Pioneer DEHP-80-RS, DEHP-88-RS, DEHP-880-PRS Service manual

ORDER NO.

CRT3650

DEH-P880PRS/XN/UC

MULTI-CD CONTROL HIGH POWER CD/MP3/WMA/AAC PLAYER WITH FM/AM TUNER

DEH-P880PRS

DEH-P80RS

MULTI-CD CONTROL DSP HIGH POWER CD/MP3/WMA/AAC PLAYER WITH RDS TUNER

DEH-P88RS

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-3164 CRT3583 S10.5COMP1 CD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

/XN/ES

/XN/EW5

/XN/UC

For details, refer to "Important Check Points for Good Servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

Z-ZZW. MAR. 2006 Printed in Japan

y

y

.

g

p

-

esults.

Caution:

.

.

ARNING

eadlde

d

ta

ectrica

to

the

cause cancer

5

:

JUS

OUS

OSURE.

ON

1234

SAFETY INFORMATION

AUTI

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessar

repair complex products such as those covered by this manual

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk tryin

and refer the re

ARNING

air to a qualified service technician.

test equipment and tools, and have been trained to properly and safel

to do so

Thisroduct

lifornia to

Health & Safety Code Section 25249.6 - Proposition 6

B

Safety Precautions for those who Service this Unit.

r

During repair or tests, minimum distance of 13cm from the focus lens must be kept

During repair or tests, do not view laser beam for 10 seconds or longer

C

D

AUTION

PECIFIED HEREIN MAY RESULT IN HAZARD

ntainsl

E OF CONTROLS OR AD

r

n

TMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

in

l

l

arts

ntain

hemicalswhich

RADIATION EXP

known

E

F

2

1234

CLASS 1

LASER PRODUCT

DEH-P880PRS/XN/UC

5678

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

A

Laser diode characteristics

Wave length : 785~814nm

Maximum output : 1190µW(Emitting period : unlimited)

Additional Laser Caution

Transistors Q101 in PCB drive the laser diodes.

When Q101 is shorted between their terminals, the laser diodes will radiate beam.

If the top cover is removed with no disc loaded while such short-circuit is continued,

the naked eyes may be exposed to the laser beam.

- Service Precautions

1. You should conform to the regulations governing the product (safety, radio and noise, and other

regulations), and should keep the safety during servicing by following the safety instructions

described in this manual.

2. This product memorizes every audio setting value during operating product such as VOL position and

EQ setting. As the setting value is recorded in the built-in EEPROM, it does not return to the initial setting

value even if you press RESET key.

If you return it to the initial setting value, execute the Audio Reset in the initial setting menu.

However, if you execute it, the user setting is deleted.

If you change the audio setting when repairing the product, the product is returned to the user with that

setting, so take care of it.

Method of Audio Reset

After pressing MULTI-CONTROL key for two seconds, select Audio Reset by right and left rotation.

After shifting to the reset confirmation screen by right-pressing MULTI-CONTROL key and execute the

reset by center-pressing.

B

C

D

- CD Section Precaution

1. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside the unit.

2. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY".

3. After replacing the pickup unit, be sure to check the grating.

56

DEH-P880PRS/XN/UC

7

E

F

8

3

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

B

C

D

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

DEH-P880PRS/XN/UC

5678

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SPECIFICATIONS .............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST...........................................................................................................12

2.1 PACKING(UC, ES MODEL)......................................................................................................................12

2.2 PACKING(EW5 MODEL)..........................................................................................................................14

2.3 EXTERIOR(1)(UC, ES MODEL)...............................................................................................................16

2.4 EXTERIOR(1)(EW5 MODEL)...................................................................................................................18

2.5 EXTERIOR(2)...........................................................................................................................................20

2.6 CD MECHANISM MODULE .....................................................................................................................22

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................24

3.1 BLOCK DIAGRAM....................................................................................................................................24

3.2 OVERALL CONNECTION DIAGRAM(UC, ES MODEL)(GUIDE PAGE) ..................................................28

3.3 OVERALL CONNECTION DIAGRAM(EW5 MODEL)(GUIDE PAGE) ......................................................34

3.4 KEYBOARD UNIT ....................................................................................................................................40

3.5 CD MECHANISM MODULE(GUIDE PAGE).............................................................................................42

4. PCB CONNECTION DIAGRAM ......................................................................................................................52

4.1 TUNER AMP UNIT ...................................................................................................................................52

4.2 KEYBOARD UNIT ....................................................................................................................................56

4.3 CD CORE UNIT(S10.5COMP1) ...............................................................................................................58

4.4 SWITCH UNIT ..........................................................................................................................................60

5. ELECTRICAL PARTS LIST .............................................................................................................................61

6. ADJUSTMENT ................................................................................................................................................76

6.1 OEL ADJUSTMENT .................................................................................................................................76

6.2 CD ADJUSTMENT ...................................................................................................................................77

6.3 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT.....................................................79

6.4 ERROR MODE.........................................................................................................................................81

6.5 E.VOL IC OSCILLATING FREQUENCY ADJUSTMENT..........................................................................82

6.6 SYSTEM MICROCOMPUTER TEST PROGRAM....................................................................................82

7. GENERAL INFORMATION .............................................................................................................................83

7.1 DIAGNOSIS..............................................................................................................................................83

7.1.1 DISASSEMBLY......................................................................................................................................83

7.1.2 CONNECTOR FUNCTION DESCRIPTION ..........................................................................................87

7.2 IC ..............................................................................................................................................................88

7.3 OPERATIONAL FLOW CHART..............................................................................................................103

8. OPERATIONS ...............................................................................................................................................104

A

B

C

D

E

F

56

DEH-P880PRS/XN/UC

7

8

5

1234

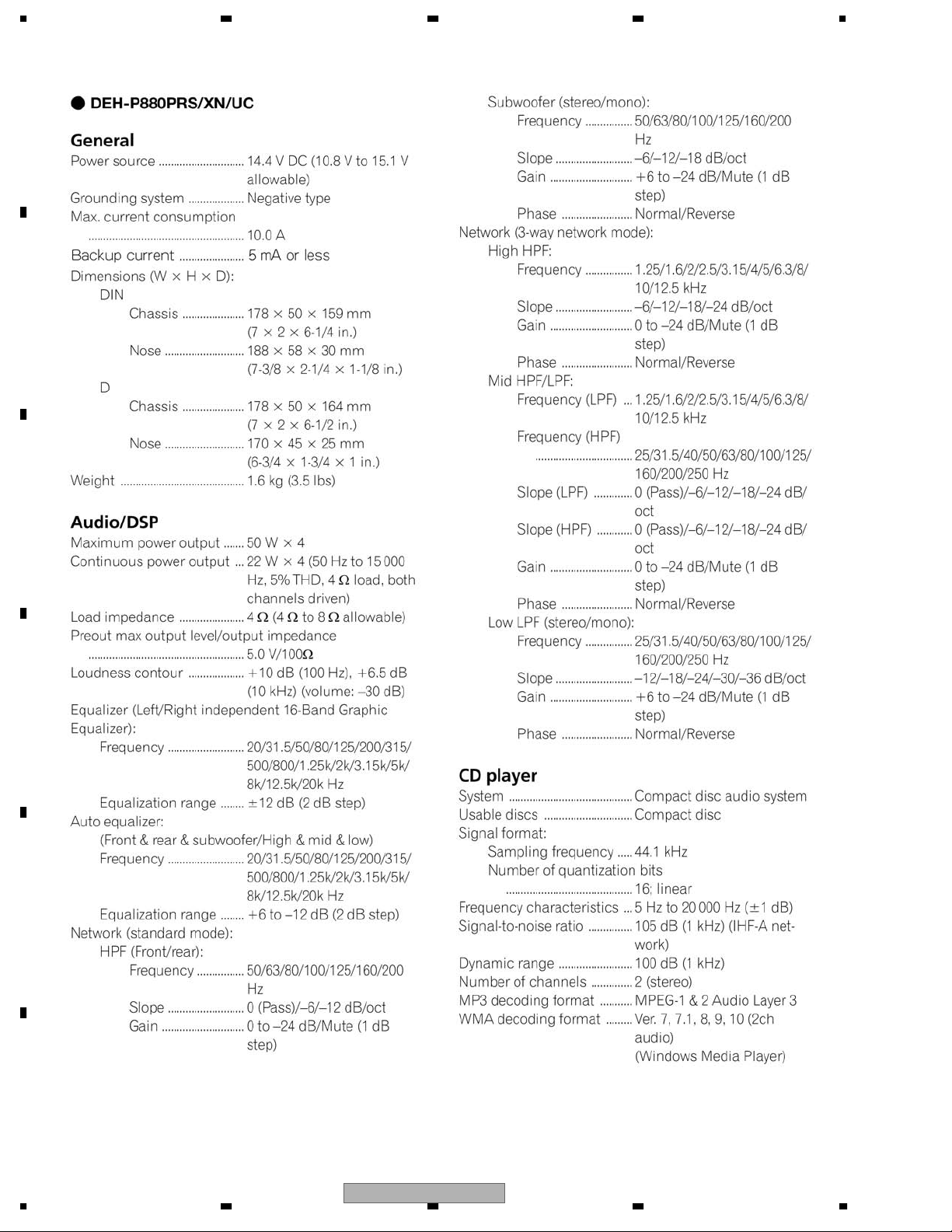

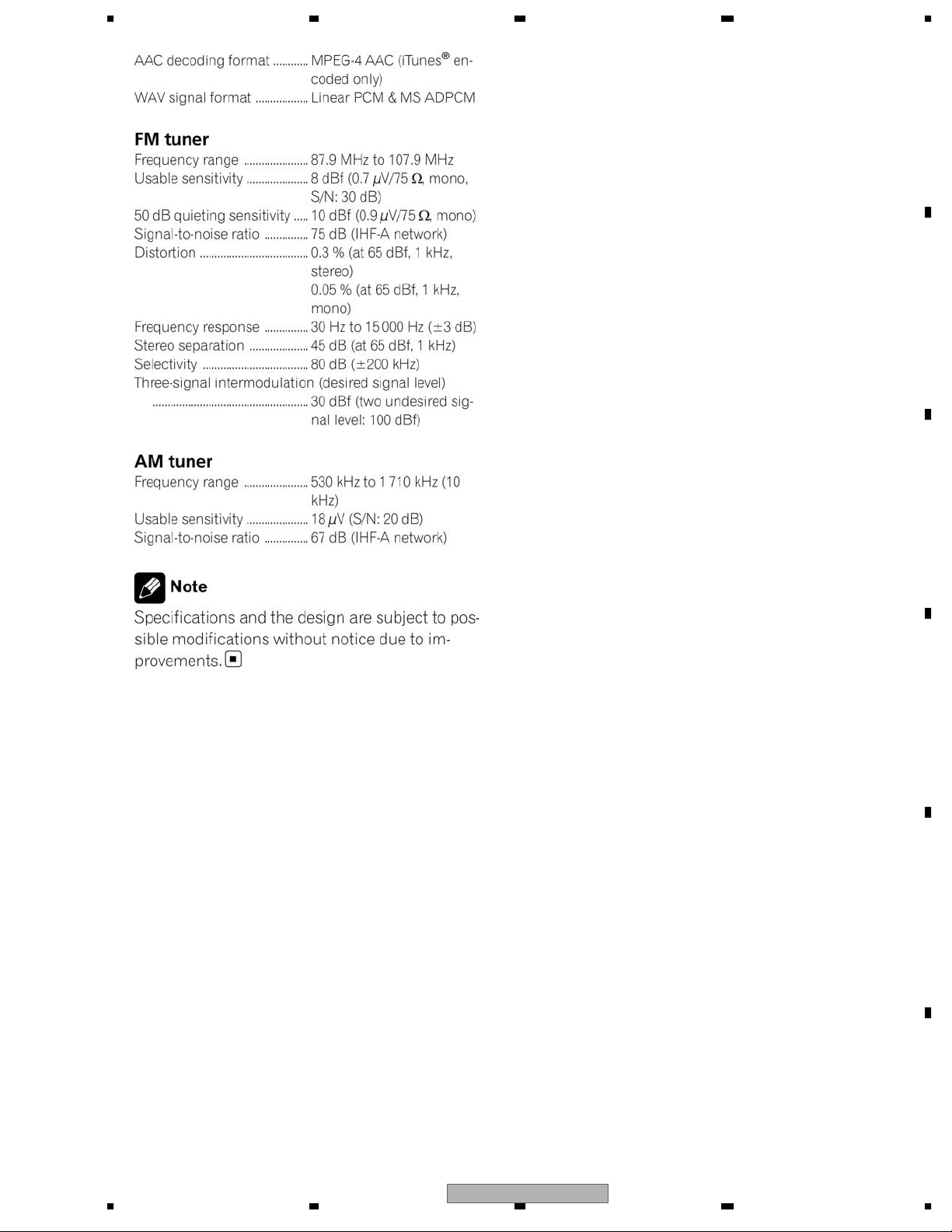

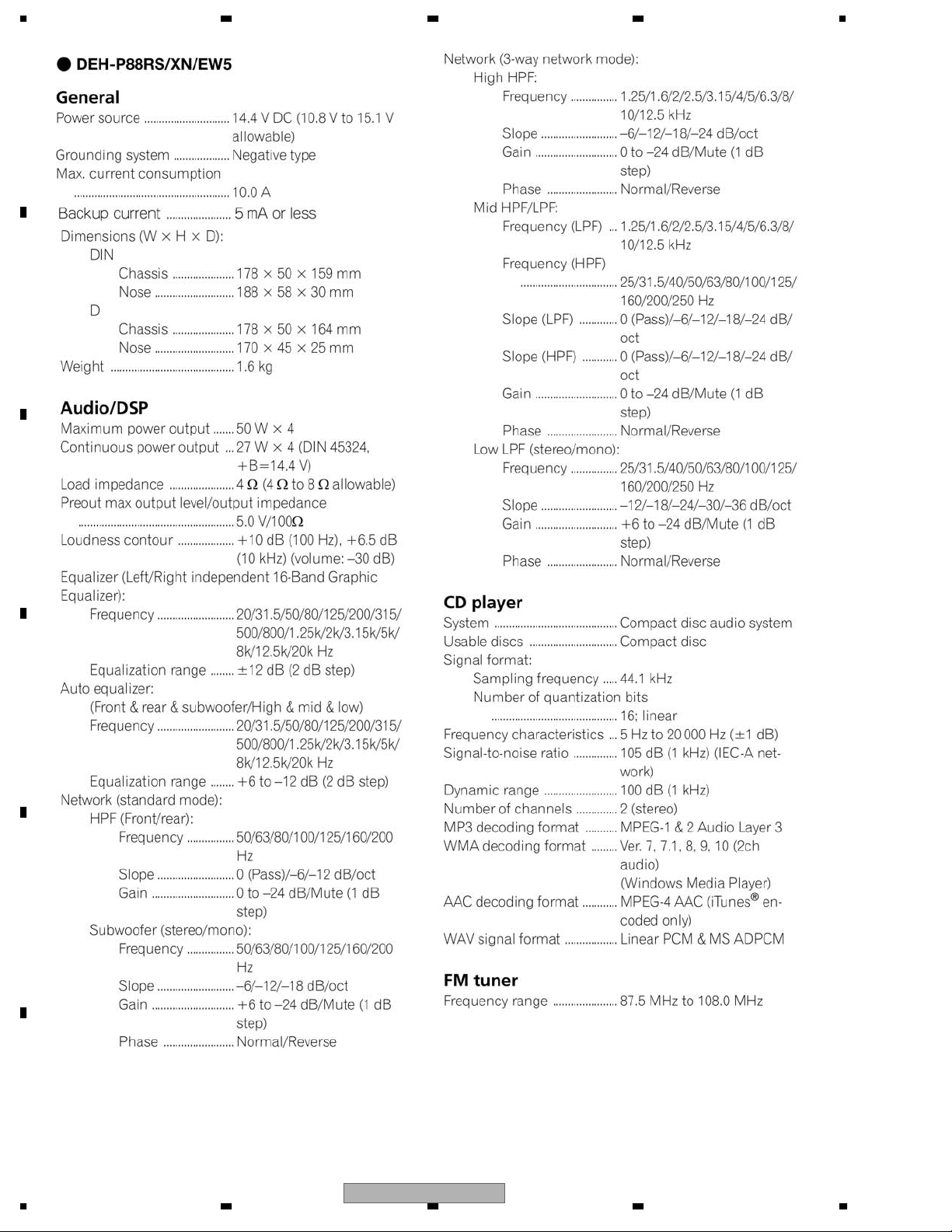

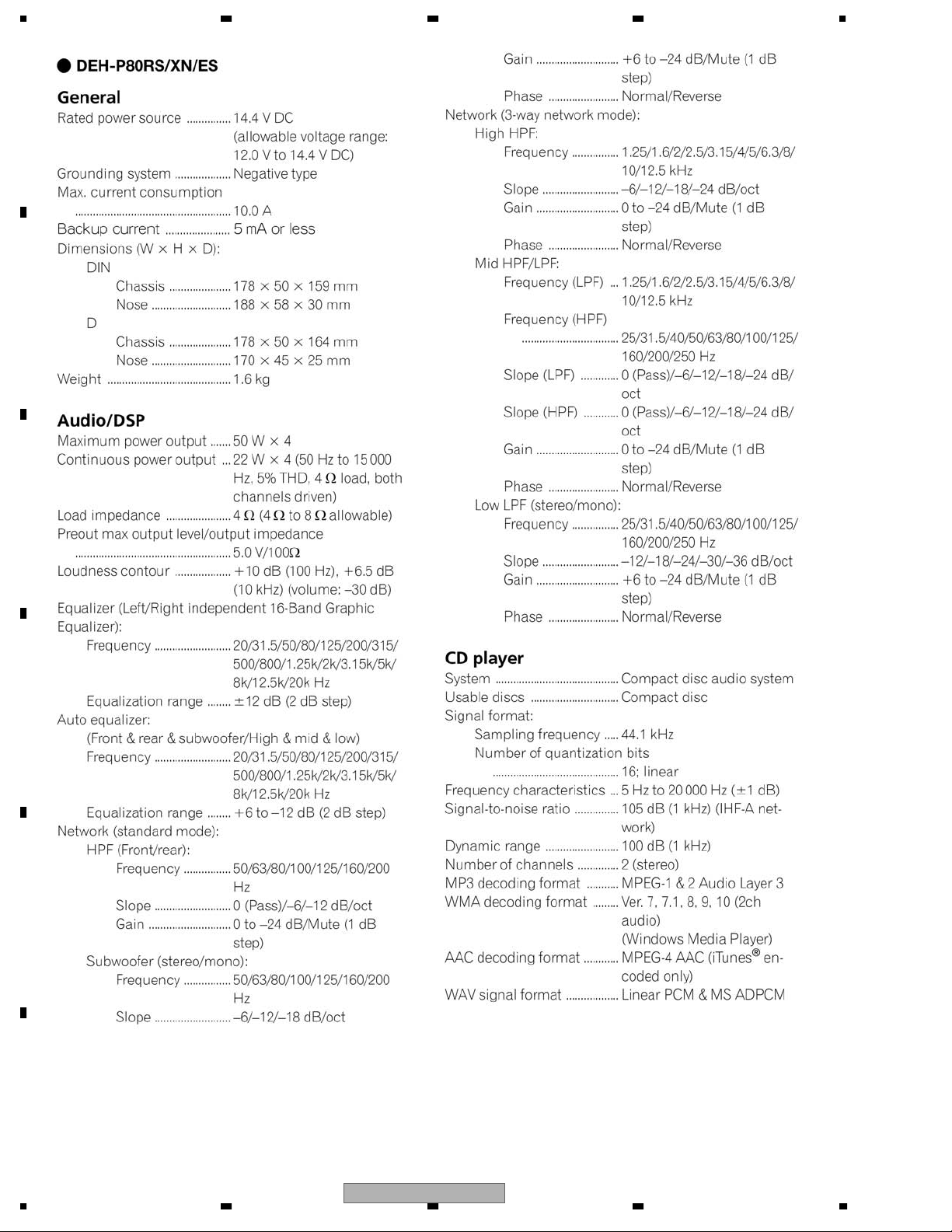

1. SPECIFICATIONS

A

B

C

D

E

F

6

1234

DEH-P880PRS/XN/UC

5678

A

B

C

D

E

56

DEH-P880PRS/XN/UC

F

7

8

7

1234

A

B

C

D

E

F

8

1234

DEH-P880PRS/XN/UC

5678

A

B

C

D

E

56

DEH-P880PRS/XN/UC

F

7

8

9

1234

A

B

C

D

E

F

10

1234

DEH-P880PRS/XN/UC

5678

A

B

C

D

E

56

DEH-P880PRS/XN/UC

F

7

8

11

N

9

0

5

1234

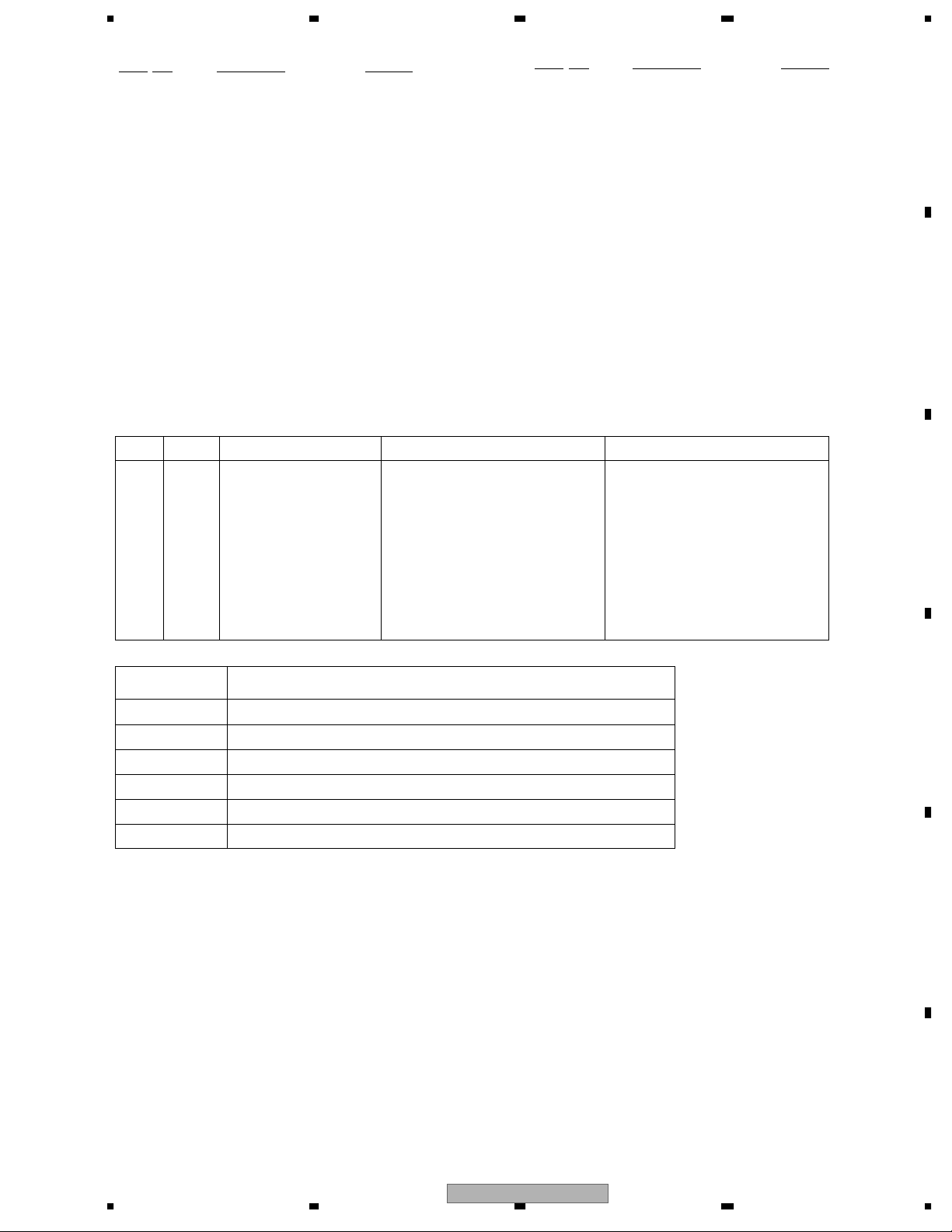

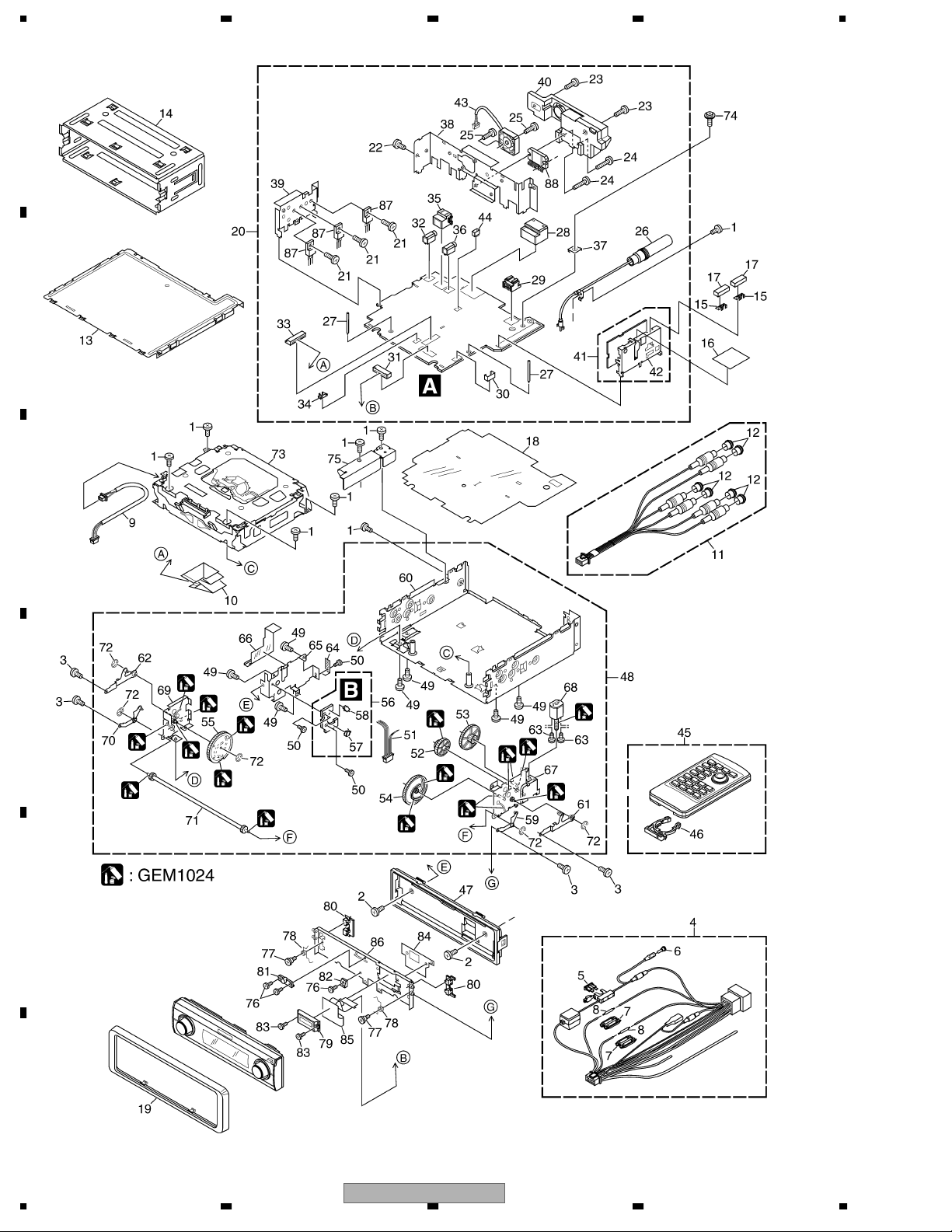

2. EXPLODED VIEWS AND PARTS LIST

OTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

• The > mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

2.1 PACKING(UC, ES MODEL)

B

"

5

1

9

2

2

C

16

D

E

18

1

1

12

F

12

1234

DEH-P880PRS/XN/UC

5678

(1) PACKING(UC, ES MODEL) SECTION PARTS LIST

Mark No. Description Part No.

1 Cord Assy CDE7701

2 Cord Assy CDE8275

3 Screw Assy See Contrast table(2)

4 Screw CBA1650

* 5 Polyethylene Bag CEG-127

6 Screw CRZ50P090FTC

7 Screw See Contrast table(2)

8 Screw TRZ50P080FTC

* 9 Polyethylene Bag CEG-158

10 Polyethylene Bag See Contrast table(2)

11 Carton See Contrast table(2)

12 Contain Box See Contrast table(2)

13 Protector XHP7007

14 Protector XHP7008

Mark No. Description Part No.

15 Microphone Assy CPM1054

16-1 Polyethylene Bag CEG1116

16-2 Owner's Manual See Contrast table(2)

16-3 Owner's Manual See Contrast table(2)

16-4 Owner's Manual See Contrast table(2)

16-5 Installation Manual See Contrast table(2)

16-6 Caution Card CRP1310

* 16-7 Warranty Card See Contrast table(2)

* 16-8 Caution Card XRP7002

17 Case Assy CXB3520

18 Remote Control Unit CXC5717

19 Handle CNC5395

20 Bush CNV3930

(2) CONTRAST TABLE

DEH-P880PRS/XN/UC and DEH-P80RS/XN/ES are constructed the same except for the following:

Mark No. Description DEH-P880PRS/XN/UC DEH-P80RS/XN/ES

3 Screw Assy CEA5322 CEA3849

7 Screw JPZ20P060FTB Not used

10 Polyethylene Bag CEG1368 CEG1227

11 Carton CHG5735 CHG5736

12 Contain Box CHL5735 CHL5736

16-2 Owner's Manual CRD4080 CRD4082

16-3 Owner's Manual Not used CRD4083

16-4 Owner's Manual Not used CRB2177

16-5 Installation Manual CRD4081 CRD4084

* 16-7 Warranty Card CRY1070 Not used

Owner's Manual,Installation Manual

A

B

C

Part No. Language

CRD4080 English, French

CRD4081 English, French

CRD4082 English, Spanish

CRD4083 Portuguese(B), Traditional Chinese

CRB2177 Arabic

CRD4084 English, Spanish, Portuguese(B), Traditional Chinese, Arabic

D

E

F

56

DEH-P880PRS/XN/UC

7

8

13

1234

3

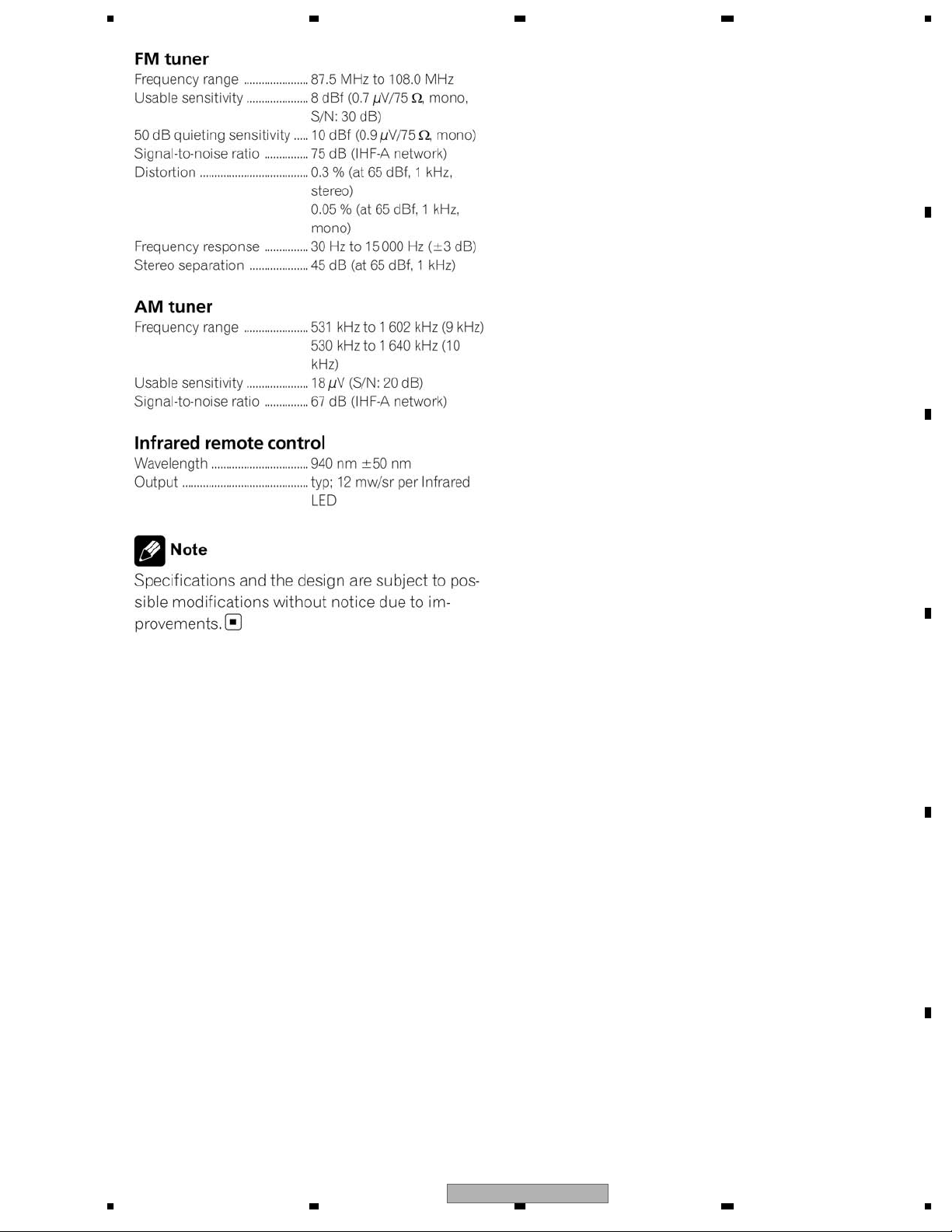

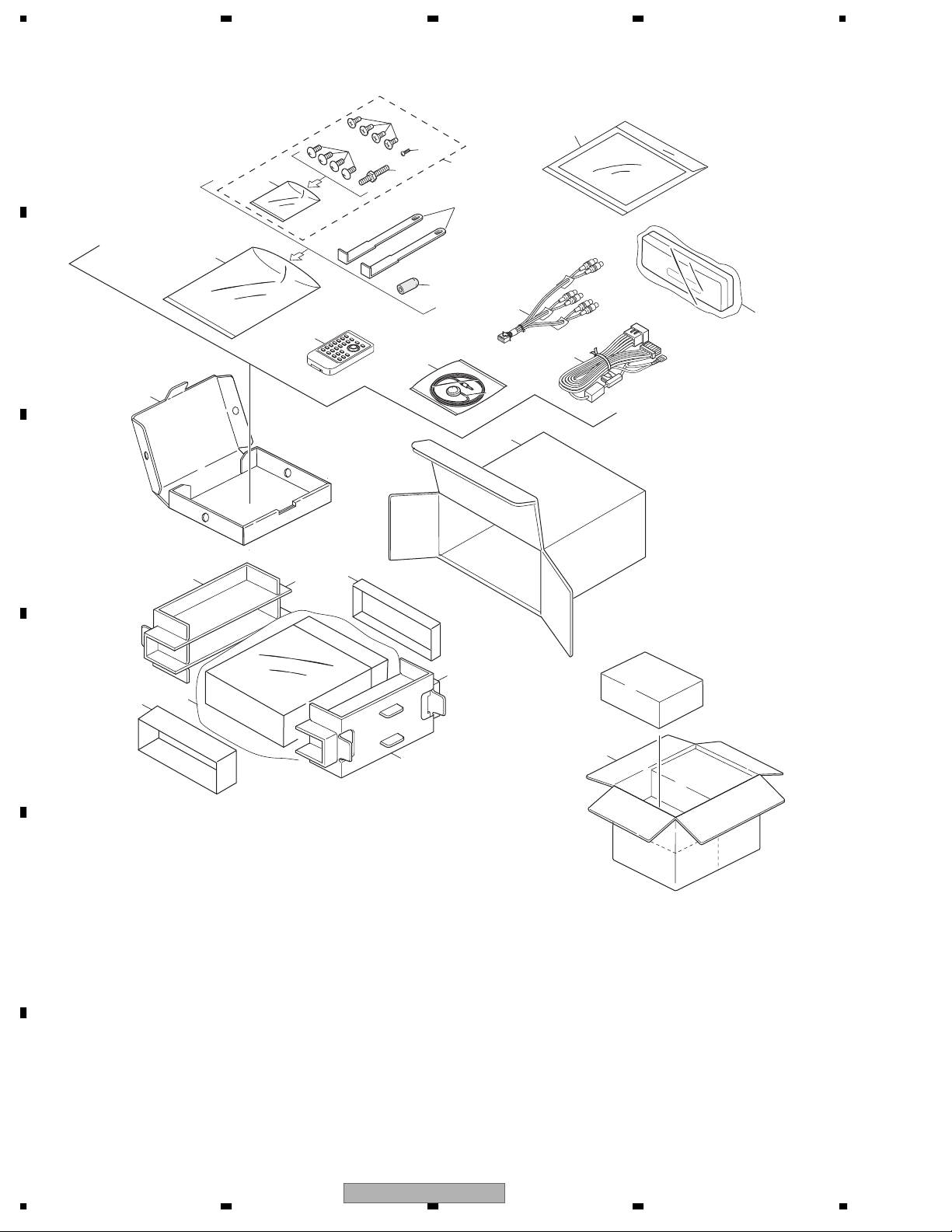

2.2 PACKING(EW5 MODEL)

A

5

9

B

11

21

19

2

18

2

1

12

20

C

14

10

D

E

16

15

17

14

15

13

F

14

1234

DEH-P880PRS/XN/UC

5678

(1)PACKING(EW5 MODEL) SECTION PARTS LIST

Mark No. Description Part No.

1 Cord Assy CDE6562

2 Cord Assy CDE8274

3 Screw Assy CEA5322

4 Screw CBA1650

* 5 Polyethylene Bag CEG-127

6 Screw CRZ50P090FTC

7 Screw JPZ20P060FTB

8 Screw TRZ50P080FTC

* 9 Polyethylene Bag CEG-158

10 Polyethylene Bag CEG-162

11 Sub Carton CHG5195

12 Carton CHG5882

13 Contain Box CHL5882

14 Protector CHP2797

15 Protector CHP2798

16 Protector CHP2812

Mark No. Description Part No.

17 Protector CHP3184

18 Microphone Assy CPM1054

* 19-1 Polyethylene Bag E36-634

19-2 Owner's Manual CRB2176

19-3 Owner's Manual CRD4076

19-4 Owner's Manual CRD4077

19-5 Owner's Manual CRD4078

19-6 Installation Manual CRD4079

* 19-7 Caution Card CRP1335

* 19-8 Passport CRY1013

* 19-9 Warranty Card CRY1157

20 Case Assy CXB3520

21 Remote Control Unit CXC5717

22 Handle CNC5395

23 Bush CNV3930

A

B

Owner's Manual,Installation Manual

Part No. Language

CRD4076 English, Spanish

CRD4077 German, French

CRD4078 Italian, Dutch

CRB2176 Russian

CRD4079 English, Spanish, German, French, Italian, Dutch, Russian

C

D

56

DEH-P880PRS/XN/UC

E

F

7

8

15

1234

2.3 EXTERIOR(1)(UC, ES MODEL)

A

B

C

D

E

F

16

1234

DEH-P880PRS/XN/UC

5678

EXTERIOR(1)(UC, ES MODEL) SECTION PARTS LIST

Mark No. Description Part No.

1 Screw BSZ26P060FTC

2 Screw(M2.6 x 4) CBA1828

3 Screw(M2 x 2.5) CBA1924

4 Cord Assy CDE7701

> 5 Fuse(10 A) CEK1136

6 •••••

7 Cap CNS1472

8 Resistor RS1/2PMF102J

9 Cord Assy CDE7817

10 Cable CDE8067

11 Cord Assy CDE8275

12 Cap CNV6727

13 Case Assy CXC6908

14 Holder CNC8659

15 Earth Plate CND2171

16 Insulator CNM8790

17 Cushion CNM9126

18 Insulator CNM9936

19 Panel CNS8516

20 Tuner Amp Unit(UC) CWN1478

Tuner Amp Unit(ES) CWN1479

21 Screw ASZ26P060FTC

22 Screw BMZ26P040FTC

23 Screw BMZ26P120FTC

24 Screw BMZ26P180FTC

25 Screw(M2.6 x 14) CBA1632

26 Antenna Cable CDH1336

27 Clamper CEF1040

28 Plug(CN901) CKM1278

29 Connector(CN351) CKM1389

30 Plug(CN871) CKS-786

31 Connector(CN471) CKS3834

32 Connector(CN581)(UC) CKS4124

33 Connector(CN801) CKS4811

34 Connector(CN472) CKS4822

35 Connector(CN101) CKS5271

36 •••••

37 Holder(CN402) CNC5399

38 Holder(UC) CND3158

Holder(ES) CND3159

39 Holder CND3133

40 Heat Sink CNR1837

41 FM/AM Tuner Unit(Y401) CWE1802

42 Holder CND2144

43 Fan Motor CXM1288

Mark No. Description Part No.

48 Drive Unit CXC6620

49 Screw BMZ26P040FTC

50 Screw(M2 x 2) CBA1871

51 Cord CDE7392

52 Gear CNV7752

53 Gear CNV7753

54 Gear CNV7754

55 Gear CNV7755

56 Switch Unit CWS1389

57 Switch(S1) CSN1051

58 Spring Switch(S2) CSN1052

59 Arm Unit CXC2199

* 60 Chassis Unit CXC5680

61 Arm Unit CXC6623

62 Arm Unit CXC6624

63 Screw JFZ20P020FTC

64 Spring XBL7003

* 65 Holder XNC7017

* 66 Insulator XNM7119

* 67 Holder Unit XXA7399

* 68 Motor Unit(M10) XXA7400

* 69 Holder Unit XXA7401

* 70 Arm Unit XXA7403

* 71 Gear Unit XXA7424

72 Washer YE15FTC

73 CD Mechanism Module(S10.5) CXK5753

74 Screw ISS26P055FTC

75 Holder CND3606

76 Screw(M2 x 2) CBA1871

77 Screw CBA1935

78 Spring CBH2530

79 Connector CKS5273

80 Arm CNV6962

81 Guide CNV6967

82 Guide CNV8048

83 Screw(M2 x 3.5) XBA7002

84 Holder XNC7019

85 Flexible PCB XNP7026

86 Case Unit XXA7426

87 Transistor(Q462,701,711) 2SD2396

88 IC(IC331) PAL007B

A

B

C

D

E

44 Connector(CN591) VKN1928

45 Remote Control Unit CXC5717

46 Cover CZN5357

47 Panel Unit CXC5737

56

DEH-P880PRS/XN/UC

F

7

8

17

1234

2.4 EXTERIOR(1)(EW5 MODEL)

A

B

C

D

E

F

18

1234

DEH-P880PRS/XN/UC

5678

EXTERIOR(1)(EW5 MODEL) SECTION PARTS LIST

Mark No. Description Part No.

1 Screw BSZ26P060FTC

2 Screw(M2.6 x 4) CBA1828

3 Screw(M2 x 2.5) CBA1924

4 Cord Assy CDE6562

> 5 Fuse(10 A) CEK1136

6 Cap CKX-003

7 Cap CNS1472

8 Resistor RS1/2PMF102J

9 Cord Assy CDE7817

10 Cable CDE8067

11 Cord Assy CDE8274

12 Cap CNV6727

13 Case Assy CXC6908

14 Holder CNC8659

15 Earth Plate CND2171

16 Insulator CNM8790

17 Cushion CNM9126

18 Insulator CNM9936

19 Panel CNS8516

20 Tuner Amp Unit CWN1477

21 Screw ASZ26P060FTC

22 Screw BMZ26P040FTC

23 Screw BMZ26P120FTC

24 Screw BMZ26P180FTC

25 Screw(M2.6 x 14) CBA1632

26 Antenna Cable CDH1336

27 Clamper CEF1040

28 Plug(CN901) CKM1278

29 Connector(CN351) CKM1389

30 Plug(CN871) CKS-786

31 Connector(CN471) CKS3834

32 Connector(CN581) CKS4124

33 Connector(CN801) CKS4811

34 Connector(CN472) CKS4822

35 Connector(CN101) CKS5271

36 Connector(CN541) CKS5523

37 Holder(CN402) CNC5399

38 Holder CND3129

39 Holder CND3133

40 Heat Sink CNR1837

Mark No. Description Part No.

50 Screw(M2 x 2) CBA1871

51 Cord CDE7392

52 Gear CNV7752

53 Gear CNV7753

54 Gear CNV7754

55 Gear CNV7755

56 Switch Unit CWS1389

57 Switch(S1) CSN1051

58 Spring Switch(S2) CSN1052

59 Arm Unit CXC2199

* 60 Chassis Unit CXC5680

61 Arm Unit CXC6623

62 Arm Unit CXC6624

63 Screw JFZ20P020FTC

64 Spring XBL7003

* 65 Holder XNC7017

* 66 Insulator XNM7119

* 67 Holder Unit XXA7399

* 68 Motor Unit(M10) XXA7400

* 69 Holder Unit XXA7401

* 70 Arm Unit XXA7403

* 71 Gear Unit XXA7424

72 Washer YE15FTC

73 CD Mechanism Module(S10.5) CXK5753

74 Screw ISS26P055FTC

75 Holder CND3606

76 Screw(M2 x 2) CBA1871

77 Screw CBA1935

78 Spring CBH2530

79 Connector CKS5273

80 Arm CNV6962

81 Guide CNV6967

82 Guide CNV8048

83 Screw(M2 x 3.5) XBA7002

84 Holder XNC7019

85 Flexible PCB XNP7026

86 Case Unit XXA7426

87 Transistor(Q462,701,711) 2SD2396

88 IC(IC331) PAL007B

A

B

C

D

E

41 FM/AM Tuner Unit(Y401) CWE1801

42 Holder CND2144

43 Fan Motor CXM1288

44 Connector(CN591) VKN1928

45 Remote Control Unit CXC5717

46 Cover CZN5357

47 Panel Unit CXC5737

48 Drive Unit CXC6620

49 Screw BMZ26P040FTC

56

DEH-P880PRS/XN/UC

F

7

8

19

1234

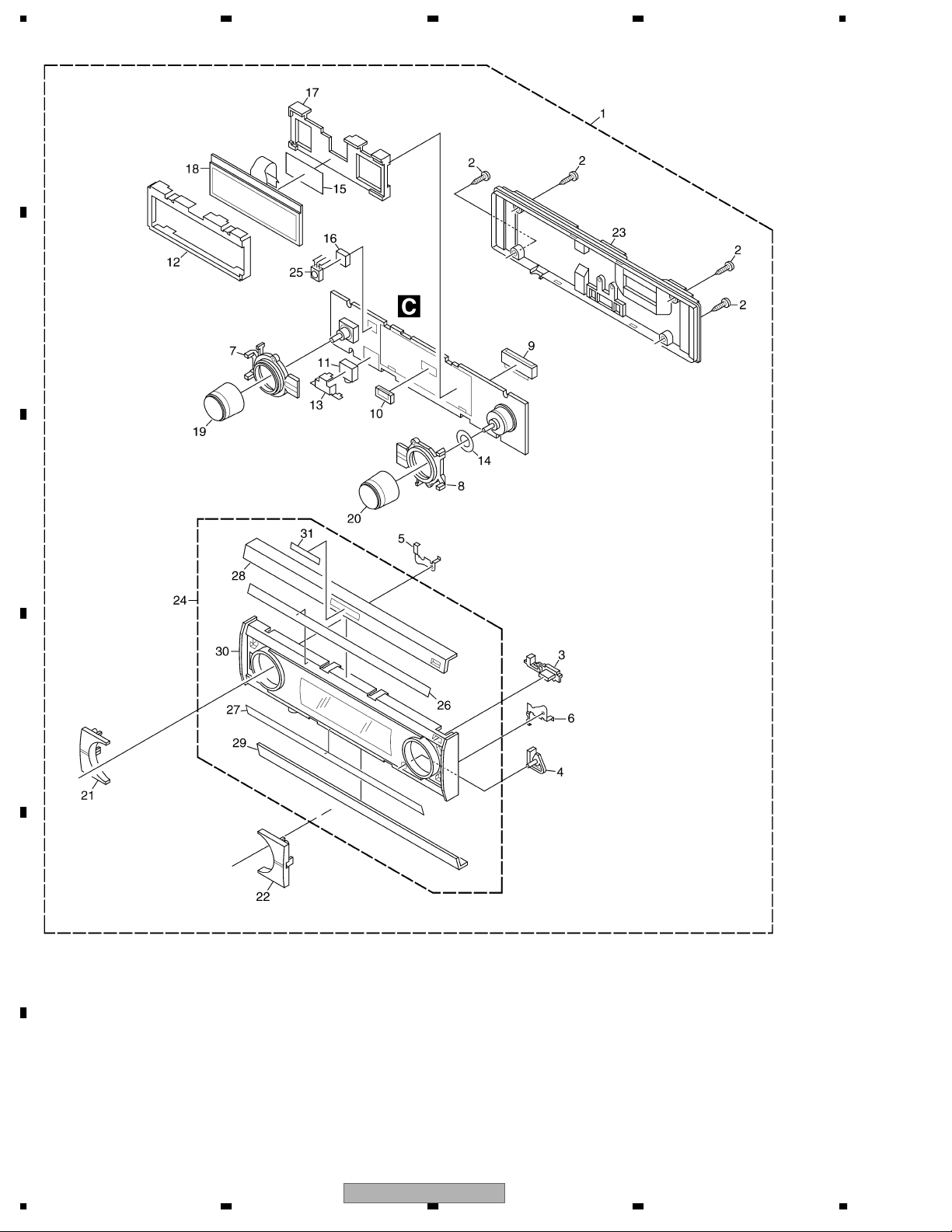

2.5 EXTERIOR(2)

A

B

C

D

E

F

20

1234

DEH-P880PRS/XN/UC

5678

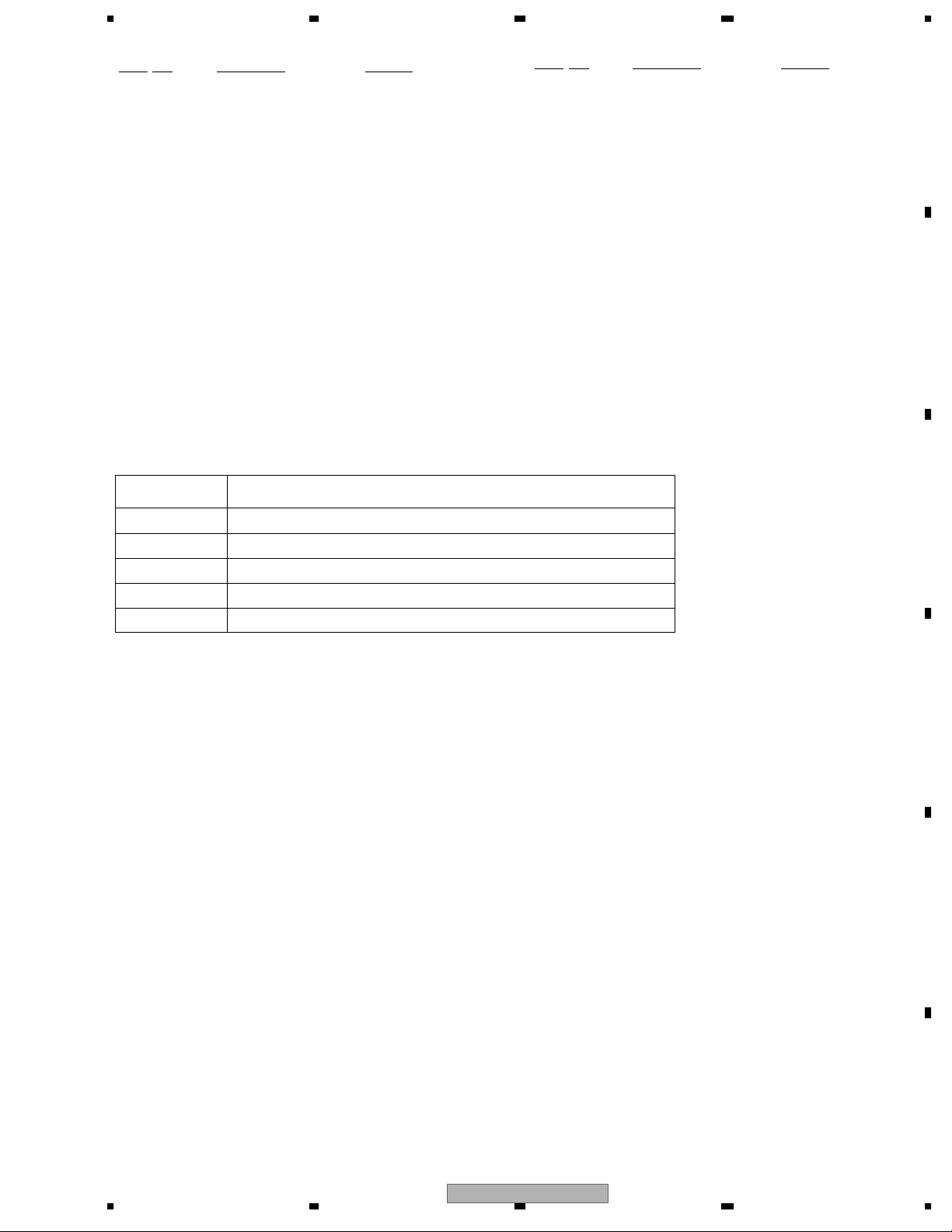

(1) EXTERIOR(2) SECTION PARTS LIST

Mark No. Description Part No.

1 Detach Grille Assy See Contrast table(2)

2 Screw BPZ20P080FTB

3 Button(EJECT) CAC9616

4 Button(RESET) CAC9617

5 Earth Plate CND3149

6 Earth Plate CND3150

7 Lighting Conductor CNV8923

8 Lighting Conductor CNV8924

9 Connector(CN1801) CKS5272

10 Connector(CN1861) CKS5545

11 Connector(CN1802) See Contrast table(2)

12 Holder CND3151

13 Holder CND3152

14 Sheet CNM8658

15 Double Sided Seal CNM8673

16 Cushion CNM9946

Mark No. Description Part No.

17 Holder CNV8925

18 OEL Unit MXS8232

19 Knob Unit(SOURCE,VOLUME) CXC5740

20 Knob Unit(MULTI-CONTROL) CXC5741

21 Button Unit(EQ/CLK) See Contrast table(2)

22 Button Unit(BAND/DISP) CXC5748

23 Cover Unit CXC5749

24 Sub Grille Assy See Contrast table(2)

25 IC(IC1902) GP1UX51RK

26 Double Sided Seal CNM9942

27 Double Sided Seal CNM9943

28 Panel See Contrast table(2)

29 Panel See Contrast table(2)

30 Grille Unit CXC5732

* 31 Badge See Contrast table(2)

A

B

(2) CONTRAST TABLE

DEH-P880PRS/XN/UC, DEH-P88RS/XN/EW5 and DEH-P80RS/XN/ES are constructed the same except for the

following:

Mark No. Description DEH-P880PRS/XN/UC DEH-P88RS/XN/EW5 DEH-P80RS/XN/ES

1 Detach Grille Assy CXC5764 CXC5763 CXC5765

11 Connector(CN1802) CKS5575 CKS3120(Mini Jack) CKS5575

21 Button Unit(EQ/CLK) CXC5745 CXC5744(EQ/TA) CXC5746

24 Sub Grille Assy CXC5823 CXC5822 CXC5824

28 Panel CNR1843 CNR1842 CNR1844

29 Panel CNR1847 CNR1846 CNR1846

* 31 Badge CAH1956 CAH1925 CAH1925

C

D

56

DEH-P880PRS/XN/UC

E

F

7

8

21

1234

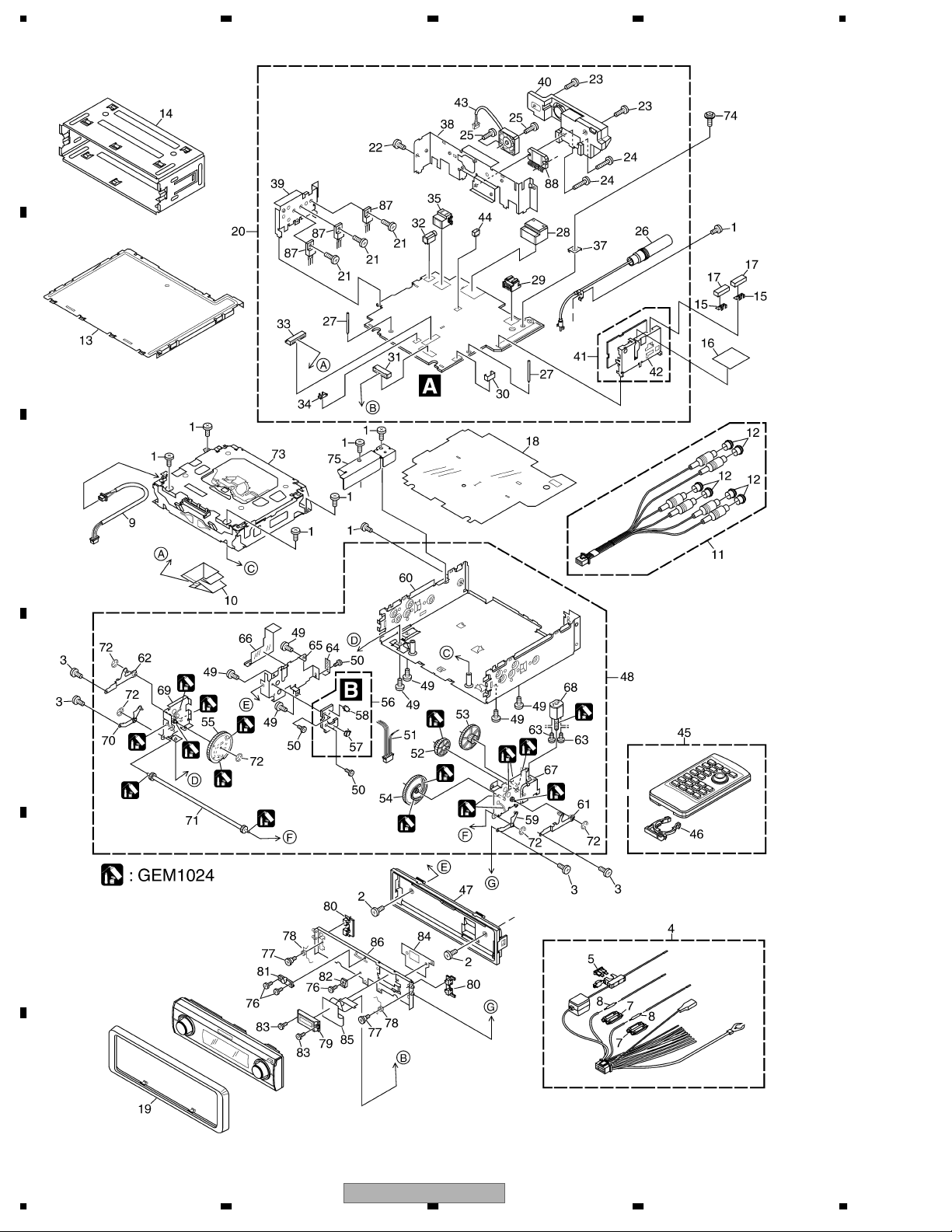

2.6 CD MECHANISM MODULE

A

B

C

D

E

F

22

1234

DEH-P880PRS/XN/UC

5678

CD MECHANISM MODULE SECTION PARTS LIST

Mark No. Description Part No.

1 CD Core Unit(S10.5COMP1) CWX3381

2 Connector(CN101) CKS4182

3 Connector(CN901) CKS4187

4 Screw BMZ20P025FTC

5 Screw BSZ20P040FTC

6 Screw(M2 x 3) CBA1511

7 Screw(M2 x 4) CBA1835

8 Washer CBF1038

9 •••••

10 Spring CBH2609

11 Spring CBH2612

12 Spring CBH2614

13 Spring CBH2616

14 Spring CBH2617

15 Spring CBH2620

16 Spring CBH2855

17 Spring CBH2937

18 Spring CBH2735

19 Spring CBH2854

20 Spring CBH2642

21 Spring CBH2856

22 Spring CBH2857

23 Spring CBH2860

24 Spring CBH2861

25 Spring CBL1686

26 Arm CND1909

27 Frame CND2582

28 Bracket CND2583

29 Arm CND2584

30 Lever CND2585

Mark No. Description Part No.

50 Rack CNV8342

51 Roller CNV8343

52 Holder CNV8344

53 Arm CNV8345

54 Guide CNV8347

55 Arm CNV8348

56 Arm CNV8349

57 Arm CNV8350

58 Clamper CNV8365

59 Arm CNV8386

60 Guide CNV8396

61 Arm CNV8413

62 Collar CNV8938

63 Motor Unit(M2) CXC4026

64 Arm Unit CXC4027

65 Chassis Unit CXC4028

66 Gear Unit CXC4029

67 Frame Unit CXC4031

68 Motor Unit(M1) CXC6742

69 Screw Unit CXC6359

70 Screw JFZ20P020FTC

71 Screw JGZ17P022FTC

72 Washer YE20FTC

73 Pickup Unit(P10.5)(Service) CXX1942

74 Screw IMS26P030FTC

75 Connector(CN902) CKS4979

A

B

C

D

31 Arm CND2586

32 Bracket CND2587

33 Arm CND2588

34 Lever CND2589

35 Holder CNV7201

36 Gear CNV7207

37 Gear CNV7208

38 Gear CNV7209

39 Gear CNV7210

40 Gear CNV7211

41 Gear CNV7212

42 Rack CNV7214

43 Arm CNV7216

44 Roller CNV7218

45 Gear CNV7219

46 Guide CNV7361

47 Gear CNV7595

48 Guide CNV7799

49 Arm CNV7805

56

DEH-P880PRS/XN/UC

E

F

7

8

23

U

V

E

M

O

O

P

C

P

L

T

E

E

E

C

K

C

3

3

T

P

C

O

N

O

S

O

K

8

7

7

_

/

_

Y

1234

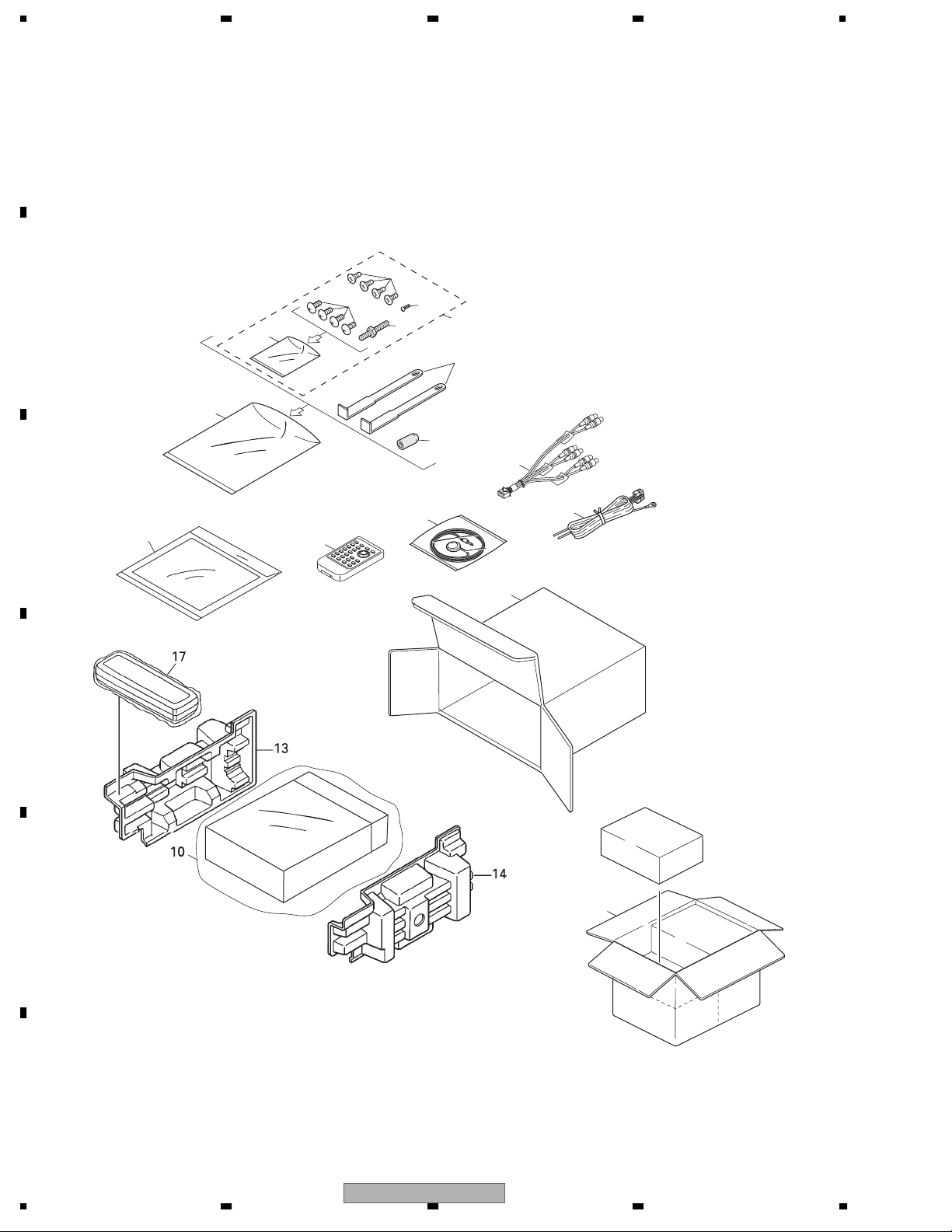

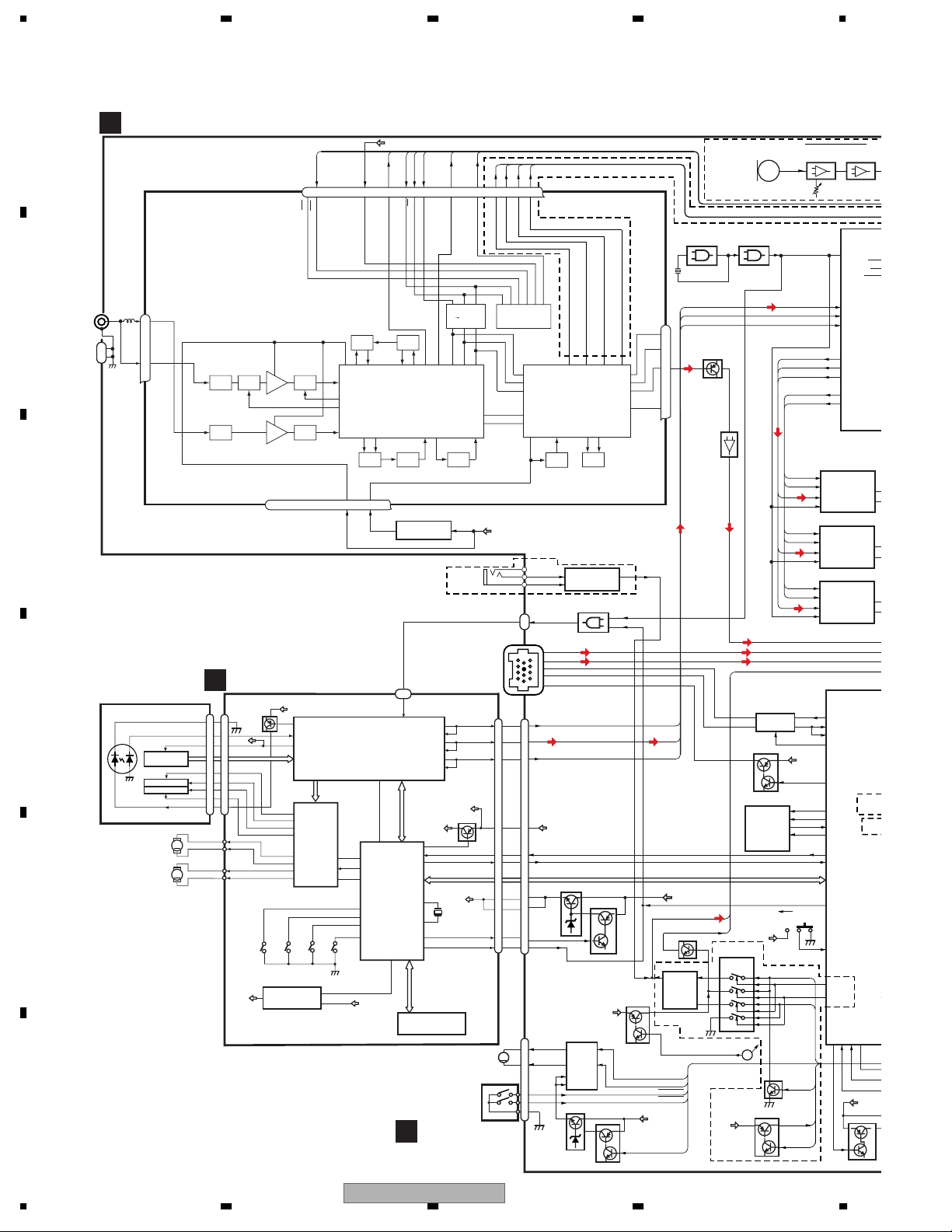

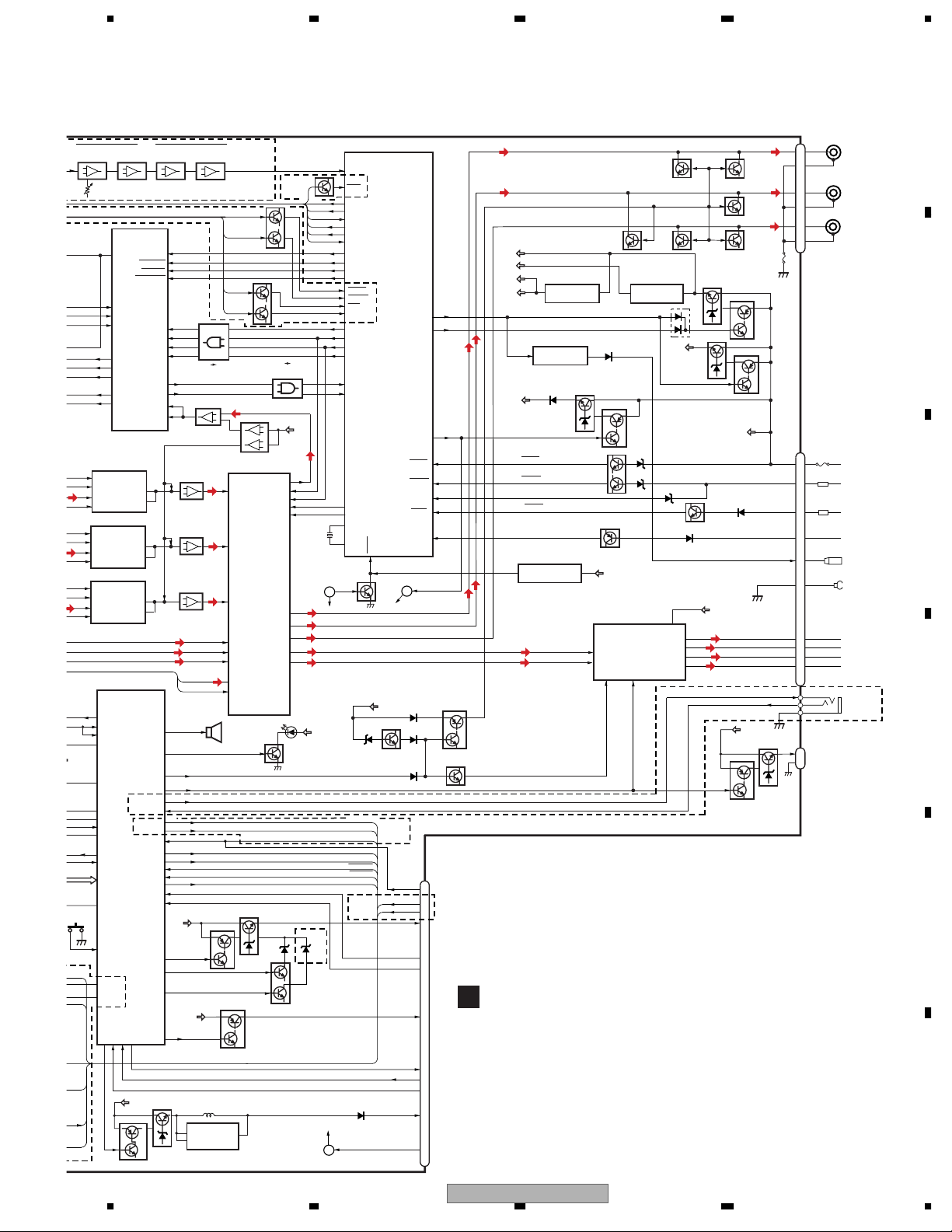

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

A

TUNER AMP UNIT

CE2

713510811

FM/AM TUNER UNIT

CN401

B

C

D

ANTENNA

1

2,3

1

2

CN402

PICKUP UNIT

(P10.5)(SERVICE)

LASER

DIODE

MONITOR

DIODE

LOAD/

AMANT

1

FMANT

3

HOLOGRAM

UNIT

FOCUS ACT.

TRACKING ACT.

SPINDLE

MOTOR

CARRIAGE

MOTOR

ATT

ATT

CD CORE UNIT(S10.5COMP1)

D

CN101

LD-

15

15

VREF

MD

FOM

FOP

TOP

TOM

LD+

Q101

5

5

REFO

88

AC,BD

F,E

FOM

33

FOP

2

2

TOP

1

1

TOM

44

14

14

M

M

69

WC

CE2

TANK

RFTANK

LPF

RF

RFGND

OSCGND

DGND

212 15 4 17

V3R3D

142

LD

143

PD

133

REFOUT

RF-AMP,CD DECODER,

MP3 , WMA, DECODER,

DIGITAL SERVO / DATA PROCESSOR

TD,FD

SD,MD

CD

12

FOM

DRIVER

11

FOP

14

TOP

13

TOM

IC301

BA5835FP

16

15

18

17

SOP

SOM

LCOP

LCOM

CLCONT

CONT

LOEJ

21

22

9

E

S905

S904

8EJ

12EJ

IC203

4

V3R3D

NJM2886DL3-33

+3.3V REGULATOR

F

A:DEH-P88RS/XN/EW5

S903

DSCSNS

S901

HOME

1

3

B:DEH-P880PRS/XN/UC

C:DEH-P80RS/XN/ES

ROMVDD

VCC

VDD

TUN3V

CN902

IC201

UPD63763CGJ

LOCK/RFOK

56

63

LOCK

41

CLCONT

40

LOEJ

47

CONT

PE5561A

CD CONTROLLER

32

12EJ

31

8EJ

30

DSCSNS

42

HOME

CD3VON

VD

VDD

SL

CK

DO

CE1

DI

SL

CK

CE1

LPFVCO

IC1

MIX/IF/PLL

TUN3V REGULATOR

IC401

3

NJM2885DL1-33

1

34

XTAL

LRCK

LRCKIN

DOUT

DIN

SCKO

SCKIN

SWVDD

XSO,XSI,WAIT,XINT

XRST,XASTB,ADO,XCK,

43

/CD3VON

14

RESET

44

LRCKOK

IC701

12

X1

13

X2

49

VDCONT

46

CD3VON

46

RO MD ATA

ROMCS,ROMCK,

IC704

BR93L56RFVM-W

EEPROM

SWITCH UNIT

B

DI

LDET

14 18

DO

LDET

IC4

5V 3.3V

1

REAR

AUX

A

IP-BUS

CN901

LRCK

50

49

DATA

46

45

BCLK

48

47

VDD

Q701

/RESET

LRCKOK

BRST,BRXEN,BSRQ

BDATA,BSCK

VD

X701

4.00MHz

VDCONT

MCKRQ

AUTO FLAP

AS

IC562(2/2)

MIC

4

MCK

IC101

HA12241FP

8

CSB

SCK

Q521

OUT

F

R

SW

SW

IPPW

SO

SI

S651

LRCKO

BCKO

LRCKO

BCKO

F

MCK

LRCKO

BCKO

R

MCK

LRCKO

BCKO

1

2

1

2

5

6

(NETWORK)

AUXL/MIC

AUXGND

JSNSON1

JCKSNS

JSNSON2

IC562(1/2)

NJM4558V

3

2

VR521

D/A CONVERTER

1

LRCK

2

BCK

3

DATA

5

SCK

D/A CONVERTER

1

LRCK

2

BCK

3

DATA

5

SCK

D/A CONVERTER

1

LRCK

2

BCK

3

DATA

5

SCK

28

TX

27

RX

19

8

BUP

9

70

68

69

67

53

51

36

NW

61

84

83

58

NJM4558V

1

5

DSP

IC121

AK7732V

43

XTI

CK_R

INIT_R

22

SDIN5A/JX0

25

BITCLK_I

26

LRCLK_I

37

SDOUT1

36

SDOUT2

35

SDOUT3

39

LRCLK_O

38

BITCLK_O

IC161

PCM1793DB

VoutL-

VoutL+

IC171

PCM1793DB

VoutL-

VoutL+

IC181

PCM1793DB

VoutL-

VoutL+

TUN L

BUSL+

BUSL-

SYSTEM

CONTROLLE

IC601(2/2)

PEG176A:A

PEG178A:B,

TX

RX

RX2

IPPW

ASENBO

KEYD(

ROMCSB

ROMSO

JSNS

ROMSI

JSNS

ROMSCK

CDRST

LRCKOK

FOP

MCKRQ

DSPMOD

AUXON

AEQON

DSENS

KYDT

DPDT

OELPW

34

91

33

BUP

Q842

OELPW

OEL+B REGULA

S_R

SCL

SDIN

JCK

FLP

FLP

FCLS

DIM

(PUC

7

C

RQ/

SI/

1

1

18

1

18

17

FL

M

AM

KE

FL

R

R

IL

DIM

SW

MIC521

MICROPHONE

19

RDSCK

SYSB

16

14

15

RDSDATA

20 21

RDSLOCK

IC3

EEPROM

RDSHSLK

CN541

1

5

7

6

CN472

CN101

CN471

IC2

DET/NC/MPC/MPX/DIV/RDS

OSCX-talCFIFT

REG

3

IC541

2

BA3121F

IC493

TC7SH08FUS1

4

MCKCD

BUSL+

7

11

BUSL-

5

1

8

COMP

16

RCH

24

LCH

23

DIVER

22

1

2

1

LRCKI

CDDT

BCKI

TC7SU04FU

2

X491

16.9344MHz

CDDT

BCKI

LRCKI

A

HIGH SPEED CLOCK

IC491

TC7S04FU

2

4

BUFFER

Q431

5

IC431

NJM4558V

7

BUSL+

BUSL-

BUS-

BUS+

IC492

IP-BUS DRIVER

5

6

Q101

EEPROM

VDD

10

11

10

8

VD

1

2

9

17

VDD

RESET

11

LRCKOK

13

Q462

VD

20

19

VDCOUNT

12

MCKRQ

4

CN871

FLM02

4

M

FLM01

5

FLOR

2

FLCL

3

1

MECHA VD

AUTO FLAP

MOTOR DRIVE

IC871

BA6288FS

14

OUT2 RIN

FINOUT1

4

VM

5

VCC

Q871

Q461

VDD

11

63

Q872

Q523

BUP

1

OUT1

FLPCLS

FLPOPN

FOPNSW

FCLSSW

FLPPW

BUP

IC522

BA3121F

Q522

VM1

IN1

AUXL

AUTOEQ

3

2

11

MIC/AUX

SELECT

TC4066BF

2

4

9

DALMON

VDD

B,C

IC521

IC631

BR25L320F-W

BRST,BRXEN,BSRQ

BDATA,BSCK

STD

(DSPMODE)

VDD

1

13

3

5

8

6

10

12

E

Q524

24

1234

DEH-P880PRS/XN/UC

3

KO

O

CKO

KO

CKO

KO

K

CKO

KO

R

TX

1

RX

2

BUP

BSRQ

NW

ETWORK)

L/MIC

XGND

SON1

KSNS

SON2

IC562(1/2)

NJM4558V

2

1

1

2

3

5

1

2

3

5

IC562(2/2)

NJM4558V NJM4558V

1

5

VR521

AK7732VT

43

XTI

22

SDIN5A/JX0

25

BITCLK_I

26

LRCLK_I

37

SDOUT1

36

SDOUT2

35

SDOUT3

39

LRCLK_O

38

BITCLK_O

D/A CONVERTER

IC161

LRCK

PCM1793DB

2

BCK

VoutL-

3

DATA

VoutL+

5

SCK

D/A CONVERTER

IC171

LRCK

PCM1793DB

BCK

VoutL-

DATA

VoutL+

SCK

D/A CONVERTER

IC181

LRCK

PCM1793DB

BCK

VoutL-

DATA

VoutL+

SCK

TUN L

BUSL+

BUSL-

SYSTEM

CONTROLLER

IC601(2/2)

PEG176A:A

28

PEG178A:B,C

TX

27

RX

19

RX2

8

IPPW

9

ASENBO

70

ROMCSB

68

ROMSO

69

ROMSI

67

ROMSCK

53

CDRST

51

LRCKOK

36

MCKRQ

61

DSPMOD

84

AUXON

83

AEQON

DSENS

KYDT

OELPW

34

91

58

33

Q842

OELPW

OEL+B REGULATOR

5678

ASL

IC561(1/2)

IC561(2/2)

31

28

29

27

8

14

11

20

9

RDY

10

SO

64

63

NJM2114M

5

NJM2114M

5

NJM2114M

5

AUXL

AUTOEQ

22

PEE

77

26

18

32

92

52

85

87

80

79

81

82

78

76

75

BUP

56

54

55

57

Q841

9.2V

DC-DC CONVERTER

NJM4558V

1

5

11

3

6

8

5V 3V

IC672

TC74VHC08FTS1

INPUT ADC

7

IC261

NJM4558MD

LPF

IC201

7

LPF

IC202

7

LPF

IC203

7

SWL

VDD

SWVDD

8

CD

IC841

7

SI

NJM2360M

FL

RL

ILM+B CONTROL

7

RDSLOCK

RDSHSLK

RDSCK

RDSDATA

A

12

1

4

9

TC74VHCT08AFTS1

4

1

6

5

BUFFER

3

1,2

6,7

5

ELECTRONIC VOLUME/

SOURCE SELECTOR

19

Vi1(FL)

FCKSEL

22

Vi3(RL)

IC281

PM9009A

25

Vi15(SWL)

11

Si4L

1

Si1L+

2

Si1L-

6

Si2L

9

Si3L

BUZZER

BZ601

Q821

Q822

Q823

SWVDD

Q861

Q862

1

CS

A

Q402

Q403

3V 5V

IC671

IC251

NJM4558MD

So1L

SCK

SDA

CS

Vo5a

Vo1a

Vo3a

Vo1b

Vo3b

FLAP ILM

Q831

Q401

A5V

16

44

43

45

46

15.000MHz

33

29

31

36

38

ASLIN

LDET

6

3

CE1

CE2

X601

DI

DO

CK

SL

VDD

B

3

7

DSP

IC121

CKM[2] CKM[2]

CK_RESET

S_RESET

INIT_RESET

RQ/CAD1

SCLK/SCL

SI/CAD0

SDIN3/JX2

AINL+

AINL-

18

17

18

17

18

17

FLPILM

MUTE

AMPPW

KEYD(EW)

KEYAD

JSNSON1

JSNSON2

JCKSNS

FLPCLS

FLPOPN

FOPNSW

FCLSSW

FLPPW

ROT0

ROT1

ILMPW

DIM_WH

DIM_BL

(PUC/JP)

DPDT

SWVDD

BUP

A

RCA OUT

SWL

DAC5V

REGULATOR

5

NJM2872F05

SYSPW

DSPPW

POWER AMP

VCC1/2,VCC3/4

IC331

PAL007B

STBYMUTE

IC721

Q356

Q355Q354

1,3

SYSB

REGULATOR

ILL SENSE

6,20

FL-

FL+

RL-

RL+

TUN8V

3

5

23

21

AUDIO8V

REGULATOR

Q711

Q701

Q921

BUP

A,B

93

ASLIN

17

LDET

1

TUNPCE1

2

TUNPCE2

98

TUNPDI

99

TUNPDO

100

TUNPCK

95

SL

44

42

CK_RST

43

DSPS_RST

41

INT_RST

89

RDSLK

39

RDS57K

16

RCK

90

RDT

46

DSPRQ

5

DSPCK

3

DSPOUT

40

RAMCLR

47

DSPRDY

4

DSPIN

21

EVOLCS

20

FCKSEL

13

XIN

11

XOUT

Q661

RST1

D

SWL

FL

RL

FL

RL

JSNSON1

JSNSON2

JCKSNS

FLPCLS

FLPOPN

FOPNSW

FCLSSW

FLPPW

B,C

D

SYSTEM

CONTROLLER

IC601(1/2)

PEG176A:A

PEG178A:B,C

DALMON

RESET

10

RESET

E

BUP

Q381

B,C

CN801

JACKSNS

AUXL

AUXGND

ROT0

ROT1

G5V

DPDT

KYDT

DSENS

OELB

RST

SYSPW

DSPPW

BSENS

ASENS

BATIND

ISENS

TELIN

DALMON

PRE-OUTMUTE

3

12

4

13

ILB

8

9

10

6

7

2

15

5

23

24

25

73

72

88

74

66

Q382

AMPMUTE

Q331

CN1801

C

FL

A8V

A5V

A3V

D3V

VDD

6

DALMON

BSENS

ASENS

BATIND

ISENS

TELIN

1

S-80835CNMC-B8U

AUDIO3V

REGULATOR

3

IC731

NJM2885DL1-33

B.REM

IC941

TPD1018F

BACKUP SENSE

ACC SENSE

RESET

IC661

FL

RL

1

1

VDD REGULATOR

Q751

Q752

Q911

Q931

TEL IN

2

VDD

12

FLIN

14

RLIN

22 4

AMPPW

SWL

Q353

Q351

Q352

Q712

Q702

BUP

BUP

FAN DRIVE

Q592

CN351

9

10

FL

1

2

RL

5

6

FU351

SW L

FRONT L

REAR L

B

CN901

Q591

BRE

KEYD

KEYAD

BUP

ACC

TEL

FL2

FL1

RL2

RL1

CN591

ILL

10

12

11

BUP

1

ACC

5

ILL

3

8

TEL

4

B.REM

2

GND

FL-

FL+

9

RL-

RL+

CN581

WIRED

REOTE

2

FAN

1

C

D

E

F

56

DEH-P880PRS/XN/UC

7

8

25

1234

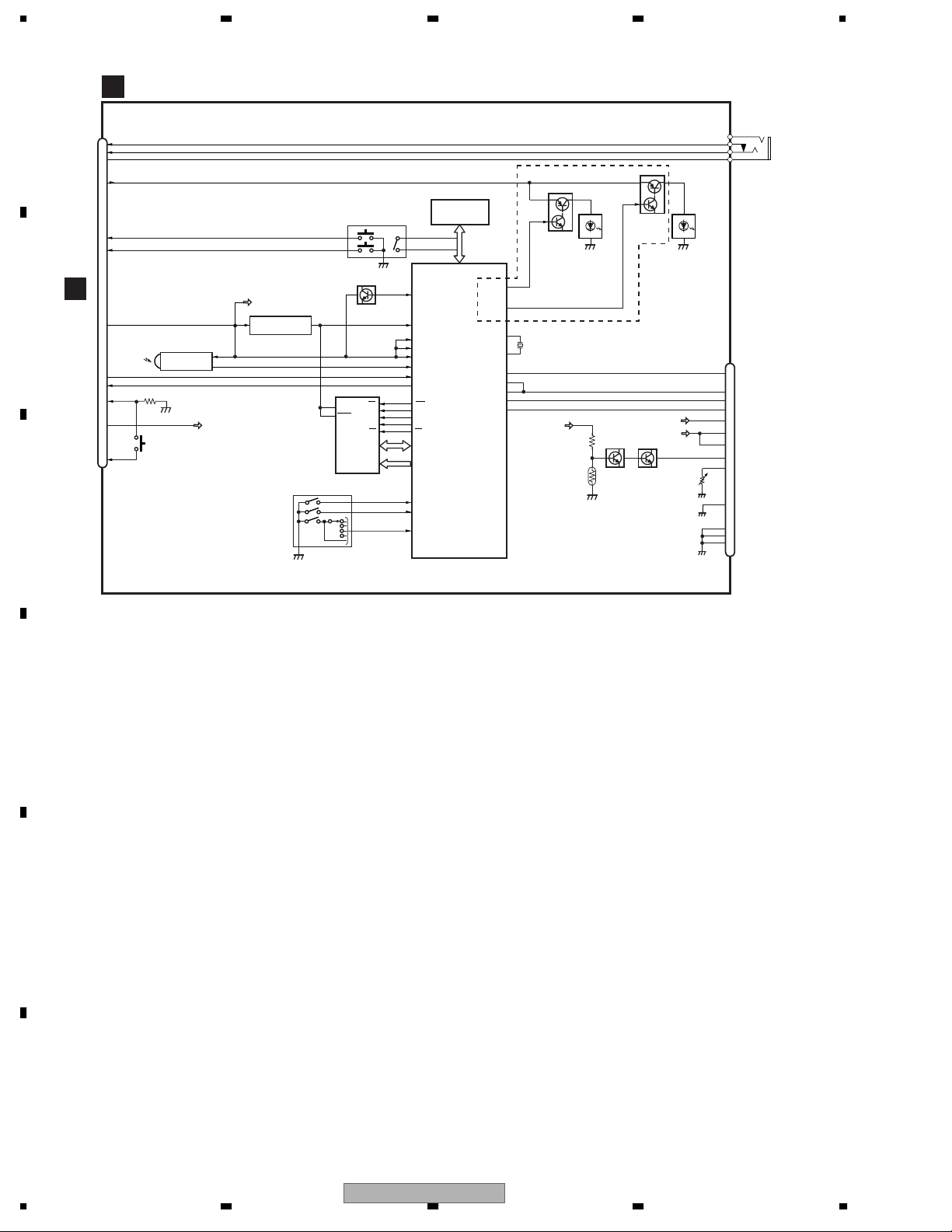

C

KEYBOARD UNIT

A

CN801

B

C

A

2

11

3

12

7

8

9

5

6

1

14

4

CN1801

JCKSENS

AUXL/MIC

AGND

ILM+B

ROT0

ROT1

SWVDD

DSENS

OEL+B

RST

OPT IN

(RESET)

REMOTE CONTROL

SENSOR

IC1902

GP1UX51RK

S1801

OEL+B

1

3

SWVDD

3V REGULATOR

4,5

S-818A33AUC-BGN

IC1904

1

23

VCC

33

BYTE/VPP

MULTI-CONTROL

S1811

VOL/ SOURCE

S1831

Q1833

ROM

CE

A17

A18

A19

OE

IC1905

PD8160A

12

3

2

43

14

DATA

ADDRESS

87

60

14

97

96

4

27

28

48

47

46

45

42

29

30

88

KEY MATRIX

S1832-S1836

KS0

KD2

KEY/OEL CONTROLLER

IC1903

PEG179A

OFFMODE

VCC2

VCC1

AVCC

Vref

REM

DPDT

KYDT

CSO

BANK0

BANK1

BANK2

RD

ROT1

ROT2

JOYST

KD0-2,KS0-1

BLUE

WHITE

XOUT

CLK0

OELD

DSEL

CN1802

AUXSENS

AUXL

AUXGND

CN1861

AVCC1

AVCC2

PGND1

PGND2

PGND3

VDD

CVCC

IREF

DGND

AUX/AEQ

CONNECTOR

12

11

10

9

8

5

6

OEL UNIT

14

2

7

1

13

15

Q1861

B

Q1832

Q1862

ILLUMINATION

(WHITE)

SWDVDD

OEL+B

VR1861

LED DRIVE

Q1831

ILLUMINATION

(BLUE)

90

89

13

XIN

X1901

11

16MHz

26

LS

24

CKD

35

33

22

OEL+B

A:DEH-P88RS/XN/EW5

B:DEH-P880PRS/XN/UC

C:DEH-P80RS/XN/ES

D

E

F

26

1234

DEH-P880PRS/XN/UC

5678

A

B

C

D

E

56

DEH-P880PRS/XN/UC

F

7

8

27

1234

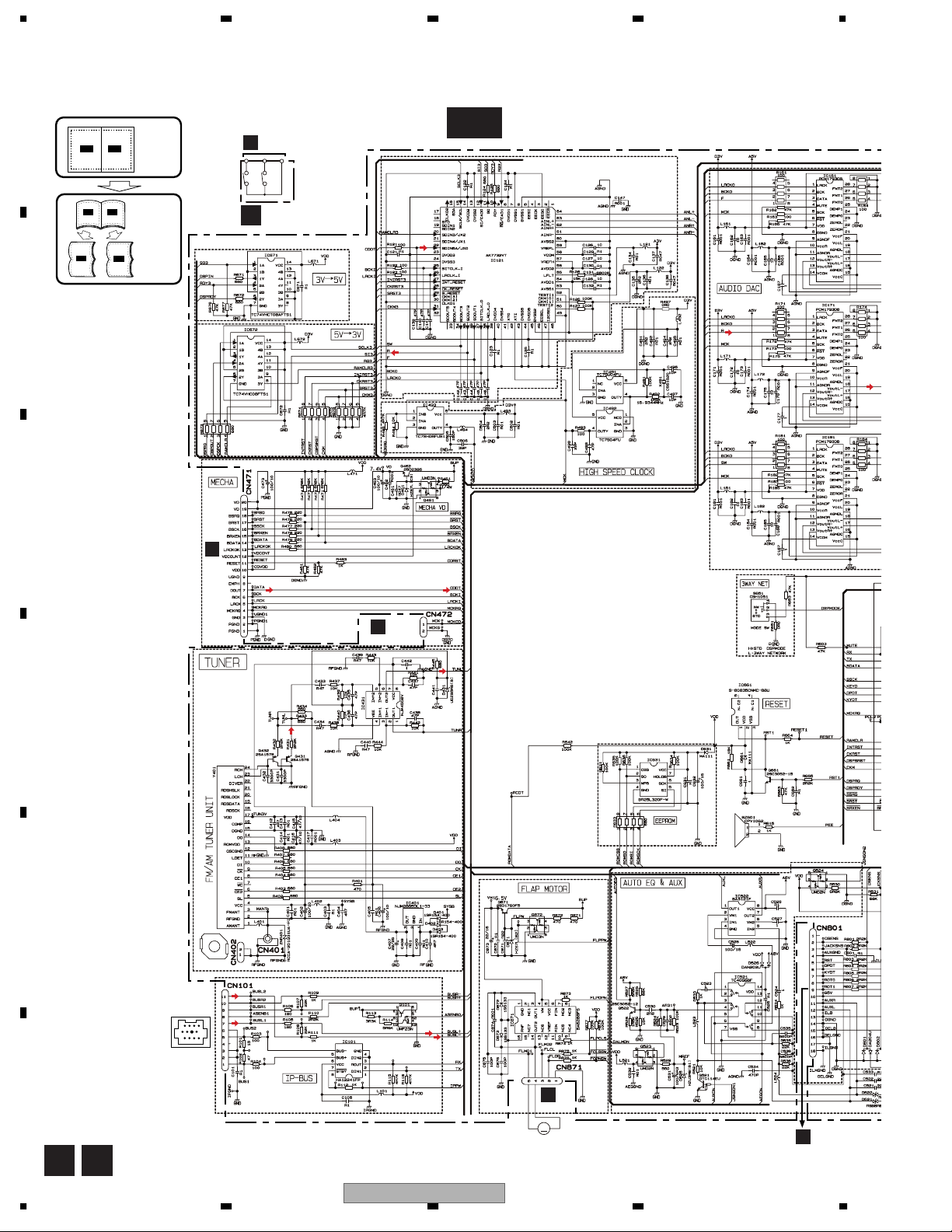

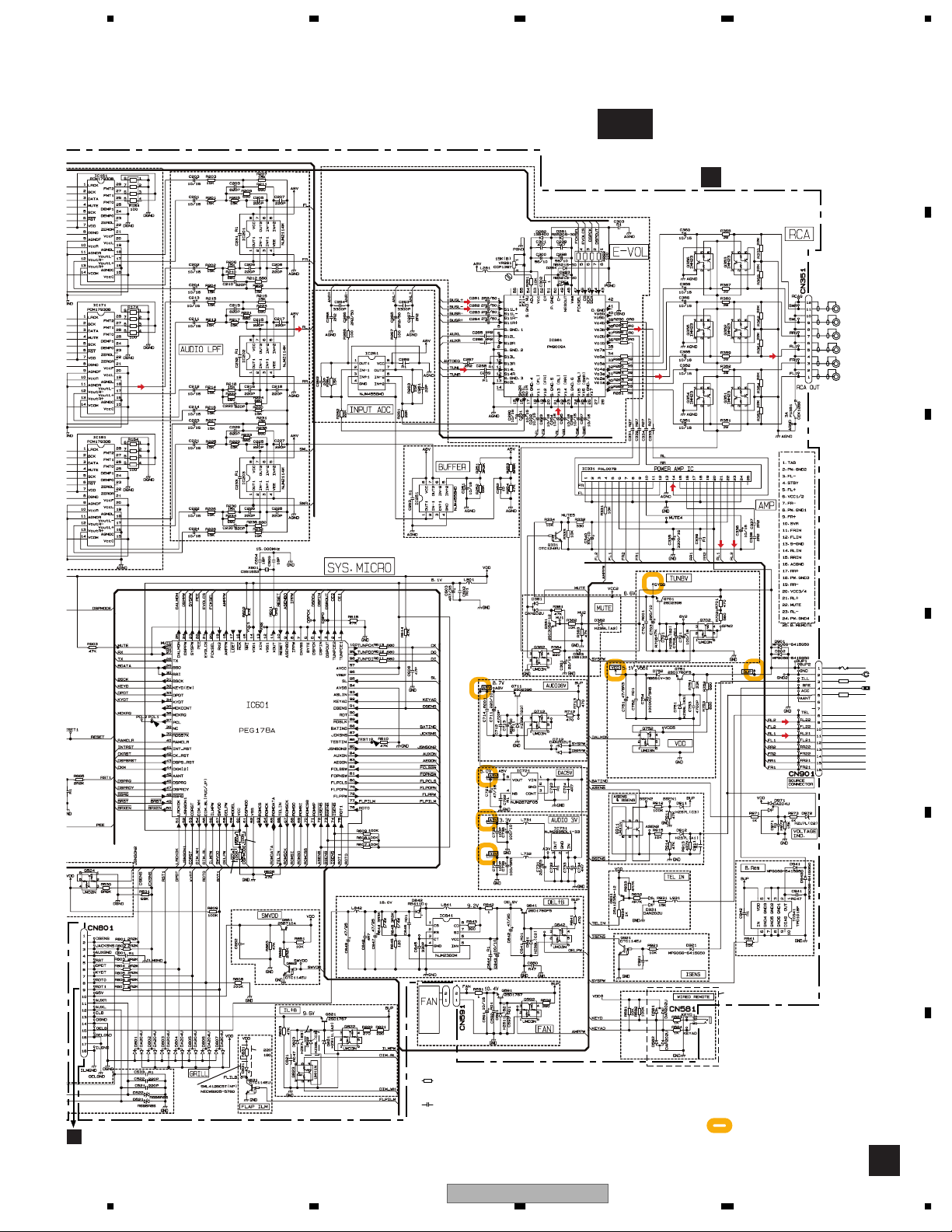

3.2 OVERALL CONNECTION DIAGRAM(UC, ES MODEL)(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A

A-a

A-a A-b

A-a

A-b

Large size

SCH diagram

Guide page

CN871

A

231

CSN1052

S2 OPEN

CSN1051

S1 CLOSE

SWITCH UNIT

B

A-b

Detailed page

A-a

B

C

D

CN901

CD:0dBs

: DEH-P880PRS/XN/UC

A

: DEH-P80RS/XN/ES

B

CN902

D

D

E

F

A B

28

FM(30%):-30.00dBs

AM(30%):-30.00dBs

CWE1802

IP-BUS:+2.20dBs

111098

65

7

2143

B

M

M10

FLAP MOTOR

XXA7400

C

CN1801

DEH-P880PRS/XN/UC

1234

5678

A

A-b

TUNER AMP UNIT

FM:-5.78dBs

AM:-5.78dBs

IP-BUS:+10.32dBs

CD:+10.08dBs

A

>

FM:+0.22dBs

AM:+0.22dBs

IP-BUS:+16.32dBs

CD:+16.08dBs

SUB

WOOFER

R CH

SUB

WOOFER

L CH

REAR

R CH

REAR

L CH

FRONT

R CH

FRONT

L CH

B

C

FM:+20.22dBs

AM:+20.22dBs

IP-BUS:+36.32dBs

CD:+36.08dBs

CEK1136

10A

>

BACKUP

GND

ILL

1K(1/2W)

B.REM

ACC

1K(1/2W)

TEL MUTE

RLFLRL+

FL+

RRFRRR+

FR+

D

B

A

E

C

CN1801

A

A :

B :

NOTE :

A :

B :

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

DEH-P880PRS/XN/UC

56

Decimal points for resistor

and capacitor fixed values

are expressed as :

←

2.2 2R2

←

0.022 R022

7

A

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

: The power supply is shown with the marked box.

8

F

A

29

A

B

A-b

1234

1 2 3

C

: DEH-P880PRS/XN/UC

: DEH-P80RS/XN/ES

A

B

A-b

A-a

A-a

D

CN902

D

E

F

A-a

30

CSN1052

CN871

231

A

S2 OPEN

CSN1051

SWITCH UNIT

S1 CLOSE

B

D

CD:0dBs

CN901

B

1234

DEH-P880PRS/XN/UC

Loading...

Loading...