Page 1

Piaggio would like to thank you

for choosing one of its products. We have drawn up this booklet to show you all features of our product. Please read the booklet carefully before using

your vehicle. It includes information, suggestions and warnings regarding your vehicle. You will also be informed of features, details and devices that

will prove the excellence of your choice. We believe that if you follow our suggestions you will soon tune in with your vehicle and use it for a long time

at full satisfaction.

This booklet is an integral part of the vehicle, and upon sale, it should be transferred to the new owner.

Ape TM - Ape TM Diesel

Ed. 01_02/2012

Page 2

INSTRUCTIONS

The instructions given in this booklet are intended to provide a clear, simple guide to using your scooter; details are also given of routine maintenance

procedures and regular checks that should be carried out on the vehicle at an Authorised PIAGGIO Dealer or Service Centre. The booklet also

contains instructions for simple repairs. Any operations not specifically described in this booklet require the use of special tools and/or particular technical

knowledge: to carry out these operations refer to any authorised PIAGGIO Dealer of Service Centre. Read this booklet carefully before using your

vehicle. Follow the instructions contained in this booklet for your personal safety and to ensure long-lasting use of your vehicle. Failure to observe these

instructions may cause personal injury or damage to the vehicle.

2

Page 3

Personal safety

Failure to completely observe these instructions will result in serious risk of personal

Safeguarding the environment

Sections marked with this symbol indicate the correct use of the vehicle to prevent dam-

aging the environment.

The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

The signs indicated on this page are very important, they highlight the parts of the booklet

that should be read with particular care. Each sign consists of a different graphic symbol,

making it quick and easy to locate the various topics.

injury.

Vehicle intactness

3

Page 4

4

Page 5

INDEX

IDENTIFICATION......................................................................... 7

Vehicle identification number.................................................... 8

SAFE RIDING.............................................................................. 11

Safe drive.................................................................................. 12

Running-in period...................................................................... 12

VEHICLE USE.............................................................................. 13

Checks...................................................................................... 14

Before starting the engine......................................................... 18

Engine start up.......................................................................... 19

Stopping the engine.................................................................. 21

Starting difficulties..................................................................... 21

Gear position............................................................................. 22

Driving Tips............................................................................... 23

DOORS AND LOCKS.................................................................. 27

Keys.......................................................................................... 28

Door locking/unlocking by key............................................... 28

Front door windows................................................................... 29

Engine inspection port.............................................................. 30

SEATS AND SAFETY BELTS..................................................... 31

Using the safety belts................................................................ 32

Fasting the safety belt........................................................... 33

Adjusting the safety belt........................................................ 34

To release the safety belt...................................................... 34

INSTRUMENT PANEL AND CONTROLS................................... 35

Handlebars............................................................................ 36

Steering wheel....................................................................... 39

Controls..................................................................................... 43

Ignition switch........................................................................... 53

GAUGES AND WARNING LIGHTS............................................ 55

Instrument unit and indicators................................................... 56

AIR CONTROL SYSTEM............................................................. 57

Heating.................................................................................. 58

Heating and demisting........................................................... 59

Demisting.............................................................................. 59

MIRRORS AND WINDOW GLASSES......................................... 61

Adjusting the mirror............................................................... 62

Wipers and Brushes.................................................................. 62

INSIDE EQUIPMENT................................................................... 65

ELECTRICAL SYSTEM............................................................... 67

Fuel version.............................................................................. 68

Diesel version........................................................................... 68

EMERGENCY.............................................................................. 71

Wheel replacement................................................................... 72

Maintenance instructions....................................................... 72

MAINTENANCE........................................................................... 75

Check engine oil level........................................................... 76

Oil change and oil filter replacement..................................... 76

Checking the brake fluid level................................................... 79

Gear box oil level...................................................................... 81

Window washer fluid level......................................................... 83

Cooled fluid............................................................................... 83

Changing the engine cooling fluid......................................... 84

Checking and replacing the air cleaner element....................... 84

Replacing the fuel filter............................................................. 85

Air bleeding........................................................................... 86

Fuel exhaustion..................................................................... 86

Checking and replacing the pre-heating plugs.......................... 87

Fuses........................................................................................ 88

Exhaust circulation system (EGR)......................................... 91

Tyres......................................................................................... 91

Pressure................................................................................ 92

Periods of inactivity................................................................... 92

Troubleshooting / What to do if................................................. 98

SPARE PARTS AND ACCESSORIES........................................ 107

Warnings................................................................................... 108

TIPPER VERSION....................................................................... 109

5

Page 6

System Operation..................................................................... 110

Warnings for Loading and Unloading Operations..................... 111

Scheduled Maintenance........................................................... 114

Extraordinary Maintenance....................................................... 116

Trouble-Shooting...................................................................... 117

Warning Plate Symbols............................................................. 120

technical sheet for EC conformity declaration........................... 123

Preface.................................................................................. 123

Equipment Layout................................................................. 124

Analysis of Risks Connected with the Layout and Operation

of the Equipment................................................................... 127

TECHNICAL DATA...................................................................... 135

Vehicle...................................................................................... 138

SCHEDULED MAINTENANCE - CHECKS................................. 149

Scheduled maintenance service............................................... 150

6

Page 7

Ape TM - Ape TM Diesel

Chap. 01

Identification

7

Page 8

01_01

01_02

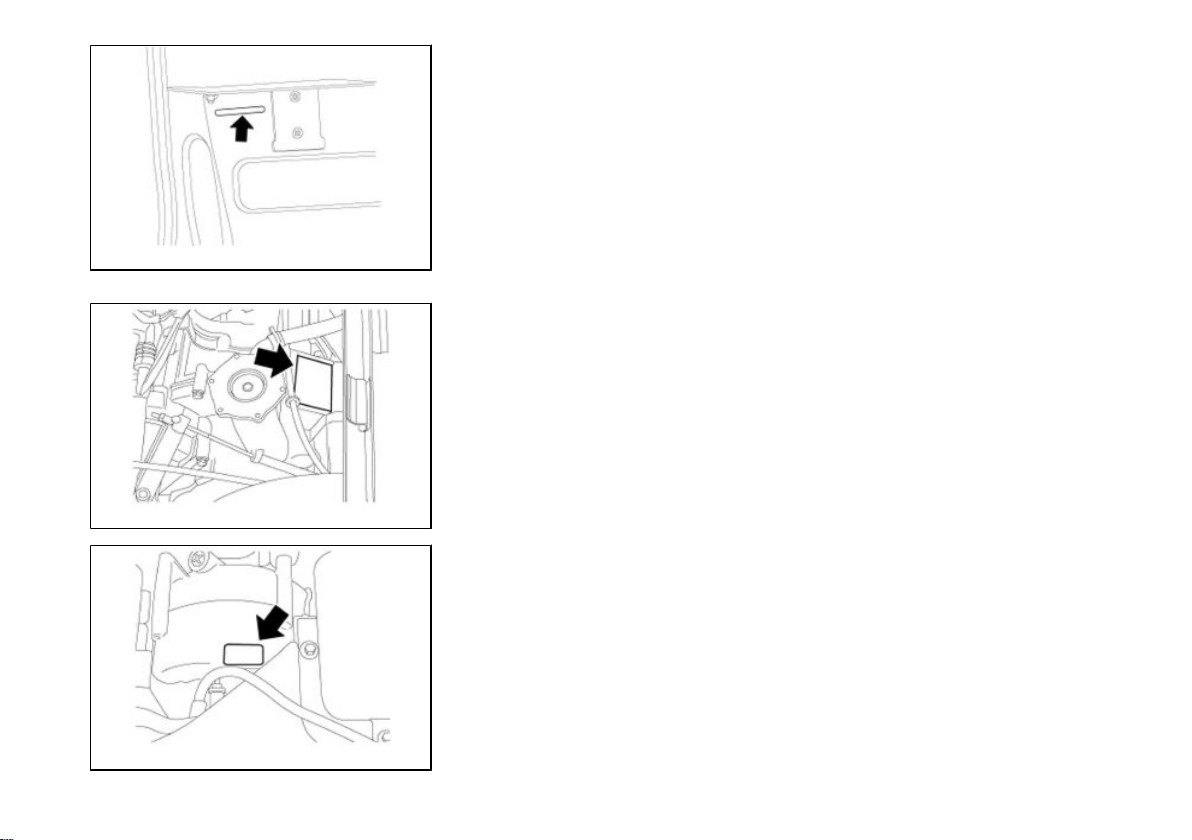

Vehicle identification number (01_01, 01_02, 01_03)

The identification codes consist of a prefix followed by a number punched on the

chassis and on the engine, respectively.

Always quote the serial numbers when ordering spare parts.

The chassis identification number is located on the crossmember under the seat as

shown in the figure.

The frame identification code is:

ZAPT1000000001001

Check that the chassis prefix and number punched on the vehicle correspond to that

shown on the vehicle documents.

The engine identification number is printed as shown in the figure.

The first indicates the location of the plate on the diesel engine, while the second is

on the gasoline engine.

The gasoline version engine identification initials are:

ATM2M

The diesel version engine identification initials are:

LDW 422

01_03

8

Page 9

1 Identification

CAUTION

BE REMINDED THAT ALTERING IDENTIFICATION REGISTRATION NUMBERS

MAY LEAD TO SERIOUS PENAL SANCTIONS (IMPOUNDING OF THE VEHICLE.

ETC.)

9

Page 10

10

Page 11

Ape TM - Ape TM Diesel

Chap. 02

Safe riding

11

Page 12

02_01

Safe drive (02_01)

ENSURE THE SPARE WHEEL IS CORRECTLY SECURED TO THE SEAT

THROUGH THE RETAINING STRAP, IN ORDER TO PREVENT IT FROM MOVING

IN THE EVENT OF AN EMERGENCY STOP.

Running-in period

During the first 1000 km, do not twist the throttle fully open and avoid driving at constant

speed over long stretches of roads. After the first 1000 km gradually increase speed

until reaching the maximum performance.

12

Page 13

Ape TM - Ape TM Diesel

Chap. 03

Vehicle use

13

Page 14

TYRE PRESSURE

Front tyre pressure 2.5 atm

Rear tyre pressure 4.5 atm

Checks (03_01, 03_02, 03_03, 03_04)

Before using the vehicle, check:

1. That the oil and fuel (for fuel versions) tanks are filled.

2. The engine/transmission oil level (for diesel versions).

3. The brake fluid level.

4. That the tyre inflation pressure is correct.

5. Correct operation of side/taillights, headlights and turn indicators.

6. Front and rear brake operation.

7. Gearbox oil level (for petrol versions).

8. Electrolyte and battery charge check.

9. Check coolant (diesel version)

CAUTION

TYRE PRESSURE SHOULD BE CHECKED WHEN TYRES ARE COLD.

Fuel tank

14

Page 15

3 Vehicle use

The fuel filler cap is fitted with a lock.

To open: insert the supplied key and turn it anticlockwise.

To close: put the filler cap back in position, turn the key clockwise and remove.

For petrol versions, the recommended fuel is as follows:

- unleaded petrol.

For diesel versions, the recommended fuel is as follows:

- diesel normally found on the market.

To this purpose please note that at low temperatures the paraffin elements contained

in diesel spontaneously dissociate, thereby decreasing fluidity. If it is not possible to

use winter type diesel, mix diesel with a special additive in the amounts indicated on

the container.

The additive must be poured into the tank before the diesel and before the process

described above since a late addition generates no effects.

CAUTION

•

WHEN REFUELLING, KEEP THE CAP CLEAN FROM DUST AND DIRT.

CAUTION

BEFORE REFUELLING, STOP THE ENGINE. PETROL IS HIGHLY INFLAMMABLE. DO NOT DROP PETROL ON HOT ENGINE PARTS. DO NOT SMOKE. KEEP

NAKED FLAMES AWAY: FIRE HAZARD. DO NOT INHALE PETROL FUMES.

15

Page 16

FUEL

Total capacity: 15 litres

Fuel (Unleaded petrol)

03_01

Oil tank (for petrol versions)

The oil tank is provided with a light reserve indicator on the instrument panel.

To top up, remove cap «B» and pour in new oil.

CAUTION

03_02

USING OTHER TYPES OF OIL CAN COMPROMISE ENGINE DURABILITY.

Recommended products

AGIP CITY TEC 2T

Oil for 2-stroke petrol engines

JASO FC, ISO-L-EGD Specifications

16

Page 17

3 Vehicle use

Characteristic

Mixer oil (2.0 l)

RESERVE: 0.6 l

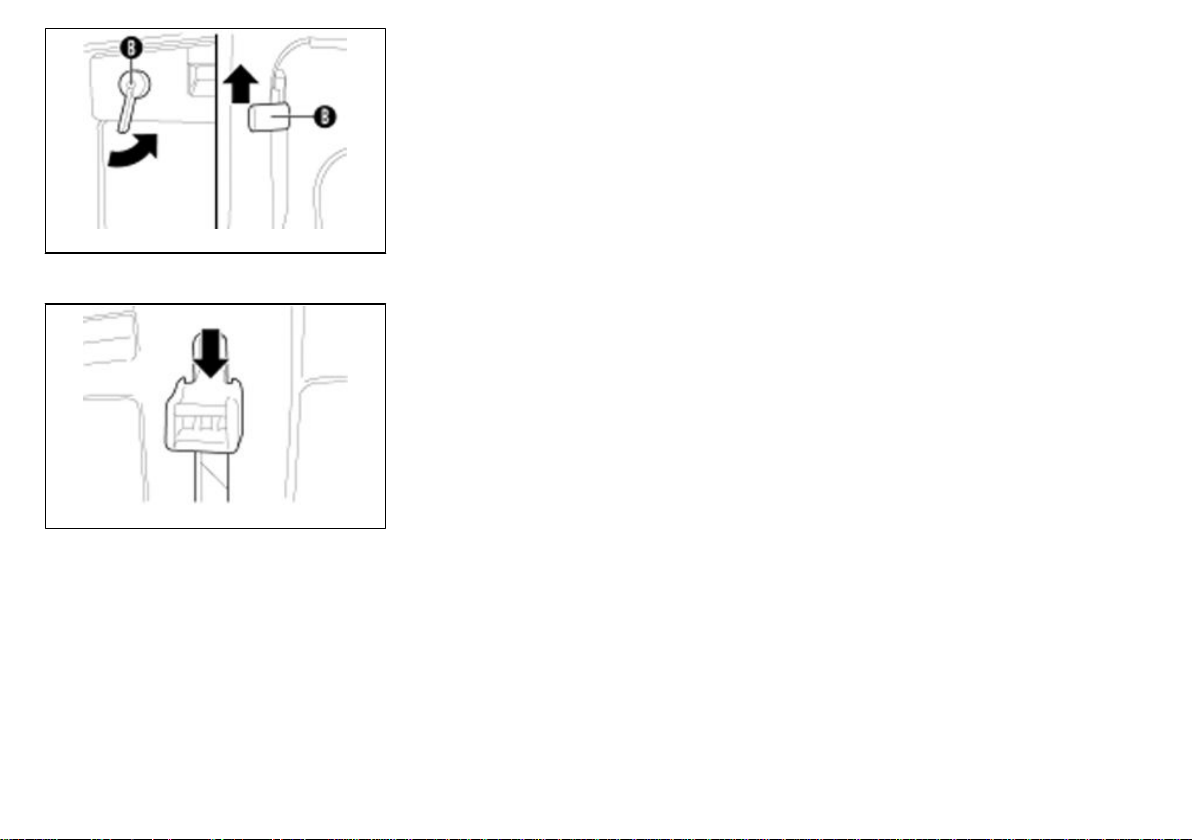

Removing the battery

The battery is located under the seat. The latter can be easily tilted removing the two

nuts «A» located at the two ends below the seat, as shown in the figure.

If it is necessary to remove the battery from its housing (for replacing or charging it),

disconnect the cables, remove nut «B» and release the battery from the locking

bracket «C».

CAUTION

03_03

NEVER DISCONNECT THE BATTERY WHEN THE ENGINE IS RUNNING TO

AVOID DAMAGING THE ELECTRICAL SYSTEM.

BATTERY ELECTROLYTE CONTAINS SULPHURIC ACID: AVOID CONTACT

WITH EYES, SKIN AND CLOTHES. IN THE EVENT OF ACCIDENTAL CONTACT,

RINSE WITH PLENTY OF WATER AND SEEK MEDICAL ADVICE

WARNING

03_04

USED BATTERIES ARE HARMFUL FOR THE ENVIRONMENT AND MUST BE

COLLECTED AND DISPOSED OF IN COMPLIANCE WITH THE LAW.

17

Page 18

Installing a new battery

Make sure the terminals are fitted correctly. The battery is an electrical device that

requires careful checks and diligent maintenance.

CAUTION

DO NOT INVERT THE POLARITIES: DANGER OF SHORT-CIRCUIT AND FAULTS

IN THE ELECTRICAL DEVICES.

Checking electrolyte level

The electrolyte level must be checked frequently and must reach the maximum level.

Top up exclusively with distilled water.

If the battery requires topping up too frequently, check the electrical system - the battery is probably working in overload conditions, which will lead to rapid deterioration.

Before starting the engine

- Ensure that the parking brake is released.

- Ensure that the reverse gear control lever is forward or backward according to

whether you want to move forward or in reverse.

- Ensure that the gear control lever is in neutral position: position N for the handlebar

version, central lever position for the steering wheel version.

THIS PRELIMINARY OPERATION IS NOT REQUIRED IN THE STEERING WHEEL

DIESEL VERSION.

18

Page 19

3 Vehicle use

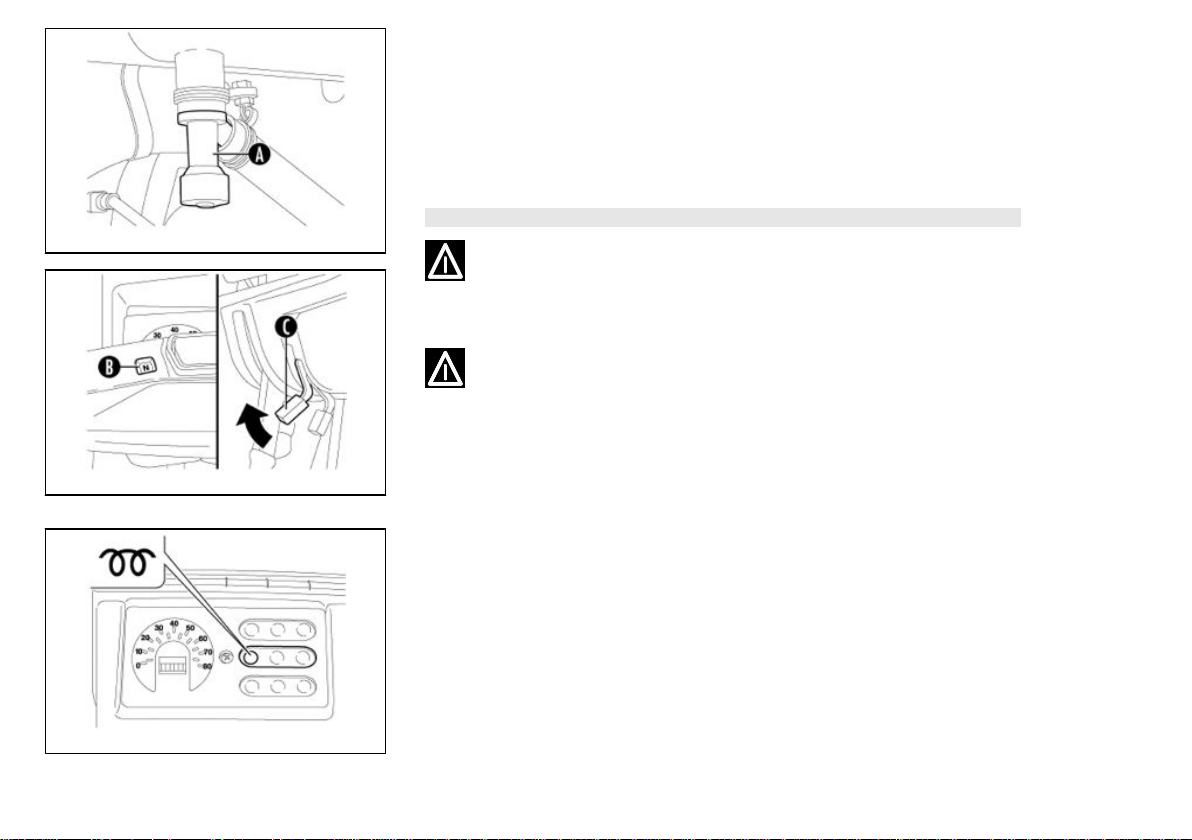

Engine start up (03_05, 03_06)

Engine ignition (gasoline version)

Open the fuel cock «A» (turn it counter clockwise to open and clockwise to close).

With cold engine, pull the starter lever «C» and insert the start key into the key switch,

then turn it to position 2 and at the same time press the accelerator control.

After start up, release the key that will automatically return to position 1.

WARNING

03_05

EXHAUST GASES ARE TOXIC. DO NOT START THE ENGINE IN A CLOSED

PLACE.

WHEN THE ENGINE IS ON, DO NOT HANDLE PARTS AND CONNECTIONS OF

THE ELECTRIC SYSTEM, ESPECIALLY THE SPARK PLUG CABLE.

03_06

Engine start up (03_06, 03_07)

Engine ignition (diesel version)

Introduce the start key into the switch and move it to position 1. On the instrument

panel, the glow plug preheat indicator will light up. The hotter the engine, the sooner

the indicator will turn off. Then move the key to position 2 while pressing the accelerator control at the same time. After start up, release the key that will automatically

return to position 1.

03_07

19

Page 20

WARNING

EXHAUST GASES ARE TOXIC. DO NOT START THE ENGINE IN A CLOSED

PLACE.

Engine start up (03_07, 03_08)

Starting off (versions with handlebar)

With idle engine, pull the clutch lever «A» and turn the gear knob to the 1st gear

(position 1 on the gear indicator «B »). To start off, release the clutch lever «A»

smoothly and accelerate by turning the throttle twist grip «C».

WARNING

03_08

03_09

EXHAUST GASES ARE TOXIC. DO NOT START THE ENGINE IN A CLOSED

PLACE.

Engine start up (03_08, 03_09)

Start-up (handlebar versions)

With idle engine, press the clutch pedal «A» and engage the first gear with the gearbox

lever. Gently release the clutch pedal while gradually pressing the accelerator pedal

«B».

20

Page 21

Stopping the engine

3 Vehicle use

Stopping the engine (handlebar)

Before stopping the engine, shift to neutral (position «N» on the gear indicator « B »).

Then turn the ignition key to «A».

Stopping the engine (steering wheel)

Before stopping the engine, move the gearbox to neutral (central position), then turn

the switch key to position «A».

Starting difficulties

Engine starting difficulties (gasoline version)

Possible causes and suggested actions:

- Carburettor flooded.

Close the fuel cock, turn the start key to position "1"; with closed starter open the gas

thoroughly and actuate the key switch, moving it to position "2"; open the fuel cock

again and move the key switch to position "2". In any case, do not try starting for more

than 5-6 times.

- Dynamotor or battery inefficiency.

Use an auxiliary battery with equivalent or slightly higher specifications with respect

to the original battery.

If you need to bump start the vehicle (by pushing or towing), follow these instructions:

engage a high gear (2nd or 3rd), do not exceed 20 kph (even when freewheeling),

release the clutch pedal or lever gradually.

21

Page 22

03_10

Before performing this operation, check the reverse lever position. If you cannot start

the engine even with the procedure described above, contact an Authorised PIAG-

GIO Service Centre.

CAUTION

NEVER STRESS THE ENGINE AT LOW TEMPERATURES IN ORDER TO AVOID

POSSIBLE DAMAGE. WHEN DRIVING DOWNHILL, DO NOT EXCEED TOP

SPEED OR THE ENGINE COULD BE DAMAGED BY PROLONGED OVERREVVING.

CAUTION

•

AFTER A LONG JOURNEY ALLOW THE ENGINE TO RUN AT IDLE

SPEED FOR A FEW SECONDS BEFORE SWITCHING IT OFF.

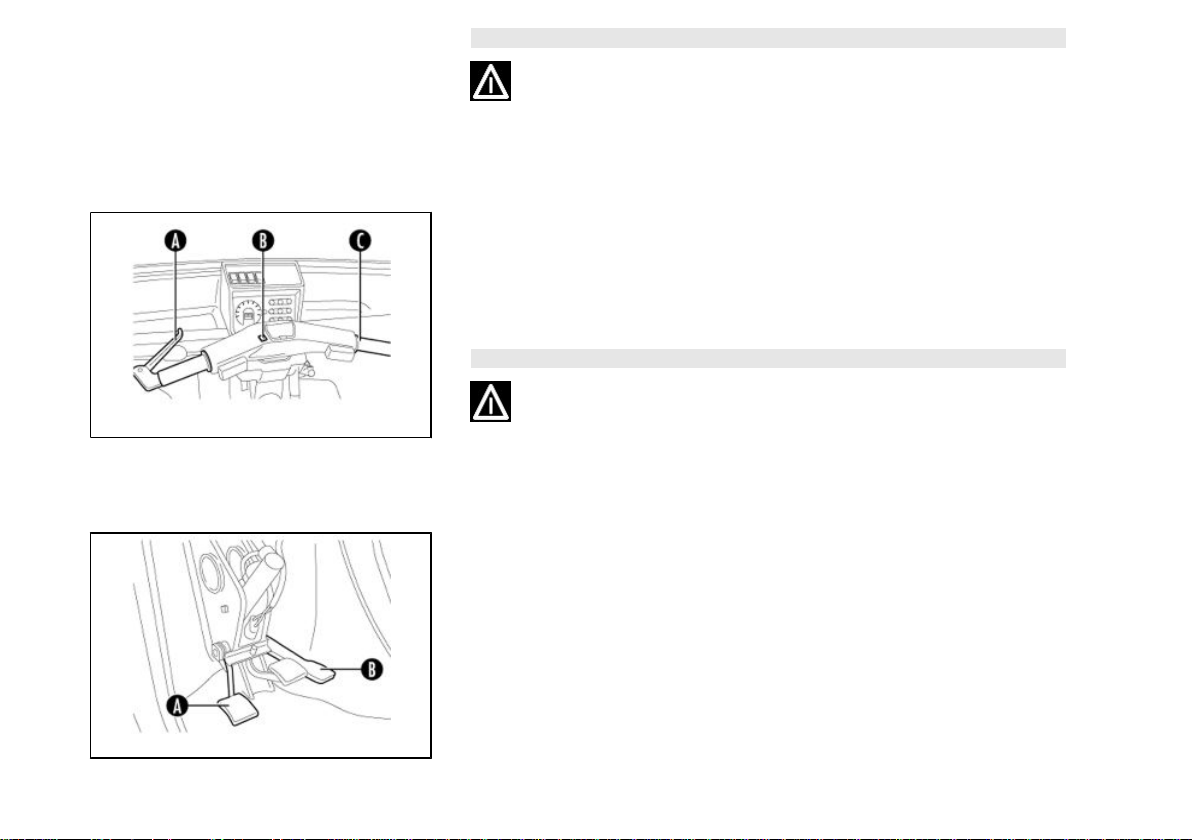

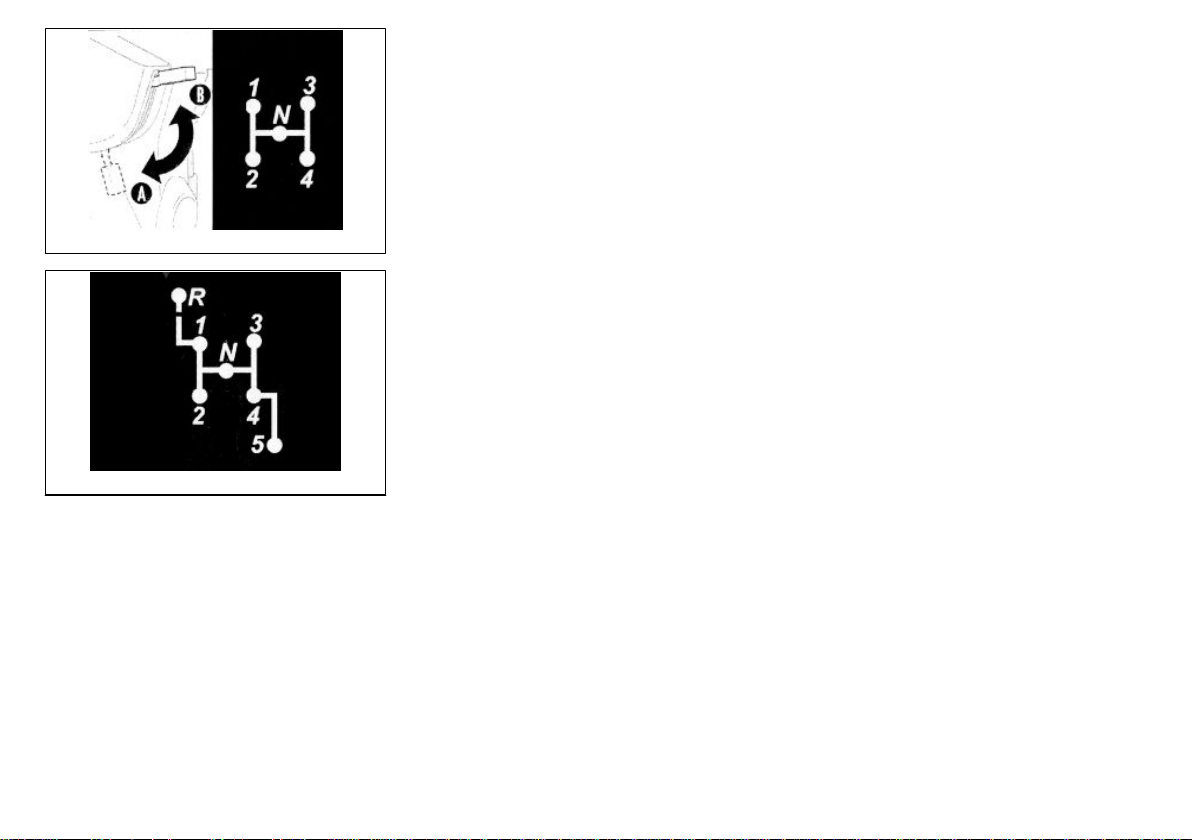

Gear position (03_10, 03_11, 03_12)

To reverse the vehicle, proceed as follows:

1. Stop the vehicle completely and turn the gear selector to neutral (position «N» on

the gear indicator «B») while the engine is idling;

2. For gasoline versions, lift the reverse gear control lever from position «A» to position

«B».

3. Diesel versions are not equipped with a reverse gear control lever.

4. Use the gear control lever to engage gears; («1stgear» for the gasoline version,

«R» for the handlebar version), and gently release the clutch pedal while gradually

pressing the accelerator pedal.

22

Page 23

3 Vehicle use

5. To shift from reverse gear to the forward gears repeat the previously described

procedures and move the reverse gear control lever to the «A» position (in the gasoline version and in the handlebar version).

Note: in the diesel handlebar version, once the reverse gear control lever has been

moved to the «B» position, both the reverse gear and the «1st gear» can be used for

vehicle parking manoeuvring; engagement of higher gears remains disabled until the

reverse gear control lever is set to the «A» position.

03_11

03_12

Driving Tips

Follow these simple recommendations to use your vehicle every day, confidently and

safely.

Your ability and your mechanical knowledge form the basis of safe riding. Practice

driving in a traffic-free area until you acquire a good knowledge of the vehicle.

1. Always drive within the limits of your ability, strictly following the road regulations of

the country where you are driving.

23

Page 24

2. Carefully adjust the position of rear-view mirrors, to easily check the road behind

you.

3. Ensure nothing hinders the pedals stroke (mats, etc.)

4. Ensure that headlights are working properly.

5. To start the vehicle, with idle engine, engage the first gear and gently release the

clutch lever, accelerating at the same time.

6. Reduce speed on badly surfaced roads and drive with caution.

7. Do not brake fully on wet, unsurfaced or slippery roads.

8. Do not shift down when the engine is running at high revs to avoid dangerous over-

revving.

9. On a downhill, do not keep the gearbox to neutral position or the engine off, but

decrease speed closing the accelerator. To facilitate the decrease of speed, use the

brakes without pulling them for too long, to prevent dangerous overheating that would

decrease their efficiency. Shift down to increase the engine brake effect.

10. For rapid pick-up, e.g. for overtaking, shift down a gear to employ all the required

power.

11. When driving up demanding slopes, shift down to employ all the required power.

12. Check that the load is evenly distributed on the loading body, and do not exceed

the provided loads (see chapter: "Technical data -performance") to prevent tilting while

turning on a corner.

ALWAYS DRIVE YOUR VEHICLE WITHIN THE LIMITS OF YOUR ABILITY. DRIVING WHILE DRUNK OR UNDER THE EFFECT OF DRUGS OR CERTAIN MEDICINES IS EXTREMELY DANGEROUS AND INFRINGES THE ROAD REGULATIONS.

24

Page 25

3 Vehicle use

ANY CHANGES TO VEHICLE PERFORMANCE, AS WELL AS ALTERATIONS TO

ORIGINAL STRUCTURE PARTS, RENDERS THE VEHICLE NO LONGER CONFORMING TO THE APPROVED TYPE AND THEREFORE DANGEROUS FOR

DRIVING SAFELY.

25

Page 26

26

Page 27

Ape TM - Ape TM Diesel

Chap. 04

Doors and locks

27

Page 28

04_01

04_02

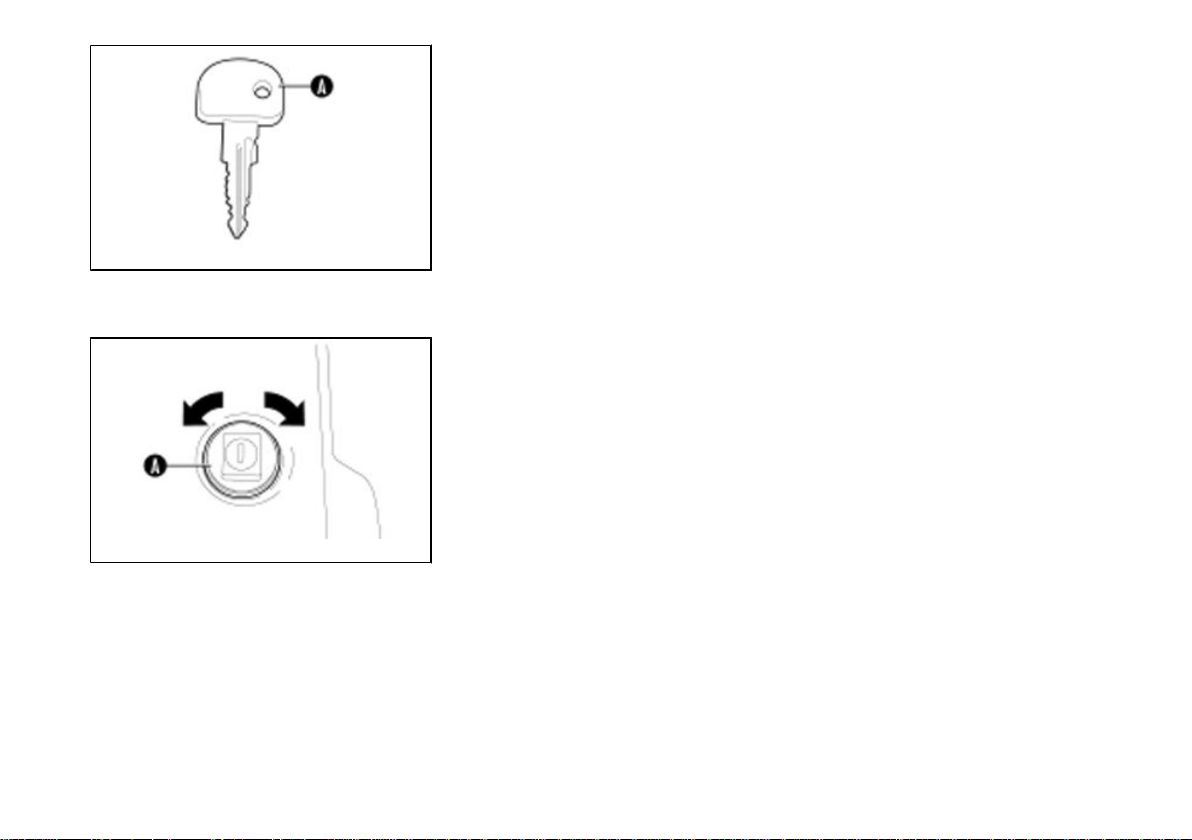

Keys (04_01)

The vehicle is supplied with two copies of the key.

«A»: key for the ignition and start-up switch, the door lock and the fuel tank cover.

The code numbers, in fact, are the only way to identify the key for future copies.

YOU SHOULD KEEP A DUPLICATED KEY AND ITS CORRESPONDING CODE IN

ANY PLACE OTHER THAN THE VEHICLE.

Door locking/unlocking by key (04_02, 04_03)

The doors are provided with antitheft device. To open turn the key clockwise and press

button «A». To close turn the key anticlockwise.

28

Page 29

4 Doors and locks

To open both doors from the inside, use the special release control «B».

For the handlebar version, the release control «B» must be lifted, while for the steering

wheel version it must be pushed rightwards.

MAKE SURE IT IS SAFE TO OPEN THE DOORS BEFORE OPENING THEM. BEFORE STARTING OFF, MAKE SURE THE DOORS ARE CLOSED AND LOCKED.

THIS PRECAUTION WILL ENSURE THEY DO NOT OPEN ACCIDENTALLY

WHICH WOULD BE A HAZARD FOR THE DRIVER

04_03

Front door windows (04_04)

To open the windows, press the release lever while moving the handle downwards.

(7 fixed positions are available).

To close the windows, move the handle to "travel end top" position.

04_04

29

Page 30

04_05

Engine inspection port (04_05)

Lower the rear side board and grip the handle «A» pulling it upwards to release the

retain clips «B».

On the vehicles with loading body in light alloy with tilting, to access the engine compartment it is necessary to lower the side and rear boards and then tilt the loading

body.

Use the special safety bar to secure the loading body in tilted position.

NEVER WORK UNDERNEATH THE LOADING BODY WHEN IT IS TILTED WITHOUT HAVING FIRST SECURED THE SAFETY BAR. DANGER OF SERIOUS INJURY.

30

Page 31

Ape TM - Ape TM Diesel

Chap. 05

Seats and safety

belts

31

Page 32

Using the safety belts

Observe the following suggestions for using the seat belts correctly. Failure to follow

these instructions may lead to severe injury in the event of an accident or sudden

braking. Check the seat belts periodically to ensure proper functioning. If its operation

appears faulty, have it checked at an Authorised PIAGGIO Service Centre immediately.

Pregnant women: PIAGGIO recommends using the seat belt. The waist height seat

belt length should adhere snugly to your body as low as possible (on the hips) and not

at your waist. Ask your doctor for advice.

Injured people: PIAGGIO recommends using the seat belt. Ask your doctor for advice.

WARNING

THE SAFETY BELTS ARE DESIGNED TO EXERT THEIR ACTION ON THE BONE

STRUCTURE OF YOUR BODY. THE DIFFERENT BELT SECTIONS SHOULD FIT

SNUGLY TO THE PELVIS, THE CHEST AND SHOULDERS. DO NOT WEAR THE

SECTION WHICH IS SUPPOSED TO FIT ON THE HIPS OVER THE ABDOMEN.

SAFETY BELTS SHOULD BE ADJUSTED TO FIT SNUGLY AND SHOULD BE

ADAPTED TO THE PERSON WEARING THEM, SO AS TO OFFER THE PROTECTION THEY ARE DESIGNED FOR. A LOOSE BELT WOULD CONSIDERABLY

REDUCE PROTECTION TO THE PASSENGER WEARING IT. BE CAREFUL NOT

TO DAMAGE BELTS WHEN CLOSING THE DOORS. DO NOT REMOVE BELTS

FOR CLEANING. WASH THEM WITH WATER AND NEUTRAL SOAP, RINSE AND

LET DRY IN A WARM PLACE. PAY SPECIAL ATTENTION NOT TO DAMAGE THE

SEAT BELTS WITH CLEANING PRODUCTS, OIL, ABRASIVE DETERGENTS,

CHEMICAL AGENTS OR BATTERY FLUIDS

.

32

Page 33

5 Seats and safety belts

WARNING

AFTER A SEVERE ACCIDENT, IT IS ESSENTIAL TO HAVE THE ENTIRE SEAT

BELT ASSEMBLY REPLACED, EVEN IF IT MAY NOT APPEAR DAMAGED. DO

NOT WEAR A TWISTED SEAT BELT. DO NOT WEAR THE SEAT BELT WITH THE

SHOULDER LENGTH UNDER YOUR ARM OR BEHIND YOUR BACK. DO NOT

FASTEN THE SEAT BELT OVER HARD OR FRAGILE OBJECTS, SUCH AS

GLASSES, JEWELLERY, PENS, KEYS. DO NOT WEAR THE SEAT BELT OVER

VERY THICK CLOTHES, AS THIS MAY PREVENT IT FROM BEING POSITIONED

CORRECTLY. DO NOT MODIFY OR DISASSEMBLE THE SEAT BELT ASSEMBLY. AFTER AN ACCIDENT OF A CERTAIN SEVERITY, WE RECOMMEND THAT

YOU HAVE THE SEAT BELT WHICH WAS BEING WORN REPLACED AT AN AUTHORISED PIAGGIO SERVICE CENTRE, EVEN IF IT DOES NOT APPEAR DAMAGED.

Fasting the safety belt (05_01)

Take the metal tongue from its housing.

Insert the metal tongue in the buckle until it clicks.

CAUTION

05_01

TO GUARANTEE THE OPTIMAL PERFORMANCE OF THE SEAT BELT, AFTER

HAVING INSERTED THE METAL TONGUE INTO THE BUCKLE, CHECK IT IS SECURELY BLOCKED AND THE SEAT BELT IS NOT TWISTED.

33

Page 34

05_02

05_03

Adjusting the safety belt (05_02)

Position the seat belt as low as possible on your hips and not at your waist.

Adjust the seat belt so that you can slide your fist between the belt and your chest.

Hold the anchoring at a right angle with respect to the belt and pull the belt to lengthen

or shorten it.

A: wrong

B: right

To release the safety belt (05_03)

Press the button. Insert the metal tongue in its housing when it is not in use.

CAUTION

TO PREVENT DAMAGING SEAT BELTS CHECK THEY DO NOT REMAIN

PINCHED BETWEEN A DOOR AND THE CAR BODY, OR BEHIND THE SEAT

BACK.

34

Page 35

Ape TM - Ape TM Diesel

Chap. 06

Instrument panel

and controls

35

Page 36

Handlebars (06_01)

Apetm

1. External light control switch

2. Tachometer and odometer

3. Ashtray

4. Gear indicator

5. Clutch lever

6. Cigar lighter

7. Turn indicator selector

8. Reverse gear command lever

9. Key switch

10. Emergency or parking brake

11. Heater control lever (red)

12. Starter lever (only in the gasoline version)

13. Brake pedal

14. Headlight switch

15. Horn button

16. Accelerator control

17. Light indicators unit

18. Emergency light switch

19. Rear fog light switch

20. Windscreen wiper control switch

36

Page 37

6 Instrument panel and controls

06_01

Handlebars (06_01, 06_02)

ApetmD

1. External light control switch

2. Tachometer and odometer

3. Ashtray

4. Gear indicator

5. Clutch lever

6. Cigar lighter

37

Page 38

7. Turn indicator selector

8. Reverse gear command lever

9. Key switch

10. Emergency or parking brake

11. Heater control lever (red)

12. Airflow deflector lever: windscreen - floor heating

13. Brake pedal

14. Headlight switch

15. Horn button

16. Accelerator control

17. Light indicators unit

18. Heater fan switch

19. Rear fog light switch

20. Windscreen wiper control switch.

21. Emergency light switch

22. Body tilting button (where available).

38

Page 39

6 Instrument panel and controls

06_02

Steering wheel (06_03)

Apetm

1. Steering wheel

2. Flashing light switch lever

3. Light and horn switch lever

4. Key switch

5. Clutch pedal

6. Brake pedal

39

Page 40

7. Accelerator pedal

8. External light control switch

9. Windscreen wiper control switch

10. Reverse gear control lever

11. Gearbox control lever

12. Emergency or parking brake

13. Heating control lever (red)

14. Starter lever (only gasoline version) (black)

15. Rear fog light switch

16. Cigar lighter

17. Emergency light switch

18. Ashtray

19. Light indicators unit

20. Tachometer and odometer

40

Page 41

6 Instrument panel and controls

06_03

Steering wheel (06_03, 06_04)

ApetmD

1. Steering wheel

2. Flashing light switch lever

3. Light and horn switch lever

4. Key switch

5. Clutch pedal

6. Brake pedal

41

Page 42

7. Accelerator pedal

8. External light control switch

9. Windscreen wiper control switch

10. Reverse gear control lever

11. Gearbox control lever

12. Emergency or parking brake

13. Heating control lever (red)

14. Airflow deflector lever: windscreen - floor heating

15. Rear fog light switch

16. Cigar lighter

17. Heater fan switch

18. Ashtray

19. Light indicators unit

20. Tachometer and odometer

21. Emergency light switch

22. Body tilting button (where available).

42

Page 43

6 Instrument panel and controls

06_04

Controls (06_05, 06_06, 06_07, 06_08, 06_09)

HANDLEBAR VERSION - GASOLINE

External light control switch «A»

0 = Lights off;

1 = Front and rear side/taillights and instrument panel lights on;

2 = Headlights (high or dipped beams on).

43

Page 44

06_05

Windscreen wiper control switch «B»

0 = Disabled;

1 = Windscreen wiper enabled.

2 = Windscreen wiper + sprayer enabled.

Light selector «A»

1 = High beams on.

2 = Dipped beams;

THE SWITCH POSITIONS ARE SUBJECT TO THE OUTSIDE LIGHT CONTROL

SWITCH POSITION.

Horn button

B = horn button.

06_06

44

Page 45

6 Instrument panel and controls

Turn indicator selector «C»

0 = Lights off;

S = Left turn indicators flashing;

D = Right turn indicators flashing.

06_07

Emergency light switch «B»

0 = Lights off;

1 = Direction indicators flashing

Rear fog light switch «A»

0 = Light off;

1 = Rear fog light on.

06_08

STEERING WHEEL VERSION - GASOLINE

Light and horn switch lever «A»

With external light control switch «B» in position enabled.

45

Page 46

1 = Taillights on;

2 = Dipped beams on;

3 = High beams on.

To actuate the horn, press lever «A» upwards.

THE LIGHT SWITCH LEVER POSITIONS ARE SUBJECT TO THE OUTSIDE LIGHT

CONTROL SWITCH POSITION.

Flashing light switch lever «C»

0 = Lights off;

S = Left turn indicators flashing;

D = Right turn indicators flashing.

External light control switch «A»

0 = Lights off;

1 = Lights on.

Windscreen wiper control switch «B»

0 = Disabled;

1 = Windscreen wiper enabled.

2 = Windscreen wiper + sprayer enabled.

Rear fog light switch «C»

0 = Light off;

46

Page 47

1 = Rear fog light on.

6 Instrument panel and controls

Emergency light switch «D»

0 = Lights off;

1 = Direction indicators flashing

Cigar lighter«E»

Press the lighter button and wait until it automatically returns to its initial position. The

lighter is ready for use.

06_09

Controls (06_09, 06_10, 06_11, 06_12, 06_13, 06_14)

HANDLEBAR VERSION - DIESEL

External light control switch «A»

0 = Lights off;

1 = Front and rear side/taillights and instrument panel lights on;

2 = Headlights (high or dipped beams on).

47

Page 48

06_10

Windscreen wiper control switch «B»

0 = Disabled;

1 = Windscreen wiper enabled.

2 = Windscreen wiper + sprayer enabled.

Light selector «A»

1 = High beams on.

2 = Dipped beams;

THE SWITCH POSITIONS ARE SUBJECT TO THE OUTSIDE LIGHT CONTROL

SWITCH POSITION.

Horn button

B = horn button.

06_11

48

Page 49

6 Instrument panel and controls

Turn indicator selector «C»

0 = Lights off;

S = Left turn indicators flashing;

D = Right turn indicators flashing.

06_12

Rear fog light switch «A»

0 = Light off;

1 = Rear fog light on.

Heater fan switch «B»

0 = Fan off

1 = First gear

2 = Second gear

Emergency light switch «A»

0 = Lights off;

1 = Direction indicators flashing

49

Page 50

06_13

Body tilting button «B» (where available)

0 = Body down

1 = Body up

In order to improve safety and prevent unintentional operations, the lifting controls only

becomes live after releasing the safety lever on the right hand side at the back of the

cabin.

Remember to bring the safety lever back onto the 'blocked' position once all tilting

operations are completed.

•

THE BODY LIFTING OPERATIONS MUST BE CARRIED OUT WITH THE

VEHICLE STOPPED AND THE EMERGENCY/PARKING BRAKE ACTIVATED.

STEERING WHEEL VERSION - DIESEL

Light and horn switch lever «A»

With external light control switch «B» in position enabled.

1 = Taillights on;

2 = Dipped beams on;

3 = High beams on.

To actuate the horn, press lever «A» upwards.

THE LIGHT SWITCH LEVER POSITIONS ARE SUBJECT TO THE OUTSIDE LIGHT

CONTROL SWITCH POSITION.

Flashing light switch lever «C»

0 = Lights off;

S = Left turn indicators flashing;

50

Page 51

D = Right turn indicators flashing.

6 Instrument panel and controls

External light control switch «A»

0 = Lights off;

1 = Lights on.

Windscreen wiper control switch «B»

0 = Disabled;

1 = Windscreen wiper enabled.

2 = Windscreen wiper + sprayer enabled.

Rear fog light switch «C»

0 = Light off;

1 = Rear fog light on.

Heater fan switch «D»

0 = Fan off

1 = First gear

2 = Second gear

51

Page 52

06_14

Cigar lighter«E»

Press the lighter button and wait until it automatically returns to its initial position. The

lighter is ready for use.

Emergency light switch «F»

0 = Lights off;

1 = Emergency light on.

Body tilting button «G»

0 = Body down

1 = Body up

52

Page 53

6 Instrument panel and controls

06_15

06_16

In order to improve safety and prevent unintentional operations, the lifting control only

becomes live after releasing the safety lever on the right hand side at the back of the

cabin.

Remember to bring the safety lever back onto the 'blocked' position once all tilting

operations are completed.

•

TIPPING ACTIONS OF THE PLATFORM MUST BE CARRIED OUT WHEN

THE VEHICLE IS STOPPED AND THE HANDBRAKE ENGAGED.

Ignition switch (06_16, 06_17)

According to the version (steering wheel or handlebar), the key switch is on the left of

the steering wheel or on the front side, on the steering column cover.

The key can turn to 3 different positions:

0 = Ignition off, key can be removed, steering locked.

1 = Running position - arrangement of utilities and external lights and start up of pre-

heating glow plug (for diesel versions).

2 = Engine start up (after start up, the key automatically returns to the running position

"1").

Locking the steering (antitheft): with the key switch set to 0, extract the key and turn

the steering wheel leftwards (travel end).

Unlocking the steering: insert the key and turn it to 1.

Steering wheel lock (antitheft): with the key switch set to 0, extract the key and turn

the steering wheel to lock it.

Steering wheel release: insert the key and turn it to 1.

53

Page 54

DO NOT TURN THE KEY TO POSITION 0 WHILE DRIVING.

WARNING

06_17

SHOULD THE STARTING DEVICE BE TAMPERED WITH (E.G. A THEFT ATTEMPT) HAVE IT CHECKED AT THE EARLIEST OPPORTUNITY BY A DEALER

OR AN AUTHORISED PIAGGIO SERVICE CENTRE BEFORE YOU START DRIVING AGAIN.

WHEN YOU LEAVE THE VEHICLE, ALWAYS REMOVE THE KEY TO PREVENT

SOMEBODY FROM ACCIDENTALLY ACTUATING THE CONTROLS. ENGAGE

THE PARKING BRAKE AND THE FIRST OR REVERSE GEAR ACCORDING TO

WHETHER THE VEHICLE IS UPHILL OR DOWNHILL. SUITABLY TURN THE

STEERING WHEEL TO PREVENT BLOCKING THE ROAD IN CASE OF AN ACCIDENTAL RELEASE OF THE EMERGENCY OR PARKING BRAKES.

54

Page 55

Ape TM - Ape TM Diesel

Chap. 07

Gauges and

Warning Lights

55

Page 56

07_01

Instrument unit and indicators (07_01)

A = Speedometer, odometer/mileometre.

B = Preheat glow plug indicator (only on diesel versions - amber colour).

C = Flashing lights on indicator (green colour).

D = High beams on indicator (blue colour).

E = Taillights on indicator (green colour).

F = Rear fog light on indicator (amber colour).

G = High water temperature indicator (only on diesel versions - red colour).

H = Oil reserve indicator (for gasoline versions). Inadequate oil pressure indicator (for

diesel versions).

I = Fuel reserve indicator (amber colour).

L = Battery charge voltage low indicator (red colour).

56

Page 57

Ape TM - Ape TM Diesel

Chap. 08

Air control

system

57

Page 58

08_01

08_02

Heating (08_01)

Cabin heater controls (gasoline):

Lever «A» (with red grip): in position 1.

Control bar «B»: in position 1 (travel end back) located below the driver's seat to allow

opening diaphragm «C».

Shuttering outlets «D» in position 1 (OPEN).

The cabin heater can be disabled by the shuttering outlets «D» or directly by returning

lever «A» to neutral position (position 2).

Heating (08_01, 08_02)

Cabin heating controls (diesel):

Lever «A» (with red grip): position 1, warm air.

Lever «B»: position 1, warm air towards feet.

Lever «B»: position 2, warm air towards the windscreen.

58

Page 59

8 Air control system

Heating and demisting (08_03)

Cabin defrosting/heating controls (gasoline):

Control bar «B» in position 2 (travel end forward).

Shuttering outlets «D» in position 1 (OPEN).

08_03

Heating and demisting (08_03, 08_04)

Cabin defrosting/heating controls (diesel):

Control bar «B» in position 2.

08_04

Demisting (08_05)

Cabin defrosting controls (gasoline):

Control bar «B» in position 2 (travel end forward).

Shuttering outlets «D» in position 2 (CLOSED).

The hot air flow is thus sent to the windscreen only, through the two outlets shown in

the figure.

08_05

59

Page 60

08_06

Demisting (08_05, 08_06)

Cabin heating controls (diesel):

Control lever «B» in position 1.

The hot air flow may be partitioned through the two outlets «D».

60

Page 61

Ape TM - Ape TM Diesel

Chap. 09

Mirrors and

Window Glasses

61

Page 62

9_01

Adjusting the mirror (9_01)

Rear-view mirrors are adjusted by moving the mirror body manually until the ideal

angle is obtained to guarantee full visibility.

CAUTION

NEVER ADJUST MIRRORS WHILE DRIVING AS YOU MAY LOSE CONTROL OF

THE VEHICLE.

Wipers and Brushes (9_02, 9_03)

Blade

•

Clean regularly the rubber part with specific products.

•

Replace the blade if the rubber is misshapen or worn. In any case, blades

should be replaced approximately once a year.

Some simple recommendations can minimise the possibility of damage to the blade:

•

- If the temperature is below zero, make sure the rubber part is not frozen to

the windscreen. If required, use a de-icing product to release the blade.

•

- Remove any snow from the windscreen: this will protect the blade and avoid

overloading and overheating the electric motor.

•

Do not operate the windscreen wiper on a dry windscreen.

DRIVING WITH A WORN WINDSCREEN WIPER BLADE CAN BE EXTREMELY

DANGEROUS AS VISIBILITY IS DECREASED IN POOR WEATHER CONDITIONS.

62

Page 63

9 Mirrors and Window Glasses

9_02

9_03

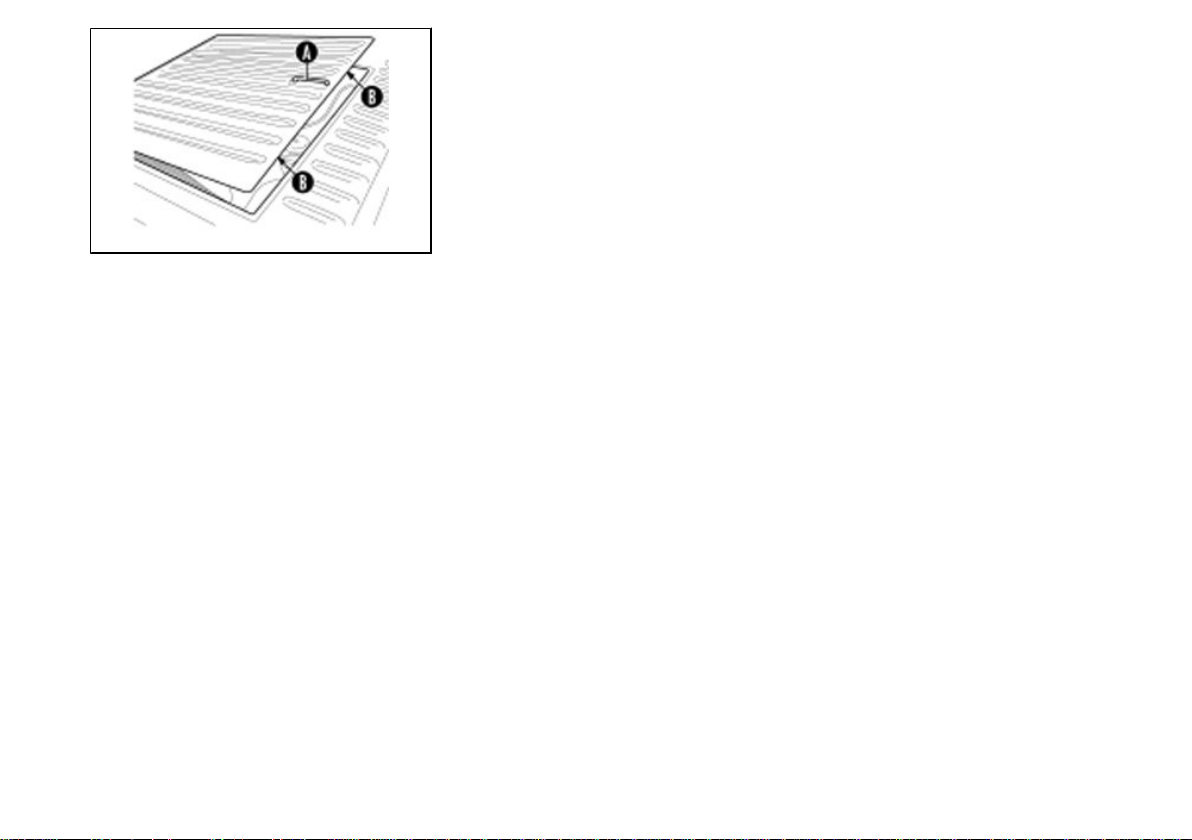

Replacing the windscreen wiper blade

Replace the windscreen wiper blade as follows:

•

Lift the windscreen wiper arm "A" and position the blade so that it forms a

right angle with the arm;

•

Press retainer tab "B" of the latching spring and extract the blade for arm

"A";

•

Fit a new blade. Insert the tab in its seat on the arm. Make sure it is locked.

Nozzles

•

If there is no jet of fluid, first of all check whether the windscreen washer

reservoir is full.

•

Check whether the holes «A» are clogged. If so, open them with a pin.

•

Direct the windscreen washer nozzles so that the jets are directed towards

the highest position of the blade stroke.

63

Page 64

64

Page 65

Ape TM - Ape TM Diesel

Chap. 10

Inside

equipment

65

Page 66

66

Page 67

Ape TM - Ape TM Diesel

Chap. 11

Electrical

system

67

Page 68

Fuel version

The power for the lighting and indication system devices is provided in direct current

by a dynamotor/battery unit, with a voltage regulator separated by the remote control

switch unit, both installed under the seat in the compartment. The dynamotor acts as

a generator-dynamo and as a starter motor: in particular, upon start-up, it absorbs

current from the battery and operates as an electric motor.

After starting the engine and reaching a certain speed, the dynamotor acts as a normal

dynamo, charging the battery and powering the vehicle system.

Electric characteristic

Battery

12V-32Ah

Diesel version

The power for the lighting and indication system devices is provided in direct current

by a special battery.

The engine is equipped with an 18-pole rotor stator unit, three-phase, 330W MAX.

The preheating device for starting the engine, which is fitted with a light indicator,

controls the special preheat glow plug.

FOR ESPECIALLY COLD AREAS, WE RECOMMEND INSTALLING A 12V-60AH

BATTERY.

WHEN INTERVENING ON THE ELECTRICAL SYSTEM, MAKE ESPECIALLY

SURE THAT THE WIRES LEADING TO THE ELECTRONIC CONTROL UNIT ARE

CORRECTLY CONNECTED AND RESPECT THE COLOUR CODING GIVEN ON

THE CONTROL UNIT.

Electric characteristic

Battery

68

Page 69

11 Electrical system

12V-50Ah

69

Page 70

70

Page 71

Ape TM - Ape TM Diesel

Chap. 12

Emergency

71

Page 72

12_01

12_02

Wheel replacement (12_01, 12_02)

The tyre replacement operation and the use of jack require some precautions which

are given below.

WARNING

SIGNAL THE PRESENCE OF THE VEHICLE AS PRESCRIBED BY THE HIGHWAY

CODE IN FORCE.

PLACE THE JACK IN THE POSITIONS SHOWN SO AS NOT TO DAMAGE MECHANICAL PARTS OR THE BODY

WARNING

WHENEVER POSSIBLE, REPLACE TYRES WITH THE VEHICLE ON LEVEL

GROUND. IF THE GROUND IS SLOPING OR BADLY SURFACED, PUT WEDGES

OR ANY OTHER SUITABLE MATERIAL UNDER THE WHEELS TO BLOCK THE

VEHICLE. DO NOT GREASE BOLT THREADS BEFORE REFITTING: THEY

COULD COME UNDONE SPONTANEOUSLY.

NEVER TAMPER WITH THE INFLATION VALVE. DO NOT PLACE TOOLS BETWEEN RIM AND TYRE.

Maintenance instructions

They are located into the compartment, below the seat.

72

Page 73

CAUTION

12 Emergency

THE JACK CAN ONLY BE USED TO REPLACE THE WHEELS. NEVER USE THE

JACK TO PERFORM REPAIRS UNDER THE VEHICLE. THE VEHICLE MAY FALL

IF THE JACK IS NOT POSITIONED CORRECTLY

CAUTION

PERIODICALLY CHECK TYRE PRESSURE ACCORDING TO THE VALUES GIVEN IN THE: «MAINTENANCE

».

73

Page 74

74

Page 75

Ape TM - Ape TM Diesel

Chap. 13

Maintenance

75

Page 76

13_01

13_02

Check engine oil level (13_01)

Engine oil level check (diesel version)

To check the engine oil level, proceed as follows:

1. Check with engine off and vehicle on a flat surface;

2. Extract the level bar from the rear side of the vehicle and check that the level is

between the MIN and MAX positions;

3. If a top up is required, add new oil by the filler located into the engine compartment;

WARNING

TOP UP USING OIL OF THE SAME TYPE ALREADY CONTAINED INTO THE ENGINE.

Oil change and oil filter replacement (13_02, 13_03, 13_04)

Replacing the engine oil (diesel version)

To replace the engine oil proceed as follows:

1. Loosen the drainage cap «A» and drain the oil;

2. When drainage is complete, tighten cap «A», remove cap «B» and pour new oil by

the filler; the oil level must always be between the MIN and MAX positions marked on

bar «C»;

3. Periodically check the oil level;

76

Page 77

13 Maintenance

WARNING

REPLACE THE OIL WHEN THE ENGINE IS WARM.

CAUTION

13_03

13_04

RUNNING THE ENGINE WITH INSUFFICIENT LUBRICATION OR IMPROPER LUBRICANTS ACCELERATES THE WEAR OF ALL MOVING PARTS AND MAY

RESULT IN SERIOUS DAMAGES.

CAUTION

USED OIL IS HARMFUL TO THE ENVIRONMENT. WHEN REPLACING THE OIL,

WE SUGGEST TO CONTACT A PIAGGIO AUTHORISED SERVICE POINTS

EQUIPPED FOR DISPOSING SPENT OILS IN THE RESPECT OF NATURE AND

IN COMPLIANCE WITH THE LAWS IN FORCE.

Characteristic

new oil:

2.8 litres

77

Page 78

13_05

Oil change and oil filter replacement (13_04, 13_05)

Engine oil cartridge replacement (Diesel version)

To gain access to the oil cartridge proceed as follows:

1. Remove the engine inspection door (or lift the metal alloy plate);

2. Drain the engine crankcase;

3. Remove the filtering body «F»;

4. Lubricate the new cartridge seal and screw it in as far as it will go, and then tighten

it by hand by half a turn;

5. Fill up with fresh oil, then start the engine whilst inspecting for oil leaks.

WARNING

TO PREVENT DAMAGING THE ENGINE, FILL THE FILTER WITH NEW OIL BEFORE PROCEEDING TO THE REASSEMBLY.

IN CASE OF REPLACEMENT OF THE FILTER, THE AMOUNT OF OIL CONTAINED INTO THE CRANKCASE IS OF ABOUT 2.8 LITRES (THE TOTAL CIRCUIT

CAPACITY IS 3.5 LITRES).

WARNING

USING NON-ORIGINAL SPARES SERIOUSLY IMPAIRS THE VEHICLE PERFORMANCE AND LIFE.

78

Page 79

13 Maintenance

13_06

WARNING

TO DISPOSE OF OLD FILTERS, TURN TO A PIAGGIO SERVICE CENTRE. FOLLOW THE SPECIFIC ENVIRONMENT-RELATED REGULATIONS IN FORCE.

Checking the brake fluid level (13_06)

Checking level (gasoline version)

The rear brake fluid tank is located into the driver compartment, above the brake pedal.

Check the level as follows:

1. Stop the vehicle on level ground;

2. Check the oil level is between 1 cm under the surface of cap «A» (MAX level) and

1 cm over the bottom of the reservoir (MIN level).

If the oil is under the minimum level contact a PIAGGIO Dealer or Authorised Service

Centre to have the brake system checked.

Topping up brake fluid

To fill the reservoir, unscrew cap «A» and top up.

In normal climates, replace the fluid every 20,000 km or every 2 years.

Qualified and skilled personnel is required for this operation. We recommend you go

to a PIAGGIO Dealer or Authorised Service Centre.

Recommended products

AGIP DOT4 BRAKE FLUID

Brake fluid

79

Page 80

13_07

FMVSS DOT 4

Checking the brake fluid level (13_06, 13_07)

Level check (Diesel version)

The rear brake fluid reservoir is located inside the vehicle, underneath the cover on

the right-hand side of the instrument panel.

To check the level, remove the two fixing screws and the cover, then follow the procedure outlined in the previous paragraph.

CAUTION

ONLY USE DOT 4 CLASSIFIED BRAKE FLUIDS.

CAUTION

BRAKE FLUID IS HAZARDOUS: WASH WITH WATER IN THE EVENT OF ACCIDENTAL CONTACT.

CAUTION

BRAKING CIRCUIT FLUID IS VERY CORROSIVE; AVOID CONTACT WITH PAINTED PARTS.

THE BRAKING CIRCUIT FLUID IS HYGROSCOPIC, I.E., IT ABSORBS HUMIDITY

FROM THE SURROUNDING AIR. IF THE HUMIDITY IN THE BRAKE FLUID EX-

80

Page 81

13 Maintenance

13_08

13_09

CEEDS A CERTAIN VALUE, IT WILL LEAD TO INEFFICIENT BRAKING. NEVER

USE BRAKE FLUID FROM PREVIOUSLY OPENED OR PARTLY-EMPTY CONTAINERS.

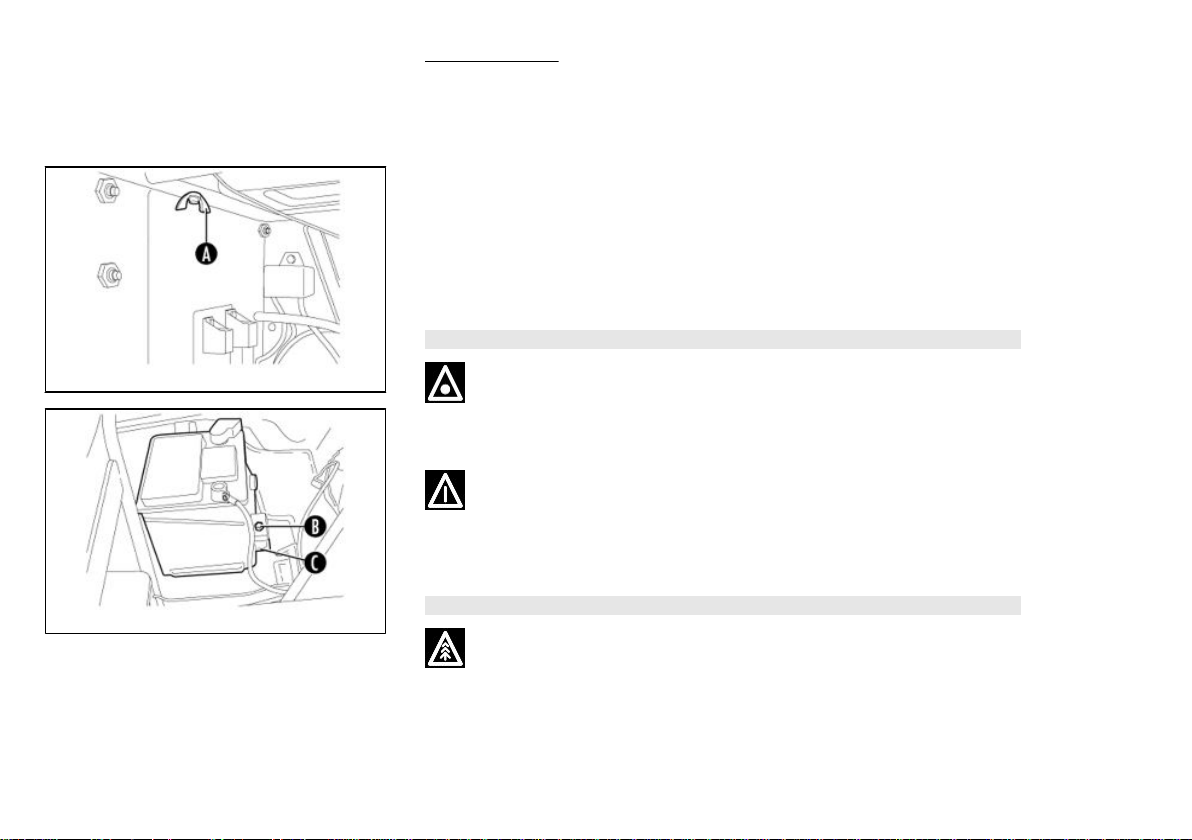

Gear box oil level (13_08, 13_09, 13_10)

To check the gearbox oil, proceed as follows:

1. Check with engine off and vehicle on a flat surface;

2. Loosen the two screws fixing the SAS to the support bracket and move the SAS so

as to access the cap «A»;

3. Loosen the inspection cap «A», then check that the oil level is between the MIN

and MAX references on the bar contained into the cap;

4. If you need to top up the level, extract the cap with the bar and restore the level;

5. Replace the SAS to the original position.

TOP UP USING OIL OF THE SAME TYPE ALREADY CONTAINED INTO THE

GEARBOX.

81

Page 82

13_10

To replace the gearbox oil proceed as follows:

1. Remove the cap «A», loosen cap «B» and drain the oil; when drainage is complete,

replace cap «B».

2. Pour some oil into the top hole and let the engine run for a few seconds; then, drain

the crankcase again.

3. Refill with new oil, periodically checking the level with the bar until the mark MAX

is reached.

WARNING

REPLACE THE OIL WHEN THE ENGINE IS WARM.

•

AN EXCESSIVE AMOUNT OF OIL CAN SPILL OUT AND DIRTY THE ENGINE.

WARNING

•

USED OIL CONTAINS SUBSTANCES HARMFUL TO THE ENVIRONMENT. FOR OIL REPLACEMENT, CONTACT ANY AUTHORISED PIAGGIO SERVICE CENTRE AS THEY ARE EQUIPPED WITH LAW-ABIDING

ENVIRONMENTALLY- FRIENDLY OIL DISPOSAL SYSTEMS

Recommended products

AGIP ROTRA MP 80W-90

Oil with specifications SAE 80W-90, API GL-5

Gearbox oil

Characteristic

Oil amount for gasoline version:

82

Page 83

13 Maintenance

13_11

13_12

885 grams (approx. 1000 cm3)

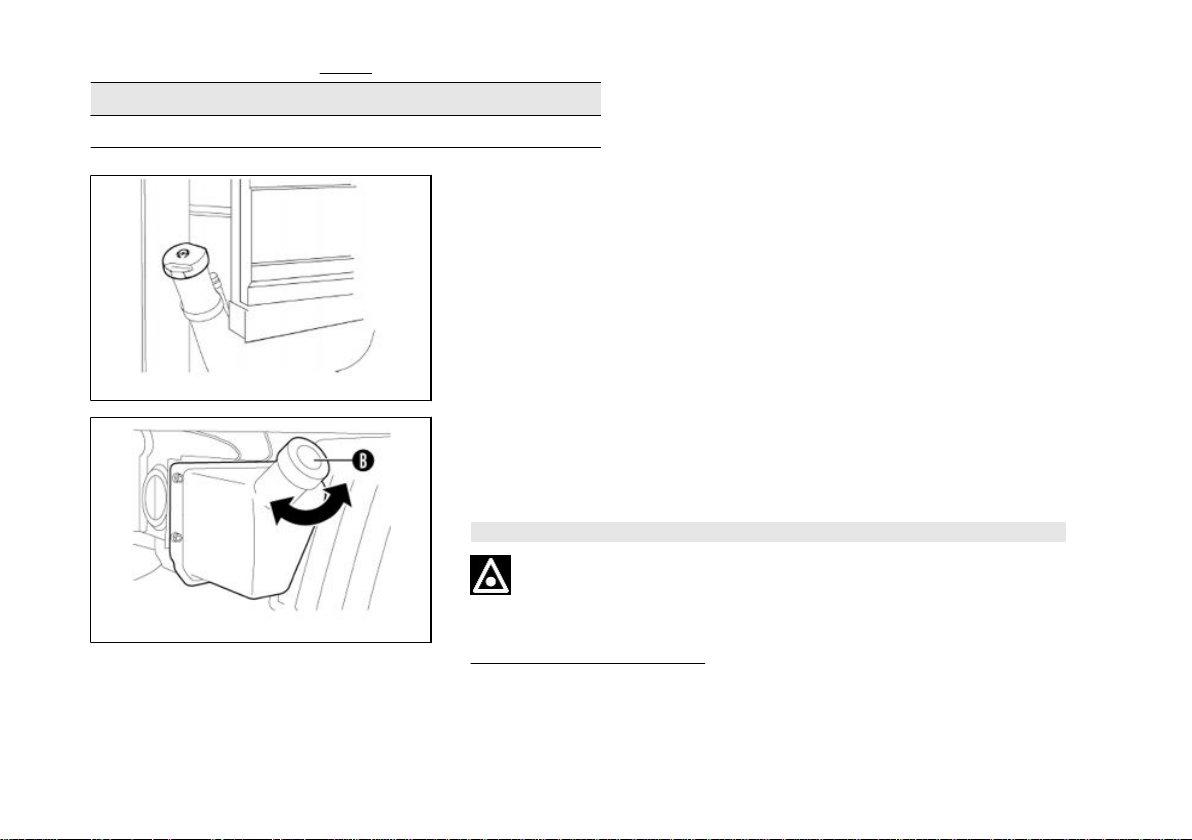

Window washer fluid level (13_11)

Topping up windscreen washer fluid

The windscreen washer fluid reservoir is located inside the cab on the front right panel.

To fill the reservoir, unscrew cap «A» and top up. Use a specific detergent.

Cooled fluid (13_12)

Coolant top-ups (Diesel version)

Loosen the filler cap on the expansion tank.

Fill up the tank with coolant (permanent 50% water + ethyl glycol fluid recommended).

The correct level is indicated on the expansion tank by the LEVEL reference mark.

Circuit air-bleed: start the engine up and let it run at idle so to allow for any air bubble

trapped inside the circuit to leave the cooling system.

The coolant level will gradually decrease and then settle. Stop the engine and top-up

the circuit as explained in the previous paragraph. After a few hours of normal use,

check the level with the engine cold.

Cooling circuit hose inspection (every 10,000 Km)

83

Page 84

13_13

Check the coolant circuit hoses for signs of wear (alligatoring of the rubber) and also

check that all fittings are properly sealed. If any of the hoses is worn, please contact

your nearest Authorised Piaggio Service Centre to have it replaced.

Changing the engine cooling fluid

Drain the circuit completely and refill following the procedure given in the previous

paragraphs.

Checking and replacing the air cleaner element (13_13, 13_14)

Replacing the air filter (gasoline version)

To replace the air filter, proceed as follows:

1. Lower the rear side and remove the engine cover;

2. Loosen the three knobs «A» fixing the filter cover, then remove the cover;

3. Remove the filtering element «B»;

4. Replace the filtering element and refit the cover.

13_14

84

Page 85

Checking and replacing the air cleaner element (13_14, 13_15,

13 Maintenance

13_16)

13_15

13_16

Replacing the air filter (diesel version)

To replace the air filter, proceed as follows:

1. Loosen the fixing know «A» and remove the filter box cover «B»;

2. Extract the filtering element «C» and replace it with a new one;

3. Refit the cover and tighten the knob «A».

CAUTION

THE FILTERING ELEMENT MUST BE REPOSITIONED INSIDE THE AIR-BOX

PROPERLY, FOLLOWING THE REMOVAL OPERATIONS BUT IN REVERSE ORDER.

Replacing the fuel filter (13_17)

Replacing the diesel filter

The diesel filter «A» can be removed by turning it anticlockwise.

At the bottom of the cartridge there is the screw «B» for draining condensation water.

To drain the condensation water, loosen the screw «B»; tighten it again when diesel

without water comes out.

13_17

85

Page 86

13_18

13_19

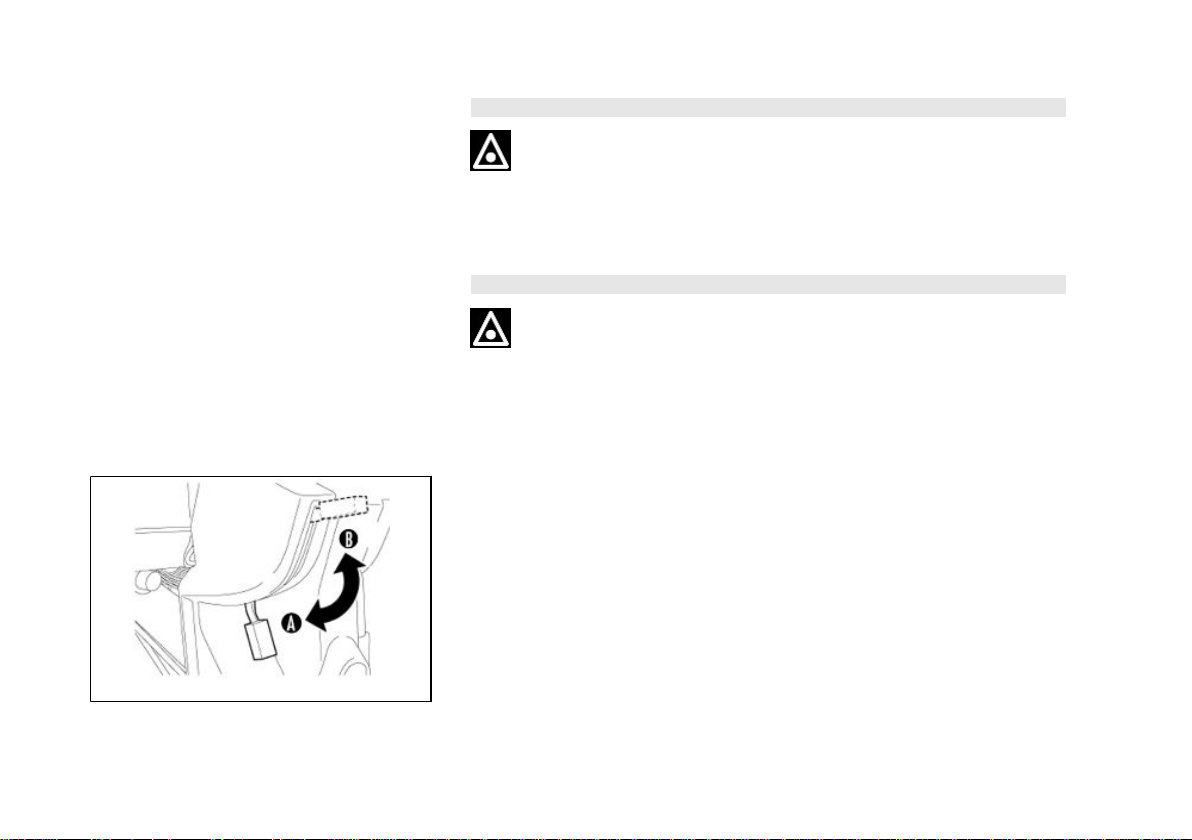

Air bleeding (13_18)

Bleed air once the injection system has been emptied for checking due to running out

of fuel.

To this purpose, repeatedly actuate the lever controlling the hand pump, until you feel

a resistance during the pumping phase.

Normally, a totally empty system is filled with about 40 pumping actions.

Fuel exhaustion (13_19)

Running out of fuel (diesel version)

If you run out of fuel, refuel and then actuate the lever controlling the hand pump, as

described for the air bleeding, until you feel a certain resistance during the pumping

phase.

Then, start the engine according to the standard procedure.

If you feel a certain resistance in the pumping and the stroke of the hand pump control

lever is not complete, turn the driving shaft by another revolution to return the mark

«D» at the reference «E».

Actuate the hand pump again until the injection system is totally bled.

N.B.

IN CASE OF AIR BLEEDING AND OF RUNNING OUT OF FUEL, IN ORDER TO

OBTAIN THE MAXIMUM CAPACITY OF THE HAND PUMP IT IS NECESSARY TO

TURN THE DRIVING SHAFT UNTIL THE MARK «D» PUNCHED ON THE CLUTCH

BOX MATCHES THE REFERENCE «E» (TDC) OF THE CRANKCASE.

86

Page 87

13 Maintenance

13_20

Checking and replacing the pre-heating plugs (13_20)

Access the spark plugs as follows:

1. remove the plate releasing the three fixing clamps;

2. disconnect the high voltage wire cap «A» from the spark plug «B»;

3. remove the spark plug using the provided tool;

4. when refitting, place the spark plug in place at the correct slant and screw it by hand.

Use the tool for locking only;

5. insert cap «A» fully on the spark plug and refit the rear washer.

THE SPARK PLUG SHOULD BE REMOVED ONLY WHEN THE ENGINE IS COLD.

CHANGE THE SPARK PLUG EVERY 4,000 KM. USING SPARK PLUGS WITH

DIFFERENT VALUE WITH RESPECT TO THE PRESCRIPTIONS OR WITH INCORRECT THREADING CAN SEVERELY DAMAGE THE ENGINE.

Characteristic

Recommended spark plugs:

BOSCH W3AC

CHAMPION RL78C

NGK BR8HS

87

Page 88

13_21

13_22

Fuses (13_21, 13_22, 13_23)

The electrical system is protected by six 8A fuses located underneath the instrument

panel, to the left of the steering column.

To the left of the fuse-box are two fuses: 15A fuse «G» protecting the cigarette lighter,

and 15A fuse «I» guarding the heater fan.

Van versions are also fitted with an 8A fuse located underneath the right-hand side

seat and protecting the van lighting circuit.

The vehicle is also protected by the main fuse «H» located underneath the passenger

seat.

The function of general fuse «H» varies according to the version:

- Gasoline = 40 A Safeguarding all services with the exception of the start-up power

circuit.

- Diesel = 40 A Safeguarding the preheating and charging circuits.

Next to the main fuse, on the tipper version, is an additional 80A fuse safeguarding

the body tilting system.

The six 8 A fuses safeguard different circuits depending on the vehicle's version.

BEFORE REPLACING THE BLOWN FUSE, TRY TO ELIMINATE THE FAULT

THAT CAUSED IT TO BLOW. NEVER ATTEMPT TO REPLACE A FUSE USING A

DIFFERENT MATERIAL (I.E. A PIECE OF ELECTRIC WIRE) OR A HIGHER AMP

FUSE.

13_23

88

Page 89

13 Maintenance

IF YOU WANT TO FIT ADDITIONAL UNITS ON THE VEHICLE (E.G. ADDITIONAL

LIGHTS) WE POINT OUT THAT INCORRECT DERIVATIONS ON THE ELECTRIC

CONNECTIONS MAY CAUSE DAMAGE TO THE INSTALLATION.

Handlebar gasoline version

A. Dipped beams (left and right), rear fog light circuit.

B. High beams (left and right), high beams indicator.

C. Emergency (key OFF), windscreen wiper, horn, glass bowl.

D. Emergency (key ON), flashing lights, indicator circuits (recharge, oil reserve, fuel

reserve, tilting), stop lights, reverse gear lights.

E. Instrument lighting, light indicator, number plate lighting, taillights (left rear and

front), cigar lighter lighting.

F. Taillights (right rear and front).

Steering wheel gasoline version

A. Emergency (key OFF), windscreen wiper, horn, glass bowl.

B. Emergency (key ON), flashing lights, indicator circuits (recharge, oil reserve, fuel

reserve, tilting), stop lights, reverse gear lights.

C. Right dipped beam.

D. Left dipped beam, rear fog light circuit.

E. Instrument lighting, light indicator, number plate lighting, taillights (left rear and

front), cigar lighter lighting.

F. Taillights (right rear and front).

89

Page 90

Handlebar diesel version

A. Emergency (key OFF), windscreen wiper, horn, glass bowl.

B. Emergency (key ON), flashing lights, indicator circuits (recharge, oil pressure, oil

temperature, fuel reserve, preheating, tilting), stop lights, reverse gear lights, solenoid

valve, preheating (power circuit excluded).

C. Right dipped beam.

D. Left dipped beam, rear fog light circuit.

E. Instrument lighting, light indicator, number plate lighting, taillights (left rear and

front), cigarette lighter lighting.

F. Taillights (right rear and front).

Handlebar diesel version

A. Dipped beams (left and right), rear fog light circuit.

B. High beams (left and right), high beams indicator.

C. Emergency (key OFF), windscreen wiper, horn, glass bowl.

D. Emergency (key ON), flashing lights, indicator circuits (recharge, oil pressure, oil

temperature, fuel reserve, tilting, preheating), stop lights, reverse gear lights.

E. Instrument lighting, light indicator, number plate lighting, taillights (left rear and

front), cigarette lighter lighting.

F. Taillights (right rear and front).

90

Page 91

13 Maintenance

13_24

13_25

Exhaust circulation system (EGR) (13_24)

Secondary air box - SAS (gasoline version)

Remove the two screws «A» of the aluminium SAS cover, without extracting the metal

pipe from the cover/sleeve. Remove the plastic cover and the plate, pull the sponge

out and wash with soap and water.

Dry with compressed air before reassembling. Reinstall the plate into the seat on the

two plastic and aluminium covers.

Replace the box sealing O-Ring housed in the cover seat at every disassembly.

TURN TO AN AUTHORISED PIAGGIO SERVICE CENTRE FOR THIS OPERATION.

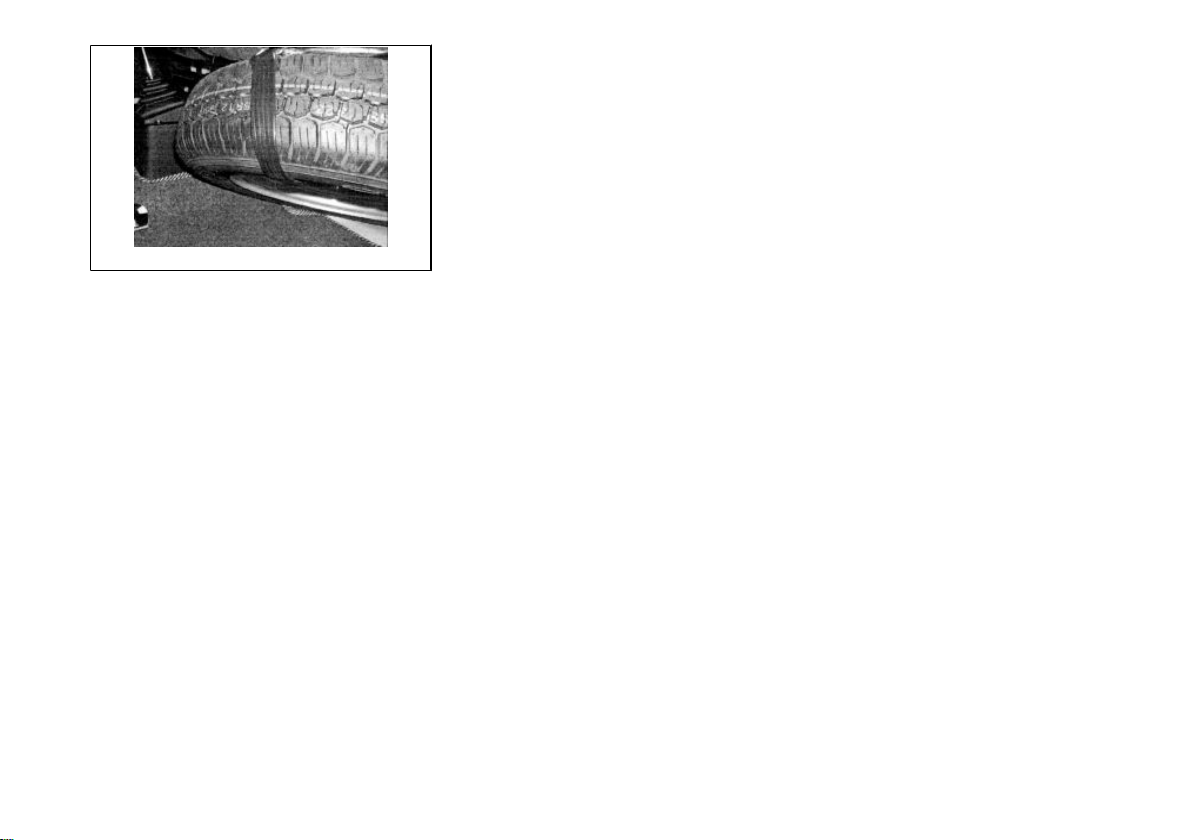

Tyres (13_25)

•

Periodically check the inflation pressure of each tyre.

•

Tyres feature wear indicators; replace tyres as soon as these indicators become visible on the tyre tread.

•

Also check that there are no cuts on the sides of the tyres or irregular tread

wear; in such cases, contact an authorised service centre for the replacement.

Characteristic

TYRES

4.50 - 10''

91

Page 92

TYRE PRESSURE

Front tyre pressure 2.5 atm

Rear tyre pressure 4.5 atm

Pressure

ACCORDING TO THE PROVISIONS OF THE REGULATIONS IN FORCE, THE

TYRE TREADS MUST BE OVER 1.6 MM THICK.

CHECK TYRE PRESSURE WHEN COLD. INCORRECT TYRE INFLATION PRESSURE WILL CAUSE UNEVEN THREAD WEAR AND MAKE DRIVING DANGEROUS.THE TYRE MUST BE REPLACED WHEN THE TREAD REACHES THE WEAR

LIMITS SET FORTH BY LAW.

Periods of inactivity

Prolonged inactivity

If the vehicle is not to be used for long periods, the battery must be charged periodically

(when not in use, the battery will discharge over a period of about three months). If

the battery is removed, make sure you connect the leads correctly at the time of installation

Perform the following operations:

1. Clean the vehicle;

92

Page 93

13 Maintenance

NO START-UP (GASOLINE VERSION)

Connectors to the spark plug

disconnected

DIFFICULTIES WHEN STARTING (GASOLINE

VERSION)

Fuel tank empty Refuel

Clogged or dirty filters, jets or

carburettor

Starter control lever in lowered

position

2. Remove the air filter and close the intake and exhaust ducts;

3. Lift the vehicle from the ground, resting the wheels on wooden supports;

4. Drain the fuel tank. Cover the unpainted metal parts with rustproof grease;

5. For the battery, follow the procedures indicated in the «Maintenance» section.

FOR THE GASOLINE VERSION WITH ENGINE ON AND AT LOW SPEED, POUR

30 CC OF SAE 40 OIL THROUGH THE CARBURETTOR CHOKE.

Restore connection

Contact an Authorised PIAGGIO

Service Centre

Move it to lifted position

93

Page 94

DIFFICULTIES WHEN STARTING (DIESEL VERSION)

Connectors to the glow plug

disconnected, or inefficient glow

plug

No fuel in tank Refuel

Air into the injection system Bleed the air

Water in the diesel Drain the water and replace the

Injector dirty or faulty Contact an Authorised PIAGGIO

Restore the connection or replace

the preheating glow plug

filter, if required, then bleed the air

Service Centre

IGNITION FAILURE (GASOLINE VERSION)

No spark on spark plug Check whether the electrodes are

clean (clean with white spirit and

wire brush or sandpaper).

Check spark plug insulation: if

cracked or broken, replace the

spark plug. If the spark plug is in

good conditions, contact an

Authorised PIAGGIO Service

Centre.

CAUSE: HIGH VOLTAGE. THIS INSPECTION SHOULD BE

CARRIED OUT BY A SKILLED MECHANIC.

94

Page 95

POOR COMPRESSION (GASOLINE VERSION)

13 Maintenance

Spark plug seat threading

damaged; head bolts insufficiently

torqued, piston seals worn

Contact an Authorised PIAGGIO

Service Centre

HIGH FUEL CONSUMPTION AND POOR

PERFORMANCE (GASOLINE VERSION)

Air filter blocked or dirty Replace the air filter

ENGINE IRREGULAR OPERATION (DIESEL VERSION)

Injector faulty Contact an Authorised PIAGGIO

Air into the injection system Bleed the air

Diesel filter clogged Replace the filter and bleed the air

Service Centre

POOR PERFORMANCE (DIESEL VERSION)

Injector faulty Contact an Authorised PIAGGIO

Diesel filter clogged Replace the filter and bleed the air

Service Centre

95

Page 96

WHITE FUMES UPON EXHAUST (DIESEL VERSION)

Injector faulty Contact an Authorised PIAGGIO

Delayed injection Contact an Authorised PIAGGIO

Service Centre

Service Centre

BLACK FUMES UPON EXHAUST (DIESEL VERSION)

Air filter clogged Replace the air filter

Wrong injection pump calibration Contact an Authorised PIAGGIO

Injector faulty Contact an Authorised PIAGGIO

Service Centre

Service Centre

THE ENGINE KNOCKS

Injection advanced Contact an Authorised PIAGGIO

Injector faulty Contact an Authorised PIAGGIO

Service Centre

Service Centre

96

Page 97

POOR SUSPENSION

13 Maintenance

Oil leaks or inadequate spring

loading; stroke end bumpers worn.

Contact an Authorised PIAGGIO

Service Centre

TRANSMISSION IS NOT SMOOTH

Gearbox failure Contact an Authorised PIAGGIO

Gearcase noise Contact an Authorised PIAGGIO

Service Centre

Service Centre

POOR BRAKING ACTION

Drums greasy, brake shoes worn Contact an Authorised PIAGGIO

Air into the circuit pipes Bleed the air

Shoe self-adjustment device faulty Contact an Authorised PIAGGIO

Irregular friction material wear Contact an Authorised PIAGGIO

Oil leaks from the circuit Contact an Authorised PIAGGIO

Air in the brake circuit Bleed the air Contact an

Service Centre

Service Centre

Service Centre

Service Centre

authorised PIAGGIO service

centre.

97

Page 98

ELECTRIC SYSTEM INEFFICIENCY

Faulty controls (switches) or lights

and indicators

Battery inefficient Contact an Authorised PIAGGIO

Contact an Authorised PIAGGIO

Service Centre

Service Centre

Troubleshooting / What to do if... (13_26)

Idle adjustment

Adjust the idle speed as follows:

1. Release the three clamps and remove the plate.

2. Start the engine and take it to its normal operating temperature, i.e., 5 minutes run

at a medium speed.

3. Turn the gas valve travel end adjustment knob «A» to approach the minimum stop

13_26

limit of engine spontaneous stop.

4. Then, adjust the mixture flow adjustment screw «B» to reach the highest rpm number. If the rpm number reached is excessive, decrease it by knob «A» to reach a

regular minimum speed.

If this is problematic, go to a PIAGGIO Dealer or Authorised Service Centre.

THE IDLE ADJUSTMENT MUST BE PERFORMED WITH HOT ENGINE AND ACTIVE CATALYTIC CONVERTER. BEFORE PROCEEDING, CHECK THAT THERE

IS NO PLAY ON THE THROTTLE CONTROL. IF REQUIRED, GO TO A PIAGGIO

DEALER OR AUTHORISED SERVICE CENTRE TO HAVE THE THROTTLE CONTROL PLAY ADJUSTED.

98

Page 99

13 Maintenance

CAUTION

IN CASE OF PROBLEMS WHEN ADJUSTING THE IDLE SPEED, IT MAY BE NEC-

ESSARY TO ADJUST EXHAUST EMISSIONS (CO). THIS OPERATION MUST BE

PERFORMED AT AN AUTHORISED PIAGGIO SERVICE CENTRE.

Characteristic

Idle adjustment

(approx. 1250 - 1450 rpm)

Troubleshooting / What to do if... (13_26, 13_27)

Brakes adjustment

The brake shoes are provided with a self-adjustment device that automatically restores the proper clearance between blocks and drums, regardless of the friction

material wear, so it is not necessary to perform manual adjustments.

The brake drums are provided with hole with screw cap «A» through which it is possible to inspect the wear of the friction material: In case of excessive wear, replace

the brake shoes. For this operation, turn to a Concessionaire or to an Authorised

PIAGGIO Service Centre.

13_27

Troubleshooting / What to do if... (13_27, 13_28)

Parking brake

Pull the lever to engage parking brake. Lift the lever slightly to release the brake, press

the button with the thumb and lower the lever completely.

13_28

•

BEFORE SETTING OFF ENSURE THE PARKING BRAKE IS FULLY RELEASED AND THE WARNING LIGHT IS OFF. SHOULD THE PARKING

BRAKE BE PARTIALLY PULLED, THIS WOULD CAUSE THE BRAKES

99

Page 100

13_29

TO OVERHEAT RESULTING IN LOSS OF BRAKING EFFICIENCY AND

EARLY WEAR OF THE FRICTION MATERIAL.

WHEN PARKING THE VEHICLE ON HILL ROADS, ALWAYS PULL THE PARKING

BRAKE LEVER FULLY AND MOVE INTO THE LOWEST GEAR OPPOSITE THE

DIRECTION FACED BY THE VEHICLE. IN ADDITION, POSITION WEDGES BEHIND THE WHEELS.

•

TO IMPROVE SAFETY AND AVOID ACCIDENTAL ACTIVATIONS, WE

SUGGEST YOU ALWAYS PULL THE PARKING BRAKE BEFORE, OPERATING THE LIFTING/LOWERING BODY CONTROL.

Troubleshooting / What to do if... (13_28, 13_29)

Air bleeding from the braking system

In case of anomalies of the brake performance, accompanied by idle pumping, have

the system drained by the Concessionaires or Authorised PIAGGIO Service Cen-

tres.

IN FACT, THE BRAKE FLUID IS HIGHLY CORROSIVE AND IT MUST BE DIS-

POSED ACCORDING TO PRECISE REGULATIONS. MOREOVER, ANY INTERVENTION TO THE BRAKING SYSTEM MUST BE CARRIED OUT ONLY BY

QUALIFIED PERSONNEL.

100

Loading...

Loading...