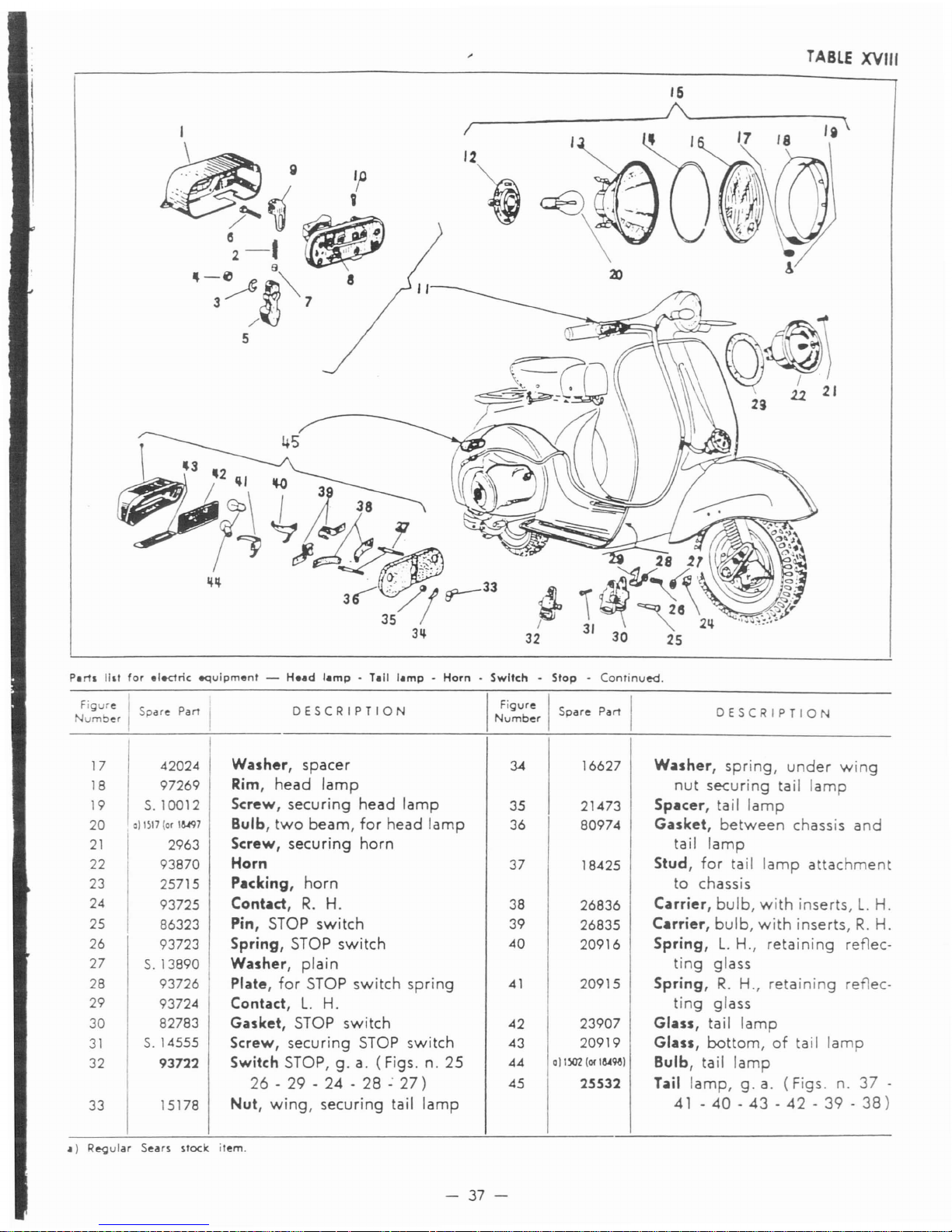

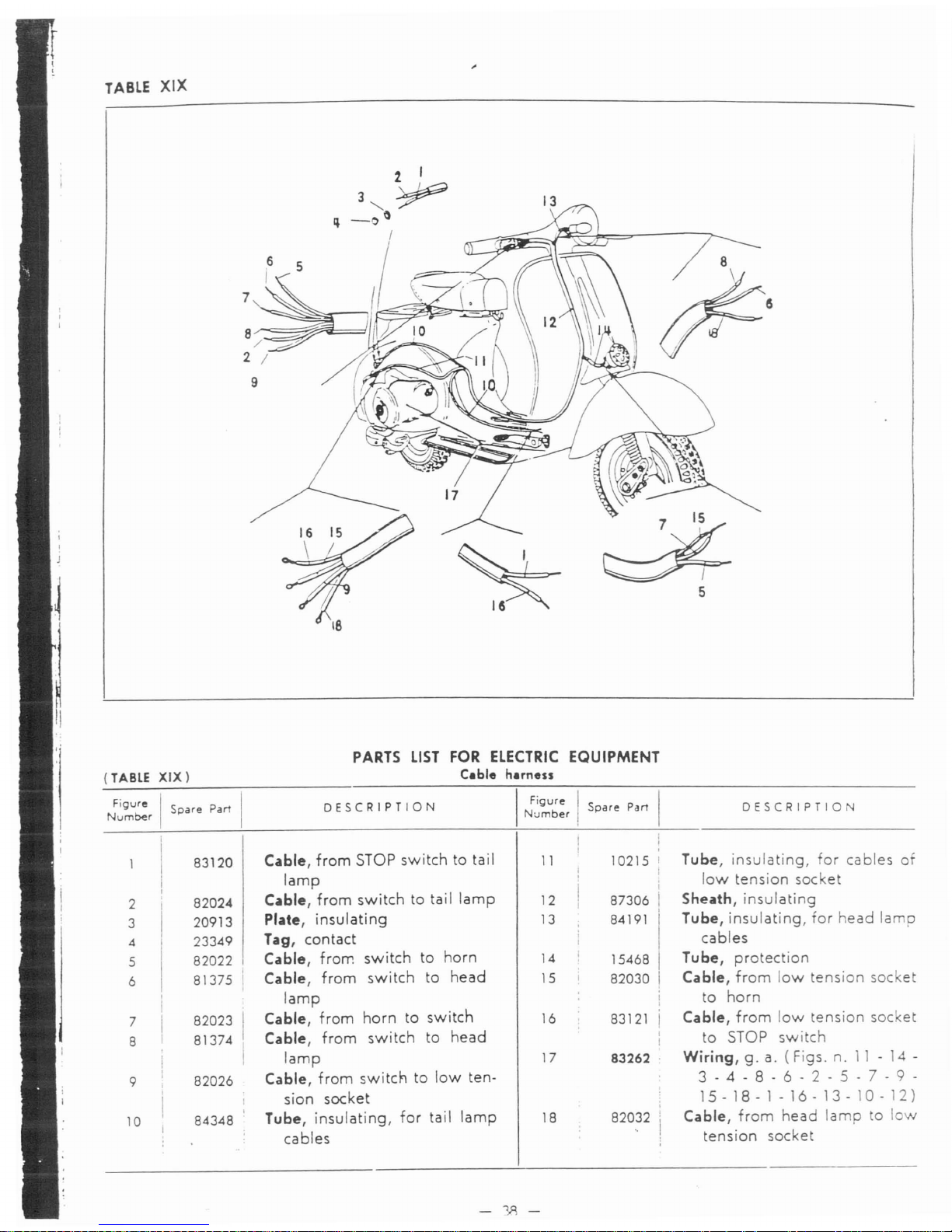

Page 1

OPERATING

INSTRUCTIONS

AND

PARTS

LIST

FOR

MOTOR SCOOTER

r------

MODEL NUMBER 788.94331

This is

the

Model

Numberofyour

Allstate

Motor

Scooter.

It will

be

found

onaplate

fastenedtothe

chassis

under

the

fuel

cock.

Always

mention

this

number

when

communicating

with

us

regarding

the

Scooter,orwhen

ordering

repair

parts.

r-----

HOW TO ORDER REPAIR PARTS

All

parts

listed

herein

may

be

ordered

through

any

Sears

retail

or

mail

order

store. In

ordering

parts

by

mail

from

the

mail

order

store

which

selVes

the

territory

in

which

you

live, Selling

Prices

will

be

furnished

on

request

or

parts

will

be

shipped

at

prevailing

prices

and

you

willbebilled

accordingly.

WHEN

ORDERING REPAIR PARTS, ALWAYS GIVE

THE

FOLLOWING INFORMATION:

1.

The

Part

Numberinthis List.

2.

The

Part

Nameinthis List.

3.

The

Model

Numberofthe

item.

This list is valuable. It will

assure

your

being

able

to

obtain

proper

parts

service

at

all

times.

We

suggest

you

keep

it

with

other

valuable

papers.

SEARS, ROEBUCK

AND

CO.

Scooterworks USA Inc.

5709

N.

Ravenswood

Chicago,IL60660

ph: 773.271.4242

fx:

773.271.5012

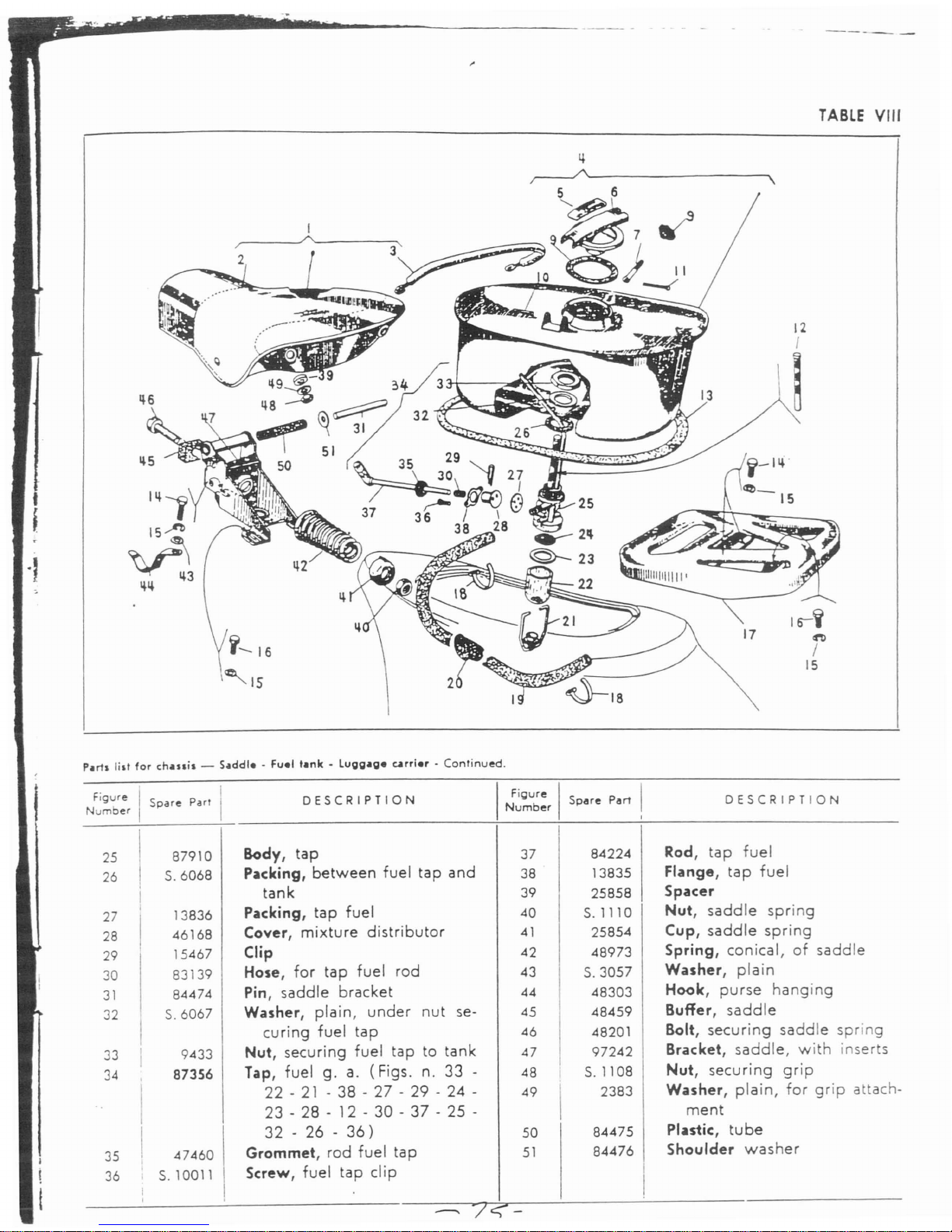

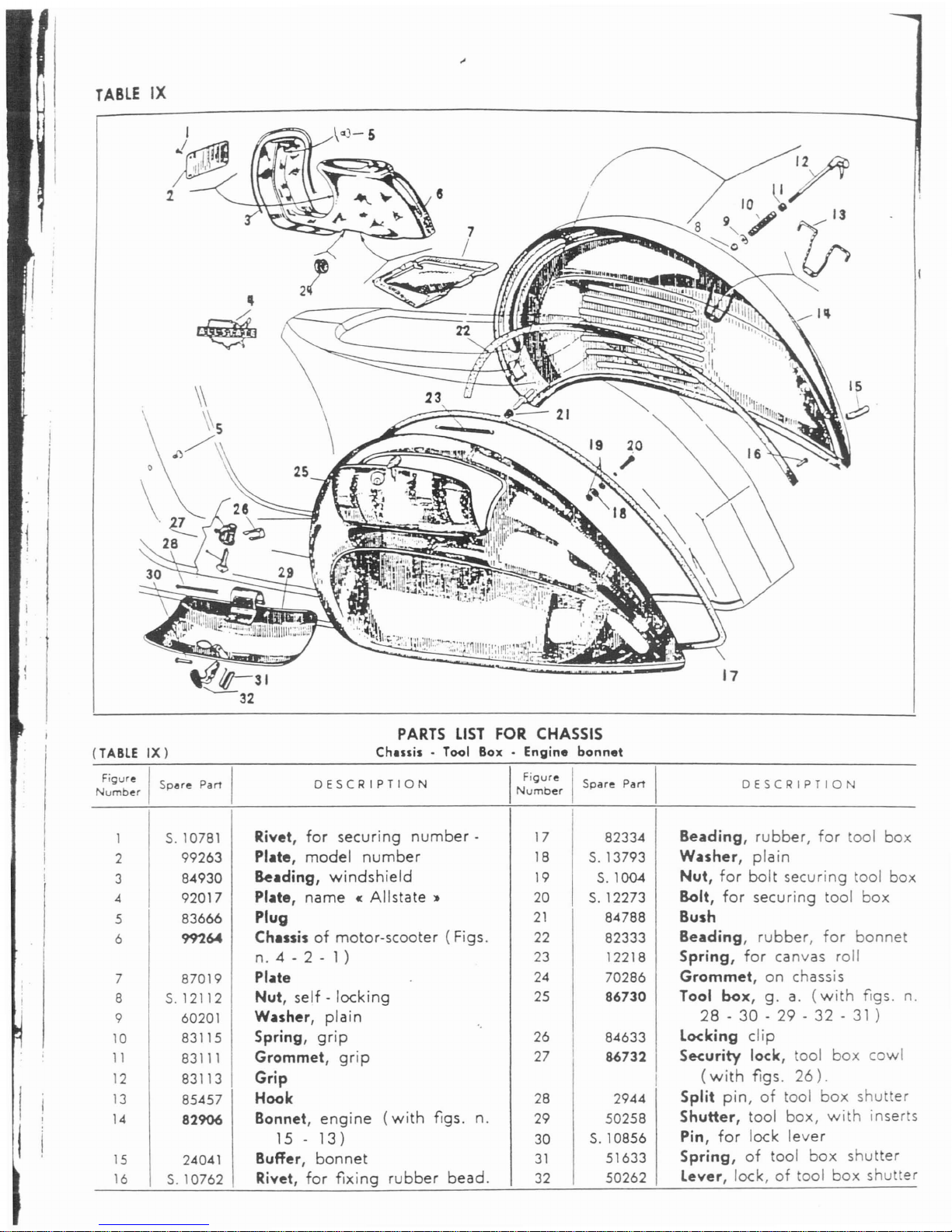

Page 2

Page 3

Fig. 1 .

AUST"TE•

Crui.aira•Motor

xoot.r

WARNING

lO<ltlon

of

fnm.

Number

lo<ationof."9in.

Number

Fig. 2 •

lO<ltlonof..

rill

number

Serill

numbers

are

preceded

by

pretixM:

V A1~T,

for

frame;

VNB 5 M, for

1"9;n

•.

In

order

to keep

your

ALLSTATE

Scooterinperfect

running

condition

and

nottovoid

the

guarantee,

always

have

your

machine

repaired

at a Sears, Roebuck

and

Co. Store.

Special care

shouldbetaken

with

regardtothe

fuel

mixture

which

should

be

regular

gasoline

and

oil

of

the

make,

grade

and

in

the

amount

prescribed

in this

booklet.

Ethyl

~asoline

should

never

be used.

Do

not

use

Allstate

compounded

motor

oilorother

Praemium

Huvy

Duty

Oil

with

detergents.

The

inexperienced

operator

should

exercise

caution

in

applying

front

wheel

brake,

to

avoid

locking.

C\-

\

'lg.

3 •

Control.of"Ilstat.

xoot.r

1.

Gear

chenge

twistgriO

with

clutch control

lever·2.Front

brake

lever·

3. Throttle con-

trol

grip.•.

light

and

dimmer

,witch

.

S.

Front

brake

iaws

..6.Rear

brake

pedal.

7.

Kickstarter

.•.

Gear

,hi

Iter

. 9. Rear

brake

iaws.•10.

Clutch.11.

Carburettor,

air

cleaner.

12.

Starter

push

pull

rod·

13.

F"el

cock.

Page 4

";.

4 • l"9In.

Inltallatlon

and

....

p4n.I.M.

1

r--------/-I

6

Ignition.•By

flywheel

magneto.

Engin.

to

wheel

trensmission

retios:

First 13.35 0 1

Second

9.32

to

1

Third

6.64

0 1

Fourth 4.85

to

1

fit. 5 • 1

..

1ti_

ojl

......

1.

Ignillon

coli in

flywh_1

mlQn.«>

··2.

Rolor

~m

•J.Brea

.....~.Con-

danlO".5.

Sparlcplvg .,.Engin.

cvl·

""eon.wilch.

Clutch..Wet

type;

multiplate,

with

facingsofcod

..

composition

applied

to

the

driving

discs.

Geer

box..4 -

speed

drive

with

mesh

gears

in

od

bath.

Its

two-<able

controliscoupled

with

that

of~e

clutch,

on

left

hand

side

of

handlebars.

123.4 cc.

(7.53

cu.

in.)

52.5

mm.

(2.06

in.)

57

mm.

(2.24

in.)

4.6

HP

7 : 1

5000

rpm

MAIN

SPECIFICATIONS

Trtlnlmlulon.

Oi

re<:tly

from

engine

to

rearwheel

gh

clutch,

cushion

drive

and

gear

box.

SYrtlng

..

By

means

of

kickstlHter,

right

hand

side

SCooter.

1.

~

c.olvmn

and

Irone

svspension

. 2. Engln

...J.Cranlcc

....

half,

c1vtch

sid.,

wilh

swinging

arm.4.

Raar

svspension

spring

with

hy-

dravlic

damper.

IIv.f

eonsumption:

1M.

oil

milcture)

130

miles

per

gal.

'P"d

.

46.6

m.p.h.

bue .

46.4

in.

wldttt

on

hendlebus

25.7 in.

~;tn

of

the

scooter

68 in.

~Ight.

. . . . 38.7 in.

~Ight

of.

·f1oorboud

8 in.

drcl.

59 in.

(

un'ed.n)

. 182 Ibs.

~.m

•..

Of

pressed

and

spot-welded

steel

sheet,

th

Itreem-lined

monocoque-type

structure.

M~nslon

.•

Front

wheel:

coil

spring.

Rear

wheel:

I9

rin

g

and

coaxial

hydraulic

shock

absorber.

L,gln

•..

Two·

stroke,

flat

cast

iron

cylinder

and

Iluminium

alloy

cylinder

head.

Cooling

effected

by

rifugal fan w ichisembodied

in

the

flywheel

of

tn4Igneto.

lacement

-4-

Page 5

lubrication.

- By the

oilinfuel

mixture

for

piston,

cylinder,

wrist

pin,

con. rod, cranks

aft,

main

bea-

rings.

Both clutch

and

gear

box

operate

in oil

bath.

Carburettor.-With

float-cham-

ber

(see

fig.11);

air cleaner

moun-

ted on the

engine.

Air

goes to the

carburettor

through

a

large

inlet

tube

and a silencing

chamber

with

filter.

Modelofcarburettor:

Dell'Or-

to

51

20/15

C -

Venturi

15

mm.

(0".59)

-

Main

jet

82/100

(0".

0323)

-Idler

iet

42/100

(0".0163)

-

Air-vent

for

main

jet

120/100

(0".0473)-Air

holeonmixer

top

150/100

(0".05)-Mixer

tipe

BE

1.

-

Air-vent

to

idler

jet

140/100

(0"

.055)

- Spray nozzle

200/100

(0"

.0788)

-

Sta

rter

jet

55/100

(0".0216)

- Float

chamber

fuel le-

vel

20.5 ± 1

mm.

(0"

.87)-Oil

recovery

vent

50/100

(0".0197).

Feeding. - Fuel

feed

to the

carburettor

is

pr.ovided

for

by

gravity

(see

fig.

11)

with

gasoline-oil

mixture.

Fuel

tank.

- Total

capacity:

2,03

gals.;

Reserve:

V1

1/3

gal.;

Three-way

cock:

«open»

. «

closed»

- « reserve

».

Mumer.-Expansion

and

absorption

combined

type.

Handleb.rs

..

Pressure

die

cast in

light

alloy

and

designed

so

as

to house

both

headlamp

and

speedo-

meter.

All

the

control

cables

and

electrical

wi

res to

this

group

are concealed

therein.

(See

fig.

3).

Steering

column..The

steering

column

bears the

handlbears,

clamped

on its

top

end,

and

the

front

wheel

swinging

hub,

pivoted

at its

bottom

end

throughastub

axle.

lighting

.nd

hom.

- By

flywheel

magneto,

feeding

both

head

lamp

(two-beam),

tail

lamp,

horn

and stop

light

(see

fig.

9).

Brakes. -

Expanding

type.

Front

brake:

control

lever

on

right

hand

side

of

handlebars.

Rear

brake:

control

pedal

on

right

hand

side

of

floorboard.

The rear

brake

jaws

are

hinged

on

indepen-

dent

pivots.

Wheels. -

Of

pressed steel sheet,

interchangeable

and

easily

removable,

since

they

are

assembledinan

auto-

mobile-like

system.

Tires:

dia.

3.50

x 8

in.

Steering

lock..A

suitable

security

lockisarranged

on the

frame,

near

the

handlebars.

Turning

the

key

counter-clockwise

and

the

handlebars

to

the

left,

the

lock engages

the

lugs

welded

on

the

steering

column,

so that the

machine

can

only

turn

around.

Turn the

key

clockwise

and

the

handlebars

back

to

normal

position

for

releasing

the

steering

system

(see

Fig.

7).

Do

not

Fig. 6 •

Sealon0/engine

1. Air

cleaner

and

carbvrettor

. 2..Piston·

3.

Cranksnaft-4.

Clutcn

S.

Mainsnaft

. 6.

Gear

snifter.

7.

Fliywneel

magneto·

•.

Kid

starter

9.

Crankcase

n.lf.

clutcn

side.

witn

swinging

arm.

attempt

to

ride

the

machine

unless

the

keyisin,

and

re-

mainsinthe

lock,

and

the

handlebars

are

moving

freely.

Do

not

lubricate

the

steering

lock.

Security

lock

on

tool

box

wing.

- The

compartment

flap

on the

left

wing

of

the

vehicle

is

equiped

with

a

key

operated

security

lock.

Centr.1 Stan. - A

two-legged

standisarranged

un-

der

the

floorboard.

A

strong

return

spring

holds

it in

~.

7 -

s.cvrity

Io«k

1. Norm.1

position.

2.

Closed

- 5 -

Page 6

'IV·

• -

Spar.

wh

••

1

and

buck.t

...

...

,

\

\

\

I

I

I

I

"

~

//

-~~---

\/

",

10

5

,-------------------

..

"'Tt---------..

--~!:O~~~__+_---.(O

------+-+-----+r"'"

Tool Kit. - 1

four-ended

box

wrench

(11

- 14 -

21

22

m);1double

open-enQed

wrench

(8

- 14

mm);

1

single

open·

ended

wrench

(7

mm);

1

screw-driver.

These

hand

tools

are

containedina roll

whichisplaced

in

the

left

wing.

Speedometer.-The

speedometer

has

its

housing

in

the

middle

of

the

handlebars

and

adds

to

the

perfor-

mance

and

appearance

of

the

scooter.

Accessories

(See

Table

XX).-On

request

the

Allstate

scooter

can

be

equipped

with

the

spare

wheel

and

bracket.

A

FiV.

9 -

Schem.

of

EIKtTic Wlri"",

contact

witt'e

oorboard

and

keepsitfrom

:ibrating

wnile

the

scooterisbeing

ridden.

Spare

wheel

.nd

br.cket

(see

fig.

8).

- The

wheel

bracket

sheet

steel

pressing,

canbesecuredtothe

scooter

frame

behind

luggage

carrier

(see

Table

XX,

«Spare

parts

list»).

_

Itisvery

robust

and

simple

and

holds

the

wheel

in

such a

position

whereitis

easily

accessible.

1.

Flywh~~1

m~n~to

-2.low

t~nsion

t~rminal

1.

STOP

li~ht

(6

V . 3 w

bulb)

-4.Toil

lamp

(6

V . 3 w

bulb)

- S.

Spar"plu~

-6.STOP

switch

.7.light

and

dimm~r

switch

-a.6V·22/22

W

doubl~

r.lam~nl

bulb-9.

Horn.10.

Insid~

vi~w

of

heed

lamp.A:

Engin~

cuI·

out:

B:

li~hls

off

.

c:

H~ad

lamp

and

toil

lampon.

0:

L~v~r

for

country

and

lrafioc

beam.E:

Horn

button.

Page 7

OPERATION

IF

THE

SPEEDOMETER

(WITH

MilE

DIAL)

HAS

BEEN

DISMANTlED,

FOR

REASSEMBliNG

PROCEED

AS

FOllOWS:

(See

fig.

10)

Filii.

10·

How

10

aU41mble

the

Ip

..

dome4er

unit

lodged

in

the

square

cut·

out

of

the

speedo.

drive

pinion.

Make

sure

that

the

end

of

the

flex

drive

enters

the

square

section

hole

of

the

speedometer

drive

pinion.

Rotate

the

wheel

by

hand

for

several

timesinorder

to

make

sure

thatitturns

freely.

Grease

pinion

c I

~

.

support

bush

c L

~

assy

through

lubricator

on

ring

c K

~.

Duetothe

simple

and

conventional

design

of

the

Allstate

scooter,

no

particular

skill

is

required

for

its

operation,

nor

skilled

personnel

for

its

maintenance.

The tasks can be

quite

well

carried

out

by

.,ny

customer,

even

inexperienced,

by

carefully

following

some

general

rules.

Running-

in.-Important

rulestobe

followed

while

running.

in

(1200

miles)

:

Do

not

exceed

following

speeds:

1st

gear

13

mph.

2nd

gear

19

mph.

3rd ge1H

25

mph.

4th

gear

37

mph.

Do

not

hold

these

max

speeds

for

long

periods

neither

use

full

throttle

opening

up-hill.

Change

oil

in

the

gear

box

and

check

thl!lt

nuts

and

bolts

are

not

slack

after

the

first

600

miles.

to

flow

out;

otherwise

top

up

with

ALLSTATE REGULAR

S.A.E.

30.

With

the

help

of.,pilot

wire

slide

the sheath c A

~

for

the

flex

drive,

into

the

steering

column,

from

the

top

end,

untilitemerges

from

the

bottom

end

(indicated

with

an

arrowinthe

figure).

Pull

the

pilot

wire

outofthe sheath,

grease

the

flex

drive

generously

and

slide it

in.

Assemble

packing

c C

~

and

then

the

speedometer

head

c B

~

on the

bracketE,already

mounted

with

rubber

buffer

c F

~

fixing

with

the

apposite

screw

c U

~

and

spring

washer

c T

~

ensuring

that

said

screwisnot

tightened

too

firmlytoavoid

deformation

of

the

speedometer

head.

Insert

the

upper

end

of

the

flex

drive

into

housing

in

the

speedometer

head

and

secure

both

flex

drive

and

sheath

by

meansofknurled

ring

nut

c G

~.

Now

secure the

group

speedometer

and

bracket

to

the

handlebars

by

means

of

the

screw

c S

~

and

plain

washer

c R

~.

Completed

the

above

operations

reassemble

the

head·

lamp.

Fill

up

hub

with

grease in

order

to

lubricate

the

portion

of

the

wheel

spindle

meshing

with

the

spee-

dometer

drive

pinion

c I

~.

Mate

the

pinion

c I

~

to the

support

bush

c L

~,

then

mount

ring

(with

lubricator)

c K

~

on

the

latter;

screw

the

support

bush

c L

~

on

the

wheel

hub.Ifan

axial

play

between

drive

pinion

and

centre

pin

of

0.25to0.8

mm.

(0".01

to

0".03)

is

not

obtained

on

assembling

the

part

c L

~

into

the

hub,

interpose

the

spacer

washer

c M

~.

Slide

the

rubber

cap c N~,the

threaded

ring

c 0

~

and

biconical

ring

c P

~

over

the

sheath

end;

fit

the

washer

c Q

~

on

the

cable

portion

which

protrudes

from

the

sheath, P.,ss

the

I.,tter

between

the

front

brake

control

cable

.,nd

the

wheel,

then

screw

and

tighten

threaded

ring

c 0

~

on

bush

c L

~

and

po-

sition

rubber

cap c N

~.

Ensure

that

the

end

of

the

flex

drive

is

accurately

-1-

Keep

the

breather

of

filling

cap

clean.

Fuel

$upply..Fuel

mixture,

both

during

and

after

running

in,

should

be

composed

of

regular

gasoline

and

pure

mineral

oil

SAE

30at2%,i.e.:

-

If.I.

pint

of

oil

1%

gallons

of

gasoline.

When

using

pre-diluted

or

additive

oils,oroils

for

outboard

motors,

mix

1,4

pint

of

oil

per

gal.

Oil

level.

- Remove

the

level

screw,

on

crankcase,

markedcOLIO~as

indicated

on

page

11

Fig.

20,

to

check

oil

level

in

gear

box

before

starting

the

engine.

The

scooter

standing

upright,

oil

should

just

be

about

Page 8

----

Stlrtinlil·.Open

:ne

fuel

valve,

put

the

gear",

box

in

neutral

and

slightly

open

the

throttle

in

slow

running

position,

kick

the

starting

lever.

With

cold

engine,

operate

starter

push

pull

rod.

Push

said

rod

backassoonasthe

engine

fires.

See

Fig.11;

note

the

three

positionsofthe

fuel

valve:

open,

closed,

reserve.

C.ution

..

Do

not

open

throttle

wide

when

releasing

clutch.

In

case

of

starting

troubles,

due

to

engine

being

flooded

(unvaporized

fuel

mixture

has

reached

the

cy.

linder

and

combustion

becomes

therefore

very

difficult),

proceed

accordingtoeither

oneofthe

following

methods:

a)

Push·

start

the

scooter:

shift

into

second

gear,

declu

ch

and

push

the

machine;

quickly

release

the

clutch

lever

and

pullitbackassoonasthe

engine

starts.

b)

Close

the

fuel

cock,

remove

the

spark

plug

and

rotate

the

engine

by

means

of

the

kickstarter.

Wipe

the

plug

dry

and

replace.

Open

the

fuel

cock

and

kick

the

starting

lever.

FiQ.11.

Feeding

circuit

1. Fuel

cock

lever:

A)

Reserve.

B J

Open.C)Closed·2.Floal .J.Air

eleaner

and

carburellor.J/l.

Air

filler

.•.

Slaner

iel.5.

Sel

screw

for

lhrollie

slide·6.ThrOllle

slide·

7. Air

venl

for

main

jel .a.Hole

on

mixer

top·

9.

Mixer·

10.

Main

jel.11.

Idling

let.

12.

Air

venl

for

idling

iel.1J.

Plug for

inlet

hole

for

oil:

for

layingup. 1•.Idling

adju'ter.15.

Slaner

valve·

16.

Intake

port·

17.

Tran,fer

pon,

.

11.

ExhauH

duct.

FiQ.

1::l•Opentlon.

to

clrry

out

I.,

ttlrtl"9

tho

e"9;n.

"':

open

lhe

fuel cock .B:'electcneulral•.C:

operlle

'larter

push

pull

rod

(with

cold'

engine).0:

lhrollie

conlrol

gripinidling

po,ition.E:

deprell

the

kick'larter

and

turn

grip•O.

by

,hort

'lroke,.

- 8 -

Page 9

1

:1

I

i

i

For

acceutothe

engin.,

take

off

the

engine

cowlin~

then

proceed

as

follows.

Pull the

lever

« 1

~

(Fig.

13)

and

turnitso

as

to

release

it

from

bonnet.

Then

move

the

bonnet

slightly

outwards,

until

front

pivott(2~is

extracted

from

the

hole

on

the

frame.

Push the

bonnet

from

the

front

upwards

and

turn

it

(see

position

indicatedbydotted

line),

thus releasing

the

fixing

hook

« 3

~

from

frame.

Move

bonnet

outwards

round

its

hooked

pivot

« 4

~

until

the

latter

disengages

from

the

hole

on

frame.

Thus the

bonnetisremoved.

Forre-

assembly,

follow

the

reverse

procedure.

Setting

the

machineinmotion.-Let

the

engine

idle,

depress the

clutch

and

turn

the

gear

change

twistgrip

so

that the

line

engraved

onitcoincides

with

the

figure

«1~(1st

gear)

engraved

on

handlebars

(see

Fig.

14).

Now

letinthe

clutch

gently,

while

opening

the

throttle

gradually

to set

the

machineinmotion.

Gear

change.-On

attaining

the

required

speed in

1

st

gear,

quickly

close

the

throttle,

release the

clutch

and

turn

the

gear

change

twistgrip

so

that

the

engraved

line

coincides

with

figure

« 2

~

(2nd

gear);

let in

the

clutch

and

open

the

throttle.

FJ9.

13

•

(nvI-

bonnet

,..

....

0

...

1

1.

EnQine

bonnet

locking

lever.2.

Front

pivot•3.

Fixing

hook

•

4.

Hooked

pivot

Repeat

this

procedure

for

changing

into

3rd

and

4th

gear

and

for

changing

down.

See the

drive

system

on

Fig. 14.

When

you

reduce

the

speedofyour

machine,

change

down

without

delary

to

avoid

irregular

engine

running

and

stallingatlow

revs.

"9.1•.

Od".

"y"t.m

1.

Gear

change

twistgrip.2.

Clutch

control

lever.3.

Gear

chan9"

control

c.ble.-•.

Gear

.hifter•5.

Sele<tor

stem·

6.

Selector·

7.1st

gear·•.2nd

gear-,.

3rd

gear·

10.

4th

gear·

11.

Mainshaft_12.

Cush

gear.13.

Clutch.

N.II..

Positions

1·2

- 3-.of

the

gelr

ch.nge

twi.tgrip

correspond

to

1st.

2nd.

3rd

.nd

4th

gear

respectively;

«0.

indicales

the

n~utr.1

position.

Do

not

turn

the

gear

change

twistgrip

while

the

engineisnot

running.

As soon

as

gear

change

troubles

arise,

particularly

when

the

control

becomes

hard,

customers

should

have

their

machines

adjusted

by

a Sears

Store.

Slow

running

adjustment••No

hand

toolisrequir.

ed

for

this

job.

Idling

revs can be

raised

or

reduced

respectively

by

simply

tightening

or

slackening

the

knurled

slotted

screw

on

air

cleaner

steel

sheet

cover

(No.5,

Fig.

11).

This

screw

controls

the

throttle

slide

valve.

The

adjuster

screw

for

the

throttle

control

cable

is

installed

on

the

air

cleaner

case. This

screw

is

to be

reset

only

when

necessary

and

while

dismantling

and

re •

assembling.

Opposite

to

said

adjuster

screw

there

is

on

the

air

cleaner

case a

plugged

hole

for

access

to

another

screw

(spring

loaded);

see Fig.

11

No.

14.

This

screw

controls

the

flow

of

carburated

air

through

the

duct

from

the

idling

jet,

and

consequently

the

idling

revs.

We

recommend

that

customers

refrain

from

re-

setting

this

screw

unless

absolutely

necessary

or

during

-9-

Page 10

:'

FiV·

15 . Olsmlntlir>g

th.

frontwh••

1.

dismantling

and

re -

assembling

operations

that

should.

anyway,

be

entrusted

to a

Sears

Store.

Stopping

the

engine

..

Push

the

earthing

button.

This will

leave

the

cylinder

fulloffuel

vapours,

and

the

next

start

will be

much

easier.

Tires. - The

wheels

are

interchangeable,

i.e.they

can

be

assembled

either

in

front

or

rear,

provided

of

course

that

they

are

inflated

to

pressures

respectively

hereunder

prescribed.

When

a flat tireisto

be

replaced,

unscrew

the

four

nuts

which

secure

the

wheel

to

its

flange,

pull

wheel

sideways

off

the

studs

(see

Fig.

15),

repairitor

replace

with

spare

wheel.

To

remove

the

tube,

first

deflate,

then

separate

the

felloe

from

the

ring

by

unscrewing

the

nuts

which

join

them

(see

Fig.

16).

Av·

16.h",o.ir>g

Ik.

Inno,

IUbo

Tire

pressure

should

be

18

-;.20psi

on

rear

wh~

14

.'c- 15,.5

psi

on

front

wheel.Ift e

AllstateISordi

aril

ridden

by

both

driver

and

passenger.

he

pressure

c

he

re,H

tire

should

be

28.5

-;.

31

psi.

®

F1V·17.

8,.lto

Idjurtmont

Br.ke

.djustment.-Brakes

are

properly

adjus

ed

if:

the

wheel

rotates

freely

when

respective

control

le-

ver

or

pe~t

ire

in

resting

position;

the

braking

action

starts

as

soon

as

respective

con-

trols

are

operated.

These

conditions

are

achieved

adjusting

the

cables

by

means

of

screws

indicllted

with

an

arrow

in Fig. 17.

a

F19.

1••Adjustmontofclut.:h

control

.)

Adjusting

nut•b)

Clutch

lever.

eng,ne

.ide

- 10 -

Page 11

MAINTENANCE

I

i

~

Adiustment

of

clutch

control..Adlustment

of

clutch

controls

is

achieved

operating

on

adjusting

nut

(a),

screwed

to

the

engine

bracket

(see

Fig.

18),

by

means

of

open

ended

wrench

82199

in

the

tool roll.

The

cable

is

to

be

tensioned

or

loosened,

as

the

Cleaning

the

scooter.-Brushing

kerosene

and

wi·

ping

dry

clean

rags

is

advisable

for

external

cleaning

of

engine.

All

painted

surfaces

should

be

washed

with

water,

rinsed

by

means

ofasponge

and

wiped

dry

with

a

chamois.

Do

not

use

kerosene

on

such

surfaces,

since

it

damages

paint

and

turnsitdull

..

If

necessary,

blow

the

head

lamp

reflector

clean

or

wipe

off

dust

withavery

soft

feather.

Do

not

use

a

cloth

and

keep

your

fingers

off

reflector

surface.

Before

setting

the

machineinmotion,

(ifithas

been

delivered

directly

to

the

customer

by

the

Factory)

check

oil

level

in

gear

box

by

unscrewing

the

level

screw

marked"

OLIO,.

from

the

cranckase

(see

Fig.

21

).

The

scooter

standing

upright,

oil

should

just

be

about

to

flow

out.

After

the

fint

600

miles.-Replace

oil in

the

gear

box

by

the

procedure

as

explained

in

the

lubrication

chart,

page

13.

The

crankcase

can

be

drained

through

the

hole

indicated

in Fig. 21.

Every

2.500

miles:

(1)-

Remove

air

cleaner

cover

and

unscrew

the

two

filter

retainer

screws.

Extract

the

filter

(n.

3/1

fig.

11

)

from

carburettor,

w~sh

in

gasoline

and

if

possible

air

blast

dry.

(2)

Check

oil

level

in

the

gear

box

(see

above).

(3)

Grease

all

joints

on

the

brake

controls.

(4)

Clean

the

sparkplug

electrodes

with

very

fine

emery

cloth

or

suitable

files,

and

adjust

the

gap

to

0.6

mm.

(0.023").

Inspect

the

insulation

material

of

sparkplug;

re-

place

the

latterifthe

porcelain

is

cracked.

Wash

with

neat

gasoline.

Use

the

sparkplug

type

Marelli

CW

230

A-

T;

Marell;

CW

225

N -T;Bosch W

225

T 1 ;

Champion

L

86;

AC

43

F;

KLG

F 70orF

75.

Important:

using

the

proper

type

of

sparkplug

will

eliminate

many

engine

troubles.

(5)-Grease

the

felt

which

lubricates

the

cam

of

fly-

wheel

magneto.

(6)-Clean

the

two

lubricators

on

front

wheel

hub

and

refil

them

by

means

ofagrease

gun.

N. B.•All

operations

indicated

hereunder

should

1M

carned

out

by

a SEARS

store.

case

m~y

besothat

control

lever,

on

h~ndlebMs,

makes

a

strokeof2

mm.

(0.078")

before

lever

(b),

on

engine

starts

moving.

Wrong

play

in

the

control

may

cause

the

clutch

plates

burning

out

even

in

normal

running

conditions.

(7)

-

Lubricate

the

speedometer

drive

pinion

and

flex

drive.

(8)

-

Clean

the

muffler

and

decarbonize

the

engine

as

explained

hereunder.

Remove

the

muffler,

the

cooling

hood,

the

cylinder

head

and

the

cylinder

(see

Fig.

20).

Decarbonize

the

piston

crown

and

the

cylinder

ports

from

all

carbon

deposits.

Decar.

bonize

the

inner

side

of

the

cylinder

head.

Care.

fully

clear

the

cylinder

carbon

deposits.

Heat

the

exhaust

pipe

of

the

muffler

and

clean

it

either

by

scraping

internally

withahooked

wire

or

blowing

air

through

from

the

other

orifKe;

in

both

cases

the

muffler

should

be

held

so

that

the

exhaust

pipe

is

turned

downwards.

'i9.19.

Bruhr

points

..

) Max.

gapofbr.a'.r

points

cA.

should

~

0.0

II"

. 0

019"

In

case

of

shock·

absorber

troubles,

overhaul

or

simply

clean

the

assembly

and

changeoiI.

These

operations

should

be

carried

out

by

your

SEARS

store.

Page 12

(1)

.

Every .5.000

mil..:

Clean

the

breaker

points.

In

order

to

avoid

ignition

troubles

or

abnormal

running,

have

the

breaker

points

adjusted

in a

Sears

stores;

the

gap

should

not

be

more

than

0.011"

. 0.019"

(see

Fig. 19)

and

the

points

should

begin

to

open

when

the

current

in the

primary

ignition

circuit

has

attained

its

peak

value.

(2)

Grease

the

control

cables.

(3)

Change

the

oil

in the

gear

box,

as

stated

on

page

13.

(4)

.

Grease

the ratchet

quadrant

of

the

gear

shifter.

Disuse:

(

1)

In such a case,

cleaning

the

scooter

throughly

is

advisable.

(2)-With

engine

not

running

and

with

throttle

control

twistgrip

completely

rotated,

(full

throttle

opening)

pump

40

cc.

of

Allst.te.

Regulu

Oil

SAE

30

or

AlIst.te

Outboud

Motor

Oil

through

hole

in the

air

cleaner

cover

into

the

carburettor

intake,

by

means

of

an

oiler.

Then

operate

the

kickstarter

three

of

four

times.

(3)

Rest

the

floorboard

on

two

wooden

blocksinorder

to

take

the

weight

off

the

tyres.

(4)

Drain

all

fuel

from

both

tank

and

carburettor.

(5)

Grease

all

unpainted

metal

parts.

-

12

-

Fill·20.Cl..

ninq

the

cyllnd.,

hNd,

cyllnd.,

and

pinon

Page 13

LUBRICATION

CHART

PoUTTOBE

O'ElATION

I

TIM

E

I

THE

OF

lUB_ICANT

lUBlllCA

TED

i

I

I

Mix

gasoline

with

the

following

amount

t

At

each

refillingofthe

fuel

i

Pure

mineral

oil

SAE

30.

Engine

I

of

lubricating

oil:

tank.

I

-

~~

pintofoil

to/Vz

gallonsofgasoline.

I

I

N.B.-

With

pre-dilutedoradditive

oils,

!

mix~~pintofoil to each

gallon

I

of

gasoline.

I

Gear Box

Warm

up

the

engine

and

drain

off

oil.

I

After

the first

600

miles

I

Allsta e

Regular

SAE

30.

I

Pour some fresh

oil

in and run the en-

and

every

5000

miles.

I

I

gine

forafew

seconds. Flush and

refil

I

I

with

new

oil

(about7oz.).

I

Refill

with

new

oil

to

oil

level

hole.

I

Every

5000

miles.

I

I

Front

wheel

hub

I I

Speedometer

I

Lubricate

with

grease

gun.

Every

2500

miles.

High

Pressu

re

Chassis

flex

drive

and

I

pinion

!

Joints

on

brake

I

Grease.

I

Every

2500

miles.

Allstate

all -

purpose.

controls

Gear

Lubricator

SAE

140.

Shock-a

bsorber

I

Change

oil.

Only

when

the

shock·

abo

Allstate

Shock.

sorber

is

out

of

order.

Absorber

Fluid.

Control

cablesIClean and

lubricate.

Every

5000

miles.

Allstate

all -

purpose.

I

I

Gear

Lubriclltor

SAE

140.

I

Feltofflywheel

I

Small

spot

of

grease

on

the

felt.

Every

2500

miles.

Allstate

Bearing

Grease.

cam

Ratchet qua-

Grease.

I

Every

5000

miles.

Allstate

all -

purpose.

drant

of

gear

I

Gear

Lubricator

SAE

140.

I

shifte

r

I

I

HIGH

PRESSURE

CHASSIS

GREASE

'19.

21 -

lubrication

Kheme

1. Filling

hole·

2.

Draining

ho!e

ENGlNE

LUBRICATED

B

Page 14

LOCATING

TROUBLES

...

ANO RUNNING

IRREGULARITIES

C.rry

out

following

cnecKs

wnen

tn.

engine

does

not

sbrt

euily

or

runs

irregul.rly.

lo<atin<jl

tha

troubla

OlnlCULT

STAITING

Top

up

oil

leyel.

Tighten

on

draining

hole.

~

ReoloSe

e

I

Replace

both

plates

and

springs.

Adiust

(see

r,g.

18).

I

Gaar

pinionl

dl"f>9Age

of

own.

a«ond.

a)

Clutch

snatches·

Gear

pinions

c,~

lubricated

pro-

p"r1y.

Clutch

slip.,

Springs

f""ble.

Plates

womorbumt.

s.

dry.

i

I

Turntoc

reserve

t.

~efll

cB

soon

IS

b)

pOSSible.

i

~

Remoye

and

washingasoline.

Blowc)Clutch

does

not

diseng,oge

Com.

pletely,

Excessive

playonconlrol

cable

Clogged.

dirty

1

.•

Fual

systam.

Fuel

lank

emply.

Filteroncarburettor

I

Fuel

lap

body

C.,bureltor

body

Main

iel

,

Atomizer

Pocking01lu,,1

tap

2

..

Cari><Jratlon

Timing

wrong.

Breaker

points

complelely

worn

pilted.

c..ar

change

control

cobles

OutofAdjull.

adiuslm"nt.

Engine

/loading

Float

perforoled

Air

c1ean"r

chokedordirty

Starter

valve

sticking

3

..

Ignition

Sparkplug

dirty

Porc"lain01sparkplug

crocked

Br

...

ker

points

dirty.

pHtially

or

pitted.

Gap

b..lw""n

br"aker

poinls

reel.

j

Seepag"

8.

I

Replace.

I

I

Clean

(se"

page

I 1 ).

Release.

I

I

,Disconn"ct

the

plug

lead.

Ch"ck

il

I

sparking

occurs

b..tw""n

lead

and

I

crankase

when

th"

kic",tart"r

is

I

operated.

i

CI"an.

Correct

gap'

to

0.6

mm.

(023").

i

;

Replace

the

plug.

I

wornrClean

with

suitable

fdesorvery

fIne

I

emery

paper.

incor·

Correct

(see

fog.

19).

or

Qep/ace.

I

Re·

time

ignition.

Springofstirrup

broken.

le"ble

missing.

s"lector

amns

chamfered.

Dogs

of

9"ar

pinions

chipped

worn.

6.

High

fual

cons~mptlon.

Should

the

centrol

have

exceSSr"'e

play

in

neutral,

tensIon

con:r::!!

cables

by

screwing

back

Ihe

ro-

spective

adjuster

screw

(on

coble

sh"ath

end.

rolenet

quadrant

siCe)

withan8

mm.

open

ended

wrench

If

the

ceble

tensioninneutral

is

correct

but

the

reference

marks

of

the

handl"barsdonot

tally.

tighlen

one

of

the

adiuster

scr"w

.'d

unscrew

the

ocher

onetothe

U:;"le

extent.

so

Ihat

the

cable

tensien

is noc

altered.

or

Replace.

I

I

:

Replace

Ihe

seleclor.

orIReplace

the

pinion.

:

:

INCORRECT

RUNNING

Elhaust

port

partially

closedbycar·

D",arbonize

cylind"r.

piston

and

cy.

bon

deposit.

Iind"r

h"ad.

Clean

with

pure

gasoline

and

blo

..

dry.

:

Dismount

and

clean

carburettor

:n

gasoline

and

compressed

air.

For

type

and

diameter

01

j"ts

ane

vents.

see

pa9"

5.

I Fuel

level

too

highincarb'J.

retlor,

Float

perforato-d.

Replace.

II

Air

clean",

cho"",,dordirty.

III

Jeborv"nbofthe

carburetlor

blocked

or

dirty;

incorrect

or

incre.sed

diameter.

CI"an

(s"e

pa9"

11).

Replace.

1. . loclrofpowa,.

Muffler

outl"t

pip"

carbonized

Cylinder

bOle

9asket

not

sealing

Sparkplug

not

w,,11

Icrew"d

downInTighten

(21

mm.

box

wrench).

cylind"r

head.

IV

Reta,ded

ignition.

V

Poor

compression.

7

.•

Control.

not

oparatlng

properly.

R,,·

time.

Se"

No.2of

this

paragraph.

Lubricate

or,

if

necessary,

replace.

Adjust.

•.•St..rin<jl

column

ba<oma.

ttl".

Top

race

01

top

ball

b..aring

100

Slacken.

tight.

CI

...nthe

rings

and

grooves.

PisIon

rings

gumm"d

up.

Cylinder

heed

not

fitting

properly

s"t

the

h"ad

properly

and

tighten

Inner

cables

rusted.

inlO

the

spigotontopofcylinder

the

nuts.

Exc"ssive

play.

1.

ExpiOilon.a'mu"'--

ar

carb

...

,.ttor.

Sparki"Q

plug

carbon·

coatedorwith

Replaceorclean

th"

plu9

and

cor·

Bottom

race'

of

the

two

b..arings

Replace.

excessive

el"'trode

gap

rect

th"

gap

to

0.6

mm

(.023").

pitied.

Carbon

pearls

on

sparkplug

insula·CI...

n.

tion.

9

.•

Ellcaul

..a

play

of

rt

..

r1nv

column

Pre·

ignition.

a)

Fitona

proper

Iype01sparkplug.

Top

raceoftop

b..aring

loose.

b)

Re·

time

the

ignilion.

Tighten.

Not

enough

mixture

flowing10th"

s""

paragraph

carbur"tlor.

No.

I.

Tipofcontact

break"r

loose.

Condens"r

screw

loose.

Replac".

Tighten.

10

.•

I'oor

bralr1nv.

Stroke01p"d

liar

lev"i

too

lon9.

Adiust

(see

Fig.

17).

Brake

linings

oily

or

worn

down

Wash

with

gasoline

or

replace.

c DiffICult

starting

>.

Brake

drums

and

linings

scratched.

R"place.

14

-

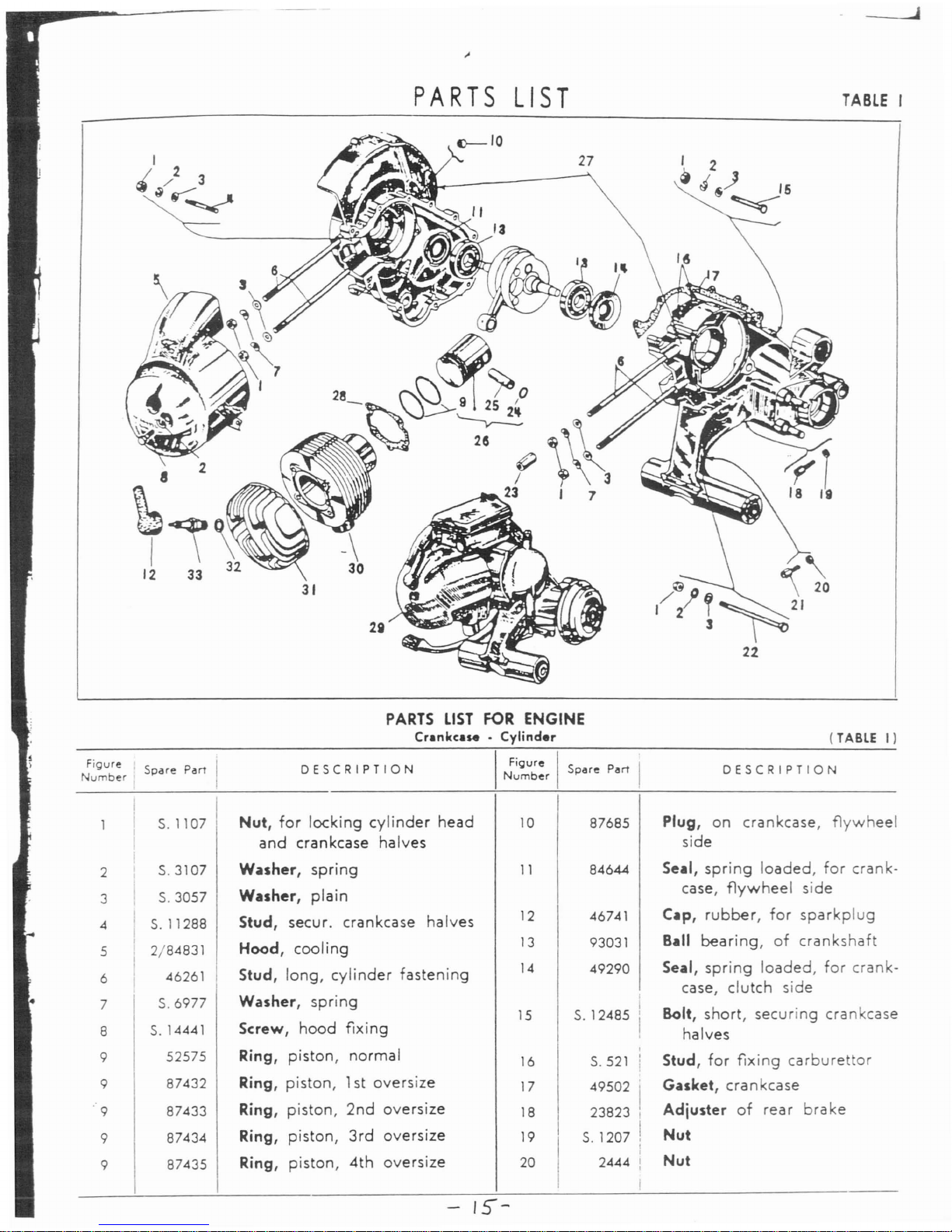

Page 15

PARTS

LIST

27

a

;\~

12

33 32

31

2a

PARTS

LIST

FOR

ENGINE

Cr.nkc.se

. Cylinder

TABLE

I

(TABLE

I)

.J

Figure I I

N b

. Spare

Part

urn

er

I

DESCRIPTION

I

Fi<;lure

I I

Number

Spare

Pl!IrT

DESCRIPTION

2

3

4

5

6

7

8

9

9

'9

9

9

S.1107

5.3107

5.3057

S.11288

2/84831

46261

5.6977

S.14441

52575

87432

87433

87434

87435

Nut,

for

locking

cylinder

head

and

crankcase

halves

Washer,

spring

Washer,

plain

Stud,

secur.

crankcase

halves

Hood,

cooling

Stud,

long,

cylinder

fastening

Washer,

spring

Screw,

hood

fixing

Ring,

piston,

normal

Ring,

piston,

1st

oversize

Ring,

piston,

2nd

oversize

Ring,

piston,

3rd

oversize

Ring,

piston,

4th

oversize

10

11

12

13

14

15

16

17

18

19

20

87685

84644

46741

93031

49290

5.12485

S.521

49502

I

23823 I

I

S,

1207 ,

I

I

2444 :

I

Plug,

on

crankcase,

flywheel

side

Se.l,

spring

loaded,

for

crank-

case,

flywheel

side

C.p,

rubber,

for

sparkplug

B.II

bearing,

of

crankshaft

Seal,

spring

loaded,

for

crank-

case,

clutch

side

Bolt,

short,

securing

crankcase

halves

Stud,

for

fixing

carburettor

Gasket,

crankcase

Adjuster

of

rear

brake

Nut

Nut

Page 16

P.rt,

II"

for

.nQin.

- Cranke:.t,. -

Cylind.r

-

C~r':

ue<:J

"

89267

4 267

Piston,

4th

oversize

with

Wr

pin

(with

figs.

24-25

- S

Crankcase

assy.

(Figs.

n.

t.

22-17

- 10 - 1 - 3 - 2 - <

15-16T.I;

27-28-3C

9 -

10-31

-

32

-

26

T. I

1 - 4 -

26-24-25

- 3 - :

23-7T.IV;

31-33-3L

41

T.

"I).

Gasket,

cylinder

base

Engine,

g.

a.

Cylinder

Head,

cylinder

Gasket,

copper,

of

sparkplul

Sparkplug,

with

gasket

DESCRIPTION

(TABLE

II

DESCRIPTION

Washer,

shim,

of

clutch

gear

Washer,

plain,

for

securing

clutch

cover

Washer,

spring

Screw,

securing

clutch

cover

Gasket,

between

clutch

cover

and

crankcase

Breather,

with

inserts

Plate,

clutch

centralizing

Spring,

for

fixing

clutch

cen·

tralizing

plate

Thruster,

clutch

lever,

inner,

clutch

Cover,

clutch,

with

inserts

Packing,

between

clutch

cover

and

outer

lever

Spring,

return,

of

outer

clutch

control

lever

87423

97453

89120

99262

93808

92230

318

13903

19301

16821

14457

46740

89858

83806

50100

5.6708

48834

5. 3056

5.3106

5.14413

:7781

26

12

13

27

17

18

19

24

14

15

16

23

28

29

30

31

32

33

20

21

22

I

Figure

NumberISpare

Part

Adjuster

of

clutch

Bolt,

securing

crankcase

halves

Nut,

spacer,

hood

fixing

Circlip,

for

locking

wrist

pin

Wrist

pin

Wrist

pin,1st

oversize

Wrist

pin,

2nd

oversize

Piston,

with

standard

wrist

pin

(with

figs.

24-25-9).

Piston,1st

oversize,

with

wrist

pin

(with

figs.

24-25-9).

Piston,

2nd

oversize

with

wrist

pin

(with

figs.

24-25-9).

Piston,

3rd

oversize

with

wrist

pin

(with

figs.

24-25-9).

DESCRIPTION

DESCRIPTION

I

~~~u~:r

I

Spare

Part I

-

16

-

PARTS

LIST

FOR

ENGINE

Crankshaft.

Clutch

Crankshaft

(with

partn.87442

fig.

5)

Nut,

securing

flywheel

Washer,

shake

proof,

for

nut

securing

flywheel

Key,

woodruff,

for

crankshaft

(flywheel

side)

Bronze

bush

of

con.

rod

small

end

Key,

woodruff,

for

crankshaft

(clutch

side).

Washer

spring,

for

castle

nut

securing

clutch

Nut,

castle,

for

securing

clutch

Spindle,

hollow,

for

hydraulic

shockabsorber

Bush,

bottom,

rubber,ofshock-

absorber

Circlip,

locking

spacer

87421

87422

87

..20 I

2040

46684

5.

1447

5.6615

2/51992

87436

87437

86944

6 97

5

87442

8 20375

9

94727

2

5.12066

I

3 686

7 22313

11

46266 I

21

22

23

24

25

25

25

26

10

40316

26

26

26

Fi"ure

I

.,.

Spare

Parr

Number

I

FiQure I

Spdle

Part

Number

Page 17

_

17_

TABLE

1/

DESCRIPTION

13

\

I~

G I

15

@~

16

2

II

I

Figure

I I

Number

Spllre

Part

DESCRIPTION

25

97984

lever,

outer,

clutch

33

32005

Ring,

elastic,

for

stopping

26

a)

47946

Sp~cer,

clutch

side

clutch

plat~

27

59588

Bush,

rubber,

clutch

side

34

94780

Driving

disc,

external,ofclutch

28

59590

Washer,

plain

35

94425

Plate,

~mooth,

of

clutch

29

98028

Clutch,

g.a.(Figs.

n. 41 -

40

-

36

94743

Plate,

clutch,

with

linings

I

33-42-37-39-38-35

-

37

59109

Washer,

spacer

34-36).

38

94380 Gear,

clutch

30

I

59589

Bush,

rubber,

flywheel

side

39

94379

Plate,

spring,

of

clutch

31

I

47944 Spindle,

hollow,

for

engine

40 22821 Spring,

clutch

I

I

suspension

41

21868

Cup,

clutch

spring

I

32

I

47945 Spacer,

flywheel

side

42

59369

Body,

clutch

I

36

Figure

i I

NumberISpare

Part

Puts

""

of

engine

-

Crankule

• Clutch -

Continued.

.)

Parts

48988or48989

canbeassembled

insteadofspacer

47946,toatlainanaxial

forceinthe

bush

59588togive0-;-

1,5 mm.

(0

-;-

.06")

compression.

Page 18

r

I

TABLE

III

.)

The

total

axial

playofthe

assemblyofthe4gear

pinionsinrespecttotheir

seat

must

be

contained

between

.006"

and

.012".

Should

this

play

exceed

said

tolerances,

the

normal

shoulder

washer

must

be

repla.~ed

by

another

with

proper

oversize.

1

I

S.12131

Nut,

for

securing

wheel

10

46700

Circlip

2 S.3111

Washer,

spring,

for

nut

secu-

11

97181

Axle,

cam,

of

rear

brake

with

ring

wheel

packing

(

fig.

12)

.

3

87714

Washer,

plain,

for

nut

securing

12

S.6714

Packing

wheel

flange

13

78522

Spring,

return,

of

brake

jaws

4 S.12787

Split pin,

for

locking

castle

nut

14

46688

Ring,

locking

ball

bearing

5

S.2314

Nut,

castle,

for

securing

wheel

15

17821

Seledor,

gear

flange

16

7563

Ball

bearing

of

mainshaft

6

2021

Screw,

for

joining

brake

drum

17

7886

Pad

to

flange

18

78170

Jaw,

rear

brake,

with

lining

7

23831

Drum, rear

brake

19

61

Clip,

spring,

for

brake

jaws

8

94535

Flange,

female

spline,

with

20

85673

Bolt,

for

securing cable to

(fig.

1)

brake

links

9

46699

Seal,

spring-loaded

of

main-

21

S.

3204

Split pin, on

pin

for

brake

links

shaft

22

a)

82085

Mainshaft

DESCRIPTION

PARTS

LIST

FOR

ENGINE

Gear

box . R..r

wheel

fl.nge

DESCRIPTION

I

~~~~:r

I

Spare

Part

N

FiQubreISpare

Part

um

er

-

18-

(TABLE

III)

Page 19

Pam

lilt

for

engine.GMr

box

.

Rear

wheel

flange-Ccntlnued.

FigureISpare

Part

umber

23

24

25

26

27

29

30

31

32

33

34

35

36

37

38

42048

94779

42047

S.1426

S.3109

42043

5.

3208

78171

78521

78164

78163

92098

5.13768

47190

a)

18558

DESCRIPTION

Pin,

for

rear

brake

links

link,

brake

link,

brake

Nut,

on

bolt

securing

brake

links

Washer,

spring

Arm,

rear

brake

control

Split

pin,

for

cam

axle

Dust

cover

Packing

washer

Packing

washer

Packing

washer

Stem,

selector

Washer,

tab,

on

selecto(

stem

Bush,

guide,

of

selector

stem

Washer,

shoulder,

normal,

of

gear

pinions

I

FigureISpare

Par

Numoer

38

a)

20321

38

a)

20322

38

a)

20323

38

a)

20324

39

18447

40

a)

51123

41

12869

42 92240

43

a)

59007

44

a)

51124

DESCRIPTION

Washer,

shoulder,

1st

oversize

(thickness:

2,2

mm.

=

0".086)

Washer,

shoulder

2nd

oversize

(thickness:

2,35

mm.

=

0".092)

Washer,

shoulder

3rd

oversize

(thickness:

2,50

mm.

=

0".098)

Washer,

shoulder

4th

oversize

(thickness:

2,65

mm.

=

0".104)

Circlip,

retaining

shoulder

washer

Gear,

3rd

speed

Screw,

for

dust

cover

Gear,

4th

speed

Gear,

2nd

speed

Gear,

low

speed

aj

The

alai

axial

play

of

he

assembly

of

the4gear

pinioninrespect

to

their

seat

must

be

contained

between

.006"

and

.012".

Should

I

IS

play

exceed

saId

tolerances,

the

normal

shoulder

washer

mustbereplaced

by

another

with

proper

oversize.

Figure

I I

Number

Spare

Part

PARTS

LIST

FOR ENGINE

Cush

gear•Kickmrter

DESCRIPTION

I

Figure

I 5

dre

Number

p

(TABLE

IV)

DESCRIPTION

i

1

47160

I

Race,

roller

bearing

of

main-

18

89913

Washer,

plate,

of

cush

drive

shaft

springs

2

82086

Cage,

roller

bearing

19

17887

Spring,ofcush

drive

3

81842

Roller

20

92074

Drive,

cushion,

g.

a.

(Figs.

n.

4

47161

Washer,

shoulder,

roller

bea-

19-21-22

- 18 -

17)

ring

21

58677

Gear,

multiple

5

I

47218

Spring,

return,

of

kickstarter

22

89911

Gear,

outer,

of

cush

drive

6

I

77413

Sedor,

starting

23

S.10790

Rivet,

for

securing

blades

7

I

46631

Plug

24

48002

Pad,

blades

I

8

I

97338

Kickstarter

g.

a.

(Figs.

n. 9 -

25

54071

Blade,

long,

for

sta

rtingsector

I

10-11

-12-13)

26

48000

Blade,

short,

for

starting

sector

9 49642

Rubber

sleeve

27

5.6637

Circlip,

for

locking

multiple

10

I

5.8507

Bolt,

securing

kickstarter

gear

ball

bearing

11

I

S.3109

Washer,

spring

28

2457

Roller,

for

multiple

gear

12

I

5.3060

Washer,

plain,

of

kickstarter

29

94417

Layshaft

13

S.1109

Nut

30 32494

Ball

bearing,

of

multiple

gear

14

S.6721

Packing

31

S.13940

Wuher,

plain,

for

nut

securing

15

46742

Buffer,

for

starting

sector

layshaft

16

58680

Geary

starting

32

58560

Washer,

spring,

for

nut

secu-

17

5.

10776

Rivet,

for

sec.

plate

washer

ring

layshaft

I

I

I

Page 20

TABLE

IV

5--

-

31

'---------

~-----~/

20

PARTS

LIST

FOR

ENGINE

Flywheel

M.gneto•Fin

(TABLE

V)

Figure

IS P rt

Number

pare

a

DESCRIPTION

I

Figure

I I

Number

Spare

Part

DESCRIPTION

6

S.

3055

7 S.3105

8

S.

10047

. 9

46675

10

97191

1

2

3

4

5

46764

14501

662

674

87594

Cable,

earth,

with

terminal

Terminal

Terminal

Circlip,

for

flywheel

extraction

Stator,g.a.

(Figs.n.42-23

-

33-22-34-36-24-30

-

32-37-46

- 1 -

38-39

-

45-21-44-47

- 6 -

35

-

7 -

27-31-28-29).

Washer,

plain,

for

screws

se-

curing

stator

and

coils

Washer,

spring,

for

screw

se-

curing

stator

Screw,

for

securing

stator

Cam

Flywheel

fan

(Figs.n.16

- 12 -

9-14-13-15)

11

12

13

14

15

16

17

18

19

20

21

22

23

97189

6562

S.10775

78070

S.

12533

2946

S.

3056

2856

47577

S.3106

83408

625

622

Flywheel,

magneto

g. a.

(Figs.

n.5-10)

Washer,

plain,

of

cam

Rivet,

for

securing

cam

Dust

cover

Washer,

spring

Screw,

short,

for

securing

fan

casing

cover

and

dust

cover

Washer,

spring

Screw,

long,

for

securing

fan

casing

cover

Cover,

fan

casing

Washer,

spring

Pad,

securing

low

tension

coil

No.3

Fork

spring

Washer,

shim,

of

breaker

_

?n

_

Page 21

TABLE

V

22

r

'Wi

07

~ir

'/1

):I}I5

I.

12

13

l~

6

l

9

/

40

Puts

list

for

engine

-

Flywheel

Magneto•Fan-Continued.

Figure

I I

Number

Spare

Part

DESCRIPTION

I

Figure

II

I

Number

Spare

Part

DESCRIPTION

-21

24

25

26

27

28

29

30

31

32

33

34

35

36

97478

94357

16418

5.12331

S.

13800

5.13801

16419

S.

12332

16420

624

3213

S.3103

16417

i

Gusset-breaker

assy

(Figs.

n.

25 -

26)

Breaker

with

platinum

point

Gusset,

contact

Bolt,

retaining

coil

terminals,

condenser

and

breaker

blade

Washer,

plain

Washer,

insulating

Ring,

insulating

Screw,

securing

blade

with

cam

greasing

felt

Cam

Nut

Screw,

securing

condenser

and

felt

blad~

Washer,

spring

for

felt

blade

Axle,

breaker

37

16421

38

83386

39

83125

40

84737

41

86475

42

603

43

46766

44

83545

45

83387

46

46750

47

86482

48

86483

Blade

felt,

with

inserts

Coil,

low

tension,

No.

Stator

Tube,

for

part

86475

(Fig.41)

lead,

plug,

with

inserts

Screw,

for

securing

coils

Grommet

Coil,

low

tension,

NO.3

Coil,

low

tension,

No. 2

Condenser

Coil,

H.

T.

Coil,

ignition,g.a.

(Figs.n.41

43-47).

Page 22

·1

I

TABLE

VI

9

19

~

PARTS

LIST

FOR

ENGINE

(TABLE

VI)

Cuburettor

. Air

Cleaner

Figure

I

Spare

Part

I

DESCRIPTION

I

Figure

I

Spare

Part

DESCRIPTION

Number

Number

I

87856

I

Cover,

air

cleaner,

with

plug

15

50274

Plug

(

fig.

2)

16

59708

Air

cleaner,

body

2

87975

Plug,

on

air

cleaner

17

94245

Joint

3

58364

Packing

18

92181

Carburettor,

Dell

'Orto

SI

20/15

4

84797

Puking,

air

cleaner

C -

Typeg.a.

(Figs.

n.

41

-

5

S.

14436

Screw,

for

air

cleaner

body

56-27-58-55-60-57

-

6

S.3105

Washer,

spring

59-33-37-50-46-48

-

7

S.

10074

Screw,

for

air

cleaner

body

40-45-51-49-53

- 32 -

8

59710

I

Air

filter

26-35-36

- 20 -38-39-

9

92263

I

Air

cleaner,

g.a.(Figs. n. 15 -

43

- 22 - 25 -23- 24 -

44

-

3 - 16 - 8

- 4 - 1 -

6·7-

52-47-54

- 34 -

42-21

5 -

19)

I

61

)

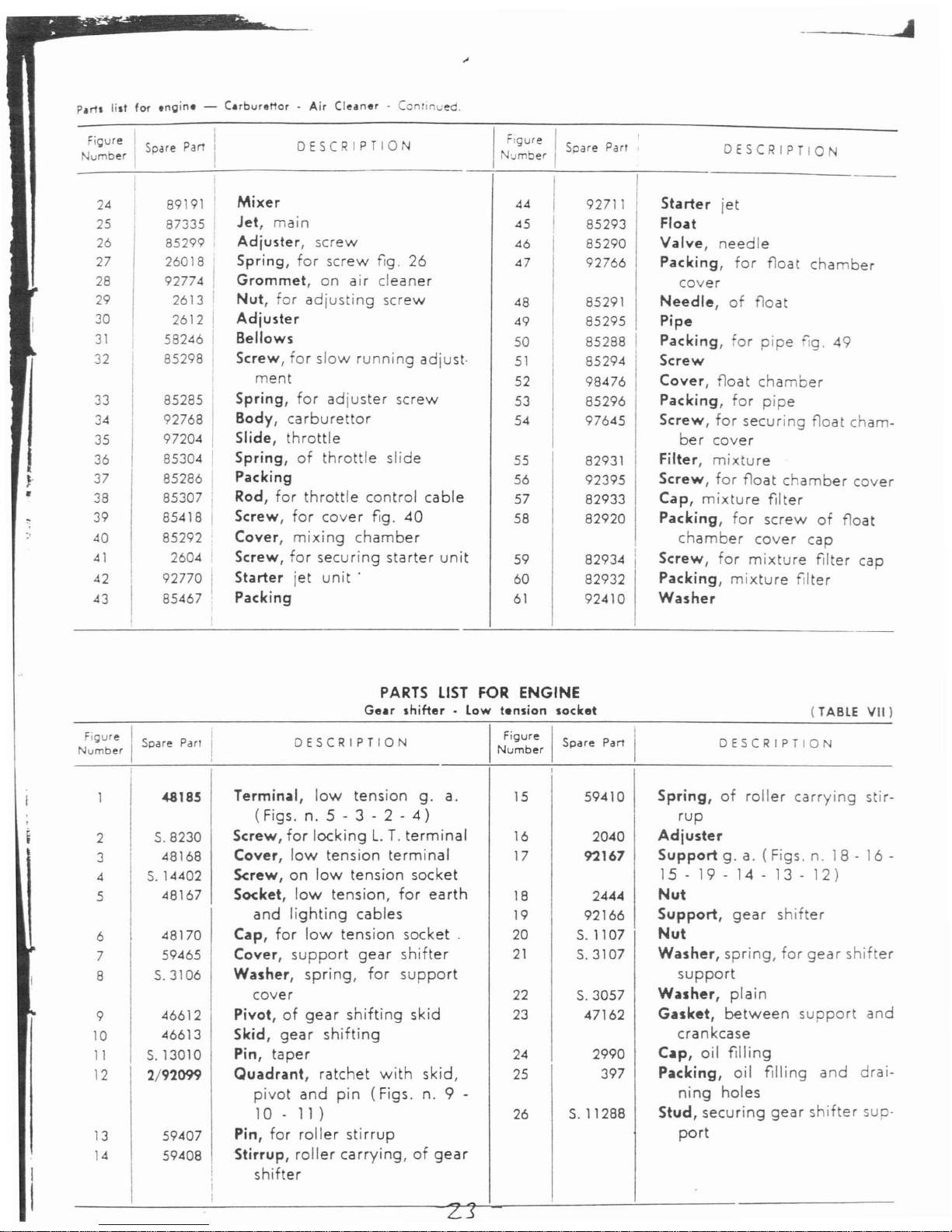

10

49542

Screw,

for

securing

carburettor

19

S.

14583 I

Screw,

for

air

cleaner

Washer,

spring

I

Screw,

fo