Pioneer a-10-k, 20-k, 30-k Service Manual

INTEGRATED AMPLIFIER

A-30-K

A-30-S

A-20-K

A-20-S

A-20

ORDER NO.

RRV4297

A-30-K

A-10-K

A-10-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

A-30-K/-S PWSYXE8 AC 220 V to 230 V

A-20-K/-S PWSYXE8 AC 220 V to 230 V

A-20 CUXE AC 120 V

A-10-K/-S SYXE8 AC 220 V to 230 V

1

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Ser

vice Manua

l.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage T est

(FOR USA MODEL ONLY)

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

56 noitisoporP - 6.94252 noitceS edoC ytefaS & htlaeH

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

A-30-K

5

6 7 8

CONTENTS

SAFETY INFORMATION..........................................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................... ..... ...... ..... .................................................4

1.1 NOTES ON SOLDERING...............................................................................................................................................4

2. SPECIFICATIONS........................................................ ...... ...... ..... ........................................................................................5

2.1 ACCESSORIES..............................................................................................................................................................5

2.2 SPECIFICATIONS..........................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE ..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ...........................................................................................................................6

3.2 PCB LOCATIONS...........................................................................................................................................................7

3.3 JIGS LIST.......................................................................................................................................................................7

4. BLOCK DIAGRAM .................................................. ..... ...... ...... ..... ........................................................................................8

4.1 OVERALL CONNECTION DIAGRAM.............................................................................................................................8

4.2 BLOCK DIAGRAM........................................................................................................................................................10

5. DIAGNOSIS ................................................ ...... ...... ..... ............................................. ..........................................................12

5.1 TROUBLESHOOTING..................................................................................................................................................12

5.2 PROTECTION CIRCUIT DESCRIPTION .....................................................................................................................15

5.3 IC INFORMATION........................................................................................................................................................17

6. SERVICE MODE.......................................................... ...... ...... ..... ...... ..... ...........................................................................21

7. DISASSEMBLY ........................................... ...... ...... ..... ...... ...... ...........................................................................................22

8. EACH SETTING AND ADJUSTMENT..................................................... ...... ...... ..... ...... ....................................................29

8.1 HOW TO CHECK THE FIRMWARE VERSION............................................................................................................29

8.2 FARMWARE UPDATING..............................................................................................................................................29

8.3 HOW TO ADJUST THE IDLE CURRENT ....................................................................................................................31

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................32

9.1 PACKING SECTION.....................................................................................................................................................32

9.2 EXTERIOR SECTION (A-30/A-20)...............................................................................................................................34

9.3 EXTERIOR SECTION (A-10).......................................................................................................................................38

10. SCHEMATIC DIAGRAM....................................................................................................................................................40

10.1 MAIN ASSY................................................................................................................................................................40

10.2 FRONT ASSY and SECOND POWER SW ASSY (A-30/A-20)..................................................................................42

10.3 MASTER VOLUME ASSY, TONE ASSY and HEADPHONE ASSY ...........................................................................44

11. PCB CONNECTION DIAGRAM........................................................................................................................................46

11.1 MAIN ASSY................................................................................................................................................................46

11.2 FRONT ASSY.............................................................................................................................................................50

11.3 MASTER VOLUME ASSY..........................................................................................................................................52

11.4 TONE ASSY...............................................................................................................................................................53

11.5 HEADPHONE ASSY and SECOND POWER SW ASSY (A-30/A-20)........................................................................54

12. PCB PARTS LIST..............................................................................................................................................................55

A

B

C

D

E

F

A-30-K

5

6 7 8

3

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

4

1

2 3 4

A-30-K

5

Remote control unit (A-30-K/-S : CARTA30)

(A-20-K/-S,A-20 : CARTA20)

AAA/R03 dry cell battery x 2 (A-30-K/-S, A-20-K/-S, A-20)

AC Power cord (A-30-K/-S : CJA2B054Z)

(A-20-K/-S, A-10-K/-S : CJA2B020Z)

Warranty card (A-30-K/-S, A-20-K/-S, A-10-K/-S : CQE1A541Z)

Operating instructions (A-30-K/-S, A-20-K/-S, A-10-K/-S : CQX1A1640Y)

(A-20 : CQX1A1644Z)

Amplifier section

Power output specification is for when power supply is 230 V.

(A-30-K/-S, A-20-K/-S, A-10-K/-S)

Power output specification is for when power supply is 120 V.

(A-20)

•Continuous power output (both

channels driven at 20 Hz to 20 kHz)

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 W + 70 W

A-20, A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 W + 50 W

(THD 0.1 %, 4 Ω)

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 W+40 W

A-20, A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 W+30 W

(THD 0.05 %, 8 Ω)

Audio section

•Input (Sensitivity/Impedance)

SACD/CD, NETWORK, TUNER, AUX, RECORDER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 mV/50 kΩ

POWER AMP DIRECT (A-30 only). . . . . . . . . . . . .1 V/10 kΩ

PHONO (MM). . . . . . . . . . . . . . . . . . . . . . . . . 2.8 mV/50 kΩ

•Output (Level/Impedance)

RECORDER OUT . . . . . . . . . . . . . . . . . . . . . 200 mV/2.2 kΩ

PHONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 mV/32 Ω

•Frequency response

SACD/CD, NETWORK, TUNER, AUX, RECORDER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Hz to 100 kHz dB*

PHONO (MM). . . . . . . . . . . . . . . .20 Hz to 20 kHz ±0.5 dB*

* Measured with DIRECT button switched on.

•Tone control

(When VOLUME is set to

-

30 dB)

Bass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 10 dB (100 Hz)

Treble. . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 10 dB (10 kHz)

•Signal-to-Noise Ratio (IHF SHORTED,

A-NETWORK)

SACD/CD, NETWORK, TUNER, AUX, RECORDER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 dB*

PHONO (MM, 2.8 mV input) . . . . . . . . . . . . . . . . . . .77 dB*

* Measured with DIRECT button switched on.

•Speaker load impedance

A, B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Ω to 16 Ω

A+B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Ω to 32 Ω

Bi-wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Ω to 16 Ω

Miscellaneous

Power requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . AC 220 V to 230 V, 50 Hz

(A-30-K/-S, A-20-K/-S, A-10-K/-S)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AC 120 V, 60 Hz

(A-20)

Power consumption

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 W

A-20/A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 W

In standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 W

Dimensions

. . . . . . . . . . . . . . .435 mm (W) x 128 mm (H) x 360 mm (D)

Weight (without package)

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 kg

A-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2 kg

A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 kg

Note

•Specifications and the design are subject to

possible modifications without notice, due to

improvements.

•Corporation and product names mentioned herein

are trademarks or registered trademarks of the

respective corporations.

2. SPECIFICATIONS

2.1 ACCESSORIES

6 7 8

A

2.2 SPECIFICATIONS

B

C

D

5

A-30-K

6 7 8

E

F

5

1

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding audio.

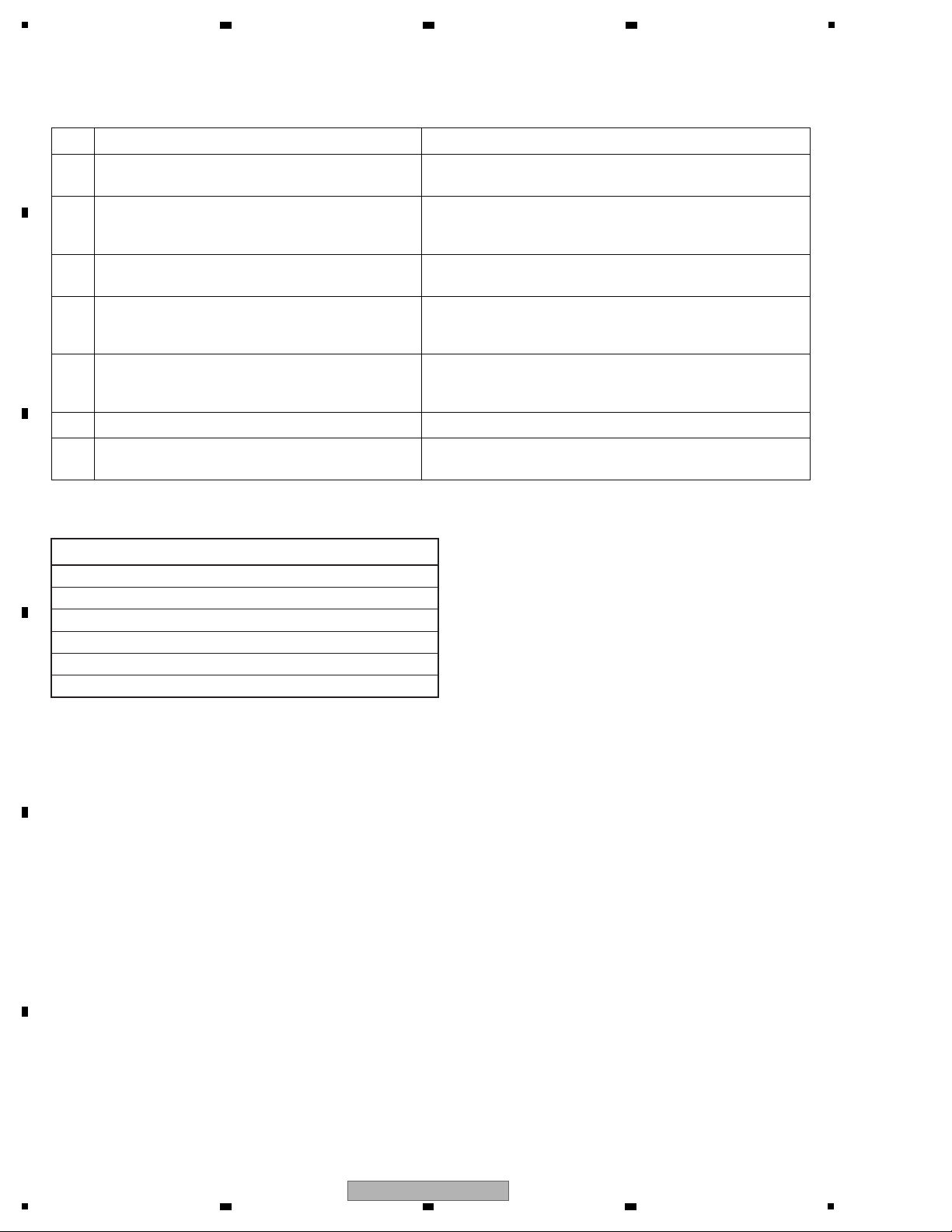

No. Procedures Check points

1

Check the symptom pointed out by a customer The pointed content should not reoccur

Sound and operation should not be defective

2

Check each input and main VOL (check the

operation of selector)

The sound is output by selecting an analog-connected input

with a selector and the sound volume should change by

rotating main VOL knob

3

Check the tone control, balance, and function The sound quality or right and left balances should change

by rotating each V OL knob

4

Check LOUDNESS and DIRECT functions The sound quality should change by setting LOUDNESS

function to ON. LOUDNESS function should be disabled by

setting DIRECT function to ON.

5

Check POWER AMP DIRECT terminal (only A-30)

(connected from pre-out terminal of AV AMP to

POWER AMP DIRECT terminal)

The sound volume should change by adjusting the sound

volume of connected AV AMP. The sound volum e shoul d not

be changed by the main VOL on the main unit.

6 Check SPEAKER A/B and headphone terminal There should not be defect in sound such as noise

7

Check the external package Check scratch or taint is not generated after accept ing the

repair

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

6

1

2 3 4

A-30-K

5

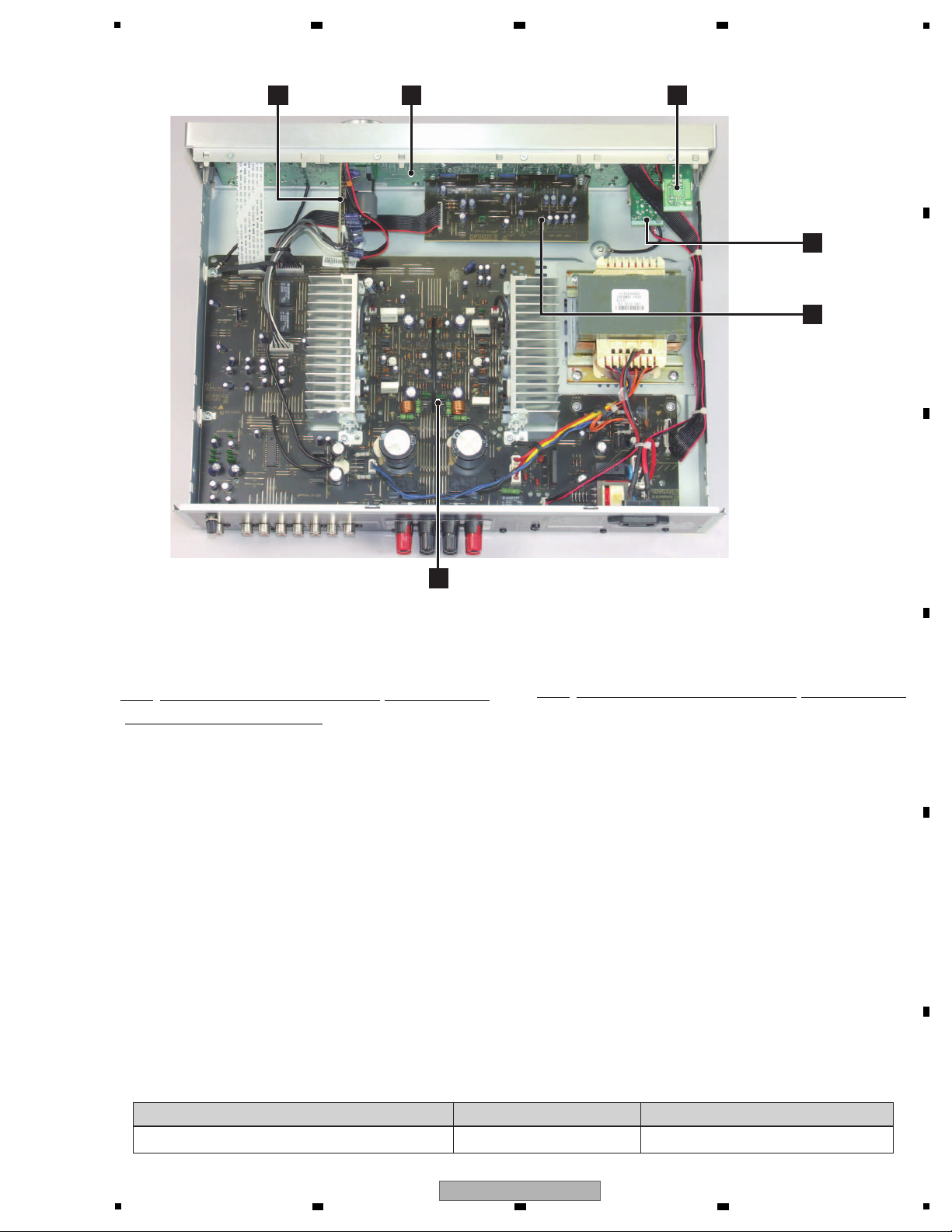

SECOND POWER SW ASSY

MAIN ASSY

A

MASTER VOLUME ASSY

C F

HEADPHONE ASSY

E

TONE ASSY

D

FRONT ASSY

B

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Name Jig No. Remarks

UPDATE JIG GGF1675 Farmware Update

3.2 PCB LOCATIONS

6 7 8

A

B

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP 1..MAIN ASSY (A-30-K/-S) COP12421B

2..MAIN ASSY AZW7487

NSP 1..MAIN ASSY (A-20-K/-S) COP12421D

2..MAIN ASSY AZW7489

NSP 1..MAIN ASSY (A-20) COP12421E

2..MAIN ASSY AZW7490

NSP 1..MAIN ASSY (A-10-K/-S) COP12421F

2..MAIN ASSY AZW7491

NSP 1..FRONT ASSY (A-30-K/-S) COP12422B

2..FRONT ASSY AZW7482

2..MASTER VOLUME ASSY AZW7476

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

Mark No. Description Part No.

NSP 1..FRONT ASSY (A-20-K/-S) COP12422C

2..FRONT ASSY AZW7483

2..MASTER V OLU ME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

NSP 1..FRONT ASSY (A-20) COP12422G

2..FRONT ASSY AZW7484

2..MASTER V OLU ME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

NSP 1..FRONT ASSY (A-10-K/-S) COP12422D

2..FRONT ASSY AZW7485

2..MASTER V OLU ME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

C

D

E

3.3 JIGS LIST

5

6 7 8

A-30-K

F

7

1

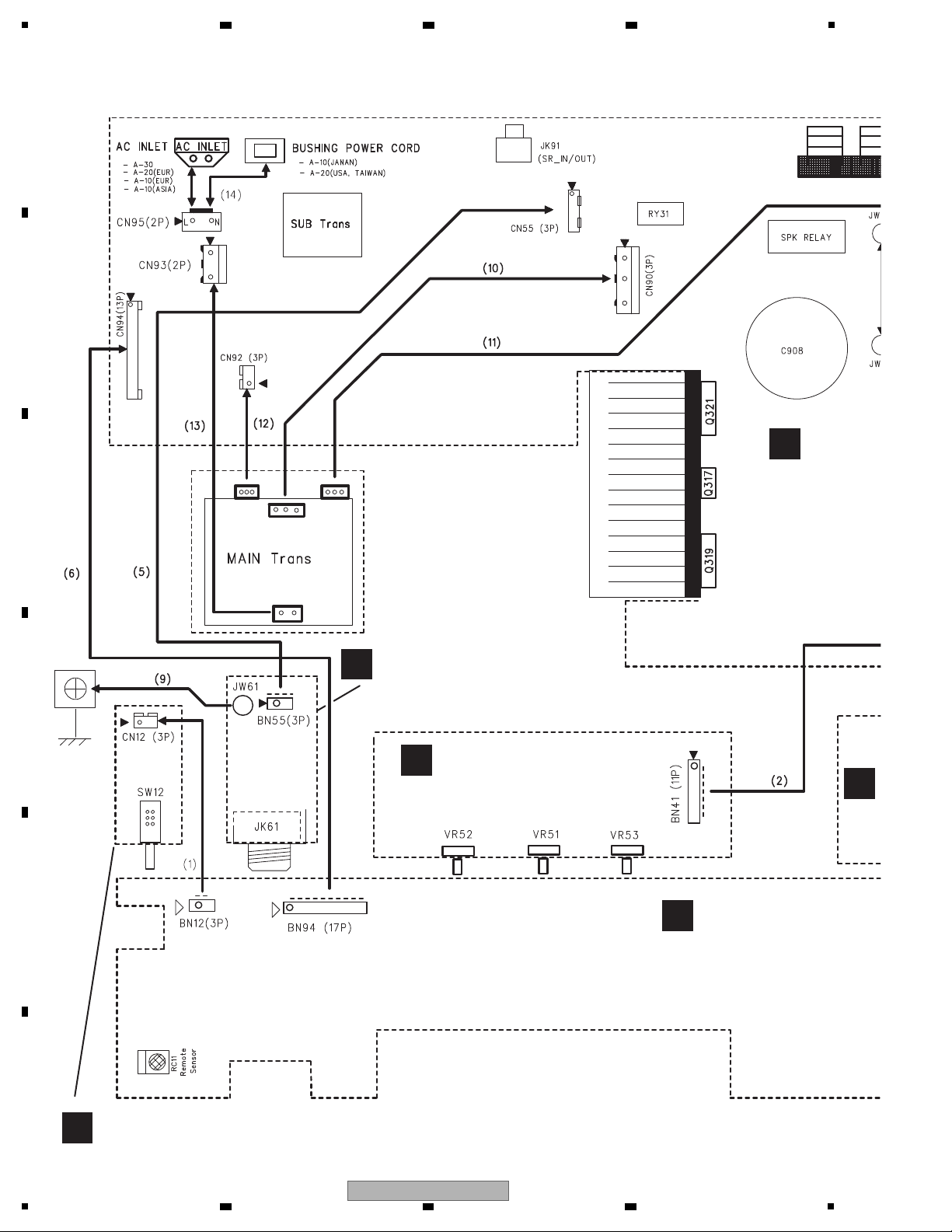

MAIN AS

(A-30-K/

(A-20-K/

(A-20

(A-10-K/

A

FRONT ASSY

(A-30-K/-S : AZW748

(A-20-K/-S : AZW748

(A-20 : AZW748

(A-10-K/-S : AZW748

B

SECOND POWER SW ASSY

(A-30-K/-S, A-20-K/-S, A-20 : AZW7478)

F

C

TONE ASSY

(AZW7477)

D

HEADPHONE ASSY

(AZW7479)

E

2 3 4

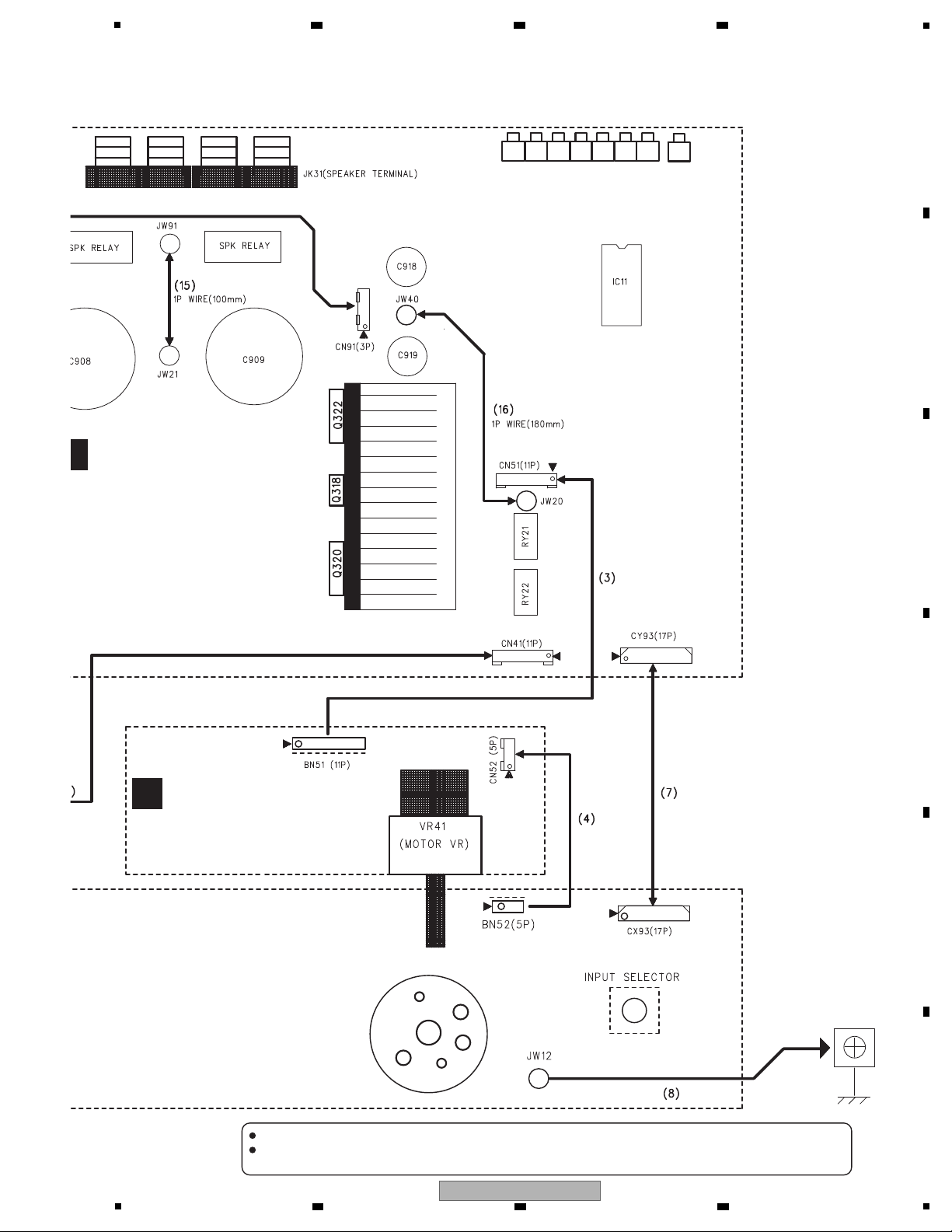

4. BLOCK DIAGRAM

4.1 OVERALL CONNECTION DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

A-30-K

5

MAIN ASSY

(A-30-K/-S : AZW7487)

(A-20-K/-S : AZW7489)

(A-20 : AZW7490)

(A-10-K/-S : AZW7491)

S : AZW7482)

S : AZW7483)

: AZW7484)

S : AZW7485)

MASTER VOLUME ASSY

(A-30-K/-S : AZW7476)

(A-20-K/-S, A-20,

A-10-K/-S : AZW7481)

C

Therefore, when replacing, be sure to use parts of identical designation.

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor of the part.

6 7 8

A

B

C

D

E

5

6 7 8

A-30-K

F

9

1

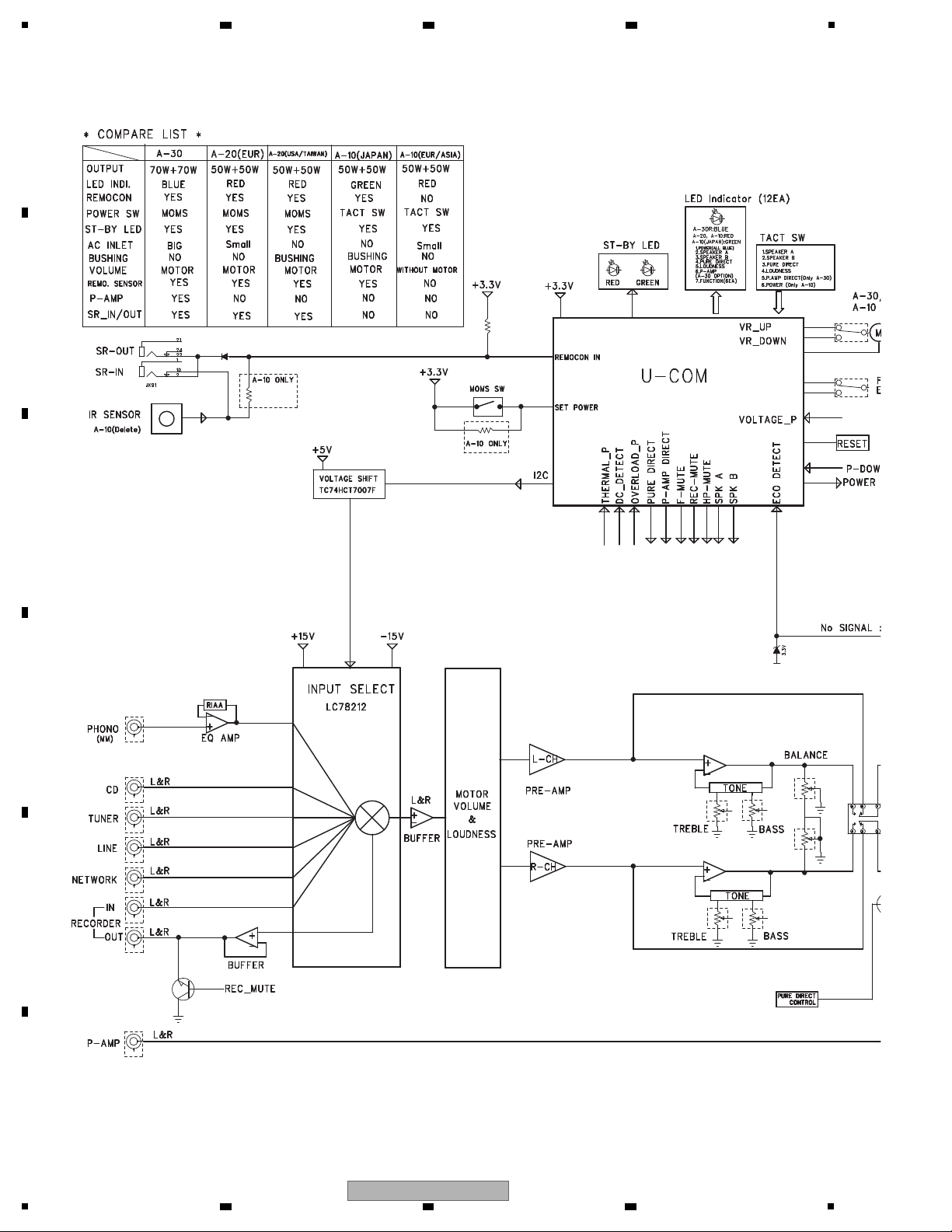

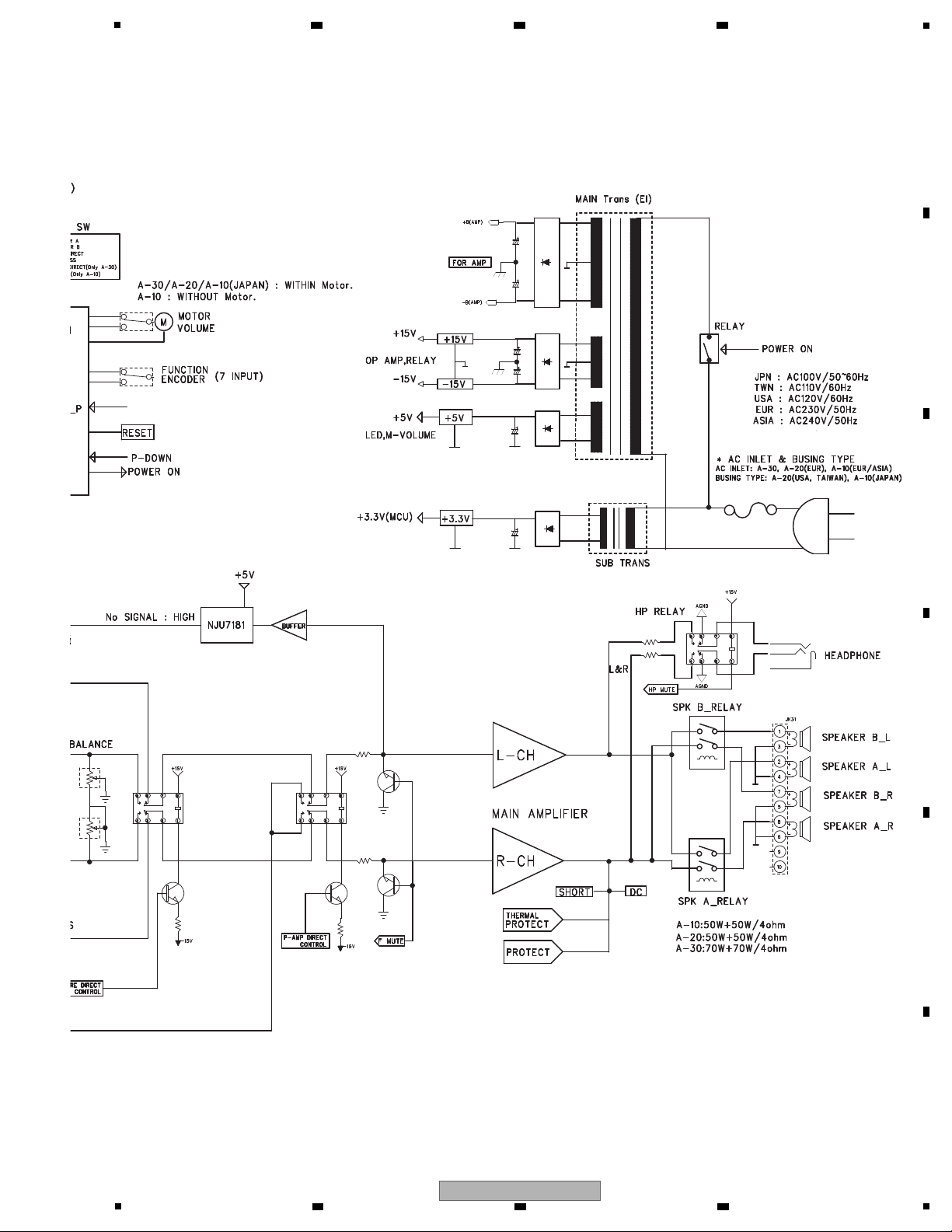

4.2 BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

10

1

2 3 4

A-30-K

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

11

1

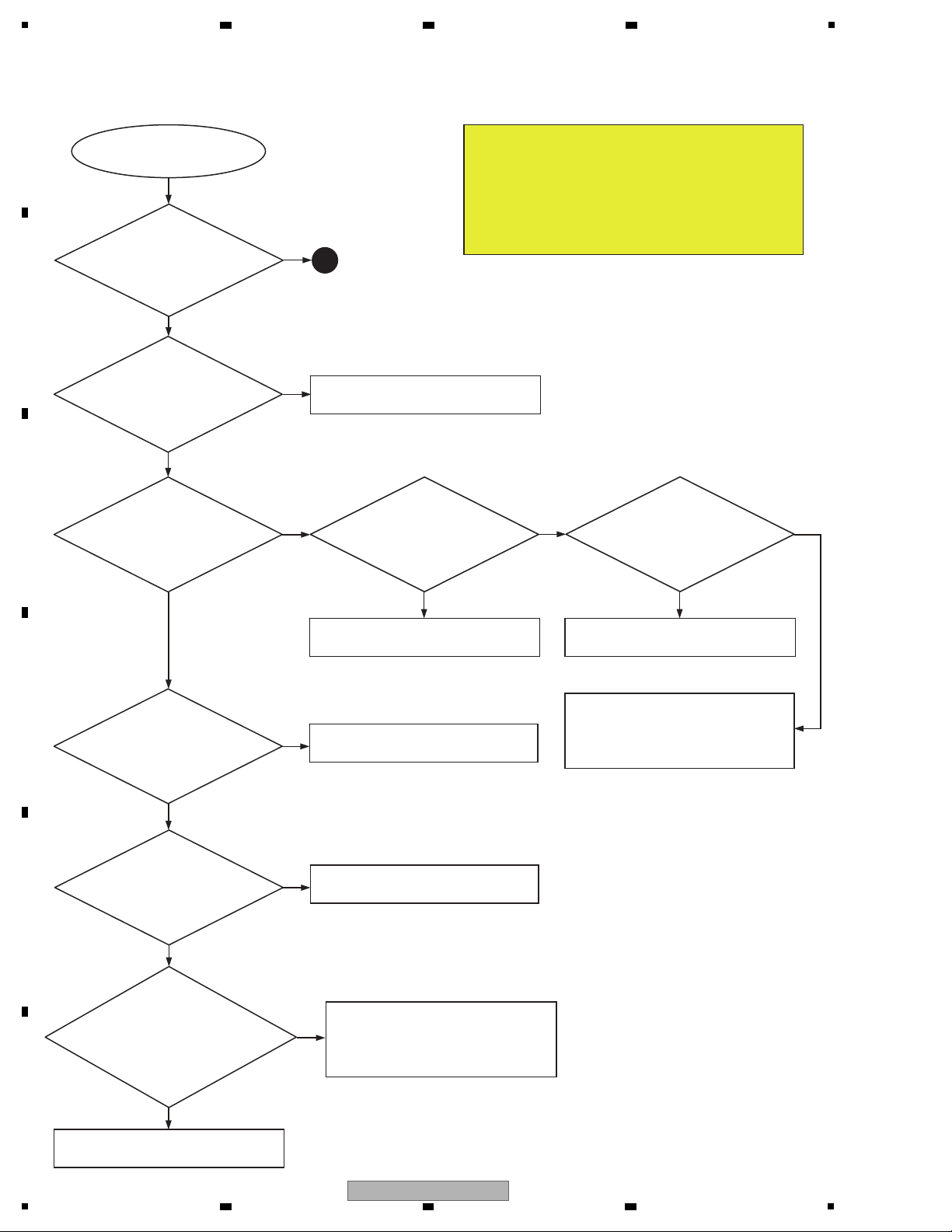

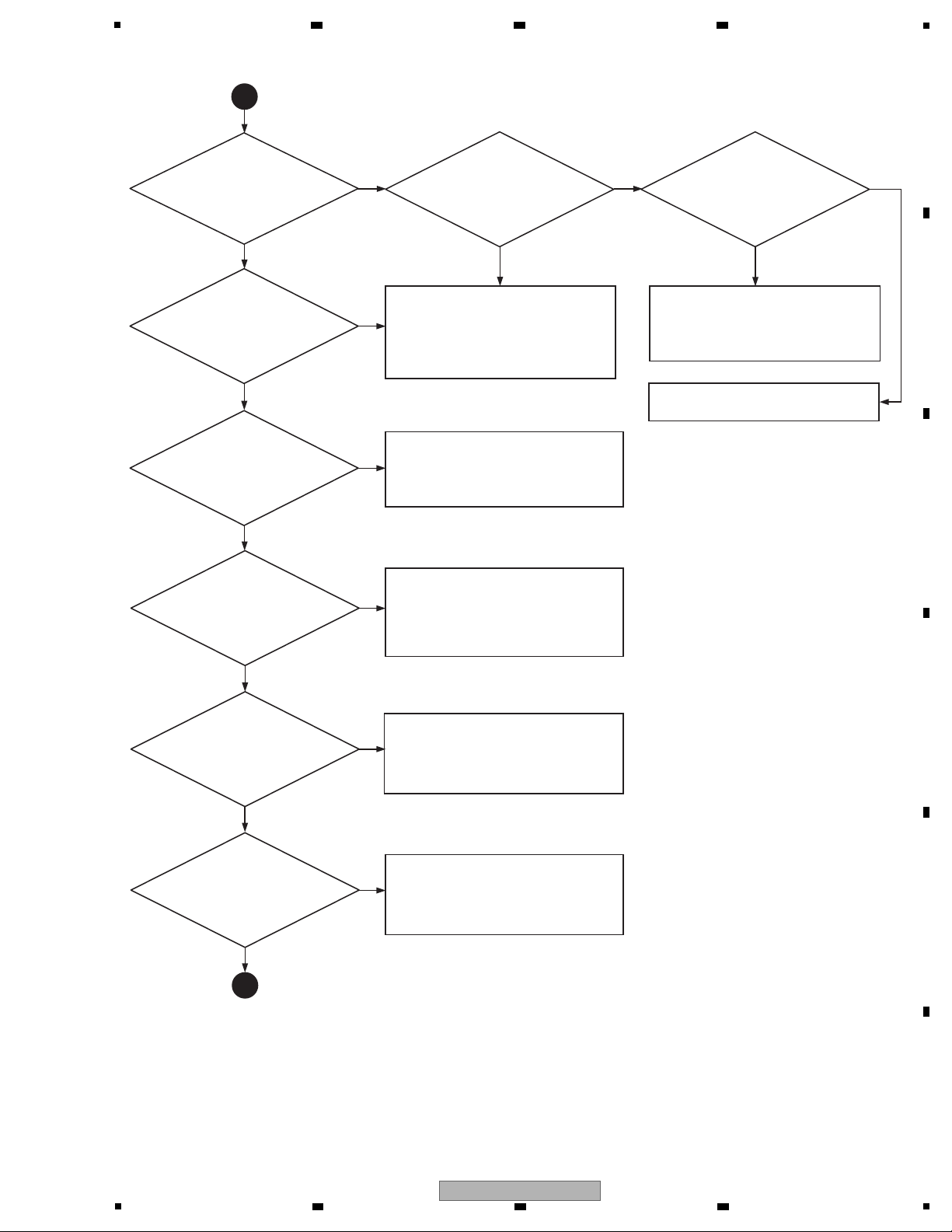

Is the Power supply

turned ON ?

A

No

No

Yes

Yes

No No No

Yes Yes

Yes

Yes

Yes

Yes

No

No

No

[Status of product]

Insert AC Power cord

Main unit POWER SW: ON (A-30/A-20)

POWER ON operation by remote control Unit

Select SPEAKER-A

INPUT : SACD/CD

Is the standby LED blinking ?

No sound

The protection circuit is operating

Is the voltage of ST_+3.3V

(CN94: 4, 5 pins) +3.3V ?

Is the voltage of IC91: 2 pin

approximately 5V ?

Is there AC waveform on

D913 anode side ?

IC91 failure

D913 failure

D914 failure

Is BACK UP line set to "H" ?

(CN94: 7 pin)

Q903, D917 failure

F901 failure

T901 failure

Is voltage of IC11: 1 pin +3.3V ?

IC12 failure

Is there

a waveform of Remote

Controller signal at IC11: 59 pin

(REMOTE IN) when POWER key

on the Remote Control

Unit pressed ?

IC11 failure

RC11 failure

Connection failure between BN94

and CN94(A-30/A-20)

(For the type, refer to the 5.2 PROTECTION CIRCUIT DESCRIPTION)

No sound

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

12

1

2 3 4

A-30-K

A

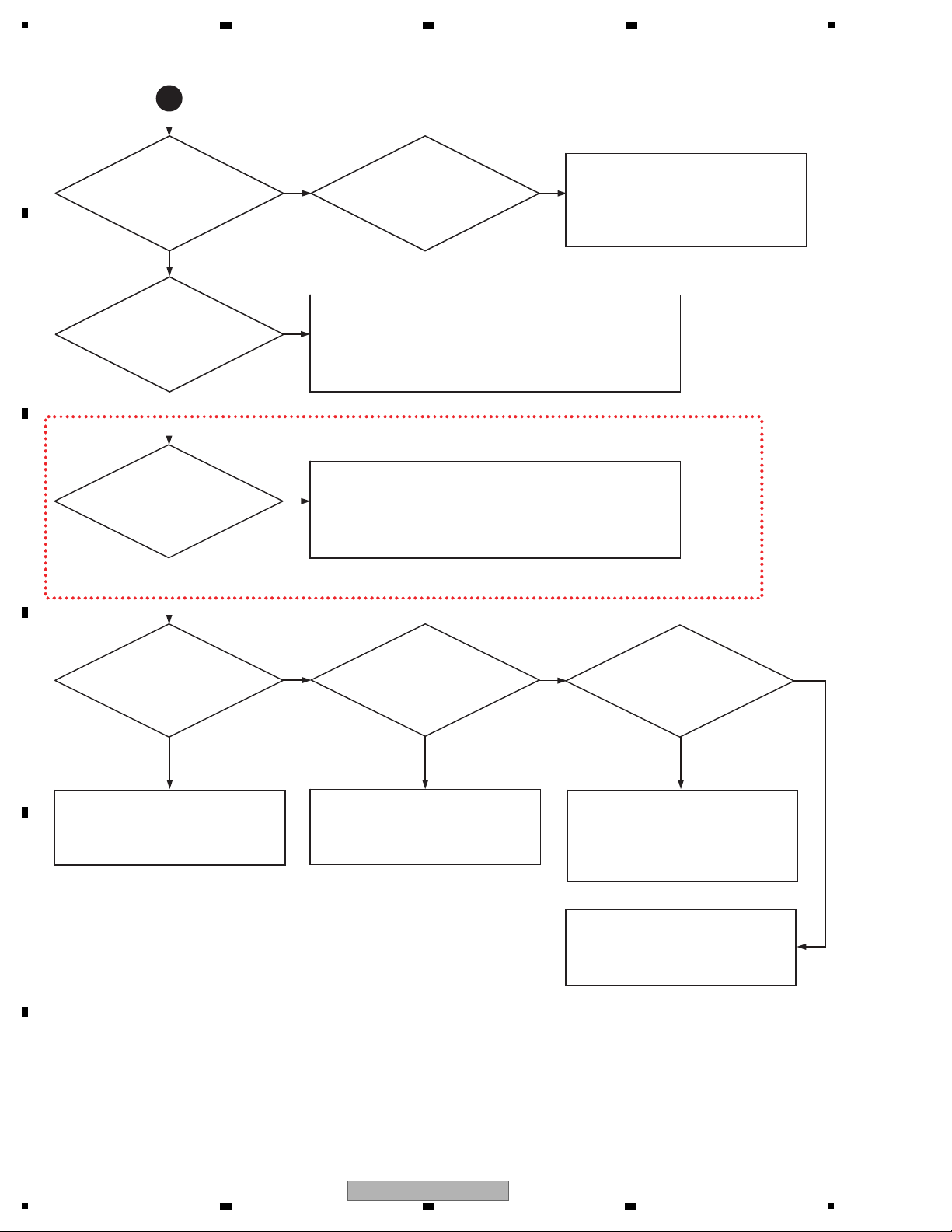

No

No

No

No

No

No No No

B

Yes

Yes

Yes

Yes

Yes

Yes

Yes Yes

Does the protection

relay "click" and is it turned ON

after the power supply

is turned ON ?

Is IC11: 50 pin

(SPEAKER A) set to "H" ?

Is SPEAKER A LED

lighting ?

Is there output at

HP terminal ?

Relay power supply resistance

(R392, R394) failure

RY33 failure

Connection failure between

CY93 and CX93

S103 failure

IC11 failure

IC11 failure

Is there output at

REC OUT terminal ?

IC21 failure, communication failure

Connection failure between

CY93 and CX93

Solder failure of input pin jack

Is there a signal at

BN51:1, 9 pins ?

IC23 failure

Solder failure of IC23 I/O coupling

electrolysis capacitor

Connection failure between

CN51 and BN51

Is there a signal at

BN51:3, 7 pins ?

IC41 failure

Solder failure of IC41 I/O coupling

electrolysis capacitor

Check IC42 power supply (±7.5V)

Is there a signal at

BN51:3, 7 pins ?

IC41 failure

Solder failure of IC41 I/O coupling

electrolysis capacitor

Check IC42 power supply (±7.5V)

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

13

1

A-30 ONLY

B

Yes

Yes

No

Yes

No

No

No

No

Yes

Yes Yes Yes

No

Isn't the

symptom changed by

DIRECT ON/OFF ?

Only DIRECT OFF

is not output

Solder failure of R503, R514

Connection failure between

CN41 and BN41

IC51, IC52 failure

Is there

a signal at J208 and

J209 (RY21 output) ?

PURE DIRECT control signal circuit

failure (Q203, Q204, R259, R261)

Connection failure between CY93 and CX93

RY21 failure

Is there

a signal at J215

(RY22 output) ?

P_AMP DIRECT control signal circuit

failure (Q205, Q206, R260, R262)

Connection failure between CY93 and CX93

RY22 failure

Is there a

signal at power amplifier

input (R301, R302) ?

Isn't F_MUTE

set to "H" ?

(Isn't the sound

muted ?)

Is ±15V of

MUTE circuit properly

supplied ?

Solder failure of R301,

R302, C301, C302

Reset MUTE

Solder failure of IC11:

44 pin

F_MUTE control signal

circuit failure (Q207-Q212)

Connection failure

between CY93 and CX93

D250 failure

Solder failure of R275

A

2 3 4

B

C

D

E

F

14

1

2 3 4

A-30-K

5

1. PROTECTION operation

Purpose of PROTECTION operation

Protection of operation due to failure of product

Protection of operation due to wrong use by a user

e.g.) Rare short of speaker connection is generated, or product is installed by

blocking the heat release hole

1.1 DC DETECT

After DC DETECT is detected, MUTE ON & PROTECTION RELAY OFF are carried out.

If DC DETECT is detected for 3 seconds or more continuously, it is evaluated as "1.1.1 AMP failure" shown below.

If DC DETECT is detected for less than 3 seconds, it is evaluated as 1.1.2 SIGNAL CLIP" shown below.

1.1.1 AMP failure

If DC DETECT is detected for 3 seconds or more continuously, it is evaluated as "AMP failure" and

the power is turned OFF.

If the power supply is automatically turned OFF after AMP failure is detected, all key operations are prohibited

(power ON is prohibited).

For turn ON the power supply again, refer to "3. How to reset the prohibition of power ON" shown below.

1.1.2 SIGNAL CLIP

If DC DETECT is detected for less than 3 seconds, it is evaluated as "SIGNAL CLIP".

If the detection of DC DETECT is reset within 3 seconds, MUTE OFF & PROTECTION RELAY ON

are carried out.

NOTE) If the detection of DC DETECT is reset within 3 seconds and DC detection functions immediately,

PROTECTION RELAY OFF/ON is repeated, however, there is no problem.

1.2 OVER LOAD

MUTE ON & PROTECTION RELAY OFF are carried out immediately after the detection and the power is

turned OFF.

After OVER LOAD is detected, the key operation is not prohibited (the power supply can be turned ON).

NOTE) If a short of speaker cable may be generated, the connection is made again and the power supply

cannot be turned ON by a user, so a complaint is generated.

If AMP is broken actually, DC detection operates, so there is no problem.

1.3 Temperature PROTECTION

MUTE ON & PROTECTION RELAY OFF are carried out immediately after the detection and the power is

turned OFF.

After temperature PROTECTION is detected, the key operation is not prohibited (the power supply

can be turned ON).

NOTE) After the detection, if the temperature is still high even by turning ON the power supply,

the temperature PROTECTION is detected again and the power supply is turned OFF.

1.4 Power PROTECTION

MUTE ON & PROTECTION RELAY OFF are carried out immediately after the detection and the power is

turned OFF.

If the power supply is automatically turned OFF after the power PROTECTION is detected, all key operations are

prohibited (power ON is prohibited).

For turn ON the power supply again, refer to "3. How to reset the prohibition of power ON" shown below.

2. Keeping the prohibition of power ON after 1.1.1 AMP failure is detected and 1.4 power

PROTECTION is detected

If the power supply is automatically turned OFF after AMP failure is detected and power PROTECTION is detected,

all key operations are prohibited (power ON is prohibited).

The power ON prohibition status is kept even if the backup is carried out and the power cord is disconnected and

inserted.

For turn ON the power supply again, refer to "3. How to reset the prohibition of power ON" shown below.

5.2 PROTECTION CIRCUIT DESCRIPTION

6 7 8

A

B

C

5

6 7 8

A-30-K

D

E

F

15

1

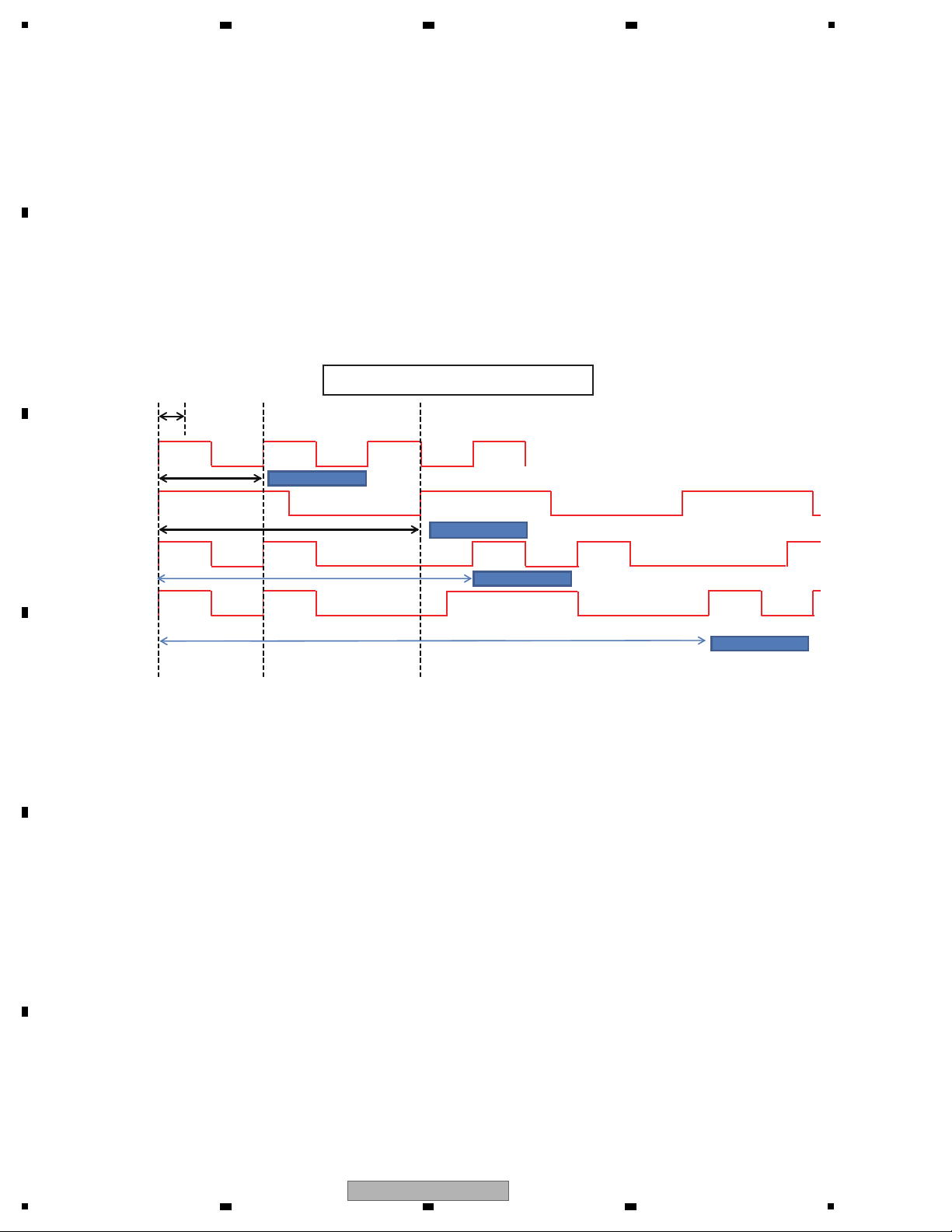

200ms

On

Temperature

Protection

Off

AMP Overload

Protection

1CYCLE : 1.4S

DC DETECT

(DC Balance)

Power

Protection

1TIME : 800mS

1TIME : 2.4S

1TIME: 4.2S

1TIME : 2S

Protect LED display specifications

3. How to reset the prohibition of power ON

Press Front Key [ DIRECT ] + [ SPEAKER B ] at the same time for 2 seconds or more continuously.

The key prohibition mode after 1.1.1 AMP failure is detected and 1.4. power PROTECTION is detected is released and

the power supply is turned ON.

4. STANDBY LED display after PROTECTION is detected

Each PROTECTION operations above are identified by blinking timing of STANDBY LED.

The blinking of LED is continued until the power supply is turned ON again.

For the blinking specification of LED, refer to "Protect LED display specifications" shown below.

A

B

2 3 4

C

D

E

F

16

1

2 3 4

A-30-K

5

1/1

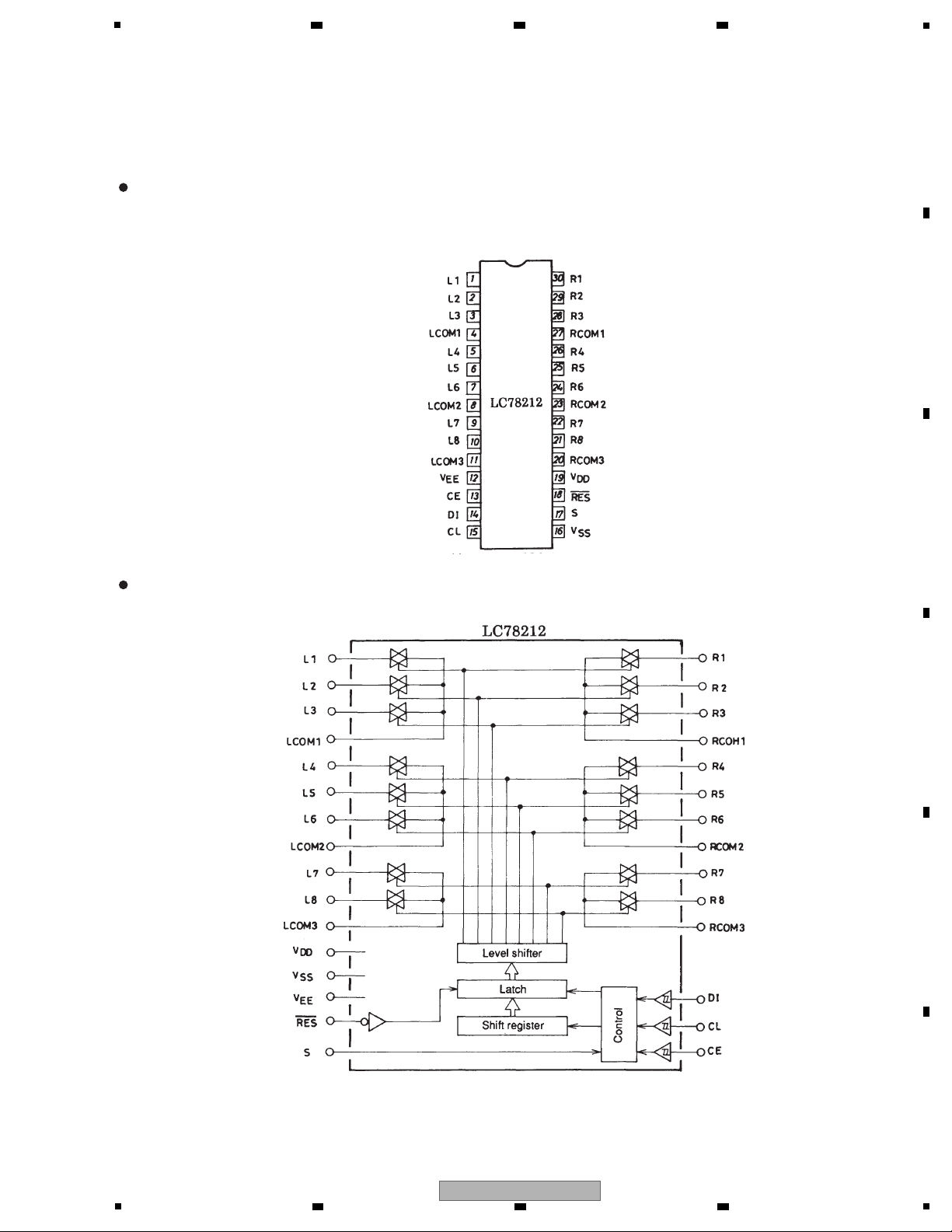

HVILC78212

(Analog Function Switch)

(Top View)

Pin Layout

Block Diagram

5.3 IC INFORMATION

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

17

1

1/1

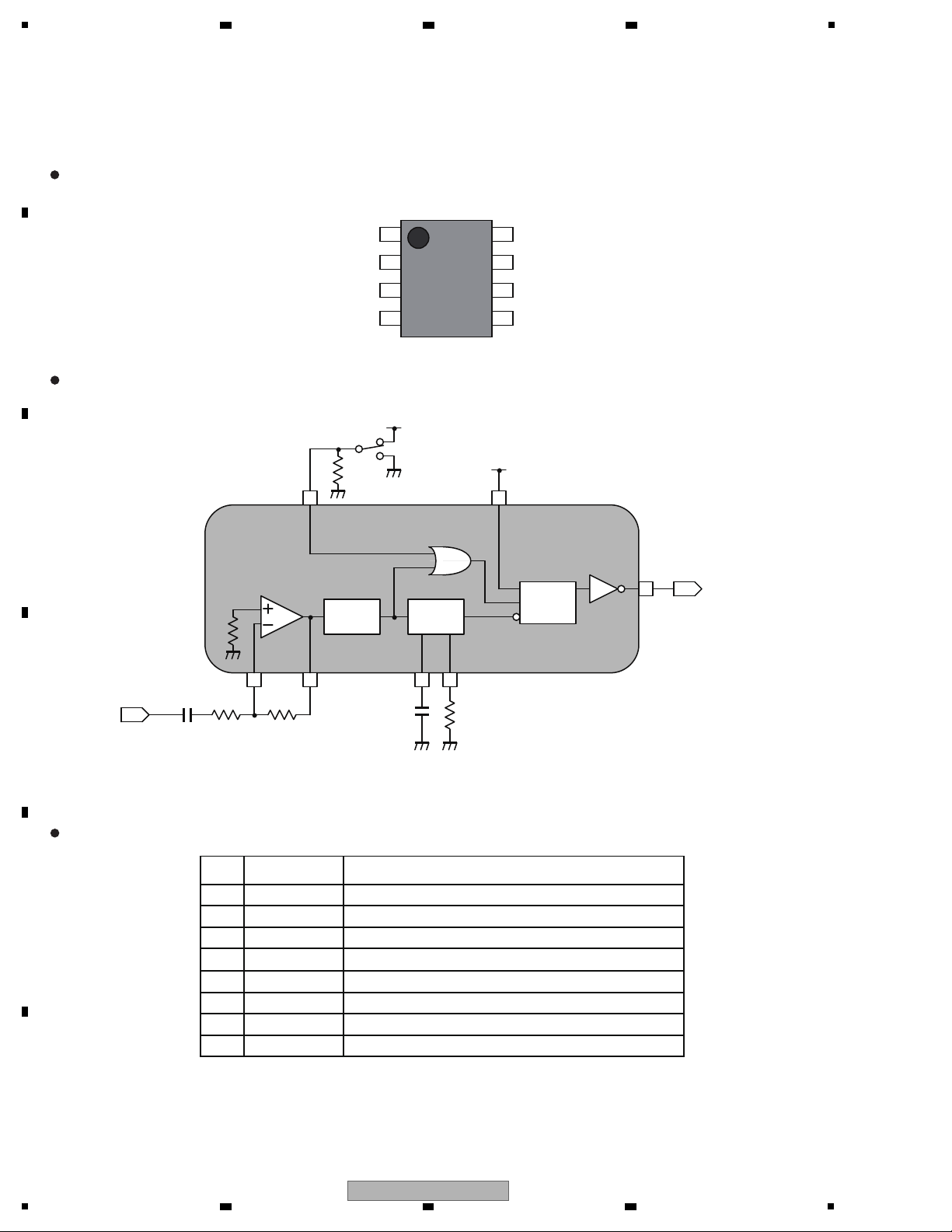

CVINJU7181RB1

(Signal Level Sensor System)

(TVSP8)

Level

Detector

Delay

Latch

CLR

D

L

IN

OUT

V

+

V

+

ON

OFF

External Trigger

18

54

Pin Layout

Block Diagram

Pin Function

(Top View)

1 IN AC Input

2 AMP_OUT Amplifier Output

3 TRIN External Trigger Input

4 GND Ground

5 CAP_D Capacitor connection terminal for delay time setting

6 RES_D Resister connection terminal for delay time setting

7 OUT DC Output

8 V

+

Power Supply Voltage

FunctionPin NameNo.

A

2 3 4

B

C

D

E

F

18

1

A-30-K

2 3 4

Loading...

Loading...