Pioneer DJM-350 Service manual

2010

DJM-350

For details, refer to "Important Check Points for good servicing".

DJ MIXER

DJM-350

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

DJM-350 SYXJ8 AC 220 V to 240 V

DJM-350 CUXJ AC 120 V

DJM-350 LXJ AC 110 V to 120 V or 220 V to 240 V

DJM-350 KXJ5 AC 220 V

DJM-350 AXJ5 AC 220 V to 240 V

ORDER NO.

RRV4063

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-IZV MAY

2010 Printed in Japan

1

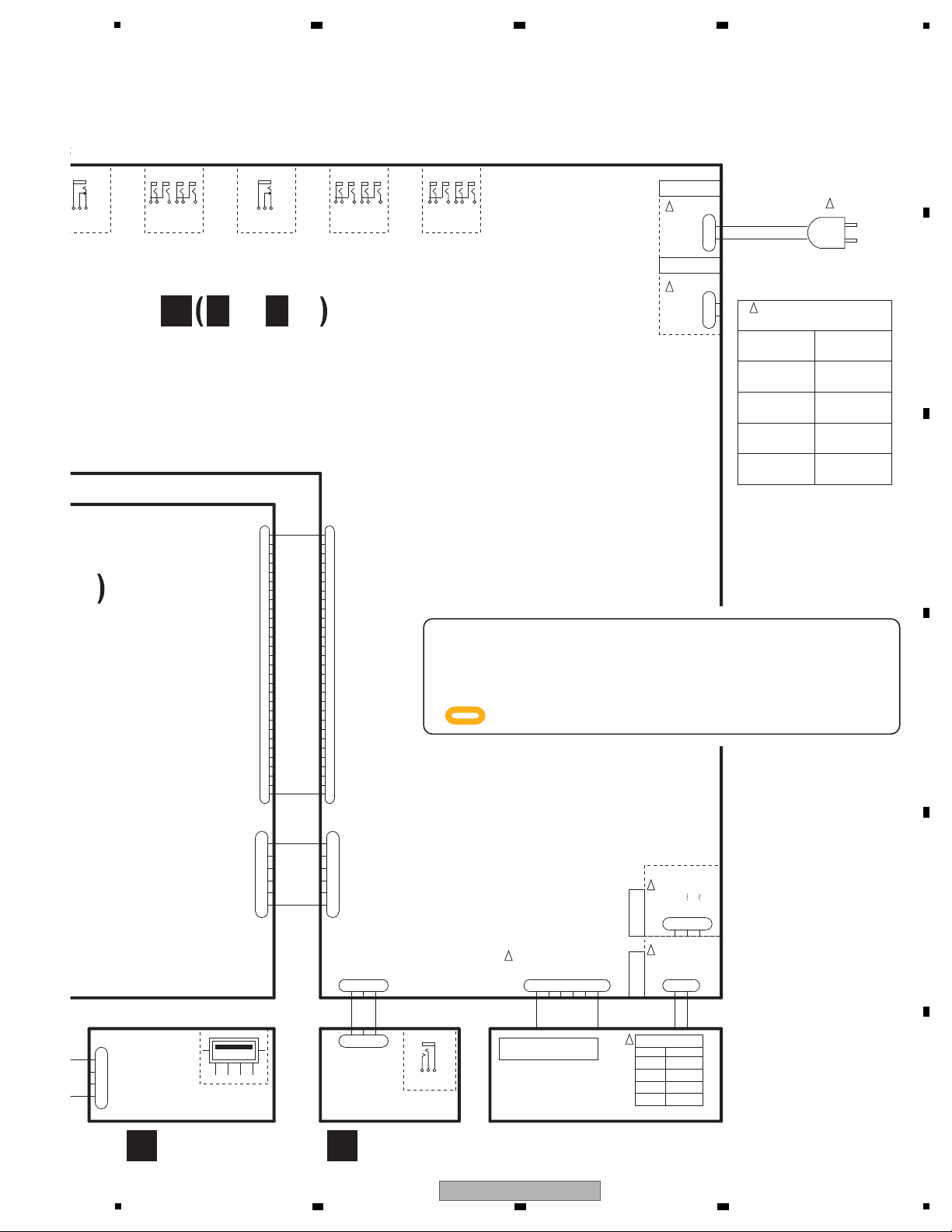

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

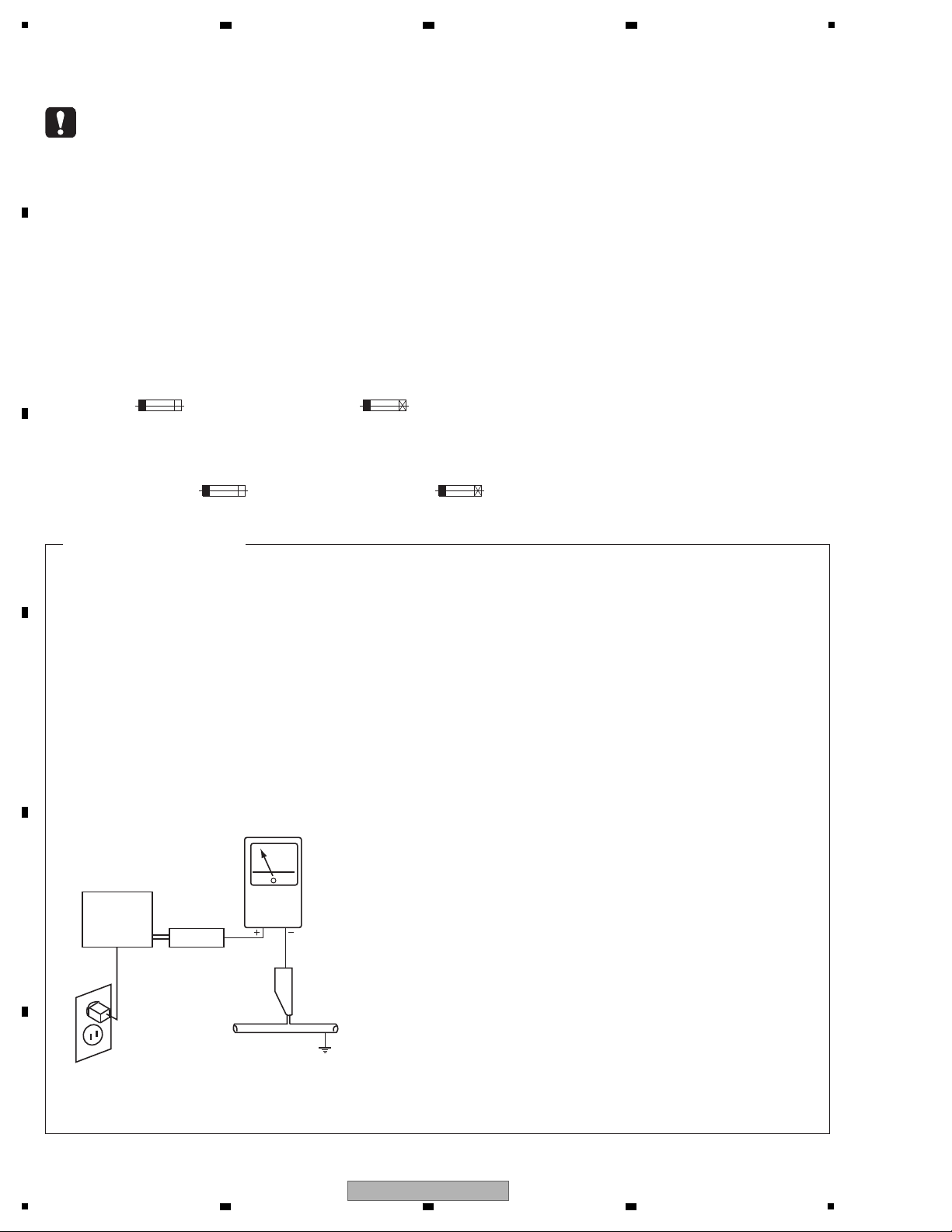

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

(FOR USA MODEL ONLY)

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY )

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

DJM-350

5

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

6 7 8

A

B

C

D

5

DJM-350

6 7 8

E

F

3

1

2 3 4

CONTENTS

SAFETY INFORMATION ..........................................................................................................................................................2

1. SERVICE PRECAUTIONS ....................................................................................................................................................5

A

B

C

D

E

1.1 NOTES ON SOLDERING ...............................................................................................................................................5

1.2 FOR VOLTAGE MONITORING .......................................................................................................................................6

2. SPECIFICATIONS .................................................................................................................................................................7

2.1 SPECIFICATIONS...........................................................................................................................................................7

2.2 PANEL FACILITIES .........................................................................................................................................................8

3. BASIC ITEMS FOR SERVICE.............................................................................................................................................10

3.1 CHECK POINTS AFTER SERVICING..........................................................................................................................10

3.2 PCB LOCATIONS .........................................................................................................................................................11

4. BLOCK DIAGRAM...............................................................................................................................................................12

4.1 OVERALL WIRING DIAGRAM......................................................................................................................................12

4.2 OVERALL BLOCK DIAGRAM.......................................................................................................................................14

4.3 POWER BLOCK DIAGRAM..........................................................................................................................................16

5. DIAGNOSIS.........................................................................................................................................................................17

5.1 POWER ON SEQUENCE.............................................................................................................................................17

5.2 TROUBLESHOOTING ..................................................................................................................................................19

5.3 ERROR INDICATION....................................................................................................................................................25

5.4 OPERATION CHECK OF RECORDING / PLAYING / TO FROM A USB DEVICE.......................................................26

6. SERVICE MODE .................................................................................................................................................................27

6.1 TEST MODE .................................................................................................................................................................27

6.2 TEST MODE 2 (REFERENCE INFORMATION)...........................................................................................................32

7. DISASSEMBLY....................................................................................................................................................................33

8. EACH SETTING AND ADJUSTMENT ................................................................................................................................36

8.1 NECESSARY ITEMS TO BE NOTED ...........................................................................................................................36

8.3 USER SETABLE ITEMS ...............................................................................................................................................38

8.4 LIST OF

DEVICES WHOSE OPERATION HAS BEEN CONFIRMED .........................................................................39

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................40

9.1 PACKING SECTION......................................................................................................................................................40

9.2 EXTERIOR SECTION...................................................................................................................................................42

9.3 CONTROL PANEL SECTION .......................................................................................................................................44

10. SCHEMATIC DIAGRAM ....................................................................................................................................................46

10.1 JACK ASSY (1/5)........................................................................................................................................................46

10.2 JACK ASSY (2/5)........................................................................................................................................................48

10.3 JACK ASSY (3/5)........................................................................................................................................................50

10.4 JACK (4/5) and HPJK ASSYS.....................................................................................................................................52

10.5 JACK ASSY (5/5)........................................................................................................................................................54

10.6 VRSW ASSY (1/3) ......................................................................................................................................................56

10.7 VRSW ASSY (2/3) ......................................................................................................................................................58

10.8 VRSW ASSY (3/3) ......................................................................................................................................................60

10.9 CRFD ASSY................................................................................................................................................................61

10.10 FADR and USJK ASSYS ..........................................................................................................................................62

10.11 MAIN ASSY (1/3) ......................................................................................................................................................64

10.12 MAIN ASSY (2/3) ......................................................................................................................................................70

10.13 MAIN ASSY (3/3) ......................................................................................................................................................72

PCB CONNECTION DIAGRAM ........................................................................................................................................74

11.

11.1 JACK ASSY.................................................................................................................................................................74

11.2 HPJK and VRSW ASSYS ...........................................................................................................................................78

11.3 CRFD, FADR and USJK ASSYS.................................................................................................................................82

11.4 MAIN ASSY.................................................................................................................................................................84

12. PCB PARTS LIST ..............................................................................................................................................................88

F

4

1

2 3 4

DJM-350

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

DJM-350

5

6 7 8

5

1

This unit always monitors for power failure and will shut itself off immediately after an error is detected. If an error is generated,

the STANDBY LED will flash after the unit shuts itself off, and no key will be operable.

(In a case of power failure, power supply to not all circuits is stopped. The circuits to which the standby transformer supplies

power will be continued to be powered until the power cord is unplugged.)

Repair the unit, according to “5.2 TROUBLESHOOTING.”

2 3 4

1.2 FOR VOLTAGE MONITORING

A

B

C

D

E

F

6

1

2 3 4

DJM-350

5

General

Power requirements........................AC 220 V to 240 V, 50 Hz/ 60 Hz

(SYXJ8, AXJ5)

AC 120 V, 60 Hz (CUXJ)

AC 110 V to 120 V or 220 V to 240 V, 50 Hz/ 60 Hz (LXJ)

AC 220 V, 60 Hz (KXJ5)

Power consumption.....................17 W (SYXJ8, CUXJ, KXJ5, AXJ5)

18 W (LXJ)

Power consumption (standby)...................................................0.4 W

Main unit weight.........................3.2 kg (SYXJ8, CUXJ, KXJ5, AXJ5)

3.3 kg (LXJ)

Max. dimensions...............218 mm (W) × 107 mm (H) × 301 mm (D)

Tolerable operating temperature...............................+5 °C to +35 °C

Tolerable operating humidity..............5 % to 85 % (no condensation)

Audio Section

Sampling rate..........................................................................48 kHz

A/ D, D/ A converter.................................................................24 bits

Frequency characteristic

CD/ LINE/ MIC.....................................................20 Hz to 20 kHz

S/ N ratio (rated output)

CD........................................................................................97 dB

PHONO................................................................................86 dB

MIC......................................................................................80 dB

Total harmonic distortion (LINE — MASTER1).....................0.007 %

Standard input level / Input impedance

CD....................................................................... –12 dBu/ 36 kΩ

PHONO............................................................... –52 dBu/ 47 kΩ

MIC...................................................................... –52 dBu/ 10 kΩ

AUX..................................................................... –12 dBu/ 27 kΩ

Standard output level / Load impedance / Output impedance

MASTER OUT.............................................+2 dBu/ 10 kΩ/ 2.5 Ω

PHONES......................................................+2 dBu/ 32 Ω/ 150 Ω

Rated output level / Load impedance

MASTER OUT..................................................... +18 dBu/ 10 kΩ

Crosstalk (LINE).......................................................................78 dB

Channel equalizer characteristic

HI...............................................................–∞ to + 9 dB (13 kHz)

MID..............................................................–∞ to + 9 dB (1 kHz)

LOW..............................................................–∞ to +9 dB (70 Hz)

MIC/ AUX equalizer characteristics

HI....................................................... –12 dB to +12 dB (10 kHz)

LOW................................................... –12 dB to +12 dB (100 Hz)

Input/ output terminals

CD input terminal

RCA pin jack........................................................................2 sets

PHONO input terminal

RCA pin jack........................................................................2 sets

MIC input terminal

Phone jack (Ø 6.3 mm)......................................................... 1 set

AUX input terminal

RCA pin jack........................................................................1 sets

MASTER output terminal

RCA pin jack........................................................................2 sets

PHONES output terminal

Stereo phone jack (Ø 6.3 mm).............................................. 1 set

USB terminal

Type A................................................................................... 1 set

CONTROL terminal

Mini phone jack (Ø 3.5 mm).................................................2 sets

• The specifications and design of this product are subject to

change without notice.

2. SPECIFICATIONS

2.1 SPECIFICATIONS

6 7 8

A

B

C

D

5

DJM-350

6 7 8

E

F

7

1

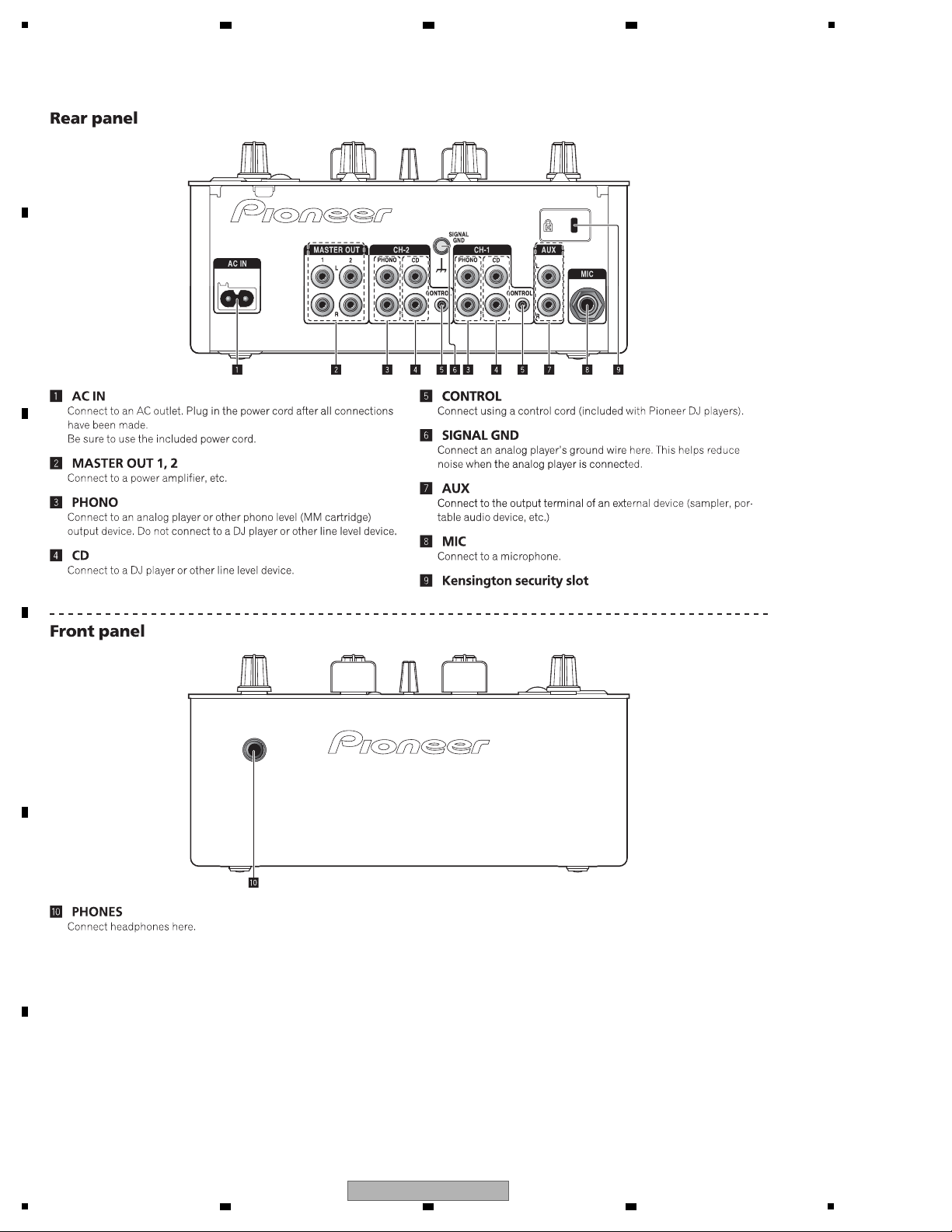

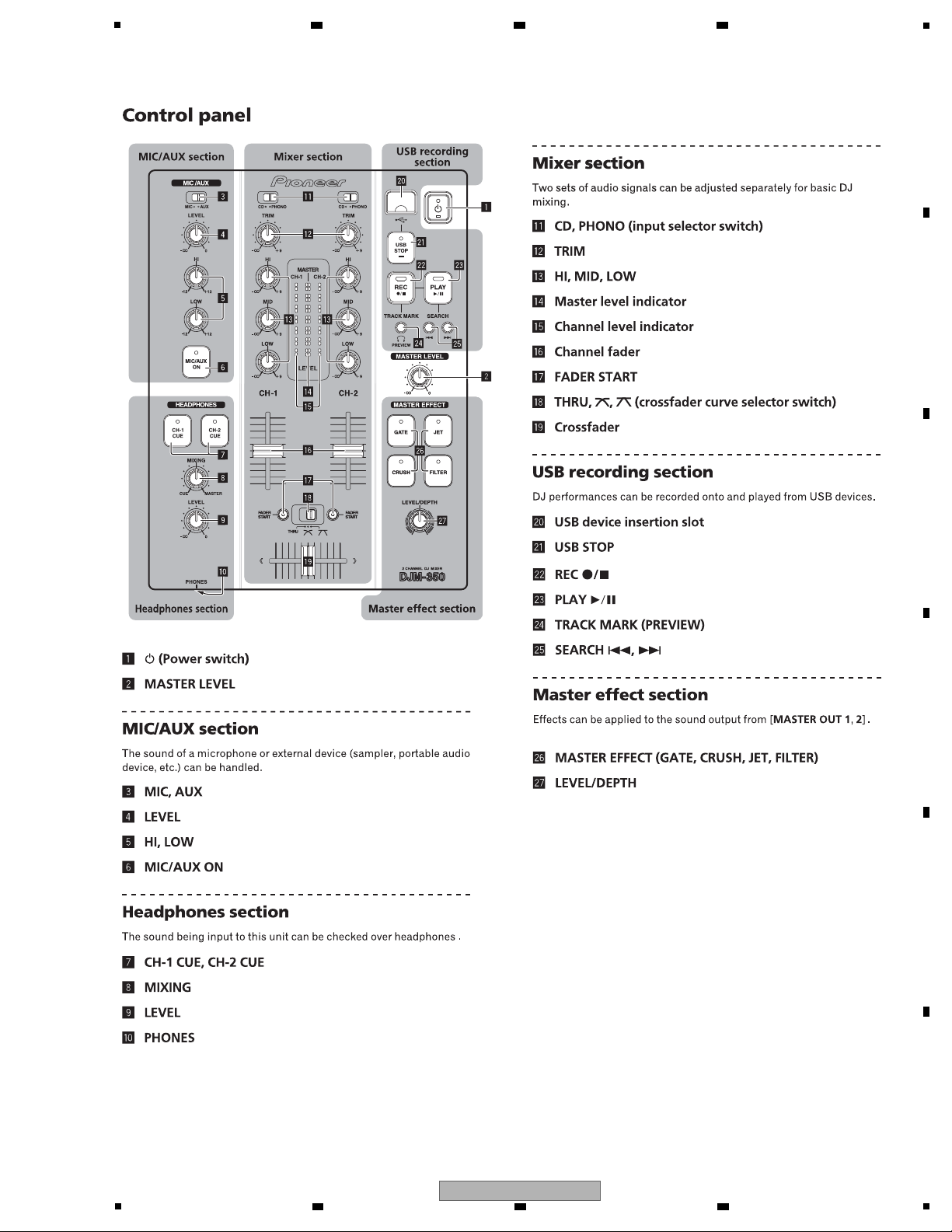

2.2 PANEL FACILITIES

A

B

2 3 4

C

D

E

F

8

1

2 3 4

DJM-350

5

6 7 8

A

B

C

D

E

F

DJM-350

5

6 7 8

9

1

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

No. Procedures Check points

1

2

3

4

5

6

7

Playback data contained in the device connected to USB A Audio and operations must be normal.

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific source, such

as Mic, each Input, Fader, Equalizer, and Trim, input that

specific source for checking.

The customer complain must not be reappeared.

Audio and operations must be normal.

Check the analog audio playback.

(Make the analog connections with a CDJ player.)

Audio for each channel and operations must be normal.

Check playback by Fader operation.

(Select Fader and check the multichannel operations via the

CPU.)

Audio for each channel and operations must be normal.

Check the master outputs.

(Connect with a CDJ player.)

Audio and operations must be normal.

Check the sound from headphone output. Sound must be normal, without noise.

Check the appearance of the product. No scratches or dirt on its appearance after receiving it for

service.

Items to be checked after servicing / DJM

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding audio.

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

10

1

2 3 4

DJM-350

5

A

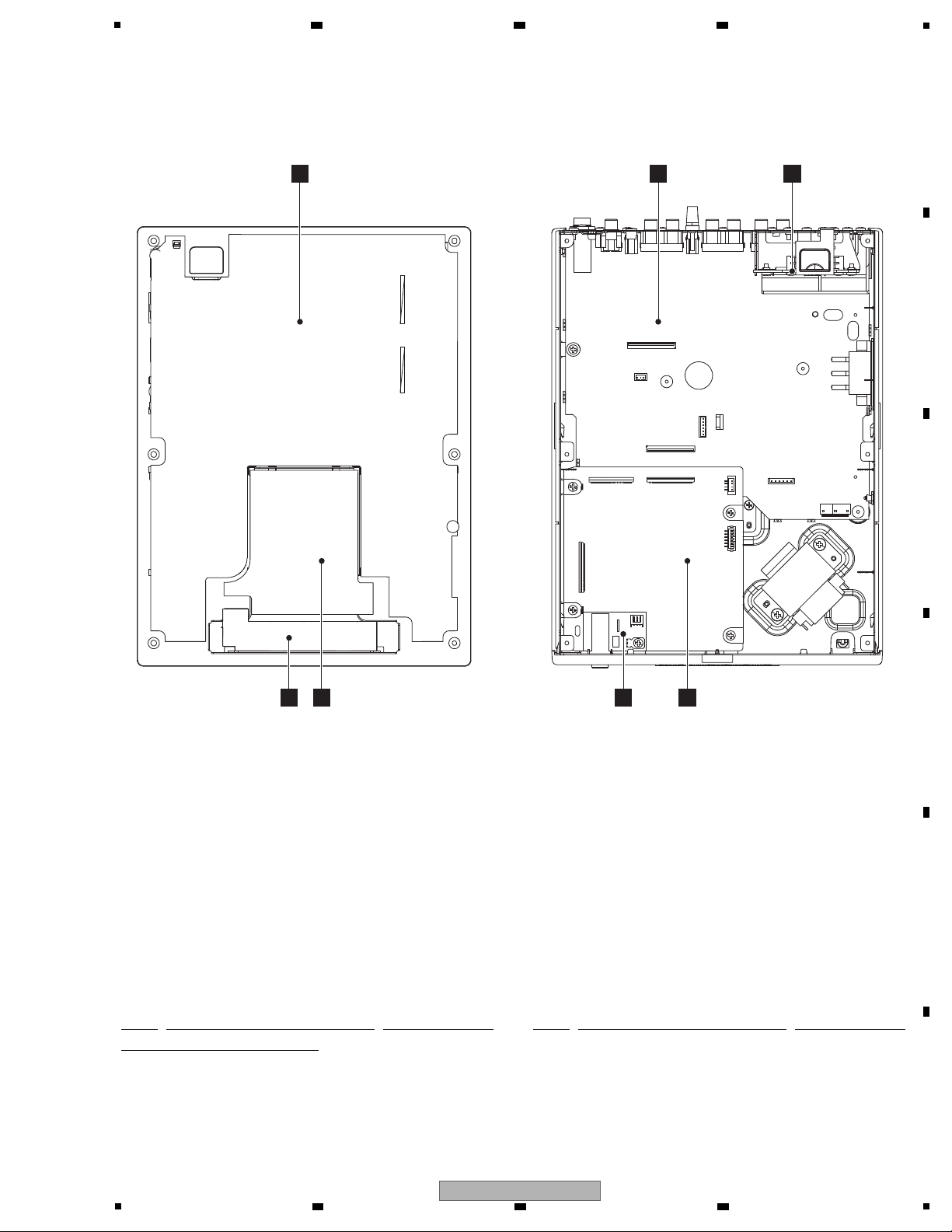

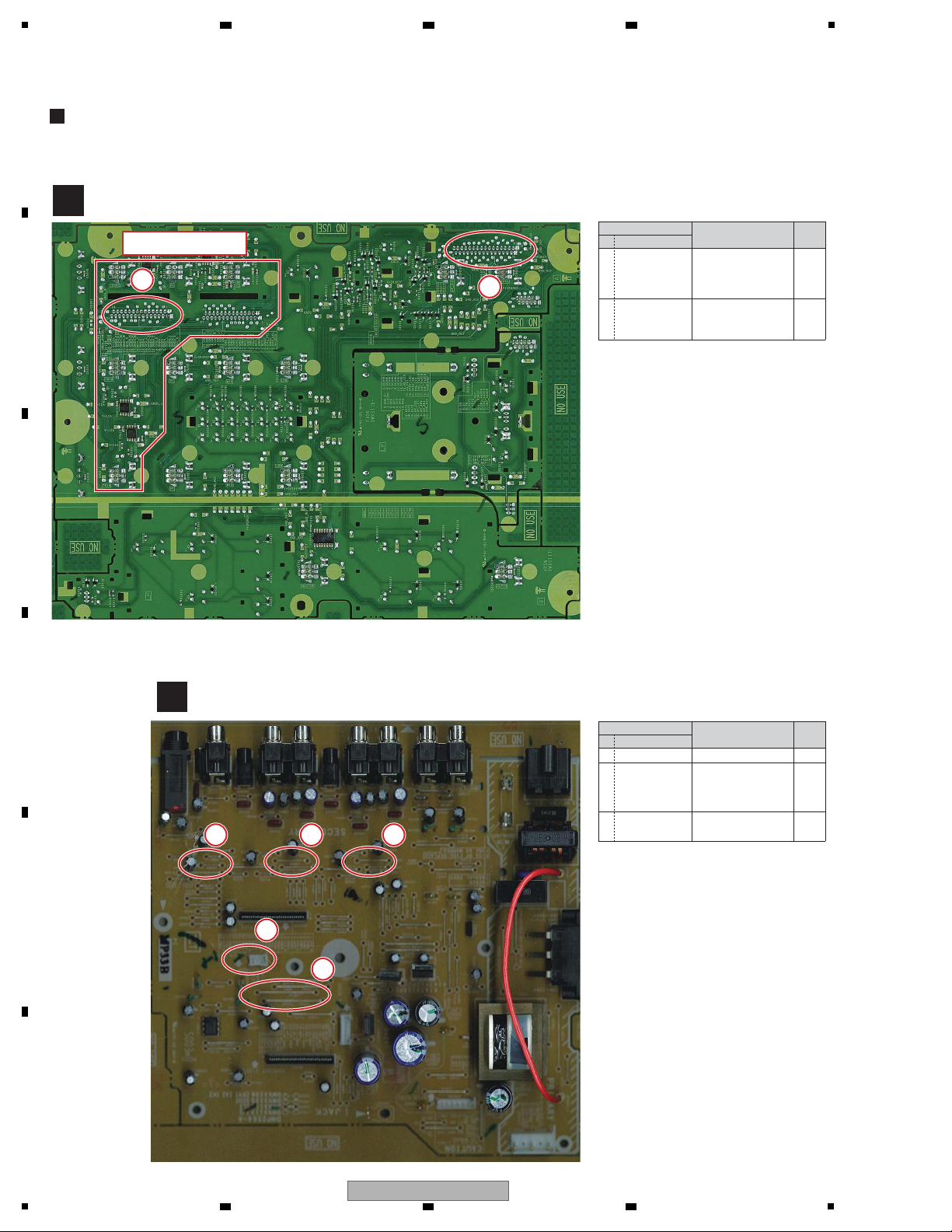

JACK ASSY

C

VRSW ASSY

• Bottom view

F

USJK ASSY

G

MAIN ASSY

E

FADR ASSY

B

HPJK ASSY

D

CRFD ASSY

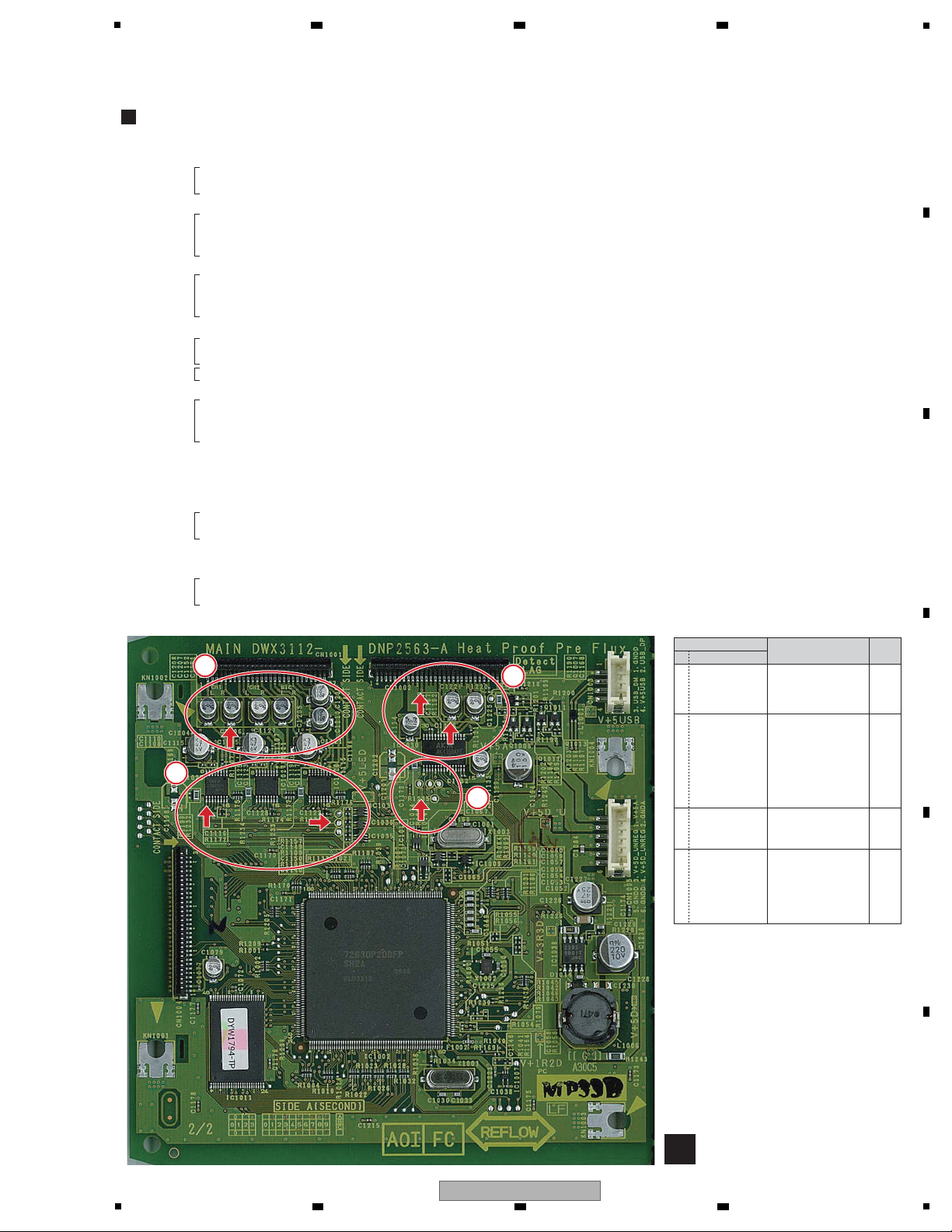

1..MAIN ASSY DWX3112

1..JACK ASSY (SYXJ8, KXJ5, AXJ5) DWX3136

1..JACK ASSY (CUXJ) DWX3135

1..JACK ASSY (LXJ) DWX3116

NSP 1..PANL ASSY DWM2383

2..HPJK ASSY DWX3114

2..USJK ASSY DWX3115

2..VRSW ASSY DWX3117

2..FADR ASSY DWX3118

2..CRFD ASSY DWX3119

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

3.2 PCB LOCATIONS

6 7 8

A

B

C

5

6 7 8

DJM-350

D

E

F

11

1

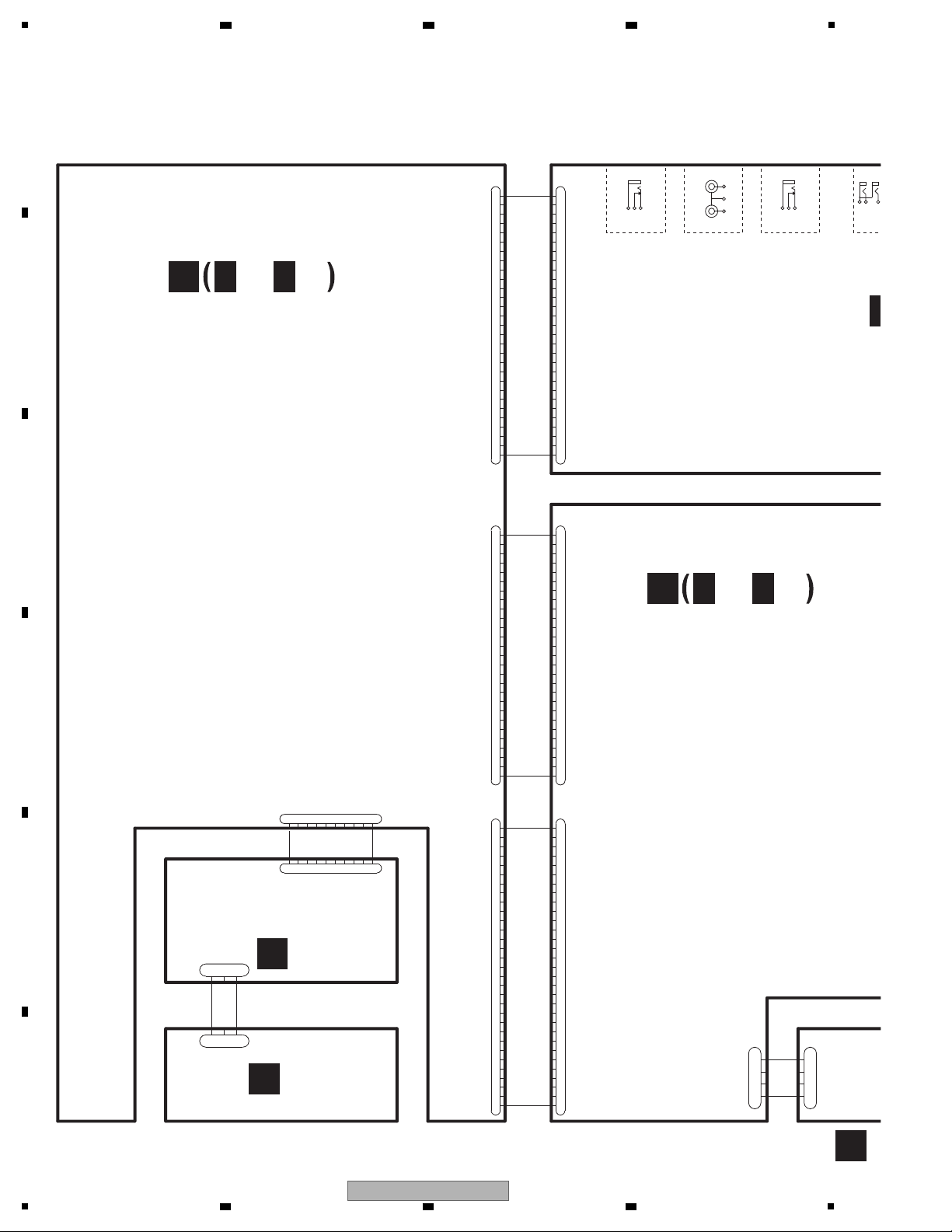

D

CRFD ASSY

(DWX3119)

E

FADR ASSY

(DWX3118)

F

U

(D

VRSW ASSY

(DWX3117)

C

C C

1/3- 3/3

JA

(S

(C

(L

A

MAIN ASSY

(DWX3112)

G

G G

1/3- 3/3

MIC AUX CONT_1

CH1

CD/P

CN 1003

AKM1275-A

1

GN DD

2

USB_DP

3

USB_DM

4

V+5USB

JA3

DKB

456

JA3005

DKB1103-A

3

R

2

1

L

JA3004

DKN1614-A

231

JA3006

VKB1243-A

231

VKN 1431-A

CN 1001

1

CH1_L

2

GN DA

3

GN DA

4

GN DA

5

CH1_R

6

GN DA

7

GN DA

8

GN DA

9

CH2_L

10

GN DA

11

GN DA

12

GN DA

13

CH2_R

14

GN DA

15

GN DA

16

MIC_L

17

GN DA

18

GN DA

19

GN DA

20

MIC_R

21

GN DA

22

MIC_SEL

23

GN DA

24

CH1_SEL

25

GN DA

26

CH2_SEL

27

V+3R3D

VKN 1435-A

CN 1004

1

V+3R3REF

2

GN D_REF

3

CH1_FADER

4

AD_AN1

5

CH2_FADER

6

AD_AN0

7

CRS_FADER

8

HP_LEV

9

POWER_ON_LED

10

HP_CUE

11

STBY_SW

12

KEY2

13

STBY_ON_LED

14

KEY1

15

AD_CE1

16

KEY0

17

AD_CE0

18

GR4

19

SCAN6

20

GR3

21

SCAN5

22

GR2

23

SCAN4

24

GR1

25

SCAN3

26

GR0

27

SCAN2

28

V+5LED

29

SCAN1

30

GN DD

31

SCAN0

VKN 1260-A

CN 5001

1

GN DA_POWER

2

V+12V

3

GN DA_POWER

4

GN DA_POWER

5

V-12V

6

GN DA_POWER

7

GN DA_POWER

8

GN DA_M

9

GN DA_M

10

MIC_R

11

GN DA_M

12

GN DA_M

13

GN DA_M

14

MIC_L

15

GN DA

16

GN DA

17

CH2_L

18

GN DA_2

19

GN DA_2

20

GN DA_2

21

CH2_R

22

GN DA

23

GN DA

24

GN DA

25

CH1_L

26

GN DA_1

27

GN DA_1

28

GN DA_1

29

CH1_R

VKN 1258-A

CN 5002

1

V+3R3D

2

CH2_SEL

3

GN DA

4

CH1_SEL

5

GN DA

6

MIC_SEL

7

GN DA(MIC)

8

MIC_R

9

GN DA(MIC)

10

GN DA(MIC)

11

GN DA(MIC)

12

MIC_L

13

GN DA(MIC)

14

GN DA(CH2)

15

CH2_R

16

GN DA(CH2)

17

GN DA(CH2)

18

GN DA(CH2)

19

CH2_L

20

GN DA(CH2)

21

GN DA(CH1)

22

GN DA(CH1)

23

CH1_R

24

GN DA(CH1)

25

GN DA(CH1)

26

GN DA(CH1)

27

CH1_L

VKN 1291-A

CN 5004

1

SCAN0

2

GN D_D

3

SCAN1

4

V+5LED

5

SCAN2

6

GR0

7

SCAN3

8

GR1

9

SCAN4

10

GR2

11

SCAN5

12

GR3

13

SCAN6

14

GR4

15

AD_CE0

16

KEY0

17

AD_CE1

18

KEY1

19

STBY_LED

20

KEY2

21

STBY_SW

22

HP_CUE

23

PON_LED

24

HP_LEV

25

CRS_FADER

26

AD_AN0

27

CH2_FADER

28

AD_AN1

29

CH1_FADER

30

GN D_REF

31

V+3R3REF

VKN 1241-A

CN 6001

1

CH2_FADER

2

CH1_FADER

3

CRS_FADER

4

V+3R3REF

5

GN D_REF

6

KEY27KEY1

8

S09S1

10

G4

CN 6002

52147-0310

1

V+3R3REF2CRS_FADER3GN D_REF

51048-0300

JH7001

1

V+3R3REF

2

CRS_FADER

3

GN D_REF

VKN 1241-A

CN 5003

1

CH2_FADER

2

CH1_FADER

3

CRS_FADER

4

V+3R3REF

5

GN D_REF

6

KEY27KEY1

8S09

S110G4

VKN 1260-A

CN 3005

1

CH1_R

2

GN DA

3

GN DA

4

GN DA

5

CH1_L

6

GN DA

7

GN DA

8

GN DA

9

CH2_R

10

GN DA

11

GN DA

12

GN DA

13

CH2_L

14

GN DA

15

GN DA

16

MIC_L

17

GN DA

18

GN DA

19

GN DA

20

MIC_R

21

GN DA

22

GN DA

23

GN DA

24

GN DA

25

V-12V

26

GN DA

27

GN DA

28

V+12V

29

GN DA

CN 4501

KM200NA4L

1

GN DD

2

USB_DP

3

USB_DM

4

V+5USB

DDD1529-

FFC 31PIN

P=1.0 L=155mm

REVERSE

D20PDY0305E

JUMPER 3PIN

P=2.0 L=50mm

DDD1530-

FFC 27PIN

P=1.0 L=245mm

REVERSE

DDD1531-

FFC 29PIN

P=1.0 L=240mm

REVERSE

DKP38674PIN PH-PH

P=2.0 L=190mm

DDD1533FFC 10PIN

P=1.0 L=55mm

STRAIGHT

2 3 4

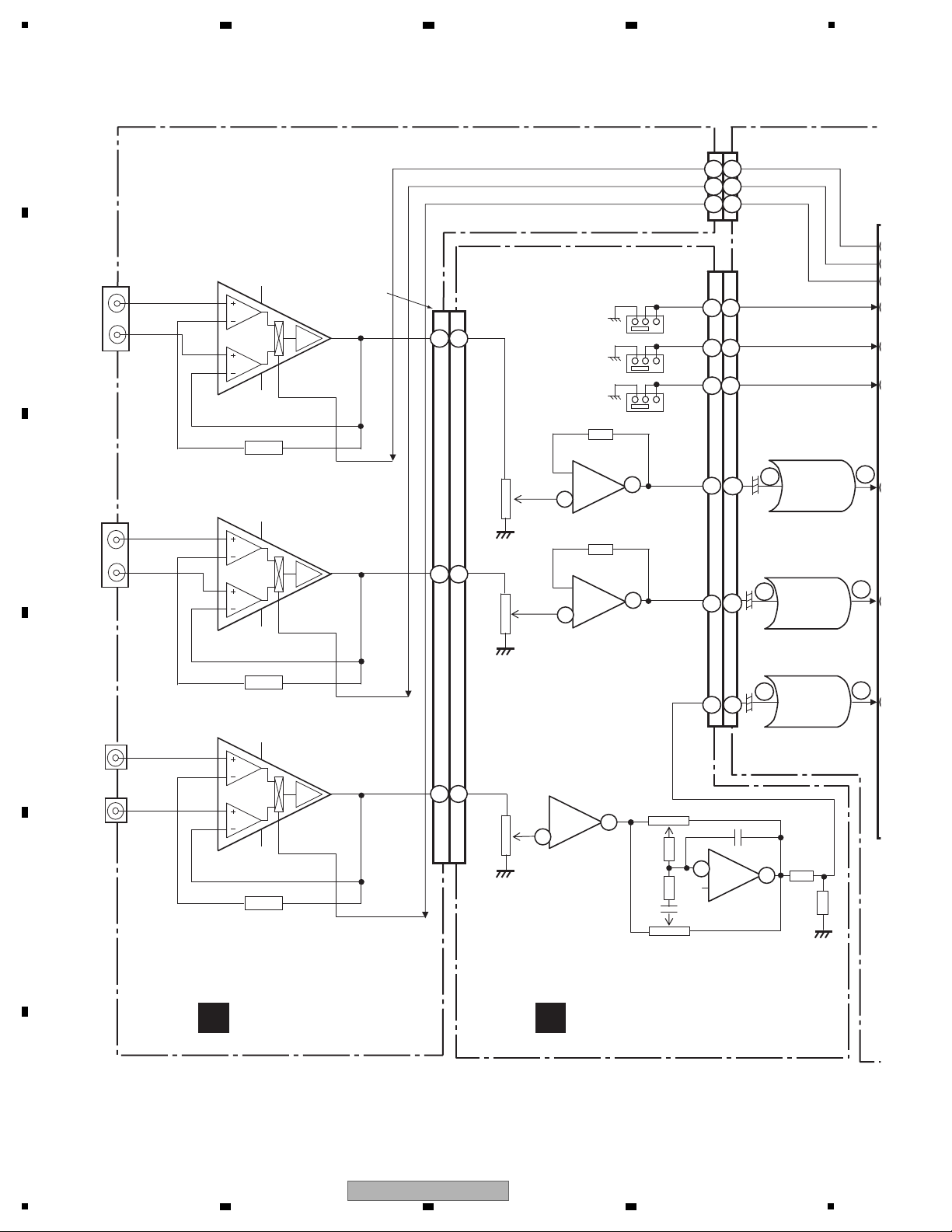

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

12

1

2 3 4

DJM-350

5

F

USJK ASSY

(DWX3115)

B

HPJK ASSY

(DWX3114)

JACK ASSY

(SYXJ8,KXJ5,AXJ5: DWX3136)

(CUXJ: DWX3135)

(LXJ: DWX3116)

A

A A

1/5- 5/5

3/3

CH1

CD/PHONOCONT_2

CH2

CD/PHONO MASTER1/2_OUT

MAIN TRAN S

AXJ5 DTT1253LXJ DTT1250-

DTT1253-

DTT1253-

SYXJ8

CUXJ DTT1252KXJ5

!

!

!

!

!

!

!

!

JA3003

DKB1083-A

12345

6

JA3002

DKB1083-A

12345

6

CN 3006

KM200NA3

1

HP_L

2

GN DHP

3

HP_R

JA3008

DKB1083-A

12345

6

A3006

KB1243-A

231

JA3007

VKB1243-A

231

VKN 1433-A

CN1002

1

CH1_SEL_OUT

2

CONT2-2

3

CONT1-1

4

CONT2-1

5

CONT1-2

6

CH2_SEL_OUT

7

MIC_SEL_OUT

8

GN D_HP

9

GN D_HP

10

GN D_HP

11

HP_L

12

GN D_HP

13

GN D_HP

14

GN D_HP

15

HP_R

16

GN D_MAS

17

GN D_MAS

18

MAS_L

19

GN D_MAS

20

GN D_MAS

21

GN D_MAS

22

MAS_R

23

GN D_MAS

24

GN D_MAS

25

POWER_DOWN

26

XPROTECT

27

CPU_MUTE

28

GN DD

29

RELAY

VKN 1260-A

CN3007

1

CH1_SEL

2

CONT2-2

3

CONT1-1

4

CONT2-1

5

CONT1-2

6

CH2_SEL

7

MIC_SEL

8

GN DA

9

GN DA

10

GN DA

11

HP_L

12

GN DA

13

GN DA

14

GN DA

15

HP_R

16

GN DA

17

GN DA

18

MAS_L

19

GN DA

20

GN DA

21

GN DA

22

MAS_R

23

GN DA

24

GN DA

25

POWER_DOWN

26

XPROTECT

27

CPU_MUTE

28

GN DD

29

RELAY_CTRL

JA3001

DKP3860-A

1

LIVE

2

NEUTRAL

B6B-EH

CN 3003

1

2

345

6

CN 4001

KM200NA3L

1

HP_L

2

GN DHP

3

HP_R

CN 4501

KM200NA4L

1

GN DD

2

USB_DP

3

USB_DM

4

V+5USB

JA4001

DKN1622-A

2

3

1

DKB1106-A

JA4502

123

4

RT1

RT2

JA3001

DKP3861-A

1

LIVE

2

NEUTRAL

B2P3-VH

CN 3002

1

NEUTRAL2LIVE

B3P5-VH

CN 3001

1

NEUTRAL

2

110

120V

3

220

240V

KM200NA6

CN3004

1

V+5A

2

GN DA

3

V+5D_UN REG

4

V+5D_UN REG

5

GN DD

6

GN DD

AKM1277-A

CN1005

1

V+5A

2

GN DA

3

V+5D_UN REG

4

V+5D_UN REG

5

GN DD

6

GN DD

L=190mm

DDD1532-

FFC 29PIN

P=1.0 L=95mm

STRAIGHT

DKP38683PIN PH-PH

P=2.0 L=200mm

VH 2PIN

L=160mm

EH 6PIN

L=145mm

MAIN TRAN S

AC CORD

SYXJ8

CUXJ

KXJ5

AXJ5

LXJ

ADG7022-

ADG7079-

ADG1154-

ADG1154-

XDG3054-

AC INLET

(CUXJ only)

AC1

AC2

GN DA

AC3

AC4

AC5

LXJ only

PF06PP-S12

6PIN PH-PH

P=2.0 L=130

AC INLET

(others)

others

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS

and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance

of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

6 7 8

A

B

C

D

E

F

5

6 7 8

DJM-350

13

1

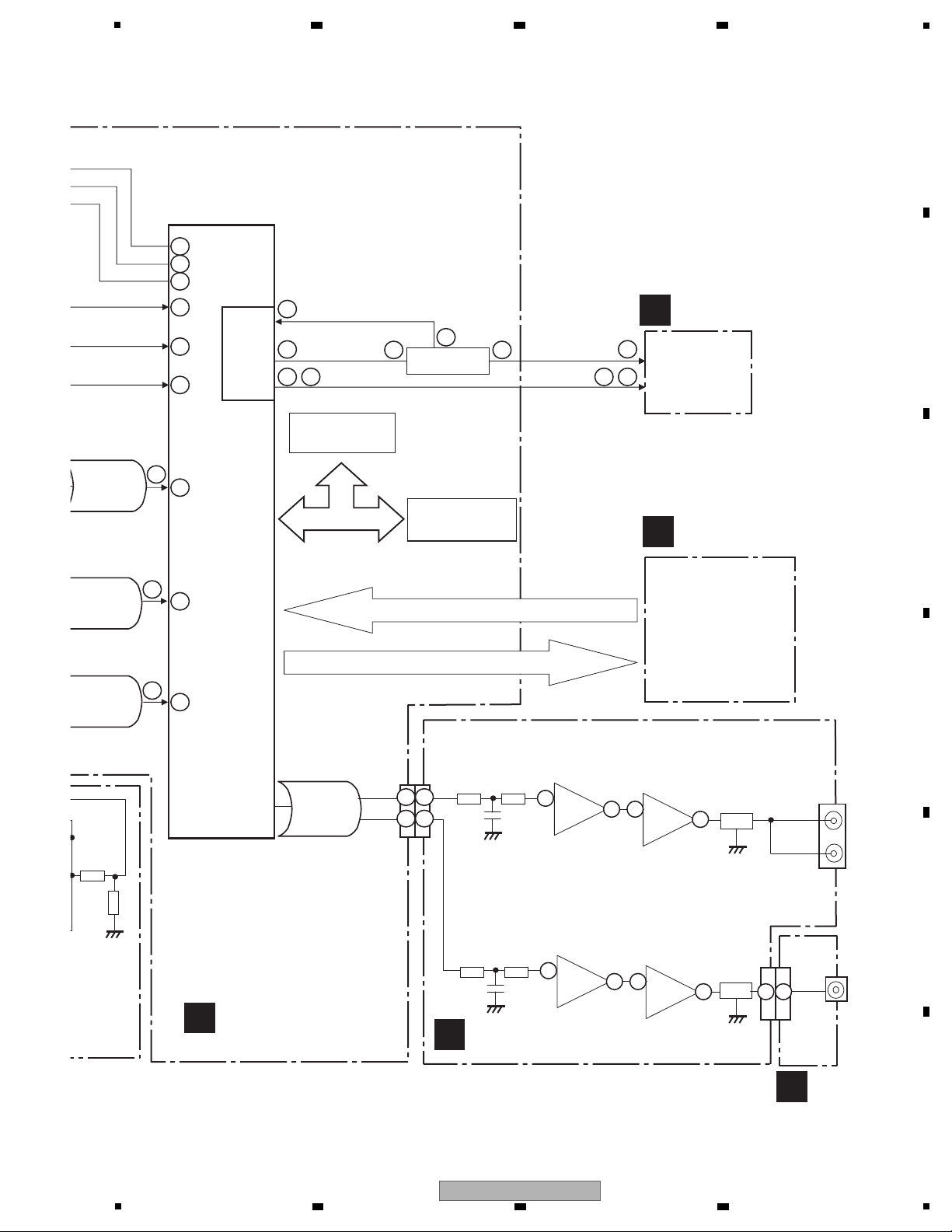

INPUT SW select

CH1

CH2

MIC/AUX

RIAA RIAA

RIAA RIAA

40dB

-

+

-

+

-

+

IC1025

AK5358AET

ADC(CH-1)

IC1027

AK5358AET

ADC(CH-2)

IC1026

AK5358AET

ADC(MIC)

-

+

Hi

Lo

CN3007(2/2) CN1002(2/2)

IC5003(2/2)

NJM4565MD

7

6

7

5

IC5004(2/2)

NJM4565MD

7

5

7

5

IC5002(2/2)

NJM4565MD

IC5001(2/2)

NJM4565MD

9

19

16

12

1

27

226

262

24

4

CN5002 CN1001

16

1313

55

16

CN5002

CN1001

MIC TRIM

CH2 TRIM

CH1 TRIM

MIC

AUX

PHONO

CD

PHONO

CD

CH 1

CH 2

JA3002

JA3003

JA3004

JA3005

3

8

ch A

ch B

1

2

5

7

6

4

3

8

ch A

ch B

1

2

5

7

6

4

3

8

ch A

ch B

1

2

5

7

6

4

JACK ASSY (1/2)

A

VRSW ASSY (1/2)

C

2

2

2

9

9

9

77

66

11

2 3 4

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

14

1

2 3 4

DJM-350

5

Over-current Detecion

,

IC1002

CPU

R5S72630P200FP

KEY, SW, FADER etc

DM, DP

VBUS

LEVEL METER etc

VR, SW

IC1011

DYW1794

FLASH 8Mbit

LED

BUS

IC1019

R5523N001B

USB

Function

Mute

Mute

Mute

PHONES

MASTER

OUT

IC1025

AK5358AET

ADC(CH-1)

IC1027

AK5358AET

ADC(CH-2)

IC1026

AK5358AET

ADC(MIC)

IC1030

AK4359AEF

Multi-DAC

IC3013(1/2)

RNB4580F

IC1010

K4S641632N-LC75

SDRAM 64M

7

7

6

-

+

6

-

+

IC3012(2/2)

NJM4565MD

IC3011(1/2)

NJM4556AD

7

1 6

-

+

-

+

IC3010(1/2)

NJM4565MD

2

CN3007(1/2)

18

18

11

11

1

1

CN1002(1/2)

MAIN ASSY

G

JACK ASSY (2/2)

A

HPJK ASSY

B

VRSW ASSY (2/2)

C

USJK ASSY

F

9

9

9

145

86

69

102

101 100

,

3 2

4

4 5

3

83

85

150

149

158

139

134

6 7 8

A

B

C

D

5

6 7 8

DJM-350

E

F

15

1

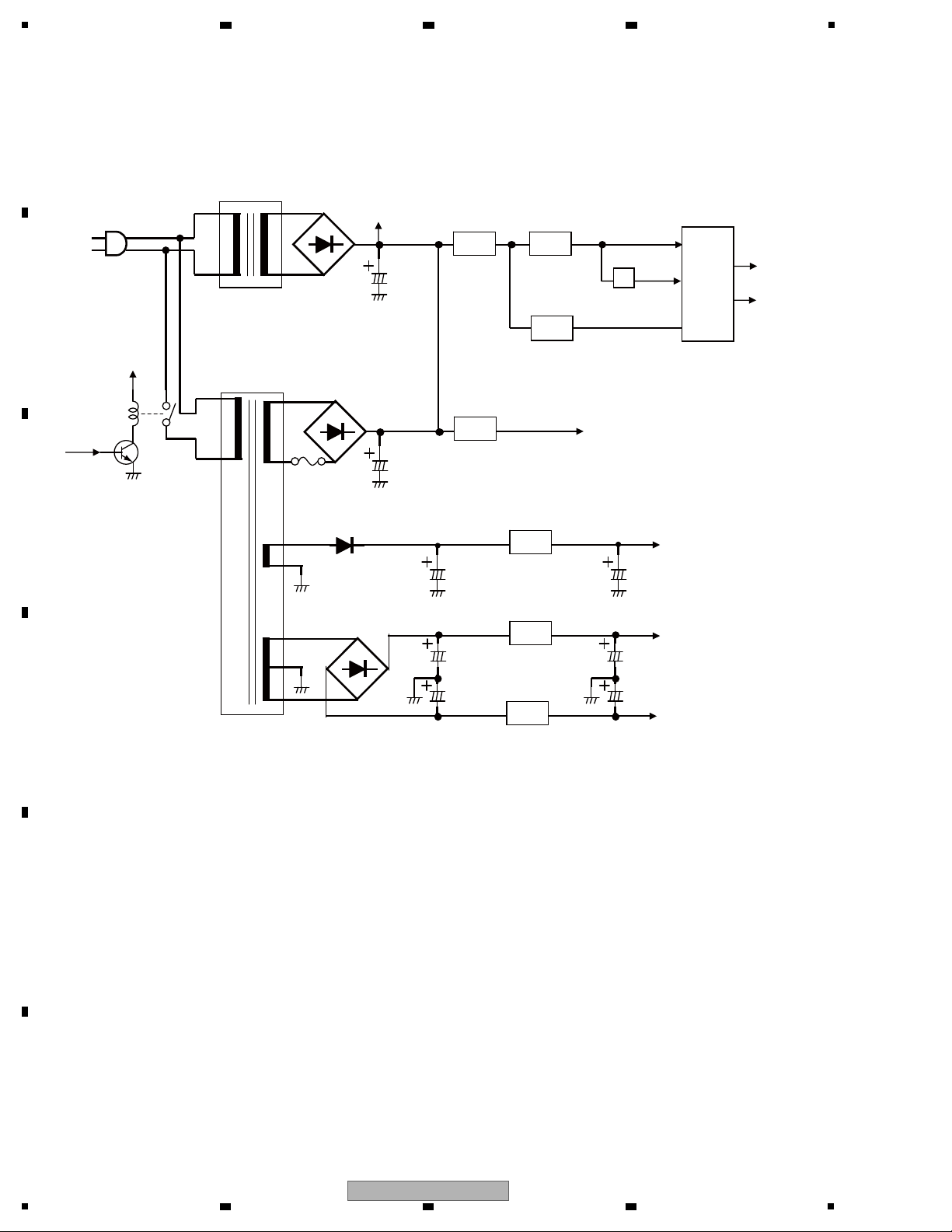

IC1018

BD9326EFJ

V+5USB

V+LED

2200uF

/25V

V+5D_UNREG

(7-16V)

V+3.3D

V+1.2D

IC1039

BH33FB1WG

SH7263

MUTE

Reset

Signal

IC1020

BD9106FVM

IC1038

NJM2392M

Relay Cont

Relay Cont

MAIN TRANS.

STANDBY TRANS.

T3001

V+5D_UNREG

V+5A

2200uF

/35V

IC3001

BA05T

100uF

/16V

IC3002

KIA7812API

1000uF

/35V

V+12A

+

+

+

++

+

V-12A

IC3003

KIA7912PI

1000uF

/35V

100uF

/16V

100uF

/16V

P3002

2200uF

/25V

+

4.3 POWER BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

16

1

2 3 4

DJM-350

5

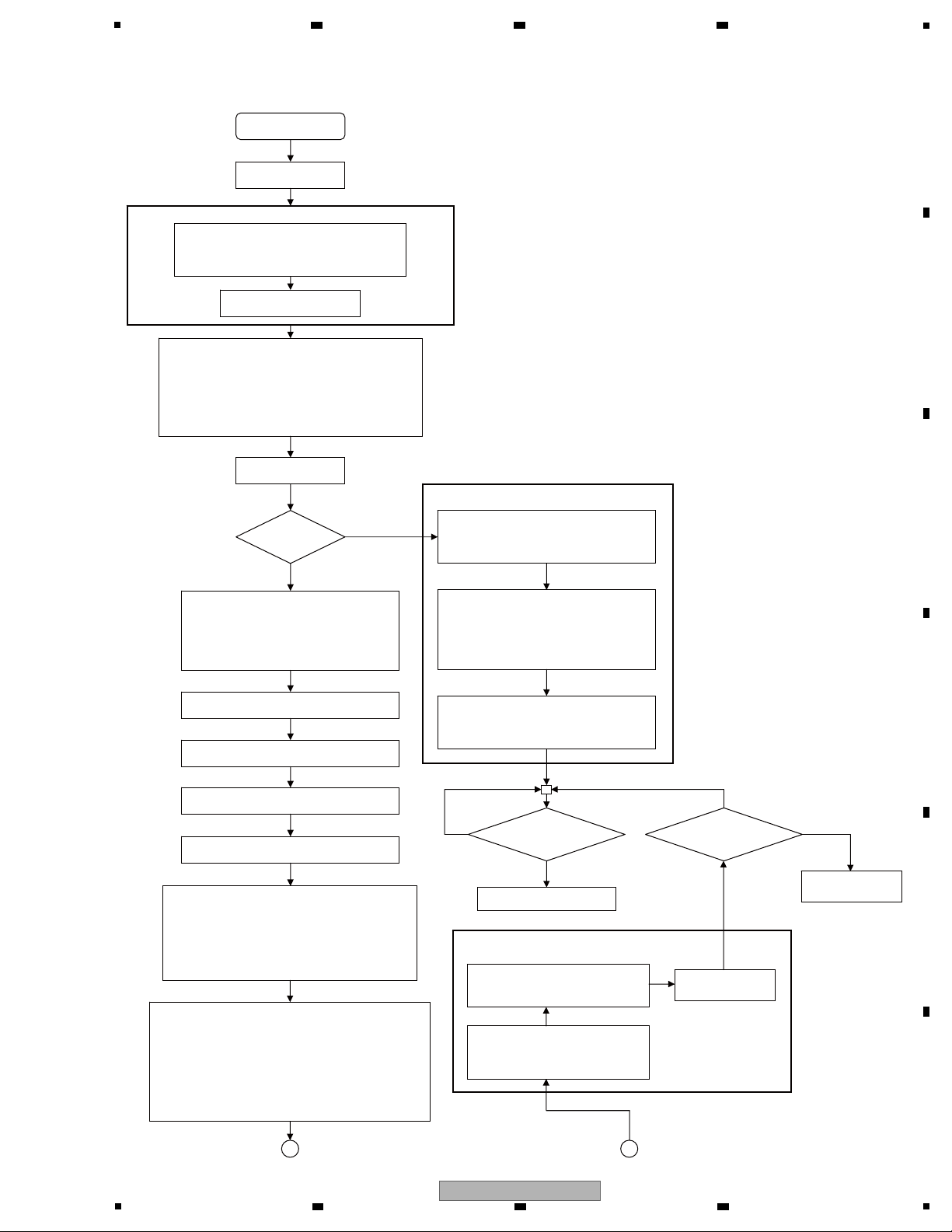

Setting for shifting to Standby at startup

Eco mode at startup

AC OFF to AC IN

[Set the CPU operation clock to the minimum value.]

Internal: 133 MHz, Bus: 66 MHz, Periphery: 33 MHz

↓

Internal: 133 MHz, Bus: 66 MHz, Periphery: 11 MHz

Reading Standby

flag register

Is Standby

canceled?

[Port setting for Standby mode]

MIC/CH1/CH2 input selector port: Low output

Is the Standby

button released?

Standby mode

NO

YES

NO

YES

[SDRAM self-refreshment]

[Essential GPIO settings]

CPU_MUTE port setting : MUTE ON

Main transformer relay port setting: Relay OFF

V+5LED port setting : OFF

Power LED port setting : Red LED: Lit, Green LED: Unlit

Standby button port setting : Input port

AD/DA converter port setting : Reset state

Port setting for M clock : OFF

[Standby setting]

• Standby register setting

• FLASH: Low power-consumption setting

• SDRAM self-refreshment setting

[Preprocessing of relay ON]

• Green Power LED: Lights.

• Preceding canceling of CMT module standby

• Muting ON

• DA/AD powerdown

• Stop of M clock

[Relay ON]

Waiting for 300 msec for power stabilization

[V+5LED ON]

Waiting for 300 msec for stabilization of V+5LED

[Port setting 2 for Standby mode]

SSI data output port: Fixed at low

LED scan port: Low output

AD multiplexer selection port: Low output

Green power LED port: Input enabling HiZ

Is an abnormal voltage

a cause of error?

Detection of

abnormal voltage

YES

NO

START

Final setting for shifting to Standby mode

during operation

[HW setup for normal operation]

CPG setting : Internal: 200 MHz, Bus: 66 MHz,

Periphery: 33 MHz

PFC setting : Settings of all ports (V+5USB: ON)

BSC setting : For SDRAM

INTC setting : Setting for disabling interruption,

Register bank ALL setting

SCIF setting : Serial setting for DAC

[Determination of Startup mode]

Reading of all corresponding keys

No key pressed: Normal mode

[CH1 FADER START] + [CH2 FADER START]: Update mode

[SEARCH FWD] + [SEARCH BACK]: EUP Setup mode

[CH1 CUE] + [CH1 FADER START] + [GATE]: TEST1

[CH1 CUE] + [CH1 FADER START] + [JET] = TEST2

[CRUSH] + [FILTER]: Version indication

[GATE] + [JET]: All LEDs lit

[Standby setting]

• Standby resistor setting

• FLASH: Low power-consumption setting

• SDRAM self-refreshment setting

[Main transformer relay OFF]

V+5LED is set to OFF to set the main

transformer relay to OFF.

Waiting for 1.6 sec

A B

5. DIAGNOSIS

5.1 POWER ON SEQUENCE

6 7 8

A

B

5

6 7 8

DJM-350

C

D

E

F

17

1

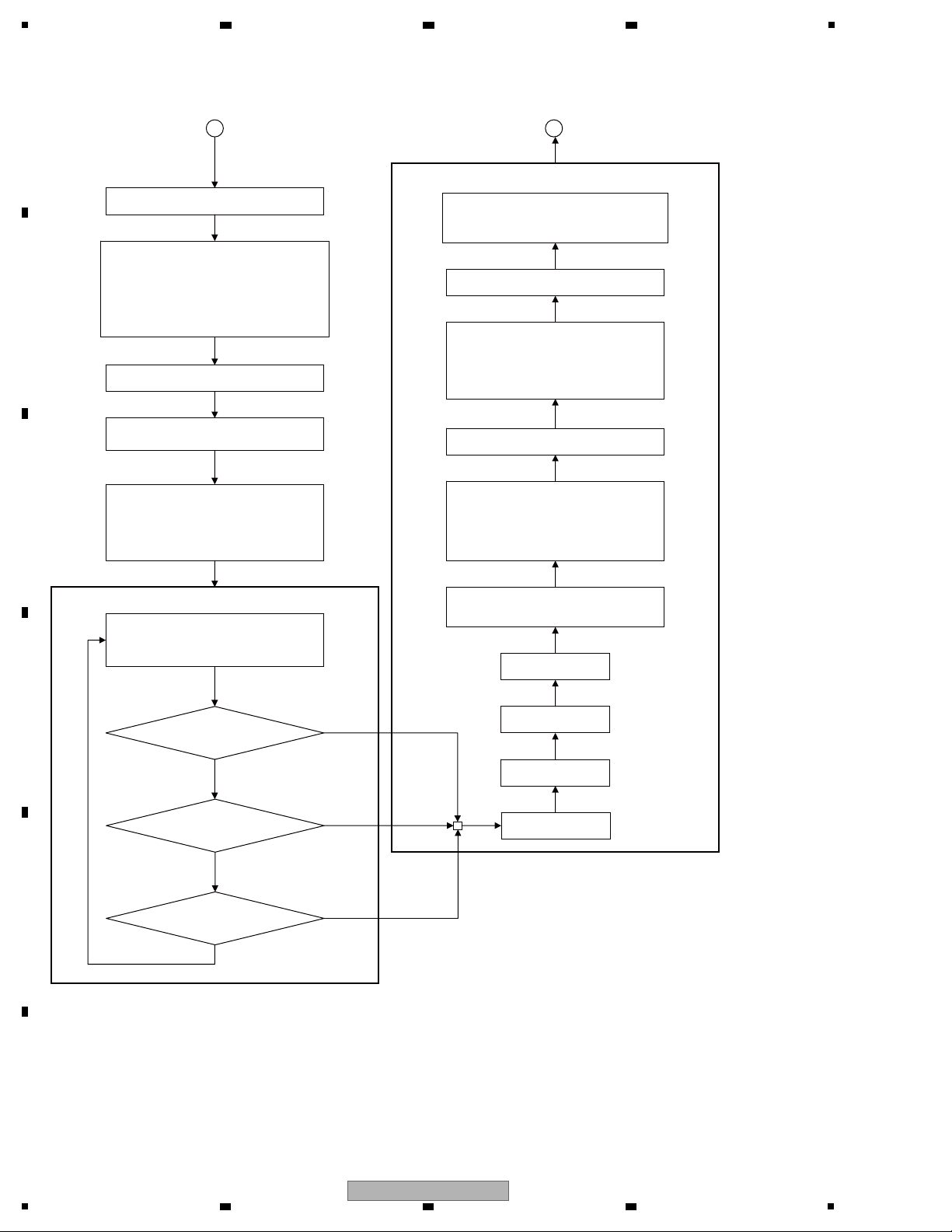

Setting for shifting to Standby mode during operation

Power ON

[Normal mode]

Process corresponding to each mode

Is shifting to Standby mode

commanded by Standby button?

YES

NO

YES

V+5USB to OFF, corresponding to Startup mode.

[RAM initialization and loading of essential programs]

• All regions of SDRAM: Null

• Null everything other than internal RAM stack.

• Transferring a temporary vector table and entity to

internal RAM.

• Transferring a slow-operation program for Eco

mode to retention RAM.

• Transferring IPL from FLASH-ROM to SDRAM.

Setting vector base register to internal RAM

[Cache setting]

Enables only instruction cache

[Jumping to program loader]

• If an error in firmware updating is detected,

the program for emergency booting will be

transferred to the SDRAM.

• In cases other than the above, the program for

normal startup will be transferred to the SDRAM.

V+5USB: OFF

PWM output: OFF

AD conversion: Stop

[Port setting for Standby mode]

MIC/CH1/CH2 input selector port: Low output

SRC : Stop

SSI output : Muting

ADC power : OFF

SSI input : Muting

DAC power : OFF

Stop of M clock

DMA: Stop

All modules other than CMT: Standby

Is the AC-OFF flag ON?

Is the Power failure flag ON?

NO

YES

NO

Muting ON

A B

[Set the CPU operation clock to the minimum value.]

Internal: 133 MHz, Bus: 66 MHz, Periphery: 33 MHz

↓

Internal: 133 MHz, Bus: 66 MHz, Periphery: 11 MHz

[Port setting 2 for Standby mode]

SSI data output port: Fixed at low

LED scan port: Low output

AD multiplexer selection port: Low output

Green power LED port: Input enabling HiZ

* Eco mode:

Low-speed and low-power-consumption mode provided for the CPU

to be operated only on power supply from the standby transformer.

2 3 4

A

B

C

D

E

F

18

1

2 3 4

DJM-350

5

11

2 2

(MAIN)

(JACK) (JACK)

(MAIN)

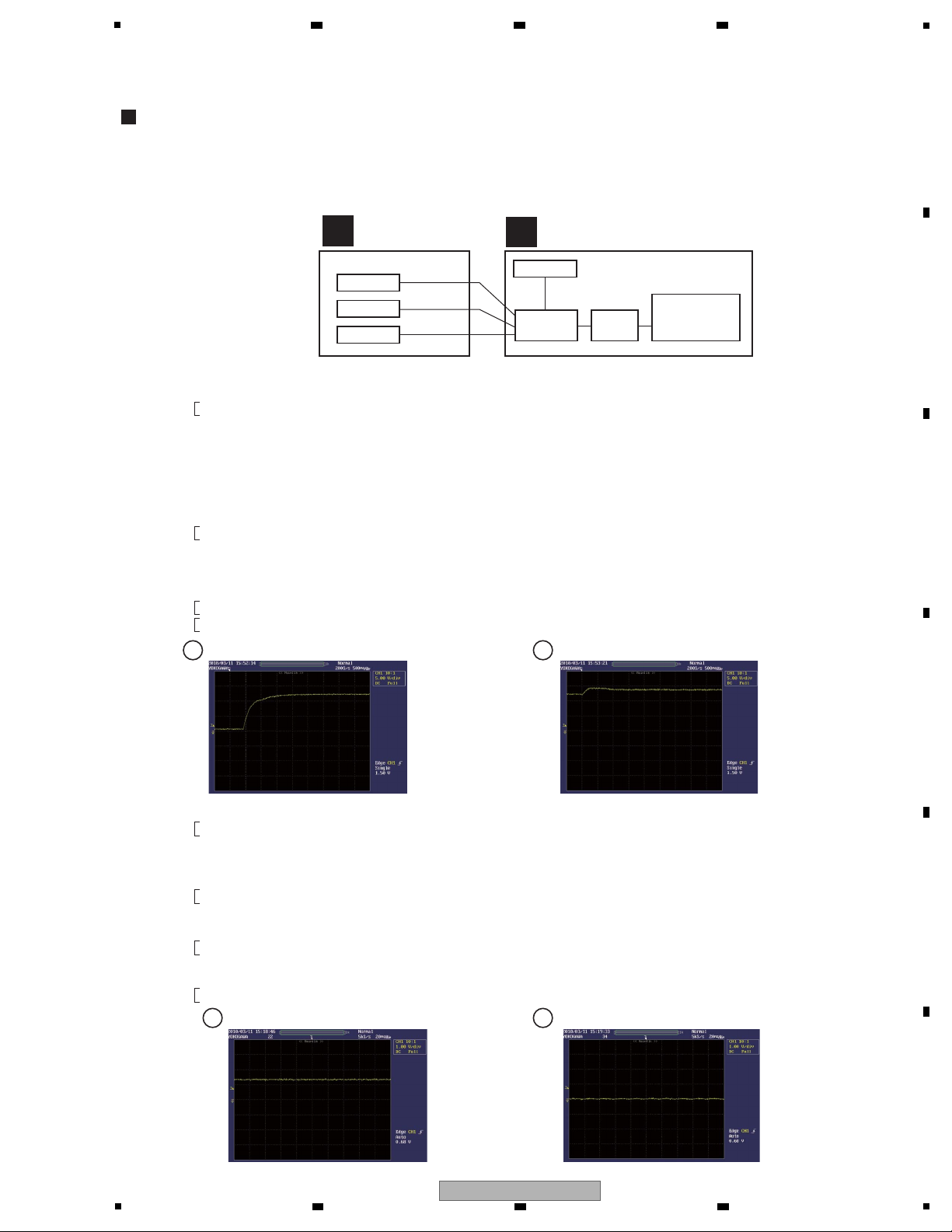

Symptom: The STBY LED flashes and no key is operable.

Status of the product:

The CPU, detecting that a power failure had been generated, shut the main transformer off, instructed the STBY LED to flash,

and disabled the keys. (When the main transformer is shut off, the relay (RY3001) is set to OFF and power is not supplied

to the main transformer.)

Troubleshooting of the Power System

Circuit block diagram

Diagnostic procedure

For diagnosis, plug in then unplug the AC power cord for each measurement, and perform measurement of

each point within about 10 sec.

1 While the STBY LED is flashing, check that the output from the TEST pin (Detect FLAG) near R1190 is

low (abnormal). *If it is high, nothing is wrong with the voltage.

2 Remove R1190 and plug the AC power cord in.

*Unplug the AC power cord after about 10 sec, because power will be forcibly supplied to the main transformer

even if any voltage is abnormal. (If abnormal voltage continues, the defective point may produce heat, which

may be dangerous.)

3 Check the voltages at the diagnostic points described below.

The circuit or power IC that is connected to the part whose voltage is abnormal may be defective.

JACK Assy: Voltages can be checked at the J3023, J3054, and J3038 jumpers.

Note: After diagnosis is completed, be sure to place R1190 to its original position.

Symptom: The STBY LED does not light and the product does not operate at all, even after the AC

power cord is plugged in.

1 Check the voltage of V+5D_U power.

⇒ If the voltage does not become high, check conduction at the protector (P3002).

Symptoms caused by other power failure

Symptom: Malfunction of a USB device

2 If the protector is intact, check each voltage on the MAIN Assy.

• V+5D ⇒ +5 V, • V+3R3D ⇒ +3.3 V, • V+1R2D ⇒ +1.2 V,

Check that the voltage of V+5USB power is +5 V.

IC3002

V+12A

V-12A

V+5A

V+5LED

IC1018

IC3003

IC3001

Detection

Circuit

CPU (IC1002)

pin 66

Detect FLAG

R1190

(0 Ω)

Change in V+5D_U when the AC power cord is plugged in Change in V+5D_U when the power switch is set to ON

While power is ON (relay: ON) Section H (J3067) During STBY (relay: OFF) Section H (J3067)

A

JACK ASSY

G

MAIN ASSY

Section A

Section B

Section C

Section D

Section E

Section F

Symptom: Defective operations of various VRs, such as equalizers, etc.

Check that the positive voltage of the capacitor at Section F is +3.3 V.

Section F

Symptom: Power is not supplied to the main transformer.

Check that the proper control signal is input to the relay circuit (J3067).

Section H

6 7 8

5.2 TROUBLESHOOTING

A

B

C

D

5

6 7 8

DJM-350

E

F

19

1

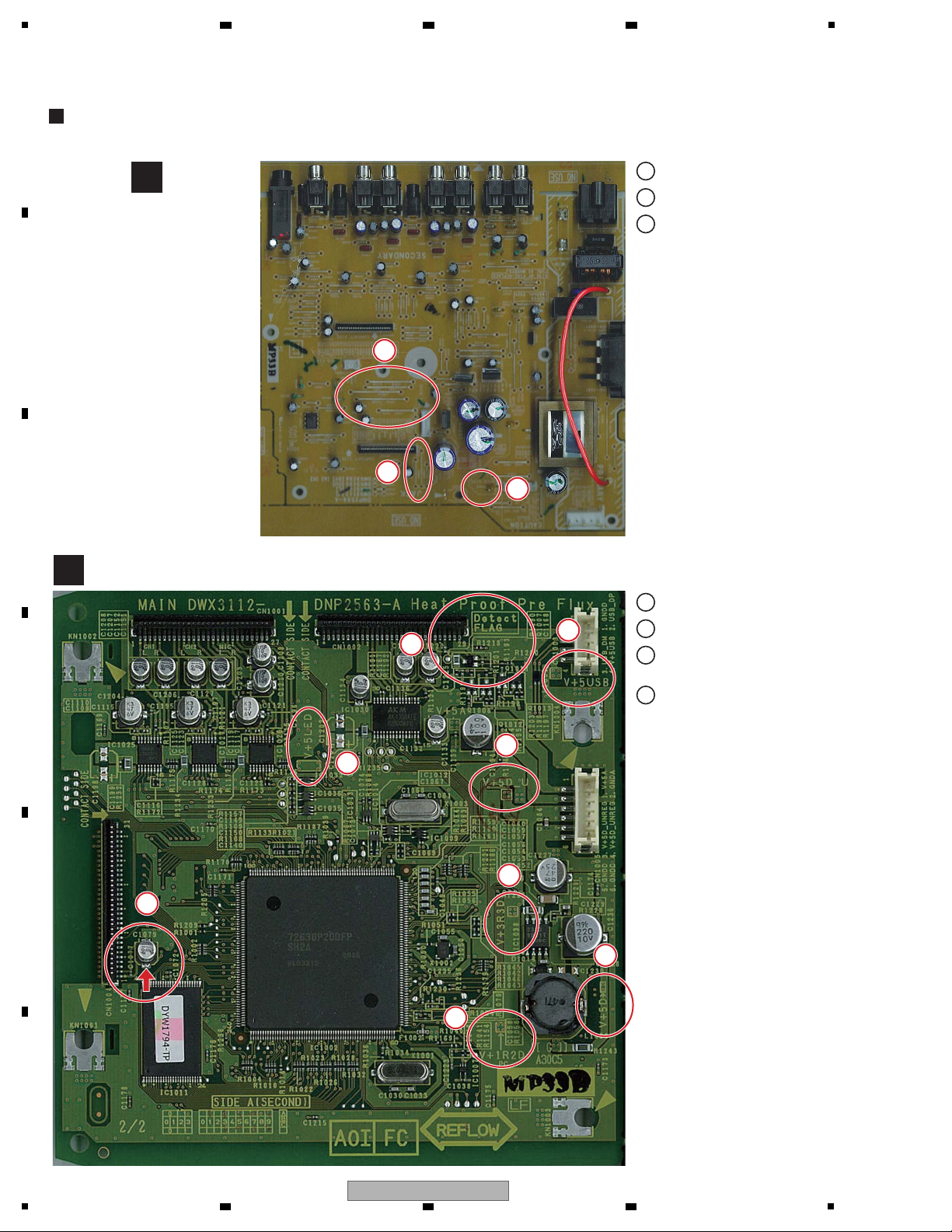

A

JACK ASSY

G

MAIN ASSY

B

B

H

D

A

F

C

F

E

E

E

F

: J3023, J3054, J3038

D

: P3002

H

: J3067

A

: Test p / Detect FLAG

C

: Test p / V+5D_U

E

: Test p / V+5D, V+3R3D,

V+1R2D

F

: Test p / V+5USB, V+5LED,

C1079 (+) pin

Measuring Points of the Power System

A

2 3 4

B

C

D

E

F

20

1

2 3 4

DJM-350

5

Symptom: Audio is not output.

Diagnostic points:

Symptom: The CD and PHONO inputs cannot be switched.

• Is a signal input to the ADC (IC1025: ch1, IC1026: mic, IC1027: ch2 → Pins 1 and 2)?

⇒ If it is not, something is wrong with the analog-circuit block.

• Are analog signals input to the VRSW Assy?

⇒ If they are not, something is wrong with the input-circuit section on the JACK Assy.

If they are, something is wrong with the analog block on the VRSW Assy.

• Is a digital signal output from the ADC (IC1025: ch1, IC1026: mic, IC1027: ch2 → Pin 9)?

Is a CLK signal input to the ADC (IC1025: ch1, IC1026: mic, IC1027: ch2 → Pins a, b, and c)?

⇒ If there is no output from Pin 9 although the CLK signal is input, the ADC may be in failure.

• Is a signal output from analog output of the DAC (IC1030 → Pins l and m: MASTER, Pins o and p: HP)?

⇒ If it is, something is wrong with the JACK Assy.

The MUTE circuit (J3015) may be in failure.

• Is a signal input to the digital input of the DAC (IC1030 → Pin 3)?

Is a CLK signal input to the DAC (IC1030 → Pins 1, 2, and 4)?

⇒ If no signal is output even if a digital signal is input properly, the DAC may be in failure.

The VRs may be in failure.

Check operations of each VR in Service mode.

• Is a normal switching signal input to each input operational amp (J3028: ch1, J3058: ch2)?

⇒ If it is, an input operational amp may be in failure.

Symptom: The MIC and AUX inputs cannot be switched.

• Is a normal switching signal input to each input operational amp (J3093: mic)?

⇒ If it is, an input operational amp may be in failure.

Troubleshooting of the Analog Signal System

Section A

G

MAIN ASSY

A

C

D

F

Diagnosis Point

Point

Measurement Point

CN1001

1, 5 pin

9, d pin

g, k pin

A/DC input

CH1_L, R

CH2_L, R

MIC_L, R

IC1025 9 pin

IC1027 9 pin

IC1026 9 pin

R1157

R1109

R1108

A/DC Digital output

CH1

CH2

MIC

A/DC CLK

AUDIO_CLK2

AD_3R072M

AD_48k

IC1030 3 pin

IC1030 1 pin

IC1030 2 pin

IC1030 4 pin

D/AC Digital input

MASTER/HP_DATA

D/AC CLK

AUDIO_CLK3

DA_6R144M

DA_48k

A

C

4

CN1002

i, m pin

b, f pin

D/AC Analog output

MASTER_L, R

HP_L, R

D

F

6

e

f

g

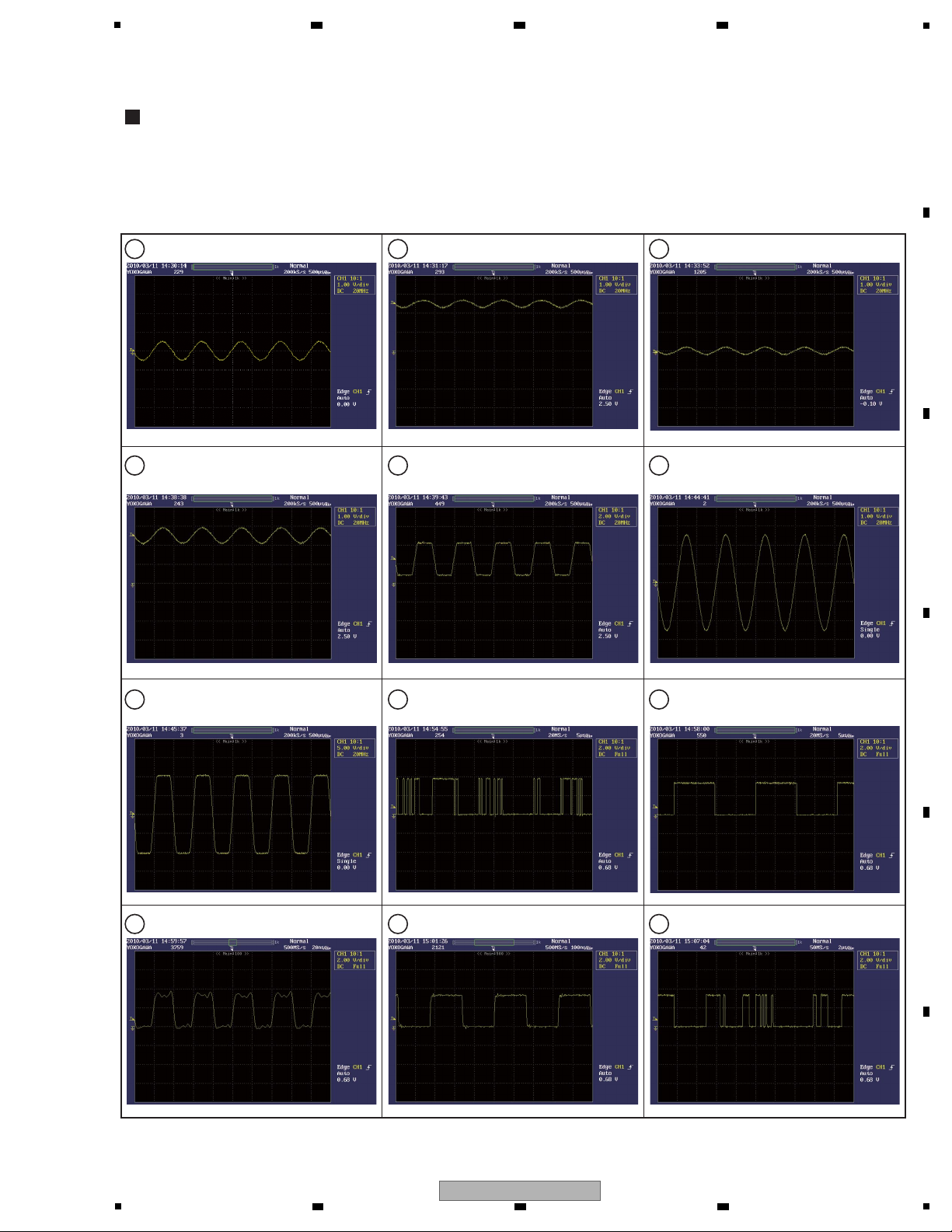

h

7

a

b

c

d

Measurement Signal

Waveform

No.

Section B

Section C

Section F

Section G

Section G

Section D

Section E

6 7 8

A

B

C

D

E

F

DJM-350

5

6 7 8

21

1

A

JACK ASSY

C

VRSW ASSY

B

I

H

E

G G G

Analog Block

Diagnosis Point

Point

Measurement Point

CN5001

1, 5 pin

9, d pin

g, k pin

VRSW Assy Analog input

CH1_R, L

CH2_R, L

MIC_L, R

CN5004

1 pin

6 pin

LED lit, Key read related signal

SCAN0

GR0

B

I

5

k

l

Measurement Signal

Waveform

No.

Diagnosis Point

Point

Measurement Point

J3015 MUTE

E

G

i

j

CN3006

1, 3 pin

Headphone output

HP_L, R

J3028

J3058

J3093

CD/PHONO switch

CH1_L

CH2_L

MIC/AUX switch

H

9

Measurement Signal

Waveform

No.

Measuring Points of the Analog Signal System

A

2 3 4

B

C

D

E

F

22

1

2 3 4

DJM-350

5

CD1L input (JACK) PIN JACK ADC input (MAIN) Section A PANEL input (VRSW) Section B

DAC output (MASTER) (MAIN)

Section D

DAC output (HP) (MAIN)

Section D

HP OUT (no termination) (JACK)

Section H

ADC 9 pin (MAIN)

Section C

ADC 10 pin (MAIN)

Section C

ADC 11 pin (MAIN) Section C ADC 12 pin (MAIN) Section C DAC 3 pin (MAIN) Section F

MASTER1L output (JACK)

PIN JACK

3 4 5

6 7 8

9 10 11

12 13 14

Setting of each control:

TRIM, MASTER LEVEL, HP LEVEL, and CH FADER: to MAX

Set other VRs to their center positions. Set the curve switch to THRU.

Set the input to CH1-CD L, 1.0 Vp-p/1 kHz. Set the output to OPEN.

Normal Waveforms at Each Section

6 7 8

A

B

C

D

E

DJM-350

5

6 7 8

F

23

1

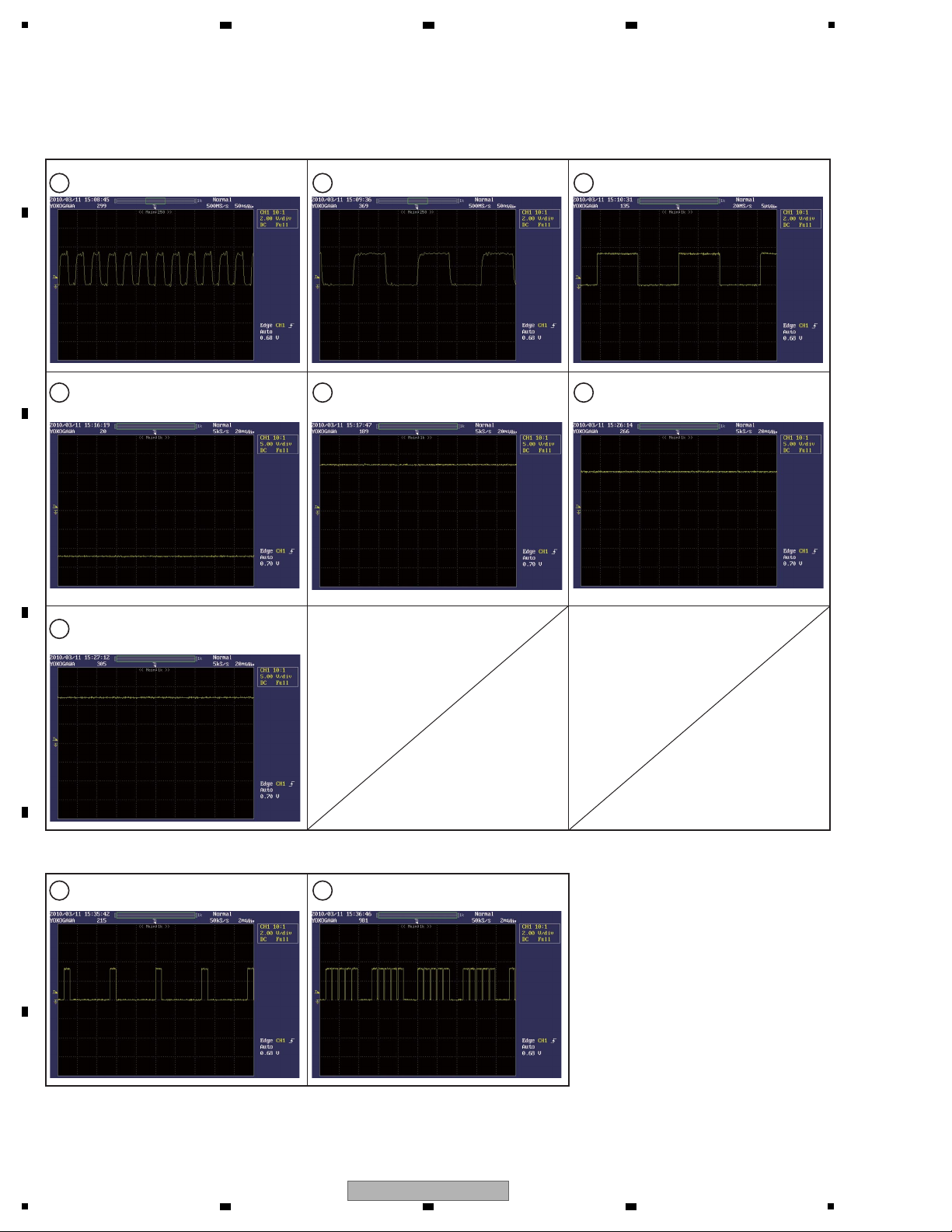

15 16 17

18

19

18

20 21

19

DAC 1 pin (MAIN) DAC 2 pin (MAIN) Section F DAC 4 pin (MAIN) Section F

MUTE (power ON): MUTE is turned OFF.

(JACK)

Section E (J3015) Section E (J3015) Section G (J3028)

Section G (J3028)

Section F

MUTE (Standby): MUTE is turned ON.

(JACK)

PHONO is selected for CH1 input. (JACK)

(Reference) Signals related to lighting of the LEDs and reading of key data

SCAN0 (VRSW) Section I Section IGR0 (VRSW)

CD is selected for CH1 input. (JACK)

A

2 3 4

B

C

D

E

F

24

1

2 3 4

DJM-350

5

0

About errors

If this unit cannot operate normally, the [u] (the power switch), [USB STOP] and [PLAY f] indicators flash to indicate

an error.

Check the table below and take the measures indicated.

If the [USB STOP] indicator flashes repeatedly 2 to 5 times

1 Disconnect the USB device.

2 Press [USB STOP].

Check the table below and take the measures indicated.

About the [USB STOP] indicator’s error indication

Indicator

name

Number

of times

indicator

flashes

Description of

error

Cause Measure

USB STOP

2 times

repeatedly

File format problem

USB device is not formatted.

Use a USB device formatted with a file system sup

ported by this unit (FAT or HFS+).

-

You are using a USB device with a file system that is not

supported by this unit.

3 times

repeatedly

USB class problem

A device other than a USB mass storage class device is

connected.

Connect a USB mass storage class USB device.

A USB hub is connected. Do not connect USB hubs.

4 times

repeatedly

Problem writing

on the USB device

Not enough free space on the USB device. Use a USB device with sufficient free space.

There is a file name “REC999.WAV” in the recorded data

storage folder (PIONEER DJM / DJM350 REC).

Files created through recording are given a 3-digit number.

Once the number 999 is reached, no new files can be

created in the folder. If this happens, move the files in the

folder to a different folder.

USB device’s write protect switch is set to the on position. Set the USB device’s write-protect switch to the off

position.

You are using a USB device with a security function. Use a USB device without a security function.

The recorded data storage folder (PIONEER DJM /

DJM350 REC) is set to “Read Only”.

Change the setting so that the recorded data storage

folder is writable.

5 times

repeatedly

USB device over

current detected

-

You are using a USB device (such as a bus power-driven

hard disk) whose current is higher than this unit’s rated

current (500 mA).

Use a USB device within this unit’s rated current (such

as a hard disk driven by an AC adapter or other external

power supply).

PLAY f

3 times Playback error

There are no playable files in the recorded data storage

folder (PIONEER DJM / DJM350 REC).

Perform the recording operation on this unit to create

playable files before playing them.

u (power

switch)

Continuous Circuit problem There is a problem in the internal circuitry. Unplug this unit’s power cord from the power outlet.

6 7 8

5.3 ERROR INDICATION

A

B

C

D

E

F

DJM-350

5

6 7 8

25

1

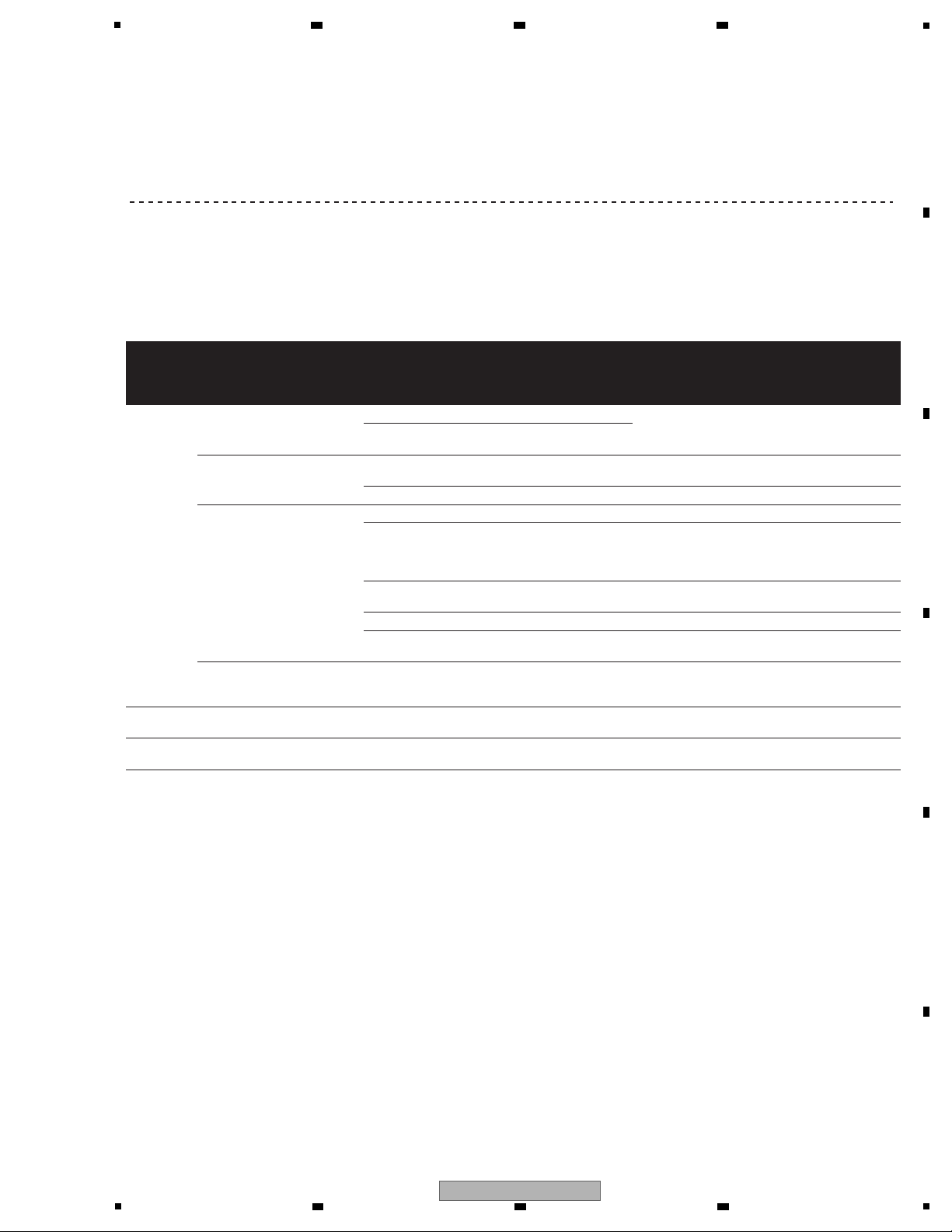

With this unit, DJ-played music (audio signals output from the MASTER OUT 1 and 2 connectors) can be recorded

into a USB device, such as a USB memory device, as a WAV file.

Follow the procedures below to check each operation.

For details, refer to "Recording musical performance," page 12 of the Operating instructions.

Immediately after a USB device is plugged into the USB device connector (1), the USB STOP indicator (2) starts flashing.

After a while, the USB STOP indicator stops flashing and stays lit, and the unit will be ready for recording.

To start recording, press the REC k/g key (3). The REC k/g indicator (3) will light.

To stop recording, press the REC k/g key again. The REC k/g indicator goes off.

To start playing back the recorded track, press the PLAY f key (4). The PLAY f indicator (4) will light.

To pause playback, press the PLAY f key again.

• Checking Fast Forward/Rewind operations

For Fast Forward or Rewind operation, hold the SEARCH o key or the SEARCH p key (6) pressed

during playback, respectively.

During Fast Forward/Rewind operation, the PLAY f indicator flashes.

• Preview check via the headphones

Turn and set the MIXING control to the leftward position from the center then hold the TRACK MARK (PREVIEW)

key (5) pressed. You can listen to the sound of the recorded tracks via the headphones while the key is being held.

From the headphones, sound of the WAV file mixed with CH-1 and CH-2 sound will be output.

1. Procedures for checking recording into a USB device

2. Procedures for checking playback of data in a USB device

2

1

3

5

6

4

5.4

OPERATION CHECK OF RECORDING / PLAYING / TO FROM A USB DEVICE

A

2 3 4

B

C

D

E

F

26

1

2 3 4

DJM-350

5

CH-1

FADER

START

button

GATE

button

CH-1

CUE

button

Mode 0

POWER ON

Mode 1 Mode 2

Mode 7 Mode 6 Mode 5

Mode 3

Mode 4

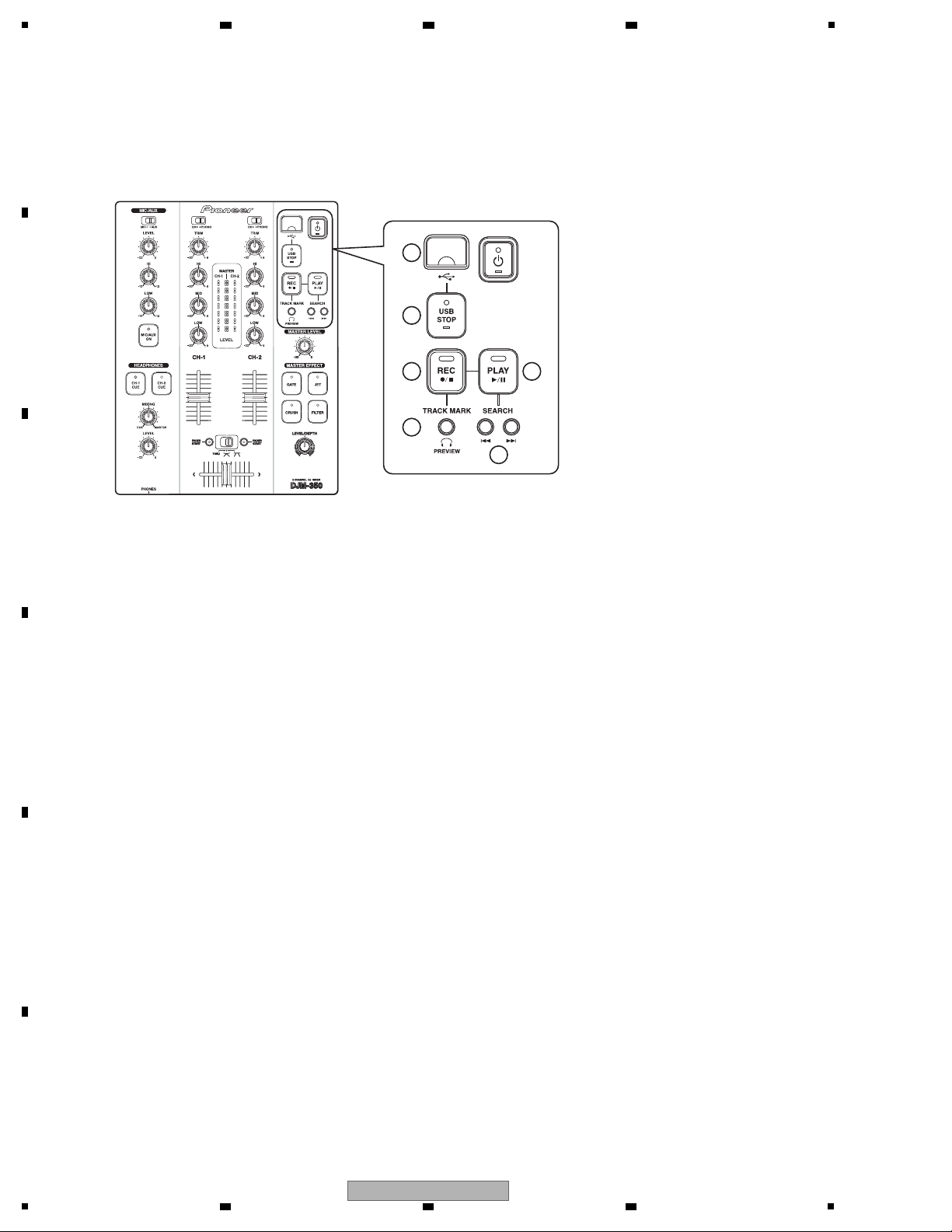

1. Description of Test Modes

2. Test Mode

Test Mode

(Mode 0)

Test Mode : ON

Test Mode : CANCEL

• Press the p key to shift to the next mode.

• Press the o key to shift to the previous mode.

• You can confirm the current mode number while you hold

the TRACK MARK (PREVIEW) key pressed (the level

meter indicates a numeric value).

POWER OFF

In Test mode, no audio processing is performed (no mixing function is available). To avoid any accidental failure,

never connect anything to the MASTER OUT connector or HEADPHONES output connector in Test mode.

Mode No. Description of The Modes Purpose of Use

0 Mode for version confirmation Confirmation of the version of the firmware

1 Mode for making all LEDs unlit

Confirmation of LED operations

2 Mode for making all LEDs lit

3 Mode for confirmation of individual keys Confirmation of operations of individual keys

4 Mode for confirmation of individual switches Confirmation of operations of individual switches

5 Mode for confirmation of the values of the rotary variable controls

Confirmation of operations of individual variable controls

6

Mode for confirmation of fluctuated values of the rotary variable controls

7 Mode for confirmation of the meter LEDs Confirmation of meter-LED operations

The Following eight test modes are provided for this unit:

6 7 8

6. SERVICE MODE

6.1 TEST MODE

A

B

C

D

E

F

DJM-350

5

6 7 8

27

1

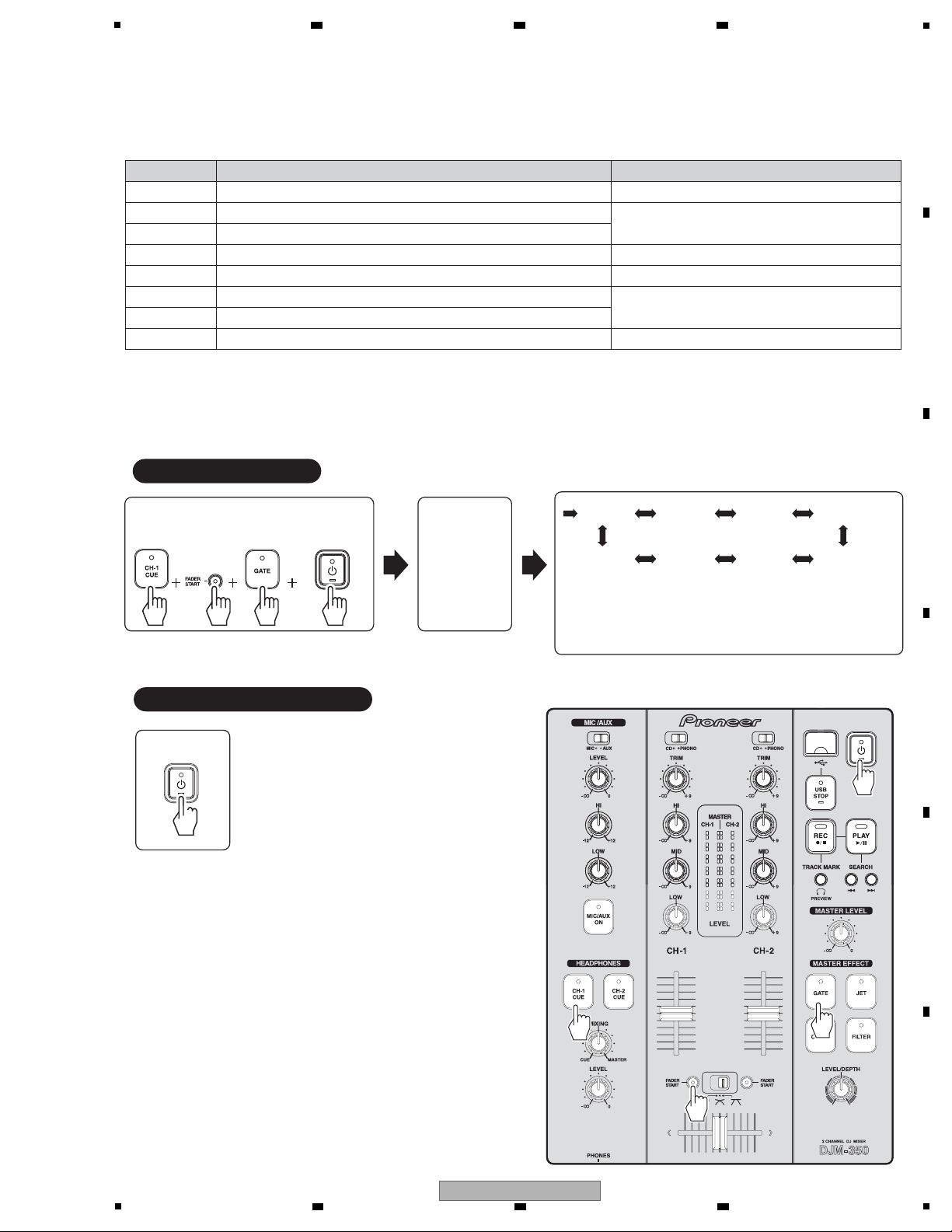

3. Test Possible Area

• The MIC LEVEL control is an exception to testing.

• The MIC equalizer (HI and LOW) controls are exceptions

to testing.

• The TRIM control is an exception to testing.

(The right controls are operating elements that are not

managed by the microcomputer.)

4. Basic Operation Method

Basic Operation Method

To switch Test modes, use the SEARCH key.

With this unit, the Test mode No. is not normally

indicated.

The Test mode No. is indicated on the level meter

while the TRACK MARK key is held pressed.

If the Test mode is advanced, the PLAY LED flashes

once.

If the Test mode is backtracked, the PLAY LED flashes

twice.

Basic Operation Method 2

(For details, see the descriptions for each mode):

In Test 6 mode, the individual operating elements can

be tested. In Test 6 mode, select an operating element,

using the CH-1 CUE or CH-2 CUE key.

If an unintended erroneous value is displayed when an

operating element is operated, you can reset it by

pressing the MIC/AUX ON key.

In Test 7 mode, the individual LEDs of the level meters

can be tested.

You can light the individual LEDs one after another,

using the CH-1 CUE, CH-2 CUE, or MIC/AUX ON key.

For indicating a

Test mode No.

[Mode 6]

Reset button

[Mode 7]

MASTER-LED button

[Mode 6]

For going forward/back one operating

element to be tested

[Mode 7]

CH1 and CH2-LED buttons

For going forward

/back one mode

A

2 3 4

B

C

D

E

F

28

1

2 3 4

DJM-350

Loading...

Loading...