Philips VR407/77, VR625/77, VR620/77 Service Manual

Video Cassette Recorder VR407/77, VR620/77, VR625/77

VR407/77

Contents

Chapter

1 Disassembly

2 Mechanism adjustments

3 Electrical adjustments

4 Charts and diagrams

5 Parts lists

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified be

used.

Specification:

Video recording system: VR407/77 - 4-head helical scan system

VR620,VR625/77 - 6-head helical scan

system (2 Audio heads)

Antenna input Signal: PAL-N, NTSC

Antenna: VHF/ UHF 75Ω external antenna terminal

Video Output Channel: Channel 3 or 4 (selectable)

75Ω unbalanced

Power requirement: AC110V – 240V, 50/60Hz

Power consumption: VR407/77 - 14W

VR620/77, VR625/77 - 16W

Operating temperature: 41°F(5°C) a104°F(40°C)

Relative humidity: 10% to 80%

Weight: 3.0kg

Dimensions: VR407/77 - 360 x 94 x 251mm

VR620/77, VR625/77 - 360 x 94 x 242mm

Published by CFC2001PJVM Videq Service Department Printed in the Netherlands © Copyright reserved Subject to modification

01A40777.pm5

3103 785 20870

VR407/77, VR620/77, VR625/77

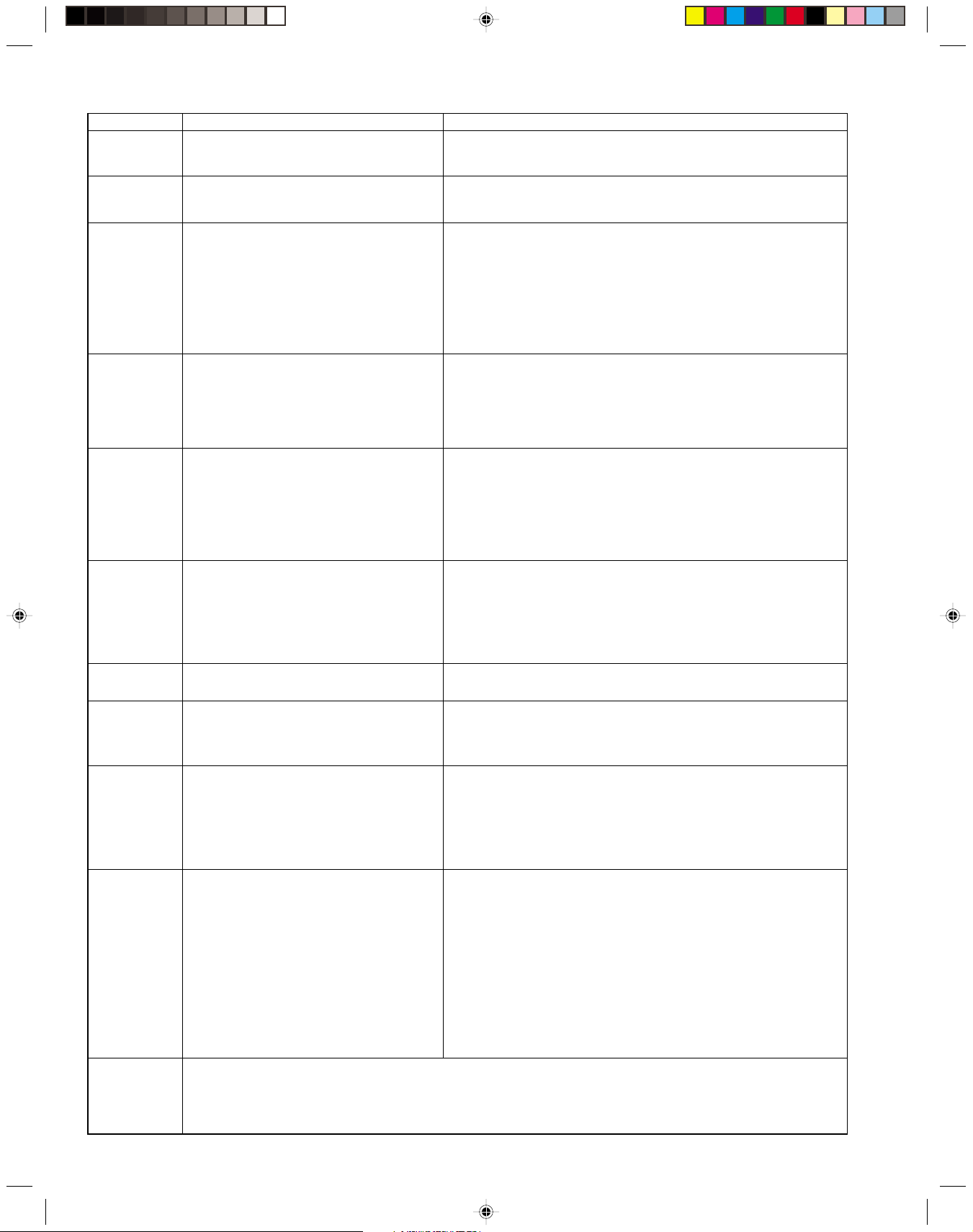

1. ACCESSORIES

306 9965 000 04494 REMOTE CONTROLLER,VR407/77

9965 000 07845 REMOTE CONTROLLER,VR620/77,

VR625/77

306A 9965 000 04496 COVER(BATTERY),VR407/77

310 9965 000 08713 INST BOOK(SP),VR407/77

9965 000 08704 INST BOOK(SP),VR620,VR625/77

2. CABINET AND CHASSIS ASSEMBLY

501 ! 9965 000 08701 FRONT PANEL ASSY,VR620/77

! 9965 000 08714 FRONT PANEL ASSY,VR625/77

! 9965 000 08715 FRONT PANEL ASSY,VR407/77

501A 9965 000 07920 CASS DOOR,VR620/77,VR625/77

9965 000 07878 CASS DOOR,VR407/77

501B 4822 492 42781 TORSION SPRING

501C 9965 000 08702 DISPLAY WINDOW,VR620/77,

VR625/77

9965 000 08716 DISPLAY WINDOW,VR407/77

501D 9965 000 08717 ORNAMENT,VR625/77

9965 000 07921 ORNAMENT,VR620/77

501E 9965 000 07922 DOOR(JACK),VR620/77,VR625/77

502 ! 9965 000 07923 TOP COVER,VR620/77,VR625/77

! 9965 000 07884 TOP COVER,VR407/77

505 9965 000 07839 DRUM SUB ASSY,VR620//77,

VR625/77

9965 000 08010 DRUM SUB ASSY,VR407/77

505E 4822 265 11367 CONTACT

505F 4822 492 11671 COMPRESSION SPRING

506 4822 362 10293 ROTOR ASSY

508 ! 9965 000 08089 STATOR ASSY

512 ! 9965 000 08090 BOTTOM COVER

518 9965 000 00881 CLEANER ASSY

TOOLS

001 4822 395 90904 ROLLER DRIVER

002 4822 395 90916 A/C HEAD POSITIONING TOOL

003 4822 395 80196 TORQUE GAUGE

004 4822 395 90615 BACK TENSION CASS GAUGE

005 9965 000 03915 JIG RCU

006 9965 000 05830 ALIGNMENT TAPE,SP PAL

007 9965 000 05831 ALIGNMENT TAPE,LP PAL

WIRES

WR1 9965 000 07886 FFC W,DRUM CN3002

WR2 4822 320 12468 E-CARD W,A/C HEAD CN2001

WR3 9965 000 03708 FFC W,FRONT,VR620/77,VR625/77

VR407/77, VR620/77, VR625/77

3. MECHANISM ASSEMBLY

1 9965 000 07887 MAIN DECK ASSY

3 4822 402 11363 GUIDE POLE GUARD

4 4822 249 10558 FULL ERASE HEAD

5 4822 463 11208 GUIDE POLE(SUPPLY)

7 9965 000 05123 TENSION STUD BASE ASSY

11 9965 000 00838 UV CATCHER 2

12 9965 000 00838 UV CATCHER 2

15 4822 535 10568 LOADING ARM GEAR SHAFT

18 9965 000 07888 LOADING ARM GEAR(SUPPLY)

19 4822 492 11636 TORSION ARM

20 4822 535 10566 PIN

21 9965 000 05124 POLE BASE ASSY(SUPPLY)

23 9965 000 00840 LOADING ARM GEAR(TAKE UP)

24 4822 492 11636 TORSION ARM

25 9965 000 08124 PIN

26 9965 000 05125 POLE BASE ASSY(TAKE UP)

31 9965 000 03709 ROTARY ENCODER GUIDE

34 9965 000 07889 CONTROL PLATE GUIDE

36 4822 402 11046 TAKE UP LEVER

37 4822 492 11631 TENSION SPRING

38 4822 402 11047 TAKE UP HEAD

39 4822 463 11196 LID GUIDE

42 9965 000 07890 PINCH ROLLER ARM ASSY

43 9965 000 07891 PINCH ROLLER SHEET3

44 4822 492 11634 TORSION SPRING

46 4822 402 11057 PRESS LEVER ASSY

49 9965 000 00844 GUIDE ARM ASSY

51 9965 000 00845 TENSION SPRING

52 9965 000 07892 AC HEAD

53 4822 464 10456 HEAD BASE

54 4822 492 11671 COMPRESSION SPRING,X3

55 4822 492 11672 COMPRESSION SPRING

59 4822 361 11095 LOADING MOTOR

60 4822 528 81557 MOTOR PULLEY

61 4822 463 11198 MOTOR GUIDE

63 4822 358 10204 BELT,LOADING MOTOR

64 4822 528 11256 CONTROL CAM

65 4822 532 11784 SLIT WASHER

66 4822 522 10697 WORM GEAR

67 4822 402 11049 LINK LEVER ASSY

68 4822 532 11784 SLIT WASHER

69 9965 000 00848 CONTROL PLATE

70 4822 402 11052 CONTROL BRACKET(1)

72 4822 402 11043 TENSION ARM ASSY

73 4822 492 11629 TENSION SPRING

74 4822 402 11056 TENSION BRAKE ASSY

75 4822 535 10317 ADJUST PIN

76 4822 532 13037 TENSION ARM BEARING

78 9965 000 07893 MAIN BRAKE ASSY (SUPPLY)

80 9965 000 03712 MAIN BRAKE ASSY (TAKE UP)

81 9965 000 03713 TENSION SPRING

82 9965 000 00852 SUB BRAKE ASSY(TAKE UP)

83 4822 492 11633 TENSION SPRING

84 4822 535 10644 CAPSTAN BRAKE ASSY

85 9965 000 07894 CAPSTAN MOTOR

87 4822 358 10274 BELT,CAPSTAN MOTOR

88 9965 000 07895 IDLER ARM ASSY

89 9965 000 07896 WASHER

90 9965 000 03715 CLUTCH UNIT 3

91 9965 000 07897 SPACER,CAPSTAN MOTOR

92 4822 532 12326 SLIT WASHER

93 9965 000 05135 CLUTCH GEAR 4

94 9965 000 05562 COUPLING GEAR

95 9965 000 05137 COMPRESSION SPRING

96 4822 522 10699 DIRECT GEAR

97 4822 532 13043 SPACER

99 4822 492 11764 COMPRESSION SPRING

100 4822 532 13041 SLIT WASHER

102 9965 000 00857 CHANGE LEVER ASSY

103 9965 000 00858 COMPRESSION SPRING

104 9965 000 07898 IDLER LEVER

105 4822 528 11257 REEL DISK (SUPPLY)

106 4822 528 11258 REEL DISK (TAKE UP)

107 4822 532 13043 SPACER,X2

108 4822 273 10349 ROTARY ENCODER

110 4822 522 10698 CASS GEAR

111 4822 522 10704 LIMIT GEAR(1)

112 9965 000 00859 LIMIT GEAR(2)

113 4822 492 11674 TORSION SPRING

114 4822 522 10703 RELAY GEAR

115 9965 000 01731 OPENER GUIDE

116 4822 492 11787 TORSION SPRING

117 9965 000 00887 C.H.BRACKET

118 4822 532 12326 SLIT WASHER,X2

119 9965 000 00860 DRIVE GEAR

120 9965 000 07899 DRIVE ARM

121 4822 492 11673 TORSION SPRING

122 4822 256 10498 SIDE HOLDER(L)

123 9965 000 00862 SIDE HOLDER(R)

124 9965 000 00863 LOCK LEVER(L)

127 9965 000 00864 LOCK LEVER(R)

128 9965 000 06212 TORSION SPRING(L)

129 4822 492 11665 TORSION SPRING(R)

130 9965 000 01670 CASS HOLDER

132 4822 463 11206 GUIDE RAIL

134 9965 000 07900 REC SAFETY LEVER

135 4822 492 11668 TENSION SPRING

137 4822 460 11144 TOP GUIDE

138 4822 460 11145 HOLD PLATE

139 4822 462 11192 PAD,X2

140 9965 000 03713 TENSION SPRING

141 4822 492 11786 TENSION SPRING

142 4822 528 11349 ROLLER CAM ASSY

143 9965 000 00356 PAD,X2

151 9965 000 03716 DOOR OPENER

VR407/77, VR620/77, VR625/77

MG RES 82Ω,1/10W

4822 130 82686

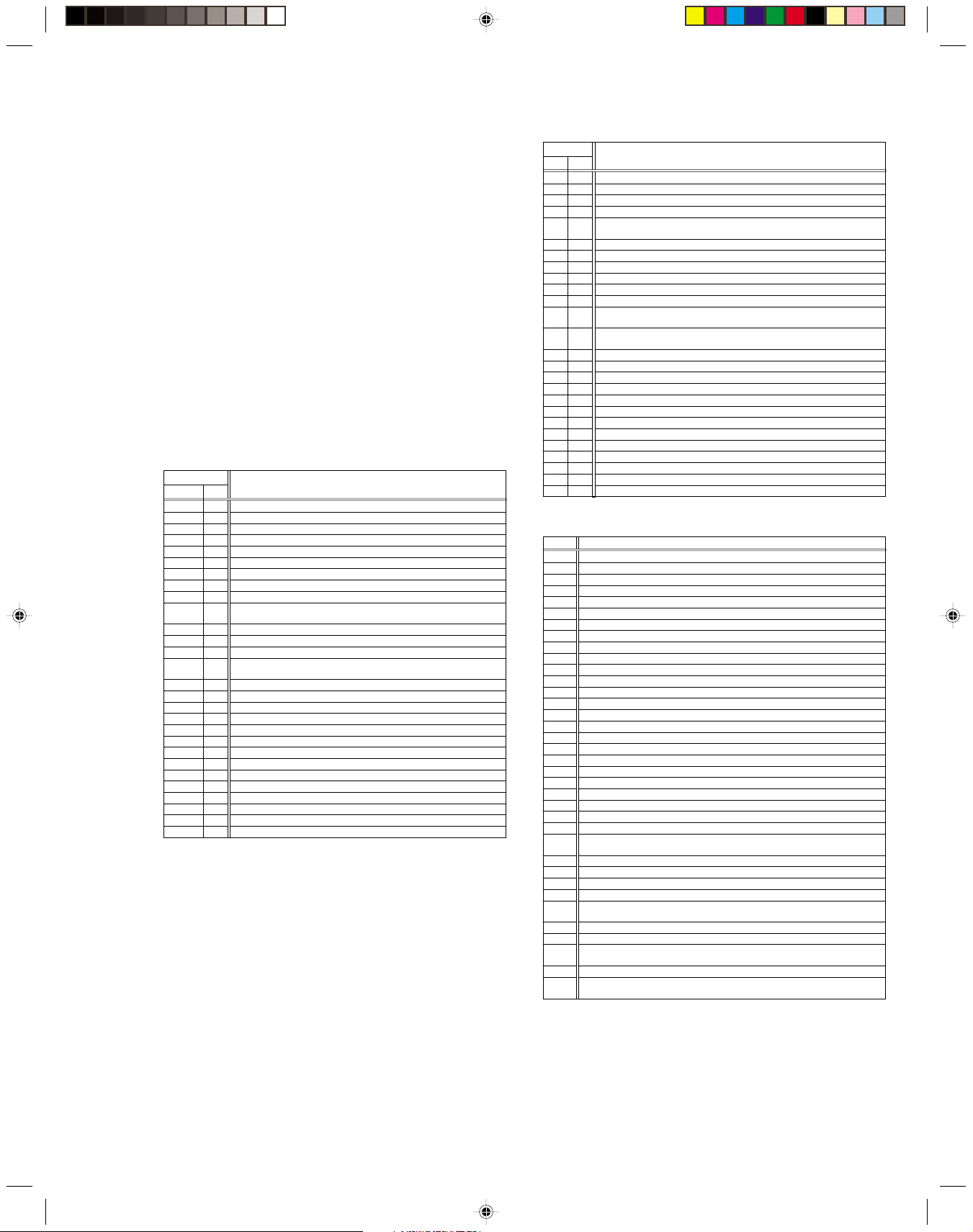

4. MAIN BOARD ASSEMBLY

INTEGRATED CIRCUITS

IC1 9965 000 04581 JCP8021-MVD

IC2201 ! 9965 000 07817 AN3663FBP

IC3001 9965 000 08688 MN101D02GWG

IC3002 9965 000 03719 BA6956AN

IC3003 9965 000 07819 S-80823ANNP-W

IC3004 9965 000 07728 AT24C32N-10SC-X

IC5301 9965 000 02082 L5431

IC7002 4822 130 10959 GP1U290Q

IC7042 4822 130 10959 GP1U290Q

TRANSISTORS

Q1 9965 000 00463 2SC4081/S/-X

Q2 9965 000 00463 2SC4081/S/-X

Q3 9965 000 00463 2SC4081/S/-X

Q4 9965 000 00463 2SC4081/S/-X

Q12 4822 130 60862 2SA1576A/QR/-X

Q22 4822 130 60669 2SC4081/QRS/-X

Q32 4822 130 60997 DTC144WU

Q38 4822 130 60669 2SC4081/QRS/-X

Q901 4822 130 60862 2SA1576A/QRS/-X

Q2001 4822 130 60669 2SC4081/QRS/-X

Q2002 4822 130 60669 2SC4081/QRS/-X

Q2003 4822 130 61524 DTA144WU

Q2051 4822 130 60669 2SC4081/QRS/-X

Q2052 4822 130 60862 2SA1576A/QR/-X

Q2053 4822 130 60997 DTC144WU

Q2054 4822 130 60862 2SA1576A/QR/-X

Q2055 4822 130 60997 DTC144WU

Q2201 4822 130 61524 DTA144WU

Q2202 4822 130 60997 DTC144WU

Q2203 4822 130 60669 2SC4081/QRS/-X

Q2204 4822 130 60669 2SC4081/QRS/-X

Q3001 9965 000 03720 PTZ-NV16A

Q3002 9965 000 03720 PTZ-NV16A

Q3004 4822 130 60873 2SD1819A/QRS/-X

Q4001 4822 130 61287 UN5211

Q4002 4822 130 60873 2SD1819A/QRS/-X

Q5101 4822 130 10437 2SK2632-CB14

Q5102 4822 130 61892 2SD2144S/UV/-T

Q5301 4822 130 63596 2SB1256

Q5303 4822 130 60873 2SD1819A/RS/-X

Q5304 4822 130 61892 2SD2144S/UV/-T

Q5305 4822 130 61903 DTA114EU

Q5306 4822 130 61906 DTC114EU

Q5311 4822 130 63496 DTC114TU

Q5321 4822 130 62794 2SC3616/ML/-T

Q6030 4822 130 61075 2SB1218A/QR/-X

Q7001 9965 000 07901 DTA143TU

Q7002 9965 000 07901 DTA143TU

Q7003 9965 000 07901 DTA143TU

Q7004 9965 000 07901 DTA143TU

Q7005 9965 000 07901 DTA143TU

Q7006 4822 130 61908 DTC143TU

Q7007 4822 130 61908 DTC143TU

Q7008 4822 130 61908 DTC143TU

Q7009 4822 130 61908 DTC143TU

Q7010 4822 130 61908 DTC143TU

Q7011 4822 130 61908 DTC143TU

Q7012 4822 130 61908 DTC143TU

DIODES

D3001 4822 130 11345 LNB2301L01VI

D3002 4822 130 32778 1SS133

D3004 4822 130 81748 11ES2

D3005 4822 130 81748 11ES2

D3006 4822 130 34142 RD33ES/B2/-T2

D3008 ! 4822 130 83426 RB721Q-40-T2

D3017 4822 130 32778 1SS133

D5001 9965 000 04514 S1WB/A/60-4102

D5101

9965 000 07582 IC,VR407/77

AU01

D5103 4822 130 32778 1SS133

D5105 4822 130 32778 1SS133

D5201 4822 130 82686 AU01Z

D5203 4822 130 82686 AU01Z

D5204 4822 130 82686 AU01Z

D5207 4822 130 81377 AK04

D5209 4822 130 82686 1SR153-400-T2

D5210 4822 130 82686 AU01Z

D5301 9965 000 07902 MTZJ15C

D5302 QUY153-050Y

D5303 4822 130 83314 RD5.1JS/B2/-T2

D5304 4822 130 32778 1SS133

D5307 9965 000 07903 QUY160-100Y

11ES2 4822 130 81748 DIODE,VR620/77,VR625/77

D5316 9965 000 07903 QUY160-100Y

D6002 4822 130 83157 HZ30-2L-T2

D7003 4822 130 32778 1SS133

D7043 4822 130 32778 1SS133

RESISTORS

R1 MG RES 6.8kΩ,1/16W

R2 MG RES 1.5k

R3 MG RES 8.2k

R6 MG RES 27k

R7 MG RES 680

R8 MG RES 0

R9 MG RES 0

R12 IM BUS W

R21 MG RES, 1K

R22 MG RES, 1K

R37 MG RES 0

R42 MG RES 680

R44 MG RES 8.2k

R45 MG RES 10k

R49 MG RES 560

R66 MG RES 100k

R77 MG RES 10k

R90 MG RES 390

R92 MG RES 1.5k

R93 MG RES 2.2k

R104 MG RES 6.8k

R118 MG RES 0

R201 MG RES 3.3k

R202 MG RES 2.2k

R203 MG RES 100

R204 MG RES 100

R901 MG RES 75

R904 RES 330

R905 MG RES 100

R911 MG RES 75

R912 MG RES, 75

R2001 MG RES,VR407/77 100

R2003 MG RES, 100

R2004 MG RES,VR407/77 2.7K

R2005 MG RES,VR407/77 33k

R2007 MG RES, 12K

R2008 MG RES,VR407/77 47k

R2010 MG RES, 12K

R2013 MG RES 6.8k

R2014 MG RES 220k

R2015 MG RES 120

R2016 MG RES 47k

R2017 MG RES 18k

R2018 MG RES 4.7k

R2019 MG RES 4.7k

R2024 MG RES 3.3k

R2053 MG RES 5.6k

R2054 MG RES 12k

R2055 MG RES 3.3

R2056

VR625/77.

VR625/77

VR625/77

VR625/77

MG RES,VR407/77 680

VR625/77

MG RES,VR407/77 47k

VR625/77

MG RES,VR407/77 6.8K

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/10W VR620/77,

Ω,1/16W VR620/77,

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/2W

Ω,1/10W

Ω,1/10W

Ω,1/10W VR620/77,

Ω,1/10W

Ω,1/10W VR620/77,

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W VR620/77,

Ω,1/10W

Ω,1/10W

Ω,1/10WVR620/77,

Ω,1/10W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/16W

Ω,1/10W

Ω,1/10W

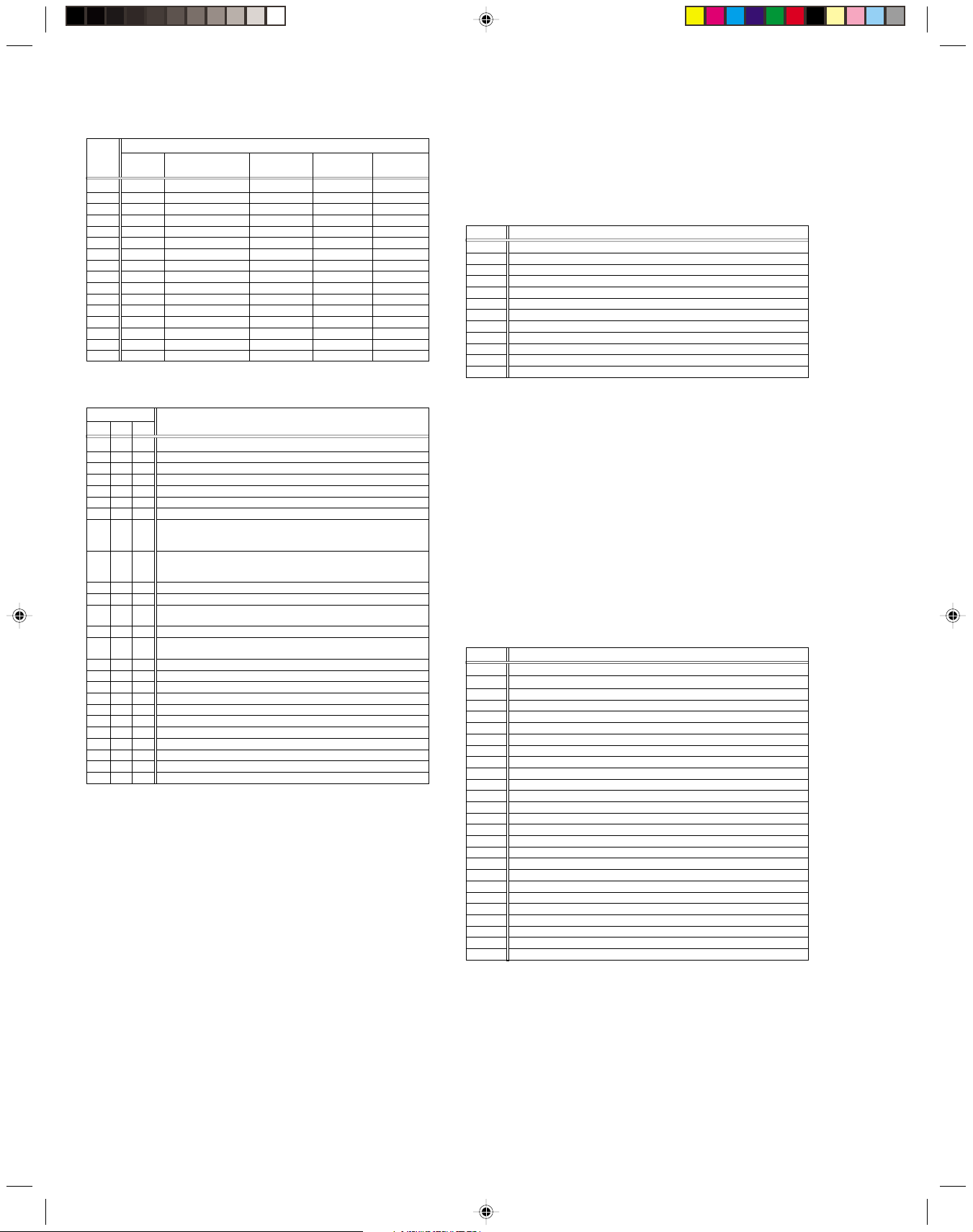

VR407/77, VR620/77, VR625/77

,1/4W

,1/10W

R3215 MG RES 27k

Ω

R2058 MG RES 18kΩ,1/10W

R2059 MG RES 47k

R2060 MG RES 18k

R2201 MG RES,VR620/77,VR625/77

R2202 MG RES,VR620/77,VR6225/77

R2203 MG RES,VR620/77,VR625/77

R2204 MG RES,VR620/77,VR6225/77

R2205 MG RES,VR620/77,VR625/77

R2206 MG RES,VR620/77,VR625/77

R2207 MG RES,VR620/77,VR625/77

R2208 MG RES,VR620/77,VR625/77

R2209 MG RES,VR620/77,VR625/77

R2210 MG RES,VR620/77,VR625/77

R2211 MG RES,VR620/77,VR625/77

R2212 MG RES,VR620/77,VR625/77

R2213 MG RES,VR620/77,VR625/77

R2214 MG RES,VR620/77,VR625/77

R2215 RES,VR620/77,VR625/77

R2216 MG RES,VR620/77,VR625/77

R2217 MG RES,VR620/77,VR625/77

R2218 MG RES,VR620/77,VR625/77

R2219 MG RES,VR620/77,VR625/77

R2220 MG RES,VR620/77,VR625/77

R2221 RES,VR620/77,VR625/77

R2222 MG RES,VR620/77,VR625/77

R2225 MG RES,VR620/77,VR625/77

R2251 MG RES,VR620/77,VR625/77

R2252 MG RES,VR620/77,VR625/77

R2253 RES,VR620/77,VR625/77

R2255 MG RES,VR620/77,VR625/77

R3001 MG RES 0

R3017 MG RES 1k

R3018 MG RES 1k

R3021 IM BUS W

R3027 IM BUS W

R3028 MG RES 1k

R3042 MG RES 0

R3056 MG RES 1k

R3057 MG RES 1k

R3060 MG RES 0

R3090 MG RES 1k

R3116 MG RES 10k

R3117 MG RES 10k

R3201 MG RES 3.3k

R3206 MG RES 10k

R3207 MG RES 10k

R3208 MG RES 10k

R3209 RES 180

R3210 RES,VR620/77,VR625/77

R3211 MG RES 18k

R3212 MG RES 180

R3213 RES 27k

R3214 MG RES 180

Ω,1/10W

47K

Ω,1/10W

6.8K

Ω,1/10W

47K

Ω,1/10W

6.8K

Ω,1/10W

47K

Ω,1/10W

6.8K

Ω,1/10W

47K

Ω,1/10W

6.8K

Ω,1/10W

100

Ω,1/10W

4.7K

Ω,1/10W

3.3K

Ω,1/10W

3.3K

Ω,1/10W

4.7K

Ω,1/10W

100

Ω,1/4W

220

Ω,1/10W

1K

Ω, 1/10W

4.7K

Ω,1/10W

3.9K

Ω,1/10W

1K

Ω,1/10W

1K

Ω,1/4W

1K

Ω,1/10W

0

Ω,1/10W

0

Ω,1/16W

4.7K

Ω,1/16W

3.3K

Ω,1/4W

100

Ω,1/16W

27K

Ω,1/4W

18K

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/16W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/4W

Ω,1/10W

Ω,1/10W

Ω,1/4W

Ω

R3216 MG RES 470kΩ,1/10W

R3217 MG RES 330k

R3218 MG RES 5.6k

R3219 RES 10k

R3220 MG RES 10k

R3222 MG RES 4.7k

R3223 MG RES 1M

R3224 MG RES 100

R3226 MG RES 10k

R3227 MG RES 10k

R3232 RES 100k

R3233 MG RES 4.7k

R3234 MG RES 4.7k

R3235 ! MG RES,VR620/77,VR625/77

R3237 MG RES 4.7k

R3238 MG RES 4.7k

R4001 RES 2.2k

R4002 RES 5.6k

R4003 MG RES 2.2k

R4004 IM BUS W

R4006 MG RES 4.7k

R4010 MG RES 470

R4011 MG RES 470

R4012 MG RES 15k

R4013 MG RES 1k

R4018 MG RES 10k

R4019 MG RES 1k

R4020 MG RES 1k

R4021 MG RES 10k

R4024 RES 10k

R5101 RES 220k

R5102 RES 220k

R5103 RES 68k

R5104 4822 053 11683 OMF RES 68k

R5106 4822 117 11745 MF RES 0.39

R5107 RES 330

R5108 MG RES 1.2k

R5109 RES 680

R5110 MG RES 220k

R5111 MG RES 820

R5112 MG RES 220

R5301 MG RES 4.7k

R5302 MG RES 1.5k

R5303 MG RES 1.5k

R5304 MG RES 470

R5305 MG RES 1k

R5306 MG RES 470

R5308 MG RES 470

R5309 MG RES 10k

R5310 MG RES 470

R5311 MG RES 47k

R5312 9965 000 00519 CMF RES 3.3k

R5313 9965 000 07904 CMF RES 3.6k

R5314 MG RES 3.3k

R5316 9965 000 07905 CMF RES 8.2k

R5324 MG RES,VR620/77,VR625/77

R5325 MG RES,VR620/77,VR625/77

R5330 MG RES,VR620/77,VR625/77

R5331 9965 000 07906 OMF RES 100

R5332 RES 2.2k

R5333 4822 117 10423 OMF RES 390

R5334 4822 117 10423 OMF RES 390

R6020 MG RES 1k

R6021 MG RES 1k

R6030 MG RES 3.3k

R6031 IM BUS W

R6032 MG RES,VR407/77 15k

R6033 MG RES,VR407/77 10k

R6050 IM BUS W

R6054 MG RES 1k

R6502 MG RES,VR620/77,VR625/77

R6503 MR RES,VR620/77,VR625/77

R6504 MG RES,VR620/77,VR625/77

R7001 RES 330

Ω,1/10W

1K

4.7K

2.2K

Ω,1/10W

1K

3.3K

Ω,1/10W

15K

Ω,1/10W

10K

Ω,1/10W

Ω 1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/4W

Ω,1/10W

Ω,1/10W

Ω,1/16W

Ω,1/16W

Ω,1/10W

Ω,1/10W

Ω,1/4W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/4W

Ω,1/4W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/4W

Ω,1/4W

Ω,1/4W

Ω,1/4W

Ω,2W

Ω,1W

Ω,1/2W

Ω,1/10W

Ω,1/4W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,2W

Ω,1/4W

Ω,2W

Ω,2W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω

VR407/77, VR620/77, VR625/77

22µF, 16V

CAP 0.22µF,16V

R7002 MG RES 330Ω,1/10W

R7003 MG RES 330

R7004 MG RES 330

R7005 MG RES 330

R7006 MG RES 330

R7007 MG RES 330

R7015 RES,VR620/77,VR625/77

R7020 MG RES 10k

R7021 MG RES 1.2k

R7022 MG RES 1.8k

R7023 MG RES 2.2k

R7024 MG RES 2.7k

R7025 MG RES 4.7k

R7030 MG RES 10k

R7031 MG RES 1.2k

R7032 MG RES 1.8k

R7033 MG RES 2.2k

R7034 MG RES,VR620/77,VR625/77

R7035 MG RES,VR407/77 4.7K

R7036 MG RES,VR407/77 6.8K

R7037 MG RES 56k

R7046 RES,VR407/77 100k

B6 MG RES 0

B201 MG RES 0

B2001 IM BUS W,VR407/77

B2002 IM BUS W,VR407/77

B5001 IM BUS W

B5002 IM BUS W

B5301 MG RES 0

B6020 IM BUS W

B7001 MG RES,VR620/77,VR625/77

B7009 MG RES 0

100K

Ω,1/10W

0

MG RES,VR407/77 2.7K

Ω,1/10W

0

Ω,1/10W

Ω,1/10W

Ω,1/16W

Ω,1/10W

Ω,1/16W

Ω,1/4W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω,1/10W

Ω, 1/4W

Ω,1/16W

Ω,1/10W

Ω,1/10W

Ω,1/10W

CAPACITORS

C1 CAP,VR620/77,VR625/77

C2 CAP,VR407/77 0.1µF,16V

C3 CAP,VR407/77 0.1µF,16V

C4 CAP,VR407/77 0.1µF,16V

C5 E CAP 47µF,16V

C6 CAP 0.1µF,25V

C7 CAP 470pF,50V

C8 CAP 0.1µF,16V

C9 CAP 0.01µF,25V

C10 CAP 150pF,50V

C11 CAP 0.1µF,16V

C12 CAP 47pF,50V

C14 CAP 0.1µF,16V

C15 CAP 0.01µF,25V

C16 CAP 0.1µF,16V

C17 E CAP 3.3µF,50V

C18 E CAP 1µF,50V

C19 E CAP 2.2µF,50V

C20 E CAP 1µF,50V

C21 CAP 0.1µF,16V

C22 E CAP 47µF,6.3V

C23 CAP 0.022µF,16V

C24 CAP 0.1µF,50V

C25 CAP 5pF,50V

C26 CAP 0.022µF,16V

C27 CAP 0.022µF,25V

C28 E CAP 3.3µF,50V

C29 CAP 0.033µF,16V

C30 E CAP 0.47µF,50V

C31 E CAP 47µF,6.3V

C32 CAP 0.01µF,16V

C33 E CAP 2.2µF,50V

C34

0.01µF,25V

cAP,VR407/77 0.1µF,16V

CAP,VR620/77,VR625/77

0.01µF,25V

CAP,VR620/77,VR625/77

0.01µF,25V

CAP,VR620/77,VR625/77

0.01µF,25V

C35 CAP,VR620/77,VR625/77

0.033µF,16V

CAP,VR407/77 0.01µF,25V

C36 E CAP 4.7µF,25V

C37 E CAP 1µF,50V

C38 E CAP 47µF,6.3V

C39 CAP 0.022µF,16V

C40 E CAP 10µF,16V

C51 E CAP,VR620/77,VR625/77

1µF,50V

C54 CAP 0.01µF,25V

C62 CAP 0.1µF,16V

C69 CAP,VR620/77,VR625/77

0.01µF,25V

C70 CAP,VR620/77,VR625/77

0.01µF,25V

C106 CAP 820pF,50V

C109 CAP 0.22µF,10V

C110 CAP 82pF,50V

C201 E CAP,VR620/77,VR625/77

47µF,6.3V

E CAP,VR407/77 100µF,6.3V

C202 CAP 0.022µF,25V

C203 E CAP 1µF,50V

C205 CAP 100pF,50V

C207 CAP 1µF,16V

C208 CAP 100pF,50V

C209 CAP 0.01µF,50V

C210 CAP 0.0022µF,50V

C211 CAP 0.01µF,50V

C901 E CAP 470µF,6.3V

C904 CAP 0.022µF,25V

C2001 E CAP 4.7µF,50V

C2002 E CAP 1µF,50V

C2003 E CAP 47µF,6.3V

C2005 E CAP 4.7µF,50V

C2006 CAP 0.012µF,25V

C2007 E CAP 22µF,16V

C2008 E CAP 4.7µF,50V

C2009 CAP 0.001µF,50V

C2010 CAP 0.0022µF,50V

C2011 E CAP 4.7µF,50V

C2012 E CAP 4.7µF,50V

C2051 CAP 330pF,50V

C2052 4822 121 43968 F CAP 0.082µF,50V

C2053 CAP 0.0047µF,50V

C2054 CAP 0.022µF,25V

C2055 E CAP 10µF,25V

C2201 E CAP,VR620/77,VR625/77

10µF, 25V

C2202 E CAP,VR620/77,VR625/77

4.7µF, 50V

C2203 E CAP,VR620/77,VR625/77

4.7µF, 50V

C2204 E CAP,VR620/77,VR625/77

33µF, 6.3V

C2205 E CAP,VR620/77,VR625/77

10µF, 25V

C2206 E CAP,VR620/77,VR625/77

10µF, 25V

C2207 CAP,VR620/77,VR625/77

0.015µF, 25V

C2208 CAP,VR620/77,VR625/77

0.015µF, 25V

C2209 E CAP,VR620/77,VR625/77

10µF, 25V

C2210 E CAP,VR620/77,VR625/77

10µF,25V

C2211 E CAP,VR620/77,VR625/77

33µF, 6.3V

C2212 E CAP,VR620/77,VR625/77

47µF, 6.3V

C2214 E CAP,VR620/77,VR625/77

10µF, 25V

C2215 E CAP,VR620/77,VR625/77

10µF, 25V

C2216 E CAP,VR620/77,VR625/77

47µF, 16V

C2218 E CAP,VR620/77,VR625/77

10µF, 25V

C2219 E CAP,VR620/77,VR625/77

VR407/77, VR620/77, VR625/77

C5302 E CAP 10µF,25V

C2220 E CAP,VR620/77,VR625/77

C2221 CAP,VR620/77,VR625/77

C2222 CAP,VR620/77,VR625/77

C2251 CAP,VR620/77,VR625/77

C2252 CAP,VR620/77,VR625/77

C2253 CAP,VR620/77,VR625/77

C2254 E CAP,VR620/77,VR625/77

C2255 CAP,VR620/77,VR625/77

C2256 CAP,VR620/77,VR625/77

C2257 CAP,VR620/77,VR625/77

C2259 E CAP,VR620/77,VR625/77

C2260 MG RES,VR620/77,VR625/77

C2261 CAP,VR620/77,VR625/77

C2262 CAP,VR620/77,VR625/77

C3001 CAP 0.022µF,25V

C3003 E CAP 10µF,16V

C3004 CAP 100pF,50V

C3008 CAP 0.01µF,50V

C3013 E CAP 10µF,16V

C3015 CAP 0.0022µF,50V

C3016 CAP 18pF,50V

C3017 CAP 27pF,50V

C3018 4822 125 11112 T CAP

C3019 CAP 10pF,50V

C3020 CAP 18pF,50V

C3022 CAP 0.01µF,50V

C3023 CAP 1µF,16V

C3028 E CAP 1000µF,6.3V

C3035 CAP 0.022µF,25V

C3036 E CAP 100µF,6.3V

C3041 CAP 100pF,50V

C3042 CAP 100pF,50V

C3049 CAP 0.01µF,50V

C3050 CAP 0.01µF,50V

C3052 CAP 0.01µF,50V

C3053 CAP 0.01µF,16V

C4001 CAP 0.1µF,25V

C4002 E CAP 1µF,50V

C4004 E CAP 33µF,10V

C4006 CAP 0.056µF,25V

C4007 CAP 0.01µF,50V

C4009 CAP 0.001µF,50V

C4010 E CAP 47µF,6.3V

C4011 CAP 0.22µF,16V

C4014 CAP 100pF,50V

C4015 CAP 100pF,50V

C4019 CAP 0.01µF,50V

C4022 CAP 100pF,50V

C5001 ! 9965 000 02094 F CAP 0.068µF,250V

C5004 ! 4822 126 14039 CAP 0.0022µF,250V

C5006 E CAP 68µF,400V

C5101 CAP 0.0047µF,1kV

C5102 CAP 100pF,1kV

C5104 E CAP 1µF,50V

C5105 4822 121 70419 F CAP 0.018µF,50V

C5106 CAP 270pF,50V

C5107 4822 121 43972 F CAP 0.1µF,50V

C5201 E CAP,VR620/77,VR625/77

C5202 E CAP 680µF,16V

C5203 E CAP 680µF,10V

C5204 E CAP 4.7µF,100V

C5206 E CAP 47µF,16V

C5207 E CAP 100µF,16V

C5208 E CAP,VR620/77,VR625/77

C5301 E CAP 100µF,16V

10µF, 25V

0.022µF, 25V

0.01µF, 25V

0.01µF, 50V

0.01µF, 25V

0.01µF, 25V

47µF, 6.3V

0.01µF, 25V

0.01µF, 50V

0.01µF, 25V

0.33µF, 50V

680K

Ω,1/16W

47pF, 50V

47pF, 50V

100µf, 16V

180µF, 25V

C5303 E CAP 100µF,16V

C5304 9965 000 07908 F CAP 0.001µF,50V

C5305 9965 000 07909 F CAP 0.15µF,50V

C6008 CAP,VR620/77,VR625/77

C6021 CAP,VR620/77,VR625/77

C6029 MG RES 0

C6031 E CAP,VR407/77 10µF, 25V

C6053 CAP,VR620/77,VR625/77

C6501 CAP,VR620/77,VR625/77

C6502 E CAP,VR620/77,VR625/77

C6503 E CAP,VR620/77,VR625/77

C6504 CAP,VR620/77,VR625/77

C6506 E CAP,VR620/77,VR625/77

C6508 CAP,VR620/77,VR625/77

C6509 CAP,VR620/77,VR625/77

C6512 CAP,VR620/77,VR625/77

C6513 E CAP,VR620/77,VR625/77

C6514 CAP,VR620/77,VR625/77

C6515 E CAP,VR620/77,VR625/77

C6516 E CAP,VR620/77,VR625/77

C6517 CAP,VR620/77,VR625/77

C6519 CAP,VR407/77 0.012µF, 50V

C7011 E CAP,VR620/77,VR625/77

C7012 CAP,VR620/77,VR625/77

C7013 CAP 0.01µF,50V

C7014 CAP,VR407/77 0.01µF, 50V

C7041 E CAP 220µF,6.3V

C7042 CAP,VR407/77 0.0033µF, 50V

0.01µF, 50V

0.01µF, 50V

Ω,1/10W

0.001µF, 50V

0.1µF, 25V

10µF,50V

1µF, 50V

01µF,50V

1µF,50V

0.022µF, 25V

0.1µF, 25V

0.022µF, 25V

2..2µF, 50V

0.022µF, 50V

3.3µF,50V

4.7µF,50V

0.22µF, 16V

220µF, 6.3V

0.0033µF,50V

COILS

L1 4822 157 11354 COIL 10µH

L2 IM BUS W

L3 4822 157 11354 COIL 10µH

L4 4822 157 11354 COIL 10µH

L5 4822 157 11354 COIL 10µH

L11 4822 157 11515 COIL 12µH

L24 9965 000 01219 COIL 27µH

L28 4822 157 11153 COIL 68µH

L201 IM BUS W

L203 4822 157 71249 COIL 4.7µH

L901 4822 157 11354 COIL 10µH

L2001 IM BUS W

L2201 IM BUS W,VR620/77,VR625/77

L2251 4822 157 11354 COIL,VR620/77,VR625/77 4.7µH

L5201 4822 157 11287 COIL 33µH

L5202 4822 157 11287 COIL 33µH

L6001 IM BUS W

L6003 IM BUS W

L6032 IM BUS W

L6050 IM BUS W

L6501 IM BUS W,VR620/77,VR625/77

CRYSTALS

X1 9965 000 04098 CRYSTAL RESONATOR

X2 9965 000 03721 CRYSTAL RESONATOR

X3001 4822 242 11048 CRYSTAL RESONATOR

X3002 4822 242 10939 CRYSTAL RESONATOR

VR407/77, VR620/77, VR625/77

CONN,(1-8)CAPSTAN MOTOR

SWITCHES

S3001 9965 000 03723 PUSH SW,REC.SAFETY

S7001 4822 276 14029 TACT SW,POWER,VR620/ 77,

VR625/77

S7002 4822 276 14029 TACT SW,PAUSE,VR620/77,

VR625/77

4822 276 14029 TACT SW,POWER,VR407/77

S7004 4822 276 14029 TACT SW,MENU,VR620,VR625/77

TACT SW,FF/CH+,VR407/77

S7006 4822 276 14029 TACT SW,OK,VR620/77,VR625/77

TACT SW,CH,VR407/77

S7008 4822 276 14029 TACT SW,REC,VR620/77,VR625/77

TACT SW,STOP/EJECT,VR407/77

S7010 4822 276 14029 TACT SW,CH-,VR620/77,VR625/77

S7011 4822 276 14029 TACT SW,CH-,VR620/77,VR625/77

S7016 4822 276 14029 TACT SW,VCR/TV,VR620/ 77,

VR625/77

S7017 4822 276 14029 TACT SW,REC,VR407/77

S7018 4822 276 14029 TACT SW,REW/CH-,VR407/77

S7019 4822 276 14029 TACT SW,PLAY,VR407/77

FERRITE BEAD

K5101 4822 526 10699 FERRITE BEAD

K5102 IM BUS W

PHOTO COUPLERS

PC3001 4822 130 11171 GP3S123

PC3002 4822 130 11171 GP3S123

PC5101 ! 9965 000 04099 PS2561L1-1/WL/

TRANSFORMERS

T2051 4822 148 81344 OSC TRANSFORMER

T5001 ! 9965 000 00332 SW TRANSFORMER,VR620/77,

VR625/77

! 9965 000 07910 SW TRANSFORMER,VR407/77

CN3002 4822 265 11171 FPC CONN,(1-5)DRUM MDA

CN3003 4822 265 11356 CONN,(1-2)LOADING MOTOR

CN3004 4822 265 11358 CONN,(1-4)ROTARY ENCODER

CN5001 ! 4822 265 11371 CONN,(1-2)AC IN

CN7001 9965 000 03729 EPC CONN, (1-9) FRONT,VR620/77,

VR625/77

CIRCUIT PROTECTORS

CP4001 ! 4822 209 63612 ICP-N25 CIRCUIT PROTECTOR

CP5302 ! 4822 209 63612 ICP-N25 CIRCUIT PROTECTOR

5. AUDIO CONTROL BOARD ASSEMBLY

CONNECTOR

CN1 4822 265 11361 FPC CONN

6. MINI FRONT BOARD ASSEMBLY

(VR620/77,VR625/77 only)

RESISTORS

R7043 RES 2.7kΩ,1/4W

R7044 RES 4.7k

R7045 RES 6.8k

SWITCHES

Ω,1/4W

Ω,1/4W

TERMINAL BOARDS

TB1 ! 9965 000 08705 TERMINAL BOARD,VR620/77,

VR625/77

! 9965 000 08091 TERMINAL BOARD,VR407/77

TUNERS & PIN JACKS

TU6001 9965 000 07913 TUNER,VR407/77

9965 000 08685 TUNER,VR620/77,VR625/77

J1 9965 000 00324 PIN JACK,A/V IN,VR407/77

9965 000 07925 PIN JACK,A/V IN,VR620/77,

VR625/77

J2 4822 265 11632 PIN JACK,A/V OUT,VR620,625/77

9965 000 00324 PIN JACK,A/V OUT,VR407/77

FW7106 9965 000 08686 PARA RIBON W,VR620, VR625/77

J7101 9965 000 07926 PIN JACK,FRONT IN,VR620/77,

VR625/77

FILTER & VARISTOR

LF5002 ! 4822 157 11291 LINE FILTER

VA5003 ! 4822 117 13663 VARISTOR

CONNECTORS

CN1 4822 264 10399 FPC CONN,(1-11)U.DRUM,VR620/77

VR625/77

4822 264 10398 FPC CONN,(1-8)U.DRUM VR407/77

CN2001 4822 265 11355 FPC CONN,(1-7)A/C HEAD

CN2002 4822 265 11356 CONN,(1-2)FE HEAD

CN3001 4822 265 11621

S7024 4822 276 14029 TACT SW,PLAY

S7025 4822 276 14029 TACT SW,STOP/EJECT

S7026 4822 276 14029 TACT SW,FF

S7027 4822 276 14029 TACT SW,REW

CONNECTOR

CN7002 9965 000 03729 FPC CONN,(1-9)MAIN

7. LOADING MOTOR BOARD ASSEMBLY

CONNECTOR

CN1 4822 265 11363 CONN

8. LT BATTERY BOARD ASSEMBLY

(VR620/77,VR625/77 only)

BT3001 4822 256 10412 BATTERY HOLDER

SECTION 1

DISASSEMBLY

1.1 Disassembly flow chart

This flowchart lists the disassembling steps for the cabinet

parts and P.C. boards in order to gain access to item(s) to

be serviced. When reassembling, perform the step(s) in reverse order. Bend, route and dress the flat cables as they

were originally laid.

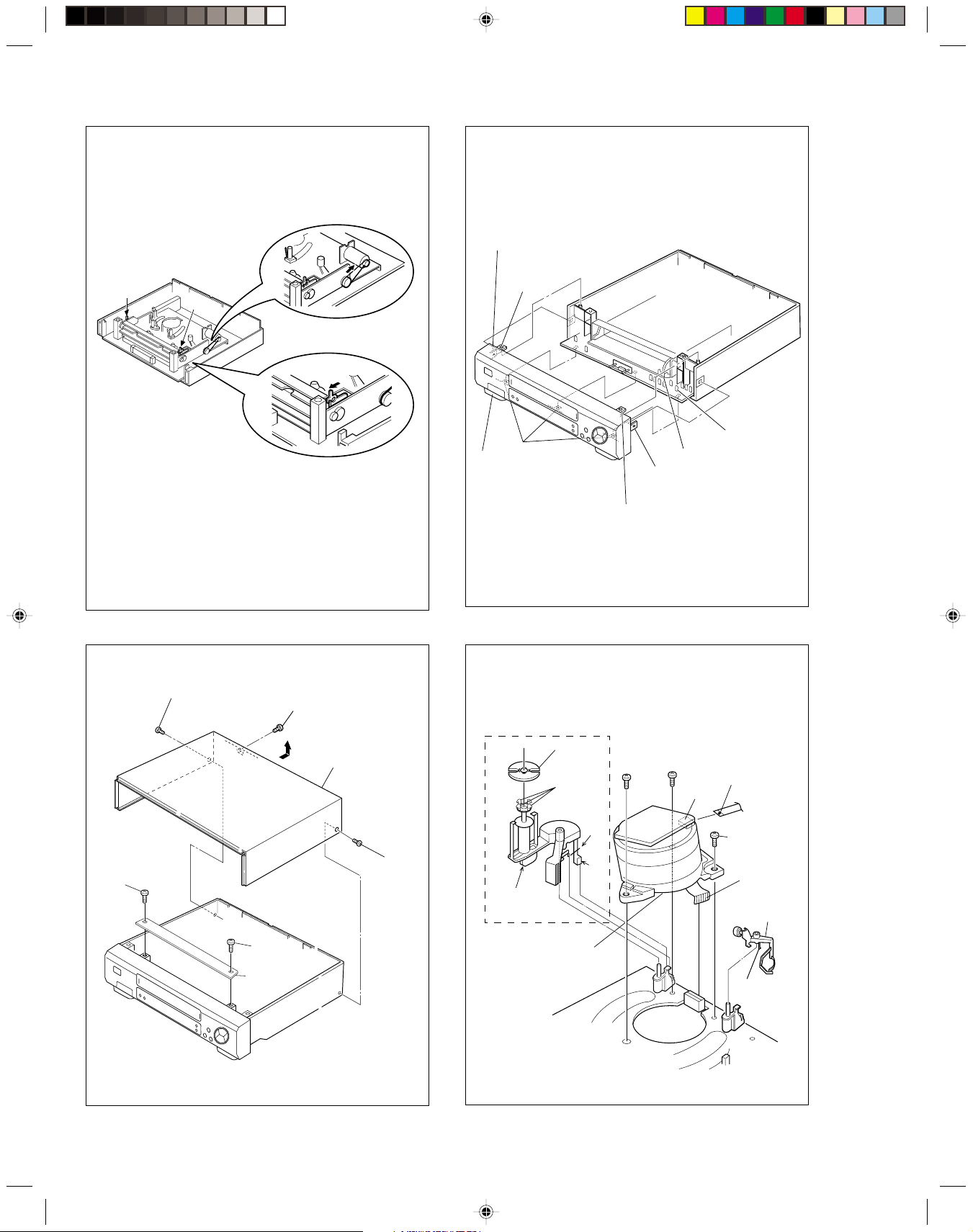

[1]

[2]

[3]

[4]

[5]

[6]

How to read the disassembly and assembly

1.2

Top cover, Bracket

Front panel assembly

Drum assembly

Mechanism assembly

Mini front board assembly,

Main board assembly

Bottom cover

<Example>

Step/

Loc No.

[1] Top cover, D1

(1) (2) (3) (4) (5)

Part Name

Bracket 2(S1c)

Fig.

No.

Point Note

4(S1a),(S1b),3(L1a), <Note 1a>

2(SD1a),(P1a),(W1a),

CN1(WR1a),

(1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse order.

These numbers are also used as the identification (location) No.

of parts Figures.

(2) Part name to be removed or installed.

(3) Fig. No. showing procedure or part location.

(4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P= Spring, W= Washer, S= Screw, L= Locking tab, SD= Solder,

CN**(WR**)= Remove the wire (WR**) from the connector

(CN**).

Note:

•

The bracketed ( ) WR of the connector symbol are assigned nos. in priority order and do not correspond to

those on the spare parts list.

(5) Adjustment information for installation

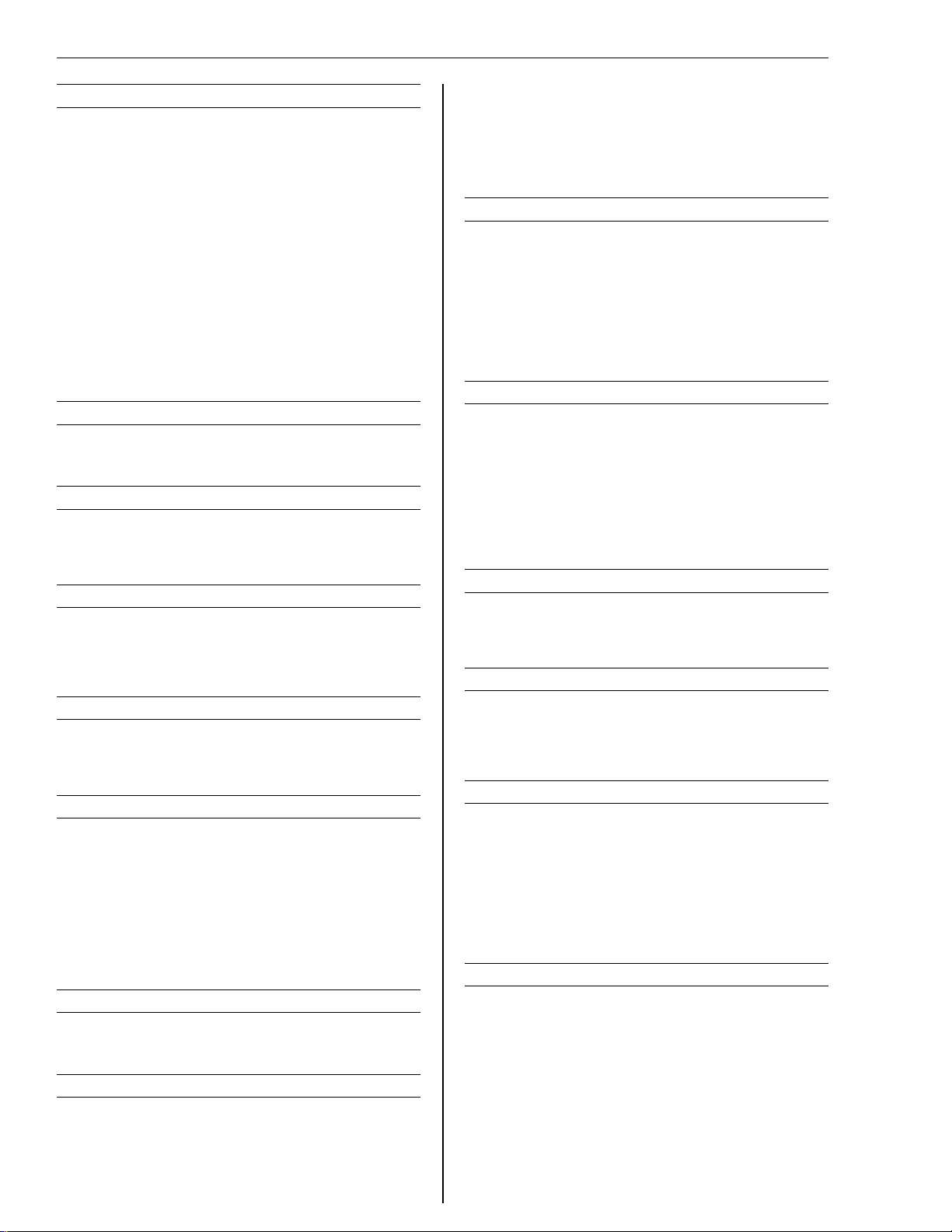

1.3 Disassembly/assembly method

Step/

Loc No.

[1] Top cover, D1 2(S1a),

[2] Front panel assembly D2 7(L2a) <Note 2a>

[3] Drum assembly D3 CON1(WR3a),

[4] Mechanism assembly D4 CN2001(WR4a), <Note 3a>

[5] Main board assembly D5a 2(S5a), (L5a)

[6] Bottom cover D6 2(L6a), 6(L6b) <Note 6a>

Part Name

Bracket 2(S1c)

(Cleaner assy) (L3a)

-------------------------------------------------

Mini front board

assembly

Main board assembly (S5a), 2(S5b), (L5b)

Fig.

No.

-----------------

Point Note

(S1b)

[VR620/77,VR625/77]

[VR620/77,VR625/77]

5(L2a)[VR407/77]

CN1(WR3b),

(S3a), (S3b), (S3c)

(S4a), (S4b), <Note 4a>

2(S4c),

(L5a),CN7001(WR5a)

-----------------

<Note 2b>

<Note 3a>

<Note 3a>

<Note 2a>

• When reattaching the Front panel assembly, make sure that

the door opener “a” of the Cassette holder assembly is lowered in position prior to the reinstallation.

<Note 2b>

• When reattaching the Front panel assembly, pay careful attention to the switch lever not to make it touch the switch

knob “b” of the Main board assembly from the side.

<Note 3a>

• Be careful not to damage the connector and wire etc. during

connection and disconnection.

When connecting the wire to the connector, be careful with

the wire direction.

<Note 4a>

• When it is required to remove the screws (S4a to S4b) retaining the Mechanism assembly, please refer to the “Procedures for Lowering the Cassette holder assembly”(See

on page 1-2).

• When reattaching the Mechanism assembly to the Main

board assembly, take care not to damage the sensors on

the Main board assembly.

<Note 6a>

When removing the bottom cover, push down the two tabs

(L6a) to slide the bottom cover.

1-1

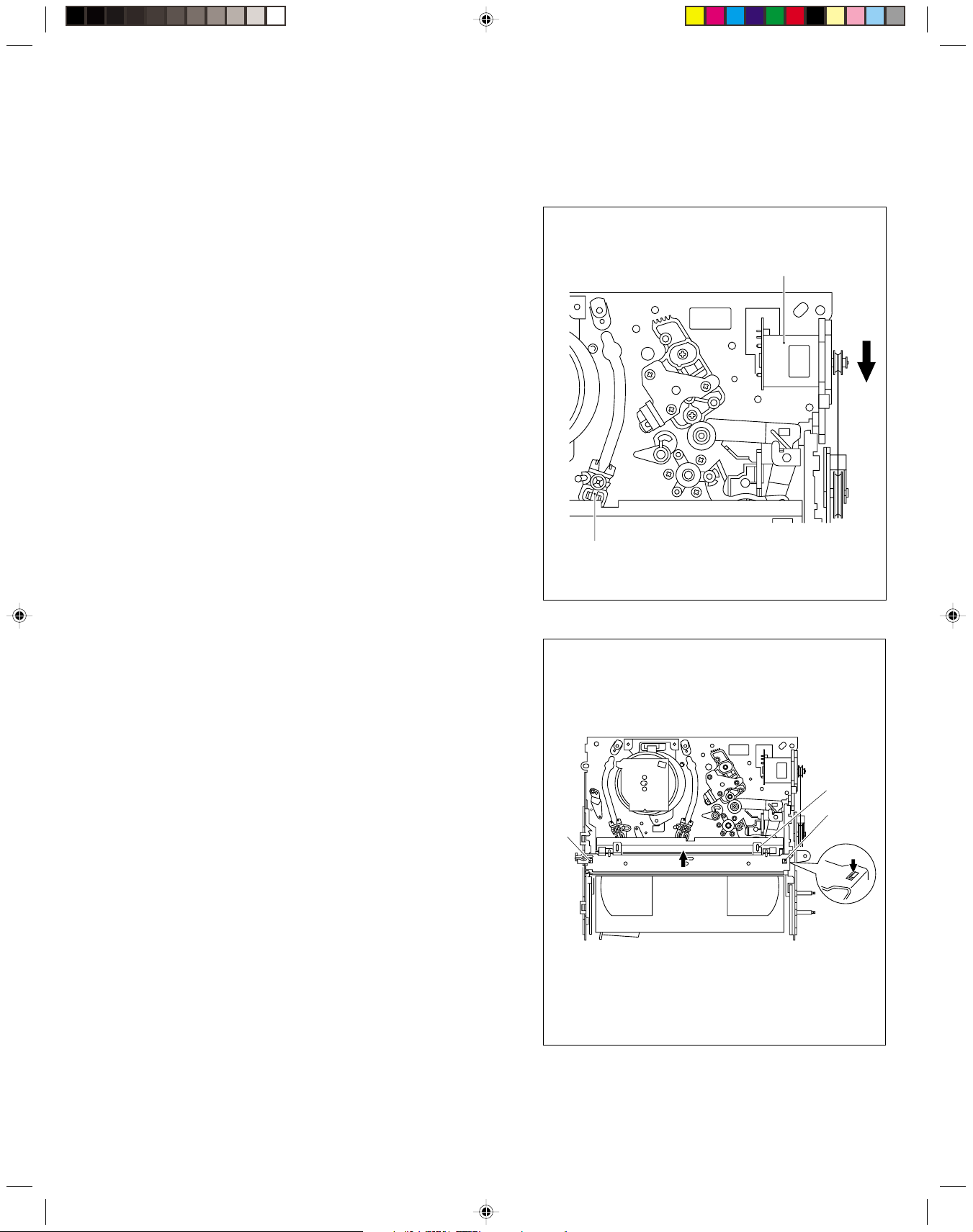

Procedures for Lowering the Cassette holder assembly

As the mechanism of this unit is integrated with the Housing

assembly, the holder must be lowered and the two screws unscrewed when removing the Mechanism assembly.

(L2a)

[VR620/77, VR625/77]

(A)

(B)

Fig. 2

Fig. 1

Fig. 3

Turn the loading motor pulley in the direction as indicated by

Fig.2. As both (A) and (B) levers are lodged twice, push the

levers in the direction as indicated by Fig.3 to release them.

When pushing the levers, do it in the order of (A), (B), (B),

(A). When the holder has been lowered, turn the pulley until

the cassette holder is securely in place without allowing any

up/down movement.

Procedures for Lowering the Cassette holder assembly

(S1a)

[VR620/77, VR625/77]

(S1b)

(L2a)

<Note 2b>

(L2a)

[2]

Front panel

assembly

“a”

(L2a)

[VR620/77, VR625/77]

(L2a)

“b”

<Note 2a>

Fig. D2

Note:

When installing the Drum assembly, secure the screws (S3a to

S3c) in the order of a, b, c.

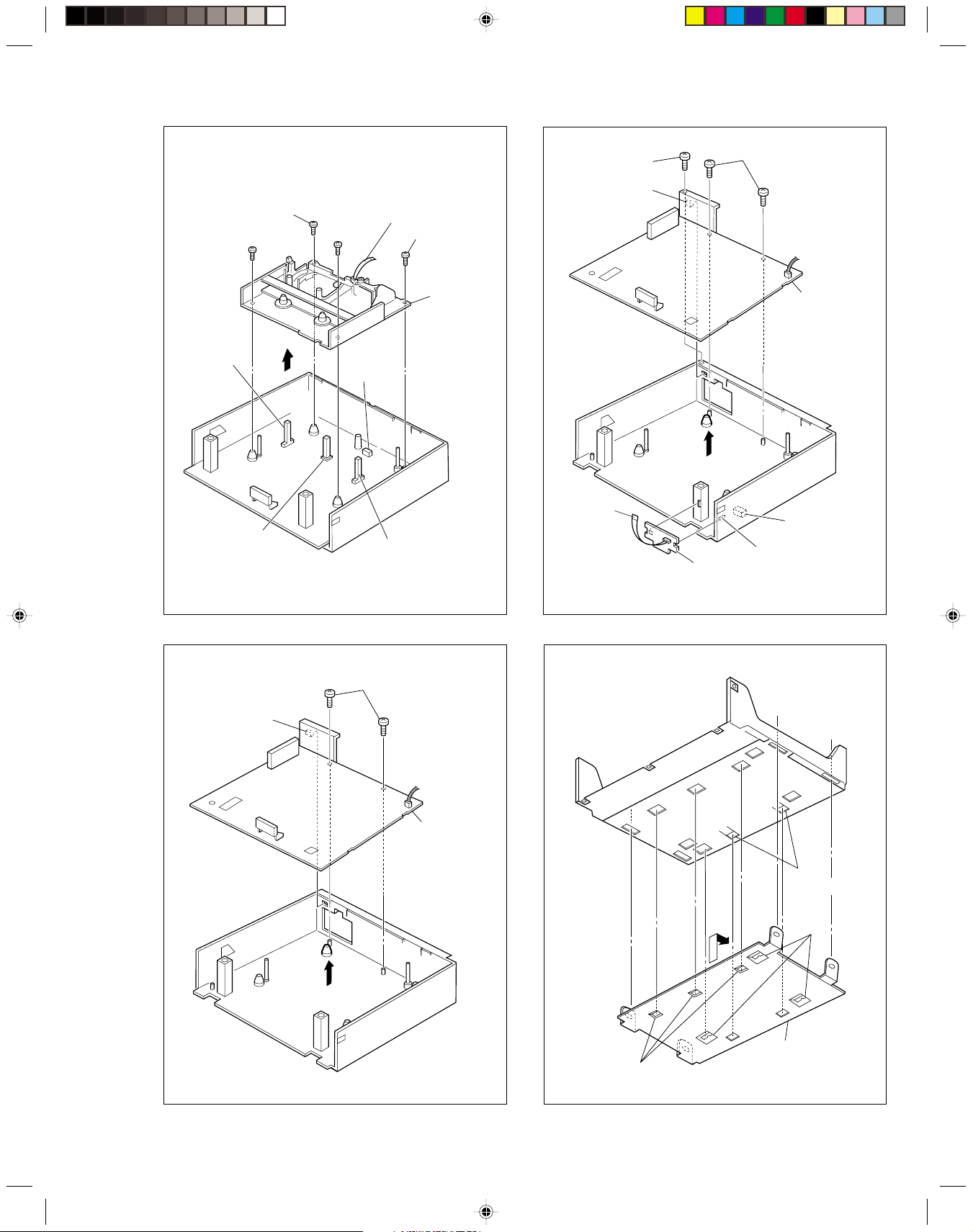

(S1c)

Inertia plate

(S1c)

[1]

Bracket

[1] Top cover

(S1a)

Roller arm

assy

(L3a)

Not used

[3]

Drum

assembly

(S3a)

(P3)

(L3b)

Fig. D1 Fig. D3

(S3c)

CN1

CON1

WR3a

<Note 3a>

(S3b)

WR3b

<Note 3a>

Cleaner assy

(L3a)

1-2

Note:

[6]

Bottom cover

(L6b)

(L6b)

(L6a)

<Note 6a>

When installing the Mechanism assembly, secure the

screws (S4a to S4b) in the order of a, b.

WR4a

<Note 3a>

(S4c)

(S4b)

<Note 4a>

(S4c)

(S4a)

<Note 4a>

(S5a)

(L5a)

(S5b)

Q3002

End sensor

<Note 4a>

D3001

LED

<Note 4a>

CN2001

Fig. D4

[4]

Mechanism

assembly

Q3001

Start sensor

[VR620/77, VR625/77]

<Note 4a>

(S5a)

WR5a

<Note 3a>

CN7001

(L5a)

[5] Mini front board assembly

[VR620/77, VR625/77]

Fig. D5b

[5]

Main board

assembly

(L5a)

Fig. D5a

[5]

Main board

assembly

[VR407/77]

Fig. D8

1-3

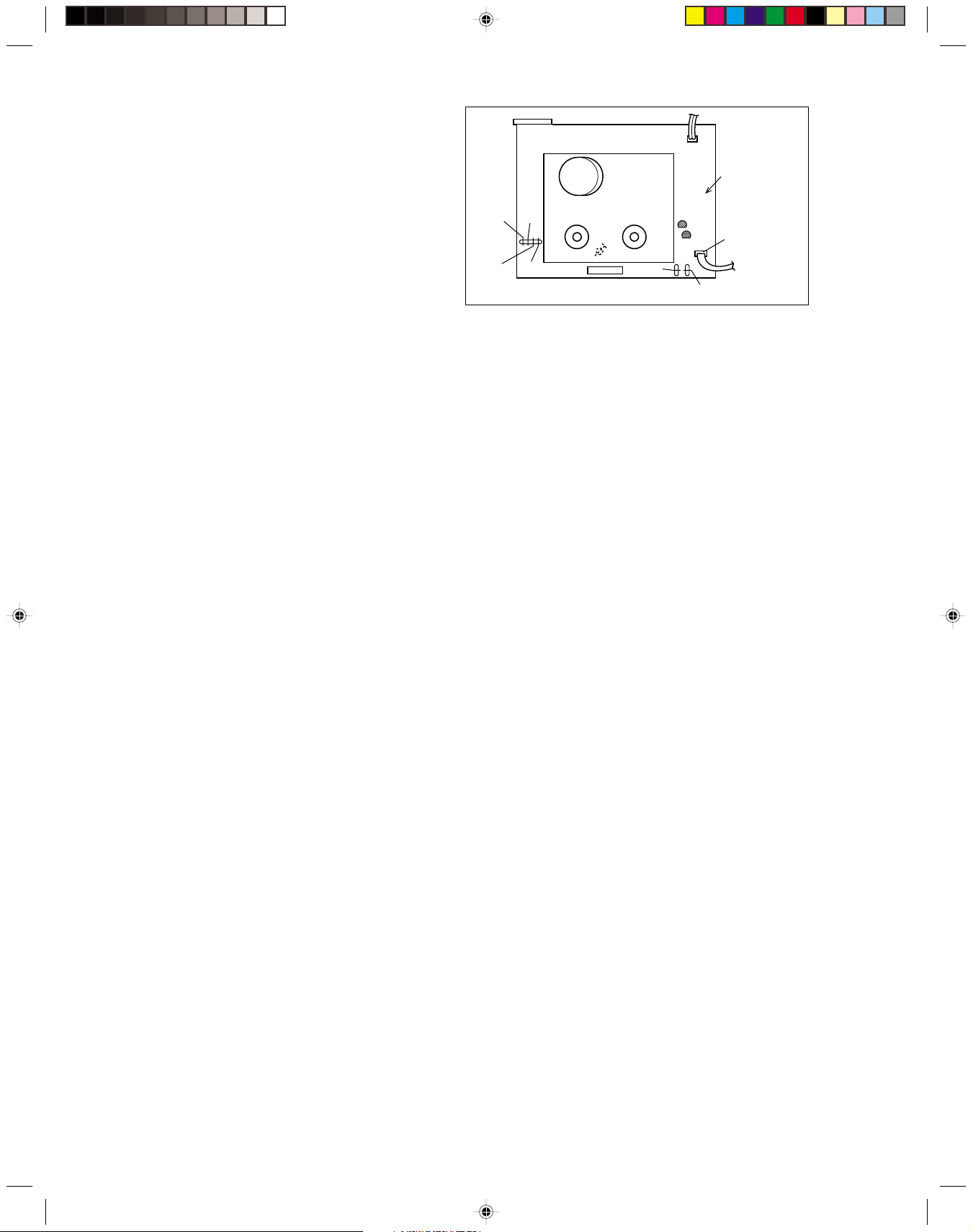

1.4 Service position

This unit has been designed so that the Mechanism and

Main board assemblies can be removed together from the

chassis assembly. Before diagnosing or servicing the circuit boards, take out the major parts from the chassis assembly.

1.4.1 How to set the “Service position”

(1) Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing the Drum

assembly.

(2) Lower the cassette holder to prepare for the removal of

the Mechanism assembly screws. (Refer to the “Proce-

dures for lowering the Cassette holder assembly” of 1.3

Disassembly/assembly method.)

(3) Remove the combined Mechanism and Main board as-

semblies.

(4) Connect the wires and connectors of the major parts that

have been removed in step (1). (Refer to Fig.1-4-1a.)

(5) Place the combined Mechanism and Main board assem-

blies upside down.

(6) Insert the power cord plug into the power outlet and then

proceed with the diagnostics and servicing of the board

assembly.

Notes:

• Before inserting the power cord plug into the power

outlet, make sure that none of the electrical parts are

able to short-circuit between the workbench and the

board assembly.

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see “1.3 Disassembly/assembly method”.

• If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, be

sure to remove them ( including wires connected to the

major parts ) first before performing step (2).

• When carrying out diagnosis and repair of the Main

board assembly in the “Service position”, be sure to

ground both the Main board and Mechanism assemblies. If they are improperly grounded, there may be

noise on the playback picture or FDP counter display

may move even when the mechanism is kept in an inoperative status.

• In order to diagnose the playback or recording of the

cassette tape, set the Mechanism assembly to the required mode before placing it upside down. If the

mechanism mode is changed (including ejection) while

it is in an upside down position the tape inside may

be damaged.

• The mechanism and board assemblies of this unit are

attached by connectors only.

When carrying out a diagnosis or repair of the boards

in the “Service position”, make sure that the connectors are not disconnected.

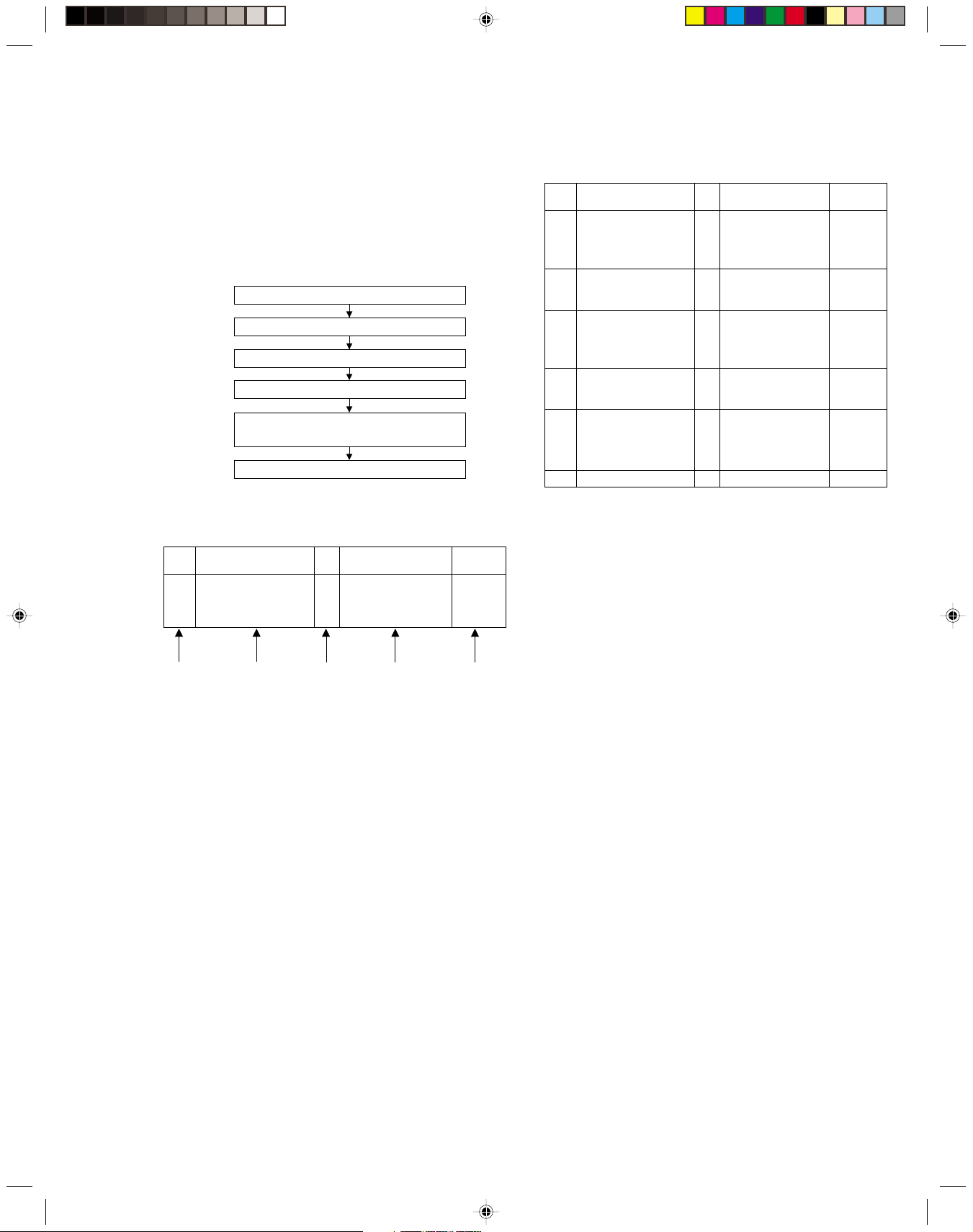

Main board

assembly

TP2253

A.PB.FM

[VR620/77,

TP106

VR625/77]

TP4001

CTL.P

PB.FM

TP111

D.FF

C3018

Timer clock

TPGND

CP4001

CP5302

TP7001

TEST

CN7001

[VR620/77, VR625/77]

To Mini front board

assembly

[VR620/77, VR625/77]

Fig. 1-4-1a

1.5 Mechanism service mode

This model has a unique function to enter the mechanism

into every operation mode without loading of any cassette

tape. This function is called the “Mechanism service mode”.

1.5.1 How to set the “Mechanism service mode”

(1) Unplug the power cord plug from the power outlet.

(2) Connect TPGND and TP7001(TEST) on the Main board

assembly with a jump wire.

(3) Insert the power cord plug into the power outlet.

(4) With lock levers (A) (B) on the left and right of the Cas-

sette holder assembly pulled toward the front, slide the

holder in the same direction as the cassette insertion di-

rection. (For the positions of lock levers (A) (B), refer to

the “Procedures for lowering the Cassette holder assem-

bly” of 1.3 Disassembly/assembly method.)

(5) The cassette holder lowers and, when the loading has

completed, the mechanism enters the desired mode.

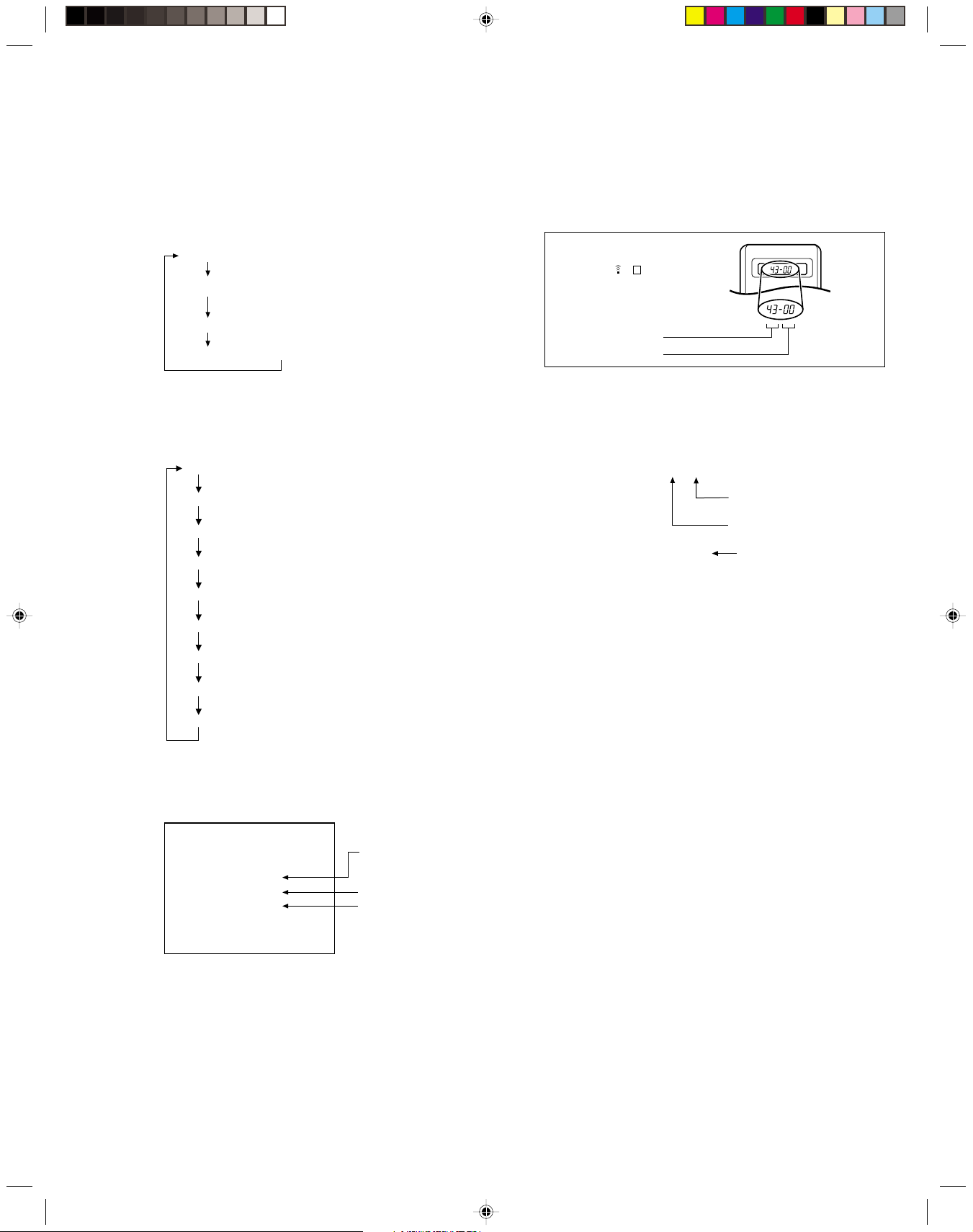

1.6 Jig RCU mode

This unit uses the following two modes for receiving remote

control codes.

1) User RCU mode : Ordinary mode for use by the user.

2) Jig RCU mode : Mode for use in production and serv-

icing.

When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the Jig

RCU can be received). As both of the above two modes

are stored in the EEPROM, it is required to set the VCR

back to the User RCU mode each time that an adjustment

is made or to check that the necessary operations have

been completed. These modes can be set by the operations described below.

1.6.1 Setting the Jig RCU mode

(1) Unplug the power cord plug from the power outlet.

(2) Press and hold the “REC” and “PAUSE” buttons on the

VCR simultaneously, while plugging the power cord plug

into the power outlet.

When the VCR is set to the Jig RCU mode, the symbols

( “ : ” ) in the time display of the FDP are turned off.

1-4

1.6.2 Setting the User RCU mode

(1) Turn off the power.

(2) Press the “REC” and “PAUSE” buttons of the VCR si-

multaneously. Alternatively, transmit the code “80” from

the Jig RCU.

1.7 Emergency display function

This unit has a function for storing the history of the past two

emergencies (EMG) and displaying them on each FDP (or

OSD). With the status of the VCR and mechanism at the moment an emergency occurred can also be confirmed.

FDP display model

[FDP display]

0 : 00 : 00

E:**:**

*1 : *2 : 34

*5: *6 : *7

FDP (7segment LED) display model

[FDP display]

0: 00

E: **

1: **

2: *1

3: *2

4: 34

5: *5

6: *6

7: *7

OSD display model

[OSD display]

Normal display

EMG content display

(E:Latest:Previous)

EMG detail information <1>

EMG detail information <2>

Normal display

EMG content display (Latest)

EMG content display (Previous)

EMG detail information <1>

[Deck operation mode]

EMG detail information <1>

[Mechanism operation mode]

EMG detail information <1>

[Mechanism sensor information and Mechanism mode position]

EMG detail information <2>

[Type of the cassette tape in use <1>]

EMG detail information <2>

[Winding position of the cassette tape in use]

EMG detail information <2>

[Type of the cassette tape in use <2> (Winding area)]

EMG

E: **:**

*1 : *2 : 34

*5: *6 : *7

EMG content display

(E:Latest:Previous)

EMG detail information <1>

EMG detail information <2>

Notes:

•

The EMG detail information <1><2> show the information

on the latest EMG.

It becomes “ – – : – – : – –” when there is no latest EMG

record.

•

When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the Jig

RCU can be received).

Jig RCU

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

CUSTOM CODE

43: A CODE

53: B CODE

DATA CODE

INITIAL MODE

Fig. 1-7a Jig RCU

1.7.1 Displaying the EMG information

(1) Transmit the code “59” from the Jig RCU.

The FDP shows the EMG content in the form of “E:**:**”.

<Example 1> E : 01 : 03

Previous EMG

Latest EMG

<Example 2> E : –– : ––

No EMG record

(2) Transmit the code “59” from the Jig RCU again.

The FDP shows the EMG detail information <1> in the form

of “ * 1 : * 2 : 34 ”.

* 1 : Deck operation mode at the moment of EMG

* 2 : Mechanism operation mode at the moment of EMG

3– : Mechanism sensor information at the moment of

EMG

–4 : Mechanism mode position at the moment of EMG

(3) Transmit the code “59” from the Jig RCU once again.

The FDP shows the EMG detail information <2> in the form

of “ *5 : *6 : *7 ”.

* 5 : Type of the cassette tape in use <1> .

* 6 : Winding position of the cassette tape in use

* 7 : Type of the cassette tape in use <2> (Winding area)

(4) Transmit the code “59” from the Jig RCU once again to re-

set the display.

Notes:

•

For the OSD display model, all EMG information are

showed by transmitting first code from the Jig RCU.

•

For the EMG content, see “1.7.3 EMG content description”.

•

For the EMG detail information <1> , see “1.7.4 EMG detail information <1> ”.

•

For the EMG detail information <2> , see “1.7.5 EMG detail information <2>”.

1.7.2 Clearing the EMG history

(1) Display the EMG history.

(2) Transmit the code “36” from the Jig RCU.

(3) Reset the EMG display.

(EMG-02e)

1-5

1.7.3 EMG content description

EMG contents “E08/E09” are for the model with Dynamic Drum (DD).

Note:

FDP CONTENT CAUSE

E01: Loading EMG

E02:

Unloading EMG

E03: Take Up Reel

Pulse EMG

E04: Drum FG

EMG

E05: Cassette Eject

EMG

E06: Capstan FG

EMG

E07: SW Power

Short-Circuit

EMG

E08:

DD Initialized

(Absolute

Position

Sensor)

EMG

E09: DD FG EMG

E0A:Supply Reel

Pulse EMG

EC1 or EU1:

Head clog warning

When the mechanism mode cannot be changed to another mode even when the loading motor has rotated

for more than 4 seconds in the loading direction, [E:01]

is identified and the power is turned off.

When the mechanism mode cannot be changed to another mode even when the loading motor has rotated

for more than 4 seconds in the unloading direction, [E:02]

is identified and the power is turned off.

When the take-up reel pulse has not been generated for

more than 4 seconds in the capstan rotating mode, [E:03]

is identified, the pinch rollers are turned off and stopped,

and the power is turned off. However, the reel EMG is

not detected in STILL/SLOW modes.

When the drum FG pulse has not been input for more

than 3 seconds in the drum rotating mode, [E:04] is identified, the pinch rollers are turned off and stopped, and

the power is turned off.

When the eject operation does not complete in 3 seconds after the start, [E:05] is identified, the pinch rollers

are turned off and stopped, and the power is turned off.

When the cassette insertion operation does not complete

in 3 seconds after the start, the cassette is ejected. In

addition, when the operation does not complete within

3 seconds after the start, [E:05] is also identified and the

power is turned off immediately.

When the capstan FG pulse has not been generated for

more than 1 second in the capstan rotating mode, [E:06]

is identified, the pinch rollers are turned off and stopped,

and the power is turned off.However, the capstan EMG

is not detected in STILL/SLOW/FF/REW modes.

When short-circuiting of the SW power supply with GND

has lasted for 0.5 second or more, [E:07] is identified,

all the motors are stopped and the power is turned off.

When DD tilting does not complete in 4 seconds, [E:08]

is identified, the tilt motor is stopped and the power is

turned off.

When the DD FG pulse is not generated within 2.5 seconds, [E:09] is identified, the tilt motor is stopped and

the power is turned off.

When the supply reel pulse has not been generated for

more than 10 seconds in the capstan rotating mode,

[E:0A] is identified and the cassette is ejected (but the

power is not turned off). However, note that the reel EMG

is not detected in the SLOW/STILL mode.

Presupposing the presence of the control pulse output in the PLAY mode, when the value obtained by mixing the two V.FM output

channels (without regard to the A.FM output) has remained below a certain threshold level for more than 10 seconds, [E:C1] or [E:U1]

is identified and recorded in the emergency history. During the period in which a head clog is detected, the FDP and OSD repeat the

“3-second warning display” and “7-second noise picture display” alternately.

EMG code : “E:C1” or “E:U1” / FDP : “U:01” / OSD : “Try cleaning tape.” or “Use cleaning cassette.”

The head clog warning is reset when the above-mentioned threshold has been exceeded for more than 2 seconds or the mode is

changed to another mode than PLAY.

The mechanism is locked in the middle of mode transition.

1.

2

. The mechanism is locked at the loading end due to the encoder position

reading error during mode transition.

3.

Power is not supplied to the loading MDA.

1.

The mechanism is locked in the middle of mode transition.

2.

The mechanism is locked at the unloading end due to the encoder position reading error during mode transition.

3.

Power is not supplied to the loading MDA.

1.

The take-up reel pulse is not generated in the FWD transport modes (PLAY/

FWD SEARCH/FF, etc.) because;

1) The idler gear is not meshed with the take-up reel gear;

The idler gear is meshed with the take-up reel gear, but incapable of wind-

2)

ing due to too large mechanical load (abnormal tension);

3) The take-up reel sensor does not output the FG pulse.

2.

The supply reel pulse is not generated in the REV transport modes (REV

SEARCH/REW, etc.) because;

1) The idler gear is not meshed with the supply reel gear.

2) The idler gear is meshed with the supply reel gear, but incapable of wind-

ing due to too large a mechanical load (abnormal tension);

3) The supply reel sensor does not output the FG pulse.

3.

Power is not supplied to the reel sensors.

1.

The drum could not start or the drum rotation has stopped due to too large

a load on the tape, because;

1) The tape tension is abnormally high;

The tape is damaged or a foreign object (grease, etc.) adheres to the tape.

2)

2.

The drum FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (hall device) of the drum is faulty.

3.

The drum control voltage (DRUM CTL V) is not supplied to the MDA.

4.

Power is not supplied to the drum MDA.

1.

The cassette cannot be ejected due to a failure in the drive mechanism of

the housing.

2.

When the housing load increases during ejection, the loading motor is

stopped because of lack of headroom in its drive torque.

Housing load increasing factors: Temperature environment (low temperature, etc.), mechanism wear or failure.

3.

The sensor/switch for detecting the end of ejection are not functioning normally.

4.

The loading motor drive voltage is lower than specified or power is not supplied to the motor (MDA).

5.

When the user attempted to eject a cassette, a foreign object (or perhaps

the user's hand) was caught in the opening of the housing.

1.

The capstan could not start or the capstan rotation has stopped due to too

large a load on the tape, because;

1) The tape tension is abnormally high (mechanical lock);

2) The tape is damaged or a foreign object (grease, etc.) is adhered to the

tape (occurrence of tape entangling, etc.).

2.

The capstan FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (MR device) of the capstans is faulty.

3.

The capstan control voltage (CAPSTAN CTL V) is not supplied to the MDA.

4.

Power is not supplied to the capstan MDA.

1.

The SW 5 V power supply circuit is shorted with GND.

2.

The SW 12 V power supply circuit is shorted with GND.

1. The absolute value sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the absolute sensor output is defective. (The soldered parts

have separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the

absolute value sensor.

The absolute value sensor data is not sent to the System Controller CPU.

4.

1. The FG sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the FG sensor output is defective. (The soldered parts have

separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the FG sensor.

4. The power to the sensor is not supplied. (Connection failure/soldering failure)

5. The FG pulse is not sent to the System Controller CPU.

The tilt motor is defective. (The soldered parts have separated.)

6.

7. The drive power to the tilt motor is not supplied. (Connection failure/soldering failure)

8. The tilt motor drive MDA - IC is defective.

9. Auto-recovery of the DD tilting cannot take place due to overrun.

1.

The supply reel pulse is not generated in the FWD transport mode (PLAY/

FWD SEARCH/FF, etc.) because;

1) PLAY/FWD or SEARCH/FF is started while the tape in the inserted cas-

sette is cut in the middle;

2) A mechanical factor caused tape slack inside and outside the supply

reel side of the cassette shell. In this case, the supply reel will not rotate

until the tape slack is removed by the FWD transport, so the pulse is not

generated until then;

3) The FG pulse output from the supply reel sensor is absent.

2.

The take-up reel pulse is not generated in the REV transport mode (REV

SEARCH/REW, etc.).

1) REV SEARCH/REW is started when the tape in the inserted cassette

has been cut in the middle;

2) A mechanical factor caused tape slack inside and outside the take-up

reel side of the cassette shell. In this case, the supply reel will not rotate

until the tape slack is removed by the REV transport, so the pulse will

not be generated until that time;

3) The FG pulse output from the take-up reel sensor is absent.

3.

The power to a reel sensor is not supplied.

1-6

Table 1-7-3a

1.7.4 EMG detail information <1>

The status (electrical operation mode) of the VCR and the status (mechanism operation mode/sensor information) of the

mechanism in the latest EMG can be confirmed based on the

figure in EMG detail information <1> .

[FDP/OSD display]

* 1 : * 2 : 34

* 1 : Deck operation mode at the moment of EMG

* 2 : Mechanism operation mode at the moment of EMG

3– : Mechanism sensor information at the moment of EMG

–4 : Mechanism mod

e position at the moment of EMG

Note:

•

For EMG detailed information <1>, the content of the code

that is shown on the FDP (or OSD) differs depending on

the parts number of the system control microprocessor

(IC3001) of the VCR. The system control microprocessor

parts number starts with two letters, refer these to the corresponding table.

* 1 : Deck operation mode

[Common table of MN*, HD* and M3*]

Display

MN*/M3* HD*

00 - Mechanism being initialized

01 00 STOP with pinch roller pressure off (or tape present with P.OFF)

02 01 STOP with pinch roller pressure on

03 - POWER OFF as a result of EMG

04 04 PLAY

0C 0E REC

10 11 Cassette ejected

20 22 FF

21 - Tape fully loaded, START sensor ON, short FF

22 - Cassette identification FWD SEARCH before transition to FF (SP

24 26 FWD SEARCH (variable speed) including x2-speed

2C 2E INSERT REC

40 43 REW

42 - Cassette identification REV SEARCH before transition to REW (SP

44 47 REV SEARCH (variable speed)

4C 4C AUDIO DUB

6C 6E INSERT REC (VIDEO + AUDIO)

84 84 FWD STILL / SLOW

85 85 REV STILL / SLOW

8C 8F REC PAUSE

8D - Back spacing

8E - Forward spacing (FWD transport mode with BEST function)

AC AF INSERT REC PAUSE

AD - INSERT REC back spacing

CC CD AUDIO DUB PAUSE

CD - AUDIO DUB back spacing

EC EF INSERT REC (VIDEO + AUDIO) PAUSE

ED - INSERT REC (VIDEO + AUDIO) back spacing

x7-speed)

x7-speed)

Deck operation mode

* 2 : Mechanism operation mode

[Common table of MN* and M3*]

Display

MN* M3*

00 00 Command standby (Status without executing command)

02 02 POWER OFF by EMG occurrence

04 04 Moving to the adjacent position in the LOAD direction

06 06 Moving to the adjacent position in the UNLOAD direction

08 08 Cassette ejection being executed / Cassette housing ejection being

- 0A Mode transition to STOP with cassette ejection end

0A 0C Cassette insertion being executed

0C 0E Tape being loaded

0E 10 Tape being unloaded

10 12 Mode transition to STOP with pinch roller compression ON

12 14 Mode transition to STOP with pinch roller compression OFF

14 16

16 18

18 1A Mode transition to PLAY

1A 1C Mode transition to FWD SEARCH

1C 1E Mode transition to REC

1E 20 Mode transition to FWD STILL / SLOW

20 22 Mode transition to REV STILL / SLOW

22 24 Mode transition to REV SEARCH

24 26 Mode transition from FF / REW to STOP

26 28 Mode transition to FF

28 2A Mode transition to REW

2A 2C 4 sec. of REV as a result of END sensor going ON during loading

2C 2E

2E 30 Mechanism position being corrected due to overrun

80 80 Mechanism in initial position (Dummy command)

executed

Mode transition to STOP with pinch roller compression OFF as a result

of POWER OFF

Mode transition to STOP with pinch roller compression ON as a result

of POWER ON

Short FF / REV as a result of END sensor going ON during unloading

Mechanism operation mode

[Table of HD*]

Display

00 STOP with pinch roller pressure off

01 STOP with pinch roller pressure on

02 U/L STOP (or tape being loaded)

04 PLAY

05 PLAY (x1-speed playback using JOG)

0E REC

11 Cassette ejected

22 FF

26 FWD SEARCH (variable speed) including x2-speed

2E INSERT REC

43 REW

47 REV SEARCH

4C AUDIO DUB

6E INSERT REC (VIDEO + AUDIO)

84 FWD STILL/SLOW

85 REV STILL/SLOW

8F REC PAUSE

AF INSERT REC PAUSE

C7 REV SEARCH (x1-speed reverse playback using JOG)

CD AUDIO DUB PAUSE

EF INSERT REC (VIDEO + AUDIO) PAUSE

F0 Mechanism being initialized

F1 POWER OFF as a result of EMG

F2 Cassette being inserted

F3 Cassette being ejected

F4 Transition from STOP with pinch roller pressure on to STOP with pinch

roller pressure off

F5 Transition from STOP with pinch roller pressure on to PLAY

F6 Transition from STOP with pinch roller pressure on to REC

F7 Cassette type detection SEARCH before FF/REW is being executed

F8 Tape being unloaded

F9 Transition from STOP with pinch roller pressure off to STOP with pinch

roller pressure on

FA Transition from STOP with pinch roller pressure off to FF/REW

FB Transition from STOP with pinch roller pressure off to REC.P (T.REC,etc.)

FC Transition from STOP with pinch roller pressure off to cassette type de-

tection SEARCH

FD Short REV being executed after END sensor on during unloading

FE Tension loosening being executed after tape loading (STOP with pinch

roller pressure on)

Mechanism operation mode

1-7

3– : Mechanism sensor information

[Common table of MN*, HD* and M3*]

Display

MN* / HD* M3* REC safety Start End

S-VHS SW CASS SW SW sensor sensor

0- VHS Cassette insertion Tab broken ON ON

1- VHS Cassette insertion Tab broken ON OFF

2- VHS Cassette insertion Tab broken OFF ON

3- VHS Cassette insertion Tab broken OFF OFF

4- VHS Cassette insertion Tab present ON ON

5- VHS Cassette insertion Tab present ON OFF

6- VHS Cassette insertion Tab present OFF ON

7- VHS Cassette insertion Tab present OFF OFF

8- S-VHS Cassette ejection Tab broken ON ON

9- S-VHS Cassette ejection Tab broken ON OFF

A- S-VHS Cassette ejection Tab broken OFF ON

B- S-VHS Cassette ejection Tab broken OFF OFF

C- S-VHS Cassette ejection Tab present ON ON

D- S-VHS Cassette ejection Tab present ON OFF

E- S-VHS Cassette ejection Tab present OFF ON

F- S-VHS Cassette ejection Tab present OFF OFF

Mechanism sensor information

–4 : Mechanism mode position

[Common table of MN*, HD* and M3*]

Display Mechanism mode position

MN* HD* M3*

-0 -7 - Initial value

-1 -0 - EJECT position

- - -0 EJECT position (Cassette housing drive mode)

-2 -7 - Housing operating

- - -1 Between EJECT and U / L STOP

-3 -1 -2 U / L STOP position

- - -3 Guide arm drive position

-4 -7 -4 Tape being loaded / unloaded (When the pole base is

-5 -2 -5 Tape being loaded / unloaded (When the pole base is

-6 -7 -6 Pole base compressed position

-7 -3 -F FF / REW position

-8 -7 -F Between FF / REW and STOP with pinch roller compres-

-9 -4 -F STOP with pinch roller compression OFF

-A -7 -E Between STOP with pinch roller compression OFF and

-B -5 - REV (REV STILL / SLOW) position

- - -D REV position

- - -C Between REV and REV STILL / SLOW

- - -B REV STILL / SLOW position

-C -7 - Between REV and FWD

- - -A Between REV STILL / SLOW and FWD STILL / SLOW

-D -6 - FWD (FWD STILL / SLOW) position

- - -9 FWD STILL / SLOW position

-E -7 - Between FWD and PLAY

- - -8 Between FWD STILL / SLOW and PLAY

-F -6 -7 PLAY position

located on the front side of the position just beside the

drum)

located on the rear side of the position just beside the

drum)

sion ON

REV

Note:

• In the case of the "HD*” microprocessor, as the display is

always "-7” at any intermediate position between modes,

the position of transitory EMG may sometimes not be located.

1.7.5 EMG detail information <2>

The type of the cassette tape and the cassette tape winding position can be confirmed based on the figure in EMG detail information <2> .

[FDP/OSD display]

*5 : *6 : *7

* 5 : Type of the cassette tape in use <1>

* 6 : Winding position of the cassette tape in use

* 7 : Type of th

e cassette tape in use

<2>

(Winding area)

Note:

• EMG detail information <2> is the reference information

stored using the remaining tape detection function of the

cassette tape. As a result, it may not identify cassette correctly when a special cassette tape is used or when the

tape has variable thickness.

* 5 : Cassette tape type <1>

Display Cassette tape type <1>

00 Cassette type not identified

16

Large reel/small reel (T-0 to T-15/T-130 to T-210) not classified

82 Small reel, thick tape (T-120) identified/thin tape (T-140) identified

84 Large reel (T-0 to T-60) identified

92

Small reel, thick tape (T-130) identified/thin tape (T-160 to T-210) identified

93

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) not classified

C3

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) being classified

D3

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) being classified

E1 C cassette, thick tape (TC-10 to TC-20) identified

E2 Small reel, thick tape (T-0 to T-100) identified

E9 C cassette, thin tape (TC-30 to TC-40) identified

F1

C cassette, thick tape/thin tape (TC-10 to TC-40) not classified

Notes:

•

Cassette tape type

<1>

is identified a few times during mode

transition and the identification count is variable depending on

the cassette tape type. If an EMG occurs in the middle of identification, the cassette tape type may not be able to be identified.

•

If other value than those listed in the above table is displayed,

the cassette tape type is not identified.

* 6 : Cassette tape winding position

The cassette tape winding position at the moment of EMG is

displayed by dividing the entire tape (from the beginning to the

end) in 22 sections using a hex number from “00” to “15”.

“00” : End of winding

“15” : Beginning of winding

“FF or ––” : Tape position not identified

* 7 : Cassette tape type <2> (Winding area)

Display Cassette tape type <2>

00 Cassette type not identified

07 Small reel, thick tape T-5

08 - 0E C cassette, thick tape TC-10

09 - 15 C cassette, thick tape TC-20P

0A - 0B Small reel, thick tape T-20

0A - 16 C cassette, thin tape TC-30

0A - 16 C cassette, thin tape TC-40

0D - 0F Small reel, thick tape T-40

11 - 14 Small reel, thick tape T-60

15 - 18 Small reel, thick tape T-80 / DF-160

17 - 1A Small reel, thick tape T-90 / DF-180

19 - 1D Small reel, thick tape T-100

1D - 21 Small reel, thick tape T-120 / DF-240

1E - 1F Small reel, thin tape T-140

1F - 23 Small reel, thick tape T-130

21 - 23 Small reel, thin tape T-160

21 - 23 Small reel, thin tape T-168

22 - 24 Small reel, thick tape DF-300

22 - 24 Small reel, thin tape T-180 / DF-360

22 - 24 Small reel, thin tape T-210 / DF-420

22 - 23 Large reel T-5

23 - 24 Large reel T-10

25 - 26 Large reel T-20

27 - 29 Large reel T-30

29 - 2B Large reel T-40

2D - 2F Large reel T-60

Note:

•

The values of cassette tape type <2> in the above table

are typical values with representative cassette tapes.

1-8

SECTION 2

Press

(C)

(A)

(B)

MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment

2.1.1 Precautions

(1) Unplug the power cord plug of the VCR before using your

soldering iron.

(2) Take care not to cause any damage to the conductor

wires when plugging and unplugging the connectors.

(3) Do not randomly handle the parts without identifying

where the trouble is.

(4) Exercise enough care not to damage the lugs, etc. dur-

ing the repair work.

(5) When reattaching the front panel assembly, make sure

that the door opener of the cassette holder assembly is

lowered in position prior to the reinstallation. (See SECTION 1 DISASSEMBLY.)

(6) When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the

Jig RCU can be received). (See SECTION 1 DISASSEMBLY.)

Loading motor

2.1.2 Checking for proper mechanical operations

Enter the mechanism service mode when you want to operate the mechanism when no cassette is loaded. (See SECTION 1 DISASSEMBLY.)

2.1.3 Manually removing the cassette tape

1. In case of electrical failures

If you cannot remove the cassette tape which is loaded because of any electrical failure, manually remove it by taking

the following steps.

(1) Unplug the power cord plug from the power outlet.

(2) Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing the drum

assembly.

(3) Unload the pole base assembly by manually turning the

loading motor of the mechanism assembly toward the

front. In doing so, hold the tape by the hand to keep the

slack away from any grease. (See Fig.2-1-3a.)

(4) Bring the pole base assembly to a pause when it reaches

the position where it is hidden behind the cassette tape.

(5) Move the top guide toward the drum while holding down

the lug (A) of the bracket retaining the top guide. Likewise hold part (B) down and remove the top guide.

Section (C) of the top guide is then brought under the

cassette lid. Then remove the top guide by pressing the

whole cassette tape down. (See Fig.2-1-3b.)

(6) Remove the cassette tape by holding both the slackened

tape and the cassette lid.

(7) Take up the slack of the tape into the cassette. This com-

pletes removal of the cassette tape.

Note:

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see “SECTION

1 DISASSEMBLY”.

Pole base assembly

Fig. 2-1-3a

Fig. 2-1-3b

2-1

2. In case of mechanical failure

If you cannot remove the cassette tape which is loaded because of any mechanical failure, manually remove it by taking the following steps.

(1) Unplug the power cable and remove the top cover, front

panel assembly and others so that the mechanism assembly is visible. (See SECTION 1 DASASSEMBLY.)

(2) While keeping the tension arm assembly of the mecha-

nism assembly free from tension, pull the tape on the pole

base assembly (supply or take-up side) out of the guide

roller. (See Fig.2-1-3c.)

(3) Take the spring of the pinch roller arm assembly off the

hook of the press lever assembly, and detach it from the

tape. (See Fig.2-1-3d.)

(4) In the same way as in the electrical failure instructions in

2.1.3-1(5), remove the top guide.

(5) Raise the cassette tape cover. By keeping it in that posi-

tion, draw out the cassette tape case from the cassette

holder and take out the tape.

(6) By hanging the pinch roller arm assembly spring back

on the hook, take up the slack of the tape into the cassette.

Pole base assembly (take-up side)

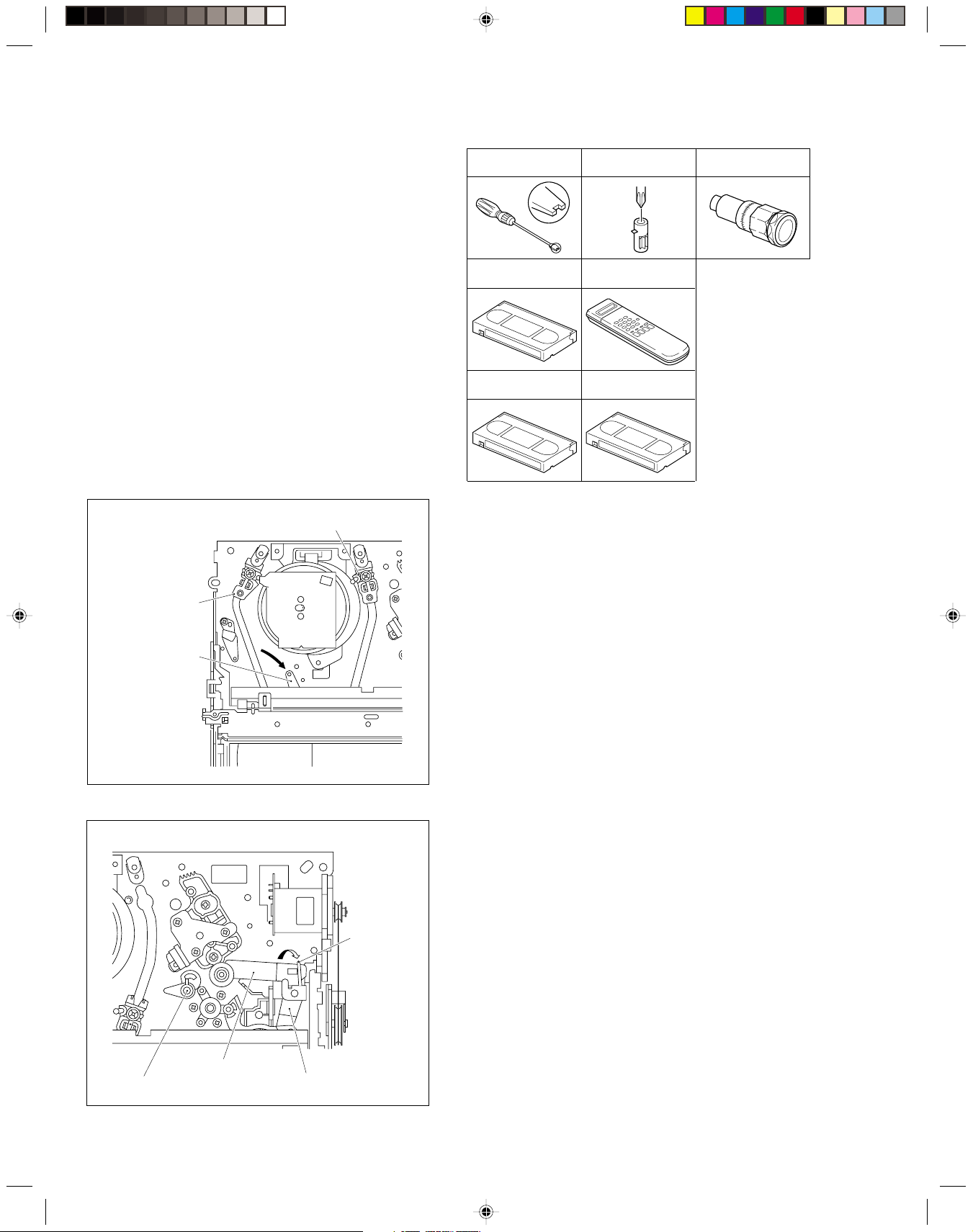

2.1.4 Jigs and tools required for adjustment

Roller driver A/C head positioning tool

Back tension cassette gauge

Alignment tape

(SP, stairstep, PAL)

Alignment tape

(LP, stairstep, PAL)

Jig RCU

Torque gauge

Pole base assembly

(supply side)

Tension arm assembly

Fig. 2-1-3c

Take the spring

off the hook, and

detach it from the

tape.

Pinch roller arm assembly

Guide pole guard

2-2

Press lever assembly

Fig. 2-1-3d

Loading...

Loading...