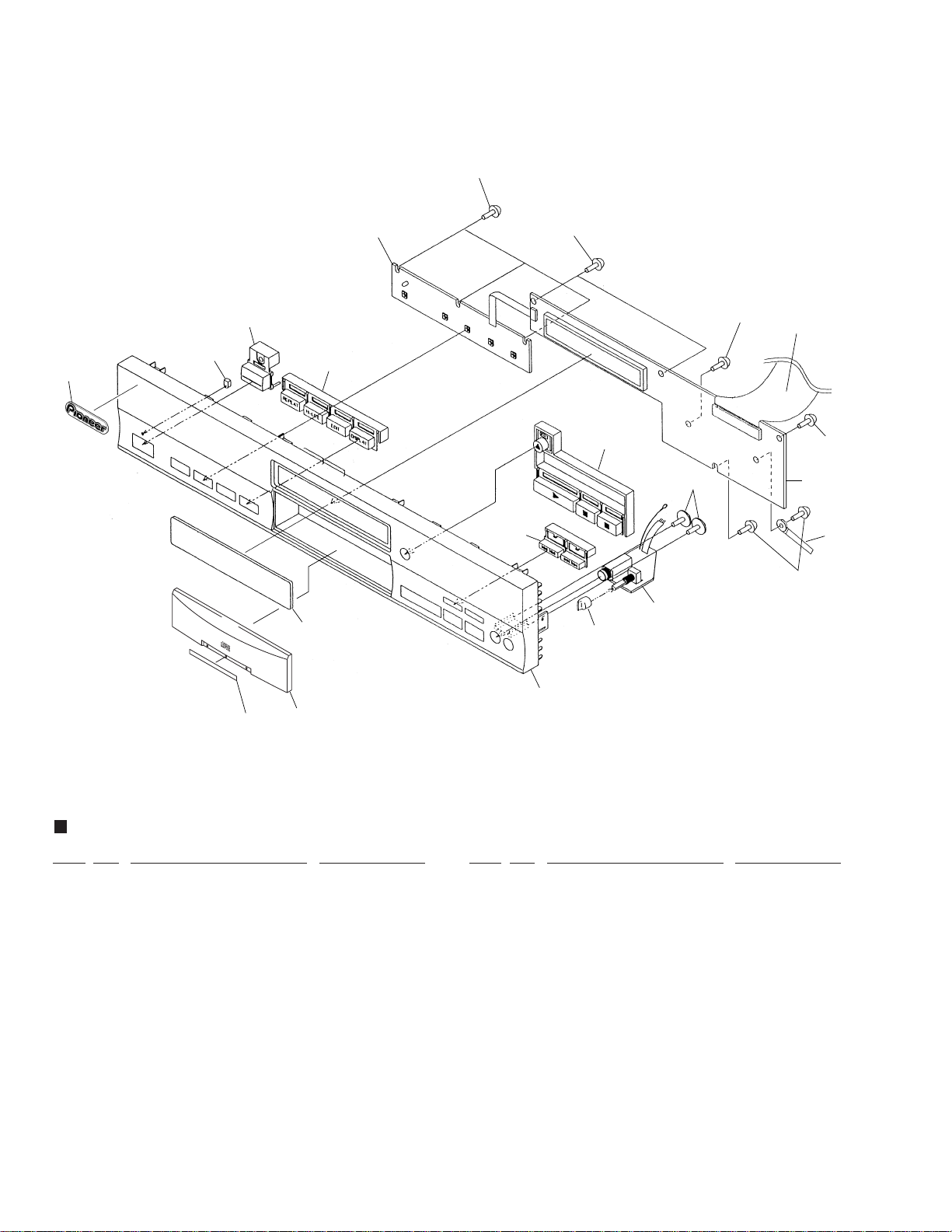

2.2 EXTERIOR

25

8

21

Refer to "2.4 LOADING

MECHANISM ASSY T 96".

13

19

26

7

12

25

5

8

26

4

8

6

28

8

2

16

7

10

7

3

22

20

7

1

11

For MVXK type

5

8

24

: MVXK type Only

29

Fuse Holder

24

24

8

14

17

15

7

24

Refer to "2.3 FRONT PANEL

SECTION".

18

9

4

Removal of the Tray Panel

2

15

7

18

7

17

15

7

24

9

15

7

1

(1) EXTERIOR PARTS LIST

PD-S507

Mark No. Description Part No.

1 MAIN BOARD ASSY

2 POWER BOARD ASSY PWZ3770

3 COAXIAL OUTPUT BOARD ASSY

4 Strain Relief CM–22B

5 AC Power Cord

6 Power Transformer PTT1236

7 Screw ABA1011

8 Screw (3 × 6) ABA1207

9 Insulator AMR7198

10 Rubber Spacer B PEB1281

NSP 11 PCB Spacer PEB1304

12 Bonnet PYY1162

NSP 13 Under Base 56 PNA2214

14 Rear Base

15 Cushion 55 PNM1316

NSP 16 PCB Holder PNW2100

17 Insulator PNW2766

18 Disc Guard REC1305

NSP 19 Loading Mechanism Assy T96 PXA1604

20 Caution Label HE

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

Mark No. Description Part No.

21 Caution Label PRW1244

22 Caution Label

23 .............................

24 Screw BBZ30P080FCC

25 Screw BSZ30P070FMC

26 Screw FBT40P080FZK

27 .............................

28 Binder (SKB–90BK) ZCA–SKB90BK

29 Fuse (5A)

(2) CONTRAST TABLE

PD-S507/MYXK and MVXK are constructed the same except for the following:

See Contrast table (2)

See Contrast table (2)

Mark

No.

Part No.

MYXK type MVXK type

1 MAIN BOARD ASSY PWZ3762 PWZ3763

3 COAXIAL OUTPUT BOARD ASSY Not used PWZ3775

5 AC Power Cord PDG1043 PDG1055

14 Rear Base PNA2419 PNA2442

20 Caution Label HE PRW1233 Not used

22 Caution Label VRW1094 PRW1018

29 Fuse (5A) Not used PEK1003

RemarksSymbol and Description

5

PD-S507

2.3 FRONT PANEL SECTION

14

10

11

2

8

6

7

9

14

14

13

4

3

5

15

14

1

18

14

16

17

FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

1 SWITCH BOARD ASSY PWZ3766

2 MODE BOARD ASSY PWZ3768

3 HEADPHONE BOARD ASSY PWZ3773

4 Screw (FE) ABA7009

5 HEADPHONE Knob PAC1707

6 MODE Button PAC1887

7 MANUAL Button PAC1889

8 POWER Knob PAC1891

9 Display Window PAM1759

10 Name Plate PAM1776

12

Mark No. Description Part No.

11 LED Lens PNW2019

12 Function Panel PNW2807

13 PLAY Button B RAC2204

14 Screw PPZ30P080FMC

15 26P FFC/30V PDD1142

NSP 16 Tray Badge PAN1358

17 Tray Name Plate PNW2806

18 Cord Clamper RNH–184

6

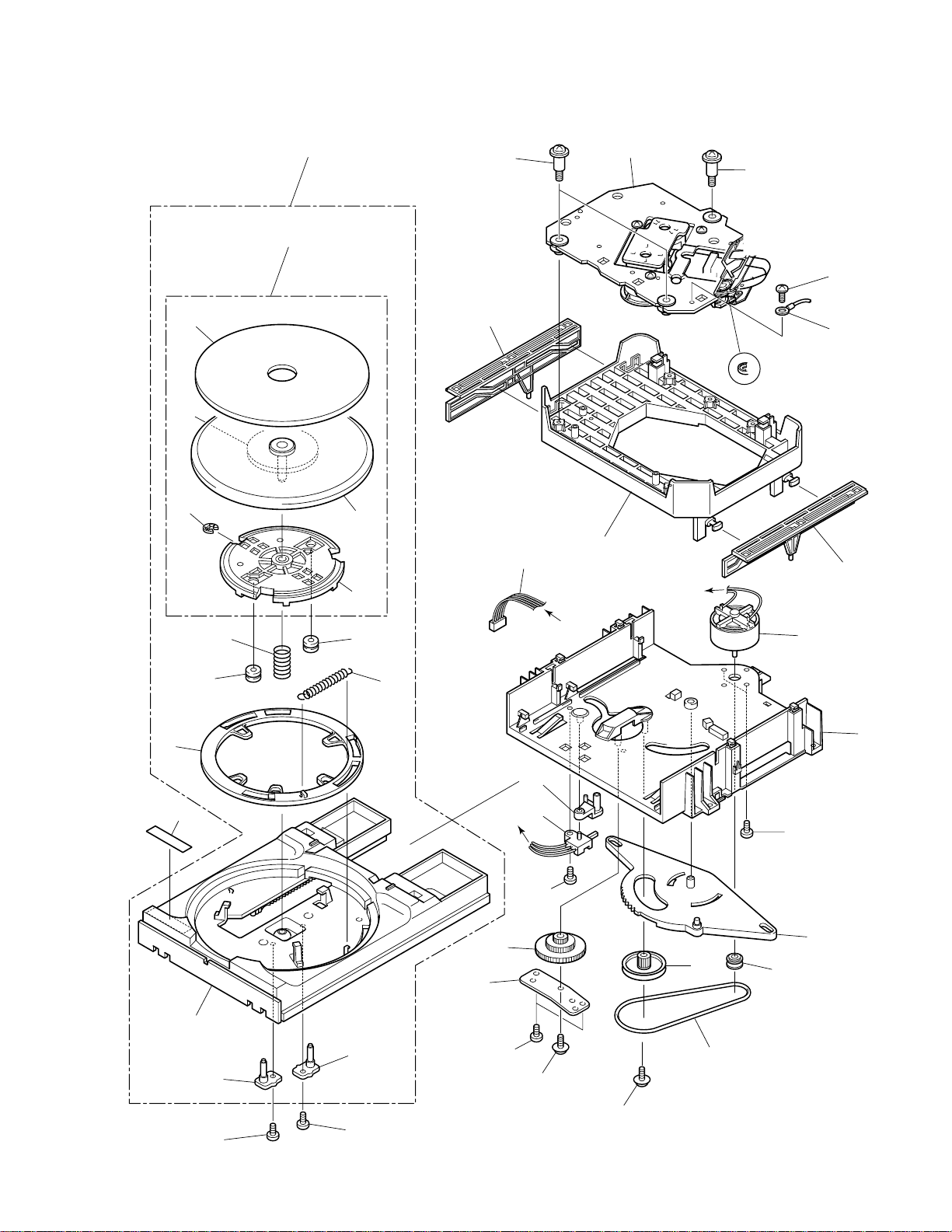

2.4 LOADING MECHANISM ASSY T96

36

PD-S507

2

27

2

35

28

15

14

12

23

14

26

25

13

10

34

Refer to " 2.5 SERVO

MECHANISM ASSY T96".

31

32

Spacer

9

11

A

A

19

18

33

16

17

21

17

21

29

24

8

1

A

30

5

7

30

22

22

3

20

6

4

7

PD-S507

LOADING MECHANISM ASSY T96 PARTS LIST

Mark No. Description Parts No.

Mark No. Description Parts No.

1 Lever Switch (S601) DSK1003

2 Float Screw PBA1027

3 Rubber Belt PEB1186

4 Motor Pulley PNW1634

5 Drive Gear PNW1996

6 Synchronized Lever PNW2168

7 Gear Pulley PNW1998

8 SW Head PNW1999

9 Float Base PNW2767

10 Left Cam PNW2001

11 Right Cam PNW2002

12 Float Spring PBH1120

13 Lock Spring PBH1121

14 Float Rubber PEB1014

15 Table Rubber Sheet PEB1181

16 Tray PNW2760

17 Table Guide PNW2004

18 Lock Plate PNW2005

19 D.C. Motor (0.75W, LOADING) PXM1010

20 Screw BMZ26P040FMC

21 Screw IPZ26P060FCU

22 Screw IPZ20P080FMC

23 Turn Table Assy PEA1199

24 Loading Base PNW2761

25 Table Shaft Holder Assy PXA1383

26 Turn Table PNR1044

NSP 27 Servo Mechanism Assy T96 PXA1606

28 E Ring YE20FUC

29 Shaft Holder PNB1382

30 Screw BPZ26P060FMC

31 Screw BBZ26P060FMC

NSP 32 Earth Lead DE010VF0

33 Caution Label PRW1244

34 Connector Assy 5P PDE1243

NSP 35 Table Base PXA1382

NSP 36 Tray Assy TT PXA1449

How to Install the Disc Table

¶

1

Use nipper or other tool to cut the three sections marked

A

in figure 1. Then remove the spacer

2

While supporting the spindle motor shaft with the

stopper, put spacer on top of the carriage base, and stick

the disc table on top (takes about 9kg pressure). Take

off the spacer.

1

A

Spacer

FFC Holder

A

2

Spacer

Spacer setting

Position

(Pressure of about 9kg)

Spindle motor

Disc table

PCB

Stopper

2.1mm

Carriage

Base

8

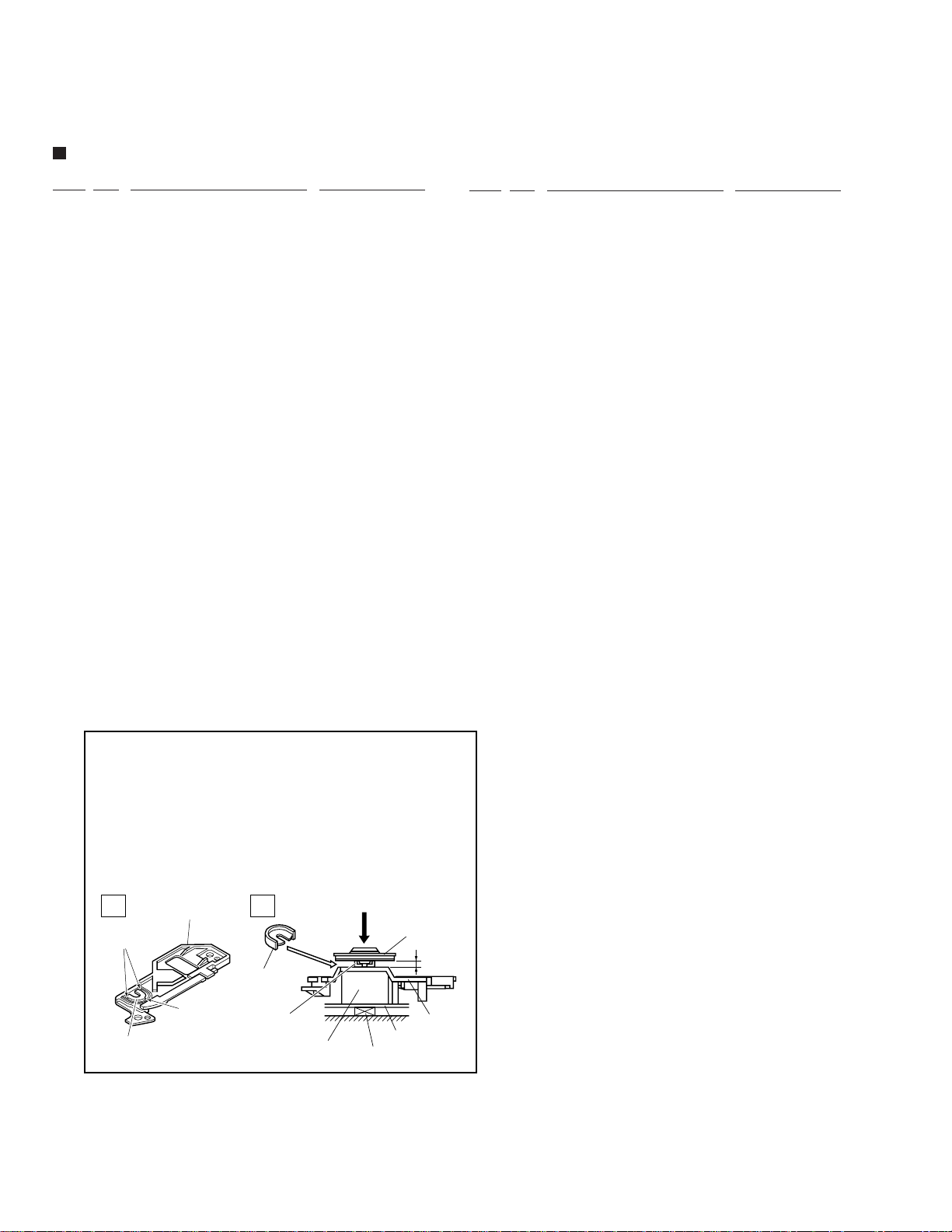

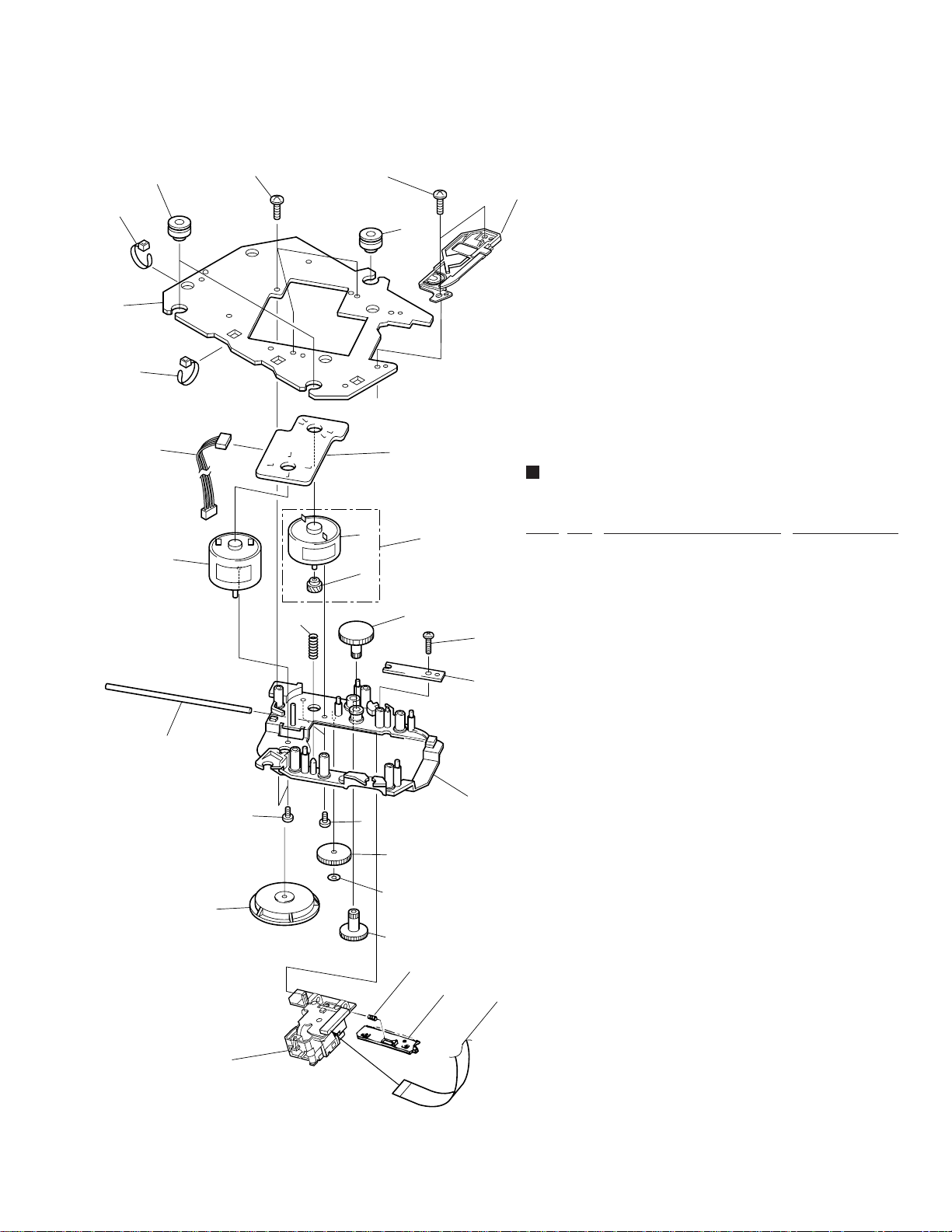

2.5 SERVO MECHANISM ASSY T96

PD-S507

17

20

20

24

21

12

18

18

23

22

19

SERVO MECHANISM ASSY T96

PARTS LIST

1

3

16

6

5

2

7

25

13

15

14

4

8

10

Mark No. Description Parts No.

1 Carriage D.C. Motor (0.3W) PXM1027

2 Pinion Gear PNW2055

3 Spindle Motor Assy PEA1236

(SPINDLE, with Oil)

4 Carriage Base PNW2699

5 Disc Table PNW1067

6 Screw JFZ20P030FNI

7 Screw JFZ17P025FZK

8 Gear 3 PNW2054

9 Gear 2 PNW2053

10 Washer WT12D032D025

11 Pickup Assy PEA1335

12 Guide Bar PLA1094

13 Gear 1 PNW2052

14 Gear Stopper PNB1303

15 Screw BPZ20P060FMC

16 Earth Spring PBH1132

NSP 17 Mechanism Base T.T.96 PNB1592

18 Screw BPZ26P100FMC

19 Mechanism Board Assy PWX1192

20 Binder PEC–107

11

9

26

27

28

21 Float Rubber PEB1031

22 Float Rubber PEB1170

23 FFC Holder PNW2734

24 Connector Assy 4P PDE1238

25 Carriage Motor Assy PEA1246

(CARRIAGE)

26 Rack Spring PBH1128

27 Rack Holder PNW2056

28 F.F.C.(16P) PDD1185

9

1

234

PD-S507

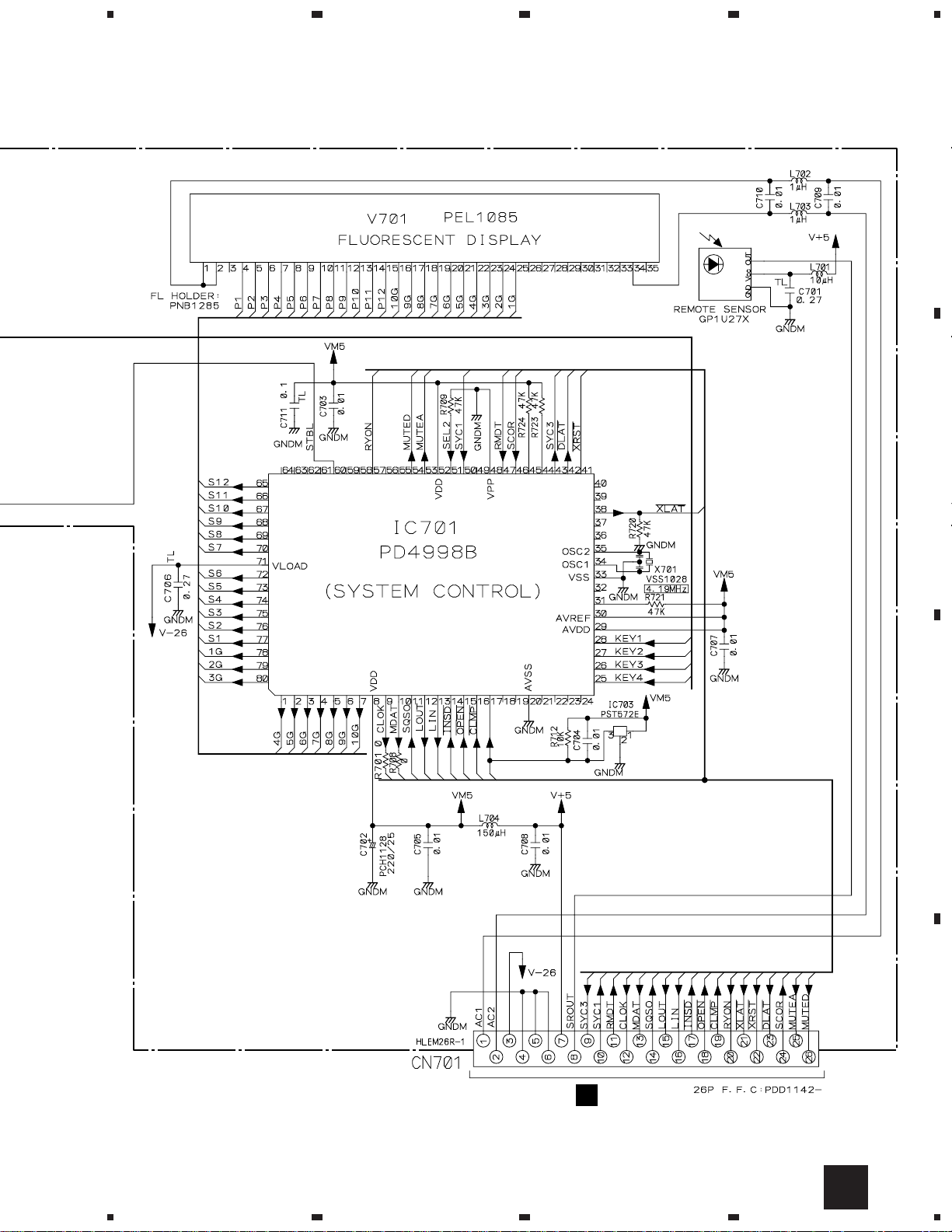

3. SCHEMATIC DIAGRAM

Note: When ordering service parts, be sure to refer to "EXPLODED VIEWS AND PARTS LIST" or "PCB PARTS

A

LIST".

3.1 OVERALL SCHEMATIC DIAGRAM

LOADING MECHANISM

ASSY T 96 (PXA1604)

PICK UP ASSY

PEA1335

CN201

CN11

KPD7

CN131

SLW16S-IC7

B

CN 501

52147-0410

MAIN BOARD ASSY

B

(PWZ3762: MYXK)

(PWZ3763: MVXK)

SERVO MECHANISM

ASSY T96 (PXA1606)

DSG1016

SPINDLE

MOTOR

ASSY

PEA1236

CARRIAGE

MOTOR

ASSY

PEA1246

C

A

MECHANISM BOARD

ASSY (PWX1192)

S601:DSK1003

CLAMP SW

PXM1010

LOADING MOTOR

CN610

CLMP

OPEN

LOAD

CN202

CN205

CN 331

52147-0310

CN351

HLEM26S-1

26

25

24

23

22

21

20

19

18

17

16

15

26

25

24

23

22

21

20

19

18

17

16

15

D

10

A

1234

5

67

8

PD-S507

A

J11

DYY07-200-2651

POWER BOARD

E

ASSY (PWZ3770: MYXK/MVXK)

Power Transformer

(PTT1236: MYXK/MVXK)

PHONE BOARD

C

ASSY (PWZ3773:MYXK

/MVXK)

J501

D20PDY0406B

WHT

YEL

V+5D

DOUT

D

GND

NEUTRAL

LIVE

AC Power cord

PDG1003: MYXK

AC220-230V 50/60Hz

PDG1055: MVXK

AC220-230V 50Hz

B

PD-S507/MVXK Only

COAXIAL OUTPUT

ASSY (PWZ3775:

/MVXK) Only

26

25

24

23

22

21

20

19

18

17

16

15

PDD1142

5

CN701

HLEM26R-1

26

25

24

23

22

21

20

19

18

17

16

15

C

SWITCH BOARD ASSY

F

(PWZ3766:MYXK/MVXK)

CN751

52151-0410

J751

D20PDY0410E

MODE BOARD

G

ASSY (PWZ3768)

D

11

6

7

8

1

234

PD-S507

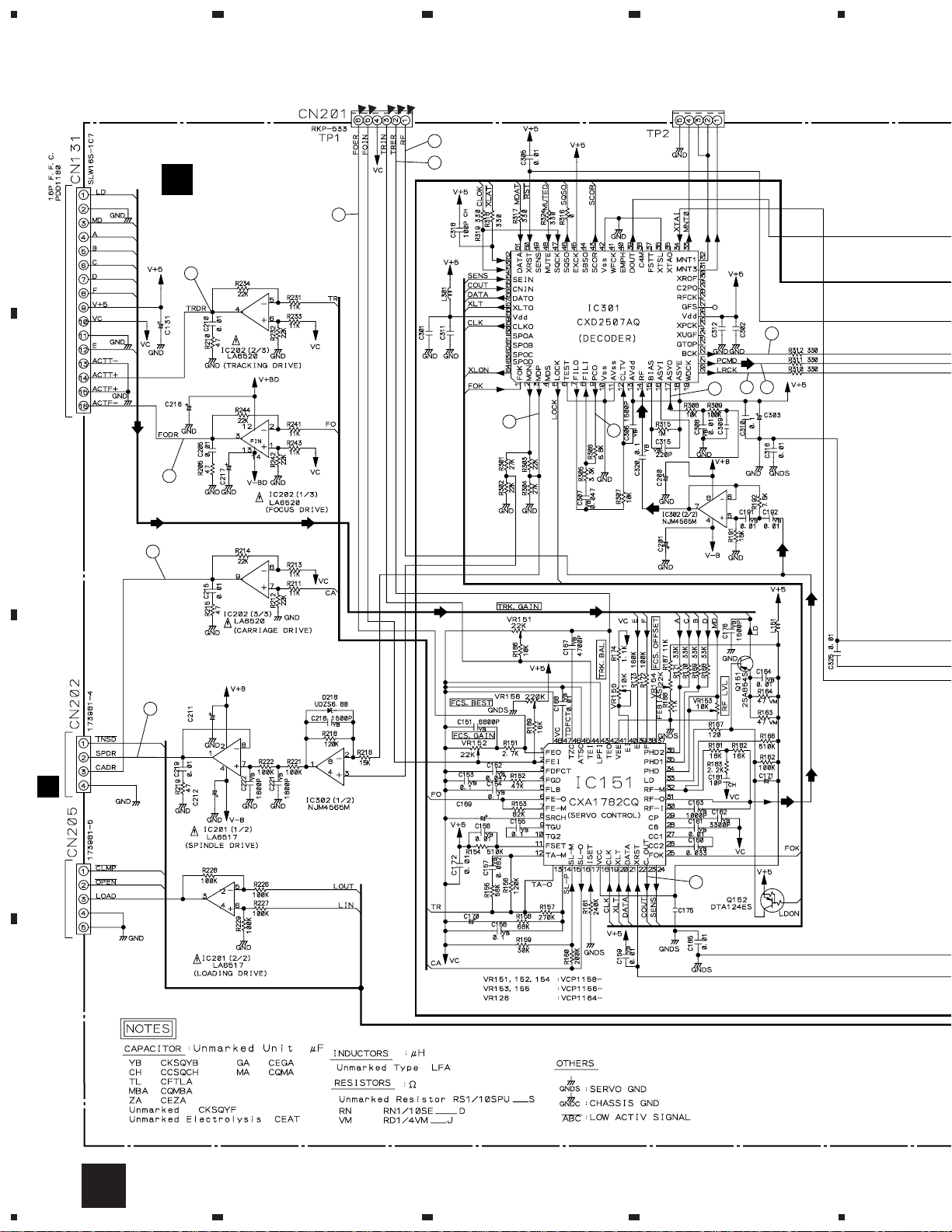

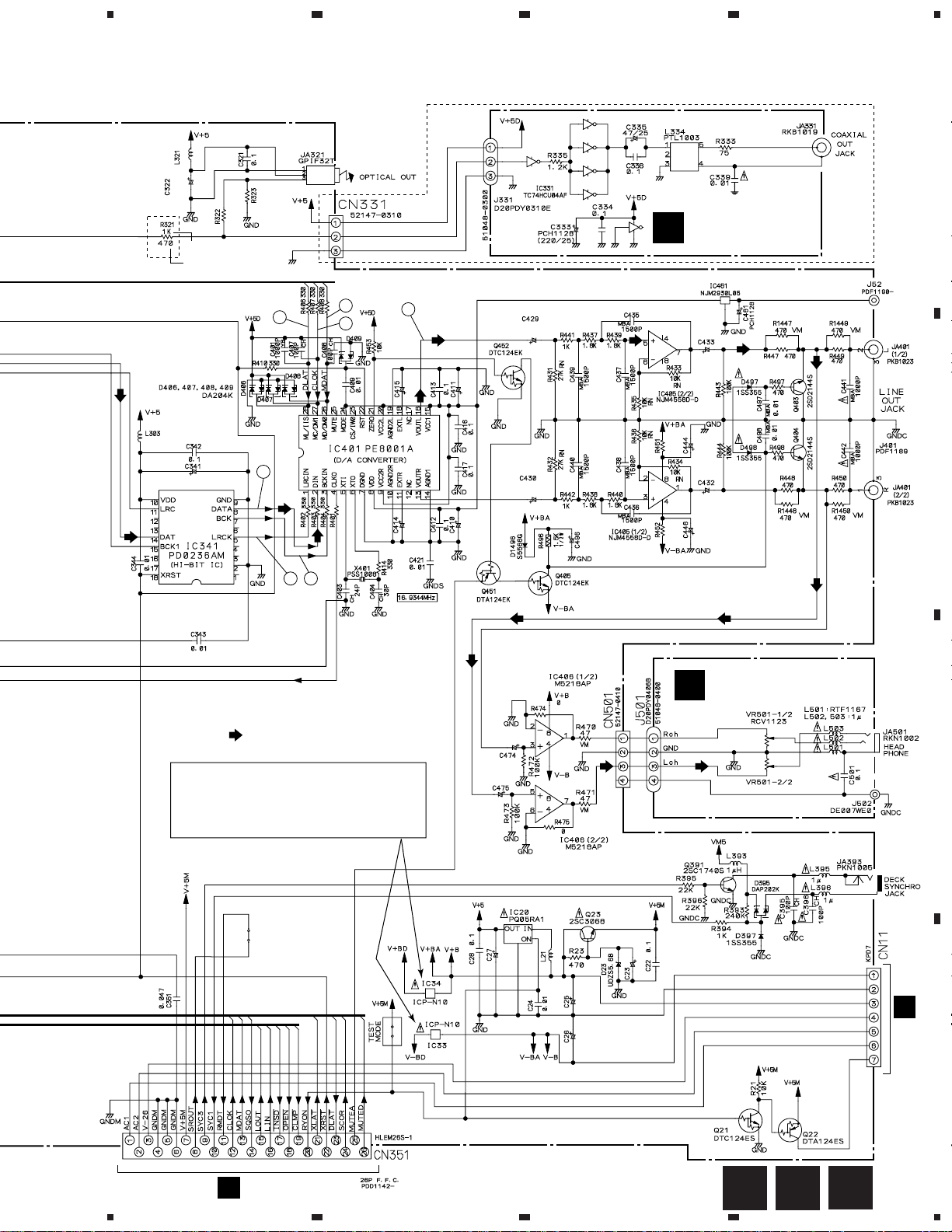

3.2 MAIN BOARD ASSY, PHONE BOARD ASSY and COAXIAL OUTPUT ASSY

2

A

To PICKUP ASSY

B

MAIN BOARD ASSY

(PWZ3762: MYXK)

B

(PWZ3763: MVXK)

6

220/25 (PCH1128)

220/25

(PCH1128)

5

220/25

(PCH1128)

4

3

10 µH

MA

0.1

0.15

33

53

220/25

(PCH1128)

MA

0.1

18

9

0.47

TL

0.15

19

(PCH1122)

16

1000/16

8

7

C

CN610

A

220/25

(PCH1128)

220/25

(PCH1128)

4.7/50

(PCH1127)

220/25

(PCH1128)

10 µH

100/50

(PCH1126)

23

MA

4.7/50

(PCH1127)

0.15

To Loading Motor and S601

D

12

B

1234

5

67

8

PD-S507

MVXK ONLY

150 µH

RTF1068

220/25

(PCH1128)

MYXK

MVXK

1000/16

(PCH1122)

1.5k: MVXK

0: MYXK

56

1.5k : MYXK

3k: MVXK

60

A

COAXIAL OUTPUT

D

ASSY (PWZ3775)

59

58

100

5455

65

GA

4.7/50

GA

4.7/25

1000/16

(PCH1122)

GA

47/50

47/50

(PCH1124)

47/50

(PCH1124)

220/25

(PCH1128)

100

100

(1/2W)

(1/2W)

100/50

(PCH1126)

220/25

(PCH1128)

100/50

(PCH1126)

220/25

(PCH1128)

B

SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

CAUTION: FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TIME

NO. ICP-N10, MFD BY ROHM CO.,

LTD. FOR IC33 and IC34.

(PCH1127)

4.7/50

(PCH1127)

4.7/50

220/25

(PCH1128)

RTF1167

4700/16

(PCH1119)

4700/16

(PCH1119)

PHONE BOARD ASSY

(PWZ3773)

C

C

GA

4.7/50

E

J11

D

F

CN701

5

6

7

B C

D

8

13

1

234

PD-S507

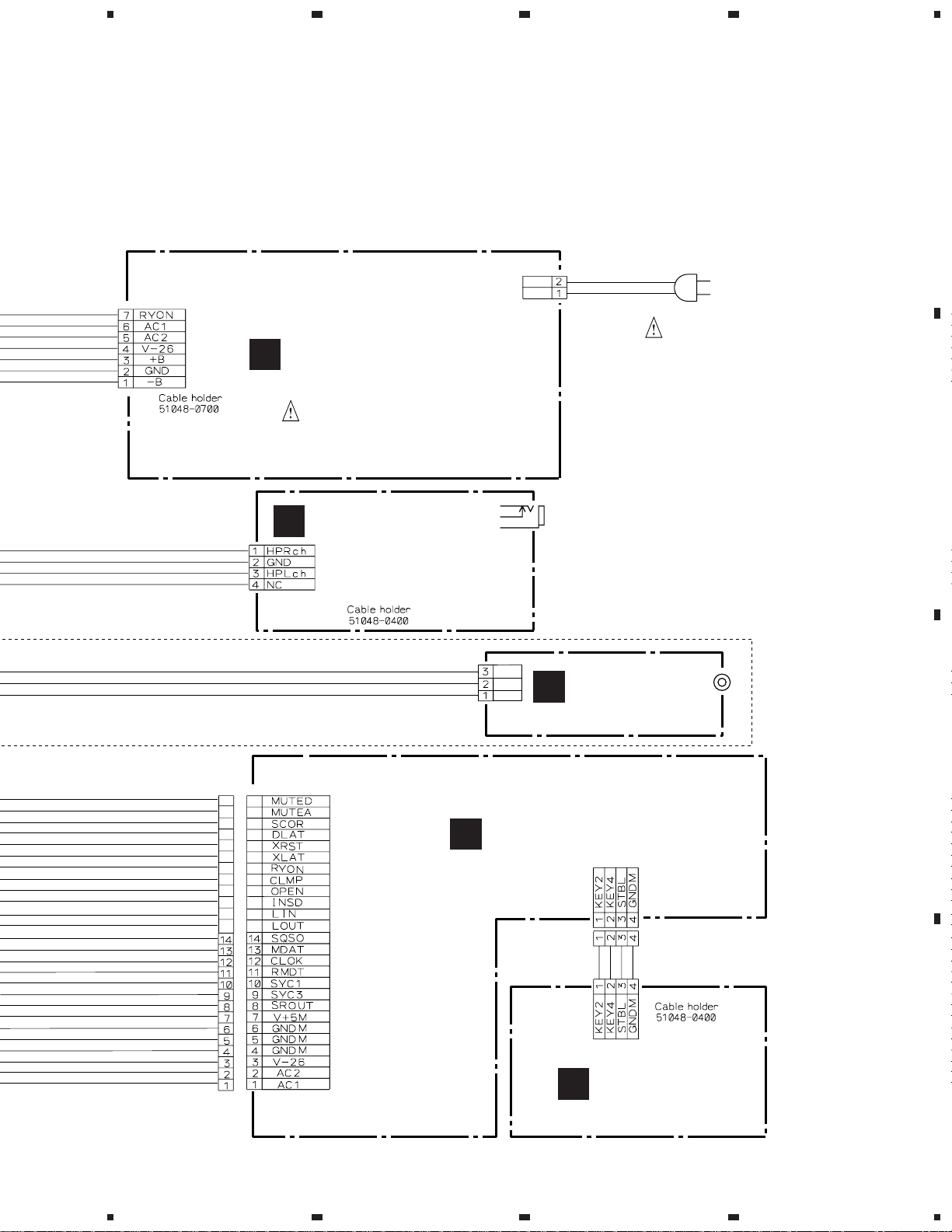

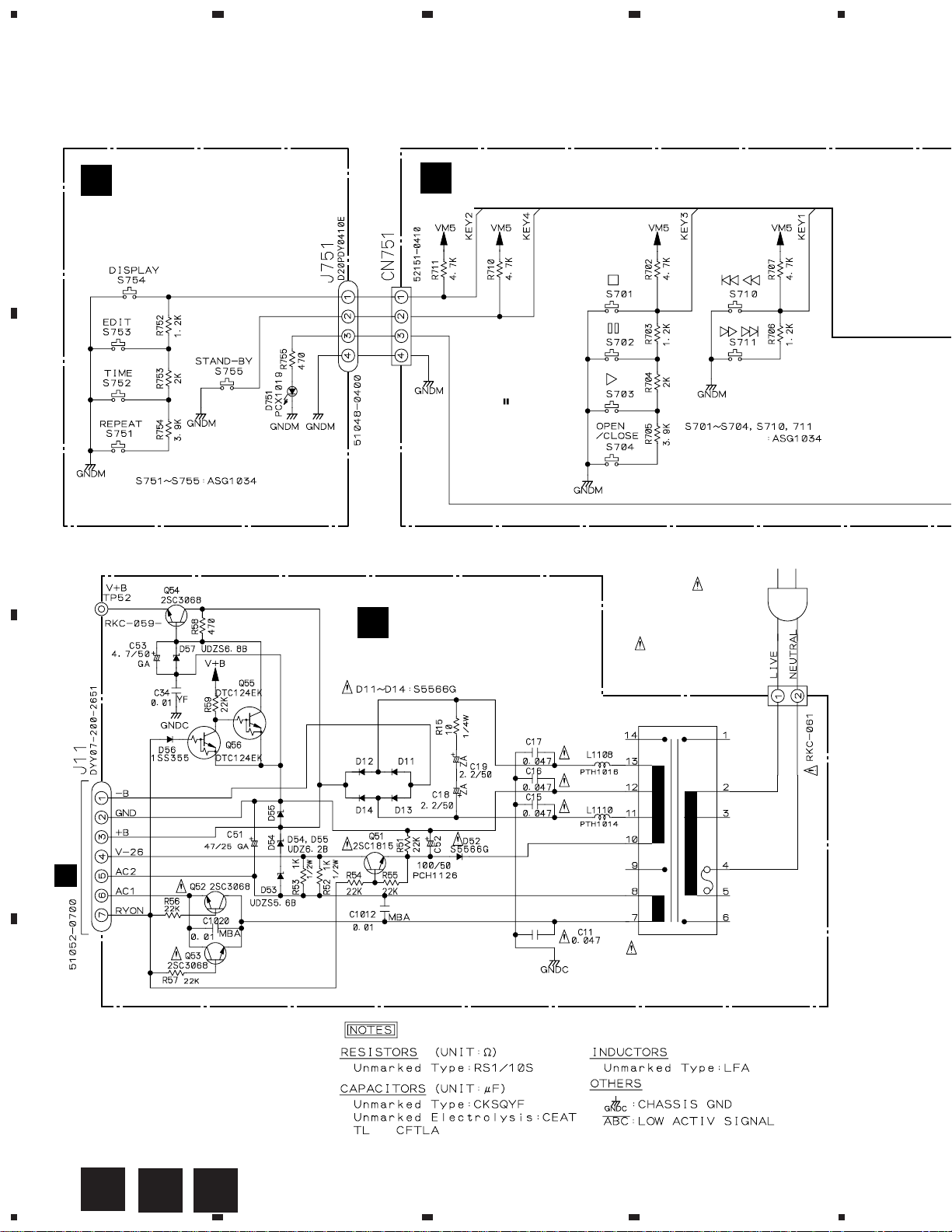

3.3 POWER BOARD ASSY, SWITCH BOARD ASSY and MODE BOARD ASSY

A

B

MODE BOARD ASSY

G

(PWZ3768)

SWITCHES

S751: REPEAT

S752: TIME

S753: EDIT

S754: DISPLAY

S755: STANDBY

POWER BOARD ASSY

E

(PWZ3770)

SWITCH BOARD ASSY

F

(PWZ3766)

SWITCHES

S701: 7

S702:

S703: 3

S704: OPEN/CLOSE

S710: 4 1

S711: ¡ ¢

AC220–230V 50/60 Hz

AC POWER CORD

PDG1003: MYXK

PDG1055: MVXK

FUSE (5A): PEK1003

(MVXK ONLY)

C

CN11

B

POWER TRANSFORMER

PTT1236

D

14

E

F G

1234

5

67

8

PD-S507

A

B

C

D

B

CN351

F

5

6

7

8

15

Loading...

Loading...