Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

ORDER NO.

ARP3221

PDP-5004

PLASMA DISPLAY

PDP-5004

PDP-4304

PDP-5014

PDP-4314

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PDP-5004 KUC AC120V

PDP-5014 KUC AC120V

PDP-4304 KUC AC120V

PDP-4314 KUC AC120V

This service manual should be used together with the following manual(s).

Model No. Order No. Remarks

PDP-5004, PDP-5014

PDP-4304, PDP-4314

ARP3222 SCHEMATIC DIAGRAM, PCB CONNECTION DIAGRAM

For details, refer to "Important Check Points for Good Servicing".

T-ZZY SEPT. 2004 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

C

Health & Safety Code Section 25249.6 - Proposition 65

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

D

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

E

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

F

2

1234

PDP-5004

Page 3

5678

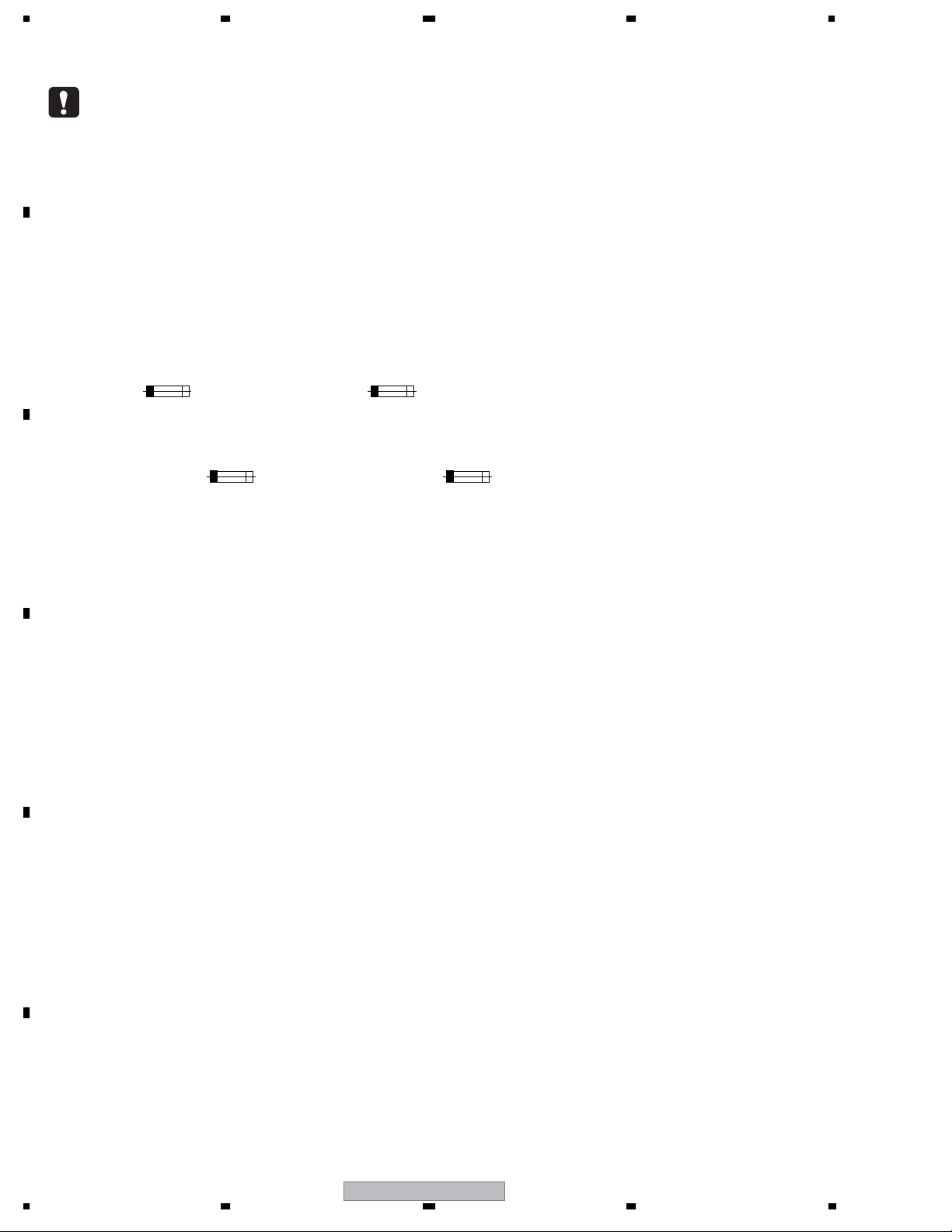

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which

requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Device

under

test

Leakage

current

tester

Test all

exposed metal

surfaces

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

A

B

C

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

D

E

F

56

PDP-5004

3

7

8

Page 4

1234

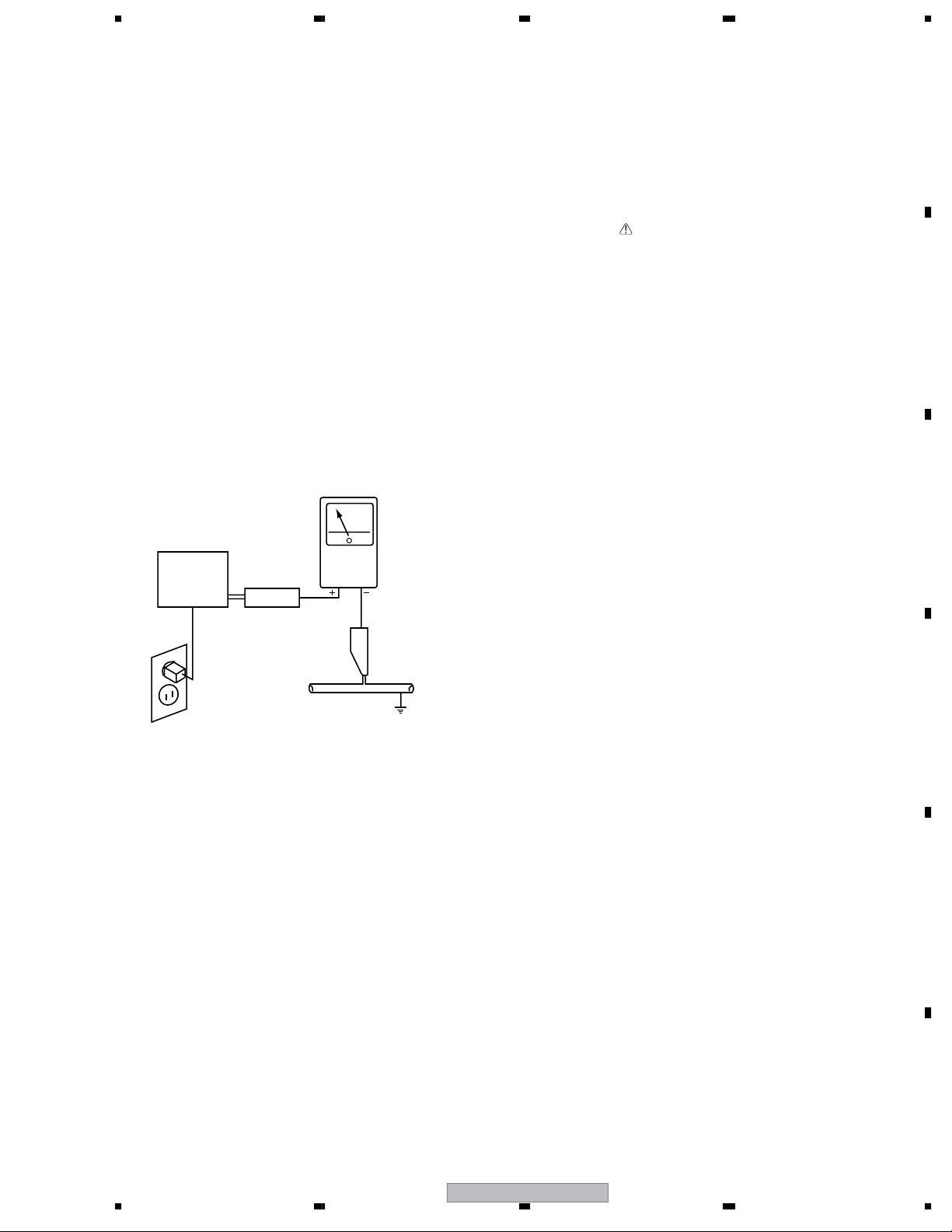

Charged Section

The places where the commercial AC power is used without

A

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

B

4. Fuse (In the POWER SUPPLY Unit)

5. STB Transformer and Converter Transformer

(In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

For 50 inch model

(PDP-5004, PDP-5014)

C

50 SCAN B Assy 50 Y DRIVE Assy 50 X DRIVE Assy

High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. POWER SUPPLY Unit.....................................................(223V)

2. 50 X DRIVE Assy ...........................................(–230V to 223V)

3. 50 Y DRIVE Assy ........................................................... (353V)

4. 50 SCAN A Assy ............................................................ (353V)

5. 50 SCAN B Assy ............................................................(353V)

6. X CONNECTOR A Assy..................................(–230V to 223V)

7. X CONNECTOR B Assy..................................(–230V to 223V)

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

POWER SUPPLY Unit

X CONNECTOR

B Assy

D

E

50 SCAN A Assy

F

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

Power Switch

(S1)

AC Inlet with Filter

X CONNECTOR

A Assy

Power Cord

4

1234

PDP-5004

Page 5

5678

Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the POWER SUPPLY Unit)

5. STB Transformer and Converter Transformer

(In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

For 43 inch model

(PDP-4304, PDP-4314)

High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. POWER SUPPLY Unit................................................... (215V)

2. 43 X DRIVE Assy .......................................... (–225V to 215V)

3. 43 Y DRIVE Assy .......................................................... (345V)

4. 43 SCAN A Assy ............................................................ (345V)

5. 43 SCAN B Assy ............................................................(345V)

6. X CONNECTOR AAssy ................................ (–225V to 215V)

7. X CONNECTOR B Assy ............................... (–225V to 215V)

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

A

B

C

43 SCAN B Assy

43 SCAN A Assy

43 Y DRIVE Assy

POWER SUPPLY Unit

Power Switch

(S1)

43 X DRIVE Assy

X CONNECTOR

B Assy

D

E

X CONNECTOR

A Assy

Fig.2 Charged Section and High Voltage Generating Point (Rear View)

PDP-5004

56

AC Inlet with Filter

7

Power Cord

F

5

8

Page 6

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

6

1234

PDP-5004

Page 7

5678

COTENTS

SAFETY INFORMATION

1. SPECIFICATIONS

2. EXPLODED VIEWS AND PARTS LIST...........................................................................................................10

2.1 PACKING for PDP-5004, PDP-5014, PDP-4304 and PDP-4314 models.................................................10

2.1.1 PACKING............................................................................................................................................10

2.2 PDP-5004, PDP-5014 models

2.2.1 CHASSIS SECTION (1) .....................................................................................................................12

2.2.2 CHASSIS SECTION (2) .....................................................................................................................14

2.2.3 FRAME SECTION..............................................................................................................................16

2.2.4 TERMINAL PANEL and REAR SECTION ..........................................................................................18

2.2.5 FRONT SECTION..............................................................................................................................20

2.2.6 PANEL CHASSIS (50) ASSY (AWU1099)..........................................................................................22

2.2.7 PDP SERVICE ASSY (AWU1108) .....................................................................................................23

2.3 PDP-4304, PDP-4314 models..................................................................................................................24

2.3.1 CHASSIS SECTION (1) .....................................................................................................................24

2.3.2 CHASSIS SECTION (2) .....................................................................................................................26

2.3.3 FRAME SECTION..............................................................................................................................28

2.3.4 TERMINAL PANEL and REAR SECTION ..........................................................................................30

2.3.5 FRONT SECTION..............................................................................................................................32

2.3.6 PANEL CHASSIS (43) ASSY (AWU1098)..........................................................................................34

2.3.7 PDP SERVICE ASSY (AWU1109) .....................................................................................................35

2.4 MULTI BASE SECTION for PDP-5004, PDP-5014, PDP-4304 and PDP-4314 .......................................36

2.4.1 MULTI BASE SECTION .....................................................................................................................36

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM (Refer to “Service Manual: ARP3222”).............................38

3.1 BLOCK DIAGRAM....................................................................................................................................38

3.1.1 OVERALL BLOCK DIAGRAM (1/2) for PDP-5004 and PDP-5014 models

3.1.2 OVERALL BLOCK DIAGRAM (1/2) for PDP-4304, PDP-4314 models

3.1.3 OVERALL BLOCK DIAGRAM (2/2) for PDP-5004, PDP-5014, PDP-4304 and PDP-4314 models...42

3.1.4 SIGNAL ROUTE.................................................................................................................................44

3.1.5 50 Y DRIVE ASSY

3.1.6 43 Y DRIVE ASSY..............................................................................................................................46

3.1.7 50 X DRIVE ASSY .............................................................................................................................47

3.1.8 43 X DRIVE ASSY .............................................................................................................................48

3.1.9 DIGITAL VIDEO ASSY

3.1.10 AV I/O ASSY

3.1.11 RGB ASSY

3.1.12 AUDIO AMP and COMM SLOT ASSYS

3.1.13 VIDEO SLOT 2 ASSY

3.2 WAVEFORMS

3.3 VOLTAGES................................................................................................................................................61

4. PCB CONNECTION DIAGRAM (Refer to “Service Manual: ARP3222”)

5. PCB PARTS LIST

6. ADJUSTMENT ................................................................................................................................................88

6.1 ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED........................................88

6.2 SERVICE FACTORY MODE.....................................................................................................................89

6.3 HOW TO ENTER FACTORY MODE.........................................................................................................90

6.4 METHOD FOR REPLACING THE SERVICE PANEL ASSY ..................................................................114

6.5 COMMAND DESCRIPTION ...................................................................................................................115

7. GENERAL INFORMATION ...........................................................................................................................125

7.1 DIAGNOSIS............................................................................................................................................125

7.1.1 CONFIGURATION OF THE PC BOARD

7.1.2 DIAGNOSIS FOR SHUTDOWN AND POWER-DOWN BY LED

7.1.3 PROCESSING AT THE TIME OF ABNORMALITIES.......................................................................133

7.1.4 TEMPERATURE COMPENSATION OF DRIVE SYSTEM VOLTAGE ..............................................133

7.1.5 POWER ON/OFF FUNCTION FOR THE LARGE-SIGNAL SYSTEM..............................................134

7.1.6 BACKUP THE ADJUSTMENT VALUES FOR THE MAIN UNIT.......................................................135

7.1.7 TROUBLESHOOTING......................................................................................................................137

7.1.8 CANCELING DETECTION BY THE TRAP SWITCH .......................................................................139

7.1.9 DISASSEMBLY ................................................................................................................................140

7.2 IC INFORMATIION

8. PANEL FACILITIES

12

38

40

45

49

50

51

52

53

54

69

125

126

146

186

2

8

A

B

C

D

E

F

56

PDP-5004

7

7

8

Page 8

1234

1. SPECIFICATIONS

PLASMA DISPLAY

A

General (PDP-5004 /PDP-5014)

Light emission panel .................. 50-inch AC Plasma Panel

109.8 (W) x 62.1 (H) x 126.1 (diagonal) cm

Number of pixels .............................................. 1280 x 768

Power supply ........................................... AC 120 V, 60 Hz

Rated current ............................................................. 3.1 A

Standby power consumption ................................... 0.6 W

External dimensions

.... 1218 (W) x 714 (H) x 98 (D: Not including handles) mm

B

Weight ................................................41.0 kg (90 lbs. 7 oz)

Operating temperature range ........ 0 to 40 °C (32 to 104˚F)

General (PDP-4304/ PDP-4314)

Light emission panel .................. 43-inch AC Plasma Panel

95.2 (W) x 53.6 (H) x 109.3 (diagonal) cm

Number of pixels .............................................. 1024 x 768

Power supply ........................................... AC 120 V, 60 Hz

Rated current ............................................................. 2.6 A

C

Standby power consumption ................................... 0.6 W

External dimensions

.... 1070 (W) x 630 (H) x 98 (D: Not including handles) mm

Weight ............................................. 33.5 kg (73 lbs. 14 oz)

Operating temperature range ........ 0 to 40 °C (32 to 104˚F)

Input/output

Video

D

INPUT1

Input Mini D-sub 15 pin (socket connector)

• RGB signal (G ON SYNC compatible)

RGB ... 0.7 Vp-p/75 /no sync.

HD/CS, VD ... TTL level

G ON SYNC

*Compatible with Microsoft Plug & Play

E

(VESA DDC1/2B)

• Component video signal

Y ... 1 Vp-p/75 negative sync.

B/PB, CR/PR ... 0.7 Vp-p (color100%)/75

C

47-31/32 (W) x 28-1/8 (H) x 3-7/8

(D: Not including handles) in.

42-1/8 (W) x 24-13/16 (H) x 3-7/8

(D: Not including handles) in.

Ω

/positive and negative polarity

Ω

/2.2 k

... 1 Vp-p/75 /negative sync.

Ω

Ω

INPUT2

Input HDMI

• Digital signal

3.3V T.M.D.S. /50

INPUT3

Input S jack (Mini DIN 4 pin)

• Y/C separate video signal

Y . . . 1 Vp-p/75 /negative sync.

0.286 Vp-p/75

C . . .

(Color Burst Level)

INPUT4

Input RCA jack

• Composite video signal

1 Vp-p/75 /negative sync.

Output RCA jack

75 /with buffer

INPUT5

Input RCA jack

• Component video signal

Y…1 Vp-p /75 negative sync.

B/PB, CR/PR…

C

• RGB signal

G ON SYNC ...

R/B ... 0.7 Vp-p/75 /no sync.

Audio

Input AUDIO INPUT (for INPUT1)

Pin jack (x2)

L/R ... 500 mVrms/more than 10 k

AUDIO INPUT (for INPUT2)

Pin jack (x2)

L/R ... 500 mVrms/more than 10 k

AUDIO INPUT (for INPUT3)

Pin jack (x2)

L/R ... 500mVrms/more than 10 k

AUDIO INPUT (for INPUT4)

Pin jack (x2)

L/R ... 500mVrms/more than 10 k

AUDIO INPUT (for INPUT5)

Pin jack (x2)

L/R ... 500mVrms/more than 10 k

Ω

Output SPEAKER

L/R ... 8 – 16 /7 W +7 W (at 8 )

Ω

Ω

0.7 Vp-p (color 100%) / 75

1 Vp-p/75 /negative sync.

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

ΩΩ

Control

RS-232C... D-sub 9 pin (pin connector)

F

8

1234

PDP-5004

Page 9

5678

Accessories

Power Cord (ADG1215)

A

Remote Control Unit for PDP-5004, PDP-4304

(AXD1496)

B

Cleaning Cloth (for wiping front panel)

(AED1208)

Binder Assy (AEC1758)

Speed Clamp (×2)

Bead Bands (×2)

Remote Control Unit for PDP-5014, PDP-4314

(AXD1497)

C

Dry Cell Battery (R6P, AA)

D

56

PDP-5004

E

F

9

7

8

Page 10

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

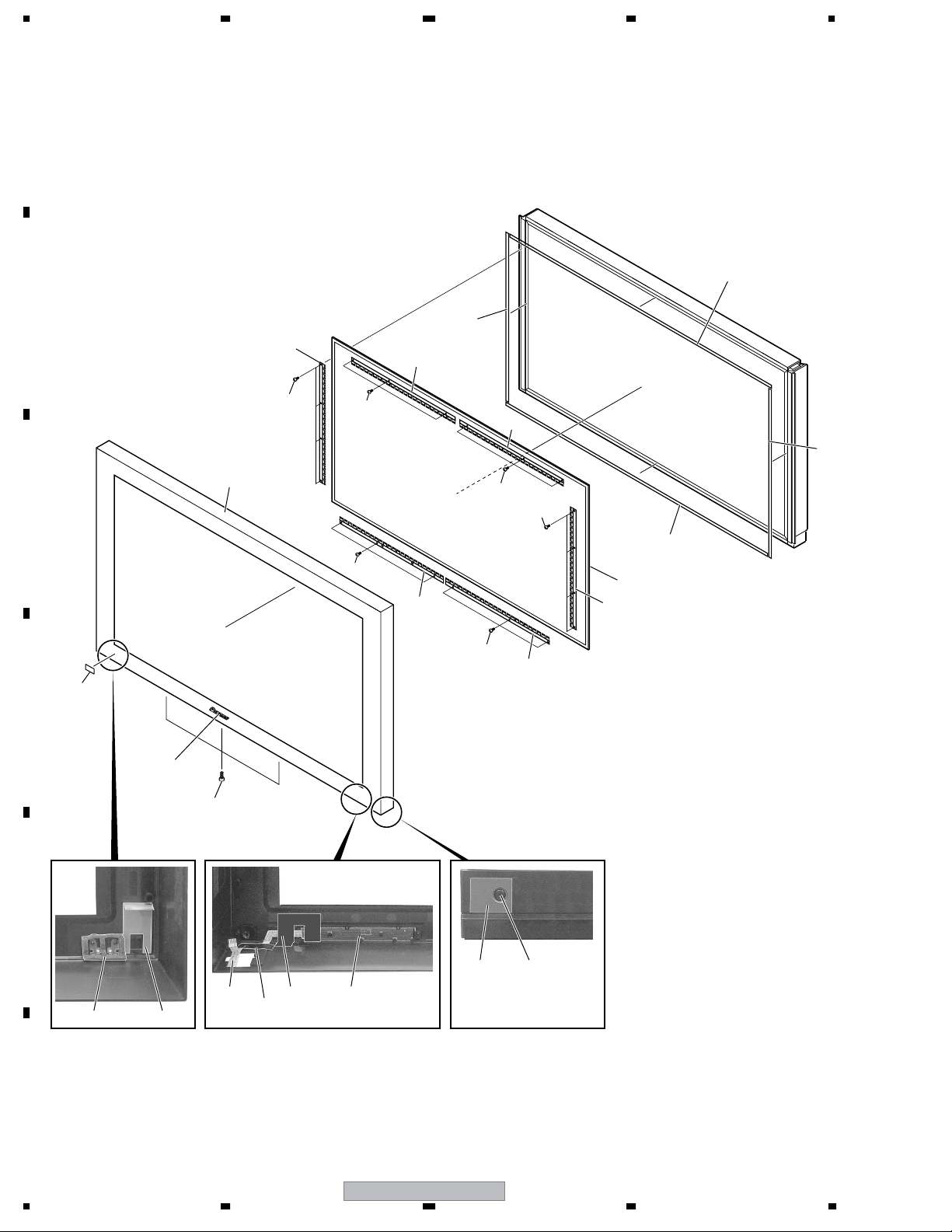

2.1 PACKING for PDP-5004, PDP-5014, PDP-4304 and PDP-4314 models

2.1.1 PACKING

21

B

14

C

20

12

15 (for PDP-5004, PDP-5014)

16 (for PDP-4304, PDP-4314)

D

E

18

11

19

15 (for PDP-5004, PDP-5014)

17 (for PDP-4304, PDP-4314)

1

8, 9, 10, 13

7

2

4

3

5

6

F

10

1234

20

PDP-5004

Page 11

5678

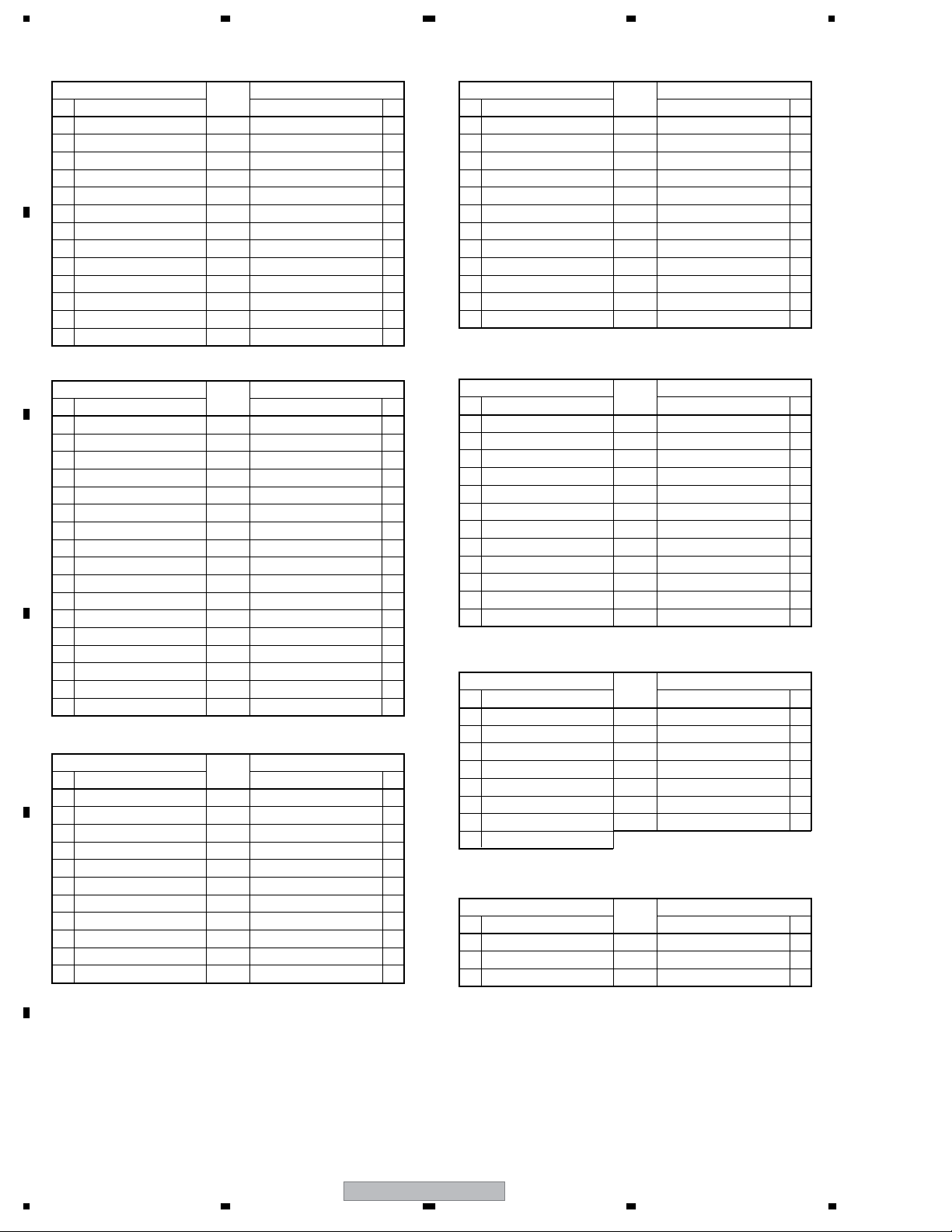

PACKING Parts List

No. Description Part No.

No. Description Part No.

Mark

1Power Cord ADG1215

2 Remote Control Unit See Contrast table (2)

3 Battery Cover AZN2462

NSP 4 Dry Cell Battery (R6P, AA) AEX1026

5 Wiping Cloth (for screen) AED1208

6 Binder Assy AEC1758

(Speed Clamp x2, Bead Band x2)

7 Operating Instructions ARE1386

(English / French / Spanish)

8 Plasma Caution Sheet ARM1145

9 Caution Sheet ARM1176

10 Caution Sheet ARM1194

11 Caution Sheet ARM1201

NSP 12 Warranty Card ARY1138

NSP 13 Card VRY1132

Mark

14 Vinyl Bag AHG1310

15 Pad See Contrast table (2)

16 Pad (43U) See Contrast table (2)

17 Pad (43L) See Contrast table (2)

18 Mirror Mat AHG1284

19 Accessory Case AHC1036

20 Under Carton See Contrast table (2)

21 Upper Carton See Contrast table (2)

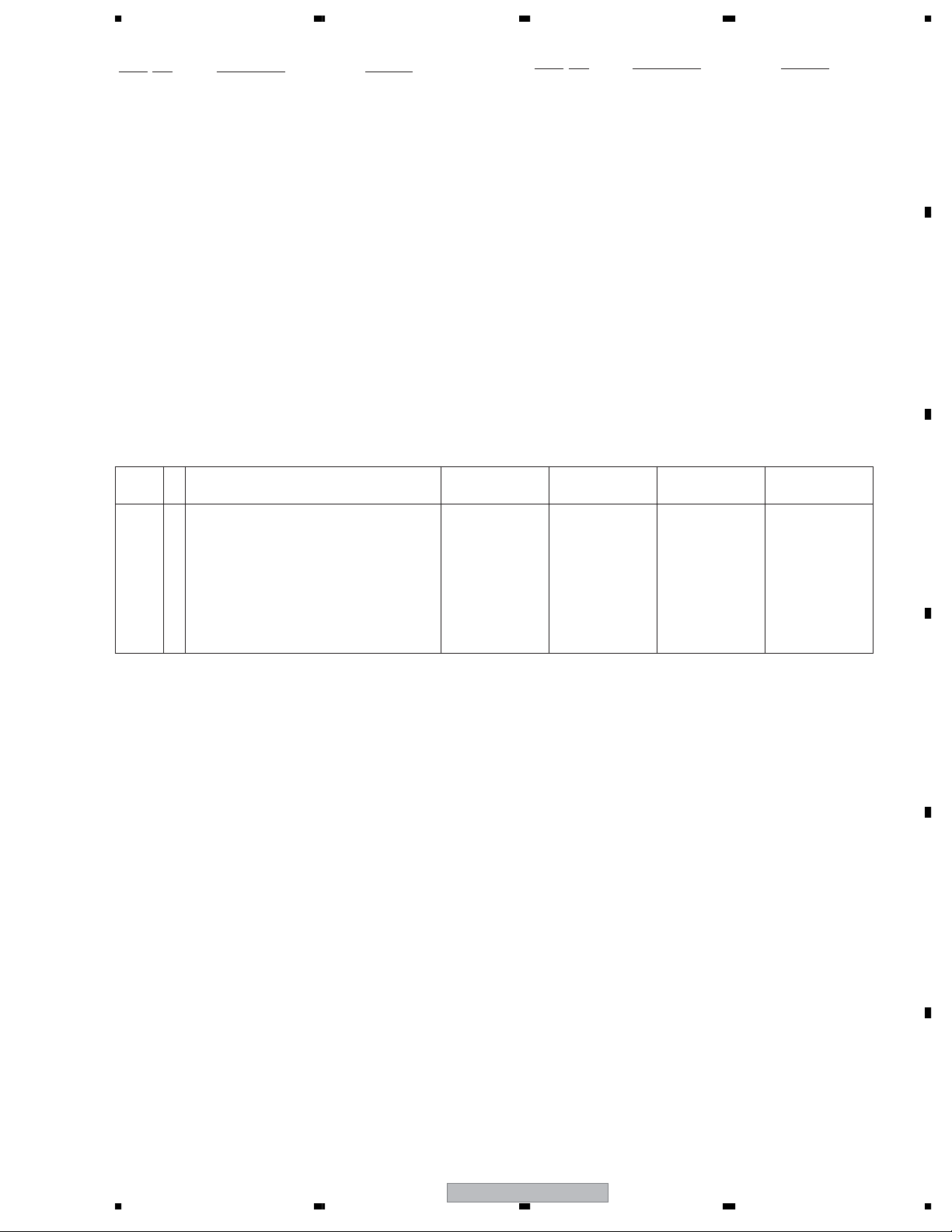

(2) CONTRAST TABLE

PDP-5004/KUC, PDP-5014/KUC, PDP-4304/KUC and PDP-4314/KUC are constructed the same except for the following:

Mark No. Symbol and Description

2 Remote Control Unit AXD1496 AXD1497 AXD1496 AXD1497

PDP-5004/

KUC

PDP-5014/

KUC

PDP-4304/

KUC

PDP-4314/

KUC

A

B

C

15 Pad AHA2280 AHA2280 Not used Not used

16 Pad (43U) Not used Not used

17 Pad (43L) Not used Not used

20 Under Carton AHD3037 AHD3037

21 Upper Carton AHD3286 AHD3288 AHD3287 AHD3289

AHA2282 AHA2282

AHA2283 AHA2283

AHD3100 AHD3100

D

E

56

PDP-5004

>

F

11

7

8

Page 12

1234

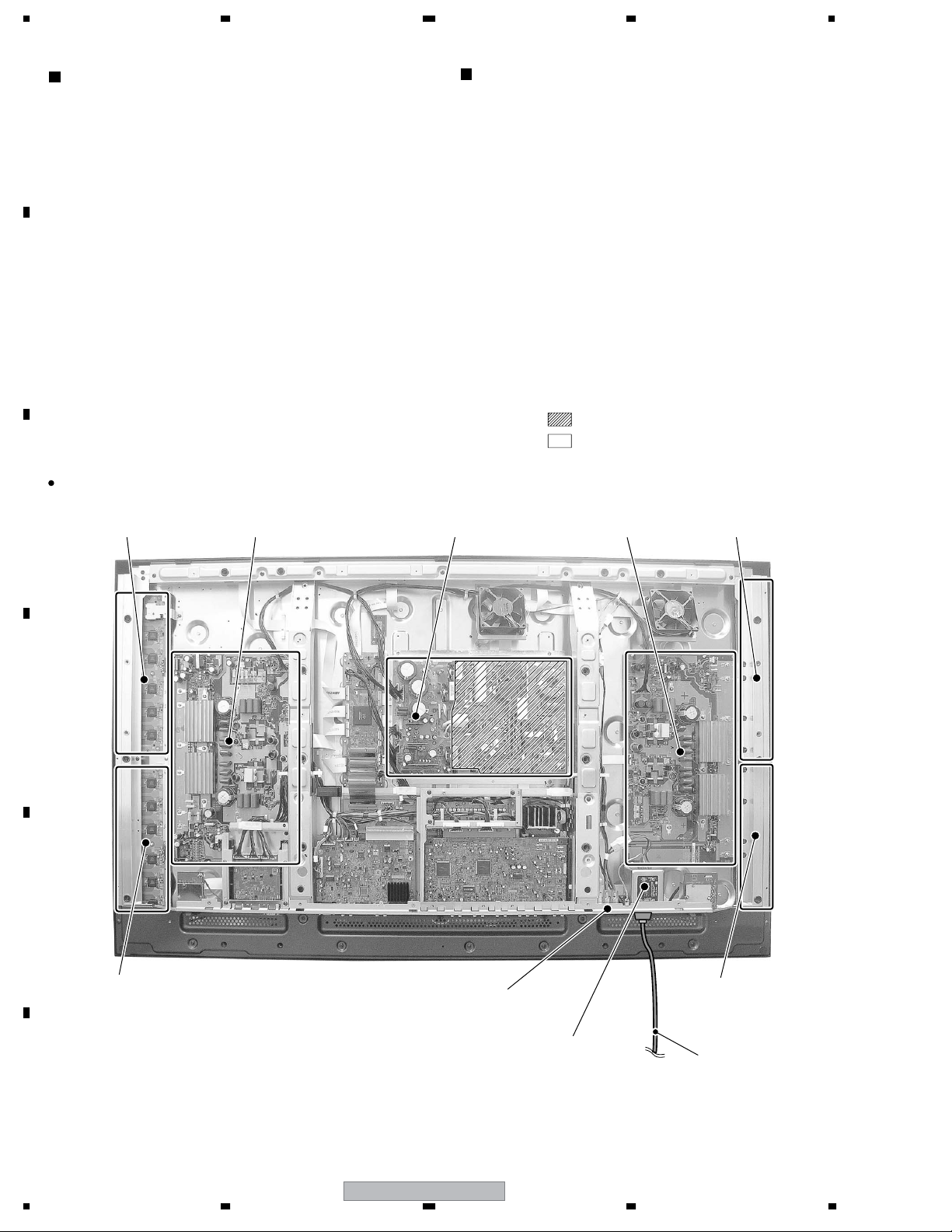

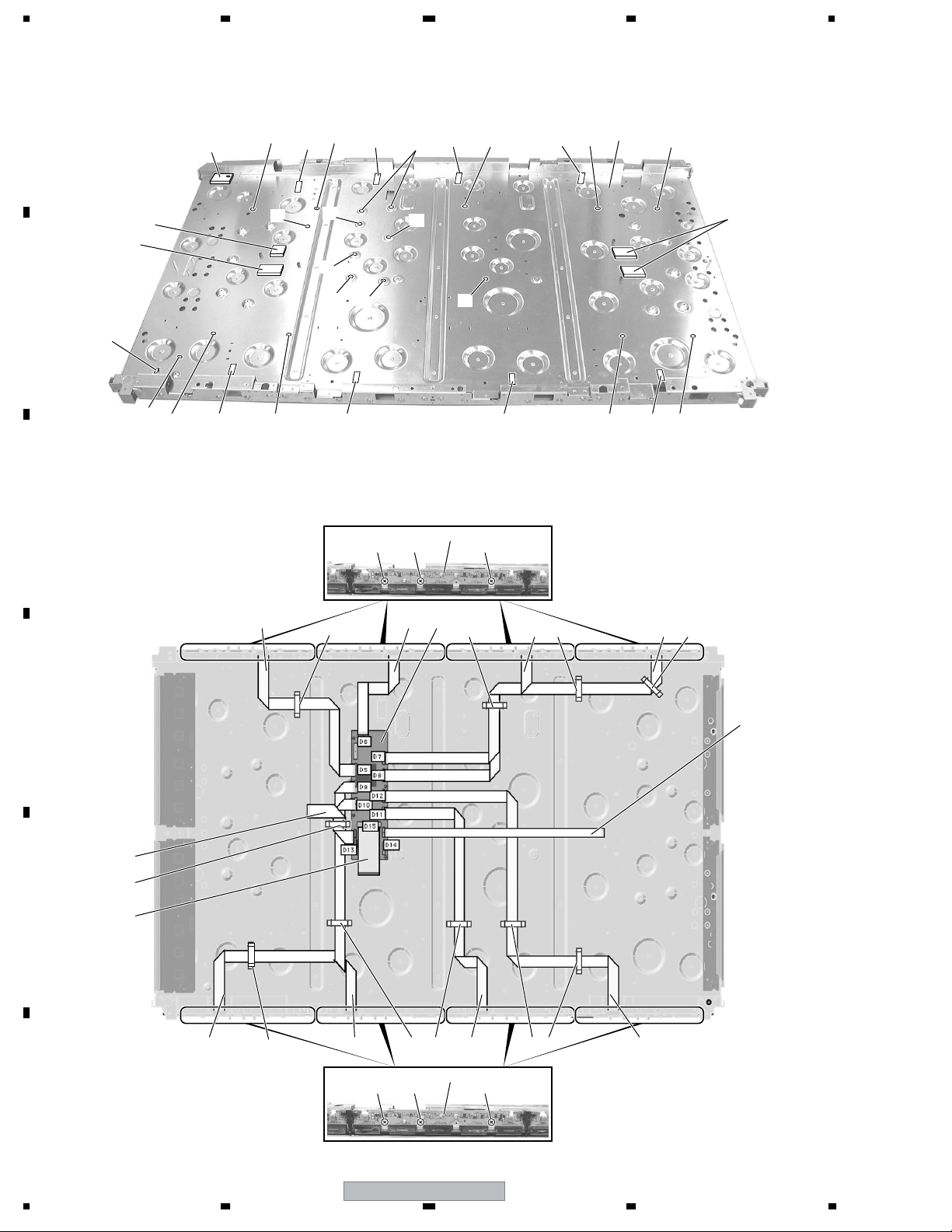

2.2 PDP-5004, PDP-5014 models

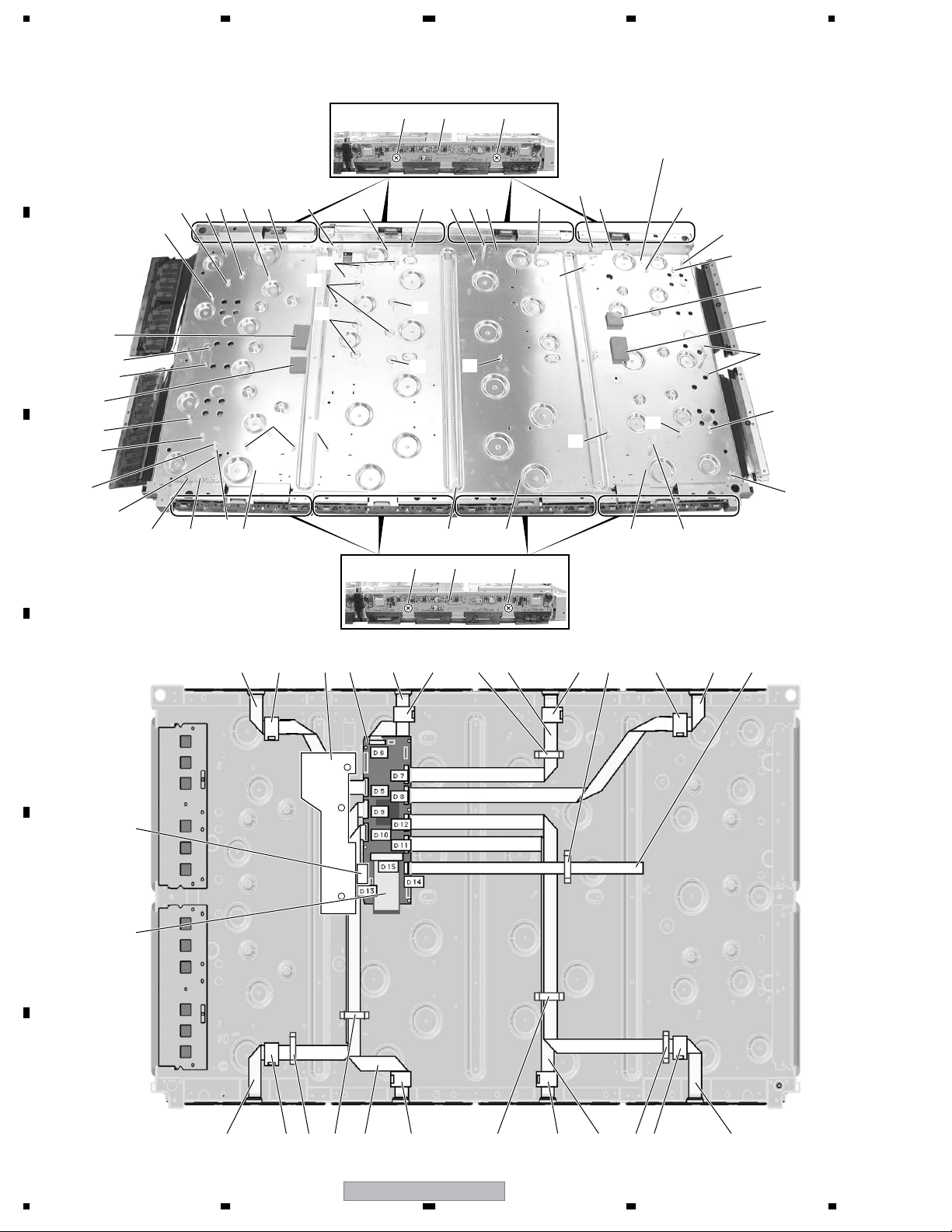

2.2.1 CHASSIS SECTION (1)

A

15

25

17

15

17

15

17 18

24

15

1

15

15

16

15

14

15

15

22 22 22

2

23 3

18

1717

6 14 1414 7

17

21

15

20

21

B

19

18

C

17 151515

16

5

D

8

14

E

F

4

10

14

11 14 14

22 22 22

12

2

1414

13

9

12

PDP-5004

1234

Page 13

5678

CHASSIS SECTION (1) parts List

No. Description Part No.

Mark

NSP 1 P. Chassis (50) Assy AWU1099

NSP 2 50 ADDRESS Assy AWZ6839

3 DIGITAL VIDEO Assy AWV2100

4 FPC (114P) ADY1081

5 Flexible Cable (J201) ADD1248

6 Flexible Cable (J203) ADD1250

7 Flexible Cable (J204) ADD1251

8 Flexible Cable (J209) ADD1236

9 Flexible Cable (J210) ADD1237

10 Flexible Cable (J205) ADD1252

11 Flexible Cable (J206) ADD1253

12 Flexible Cable (J207) ADD1254

13 Flexible Cable (J208) ADD1255

14 Flat Clamp AEC1879

No. Description Part No.

Mark

15 PCB Spacer AEC1941

16 PCB Support AEC1938

17 Wire Saddle AEC1745

18 PCB Spacer AEC1947

19 Locking Wire Saddle AEC1948

20 Drive Silicone Sheet C AEH1066

21 Drive Silicone Sheet B AEH1065

22 Screw VBB30P080FNI

23 Flexible Cable (J202) ADD1249

24 Locking Wire Saddle AEC1992

25 SCAN Silicone Sheet AEH1080

A

B

C

D

E

56

PDP-5004

F

13

7

8

Page 14

1234

2.2.2 CHASSIS SECTION (2)

A

19

9

20

B

17

13

C

23

25

22

8

20

3

15

15

100V

15

15

15

24

15 14

15

19

10

15

15

15

D

17

16

E

21

21

Upper

F

side

16

7

11

16

26 2827

17

2

17

16

6

16

16

21

21

12

21

21

18

17

21

18

17

1

16

45

21

21

Upper

side

18

17

21

14

PDP-5004

1234

Page 15

5678

CHASSIS SECTION (2) parts List

Mark No. Description Part No.

1 50 X DRIVE Assy AWZ6959

2 50 Y DRIVE Assy AWV2144

> 3POWER SUPPLY Unit AXY1083

NSP 4 X CONNECTOR B Assy AWZ6812

NSP 5 X CONNECTOR A Assy AWZ6811

NSP 6 50 SCAN A Assy AWZ6809

NSP 7 50 SCAN B Assy AWZ6810

8PANEL SENSOR Assy AWZ6795

9Fan Motor (80 x 25) AXM1044

10 Fan Angle (504) ANG2609

11 Front Chassis VL (50M) ANA1753

12 Front Chassis VR (50M) ANA1754

13 SCAN Heatsink ANH1630

14 Housing Wire (J117) ADX2897

15 Screw ABZ30P060FMC

16 Screw PMB30P060FNI

17 Screw VBB30P080FNI

18 Screw PMB40P080FZK

19 Screw PPZ50P100FZK

20 Nylon Rivet AEC1671

21 Screw AMZ30P060FZK

22 3P Housing Wire (J109) ADX2847

23 11P Housing Wire (J102) ADX2853

24 12P Housing Wire (J103) ADX2854

25 Wire A (J101) ADX2839

26 WireD (J118) ADX3030

27 5P Housing Wire (J119) ADX3031

28 9P Housing Wire (J115) ADX2895

A

B

C

D

56

PDP-5004

E

F

15

7

8

Page 16

1234

2.2.3 FRAME SECTION

A

B

C

24

17

6

7 7 7 7 7 7

17

25

11

1618 1618

17

17 17 8 17 17 17

16

9 954

11

10

18

17

Upper

side

16

11

11

22

19

D

2

E

F

17

6

• Rear view

13

23

17

14

12

19

16

1

1616

7

7 7 7 7 7

26

17 17 17 17 17 17

8

27 27

16

17

181818

14

3

15

20

21

16

PDP-5004

1234

Page 17

5678

FRAME SECTION parts List

Mark No. Description Part No.

1 IR RECEIVE Assy AWZ6855

2 KEY CONTROL Assy AWZ6969

3 LED Assy AWZ6966

4 Sub Frame L Assy (50M) ANG2596

5 Sub Frame R Assy (50M) ANG2598

6Front Chassis H (50) ANA1733

7Front Spacer (CMX) AMR3384

8 Rear Frame (50M) ANG2602

9 Locking Wire Saddle AEC1948

10 Locking Wire Saddle AEC1992

11 Wire Saddle AEC1745

NSP 12 IR Holder ANG2551

13 Nylon Rivet AEC1671

14 Flat Clamp AEC1879

15 Enclosure Sheet 1 AMR3405

16 Screw AMZ30P080FMC

17 Screw AMZ30P060FZK

18 Screw APZ30P080FZK

19 Screw ABZ30P060FMC

20 Nylon Rivet AEC1997

21 Screw BBZ30P050FMC

22 Enclosure Sheet 2 (V) AMR3411

23 Enclosure Sheet 3 AMR3407

24 Power Switch (S2)(TRAP) ASG1089

25 3P Housing Wire (J114) ADX3032

26 Gasket S (CM) ANK1749

27 Gasket (CM) ANK1748

A

B

C

D

E

F

56

PDP-5004

17

7

8

Page 18

1234

2.2.4 TERMINAL PANEL and REAR SECTION

28

(1/4)

A

36

30

18

18

18

26

29

18 18

36

(2/4)

30

18

18

18

18

39

18

31

36

32

32

30

30

(4/4)

32

31

32

30

B

30

36

(3/4)

C

18

6 6

27

18

24

18

23

18 18

33

17

9

8

18

18

18

18

34 35

1

17

8

18

8

30

4

25

18

18

38

11

7

2 38

15

16

18

18

18

20

17

17

40

38

D

E

Rear view

F

37

38

18

14 14

13 13 11

18

21

18

3

22

18

18

5

25

30

10

18

PDP-5004

1234

Page 19

5678

TERMINAL PANEL and REAR SECTION parts List

Mark No. Description Part No.

1 COMM SLOT I/F Assy AWZ6964

2 COMM SLOT Assy AWZ6968

> 3AC Inlet (CN1) AKP1244

4 SP TERMINAL R Assy AWZ6857

5 SP TERMINAL L Assy AWZ6856

6 Guide Rail EX AEC1994

7 6P Housing Wire (J108) ADX3029

8 Wire Saddle AEC1745

9 Clamp AEC1884

10 Terminal Panel (F50) ANG2685

11 Gasket SP-T ANK1734

12 • • • • •

13 Slot Spring B126 ABK1033

14 Slot Spring T130 ABK1032

15 Slot Spring T94 ABK1034

16 Slot Spring B92 ABK1035

17 Screw VBB30P080FNI

18 Screw AMZ30P060FZK

19 • • • • •

20 Hexagon Head Screw BBA1051

Mark No. Description Part No.

> 21 Power Switch (S1) ASG1094

22 Housing Wire (MX)(J116) ADX2896

23 COMM Stay A ANG2605

24 COMM Stay B ANG2606

25 Screw APZ30P080FZK

26 Rear Case (50M) ANE1623

27 Gasket T-R50 ANK1735

NSP 28 Name Label See Contrast table (2)

29 Caution Label AAX3048

30 Screw TBZ40P080FZK

31 Grip AMR3380

32 Screw HMB50P140FZK

33 Terminal Label R (SF50C) AAX3126

34 Terminal Label C (SF50C) AAX3130

35 Terminal Label V (CM) AAX3137

36 Rear Corner Label (15) AAX3081

37 VIDEO SLOT 2 Assy AWV2159

38 Screw ABA1300

39 Terminal Label L (50M) AAX3061

40 Screw BMZ30P080FZK

A

B

C

(2) CONTRAST TABLE

PDP-5004/KUC and PDP-5014/KUC are constructed the same except for the following:

Mark No. Symbol and Description

NSP 28 Name Label (SF50C) AAL2593 Not used

NSP 28 Name Label (SF50S) Not used AAL2595

PDP-5004/

KUC

PDP-5014/

KUC

D

E

56

PDP-5004

F

19

7

8

Page 20

1234

2.2.5 FRONT SECTION

A

4

B

6

13

8

C

9

D

14

14

6

6

3

6

3

14

13

4

5

6

14

6

2

15

E

16 17

11 12

10 7

F

18

20

1234

1

PDP-5004

Page 21

5678

FRONT SECTION parts List

Mark No. Description Part No.

1FRONT KEY Assy AWZ6970

2 PIONEER Badge AAM1091

3Panel Cushion V AED1199

4Panel Cushion H AED1226

> 5 Protect Panel Assy (50) AMR3348

6Panel Holder (50) ANG2563

7 Earth Plate (MX) AMR3432

8Front Case Assy See Contrast table (2)

NSP 9 Energy Star Label AAX8022

10 Blind Cushion AEB1400

Mark No. Description Part No.

11 Flexible Cable (J211) ADD1281

12 Flexible Seal (P) AEH1072

13 Screw ABZ30P060FMC

14 Screw APZ30P080FZK

15 Screw APZ30P120FZK

16 Lead Cover See Contrast table (2)

17 Rivet AEC1877

18 Flexible Seal (SF) AEH1082

(2) CONTRAST TABLE

PDP-5004/KUC and PDP-5014/KUC are constructed the same except for the following:

Mark No. Symbol and Description

8Front Case Assy (F50C) AMB2843 Not used

8Front Case Assy (F50S) Not used AMB2844

16 Lead Cover (SF) AMR3436 Not used

16 Lead Cover (4G) Not used AMR3395

PDP-5004/

KUC

PDP-5014/

KUC

A

B

C

D

E

56

PDP-5004

F

21

7

8

Page 22

1234

2.2.6 PANEL CHASSIS (50) ASSY (AWU1099)

Panel Chassis (50) Assy (AWU1099)

No. Description Part No.

Mark

A

NSP 1..50 ADDRESS Assy AWV2121

NSP 2..50 ADDRESS Assy AWZ6839

NSP 1..50 SCAN FUKUGO Assy AWV2036

NSP 2..50 SCAN A Assy AWZ6809

NSP 2..50 SCAN B Assy AWZ6810

NSP 2..X CONNECTOR A Assy AWZ6811

NSP 2..X CONNECTOR B Assy AWZ6812

NSP Address Module (IC1-IC40) AXF1124

NSP Plasma Panel Assy (50")(V1) AAV1251

B

NSP FPC (50XGA-X) ADY1084

NSP FPC (50XGA-Y) ADY1085

NSP Chassis Assy (50) ANA1774

Edge Card Spacer AEC1998

PCB Spacer AEC1944

PCB Support AEC1958

Rivet AMR1066

FC Spacer AMR3370

NSP Adhesive ZBA-KE3424S

C

NSP Cleaner ZLX-AP7

NSP Tape ZTA-8101-12

NSP Double Faced Tape ZTB-5015-18

NSP Tape ZTC-POLYCA-11

NSP Tape ZTC-POLYCA-20

NSP Double Faced Tape ZTB-5015-9

NSP Tape ZTC-900UL-15

NSP Silicone Rubber ZTX-HC20-15

NSP Wiping Cloth ZTX-MX100-13

D

NSP Film ZTX-2102Y35-2R5

NSP Film ZTX-2102Y45-5

NSP Silicone Rubber ZTX-HC50-15

NSP Silicone Rubber

ZTC-EM7KBOR85T-15W

E

F

22

1234

PDP-5004

Page 23

5678

2.2.7 PDP SERVICE ASSY (AWU1108)

PDP SERVICE Assy (AWU1108)

No. Description Part No.

Mark

NSP P. Chassis (50) Assy AWU1099

NSP Front Chassis H (50) ANA1733

F. Chassis VL (50M) ANA1765

F. Chassis VR (50M) ANA1766

Sub Frame R Assy (50M) ANG2561

Spacer AEB1397

Wire Saddle AEC1745

Clamp AEC1884

PCB Support AEC1938

PCB Spacer AEC1941

PCB Spacer AEC1947

Wire Clip AEC1948

Wire Clip AEC1992

Panel Cushion V AED1199

Panel Cushion H AED1226

Siricon Sheet SC AEH1080

Front Spacer AMR3369

Caution Label AAX3031

NSP Drive Voltage Label ARW1097

Screw ABZ30P100FZK

Screw AMZ30P080FMC

Screw APZ30P080FZK

NSP Front Case (504 SVC) AMB2811

Rear Case (50P) ARM1247

Caution Card (SVC) AHA2280

Pad (PP T-L) AHA2315

Pad (PP T-R) AHA2316

Center Pad (50) AHA2335

Pad (PP B-L) AHA2343

Pad (PP B-R) AHA2344

NSP Upper Carton (504SVC) AHD3212

Sub Frame L Assy (50M) ANG2638

Scan Heatsink ANH1630

Screw AMZ30P060FZK

Sub Carton AHB1248

Carton (50) AHD3177

Protect Sheet AHG1331

A

B

C

D

E

56

PDP-5004

F

23

7

8

Page 24

1234

2.3 PDP-4304, PDP-4314 models

2.3.1 CHASSIS SECTION (1)

A

17 16

19

31

18

B

25

31

31

24

18

19

17

C

22

31

23

20 21 21 21 21

17

16

17

30

20

20 2022 20

16

16

2

27 27

29

16

16

16

27 27

22

16

21 20 20 21

2

1

16

18

17

24

25

18

17

16

18

5

14 1428 14 146 7 915 1526 3

D

8

E

4

F

24

14

14 14 12 13141115 15 15 1510

PDP-5004

1234

Page 25

5678

CHASSIS SECTION (1) parts List

No. Description Part No.

Mark

NSP 1 P. Chassis (43) Assy AWU1098

NSP 2 43 ADDRESS Assy AWZ6793

3 DIGITAL VIDEO Assy AWV2100

4 FPC (114P) ADY1081

5 Flexible Cable (J201) ADD1257

6 Flexible Cable (J203) ADD1259

7 Flexible Cable (J204) ADD1260

8 Flexible Cable (J209) ADD1223

9 Flexible Cable (J210) ADD1224

10 Flexible Cable (J205) ADD1261

11 Flexible Cable (J206) ADD1262

12 Flexible Cable (J207) ADD1263

13 Flexible Cable (J208) ADD1264

14 Ferrite Core ATX1048

15 Flat Clamp AEC1879

16 PCB Spacer AEC1941

17 PCB Support AEC1938

18 PCB Spacer AEC1944

19 PCB Support AEC1958

20 Ferrite Clamp AEC1986

21 Wire Saddle AEC1745

22 PCB Spacer AEC1947

23 Locking Wire Saddle AEC1948

24 Drive Silicone Sheet C AEH1066

25 Drive Silicone Sheet B AEH1065

26 Y Drive Protection Sheet AMR3346

27 Screw VBB30P080FNI

28 Flexible Cable (J202) ADD1258

29 Locking Wire Saddle AEC1992

30 Harness Lifter 18 AEC1980

31 Edge Card Spacer AEC1998

A

B

C

D

56

PDP-5004

E

F

25

7

8

Page 26

1234

2.3.2 CHASSIS SECTION (2)

20

A

8

100V

14

19

19

9

Upper

side

32

15

11

19

15

15

19

B

C

32

10

Upper

side

15

9

2627

20

31

29 30

23

15

28

3

152225

31

1524

15

15

15

D

31

17

16

E

21

21

Upper

F

side

7 6

18

17

21

12

17

16

2

21

21 21 21

21

31

16

17

18 18

17

21

13

1

17

16

45

21

Upper

side

26

PDP-5004

1234

Page 27

5678

CHASSIS SECTION (2) parts List

No. Description Part No.

Mark

>

1 43 X DRIVE Assy AWZ6840

2 43 Y DRIVE Assy AWV2022

3POWER SUPPLY Unit AXY1083

NSP 4 X CONNECTOR B Assy AWZ6799

NSP 5 X CONNECTOR A Assy AWZ6798

NSP 6 43 SCAN A Assy AWZ6796

NSP 7 43 SCAN B Assy AWZ6797

8PANEL SENSOR Assy AWZ6795

9Fan Motor (80 x 25) AXM1044

10 Fan Angle L (43M) ANG2655

11 Fan Angle R (43M) ANG2656

12 Front Chassis VL (43M) ANA1755

13 Front Chassis VR (43M) ANA1756

14 Housing Wire for Fan (J117) ADX2904

15 Screw ABZ30P060FMC

16 Screw PMB30P060FNI

17 Screw VBB30P080FNI

18 Screw PMB40P080FZK

19 Screw PPZ50P100FZK

20 Nyron Rivet AEC1671

21 Screw AMZ30P060FZK

22 3P Housing Wire (J109) ADX2847

23 11P Housing Wire (J102) ADX2840

24 12P Housing Wire (J103) ADX2841

25 Wire A (J101) ADX2839

26 Wire G (J118) ADX3034

27 5P Housing Wire (J119) ADX3035

28 9P Housing Wire (J115) ADX2902

29 Sub Frame L Assy (43M) ANG2623

30 Sub Frame R Assy (43M) ANG2625

31 Screw AMZ30P080FMC

32 Locking Wire Saddle AEC1948

>

A

B

C

D

56

PDP-5004

E

F

27

7

8

Page 28

1234

2.3.3 FRAME SECTION

A

B

C

5

17

7 7 7

24

17

4

16

18

6

17

8

25

10

18

17

16

18

17 17

9

10

11

7 77

11

17

24

Rear view

Upper

side

15

26

D

E

22

19

2

17

24

14

19

23

13

16

6

12

20

16

7 77777

21

17

24

Rear view

14

3

F

28

1234

1

PDP-5004

Page 29

5678

FRAME SECTION parts List

No. Description Part No.

Mark

1 IR RECEIVE Assy AWZ6855

2 KEY CONTROL Assy AWZ6969

3 LED Assy AWZ6966

4Power Switch (S2)(TRAP) ASG1089

5 3P Housing Wire (J114) ADX3036

6Front Chassis H (43) ANA1714

7Front Spacer (CMX) AMR3384

8 Rear Frame (43M) ANG2613

9 Locking Wire Saddle AEC1948

10 Locking Wire Saddle AEC1992

11 Wire Saddle AEC1745

NSP 12 IR Holder ANG2551

13 Nyron Rivet AEC1671

14 Flat Clamp AEC1879

15 Enclosure Sheet 1 AMR3405

16 Screw AMZ30P080FMC

17 Screw AMZ30P060FZK

18 Screw APZ30P080FZK

19 Screw ABZ30P060FMC

20 Nyron Rivet AEC1997

21 Screw BBZ30P050FMC

22 Enclosure Sheet 2 (V) AMR3411

23 Enclosure Sheet 3 AMR3407

24 Screw PMB30P060FNI

25 Cable Cover AMR3431

NSP 26 Front Case Spacer AMR3430

A

B

C

D

E

F

56

PDP-5004

29

7

8

Page 30

1234

2.3.4 TERMINAL PANEL and REAR SECTION

18

A

36

(1/4)

30

28

18

26

18

29

18

36

(2/4)

30

18

18

18

18

12

18

36

32

31

30

32

30

(4/4)

18

32

30

31

18

32

36

6 6

30

(3/4)

18

27

24

23

18

33

18

8

B

C

17

18

18

18

18

34 35

1

17

9

8

18

5

25

30

37373737

10

11

21

18

3

18

4

30

25

18

8

2 39

39

11

15

7

16

18

17

17

19

20

18 18

1818

39

18

38

13 13

14

14

39

18

D

E

Rear view

F

22

30

PDP-5004

1234

Page 31

5678

TERMINAL PANEL and REAR SECTION parts List

No. Description Part No.

Mark

>

>

1 COMM SLOT I/F Assy AWZ6964

2 COMM SLOT Assy AWZ6968

3AC Inlet (CN1) AKP1244

4 SP TERMINAL R Assy AWZ6857

5 SP TERMINAL L Assy AWZ6856

6 Guide Rail EX AEC1994

7 6P Housing Wire (J108) ADX3033

8 Wire Saddle AEC1745

9 Clamp AEC1884

10 Terminal Panel (F43) ANG2687

11 Gasket SP-T ANK1734

12 Terminal Label L (43M) AAX3062

13 Slot Spring B126 ABK1033

14 Slot Spring T130 ABK1032

15 Slot Spring T94 ABK1034

16 Slot Spring B92 ABK1035

17 Screw VBB30P080FNI

18 Screw AMZ30P060FZK

19 Screw BMZ30P080FZK

20 Hexagon Head Screw BBA1051

No. Description Part No.

Mark

21 Power Switch (S1) ASG1094

22 Housing Wire (MX)(J116) ADX2896

23 COMM Stay A ANG2605

24 COMM Stay B ANG2606

25 Screw APZ30P080FZK

26 Rear Case (43M) ANE1624

27 Gasket T-R43 ANK1736

NSP 28 Name Label See Contrast table (2)

29 Caution Label (M) AAX3048

30 Screw TBZ40P080FZK

31 Grip AMR3380

32 Screw HMB50P140FZK

33 Terminal Label R (SF43C) AAX3128

34 Terminal Label C (SF43C) AAX3130

35 Terminal Label V (CM) AAX3137

36 Rear Corner Label (15) AAX3081

37 Spacer AMR3433

38 VIDEO SLOT 2 Assy AWV2159

39 Screw ABA1300

A

B

C

(2) CONTRAST TABLE

PDP-4304/KUC and PDP-4314/KUC are constructed the same except for the following:

Mark No. Symbol and Description

NSP 28 Name Label (SF43C) AAL2594 Not used

NSP 28 Name Label (SF43S) Not used AAL2596

PDP-4304/

KUC

PDP-4314/

KUC

D

E

56

PDP-5004

F

31

7

8

Page 32

1234

2.3.5 FRONT SECTION

A

4

B

6

6

13

14

8

C

14

6

9

D

2

3

6

3

14

13

4

5

6

14

6

15

E

16 17

11 12

10 18

F

7

32

1234

1

PDP-5004

Page 33

5678

FRONT SECTION (1) parts List

No. Description Part No.

No. Description Part No.

Mark

>

1FRONT KEY Assy AWZ6970

2 Pioneer Name Plate AAM1091

3Panel Cushion V (43M) AED1254

4Panel Cushion H (43M) AED1253

5 Protect Panel Assy (43) AMR3345

NSP 6 Panel Holder (43) ANG2552

7 Flexible Seal (SF) AEH1082

8Front Case Assy See Contrast table (2)

9 Energy Star Label AAX8022

10 Blind Cushion AEB1400

Mark

11 Flexible Cable (J211) ADD1281

12 Flexible Seal (P) AEH1072

13 Screw ABZ30P060FMC

14 Screw APZ30P080FZK

15 Screw APZ30P120FZK

16 Lead Cover See Contrast table (2)

17 Rivet AEC1877

18 Earth Plate (MX) AMR3432

(2) CONTRAST TABLE

PDP-4304/KUC and PDP-4314/KUC are constructed the same except for the following:

Mark No. Symbol and Description

8Front Case Assy (F43C) AMB2846 Not used

8Front Case Assy (F43S) Not used AMB2847

16 Lead Cover (SF) AMR3436 Not used

16 Lead Cover (4G) Not used AMR3395

PDP-4304/

KUC

PDP-4314/

KUC

A

B

C

D

E

56

PDP-5004

F

33

7

8

Page 34

1234

2.3.6 PANEL CHASSIS (43) ASSY (AWU1098)

Panel Chassis (43) Assy (AWU1098)

• Parts List

Mark

A

B

C

D

No. Description Part No.

NSP 1..43 ADDRESS Assy AWV2120

NSP 2..43 ADDRESS Assy AWZ6793

NSP 1..43 SCAN FUKUGO Assy AWV2023

NSP 2..43 SCAN A Assy AWZ6796

NSP 2..43 SCAN B Assy AWZ6797

NSP 2..X CONNECTOR A Assy AWZ6798

NSP 2..X CONNECTOR B Assy AWZ6799

NSP Address Module (IC1-IC32) AXF1124

NSP Plasma Panel Assy (43")(V1) AAV1250

NSP FPC (43XGA-X) ADY1079

NSP FPC (43XGA-Y) ADY1080

NSP Chassis Assy (43) ANA1773

PCB Spacer AEC1944

PCB Support AEC1958

Edge Card Spacer AEC1998

Rivet AMR1066

FC Spacer AMR3370

NSP Adhesive ZBA-KE3424S

NSP Cleaner ZLX-AP7

NSP Tape ZTA-8101-12

NSP Double Faced Tape ZTB-5015-18

NSP Double Faced Tape ZTB-5015-9

NSP Tape ZTC-POLYCA-11

NSP Tape ZTC-POLYCA-20

NSP Tape ZTC-900UL-15

NSP Wiping Cloth ZTX-MX100-13

NSP Film ZTX-2102Y35-2R5

NSP Film ZTX-2102Y45-2R5

NSP Film ZTX-2102Y45-5

NSP Silicone Rubber

NSP Silicone Rubber ZTX-HC50-15

NSP Silicone Rubber ZTX-HC20-15

ZTC-EM7KB0R85T-15W

E

F

34

1234

PDP-5004

Page 35

5678

2.3.7 PDP SERVICE ASSY (AWU1109)

PDP SERVICE Assy (AWU1109)

• Parts List

No. Description Part No.

Mark

NSP P. Chassis (43) Assy AWU1098

NSP Front Chassis H (43) ANA1714

F Chassis VL (43M) ANA1762

F Chassis VR (43M) ANA1763

Sub Frame L Assy (43M) ANG2545

Sub Frame R Assy (43M) ANG2548

Spacer AEB1397

Edging Saddle AEC1737

Wire Saddle AEC1745

Clamp AEC1884

PCB Support AEC1938

PCB Spacer AEC1941

PCB Spacer AEC1947

Locking Wire Saddle AEC1948

HL18 AEC1980

Ferrite Clamp AEC1986

Locking Wire Saddle AEC1992

Panel Cushion H (43M) AED1253

Panel Cushion V (43M) AED1254

Y Drive Protection Sheet AMR3346

Front Spacer AMR3369

Caution Label AAX3031

NSP Drive Voltage Label ARW1097

Screw ABZ30P100FZK

Screw AMZ30P060FZK

Screw AMZ30P080FMC

Screw APZ30P080FZK

Screw VBB30P080FNI

NSP Front Case (434 SVC) AMB2810

Rear Case (43P) ANE1612

NSP Exchange Panel Sheet ARM1250

Pad (PP T-L) AHA2315

Pad (PP T-R) AHA2316

Center Pad (43) AHA2336

Pad (PP B-L) AHA2343

Pad (PP B-R) AHA2344

Carton (43PU) AHD3193

Upper Carton (434S) AHD3204

Protect Sheet AHG1331

A

B

C

D

E

56

PDP-5004

F

35

7

8

Page 36

1234

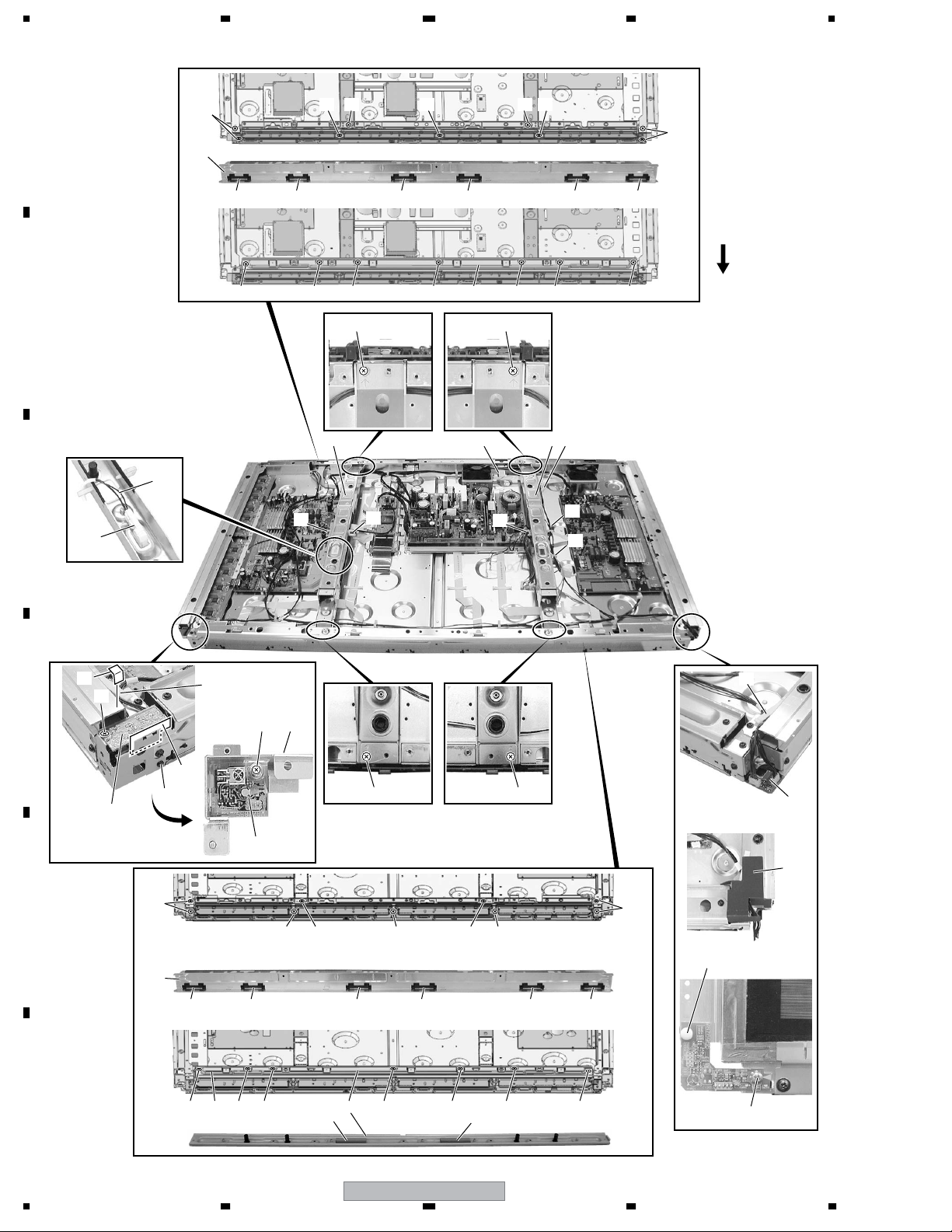

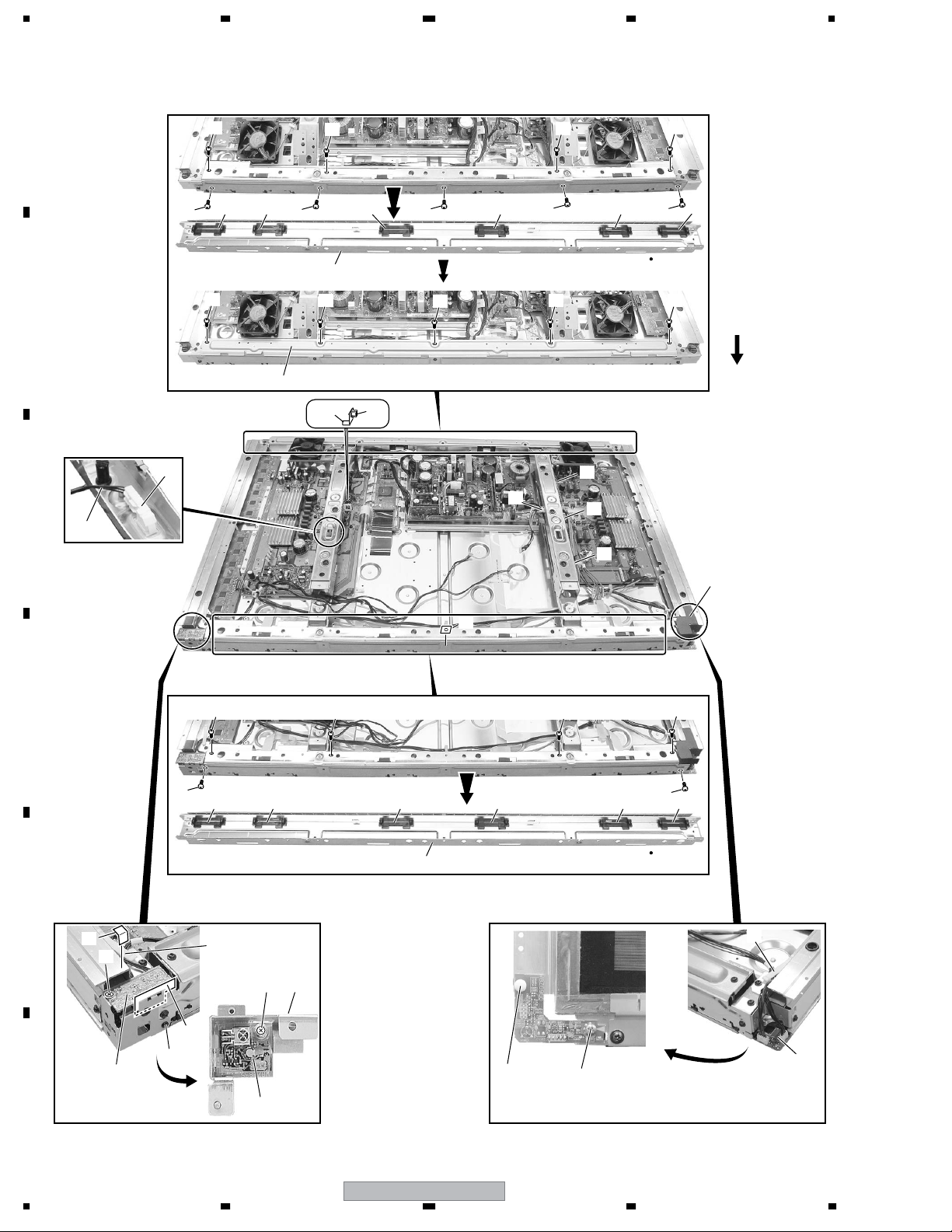

2.4 MULTI BASE SECTION for PDP-5004, PDP-5014, PDP-4304 and PDP-4314

2.4.1 MULTI BASE SECTION

Note : This illustration is PDP-5004.

A

28

28

3

B

17

13

29

C

34

5

27

30 30 30

12

19 32

1813

31

28

27

2026

23

28

2524 25

16

14

14

26

29

Rear view

12

13

29

21

15

22

15

23

28

33

6

7

11

7

11

9

8

7

33

4 2 1

D

E

10 10

10

7

7

7

11

28

7

7

11

7

Bottom view

9

F

36

1234

PDP-5004

Page 37

5678

MULTI BASE SECTION parts List

No. Description Part No.

Mark

1AUDIO AMP Assy AWZ6848

2 RGB Assy AWZ6961

3 VIDEO SLOT I/F Assy AWZ6851

4AV I/O Assy See Contrast table (2)

5AV I/O I/F Assy AWZ6859

6 Multi Base (CMX) ANA1757

7 PCB Holder AEC1088

8 PCB Spacer AEC1991

9 Gasket C-M ANK1737

10 Locking Card Spacer AEC1429

11 Ground Finger ANG2468

12 Clamp AEC1884

13 Wire Saddle AEC1989

14 Mini Clamp AEC1971

15 Double Locking Spacer AEC1988

16 15P/16P Housing Wire (J106) ADX3028

17 Cable Clamp AEC1707

18 10/11P Housing Wire (J110) See Contrast table (2)

No. Description Part No.

Mark

19 10P Housing Wire (J113) ADX2908

20 12P Housing Wire (J112) ADX2892

21 13P/6P Housing Wire (J104) ADX2910

22 COVER Assy AWZ6858

23 Guide Rail EX AEC1994

24 Slot Stay ANG2608

25 Wire Saddle AEC1745

26 11P Housing Wire (J111) See Contrast table (2)

27 Flat Clamp AEC1879

28 Screw AMZ30P060FZK

29 Screw PMB30P060FNI

30 Screw VBB30P080FNI

31 Pin Grommet AEC1015

32 Video Stay ANG2607

33 Gasket M-T 150 ANK1738

34 Shield Sheet AEC2004

A

B

(2) CONTRAST TABLE

PDP-5004/KUC, PDP-5014/KUC, PDP-4304/KUC and PDP-4314/KUC are constructed the same except for the following:

Mark No. Symbol and Description

4AV I/O Assy AWZ6967 AWZ6971 AWZ6967 AWZ6971

18 10/11P Housing Wire (J110) ADX2890 ADX2890

26 11P Housing Wire (J111) ADX2891 ADX2891 ADX2913

PDP-5004/

KUC

PDP-5014/

KUC

PDP-4304/

KUC

ADX2912 ADX2912

PDP-4314/

KUC

ADX2913

C

D

E

56

PDP-5004

F

37

7

8

Page 38

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

3.1.1 OVERALL BLOCK DIAGRAM (1/2) for PDP-5004 and PDP-5014 models

A

DRIVER IC

IC1551

DRIVER IC

IC1552

DRIVER IC

IC1553

DRIVER IC

IC1554

DRIVER IC

IC1555

DRIVER IC

IC1551

DRIVER IC

IC1552

DRIVER IC

IC1553

DRIVER IC

IC1554

DRIVER IC

IC1555

V+5V

V+9V

V+3V_IC5

V+3V_PLLV+3V_LVDS

AD1

IC1501

CN1501

V+ADR

RESONANCE

BLOCK

50 ADDRESS ASSY

V+60V

V+5V

V+9V

V+3V_IC5

V+3V_PLLV+3V_LVDS

AD1

IC1501

CN1501

V+ADR

RESONANCE

BLOCK

50 ADDRESS ASSY

V+60V

PANEL SENSOR ASSY

SENSOR

IC1072

B

50 SCAN B ASSY

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

PSUS

PSUS

SB1 Y2

SCAN

CN3201

SCAN

CN3001

SA1 Y3

CN2101

CN2102

IC5V

ADD

SEL_PULSE

IC3201

IC5V

ADD

SEL_PULSE

IC3202

IC5V

ADD

SEL_PULSE

IC3203

C

D

E

IC5V

ADD

SEL_PULSE

IC3204

IC5V

ADD

SEL_PULSE

IC3205

IC5V

ADD

SEL_PULSE

IC3206

IC5V

ADD

SEL_PULSE

IC3001

IC5V

ADD

SEL_PULSE

IC3002

IC5V

ADD

SEL_PULSE

IC3003

IC5V

ADD

SEL_PULSE

IC3004

IC5V

ADD

SEL_PULSE

IC3005

IC5V

ADD

SEL_PULSE

IC3006

50 SCAN A ASSY

CN1071

TE1

V_IC5V

VCC_VH

+16.5V

+5V

PSUSPSUS

MASK MOD

+16.5V

SOFT-D

BLOCK

+16.5V

VSUS

+RESET

BLOCK

+5V +15V VSUS

MASK MOD

VC_VF+ VC_VF- V_OFS

VCC_VH

V_IC5V

Scan Signal

50 Y DRIVE ASSY

V_OFS

VC_VF-

VC_VF+

+5V

VSUS

IC2307

+5V

RESONANCE

BLOCK

IC2303

OFFSET

BLOCK

V_IC5V

Photo Coupler

BLOCK

Drive

Signal

+16.5V

Signal

DC_DC

CONV

BLOCK

REGULATOR

Drive

Drive

Signal

V_IC5VVCC_VH

LOGIC

BLOCK

VSUS

+5V

Y4

CN2301

+6.5V

Y1 D13

SCAN

YSUS

CN2001

VH_UV_PD

YDRIVE_PD

YRESNC_PD

YDD_CHV_PD

IC5V_UV_PD

ADR_

PD0

OR

CN5202

D4

CN5521

OR

ADR_

PD4

CN5501

CN5505

D5

ADR_PD1

LVDS

V+3V_D

V+1V_D

DCC_PD

FLASH MEMORY

SUB-FILD CONV.

XY DRV SEQUENCE

PATTERN GEN.

MASK

Vofs

MODULE UCOM

LVDS

ADR_PD5

D9

CN5502

D6

ADR_PD2

CN5503

DIGITAL VIDEO ASSY

V+12V

DC-DC

CONVERTER

MODULE

AXY1066

IC5305

IC5401

PD5856A

IC5201

CN5506

&

ADR_PD6

D10

OR

OR

PD_MUTE

RELAY, PD_TRIGGER

CN5507

D7

ADR_PD3

PD

ADR_PD7

D11

CN5504

V+60V

V+6.5V

V+12V

Vsus_ADJ.

PD_PWDN

XSUS

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

DCLK, DE

HD, VD

RA IN, GA IN, BA IN

RB IN, GB IN, BB IN

V+3V_D

V+1V_D

CN5508

D15

D12

D8

D2

CN5601 CN5602

D1

D14

CN5511CN5002

CN5001

D3

CN1501

AD1

V+3V_PLLV+3V_LVDS

F

V+5V

DRIVER IC

IC1551

DRIVER IC

IC1552

V+3V_IC5

DRIVER IC

IC1553

38

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

BLOCK

V+ADR

IC1501

V+9V

DRIVER IC

IC1555

PDP-5004

V+60V

V+5V

DRIVER IC

IC1551

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

AD1

V+3V_IC5

DRIVER IC

IC1553

CN1501

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

V+ADR

IC1501

BLOCK

DRIVER IC

IC1555

V+9V

V+60V

1234

Page 39

5678

V+5V

DRIVER IC

IC1551

P4

P3

P5

P2

Vsus_ADJ.

EXT.PD

R10

CN7101

+6.5V

VADR

+12V

PS.PD

RELAY

RGB ASSY

DRIVER IC

VSUS

M111

IC1552

+6.5V

+16.5V

V+3V_PLLV+3V_LVDS

VSUS_

CONT

DRIVER IC

IC1553

V+3V_IC5

AD1

SECONDARY

STB

+6.5V

3.3V

P8 P6

CN7404

R1

T105

T103

T101

T102

T104

DRIVER IC

IC1554

V+ADR

IC1501

CN1501

RESONANCE

50 ADDRESS ASSY

Switching

Switching

Q116

Switching

Q117

Switching

M105

Switching

PRIMARY

POWER SUPPLY UNIT

AV I/O

I/F ASSY

DRIVER IC

BLOCK

Q120

Q119

+390V

D131,D134

IC1555

D133

AV I/O

ASSY

V+9V

M107

PFC

Q101,

Q102

V+60V

RL101

RELAY

& PD

LIVE

DRIVER IC

P7

DRIVER IC

V+5V

RC101

NEUTRAL

CN5002

AP1

IC1551

AUDIO

AMP

ASSY

KEY CONTROL

ASSY

IC1552

V+3V_PLLV+3V_LVDS

DRIVER IC

V+3V_IC5

AD1

X2

VSUS

+6.5V

X1

CN1001 CN1201

IC1553

REGULATOR

+5V

LOGIC

BLOCK

DRIVER IC

IC1554

V+ADR

IC1501

50 ADDRESS ASSY

CN1501

50 X DRIVE ASSY

DC_DC

CONV

BLOCK

Drive

Signal

Drive

Signal

V_RN

+16.5V

RESONANCE

BLOCK

DRIVER IC

IC1555

V+9V

RESONANCE

BLOCK

S1

MAIN POWER

LIVE

NEUTRAL

+5V

+16.5V

VSUS

MASK MOD

IC1203

SUS

OUT

+5V

V_RN

SUS

OUT

MASK MOD

IC1207

+16.5V

-RESET

PULSE

BLOCK

SP TERMINAL

L ASSY

V+60V

+5V

+5V+16.5VVSUS

X CONNECTOR

B ASSY

PSUS

PSUS

X CONNECTOR

A ASSY

A

AC INLET

B

C

D

V+5V

R5

CN7408

DRIVER IC

IC1551

LED ASSY

COMM SLOT

ASSY

COMM

SLOT

I/F

FAN (R) TRAP SWFAN (L)

ASSY

IR RECEIVE

ASSY

VIDEO SLOT

I/F ASSY

CN1501

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

AD1

V+3V_IC5

DRIVER IC

IC1553

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

BLOCK

V+ADR

IC1501

DRIVER IC

IC1555

V+9V

V+60V

V+5V

DRIVER IC

IC1551

PDP-5004

56

FRONT KEY

ASSY

Refer to the section

3.1.3 OVERALL BLOCK

DIAGRAM (2/2).

VIDEO SLOT 2 ASSY

CN1501

AD1

V+3V_IC5

DRIVER IC

IC1553

7

IC1501

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

SP TERMINAL

R ASSY

50 ADDRESS ASSY

RESONANCE

BLOCK

DRIVER IC

IC1554

V+ADR

V+9V

DRIVER IC

IC1555

V+60V

E

F

39

8

Page 40

1234

3.1.2 OVERALL BLOCK DIAGRAM (1/2) for PDP-4304, PDP-4314 models

A

V+5V

DRIVER IC

IC1552

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1553

V+3V_IC5

AD1

DRIVER IC

IC1554

V+ADR

IC1501

CN1501

RESONANCE

43 ADDRESS ASSY

DRIVER IC

BLOCK

IC1555

V+9V

V+60V

V+5V

DRIVER IC

IC1552

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1553

V+3V_IC5

AD1

DRIVER IC

IC1554

V+ADR

IC1501

CN1501

RESONANCE

43 ADDRESS ASSY

DRIVER IC

BLOCK

IC1555

V+9V

V+60V

PANEL SENSOR ASSY

SENSOR

IC1072

B

43 SCAN B ASSY

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

PSUS

PSUS

SB1 Y2

SCAN

CN3201

SCAN

CN3001

SA1 Y3

CN2101

CN2102

IC5V

ADD

SEL_PULSE

IC3201

IC5V

ADD

SEL_PULSE

IC3202

IC5V

ADD

SEL_PULSE

IC3203

C

D

E

IC5V

ADD

SEL_PULSE

IC3204

IC5V

ADD

SEL_PULSE

IC3205

IC5V

ADD

SEL_PULSE

IC3206

IC5V

ADD

SEL_PULSE

IC3001

IC5V

ADD

SEL_PULSE

IC3002

IC5V

ADD

SEL_PULSE

IC3003

IC5V

ADD

SEL_PULSE

IC3004

IC5V

ADD

SEL_PULSE

IC3005

IC5V

ADD

SEL_PULSE

IC3006

43 SCAN A ASSY

CN1071

TE1

V_IC5V

VCC_VH

+16.5V

+5V

PSUSPSUS

MASK MOD

+16.5V

SOFT-D

BLOCK

+16.5V

VSUS

+RESET

BLOCK

+5V +15V VSUS

MASK MOD

VC_VF+ VC_VF- V_OFS

VCC_VH

V_IC5V

Scan Signal

43 Y DRIVE ASSY

V_OFS

VC_VF-

VC_VF+

+5V

VSUS

IC2307

+5V

RESONANCE

BLOCK

IC2303

OFFSET

BLOCK

V_IC5V

Photo Coupler

BLOCK

Drive

Signal

+16.5V

Signal

DC_DC

CONV

BLOCK

REGULATOR

Drive

Drive

Signal

V_IC5VVCC_VH

LOGIC

BLOCK

VSUS

+5V

Y4

CN2301

+6.5V

Y1 D13

SCAN

YSUS

CN2001

VH_UV_PD

YDRIVE_PD

YRESNC_PD

YDD_CHV_PD

IC5V_UV_PD

ADR_

PD0

OR

CN5202

D4

CN5521

OR

ADR_

PD4

CN5501

CN5505

D5

ADR_PD1

LVDS

V+3V_D

V+1V_D

DCC_PD

FLASH MEMORY

SUB-FILD CONV.

XY DRV SEQUENCE

PATTERN GEN.

MASK

Vofs

MODULE UCOM

LVDS

ADR_PD5

D9

CN5502

D6

ADR_PD2

CN5503

DIGITAL VIDEO ASSY

V+12V

DC-DC

CONVERTER

MODULE

AXY1066

IC5305

IC5401

PD5856A

IC5201

CN5506

&

ADR_PD6

D10

OR

OR

PD_MUTE

RELAY, PD_TRIGGER

CN5507

D7

ADR_PD3

PD

ADR_PD7

D11

CN5504

V+60V

V+6.5V

V+12V

Vsus_ADJ.

PD_PWDN

XSUS

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

DCLK, DE

HD, VD

RA IN, GA IN, BA IN

RB IN, GB IN, BB IN

V+3V_D

V+1V_D

CN5508

D15

D12

D8

D2

CN5601 CN5602

D1

D14

CN5511CN5002

CN5001

D3

CN1501

AD1

V+3V_PLLV+3V_LVDS

F

V+5V

DRIVER IC

IC1552

V+3V_IC5

DRIVER IC

IC1553

40

43 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

BLOCK

V+ADR

IC1501

V+9V

DRIVER IC

IC1555

PDP-5004

V+60V

V+5V

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

AD1

V+3V_IC5

DRIVER IC

IC1553

CN1501

43 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

V+ADR

IC1501

BLOCK

DRIVER IC

IC1555

V+9V

V+60V

1234

Page 41

5678

V+5V

P4

VSUS

M111

P3

P5

+6.5V

VADR

P2

Vsus_ADJ.

+12V

PS.PD

EXT.PD

RELAY

P8 P6

R1

R10

RGB ASSY

CN7101

DRIVER IC

IC1552

V+3V_PLLV+3V_LVDS

+6.5V

+16.5V

VSUS_

CONT

STB

3.3V

CN7404

DRIVER IC

IC1553

V+3V_IC5

AD1

T105

T103

T101

T102

T104

SECONDARY

+6.5V

DRIVER IC

IC1554

V+ADR

IC1501

CN1501

RESONANCE

43 ADDRESS ASSY

Switching

Switching

Q116

Switching

Q117

Switching

M105

Switching

PRIMARY

POWER SUPPLY UNIT

AV I/O

I/F ASSY

DRIVER IC

BLOCK

Q120

Q119

+390V

D131,D134

IC1555

D133

AV I/O

ASSY

V+9V

M107

PFC

Q101,

Q102

V+60V

RL101

RELAY

& PD

DRIVER IC

V+5V

RC101

P7

LIVE

NEUTRAL

CN5002

AP1

AUDIO

AMP

ASSY

KEY CONTROL

ASSY

IC1552

V+3V_PLLV+3V_LVDS

DRIVER IC

V+3V_IC5

AD1

X2

VSUS

+6.5V

X1

CN1001 CN1201

IC1553

REGULATOR

+5V

LOGIC

BLOCK

DRIVER IC

IC1554

IC1501

CN1501

V+ADR

43 ADDRESS ASSY

43 X DRIVE ASSY

DC_DC

CONV

BLOCK

Drive

Signal

Drive

Signal

V_RN

+16.5V

RESONANCE

BLOCK

DRIVER IC

IC1555

V+9V

RESONANCE

BLOCK

S1

MAIN POWER

LIVE

NEUTRAL

+5V

+16.5V

VSUS

MASK MOD

IC1203

SUS

OUT

+5V

V_RN

SUS

OUT

MASK MOD

IC1207

+16.5V

-RESET

PULSE

BLOCK

SP TERMINAL

L ASSY

V+60V

+5V

+5V+16.5VVSUS

X CONNECTOR

B ASSY

PSUS

PSUS

X CONNECTOR

A ASSY

A

AC INLET

B

C

D

V+5V

R5

CN7408

LED ASSY

COMM SLOT

ASSY

COMM

SLOT

I/F

FAN (R)FAN (L)

TRAP SW

ASSY

IR RECEIVE

ASSY

VIDEO SLOT

I/F ASSY

CN1501

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

AD1

V+3V_IC5

DRIVER IC

IC1553

43 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

BLOCK

V+ADR

IC1501

DRIVER IC

IC1555

V+9V

V+60V

V+5V

PDP-5004

56

FRONT KEY

ASSY

Refer to the section

3.1.3 OVERALL BLOCK

DIAGRAM (2/2).

VIDEO SLOT 2 ASSY

CN1501

AD1

V+3V_IC5

DRIVER IC

IC1553

7

IC1501

DRIVER IC

IC1554

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

SP TERMINAL

R ASSY

43 ADDRESS ASSY

RESONANCE

BLOCK

V+ADR

V+9V

DRIVER IC

IC1555

V+60V

E

F

41

8

Page 42

1234

3.1.3 OVERALL BLOCK DIAGRAM (2/2) for PDP-5004, PDP-5014, PDP-4304 and PDP-4314

models

A

P6

CN5002

AV I/O ASSY

IC7606

INPUT 1

AUDIO

INPUT 2

AUDIO

IC7601

SELECTOR

B

IC7602

L/R

IC7603

VOLUME

IC7607

AV1

+L/+R

-L/-R

V+12V

AP2 AP3

+L

-L

+R

-R

V+12V

CN7601

CN5001

AP1

IC5002

L

R

V+3V

V+6.5V

AUDIO AMP ASSY

V+16

IC5003

POWER AMP

+L

-L

+R

CN5003

-R

LO1

CN8703

CN9651

KY1

KEY CONTROL

CN9001

CN8702

ASSY

CN8704

CN8705

LED ASSY

AV6

AV I/O I/F

ASSY

CN2101

KY2

CN9002

CN2102

IC7613

INPUT 1

D-SUB

RGB/Y,Cb,Cr

H,V

IC7610

6dB AMP

SELECTOR

C

HDMI

IC9451

232C

DRIVER

AUDIO

Y,Cb,Cr,H,V,

INPUT 2

HDMI

D

232C

IC6810

RECEIVER

JA9453

COMM SLOT ASSY

CLK,DE

RGB/Y,Cb,Cr

H,V

IC7608

SELECTOR

BUFFER

TXD/

RXD

H,V

CN7605

CN9454

RGB/Y,Cb,Cr

IC7612

DAC

Y,Cb,Cr,H,V,CLK,DE

AV4

COMM SLOT

I/F ASSY

CS5

CN8904

CS3

CN8903 CN8902

IC8707

IF UCOM

V+3.3V_STB

V+3.3V_STB

CS1

CS4

CS2

V+6.5V

V+5V

LED

KEY

232C

CN8905CN8901

AV3

AV2

AV5

RE1

IR RECEIVE

ASSY

CN4901

CN8952

CN7902

VS2

VS4

CN8953CN8955CN8951

VS3

CN8954

VS1VS5

VIDEO

SLOT I/F

ASSY

INPUT 3

IC7801

VIDEO AMP

E

INPUT 4

OUTPUT

INPUT 5

INPUT 3

F

INPUT 4

INPUT 5

IC7802

VIDEO AMP

IC7803

3-1 SEL

PD0278A

PD0278A

L/R

IC6255

IC6107

IC7902

2-1 SEL

6dB AMP

YCbCr

HD/VD

V+13V

V+12V

YCbCr

RGB

HV

V+3V

VIDEO SLOT 2 ASSY

42

1234

PDP-5004

Page 43

SP1

SP TERMINAL

L ASSY

CN9702

SP2

SP TERMINAL

R ASSY

CN9801

5678

A

B

KY4

FRONT KEY

CN9400

ASSY

R9

RGB H/V

CN5701

R2

CN6401CN6402

R13

R3

CN7406

PD6435A

PD6435A

SELECTOR

RGB

RGB

IC5701

IC5801

IC6483

IC6601

SELECTOR

LPF

R5

CN5002

D3

V+1V

_DD

RGB H/V

RGB

IC6401

LPF

C SYNC

V+3V

_DD

G ON

SYNC

IC6602

A/D PLL

IC6001

A/D PLL

IC6694

SYNC SEP

CN7404CN7408

V+6.5V

P8

V+3V

_STB

H/V

H/V

IC6607

SELECTOR

H/V

V+16.5V

IC7004

PE5362A

H/V

TRAP SW

FAN L

FAN R

R1

H/VH/V

CN7402

RGB

RGB

R8 R6

FAN_12V TRAP_SW

IC7101

PD5855A

DRIVER

IC7207

UCOM

CN5801

CN7204

MAIN

H/V

RGB

TXD_MD

RXD_MD

R10

CN7101

C

CN5001

D15

D

R12

H/V

IC6604

SYNC SEP

H/V

IC6607

SELECTOR

CN7405CN7410CN7407

R11

R4

H/V

H/V

H/V

H/V

IC6603