Pioneer DJM-700-K, DJM-700-S Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

DJM-700-S

For details, refer to "Important Check Points for good servicing".

DJ MIXER

DJM-700-S

DJM-700-K

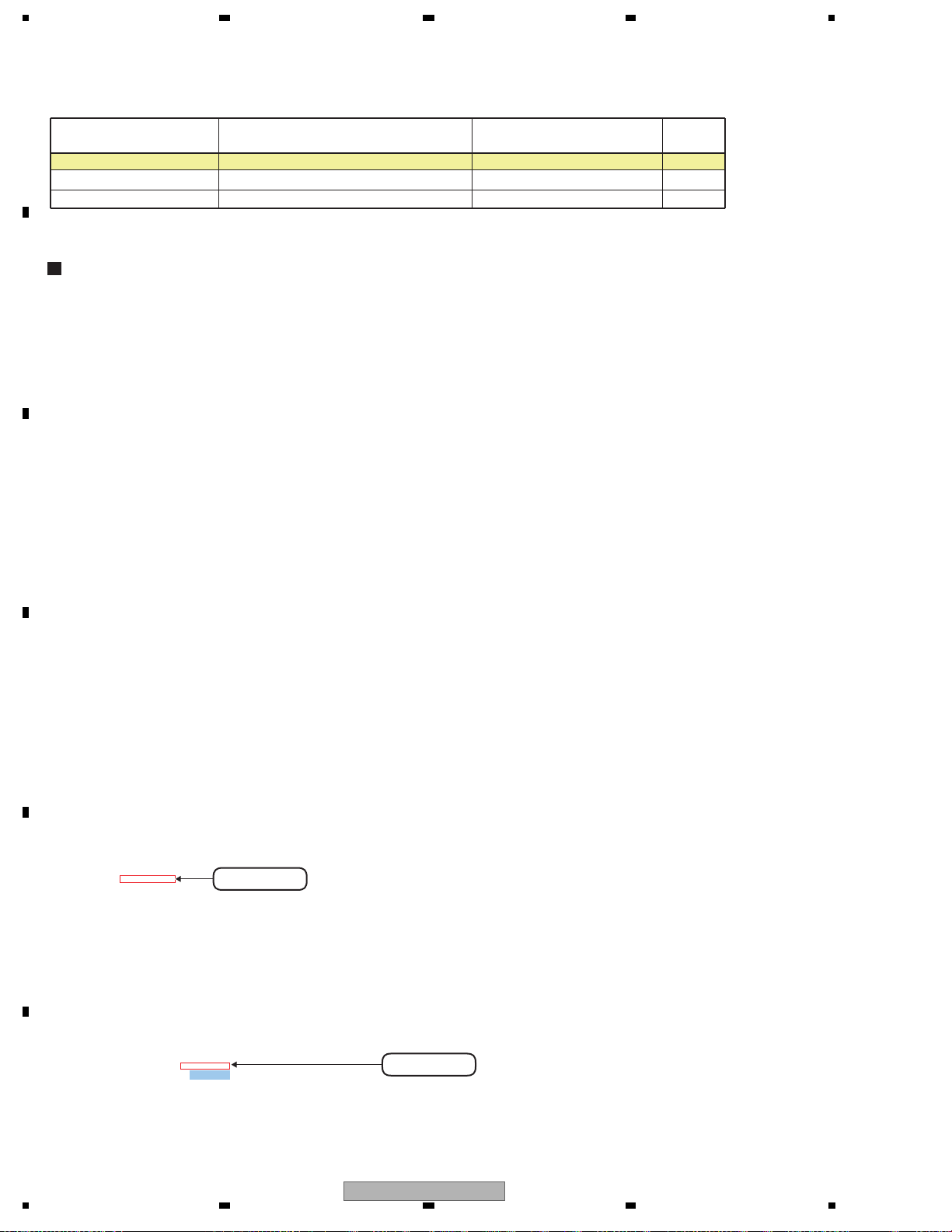

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

DJM-700-S KUCXJ AC 120 V

DJM-700-K

DJM-700-S WYXJ5 AC 220 V to 240 V

DJM-700-K

DJM-700-S RLXJ AC 110 V to 120 V / AC 220 V to 240 V

DJM-700-K

ORDER NO.

RRV3644

T-ZZR SEPT. 2007 printed in Japan

1234

1 234

C

D

F

A

B

E

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

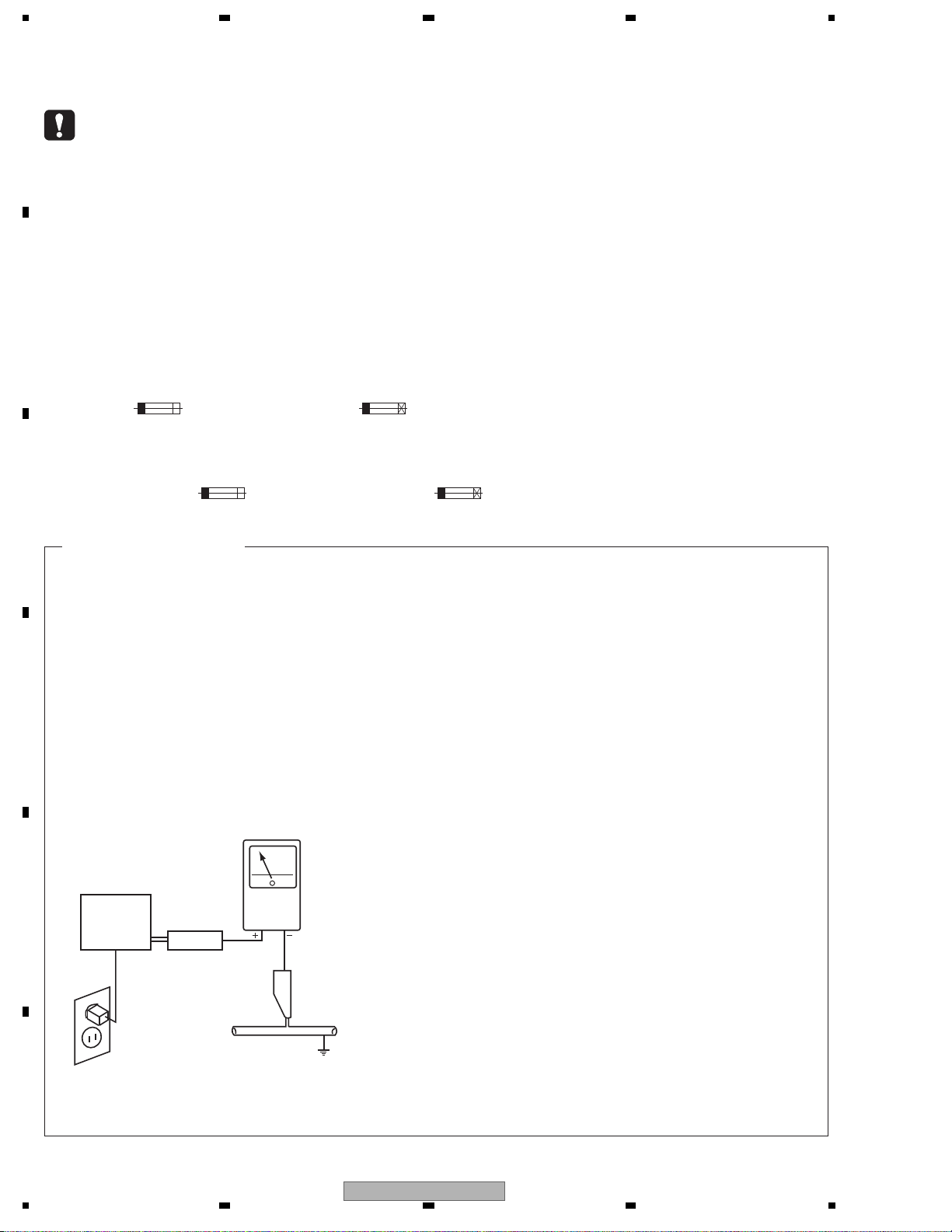

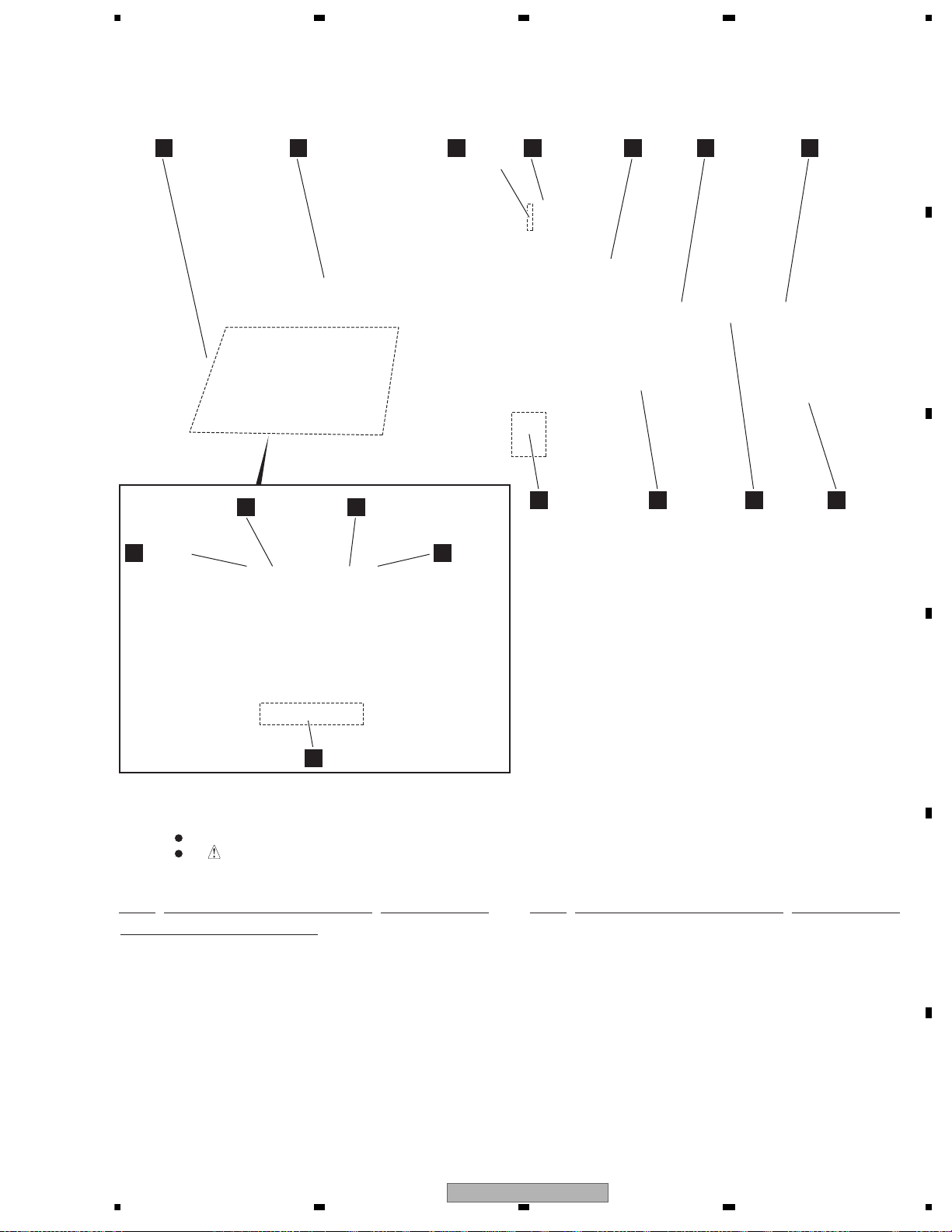

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

(FOR USA MODEL ONLY)

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

SAFETY INFORMATION

2

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

DJM-700-S

3

1234

1 234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION ..........................................................................................................................................................2

1. SERVICE PRECAUTIONS ....................................................................................................................................................5

1.1 NOTES ON SOLDERING ...............................................................................................................................................5

2. SPECIFICATIONS .................................................................................................................................................................6

2.1 ACCESSORIES ..............................................................................................................................................................6

2.2 SPECIFICATIONS...........................................................................................................................................................6

2.3 PANEL FACILITIES .........................................................................................................................................................7

3. BASIC ITEMS FOR SERVICE.............................................................................................................................................12

3.1 CHECK POINTS AFTER SERVICING..........................................................................................................................12

3.2 PCB LOCATIONS .........................................................................................................................................................13

3.3 JIGS LIST .....................................................................................................................................................................14

4. BLOCK DIAGRAM...............................................................................................................................................................16

4.1 OVERALL WIRING DIAGRAM......................................................................................................................................16

4.2 OVERALL BLOCK DIAGRAM.......................................................................................................................................18

4.3 MAIN BLOCK DIAGRAM ..............................................................................................................................................20

5. DIAGNOSIS.........................................................................................................................................................................22

5.1 TEST MODE .................................................................................................................................................................22

5.2 UPDATING OF THE FIRMWARE .................................................................................................................................29

5.3 HOW TO UPDATE.........................................................................................................................................................33

5.4 POWER ON SEQUENCE .............................................................................................................................................38

6. SERVICE MODE .................................................................................................................................................................41

7. DISASSEMBLY....................................................................................................................................................................42

8. EACH SETTING AND ADJUSTMENT ................................................................................................................................46

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................48

9.1 PACKING SECTION .....................................................................................................................................................48

9.2 EXTERIOR SECTION...................................................................................................................................................50

9.3 CONTROL PANEL SECTION .......................................................................................................................................54

10. SCHEMATIC DIAGRAM ....................................................................................................................................................56

10.1 INPUT ASSY (1/6) ......................................................................................................................................................56

10.2 INPUT ASSY (2/6) ......................................................................................................................................................58

10.3 INPUT ASSY (3/6) ......................................................................................................................................................60

10.4 INPUT ASSY (4/6) ......................................................................................................................................................62

10.5 INPUT ASSY (5/6) ......................................................................................................................................................64

10.6 INPUT ASSY (6/6) ......................................................................................................................................................66

10.7 MIC1 JACK ASSY .......................................................................................................................................................68

10.8 MIC VR ASSY.............................................................................................................................................................69

10.9 MAIN ASSY (1/4) ........................................................................................................................................................70

10.10 MAIN ASSY (2/4)......................................................................................................................................................72

10.11 MAIN ASSY (3/4)......................................................................................................................................................74

10.12 MAIN ASSY (4/4)......................................................................................................................................................76

10.13 PANEL 1 ASSY .........................................................................................................................................................78

10.14 PANEL 2 ASSY .........................................................................................................................................................80

10.15 OUTPUT ASSY (1/6) ................................................................................................................................................82

10.16 OUTPUT ASSY (2/6) ................................................................................................................................................84

10.17 OUTPUT ASSY (3/6) ................................................................................................................................................86

10.18 OUTPUT ASSY (4/6) ................................................................................................................................................88

10.19 OUTPUT ASSY (5/6) ................................................................................................................................................90

10.20 OUTPUT ASSY (6/6) ................................................................................................................................................92

10.21 FADER (CROSS), (CH1), (CH2), (CH3) and (CH4) ASSYS.....................................................................................94

10.22 HP JACK ASSY ........................................................................................................................................................95

10.23 REG ASSY.................................................................................................................

.24 TRANS ASSY ...........................................................................................................................................................97

10

10.25 PRIMARY ASSY .......................................................................................................................................................98

10.26 VOLTAGES..............................................................................................................................................................100

10.27 WAVEFORMS.........................................................................................................................................................105

11. PCB CONNECTION DIAGRAM ......................................................................................................................................110

11.1 INPUT, MIC1 JACK and MIC VR ASSYS..................................................................................................................110

11.2 MAIN ASSY ..............................................................................................................................................................114

11.3 PANEL 1 ASSY .........................................................................................................................................................118

11.4 PANEL 2, FADER (CROSS), (CH1), (CH2), (CH3) and (CH4) ASSYS ....................................................................122

11.5 OUTPUT and HP JACK ASSYS ...............................................................................................................................126

11.6 REG, TRANS and PRIMARY ASSYS.......................................................................................................................130

12. PCB PARTS LIST ............................................................................................................................................................134

...............................................96

4

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 °C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 °C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

DJM-700-S

5

1234

1 234

C

D

F

A

B

E

• Operating Instructions

(KUCXJ: DRB1426)

(WYXJ5: DRB1425)

(RLXJ: DRB1427)

Accessories

• Warranty Card

1 General

Power source...............................................................AC 120 V, 60 Hz

Power consumption....................................................................... 34 W

Operating temperature .............. +5 °C to +35 °C (+41 °F to +95 °F)

Operating humidity ........................5 % to 85 % (without condensation)

Weight ........................................................................... 6.6 kg (14.6 lb)

Maximum dimensions

...................................... 320 mm (W) x 378.4 mm(D) x 107.9 mm (H)

12.6 in (W) x 15.3 in (D) x 4.3 in (H)

2 Audio section

Sampling rate .............................................................................96 kHz

A/D, D/A converter.......................................................................24 bits

Frequency response

LINE..........................................................................20 Hz to 20 kHz

MIC...........................................................................20 Hz to 20 kHz

PHONO ........................................................20 Hz to 20 kHz (RIAA)

S/N ratio (at rated output)

LINE........................................................................................ 104 dB

PHONO ....................................................................................94 dB

MIC........................................................................................... 82 dB

Distortion (LINE-MASTER 1).................................................... 0.005 %

Standard input level/Input impedance

PHONO 2 to 4 ............................................................–52 dBu/47 kΩ

MIC 1..........................................................................–52 dBu/22 kΩ

LINE, LINE/CD 1 to 4 .................................................–12 dBu/22 kΩ

RETURN.....................................................................–16 dBu/47 kΩ

Standard output level/Load impedance/Output impedance

MASTER 1............................................... +8 dBu/10 kΩ/22 Ω or less

MASTER 2...........................................................+2 dBu/10 kΩ/10 Ω

REC.....................................................................–8 dBu/10 kΩ/10 Ω

BOOTH................................................................+2 dBu/10 kΩ/22 Ω

SEND................................................................. –12 dBu/10 kΩ/1 kΩ

PHONES ................................................+8.5 dBu/32 Ω/22 Ω or less

Rated output level/Load impedance

MASTER 1................................................................. +25 dBu/10 kΩ

MASTER 2................................................................. +20 dBu/10 kΩ

Crosstalk (LINE) ........................................................................... 80 dB

Channel equalizer response

HI............................................................... –26 dB to +6 dB (13 kHz)

MID.............................................................. –26 dB to +6 dB (1 kHz)

LOW ............................................................–26 dB to +6 dB (70 Hz)

Microphone equalizer response

HI............................................................. –12 dB to +12 dB (10 kHz)

LOW ........................................................–12 dB to +12 dB (100 Hz)

3 Input/output connector systems

PHONO input connectors

RCA pin jacks...................................................................................3

CD input connectors

RCA pin jacks...................................................................................2

LINE input connectors

RCA pin jacks...................................................................................3

MIC input connectors

XLR connector..................................................................................1

Phone jack (Ø6.3 mm)......................................................................1

RETURN input connectors

Phone jacks (Ø6.3 mm)....................................................................1

MASTER output connectors

XLR connectors................................................................................1

RCA pin jacks...................................................................................1

BOOTH output connectors

RCA pin jacks...................................................................................1

REC output connectors

RCA pin jacks...................................................................................1

SEND output connectors

Phone jacks (Ø6.3 mm)....................................................................1

DIGITAL coaxial output connector

RCA pin jack.....................................................................................1

MIDI OUT connector

5P DIN..............................................................................................1

PHONES output connector

Stereo phone jack (Ø6.3 mm) ..........................................................1

CONTROL connector

Mini phone jacks (Ø3.5 mm).............................................................2

4 Accessories

Operating Instructions ......................................................................... 1

Warranty card...................................................................................... 1

Specifications and appearance are subject to change without

notice.

2. SPECIFICATIONS

2.1 ACCESSORIES

2.2 SPECIFICATIONS

6

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

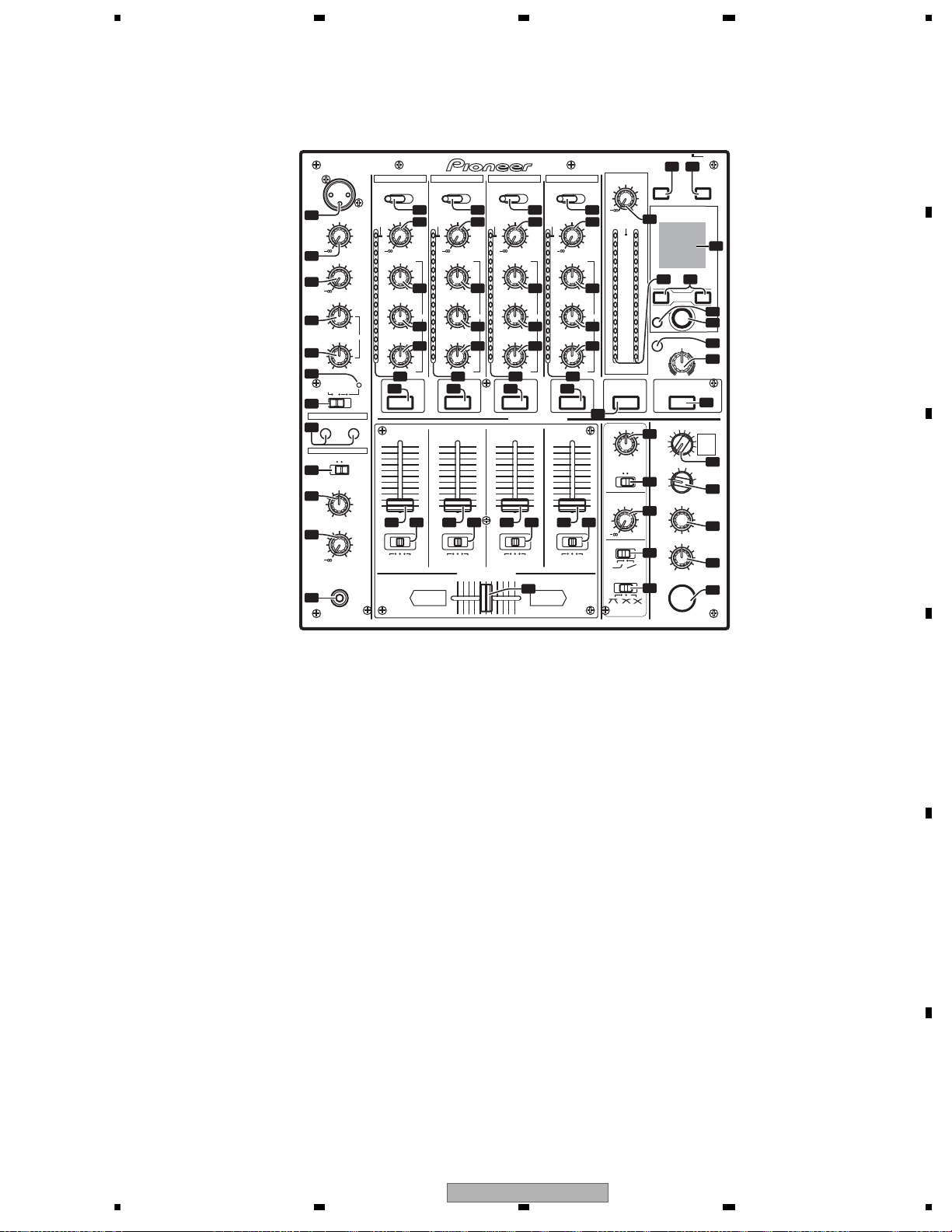

DJM–700

PROFESSIONAL MIXIER

TRIM

+9

TRIM

+9

TRIM

+9

TRIM

+9

0

MID

+6-26

MID

+6-26

MID

+6-26

MID

+6-26

HI

+6-26

HI

+6-26

HI

+6-26

HI

+6-26

LOW

+6-26

LOW

+6-26

LOW

+6-26

LOW

+6-26

FREQUENCY

HPFLPF

FILTER

BALANCE

RL

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dBLR

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

EQEQEQEQ

LINE PHONOLINEPHONOLINEPHONOCDCD

POWER

MASTER

LEVEL

CH-1 CH-2 CH-3 CH-4

1234

HEADPHONES CUE

MASTER EFFECTS

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

A THRU B A THRU B A THRU B A THRU B

BA

CROSS FADER ASSIGN

BOOTH MONITOR

LEVEL

0

CH FADER

CROSS FADER

AUTO

ON/OFF START/STOP

TAP

BEAT

MIDI

BEAT EFFECTS

LEVEL/DEPTH

TIME

MAX

ON/OFF

MIN

DELAY

1

2

3

4

MIC

CF.A

CF.B

MASTER

TRANS

DOWN

FILTER

UP

FLANGER

REVERSE

PHASER

ROLL

REVERB

CRUSH ROLL

ROBOT

ECHO

SND/RTN

cd

FADER START

MIC1

HEADPHONES

MIC1 LEVEL

0

MIC2 LEVEL

0

LEVEL

0

HI

MIC

CH-1 CH-2

OFF ON

TALK

OVER

+12-12

LOW

+12-12

MIXING

MASTERCUE

EQ

MONO SPLIT STEREO

PHONES

MONO STEREO

3

4

5

29

30

23

17

18 19 18 19

18 19 18 19

33 34

20

26

21

6

7

28

31

24 32

36

41

42

40

39

43

38

35

37

22

1

2

16

16

11

13

14

8

12

15

11

13

14

9

12

15

11

13

14

10

12

15

11

13

14

10

12

15

25

27

44

16 16 16 16

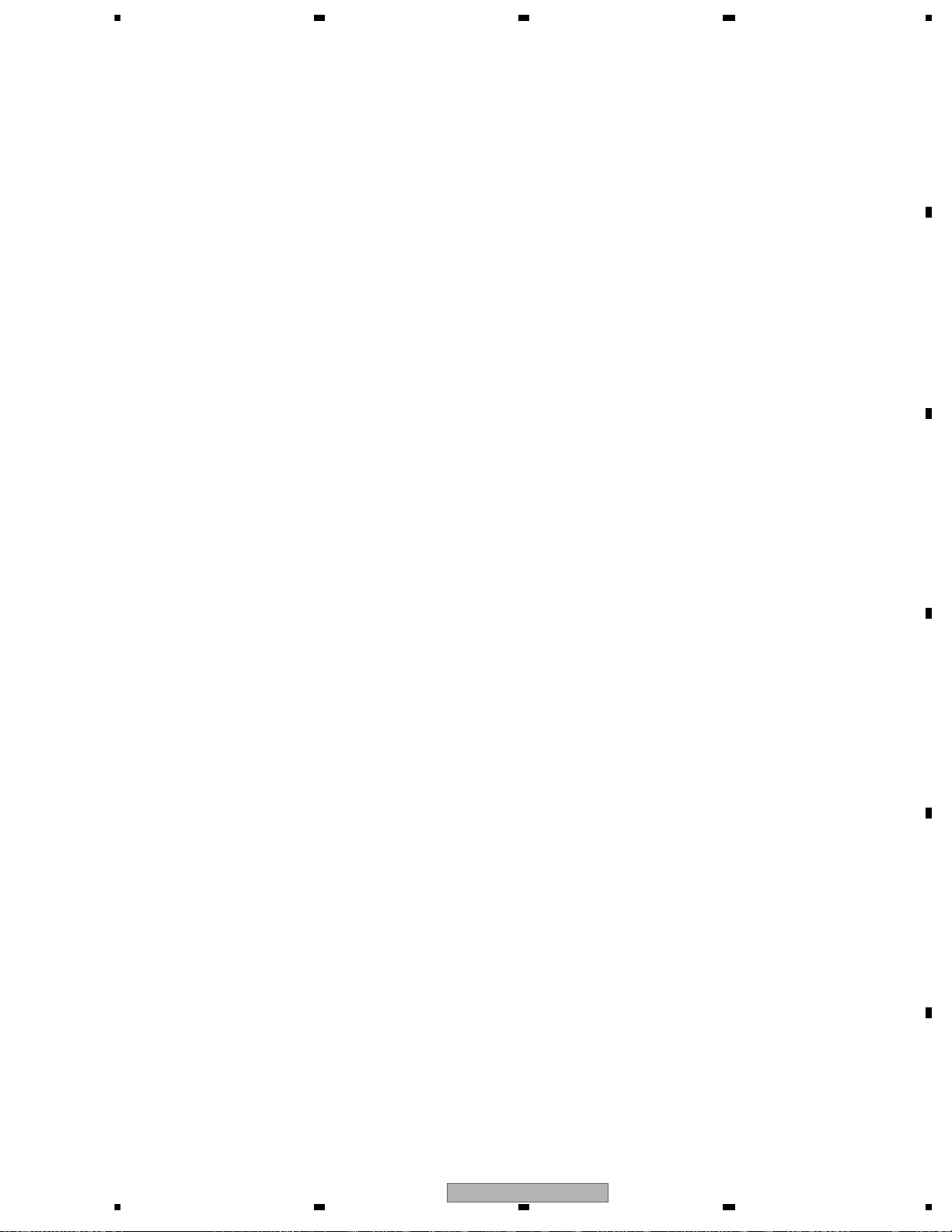

OPERATION PANEL

1 Microphone 1 input jack (MIC 1)

Connect microphone with XLR-type plug.

2 Microphone 1 level control dial (MIC 1 LEVEL)

Use to adjust the volume of microphone 1. (adjustable range –∞to

0 dB)

3 Microphone 2 level control dial (MIC 2 LEVEL)

Use to adjust the volume of microphone 2. (adjustable range –∞to

0 dB)

4 Microphone equalizer high-range control dial (HI)

Use to adjust the treble (high-range) frequencies of microphones 1

and 2. (adjustable range –12 dB to +12 dB)

5 Microphone equalizer low-range control dial (LOW)

Use to adjust the bass (low-range) frequencies of microphones 1

and 2. (adjustable range –12 dB to +12 dB)

6 Microphone function indicator

Lights when microphone is ON; flashes when TALK OVER is ON.

7 Microphone function selector switch (MIC)

OFF:

No microphone sound is output.

ON:

Microphone sound is output normally.

TALK OVER:

Microphone sound is output; when sound is input to a connected

microphone, the TALK OVER function operates and all sound

other than that from the microphone is attenuated by 20 dB.

• When not using the TALK OVER function, it is recommended to

set the switch to the [OFF] or [ON] position.

8 Channel 1 input selector switch

CD:

Selects CD input (line level analog input).

LINE:

Use to select LINE input connectors.

9 Channel 2 input selector switch

CD:

Use to select CD input (line level analog input).

PHONO:

Use to select PHONO input connectors (analog turntable input).

10 Channel 3, 4 input selector switch

LINE:

Use to select LINE input (line level analog input).

PHONO:

Use to select PHONO input connectors (analog turntable input).

11 TRIM adjust dial

Use to adjust the input level for each channel. (adjustable range: –

∞ to +9 dB, mid-position is about 0 dB)

12 Channel equalizer high-range adjust dial (HI)

Use to adjust the treble (high-range) frequency sound for each

channel. (adjustable range: –26 dB to +6 dB)

2.3 PANEL FACILITIES

DJM-700-S

7

1234

1 234

C

D

F

A

B

E

13 Channel equalizer mid-range adjust dial (MID)

Use to adjust the mid-range frequency sound for each channel.

(adjustable range: –26 dB to +6 dB)

14 Channel equalizer low-range adjust dial (LOW)

Use to adjust the bass (low-range) frequency sound for each

channel. (adjustable range: –26 dB to +6 dB)

15 Channel level indicator

Displays the current level for each channel, with two-second peak

hold.

16 HEADPHONES CUE buttons/indicators

These buttons are used to select from 1 to 4,MASTER, or

EFFECTS, to allow you to monitor the desired source through

headphones. If multiple buttons are pressed simultaneously, the

selected audio sources are mixed. Press the button once more to

cancel the selected source. Unselected buttons glow darkly, while

selected source buttons light brightly.

17 Fader start button/indicator (FADER START CH-1, CH-2)

Enables the fader start/back cue function for the channel to which

a DJ CD player is connected. The button lights when set to ON.

When enabled, the operation differs depending on the setting of

the CROSS FADER ASSIGN switch.

• When the CROSS FADER ASSIGN switch is set to the [A] or [B]

position, fader start button operation is linked to the operation of

the cross fader (and unlinked to channel fader).

• When the CROSS FADER ASSIGN switch is set to the [THRU]

position, fader start button operation is linked to the operation of

the channel fader (and unlinked to cross fader).

18 Channel fader lever

Use to adjust sound volumes for each channel. (adjustable range:

–∞ to 0 dB)

Output is in accordance with the channel fader curve selected

with the CH FADER curve switch.

19 CROSS FADER ASSIGN switch

This switch assigns each channel’s output to either right or left

side of the cross fader (if multiple channels are assigned to the

same side, the result will be the combined sum of the channels).

A:

The selected channel is assigned to the cross fader’s A (left) side.

THRU:

The channel fader’s output is sent as is to the master output,

without being passed through the cross fader.

B:

The selected channel is assigned to the cross fader’s B (right) side.

20 Channel fader curve switch (CH FADER)

This switch allows the user to select from two types of channel

fader curve response. This setting is applied equally to channels

1 to 4.

• At the left setting, the curve operates to produce a rapid rise as

the channel fader approaches its distant position.

• At the right setting, the curve operates to produce an even,

neutral rise throughout the channel fader’s movement.

21 Cross fader curve switch (CROSS FADER)

This switch allows the user to select from three types of cross fader

curve response.

• At the left setting, the curve produces a rapid signal rise. (As

soon as the cross fader lever leaves the [A] side, the [B] channel

sound is produced.)

• At the right setting, the curve operates to produce an even,

neutral rise throughout the cross fader’s movement.

• At the middle setting, an intermediate curve is produced,

midway between the two curves noted above.

22 Cross fader lever

Outputs sound assigned to [A] and [B] sides in accordance with

setting of the CROSS FADER ASSIGN switch, and subject to the

cross fader curve selected with the CROSS FADER curve switch.

23 Master output level dial (MASTER LEVEL)

Use to adjust the master output level. (adjustable range: –∞ to

0 dB)

The master output is the sum combination of the sound from

channels set to [THRU] with the CROSS FADER ASSIGN switch;

the signal passed through the cross fader; and the signals from

microphone 1 and microphone 2 (if the effect selector is set to

[SND/RTN], the RETURN input is also added).

24 Master level indicator (MASTER L, R)

These segment indicators display the output level from L and R

channels. The indicators have a two-second peak hold.

25 Master balance dial (BALANCE)

Use to adjust the L/R channel balance for master output, booth

monitor output, recording output, and digital output.

26 Master output MONO/STEREO selector switch

When set to the [MONO] position, master output, booth monitor

output, recording output, digital output are all produced in L+R

monaural.

27 BOOTH MONITOR LEVEL control dial

This dial is used to adjust the booth monitor output volume.

The volume can be adjusted independently of the master output

level. (adjustable range: –∞ to 0 dB)

28 Headphones output switch (MONO SPLIT/STEREO)

MONO SPLIT:

When HEADPHONES CUE (1,2,3,4 or EFFECTS) button is

selected, the selected audio is output to the L channel. When

HEADPHONES CUE (MASTER) button is selected, the master

audio is output from the R channel.

STEREO:

The audio source selected with the HEADPHONES CUE button is

output in stereo.

29 Headphones mixing dial (MIXING)

When rotated clockwise (toward [MASTER]), the master output

audio is produced at the headphones (only when [MASTER] has

been selected with the HEADPHONES CUEbutton); when rotated

counterclockwise (toward [CUE]), the headphones output

becomes the mixture of the effect monitor and the channel

selected with the HEADPHONES CUE button.

In the middle position, the audio from [MASTER] and [CUE] will be

output.

30 Headphones level adjust dial (LEVEL)

Adjusts the output level of the headphones jack. (adjustable range:

–∞ to 0 dB)

8

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

31 Headphones jack (PHONES)

Connect to headphones equipped with phone-type jack.

32 Beat select buttons ( BEAT )

(Beat up):Doubles the calculated BPM.

(Beat down):Halves the calculated BPM.

• Some effects can be set for “3/4”.

With some effects, these are used for functions other than setting

the beat.

33 MIDI ON/OFF button

Sets MIDI output function (not including timing lock) to ON/OFF.

When power is first turned ON, automatically defaults to OFF.

34 MIDI start/stop button (MIDI START/STOP)

Outputs START/STOP signal for MIDI control function.

When this control is enabled, the [MIDI START (STOP)] message

appears for two seconds on the display.

MIDI SNAP SHOT:

When the

MIDI START/STOP

button is held depressed, a snapshot

is sent to the external MIDI component.

35 BPM measuring mode button (AUTO)

Switches between the BPM measuring modes AUTO and TAP.

When [AUTO] indicator on the display is lighted, the BPM will be

measured automatically.

36

TAP

button

The BPM is calculated from the intervals at which the TAP button

is struck. If the TAP button is pressed in the AUTO mode, the mode

automatically switches to the TAP mode (manual input).

37 MANUAL/EFFECT Frequency filter button

Use to switch between manual filter and effect frequency filter.

When power is first turned ON, defaults to effect frequency filter

and the button indicator lights. When manual filter is selected, the

button indicator does not light.

38 Manual filter adjust dial (FREQUENCY)

Use to adjust the cutoff frequency of the selected filter.

39 Effect selector (DELAY, ECHO, TRANS, FILTER, FLANGER,

PHASER, REVERB, ROBOT (ROBOT VOCODER), CRUSH, ROLL,

REVERSE (REVERSE ROLL), UP (UP ROLL), DOWN (DOWN

ROLL), SND/RTN (SEND/RETURN))

Use to select desired type of effect.

When using an external effector connected to the SEND and

RETURN connectors, set to the [SND/RTN] position.

40 Effect channel selector (1, 2, 3, 4, MIC, CF.A, CF.B, MASTER)

Use to select the channel to which effects are applied.

When [MIC] is selected, effects are applied to both microphone 1

and microphone 2.

41 Effect parameter 1 dial [TIME (PARAMETER 1)]

Adjusts time parameter for selected effect (With some effects,

this is used for adjustments other than time parameters.)

• If the

TIME

dial is rotated while depressing the TAP button,

direct BPM can be set manually.

• If the

TIME

dial is rotated while holding the TAP button and

AUTO/TAP buttons depressed, the BPM can be set in 0.1 units.

42 Effect parameter 2 dial [LEVEL/DEPTH (PARAMETER 2)]

Adjusts quantitative parameters for selected effect.

43 Effect button/indicator (ON/OFF)

Sets selected effect ON/OFF. When power is first turned ON,

defaults to effect OFF. When set to effect OFF, the button

indicator lights. When effects are enabled (ON), the button

flashes.

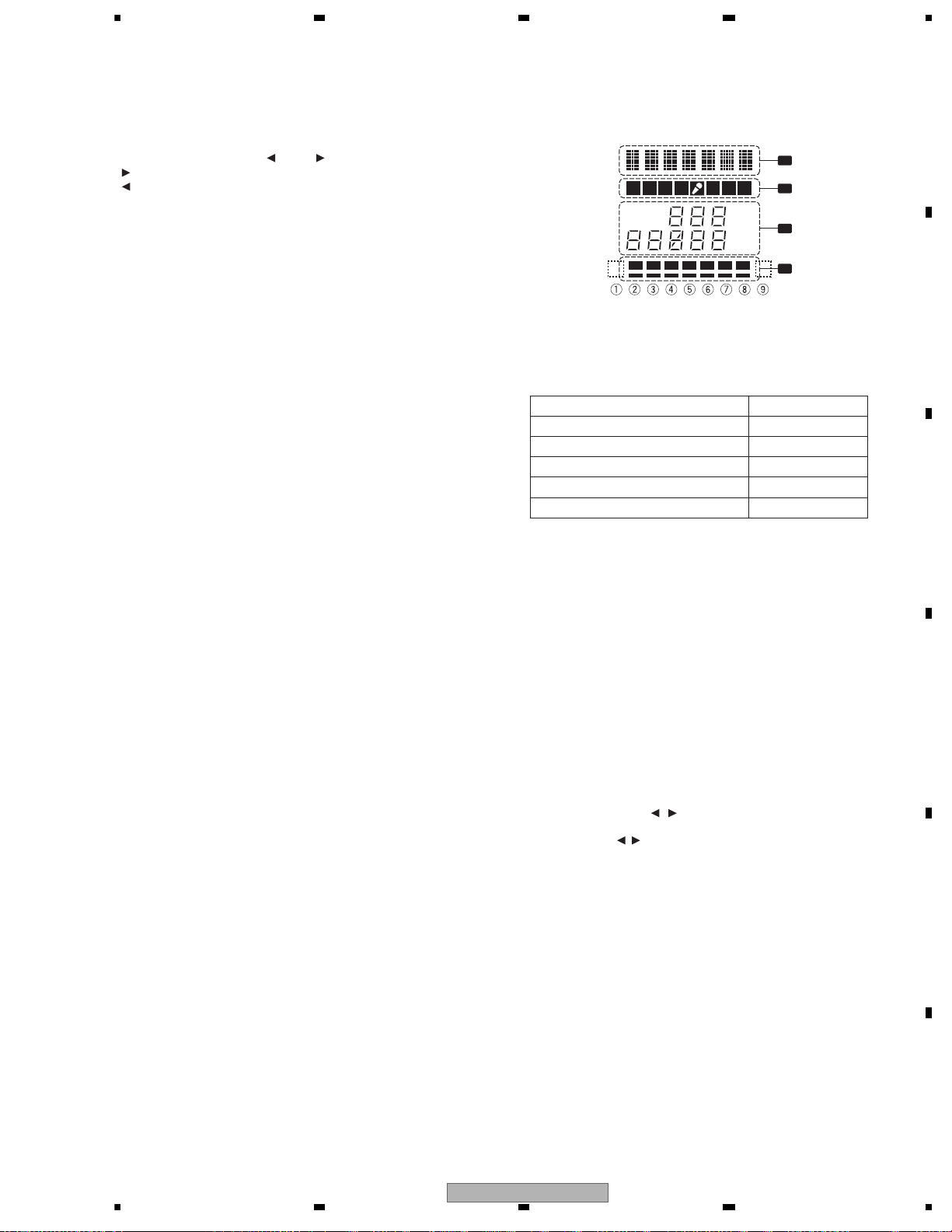

44 Display

DISPLAY SECTION

1 Effects display section

Text display (7 characters) displays effect name as shown in

accompanying table. Also, when one of the change operations is

performed as noted in the table, the corresponding characters are

displayed for two seconds, after which the display returns to the

original effect name.

2 Channel select display section

Lights position selected by effect channel selector.

3 Parameter display section

AUTO/TAP:

[AUTO] lights when the BPM measuring mode is set to AUTO, and

[TAP] lights when the BPM measuring mode is set to manual

(TAP).

BPM counter display (3 digits):

In AUTO mode, displays the automatically detected BPM value. If

the BPM count cannot be detected automatically, the display will

flash at the previously detected value. In manual (TAP) mode,

displays the BPM value designated by TAP input, etc.

BPM:

Lights constantly.

MIDI:

Indicates status of MIDI output function ON/OFF.

• Lights when MIDI output function is ON.

• Not lighted when MIDI output function is OFF.

Parameter 1 display (5 digits):

Displays parameters designated for each effect. When the beat

select buttons (

BEAT ,

) are pressed, the corresponding beat

multiple change is displayed for two seconds. If the beat select

buttons (

BEAT

, ) are used to designate a value outside the

parameter range, the current number will flash but will not

change.

Unit Display (%/ms):

Lights in accordance with the unit used for each effect.

Switching Operation Display

STARTAt MIDI start

STOPAt MIDI stop

SNAPMIDI snapshot

When MIDI output function is ON MIDI On

When MIDI output function is OFF MIDIOff

A B M

MIDI

BPM

%

mS

123 4

AUTO

TAP

1

2

3

4

DJM-700-S

9

1234

1 234

C

D

F

A

B

E

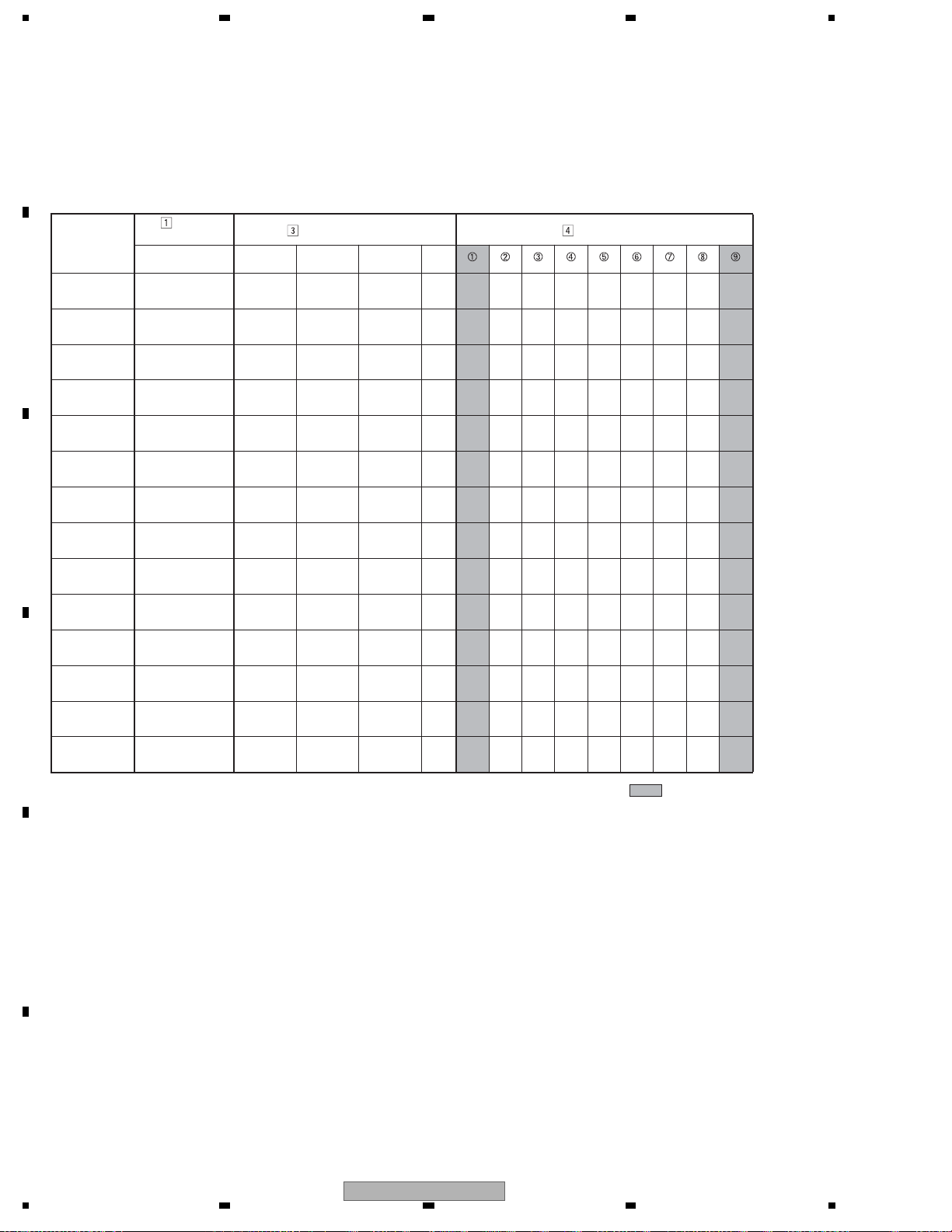

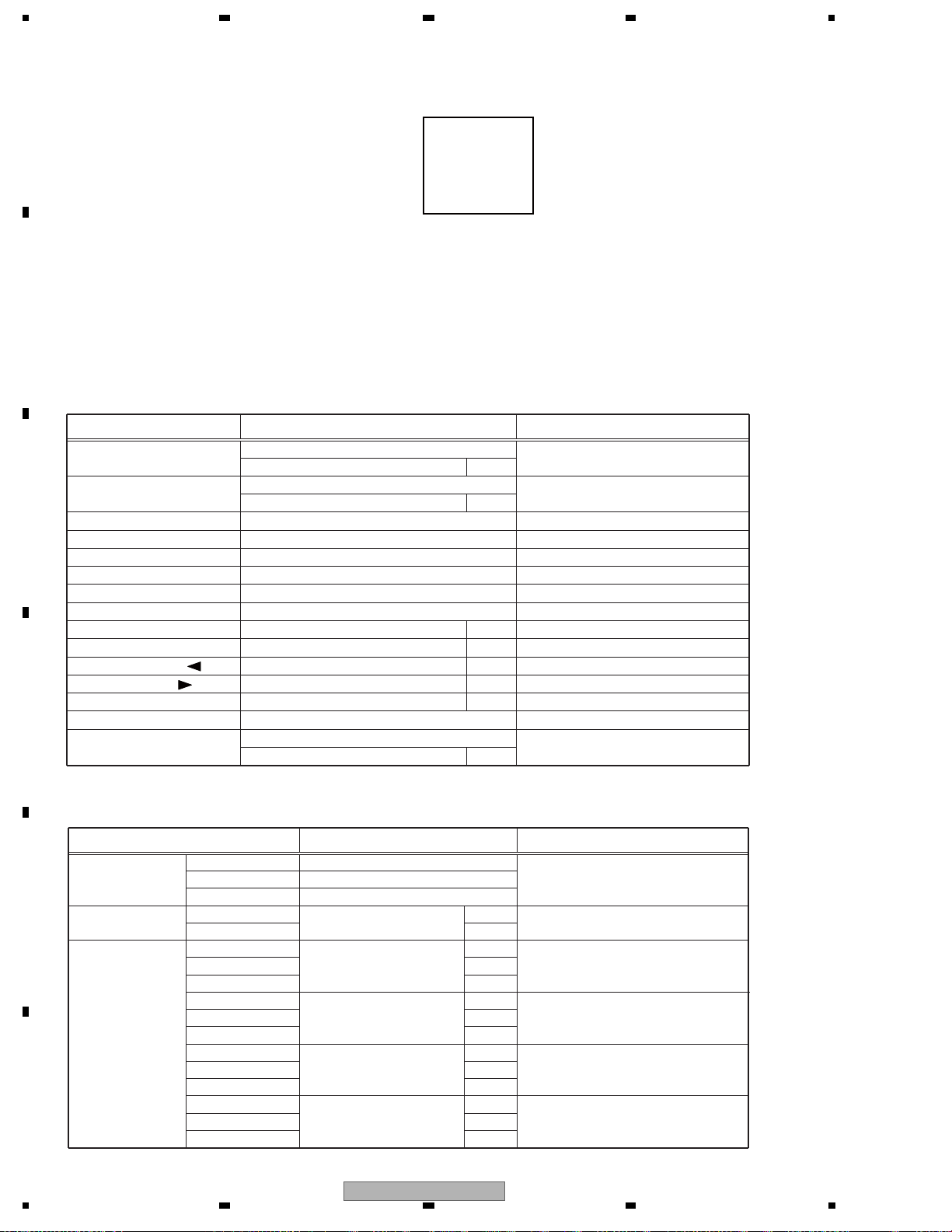

Shaded items are not displayed.

DELAY 1/8 16/1

ECHO 1/8 16/1

TRANS 1/16 16/1

FILTER 1/4 64/1

FLANGER 1/4 64/1

PHASER 1/4 64/1

REVERB 10 90

ROBOT —

–100

–66 —

CRUSH 1/4 64/1

ROLL 1/16 16/1

REV ROLL 1/16 16/1

UP ROLL 1/16 16/1

DOWN ROLL

DELAY

ECHO

TRANS

FILTER

FLANGER

PHASER

REVERB

ROBOT

CRUSH

ROLL

REVROLL

UP ROLL

DWNROLL

1

1

10

10

10

10

1

-100

10

10

10

10

10

ms

ms

ms

ms

ms

ms

%

%

ms

ms

ms

ms

ms

4 000

4 000

16 000

32 000

32 000

32 000

100

100

32 000

4 000

4 000

4 000

4 000

500

500

500

2 000

2 000

2 000

50

0

2 000

500

500

500

500 1/16

1/4

1/4

1/8

1/2

1/2

1/2

20

1/2

1/8

1/8

1/8

1/8

1/2

1/2

1/4

1/1

1/1

1/1

30

1/1

1/4

1/4

1/4

1/4

–50

3/4

3/4

1/2

2/1

2/1

2/1

40

2/1

1/2

1/2

1/2

1/2

0

1/1

1/1

1/1

4/1

4/1

4/1

50

4/1

1/1

1/1

1/1

1/1

26

2/1

2/1

2/1

8/1

8/1

8/1

60

8/1

2/1

2/1

2/1

2/1

50

4/1

4/1

4/1

16/1

16/1

16/1

70

16/1

4/1

4/1

4/1

4/1

100

8/1

8/1

8/1

32/1

32/1

32/1

80

32/1

8/1

8/1

8/1

8/1

16/1

SND/RTN SND/RTN

4 Beat display section

Displays the location of parameter 1 relative to BPM (1/1 beat). The

lower row is lighted constantly. When the parameter 1 location

approaches a threshold value, the corresponding indicator is

lighted. When the parameter 1 is between threshold values, the

indicator flashes. Although the display includes seven actual

indicators, the values of the two ends can also be considered to

represent indicators, with the result that nine positions can be

logically assumed. When the values are at the two ends, no

indicators light.

Effect

selector

Effect

display

Beat displayParameter display

Effect name

Minimum

value

Maximum

value

Default Unit

10

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

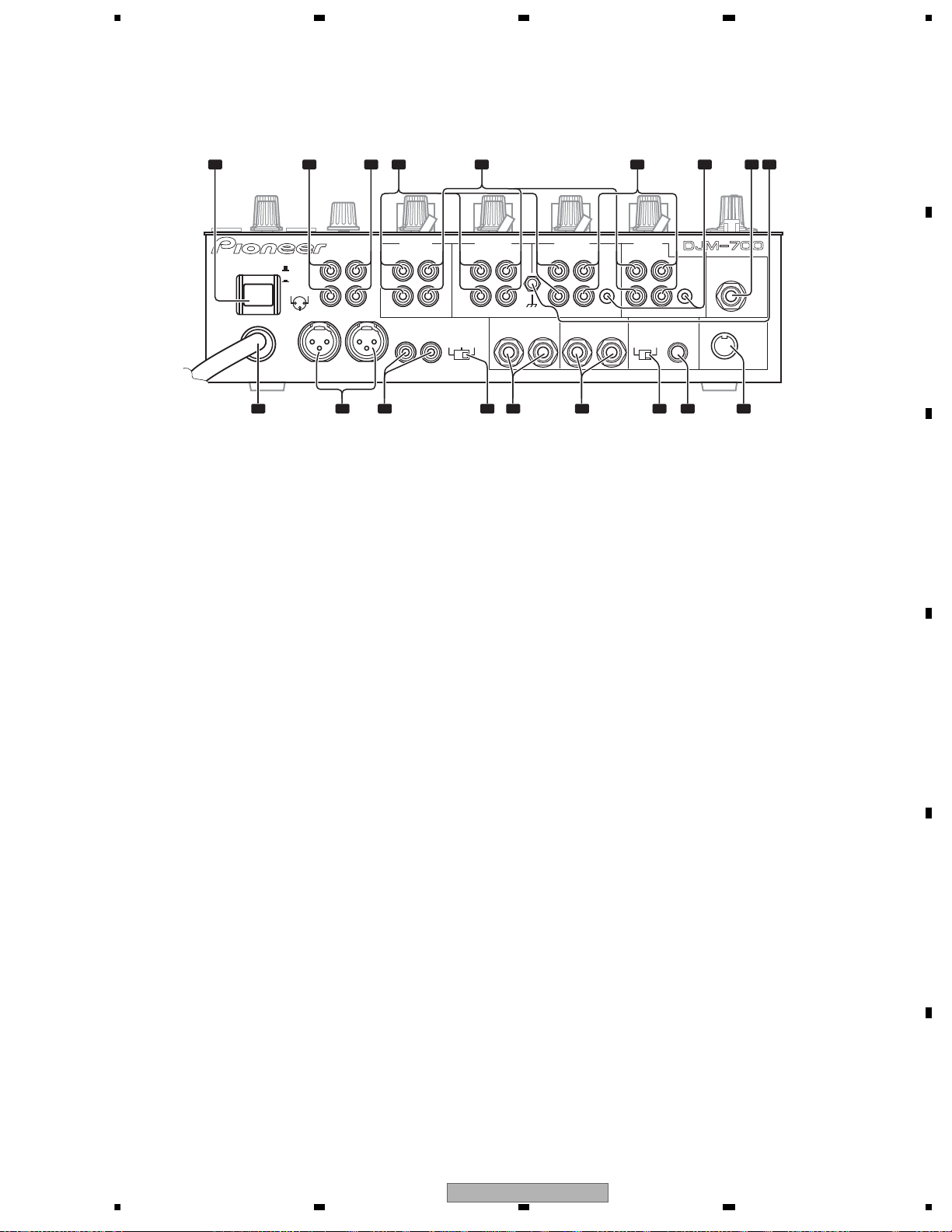

CONNECTION PANEL

1 POWER switch

2 BOOTH monitor output connectors

RCA-type booth monitor output jack.

The sound level from these connectors is controlled independently

by the BOOTH MONITOR LEVEL dial, regardless of the position of

the MASTER LEVEL dial.

3 Recording output connectors (REC)

RCA type output connectors for recording.

4 PHONO input connectors

RCA type phono level (MM cartridge) input connectors.

Do not use for inputting line level signals.

5 LINE input connectors

RCA type line level input connectors.

Use to connect a cassette deck or other line level output

component.

6 CD input connectors

RCA type line level input connectors.

Use to connect a DJ CD player or other line level output

component.

7 CONTROL connectors

Ø3.5 mm mini-connector. Use to connect to the control connector

of a Pioneer DJ CD player.

When the connectors are connected, the DJM-700-S/DJM-700-K’s

fader can be used to perform start/stop on the DJ CD player.

8 Two microphone input jacks (MIC 2)

Connect microphones equipped with phone-type plugs.

9 Signal grounding terminals (SIGNAL GND)

Reduces noise when connecting an analog turntable.

10 MIDI OUT connector

DIN type output connector.

Use to connect to other MIDI component.

11 DIGITAL OUT connector

RCA type digital coaxial output connector.

Master audio digital output.

12 Sampling frequency selector switch (fs 48 k/96 k)

Use to set the sampling frequency of the digital output to 96 kHz/

24-bit format or 48 kHz/24-bit format.

• Turn power off before changing this switch position.

13 RETURN connectors

Ø6.3 mm phone-type input connectors.

Use to connect to the output connectors of external effectors or

similar components.

When the L channel only is connected, the L channel input is

simultaneously input to the R channel.

14 SEND output connectors

Ø6.3 mm phone-type output connectors.

Use to connect to the input connectors of external effectors or

other similar components. When the L channel only is connected,

a L+R monaural signal is output.

15 Master output attenuator switch (MASTER ATT)

Use to attenuate the level of the master 1 and master 2 outputs.

Attenuation can be set to 0 dB, –3 dB, or –6 dB.

16 MASTER 2 output connectors

RCA type unbalanced output.

17 MASTER 1 output connectors

XLR type (male) balanced output.

• When using a cord with RCA-type plug, users are recommended

to connect the plug directly to the MASTER 2 connectors

without using an XLR/RCA converter plug.

18 Power cord

Connect to ordinary AC outlet.

POWER

ON

OFF

BOOTH REC

L

R

L

R

L

R

L

R

L

R

PHONO LINE PHONO PHONOLINE

CH-4 CH-3 CH-2 CH-1

SIGNAL GND

SEND

DIGITAL OUT

(MONO)

CD LINE

CONTROL

CONTROL

CD

1 GND

3 COLD

2 HOT

-6dB -3dB 0dB

MIC 2

RETURN

(MONO)

RLRL

RL

RL

MASTER1

MASTER2

MASTER

ATT.

48k 96k

fs(Hz)

MIDI OUT

1234 789

101112151718 1316 14

56

DJM-700-S

11

1234

1 234

C

D

F

A

B

E

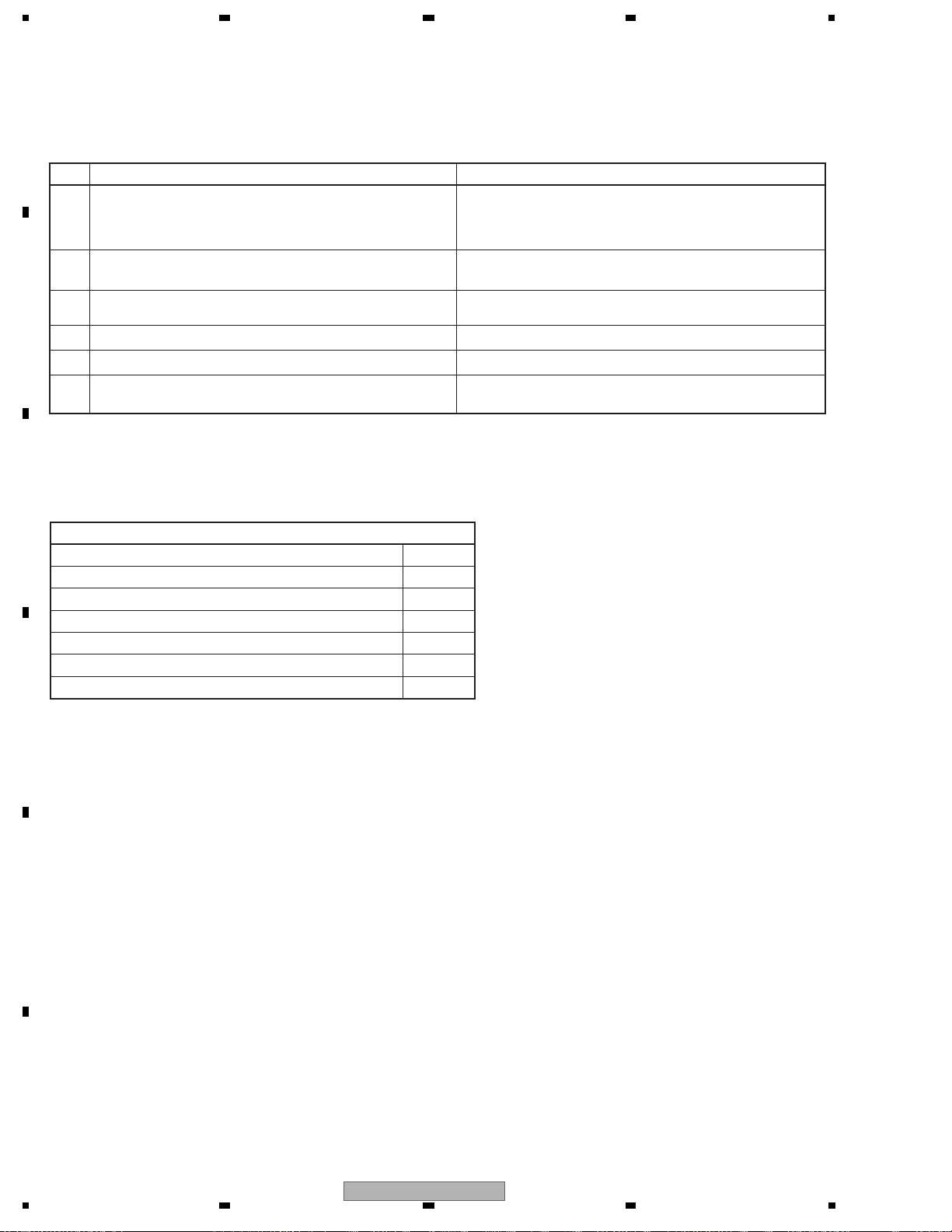

To ensure the quality of the product after repair, check the recommended items shown below:

See the table below for the items to be checked regarding audio:

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

No. Procedures Item to be checked

1

Check if all the symptoms pointed out by the customer have been

addressed. If a symptom pointed out by the customer is

attributable to a particular source, such as Mic, each Input, Fader,

Equalizer, and Trim, input that particular source for checking.

The symptoms in question must not be reproduced.

Audio and operations must be normal.

2

Check the analog audio inputs. (Make connections for analog

audio signals with a CDJ player.)

Audio for each channel and operations must be normal.

3

Check Fader playback. (Select Fader and check the multichannel

operations via the DSP.)

Audio for each channel and operations must be normal.

4 Check the master outputs. (Connect with a CDJ player.) Audio and operations must be normal.

5 Check the audio from headphone output. Audio must be normal, without noise.

6 Check the exterior section.

Check for any scratches or dirt that have been made or attached

on the exterior section after receiving the product for repair.

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

12

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

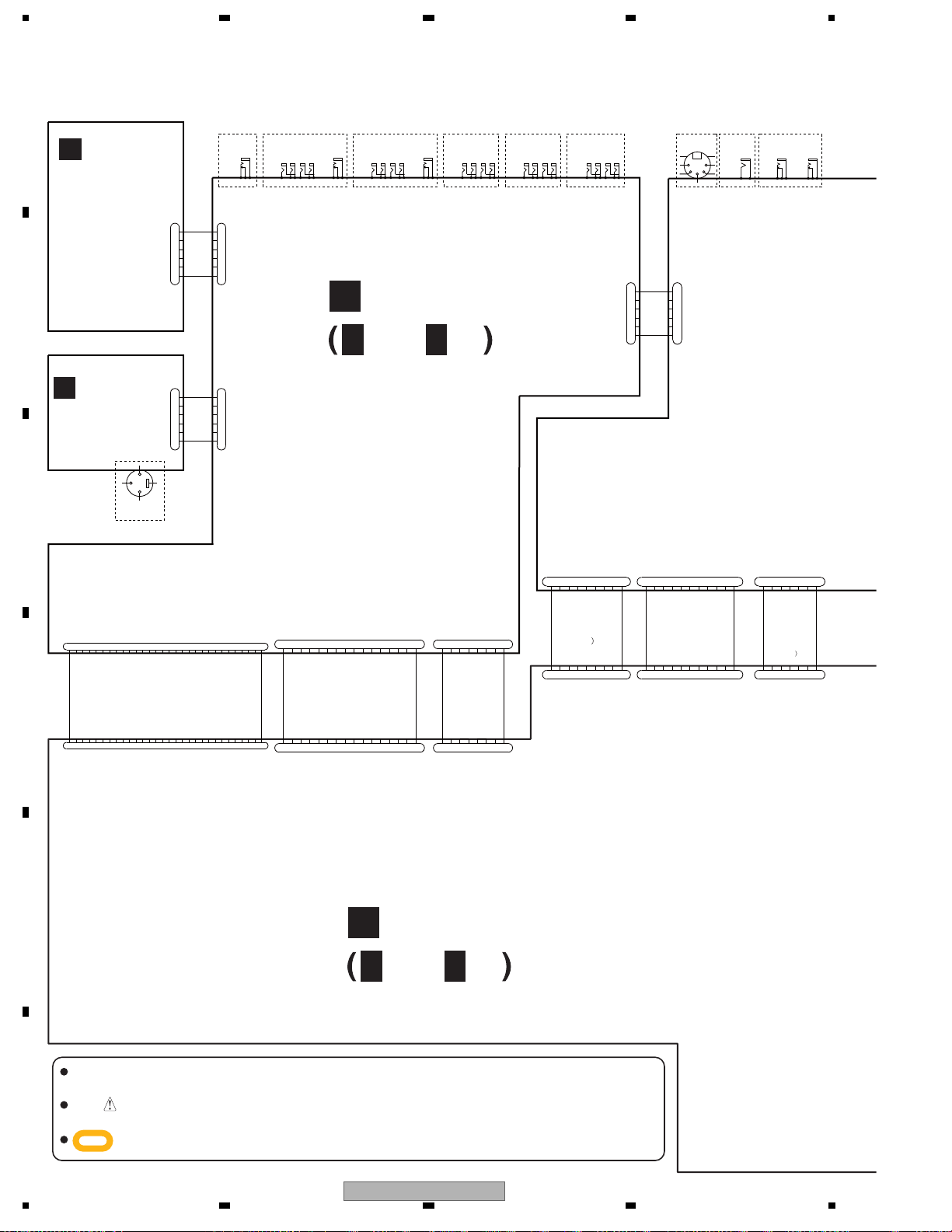

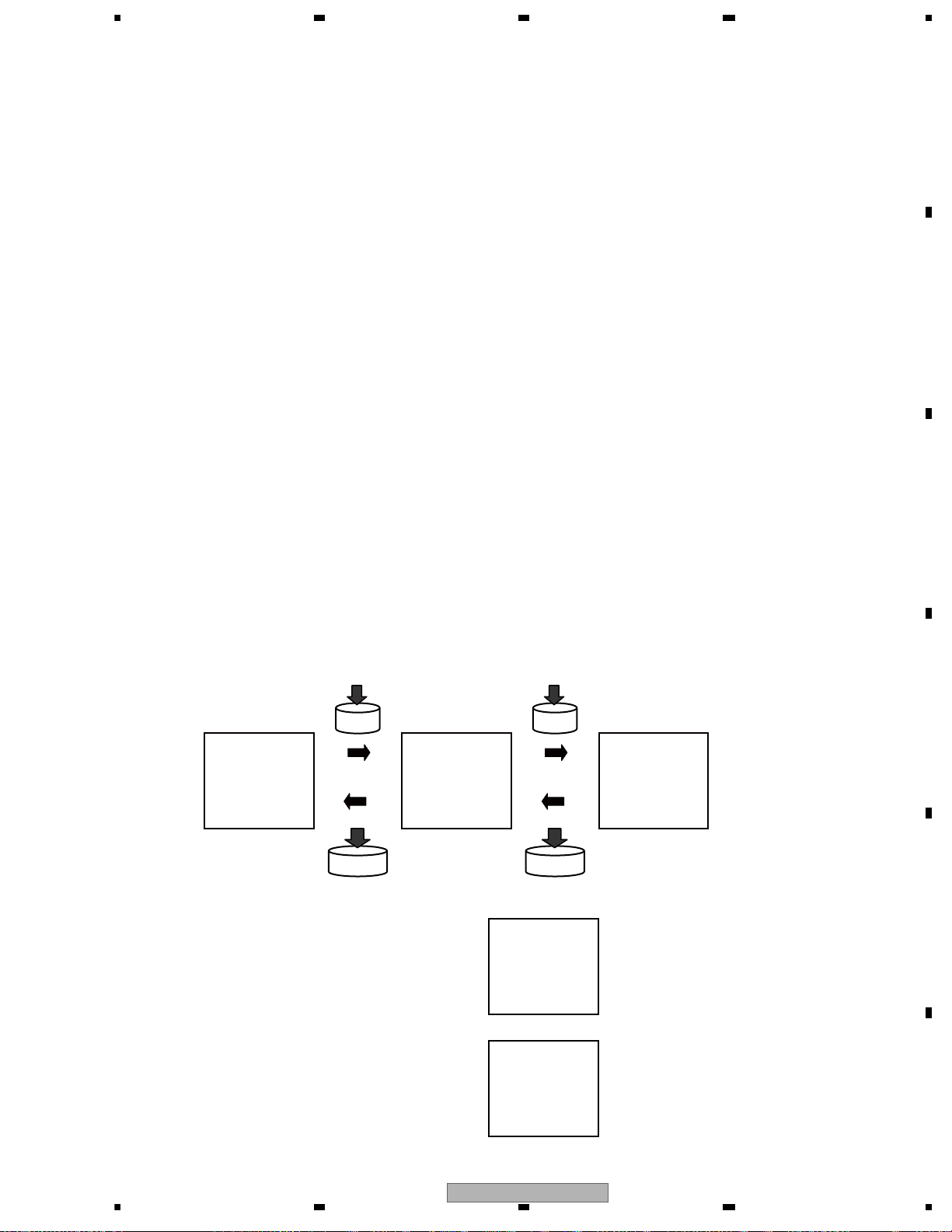

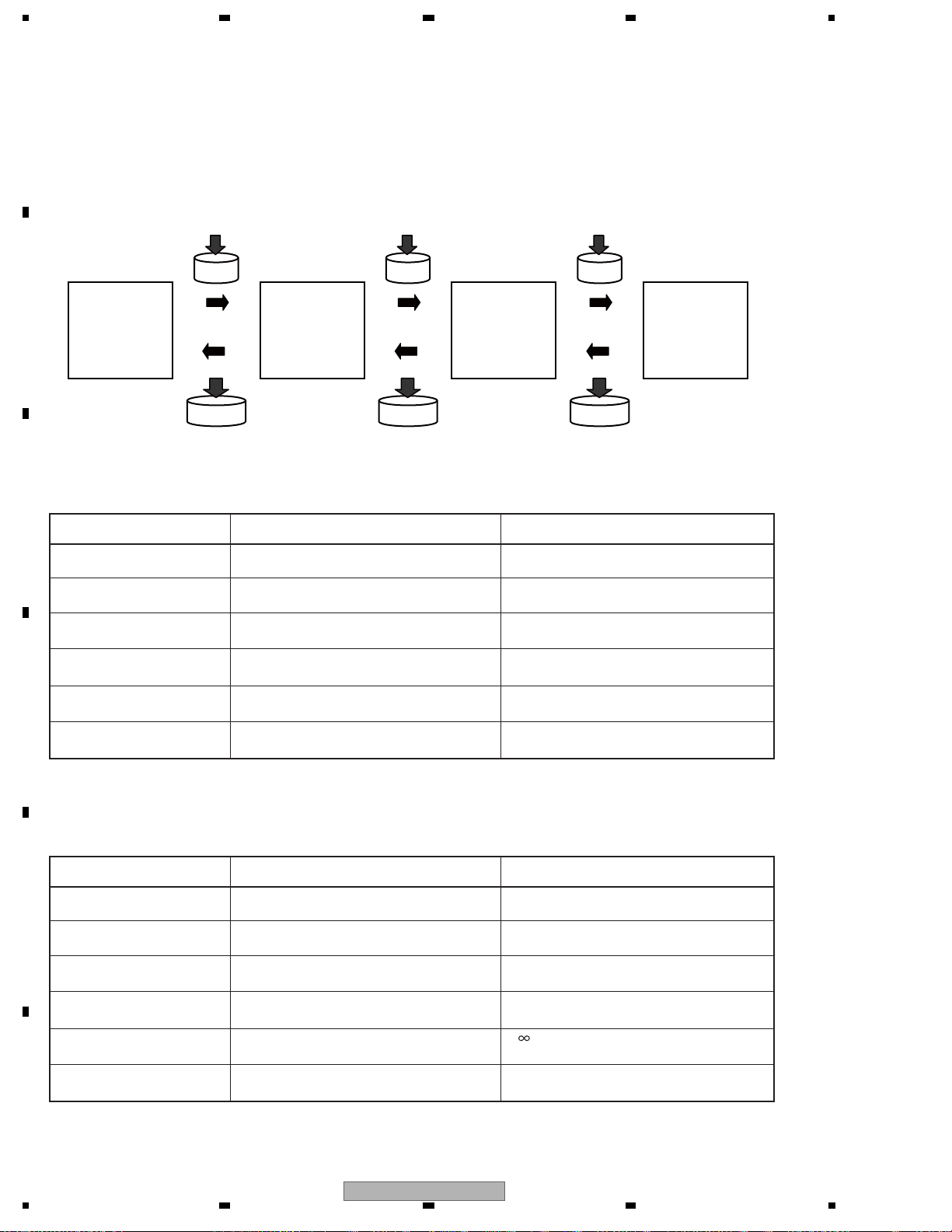

INPUT

ASSY

A

OUTPUT

ASSY

G

PRIMARY

ASSY

P

PANEL 1 ASSY

E

PANEL 2 ASSY

F

MAIN

ASSY

D

HP JACK

ASSY

M

FADER (CROSS) ASSY

H

FADER (CH2)

ASSY

J

FADER (CH3)

ASSY

K

FAD ER

(CH4)

ASSY

L

FADER

(CH1)

ASSY

I

TRANS

ASSY

O

REG

ASSY

N

MIC1 JACK

ASSY

B

MIC VR

ASSY

C

1..MAIN ASSY DWX2674

NSP 1..INPL ASSY DWM2309

2..INPUT ASSY DWX2675

2..PANEL 2 ASSY DWX2678

2..MIC1 JACK ASSY DWX2685

2..MIC VR ASSY DWX2686

NSP 1..PANL ASSY DWM2311

2..PANEL 1 ASSY DWX2677

2..FADER (CROSS) ASSY DWX2680

2..FADER (CH1) ASSY DWX2681

2..FADER (CH2) ASSY DWX2682

2..FADER (CH3) ASSY DWX2683

2..FADER (CH4) ASSY DWX2684

• For KUCXJ and WYXJ5 types

NSP 1..OUPW ASSY DWM2310

2..OUTPUT ASSY DWX2676

> 2..PRIMARY ASSY DWX2687

2..TRANS ASSY DWX2688

2..REG ASSY DWX2689

2..HP JACK ASSY DWX2690

• For RLXJ type

NSP 1..OUPW ASSY DWM2315

2..OUTPUT ASSY DWX2676

> 2..PRIMARY ASSY DWX2692

2..TRANS ASSY DWX2757

2..REG ASSY DWX2689

2..HP JACK ASSY DWX2690

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

NOTES:

Mark No. Description Part No.

LIST OF ASSEMBLIES

Mark No. Description Part No.

3.2 PCB LOCATIONS

DJM-700-S

13

1234

1 234

C

D

F

A

B

E

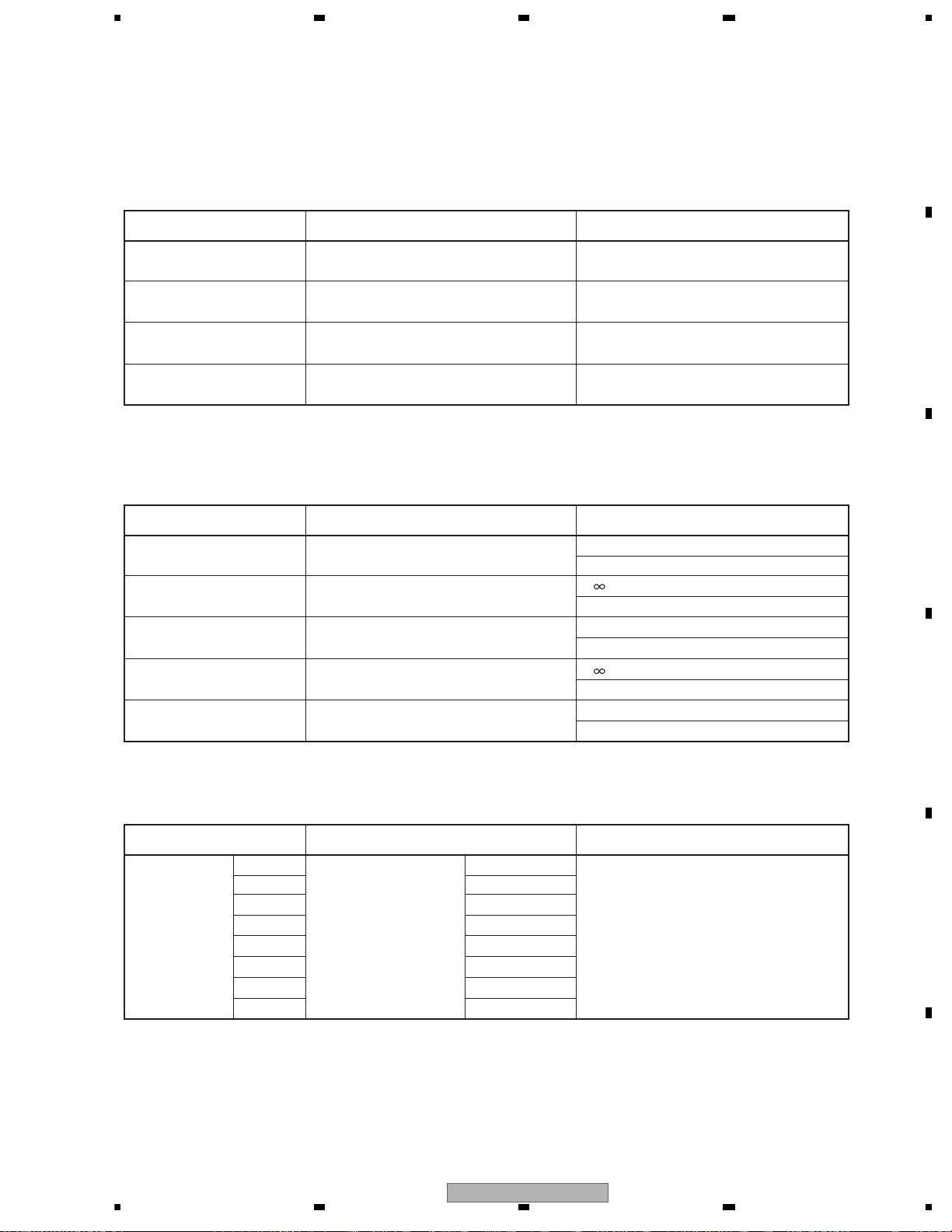

3.3 JIGS LIST

Dedicated cable

GGD1530

Used for connector conversion

Jig Name Jig No. Remarks

Jigs list

Interface device GGF1605

Used for firmware download

14

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

DJM-700-S

15

1234

1 234

C

D

F

A

B

E

JA3002

RKN1004-A

231

JA7501

DKN1136-A

2

4

1

3

CKS3153-A

1

2

3

4

5

6

S6B-PH-K-S

1

2

3

4

5

6

JA4005

DKN1452-A

231

JA4009

DKN1188-A

1

2

3

45

67

CKS2643-A

1

2

3

4

5

6

JA3012

DKN1452-A

231

VKN1290-A

123456789

101112131415161718192021222324252627282930

JA3005

VKB1132-A

12345

6

JA3006

RKN1004-A

231

JA4008

PKB1033-A

2

1

CKS3153-A

1

2

3

4

5

6

JA3001

VKB1132-A

12345

6

JA4004

DKN1452-A

231

CKS2643-A

1

2

3

4

5

6

JA3008

VKB1132-A

12345

6

JA3010

VKB1132-A

12345

6

JA3007

VKB1132-A

12345

6

B6B-PH-K-S

1

2

3

4

5

6

VKN1434-A

12345

6

789

101112131415161718192021222324252627282930

S8B-PH-K-S

1

2

34567

8

VKN1413-A

1

2

3456789

VKN1240-A

1

2

3456789

AKM1282-A

123456789

10

11

AKM1278-A

1234567

VKN1276-A

123456789

10111213141516

B7B-PH-K-S

1234567

B11B-PH-K-S

123456789

10

11

VKN1420-A

123456789

10111213141516

AKM1279-A

1234567

8

MIC2_IN

CH1_L

GNDA(MIC)

GNDA(MIC)

SEL_CH1

GNDA(MIC)GNDA(MIC)

FADRE_ST_1-

GNDA

GNDA(CH2)

V-15A

GNDA

MIC1

GNDA(MIC)

V+15A

RETURN

V+15A

MIC2

GNDA(CH1)

FADER_ST_2+

FADRE_ST_1-

GNDA

MIC1-

MIC2

MIC1_GND

MIC1+

GNDA(CH1)

MIC1+

MIC2

FADER_ST_2+

V-15A

GNDA(CH1)

MIC1-

MIC2_GND

GNDA(CH2)

MIC1-

GNDA(CH2)

MIC2

GNDA(CH1)

GNDA

GNDA

GNDA(CH1)

BOOTH/REC

GNDA(CH1)

GNDA(CH2)

MIC2_IN

GNDA(MIC)

MIC2

FADER_ST_2-

30P FFC

V+5D

FADER_ST_2-

L=120mm (1.0mmP)

GNDA(CH1)

MIC1_GND

GNDA(CH2)

CH1_R

GNDA(CH1)

GNDA(CH2)

GNDA(CH2)

MIC1+

MIDI

GNDA(MIC)

GNDA(MIC)

CH2_L

CH2_R

MUTE

GNDA(MIC)

CH2_R

MIC1_IN

GNDA(CH1)

CH2_L

SEL_CH2

FADER_ST_1+

MIC1+

6P

L=100mm

GNDA

MUTE

V+5D

CH1

GNDA(CH2)

SEL_CH1

CH3

GNDA(CH2)

MIC1-

GNDA(MIC)

MIC1

FADER_ST_1+

MIC1_IN

MIC1

SEL_CH2

GNDA(CH2)

6P PH

GNDA(MIC)

GNDA(CH2)

MIC1

PF06PP-D10

CH4

GNDA(CH1)

6P

DDD1362-A

GNDA(MIC)

GNDA(CH1)

MIC2_GND

B to B

B to B

GNDA(CH2)

CH2

D_OUT

CH1_L

GNDA

CH1_R

GNDA

GNDA(CH1)

REVERSE

GNDA(BOOTH)

BOOTH_R

GNDA(BOOTH)

BOOTH_L

GNDA(REC)

REC_R

GNDA(REC)

REC_L

GNDA(CH3)

CH3_L

GNDA(CH3)

GNDA(CH3)

GNDA(CH3)

CH3_R

GNDA(CH3)

SEL_CH3

GNDA(CH4)

CH4_L

GNDA(CH4)

GNDA(CH4)

CH4_R

GNDA(CH4)

SEL_CH4

GNDA(CH4)

MASTER_L-

FL_VHCTRL

MASTER_R-

RETURN_L

GNDA(M)

HP_R

CPU_MUTE

MUTE2

RETURN_R

SEND_R

HP_L

MASTER_R+

SEND_L

POWER_RESET

MASTER_L+

GNDA(HP)

MIDI_OUT

GNDD

D_OUT

48/96_SW

GNDD

GNDA(HP)

GNDA(RETURN)

GNDA(SEND)

GNDA(SEND)

GNDA(M)

GNDA(M)

GNDA(CH3)

GNDA(CH3)

GNDA(CH3)

SEL_CH3

GNDA(CH4)

CH4_L

GNDA(CH4)

GNDA(CH4)

CH4_R

GNDA(CH4)

SEL_CH4

GNDA(CH4)

CH3_L

CH3_R

GNDA(CH3)

GNDA(CH3)

GNDA(BOOTH)

BOOTH_R

GNDA(BOOTH)

BOOTH_L

GNDA(REC)

REC_R

GNDA(REC)

REC_L

CPU_MUTE

MUTE2

POWER_RESET

FL_VHCTRL

MIDI_OUT

GNDD

D_OUT

48/96_SW

GNDD

RETURN_L

HP_R

RETURN_R

SEND_R

HP_L

SEND_L

GNDA(HP)

GNDA(SEND)

GNDA(RETURN)

GNDA(HP)

GNDA(SEND)

MASTER_R-

GNDA

MASTER_R+

MASTER_L+

MASTER_L-

GNDA

GNDA

L=120mm (1.0mmP)

DDD1363-A

16P FFC

L=125mm

8P PH

PF08PP-D12

9P FFC

DDD1364-A

L=80 mm

PF11PP-D07

L=75 mm

11P PH

7P PH

DKP3787-A

L=115 mm

(Shield

(1.0 mmP

REVERSE

REVERSE

CN3003

CN7502

CN7601

CN3013

CN3011

CN302

CN3004

CN1501

CN3015

CN3014

CN1502

CN1503

CN1701

CN4003

CN1602

CN4001

CN1603

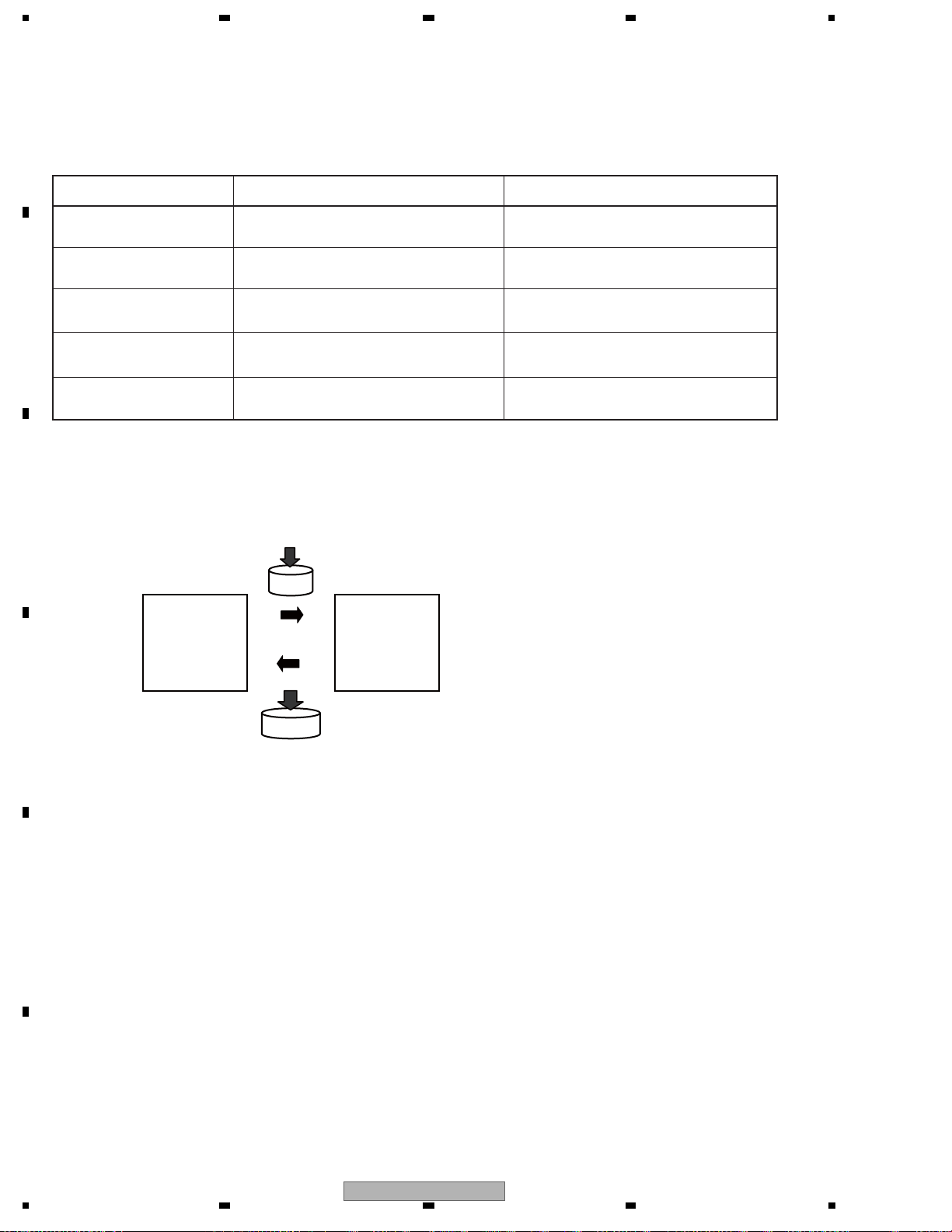

CN4002

A 1/6 − A 6/6

INPUT ASSY

(DWX2675)

A

D 1/4 − D 4/4

MAIN ASSY

(DWX2674)

D

MIC1 JACK

ASSY

(DWX2685)

B

MIC VR

ASSY

(DWX2686)

C

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

The mark found on some component parts indicates the importance of the safety factor of

the part. Therefore, when replacing, be sure to use parts of identical designation.

: The power supply is shown with the marked box.

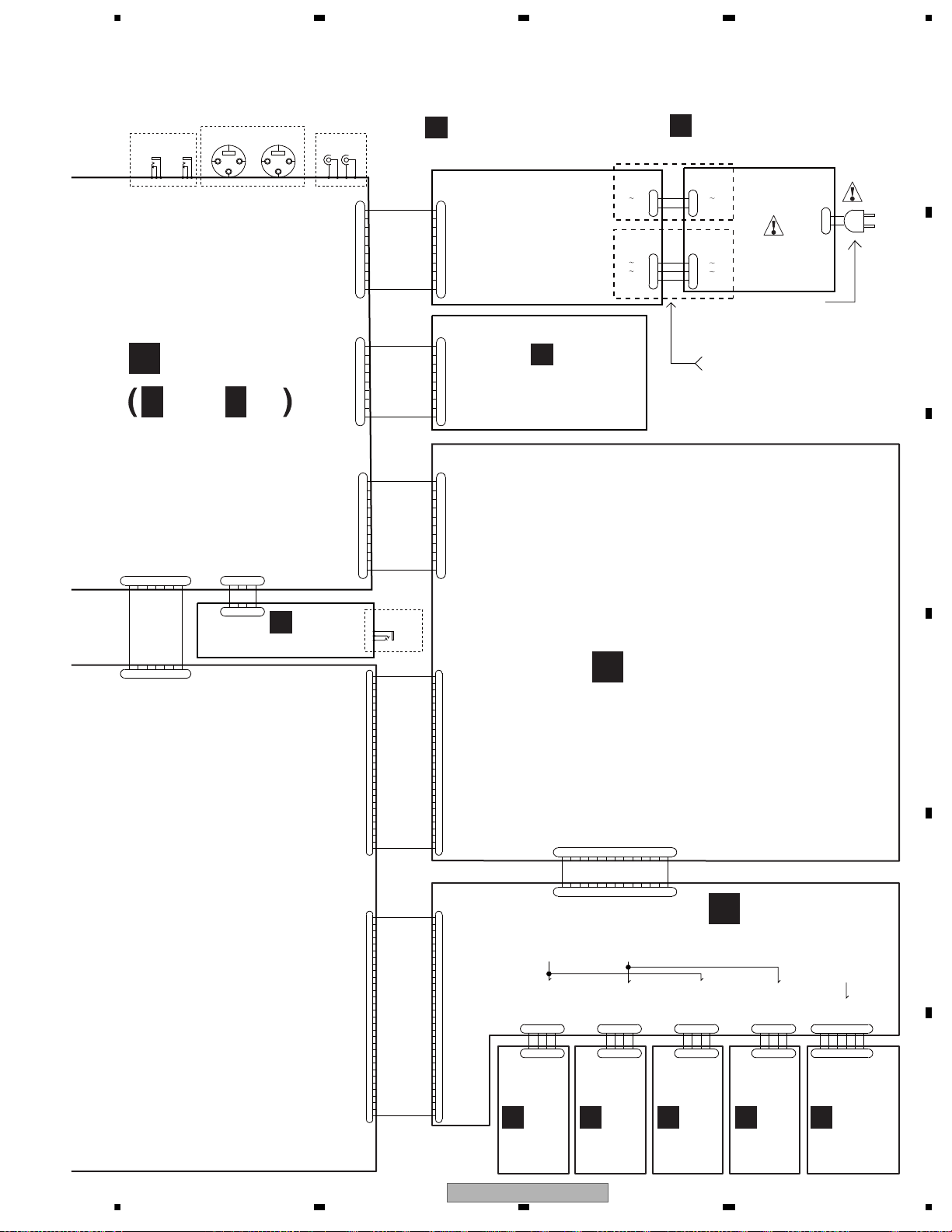

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

16

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

52492-1320

12345

6

789

101112

13

CN4004

B4B-PH-K-S

1

2

3

4

B10B-EH

1

2

3

4

5

6

7

8

9

10

VKN1262-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

B10B-EH

1

2

3

4

5

6

7

8

9

10

1

2

51048-0900

1

2

3

4

5

6

7

8

9

CN304

B7B-PH-K-S

1234567

1

2

3

VKN1431-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

JA4006

DKN1452-A

231

PG06MR-E07

12345

6

VKN1242-A

1

2

3

4

5

6

7

8

9

10

11

JA4007

DKN1452-A

231

173979-6

1

2

345

6

52492-1320

1234567

8

9

10

11

12

13

JA4003

PKB1034-A

S_WT_W S_RT_R

VKN1242-A

1

2

3

4

5

6

7

8

9

10

11

JA7702

DKN1281-A

2

3

1

52147-0910

1

2

3

4

5

6

7

8

9

B3P5-VH

1

2

3

VKN1258-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

B2P3-VH

1

2

VKN1435-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

AKM1293-A

CN1001

1234567

CN7701

1

2

3

4

RKP1751-A

1

2

B4B-PH-K-Y

1

2

3

4

B4B-PH-K-Y

1

2

3

4

B4B-PH-K-S

1

2

3

4

B4B-PH-K-S

1

2

3

4

S4B-PH-K-Y

1

2

3

4

S4B-PH-K-Y

1

2

3

4

S4B-PH-K-S

1

2

3

4

S4B-PH-K-S

1

2

3

4

C0

R19

NC

NC

FLAC2

C3

C4

GNDA

R5

D20PDY0910E

VR_FD2

VR_FD4

R18

GNDREF2

V-15A

C5

V+5D_AC1

V+3R3REF1

C2

C3

V-15A

N

N

1

GNDA

V+5D

V-15_AC

GNDD

VR_IN1

4P PH

HP_R

FLAC1

GNDD

C0

R1

NC

GNDREF2

R7

TIME_1

GNDD

2

(1.0mmP)

C2

DKB1077-A

VR_IN4

GNDREF2

7P PH

4

L=125mm

R12

V-15_UNREG

1

V+15A

VRSEL2_b0

4

R8

R20

10P EH

L=225 mm

FL_CLK

VR_IN3

FL_CLK

R11

GNDHP

EF_LED

R17

EF_SW

NC

V+5_UNREG

L=50mm

FL_LAT

3

FL_30V

FLAC1

R2

GNDA

L=50mm

PF04PP-B05

V+5D

NC

L=100 mm

R15

PF04PP4B05

V+5D(LED)

V+3R3REF2

13P FFC

NC

SEND

4P PH

(2.0 mmP)

C3

R6

L=75mm

R0

NC

VR_FD3

R7

NC

V+15_UNREG

GNDHP

FL_DATA

V+3R3REF2

31P FFC

GNDD

FL_CLK

Straight

HP_L

C3

V3R3(NC)

L=275mm

V+3R3REF2

GNDREF2

V+5D

R5

PF04PP-D27

NC

V+15A

R16

R19

GNDREF2

R4

GNDA

2

V-15_AC

V+5D_AC1

GNDREF1

FLAC2

TAP_SW

3

R13

V+3R3REF2

VR_FD4

R3

C6

V+5A

110 120V

110 120V

JA4002

V-15_UNREG

KUCXJ, WYXJ5

V+15A

V-15A

GNDA

C0

C6

R8

V+3R3REF2

DDD1367-A

GNDA

27P FFC

VR_IN5

V+5D(LED)

110 120V

110 120V

VRSEL2_b0

R16

GNDREF1

GNDA

V+5D_AC2

VR_FD4

JA4001

FLAC1

FL_LAT

R20

TIME_1

L=280 mm(1.0 mmP)

220 240V

C5

FL_BK

GNDHP

GNDREF2

FL_BK

GNDD

R3

N

N

GNDD

FL_LAT

VR_FD1

R10

FL_DATA

VR_IN2

FLAC1

V+3R3REF2

R17

FL_GND

VR_IN0

GNDD

TIME_0

EF_LED

V+3R3REF2

V+5D

VR_IN2

V+5D_AC2

FLAC1

L=350 mm

R11

GNDREF2

TAP_SW

V+5A_AC

V+15_AC

V+3R3REF2

C4

GNDREF2

GNDD

V+5A

C2

VR_FD2

VR_CFD

C6

FL_DATA

R1

FL_DATA

R9

R18

VRSEL2_b1

DDD1369-A

R15

VR_FD1

VRSEL1_b1

FL_BK

VR_FD3

VR_CFD

FL_LAT

V+3R3REF1

VR_FD3

R14

220 240V

VR_FD2

V+3R3REF2

V3R3(NC)

VR_CFD

NC

C1

R6

V+5A_AC

R14

VR_FD1

FL_GND

VR_FD4

GNDHP

GNDREF2

V+5_UNREG

R2

FL_30V

C1

V+5A

GNDA

VR_IN3

V+30_AC

GNDA

VR_SEL1_b1

C4

MUTE2

VR_IN0

VR_FD1

HP_L

C6

C2

DDD1366-A

VRSEL2_b1

11P FFC

R21

FLAC2

VR_FD3

FL_CLK

V+5A

V-15A

(1.25mmP)

FLAC1

GNDREF2

L=100mm

GNDD

R0

MASTER2

TIME_0

DDD1368-A

R13

HP_R

VR_IN5

FLAC2

MASTER1

4P PH

FLAC2

NC

FLAC2

R21

C1

VR_CFD

EF_SW

V+3R3REF2

GNDA

V+15A

C5

GNDA

VR_IN1

V+15_UNREG

V+3R3REF2

R4

V+5D

R10

RLXJ

V+5D

C1R9C0

MUTE2

VR_IN4

R12

C4

GNDREF2

GNDREF2

GNDD

NC

VRSEL1_b0

V+15_AC

VRSEL1_b0

NC

V+3R3REF2

PF10EE-S22

NC

L=270mm

GNDA

VR_FD2

PF07PP-S12

DKB1077-A

FL_BK

C5

V+30_AC

S4B-PH-K-S

J2=DKP3785-A(2P)

J3=DKP3786-A(3P)

REVERSE

REVERSE

Straight

L=110

AC CORD

VDG1075: KUCXJ

VDG1061: WYXJ5, RLXJ

Parallel

(1.0 mmP)

CN102

CN301

JH201

CN5002

CN305

CN303

J2

J3

CN4

CN5

CN6

CN6001

CN1101

CN5000

CN1201

CN5001

CN6007

CN6005

CN7001

CN6002

CN6004

CN6006

CN6003

CN7301

CN7101

CN7401

CN7201

PANEL 1 ASSY

(DWX2677)

E

PANEL 2 ASSY

(DWX2678)

F

G 1/6 − G 6/6

OUTPUT ASSY

(DWX2676)

G

TRANS ASSY

(DWX2688: KUCXJ, WYXJ5)

(DWX2757: RLXJ)

O

FAD ER

(CROSS) ASSY

(DWX2680)

H

FAD ER

(CH1) ASSY

(DWX2681)

I

FAD ER

(CH2) ASSY

(DWX2682)

J

FAD ER

(CH3) ASSY

(DWX2683)

K

FAD ER

(CH4) ASSY

(DWX2684)

L

PRIMARY ASSY

(DWX2687: KUCXJ, WYXJ5)

(DWX2692: RLXJ

P

REG ASSY

(DWX2689)

N

HP JACK

ASSY

(DWX2690)

M

DJM-700-S

17

1234

1 234

C

D

F

A

B

E

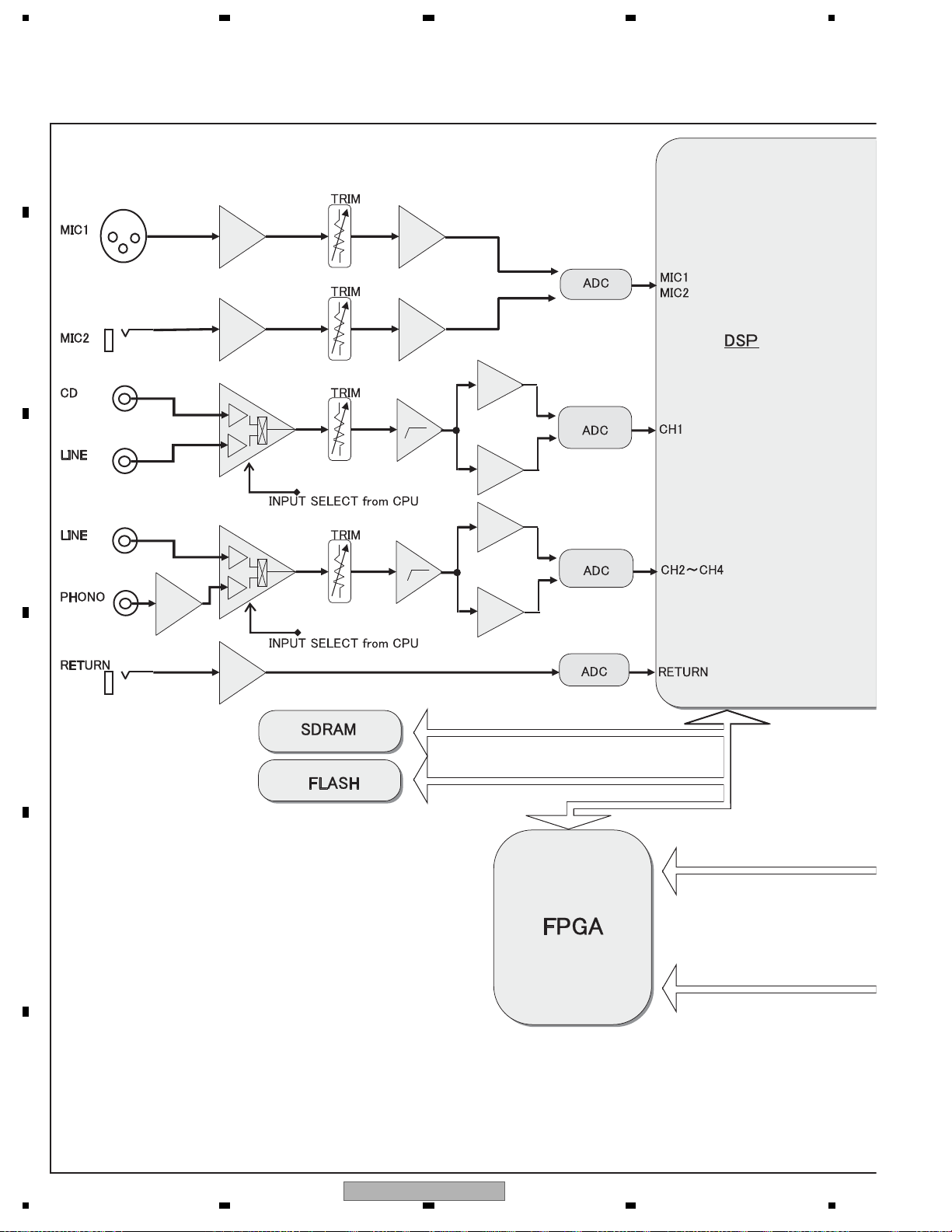

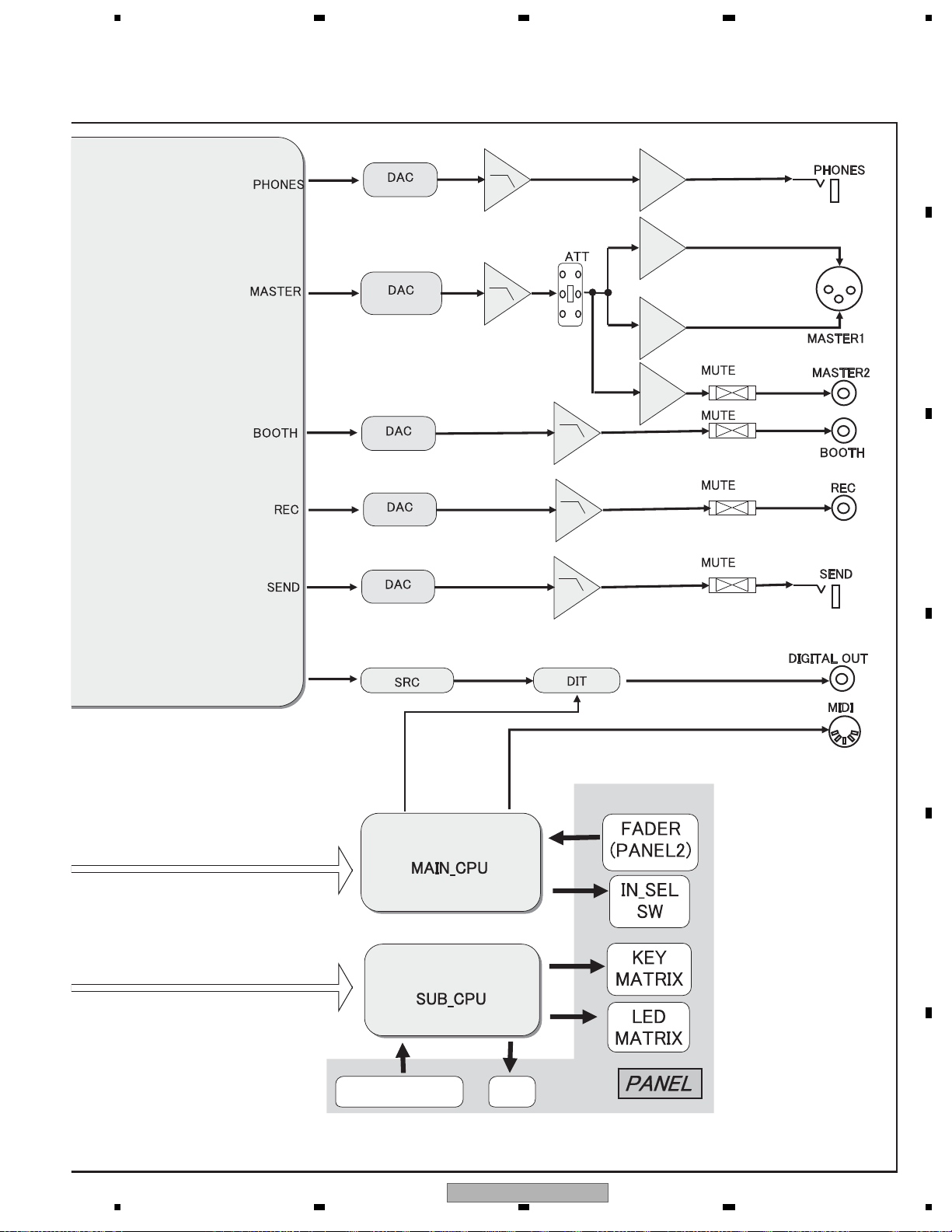

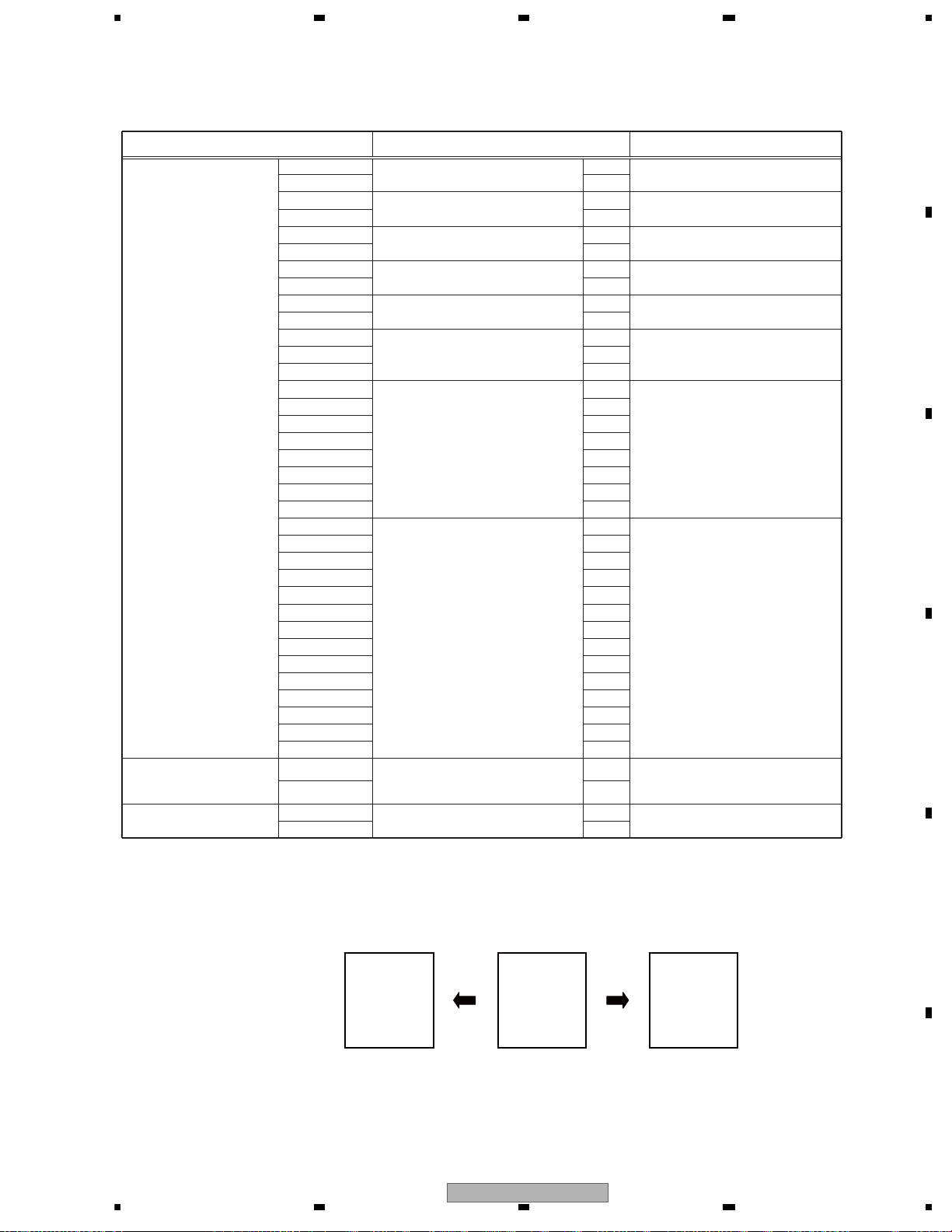

4.2 OVERALL BLOCK DIAGRAM

IC3026 IC3027

IC1604

IC1511

IC1401

IC3028

IC3026

IC3007-

IC3008

IC3006

IC4008

IC1402

IC1506

IC1502

IC1505

IC1501

IC1610

IC1512 IC1514

IC1403

IC1304

IC3001- IC3002

18

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

DIGITAL

OUT

VR(PANEL1)

FL

IC1605

IC1603

IC1602

IC1601

IC1611

IC1702

IC1703

IC1205

IC1101

DJM-700-S

19

1234

1 234

C

D

F

A

B

E

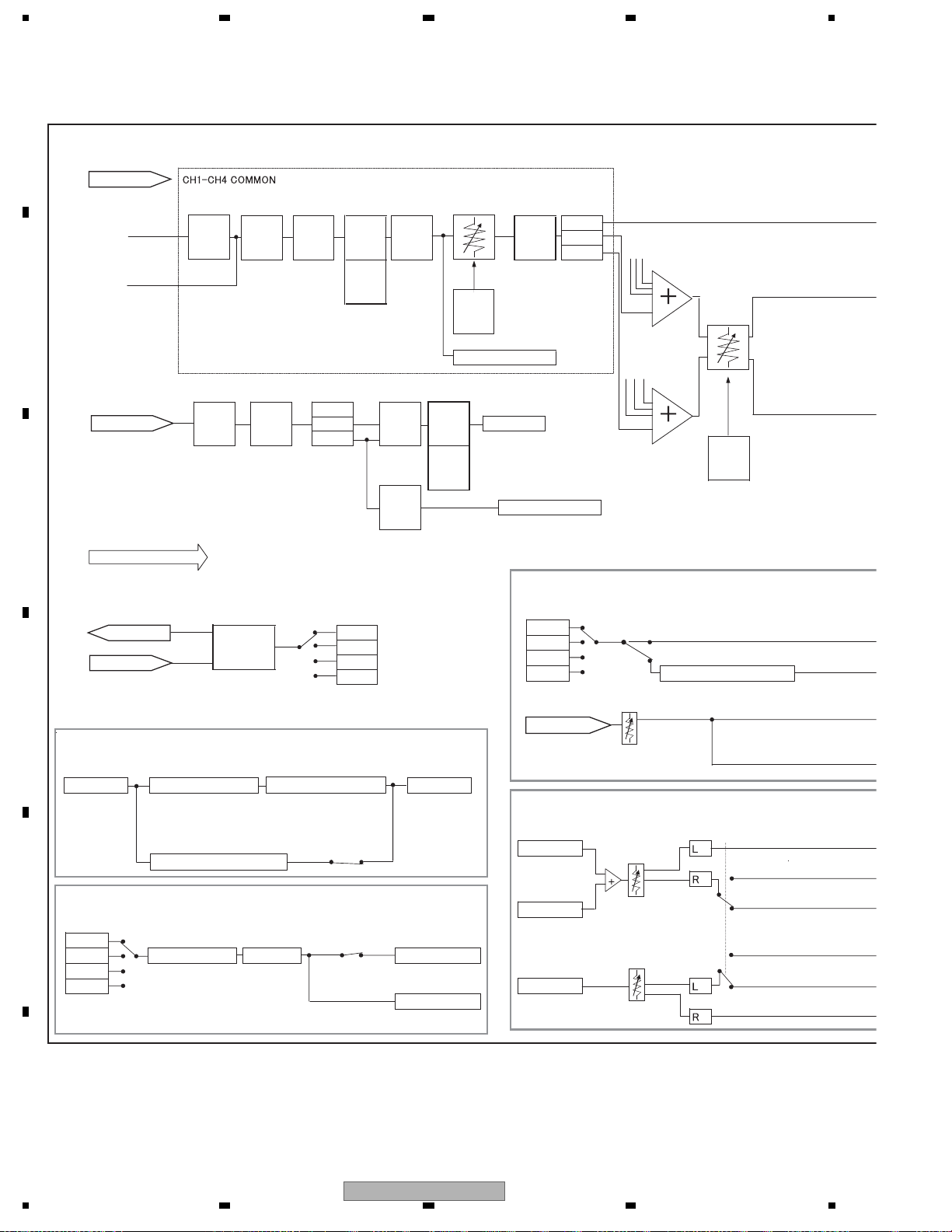

4.3 MAIN BLOCK DIAGRAM

BEAT EFFECT(Misc.)

Effect Frequency Filter(For Roll etc.)

H.P. MIX

Phono in

(ch2-4)

PHONO

EQ

BPM

detect

CHx

3Band

CHn

EQ

BEAT

EFFECTS

[CHx(pre)]

BEAT

EFFECTS

[CHx(post)]

Thru

CF_A

CF_B

3 posi

2 posi

CF Assign

CHx

CROSS

Fader

Cross

Fader

Curve

3 posi

CHx

CHn Fader

Send

Return

[CHx]

MIC1,2 In

CHn In

micon I/F

volume, Switch, Command

Send Out

Return In

BEAT

EFFECTS

(SND/RTN)

Effect CH Select

CH1-4

CF_A/B

MIC

Master

Effect CH Select

CH1-4

CF_A/B

MIC

Master

CHx CUE

CUE Balance

Master Balance

H.P.MONOSPLIT/STEREO SW

Mono Split

Stereo

Mono Split

Stereo

EFFECT CUE

Master CUE

Filter Sw

Effect ch In

Beat Effect Processing

Effect Frequency Filter

Effect Frequency Filter 2

Filter Sw

Effect Out

Effect SW

Effect Frequency Filter 1

Return Level

EFFECT Processing

MIX RATIO

Return In

Effect Out

EFFECT CUE

BEAT EFFECT(SND/RTN)

Effect CH Select

CH1-4

CF_A/B

MIC

Master

2Band

MIC

EQ

BPM

detect

[MIC]

BEAT

EFFECTS

[MIC]

MIC Data

Send

Return

[MIC]

MIC

Filter

Talk Over On/Off

MIC 1,2

MIX

3 posi

MIC SW

Off

On

TalkOver

CH

Fader

Curve

CHx Level Meter

CUE

Monitor

[CHx]

CDin/Line in

(ch1-4)

20

DJM-700-S

5678

56

7

8

C

D

F

A

B

E

Effect Frequency Filter(For effects other than Roll)

BPM Detection Process

BPM

detect

[CF_A]

Send

Return

[CF_A]

BEAT

EFFECTS

[CF_A(post)]

BPM

detect

[CF_B]

Send

Return

[CF_B]

BEAT

EFFECTS

[CF_B(post)]

DSP Status

BPM Detect data

Level Meter data

SD-RAM

micon I/F

Booth Level

Master CUE

CHx CUE

Talk Over On/Off

Effect CUE

EFFET

Processing

BPM

detect

[Master]

BEAT

EFFECTS

[Master]

Send

Return

[Master]

Master

Mono

Stereo

Master

Balance

Talk

Over

MIC Data

Master Level

Rec Out

Master Out2

Digital Out

Master Level Meter

H.P.Level

H.P.

MIX

H.P. Out

Booth Out

Master Out1

Effect CH Select

CH1-4

CF_A/B

MIC

Master

BPM Detection

Process

BPM is sent to CPU

H.P.Level.

H.P.Level.

H.P. Out Lch

H.P. Out Rch

Effect ch In

Effect Frequencty Filter 1

Effect Frequencty Filter 2

Filter Sw

Effect Out

Beat Effect Processing

SEND Out

Effect Out

EFFECT CUE

DJM-700-S

21

1234

1 234

C

D

F

A

B

E

TAP

Feder

Stat

CH-2

CH-1

CUE

button

TA P

button

Mode 1

POWER ON

POWER SW

(Rear panel)

Mode 2 Mode 3

Mode 7

Mode 6 Mode 5

Mode 4Mode 8

POWER OFF

(Rear panel)

DJM–700

PROFESSIONAL MIXIER

TRIM

+9

TRIM

+9

TRIM

+9

TRIM

+9

0

MID

+6-26

MID

+6-26

MID

+6-26

MID

+6-26

HI

+6-26

HI

+6-26

HI

+6-26

HI

+6-26

LOW

+6-26

LOW

+6-26

LOW

+6-26

LOW

+6-26

FREQUENCY

HPFLPF

FILTER

BALANCE

RL

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dB

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

dBLR

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

–15

–24

EQEQEQEQ

LINE PHONOLINEPHONOLINEPHONOCDCD

POWER

MASTER

LEVEL

CH-1 CH-2 CH-3 CH-4

1234

HEADPHONES CUE

MASTER EFFECTS

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

A THRU B A THRU B A THRU B A THRU B

BA

CROSS FADER ASSIGN

BOOTH MONITOR

LEVEL

0

CH FADER

CROSS FADER

AUTO

ON/OFF START/STOP

TAP

BEAT

MIDI

BEAT EFFECTS

LEVEL/DEPTH

TIME

MAX

ON/OFF

MIN

DELAY

1

2

3

4

MIC

CF.A

CF.B

MASTER

TRANS

DOWN

FILTER

UP

FLANGER

REVERSE

PHASER

ROLL

REVERB

CRUSH ROLL

ROBOT

ECHO

SND/RTN

cd

FADER START

MIC1

HEADPHONES

MIC1 LEVEL

0

MIC2 LEVEL

0

LEVEL

0

HI

MIC

CH-1 CH-2

OFF ON

TALK

OVER

+12-12

LOW

+12-12

MIXING

MASTERCUE

EQ

MONO SPLIT STEREO

PHONES

MONO STEREO

CH-2

Feder

Stat

CH-1

CH-1

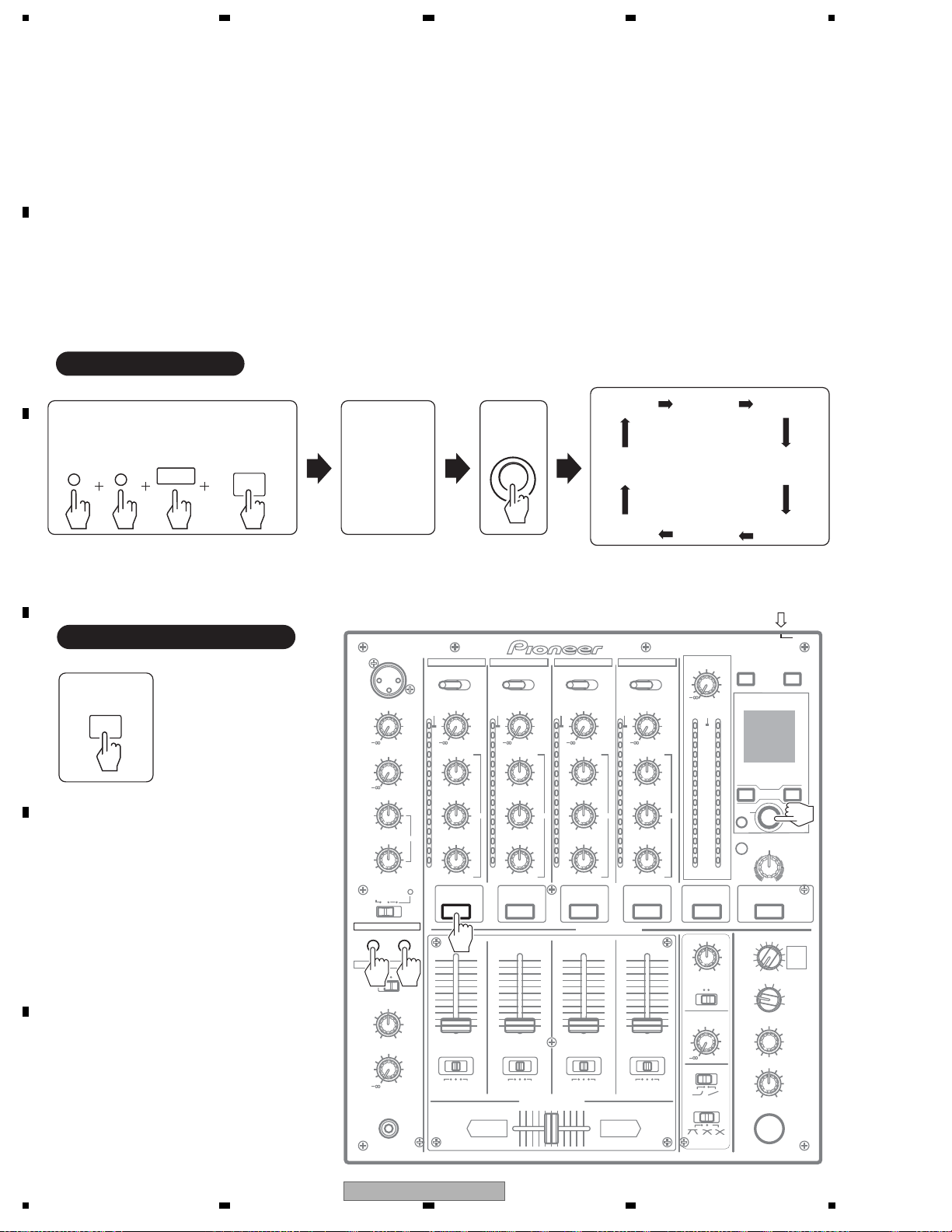

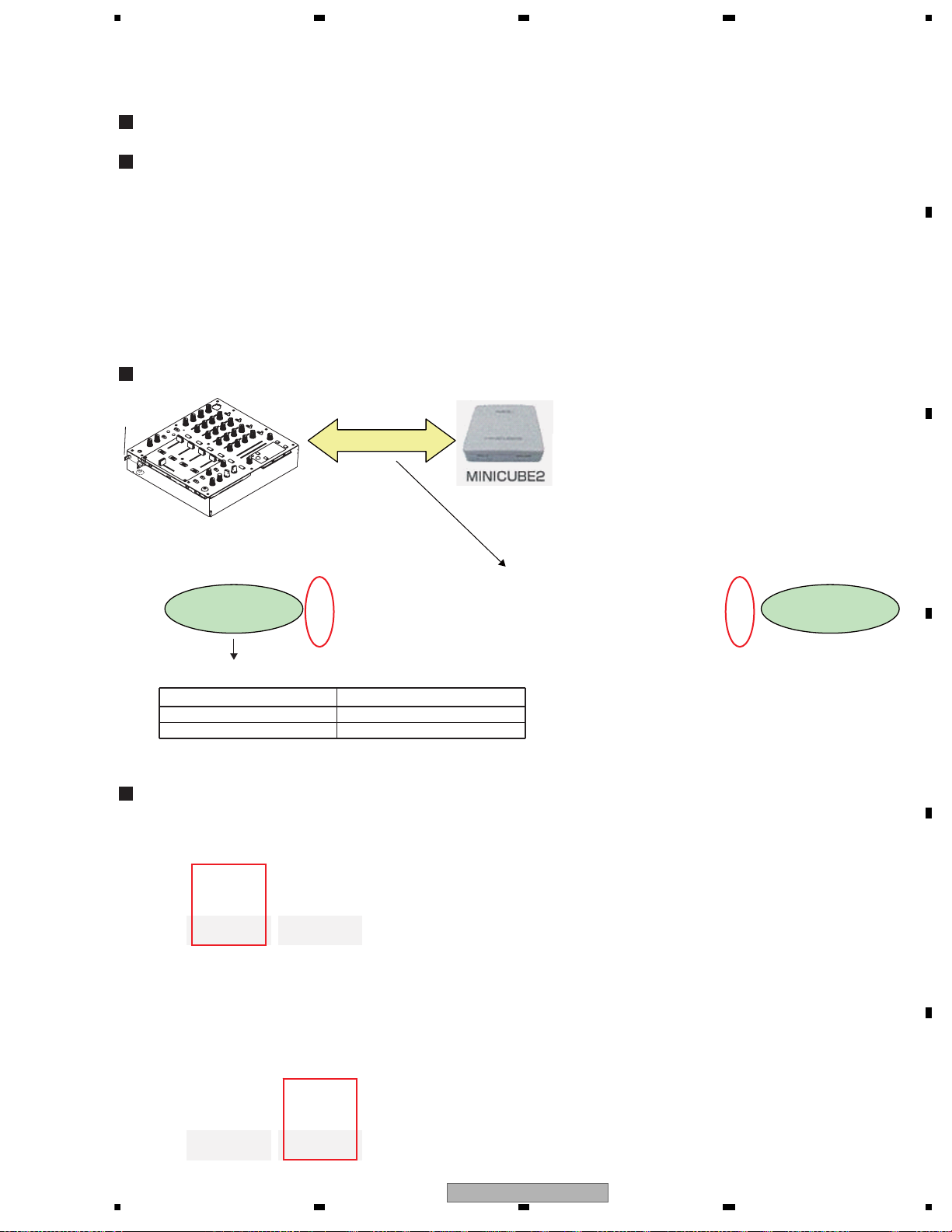

1. Description of Test Modes

The Following eight test modes are provided for this unit:

2. Test Mode

1 Mode 1 : Confirmation of software version.

2 Mode 2 : ALL LED & FL display ”OFF” MODE. ”ALL CLR”

3 Mode 3 : ALL LED & FL display ”ON” MODE. ”ALL SET”

4 Mode 4 : KEY OPERATING TEST. ”KEY TEST”

Test Mode

(Mode 1)

Cyclic operation

Test Mode : ON

Test Mode : CANCEL

5 Mode 5 : SELECT SW Operating Test. ”SW TEST”

6 Mode 6 : Volume Test. “VOLTEST”

7 Mode 7 : Fader Test. “FDRTEST”

8 Mode 8 : Meter LED Test. “LEDTEST”

5. DIAGNOSIS

5.1 TEST MODE

DJM-700-S

22

5678

56

7

8

C

D

F

A

B

E

1. Test mode contents.

1 Mode 1 : Confirmation of software version.

2 Mode 2 : ALL LED & FL display ”OFF” MODE. ”ALL CLR”

3 Mode 3 : ALL LED & FL display ”ON” MODE. ”ALL SET”

4 Mode 4 : KEY OPERATING TEST. ”KEY TEST”

5 Mode 5 : SELECT SW Operating Test. ”SW TEST”

6 Mode 6 : Volume Test. “VOLTEST”

7 Mode 7 : Fader Test. “FDRTEST”

8 Mode 8 : Meter LED Test. “LEDTEST”

2. How to start the Test Mode.

To enter test mode, turn the Power button while pressing all of the FADER START CH1,FADER START CH2,CUE

CH1 buttons.

There are 8 modes in this Test Mode.

If the TAP button is pressed, Mode1-8 can be selected by selector switch.

When set up mode is started, Mode 1 is selected automatically.

Once Test Mode starts, it keeps the test mode until turning the Power off.

3. Test mode

1 Mode 1 : Confirmation of software version.

• Mode that confirms version of microcomputer(MAIN),microcomputer(SUB), DSP (program), DSP (data), and FPGA.

• There are 3 screens for displaying each version of microcomputer, DSP, and FPGA in this Mode.

Those screens is changed by pressing BEAT UP or DOWN buttons.

It is displayed a version of firmware by FL display.

• Microcomputer versions display

For exsample

Microcomputer(MAIN) : 1.000

Microcomputer(SUB) : 2.000

• DSP versions display

For exsample

DSP(program) : 3.000

DSP(data) : 4.000

M:1.000

2-000

D:3.000

4-000

F:5.000

BEAT

UP

BEAT

UP

BEAT

DOWN

BEAT

DOWN

M:1.000

2-000

D:3.000

4-000

DJM-700-S

23

1234

1 234

C

D

F

A

B

E

• FPGA versions display

For exsample

FPGA : 5.000

2 Mode 2 : ALL LED & FL display ”OFF” MODE. ”ALL CLR”

• It displays "ALL CLR" on the FL display in the first 2 seconds.