Page 1

The service manual ARP3075

was revised in October, 2000.

Please use this revised edition

instead of the 1st one.

PLASMA DISPLAY

PDP-502MX

PDP-502MXE

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type Power Requirement

LUCBW/1 –– AC100 – 120V

YVLDK/1 –– AC100 – 240V

PDP-502MX PDP-502MXE

Model

ORDER NO.

ARP3075

Remarks

¶ This service manual should be used together with the following manual(s).

Model No. Order No. Remarks

PDP-502MX ARP3078

In PDP-502MX and PDP-502MXE, there are two different models (original model and

value analysis model) respectively. Confirm the mark and serial No. of the product Rear

side, and use each service manual. Refer to "Confirm it".

SCHEMATIC DIAGRAM, PCB DIAGRAM, PCB PARTS LIST and

IC INFORMATION

CONTENTS

Confirm it ......................................................... 2

1. SAFETY INFORMATION....................................3

2. EXPLODED VIEWS AND PARTS LIST ............. 6

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

.......................................................18

(For SCHEMATIC DIAGRAM, refer to ARP3078)

4. PCB DIAGRAM....................... Refer to ARP3078

5. PCB PARTS LIST................... Refer to ARP3078

6. ADJUSTMENT.................................................. 46

7. GENERAL INFORMATION .............................. 60

7.1 DIAGNOSIS................................................60

7.1.1 DIAGNOSIS METHOD......................60

7.1.2 DISASSEMBLY .................................70

7.1.3 WIRING ............................................. 72

7.2 IC ............................. Refer to ARP3078

8. PANEL FACILITIES AND SPECIFICATIONS

.......................................................76

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2000

T–ZZA NOV. 2000 Printed in Japan

Page 2

PDP-502MX, PDP-502MXE

Confirm it

Confirm it

PRODUCT REAR SIDE

Serial No.

(

1

∗ ∗ ∗ ∗ ∗ )

Discrimination seal

(SILVER)

SERIAL NO.

Serial No. Service Manual

1 ∗ ∗ ∗ ∗ ∗

OTHER

ARP3075 [This manual]

ARP3078

ARP3037

ARP3044

2

Page 3

PDP-502MX, PDP-502MXE

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

1.1 SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes located

on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an isolation

transformer should be inserted between the power line and the

set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit diagram

should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

service technician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Ground, Rear Cover, Shield Case) surely after

disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the connector

will cause it to peel off from the panel.

8. Pay attention to the following.

• Be sure to wire the fan. If the fan does not work, the temperature

will rise and cause the protection circuit to operate.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to the

chassis should have a minimum resistor reading of 0.3MΩ and a

maximum resistor reading of 5MΩ. Any resistor value below or

above this range indicates an abnormality which requires corrective

action. Exposed metal parts not having a return path to the chassis

will indicate an open circuit.

3

Page 4

PDP-502MX, PDP-502MXE

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not use

an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229 equivalent)",

measure for current from all exposed metal parts of the cabinet

(input/output terminals, screwheads, metal overlays, control shaft,

etc.), particularly any exposed metal part having a return path to the

chassis, to a known earth ground (water pipe, conduit, etc.). Any

current measured must not exceed 0.5mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

1.2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have special

safety related characteristics. These are often not evident from

visual inspection nor the protection afforded by them necessarily

can be obtained by using replacement components rated for higher

voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in this Service Manual.

Electrical components having such features are identified by marking

with a

Manual.

The use of a substitute replacement component which dose not have

the same safety characteristics as the PIONEER recommended

replacement one, shown in the parts list in this Service Manual, may

create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to, or

additional copies of, PIONEER Service Manual may be obtained at

a nominal charge from PIONEER.

on the schematics and on the parts list in this Service

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

4

Page 5

PDP-502MX, PDP-502MXE

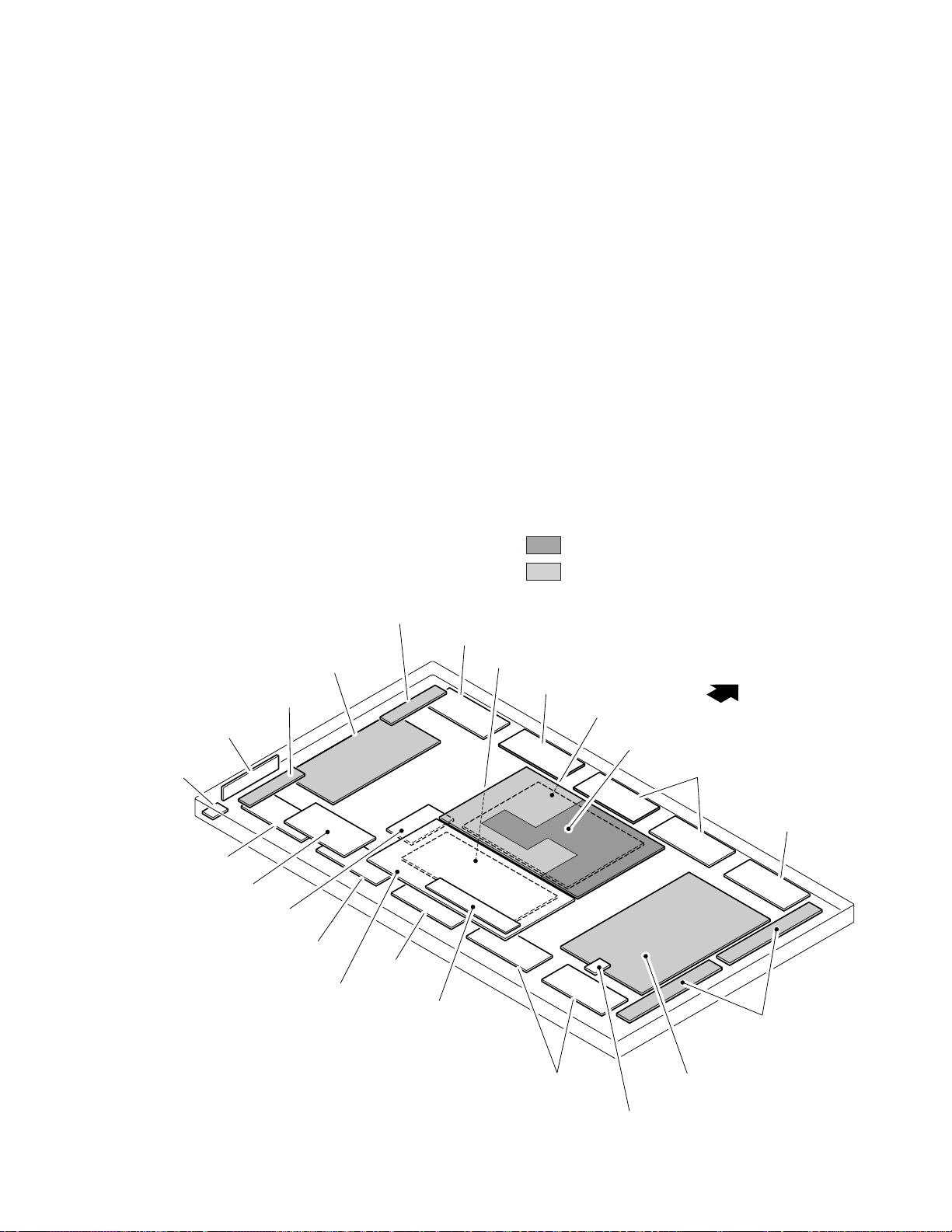

1.3 CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT

7 Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In addition,

the measuring equipment can be damaged if it is connected to the

GND of the charged section and the GND of the non-charged

section while connecting the set directly to the commercial AC

power supply. Therefore, be sure to connect the set via an insulated

transformer and supply the current.

7 Charged Section

(Power supply primary side)

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the MAIN POWER ASSY)

5. STB Transformer and Converter Transformer

(In the MAIN POWER ASSY)

6. Other primary side of the MAIN POWER ASSY

X CABLE U ASSY

CABLE ASSY

X DRIVE ASSY

X CABLE D ASSY

SIDE SW ASSY

7 High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. POWER SUPPLY MODULE (170V)

2. X DRIVE ASSY (170V)

3. Y DRIVE ASSY (–200V to 250V)

4. SCAN ASSY (250V)

For the places, refer to the EXPLODED VIEWS, the SCHEMATIC

DIAGRAM and the PCB CONNECTION DIAGRAM sections.

Part is charged section.

Part is the high voltage generating points other than the

charged section.

U-COM ASSY

CABLE ASSY

DIGIT AL VIDEO ASSY

MAIN POWER ASSY

TOP

IR RECEIVE ASSY

CABLE ASSY

CONTROL ASSY

AUDIO AMP ASSY

CABLE ASSY

VIDEO ASSY

CABLE ASSY

INPUT ASSY

CABLE ASSY

SP TERMINAL (L) ASSY

CABLE ASSY

CABLE ASSY

SCAN ASSY

Y DRIVE ASSY

5

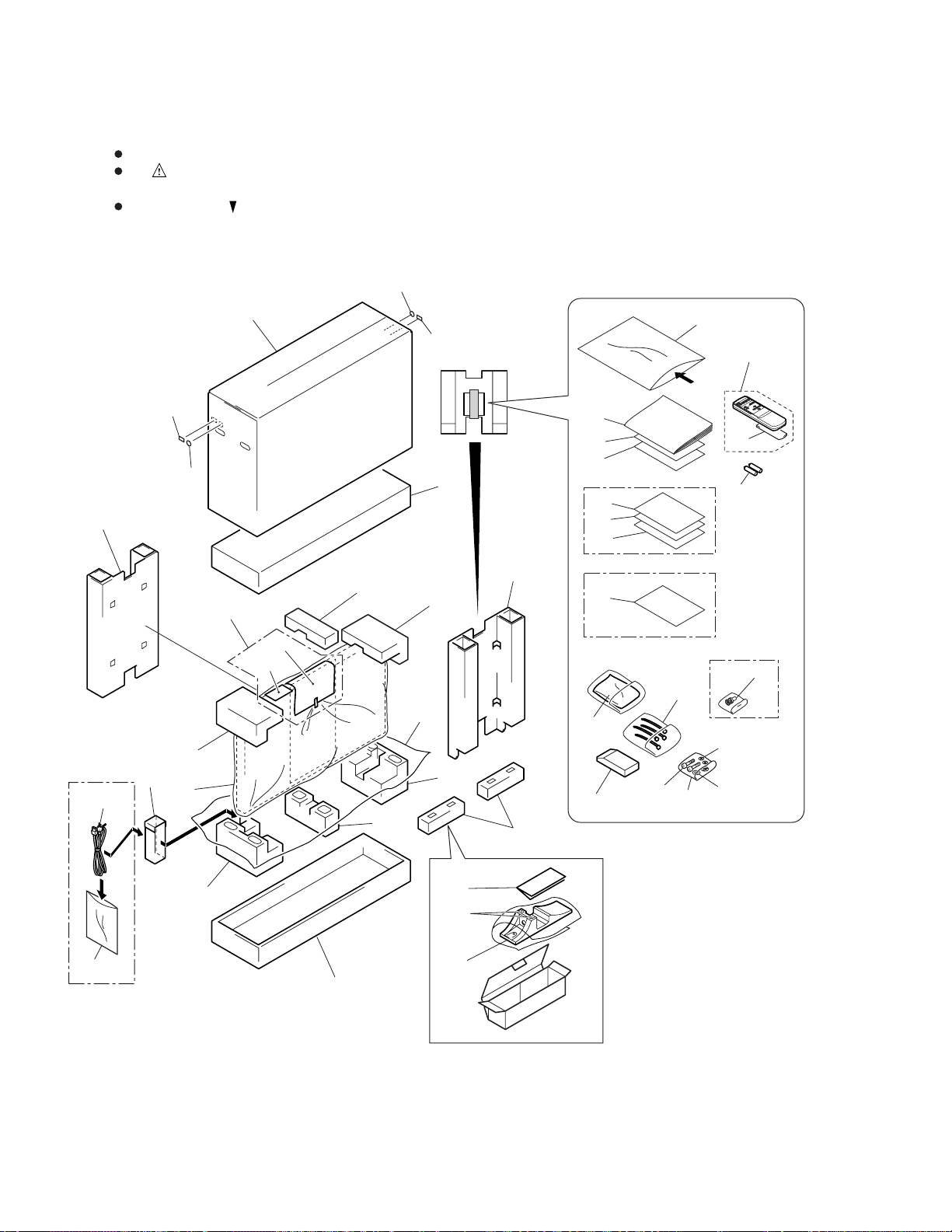

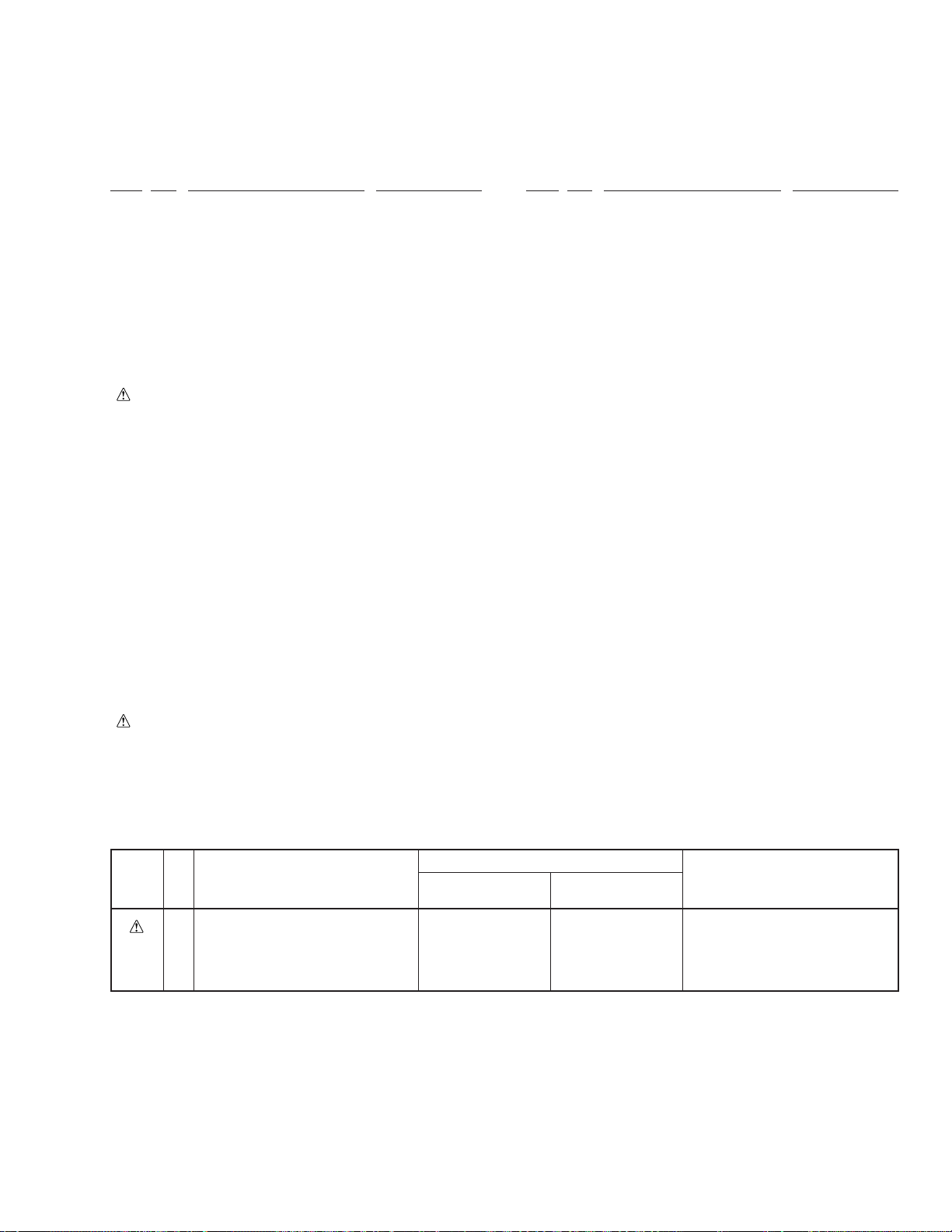

Page 6

PDP-502MX, PDP-502MXE

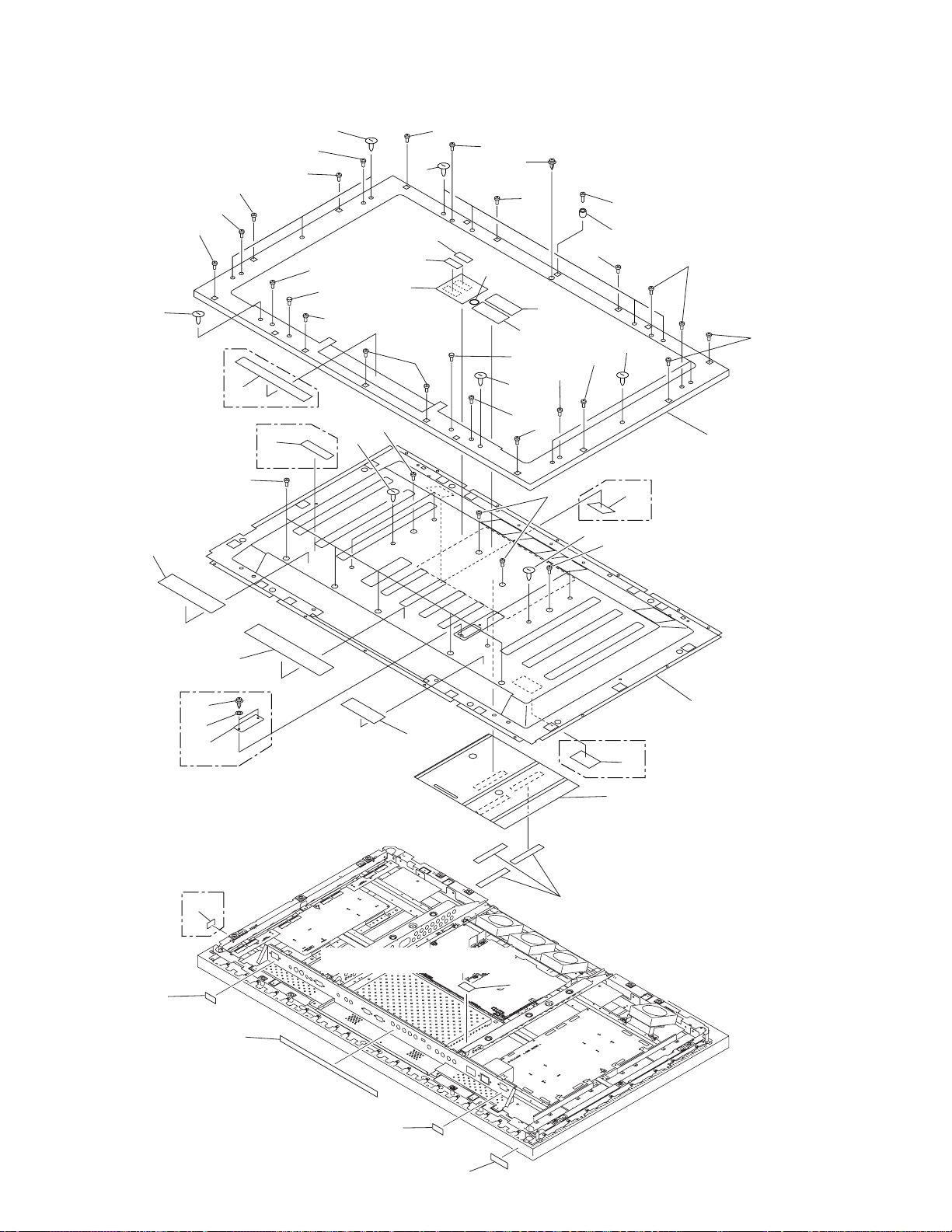

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

2.1 PACKING

41

8

26

42

41

PDP-502MX Only

4

9

12

10

20, 22

21

30

42

15

18

44

11

7

5

6

3

13

1

32

16

17

19

PDP-502MX Only

40

PDP-502MXE Only

28

36

37

27

29

23

24

25

31

PDP-502MX Only

39

38

30

PDP-502MX Only

6

2

11

35

34

33

Page 7

(1) PACKING PARTS LIST

Mark No. Description Part No.

PDP-502MX, PDP-502MXE

Mark No. Description Part No.

1 Under Pad R AHA2239

2 Under Pad L AHA2240

3 Upper Pad R AHA2241

4 Upper Pad L AHA2242

5 Upper Pad C AHA2243

6 Under Pad C AHA2245

7 Front Carton AHB1210

8 Rear Carton AHB1211

9 Code Case AHC1033

10 Upper Carton

11 Under Carton AHD3037

12 Mirror Mat AHG1284

13 Polyethirene Sheet AHG1302

14 ……………………………

15 Operating Instructions

16 Plasma Caution Sheet

17 Plasma Caution Sheet

18 Caution Sheet ARM1168

19 Caution Sheet

NSP 20 Warranty Card

NSP 21 Warranty Card

NSP 22 Vinyl Pouch

23 Remote Control Unit AXD1446

(CU-V159)

24 Battery Cover AZN2098

NSP 25 AA (R6/UM-3) Batteries

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

26 AC Power Cord

27 Binder Assy AEC1758

28 Cleaning Cloth AED1174

NSP 29 Vinyl Bag (for Screw, Nut) AHG-064

NSP 30 Literature Bag AHG-117

31 Pin/BNC Conversion Adaptor

32 Diaplay Stand AMR3225

NSP 33 Stand Bracket ANG2351

34 Screw CPZ30P080FZK

35 Caution Sheet ARM1175

36 Remote Control Unit Case AMR3231

37 Hex Hole Bolt (M8×40) SMZ80H400FZB

38 Washer WAX1F200K320

39 Washer WB80FZB

40 Plasma Caution Sheet

41 Seal AAX2817

NSP 42 Label VRW1629

43 Pad Set AHA2269

44 Caution Sheet ARM1194

See contrast table (2)

See contrast table (2)

See contrast table (2)

Pad set (AHA2269) is composed of the following parts.

43 Pad Set AHA2269

1 Under Pad R AHA2239

2 Under Pad L AHA2240

3 Upper Pad R AHA2241

4 Upper Pad L AHA2242

5 Upper Pad C AHA2243

6 Under Pad C AHA2245

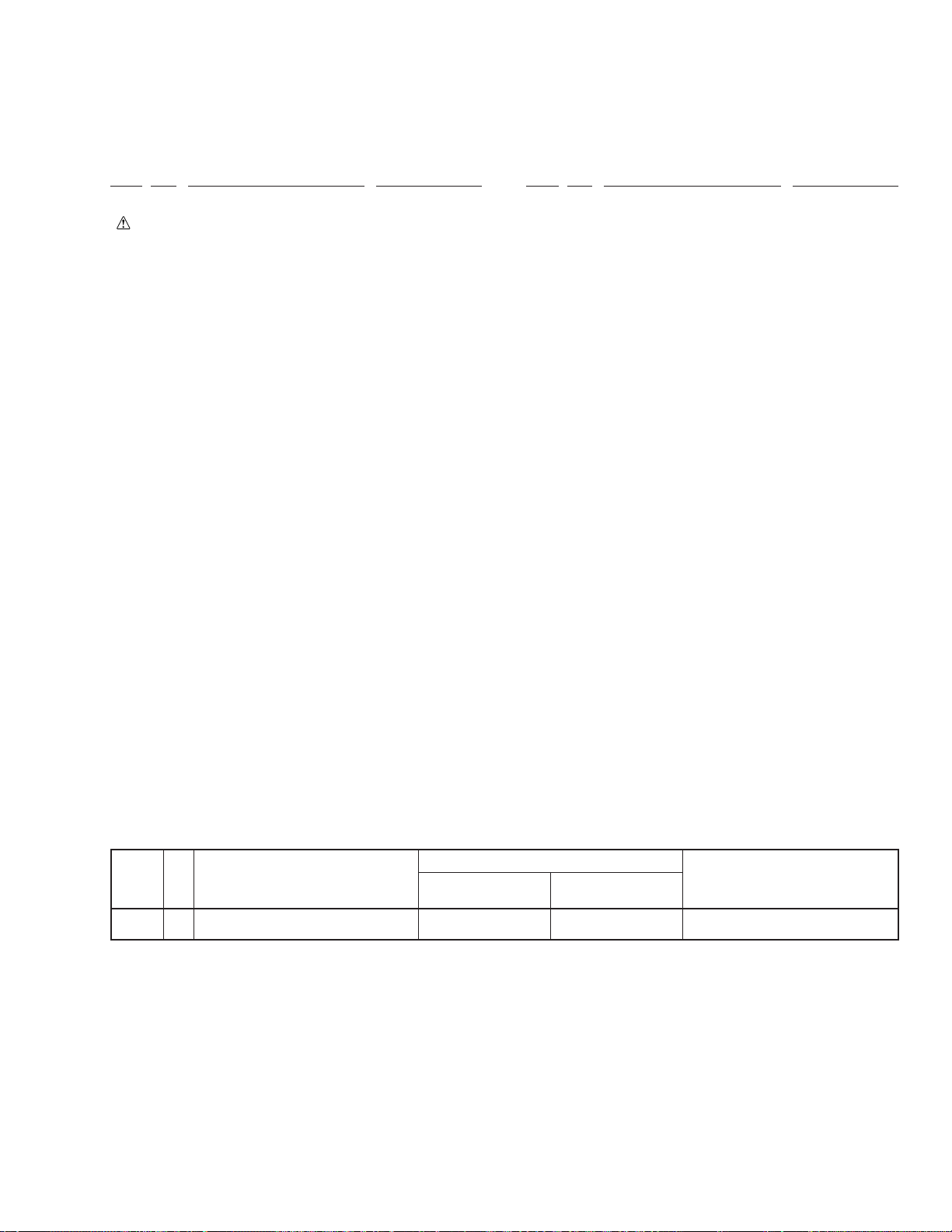

(2) CONTRAST TABLE

PDP-502MX/LUCBW/1 and PDP-502MXE/YVLDK/1 are constructed the same except for the following:

Part No.

Mark

10 Upper Carton AHD3035 AHD3043

15 Operating Instructions ARD1039 Not used

15 Operating Instructions Not used ARE1358

16 Plasma Caution Sheet ARM1145 Not used

17 Plasma Caution Sheet ARM1147 Not used

19 Caution Sheet ARM1176 Not used

NSP 20 Warranty Card ARY1093 Not used

NSP 21 Warranty Card ARY1102 Not used

NSP 22 Vinyl Pouch AHG–195 Not used

NSP 25 AA (R6/UM-3) Batteries AEX1025 VEM1011

26 AC Power Cord ADG1178 Not used

31 Pin/BNC Conversion Adaptor AKX1052 Not used

40 Plasma Caution Sheet Not used ARM1149

Symbol and DescriptionNo.

(English/French/Japanese)

(English/French/German/Italian/

Dutch/Spanish)

PDP-502MX PDP-502MXE

LUCBW/1 YVLDK/1

Remarks

7

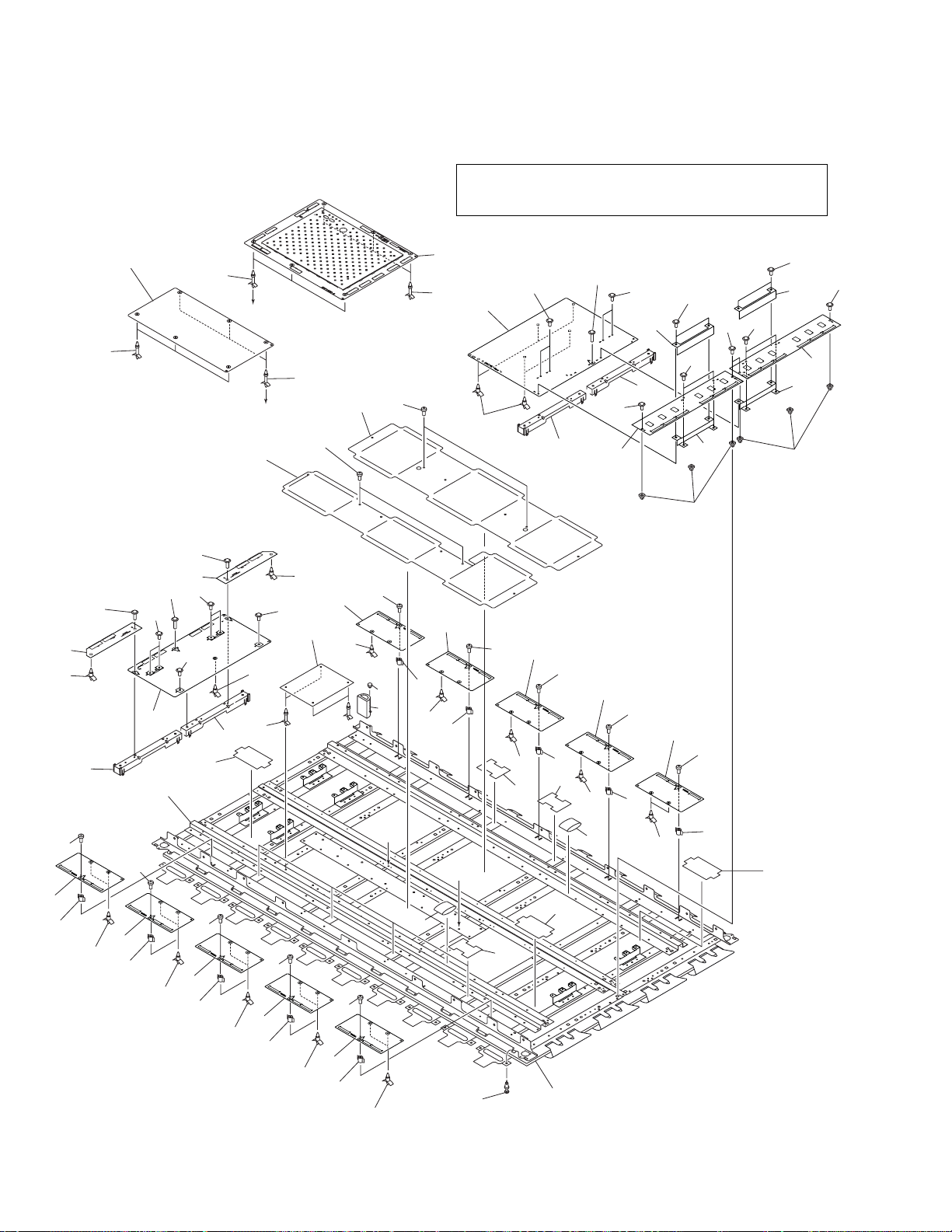

Page 8

PDP-502MX, PDP-502MXE

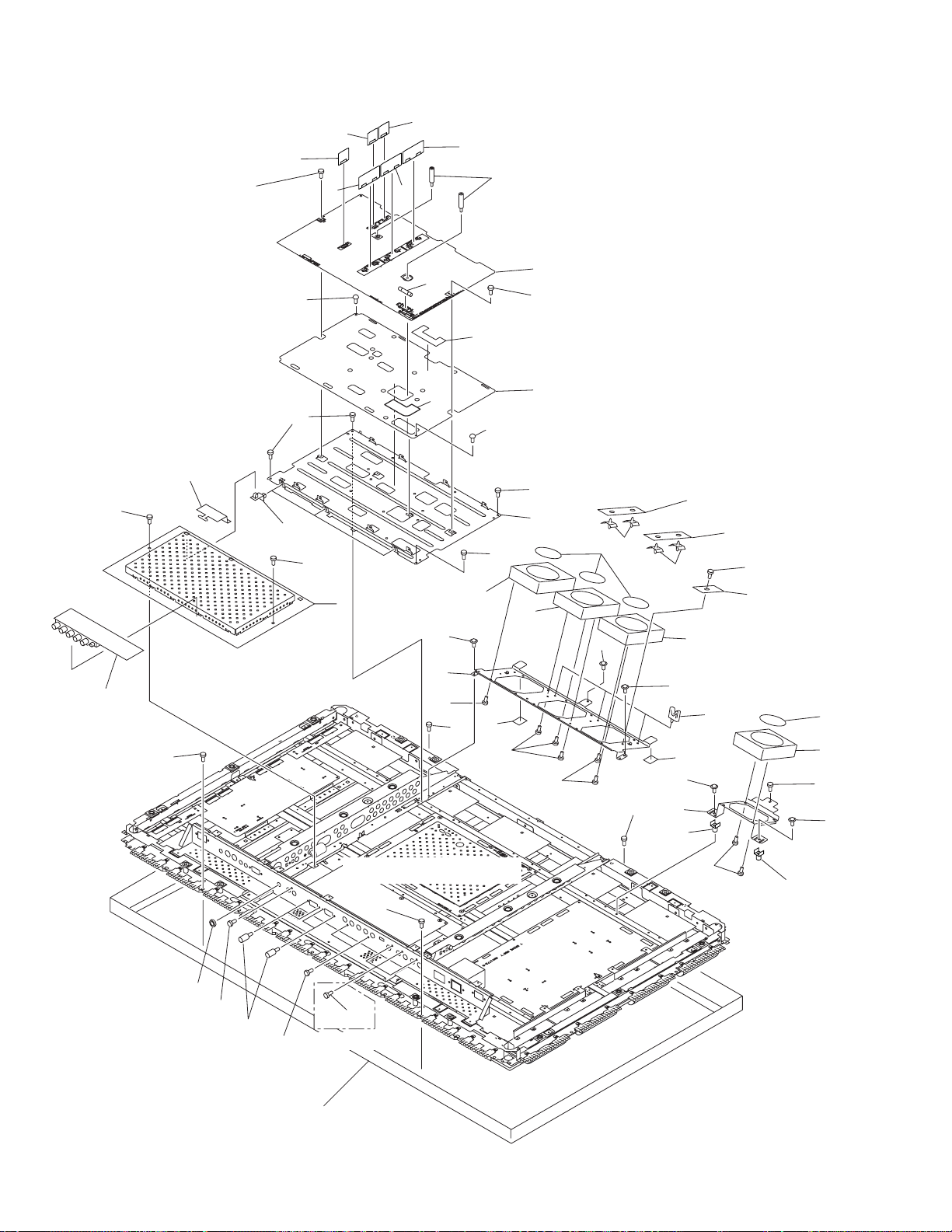

2.2 REAR CASE SECTION

4

10

PDP-502MXE

Only

PDP-502MX

Only

16

10

27 (MXE)

22

4

4

9

12

33

10

4

20

21

7

9

9

4

9

10

4

8

4

10

4

28

9

9

4

5

PDP-502MX

Only

10

9

17

4

10

27 (MX)

9

9

7

4

4

9

32

9

19 (MX)

30 (MXE)

12

31

29

PDP-502MXE

Only

PDP-502MX

Only

26

13

15

18

Refer to "2.3 EXTERIOR (1/3)".

6

PDP-502MX Only

11

3

1

24

14

25

8

Page 9

(1) REAR CASE SECTION PARTS LIST

PDP-502MX, PDP-502MXE

Mark No. Description Part No.

1 Siricon Sheet L AEH1034

2 ……………………………

3 Barrier AMR3166

4 Screw BBZ40P160FZK

5 Rear Case Frame

NSP 6 Rear Case

7 Stand Bolt ABA1277

8 Screw Collar AEC1848

9 Screw AMZ30P100FZK

10 Hole Rivet AMR2969

11 Solder Warning Label

12 Screw Rivet AEC1852

13 Terminal Label D AAX2721

14 Terminal Label F AAX2723

15 Terminal Label G

16 Terminal Label A

17 Caution Label

18 Terminal Label C

19 Terminal Label B

20 Bolt Caution Label

21 Cleaning Label

NSP 22 Name Label

23 ……………………………

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

Mark No. Description Part No.

NSP 24 Earth Label BAX1014

25 Serial Seal AAX2609

NSP 26 Display Label

NSP 27 Label VRW1629

28 Barrier Caution Label

29 Connector Cover

30 Earth Plate

31 Washer

32 Terminal Label N

33 Seal AAX2816

34 Rear Case Service Assy

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

Note) Rear Case Service Assy is composed of the following parts.

34 Rear Case Service Assy AWL1461 (MX)

3 Barrier AMR3166

NSP 6 Rear Case ANE1596 (MX)

11 Solder Warning Label AAX2644

20 Bolt Caution Label AAX2728

28 Barrier Caution Label AAX2759

30 Earth Plate ANK1639

AWL1457 (MXE)

ANE1587 (MXE)

(MXE only)

(MXE only)

(2) CONTRAST TABLE

PDP-502MX/LUCBW/1 and PDP-502MXE/YVLDK/1 are constructed the same except for the following:

Part No.

Mark

5 Rear Case Frame AMR3147 AMR3170

NSP 6 Rear Case ANE1596 ANE1587

11 Solder Warning Label AAX2644 Not used

15 Terminal Label G AAX2724 Not used

15 Terminal Label E Not used AAX2722

16 Terminal Label A AAX2718 Not used

16 Terminal Label L Not used AAX2734

17 Caution Label ARW1087 Not used

18 Terminal Label C AAX2720 Not used

18 Terminal Label M Not used AAX2735

19 Terminal Label B AAX2719 Not used

20 Bolt Caution Label AAX2727 AAX2728

21 Cleaning Label AAX2751 AAX2766

NSP 22 Name Label AAL2309 AAL2313

NSP 26 Display Label AAX–359 Not used

28 Barrier Caution Label AAX2759 Not used

29 Connector Cover Not used ANG2355

30 Earth Plate Not used ANK1641

31 Washer Not used ABE1077

32 Terminal Label N Not used AAX2736

34 Rear Case Service Assy AWL1461 AWL1457 Note

Symbol and DescriptionNo.

PDP-502MX PDP-502MXE

Remarks

LUCBW/1 YVLDK/1

9

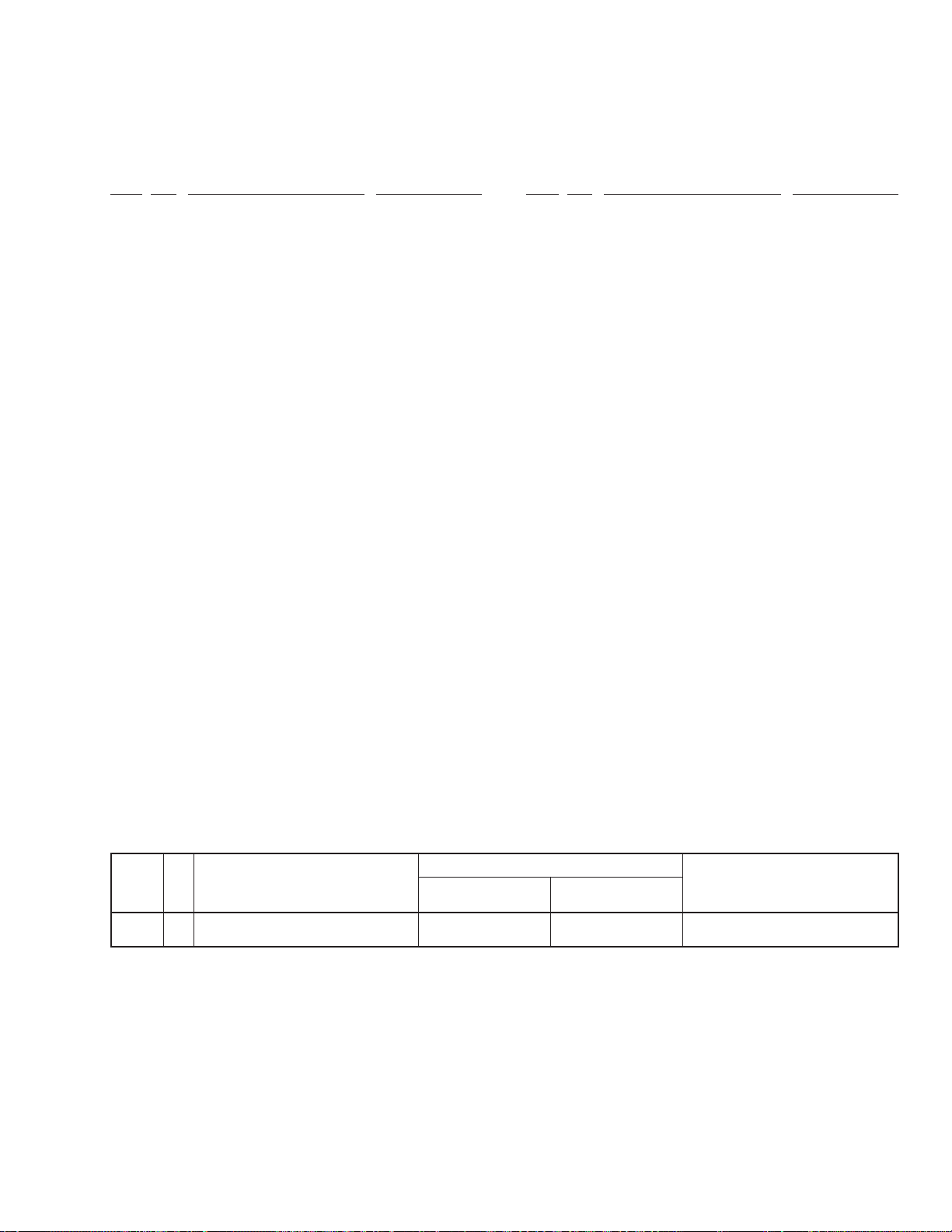

Page 10

PDP-502MX, PDP-502MXE

2.3 EXTERIOR (1/3)

23

34

20

40

33

24

34

34

37

39

38

35

22

36

34

13

34

1

20

8

19

7

15

14

15

34

18

34

17

13

2

44

45

24

3

13

34

11

21

Refer to "2.4 EXTERIOR (2/3)".

43

41

42

41

Refer to "2.6 FRONT CASE SECTION".

41

PDP-502MX Only

21

12

32

21

31

32

32

21

34

30

27

10

31

9

32

14

13

20

30

27

10

Page 11

(1) EXTERIOR (1/3) SECTION PARTS LIST

PDP-502MX, PDP-502MXE

Mark No. Description Part No.

1 MAIN POWER ASSY AWZ6506

2 Fuse (10A, FU101) AEK1071

3 VIDEO ASSY

4 ……………………………

5 ……………………………

6 ……………………………

NSP 7 Chassis ANA1605

8 Insulating Sheet AMR3199

9 Fan Frame A ANG2330

10 Wire Saddle AEC1745

11 INPUT ASSY AWZ6496

NSP 12 Fan Frame C ANG2393

13 Fan Motor AXM1036

14 Fan Label AAX2785

15 Locking Card Spacer AEC1736

16 ……………………………

17 SENSOR (A) ASSY AWZ6501

18 FAN CABLE (A) ASSY AWZ6502

19 FAN CABLE (B) ASSY AWZ6497

20 Screw BMZ30P060FCU

21 Screw BBZ40P160FZK

22 Spacer Screw AEF1028

23 Wire Barrier AMR3209

24 Nylon Rivet AEC1671

25 ……………………………

See contrast table (2)

Mark No. Description Part No.

31 Fan Angle Cushion AED1193

32 Screw PPZ50P100FZK

33 PCB Hinge AEC1807

34 Screw AMZ30P060FMC

35 RCC CONTROL A ASSY AWZ6507

36 RCC CONTROL B ASSY AWZ6508

37 RCC CONTROL C ASSY AWZ6509

38 OTL CONTROL A ASSY AWZ6510

39 OTL CONTROL B ASSY AWZ6511

40 OTL CONTROL C ASSY AWZ6512

41 Screw BPZ30P080FZK

42 Hexagon Screw BBA1051

43 Nut ABN1033

44 Insulation Sheet S AMR3233

45 Insulation Sheet L AMR3234

26 ……………………………

27 PCB Mold AMR2115

28 ……………………………

29 ……………………………

30 Screw ABZ30P160FCU

(2) CONTRAST TABLE

PDP-502MX/LUCBW/1 and PDP-502MXE/YVLDK/1 are constructed the same except for the following:

Part No.

Mark

3 VIDEO ASSY AWZ6495 AWZ6516

Symbol and DescriptionNo.

PDP-502MX PDP-502MXE

Remarks

LUCBW/1 YVLDK/1

11

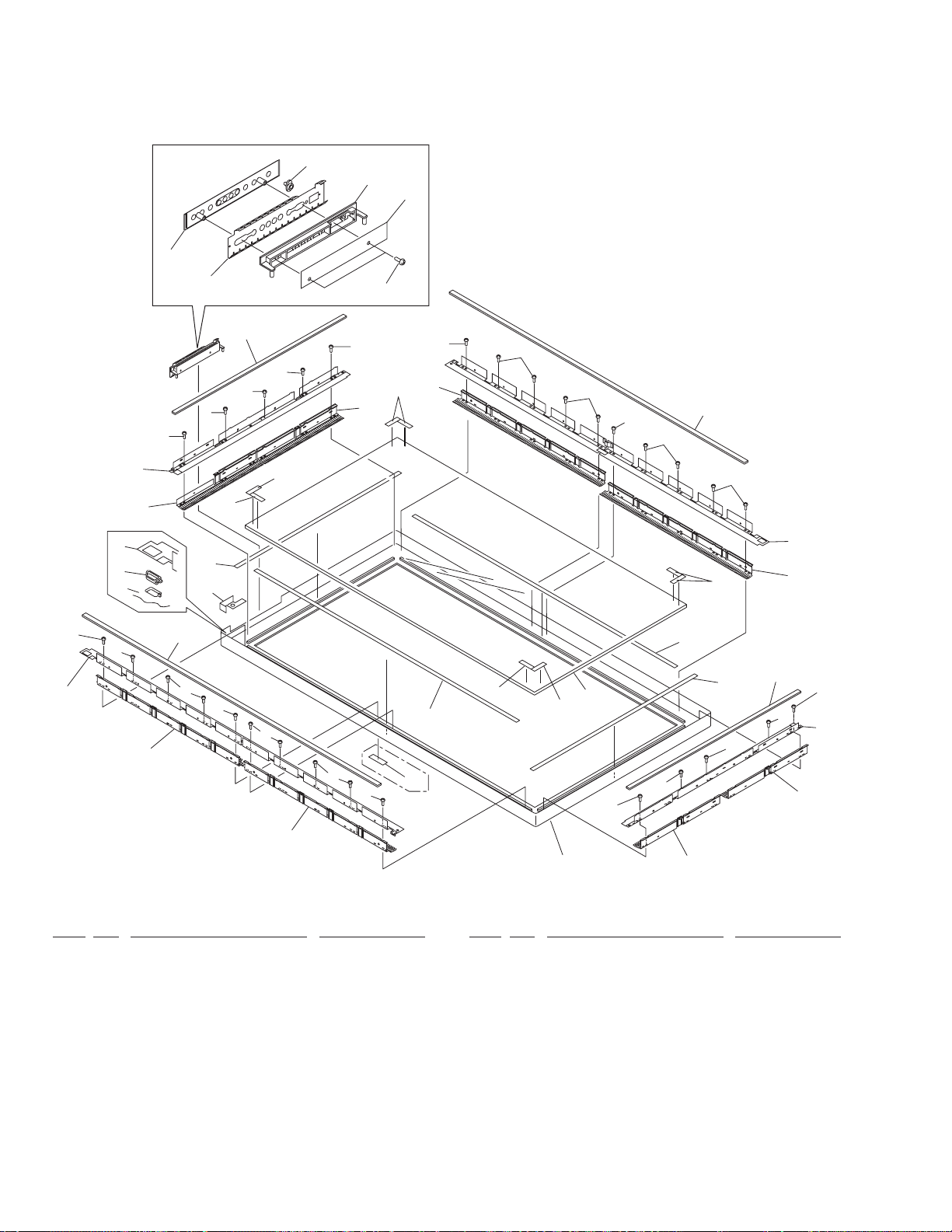

Page 12

PDP-502MX, PDP-502MXE

2.4 EXTERIOR (2/3)

22

18

28

20

16

23

45

24

4

38

21

23

23

26

33

23

45

15

29

13

22

4

5

26

A

12

40

23

41

13

22

22

3

2

22

1

41

14

19

37

5

19

1

31

30

32

11

23

23

12

40

22

22

21

45

A

1

39

45

23

2

Refer to "2.5 EXTERIOR (3/3)".

B

35

43

22

10

8

45

9

9

44

9

22

1

25

B

6

1

10

7

42

1

3

21

22

45

1

22

5

22

22

12

1

1

1

22

21

22

5

4

22

4

Page 13

(1) EXTERIOR (2/3) SECTION PARTS LIST

PDP-502MX, PDP-502MXE

Mark No. Description Part No.

1 Frame Shield H ANK1609

2 Frame H ANG2396

3 Frame V ANG2344

4 Frame Shield V ANK1610

5 Corner Holder ANG2347

6 Ferrite Core (L1) ATX1037

7 Sub Frame R ANG2395

8 Sub Frame L ANG2419

9 Bush C AEC1740

10 Wire Saddle AEC1745

11 AC Inlet with Filter (CN1)

12 Shield Gasket B ANK1646

13 Shield Gasket D

14 Shield Gasket C ANK1647

15 Terminal Panel

16 Shield Gasket E

17 ……………………………

NSP 18 IR Holder ANG2346

19 Edging Saddle AEC1737

20 Nylon Rivet AEC1671

21 Screw AMZ30P080FCU

22 Screw AMZ30P060FMC

23 Screw BMZ30P060FCU

24 Hexagon Screw BBA1051

25 Ferrite Core Holder AEC1818

See contrast table (2)

See contrast table (2)

See contrast table (2)

See contrast table (2)

Mark No. Description Part No.

NSP 31 Control Shield Case ANK1626

NSP 32 Control Shield Cover ANK1627

NSP 33 Control Shield Plate ANG2380

34 ……………………………

35 SP TERMINAL (L) ASSY AWZ6505

36 ……………………………

37 Spacer AEC1847

38 Screw AMZ30P100FZK

NSP 39 Drive Voltage Label ARW1097

40 Screw BPZ30P080FZK

41 Nut ABN1033

42 Screw PMB40P080FMC

43 Ferrite Core (L2) ATX1031

44 Binder AEC1851

45 Dust Guard AEB1362

26 FPC Cushion AEB1341

27 ……………………………

28 IR RECEIVE ASSY AWZ6498

29 Power Switch (S1) BSM1006

30 CONTROL ASSY AWZ6504

(2) CONTRAST TABLE

PDP-502MX/LUCBW/1 and PDP-502MXE/YVLDK/1 are constructed the same except for the following:

Part No.

Mark

11 AC Inlet with Filter (CN1) AKP1210 AKP1209

13 Shield Gasket D ANK1648 ANK1614

15 Terminal Panel ANG2341 ANG2353

16 Shield Gasket E ANK1649 ANK1634

Symbol and DescriptionNo.

PDP-502MX PDP-502MXE

Remarks

LUCBW/1 YVLDK/1

13

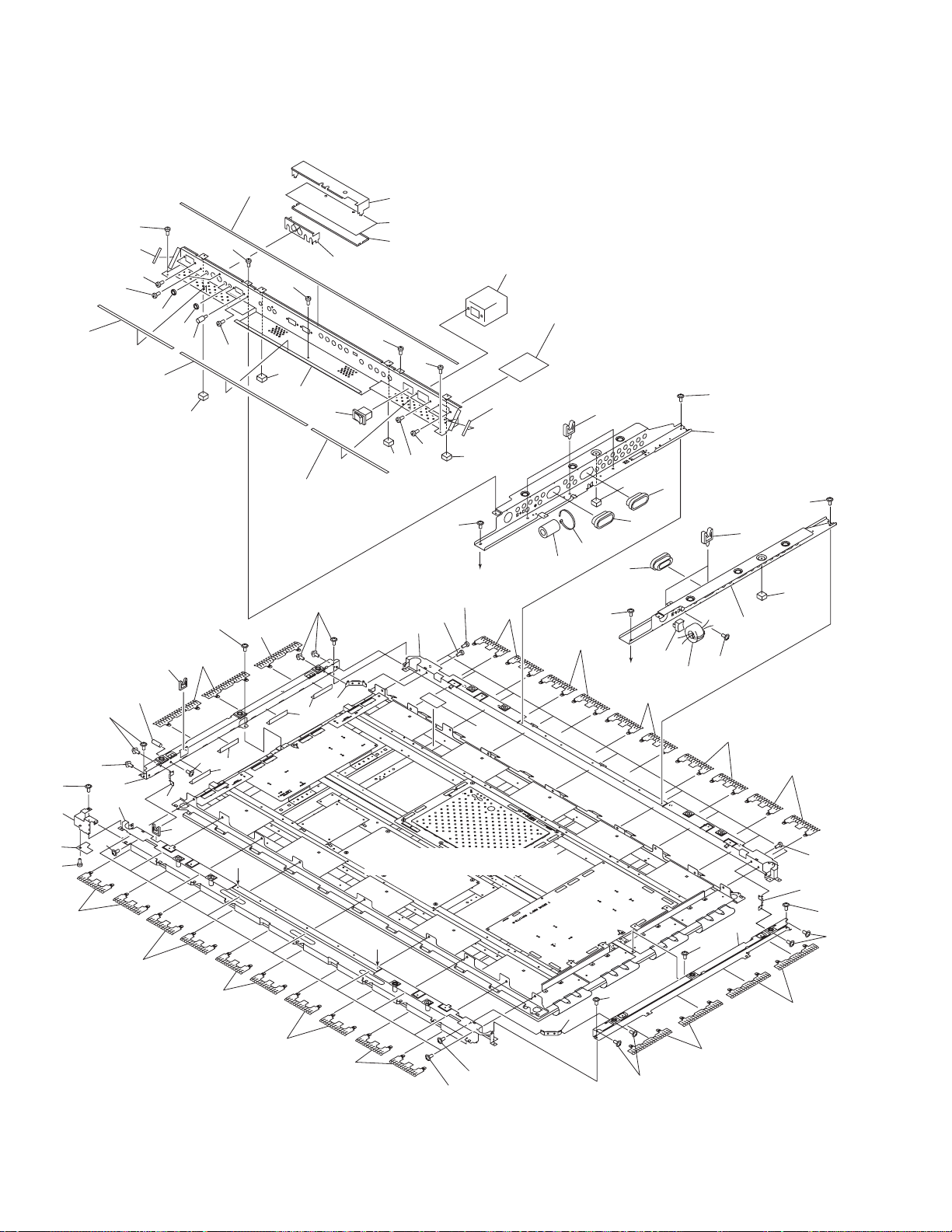

Page 14

PDP-502MX, PDP-502MXE

2.5 EXTERIOR (3/3)

Note*: No.47 is a special screw. Please fix to an original place.

Please never use other screws.

30

13

22

23

16

28

11

22

12

30

46

23

34

47

11

34

22

41

47

∗

39

45

9

40

9

46

23

5

11

46

11

22

40

48

36

24

46

∗

17

28

14

47

41

∗

3

39

9

47

39

15

47

28

A

28

44

44

11

2

46

23

B

1

30

∗

47

∗

32

∗

38

20

19

33

9

35

48

24

39

45

40

4

36

11

22

46

14

23

11

22

46

23

11

22

46

23

11

22

46

23

11

22

46

23

A

B

49

34

(× 40)

31

42

35

49

23

22

35

Page 15

(1) EXTERIOR (3/3) SECTION PARTS LIST

PDP-502MX, PDP-502MXE

Mark No. Description Part No.

NSP 1 Panel Shield S ANK1633

NSP 2 Panel Shield L ANK1632

NSP 3 Frame Assy ANA1633

NSP 19 Tube Cover AMR3036

NSP 20 Push Rivet AEC1748

4 SCAN (A) ASSY AWZ6518

5 SCAN (B) ASSY AWZ6519

6 ……………………………

7 ……………………………

8 ……………………………

9 PCB Spacer AMR3155

10 ……………………………

11 CABLE ASSY AWV1843

12 Y DRIVE ASSY AWV1847

13 X CABLE D ASSY AWZ6515

14 X DRIVE ASSY AWV1842

15 X CABLE U ASSY AWZ6514

16 DIGITAL VIDEO ASSY AWV1841

17 UCOM ASSY

18 ……………………………

21 ……………………………

22 Dust Guard Collar AMR3227

23 Locking Spacer AEC1794

24 Screw Grommet AEC1857

25 ……………………………

See contrast table (2)

Mark No. Description Part No.

31 Plastic Rivet AMR1066

32 AUDIO AMP ASSY AWZ6503

NSP 33 PCB Spacer AEC1446

NSP 34 Blind Sheet S AMR3202

NSP 35 Blind Sheet L AMR3203

NSP 36 Hot Plate ANG2416

37 ……………………………

38 Circuit Board Spacer AEC1795

39 Screw ABZ30P160FCU

40 Screw BBZ40P120FZK

41 Screw IBZ30P250FCU

NSP 42 Plasma Panel Assy AAV1236

43 ……………………………

44 Screw ABZ30P060FCU

45 Hot Plate Barrier AMR3223

46 Screw ABA1056

47 Screw ABA1200

48 Screw ABZ30P060FCU

49 Ferrite Core (L4, L5) ATX1041

NSP 26 ……………………………

27 ……………………………

NSP 28 Circuit Board Spacer AEC1744

29 ……………………………

30 Locking Spacer AEC1796

(2) CONTRAST TABLE

PDP-502MX/LUCBW/1 and PDP-502MXE/YVLDK/1 are constructed the same except for the following:

Part No.

Mark

17 UCOM ASSY AWZ6499 AWZ6520

Symbol and DescriptionNo.

PDP-502MX PDP-502MXE

Remarks

LUCBW/1 YVLDK/1

15

Page 16

PDP-502MX, PDP-502MXE

2.6 FRONT CASE SECTION

2

3

4

5

1

22

18

8

8

8

8

17

20

7

6

15

8

8

7

10

9

14

13

23

8

8

14

8

8

14

16

8

8

8

9

11

21

PDP-502MX

Only

14

8

14

8

8

12

8

10

8

8

7

18

9

8

8

17

16

14

11

13

8

8

9

(1) FRONT CASE SECTION PARTS LIST

Mark No. Description Part No.

1 SIDE SW ASSY AWZ6500

2 LED Lens AAK2695

3 Control Name Plate AAK2757

4 Control Shield ANK1606

5 Control Button AAC1540

6 Lens AAK2741

NSP 7 Panel Holder Assy ANG2386

8 Screw BPZ30P080FZK

9 Panel Shield H ANK1603

10 Panel Cushion H AED1189

11 Front Cushion H AED1191

12 Protect Panel Assy AMR3228

16

15

16

Mark No. Description Part No.

13 Front Cushion V AED1192

14 Corner Cushion AEB1360

15 Front Case

16 Panel Shield V ANK1604

NSP 17 Panel Holder V ANG2337

18 Panel Cushion V AED1190

19 ……………………………

NSP 20 Panel Shield VM ANK1605

21 Pioneer Seal

22 Screw BBZ30P080FMC

23 Corner Shield ANK1665

See contrast table (2)

See contrast table (2)

Page 17

PDP-502MX, PDP-502MXE

(2) CONTRAST TABLE

PDP-502MX/LUCBW/1 and PDP-502MXE/YVLDK/1 are constructed the same except for the following:

Part No.

Mark

15 Front Case AMB2649 AMB2679

21 Pioneer Seal ARW1091 Not used

Symbol and DescriptionNo.

PDP-502MX PDP-502MXE

Remarks

LUCBW/1 YVLDK/1

2.7 PDP SERVICE ASSY (AWU1030)

PDP SERVICE ASSY (AWU1030) is composed of the following parts.

Please refer to 2.4 and 2.5 for the illustrations of each part.

Mark No. Description Part No.

2.4 EXTERIOR (2/3)

1 Frame Shield H ANK1609

2 Frame H ANG2396

3 Frame V ANG2344

4 Frame Shield V ANK1610

5 Corner Holder ANG2347

21 Screw AMZ30P080FCU

22 Screw AMZ30P060FMC

26 FPC Cushion AEB1341

37 Spacer AEC1847

38 Screw AMZ30P100FZK

NSP 39 Drive Voltage Label ARW1097

2.5 EXTERIOR (3/3)

NSP 3 Frame Assy ANA1633

NSP 19 Tube Cover AMR3036

NSP 20 Push Rivet AEC1748

23 Locking Spacer AEC1794

24 Screw Grommet AEC1857

NSP 28 Circuit Board Spacer AEC1744

30 Locking Spacer AEC1796

31 Plastic Rivet AMR1066

NSP 33 PCB Spacer AEC1446

NSP 34 Blind Sheet S AMR3202

Mark No. Description Part No.

OTHERS

Wire Saddle AEC1797

Flat Clamp AEC1858

Cable Clip AEC1859

NSP FPC (XGA2-Y) ADY1047

NSP FPC (XGA2-X) ADY1053

NSP Address Mojule (IC21–IC40) MC-16340

PACKING

Button Bolt ABA1259

Corner Pad AHA2203

Corner Carton AHA2204

Upper Carton AHD2970

Under Carton AHD2971

Packing Sheet AHG1291

Holder Plate AHK1008

Washer WB80FZB

NSP 35 Blind Sheet L AMR3203

38 Circuit Board Spacer AEC1795

NSP 42 Plasma Panel Assy AAV1236

17

Page 18

1

3

2

L

Y

S

C

P

-

E

234

PDP-502MX, PDP-502MXE

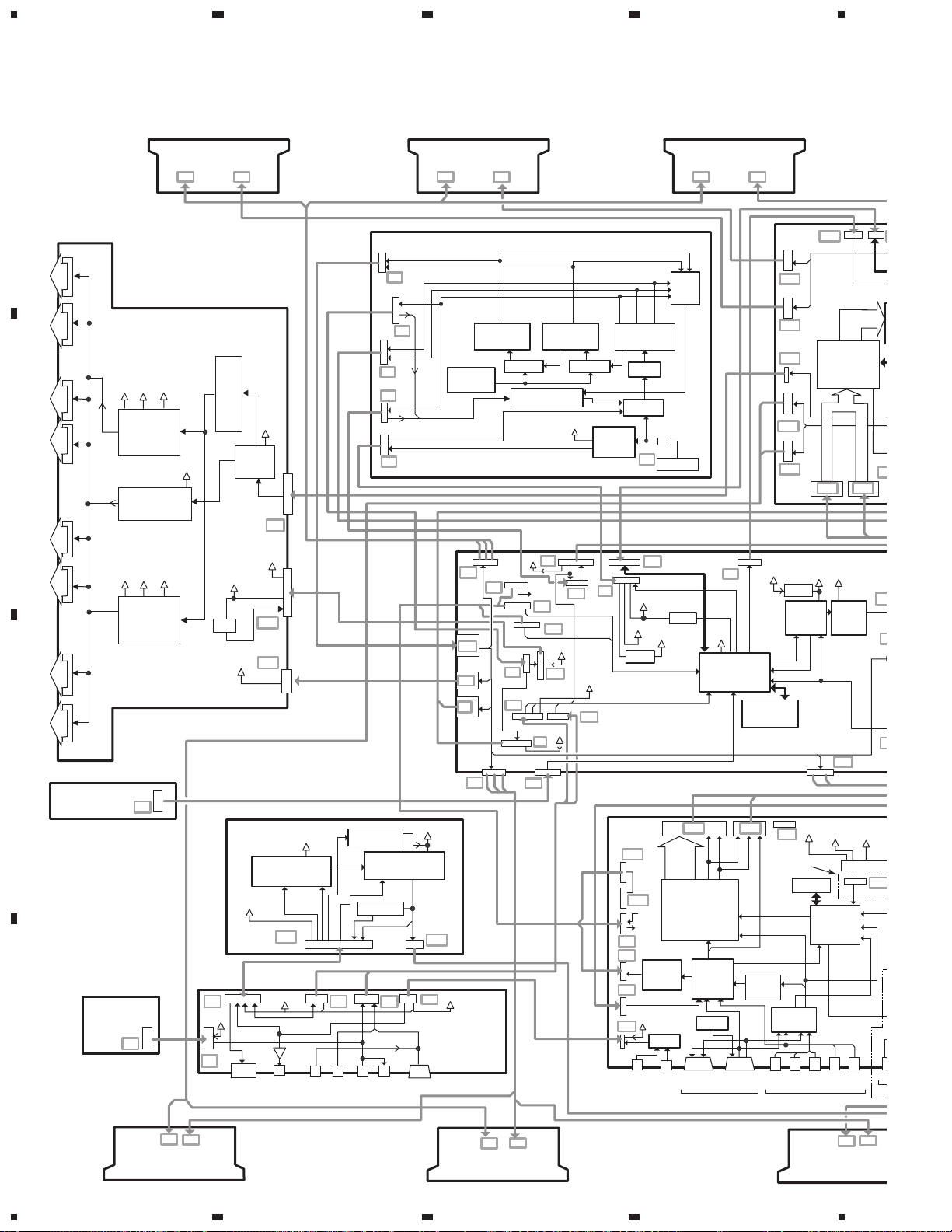

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

For "SCHEMATIC DIAGRAM", refer to the service manual ARP3078 for PDP-502MX.

3.1 OVERALL BLOCK DIAGRAM

A

To Panel X-Electrode

B

To Panel X-Electrode

C

SIDE SW

ASSY

D

SUS

Psus(X)

OUT

+RST

OUT

Psus(X)

SUS

OUT

Psus(X)

IR

RECEIVE

ASSY

Vsus

12V

5V

Sustain

Pulse Gen.

IC3405

Vsus

+ Reset Pulse

Gen.

5V

Vsus

12V

Sustain

Pulse Gen.

IC3402

X DRIVE ASSY

S1

U1

CABLE ASSY

K2

SUS

K1

BLK

Isolation (PC)

Logic

BLK

RST

12V

PD

OC

Vsus

AUDIO AMP ASSY

12V

STB5V

C6

S5V

R

C1

R OUT

5V

DRV

Sig.

F7

5V

F6

F5

VOL CONT

(Main/Sub)

B2

13V,S5V

REM

Audio

Out

LR

PD, VOL

12V

VOL

13V

C5

Combi

In Out

MAIN POWER ASSY

P5

P3

P6

P4

P1

CON

D-D

PWR AMP

LR

IC4502

MUTE

DC

DET

PD

R

SRInSR

L

C4

LR

Out

CABLE ASSY

K2

HI PWR

OFF SW

PWR

E35

E18

Vsus

E17

E7

Vsus

Vadr

E12

15V

B3

12V

C2

CONTROL

Tx

Rx

ASSY

K1

Vsus

Vsus

VSUS

SW PWR

PD

Vadr

E21

E1

E22

10V

PD CONT

STB5V

5V

SDA

SCK

E24

E8

E10

Vadr

VADR

SW PWR

STB12V

E3

E19

E23

5V

E16

5V

12V

DELAYDELAY

PD

STBY

PWR

12V

5V

E2

PD

13V

REM, Tx, Rx,Vol, Mute

E15

KEY, LED

8V

-8V

14V

VCC

SW PWR

+B

PFC

Relay

FU101

P7

AC IN

E5

S5V

14V

R5V

REG

DAT, CLK

SDet, FDet

U-COM ASSY

A19

A20

SDet

AMP/AD/PLL

DAT

CLK

A1

A2

Sync

U-Com

F-DET

A3

CLP,HV

12V

BLK

A5

SEL

LRLR

Audio

Audio

1/2

3/4

CABLE ASSY

K2

OC

OVC

E6

PWR

RST

S5V

SYSTEM

CONT CPU

IC3604

A33 A35

RGB

CLK

(A), (B)

HD

IC2402

HD

HD,VD

Sync

SEL

CONT

P&P

RGB

OUT

IN 4

RGB

In

CLK

K1

14V

OSD DAT

EEPROM

IC3601

HD

VD

CLP,HV

BLK

Sync

Sepa

HD

VD

Pr

D1

D19

D4

D18

D12

FAN

MAX

SD

SENS

A17

502MXE

Only

RGB

RGB

G/Y

In3/In4

SEL

R

R10V

REG

FAN

CONT

BLK

Vadr

12V

V.ROM

GYB

IN 3

D13

Process

CLP Pulse

Gen.

RGB DAT

D20 D22

Vadr

14V

FAN

DRV

E33

9V_PIC

9V_SIG

RGB

Decoder

IC1401

Y

YPbPr

HDVD

HD

CS

Pb

RGB

DAT

IP

VD

HD,VD

5APLL

5VBPLL

RGB

YCb

YPb

C

D

E

E

E

R

A30

18

K1

K2

CABLE ASSY

K2

K1

CABLE ASSY

CABLE ASS

K2

K1

1234

Page 19

CLP Pulse

Y

2

,

,

,

,

,

RGB DAT

D20 D22

14V

R10V

EG

AN

ONT

LK

adr

9V_PIC

12V

9V_SIG

MXE

ly

V.ROM

B

B

In4

L

B

Pb

RGB

Decoder

IC1401

HD

CS

IN 3

CABLE ASSY

5

67

PDP-502MX, PDP-502MXE

Notes: When ordering service parts, be sure to refer to "EXPLODED VIEWS AND PARTS LIST" or "PCB PARTS LIST".

For "PCB PARTS LIST", refer to the service manual ARP3078 for PDP-502MX.

RGB

DAT

IP

Process

Gen.

Vadr

FAN

DRV

E33

5APLL

5VBPLL

RGB

Y

YPbPr

HDVD

K1

Aspect

Conv.

FIFO

CPU

CLP

HD,VD

D17

E26

E38

E27

-5V_IO

5V_AD

REG

A30 A31

YCbCr

YPbPr

Sync

SEL

K2

D6D13 D14

OSD

Gen

RGB

DAT

IP

Panel

CPU

5V

3.3V

REG

12V

OC

UPV

D16

PD

5V_PIC

A13

5_PLD

5V_RGB

13V, 8V, -8V

SCL, SDA

Y,C

Y, Col diff Decoder

Sync

Sepa

Y

In1/In2

YCSVD

VBS

CABLE ASSY

K2

D3

Gamma-1

ABL

Dither

OSD Add

Sequence

D11

FAN CABLE B

ASSY

ASSY

R10V

SENS A

IC1201

SEL

OUT

IN 1IN 2

K1

TOP ADR DAT

(64bit * RGB * 20)

Xtal

60M

RGB

DAT

Xtal

50M

Sub-Field

MEM

Conv.

* Field

20

20

XY DRV

VADR Cont

pattern

Gen.

BOTTOM ADR DAT

(64bit * RGB * 20)

DRV

Sig

DIGITAL VIDEO ASSY

FAN A

FAN

DRV B

FAN

DRV B

FAN

DRV A

FAN CABLE A

SENSOR A ASSY

SENS

SDAT

SER

PARA

CONV.

CONT

3DY/Y/SY SEL

3DY Y

3D Y/C for

C

V/Y

V/Y

TEMP

SENS

IC4101

NTSC

FAN B

FAN C

FAN D

Y

BW_Y

3DC

C

IC IC IC IC

VADR

RGB

RGB

RGB

CLKB CLKBCLK

ADR

U/B/

D/G

VADR

Gen.

DEF DEF DEF DEF

VADR

K2

DAT3

D5

D7

Y DRIVE ASSY

D8

5V

D9

D10

DRV Sig.

H1

Logic

BLK

Vsus

10V

RN

H5

5V

- Reset

Pulse

VRN

14V

12V

Gen.

PD

-8V

OC

VFZ

D-D

CONV

BLK

OVP

D-D CONV

Vofs

12V

BLK

14V

-8V

Vsus

10V

UVP

OVP

IC5V

Vsus

Vofs

VIDEO ASSY

Y SEL C SEL

NT

PALY

SEC Y

SEC

FIL

3Line Y/C

for

PAL/60PAL

V/Y

PAL

FIL

FIL

C SEL

C

C

FILTER

C

502MX Only

K2

K1

L1

CABLE ASSY CABLE ASSY

RGB

(64bit)

Vsus

H4

OFS

Pulse

Gen.

Vcp

BLK

VRN

SP(L)

ASSY

DAT2

(64bit)

SI ,CLK

CP MSK, OFS

OFS

CP

MSK

Vcp

VH

IC IC IC IC

VADR

RGB

RGB

CLK

12V

5V

3.3V

K1

DAT1

RGB

(64bit)

DAT0

RGB

(64bit)

CABLE ASSY

5V

Vsus12V

Sustain

Pulse Gen.

IC3702

SUS

-RST

OFS

Vcp

Y-SUS

MASK

BLK

5V

Vsus12V

Sustain

SUS

Pulse Gen.

IC3707

VH

IC5V

H2

SUS OUT

VH

IC5V

H3

SUS OUT

K1

K2

8

SCAN (A) ASSY

IC5V

VH

ADD

SEL

PULSE

IC5V

VH

ADD

SEL

PULSE

IC5V

VH

ADD

SEL

PULSE

IC5V

VH

ADD

IC5V

IC5V

IC5V

IC5V

IC5V

IC5V

IC5V

IC5V

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

ADD

SEL

PULSE

VH

VH

VH

VH

VH

VH

VH

VH

Psus(Y)

V7

Psus(Y)

V14

Psus(Y)

SCAN (B) ASSY

A

V1

V2

V3

V4

To Panel Y-Electrode

V5

B

V6

V8

V9

V10

V11

To Panel Y-Electrode

C

V12

V13

D

L OUT

5

6

7

8

19

Page 20

1

234

PDP-502MX, PDP-502MXE

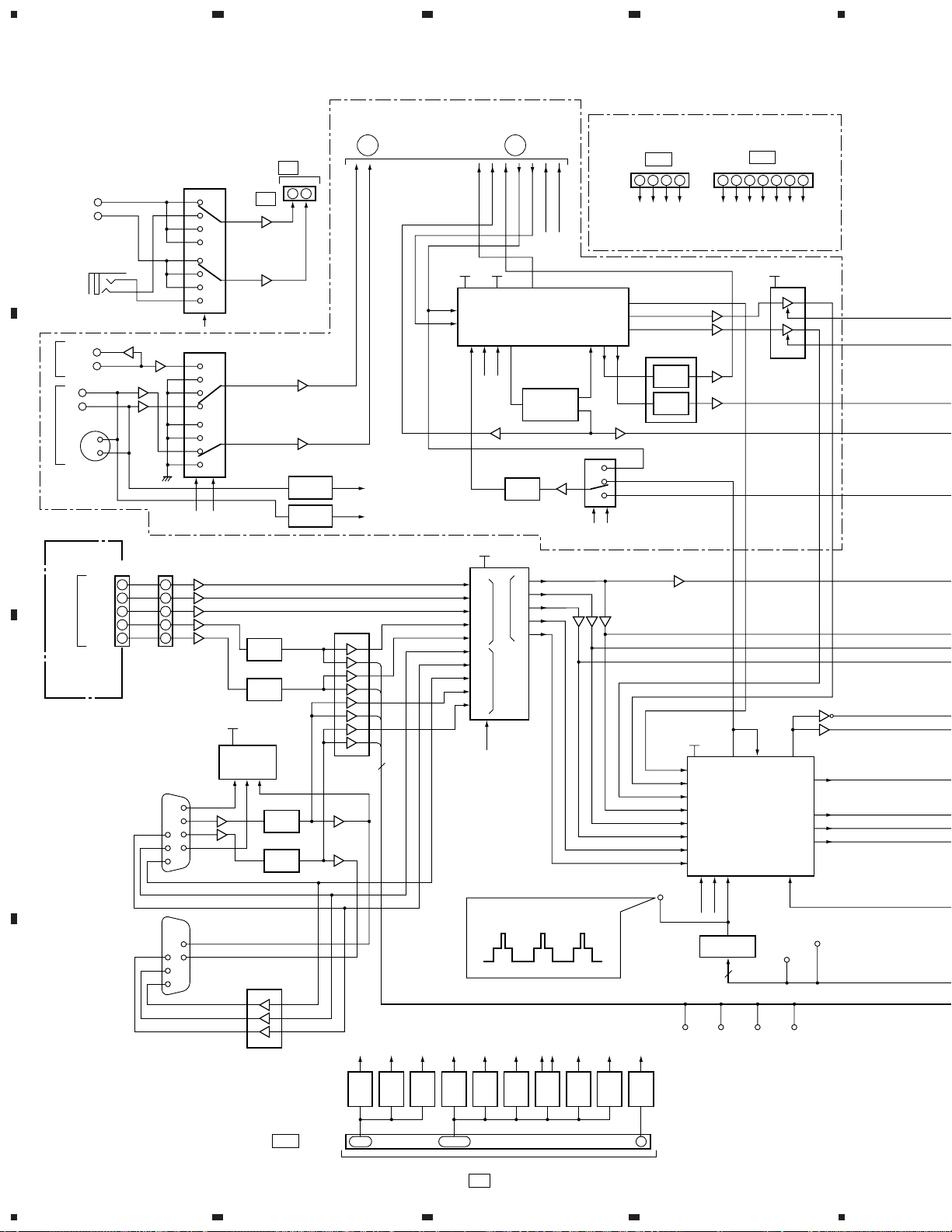

3.2 VIDEO ASSY SECTION (1/2)

A

B

C

D

R

L

AUDIO

INPUT1 (502MX)

INPUT3 (502MXE)

AUDIO

INPUT2 (502MX)

INPUT4 (502MXE)

OUTPUT

INPUT

INPUT1

C

Y

SINC

INPUT2

SINY

CN3506

Y/G

Pb/B

Pr/R

HD/CS

VD

INPUT3 (RGB1)

INPUT ASSY

(AWZ6496)

L

R

CN303

2

4

6

8

10

RGB2 INRGB2 OUT

G

R

G

R

B

B

2

4

6

8

10

To CONTROL ASSY

CN4703

IC651

1

2

4

5

11

12

14

15

FNC_1

IC102

1

2

4

5

11

12

14

15

MR_V_SW

FNC_2

5V_RGB

SCL

VD

HD

SDA

VD

HD

CN302

A5

3R

13

L

YC_VY

3

YC_C

13

IC301

Comp

IC303

Comp

IC507

(24LCS21A)

Plug & Play

ROM

IC506

15

12

10

VCLK

IC503

Comp

IC501

Comp

C2

S2_DET

2

5

7

1

3

S_DET

PDP-502MX Only

To VIDEO Assy (2/2)

A B

YC_C

YC_VY

9V_SIG

45

42YC

51

S_DET

S2_DET

+5V_RGB

9V_PIC

9V

Reg

24

12

11

23

13

5V_RGB

5V

IC305

12V

12V

Reg

4

9V_SIG

9V

Reg

PDP-502MXE Only

Y

C

FSC

HBLK_CNR

5V_PIC

Y/B–Y/R–Y DECODER SYNC SEPA.

10

SCL

SDA

SYNC

1

G1

3

B1

5

R1

HD1

VD1

7

G2

9

B2

R2

HD2

VD2

VIDEO SW

(BA7657F)

FNC_0

SAND CASTLE PULSE GEN.

HBLK/VBLK/CLP added

5V_PIC

5V

Reg

Reg

SCL

CLP_CNR

27

TV JUNGLE IC

IC1201

(TB1227BW)

4

IC1202

(TC74HC4538AF)

HOUT

4

HBLK Gen.

2MHz

LPF

21

G

19

B

15

R

22

HD

14

VD

IC306

5V_PLD

+5A_PLL

+5D_PLL

5V

5V

Reg

Reg

SDA

MAI_SW

7

5V

6

9

10

+5AD

Reg

1569

5

1

3

IC1207

SHP_SW

+3.3AD

Reg

3.3V

CN304

A31

123

SCL

SDA

37

Y

36

B–Y

35

R–Y

IC1205

(NJN1319M)

4

10

Y

Y SYNC

RGB SYNC

INT_Y

INT_Cb

INT_Cr

EXT_Y

EXT_Pb

EXT_Pr

EXT_HD

EXT_VD

K1404

–5V_IO

–5V

Reg

5

135

8V

13.5V

INT_Cr

12

Comp

7

Comp

9V_PIC

5

4

3

Multi Component Processor

11

10

RGB Matrix

(CXA2101AQ)

9

7

RGB DECODER

8

55 56 31 43

SCL

SDA

SCP

SCP Gen.

3

K2024

K2023

VD3

HD3

CN503

A30

INT_Y

INT_Cb

IC1401

K2025

HD4

9

7

11

L

VD_PLD

HD_PLD

5V_PIC

7

1

IC1204

(BA7655AF)

7976 75

P_ACL

K2013

HBLK

K2026

VD4

13

R

5

6

3

2

80

37

39

35

K2014

VBLK

20

A13

CN3401

2

567

11

1

To POWER SUPPLY ASSY

CN306

P6

1234

Page 21

5

67

8

PDP-502MX, PDP-502MXE

IN Screen K2904

NTSC 4:3 60 15.734k 40.28M Single (A) IP

PAL Wide 50 15.625k 53.63M Single (A) IP

PC

XGA (60)

B-Y_LEV

R-Y_LEV

VD_PLD

HD_PLD

IC1404

12

14

13

SEL_Vout V_STATE

G-Out

B-Out

R-Out

K2015

CLP

K2903

K2901

(VD)

(HD)

ORG 60 48.36k 32.50M Dual (A/B) Through

(CLK)

5V_PIC

Video Data

ROM

K2420

AD OUT IP Process

K2418

K2422

IC104

(24LC01B)

56

SCL

SDA

G/Y

K2004

HD_PLD

K2033

VD_PLD

K2032

K2021K2020

VD_FIL

HD_FIL

19

MMV

MMV

HD/VD

NOISE GATE

PULSE Gen.

IC2004

(TC74VHC123AFT)

12

5V_PIC

4

HBLK_MAT/VBLK_MAT/CLP_MAT

HD3/VD3/HD4/VD4

FNC_2

S_DET

R-Y_LEV

B-Y_LEV

MAT_SW

6

5432

D/A

IC2301

(CXA1875AM)

1514

K2419

FNC_0

K2421

V_STATE

HD_PLD

VD_PLD

VD_FIL

HD_FIL

HD_MASK

FNC_1

P_ACL_SW

10971

K2417

P_ACL_SW

142

110

112

102

107

106

103

VD_MASK

KU_SW

INT_RINT_R

124

INT_GINT_G

133

INT_BINT_B

139

EXT_REXT_R

126

EXT_GEXT_G

136

EXT_BEXT_B

141

K2012

K2029

K2030

Sync. Sepa for Y/G

IC2002

(M52346SP)

–HS

84

4

3

+5V_PLL

AMP/AD/PLL

(CXA3506R)

1

3

143

R

G

B

Peak ACL

12V

+VS

VD_SEP

HD_SEP

88

9896103

100

Sync. Control

Sync. Select

PLD

IC2005

(PDY069)

128

131

132

+3.3AD

+5AD

IC2402

113

111

HD_PLL

CLP_AMP

CLP_AMP

HD_PLL

HD_u, VD_u

2 22,23

5V_PIC

104

11910

106

PLL_CE

ULK_PLL

HOLD_PLL

HOLD_PLL

ULK_PLL

120

114

5V_PLD

CLK

DATA

+3.3AD

VD

137

Reset

Sync. U-COM

IC2201

(PD2060A9)

Input Freq. Det.

R (B)

G (B)

B (B)

R (A)

G (A)

B (A)

98

101

103

K2012

1_2CLK

K2012

K2012

K2012

11

XCLK

1_2CLK

HD

XCLK

HD

VD

18

19

31

16

8

8

8

8

8

K2210

4

CLK

Gate

DA_0_SV

PLL_CE

K2211

K2212

DATA

CLK

K2209

K2213

K2202

K2203

XCLK

1_2CLK

K2201

K2204

A33

CN2901

8

8

8

8

8

88

A35

CN2903

HD

VD

CN2203

A2

4

S2_DET

SDA

SCL

CLP1

CLP2

HBLK

VBLK

D20

To DIGITAL VIDEO ASSY

CN3403

1

3

D22

5

7

To DIGITAL VIDEO ASSY

CN3405

3

E24

4

5

6

To U-COM ASSY

CN3612

CN2202

A1

E23

2

3

4

5

6

To U-COM ASSY

CN2202

CN2001

A3

8

D17

9

10

11

To DIGITAL VIDEO ASSY

CN3402

A

B

C

D

SCL

SDA

21

5

6

7

8

Page 22

1

VC_YV

3D_Yin

3D_Cin

5V

REG.

LPF

(6.7MHz)

LPF

(6.7MHz)

LPF (6.7MHz)

IC803

Low Lum.

CNR

Clamp

Delay

250nS

3.58 BPF

D/A

IC703

(CXA1875AM)

SCL

SDA

54

4.43 BPF

21 345679

12

15

2

3

5

13

12

111214

2

1

3

14

4

1

15

13

4

14

131514

21435

IC1105

IC1103

IC1104

IC1004

Sin_C

3L_Vin

SCL

SDA

IC802

IC801

NTSC

NTSC

PAL

PAL

SECAM

SECAM_C

SINC

SECAM

3.3V

REG.

IC1101

(UPD64082GF-3BA)

IC1001

(CXD2064Q)

IS41C16256–35K

IC1106

LPF (6.7MHz)

4M DRAM

SECAM

Chroma Trap

5V

REG.

YC_C

1

4

768896

57

59

84

3D_Y

3D_C

18

5

4

83

60

8

CSI

AYI

3DRST

CLPO

ADIN

AYO

ACO

9

7

8

5

1

2

1

4

37

23 2517 26

FIN

MN

BPF

SW

VS

TRP1

TRP2

VS

BW

NP

MN

TRP0

TRP1

TRP0

TRP1

TRP2

DLSW

10

BPFSW

DLSW

TRP2

TRP2

VS/BW

NP

ACI

RSTB

5

IC1003

IC1002

1

4

8

5

5V_3D

5V_3D

AYO

ACO

5V_3L

5V_3L

3.3V_3D

3.3V_3D

5V_PIC

5V_SIG

TRP2

FSC

HBLK_CNR

CLP_CNRYC

SCL

SDA

8V

3D Y/C

3Line Y/C

MA (0:8)

MD (0:15)

To VIDEO Assy (1/2)

To VIDEO Assy (1/2)

3L_Y

3D_C

NTSC_C

PAL_C

A

B

234

PDP-502MX, PDP-502MXE

3.3 VIDEO ASSY SECTION (2/2)

A

B

C

D

22

1234

Page 23

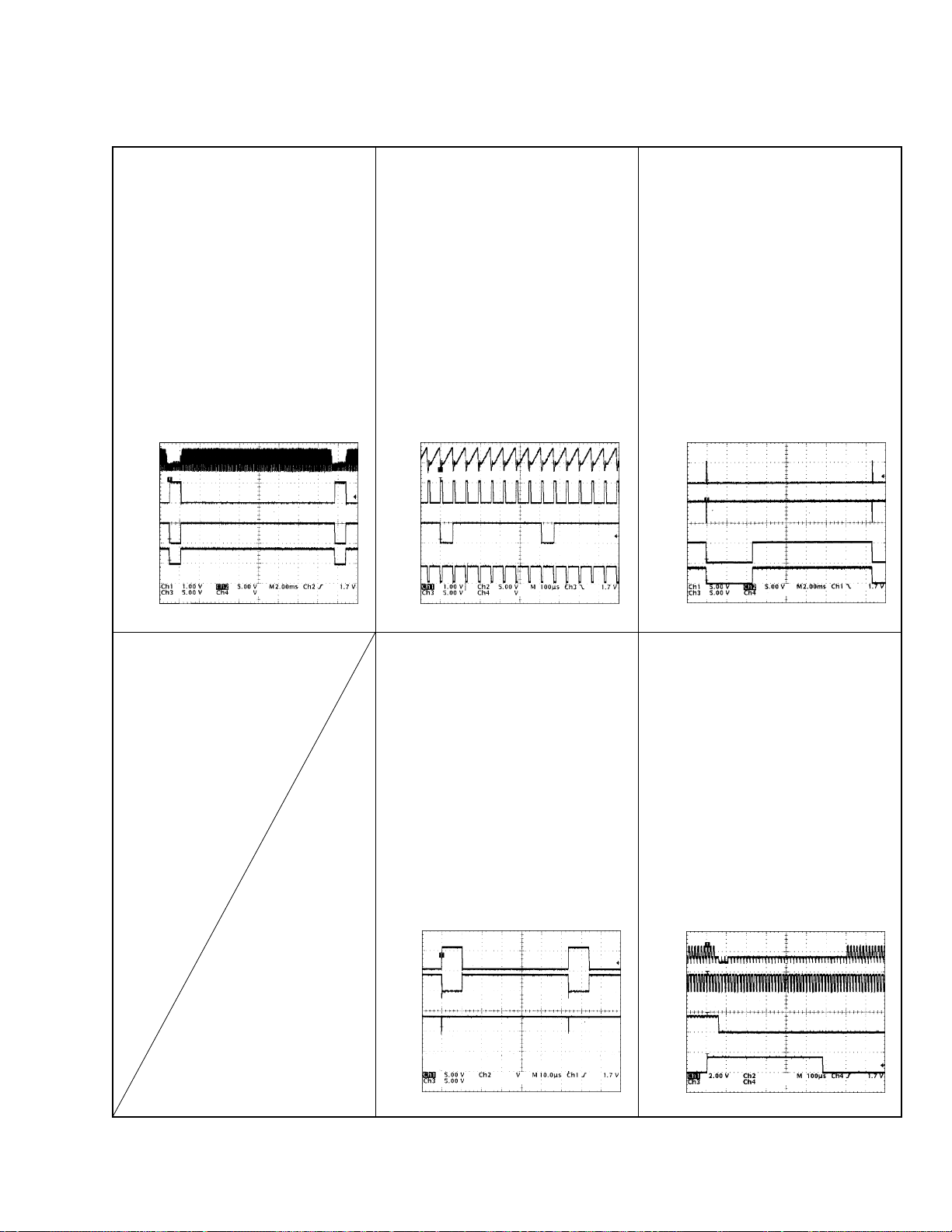

Waveforms of VIDEO ASSY

PDP-502MX, PDP-502MXE

Synchronous Signal Processing Block

(When INPUT1 NTSC RAMP signal is input)

CH1: VIDEO input

V : 1V/div H : 2msec/div

CH2: K2032 (VD_PLD), IC2005 Pin 112

V : 5V/div H : 2msec/div

CH3: K2018 (VD_u), IC2005 Pin 34

V : 5V/div H : 2msec/div

CH4: K2031 (VD_DSEL), IC2005 Pin 137

V : 3.3V/div H : 2msec/div

Synchronous Signal Processing Block

(When INPUT1 NTSC RAMP signal is input)

CH1: VIDEO input

V : 1V/div H : 100msec/div

CH2: K2033 (HD_PLD), IC2005 Pin 110

V : 5V/div H : 100msec/div

CH3: K2019 (HD_u), IC2005 Pin 32

V : 5V/div H : 100msec/div

CH4: K2029 (HD_PLL), IC2005 Pin 118

V : 3.3V/div H : 100msec/div

Synchronous Signal Processing Block 2

(INPUT4 PC siganl VESA:

1280x1024@60Hz (SXGA@60Hz)

when there is signal input [ separate H, V ]

CH1: K2026 (VD_4),

IC2005 Pin71 (VD input)

V: 5V/div H: 2msec/div

CH2: K2020 (VD_FIL), IC2005 Pin 102

V: 5V/div H: 2msec/div

CH3: K2018 (VD_u), IC2005 Pin 34

V : 5V/div H : 2msec/div

CH4: K2031 (VD_DSEL), IC2005 Pin 137

V : 3.3V/div H : 2msec/div

Synchronous Signal Processing Block

(When INPUT1 NTSC RAMP signal is input)

CH1: K2033 (HD_PLD), IC2005 Pin 110

V : 5V/div H : 10msec/div

CH2: K2029 (HD_PLL), IC2005 Pin 118

V : 3.3V/div H : 10msec/div

CH3: K2432 (DIVOUT), IC2402 Pin 103

V : 5V/div H : 10msec/div

Synchronous Signal Processing Block 2

(INPUT4 PC siganl VESA:

1280x1024@60Hz (SXGA@60Hz)

when there is signal input [ separate H, V ]

CH1: K2004

(SYNC_SEP: input Green signal),

IC2002 Pin4

V : 2V/div H : 100msec/div

CH2: K2029 (HD_PLL), IC2005 Pin 118

V : 3.3V/div H : 100msec/div

CH3: K2031 (VD_DSEL), IC2005 Pin 137

V : 3.3V/div H : 100msec/div

CH4: K2030 (HOLD_PLL), IC2005 Pin 120

V : 3.3V/div H : 100msec/div

23

Page 24

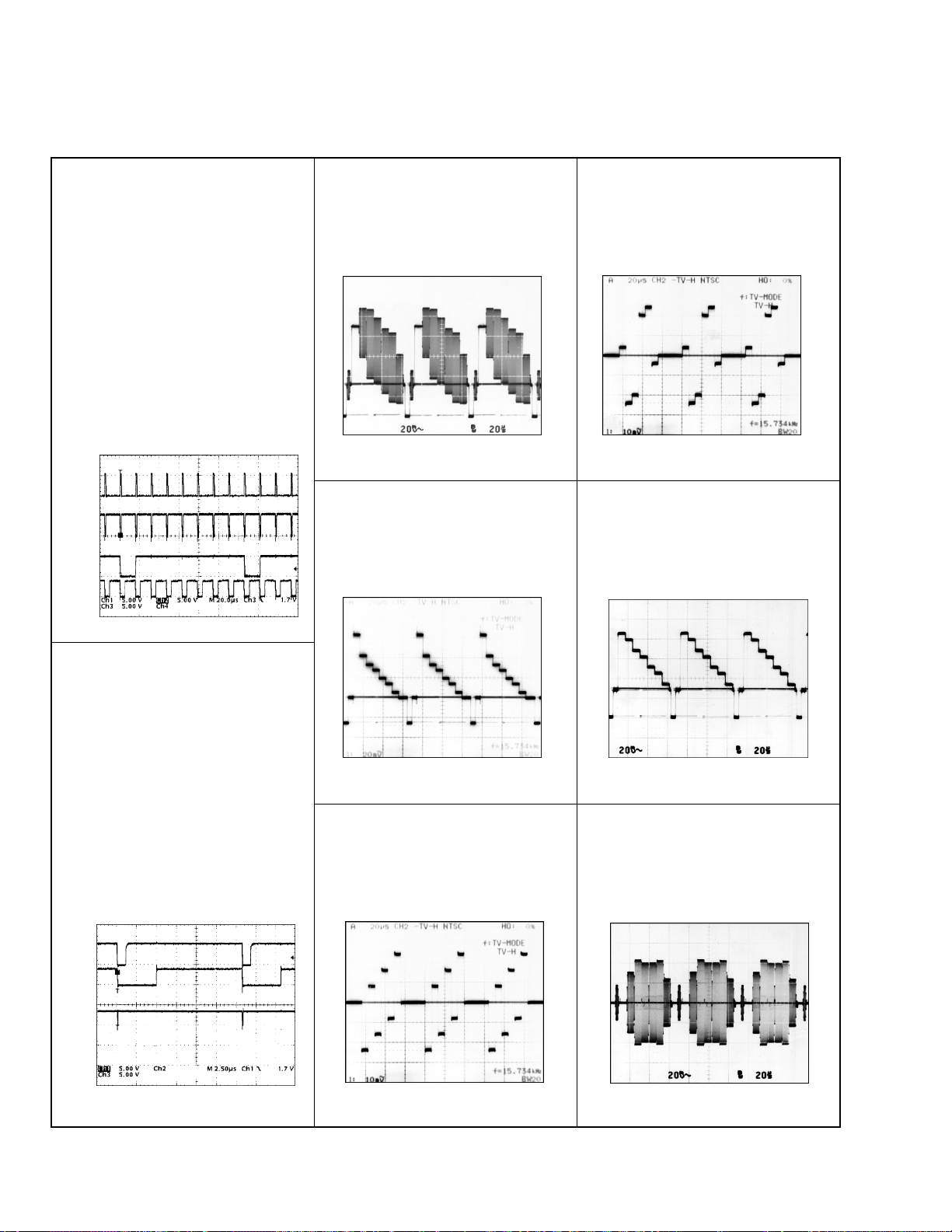

PDP-502MX, PDP-502MXE

Synchronous Signal Processing Block 2

(INPUT4 PC siganl VESA:

1280x1024@60Hz (SXGA@60Hz)

when there is signal input [ separate H, V ]

CH1: K2025 (HD_4),

IC2005 Pin69 (HD input)

V : 5V/div H : 20msec/div

CH2: K2021 (HD_FIL), IC2005 Pin 107

V : 5V/div H : 20msec/div

CH3: K2019 (HD_u), IC2005 Pin 32

V : 5V/div H : 20msec/div

CH4: K2029 (HD_PLL), IC2005 Pin 118

V : 3.3V/div H : 20msec/div

YC_VY

(INPUT1 NTSC Color Bar)

CN104 Pin1

V : 20mV/div H : 20msec/div

R output

(INPUT3, 4 NTSC Color Bar Y/Cb/Cr)

IC306

V : 10mV/div H : 20msec/div

Synchronous Signal Processing Block 2

(INPUT4 PC siganl VESA:

1280x1024@60Hz (SXGA@60Hz)

when there is signal input [ separate H, V ]

CH1: K2021 (HD_FIL), IC2005 Pin 107

V : 5V/div H : 2.5msec/div

CH2: K2029 (HD_PLL), IC2005 Pin 118

V : 3.3V/div H : 2.5msec/div

CH3: K2432 (DIVOUT), IC2402 Pin 103

V : 5V/div H : 2.5msec/div

G output

(INPUT3, 4 NTSC Color Bar Y/Cb/Cr)

IC306

V : 20mV/div H : 20msec/div

B output

(INPUT3, 4 NTSC Color Bar Y/Cb/Cr)

IC306

V : 10mV/div H : 20msec/div

Y input

(INPUT1 NTSC Color Bar)

IC1201

V : 20mV/div H : 20msec/div

C input

(INPUT1 NTSC Color Bar)

IC1201

V : 20mV/div H : 20msec/div

24

Page 25

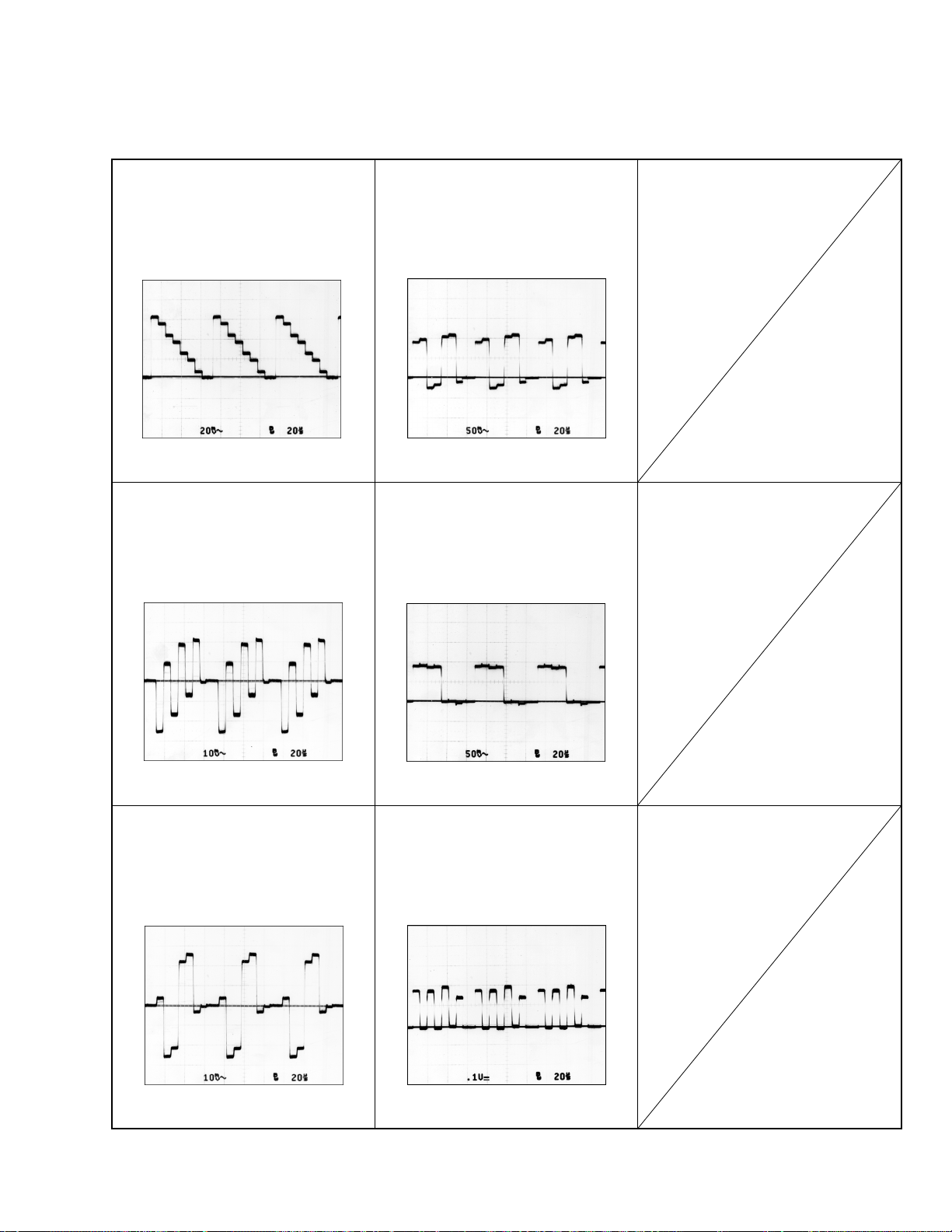

PDP-502MX, PDP-502MXE

INT_Y input

(INPUT1 NTSC Color Bar)

IC1401

V : 20mV/div H : 20msec/div

INT_Cb input

(INPUT1 NTSC Color Bar)

IC1401

V : 10mV/div H : 20msec/div

R input

(INPUT1 NTSC Color Bar)

IC1701

V : 50mV/div H : 20msec/div

G input

(INPUT1 NTSC Color Bar)

IC1701

V : 50mV/div H : 20msec/div

INT_Cr input

(INPUT1 NTSC Color Bar)

IC1401

V : 10mV/div H : 20msec/div

B input

(INPUT1 NTSC Color Bar)

IC1701

V : 50mV/div H : 20msec/div

25

Page 26

1

234

PDP-502MX, PDP-502MXE

3.4 SYNC SIGNAL PROCESSING BLOCK

A

B

Input from IC1201

(Jungle-IC)

in Comp/S input

(Positive polarity)

Separate HD/CS,

VD SYNC signal

input from BNC/Dsub 15p

Noise cancel processing

Countermeasure for copy guard

Limit to U-com processing velocity

(Max: 200kHz)

TC74VHC123

Control signal for switching

mask width (Lo : In PC input)

Noise cancel processing

Limit to U-com processing

velocity (Max: 200Hz)

HD/VD SYNC signal selected by input function

for generating Mask pulse

(except for when selecting HD_PLD, VD_PLD)

HD_PLD

VD_PLD

HD_3

HD_4

VD_3

VD_4

K2033

K2032

K2023

K2025

K2024

K2026

MASK_DSW

IC2004(2/2)

TC74VHC123

K2020

IC2004(2/2)

K2021

HD_MASK

VD_MASK

VD_FIL

HD_FIL

SYNC signal output

separated from Y/G

ON SYNC signal

SYNC CONTROL PLD

IC2005(PDY069)

Noise

Mask

Gate

Noise

Mask

Gate

SYNC signal selected based on

input function & HD/VD signal

detected (Unify the polarity to

negative polarity)

C

Y/G ON SYNC signal

in inputting Y colordifference or RGB

signals

D

Clamp & Blanking pulse

output to Analog Video

block

SYNC_SEPA

CLP_AMP

CLP_MAT

HBLK_MAT

VBLK_MAT

K2004

4pin

SYNC SEPA IC

IC2002

(M52346S)

K2012

K2015

K2013

K2014

14pin

15pin

13pin

6pin

8pin

2pin

1 pin

18pin

19pin

17pin

HD_+

HD_–

VD_+

HD_SEP

VD_SEP

Selected HD/VD signal

used for Separate input

SYNC signal detection

HSTATE

VSTATE

HPOL

VPOL

Information on detecting Separate

input SYNC signal & the polarity

CLP_SW1,2

CLP_SEP (Switching

Clamp pulse width

Clamp pulse generated by SYNC

Separate IC (Used in PC input)

CLP_SEPA

Signal

selector for

SYNC signal

Circuit for

switching

polarity

Decoding

HD/VD signal

detected

CONTROL

LOGIC

Selecting input

SYNC signal

Setting value of

HOLD Pulse width

CLAMP/

BLANKING

PULSE

CONTROL

&

20 bit /

Parallel

data

26

1234

Page 27

5

HOLD signal

generation circuit for

PLL control

Line

Number

Counter

HD Freq

Counter

67

PLL output HD for A/D sampling &

clock SYNC reference

K2432

K2029

HOLD controlling signal for comparing

K2030

K2408

Signal for detecting abnormal SYNC signal (Hi: in detecting)

Count value in the period of 1H by 16MHz clock (11-bit data)

Data is updated at the rate of HD1/8 dividing

K2019

K2018

PLL phase comparison.

PLL unlock information

(Hi: When PLL is not locked)

Vertical line number count value (11-bit data)

Data is updated every 1 V sync.

Timing signal for capturing horizontal frequency

count value (HD 1/8 dividing)

DIVOUT

HD_PLL

PLL input HD

HOLD_PLL

ULK_PLL

LINE(0:10)

SYNC STATE

H_COUNT(0:10)

HD_U

VD_U

8

PDP-502MX, PDP-502MXE

AMP/AD/PLL IC

IC2701

(CXA3106Q)

1_2CLK

XCLK

HD_DSEL

Signal Frequency DET

U-COM

IC2201

( PD2060A )

*Input signal detection

(stability)

*No signal input detection

*Detecting vertical frequency

*Controlling V_STD

(detecting frequency value)

A

B

SER-->PARA

CONV

5

Vertical SYNC signal for

input signal detection

Signal for detecting vertical frequency limit

Lo: Vertical frequency value is higher than

standard value (In PC input : fixed Hi)

Inverted PLL unlock information (Lo: When PLL is not locked)

Serial Control sig

PLD_CE

DATA

CLK

K2031

VD_DSEL

VD SYNC signal sent to Digital Assy

CLP1

CLP2

HBLK1

VBLK2

Clamp & Blanking signal output from

Digital Assy

K2027

V_STD

6

Serial data

REQ_Su

HOLD_Su

7

Sending

*Data of vertical frequency

*Data of horizontal frequency

*Data of total numbers of lines

*Information on inapplicable

frequency

U-COM ASSY

DIGITAL VIDEO ASSY

8

1_2CLK

XCLK

HD_DSEL

27

C

D

Page 28

1

0

C

E

S

E

234

PDP-502MX, PDP-502MXE

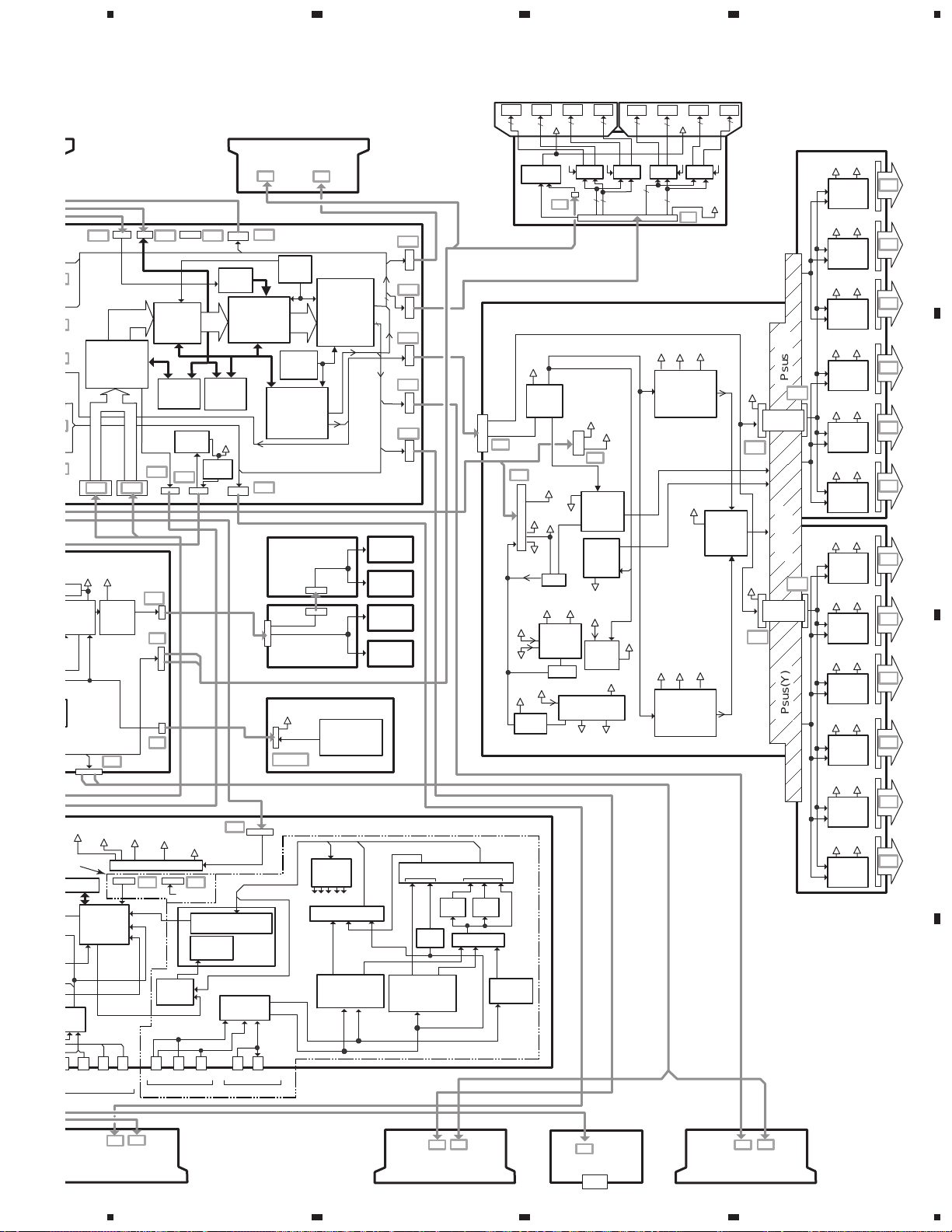

3.5 DIGITAL VIDEO ASSY SECTION

D20

CN3403

A

A33

To VIDEO ASSY CN2901

D22

CN3405

B

1

A35

3

5

7

To VIDEO ASSY

CN2903

D17

A3

CN3402

5

8

9

10

11

12

8

8

8

8

8

8

XCLK

1_2CLK

HD

VD

ULK_PLL

CLP1

CLP2

HBLK1

VBLK1

V_STD

R (B)

G (B)

B (B)

R (A)

G (A)

B (A)

R (A)/G (A)/B (A)

IC3401, IC3402

R (B)/G (B)/B (B)

SGLB

TP3414

CLK_102

TP3411

CLK_101

TP3413

HD_IP

VD_IP

TP3410

IP PROCESSOR

+3.3V

IC1801

(PE5067A)

3

+3.3V

IC1901

(PE5066A)

I/F

Y (8bit)

Pb (8bit)

Pr (8bit)

RGB

≠

YPbPr

Sync CONT

CLAMP PULSE

GEN.

(IC#102)

5

+5V

IC2001

IP U-com.

IP

Process

Y (16bit)

Pb (16bit)

Pr (16bit)

Sharpness

Arrange

YPbPr

RGB

(IC#101)

≠

67

X Speed

X dencity

Y (8bit)

Pb (8bit)

Pr (8bit)

8bit × 2

RA_102

RB_102

GA_102

GB_102

BA_102

BB_102

HD_102

VD_102

TP2102

TP2103

DE_102

FLD_102

+3.3V

IC1951

(UPD4811650GF-A10)

16M SGRAM

+3.3V

IC1952

(UPD4811650GF-A10)

16M SGRAM

ASPECT

RATIO

CONV.

Sync

62M

+3.3V

Process

R

FIFO

W

IC2101

(PE5061A)

(IC#20)

+5V

(PD5538B)

Ser=Para

IC2251

OSD IC

WRITE CLK (SYSTEM CLK)

+3.3V

8bit × 2

RAI/RBI

GAI/GBI

BAI/BBI

7

H

V

FLD

VLD

6

RGB

MASK CONT

OSD MIX

CLK

OSD_H

+5V

OSD_V

IC2260

(PDY061A)

OSD

PROCESSOR

(PE5062A)

3

–1

γ

IC2151

6

ABL

R

G

B

BLK

2

To VIDEO ASSY CN2001

E6

C

D13

CN3273

4

5

6

7

8

9

From U-COM ASSY CN3606

D14

CN3271

1

E5

2

4

5

6

7

D

8

9

10

11

12

To U-COM ASSY CN3608

OSD_DATA1

OSD_CLK1

OSD_CE1

OSD_CLR1

SDATA1

SCLK1

PN_MUTEY

PN_MUTEX

PBUSY0

PERR0

IPBUSY0

IPERR0

RMT0

RESET_RET

D_CLK1

D_DATA1

PN_RST1

TP3408

TP3409

TP3407

TP3406

TP3405

X2001

20M

X2301

20M

+5V

67

PANEL U-com.

S2301

RST

IC2301

RST

+5V

IC2255

(MBM29F200BC-70PFTN-K)

FLASH ROM

5

TP2303

+5V

(LC3564BM)

G (IP ERR)

R (IP BUSY)

R (P BUSY)

G (STOP B)

IC2256

64k SRAM

RG

(P ERR)

D2306

D2302

+3.3V

(P

DRIVE

PATT

I

28

1234

Page 29

5

67

8

PDP-502MX, PDP-502MXE

EM CLK)

SK CONT

(PE5062A)

LK

SD_H

SD_V

2260

061A)

SD

ESSOR

205

–1

γ

ABL

IC2151

R

3

G

6

B

BLK

+3.3V

IC2201

(PE5064A)

DRIVE SEQUENCE

PATTERN GEN.

Dither

SYNC

CONT

X3201

62MHz

OSC

(IC#21)

D6

LUT

(IC#23)

VACANT

To Panel U-com

16bit × 2

VLD_A

VLD_B

FIELD

RA/RB

GA/GB

BA/BB

H

V

50M

25M

TP2154

TP2155

8

CD

25

8

24

3

X3202

50MHz

OSC

+3.3V

W

DATA

ARRANGE

R

DATA

CONVERT

CONT

IC2601

(PE5063A)

SUB FIELD

CONVERSION

W

DATA

ARRANGE

R

DATA

CONVERT

CONT

IC2701

(PE5063A)

SUB FIELD

CONVERSION

W

DATA

ARRANGE

R

DATA

CONVERT

CONT

(PE5063A)

SUB FIELD

CONVERSION

ADR/LBLK

MN (X Drive Gen. Pulse)

EF/GH/IJ (Y Drive Gen. Pulse)

1/2

SGRAM • READ OUT

MASTER CLOCK

(IC#22)

R

(IC#22)

G

(IC#22)

IC2801

B

+3.3V

IC2602

(HY58163210TQ-10)

16M SGRAM

+3.3V

IC2603

(HY58163210TQ-10)

16M SGRAM

+3.3V

IC2702

(HY58163210TQ-10)

16M SGRAM

+3.3V

IC2703

(HY58163210TQ-10)

16M SGRAM

+3.3V

IC2802

(HY58163210TQ-10)

16M SGRAM

+3.3V

IC2803

(HY58163210TQ-10)

16M SGRAM

IC3101

X DRIVE BUFFER

40

RDAT

40

GDAT

BDAT

40

XSUS-B/U/D/G

XPR, XR

ADR

BUFFER

IC2901–IC2910

IC3001–IC3010

IC3301–IC3304

IC3308, IC3309

IC3311, IC3312

D4

CN3256

A

B

To ADDRESS MODULE

C

F9

To X DRIVE ASSY

CN3402

TP553

+

Q554

IC551

REG

Q605

IC601

REG

TP601

+12V

)

6

+

2

Digital P.D.

CN551

D16

D555

TP555

+5V OVP

Q551

Q552

D605

Q601

Q602

TP604

+3.3V OVP

D556

TP556

+5V UVP

Q553

D606

+5V

TP603

+3.3V UVP

Q603

IC3102–IC3104

Y DRIVE BUFFER

+3.3V

YSUS-B/U/D/G

SI, MSK, CLK, PFS,

OE, YNR, YR

CN3252

D9

H1

D

To Y DRIVE ASSY

CN3751

29

5

6

7

8

Page 30

PDP-502MX, PDP-502MXE

Waveforms of DIGITAL VIDEO ASSY

Blanking waveform for analog use

CH1: TP3410 (HDIP)

CH2: TP3405 (CLP1)

CH3: TP3406 (CLP2)

CH4: TP3407 (HBLK1)

V : 5V/div H : 10msec/div

I-P V synchronous waveform

CH1: TP3411 (VD_IP)

CH2: IC1801 Pin 167 (Vi) –– IC1901 Pin 58

CH3: IC1901 Pin 56 (Vp) –– IC1801 Pin 169

CH4: IC1801 Pin 97 (VD_102)

V : 5V/div H : 2msec/div

I-P H synchronous waveform

CH1: TP3410 (HD_IP)

CH2: IC1801 Pin 168 (Hi) –– IC1901 Pin 57

CH3: IC1901 Pin 55 (Hp) –– IC1801 Pin 170

CH4: IC1801 Pin 98 (HD_102)

V : 5V/div H : 10msec/div

I-P clock waveform

CH1: IC1801 Pin 3 (CLK_102)

CH2: IC1901 Pin 239 (CLK_101)

V : 1V/div H : 5nsec/div

H synchronous waveform

TP2155

V : 1V/div H : 2msec/div

STOP B waveform

TP2205

V : 1V/div H : 2msec/div

I-P V synchronous waveform (enlarged)

CH1: TP3411 (VD_IP)

CH2: IC1801 Pin 167 (Vi) –– IC1901 Pin 58

CH3: IC1901 Pin 56 (Vp) –– IC1801 Pin 169

CH4: IC1801 Pin 97 (VD_102)

V : 5V/div H : 200msec/div

30

V synchronous waveform

TP2154

V : 1V/div H : 2msec/div

ADR resonant control signal waveform

CH1: IC3303 Pin11 (ADR_U)

CH2: IC3303 Pin12 (ADR_B)

CH3: IC3303 Pin13 (ADR_D)

V : 5V/div H : 1msec/div

Page 31

PDP-502MX, PDP-502MXE

Address resonant output waveform

IC2910 Pin 13

V : 1V/div H : 2msec/div

X drive waveform

CH1: IC3101 Pin 12 (XSUS_U)

CH2: IC3101 Pin 15 (XPR_U)

V : 0.5V/div H : 2msec/div

IC1801 HD input waveform

CN3404 Pin 29 (HD_IP), TP3410

V : 1V/div H : 10msec/div

GA input waveform

IC1801 Pin 31 (GA_IP (O))

V : 1V/div H : 0.1msec/div

IC1901 clock input waveform

CN3404 Pin 26 (CLK_101), TP3413

V : 1V/div H : 20nsec/div

VD input waveform

IC2101 Pin 236 (VD_102), TP2102

V : 1V/div H : 2msec/div

IC1801 VD input waveform

CN3404 Pin 30 (VD_IP), TP3411

V : 1V/div H : 2msec/div

GA output waveform

IC1801 Pin 121 (GA_102 (O))

V : 1V/div H : 0.1msec/div

HD input waveform

IC2101 Pin 235 (HD_102), TP2103

V : 1V/div H : 2msec/div

31

Page 32

PDP-502MX, PDP-502MXE

Address control signal

IC3304 Pin 11 (LBLK)

V : 1V/div H : 2msec/div

Address control signal

IC3308 Pin 15 (CLKDUI)

V : 1V/div H : 0.1msec/div

Address control signal

CN3275 Pin 26 (LEDUI)

V : 1V/div H : 0.5msec/div

32

Page 33

1

XSUS-B

R3435

IC3404

IC3404

R3424

IC3403

(TC74AC11F)

PDP Pulse Module

IC3402

(STK795-450)

+RESET BLOCK

LOGIC BLOCK

IC3408

(TC74AC08F)

IC3403

R3406

R3438

+5V

Q3406

Q3405

D3408

K3410

P.D. (X.C.P)

C3404

Q3404

Q3401–Q3403

11

XSUS-V

XSUS-D

XSUS-G

XPR-U

9

7

135

5

6

6

3

8

3

9

2

1

5

4

4

11

10

SUS-B

1

13

12

SUS-D

K3412

SUS-G

K3414

SUS-U

K3411

SUS-B

K3413

PR-U

K3409

2

+12V

7

5

3

+5V

+5V

VSUS

(175V)

1

+12V

XPD

367

5

VSUS

(175V)

1

SUS

GND

234

PD

DET.

12V

O. C DET.

SUS-U

21

26

29

40

20

18

14

16

1

175V

175V

0V

VSUS

(175V)

P-SUS (X)

SUS

GND

SUS

GND

SUS

GND

To

PANEL

24

VSUS/2

VSUS

SUSOUT

SUSGND

SUS-D

VDD

VCC

32

SUS-G

VSUS

SUS-G

SUS-U

SUS-B

SUS-D

175V

0V

R3410

R3411

D3403

D3402

t

t

X-PSUS

SUS

GND

VSUS

RP-U

F6

F5

F7

D4

From DIGITAL VIDEO Assy

E17

From U-COM Assy

E16

From U-COM Assy

PDP Pulse Module

IC3405

(STK795-450)

SUS-B

SUS-U

21

26

29

40

20

18

14

16

1

VSUS

(175V)

SUS

GND

SUS

GND

24

VSUS/2

VSUS

SUSOUT

SUSGND

SUS-D

VDD

VCC

32

SUS-G

3.6 X DRIVE ASSY SECTION

23

PDP-502MX, PDP-502MXE

4

A

B

1

C

2

3

D

33

4

Page 34

1

234

PDP-502MX, PDP-502MXE

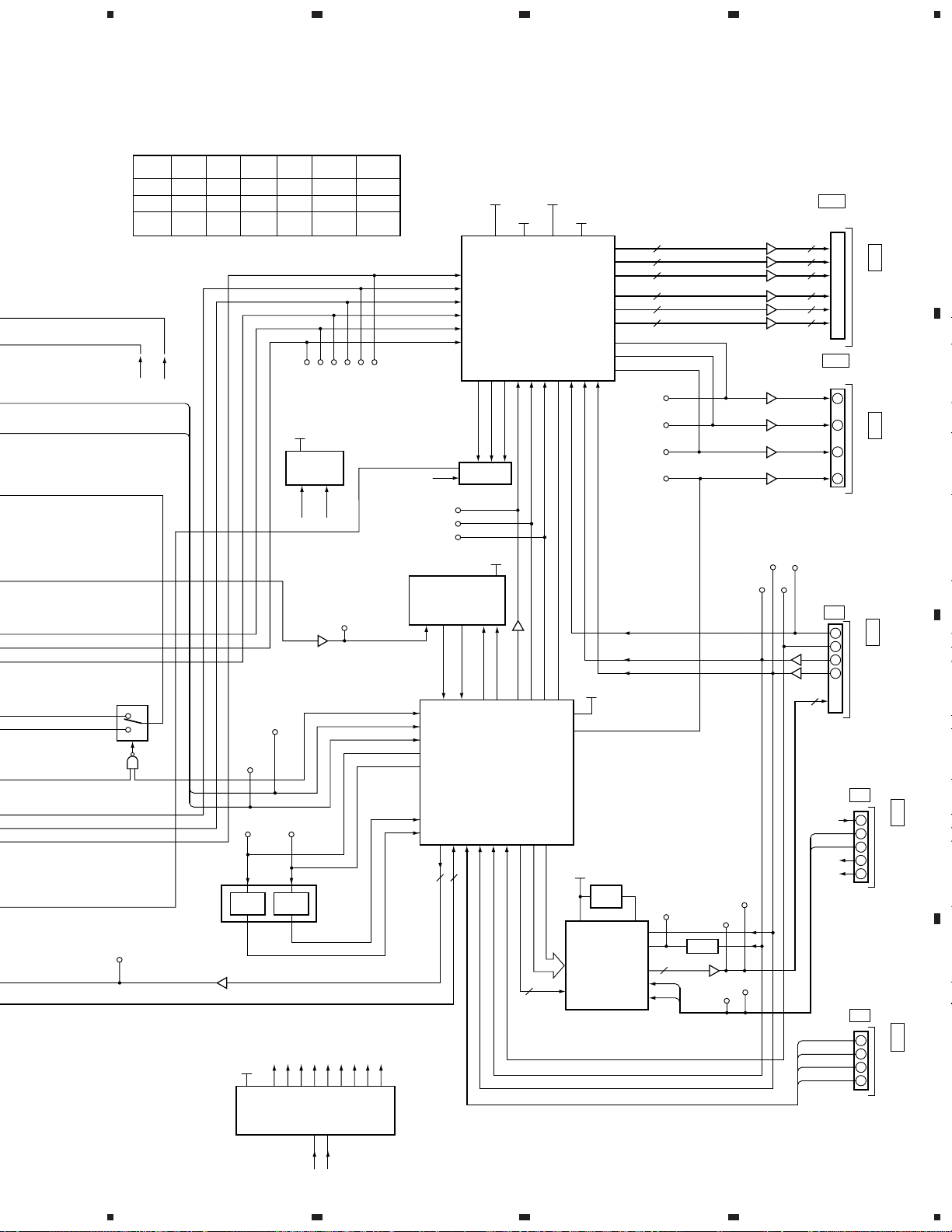

3.7 Y DRIVE ASSY SECTION

HBLK1

TP3600

IC3607

IC5V

5

A

R3645

IC3602

IC3611

IC3610

IC3604

IC3609

IC3605

R3636

TP3608

PN_MUTEY

5

5

5

5

5

5

IC3613

(PDT043A)

2

3

4

5

7

8

PLD & MUTE

9

6

11

MUTE

14

15

16

17

18

13

12

19

SUS-B

SUS-U

SUS-D

SUS-G

YCP-MSK

YSUS-MSK

OFS

YNR-D

VH

IC5V

PSUS

SI DATA

IC3601

(TC74ACT541FT)

13

14

15

16

17

12

11

18

SCAN (A) ASSY

(UPPER)

SCAN (B) ASSY

(LOWER)

H2

H3

SUS-B

TP3703

SUS-U

TP3704

SUS-G

SUS-D

TP3705

TP3706

SI

TP3604

SCAN BLOCK

CLK

TP3601

IC3600

R3602

CN3605

B

D8

From DIGITAL VIDEO ASSY

PN_MUTEY

HBLK1

CLK

LE_S

CLR

HBLK2

LBLK

YSUS-B

YSUS-U

YSUS-D

YSUS-G

YNR-D

YNR-U

SUS-MSK

CP-MSK

OFS

H1

44

42

SI

40

38

36

34

32

30

28

R3619

26

24

22

20

18

16

14

6

R3654

R3655

(TC74VHC541FT)

4

5

6

7

8

9

R3603

IC3606

(TC74VHC541FT)

R3614

(TC74VHC541FT)

2

3

7

IC3614

2

3

4

5

6

7

8

9

18

17

13

16

15

14

13

12

11

HBLK2

TP3606

TP3603

LBLK

18

17

16

15

14

13

12

11

TP3605

IC3612

IC3612

LE

CLR

TP3602

C

E8

From U-COM ASSY

E7

From U-COM ASSY

D

CN3701

+5V

+12V

DRV PD

YDC_DC. PD

+14V

–8V

VSUS

SUS GND

VSUS

+10V

CN3700

H5

H4

1

3

7

8

5

6

1

4

6

VSUS

175V

SUS

GND

D853

D758

D761

D709

D710

D811

D814

TP853

IC5V OVP

TP752

VH OVP

TP754

VH UVP

TP706

VOFS OVP

TP707

VOFS UVP

TP802

VRN OVP

TP804

VRN UVP

Q802

Q750

Q752

Q700

Q800

–8V

IC5V, VF

14V

DC–DC CONV.

IC850, IC851

T850

VSUS

VH DC–DC

CONV.

IC750, IC751

T750

VSUS

SUS GND

VOFS

DC–DC CONV.

IC701, IC702

T700

DC–DC CONVERT BLOCK

D890

TP855 TP856

VFZ+

+

VFZ–

IC5V

+

TP851

VH

D753

+

PSUS

D802

TP751

TP753

D700

TP800

TP803

VRN

(–200V)

+

TP3707

VOFS

TP705

SUS

GND

OFS

+

SUS

GND

R3766

IC3710

TP702

IC3711

VRN

+ 5V

REG.

5

OFS BLOCK

VOFS

7

5

IC3712

R3768

R3769

R3772

R3773

R3774

Q3714

Q3716

34

1234

Page 35

5

67

8

PDP-502MX, PDP-502MXE

+5V For

Logic Block

Q3701

+12V

O. C DET.

PD

DET.

R3708

R3710

R3700

Q3703

SUSTAIN BLOCK

PDP Pulse Module

(STK795-450)

VCC

16

SUS-B

20

SUS-U

VDD

18

SUS-D

14

SUS-G

PDP Pulse Module

(STK795-450)

VCC

16

SUS-B

20

SUS-U

VDD

18

SUS-D

14

SUS-G

IC3702

IC3707

VSUS

SUSOUT

VSUS/2

SUSGND

VSUS

SUSOUT

VSUS/2

SUSGND

VSUS

(175V)

1

40

26

21

24

32

SUS

GND

VSUS

(175V)

1

40

26

21

24

32

SUS

GND

175V

0V

175V

A

SUS

GND

B

0V

SUS

GND

R3768

R3769

R3772

R3773

R3774

Q3714

Q3716

IC3713

R3781

7

2

5

4

R3788

Q3721

D3720

–RESET BLOCK

YSUS-MSK

SUS

GND

R3712

D3714

R3776

R3777

R3709

VCP BLOCK

D3713

Q3719

R3784

R3705

D3717

Q3704

D3700

I

VCP

IC3700

+ 5V

REG.

G

TP3700

VCP

O

IC3703

5

R3714

IC3701

R3734

18

17

16

15

14

13

12

11

D3709

IC3706

7

5

7

5

IC3708

R3794

R3794

R3795

R3795

Q3709

Q3710

IC3704

Q3708

Q3711

7

5

R3796

7

5

IC3709

R3793

R3793

R3796

Q3706

Q3712

K3716

PSUS

Q3705

Q3713

C

D

PSUS

To SCAN MODULE

Copper Plate

SUSTAIN MASK BLOCK

35

5

6

7

8

Page 36

PDP-502MX, PDP-502MXE

Waveforms of X DRIVE Assy, Y DRIVE Assy and SCAN MODULE

Sustained waveform

CH1: P.SUS TP3716 (P.SUS) – TP3713 (SUS.GND)

CH2: YSUS-B TP3703 (YSUS-B) – TP3609 (D.GND)

CH3: YSUS-U TP3704 (YSUS_U) – TP3609 (D.GND)

CH4: YSUS-D TP3705 (YSUS_D) – TP3609 (D.GND)

CH5: YSUS-G TP3706 (YSUS-G) – TP3609 (D.GND)

CH1

CH2

CH3

CH4

CH5

V: 50V/div., H: 500nsec/div.

V: 10V/div., H: 500nsec/div.

V: 10V/div., H: 500nsec/div.

V: 10V/div., H: 500nsec/div.

V: 10V/div., H: 500nsec/div.

–GND

–GND

–GND

–GND

–GND