Page 1

Service

TA

EQ

Manual

DEH-P4400R/XN/EW

MULTI-CD CONTROL HIGH POWER CD PLAYER WITH RDS TUNER

AUDIO

SELECT

SFEQ

ORDER NO.

CRT2772

DEH-P4400R

DEH-P4400R

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-977 CRT2624 S9 CD Mech. Module:Circuit Description,Mech. Description,Disassembly

/XN/EW

B

/XN/EW

/XN/EW

CONTENTS

1.SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . 3

2.EXPLODED VIEWS AND PARTS LIST . . . . . . . . 4

3.BLOCK DIAGRAM AND SCHEMATIC DIAGRAM 10

4.PCB CONNECTION DIAGRAM . . . . . . . . . . . . . . 24

5.ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . 32

6.ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.GENERAL INFORMATION . . . . . . . . . . . . . . . . . 46

7.1 DIAGNOSIS. . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1. 1 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . 46

7.1.2 CONNECTOR FUNCTION DESCRIPTION 49

7.2 PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.1 IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.2 DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.3 OPERATIONAL FLOW CHART . . . . . . . . . . . 61

7.4 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.OPERATIONS AND SPECIFICATIONS . . . . . . . . 62

For details, refer to "Important symbols for good services" on the next page.

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE NV Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2001

K-ZZU.NOV.20012000.printed in Japan

K-ZZU.NOV.2001.printed in Japan

Page 2

1234

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

A

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

B

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

- CD Player Service Precautions

1. For pickup unit(CXX1480) handling, please refer

to"Disassembly"(see page 46).

During replacement, handling precautions shall be

taken to prevent an electrostatic discharge(protection

by a jumper-solder).

2. During disassembly, be sure to turn the power off

C

since an internal IC might be destroyed when a connector is plugged or unplugged.

3. Please checking the grating after changing the pickup

unit(see page 40).

4. In this product, because the memory capacity of the

microcomputer is insufficient, the test mode is not

installed. However grating of the pickup unit can be

confirmed.

D

2

1234

DEH-P4400R/XN/EW

Page 3

A

B

5678

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

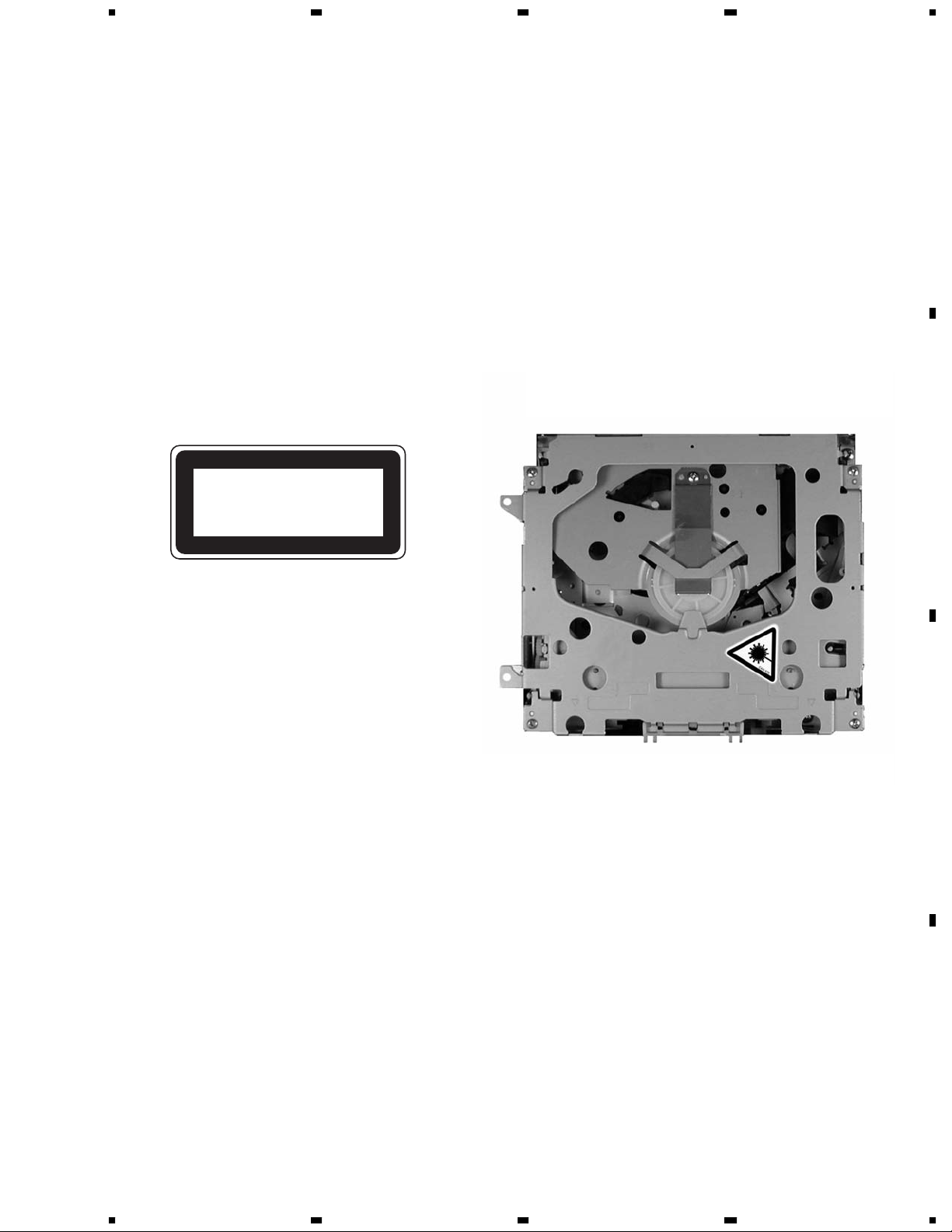

1. Safety Precautions for those who Service this Unit.

• When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer.

2. A “CLASS 1 LASER PRODUCT” label is affixed to the

bottom of the player.

3. The triangular label is attached to the mechanism

unit frame.

CLASS 1

LASER PRODUCT

4. Specifications of Laser Diode

Specifications of laser radiation fields to which human access is possible during service.

Wavelength = 800 nanometers

C

DEH-P4400R/XN/EW

56

D

3

7

8

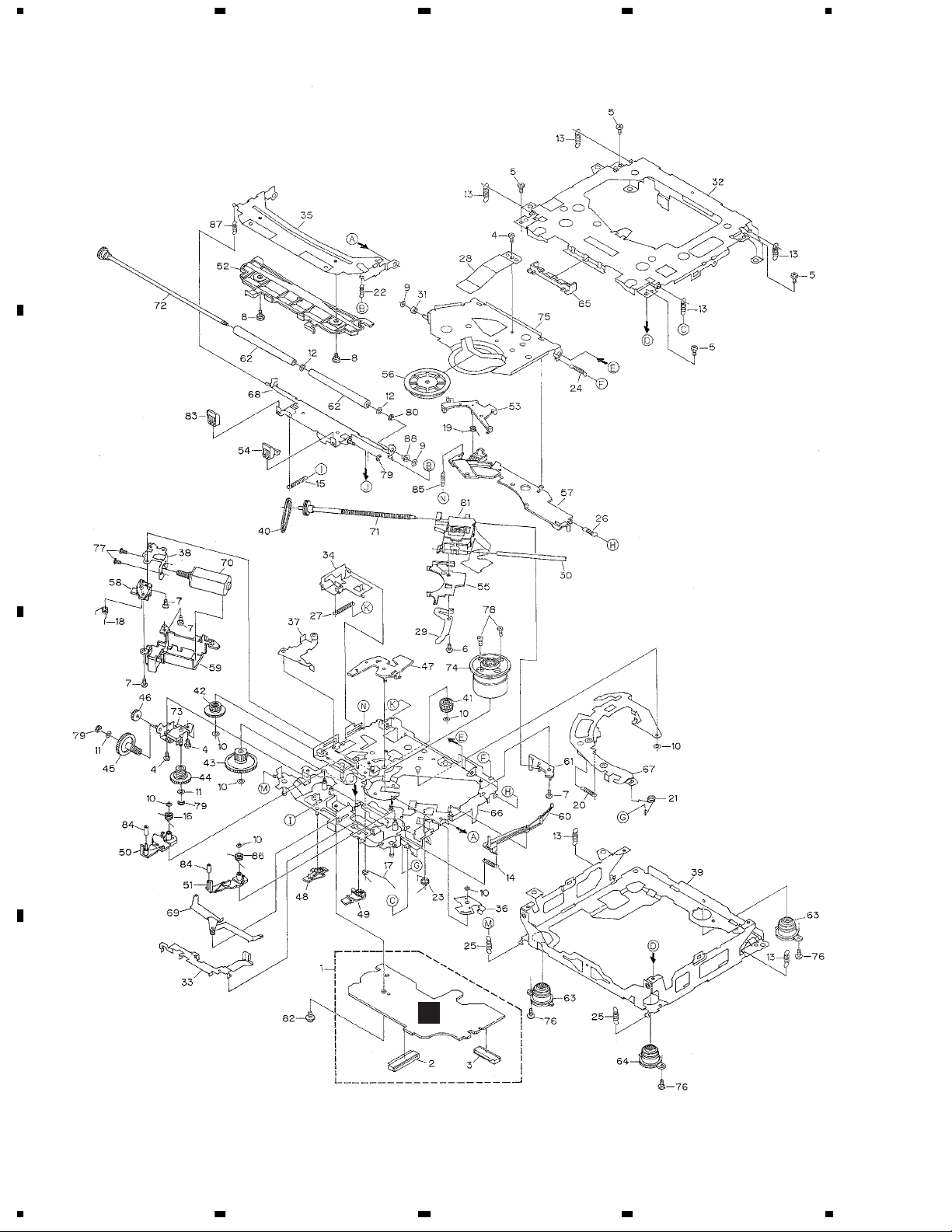

Page 4

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES : • Parts marked by "*" are generally unavailable because they are not in our Master Spare Parts List.

• Screw adjacent to mark on the product are used for disassembly.

"

• For the applying amount of lobricants or glue, follow the instructions in this manual.

A

(In the case of no amount instructions,apply as you think it appropriate.)

2.1 PACKING

3

4

12

10

B

5

6

7

15

16

14

8

2

1

9

PACKING PARTS LIST

C

Mark

No. Description Part No.

1 Cord Assy CDE6435

2 Inner Box CHW1754

3 Accessory Assy CEA3062

4 Screw CBA1002

5 Handle CNC5395

6 Bush CNV3930

* 7 Polyethylene Bag E36-615

8 Polyethylene Bag CEG-162

9 Carton(P4400R) CHG4552

Carton(P4400RB) CHG4555

10 Contain Box(P4400R) CHL4552

Contain Box(P4400RB) CHL4555

11 Protector CHP2251

D

12 Protector CHP2252

13-1 Polyethylene Bag CEG1116

13

11

Mark No. Description Part No.

13-2 Owner's Manual CRD3540

13-3 Owner's Manual CRD3541

13-4 Installation Manual CRD3555

* 13-5 Passport CRY1013

* 13-6 Warranty Card CRY1157

14 Case Assy CXB3520

15 Earth Plate CNC9450

16 Screw BPZ20P060FZK

4

1234

DEH-P4400R/XN/EW

Page 5

A

B

5678

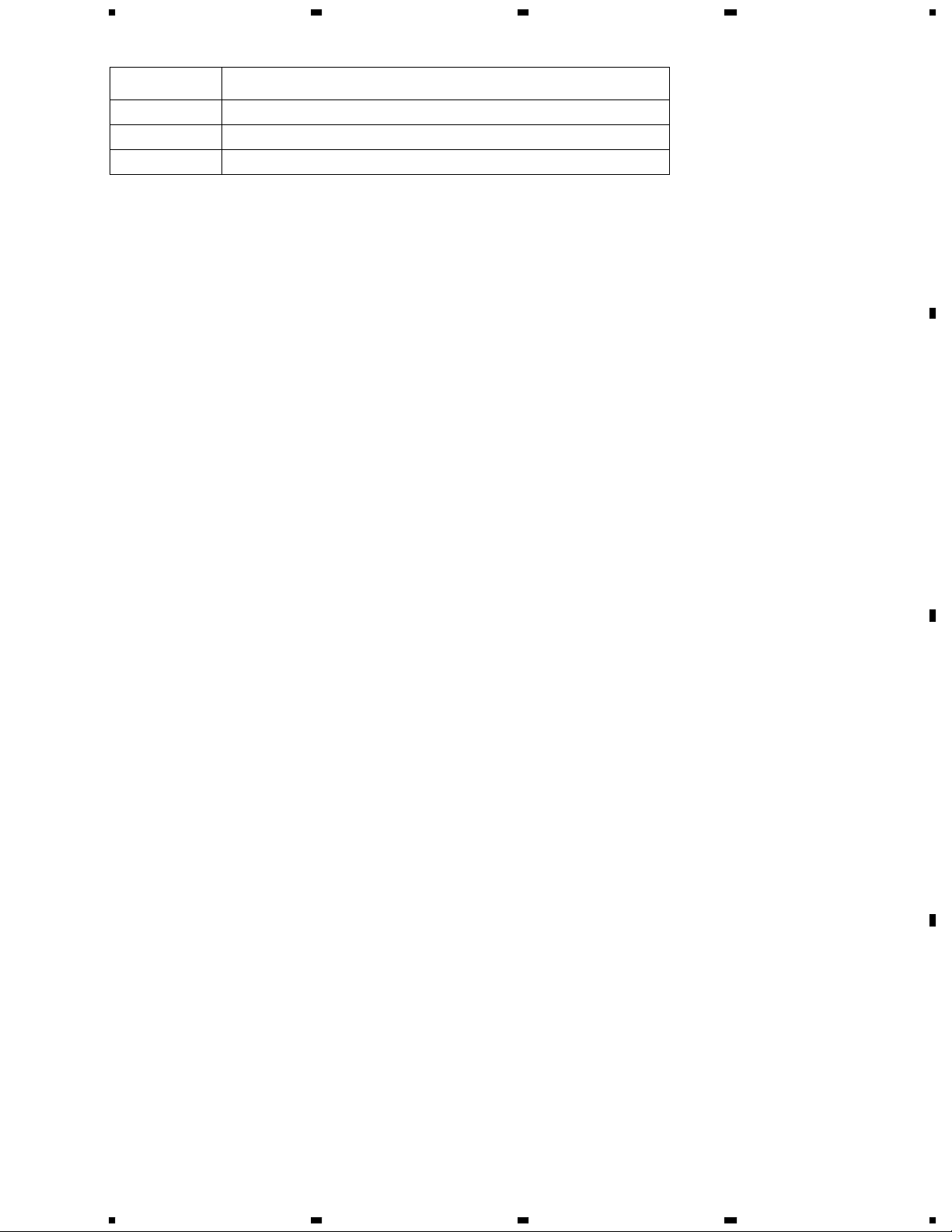

Owner's Manual,Installation Manual

Part No. Language

CRD3540 English, Spanish, German

CRD3541 French, Italian, Dutch

CRD3555 English, Spanish, German, French, Italian, Dutch

C

DEH-P4400R/XN/EW

56

D

5

7

8

Page 6

1234

2.2 EXTERIOR

A

B

C

D

6

1234

DEH-P4400R/XN/EW

Page 7

A

B

5678

EXTERIOR PARTS LIST

Mark

No. Description Part No.

1 Screw BMZ30P040FZK

2 Screw BMZ30P100FMC

3 Screw BSZ26P060FMC

4 Screw BSZ30P060FMC

5 Cord Assy CDE6435

6 Cap CKX-003

7 Cable CDE6610

8 Fuse(10A) CEK1136

9 Case CNB2686

10 Holder CNC5704

11 Holder CNC8659

12 Cushion CNM4870

13 Insulator CNM6948

14 Tuner Amp Unit CWM8010

15 Screw ASZ26P060FMC

16 Screw BPZ26P120FMC

17 Screw BSZ26P160FMC

18 Pin Jack(CN351) CKB1035

19 Holder(CN403) CNC5399

20 Plug(CN901) CKM1330

21 Plug(CN750) CKS3537

22 Connector(CN501) CKS3835

23 Antenna Jack(CN402) CKX1056

24 Holder CNC8615

25 Holder CNC9469

26 Insulator CNM6949

27 Heat Sink CNR1583

28 FM/AM Tuner Unit CWE1562

29 Holder CNC8815

30 Chassis Unit(P4400R) CXB8373

Chassis Unit(P4400RB) CXB8374

31 Button CAC6839

32 Screw(M2x2) CBA1176

33 Washer CBF1038

34 Washer CBF1039

35 Spring CBH2428

36 Spring CBH2429

37 Spring CBL1512

38 Holder CNC9096

39 Cover CNM6854

40 Panel CNS6930

41 Pin CNV6486

42 Lighting Conductor CNV6487

43 Gear CNV6507

44 Arm CNV6508

45 Panel Unit CWM7375

No. Description Part No.

Mark

46 Socket(CN1950) CKS3550

47 Connector(CN1951) CKS4206

48 Damper Unit CXB5070

49 Holder Unit CXB6356

50 Holder Unit CXB6357

51 Clutch Unit CXB6358

52 Screw IMS20P045FZK

53 Detach Grille Assy(P4400R) CXB8404

Detach Grille Assy(P4400RB) CXB8405

54 Screw BPZ20P100FZK

55 Button(1-6,SOURCE) CAC7225

56 Button(OPEN) CAC7227

57 Button(SFEQ) CAC7221

58 Button(EQ) CAC7231

59 Button(TA) CAC7232

60 Button(AUDIO) CAC7234

61 Button(LOCAL) CAC7235

62 Button(BSM) CAC7236

63 Knob CAA2699

64 Spring CBH2430

65 Spring CBH2431

66 Spring CBH2630

67 Cover CNS6740

68 Holder CNV6505

69 Holder CNV6506

70 Keyboard Unit(P4400R) CWM8306

Keyboard Unit(P4400RB) CWM8307

71 LCD(P4400R) CAW1627

LCD(P4400RB) CAW1668

72 Connector(CN1901) CKS4524

73 Holder CNC9053

74 Sheet CNM7647

75 Connector CNV6440

76 Lighting Conductor CNV6441

77 Sub Grille Assy(P4400R) CXB8612

Sub Grille Assy(P4400RB) CXB8613

78 CD Mechanism Module(S9ANA)CXK5501

79 Screw ISS26P055FUC

80 Transistor(Q510,Q910) 2SD2396

81 IC(IC361) PAL007A

82 Spring CBL1470

83 Cord Assy CDE6494

84 Cord Assy CDE6495

85 Clamper CEF1007

86 Connector(CN701) CKS3408

* 87 Plug(CN201) CKS1052

88 Connector(CN331) CKS3598

89 Film(P4400RB) CNM6983

C

D

DEH-P4400R/XN/EW

56

7

7

8

Page 8

1234

2.3 CD MECHANISM MODULE

A

B

C

D

D

8

1234

DEH-P4400R/XN/EW

Page 9

A

B

5678

CD MECHANISM MODULE PARTS LIST

Mark

No. Description Part No.

1 Control Unit CWX2481

2 Connector(CN701) CKS1959

3 Connector(CN101) CKS3486

4 Screw BMZ20P025FMC

5 Screw BSZ20P040FMC

6 Screw(M2x4) CBA1362

7 Screw(M2x3) CBA1527

8 Screw CBA1545

9 Washer CBF1037

10 Washer CBF1038

11 Washer CBF1039

12 Washer CBF1060

13 Spring CBH2378

14 Spring CBH2379

15 Spring CBH2514

16 Spring CBH2533

17 Spring CBH2382

18 Spring CBH2383

19 Spring CBH2384

20 Spring CBH2527

21 Spring CBH2386

22 Spring CBH2537

23 Spring CBH2390

24 Spring CBH2391

25 Spring CBH2523

26 Spring CBH2426

27 Spring CBH2444

28 Spring CBL1561

29 Spring CBL1553

30 Shaft CLA3845

31 Roller CLA3910

32 Frame CNC9654

33 Lever CNC9664

34 Lever CNC8949

35 Arm CNC9661

36 Arm CNC9016

37 Arm CNC9017

38 Bracket CNC9123

39 Frame CNC9656

40 Belt CNT1086

41 Gear CNV6886

42 Gear CNV6316

43 Gear CNV6317

44 Gear CNV6318

45 Gear CNV6319

No. Description Part No.

Mark

46 Gear CNV6320

47 Arm CNV6322

48 Arm CNV6323

49 Arm CNV6324

50 Arm CNV6888

51 Arm CNV6889

52 Guide CNV6327

53 Arm CNV6924

54 Guide CNV6921

55 Rack CNV6923

56 Clamper CNV6331

57 Arm CNV6332

58 Guide CNV6333

59 Cover CNV6334

60 Arm CNV6335

61 Guide CNV6336

62 Roller CNV6338

63 Damper CNV6339

64 Damper CNV6340

65 Guide CNV6925

66 Chassis Unit CXB7980

* 67 Arm Unit CXB7983

68 Arm Unit CXB7984

69 Arm Unit CXB7985

70 Motor Unit(M2) CXB5903

71 Screw Unit CXB5904

72 Gear Unit CXB8076

73 Bracket Unit CXB7982

74 Motor Unit(M1) CXB6007

75 Arm Unit CXB8504

76 Screw(M2x5) EBA1028

77 Screw JFZ20P020FMC

78 Screw JGZ17P020FZK

79 Washer YE15FUC

80 Washer YE20FUC

81 Pickup Unit(Service)(P9) CXX1480

82 Screw IMS26P030FMC

83 Guide CNV6922

84 Roller CNV6887

85 Spring CBH2509

86 Spring CBH2512

87 Spring CBH2536

88 Collar CNV6906

C

D

DEH-P4400R/XN/EW

56

9

7

8

Page 10

E

K

e

O

N

S

C

5

N

C

C

8

T

m

P

1234

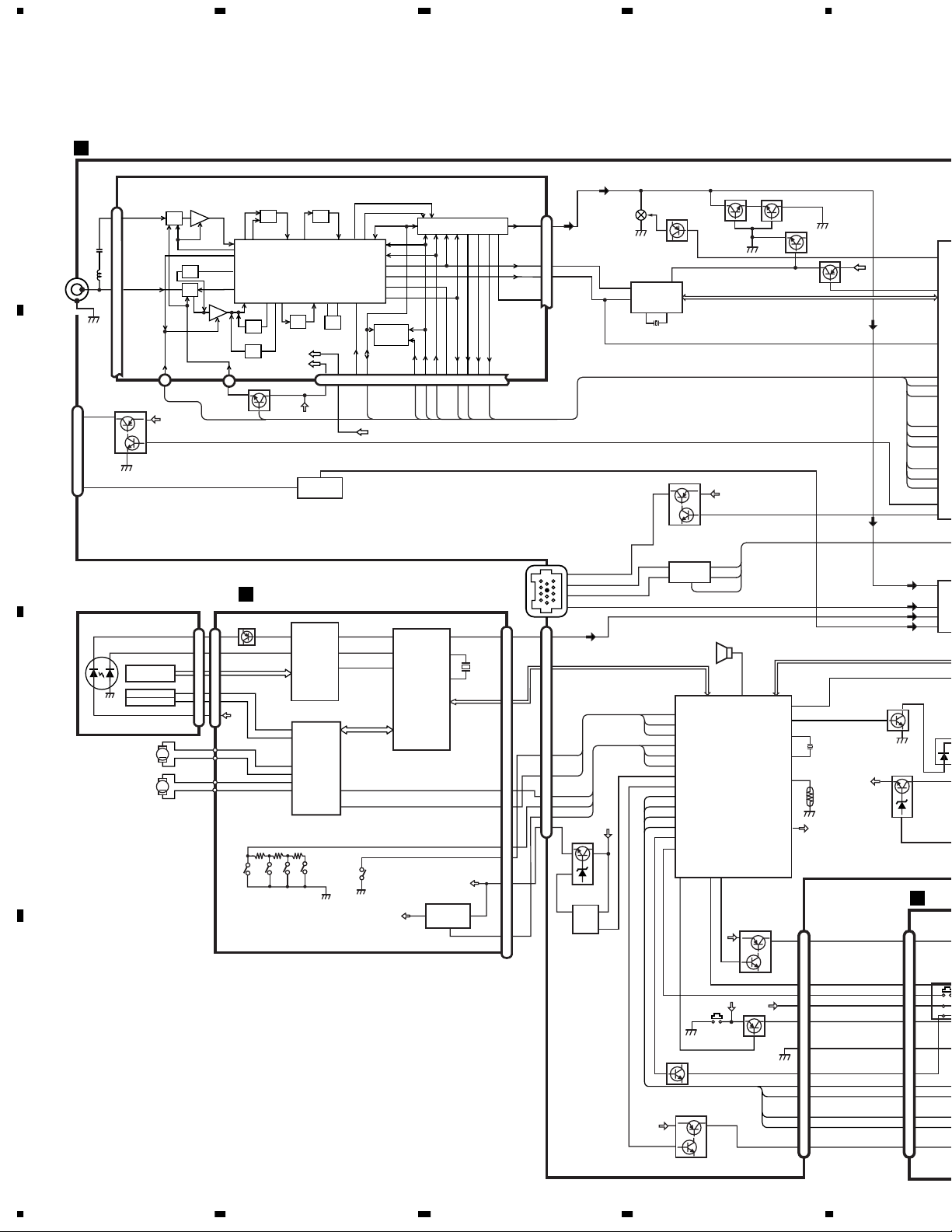

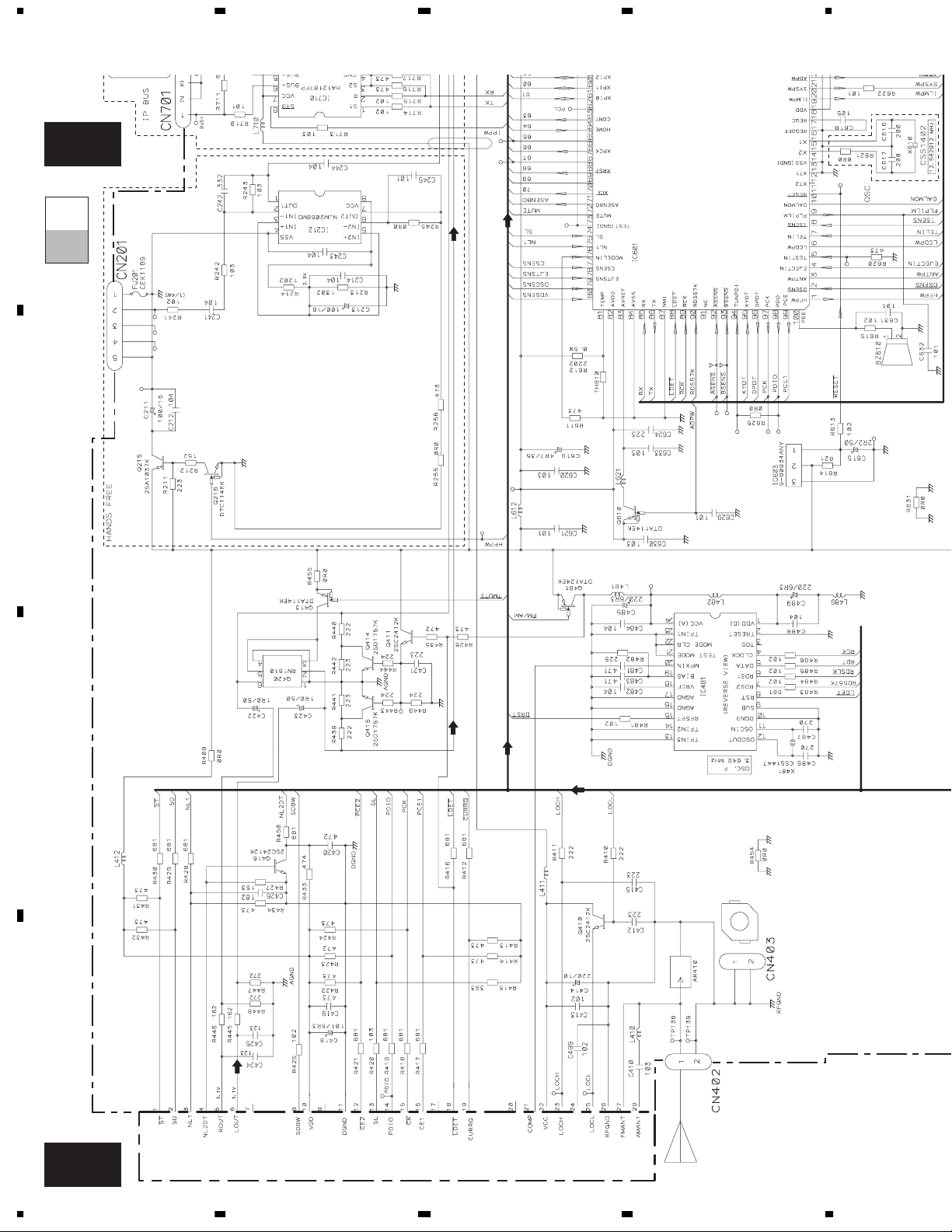

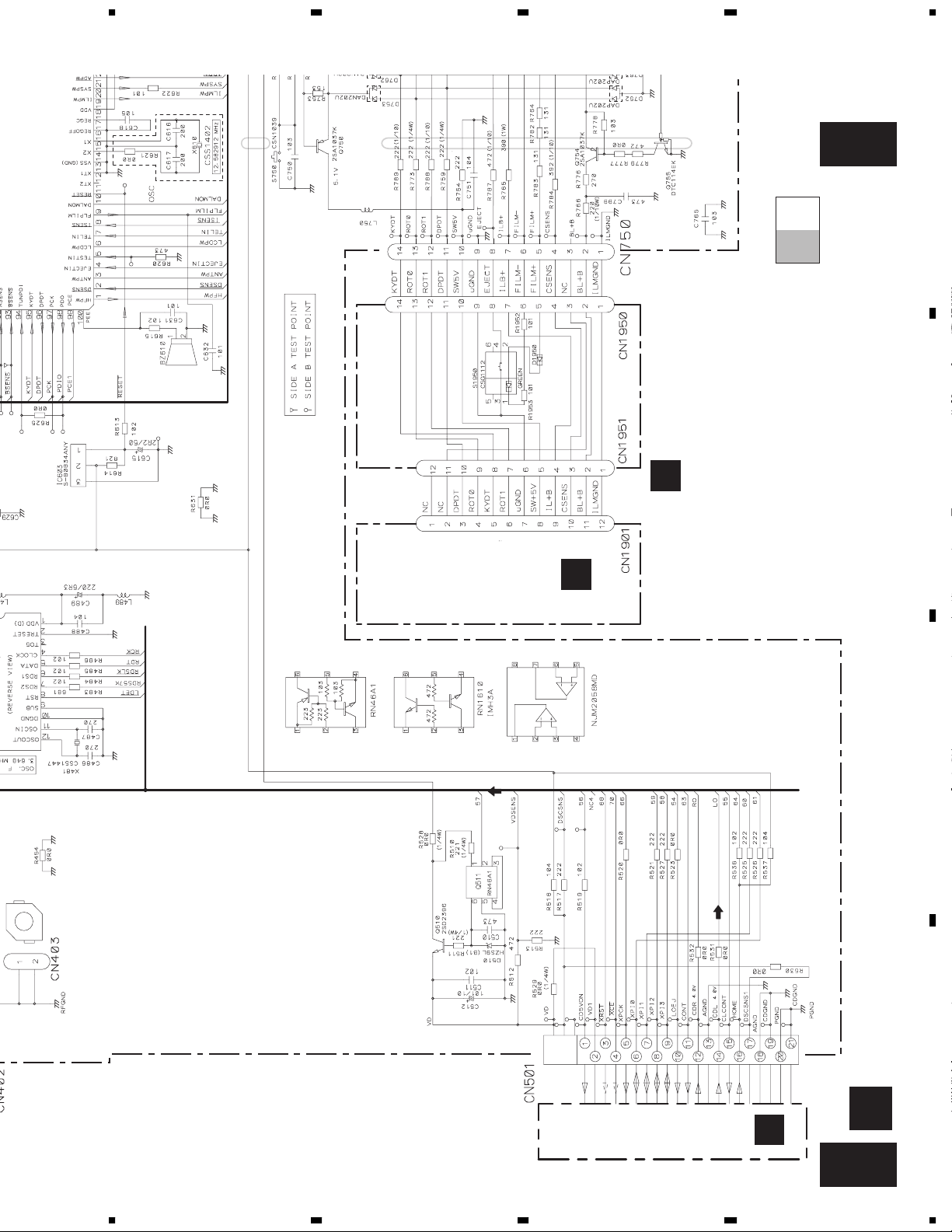

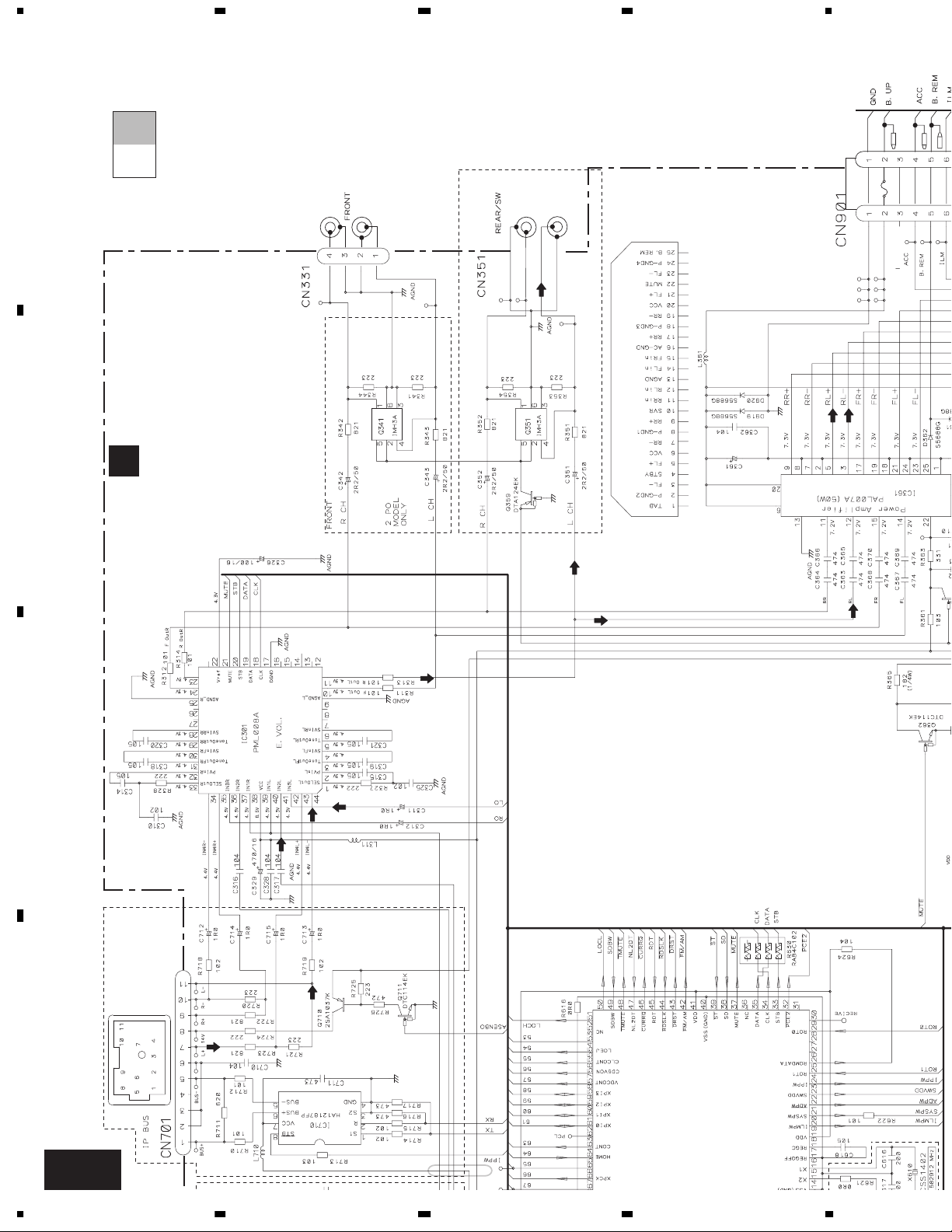

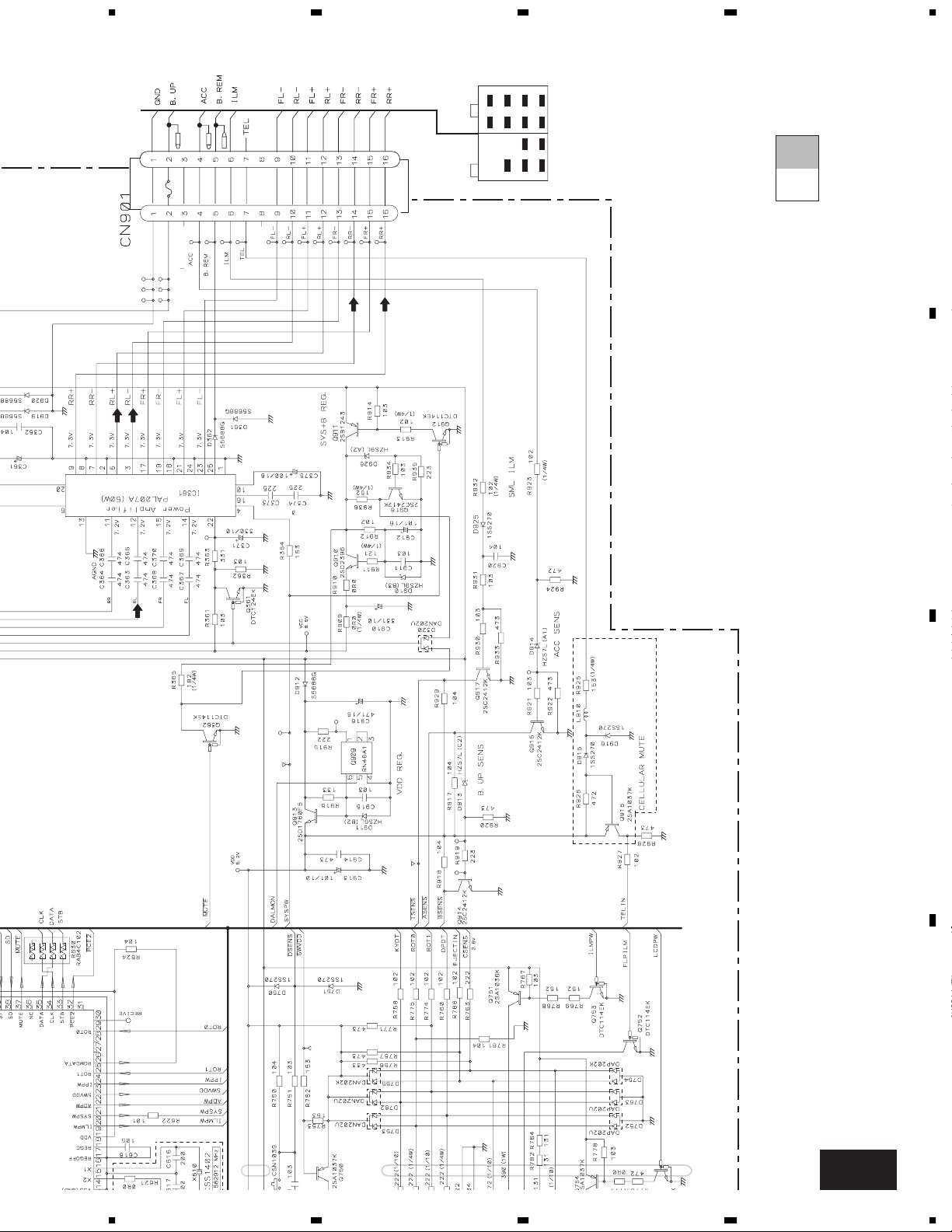

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

TUNER AMP UNIT

A

B

C

D

A

FM/AM TUNER UNIT

AMANT

28

ANT

CN402

27

7

9

11

17

20

24

26

CN201

5

2

PICKUP UNIT(SERVICE)(P9)

LASER

DIODE

MONITOR

DIODE

LOAD/

10

1234

FMANT

WC

NC

DGND

NC

NC

FMLOCL

RFGND

Q215

Q216

HOLOGRAM

UNIT

FOCUS ACT.

TRACKING ACT.

SPINDLE

MOTOR

CARRIAGE

MOTOR

ATT

LOCH

23

VDD

M

M

AMRF

ANT ADJ

ATT

LD-

MD

FO+

TO+

LD+

FM/AM 1ST IF 10.7MHz

FMRF

IMG ADJ

RF ADJ

LOCL

25

LOCH

D

CN101

Q101

15

5

AC,BD

F,E

FOP

4

TOP

1

14

VDD

CLAMP

SENSE

T51 Q51 CF51

CF52 CF53

IC1

MIXER, IF AMP, DET.

CF202

AM 2ND IF

10.25MHz

450kHz

VDD

VCC

Q410

VCC

LOCL

1

2

IC 212

NJM2068MD

CONTROL UNIT

9

LDO

RFRPIN

8

MDI

RF-AMP

IC 101

TA2153FN

12

FOP

14

TOP

CD

DRIVER

16

SOP

15

SOM

17

LCOP

18

LCOM

IC 401

BA5996FM

12EJ

DISC

SENSE

SENSE

8EJ

SENSE

MPXREF 41kHz

AMDET

X901

22 19 12 15 16 8

10

FEO

TEO

LOEJ

MUTE

S901

HOME

IC 3

EEPROM

DI/DO

CREQ

14

PDIO

24

16

14

TD/FD

SD/MD

22

9

CE2CKCE1

VDD

38

43

46

RFI

FEI

TEI

SERVO

CONTROL,

DSP,

LPF, DAC

IC 201

TC9495F2

L_OUT

+5V REGULATOR

4

VDD

BA05SFP

DEH-P4400R/XN/EW

IC 2 FM MPX

SDBWSLFMSD

13 3

2

85

78

79

VD

IC 701

1

NL1

CN701

L-OUT

CONT

DSCSNS

HOME

2

CD5VON

STIND

1

LOEJ

Q420

20

8

COMP

LDET

L ch

6

21

18

NL2

4

CN701

8

BUS–

5

BUS+

1

BUS+L

7

14

16

11

10

17

1

2

CN501

6

Q510

Q511

B.U

1

5

14

10

11

17

16

VD

2

1

RDS

DECODER

IC 481

PM4009A

X481

Q416

IP-BUS DRIVER

B.U

Q413

1211

Q710

Q711

5

IC 710

6

HA12187FP

BUZZER

64

HOME

53

EJECT

63

CONT

54

LOEJ

79

DSCSNS

56

CD5VON

57

VDCONT

6

LCDPW

96

DPDT

95

KYDT

29

ROT0

25

ROT1

9

FLPILM

4

EJECTIN

Q752

1

2

8

IPPW

BZ610

ALARM

CONTROLLER

CSENS

SWVDD

23 20

77

S750

DETACH

SENSE SW

Q754

Q755

Q415

B.U

TX

RX

100

PEE

SYSTEM

IC 601(2/2)

PE5245A

ILMPW

B.U

VDD

Q751

Q753

Q414

Q411

MUTE

mute

TEMP

SYSPW

Q481

72

37

16

X1

X2

15

81

21

X610

TH601

SYSPW

VDD

Q362

mute

Q910

VCC

CN750

ILB+

7

CSENS

4

EJECT

8

FILM+

55

B.U

SW5V

10

Q750

99

FILM–

66

DPDT

11

KYDT

14

ROT1

12

ROT0

13

BL+B

2

7

4

8

10

11

14

12

13

2

42

88

32

38

39

50

51

74

97

98

99

71

41

44

42

40

B

CN1950

48

1

PA

EJEC

t

pc

SD

st

LO

LO

SL

PC

PD

PC

HF

AS

TU

BU

CD

IN1

Q91

S19

Page 11

A

B

R

5678

100

EE

TEM

OLLER

1(2/2)

245A

Q414

MUTE

mute

TEMP

SYSPW

RESET

1

IC 603

S-80834ANY

Q411

Q481

72

37

16

X1

X2

15

81

21

X610

TH601

SYSPW

VDD

32

38

39

50

51

74

97

98

99

71

41

44

42

40

Q362

mute

Q910

VCC

11

48

tmute

reset

42

88

1

SYSTEM

CONTROLLER

IC 601(1/2)

PE5245A

pce@

SD

st

LOCL

LOCH

SL

PCK

PDO

PCE1

HFPW

ASENBO

ELECTRONIC VOLUME/

SOURCE SELECTOR

TUN L

BUS+L

CD L

IN1L

Q918

86 85 24

IC 301

PML008A

MUTE

20

TXRXIPPW

Q911

Q912

2

adpw

AVREF

DALMON

bsens

asens

isens

Fout L

Rout L

SYSPW

VDD

Q913

VDD

1

VDD

Q610

22

83

10

93

92

8

6

Q909

5

B.U

Q914

Q915

Q917

CN901

BACK UP

B.U

B.U

GND

ACC

15

16

13

ILM

11

BACK UP

15

GND

16

ACC

13

ILM

11

10

11

Q361

B.U

14

FLIN

12

RLIN

22 4 25

VCC

IC 361

PAL007A

SYSPW

POWER AMP

RL–

RL+

FL–

FL+

B.REMSTBYMUTE

Q359

3

5 RL+

23 FL–

21 FL+

B.REM

Q341

Q351

RL–

CN331

CN351

7

5

8

6

12

1

2

Lch

5

8

6

12

FRONT

REAR/SW

RL+

FL–

FL+

B.REM

BACK UP

ILL

GND

B.REM

ACC

RR–

FR–

FL–

RL–

RR+

FR+

FL+

RL+

C

RL–

7

Q751

Q753

KEYBOARD UNIT

KEY MATRIX

7

C

D

LCD

11

8

PANEL UNIT

B

CN750

ILB+

7

CSENS

4

EJECT

8

FILM+

B.U

55

SW5V

10

Q750

99

FILM–

66

DPDT

11

KYDT

14

ROT1

12

ROT0

13

BL+B

2

CN1950

7

4

8

10

11

14

12

13

2

CN1951

EJECT SW

S1950

CN1901

IL+B

4

9

CSENS

3

10

µGND

6

7

SW5V

5

8

DPDT

10

3

KYDT

8

5

7

6

9

4

2

11

RDT1

RDT0

BL+B

S1922

REMOTE CONTROL

SENSOR

IC 1902

OPT IN

RS-140

X1901

Q1905

1

3

23 10

VDD

9

REMIN

DPDT

8

KYDT

X0

X1

DIMMER

7

LCD DRIVER

IC 1903

PD6294A

3

2

KEY DATA

LCD DATA

DEH-P4400R/XN/EW

56

Page 12

d

e

i

A-a

A-b

A-a

A-b

A-b

A-a

1234

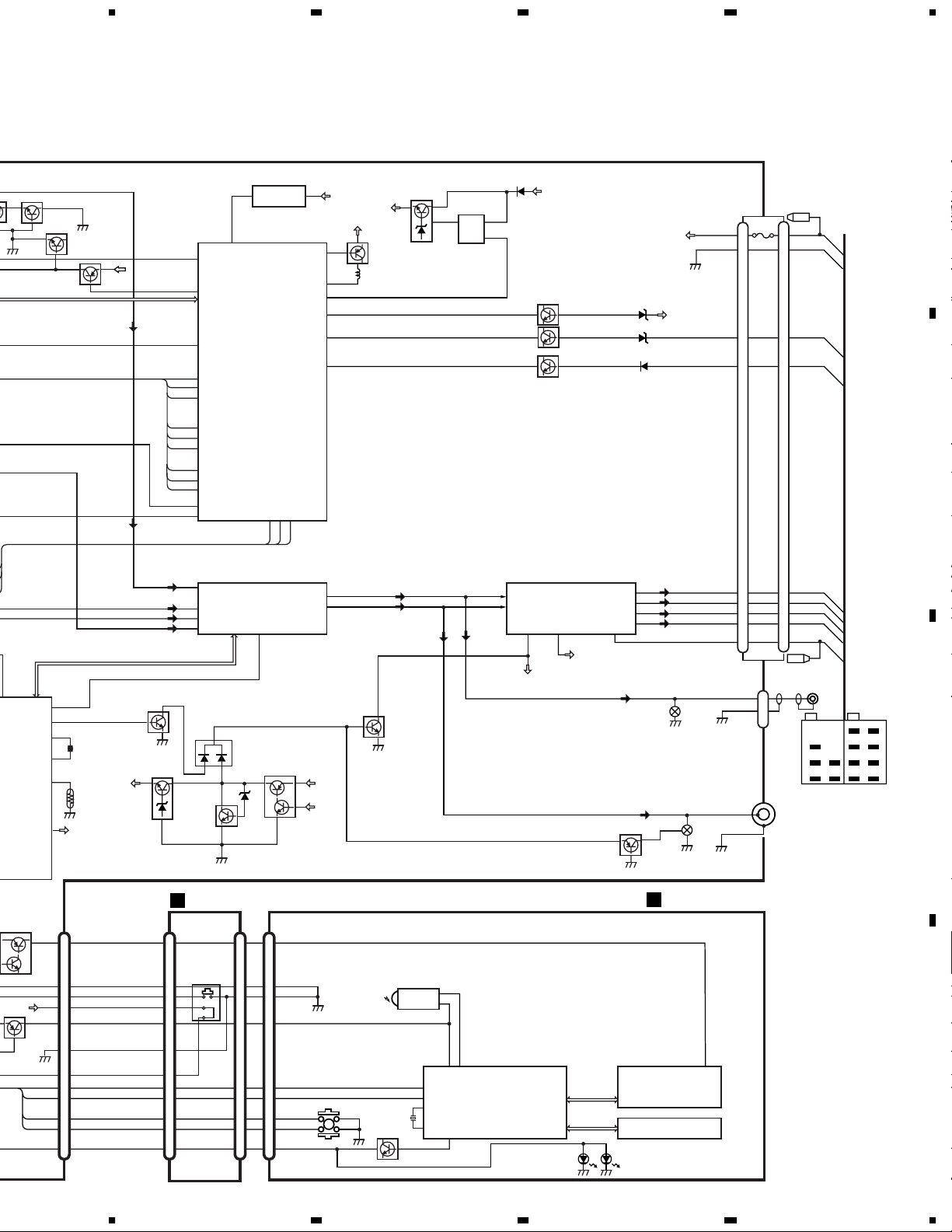

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A

A-a

A-a

A-b

A-b

Large size

SCH diagram

Guide page

FM(100%):-15.5dBs

AM(30%) :-26dBs

A-a

MIC, TEL

>

200mA

A-b

Detailed page

FM/AM TUNER UNIT

A-a

B

PE5245A

DSP-201M

PM4009A

SYSTEM CONTROLLER

DETACH SENSE SW

C

D

12

A B

EJECT

KEYBOARD UNIT

C

PANEL UNIT

B

CD:+4.1dBs

CONTROL UNIT

D

DEH-P4400R/XN/EW

1234

The > mark foun

the importance of

Therefore, when r

identical designat

Page 13

A

B

5678

" or

MIC, TEL

>

200mA

PE5245A

SYSTEM CONTROLLER

IP-BUS:+2.2dBs

CD: +4.1dBs

IP-BUS: +2.2dBs

AM(30%): -26dBs

FM(100%):-15.5dBs

FM(100%): +6.6dBs

AM(30%): -3.9dBs

CD:+10.2dBs

IP-BUS:+10.3dBs

A-b

TUNER AMP UNIT

A

600µH

472/16

CD:+9.4dBs

DETACH SENSE SW

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

>

CEK1136

10A

For resistors and capacitors in the circuit diagrams, their resistance values or

capacitance values are expressed in codes:

Ex. *Resistors

Code Practical value

123 12k ohms

103 10k ohms

*Capacitors

Code Practical value

103 0.01uF

101/10 100uF/10V

FM(100%):+32.6dBs

AM(30%):+23.1dBs

IP-BUS:+36.3dBs

FUSE

BACK UP

ILL

B.REM

GND

ACC

CD:+36.2dBs

RR—

RR+

FR—

FR+

FL—

FL+

RL—

RL+

C

D

DEH-P4400R/XN/EW

56

A

13

7

8

Page 14

2

R

A-b

A

1234

1

SYSTEM CONTROLLE

A-b

A-a

MIC, TEL

B

200mA

>

PE5245A

C

D

14

A-a

PM4009A

DSP-201M

AM(30%) :-26dBs

FM(100%):-15.5dBs

FM/AM TUNER UNIT

DEH-P4400R/XN/EW

1234

Page 15

A

B

R

PM4009A

SYSTEM CONTROLLE

5678

Thethe

Theide

DETACH SENSE

2

EJECT

3

A-b

A-b

A-a

PANEL UNIT

C

KEYBOARD UNIT

B

C

DEH-P4400R/XN/EW

56

CD:+4.1dBs

D

D

CONTROL UNIT

B

A-a

15

7

8

Page 16

1234

A-b

A

B

A-a

TUNER AMP UNIT

A

CD:+9.4dBs

600µH

472/16

CD:+36.2dBs

IP-BUS:+36.3dBs

AM(30%):+23.1dBs

FM(100%):+32.6dBs

FUSE

>

CEK1136

10A

C

D

A-b

16

CD:+10.2dBs

IP-BUS:+10.3dBs

AM(30%): -3.9dBs

FM(100%): +6.6dBs

IP-BUS: +2.2dBs

CD: +4.1dBs

AM(30%): -26dBs

FM(100%):-15.5dBs

IP-BUS:+2.2dBs

1

A

DEH-P4400R/XN/EW

1234

M CONTROLLER

Page 17

A

B

600µH

5678

FL+

RL+

FR+

RR+

FL—

RL—

FR—

CD:+36.2dBs

IP-BUS:+36.3dBs

AM(30%):+23.1dBs

FM(100%):+32.6dBs

FUSE

CEK1136

10A

>

472/16

RR—

CC

B CK UP

B.REM

ILL

GND

A-b

A-a

For resistors and capacitors in the circuit diagrams, their resistance values or

capacitance values are expressed in codes:

Ex. *Resistors

Code Practical value

123 12k ohms

103 10k ohms

*Capacitors

Code Practical value

103 0.01uF

101/10 100uF/10V

C

M CONTROLLER

DETACH SENSE SW

DEH-P4400R/XN/EW

56

D

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

3

A-b

17

7

8

Page 18

1234

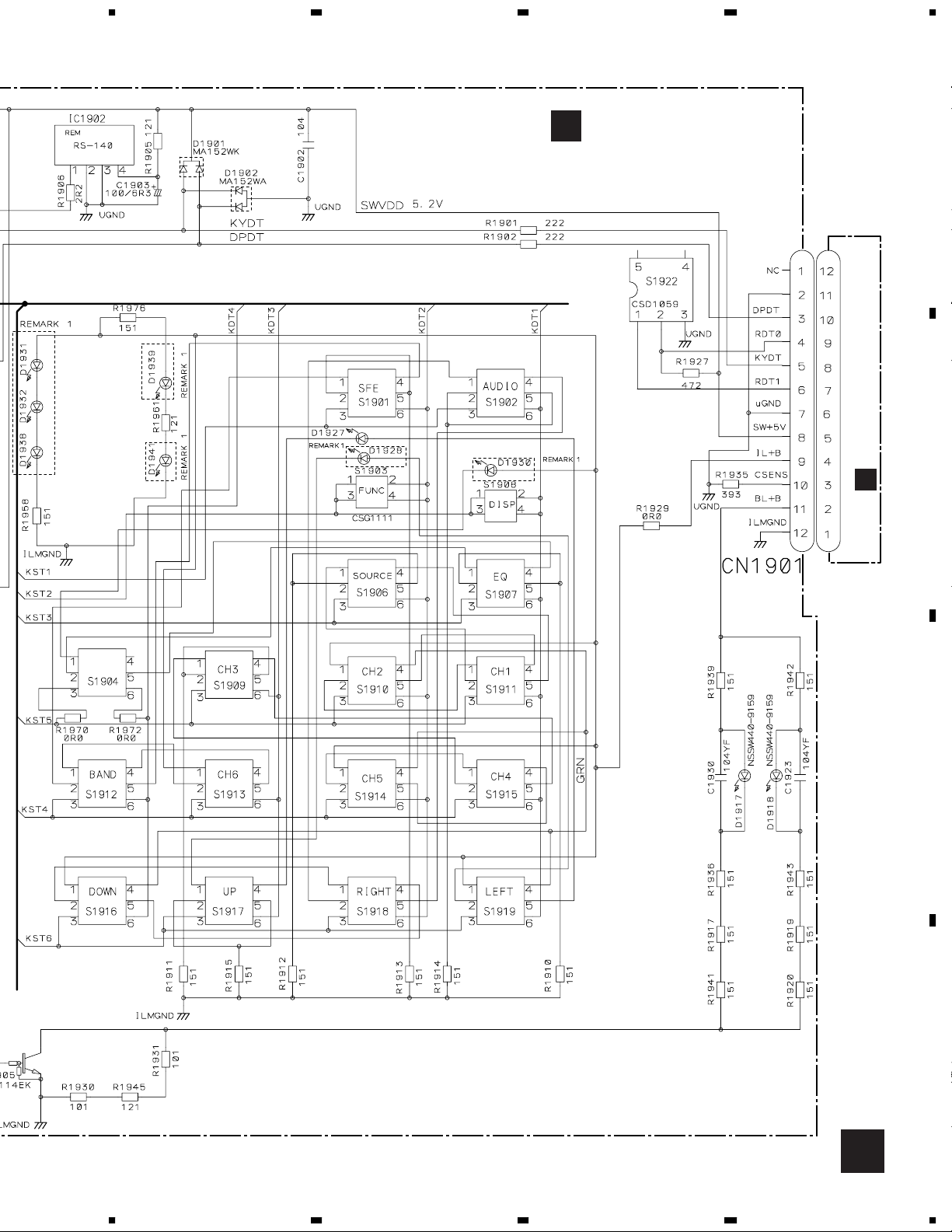

3.3 KEYBOARD UNIT

A

B

PGM

C

S1901,S1902,

S1904,S1906,

S1907,S1909-S1919

CAW1627(P4400R),CAW1668(P4400RB)

CSG1107

CSG1133

Model

DEH-P4400R/XN/EW

DEH-P4400RB/XN/EW

Model

DEH-P4400R/XN/EW

DEH-P4400RB/XN/EW

D

C

18

1234

DEH-P4400R/XN/EW

Page 19

A

B

5678

KEYBOARD UNIT

C

PGM

CSG1111

CN1951

B

C

DEH-P4400R/XN/EW

56

D

C

19

7

8

Page 20

1234

5

S

L

O

A

E

J

r

o

s

o

o

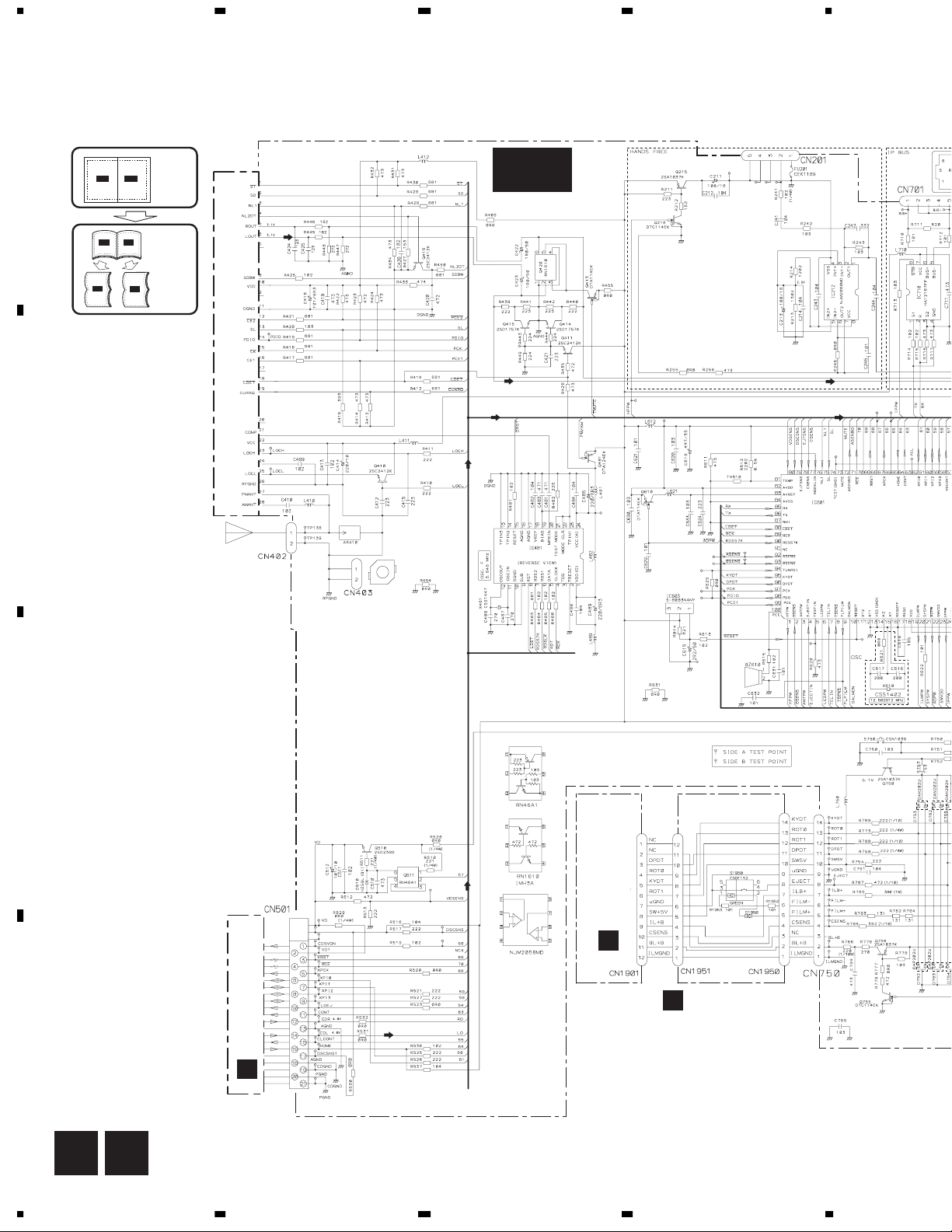

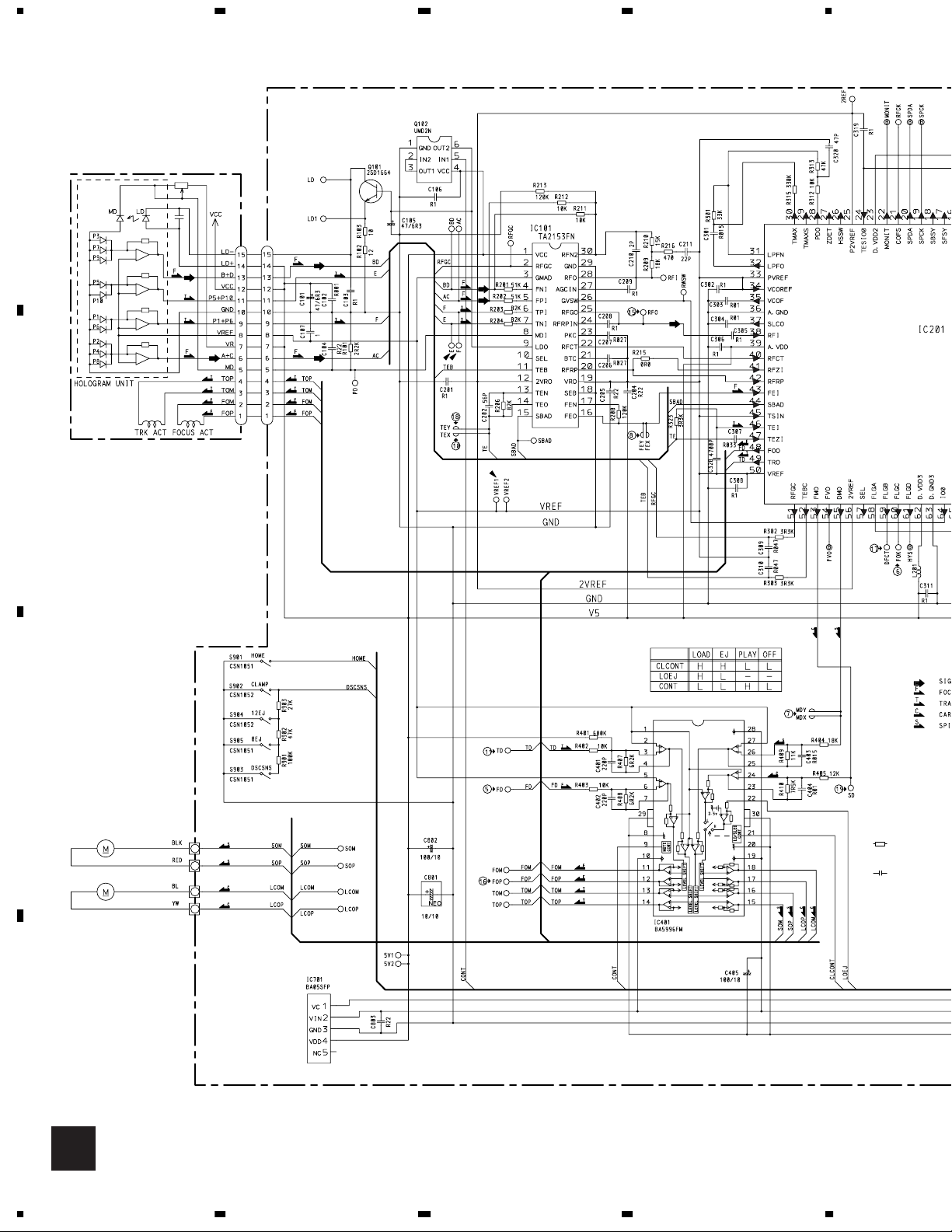

3.4 CD MECHANISM MODULE

A

PICKUP UNIT(SERVICE)(P9)

RF AMP

CN101

SERVO CON

TC949

B

ACT/MOTOR DRIVER

SWITCHE

NOTE :

Symbol indicate

No differentiati

discrete resistor

Symbol indicate

No differentiati

discrete capacit

CONTRO

S901 : H

S902 : CL

S903 : DS

S904 : 12

S905 : 8E

The unde

C

SPINDLE

M1 CXB6007

LOADING/CARRIAGE

M2 CXB5903

D

5V REGULATOR

20

D

DEH-P4400R/XN/EW

1234

Page 21

A

B

5678

SERVO CONTROL/DSP/DAC/LPF

TC9495F2

CONTROL UNIT

D

R DRIVER

SWITCHES:

CONTROL UNIT

S901 : HOME SWITCH.....ON-OFF

S902 : CLAMP SWITCH....ON-OFF

S903 : DSCSNS SWITCH....ON-OFF

S904 : 12EJ SWITCH....ON-OFF

S905 : 8EJ SWITCH....ON-OFF

The underlined indicates the switch position.

NOTE :

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

16.934MHz

Decimal points for resistor

and capacitor fixed values

are expressed as :

←

2.2 2R2

←

0.022 R022

C

DEH-P4400R/XN/EW

56

CN701

A

CN501

D

D

21

7

8

Page 22

1234

- Waveforms

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

A

3 CH3:LOEJ 5V/div.

4 CH4:VD 10V/div.

When loading (12 cm CD)

500ms/div.

Note:1. The encircled numbers denote measuring pointes in the circuit diagram.

2. Reference voltage

VREF:2.1V

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

500ms/div.

5 CH1:FD 500mV/div.

6 CH2:FOK 5V/div.

7 CH3:MD 5V/div.

500ms/div.

4 CH4:VD 10V/div.

When loading (8 cm CD)

When setting up "Source On"

Ref. :

GND

Mode :

Normal

5 CH1:FD 500mV/div.

6 CH2:FOK 5V/div.

7 CH3:MD 5V/div.

Magnified drawing for "time"

B

Ref. :

VREF

Mode :

Normal

8 CH1:FE 500mV/div.

5 CH2:FD 500mV/div.

0 CH3:TE 500mV/div.

! CH4:TD 500mV/div.

During "Play"

100ms/div.

1ms/div.

Ref. :

GND

Mode :

Normal

8 CH1:FE 500mV/div.

9 CH2:FOON 5V/div.

When setting up "Source On"

Ref. :

VREF

Mode :

Normal

@ CH1:BCK 2V/div.

During "Play"

500ms/div.

1µs/div.

Ref. :

VREF

Mode :

Normal

0 CH1:TE 500mV/div.

8 CH2:FE 500mV/div.

When setting up "Source On"

Ref. :

VREF

Mode :

Normal

# CH1:LRCK 2V/div.

$ CH2:DOUT 2V/div.

During "Play"

200ms/div.

10µs/div.

Ref. :

VREF

C

Mode :

Normal

7 CH1:MD 500mV/div.

During "Play"

Ref. :

VREF

Mode :

Normal

D

10µs/div.

Ref. :

VREF

Mode :

Normal

% CH1:RFO 500mV/div.

During "Play"

Ref. :

VREF

Mode :

Normal

0.5µs/div.

Ref. :

VREF

Mode :

Normal

% CH1:RFO 500mV/div.

0 CH2:TE 500mV/div.

During "Tracking Open"

Ref. :

VREF

Mode :

Test

2ms/div.

22

1234

DEH-P4400R/XN/EW

Page 23

A

B

5678

5 CH1:FD 1V/div.

^ CH2:FOP 2V/div.

With no disk inserted

During "Focus Close"

Ref. :

VREF

Mode :

Test

% CH1:RFO 1V/div.

0 CH2:TE 1V/div.

! CH3:TD 1V/div.

100 Track Jump

Ref. :

VREF

Mode :

Test

200ms/div.

5ms/div.

% CH1:RFO 1V/div.

0 CH2:TE 500mV/div.

500µs/div.

! CH3:TD 1V/div.

1 Track Jump

Ref. :

VREF

Mode :

Test

% CH1:RFO 2V/div.

& CH2:DFCT 5V/div.

5 CH3:FD 1V/div.

500µs/div.

! CH4:TD 2V/div.

When reproducing black dots (800µm)

Ref. :

VREF

Mode :

Normal

% CH1:RFO 1V/div.

0 CH2:TE 1V/div.

! CH3:TD 1V/div.

32 Track Jump

Ref. :

VREF

Mode :

Test

% CH1:RFO 1V/div.

0 CH2:TE 500mV/div.

& CH3:DFCT 5V/div.

During inside/outside search

Ref. :

VREF

Mode :

Normal

5ms/div.

200ms/div.

* CH1:TEY 500mV/div.

( CH2:SD 2V/div.

During inside/outside search

Ref. :

VREF

Mode :

Normal

) CH1:LOUT 2V/div.

⁄ CH2:ROUT 2V/div.

"Play" in 1kHz, 0dB

Ref. :

GND

Mode :

Normal

200ms/div.

200µs/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

When "Eject" (12 cm CD)

Ref. :

GND

Mode :

Normal

200ms/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

When "Eject" (8cm CD)

Ref. :

GND

Mode :

Normal

200ms/div.

C

DEH-P4400R/XN/EW

56

D

23

7

8

Page 24

1234

4. PCB CONNECTION DIAGRAM

4.1 TUNER AMP UNIT

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

A

B

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

Connector

P.C.Board

Capacitor

Chip Part

SIDE A

SIDE B

TUNER AMP UNIT

A

CORD ASSY

C

D

DETACH

SENSE SW

D

24

A

DEH-P4400R/XN/EW

1234

CN701

Page 25

A

B

5678

SIDE A

REAR OUTPUT

IP-BUS INPUT

ANTENNA

JACK

CORD ASSY

C

FM/AM TUNER UNIT

CN1950

B

FRONT

DEH-P4400R/XN/EW

56

D

A

25

7

8

Page 26

1234

TUNER AMP UNIT

A

A

B

C

D

A

26

1234

DEH-P4400R/XN/EW

Page 27

A

B

5678

SIDE B

C

DEH-P4400R/XN/EW

56

D

A

27

7

8

Page 28

1234

4.2 PANEL UNIT

PANEL UNIT

B

A

EJECT

B

SIDE A SIDE B

PANEL UNIT

B

C

A

CN750

C

CN1901

D

B

28

1234

DEH-P4400R/XN/EW

Page 29

A

B

5678

4.3 KEYBOARD UNIT

KEYBOARD UNIT

C

EQ

SOURCE

1

2

VOLUME

SIDE A SIDE B

PGM

DISPLAY

KEYBOARD UNIT

C

3

4

5

6

BAND

C

B

CN1951

FUNCTION

D

SFE

AUDIO

DEH-P4400R/XN/EW

56

C

29

7

8

Page 30

1234

4.4 CD MECHANISM MODULE

CONTROL UNIT

D

A

M2 LOADING/CARRIAGE MOTOR

M1 SPINDLE MOTOR

B

12EJ

DSCSNS

SIDE A

A

CN501

HOME

C

PICKUP UNIT(SERVICE)(P9)

D

30

D

DEH-P4400R/XN/EW

1234

Page 31

A

B

5678

CONTROL UNIT

D

SIDE B

8EJ

CLAMP

DEH-P4400R/XN/EW

56

C

D

D

31

7

8

Page 32

1234

5. ELECTRICAL PARTS LIST

NOTE:

• Parts whose parts numbers are omitted are subject to being not supplied.

• The part numbers shown below indicate chip components.

A

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

cuit Symbol and No. Part NameParts No.

Circuit Symbol and No. Part NameParts No.

A

Unit Number:CWM8010

Unit Name:Tuner Amp Unit

MISCELLANEOUS

B

IC 212 IC NJM2068MD

IC 301 IC PML008A

IC 361 IC PAL007A

IC 481 IC PM4009A

IC 601 IC PE5245A

IC 603 IC S-80834ANY

IC 710 IC HA12187FP

Q 215 Transistor 2SA1037K

Q 216 Transistor DTC114EK

Q 341 Transistor IMH3A

Q 351 Transistor IMH3A

Q 359 Transistor DTA124EK

Q 361 Transistor DTC124EK

Q 362 Transistor DTC114EK

Q 410 Transistor 2SC2412K

Q 411 Transistor 2SC2412K

C

Q 413 Transistor DTA114EK

Q 414 Transistor 2SD1757K

Q 415 Transistor 2SD1757K

Q 416 Transistor 2SC2412K

Q 420 Transistor RN1610

Q 481 Transistor DTA124EK

Q 510 Transistor 2SD2396

Q 511 Transistor RN46A1

Q 610 Transistor DTA114EK

Q 710 Transistor 2SA1037K

Q 711 Transistor DTC114EK

Q 750 Transistor 2SA1037K

Q 751 Transistor 2SA1036K

Q 752 Transistor DTC114EK

Q 753 Transistor DTC114EK

Q 754 Transistor 2SA1037K

D

Q 755 Transistor DTC114EK

Q 909 Transistor RN46A1

Q 910 Transistor 2SD2396

Cir

Q 911 Transistor 2SB1243

Q 912 Transistor DTC114EK

Q 913 Transistor 2SD1760F5

Q 914 Transistor 2SC2412K

Q 915 Transistor 2SC2412K

Q 916 Transistor 2SA1037K

Q 917 Transistor 2SC2412K

Q 918 Transistor 2SC2412K

D 320 Diode DAN202U

D 361 Diode S5688G

D 362 Diode S5688G

D 510 Diode HZS9L(B1)

D 750 Diode 1SS270

D 751 Diode 1SS270

D 752 Diode DAP202U

D 753 Diode DAN202U

D 754 Diode DAP202K

D 755 Diode DAN202K

D 762 Diode DAN202U

D 763 Diode DAP202U

D 910 Diode HZS9L(B3)

D 911 Diode HZS6L(B2)

D 912 Diode S5688G

D 913 Diode HZS7L(C2)

D 914 Diode HZS7L(A1)

D 915 Diode 1SS270

D 916 Diode 1SS270

D 919 Diode S5688G

D 920 Diode S5688G

D 925 Diode 1SS270

D 926 Diode HZS9L(A2)

L 311 Ferri-Inductor LAU4R7K

L 361 Choke Coil 600µH CTH1221

L 410 Ferri-Inductor LAU4R7K

L 411 Ferri-Inductor LAU2R2K

L 412 Ferri-Inductor LAU2R2K

L 481 Inductor LAU100K

L 482 Ferri-Inductor LAU101K

L 489 Inductor CTF1346

L 612 Inductor LAU100K

L 621 Inductor CTF1346

L 710 Ferri-Inductor LAU2R2K

L 750 Ferri-Inductor LAU2R2K

L 910 Ferri-Inductor LAU2R2K

TH 610 Thermistor CCX1037

32

1234

DEH-P4400R/XN/EW

Page 33

A

B

5678

cuit Symbol and No. Part NameParts No.

Cir

X 481 Crystal Resonator 3.648MHzCSS1447

X 610 Radiator 12.58291MHz CSS1402

S 750 Switch(DETACH SENSE) CSN1039

FU 210 Fuse 200mA CEK1189

FM/AM Tuner Unit CWE1562

BZ 610 Buzzer CPV1050

AR 410 Arrester DSP-201M

RESISTORS

R 211 RS1/16S223J

R 212 RS1/16S152J

R 213 RN1/16SE1302D

R 214 RN1/16SE1002D

R 241 RD1/4PU102J

R 242 RS1/16S103J

R 243 RS1/16S103J

R 245 RS1/16S0R0J

R 255 RS1/16S0R0J

R 256 RS1/16S473J

R 311 RS1/16S101J

R 312 RS1/16S101J

R 313 RS1/16S101J

R 314 RS1/16S101J

R 327 RS1/16S222J

R 328 RS1/16S222J

R 341 RS1/16S223J

R 342 RS1/16S821J

R 343 RS1/16S821J

R 344 RS1/16S223J

R 351 RS1/16S821J

R 352 RS1/16S821J

R 353 RS1/16S223J

R 354 RS1/16S223J

R 361 RS1/16S103J

R 362 RS1/16S103J

R 363 RS1/16S331J

R 364 RS1/16S153J

R 365 RD1/4PU182J

R 409 RS1/16S0R0J

R 410 RS1/16S222J

R 411 RS1/16S222J

R 412 RS1/16S681J

R 413 RS1/16S473J

R 414 RS1/16S473J

R 415 RS1/16S393J

R 416 RS1/16S681J

R 417 RS1/16S681J

R 418 RS1/16S681J

R 419 RS1/16S681J

R 420 RS1/16S103J

R 421 RS1/16S681J

R 422 RS1/16S473J

R 423 RS1/16S472J

R 424 RS1/16S473J

R 425 RS1/16S102J

R 426 RS1/16S473J

R 427 RS1/16S153J

R 428 RS1/16S681J

R 429 RS1/16S681J

DEH-P4400R/XN/EW

56

cuit Symbol and No. Part NameParts No.

Cir

R 430 RS1/16S681J

R 431 RS1/16S473J

R 432 RS1/16S473J

R 433 RS1/16S474J

R 434 RS1/16S473J

R 435 RS1/16S472J

R 439 RS1/16S222J

R 440 RS1/16S222J

R 441 RS1/16S223J

R 442 RS1/16S223J

R 443 RS1/16S224J

R 444 RS1/16S224J

R 445 RS1/16S162J

R 446 RS1/16S162J

R 447 RS1/16S272J

R 448 RS1/16S272J

R 449 RS1/16S224J

R 450 RS1/16S681J

R 454 RS1/16S0R0J

R 455 RS1/16S0R0J

R 481 RS1/16S102J

R 482 RS1/16S225J

R 483 RS1/16S681J

R 484 RS1/16S102J

R 485 RS1/16S102J

R 486 RS1/16S102J

R 510 RD1/4PU221J

R 511 RD1/4PU221J

R 512 RS1/16S472J

R 513 RS1/16S222J

R 516 RS1/16S104J

R 517 RS1/16S222J

R 519 RS1/16S102J

R 520 RS1/16S0R0J

R 521 RS1/16S222J

R 523 RS1/16S0R0J

R 525 RS1/16S222J

R 526 RS1/16S222J

R 527 RS1/16S222J

R 528 RD1/4PU0R0J

R 529 RD1/4PU0R0J

R 530 RS1/16S0R0J

R 531 RS1/16S0R0J

R 532 RS1/16S0R0J

R 536 RS1/16S102J

R 537 RS1/16S104J

R 611 RS1/16S473J

R 612 RS1/16S2202F

R 613 RS1/16S102J

R 614 RS1/16S821J

R 615 RS1/16S102J

R 616 RS1/16S0R0J

R 620 RS1/16S473J

R 621 RS1/16S0R0J

R 622 RS1/16S101J

R 624 RS1/16S104J

R 625 RS1/16S0R0J

R 630 RAB4C102J

R 631 RS1/16S0R0J

R 710 RS1/16S101J

7

8

C

D

33

Page 34

1234

cuit Symbol and No. Part NameParts No.

Cir

R 711 RS1/16S620J

R 712 RS1/16S101J

R 713 RS1/16S103J

R 714 RS1/16S102J

R 715 RS1/16S102J

A

R 716 RS1/16S473J

R 717 RS1/16S473J

R 718 RS1/16S102J

R 719 RS1/16S102J

R 720 RS1/16S223J

R 721 RS1/16S223J

R 722 RS1/16S821J

R 723 RS1/16S821J

R 724 RS1/16S222J

R 725 RS1/16S223J

R 726 RS1/16S472J

R 750 RS1/16S104J

R 751 RS1/16S103J

R 752 RS1/16S153J

R 753 RS1/16S153J

R 754 RS1/16S222J

R 756 RS1/16S433J

B

R 757 RS1/16S473J

R 758 RS1/16S102J

R 759 RD1/4PU222J

R 760 RS1/16S102J

R 763 RS1/16S222J

R 764 RS1/16S131J

R 765 RS1PMF390J

R 766 RS1/10S270J

R 767 RS1/16S103J

R 768 RS1/16S152J

R 769 RS1/16S152J

R 771 RS1/16S473J

R 773 RD1/4PU222J

R 774 RS1/16S102J

R 775 RS1/16S102J

R 776 RS1/16S220J

C

R 777 RS1/16S0R0J

R 778 RS1/16S103J

R 779 RS1/16S472J

R 781 RS1/16S104J

R 782 RS1/16S131J

R 783 RS1/16S131J

R 784 RS1/10S392J

R 786 RS1/16S102J

R 787 RS1/10S472J

R 788 RS1/10S222J

R 789 RS1/10S222J

R 909 RD1/4PU0R0J

R 910 RS1/16S0R0J

R 911 RD1/4PU121J

R 912 RS1/16S102J

R 913 RD1/4PU102J

R 914 RS1/16S103J

D

R 915 RS1/16S222J

R 916 RS1/16S133J

R 917 RS1/16S104J

R 918 RS1/16S104J

R 919 RS1/16S223J

cuit Symbol and No. Part NameParts No.

Cir

R 920 RS1/16S473J

R 921 RS1/16S103J

R 922 RS1/16S473J

R 923 RD1/4PU102J

R 924 RS1/16S472J

R 925 RD1/4PU153J

R 926 RS1/16S472J

R 927 RS1/16S102J

R 928 RS1/16S473J

R 929 RS1/16S104J

R 930 RS1/16S103J

R 931 RS1/16S103J

R 932 RD1/4PU102J

R 933 RS1/16S473J

R 934 RS1/16S103J

R 935 RS1/16S223J

R 936 RD1/4PU152J

CAPACITORS

C 211 CEJA100M16

C 212 CKSRYB104K16

C 213 CEJA100M16

C 214 CKSRYB104K16

C 241 CKSRYB104K16

C 242 CKSRYB332K50

C 243 CKSRYB104K16

C 244 CKSRYB104K16

C 245 CCSRCH101J50

C 310 CKSRYB102K50

C 311 CEJA1R0M50

C 312 CEJA1R0M50

C 314 CKSRYB105K6R3

C 315 CKSRYB105K6R3

C 316 CKSRYB104K16

C 317 CKSRYB104K16

C 318 CKSRYB105K6R3

C 319 CKSRYB105K6R3

C 320 CKSRYB105K6R3

C 321 CKSRYB105K6R3

C 325 CKSRYB102K50

C 326 CEJA100M16

C 328 CKSRYB104K16

C 329 CEJA470M10

C 342 CEJA2R2M50

C 343 CEJA2R2M50

C 351 CEJA2R2M50

C 352 CEJA2R2M50

C 361 4700µF/16V CCH1367

C 362 CKSQYB104K16

C 363 CKSQYB474K16

C 364 CKSQYB474K16

C 365 CKSQYB474K16

C 366 CKSQYB474K16

C 367 CKSQYB474K16

C 368 CKSQYB474K16

C 369 CKSQYB474K16

C 370 CKSQYB474K16

C 371 CEJA330M10

C 373 CKSQYB225K10

34

1234

DEH-P4400R/XN/EW

Page 35

A

B

5678

cuit Symbol and No. Part NameParts No.

Cir

C 374 CKSQYB225K10

C 375 CEJA100M16

C 410 CKSQYB103K50

C 412 CKSRYB223K25

C 413 CKSRYB102K50

C 414 CEJA220M10

C 415 CKSRYB223K25

C 418 CEAL101M10

C 419 CKSRYB473K16

C 420 CKSRYB472K50

C 421 CKSRYB223K25

C 422 CEJA1R0M50

C 423 CEJA1R0M50

C 424 CKSRYB123K25

C 425 CKSRYB123K25

C 426 CKSRYB182K50

C 481 CCSRCH471J50

C 482 CKSRYB104K16

C 483 CKSRYB471K50

C 484 CKSRYB104K16

C 485 CEAL220M6R3

C 486 CCSRCH270J50

C 487 CCSRCH270J50

C 488 CKSRYB104K16

C 489 CEAL220M6R3

C 499 CKSRYB102K50

C 510 CKSRYB473K16

C 511 CKSRYB102K50

C 512 CEJA101M16

C 615 CEAL2R2M50

C 616 CCSRCH200J50

C 617 CCSRCH200J50

C 618 CKSRYB105K6R3

C 619 CEAL4R7M35

C 620 CKSRYB103K50

C 621 CCSRCH101J50

C 624 CKSRYB223K25

C 629 CCSRCH101J50

C 630 CKSRYB103K50

C 631 CCSRCH101J50

C 632 CCSRCH101J50

C 633 CKSRYB103K50

C 634 CKSRYB472K50

C 710 CKSRYB104K16

C 711 CKSRYB473K16

C 712 CEJA1R0M50

C 713 CEJA1R0M50

C 714 CEJA1R0M50

C 715 CEJA1R0M50

C 750 CKSRYB103K25

C 751 CKSQYB104K16

C 765 CKSQYB103K50

C 799 CKSQYB473K16

C 910 330µF/16V CCH1326

C 911 CKSRYB103K25

C 912 CEJA101M16

C 913 CEJA101M10

C 914 CKSRYB473K16

C 915 CKSRYB103K25

C 916 470µF/16V CCH1331

DEH-P4400R/XN/EW

56

cuit Symbol and No. Part NameParts No.

Cir

C 920 CKSRYB104K16

C 921 CKSQYB104K16

C

Unit Number:CWM8306(DEH-P4400R)

:CWM8307(DEH-P4400RB)

Unit Name:Keyboard Unit

MISCELLANEOUS

IC 1902 HIC RS-140

IC 1903 IC PD6294A

Q 1905 Transistor DTC114EK

D 1901 Diode MA152WK

D 1902 Diode MA152WA

D 1917 LED NSSW440-9159

D 1918 LED NSSW440-9159

D 1928 LED(DEH-P4400R) SML-310PT

D 1928 LED(DEH-P4400RB) SML-310VT

D 1930 LED(DEH-P4400R) SML-310PT

D 1930 LED(DEH-P4400RB) SML-310VT

D 1931 LED(DEH-P4400R) SML-310PT

D 1931 LED(DEH-P4400RB) SML-310VT

D 1932 LED(DEH-P4400R) SML-310PT

D 1932 LED(DEH-P4400RB) SML-310VT

D 1938 LED(DEH-P4400R) SML-310PT

D 1938 LED(DEH-P4400RB) SML-310VT

D 1939 LED(DEH-P4400R) SML-310PT

D 1939 LED(DEH-P4400RB) SML-310VT

D 1941 LED(DEH-P4400R) SML-310PT

D 1941 LED(DEH-P4400RB) SML-310VT

X 1901 Ceramic Resonator 5MHz CSS1547

S 1901 Switch(DEH-P4400R) CSG1107

S 1901 Switch(DEH-P4400RB) CSG1133

S 1902 Switch(DEH-P4400R) CSG1107

S 1902 Switch(DEH-P4400RB) CSG1133

S 1903 Push Switch CSG1111

S 1904 Switch(DEH-P4400R) CSG1107

S 1904 Switch(DEH-P4400RB) CSG1133

S 1906 Switch(DEH-P4400R) CSG1107

S 1906 Switch(DEH-P4400RB) CSG1133

S 1907 Switch(DEH-P4400R) CSG1107

S 1907 Switch(DEH-P4400RB) CSG1133

S 1908 Push Switch CSG1111

S 1909 Switch(DEH-P4400R) CSG1107

S 1909 Switch(DEH-P4400RB) CSG1133

S 1910 Switch(DEH-P4400R) CSG1107

S 1910 Switch(DEH-P4400RB) CSG1133

S 1911 Switch(DEH-P4400R) CSG1107

S 1911 Switch(DEH-P4400RB) CSG1133

S 1912 Switch(DEH-P4400R) CSG1107

S 1912 Switch(DEH-P4400RB) CSG1133

S 1913 Switch(DEH-P4400R) CSG1107

S 1913 Switch(DEH-P4400RB) CSG1133

S 1914 Switch(DEH-P4400R) CSG1107

7

35

8

C

D

Page 36

1234

cuit Symbol and No. Part NameParts No.

Cir

S 1914 Switch(DEH-P4400RB) CSG1133

S 1915 Switch(DEH-P4400R) CSG1107

S 1915 Switch(DEH-P4400RB) CSG1133

S 1916 Switch(DEH-P4400R) CSG1107

S 1916 Switch(DEH-P4400RB) CSG1133

A

S 1917 Switch(DEH-P4400R) CSG1107

S 1917 Switch(DEH-P4400RB) CSG1133

S 1918 Switch(DEH-P4400R) CSG1107

S 1918 Switch(DEH-P4400RB) CSG1133

S 1919 Switch(DEH-P4400R) CSG1107

S 1919 Switch(DEH-P4400RB) CSG1133

S 1922 Encoder CSD1059

LCD(DEH-P4400R) CAW1627

LCD(DEH-P4400RB) CAW1668

RESISTORS

R 1901 RS1/16S222J

R 1902 RS1/16S222J

R 1903 RS1/16S470J

R 1904 RS1/16S470J

R 1905 RS1/16S121J

R 1906 RS1/16S2R2J

B

R 1910 RS1/16S151J

R 1911 RS1/16S151J

R 1912 RS1/16S151J

R 1913 RS1/16S151J

R 1914 RS1/16S151J

R 1915 RS1/16S151J

R 1917 RS1/16S151J

R 1919 RS1/16S151J

R 1920 RS1/16S151J

R 1927 RS1/16S472J

R 1929 RS1/16S0R0J

R 1930 RS1/16S101J

R 1931 RS1/16S101J

R 1935 RS1/16S393J

R 1936 RS1/16S151J

R 1939 RS1/16S151J

C

R 1941 RS1/16S151J

R 1942 RS1/16S151J

R 1943 RS1/16S151J

R 1945 RS1/16S121J

R 1958 RS1/16S151J

R 1961 RS1/16S121J

R 1970 RS1/16S0R0J

R 1972 RS1/16S0R0J

R 1976 RS1/16S151J

CAPACITORS

C 1902 CKSRYB104K16

C 1903 CSZS100M6R3

C 1905 CKSRYB104K16

C 1906 CKSRYB104K16

C 1907 CKSRYB104K16

D

C 1923 CKSQYF104Z50

C 1930 CKSQYF104Z50

Unit Number:CWM7375

Unit Name:Panel Unit

D 1950 LED CL220PGC

S 1950 Push Switch(EJECT) CSG1112

R 1952 RS1/16S101J

R 1953 RS1/16S101J

Unit Number:CWX2481

Unit Name:Control Unit

MISCELLANEOUS

IC 101 IC TA2153FN

IC 201 IC TC9495F2

IC 401 IC BA5996FM

IC 701 IC BA05SFP

Q 101 Transistor 2SD1664

Q 102 Transistor UMD2N

L 201 Inductor CTF1546

L 202 Inductor CTF1546

X 301 Ceramic Resonator 16.934MHz CSS1525

S 901 Spring Switch(HOME) CSN1051

S 902 Spring Switch(CLAMP) CSN1052

S 903 Spring Switch(DSCSNS) CSN1051

S 904 Spring Switch(12EJ) CSN1052

S 905 Spring Switch(8EJ) CSN1051

RESISTORS

R 101 RS1/16S222J

R 102 RS1/8S120J

R 103 RS1/8S100J

R 201 RS1/16S513J

R 202 RS1/16S513J

R 203 RS1/16S823J

R 204 RS1/16S823J

R 206 RS1/16S823J

R 208 RS1/16S124J

R 209 RS1/16S183J

R 210 RS1/16S153J

R 211 RS1/16S103J

R 212 RS1/16S103J

R 213 RS1/16S124J

R 215 RS1/16S0R0J

R 216 RS1/16S471J

R 301 RS1/16S333J

R 302 RS1/16S332J

R 303 RS1/16S332J

R 304 RS1/16S514J

cuit Symbol and No. Part NameParts No.

Cir

B

D

36

1234

DEH-P4400R/XN/EW

Page 37

A

B

5678

cuit Symbol and No. Part NameParts No.

Cir

R 306 RS1/16S102J

R 307 RS1/16S102J

R 312 RS1/16S103J

R 313 RS1/16S473J

R 315 RS1/16S334J

R 321 RS1/16S331J

R 322 RS1/16S0R0J

R 323 RS1/16S332J

R 401 RS1/16S684J

R 402 RS1/16S103J

R 403 RS1/16S103J

R 404 RS1/16S183J

R 405 RS1/16S123J

R 407 RS1/16S622J

R 408 RS1/16S622J

R 409 RS1/16S113J

R 410 RS1/16S752J

R 701 RS1/16S102J

R 702 RS1/16S221J

R 703 RS1/16S221J

R 704 RS1/16S221J

R 705 RS1/16S221J

R 706 RS1/16S221J

R 707 RS1/16S221J

R 708 RS1/16S102J

R 709 RS1/16S102J

R 710 RS1/16S102J

R 901 RS1/16S104J

R 902 RS1/16S473J

R 903 RS1/16S273J

CAPACITORS

C 101 CEV470M6R3

C 102 CKSRYB102K50

C 103 CKSRYB104K16

C 104 CKSRYB224K16

C 105 CEV470M6R3

C 106 CKSRYB104K16

C 107 CKSRYB105K6R3

C 201 CKSRYB104K16

C 202 CCSRCH560J50

C 204 CKSRYB224K16

C 205 CKSRYB224K16

C 206 CKSRYB273K25

C 207 CKSRYB273K25

C 208 CKSRYB104K16

C 209 CKSRYB104K16

C 210 CCSRCK2R0C50

C 211 CCSRCH220J50

C 301 CKSRYB153K25

C 302 CKSRYB104K16

C 303 CKSRYB103K50

C 304 CKSRYB103K50

C 305 CKSRYB104K16

C 306 CKSRYB104K16

C 307 CKSRYB333K16

C 308 CKSRYB104K16

Cir

cuit Symbol and No. Part NameParts No.

C 309 CKSRYB473K16

C 310 CKSRYB473K16

C 311 CKSRYB104K16

C 312 CKSRYB104K16

C 315 CEV220M6R3

C 317 CKSRYB104K16

C 318 CKSRYB104K16

C 319 CKSRYB104K16

C 320 CCSRCH470J50

C 325 CKSRYB471K50

C 328 CKSRYB472K50

C 329 CKSRYB104K16

C 330 CKSRYB104K16

C 331 CKSRYB104K16

C 401 CKSRYB221K50

C 402 CKSRYB221K50

C 403 CKSRYB153K25

C 404 CKSRYB103K50

C 405 CEV101M10

C 702 CKSRYB104K16

C 703 CKSRYB104K16

C 801 10µF/10V CCH1349

C 802 CEV101M10

C 803 CKSRYB224K16

Miscellaneous Parts List

Pickup Unit(Service)(P9) CXX1480

M 1 Motor Unit(SPINDLE) CXB6007

M2 Motor Unit(LOADING/CARRIAGE) CXB5903

C

D

DEH-P4400R/XN/EW

56

37

7

8

Page 38

1234

6. ADJUSTMENT

6.1 CD ADJUSTMENT

1) Precautions

• This unit uses a single power supply (+5V) for the reg-

A

B

ulator. The signal reference potential, therefore, is

connected to VREF(approx. 2.1V) instead of GND.

If VREF and GND are connected to each other by mistake during adjustments, not only will it be impossible to measure the potential correctly, but the servo

will malfunction and a severe shock will be applied to

the pick-up. To avoid this, take special note of the following.

Do not connect the negative probe of the measuring

equipment to VREF and GND together. It is especially

important not to connect the channel 1 negative

probe of the oscilloscope to VREF with the channel 2

negative probe connected to GND.

Since the frame of the measuring instrument is usually at the same potential as the negative probe, change

the frame of the measuring instrument to floating status.

If by accident VREF comes in contact with GND,

immediately switch the regulator or power OFF.

• Always make sure the regulator is OFF when connecting and disconnecting the various filters and wiring

required for measurements.

• Before proceeding to further adjustments and measurements after switching regulator ON, let the player

run for about one minute to allow the circuits to stabilize.

2) Test Mode

This mode is used for adjusting the CD mechanism

module of the device.

• Test mode starting procedure

Reset while pressing the 4 and 6 keys together.

• Test mode cancellation

Switch ACC, back-up OFF.

• After pressing the EJECT key, do not press any other

key until the disk is completely ejected.

• If the ] or [ key is pressed while focus search is in

progress, immediately turn the power off (otherwise

the actuator may be damaged due to adhesion of the

lenses).

• Jump operation of TRs other than 100TR continues

after releasing the key. CRG move and 100TR jump

operations are brought into the “Tracking close” status when the key is released.

• Powering Off/On resets the jump mode to “Single

TR(91)”, the RF AMP gain setting to 0 dB, and the

automatic adjustment value to the initial value.

• Since the protective systems in the unit's software are

rendered inoperative in test mode, be very careful to

avoid mechanical and /or electrical shocks to the system when making adjustment.

• The RFI and RFO signals are easy to oscillate because

C

D

of a wide band. When observing them, insert a resistor of about 1 kΩ to the series.

• This equipment will not guarantee the load ejection

operation when the mechanical unit is turned upside

down. In particular, if the ejection operation is incorrectly performed and recover

ery is enabled by resetting a product or turning ACC

off to on.

y is disabled, the recov-

38

1234

DEH-P4400R/XN/EW

Page 39

A

B

*1)

+12dB

TRK12 MIN12 SEC

12

TYP

TRK MIN SEC

*2) S. curve check setting

TRK01 MIN01 SEC

01

Focus Close setting

TRK00 MIN00 SEC

00

or

TRK99 MIN99 SEC

99

*8) CRG motor voltage = 2 [V]

*3)

T.Offset

Display

Switch to the order of the original display

F.Offset

Display

*7)

F.AGC

Gain

RF AGC

Gain

TRK/MIN/SEC

T.AGC

Gain

*5

Single TR

TRK

91

MIN

91

SEC

91

or

TRK

81

MIN

81

SEC

81

32TR

TRK

92

MIN

92

SEC

92

or

TRK

82

MIN

82

SEC

82

100TR

TRK

93

MIN

93

SEC

93

or

TRK

83

MIN

83

SEC

83

CRG Move

TRK

94

MIN

94

SEC

94

or

TRK

84

MIN

84

SEC

84

*4) 1TR/32TR/100TR

*6) Only at the time of CRG move or 100TR jump

[BAND]

Power On

(T. offset is adjusted)

TRK

00

MIN

00

SEC

00

[CD] or [SOURCE]

Source On

TRK MIN

[4]+[6]+Reset

Test Mode In

[3]

Power On

(T. offset is not adjusted)

TRK

99

MIN

99

SEC

99

[2]

RF AMP

Gain switching

*1

TRK

GG

MIN

GG

SEC

GG

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[3]

Focus Close /

S. curve check

TRK

91

MIN

91

SEC

91

[6]

Focus Mode switching

*2

TRK

0x

MIN

0x

SEC

0x

[1]

Tracking Servo

Close

TRK

00

MIN

00

SEC

00

or

TRK

99

MIN

99

SEC

99

[[]

CRG-

*8

TRK

00

MIN

00

SEC

00

or

TRK

99

MIN

99

SEC

99

[]]

CRG+

*8

TRK

00

MIN

00

SEC

00

or

TRK

99

MIN

99

SEC

99

[6]

New Test Mode

[2]

Automatic adjustment value

display switching

*3

TRK

??

MIN

??

SEC

??

[1]

T.CLS and F,T AGC

and RF AGC and

Applicable servomechanism

TRK

xx

MIN

xx

SEC

xx

[6]

T.Close and

Applicable servomechanism

TRK

xx

MIN

xx

SEC

xx

[3]

RF AGC /

RF AGC coefficient display

TRK

??

MIN

??

SEC

??

[]]

CRG+

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

[[]

CRG-

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

[2]

T.Balance adjustment /

T.Balance coefficient display

TRK

??

MIN

??

SEC

??

[1]

F,T,RF AGC /

F.Bias display switching

*7

TRK

??

MIN

??

SEC

??

[3]

F,T AGC,F.Bias

and RF AGC

TRK

xx

MIN

xx

SEC

xx

[6]

CRG/TR jump value

*5

switching

TRK

xx

MIN

xx

SEC

xx

[]]

CRG+/TR Jump+

*4

TRK

xx

MIN

xx

SEC

xx

[[]

CRG-/TR Jump-

*4

TRK

xx

MIN

xx

SEC

xx

[2]

Tracking Open

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

[2]

Tracking Open

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

F. EQ measurement setting

TRK02 MIN02 SEC

02

[Key]

[BAND]

[]]

[[]

[1]

[2]

[3]

[6]

-

-

Power On/Off

CRG +/TR Jump+

(Direction of the external surface)

CRG -/TR Jump(Direction of the internal surface)

T.CLS and AGC and Applicable servomechanism/

AGC,AGC display switching

RF Gain switching/Offset adjustment display/

T.Balance adjustment/T.OPN

F.CLS,S.Curve/Rough Servo and RF AGC/

F,T,RF AGC

SPDL 1X/2X switching

(Double-speed compatibility only)

Error rate measurement

F.Mode switching/T.CLS/CRG,TR

Jump switching

Test Mode New Test Mode

Operation

Error occurrence time/

cause display switching

TRK+/FF

TRK-/REV

SCAN

MODE

(ITP)

-

-

Auto/Manual switching

F.Bias

[KEY]

Contents

Display

- Flow Chart

5678

56

DEH-P4400R/XN/EW

7

C

D

39

8

Page 40

1234

6.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT

A

• Note :

The grating angle of the PU unit cannot be adjusted after the PU unit is changed. The PU unit in the CD mecha-

nism module is adjusted on the production line to match the CD mechanism module and is thus the best adjusted

PU unit for the CD mechanism module. Changing the PU unit is thus best considered as a last resort. However, if

the PU unit must be changed, the grating should be checked using the procedure below.

• Purpose :

To check that the grating is within an acceptable range when the PU unit is changed.

• Symptoms of Mal-adjustment :

If the grating is off by a large amount symptoms such as being unable to close tracking, being unable to perform

track search operations, or taking a long time for track searching.

• Method :

• Measuring Equipment • Oscilloscope, Two L.P.F.

• Measuring Points • E, F, VREF

• Disc • ABEX TCD-784

• Mode • TEST MODE

B

CONTROL UNIT

L.P.F.

E

100kΩ

VREF

F

VREF

VREF

E

F

C

390pF

100kΩ

390pF

L.P.F.

Xch Ych

Oscilloscope

• Checking Procedure

1. In test mode, load the disc and switch the 5V regulator on.

2. Using the ] and [ buttons, move the PU unit to the innermost track.

3. Press key 3 to close focus, the display should read "91". Press key 2 to implement the tracking balance adjust-

ment the display should now read "81". Press key 3. The display will change, returning to "81" on the fourth

press.

4. As shown in the diagram above, monitor the LPF outputs using the oscilloscope and check that the phase differ-

ence is within 75° . Refer to the photographs supplied to determine the phase angle.

5. If the phase difference is determined to be greater than 75° try changing the PU unit to see if there is any

improvement. If, after trying this a number of times, the grating angle does not become less than 75° then the

mechanism should be judged to be at fault.

• Note

Because of eccentricity in the disc and a slight misalignment of the clamping center the grating wavefor

seen to "wobble" ( the phase difference changes as the disc rotates). The angle specified above indicates the average angle.

m may be

D

• Hint

Reloading the disc changes the clamp position and may decrease the "wobble".

40

1234

DEH-P4400R/XN/EW

Page 41

A

B

5678

Grating waveform

0°

45°

Ech → Xch 20mV/div, AC

Fch → Ych 20mV/div, AC

30°

60°

75°

90°

DEH-P4400R/XN/EW

56

C

D

41

7

8

Page 42

1234

6.3 TEST MODE

- Error Messages

If a CD is not operative or stopped during operation due to an error, the error mode is turned on and cause(s) of the

A

B

C

error is indicated with a corresponding number. This arrangement is intended at reducing nonsense calls from the

users and also for facilitating trouble analysis and repair work in servicing.

(1) Basic Indication Method

1) When SERRORM is selected for the CSMOD (CD mode area for the system), error codes are written to DMIN (minutes display area) and DSEC (seconds display area). The same data is written to DMIN and DSEC. DTNO r

in blank as before.

2) Head unit display examples

Depending on display capability of LCD used, display will vary as shown below. xx contains the error number.

8-digit display 6-digit display 4-digit display

ERROR–xx ERR–xx E–xx

(2) Error Code List

Code Class Displayed error code Description of the code and potential cause(s)

10 Electricity Carriage Home NG CRG can't be moved to inner diameter.

SERVO LSI Com- CRG can't be moved from inner diameter.

munication Error → Failure on home switch or CRG move mechanism.

Communication error between microcomputer and SERVO LSI.

11 Electricity Focus Servo NG Focusing not available.

→ Stains on rear side of disc or excessive vibrations on REWRITABLE.

12 Electricity Spindle Lock NG Spindle not locked. Sub-code is strange (not readable).

Subcode NG → Failure on spindle, stains or damages on disc, or excessive vibrations.

A disc not containing CD-R data is found.

Turned over disc are found, though rarely.

CD signal error.

17 Electricity Setup NG AGC protection doesn't work. Focus can be easily lost.

→ Damages or stains on disc, or excessive vibrations on REWRITABLE.

30 Electricity Search Time Out Failed to reach target address.

→ CRG tracking error or damages on disc.

44 Electricity ALL Skip Skip setting for all track.

(CD-R/RW)

50

Mechanism

CD On Mech Error Mechanical error during CD ON.

→ Defective loading motor, mechanical lock and mechanical sensor.

A0 System Power Supply NG Power (VD) is ground faulted.

→ Failure on SW transistor or power supply (failure on connector).

Remarks: Mechanical errors are not displayed (because a CD is turned off in these errors).

Unreadable TOC does not constitute an error. An intended operation continues in this case.

Upper digits of an error code are subdivided as shown below:

1x: Setup relevant errors, 3x: Search relevant errors, Ax: Other errors.

emains

D

42

1234

DEH-P4400R/XN/EW

Page 43

A

B

5678

- New Test Mode

S-CD plays the same way as before.

If an error such as off focus, spindle unlocking, unreadable sub-code, or sound skipping occurs after setup, its

cause and time occurred (in absolute time) are displayed.

During setup, operational status of the control software is displayed.

These displays and functions are prepared for enhancing aging in the servicing and efficiency of trouble analysis.

(1) Shifting to the New Test Mode

1 Turn on the current test mode by starting the reset from the key.

2 Select S-CD for the source through the specified procedure including use of the [SOURCE] key, and inser

disc. Then, press the [Jump Mode Selector] key while maintaining the regulator turned off.

3 After the above operations, the new test mode remains on irrespective of whether the S-CD is turned on or off.

You can reset the new test mode by turning on the reset start.

(2) Key Correspondence

Key Test mode New test mode

Regulator Off Regulator On In-play Error Production

BAND To regulator on To regulator off – Time/Err.No. switching

] – FWD-Kick FF/TR+ –

[ – REV-Kick REV/TR- –

1 – Tracking Close Scan –

2 – Tracking Open Mode –

3 – Focus Close ––

–– Focus Open ––

–– Jump Of

f ––

6 To new test mode

Jump mode switching Auto/Manu –

Note: Eject and CD on/off is perfor

med in the same procedure as that for the normal mode.

(3) Cause of Error and Er

ror Code

Code Class Contents

Description and cause

40 Electricity Of

f focus detected. FOK goes low.

→ Damages/stains on disc, vibrations or failur

e on servo.

41 Electricity Spindle unlocked. LOCK = Low continued for 150 msec.

→ Damages/stains on disc, vibrations or failure on servo.

42 Electricity Sub-code unreadable. Sub-code was unreadable for 500 msec.

→ Damages/stains on disc, vibrations or failure on servo.

43 Electricity Sound skipping detected. Last address memory function was activated.

→ Damages/stains on disc, vibrations or failure on servo.

Note: Mechanical errors during aging are not displayed.

ting the

56

DEH-P4400R/XN/EW

7

C

D

43

8

Page 44

1234

(4) Display of Operational Status during Setup

Status No. Contents Protective action

21 Focus search start Focus search timeout.

22 Focus search 2 Focus search timeout.

23 Focus search 3 Focus search timeout.

A

24 Focus search 4 Focus search timeout.

25 Focus search(Setup protection) Focus slips off.

26 Focus search(Fast recovery) Focus slips off.

27 RF detection Focus slips off.

28 Spindle rough servocontrol Focus slips off.

29 Tracking balance adjustment start Focus slips off.

30 Tracking balance adjustment 2 Focus slips off.

31 Tracking balance adjustment 3 Focus slips off.

32

Tracking close start(Spindle stationary servocontrol setting)

Focus slips off.

33 Tracking close 2 Focus slips off.

34 Tracking close 3 Focus slips off.

35 Focus/Tracking AGC start Focus slips off.

36 Focus/Tracking AGC 2 Focus slips off.

37 Focus/Tracking AGC 3 Focus slips off.

38 Focus/Tracking AGC 4 Focus slips off.

39 Focus/Tracking AGC 5 Focus slips off.

B

40 Focus/Tracking AGC 6 Focus slips off.

41 Focus/Tracking AGC 7 Focus slips off.

42 Focus/Tracking AGC 8 Focus slips off.

43 FE bias start Focus slips off.

44 FE bias 2 Focus slips off.

45 RF AGC start Focus slips off.

46 RF AGC 2 Focus slips off.

47 Lock check start Focus slips off.

48 Lock is being checked Focus slips off.

49 Subcode check start Focus slips off, spindle lock is not performed.

50 Subcode is being checked Focus slips off, no subcode can be read.

C

D

44

1234

DEH-P4400R/XN/EW

Page 45

A

B

5678

(5) Display Examples

1) During Setup

8-digit display, 6-digit display 4-digit display(Auto setting) 4-digit display(Manual setting)

TNO. Min Sec TNO. Min Sec

11 11' 11" 11 11' 11"

2) During Operation (TOC read, TRK search, Play, FF and REV)

The same as in the normal mode.

3) When a Protection Error Occurred

(A) Error display ((A)←→(B), (C) : BAND key)

8-digit display 6-digit display 4-digit display

ERROR-xx ERR-xx E-xx

(B) Error occurrence timing display in track no. ((B)←→(C) : Auto/Manual key)

8-digit display, 6-digit display 4-digit display(Auto setting)

TNO. Min Sec TNO.

10 40' 05" 10

(C) Error occurrence timing display in absolute time. ((B)←→(C) : Auto/Manual key)

8-digit display, 6-digit display 4-digit display(Manual setting)

TNO. Min Sec Min Sec

10 40' 05" 40' 05"

C

DEH-P4400R/XN/EW

56

D

45

7

8

Page 46

1234

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 DISASSEMBLY

-

Removing the Case (not shown)

A

1. Remove the Case.

- Removing the CD Mechanism Module (Fig.1)

Remove the four screws.

Disconnect the connector and then remove the CD

Mechanism Module.

Removing the Grille Panel Assy (Fig.1)

-

CD Mechanism Module

Remove the two screws and then r

Grille Panel Assy.

B

- Removing the Tuner Amp Unit (Fig.2)

Remove the two screws.

Straight the tabs at three locations indicated.

Remove the screw.

C

Remove the three screws and then remove

the Tuner Amp Unit.

emove the

Grille Panel Assy

Fig.1

*) Tuner Amp Unit is different partially from this

photo.

D

46

1234

Tuner Amp Unit

Fig.2

DEH-P4400R/XN/EW

Page 47

A

B

5678

- How to hold the Mechanical Unit

1.Hold the top and bottom frame.

2.Do not squeeze top frame's front portion too tight,

because it is fragile.

- How to remove the Top and Bottom Frame

1.When the disk is "clamp" state, unlock Spring A (6

pieces) and Spring B (2 pieces), and unscrew screws

(4 pieces).

2.Unlock each 1 of pawl at the both side of the frame,

then remove the top frame.

3.Remove the Carriage Mechanical part in such way

that; you remove the mechanical part from 3 pieces

of Damper while slowly pulling up the part.

4.Now, the top frame has been removed, and under

this state, fix the genuine Connector again, and eject

the disk.

(Caution)

When you reassemble the Carriage Mechanical part,

apply a bit of alcohol to Dampers.

- How to remove the Guide Arm Assy

1.Unlock the spring (1 piece) at the right side of the

assembly.

2.Unscrew screws (2 pieces), then remove the Screw

Gear Bracket.

3.Shift the Guide Arm Assy to the left and slowly rotate

it to the upper direction.

4.When the Guide Arm Assy rotates approximately 45

degree, shift the Assy to the right side dir

ection and

remove it.

Top Frame

Bottom Frame

Damper

Screw Gear Bracket

Guide Arm

Assy

Carriage

Mechanical

Par

t

Do not squeeze.

C

56

DEH-P4400R/XN/EW

7

D

47

8

Page 48

1234

- How to remove the Control Unit

1.Give jumper-solder treatment to the Flexible Wire of

the Pickup unit, then remove the wire from the

Connector.

A

2.Remove all 4 points of solder-treatment on the Lead

Wire. Also, unscrew the screw(1 piece).

3.Then, Remove the Control unit.

(Caution)

Be careful not to damage SW when you reassemble

the Control Unit into the device.

- How to remove the Loading Arm Assy

1.Unlock the spring (1 piece) and remove the E ring (1

B

piece) of the Fulcrum Shaft.

2.Shift the arm to the left side direction and unlock pins

(2 pieces).

Jumper-Solder

Control Unit

Solder

C

- How to remove the Pickup Unit

1.Unscrew 2 pieces of screws, then remove the Pulley

Cover.

2.Remove the Feed Screw unit from the pawl of the

Feed Screw Guide (The pawl is located inside the

guide).

3.Remove the belt from the Pulley, then remove the

Pickup unit.

(Caution)

Make sure not to stain the belt with gr

fix the belt.

D

ease when you

Loading Arm Assy

Pulley Cover

GEM1035

ease Application

Gr

Grease Application

GEM1035

Pickup Unit

UD321BR

Gr

ease Application

Belt

Feed Screw Guide

48

1234

DEH-P4400R/XN/EW

Page 49

A

B

5678

111098

765

4321

RCA

BUSH

H/F

BUSH

15

16

10

2

51

REAR OUTPUT

ANTENNA JACK

FUSE 10A

1. BUS+

2. GND

3. GND

4. NC

5. BUS-

6. GND

7. BUS L+ INPUT

8. ASENB

9. BUS R+ INPUT

10. BUS R- INPUT

11. BUS L- INPUT

FRONT

OUTPUT

TEL

1. GND

2. B.UP

3. ACC

4. NC

5. ILM

6. B.REM

7.TELMUTE

8. NC

9. RL-

10. FL-

11. RL+

12. FL+

13. RR-

14. FR-

15. RR+

16. FR+

7.1.2 CONNECTOR FUNCTION DESCRIPTION

DEH-P4400R/XN/EW

56

C

D

49

7

8

Page 50

1234

7.2 PARTS

7.2.1 IC

PAL007A

A

Protector;

TAB

P-GND2

OUT2-

STBY

OUT2+

VCC

OUT1-

P-GND1

OUT1+

B

SVR

IN1

IN2

S-GND

IN4

IN3

AC-GND

OUT3+

P-GND3

OUT3-

VCC

OUT4+

C

MUTE

OUT4-

P-GND4

SWITCH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Over voltage

Protector;

Short circuit

Protector;

Over current limit

Stand-by

Circuit

Offset

Detection

Offset

Detection

Offset

Detection

Offset

Detection

stby

amp_vcc

+

-

+

+

-

+

+

-

+

+

-

+

sw_vcc

amp_vcc

sw_vcc

Protector;

Thermal

Reference

Mute circuit

D

50

DEH-P4400R/XN/EW

1234

Page 51

A

B

5678

DGND

CLK

Vref