Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

ORDER NO.

CRT3655

DVD MECHANISM MODULE(MS4)

CX-3183

This service manual describes the operation of the DVD mechanism modules

incorporated in the models listed below.

When performing repairs use this manual together with the specific manual for the

model under repair.

Model No. Service Manual DVD Mechanism Module

AVH-P7800DVD/UC CRT3681 CXK6500

AVH-P7800DVD/RE CRT3682 CXK6500

CONTENTS

1. CIRCUIT DESCRIPTIONS(FE PART) . . . . . . . . . . . . . . . . . . . . . . . 2

2. CIRCUIT DESCRIPTIONS(BE PART) . . . . . . . . . . . . . . . . . . . . . . 11

3. MECHANISM DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4. DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

K-ZZU. MAY 2006 printed in Japan

Page 2

1234

1. CIRCUIT DESCRIPTIONS(FE PART)

A

1 Front End Part (MN2DS09AAUB:IC1501)

MN2DS09AAUB are 1-chip LSI for DVD-Player. The connection of this LSI to the Driver IC,

SDRAM, Flash-ROM, Audio-DAC, etc. can configure the DVD-Player System.

This LSI contains Front End (SODC/FE) that performs RF signal /Servo /Decode processings, Back End

(AV decoder/BE) that performs the video decode processing such as MPEG1/MPEG2/JPEG and audio decode

processing such as DVD-Audio/Dolby Dijital/DTS/MP3, and the system controller (Siscon) for controlling

the system.

Front End part realizes the arithmetic processing of optical head signal and RF signal processing,

the digital signal processing for DVD-ROM reproduction that conforms to DVD standards (16-8 Demodulation,

Error correction), the digital signal processing for CD-DA/CD-ROM (Error correction), AV decoder transmission,

servo control, spindle motor control and seek control.

Please take note that, The waveform of servo system on the front end, FE, TE and AS is not

B

seen in MN2DS09AAUB,like the DVD mecha-module (MS3V1) of CX-3078.

1.1 Analog Block (MN2DS09AAUB:IC1501)

An analog block becomes the following functions.

1.Standard power supply circuit

2.The servo system/ The DPD signal processing system circuit

Gain change amplifier an Low pass filter(LPF)

3.RF signal processing system circuit

RF addition circuit , Inline circuit and Variable Gain Amplifire(VGA) circuit

4.Laser power control (LPC) circuit

C

5.The A/D converter for servo (10bit, 5bit-4ch) , PWM

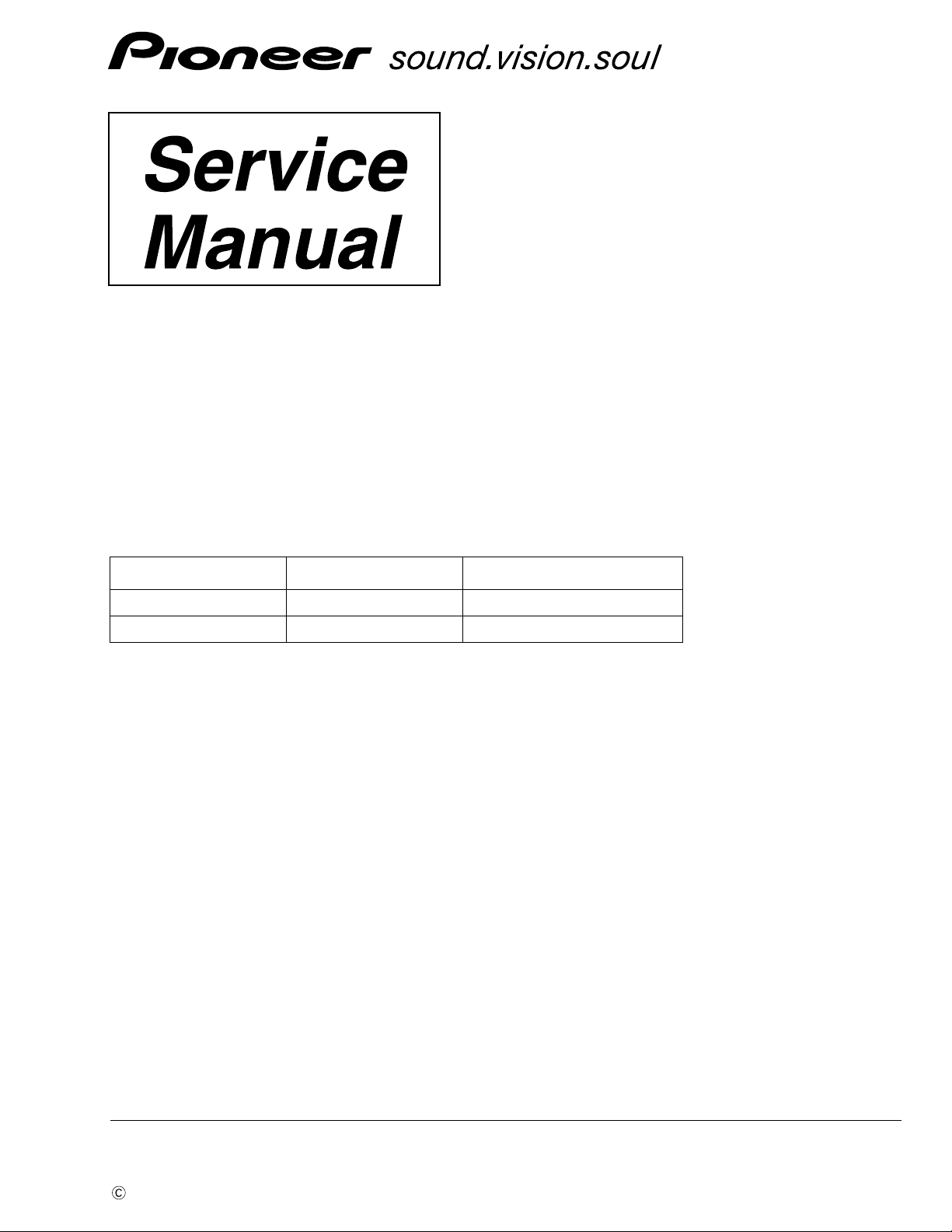

1.1.1 APC Circuit

The optical output for the laser diode (LD) has large minus temperature characteristics. Therefore, the constant

optical output cannot be obtained when LD is driven by the constant current. APC circuit controls the electric

current so as to provide constant output at the monitor diode (MD). MN2DS09AAUB contain two

types of APC circuits, one for DVD and another for CD. The LD electric current for DVD (CD) can be obtained by

dividing the voltage measurements between DVDLD1 (CDLD1) and 5V by 6 Ω (1.5 Ω x 4=6 Ω ). For DVD (CD),

the results are approx. 50 mA (45 mA).

The potential difference between DVDLD1(CDLD1) and 5 V is set to approx. 300 mV (270 mV).

D

IC1501

CDLPCPOWON

DVDLPCPOWON

5 bit DAC

E

LPCOFS

[4.0]

LPCADJMODE

-

amp1

+

Standard voltage

LPCPW[3.0]

-

amp2

+

DVD : 180 mV

CD : 170 mV

126

125

124

123

LPCO2

LPC2

LPCO1

LPC1

+5 V

+5 V

1.5 Ω 1.5 Ω 1.5 Ω 1.5 Ω

+

1.5 Ω 1.5 Ω 1.5 Ω 1.5 Ω

+

+

CDLD0

DVDLD0

CDLD1

DVDLD1

CN1101

24

5

25

15

78 LD

78 MD

65 LD

65 MD

CDLDDVD

LD

PU Unit

+5 V

MD

F

1234

CX-31832

Page 3

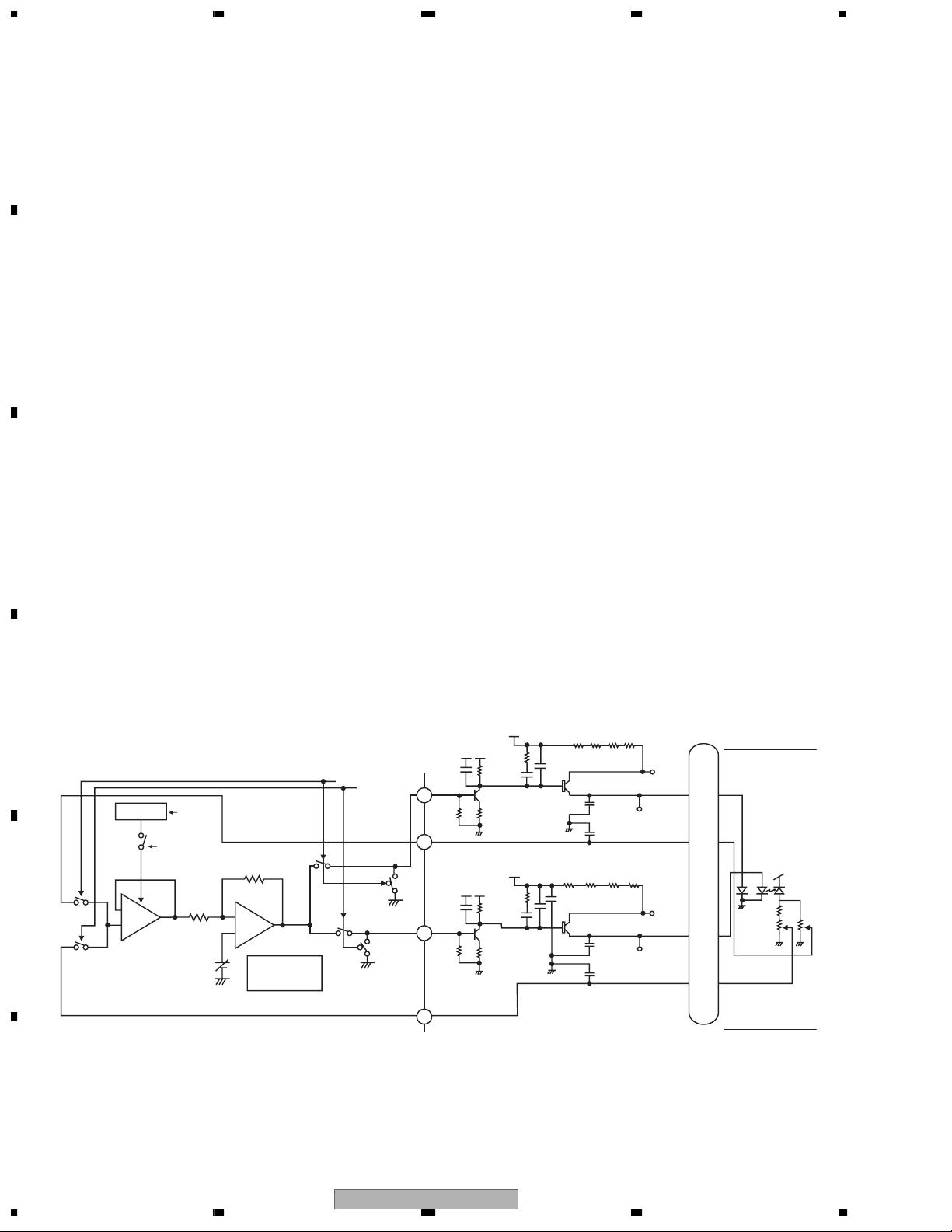

1.1.2 FE Generation Circuit

Focus Error (FE) Generation Circuit

In IC1501 inside, the AD translation of the signals RF1 and RF2 from PU is carried out, and they are taken in.

Then, offset cancellation is considered, differential is taken and it is set to FE.

FE = (FE1) - (FE2)

After 10bit ADC

FE2

VIN8

VIN7

12

11

VIN78

OFS[1:0]

VIN78 G

[1:0]

FE1

CN1101

LPF

Fc=

50 kHz

Selector

Buffer

amplifier

ADC drive amplifier

MAX:2 V[P-P]

G=6/ 7.5/ 9/

10.5/ 12/13.5/

15/ 16.5/ 17/

19.5 dB

10 bit

ADC

0 - AVDD

64 step

GAVIN5

G = 3/9 dB

Pvin7ofs

Dfepsv

1+ Pfbal0,1 / 0x0100

+

-

Pfe_g

FE1

FE

FE2

+

+

GAVIN[4:0]

LPF

Fc=

50 kHz

offset adj.

6 bit DAC

OFFVIN[5:0]

Pvin8ofs

Dfemsv

+

+

1- Pfbal0,1 / 0x0100

134

133

Offset is set up so that it may be settled in

input D range of 10 bit ADC

at the time of Max:2 V[P-P] typ:1.6 V[P-P].

Input D range

max 0-3.3 V

(It is dependent on

power supply voltage)

5678

A

B

C

D

CX-3183

56

E

F

7

8

3

Page 4

1234

1.1.3 TE Generation Circuit

Trackings Error (TE) Generation Circuit

A

For DVD, TE is generated, with the application of a phase contrast method, from the phase difference of (B2+B4)

and (B1+B3). For CD, TE is generated, with the application of a 3-beam method, by sending the signal to the

variable amp set for the tracking offset adjustment via outer-attached resistance and then by AD-converting it to

make the formula of TE=A

DVD (TE from phase difference)

CN1101

-

C.

115

116

118

117

B

C

B

A

D

C

7

VIN1RF

8

VIN2RF

VIN3RF

11

VIN4RF

9

VIN1RFOUT

VIN2RFOUT

VIN3RFOUT

VIN4RFOUT

LPF

11.3 M/5.7 MHz

LPF

11.3 M/5.7 MHz

LPF

11.3 M/5.7 MHz

LPF

11.3 M/5.7 MHz

HPF

100 kHz

HPF

100 kHz

HPF

100 kHz

HPF

100 kHz

OFFVIN[5:0]

CD (3-beam TE)

D

offset adj.

6 bit DAC

DPDOUT1

DPDOUT2

DPDOUT3

DPDOUT4

0 - AVDD

64 step

5 bit

ADC

5 bit

ADC

DPD

5 bit

ADC

5 bit

ADC

Input D range

max 0-3.3 V

(It is dependent on

power supply voltage)

TE

VIN10

F+H

_G+H

E

E+G

_F+H

CN1101

F

21

22

VIN9

134

133

VIN78

OFS[1:0]

VIN78 G

[1:0]

LPF

Fc=

50 kHz

LPF

Fc=

50 kHz

Selector

Buffer

amplifier

GAVIN5

G = 3/9 dB

ADC drive amplifier

MAX:

2 V[P-P]

G=6/ 7.5/ 9/

10.5/ 12/13.5/

15/ 16.5/ 17/

19.5 dB

GAVIN[4:0]

Offset is set up so that it may be settled in

input D range of 10 bit ADC

at the time of Max:2 V[P-P] typ:1.6 V[P-P].

10 bit

ADC

CX-31834

1234

Page 5

After 10bit ADC

Pvin9ofs

Dtepsv

1+ Ptbal0,1 / 0x0100

+

-

Pfe_g

E+G_E+F

TE

F+H_G+H

+

+

Pvin10ofs

Dtemsv

+

+

1- Ptbal0,1 / 0x0100

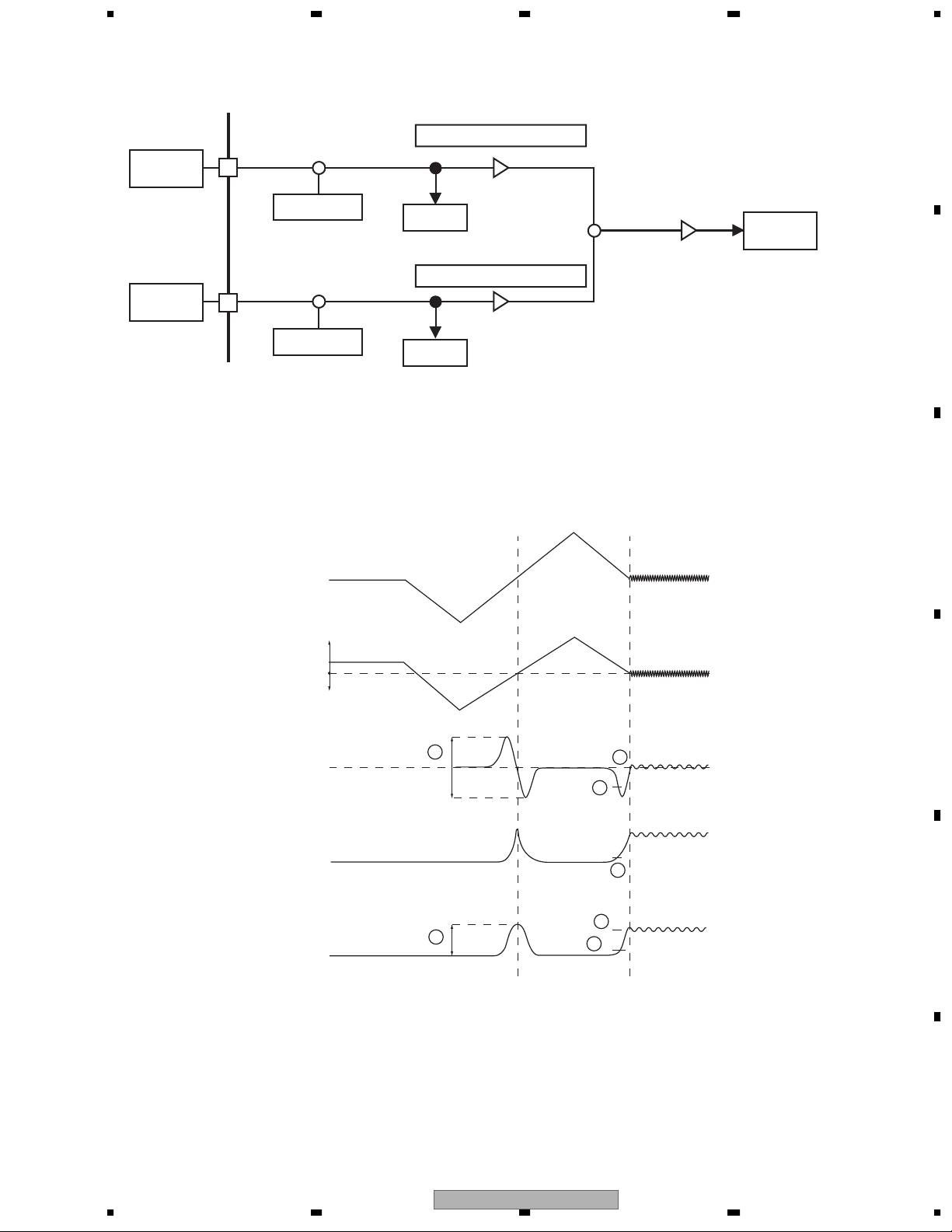

1.2 Servo Block (MN2DS09AAUB:IC1501)

Servo block performs focus, tracking, servo control for traverse, spindle motor control and seek control.

1.2.1 Focus Close

3

6

7

4

5

1

2

Far from disc

Close to disc

Lens

VHALF

Focal point

FE

RFENV

AS

FODRV

5678

A

B

C

D

E

F

56

CX-3183

7

8

5

Page 6

1234

After issuing the focus close command, the following processes are taken for both DVD and CD.

A

1. Measure and optimize signal levels

First drive PU lens far from the disc and then drive closer to the disc. At the focal point met in the process of

this move, measure signal levels of FE, AS and RFENV respectively, and optimize their levels for FE and AS

(1 & 2 in the above figure).

2. Focus closing

Next, drive the lens far from the disc again to detect the closing levels of FE and AS.

Then activate focus loop filter for closing focus (3 6).

3. Check closing

Check the closing with signal levels of AS and RFENV (6 & 7).

Focus search in test mode can check the signal levels and focus drive voltages for FE, AS and RFEV.

B

C

1.2.2 Tracking Close

After issuing the tracking close command, the following processes are taken for both DVD and CD

1. Tracking brake

Measure one half cycle of the tracking cross and if the cycle is within the range of designation, output the brake

pals.

Output direction of brake pals is determined by the phase relations of OFTR and TKC (TE's binarization) signals.

After confirming that the swing of lens against disc is controlled, the brake stops and the closing begins. If the

closing condition is not met within 10msec. after outputting brake, the brake stops and the closing begins.

2. Tracking closing

Process the tracking drive hold with OFTR signal.

3. Check closing

Check whether or not the track jump does not exceed the designated number within the designated term.

Closing check will be time-out at 20msec. Retry using a command from the microcomputer.

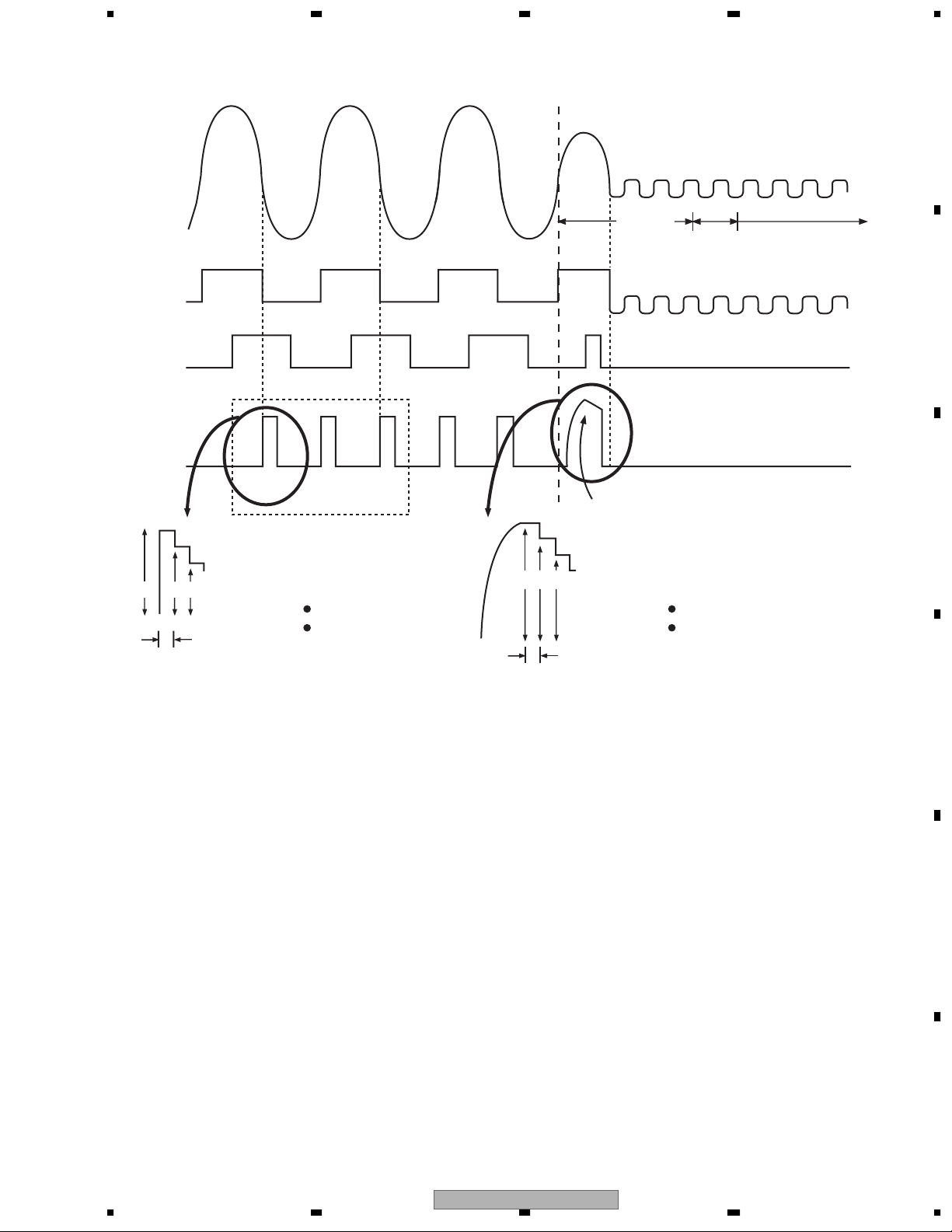

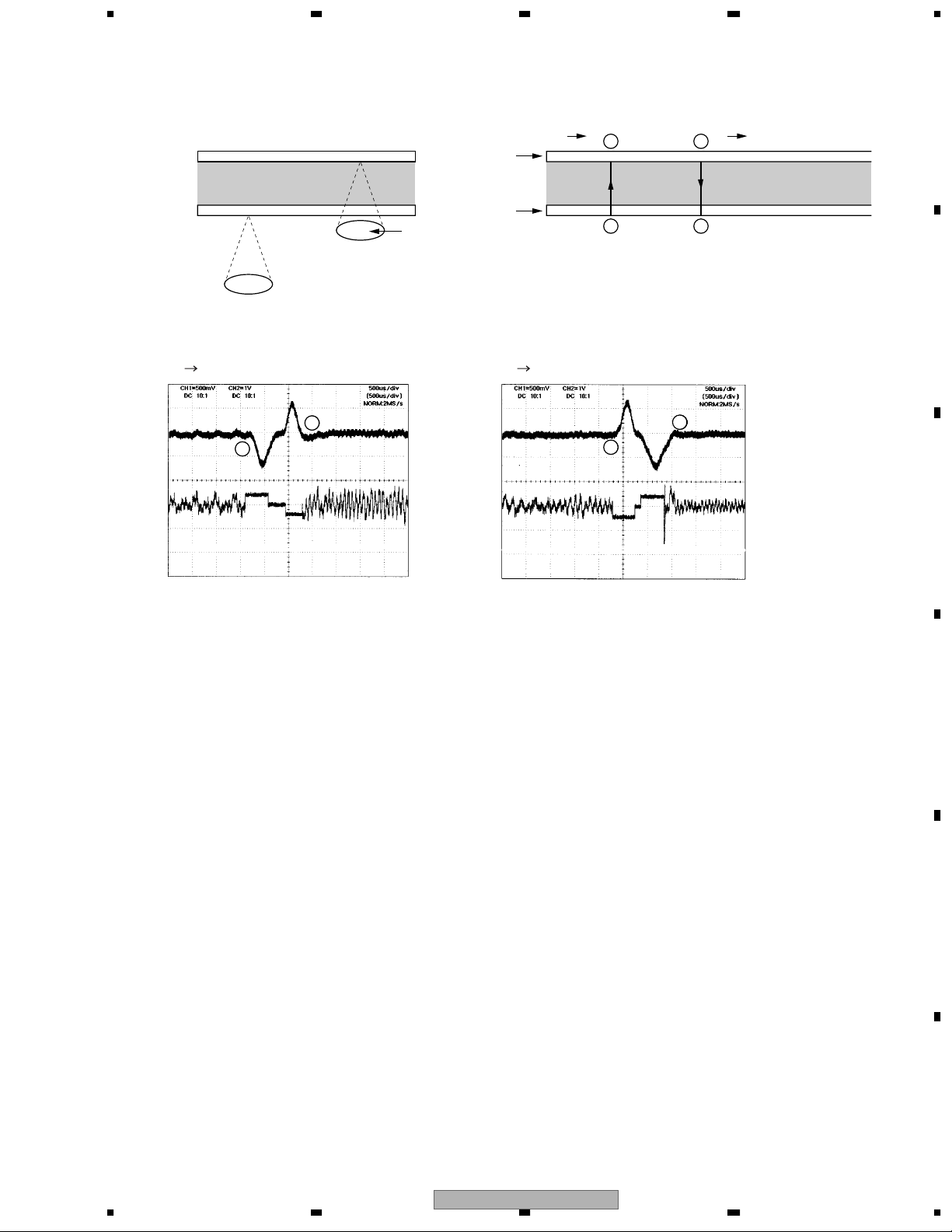

1.2.3 Track Jump

The system selects from three types of methods; i.e. interval jump, multi jump and traverse seek,

according to the target number of moving tracks.

1. Interval Jump

The detailed seek is capable due to the execution of repetitive one-track jumps.

It is used when approaching to the target track or seek-operating to an adjacent track.

2. Multi Jump

It counts both edges of the track cross signal TKC and moves for designated number of track counts.

D

3. Traverse Seek

It controls the movement speed by measuring the time of the track cross signal TKC and manages the

vibration of pickup generated upon movement to the minimum.

Types of target number of moving jumps illustrating the jump switch setting for both DVD and CD

DVD

1-10 Interval Jump

11-100 Multi Jump

101-500 Combination of Multi Jump and Interval Jump

Over 501 Traverse Seek

The waveforms of track jumps are shown in the next page.

E

F

CX-31836

1234

CD

1-10 Interval Jump

11-32 Multi Jump

33-500 Combination of Multi Jump and Interval Jump

Over 501 Traverse Seek

Page 7

5678

Tracking-on process

TE

TKC

OFTR

TRDRV

Tracking brake

Tracking on

CLPTM

TROK_TM

Drive hold by OFTR

A

Tracking failure

detaction

B

C

V1 V2 V3

Ts

V2=V1 X TKCLP:L/256

V3=V2 X TKCLP:L/256

#In this case,

int TKCLP:L=0

V2=0

V4 V5 V6

Ts

V5=V4 X TKCLP:H/256

V6=V5 X TKCLP:H/256

D

E

56

CX-3183

F

7

8

7

Page 8

1234

Interval Jump (1 Track)

Outer Jump Inner Jump

A

TE

TD

B

Multi Jump (32 Track)

Outer Jump Inner Jump

TE

TD

C

Traverse Seek (501 Track)

Outer Jump Inner Jump

TE

D

TD

CO

Traverse Seek (5000 Track)

Outer Jump Inner Jump

E

TE

TD

CO

F

CX-31838

1234

Page 9

5678

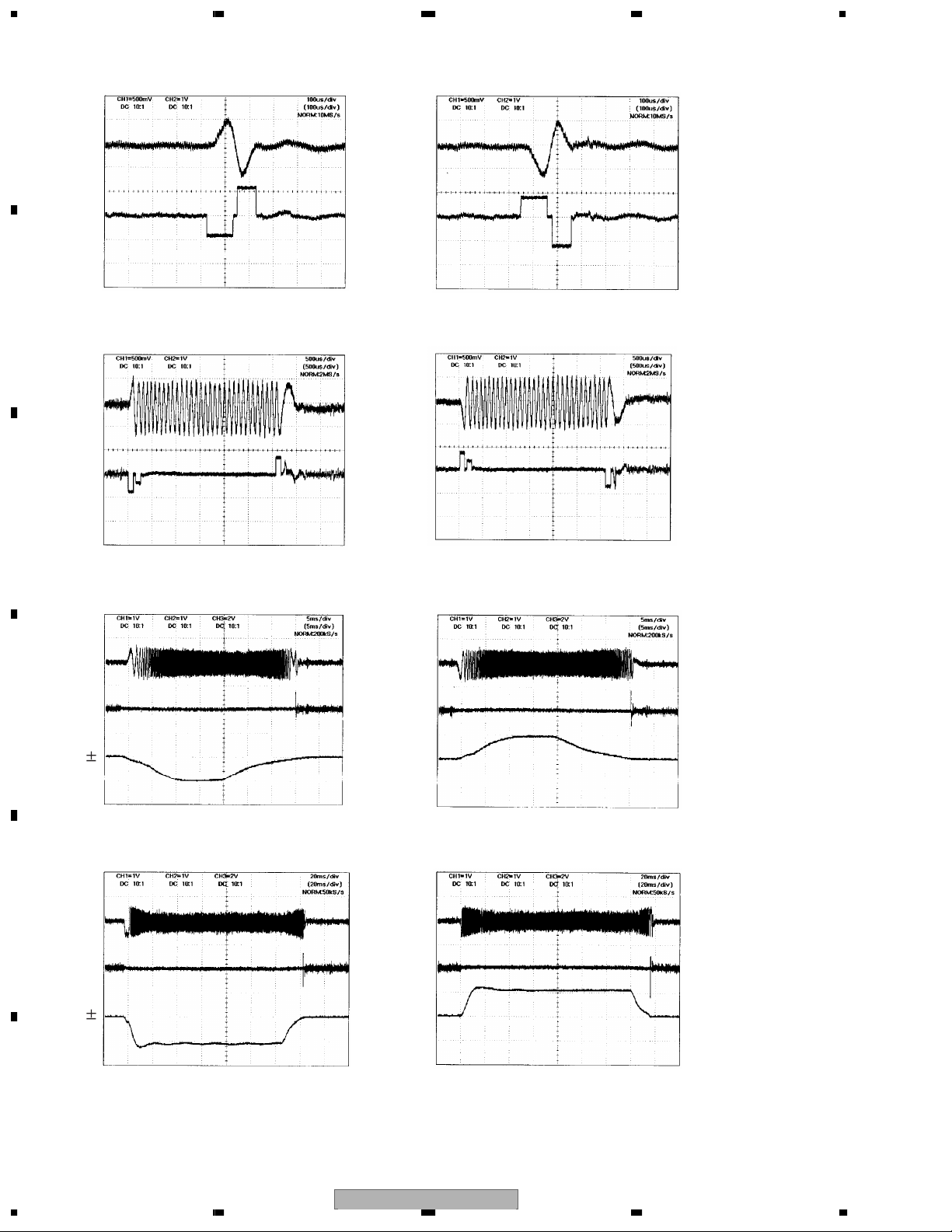

1.2.4 Focus Jump

Focus jump is a function corresponding to the single-sided or both-sided two-layers.

Seen from the object lens, a forward layer is called 0 Layer (L0) and a farther one is called 1 Layer (L1).

A

(1 Layer)

(0 Layer)

L1

L0

object lens

The waveforms of focus jump are shown below.

The waveforms of focus jump

L0 L1

FE

A

B

FD

L1

L0

L1 L0

L0 L1

B C

A D

D

C

L1 L0

B

C

The flow of focus jump is shown below

1. Open tracking at the layer during play.

2. Issue a command to execute jump to the target layer.

3. At the jumped layer, replay by closing the tracking.

Also, the processes when issuing a jump command are as follows

1. Accelerate the lens to the target layer until FE signal detects the acceleration completion level for focus jump.

However, if the time of acceleration time-out reaches before detecting the acceleration completion level,

the acceleration will compulsively stop.

2. Move lens with inertia instead of outputting the drive voltage until FE signal detects the deceleration initiation

level.

3. Decelerate lens for the duration from detection of the deceleration initiation level to the deceleration

completion level.

However, if the time of deceleration time-out reaches before detecting the deceleration completion level,

the deceleration will compulsively stop.

1.3 Automatic Adjustment Function

This system totally automates the circuit adjustments.

The details of automatic adjustments are explained respectively as follows:

1.3.1 VIN7,VIN8,VIN9 and VIN10 Offset Cancel

Each of analog signals for VIN7, VIN8, VIN9 and VIN10 generated at FEP is converted into a digital signal by A/D

converter inside servo block. Offset cancel is a function to cancel the input offset of A/D converter when the power is on.

1.3.2 VCO Gain Adjustment (VARI Adjustment)

It has a function to absorb dispersion of VCO gains among LSI solid by learning and to automatically adjust

VCO gains for the constant allocation. Lock VCO to standard frequency for study,

read Frequency Control Value (FCNT), and then adjust VARI register so that the value becomes

equivalent to the target FCNT value.

D

E

56

CX-3183

F

7

8

9

Page 10

1234

1.3.3 FE Normalization Adjustment

After A/D-converting FE signal level at servo block which was measured at focus close, adjust it to 190LSB at

A

the digital equalizer input stage.

1.3.4 Tracking Balance (TBAL) Adjustment

By applying Newton-Raphson method, search for a balanced point at which DC offset becomes 0 by vibrating

lens toward track direction at the time of the focus close and the tracking open.

1.3.5 Tracking Error Amplitude Learning

After vibrating lens toward track direction at the time of the focus close and the tracking open,

the Tracking Error

amplitude level, adjust it to 190LSB at the digital equalizer input stage

1.3.6 Focus Balance (FBAL) Adjustment

Adjust the focus position so that RFENV becomes maximum at the tracking close.

1.3.7 Focus Gain Adjustment and Tracking Gain Adjustment

B

Insert disturbance to servo loop at the tracking close and adjust to a target gain intersection.

1.3.8 AS Normalization Adjustment

After measuring AS signal levels for the designated number of samplings at the tracking close,

the precise adjustment is made to set 64LSB at the digital equalizer input stage.

All automatic adjustments can be confirmed by indicating their results at test mode.

List of Automatic Adjustment Coefficients

States

Power On

C

D

F Close

F Close (after TBAL)

T Close

Coefficients

VIN7 Offset

VIN8 Offset

VIN9 Offset

VIN10 Offset

FE MAX

FE MIN

AS MAX

FE Normalization

TE MAX

TE MIN

TE Normalization

F Gain

T Gain

AS Normalization

06B7 08CD

06B7 08CD

0E48 36CD

C933 F1B8

0981 3384

01BB 06A7

1A90 4D58

B2A8 E570

0145 02E9

0100 0400

0100 0400

013E 06BC

DVD

06E1 08A3

06E1 08A3

06B7 08CD

06B7 08CD

13A5 469A

B966 EC5B

0A23 3600

0158 04D3

0337 381A

C7E6 FCC9

01B1 1D85

012F 0650

CD

Note: Coefficients are indicated in hexadecimal numbers.

All figures describe specifications at the production line.

Disc applies DVD

-

REF-A1 for DVD and TCD-782 for CD.

1.4 CIRC Block (MN2DS09AAUB:IC1501)

CIRC block contains digital signal processing function for CD-DA and CD-ROM (EFM demodulation and error

correction), digital servo processing for spindle motor.

E

F

1.5 DRC Block (MN2DS09AAUB:IC1501)

Digital Read Channel (DRC) provides A/D converter, adaptive equalization, bit-a-bit detector, digital PLL circuit,

Digital equalizer(DEQ),RISC interface and peripheral circuits for reading signals of optical disks.

CX-318310

1234

Page 11

5678

2. CIRCUIT DESCRIPTIONS(BE PART)

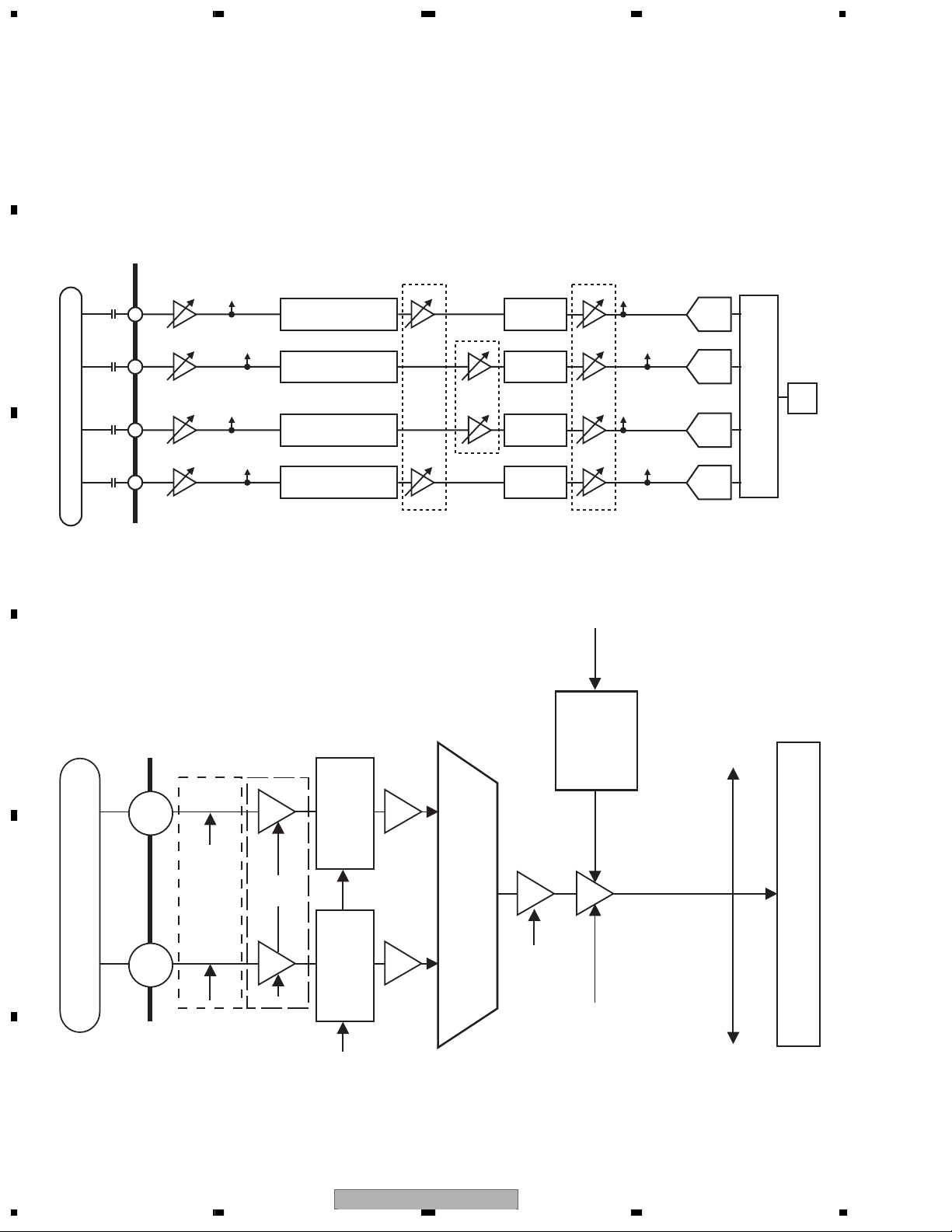

2.1 POWER SUPPLY MAP

HOST

Power Supply

VD8(Reg)

8V+/-0.4V

VD8V

Mecha inside

Power Supply

5V Reg(VCC5)

5.0v +/-0.1v

IC1004

NJM2880U05

5V Reg(AVCC5)

5.0v +/-0.1v

IC1005

S-L2980A50MC-C7J

Supply

IC

Pick Up Unit

CGY4700

LD

Photo IC

ADAC+LPF

IC1821 PCM1753DBQ

IC1822 NJM2140R

IC1823 NJM2100V

Video circuit

A

B

VD8

8V+/-0.4V

VDD5

5V+/-0.4V

3.3

DC/DC(VCC33)

3.21V ---> 3.41V

2ch DC/DC Converter

IC1003

BD9851EFV

Disc detect LED

C

1chip Driver

IC1201

BD7967EFS

1chip Driver(8V)

1chip Driver(5V)

D

SDRAM

IC1481

EDS1232AATA-75-E

Flash-ROM

IC1402

S99AL016DBT1

Other

E

DVD LSI

IC1501

MN2DS09AAUB

1.2

DC/DC(VCC12)

1.19V ---> 1.25V

SRVDD

3V+/-0.15V

CX-3183

56

DVD1chip(3.3V)

DVD1chip(1.2V)

SRAM

IC1452

M5M5V216ATP-70HI

7

F

11

8

Page 12

1234

A

IC1821

Audio-DAC

PCM1753DBQ

B

SCK

16pin

R1523

C

L1503

CTF1387 27 Ω

DACCLK

33.8688 MHz or 36.864 MHz

D

E

166pin

DACCLK

OSCI

162pin

R1531

1 MΩ

X1501

CSS1697

C1519

7pF or 8 pF

27 MHz

IC1501

DVD-LSI

OSCO

163pin

1 kΩ

R1532

MN2DS09AAUB

[Outline]

Connecting 27MHz crystal resonator to the DVD-LSI (IC1501) will generate and provide DACCLK for the external connection of Audio-DAC

at the clock generator inside DVD-LSI other than the clock used inside LSI.

F

2.2 Clock Circuit

CX-318312

1234

8 pF

C1518

Page 13

5678

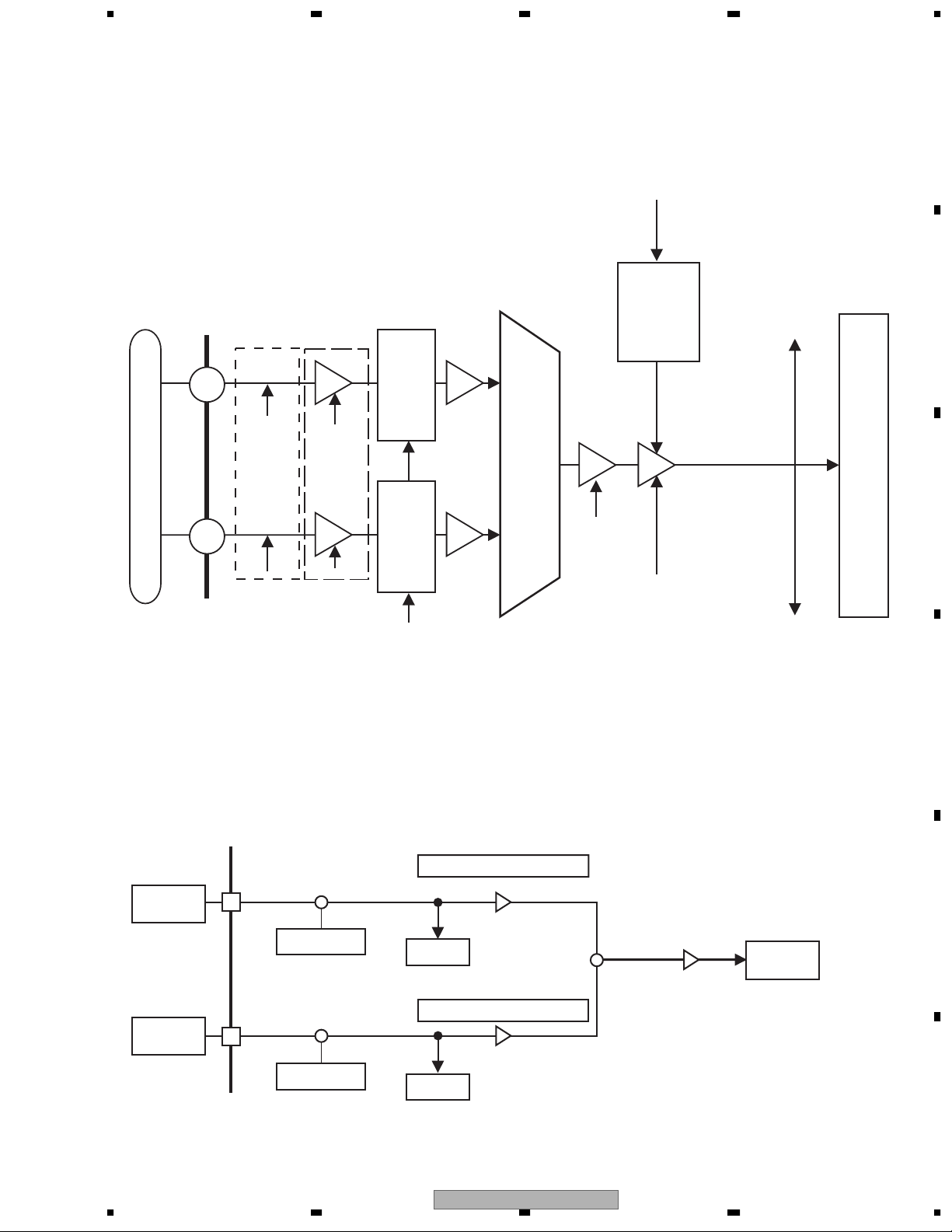

2.3 Audio Circuit

[Outline]

2.3.1 Analog Audio Signal

The serial 3-line digital output+DACCLK [digital serial audio data] that outputs from DVD-LSI (IC1501) is converted to

the analog audio signal by Audio-DAC (IC1821) for an output from HOST IF (CN1901).

Also, the analog MUTE signal is simultaneously output from DVD-LSI (IC1501) via HOST IF (CN1901).

2.3.2 Digital Audio Signal (IEC60958/IEC61937)

The digital audio signal (IEC60958/IEC61937) that outputs from DVD-LSI (IC1501) is generated

via Multi-ch/Ripping IF (CN1851).

2.3.3 Digital Multi-channel Audio Serial Signal

The serial 6-line output that outputs from DVD-LSI (IC1501) is generated via Multi-ch/Ripping IF (CN1851).

2.3.4 CD-DA Ripping Signal

The serial 3-line digital output+SUB-CODE signal that outputs from DVD-LSI (IC1501) is generated at quadruple

speed via Multi-ch/Ripping IF (CN1851).

[Analog audio signal]

MS4 Mechanism Module

AVCC5

AVCC5

27PIN:Analog

Rch29PIN:Analog

Lch26,28,30PIN:Audio

GND20PIN:AMUTE

Audio

DAC

PCM1753

fc=88 kHz

820ohm

470pF

4.7uF

100 kohm

CN1901

Audio circuit

47 kohm

or more

A

B

C

AGND

IC1821

AVCC5

470pF

820 ohm

100 kohm

4.7 µF

AMUTE

Audio

MUTE

CIRCUIT

GND

47 kohm

or more

D

E

56

CX-3183

F

7

8

13

Page 14

1234

[Digital Audio Signal]

A

166pin

168pin

167pin

169pin

173pin

DACCLK

BCK

LRCK

ADOUT3

IC1821

ADAC

(Stereo)

IECOUT

TC74VHC125FTx2

IC1851

BCK

B

171pin

170pin

172pin

ADOUT0

ADOUT1

ADOUT2

DATAOUT

DVD_LSI

IC1501

CN1851

LRCK

C

24PIN Multich Output(Digital)

IC1852

95pin

97pin

IC1853

80pin

BMUTE

MCKENA

Pull-up

RIPP

"H"output

EMPH

[CD-DA Ripping Signal]

D

E

F

DVD_LSI

IC1501

173pin

168pin

172pin

171pin

170pin

169pin

167pin

190pin

97pin

80pin

TC74VHC125FTx2

IC1851

NCLDCK

DATAOUT

IC1852

MCKENA

IC1853

"L"output

IPFLAG

BCK

SUBC

BLKCK

LRCK

SBCK

Pull-up

RIPP

EMPH

CN1851

24PIN Ripping Data & Sub code Output

1234

CX-318314

Page 15

5678

Video Circuit

Composite Video Signal and Component Signal is output from DVD-LSI(IC1501) circuit part.

Output from HOST I/F(CN1901) via Buffer circuit.

A

MS4 MECHANISM MODULE

DVD LSI

(DV3.2)

Video DAC

(CVBS,Y/Pb/Pr)

156pin : CVBS

149pin : Component Y

148pin : Component Cb

147pin : Component Cr

AVCC5

Q1803 : CVBS

Q1801 : Component Y

Q1802 : Component Cb

Q1804 : Component Cr

Zo=75 ohm

CVBS:32Pin

Y:34Pin

Cb(Pb):36Pin

Cr(Pr):38Pin

VIDEO GND

31,33,35,

37,39Pin

VIDEO AMP

(with LPF &

75 ohm DRIVER)

(*1)

B

C

D

56

CX-3183

E

F

7

8

15

Page 16

1234

2.4 SDRAM I/F

A

[Outline]

It is a memory to realize AV decoding function for DVD-LSI (IC1501). It is used for the buffering of stream data before

decoding, the work domain upon decoding, the storage of AV data and output data after decoding and manyother purposes.

SDRAM Interface

*Seen from DVD-LSI

Signal Name Bits I/O

MDQ[31:0] 32 I/O

MA[11:0] 12 O

B

BA[1:0] 2 O

NRAS 1 O

NCAS 1 O

NEW 1 O

NCS 1 O

DQM[0] 1 O

DQM[1] 1 O

DQM[2] 1 O

DQM[3] 1 O

MCK 1 O

C

MCKI 1 I

Description

Data bus for external SDRAM

SDRAM address

SDRAM bank address

RAS signal in SDRAM

CAS signal in SDRAM

Write enable signal in SDRAM

Chip select signal in SDRAM

Mask signal writing lower byte among the lower 2 bytes in SDRAM

Mask signal writing higher byte among the lower 2 bytes in SDRAM

Mask signal writing lower byte among the higher 2 bytes in SDRAM

Mask signal writing higher byte among the higher 2 bytes in SDRAM

Clock input into SDRAM

Clock input for data input from SDRAM

SDRAM Specifications

• Data bus width : 32bit

• Operating frequency : 121.5 MHz

• CAS latency = 3

• 8-word burst transfer

• CAS before RAS refresh (Auto refresh)

D

Configuration of SDRAM Connection

DVD-LSI SDRAM

MDQ[31:0] DQ[31:0]

MA[11:0] A[11:0]

BA[1:0] BA[1:0]

NRAS XRAS

NCAS XCAS

NEW XWE

DQM[3:0] DQM[3:0]

E

NCS XCS

MCK CLK

MCKI

F

CX-318316

1234

Page 17

5678

3. MECHANISM DESCRIPTIONS

Configuration

PU unit

Spindle

motor

A

CRG motor

B

Load motor

C

SW4

8/12 detection lever L

SW6

SW1

D

SW5

(CLAMP SW)

SW2

SW3

8/12 detection lever R

E

F

56

CX-3183

7

8

17

Page 18

1234

3.1 Disc loading operation

A

1. When a disc is inserted,

from ON to OFF, which triggers the operation of the loading motor.

2. For a 12cm disc, the switch SW3 is turned OFF and SW4 is ON during disc transportation. The microcomputer

senses that a 12cm disc is loaded.

B

the 8/12-detection levers R and L slide. Either of the switches SW1 and SW2 is shifted

C

12 cm disk

3. For an 8cm disc, neither the switch SW3 nor SW4 will be shifted to the above states (SW3: OFF, SW4:ON)

during disc transportation. The operation mode proceeds to the clamp operation. The microcomputer senses that an

8cm disc is loaded.

D

E

8 cm disk

F

1234

CX-318318

Page 19

5678

3.2 Disc centering mechanism

1. With a 12cm disc loaded, the disc pushes both of the lock arms R and L to open the centering arms R and L. Then,

the clamp arm or the stopper of the centering arm R stops the disc for centering. The operation mode

proceeds

to the clamp operation.

A

Centering arm

Clamp arm

12 cm disk latching section

Lock arm

12 cm disk latching section

B

Centering arm

C

2. With an 8cm disc loaded, the disc pushes either of the lock arms R and L. The lock arms R and L are connected

each other via the centering arms R and L. The lock arms R and L will be kept locked unless the disc pushes them

at the same time. Therefore, the lock arm blocks the disc for centering. During disc centering, the disc pushes

out the disc detection arm. When the detection arm completes moving, the disc stops. The operation mode

proceeds to the clamp operation.

8 cm disk latching section

D

E

F

56

CX-3183

7

8

19

Page 20

1234

2.3 Clamp operation

1. When an 8 or 12 cm disc is centered over the spindle, the disc detection arm moves the clamp lever. The loading

A

rack driven by the clamp lever is engaged with the lever driving gear , which triggers the disc clamp operation.

Disc detection arm

Disc positioning section

Clamp lever

Loading rack

B

Load lever R

Clamp switch

C

2. When pressed by the loading rack, the load lever R moves toward the front side, and the roller shaft, which is

connected to the cam of the load lever R, moves downward. The roller shaft is connected to the cam of the cam

ring also. Therefore, the drive of the roller shaft is transferred to the load lever L via the cam ring. The load lever

L moves toward the front side. The load lever cams are released from the three shafts for the CRG chassis unit

and the clamp arm shaft. When the load lever R turns on the clamp switch, the clamp operation ends.

D

CRG chassis

linked with the cam

shaft

Clamp arm shaft

linked with the cam

E

CRG chassis shaft

linked with the cam

CRG chassis

linked with the ca m

2.4 Eject operation

1. When the loading motor turns in reverse, the disc eject operation begins.

2. With a 12cm disc loaded, when the SW4 is shifted from OFF to ON, and then OFF again, the eject operatio n

F

ends.

3. With an 8cm disc loaded, when the SW3 or SW6 is shifted from ON to OFF,and then both switches are turned

ON, the eject operation ends.

CX-318320

1234

shaft

Page 21

5678

4. DISASSEMBLY

- Precautions on handling the mechanism module

1. Hold the upper and main frames.

2. Do not hold the front portion of the upper frame. It is a delicate part.

3. Do not touch the switches on the top panel.

4. Be careful not to catch the flexible cables.

(Fig.1)

A

B

Do not touch here. Do not touch here.

Do not hold this delicate portion.

Fig. 1

- Removing the module pc board (Fig.2 and 3)

1. Set the mechanism to the lock position (disc load standby position).

2. Place the mechanism module upside down.

3. Short the two lands on the pickup flexible cable as shown below.

4. Be sure to disconnect the pickup flexible cable and the SPDL flexible cable from the connectors

to protect them from damages.

5. Remove solder from the load motor leads and clamp SW leads.

6. Loosen the two fixing screws. Lift the position A of the module pc board lightly and move it

in the direction B to remove it. Be careful not to damage the flexible cable C.

7. Disconnect the 8/12 detection flexible-cable from the connector.

Short here.

Fig. 2

Connector

(for pickup flexible cable)

(for 8/12 detection

flexible cable)

C

D

Module pc board

E

Connector

Solder land

(Load motor

leads and clamp SW leads)

56

Connector

(for SPDL flexible cable)

CX-3183

B

A

C

Fig. 3

F

7

8

21

Page 22

1234

- Removing the pickup unit (Fig. 4)

1. Remove the module pc board in accordance with the procedure of "Removing the module pc board.”

A

2. A principal-axis control spring is hung on a CRG chassis.

3. While holding the pickup case, remove the skew screw (main).

4. Lifting the end of the pickup rack, slide the main shaft, and remove the pickup unit.

Notes:

Replacing the pickup unit requires the skew adjustment .

Remove glue from both ends of the main and sub shafts, and skew stud.

Do not reuse the old skew screw . Be sure to use a brand-new skew screw supplied with a new pickup unit.

Fix the locking agents(1401M : produced by THREE BOND) after adjustment.

B

Hang on a position based on a principal-axis control spring.

Skew screw (main)

Main shaft

Pickup unit

C

Principal-axis control spring

Skew screw(Sub)

Skew screw(Sub)

Sub shaft

D

The position of the CRG chassis hung temporarily

Fig. 4

It hangs temporarily It hooks perfectly.

E

F

CX-318322

1234

Page 23

5678

- Removing the spindle motor (Fig.5)

1. Remove the module pc board in accordance with the procedure of "Removing the module pc board."

2. Remove the three fixing screws for the SPDL motor . Be careful not to deform the CRG chassis when replacing

the SPDL motor.

3. After removing the lead of a CRG motor from a hook, it removes from a flexible land.

- Removing the CRG motor assy (Fig.5)

1. Remove the module pc board in accordance with the procedure of "Removing the module pc board.

2. Remove the module pc board in accordance with the procedure of "Removing the spindle motor."

3. Remove the feed screw.

4. Remove the fixing screw , and remove the feed screw holder together with the 2-stage gear .

5. Remove the fixing two screws and CRG motor assy .

Caution:

When replacing the CRG motor assy, be careful not to damage the gears, especially the 2-stage gear that is

very delicate. When lifting the pickup rack to install the motor , be careful not to damage the gear teeth.

When you remove a feed screw, be careful for a feed screw holder not to separate.

”

A

B

Feed screw holder

CRG motor assy

Screw(CRG)

Screw(CRG)

Hook

Feed screw

Pickup rack

Solder land

2-stage gear

Feed holder

Hook

Screw(holder)

Screw(spindle)

Hook

SPDL motor

Screw(spindle)

Screw(spindle)

Fig. 5

- Removing the upper frame assy (Fig. 6)

1. Remove the module pc board in accordance with the procedure of "Removing the module pc board. ”

2. Remove the spring.

3. Remove the four screws and remove the upper frame assy .

Screw

Screw

C

D

Screw

Fig. 6

CX-3183

56

Spring

Upper frame assy

Screw

7

E

F

23

8

Page 24

1234

- Removing the load gear assy (Fig. 7)

1. Remove the module pc board in accordance with the procedure of "Removing the module pc board.”

A

2. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy.”

3. Remove the two screws and remove the load gear assy .

Screw

Load gear assy

B

Screw

Fig.

7

C

- Setting the quasi-clamp mode by driving the loading motor (Fig. 8)

1. While driving the loading motor in the clamping direction, pull the clamp lever toward the front side.

2. Even after the clamp lever pushes the loading rack (clamp mode), keep the clamp lever pulled lightly.

Prevent the clamp lever bar ring from coming into the clamp spring. If not, ejection will not be impossible.

3. After the clamp operation ends, stop the operation before the objection of the loading rack touches the load

lever R.

D

(fig. 10)

Clamp lever

Pull toward the front side.

E

8

Fig.

F

CX-318324

1234

Page 25

5678

Clamp lever

bar rin g

A

Clamp spring

B

Prevent the clamp lever bar rin g

from coming into the clamp

spring (the above condition is NG)

Fig. 9

Load lever R

Stop before this

clearance

becomes zero.

C

Loading rack

D

E

56

CX-3183

Fig. 10

7

F

25

8

Page 26

1234

- Setting the quasi-clamp mode manually (Fig. 11)

1. Remove the module pc board in accordance with the procedure of "Removing the module printed circuit board.”

A

2. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy .”

3. Remove the load gear assy in accordance with the procedure of "Removing the load gear assy ."

4. While pulling the clamp lever toward the front side, pull the fixed portion of the load lever R toward the front

side

until the mode enters the clamp position.

Clamp lever

B

load lever R forward.

Load lever R

Fig. 11

Pull this portion of the

C

- Removing the load motor assy (Fig. 12)

1. Remove the module pc board in accordance with the procedure of "Removing the module printed circuit board. ”

2. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy.”

3. Remove the load gear assy in accordance with the procedure of "Removing the load gear assy ."

4. Enter the quasi-clamp mode in accordance with the procedure of “Setting the quasi-clamp mode manually .”

5. Remove the screw . Slide the load motor assy to pull it out .

D

E

Screw

Slide to remove.

Fig. 12

F

1234

CX-318326

Page 27

5678

- Removing the CRG assy (Fig. 13)

1. Enter the quasi-clamp mode in accordance with the procedure of “Setting the quasi-clamp mode by driving

loading motor .”

the

2. Remove the module pc board in accordance with the procedure of "Removing the module pc board. ”

3. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy .”

4. Remove the four springs.

5. Lift the CRG assy until the shafts come from the dampers, and then remove it.

- Removing the disc guide assy (Fig. 13)

1. Enter the quasi-clamp mode in accordance with the procedure of “Setting the quasi-clamp mode by driving

loading motor .”

the

2. Remove the module pc board in accordance with the procedure of "Removing the module pc board. ”

3. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy.”

4. Remove the two disc guide springs. While lifting the disc guide and keeping the lifting angle around 45

degrees,

slide the guide in the left side to remove it.

A

B

Spring

Disc guide spring

Spring CRG assy

Disc guide

Disc guide spring

Spring

C

D

Fig. 13

56

CX-3183

E

F

7

8

27

Page 28

1234

- Removing the roller assy (Fig. 14)

1. Remove the module pc board in accordance with the procedure of "Removing the module pc board.”

A

2. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy.”

3. Remove the tension spring.

4. Remove the load gear assy in accordance with the procedure of "Removing the load gear assy."

5. Enter the quasi-clamp mode in accordance with the procedure of “Setting the quasi-clamp mode manually.”

6. Remove the disc guide assy in accordance with the procedure of “Removing the disc guide assy.”

7. Remove the CRG assy in accordance with the steps 4 and 5 in the procedure of “Removing the CRG assy .”

8. By pushing the fixed portion of the load lever R, move the load lever R to the rear side completely.

9. Remove the load levers R and L. Unhook the end of the roller arm spring R from the load lever R.

10. While lifting the roller assy to the highest position, slide it to the right side. Lightly bend the whole slot guide by

B

pushing the ends with your fingers and remove the roller assy .

Caution : A shutter is not changed when removing Roller Assy.

Load lever R

C

Move to the rear

side

Roller arm spring R

Roller arm spring L

Shutter

D

Roller assy

Tension spring

Shutter

Fig. 14

E

F

CX-318328

1234

Page 29

5678

- Removing the dampers (Fig. 15)

1. Enter the quasi-clamp mode in accordance with the procedure of “Setting the quasi-clamp mode by driving

the

loading motor .”

2. Remove the module pc board in accordance with the procedure of "Removing the module pc board. ”

3. Remove the upper frame assy in accordance with the procedure of "Removing the upper frame assy.”

4. Remove the three springs.

5. Remove the CRG assy in accordance with the steps 4 and 5 in the procedure of "Removing the CRG assy.”

6. Release each of the three dampers from the clinches as follows:

6.1 By using a pair of pliers, hold the portion A and turn them in the direction B. While making a gap in the portion

C, release the damper from the clinches.

6.2 Insert a flat-type screwdriver into the portion D. Slightly raise the plate and release the damper from the

clinches.

7. Remove the CRG motor assy in accordance with the steps 3 through 5 in the procedure of "Removing the CRG

motor assy .”

8. Remove the dampers.

A

B

C

A

C

B

D

Fig. 15

D

56

CX-3183

E

F

7

8

29

Loading...

Loading...