Pioneer PDP-503PE, PDP-503PU Service Manual

PLASMA DISPLAY

PDP-503PE

PDP-503PU

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

WYVI6 ? − AC220 - 240V

KUC − ? AC120V

PDP-503PE PDP-503PU

This Service Manual should be used together with the following manual(s).

Model No. Order No. Remarks

PDP-503PE

PDP-503PU

Model

Power Requirement Remarks

ARP3108 SCHEMATIC DIAGRAM and PCB DIAGRAM

ORDER NO.

ARP3107

This product is component of system.

Component System Service Manual Remaks

Plasma Display System PDP-503HDE

Media Receiver PDP-R03E

Plasma Display PDP-503PE

For details, refer to "Important symbols for good services".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 2002

PDP-5030HD

PDP-R03U

PDP-503PU

PDP-R03E : ARP3110

PDP-R03U : ARP3113

ARP3107

ARP3108

This service manual

T – IZE JAN. 2002 Printed in Japan

PDP-503PE, PDP-503PU

SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 – Proposition 65

SAFETY PRECAUTIONS

NOTICE :Comply with all cautions and safety related notes located

on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an isolation

transformer should be inserted between the power line and the

set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit diagram

should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

service technician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the connector

will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

2

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to the

chassis should have a minimum resistor reading of 0.3MΩ and a

maximum resistor reading of 5MΩ. Any resistor value below or

above this range indicates an abnormality which requires corrective

action. Exposed metal parts not having a return path to the chassis

will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not use

an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229 equivalent)",

measure for current from all exposed metal parts of the cabinet

(input/output terminals, screwheads, metal overlays, control shaft,

etc.), particularly any exposed metal part having a return path to the

chassis, to a known earth ground (water pipe, conduit, etc.). Any

current measured must not exceed 0.5mA.

PDP-503PE, PDP-503PU

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have special

safety related characteristics. These are often not evident from

visual inspection nor the protection afforded by them necessarily

can be obtained by using replacement components rated for higher

voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in this Service Manual.

Electrical components having such features are identified by marking

with a

Manual.

The use of a substitute replacement component which dose not have

the same safety characteristics as the PIONEER recommended

replacement one, shown in the parts list in this Service Manual, may

create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to, or

additional copies of, PIONEER Service Manual may be obtained at

a nominal charge from PIONEER.

on the schematics and on the parts list in this Service

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Test all exposed

metal surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

3

PDP-503PE, PDP-503PU

CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT

7 Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In addition,

the measuring equipment can be damaged if it is connected to the

GND of the charged section and the GND of the non-charged

section while connecting the set directly to the commercial AC

power supply. Therefore, be sure to connect the set via an insulated

transformer and supply the current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the SW POWER SUPPLY Module)

5. STB Transformer and Converter Transformer

(In the SW POWER SUPPLY Module)

6. Other primary side of the SW POWER SUPPLY Module

Y DRIVE

Assy

SCAN (A)

Assy

7 High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. SW POWER SUPPLY Module ...................................... (225V)

2. X DRIVE Assy .............................................. (–300V to 225V)

3. Y DRIVE Assy ............................................................... (355V)

4. SCAN (A) Assy .............................................................. (355V)

5. SCAN (B) Assy ............................................................... (355V)

6. X CONNECTOR (A) Assy ........................... (–300V to 225V)

7. X CONNECTOR (B) Assy ............................ (–300V to 225V)

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

SCAN (B)

Assy

∗ Remove the IF Earth Metal (No.14 on the page 25)

beforehand when inclines the power supply unit

as the right figure.

SW POWER SUPPLY

Module

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

AC Inlet with Filter

Power Cord

Top

Front

X CONNECTOR (A)

Assy

X DRIVE

Assy

X CONNECTOR (B)

Assy

Power Switch

(S1)

4

PDP-503PE, PDP-503PU

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

5

PDP-503PE, PDP-503PU

CONTENTS

1. SPECIFICATIONS

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.2 IC INFORMATION

8. PANEL FACILITIES

.................................................

.................

...

(For SCHEMATIC DIAGRAM, refer to ARP3108)

...

Refer to ARP3108

................................................

.....................................................

................................

..................................................

7.1.1 PCB LOCATION

7.1.2 SHUT DOWN/POWER DOWN

DIAGNOSIS BY LED DISPLAY

7.1.3 DISASSEMBLY

...................................

...........

.....................................

........................................

..........................................

7

8

30

46

57

77

77

77

78

85

89

108

6

PDP-503PE, PDP-503PU

1. SPECIFICATIONS

Item Model: PDP-503PE Model: PDP-503PU

Number of Pixels 1280 × 768 pixels

Audio Amplifier 12 W + 12 W (10% distortion)

Power Requirement AC 220–240 V, 50/60 Hz, 356 W (0.6 W Standby) AC 120 V, 60 Hz, 370 W (0.6 W Standby)

Dimensions 1218 (W) × 714 (H) × 98 (D) mm [47

Weight 38.9 kg (85.8 lbs)

31/32

(W) × 28

1/8

(H) × 3

7/8

(D) inch]

Accessories

• Design and specifications are subject to change without notice.

Power Cord, Cleaning Cloth, Three speed clamps, Three bead bands,

Warranty card

Accessories

Power cord

(ADG1173)

(For Europe, except U.K. and Eire)

Binder Assy (AEC1908)

(ADG1193) (ADG1178)

(For U.K., and Eir (For North America)e)

Three speed clamps

Three bead bands

Cleaning cloth

(AED1197)

Warranty card

7

PDP-503PE, PDP-503PU

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

For the applying amount of lubricants or glue, follow the instructions in this manual.

•

(In the case of no amount instructions, apply as you think it appropriate.)

(1) PACKING PARTS LIST

1

Mark No. Description Part No.

1 Upper Carton See Contrast table (2)

2 Under Carton AHD3037

3 Pad AHA2280

4 Mirror Mat AHG1284

5 Caution Sheet ARM1201

PDP-503PU

Only

PDP-503PE

Only

17

11

11

16

15

11

14

13

NSP 6 Warranty Card See Contrast table (2)

2

3

16 Power Cord See Contrast table (2)

17 Power Cord See Contrast table (2)

4

8

3

9

7

11

6

5

7 Polyethylene Sheet AHG1302

8 Front Sheet AHB1241

9 Cord Case AHC1037

10 • • • • •

11 Vinyl Bag AHG1310

12 • • • • •

13 Wiping Cloth AED1197

14 Binder Assy AEC1908

(Speed Clamp × 3, Bead Band × 3)

15 Power Cord See Contrast table (2)

2

(2) CONTRAST TABLE

PDP-503PE/WYVI6 and PDP-503PU/KUC are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

NSP16

Upper Carton

Warranty Card

15

Power Cord

16

Power Cord

17

Power Cord

8

PDP-503PE PDP-503PU

WYVI6 KUC

AHD3104

ARY1114

ADG1173

ADG1193

Not used

Remarks

AHD3103

ARY1112

Not used

Not used

ADG1178

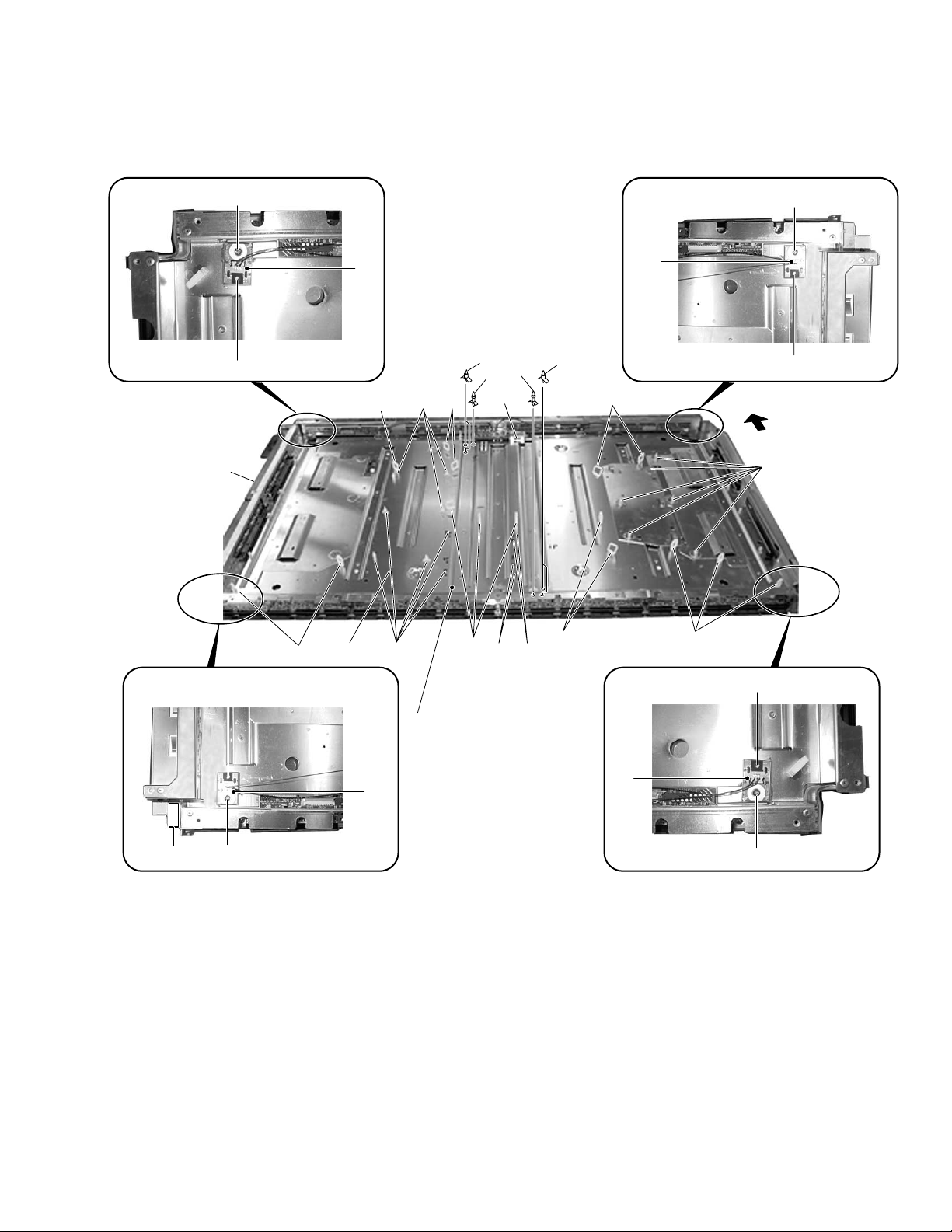

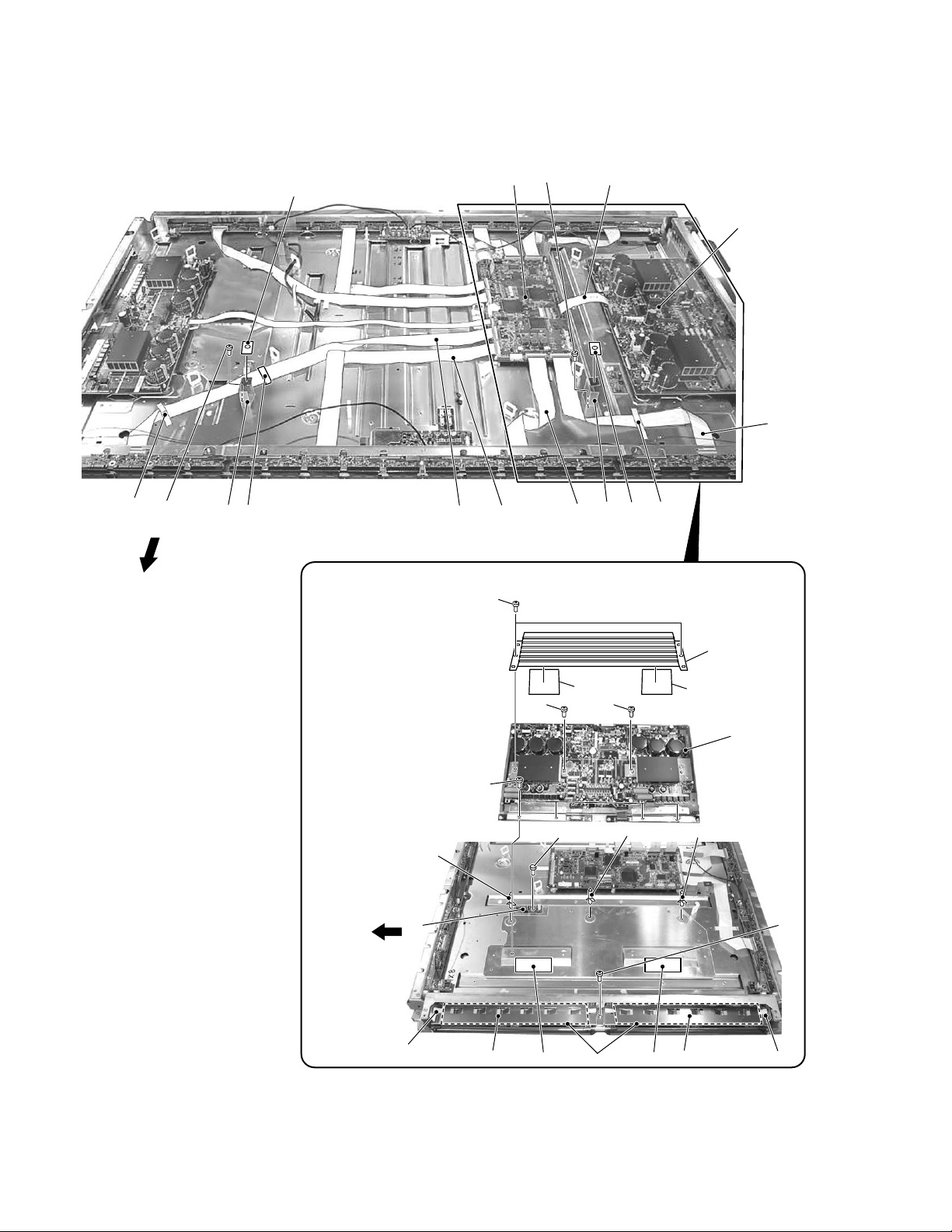

2.2 UNDER LAYER SECTION (1)

PDP-503PE, PDP-503PU

11

1

8

10

6

5

6

6

777

67

9

9

6

6

8

6

2

6

Upper side

6

11

10

7

10

5

Refer to

"2.14 PANEL CHASSIS ASSY

(AWU1037)".

3

1112

UNDER LAYER SECTION (1) PARTS LIST

•

4

10

11

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 CLAMP A Assy AWZ6650

NSP 2 CLAMP B Assy AWZ6651

NSP 3 CLAMP C Assy AWZ6652

NSP 4 CLAMP D Assy AWZ6653

5 Panel Chassis (50) Assy AWU1037

[Refer to "2.14 PANEL CHASSIS (50) ASSY".]

NSP 9 PCB Support AEC1253

6 Wire Saddle AEC1904

7 Circuit Board Spacer AEC1872

8 Circuit Board Spacer AEC1873

10 Locking Card Spacer AEC1736

11 Screw ABA1301

12 V Cushion AED1205

9

PDP-503PE, PDP-503PU

2.3 UNDER LAYER SECTION (2)

11 11 11 11 11 11 11 11

11

11 11 11

1

2 3 4

10

11

9

15

2

36 4

10

5 or 6

Upper side

10

11

11

4

4

7

3 2 1

10

11

3

9

11 11 11

11

2

7 or 8

111111111111

1

8

10

UNDER LAYER SECTION (2) PARTS LIST

•

Mark No. Description Part No.

NSP 1 ADR CONNECT A Assy AWZ6626

NSP 2 ADR CONNECT B Assy AWZ6627

NSP 3 ADR CONNECT C Assy AWZ6628

NSP 4 ADR CONNECT D Assy AWZ6629

NSP 5 BRIDGE A Assy AWZ6620

NSP 6 BRIDGE B Assy AWZ6621

NSP 7 BRIDGE C Assy AWZ6622

NSP 8 BRIDGE D Assy AWZ6623

9 ADR RESONANCE Assy AWZ6691

10 Screw ABA1301

11 Screw VBB30P100FNI

PDP-503PE, PDP-503PU

11

PDP-503PE, PDP-503PU

2.4 UNDER LAYER SECTION (3)

Upper side

1

13

2

13

26

22

11

26

3

17152716

18

28

12

1212

249

6

21

29

20

11

7 (Upper Side)

8 (Bottom Side)

19

14

13

13

28

12

25

29

13

27

28

23

25

3

11

12

510

10 4

Upper side

PDP-503PE, PDP-503PU

UNDER LAYER SECTION (3) PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

1 DIGITAL VIDEO Assy AWV1903

2 V MID CLAMP Assy AWV1934

3 X DRIVE Assy AWV1901

NSP 4 X CONNECTOR (A) Assy AWZ6618

NSP 5 X CONNECTOR (B) Assy AWZ6619

6 ADR RESONANCE Assy AWZ6691

7 SUB ADDRESS A Assy AWZ6689

8 SUB ADDRESS B Assy AWZ6690

NSP 9 Scan Heat Sink ANH1594

10 Coil Silicone Sheet AEH1048

11 Circuit Board Spacer AEC1873

12 Screw ABZ30P060FMC

13 Screw VBB30P100FNI

14 Screw PMB30P060FNI

15 J201 Flexible Flat Cable ADD1194

16 J202 Flexible Flat Cable ADD1194

17 J209 Flexible Flat Cable ADD1191

18 J204 Flexible Flat Cable ADD1196

19 J210 Flexible Flat Cable ADD1190

20 J211 Flexible Flat Cable ADD1186

21 J212 Flexible Flat Cable ADD1188

NSP 22 Holder ANG2509

NSP 23 Drive Heatsink Assy ANH1598

24 Silicone Sheet AEH1039

25 Drive Silicone Sheet AEH1041

26 Niplocker BEC1136

27 Insulation Sheet AMR3263

28 Flat Clamp AEC1879

NSP 29 Metal Fittings ANG2464

13

PDP-503PE, PDP-503PU

2.5 UNDER LAYER SECTION (4)

7

16

Upper side

6

8

7

19

18

16

20

23

211

2

22

7

68

Upper side

24

25

14

18

15

13

18

17

15

5

3

11

10

10

12

25

2

15

17

4

14

PDP-503PE, PDP-503PU

UNDER LAYER SECTION (4) PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

1 DIGITAL VIDEO Assy AWV1903

2 Y DRIVE Assy AWZ6645

NSP 3 SCAN (A) Assy AWZ6617

NSP 4 SCAN (B) Assy AWZ6616

5 THERMAL SENSOR Assy AWZ6660

11 Scan IC Spring (L) ABK1026

12 Scan IC Spring (R) ABK1027

13 Scan Insulation Sheet AMR3271

14 Rivet BEC1066

15 Circuit Board Spacer AEC1872

6 Insulation Sheet AMR3263

7 Flat Clamp AEC1879

8 Metal Fittings ANG2464

9 • • • • •

10 Coil Silicone Sheet AEH1048

16 Screw ABZ30P060FMC

17 Screw PMB30P060FNI

18 Screw VBB30P100FNI

19 J208 Flexible Flat Cable ADD1191

20 J207 Flexible Flat Cable ADD1190

21 J203 Flexible Flat Cable ADD1184

22 J205 Flexible Flat Cable ADD1189

23 J206 Flexible Flat Cable ADD1187

NSP 24 Drive Heatsink Assy ANH1598

25 Drive Silicone Sheet AEH1041

15

PDP-503PE, PDP-503PU

2.6 UNDER LAYER SECTION (5)

12

24

15

14

13

27

1 22 16

Y1

2

26

8 10

SA1 SA2

25

K3

3 422

5

29 23

9

31

28

TE1

D9D8

D16

D1

D18

Y2

D6

D10

D11

D7

D15

D14

D2

D3

D13D12

D17

SA2 SA1

K3

K3

CN9002

CN9001

X1

X2

17

19

20

18

21

1 22 22222 30 2232 3 46 75 11

16

PDP-503PE, PDP-503PU

UNDER LAYER SECTION (5) PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 ADR CONNECT A Assy AWZ6626

NSP 2 ADR CONNECT B Assy AWZ6627

NSP 3 ADR CONNECT C Assy AWZ6628

NSP 4 ADR CONNECT D Assy AWZ6629

5 ADR RESONANCE Assy AWZ6691

NSP 6 BRIDGE A Assy AWZ6620

NSP 7 BRIDGE B Assy AWZ6621

NSP 8 BRIDGE C Assy AWZ6622

NSP 9 BRIDGE D Assy AWZ6623

10 SUB ADDRESS A Assy AWZ6689

11 SUB ADDRESS B Assy AWZ6690

NSP 12 SCAN (A) Assy AWZ6617

NSP 13 SCAN (B) Assy AWZ6616

14 Y DRIVE Assy AWZ6645

15 DIGITAL VIDEO Assy AWV1903

16 THERMAL SENSOR Assy AWZ6660

NSP 17 X CONNECTOR (A) Assy AWZ6618

NSP 18 X CONNECTOR (B) Assy AWZ6619

19 X DRIVE Assy AWV1901

20 V MID CLAMP Assy AWV1934

21 J121 5P Housing Wire ADX2759

22 Flat Clamp AEC1879

23 J120 5P Housing Wire ADX2761

24 J110 3P Housing Wire ADX2704

25 J108 8P Housing Wire ADX2701

26 J101 Wire F ADX2726

27 J102 Wire E ADX2694

28 J103 13P Housing Wire ADX2700

29 J116 4P Housing SP Wire ADX2756

30 J109 Wire G ADX2720

31 Binder AEC-093

32 J117 4P Housing SP Wire ADX2756

17

PDP-503PE, PDP-503PU

2.7 MIDDLE LAYER SECTION (1)

16

11

17

7

6

11

16

11

6

11

7

12

9

9

9

9

7

9

10

8

18

13

9

2726

19

4

8

9

15

9

14

8

22

9

5

8

13

29

9

9

9

9

7

9

10

12

18

24

3

21

20

24

2

28

1

25

21

25

24

30

23

32

PDP-503PE, PDP-503PU

MIDDLE LAYER SECTION (1) PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

1 IR (P) Assy AWZ6658

2 LED Assy AWZ6655

3 FRONT KEY CONN Assy AWZ6657

NSP 4 Sub Frame L ANG2455

NSP 5 Sub Frame R ANG2456

6 FPC Cushion AEB1370

NSP 7 Front Chassis V ANA1661

8 Screw ABA1283

9 Screw ABA1294

10 Screw BMZ30P060FMC

11 V Cushion AED1205

NSP 12 Card Spacer AEC1902

13 Spacer B AMR3300

14 Power Sheet AMR3291

15 Rivet BEC1066

16 Card Corner Holder BEC1144

17 Niplocker BEC1136

18 J113 Wire J ADX2718

NSP 19 Front Chassis H ANA1683

NSP 20 IR Holder ANG2494

21 Nyron Rivet AEC1671

22 J104 3P Housing Wire ADX2732

NSP 23 Switch Holder ANG2493

24 Screw BMZ30P040FMC

25 Screw ABZ30P050FZK

26 Ferrite Core (L6) ATX1037

27 Ferrite Core Holder AEC1818

28 Power Switch (S1) ASG1082

29 J106 Wire PC ADX2723

30 Screw BMZ30P060FZK

31 • • • • •

32 Gascket R ANK1695

19

PDP-503PE, PDP-503PU

2.8 MIDDLE LAYER SECTION (2)

12

7

17

1

6

3

4

2

5

5

16

8

10

9

8

11

10

13

14

11

11

15

13

20

10

8

5

5

MIDDLE LAYER SECTION (2) PARTS LIST

•

Mark No. Description Part No.

1 AUDIO AMP Assy AWZ6687

2 Toroidal Core (L2) ATX1042

3 Screw ABA1294

4 Edge Saddle AEC1571

5 Wire Saddle AEC1745

6 IF Sheet AMR3298

7 Nyron Rivet AEP-211

8 PCB Spacer AEC1570

9 Audio Base ANA1687

10 Spacer AEC1360

11 Screw AMZ30P060FZK

12 IF Shield ANA1675

13 Screw PMB30P060FNI

14 J215 3P Housing Wire ADX2757

15 Power Switch (S2) ASG1089

16 Niplocker BEC1136

17 J214 3P Housing Wire ADX2735

PDP-503PE, PDP-503PU

21

PDP-503PE, PDP-503PU

2.9 UPPER LAYER SECTION (1)

4

3

3

2

2

3

3

7

J201

J202

112

2

6

J5002 15

2

5

10

16

14

813

Caution in the MR INTERFACE Assy Replacement

Set the slide switches in accordance with applicable

model when replacing the MR INTERFACE Assy.

S4001

CBIT_1

PDP-503P → →

PDP-503PE ← →

PDP-503PU → →

Note 1 : When there is not S4004, set only S4001.

Note 2 : When there are not S4001 and S4004, setting

is unnecessary.

22

S4004

CBIT_0

9

S4001

(CBIT_1)

S4004

(CBIT_0)

UPPER LAYER SECTION (1) PARTS LIST

•

Mark No. Description Part No.

1 MR INTERFACE Assy AWZ6654

2 Screw AMZ30P060FZK

3 Screw TBZ40P080FZK

4 Terminal Panel P ANG2472

5 Screw PMZ26P030FZK

6 Hexagonal Head Screw BBA1051

7 J201 Flexible Flat Cable ADD1194

8 J202 Flexible Flat Cable ADD1194

9 J104 3P Housing Wire ADX2732

10 J214 3P Housing Wire ADX2735

11 • • • • •

12 J118 Wire P ADX2765

13 J113 Wire PJ ADX2718

14 Toroidal Core (L3) ATX1042

15 Screw ABA1294

16 J111 14P Housing Wire ADX2730

PDP-503PE, PDP-503PU

23

PDP-503PE, PDP-503PU

2.10 UPPER LAYER SECTION (2)

13

89

PDP-503PU Only

17

15

14

1

J5003

3

11

16

10

13

18

12

4

6

5

127

P1

2

P2

P6

P5

P4

P3

100V

SW101

200V

24

(1) UPPER LAYER SECTION (2) PARTS LIST

Mark No. Description Part No.

PDP-503PE, PDP-503PU

2 SW Power Supply Module AXY1053

4 AC Inlet with Noise Filter (CN1) AKP1223

6 Ferrite Core (L1) ATX1032

7 Fuse (10A) See Contrast table (2)

1 SP TERMINAL Assy AWZ6688

3 Screw BPZ30P080FZK

5 Screw BMZ30P060FZK

8 J118 Wire P ADX2765

9 J101 13P Housing Wire ADX2726

10 J103 13P Housing Wire ADX2700

11 J102 Wire E ADX2694

12 J105 Wire PB ADX2722

13 Screw AMZ30P060FZK

14 IF Earth Metal ANA1690

15 Screw PMB30P060FNI

16 Silicone Sheet AEH1035

17 Solder Warning Label See Contrast table (2)

18 J114 Earth Wire ADX2709

(2) CONTRAST TABLE

PDP-503PE/WYVI6 and PDP-503PU/KUC are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

717Fuse (10A)

Solder Warning Label

PDP-503PE PDP-503PU

WYVI6 KUC

AEK1071

Not used

Remarks

AEK1069

AAX2644

25

PDP-503PE, PDP-503PU

2.11 FRONT CASE SECTION

16

24

23

16

10

2

PDP-503PU

Only

1819

(1) FRONT CASE SECTION PARTS LIST

Mark No. Description Part No.

1 FRONT KEY Assy AWZ6656

2 Front Case 50 (P) AMB2722

3 Rivet AEC1877

4 • • • • •

5 • • • • •

6 Ferrite Core (L5) ATX1043

7 Lead Cover (P) AMB2704

8 Pioneer Badge AAM1091

8

16

21

22

12

25

Foil Side

10

6

7

3

17

20

1

16

NSP 10 Panel Holder ANG2508

NSP 22 Flexible Seal (P) AEH1052

9 • • • • •

11 Front Spacer AEC1896

12 • • • • •

13 Panel Cushion V AED1199

14 Panel Cushion H AED1198

15 Protect Panel Assy AMR3304

16 Screw ABZ30P050FZK

17 Screw VMZ30P060FZK

18 Energy Star Label See Contrast table (2)

19 HDTV Label See Contrast table (2)

20 PCB Spacer AEC1913

21 J213 Flexible Flat Cable ADD1193

23 Power Button AAD4113

24 Coil Spring ABH1108

25 Serial Sheet AAX2609

10

13

16

11

14

11

14

10

16

10

15

11

11

10

13

(2) CONTRAST TABLE

PDP-503PE/WYVI6 and PDP-503PU/KUC are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

1819Energy Star Label

HDTV Label

PDP-503PE PDP-503PU

WYVI6 KUC

Not used

Not used

Remarks

AAX2865

AAX2891

26

2.12 REAR SECTION

PDP-503PE, PDP-503PU

3 3 3 3

1

4

4

4

4

3

2

5

3 38 93

Bottom View

4

67

3 3

4

4

4

4

1

(1) REAR SECTION PARTS LIST

Mark No. Description Part No.

1 Rear Case (50P) ANE1598

2 Gascket A ANK1688

3 Screw AMZ30P060FZK

4 Screw TBZ40P080FZK

5 Cleaning Label AAX2751

NSP 6 Name Label (HD) See Contrast table (2)

7 Bolt Caution Label AAX2852

8 Terminal Display Label P AAX2858

9 Terminal Display Label L See Contrast table (2)

(2) CONTRAST TABLE

PDP-503PE/WYVI6 and PDP-503PU/KUC are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

NSP 69Name Label (HD)

Terminal Display Label L

PDP-503PE PDP-503PU

WYVI6 KUC

AAL2358

AAX2860

Remarks

AAL2357

AAX2859

27

PDP-503PE, PDP-503PU

2.13 PDP SERVICE ASSY 503 (AWU1040)

PDP Service Assy 503 (AWU1040) consists of the following parts.

PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

NSP Front Chassis V ANA1661

Panel Chassis (50) Assy AWU1037

NSP Front CHassis H (W) ANA1679

NSP Front Chassis H ANA1683

NSP Sub Frame L ANG2499

NSP Sub Frame R ANG2500

Scan IC Spring (L) ABK1026

Scan IC Spring (R) ABK1027

NSP Metal Fitting ANG2464

FPC Cushion 50 AEB1370

NSP PCB Spacer AEC1211

Locking Card Spacer AEC1736

Circuit Board Spacer AEC1872

Circuit Board Spacer AEC1873

Spacer AEC1896

NSP Card Spacer AEC1902

Wire Saddle AEC1904

Panel Cushion H AED1198

Panel Cushion V AED1199

V Cushion AED1205

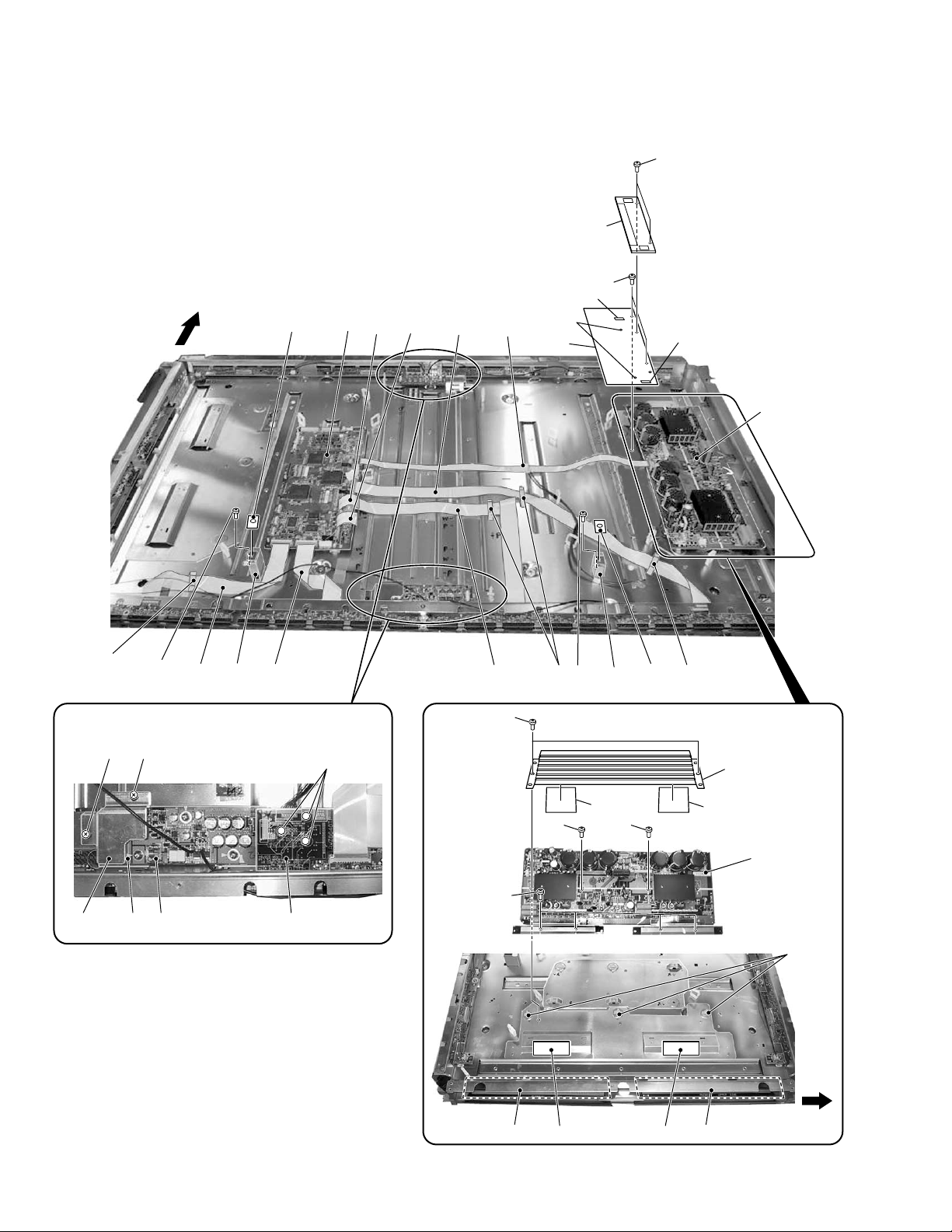

2.14 PANEL CHASSIS (50) ASSY (AWU1037)

Panel Chassis (50) Assy (AWU1037) consists of the following parts.

Insullation Sheet AMR3263

Scan Insullation Sheet AMR3271

Niplocker BEC1136

Card Corner Holder BEC1144

Screw ABA1283

Screw ABA1294

Screw ABZ30P060FMC

Screw BMZ30P060FMC

Screw PMB30P060FNI

Screw VBB30P100FNI

Bolt ABA1259

Corner Pad AHA2203

Corner Pad AHA2204

Upper Carton AHD3119

Under Carton AHD3120

Packing Sheet AHG1291

Fitting Board AHK1012

Washer WB80FZB

PARTS LIST

•

Mark No. Description Part No.

NSP SCAN FUKUGO ASSY AWV1898 ∗

NSP Address Module (IC1 - IC40) AXF1110

NSP FPC (0003) ADY1065

NSP FPC (J0001) ADY1066

NSP Chassis Assy ANA1696

NSP Chassis ANA1655

NSP Base Chassis ANA1656

NSP Scan Heatsink ANH1595

NSP Corner Angle A ANG2457

NSP Corner Angle B ANG2458

NSP Tube Cover AMR3262

NSP Plasma Panel Assy AAV1238

ADDRESS FUKUGO ASSY AWV1900 ∗

Panel Silicone Sheet AEH1055

Silicone Sheet 50 AEH1037

Adhesive Tape 50 AEH1038

Adhesive Tape B (50) AEH1051

Pin Grommet AEC1015

Card Spacer AEC1889

Scan Silicone Sheet AEH1040

Screw VBB30P100FNI

28

LIST OF ASSY

•

Mark No. Description Part No.

NSP SCAN FUKUGO ASSY AWV1898

NSP SCAN (A) ASSY AWZ6616

NSP SCAN (B) ASSY AWZ6617

NSP X CONNECTOR (A) ASSY AWZ6618

NSP X CONNECTOR (B) ASSY AWZ6619

NSP BRIDGE A ASSY AWZ6620

NSP BRIDGE B ASSY AWZ6621

NSP BRIDGE C ASSY AWZ6622

NSP BRIDGE D ASSY AWZ6623

NSP CLAMP A ASSY AWZ6650

NSP CLAMP B ASSY AWZ6651

NSP CLAMP C ASSY AWZ6652

NSP CLAMP D ASSY AWZ6653

NSP ADR CONNECT A ASSY AWZ6626

NSP ADR CONNECT B ASSY AWZ6627

NSP ADR CONNECT C ASSY AWZ6628

NSP ADR CONNECT D ASSY AWZ6629

ADDRESS FUKUGO ASSY AWV1900

ADR RESONANCE ASSY AWZ6630

PDP-503PE, PDP-503PU

Caution in Replacement of Chassis Block

Please order the PDP Service Assy 503 (AWU1040) when replacing the Chassis block.

PDP Service Assy 503 is all common use parts of for business, public use and module.

Supply it by the state that installed Circuit Board Spacer (AEC1872) and Wire Saddle (AEC1904) as follows.

Therefore need to remove it in accordance with model.

Confirm character carved a seal near the parts, and remove it.

P : Public exclusive use

W : Module exclusive use

PW : Common use of public use and module

∗ In case of this unit, the parts that "W" is marked removes all.

PDP Service Assy 503 (AWU1040)

Wire Saddle

(AEC1904)

(There is marking of "P" nearby.)

Circuit Board Spacer

(AEC1872)

Circuit Board Spacer

(AEC1872)

29

1

23

PDP-503PE, PDP-503PU

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

3.1.1 OVERALL DIAGRAM

DriverICDriver

A

IC

DriverICDriver

DriverICDriver

IC

DriverICDriver

IC

IC

DriverICDriver

IC

DriverICDriver

IC

DriverICDriver

IC

DriverICDriver

4

IC

DriverICDriver

IC

DriverICDriver

IC

B

C

VADR2

CLA1

CLAMP A

ASSY

SCAN (B) ASSY

(UPPER)

SCAN (A) ASSY

(LOWER)

FRONT KEY

ASSY

ADR CONNECT A

ASSY

CLAMP

IC5

VCC_VH

IC6201

ADD

PSUS

SEL_PULSE

IC5

VCC_VH

IC6202

ADD

SEL_PULSE

IC5

VCC_VH

IC6203

ADD

SEL_PULSE

IC5

VCC_VH

IC6204

ADD

SEL_PULSE

IC5

VCC_VH

IC6205

ADD

SEL_PULSE

IC5

VCC_VH

IC6206

ADD

SEL_PULSE

SEL_PULSE

SEL_PULSE

SEL_PULSE

SEL_PULSE

SEL_PULSE

SEL_PULSE

FRONT KEY CONN

ASSY

IC5

IC6001

ADD

IC5

IC6002

ADD

IC5

IC6003

ADD

IC5

IC6004

ADD

IC5

IC6005

ADD

IC5

IC6006

ADD

VCC_VH

SCAN

VCC_VH

VCC_VH

VCC_VH

VCC_VH

VCC_VH

SCAN

PSUS

AA1

Y DRIVE ASSY

Y4

PSUS

VCC_VH

V_IC5V

Y3

VCC_VH

V_IC5V

Y5

PSUS

Y6

CLK/LE

IC6501

Buffer IC

THERMAL

SENSOR

ASSY

VC_VF+ VC_VF- V_OFS VCC_VH V_IC5V

DC/DC Conv.

VCP

Y-SUS

MASK

Block

VCP

Y-SUS

MASK

Block

Scan Signal

VC_VF+

Block

+5V +15V

VSUS

IC2206

Pulse Module

+15V VSUS

+Reset Block

+5V +15V VSUS

IC2204

Pulse Module

+15V

Soft-D

Block

VC_VF- V_OFS

Offset

Block

V_IC5V

Photo Coupler

Block

Drive

Signal

Drive

Signal

VADR2

BGA1

BRIDGE A

ASSY

TE1

Y1

Y2

Logic

Block

VADR2

CLAMP

ADR CONNECT B

ASSY

AB1

D8 D9 D16

D1

+12V

V+5V_STB

+12V

DC/DC Conv.

V+3V

IC1703

XY Drive

Gen.

TXD/RX

Module

DIGITAL VIDEO

ASSY

KL_U0:2

XDRV_SIG

ADL_LE_UL

ADL_LE_DL

V+3V

X180

Clock

Gen.

IC1301 (IC31 L)

Sub-Field Conv.

for Left with Field Memory

V+3V

IC1101

Panel UCOM

+12V

D18

D6

Sequence Pattern

YDRV_SIG

SCAN_SIG

V+3V_I

V+2V_I

IC1401 (IC31 R)

Sub-Field Conv.

for Right with Field Memory

ADCLK_DR

V+5V_STB

IC120

Module

UCOM

D13D12

ADR RESONANCE

ASSY

SUB ADDRESS A

ASSY

V+5V

V+3V

V+2V

V+2V

V+3V

V+3V_IC

V+2V_IC

V+3V

IC119

Flash

ROM

CLK/LE

V+5V_STB

BA2:9

BB2:9

GA2:9

GB2:9

RA2:9

RB2:9

TXD0/RX0

RE

LED_SIG

I2

IC6601

Buffer IC

D2

D3D17

K2

K1

SAA3

+60

SAA1 SAA2

D10

D11

D7

D4

D15

D14

VADR2

Q6706 - Q6711

VADR Gen.

ADR_CO

CLAMP C

D

ASSY

SW21 KL21 KL22

IR (P)

ASSY

RE1

CLC1

CLAMP

ADR CONNECT D

VADR2

ASSY

Driver

Driver

IC

IC

30

1234

DriverICDriver

SUB ADDRESS B

ASSY

ADR RESONANCE

DriverICDriver

ASSY

IC

CLK/LE

IC6801

Buffer IC

DriverICDriver

BRIDGE C

ASSY

BGC1

IC

VADR2

CLAMP

VADR2

DriverICDriver

ADR CONNECT C

ASSY

IC

DriverICDriver

AC1

IC

AD1

DriverICDriver

IC

IC

CLK/LE

IC6901

Buffer IC

DriverICDriver

IC

DriverICDriver

SAB1 SAB2

+60

SAB3

K2

IC

DriverICDriver

K1

ADR_CO

Q6706 - Q6711

VADR Gen.

VADR2

IC

Loading...

Loading...