Page 1

FILE–TYPE

COMPACT DISC PLAYER

◊Û¿X/.˘

STANDBY / ON

SINGLE LOADER

ACSESS

@

°

@

°

@

°

@

°

@

'

°

@

°

@

FILE –TYME CD MECHANISM

°

@

°

@

°

@

PLAY

°

@

°

@

°

@

°

@

°

MODE HI-LITE

CLEAR PROGRAM

OPEN/

CLOSE

Î

UNLOAD

TRACK MIN SECDISC

CUSTOM

RDM

ALL BEST CD TEXT

REPEAT

PGM 1

PREVIOUSSINGLE

SCANDISC

DISPLAY BEST PREVIOUS

DISCTITLE

INPUT

4 1

6

7

REMAIN

¡ ¢

FILE-TYPE COMPACT DISC PLAYER

PD-F958

PD-F908

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2085

Type

PD-F958

Model

Power Requirement

PD-F908

KUXQ – O AC120V

KCXQ – O AC120V

KUXQ/CA O – AC120V

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............3

3. SCHEMATIC DIAGRAM................................... 11

4. PCB CONNECTION DIAGRAM .......................19

5. PCB PARTS LIST.............................................24

6. ADJUSTMENT.................................................. 28

7.GENERAL INFORMATION ............................... 36

7.1 PARTS........................................................36

7.1.1 IC ..........................................................36

7.1.2 DISPLAY...............................................37

Remarks

7.2 DIAGNOSIS................................................39

7.2.1 ERROR CORD DISPLAY .................39

7.2.2 ERROR HISTORY AND DISPLAY ... 39

7.2.3 ERROR HISTORY DISPLAY............ 40

7.2.4 DISASSEMBLY................................. 41

7.3 BLOCK DIAGRAM...................................... 49

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................................50

Page 2

PD-F958, PD-F908

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

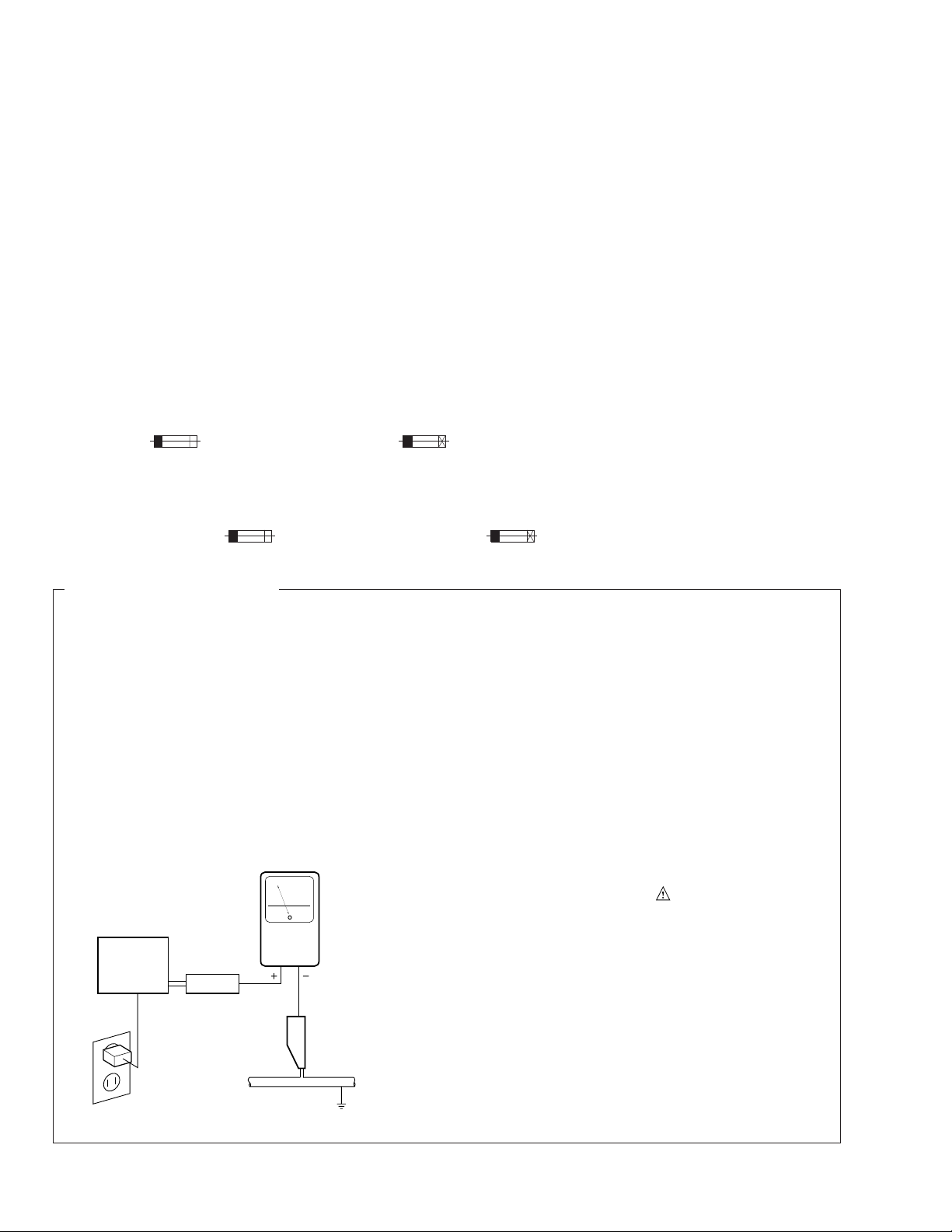

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

Page 3

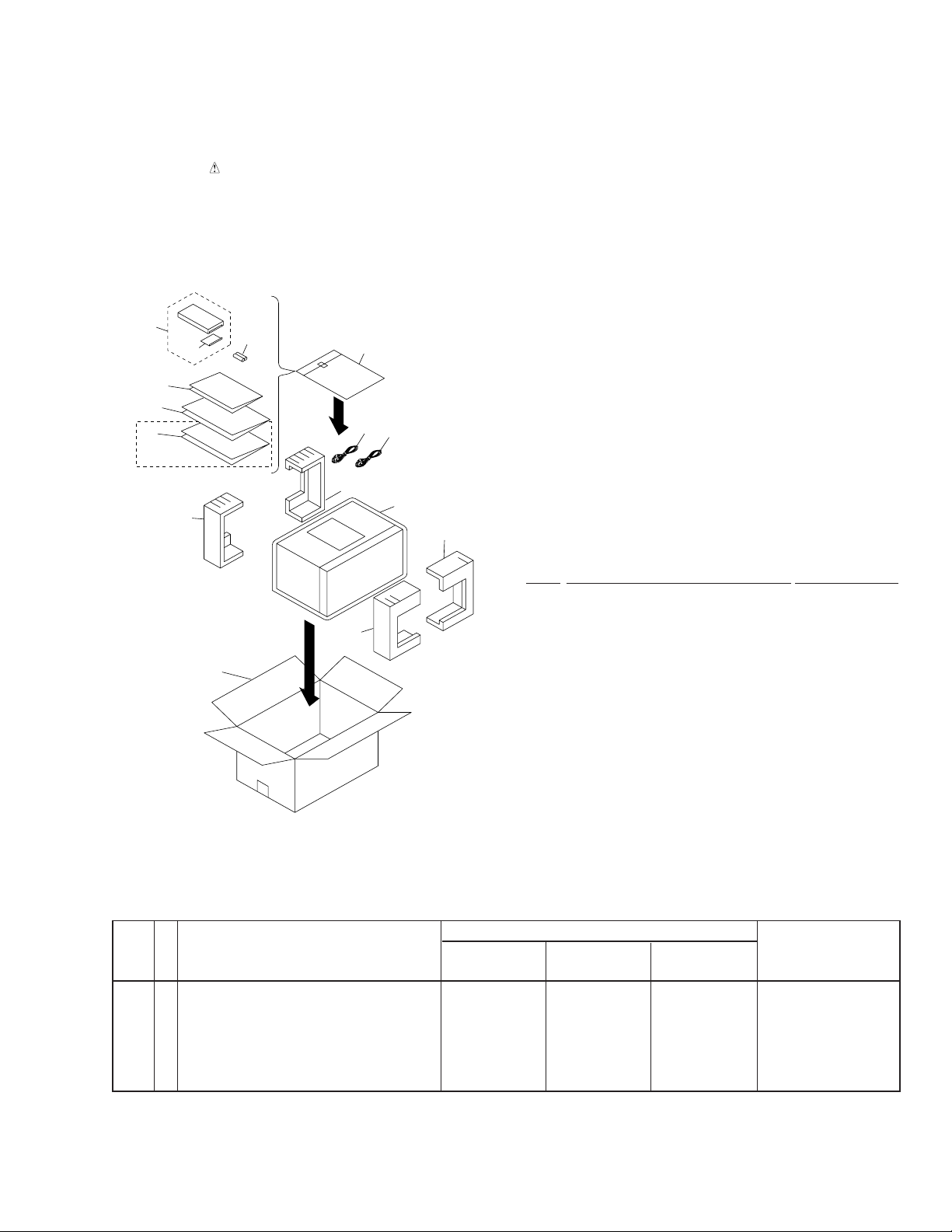

PD-F958, PD-F908

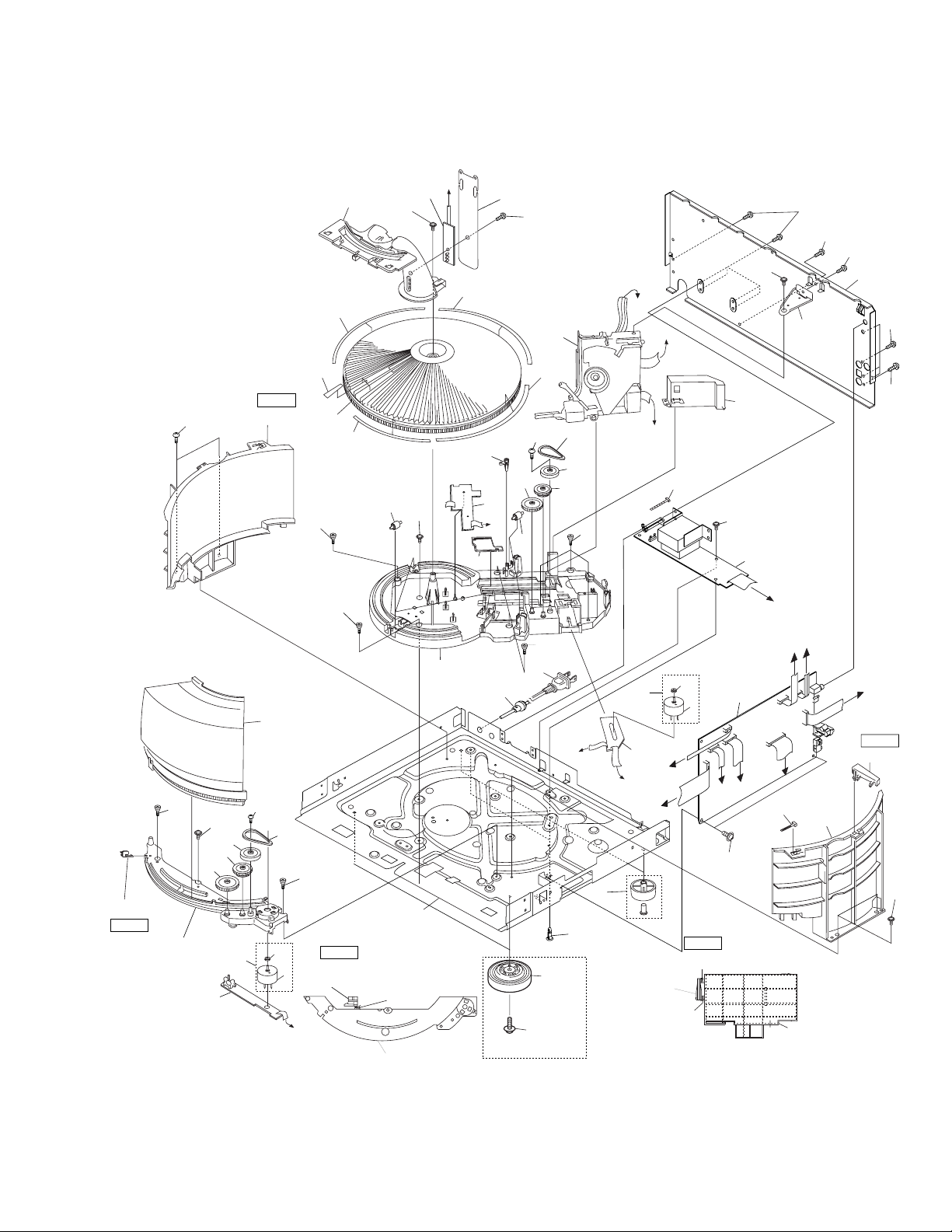

2. EXPLODED VIEWS AND PARTS LIST

NOTES : ÷ Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

÷ The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

÷ Screw adjacent to

2.1 PACKING

mark on the product are used for disassembly.

∞

3

4

5

6

7

PD-F908/KCXQ only

10(1/2)

13

11

10(2/2)

Front

9(1/2)

8

2

1

12

9(2/2)

(1) PARTS LIST

Mark No. Description Part No.

1 Control Cable (L=1.0m) PDE1247

2 Output Cable (L=1.0m) PDE1248

3 Remote Control Unit See Contrast table (2)

4 Battery Cover PZN1105

NSP 5 Warranty Card See Contrast table (2)

6 Operating Instructions (English) See Contrast table (2)

7 Operating Instructions (French)) See Contrast table (2)

8 Polyethlene Bag Z21 - 038

9 Styrol Protector F PHA1333

10 Styrol Protector R PHA1334

11 Packing Case See Contrast table (2)

12 Mirror Mat PHF1001

NSP 13 Battery (R6P, AA) VEM 1010

(2) CONTRAST TABLE

PD-F908/KUXQ,KCXQ and PD-F958/KUXQ/CA have the same construction except for the following:

Part No.

Mark No. Symbol & Description Remarks

3 Remote Control Unit PWW1148 PWW1147 PWW1147

NSP 5 Warranty Card ARY7023 ARY7023 ARY7024

6 Operating Instructions (English) PRB1278 PRB1277 PRB1277

7 Operating Instructions (French) Not used Not used PRD1034

11 Packing Case PHG2337 PHG2334 PHG2335

PD-F958/ PD-F908/ PD-F908/

KUXQ/CA KUXQ KCXQ

(CU-PD101) (CU-PD100) (CU-PD100)

3

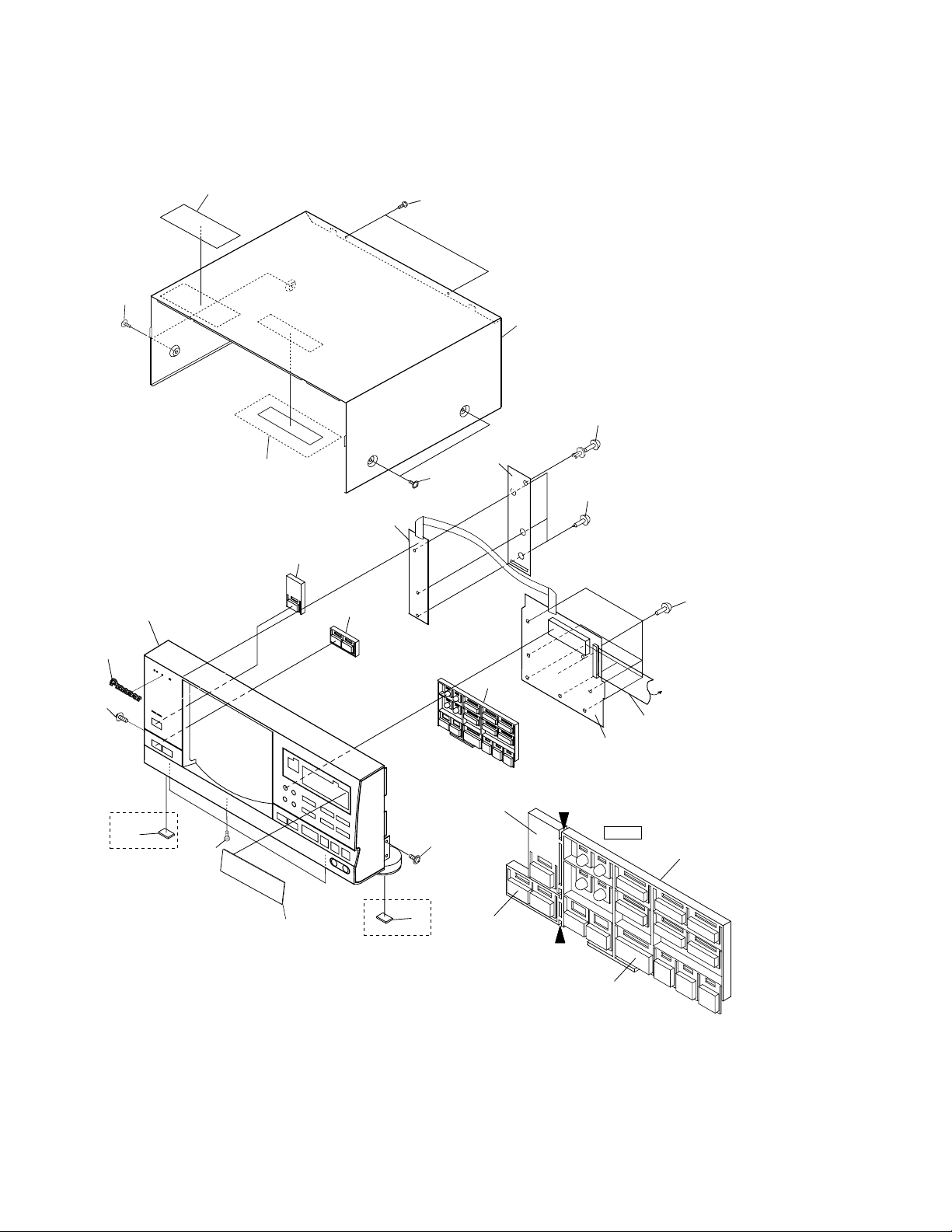

Page 4

PD-F958, PD-F908

2.2 EXTERIOR

57

62

KUXQ/CA,KUXQ type only

50

54

55

61

51

58

53

62

68

4

44 (A)

68

44 (B)

46

63

13

PD-F908 only

60

47

13

PD-F908 only

No.44(A)

Power button

63

No.44(B)

Single loader

button

44 (C)

Cutting

Cutting

No.44(C)

Function button

A

11

3

Cutting position

Note

No.44(Function button)

4

Page 5

27

32(4/4)

65

6

D

32(3/4)

24

67

Refer to

''2.3 LOADING

MECHANISM

ASSY''

31

PD-F958, PD-F908

61

61

61

16

J

F

19

18

61

26(2/2)

Note2

63

15

26(1/2)

63

29

56

Note1

21(1/2)

52

64

30

28

25

5

23

34

59

15

26(2/2)

B

15

Note2

35

32(1/4)

42

15

cutting position

No.26(Hood Base)

cutting

26(1/2)

40

63

39

36

17

32(2/4)

64

38

8

H

42

15

12

10

20

60

PD-F958 Only

33

37

43

H

22

15

14

25

7

C

21(2/2)

E

D

A

69

34

59

cutting

cutting

41

63

2

G

J

E

1

G

C

B

69

21(1/2)

63

cutting positionNote1

No.21(Back Fence)

21(1/2)

66

F

Note1

21 (2/2)

63

5

Page 6

PD-F958, PD-F908

(1) EXTERIOR PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Main Board Assy See Contrast table(2)

2 Power Board Assy See Contrast table(2)

NSP 4 Switch Board Assy See Contrast table(2)

NSP 5 Door Board Assy See Contrast table(2)

NSP 6 Center LED Board Assy See Contrast table(2)

NSP 7 Select Motor Board Assy PWZ3324

NSP 8 Sensor Board Assy PWZ3327

10 Cord Stopper CM - 22C

12 AC Power Cord PDG1064

NSP 17 Under Base PNA2255

3 Display Board Assy See Contrast table(2)

.............

9

11 F.F.C/30V See Contrast table(2)

13 Rubber Sheet See Contrast table(2)

14 Foot Assy REC1263

15 Screw C PBA1106

16 Screw PBA1108

18 Rear Base See Contrast table(2)

19 Stopper Angle PNB1559

Insulator See Contrast table(2)

20

21 Back Fence PNW2671

22 Locking Card Spacer VEC1596

23 Belt PEB1288

24 Cover PNM1294

25 Motor Assy PEA1333

26 Hood Base PNW2633

27 Center Pole PNW2634

28 Gear (Middle) PNW2906

29 Gear (Twin) PNW2642

30 Gear Pulley VNL1662

31 Loading Mechanism Assy PXA1589

32 Rack Label PAM1783

33 Belt PEB1288

34 Motor Pulley PNW1634

35 Disc Rack PNW2845

36 Mecha Base PNW2639

37 Gear PNW2906

38 Gear PNW2642

39 Slider PNW2643

40 Lock Lever PNW2644

41 Mecha Stopper PNW2646

42 Roller PNW2647

43 Gear Pulley VNL1662

44 Function Button See Contrast table(2)

.............

45

46 Name Plate PAM1776

47 Display Window See Contrast table(2)

.............

48

.............

49

50 Operation Panel See Contrast table(2)

51 Bonnet Case PYY1191

52 Hood PNW2865

53 Side Cover PNM1322

.............

54

55 65 Label See Contrast table (2)

56 Label PRW1520

57 Label PRW1523

58 Rivet RBM-003

59 Slider Motor VXM1033

Screw IBZ30P080FZK

60

61 Screw BBZ30P080FZK

62 Screw FBT40P080FZK

63 Screw IBZ30P060FMC

64 Screw IPZ20P080FMC

65 Screw IPZ30P080FCU

66 Screw PMZ30P060FZK

67 Screw PPZ30P050FMC

68 Screw PPZ30P100FMC

69 Binder ZCA-SKB90BK

6

Page 7

PD-F958, PD-F908

(2) CONTRAST TABLE

PD-F908/KUXQ,KCXQ and PD-F958/KUXQ/CA have the same construction except for the following:

Part No.

Mark No. Symbol & Description Remarks

1 Main Board Assy PWZ3895 PWZ3876 PWZ3876

2 Power Board Assy PWZ3900 PWZ3879 PWZ3879

3 Display Board Assy PWZ3904 PWZ3882 PWZ3882

NSP 4 Switch Board Assy PWZ3907 PWZ3885 PWZ3885

NSP 5 Door Board Assy PWZ3913 PWZ3890 PWZ3890

NSP 6 Center LED Board Assy PWZ3915 PWZ3892 PWZ3892

11 F.F.C/30V PDD1186 PDD1167 PDD1167

13 Rubber Sheet Not Used AEB1111 AEB1111

18 Rear Base PNA2452 PNA2450 PNA2450

20 Insulator PNW2766 Not Used Not Used

44 Function Button PAC1908 PAC1905 PAC1905

47 Display Window PAM1772 PAM1774 PAM1774

50 Operation panel PNW2869 PNW2867 PNW2867

55 65 Label ORW1069 ORW1069 Not used

PD-F958/ PD-F908/ PD-F908/

KUXQ/CA KUXQ KCXQ

(40P F.F.C) (32P F.F.C) (32P F.F.C)

7

Page 8

PD-F958, PD-F908

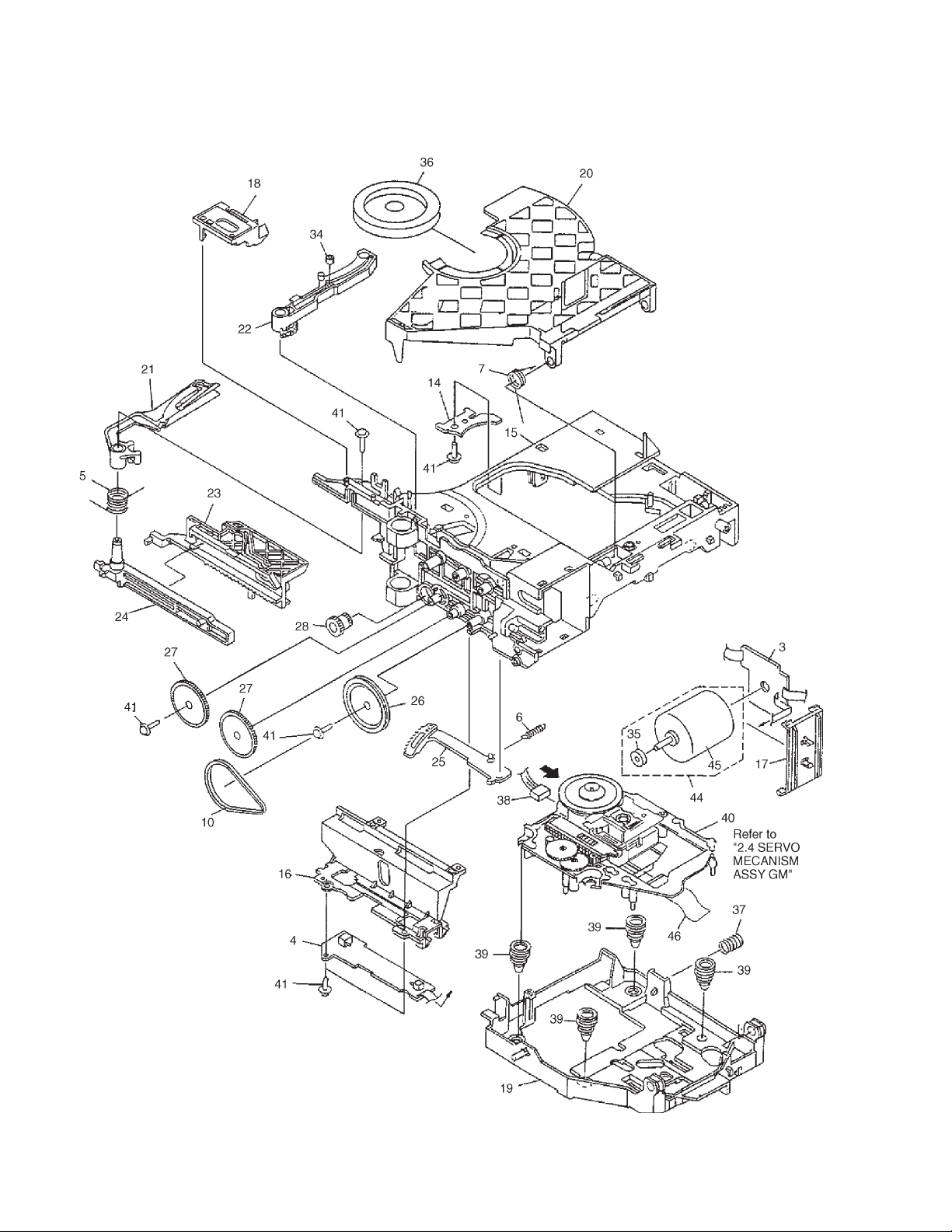

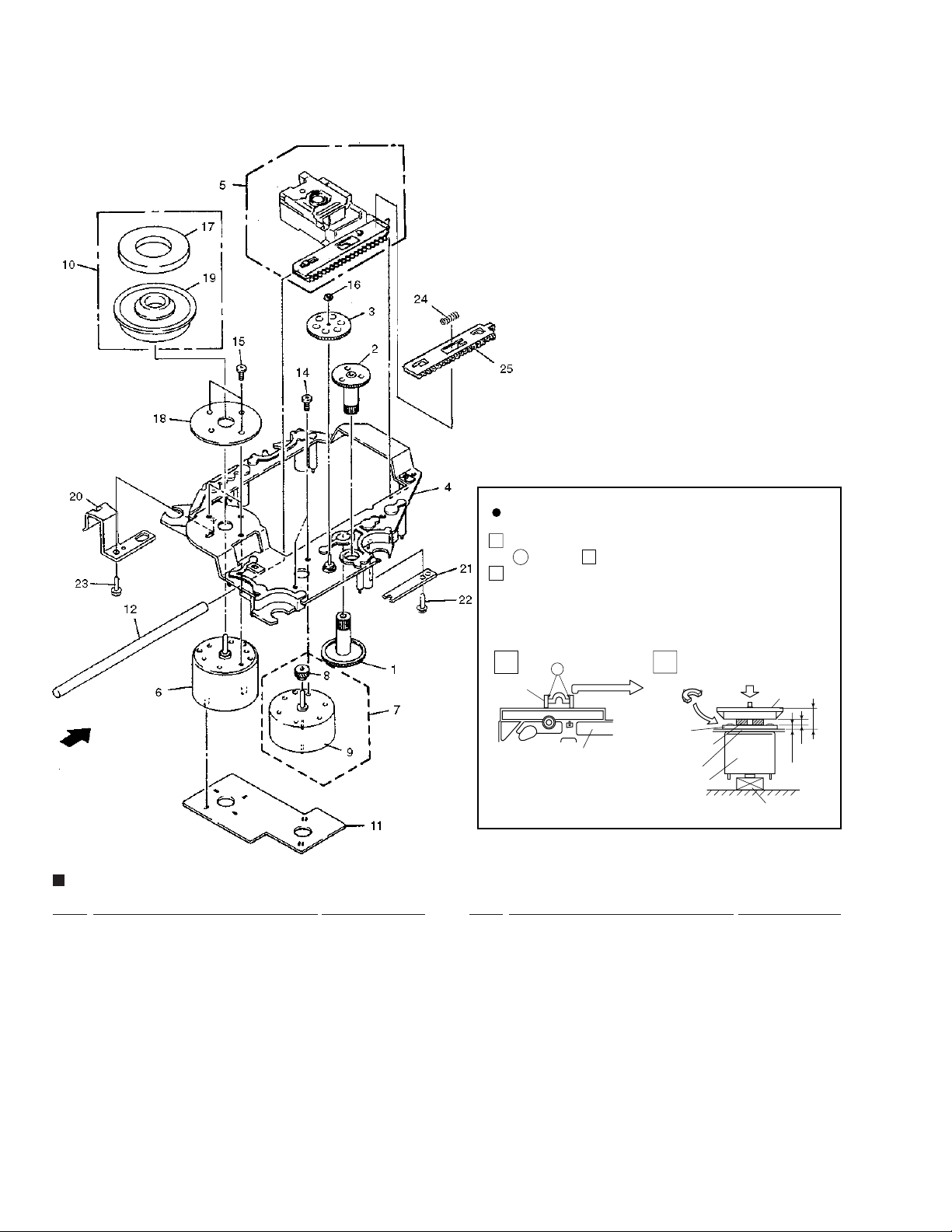

2.3 LOADING MECHANISM ASSY

8

Page 9

LOADING MECHANISM ASSY PARTS LIST

Mark No. Description Part No.

…………

1

…………

NSP 3 Loading Motor Board Assy PWZ3337

NSP 4 Load SW Board Assy PWZ3334

NSP 14 Servo Stopper S ANB7047

2

5 Arm A Spring2 ABH7124

6 Gear Plate Spring ABH7051

7 Clamp Spring ABH7107

…………

8

…………

9

10 Loading Belt AEB7029

…………

11

…………

12

…………

13

15 Loading Base ANW7086

16 Cam Cover ANW7052

17 Motor Holder ANW7053

18 Sensor Holder ANW7119

19 Float Base 96 PNW2700

20 Clamper Holder ANW7117

PD-F958, PD-F908

21 Arm A2 ANW7128

22 Arm (B) ANW7058

23 Drive Plate ANW7059

24 Arm Plate ANW7060

25 Gear Plate ANW7111

26 Gear Pulley (B) ANW7062

27 Gear A ANW7063

28 Drive Gear ANW7064

…………

29

…………

30

…………

31

…………

32

…………

33

34 Roller B ANW7075

35 Motor Pulley PNW1634

36 Clamper PNW2743

37 Float Spring ABH7049

38 Connector Assy (4P) RDE1043

39 Float Rubber AEB7028

NSP 40 Servo Mechanism Assy GM PXA1591

41 Screw IPZ20P080FMC

…………

42

…………

43

44 Motor Assy AEA7006

45 Loading Motor VXM1034

46 16P FFC/30V PDD1180

Froil (for Service) GYA1001

Ha Narl (for Service) GEM1016

9

Page 10

PD-F958, PD-F908

2.4 SERVO MECHANISM ASSY GM

Use nipper or other tool to cut the three sections marked

SERVO MECHANISM ASSY GM PARTS LIST

Mark No. Description Part No.

1 Gear 1 PNW2052

2 Gear 2 PNW2053

3 Gear 3 PNW2054

4 Carriage Base PNW2699

5 Pickup Assy - S PEA1335

6 D.C. Motor Assy (SPINDLE) PEA1235

7 Carriage DC Motor Assy PEA1246

8 Pinion Gear PNW2055

9 Carriage DC Motor/0.3W PXM1027

10 Disc Table Assy PEA1314

11 Mechanism Board Assy PWX1192

12 Guide Bar PLA1094

Mark No. Description Part No.

NSP 19 Disc Table PNW2410

NSP 20 Float Angle ANB7020

How to Install the Disc Table

1

A

in figure . Then remove the spacer

While supporting the spindle motor shaft with the

2

stopper, put spacer on top of the yoke M, and stick the

disc table on top (takes about 9kg pressure). Detach the

spacer.

1

Spacer

13

14 Screw JFZ17P025FZK

15 Screw JFZ20P040FMC

16 Washer WT12D032D025

17 Clamp Magnet PMF1014

18 Yoke M PNB1312

21 Gear Stopper PNB1303

22 Screw BPZ20P060FMC

23 Screw BPZ26P100FMC

24 PU Rack Spring ABH7077

25 Rack Holder PNW2056

A

Float Base

…………

1

2

Spacer

Yoke M

Spacer Setting

Position

Carriage Base

Spindle Motor

(Pressure of about 9 kg)

Disc Table

1.2mm

Stopper

0.9mm

±0.05mm

6.9mm

10

Page 11

1

23

4

PD-F958, PD-F908

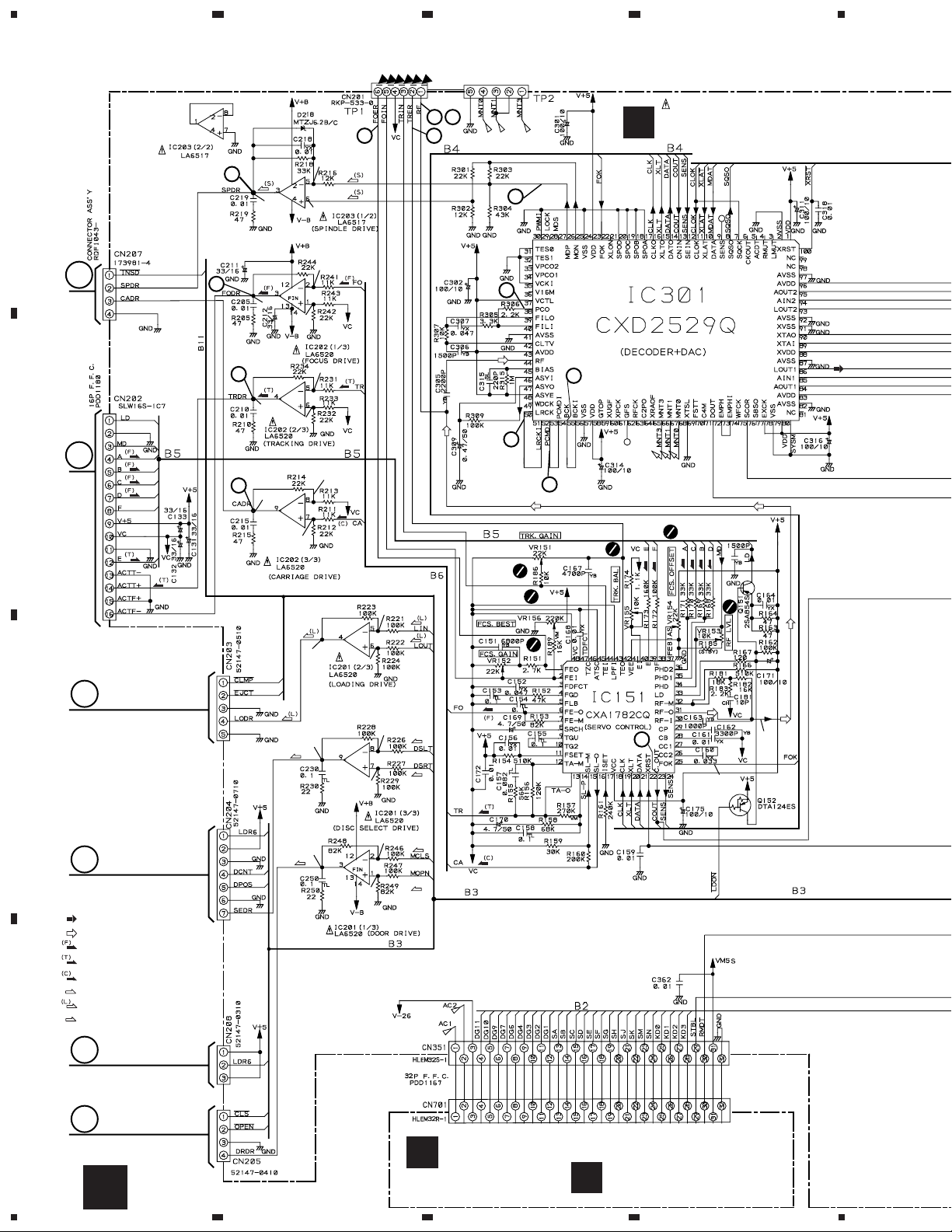

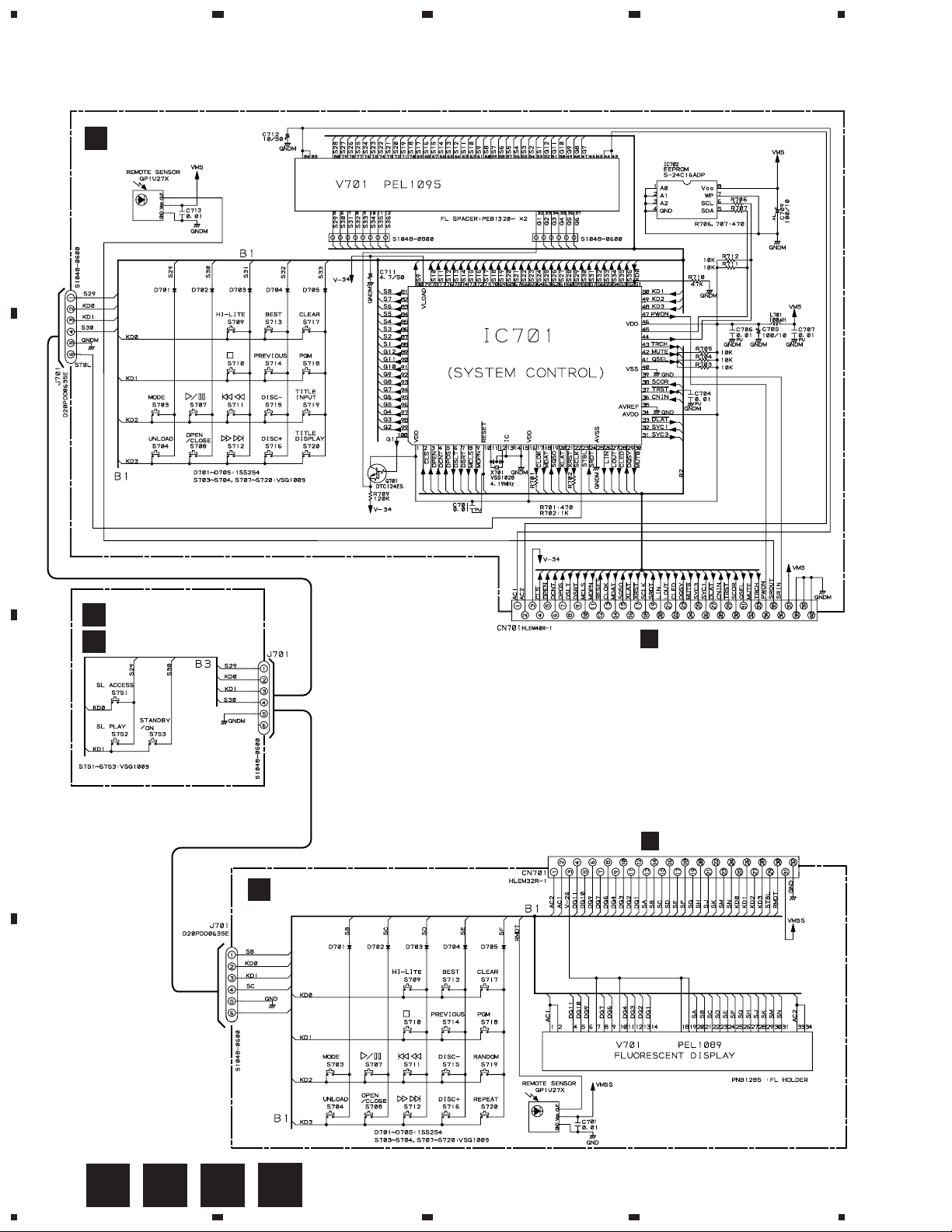

3. SCHEMATIC DIAGRAM

Note: When ordering service parts, be sure to refer to "EXPLODED VIEW AND PARTS LIST" or "PCB PARTS LIST".

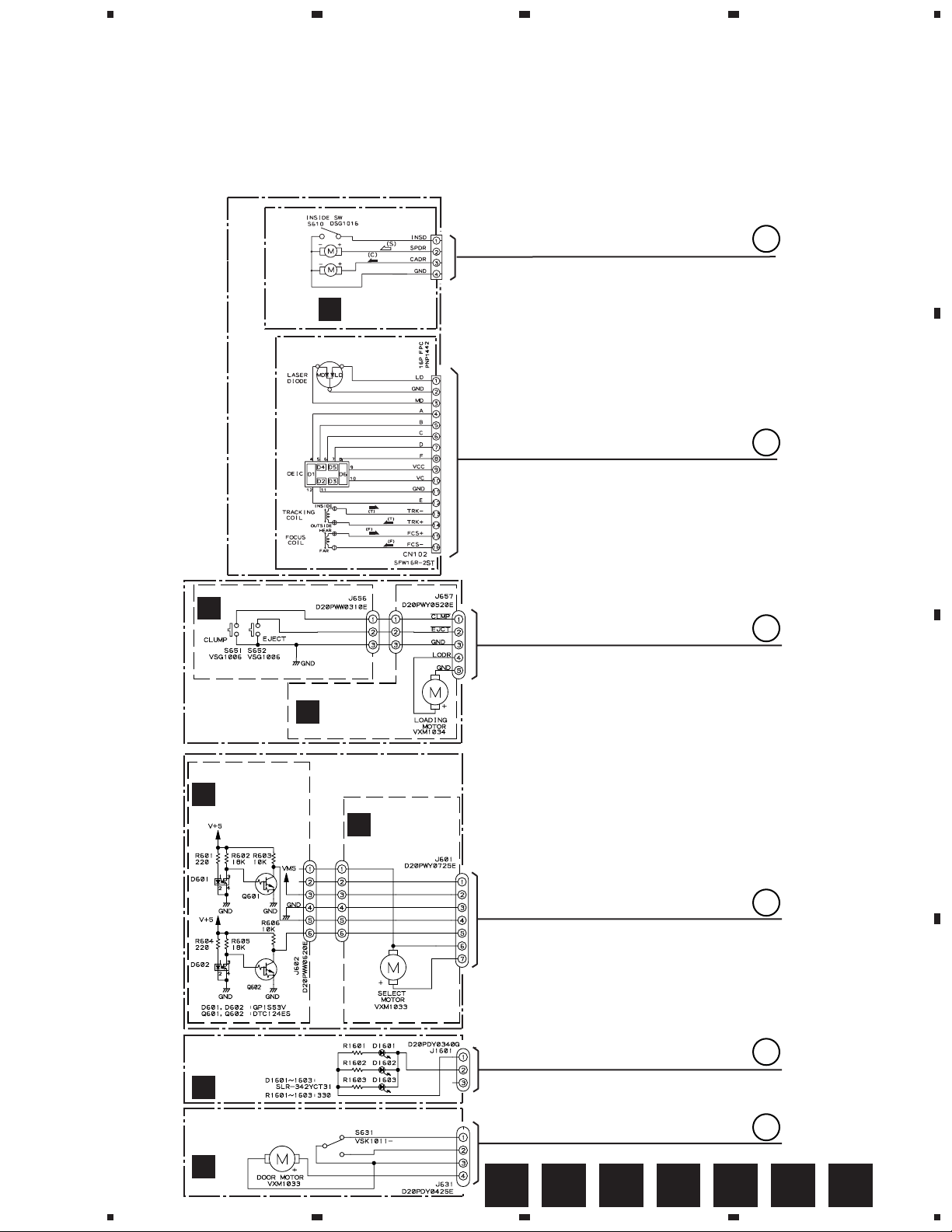

3.1 MECHANISM BOARD ASSY,SENSOR BOARD ASSY,LOAD SW BOARD ASSY,SELECT

MOTOR BOARD ASSY,LOADING MOTOR BOARD ASSY,CENTER LED BOARD ASSY,

DOOR BOARD ASSY and PICKUP ASSY

A

SPINDLE

MOTOR

ASSY

PEA1235

CARRIAGE

MOTOR

ASSY

PEA1246

PICK UP ASSY

(PEA1335)

(PXA1591)

SERVO MECHANISM ASSY GM

LOAD SW BOARD

ASSY (PWZ3334 )

B

A

MECHANISM

BOARD ASSY

(PWX1192)

A

CN610

173979-4

B

B

C

LOADING MECHA

BOARD ASSY

(PWX1474)

SENSOR BOARD

ASSY

(PWZ3327)

D

CENTER LED BOARD ASSY

PD-F958/KU/CA:(PWZ3915)

PD-F908/KU,KC:(PWZ3892)

C

F

DOOR BOARD ASSY

PD-F958/KU/CA:(PWZ3913)

PD-F908/KU,KC:(PWZ3890)

LOADING MOTOR

BOARD ASSY

(PWZ3337)

SELECT MECHA

BOARD ASSY

(PWX1465)

SELECT MOTOR

BOARD ASSY

(PWZ3324)

E

C

D

E

D

F

G

E F GA B C D

1

2

3

4

11

Page 12

1

234

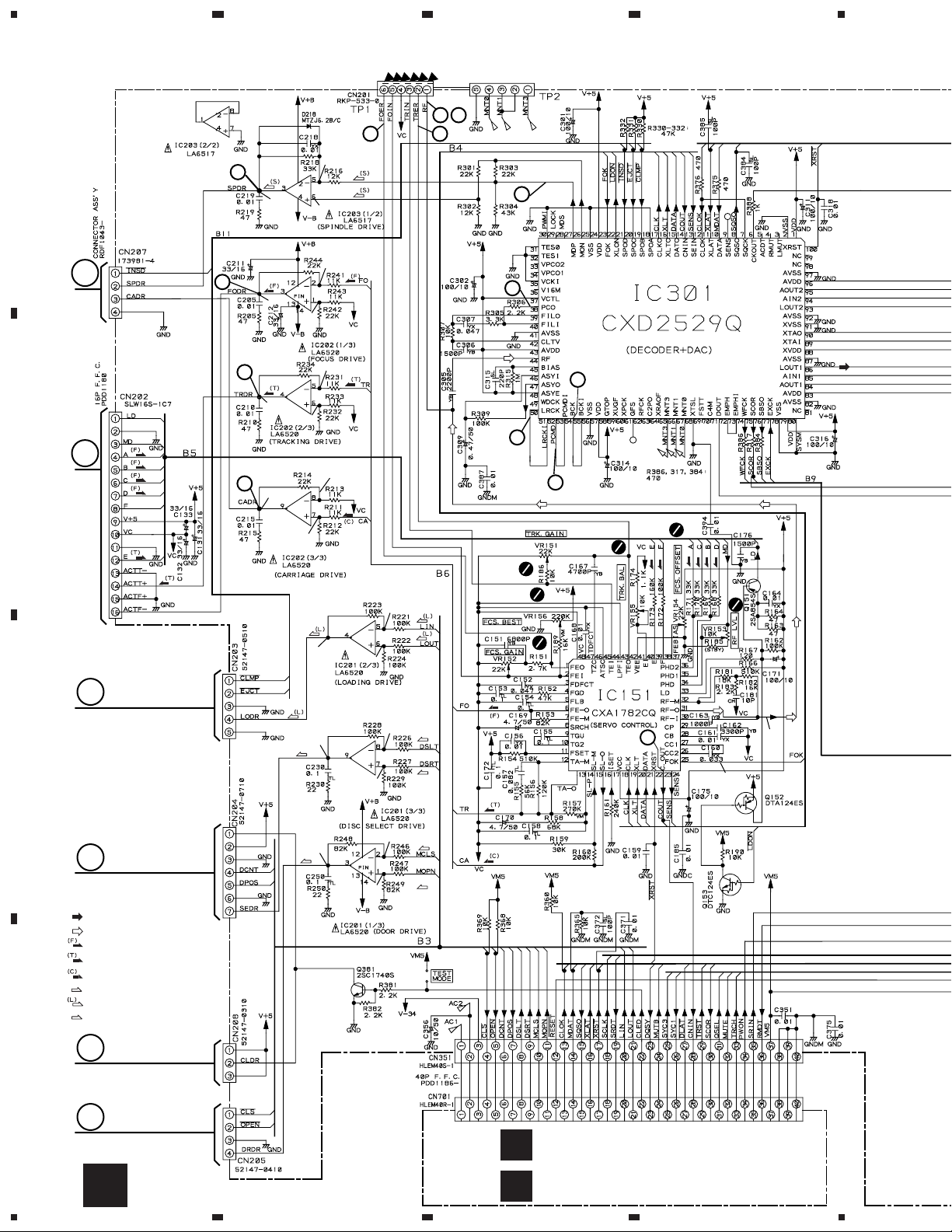

PD-F958, PD-F908

3.2 MAIN BOARD ASSY and POWER BOARD ASSY (FOR PD-F958)

2

23

43

1.6V

1.6V

1.7V

1.8V

1.8V

1.6V

1.6V

1.7V

33

53

16

18

19

(F)

(F)

(F)

(F)

(T)

(T)

0V

A

A

B

B

7

-O.7V

5

OV

6

OV

8

0.2V

0V

0V

C

0V

0V

(SEL)

C

0V

0V

D

SIGNAL ROUTE

: AUDIO SIGNAL

: EFM SIGNAL

: FOCUS SERVO LOOP

: TRACKING SERVO LOOP

: CARRIAGE SERVO LOOP

(S)

: SPINDLE DRIVE

: LOADING DRIVE

(D)

: DOOR DRIVE

(D)

0V

(SEL)

(SEL)

0V

(D)

(D)

23

B12

3.4V

5.0V

E

D

12

F

DISPLAY BOARD ASSY

L

H

1234

M

(PWZ3904)

SWITCH BOARD ASSY

(PWZ3907)

Page 13

5

67

8

PD-F958, PD-F908

IC301(CXD2529Q) :PLAY MODE

PIN No.

Voltage(V)

PIN No.

Voltage(V)

PIN No.

Voltage(V)

10

1 2 3 - 4 7 8 9 10 11 12 13 14 16 17 23 24 25

5

26 27 38 39 40 41 42 43 44 45 46 47 48 50-55 56 57

5

2.6-2.7

61 71 75 78 79 82 83 87 88 89-9084-86 91-92 93-95 9796 100

5

2.5 2.5 2.5 2.5

4.7

2.5

3.1 3.12.5 2.5 0.9 2.5 2.5 2.5

00 505 0 5 0 50 5

0 50

1.6V

1.6V

55550 00

4.4 4.7 4.7 4.71.2-1.41.2-1.3

55

0V

0V

0.05

0V

-9.2

0V

-9.2

0V

LINE OUT

JACK

A

B

H

MAIN BOARD ASSY

(PWZ3895)

B12

(UNIT : Ω )

(UNIT : µF)

(UNIT : µH)

B1

AC120V

60Hz

AC POWER CORD

:PDG1064

POWER BOARD ASSY

I

(PWZ3900)

C

D

P0WER TRANSFORMER

5

6

7

H

8

I

13

Page 14

1

234

PD-F958, PD-F908

3.3 MAIN BOARD ASSY and POWER BOARD ASSY (FOR PD-F908)

2

23

43

J

MAIN BOARD ASSY

(PWZ3876)

1.6V

1.6V

1.7V

1.8V

1.8V

1.6V

1.6V

1.7V

33

53

16

18

19

(F)

(F)

(F)

(F)

(T)

(T)

0V

A

A

B

B

7

-O.7V

5

OV

6

OV

8

0.2V

B3

0V

0V

C

0V

(SEL)

0V

(SEL)

23

C

(SEL)

0V

(D)

(D)

D

SIGNAL ROUTE

: AUDIO SIGNAL

: EFM SIGNAL

: FOCUS SERVO LOOP

: TRACKING SERVO LOOP

: CARRIAGE SERVO LOOP

(S)

: SPINDLE DRIVE

: LOADING DRIVE

(D)

: DOOR DRIVE

0V

0V

(D)

0V

3.4V

5.0V

E

D

14

F

DISPLAY BOARD ASSY

N

(PWZ3882)

J

1234

SWITCH BOARD ASSY

O

(PWZ3885)

Page 15

5

67

8

PD-F958, PD-F908

IC301(CXD2529Q) :PLAY MODE

PIN No.

Voltage(V)

PIN No.

Voltage(V)

PIN No.

Voltage(V)

10

1 2 3 - 4 7 8 9 10 11 12 13 14 16 17 23 24 25

5

26 27 38 39 40 41 42 43 44 45 46 47 48 50-55 56 57

5

2.6-2.7

61 71 75 78 79 82 83 87 88 89-9084-86 91-92 93-95 9796 100

5

2.5 2.5 2.5 2.5

4.7

2.5

3.1 3.12.5 2.5 0.9 2.5 2.5 2.5

00 505 0 5 0 50 5

0 50

1.6V

1.6V

55550 00

4.4 4.7 4.7 4.71.2-1.41.2-1.3

55

0V

0V

0.05

0V

-9.2

0V

-9.2

0V

LINE OUT

JACK

A

B

C

AC 120V

60 Hz

AC POWER CORD

K

POWER BOARD ASSY

(PWZ3879)

POWER TRANSFORMER

D

J

5

6

7

8

K

15

Page 16

PD-F958, PD-F908

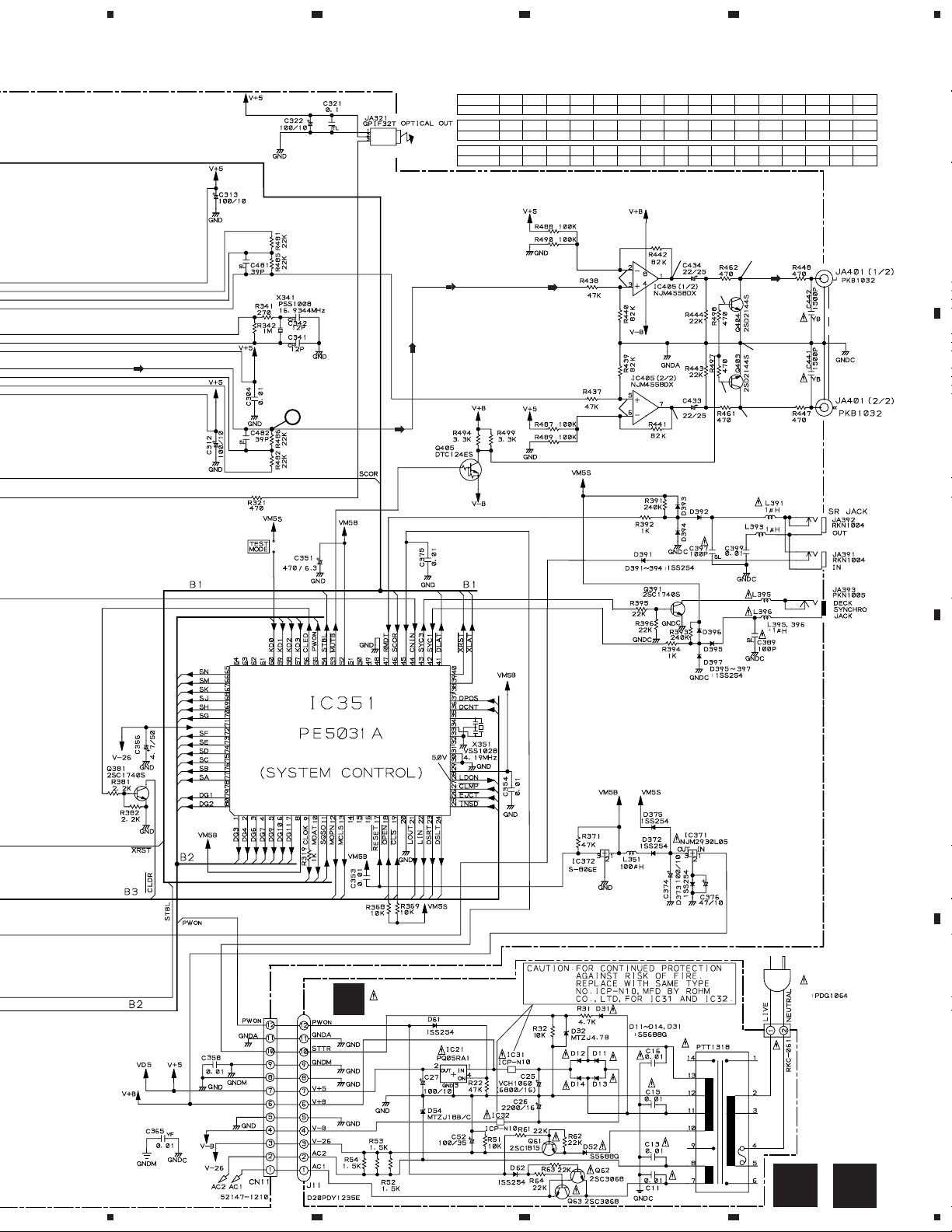

Waveforms (

Note: The encircled numbers denote measuring point in the schematic diagram.

TP1-Pin 1: PLAY MODE (RF)

2

500mV/div 500nsec/div

TP1-Pin 1: TRACK SEARCH MODE

25

(RF)

500 mV/div 200 µsec/div

H,H )

H

)

J

,

TP1-Pin 2: 50T - JUMP (*1) MODE

(TRER)

200mV/div 1msec/div

– VC

IC202-Pin 3: FOCUS-IN (*2) MODE

(FODR)

1V/div 200msec/div

– VC

– VC

– GND

∗1 50T-JUMP: After switching to the pause mode, press

the manual search key.

∗2 FOCUS-IN: Press the play key without loading a disc.

IC202-Pin 4: 50T - JUMP (*1) MODE

6'4'

(TRDR)

500mV/div 1msec/div

– GND

IC203-Pin 3: PLAY MODE (SPDR)

7

1V/div 50msec/div

– GND

TP1-Pin 6: PLAY MODE (FOER)

3

100mV/div 10msec/div

TP1-Pin 2: PLAY MODE (TRER)

4

200mV/div 1msec/div

– VC

– VC

IC202-Pin 3: PLAY MODE (FODR)

5

1V/div 1msec/div

IC202-Pin 4: PLAY MODE (TRDR)

6

500mV/div 1msec/div

– GND

– GND

IC203-Pin 3: TRACK SEARCH MODE

7

(SPDR)

2V/div 50msec/div

IC202-Pin 9: PLAY MODE (CADR)

8

0.2V/div 2sec/div

– GND

– GND

16

Page 17

Waveforms

PD-F958, PD-F908

IC202-Pin 9: TRACK SEARCH MODE

8

(CADR)

2V/div 200msec/div

IC301-Pin 54 : PLAY MODE (1kHz)

16

(BCK)

2V/div 500nsec/div

IC301-Pin 50 : PLAY MODE (1kHz)

18

(LRCK)

2V/div 10 µsec/div

– GND– GND

– GND

IC301-Pin 27 : PLAY MODE (MDP)

33

2V/div 2 µsec/div

– GND

IC301-Pin 86 : PLAY MODE (1kHz)

10

(LOUT 1)

1V/div 200msec/div

– GND

IC301-Pin 52 : PLAY MODE (1kHz)

19

(PCMD)

2V/div 500nsec/div

TRACK SEARCH MODE

23

Upper : TP1-Pin 1 (RF) 1V/div

Lower : IC151-Pin 23 (C.OUT)

2V/div 50 µsec/div

– GND

– GND

– GND

IC301-Pin 38 : PLAY MODE

53

(PCO)

2V/div 10 µsec/div

– GND

17

Page 18

1

234

PD-F958, PD-F908

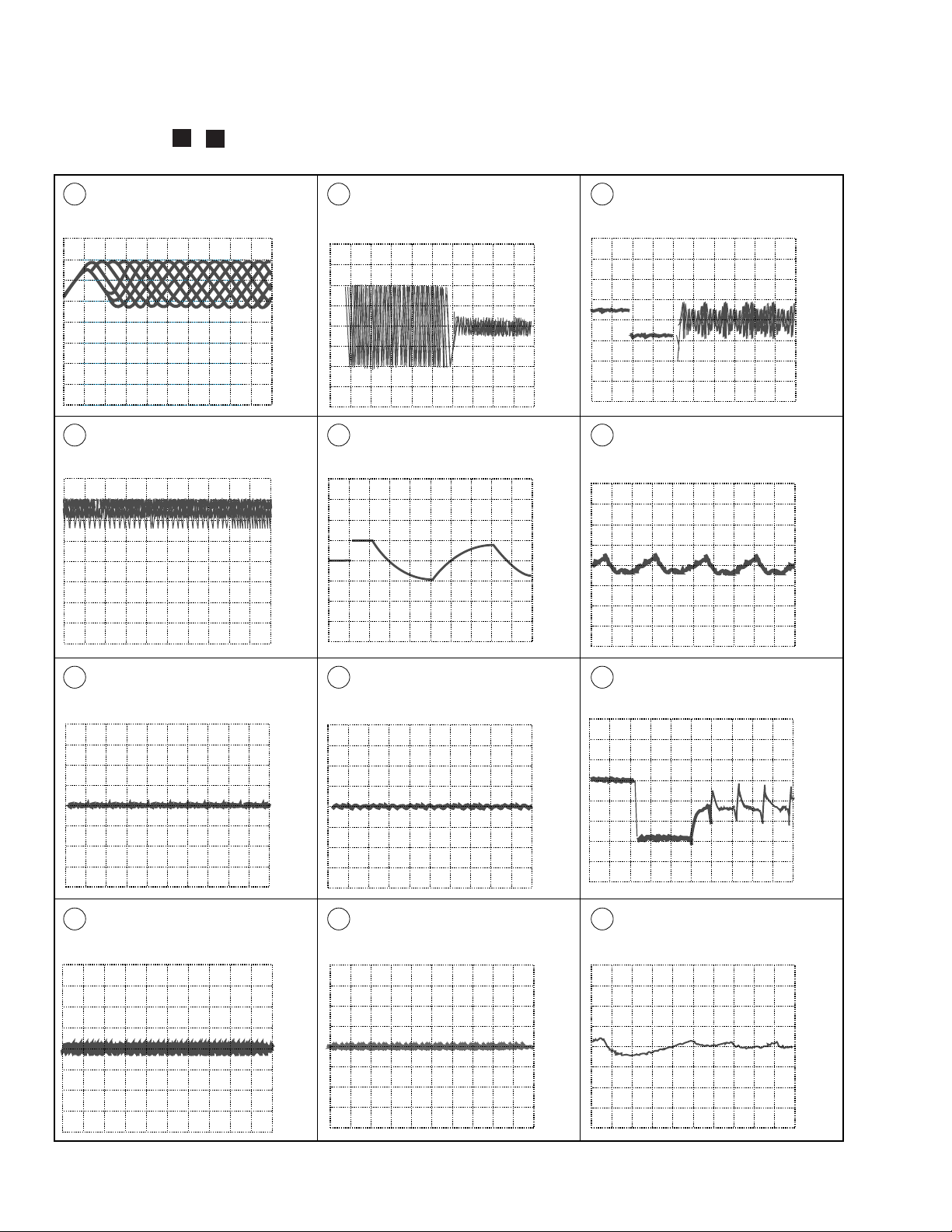

3.4 DISPLAY BOARD ASSY and SWITCH BOARD ASSY

DISPLAY BOARD ASSY

L

PD-F958/KU/CA:(PWZ3904)

A

B

PE5032A

SWITCH BOARD ASSY

PD-F958/KU/CA: (PWZ3907)

M

H

PD-F908/KU,KC: (PWZ3885)

O

SWITCHES

SWITCH BOARD ASSY

S751 : SL ACCESS

S752 : SL PLAY

S753 : POWER STANDBY/ON

C

DISPLAY BOARD ASSY

N

PD-F908/KU,KC:(PWZ3882)

DISPLAY BOARD ASSY

S703 : MODE

S704 : UNLOAD

S707 : 6

S708 : OPEN/CLOSE

S709 : HI-LITE

S710 : 7

S711 : 4 1

S712 : ¡ ¢

S713 : BEST

S714 : PREVIOUS

CN351

S715 : DISC –

S716 : DISC +

S717 : CLEAR

S718 : PGM

S719 : TITLE INPUT (PD-F958)

: RANDOM (PD-F908)

S720 : TITLE DISPLAY (PD-F958)

: REPEAT (PD-F908)

J

CN351

D

18

L

M N

1234

O

Page 19

1

23

PD-F958, PD-F908

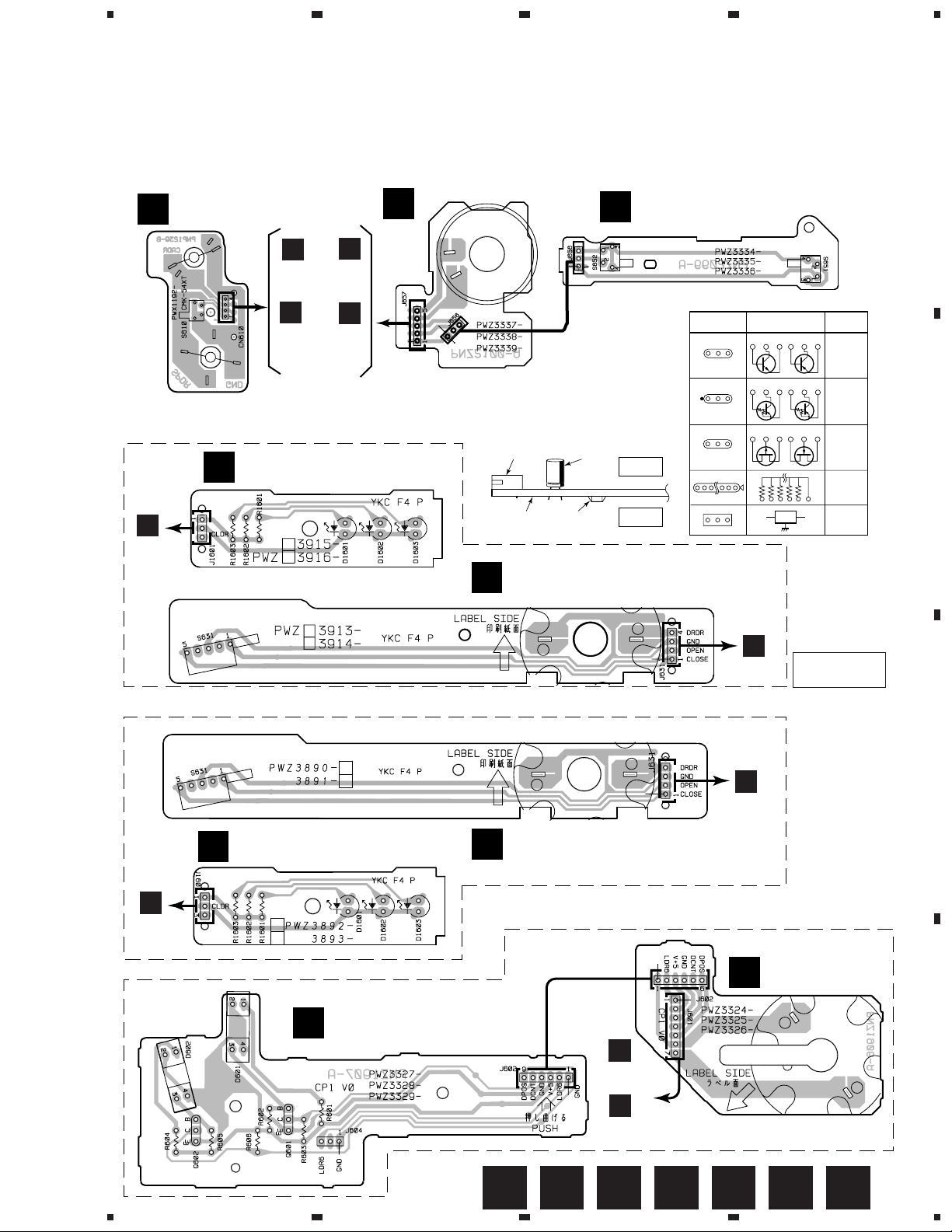

4. PCB CONNECTION DIAGRAM

4.1 MECHANISM BOARD ASSY, SENSOR BOARD ASSY, LOAD SW BOARD ASSY,

SELECT MOTOR BOARD ASSY, LOADING MOTOR BOARD ASSY,

CENTER LED BOARD ASSY and DOOR BOARD ASSY

LOADING MOTOR BOARD ASSY

MECHANISM BOARD ASSY

A

C

LOAD SW BOARD ASSY

B

4

A

M

CARRIAGE

MOTOR

INSIDE

SPINDLE

MOTOR

PNP1239-B

For PD-F958

H

CN208

H

CN207 CN203

(PD-F958)

J

CN207 CN203

M

F

(PD-F908)

NOTE FOR PCB DIAGRAMS:

1. Part numbers in PCB diagrams match those in the

schematic diagrams.

2. A comparison between the main parts of PCB and

schematic diagrams is shown below.

CENTER LED BOARD ASSY

H

J

3. The parts mounted on this PCB include all necessary

parts for several destination.

For further information for respective destinations,

be sure to check with the schematic diagram.

4. Viewpoint of PCB diagrams

P. C. Board Chip Part

DOOR BOARD ASSY

G

CapacitorConnector

SIDE A

SIDE B

PNP1458-A

Symbol in PCB

Diagrams

BCE

BCE

DGS

PNP1455-B

H

CN205

Symbol in Schematic

Diagrams

BCE

BCE

BCEBCE

DGSDGS

SIDE A

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor

array

3-terminal

regulator

B

For PD-F908

F

J

CN208

CENTER LED BOARD ASSY

SENSOR BOARD ASSY

D

DOOR BOARD ASSY

G

H

CN204

(PD-F958)

J

CN204

(PD-F908)

J

CN205

PNP1454-A

SELECT MECHA BOARD ASSY

SELECT MOTOR

E

BOARD ASSY

PNP1457–A

C

D

1

2

3

4

GD E FA B C

19

Page 20

1

PD-F958, PD-F908

234

4.2 MAIN BOARD ASSY (FOR PD-F958)

MAIN BOARD ASSY

H

A

A

CN610

I

J11

B

C

J657

To PICKUP ASSY

SIDE A

VR156

VR155 VR154 VR153

VR152

VR151

Q151 Q391IC203Q153IC201

Q405Q452Q321

IC401 IC405 IC406Q451 Q454 Q403Q453

C

D

E

J601

F

J1601

G

J631

L

CN701

IC202 IC151 Q152

IC301 Q406 Q404

IC372

Q381

20

PNP1455-B

H

1234

Page 21

1

23

PD-F958, PD-F908

4.3 DISPLAY BOARD ASSY, SWITCH BOARD ASSY and POWER BOARD ASSY

(FOR PD-F958)

SWITCH BOARD

M

ASSY

L

DISPLAY BOARD ASSY

H

CN351

4

SIDE A

A

B

I

POWER BOARD ASSY

AC IN

1

Q701IC701Q702 IC702

H

CN11

Q61

Q62 Q63

I

2

3

IC21 IC371

IC31 IC32

L

PNP1455-B

M

4

21

C

D

Page 22

1

PD-F958, PD-F908

234

4.4 MAIN BOARD ASSY(FOR PD-F908)

MAIN BOARD ASSY

J

A

A

CN610

K

J11

B

C

J657

To PICKUP ASSY

SIDE A

Q151 Q391IC203IC201IC351IC372 Q381

VR156

VR155 VR154 VR153

Q403 Q453

Q454

Q405

Q452IC371

C

E

J601

F

J1601

VR152

VR151

IC202 IC151 Q152

IC301Q372 Q404

Q322 Q341 IC401 IC405 IC406Q451

D

G

J631

N

CN701

22

PNP1454–A

J

1234

Page 23

1

23

PD-F958, PD-F908

4.5 DISPLAY BOARD ASSY, SWITCH BOARD ASSY and POWER BOARD ASSY

(FOR PD-F908)

SWITCH BOARD

O

ASSY

N

DISPLAY BOARD ASSY

J

CN351

4

SIDE A

A

B

K

POWER BOARD ASSY

AC IN

1

Q711

C

J

CN11

D

IC32 IC31 Q62

K

2

3

Q63

IC21Q61

PNP1454-A

ON

4

23

Page 24

PD-F958, PD-F908

5. PCB PARTS LIST

NOTES : ÷ Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

÷ The

÷ When ordering resistors, first convert resistance values into code form as shown in the following examples.

LIST OF WHOLE PCB ASSEMBLIES

Mark Symbol and Description Remarks

NSP MOTHER BOARD ASSY PWM2269 PWM2266 PWM2266

NSP SWITCH BOARD ASSY PWZ3907 PWZ3885 PWZ3885

NSP DOOR BOARD ASSY PWZ3913 PWZ3890 PWZ3890

NSP CENTER LED ASSY PWZ3915 PWZ3892 PWZ3892

mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Ex. 1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by

J = 5%, and K = 10%).

560 Ω = 56 × 10

47k Ω = 47 × 10

0.5 Ω = R50 ...................................................................... RN2H Â 5 0 K

1 Ω = 1R0 ......................................................................... RS1P 1 Â 0 K

Ex. 2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω = 562 × 10

MAIN BOARD ASSY PWZ3895 PWZ3876 PWZ3876

POWER BOARD ASSY PWZ3900 PWZ3879 PWZ3879

DISPLAY BOARD ASSY PWZ3904 PWZ3882 PWZ3882

1

= 561................................................... RD1/4PU 5 6 1 J

3

= 473 .................................................. RD1/4PU 4 7 3 J

1

= 5621 ........................................... RN1/4PC 5 6 2 1 F

Part No.

PD-F958/ PD-F908/ PD-F908/

KU/CA KU KC

NSP SELECT MECHA BOARD ASSY PWX1465 PWX1465 PWX1465

NSP SELECT MOTOR BOARD ASSY PWZ3324 PWZ3324 PWZ3324

NSP SENSOR BOARD ASSY PWZ3327 PWZ3327 PWZ3327

NSP LOADING MECHA BOARD ASSY PWX1474 PWX1474 PWX1474

NSP LOAD SW BOARD ASSY PWZ3334 PWZ3334 PWZ3334

NSP LOADING MOTOR BOARD ASSY PWZ3337 PWZ3337 PWZ3337

NSP SERVO MECHANISM ASSY GM PXA1591 PXA1591 PXA1591

LOADING MECHANISM ASSY PXA1589 PXA1589 PXA1589

MECHANISM BOARD ASSY PWX1192 PWX1192 PWX1192

CONTRAST OF PCB ASSEMBLIES

SWITCH BOARD Assy

Although PWZ3907 and PWZ3885 are different in part number, they consist of the same components.

DOOR BOARD Assy

Although PWZ3913 and PWZ3890 are different in part number, they consist of the same components.

CENTER LED BOARD Assy

Although PWZ3915 and PWZ3892 are different in part number, they consist of the same components.

24

Page 25

PARTS LIST FOR PD-F958/KU/CA

PD-F958, PD-F908

Mark No. Description Part No.

MAIN BOARD ASSY (PWZ3895)

H

SEMICONDUCTORS

IC151 CXA1782CQ

IC301 CXD2529Q

IC203 LA6517

IC201, IC202 LA6520

IC302 LC89170M

IC372 S-806E

IC405 NJM4558DX

Q151 2SA854S

Q381, Q391 2SC1740S

Q403, Q404 2SD2144S

Q152, Q406 DTA124ES

Q153, Q321, Q405 DTC124ES

D1301– D1309, D1312– D1314, D321 1SS254

D341, D391– D397 1SS254

D218 MTZJ6.2B

COILS AND FILTERS

L391, L395, L396 LAU1R0J

CAPACITORS

C181 CCCCH100D50

C341, C342 CCCCH120J50

C372, C373, C384, C385, C397 CCCSL101J50

C315 CCCSL221J50

C481, C482 CCCSL390J50

C356 CEAT100M50

C171, C175, C301, C302 CEAT101M10

C311– C314, C316, C322, C380 CEAT101M10

C433, C434 CEAT220M25

C131– C133, C211, C212 CEAT330M16

C169, C170 CEAT4R7M50

C309 CEATR47M50

C153– C155, C158, C172, C230 CFTLA104J50

C250, C321 CFTLA104J50

C157 CFTLA823J50

C156, C161, C164, C168, C218 CGCYX103K25

C160 CGCYX333K25

C152, C307 CGCYX473K25

C163 CKCYB102K50

C176, C306, C441, C442 CKCYB152K50

C305 CKCYB222K50

C162 CKCYB332K50

C167 CKCYB472K50

C151 CKCYB682K50

C159, C185, C205, C210, C215 CKCYF103Z50

C219, C304, C318, C323, C351 CKCYF103Z50

C355, C371, C375 CKCYF103Z50

C381, C382, C387, C394, C398 CKCYF103Z50

RESISTORS

R189 RD1/4VM163J

R157 RD1/4VM274J

VR153, VR155 (10k Ω) VCP1156

VR151, VR152, VR154 (22k Ω) VCP1158

VR156 (220k Ω) VCP1164

Mark No. Description Part No.

Other Resistors RD1/4PU&&&J

OTHERS

CN207 MT 4P CONNECTOR 173981-4

CN208 3P JUMPER CONNECTOR 52147-0310

CN205 4P JUMPER CONNECTOR 52147-0410

CN203 5P JUMPER CONNECTOR 52147-0510

CN204 7P JUMPER CONNECTOR 52147-0710

CN11 12P JUMPER CONNECTOR 52147-1210

JA394 I/O INTERFACE JACK DKN1035

JA321 OPTICAL LINK OUT GP1F32T

CN351 FFC CONNECTOR 40P HLEM40S-1

JA401 2P JACK PKB1032

JA393 JACK PKN1005

X341 X TAL.RES.(16.9344MHz) PSS1008

JA391, JA392 JACK RKN1004

CN201 CONNECTOR 6P RKP-533

CN202 FFC CONNECTOR SLW16S-1C7

SCREW PLATE VNE1948

POWER BOARD ASSY (PWZ3900)

I

SEMICONDUCTORS

IC31, IC32 ICP-N10

IC37 NJM2930L05

IC21 PQ05RA1

Q61 2SC1815

Q62, Q63 2SC3068

D54 MTZJ24B

D11– D14, D52 S5688G

D61, D62 1SS254

CAPACITORS

C27, C374 CEAT101M10

C52 CEAT101M35

C26 CEAT222M16

C11, C13, C15, C16 CKCYF103Z50

C25 (6800 µF/16V) VCH1060

RESISTORS

All Resistors RD1/4PU&&&J

OTHERS

12P CABLE HOLDER 51048-1200

J11 JUMPER WIRE D20PDY1235E

POWER TRANSFORMER PTT1342

TERMINAL RKC-061

DISPLAY BOARD ASSY (PWZ3904)

L

SEMICONDUCTORS

IC701 PE5032A

IC702 S-24C16ADP

Q701 DTC124ES

D701– D705 1SS254

COILS AND FILTERS

L701 AXIAL INDUCTOR LAU101J

25

Page 26

PD-F958, PD-F908

Mark No. Description Part No.

SWITCHES

S703, S704, S707– S720 VSG1009

CAPACITORS

C712 CEAT100M50

C705, C709 CEAT101M6R3

C711 CEAT4R7M50

C708, C713 CKCYF103Z50

C701, C704, C706, C707 CKPUYY103M16

RESISTORS

All Resistors RD1/4PU&&&J

OTHERS

6P CABLE HOLDER 51048-0600

8P CABLE HOLDER 51048-0800

CN701 FFC CONNECTOR 40P HLEM40R-1

V701 FL INDICATOR TUBE PEL1095

X701 CERAMIC RES.(4.19MHz) VSS1028

J701 JUMPER WIRE 6P D20PDD0635E

REMOTE RECEIVER UNIT GP1U27X

SWITCH BOARD ASSY

M

SWITCHES AND RELAYS

S751– S753 VSG1009

OTHER

6P CABLE HOLDER 51048-0600

Mark No. Description Part No.

OTHER

J602 JUMPER WIRE D20PWW0620E

LOAD SW BOARD ASSY

B

SWITCHES AND RELAYS

S651, S652 VSG1006

OTHER

J656 3P JUMPER WIRE D20PWW0310E

LOADING MOTOR BOARD ASSY

C

OTHER

J657 5P JUMPER WIRE D20PWY0520E

MECHANISM BOARD ASSY

A

SWITCHE

S610 DSG1016

OTHER

CN610 MT 4P CONNECTOR 173979-4

DOOR BOARD ASSY

G

OTHERS

4P CABLE HOLDER 51048-0400

REAF SWITCH VSK1011

JUMPER WIRE D20PDY0425E

CENTER LED BOARD ASSY

F

SEMICONDUCTORS

D1601– D1603 SLR-342YCT31

RESISTORS

All Resistors RD1/4PU&&&J

OTHERS

3P CABLE HOLDER 51048-0300

J1601 JUMPER WIRE D20PDY0340G

SELECT MOTOR BOARD ASSY

E

OTHER

J601 JUMPER WIRE D20PWY0725E

D

SENSOR BOARD ASSY

SEMICONDUCTORS

Q601, Q602 DTC124ES

D601, D602 GP1S53V

RESISTORS

All Resistors RD1/4PU&&&J

26

Page 27

PD-F958, PD-F908

PARTS LIST FOR PD-F908/KU/KC

Mark No. Description Part No. Mark No. Description Part No.

MAIN BOARD ASSY(PWZ3876)

J

SEMICONDUCTORS

IC151 CXA1782CQ

IC301 CXD2529Q

IC203 LA6517

IC201, IC202 LA6520

IC371 NJM2930L05

IC405 NJM4558DX

IC372 S-806E

IC351 PE5031A

Q151 2SA854S

Q381, Q391 2SC1740S

Q403, Q404 2SD2144S

Q152, DTA124ES

Q405 DTC124ES

D372, D373, D375, D391– D397 1SS254

D218 MTZJ6.2B

COILS AND FILTERS

L391, L395, L396, L393 LAU1R0J

L351 AXIAL INDUCTOR LAU101J

CAPACITORS

C181 CCCCH100D50

C341, C342 CCCCH120J50

C389, C397 CCCSL101J50

C315 CCCSL221J50

C481, C482 CCCSL390J50

C171, C175, C301, C302 CEAS101M10

C311– C314, C316, C322, C374 CEAS101M10

C73 CEAS101M10

C371 CEAS1R0M50

C433, C434 CEAS220M25

C131– C133, C211, C212 CEAS330M16

C376 CEAS470M10

C351 CEAS471M6R3

C169, C170, C356 CEAS4R7M50

C309 CEASR47M50

C153 – C155, C158, C230 CFTXA104J50

C250, C321 CFTXA104J50

C157 CFTXA823J50

C156, C161, C164, C168, C218 CGCYX103K25

C160 CGCYX333K25

C152, C307 CGCYX473K25

C163 CKCYB102K50

C176, C306, C441, C442 CKCYB152K50

C305 CKCYB222K50

C162 CKCYB332K50

C167 CKCYB472K50

C151 CKCYB682K50

C159, C172, C205, C210, C215 CKCYF103Z50

C219, C304, C318, C353 CKCYF103Z50

C354, C358, C362, C365, C366 CKCYF103Z50

C375, C399 CKCYF103Z50

RESISTORS

R189 RD1/4VM163J

R157 RD1/4VM274J

VR153, VR155 (10k Ω) VCP1156

VR151, VR152, VR154 (22k Ω) VCP1158

VR156 (220k Ω) VCP1164

Other Resistors RD1/4PU&&&J

OTHERS

CN207 MT 4P CONNECTOR 173981-4

CN208 3P JUMPER CONNECTOR 52147-0310

CN205 4P JUMPER CONNECTOR 52147-0410

CN203 5P JUMPER CONNECTOR 52147-0510

CN204 7P JUMPER CONNECTOR 52147-0710

CN11 12P JUMPER CONNECTOR 52147-1210

JA321 OPTICAL LINK OUT GP1F32T

CN351 FFC CONNECTOR 32P HLEM32S-1

JA401 2P JACK PKB1032

JA393 JACK PKN1005

X341 X TAL.RES.(16.9344MHz) PSS1008

JA391, JA392 JACK RKN1004

CN201 CONNECTOR 6P RKP-533

CN202 FFC CONNECTOR SLW16S-1C7

SCREW PLATE VNE1948

X351 CERAMIC RES.(4.19MHz) VSS1028

POWER BOARD ASSY (PWZ3879)

K

SEMICONDUCTORS

IC31, IC32 ICP-N10T

IC21 PQ05RA1

Q61 2SC1815

Q62, Q63 2SC3068

D54 MTZJ18B/C

D11– D14, D31, D52 S5688G

D61, D62 1SS254

D32 MTZJ4.7B

CAPACITORS

C27 CEAS101M10

C52 CEAS101M35

C26 CEAS222M16

C11, C13, C15, C16 CKCYF103Z50

C25 (6800 µF/16V) VCH1060

RESISTORS

All Resistors RD1/4PU&&&J

OTHERS

J11 JUMPER WIRE D20PDY1235E

POWER TRANSFORMER PTT1318

TERMINAL RKC-061

DISPLAY BOARD ASSY (PWZ3882)

N

SEMICONDUCTORS

D701– D705 1SS254

CAPACITOR

C701 CKCYF103Z50

SWITCHES

S703, S704, S707– S720 VSG1009

OTHERS

CN701 FFC CONNECTOR 32P HLEM32R-1

V701 FL INDICATOR TUBE PEL1089

J701 JUMPER WIRE D20PDD0635E

REMOTE RECEIVER UNIT GP1U27X

6P CABLE HOLDER 51048-0600

27

Page 28

PD-F958, PD-F908

6. ADJUSTMENT

6.1 PREPARATIONS

6.1.1 Jigs and Measuring Instruments

39 kΩ

0.001µF

CD TEST DISC

(YEDS-7)

Precise

screwdriver

screwdriver

(small)

Ball point hexagon wrench

(size: 1.5mm)

GGK1002

6.1.2 Necessary Adjustment Points

When Adjustment points

Exchange

PICKUP

screwdriver

(medium)

Low-frequency

oscillator

1.2.3.4.5.6.7.

8.9.10.11.12

screwdriver

(large)

Dual-trace

oscilloscope

(10 : 1 probe)

= Page 30 - 35

Low pass filter 1

(39 kΩ + 0.001µF)

56 kΩ

0.001µF

Low pass filter 2

(56 kΩ + 0.001µF)

Exchange

MAIN BOARD ASSY

Exchange

SERVO MECH ASSY

Exchange

SPINDLE MOTOR

28

1.3.5.6.7.8.

9.10.11.12

1.2.3.4.5.6.7.

8.9.10.11.12

= Page 30 - 35

= Page 30 - 35

ADJ = Page 10

Page 29

6.2 ADJUSTMENT

6.2.1 How to Start/Cancel Test Mode

TEST MODE : ON

PD-F958 MODEL PD-F958 MODEL

W103

W102

PD-F958, PD-F908

W103

W102

Short Point

MAIN BOARD ASSY

PD-F908 MODEL

W161

W165

Short Point

MAIN BOARD ASSY

TEST MODE : PLAY

TEST DISC : YEDS-7

No.1 SLOT

4 / 1 ¡ / ¢

inwards outwards

Pickup Move

TEST MODE : STOP = CANCEL

7

STOP all operations.

MODE

Focus servo : CLOSE

6

Spindle motor : START

Spindle servo : CLOSE

PD-F958 MODEL

Short Point

MAIN BOARD ASSY

PD-F908 MODEL

W161

W165

Short Point

MAIN BOARD ASSY

6 6

CLOSE OPEN

Tracking servo :

6.2.2 Adjustment Location

Upper

Adjustment screw

(Tangential tilt direction)

Grating adjustment

FRONT

PICKUP ASSY

Adjustment screw

(Radial tilt direction)

CN201

6

5

4

3

2

1

TP1

6.FCER

5.FC IN

4.VC

3.TR IN

2.TRER

1.RF

CN201

VR153

RF LEVEL

VR154

VR156

FO.BEST

VR151

TR. GAIN

FO. OFS

VR155

TR. BAL

W103

6

......

1

VR152

FO. GAIN

W102

MAIN BOARD ASSY

PD-F908 MODEL

CN201

VR153

RF LEVEL

VR154

VR156

FO.BEST

VR151

TR. GAIN

FO. OFS

VR155

TR. BAL

W165

6

......

1

VR152

FO. GAIN

W161

MAIN BOARD ASSY

29

Page 30

PD-F958, PD-F908

6.2.3 Check and Adjustment

1. Focus Offset Adjustment

Test mode

None disc

START

(CN201)

FE

VC

MAIN BOARD ASSY

TP1

6

4

Player

2. Grating Adjustment

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

PLAY

CLOSE

=

CLOSE

=

OPEN

=

Innermost

circumference

(1 TRK)

VR154

MAIN BOARD ASSY

Prove (10:1)

GND

Turn counterclockwise

from null.

PICKUP

DC voltage

0±50mV

Oscilloscope

DC Mode

V: 5mV/div

H: 10mSec/div

Locate null.

Counterclockwise, Maximum amplitude.

30

START

TE

VC

MAIN BOARD ASSY

TP1

(CN201)

2

4

Player

Low pass filter 1

Oscilloscope

DC Mode

V: 10mV/div

H: 5mSec/div

Prove (10:1)

39kΩ

0.001µF

GND

Page 31

3. Tracking Error Balance Adjustment

PD-F958, PD-F908

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

PLAY

START

(CN201)

TE

VC

MAIN BOARD ASSY

CLOSE

=

CLOSE

=

OPEN

=

Innermost

circumference

(1 TRK)

TP1

2

4

Player

VR155

MAIN BOARD ASSY

Low pass filter 1

39kΩ

0.001µF

A=B

A

VC

B

Oscilloscope

DC Mode

V: 10mV/div

H: 5mSec/div

Probe (10:1)

GND

4. Pickup 1Radial/ 2Tangential Direction Tilt Adjustment

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

PLAY

Position where the screw is

visible through the adjustment

hole of the float base after

moving toward the outer

peripheral.

=

=

=

CLOSE

CLOSE

CLOSE

START

TP1

(CN201)

RF

1

VC

4

MAIN BOARD ASSY

1

TEST DISC

Remove lock tight.

Player

2

2

Probe (10:1)

GND

1

Eye pattern

OK (Smooth)

Oscilloscope

AC Mode

V: 20mV/div

H: 200nSec/div

NG

31

Page 32

PD-F958, PD-F908

5. RF Level Adjustment

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

START

MAIN BOARD ASSY

PLAY

=

=

=

Innermost

circumference

(1 TRK)

TP1

(CN201)

RF

VC

CLOSE

CLOSE

CLOSE

1

1

4

VR153

MAIN BOARD ASSY

Player

GND

Prove (10:1)

1.2VP-P

±0.1V

Oscilloscope

AC Mode

V: 50mV/div

H: 10mSec/div

6. Focus Best Adjustment

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

START

MAIN BOARD ASSY

PLAY

(CN201)

FE

RF

VC

TP1

=

CLOSE

=

CLOSE

=

CLOSE

Innermost

circumference

(1 TRK)

6

1

4

MAIN BOARD ASSY

Player

VR156

GND

MAX

Adjust the RF level to maximum, with the

focus error voltage within ±150mV.

Oscilloscope

DC Mode

CH1: 5mV/div

CH2: 20mV/div

H: 200ns/div

Prove(10:1)

Prove(10:1)

GND

32

Page 33

1

1

4

7. RF Level Adjustment

1.2VP-P

±0.1V

Oscilloscope

AC Mode

V: 50mV/div

H: 10mSec/div

START

TP1

(CN201)

Player

RF

VC

GND

Prove (10:1)

8. Focus Servo Loop Gain Adjustment

UNDER

Oscilloscope

X-Y Mode

X: 20mV/div

Y: 5mV/div

GND

Prove (10:1)

Player

START

TP1

(CN201)

FI

VC

UPPER

JUST

Low-frequency

oscillator

1.2kHz

1Vp-p

GND

GND

Prove (10:1)

56kΩ

0.001µF

Low pass filter 2

100kΩ

FE

Make adjustment if

the value exceeds

the specified range.

Check

6

5

4

Lissajous Waveform

MAIN BOARD ASSY

MAIN BOARD ASSY

VR153

MAIN BOARD ASSY

Test mode

SPDL servo

FOCUS servo

TRKG servo

=

=

=

CLOSE

CLOSE

CLOSE

TEST DISC

PLAY

Innermost

circumference

(1 TRK)

Test mode

SPDL servo

FOCUS servo

TRKG servo

=

=

=

CLOSE

CLOSE

CLOSE

TEST DISC

PLAY

Innermost

circumference

(1 TRK)

VR152

MAIN BOARD ASSY

PD-F958, PD-F908

33

Page 34

PD-F958, PD-F908

9. Focus Best Adjustment

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

START

=

CLOSE

CLOSE

=

CLOSE

=

Innermost

circumference

(1 TRK)

PLAY

TP1

(CN201)

FE

6

RF

1

VC

4

MAIN BOARD ASSY

VR156

MAIN BOARD ASSY

Player

GND

MAX

Adjust the RF level to maximum, with

the focus error voltage within ±150mV.

Oscilloscope

DC Mode

CH1: 5mV/div

CH2: 20mV/div

H: 200ns/div

Prove (10:1)

Prove (10:1)

GND

10. Focus Servo Loop Gain Adjustment

Test mode

SPDL servo

FOCUS servo

TRKG servo

TEST DISC

START

VC

PLAY

TP1

(CN201)

FE

FI

=

CLOSE

CLOSE

=

CLOSE

=

Innermost

circumference

(1 TRK)

6

5

4

VR152

MAIN BOARD ASSY

Readjust if

adjustment

is incorrect.

Player

56kΩ

100kΩ

0.001µF

UNDER

Prove (10:1)

Prove (10:1)

GND

GND

Check

UPPER

JUST

Lissajous Waveform

Oscilloscope

X-Y Mode

X: 20mV/div

Y: 5mV/div

Low-frequency

oscillator

1.2kHz

1Vp-p

34

MAIN BOARD ASSY

GND

Low pass filter 2

Page 35

11. Focus Best Adjustment

Oscilloscope

DC Mode

CH1: 5mV/div

CH2: 20mV/div

H: 200ns/div

Prove (10:1)

Player

START

TP1

(CN201)

RF

VC

MAX

GND

Prove (10:1)

FE

6

1

4

GND

Adjust the RF level to maximum, with

the focus error voltage within ±150mV.

Adjust this point only if adjustment was made in item 10.

MAIN BOARD ASSY

VR156

MAIN BOARD ASSY

Test mode

SPDL servo

FOCUS servo

TRKG servo

=

=

=

CLOSE

CLOSE

CLOSE

TEST DISC

PLAY

Innermost

circumference

(1 TRK)

12. Tracking Servo Loop Gain Adjustment

UNDER

Oscilloscope

X-Y Mode

X: 20mV/div

Y: 10mV/div

GND

Prove (10:1)

Player

START

TP1

(CN201)

TI

VC

UPPER

JUST

Low-frequency

oscillator

1.2kHz

1Vp-p

GND

GND

Prove (10:1)

100kΩ

TE

2

3

4

Lissajous Waveform

MAIN BOARD ASSY

Test mode

SPDL servo

FOCUS servo

TRKG servo

=

=

=

CLOSE

CLOSE

CLOSE

TEST DISC

PLAY

Innermost

circumference

(1 TRK)

VR151

MAIN BOARD ASSY

PD-F958, PD-F908

35

Page 36

PD-F958, PD-F908

7. GENERAL INFORMATION

7.1 PARTS

7.1.1 IC

PE5032A (IC701:DISPLAY BOARD ASSY)

SYSTEM CONTROL MICRO COMPUTER

Pin Function

No. Pin Name I/O Function

1 VDD +5V +5V

2 CLS I Hood open/close SW input.

3 OPEN I Open (CLS:H ,OPEN:L),Close (CLS :L,OPEN:H)

4 DCNT I Disc count pulse input.

5 DPOS I Disc position detection pulse input.

6 DSLT O Selecter output.

7 DSRT O

8 MCLS O Hood motor output.

9 MOPN O

10 RESET I CPU Reset.(L: RESET )

11 X2 – Crystal connection for system clock oscillation

12 X1 – :4.19MHz.

13 IC GND GND

14 XT2 – NC (OPEN)

15 GND I GND

16 VDD +5V +5V

17

CLOK

18

MDAT

19

SQSO

20 XLAT O LSI control data latch pulse output.

21 XRST O Reset input fof each LSI.

22 SCLK O CD TEXT timing data clock output.

23 STBL O L: output.

24 SRDT I CD TEXT data input.

25 AVSS – GND

26

LIN

LOUT

27

28 CLED I/O Center LED control (ON:H , OFF:input)

29 DQSY I CD TEXT data input.

30 MUTB O Muting output (L:MUTE)

31 SYC3 O Synchronous output.

32 SYC1 I Synchronous input.

33 DLAT O DAC control data latch pulse output.

34 AVDD +5V +5V

35 AVREF GND GND

36 CNIN I C.OUT input.

37 TRST O CD TEXT decooder reset output. (L: reset)

38 SCOR I Subcode sync SO+S1 input.

39 SR IN I Remote control data input.

40

VSS

41 QSEL O Signal output for Q DATA expansion

42 MUTE O Muting output for expansion. (MUTE:H)

43 TRCH O Data serial output for expansion.

44 SCL O EEPROM clock output

45 SDA I/O EEPROM data IN/OUTPUT

46 VDD +5V +5V

O Serial clock.

O LSI control data.

I Serial input.(

O Lauding motor output.

O

GND GND

Count up(DSRT:L,DSLT:H)

Count down(DSRT:H,DSLT:L)

Stop(DSRT:L,DSLT:L)

Open(MOPN:H,MCLS:L)

Close(MOPN:L,MCLS:H)

Stop(MOPN:L,MCLS:L)

Q data/fcok/gfs/sens/clmp/eject/insd

IN(LIN:H,LOUT:L)

OUT(LIN:L,LOUT:H)

Stop(LIN:L,LOUT:L)

The information shown in the list is basic information and may

not correspond exactly to that shown in the schematic diagrams.

No. Pin Name I/O Function

47 PW ON O Standby - led /osce.

48 KD3 I

49 KD2 I Key data input.

50 KD1 I

51 KD0 I

52 S36 O

53 S35 O

54 S34 O

55 S33 O

56 S32 O

57 S31 O

58 S30 O

59 S29 O

60 S28 O

61 S27 O

62 S26 O

63 S25 O

64 S24 O FL driving segment output.

65 S23 O

66 S22 O

67 S21 O

68 S20 O

69 S19 O

70 S18 O

71 S17 O

72 S16 O

73 S15 O

)

74 S14 O

75 S13 O

76 S12 O

77 S11 O

78 S10 O

79 VLOAD -34V -34V

80 S9 O

81 S8 O

82 S7 O

83 S6 O

84 S5 O

85 S4 O

86 S3 O

87 S2 O

88 S1 O

89 G12 O

90 G11 O FL driving segment output.

91 G10 O

92 G9 O

93 G8 O

94 G7 O

95 G6 O

96 G5 O

97 G4 O

98 G3 O

99 G2 O

100 G1 O

36

Page 37

7.1.2 DISPLAY

42

43

1

84

CUSTOM

ALL

SINGLE PREVIOUS DISC SCAN ADLC REMAIN

RDM PGM BEST REPEAT 1 CDTEXT

PEL1095 (V701: DISPLAY BOARD ASSY) : FOR PD-F958

¶ Pin Assignment

PD-F958, PD-F908

¶ Anode Grid Assignment

¶ Pin Connection

37

Page 38

PD-F958, PD-F908

PEL1089 (V701: DISPLAY BOARD ASSY) : FOR PD-F908

¶ Pin Assignment

¶ Anode Grid Assignment

¶ Pin Connection

38

Page 39

PD-F958, PD-F908

7.2 DIAGNOSIS

7.2.1 ERROR CODE DISPLAY

If a failure occurs in the Loading mechanism, the error symbol is automatically displayed on the fluorescent display screen of the front panel.

7.2.2 ERROR HISTORY and DISPLAY

Error history display in test mode

The previously generated errors (NG processing) can be confirmed in the test mode. Since the has a backup function, the error history is

memorized even if the power is turned off. (Memory holding time : About two days)

TEST MODE: ON

PD-F958 MODEL

W103

W102

Short Point

MAIN BOARD ASSY

PD-F908 MODEL PD-F908 MODEL

W161

W165

Short Point

MAIN BOARD ASSY

TEST MODE: STOP CANCEL

7

STOP all operations.

Press the "BEST" button of the keys on the main body.

MODE

PD-F958 MODEL

W103

W102

Short Point

MAIN BOARD ASSY

W161

W165

Short Point

MAIN BOARD ASSY

Focus servo : CLOSE

An error appears on the fluorescent indicator display by the above operation.

AB C

A0 01 36 : 15

The previously generated 16 error codes (maximum) can be memorized. These error codes are displayed one at a time in the ascending order

by pressing the "BEST" button again.

Note : A product performs fail safe operation when an error occurs. At that time, an error code is memorized by the fail safe operation

after the error is eliminated.

A: Disc No. : Error code

B: Track No. : Error sequence

C: Minute:second No. : Error generation mode

(Only 10’s digit is valid.)

39

Page 40

PD-F958, PD-F908

7.2.3 ERROR HISTORY DISPLAY

(1) Disc No. A : Detail of error code at portion

<Note> The user display appears only when the normal operation cannot be returned even if the fail safe operation is executed after each

error occurs.

User display Description

None A0 • A disc couldn’t be detected for playback after loading because;

No disc existed.

A disc was turned upside down.

A disc was dirty.

A disc was loaded incompletely.

• The focus got out of place during playback due to the crack

and stain on the disc.

None A1 • The servo mechanism couldn’t move to the desired tune

position within a fixed time during selection of a tune from

playback or during playback.

A3 • A disc couldn’t be loaded within a fixed time.

(A disc couldn’t be carried from the rack block.)

U1

A4 • A disc couldn’t be unloaded within a fixed time. (A disc couldn’t

be returned to the rack block.)

A2 • The LOADING mechanism couldn’t move to the desired disc

position within a fixed time during selection of a disc from

playback or during playback start from stop.

U2

A5 • The LOADING mechanism couldn’t be forcibly returned to

the home position (left position when viewed from the front)

within a fixed time after it is initialized or becomes NG.

None A6 • A disc couldn’t be normally rotated for playback after loading

because;

A disc was turned upside down.

A disc was dirty

A disc was loaded incompletely.

• A disc couldn’t be normally rotated during playback due to the

crack and stain on the disc.

User display Description

None A7 • Mechanism position just before the LOADING mechanism

None A8 • Discrepancy has occurred between the detected disc position

None A9 • Mechanism position during disc loading when the DCNT pin

None AA • The pickup block cannot return to the innermost circumference

shifts to the disc selection operation when the DCNT pin is

low. (The DCNT pin is usually high when the LOADING

mechanism is in the stop state. The mechanism position is

thus judged to have been shifted for some reason. The shifted

mechanism position may cause a failure.)

and the current disc position during movement of the loading

mechanism. (The system may incorrectly counted the

waveforms of the DCNT and DPOS terminals. If counting is

incorrect, the position of the disc No. displayed does not match

the disc position counted.)

is low. (The DCNT pin is usually high when the LOADING

mechanism is in the stop state. The mechanism position is

thus judged to have been shifted for some reason. The shifted

mechanism position may cause a failure.)

when the playback is

completed or another disc is shifted.

Hood section

User display Description

U3 P0 The hood did not open within the specified time. The switch of

the hood was malfunctioning.

P1 The hood did not close within the specified time. The switch of

the hood was malfunctioning.

P2 The hood was attempted to be opened with force when it was

completely closed. The switch of the hood was malfunctioning.

(2) Track No. B : Error sequence in portion

The display of 1 to 16 appears. The low number indicates the recently generated error. The error whose number is “1” was generated most

recently.

(3) Minute : Second No. C : Detail of error generation mode in portion

Indicates the internal mode in which the displayed error is generated. The upper digit in “minute : second” has the meaning.

Digit of minute Digit of second

Display Contents Display Contents

0 * Spindle stop operation 0 *

1 * Disc return operation

2 * Disc selection operation

3 * Setup operation 1 *

4 * CD-R setup operation

5 * TOC read

6 * Track search operation

7 * Play

8 * Pause

9 * Manual search

During closing of the hood

and when the hood is completely close

During opening of the hood

and when the hood is completely open

40

Page 41

7.2.4 DISASSEMBLY

Push

Push

Mecha Base

Loading Mechanism ASSY

11

11

11

12

14

13

REMOVING THE LOADING MECHANISM ASSY

PD-F958, PD-F908

Remove the Bonnet.

1

2

45

6 7

8 10

Remove the Screws and Stopper Angle.

3

Remove the Screws and Rear Base.

Remove the Screws and Back Fence.

Stopper AngleStopper Angle

While holding down the hook of the Mecha

Base, slide the Mechanism Stopper toward the

right to pull up and remove the Mecha Stopper.

22

Back Fence

33

44

44

44

Remove the each wire.

11

12

6

7

Rear BaseRear Base

55

22

44

4

44

44

While holding down the hook of the Mecha

14

Base, slide the Loading Mechanism Assy to

pull up and remove the Loading Mechanism

Assy.

10

9

Mecha Stopper Mecha Base

Loading Mechanism ASSY

Push

8

Push

Hook

41

Page 42

PD-F958, PD-F908

REMOVING THE OPERATION PANEL

Remove the Bonnet.

1

Remove the Screws.

2

Cut the Binder securing the wire material.

3

Remove the Center Pole. (Refer to the “REMOVING THE DISC RACK”)

4

Shift the Front Panel slightly toward you while paying attention to the back side hooks on the Chassis.

5

2

5

5

Hook Hook

sectionsection

REMOVING THE DISC RACK

Open the Hood.

1

Remove the Screws.

2

34

Press the 2 hooks to remove the Center Pole from the Operation Panel.

2

Center PoleCenter Pole

3

2

2

4

3 3

42

OPENOPEN

1

HoodHood

Disc RackDisc Rack

Operation PanelOperation Panel

Page 43

REMOVE THE HOOD and HOOD BASE

Remove the Bonnet.

1

Remove the Operation Panel. (Refer to the “REMOVING THE OPERATION PANEL”)

2

Remove the Screws.

3

Remove the Back Fence.

4

Press the hook of the Stopper of the Hood Base to remove the Stopper. Slide the Hood toward the left to remove the Hood.

7

5

Remove the Screws.

8

Remove the Hood Base.

9

PD-F958, PD-F908

Back Fence

Hook

section

Push

5

6

Stopper

8

7

Turning

8

Hood

3

4

8

9

Hood Base

43

Page 44

PD-F958, PD-F908

INSTALLING THE LOADING MECHANISM ASSY

1

Loading Mechanism Assy

Slider

The projection of the Drive Plate

should be engaged with the

corresponding part of the slider

INSTALLING THE DISC RACK

1

The hook of the Mecha Base should

should be on the top of the Disc Rack

Disc Rack

Loading Mechanism Assy

Gear

Place the Disc Rack below

the hook of the Mecha Base,

then let the center hole of the Disc

Rack pass through the Center Boss.

44

The Gear should be

engaged with Disc Rack

Mecha Base

Center Boss of the

Mecha Base

Page 45

REMOVING THE SERVO MECHANISM ASSY GM

Arm A2

Turn

Gear Pulley(B)

45

Servo Stopper S

Float Base

Connector Assy(4P)

Float Angle

Float Spring

Remove

Flloat Base

Hook

Loading Base

Move

Remove

Float Base

Float Rubber

Servo Mechanism Assy Gm

2

2

3

4

5

6

1

7

Push

PD-F958, PD-F908

Turn gear pulley (B) and position Arm A2 as shown

1

below.

2

Remove the connector ASSY (4P) from the float base.

6

Remove the float spring. (To install this part, line up

7

the float angle side of the Servo Mechanism ASSY

GM first, and press down on the float base side.)

3 5

Slide the float base in the direction of the arrow

while pressing down on the loading base

4

hook, and, lifting it gently, pull it out in the

direction of the arrow .

5

Remove the float rubber from the Servo Mechanism

8

ASSY GM. At this time the float rubber should remain on the float base side. (To install it on the float

base when it has been removed, push it into place with

a thin cylindrical object.

45

Page 46

PD-F958, PD-F908

g

REMOVING THE ARM A2

Remove the float base together with the Servo

1

Mechanism ASSY GM. (Refer to Steps for

“ Removing the Servo Mechanism ASSY GM” .)

1 5

2

Remove the clamp spring and remove the clamper holder.

Clamp Spring

4

5

7

3

Clamper Holder

3

Remove

2

Turn gear pulley (B) and position Arm A2 as shown

below.

Remove Arm (B) while pressing the hook in

6

the direction of the arrow.

Remove screw 7.

Turn gear pulley (B) and position Arm A2 as shown

8

below.

Remove the Arm A spring2 from its hook.

9

Note: Do not hold the tip (blade) of arm (A) during

operation.

Gear Pulley(B)

8

9

Hook

Arm A Sprin

2

10 12

Cam Cover

10

Arm A2

46

Arm(B)

Arm A2

Screw

Remove

Gear Pulley(B)

7

10

4

5

Push

Arm(B)

Hook

6

10

12

Lift

11

Remove drive plate, Arm plate, Arm A spring2 and Arm

13

(A). (Refer to Steps 3-4 on page 47.)

Page 47

PD-F958, PD-F908

5

6

7

7

FOR REASSEMBLY , REVERSE THE DISASSEMBLY PROCEDURE, and IN ADDITION CARRY OUT

THE FOLLOWING ITEMS.

Assemble the arm plate as shown below, watching out

1

for the drive plate hook.

Drive Plate

Hook

Arm Plate

Place Arm A2 and the Arm A spring2 on the loading

2

base, being careful to keep them in the position shown

below.

Loading Base

Set Position

Arm A2

5

8

7

Turn gear pulley (B) and position Arm A2 as shown

below.

9

Arm Spring2

Arm A2

Set the drive plate and arm plate, which were assem-

3

bled in Step , on the Arm A2 side as shown below.

At this time be careful to keep Arm A2 in the position

described in Step .

Insert the gear plate boss into the drive plate groove

4

and pull it toward you.

Drive Plate

4

Arm Plate

1

2

Gear Plate Boss

ArmA2

3

Note : Do not hold the tip (blade) of arm A2 during

operation.

Gear Pulley(B)

8

Tun

9

Hook

ArmA Spring

Arm A2

47

Page 48

PD-F958, PD-F908

10

Arm(B)

Arm A2

12

Arm(B)

12

Gear Plate

Arm(B)

Gear Pulley(B)

10

Turn

11

Install

13

Gear Pulley(B)

15

Clamp Spring

15

13

Clamper Holder

45°

14

48

Page 49

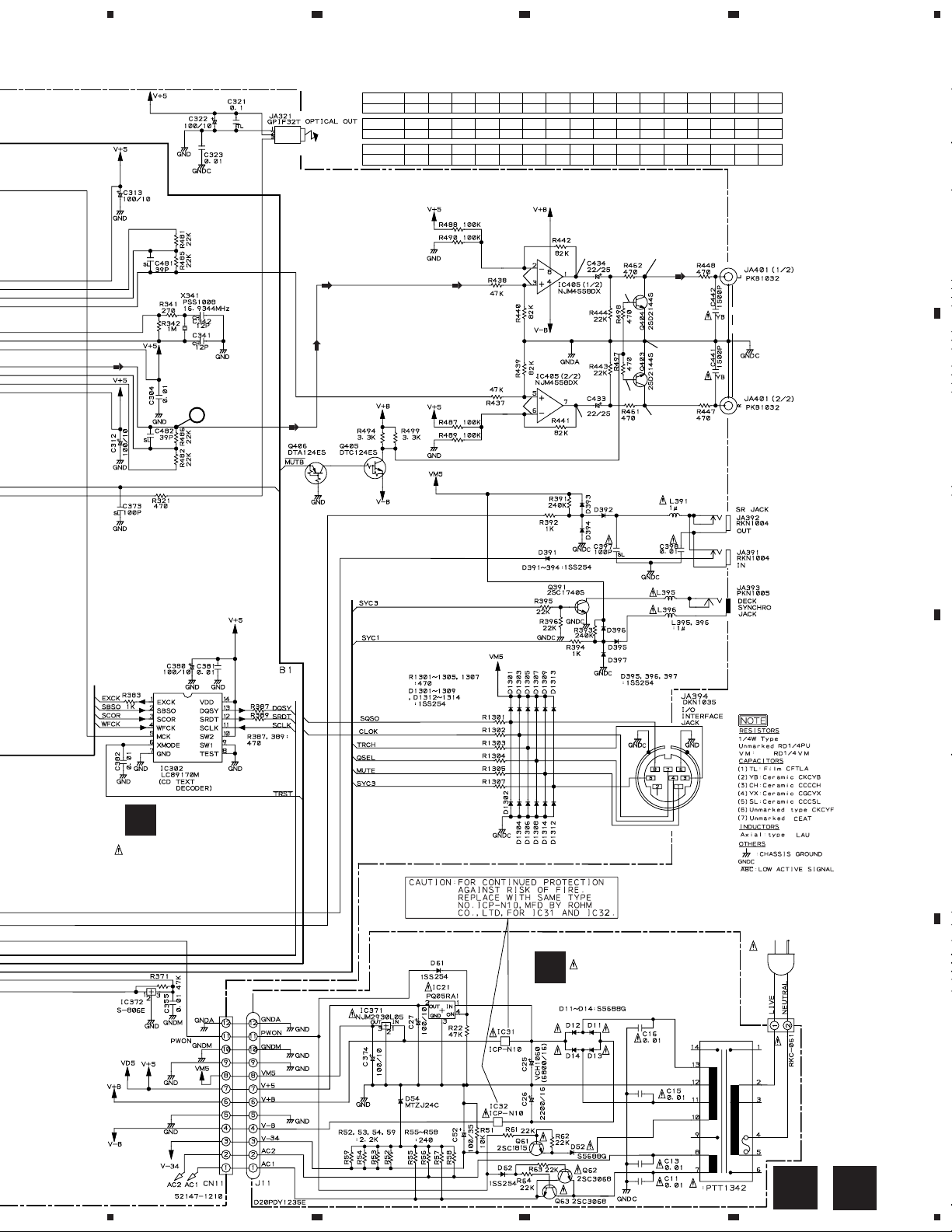

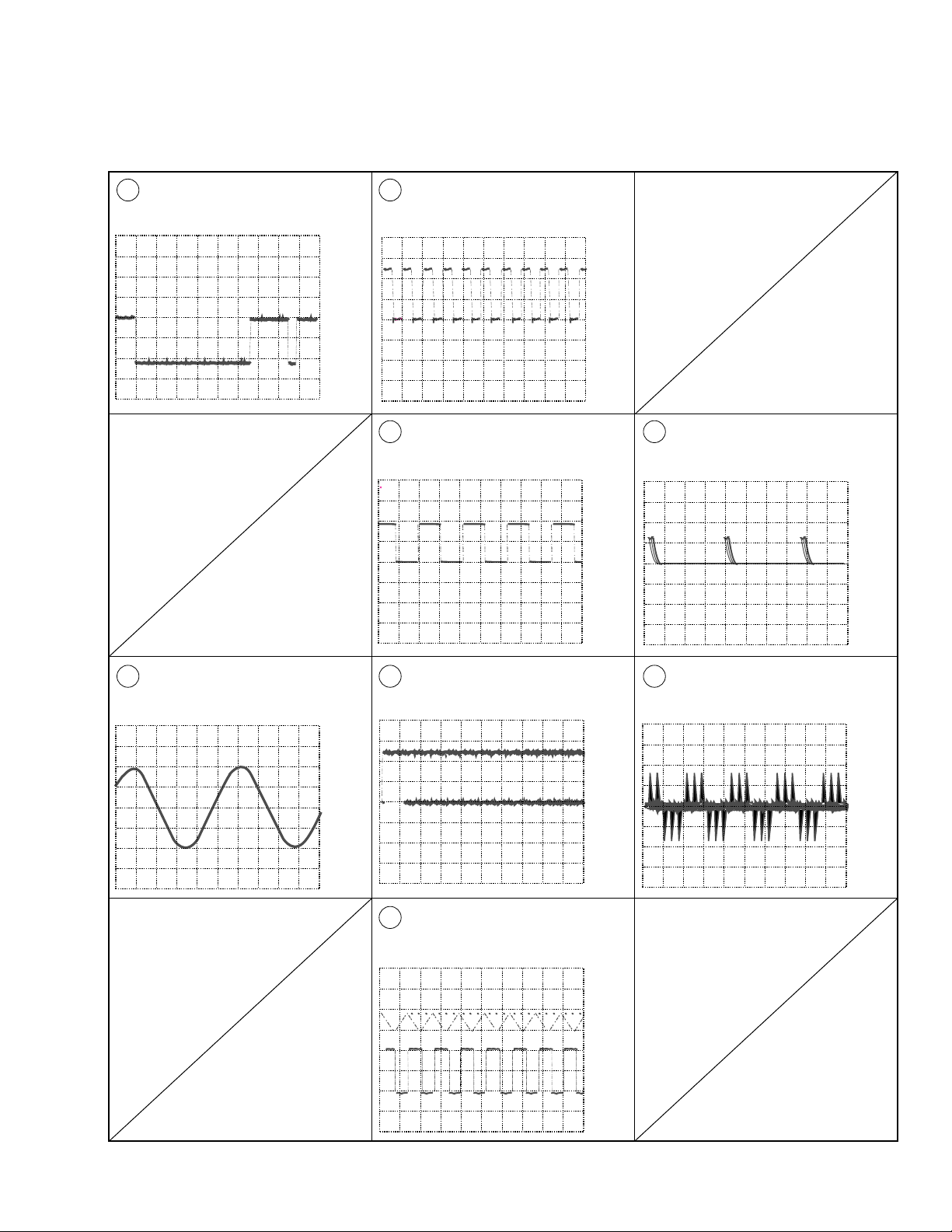

7.3 BLOCK DIAGRAM

AUDIO

OUTPUT

OPTICAL

OUT

AUDIO

MUTE

DECK

SYNCHRO

PD-F958, PD-F908

SR

X341

89 90

71

44

RF31

86,93

(IC301)

CXD2529Q

DECODER+DAC

26,27

DATA

FOK25 23

(IC151)

SERVO

34

CXA1782CQ

CONTROLLER

COUT

23 14

33

53

75

11

10

12,

100

8

SQSO

SENS

RESET

22

MOTOR DRIVE

6,

13,

16

FCOK

SCOR

LATCH

CLOCK, DATA

RESET

X351

AMP

39 46

9,

10

40

11

34 35

44

IC202)

(IC201,

LA6520

21,22,

23,24,

(IC203)

LA6517

12,13

25

DRIVE

MOTOR

IN-SIDE SW

42,43

CPU

28

LD-ON

47

PD-F958:PE5031A (IC351)

PD-F908:PE5032A (IC701)

56

18,19

26,27,37,36

DOOR SW

A-F

MD

PICK-UP

ASSEMBLY

LD

TRACKING DRIVE

FOCUS DRIVE

M

CARRIAGE DRIVE

SPINDLE DRIVE

DISC SELECT DRIVE

LOADING DRIVE

DOOR DRIVE

IN-SIDE SW

EJECT SW

CLAMP SW

DISC-COUNT

DISC-POSITION

FLOURESCENT

DISPLAY

FUNCTION KEY

LED

49

Page 50

PD-F958, PD-F908

8. PANEL FACILITIES AND SPECIFICATIONS

FRONT PANEL

STANDBY/ON

switch

SINGLE LOADER

ACCESS button

SINGLE LOADER

PLAY button

FILE–TYPE

COMPACT DISC PLAYER

◊Û¿X/.˘

STANDBY / ON

SINGLE LOADER

ACSESS

PLAY

MODE button

Hood

CLEAR button

@

°

@

°

@

°

@

°

'

@

°

@

°

FILE –TYME CD MECHANISM

@

°

@

°

@

°

@

°

@

°

@

°

@

°

@

°

OPEN/CLOSE button

UNLOAD button

Remote sensor

HI-LITE button

PROGRAM button

TITLE DISPLAY button

Î

MODE HI-LITE

CLEAR PROGRAM

OPEN/

CLOSE

UNLOAD

TRACK MIN SECDISC

CUSTOM

RDM

ALL BEST CD TEXT

PGM 1

PREVIOUSSINGLE

DISPLAY BEST PREVIOUS

INPUT

6

7

PULSEFLOW

D/A CONVERTER

Stop button (7)

Play/Pause button (6)

REPEAT

REMAIN

SCANDISC

DISCTITLE

4 1

PHONES LEVEL

BEST button

PREVIOUS button

DISC (–/+) buttons

¡ ¢

TITLE INPUT button

Track/Manual search

buttons (41/¡¢)

DISPLAY

Lights when the PROGRAM (PGM)

button is pressed.

Lights during random play.

Lights when you choose the play mode.

Lights when a CD is being played.

Lights during pause mode.

Lights during custom programming and

play.

CUSTOM

Lights when the BEST button is pressed.

Lights during repeat play.

Lights during CD TEXT disc

playback.

TRACK MIN SECDISC

RDM

ALL BEST

SINGLE

PGM 1

PREVIOUS

REPEAT

SCANDISC

CD TEXT

REMAIN

Lights when the remaining time is

displayed.

Blinks during TRACK SCAN.

Blinks during DISC SCAN.

Blinks when the PREVIOUS button is pressed.

50

Page 51

SPECIFICATION

PD-F958, PD-F908

1. General

Type ........................................... Compact disc digital audio system

Power requirements

U.S. and Canadian models ............................... AC 120V, 60 Hz

U.K. and European models................... AC 220-230V, 50/60 Hz

Power consumption

U.S. and Canadian models ..................................................12W

U.K. and European models.................................................. 14W

Power consumption in standby mode ......................................... 3W

Operating temperature ................................................+5°C - +35°C

(+41°F - +95°F)

Weight ( without package ) ................................ 6.5 kg (14 lb 3 oz.)

External dimensions........................420(W) X 402(D) X 193(H) mm

16-9/16(W) X 15-13/16(D) X 7-10/16(H) in.

2. Audio section

Frequency response .................................................. 2 Hz - 20 kHz

S/N ratio ......................................................... 98 dB or more (EIAJ)

Dynamic range ............................................... 96 dB or more (EIAJ)

Channel separation ........................................ 96 dB or more (EIAJ)

Harmonic distortion ...................................... 0.003 % or less (EIAJ)

Level difference between channels................. 1.0 dB or less (EIAJ)

Output voltage............................................................ 2 Vrms (EIAJ)

Wow and flutter ................................ less than ±0.001 % (W.PEAK)

( below measurable level ) (EIAJ)

Channels ........................................................... 2-channel ( stereo )

3. Output terminal

Audio line output

Control input jack (Except for U.K. model)

Control output jack (Except for European and U.K. models)

CD-DECK SYNCHRO jack

Optical digital output jack

I/O interface (Except for U.K. and F908 models)

Head phone jack with volume control

(Except for U.S. and Canadian models)

4. Accessories

÷ Remote control unit................................................................... 1

÷ Size AA/R6P dry cell batteries.................................................. 2

÷ Output cable.............................................................................. 1

÷ Control cable (Except for European and U.K. models) ............. 1

÷ CD liner notes file (Except for U.S. and Canadian models) ...... 1

÷ Index label sheet (Except for U.S. and Canadian models) ....... 1

÷ Operating instructions ............................................................... 1

Note.

Specifications and design subject to possible modification without notice,

due to improvements.

ACCESSORIES

Remote control unit

(PWW1148 : CU-PD101)

HI-LITE BEST

PREVIOUS

MODE CLEARPGMREPEAT

ABC2DEF

1

GHI4JKL

PQRS7TUV

DISC

SET

CURSOR

<>

1¡4¢

783

FILE-TYPE CD PLAYER

REMOTE CONTROL UNIT

TIME/

3

CHARA

MNO

TITLE

5

6

DISPLAY

TITLE

WXYZ

INPUT

8

9

TRACK

MARK

SET

0

DISC

–

+

RANDOM

Î

Size AA/R6P dry cell

batteries ( VEM1010 )

Output cable

( PDE1248 : L=1.0m )

Control cable

( PDE1247 : L=1.0m )

51

Page 52

ORDER NO.

RRV2106

FILE-TYPE COMPACT DISC PLAYER

PD-F958

¶ Refer to the service manual RRV2085 for PD-F958/KUXQ/CA.

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

MYXQ O AC220-230V

MVXQ O AC220-230V

Model

PD-F958

Power Requirement

Remarks

CONTENTS

1. SAFETY INFORMATION....................................2

2. CONTRAST OF MISCELLANEOUS PARTS .....3

3. SCHEMATIC DIAGRAM.................................... 8

4. PCB CONNECTION DIAGRAM .......................11

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER ELECTRONIC CORPORATION 1999

T–ZZR FEB. 1999 Printed in Japan

Page 53

PD-F958

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty . If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

THIS PIONEER APPARATUS CONTAINS

IMPORTANT

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 7 mw

WAVELENGTH: 780 – 785 nm

LABEL CHECK for (PD-F958/MYXQ and PD-F958/MVXQ types)

PD-F958/MYXQ only

Additional Laser Caution

1.Laser Interlock Mechanism

The position of the switch (S651) for detecting loading

state is detected by the system microprocessor, and

the design prevents laser diode oscillation when the

switch (S651) is not on CLMP terminal side (CLMP

REAR

signal is OFF or high level).

Thus, the interlock will no longer function if the switch (S651)

is deliberatery set to CLMP terminal side. (low level)

The interlock also does not function in the test mode *.

Laser diode oscillation will continue, if pin 33 of

CXA1782CQ (IC151) on the MOTHER BOARD ASSY

is connected to GND, or pin 22 of IC301 (LDON) is

connected to low level (ON), or else the terminals of

Q151 are shorted to each other (fault condition).

2.When the cover is opened, close viewing of the

objective lens with the naked eye will cause exposure

to a Class 1 laser beam.

*

: Refer to page 29. on the service manual RRV2085.

PD-F958/MVXQ only

2

Page 54