Philips VAD-8031 Service Manual

DVD-Video Recorder DVD+RW Basic Engine

VAD8031

Contents Page Contents Page

1 Technical Specifications 2

2 Safety Instructions, Warnings and Notes 3

3 Directions for Use (No DFU necessary) 4

4 Mechanical Instructions 5

5 Service Modes, Error Codes and Fault Finding 8

6

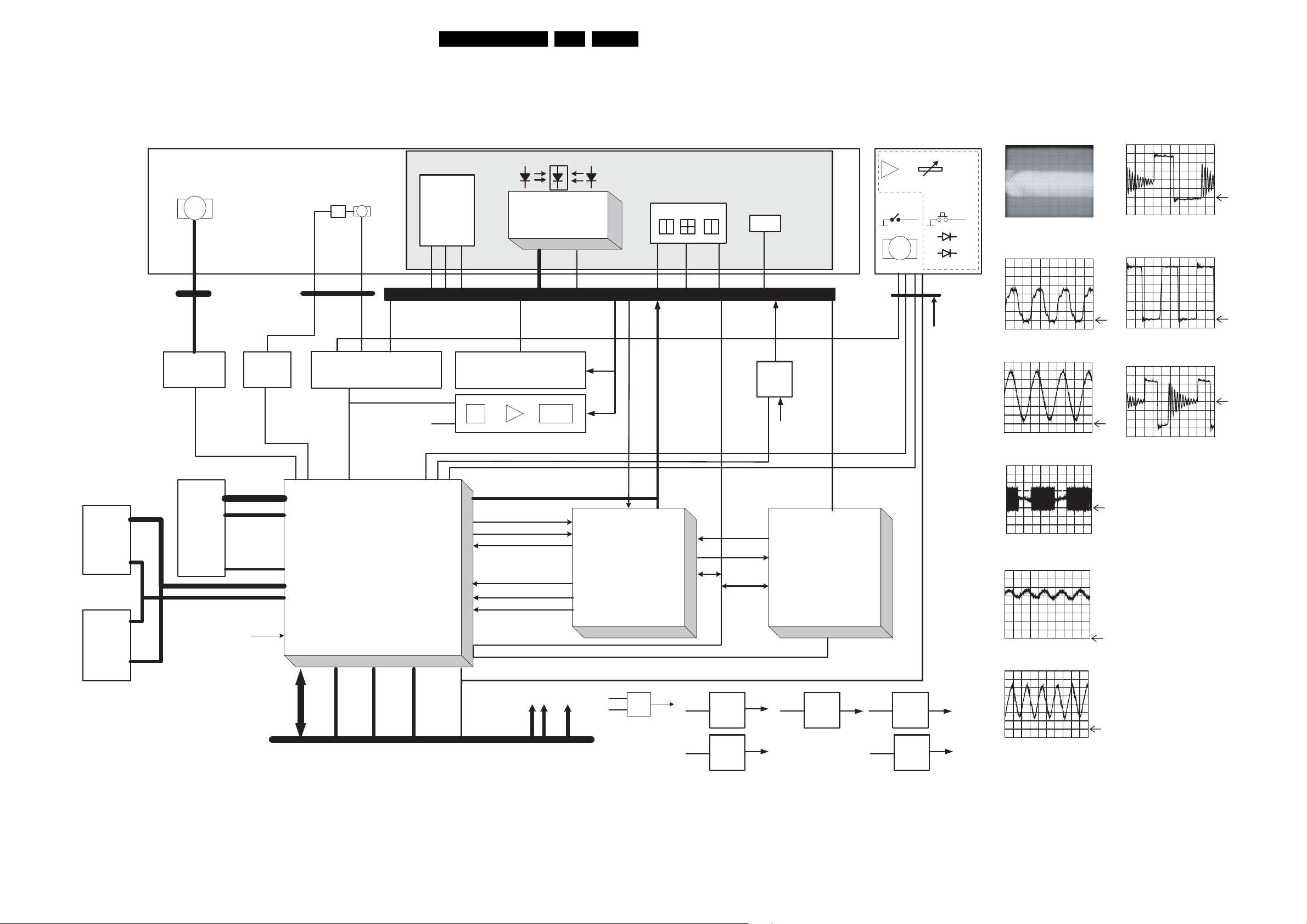

Block Diagrams, Waveforms, Wiring Diagram 13

Block Diagram 13

7

Electrical Diagrams and Print-Layouts Diagram PWB

Servo Board: OPU Interface (Diagram 1) 14 28-29

Servo Board: Cheetah (Diagram 2

Servo Board: Laconic (Diagram 3) 16 28-29

Servo Board: Drivers (Diagram 4) 17 28-29

Servo Board: Centaurus (Diagram 5) 20 28-29

Servo Board: Power, Connectors (Diagram 6) 26 28-29

Servo Board: Tray Motor Connect.(Diagram 7) 27 28-29

8 Alignments 31

9 Circuit-, IC Descriptions and List

of Abbreviations 32

10 Electrical Parts List 47

) 15 28-29

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by GH03 0395 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 13680

EN 2 VAD 80311.

Technical Specifications and Connection Facilities

1. Technical Specifications and Connection Facilities

1.1 VAD8031 functionality:

• Loading of 8 cm and 12 cm discs by a motorized tray

• Disc type recognition and in case of a DVD+RW disc laser

power calibration

• Servo control for disc rotation, sledge movements, tilt,

focus and actuator position

• EFM+ encoding / decoding for DVD, and EFM decoding for

CD

• Writes and read DVD+RW discs and reads DVD, CD and

CD-R/RW discs

• Linking control, header insertion and sector number

updating at record

• Interfacing to the MPEG back-end for control and for data

• The back-end has to provide MPEG data processing, data

buffering, construction of logical format for Lead-in, Data

area and Lead-out part of the DVD+RW disc

1.2 Connections

The following interfaces are provided for connecting the drive

to the MPEG back-end Application:

• Power Connector: 4-pin supply interface

• IDE Connector: 40-pin command and data transfer

interface

IDE Bus selection:

• Jumper Selection: 6-pin IDE Bus selector

Attention: Jumper has to be in position "Master"

1.3 Read and Write Speeds

Type of Disc (Function) Disc Rotation Speed

Read Speed CD CAV 7x

Read Speed DVD CAV 4x

Write Speed DVD+RW

Write Speed DVD+R

ZCAV 2.4x

ZCAV 2.4x

Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

EN 3VAD 8031 2.

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains plug

and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the 'on' position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains plug

and the front panel, controls, and chassis bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, symbol ). Careless

handling during repair can reduce life drastically. Make

sure that, during repair, you are at the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage section.

The primary side of the power supply (pos. 1005), including

the heatsink, carries live mains voltage when you connect

the player to the mains (even when the player is 'off'!). It is

possible to touch copper tracks and/or components in this

unshielded primary area, when you service the player.

Service personnel must take precautions to prevent

touching this area or components in this area. A 'lightning

stroke' and a stripe-marked printing on the printed wiring

board, indicate the primary side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW (DVD+RW

writing)

: 0.8 mW (DVD

reading)

: 0.3 mW (VCD/CD

reading)

Beam divergence : 60 degree

Figure 2-1 Class 1 Laser Product

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

Figure 2-2 Warning text

EN 4 VAD 80313.

3. Directions For Use

Not applicable

Directions For Use

4. Mechanical Instructions

Mechanical Instructions

EN 5VAD 8031 4.

Note that exploded views can be found in chapter 10

4.1 General

Follow the dismantling instructions in described order.

Do not place the unit with its PWB on a hard surface (e.g.

table), as it could damage the components on it.

Always place something soft (a towel or foam cushion) under it.

Never touch the lens of the OPU.

Take sufficient ESD measures during handling.

4.2 Dismantling

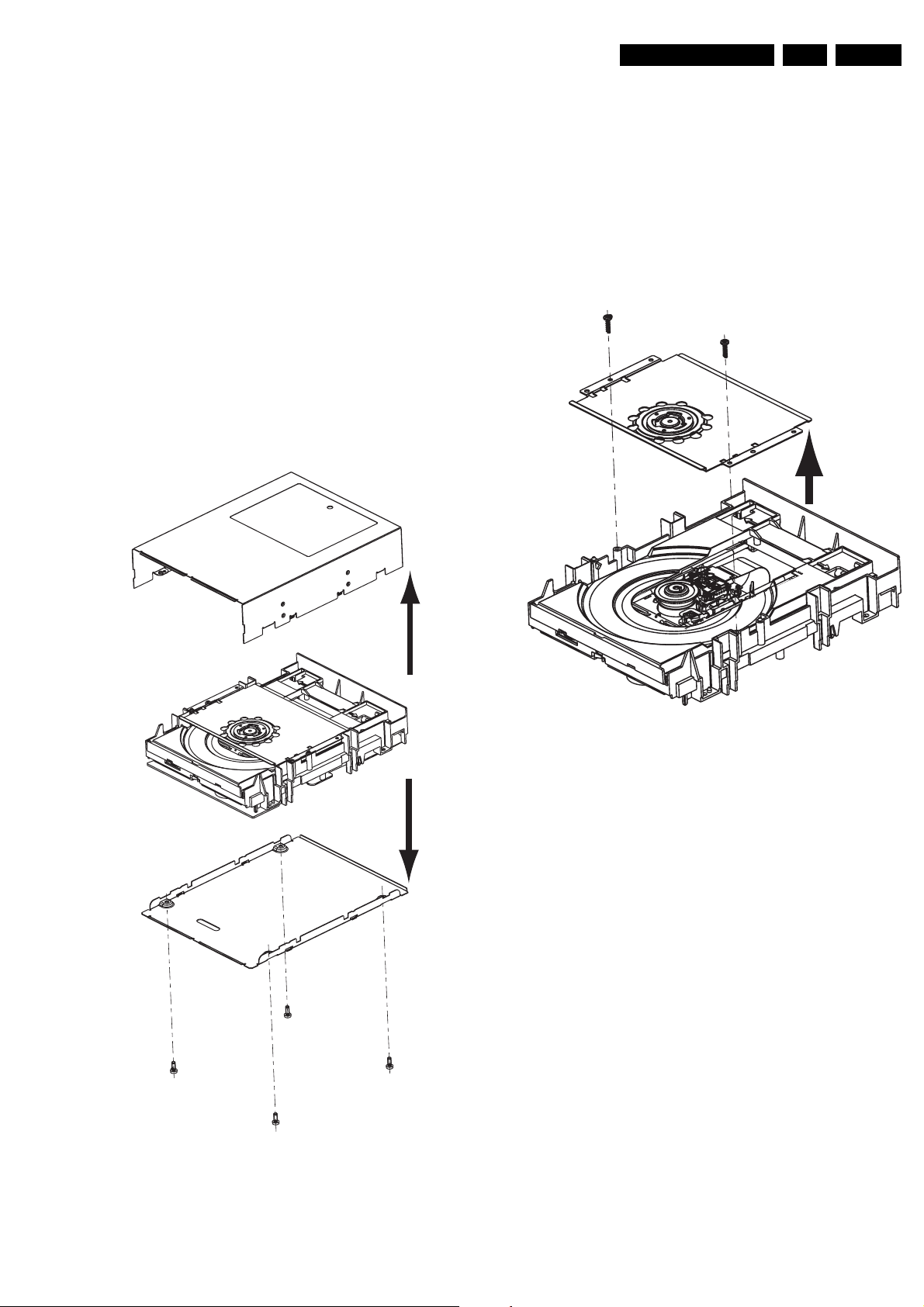

You can divide the Basic Engine into the following parts:

1. Loader (frame and tray, clamp)

2. PWB (or 'mono board')

3. DVD-Module (OPU, turntable motor, and sledge-motor

assy)

4. Encasing

4.3 Cab inet and Clamper Bridge

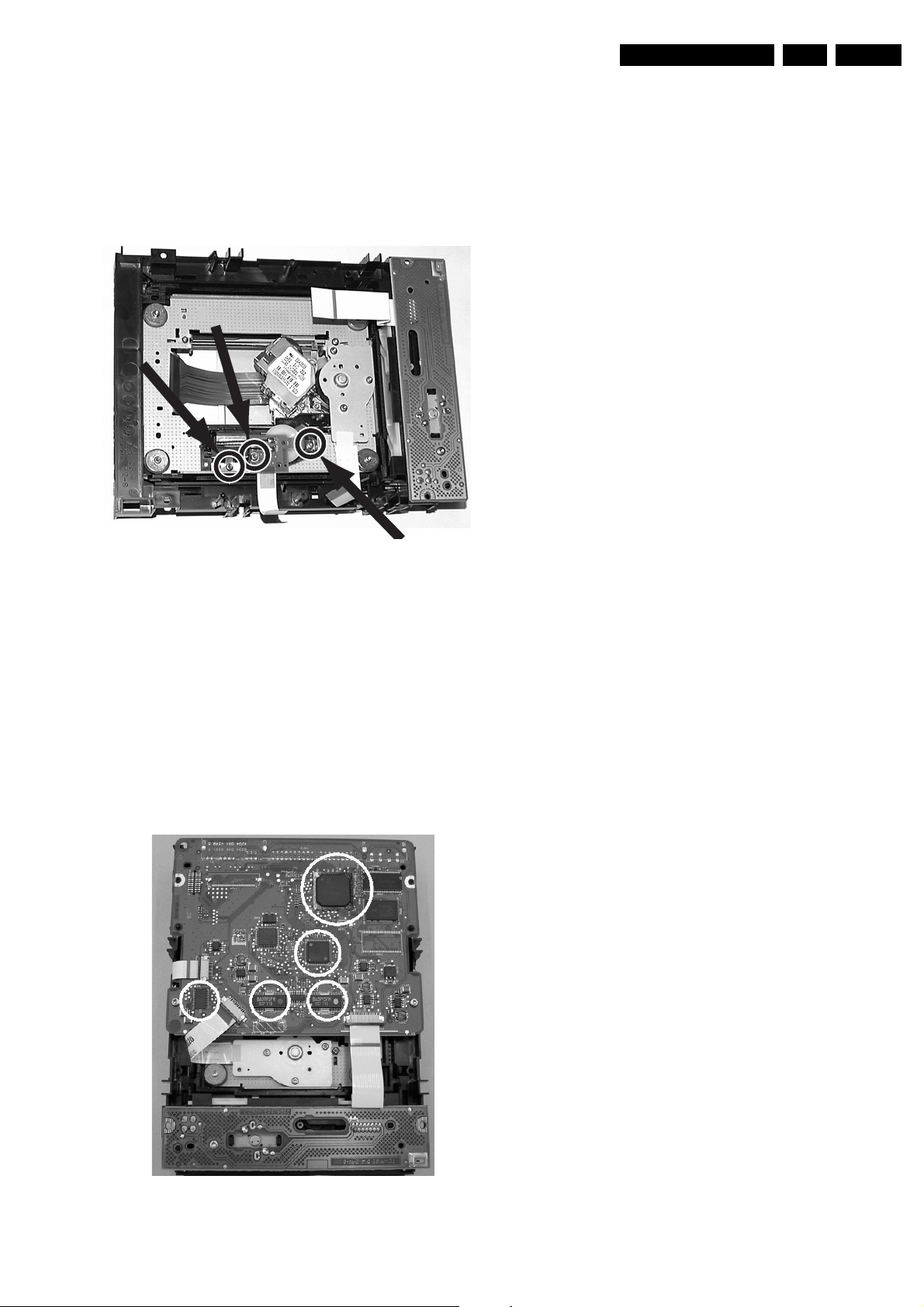

– Remove the encasing by releasing the four screws [1], see

figure 4-1

– Make sure that you do not lose the 5 heat paths (gray

rubber pieces that conduct the heat from the ICs to the

case)!

– Remove the clamper bridge assy, by releasing the two

screws [1], see figure 4-2

1

1

2

1

2

Figure 4-2 Remove Clamper Bridge

2

1

1

1

Figure 4-1 Basic Engine dismantling (part1)

EN 6 VAD 80314.

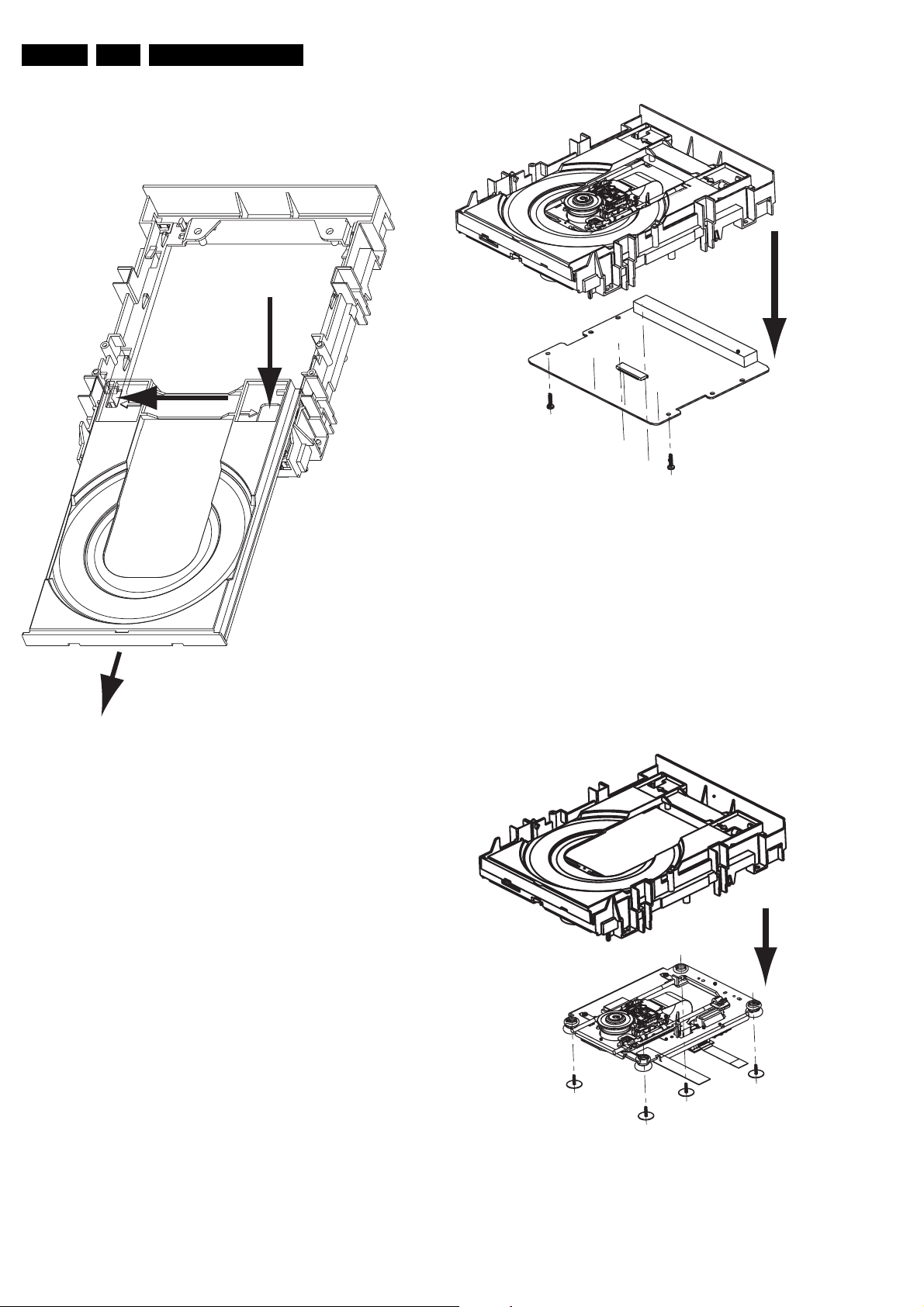

4.4 Tray

– Remove encasing as as described in 4.3

– Disengage the two holders that fix the tray [1], see figure 4-

3, and pull out the tray [2]

1

1

Mechanical Instructions

2

1

1

2

Figure 4-3 Remove Tray

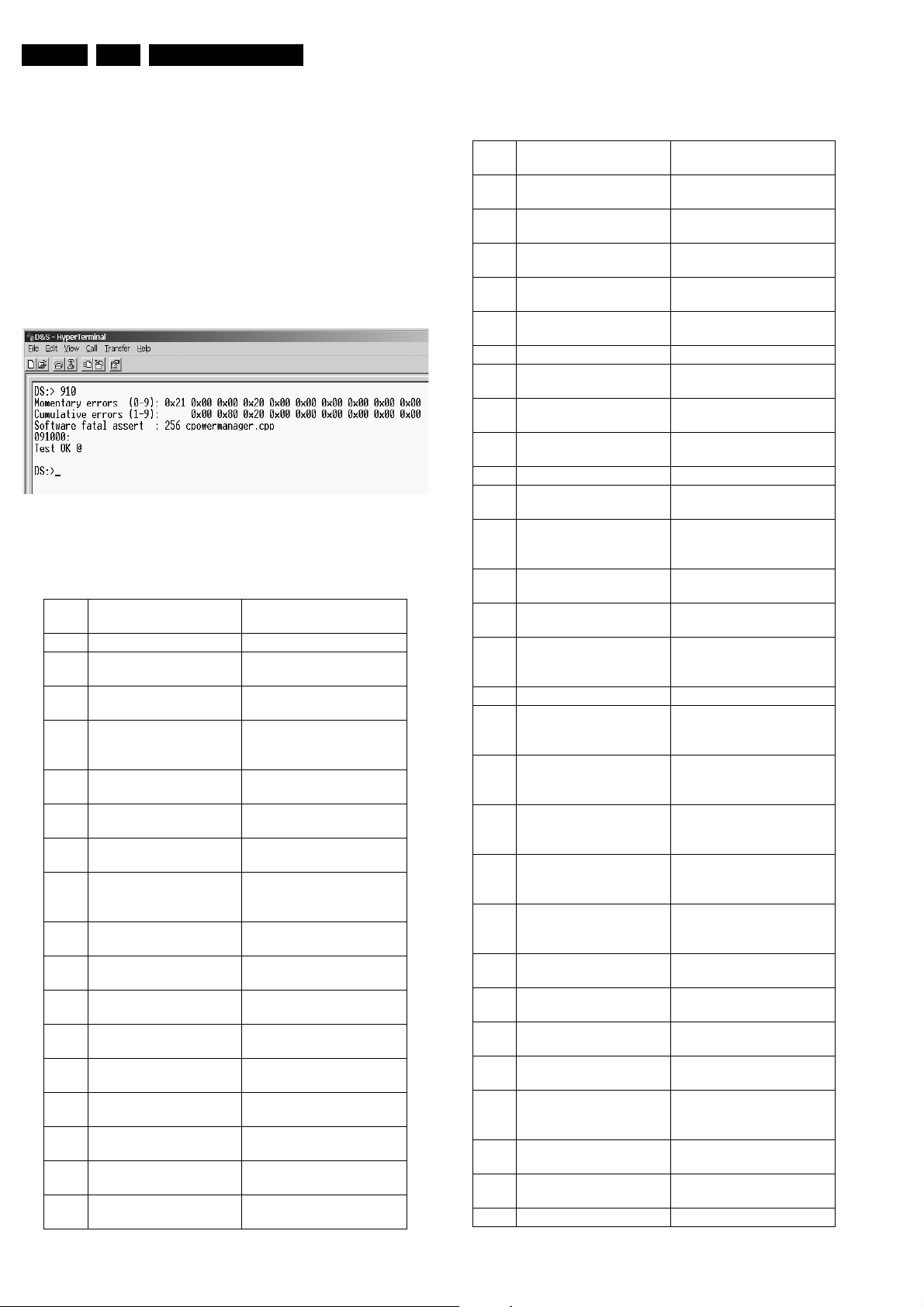

4.5 Printed Board

Note: After Exchanging the PWB (or the DVD-M) the complete

drive has to be adjusted! Refer to chapter 8 for adjustment

instructions!

– Remove encasing and clamper bridge as described in 4.3

– Disconnect the four flex foils from the PWB connectors

– Remove the 2 screws that hold the PWB, see figure 4-4

– At assembly make sure that the 5 heat paths (gray rubber

pieces) are placed on the ICs!

Figure 4-4 Remove PWB

4.6 DVD-M

Caution: Never try to align or repair the DVD-Module itself!

Only the factory can do this properly. Service engineers are

only allowed to exchange the sledge motor assy.

After Exchanging the DVD-M (or the PWB) the complete drive

has to be adjusted! Refer to chapter 8 for adjustment

instructions!

– Remove encasing, clamper bridge and PWB as described

in 4-3 and 4-5

– Remove the four screws [1], see figure 4-5.

– Now you can remove the DVDM

2

1

1

Figure 4-5 Remove DVDM

1

1

4.7 Sledge Motor Assembly

Caution: Never try to align or repair the DVD-Module itself!

Only the factory can do this properly. Service engineers are

only allowed to exchange the sledge motor assy.

– Place the DVD-Module, with the laser facing downwards

on a soft surface.

– Remove the three screws that hold the sledge-motor assy

and lift the assy upwards. You can replace it now.

Mechanical Instructions

EN 7VAD 8031 4.

Figure 4-6 Remove Sledge Motor Assy

4.8 Re-assembly

To re-assemble the module, do all processes in reverse order.

Take care of the following:

• Sledge-motor assy: Mesh the teeth of the sledge motor

and sledge rack properly, during mounting of the sledge

motor assy.

• Heat Paths: Put the 5 heat paths (gray rubber pieces) back

to their position on the ICs, see figure 4-7.

• Complete module: Place all wires/cables in their original

positions

• Emergency opening slot: Be sure that the slot for the

emergency tray opener is covered by adhesive tape!

• Jumper selection: Jumper has to be in position "Master"!

Figure 4-7 Heat Paths

EN 8 VAD 80315.

5. Diagnostic Software

Diagnostic Software

5.1 General

Please refer to the service manual of the recorder for a

description of the complete Diagnostics Software. In this

manual only drive specific error codes are explained.

5.2 Error Codes

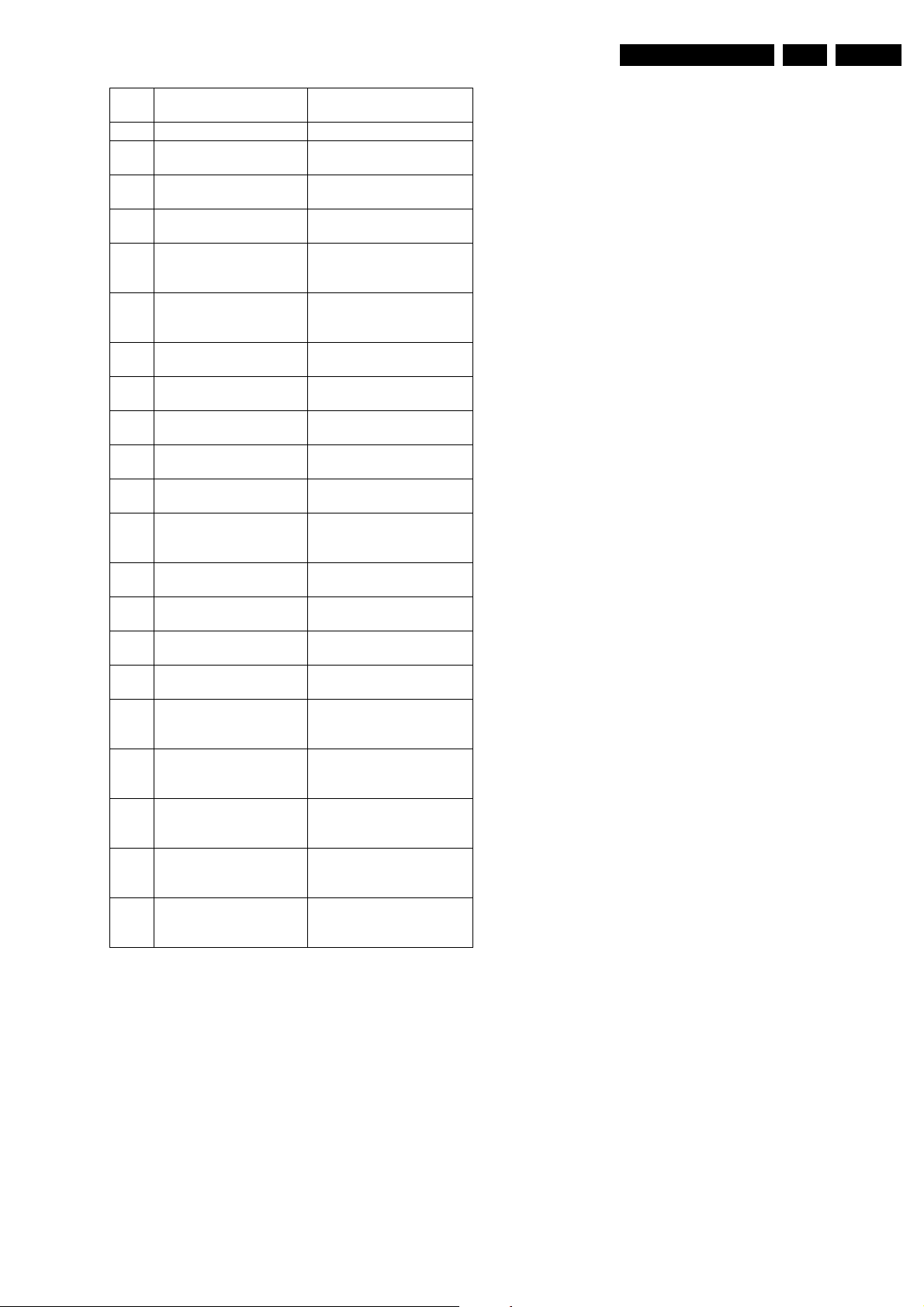

With DSW command 910 (Digital Board Chrysalis) the set

software can retrieve an overview of all occurred engine errors.

5.2.1 Momentary Errors

Byte 0: latest error:

Overview of the BE error codes.

error

error meaning

code

0x00 no_error No error has occurred

0x01 illegal_command_error Command not allowed in this

state or unknown command

0x02 illegal_parameter_error Parameter(s) not valid for

0x03 command_timeout_error The maximum execution

0x04 sledge_home_error The sledge could not be

0x05 sledge_calibration_error An error occurred during cal-

0x06 sledge_unstable_error The sledge detected unsta-

0x07 speed_timeout_error Spindle motor could not

0x08 speed_window_error Measured spinning speed is

0x09 focus_timeout_error Focus could not be achieved

0x0A focus_retries_error The amount of focus retries

0x0B focus_agc_error The focus agc results are out

0x0C radial_timeout_error Servo didn’t get on track

0x0D radial_retries_error Servo didn’t get on track after

0x0E radial_agc_error The radial agc results are out

0x0F radial_init_error Unreliable signal scaling af-

0x10 hf_pll_error HF-decoder pll could not lock

this command

time for the command has

exceeded

moved home

ibration of the sledge

ble control

reach its target speed within

timeout

not within expected window

within the timeout

expired

of range

within the timeout

several retries

of range

ter the radial initialisation

to HF signal

0x11 wobble_pll_error Wobble pll could not lock to

wobble signal

0x12 subcode_timeout_error Subcode information could

not be read

0x13 subcode_notfound_error Requested subcode item

0x14 header_timeout_error Header information could not

0x15 adip_timeout_error Adip information could not be

0x16 adip_window_error Adip address was not within

0x17 adip_sync_error No adip sync was detected

0x18 atip_timeout_error Atip information could not be

0x19 atip_notfound_error Requested atip item could

0x1A atip_window_error Atip address was not within

0x1B atip_sync_error No atip sync was detected

0x1C tray_error Tray could not be closed or

0x1D seek_error T he requested seek couldn’t

0x1E no_hf_present_error Attempt to read from a blank

0x1F record_error An error occurred during the

0x20 illegal_stopaddress_error The requested stopaddress

0x21 no_disc_error No disc is detected

0x22 not_initialised_error The system is not initialised

0x23 illegal_medium_error BE detected an unsupported

0x24 cd_frequency_error Measured HF frequency is

0x25 dvd_frequency_error Measured HF frequency is

0x26 re-

served(non_existing_bca_

error)

0x27 reserved(bca_read_error) An error occurred during

0x28 selftest_error An error occurred during the

0x29 i2c_error The I2C interface does not

0x2A laser_pll_error Laser control pll did not lock

0x2B laser_forward_sense_errorForward sense value didn’t

0x2C jitter_optimisation_error An error occurred during op-

0x2D tilt_calibration_error An error occurred during cal-

0x2E reserved

could not be found

be read

read

expected window

read

not be found

expected window

opened within the timeout

be performed within the timeout

area

recording

with modify-stop-address is

not valid

(e.g. seek on unknown disctype)

medium during disc recognition

not within CD frequency

range

not within DVD frequency

range

Attempt to read non-existing

bca information

reading of bca information

self-test of the BE

operate

or lost lock on write clock

change with changing laser

power

timisation of the jitter

ibration of the tilt frame

Diagnostic Software

EN 9VAD 8031 5.

0x2F frontend_offset_calib_errorThe offset in the frontend

0x30 reserved

0x31 wsg_calculation_error An error occurred in the cal-

0x32 buffer_overrun_error The buffer input stream over-

0x33 return_value_invalid_error The requested information is

0x34 illegal_recording_speed_e

rror

0x35 opc_media_parameter_errorThe media parameters (info

0x36 opc_record_power_error The final optimum power was

0x37 opc_start_power_low_errorOPC start power too low (op-

0x38 opc_start_power_high_errorOPC start power too high

0x39 opc_power_calculation_er

ror

0x3A opc_test_zone_full_error OPC can’t be performed be-

0x3B opc_bad_jitter_measurem

ent_error

0x3C opc_read_samples_error An error occurred during

0x3D ropc_alpha_overflow_error The determined value for the

0x3E ropc_alpha_ref_current_er

ror

0x3F ropc_alpha_gain_error The alpha measurement al-

0x40 beta_over_under_flow_errorDuring the walking OPC a

0x41 not_enough_calib_points_

error

0x42 not_enough_power_error The calculated power during

0x43 illegal_reading_speed_errorThe selected speed is not al-

0x44 servo_fatal_error The actuator dissipation be-

couldn’t be calibrated

culation of the write strategy

ran the buffer output stream

not available for this inquiry

The selected speed is not al-

lowed for a recording on this

medium

in ATIP/ADIP) are invalid or

not read

not reached

timum power is higher)

(optimum power is lower)

Error during OPC power cal-

culation (samples are wrong)

cause test zone is full

The jitter measurement dur-

ing OPC samples readback

failed

OPC readback sampling

optimum power is too high

The alpha measurement ref-

erence current is wrong (IAN)

pha gain is wrong

beta over-/under-flow was

detected

Not enough valid calibration

points available for re-calibration

re-calibration exceeds max

power

lowed for the requested command

came too high during a servo

recovery

This error is overwritten by the next player / inquiry command.

EN 10 VAD 80315.

Diagnostic Software

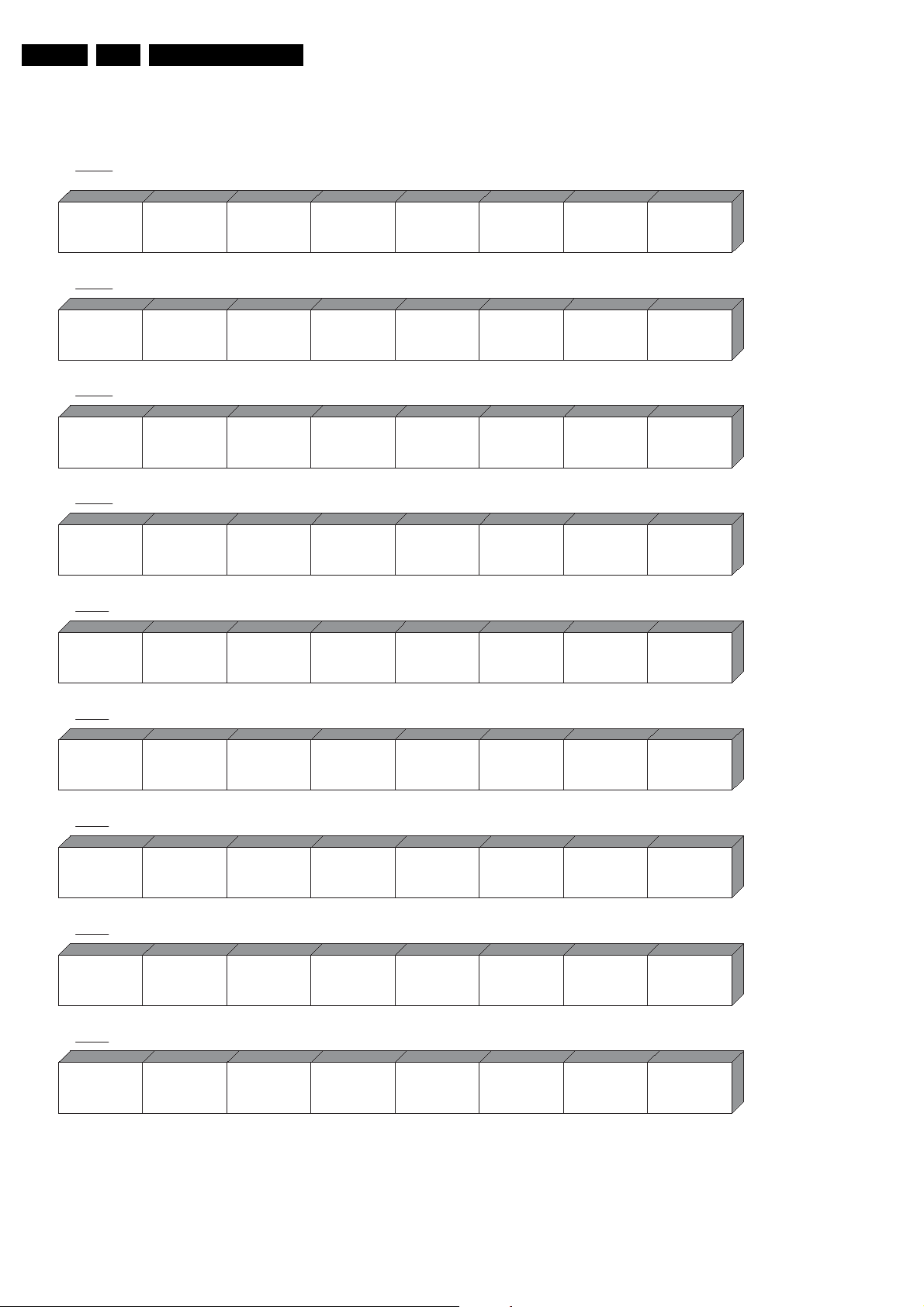

Byte 1 - 9: cumulative errors of previous error occurences.

Format of the BE error bytes

Every individual error has its own bit in the 9-byte structure as

described in the drawing below:

byte 1

b7 b6 b5 b4 b3 b2 b1 b0

reserved

FOCUS

AGC

ERROR

FOCUS

RETRIES

ERROR

FOCUS

TIMEOUT

ERROR

RADIAL

AGC

ERROR

RADIAL

RETRIES

ERROR

RADIAL

TIMEOUT

ERROR

byte 2

TRAY

ERROR

reserved

JITTER

OPTIMIZATION

ERROR

SLEDGE

HOME

ERROR

SLEDGE

UNSTABLE

ERROR

SLEDGE

CALIBRATION

ERROR

TILT SENSOR

OFFSET

CALIBRATION

ERROR

byte 3

RECORD

ERROR

SEEK

ERROR

NO DISC

ERROR

NOT

INITIALISED

ERROR

ILLEGAL

STOPADDRESS

ERROR

ILLEGAL

PARAMETER

ERROR

ILLEGAL

COMMAND

ERROR

byte 4

SERVO

FATAL

ERROR

reserved reserved

HF PLL

ERROR

NO HF

PRESENT

ERROR

HEADER

TIMEOUT

ERROR

SUBCODE

NOTFOUND

ERROR

RADIAL

INIT

ERROR

TILT

CALIBRATION

ERROR

COMMAND

TIMEOUT

ERROR

SUBCODE

TIMEOUT

ERROR

byte5

WOBBLE PLL

ERROR

byte6

WSG

CALCULATION

ERROR

byte7

LASER

FORWARD

SENSE

ERROR

byte8

OPC

READ

SAMPLES

ERROR

byte9

ADIP

SYNC

ERROR

DVD

FREQUENCY

ERROR

NVRAM

CHECKSUM

UPDATE

ERROR

OPC

BAD JITTER

MEASUREMENT

ERROR

ADIP

WINDOW

ERROR

CD

FREQUENCY

ERROR

FRONTEND

OFFSET

CALIBRATION

ERROR

OPC

TEST ZONE

FULL

ERROR

ADIP

TIMEOUT

ERROR

ILLEGAL

RECORDING

SPEED

ERROR

LASER PLL

ERROR

OPC

POWER

CALCULATION

ERROR

ATIP

NOTFOUND

ERROR

SPEED

WINDOW

ERROR

ILLEGAL

READING

SPEED

ERROR

OPC

START

POWER HIGH

ERROR

ATIP

SYNC

ERROR

SPEED

TIMEOUT

ERROR

ILLEGAL

MEDIUM

ERROR

OPC

START

POWER LOW

ERROR

ATIP

WINDOW

ERROR

NON

EXISTING

BCA

ERROR

SELFTEST

ERROR

OPC

RECORD

POWER

ERROR

ATIP

TIMEOUT

ERROR

BCA

READ

ERROR

I2C

ERROR

OPC

MEDIA

PARAMETER

ERROR

RETURN

VALUE

INVALID

ERROR

BUFFER

OVERRUN

ERROR

BETA

OVER/UNDER

FLOW

ERROR

NOT ENOUGH

CALIB POINTS

ERROR

These errors are kept in memory until a power down of the

drive (e.g. when recorder goes to standby) or reset of the drive.

NOT ENOUGH

POWER

ERROR

ROPC

ALPHA

GAIN

ERROR

ROPC

ALPHA

REF CURRENT

ERROR

ROPC

ALPHA

OVERFLOW

ERROR

5.2.2 Cumulative errors

These errors are stored in EEPROM and are thus non-volatile

showing the complete error history of the drive.

Byte 1 - 9: cumulative errors of previous player / inquiry error

occurences. These bytes are the same as the nine bytes (1-9)

of the Momentary errors

5.2.3 Software fatal assert

Gives row number and file name in the source code of the

firmware of the data path of the AV

Diagnostic Software

EN 11VAD 8031 5.

EN 12 VAD 80315.

Diagnostic Software

6. Block Diagram.

Block Diagram

Disc Motor

M

11P

1401

7402

Disc Motor Driver

option

SRAM

7503

TZA1015

7504

SDRAM

16MB

U,V,W coil

U+,UV+,VW+,WHall+ ,Hall-

MOTO1

MOTOR-ON

VMOTO10

T1

7400

XDD0..15

XDA0..11

DATA_MASK

DA0..15

AD0..19

PCS-p re_amp

SIN H

COSPH

REFSIN

REFCOS

7500

XWR

XRAS

SDCK

XCASL

XCASH

1400

LOADER

+SI N , - SIN

+COS, -COS

7409

ROHM

Block Diagram.

PCS

Sled g e

M

9P

SL-

SL+

Servo D ri v e r

BA5995FM

SL

FO+

FORA

TRAY-INOUT

TRAY-ONOFF

DRIVER-ON

CENTAURUS

FOC+

FOC-

Actuator

RADIAL

FOCUS

TILT

1V65

7408

7405

DC

level

laser 650nm

RAD

Servo D r iv er

BA5995FM

SID A , SILD, SICL

RFREF

RFN3 ,RFP3

A1,2

CALF

XDN

FTC

D1..4

PPNO

F S diode

E la ntec 6295

SCLK

SDI O

SEN

offset

gain

TRAYSW

EJECTKEY

DEBUG1,2,4,5

laser 780nm

EFM

R/ W

SERVO-M EA S

SERVO-COM M

FOC-

FOC+

13VAD 8031 6.

650nm PD

RAD

OPU66

PAEDIC

TZA 1045

CD-MO DE

VIA..H RF P ,R F N IIC

HIGH-GAIN

VIA..H

RFP

RFN

E FMDATAP

EFM _ D A TA

EFM CLKN

EFM CLKP

EFM _ RWN

7201

highpower

IIC

LASP

ALFA

EEpr o m

7104

PAEDIC

power

7300

4V6

1002 Tr a y Motor PWB Assy

option

for Data

Drive

Headphones

Tray Switch

Eject key

R F N3 / R F P3, IC 7201 P in 38/39

A:AC, 50mV/Div

50ns/Div

M

15P

5V

3V3

LED

1702

Tr a y Motor

OPU Flex 45p

1100

Iodel

IOthr

IAPC

WSB

SCLK

SDIO

SEN

RW-Del

Vdel

5V

VREF

Vthr

HIGH-GAIN

CD- M ODE

LACONICCHEETA H

TR+

TR-

IC7300 Pin 4

A: DC , 1 V /Div, 20ns/Div

IC7300 Pin 5

A: DC , 500mV/Div, 20ns/Div

1401 Pin 9/10/11

A: DC , 5 V /Div, 500us/Div

1400-2,3,4,6,7, 8

IC 7604 P in 4

A: DC , 1 V/Div, 1us/Div

IC 7606 P in 1

A: DC , 2 V/Div, 1us/Div

IC 7605 P in 7

A: DC , 2 V/Div, 1us/Div

FLASH

PROM

1600

PORN

HD0..15

IDE

HDASPN

CS0

CS1

HA0

HA1

HA2

HPDIAGN

HIRQ

HDACKN

IOR DY

HDRN

HRWN

HDRQ

RX1_MASTER

TX1

TX2

DEBUG11

AUDIOR

AUDIOL

IEC958

5V

From/To DVD Recorder application

GND

12V

IR Q N,OSTR,EFM_RW N

1V8

3V3

RESET

PORN

7502

7603

5V

12V

3v3 1V8

5V25

5V

7606

7604

TOSTOCEN

A: DC , 500mV/Div, 2ms/Div

IC7504 Pin 38

7605

5V

-5V

1V65

TR 15001_002

100903

A: DC , 500mV /Div, 5ns/Div

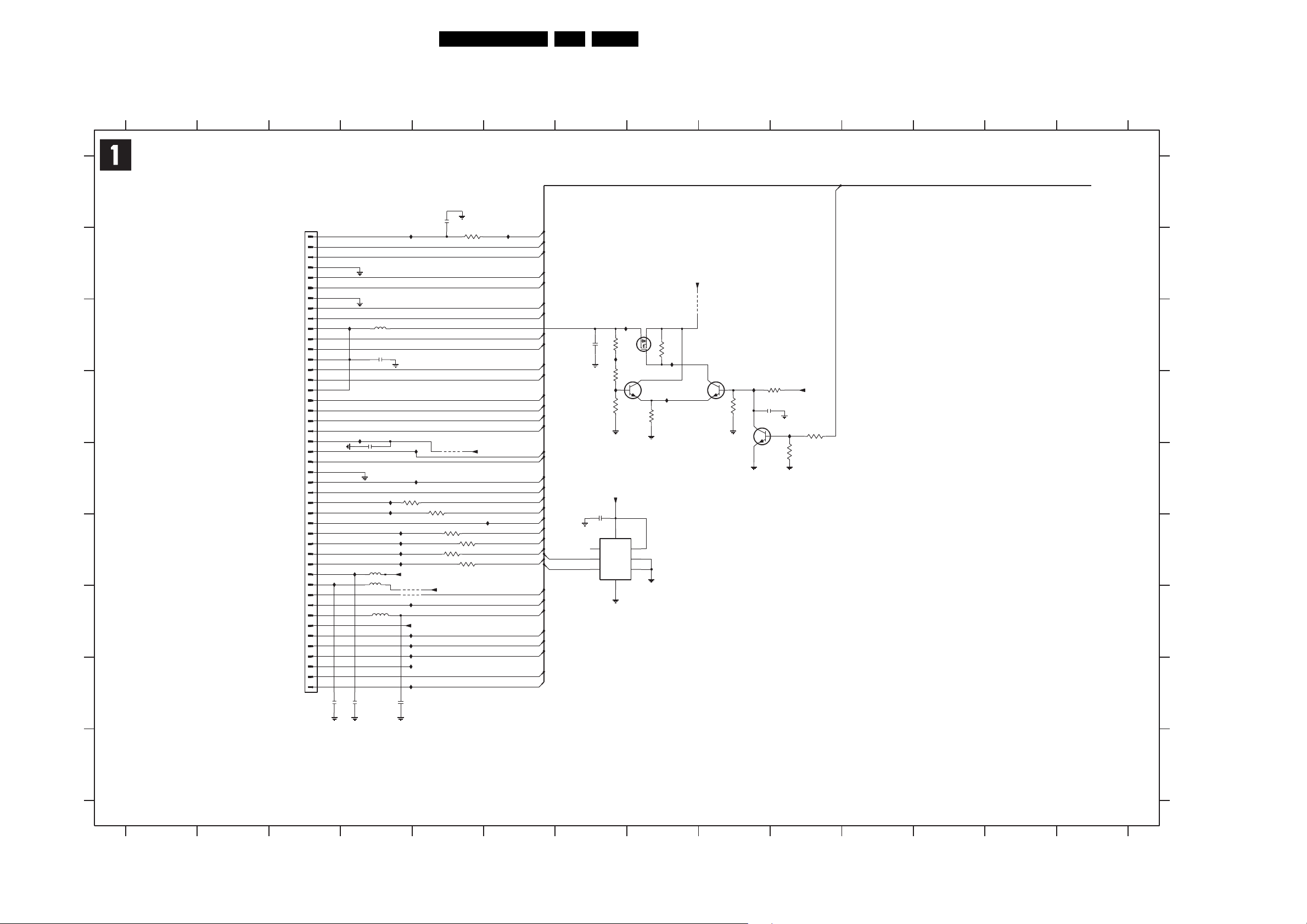

Electrical Diagrams and Print-Layouts

7. Electrical Diagrams and Print-Layouts

Servo Board: OPU Interface

14VAD 8031 7.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

1100 A3

2100 C4

2101 H4

A

2102 E4

2103 A5

2104 H3

2105 H4

2106 D9

TO CHEETAH_QD/DRIVERS/CENTAURUS-DRAM-FLASHROM/DEBUG-AND-FLASH

{SERVO-MEAS,VREF,Vdel,Vthr,ENA,RW-Del,HIGH-GAIN,CD-MODE,VIG,VIE,VIA,VID,RFP,RFN,VIB,VIC,VIH,VIF,SERVO-COMM,FOC-,FOC+,RAD,IOthr,EFM-DATAP,EFM-DATAN,EFM-CLKP,EFM-CLKN,EFM_RWN,SCLK,SDIO,SEN,BUSY,IoDel,WSB,SCL,SDA,HIGHPOWER}

A

2107 C7

B

C

D

E

F

G

H

2108 F7

2110 B7

3100 E5

3101 E4

3103 F5

3104 B5

3105 F5

3106 F5

3107 F5

3110 D10

3111 E10

3112 D9

3113 D10

3114 D8

3115 C8

3116 C7

3117 D7

3118 D7

3119 B7

3120 A7

4100 D7

4105 G4

4106 C8

4107 C8

4108 C8

4109 D5

4110 E5

4111 F4

4112 G4

5101 C4

5102 F4

5103 F4

5104 G4

7101 D9

7102 D9

7103 D8

7104 C8

7105 F7

7107 B8

I100 B4

I101 B6

I102 F6

I103 G4

I104 G4

I106 G4

I107 H4

I108 G5

I110 E4

I111 E4

I115 D4

I116 F4

I117 F4

I118 F4

I119 F4

I120 C4

I121 C8

1100

AF3

45

44

43

B

C

D

E

F

G

42

41

40

39

38

37

I120

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

I115

100n

I128

I129

5102

5103

2102

5101

2100

100n

5104

I100

I130

I131

I110

3101

I111

82R

I116

I117

I118

I119

D3V3

4112

4105

I104

I103

I106

L100

I107

I108

+12V

10u

3100

100p

2103

3104

100R

4110

82R

3103

1K1K3105

3106

1K

3107

1K

+5V25

+5V25

I102

I101

HIGH-GAIN

EFM-DATAP

EFM-DATAN

SERVO-MEAS

SERVO-COMM

RW-Del

CD-MODE

VREF

SDIO

SCLK

EFM_RWN

EFM-CLKN

EFM-CLKP

WSB

IOthr

IoDel

FOC-

FOC+

RAD

VIG

VIE

VID

VIA

RFN

RFP

VIC

VIB

VIH

VIF

SCL

SDA

Vdel

Vthr

SEN

SDA

SCL

2107

2108

100n

LM75ADP

3

1

2

I121

1K5

22u

3116

7104

BSH205

7103

BC847B

7

6

5

3114

3115

820R

I122

3117

220R

I124

1K

3118

D3V3

8

7105

+VS

A0

OS

SDA

A1

SCL

A2

GND

4

+5V25

4108

3K3

I123

3112

1K

7102

BC847B

I125

2106

100n

7101

BC847B

I126

3113

3V3

1K0

I127

10K

3111

HIGHPOWER

3110

10K

H

2101

2104

100n

2105

100n

220p

I122 C7

I123 C8

I124 D7

I125 D9

I126 D8

I

I

I127 D10

I128 F4

I129 F3

I130 E5

I131 E5

TR 15002_001

100903

I132 A8

I133 B7

L100 H4

1 2 3 4 5 6 7 8 9 10 11 12 13 14

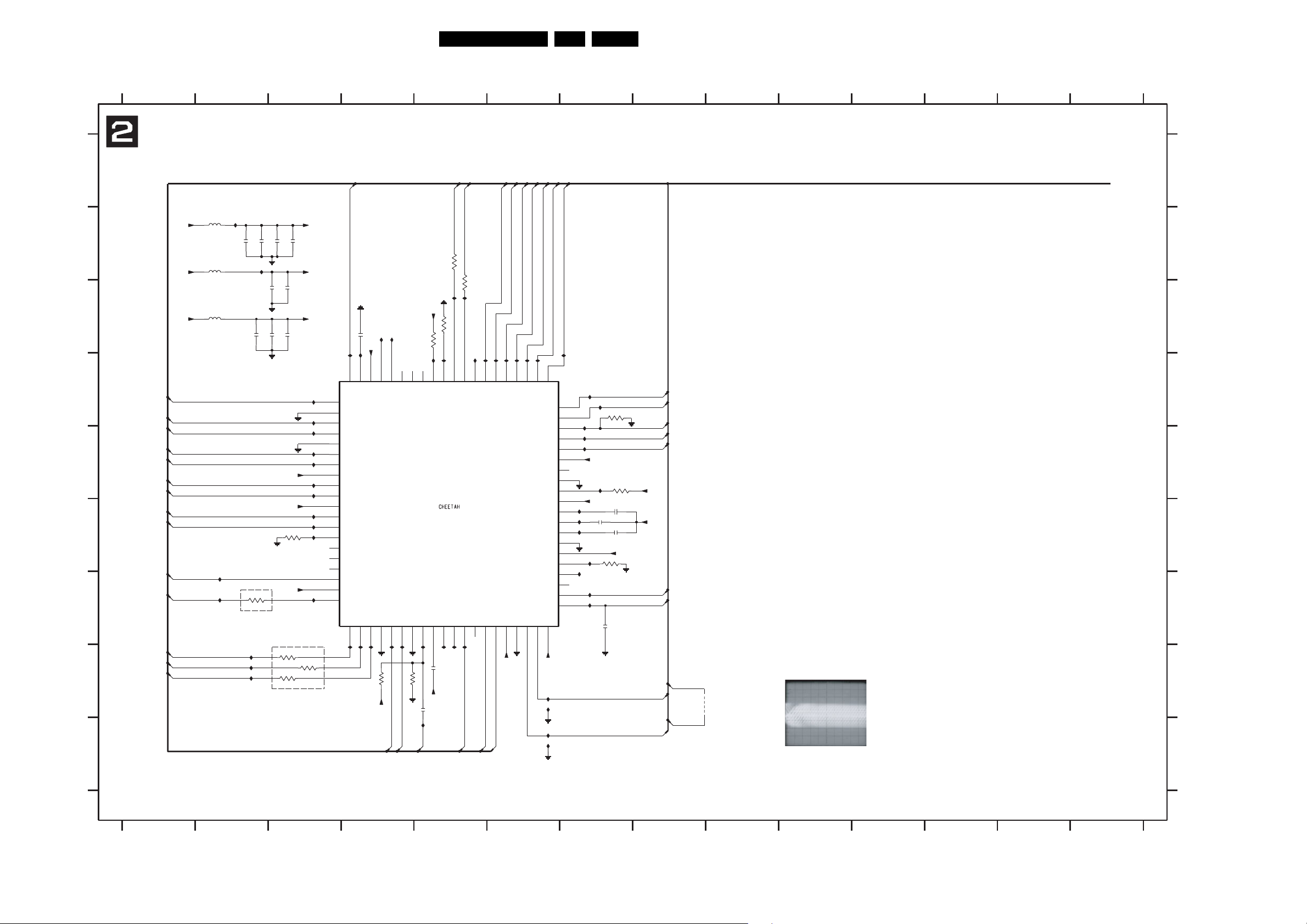

Servo Board: Cheetah

Electrical Diagrams and Print-Layouts

15VAD 8031 7.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

5202

5204

5201

I201

2209

100n

5VA

B

-5V

C

-5V

2206

D

VIH

VIC

VIB

RFN

E

RFP

VID

VIA

VIE

VIG

F

TIMOUT

EFM-CLKN

G

EFM-CLKP

EFM-DATAN

H

EFM-DATAP

I253

I254

CLOSE TO IC7500

3209

1K8

I261

I262

I263

I

{TIMOUT,RFP,RFN,VIA,VIB,VIC,VID,VIE,VIF,VIG,VIH,EFM-CLKP,EFM-CLKN,EFM-DATAP,EFM-DATAN,TS1,TS2,LASP,PPNO,RFP3,RFN3,RFREF,CALF,A1,A2,XDN,D1_TILTN,D2_TLN,D3_REN,D4_FEN,S1_MIRN,S2,MON1,MON2,SIDA,SICL,SILD,SDA,SCL,ALFA,FTC,VERSION0,VERSION1,RW-Del,R-W,GEN-INP0,GEN-INP1,EFMCLK-O,EFM_DATA_P_del,EFM_DATA_N_del,EFM-DATAP,EFM-DATAN,RWN,PORN,EFM_RWN}

A1

VIF

LASP

ALFA

A2

CALF

XDN

D2_TLN

D1_TILTN

D3_REN

TO OPU/EPLD-LADIC-CON/LACONIC_IC/CENTAURUS

+5Vd

2212

100n

100n

2211

100n

2210

3201

3205

I225

72

NC8

CFTC

29

2217

10n

I243

10K

3203

1%

47K

I209

71

TEST

TZA1039HL

30

I246

I245

47n

100R

3200

100R

I242I244

I203

D163D262D3

VDD1-3

GND1-4

VSS1-2

CCALF

GND1-3

VSS1-1

SERTST

RFREF

RFP

RFN

39

-5Va

61

MON2

MON1

CMPP

RREF

CA2

CA1

PPN

NC7

NC6

VSS2

I202

I216

I217

60

D4

59

S1

58

S2

57

56

55

54

53

52

51

I234

50

I237

49

I239

48

47

46

45

L201

44

43

42

41

40

I219

I221

I222

I236

I238

I241

+5Vd

I228

-5Va

2214

3214

27K

2213

2215

10n

10n

3208

10K

2223

27n

100n

3206

47K

-5Vd

D4_FEN

S1_MIRN

S2

MON2

MON1

-5Va

1%

-5Va

PPNO

RFREF

69

70

ALFA

LASP

TS131TS2

SILD

32

SROUT

NC5

33

A167A2

34

65

64

XDN

CALF

VDD2

SICL35SIDA

GND2

37

36

38

I204

I207

I205

I208

I206

L200

68

66

+5Vd

RFN3 / RFP3, IC7201 Pin 38/39

TIMOUT

RFN3

4201

RW-Del

RFP3

SILD

SIDA

SICL

I257

I258

I259

I260

I256

100n

2219

2207

-5Vd

100n

2220

100n

-5Va

100n

2222

100n

I215

I218

I220

I224

I226

+5Vd

I227

I229

+5Vd

I231

I233

I235

3207

10K

-5Vd

I240

CLOSE TO IC7500

3210

3211

1K8

3212

1K8

1K8

7201

-5Va

100n

2221

I223

I214

-5Va

I212

I265

78

79

80

VIF

VREF

VIH

GND1-1

VIC

VIB

GND1-2

RFNIN

RFPIN

VDD1-1

VID

VIA

VDD1-2

VIE

VIG

R|W

NC1

NC2

NC3

TIMOUT

VSSD

EFMCN

I252

EFMCP21EFMDN

22

I251

I250

VSS1-3

EFMDP

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

3217

77

WRF

GNDD

74MI73

75

76

LD

RRF

VDDL

SCL26SDA

NC4

I248

27

3213

FTC

28

I247

18K

24

25

I249

33K

-5Va

+5Vd

2218

I264

SDA

SCL

FTC

A:AC, 50mV/Div

50ns/Div

2204 B5

2205 B5

2206 C2

2207 C3

2209 B2

2210 B2

2211 B3

2212 B3

2213 F7

2214 F7

2215 F7

2217 H5

2218 H5

A

2219 C3

2220 C3

2221 C4

2222 C3

2223 G7

3200 C5

3201 B5

3202 C4

3203 C5

3204 C4

3205 C5

3206 E7

B

3207 F3

3208 F7

3209 G2

3210 H3

3211 H3

3212 H3

3213 H4

3214 D7

3215 D3

3216 D3

3217 H4

4200 H9

C

4201 H8

5201 C2

5202 B2

5204 B2

7201 D3

I201 B2

I202 D6

I203 D6

I204 D6

I205 D6

I206 D6

D

I207 D6

I208 D5

I209 D5

I212 D4

I214 C4

I215 D3

I216 D7

I217 D7

I218 D3

I219 D7

I220 E3

I221 E7

E

I222 E7

I223 C4

I224 E3

I225 D5

I226 E3

I227 E3

I228 E7

I229 E3

I231 F3

I233 F3

I234 F7

I235 F3

F

I236 F7

I237 F7

I238 G7

I239 F7

I240 G3

I241 G7

I242 C5

I243 C5

I244 H5

I245 H5

I246 H5

G

I247 H5

I248 H4

I249 H4

I250 H4

I251 H4

I252 H4

I253 G2

I254 G2

I256 B2

I257 H6

I258 H6

I259 I6

H

I260 I6

I261 H2

I262 H2

I263 H2

I264 I5

I265 D4

L200 D5

L201 F7

I

TR 15003_001

1 2 3 4 5 6 7 8 9 10 11 12 13 14

100903

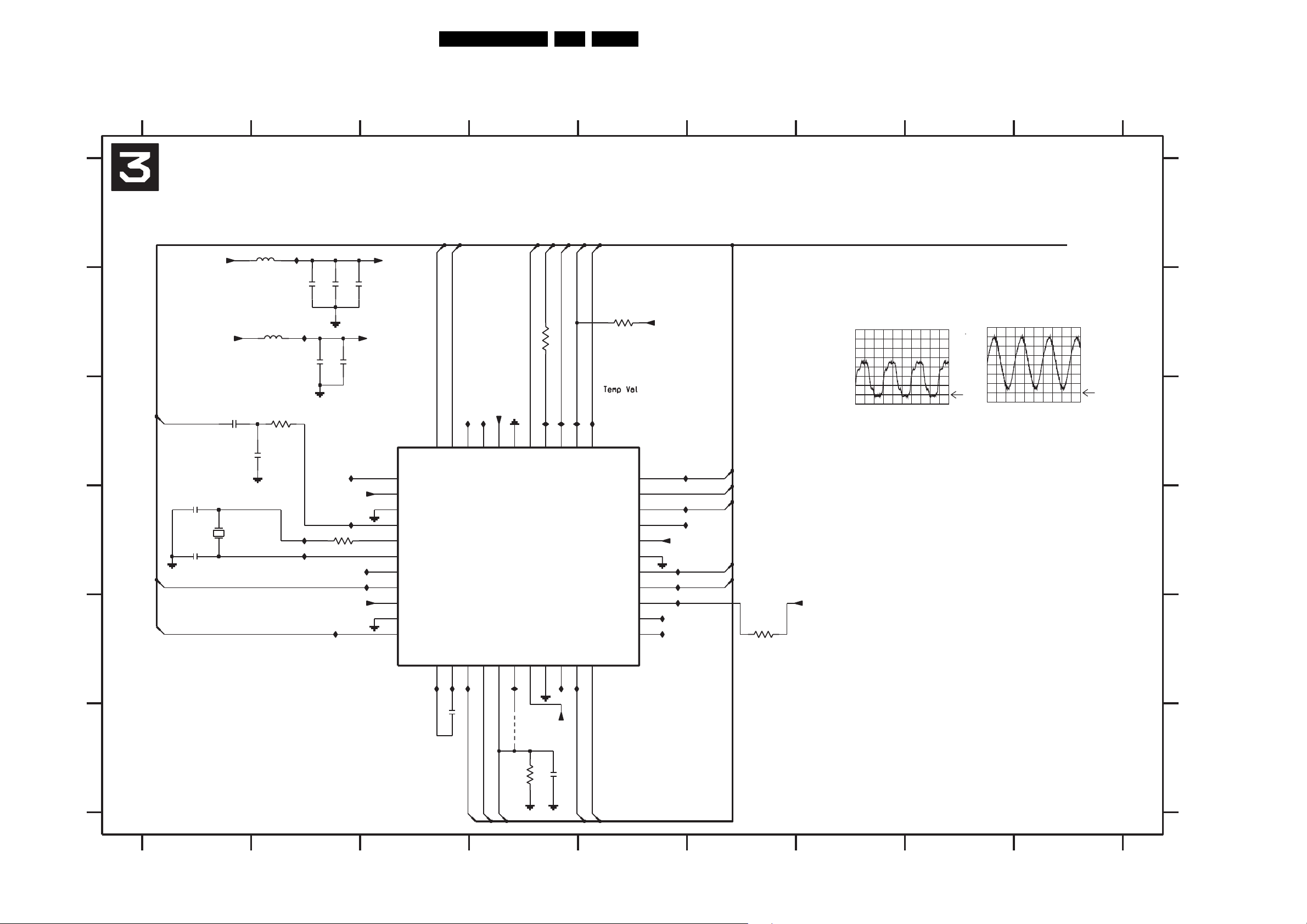

Servo Board: Laconic

A

B

OSC_IN

C

2303

D

ALFA

LASP

E

Electrical Diagrams and Print-Layouts

16VAD 8031 7.

1 2 3 4 5 6 7 8 9

TO OPU/EPLD/CENTAURUS

{WSB,RW-Del,R-W-Delayed,TIMOUT,OSC_IN,PORN,VERSION0,VERSION1,SCL,SDA,SCLK,SDIO,SEN,BUSY,ENA,HIGH-GAIN,CD-MODE,GEN-INP0,GEN-INP1,EFM-CLKP,EFM-CLKN,EFMDATA-3P,EFMDATA-3N,ALFA,LASP,Vdel,Vthr,VREF,IOthr,CD-MODE,HIGH-GAIN,IRQN,OSTR,RWN,SDA,SCL,IoDel}

5300

5301

15p

3303

150R

I303

I313

I308

I310

2301

2306

2302

100n

100n

I312

D3V3

A3V3 3V3A

2311

1n0

2312

15p

1302

16M93

2304

15p

CX-16F

2307

3315

33R

100n

2300

100n

3V3D

I320

3V3A

L308

L303

I311

100n

3V3D

1

2

3

4

5

6

7

8

9

10

11

AEZ

Vddd3

Vssd3

ClckOut

Osco

Osci

Test1d

Ameas

Vdda1

Vssa1

LasP

SCL

I316

SDA

44

SCL

VRefL

12

I317

L301

43

SDA

VRefH

13

L305

L307

42

Test2d

VDel

14

3V3D

41

Bank

VThr

15

39

40

Vssd2

Vddd2

7300

LACONIC

Vopuref16Vrefin

17

I314

RW-Del

38

RWn

Vdda2

18

PORN

3302

I304

37

Resetn

Vssa2

19

OSTR

1R

I305

36

OSTR

Test1a

20

L306

IRQN

I306

35

IRQn

IoDel

21

L310

WSB

L311

34

WSB

IoThr

22

3316

10K

SCLK

SDIO

SEN

Busy

Vddd1

Vssd1

HiLo

DvdCd

EnR1

EnR2

Test2a

3V3D

L309

L304

3V3D

I302

I315

I318

I300

I301

I319

SCLK

SDIO

SEN

HIGH-GAIN

CD-MODE

3V3D

3301

10K

33

32

31

30

29

28

27

26

25

24

23

IC7300 Pin 4

A: DC, 1 V/Div, 20ns/Div

IC7300 Pin 5

A: DC, 500mV/Div, 20ns/Div

A

B

C

D

E

1302 D1

2300 B2

2301 B2

2302 B2

2303 D1

2304 D1

2305 F3

2306 B2

2307 B2

2308 B5

2309 E6

2310 F4

2311 C1

2312 C2

3300 D2

3301 E6

3302 B4

3303 C2

3304 E5

3305 E5

3306 E6

3308 F4

3309 F4

3315 D2

3316 B5

4303 F4

5300 A2

5301 B2

7300 D4

I300 C5

I301 D5

I302 D5

I303 A2

I304 C4

I305 C4

I306 C4

I307 C1

I308 D2

I310 D2

I311 D3

I312 E2

I313 B2

I314 E4

I315 D5

I316 E3

I317 E3

I318 D5

I319 D5

I320 D2

L301 C3

L303 D3

L304 E5

L305 E3

L306 E4

L307 C4

L308 C3

L309 E5

L310 E4

L311 C5

F

22n

2305

Vdel

Vthr

4303

VREF

3309

1K8

3V3A

2310

100n

IoDel

IOthr

1 2 3 4 5 6 7 8 9

TR 15004_001

100903

F

Loading...

Loading...