PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2002

Î

DV-C505

DVD PLAYER

DV-C505

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2619

Model Type Power Requirement

DV-C505 KUXU AC120V 1

DV-C505 KCXU AC120V 1

Reginal restriction

codes (Region No.)

Remarks

For details, refer to "Important symbols for good services" .

T-ZZR JULY 2002 printed in Japan

1234

SAFTY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

D

E

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

DV-C505

5678

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

A

B

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

Discs compatible with this

player

Any disc that displays one of the following

logos should play in this player. Other

formats, including DVD-Audio, DVD-RAM,

DVD-ROM, CD-ROM (except those that

contain MP3 files), SACD and Photo CD will

not play.

DVD-Video

Audio-CD

Video-CD CD-R CD-RW

C

D

56

DV-C505

E

F

7

8

3

1234

CONTENTS

SAFTY INFORMATION .......................................................................................................................................2

A

B

C

D

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 TABLE MECHANISM SECTION .............................................................................................................. 10

2.4 TRAVERSE MECHANISM ASSY-S ......................................................................................................... 12

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................14

3.1 BLOCK DIAGRAM ................................................................................................................................... 14

3.2 OVERALL WIRING DIAGRAM................................................................................................................. 18

3.3 FJMB ASSY(1/5)...................................................................................................................................... 20

3.4 FJMB ASSY(2/5)...................................................................................................................................... 22

3.5 FJMB ASSY(3/5)...................................................................................................................................... 24

3.6 FJMB ASSY(4/5)...................................................................................................................................... 26

3.7 FJMB ASSY(5/5)...................................................................................................................................... 28

3.8 FLKY, DSSB and PWSB ASSYS ............................................................................................................. 30

3.9 POWER SUPPLY UNIT............................................................................................................................ 32

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 33

4.1 TRSB, SSRB, LOMB and SSIB ASSYS................................................................................................... 33

4.2 FJMB ASSY ............................................................................................................................................. 34

4.3 FLKY, DSSB and PWSB ASSYS ............................................................................................................. 38

4.4 POWER SUPPLY UNIT............................................................................................................................ 40

5. PCB PARTS LIST ........................................................................................................................................... 41

6. ADJUSTMENT ............................................................................................................................................... 44

6.1 ADJUSTMENT ITEMS and LOCATION................................................................................................... 44

6.2 JIGS and MEASURING INSTRUMENTS ................................................................................................44

6.3 NECESSARY ADJUSTMENT POINTS ...................................................................................................45

6.4 TEST MODE ............................................................................................................................................ 46

6.5 MECHANISM ADJUSTMENT.................................................................................................................. 47

7. GENERAL INFORMATION............................................................................................................................. 50

7.1 DIAGNOSIS ............................................................................................................................................. 50

7.1.1 TEST MODE ......................................................................................................................................... 50

7.1.2 DISPLAY OF THE MECHANISM ERROR HISTORY............................................................................ 56

7.1.3 TEST POINT LOCATION...................................................................................................................... 60

7.1.4 TROUBLE SHOOTING ......................................................................................................................... 64

7.1.5 SEQUENCE AFTER THE POWER ON ................................................................................................ 66

7.1.6 DISASSEMBLY ..................................................................................................................................... 67

7.1.7 TROUBLE SHOOTING FOR MECHANISM SECTION......................................................................... 77

7.2 PARTS...................................................................................................................................................... 79

7.2.1 IC .......................................................................................................................................................... 79

7.2.2 DISPLAY ............................................................................................................................................... 96

7.3 CLEANING............................................................................................................................................... 97

8. PANEL FACILITIES ........................................................................................................................................ 98

E

F

4

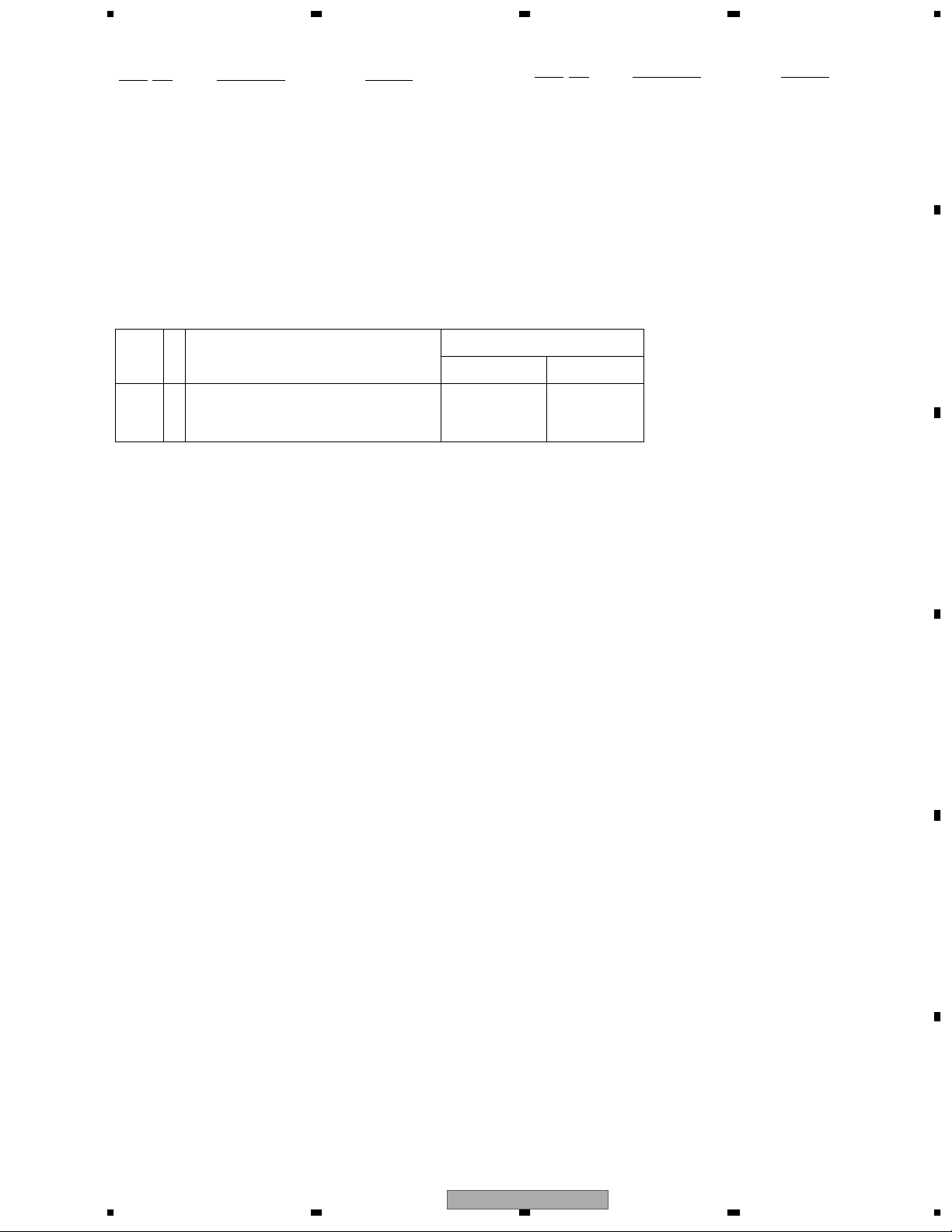

1234

DV-C505

General

System ........................................... DVD player

Power requirements ............... AC 120 V, 60 Hz

Power consumption ................................. 13 W

Power consumption (standby)

......................0.3 W

Weight .....................................4.5 kg (9lb 15oz)

Dimensions .....420 (W) x 100 (H) x 374 (D) mm

(16

9

/16 (W) x 3 15/16 (H) x 14 12/16 (D) in.)

Operating temperature..............+5 °C to +35°C

(+41°F to +96°F)

Operating humidity ..........................5% to 85%

(no condensation)

S-Video output

Y (luminance) - Output level ........ 1 Vp-p (75 Ω)

C (color) - Output level ......... 286 mVp-p (75 )

Jack ..................................................... S-Video

Video output

Output level ................................ 1 Vp-p (75 )

Jack ..........................................................RCA

Component V ideo output (Y , PB, PR)

Output level .......................... Y: 1.0 Vp-p (75 )

P

B

, PR: 0.7 Vp-p (75 )

Jacks ....................................................... RCA

Audio output (2 ster

eo pair)

Output level ....................... During audio output

200 mVrms (1 kHz, –20 dB)

Number of channels .......................................... 2

Jacks .............................................................RCA

Digital audio characteristics

Frequency response..................... 4 Hz to 44 kHz

(DVD fs: 96 kHz)

S/N ratio .................................................... 118 dB

Dynamic range ......................................... 101 dB

Total harmonic distortion ..................... 0.0016 %

Wow and flutter .............. Limit of measurement

(

±

0.001% W. . PEAK) or lower

Digital output

Optical digital output ...................... EIAJ Optical

Coaxial digital output................................... RCA

Accessories

Stereo audio cable............................................. 1

Video cable ......................................................... 1

Power cable ........................................................ 1

Remote control ................................................... 1

AA/R6P dry cell batteries .................................. 2

Operating Instructions ...................................... 1

Warranty card ..................................................... 1

• The specifications and design of this

product are subject to change without

notice, due to improvement.

Ω

Ω

Ω

Ω

• Manufactured under license from Dolby

Laboratories. “Dolby” and the double-D

symbol are trademarks of Dolby Laboratories.

• “DTS” is a registered trademark of Digital

Theater Systems, Inc.

• TruSurround and the

® symbol are

trademarks of SRS Labs, Inc. TruSurround

technology is incorporated under license from

SRS Labs, Inc.

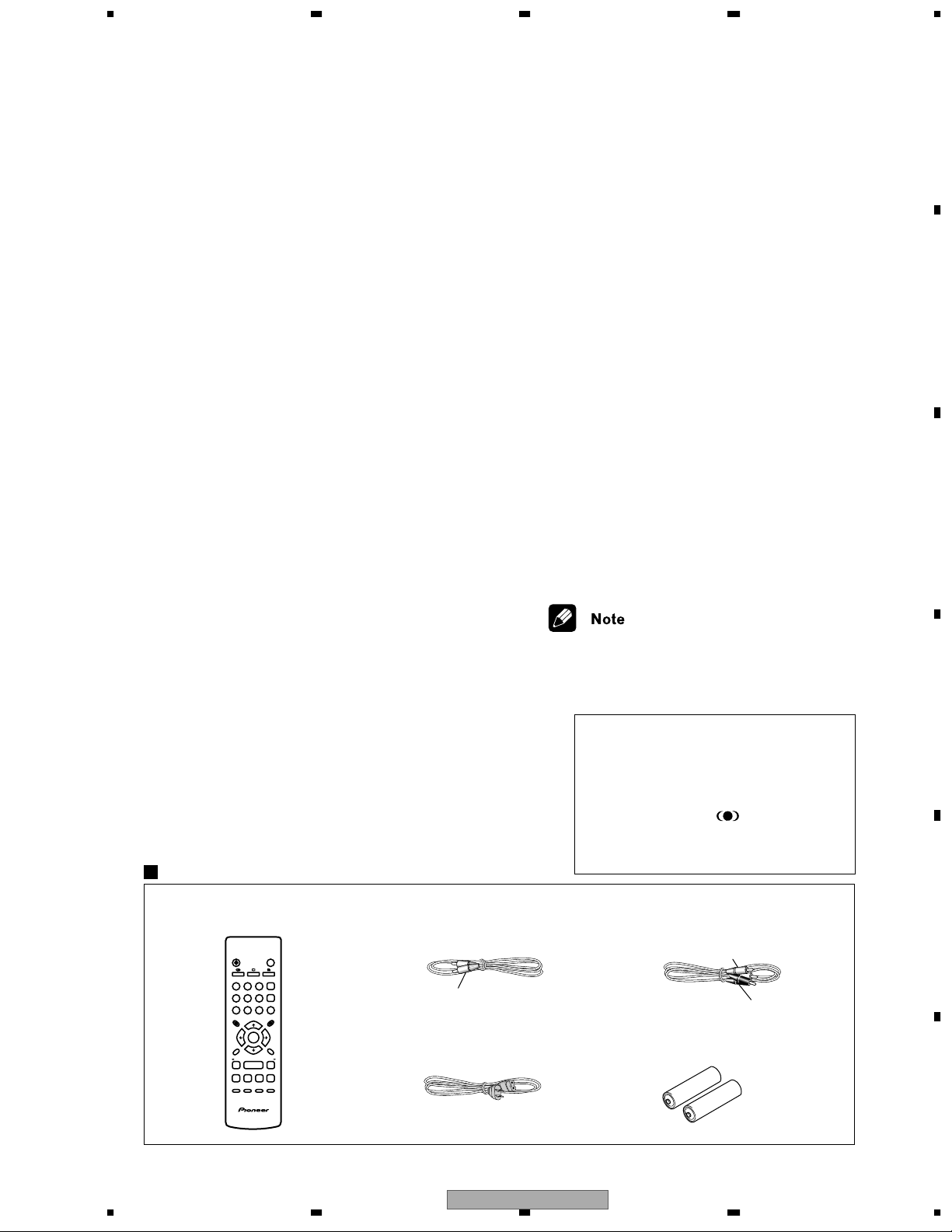

Video Cable (L=1.5m): VDE1055 Audio Cable (L=1.5m): VDE1054

AA/R6P Dry Cell Batteries

Power Cable : ADG7022

Remote Control : VXX2811

Accessories

White

Red

Yellow

0

1

23

4

56

789

CLEAR

ENTER

ANGLEAUDIO

TOP MENU

SETUP

SUBTITLE

PLAY MODE SURROUND ZOOM DISPLAY

MENU

RETURN

ENTER

STANDBY/ON

OPEN/CLOSE

4

/e

E/

13

¡

¢

8

7

0

5678

1. SPECIFICATIONS

A

B

C

D

E

F

56

DV-C505

7

8

5

1234

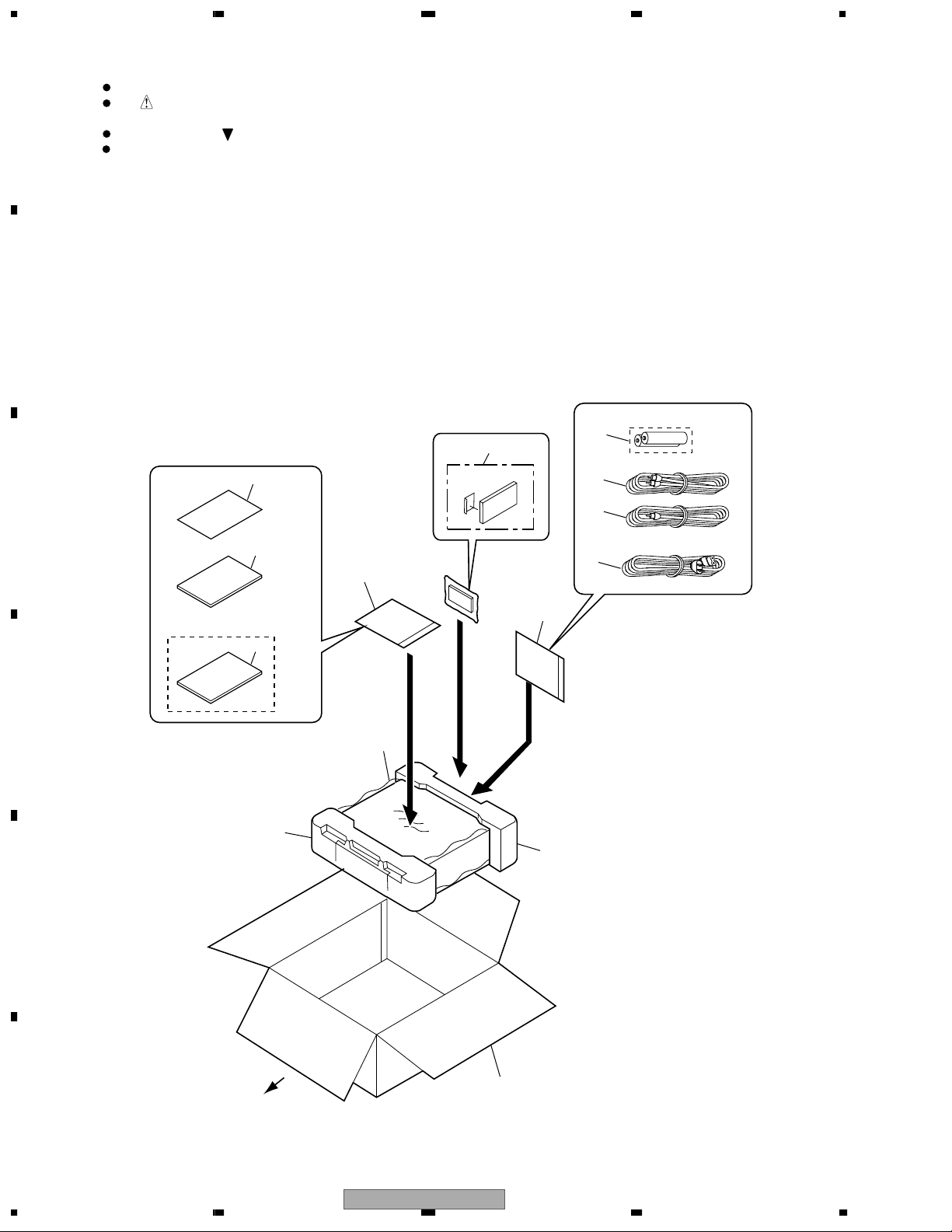

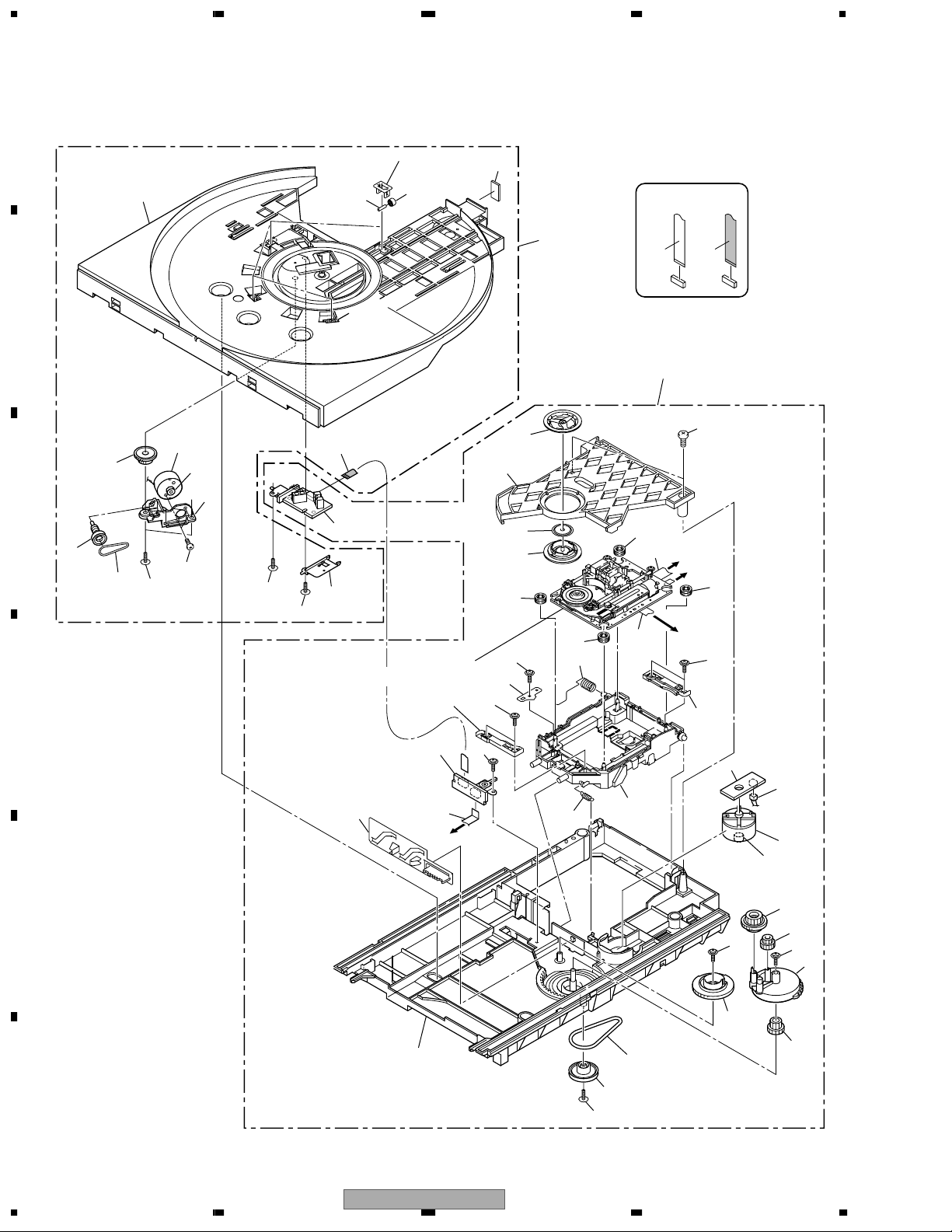

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

B

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

4

8

5

2

3

6

13

13

KCXU Type Only

7

D

12

9

10

E

1

11

F

6

1234

FRONT

DV-C505

>

5678

PACKING parts List

Mark No. Description Part No.

1 Power Cord ADG7022

2 Audio Cord (L = 1.5m) VDE1054

3 Video Cord (L = 1.5m) VDE1055

4 Remote Control Unit VXX2811

NSP 5 Dry Cell Battery (R6P, AA) VEM1010

6 Operating Instructions VRB1291

(English)

7 Operating Instructions See Contrast table (2)

Mark

No. Description Part No.

(French)

NSP 8 Warranty Card See Contrast table (2)

9 Pad F VHA1299

10 Pad R VHA1300

11 Packing Case See Contrast table (2)

12 Sheet RHX1006

13 Polyethylene Bag VHL1051

A

(2) CONTRAST TABLE

DV-C505/KUXU and KCXU are constructed the same except for the following :

Mark No. Symbol and Description

DV-C505/KUXU

7 Operating Instructions (French) Not used VRC1159

NSP 8 Warranty Card ARY7057 ARY7045

11 Packing Case VHG2236 VHG2241

Part No.

DV-C505/KCXU

B

C

D

56

DV-C505

E

F

7

8

7

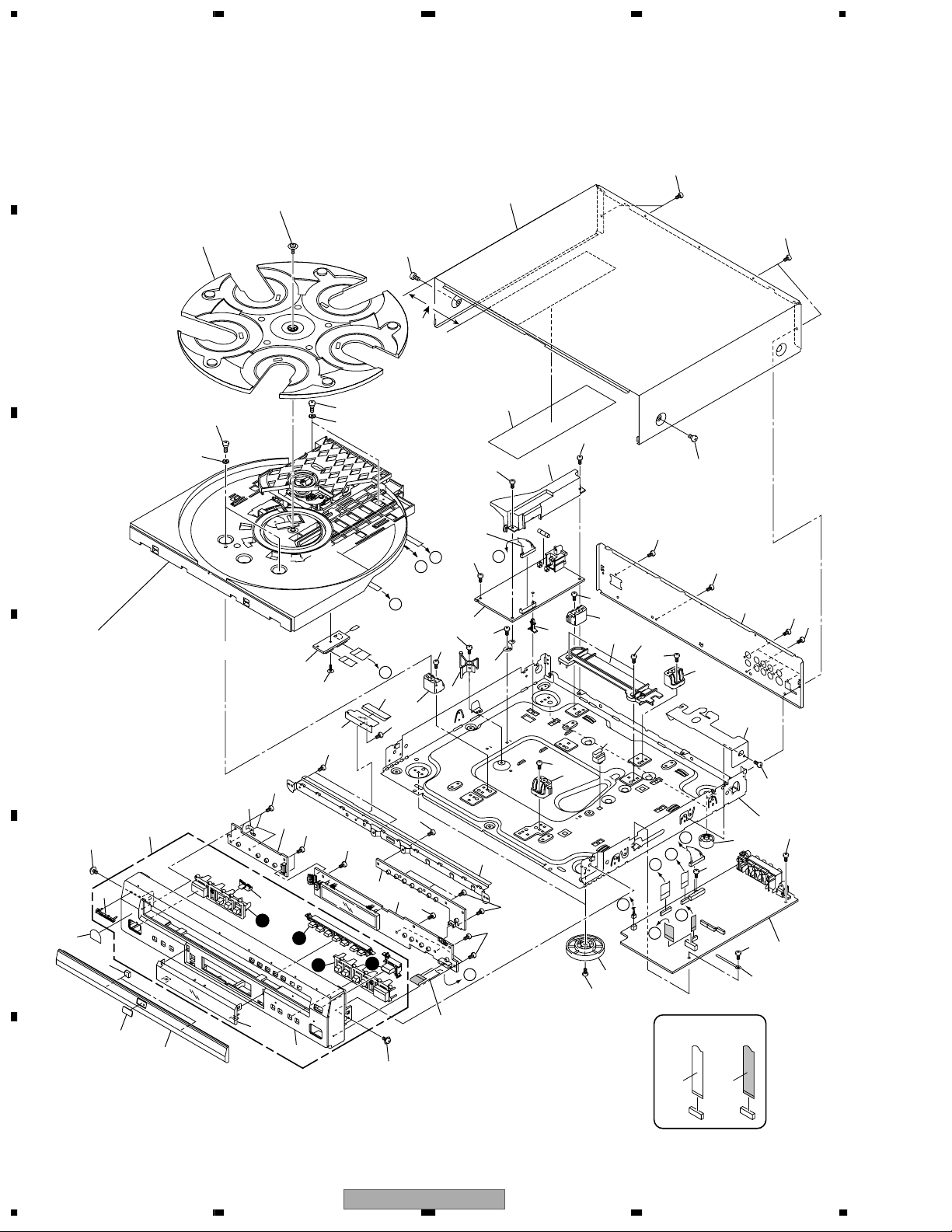

1234

2.2 EXTERIOR SECTION

A

44

B

C

Refer to

"2.3 TABLE MECHANISM SECTION".

D

35

47

36

E

42

15

14

24

12

13

40

45

6

44

A

48

23

21

44

29

44

44

7

10

45

25

F

48

27

44

27

30

16

26

48

48

C

17

48

45

46

44

44

20

27

F

E

D

B

A

18

44

19

44

11

22

44

44

44

44

1

9

46

122(±3)

12

14

E

C

B

48

48

5

43

32

45

3

45

45

D

34

45

4

2

28

27

45

45

DV-C505

8

NON-CONTACT

SIDE

CONTACT SIDE

31

33

F

39

37

47

8

1234

>

5678

EXTERIOR SECTION parts List

Mark No. Description Part No.

1 FJMB Assy VWS1526

2 FLKY Assy VWG2347

3 PWSB Assy VWG2348

4 DSSB Assy VWG2349

5 SSIB Assy VWG2350

6 POWER SUPPLY Unit VWR1353

7 Connector Assy PF13PP-S40

8 Flexible Cable (13P) VDA1904

9 Screw ABA7069

NSP 10 PCB Base RNE1221

11 Cord Clamper RNH-184

12 Step Screw P9L VBA1086

13 Earth Plate VBK1121

14 Mech. Spacer (T1.5) VEB1339

15 Front Cushion VEB1340

16 PCB Hinge VEC1174

17 PCB Support VEC2184

18 Foot (Rubber) VEC2185

19 Flexible Holder VEC2290

20 Rear Panel VNA2406

21 Bonnet Case S VXX2840

NSP 22 Chassis VNA2420

23 FP Angle 2 VNE2273

24 Rotary Tray VNK4923

25 SYPS Cover VNK5008

26 Cable Cover VNK5009

27 Mecha Holder 2 VNL1937

28 Mecha Support 2 VNL1938

29 Large Label VRW1854

30 Insulator VXA2503

31 DVD V Plate VAM1120

32 FPA Sheet VEC2311

33 Tray Panel VNK5005

34 Large Label S VRW1934

35 Front Panel Assy VXA2507

36 Pioneer Badge VAM1130

NSP 37 Front Panel VNK5003

NSP 38 Main Key VNK5004

NSP 39 FL Lens VNK5006

40 LED Lens VNK5007

NSP 41 Main Key VNK5083

NSP 42 Energy Star Label AAX7876

43 Screw Z39-019

44 Screw BBZ30P080FZK

45 Screw BBZ30P100FZK

46 Screw BCZ40P060FZK

47 Screw IBZ30P080FMC

48 Screw BBZ30P060FMC

56

DV-C505

A

B

C

D

E

F

7

8

9

1234

2.3 TABLE MECHANISM SECTION

A

37

(1/6)

36

37

(2/6 - 5/6)

[Roller Cover]

35

28

2

NON-CONTACT

SIDE

CONTACT SIDE

B

1

29

40

31

33

32

43

20

38

C

4

39

30

41

30

37

(6/6)

[PCB Cover]

30

34

Refer to

"2.4 TRAVERSE MECHANISM ASSY-S".

19

(3/3)

D

16

18

14

14

30

6

45

14

8

7

To FJMB

CN151

To SSIB

To SSIB

CN1

CN2

14

30

44

30

19

(2/3)

30

3

5

10

21

To FJMB

CN16

19

9

13

(1/3)

From

FJMB CN15

11

12

E

30

26

25

30

22

27

17

15

24

23

F

10

DV-C505

30

1234

5678

TABLE MECHANISM SECTION parts List

Mark No. Description Part No.

NSP 1 5C Mechanism Base Assy VWT1194

NSP 2 5C Table Mechanism Assy VWT1195

NSP 3 TRSB Assy VWG2179

NSP 4 SSRB Assy VWG2180

NSP 5 LOMB Assy VWG2181

6 Traverse Mechanism Assy-S VXX2782

7 Flat Flexible Cable (26P) VDA1900

8 Flat Flexible Cable (17P) VDA1901

9 Flat Flexible Cable (8P) VDA1902

10 Housing Assy (2P) VKP2249

11 Carriage Motor (LOADING) VXM1033

12 Motor Pulley PNW1634

13 Spring VBH1633

14 Floating Rubber VEB1327

15 Load Belt VEB1316

16 Clamper Plate VNE2251

17 Mechanism Base VNK5010

18 Clamper VNL1935

19 Float Base VNL1933

20 Clamper Holder VNL1939

21 Clamp Cam VNL1934

22 Planet Base VNL1874

23 Gear Pulley VNL1876

24 Loading Gear 1 VNL1877

25 Loading Gear 2 VNL1908

26 Drive Gear VNL1879

27 Change Gear VNL1904

28 CR Cushion T2 XEB3020

29 Screw BPZ30P080FMC

30 Screw Z39-019

31 Motor (TRAY) DXM1143

32 Flat Flexible Cable (7P) VDA1835

33 Motor Pulley PNW1634

34 Tray Belt VEB1317

35 Rubber Roller VEB1318

36 Roller Shaft VLL1511

37 Slide Table VNK4751

38 Motor Holder VNL1880

39 Worm Gear VNL1881

40 Tray Gear VNL1932

41 Screw JGZ17P028FMC

42 • • • • •

43 Cap VNL1936

44 TM Stopper VNE2294

45 Thrust Spring VBH1339

A

B

C

D

E

56

DV-C505

F

7

8

11

1234

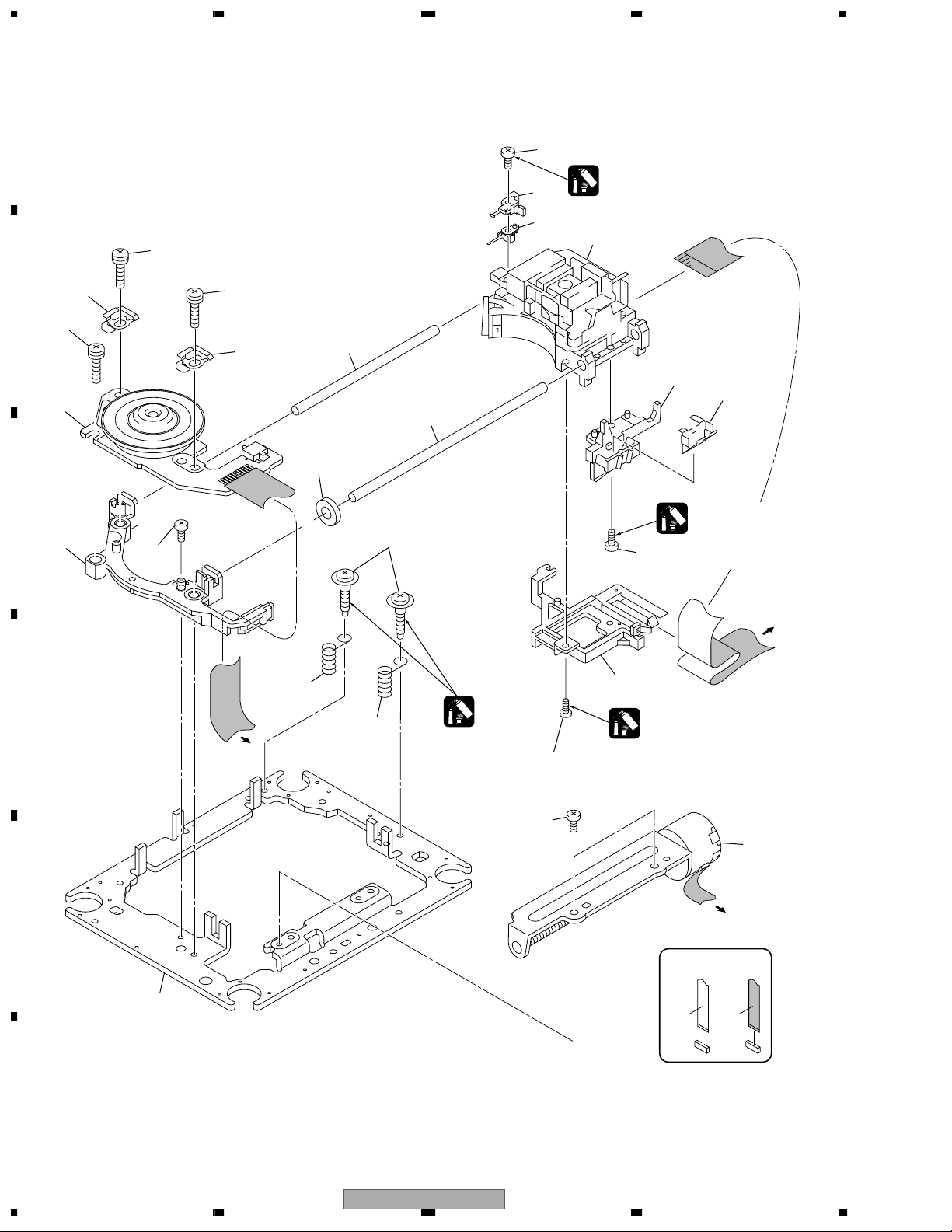

2.4 TRAVERSE MECHANISM ASSY-S

A

18

17 (Torque : 0.12 ± 0.01 N•m)

Silicone Adhesive

12

8

GEM1037

3

10

B

18

1

C

13

D

16

18

10

To SSIB

CN1

7

14

6

19

4 (Adjustment Screw)

5

Screw Tight

5

GYL1001

17 (Torque : 0.12 ± 0.01 N•m)

17 (Torque : 0.12 ± 0.01 N•m)

15

Silicone Adhesive

GEM1037

9

Silicone Adhesive

GEM1037

FJMB

CN151

To

16

2

E

11

NON-CONTACT

F

12

1234

DV-C505

To SSIB

SIDE

CN2

CONTACT SIDE

5678

TRAVERSE MECHANISM ASSY-S parts List

Mark No. Description Part No.

1 Spindle Motor VXM1088

2 Stepping Motor VXM1090

3 Pickup Assy-S OXX8003

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Hold Spring VNC1017

9 Joint Spring VNC1019

10 Support Spring VNC1020

NSP 11 Mechanism Chassis VNE2248

12 Slider VNL1811

13 Spacer VNL1913

14 Joint VNL1914

15 FFC Holder VNL1915

16 Screw BBZ20P050FZK

17 Tapping Screw OBA8009

18 Screw PMA26P100FMC

19 Damper Sheet VEB1335

A

B

C

D

E

F

56

DV-C505

7

8

13

1234

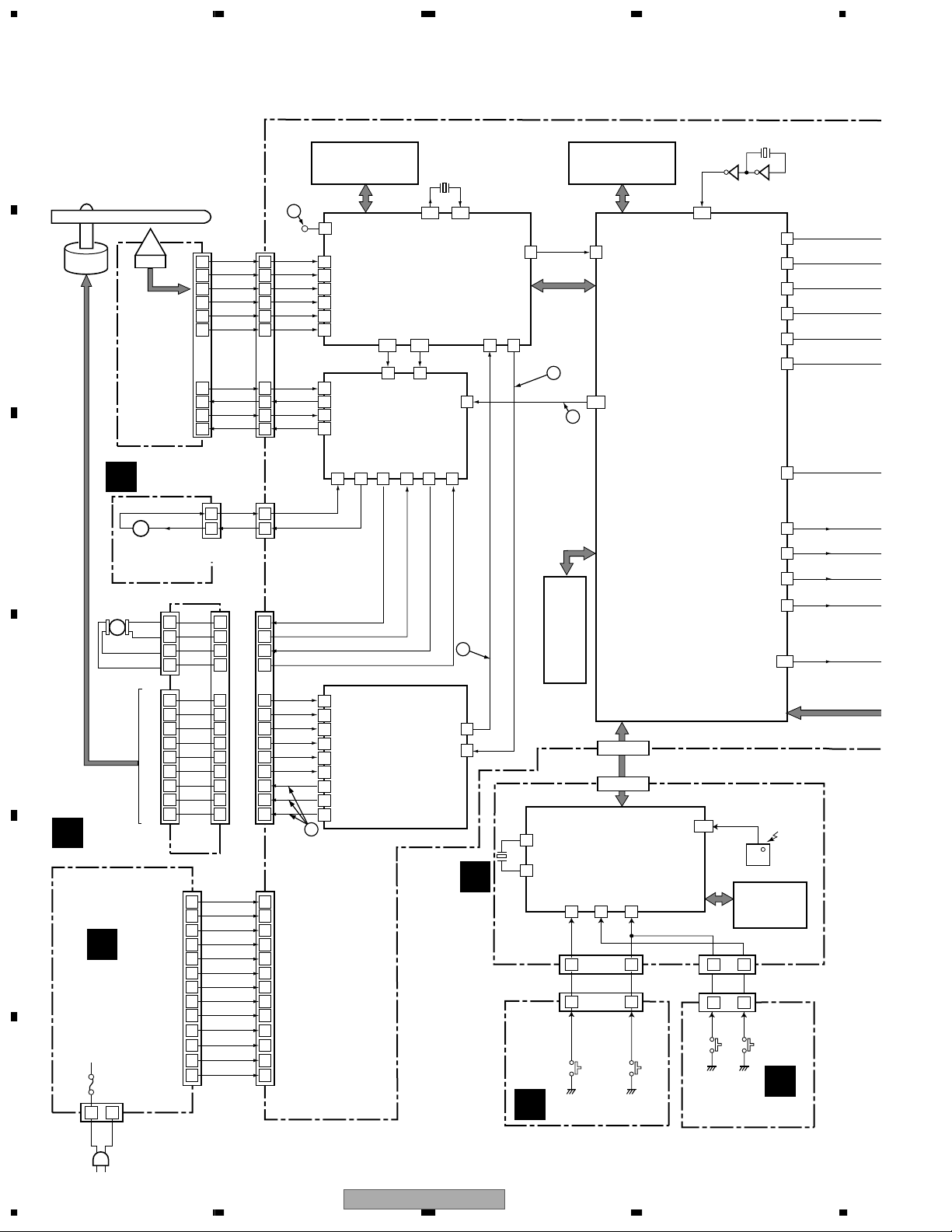

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

Work RAM for Error Correction

IC302

K6T1008V2E-TB70

1M SRAM

1

RF(TP)

Spindle

Motor

B

PICKUP

ASSY

(26P)

20

21

15

16

19

17

T_RTN

24

T_DRV

25

F_RTN

26

F_DRV

23

CN151

B1

B2

B3

B4

(26P)

7

6

12

11

A

8

C

10

3

2

1

4

3

10

12

18

16

25

24

13

12

10

9

RFSACD

A

B

C

D

E

F

VM4VM4+

VM3+

VM3-

FRONT END IC

L6315ATXXTY

• RF Demodulation

• Servo Control

• Servo Decode

• Error Correction

FACT

123

3 20

IN3-

IC351

M56788AFP

FTS Driver

Focus, Tracking,

131

FREOUT FREIN

IC301

TACT

124

FDO

TDO

IN4-

X301

20MHz

132

OUT_DATA(0) S_DATA

PC(2) PC(6)

FG

IN5-

17

Stepper and

Loading Drive

VM1+

VM1-35VM2-31VM2+

17

VM5-15VM5+

H1+

9

H1-

10

H2+

11

H2-

12

H3+

13

H3-

14

A1

7

A2

4

A3

2

LOMB ASSY

C

LOD-

3

4

2

1

9

8

7

6

5

4

10

11

12

(13P)

1

2

3

4

5

6

7

8

9

10

11

12

13

2

1

1

CN31

(2P)

EV+6V(B)

EV+6V(A)

FLDC+

FLDC-

P-CONT

SW+12V

EV+4V

SW+3.3V

1,3

10

11

12

13

14

C

Stepping

(Carriage)

D

SSIB

D

ASSY

M

Motor

Assy

M

Loading

Motor

Assy

ST1+

ST1-

ST2+

ST2-

H1+

H1-

H2+

H2-

H3+

H3-

+–

CN2

(4P)

A1

A2

A3

CN1

(12P)

VWR1353: CN2

E

I

POWER

SUPPLY

UNIT

F1

CN1

(2P)

F

LIVE

1 2

NEUTRAL

2

4

5

9

8

7

6

CN3

(17P)

-28V

GND

GND

GND

GND

LOD+

ST1+

ST1-

ST2+

ST2-

H1+

H1-

H2+

H2-

H3+

H3-

A1

A2

A3

1

2

CN15

15,17

16

14

13

9

8

7

6

5

4

10

11

12

CN401

1

2

3

4

5

6

7

8

9

10

11

12

13

(2P)

CN61

(17P)

(13P)

34

14

IC251

BA6664FM

Spindle

Driver

• Spindle Drive

• FG Detection

32

2

FG

24

FG

EC

22

SPDL PDM

F

FLKY

ASSY

X101

5MHz

Work RAM for MPEG Decode

IC604

K4S641632F-TC75

64M SDRAM

FE_DATA

84

4238

SPDL

PDM

LOAD_DRV

16

15

16

116

HSYNC

_PWM0

STI5519AVB-B0C

(16M)

IC603

FLASH ROM

2

CN101

(13P)

IC101 PE5314B

3

4

FL CONTROL

X1

MICROCOMPUTER

• Main Unit Key Input

X2

• Remote Control Receive

• FL Display Control

KEY1

KEY2

20

21

CN102

(6P)

5 6 2 3

KEY2 KEY0

5 6

CN201

(6P)

PWSB ASSY

H

IC605 TC7WU04FU

120

PIXCLK

IC601

BACK END IC

• System Control

• MPEG Video Decode

• Video Encode

• Video DAC

• Audio Decode

(MP3, Dolby)

• Sub-picture Decode

CN12

(13P)

7

to

127

to

IR

KEY0

22

KEY0 KEY1

DAC_SCLK

PCMDATA0

17

2 3

DSSB ASSY

X601

27MHz

3562

B_OUT

G_OUT

R_OUT

Y_OUT

C_OUT

CV_OUT

SPDIF

PCKCLK

LRCLK

REMOTE

RECEIVER

UNIT

IC103

SPS-444L-H

V101

FL TUBE

VAW1072

CN103

(4P)

CN301

(4P)

G

25

26

27

32

33

34

57

51

52

55

56

ROT_DRV

114

DOUT

A_BCK

A_DATA0

A_MCLK

A_LRCK

14

AC IN

DV-C505

1234

5678

A

Q607

Q606

Q605

Q604

Q603

Q602

R721

R722

R723

B/CB

G/Y

R/CR

S_Y

S_C

V

4 7

8

3

5 6

FJMB ASSY

E

Cb IN

14

CY IN

12

16

6

2

4

Cr IN

Y IN

C IN

V IN

1

2

16

3

25

BCKIN

DATA

MCLK

LRCKIN

MM1567AJ

6 IN • 6 OUT

VIDEO AMP

• LPF

• AMP

• Driver

5DISC TURN DRIVER

YOUT b

IC801

YOUT a

CONT

VOUT b

VOUT a

CYOUT b

CYOUT a

CrOUT b

CrOUT a

CbOUT b

CbOUT a

IC711

PCM1742KE

Audio 2ch DAC

IC271

BA6195FP

Y

28

27

C

33

V

31

30

G/Y

25

24

R/Cr

19

18

B/Cb

22

21

Vout L

Vout R 8

1– $: Refer to "3.1.3 WAVEFORMS".

13

C832

14

C822

9

C812

10

C842

12

C862

11

C852

AUDIO LPF

BA4560F

IC731-1/2

LOUT

7

ROUT

12

13

2

3

IC731-2/2

5

6

1

7

JA950

Q941

Y

C

(GREEN)

(BLUE)

(WHITE)

JA702

S VIDEO

OUT

COMPOSITE

VIDEO OUT

(YELLOW)

Y

COMPONENT

Cr

VIDEO OUT

(RED)

Cb

OPTICAL

COAXIAL

L

R(RED)

L

(WHITE)

R(RED)

AC-3/PCM

DIGITAL

OUT

AUDIO

OUT

B

C

LOAD POS, TRAY POS, DISCSENS, CLAMP

CLAMP

LOADPOS

S11

DISC CLAMP

DET. SW

S21

LOADING

POSITION

DET. SW

TRAYPOS

18 19

54 1238

45 8763

DISCSENS

31 425

57 463

PC21

DISC DET.

SENSOR

PC22

DISC TRAY

POSITION

DET.

SENSOR

19

SEDR+

SEDR-

CN16

(8P)

CN11

(8P)

CN12

(7P)

CN21

(7P)

TRSB ASSY

A

+-

M

TRAY

Motor

SSRB ASSY

B

D

E

F

56

DV-C505

7

8

15

1234

A

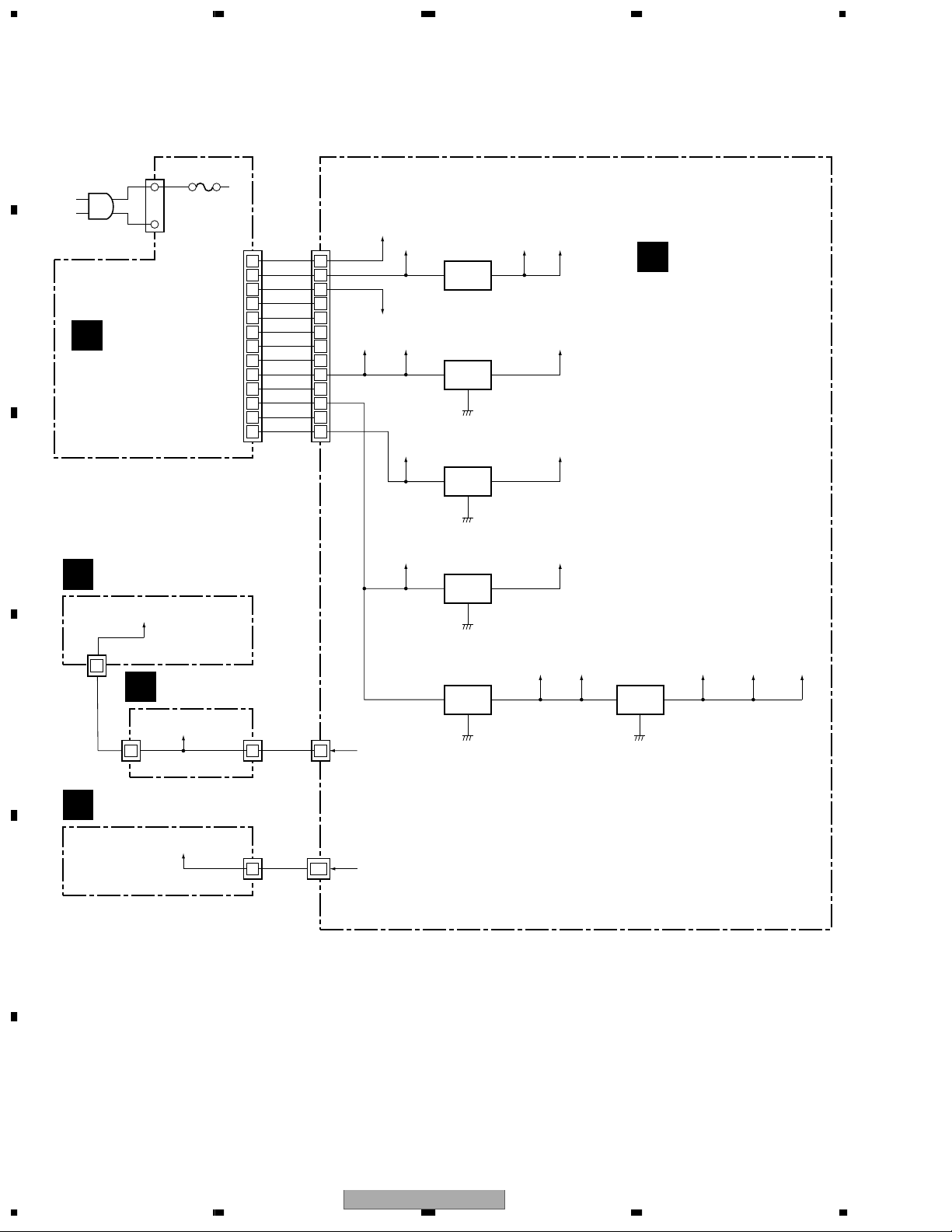

3.1.2 POWER SUPPLY BLOCK

CN1

(2P)

LIVE

AC IN

NEUTRAL

B

I

POWER SUPPLY

ASSY

C

SSRB ASSY

B

1

F1

2

VWR1353: CN2

(13P)

1

2

3

4

5

6

7

8

9

10

11

12

13

EV+6V (B)

EV+6V (A)

-28V

FLDC+

FLDC-

GND

P-CONT

GND

SW+12V

GND

EV+4V

GND

SW+3.3V

CN401

1

2

3

4

5

6

7

8

9

10

11

12

13

(13P)

V+6B

V+6A

-28V

V+12M V+5AV+12D

IC421

MM1565AF

+5V Reg.

V+5S V+5V

IC901

NJM78L05A

+5V Reg.

31

2

IC431

PQ025EZ01ZP

V+3D V+2R5

+2.5V Reg.

IN OUT

IC451

MM1385EN

V+4E

+3V Reg.

IN OUT

V+3E

FJMB ASSY

E

V+3D

CN21

(7P)

2

TRSB ASSY

A

D

CN12

(7P)

FLKY ASSY

F

V+3D

V+3E

CN11

(8P)

CN101

(13P)

26

3 13

7

CN16

(8P)

CN12

(13P)

V+3D

V+3E

IC441

PQ070XZ02ZP

+3.5V Reg.

VIN VOUT

V+3R5D V+3R5A V+1RBD V+1RBA1 V+1RBA2

IC303

BA18BC0FP

+1.8V Reg.

13

2

E

F

16

DV-C505

1234

1

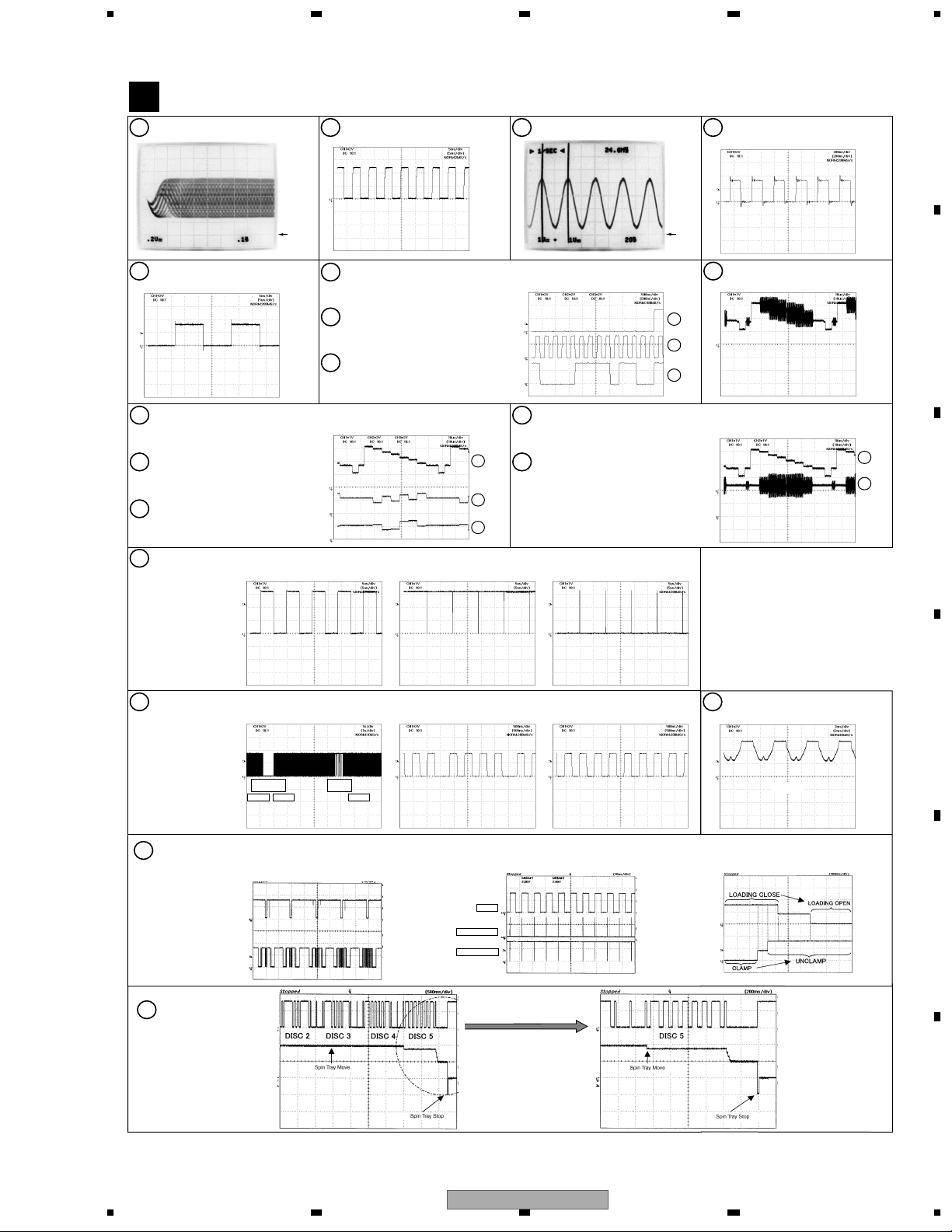

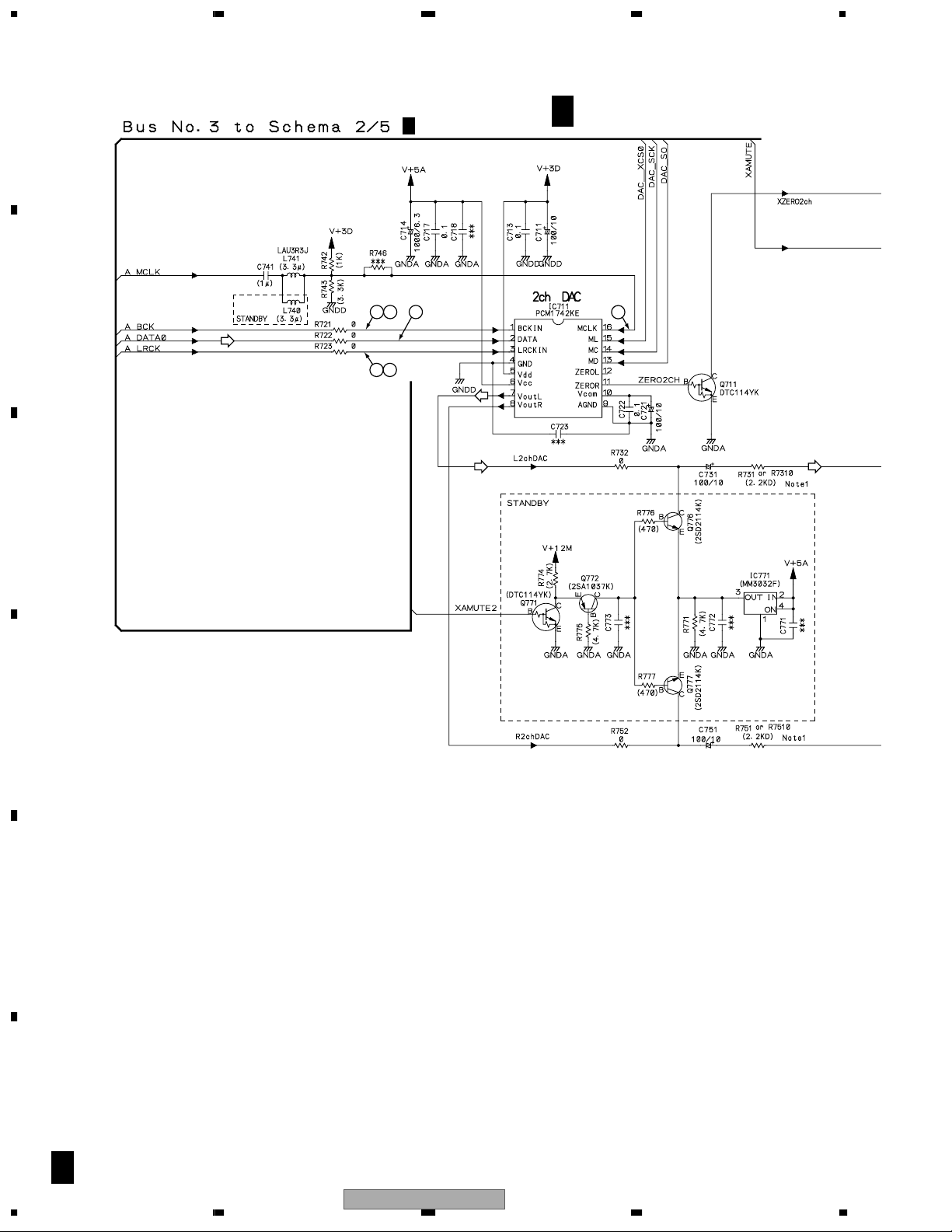

IC301 - pin 3 [RF]

V: 200mV/div. H: 0.1µsec/div.

5

Foot of R723 (IC711 - pin 3)

[AUDIO DAC -LRCK]

V: 2V/div. H: 5µsec/div.

2

IC251 - pin 24 [FG]

V: 1V/div. H: 5msec/div.

3 4

IC711 - pin 16 [AUDIO DAC -MCK]

V: 1V/div. H: 20nsec/div.

Foot of R721 (IC711 - pin 1)

[AUDIO DAC -BCK]

V: 2V/div. H: 200nsec/div.

GND

15

IC601 - pin 116 [LOAD_DRV]

V: 1V/div. H: 5µsec/div.

16

IC301 - pin 42 [SPDL_PDM]

CN16 - pin 4, 5, 3, 6

IC601 - pin 114

7

6

Foot of R723 (IC711 - pin 3)

[AUDIO DAC -LRCK]

V: 2V/div. H: 500nsec/div.

Foot of R721 (IC711 - pin 1)

[AUDIO DAC -BCK]

V: 2V/div. H: 500nsec/div.

8

Foot of R722 (IC711 - pin 2)

[AUDIO DAC -DATA]

V: 2V/div. H: 500nsec/div.

10

Foot of C842 (IC801 - pin 24, 25)

[Component Video output -Y]

V: 1V/div. H: 10µsec/div.

11

Foot of C852 (IC801 - pin 18, 19)

[Component Video output -Pb]

V: 2V/div. H: 10µsec/div.

13

Foot of C832 (IC801 - pin 27, 28)

[S Video output -Y]

V: 1V/div. H: 10µsec/div.

14

Foot of C822 (IC801 - pin 33)

[S Video output -C]

V: 1V/div. H: 10µsec/div.

12

Foot of C862 (IC801 - pin 21, 22)

[Component Video output -Pr]

V: 2V/div. H: 10µsec/div.

9

Foot of C812 (IC801 - pin 30, 31)

[Composite Video output]

V: 1V/div. H: 10µsec/div.

17

18

19

CN251 - pin 12, 11, 10

(IC251 - pin 2, 4, 7)

[Spindle driver -A3, A2, A1]

FJMB ASSY

E

Note : The encircled numbers denote measuring point in the schematic diagram.

Measurement condition

: No. 1 to 2 and 9 to 14 : reference A1 (DVD), T2-chp 19, Color-bar

No. 3 to 8 : reference A1 (DVD), T2-chp 1

GND

6

7

8

10

11

13

14

12

[Tray stops][Tray is opening][Tray is closing]

[PLAY]

IC601-pin114(ROT_DRV)

Elements on larger

[PLAY]

[STOP→PLAY→STOP]

[Tray Move]

CN16-pin5(DISC SENS), CN16-pin4(TRAY POS)

[Tray Open]

CN16-pin3(LOAD POS), CN16-pin6(CLAMP)

[Tray Close]

CN16-pin4(TRAY POS)

CN16-pin1/2(Rotating

Tray Motor drive voltage)

[STOP]

STOP STOP

STOP

Right-hand

Left-hand

PLAY

Accelertar

ON

Brakes

ON

V: 2V/div. H: 500nsec/div.

V: 2V/div. H: 500µsec/div.

V: 2V/div. H: 500nsec/div.

V: 2V/div. H: 500msec/div.

V: 2V/div. H: 200msec/div.

V: 2V/div. H: 500msec/div.

V: 2V/div. H: 2msec/div.V: 2V/div. H: 1sec/div.

V: 2V/div. H: 1sec/div.

[Tray Close]

CN16-pin4(TRAY POS)

CN16-pin1/2(Rotating

Tray Motor drive voltage)

3.1.3 WAVE FORMS

5678

A

B

C

D

E

DV-C505

56

7

F

17

8

1234

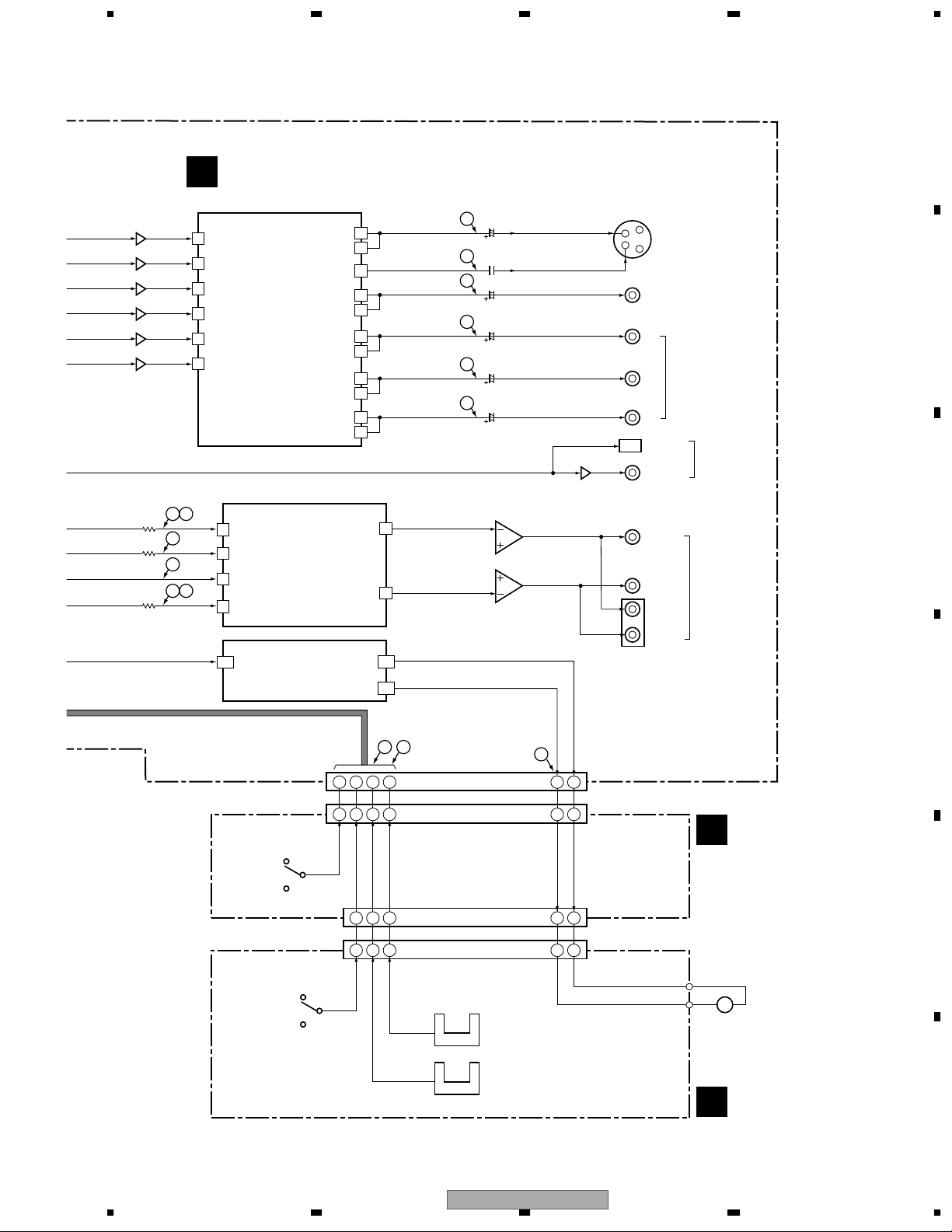

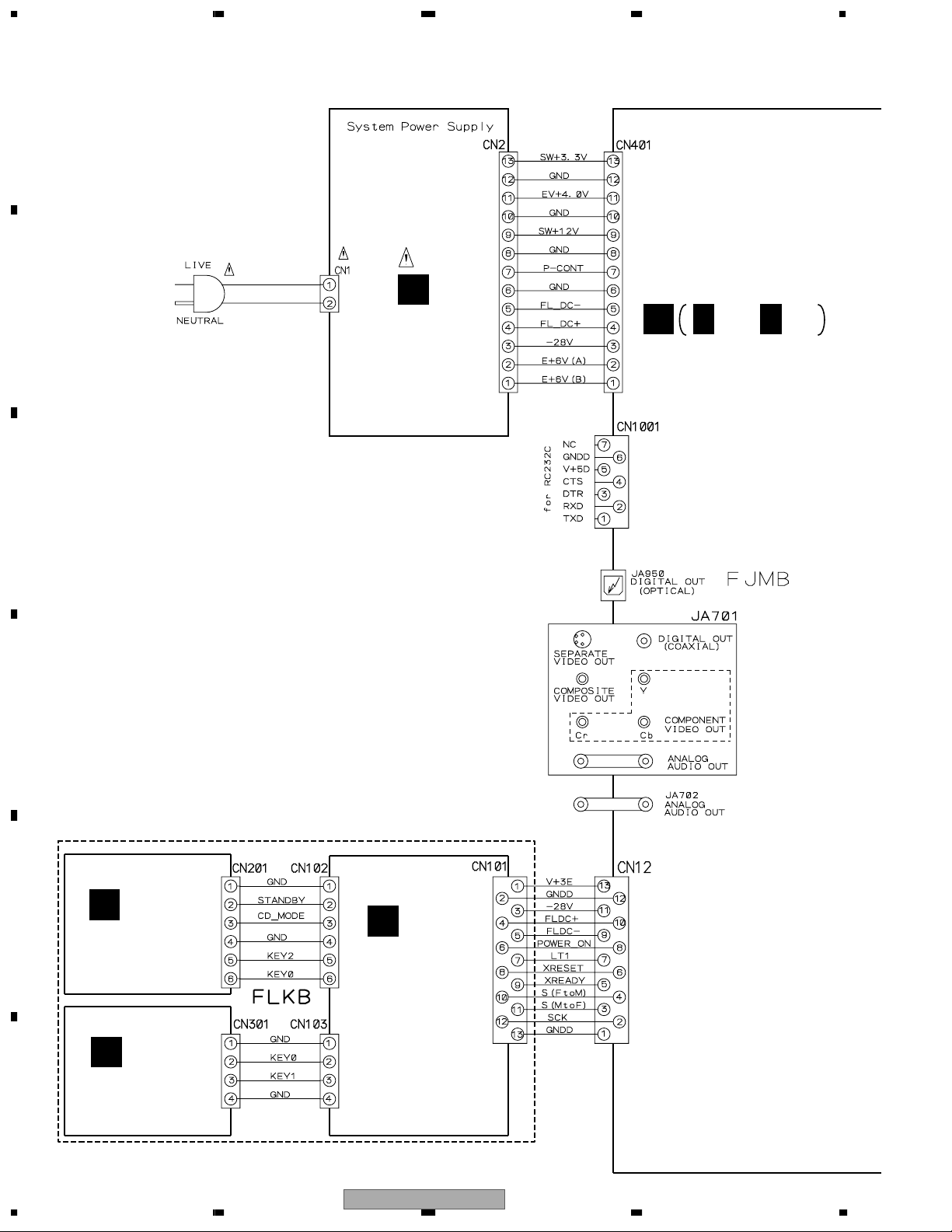

3.2 OVERALL WIRING DIAGRAM

A

POWER CORD

KUXU, KCXU : ADG7022

KUXU, KCXU : CN1

B

KUXU, KCXU :

AC120V 60Hz

C

Note : When ordering service parts, be sure to refer to

"EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

D

POWER SUPPLY UNIT

( VWR1353 )

E

E 1/5- E 5/5

F JMB ASSY

(KUXU, KCXU

: VWS1526)

I

E

H

PWSB ASSY

(VWG2348)

F

FLKY ASSY

(VWG2347)

G

DSSB ASSY

(VWG2349)

F

18

1234

DV-C505

5678

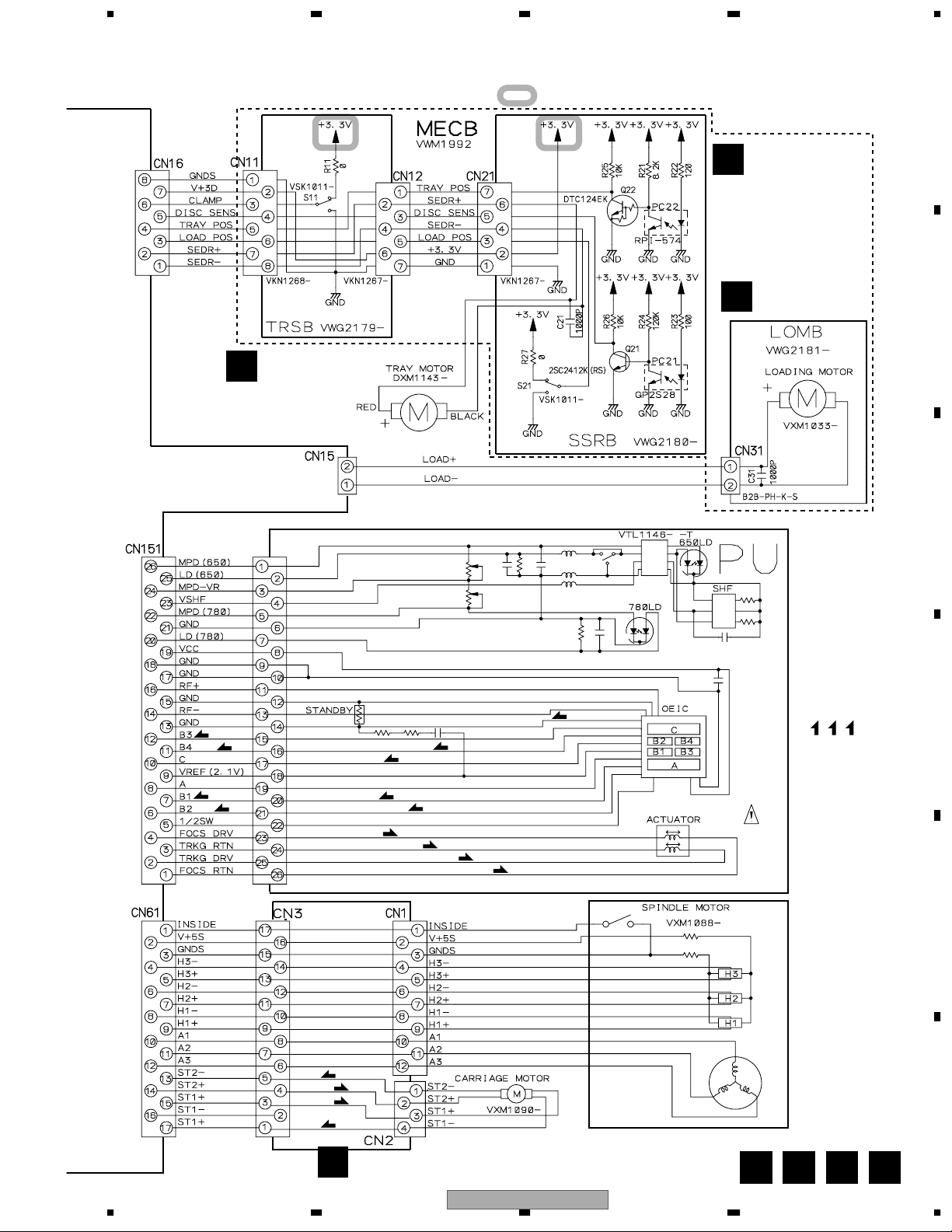

TRSB ASSY

A

(VWG2179)

: The power supply is shown with the marked box.

B

SSRB ASSY

(VWG2180)

LOMB ASSY

C

(VWG2181)

A

B

C

(F)

(F)

(F)

(F)

(F)

VKN1272

VKN1277

(S)

(S)

(S)

(S)

D

(T)

(F)

(F)

SSIB ASSY(VWG2350)

(F)

(T)

VKN1264

(F)

(T)

(F)

SPINDLE MOTOR

DV-C505

56

ASSY

: VXX1088

7

: FOCUS SERVO LOOP LINE

: TRACKING SERVO LOOP LINE

: SLIDER SERVO LOOP LINE

(F)

(T)

(S)

PICKUP ASSY-S

(OXX8003)

C DA B

8

D

E

F

19

1234

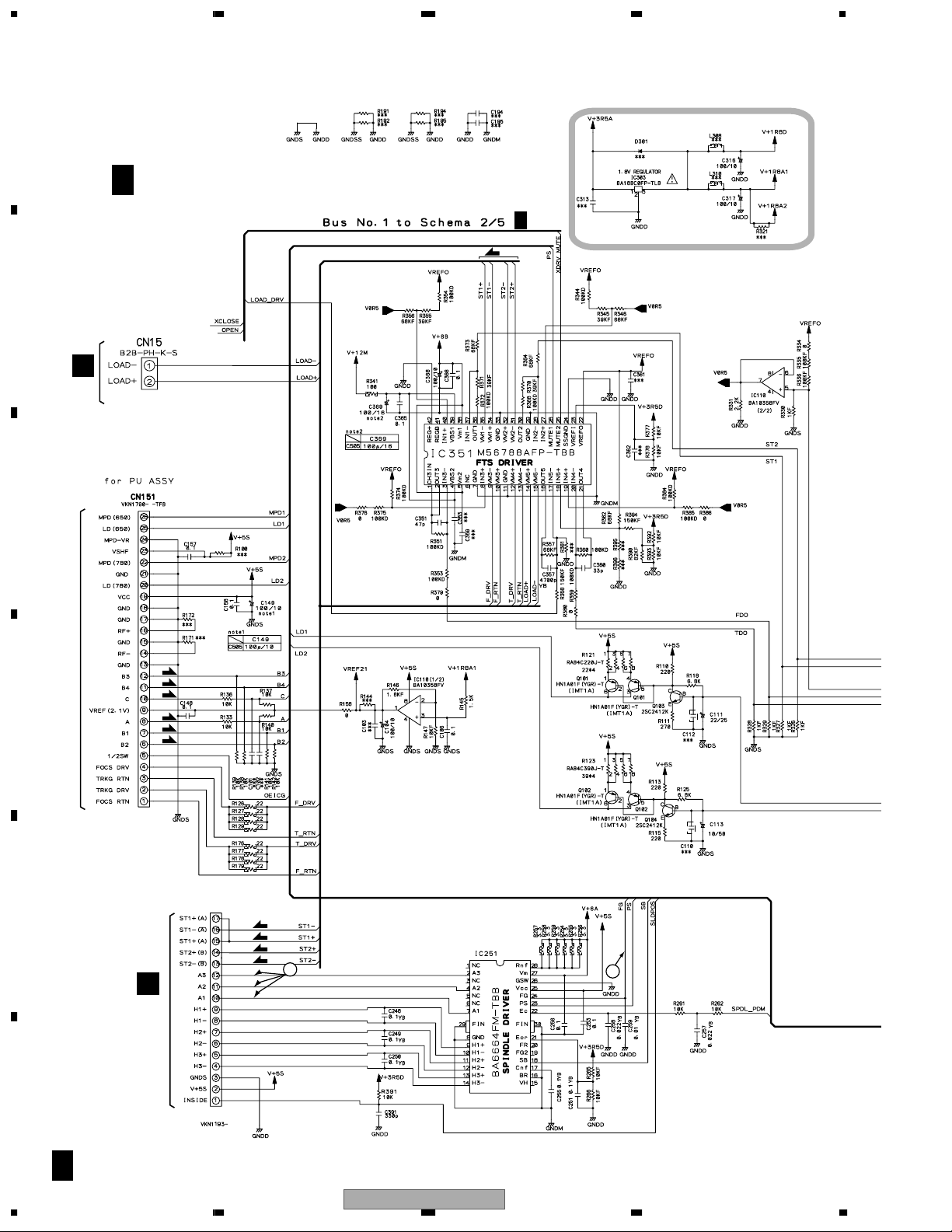

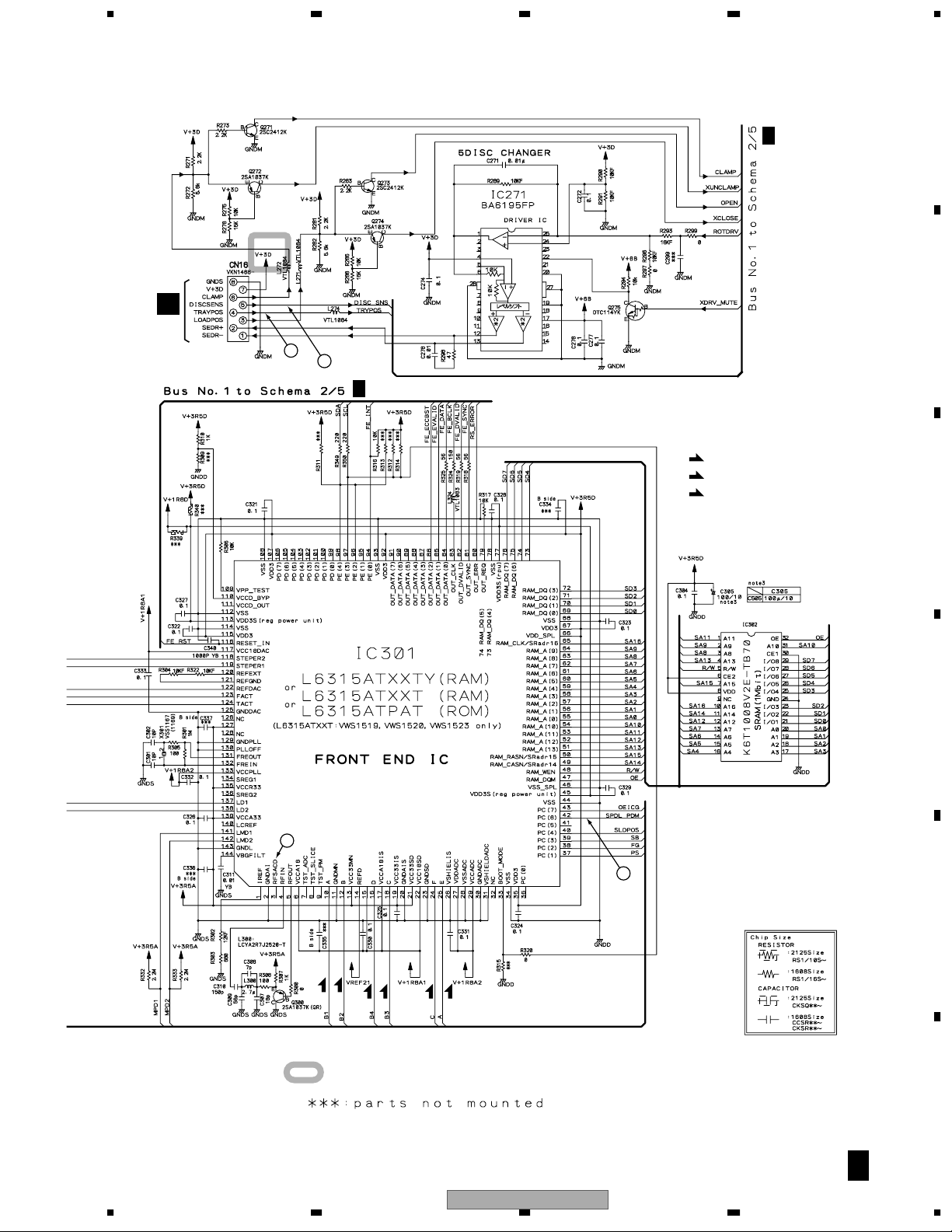

3.3 FJMB ASSY(1/5)

A

E 1/5

B

FJMB ASSY (VWS1526)

E

2/5

(S)

C

CN31

C

(F)

(F)

D

PICKUP ASSY

E

(T)

(T)

(F)

(F)

(S)

(S)

(S)

(S)

17

2

D

CN3

F

CN61

20

E

1/5

DV-C505

1234

5678

A

E

2/5

A

CN11

VCC33DAC

19

18

B

E

2/5

1,2,#,$,%,^ : Refer to "3.1.3 WAVEFORMS".

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

C

D

1

VCC18MN

(F)

(F)

(F)

(F)

(T)

(T)

: The power supply is shown with the marked box.

56

DV-C505

16

E

F

E

1/5

7

8

21

1234

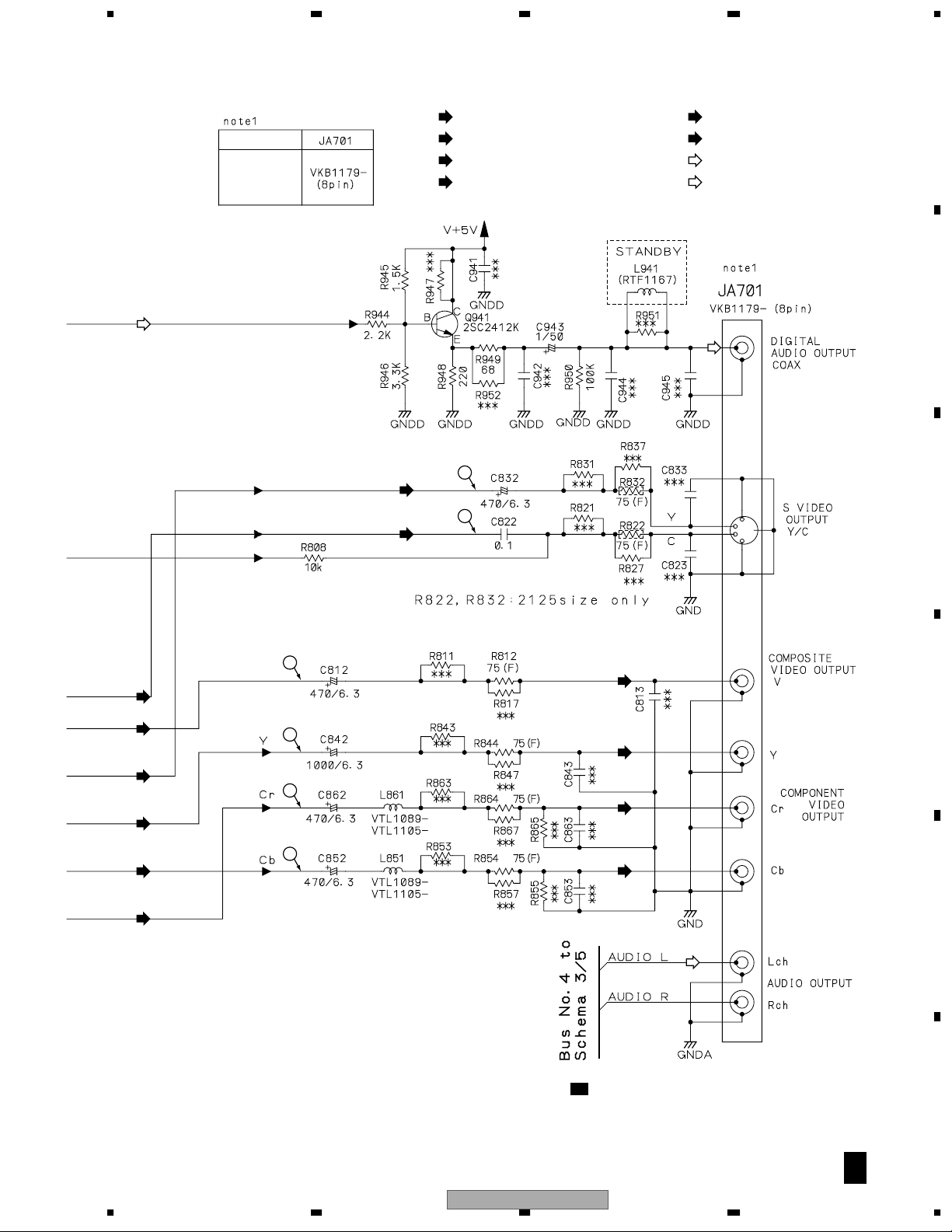

3.4 FJMB ASSY(2/5)

A

B

C

E 2/5

FJMB ASSY

(VWS1526)

(8M)

15

3/5

E

D

(B/Cb)

(G/Y)

(R/Cr)

(S_Y)

(S_C)

(V)

E

C571

47pF

F

2/5

E

22

1234

E

2/5E5/5

E

1/5

DV-C505

(D)

(D)

5678

A

5/5

E

2/5

E

B

CN2

I

(S_C)

(S_Y)

(R/Cr)

(G/Y)

: The power supply is shown with the marked box.

(V)

4/5

E

3/5

E

@: Refer to "3.1.3 WAVEFORMS".

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

(R/Cr)

: R/Cr SIGNAL ROUTE

(G/Y)

: G/Y SIGNAL ROUTE

(B/Cb)

: B/Cb SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO(DIGITAL) SIGNAL ROUTE

C

D

E

(B/Cb)

DV-C505

56

F

2/5

E

7

8

23

1234

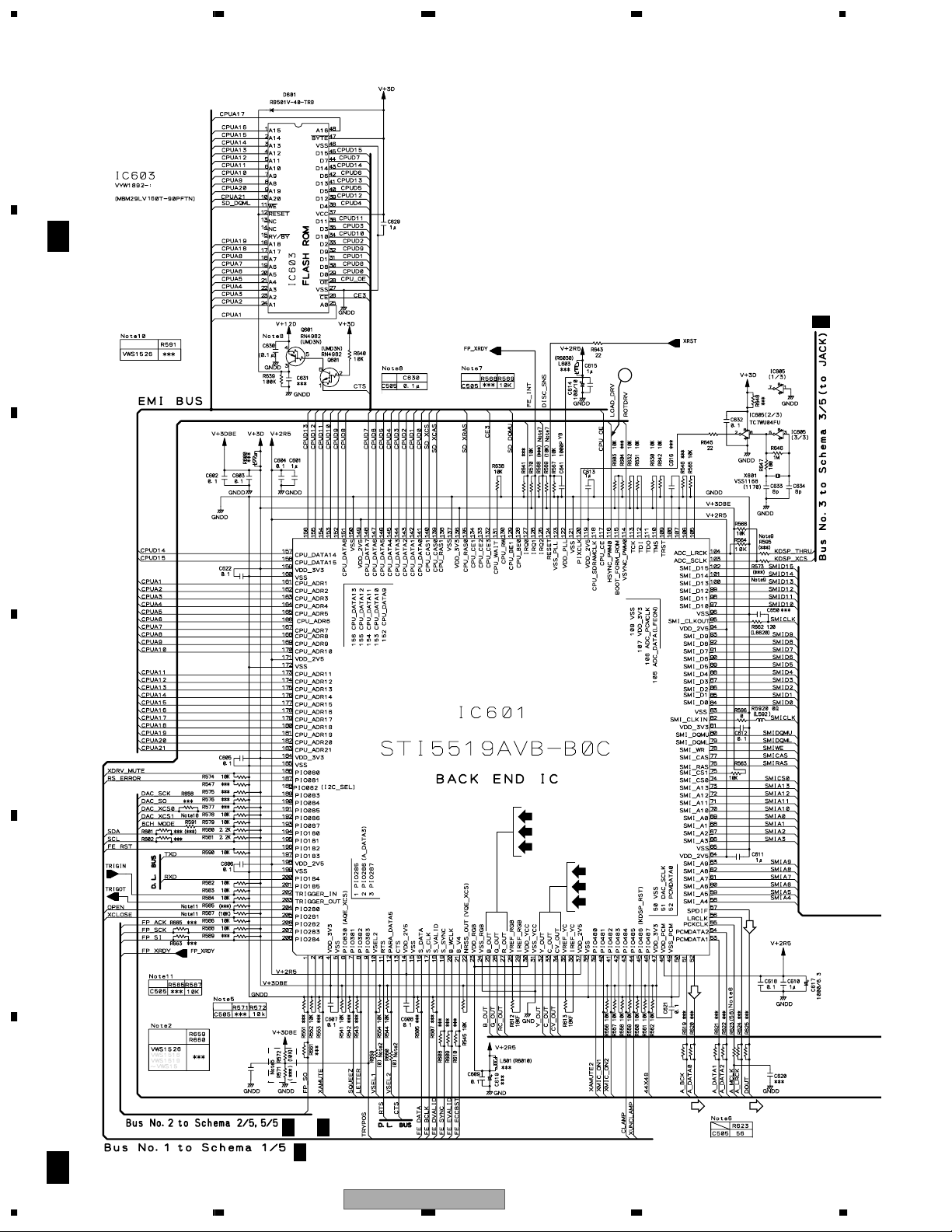

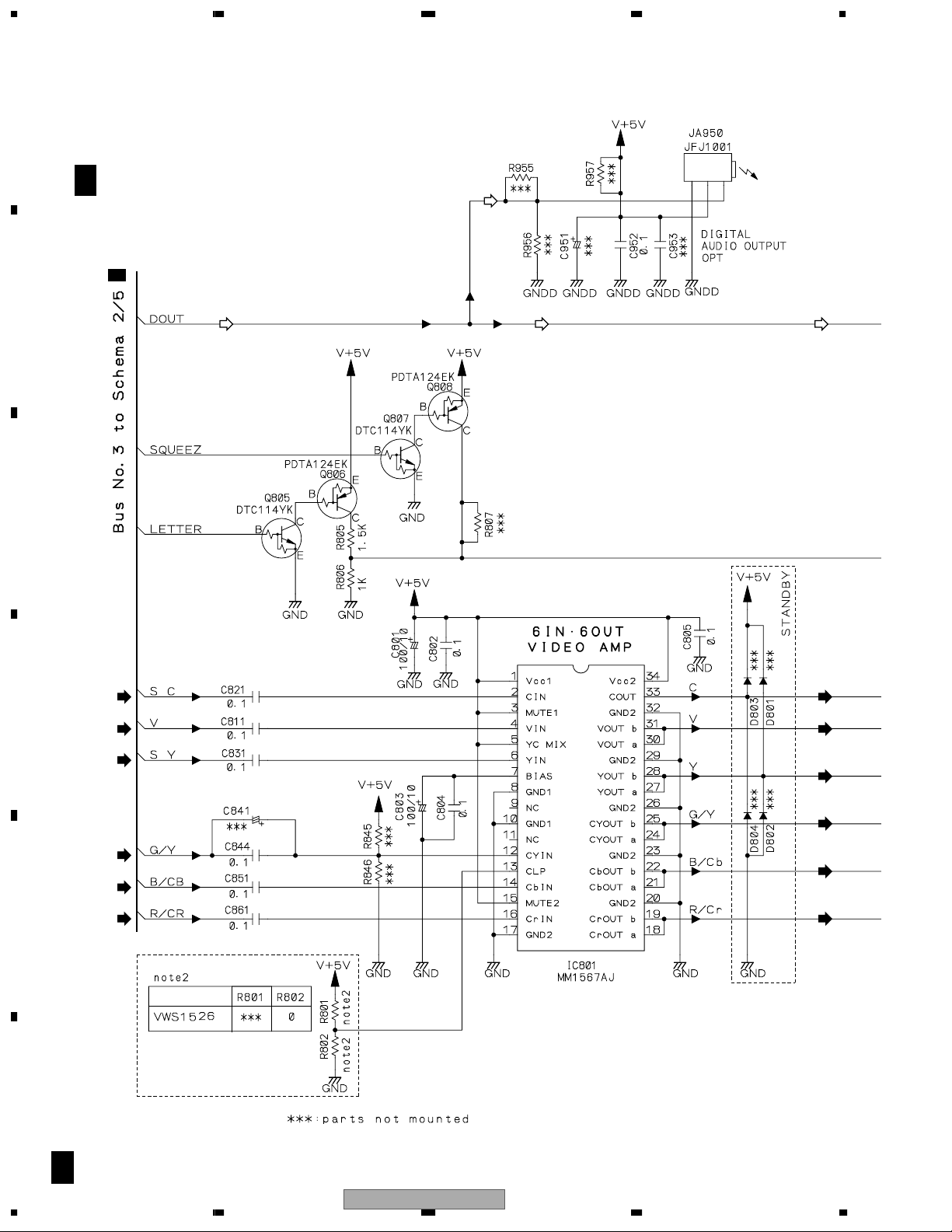

3.5 FJMB ASSY(3/5)

A

E

2/5

B

C

4 87

5 6

E 3/5

FJMB ASSY (VWS1526)

3

D

E

F

24

E

3/5

DV-C505

1234

5678

A

3– 8: Refer to "3.1.3 WAVEFORMS".

: AUDIO SIGNAL ROUTE

B

4/5

E

C

D

E

: The power supply is shown with the marked box.

DV-C505

56

F

3/5

E

7

8

25

1234

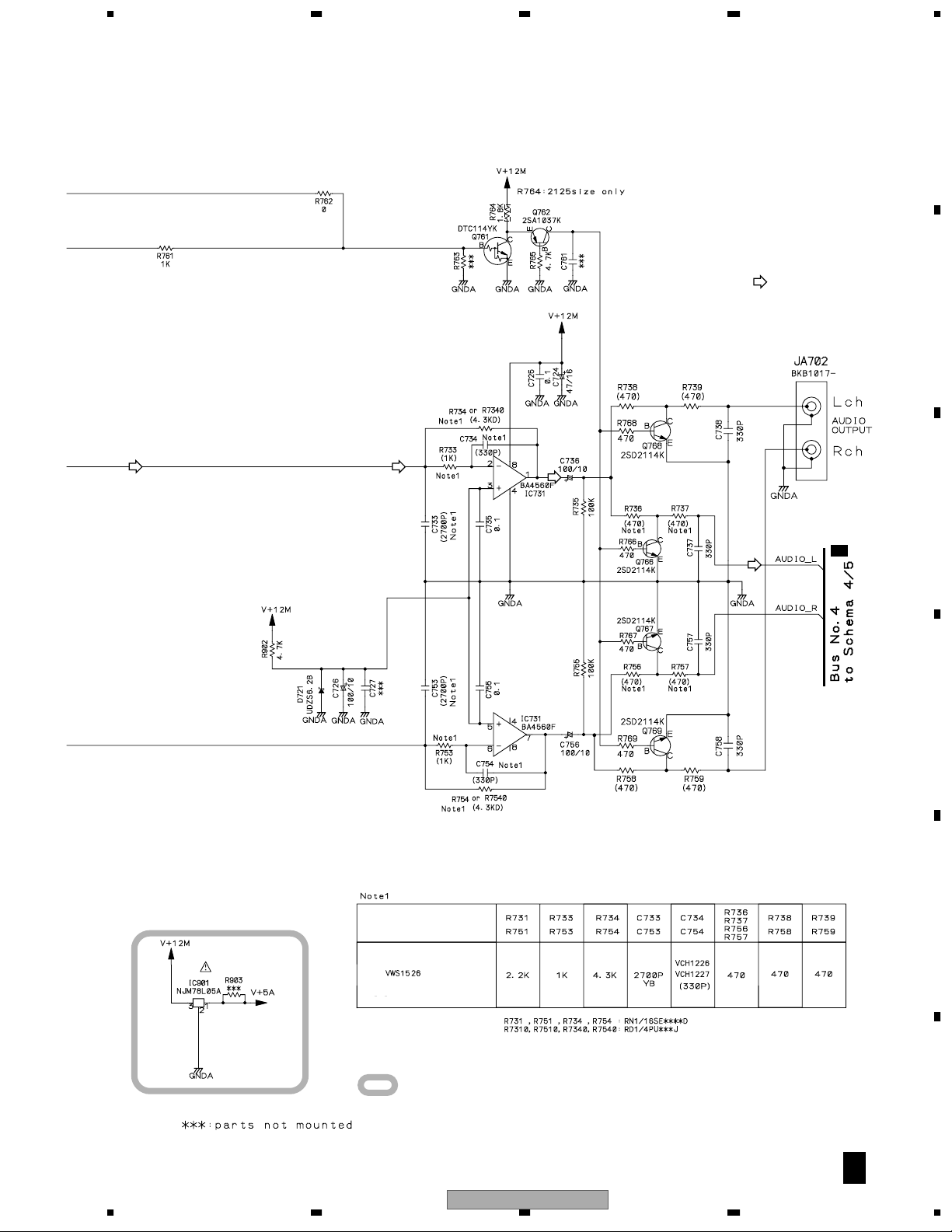

3.6 FJMB ASSY(4/5)

A

E 4/5

B

C

FJMB ASSY (VWS1526)

2/5

E

(D) (D) (D)

(D)

(S_C)

D

E

F

(V)

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

(S_C)

(V)

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

26

E

4/5

DV-C505

1234

5678

(D)

VWS1526

(S_Y)

(S_C)

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

(R/Cr)

: R/Cr SIGNAL ROUTE

13

14

(G/Y)

: G/Y SIGNAL ROUTE

(B/Cb)

: B/Cb SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO(DIGITAL) SIGNAL ROUTE

(D)

A

B

C

(S_C)

(V)

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

10

12

11

9

(V)

D

(G/Y)

(R/Cr)

(B/Cb)

E

3/5

E

9– !: Refer to "3.1.3 WAVEFORMS".

DV-C505

56

F

4/5

E

7

8

27

1234

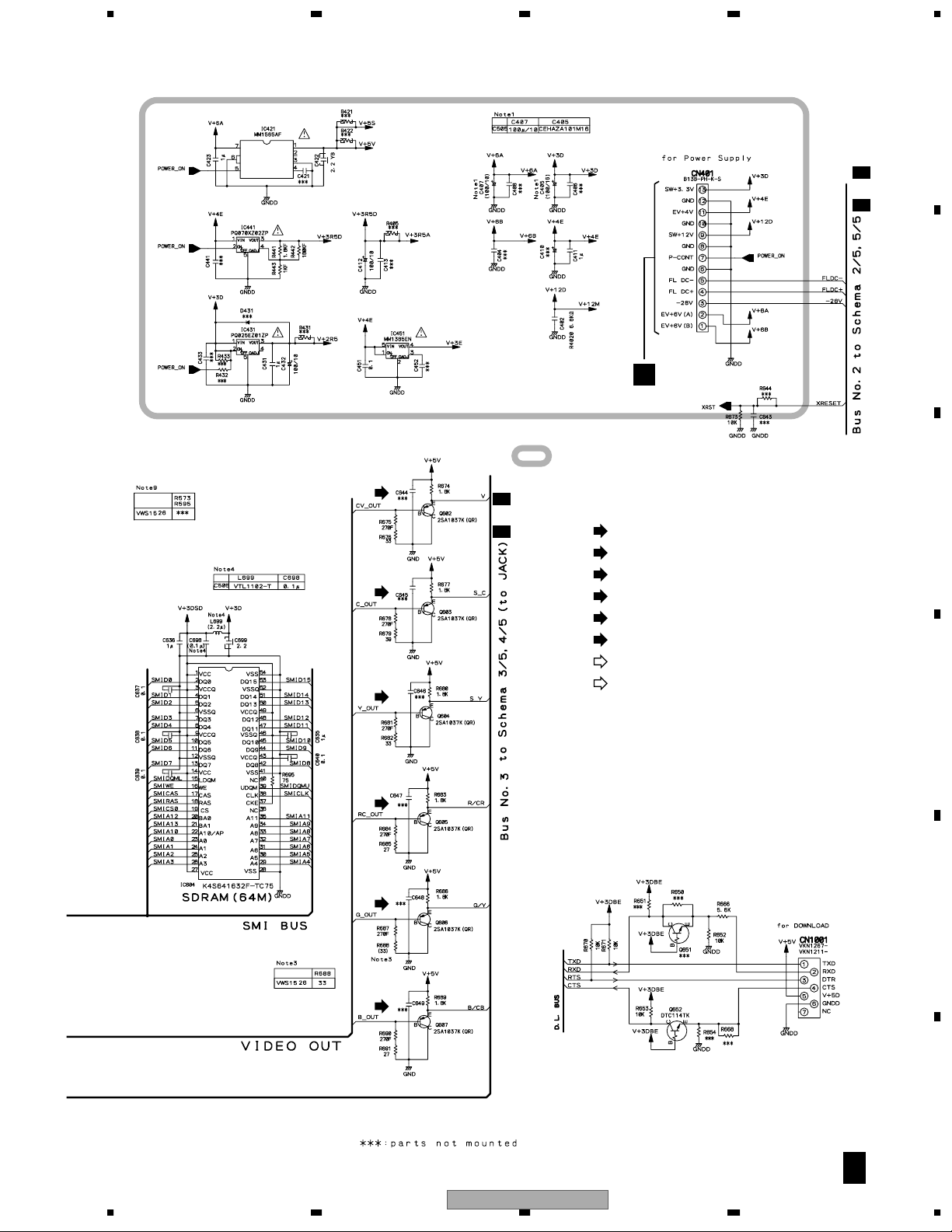

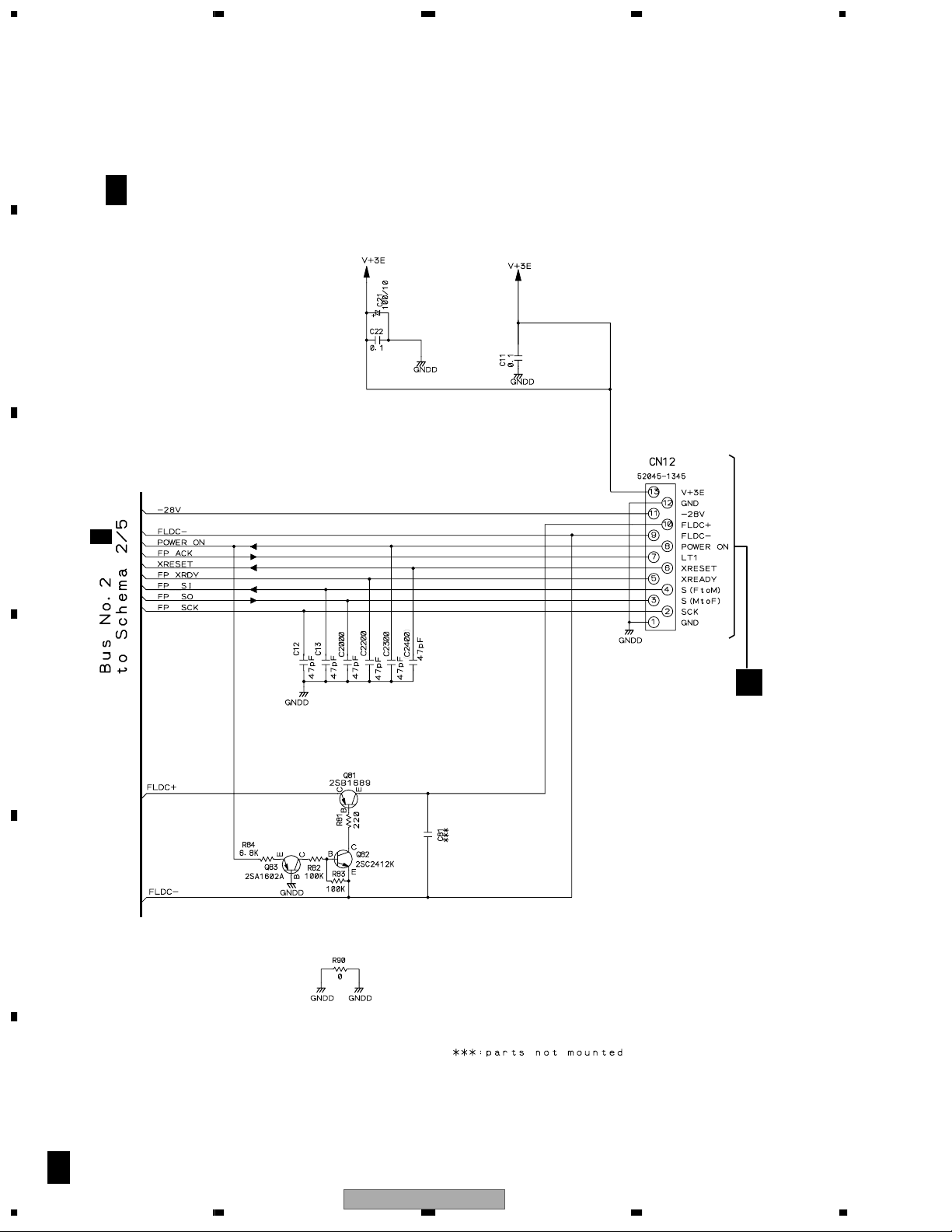

3.7 FJMB ASSY(5/5)

A

E 5/5

B

C

2/5

FJMB ASSY (VWS1526)

E

F

D

E

F

CN101

28

E

5/5

DV-C505

1234

5678

A

B

C

D

E

56

DV-C505

F

7

8

29

1234

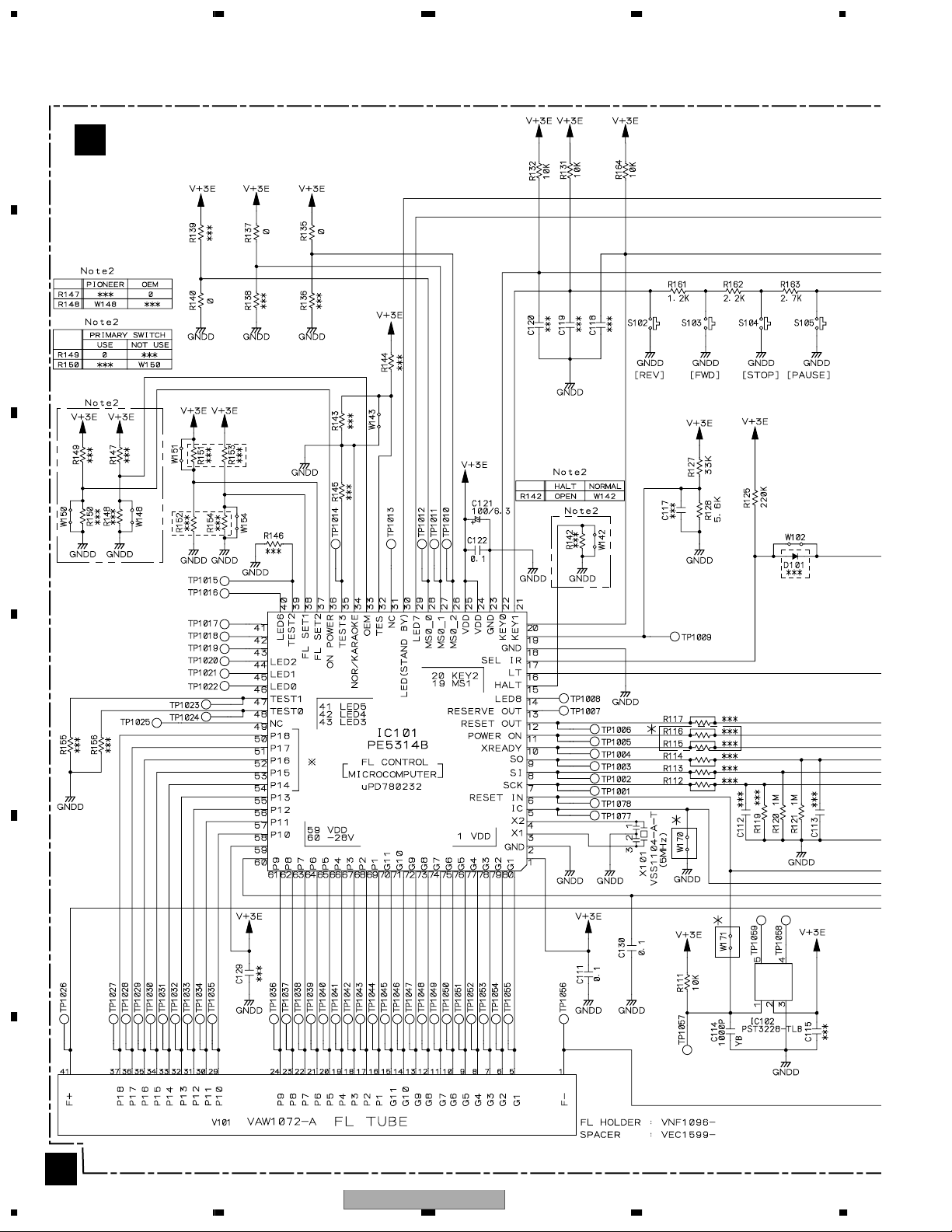

3.8 FLKY, DSSB and PWSB ASSYS

A

FLKY ASSY

F

(VWG2347)

B

S101 : PLAY

S102 : 2 REV

S103 : 3 FWD

S105 : 8 PAUSE

S104 : 7 STOP

C

D

E

F

F

30

1234

DV-C505

Loading...

Loading...