Pioneer DEH-1700 Service manual

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2014

CD RDS RECEIVER

ORDER NO.

CRT5572

DEH-1700UB/XNEW5

DEH-1700UB

DEH-1700UBA/XNEW5

DEH-1700UBB/XNEW5

DEH-1700UBG/XNEW5

This service manual should be used together with the following manual(s):

Model No. Order No. Mech. Module Remarks

CX-3287

CRT4759 S11.6STD CD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

/XNEW5

K-ZZZ JULY 2014 Printed in Japan

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

CAUTION:

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

- Safety Precautions for those who Service this Unit.

When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer.

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

Laser diode characteristics

Wave length : 785 nm to 814 nm

Maximum output : 1 190 µW(Emitting period : unlimited)

Additional Laser Caution

Transistors Q101 in PCB drive the laser diodes.

When Q101 is shorted between their terminals, the laser diodes will radiate beam.

If the top cover is removed with no disc loaded while such short-circuit is continued,

the naked eyes may be exposed to the laser beam.

CAUTION

This product is a class 1 laser product classified under the Safety of laser products, IEC

60825-1:2007.

2

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION .....................................................................................................................................2

1. SERVICE PRECAUTIONS ................................................................................................................................4

1.1 SERVICE PRECAUTIONS .........................................................................................................................4

1.2 NOTES ON SOLDERING...........................................................................................................................4

2. SPECIFICATIONS.............................................................................................................................................5

2.1 SPECIFICATIONS ......................................................................................................................................5

2.2 DISC/CONTENT FORMAT .........................................................................................................................5

3. BASIC ITEMS FOR SERVICE ..........................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING .......................................................................................................6

3.2 PCB LOCATIONS .......................................................................................................................................6

3.3 JIGS LIST ...................................................................................................................................................7

3.4 CLEANING .................................................................................................................................................7

4. BLOCK DIAGRAM ............................................................................................................................................8

4.1 BLOCK DIAGRAM......................................................................................................................................8

4.2 POWER BLOCK DIAGRAM .....................................................................................................................10

5. DIAGNOSIS ....................................................................................................................................................11

5.1 OPERATIONAL FLOWCHART.................................................................................................................11

5.2 ERROR CODE LIST.................................................................................................................................12

5.3 CONNECTOR FUNCTION DESCRIPTION .............................................................................................14

6. SERVICE MODE.............................................................................................................................................15

6.1 DISPLAY TEST MODE 1 ..........................................................................................................................15

6.2 DISPLAY TEST MODE 2 ..........................................................................................................................16

6.3 SOFTWARE VERSION UP METHOD......................................................................................................17

6.4 CD TEST MODE.......................................................................................................................................18

7. DISASSEMBLY ...............................................................................................................................................19

8. EACH SETTING AND ADJUSTMENT............................................................................................................25

8.1 CD ADJUSTMENT ...................................................................................................................................25

8.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT ....................................................26

8.3 PCL OUTPUT CONFIRMATION...............................................................................................................28

9. EXPLODED VIEWS AND PARTS LIST ..........................................................................................................30

1 PACKING ..................................................................................................................................................30

9.

9.2 EXTERIOR ...............................................................................................................................................32

9.3 CD MECHANISM MODULE .....................................................................................................................34

10. SCHEMATIC DIAGRAM................................................................................................................................36

10.1 TUNER AMP UNIT (1/2 scale) ...............................................................................................................36

10.2 KEYBOARD UNIT ..................................................................................................................................38

10.3 CD CORE UNIT (S11.6VA) ....................................................................................................................40

10.4 WAVEFORMS.........................................................................................................................................42

11. PCB CONNECTION DIAGRAM....................................................................................................................44

11.1 TUNER AMP UNIT .................................................................................................................................44

11.2 KEYBOARD UNIT ..................................................................................................................................48

11.3 CD CORE UNIT (S11.6VA) ....................................................................................................................50

12. ELECTRICAL PARTS LIST ...........................................................................................................................52

DEH-1700UB/XNEW5

3

1234

1234

C

D

F

A

B

E

1. SERVICE PRECAUTIONS

1. You should conform to the regulations governing the product (safety, radio and noise, and other

regulations), and should keep the safety during servicing by following the safety instructions

described in this manual.

2. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside the unit.

3. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY".

4. After replacing the pickup unit, be sure to check the grating.

5. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by

electrostatic induction.

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1.1 SERVICE PRECAUTIONS

1.2 NOTES ON SOLDERING

4

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

For all items except the backup current, refer to the Owner's Manual.

Backup current......................... 4.0 mA or less

2. SPECIFICATIONS

2.1 SPECIFICATIONS

2.2 DISC/CONTENT FORMAT

DEH-1700UB/XNEW5

5

1234

1234

C

D

F

A

B

E

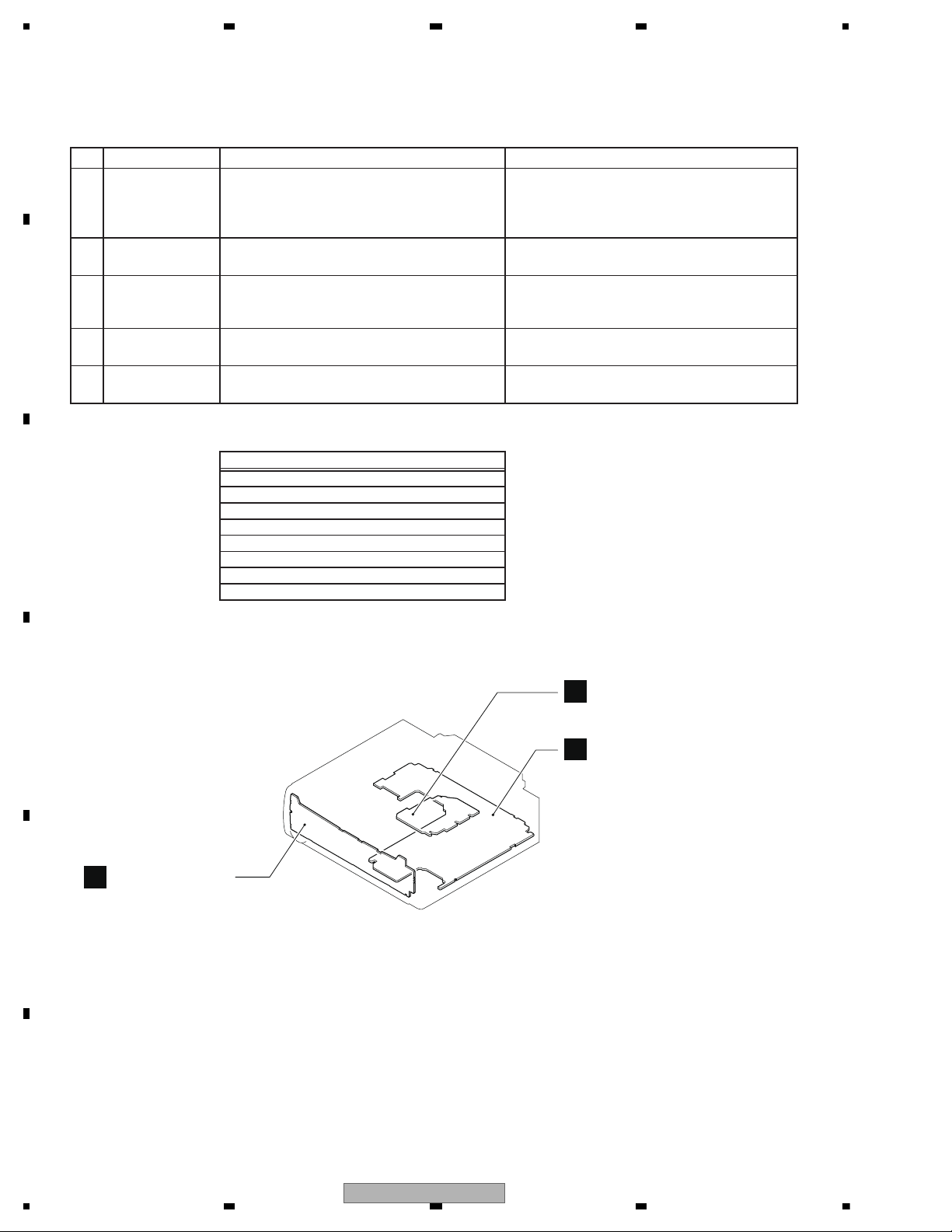

3. BASIC ITEMS FOR SERVICE

demrifnocebotmetIserudecorP.oN

1 Confirm whether the customer complain has

been solved.

If the customer complain occurs with the

specific media, use it for the operation check.

The customer complain must not be

reappeared.

Display, audio and operations must be

normal.

2 CD Play back a CD.

(Track search)

No malfunction on display, audio and

operation.

3 FM/AM tuner Check FM/AM tuner action.

(Seek, Preset)

Switch band to check both FM and AM.

Display, audio and operations must be

normal.

4 Check whether no disc is inside the product. The media used for the operating check must

be ejected.

retfaecnaraeppastinotridrosehctarcsoNkcehcecnaraeppA5

receiving it for service.

Item to be checked regarding audio

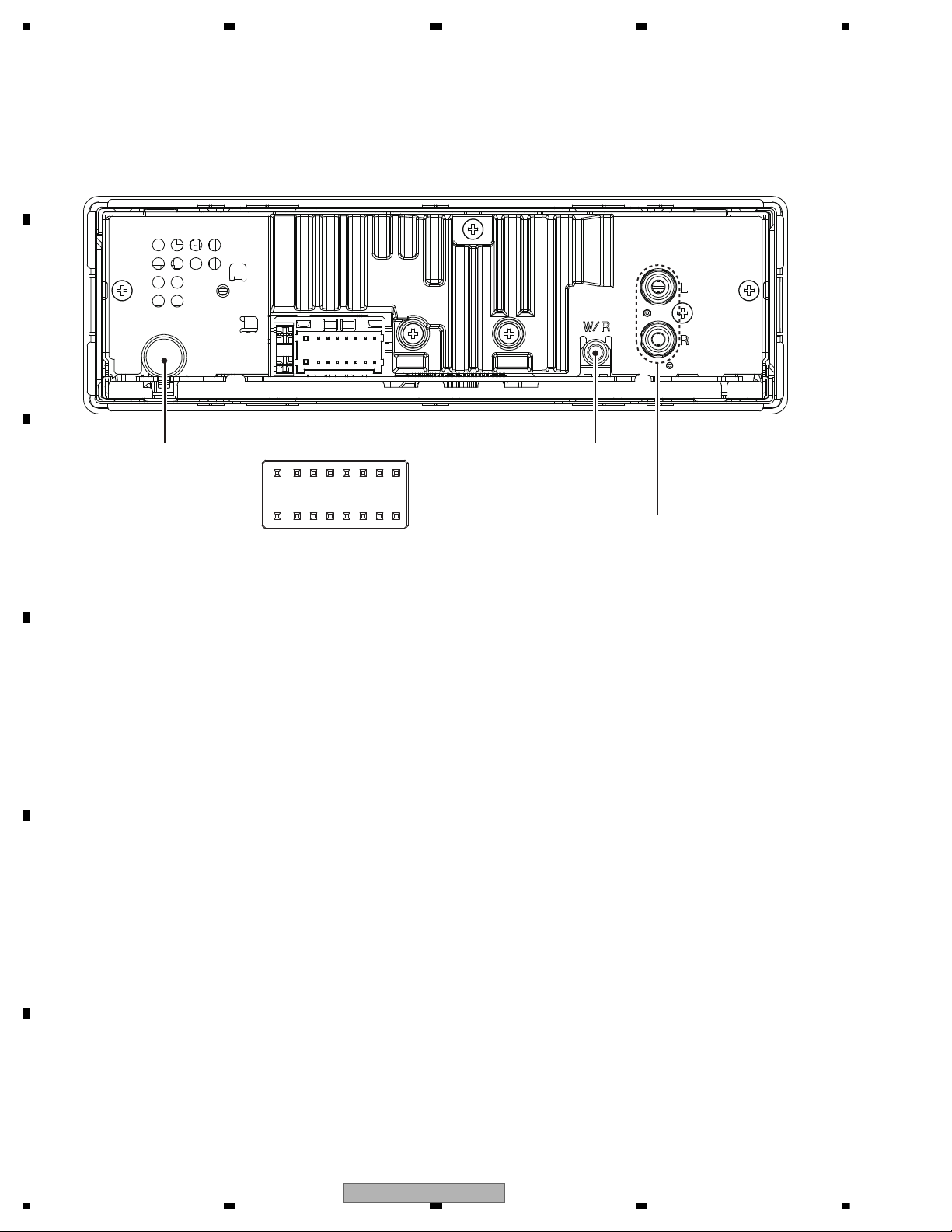

A

B

Keyboard Unit

Tuner Amp Unit

C

CD Core Unit (S11.6VA)

A:DEH-1700UB/XNEW5

B:DEH-1700UBA/XNEW5

C:DEH-1700UBB/XNEW5

D:DEH-1700UBG/XNEW5

Unit Name : Tuner Amp Uni

Unit Number : QWM3898(A)

Unit Number : QWM3900(B)

Unit Number : QWM3901(C)

Unit Number : QWM3899(D)

Unit Name : Keyboard Unit

Unit Number : (A)

Unit Number : (B)

Unit Number : (C)

Unit Number : (D)

Unit Name : CD Core Unit(S11.6VA)

Unit Number : CWX4269

3.1 CHECK POINTS AFTER SERVICING

To keep the product quality after servicing, please confirm following check points.

See the table below for the items to be checked regarding audio:

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

3.2 PCB LOCATIONS

6

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

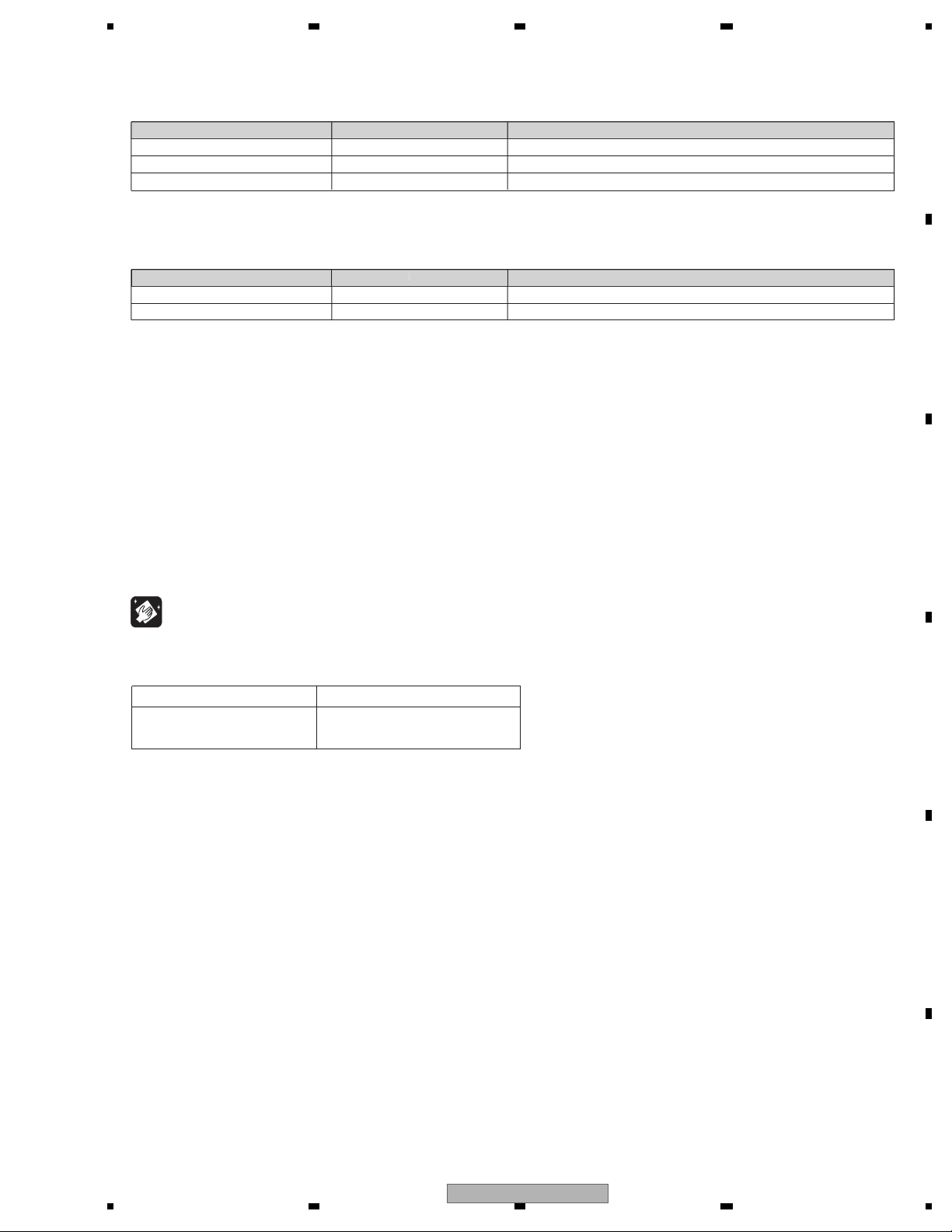

- Jigs List

- Grease List

Name

Grease

Grease

Grease No.

GEM1024

GEM1043

Remarks

CD Mechanism Module

CD Mechanism Module

e

G

.

ks

Name

16P FFC

Test Disc

L.P.F.

Jig No.

GGD1310

TCD-782

Remarks

Tuner Amp Unit - CD Core Unit

Checking the grating

Checking the grating (Two pieces)

Before shipping out the product, be sure to clean the

following portions by using the prescribed cleaning

tools:

Portions to be cleaned Cleaning tools

CD pickup lenses Cleaning liquid : GEM1004

Cleaning paper : GED-008

3.3 JIGS LIST

Nam

3.4 CLEANING

rease No

emar

DEH-1700UB/XNEW5

7

1234

1234

C

D

F

A

B

E

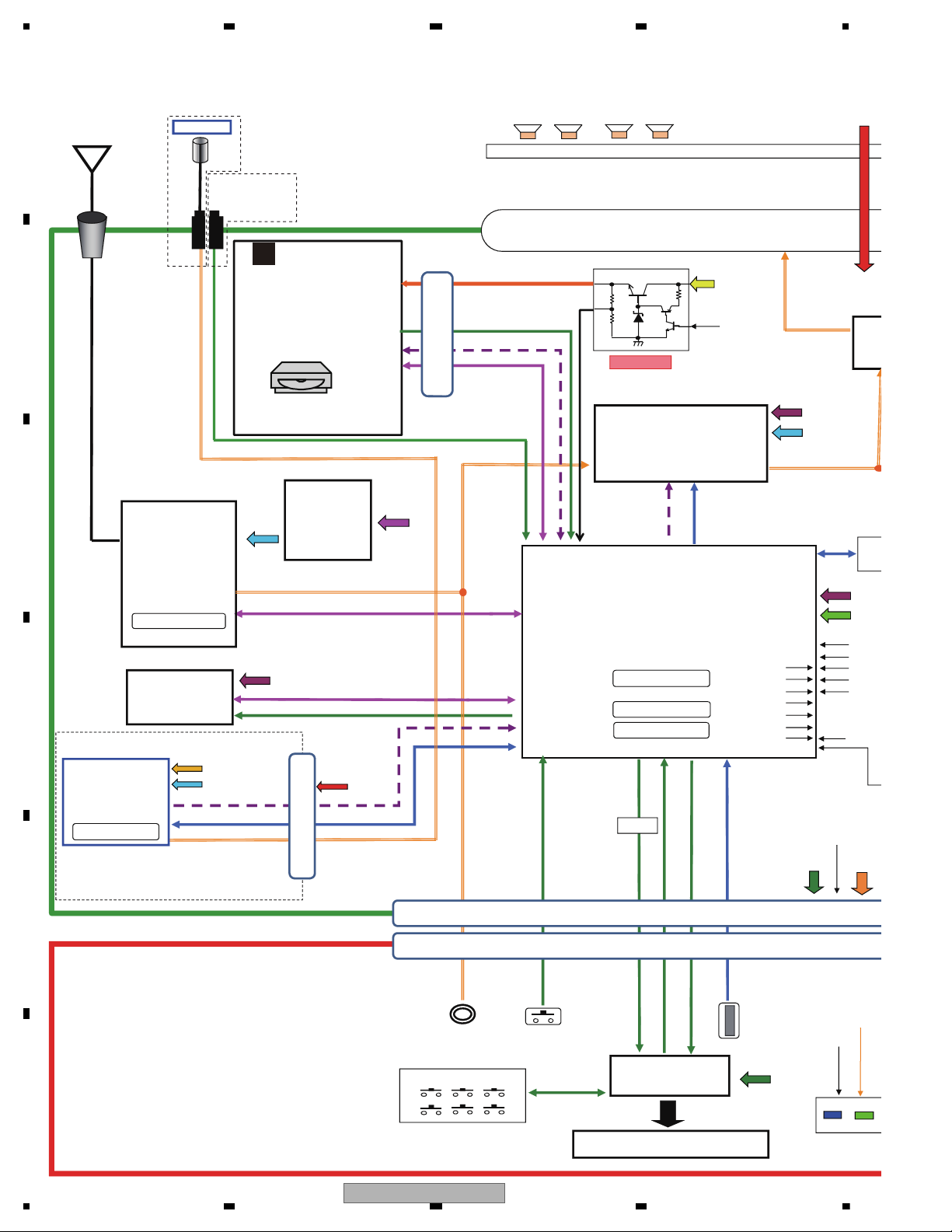

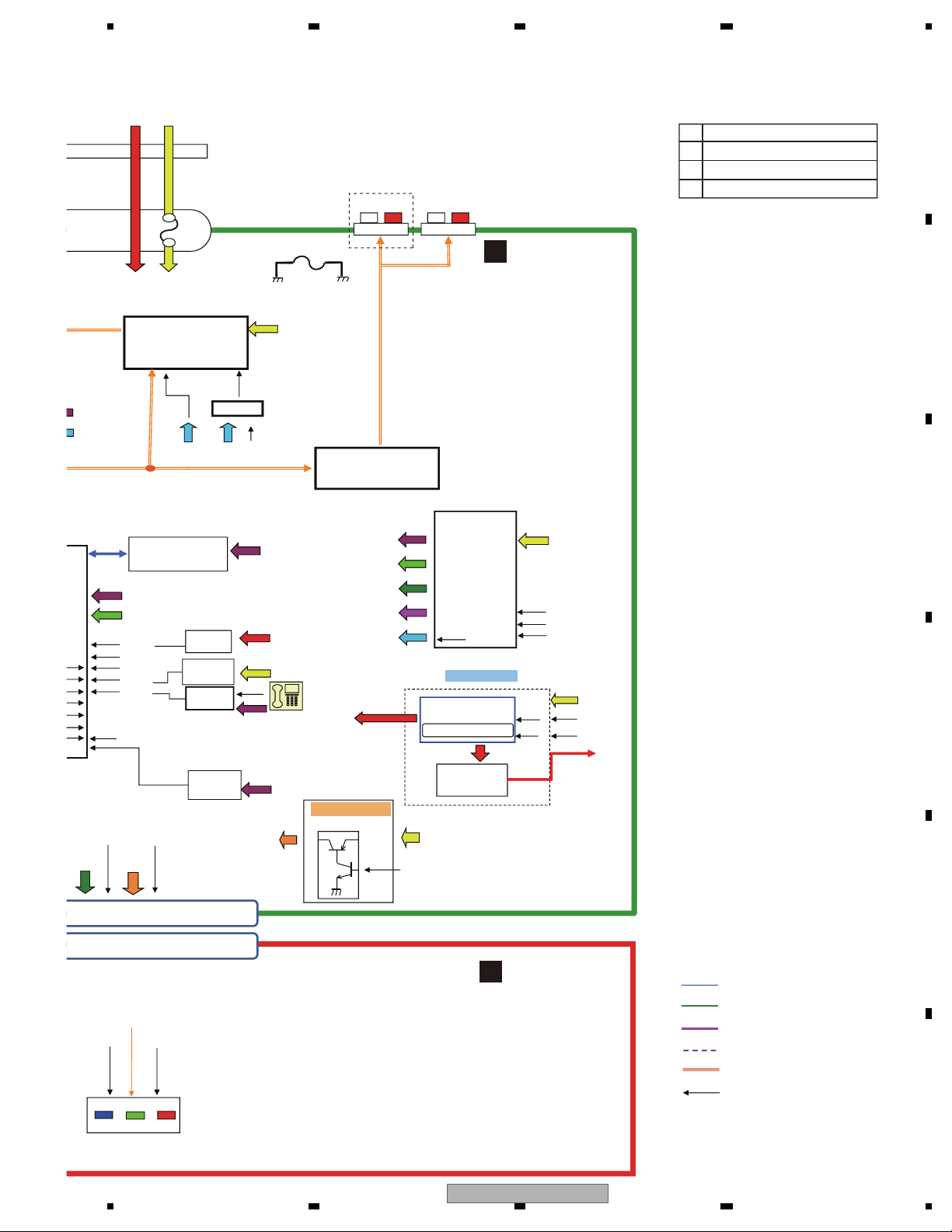

4. BLOCK DIAGRAM

Memory: 64Kbyte

ASENS

BSENS

BTPW

VDSEN

SW5VCONT

A.ANT

ILMPW

TEL.IN

SYSPW

VDCONT

MUTE

ILMPW,DIM

ANTSE

DBTPW

BTPW D

SYSTEM

R5S726A0D216FP

LCD

Display System

PD6586A8

key matrix

SWVDD

SWVDD ILM+B

3→5

KYDT

DPDT

DP,DM

iPod CP

337S3959

CP_SCL,CP_SD

CPPW,CPRST

VDD3

VDD1

VDD

E.VOL JASPER

PM 9013A

Lithio

(TEF6686HN)

X-8086

TUN 3.3V

SYS+B 5.75

VDD3.3V

Suntec BT modual

X-8075

TUNSCL,TUNSDA

MCLK,LRCLK

DATA,CLK

LRCLK,BCLK,DATA

DDCON 5V

MACHA VD

VD CONT

VD SENS

B.up

VD

TUNL TUNR

USB

NRST_CPU

SYSTOBT,BTTPSYS

7.4V

AUX

SOURC

KEYD,KEYAD

RESETB,STB

BCLK,DIN

SINGLE L

LIGTH DISP

FL FRRL/SW RR/SW

ROT0,ROT1

CN1931

1. DGND

2. ILMGND

3. SWVDD

4. ROT1

5. ILM+B

6. ROT0

7. USBGND

8. KYDT

9. USBGND

10. DPDT

11. USB5V

Connector CN 801

Connector CN1931

CN 971

1. GND

2. MICIN

3. GND

4. MICIP

5. GND

6. BTTOSYS

7. SYSTOBT

8. NRST_CPU

9. GND

10. BTLRCK

11. BTBCK

12. BTDATA

13. GND

14. GND

15. VCC

16. VCC

Connector BT

Connector flex

CD_SCL,CD_SDA

BLCK.DATA,LRCK

Connector flex

1. VD

2. VD

3. /CDSRQ

4. CDSTBY

5. SCL

6. SKIP

7. SDA

8. RESET

9. VDD

10. GND

11. DATA

12. BCLK

13. LRCK

14. GND

15. PGND

16. WAIT

CD S11.6 STD

WIRED REMOTE

JA901

Power Connector

BUP

ACC

1. FL+

2. FR+

3. FL-

4. FR-

5. RL+

6. RR+

7. RL-

8. RR-

9. TEL

10. NC

11. ILL

12. NC

13. ACC

14. BREM &

A.ANT

15. B.UP

16. GND

17. GND

18. B.UP

ANT

X401 9.216MHz

X100 26MHz

X603 16.93MHz

X601 12MHz

SW 5V

DC to DC

converter

5V to 3.3V

(MM3571A33P)

Q751 KTD2092(QR)

Q752

RN4983

BT 1.8V

BT 3.3V

For BT modual

X602 16.93MHz

Except BT modual

BT MIC

S-

CDSKIP,CDRST

CDSRQ,CDSTBY

CXK5805

IC451

IC401

IC531

IC601

IC201

IC1801

V1801

JA891

NM

B

NM

NM

JA401

CD CORE UNIT

C

4.1 BLOCK DIAGRAM

8

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

ASENS

BSENS

VDSENS

A.ANT

TEL.IN

ANTSENS

Digital Line

I2S communication line

Communication Line

Audio Line

I2C Communication line

Control line

DIMBTPW

BTPW DIM

VDD1.2V

SW5V

SYS+B

SWVDD

VDD 3.3V

IC REGULATOR

BA49183-V12

BSENS

B.up

VDCONT

SW5VCONT

SYSPW

B.up

A.SENS

ACC

SWVDD ILM+B

VDD3.3V

VDD1.2V

SYS+B 5.75

VDD3.3V

High side

RCA MUTE

IC POWER AMP

PAL013A

STBY

B.up

SYNC

SYS+B

MUTE

STBY

MUTE

ANT PW

B.up

ILMPW

DD ON

DD con

KBD9876EFJ

ILM+B

USB5V

DDCON 5V TO BT

EN

SYNC

USB&USB5V

SINGLE LED

LIGTH DISPLAY

SYS+B

RESET

VDD

B.up

TELIN

DDCON 5V

VDD

3. SWVDD

4. ROT1

5. ILM+B

6. ROT0

7. USBGND

8. KYDT

9. USBGND

10. DPDT

11. USB5V

12. BTPW

13. DM

14. DIMMER

15. DP

16. AUXGND

17. AUXR

18. SOURCE

19.AUXL

20.DSENS

B.UP

ACC

10A

Q873 2SD1767(QR)

LED SUPPLY

367.347/439.024kHz

GND

RCA GND

P251

CEK1386

YEK5001-A

S-Quad Flash

VDD

PEB155A8

3A

L

R

F

L

R

R/SW

IC301

IC911

IC551

IC681

NM

JA251

TUNER AMP UNIT

A

KEYBOARD UNIT

B

A DEH-1700UB/XNEW5

B DEH-1700UBA/XNEW5

C DEH-1700UBB/XNEW5

D DEH-1700UBG/XNEW5

DEH-1700UB/XNEW5

9

1234

1234

C

D

F

A

B

E

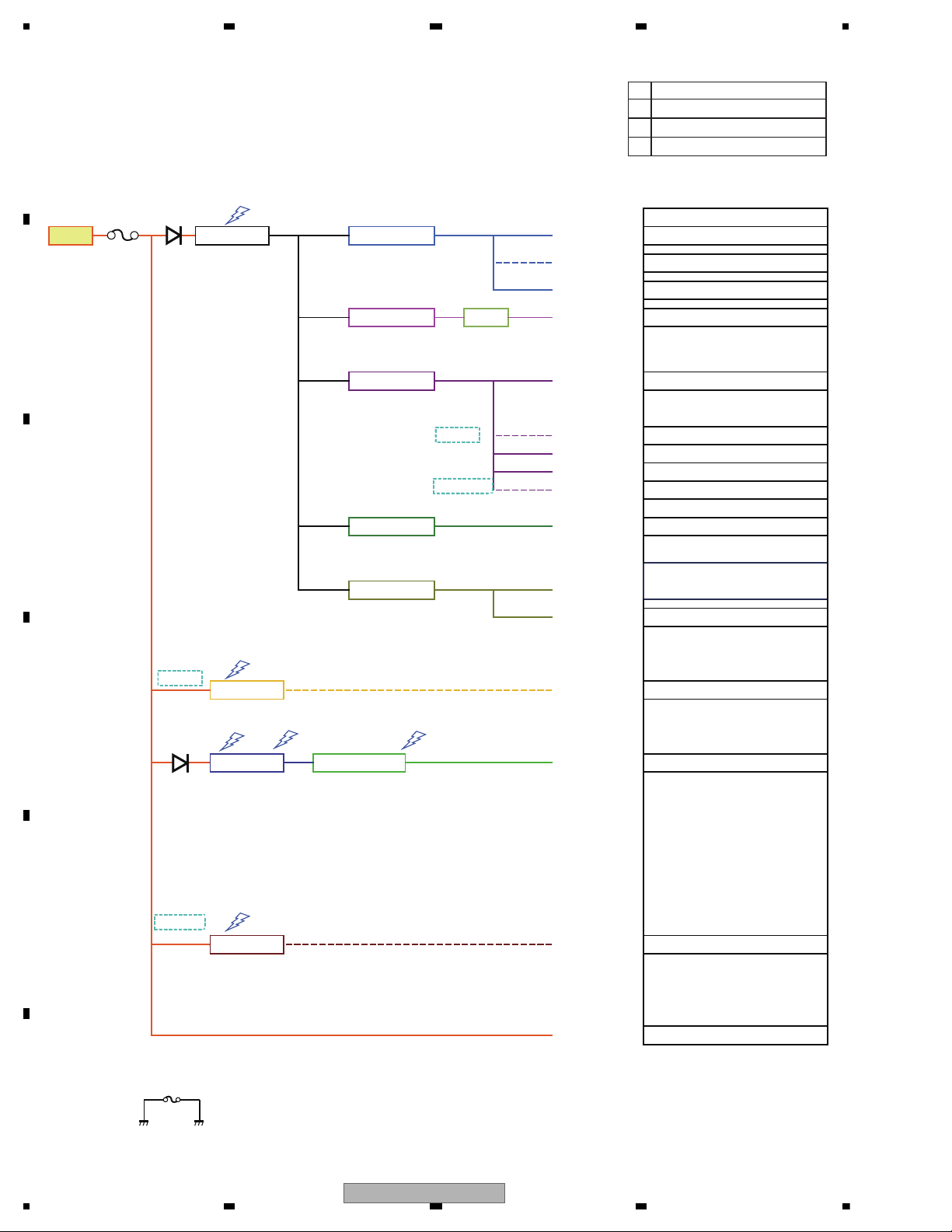

4.2 POWER BLOCK DIAGRAM

ACD

SYSPW

SW5VCNT

VDDCNT

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

VDDCONT

SYNC DDON DDON

ILMPW

7.76

5.00

300mA 185mA

Power Amp

3 --> 5 IC

Voltage

USB 5V

LED Reg

Grille low model

50.00 mA PD6586A

5.25 5.50

SWVDD

System u-con

Mecha VDD

TELIN

6.20

460.0 mA

1.30

190.0 mA

2.00 mA

171.00 mA

Grill u-com

System u-con

7.42 7.59

25.00 mA 10.00 mA

TC7SET08FUS1

1.25

60.0 mA

300 mA

Flash ROM

E-Volume(Digital)

1.20

Power Amp (Mute)

Reg 3.3

PM9013A

MX25L1633E

SH7266

SH726a

B.UP

IC REGURATER

Mecha VD 7.4V

S11.6 STD

S11.6 STD171.00 mA

Lithio

SYS+B

1100 mA

Mecha VD

216.00 mA

B.REM A.ANT

25.00 mA

10 mA

3.15 3.30 3.45

150.00 mA

MAX

18.00 mA

6.20

55.00 mA

E-Volume (Analog)

5.60

VDD 3.3V

VDD 1.2V

PART NO .

38.00 mA PM9013A

TYPE

DD-CON USB 5V

Current

140mA

1200 mA

USB 5V

1000 mA

-

5.00

SW 5V

60.00 mA

4.75

Lithio-Tuner

390.0 mA

K/B Illumi (LED)

CD model

CD model

SYNC EN

LED model

TELIN model

10A

(YEK5001-A)

EN

RCA GND Audio GND

P251

CEK1286

3A

A DEH-1700UB/XNEW5

B DEH-1700UBA/XNEW5

C DEH-1700UBB/XNEW5

D DEH-1700UBG/XNEW5

IC911

BA49183-V12

IC451

MM3571A33P

IC552

BD2232G-G

IC551

BD9876EFJ

10

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

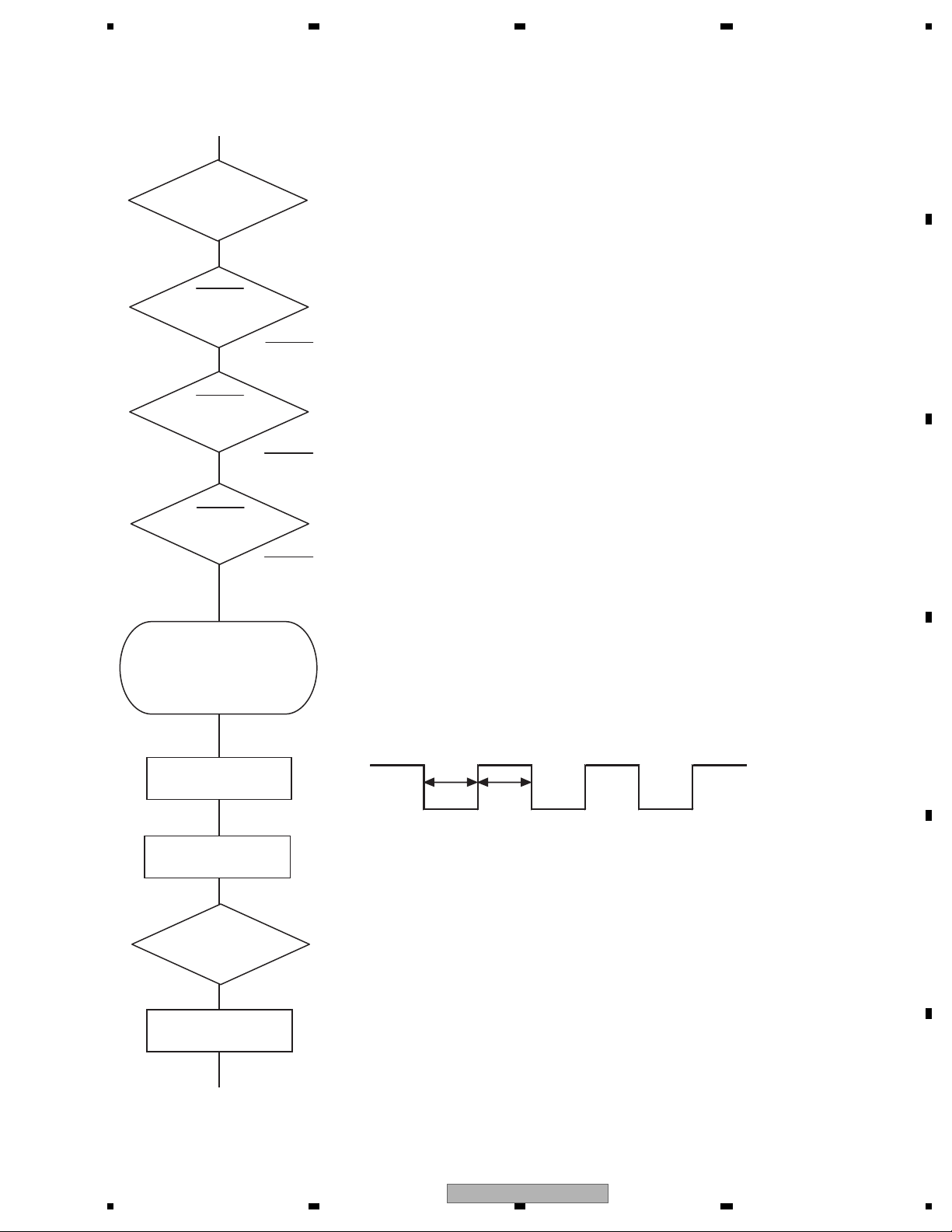

Vcc = 1.2 V

PVcc = 3.3 V

BSENS

Pin 90

ASENS

Pin 89

DSENS

Pin 34

BSENS = L

DSENS = L

Starts

communication

with Grille

microcomputer.

SWVDD <- H

Pin 1

Source keys

operative

Source ON

SYSPW <- H

Pin 8

300 ms

300 ms

In case of the above signal, the communication

with Grille microcomputer may fail.

If the time interval is not 300 msec, the oscillator

may be defective.

Completes power-on operation.

(After that, proceed to each source operation)

Power ON

ASENS = L

Vcc : Pin 12, 20, 43, 78, 86, 109

PVcc : Pin 3, 16, 28, 36, 48, 69, 82,101, 112

5. DIAGNOSIS

5.1 OPERATIONAL FLOWCHART

DEH-1700UB/XNEW5

11

1234

1234

C

D

F

A

B

E

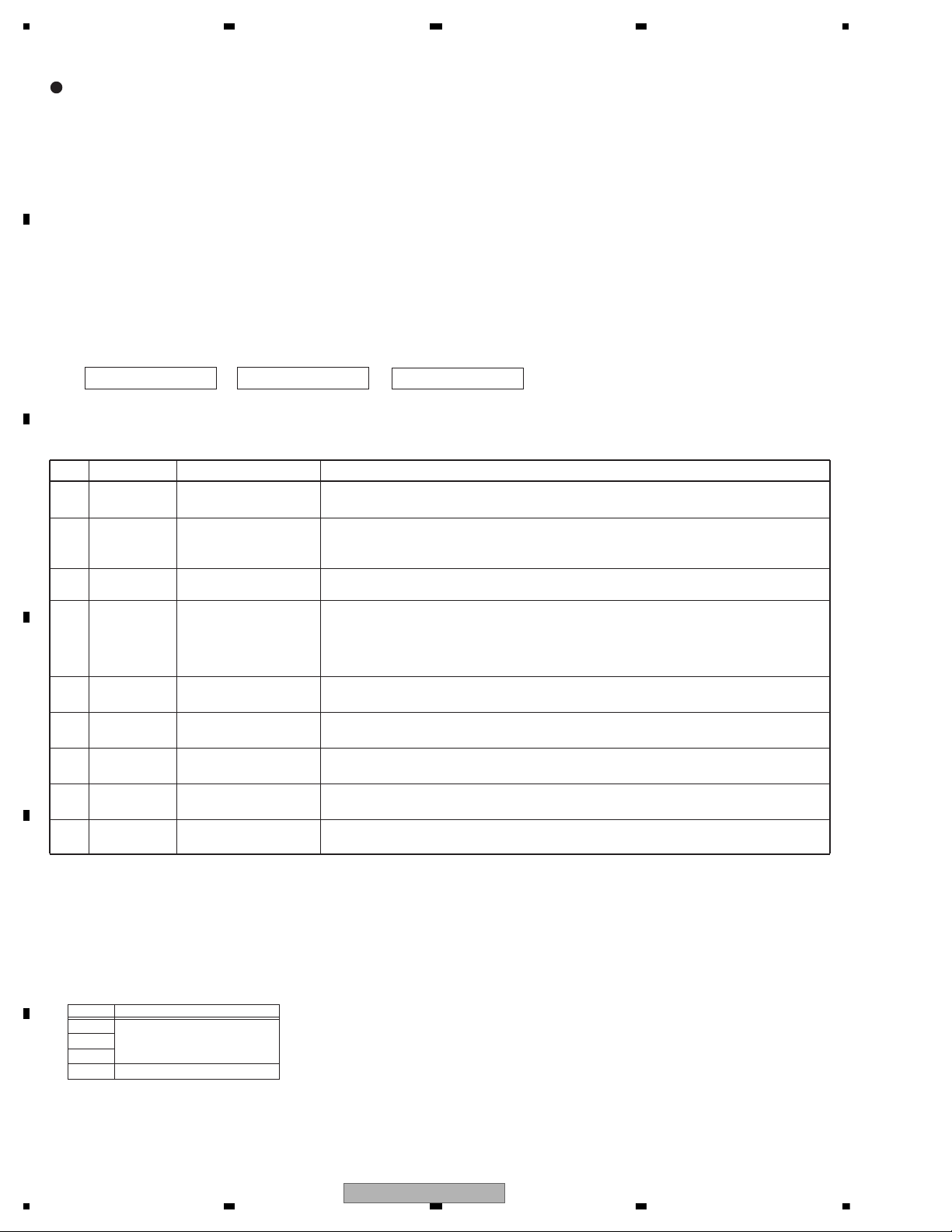

5.2 ERROR CODE LIST

8-digit display 6-digit display 4-digit display

ERROR-xx ERR-xx E-xx

(2) LIST OF CD ERROR CODES (Error Mode: 0xFD)

Code Classification

Error code to be displayed

Details and possible causes

10 Servo Carriage Home NG The pickup cannot move toward the inner track.

The CRG cannot move from the inner track.

--> Defective HOME SW; Failure in CRG movement.

07 Servo TOC reading NG TOC information cannot be read.

--> The partial disk or TOC content is illegal.

11 Servo Focus NG Focusing not available

--> Disc placed upside-down; Stains on the disc; excessive vibration.

17 Servo Setup NG The laser output cannot be adjusted. Focus can be easily lost.

--> Scratches or stains on the disc; excessive vibration.

15 Servo RF NG The digital signal from the disc cannot be detected.

--> A CD-R/RW disc that does not contain data loaded.

12 Servo Spindle Lock NG

Subcode NG

RF-amp NG

Spindle not locked. Subcode not readable.

Proper RF AMP gain not obtained.

--> Defective spindle; Scratches or stains on the disc; excessive vibration.

-->

A CD-R/RW disc that does not contain data loaded, or in a rare case, disc placed upside-down.

--> RF signal error.

30 Servo Search Time Out Failed to reach a target address. And, the search became a timeout.

--> Carriage/Tracking error; Scratches on the disc; Stains on the disc

50 Mechanism Load NG

Eject NG

Disc loading/ejection not completed

--> A foreign object inserted in the mechanism; Disc jammed.

51 Mechanism Failure in retried

turning for ejection

Disc could not be ejected even after disc turning had been retried.

--> A foreign object inserted in the mechanism; Disc jammed.

ERROR CODES

(1) DISPLAY METHOD

If “0xFD” error mode is displayed in CD MODE (CD MODE area for display), an error code will be displayed in the MIN (minute

display) and SEC (second display) areas.

The same code is displayed in the MIN and SEC areas.

The TNO area is blank (#0FFH), as it conventionally was.

• Display example of the head unit

Depending on the display capability of LCDs, the display format varies, as shown below. XX denotes an error number.

Note: In a case of an OEM product, the error display format is subject to the specifications used by the equipment

manufacturer.

If a CD memory device is inoperable, or operation of such media is stopped by an error, the error mode is established and a

cause of the error is displayed by an error code. Indication of error codes is intended to reduce the number of calls from

customers and facilitate failure analysis and repair work in servicing.

• The 2 high-order digits of an error code denote the main classification, shown below.

code classification

0x

1x Servo-related errors

3x

5x Mechanism-related errors

• How to restore from each error is shown below.

Servo-related errors(0X, 1X, 3X) : Servo-related errors CD Off, Eject, ACC Off, Back-up Off, Communication reset, Reset

Load NG/Eject NG(50) : Reload, Eject, ACC Off, Back-up Off, Communication reset, Reset

Failure in retried turning for ejection : CD On, Eject, ACC Off, Back-up Off, Communication reset, Reset

NOTES

• Indications of error codes are available only during disc operations, because CD operations are unavailable if a mechanical error is

generated.

• If the TOC cannot be read, It stops because of error 07.

• If you design a new head unit, be sure to use one of the display formats indicated in “Display example of the head unit.”

12

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

Common

NO XXXX (NO TITLE, for example)

→ There is no embedded text information.

–Switch the display or play another

track/file.

CD player

ERROR-07, 11, 12, 17, 30

→ The disc is dirty.

– Clean the disc.

→ The disc is scratched.

– Replace the disc.

ERROR-07, 10, 11, 12, 15, 17, 30, A0

→ There is an electrical or mechanical

error.

– Turn the ignition switch OFF and back

to ON, or switch to a different source,

then back to the CD player.

ERROR-15

→ The inserted disc is blank.

– Replace the disc.

ERROR-23

→ Unsupported CD format.

– Replace the disc.

FORMAT READ

→ Sometimes there is a delay between the

start of playback and when you start to

hear any sound.

– Wait until the message disappears and

you hear sound.

NO AUDIO

→ The inserted disc does not contain any

playable files.

– Replace the disc.

SKIPPED

→ The inserted disc contains DRM

protected files.

–The protected files are skipped.

PROTECT

→ All the files on the inserted disc are

embedded with DRM.

– Replace the disc.

USB device

FORMAT READ

→ Sometimes there is a delay between the

start of playback and when you start to

hear any sound.

– Wait until the message disappears and

you hear sound.

NO AUDIO

→ There are no songs.

– Transfer the audio files to the USB

device and connect.

→ The connected USB device has security

enabled.

– Follow the USB device instructions to

disable the security.

SKIPPED

→ The connected USB device contains

DRM protected files.

– The protected files are skipped.

PROTECT

→ All the files on the connected USB

device are embedded with DRM.

– Replace the USB device.

N/A USB

→ The connected USB device is not

supported by this unit.

– Disconnect your device and replace it

with a compatible USB device.

CHECK USB

→ The USB connector or USB cable has

short-circuited.

–Check that the USB connector or USB

cable is not caught in something or

damaged.

→ The connected USB device consumes

more than maximum allowable current.

– Disconnect the USB device and do not

use it. Turn the ignition switch OFF

and back to ACC or ON. Connect only

compliant USB devices.

ERROR-19

→ Communication failed.

–Perform one of the following

operations, then return to the USB

source.

• Turn the ignition switch OFF and

back to ON.

• Disconnect the USB device.

• Change to a different source.

ERROR-23

→ USB device was not formatted properly.

– Format the USB device with FAT12,

FAT16 or FAT32.

STOP

→ There are no songs in the current list.

– Select a list that contains songs.

AMP ERROR

→ This unit fails to operate or the speaker

connection is incorrect; the protection

circuit is activated.

–Check the speaker connection.

–Check the power IC and its peripheral

circuit.

DEH-1700UB/XNEW5

13

1234

1234

C

D

F

A

B

E

5.3 CONNECTOR FUNCTION DESCRIPTION

FM/AM ANTENNA INPUT

REAR OUTPUT or

SUBWOOFER OUTPUT

1 FL+

2 FR+

3 FL4 FR5 RL+

6 RR+

7 RL8 RR-

9 TEL (Except DEH-1700UBA)

NC (DEH-1700UBA Only)

10 NC

11 NC

12 NC

13 ACC

14 B.REM

15 B.UP

16 GND

16

14

12

10 8

6

42

15

13

11

97

5

31

WIRED

REMOTE

CONTROL

(Except DEH-1700UBA)

14

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

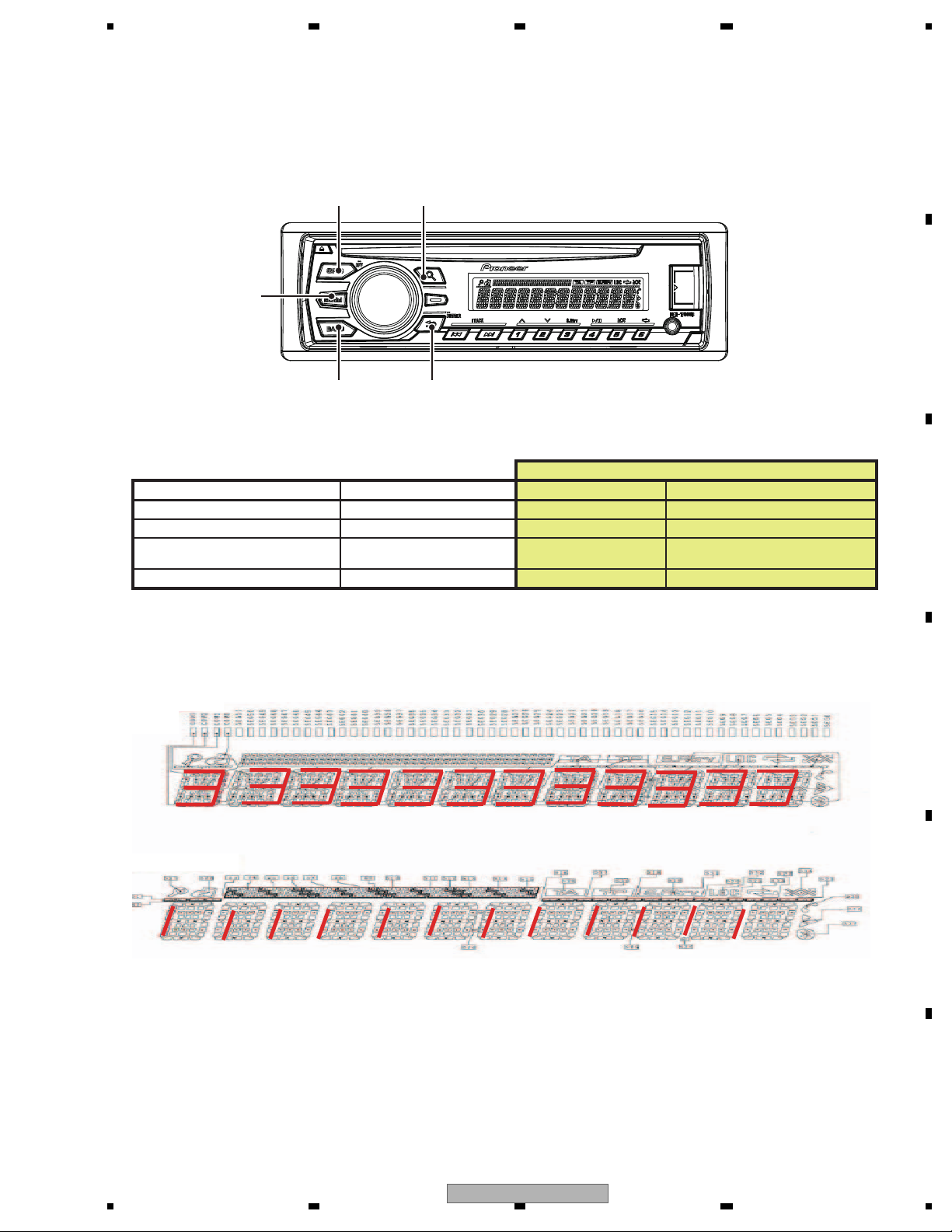

Grille condition

Conf. item Operate Show LCD ILM

All light up

EQ + LIST

Draw 1 ILM(1)

All light off SOURCE No light Draw2 No light

Conf. LCD pattern 1

(* And change ILM color)

BAND Draw 3

ILM(2)

(If not have, ILM(1) light on)

Conf. LCD pattern 2

BACK

Draw 4 ILM(1)

Drawings Style

Draw1 ALL light up

Draw2 ALL light off

Draw3

Draw4

BAND BACK

SOURCE

LIST

Press and hold "EQ" and "LIST" buttons together, and turn BUP and ACC on.

[How to enter Test mode]

EQ

6. SERVICE MODE

6.1 DISPLAY TEST MODE 1

DEH-1700UB/XNEW5

15

1234

1234

C

D

F

A

B

E

6.2 DISPLAY TEST MODE 2

* Initial

condition

$ PD number

For Ver.7.01, "701" is displayed

For PEA010A, "010A" is displayed

# System

microcomputer

version

S

$$$$

###

1 + 3

On (state when

entering test mode)

Press and hold "1" and "3" buttons together, and turn BUP and ACC on.

[Operation key]

[How to enter Test mode]

[Test items]

Start display test mode.

Press and hold "1" and "3" buttons together, and turn

BUP and ACC on.

Display is normally updated

Display update is stopped

Product operation is performed as usual, in appearance.

The screen gets still when entering this item.

On (an initial value)

On (lighting condition

of normal times)

On (an initial value or

setting value of default

menu)

On (an initial value or

setting value of default

menu)

On (an initial value or

setting value of default

menu)

Off

All off

All off

All off

Remarks

Key Illumination

Operation key Processing

Icon

Enter display test mode

Switch to next test mode

The information such as the system microcomputer version is checked.

Switching to next display

by pressing “ 1 ” + “ 3 ” buttons together.

Switching to next display

by pressing “ 1 ” + “ 3 ” buttons together.

Switching to next display

by pressing “ 1 ” + “ 3 ” buttons together.

System Version information is displayed.

16

DEH-1700UB/XNEW5

5678

56

7

8

C

D

F

A

B

E

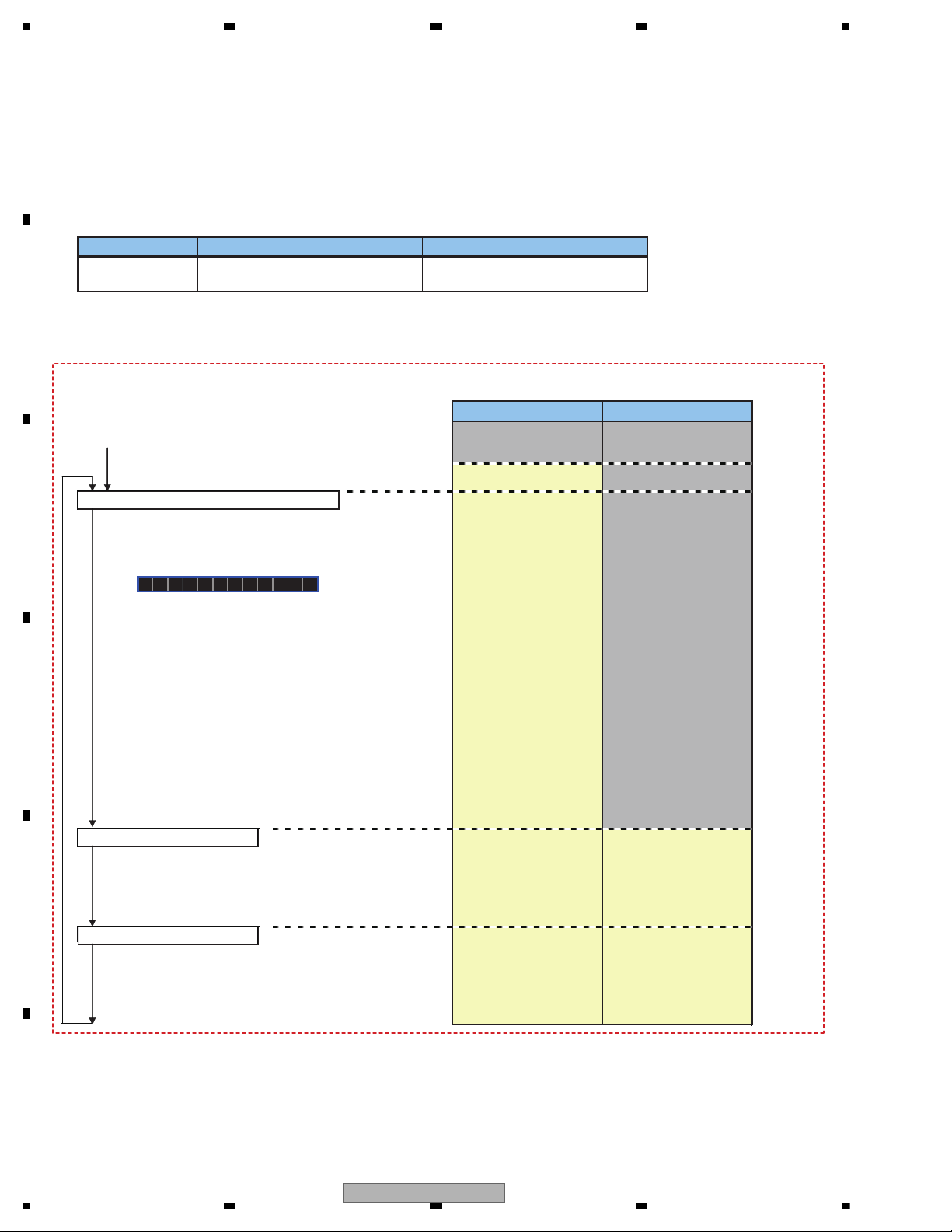

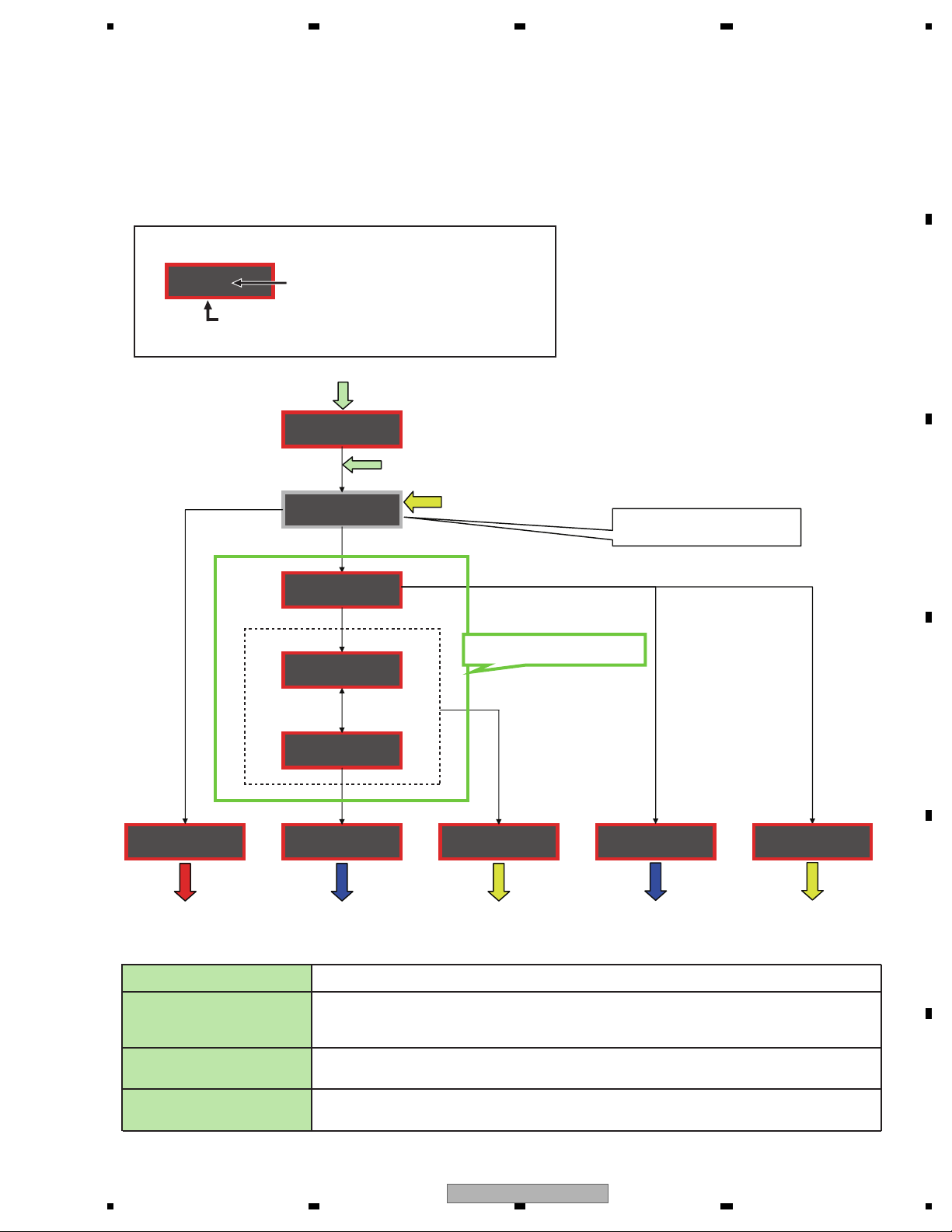

Overview

This mode is used for upgrading the MCU software of system using USB memory.

How to enter in USB rewriting mode

Press and hold "1" and "2" buttons together, and turn BUP and ACC on.

USB rewriting operation flow

Explanatory note

Screen display and ON/OFF of illumination

Characters displayed on the screen

Red frame: illumination lights up

Gray frame: illumination lights off

Blue characters: operation to be carried out by a user of USB rewriting function

Press and hold "1" and "2" buttons together, and turn BUP and ACC on.

Press LIST button

* After connecting USB memory in which upgrading file is stored, press LIST button.

(4) Retry count over

Retry rewriting

Check of upgrading file is started

(2) Upgrading file is not detected

Upgrading file error

After retryFirst time

Rewriting is started

Switched every

5 seconds

(3) Rewriting failed

(1) Rewriting succeeded

Result of rewriting

(1) Rewriting succeeded

(2) Upgrading file error

Upgrading file is not detected

(3) Rewriting failed

(4) Retry count over

FILE ERROR

DON'T STOP

PRG **/100

ERR->RETRYCAN'T UPDT

USB

START UPDT

CHECK FILE

In 5 seconds, usual operation

(OFF SOURCE)

As the reset is internally carried out,

display and illumination go out

In 5 seconds, usual operation

(OFF SOURCE)

In 5 seconds, rewriting

is retried

In 5 seconds, rewriting

is retried

Display is continued until

the power supply is turned

OFF

If the power supply is turned OFF

during rewriting, retry the rewriting.

Displayed when there is no upgrading file in USB memory or the data of upgrading file is different.

In 5 seconds, usual operation (OFF SOURCE) is started.

If the upgrading file error is detected or the upgrading file is not detected after the rewriting is retried, the rewriting is failed.

In 5 seconds, rewriting is retried.

Displayed when the retry becomes unavailable because the retry count is exceeded.

The display is continued until the power supply is turned OFF. If the power supply is turned ON again, the display is not changed.

The upgrading using USB is disabled, so it is necessary to write programs in serial Flash using E10A.

Displayed when the writing of upgrading file in serial Flash is not normally terminated.

Or, displayed if the upgrading file error is detected or the upgrading file is not detected after the rewriting is retried.

In 5 seconds, rewriting is retried.

Displayed when USB rewriting is normally terminated.

In 5 seconds, usual operation (OFF SOURCE) is started.

ERR->RETRY

COMPLETE

6.3 SOFTWARE VERSION UP METHOD

DEH-1700UB/XNEW5

17

1234

1234

C

D

F

A

B

E

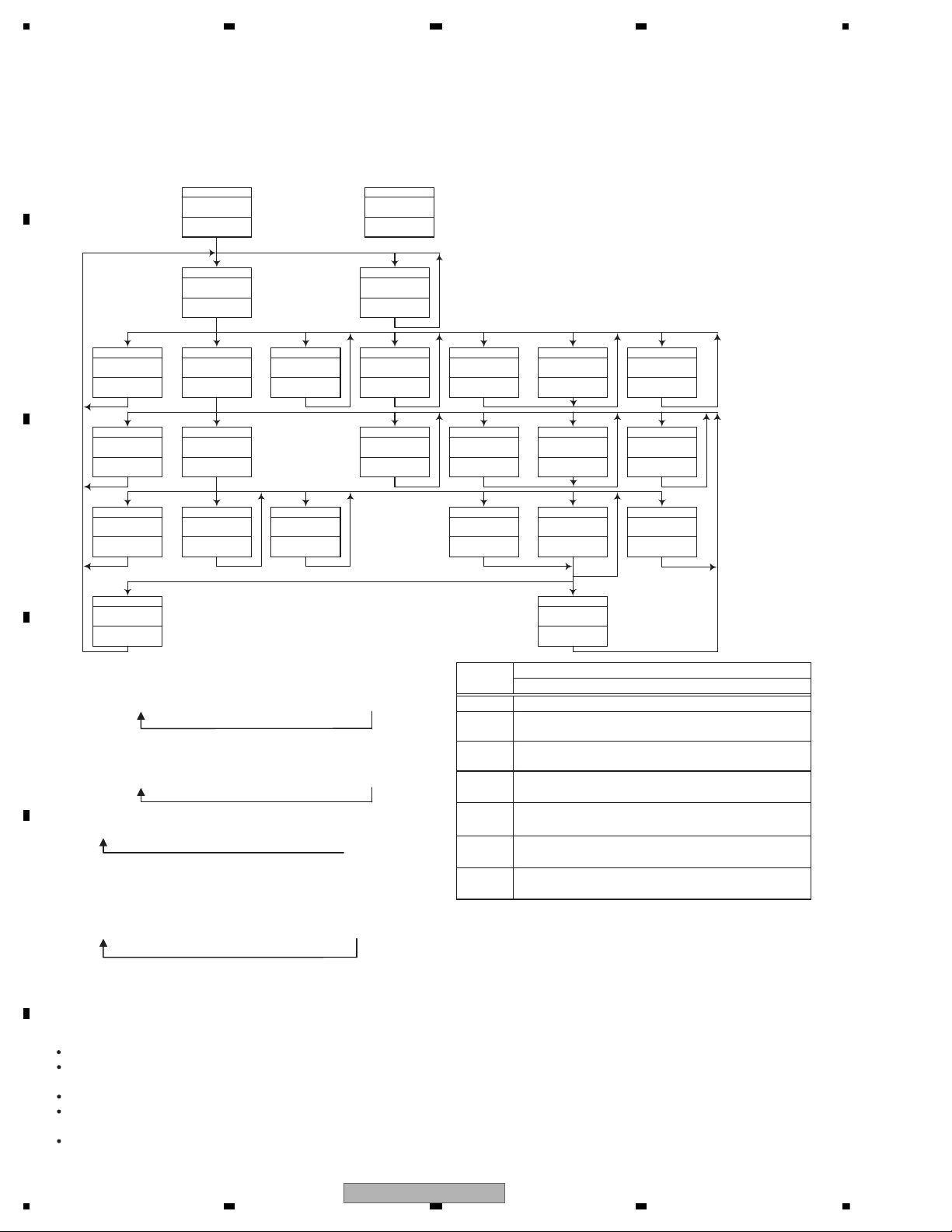

6.4 CD TEST MODE

- Flow Chart

To enter the test mode: [4] + [6] -> BUP + ACC ON

[CD] or [SOURCE]

Source ON

TRK MIN

[BAND]

Power On

(T.Offset is adjusted)

TRK MIN SEC

00 00 00

[Key]

Contents

Display

[2]

TRK MIN SEC

GG GG GG

RF AMP

Gain switching

*1

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[3]

Focus Close

S curve check

TRK MIN SEC

91 91 91

[1]

T.Close & AGC

Applicable servomechanism

TRK MIN SEC

?tr ?min ?sec

[1]

F,T,RF AGC

F.Bias display switching

TRK MIN SEC

[6]

Focus Mode switching

TRK MIN SEC

[3] [>]

*5

TRK MIN SEC

?tr ?min ?sec

0X 0X 0X

F,T AGC / F.Bias

RF AGC

*2

RF AGC coefficient display

[1]

Tracking Servo

Close

00 00 00

or 99 99 99

[3]

RF AGC /

TRK MIN SEC

?? ?? ??

[>]

CRG +

00 00 00

or 99 99 99

[>]

CRG +

8X 8X 8X

or 9X 9X 9X

CRG/TR Jump +

TRK MIN SEC

?tr ?min ?sec

[<]

CRG -

00 00 00

or 99 99 99

[<]

CRG -

8X 8X 8X

or 9X 9X 9X

[<]

*4 *4

CRG/TR Jump -

TRK MIN SEC

?tr ?min ?sec?? ?? ??

[2]

Tracking Open

8X 8X 8X

or 9X 9X 9X

*6

[2]

Self-adjusting

switching

TRK MIN SEC

[2]

T.Balance adjustment /

T.BAL coefficient display

TRK MIN SEC

[2]

or 9X 9X 9X

*3*6

?? ?? ??

?? ?? ??

Tracking Open

8X 8X 8X

*1) TYP t + 6 dB t + 12 dB

TRK

MIN

SEC

TRK06MIN06SEC

06

TRK12MIN12SEC

12

*2) Focus Close

TRK00MIN00SEC

TRK99MIN99SEC

(

t S. Curve t F EQ measurement setting

00

TRK

MIN01SEC

01

01

TRK02MIN02SEC

99)

02

[Key]

[BAND]

[>]

[<]

[1]

Power On/Off

CRG + / TR Jump +

(Direction of the external surface)

CRG - / TR Jump (Direction of the internal surface)

T. CLS & AGC & Applicable servomechanism /

Test Mode

AGC,AGC display setting

Operation

[2]

*3) F.Offset Display t

RF.Offset

t

T.Offset Display t

Switch to the order

of the original

display

*4) 100TR Jump

*5) TRK/MIN/SEC

t F.AGC t T.AGC Gain t F.Bias t RF AGC

RF Gain switching / Offset adjustment display /

T.Balance adjustment / T. Open

[3]

F. Close,S. Curve / Rough Servo and RF AGC /

F,T,RF AGC

[6]

F. Mode switching / Tracking Close

*6) CRG motor voltage = 2 [V]

After the [EJECT] key is pressed keys other than the [EJECT] key should not be pressed, until disc ejection is complete.

When the key [2] or [3] is pressed during the Focus Search, the power supply should be immediately turned off (otherwise the lens sticks

to Wall, causing the actuator to be damaged).

In the case of 100TR Jump, the mechanism shall be set to the Tracking Close mode when the key is released.

When the power is turned on/off the gain of the RFAMP is reset to 0 dB. At the same time all the self-adjusting values shall return to the

default setting.

Do not do Tracking Servo Close before doing Focus Servo Close. (Because the overcurrent flows)

18

DEH-1700UB/XNEW5

Loading...

Loading...