Philips VAE8020, VAE8015 Service Manual

DVD-Video Recorder DVD+RW Basic Engine

VAE8015

VAE8020

Contents Page Contents Page

1 Technical Specifications 2

2 Safety Instructions, Warnings and Notes 3

3 Directions for Use (No DFU necessary) 5

4 Mechanical Instructions 6

5 Service Modes, Error Codes and Fault Finding 8

6

Block Diagrams, Waveforms, Wiring Diagram

Block Diagram 15

Testpoint Overview Servo Board 43015 16

Testpoint Overview Servo Board 43353 17

7

Electrical Diagrams and Print-Layouts Diagram PWB

Servo Board 43015: Processor (Diagram 1) 18 23-24

Servo Board 43015: MACE3

Servo Board 43015: Driver

Servo Board 43015: Dec./Encoder(Diagram 4) 21 23-24

Servo Board 43015: Power (Diagram 5) 22 23-24

Servo Board 43353: Processor

Servo Board 43353: MACE3 (Diagram 2) 26 30-31

Servo Board 43353: Driver (Diagram 3) 27 30-31

Servo Board 43353: Dec./Encoder

Servo Board 43353: Power

Servo Board 43661: Processor

Servo Board 43661: MACE3 (Diagram 2) 33 37-38

Servo Board 43661: Driver (Diagram 3) 34 37-38

Servo Board 43661: Dec./Encoder

Servo Board 43661: Power (Diagram 5) 36 37-38

8 Alignments (No alignments necessary) 39

9 Circuit-, IC Descriptions and List

of Abbreviations

10 Electrical Parts List 46

11 Revision List 51

(Diagram 2) 19 23-24

(Diagram 3) 20 23-24

(Diagram 1) 25 30-31

(Diagram 4) 28 30-31

(Diagram 5) 29 30-31

(Diagram 1) 32 37-38

(Diagram 4) 35 37-38

15

39

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by GH03 0395 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12473

EN 2 VAE8015 / 80201.

Technical Specifications

1. Technical Specifications

VAE8015/VAE8020 functionality:

• Loading of 8 cm and 12 cm discs by a motorized tray

• Disc type recognition and in case of a DVD+RW disc laser

power calibration

• Servo control for disc rotation, sledge movements, tilt,

focus and actuator position

• EFM+ encoding / decoding for DVD, and EFM decoding for

CD

• Writes and read DVD+RW discs and reads DVD, CD and

CD-R/RW discs

• Linking control, header insertion and sector number

updating at record

• Interfacing to the MPEG back-end (S2B) for control and

(I2S and V4) for data

• The back-end has to provide MPEG data processing, data

buffering, construction

• of logical format for Lead-in, Data area and Lead-out part

of the DVD+RW dis

Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

EN 3VAE8015 / 8020 2.

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains plug

and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the 'on' position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains plug

and the front panel, controls, and chassis bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, symbol ). Careless

handling during repair can reduce life drastically. Make

sure that, during repair, you are at the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage section.

The primary side of the power supply (pos. 1005), including

the heatsink, carries live mains voltage when you connect

the player to the mains (even when the player is 'off'!). It is

possible to touch copper tracks and/or components in this

unshielded primary area, when you service the player.

Service personnel must take precautions to prevent

touching this area or components in this area. A 'lightning

stroke' and a stripe-marked printing on the printed wiring

board, indicate the primary side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW (DVD+RW

writing)

: 0.8 mW (DVD

reading)

: 0.3 mW (VCD/CD

reading)

Beam divergence : 60 degree

Figure 2-1 Class 1 Laser Product

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

Figure 2-2 Warning text

EN 4 VAE8015 / 80202.

Safety Instructions, Warnings and Notes

2.3 Notes

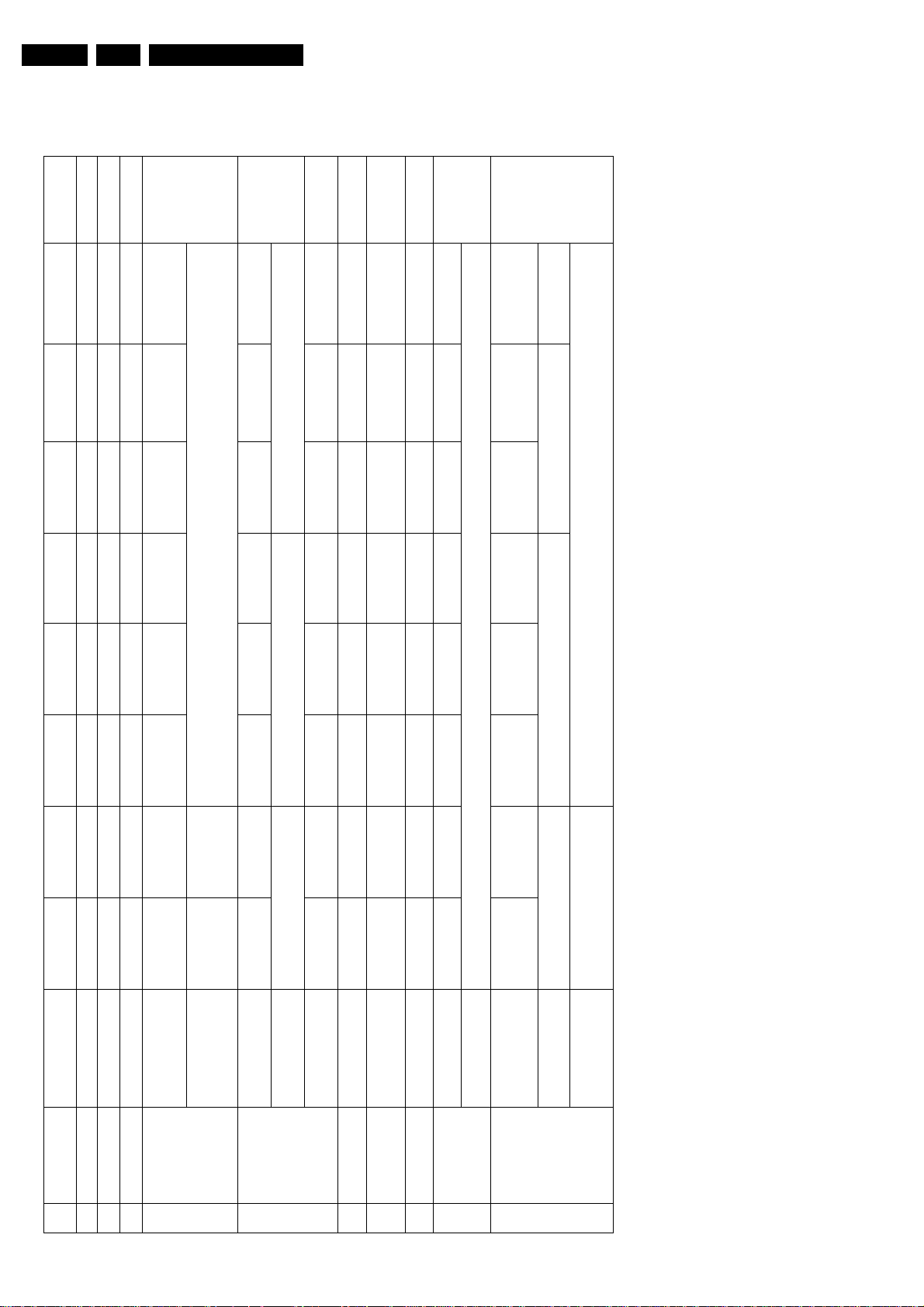

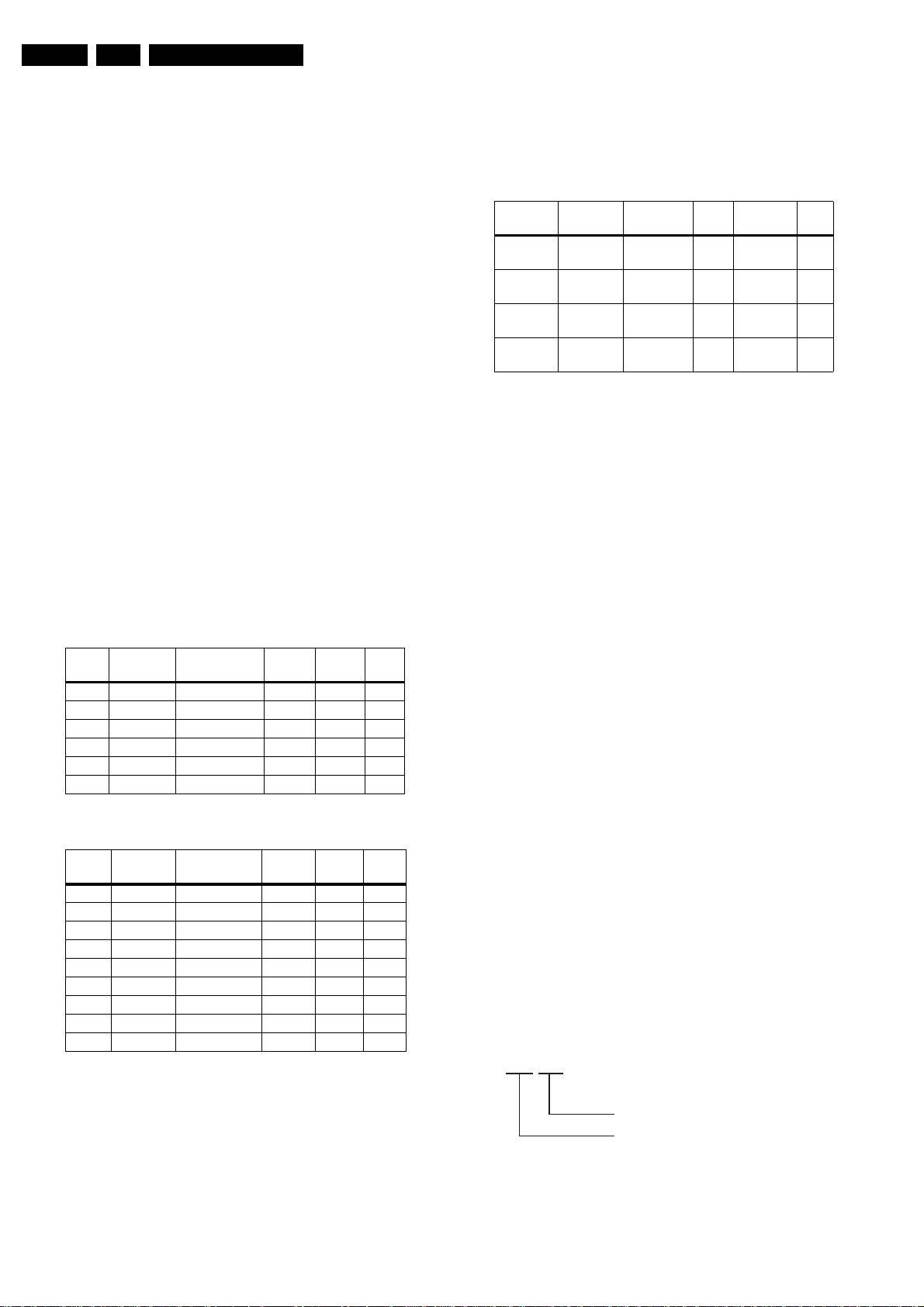

Table 2-1 Configuration matrix - Basic Engines VAE 8015 and VAE 8020

Remark

Same for all

Same for all

See remark 3

(Ladic M4,

VAE8020/15

3104 147 17481

3104 147 17471

Plastic Lens OPU

3106 148 01780

9305 011 64111

plastic lens)

See remark 1, 2

3104 128 008861

Same for all

Same for all

3104 148 01520

3104 123 4366.x

Same for all

Same for all

3104 144 07244

3104 141 22833

3104 157 12392

See remark 3

-

20.02.21

VAE8020/15

Glass Lens OPU

VAE8020/05

VAE8020/03

VAE8020/02

VAE8020/01

VAE8015/02

VAE8015/01

3104 147 17481

3104 147 17481

3104 147 17481

3104 147 17481

3104 147 17481

3104 147 17481

3104 147 17481

3104 147 17471

3104 147 17471

3104 147 17471

3104 147 17471

3104 147 17471

3104 147 17471

3104 147 17471

3106 148 01780

3106 148 01780

3106 148 01780

3106 148 01780

3106 148 01780

3106 148 01780

3106 148 01780

9305 011 64101

9305 011 64101

9305 011 64101

9305 011 64644

9305 011 64643

9305 011 64644

9305 011 64643

(Ladic M4,

(Ladic M4,

(Ladic M4,

(Ladic M3,

(Ladic M3,

(Ladic M3, glass

(Ladic M3, glass

3104 157 12392

20.02.21

20.02.21

20.01.18

20.09.13

20.09.13

15.07.12

15.07.12

20.02.21

20.03.23

20.01.21

15.07.21

glass lens)

glass lens)

9305 022 82015

glass lens)

DVDM/15 (Ladic M4, Plastic Lens)

glass lens)

glass lens)

lens)

DVDM/02

9305 022 82002

(Ladic M3, glass

lens)

DVDM/01

9305 022 82001

(Ladic M3, glass

3104 128 08881

3104 128 08322

3104 128 08322

3104 128 08262

3104 128 08262

3104 128 008861

3104 128 08322

3104 128 08861

3104 128 08321

3104 128 08321

3104 128 08261

3104 128 08261

3104 128 08861

3104 128 08322

3104 128 08262

(with Awesome 3)

(with Awesome 2)

(with Awesome 1)

3104 148 01520

3104 144 07244

3104 141 22833

3104 141 22833

3104 141 22833

3104 141 22833

3104 141 22833

3104 141 22833

3104 141 22833

3104 157 12392

3104 143 30532

3104 157 12392

3104 143 30532

3104 157 12392

3104 143 30532

3104 157 12392

3104 143 30532

3104 157 12392

3104 143 30532

3104 157 12392

3104 143 30532

3104 157 12392

3104 123 4366.x

3104 148 01520

3104 148 01520

3104 148 01520

3105 148 01520

3105 148 01520

3105 148 01520

3104 144 07244

3104 144 07244

3104 144 07244

3104 144 07244

3104 144 07244

3104 144 07244

3104 123 4366.x

3104 123 4335.x

3104 123 4335.x

3104 123 4335.x

3104 123 4301.x

3104 123 4301.x

Description

Item

Service Replacement

DVDM

0100

DVDM

Production Version

Service Replacement

PCBA

0002

PCB Layout Version

Tilt motor

OPU rack sledge

0010

0046

OPU rack spring

0047

Production Version

Service Replacement

OPU flex

0054

Service Version

Production Version

Firmware

Production

OPU Version in

Fan

Loader Assy

Sledge Motor

001

0068

0011

DVDM/15

for Glass Lens

for Plastic Lens

Service Version

The combination of Awesome1 (VAE8015 PCB) and LadicM4 (OPU6410, OPU6411) is not feasible.

Old VAE8020 PCBs 08322 have mounted Awe some-2. It is allowed to replace this with current VAE8020 PCB's (088 61) mounted with Awesome-3.

If VAE8020/01 /02 /03 /05 /15 products with glass lens OPU are repaired with DVDM/15 (with 64111 OPUs with plastic lens) the Firmware has to be updated to 20.03.23.

Use special Upgrade Software in this case!

Remarks:

Remark 1:

Remark 2:

Remark 3:

3. Directions For Use

Not applicable

Directions For Use

EN 5VAE8015 / 8020 3.

EN 6 VAE8015 / 80204.

Mechanical Instructions

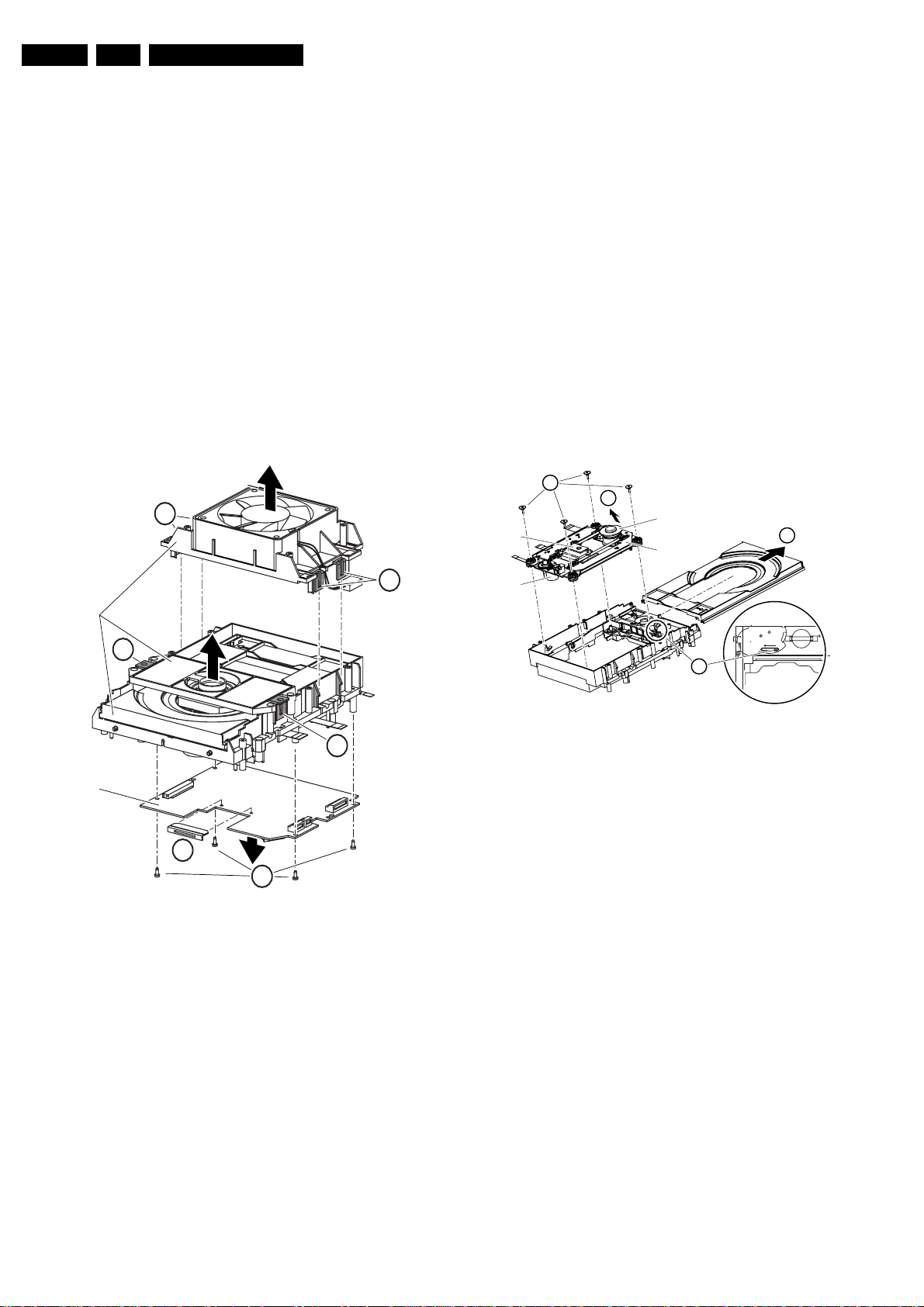

4. Mechanical Instructions

Index of this chapter:

1. General

2. Disassembly

3. Re-assembly

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

4.1 General

• Follow the disassemble instructions in described order.

• Do not place the unit with its PWB on a hard surface (e.g.

table), as it could damage the components on it. Always

place something soft (a towel or foam cushion) under it.

• Never touch the lens of the laser.

• Take sufficient ESD measures during (dis)assembly.

4.2 Disassembly

1

Loader

4.2.2 PWB

1. Flip the module180 degrees, so you can access the PWB.

2. Disconnect the four flex foils from the PWB connectors

(1100, 1300, 1302, and 1303) at the component side. For

the flex foil on connector 1100, you first must remove the

cable clamp [3]. The easiest way to do this is to push down

the two fixation pins of the clamp (via the holes in the PWB)

by means of a pencil or small screwdriver.

3. Disconnect the remaining cables (tray- and fan-motor

cable) at the solder side of the PWB

4. Remove the four screws (Torx 8) that hold the PWB [4].

5. Now you can remove the board.

4.2.3 DVD-M

Caution: Never try to align the DVD-Module! ! ! Only the factory

can do this properly. Service engineers are only allowed to

exchange the sledge motor assy.

3

4

Disc

OPU

1

monitor

Tilt

motor

DVD-M

2

2

PWB

3

4

CL 26532126_010.eps

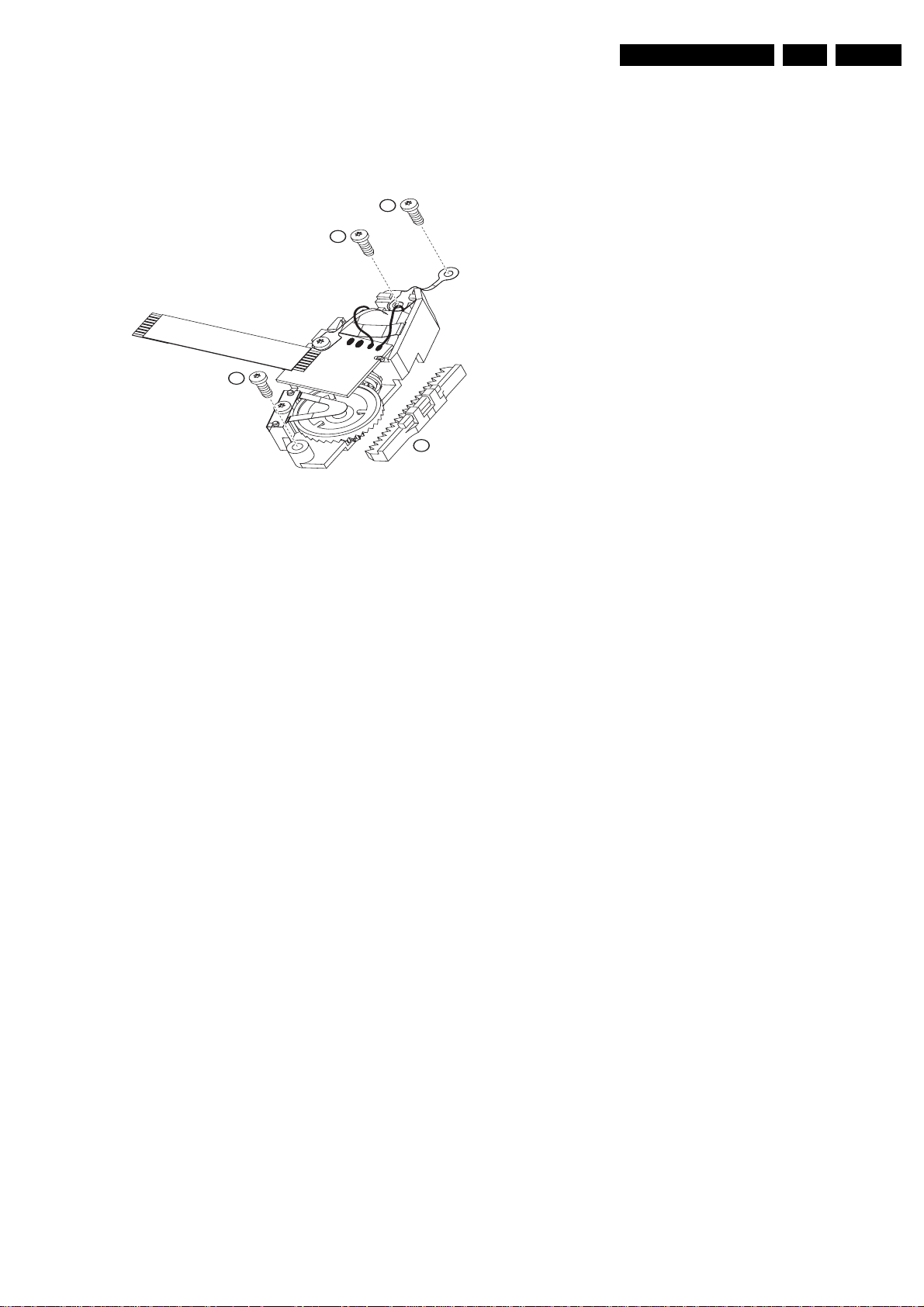

Figure 4-1 Basic Engine disassembly (part 1)

You can divide the Basic Engine into the following parts:

1. Loader (fan, clamp, and tray assy).

2. PWB (or 'mono board').

3. DVD-Module (OPU, turntable motor, and sledge-motor

assy).

4.2.1 Loader

2

191102

1

CL 26532126_011.eps

191102

Figure 4-2 Basic Engine disassembly (part 2)

1. Slide the 'tray pin' in the direction of the arrow [1], in order

to release the disc tray.

2. Flip the module180 degrees and pull out the tray [2]. Now

you can access the DVD-Module.

3. Remove the four screws [3] with a Torx 6 screwdriver, and

lift the DVD-M upwards [4] at the side of the disc-motor. It

hinges in the bracket at the side of the tilt-motor.

1. Disconnect the 2-wire fan cable from the PWB.

2. Remove the fan assy, by releasing the four side clamps [1]

while moving it upwards.

3. Remove the clamp assy, by releasing the two side clamps

[2] while moving it upwards.

4.2.4 Sledge-motor Assy

Caution: Never try to align the DVD-Module! ! ! Only the factory

can do this properly. Service engineers are only allowed to

exchange the sledge motor assy.

1

1

Mechanical Instructions

1

2

EN 7VAE8015 / 8020 4.

Figure 4-3 Sledge-motor assy

1. Place the DVD-Module, with the laser facing downwards,

on a soft surface.

2. Remove the three screws [1] that hold the sledge-motor

assy, and lift the assy upwards. You can replace it now.

3. If necessary, it is now also possible to replace the sledgerack [2] that is hinged in the sledge assy.

4.3 Re-assembly

To re-assemble the module, do all processes in reverse order.

Be sure to:

• Sledge-motor assy: Mesh the teeth of the sledge motor

and sledge rack properly, during mounting of the sledgemotor assy.

• DVD-M: Point the laser up (towards the tray), when you

mount the DVD-M in the bracket.

• Complete module: Place all wires/cables in their original

positions

CL 26532126_014.eps

191102

EN 8 VAE8015 / 80205.

Service Modes, Error Codes and Fault Finding

5. Service Modes, Error Codes and Fault Finding

Index of this chapter:

1. General

2. Start-up Measurements

3. Diagnostic Software

4. Nuclei Error Codes

5. Fault Finding

5.1 General

• Impedance of measuring-equipment should be > 1 MOhm.

• For testing the Basic Engine, connect it to a DVD-recorder

of the DVDR1000, 900, or 800 series.

• Most tests are done by software commands. Together with

the software command you will find a Ref.# nbr. This is the

number of the diagnostic nucleus used for this test. You

can find information that is more detailed in the chapter

'Diagnostic Nuclei'.

• Levels: Most measurements are digital measurements.

The signal levels specification in this document are defined

as follows:

– low < 0.3V

– high > 3.0V

– LOW < 0.4V

– HIGH > 4.5V

5.2 Start-up Measurements

5.2.1 Power Supply Check

Table 5-1 Table of supply input voltages.

Signal Test point Description Specifi-

cations

+3V3 I007 Input of supply +3.3 1% V

+5 I008 Input of supply +5 1% V

+4V6 I010 Input of supply +4.6 1% V

-5 I011 Input of supply -5 1% V

+12 I012 Input of supply +2 1% V

GND I015, I016 Input of supply

Table 5-2 Table of derived supply voltages.

Signal Test point Description Specifi-

cations

D3V3 I006 Digital 3V3 +3.3 2% V

A3V3 I007 Analogue 3V3 +3.3 2% V

+5V I008 Analogue 5V +5 2% V

D5V I009 Digital 5V +5 2% V

+3V3E F001 OPU 3V3 +3.3 2% V

-5 I011 Neg. voltage -5 2% V

+12 I012 12V +12 2% V

Vbias I014 Bias voltage -1.7 2% V

GND I017, I018 Input of supply 0 0 % V

Tolerance

Tolerance

Unit

Unit

5.2.2 Oscillator Check

Table 5-3 Table of clock signals.

Signal Test point Descrip-

tion

OSCOUT I219 Ref. Clock

MACE

CROUT I443 Ref. Clock

PSEN I223 OEN Flash

RA/FO/SL I326/I334/

I343

On the mono board, there are two external oscillators

(OSCOUT and CROUT), which are the reference for all clock

signals derived in several ICs.

To check whether the program (in the MACE microprocessor)

is running after power 'on', you can monitor the PSEN (OEn of

Flash ROM) on I223 (see test point overview in chapter 6).

You can measure the Servo clocks at I326 (RAdial), I334

(FOcus), and I343 (SLedge).

HDR65

ROM

Servo clock 2.120 +/- 20 kHz MHz

Spec. Toler-

8.483 +/- 70 kHz MHz

8.501 +/- 70 kHz MHz

5.324 +/- 70 kHz MHz

5.3 Diagnostic Software

Due to the complexity of a DVD recorder, the time to find a

defect in the recorder can become long. To reduce this time,

the recorder has been equipped with Diagnostic and Service

software (DS). The DS offers functionality to diagnose the

DVDR hardware and tests the following:

• Interconnections between components.

• Accessibility of components.

• Functionality of the audio and video paths.

This is also valid for the Basic Engine.

One can access this functionality via several interfaces:

1. End user/Dealer script interface.

2. Player script interface.

3. Command interface.

4. Menu interface (only for Digiboard Empress).

This part describes the command and menu interface.

First some definitions:

• Diagnostic Nucleus. Part of the Diagnostic Software.

Each nucleus contains an atomic and software

independent diagnostic test, testing a functional part of the

DVD player hardware on component level.

5.3.1 Menu and Command Interface

Nuclei Numeration

Each nucleus has a unique number of four digits. This number

is the input of the command mode.

Unit

ance

The module operates in power 'off' and power 'on' only. There

is no standby mode at module level. In power 'off', the module

does not respond to any communication or signal.

Before starting the measurement, connect the power supply to

the mono board via connector 1000, and the PC interface cable

to the Service Interface connector of the 'test recorder'.

[ XX YY ]

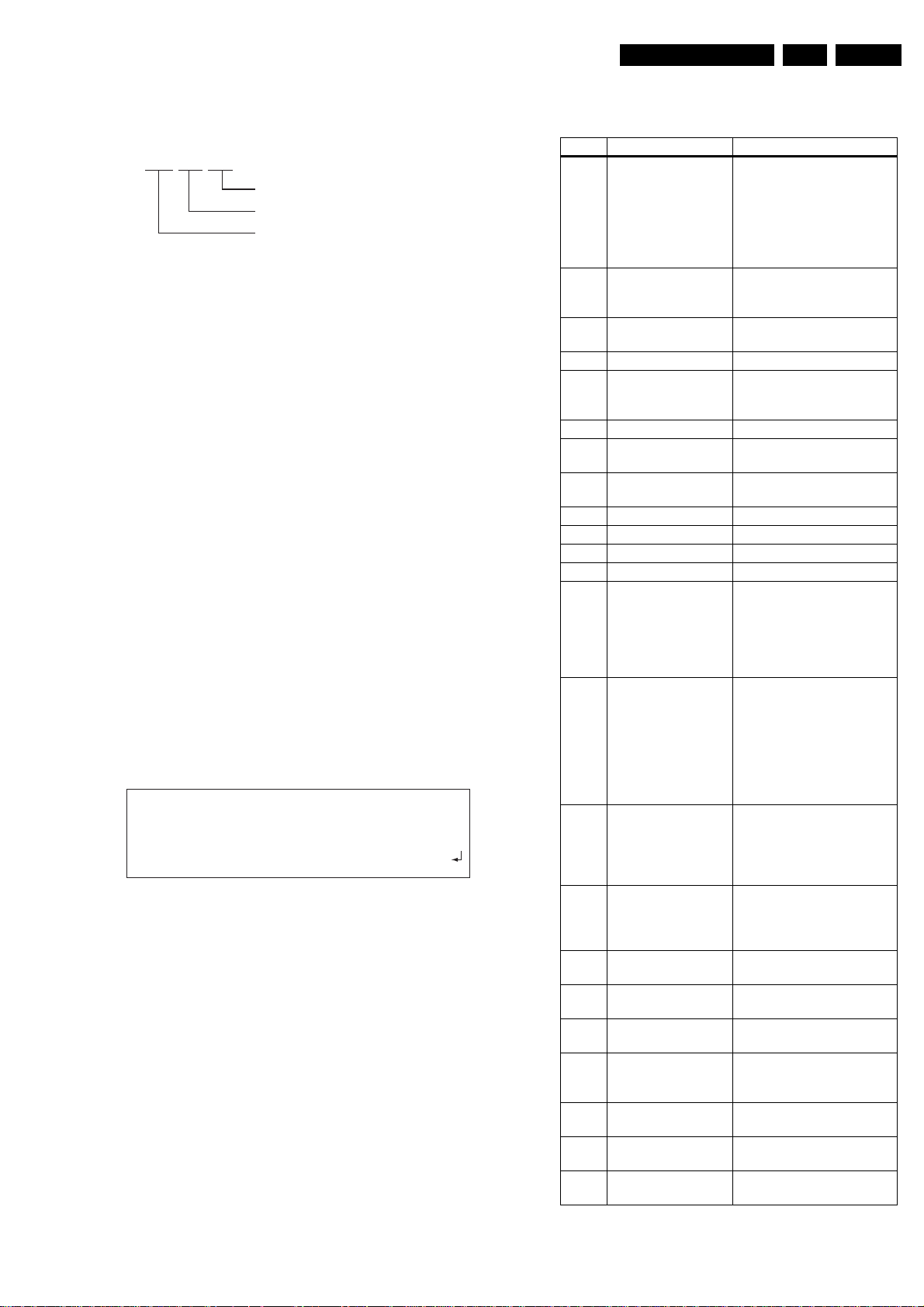

Figure 5-1 Nucleus code

Nucleus number

Nucleus group number

CL 06532152_012.eps

051200

Service Modes, Error Codes and Fault Finding

EN 9VAE8015 / 8020 5.

Error handling

Each nucleus returns an error code. This code contains six

numerals, which means:

[ XX YY ZZ ]

Error code

Nucleus number

Nucleus group number

Figure 5-2 Error code

Hardware required

•Service PC.

• One free COM port on the Service PC.

• Special cable to connect DVD recorder to Service PC.

The service PC must have a terminal emulation program (e.g.

HyperTerminal) installed and must have a free COM port (e.g.

COM1).

Activate the terminal emulation program and check that the

port settings for the free COM port are:

• 19200 bps,

• 8 data bits,

• No parity,

• 1 stop bit,

• No flow control.

Connect the free COM port via a special cable to the RS232

port of the DVD recorder. This special cable will also connect

the test pin, which is available on the connector, to ground (i.e.

activate test pin). Code number of PC interface cable: 3122

785 90017.

Command Mode Interface

Activation

Connect the recorder to the mains. The following text will

appear on the screen of the terminal (program) for Digiboard

Empress:

DVD Video Recorder Diagnostic Software version 48

Basic SDRAM Data bus test passed

Basic SDRAM Address bus test passed

Basic SDRAM Device test passed

(M) enu, (C) ommand or (S) 2B-interface? [M] : @ C

DD:>

Figure 5-3 Opening screen for Digiboard Empress

The first line indicates that the Diagnostic software has been

activated and contains the version number. The next lines are

the successful result of the SDRAM interconnection test and

the basic SDRAM test. The last line allows the user to choose

between the three possible interface forms.

If pressing 'C' has made a choice for Command Interface, the

prompt ("DD>") will appear. The diagnostic software is now

ready to receive commands. The commands that can be given

are the numbers of the nuclei.

Remark:

Digital Board Chrysalis always starts with Command Interface.

Command Overview

We provide an overview of the nuclei and their numbers. This

overview is preliminary and subject to modifications. Please

refer to the service manual of the set for the nucleus overview

of Digital Board Chrysalis.

CL 06532152_013.eps

051200

CL 16532095_073.eps

150801

Table 5-4 Nuclei overview Basic Engine Empress

Digiboard

Ref. # Function name Description

600 DS_BE_S2B_Pass It switches the RS232 port

and the S2B port in passthrough mode. This means

that the player hangs. The

only way to exit this nucleus

is via a power off of the player

601 DS_BE_S2B_Engine It checks the S2B interface

with the Basic Engine by

sending an 'echo' command

602 DS_BE_Version It returns the version number

of the Basic Engine

603 DS_BE_Reset It resets the Basic Engine

604 DS_BE_FocusOn It puts the laser of the basic

engine into focus (focus

loop)

605 DS_BE_FocusOff It switches the focus loop off

606 DS_BE_DiscMotorOn It switches the disk motor (=

spindle motor) on

607 DS_BE_DiscMotorOff It switches the disk motor (=

spindle motor) off

608 DS_BE_RadialOn It closes the radial loop

609 DS_BE_RadialOff It opens the radial loop

615 DS_BE_TrayIn It closes the disc tray

616 DS_BE_TrayOut It opens the disc tray

617 DS_BE_WriteRead It writes data to the BE which

is stored on a DVD disc and

read it back from the DVD

disc. This is only done when

the result of the self-test con-

tains no errors.

618 DS_BE_WriteReadE

ndlessLoop

It writes data to the BE which

is stored on a DVD disc and

read it back from the DVD

disc, while repeating in an

endless loop. This is only

done when the result of the

self-test contains no errors.

Errors are stored in NVRAM.

625 DS_BE_SledgeMotor

Slow

It moves the sledge full

stroke several times slow

enough to allow visual in-

spection of unhampered

movement

626 DS_BE_Tilt It tests the tilt mechanism

control loop, or allow its prop-

er functioning to be meas-

ured

627 DS_BE_ReadEepromIt reads one data byte from

the EEPROM

629 DS_BE_OptimiseJitterIt performs jitter optimisation

630 DS_BE_RadialATLS

Calibration

631 DS_BE_GetStatistics

Info

It allows the radial loop to be

calibrated.

It retrieves the statistical in-

formation from the Basic En-

gine

632 DS_BE_ResetStatisti

csInfo

It erases the statistical infor-

mation

633 DS_BE_ReadErrorlogIt retrieves the error log from

the Basic Engine

634 DS_BE_ResetErrorlogIt erases the fatal error log

and the cumulative error log

EN 10 VAE8015 / 80205.

Service Modes, Error Codes and Fault Finding

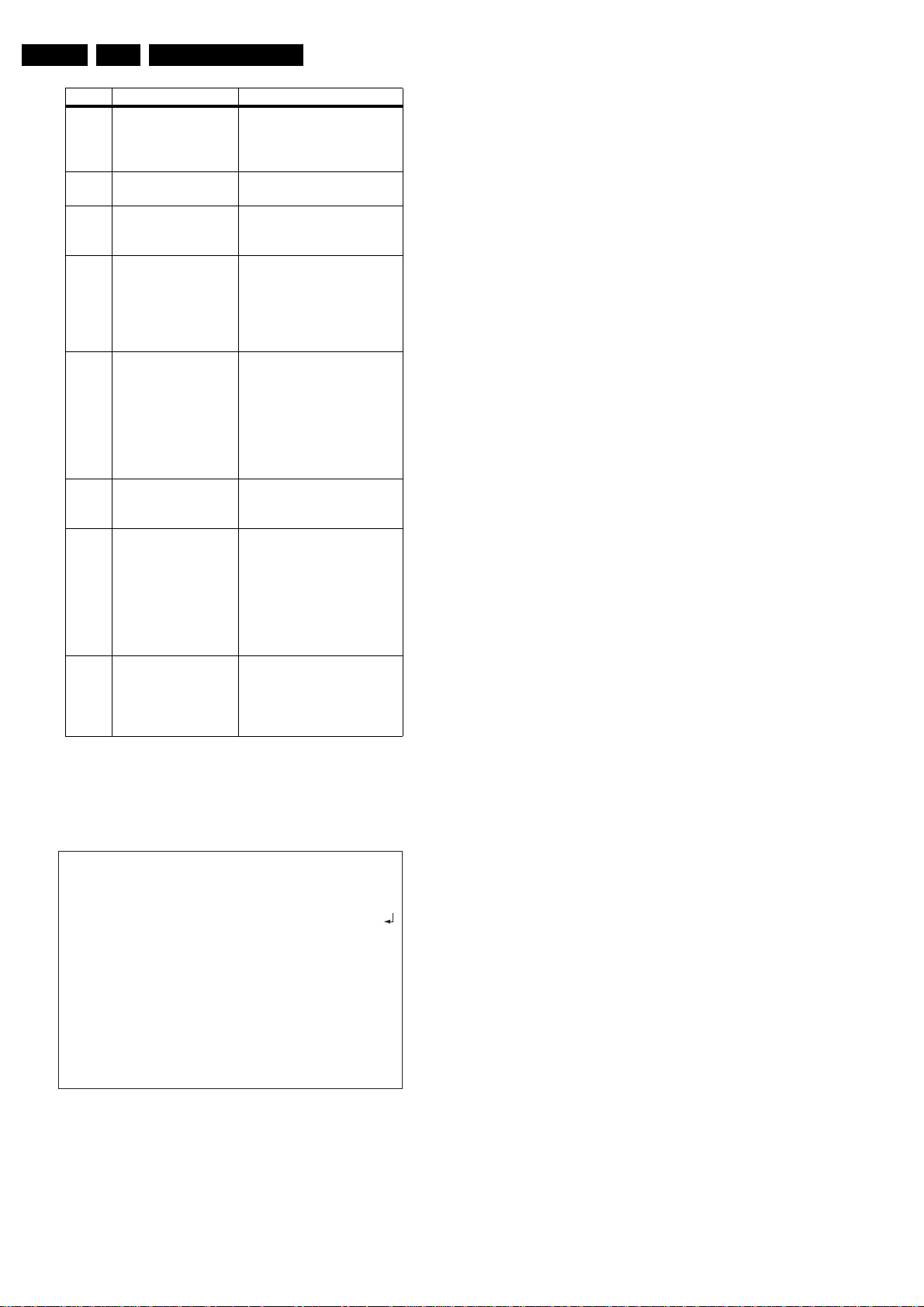

Ref. # Function name Description

638 DS_BE_GetSelfTest

Result

It retrieves the result of the

Self Test of the Basic engine,

which is executed during

power-on.

639 DS_BE_RadialInit It allows the radial initialisa-

tion

640 DS_BE_GetOPUInfo It retrieves the OPU number

from the EEPROM of the Basic engine.

641 DS_BE_WriteReadPl

usR

It writes data to the BE which

is stored on a DVD disc and

read it back from the DVD

disc. This is only done when

the result of the self-test contains no errors.

642 DS_BE_WriteReadPl

usREndlessLoop

It writes data to the BE which

is stored on a DVD disc and

read it back from the DVD

disc, while repeating in an

endless loop. This is only

done when the result of the

self-test contains no errors.

Errors are stored in NVRAM.

643 DS_BE_ReadTOC Read TOC Information

This nucleus reads the TOC

information of a disc.

644 DS_BE_GetDiscInfo Get Disc Information

This nucleus reads from the

TOC-info the disc type. If the

disc is a DVD+RW or a

DVD+R disc, also the ADIPinfo will be read to get the

disc manufacturer id and the

media type id of that disc.

645 DS_BE_DiscErase Disc Erase

This nucleus erases a

DVD+RW disc. This disc will

be recognized as an empty

disc by the application.

Menu Mode Interface (only for Digiboard Empress)

Activation

Connect the recorder to the mains. The following text will

appear on the screen of the terminal (program):

If pressing 'M' has made a choice for Menu Interface, the Main

Menu will appear.

Menu Structure

1. Digital Board

2. Analogue Board

3. Front Panel

4. Basic Engine

1. Reset

2. S2B Pass-through

3. S2B Echo

4. Focus On

5. Focus Off

6. Version

7. Self Test

8. Get Self Test Result

9. Basic Engine Test

10. Laser Test

11. Focus Test

12. Tilt Test

13. Optimise Jitter

14. Statistics Info

15. Log

1. Read Error Log

2. Reset Error LogSpindle Motor

16. Spindle Motor

1. Spindle Motor On

2. Spindle Motor Off

3. Spindle Motor Test

17. Radial

1. Radial On

2. Radial Off

3. Radial Initialisation

4. Radial ATLS Calibration

18. Sledge

1. Sledge test

2. Sledge test slow

19. Tray

1. Tray In

2. Tray Out

5. DVIO

6. Progressive Scan Board

7. Loop Tests

8. Log

9. Scripts

DVD Video Recorer Diagnostic Software version 48

Basic SDRAM Data bus test passed

Basic SDRAM Address bus test passed

Basic SDRAM Device test passed

(M) enu, (C) ommand or (S) 2B-interface? [M] : @ M

Main Menu

1. Digital Board ->

2. Analogue Board ->

3. Front Panel ->

4. Basic Engine ->

5. DVIO ->

6. Progressive Scan Board ->

7. Loop tests ->

8. Log ->

9. Scripts ->

Select>

CL 16532095_074.eps

150801

Figure 5-4 Opening screen for Menu Mode

The first line indicates that the Diagnostic software has been

activated and contains the version number. The next lines are

the successful result of the SDRAM interconnection test and

the basic SDRAM test. The last line allows the user to choose

between the three possible interface forms.

Service Modes, Error Codes and Fault Finding

5.4 Fault Finding

Below you will find faultfinding trees for all the main parts of the

Basic Engine.

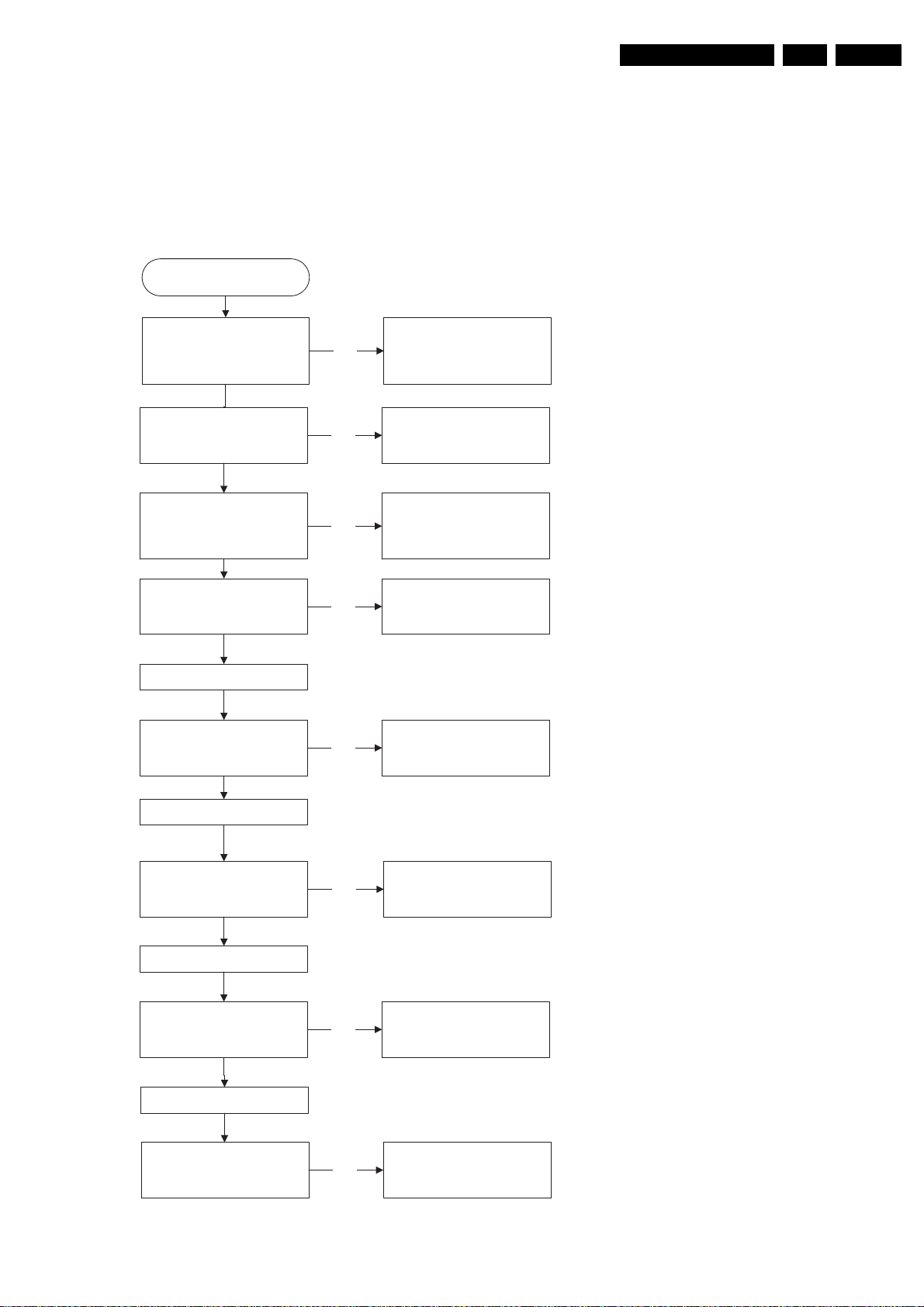

5.4.1 Basic Engine

BASIC ENGINE FUNCTIONAL TEST

Basic Engine Check

Basic Engine S2B Echo

test (communication test)

Command:601 on service

mode

nok

EN 11VAE8015 / 8020 5.

-Check/change PCB

Basic Engine selftest

Command:638 on service

mode

Basic Engine Tray Open/

Close test

Command: 616/615 on

service mode

Check BE FW version

Command:602 service

mode

Insert DWD+RW disc

DVD+RW read write test

Command:617(618)

Insert DVD DL disc

nok

nok

nok

nok

-Check/change PCB

-Check/change DVDM

-Check/change loader

-Check/change PCB

-load latest fw

-Check/change PCB

-Check/change PCB

-Check/change DVDM

-Check/change DVDM

Read test on normal mode

Insert DWD+R disc

DVD+RW read write test

Command:641(642) on

service mode

Insert CD disc

Read test on normal mode

nok

nok

nok

-Check/change DVDM

-Check/change PCB

-Check/change PCB

-Check/change DVDM

-Check/change DVDM

CL 26532126_016.eps

Figure 5-5 Basic Engine functional testing

191102

EN 12 VAE8015 / 80205.

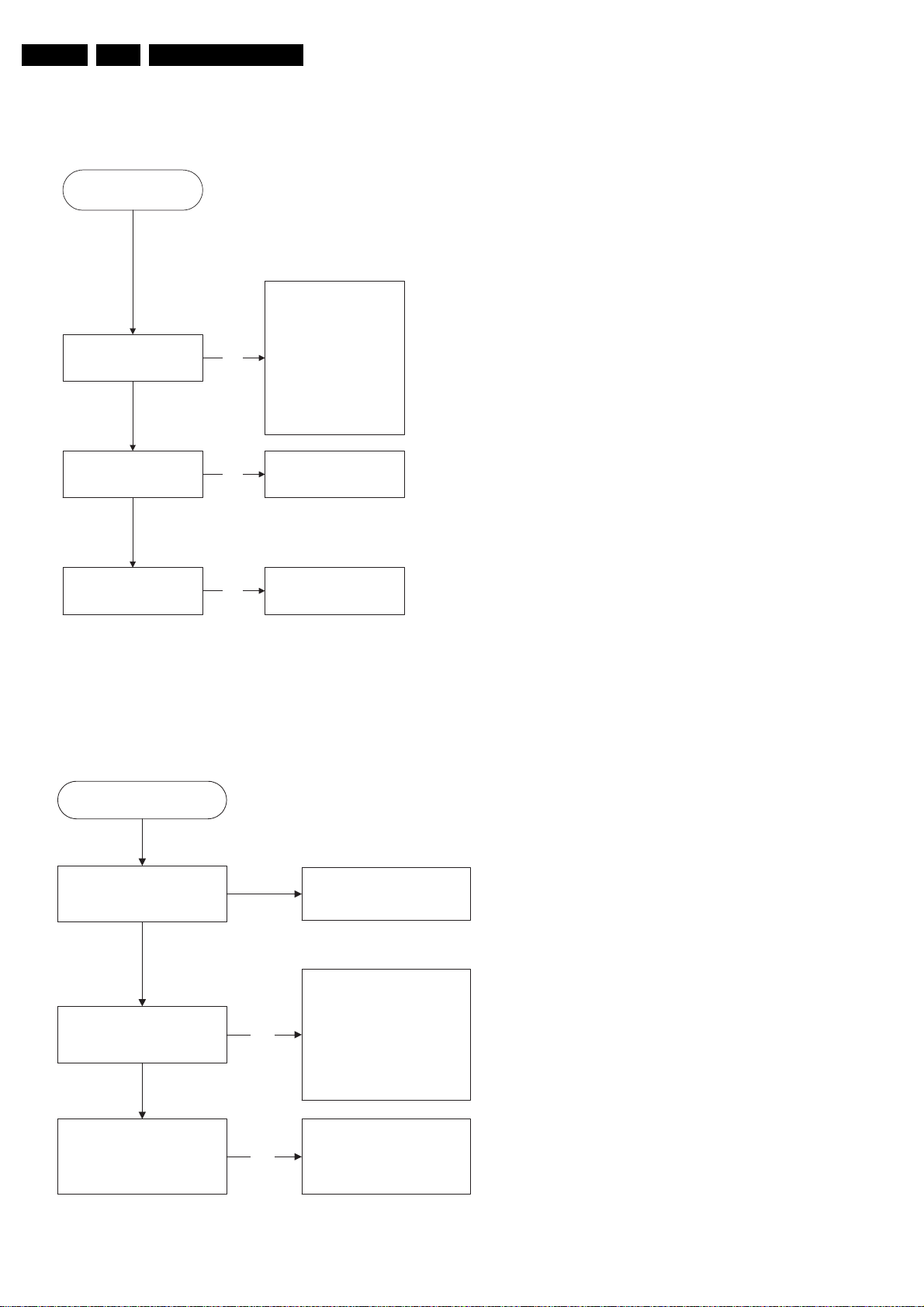

5.4.2 Loader

Loader Checking

Basic Engine Loader

Tray is not Opening/Closing

Command: 615/616

Check

-Check wire soldering on

tray motor

-Check tray motor wire

connector

-Check tray mechanical

nok

movement

-Check tray switch

-Check wire soldering at

tray switch

Service Modes, Error Codes and Fault Finding

Tray is partly opening -check movement manually

Noise under playing

5.4.3 DVD-M

DVDM checking

Basic Engine DVDM

Check

Communication

nok

-check geasing

-check clamper bridge/

nok

clamper positioning

nok

CL 26532126_017.eps

191102

Figure 5-6 Loader testing

-check OPU flex connection

(PSB and OPU side)

Read TOC with all discs

Disc error/Disc warning

DVD+R/RW

nok

nok

-check PCS PCB soldering

-main motor/sledge motor/

tilt motor flex

-OPU shafts (grease/oil)

-sledge motor/mechanism

-gearrack/gear

-hinges

- surface of turntable

-check sledge motor/

mechanism

-check gear rack/gear

CL 26532126_018.eps

191102

Figure 5-7 DVD-M testing

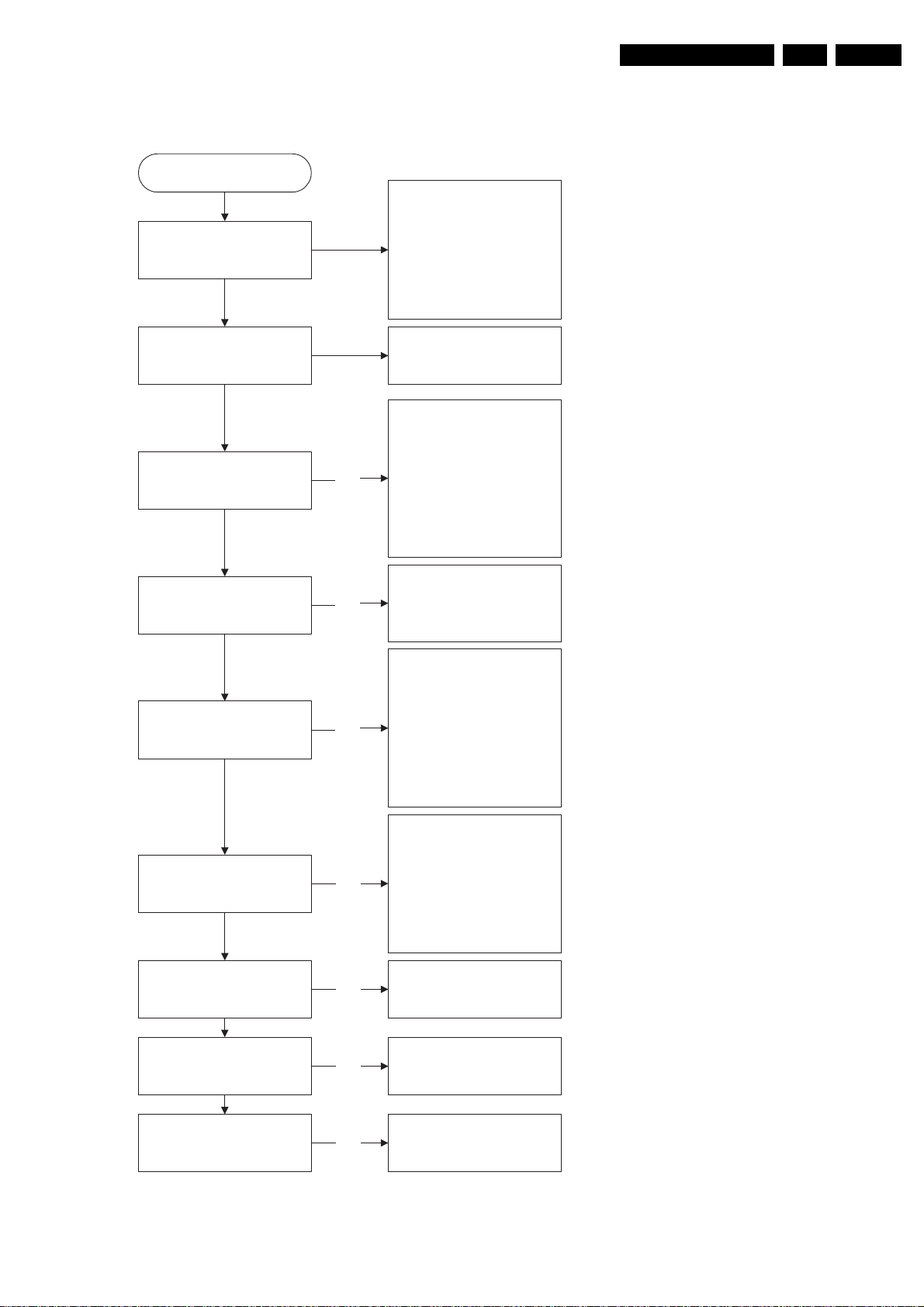

5.4.4 PWB

PCB Checking

Basic Engine PCB Check

Communication

Service Modes, Error Codes and Fault Finding

Check:

-MACE wrong

-7306 burned

nok

-7302 burned

-S2B connector

-7000 bad soldering

-power connector

-2209 missing

-2210 missing

EN 13VAE8015 / 8020 5.

selftest

Firmware upgrade

Basic Engine Tray Open/

Close

Read TOC DVD+R W ,

DVD+R (Disc error, Disc

Warning)

nok

nok

nok

nok

-MACE wrong

-S2B connector

-MACE soldering wrong

-Flash Eeprom wrong

-S2B connector

-EPLD reflow

-7206 wrong

-3204 missing

-5202 missing

-2200 missing

-2228 missing

-7302 bad soldering

-7302 burned out

-7000 bad soldering

-Mace wrong

-HDR65 wrong

-MACE wrong

-7000 bad soldering

-1300 bad soldering

-1100 bad soldering

-7302 wrong

-7202 wrong

-3342 missing

-2015 bad soldering

Read TOC DVD single and

dual layer (bad playability)

Read TOC CD

NO/BAD Recording

TOC upgrade

nok

nok

nok

nok

-HDR 65 bad soldering

-MACE wrong

-1300 bad soldering

-2020 missing

-2111 missing

-2015 broken

-5201 missing

-3335 reflow

-MACE wrong

-Awesome wrong

-S2B connector

-MACE wrong

-Awesome wrong

-S2B connector

-HDR 65 wrong

CL 26532126_019.eps

Figure 5-8 Mono board testing

191102

EN 14 VAE8015 / 80205.

Personal Notes:

Service Modes, Error Codes and Fault Finding

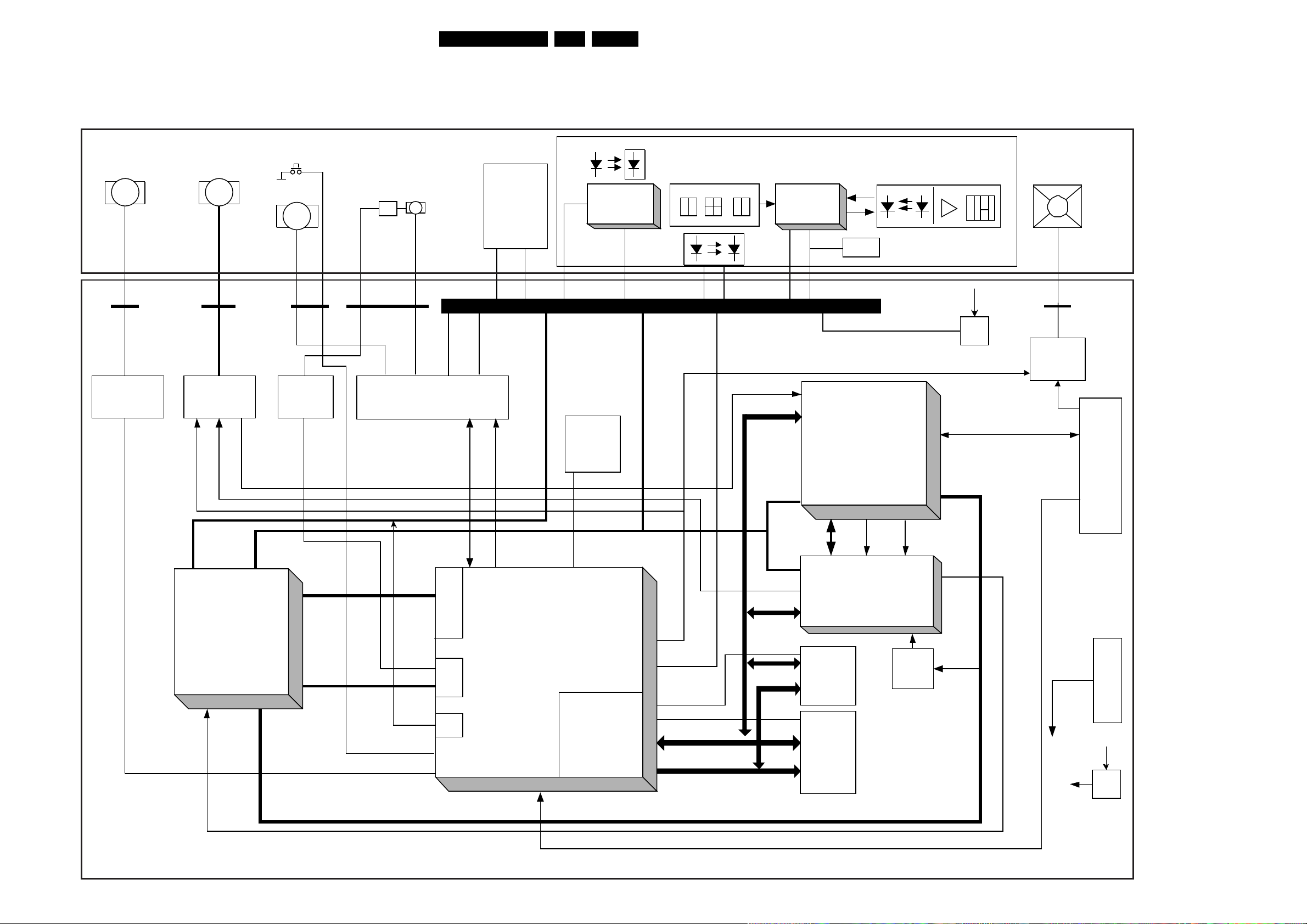

6. Block Diagram.

Block Diagram

Block Diagram.

15VAE8015 / 8020 6.

LOADER

Tilt Motor

M M

L1+, L1L2+, L2-

ROHM ROHM

Tilt Motor Driver

BA5944FP

TOC

TOS

TTEN

Disc Motor

11P 4P4P1303 1300 1301 1302

U,V,W coil

U+,UV+,VW+,WHall+,Hall-

Disc Motor Driver

BA6665FM

TACHO1

TACHO2

TACHO3

Tray Sense

Tray Motor

M

TR+

TR-

PCS-

pre_amp

SINH

COSPH

REFSIN

REFCOS

PCS

+SIN, -SIN

+COS, -COS

ROHM

Sledge

M

8P

SL-

SL+

Servo Driver

BA5938FM

73027306 7301 7304

ACT-EMFP

ACT-EMFN

RAC-SW

FOC+

FOC-

RAD+

RAD-

Actuator

RADIAL

FOCUS

RA

SL

FO

TRAYIN

TRAYOUT

laser 650nm

IIC

RFP

RFN

PPN

LASP

PD1

PD2

Q1..Q6

EPM3032AT

FS diode

650nm PD

TZA1032 TZA1030

OPU64

TZA1030

LADIC

tilt sensor

EFMCLKP

EFMCLKN

EFMDATAP

EFMDATAN

EPLD

C44-10

IIC

OSTR

FTC

IRQn

TSDEN

DA[0..7]

ALE

RD-U

WR-U

INT_HDR65

CS_HDR65

DROPPI

IIC

EEprom

VBIAS

SAA7831

7402

HDR 65

ENCODER/DECODER

780nm LDGU+OPIC

OPU Flex 45p

1100

-5V

STAB

MEN

DATA-IN

DATA-OUT

V4

FLAG

SYNC

M

2P1304

Fan

control

7312

FAN_IN

IIS

S2B

APPLICATION

TZA1031

7101

SPIDRE

SIGNAL

PROCESSOR

FEN

REN

TLN

MIRN

TILTN

PW

A1,2

CALF

XDN

offset

RFN/RFB

PCS

TRAYSW

ADC

flash

ADC

DAC

scan

SAA7830

7203

MACE 3

SERVO & uP

Micro

MEN

CE1

FWRN,PSEN-U

DA[0..7]

UA[0..19]

MOTOR

multibus 0-11

WOBBLE PROCESSOR

AWESOME

SRAM

32k

7204

Flash Rom

7202

7401

SIDA

SICL

SILD

moto1,moto2

ADC

PPNO

RFP,RFN

RF-REF

PPNO

BCA

SIDA

SICL

SILD

RXD

TXD

SUR

CPR

AIRQn

ARESETn

DLOAD

+12V

PGND

3V3

4V3

+5V

-5V

GND

3V3

to OPU64

1402

1000

POWER

4V6

3V3

7001

MONO BOARD

CL 26532126_003 .eps

081102

Test Point Overview Servo Board 43015

Block Diagram.

16VAE8015 / 8020 6.

+12V

GND

+5V

+4V6

+3V3

D3V3S

MACE dig.

5V

Spidre

Clock Mace3

8,483 Mhz

SDA

SCL

A3V3A

MACE Ana-5V

-5V

Spidre

-5V

Spidre

RFP outRFN out

Clock HDR65

8,501 Mhz

PSEN-P

5,324 Mhz

+5V

EEPROM

CL 26532126_033.eps

291102

RES-U

D3V3 DEC

HDR65

Awesome

+3V3

TDA8703

F001 A1

F101 B3

F102 B3

F104 B3

F105 B3

F106 B3

F107 A2

F108 A2

F109 B2

F110 B3

F111 B2

F112 B3

F113 B3

F121 A2

F127 B3

F128 B3

F129 B3

F130 B3

F210 A3

F211 A3

F212 A3

F213 A3

F214 A3

F215 A3

F216 A3

F217 A2

F218 A2

F222 B2

F223 A2

F226 A2

F228 A2

F229 A2

F232 A3

F237 A4

F238 A4

F239 A4

F240 A2

F241 A2

F242 A3

F302 C1

F303 C1

F304 C1

F305 B1

F306 B1

F307 A1

F308 A1

F309 A1

F310 A1

F311 A3

F312 C3

F313 C3

F314 C1

F315 C1

F316 C1

F317 C1

F318 C2

F319 C1

F320 C1

F321 C1

F322 A2

F323 A2

F400 B4

F401 B3

F402 B3

F403 B4

F404 B3

F405 B3

F406 A3

F407 A3

F409 A3

F410 B4

F411 B4

F412 B4

F413 A4

F414 A4

F415 B4

F416 B4

F417 B4

F418 B3

F419 A4

F420 A4

F421 A4

F422 A4

F423 A4

F424 A4

F425 C3

F426 B4

I006 A1

I007 A1

I008 A1

I009 A2

I010 A1

I011 A1

I012 A1

I013 A1

I014 A1

I015 A1

I016 A1

I017 C4

I018 C4

I019 B4

I020 B1

I100 A2

I102 A3

I103 A3

I104 A3

I105 A3

I106 A3

I107 A2

I108 B3

I113 B3

I114 B3

I115 B3

I119 B2

I120 B2

I121 B2

I124 A2

I125 B2

I126 B2

I127 B3

I128 B3

I129 B3

I130 B3

I131 B3

I132 B3

I133 C4

I202 A4

I203 A4

I204 A4

I205 A4

I208 A4

I211 A4

I214 A4

I215 A4

I216 B2

I217 A3

I218 A2

I219 A2

I220 A3

I221 A3

I223 A4

I224 A3

I225 A3

I226 A4

I227 A2

I228 A3

I229 A3

I230 A3

I231 A3

I234 A3

I237 A2

I238 A3

I239 B3

I240 A3

I241 A3

I244 B3

I245 A3

I246 A3

I247 B3

I258 A4

I259 A4

I260 A4

I261 A2

I262 A2

I263 A2

I264 A3

I266 A4

I267 A4

I268 A4

I269 A4

I270 A3

I271 A4

I272 A3

I273 A4

I274 A2

I275 A2

I276 A2

I277 A2

I278 A2

I279 A2

I280 A2

I281 A2

I282 A2

I283 A2

I284 A2

I285 A2

I286 A4

I287 A4

I288 A4

I289 A4

I290 A4

I291 A4

I292 A3

I293 A3

I294 A4

I295 A4

I296 A3

I297 A2

I298 A2

I299 B2

I300 B2

I301 B2

I302 C2

I304 B1

I306 C2

I307 C2

I308 B2

I309 B2

I310 C2

I311 B2

I312 B2

I314 B2

I315 B2

I316 B1

I317 B2

I319 B2

I321 B2

I322 B2

I324 B1

I325 B2

I326 A3

I327 C1

I328 C2

I329 B3

I330 C1

I331 B2

I332 B1

I333 B1

I334 A3

I335 B2

I336 C2

I337 B1

I338 C2

I339 C1

I341 B2

I342 B2

I343 A3

I344 B2

I345 B1

I346 C1

I347 C1

I349 B1

I350 C1

I351 C1

I352 B1

I353 B1

I354 A1

I355 B1

I356 B1

I357 A3

I358 B1

I359 B1

I360 B1

I361 B2

I362 A3

I363 B1

I364 A3

I365 B2

I366 B2

I367 B2

I368 A3

I369 B2

I370 A2

I371 C1

I372 C1

I373 B3

I374 B2

I375 B2

I376 C1

I377 A2

I378 A2

I401 B3

I402 B2

I403 B3

I404 B2

I405 B3

I407 B4

I408 B3

I409 B3

I410 B4

I411 B4

I412 C3

I414 B3

I415 B3

I417 B3

I418 B3

I419 B3

I420 B3

I421 C4

I422 C3

I423 B3

I425 C4

I426 C3

I429 B2

I431 B3

I432 B4

I434 B2

I435 B3

I437 B3

I438 B3

I440 B4

I441 B4

I442 B4

I443 B4

I444 B4

I445 B4

I446 B4

I447 B4

I448 B4

I449 B4

I450 C4

I451 B4

I452 B4

I453 B4

I454 C4

I455 C4

I456 C4

I457 B4

I458 C4

I459 B4

I460 B4

I461 B4

I462 B4

I463 B4

I464 B4

I465 B4

I466 B4

I467 B4

I468 B4

I469 B4

I470 B4

I471 B4

I472 B4

I473 A3

I474 B4

I475 A2

I499 B3

I900 A3

I901 A3

I902 A3

I903 A3

Loading...

Loading...