Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2009

CD RDS RECEIVER

ORDER NO.

CRT4508

DEH-5200SD/XNEW5

DEH-5200SD

CD RECEIVER

DEH-5250SD

DEH-5250SD

DEH-5290SD

This service manual should be used together with the following manual(s):

Model No. Order No. Mech. Module Remarks

CX-3269 CRT4488 S11STD-DOUT CD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

/XNES

/XNES1

/XNID

/XNEW5

For details, refer to "Important Check Points for Good Servicing".

K-ZZZ. NOV. 2009 Printed in Japan

Page 2

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

CAUTION:

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

Laser diode characteristics

Wave length : 785 nm to 814 nm

Maximum output : 1 190 µW(Emitting period : unlimited)

Additional Laser Caution

Transistors Q101 in PCB drive the laser diodes.

When Q101 is shorted between their terminals, the laser diodes will radiate beam.

If the top cover is removed with no disc loaded while such short-circuit is continued,

the naked eyes may be exposed to the laser beam.

- Safety Precautions for those who Service this Unit.

When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

CAUTION

CLASS 1M INVISIBLE LASER RADIATION WHEN OPEN. DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

2. During repair or tests, do not view laser beam for 10 seconds or longer.

2

DEH-5200SD/XNEW5

Page 3

5 678

56

7

8

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

DEH-5200SD/XNEW5

3

Page 4

1234

1234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

1. SERVICE PRECAUTIONS ............................................................................................................................... 5

1.1 SERVICE PRECAUTIONS......................................................................................................................... 5

1.2 NOTES ON SOLDERING .......................................................................................................................... 6

2. SPECIFICATIONS ............................................................................................................................................ 7

2.1 SPECIFICATIONS...................................................................................................................................... 7

2.2 DISC/CONTENT FORMAT ........................................................................................................................ 9

2.3 PANEL FACILITIES.................................................................................................................................. 10

2.4 CONNECTION DIAGRAM ....................................................................................................................... 12

3. BASIC ITEMS FOR SERVICE........................................................................................................................ 15

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 15

3.2 PCB LOCATIONS .................................................................................................................................... 16

3.3 JIGS LIST ................................................................................................................................................ 17

3.4 CLEANING............................................................................................................................................... 17

4. BLOCK DIAGRAM.......................................................................................................................................... 18

5. DIAGNOSIS.................................................................................................................................................... 21

5.1 OPERATIONAL FLOWCHART ................................................................................................................ 21

5.2 ERROR CODE LIST ................................................................................................................................ 22

5.3 CONNECTOR FUNCTION DESCRIPTION............................................................................................. 23

6. SERVICE MODE ............................................................................................................................................ 24

6.1 CD TEST MODE...................................................................................................................................... 24

6.2 DISPLAY TEST MODE ............................................................................................................................ 25

7. DISASSEMBLY............................................................................................................................................... 28

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 35

8.1 CD ADJUSTMENT................................................................................................................................... 35

8.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT.................................................... 36

8.3 PCL OUTPUT CONFIRMATION.............................................................................................................. 38

9. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 40

9.1 PACKING ................................................................................................................................................. 40

9.2 EXTERIOR(1) .......................................................................................................................................... 42

9.3 EXTERIOR(2) .......................................................................................................................................... 44

9.4 CD MECHANISM MODULE..................................................................................................................... 46

10. SCHEMATIC DIAGRAM ............................................................................................................................... 48

10.1 TUNER AMP ASSY(MAIN)(GUIDE PAGE)............................................................................................ 48

10.2 TUNER AMP ASSY(MEDIA uCOM)(GUIDE PAGE).............................................................................. 54

10.3 KEYBOARD UNIT.................................................................................................................................. 60

10.4 CD MECHANISM MODULE................................................................................................................... 62

10.5 WAVEFORMS........................................................................................................................................ 64

11. PCB CONNECTION DIAGRAM ................................................................................................................... 66

11.1 TUNER AMP ASSY ............................................................................................................................... 66

11.2 KEYBOARD UNIT.................................................................................................................................. 70

11.3 CD CORE UNIT(S11STD-DOUT).......................................................................................................... 72

12. ELECTRICAL PARTS LIST .......................................................................................................................... 74

4

DEH-5200SD/XNEW5

Page 5

5 678

56

7

8

C

D

F

A

B

E

1. You should conform to the regulations governing the product (safety, radio and noise, and other

regulations), and should keep the safety during servicing by following the safety instructions

described in this manual.

2. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside the unit.

3. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY".

4. After replacing the pickup unit, be sure to check the grating.

5. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by

electrostatic induction.

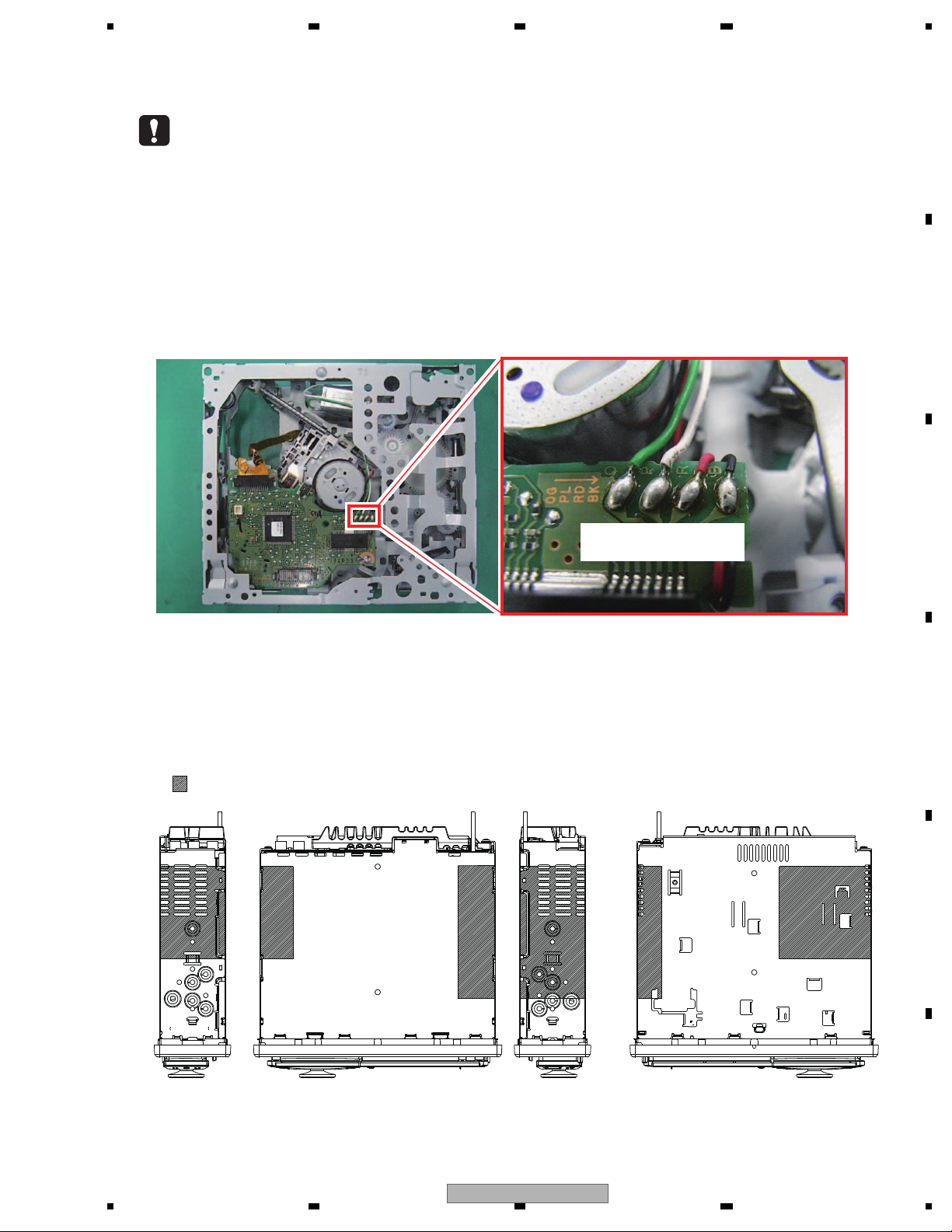

6. On CD Core Unit, actual cable colors and silk print are different.

Green Red

White Black

7. When a CD-DA (regular music CD) is played in the CD test mode, its sound quality will be temporarily

deteriorated. The CD will then repeat normal, deteriorated, normal… playback.

This is due to the difference in the playback modes between the normal operation mode and the CD test

mode, and the interval of generating deteriorated mode and the time taken to return to the normal mode

depend on the error of each clock.

The time taken to turn to the deteriorated mode is at a minimum around 20 seconds while the time to return

to the normal mode is maximum 40 seconds approximately.

Make sure to check the sound quality in the normal operation mode.

8. area and a heat sink becomes hot areas. Be careful not to burn yourself.

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

DEH-5200SD/XNEW5

5

Page 6

1234

1234

C

D

F

A

B

E

1.2 NOTES ON SOLDERING

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

6

DEH-5200SD/XNEW5

Page 7

5 678

56

7

8

C

D

F

A

B

E

2. SPECIFICATIONS

2.1 SPECIFICATIONS

DEH-5200SD/XNEW5

General

Power source ......................... 14.4 V DC (10.8 V to 15.1 V

allowable)

Grounding system................. Negative type

Maximum current consumption

...............................................10.0 A

Back up current ...................... 5.0 mA or less

Dimensions (W × H × D):

DIN

Chassis.................. 180 mm × 50 mm × 165

mm

Nose ....................... 188 mm × 58 mm × 17 mm

D

Chassis.................. 178 mm × 50 mm × 165

mm

Nose ....................... 170 mm × 46 mm × 17 mm

Weight ..................................... 1.3 kg

Audio

Maximum power output ...... 50 W × 4

50 W × 2/4 ohm + 70 W × 1/2

ohm (for subwoofer)

Continuous power output ... 22 W × 4 (50 Hz to 15 000

Hz, 5 % THD, 4 ohm load,

both channels driven)

Load impedance ................... 4 ohm to 8 ohm × 4

4 ohm to 8 ohm × 2

+ 2 ohm × 1

Preout maximum output level

.............................................. 4.0 V

Equalizer (5-Band Graphic Equalizer):

Frequency ......................100/315/1.25k/3.15k/8k Hz

Gain ................................ ±12 dB

HPF:

Frequency ..................... 50/63/80/100/125 Hz

Slope ............................... –12 dB/oct

Subwoofer (mono):

Frequency ..................... 50/63/80/100/125 Hz

Slope ............................... –18 dB/oct

Gain ................................. +6 dB to – 24 dB

Phase .............................. Normal/Reverse

Bass boost:

Gain ................................. +12 dB to 0 dB

CD player

System..................................... Compact disc audio system

Usable discs .......................... Compact disc

Signal-to-noise ratio............. 94 dB (1 kHz) (IEC-A net-

work)

Number of channels ............ 2 (stereo)

MP3 decoding format ......... MPEG-1 & 2 Audio Layer 3

WMA decoding format ....... Ver. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG -4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

WAV signal format................ Linear PCM & MS ADPCM

(Non-compressed)

USB

USB standard specification

............................................... USB 2.0 full speed

Maximum current supply ....500 mA

USB Class .............................. MSC (Mass Storage Class)

File system.............................. FAT12, FAT16, FAT32

MP3 decoding format ..........MPEG-1 & 2 Audio Layer 3

WMA decoding format ....... Ver. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG -4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

WAV signal format................ Linear PCM & MS ADPCM

(Non-compressed)

SD

Compatible physical format

.............................................. Version 2.00

Maximum memory capacity

.............................................. 32 GB (for SD and SDHC)

File system............................. FAT12, FAT16, FAT32

MP3 decoding format ......... MPEG-1 & 2 Audio Layer 3

WMA decoding format ....... Ver. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG -4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

WAV signal format................ Linear PCM & MS ADPCM

(Non-compressed)

FM tuner

Frequency range .................. 87.5 MHz to 108.0 MHz

Usable sensitivity................... 9 dBf (0.8 μV/75 ohm, mono,

S/N: 30 dB)

Signal-to-noise ratio ............ 72 dB (IEC-A network)

MW tuner

Frequency range ................. 531 kHz to 1 602 kHz (9 kHz)

Usable sensitivity................. 25 μV (S/N: 20 dB)

Signal-to-noise ratio ........... 62 dB (IEC-A network)

LW tuner

Frequency range ................ 153 kHz to 281 kHz

Usable sensitivity................. 28 μV (S/N: 20 dB)

Signal-to-noise ratio ........... 62 dB (IEC-A network)

Note

Specifications and the design are subject to modifications without notice.

DEH-5200SD/XNEW5

7

Page 8

1234

1234

C

D

F

A

B

E

WAV signal format................ Linear PCM & MS ADPCM

(Non-compressed)

USB

USB standard specification

............................................... USB 2.0 full speed

Maximum current supply ....500 mA

USB Class............................... MSC (Mass Storage Class)

File system.............................. FAT12, FAT16, FAT32

MP3 decoding format ......... MPEG-1 & 2 Audio Layer 3

WMA decoding format ........ Ver. 7,7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

WAV signal format................ Linear PCM & MS ADPCM

(Non-compressed)

SD

Compatible physical format

.............................................. Version 2.00

Maximum memory capacity

.............................................. 32 GB (for SD and SDHC)

File system.............................. FAT12, FAT16, FAT32

MP3 decoding format ......... MPEG-1 & 2 Audio Layer 3

WMA decoding format ........ Ver. 7,7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format.......... MPEG-4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

WAV signal format................ Linear PCM & MS ADPCM

(Non-compressed)

FM tuner

Frequency range .................. 87.5 MHz to 108.0 MHz

Usable sensitivity................... 9 dBf (0.8 μV/75 ohm, mono,

S/N: 30 dB)

Signal-to-noise ratio ............. 72 dB (IEC-A network)

AM tuner

Frequency range .................. 531 kHz to 1 602 kHz (9 kHz)

530 kHz to 1640 kHz (10

kHz)

Usable sensitivity................... 25 μV (S/N: 20 dB)

Signal-to-noise ratio ............ 62 dB (IEC-A network)

Infrared remote control

Wavelength............................. 940 nm ±50 nm

Output ...................................... typ; 12 mw/sr per Infrared

LED

Note

Specifications and the design are subject to modifications without notice.

General

Rated power source............. 14.4 V DC

(allowable voltage range:

12.0 V to 14.4 V DC)

Grounding system................. Negative type

Maximum current consumption

...............................................10.0 A

Dimensions (W × H × D):

DIN

Chassis.................. 178 mm × 50 mm × 165

mm

Nose ....................... 188 mm × 58 mm × 17 mm

D

Chassis.................. 178 mm × 50 mm × 165

mm

Nose ....................... 170 mm × 46 mm × 17 mm

Weight ..................................... 1.3 kg

Audio

Maximum power output ...... 50 W × 4

50 W × 2/4 ohm + 70 W × 1/2

ohm (for subwoofer)

Continuous power output ... 22 W × 4 (50 Hz to 15 000

Hz, 5 % THD, 4 ohm load,

both channels driven)

Load impedance ................... 4 ohm to 8 ohm × 4

4 ohmto 8 ohm × 2

Preout maximum output level

.............................................. 4.0 V

Equalizer (5-Band Graphic Equalizer):

Frequency ..................... 100/315/1.25k/3.15k/8k Hz

Gain ................................ ±12 dB

HPF:

Frequency ..................... 50/63/80/100/125 Hz

Slope ............................... –12 dB/oct

Subwoofer (mono):

Frequency ..................... 50/63/80/100/125 Hz

Slope ............................... –18 dB/oct

Gain ................................. +6 dB to – 24 dB

Phase .............................. Normal/Reverse

Bass boost:

Gain ................................. +12 dB to 0 dB

CD player

System..................................... Compact disc audio system

Usable discs .......................... Compact disc

Signal-to-noise ratio ............ 94 dB (1 kHz) (IEC-A net-

work)

Number of channels ............ 2 (stereo)

MP3 decoding format ......... MPEG-1 & 2 Audio Layer 3

WMA decoding format ....... Ver. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

AAC decoding format........... MPEG -4 AAC (iTunes en-

coded only) (.m4a)

(Ver. 8.2 and earlier)

Backup current ...................... 5.0 mA or less

+ 2 ohm × 1

ES, ES1

DEH-5250SD/XNES, DEH-5250SD/XNES1, DEH-5290SD/XNID

8

DEH-5200SD/XNEW5

Page 9

5 678

56

7

8

C

D

F

A

B

E

2.2 DISC/CONTENT FORMAT

DEH-5200SD/XNEW5

9

Page 10

1234

1234

C

D

F

A

B

E

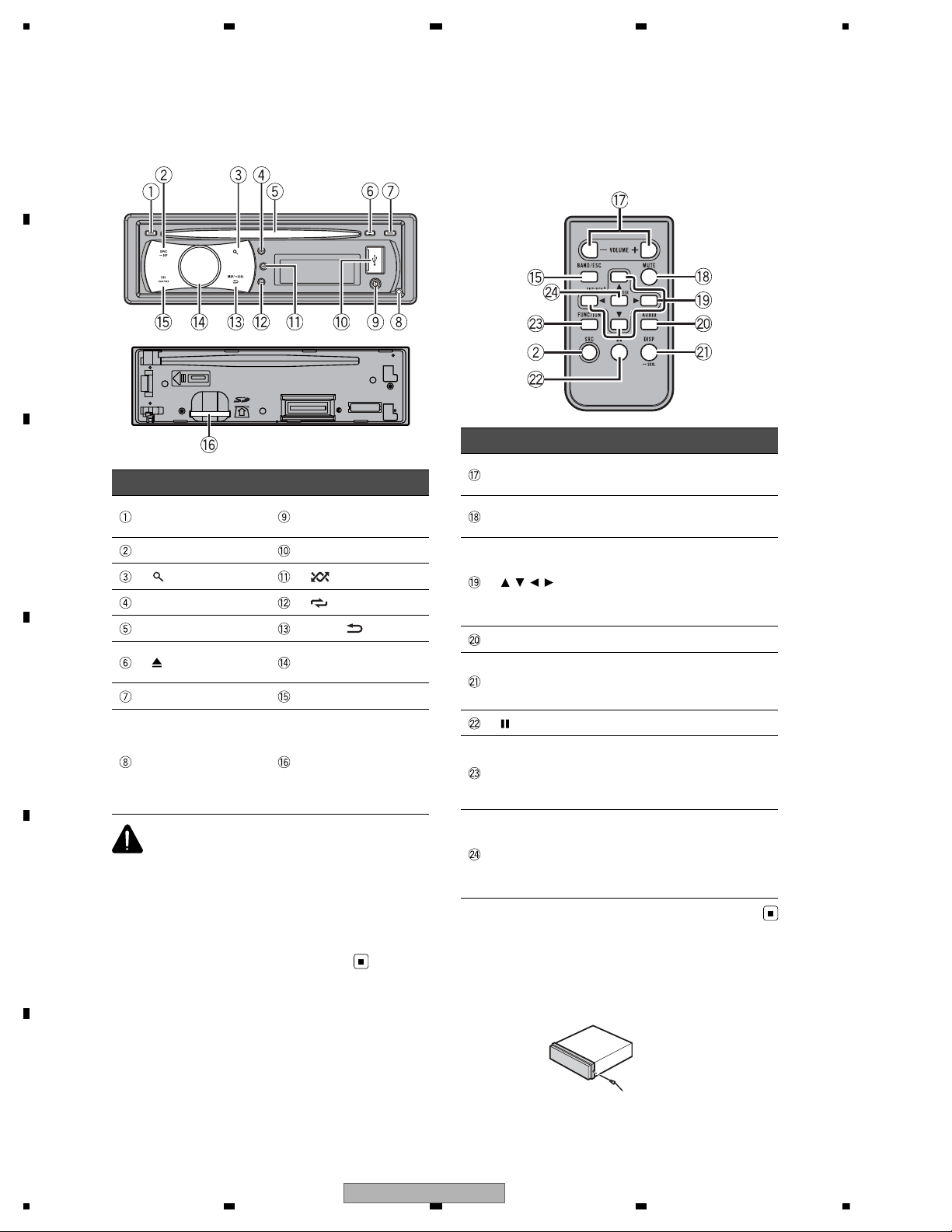

2.3 PANEL FACILITIES

Head unit

traPtraP

TA /NEWS

AUX input jack (3.5

mm stereo jack)

SRC /OFF USB port

(list) / iPod

S.Rtrv

/ LOC

Disc loading slot DISP/ / SCRL

(eject)

MULTI-CONTROL

(M.C.)

MUTE / CLK BAND / ESC

Detach button

SD memory card

slot

You can see the SD

memory card slot if

you remove the

front panel.

CAUTION

Use an optional Pioneer USB cable (CD-U50E) to

connect the USB audio player/USB memory to

the USB port. Since the USB audio player/USB

memory is projected forward from the unit, it is

dangerous to connect directly.

Do not use the unauthorized product.

Optional remote control

The remote control CD-R320 is sold separately.

Part Operation

VOLUME

Press to increase or decrease volume.

MUTE

Press to mute. Press again to unmute.

/ / /

Press to perform manual seek

tuning, fast forward, reverse and

track search controls.

Also used for controlling functions.

AUDIO Press to select an audio function.

DISP/ SCRL

Press to select different displays.

Press and hold to scroll through

the text information.

Press to pause or resume.

FUNCTION

Press to select functions.

Press and hold to recall the initial

setting menu when the sources

are off.

LIST /

ENTER

Press to display the disc title,

track title, folder, or file list depending on the source.

While in the operating menu,

press to control functions.

DEH-5200SD/XNEW5

Fastening the front panel

If you do not plan to detach the front panel,

the front panel can be fastened with supplied

screw.

Screw

BPZ20P060FTC

10

DEH-5200SD/XNEW5

Page 11

5 678

56

7

8

C

D

F

A

B

E

1

253

4

6

7

98abcde

f

g

h

o

m

2fi

l

k

n

j

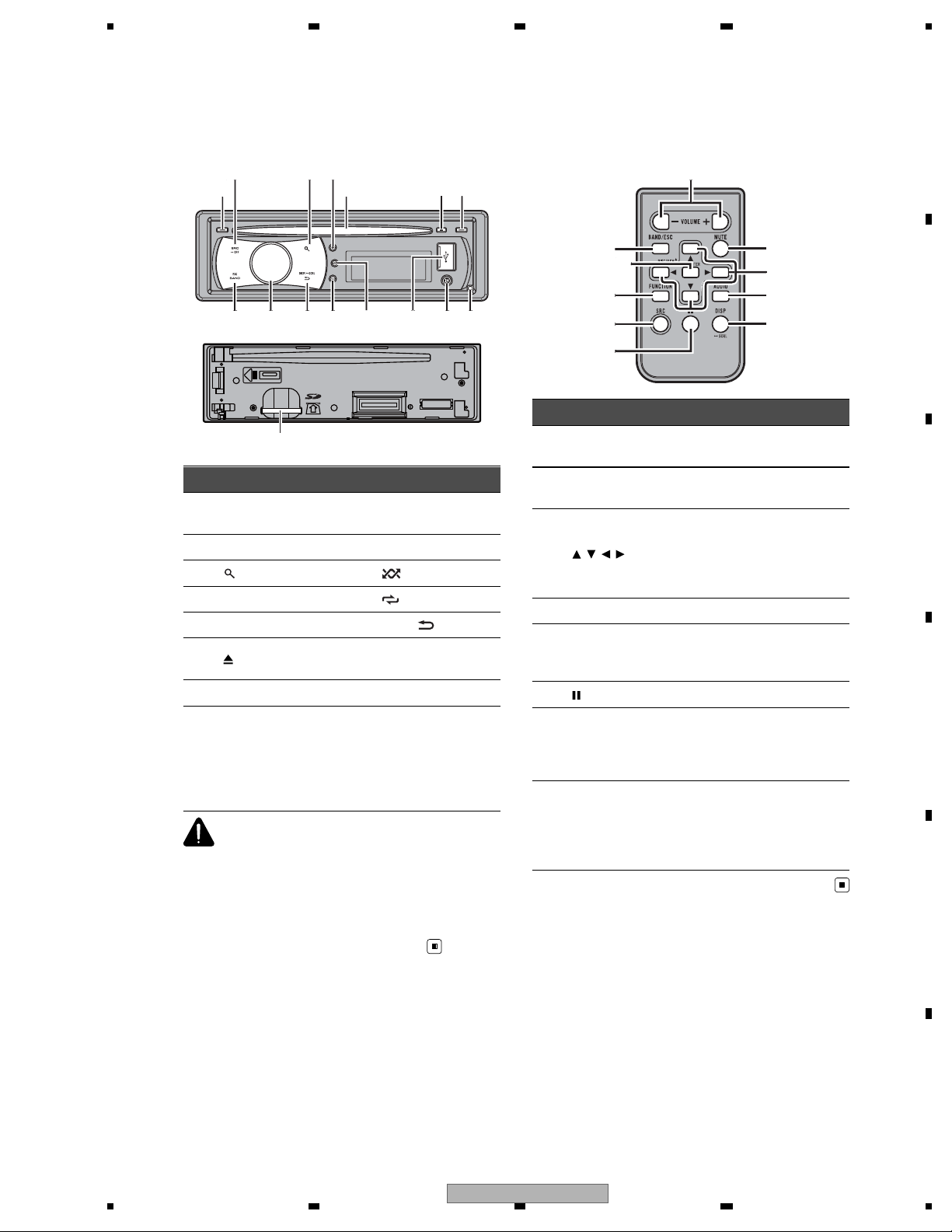

DEH-5250SD/XNES, DEH-5250SD/XNES1, DEH-5290SD/XNID

Head unit

traPtraP

1 SW/ BASS 9

2 SRC /OFF a USB port

3

4 S.Rtrv c

5 Disc loading slot d DISP/

6

7 CLK / DISP OFF f BAND /ESC

8 Detach button g

(list) b / iPod

(eject) e

CAUTION

Use an optional Pioneer USB cable (CD-U50E) to

connect the USB audio player/USB memory to

the USB port. Since the USB audio player/USB

memory is projected forward from the unit, it is

dangerous to connect directly.

Do not use the unauthorized product.

AUX input jack (3.5

mm stereo jack)

/ LOC

/ SCRL

MULTI-CONTROL

(M.C.)

SD memory card

slot

You can see the SD

memory card slot if

you remove the

front panel.

Remote control

Part Operation

h VOLUME

i MUTE

j

/ / /

k AUDIO Press to select an audio function.

l DISP/ SCRL

m

n FUNCTION

LIST/

o

ENTER

Press to increase or decrease volume.

Press to mute. Press again to unmute.

Press to perform manual seek

tuning, fast forward, reverse and

track search controls.

Also used for controlling functions.

Press to select different displays.

Press and hold to scroll through

the text information.

Press to pause or resume.

Press to select functions.

Press and hold to recall the initial

setting menu when the sources

are off.

Press to display the disc title,

track title, folder, or file list depending on the source.

While in the operating menu,

press to control functions.

DEH-5200SD/XNEW5

11

Page 12

1234

1234

C

D

F

A

B

E

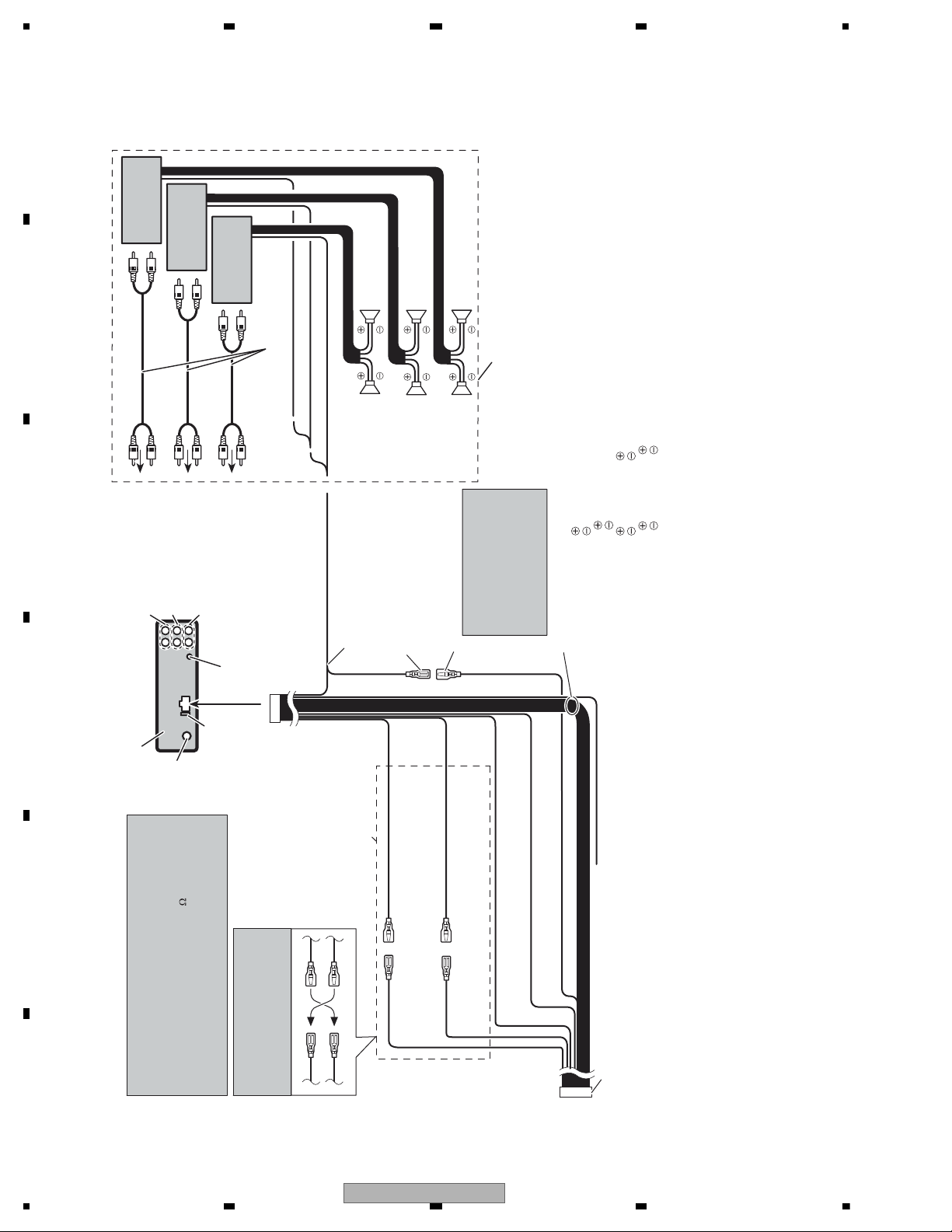

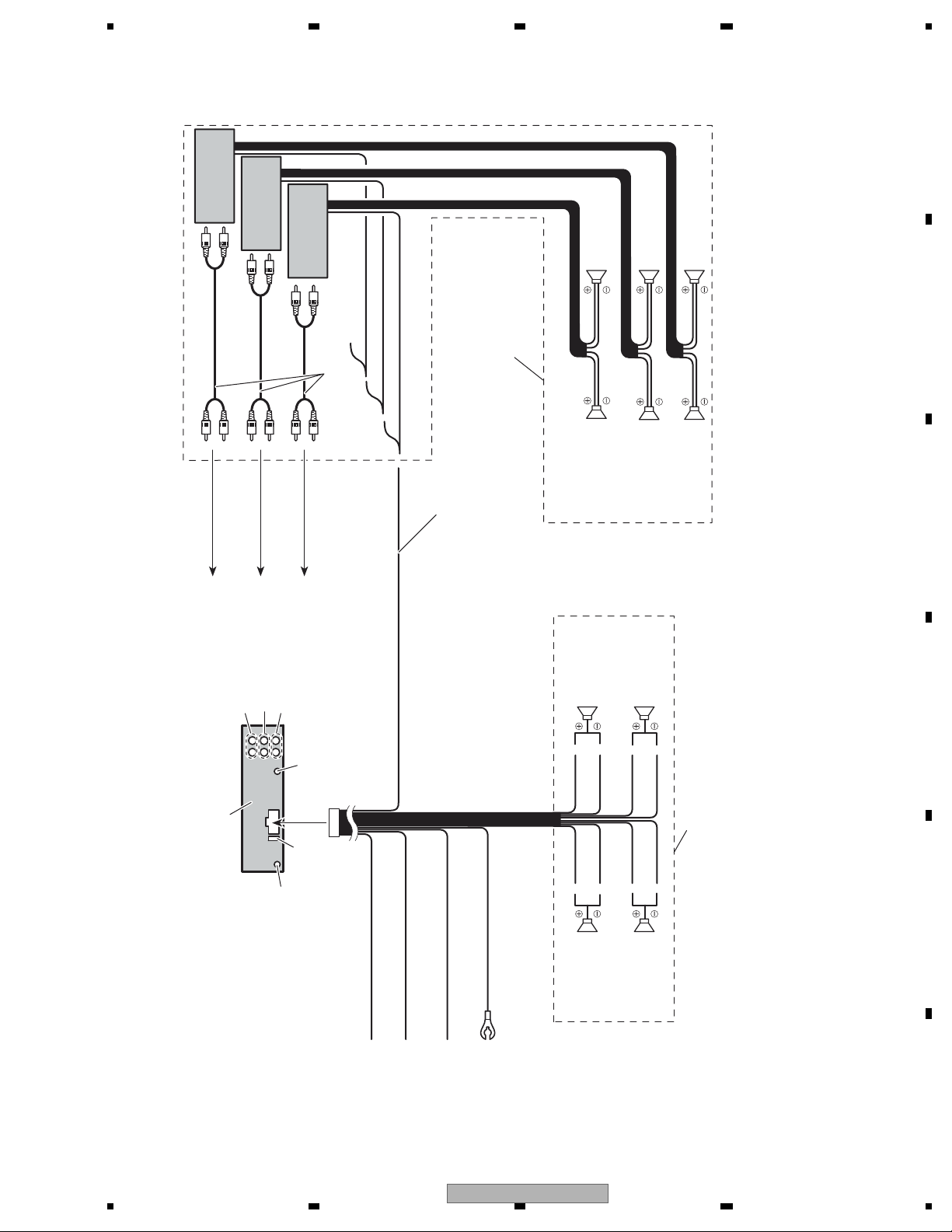

2.4 CONNECTION DIAGRAM

2* 1*

3*4*

9. Note

Depending on the kind of vehicle,

the function of 2* and 4* may be

different. In this case, be sure to

connect 1* to 4* and 3* to 2*.

10. Connect leads of the

same color to each other.

11. Yellow (2*)

Back-up (or

accessory)

13. Red (4*)

Accessory

(or back-up)

12. Yellow (1*)

Connect to the constant

12 V supply terminal.

14. Red (3*)

Connect to terminal controlled by

ignition switch (12 V DC).

16. Black (chassis ground)

Connect to a clean, paint-free metal location.

17. ISO connector

Note

In some vehicles, the ISO connector may be

divided into two. In this case, be sure to

connect to both connectors.

18. Yellow/black

If you use an equipment with Mute

function, wire this lead to the Audio Mute

lead on that equipment. If not, keep the

Audio Mute lead free of any connections.

8. Notes

• Change the initial setting of this unit (refer to the

operation manual). The subwoofer output of this unit is

monaural.

• When using a subwoofer of 70 W (2

), be sure to

connect with Violet and Violet/black leads of this unit.

Do not connect anything with Green and Green/black

leads.

15. Orange/white

Connect to lighting switch terminal.

1. This product

7. Antenna

jack

6. Fuse (10 A)

5. Wired remote input

Hard-wired remote

control adaptor can

be connected (sold

separately).

26. Power amp

(sold separately)

27. Connect with RCA cables

(sold separately)

28. System remote control

26. Power amp

(sold separately)

26. Power amp

(sold separately)

24. To front output

23. To rear output

31. Rear speaker

29. Subwoofer

30. Front speaker

31. Rear speaker

29. Subwoofer

30. Front speaker

25. To subwoofer output

32. Perform these connections when

using the optional amplifier.

22. Speaker leads

White: Front left

White/black: Front left

Gray: Front right

Gray/black: Front right

Green: Rear left or subwoofer

Green/black:Rear left or subwoofer

Violet: Rear right or subwoofer

Violet/black: Rear right or subwoofer

19. Blue/white

Connect to system control

terminal of the power amp (max.

300 mA 12 V DC).

20. Blue/white (6*)

Connect to auto-antenna relay

control terminal (max. 300 mA

12 V DC).

The pin position of the ISO

connector will differ depending

on the type of vehicle. Connect

5* and 6* when Pin 5 is an

antenna control type. In another

type of vehicle, never connect

5* and 6*.

21. Blue/white (5*)

Hcb

2. Rear output

4. Subwoofer output

3. Front output

DEH-5200SD/XNEW5

12

DEH-5200SD/XNEW5

Page 13

5 678

56

7

8

C

D

F

A

B

E

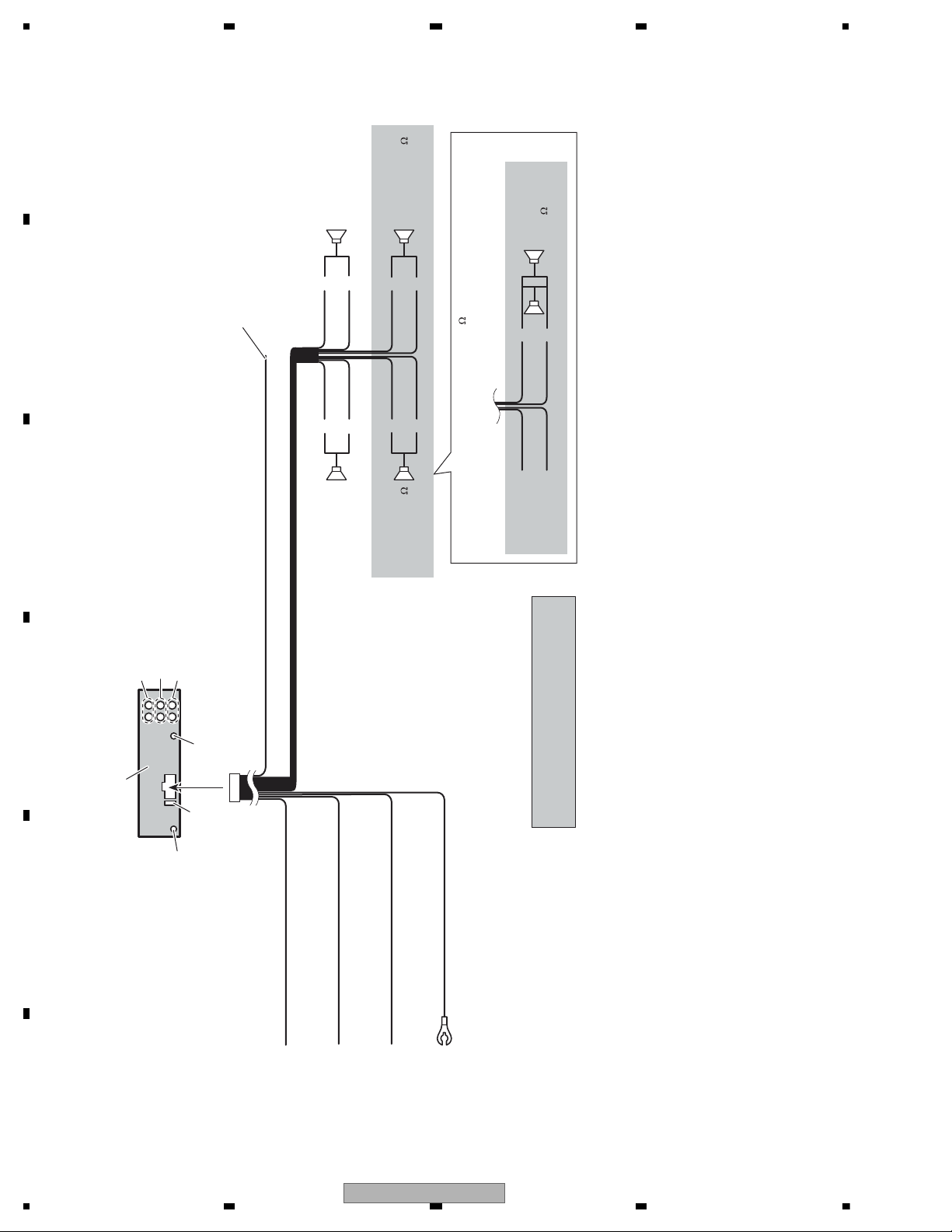

DEH-5250SD/XNES, DEH-5250SD/XNES1, DEH-5290SD/XNID

(sold separately)

29. Power amp

(sold separately)

29. Power amp

29. Power amp

(sold separately)

33. Subwoofer33. Subwoofer

16. Front speaker

23. Rear speaker23. Rear speaker

25. To rear output

2. Rear output

26. To front output

27. To subwoofer output

3. Front output

4. Subwoofer output

Hard-wired remote control adaptor

5. Wired remote input

(sold separately)

28. Connect with RCA cables

31. System remote control

Connect to system control terminal of the

power amp or auto-antenna relay control

30. Blue/white

can be connected (sold separately).

when using the optional

amplifier.

32. Perform these connections

terminal (max. 300 mA 12 V DC).

16. Front speaker

16. Front speaker

18.Right17.Left

23. Rear speaker

1. This product

6. Fuse (10 A)

7. Antenna

jack

Connect to the constant 12 V supply terminal.

8. Yellow

9. Red

Connect to lighting switch terminal.

Connect to terminal controlled by ignition

switch (12 V DC).

10. Orange/white

DEH-5200SD/XNEW5

Connect to a clean, paint-free metal location.

11. Black (chassis ground)

12. White 14. Gray

16. Front speaker

15. Gray/black13. White/black

19. Green 21. Violet

20. Green/black 22. Violet/black

23. Rear speaker

anything to the speaker leads that are

not connected to speakers.

24. With a 2 speaker system, do not connect

13

Page 14

1234

1234

C

D

F

A

B

E

34. Note

Change the initial setting of this unit.

The subwoofer output of this unit is monaural.

1. This product

3. Front output

4. Subwoofer output

6. Fuse (10 A)

2. Rear output

7. Antenna

jack

5. Wired remote input

Hard-wired remote control adaptor

can be connected (sold separately).

8. Yellow

Connect to the constant 12 V supply terminal.

9. Red

Connect to terminal controlled by ignition

switch (12 V DC).

10. Orange/white

Connect to lighting switch terminal.

11. Black (chassis ground)

Connect to a clean, paint-free metal location.

35. Subwoofer (4 )

36. When using a subwoofer of 70 W (2

), be sure to connect

with Violet and Violet/black leads of this unit.

Do not connect anything with Green and Green/black leads.

38. Subwoofer

(4

)x 2

37. Not used.

17. Left 18. Right

16. Front speaker

12. White 14. Gray

15. Gray/black13. White/black

19. Green 21. Violet

20. Green/black 22. Violet/black

16. Front speaker

30. Blue/white

Connect to system control

terminal of the power amp or

auto-antenna relay control

terminal (max. 300 mA 12 V DC).

35. Subwoofer (4

)

19. Green 21. Violet

20. Green/black 22. Violet/black

14

DEH-5200SD/XNEW5

Page 15

5 678

56

7

8

C

D

F

A

B

E

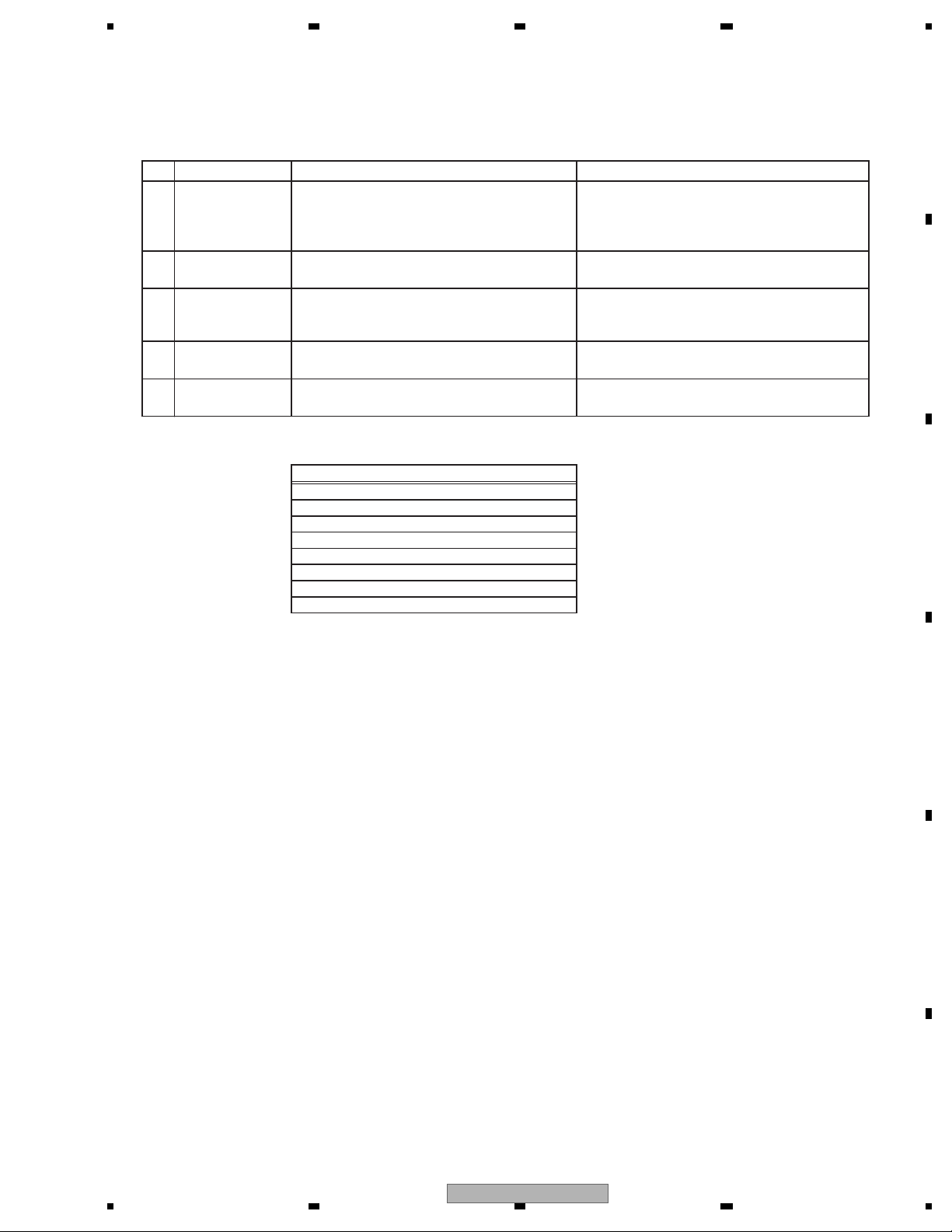

demrifnocebotmetIserudecorP.oN

1 Confirm whether the customer complain has

been solved.

If the customer complain occurs with the

specific media, use it for the operation check.

The customer complain must not be

reappeared.

Display, audio and operations must be

normal.

2 CD Play back a CD.

(Track search)

No malfunction on display, audio and

operation.

3 FM/AM tuner Check FM/AM tuner action.

(Seek, Preset)

Switch band to check both FM and AM.

Display, audio and operations must be

normal.

4 Check whether no disc is inside the product. The media used for the operating check must

be ejected.

retfaecnaraeppastinotridrosehctarcsoNkcehcecnaraeppA5

receiving it for service.

Item to be checked regarding audio

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

To keep the product quality after servicing, please confirm following check points.

See the table below for the items to be checked regarding audio:

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

DEH-5200SD/XNEW5

15

Page 16

1234

1234

C

D

F

A

B

E

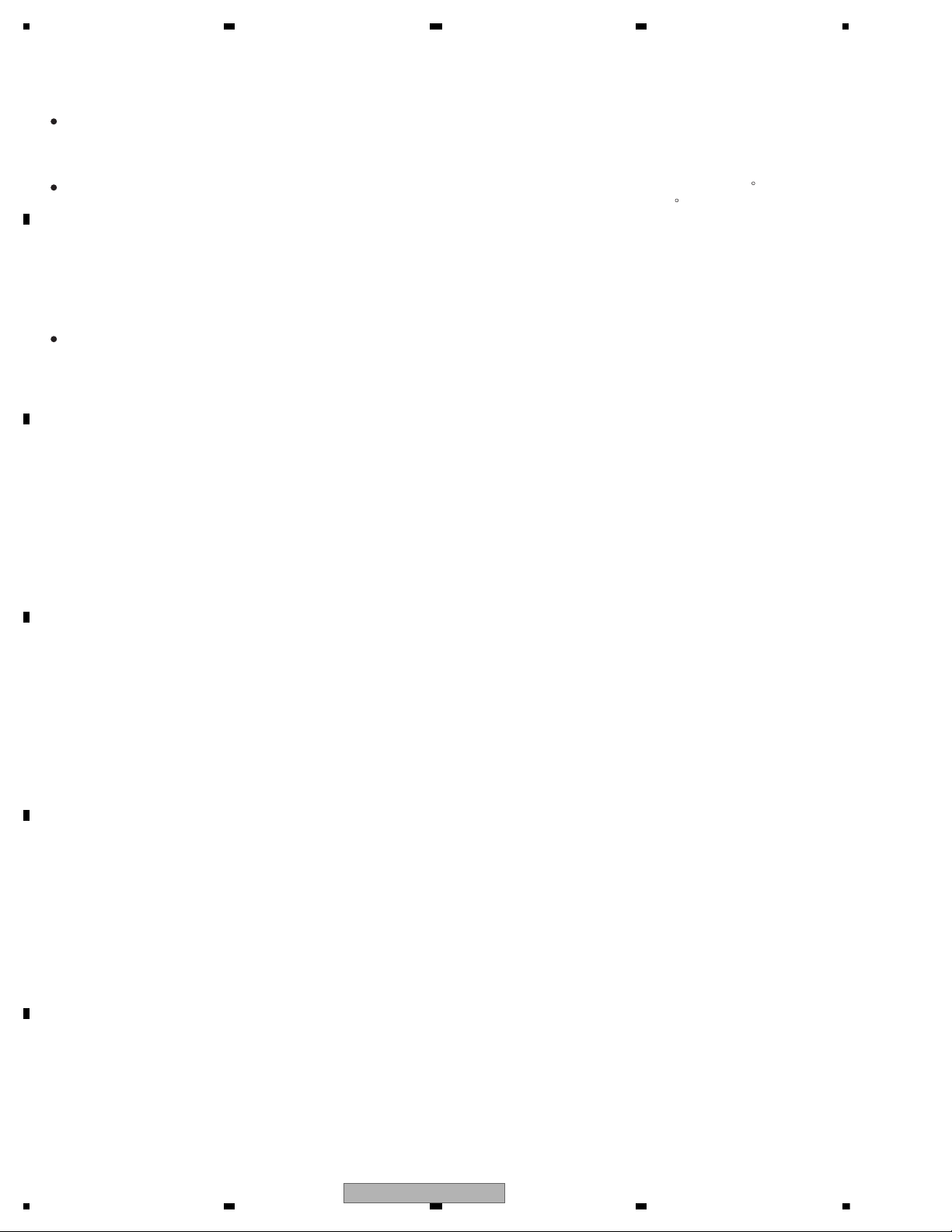

3.2 PCB LOCATIONS

A

B

Keyboard Unit

CD Core Unit (S11STD-DOUT)

C

Tuner Amp Assy

A:DEH-5200SD/XNEW5

B:DEH-5250SD/XNES

C:DEH-5250SD/XNES1

D:DEH-5290SD/XNID

Unit Number : QWM3122(A)

Unit Number : QWM3123(B,C,D)

Unit Name : Tuner Amp Assy

Unit Number :

Unit Name : Keyboard Unit

Unit Number : CWX3774

Unit Name : CD Core Unit(S11STD-DOUT)

16

DEH-5200SD/XNEW5

Page 17

5 678

56

7

8

C

D

F

A

B

E

- Jigs List

Name

Test Disc

L.P.F.

Jig No.

TCD-782

Remarks

Checking the grating

Checking the grating (Two pieces)

Name

Jig

- Grease List

Name

Grease

Grease

Grease No.

GEM1024

GEM1045

Remarks

CD Mechanism Module

CD Mechanism Module

e

Before shipping out the product, be sure to clean the

following portions by using the prescribed cleaning

tools:

Portions to be cleaned Cleaning tools

CD pickup lenses Cleaning liquid : GEM1004

Cleaning paper : GED-008

3.3 JIGS LIST

m

3.4 CLEANING

No.

rease No.

emarks

emarks

DEH-5200SD/XNEW5

17

Page 18

1234

1234

C

D

F

A

B

E

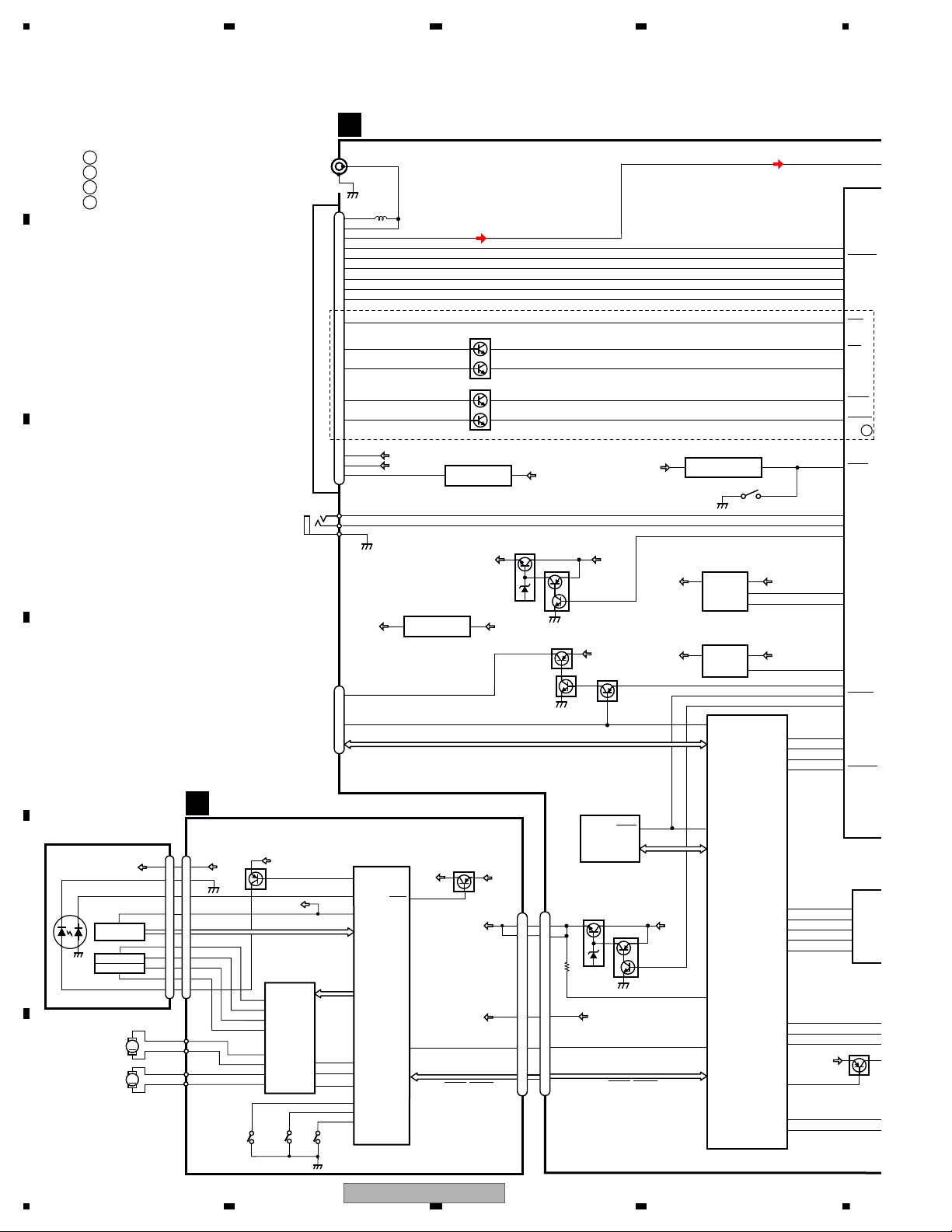

4. BLOCK DIAGRAM

M

M

IC6

COMP

PEG645B

PEG647A

SYSTEM

BUP

VDD5V

Q901

Q902

35

DALMON

10

RESET

12

S-80827CNNB-B8M

IC651

RESET

VDD3.3V

S652

:DEH-5200SD/XNEW5

:DEH-5250SD/XNES

A

:DEH-5250SD/XNES1

:DEH-5290SD/XNID

C

B

B

JA401

JA661

ANTENNA

SD CARD

SL

FM/AM TUNER UNIT

VCC

FMANT

AMANT

1

3

5

CE2

6

CE1

8

CK

9

DI

10

LDET

11

DO

14

RDS_CK

18

RDS_DATA

19

4

SYS8V

TUNER AMP ASSY

A

C

Q402

RDS_LOCK

20

RDS_HSLK

21

Q401

ROM_VDD

13

VDD3.3V

VDD_3.3

17

Lch TUNL

23

SYS8V

3 1

NJM2885DL1-33

IC431

TUNER3V REG.

USB5V DD5V

5 4

R5523N001B

IC151

USB5V REG.

VOUT VIN

1

EN

3

FLG

DD5V BUP

21

BD9781HFP

IC161

DD5V REG.

SW VIN

7

EN

VDD3.3V

32

92

KEYAD

34

MEDRX

33

MEDTX

43

MEDMUTE

41

MEDSTBY

KEYD

63

95

SL

RCK

RDS57K

MEDRST

64

TUNPCE1

TUNPCE2

65

TUNPCK

66

72

LDET

TUNPDI

67

71

TUNPDO

77

RDSDT

RDSLK

74

78

21

USBCTL

23

USBFLG

24

42

80

SDCTL

19

VDCONT

SYNC

SD_DATA0 - SD_DATA3, SD_CLK, SD_CMD

R5S7262ZD144FPU

IC501

CN701

CN781

MEDIA uCOM

114

SD_CD

113

CDRST

RESET

16

15

8

VD

9

VDD

VDD

CD

4

12

MED3.3V

Q781

Q491

Q782

63

SYS_TXD

61

59

58

BRST

MEDIA_MUTE

SYS_RXD

71

70

DM

DP

148

CP_SDA

149

CP_SCL

112

CPRST

111

CPPWR

MED3.3V

PICKUP UNIT

(P10.5)(SERVICE)

CD CORE UNIT(S11STD-DOUT)

A

LD

MD

LD-

MD

HOLOGRAM

UNIT

LD+

FOCUS ACT.

TRACKING ACT.

FOP

TOP

VREF

FOM

TOM

VCC

VCC

15

5

14

15

5

212

1

14

88

33

44

1212

RF AMP, CD DECODER, MP3&WMA DECODER

DIGITAL SERVO/DATA•PROCESSOR

CPU, USB HOST CONTROLLER

PE5706A

IC201

Q101

IC301

BA5839FP

ACTUATOR/

MOTOR DRIVER

CN101

TD,FD

AC,BD,E,F

1

2

VDD

TOP

FOP

REFO

93

FOM

TOM

PD

REFO

V+3A

LD+

GND

SPINDLE

MOTOR

LOADING/CARRIAGE

MOTOR

21

9

SD,MD

40

39

22

41

15

VO3+

16

VO3-

17

VO4+

18

VO4-

11

VO1-

14

VO2+

12

VO1+

13

VO2-

SOM

SOP

LCOM

LCOP

CNT

MUTE

LOIN

S903

S901

S905

DSCSNS HOME8SNS

35

37

38

LD

PD

CONT

CLCONT

HOME

8SNS

DSCSNS

RESET

REFOUT

LOEJ

PUEN

CN701

2

VD

1

Q102

54

V+3A

VDD

CD DATA (CDSRQ,CDSTBY,SKIP,

29

RESET

SCL,SDA,DATA,BCLK,LRCK,WAIT)

9

8

2,3

VDD5V REG.

SD3.3V REG.

KEYAD

KEYD

2

3

VDD5V

VDD3.3V

3 1

NJM2885DL1-33

IC901

VDD3.3V REG.

CWW1967

IC581

FLASH ROM 16Mbit

12

RESET

43

RESET

VD

85

VDSENS

BUP

Q751

Q752

MECHA VD

CD DATA (CDSRQ,CDSTBY,SKIP,

SCL,SDA,DATA,BCLK,LRCK,WAIT)

138

DACLRCK

137

DACDATA

139

105

136

DACCLK

DEEMPH

DACSCK

WM87

IC1

DA

1

LRCKIN

2

DIN

3

BCKIN

12

DEEMPH

14

MCLK

WIRED REMOTE

1

VDD

1

GND

Q783

18

DEH-5200SD/XNEW5

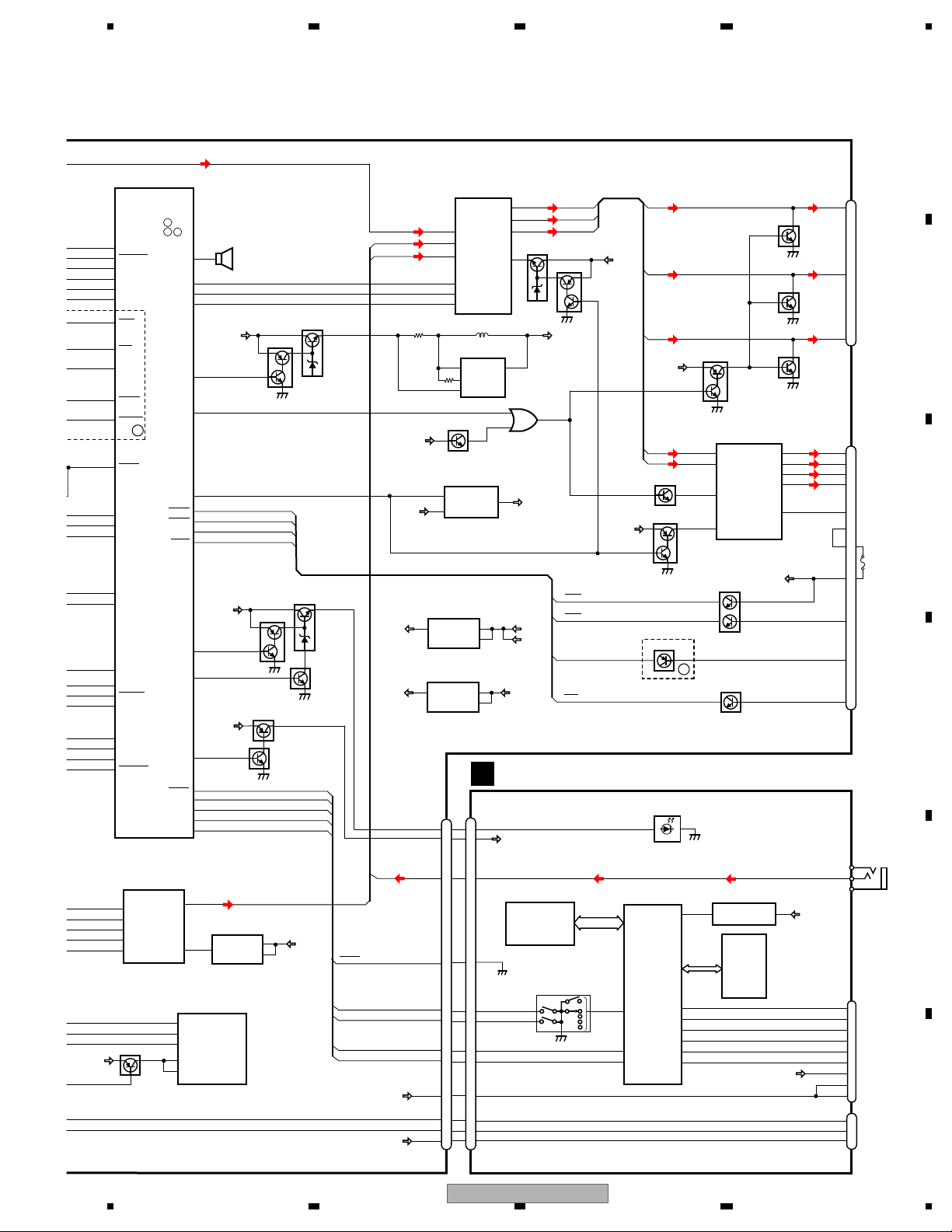

Page 19

5 678

56

7

8

C

D

F

A

B

E

IC601

COMPUTER

A

PEG645B8:

B

PEG647A8:

SYSTEM MICRO

35

DALMON

A

10

RESET

Q381

BUP

BUP

TELIN

ISENS

ASENS

BSENS

CN801

RCA OUT

KYDT

DPDT

ROT1

ROT0

3

8

11

16

19

6

10

12

14

USBDP

USBDM

15

13

VBUS

USB5V

OEL+B

AUXL

BUP OEL+B

Q851

Q852

BUP

PM9012A

IC201

E.VOL

25

OUTFL

26

FL

RL

OUTRL

36TUNL

35CDL

S5B+L

27 SWL

OUTPL

39AUXL

S1Q+L

S4B-L

21

22

CLK

STB

23

DATA

PA2030A

IC351

AMP

9

OUT1(+)

7FL-

OUT1(-)

12RL

SYSPW

11FL

IN1

FL

5RL+

OUT2(+)

3 RL-

OUT2(-)

25 BREM

H-SW/VDS-DET

IN2

22

MUTE

4

STBY

48

MUTE

32

92

KEYAD

16

18

40

TELIN

34

MEDRX

33

MEDTX

43

MEDMUTE

41

MEDSTBY

KEYD

63

95

SL

RCK

RDS57K

MEDRST

ISENS

ASENS

BSENS

64

TUNPCE1

TUNPCE2

65

TUNPCK

66

72

LDET

TUNPDI

67

71

TUNPDO

77

RDSDT

RDSLK

74

78

55

VST

54

VCK

53

VDT

50

OELPW

VDD3.3V

Q841

Q842

47

SWVDD

51

DIMMER

49

ILMPW

21

USBCTL

23

USBFLG

24

42

80

SDCTL

19

VDCONT

SYNC

JA301

SWL

4

2

JA981

FL+

1

3

5

7

18

14

B.UP

15

17

ACC

13

TEL

9

6

RL

FL

SWL

RL

Q302

Q301

Q303

Q361

ILL

11

Q951

Q931

Q382

VDD5V

Q351

Q921

Q491

2

341S2162

IC491

iPod CP

13

I2C_SDA/SPI_SOMI

12

I2C_SCL/SPI_SIMO

1

4

nRESET

5

VCC

2

MODE1/SPI_nSS

MED3.3V

8

1

7

NJM2360AM

IC851

CSSI

8

CD

6

V+

BUP

Q821

Q822

Q823

KEYBOARD UNIT

B

30

KYDT

29

DPDT

1

ROT1

2

ROT0

A

C

20

PEE

BUZZER

BZ601

OEL9V REG.

OEL+B

OEL+B

Q242

Q241

VP+B

20

VCCH

ILM+B

SWVDD

MED3.3V DD5V

VDD5V

16

S-1172B33-E6

IC591

MED3.3V REG.

VOUT VIN

3

ON/OFF

MED1.2V MED3.3V

4

3

BH12PB3WHFV

IC592

MED1.2V REG.

VOUT VIN

1

STBY

DSENS

17

5

1

NJM2872F05

IC182

DAC5V REG.

SYS8V

WM8761GED

IC181

DAC

9

VOUTL

CDL

1

LRCKIN

2

DIN

3

BCKIN

12

DEEMPH

14

MCLK

8

VDD

VIN

3

CONT

VOUT

ILM+B

SWVDD

SOURCE CONNECTOR

B.UP

BSENS

ASENS

TELMUTE

ISENS

3

16

CN1801

JA1806

SWVDD

ILLUMI

ILM+B

FRONT AUX

AUXL

AUXR

AUXGND

3

2

1

19

AUXL

ROT0

14

S1821

ROTARY COMMANDER

ROT112Phase_A

Phase_B

88

KEY MATRIX

DSENS

20

KD0-3,KS0-2

8

11

OEL+B

VBUS

6

KYDT

10

DPDT

15

USBDP

13

USBDM

28

27

SWVDD

KYDT

DPDT

O_CIN

O_SID

O_SCLK

O_DC

O_RST

O_CSB

REM

4

13

GP1UXC14RK

IC1861

JOYST

IC1871

COMPUTER

PEG652A8

PD8192B9

IC1872

ROM

CONTROL SENSOR

REMOTE

MICRO

CN1811

4

USBDP

3

USBDM

2

USB5V

SWVDD

26

33

35

22

24

23

CN1921

8

OSCIN

7

D7(SDIN)

6

D6(SCLK)

12

VCC

2

11

VDD

5

DC

4

RSTB

3

CSB

USB

VCC

OEL MODULE

DSENS

20

DSENS

SYS8V

BUP

2

1

NJM2388F84

IC911

SYS8V REG.

VOUT

VIN

4

CONTROL

SYSPW

36

DEH-5200SD/XNEW5

19

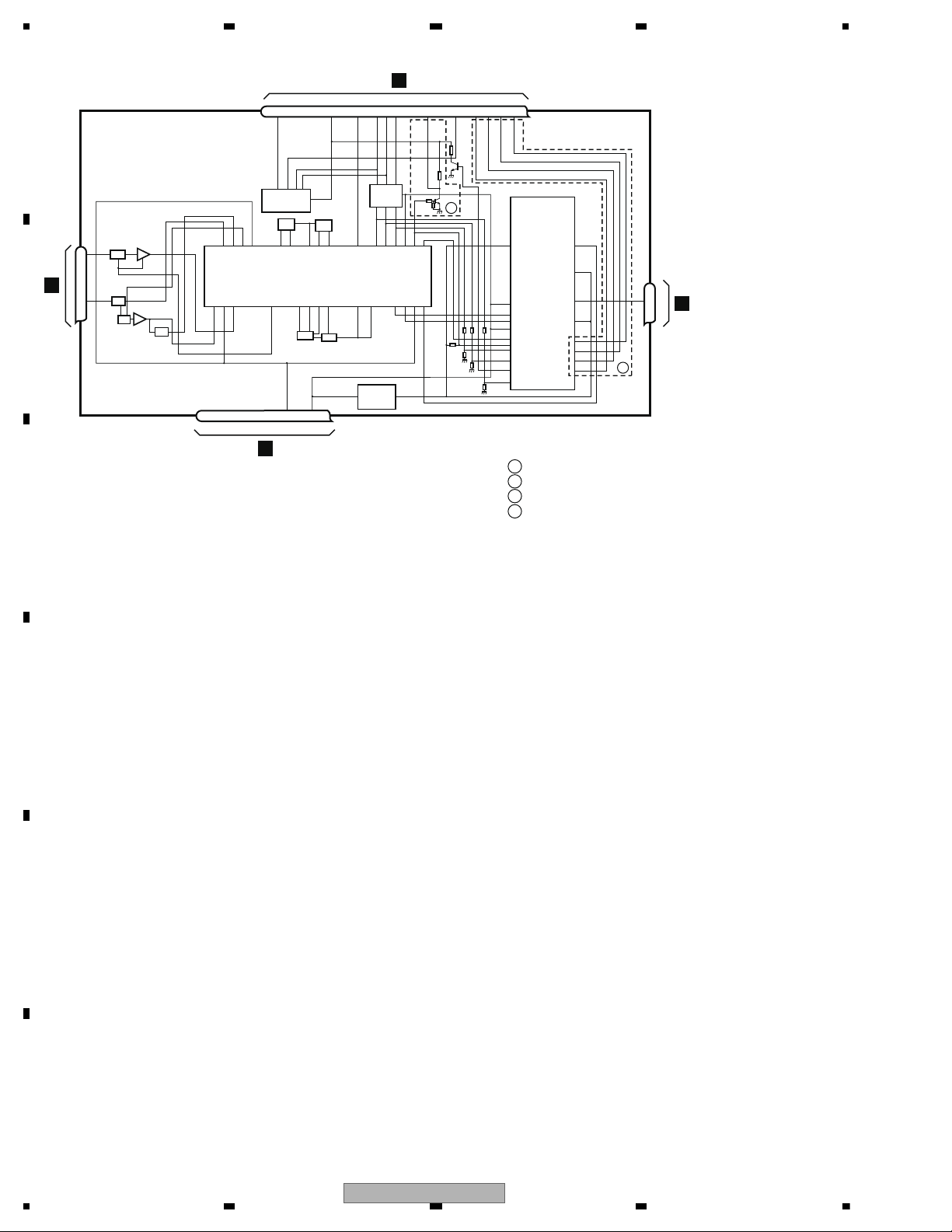

Page 20

1234

1234

C

D

F

A

B

E

FMRF

ANT adj

RF adj

FM ANT

T51

CF52

RFGND

OSCGND

DGND

AUDIOGNDNCVCC

VDD_3.3

3.3V

2.5V

IC4

2.5V

IC2

NC

CE2

ROM_VDD

SL

DI

CK

CE1

LDET

DO

RDS_CK

RDS_DATA

RDS_LOCK

RDS_HSLK

76 13 5 1098 11 14 18192021

1

3

212 1522 16 4 17

IC1

3.3V

AM ANT

FMRF

ATT

LPF

OSC

IC3

EEPROM 5.0V

IC5

ATT

MIXER, IF AMP

DET, FM MPX,

RDS DECODER

23

Lch

FM/AM TUNER UNIT

A

A

A

A

3.3V→2.5V

5V→3.3V

:DEH-5200SD/XNEW5

:DEH-5250SD/XNES

A

:DEH-5250SD/XNES1

:DEH-5290SD/XNID

C

B

B

A

A

20

DEH-5200SD/XNEW5

Page 21

5 678

56

7

8

C

D

F

A

B

E

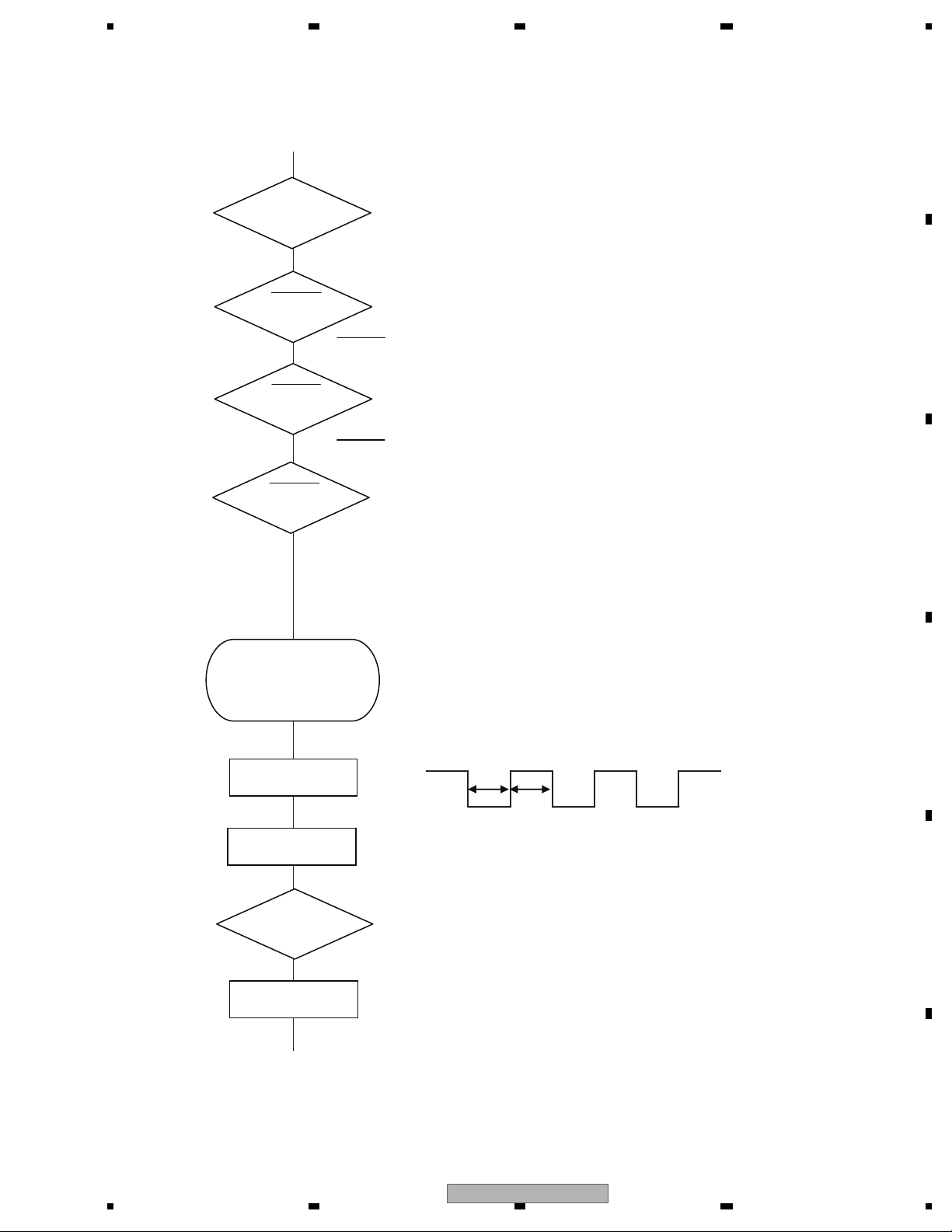

Vcc = 3.3 V

Pin 14

BSENS

Pin 16

ASENS

Pin 18

DSENS

Pin 17

BSENS = L

ASENS = L

Starts

communication

with Grille

microcom

p

uter.

SWVDD <- H

Pin 47

Source keys

operative

Source ON

SYSPW <- H

Pin 36

500 ms

500 ms

In case of the above signal, the communication

with Grille microcomputer may fail.

If the time interval is not 500 msec, the oscillator

may be defective.

Completes power-on operation.

(After that, proceed to each source operation)

Power ON

5. DIAGNOSIS

5.1 OPERATIONAL FLOWCHART

DEH-5200SD/XNEW5

21

Page 22

1234

1234

C

D

F

A

B

E

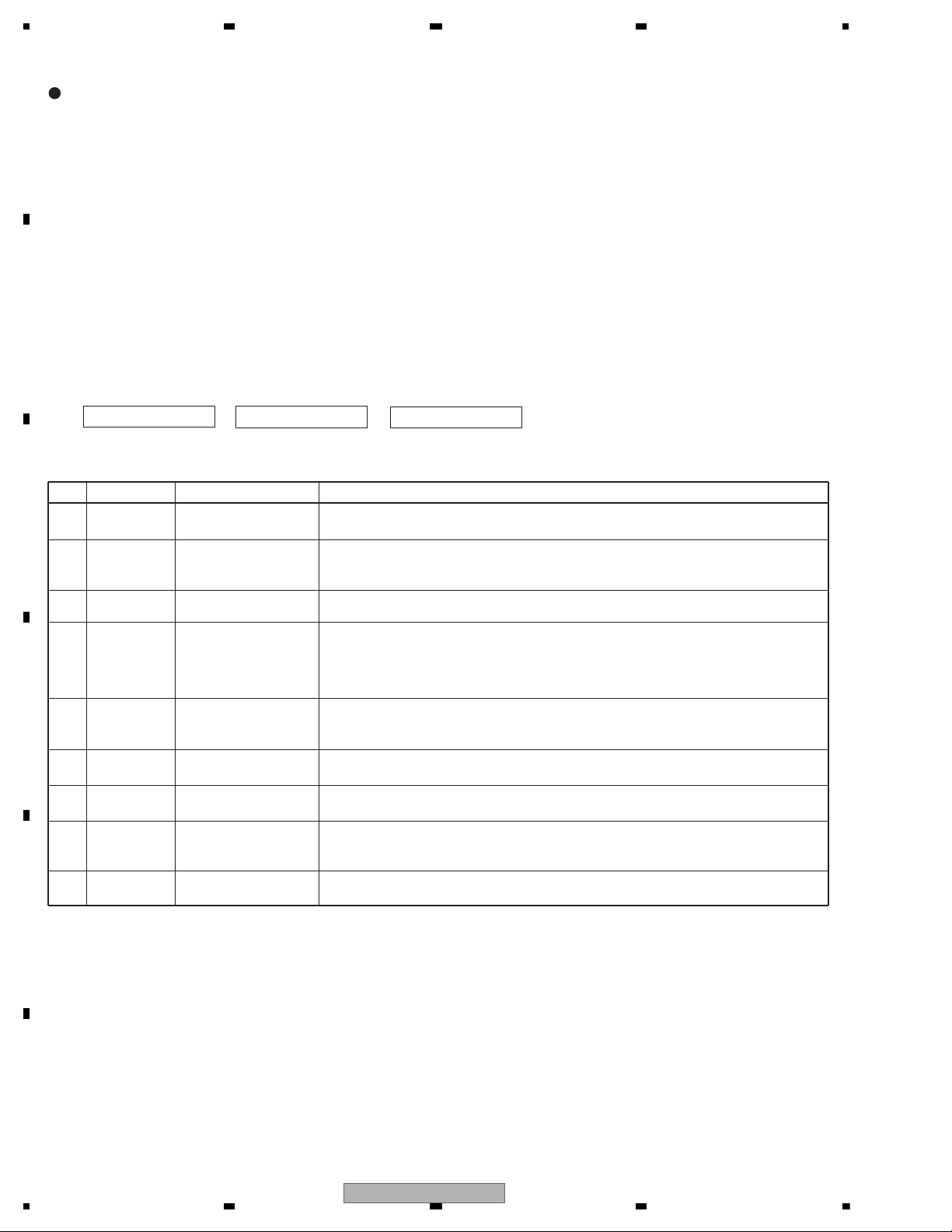

5.2 ERROR CODE LIST

8-digit display 6-digit display 4-digit display

ERROR-xx ERR-xx E-xx

(2) LIST OF CD ERROR CODES (Error Mode: 0xFD)

Code Classification

Error code to be displayed

Details and possible causes

10 Servo Carriage Home NG The CRG cannot move toward the inner track.

The CRG cannot move from the inner track.

--> Defective HOME SW; Failure in CRG movement.

7

Servo TOC reading NG TOC information cannot be read.

--> The partial disk or TOC content is illegal.

11

Servo Focus Search NG Focusing not available

--> Disc placed upside-down; Stains on the disc; excessive vibration.

17 Servo Setup NG AGC protection does not work. Focus can be easily lost.

--> Scratches or stains on the disc; excessive vibration.

15 Servo Failure in RF data RF not read

--> A CD-R disc that does not contain data loaded

--> A CD-RW disc that does not contain data loaded

12

Servo Spindle Lock NG

Subcode NG

RF-amp NG

Spindle not locked. Subcode not readable.

Proper RF AMP gain not obtained.

--> Defective spindle; Scratches or stains on the disc; excessive vibration.

-->

A CD-R disc that does not contain data loaded, or in a rare case, disc placed upside-down.

--> CD signal error.

30

Servo Search Time Out Failed to reach a target address

--> CRG tracking error; Scratches on the disc; Stains on the disc

50 Mechanism Failure in ejection

Load NG

Disc ejection not completed

Disc loading not completed

--> A foreign object inserted in the mechanism; Disc jammed.

51

Mechanism Failure in retried

turning for ejection

Disc could not be ejected even after disc turning had been retried.

--> A foreign object inserted in the mechanism; Disc jammed.

NOTES

• Indications of error codes are available only during disc operations, because CD operations are

unavailable if a mechanical error is generated.

• If the TOC cannot be read, this is not processed as an error, and operation continues accordingly.

• If you design a new head unit, be sure to use one of the display formats indicated in “Display example of

the main unit.”

ERROR CODES

(1) DISPLAY METHOD

If “0xFD” error mode is displayed in CD MODE (CD MODE area for display), an error code will be displayed in the MIN (minute

display) and SEC (second display) areas.

The same code is displayed in the MIN and SEC areas.

The TNO area is blank (#0FFH), as it conventionally was.

• Display example of the main unit

Depending on the display capability of LCDs, the display format varies, as shown below. XX denotes an error number.

Note: In a case of an OEM product, the error display format is subject to the specifications used by the equipment

manufacturer.

If a CD memory device is inoperable, or operation of such media is stopped by an error, the error mode is established and a

cause of the error is displayed by an error code. Indication of error codes is intended to reduce the number of calls from

customers and facilitate failure analysis and repair work in servicing.

• The 2 high-order digits of an error code denote the main

classification, shown below.

0x: Servo-related errors

1x: Servo-related errors

3x: Servo-related errors

5x: Mechanism-related errors

• How to restore from each error is shown below.

0x, 1x and 3x: ACC-OFF then ON, CD-OFF then ON,

Disc ejection

5X: ACC-OFF then ON, Disc ejection, Disc reloading

22

DEH-5200SD/XNEW5

Page 23

5 678

56

7

8

C

D

F

A

B

E

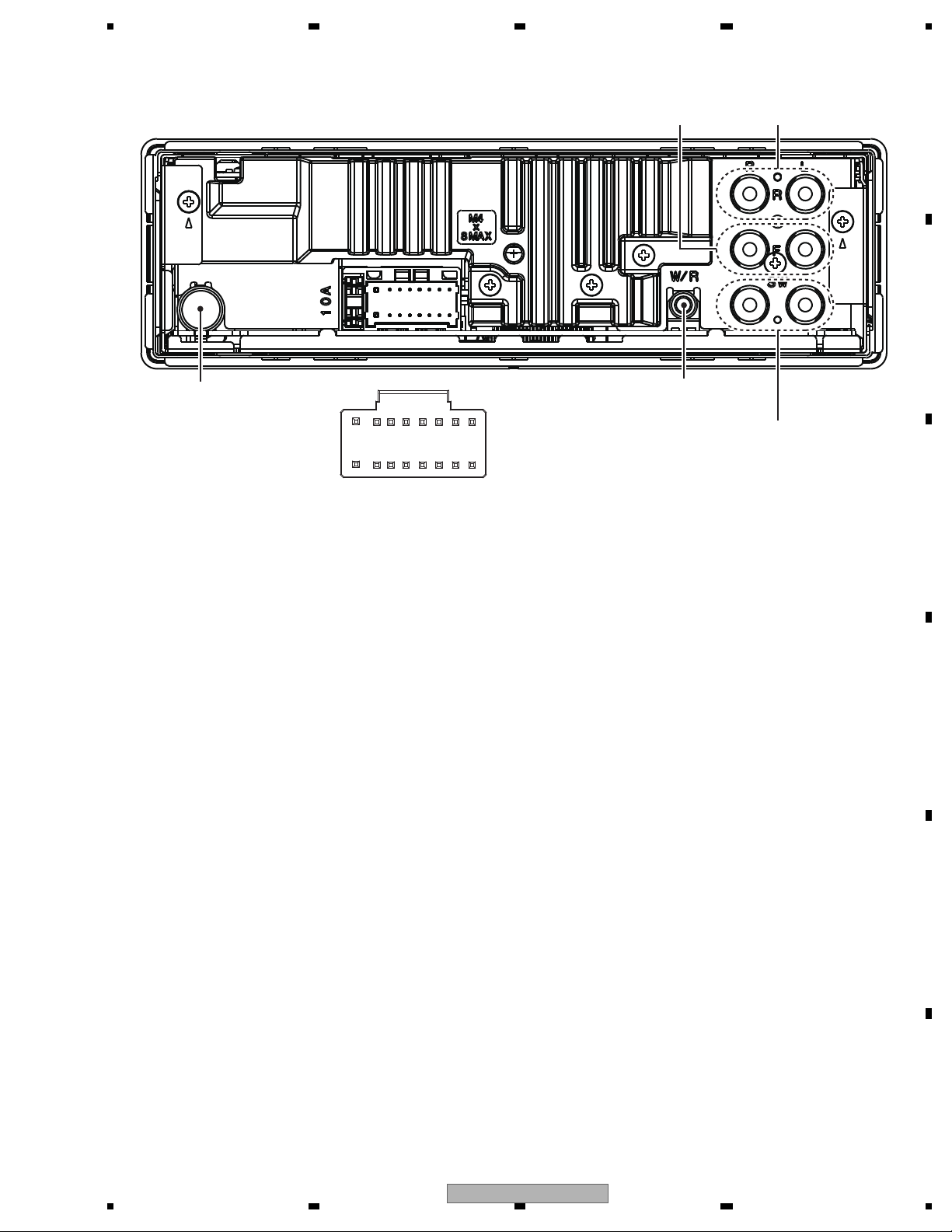

ANTENNA

REAR

OUTPUT

16

14 12 108642

15

13 11 97531

1. FL+

2. FR+

3. FL-

4. FR-

5. RL+

6. RR+

7. RL-

8. RR-

9. TEL

10. NC

11. ILL

12. A.ANT

13. ACC

14. BREM

15. B.UP

16. GND

WIRED REMOTE

CONTROL

SUBWOOFER

OUTPUT

FRONT

OUTPUT

5.3 CONNECTOR FUNCTION DESCRIPTION

DEH-5200SD/XNEW5

23

Page 24

1234

1234

C

D

F

A

B

E

6. SERVICE MODE

[Key]

Contents

Display

[BAND]

Power On

(T.Offset is adjusted)

TRK MIN SEC

00 00 00

[2]

RF AMP

Gain switching

GG GG GG

*1

[3]

Focus Close

S curve check

TRK MIN SEC

91 91 91

[6]

Focus Mode switching

0X 0X 0X

*2

[1]

Tracking Servo

Close

00 00 00

or 99 99 99

[<]

CRG +

[2]

Self-adjusting

switching

TRK MIN SEC

?? ?? ??

*3*8

[>]

CRG -

*8

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[1]

T.Close & AGC

Applicable servomechanism

TRK MIN SEC

?tr ?min ?sec

[3]

RF AGC /

RF AGC coefficient display

[<]

CRG +

8X 8X 8X

or 9X 9X 9X

[2]

T.Balance adjustment /

T.BAL coefficient display

TRK MIN SEC

?? ?? ??

[>]

CRG -

?? ?? ??

[1]

F,T,RF AGC

F.Bias display switching

TRK MIN SEC

TRK MIN SEC

TRK MIN SEC

[3] [<]

CRG/TR Jump +

[2]

Tracking Open

[>]

CRG/TR Jump -

?tr ?min ?sec

TRK MIN SEC

TRK MIN SEC

00 00 00

or 99 99 99

TRK MIN SEC

?tr ?min ?sec

8X 8X 8X

or 9X 9X 9X

8X 8X 8X

or 9X 9X 9X

00 00 00

or 99 99 99

TRK MIN SEC

?tr ?min ?sec?? ?? ??

*7

F,T AGC / F.Bias

RF AGC

8X 8X 8X

or 9X 9X 9X

[2]

Tracking Open

*6

*4 *4

Operation

[Key]

Test Mode

[BAND] Power On/Off

[<]

CRG + / TR Jump +

(Direction of the external surface)

[>]

CRG - / TR Jump (Direction of the internal surface)

[1] T. CLS & AGC & Applicable servomechanism /

AGC,AGC display setting

[2] RF Gain switching / Offset adjustment display /

T.Balance adjustment / T. Open

[3] F. Close,S. Curve / Rough Servo and RF AGC /

F,T,RF AGC

[6] F. Mode switching / Tracking Close

After the [EJECT] key is pressed keys other than the [EJECT] key should not be pressed, until disc ejection is complete.

When the key [2] or [3] is pressed during the Focus Search, the power supply should be immediately turned off (otherwise the lens sticks

to Wall, causing the actuator to be damaged).

100TR Jump, the mechanism shall be set to the Tracking Close mode when the key is released.

When the power is turned on/off the gain of the RFAMP is reset to 0 dB. At the same time all the self-adjusting values shall return to the

default setting.

Do not do Tracking Servo Close before doing Focus Servo Close. (Because the overcurrent flows)

- Flow Chart

[CD] or [SOURCE]

Source ON

TRK MIN

[BAND] + [RDM] -> Reset

Test Mode IN

NOTE

When a CD-DA (regular music CD) is played in the CD test mode, its sound quality

will be temporarily deteriorated. The CD will then repeat normal, deteriorated,

normal… playback.

This is due to the difference in the playback modes between the normal operation

mode and the CD test mode, and the interval of generating deteriorated mode and

the time taken to return to the normal mode depend on the error of each clock.

The time taken to turn to the deteriorated mode is at a minimum around 20

seconds while the time to return to the normal mode is maximum 40 seconds

approximately.

Make sure to check the sound quality in the normal operation mode.

*1) TYP t + 6 dB t + 12 dB

TRK

MIN

SEC

TRK06MIN06SEC

06

TRK12MIN12SEC

12

*2) Focus Close

t S. Curve t F EQ measurement setting

TRK00MIN00SEC

00

TRK

01

MIN01SEC

01

TRK02MIN02SEC

02

(

TRK99MIN99SEC

99)

*3) F.Offset Display t T.Offset Display t Switch to the

order of the original display

*4) 100TR Jump

*7) TRK/MIN/SEC

t F.AGC t T.AGC Gain t F.Bias t RF AGC

*8) CRG motor voltage = 2 [V]

*9) TYP (1X)

t 2X t 1X

TRK

MIN

SEC

TRK

22

MIN22SEC

22

TRK11MIN11SEC

11

*10) OFF(TYP)

t FORCUS t TRACKING

TRK

MIN

SEC

TRK

70

MIN70SEC

70

TRK71MIN71SEC

71

Key of the

head unit

Key of the

remote

control unit

6.1 CD TEST MODE

24

DEH-5200SD/XNEW5

Page 25

5 678

56

7

8

C

D

F

A

B

E

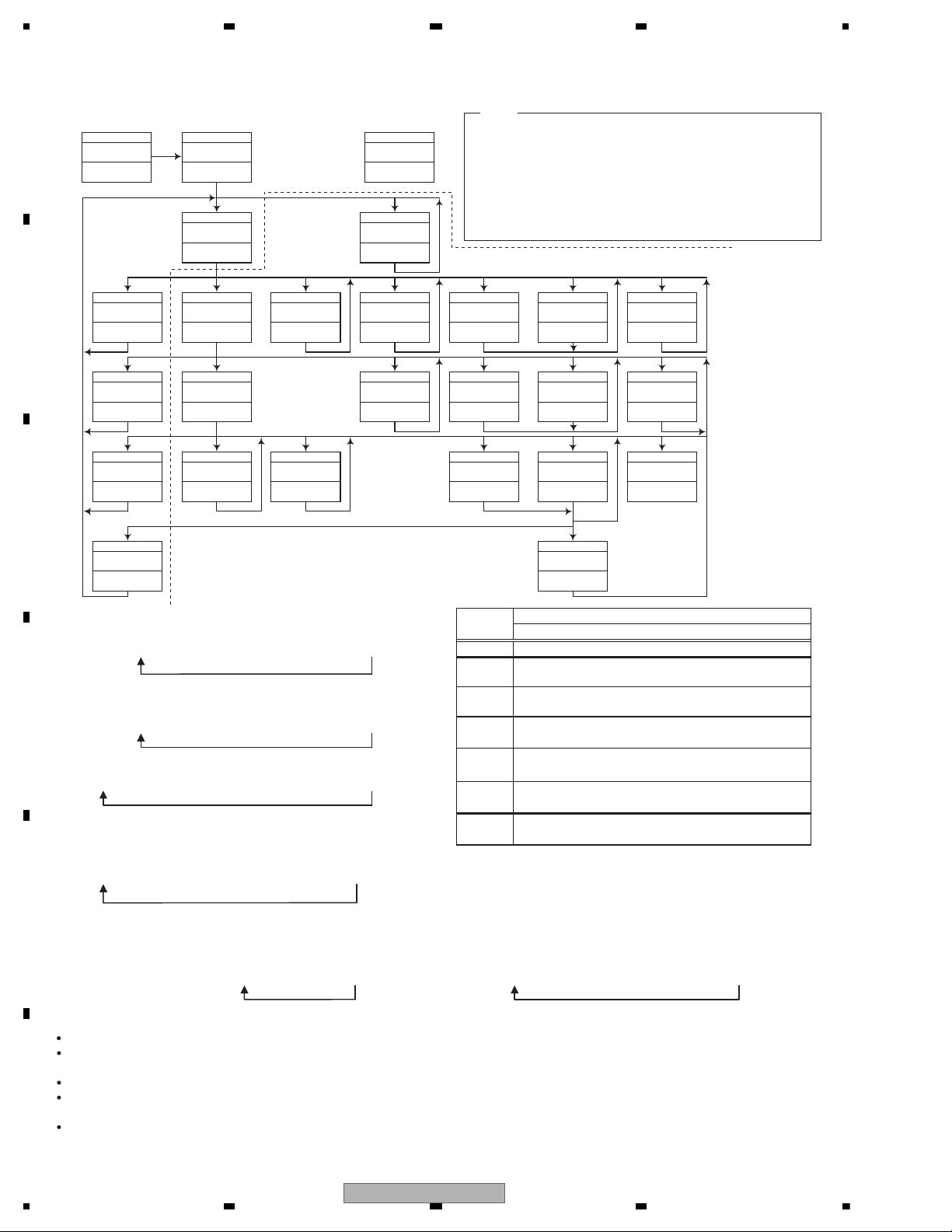

Display Test Mode

Restarted pushing reset while pushing the SRC+RDM key then the screen is changed to the display test mode.

To the display Test Mode

selection screen.

SRC+RDM key REPEAT key

Display Test Mode Service Display Test Mode

To the display of version information

REPEAT key

To the display of ROM correction

version information

REPEAT key

To all turning

REPEAT key

To all turning off

REPEAT key

Screen ROM connection confirmation

REPEAT key

Media microcomputer information

display

REPEAT key

The display mode to the

display usually.

SRC+RDM key

To the static display of

the display mode.

SRC+RDM key

To all turning

SRC+RDM key

Display Test Mode selection screen

6.2 DISPLAY TEST MODE

DEH-5200SD/XNEW5

25

Page 26

1234

1234

C

D

F

A

B

E

To all turning

If a noise is observed on the screen:

The display microcomputer may have an error, or the connection between the display microcomputer and the

OEL driver may have a problem.

If nothing is displayed on the screen:

There may be a problem with the communication, or the display microcomputer may have an error.

To the display of version information

ROM CORRECTION information display

When information couldn't be acquired from EEPROM.

When information could be acquired from EEPROM.

If nothing is displayed on the screen:

There may be a problem with the communication, or the display microcomputer may have an error.

If a number apparently strange is displayed as the EEPROM version:

There may be a problem with the communication.

If a version display is being made but the number of CH used is not displayed properly:

The connection with the EEPROM may be defective.

UNIT

: WW number

? ? ? ? : Unit number information of System microcomputer

& & & & : Unit number information of Display microcomputer

(When the Unit number is QWW3007, it is displayed as 3007.)

$ $ $ $ $ $ $ $ $ : Error information

NO_EEPROM (ROM CORRECTION is not connected)

ROM_ERROR (ROM CORRECTION data error)

: EEPROM Ver.Info

: CH use information

(1:Use / 0:Not use Corresponds from the left to CH1, CH2, CH3, CH4)

26

DEH-5200SD/XNEW5

Page 27

5 678

56

7

8

C

D

F

A

B

E

To all turning off

If a noise is observed on the screen:

The display microcomputer may have an error, or the connection between the display microcomputer and the

OEL driver may have a problem.

Screen ROM connection confirmation

If nothing is displayed on the screen:

There may be a problem with the communication, or the display microcomputer may have an error.

If NG is displayed somewhere:

The connection between the display microcomputer and the image ROM may be defective. For example, even

if NG is displayed for the data bus, it is not necessarily a data bus connection defective.

A problem with the address bus may also cause an error during data bus check.

Media microcomputer information display

If nothing is displayed on the screen:

There may be a problem with the communication, or the display microcomputer may have an error.

If a number apparently strange is displayed as the media version:

There may be a problem with the communication.

UNIT

: OK or NG

: WW number

Note:Because data is not sent from the media microcomputer,

this place becomes a blank display.

? ? ? ? : Unit number information of media microcomputer

DEH-5200SD/XNEW5

27

Page 28

1234

1234

C

D

F

A

B

E

7. DISASSEMBLY

- Removing the Case (not shown)

1. Remove the Case.

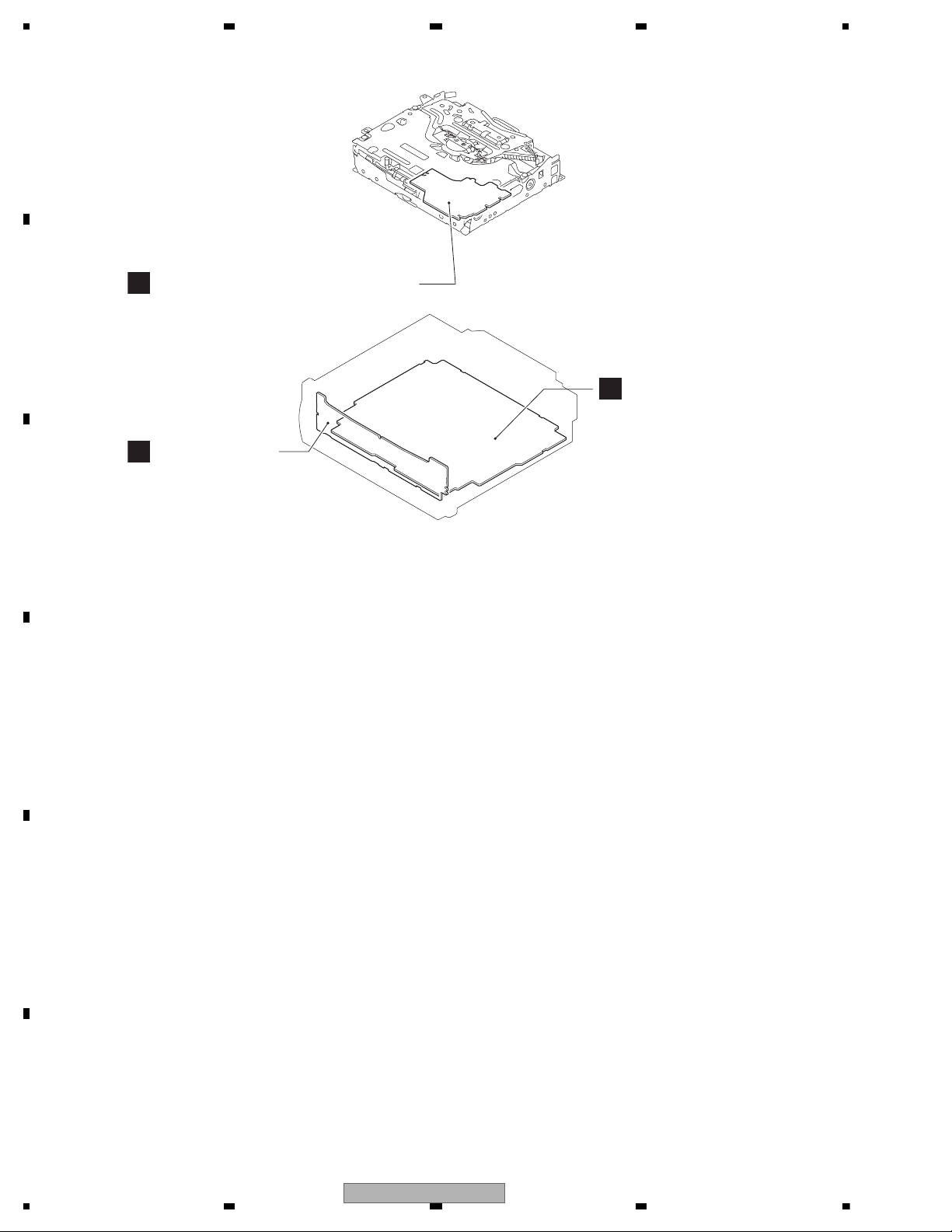

- Removing the CD Mechanism Module (Fig.1)

Release the two latches and then remove the

1

Panel Assy.

CD Mechanism Module

2

Remove the four screws.

2

2

Disconnect the connector and then remove the

CD Mechanism Module.

2

1

2

1

Panel Assy

Fig.1

- Removing the Tuner Amp Assy (Fig.2)

Remove the two screws.

1

Remove the two screws.

2

Straighten the tabs at six locations

3

indicated and then remove the Tuner

Amp Assy.

1

1

2

3

3

3

3

2

3

3

28

DEH-5200SD/XNEW5

Tuner Amp Assy

Fig.2

Page 29

5 678

56

7

8

C

D

F

A

B

E

- Removing the Cover

1

3

Cover

Remove the three hooks.

1

1

1

Remove the hooks in order of figure

and then remove the cover.

Remove the hook.

2

Remove the hook.

3

2

DEH-5200SD/XNEW5

29

Page 30

1234

1234

C

D

F

A

B

E

1. Hold the Upper and Lower Frames at the specified parts (circled with broken blue lines in the photo below).

2. You can hold the tabs of the Lower Frame (circled with broken green lines in the photo below) if you do so only while lifting

the Mechanism Unit from the table. Keeping the Mechanism Unit lifted by holding these tabs with your fingers may result in

deformation.

3. Be careful NOT to hold the front part of the Upper Frame or the CRG Mechanism and NOT to insert foreign objects into

these mechanisms. Doing so may result in deformation.

Proper handling

Improper handling

How to Hold the Mechanism Unit

30

DEH-5200SD/XNEW5

Page 31

5 678

56

7

8

C

D

F

A

B

E

1. Remove the solder from the CRG-motor lead wire (Fig. 1).

2. Push in the Disc Detection Arm while applying 4-V power to the CRG Motor (Fig. 2). (Apply 4-V power to the green lead

wire. The white lead wire is for grounding.)

The Mechanism Module is set to the clamped state, and the PU will move toward the outer track.

Note: NEVER apply power to the CRG-motor lead wire without removing the solder from the wire. Doing so may result in

damage to the ICs and the PU.

3. Stop the motor when the PU reaches around the middle track.

Note: Jumpiness will occur when the PU reaches the outermost track. Although jumpiness does not constitute a problem,

it is recommended that it occur as least frequently as possible.

Fig. 1

Note: Be aware that the colors of the lead wires do not match the

indications on the Core Board Pattern (green wire to O and

white wire to P).

Fig. 2

Disc Detection Arm

Mechanism Module: How to Set to the Quasi-Clamp State (Driven by the Motor)

DEH-5200SD/XNEW5

31

Page 32

1234

1234

C

D

F

A

B

E

How to Remove the PU Unit

How to Move the PU toward the Outer Track

1. Set the unit to the quasi-clamp state, following the procedures described in “Mechanism Module: How to Set to the Quasi Clamp State (Driven by the Motor).”

2. Temporarily change the engagement position of the bias spring of the feed screw (Fig. 2b).

Be careful not to cut yourself on the tip of the spring.

3. Hold the PU unit by parts A in Fig. 1 then slide it toward the inner track.

4. Remove the backend of the feed screw from the outer holder, by first sliding it, as shown in Fig. 3, then lifting it.

5. Remove the PU unit, by lifting it. Lifting the PU unit will disengage the PU unit from the part B of the chassis.

Note: When reassembling the PU unit, be sure to securely engage the PU unit with the part B of the chassis, as shown in

Fig. 4. Also, be sure to change the engagement position of the bias spring of the feed screw to its original position

(Fig. 2a). After reassembling, perform the PU adjustment, following the description in the service manual.

1. Set the unit to the quasi-clamp state, following the procedures described in “Mechanism Module: How to Set to the Quasi Clamp State (Driven by the Motor).”

2. Move the PU unit toward the outer track, by applying 1.5-V power to the CRG motor.

Note: After moving the PU toward the outer track and taking the necessary measures, be sure to solder the lead wires.

Fig. 4

Fig. 3

Fig. 1

Fig. 2a

Original engagement

position

Fig. 2b

Temporary engagement

position

Slide toward the inner track.

One end of the spring is engaged

beneath the resin flange and

plate bend.

Outer holder

Backend of

the feed screw

Properly assembled state

[Improper assembly]

The chassis is not properly pinched by

the PU case and PU rack.

A

B

32

DEH-5200SD/XNEW5

Page 33

5 678

56

7

8

C

D

F

A

B

E

How to Remove the PU Rack

1. Remove the PU Unit, following the procedures described in “How to Remove the PU Unit.”

2. Remove the PU Rack fixing screw (Fig. 1).

3. Remove the PU Rack, by applying force in the direction of the arrow in Fig. 2.

Notes:

While handling the PU Unit, be careful NOT to touch the actuator block shown in Fig. 6 or bang the actuator block against

your workbench.

Handle the PU and PU Unit with care, according to the description in “How to Hold the PU.”

When reattaching the PU Rack to the PU, first reassemble parts a and b shown in Fig. 3 into the PU case then attach the

boss shown in Fig. 4 to the PU case.

After reassembling the PU Rack, insert the feed screw from side c in Fig. 5 (insertion depth: Approx. 18 mm for the part

indicated in the photo).

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

PU Rack

PU Rack

fixing screw

Actuator block

18 mm

b

c

a

DEH-5200SD/XNEW5

33

Page 34

1234

1234

C

D

F

A

B

E

How to Hold the PU

1. Be sure to hold the PU at the positions shown in “Proper handling.” NEVER hold it as shown in “Improper handling.”

Do not touch the object lens

and ACT.

Do not touch the VR.

Do not touch the Hologram.

Do not pull the FPC.

Proper handling Improper handling

34

DEH-5200SD/XNEW5

Page 35

5 678

56

7

8

C

D

F

A

B

E

1) Cautions on adjustments

In this product the single voltage (3.3 V) is used for the

regulator. The reference voltage is the REFO1 (1.65 V)

instead of the GND.

If you should mistakenly short the REFO1 with the GND

during adjustment, accurate voltage will not be obtained,

and the servo’s misoperation will apply excessive shock

to the pickup. To avoid such problems:

a. Do not mix up the REFO1 with the GND when

connecting the (-) probe of measuring instruments.

Especially on an oscilloscope, avoid connecting the (-)

probe for CH1 to the GND.

b. In many cases, measuring instruments have the same

potential as that for the (-) probe. Be sure to set the

measuring instruments to the floating state.

c. If you have mistakenly connected the REFO1 to the GND,

turn off the regulator or the power immediately.

Before mounting and removing filters or leads for

adjustment, be sure to turn off the regulator.

For stable circuit operation, keep the mechanism

operating for about one minute or more after the

regulator is turned on.

In the test mode, any software protections will not

work. Avoid applying any mechanical or electrical

shock to the mechanism during adjustment.

The RFAGC and RFO signals with a wide frequency range

are easy to oscillate. When observing the signals,

insert a resistor of 1k ohms in series.

The load and eject operation is not guarantied with the

mechanism upside down. If the mechanism is blocked

due to mistaken eject operation, reset the product or

turn off and on the ACC to restore it.

2) Test mode

This mode is used to adjust the CD mechanism module.

To enter the test mode.

[BAND] + [RDM] -> Reset

To exit from the test mode.

Turn off the ACC and back up.

Notes:

a. During ejection, do not press any other keys than the

EJECT key until the loaded disc is ejected.

b. If you have pressed the (→) key or (←) key during focus

search, turn off the power immediately to protect the

actuator from damage caused by the lens stuck.

c. For the TR jump modes except 100TR, the track jump

operation will continue even if the key is released.

d. For the CRG move and 100TR jump modes, the tracking

loop will be closed at the same time when the key is

released.

e. When the power is turned off and on, the jump mode

is reset to the single TR (91), the RF amp gain is set to 0 dB,

and the auto-adjustment values are reset to the default

settings.

When a CD-DA (regular music CD) is played in the CD

test mode, its sound quality will be temporarily

deteriorated. The CD will then repeat normal, deteriorated,

normal… playback.

This is due to the difference in the playback modes

between the normal operation mode and the CD test

mode, and the interval of generating deteriorated mode

and the time taken to return to the normal mode depend

on the error of each clock.

The time taken to turn to the deteriorated mode is at a

minimum around 20 seconds while the time to return to

the normal mode is maximum 40 seconds approximately.

Make sure to check the sound quality in the normal

operation mode.

8. EACH SETTING AND ADJUSTMENT

8.1 CD ADJUSTMENT

DEH-5200SD/XNEW5

35

Page 36

1234

1234

C

D

F

A

B

E

8.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT

F

E

REFO1

CD CORE UNIT

Note :

The grating angle of the PU unit cannot be adjusted after the PU unit is changed. The PU unit in the CD mechanism

module is adjusted on the production line to match the CD mechanism module and is thus the best adjusted PU

unit for the CD mechanism module. Changing the PU unit is thus best considered as a last resort. However, if the

PU unit must be changed, the grating should be checked using the procedure below.

Purpose :

To check that the grating is within an acceptable range when the PU unit is changed.

Symptoms of Mal-adjustment :

If the grating is off by a large amount symptoms such as being unable to close tracking, being unable to perform

track search operations, or taking a long time for track searching.

Method :

Measuring Equipment

Measuring Points

Oscilloscope, Two L.P.F.

E, F, REFO1

Disc TCD-782

Mode TEST MODE

Checking Procedure

1. In test mode, load the disc and switch the 3 V regulator on.

2. Using the right and left buttons, move the PU unit to the innermost track.

3. Press key 3 to close focus, the display should read "91". Press key 2 to implement the tracking

balance adjustment the display should now read "81". Press key 3. The display will change,

returning to "81" on the fourth press.

4. As shown in the diagram above, monitor the LPF outputs using the oscilloscope and check that the phase

difference is within 75 . Refer to the photographs supplied to determine the phase angle.

5. If the phase difference is determined to be greater than 75 try changing the PU unit to see if there is any

improvement. If, after trying this a number of times, the grating angle does not become less than 75 then the

mechanism should be judged to be at fault.

Note

Because of eccentricity in the disc and a slight misalignment of the clamping center the grating waveform may be

seen to "wobble" ( the phase difference changes as the disc rotates). The angle specified above indicates the

average angle.

Hint

Reloading the disc changes the clamp position and may decrease the "wobble".

100 kohm

390 pF

100 kohm

390 pF

E

VREF

F

VREF

Xch Ych

L.P.F.

L.P.F.

Oscilloscope

36

DEH-5200SD/XNEW5

Page 37

5 678

56

7

8

C

D

F

A

B

E

Grating waveform

45 degrees

0 degrees

75 degrees

60 degrees

30 degrees

90 degrees

Ech -> Xch 20 mV/div, AC

Fch -> Ych 20 mV/div, AC

DEH-5200SD/XNEW5

37

Page 38

1234

1234

C

D

F

A

B

E

8.3 PCL OUTPUT CONFIRMATION

PCL output

In the normal operation mode (with the detachable panel installed, the ACC switched ON, the standby mode

cancelled), shift the TESTIN IC601(Pin 61) terminal to H.

The clock signal is output from the PCL terminal IC601(Pin 37).

The frequency of the clock signal is 625.0 kHz that is one 32th of the fundamental frequency.

The clock signal should be 625.0 kHz(- 10 Hz, + 15 Hz).

If the clock signal is out of the range, the X'tal (X601) should be replaced with new one.

38

DEH-5200SD/XNEW5

Page 39

5 678

56

7

8

C

D

F

A

B

E

DEH-5200SD/XNEW5

39

Page 40

1234

1234

C