Philips VAE5020, VAM5020 Service Manual

Published by DP 0170 Service DPS Hasselt Printed in the Netherlands Subject to modification

3122 785 60030

©

Copyright 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

Compact Disc Recorder 2nd Line Service Manual

CDR Mozart Module

CL 16532046_000.eps

030501

Contents Page Contents Page

1 Introduction and Technical Specifications 2

2 Safety- and Maintenance Instructions, Warnings

and Notes 4

3 Instructions for Use 7

4

Mechanical Instructions 7

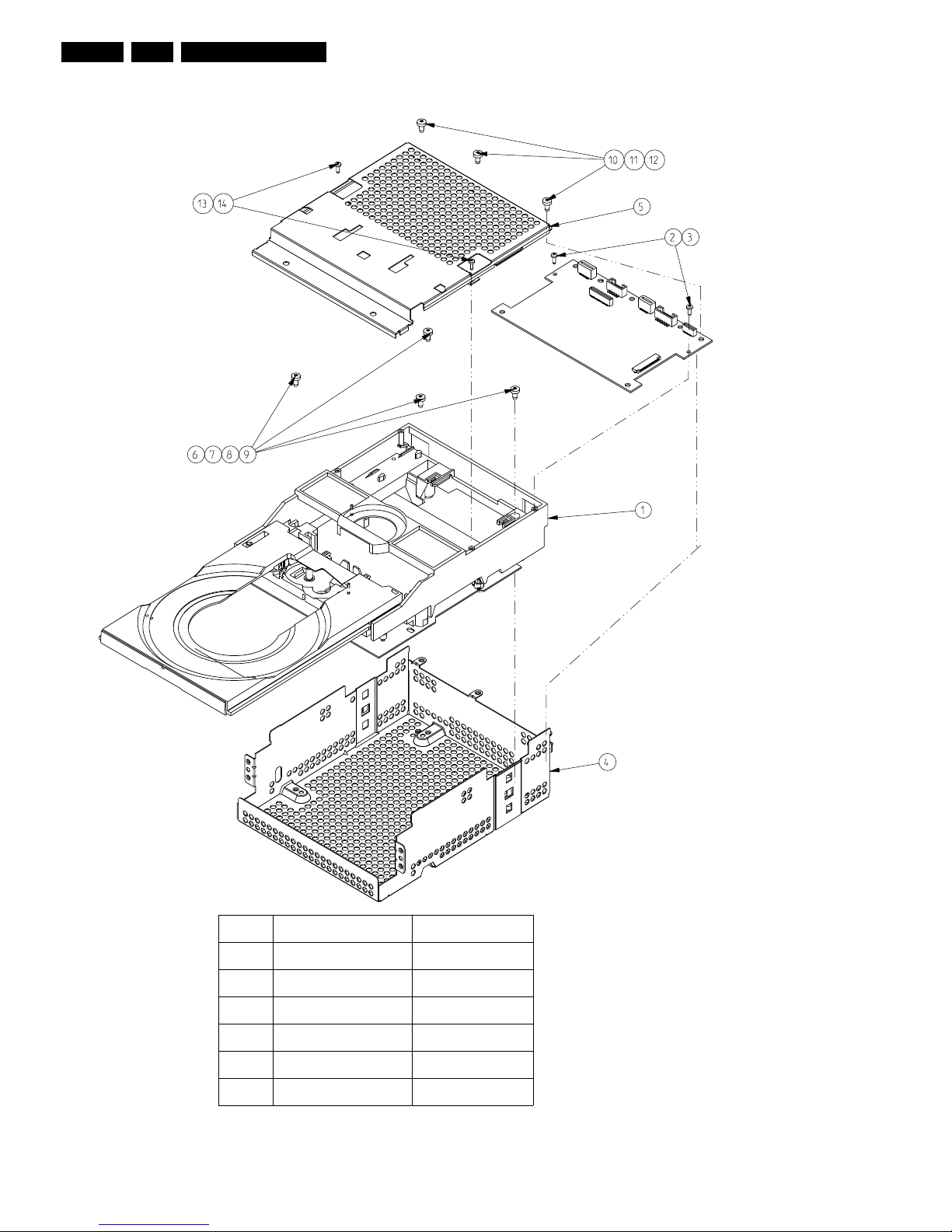

Exploded View CDR-Module 8

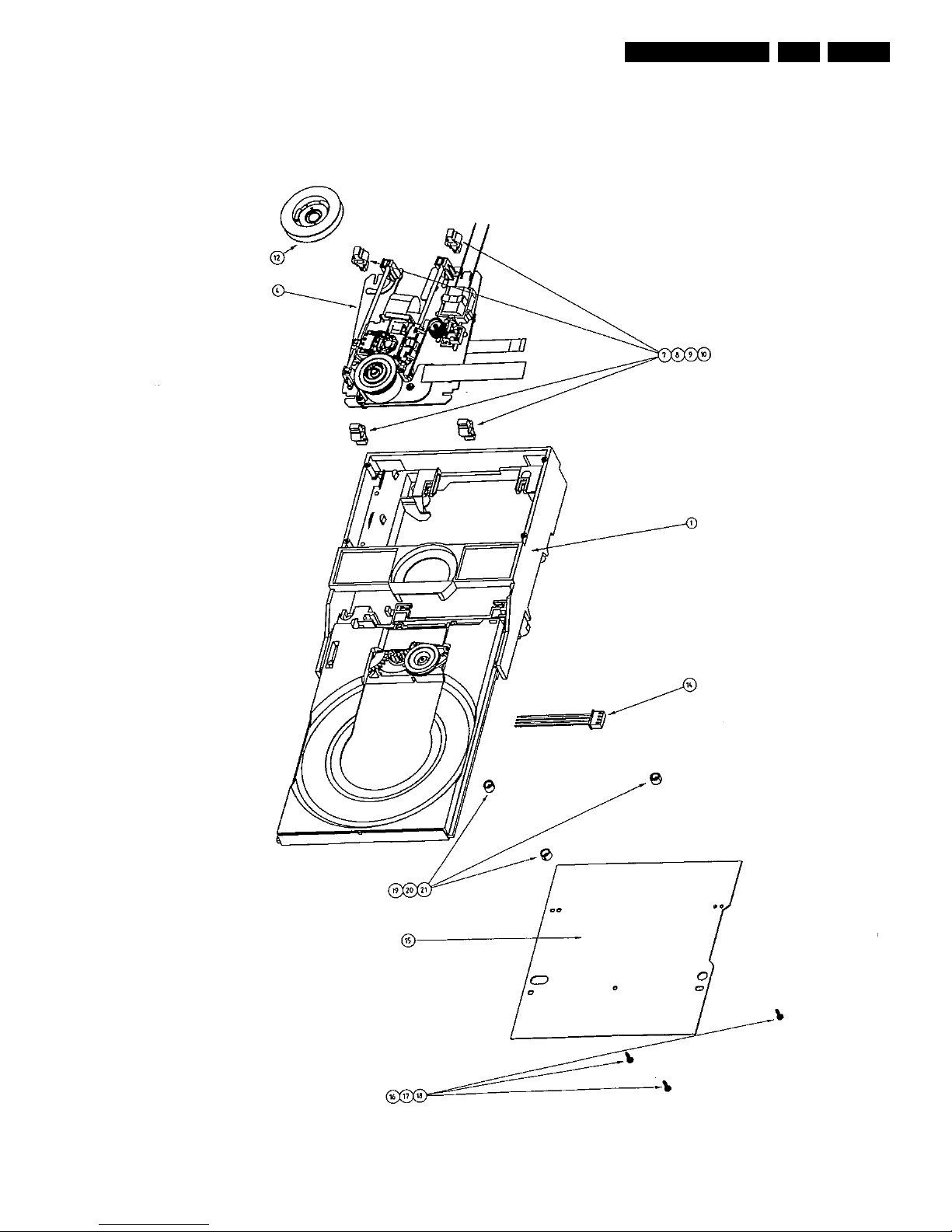

Exploded View VAE5020 9

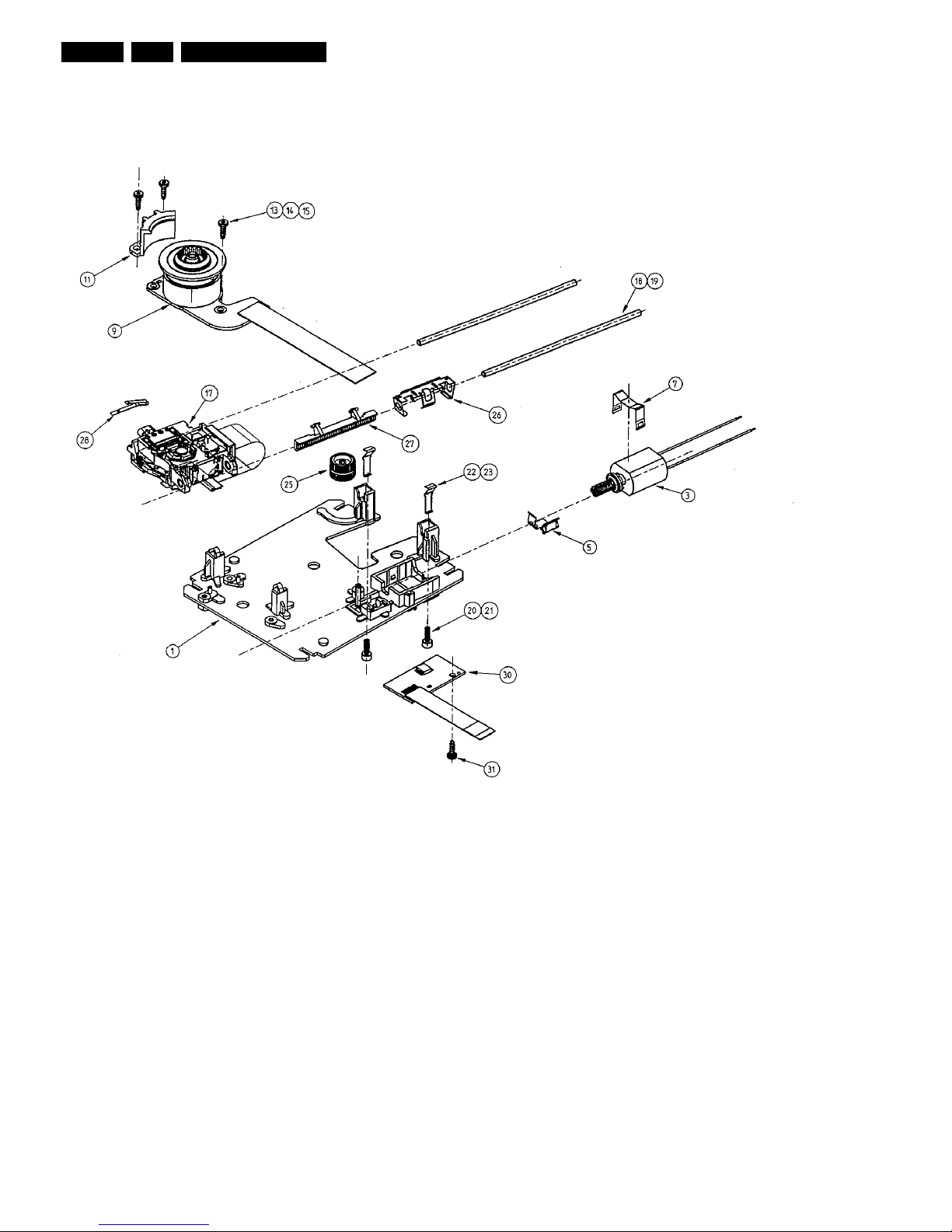

Exploded View VAM5020 10

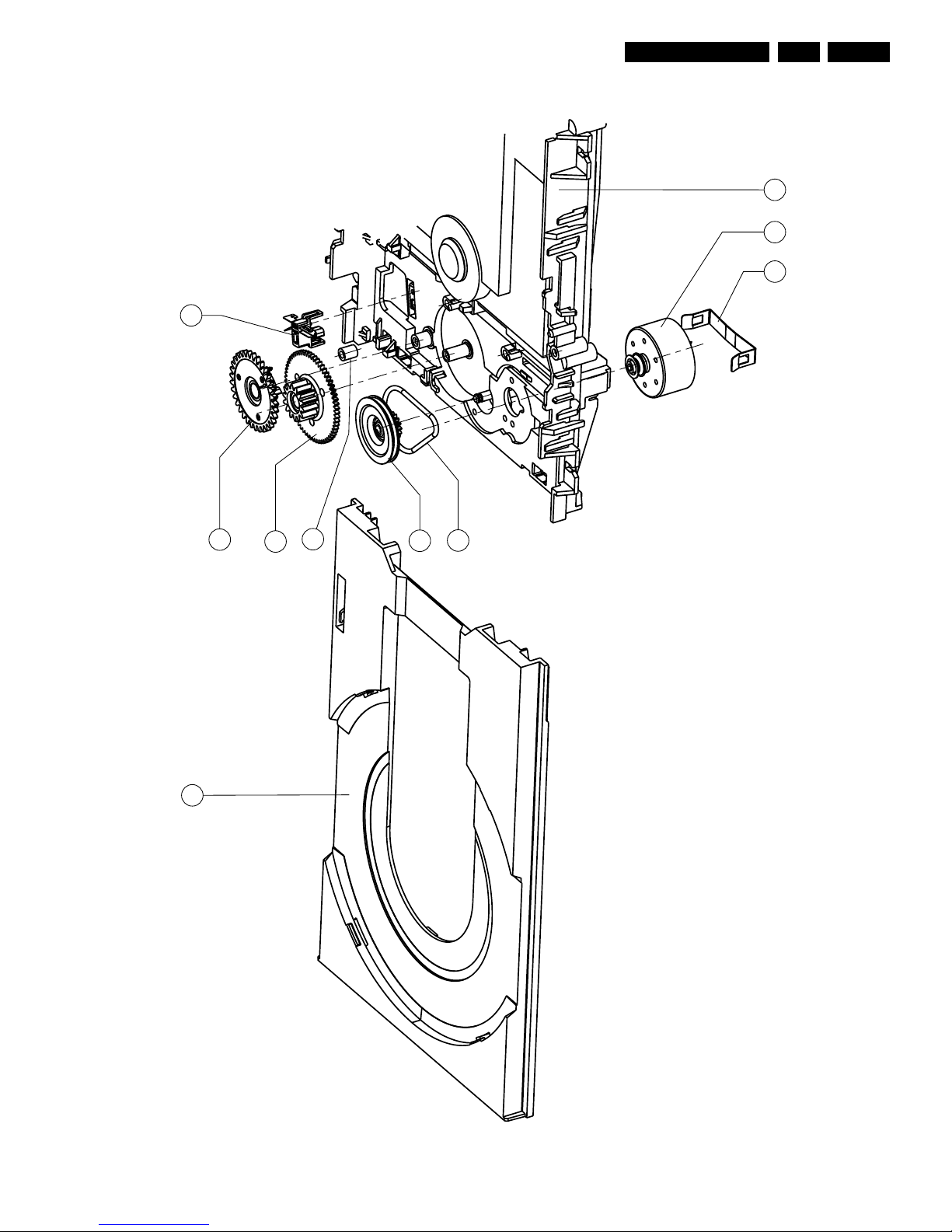

Exploded View Freya Loader 11

5 Trouble Shooting 12

6

Block Diagrams

Block Diagram Freya Module 25

Block Diagram Mozart Back-End Module 26

7

Electrical Diagrams and PWB’s Diagram PWB

Mozart Main Board(Diagram 1) 27 32-37

Mozart Main Board(Diagram 2) 28 32-37

Mozart Main Board(Diagram 3) 29 32-37

Mozart Main Board(Diagram 4) 30 32-37

Mozart Main Board(Diagram 5) 31 32-37

Mozart Main Board Testpoints 38-40

Freya Servo Board(Overview) 41 46-47

Freya Servo Board(Part 1) 42 46-47

Freya Servo Board(Part 2) 43 46-47

Freya Servo Board(Part 3) 44 46-47

Freya Servo Board(Part 4) 45 46-47

Freya Servo Board Testpoints(Bottom View) 48

8 Alignments, Adjustments 49

9 Circuit and Functional Description 50

List of Abbreviations 56

10 Mechanical and Electrical Spare Parts List 58

Introduction / Technical Specifications

GB 2 CDR Mozart1.

1. Introduction / Technical Specifications

1.1 General

CD Recording Mozart Module is a module for playback of

Audio/Data CD’s (incl. CD R/W) and recording on Audio CDR and CD-R/W Disc consisting of:

• CD (Recording) Drive Mechanism

• Tray Loading Mechanism

• Front-end Board inclusive CD -Servo control Software

• Backend Board containing Application software

• Metal Encasing (for EMC Screening and mechanical

fixation)

Not included is the User Interface that has to be handled by

the Set front application. This user interface controls

functions that are set independently like: display and key

handling.

Note: The EMC screening is not mounted in some

applications.

The CD (Recording) Drive Mechanism, Tray Loading

Mechanism and Front-end Board part of the module can

have 2 different executions. One is called FREYA the other

RACOON. As information and repair activity about

RACOON is not defined yet, this part is not included in this

Service Manual.

Notice that both Mechanisms can not be interchanged, so

RACOON has to be replaced by RACOON, FREYA by

FREYA. As both parts can only be repaired with the help of

CDR-ComPair, the ComPair tool will contain the instructions

for both mechanisms.

1.2 Key Features / Functions

Playback Capability

• standard Audio/Data CD’s

– MP3/AAC audio format

– Software up-grade possibility via CD Disc

• fully (‘Red Book included CD-extra’) or unfinalized partly

recorded CD-R and CD-R/W Discs

Recording Capability

• Audio CD-R Discs

• Recording / Erasure of CD R/W Discs

Double speed recording (from EBU input only)

4x speed (only in some applications)

CD Text (Playback and Recording)

Audio Signal Inputs

• Analog (ADC on board)

• Digital (EBU)

Audio Signal Outputs

• Analog (DAC on board)

• Digital (EBU)

CD10 (Philips) CD-decoder connection for multiple CDplayback changers

1.3 Hardware interface

Interface connectors are located at the rear of the Module

and are accessible via a horizontal slot.

1.3.1 Connector 1214: Supply Interface

1. +5 V

2. +5 V

3. Ground (D)

4. Ground (D)

5. Ground (S) (motor ground)

6. +12 V

1.3.2 Connector 1007: Control Interface

1. Ground (D) / (Shield)

2. I

C-Data

3. Ground (D)

4. I

C Clock

5. Reset

6. IRQREQ

1.3.3 Connector 1402: Audio Signal Interface

1. Analog In (Rec.) Left

2. Ground (A)

3. Analog In (Rec.) Right

4. Ground (A)

5. Analog Out (PB)Right

6. Ground (A)

7. Analog Out (PB) Left

1.3.4 Connector 1203: Digital In / out

1. +5 V

2. EBU Signal (output)

3. EBU Signal (input - optical) /Ground(D)

4. EBU Signal (input Coax)

5. Ground (D)

1.3.5 Connector 1205: CD Interface for MP3 Playback

1. Ground

2. SDA (output / input)

3. SICL

4. RAB

5. SILD

6. Reset CD10

7. EBU Signal (input)

8. EBU Ground

1.3.6 Connector 1215: I/O Interface for Separate AD/DA

connections

1. EBU_OUT_ENGINE/GND

2. PROF_DIG_OUT/GND

3. EBU_CD10

4. GND

5. IIS_DATA1 / GND

6. IIS_CLK1 / GND

7. DEEMP

8. IIS_WLK1/GND

9. PWR_ON_RESET

10. IIS_CLK4

11. GND

12. IIS_WLK4

13. MUTE

14. IIS_DATA4

15. GND

16. CLK_16

17. KILL

1.3.7 Connector 1209: External DAC and ADC interface for

Better AD/DA (Optional)

1. MUTE

2. I2S_CLK2

3. GND

4. I2S_WS2

5. DEEMP

6. I2S_DATAO2

7. GND

Introduction / Technical Specifications

GB 3CDR Mozart 1.

8. I2S_DATAI3

9. KILL

10. I2S_CLK3

11. GND

12. I2S_WS3

13. + 12Va

14. CLK_11

15. - 12Va

16. RST_ADDA

17. COPY_ANALOG

1.3.8 Connector 1201: Engine I/O

1. WCLK

2. BCLK

3. GND

4. Data_O

5. Data_I

6. GND

7. RCK

8. SFSY

9. SUB

10. FLAG

11. V4

12. MUTE

13. ATTI

14. DEEPI

15. GND

16. EBUOUT

17. GND

18. NRST

19. MAS-SLA

20. GND

21. SYSCLK

22. GND

23. EAN

24. SUR

25. CPR

26. TXD1

27. RXD1

28. +5V

29. +5V

30. GND

31. GND

32. GND

33. GND

34. +12V

35. +12V

36. +12V

1.4 Audio Performance CD Playback

Channel unbalance : < 0.3 dB

Frequency response : < 0.3dB for 20Hz -

20kHz

SNR (bipolar zero, unweighted) : > 95dB, 98 dB typ.

SNR (bipolar zero, A-weighted) : > 98dB, 100 dB typ.

Dynamic range : > 92dB, 96 dB typ

(1kHz.).

THD+N / S (20Hz - 20kHz) : > 85dB, 91 dB

typ.(1Khz)

Outband Attenuation : > 50dB for 30KHz.<

f<200kHz

Crosstalk (1kHz) : > 90dB, 100 dB typ.

Crosstalk (20Hz - 20kHz) : > 85dB, 93 dB typ.

Emphasis : 15/50s

Muting during access :

(Audio Signals Disc 1, track 1 (

99) : Typ. 69dB

unweighted

: Typ. 80dB A-

weighted

1.5 Audio Performance Analog Recording /

Digital Playback

Channel unbalance : < 0.5 dB

Frequency response : < 0.5dB for 20Hz -

20kHz

SNR (bipolar zero, unweighted) : > 84dB, 88 dB typ.

Dynamic range : > 86dB

THD + N / S (20Hz - 20kHz) : > 80dB, 85 dB typ.

Crosstalk (20Hz - 20kHz) : > 80dB at 1 kHz

Safety and Maintenance Instructions Warnings and Notes

GB 4 CDR Mozart2.

2. Safety and Maintenance Instructions Warnings and Notes

SHOCK, FIRE HAZARD SERVICE TEST:

CAUTION: After servicing this appliance and prior to returning to customer, measure the resistance between

either primary AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the

face or Front Panel of product and controls and chassis bottom,

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC

power is applied, and verified before return to user/customer.

Ref.UL Standard NO.1492.

NOTE ON SAFETY:

Symbol

: Fire or electrical shock hazard. Only original parts should be used to replace any part with symbol

Any other component substitution(other than original type), may increase risk or fire or electrical shock hazard.

F

ATTENTION

Tous les IC et beaucoup d'autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu'aucune précaution

n'est prise a leur manipulation.

Lors de réparations, s'assurer de bien être

relié au même potentiel que la masse de

l'appareil et enfiler le bracelet serti d'une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l'on utilise soient également a ce

potentiel.

D

WARNUNG

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

NL

WAARSCHUWING

Alle IC's en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell'apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

GB

WARNING

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l'apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

F

Les normes de sécurité exigent que l'appareil soit remis a l'état d'origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

CL 96532086_021.eps

080999

Safety and Maintenance Instructions Warnings and Notes

GB 5CDR Mozart 2.

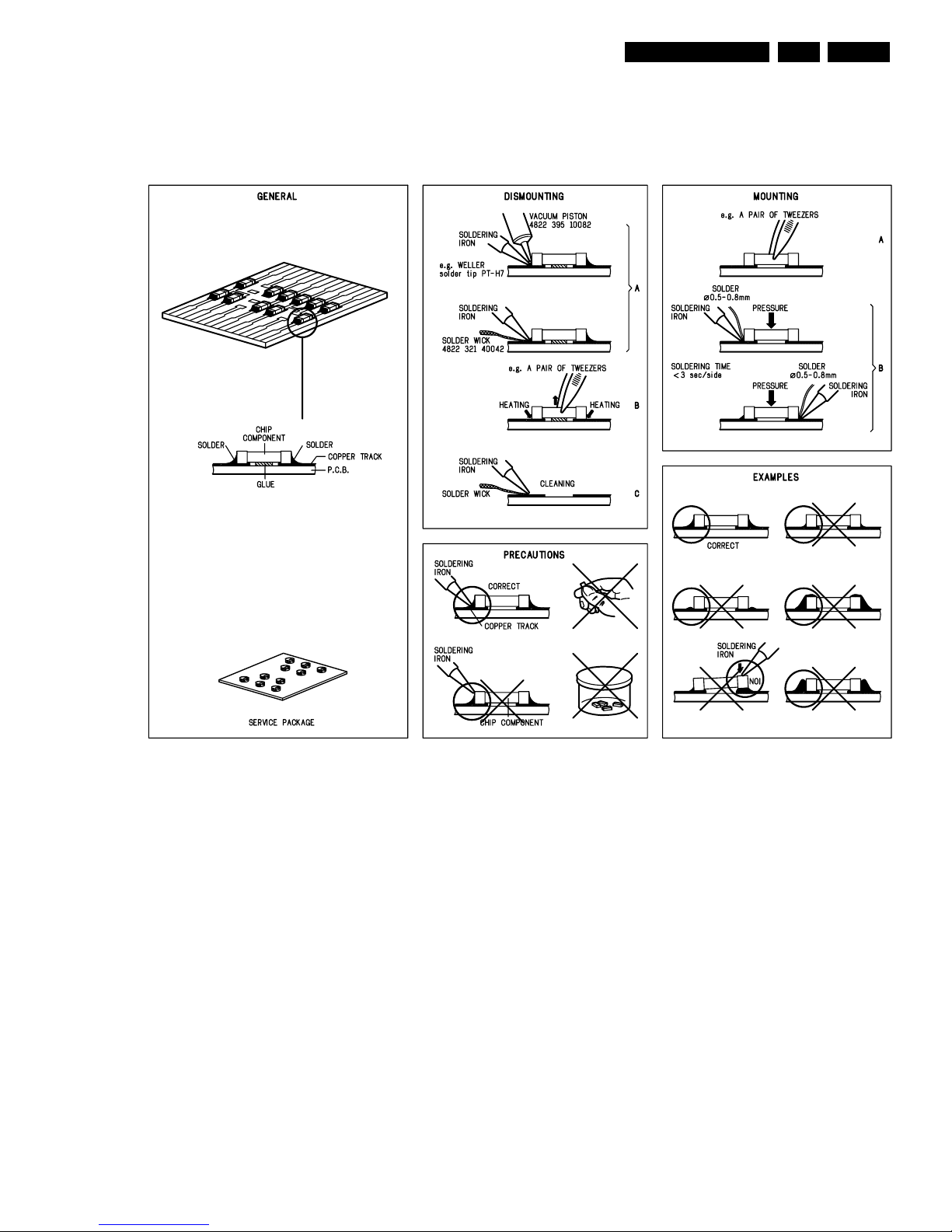

SERVICING HINTS

In the set, chip components have been applied. For disassembly and assembly check the figure below.

CL 96532086_022.eps

080999

Safety and Maintenance Instructions Warnings and Notes

GB 6 CDR Mozart2.

CL 96532086_023.eps

080999

Instructions for Use

GB 7CDR Mozart 3.

3. Instructions for Use

See Service Manual of concerned modelnumber in which the

instructions for use have been inserted. This chapter has not

been filled as this CDR Mozart Module is only a part of a

complete set.

4. Mechanical instructions

4.1 CD Recording Drive Mechanism

The CD (Recording) Drive Mechanism, Tray Loading

Mechanism and Front-end Board part of the module (also

called CD R/W BASIC ENGINE) can have 2 different

executions. One is called FREYA the other RACOON. As

information and repair activity about RACOON is not defined

yet, this part is not included in this Service Manual.

Notice that both Mechanisms can not be interchanged, so

RACOON has to be replaced by RACOON, FREYA by

FREYA. As both parts can only be repaired with the help of

CDR-ComPair, the ComPair tool will contain the instructions

for both mechanisms.

Mechanical instructions

GB 8 CDR Mozart4.

Exploded View CDR-Module

CL 16532046_001.eps

130701

1001

ITEM DESCRIPTION CODENUMBER

1 VAE 5020/01 LOADER 9305 025 52001

2-3,13-14 SCREW PLASTITE M2x6 2511 076 50002

4 SHIELDING BOTTOM 3103 301 45360

5 SHIELDING TOP 3103 301 45370

6-12 SCREW TAPTITE M3x6 2511 077 00039

1001 MOZART BOARD

Mechanical instructions

GB 9CDR Mozart 4.

Exploded View VAE5020

EXPLODED VIEW VAE5020

CL 16532046_002.eps

101001

ITEM CODENUMBER DESCRIPTION

1 3139 197 60100 FREYA LOADER ASSY

4 9305 022 52001 VAM5020/01

7 3139 194 00790 SUSPENSION

8 3139 194 00790 SUSPENSION

9 3139 194 00790 SUSPENSION

10 3139 194 00790 SUSPENSION

12 3139 197 60060 CLAMPER

15 3139 198 00280 FREYA2 SERVO BOARD

Mechanical instructions

GB 10 CDR Mozart4.

Exploded View VAM5020

EXPLODED VIEW VAM5020

CL 16532046_005.eps

101001

ITEM CODENUMBER DESCRIPTION

1 3139 197 50100 OUTSERT MOUNTING PLATE ASSY

3 3139 198 00200 SLEDGE MOTOR ASSY

5 3139 191 20380 THRUST SPRING

7 4822 402 61558 CLAMPING BRACKET

9 3139 198 00230 FREYA 2 MOTOR AND TURNTABLE

11 3139 194 00660 MOTOR CATCH

13 3139 190 40100 PLASTIC SCREW 2 X 7

14 3139 190 40100 PLASTIC SCREW 2 X 7

15 3139 190 40100 PLASTIC SCREW 2 X 7

17 9305 011 24252 OPU-24.25

18 3139 191 20370 SPINDLE

19 3139 191 20370 SPINDLE

25 3139 194 00700 COMBI WHEEL

26 3139 191 20400 RACK SPRING

27 3139 194 00770 RACK

28 3104 141 21830 THIRD BEARING SPRING

30 3139 198 00270 Board-FLEX ASSY FREYA

31 3139 190 40100 PLASTIC SCREW 2 X 7

Mechanical instructions

GB 11CDR Mozart 4.

Exploded View Freya Loader

CL 16532046_003.eps

040701

11

09

06

08

10

05

04

16 12 13

04 4822 358 10266 BELT LOADER

05 PULLEY WHEEL

06 TRAY GEAR WHEEL

08 RACK GEAR WHEEL

09 3139 198 80010 SWITCH

10 4822 532 13097 TULE

11 3139 194 00800 TRAY BLACK

12 3139 197 50060 TRAY MOTOR ASSY

13 3139 194 00740 CHASSIS

16 MOTOR SPRING

Trouble Shooting

GB 12 CDR Mozart5.

5. Trouble Shooting

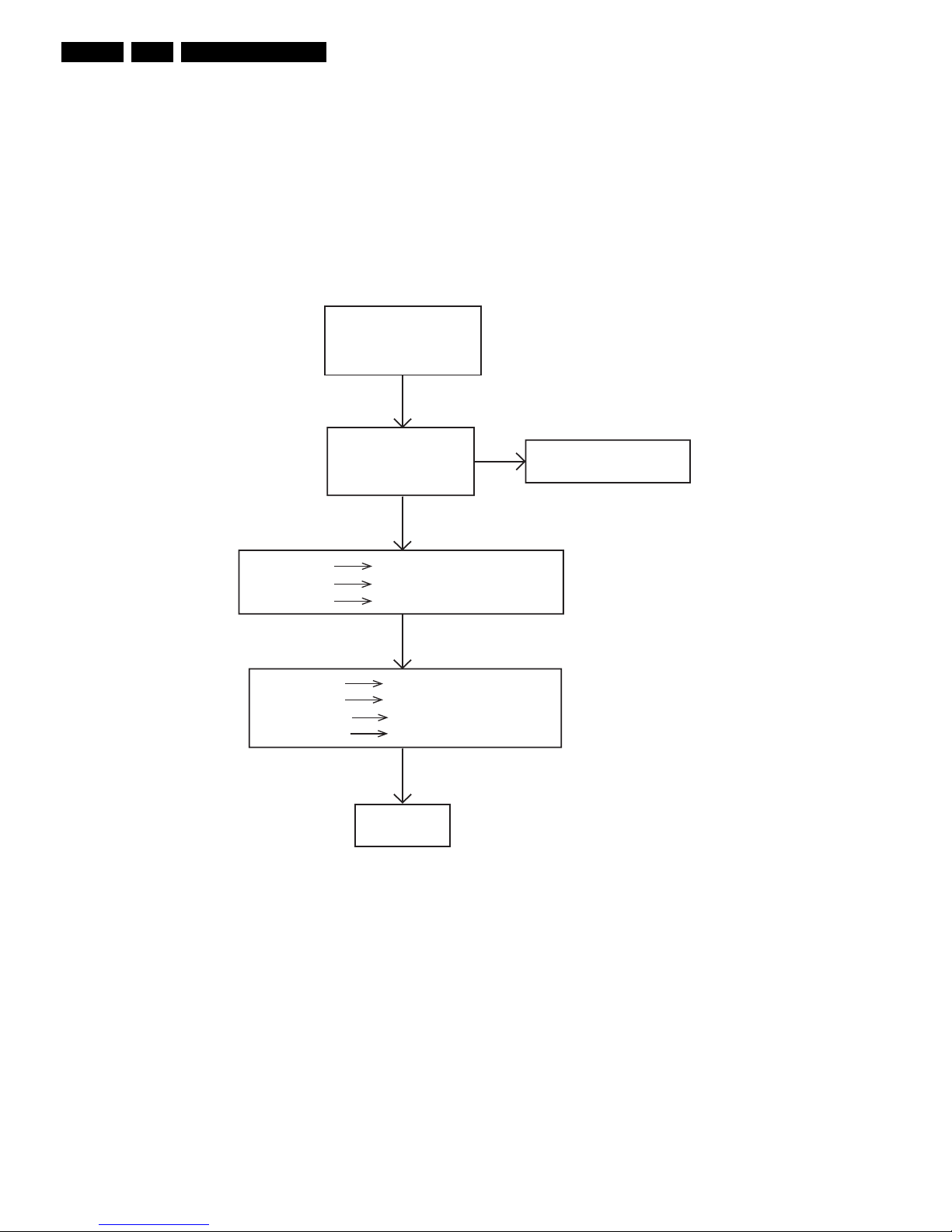

Power Part Check

Switch On

Power Supply

+12V(+/-10%) testpoint 1

+5V(+/-10%) testpoint 2

+12V_MOT testpoint 3

+5V_BE testpoint 4

Check Power Supply Unit

Check Fuse 1211 and 1212

NOK

OK

OK

OK

OK

-12V testpoint 5

NOK

NOK

NOK

Check IC 7202, R3222 and D6203

+3V3 testpoint 6

+2V5 testpoint 7

Check Voltage Regulator 7208

Check Voltage Regulator 7209

Check Voltage Regulator 7201

+8VA testpoint 8

+5VA testpoint 9

-8VA testpoint 10

-5VA testpoint 11

NOK

NOK

NOK

NOK

Check IC 6204

Check IC 7200

Check IC 7200 and Diode 6202

Power Part

Power Part Check

USE MOZART MAIN BOARD CIRCUIT DIAGRAM 3 AND MOZART MAIN BOARD BOTTOM-AND TOP VIEW: TEST POINTS

CL 16532046_006.eps

101001

Trouble Shooting

GB 13CDR Mozart 5.

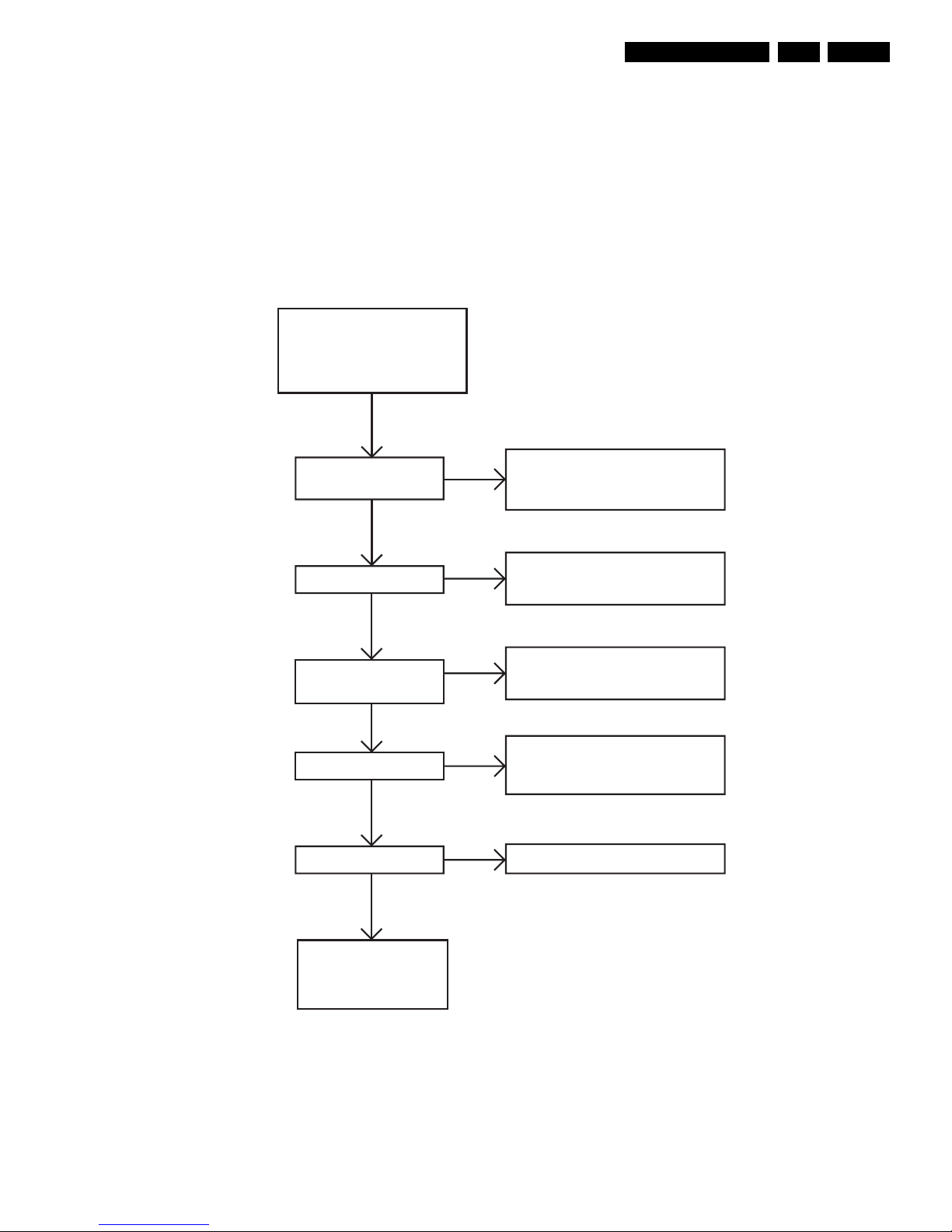

Power Part Check FREYA Servo

Board

Switch On

Power Supply

+12V testpoint 12

+3V3 testpoint 14

FS30V testpoint 15

= +27V

+5V testpoint 13

- Check Fuse 1543 and 1541

- Check D 6541, D6543

- Check Mozart Back-end board

- Check Fuse 1501

- Check T 7020

NOK

NOK

- Check D 6554

- Check L 5554

NOK

OK

OK

-8V testpoint 16

- Check D 6547

- Check L 5553

- Check T 7547

NOK

-5V testpoint 17

- Check IC 7556

NOK

OK

OK

OK

OK

Power Part

Freya mainboard

Power Part Check FREYA Servoboard

USE FREYA SERVOBOARD CIRCUIT DIAGRAM3 AND FREYA SERVOBOARD BOTTOM-AND TOP VIEW: TEST POINTS

CL 16532046_045.eps

101001

Trouble Shooting

GB 14 CDR Mozart5.

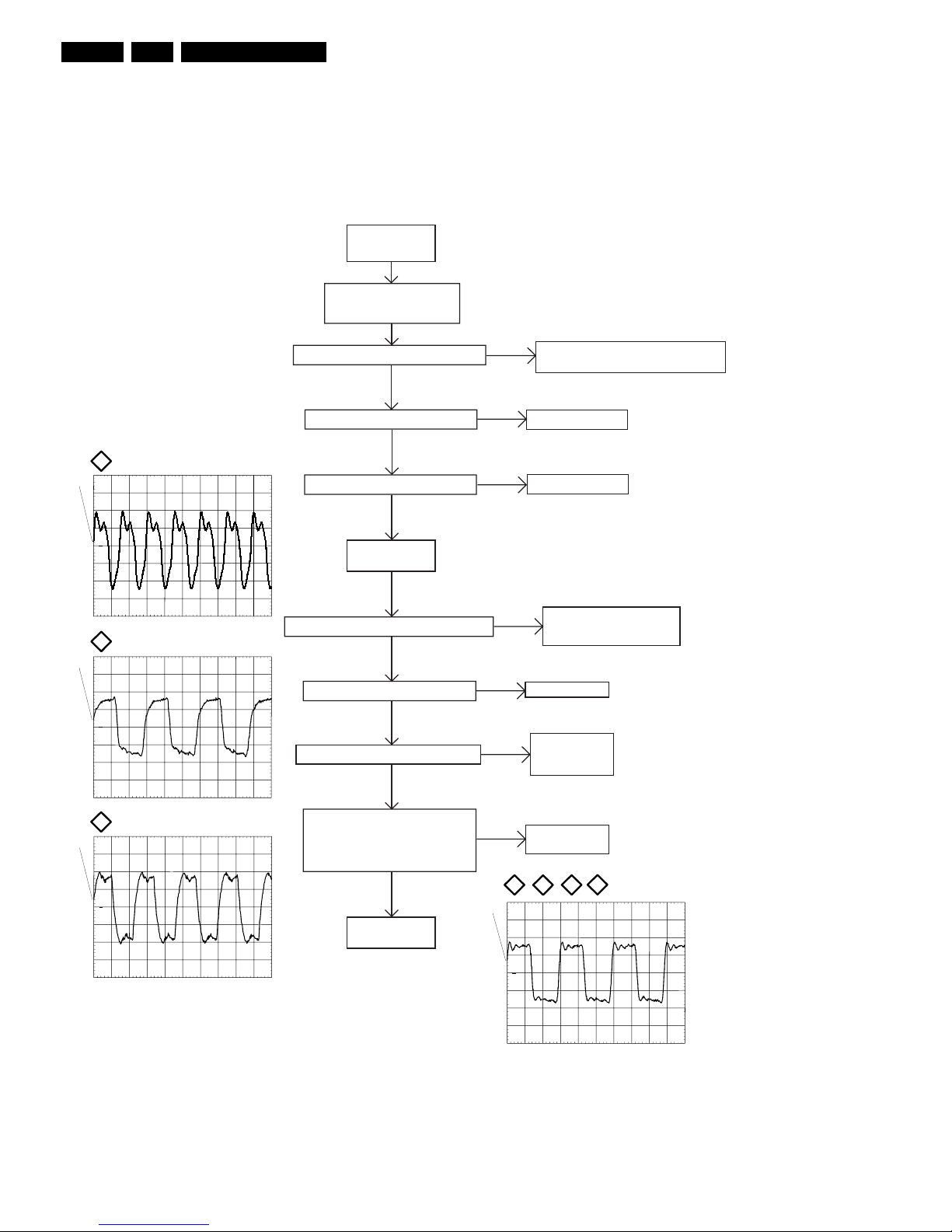

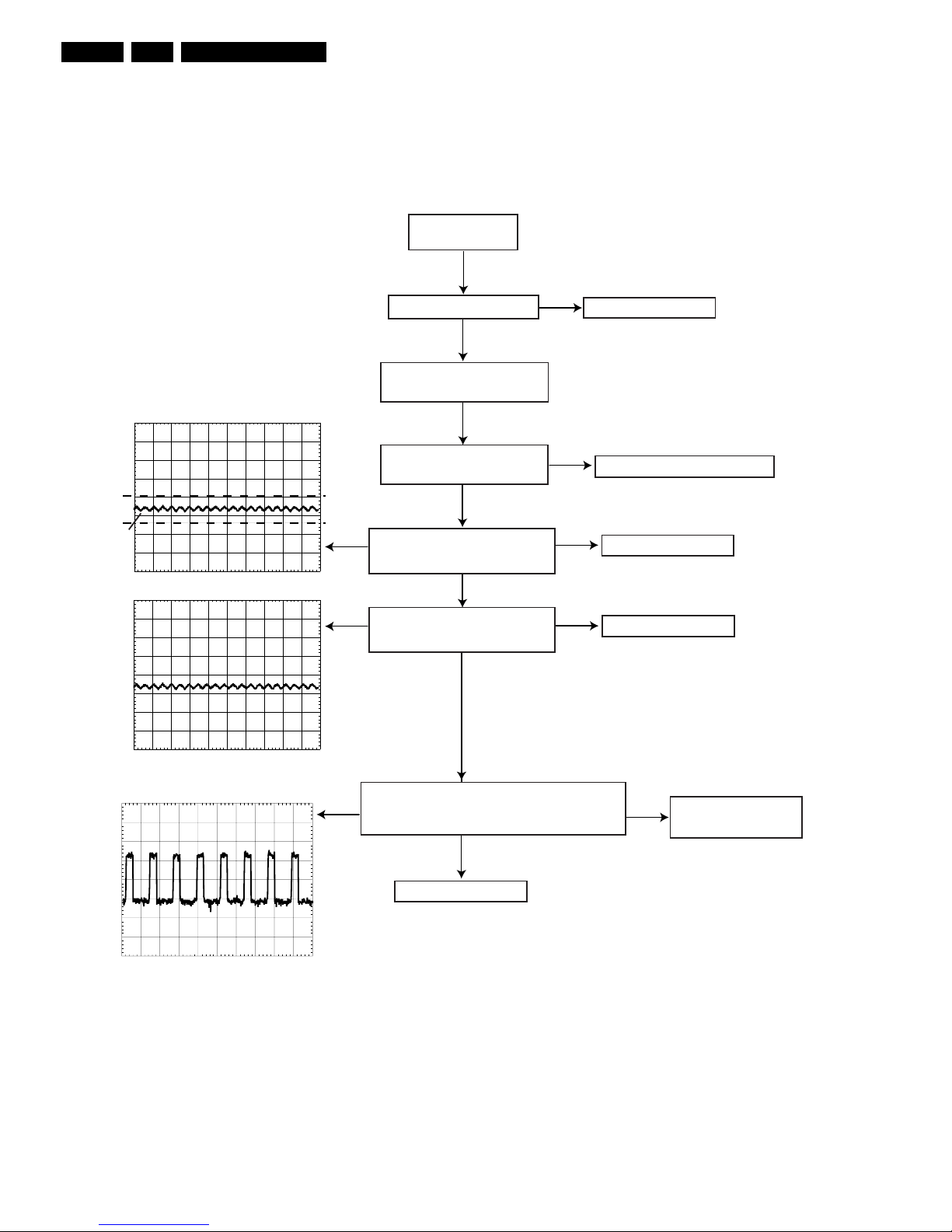

Reset & Clock Check

Switch on the

Power Supply

Power On Reset (+3V3) testpoint R1

OK

OK

OK

OK

OK

OK

OK

OK

NOK

Check IC7000

NOK

Check IC7000

Check IC7000

NOK

RST ADDA (+3V3) testpoint R2

RST FREYA (+3V3) testpoint R3

RESET Signals

OK

CLOCK Signals

OK

MAIN_CLK 33,8688MHz testpoint R4

NOK

Check X-tal 1005

Check D6002 and D6003

Check IC7000

NOK

Check IC7000

NOK

Check IC7004

SYS_CLK 16,9MHz testpoint R5

FREYA_CLK 8,5MHz testpoint R6

Check IC7012

Check R3019

NOK

Check IC7010

Check R3028

DAC_CLK 16,9MHz testpoint R7

ADC_CLK 16,9MHz testpoint R8

IO_CLK 16,9MHz testpoint R9

IO_CLK ABBA testpoint R10

RESET & CLOCK CHECK

USE MOZART MAIN BOARD CIRCUIT DIAGRAM 1 AND MOZART MAIN BOARD BOTTOM-AND TOP VIEW: TESTPOINTS

ch1

ch1: pkpk= 4.50 V

ch1: freq= 33.8MHz

CH1 1.00 V~ MTB20.0ns ch1+

1

ch1

ch1: pkpk= 3.34 V

ch1: freq= 16.9MHz

CH1 1.00 V~ MTB20.0ns ch1+

1

ch1

ch1: pkpk= 4.12 V

ch1: freq= 8.51MHz

CH1 1.00 V~ MTB50.0ns ch1+

1

ch1

ch1: pkpk= 3.50 V

ch1: freq= 16.9MHz

CH1 1.00 V~ MTB20.0ns ch1+

1

R4

R5

R6

R7

R8

R9

R10

Display uP generates

the Power On Reset

Check connection to Display board

CL 16532046_007.eps

101001

Trouble Shooting

GB 15CDR Mozart 5.

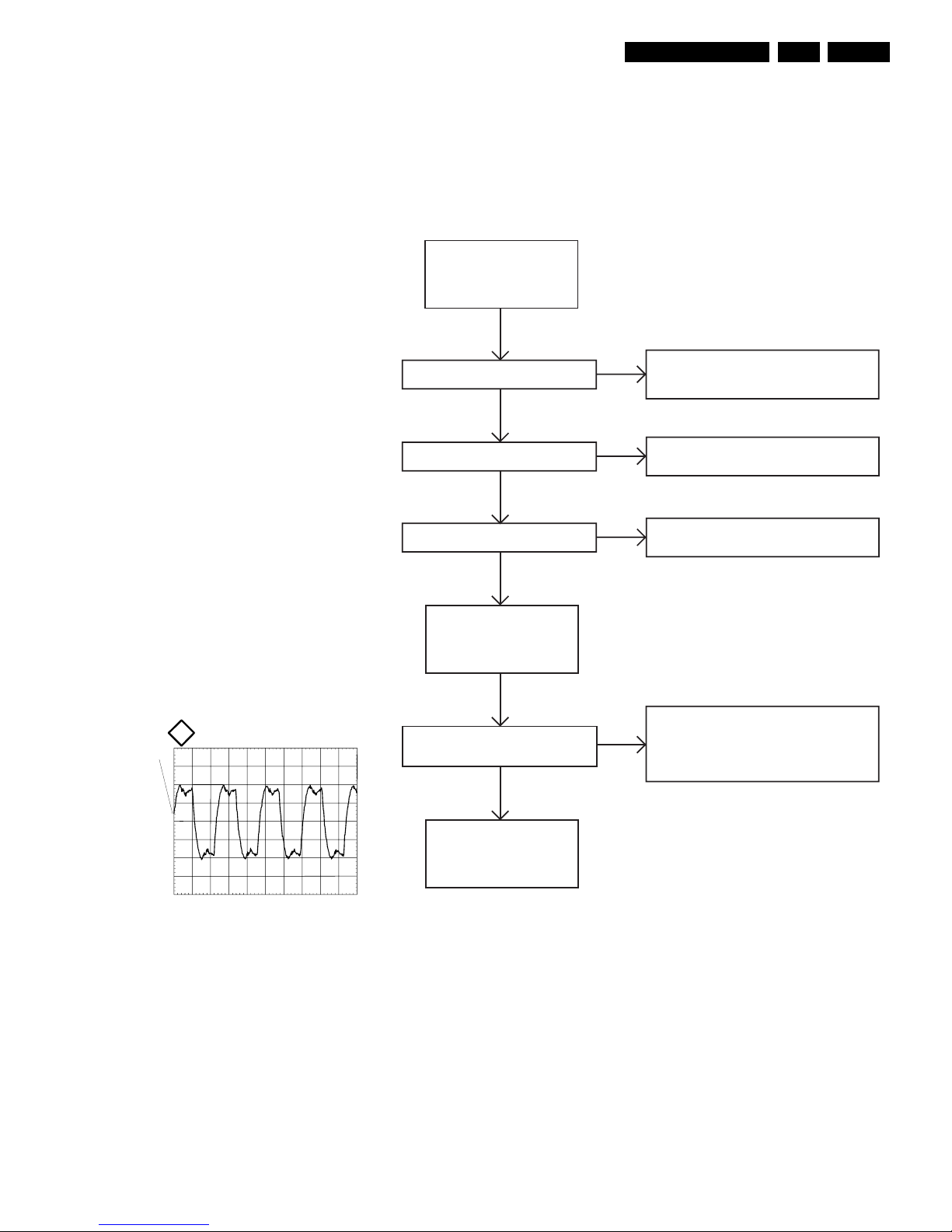

Reset & Clock Check FREYA Servo Board

Switch On

Power Supply

Check connection from CDR Freya

Servoboard connector 1000 to

connector 1201 on CDR Mozart mainboard

NOK

Check connection from CDR Freya

Servoboard connector 1000 to

connector 1201 on CDR Mozart mainboard

- Check IC 7019

- Check IC 7018

NOK

NOK

OK

OK

Reset and Clock Check FREYA Servoboard

USE FREYA SERVOBOARD CIRCUIT DIAGRAM1 AND 4 AND FREYA SERVOBOARD BOTTOM-AND TOP VIEW: TEST POINTS

+3V3 on testpoint R11

NRST-signal(+3V3) on testpoint R12

- Check T 7108

- Check D 6020 and D 6021

NOK

OK

RESET_N(low) on testpoint R13

SYSCLK = FREYA_CLK 8.5MHz

on testpoint R14

- Check T 7107

- Check R 3153

Reset part

OK

OK

Clock FREYA

OK

OK

ch1

ch1: pkpk= 4.12 V

ch1: freq= 8.51MHz

CH1 1.00 V~ MTB50.0ns ch1+

1

R14

CL 16532046_046.eps

101001

Trouble Shooting

GB 16 CDR Mozart5.

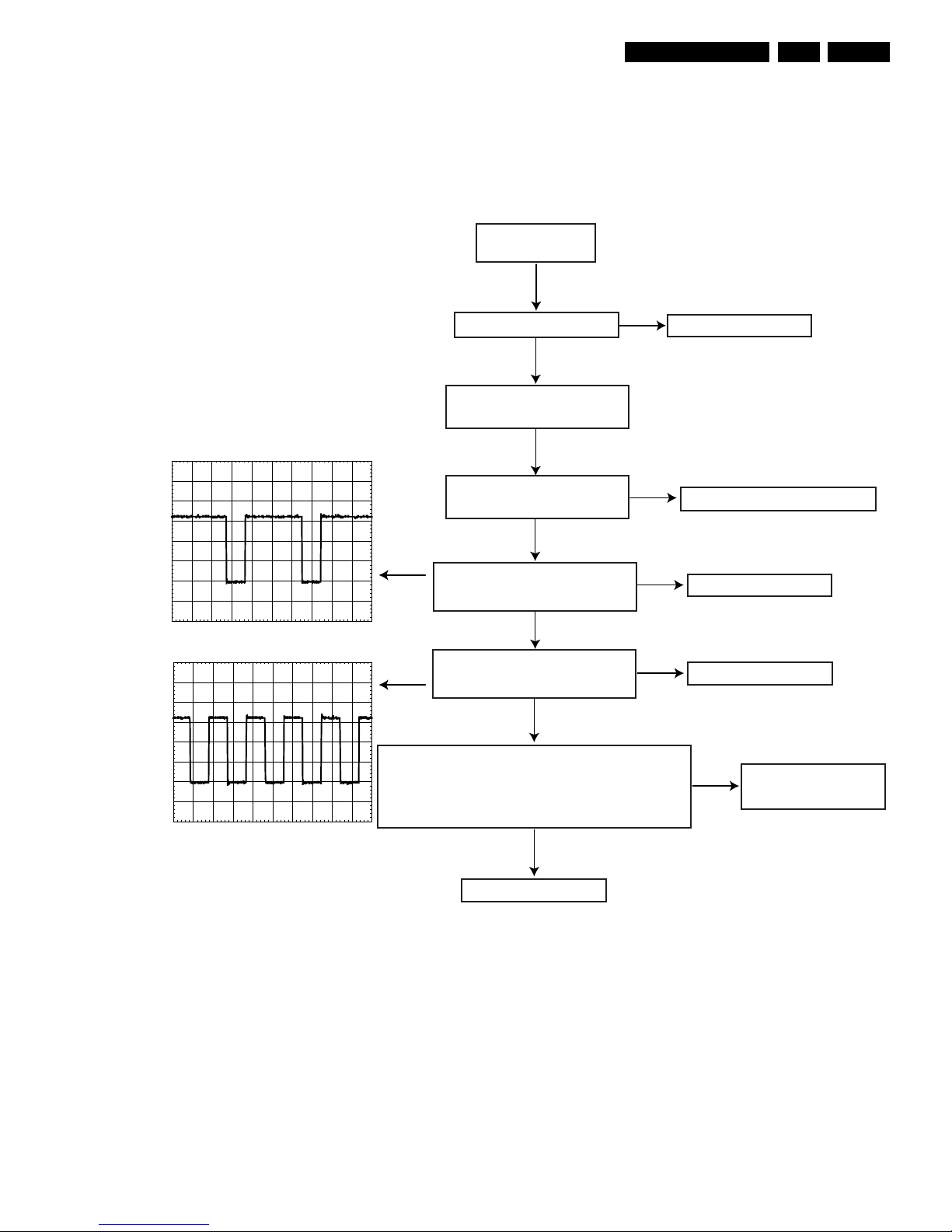

Servo Drivers Check (Focus Servo)

NOK

OK

OK

FOCUS SERVO OK

Switch on player

via ComPair mode

SERVO DRIVERS CHECK

USE FREYA2 CIRCUIT DIAGRAM 1 and 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

Execute "focus" tests

Check power part

Check reset and clock part

Check

S1V65

(=1V65) at

testpoint S9

NOK

Check R3002, R3065, C2054

OK

Check MACE 7019

OK

NOK

Check driver 7003

Check MACE 7019

Check VAM5020

OK

FOCUS SERVO OK

FOCUS SERVO

OK

NOK

Check

VFO

signal

on testpoint S16 (TP59,TP153)

Execute "focus off" test

Check MACE 7019

NOK

PM3392A

CH1:500mV= MTB2.00us

VFO

GND

PM3392A

CH1:500mV= MTB2.00us

VFO

GND

Moving between

1V3 and 2V

PM3392A

ch1: freq= 1.61 Hz

CH1:50.0mV= MTB 500ms

GND

FOC-/FOC+

CL 16532046_012.eps

101001

Check

VFO

signal

on testpoint S16 (TP59)

Execute "focus on" test

Check signal across

FOC+/FOC-

on testpoints S17 (TP57)

and S18 (TP58) when executing "focus on"

Trouble Shooting

GB 17CDR Mozart 5.

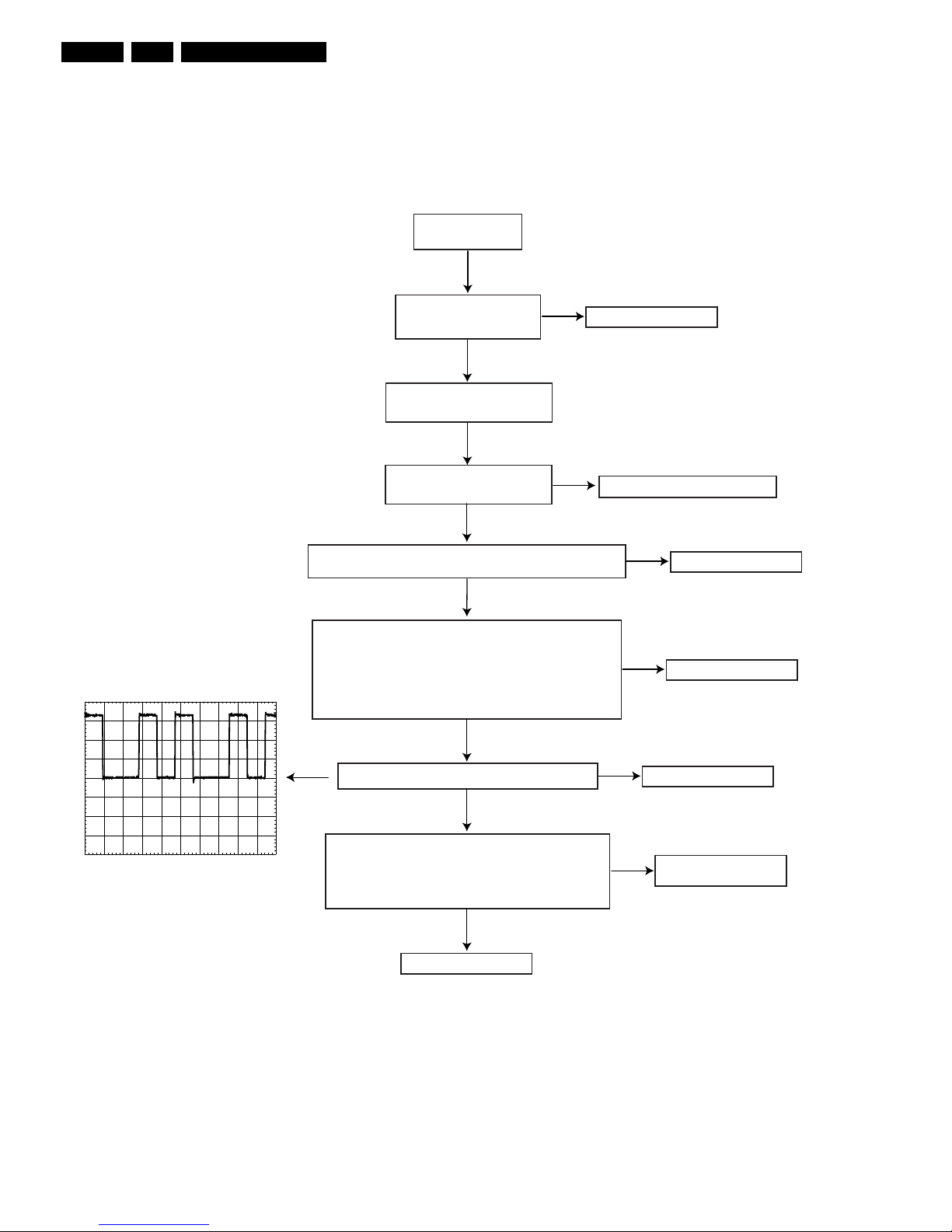

Servo Drivers Check (Radial Servo)

NOK

OK

OK

RADIAL SERVO OK

SERVO DRIVERS CHECK

USE FREYA2 CIRCUIT DIAGRAM 1 AND 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

Execute "radial control" tests

Check power part

Check reset and clock part

Check

S1V65

(=1V65) at

testpoint S9

NOK

Check R3002, R3065, C2054

OK

Check MACE 7019

OK

VRA

GND

Check

RAD+

signal on testpoint S14 (TP53):

+4V2 (going to 6V8 when executing "radial control on")

Check

RAD-

signal on testpoint S15 (TP56):

+0V65 (going to 4V3 when executing "radial control off")

NOK

OK

RADIAL SERVO OK

RADIAL SERVO

OK

Execute "radial control on" test

Check

VRA

signal on

testpoint S13 (TP152)

PM3392A

ch1:freq=532kHz

CH1:1.00 V= MTB 500ns

NOK

Execute "radial control off" test

Check

VRA

signal on

testpoint S13 (TP152)

PM3392A

ch1:freq=1.06MHz

CH1:1.00 V= MTB 500ns

VRA

GND

Check MACE 7019

NOK

Check driver 7003

Check MACE 7019

Check VAM5020

CL 16532046_013.eps

101001

Switch on player

via ComPair mode

Trouble Shooting

GB 18 CDR Mozart5.

Servo Drivers Check (Sledge Servo)

NOK

OK

OK

SLEDGE SERVO OK

SERVO DRIVERS CHECK

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 1 AND 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

Execute "sledge inwards"

and "sledge outwards" tests

Check power part

Check reset and clock part

Check voltages testpoints S4, S5, S7, S8

(TP95, TP94, TP112, TP96) : +/- 1.6V

OK

NOK

Check VAM5020

NOK

Check opamp 7010

Check voltage testpoint S1 : if S1=0V then S3=0V

(TP 146) if S1=1V65 then 1V<S3<4V

if S1=3V3 then S3=5V

Check voltage testpoint S2 : if S2=0V then S6=0V

(TP 147) if S2=1V65 then 1V<S6<4V

if S2=3V3 then S6=5V

Check

S1V65

(=1V65) at

testpoint S9

OK

NOK

Check R3002, R3065, C2054

OK

Check

VSL

signal at testpoint S10 (TP151)

NOK

Check MACE 7019

OK

PM3392A

CH1:1.00 V= MTB 500ns

VSL

GND

Check

SL+

signal at testpoint S11 (TP54) :

+3V (going to 5V4 when executing "sledge outwards")

Check

SL-

signal at testpoint S12 (TP55) :

+5V4 (going to 3V4 when executing "sledge outwards")

NOK

Check driver 7003

Check MACE 7019

OK

SLEDGE SERVO OK

SLEDGE SERVO

CL 16532046_014.eps

101001

Switch on player

via ComPair mode

Trouble Shooting

GB 19CDR Mozart 5.

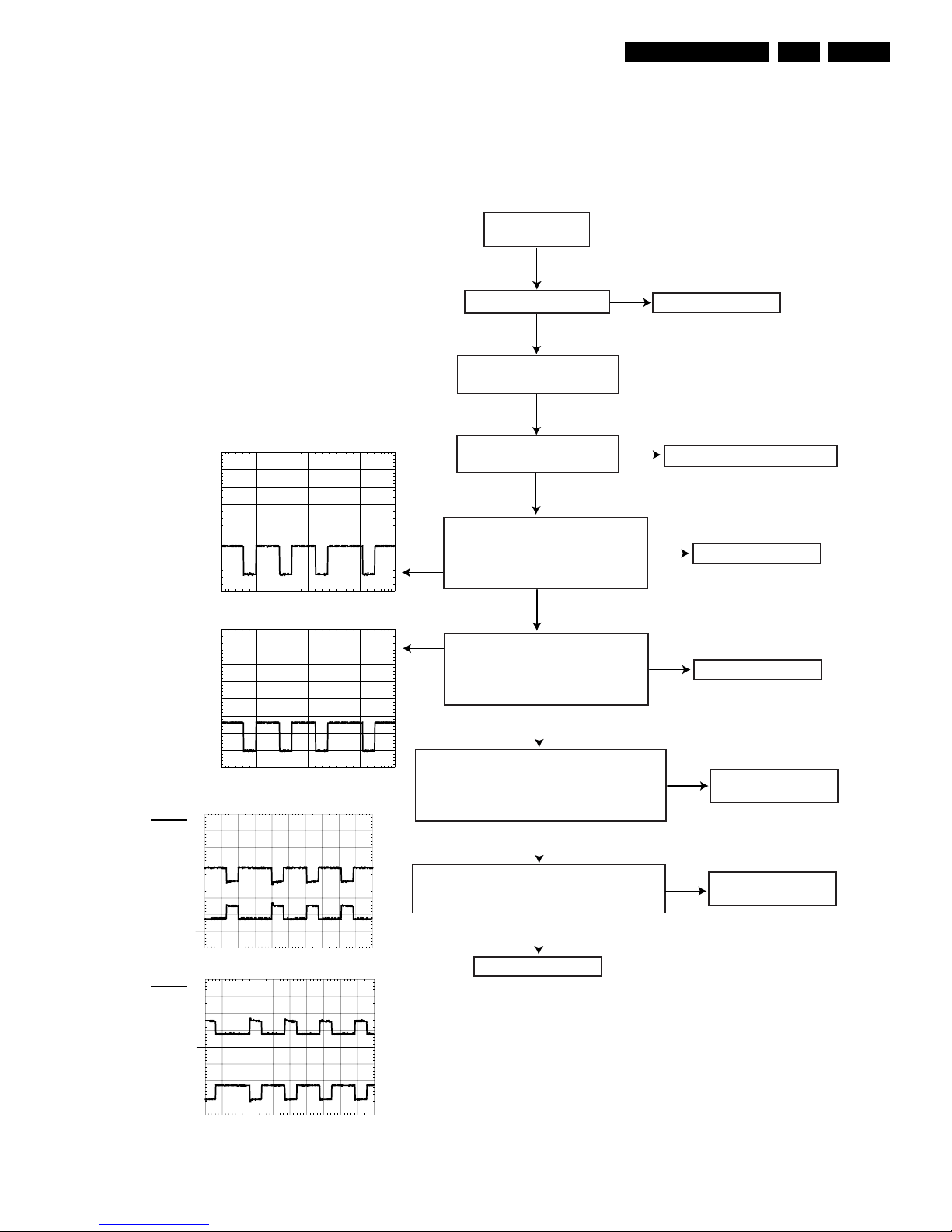

Servo Drivers Check (Tray Servo)

NOK

OK

OK

TRAY SERVO OK

SERVO DRIVERS CHECK

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 1 AND 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

Execute "TRAY" tests

Check power part

Check reset and clock part

Check

S1V65

(=1V65) at

testpoint S9

NOK

Check R3002, R3065, C2054

OK

Check MACE 7019

Check signal

TRAYSW

at testpoint S23 (TP79) :

3V3 during commands open and close,

0V after completion

Check driver 7019

Check VAL5020

OK

TRAY SERVO OK

TRAY SERVO

OK

NOK

PM3392A

CH1:2.00 V= MTB 500us

TRAYOUT

GND

Execute "tray open" test

Check

Tray Out

signal on testpoint S19

(TP177) during command

Tray In

(testpoint S20) stays at 3V2

PM3392A

CH1:2.00 V= MTB 500us

TRAYIN

GND

Check MACE 7019

OK

NOK

Execute "tray close" test

Check

Tray In

signal on testpoint S20

(TP176) during tray command

Tray Out

(testpoint S19) stays at 3V2

Check

TR+

(testpoint S21;TP77),

TR-

(testpoint S22;TP78) :

PM3392A

CH1:5.00 V=

CH2:5.00 V= MTB 500us

GNDTR-

GNDTR+

TR+

TR-

NOK

OK

PM3392A

CH1:5.00 V=

CH2:5.00 V= MTB 500us

GNDTR-

GNDTR+

osc. a

osc. b

Check VAL5020

NOK

TR+

TR-

CL 16532046_015.eps

101001

Switch on player

via ComPair mode

- values without commands 4V2

- values during "tray open" command (osc. a)

- values during "tray close" command (osc. b)

Loading...

Loading...