Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

ORDER NO.

ARP3252

PDK-50HW3

HAND WRITING DEVICE

PDK-50HW3

THIS MANUAL IS APPLICABLE TO THE FOLLOWINGMODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PDK-50HW3 UCYVBKE DC power supply Bus-powered from USB port

PDK-50HW3 Z/CN DC power supply Bus-powered from USB port

For details, refer to "Important Check Points for Good Servicing".

T-ZZK MAR. 2005 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

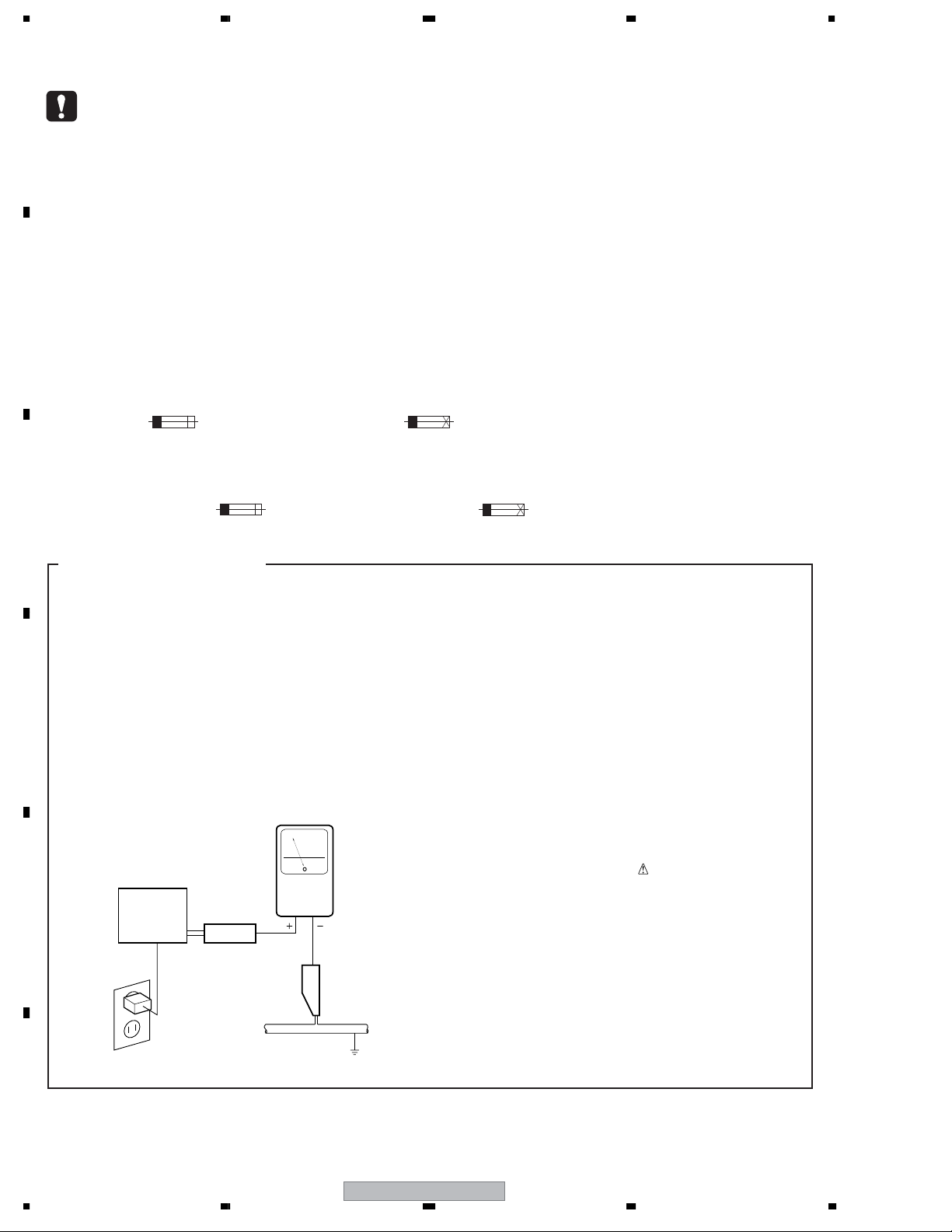

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Leakage

current

E

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

tester

Reading should

not be above

0.5 mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

PDK-50HW3

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

PDK-50HW3

E

F

3

7

8

Page 4

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

D

E

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR................................................................................................................................................. 8

2.3 PEN.......................................................................................................................................................... 10

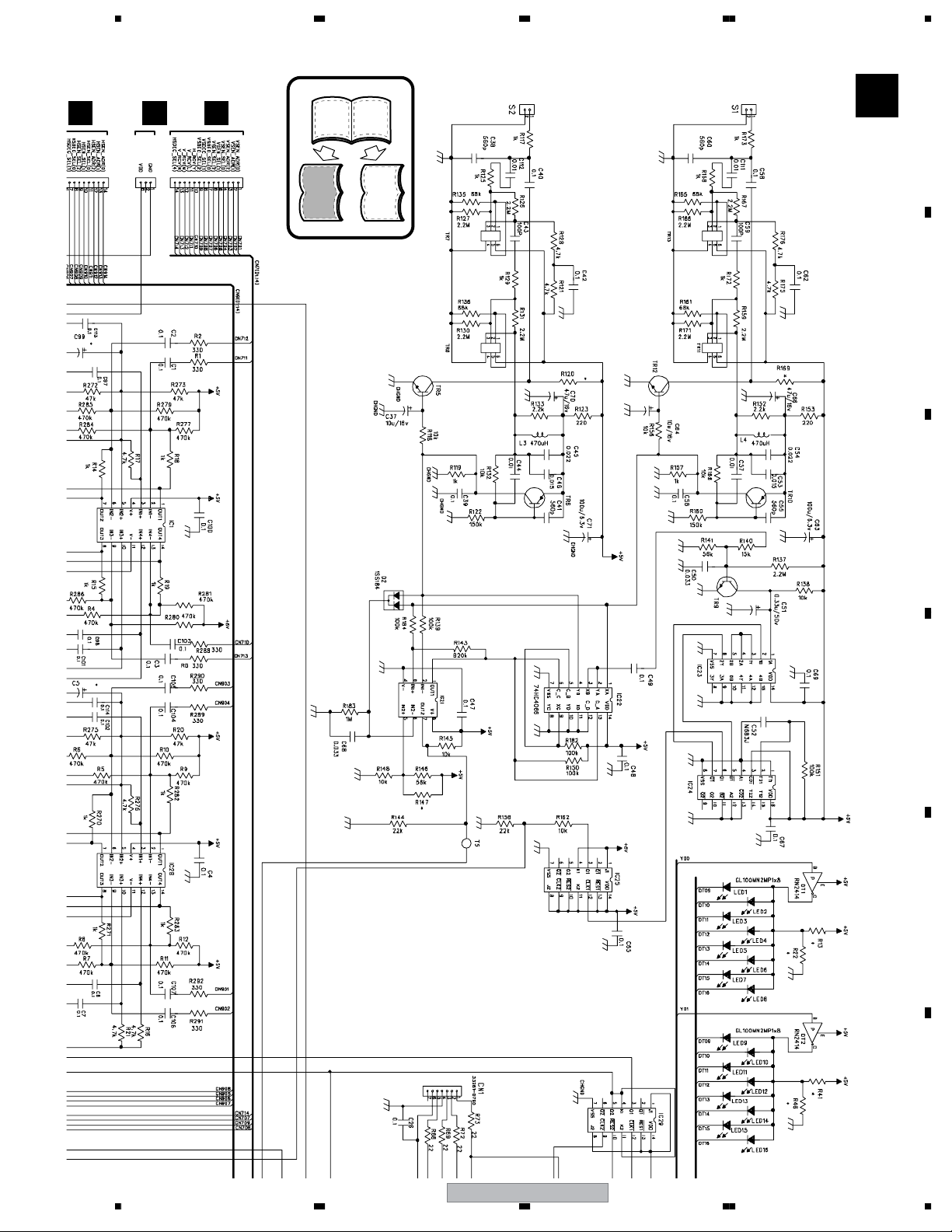

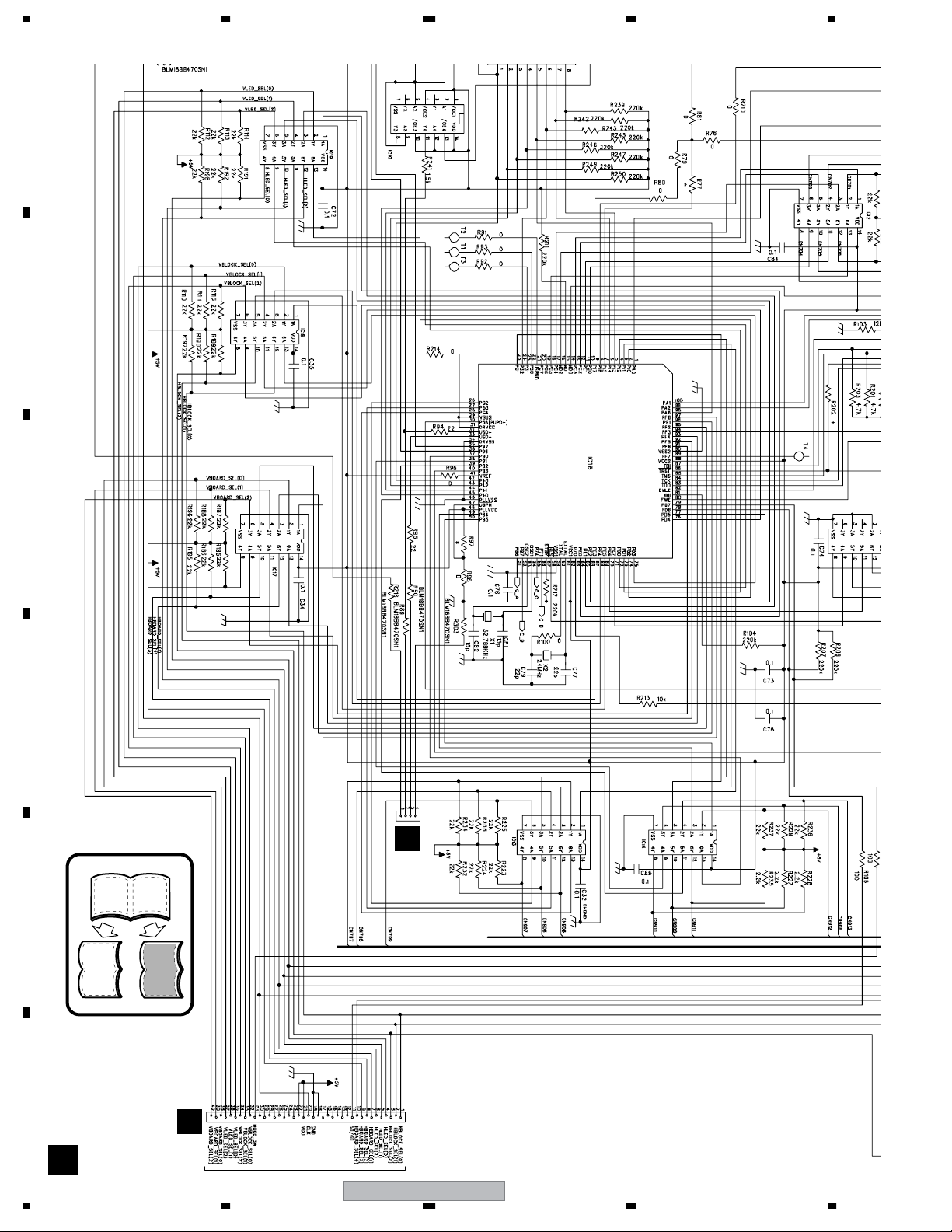

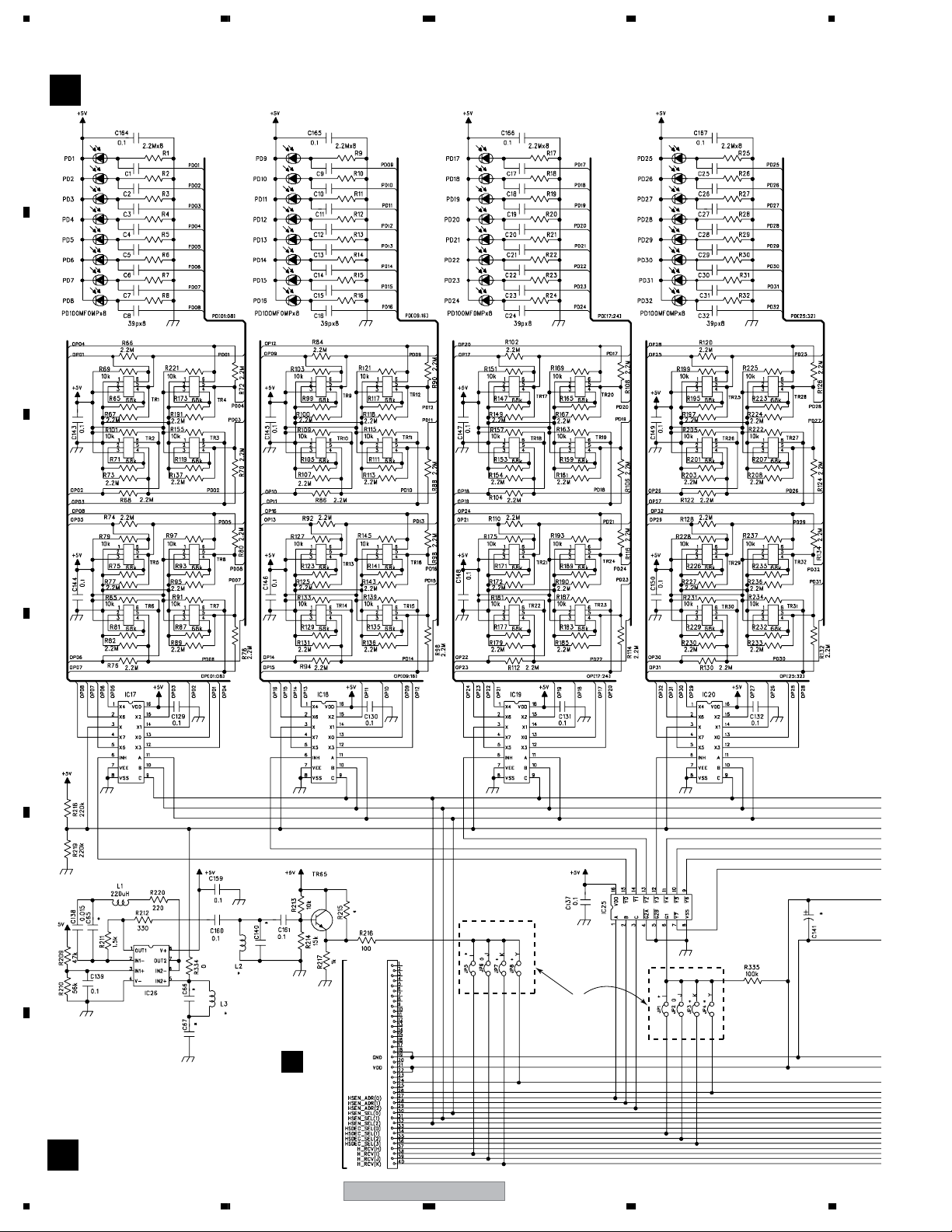

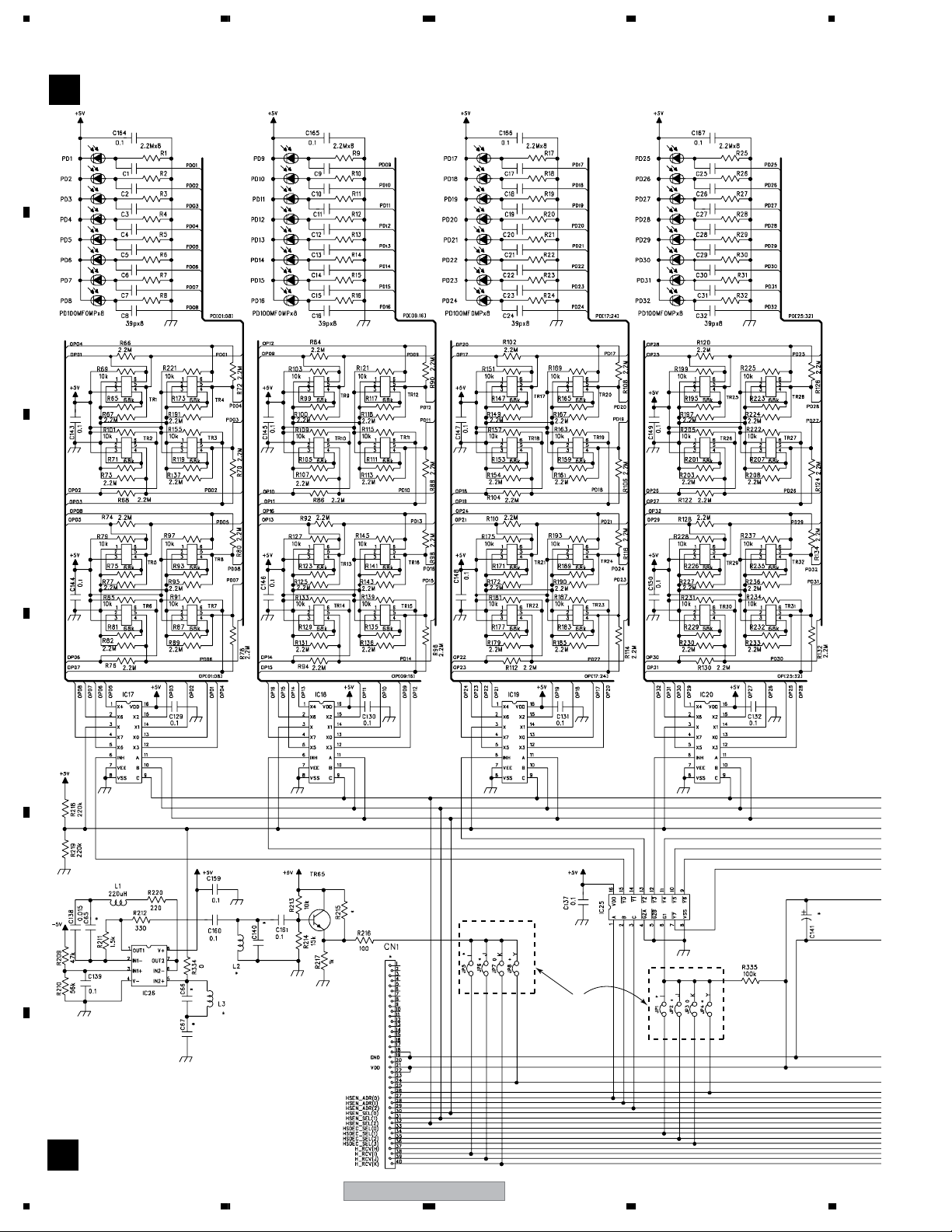

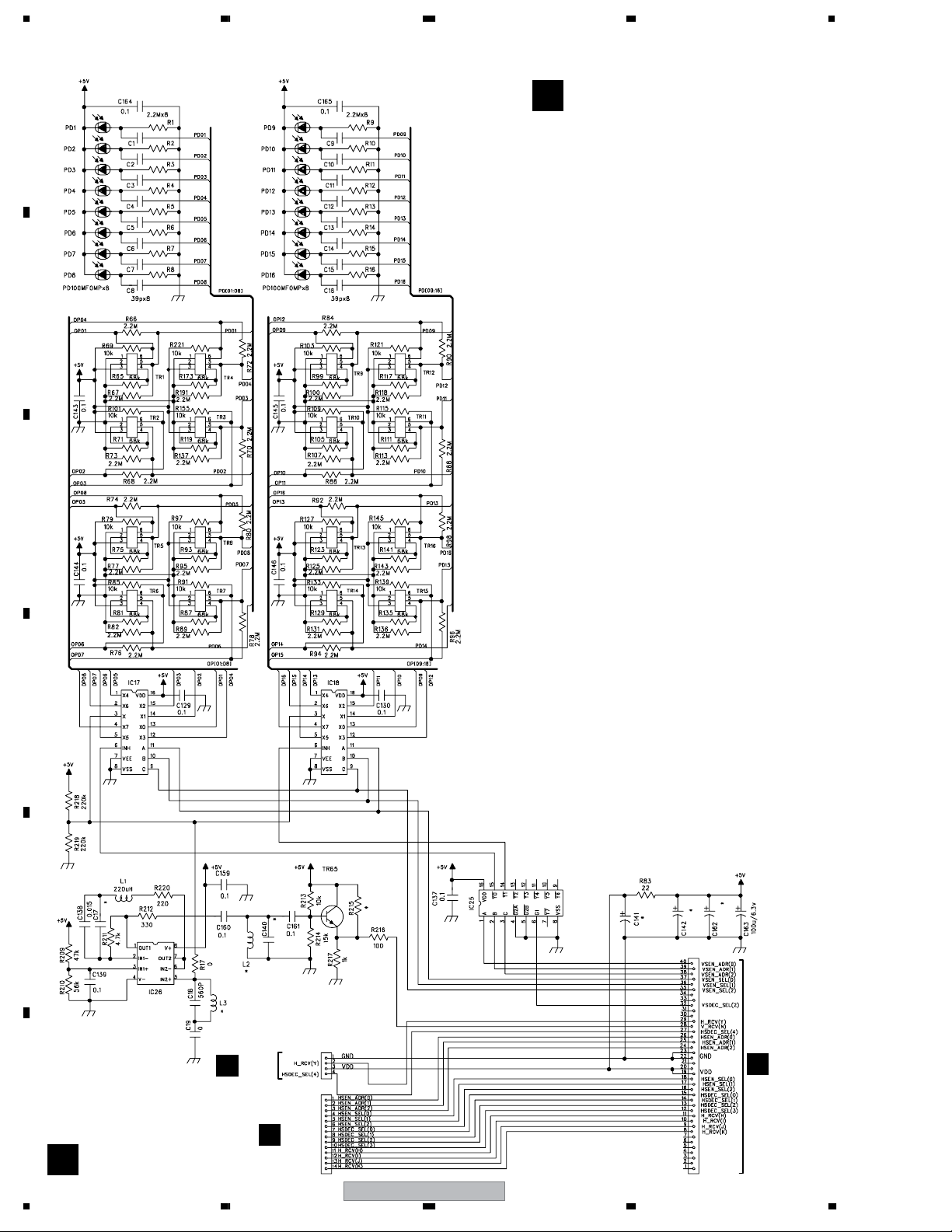

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................12

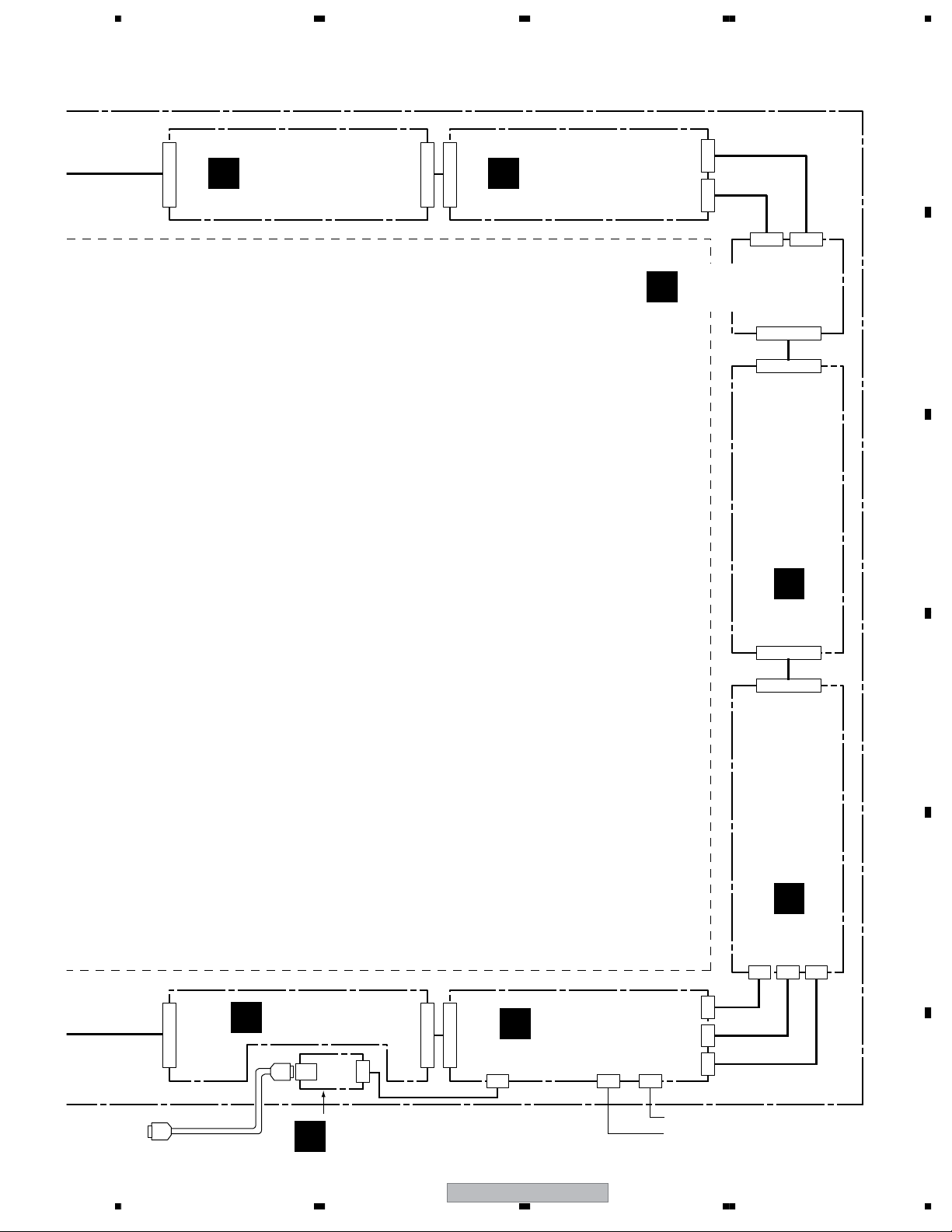

3.1 BLOCK DIAGRAM ................................................................................................................................... 12

3.1.1 OVERALL BLOCK DIAGRAM ........................................................................................................... 12

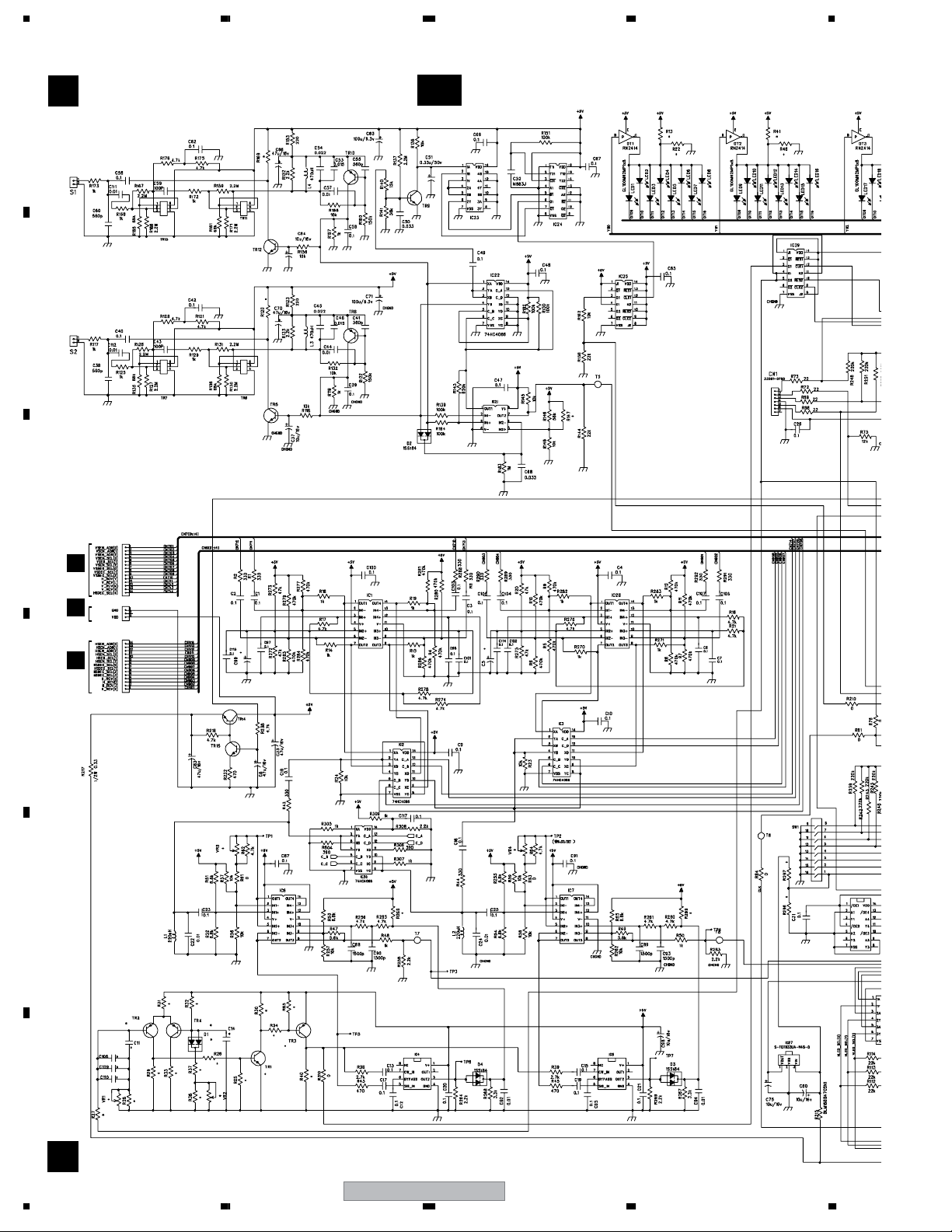

3.1.2 LED AND SENSOR BLOCK DIAGRAM............................................................................................ 14

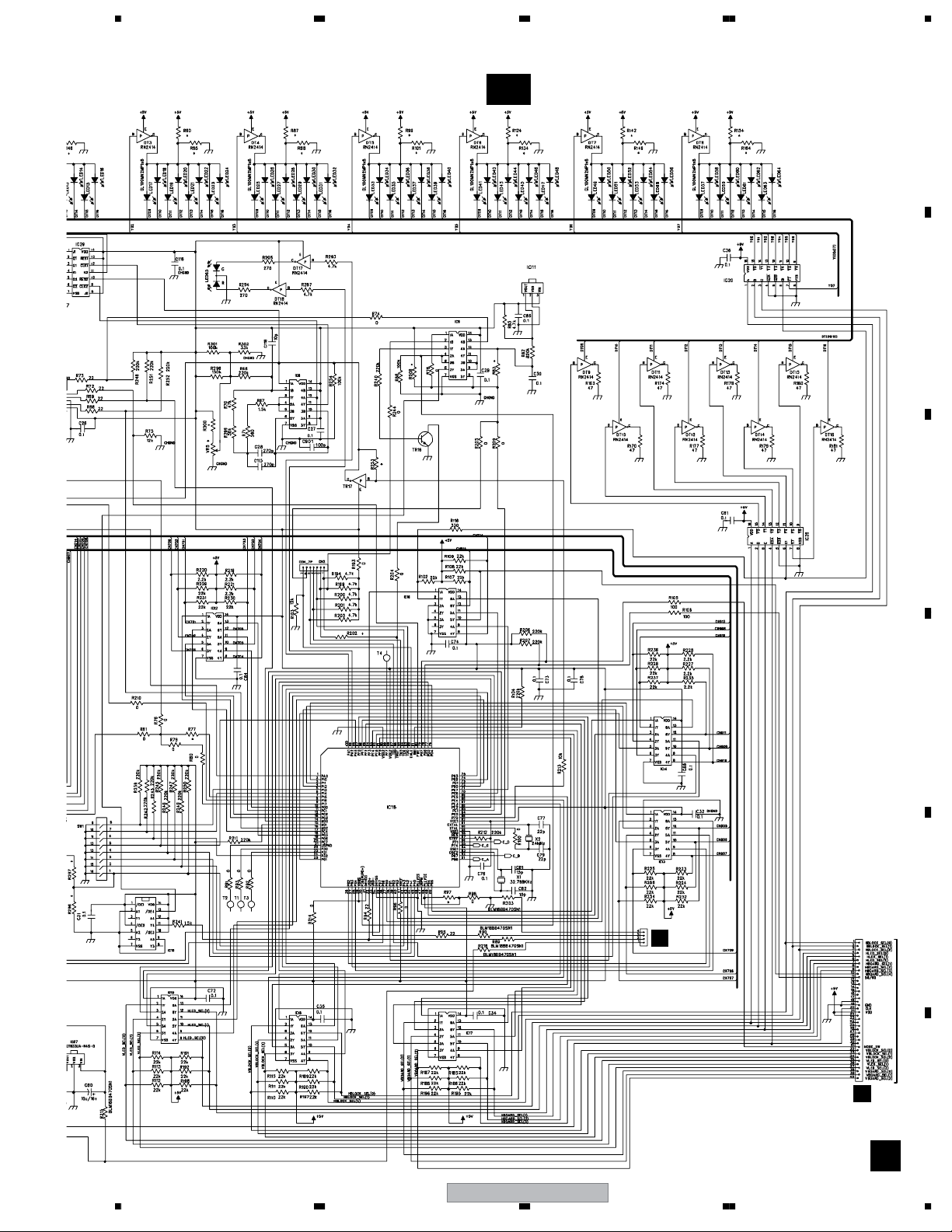

3.2 OVERALL WIRING DIAGRAM................................................................................................................. 16

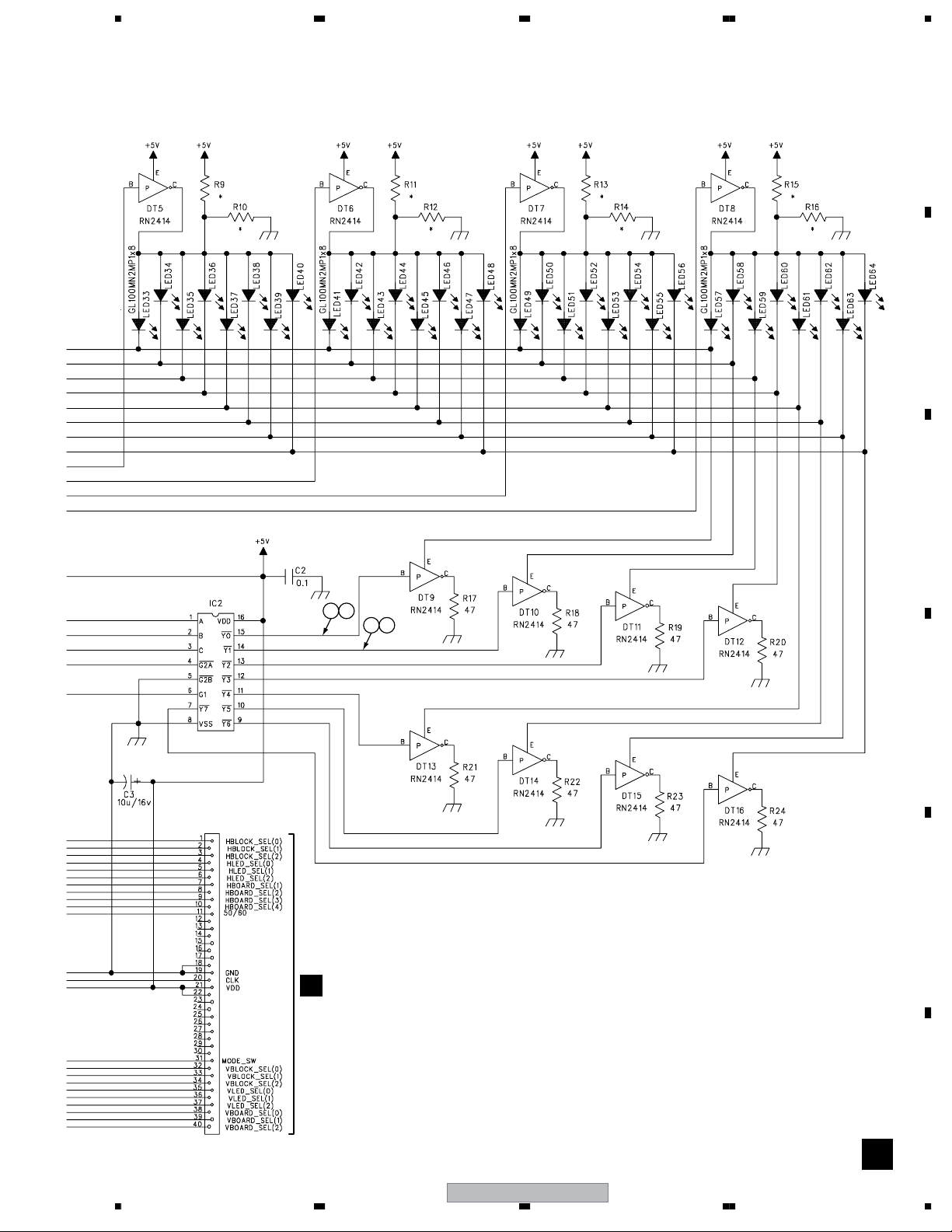

3.3 LED-A ASSY (GUIDE PAGE)................................................................................................................... 18

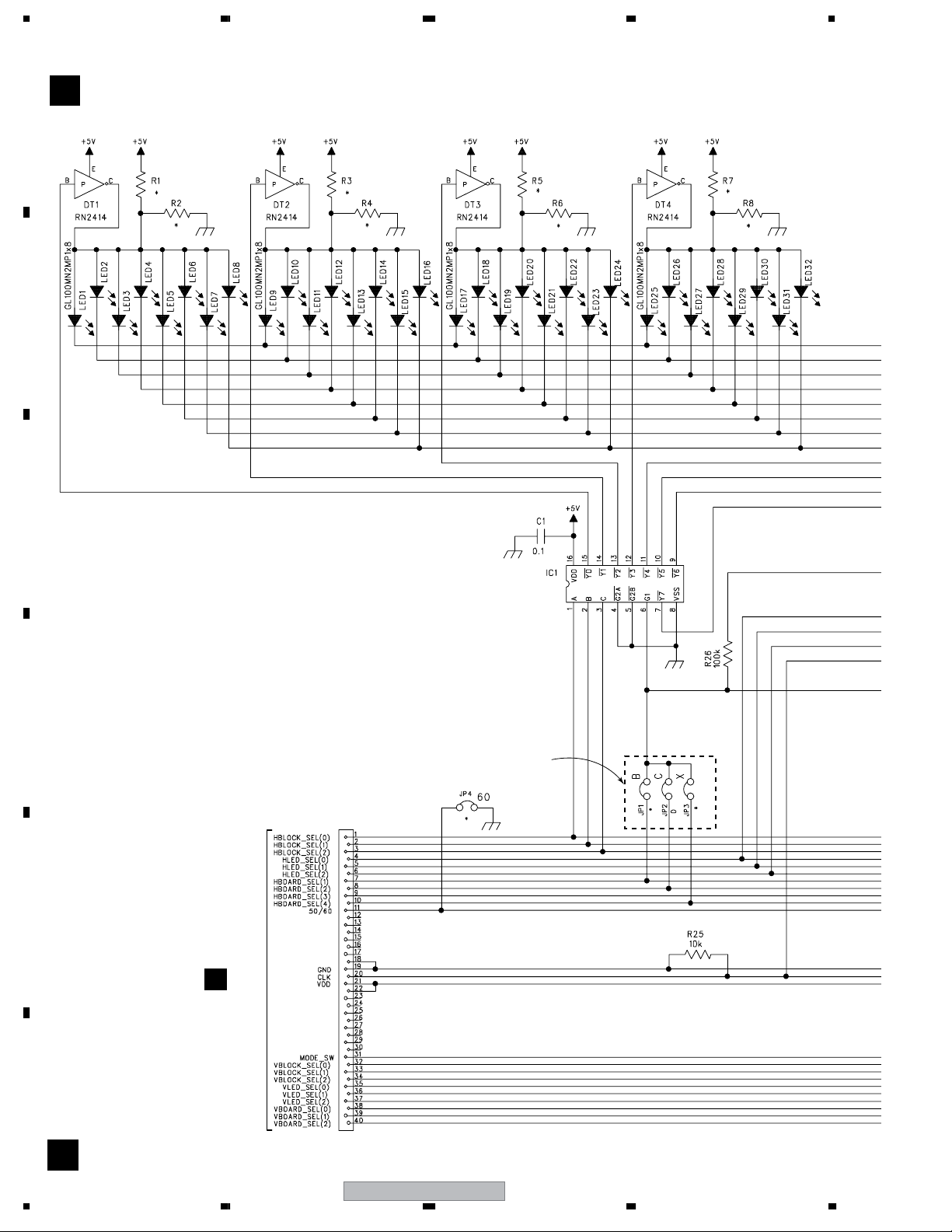

3.4 LED-A ASSY............................................................................................................................................ 20

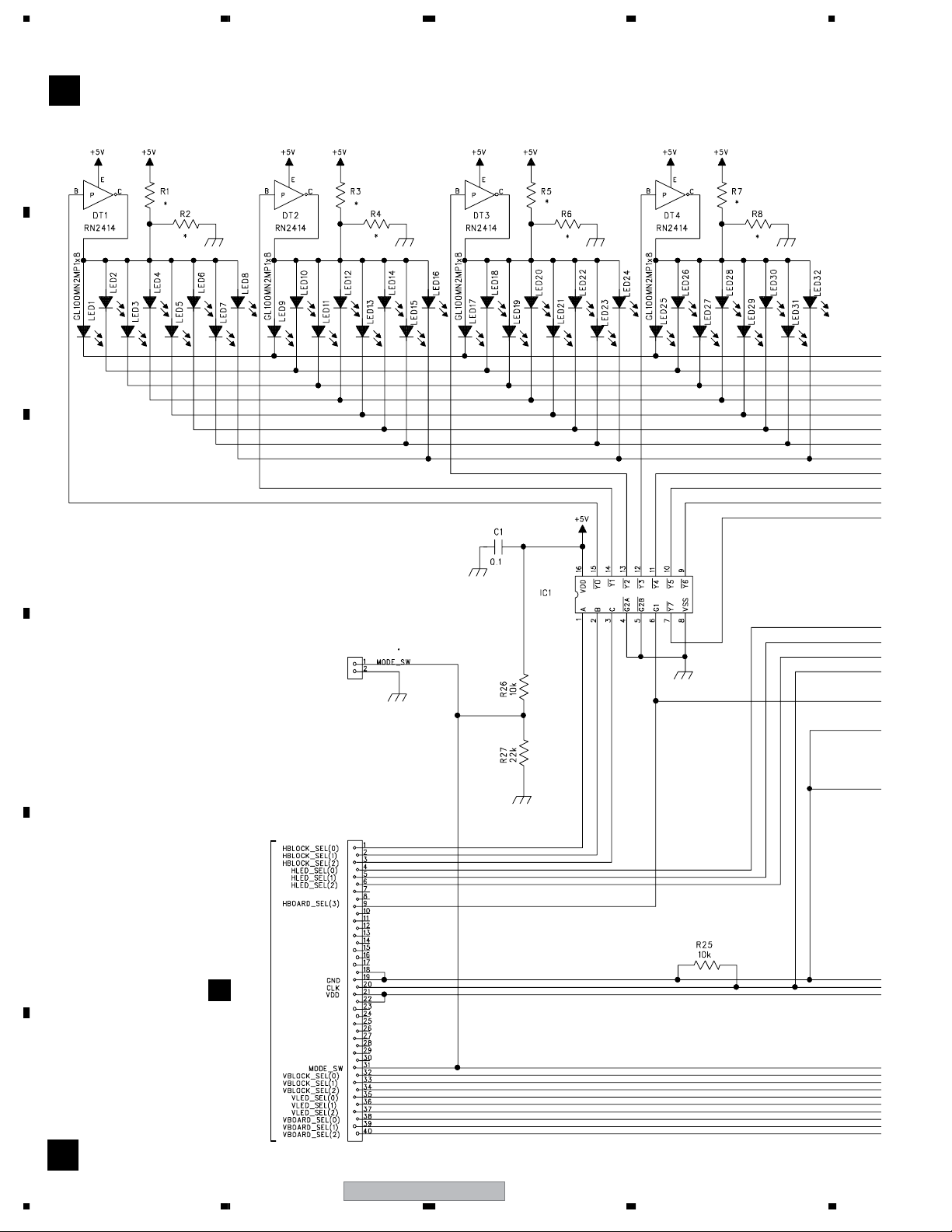

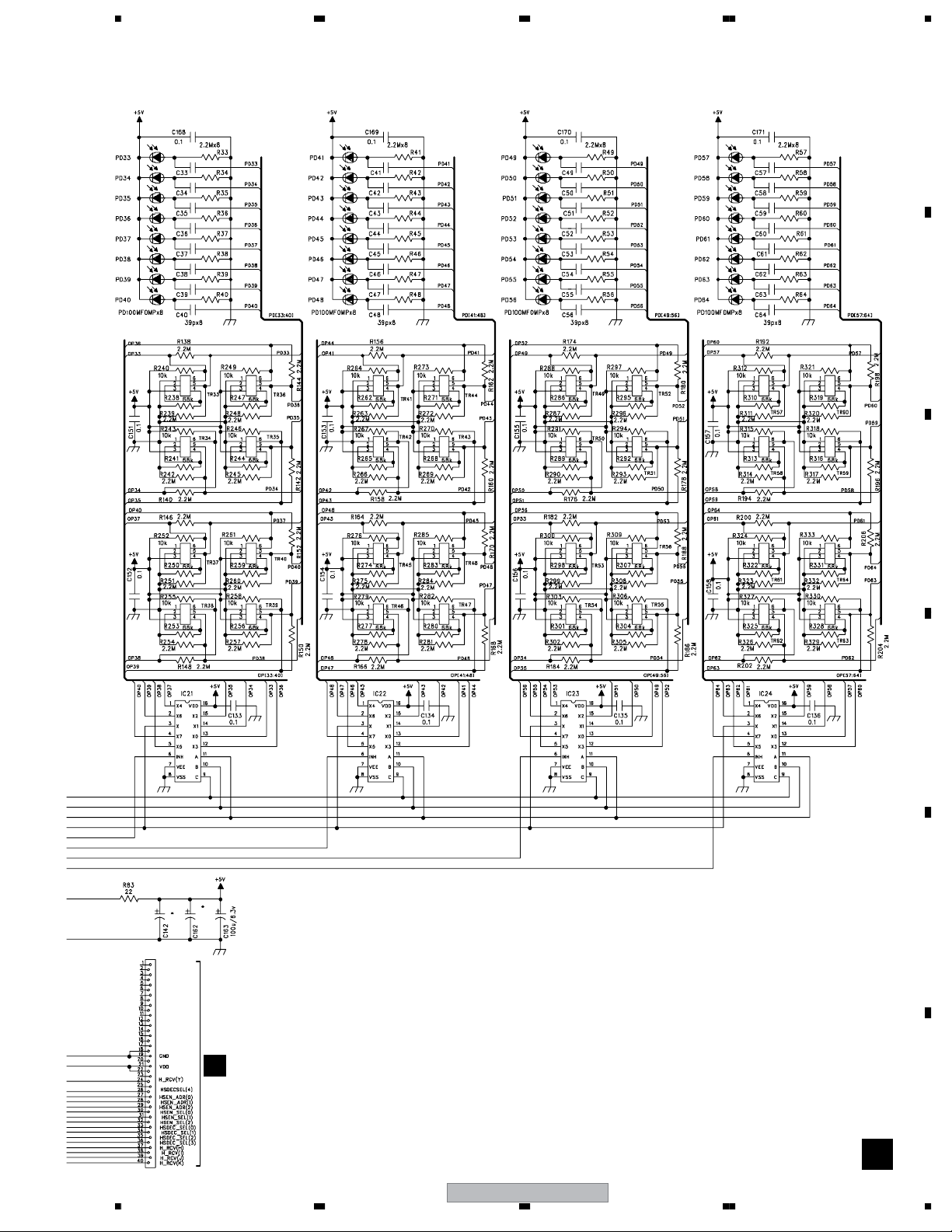

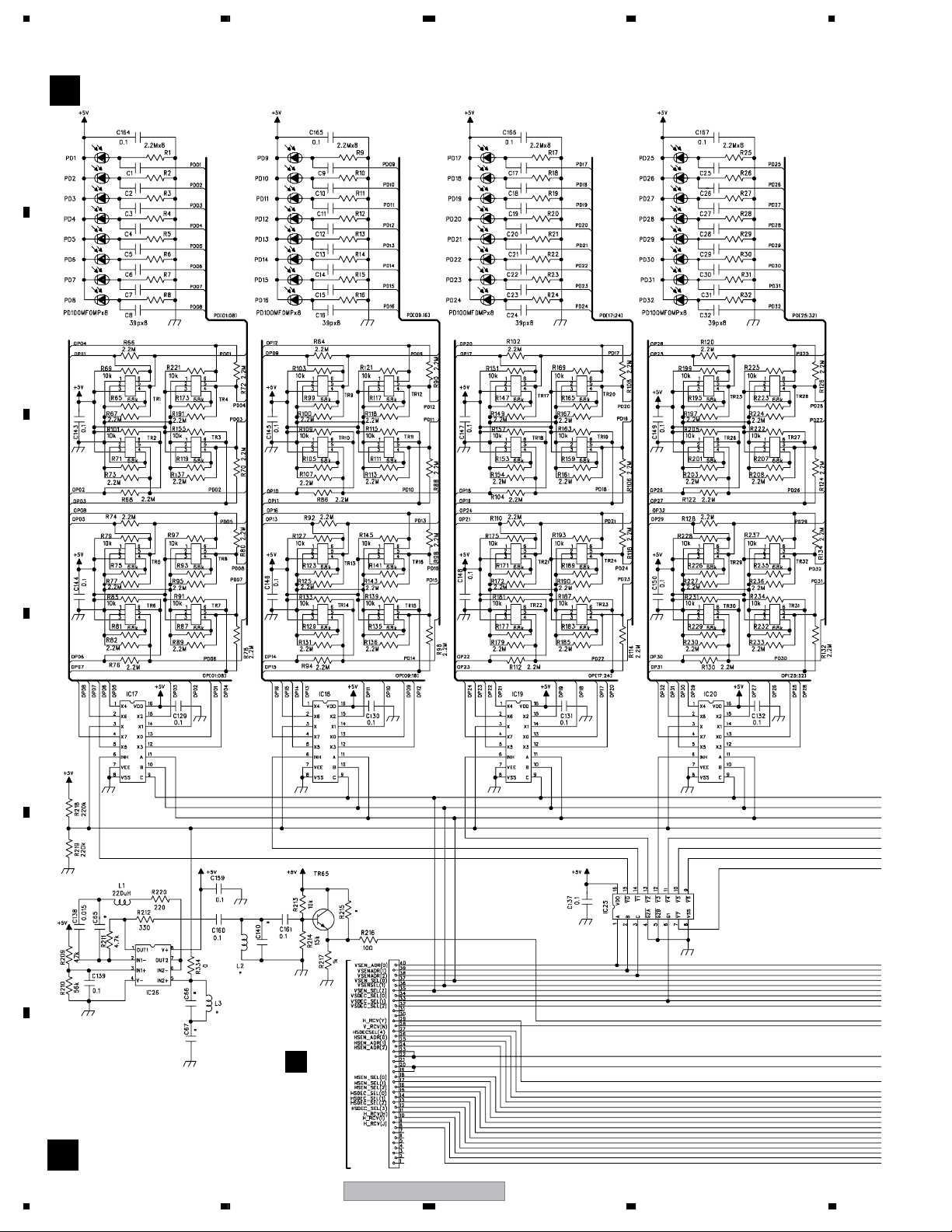

3.5 LED-B ASSY............................................................................................................................................ 24

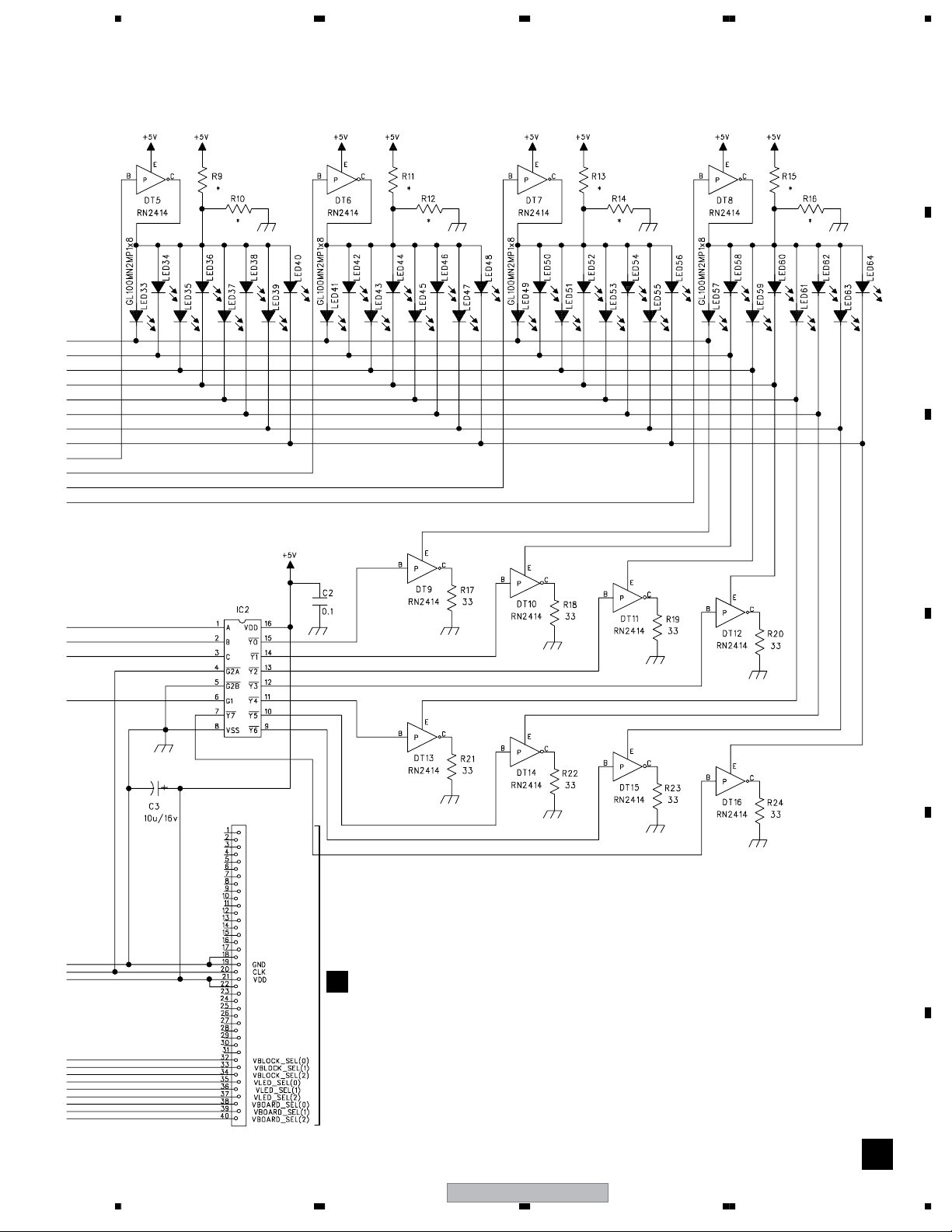

3.6 LED-C ASSY............................................................................................................................................ 26

3.7 LED-D ASSY............................................................................................................................................ 28

3.8 LED-E ASSY............................................................................................................................................ 30

3.9 LED-F ASSY ............................................................................................................................................ 32

3.10 LED-G ASSY ......................................................................................................................................... 34

3.11 SENSOR-H ASSY ................................................................................................................................. 36

3.12 SENSOR-I ASSY ................................................................................................................................... 38

3.13 SENSOR-J ASSY ..................................................................................................................................40

3.14 SENSOR-K ASSY.................................................................................................................................. 42

3.15 SENSOR-L ASSY .................................................................................................................................. 44

3.16 SENSOR-M ASSY ................................................................................................................................. 46

3.17 SENSOR-N ASSY ................................................................................................................................. 48

3.18 USB BOARD ASSY ...............................................................................................................................49

3.19 PEN PCB ASSY..................................................................................................................................... 50

3.20 WAVEFORMS ........................................................................................................................................ 52

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 53

4.1 LED-A ASSY............................................................................................................................................ 54

4.2 LED-B and LED-C ASSYS....................................................................................................................... 56

4.3 LED-D and LED-F ASSYS....................................................................................................................... 58

4.4 LED-E ASSY............................................................................................................................................ 60

4.5 LED-G ASSY ........................................................................................................................................... 62

4.6 SENSOR-H ASSY ................................................................................................................................... 64

4.7 SENSOR-I ASSY ..................................................................................................................................... 66

4.8 SENSOR-J ASSY ....................................................................................................................................68

4.9 SENSOR-K ASSY.................................................................................................................................... 70

4.10 SENSOR-L ASSY .................................................................................................................................. 72

4.11 SENSOR-M ASSY ................................................................................................................................. 74

4.12 SENSOR-N ASSY ................................................................................................................................. 76

4.13 USB BOARD ASSY ...............................................................................................................................77

4.14 PEN PCB ASSY..................................................................................................................................... 78

5. PCB PARTS LIST ........................................................................................................................................... 79

6. ADJUSTMENT ............................................................................................................................................... 86

7. GENERAL INFORMATION............................................................................................................................. 87

7.1 DIAGNOSIS ............................................................................................................................................. 87

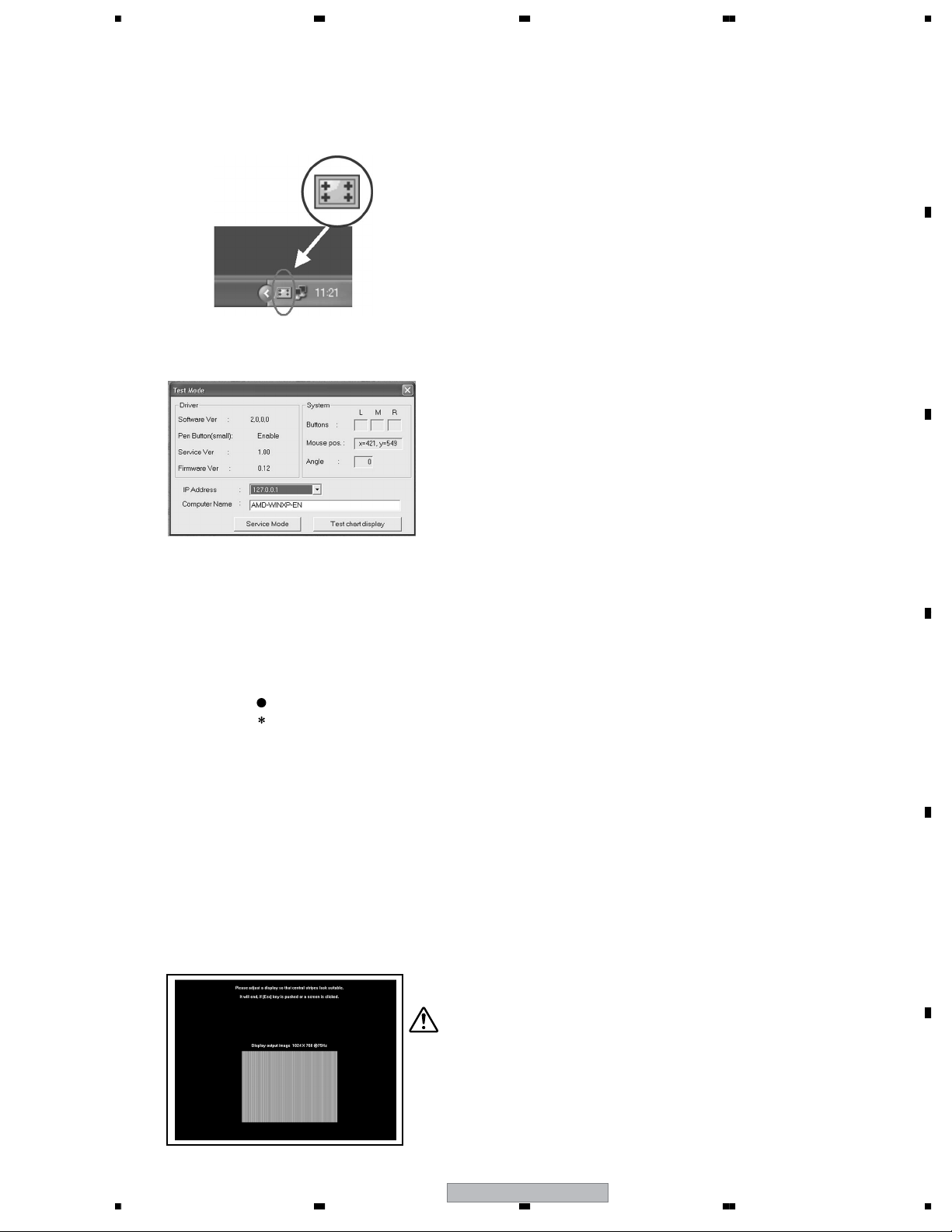

7.1.1 TEST MODE ...................................................................................................................................... 87

7.1.2 SELF TEST FUNCTION (SelfTest) .................................................................................................... 88

7.1.3 INTERNAL DIP SWITCH SETTINGS................................................................................................ 90

7.1.4 OPERATION CHECKS USING EXCHANGEABLE ASSY'S ............................................................. 91

8. PANEL FACILITIES ........................................................................................................................................ 92

F

4

1234

PDK-50HW3

Page 5

5678

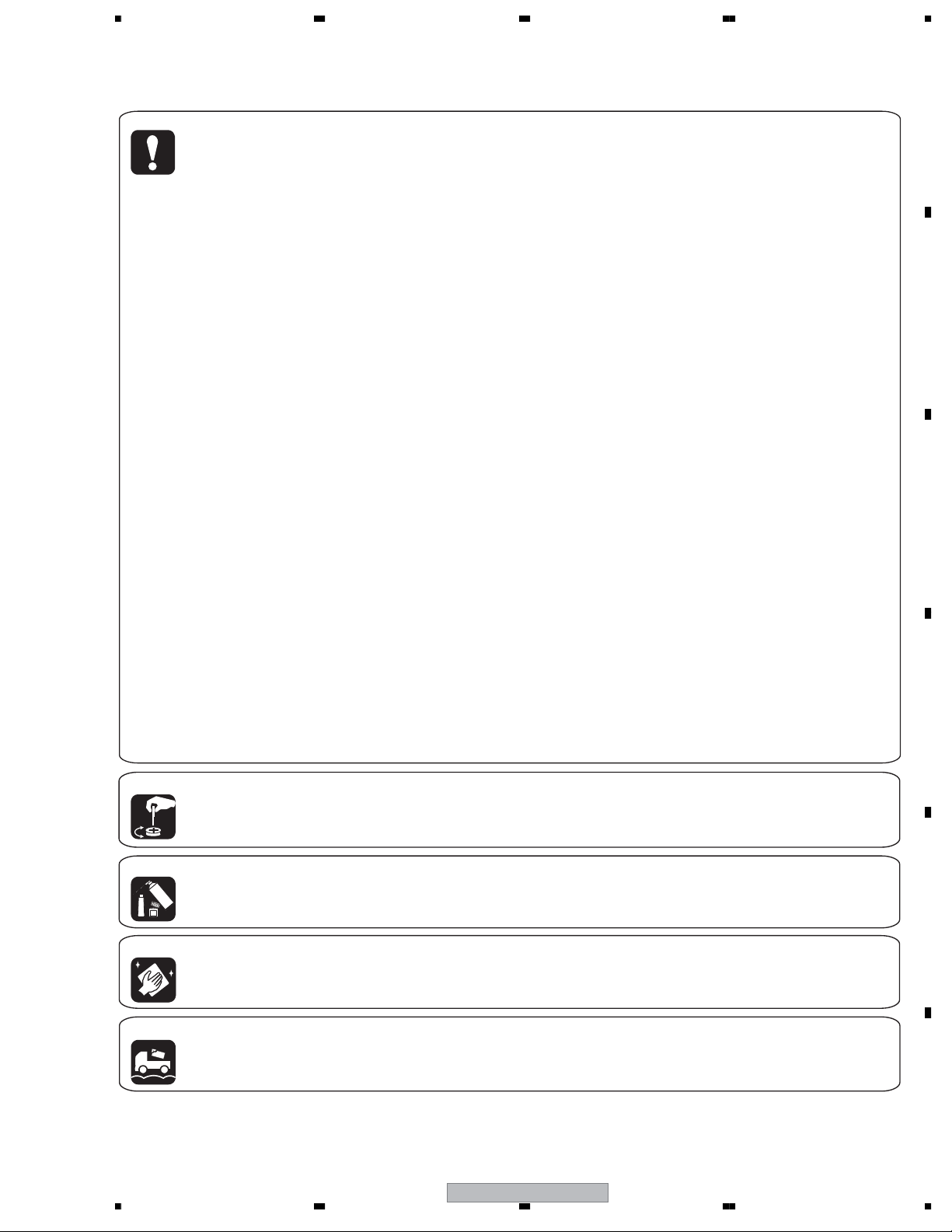

1. SPECIFICATIONS

Scanning system...........................................................................................Infrared scanning

Power indicator..................................................................................................................LED

Interface......................................................................................................................USB 1.1

Power supply..............................................................................Bus-powered from USB port

Power consumption........................................................................................Maximum 2.5W

External dimensions

(including plasma display, excluding pen stand).................1,258 (W) x 758 (H) x 115 (D) mm

Weight (excluding plasma display, including pen stand[0.6 kg]).....................................7.4 kg

Dedicated Pen

Transmission...................................................................................................Ultrasonic wave

Operation switches...............................................................................Pen tip (x1), Body (x2)

Power......................................................................................AAA (LR03) alkaline battery x 1

External dimensions..............................................................................18.5 (W) x 186 (L) mm

Weight (including battery).................................................................................................43 g

Accessories

Pen........................................................................................................................................1

AAA (LR03) alkaline batteries..................................................................................................................2

Replacement pen tips............................................................................................................2

Allen bolt................................................................................................................................1

Pen stand...............................................................................................................................1

Operating Instructions............................................................................................................1

CD-ROM(Driver software disc)..............................................................................................1

Driver Installation Guide.........................................................................................................1

¶ Specifications and appearance may change without notice.

Dimensional Diagram

(View when this unit installed on the PDP-504CMX/PDP-50MXE1)

1258

(excluding the bolt head)

74

115

92

A

B

C

Unit: mm

• Accessories

Pen (x1)

(BZX1287)

AAA (LR03)

alkaline batteries (x2)

Replacement tips (x2)

(BZE2027)

758

120220

Allen bolt (x1)

(SMZ80H200FNI)

Pen stand (x1)

(BZN2398)

Operating Instructions (x1)

CD-ROM(Driver software disc) (x1)

Driver Installation Guide (x1)

D

58

56

E

F

56

PDK-50HW3

5

7

8

Page 6

1234

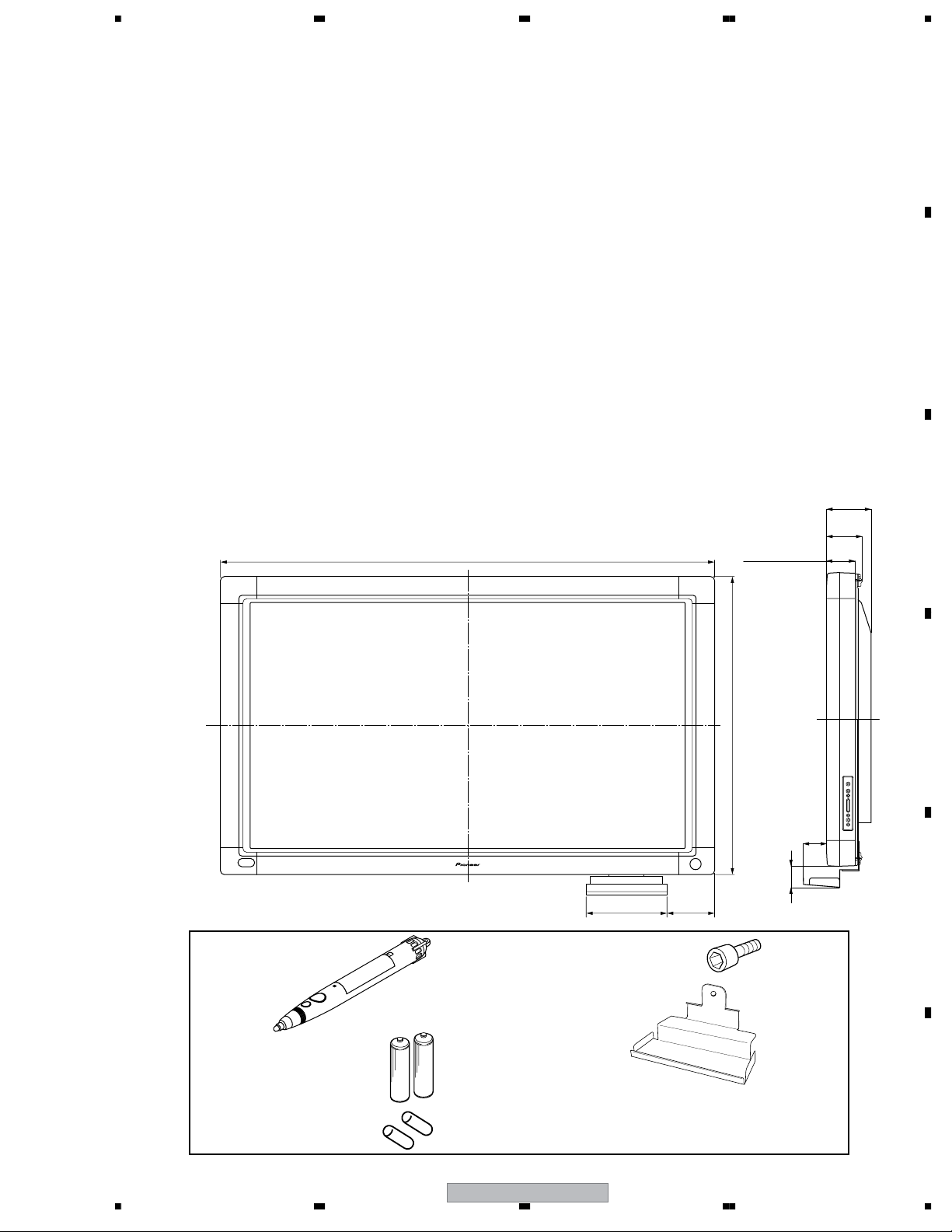

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

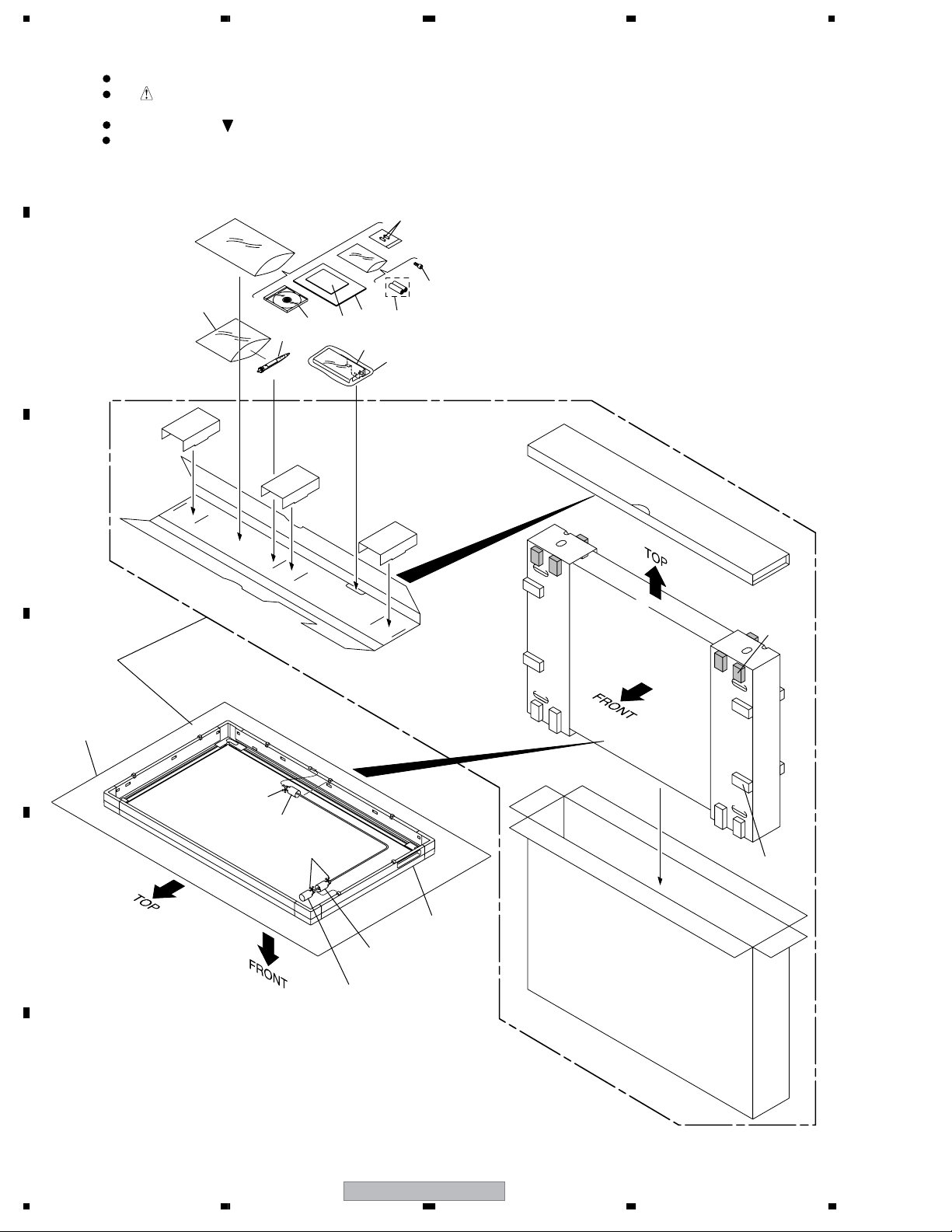

2.1 PACKING

Air Cap Bag 1 (200 x 75)

B

C

3

4

6

7

1

8

2

5

Mirror Mat (350 x 550)

D

Mirror Mat

(1400 x 1800)

E

Pink

Pad

9

vinyl tie

Air Cap Sheet

(150 x 100)

vinyl tie

White

Pad

PDK-50HW3

Air Cap Sheet

(150 x 100)

Air Cap Bag 2

(75 x 100)

F

6

1234

PDK-50HW3

Page 7

5678

PACKING SECTION PARTS LIST

No. Description Part No.

No. Description Part No.

Mark

1Pen BZX1287

2 AAA (LR03) alkaline batteries • • • • •

3 Replacement Tips BZE2027

4 Allen Bolt SMZ80H200FNI

5Pen Stand BZN2398

Mark

6 Operating Instructions See Contrast table (2)

7 CD-ROM (Driver software disc) BZR1372

8Driver Installation Guide BZR1373

9Packing Set See Contrast table (2)

10 Label See Contrast table (2)

(2) CONTRAST TABLE

PDK-50HW3/UCYVBKE and Z/CN types are constructed the same except for the following:

A

Mark No. Description

6 Operating Instructions

(Japanese, English, French, German,

Italian, Dutch, Spanish, Chinese, Korean)

6 Operating Instructions Not used BZR1374

9Packing Set BZH1557 BZH1558

10 Label BZR1383 Not used

PDK-50HW3

/UCYVBKE

BZR1370 Not used

PDK-50HW3

/Z/CN

B

C

D

56

PDK-50HW3

E

F

7

7

8

Page 8

1234

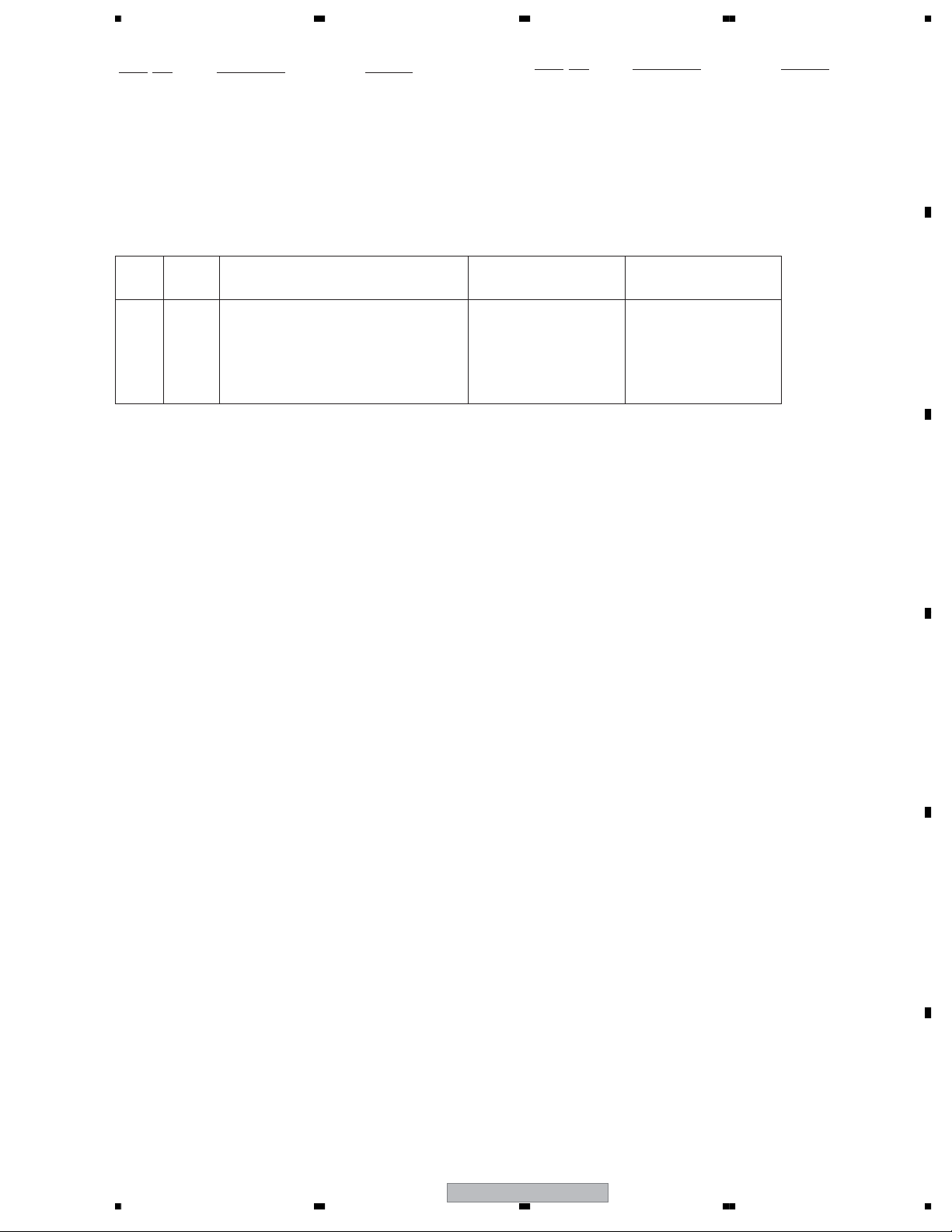

2.2 EXTERIOR

45

14

44

45

45

42

45

36

42

39

45

47

41

35

17

25

39

41

41

51

16

36

45

1

15

37

A

30

13

32

12

45

36

46

L

O

M

B

C

46

N

46

2

45

44

42

41

42

16

34

3

4

45

D

A

47

42

B

26

C

41

41

29

45

24

5

6

39

45

44

42

47

42

H

46

I

8

D

39

E

33

41

45

42

9

10

45

44

42

47

42

41

52

16

J

K

G

11

29

45

42

E

F

45

30

7

31

36

28

16

40

F

8

27

PDK-50HW3

1234

Page 9

5678

Wiring Diagram

14

18

N

21

22

18

A

1

19

15

43

A

O

49

50

48

38

B

2

D

4

18

20

23

B

12

21

L

H

8

E

5

EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 LED-A Assy BZW1509

2 LED-B Assy BZW1510

3 LED-C Assy BZW1511

4 LED-D Assy BZW1512

5 LED-E Assy BZW1513

6 LED-F Assy BZW1514

7 LED-G Assy BZW1515

8 SENSOR-H Assy BZW1516

9 SENSOR-I Assy BZW1517

10 SENSOR-J Assy BZW1518

11 SENSOR-K Assy BZW1519

12 SENSOR-L Assy BZW1520

13 SENSOR-M Assy BZW1521

14 SENSOR-N Assy BZW1522

15 USB BOARD Assy BZW1523

16 Sensor Holder AZN2425

17 Filter LED AZN2429

18 3P Connector Assy BZD1402

19 4P Connector Assy BZD1403

20 10P Connector Assy BZD1404

21 14P Connector Assy BZD1405

22 14P Connector Assy (Red) BZD1406

23 USB Cable BZD1411

24 Escutcheon BZN2376

25 Corner (Left Lower) BZN2377

26 Corner (Left Upper) BZN2379

27 Corner (Right Upper) BZN2380

No. Description Part No.

Mark

28 Filter RC BZN2381

29 Filter UL BZN2382

30 Filter LR BZN2383

31 Frame (Right) BZN2385

32 Frame (Left) BZN2386

33 Frame (Upper) BZN2388

34 Frame (Lower) BZN2389

35 Indicator Window BZN2399

36 Hook BZN2400

37 USB Cable Clamp BZN2401

38 Spacer BZN2403

39 Locking Fixture Assy BZN2404

40 Corner (Right Lower) BZN2406

41 Screw BZB1476

42 Screw BZB1477

43 Screw BZB1478

44 Screw BPZ30P080FTC

45 Screw PMB40P080FTB

NSP 46 Screw PMA30P060FTC

NSP 47 Screw PMA30P040FTC

NSP 48 Washer WC30FTC

NSP 49 Washer WS30FTC

NSP 50 Nut NA30FTC

51 SS Sensor L BZP1025

52 SS sensor R BZP1026

C

D

E

F

56

PDK-50HW3

9

7

8

Page 10

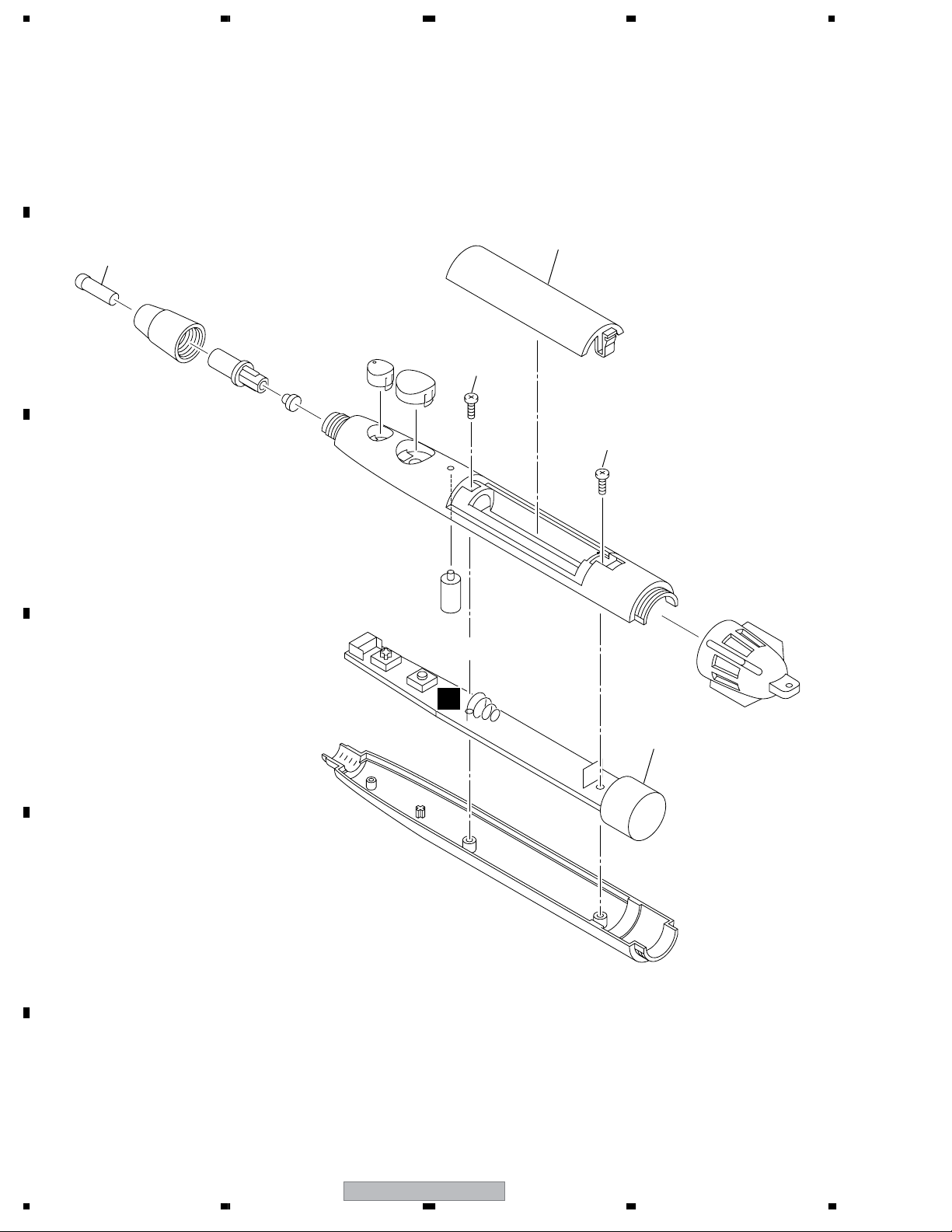

2.3 PEN

A

B

1234

2

3

4

4

C

D

E

P

1

F

10

1234

PDK-50HW3

Page 11

5678

PEN SECTION PARTS LIST

No. Description Part No.

Mark

1 PEN PCB Assy BZW1524

2 Battery Cover BZN2392

3Pen Tip BZE2027

NSP 4 Screw PBZ20P050FTB

A

B

C

D

E

56

PDK-50HW3

F

11

7

8

Page 12

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

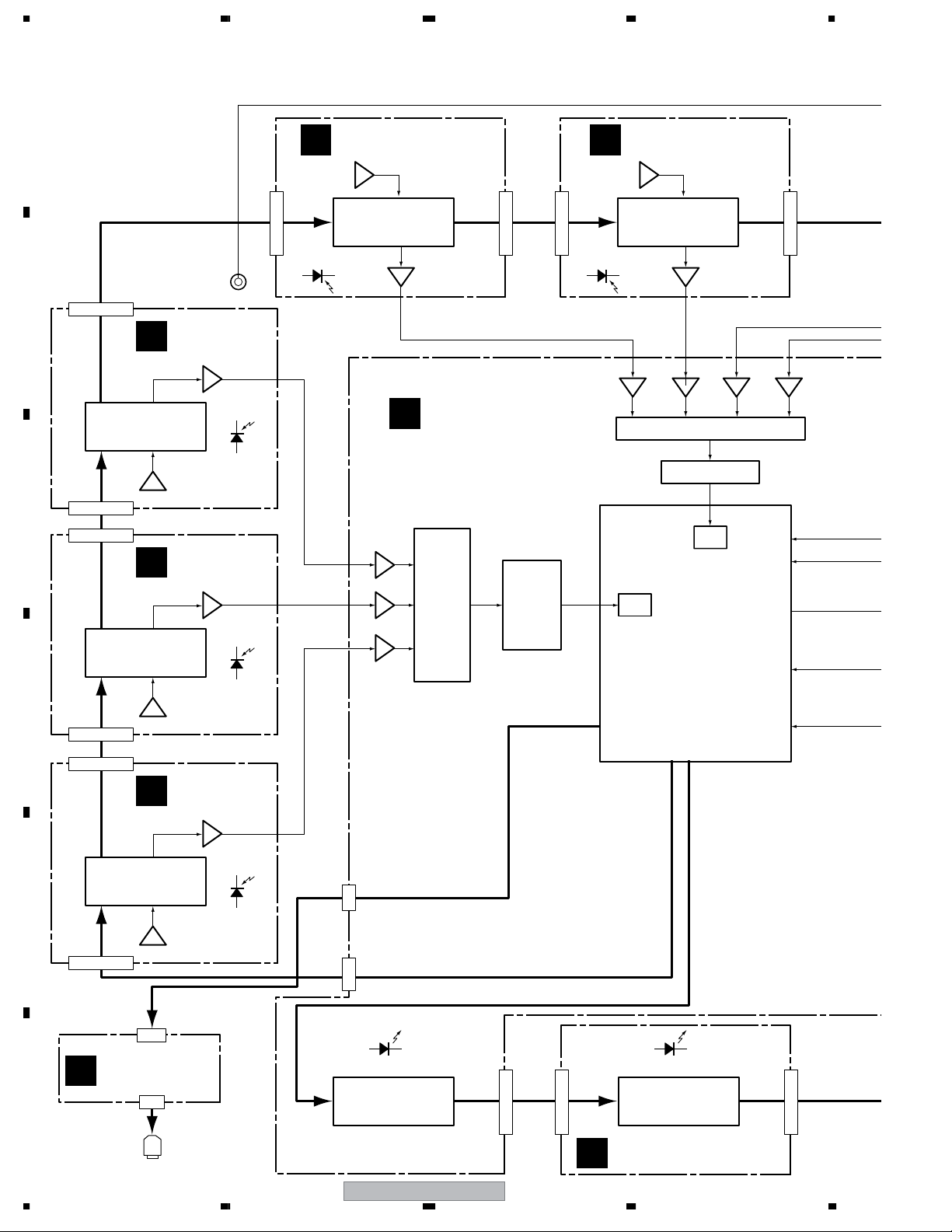

3.1.1 OVERALL BLOCK DIAGRAM

A

SENSOR-H ASSY

H

Amp

CN5,

CN6

Horizontal decoding,

sensor and address

selector

64 IR sensors

Ultra Sonic MIC

B

CN2,

CN3

Vertical decoding,

sensor and address

selector

CN4

C

CN1

Vertical decoding,

sensor and address

selector

D

CN2

SENSOR-N

N

ASSY

Amp

SENSOR-M

M

ASSY

Amp

Buffer

16 IR

sensors

Buffer

64 IR

sensors

Amp

Amp

Amp

Buffer

LED-A ASSY

A

Vertical

Sensor

Selector

CN1

64 IR sensors

Detection

SENSOR-I ASSY

I

Amp

CN4

Horizontal decoding,

sensor and address

selector

Horizontal Sensor Selector

A/D

MAIN CPU

Buffer

Amp

Detection

A/D

CN1

Amp AmpAmp

CN1

Vertical decoding,

sensor and address

selector

E

CN4CN6

USB BOARD

O

ASSY

F

USB CABLE

12

1234

SENSOR-L

L

ASSY

Amp

CN2

CN1

Buffer

64 IR

sensors

CN3

CN7-CN9

64 IR LEDs

Horizontal Board,

Block and LED

selector

PDK-50HW3

CN4

H & V sens_adr

H & V sens_sel

H & V sdec_sel

CN1

B

64 IR LEDs

Horizontal Board,

Block and LED

selector

LED-B ASSY

H & V block_sel

H & V LED_sel

H & V board_sel

CN4

Page 13

5678

A

SENSOR-J ASSY

J

CN4

Horizontal decoding,

sensor and address

selector

64 IR sensors

POWER indication

DIP switch

Amp

Buffer

CN1

Ultra Sonic

Receiver Amp

Frequency

judgement

SENSOR-K ASSY

K

CN4

Horizontal decoding,

sensor and address

selector

64 IR sensors

Ultra Sonic

Receiver Amp

Amp

Carrier

Buffer

LED-G

G

ASSY

16 IR LEDs

LED-F

F

ASSY

64 IR LEDs

Ultra Sonic MIC

B

Vertical Board,

Block and LED

selector

CN1

C

CN4

Vertical Board,

Block and LED

selector

CN1

C

64 IR LEDs

Horizontal Board,

Block and LED

selector

LED-C ASSY

CN4

CN1

D

56

64 IR LEDs

Horizontal Board,

Block and LED

selector

LED-D ASSY

PDK-50HW3

CN5,CN6

7

LED-E

E

ASSY

64 IR LEDs

PEN/

NORMAL

Vertical Board,

Block and LED

selector

CN2,CN3

CN1

CN4

8

D

E

F

13

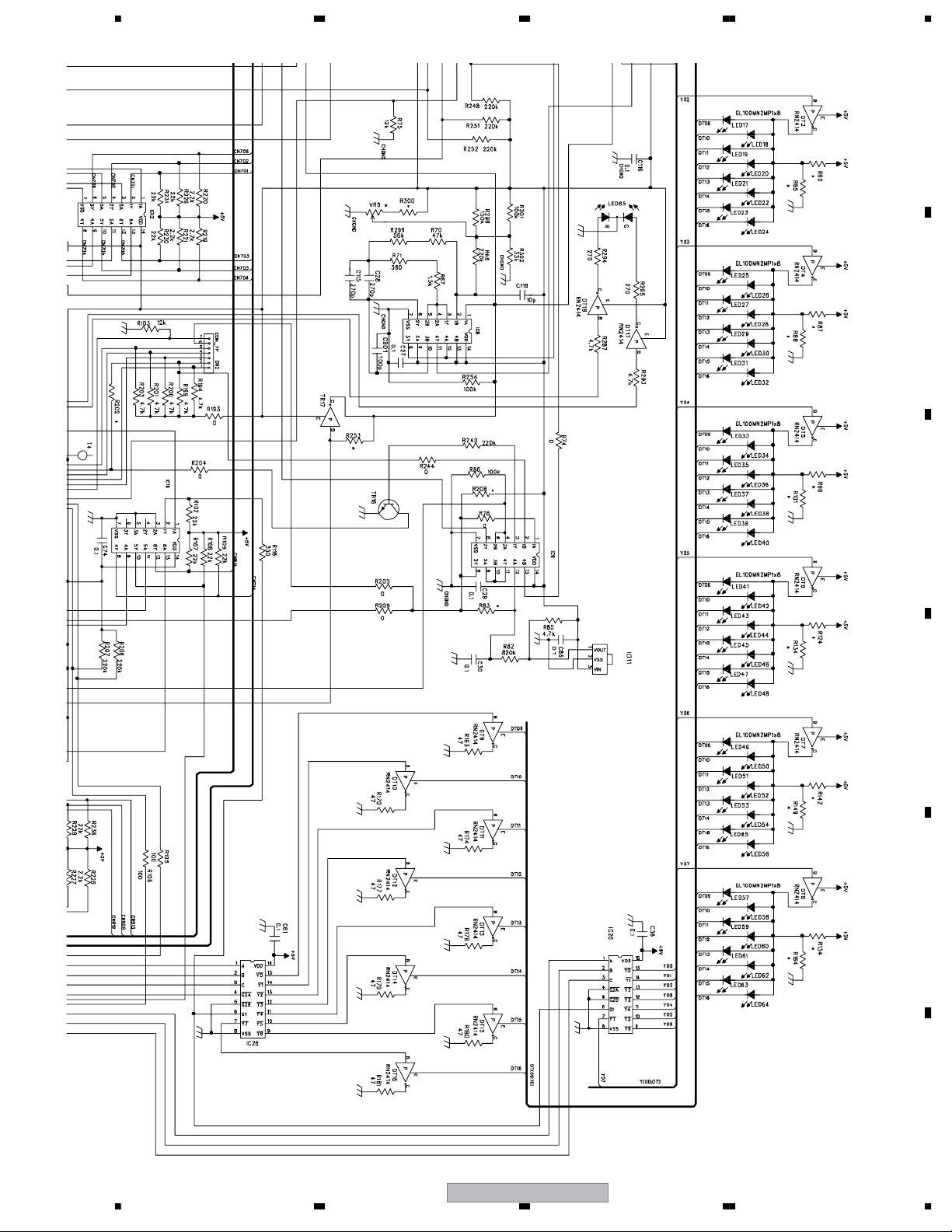

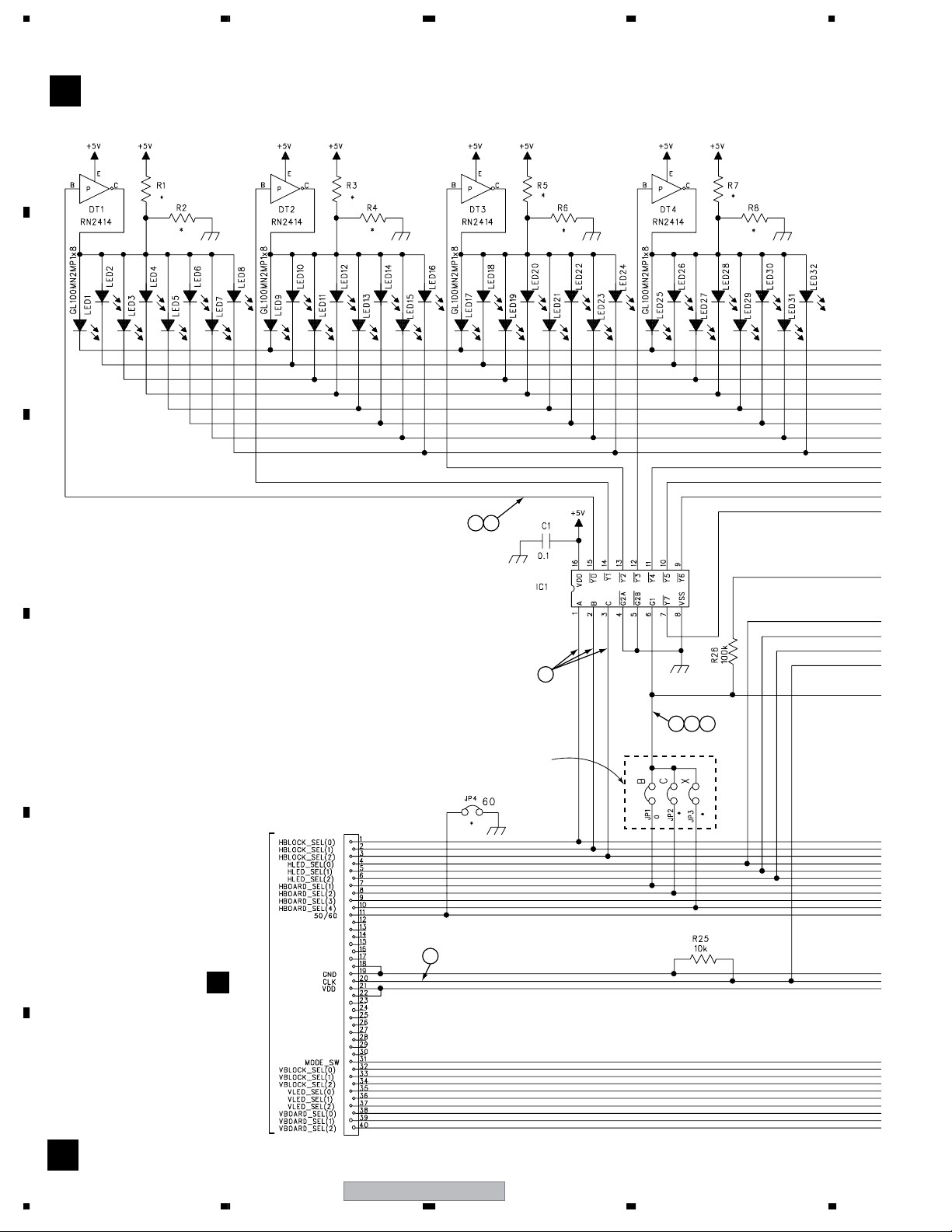

Page 14

1234

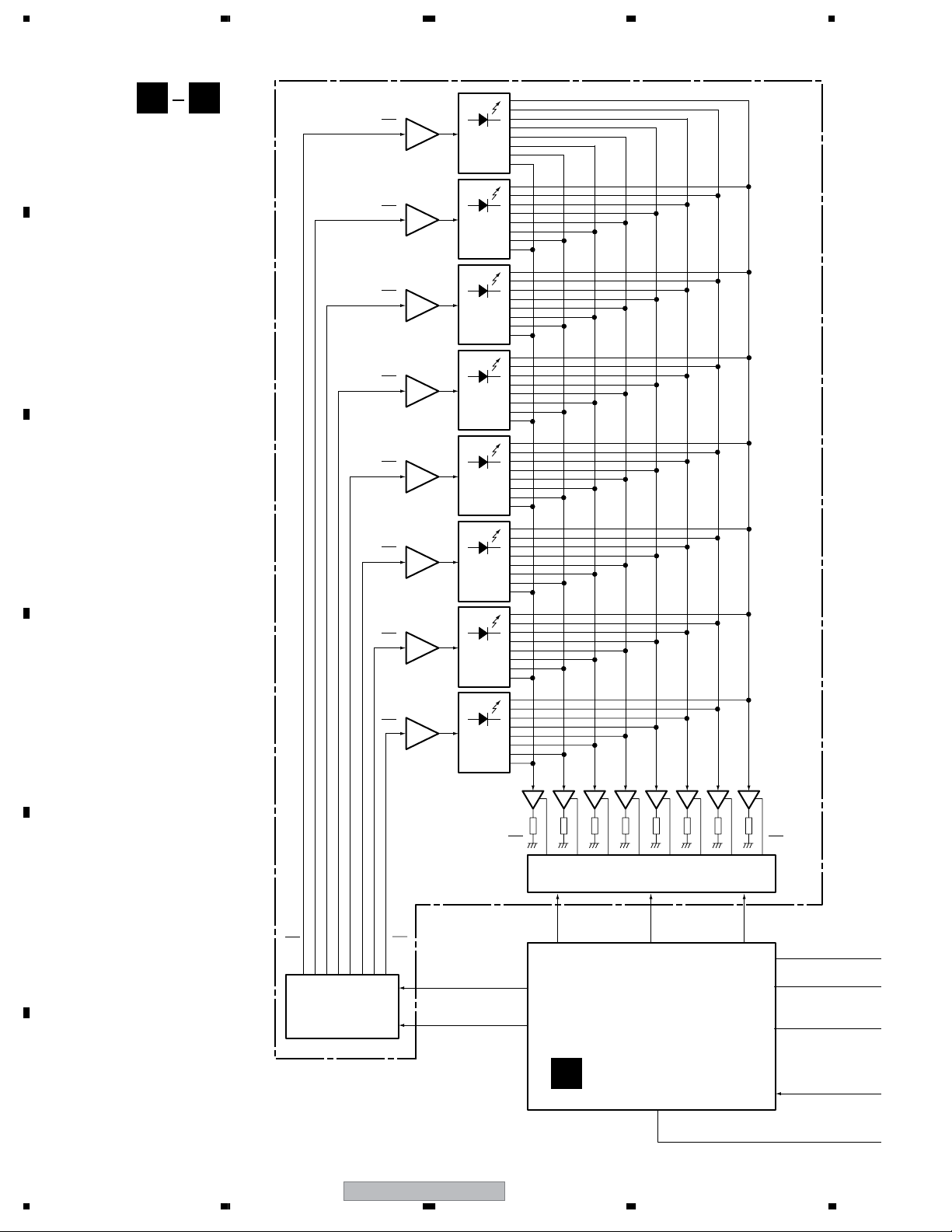

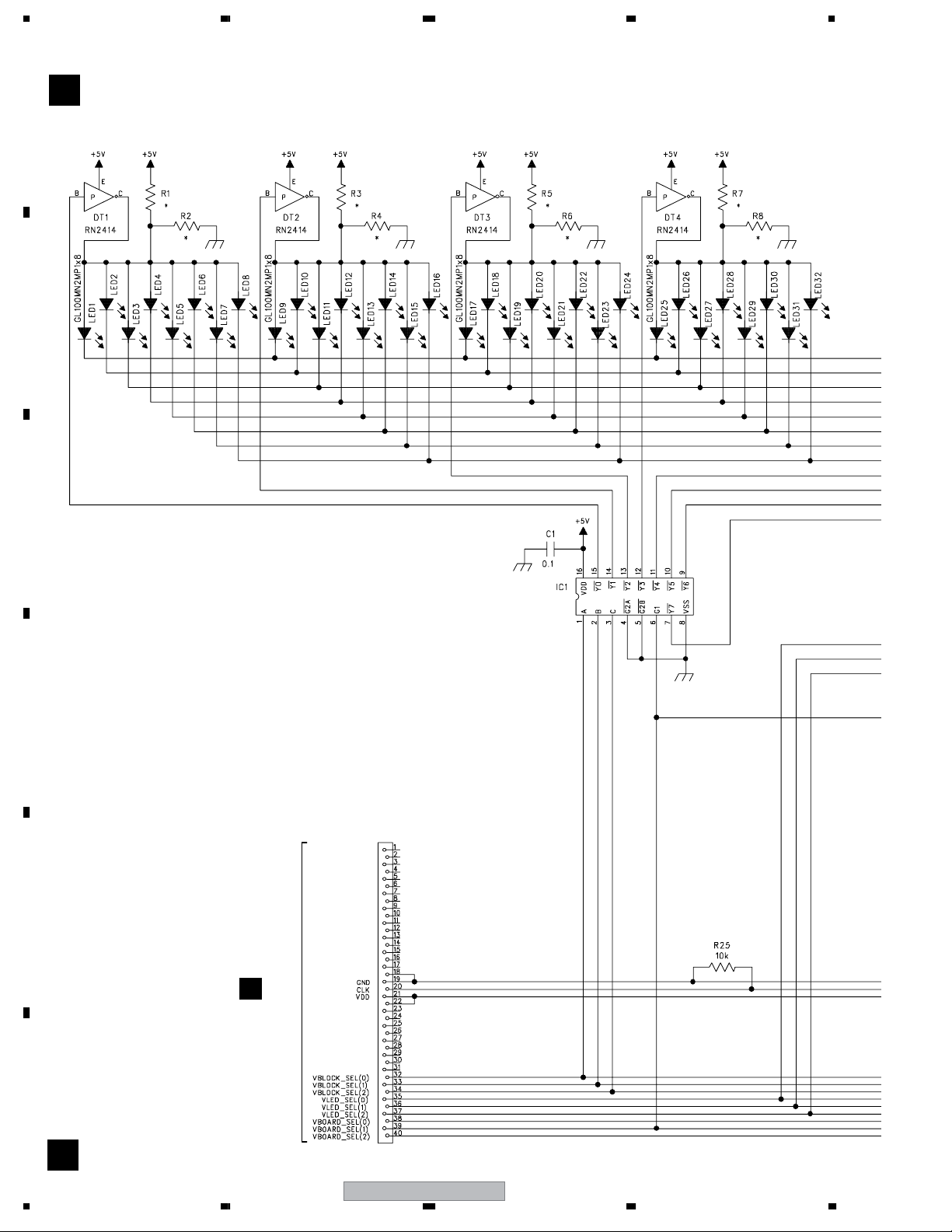

3.1.2 LED AND SENSOR BLOCK DIAGRAM

A

A G

LED-A ASSY –

LED-G ASSY

The illustration shows the block

diagram of the basic LED formation

(applicable to LED-A to LED-G Assys).

For both horizontally and vertically

formatted boards, the block structure is

the same. If any of the three problems

listed below are encountered, use the

B

checkpoints listed below.

• If the unit length of the board is a

problem

For a horizontally formatted board,

the HBOARD_SEL signal may not

be correct. Check the signal.

For a vertically formatted board,

the VBOARD_SEL signal may not

be correct. Check the signal.

• When there is a problem within the

8 LED unit

For a horizontally formatted board,

C

the HBLOCK_SEL signal may not

be correct. Check the signal.

For a vertically formatted board,

the VBLOCK_SEL signal may not

be correct. Check the signal.

Y7

Y6

Y5

Y4

Y3

Y2

DT8

DT7

DT6

DT5

DT4

DT3

LED

(x8)

LED

(x8)

LED

(x8)

LED

(x8)

LED

(x8)

LED

(x8)

• When there is a problem with the

8 LED sensor cycle

For horizontally and vertically

formatted boards, the LED_SEL

signal may not be correct. Check

the signal.

D

E

Y7

3 to 8 line

decoder / invertor

IC1

Y1

Y0

DT2

DT1

Y0

LED

(x8)

LED

(x8)

Y0 Y7

LED Block select

(0, 1, 2)

LED Board select

3 to 8 line decoder / invertor

LED Clock

94.75kHz

IC2

LED Board

select

UCOM

IC15

LED select

(0, 1, 2)

LED-A ASSY

A

F

14

1234

PDK-50HW3

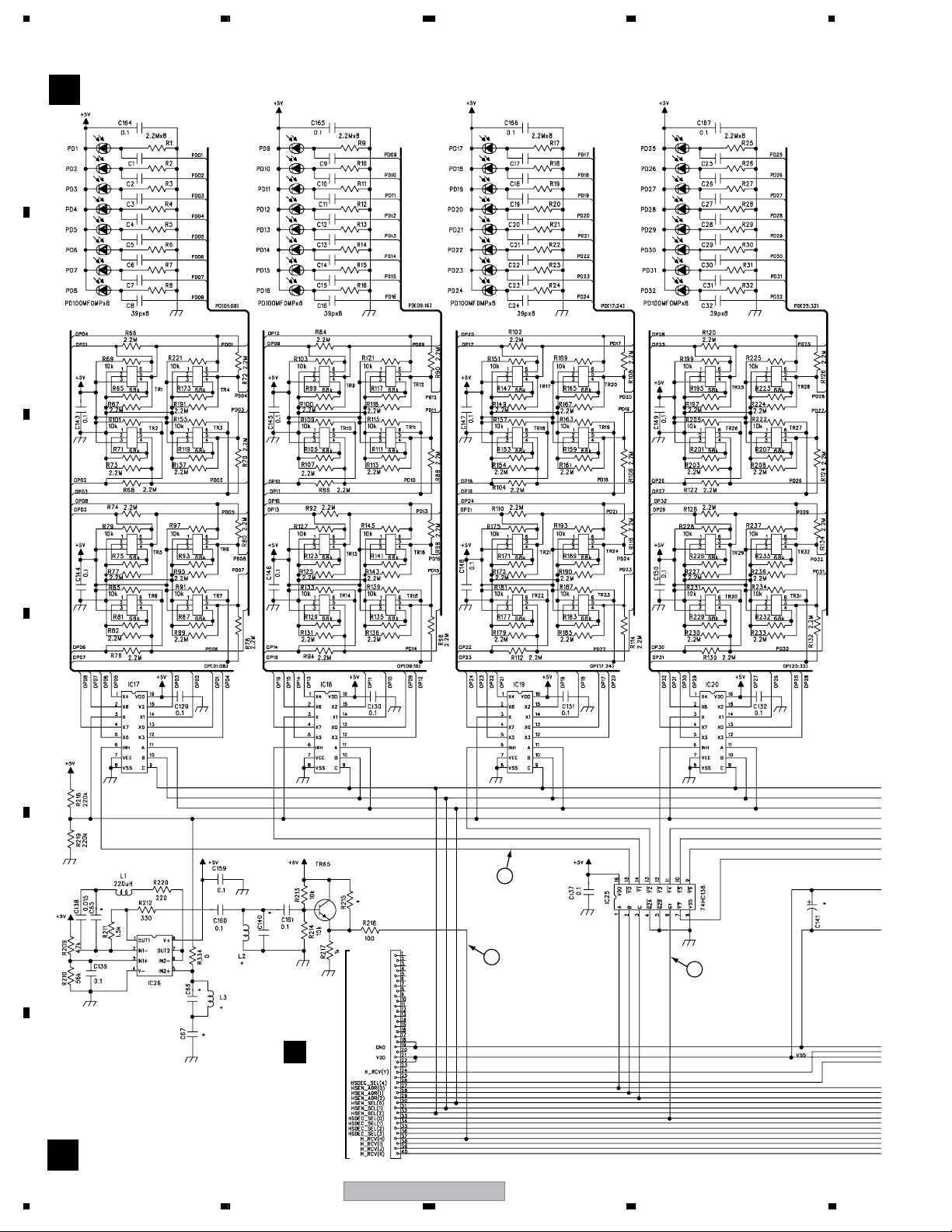

Page 15

5678

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Sensor

(x8)

+5V

Amp

Amp

Amp

Amp

Amp

Amp

Amp

Amp

Scanner

demux

IC24

Scanner

demux

IC23

Scanner

demux

IC22

Scanner

demux

IC21

Scanner

demux

IC20

Scanner

demux

IC19

Scanner

demux

IC18

Scanner

demux

IC17

Y7

Y6

Y5

Y4

Y3

Y2

Y1

Y0

H N

SENSOR-H ASSY – SENSOR-N ASSY

The illustration shows the block diagram of the sensor board

(applicable to SENSOR-H to SENSOR-N Assys).

For both horizontally and vertically formatted boards, the block

structure is the same. If any of the three problems listed below are

encountered, use the checkpoints listed below.

• If the unit length of the board is a problem

For a horizontally formatted board, the HSDEC_SEL or H_RCV

signal may not be correct. Check the signal.

For a vertically formatted board, the VSDEC_SEL or V_RCV

signal may not be correct. Check the signal.

• When there is a problem within the 8 sensor unit

For a horizontally formatted board, the HSEN_ADR signal may

not be correct. Check the signal.

For a vertically formatted board, the V HSEN_ADR signal may

not be correct. Check the signal.

• When there is a problem with the 8 LED sensor cycle

For a horizontally formatted board, the HSEN_SEL signal may

not be correct. Check the signal.

For a vertically formatted board, the VSEN_SEL signal may not

be correct. Check the signal.

A

B

C

D

Sensor select

(0, 1, 2)

Sensor Board select

Sensor Address select

(0, 1, 2)

X (RCV out)

TP

Adjustable amp

RCV Board select (0, 1)

56

3 to 8 line

decoder / invertor

IC25

4 channel analog

demultiplexer

IC2, IC3

LED-A ASSY

A

Y0

Y7

RCV data from other boards (X0, X1,...)

PDK-50HW3

E

F

15

7

8

Page 16

1234

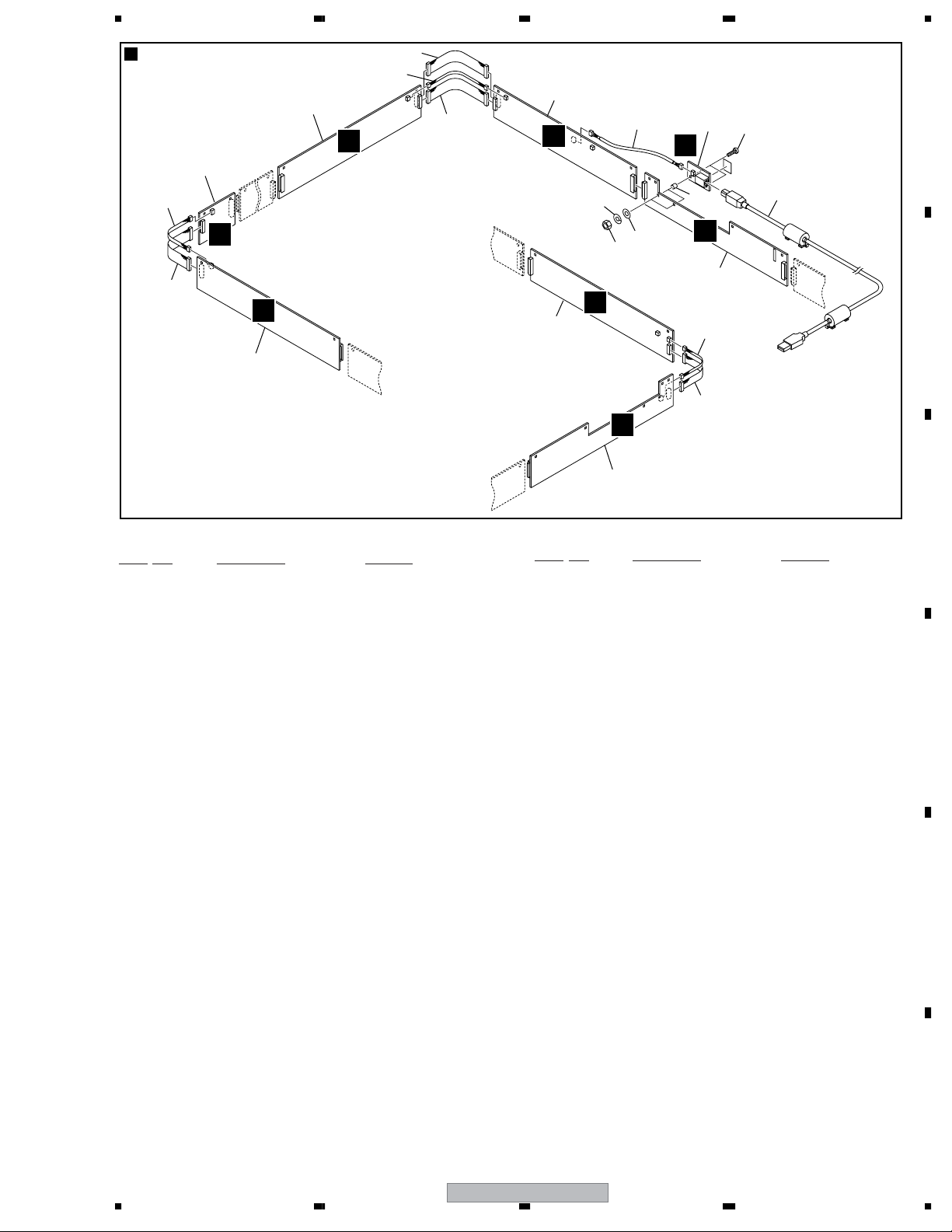

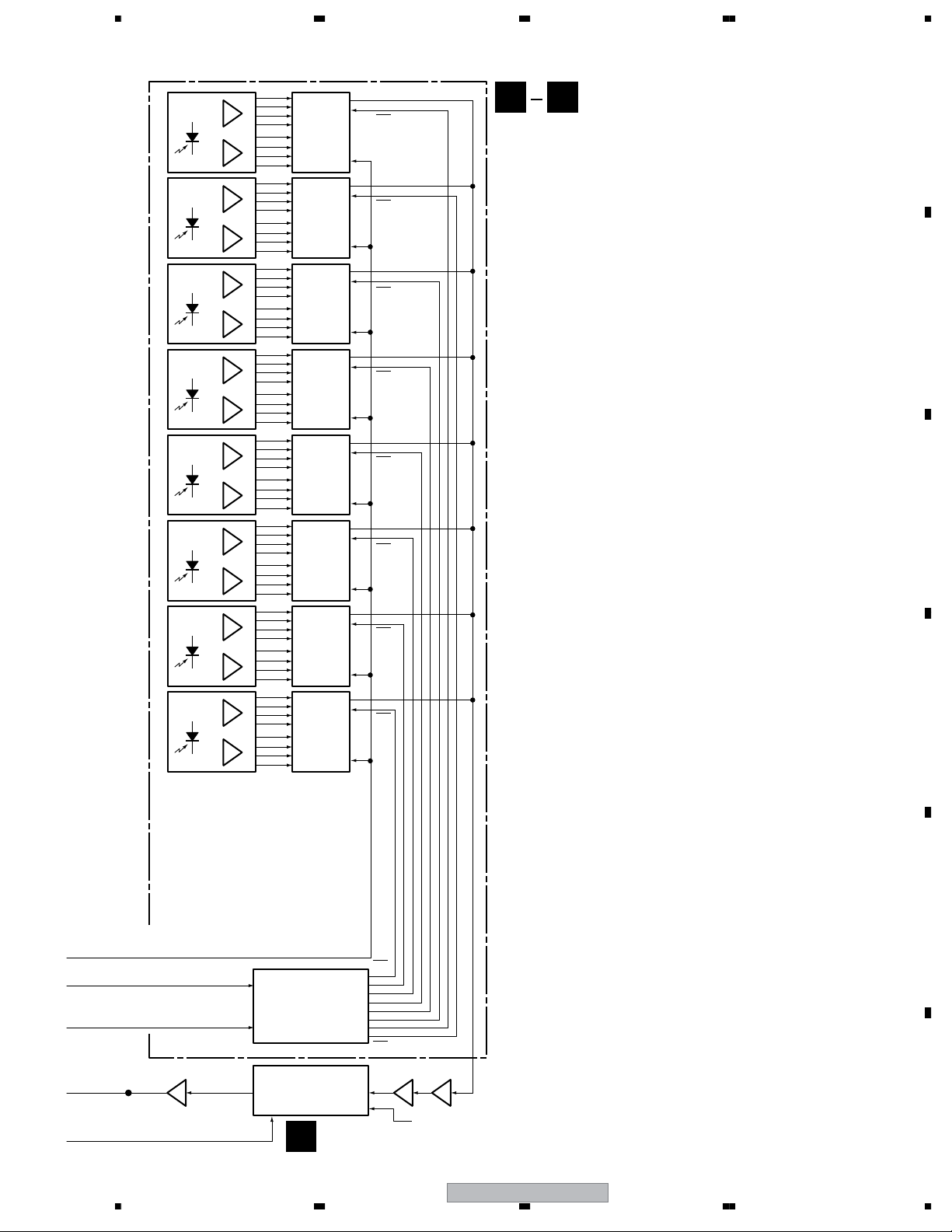

3.2 OVERALL WIRING DIAGRAM

A

SENSOR-K ASSY

K

(BZW1519)

By changing jumper-pin settings on the SENSOR-I, -J, and -K Assy's,

LED-G ASSY

G

B

C

(BZW1515)

CN1

CN4

LED-F ASSY

(BZW1514)

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

you can use the SENSOR-I, -J, and -K Assy's one in place of another.

Refer to "7.1.4 OPERATION CHECKS USING EXCHANGEABLE ASSY'S"

CN4

CN1

SENSOR-J ASSY

J

(BZW1518)

CN4

F

<BACK SIDE VIEW>

CN1

D

CN4

LED-E ASSY

(BZW1513)

E

E

CN3 CN2

CN5

CN6

LED-D ASSY

D

(BZW1512)

CN1

CN4

LED-C ASSY

C

(BZW1511)

CN1

F

16

1234

By changing jumper-pin settings on the LED-B, and -C Assy's,

you can use the LED-B Assy as the LED-C Assy, and vice versa.

Refer to "7.1.4 OPERATION CHECKS USING EXCHANGEABLE ASSY'S"

PDK-50HW3

Page 17

5678

A

CN1

SENSOR-I ASSY

I

(BZW1517)

<BACK SIDE VIEW>

CN4

CN1

SENSOR-H ASSY

H

(BZW1516)

CN5

CN6

SENSOR-N ASSY

N

(BZW1522)

CN3CN2

CN4

CN1

SENSOR-M ASSY

(BZW1521)

M

B

C

CN4

LED-B ASSY

B

(BZW1510)

CN1

CN2

CN1

CN4

LED-A ASSY

A

(BZW1509)

CN2

CN1

SENSOR-L ASSY

(BZW1520)

L

CN4

CN5

CN6

CN7

CN8

CN9

CN15

CN14CN3

D

E

USB CABLE

(BZD1411)

56

O

(BZW1523)

PDK-50HW3

USB BOARD ASSY

SENSOR HOLDER

SENSOR HOLDER

7

F

17

8

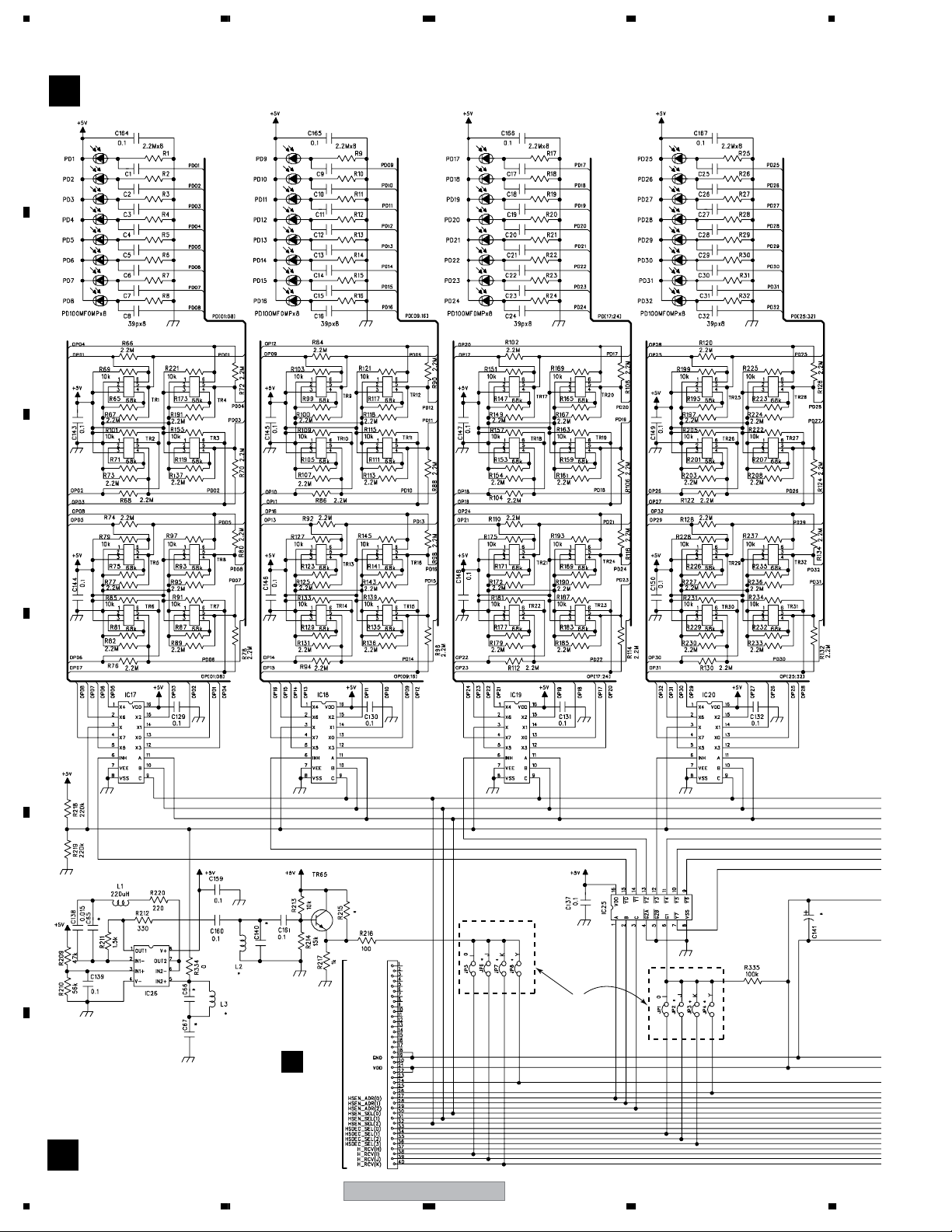

Page 18

1234

Q

3.3 LED-A ASSY (GUIDE PAGE)

LED-A ASSY (BZW1509)

A

A-a

A

BZT1701

BZT1701

BZQ1765

BZQ1765

CN14

BZK1511

HOLDER

SENSOR

BZQ1747

BZQ1747

B

CN15

BZK1511

HOLDER

SENSOR

BZQ1766

BZQ1747BZQ1747

BZQ1766

BZQ1771

BZQ1766

BZQ1770

BZQ1764

BZQ1764

BZQ1763

C

CN7

BZK1516

L

CN4

L

CN5

L

CN6

D

E

CN8

BZK1512

CN9

BZK1516

AZT1217

BZQ1766

BZQ1746

BZQ1739

BZQ1739

AZT1217

BZQ1739

BZQ1739

BZS1350

BZQ

BZ

BZQ1737 BZQ1737

F

A

18

1234

PDK-50HW3

Page 19

5678

ZQ1764

AZQ1109

BZQ1771

BZQ1768

BZQ1766

BZQ1771

A-b

BZQ1740

BZQ1772

DT1-DT18 : BZQ1768

LED1-LED64 : AZQ1108

A

B

C

1350

BZQ1745

BZQ1743

BZQ1736

BZQ1743

BZT1703

BZT1702

BZQ1743

BZQ1743

CN3

BZK1513

O

CN2

BZQ1772

CN4

BZK1518

D

E

BZQ1743

BZQ1743

BZQ1743

PDK-50HW3

56

CN1

B

F

A

19

7

8

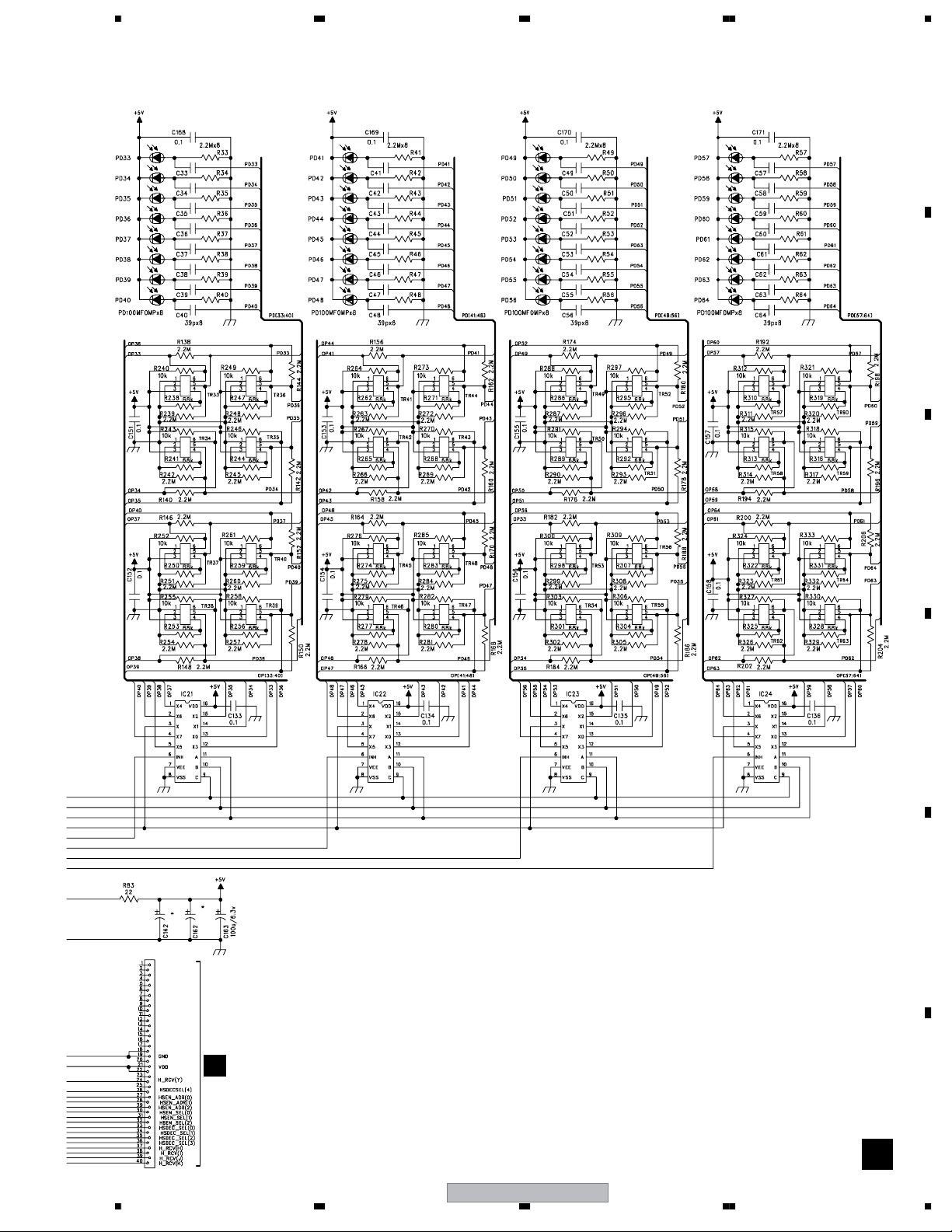

Page 20

1234

3.4 LED-A ASSY

A

BZK1512

BZQ1739

CN5

L

CN8

CN6

A

CN9

BZK1516

AZT1217

BZQ1766

B

BZQ1739

C

BZQ1746

L

BZQ1737 BZQ1737

AZT1217

D

BZQ1739

BZQ1739

E

BZS1350

F

20

1234

PDK-50HW3

Page 21

5678

L

BZQ1739

CN5

L

CN8

BZK1512

CN4

L

CN7

BZK1516

Guide page

2/2

1/2

1/21/2

Detailed page

1/22/2

BZQ1747BZQ1747

BZQ1766

SENSOR

HOLDER

BZK1511

BZT1701

BZQ1765

CN15

BZQ1747

BZQ1766

SENSOR

HOLDER

BZQ1747

BZK1511

BZT1701

CN14

BZQ1765

A

LED-A ASSY (BZW1509)

A

B

C

BZQ1739

BZQ1766

BZQ1771

BZQ1763

D

BZQ1770

BZQ1764

E

BZQ1764

PDK-50HW3

56

F

21

7

8

Page 22

1234

A

B

C

BZQ1743

BZQ1743

BZQ1743

BZQ1745

BZQ1743

BZQ1736

BZQ1743

BZT1703

BZT1702

D

CN3

O

BZK1513

BZQ1743

BZQ1743

CN2

Guide page

2/2

1/2

E

1/21/2

Detailed page

2/22/2

CN4

F

A

B

CN1

22

1234

BZK1518

PDK-50HW3

Page 23

Q

5678

A

BZ

1743

BZQ1771

BZQ1768

BZQ1743

BZQ1766

AZQ1109

B

C

BZQ1771

BZQ1740

BZQ1772

BZQ1772

DT1-DT18 : BZQ1768

LED1-LED64 : AZQ1108

D

E

F

56

PDK-50HW3

23

7

8

Page 24

1234

3.5 LED-B ASSY

LED-B ASSY (BZW1510)

B

A

B

C

9

5

BZQ1772

Block Selector

2

D

Refer to

"7.1.4 OPERATION CHECKS

USING EXCHANGEABLE ASSY'S"

CN1

BZK1517

E

3 4 8

1

CN4

A

F

B

24

1234

PDK-50HW3

Page 25

5678

DT1-DT16 : BZQ1768

LED1-LED64 : AZQ1108

A

B

C

BZQ1772

LED Selector

CN4

BZK1518

C

6

10

CN1

7

11

D

E

56

PDK-50HW3

F

B

25

7

8

Page 26

1234

3.6 LED-C ASSY

LED-C ASSY (BZW1511)

C

A

B

C

BZQ1772

Block Selector

D

Refer to

"7.1.4 OPERATION CHECKS

USING EXCHANGEABLE ASSY'S"

CN1

BZK1517

E

CN4

B

F

C

26

1234

PDK-50HW3

Page 27

5678

DT1-DT16 : BZQ1768

LED1-LED64 : AZQ1108

A

B

C

BZQ1772

LED Selector

CN4

BZK1518

CN1

D

PDK-50HW3

56

D

E

F

C

27

7

8

Page 28

1234

3.7 LED-D ASSY

LED-D ASSY (BZW1512)

D

A

B

C

BZQ1772

Block Selector

CN2

BZK1511

D

CN1

BZK1517

E

CN4

C

F

D

28

1234

PDK-50HW3

Page 29

5678

DT1-DT16 : BZQ1768

LED1-LED64 : AZQ1108

A

B

C

BZQ1772

LED Selector

CN5

BZK1512

CN2

E

CN6

BZK1515

CN3

E

PDK-50HW3

56

D

E

F

D

29

7

8

Page 30

1234

3.8 LED-E ASSY

LED-E ASSY (BZW1513)

E

A

B

C

BZQ1772

Block Selector

D

E

CN2

BZK1512

CN5

D

CN3

BZK1515

CN6

D

F

E

30

1234

PDK-50HW3

Page 31

5678

DT1-DT16 : BZQ1768

LED1-LED64 : AZQ1108

A

B

C

BZQ1772

LED Selector

CN1

F

CN4

BZK1518

PDK-50HW3

56

D

E

F

E

31

7

8

Page 32

1234

3.9 LED-F ASSY

LED-F ASSY (BZW1514)

F

A

B

C

BZQ1772

Block Selector

D

CN1

BZK1517

E

CN4

E

F

F

32

1234

PDK-50HW3

Page 33

5678

DT1-DT16 : BZQ1768

LED1-LED64 : AZQ1108

A

B

C

BZQ1772

LED Selector

CN4

BZK1518

CN1

G

PDK-50HW3

56

D

E

F

F

33

7

8

Page 34

1234

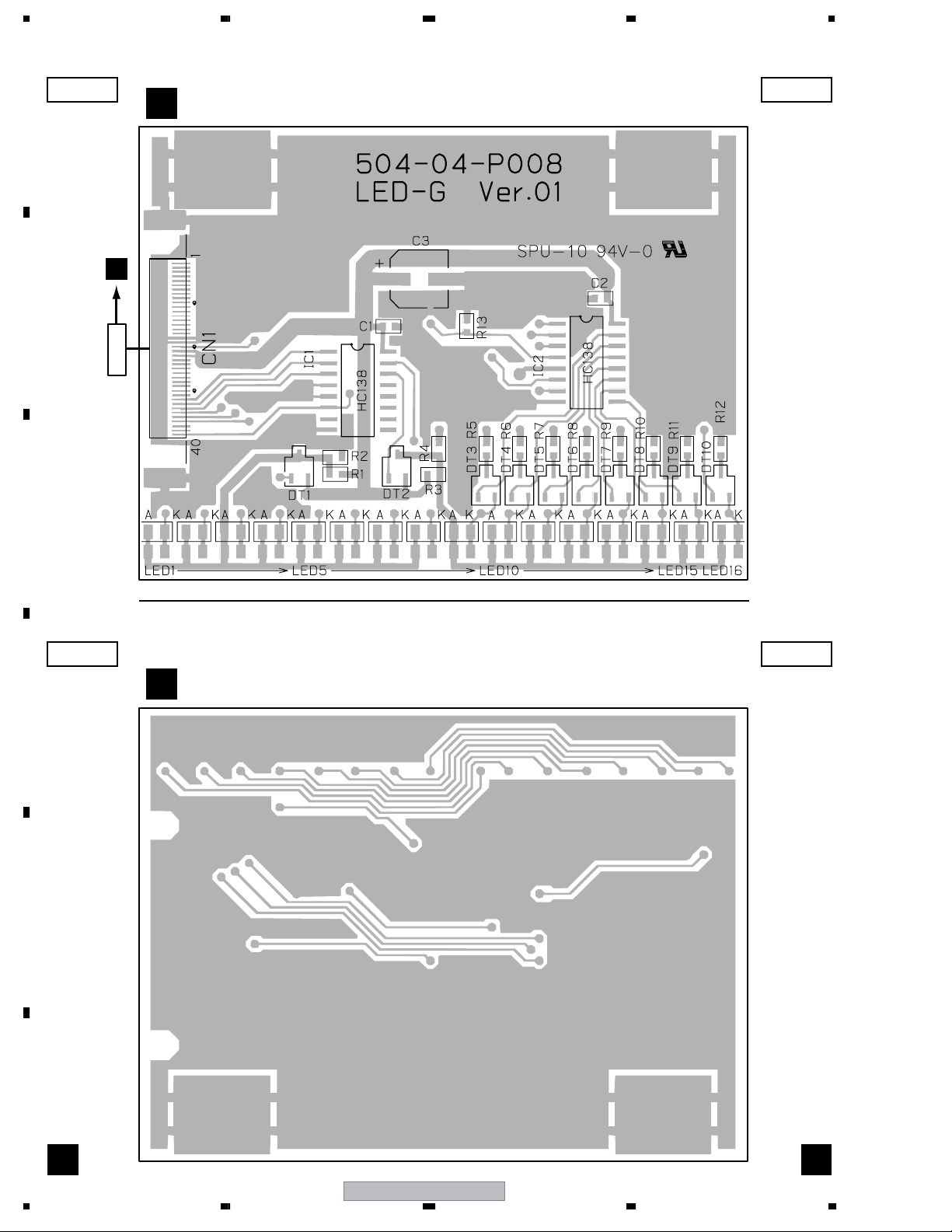

3.10 LED-G ASSY

LED-G ASSY (BZW1515)

G

A

B

C

BZQ1772

Block Selector

D

CN1

BZK1517

BZQ1772

LED Selector

E

CN4

F

F

G

34

1234

PDK-50HW3

Page 35

5678

A

LED1-LED16 : AZQ1108

B

C

D

E

DT1-DT10 : BZQ1768

PDK-50HW3

56

F

G

35

7

8

Page 36

1234

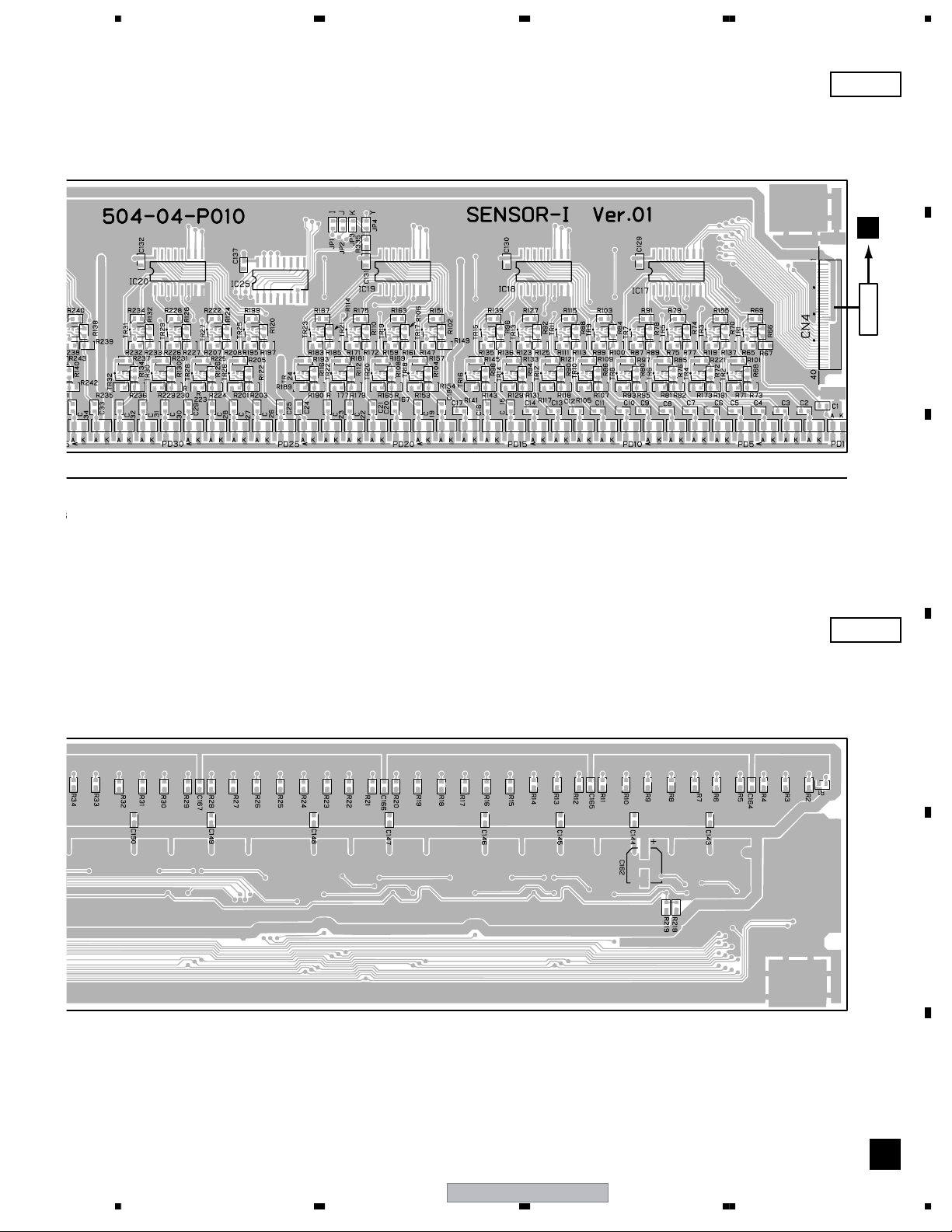

3.11 SENSOR-H ASSY

SEOSOR-H ASSY (BZW1516)

H

A

B

C

D

BZQ1769

AZT1217

E

BZQ1769

BZQ1766

CN1

BZK1517

BZQ1769

2

3

BZQ1738

BZQ1769

1

CN4

I

F

H

36

1234

PDK-50HW3

Page 37

5678

PD1-PD64 : AZQ1107

A

B

C

BZQ1769

CN5

BZK1513

BZQ1769 BZQ1769

TR1-TR64 : BZQ1747

CN3

N

CN6

BZK1516

CN2

N

PDK-50HW3

56

D

BZQ1769

E

F

H

37

7

8

Page 38

1234

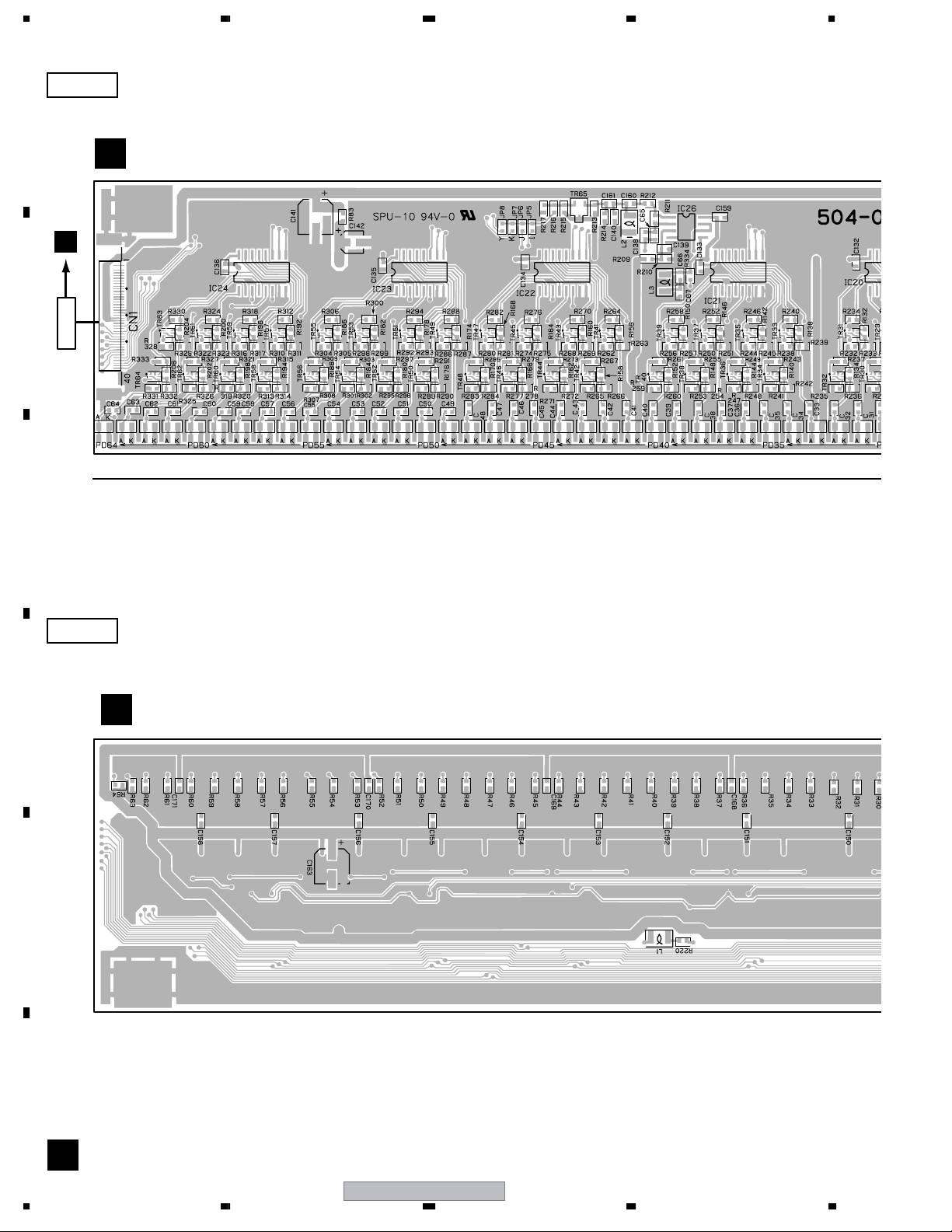

3.12 SENSOR-I ASSY

SENSOR-I ASSY (BZW1517)

I

A

B

C

D

BZQ1769BZQ1769BZQ1769BZQ1769

AZT1217

E

BZQ1766

CN1

BZK1517

BZQ1772

BZQ1738

CN4

J

F

Refer to "7.1.4

OPERATION

CHECKS USING

EXCHANGEABLE

ASSY'S"

I

38

1234

PDK-50HW3

Page 39

5678

PD1-PD64 : AZQ1107

A

B

C

BZQ1769

CN4

BZK1518

TR1-TR64 : BZQ1747

CN1

H

PDK-50HW3

56

D

BZQ1769BZQ1769BZQ1769

E

F

I

39

7

8

Page 40

1234

3.13 SENSOR-J ASSY

SENSOR-J ASSY (BZW1518)

J

A

B

C

D

BZQ1769BZQ1769BZQ1769

AZT1217

E

BZQ1766

CN1

BZK1517

BZQ1769

BZQ1772

BZQ1738

CN4

K

F

Refer to "7.1.4

OPERATION

CHECKS USING

EXCHANGEABLE

ASSY'S"

J

40

1234

PDK-50HW3

Page 41

5678

PD1-PD64 : AZQ1107

A

B

C

BZQ1769

CN4

BZK1518

BZQ1769BZQ1769

TR1-TR64 : BZQ1747

CN1

I

PDK-50HW3

56

D

BZQ1769

E

F

J

41

7

8

Page 42

1234

3.14 SENSOR-K ASSY

SENSOR-K ASSY (BZW1519)

K

A

B

C

D

BZQ1769

AZT1217

E

BZQ1766

BZQ1769BZQ1769BZQ1769

BZQ1772

BZQ1738

F

Refer to "7.1.4

OPERATION

CHECKS USING

EXCHANGEABLE

ASSY'S"

K

42

1234

PDK-50HW3

Page 43

5678

PD1-PD64 : AZQ1107

A

B

C

TR1-TR64 : BZQ1747

CN4

BZK1518

CN1

J

PDK-50HW3

56

D

BZQ1769BZQ1769BZQ1769BZQ1769

E

F

K

43

7

8

Page 44

1234

3.15 SENSOR-L ASSY

SENSOR-L ASSY (BZW1520)

L

A

B

C

D

BZQ1769

AZT1217

E

BZQ1766

CN1

BZK1517

BZQ1769BZQ1769BZQ1769

BZQ1772

BZQ1738

CN2

M

F

L

44

1234

PDK-50HW3

Page 45

5678

PD1-PD64 : AZQ1107

A

B

C

TR1-TR64 : BZQ1747

CN4

BZK1516

CN7

A

CN5

BZK1512

A

CN6

BZK1516

A

CN8

CN9

PDK-50HW3

56

D

BZQ1769BZQ1769BZQ1769BZQ1769

E

F

L

45

7

8

Page 46

1234

3.16 SENSOR-M ASSY

SENSOR-M ASSY (BZW1521)

M

A

B

C

D

BZQ1769BZQ1769BZQ1769BZQ1769

AZT1217

E

BZQ1766

CN1

BZK1517

BZQ1772

BZQ1738

CN4

N

F

M

46

1234

PDK-50HW3

Page 47

5678

PD1-PD64 : AZQ1107

A

B

C

TR1-TR64 : BZQ1747

CN2

BZK1518

CN1

L

PDK-50HW3

56

D

BZQ1769BZQ1769BZQ1769BZQ1769

E

F

M

47

7

8

Page 48

1234

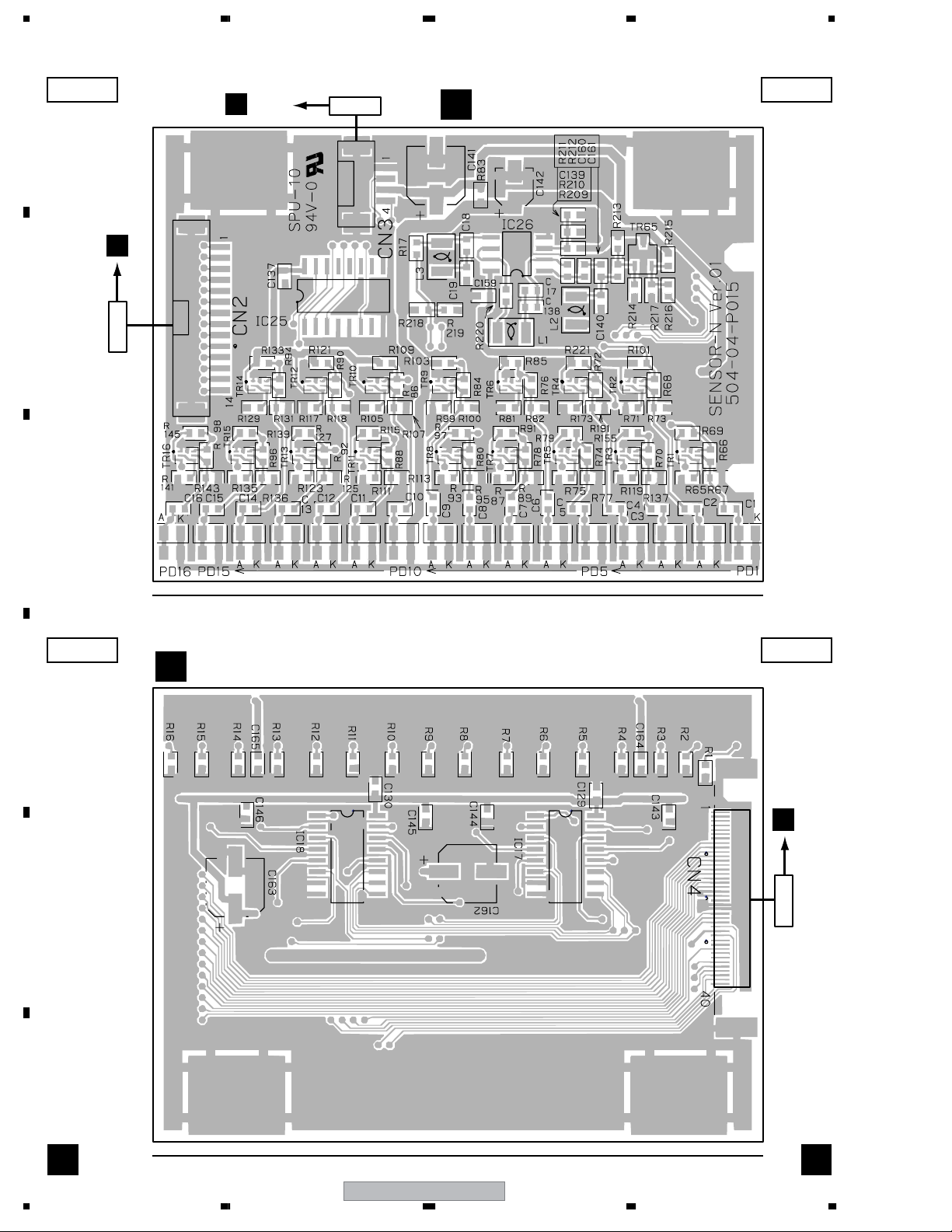

3.17 SENSOR-N ASSY

A

B

PD1-PD16 : AZQ1107

SENSOR-N ASSY (BZW1522)

N

C

TR1-TR16 : BZQ1747

D

BZQ1769BZQ1769

AZT1217

E

BZQ1766

BZQ1772

CN4

BZK1518

BZQ1738

CN3

BZK1513

CN5

H

CN2

H

BZK1516

CN6

F

M

CN1

N

48

1234

PDK-50HW3

Page 49

5678

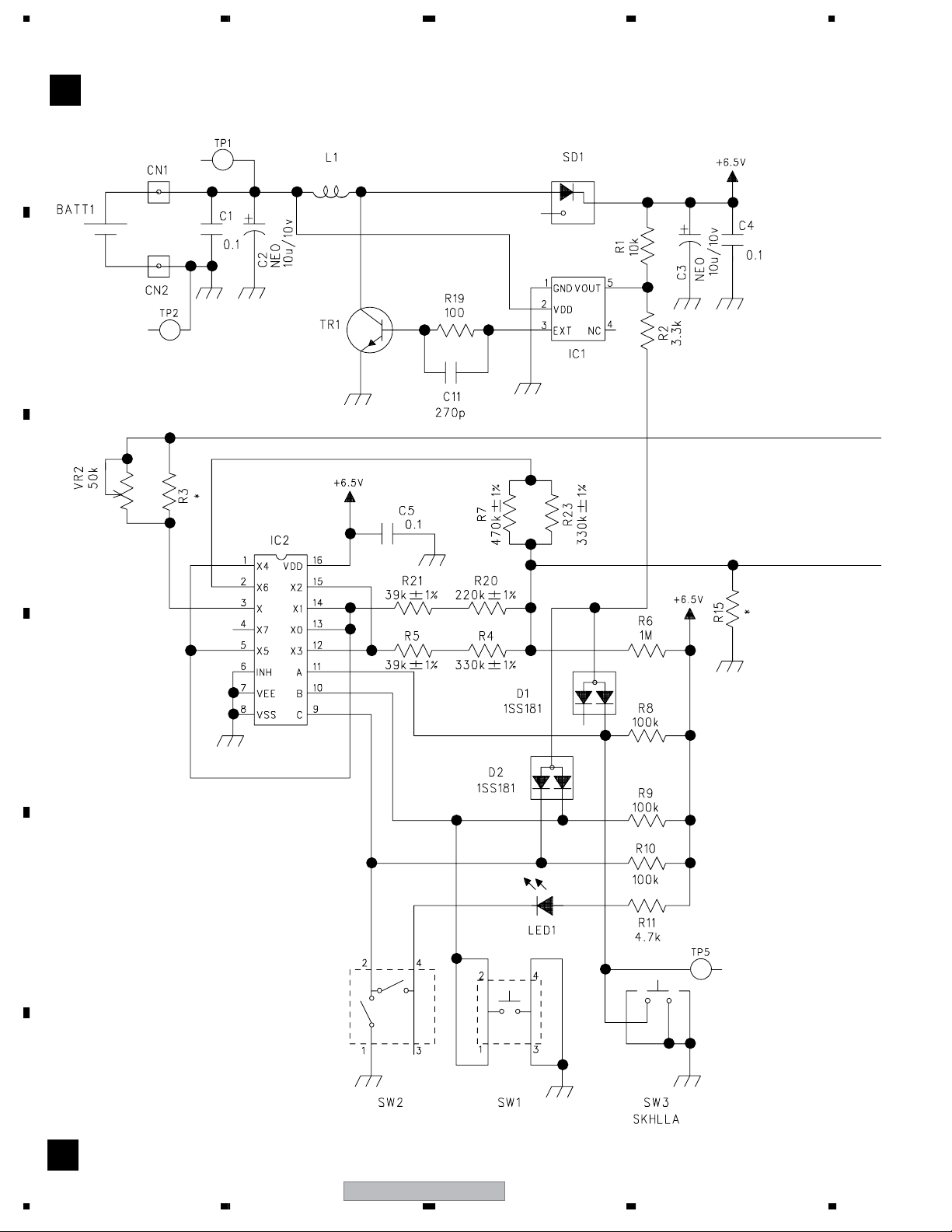

3.18 USB BOARD ASSY

USB BOARD ASSY (BZW1523)

O

A

(RED)

(WHT)

(GRN)

(BLK)

CN1

BZK1510

BZQ1759

CN2

BZK1513

CN3USB CABEL SIDE

A

B

C

D

56

PDK-50HW3

E

F

O

49

7

8

Page 50

1234

3.19 PEN PCB ASSY

PEN PCB ASSY (BZW1524)

P

A

AZT1219

B

BZQ1767

BZC2486

C

BZQ1762

BZQ1761

D

BZQ1744

E

AZQ1110

F

P

50

1234

AZS1142 AZS1140

BUTTON 2

(M)

PDK-50HW3

BUTTON 1

(R)

PEN

(L)

Page 51

5678

A

B

BZQ1742

C

BZC2483

D

AZP1163

E

56

PDK-50HW3

F

P

51

7

8

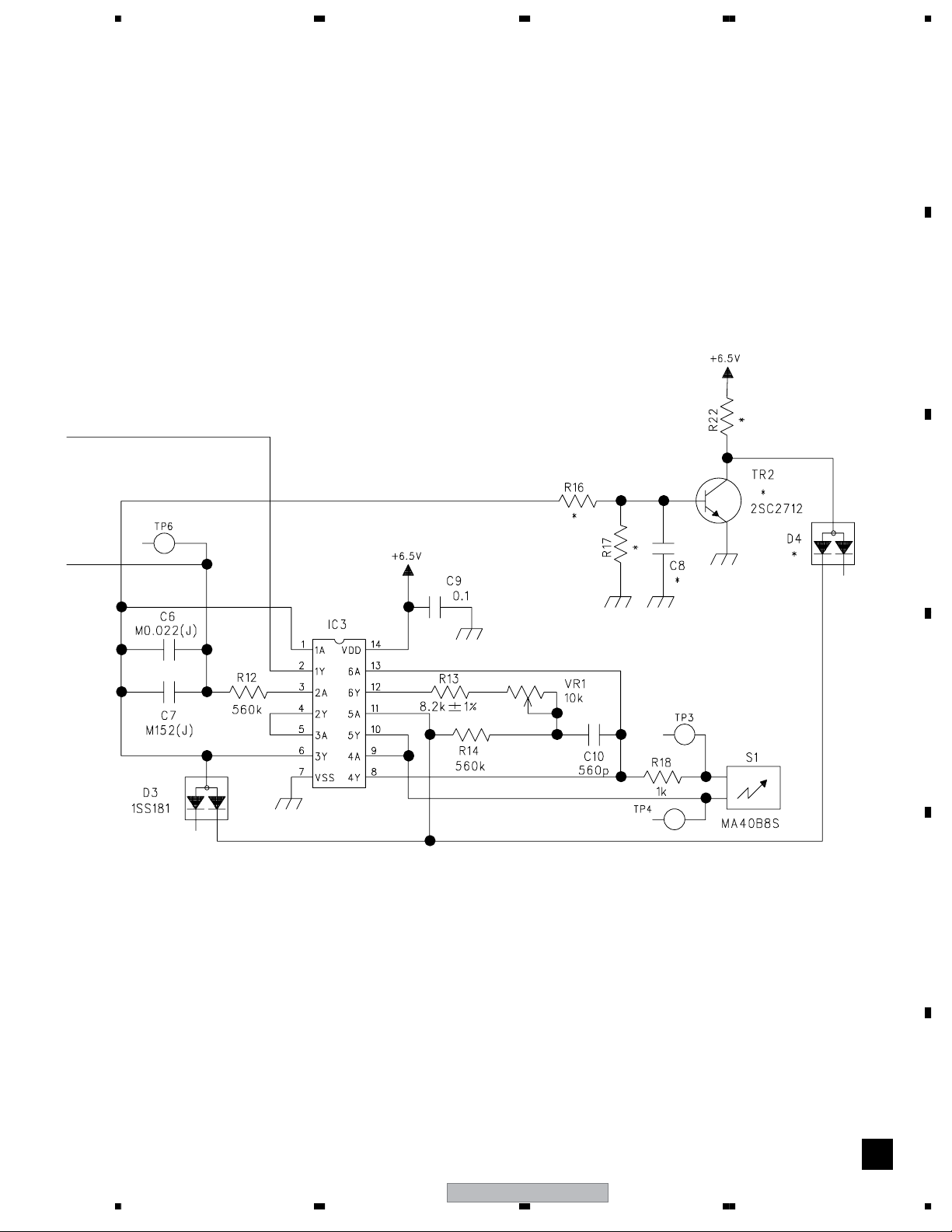

Page 52

1234

3.20 WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

A

LED-B ASSY

B

CN1 - pin 20 (CLK (100kHz))

1

V: 2V/div. H: 5µsec/div.

IC1 - pin 6 (BOARD_SELECT)

4

V: 5V/div. H: 1msec/div.

IC1 - pin 15 (BLOCK Y0)

5

V: 5V/div. H: 1msec/div.

IC2 - pin 15 (LED_SELECT Y0)

6

V: 5V/div. H: 1msec/div.

IC2 - pin 14 (LED_SELECT Y1)

7

V: 5V/div. H: 1msec/div.

B

4

5

6

7

IC1 - pin 1, 2, 3 (HBLOCK_SEL (0, 1, 2))

2

C

V: 5V/div. H: 1msec/div.

IC1 - pin 6 (BOARD_SELECT)

8

V: 5V/div. H: 1msec/div.

IC1 - pin 15 (BLOCK Y0)

9

V: 5V/div. H: 1msec/div.

IC2 - pin 15 (LED_SELECT Y0)

10

V: 5V/div. H: 1msec/div.

IC2 - pin 14 (LED_SELECT Y1)

11

V: 5V/div. H: 1msec/div.

8

9

D

10

11

IC1 - pin 6 (HBOARD_SEL (1))

3

V: 5V/div. H: 10msec/div.

E

SENSOR-H ASSY

H

IC25 - pin 6 (HSDEC_SEL (φ))

1

V: 5V/div. H: 5msec/div.

IC25 - pin 15 (HSDEC_Yφ)

2

V: 5V/div. H: 5msec/div.

CN1 - pin 37 (H_RCV (H))

3

V: 0.5V/div. H: 5msec/div.

1

2

F

3

52

1234

PDK-50HW3

Page 53

5678

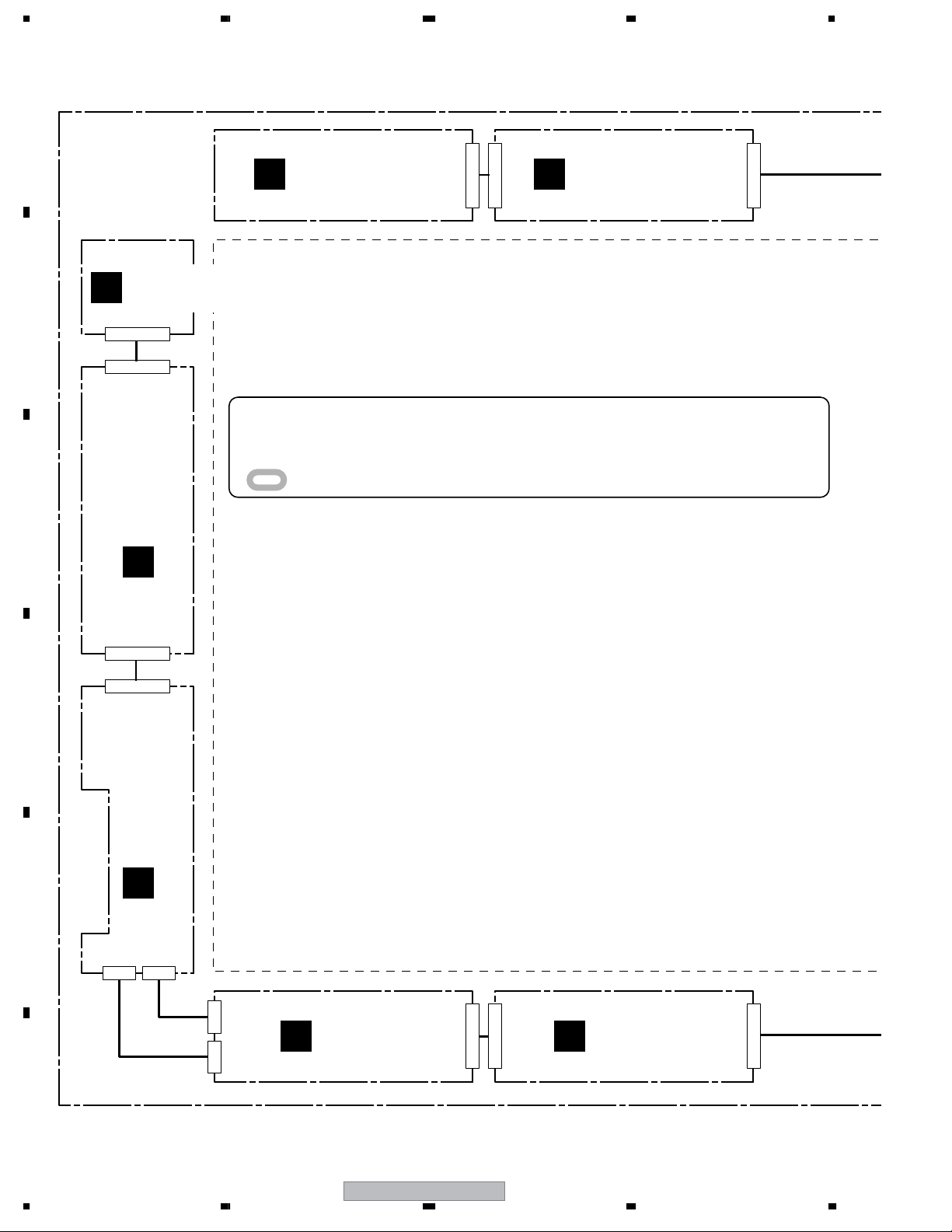

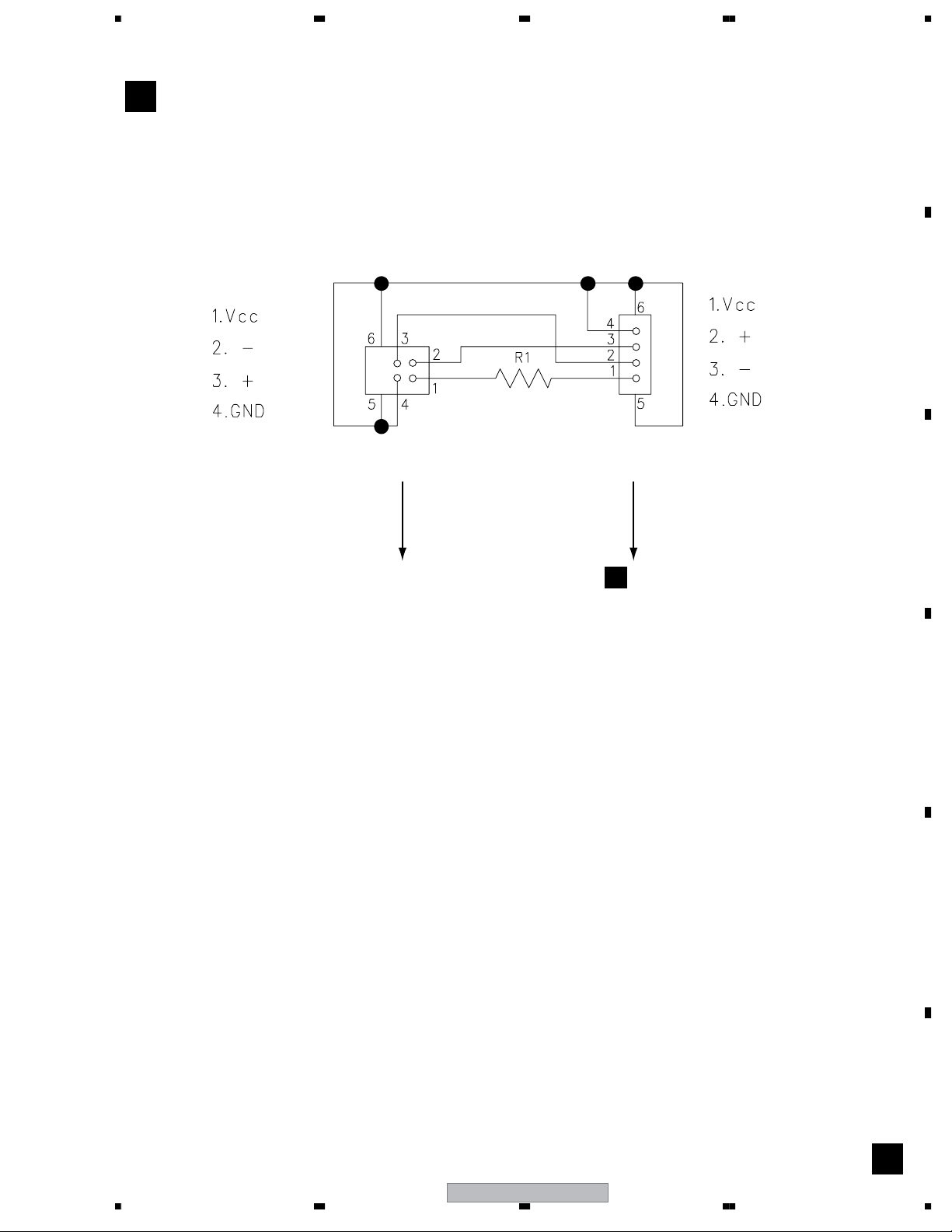

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

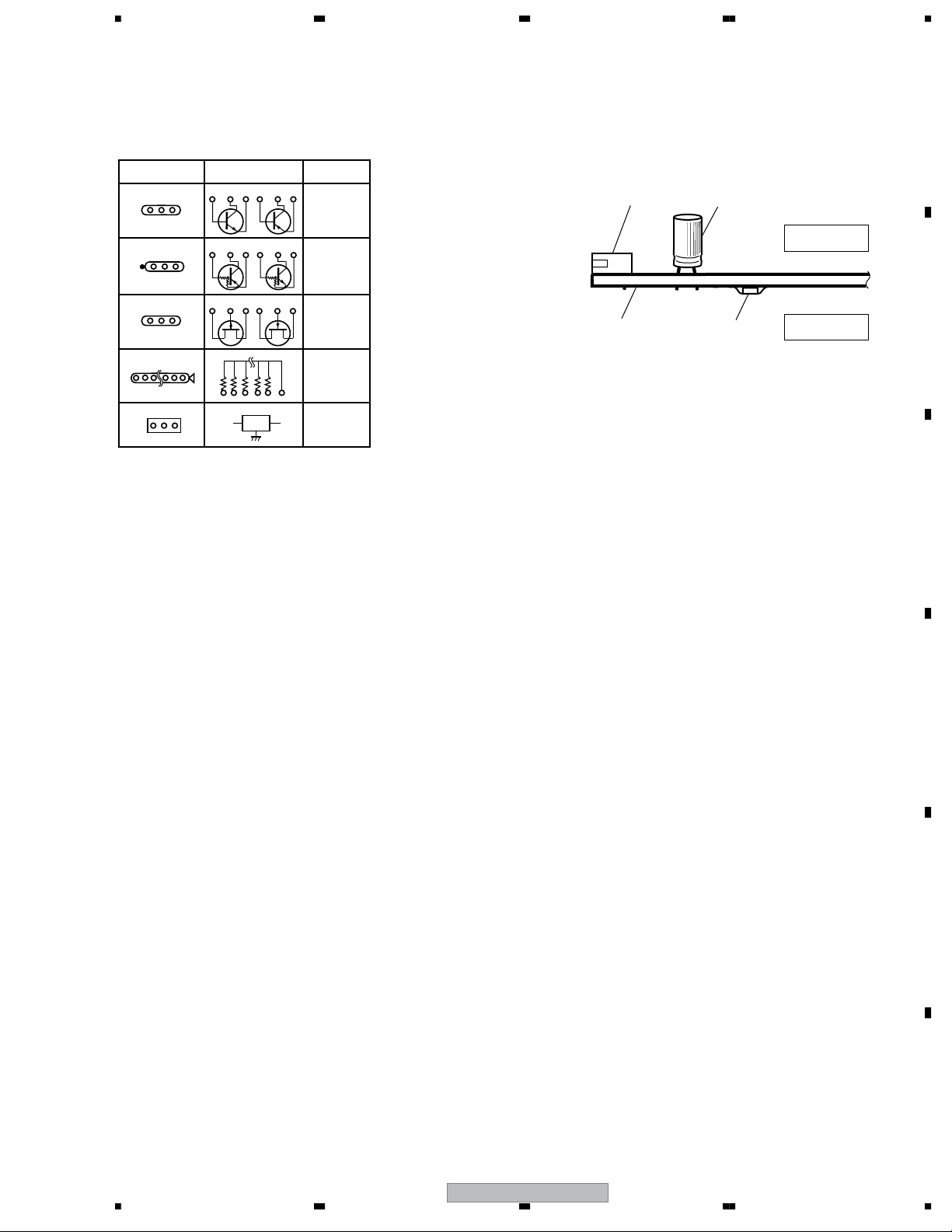

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

DGGSS

BCE

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

A

B

C

D

E

56

PDK-50HW3

F

53

7

8

Page 54

1234

N

3

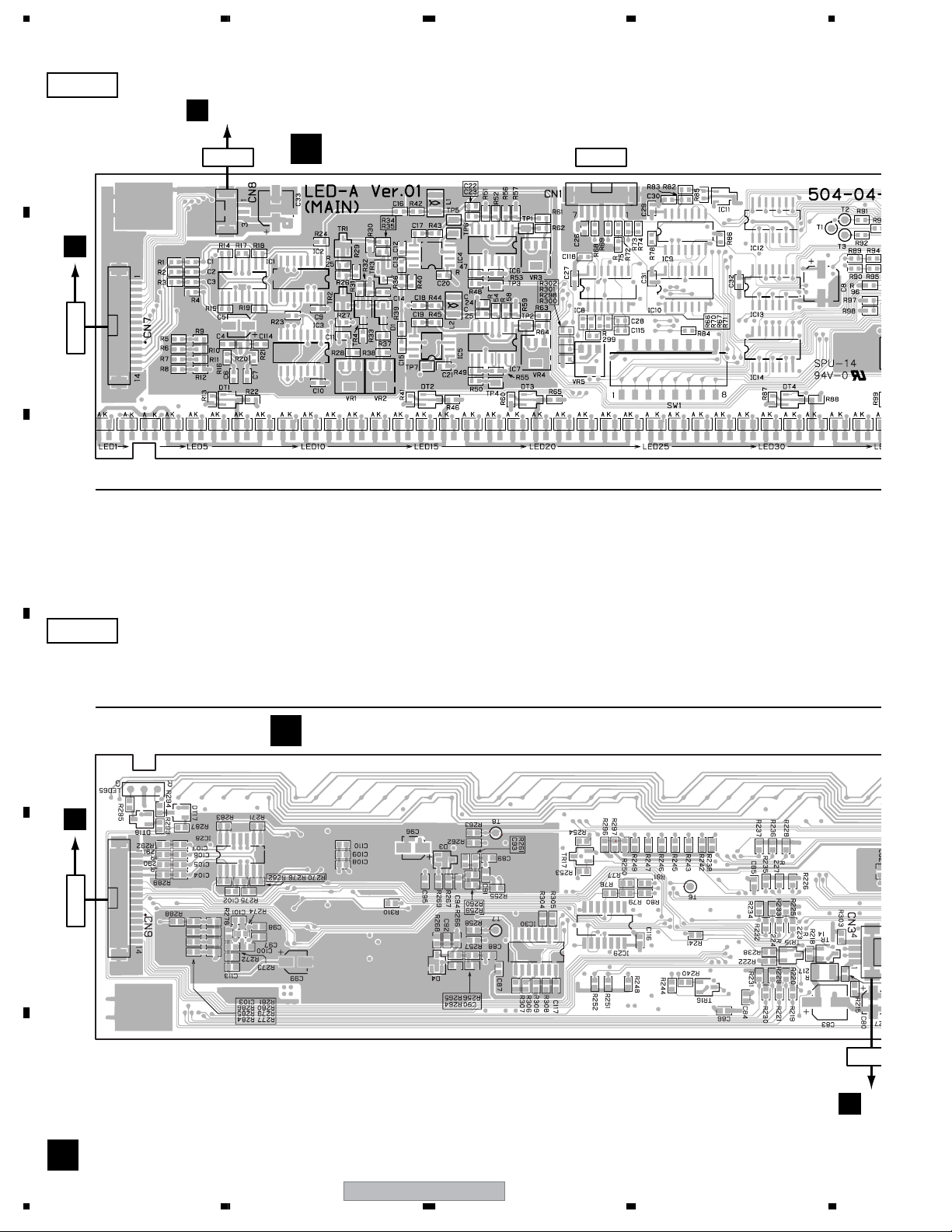

4.1 LED-A ASSY

SIDE A

A

CN4

L

B

CN7

L

CN5

LED-A ASSY

CN8 CN1

A

C

D

E

SIDE B

CN6

L

CN9

IC6

IC7

VR3

IC8 IC9 IC11 IC12

TR17

VR1 VR2 VR4 VR5

IC1 IC2

DT18 DT17 IC30 IC29

IC28

A

TR1

TR4DT1

TR2

IC3

LED-A ASSY

IC4

TR3

IC5

DT2 DT3 DT4

IC10

TR16

IC13

IC14

TR15 TR14

CN

O

C

F

A

54

1234

PDK-50HW3

Page 55

5678

DT4

To

SENSOR

HOLDER

CN2

IC15 IC16 IC17 IC21

DT5

IC18

IC19 IC20

CN15

TR5 TR6

DT6

IC22

IC23 IC24 IC25 IC26

DT7

TR10 TR12 TR13

DT8 DT9

DT10

DT11

To

SENSOR

HOLDER

CN14

DT13 DT15

DT12

DT14

SIDE A

A

CN1

B

B

CN4

C

15 IC27 DT16TR14

SIDE B

D

E

CN3

O

CN2

56

PDK-50HW3

F

A

55

7

8

Page 56

1234

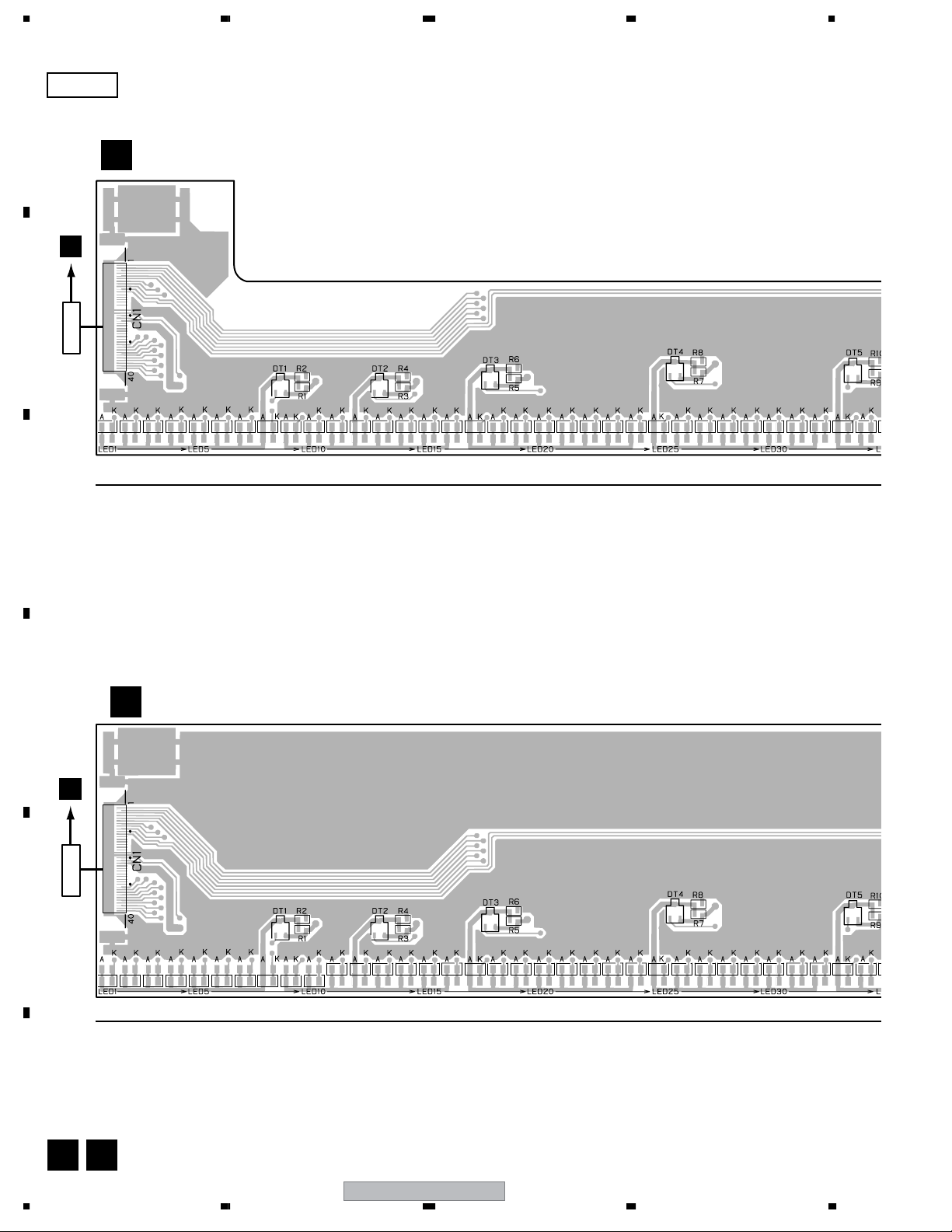

4.2 LED-B and LED-C ASSYS

SIDE A

A

LED-B ASSY

B

CN4

A

B

CN1

DT1 DT2 DT3 DT4 DT5

C

LED-C ASSY

D

C

CN4

B

CN1

E

F

56

DT1 DT2 DT3 DT4 DT5

B C

PDK-50HW3

1234

Page 57

5678

SIDE A

A

CN1

C

B

CN4

DT5 IC1 IC2

DT6

DT9

DT10

DT11

DT12

DT13

DT15 DT7 DT8

DT14

DT16

C

D

CN1

D

CN4

E

DT5 IC1 IC2

56

DT6

DT9

DT10

DT11

DT12

DT13

DT15 DT7 DT8

DT14

DT16

PDK-50HW3

F

CB

57

7

8

Page 58

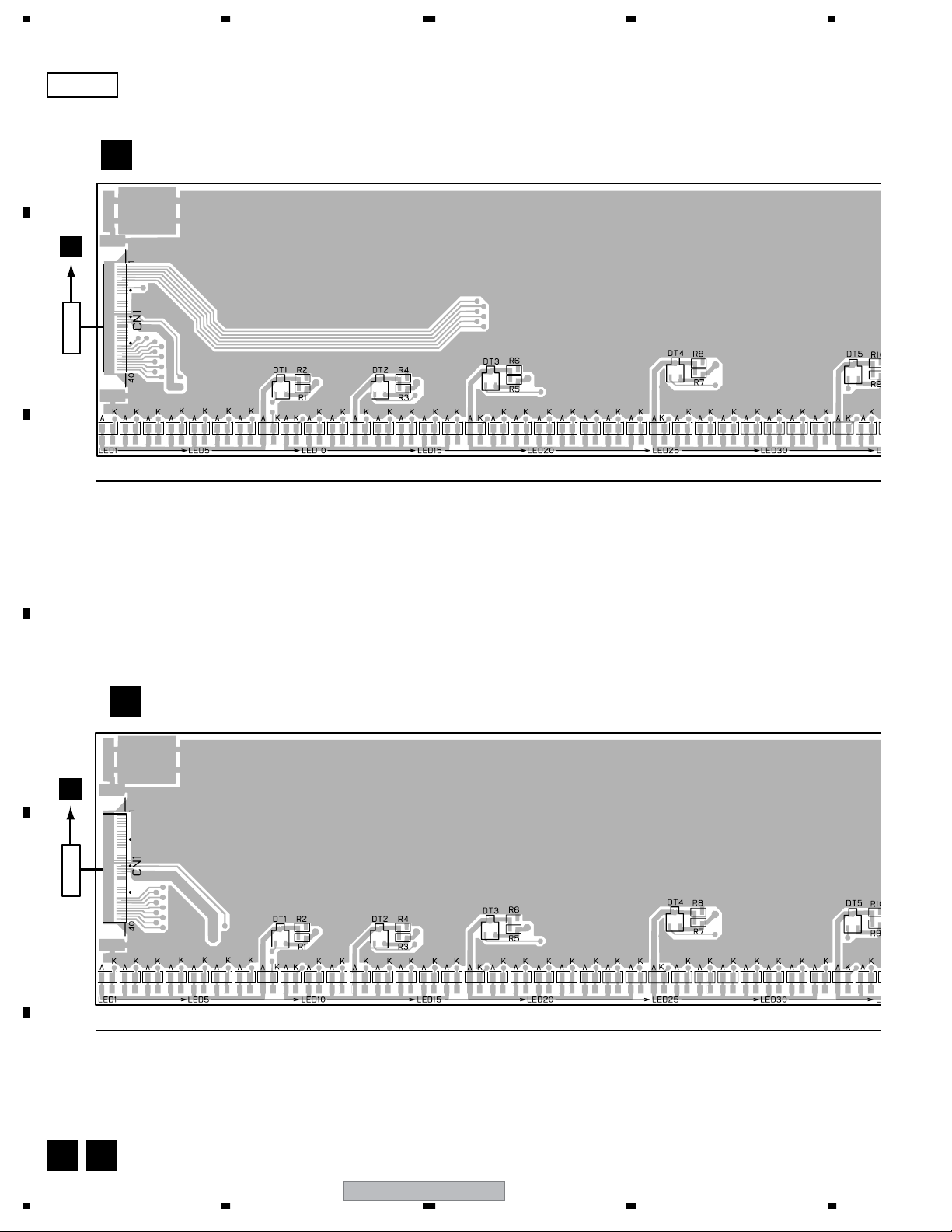

1234

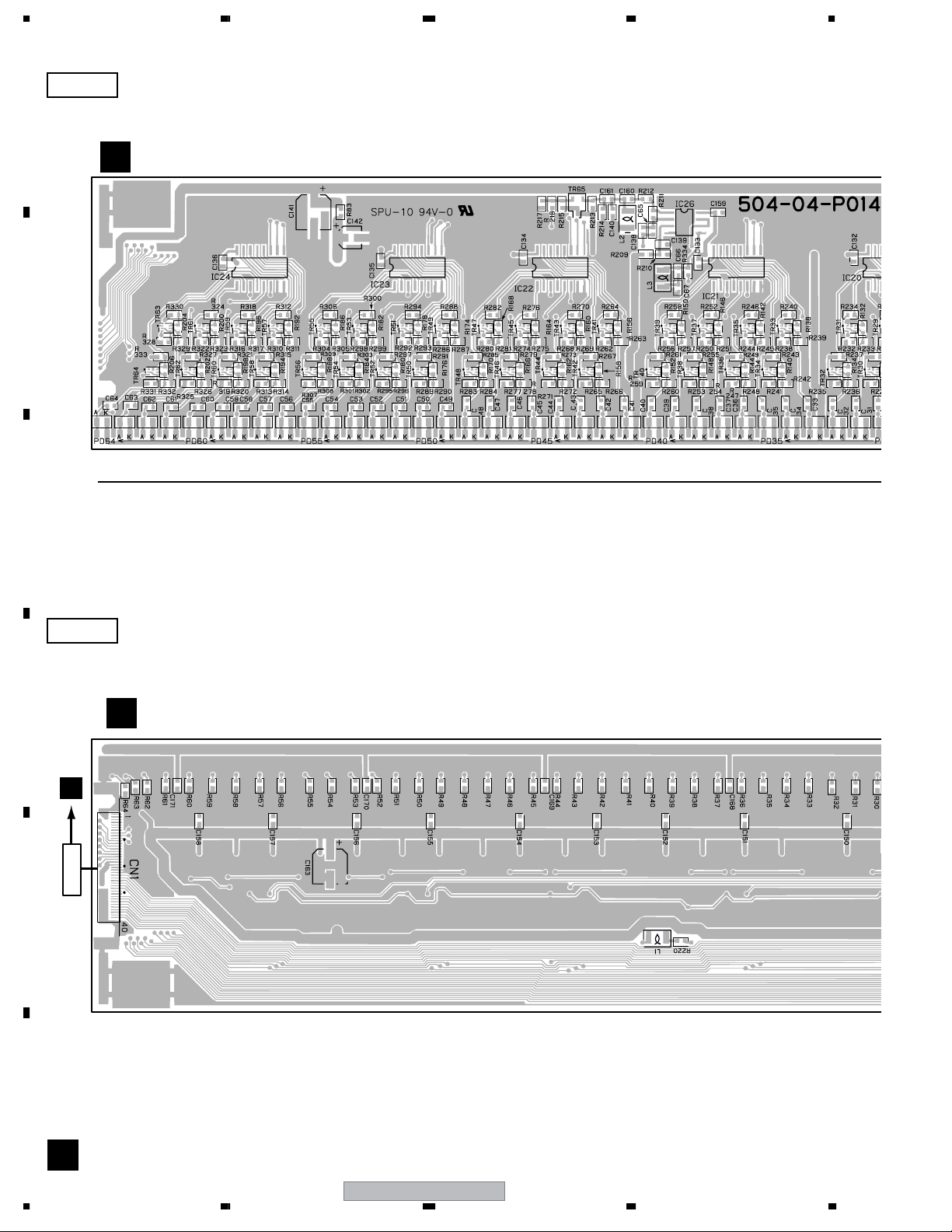

4.3 LED-D and LED-F ASSYS

SIDE A

A

LED-D ASSY

D

CN4

C

B

CN1

DT1 DT2 DT3 DT4 DT5

C

LED-F ASSY

D

F

CN4

E

CN1

E

F

58

DT1 DT2 DT3 DT4 DT5

D F

PDK-50HW3

1234

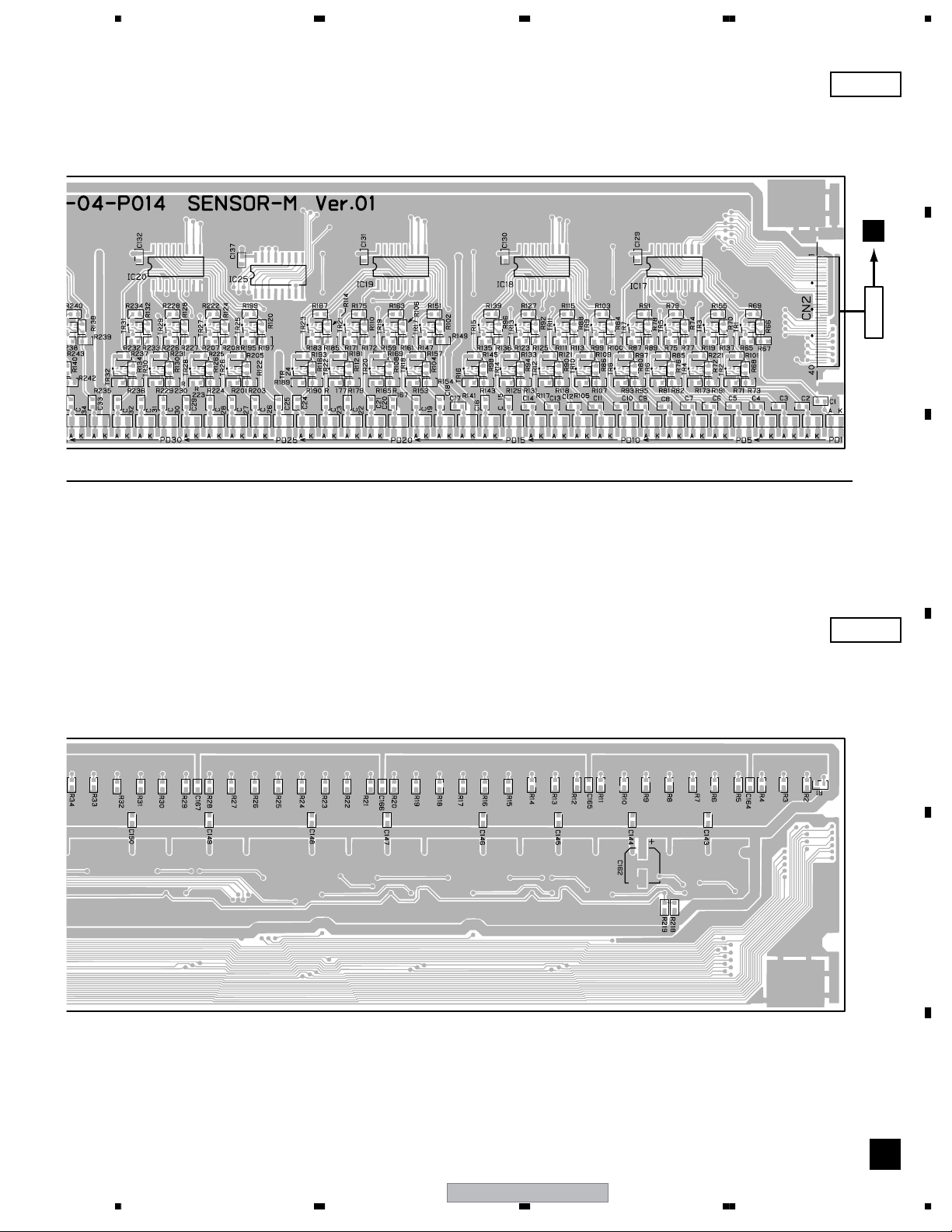

Page 59

5678

SIDE A

A

DT5 IC1 IC2

DT6

DT9

DT10

DT11

DT12

DT13

DT15 DT7 DT8

DT14

DT16

CN2

CN2

E

CN5

B

CN6

CN3

E

C

DT5 IC1 IC2

56

DT6

DT9

DT10

DT11

DT12

DT13

DT15 DT7 DT8

DT14

DT16

PDK-50HW3

D

CN1

G

CN4

E

F

FD

59

7

8

Page 60

1234

4.4 LED-E ASSY

SIDE A

A

LED-E ASSY

E

CN6

D

B

CN3

CN2

D

CN5

C

D

E

SIDE B

LED-E ASSY

E

DT1 DT2 DT3 DT4 DT5

F

E

60

1234

PDK-50HW3

Page 61

5678

SIDE A

A

CN1

F

DT5 IC1 IC2

DT6

DT9

DT10

DT11

DT12

DT13

DT15 DT7 DT8

DT14

DT16

CN4

B

C

SIDE B

D

56

PDK-50HW3

E

F

E

61

7

8

Page 62

1234

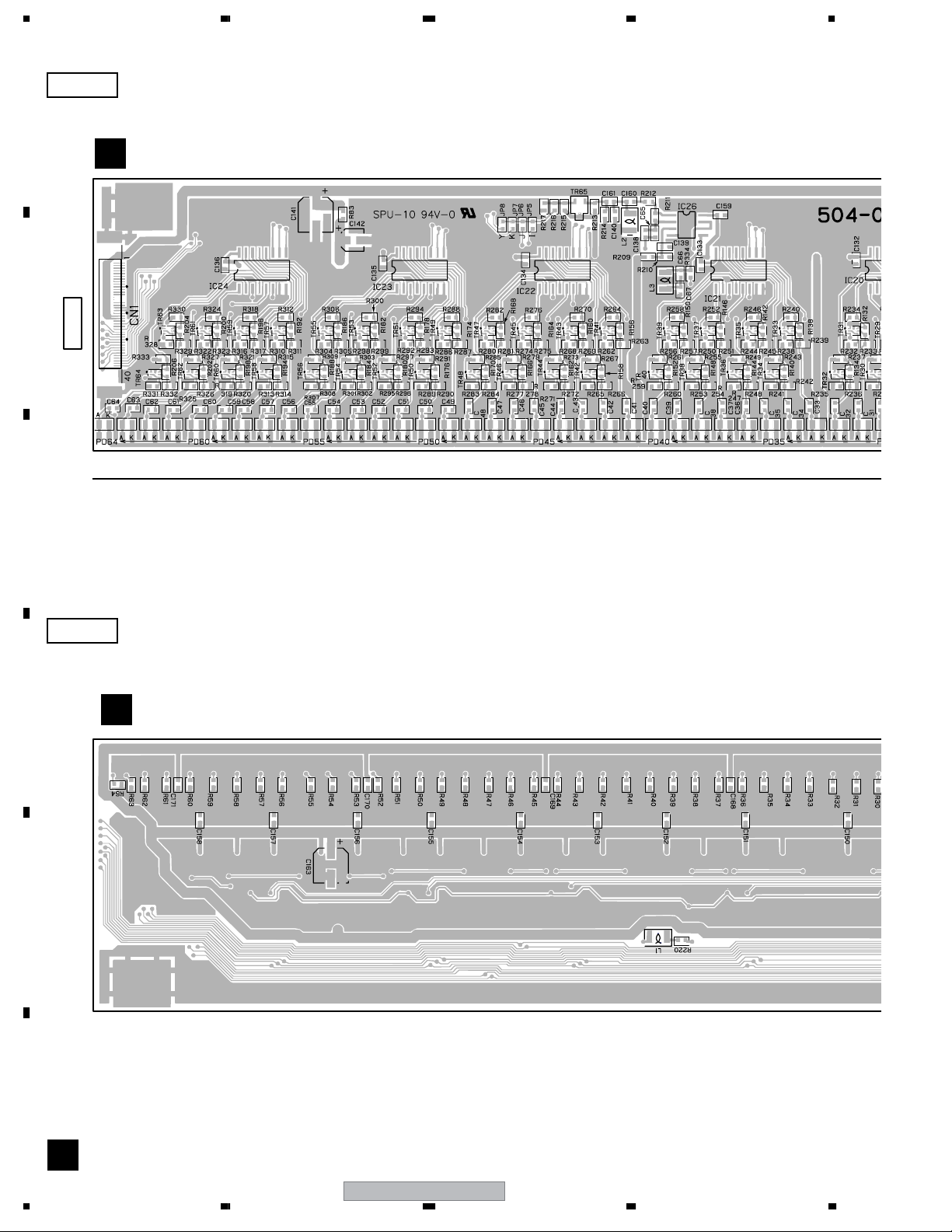

4.5 LED-G ASSY

SIDE A SIDE A

LED-G ASSY

A

G

CN4

F

B

CN1

C

DT1 DT2 DT3 DT4 DT5 DT6

IC2IC1

DT7 DT8 DT9 DT10

SIDE B SIDE B

LED-G ASSY

G

D

E

F

G G

62

1234

PDK-50HW3

Page 63

5678

A

B

C

D

E

56

PDK-50HW3

F

63

7

8

Page 64

1234

0

4.6 SENSOR-H ASSY

SIDE A

A

SENSOR-H ASSY

H

CN4

I

B

CN1

C

D

E

SIDE B

IC24

TR63

TR64 TR62 TR60 TR58 TR56 TR54 TR52 TR50

SENSOR-H ASSY

H

TR61 TR59 TR57 TR55 TR53 TR51 TR49

IC23 IC22 IC21IC26TR65

TR47 TR45 TR43 TR41 TR39 TR37 TR35 TR33

TR48 TR46 TR44 TR42 TR40 TR38 TR36 TR34

TR31 T

TR32 TR3

F

H

64

1234

PDK-50HW3

Page 65

5678

SIDE A

N

CN3

CN5

A

CN2

N

IC20 IC25 IC19 IC18 IC17

33

TR31 TR29 TR27 TR25 TR23 TR21 TR19 TR17 TR15 TR13 TR11 TR9 TR7 TR5 TR3 TR1

TR32 TR30 TR28 TR26 TR24 TR22 TR20 TR18 TR16 TR14 TR12 TR10 TR8 TR6 TR4 TR2

CN6

SIDE B

B

C

D

56

PDK-50HW3

E

F

H

65

7

8

Page 66

1234

3

T

4.7 SENSOR-I ASSY

SIDE A

A

SENSOR-I ASSY

I

CN4

J

B

CN1

C

D

E

SIDE B

IC24

TR63

TR64 TR62 TR60 TR58 TR56 TR54 TR52 TR50

SENSOR-I ASSY

I

TR61 TR59 TR57 TR55 TR53 TR51 TR49

IC23 IC22 IC21IC26TR65

TR47 TR45 TR43 TR41 TR39 TR37 TR35 TR33

TR48 TR46 TR44 TR42 TR40 TR38 TR36 TR34

TR31

TR32 TR

F

I

66

1234

PDK-50HW3

Page 67

5678

SIDE A

A

CN1

H

IC20 IC25 IC19 IC18 IC17

R33

4

TR31 TR29 TR27 TR25 TR23 TR21 TR19 TR17 TR15 TR13 TR11 TR9 TR7 TR5 TR3 TR1

TR32 TR30 TR28 TR26 TR24 TR22 TR20 TR18 TR16 TR14 TR12 TR10 TR8 TR6 TR4 TR2

CN4

SIDE B

B

C

D

56

PDK-50HW3

E

F

I

67

7

8

Page 68

1234

0

T

4.8 SENSOR-J ASSY

SIDE A

A

SENSOR-J ASSY

J

CN4

K

B

CN1

C

D

E

SIDE B

IC24

TR63

TR64 TR62 TR60 TR58 TR56 TR54 TR52 TR50

SENSOR-J ASSY

J

TR61 TR59 TR57 TR55 TR53 TR51 TR49

IC23 IC22 IC21IC26TR65

TR47 TR45 TR43 TR41 TR39 TR37 TR35 TR33

TR48 TR46 TR44 TR42 TR40 TR38 TR36 TR34

TR31

TR32 TR3

F

J

68

1234

PDK-50HW3

Page 69

5678

SIDE A

A

CN1

I

IC20 IC25 IC19 IC18 IC17

33

TR31 TR29 TR27 TR25 TR23 TR21 TR19 TR17 TR15 TR13 TR11 TR9 TR7 TR5 TR3 TR1

TR32 TR30 TR28 TR26 TR24 TR22 TR20 TR18 TR16 TR14 TR12 TR10 TR8 TR6 TR4 TR2

CN4

SIDE B

B

C

D

56

PDK-50HW3

E

F

J

69

7

8

Page 70

1234

0

T

4.9 SENSOR-K ASSY

SIDE A

A

SENSOR-K ASSY

K

B

CN1

C

D

E

SIDE B

IC24

TR63

TR64 TR62 TR60 TR58 TR56 TR54 TR52 TR50

SENSOR-K ASSY

K

TR61 TR59 TR57 TR55 TR53 TR51 TR49

IC23 IC22

TR47 TR45 TR43 TR41 TR39 TR37 TR35 TR33

TR48 TR46 TR44 TR42 TR40 TR38 TR36 TR34

IC26TR65

IC21

TR31

TR32 TR3

F

K

70

1234

PDK-50HW3

Page 71

5678

SIDE A

A

CN1

J

IC20 IC25 IC19 IC18 IC17

33

TR31 TR29 TR27 TR25 TR23 TR21 TR19 TR17 TR15 TR13 TR11 TR9 TR7 TR5 TR3 TR1

TR32 TR30 TR28 TR26 TR24 TR22 TR20 TR18 TR16 TR14 TR12 TR10 TR8 TR6 TR4 TR2

CN4

SIDE B

B

C

D

56

PDK-50HW3

E

F

K

71

7

8

Page 72

1234

0

R

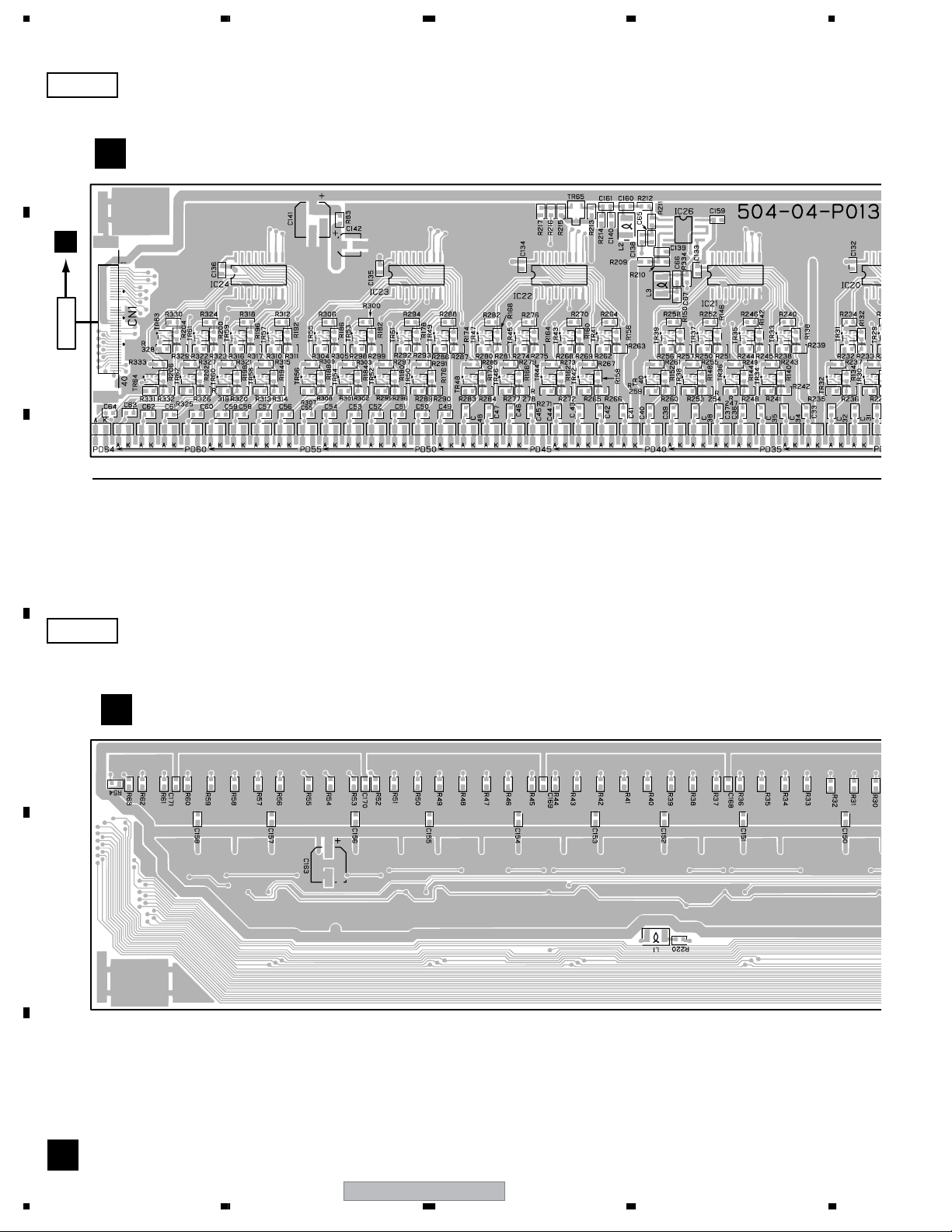

4.10 SENSOR-L ASSY

SIDE A

A

SENSOR-L ASSY

L

CN2

M

B

CN1

C

D

E

SIDE B

IC24

TR63

TR64 TR62 TR60 TR58 TR56 TR54 TR52 TR50

SENSOR-L ASSY

L

TR61 TR59 TR57 TR55 TR53 TR51 TR49

IC23 IC22

TR47 TR45 TR43 TR41 TR39 TR37 TR35 TR33

TR48 TR46 TR44 TR42 TR40 TR38 TR36 TR34

IC26TR65

IC21

TR31 T

TR32 TR3

F

L

72

1234

PDK-50HW3

Page 73

5678

SIDE A

A

CN8

CN5

A

CN7

A

IC20 IC25 IC19 IC18 IC17

33

TR31 TR29 TR27 TR25 TR23 TR21 TR19 TR17 TR15 TR13 TR11 TR9 TR7 TR5 TR3 TR1

TR32 TR30 TR28 TR26 TR24 TR22 TR20 TR18 TR16 TR14 TR12 TR10 TR8 TR6 TR4 TR2

CN4

SIDE B

B

C

D

56

PDK-50HW3

CN9

A

CN6

E

F

L

73

7

8

Page 74

1234

0

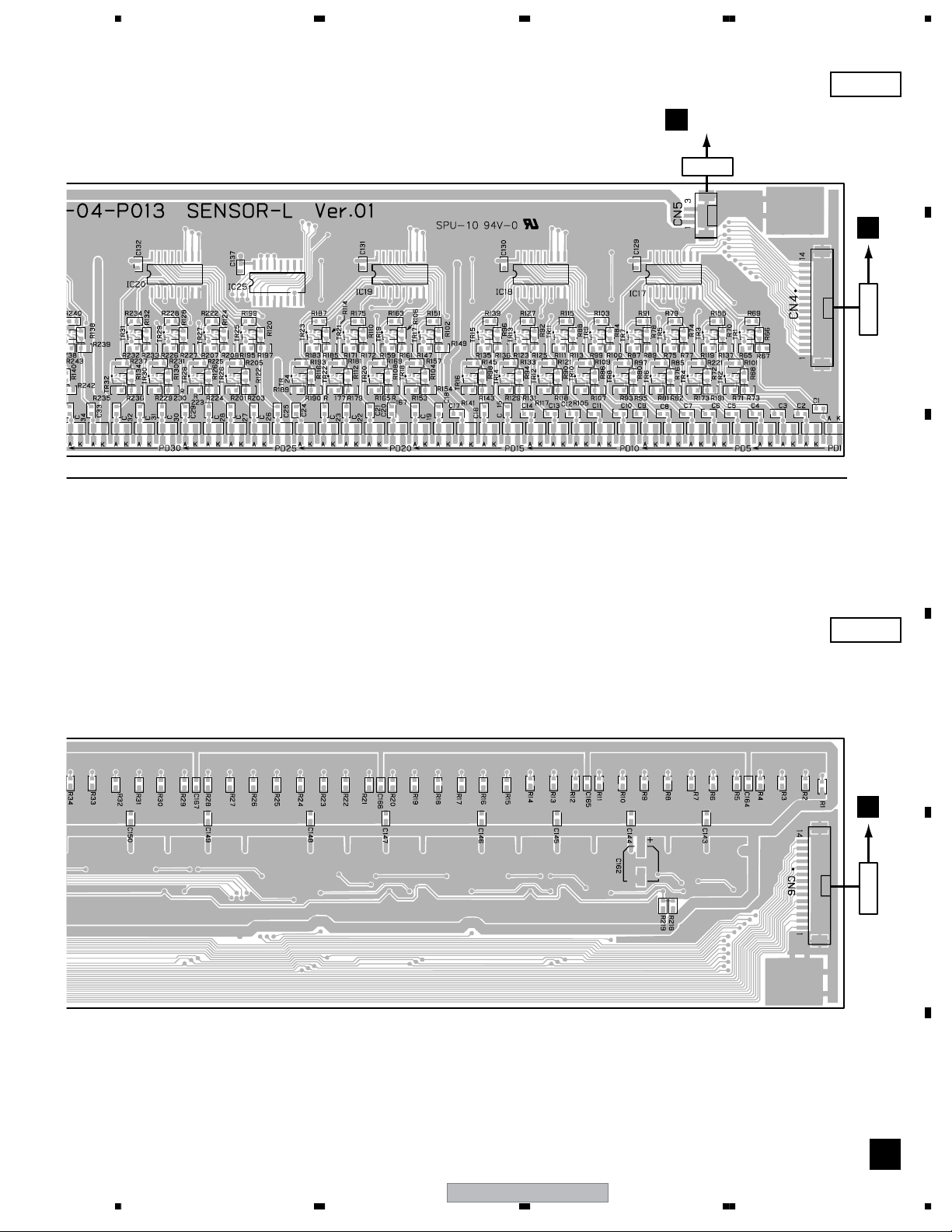

4.11 SENSOR-M ASSY

SIDE A

A

SENSOR-M ASSY

M

B

C

D

E

SIDE B

CN4

N

CN1

IC24

TR63

TR64 TR62 TR60 TR58 TR56 TR54 TR52 TR50

M

TR61 TR59 TR57 TR55 TR53 TR51 TR49

SENSOR-M ASSY

IC23 IC22

TR47 TR45 TR43 TR41 TR39 TR37 TR35 TR33

TR48 TR46 TR44 TR42 TR40 TR38 TR36 TR34

IC26TR65

IC21

TR31 T

TR32 TR3

F

M

74

1234

PDK-50HW3

Page 75

5678

SIDE A

A

CN1

L

B

CN2

IC20 IC25 IC19 IC18 IC17

33

TR31 TR29 TR27 TR25 TR23 TR21 TR19 TR17 TR15 TR13 TR11 TR9 TR7 TR5 TR3 TR1

TR32 TR30 TR28 TR26 TR24 TR22 TR20 TR18 TR16 TR14 TR12 TR10 TR8 TR6 TR4 TR2

C

SIDE B

D

E

56

PDK-50HW3

F

M

75

7

8

Page 76

1234

4.12 SENSOR-N ASSY

SIDE A SIDE A

H

A

CN5

CN3

SENSOR-N ASSY

N

CN6

H

B

CN2

C

TR14

TR15 TR13 TR11 TR8 TR7 TR5 TR3 TR1TR16

IC25 IC26 TR65

TR12 TR10 TR9 TR6 TR4 TR2

SIDE B SIDE B

SENSOR-N ASSY

N

D

E

CN1

M

CN4

F

N N

76

1234

IC18 IC17

PDK-50HW3

Page 77

5678

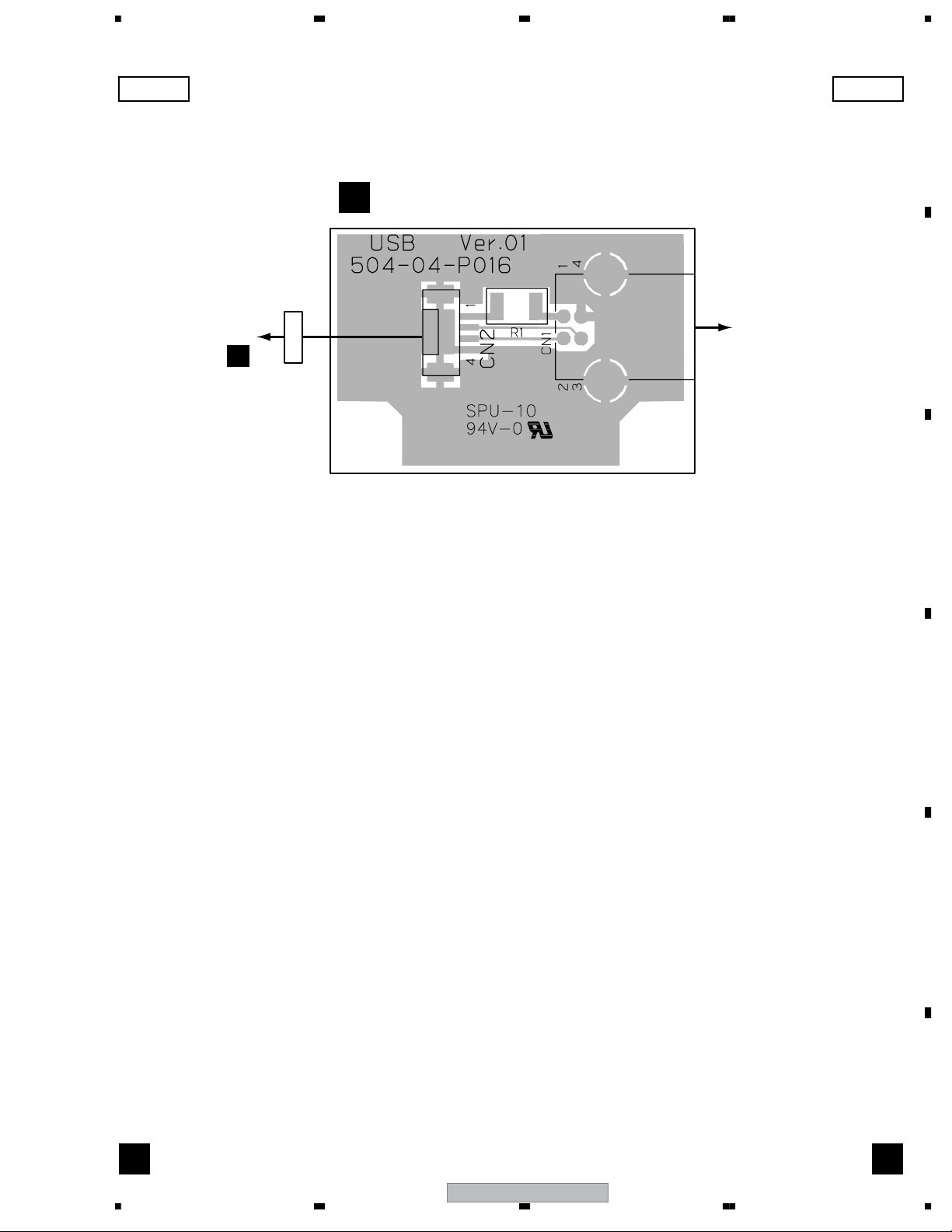

4.13 USB BOARD ASSY

SIDE A SIDE A

USB BOARD ASSY

O

CN3

A

CN2

USB CABLE

A

B

C

D

E

O O

56

PDK-50HW3

7

8

F

77

Page 78

1234

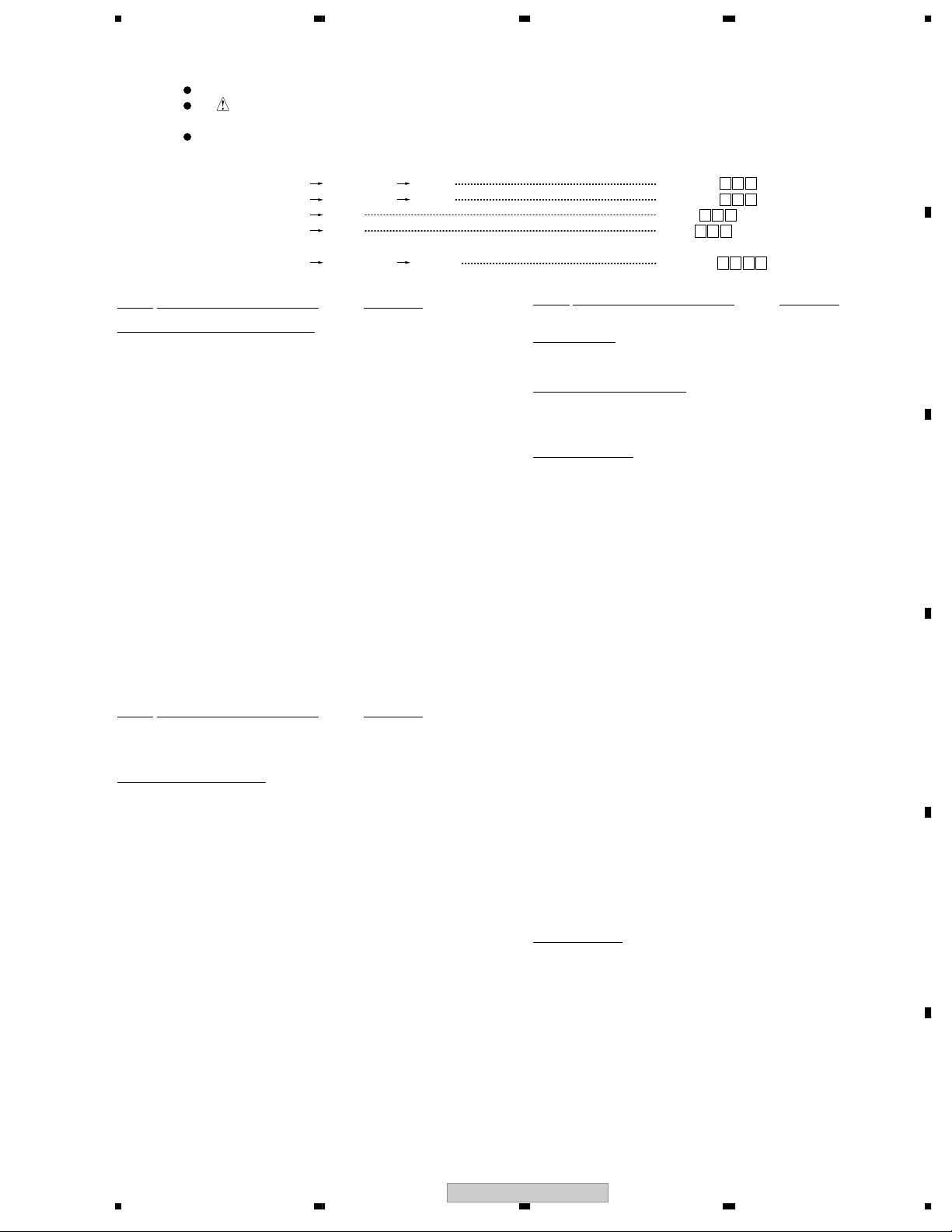

4.14 PEN PCB ASSY

SIDE A SIDE A

A

PEN PCB ASSY

P

B

SIDE B SIDE B

C

PEN PCB ASSY

P

VR2 VR1

D

E

IC2 TR2

IC3 IC1

TR1

F

P P

78

1234

PDK-50HW3

Page 79

5678

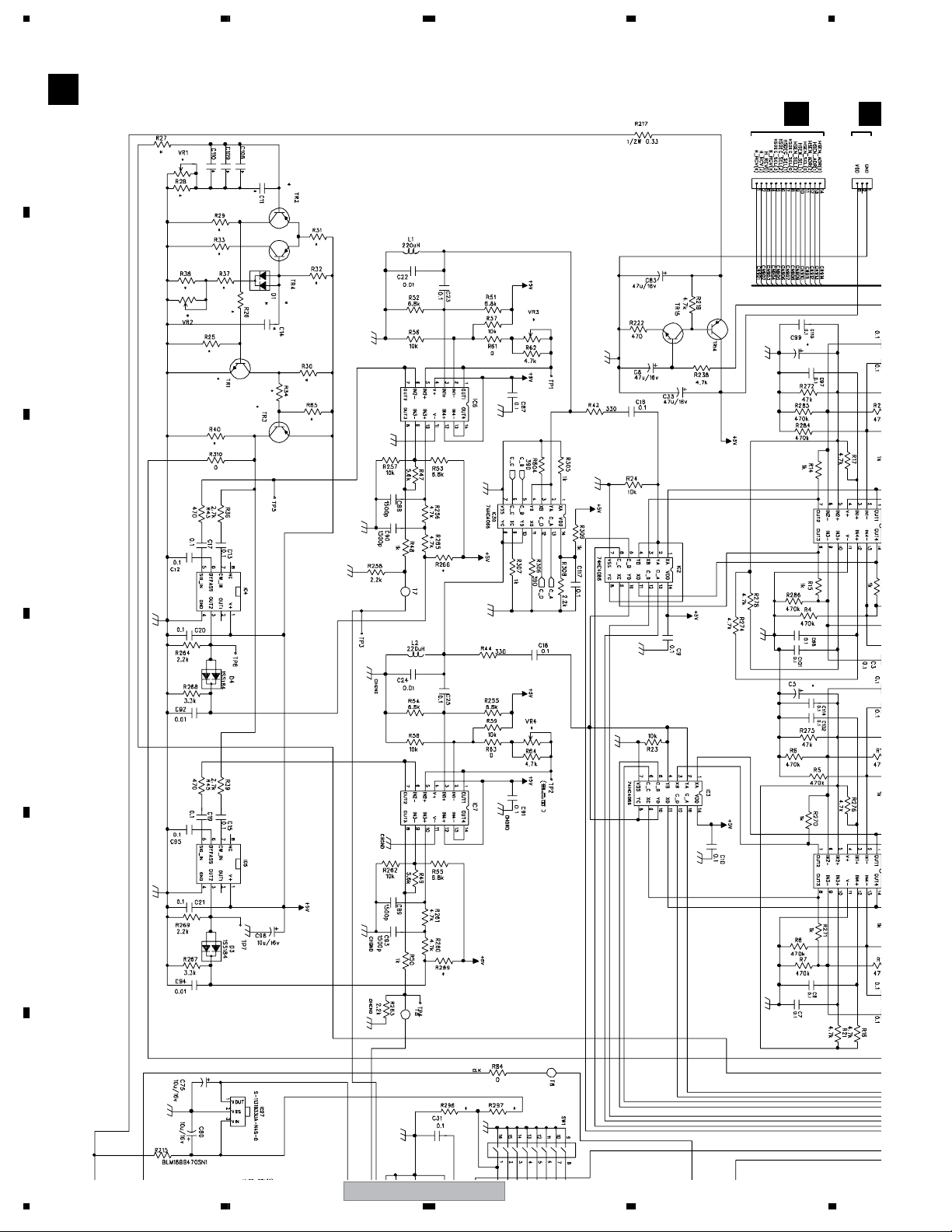

5. PCB PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω

47k Ω

0.5 Ω

1 Ω

56 x 10

47 x 10

R50

1R0

1

3

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω

1

Mark No. Description Part No.

LIST OF ASSEMBLIES

1..LED-A ASSY BZW1509

1..LED-B ASSY BZW1510

1..LED-C ASSY BZW1511

1..LED-D ASSY BZW1512

1..LED-E ASSY BZW1513

1..LED-F ASSY BZW1514

1..LED-G ASSY BZW1515

1..SENSOR-H ASSY BZW1516

1..SENSOR-I ASSY BZW1517

1..SENSOR-J ASSY BZW1518

1..SENSOR-K ASSY BZW1519

1..SENSOR-L ASSY BZW1520

1..SENSOR-M ASSY BZW1521

1..SENSOR-N ASSY BZW1522

1..USB BOARD ASSY BZW1523

1..PEN PCB ASSY BZW1524

561

473

5621

RD1/4PU J

RD1/4PU J

RN2H K

RS1P K

RN1/4PC F562 x 10

561

473

R50

1R0

5621

Mark No. Description Part No.

SWITCHES

SW1 BZS1350

COILS AND FILTERS

L1,L2 AZT1217

L3,L4 BZT1701

CAPACITORS

NSP C118 CCSRCH100D50

NSP C1-C4,C6-C7,C9,C10,C12 CKSRYB104K25

NSP C13,C15-C21,C23,C25-C27 CKSRYB104K25

NSP C29-C32,C34-36,C39-40 CKSRYB104K25

NSP C42,C47-C49,C56,C58,C61 CKSRYB104K25

NSP C62,C65,C67,C69,C72-C74 CKSRYB104K25

NSP C76,C78,C84-C87,C91,C95 CKSRYB104K25

NSP C97,C98,C100-C107,C113 CKSRYB104K25

NSP C114,C116,C117 CKSRYB104K25

NSP C22,C24,C44,C57,C92,C94 CCSRCH103K50

A

B

C

Mark No. Description Part No.

LED-A ASSY

A

SEMICONDUCTORS

IC1,IC6,IC7,IC28 BZQ1739

IC10 BZQ1745

IC11 BZQ1740

IC12-IC14,IC16-IC19 BZQ1743

NSP IC15 BZQ1736

IC20,IC26 BZQ1772

IC21 BZQ1763

IC2,IC3,IC22,IC30 TC74HC4066AF

IC24 BZQ1770

IC25,IC29 BZQ1764

IC27 BZQ1741

IC4,IC5 BZQ1737

IC8,IC9,IC23 BZQ1771

DT1-DT18,TR17 BZQ1768

TR14 BZQ1746

TR5,TR9,TR12,TR15,TR16 BZQ1766

TR6,TR10 BZQ1765

TR7,TR8,TR11,TR13 BZQ1747

D2-D4 1SS184

LED1-LED64 AZQ1108

LED65 AZQ1109

56

NSP C111,C112 CCSRCH103K50

NSP C28,C115 CCSRCH271J50

NSP C37,C64,C75,C80,C96 CEVQW100M25

NSP C38,C41,C55,C60 CCSRCH561J50

NSP C43,C59,C901 CCSRCH101J50

NSP C45,C54 CKSRYB223K50

NSP C46,C53 CKSRYB153K50

NSP C50,C68 CKSRYB333K25

NSP C51 • • • • • •

NSP C52 CFHBSP683J16

NSP C63,C71 CEVQW101M6R3

NSP C77,C79 CCSRCH220J50

NSP C8,C33,C66,C70,C83 CEVQW470M16

NSP C81-82 CCSRCH150J50

NSP C88-90,C93 CCSRCH152J50

RESISTORS

NSP R102,R107-R115,R185-R192 RS1/10SR223J

NSP R195-R198,R223-R225,R228-R234 RS1/10SR223J

NSP R236,R237,R144,R158 RS1/10SR223J

NSP R105,R106 RS1/10SR101J

NSP R122,R160,R298 RS1/10SR154J

NSP R123,R153 RS1/10SR221J

NSP R126,R127,R130,R131,R159 RS1/10SR225J

NSP R166,R167,R171,R137 RS1/10SR225J

NSP R1-R3,R42,R44,R288-R292,R116 RS1/10SR331J

NSP R133,R152,R258,R263,R264 RS1/10SR222J

NSP R269,R308,R235,R219-R221 RS1/10SR222J

NSP R226,R227 RS1/10SR222J

PDK-50HW3

D

E

F

79

7

8

Page 80

1234

Mark No. Description Part No.

NSP R135,R136,R161,R165 RS1/10SR683J

NSP R139,R150,R151,R182,R184 RS1/10SR104J

NSP R86,R254,R301 RS1/10SR104J

A

NSP R140 RS1/10SR153J

NSP R141,R146,R299 RS1/10SR563J

NSP R14,R15,R18,R19,R48,R50 RS1/10SR102J

NSP R117,R119,R125,R129,R157 RS1/10SR102J

NSP R168,R172,R173,R270,R271 RS1/10SR102J

NSP R282,R283,R305,R307,R309 RS1/10SR102J

NSP R16,R17,R21,R85,R121 RS1/10SR472J

NSP R128,R175,R176,R218,R238 RS1/10SR472J

NSP R256,R260,R261,R265,R274 RS1/10SR472J

NSP R276,R278,R194,R199-R201 RS1/10SR472J

B

NSP R203,R64,R62,R287,R293 RS1/10SR472J

NSP R163,R170,R174,R177-R181 RS1/10SR470J

NSP R183 RS1/10SR105J

NSP R213,R20,R272,R273,R275,R70 RS1/10SR473J

NSP R217 • • • • • •

NSP R23,R24,R56-R59,R118,R132 RS1/10SR103J

NSP R138,R145,R148,R155,R156 RS1/10SR103J

NSP R162,R257,R262 RS1/10SR103J

NSP R267,R268 RS1/10SR332J

NSP R294,R295 RS1/10SR271J

NSP R302 RS1/10SR333J

C

NSP R304,R306 RS1/10SR391J

NSP R36,R39 RS1/10SR272J

NSP R4-R12,R277,R279-R281 RS1/10SR474J

NSP R284-R286 RS1/10SR474J

NSP R43,R45,R222 RS1/10SR471J

NSP R47,R49 RS1/10SR562J

NSP R51-R55,R255 RS1/10SR682J

NSP R61,R63,R84,R310,R74 RS1/10SR0R0J

NSP R76,R78-R81,R91-R93,R96 RS1/10SR0R0J

NSP R98,R100,R193,R204,R205 RS1/10SR0R0J

NSP R209,R210,R214,R244 RS1/10SR0R0J

D

NSP R66,R104,R206,R207,R211 RS1/10SR224J

NSP R212,R239,R240,R242,R243 RS1/10SR224J

NSP R245-R252 RS1/10SR224J

NSP R67,R241 RS1/10SR152J

NSP R68,R69,R72,R73,R94,R95 RS1/10SR220J

NSP R71 RS1/10SR561J

NSP R75,R103 RS1/10SR123J

NSP R82,R143 RS1/10SR824J

NSP R89,R90,R215,R216,R303 BZQ1760

OTHERS

E

F

CN1,CN2 BZK1514

CN14,CN15 BZK1511

CN3 BZK1513

CN4 BZK1518

CN7,CN9 BZK1516

CN8 BZK1512

NSP TP1-TP7 • • • • • •

X1 (32.768kHz) BZT1703

X2 (24MHz) BZT1702

LED-B ASSY

B

SEMICONDUCTORS

IC1,IC2 BZQ1772

Mark No. Description Part No.

DT1-DT16 BZQ1768

LED1-LED64 AZQ1108

CAPACITORS

NSP C1,C2 CKSRYB104K25

NSP C3 CEVQW100M25

RESISTORS

NSP R17-R24 RS1/10SR470J

NSP R25 RS1/10SR103J

NSP R26 RS1/10SR104J

OTHERS

CN1 BZK1517

CN4 BZK1518

NSP JP1 RS1/10SR0R0J

LED-C ASSY

C

SEMICONDUCTORS

IC1,IC2 BZQ1772

DT1-DT16 BZQ1768

LED1-LED64 AZQ1108

CAPACITORS

NSP C1,C2 CKSRYB104K25

NSP C3 CEVQW100M25

RESISTORS

NSP R17-R24 RS1/10SR470J

NSP R25 RS1/10SR103J

NSP R26 RS1/10SR104J

OTHERS

CN1 BZK1517

CN4 BZK1518

NSP JP2 RS1/10SR0R0J

LED-D ASSY

D

SEMICONDUCTORS

IC1,IC2 BZQ1772

DT1-DT16 BZQ1768

LED1-LED64 AZQ1108

CAPACITORS

NSP C1,C2 CKSRYB104K25

NSP C3 CEVQW100M25

RESISTORS

NSP R17-R24 RS1/10SR470J

NSP R25,R26 RS1/10SR103J

NSP R27 RS1/10SR223J

OTHERS

CN1 BZK1517

CN2 BZK1511

CN5 BZK1512

CN6 BZK1515

LED-E ASSY

E

SEMICONDUCTORS

IC1,IC2 BZQ1772

DT1-DT16 BZQ1768

LED1-LED64 AZQ1108

80

PDK-50HW3

1234

Page 81

5678

Mark

No. Description Part No.

CAPACITORS

NSP C1,C2 CKSRYB104K25

NSP C3 CEVQW100M25

RESISTORS

NSP R17-R24 RS1/10SR330J

NSP R25 RS1/10SR103J

OTHERS

CN2 BZK1512

CN3 BZK1515

CN4 BZK1518

LED-F ASSY

F

SEMICONDUCTORS

IC1,IC2 BZQ1772

DT1-DT16 BZQ1768

LED1-LED64 AZQ1108

CAPACITORS

NSP C1,C2 CKSRYB104K25

NSP C3 CEVQW100M25

RESISTORS

NSP R17-R24 RS1/10SR330J

NSP R25 RS1/10SR103J

OTHERS

CN1 BZK1517

CN4 BZK1518

Mark

No. Description Part No.

NSP C139,C129-C137,C143-C161 CKSRYB104K25

NSP C164-C171 CKSRYB104K25

NSP C163 CEVQW101M6R3

NSP C1-C64 CCSRCH390J50

A

RESISTORS

NSP R1-R64,R66,R68,R70,R72 RS1/10SR225J

NSP R74,R76,R78,R80,R84,R86 RS1/10SR225J

NSP R88,R90,R92,R94,R96,R98 RS1/10SR225J

NSP R102,R104,R106,R108,R110 RS1/10SR225J

NSP R112,R114,R116,R120,R122 RS1/10SR225J

NSP R124,R126,R128,R130,R132 RS1/10SR225J

NSP R134,R138,R140,R142,R144 RS1/10SR225J

NSP R146,R148,R150,R152,R156 RS1/10SR225J

NSP R158,R160,R162,R164,R166 RS1/10SR225J

NSP R168,R170,R174,R176,R178 RS1/10SR225J

NSP R180,R182,R184,R186,R188 RS1/10SR225J

NSP R192,R194,R196,R198,R200 RS1/10SR225J

NSP R202,R204,R206,R67,R73,R77 RS1/10SR225J

NSP R82,R89,R95,R100,R107,R113 RS1/10SR225J

NSP R118,R125,R131,R136,R137 RS1/10SR225J

NSP R143,R149,R154,R161,R167 RS1/10SR225J

NSP R172,R179,R185,R190,R191 RS1/10SR225J

NSP R197,R203,R208,R224,R227 RS1/10SR225J

NSP R230,R233,R236,R239,R242 RS1/10SR225J

NSP R245,R248,R251,R254,R257 RS1/10SR225J

NSP R260,R263,R266,R269,R272 RS1/10SR225J

NSP R275,R278,R281,R284,R287 RS1/10SR225J

NSP R290,R293,R296,R299,R302 RS1/10SR225J

NSP R305,R308,R311,R314,R317 RS1/10SR225J

NSP R320,R323,R326,R329,R332 RS1/10SR225J

B

C

LED-G ASSY

G

SEMICONDUCTORS

IC1,IC2 BZQ1772

DT1-DT10 BZQ1768

LED1-LED16 AZQ1108

CAPACITORS

NSP C1,C2 CKSRYB104K25

NSP C3 CEVQW100M25

RESISTORS

NSP R13 RS1/10SR103J

NSP R5-R12 RS1/10SR330J

OTHERS

CN1 BZK1517

SENSOR-H ASSY

H

SEMICONDUCTORS

IC17-IC24 BZQ1769

IC25 BZQ1772

IC26 BZQ1738

TR1-TR64 BZQ1747

TR65 BZQ1766

PD1-PD64 AZQ1107

NSP R209 RS1/10SR473J

NSP R210 RS1/10SR563J

NSP R211 RS1/10SR152J

NSP R212 RS1/10SR331J

NSP R213,R69,R79,R85,R91,R97 RS1/10SR103J

NSP R101,R103,R109,R115,R121 RS1/10SR103J

NSP R127,R133,R139,R145,R151 RS1/10SR103J

NSP R155,R157,R163,R169,R175 RS1/10SR103J

NSP R181,R187,R193,R199,R205 RS1/10SR103J

NSP R221,R222,R225,R228,R231 RS1/10SR103J

NSP R234,R237,R240,R243,R246 RS1/10SR103J

NSP R249,R252,R255,R258,R261 RS1/10SR103J

NSP R264,R267,R270,R273,R276 RS1/10SR103J

NSP R279,R282,R285,R288,R291 RS1/10SR103J

NSP R294,R297,R300,R303,R306 RS1/10SR103J

NSP R309,R312,R315,R318,R321 RS1/10SR103J

NSP R324,R327,R330,R333 RS1/10SR103J

NSP R214 RS1/10SR153J

NSP R216 RS1/10SR101J

NSP R217 RS1/10SR102J

NSP R218,R219 RS1/10SR224J

NSP R220 RS1/10SR221J

NSP R334 RS1/10SR0R0J

NSP R65,R71,R75,R81,R87,R93 RS1/10SR683J

NSP R99,R105,R111,R117,R119 RS1/10SR683J

D

E

COILS AND FILTERS

L1 AZT1217

CAPACITORS

NSP C138 CKSRYB153K50

56

NSP R123,R129,R135,R141,R147 RS1/10SR683J

NSP R153,R159,R165,R171,R173 RS1/10SR683J

NSP R177,R183,R189,R195,R201 RS1/10SR683J

NSP R207,R223,R226,R229,R232 RS1/10SR683J

NSP R235,R238,R241,R244,R247 RS1/10SR683J

PDK-50HW3

F

81

7

8

Page 82

1234

Mark No. Description Part No.

NSP R250,R253,R256,R259,R262 RS1/10SR683J

NSP R265,R268,R271,R274,R277 RS1/10SR683J

NSP R280,R283,R286,R289,R292 RS1/10SR683J

A

NSP R295,R298,R301,R304,R307 RS1/10SR683J

NSP R310,R313,R316,R319,R322 RS1/10SR683J

NSP R325,R328,R331 RS1/10SR683J

NSP R83 RS1/10SR220J

OTHERS

CN1 BZK1517

CN5 BZK1513

CN6 BZK1516

Mark No. Description Part No.

NSP R211 RS1/10SR152J

NSP R212 RS1/10SR331J

NSP R213,R69,R79,R85,R91 RS1/10SR103J

NSP R97,R101,R103,R109,R115 RS1/10SR103J

NSP R121,R127,R133,R139,R145 RS1/10SR103J

NSP R151,R155,R157,R163,R169 RS1/10SR103J

NSP R175,R181,R187,R193,R199 RS1/10SR103J

NSP R205,R221,R222,R225,R228 RS1/10SR103J

NSP R231,R234,R237,R240,R243 RS1/10SR103J

NSP R246,R249,R252,R255,R258 RS1/10SR103J

NSP R261,R264,R267,R270,R273 RS1/10SR103J

NSP R276,R279,R282,R285,R288 RS1/10SR103J

B

SENSOR-I ASSY

I

SEMICONDUCTORS

IC17-IC24 BZQ1769

IC25 BZQ1772

IC26 BZQ1738

TR1-TR64 BZQ1747

TR65 BZQ1766

PD1-PD64 AZQ1107

COILS AND FILTERS

C

L1 AZT1217

CAPACITORS

NSP C138 CKSRYB153K50

NSP C139,C129-C137,C143-C161 CKSRYB104K25

NSP C164-C171 CKSRYB104K25

NSP C163 CEVQW101M6R3

NSP C1-C64 CCSRCH390J50

RESISTORS

NSP R1-R64,R66,R68,R70,R72 RS1/10SR225J

NSP R74,R76,R78,R80,R84,R86 RS1/10SR225J

NSP R88,R90,R92,R94,R96,R98 RS1/10SR225J

D

NSP R102,R104,R106,R108,R110 RS1/10SR225J

NSP R112,R114,R116,R120,R122 RS1/10SR225J

NSP R124,R126,R128,R130,R132 RS1/10SR225J

NSP R134,R138,R140,R142,R144 RS1/10SR225J

NSP R146,R148,R150,R152,R156 RS1/10SR225J

NSP R158,R160,R162,R164,R166 RS1/10SR225J

NSP R168,R170,R174,R176,R178 RS1/10SR225J

NSP R180,R182,R184,R186,R188 RS1/10SR225J

NSP R192,R194,R196,R198,R200 RS1/10SR225J

NSP R202,R204,R206,R67,R73,R77 RS1/10SR225J

NSP R82,R89,R95,R100,R107 RS1/10SR225J

E

NSP R113,R118,R125,R131,R136 RS1/10SR225J

NSP R137,R143,R149,R154,R161 RS1/10SR225J

NSP R167,R172,R179,R185,R190 RS1/10SR225J

NSP R191,R197,R203,R208,R224 RS1/10SR225J

NSP R227,R230,R233,R236,R239 RS1/10SR225J

NSP R242,R245,R248,R251,R254 RS1/10SR225J

NSP R257,R260,R263,R266,R269 RS1/10SR225J

NSP R272,R275,R278,R281,R284 RS1/10SR225J

NSP R287,R290,R293,R296,R299 RS1/10SR225J

NSP R302,R305,R308,R311,R314 RS1/10SR225J

NSP R317,R320,R323,R326,R329 RS1/10SR225J

F

NSP R332 RS1/10SR225J

NSP R209 RS1/10SR473J

NSP R210 RS1/10SR563J

82

1234

PDK-50HW3

NSP R291,R294,R297,R300,R303 RS1/10SR103J

NSP R306,R309,R312,R315,R318 RS1/10SR103J

NSP R321,R324,R327,R330,R333 RS1/10SR103J

NSP R214 RS1/10SR153J

NSP R216 RS1/10SR101J

NSP R217 RS1/10SR102J

NSP R218,R219 RS1/10SR224J

NSP R220 RS1/10SR221J

NSP R335 RS1/10SR104J

NSP R65,R71,R75,R81,R87,R93 RS1/10SR683J

NSP R99,R105,R111,R117,R119 RS1/10SR683J

NSP R123,R129,R135,R141,R147 RS1/10SR683J

NSP R153,R159,R165,R171,R173 RS1/10SR683J

NSP R177,R183,R189,R195,R201 RS1/10SR683J

NSP R207,R223,R226,R229,R232 RS1/10SR683J

NSP R235,R238,R241,R244,R247 RS1/10SR683J

NSP R250,R253,R256,R259,R262 RS1/10SR683J

NSP R265,R268,R271,R274,R277 RS1/10SR683J

NSP R280,R283,R286,R289,R292 RS1/10SR683J

NSP R295,R298,R301,R304,R307 RS1/10SR683J

NSP R310,R313,R316,R319,R322 RS1/10SR683J

NSP R325,R328,R331 RS1/10SR683J

NSP R83 RS1/10SR220J

OTHERS

CN1 BZK1517

CN4 BZK1518

NSP JP1,JP5,R334 RS1/10SR0R0J

SENSOR-J ASSY

J

SEMICONDUCTORS

IC17-IC24 BZQ1769

IC25 BZQ1772

IC26 BZQ1738

TR1-TR64 BZQ1747

TR65 BZQ1766

PD1-PD64 AZQ1107

COILS AND FIL

L1 AZT1217

TERS

CAPACITORS

NSP C138 CKSRYB153K50

NSP C139,C129-C137,C143-C161 CKSRYB104K25

NSP C164-C171 CKSRYB104K25

NSP C163 CEVQW101M6R3

NSP C1-C64 CCSRCH390J50

RESISTORS

Page 83

5678

Mark

No. Description Part No.

NSP R1-R64,R66,R68,R70,R72 RS1/10SR225J

NSP R74,R76,R78,R80,R84,R86 RS1/10SR225J

NSP R88,R90,R92,R94,R96,R98 RS1/10SR225J

NSP R102,R104,R106,R108,R110 RS1/10SR225J

NSP R112,R114,R116,R120,R122 RS1/10SR225J

NSP R124,R126,R128,R130,R132 RS1/10SR225J

NSP R134,R138,R140,R142,R144 RS1/10SR225J

NSP R146,R148,R150,R152,R156 RS1/10SR225J

NSP R158,R160,R162,R164,R166 RS1/10SR225J

NSP R168,R170,R174,R176,R178 RS1/10SR225J

NSP R180,R182,R184,R186,R188 RS1/10SR225J

NSP R192,R194,R196,R198,R200 RS1/10SR225J

NSP R202,R204,R206,R67,R73 RS1/10SR225J

NSP R77,R82,R89,R95,R100 RS1/10SR225J

NSP R107,R113,R118,R125,R131 RS1/10SR225J

NSP R136,R137,R143,R149,R154 RS1/10SR225J

NSP R161,R167,R172,R179,R185 RS1/10SR225J

NSP R190,R191,R197,R203,R208 RS1/10SR225J

NSP R224,R227,R230,R233,R236 RS1/10SR225J

NSP R239,R242,R245,R248,R251 RS1/10SR225J

NSP R254,R257,R260,R263,R266 RS1/10SR225J

NSP R269,R272,R275,R278,R281 RS1/10SR225J

NSP R284,R287,R290,R293,R296 RS1/10SR225J

NSP R299,R302,R305,R308,R311 RS1/10SR225J

NSP R314,R317,R320,R323,R326 RS1/10SR225J

NSP R329,R332 RS1/10SR225J

NSP R209 RS1/10SR473J

NSP R210 RS1/10SR563J

NSP R211 RS1/10SR152J

NSP R212 RS1/10SR331J

NSP R213,R69,R79,R85,R91 RS1/10SR103J

NSP R97,R101,R103,R109,R115 RS1/10SR103J

NSP R121,R127,R133,R139,R145 RS1/10SR103J

NSP R151,R155,R157,R163,R169 RS1/10SR103J

NSP R175,R181,R187,R193,R199 RS1/10SR103J

NSP R205,R221,R222,R225,R228 RS1/10SR103J

NSP R231,R234,R237,R240,R243 RS1/10SR103J

NSP R246,R249,R252,R255,R258 RS1/10SR103J

NSP R261,R264,R267,R270,R273 RS1/10SR103J

NSP R276,R279,R282,R285,R288 RS1/10SR103J

NSP R291,R294,R297,R300,R303 RS1/10SR103J

NSP R306,R309,R312,R315,R318 RS1/10SR103J