Page 1

176 S. New Holland Road

Gordonville, PA 17529

Tel: 717-768-0804

Fax: 717-768-8569

ASSEMBLY MANUAL

TreehouseLoft

Page 2

Treehouse Loft

Assembly Manual

Dear Customer,

This manual is designed to clearly explain the assembly process, however for best results we strongly

recommend having a carpenter involved in the project. Please read through the entire manual before

starting!!

For 2 men, it took 4 hours, using the tools listed below, to assemble this unit. However, it will probably take you a little longer since it will be a new project for you.

Take a deep breath and get at it, the satisfaction and enjoyment of playing in this unit is only a few

hours away. Have Fun!!!!!

Remember, it is very important that you have a level site for your Treehouse Loft, and that the floor is

level prior to setting the walls.

TOOLS NEEDED:

-7/16”,1/2”,9/16”, and 3/4” deep sockets with 1/2”

drive

-3/4” wrench

-Hammer

-Medium vise grip pliers

-#2 phillips and square drive screwdrivers or bits

-Screw gun

-Paint brushes (for touch-up)

-Utility knife

-8’ step ladder

-Level

-Square

HELPFUL TOOLS:

-Impact wrench with 1/2” drive

-Finish nail gun

-Roof nailer

-Air compressor

revised 4/18/08

Page 3

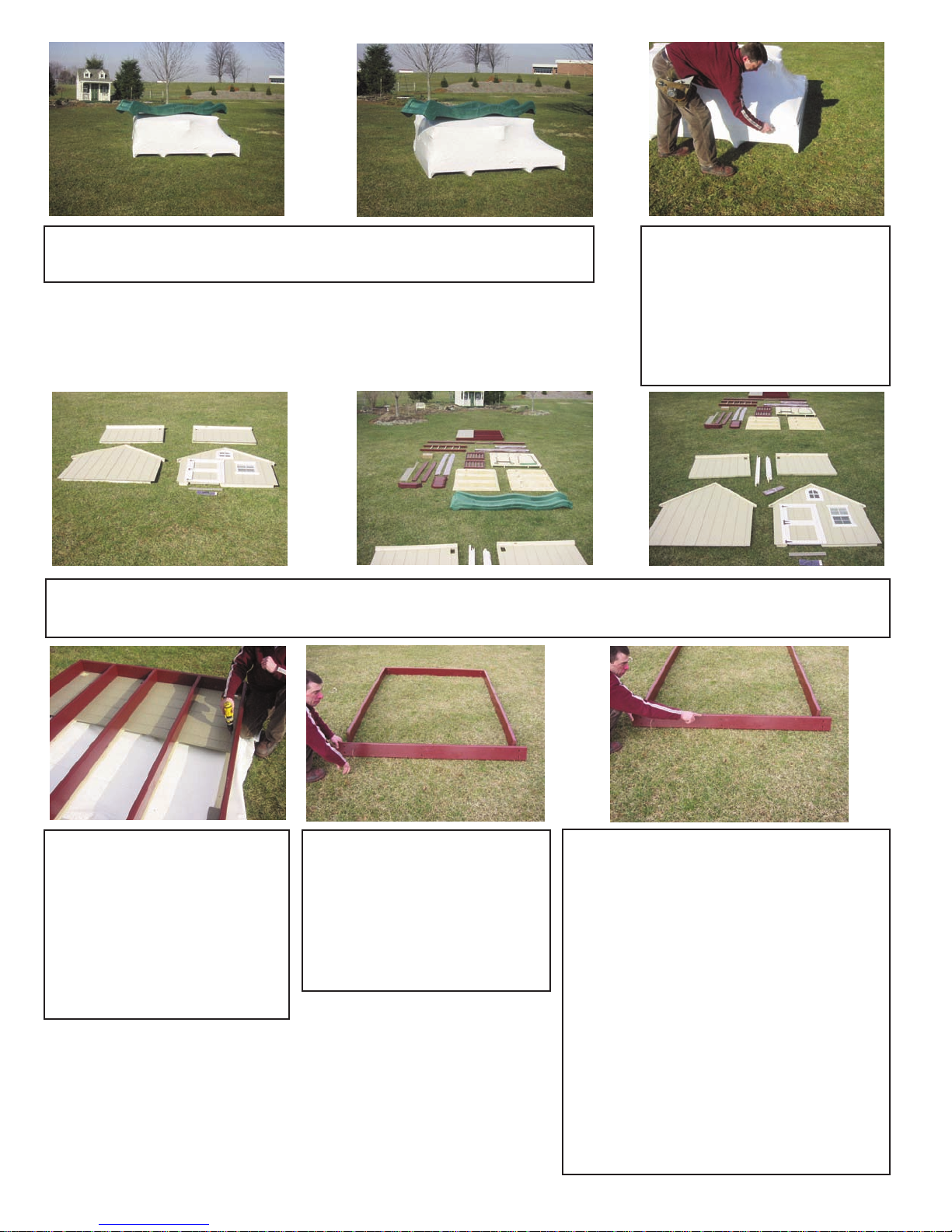

Step 1: This shows a wrapped swing set kit as it will

arrive to your destination.

Step 2: Start by cutting

open plastic shrink wrap;

slice all way around the

kit and then vertically at

each corner to remove

plastic.

Step 3: Remove all the parts from the kit and systematically lay them out on the

ground surface. Remove plastic wrapping from all parts.

Step 4: The last part in

the kit is the floor of the

play set; it may be

necessary to remove

some screws that attach

the floor to the shipping

Step 5: To start construction of your play set find

the four 2 x 6's that

make up the base. Two

are 72" and two are

86-1/4" long.

pallet.

© Pinnacle Play Systems page 3

Step 6: At the specific location

where you intend to erect your

play set, arrange the four pieces

as follows: the 72” piece with six

holes will be placed to the front,

the 72” piece with four holes will

be placed to the back, and the

two 86-1/4” pieces with no holes

will make up the sides of the

base. The 5/8” holes in the midsection of the front piece must

be left of center, to line up with

the holes in the floor.

Page 4

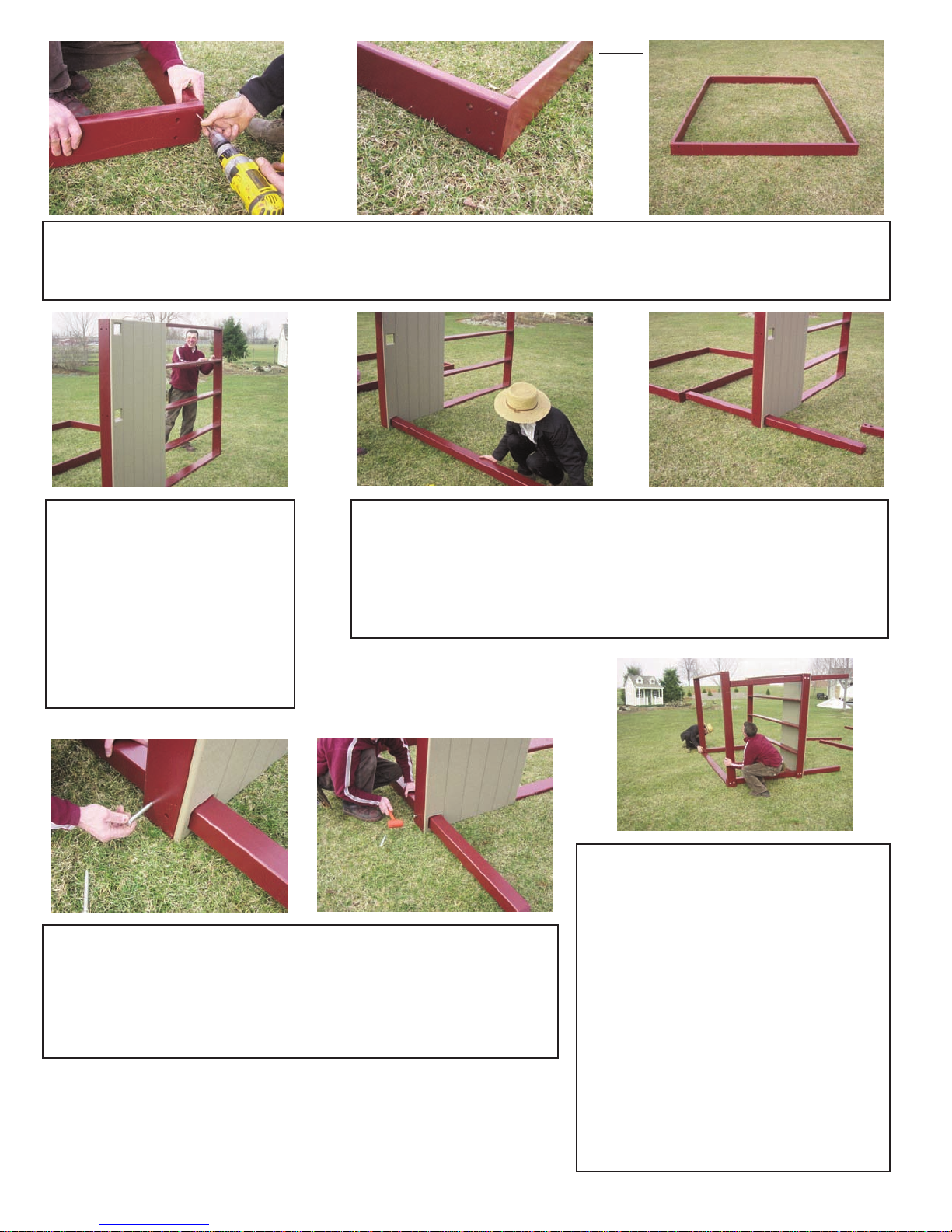

Step 7: Assemble the base by securing each corner of the base with three 2-1/2"

deck screws through the predrilled holes in the 72" front and back pieces into the

86-1/4" sides, keeping the 2 x 6's flush on the outside.

Step 8: When base is

completed stand floor

upright on its right side,

approximately 4-1/2' to

the right side of the base

Step 9: Insert three 90-1/2" 4x4 posts through the front

three post holes in the poly decking; keep the larger

recessed portion of the bolt holes in the post facing

towards the back of the play set. Also keep the

chipped top end of each post facing to the right.

with the poly decking

facing away from

base.

Step 10: When you insert posts, promptly insert 1/2"

x 4-3/4" carriage bolts through 5/8" holes in the floor

into 5/8" recessed holes in posts; line up the two

holes in floor with second set in posts, and insert

bolts.

© Pinnacle Play Systems page 4

Step 11: Install the two 54-1/2"

back posts at back corners of

your play set with the recessed

holes in the post facing towards

the front. Stand the base on the

right side as you are installing

4-3/4" carriage bolts through

the 2 x 6s in the floor and base

into the posts. The bottom

holes in the posts will line up

with the holes in the 2x6s of

the base.

Page 5

Step 12: When you have installed four 1/2" x 4-3/4" carriage bolts in each post ( twenty

total), secure bolts with 1/2" washer, lock washer, and nut on the threads of the carriage

bolts inside the recessed holes of the posts.

Step 13: Tighten 1/2" nuts with 3/4" socket wrench making sure that base and floor are square to posts. Be

careful not to over tighten, stop tightening when head of

carriage bolts start to sink into 2 x 6's.

Step 15: Check to make sure structure is square and

level. It may be necessary to add some blocks or fill

under posts to make level. Confirm that the unit is rotated exactly as you want it to be positioned in your yard.

Step 14: When all twenty

bolts are tightened the play

set is ready to stand up.

With a person on each side

stand structure upright on

base.

Step 16: Install 5'x6' floor

to playhouse, the 2x3

joists on the floor drop

down beside 2x6 joists

of the loft floor. Keep the

2x3s that are cut short

towards the back.

© Pinnacle Play Systems page 5

Page 6

Step 17: Secure 2x3s of

playhouse floor to 2x6s

with 2" deck screws,

making sure plywood is

down tight against

2x6's.

Step 18: Secure two 16" 4x4 corner braces to each corner post

underneath floor and against the

post, making sure to keep the

1/2" recessed hole towards the

post. Secure with 3/8"x 3" lag

bolts with washers at bottom.

Step 19: Secure top of

16" corner braces with

two 3" deck screws

through 2x6 floor joists

into the top of each corner brace.

Step 20: Secure 3/4" x 1-1/4" poly capping on top

of 2x6 base with 2-1/2" decking screws. Keep

screws about 2" from ends and about 18" apart.

Step 22: position 5-rung ladder at

front right opening keeping top

rung level with poly decking

Step 23: Secure 5-rung ladder with two 3/8"x 4" lag

bolts with washers through top holes in ladder into

4x4 posts.

(make sure that the top rung is

less than 3-1/2" away from floor to

leave no room for entrapment).

Step 21: Secure 28" 2x6 sand box

seat at each corner of the base.

Install two 2-1/2" deck screws

through each end of sandbox seat

through poly capping and into 2x6s

of the base. This completes the

floor and base of your play set.

© Pinnacle Play Systemspage 6

Page 7

Step 24: Position slide at front left opening of floor keeping centered between posts and no deeper than 8" from

edge of poly decking. Secure with two 1" pan head

screws through the top of slide into poly decking.

Step 25: You are ready to

start assembling your playhouse. Grab back wall with

no window and gable top.

Position at back of floor

with siding overlapping

floor at bottom.

Step 26: Keep end wall

studs 2 1/2" from each

side of the floor.

Step 29: Make sure

sidewall fits tight at back

corner, and secure bottom 2 x 3 of sidewall to

floor with four 3" deck

screws through 2x3 into

2 x 6 joist.

Step 27: Secure back wall

to floor with four 3" deck

screws through 2 x 3 bottom plate into 2 x 6 floor

joist.

Step 30: Position left sidewall on

left side of base making sure it

fits tight up against the back

wall and secure to loft with four

3" deck screws. The left sidewall will also have a 3" x 5-1/2"

opening at the top back corner

Step 28: Position right

side sidewall with the 3" x

5-1/2" opening (see step

#52) at the top back corner for the swing arm.

Step 31: Install the

front wall by lifting up

on to loft and position

be-tween sidewalls;

make sure corners fit

tightly.

for the swing arm.

© Pinnacle Play Systems page 7

Page 8

Step 32: Secure to

floor with 3" deck

screws at 18" and

36" from inside siding of right sidewall.

Step 33: Finish

securing walls with

3" deck screws at

bottom of rafters at

each corner.

Step 34: Secure

each corner where

walls meet with five

3" deck screws.

Step 35: Secure poly

strip at bottom of door

opening where plywood meets poly

decking with two 1"

screws.

Step 36: Position roof panels by lifting over sidewalls keeping 1 x 3's towards

the peak. Roof panels are interchangeable and will fit on either side.

Step 37: Make sure

rafters line up at peak

with rafters on gable

end walls and down

tight against top of side-

Step 38: Secure roof

panels with three 3"

deck screws through

each outside rafter

into gable rafters.

walls.

© Pinnacle Play Systems page 8

Step 39: Secure bottoms of each rafter with

a 3" deck screw

through 2 x 6 of sidewalls up into bottom of

rafters.

Page 9

Step 40: Secure door

handle to bottom right

corner of top door with

three screws provided

with handles.

Step 41: Secure shutters

to the left and right side

of window with eight

screws provided with

shutters. Keep contour in

shutters towards the top.

Step 42: Install plugs in

screw holes to complete

shutter installation.

Step 43: Install handles

on ladder with four 1

1/4" lag bolts using a

1/2" socket. Position

handle 2" down from top

of ladder and centered

on 4 x 4's.

Step 44: Install trim on outside of

playhouse with finish nails. Start

with four corner trim pieces

which each consist of two 1 x 3s

that are nailed together. One

piece on the corner trim will have

an angle cut that fits up against

angle on the gable end walls.

Step 46: Install the four peak

trim pieces to gable end

walls with finish nails. Start at

the peaks and keep the top

of the trim flush with the top

of the plywood roof panels.

Step 47: Install the soffit

trim keeping the ends

flush with bottom corners of the peak trim.

Step 45: Two pieces

have a notch cut out at

the bottom to fit over

poly decking on loft.

Step 48: Secure bottom

ends of peak trim to soffit trim keeping corners

flush.

© Pinnacle Play Systemspage 9

Page 10

Step 49: Position railing at front side openings of loft

between front posts and playhouse. Secure each railing

with three 2" deck screws through each end cap on the

railing and into the post and the playhouse wall.

Step 50: Layout both sections

of two piece swing arm on

ground to install two cast

iron swing hangers at each

end. You will see how they

will overlap in the middle.

Step 51: Secure swing hangers to bottom of swing arm with 1/2" x 6-1/2" carriage bolts

through the top of swing arm and swing hanger. Install 1/2" lock washer and nut on to

threads of 6 1/2" carriage bolts and tighten with 3/4" socket wrench.

Step 52: Slide one section of swing arm through 3" x 51/2" holes in each side wall.

© Pinnacle Play Systems page 10

Page 11

Step 53: Overlap swing

arm inside playhouse and

line up two 5/8" recessed

holes toward center of

swing arm.

Step 54: Secure two sections together with 1/2" x 2-1/2"

carriage bolts through 5/8" recessed holes and install

1/2" washer, lock washer, and nuts on threads of 2-1/2"

long carriage bolts. Tighten with 3/4" socket wrench.

Step 55: Line up swing

arm on back wall so

that the 1/2" recessed

holes on both sides are

centered on the outside

studs on the back wall.

Congratulations, this completes the construction of your kit! Follow

manufacturer’s instructions for applying roof shingles and paint to your

liking. It will be necessary to check for splinters and screws that protrude

through surfaces during and after the entire assembly process. Be sure to

remove sharp objects and check play set periodically for loose hardware.

Step 56: Secure swing

arm to back wall with

four 3/8" x 4" lag bolts

with washers, there are

two holes at each side.

Step 57: Install spring

clips and swings on to

swing hangers.

© Pinnacle Play Systems page 11

Page 12

© Pinnacle Play Systems

Instructions for paint touch up on a

Pinnacle Playset

A major benefit of purchasing a painted playset is that damage to the set via a pocket

knife, etc. can be rectified with caulk and touch up paint. This also applies to the splitting and checking found in all outdoor wood products made from cedar, redwood,

pine, etc. The splits seen in larger dimensional lumber are also known as checks and

are more of a cosmetic concern than a structural concern. These generally occur in

large lumber such as 4x4’s and 4x6’s.

We have constructed this manual to assist you in repairing damages, general touch

up associated with a painted set, and in filling checks that are less than 1/4” wide.

Tools Needed

- Paint scraper or putty knife

- Touch-up paint

- Sanding pad with 80 grit sandpaper

- Paintbrush or small roller

- Caulking gun with tube of acrylic latex caulk

(fast drying non shrinking formulas work best)

Page 13

Step 1: After cleaning the surface, slowly apply caulking into the

check of the wood from one end to the other. The caulking

should penetrate into the check and fill it up leaving little excess

on the outside of the wood.

Step 2: Remove excess

caulking from wood with putty

knife or scraper leaving a

smooth surface over the

check. . .

Step 2 cont... leaving minimal

excess caulk.

Step 3: Allow caulking to dry

according to manufacturer’s recommendation. If the repaired surface

of the caulking seems to have

shrunk into the check, apply a second coat of caulk and allow time to

dry.

Step 4: When caulking has

dried, sand surface lightly with

sanding pad to remove

excess caulk. The acrylic

latex paint we use tends to

stay soft and pliable. Sand

with light quick strokes, being

careful not to remove original

coat of paint.

Step 5: When applying touch-up paint to wood, apply a thick coat of paint to cover area, smooth out

with brush or roller and allow time to dry (generally less than 6 hours). The touch-up paint will work

as a primer and a topcoat. Apply a second coat of paint after the first coat has dried. The second

coat of paint is essential to provide long lasting protection and restore the repaired area to the same

luster as the original paint.

© Pinnacle Play Systems

Loading...

Loading...