Philips VR530 Service Manual

Video Cassette Recorder

Service

Service

VR530

/02/07/16

Service

Service Manual

Contents

Chapter

Adjustment Procedure

Sec. 1:

Schematic Diagrams and CBA's

Exploded Views

Mechanical and Electrical Parts Lists

Survey of versions:

/02 PAL B/G, VPS/PDC

/07 PAL I, Ireland

/16 PAL B/G, Spain

/39 SECAM L,L' & PAL B/G, I

/58 PAL/SECAM B/G, D/K

Sec. 2:

Standard Maintenance

Mechanism Alignment Procedures

Disassembly / Assembly of Mechanism

Deck Exploded Views

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

be used.

Published by BK 2002 Video Service Department Printed in The Netherlands c

Copyright reserved Subject to modification GB 3103 785 21990

MAIN SECTION

VIDEO CASSETTE RECORDER

Sec. 1: Main Section

I Adjustment Procedures

I Schematic Diagrams and CBA’s

I Exploded Views

I Mechanical and Electrical Parts List

TABLE OF CONTENTS

IMPORTANT SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

STANDARD NOTES FOR SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

FUNCTION INDICATOR SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

PREPARATION FOR SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

OPERATING CONTROLS AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

SIGNAL NAME ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

CABINET DISASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

ELECTRICAL ADJUSTMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

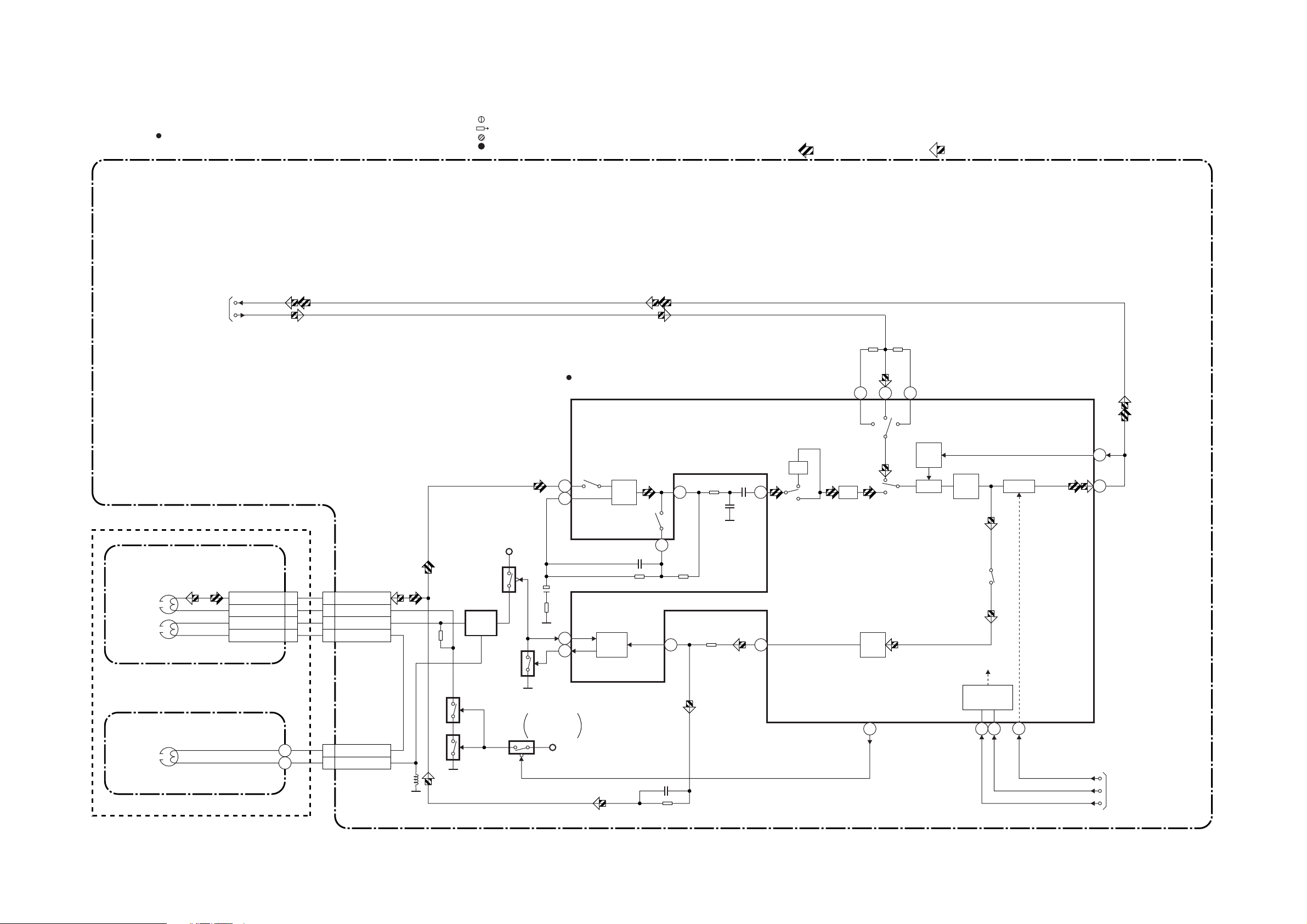

BLOCK DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

SYSTEM CONTROL TIMING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

IC PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

LEAD IDENTIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16-1

EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17-1

SET MECHANICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18-1

VR530CV

SPECIFICATIONS

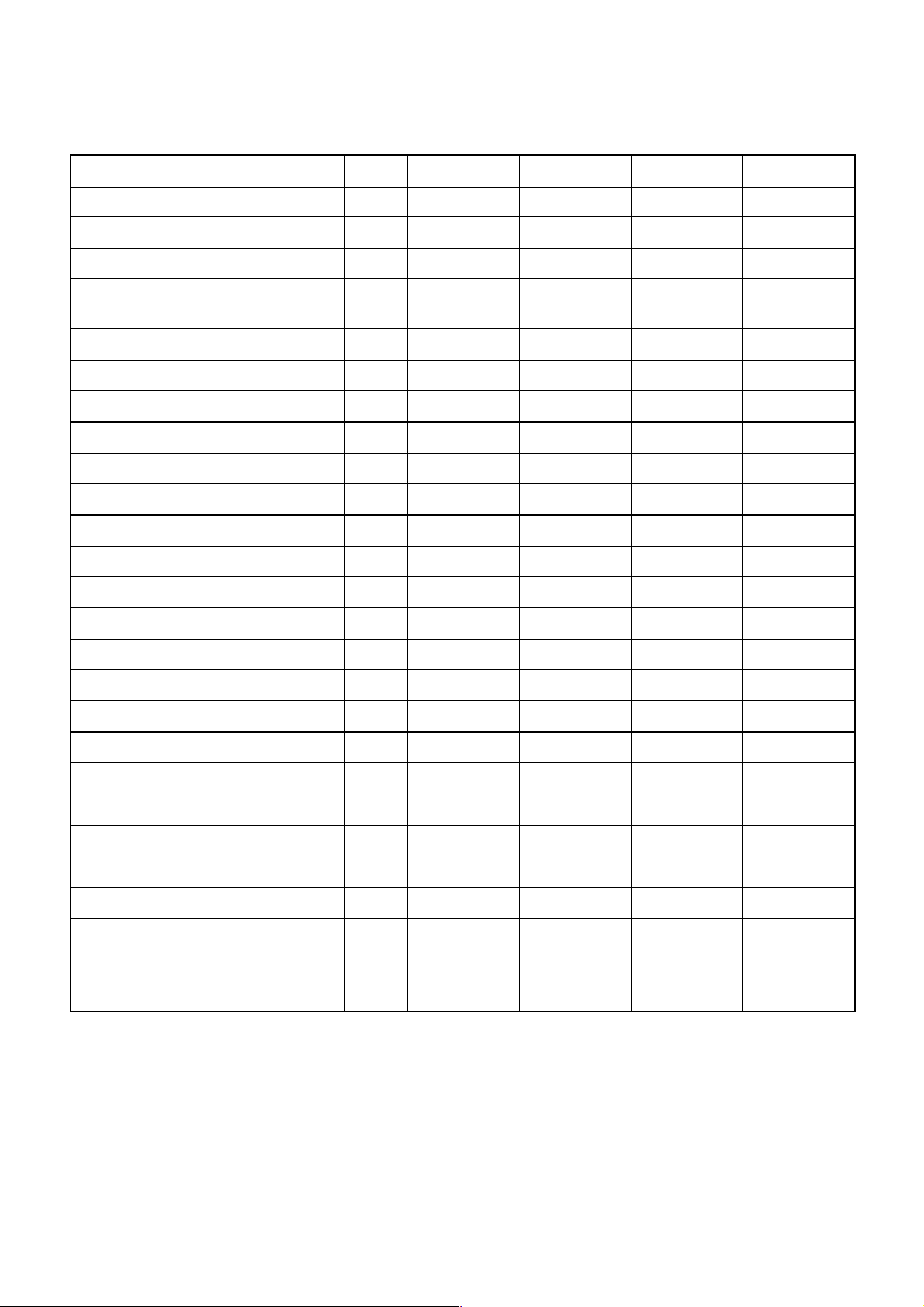

Description Unit Minimum Nominal Maximum Remark

1. Video

1-1. Video Output (PB) Vp-p 0.8 1.0 1.2 SP Mode

1-2. Video Output (R/P) Vp-p 0.8 1.0 1.2

1-3. Video S/N Y (R/P) dB 40 45

1-4. Video Color S/N AM (R/P) dB 37 41 SP Mode

1-5. Video Color S/N PM (R/P) dB 30 36 SP Mode

1-6. Resolution (PB) Line 230 245 SP Mode

2. Servo

2-1. Jitter Low µsec 0.07 0.12 SP Mode

2-2. Wow & Flutter % 0.3 0.5 SP Mode

3. Normal Audio

3-1. Output (PB) dBV -9 -6 -3 SP Mode

3-2. Output (R/P) dBV -9 -6 -1.5 SP Mode

3-3. S/N (R/P) dB 36 41 SP Mode

3-4. Distortion (R/P) % 1.0 4.0 SP Mode

3-5. Freq. resp (R/P) at 200Hz dB -7 -4 SP Mode

(-20dB ref. 1kHz) at 6kHz dB -10 -4 SP Mode

SP Mode,

W/O Burst

4. Tuner

4-1. Video output Vp-p 0.8 1.0 1.2 E-E Mode

4-2. Video S/N dB 39 42 E-E Mode

4-3. Audio output dB -10 -6 -2 E-E Mode

4-4. Audio S/N dB 40 46 E-E Mode

5. Hi-Fi Audio

5-1. Output dBV -12 -8 -4 SP Mode

5-2. Dynamic Range dB 70 85 SP Mode

5-3. Freq. resp (6dB B.W) Hz 20 ~ 20K SP Mode

: Nominal specs represent the design specs. All units should be able to approximate these – some will exceed

Note

and some may drop slightly below these specs. Limit specs represent the absolute worst condition that still might

be considered acceptable; In no case should a unit fail to meet limit specs.

HC460SP

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a ! on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review continuously and new instructions are issued whenever

appropriate. Prior to shipment from the factory, our

products are carefully inspected to confirm with the

recognized product safety and electrical codes of the

countries in which they are to be sold. However, in

order to maintain such compliance, it is equally important to implement the following precautions when a set

is being serviced

Precautions during Servicing

Parts identified by the ! symbol are critical for

A.

safety. Replace only with part number specified.

In addition to safety, other parts and assemblies

B.

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

Use specified internal wiring. Note especially:

C.

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

Use specified insulating materials for hazardous

D.

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

When replacing AC primary side components

E.

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

Observe that the wires do not contact heat produc-

F.

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.).

Check that replaced wires do not contact sharp

G.

edges or pointed parts.

When a power cord has been replaced, check that

H.

5 - 6 kg of force in any direction will not loosen it.

.

Also check areas surrounding repaired locations.

I.

Use care that foreign objects (screws, solder drop-

J.

lets, etc.) do not remain inside the set.

Crimp type wire connector

K.

The power transformer uses crimp type connectors

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important:

2)Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to the complete closure of the tool.

When connecting or disconnecting the internal con-

L.

nectors, first, disconnect the AC plug from the AC

outlet.

Do not re-use a connector. (Discard it.)

1-1-1 SFTY_06

Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deterioration. Observe that screws, parts,

and wires have been returned to their original positions. Afterwards, do the following tests and confirm

the specified values to verify compliance with safety

standards.

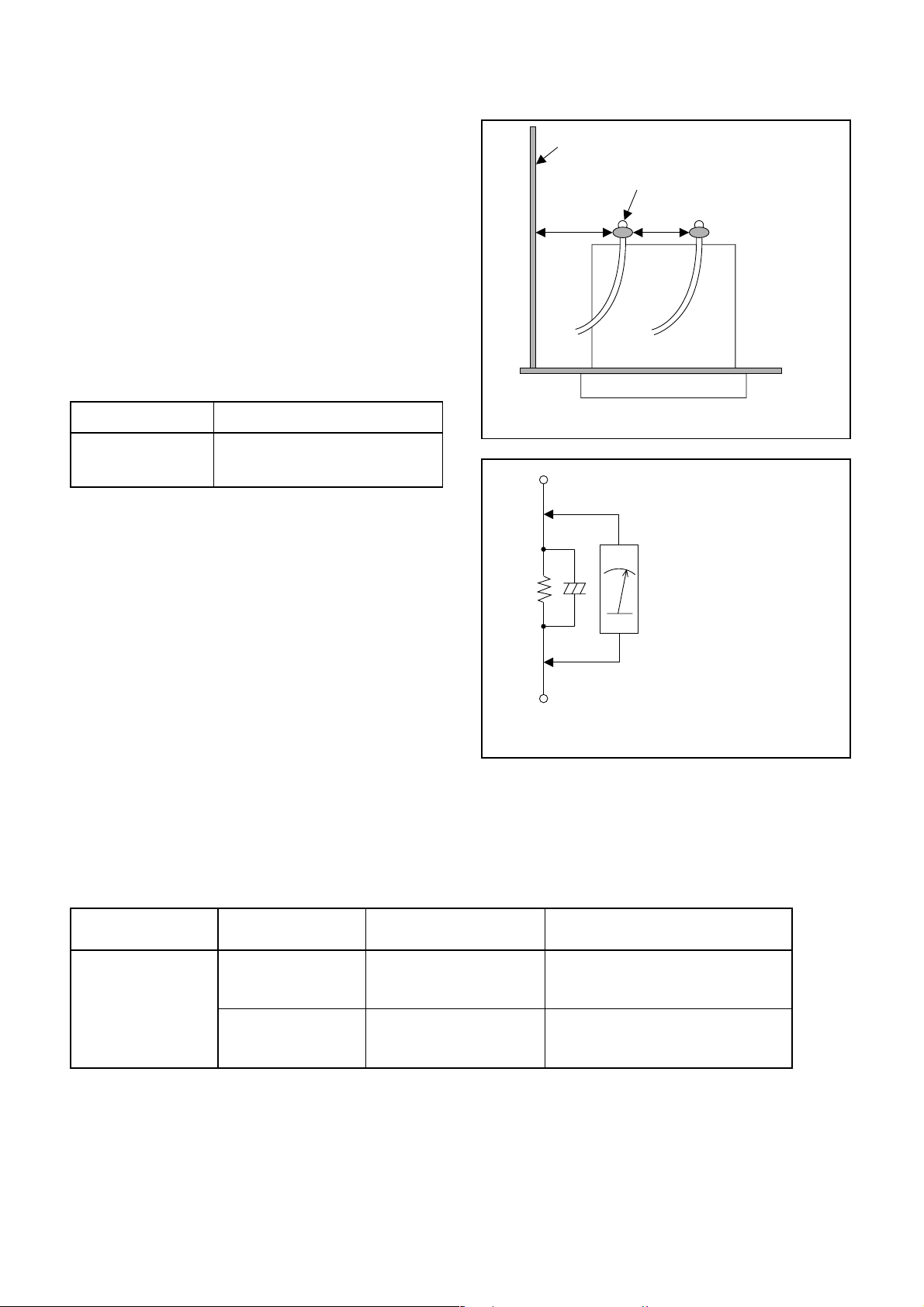

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d) (d’)

110 to 240 V

This table is unofficial and for reference only.

Note:

Be sure to confirm the precise values.

≥ 3mm(d)

≥ 6 mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across the terminals of load

Z. See Fig. 2 and the following table.

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

AC Voltmeter

(High Impedance)

Fig. 1

Fig. 2

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

110 to 240 V

This table is unofficial and for reference only. Be sure to confirm the precise values.

Note:

parallel

50kΩ RES.

Connected in

parallel

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

1-1-2 SFTY_06

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

STANDARD NOTES FOR SERVICING

Circuit Board Indications

a. The output pin of the 3 pin Regulator ICs is indi-

cated as shown.

Top View

Out

b. For other ICs, pin 1 and every fifth pin are indicated

as shown.

Input

In

Pin 1

c. The 1st pin of every male connector is indicated as

shown.

Pin 1

Bottom View

5

10

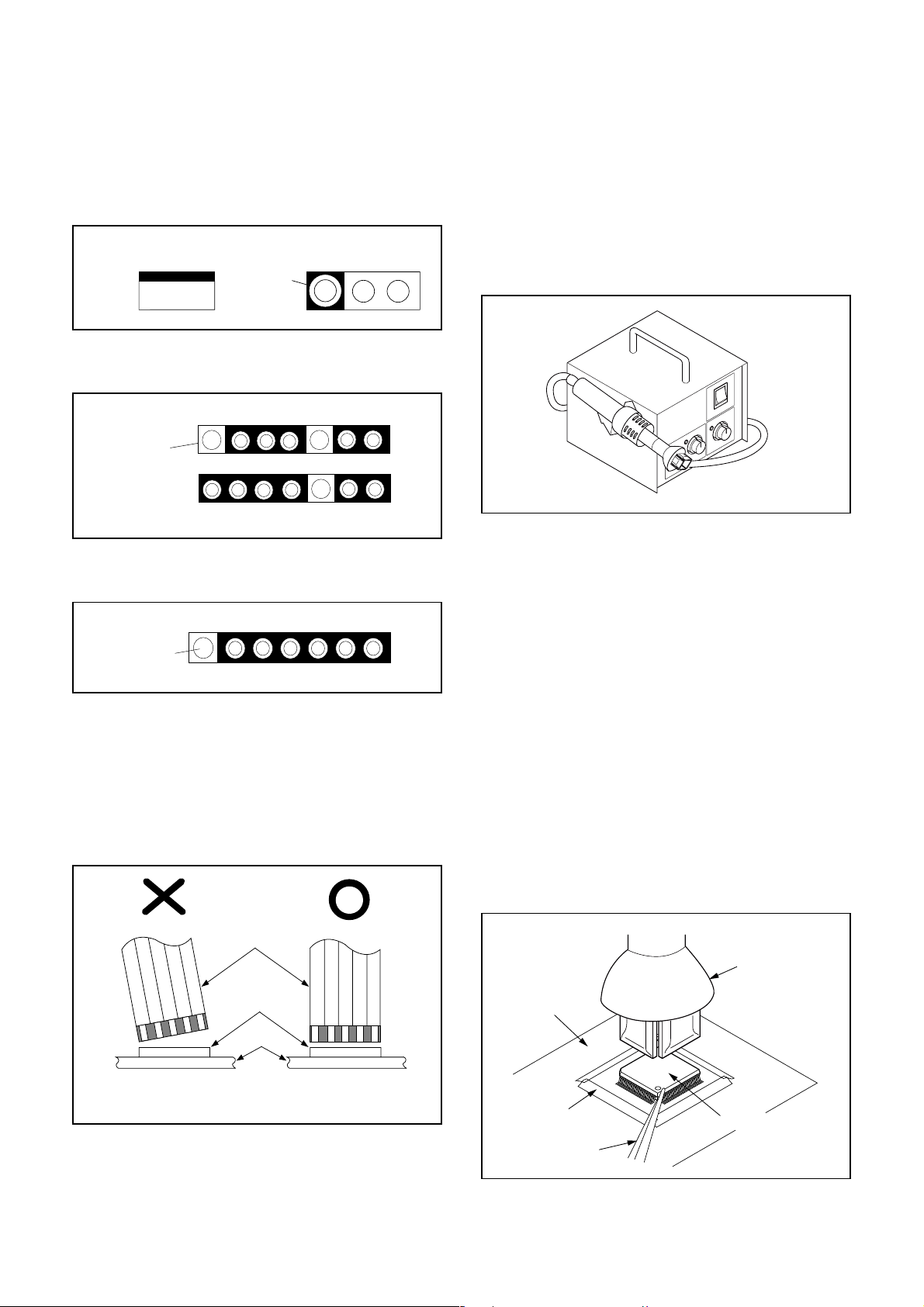

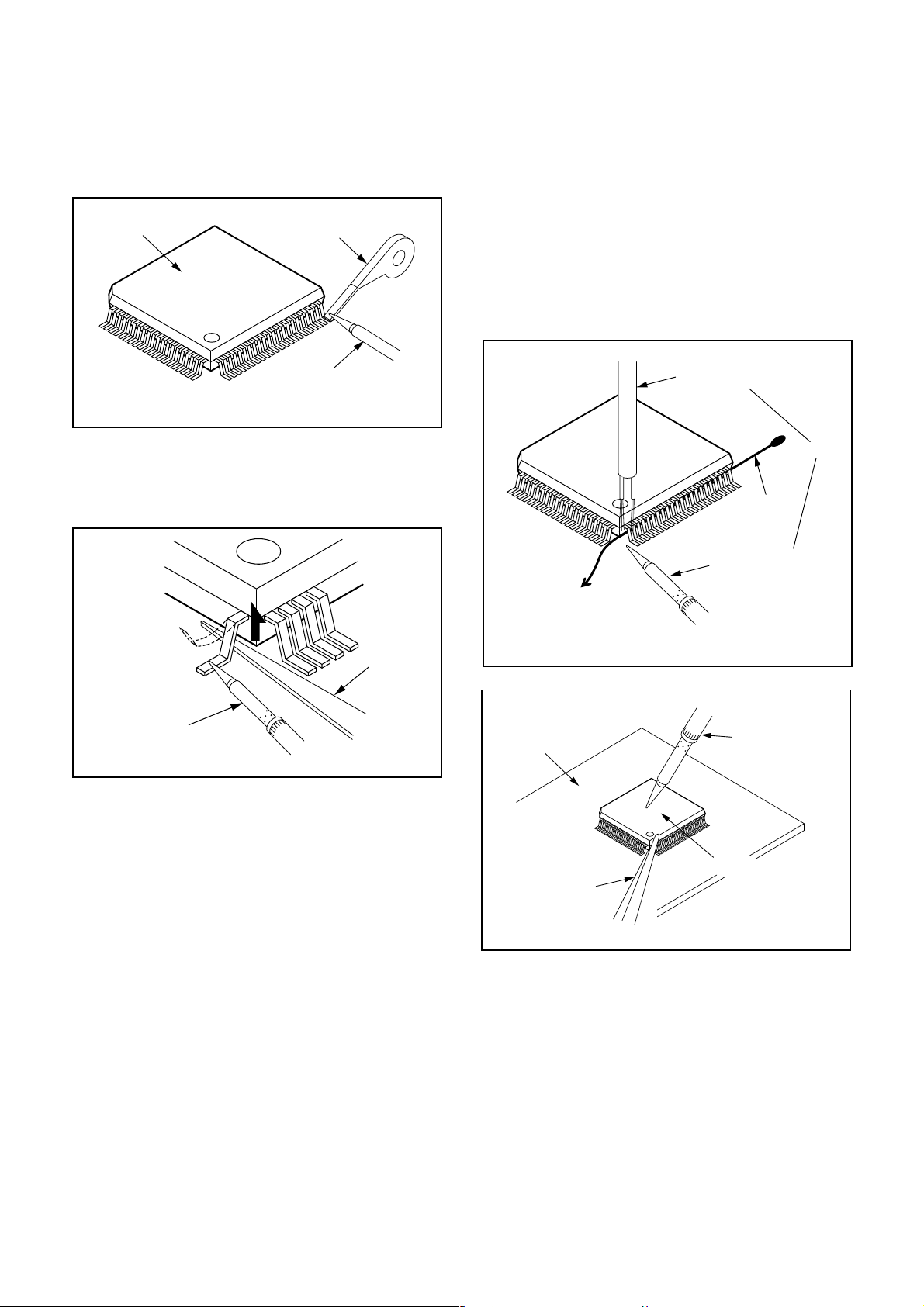

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

(1) Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

(2) Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

.

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Caution:

1. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

2. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

Machine

Flat Pack-IC

Fig. S-1-2

1-2-1 NOTE_1

With Soldering Iron:

(1) Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

(4) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a soldering iron, care must be taken

to ensure that the flat pack-IC is not being held by

glue. When the flat pack-IC is removed from the

CBA, handle it gently because it may be damaged

if force is applied.

Soldering Iron

Fig. S-1-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

(3) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

With Iron Wire:

(1) Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA contact

pads as shown in Fig. S-1-5

To Solid

Mounting Point

CBA

Tweezers

Hot Air Blower

or

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

Fig. S-1-6

1-2-2 NOTE_1

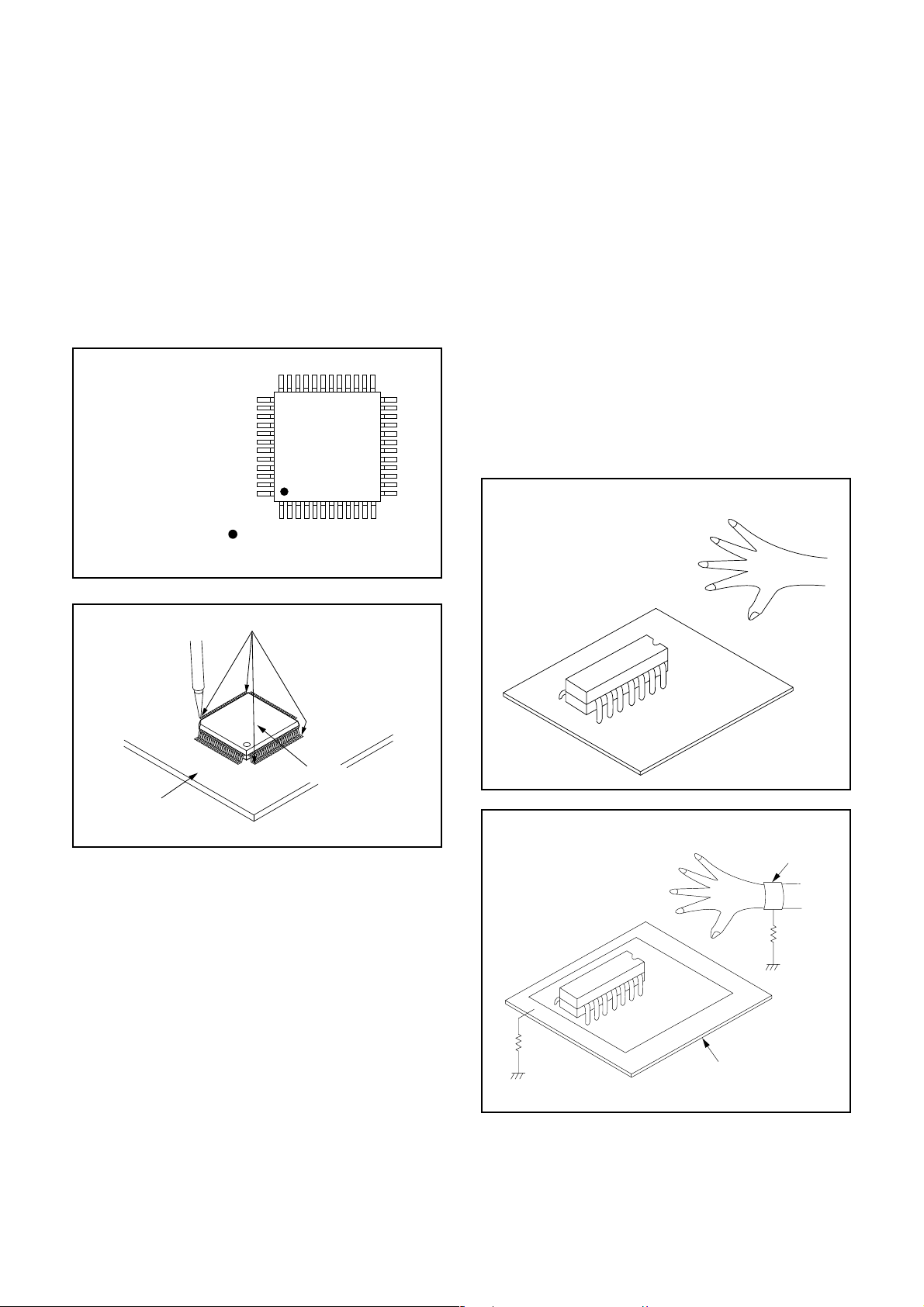

2. Installation

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

(2) The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

(3) Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly grounded to remove any static electricity that may

be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on clothing will not escape through the body grounding band,

be careful to avoid contacting semi-conductors with

your clothing.

< Incorrect >

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

CBA

< Correct >

Grounding Band

1MΩ

CBA

1MΩ

Conductive Sheet or

Copper Plate

1-2-3 NOTE_1

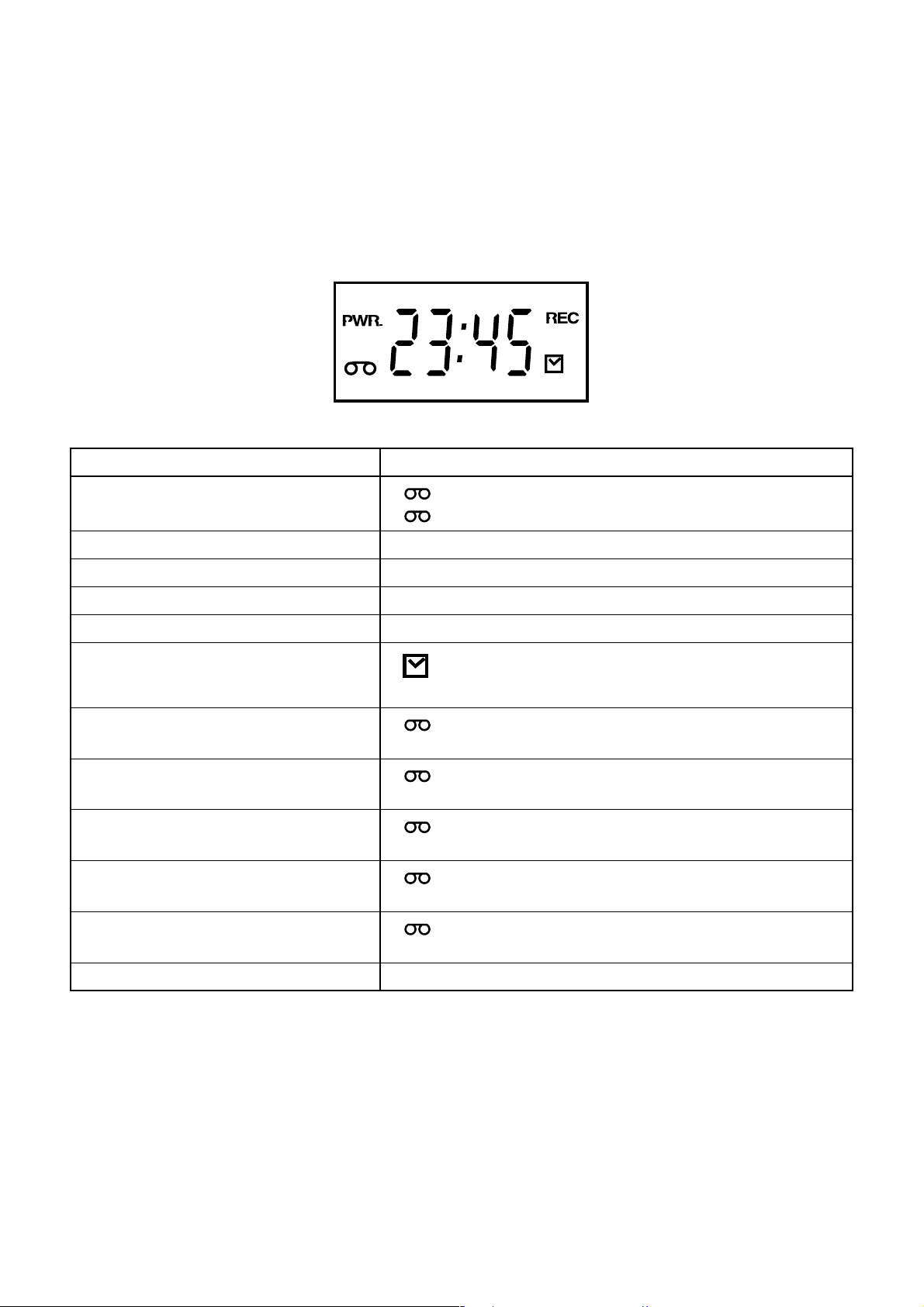

FUNCTION INDICATOR SYMBOLS

Note:

The following symbols will appear on the indicator panel to indicate the current mode or operation of the VCR.

On-screen modes will also be momentarily displayed on the tv screen when you press the operation buttons.

Display panel

" H "= LED Light on, " L "= LED Light off

LED MODE INDICATOR ACTIVE

CASSETTE "IN"

CASSETTE "OUT"

CLOCK " 88:88 ON

POWER ON " PWR." ON

REC " REC " ON

REC PAUSE " REC " Blinks at 0.8Hz interval

T-REC,OTR

When reel and capstan mechanism is not

functioning correctly

When tape loading mechanism is not functioning correctly

When cassette loading mechanism is not

functioning correctly

When the drum is not working properly

P-ON Power safety detection

" "

" "

" "

" "

" 1 "

" "

" 2 "

" "

" 3 "

" "

" 4 "

" "

" 5 "

ON

OFF

ON

(T-REC OFF,T-REC incomplete

Blinks at 0.8Hz interval)

Blinks at 0.8Hz interval

Blinks at 0.8Hz interval

Blinks at 0.8Hz interval

Blinks at 0.8Hz interval

Blinks at 0.8Hz interval

S-INH condition All modes Blinks at 0.8Hz interval

1-3-1 HC460FIS

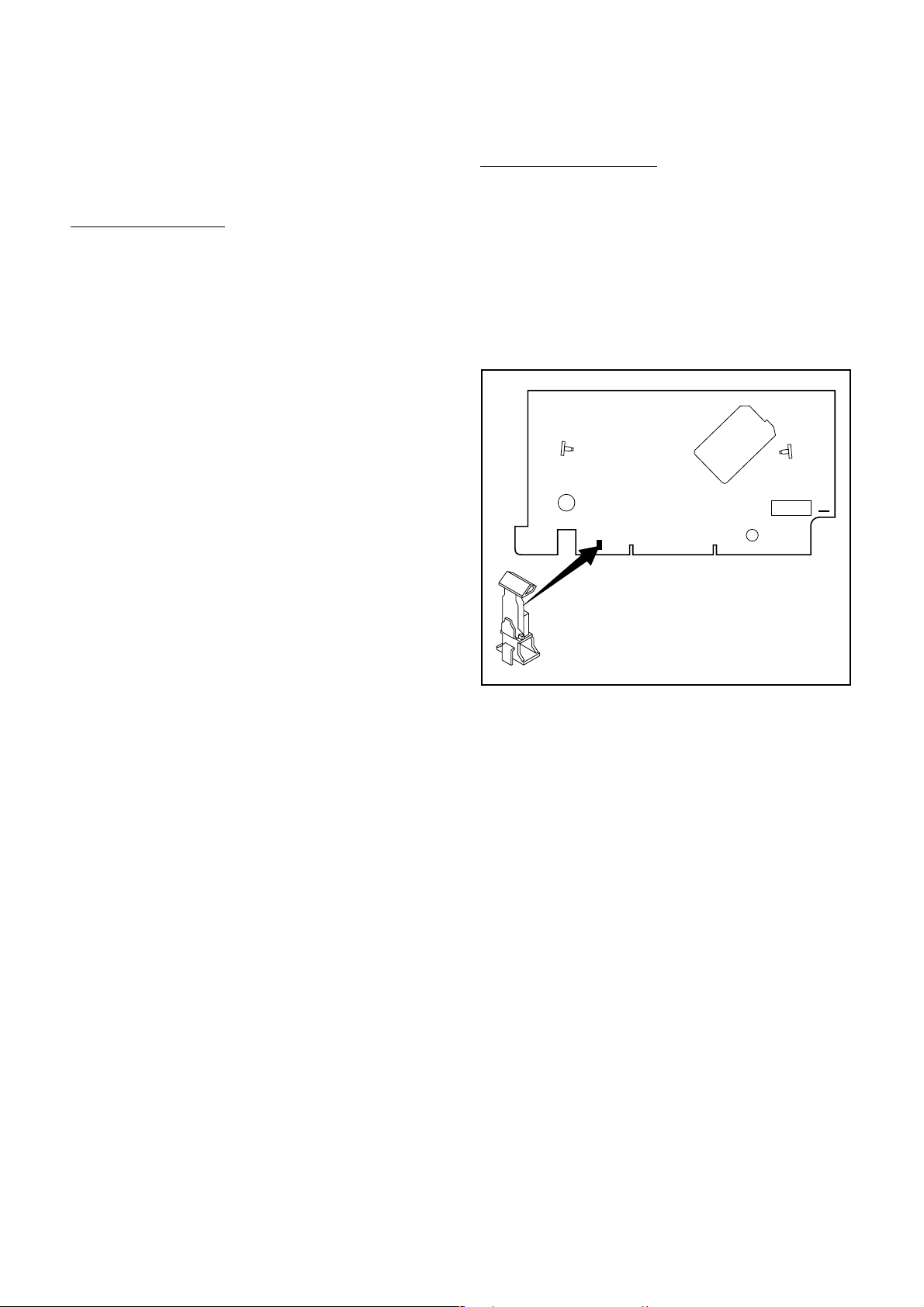

PREPARATION FOR SERVICING

How to Enter the Service Mode

About Optical Sensors

Caution:

An optical sensor system is used for the Tape Start

and End Sensors on this equipment. Carefully read

and follow the instructions below. Otherwise the unit

may operate erratically.

What to do for preparation

Insert a tape into the Deck Mechanism Assembly and

press the PLAY button. The tape will be loaded into

the Deck Mechanism Assembly. Make sure the power

is on, TP507 (SENSOR INHIBITION) to GND. This will

stop the function of Tape Start Sensor, Tape End Sensor and Reel Sensors. (If these TPs are connected

before plugging in the unit, the function of the sensors

will stay valid.) See Fig. 1.

Because the Tape End Sensors are inactive, do

Note:

not run a tape all the way to the start or the end of the

tape to avoid tape damage.

About REC-Safety Switch

Caution:

The REC-Safety Switch is directly mounted on the

Main CBA. When the Deck Mechanism Assembly is

removed from the Main CBA for servicing, this switch

does not work automatically.

What to do for preparation

In order to record, press the Rec button while pushing

REC-SAFETY SW on the Main CBA. See Fig. 1.

Q503

SW506

Q504

TP507

S-INH

(REC-SAFETY SW)

Fig. 1

1-4-1 HC460PFS

OPERATING CONTROLS AND FUNCTIONS

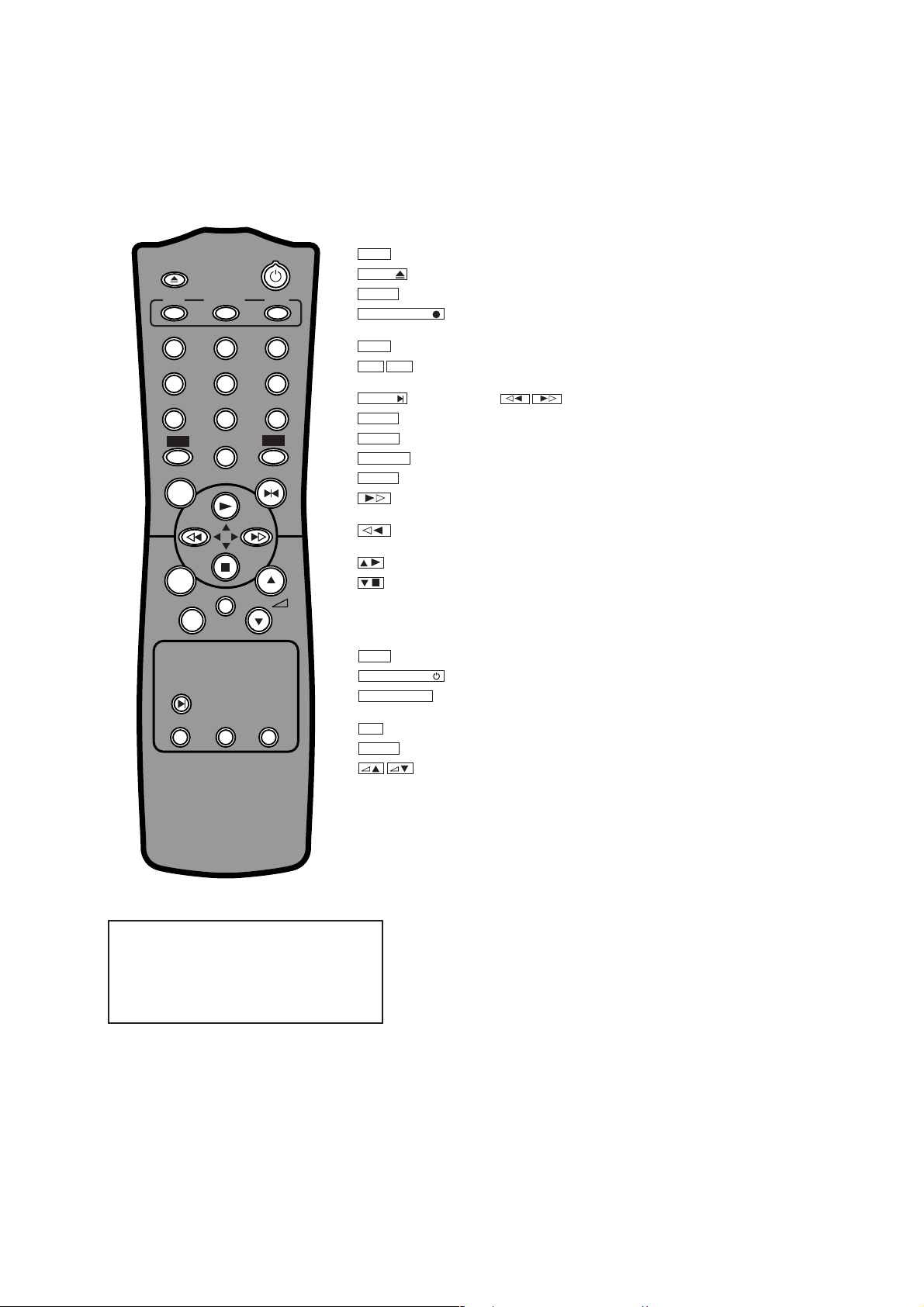

Buttons for VCR feature only

VCR

EJECT

MENU STATUS/EXIT CLEAR

STANDBY/ON

1 2 3

4 5 6

7 8

VCR

0

RECORD/OTR

STILL

P+

9

TV

To operate the VCR with the remote control.

EJECT

CLEAR

Recording.

STILL

tracking.

to fast forward the tape while the picture stay on the screen. To store or confirm entry in the menu.

rewind the tape while the picture stay on the screen.To return the cursor in the menu.

To eject the cassette.

To delete last entry/Clear programmed recording (TIMER).

RECORD/OTR

To stop the tape and slow a still picture.

P-P+

INDEX

SLOW

AUDIO

SYSTEM

MENU

When tape playback is stopped, press to fast forward the tape at high speed. During playback, press

When tape playback is stoped, press to rewind the tape at high speed. During playback, press to

To play a tape, select an item in the menu of VCR.

To stop the tape, select an item in the menu of VCR

To record the TV channel selected at this moment or press repeatedly to start a One-Touch

To select the programme number. During normal or slow motion playback, press to adjust the

In combination with :to search for previous or next recording on the cassette.

To view the picture in slow motion.

To change stereo sound and 2nd language.

Doesn’t work in these models.

To call up main menu of VCR.

MUTE

P-

INDEX

SLOW

SYSYTEM

AUDIO

STANDBY/ON

STATUS/EXIT

access or remove a status display or menu of Philips TV.

0..9

Press button VCR on the remote control

before doing VCR related functions

on the remote. By pressing button TV it

is possible to navigate some

functions on PHILIPS TV sets.

Buttons with TV feature

TV

To call up additional TV functions.

To switch VCR or Philips TV on or off, interrupt menu function.

To access or remove the VCR’s on-screen status display. To exit on-screen menus. Or, to

Press to select channels at VCR or Philips TV.

MUTE

To eliminate the TV’s sound. Press again to restore the volume.

To adjust the TV’s volume.

1-5-1 HC460IB

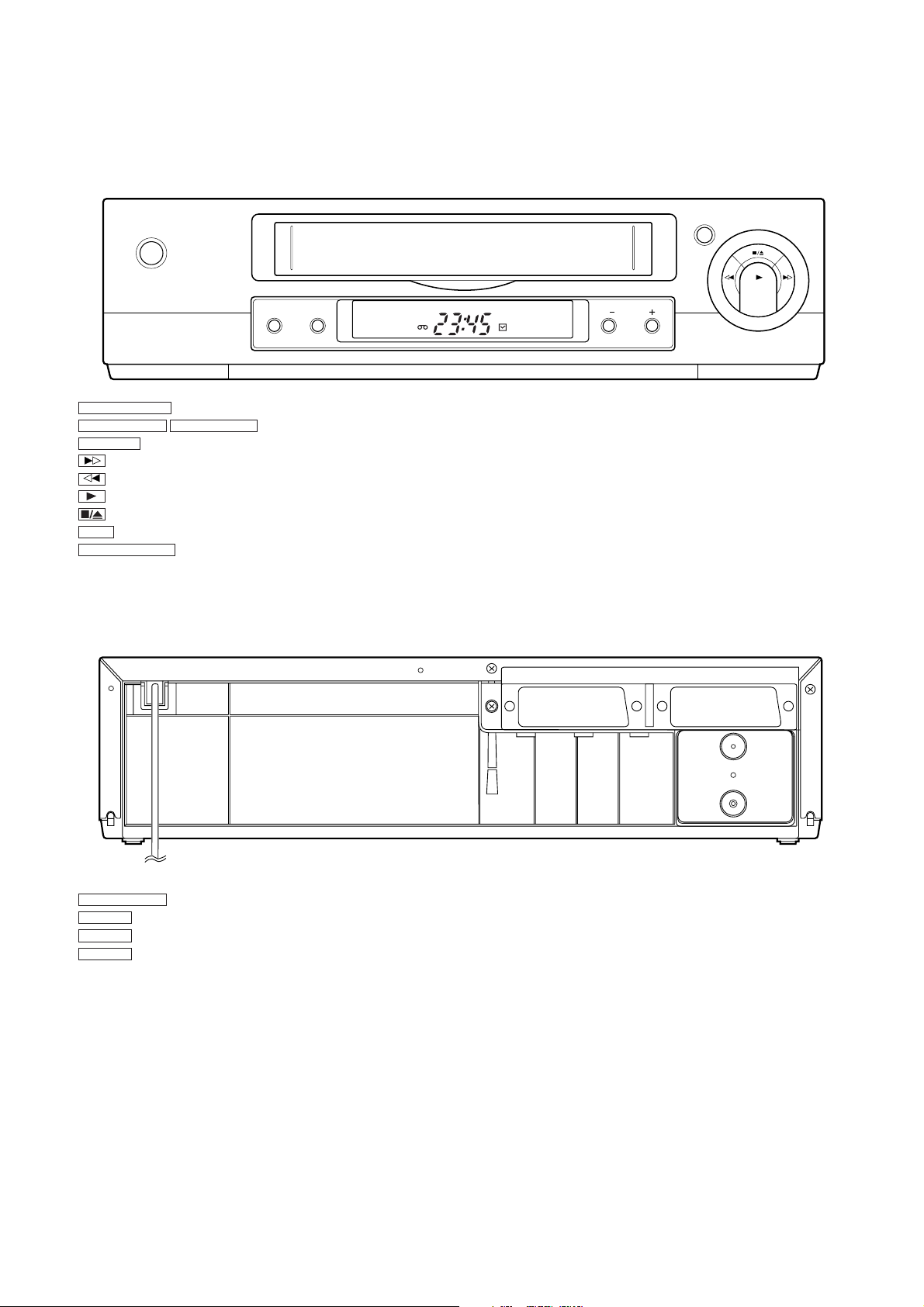

Front of the device

STANDBY/ON

STILL

PROGRAMME

STANDBY/ON

RECORD

To record the TV channel selected at this moments.

COUNTER RESET

RECORD

To switch off or on, interrupt a function.

PROGRAMME-PROGRAMME+

To select the programme number. During normal or slow motion playback, press to adjust the tracking.

PWR.

REC

When tape playback is stopped, press to fast forward the tape at hight speed. During playback, press to fast forward the tape while the picture stay on the screen.

When tape playback is stoped, press to rewind the tape at hight speed. During playback, press to rewind the tape while the picture stay on the screen.

To play a tape.

To stop the tape and eject the cassette.

STILL

To stop the tape and show a still picture.

COUNTER RESET

To reset the counter.

Back of the set

AV2 (DECODER) AV1 (TV)

AV2(DECODER)

AV1(TV)

AERIAL

RF OUT

To connect the TV set(programme number).

o connect the aerial cable.

T

To connect the TV set.

AERIAL

RF OUT

To connect a satellite receiver, decoder, video recorder,etc.

1-5-2 HC460IB

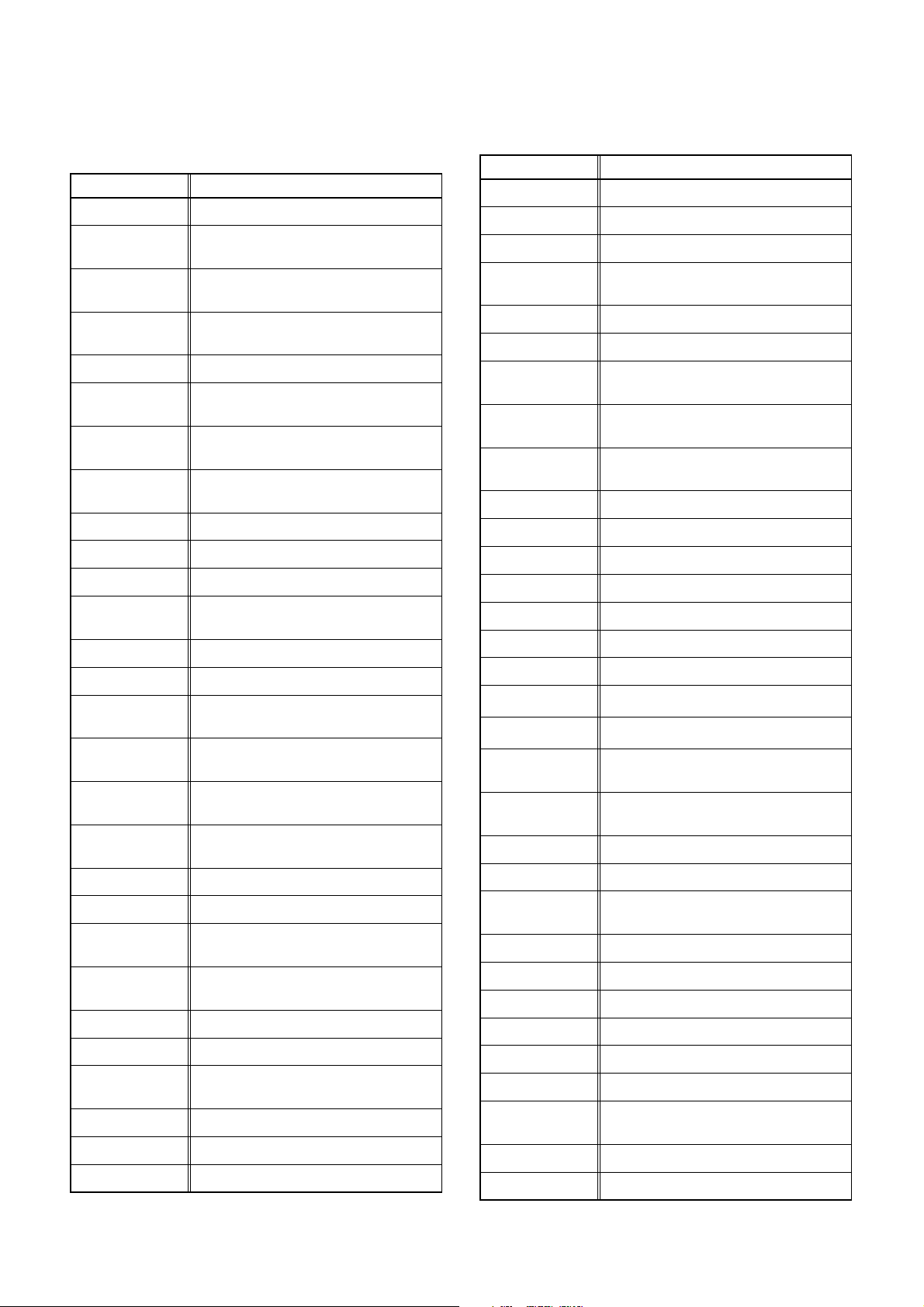

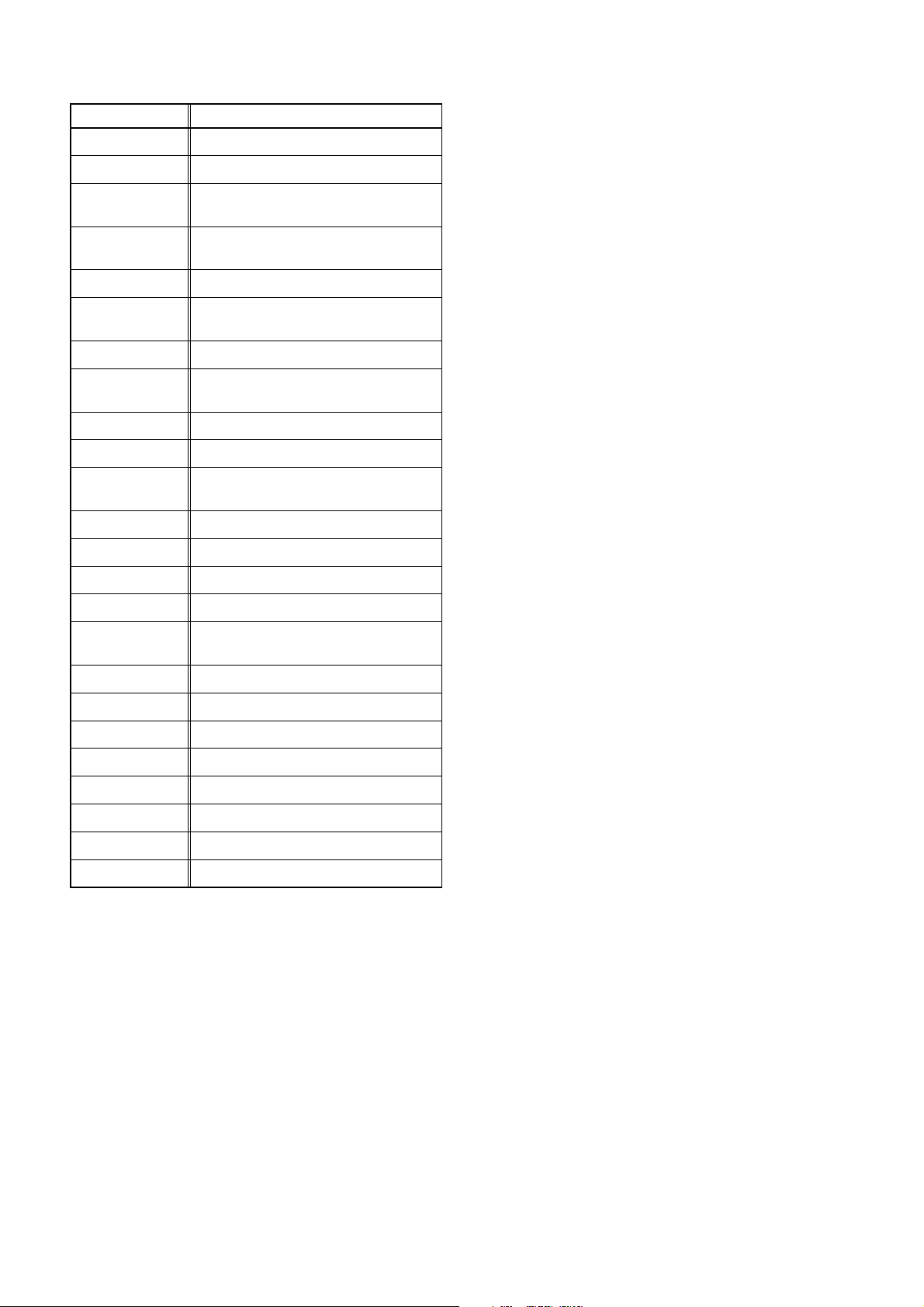

SIGNAL NAME ABBREVIATIONS

Signal Name Function

A-MODE Hi-Fi Tape Detection Signal

A-MUTE-H

A-PB/REC

AFC

AGC IF AGC Control Signal

AL+15V/+12V

AL+5V

AL+9V

AMPC CTL AMP Connected Terminal

AMPVREF

AMPVss AMPVss (GND)

AVcc

CC Terminal

C-CONT Capstan Motor Control Signal

C-F/R

C-FG

C-POWERSW

C-ROTA

C-SYNC Composite Synchronized Pulse

CLKSEL Clock Select (GND)

CTL (+)

CTL (-)

CTLAMPout To Monitor for CTL AMP Output

D-CONT Drum Motor Control Signal

D-FG

D-PG Drum Motor Pulse Generator

D-REC-H Delayed Record Signal

D-V- SYNC Dummy V-sync Output

Audio Mute Control Signal

(Mute = “H”)

Normal Audio Play Back/Record

Signal

Automatic Frequency Control

Signal

Always +15V/+12V with AC Plug

Connected

Always +5V with AC Plug

Connected

Always +9V with AC Plug

Connected

IN

V-Ref for CTL AMP

A/D Converter Power Input/

Standard Voltage Input

Capstan Motor FWD/REV Control

Signal (FWD=”L”/REV=”H”)

Capstan Motor Rotation Detection

Pulse

Capstan Power Switching Pulse

Color Phase Rotary Changeover

SIgnal

Playback/Record Control Signal

(+)

Playback/Record Control Signal

(-)

Drum Motor Rotation Detection

Pulse

Signal Name Function

DAVN-L VPS/PDC Data Receive = “L”

DRV-CLK LED Clock Driver IC Control Clock

DRV-DATA LED Clock Driver IC Control Data

DRV-STB

LED Clock Driver IC Chip Select

Signal

END-S Tape End Position Detect Signal

FE-H GND Ground for Full Erase Head

FF/REW-L

FSC-IN

[4.43MHz]

FTV-IN

CTL Amp Gain Switching Signal

(FF/REW=”L”)

4.43MHz Clock Input

Comparator Input of Video Signal

for Follow TV

H-A-COMP Head Amp Coparator Signal

H-A-SW Video Head Amp Switching Pulse

Hi-Fi-A (L) Hi-Fi Audio Head (L)

Hi-Fi-A (R) Hi-Fi Audio Head (R)

Hi-Fi-COM Hi-Fi Audio Head Common

Hi-Fi-H-SW HiFi Audio Head Switching Pulse

HLF LPF Connected Terminal (Slicer)

2

C BUS- SCL I2C BUS Control Clock

I

2

I

C BUS- SDA I2C BUS Control Data

JK1-8P-OUT-1

JK1-8P-OUT-2

SCART 1 8Pin Output Control

Signal

SCART 2 8Pin Output Control

Signal

KEY-1 Key Scan Input Signal 1

KEY-2 Key Scan Input Signal 2

LD-SW

Deck Mode Position Detector

Signal

LM-FWD/REV Loading Motor Control Signal

MOD-A Modulator Audio Output Signal

N-A-PB Normal Audio Playback

N-A-REC Normal Audio Recording

IN

OSC

OUT

OSC

P-DOWN-L

Clock Input for letter size

Clock Output for letter size

Power Voltage Down Detector

Signal

P-ON+44V +44V at Power-On Signal

P-ON+5V +5V at Power-On Signal

1-6-1 HC460SNA

Signal Name Function

P-ON+9V +9V at Power-On Signal

P-ON-H Power On Signal at High

PG-DELAY

POW-SAF

REMOCON-IN Remote Control Sensor

RESET

RF-SW Video Head Switching Pulse

RGBTHROUGH

S-REEL Supply Reel Rotation Signal

SC2-IN Input Signal from Pin 8 of SCART2

ST-S

T-REEL Take Up Reel Rotation Signal

TIMER+5V +5V at Timer

TU-AUDIO Tuner Audio Input Signal

TU-VIDEO Tuner Video Input Signal

V-ENV

Video Head Switching Pulse

Signal Adjusted Voltage

P-ON Power Detection Input

Signal

System Reset

Signal (Reset=”L”)

SCART 2 RGB Through Control

Signal

Tape Start Position Detector

Signal

Video Envelope Comparator

Signal

V-ENV Video Envelope Signal

VIDEO-IN Video Signal Input

VIDEO-OUT Video Signal Output

Vss Vss(GND)

X-IN Main Clock Input

X-OUT Main Clock Input

XC-IN Sub Clock

XC-OUT Sub Clock

1-6-2 HC460SNA

CABINET DISASSEMBLY INSTRUCTIONS

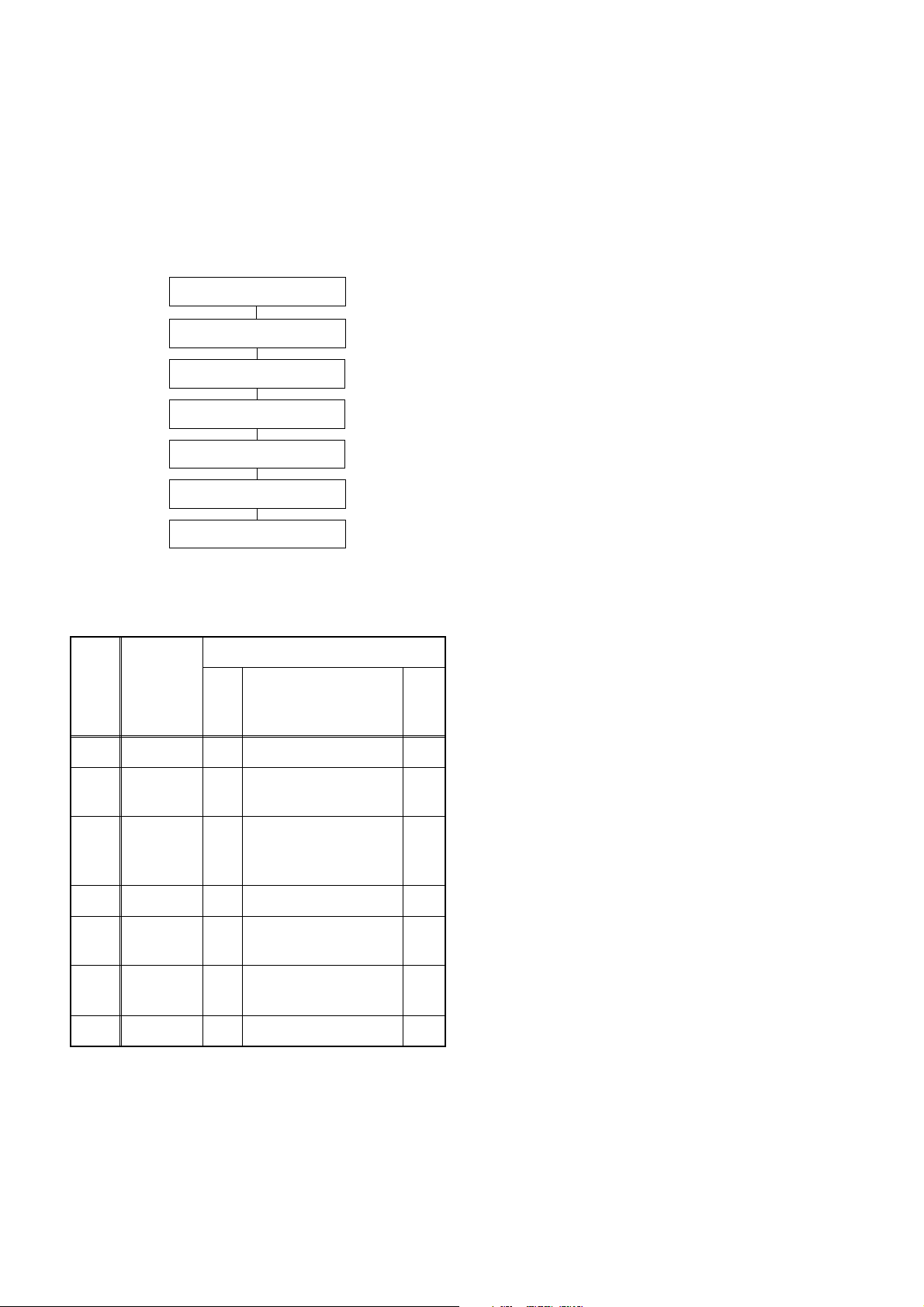

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] Top Case

[2] Front Assembly

[3] VCR Chassis Unit

[4] Jack CBA

[5] Function CBA

[6] Deck Assembly

[7] Main CBA

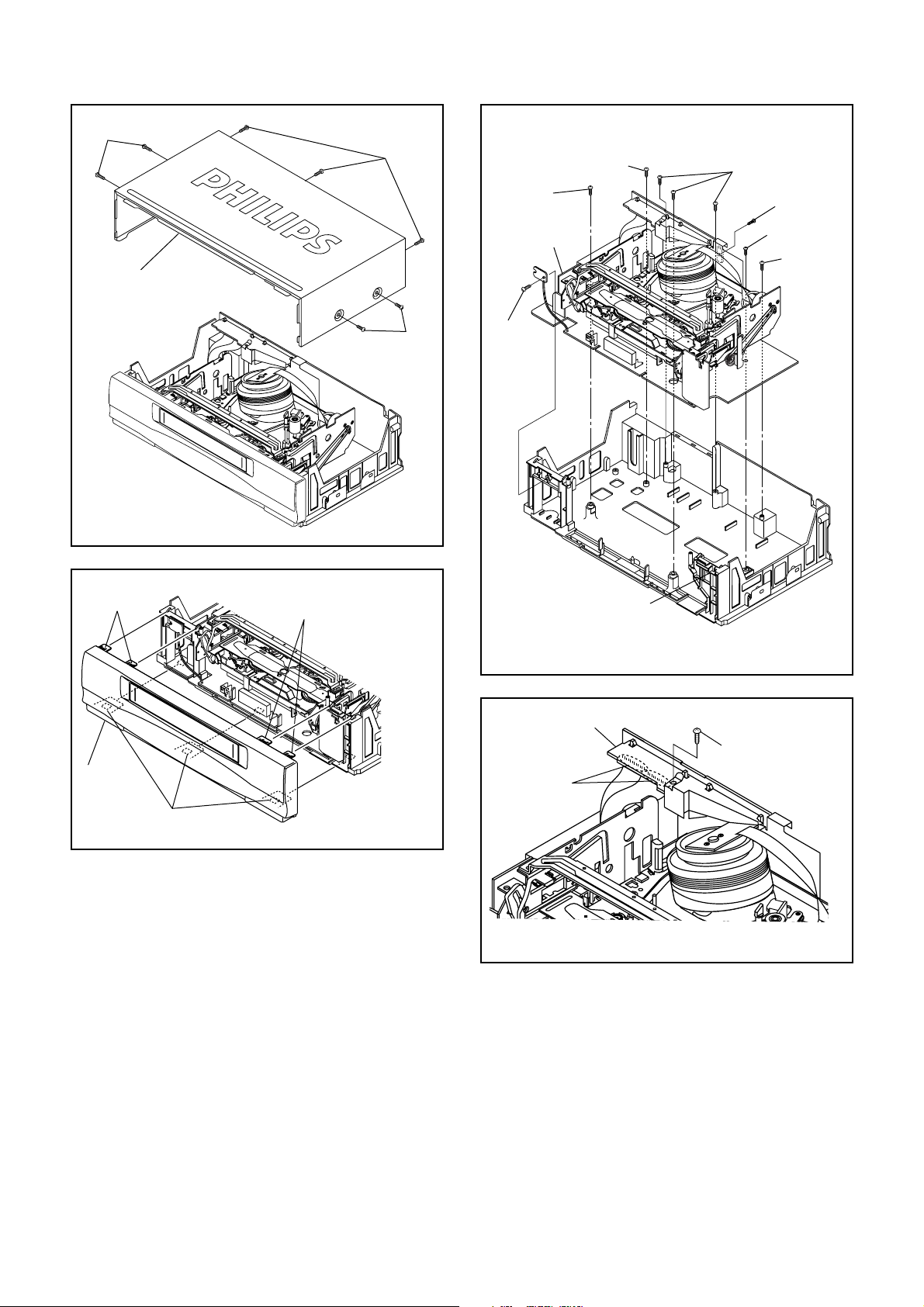

2. Disassembly Method

REMOVAL

ID/

LOC.

No.

PART

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

Note

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3): Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5): Refer to “Reference Notes.”

Reference Notes

CAUTION: Locking Tabs (L-1) and (L-2) are fragile.

Be careful not to break them.

1. Release Locking Tab (L-3) and remove Screw

(S-2), five Screws (S-3), two Screws (S-4) and

Screw (S-5). Then, slowly lift the VCR Chassis Unit

(Deck Assembly, Function CBA, Jack CBA and

Main CBA) up.

2. When reassembling, solder wire jumpers as shown

in Fig. 5.

3. Before installing the Deck Assembly, be sure to

place the pin of LD-SW on Main CBA as shown in

Fig. 6. Then, install the Deck Assembly while aligning the hole of Cam Gear with the pin of LD-SW,

the shaft of Cam Gear with the hole of LD-SW as

shown in Fig. 6.

[1] Top Case 1 7(S-1) -

Front

[2]

Assembly

VCR

[3]

Chassis

Unit

[4] Jack CBA 4 Desolder, (S-6) -

Function

[5]

CBA

Deck

[6]

Assembly

[7] Main CBA 5 ---------- -

↓

(1)

↓

(2)

2 *3(L-1),*4(L-2) -

*(L-3), (S-2), 5(S-3),

3

2(S-4), (S-5)

5 Desolder -

5,6 2(S-7), Desolder 2,3

↓

(3)

↓

(4)

(5)

1

↓

1-7-1 HC460DC

(S-1)

[1] Top Case

(S-1)

(S-3)

[3]VCR

Chassis Unit

(S-4)

(S-3)

(S-5)

(S-4)

(S-3)

(L-2)

[2] Front

Assembly

(L-2)

(S-1)

(S-2)

Fig. 1

(L-3)

Fig. 3

[4] Jack CBA

(S-6)

Desolder

(L-1)

Fig. 2

Fig. 4

1-7-2 HC460DC

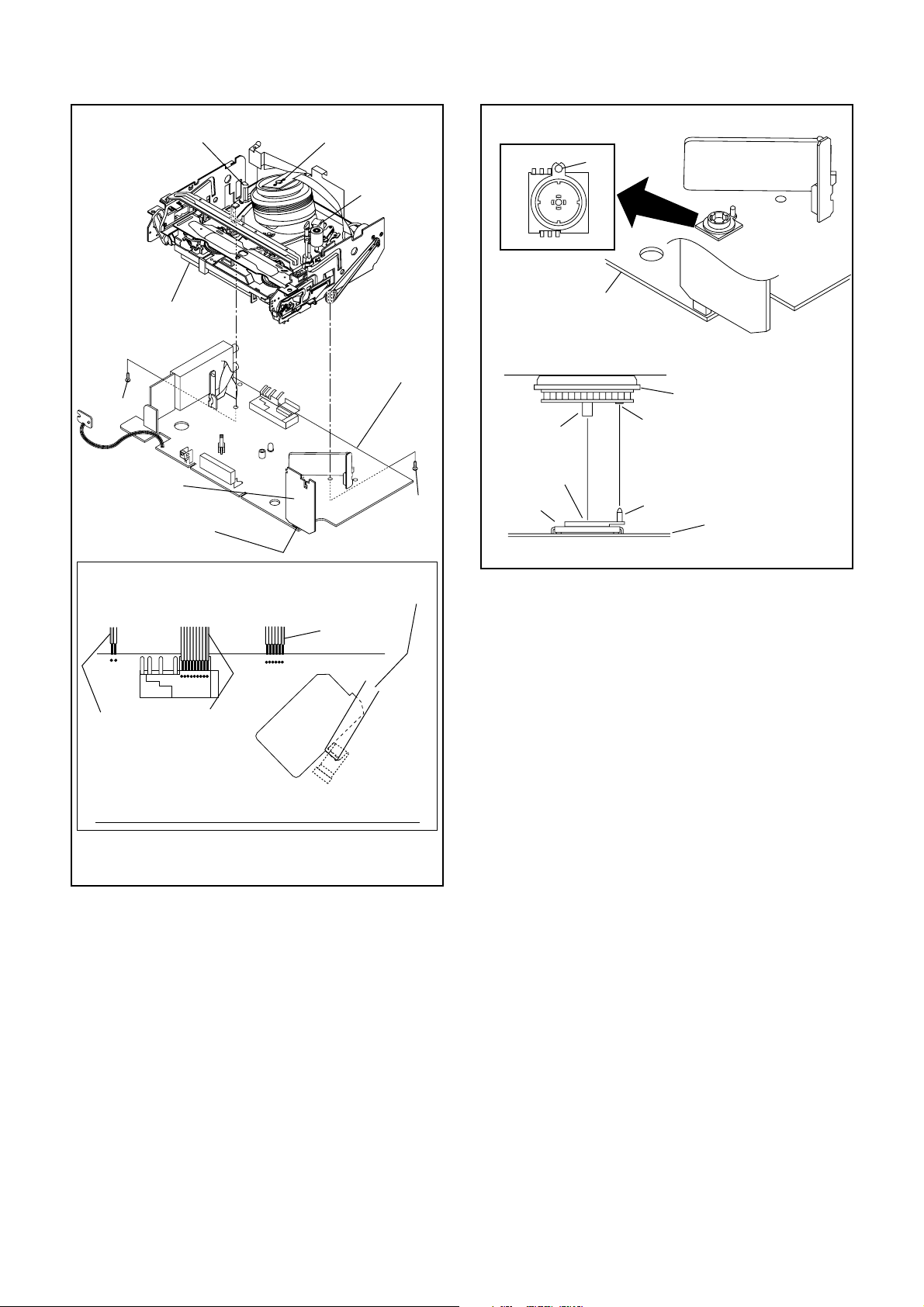

FE Head

Cylinder Assembly

AC Head

Assembly

Pin

SW507

LD-SW

[6] Deck Assembly

(S-7)

[5] Function

CBA

Desolder from

bottom

From

FE Head

Lead with

red stripe

From

Cylinder

Assembly

Lead with

white stripe

From

AC Head

Assembly

[7] Main CBA

From

Capstan Motor

Assembly

Lead with

white stripe

(S-7)

[7] Main CBA

[6] Deck Assembly

Shaft

Hole

LD-SW

Cam Gear

Hole

Pin

[7] Main CBA

Fig. 6

TOP VIEW

Lead connections of Deck Assembly and Main CBA

Fig. 5

1-7-3 HC460DC

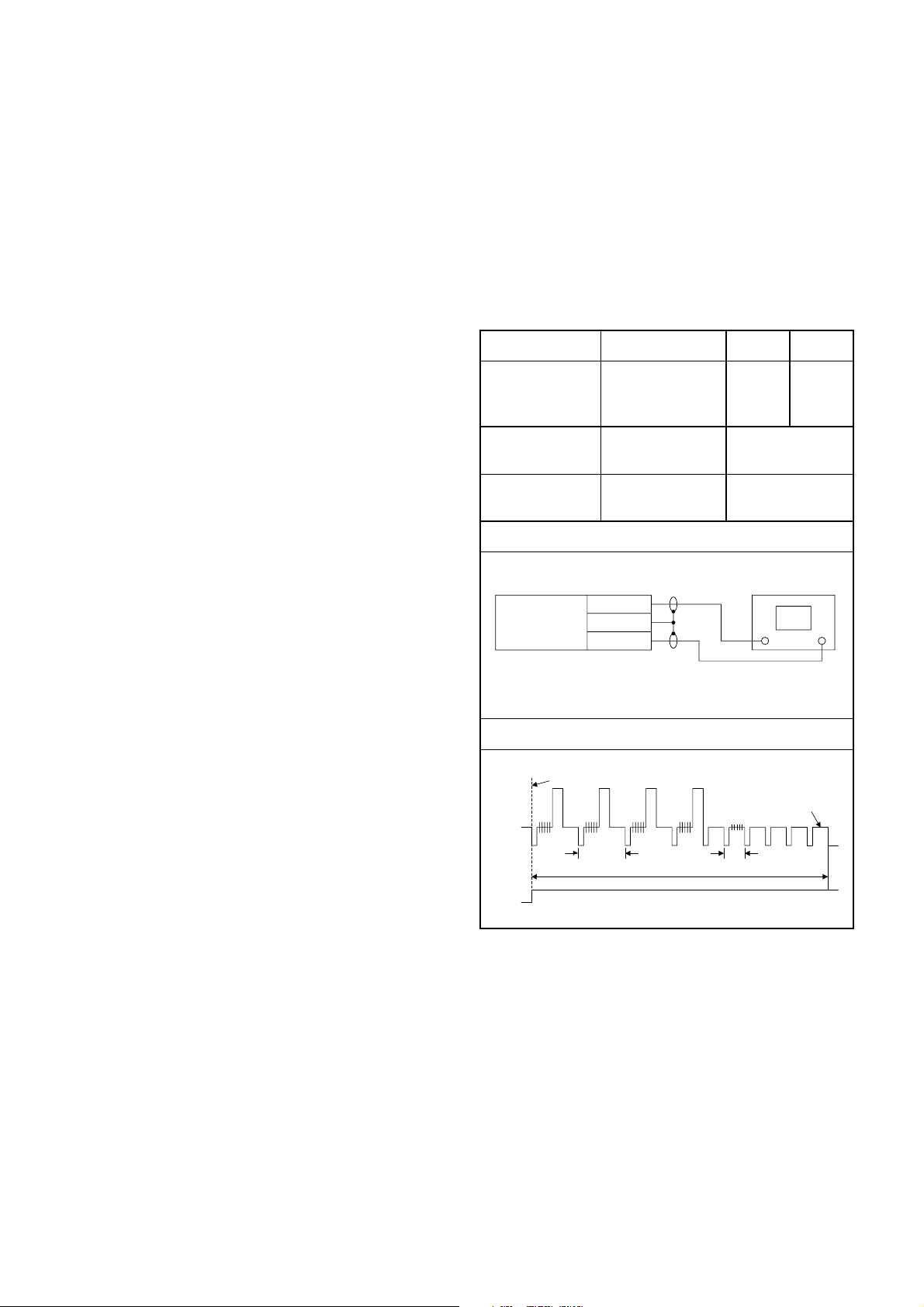

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note: "CBA" is an abbreviation for

"Circuit Board Assembly."

NOTE:

1.Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to do these adjustments only after

all repairs and replacements have been completed. Also, do not attempt these adjustments

unless the proper equipment is available.

2.To perform these alignment / confirmation procedures, make sure that the tracking control is set in

the center position: Press either "L5??" or "K" button

on the remote control unit first, then the "PLAY"

button (Front Panel only).

Test Equipment Required

1.Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div.,

F-Range: DC~AC-20MHz

2.Alignment Tape (4822 395 10283)

Head Switching Position Adjustment

Purpose:

To determine the Head Switching point during

playback.

Symptom of Misadjustment:

May cause Head Switching noise or vertical jitter

in the picture.

Test point Adj.Point Mode Input

TP751(V-OUT)

TP502(RF-SW)

GND

Tape

4822 395 10283 Oscilloscope

Connections of Measurement Equipment

Main CBA

VR501

(Switching Point)

(MAIN CBA)

Measurement

Equipment

TP751

GND

TP502

PLAY

(SP)

6.5H±1H

(412.7µs±60µs)

Oscilloscope

-----

Spec.

CH1 CH2

Trig. (+)

Figure 1

EXT. Syncronize Trigger Point

V-Sync

CH1

CH2

Reference Notes:

Play back the Alignment tape and adjust VR501 so

that the V-sync front edge of the CH1 video output

waveform is at the 6.5H(412.7µs) delayed position

from the rising edge of the CH2 head switching pulse

waveform.

1.0H

Switching Pulse

6.5H

0.5H

1-8-1 HC460EA

How to enter the factory

How to measure the standard V-

set mode

In the factory set mode, measuring the standard VENV value of Digital Studio Picture Control can be performed.

Preparation:

Input the color bar signal in line-in or tuner mode.

1. To enter the factory set mode, press the FACTORY

button on the factory remote control unit (part No.:

NA411ED or NA461ED) until the following picture

is shown on the screen with blueback.

FACTORY MODE

PLAY

REC

CLEAR

2. In the factory set mode....

- The play ( B ) button on the factory remote control

unit is not available.

- To enter the measuring the standard V-ENV value

of Digital Studio Picture Control mode, press the

RECORD/OTR button on the remote control unit.

- When pressing the CLEAR button on the remote

control unit, the unit resets the software after initializing the EEPROM.

3. "[OK]" or "[NG]" on the right of "REC: DSPC" above

picture is depended on the standard DSPC value

be written in the EEPROM. When 2 SPEED is set,

"[OK]" is shown on that location in the SP and LP

mode. When 1 SPEED is set and SP is OK, "[OK]"

is shown on that location regardless of LP value.

: NOT ACTIVE

: DSPC [OK]

: INITIAL

ENV value of Digital Studio Picture

Control

1. To enter the measuring the standard V-ENV value

of Digital Studio Picture Control mode, press the

RECORD/OTR button on the factory remote control unit in the factory set mode. The following picture is shown on the screen with superimpose.

DIGITAL STUDIO PICTURE

2. Recording starts automatically for 10 seconds in

SP mode. After that, recording starts for 10 seconds in LP mode.

3. The tape is rewinded to the recording start point.

4. The unit enters the play mode automatically and

the V-ENV levels of each SP and LP modes are

memorized into the EEPROM.

5. "COMPLETED" appears on the screen with blueback for 5 seconds, the unit enters the stop (A)

mode, and is gone out from the factory mode.

6. If SYNC. and CTL are none, "NOT COMPLETED"

appears on the screen with blueback for 5 seconds, the unit ejects the cassette and is gone out

from the factory mode. Or, also when the V-ENV

level in either of the SP and LP mode is written,

"NOT COMPLETED" appears on the screen with

blueback for 5 seconds, the unit ejects the cassette

and is gone out from the factory mode.

CLEAR button

9

TV

STILL

STANDBY/ON

EJECT

MENU STATUS/EXIT CLEAR

1 2 3

0

VCR

4 5 6

7 8

RECORD/OTR

RECORD/OTR button

Play button

P+

FACTORY button

MUTE

P-

TAPE LIST SMART PICTURE TURBO TIMER

+

SV/V

FACTORY

INDEX

AUDIO

SYSTEM

SLOW

COMPLETED

Normal

NOT COMPLETED

Abnormal

1-8-2 HC460EA

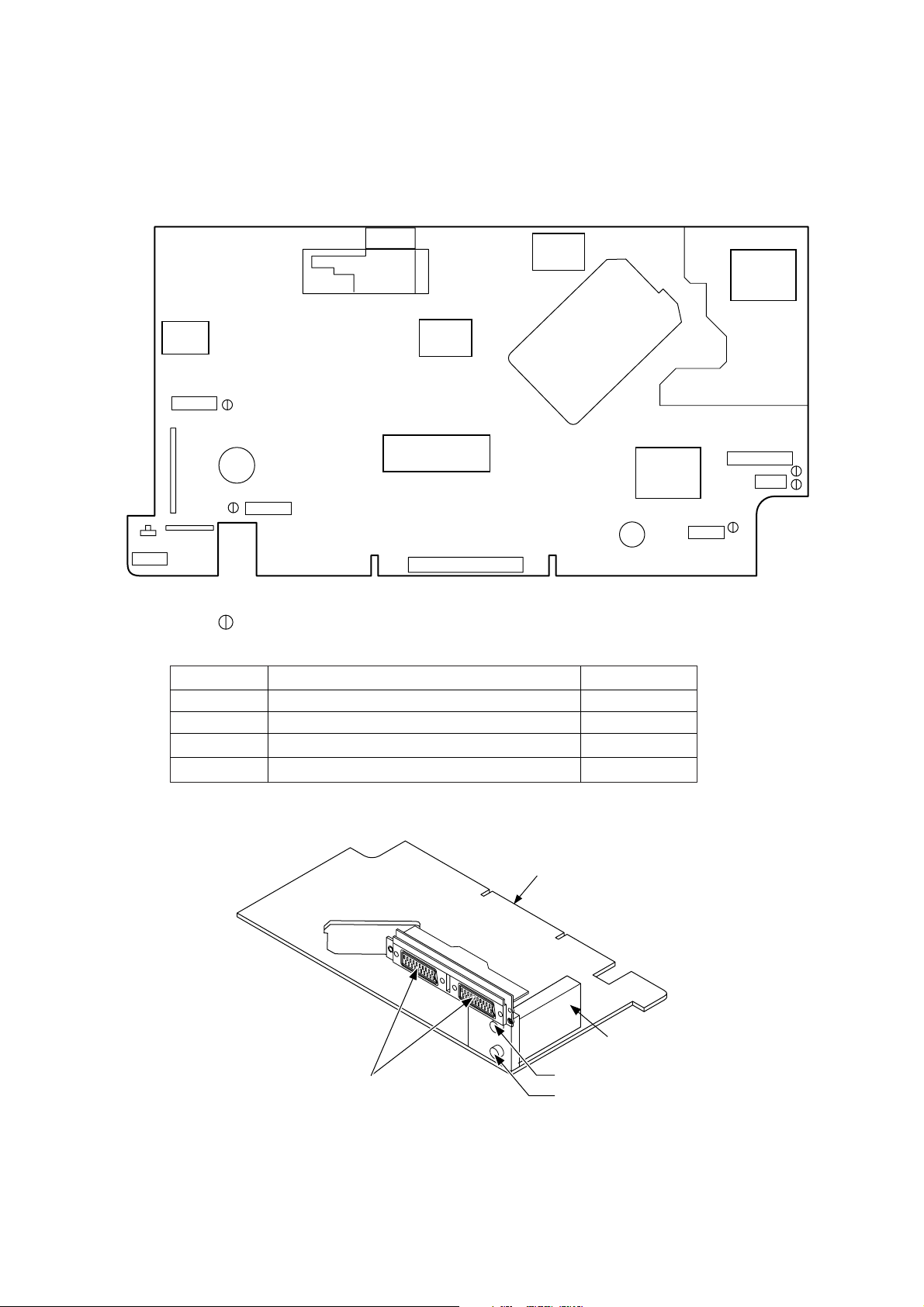

Adjustment Points and Test Points

Main CBA Top View

AUDIO

BLOCK

POWER

SUPPLY

BLOCK

TUNER

BLOCK

TP751

V-OUT

TP502

RF-SW

VR501

SW-P

VIDEO

BLOCK

SYSCON/TIMER

SERVO BLOCK

TEST POINT INFORMATION

: Indicates a test point with a jumper wire across a hole in the PCB.

TEST POINTS NOT USED IN ELECTRICAL ADJUSTMENTS

Test Point

TP301

TP502

TP501

TP507

Mechanical Alignment Procedures

Mechanical Alignment Procedures

Mechanical Alignment Procedures

Preparation for Servicing

Used in: Page No.

POWER

CTL

BLOCK

2-3-3, 2-3-4

2-3-3, 2-3-4

2-3-3

1-4-1

TP507

SENS-INH

TP501 CTL

TP301

C-PB

Audio In/Out,Video In/Out

Main CBA

Tuner Unit

Antenna In

Antenna Out

1-8-3 HC460EA

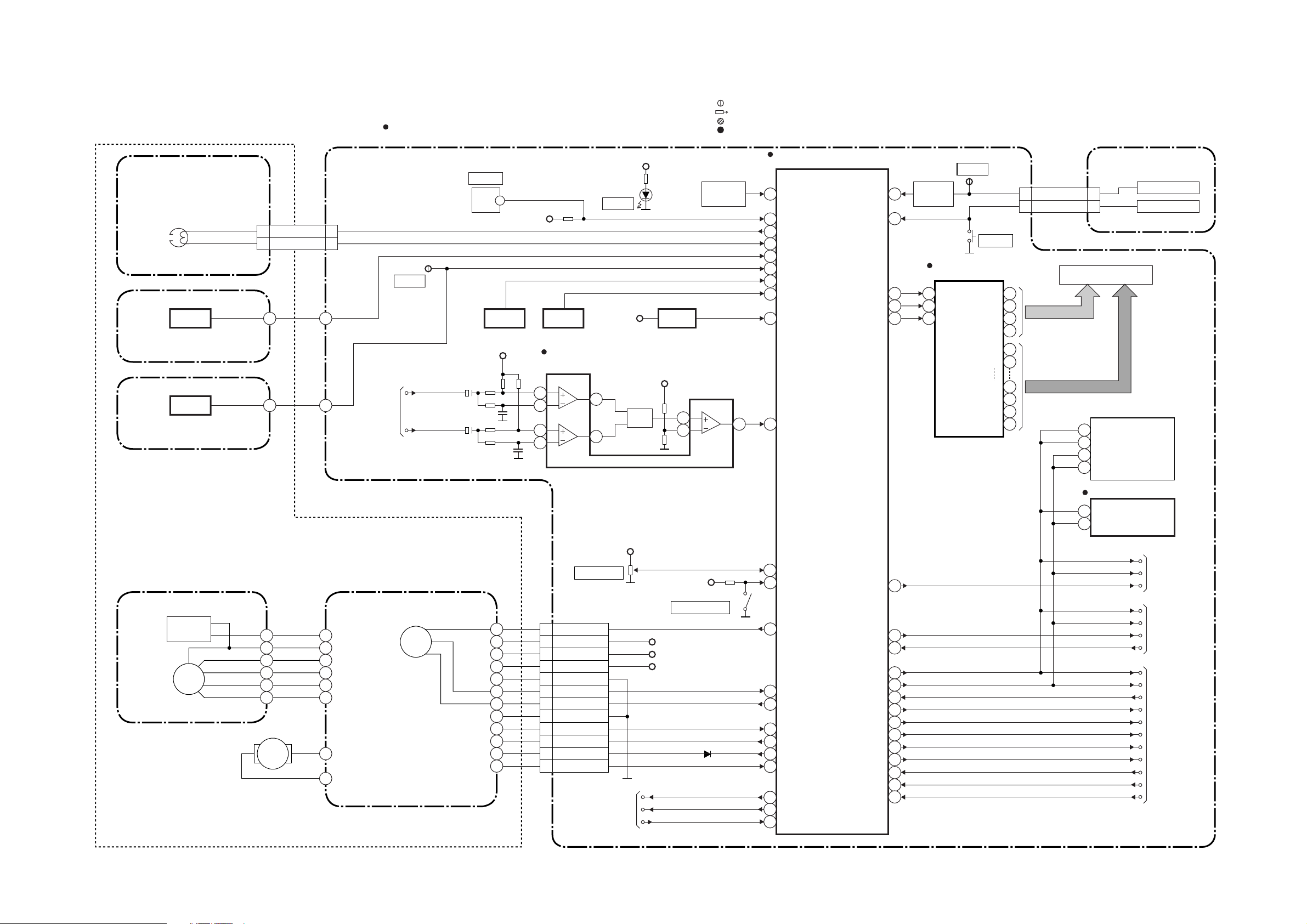

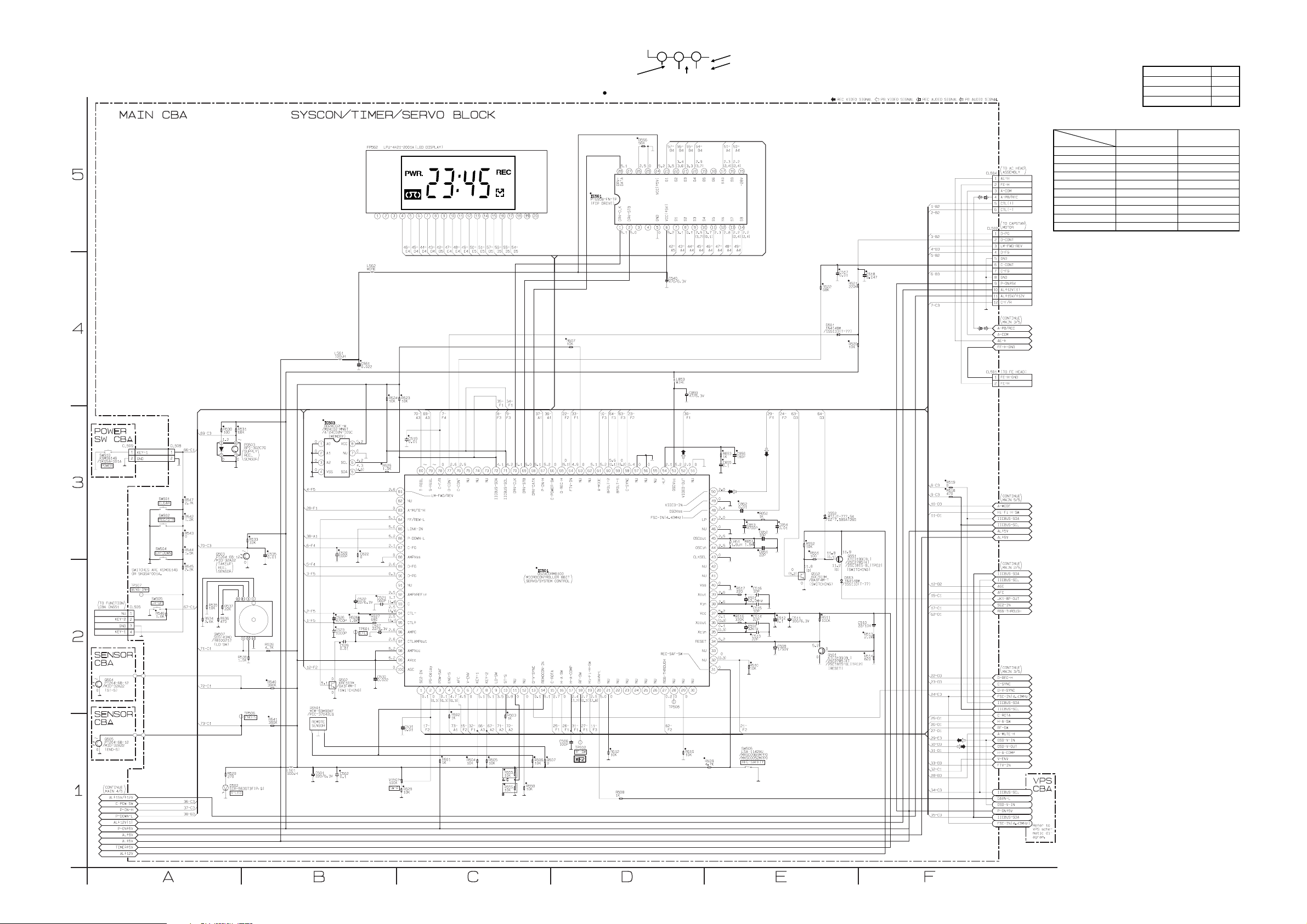

Servo/System Control Block Diagram BLOCK DIAGRAMS

(DECK ASSEMBLY)

AC HEAD ASSEMBLY

CONTROL

HEAD

Q504

ST-S

SENSOR CBA

Q505

END-S

SENSOR CBA

CL287

55CTL(+)

66CTL(-)

CL504

" " = SMD

MAIN CBA

TP506

END-S

FROM

VIDEO

BLOCK

TU-VIDEO

V-IN1

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

SW507

LD-SW

Q503

T-REEL

P-ON+5V

AL+5V

PS503

9

8

11

10

S-REEL

IC771

(COMPARATOR)

TIMER+5V

14

13

AL+5V

D502

S-LED

Q771,

Q772

AND

RESET

P-ON+5V

TEST POINT INFORMATION

RS501

REMOTE

SENSOR

Q501

4

5

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

2 64

IC501

(SERVO/SYSTEM CONTROL)

14

95

94

10

4

80

34

LD-SW9

CTL(+)

CTL(-)

ST-S

END-S

T-REEL

S-REEL79

RESET

FTV-IN

KEY- 1REMOCON-IN

KEY- 2

DRV-DATA

DRV-STB

DRV-CLK

68

69

70

7

8

KEY

SWITCH

IC561

(FIP DRIVER)

DRV-DATA

28

DRV-STB

2

DRV-CLK

1

TP507

S-INH

CL505 CN651

44KEY-1

22KEY-2

SW505

CH-UP

FP562

LED CLOCK

G1

23

22

G2

21

G3

20

G4

7

S1

S2

8

S7

13

S8

14

S9

16

S10

17

FUNCTION CBA

KEY SWITCH

KEY SWITCH

TU701(TUNER UNIT)

SDA

3

SDA

12

SCL

5

SCL

11

CYLINDER ASSEMBLY CAPSTAN MOTOR

PG

DRUM

MOTOR

SENSOR

M

LOADING

MOTOR

M

CAPSTAN

MOTOR

M

VR501

SW-POINT

CL502

12 C-F/R

11

AL+15V/+12V

10 AL+12V

P-ON+5V

9

GND

8

C-FG

7

C-CONT

6

GND

5

D-FG

4

LM-FWD/REV

3

D-CONT

2

D-PG

1

AL+5V

FROM/TO

POWER

SUPPLY

BLOCK

AL+5V

SW506

REC-SAFETY

AL+15V/+12V

AL+12V

P-ON+5V

C-POW-SW

P-ON-H

P-DOWN-L

2

PG-DELAY

31

REC-SAF-SW

78

C-F/R

87

C-FG

76

C-CONT

D-FG

89

LM-FWD/REV

81

D-CONT77

90

D-PG

C-POW-SW

66

P-ON-H

67

P-DOWN-L

86

A-MUTE-H

Hi-Fi-H-SW

A-MODE

I2C-BUS SDA

I2C-BUS SCL

DAVN-L

D-REC-H

RF-SW

C-ROTA

D-V SYNC

H-A-SW

H-A-COMP

V-ENV

C-SYNC

83

19

61

72

71

20

65

18

15

13

16

17

58

IC503 (MEMORY)

SDA

5

SCL

6

I2C-BUS SDA

I2C-BUS SCL

A-MUTE-H

I2C-BUS SDA

I2C-BUS SCL

Hi-Fi-H-SW

A-MODE

I2C-BUS SDA

I2C-BUS SCL

DAVN-L

D-REC-H

RF-SW

C-ROTA

D-V SYNC

H-A-SW

H-A-COMP

6

V-ENV

C-SYNC

TO

AUDIO BLOCK

FROM/TO

Hi-Fi AUDIO

BLOCK

FROM/TO

VIDEO BLOCK

1-9-1 1-9-2 HC460BLS

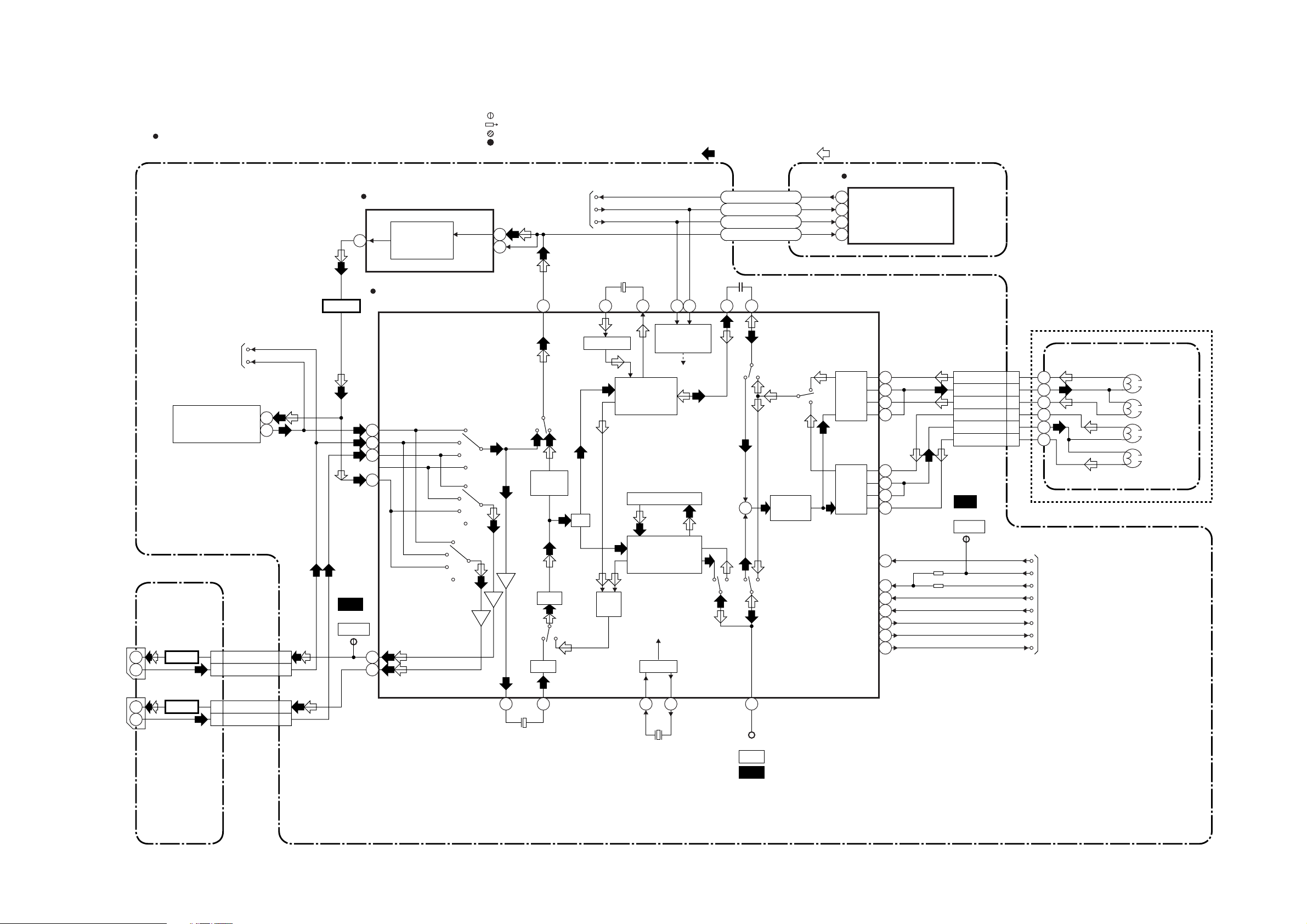

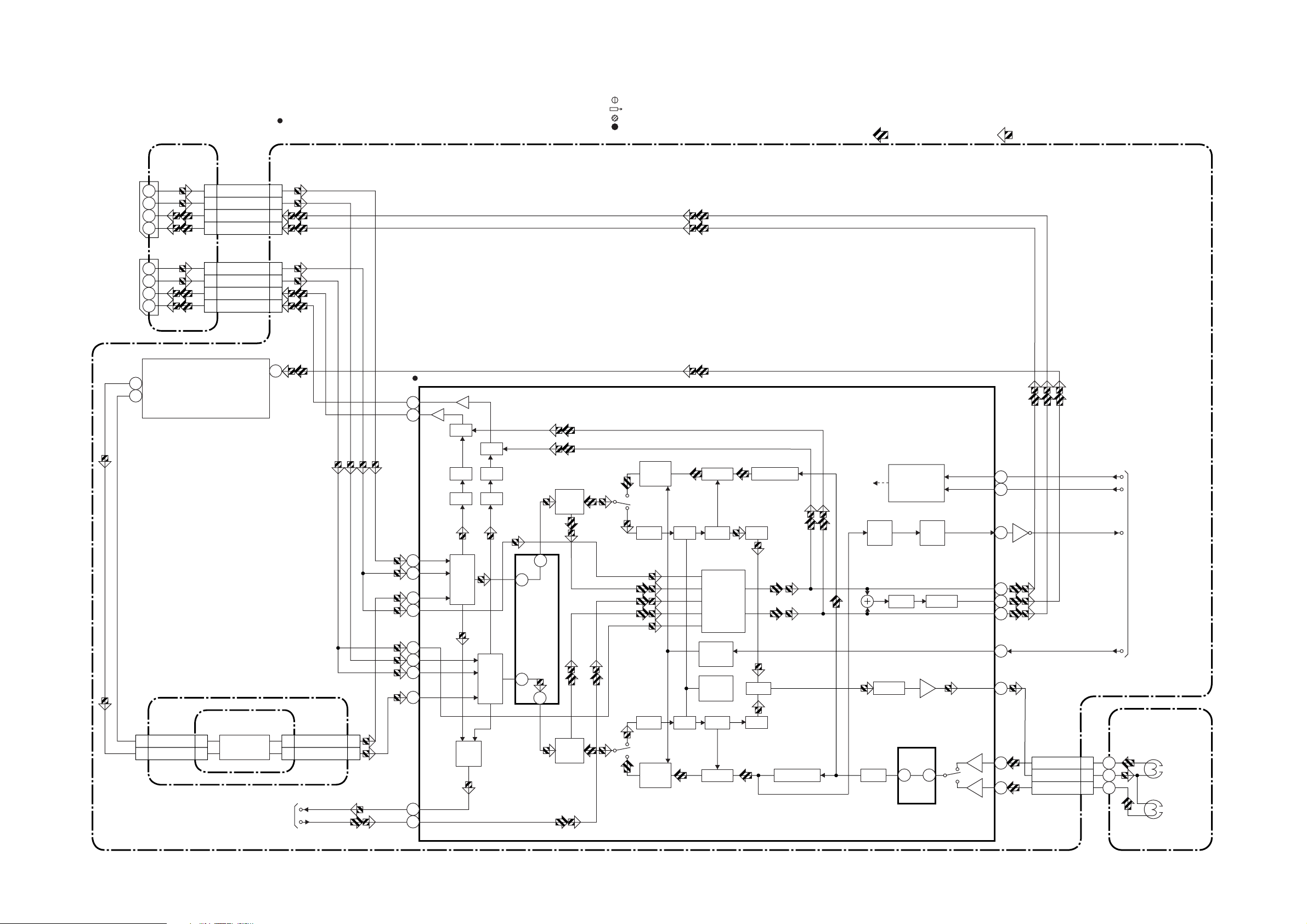

Video Block Diagram

V-OUT1

V-IN1

" " = SMD

JACK CBA

JK101

19

20

MAIN CBA

SERVO/SYSTEM

CONTROL BLOCK

TU701

VIDEO

TU-VIDEO

CL101

Q101

BUFFER

1

33

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

IC501 (OSD)

52

IC301

Q351

BUFFER

(Y/C SIGNAL PROCESS)

V-IN1TO

TU-VIDEO

6

24

48

50

52

56

WF1

TP751

V-OUT

CL151

V-OUT1

V-IN1

1

61

63

OSD

CHARACTER

MIX

TUNER

PB/EE

TUNER

IN1

PB/EE

MUTE

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

50

COLOR

-IN

IN1

IN2

FRT

IN2

FRT

MUTE

55

BYPASS

FROM

SERVO/SYSTEM

CONTROL BLOCK

DAVN-L

I2C BUS SDA

I2C BUS SCL

65

Y. DELAY

AGC

CHARA.

INS.

1/2

FBC

Y/C

MIX

PR

AGC VXO

DECORDER

LUMINANCE

SIGNAL

PROCESS

CCD 1H DELAY

CHROMINANCE

SIGNAL

PROCESS

69684643

SERIAL

REC-VIDEO SIGNAL PB-VIDEO SIGNAL MODE: SP/REC

VPS CBA

DAVN-L

I2C BUS-SDA

I2C BUS-SCL

OSD-V-IN

IC640 (VPS)

DAVN-L

14

6

I2C BUS SDA

7

I2C BUS SCL

VPS-V

16

7978

P

R

SP

EP

SP

HEAD

AMP

96

95

93

94

90

Y

REC FM

+

C

RPRP

AGC

EP

HEAD

AMP

D-REC-H

RF-SW/C-ROTA

D-V-SYNC

H-A-SW

H-A-COMP

V-ENV

C-SYNC

89

88

87

80

70

62

71

83

84

67

WF2

TP502

RF-SW

CL253

V(R)-1

V-COM

V(L)-1

V(L)-2

V-COM

V(R)-2

D-REC-H

RF-SW

C-ROTA

D-V-SYNC

H-A-SW

H-A-COMP

V-ENV

C-SYNC

(DECK ASSEMBLY)

CYLINDER ASSEMBLY

1

2

3

4

5

6

FROM/TO SERVO/SYSTEM

CONTROL BLOCK

VIDEO (R)-1

HEAD

VIDEO (L)-1

HEAD

VIDEO (L)-2

HEAD

VIDEO (R)-2

HEAD

V-OUT2

V-IN2

19

20

JK102

Q102

BUFFER

CL102

1

V-OUT2

V-IN2 3

3

CL152

1

58 59

2928

21

TP301

C-PB

WF5

1-9-3 1-9-4 HC460BLV

Audio Block Diagram

" " = SMD

TO Hi-Fi

AUDIO BLOCK

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

N-A-PB

N-A-REC

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

MAIN CBA

IC301

(AUDIO SIGNAL PROCESS)

PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC

1513 17

IN1

TUNER IN2

(DECK ASSEMBLY)

ACE HEAD ASSEMBLY

AUDIO

HEAD

AUDIO

ERASE

HEAD

FE HEAD

FULL

ERASE

HEAD

CL287

A-PB/REC 4

A-COM 3

AE-H 1

AE-H/FE-H 2

CL504

4 A-PB/REC

3 A-COM

1 AE-H

2 AE-H/FE-H

CL501

2 FE-H

1 FE-H-GND

+5V

Q401

Q402

BIAS

OSC

Q406

Q404 (PB=ON)

Q403

Q405

(PB=ON)

5

6

1

2

SWITCHING

D-REC-OFF

+5V

PB-ON

EQ

AMP

SP/LP-ON

AUTO

BIAS

ALC

INV

R

98

7

3

100

AT T

P

REC

AMP

AUDIO HD-SW

DET

ALC

LINE

AMP

REC-ON

SERIAL

DECODER

MUTE

12

11

CONTROL

16

68 69

71

I2C BUS-SDA

I2C BUS-SCL

A-MUTE-H

TO SERVO/SYSTEM

CONTROL BLOCK

1-9-5 1-9-6 HC460BLA

Hi-Fi Audio Block Diagram

" " = SMD

JACK CBA

A-IN1(R)

A-IN1(L)

A-OUT1(R)

A-OUT1(L)

JK101

2

6

1

3

CL101

10

12

A-IN1(R)

A-IN1(L) 8

8

6

A-OUT1(R)

A-OUT1(L) 12

10

6

CL151

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

REC-AUDIO SIGNALPB-AUDIO SIGNAL Mode : SP/REC

MAIN CBA

A-IN2(R)

A-IN2(L)

A-OUT2(R)

A-OUT2(L)

2

6

1

3

TU701

21

TU-AUDIO

22

SIF

JK102

CL102

11

9

A-IN2(R)

A-IN2(L) 8

8

6

A-OUT2(R)

A-OUT2(L) 11

AUDIO

9

6

2

CL152

IC451 (MTS/ SAP/ Hi-Fi AUDIO PROCESS/ Hi-Fi HEAD AMP)

76

75

SW

SW

ALC

ALC

P

R

69

73

53

65

D.C.

R-CH

INSEL

D.C.

R-CH

PNR

47

48

SW

NOISE

LIM DEV

COMP

VCO

OUTPUT

SELECT

R-CH BPF

LPF

DO

DET

SERIAL

DATA

DECODER

ENV

DET

ALC

MUTE

38

39

23

80

78

I2C-BUS SDA

I2C-BUS SCL

Q451

A-MODE

TO

SERVO/ SYSTEM

CONTROL BLOCK

2

CN701 CN1

2

SIF

TU-AUDIO 1

1

2

AFV CBA

IF SINAL

PROCESS

TO AUDIO BLOCK

4

TU-AUDIO(R)

TU-AUDIO(L)

5

N-A-REC

N-A-PB

67

7

11

53

CN701CN1

4

5

6

4

NOR

SW

L-CH

INSEL

13

14

L-CH

PNR

LIM DEV

R

P

SW

NOISE

HOLD

PULSE

NOISE

DET

VCO

COMP

MIX

LPF

L-CH BPF

LIM

COMP

31 30

1-9-7 1-9-8

40

26

Hi-Fi-H-SW

CYLINDER

ASSEMBLY

R

L

24

27

CL253

Hi-Fi-A(R) 7

Hi-Fi-COM 8

Hi-Fi-A(L) 9

Hi-Fi

AUDIO

(R) HEAD

Hi-Fi

AUDIO

(L) HEAD

HC460BLH

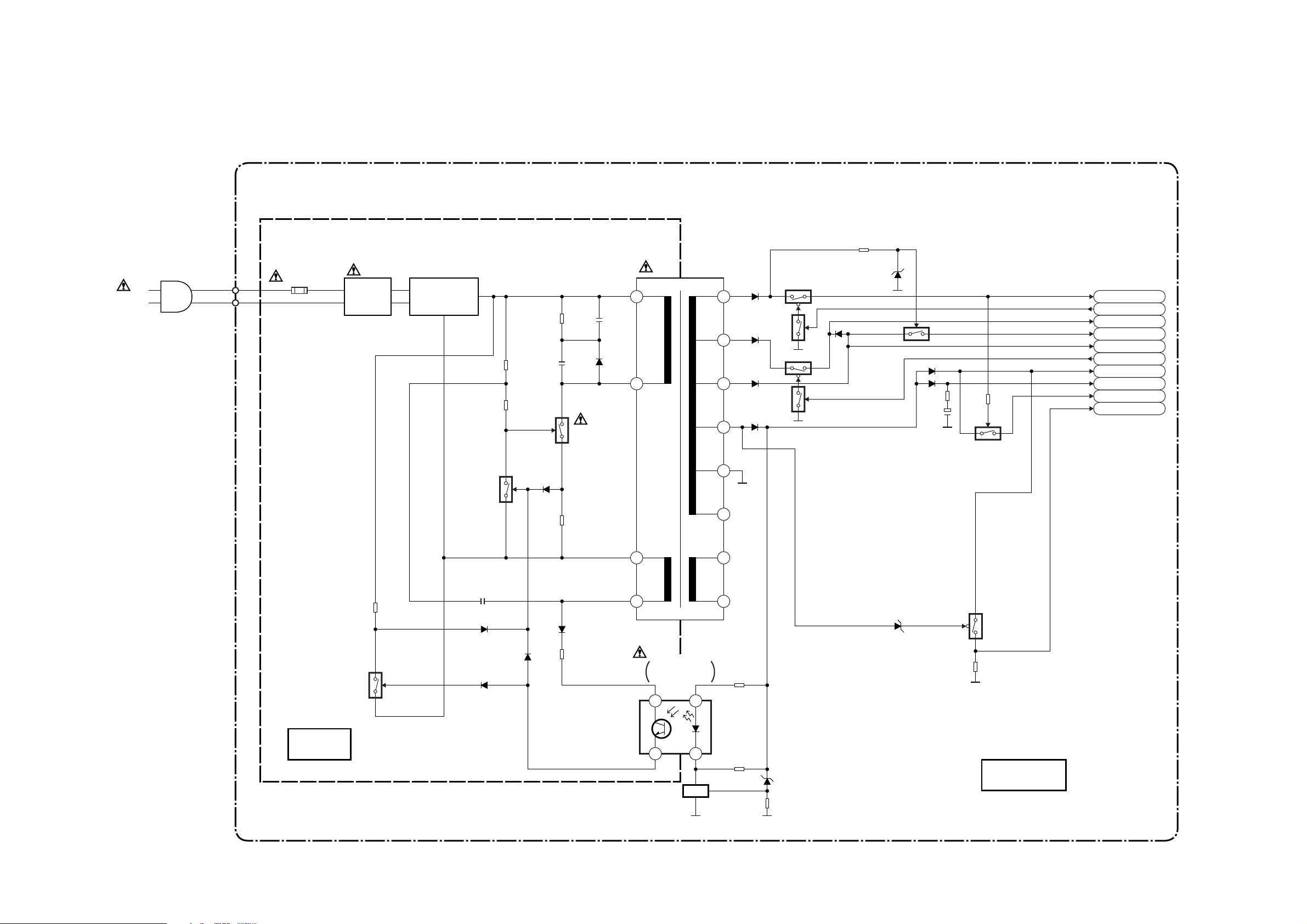

Power Supply Block Diagram

AC001

NOTE :

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

HOT CIRCUIT. BE CAREFUL.

F001 L003

T1.6A L 250V

LINE

FILTER

D001 - D004

BRIDGE

RECTIFIER

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE T1.6AL/250V FUSE.

T001

Q051

2

4

Q001

12

Q052

13

Q057

14

Q058

15

CAUTION !

Fixed voltage (or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F001) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

MAIN CBA

P-ON+44V

P-ON-H

Q053

Q054

AL+15V/+12V

AL+9V

AL+12V

C-POW-SW

AL+5V

TIMER+5V

P-ON+5V

P-DOWN-L

HOT

Q003

Q002

7

6

IC001

ERROR

VOLTAGE DET

4

3

Q004

(SHUNT REGULATOR)

16

11

17

18

Q056

1

2

COLD

REG

HC460BLP1-9-9 1-9-10

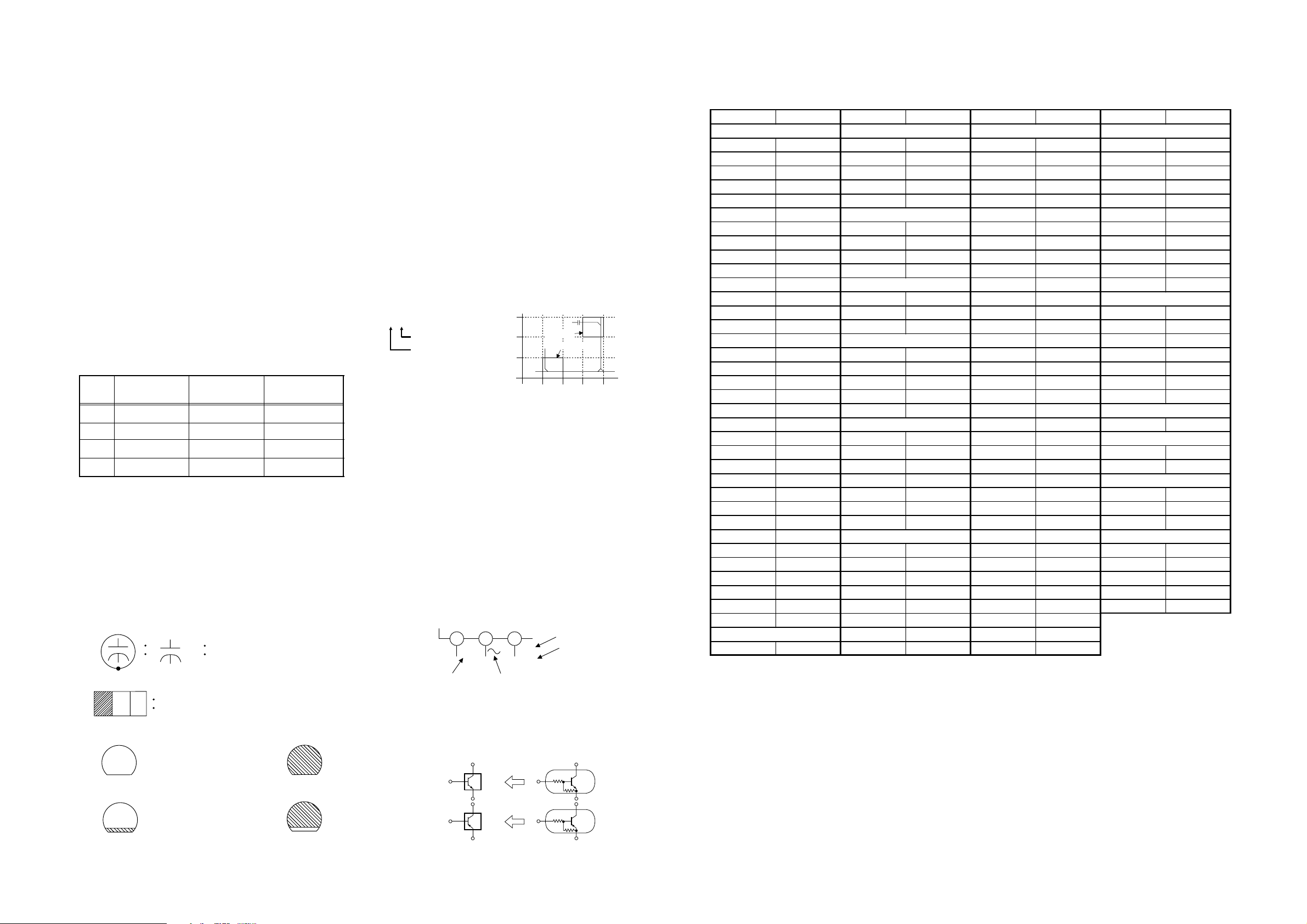

SCHEMATIC DIAGRAMS / CBA'S AND TEST POINTS

DIODES

CONNECTORS

Main 1/5 Schematic Diagram Parts Location Guide

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using replacement components rated for higher voltage, wattage,

etc. Replacement parts that have these special safety

characteristics are identified in this manual and its

supplements; electrical components having such features are identified by the mark " ! " in the schematic

diagram and the parts list. Before replacing any of

these components, read the parts list in this manual

carefully. The use of substitute replacement parts that

do not have the same safety characteristics as specified in the parts list may create shock, fire, or other

hazards.

Capacitor Temperature Markings

Mark

(B)

Capacity

change rate

10%

±

(F) +30 - 80% 20°C –25~+85°C

(SR)

(Y)

15%

±

22.5%

±

Capacitors and transistors are represented by the following symbols.

< PCB Symbols >

(Top View) (Bottom View)

(Bottom View)

Transistor or Digital Transistor

E C B

(Top View)

NPN Transistor

Standard

temperature

20°C -25~+85°C

20°C –25~+85°C

20°C –25~+85°C

+

Electrolytic Capacitor

Temperature

range

(Top View)

Notes:

1. Do not use the part number shown on these drawings for ordering. The correct part number is

shown in the parts list, and may be slightly different

or amended since these drawings were prepared.

2. To maintain original function and reliability of

repaired units, use only original replacement parts

which are listed with their part numbers in the parts

list section of the service manual.

3. Prefix symbol "CN" means "connector" (can disconnect and reconnect).

Prefix symbol "CL" means "wire-solder holes of the

PCB" (wire is soldered directly).

4. How to read converged lines.

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

(1). "1-D3" means that line number "1" goes to

area "D3."

(2). "1-B1" means that line number "1" goes to

area "B1."

5. All resistance values are indicated in ohms

3

(K=10

, M=106).

6. Resistor wattages are 1/4W or 1/6W unless otherwise specified.

7. All capacitance values are indicated in µF

-6

(P=10

µF).

8. All voltages are DC voltages unless otherwise

specified.

9. Voltage indications for PLAY and REC modes on

the schematics are as shown below.

2

1

(Unit: Volt)

The same voltage for

both PLAY & REC modes.

5.0

< Schematic Diagram Symbols >

Digital Transistor

PNP Transistor

3

AREA D3

2

1-D3

1

ABCD

3

5.0

(2.5)

Indicates that the voltage

is not consistent here.

PLAY mode

REC mode

AREA B1

1-B1

Ref No. Position Ref No. Position Ref No. Position Ref No. Position

RESISTORS

C501 B-1 C L502 F-5 R509 E-1 R552 E-3

C502 B-1 C L504 F-5 R510 E-2 R555 C-1

C506 D-1 CL505 A-2 R511 E-2 R556 C-1

C508 E-2 C L508 A-3 R513 F-2 R558 C-1

C510 F-2 CL509 A-3 R514 F-2 R566 D-5

C511 E-2 R516 E-2 R607 D-4

C512E-2D501E-4R517E-2R612D-1

C513E-2D502A-1R518F-3R616D-1

C514E-2D552E-3R519F-3R851E-3

C515E-2D553E-2R520E-4R852E-3

C516 E-2 R521 E-4 R853 E-3

C517 E-4 IC501 C-2 R522 E-4

C518 F-4 IC503 B-3 R523 C-4 SW501 A-3

C519 C-3 IC561 D-5 R524 B-4 SW502 A-3

C520 B-3 R525 B-3 SW504 A-3

C521 B-2 L501 B-1 R526 B-2 SW505 A-2

C522 B-2 L561 B-4 R527 B-2 SW506 E-1

C523 B-2 L562 B-4 R528 C-1 SW507 A-2

C526 B-2 L851 E-3 R529 A-1 SW510 A-3

C527 B-2 L853 D-4 R530 A-3

C529 B-2 R531 A-3 VR501 B-1

C530 B-2 Q501 E-2 R533 B-3

C531 C-1 Q502 B-2 R534 A-2 X501 E-2

C535B-3Q503A-3R535A-2X502E-2

C540 D-4 Q504 A-2 R536 A-2

C561 B-4 Q505 A-1 R537 A-2 FP562 B-5

C622 B-3 Q551 E-3 R538 B-2 PS503 B-3

C851 E-3 Q552 E-2 R539 B-2 RS501 B-2

C852 E-3 R540 B-2

C853 E-3 R501 C-1 R541 B-1 TP501 B-2

C854 E-3 R502 C-1 R542 A-3 TP502 D-1

C855 E-3 R503 C-1 R543 A-3 TP506 B-2

C856 E-3 R504 C-1 R544 A-3 TP507 A-2

C859 D-4 R505 C-1 R545 A-2 TP508 D-1

C862E-3R506C-1R546A-2

R507 C-1 R547 A-3

CL501 F-4 R508 D-1 R551 E-3

ICS

COILS

TRANSISTORS

RESISTORSCONNECTORSCAPACITORS

SWITCHES

VARI ABLE RESISTO RS

CRYSTAL OSCILL AT O RS

MISCELLANEOUS

TEST POI NTSRESISTORS

E C B

(Top View)

E C B

NPN Digital Transistor

E C B

(Top View)

E C B

PNP Digital

Transistor

1-10-1 SC_08

1-10-2

Main 1/5 Schematic Diagram

MODE: SP/REC

THE SAME VOLTAGE FOR

BOTH PLAY & REC MODES.

“ “ = SMD

2

1

3

5.0

5.0

~

(2.5)

INDICATES THAT THE VOLTAGE

IS NOT CONSISTENT HERE.

PLAY MODE

REC MODE

Comparison Chart of

Models and Marks

MODEL MARK

VR530/02 A

VR530/07 B

VR530/16 C

IC501 KEY VOLTAGE CHART

Pin No.

Voltage

0.00 ~ 0.51V POWER CH UP

0.51 ~ 0.9 2V ------------------------ REW

0.92 ~ 1.27V COUNTER RESET PLAY

1.27 ~ 1.61V REC/OTR FF

1.61 ~ 1.98V CH DOWN PAUSE

1.98 ~ 2. 39V S-I NH ------------------------

2.39 ~ 2.9 0V ------------------------ STOP/EJECT

2.90 ~ 3. 60V ------------------------ --------------------- ---

3.60 ~ 4. 30V ------------------------ --------------------- ---

4. 30 ~ 5.00V KEY OFF KEY OF F

KEY 1 (7PIN) KEY 2 (8 PIN)

1-10-3 1-10-4 1-10-5

HC460SCM1

Loading...

Loading...