Page 1

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER ELECTRONIC [EUROPE] N.V. Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER ELECTRONIC CORPORATION 1999

K-ZZS. FEB. 1999 Printed in Japan

ORDER NO.

CRT2376

CD MECHANISM MODULE

CX-890

CONTENTS

1. MAIN PARTS LOCATIONS........................................2

2. CIRCUIT DESCRIPTIONS ..........................................3

3. MECHANISM OPERATIONS...................................16

4. DISASSEMBLY ........................................................21

NOTE:

- This Service Manual outlines operations of the CD mechanism module used in the models listed blow.

- For repair, use this Service Manual and the Service Manual of the model used in the system.

Model Service manual CD mechanism module CD mechanism unit

CDX-PD6/UC CRT2372 CXK4701 CXB2700

Page 2

2

CX-890

1. MAIN PARTS LOCATIONS

Frame

Stage front side

Carriage motor (M4)

ELV motor (M2)

Cam gear motor (M1)

Photo interrupter (ELV)

Loading motor (M3)

Servo unit

Disc insertion detectors

Disc insertion detectors

Clamp switch

(S887)

ELV HOME switch

(S886)

Disc ejection detectors

Detection switch

(S885)

STS unit

Spindle

motor (M5)

Insertion completion

switch

Mode switch

(S803)

Door switch

(S802)

Load switch

(S801)

Do not hold the upper frame of the disc insertion slot or

the front side of the stage in the CD mechanism module when

servicing to prevent them from being deformed.

- CD Player Service Precautions

1. For pickup unit(CXX1311) handling, please refer

to"Disassembly"(Page 21).

During replacement, handling precautions shall be

taken to prevent an electrostatic discharge(protection

by a short pin).

2. During disassembly, be sure to turn the power off

since an internal IC might be destroyed when a connector is plugged or unplugged.

Page 3

3

CX-890

2. CIRCUIT DESCRIPTIONS

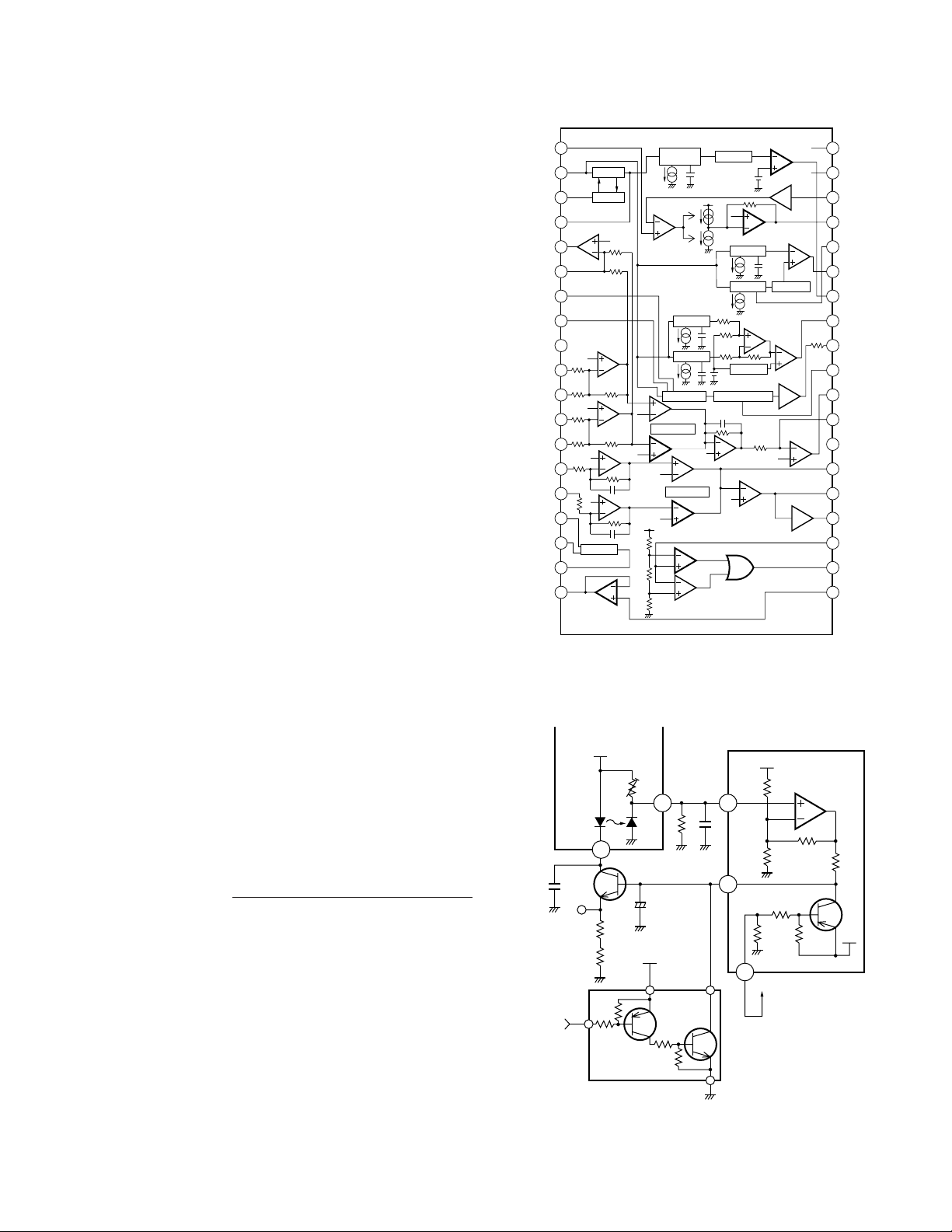

2.1 Preamplifier (UPC2572GS: IC101)

The preamplifier processes pickup output signals to

generate signals to be sent to the servo, demodulator,

and controller. The preamplifier with built-in photodetector converts signals from the pickup into intermediate voltage in the pickup. Then, addition is made in the

RF amplifier (IC101) to obtain RF, FE, TE, and TE zero

cross signals. The system consists of the UPC2572GS

and other components explained below. The system

uses a single power source (+5 V). Therefore, the reference voltage of IC101 and the reference voltage of the

power unit and servo circuit are REFOUT (+2.5 V). REFO

UT is obtained from REFOUT of servo LSI (IC201:

UPD63702GF) via a buffer, and is output from Pin 19 of

IC101. This REFOUT is used as reference for all measurements.

Note:Do NOT short-circuit REFOUT and GND during

measurement.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

X12

RF

envelope

AGC

Detection

X3

Phase detection

3T detection

Bottom

DC shift

Peak

Control

DC shift

Bottom

Peak

120kΩ

DEFECT circuit

FE

BAL

FE

BAL

Vcc

Mirror circuit

FE

BAL

APC

X2

Vcc

FE-BAL

TE-BAL

ASY

EFM-OUT

C.DEF

DEFECT

RFOK

MIRR

3T-OUT

C.FE

FE-OUT

FE-

GND

TE-

TE-OUT1

TE-OUT2

DET-IN

DET-OUT

VREF-INVREF-OUT

LDON

LD

PD

E

F

D

B

C

A

Vcc

C2.3T

C1.3T

RF-

RF-OUT

RF-IN

C AGC

AGC-OUT

EFM-IN

HPF

TE

BAL

EFM comparator

Control

Fig. 1 Block Diagram of UPC2572GS

1) Automatic Power Control (APC) circuit

Laser diode has negative temperature characteristics

with great optical output when the diode is driven with

constant current. Therefore, current must be controlled

by a monitor diode to ensure constant output. Thus

functions the APC circuit. LD current can be obtained by

measuring the voltage between LD1 and GND. The current value is approximately 35 mA.

Vcc (5V)

Vr

LD MD

UPC2572GS

16

PD

17

LD

15

Q101

2SD1664

C124

0.1µF

C101

(100µF/6.3V)

R101

10Ω

LD1

R102

12Ω

5V

CONT

Q102 UMD2N

18

5V

5V

1kΩ

150kΩ

16kΩ

R112

2.2kΩ

C104

0.33µF

5

1kΩ

2.5V

Pickup unit

Fig. 2 APC Circuit

Voltage between LD1 and GND(mv)

LD current(mA) =

10 Ω + 12 Ω

Page 4

4

CX-890

2) RF amplifier and RF AGC amplifier

Photodetector outputs (A+C) and (B+D) are added,

amplified and equalized in IC101, and output to the RFI

terminal as RF signal. (Eye pattern can be checked at

this terminal.)

Low-frequency components of voltage RFI is:

RFI = ((A + C) + (B + D)) x 3.22

where R111 is offset resistor to keep RFI signal within

the output range of the preamplifier. RFI signal is goes

under AC coupling, and is input to Pin 4 (RFIN terminal).

IC101 contains an RF AGC circuit. RFO output from Pin

2 is maintained to a constant level (1.2 ±0.2 Vp-p). The

RFO signal is used in the EFM, DFCT, and MIRR circuits.

3) EFM circuit

The EFM circuit converts RF signal into digital signals of

"0" and "1". RFO signal after AC coupling is input to Pin

1, and supplied to the EFM circuit.

Asymmetry caused during manufacturing of discs cannot be eliminated solely by AC coupling. Therefore, the

system controls the reference voltage ASY of the EFM

comparator by using the fact that probability to generate "0" and "1" is 50% in EFM signal. This reference voltage ASY is generated by output from the EFM comparator through L.P.F. EFM signal is output from Pin 35.

As signal level, amplification is 2.5 Vp-p around

REFOUT.

4) DFCT (defect) circuit

DFCT signal detects mirror defect in discs, and is output

from Pin 33. The system outputs "H" when a mirror

defect is detected.

If disc is soiled, the system determines it as lack of mirror. Therefore, the system inputs the DFCT signal output to the HOLD terminal of servo LSI. Focus and tracking servo drives change to Hold status only when DFCT

output is in "H" so that performance of the system upon

detection of defect can be improved.

5) RFOK circuit

The RFOK circuit outputs signal to show the timing of

focus closing servo, as well as the status of focus closing during playback. The signal is output from Pin 32.

The system inputs the RFOK signal output to the RFOK

terminal of servo LSI. The servo LSI issues Focus Close

command. The system outputs signal in "H" during

focus closing and playback.

CN101

13

6

DETECT

13

11

10

10kΩ

20kΩ

9.3kΩ

RFI

+5V

R111

27kΩ

Vcc

×12

ASY

12

20kΩ

(RF AGC)

AGC

RF

ENVELOPE

HPF

VDC

RFOK

20kΩ

33

36

35

34

PEAK

DEFECT

EFM

UPC2572GS

A+C

10kΩ

B+D

9.3kΩ

20kΩ

10kΩ

10kΩ

R105

6.8kΩ

C125 5pF

C105

24pF

R125

0R0

R104

8.2kΩ

RFIN

C107

4.7µF/35V

C122

0.1µF

C106

RFO

REFOUT (+2.5V)

DEFECT

BOTTOM

R107 8.2kΩ

R106 18kΩ

C111 3300pF

C110

C112 0.047µF

6 54 3 21

32

0.1µF

2200pF

HOLD

Fig. 3 RF AMP, RF AGC, EFM, DFCT, RFOK Circuit

Page 5

5

CX-890

6) Focus-error amplifier

The system outputs photodetector output (A+C) and

(B+D) as FE signal (A+C)-(B+D) from Pin 28 via the difference amplifier, then via the error amplifier.

Low-frequency components of voltage FEY is:

An S curve equivalent to approximately 1.6 Vp-p is

obtained at FE output (Pin 28) by using REFO as reference. The cut-off frequency of the amplifier of the last

layer is 12.4 kHz.

7) Tracking-error amplifier

Outputs E and F from the photodetector are output as

TE signal (E-F) from Pin 24 via the difference amplifier,

then via the error amplifier.

Low-frequency components of voltage TEY is:

TE waveforms equivalent to approximately 1.5 Vp-p are

obtained at TE output (Pin 24) by using REFO as reference. The cut-off frequency of the amplifier of the last

layer is 19.5 kHz.

8) Tracking zero-cross amplifier

Tracking zero-cross signal (TEC signal) is generated by

amplifying TE waveforms (voltage at Pin 24) by a factor

of four. The signal is used for detecting the zero-cross

point of tracking error in the servo LSI UPD63702AGF.

The purposes of detecting the zero-cross point are as

follows:

(1)To be used for counting tracks for carriage move and

track jump.

(2)To be used for detecting the direction of lens move-

ment when tracking is closed. (To be used in the

tracking brake circuit mentioned later.)

The frequency range of TEC signal is from 500 Hz to

19.5 kHz.

Voltage TEC = TE level x 4

In other words, the TEC signal level is calculated as 6

Vp-p. This level exceeds the D range of the operation

amplifier, resulting in the signal to clip. However,

there shall be no problem, since the servo LSI uses

only zero-cross point.

65

9.3kΩ

9.3kΩ

20kΩ

10kΩ

10kΩ

6

13

13

12

10kΩ

10kΩ

20kΩ

FE VCA

38

REFOUT

C114

390pF

FE

R108

33kΩ

28

27

17.2kΩ

50pF

gm=1/68.8kΩ

90kΩ

10

11

CN101

A+C

B+D

F.BAL

REFOUT (+2.5V)

gm CONDUCTANCE

UPC2572GS

Fig. 4 Focus-error amplifier

Fig. 5 Tracking-error amplifier,

Tracking zero-cross amplifier

CN101

R117

16kΩ

R116

16kΩ

14

15

9

11

31kΩ

31kΩ

50pF

63kΩ

C123

4.7nF

R114

10kΩ

R113

10kΩ

TBAL

C115

120pF

R109

68kΩ

R115

1kΩ

C126

15nF

TE

4R

R

F

E

23

TEC

C116

6.8nF

TE VCA

gm=1/17kΩ

63kΩ

37

24

5pF

TOFST

R110

130kΩ

50pF

25

REFOUT (+2.5V)

gm CONDUCTANCE

UPC2572GS

63kΩ 68kΩ

TEY=(E-F) X X

(31kΩ+16kΩ) 17kΩ

: (TE level of pickup unit x 5.36)

20kΩ 90kΩ R108

FEY=(A+C)-(B+D)X X X

10kΩ 68.8kΩ 17.2kΩ

: (FE level of pickup unit x 5.02)

Page 6

6

CX-890

9) MIRR (mirror) circuit

MIRR signal shows ON and OFF track information. The

signal is output from Pin 31.

The status of MIRR signal is as follows:

Laser beam ON track: MIRR = "L"

Laser beam OFF track: MIRR = "H"

The signal is used in the brake circuit mentioned later.

10) 3T OUT circuit

The system detects flickering of RF signal when disturbance is input to the focus servo loop, and outputs the

difference of phase between FE signal and RF-level

fluctuation signal from Pin 30. The resulting signal is

obtained through L.P.F. with a fc of 40 Hz. This signal is

used for automatic adjustment of FE bias.

MIRR

COMP

DC

shift

PeakAGC

Bottom

RFO

Detection

A

1.5V

UPC2572GS

(Peak) – (Bottom)

4

31

RFIN

B

Z

C

RFO

PEAK HOLD

BOTTOM HOLD

MIRROR

1

A

0

False MIRR caused by dirt

True MIRR

OFF TRACK

Dirt, etc.

B

C

Z

Ø

3T-OUT

FE signal

RFIN

UPC2572GS

C113

10nF

FEY

3T detection

C117

0.033µF

120kΩ

L.P.F

Phase detection

8

+

H.P.F

10kΩ

10kΩ

1kΩ

C2.3T

C109

100pF

C1.3T

C108

0.027µF

8

7

30

29

4

AGC

Differential

rectification

3T LEVEL ENVELOPE

DETECTOR

Phase

comparison

Fig.6 MIRR Circuit

Fig. 7 MIRR Circuit

Fig. 8 3T OUT Circuit

Page 7

7

CX-890

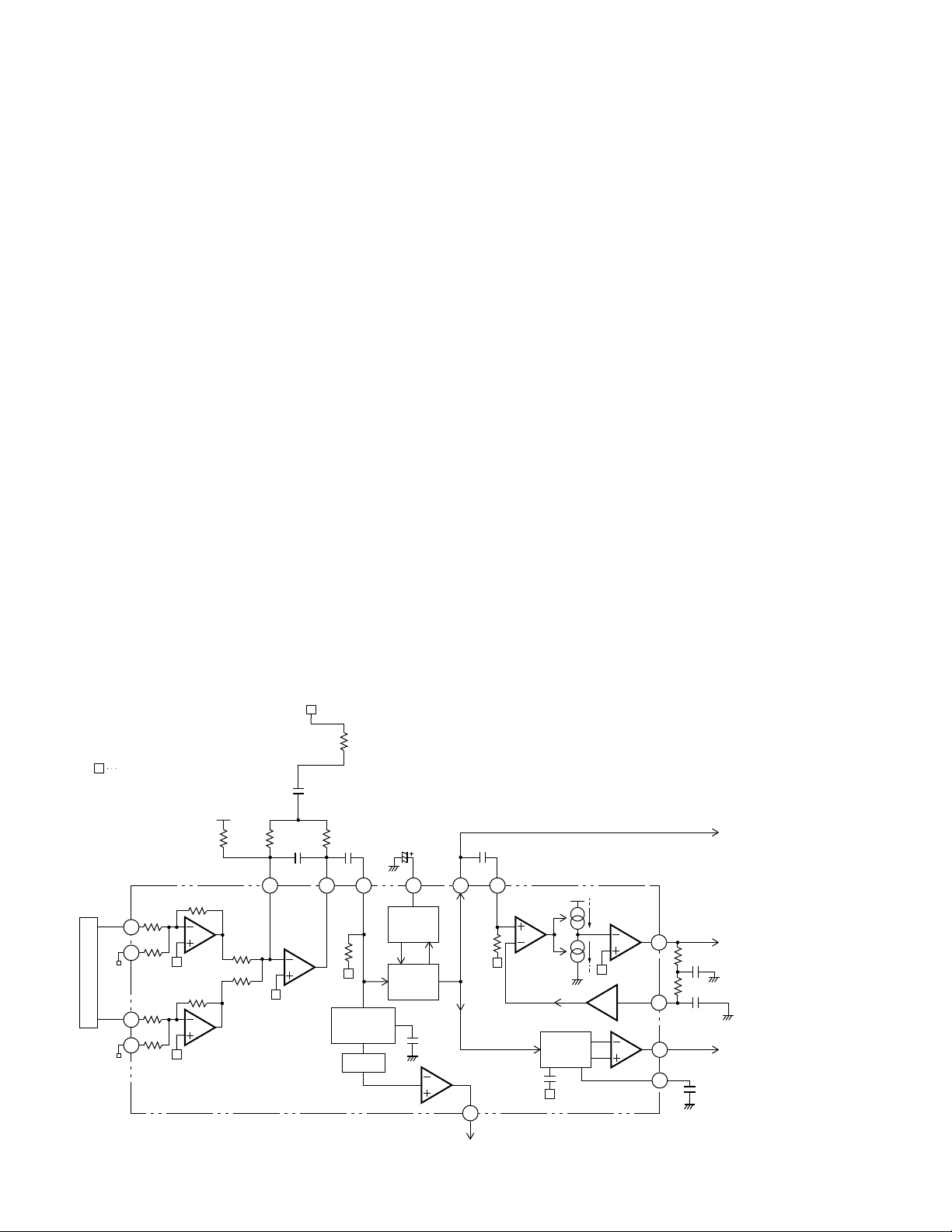

2.2 Servo (UPD63702AGF: IC201)

The servo consists of mainly two parts. The first part is

the servo processing unit to equalize error signals and

control track jump, carriage move, in focus, etc. The

second part is the signal processing unit to perform

data decoding, error correction, and interpolation.

The system converts FE and TE signals from analog to

digital in IC201, then outputs drive signals of the focus,

tracking, and carriage systems via the servo block. The

EFM signal input from the preamplifier is decoded by

the signal processing unit, and eventually output as

audio signal after conversion into analog from digital

signals via the DA converter (IC201 contains audio

DAC). Then, the system generates error signal for the

spindle servo in the decoding process, sends the signal

to the spindle servo to generate drive signal for spindle.

After that, drive signals for focus, tracking, carriage,

and spindle are amplified in IC301 and BA5986FM, and

supplied to respective actuators and motors.

1) Focus servo system

The main equalizer of focus servo is located in the

UPD63702AGF. Fig. 9 shows block diagram of the focus

servo.

For the focus servo system, the lens must be positioned within the focusing range in order to perform

focus closing. To achieve this, the system moves the

lens upward/downward by focus-search voltage of triangular waveform to detect the focusing point. During

searching, the system kicks the SPDL motor to maintain rotation speed to set speed.

The servo LSI monitors FE and RFOK signals so that

focus closing is performed automatically at an appropriate point.

Focus closing is performed when the following four

conditions are satisfied:

(1)When the lens moves nearer to the disc.

(2)RFOK = "H"

(3)FZD signal (in IC) is latched to "H"

(4)FE = 0 (REFOUT as reference)

FOCUS

ERROR

D/A

FD

FIN

DRIVER

FOP

FOM

IC301

BA5986FM

LENS

IC 201 UPD63702AGF

76

64

2

4

3

14

13

FOCUS SEARCH

TRIANGULAR WAVE

GENERATOR

DAC

DIGITAL

EQUALIZER

CONTROL

A/D

R301

10kΩ

R302

15kΩ

Fig. 9 Focus servo block diagram

Page 8

8

CX-890

When the conditions mentioned above are satisfied and

focus is closed, the XSO terminal changes from "H" to

"L". Then, the microcomputer starts monitoring RFOK

signal through L.P.F after 40 ms.

If the system judges RFOK signal as "L", the microcomputer takes actions, including protection.

Fig. 10 shows operations related to focus closing. (The

illustration shows when the system cannot perform

focus closing.) S curve, search voltage, and actual lens

behavior can be checked by pressing the Focus Close

button when "01" is shown in Focus Mode Select in Test

mode.

REFOUT

FD

LENS POSITION

RELATIVE TO DISC

NEAR

FAR

"JUST FOCUSED"

SIN

REFOUT

Expanding around "Just Focused Point"

REFOUT

RFI

FOK

FEX

FZD

THRESHOLD

LEVEL

FZD

(INTERNAL SIGNAL)

Focus closing would normally take place at these points

XSO

(IN THE EVENT

FOCUS IS

CLOSED)

LEVEL

Fig. 10 Sequence of Focus Closing

Page 9

9

CX-890

2) Tracking servo system

The main equalizer of tracking servo is located in the

UPD63702AGF. Fig. 11 shows block diagram of the

tracking servo.

a) Track jump

Track jump is automatically performed by the auto

sequence function in LSI when the LSI accepts command. The system has six types of jump (1, 4, 10, 32,

32x2, and 32x3) for truck jump during searching. In Test

mode, the system can select and check these jump

types and CRG move by selecting a mode. The microcomputer sets half of the total number of track jumps

(two tracks if the total number of tracks are four), and

counts the set number of tracks by using TEC signal.

The system outputs brake pulse for a specified time (set

by the microcomputer) from the point of time when the

set number is counted, and stops the lens. Thus, tracking is closed, and the system can continue normal playback.

To improve servo withdrawal during track jump, the

system sets the brake circuit to ON for 60 ms after

brake pulse so that gain of the tracking servo can be

increased.

FF/REV in normal mode is made by continuously performing single jump approximately ten times faster

than in normal playback.

TRACKING

ERROR

D/A

TD

TIN

DRIVER

TOP

TOM

IC301

BA5986FM

LENS

IC 201 UPD63702AGF

77

11

12

JUMP

PARAMETERS

DAC

DIGITAL

EQUALIZER

CONTROL

A/D

5

7

6

R303

10kΩ

R304

27kΩ

63

t1

t2

GAIN NORMAL

TIN

KICK

BRAKE

TEC

T. BRAKE

EQUALIZER

T. SERVO

CLOSED

OPEN

NORMAL

GAIN UP

OFF

ON

t1

TIN

TEC

(10 TRACK)

EQUALIZER

T. BRAKE

SERVO

CIN

2.8mS (4.10 TRACK JUMP)

5.8mS (32 TRACK JUMP)

GAIN UP

NORMAL

ON

OFF

OPEN

CLOSED

t2

60mS

t

Fig. 11 Tracking servo block diagram

Fig. 12 Single track jump

Fig. 13 Multi track jump

Page 10

10

CX-890

b) Brake circuit

Servo withdrawal will deteriorate during setting and

track jump. Thus, the system uses the brake circuit to

provide stable withdrawal to servo loop.

The brake circuit detects the direction of lens movement, and outputs only drive signal in the opposite

direction from the lens movement. Thus, the system

delays the speed of the lens movement to stabilize

withdrawal of the tracking servo.

The system judges sliding direction of track from TEC

and MIRR signals, as well as the relationship of their

phase.

TEC

TZC

(TEC "SQUARED UP" )

(INTERNAL SIGNAL )

MIRR

MIRR LATCHED AT

TZC EDGES

=

SWITCHING PULSE

EQUALIZER OUTPUT

(SWITCHED)

DRIVE DIRECTION

Note: In the illustration, the phase of equalizer output is shown as the same as with that of TEC.

FORWARD

LENS MOVING FORWARDS

(INNER TRACK TO OUTER)

LENS MOVING BACKWARDS

Time

REVERSE

Fig. 14 Tracking Brake Circuit

Page 11

11

CX-890

3) Carriage servo system

Output from low-frequency components (lens position

information) of the tracking equalizer is input to the carriage equalizer by the carriage servo. After obtaining a

certain gain, the system outputs drive signal from the

servo LSI. The signal is then applied to the carriage

motor via the driver IC. More specifically, the pickup

unit as a whole must be moved forward when lens offset during playback reaches a specified level. Therefore,

gain of equalizer is set so that voltage higher than the

activation voltage of the carriage motor is output. As

actual operation, a certain threshold level is set for

equalizer output in the servo LSI, and drive voltage is

output from the servo LSI only when the equalizer output level exceeds that level. Thus, power consumption

is reduced. Depending on eccentricity, etc. of disc, the

equalizer output voltage may cross the threshold level

several times before the pickup unit as a whole starts

operation. At this time, waveforms of drive voltage

from LSI are output as pulse.

D/A

SD

DRIVER

COP

COM

IC301

BA5986FM

CARRIAGE

MOTOR

IC201 UPD63702AGF

62

27

26

25

16

15

KICK, BRAKE

REGISTERS

DAC

DIGITAL

EQUALIZER

CONTROL

FROM

TRACK

EQUALIZER

M

R305

10kΩ

R306

7.5kΩ

CIN

DRIVE ON/OFF THRESHOLD

CARRIAGE MOVED AT THESE POINTS

TRACKING DRIVE

(LOW FREQUENCY)

LENS POSITION

CRG DRIVE

(INSIDE UPD63702AGF)

CRG MOTOR VOLTAGE

Fig. 15 Carriage Servo Circuit

Fig. 16 Carriage Signal Waveforms

Page 12

12

CX-890

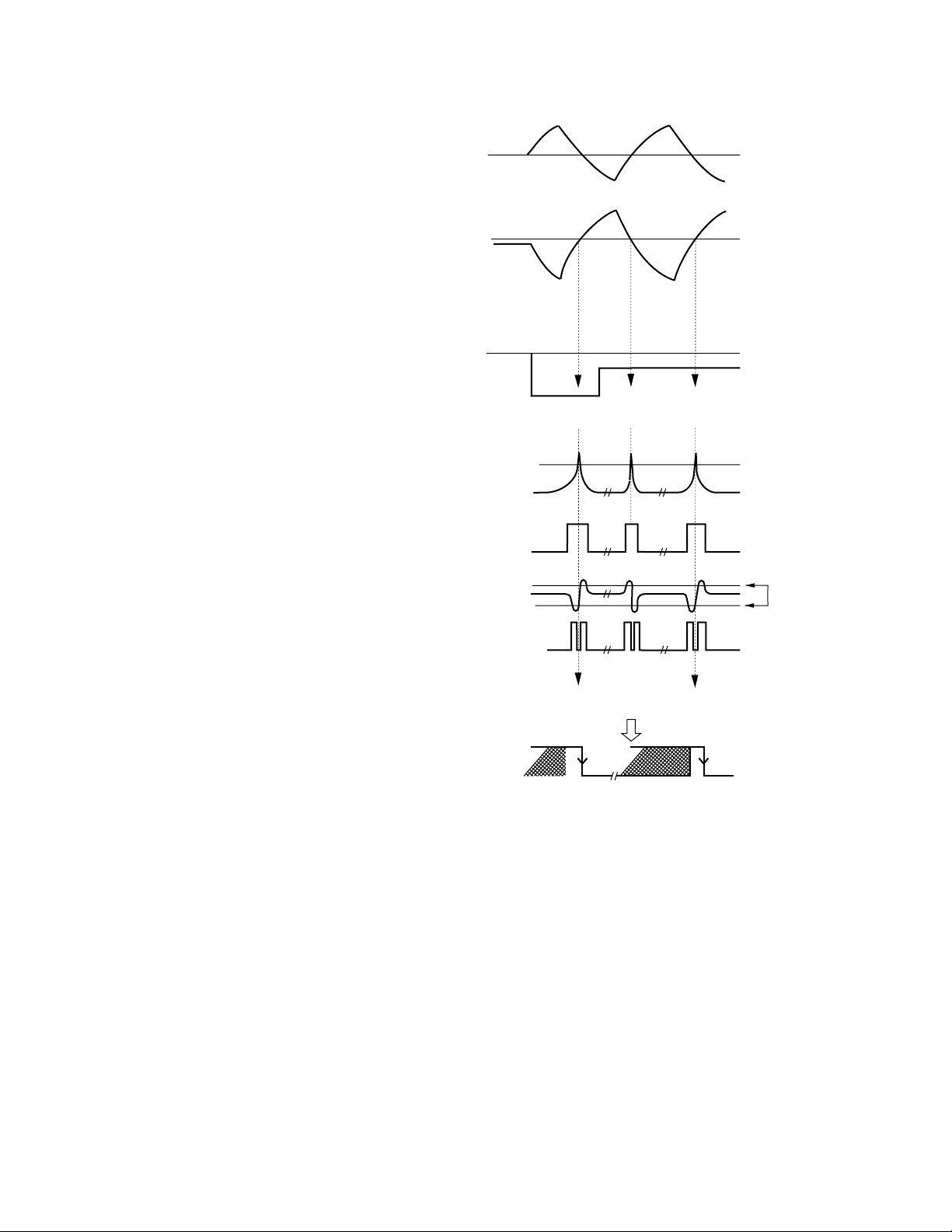

4) Spindle servo system

The spindle servo has the following modes:

(1)Kick mode:To be used for accelerating disc rotation

during setting.

(2)Offset mode:

a)To be used after completion of kick until comple

tion of spindle lock during setting.

b)If focus is out of range during playback, this mode

is used until focus is recovered. In both cases,

Offset mode is used for maintaining disc rotation

to the speed close to specified rotation.

(3)Adaptive Servo mode: CLV servo mode during nor-

mal operation. The system samples every WFCK in

16 cycles whether frame synchronous signal matches output from the internal frame counter in EFM

demodulation block, and generates signal that

shows matching/unmatching status. If signal showing unmatching status continues for 8 times, the system deems it as asynchronous status. Except this

case, the system judges as synchronous. In Adaptive

Servo mode, the system automatically selects withdrawal servo for asynchronous status, and steadystate servo for synchronous status.

(4)Brake mode: Mode to stop the spindle motor.

The microcomputer outputs brake voltage from the

servo LSI. Waveforms of EFM are monitored inside

the LSI. If the longest pattern of EFM exceeds specified intervals (if the rotation speed adequately

slowed down), flag is activated in the LSI, and the

microcomputer turns brake voltage to OFF. If no flag

is activated after a specified time, the microcomputer changes from Brake to Stop mode. This status

continues for a specified time. If the system changes

to Stop mode during ejection, disc is ejected after

the specified time mentioned above.

(5)Stop mode: To be used when the power is turned to

ON, and during ejection. In Stop mode, the end-toend voltage of the spindle motor is 0 V.

(6)Rough Servo mode: To be used when returning car-

riage (carriage move during long search, etc.). The

system calculates linear speed from waveforms of

EFM, and inputs either "H" or "L" level to the spindle

equalizer. This mode is also used for confirmation of

grating in Test mode.

MDXMDY

DRIVER

IC301

BA5986FM

IC 201 UPD63702AGF

61

24

22

23

DSP

BLOCK

DAC

DIGITAL

EQUALIZER

EFM

69

SPEED AND

PHASE ERROR SIGNAL

SIN

R308

10k

Ω

R307

10k

Ω

R206

100Ω

Fig. 17 Spindle servo block diagram

Page 13

13

CX-890

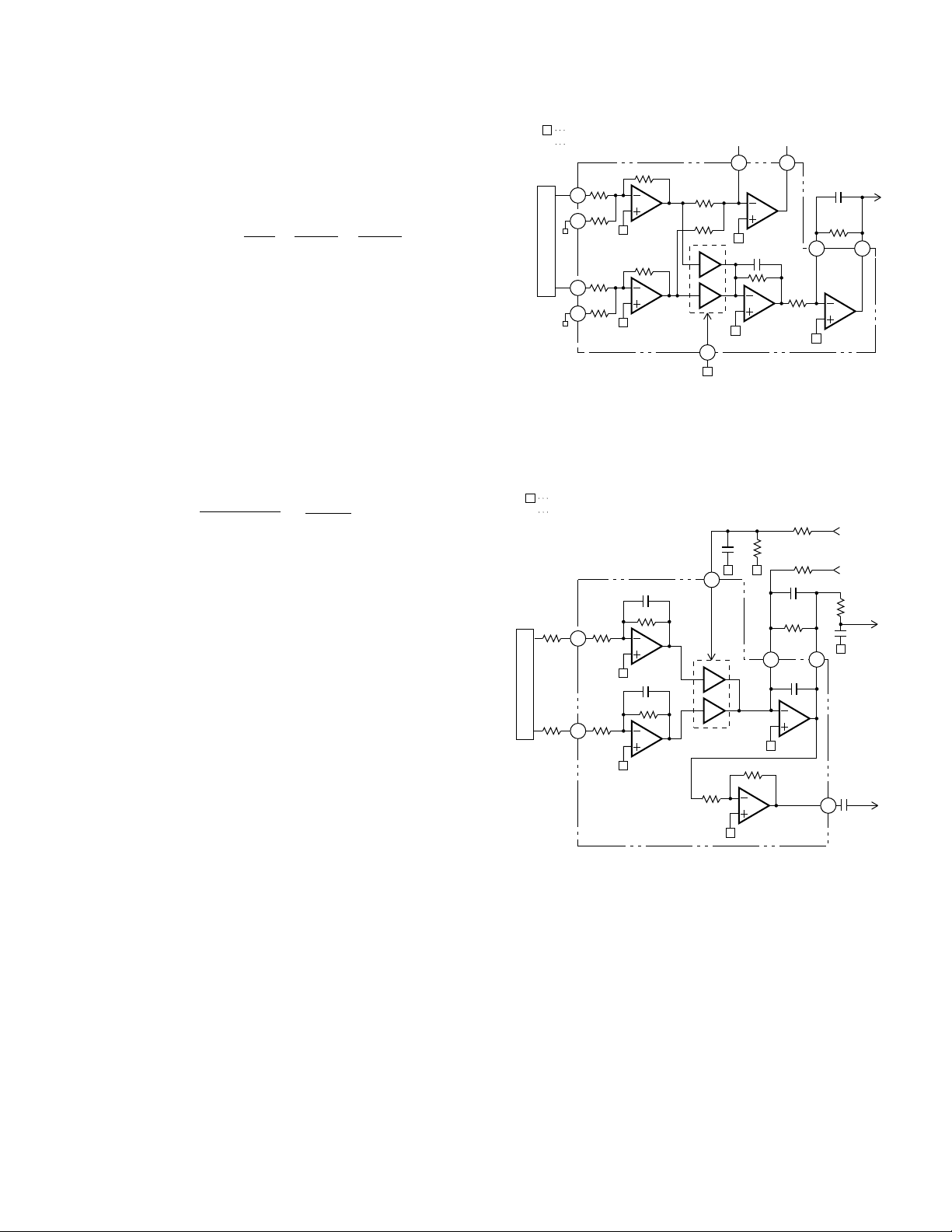

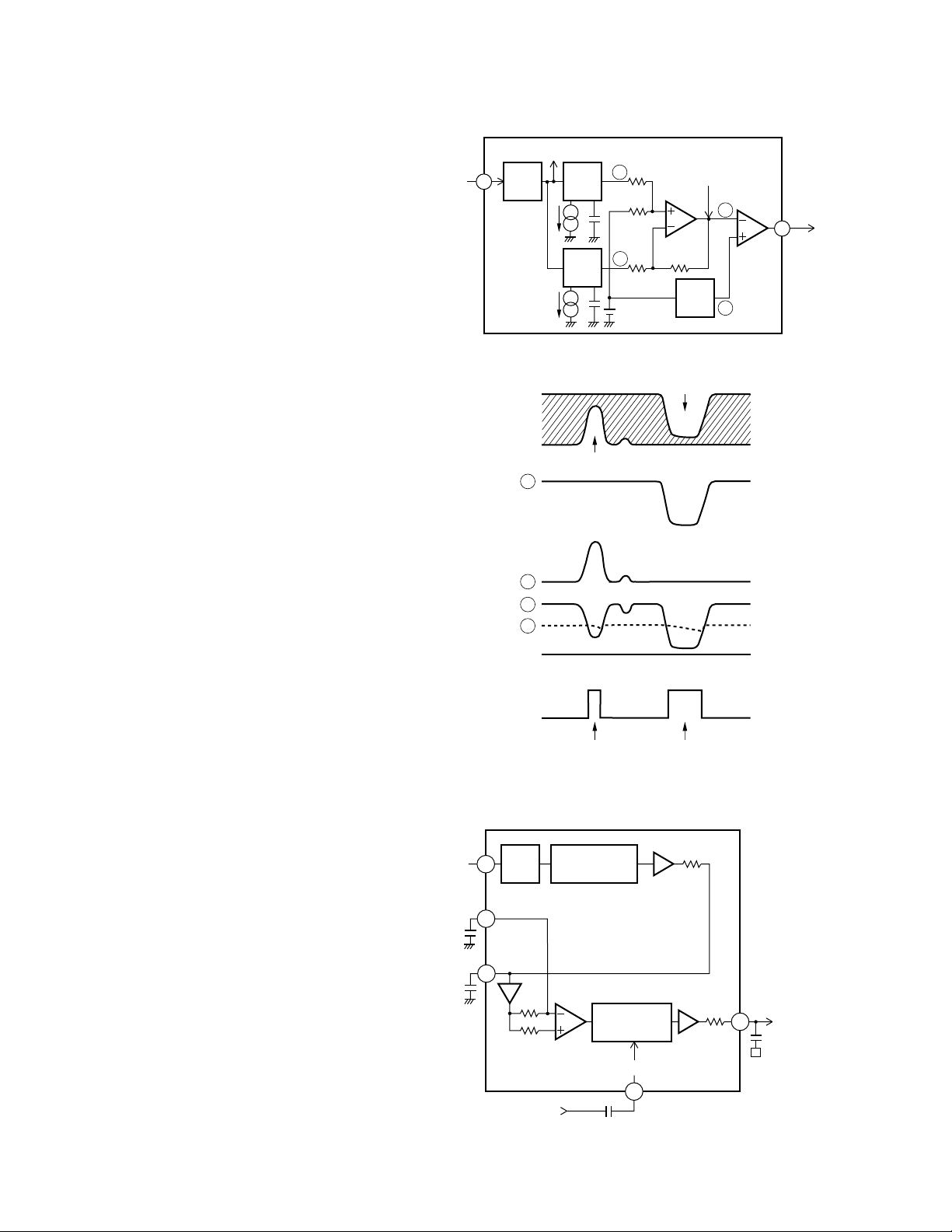

2.3 Automatic Adjustment Function

With this system, all circuit adjustments are automatically performed by using the preamplifier (UPC2572GS)

and servo LSI (UPD63702AGF). All adjustments are

automatically performed whenever disc is inserted or

CD mode is selected by the Source key. Details of automatic adjustments are as follows:

1) Setting of FZD cancellation

This setting ensures focus closing. The system reads

the FE offset level when the power is turned to ON,

then writes the inverse voltage of offset value of that

level to CRAM inside IC to cancel offset. Thus, the

threshold level of FZD can be set to a constant value

(+150 mV). As a result, "Latching FZD signal to H",

which is one of the conditions required for focus closing in IC, is ensured.

2) TE offset automatic adjustment

Adjusts TE amplifier offset of the preamplifier to 0 V

when the power is turned to ON.

Adjustment is made as follows:

(1)The microcomputer reads TE offset in LD OFF status

via the servo LSI (TE1).

(2)The microcomputer calculates the voltage to be cor-

rected using the TE1 value, and outputs from Pin 65

(pin name: TOFST) of the servo LSI. More specifically, calculation is made as follows:

TOFST2 = TOFST1 + TE1 x R110 / R109

3) Tracking balance (T.BAL) automatic adjustment

To make the sensitivity of Ech of TE output equal to that

of Fch. In fact, adjustment is made so that the upper

and lower portions of TE waveforms are symmetric to

REFOUT.

Adjustment is made in the following steps:

(1)After focus close, the system kicks the lens in the

radial direction to ensure TE waveforms to be generated.

(2)The microcomputer reads the peak bottom of TE

waveforms via the servo LSI.

(3)The microcomputer calculates the amount of offset,

then calculates the voltage to be corrected based on

that offset. The system outputs the result from Pin 66

(pin name: TBAL) of the servo LSI.

(4)The voltage output from the servo LSI is input to Pin

37 of the preamplifier (IC101: UPC2572GS). Pin 37 is

a control-voltage terminal of the TEVCA amplifier.

According to voltage input, the system changes gain

of Ech and Fch in the preamplifier, and adjusts the

tracking balance to make the upper and lower portions of TE waveforms symmetric to REFOUT.

4) FE bias automatic adjustment

Maximizes the RFI level by optimizing focus point during playback. Adjustment is made by using 3T level

waveforms of RF waveforms and the phase difference

generated by input of disturbance of focus error. Since

adjustment is made by inputting disturbance to focus

loop, the system uses the same timing as with auto

gain control (mentioned later~) for adjustment.

Adjustment is made in the following steps:

(1)Disturbance is input to focus loop by the command

from the microcomputer (inside the servo LSI).

(2)The system detects flickering of 3T components of

RF signal in the preamplifier.

(3)The system checks the phase difference between 3T

components mentioned above and FE signal caused

by input of disturbance to detect the direction of

focus deviation. The result is output as DC voltage

from Pin 30 (3TOUT) of the preamplifier.

(4)The 3TOUT voltage is input to Pin 75 (A/D port) of the

servo LSI. The microcomputer reads this 3TOUT voltage via the servo LSI.

(5)The microcomputer calculates the amount of correc-

tion required. The results are transferred to offset of

focus loop in the servo LSI.

As with auto gain control, the system repeats the

same adjustment process several times to improve

adjustment precision.

Fig. 18 Outline of Automatic Adjustment

AGC

circuit

FE signal

TE signal

Constant RF level

IC101

UPC2572GS

Corrected

voltage

output

Detection

of deviation

Items of

automatic

ADJ

FZD

TE.O

T.BAL

FE.B

F and T.G

D/A

FZD FE.B Gain

A/D

IC201

UPD63702AGF

Transfer

of amount

of correction

Reading

amount of

deviation

System

microcomputer

Calculation

of amount

of correction

RF signal

TE.O, T.BAL

Page 14

5) Auto gain control (AGC)

AGC adjustment is already used in the CD modules of

the previous generation. This function automatically

adjusts servo loop gain of focus and tracking.

Adjustment is made in the following steps:

(1)Disturbance is input to servo loop.

(2)The system extracts error signals (FE and TE) upon

input of disturbance via the B.P.F. and obtains signals

of G1 and G2.

(3)The microcomputer reads G1 and G2 signals via the

servo LSI.

(4)The microcomputer calculates required amount of

correction to adjust loop gain in the servo LSI.

The system repeats the same adjustment process

several times to improve adjustment precision.

6) Initial adjustment value

For all automatic adjustments, the system uses the previous adjustment value as initial values, except when

the power of the microcomputer has been turned to

OFF (backup is turned to OFF). If backup has been

turned to OFF, the system uses initial set value to perform automatic adjustment.

7) Display of coefficients of adjustment results

Results of automatic adjustments can be displayed in

Test mode for confirmation. Display of coefficients in

each automatic adjustment is as follows:

(1)FZD cancel, TE.OFST cancel, T.BAL, and FE bias

Reference = 32 (32: No adjustment was required)

Display is made in units of approximately 40 mV.

Example: Coefficient of FZD cancel = 35

35 - 32 = 3 3 x 40 mV = 120 mV

Corrected amount is approximately +120 mV.

Thus, FE offset before adjustment is -120 mV.

(2)Adjustment of F and T gain

Reference: Focus = 13, tracking = 20

The amount of reduced gain in comparison with the

reference is known by looking at the coefficient dis

played.

Example: AGC coefficient = 40

Amount of reduced gain = 20 log (20/40) = -6dB

2.4 Power Supply and Mechanism

Control

The power supply VM (7.5V) is produced from the

power supply VD (9.0V) supplied from the extension

P.C. board, and used as the power supply for the loading motor driver, elevation motor driver, cam gear

motor driver, and 5V Reg IC. As for the drive voltage

for the disc detection LEDs and the power supply for

the CD driver ICs, the power supply VD (9.0V) is used.

The system IC controls the ON/OFF operations of the

CD driver and laser diodes,the 5V power supply, and

the drive voltage PVD for detection LEDs with "CONT",

"POWER", and "LOAD" signals respectively.

14

CX-890

Page 15

15

CX-890

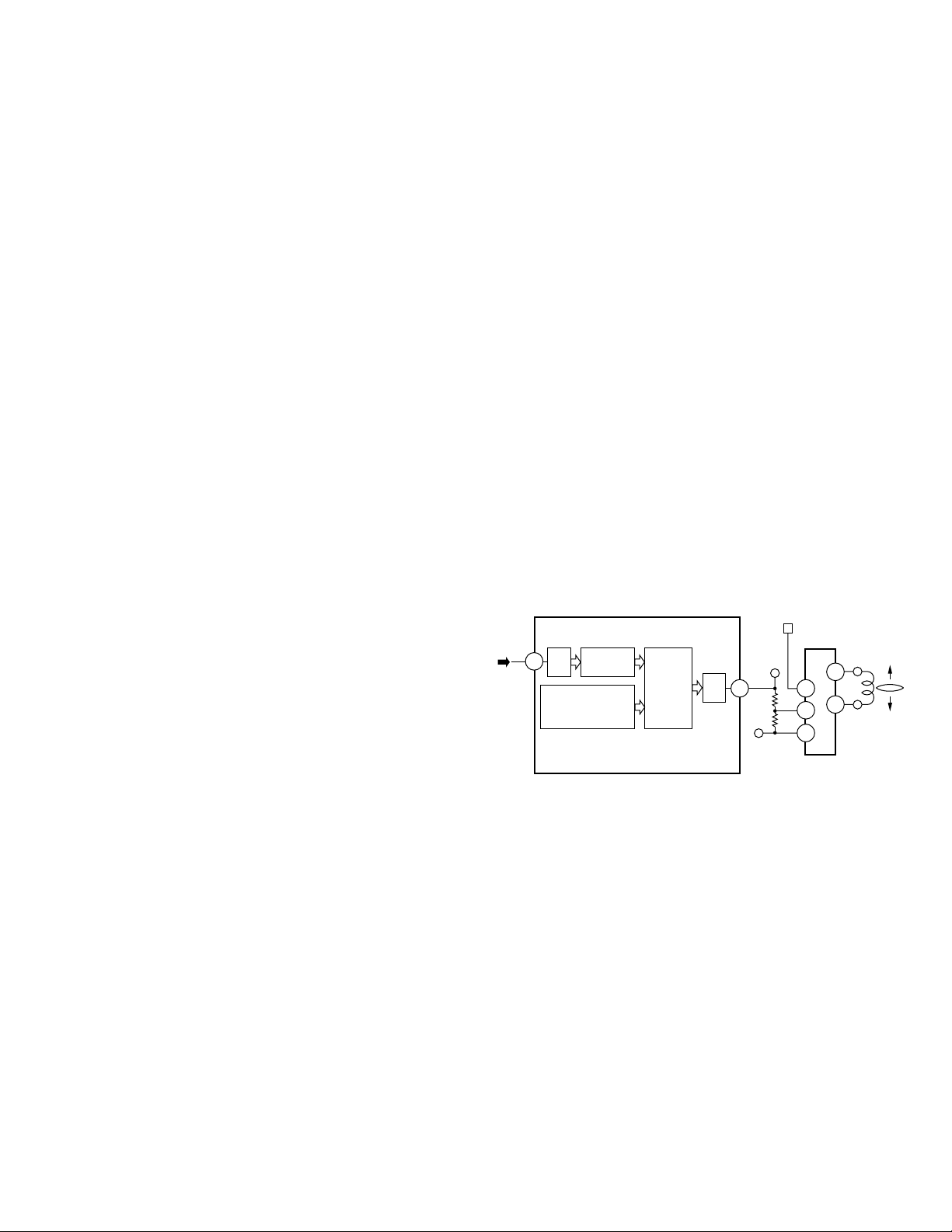

2.5 STS(Sure Track System) Circuit

By pooling the musical data read in from a compact disc into the memory, even if the pickup should go off track for

some reason, the Sure Track System enables prevention of sound interruption during recovery (approximately 3 seconds) by continuing to output data from the memory.

Operation Principle

The STS circuit is controlled by the vibration free memory controller (CXD2511R). Data read in at double speed

from a compact disc is input via the digital signal processing circuit into CXD2511R.

CXD2511R stores this DA data in DRAM (MSM5114400

DP-60TS), and reads and outputs the data at normal

speed in synchronization with the internally generated

FS system clock. In order to write the DA data at double

speed and to read out at normal speed, the DRAM

becomes full, but when it reaches capacity it will tentatively stop reading data. (The CD is in the pause mode

during this time.) When an available area is created by

data read-out from the DRAM, data writing will start

again. (The available area of the DRAM can be monitored by ADRMON. By repeating this process, the

DRAM is always used effectively, and approximately

2.67 seconds worth data can be stored. Even if the pickup should go off track due to vibrations for example, if

recovered within 2.67 seconds while using the memorized data, sound interruption can be prevented.

Fig. 19

Fig. 20

Page 16

16

CX-890

3. MECHANISM OPERATIONS

3.1 Disc Insertion

a)The Cam gear rotates to the elevation OK position

(See "How to remove the Tray Assy" on page 21). The

Stage Mech Assy moves upwards or downwards to

reach the height of the selected tray by using the elevation mechanism.

b)The Cam gear rotates counterclockwise until the

LOAD switch is turned off. The Beak arms of the

Stage Mech ASSY driven by the Cam gear's movement lift the selected tray.

c)The Stage Mech Assy with the tray lifted moves to the

top position using the elevation mechanism.

* Disc insertion/ejection is performed at the top position

(the 6th stage) irrespectively of tray position.

d)The Cam gear rotates counterclockwise to move the

LOAD arms as shown in Fig.21.

e)The LOAD arms push the disc loaded on the tray and

open the tray hooks.

f)When a disc is inserted, the disc interrupts the infrared

LED light from the photo transistors, and the Rubber

roller starts rotating.

* The photo transistors are connected in serial. When

the light is interrupted from either photo-transistor,

the start of disc insertion will be detected.

g)The disc is drawn in. Then the disc pushes the inser-

tion completion switch via the arm.

h)The LOAD arms move forward to be released from

the disc. At the same time, the tray hooks close to

hold the disc on the tray.

Cam gear

Load switch

Beak arm

Stage mech Assy

Load arm

Load arm

Insertion completion switch

Disc

Tray hook

Load arm

Photo transistors

Fig. 21: Elevation OK position

Fig. 22

Page 17

17

CX-890

3.3 Elevation Detection

a)The elevation detection (slit count) is performed by

the photo interrupter.

b)After the elevation HOME switch is turned ON, the

photo interrupter counts the slits of the elevation

levers.

* The bottom position (the 1st stage) is detected when

the elevation HOME switch is turned on (not detected

by the photo interrupter).

3.2 Elevation

a)The Cam gear rotates to the elevation OK position.

b)The ELV motor rotates to slide the elevation lever via

the gears.

c)The 2 elevation levers (left and right) can synchronize

their sliding via the joint arm.

d)The shafts of the Stage Mech Assy engage with the

stair-like grooves in the elevation levers and the verti-

cal holes in the Main chassis via the rollers.

e) When the elevation levers slide, the Stage Mech Assy

moves up and down.

ELV motor

Photo interrupter

Elevation lever

Elevation

HOME switch

joint arm

Elevation lever

Fig. 23

Page 18

18

CX-890

3.4 Disc Clamp

a)The Stage Mech Assy moves up and down to reach

the height of the selected tray, using the elevation

mechanism.

b)The Cam gear rotates clockwise, the Carriage drive

arm rotates, and then the Carriage Mech Assy moves

toward the disc via the Carriage drive shaft.

c)The Cam gear continues rotating clockwise and the

Carriage drive shaft moves the Clamp UP lever. Then

the Clamp arm touching the Clamp UP roller moves

down to clamp the disc.

d)The Cam gear stops when the Clamp switch is turned

ON.

Clamp UP lever

Clamp arm

Clamp UP roller

Carriage Mech Assy

Carriage drive shaft

Carriage drive arm

Clamp switch

Fig. 24

3.5 Disc Sense (Initializing)

a)The disc sense operation is to detect if or not a disc is

loaded on the trays 1 to 6.

b)While a disc is inserted using the robber rollers, the

disc pushes the insertion completion switch via the

arm to sense that a disc is loaded.

3.6 Disc Ejection

a)The same operations as the steps a) to e) on "3.1 Disc

insertion" are performed.

b)The rubber roller(s) rotate(s) in the direction for disc

ejection.

c)When the infrared LED light, which has been inter-

rupted by the disc, passes toward the photo transistors, the rubber rollers stops.

Page 19

19

CX-890

3.7 Mechanism Lock

a)Mechanism lock operation is to push the mechanism

downward and toward the disc slot in order to keep

the mechanism at the correct position during disc

insertion/ejection, and to leave the appropriate gap

above the mechanism.

b)The Cam gear rotates to move the Mech lock lever

toward the rear of the Mechanism. The lever pushes

the inside surface of the product. It causes the mechanism to move forward.

c)With the movement of the Mech lock lever, the Mech

lock lever (right) moves in a slanting direction as indicated by the arrow in Fig. 25 to push the mechanism

forward and downward.

d)The Mech lock lever (left) is driven by the movement

of the Mech lock lever via the Mech lock junction

lever to push the Mechanism downward.

e)The mechanism lock is released only in the disc

clamp mode.

Mech lock lever

Mech lock lever (left)

Mech lock junction

lever

Mech lock lever (right)

Fig. 25

Door switch

Door lever

Cam gear

Door open lever

Fig. 26

3.8 Door Open

a)The Door open lever pushes the door on the product

grille to open it.

b)The Cam gear rotates to move the door arm. Then,

the door arm moves the door lever.

c)The door lever moves the door open lever via the

buffer spring.

d)When the door switch is turned ON, the Cam gear

motor stops rotating.

Page 20

20

CX-890

3.9 Stage Mechanism Lock

a)To prevent the Stage mech assy from rattling during

disc play, which may adversely affect the vibrationresistant performance, the Stage lock function works

only in the disc clamp mode.

b)In the mode described at the step c) on "3.7

Mechanism lock" , the Stage lock lever (right) is driven by the movement of the Mech lock lever (right).

c)The 2 bent portions of the Stage lock lever (right) are

pressed against the gear-like portions of the chassis

to lock the right side of the Stage mech assy.

d)For the left side of the Stage mech assy, in the mode

described at the step d) on "3.7 Mechanism lock", the

Mech lock junction lever is driven to move the Stage

lock lever (left).

e)The 2 bent portions of the Stage lock lever (left) are

pressed against the gear-like portions of the chassis

to lock the left side of the Stage mech assy.

Mech lock lever (right)

Stage lock lever

(right)

Stage lock lever

(right)

Chassis gear-like portion

(View from the opposite side)

Fig. 27

Page 21

21

CX-890

4. DISASSEMBLY

- How to remove the Tray Assy

1. Apply about 6V current to the Cam gear motor until

all holes match at the position (A) (elevation OK position).

2. Hook the three springs B temporarily as shown in Fig.

28. While pushing the Tray holder lock arms (right

and left) in the direction (C), remove the Tray holder.

3. Lift up the Tray assy to remove it.

* Be careful not to remove the Tray hooks from the Tray

assy.

- How to remove the Carriage Mech Assy

1. Insert a short pin into the flexible PCB of the Pickup

unit.

2. While opening the resin hooks, remove the cover

from the Servo unit.

3. Disconnect the flexible PCBs from the connectors

CN101 and CN301.

4. Remove the Tray holder and the Tray assy. (See

above)

5. Rotate the Cam gear motor until the positions of all

holes (E) match, then stop the motor.

(The Carriage Mech assy will stop as shown in the

Fig.30.)

* When the positions of all holes match, they will be

completely covered by the Carriage mech assy.

* To rotate the Cam Gear motor, see "How to remove

the Tray assy".

6. Unhook the spring A.

7. Remove the flexible holder B (while opening the

hooks).

8. Remove the flexible PCB (C) from the motor. (The

flexible PCB (C) has been stuck on the motor with

double-sided adhesive tape.)

9. Loosen the fixing screw and remove the flexible

holder.

ELV motor

Cam gear motor

Approximately DC 6V

Tray holder

Tray holder lock arm

Tray holder

lock arm

Tray

hooks

Tray Assy

Cover

CN101

CN301

Match the hole positions

Flexible

holder

Fig.28

Fig. 29

Fig. 30

Short pin

Tray

hooks

Page 22

22

CX-890

- How to remove the Pickup unit

1. Remove the pulling spring, torsion spring and Eshaped ring. Then remove the Clamper arm.

* The spring (A) will be removed with the Clamper

arm.

10. Remove the screw, pressure spring and collar. Lift

up the Carriage mech assy to remove it.

* Screw tightening torque: 2.6kgfcm

2. Slide the Clamp UP lever (B) to remove it.

3. Loosen the 2 screws. Remove the feed-screw cover

by sliding it.

4. Remove the feed-screw pressure spring (D).

5. Loosen the 2 screws. Remove the feed-screw holder

(E).

6. Remove the belt.

7. Remove the Pickup unit together with the feed screw.

* Be careful not to lose the shaft holders at the both

ends of the feed screw.

* Be careful not to damage the 2 flexible PCBs(for the

Pickup and motor) when separating them. The flexible PCBs have been stuck each other with doublesided adhesive tape.

Carriage mech

Assy

Screw

Collar

Pressure spring

Clamper arm

E-shaped ring

Pulling spring

Torsion spring

White

Black

Pickup

unit

Feed screw

Belt

Carriage

motor

Fig. 31

Fig. 32

Fig. 33

Page 23

23

CX-890

8. Loosen the 2 screws. Remove the plate spring and

the rack.

9. Pull out the feed screw from the Pickup unit.

- How to remove the Carriage Motor Assy

1. Loosen the 2 screws (A). Remove the Carriage

motor assy.

- How to remove the Spindle Motor Assy

1. Remove the connector.

2. Loosen the 2 screws (B). Remove the Spindle motor

assy.

- How to remove the Cam gear motor and ELV

motor

1. Insert a short pin into the Pickup flexible PCB.

(See Fig. 30)

Remove the Cover from the Servo unit. (See Fig. 30)

Disconnect the flexible PCBs from the connectors

CN101 and CN301. (See Fig. 30)

2. Disconnect the the flexible PCB (Motor PCB(A)) from

the connector CN201 on the Servo unit.

3. Disconnect the flexible PCB from the connector

CN801 on the STS unit.

4. Loosen the 2 screws (A). Remove the Servo unit.

5. Loosen the screw (B). Remove the flexible PCB holder.

6. De-solder at the 4 portions (C). Remove the flexible

PCB.

Rack

Plate spring

Feed screw

Pickup

unit

Spindle motor

assy

Carriage motor

assy

Servo unit

Motor PCB (A)

Flexible holder

C

N

201

Front

Grease (White: KD-1)

Grease (Yellow:

PG-641)

Fig. 34

Fig. 35

Fig. 36

Grease (Yellow:

PG-641)

Page 24

24

CX-890

9. Remove the 5 polyslider washers, then gears and

shaft.

10. Loosen the 4 screws. Remove the Cam gear motor

and ELV motor.

7. Loosen the 2 screws (D). Remove the Gear cover.

8. Loosen the 3 screws (E). Remove the Motor bracket

assy.

- How to remove the Loading motor

1. Insert a short pin into the flexible PCB of the Pickup

unit.(See Fig. 30)

Remove the Cover from the Servo unit. (See Fig. 30)

Disconnect the flexible PCBs from the connectors

CN101 and CN301. (See Fig. 30)

Disconnect the the flexible PCB (Motor PCB (A)) from

the connector CN201 on the Servo unit. (See Fig. 36)

2. Unhook the spring. Remove the Door open lever.

3. Loosen the 3 screws. Remove the PCB units (C) & (D)

and the frame.

4. Remove the spring (A).

Gear cover

Motor bracket

assy

Front

Cam gear motor

ELV

motor

Spring

Door open lever

PCB (C)

Frame

Black

White

PCB (D)

Apply grease (White:EM50L) to the Shaft and

gears.

Fig. 37

Fig. 38

Fig. 39

Shaft

Black

Page 25

25

CX-890

5. Remove the belt (large).

6. De-solder at the points (B) and (C).

7. Loosen the 2 screws. Remove the Loading motor

bracket.

8. Remove the belt (small).

9. Loosen the 2 screws. Remove the Loading motor.

- How to remove the Stage Mech Assy

1. Remove the Tray holder and the Tray assy. (See Fig.

28)

Remove the Carriage mech assy. (See Fig. 30 and

31)

Remove the Servo unit. (See Fig. 36)

Remove the Motor PCB (A). (See Fig. 36)

Remove the Gear cover. (Fig. 37)

2. Unhook the Spring (C). Remove the Door-open lever.

3. Loosen the screws (D), (E), and (F). Remove the PCB

(C) and (D), and the frame.

4. Unhook the springs (A) and (B).

5. Pull out the Load arm assy (right) upward.

6. Unhook the spring (G). Remove the belt (large).

7. Loosen the screw (H). Remove the Load arm assy

PCB (E)

Loading motor

Loading motor bracket

Belt

(small)

Belt (large)

PCB (D)

Door open lever

Load arm

assy (left)

Load arm assy (right)

PCB (C)

Frame

Fig. 40

Fig. 41

Page 26

CX-890

(left) including the Loading motor.

8. Loosen the 4 screws. Remove the Motor bracket

assy and Photo interrupter.

9. Remove the 4 E-shaped rings (A) and 3 wash-

ers (B).

10. Remove the Mech lock lever (left).

11. Remove the 2 rollers (C).

12. Remove the Elevation lever (left). (Pay

attention to the mounting direction.)

13. Remove the Mech lock junction lever and

and roller (D).

(Pay attention to the mounting direction.)

14. Remove the 2 E-shaped rings (A) and 2 washers (B).

15. Remove the Elevation lever (right).

16. Remove the 2 rollers (C). (Pay attention to the

mounting direction.)

17. Remove the Mech lock lever (right).

18. Lift up the Stage mech assy to remove it.

Motor bracket assy

Photo interrupter

Front

Mech lock junction lever

Elevation lever (left)

Mech lock lever (left)

Mech lock lever (right)

Elevation lever (right)

Stage mech assy

Fig. 42

Fig. 43

Fig. 44

Loading...

Loading...