Philips UZZ9000 Datasheet

DISCRETE SEMICONDUCTORS

DATA SH EET

UZZ9000

Sensor Conditioning Electronic

Product specification

Supersedes data of 2000 May 19

2000 Nov 27

Philips Semiconductors Product specification

Sensor Conditioning Electronic UZZ9000

FEATURES

• One chip fully integrated signal conditioning IC

• Accuracy better than 1° together with KMZ41 in 100°

angle range

• Temperature range from −40 to 150 °C

• Adjustable angle range

• Adjustable zero point.

GENERAL DESCRIPTION

The UZZ9000 is an integrated circuit that combines two

sinusoidal signals (sine and cosine) into one single linear

output signal. When used in conjunction with the

magnetoresistive sensor KMZ41 it provides a

measurement systemfor angles up to 180°. The UZZ9000

can also be used for other applications in which an angle

has to be calculated from a sine and a cosine signal.

A typical application would be any kind of resolver

application.

The two input signalsare convertedinto thedigital domain

with two separate AD-converters. A CORDIC algorithm

performsthe inverse tangenttransformation.Sincetoday’s

applications typically require analog output signals

(e.g. potentiometers), the resulting signal is transferred

back to the analog domain.

TheUZZ9000 enablesthe userto setboth the anglerange

and the zero point offset. Theseranges areset byexternal

voltage dividers.

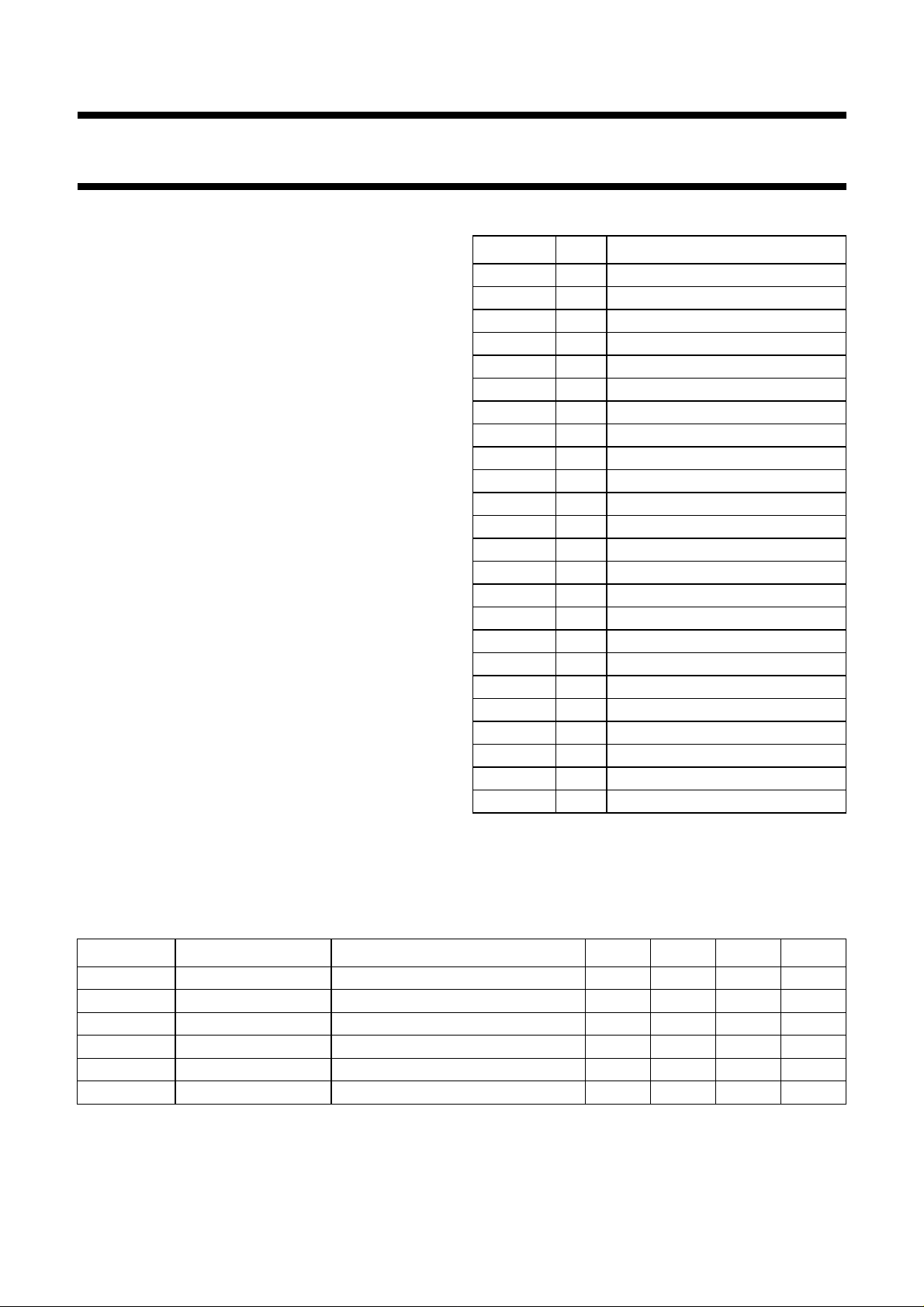

PINNING

SYMBOL PIN DESCRIPTION

+V

+V

V

V

O2

O1

DD2

SS

1 sensor 2 positive differential input

2 sensor 1 positive differential input

3 digital supply voltage

4 digital ground

GND 5 analog ground

RST 6 reset of the digital part; note 1

TEST1 7 for production test; note 1

TEST2 8 note 2

DATA_CLK 9 trim-mode data-clock; note 1

SMODE 10 serial mode programmer; note 1

TEST3 11 note 2

V

OUT

12 output voltage

Var 13 angle-range input set

V

offin

14 offset input set

OFFS2 15 offset trimming input sensor 2

OFFS1 16 offset trimming input sensor 1

V

DDA

17 analog supply voltage

GND 18 analog ground

TEST4 19 for production test; note 1

TEST5 20 for production test; note 1

V

T

−V

−V

DD1

out

O2

O1

21 digital supply voltage

22 test output

23 sensor 2 negative differential input

24 sensor 1 negative differential input

Notes

1. Connected to ground.

2. Pin to be left unconnected.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DDA

V

DD1

V

DD2

I

CCtot

supply voltage note 1 4.5 5 5.5 V

supply voltage note 1 4.5 5 5.5 V

supply voltage note 1 4.5 5 5.5 V

total supply current − 13 15 mA

A angle range in 10° steps with KMZ41 30 − 180 deg

A accuracy with ideal input signal; range = 100°±0.45 −−deg

Note

1. V

DDA

, V

DD1

and V

must be connected to the same supply voltage.

DD2

2000 Nov 27 2

Philips Semiconductors Product specification

Sensor Conditioning Electronic UZZ9000

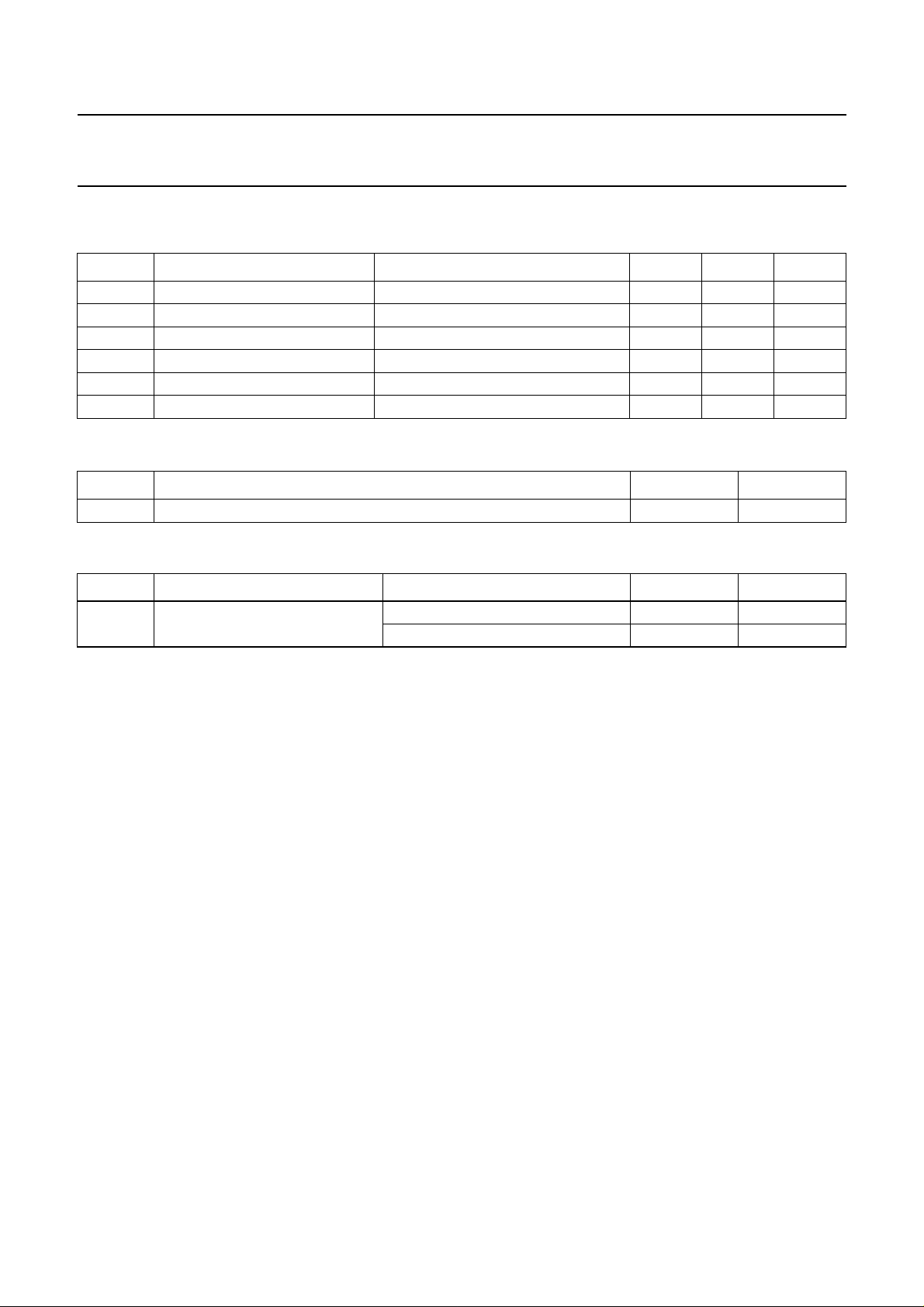

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DDA

V

DD1

V

DD2

V

pin

T

stg

T

j

THERMAL CHARACTERISTICS

SYMBOL PARAMETER VALUE UNIT

R

th j-a

supply voltage −0.3 +6 V

supply voltage −0.3 +6 V

supply voltage −0.3 +6 V

voltage at all pins −0.3 V

DD

V

storage temperature −55 +150 °C

operating temperature 125 to 150 °C; max 200 hours −40 +150 °C

thermal resistance from junction to ambient 80 K/W

ESD SENSITIVITY

SYMBOL PARAMETER CONDITIONS VALUE UNIT

ESD ESD sensitivity human body model 2 kV

machine model ±150 V

2000 Nov 27 3

Philips Semiconductors Product specification

Sensor Conditioning Electronic UZZ9000

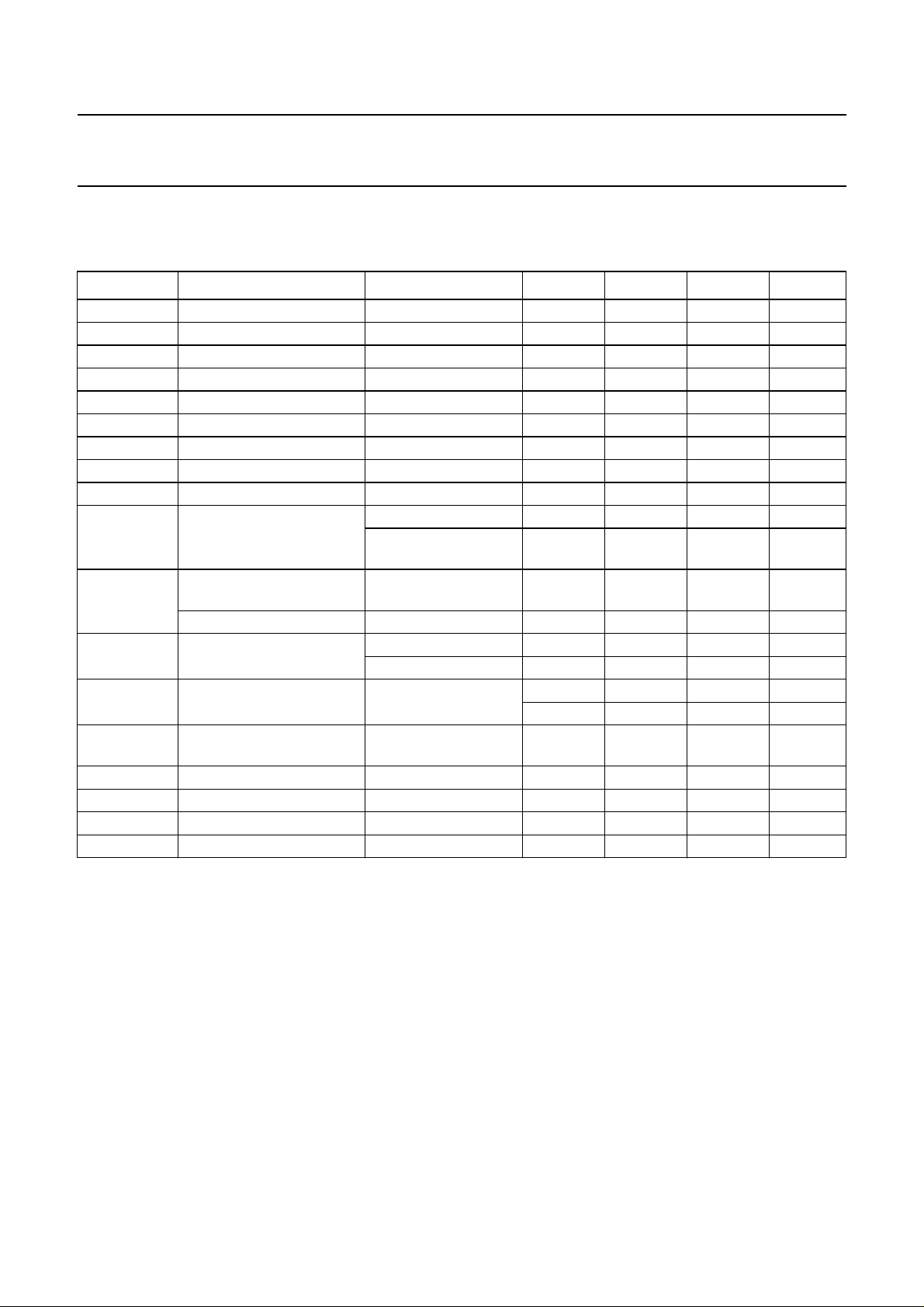

ELECTRICAL CHARACTERISTICS

T

= −40 to +150 °C; VDD= 4.5 to 5.5 V; typical characteristics for T

amb

specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DDA

V

DD1

V

DD2

I

DD

(+V

)-(−VO) differential input voltage referred to V

O

f

ext

f

int

C

load

supply voltage 4.5 5 5.5 V

supply voltage 4.5 5 5.5 V

supply voltage 4.5 5 5.5 V

supply current without load − 10 15 mA

DD

common mode range referred to V

lost magnet threshold referred to V

DD

DD

external clock frequency for trim interface 0.1 − 1 MHz

internal clock frequency Tj= −40 to 150 °C 2.3 4 5.7 MHz

output load −−50 pF

with series resistance

>300 Ω

V

reset

switchingvoltagethreshold

for power on/off

between falling and

rising V

DD

hysteresis − 0.3 −

V

out

V

d

output voltage range for

valid ranges

lower bound 5 − 6% V

upper bound 94 − 95 % V

diagnostic area for irregular input

signal

A accuracy with ideal input signal;

range = 100°

Res resolution range = 100° 0.1 −−degree

t

on

t

r

V

LM

power up time −−20 ms

response time to 95% of final value − 0.7 1.2 ms

sensor voltage lost magnet threshold 12 15 20 mV

=25°C and VDD= 5 V unless otherwise

amb

±6.6 −±28 mV/V

490 − 510 mV/V

− 3 − mV/V

−−200 nF

2.8 − 4.5 V

DD

DD

0 − 4% V

96 − 100 % V

DD

DD

±0.45 −−degree

FUNCTIONAL DESCRIPTION

The UZZ9000is a mixedsignal IC for angle measurement

systems. The UZZ9000 has been designed for the double

sensor KMZ41. It combines two analog signals (sine and

cosine) into a linear output signal. The analog

measurement signals on the IC input are converted to

digital data by two ADC’s. Each ADC is a Sigma-Delta

modulator employing a 4th order continuous time

architecture with an over-sampling ratio of 128 to achieve

high resolution. The converteroutput isa digitalbit-stream

with an over-sampling frequency of typically 500 kHz.

The bit-stream is fed into a decimation filter which

2000 Nov 27 4

performs both low pass filtering and down-sampling. The

IC has twoinput channels each of which has its own ADC

and decimationfilter. The twodecimation filter outputsare

15-bit digital words at a lower frequency of typically

3.9 kHz which is the typical sampling frequency of the

sensor system. The digital representations of the two

signals arethen used to calculatethe current angleby the

ALU. This calculation is carried out using the so-called

CORDIC algorithm. The angle is represented by a 13-bit

resolution. A DAC converts the digital signal back to the

analog domain.

Philips Semiconductors Product specification

Sensor Conditioning Electronic UZZ9000

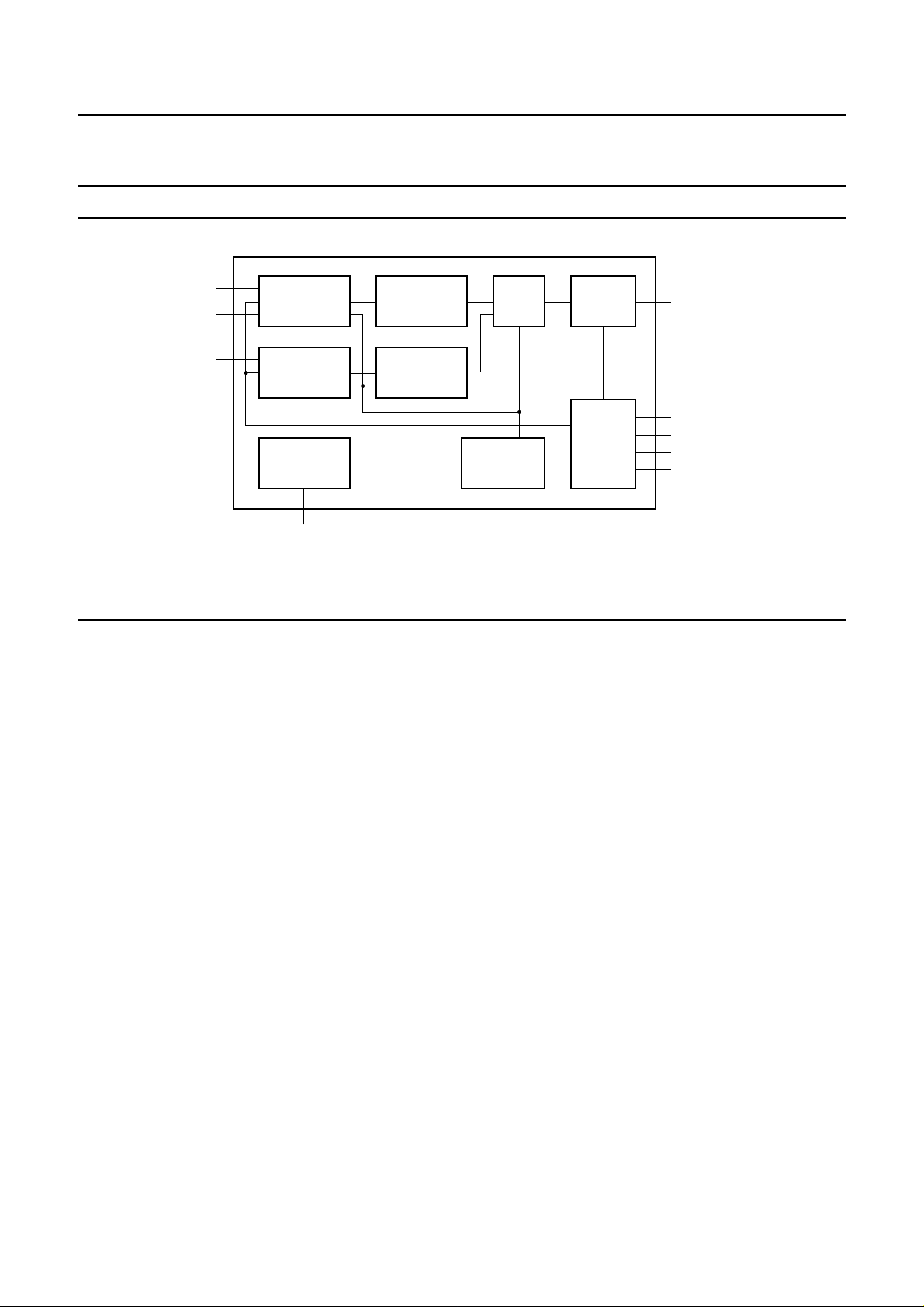

handbook, full pagewidth

+V

−V

+V

−V

O1

O1

O2

O2

ADC1

ADC2

RESET

DECIMATION

FILTER

DECIMATION

FILTER

UZZ9000

ALU DAC output

CONTROL

OSCILLATOR

angle range

offset

DATA-CLK

SMODE

reset

Fig.1 Block diagram.

The following list gives a short description of the relevant

block functions:

1. The ADC block contains two Sigma Delta AD

converters, sensor offset correction circuitry and the

circuitry required for the sensitivity and offset

adjustment of the chip output voltage curve.

2. The decimation filter block comprises two digital low

pass decimation filtersconvert the low resolution high

speed bit stream output from the ADC’s into a low

speed digital word.

3. The ALU block derives an angle value from the two

digital inputs using the CORDIC algorithm.

4. The DAC converts the output of the ALU block to an

analog signal.

5. The CONTROL block provides the clock and the

control signals for the chip.

6. The RESET block supplies a reset signal during

power-up and power-down when the power supply is

below a certain value.

7. The Oscillator generates the master clock.

MHB694

Angle range selection

In order to accommodate varying applications, both the

mechanical input angular range of the UZZ9000 and the

zeropoint oftheoutput curveareuser programmable.This

section describes how to select a desired mode.

The output curve is adjusted by changing the angular

range asshown inFig.2. Without anyzero pointoffset, the

ramp-up starts at mechanical 0° (α1=0°). When using a

KMZ41 sensor, the maximum angular range ∆α

is 0° to 180°. For the UZZ9000, smaller angular ranges

can be set. In this case, α2 becomes smaller than 180°

and the output curve is clipped at this position. The

location of discontinuity XD (change from lower to upper

clipping area) depends on the adjusted range and can be

calculated as follows:

180°∆α–

∆α

X

D

+=

-------------------------2

Inorder tocompensate fortolerances, thezero point ofthe

output curve can be shifted by ±5˚ in steps of 0.5°. The

effect of this measure is shown in Fig.3. Now α1 is no

longer identicalwith mechanical 0˚,but with the zero point

shift X

. Consequently, the location of discontinuity X

off

D

can be calculated as follows:

2000 Nov 27 5

X

Dxoff

∆α+

180°∆α–

+=

-------------------------2

Loading...

Loading...