INTEGRATED CIRCUITS

DATA SH EET

TZA1038HW

High speed advanced analog DVD

signal processor and laser supply

Product specification 2003 Sep 03

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 QUICK REFERENCE DATA

5 BLOCK DIAGRAM

6 PINNING

7 FUNCTIONAL DESCRIPTION

7.1 RF data processing

7.2 Servo signal processing

7.2.1 Servo signal path set-up

7.2.2 Focus servo

7.2.3 Radial servo

7.2.4 Differential phase detection

7.2.4.1 Drop-out concealment

7.2.4.2 Push-pull and three-beam push-pull

7.2.4.3 Enhanced push-pull (dynamic offset

compensation for beam landing)

7.2.4.4 Offset compensation

7.2.5 Automatic dual laser supply

7.2.6 Power-on reset and general power on

7.2.7 Compatibility with TZA1033HL/V1

7.2.7.1 Software compatibility

7.2.7.2 Hardware compatibility

7.2.8 Interface to the system controller

7.3 Control registers

7.3.1 Register 0: power control

7.3.2 Register 1: servo and RF modes

7.3.3 Register 2: focus offset DAC

7.3.4 Register 3: RF path gain

7.3.5 Register 4: RF left and right, or sum offset

compensation

7.3.6 Register 5: RF sum offset compensation

7.3.7 Register 6: servo gain and dynamic radial

offset compensation factor

7.3.8 Register 7: servopath gain and bandwidth and

RF path bandwidth and pre-emphasis

7.3.9 Register 8: RF channel selection

7.3.10 Register 11: radial servo offset cancellation

7.3.11 Register 12: central servo offset cancellation

inputs A and B

7.3.12 Register 13: central servo offset cancellation

inputs C and D

7.3.13 Register 14: RF filter settings

7.3.14 Register 15: DPD filter settings

TZA1038HW

7.4 Internal digital control, serial bus and external

digital input signal relationships

7.4.1 STANDBY mode

7.4.2 RF only mode

7.5 Signal descriptions

7.5.1 Data path signals through pins A to D

7.5.2 Data signal path through input pins RFSUMP

and RFSUMN

7.5.3 HF filtering

7.5.4 Focus signals

7.5.5 Radial signals

7.5.5.1 DPD signals (DVD-ROM mode) with no

drop-out concealment

7.5.5.2 DPD signals (DVD-ROM mode) with

drop-out concealment

7.5.5.3 Three-beam push-pull (CD mode)

7.5.5.4 Enhanced push-pull

8 LIMITING VALUES

9 THERMAL CHARACTERISTICS

10 CHARACTERISTICS

11 APPLICATION INFORMATION

11.1 Signal relationships

11.1.1 Data path

11.1.2 Servo path

11.2 Programming examples

11.3 Energy saving

11.4 Initial DC and gain setting strategy

11.4.1 Electrical offset from pick-up

11.4.2 Gain setting servo

11.4.3 DC level in RF path

11.4.4 Gain setting RF path

12 PACKAGE OUTLINE

13 SOLDERING

13.1 Introduction to soldering surface mount

packages

13.2 Reflow soldering

13.3 Wave soldering

13.4 Manual soldering

13.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

14 DATA SHEET STATUS

15 DEFINITIONS

16 DISCLAIMERS

2003 Sep 03 2

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

1 FEATURES

• Operates with DVD-ROM, DVD+RW, DVD-RW,

CD-ROM and CD-RW

• Operates up to 64 × CD-ROM and 12 × DVD-ROM

• RF data amplifier with wide, fine pitch programmable

noise filter and equalizer equivalent to 64 × CD or

12 × DVD

• Programmable RF gain for DVD-ROM, CD-RW and

CD-ROM applications (approximately 50 dB range to

cover a large range of disc-reflectivity and OPUs)

• Additional RF sum input

• Balanced RF data signal transfer

• Universal photodiode IC interface using internal

conversion resistors and offset cancellation

• Input buffers and amplifiers with low-pass filtering

• Three different tracking servo strategies:

– Conventional three-beam tracking for CD

– Differential Phase Detection (DPD) for DVD-ROM,

including option to emulate traditional drop-out

detection: Drop-Out Concealment (DOC)

– Advanced push-pull with dynamic offset

compensation.

• Enhanced signal conditioning in DPD circuit for optimal

tracking performance under noisy conditions

• Radial error signal for Fast Track Counting (FTC)

• RF onlymode: servo outputs canbeset to 3-state, while

RF data path remains active

• Radial servo polarity switch

• Flexible adaption to different light pen configurations

• Two fully automatic laser controls for red and infrared

lasers, including stabilization and an on/off switch

• Automatic selection of monitor diode polarity

• Digital interface with 3 and 5 V compatibility.

TZA1038HW

2 GENERAL DESCRIPTION

The TZA1038HW is an analog preprocessor and laser

supply circuit for DVD and CD read-only players. The

device contains data amplifiers, several options for radial

tracking and focus control. The preamplifier forms a

versatile, programmable interface between single light

path voltage output CD or DVD mechanisms to Philips

digital signal processor family for CD and DVD (for

example, Gecko, HDR65 or Iguana). A separate

high-speed RFSUM input is available.

The device contains several options for radial tracking:

• Conventional three-beam tracking for CD

• Differential phase detector for DVD

• Push-pull with flexible left and right weighting to

compensate dynamic offsets e.g. beam landing offset

• A radial error signal to allow Fast Track Count (FTC)

during track jumps.

The dynamic range of this preamplifier and processor

combination can be optimized for LF servo and RF data

paths. The gain in both channels can be programmed

separately and so guarantees optimal playability for all

disc types.

The RF path is fully DC coupled. The DC content

compensation techniques provide fast settling after disc

errors.

The device can accommodate astigmatic, single foucault

anddoublefoucault detectors and can beusedwithP-type

lasers with N-sub or P-sub monitor diodes. After an initial

adjustment, the circuit will maintain control over the laser

diode current. With an on-chip reference voltage

generator, a constant stabilized output power is ensured

and is independent of ageing.

An internal Power-on reset circuit ensures a safe start-up

condition.

2003 Sep 03 3

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

3 ORDERING INFORMATION

TYPE NUMBER

NAME DESCRIPTION VERSION

TZA1038HW HTQFP48 plastic thermal enhanced thin quad flat package; 48 leads;

body 7 × 7 × 1 mm; exposed die pad

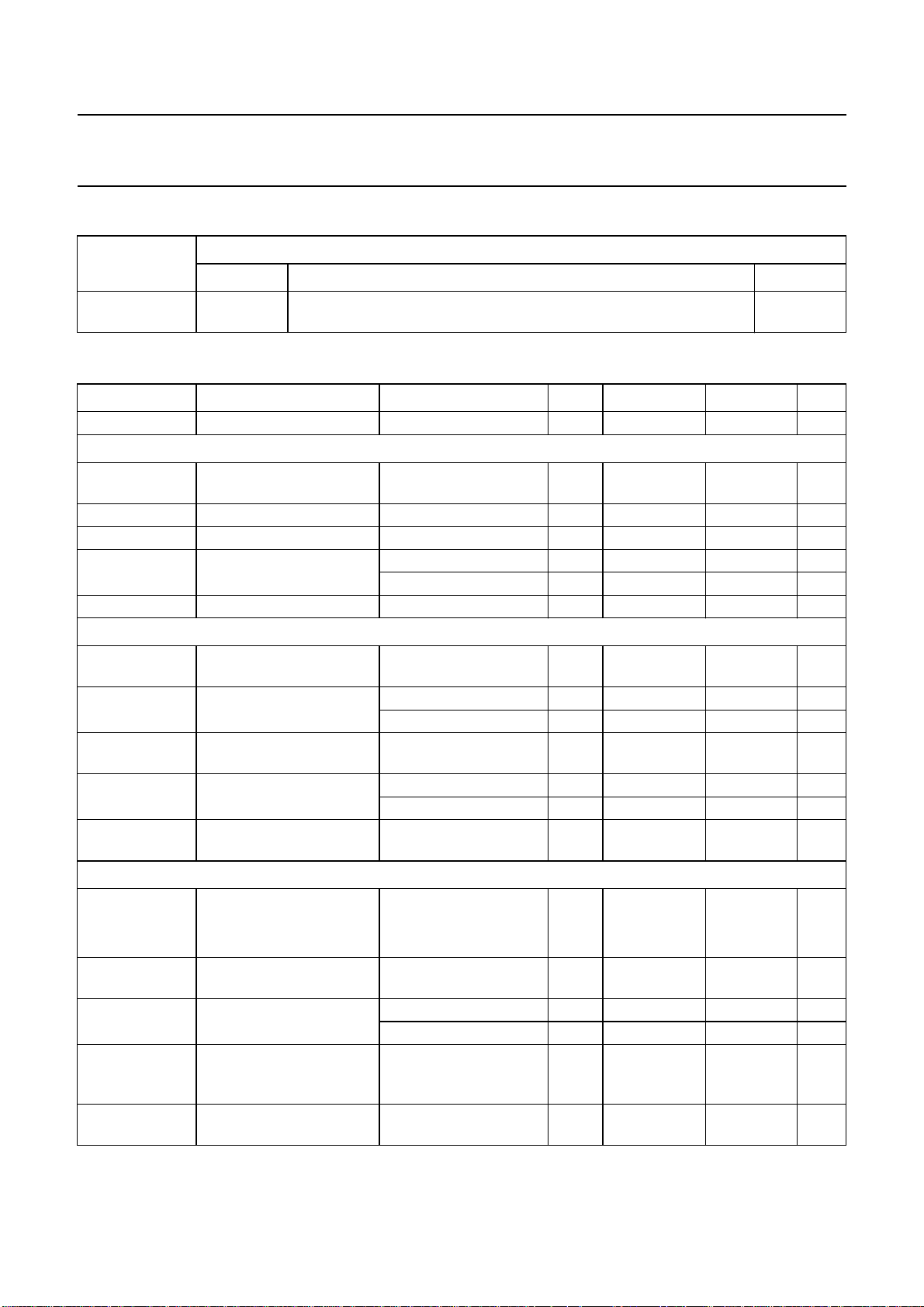

4 QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

T

amb

ambient temperature −40 − +85 °C

Supplies

V

DDA1

V

DDA3

V

DDD3

V

DDD5

I

DD

, V

, V

DDA2

DDA4

,

analog supply voltage 4.5 5.0 5.5 V

3 V digital supply voltage 2.7 3.3 5.5 V

5 V digital supply voltage 4.5 5.0 5.5 V

supply current without laser supply − 98 120 mA

STANDBY mode −− 1mA

V

I(logic)

logic input compatibility note 1 2.7 3.3 5.5 V

Servo signal processing

B

LF(−3dB)

−3 dB bandwidth of

LF path

I

O(LF)

output current focus servo output 0 − 12 µA

radial servo output 0 − 12 µA

V

O(FTC)(p-p)

FTC output voltage

(peak-to-peak value)

B

FTC

FTC bandwidth FTCHBW = 0 − 600 − kHz

FTCHBW = 1; note 2 − 1200 − kHz

V

I(FTCREF)

FTC reference input

voltage

RF data processing

A

RF

linear current gain programmable gain

RF channels 6 − 49 dB

RFSUM channels −6 − +31 dB

B

RF(−3dB)

f

0(RF)

t

d(RF)

−3 dB bandwidth of RFP

and RFN signal path

noise filter and equalizer

corner frequency

flatness delay in RF data

path

RFEQEN = 0;

RFNFEN = 0

BWRF = 0 8 12.0 14.5 MHz

BWRF = 127 100 145 182 MHz

equalizer on; flat from

0 to 100 MHz;

BWRF = 127

Z

i

input impedance of

pins A to D

PACKAGE

SOT545-2

60 75 100 kHz

2.0 −−V

1.25 − 2.75 V

200 300 − MHz

−− 0.5 ns

100 −−kΩ

2003 Sep 03 4

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

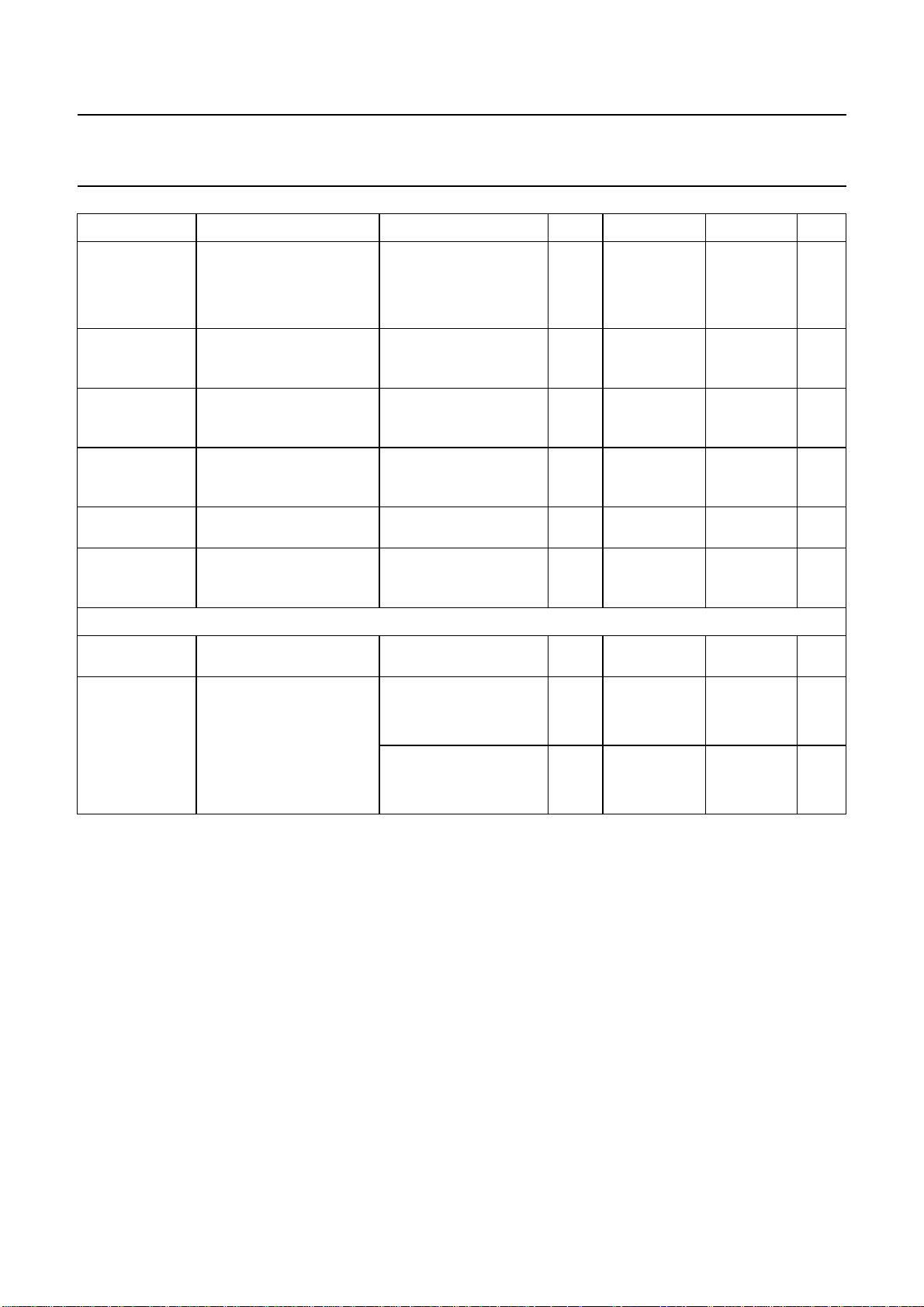

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

i(RF)(FS)

V

i(SUM)(dif)

V

I(DC)

V

o(RF)(dif)(p-p)

V

O(RF)(DC)

V

i(RFREF)(CM)

Laser supply

I

o(laser)(max)

V

i(mon)

input voltage on

pins A to D for full-scale at

output

differential input voltage

on pins RFSUMP and

RFSUMN

DC input voltage range on

pins RFSUMP and

RFSUMN

differential output voltage

on pins RFP and RFN

(peak-to-peak value)

DC output voltage on

pins RFP and RFN

input reference voltage on

pin RFREF for common

mode output

maximum current output

to laser

input voltage from laser

monitor diode

atthe appropriate signal

path gain setting

RF signal path −− 600 mV

LF signal path −− 700 mV

G

with respect to V

= −6dB −− 1800 mV

RFSUM

SS

1.3 − V

DDA

− 1.0 V

−− 1.4 V

0.35 − V

DDA

− 1.9 V

0.8 1.2 2.1 V

−120 −−mA

P-type monitor diode

LOW level voltage − V

HIGH level voltage − V

− 0.155 − V

DDA4

− 0.190 − V

DDA4

N-type monitor diode

LOW level voltage − 0.155 − V

HIGH level voltage − 0.185 − V

Notes

1. Input logic voltage level follows the supply voltage applied at pin V

2. High FTC bandwidth is achieved when IS1and IS2> 1.5 µA.

2003 Sep 03 5

DDD3

.

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

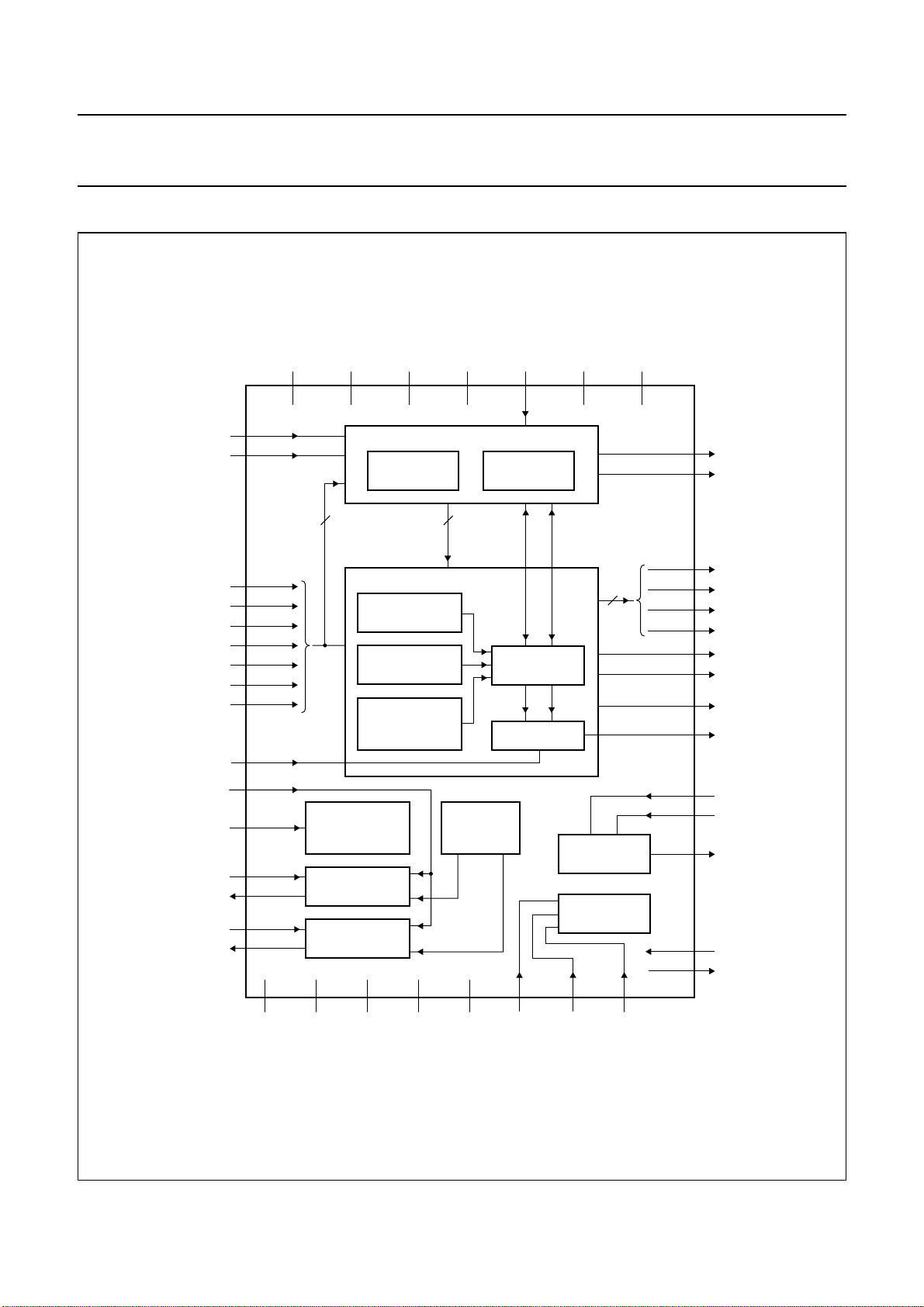

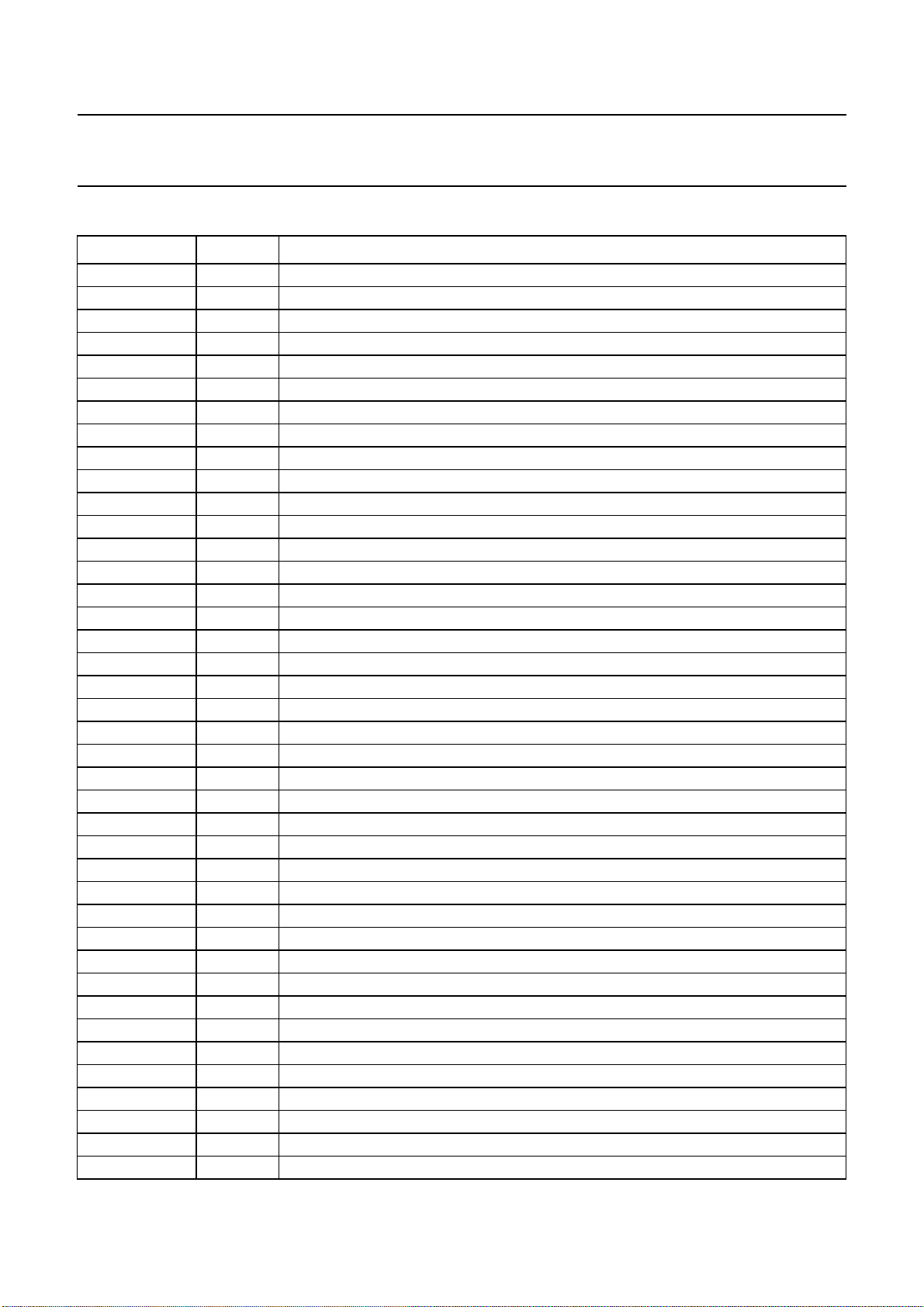

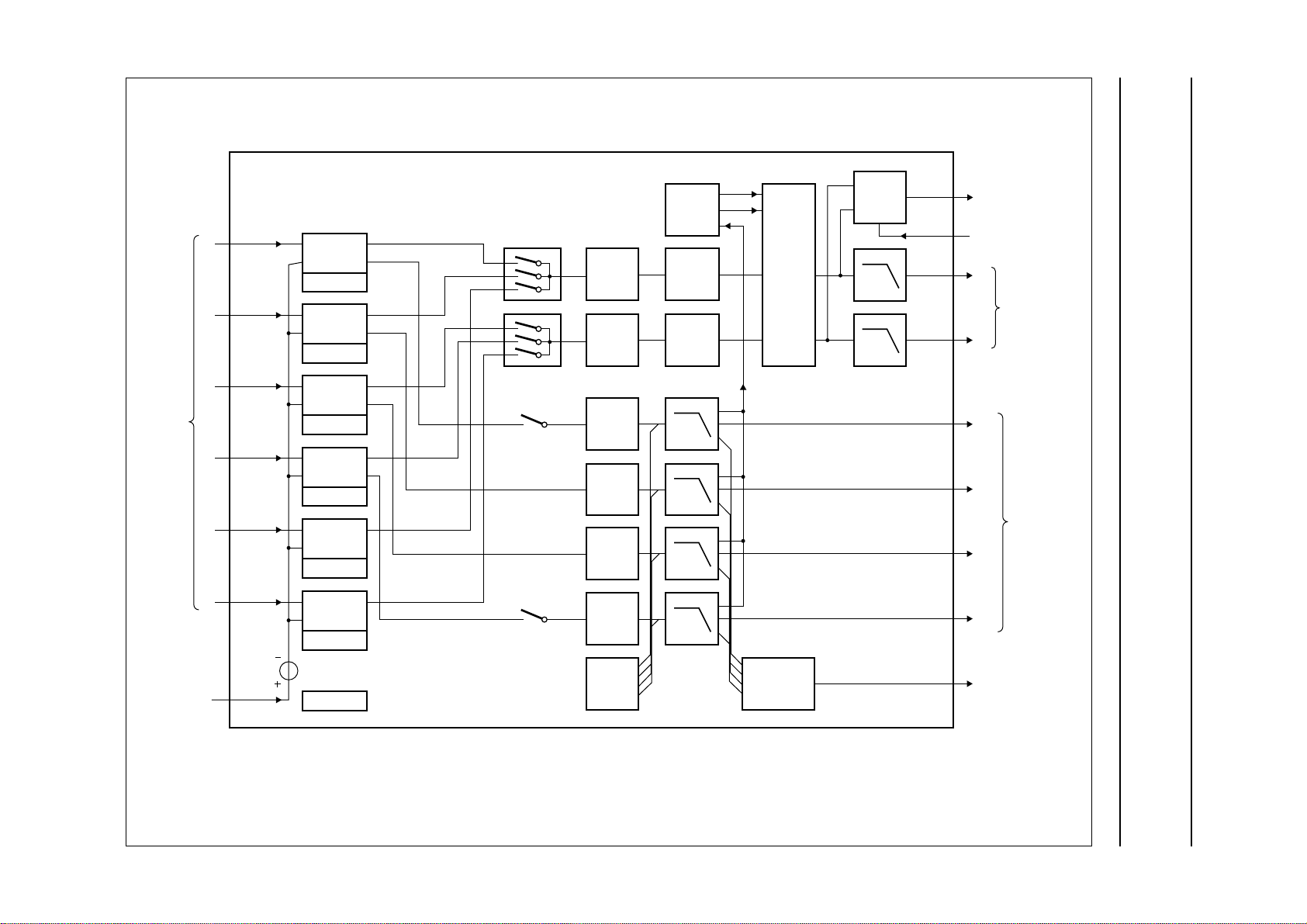

5 BLOCK DIAGRAM

handbook, full pagewidth

RFSUMP

RFSUMN

OPUREF

FTCREF

V

DDL

REXT

CDMI

CDLO

DVDMI

DVDLO

V

DDA1

1

2

OPUREF

8

A

9

B

10

C

11

D

3

E

4

F

12

27

47

44

46

45

7

48

6

V

SSA1

5

A to D

5

VOLTAGE AND

REFERENCES

42

V

SSA2

V

DDA2

CURRENT

LASER 1

LASER 2

V

DDA3

43

SERVO SIGNAL PROCESSING

COMPENSATION

V

SSA3

37

RF DATA PROCESSING

MULTIPLEXER

4

3-BEAM

TRACKING

DPD

PUSH-PULL

OFFSET

41

V

SSA4

31

V

DDA4

DUAL

LASER

SUPPLY

V

SSD

RFREF

32

VARIABLE

GAIN STAGES

SELECT; SWAP

S1 S2

19

SIDA

38

FTC

16

V

DDD3

V

15

TZA1038HW

4

FTC

COMPARATOR

SERIAL

INTERFACE

17 18

SICL SILD

DDD5

23

TZA1038HW

39

RFP

40

RFN

36

OA

35

OB

34

OC

33

OD

30

S1

29

S2

28

OCENTRAL

25

FTC

20

COP

21

COM

22

COO

14

TM

26

TDO

MCE466

Fig.1 Block diagram.

2003 Sep 03 6

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

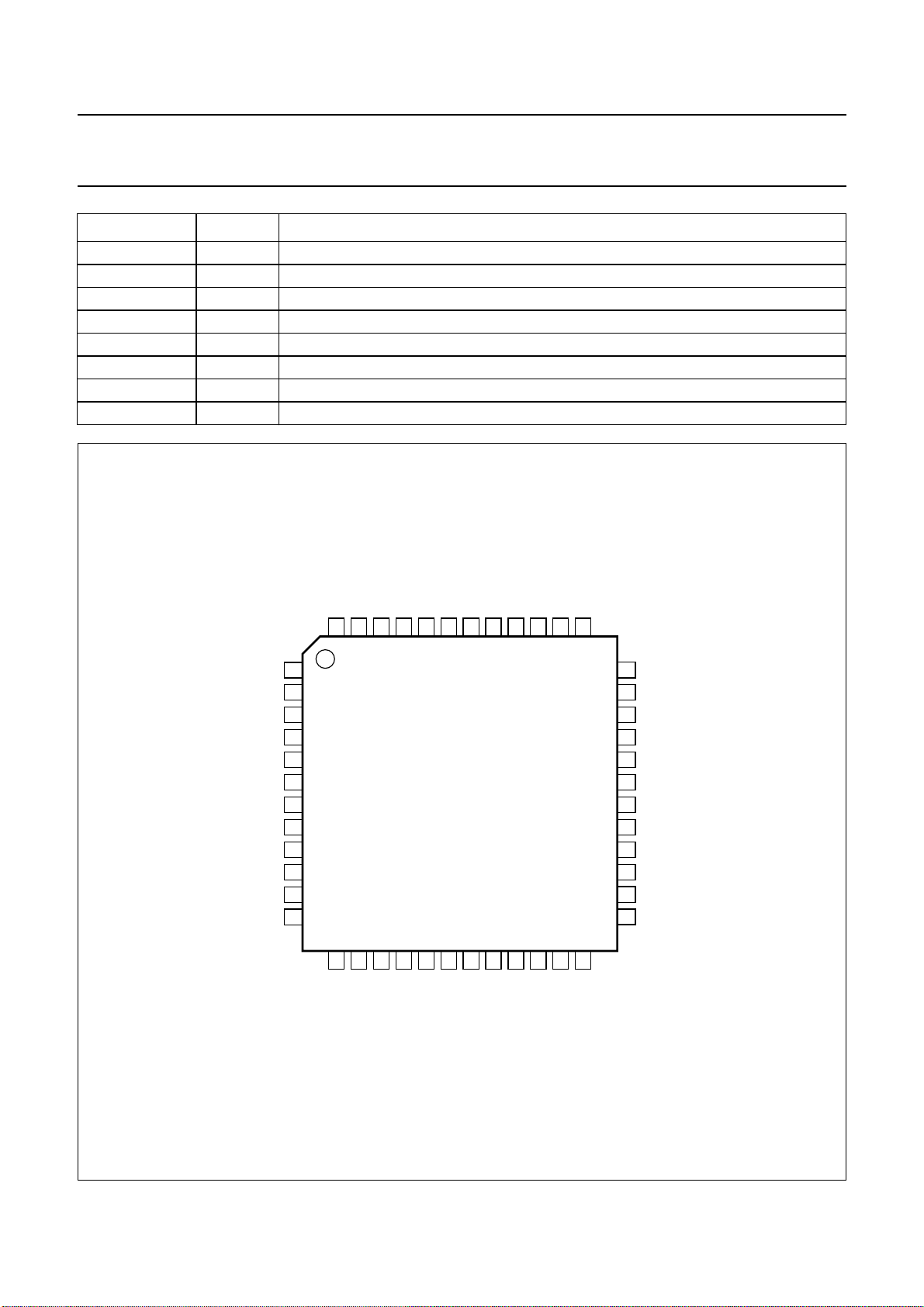

6 PINNING

SYMBOL PIN DESCRIPTION

RFSUMP 1 positive RF sum input

RFSUMN 2 negative RF sum input

E 3 input E

F 4 input F

V

DDA1

V

SSA1

DVDMI 7 input signal from DVD laser monitor diode

A 8 input A

B 9 input B

C 10 input C

D 11 input D

OPUREF 12 reference input from Optical Pick-Up (OPU)

n.c. 13 not connected

TM 14 test mode input (factory test only)

V

DDD3

SIDA 16 serial host interface data input

SICL 17 serial host interface clock input

SILD 18 serial host interface load

V

SSD

COP 20 positive FTC comparator input

COM 21 inverting FTC comparator input

COO 22 FTC comparator output

V

DDD5

n.c. 24 not connected

FTC 25 fast track count output

TDO 26 test data output (factory test only)

FTCREF 27 FTC reference input

OCENTRAL 28 test pin for offset cancellation

S2 29 servo current output 2 for radial tracking

S1 30 servo current output 1 for radial tracking

V

SSA4

V

DDA4

OD 33 servo current output for focus D

OC 34 servo current output for focus C

OB 35 servo current output for focus B

OA 36 servo current output for focus A

V

DDA3

RFREF 38 DC reference input for RF channel common mode output voltage

RFP 39 positive RF output

RFN 40 negative RF output

5 analog supply voltage 1 (RF input stage)

6 analog ground 1

15 digital supply voltage (serial interface 3 V I/O pads and FTC comparator)

19 digital ground

23 digital supply voltage (5 V digital core)

31 analog ground 4

32 analog supply voltage 4 (servo signal processing)

37 analog supply voltage 3 (RF output stage)

TZA1038HW

2003 Sep 03 7

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

SYMBOL PIN DESCRIPTION

V

SSA3

V

SSA2

V

DDA2

REXT 44 reference current input (connect via 12.1 kΩ to V

CDLO 45 CD laser output

CDMI 46 input signal from CD laser monitor diode

V

DDL

DVDLO 48 DVD laser output

41 analog ground 3

42 analog ground 2

43 analog supply voltage 2 (internal RF data processing)

47 laser supply voltage

SSA4

TZA1038HW

)

handbook, full pagewidth

RFSUMP

RFSUMN

V

DDA1

V

SSA1

DVDMI

OPUREF

SSA3

SSA2

DDL

CDLO

CDMI

V

DVDLOn.c.

48

47

46

45

1

2

3

E

4

F

5

6

7

8

A

9

B

10

C

D

11

12

13

14

15

16

TM

SIDA

DDD3

V

DDA2

V

V

REXT

43

42

44

TZA1038HW

17

18

19

SILD

SSD

V

SICL

V

41

20

COP

RFN

40

21

COM

RFP

39

22

COO

RFREF

38

23

DDD5

V

DDA3

V

37

24

n.c.

36

OA

35

OB

34

OC

33

OD

V

32

V

31

30

S1

29

S2

28

OCENTRAL

27

FTCREF

26

TDO

25

FTC

MCE467

DDA4

SSA4

Fig.2 Pin configuration.

2003 Sep 03 8

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

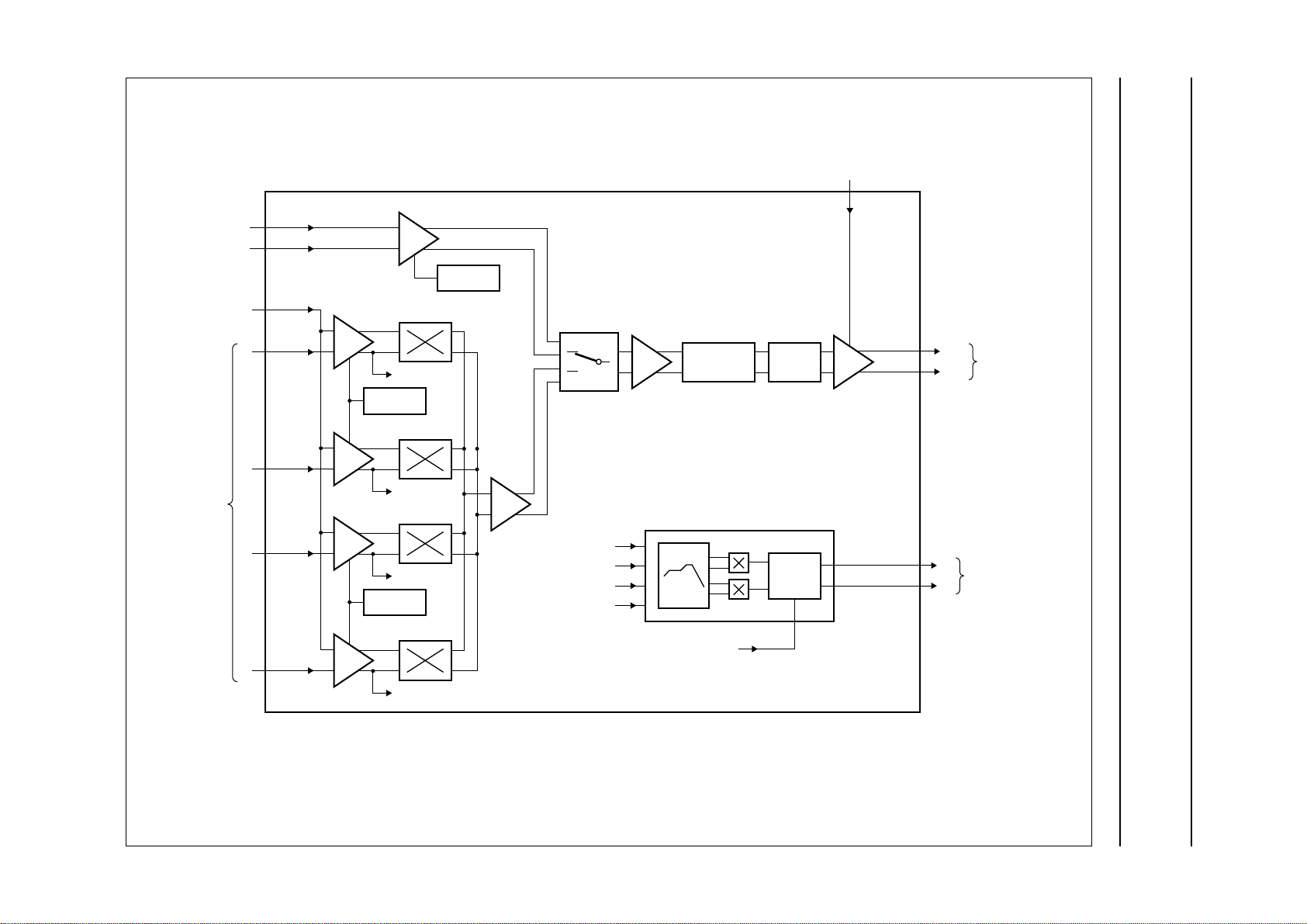

7 FUNCTIONAL DESCRIPTION

7.1 RF data processing

The RF data path is a fully DC-coupled, multi-stage

amplifier (see Fig.3). The input signal for data can be

selected from RF inputs A to D or from the summed

RF inputsRFSUMPandRFSUMN.Switchingbetweenthe

two sets of signals is performed by an internal multiplexer.

The signals are fully balanced internally to improve signal

quality and reduce power supply interference.

RF outputs RFP and RFN can be DC coupled to the

Analog-to-Digital Converter (ADC) of the decoder.

The RF input signals are from photodiodes and have

a largeDC content by nature. This DCcomponentmust be

removed from the signals for good system performance.

Built-in DACs, located after the input stages

G1and RFSUM,have the ability to dothis. The DAC range

and resolution is scaled with the gain setting of the first

amplifier stage. When the DC content is removed, the

RF signal can be DC coupled to the decoder. The main

advantage of DC coupling is fast recovery from signal

swings due to disc defects since there is no AC coupling

capacitance to slow the recovery. When using DC

coupling, both AC and DC content in the data signal is

known. The Philips Iguana decoders have on-chip control

loops to support Automatic Gain Control (AGC) and DC

cancellation.

Two separate DACs are available for cases where the left

and right side DC conditions can be different.

TZA1038HW

When it is not possible to have a DC connection between

the TZA1038HW and the decoder, the signals on servo

outputs OA to OD can be used as they contain the same

LP-filtered and DC coupled information.

Summing of the photodiode signals A to D is performed in

the second amplifier stage G2. Each individual diode

channel can be switched on, off or inverted with switches

SW-A to SW-D.

Switching between photodiode signals and RFSUM input

is performed immediately before the third amplifier

stage G3. This stage has a variable gain with fine

resolution to allow automatic gain adjustment to be

controlled by the decoder.

The filter stage limits the bandwidth according to the

maximum playback speed of the disc. This is to optimize

the noise performance. The filter stage consists of an

equalizer and a noise filter, both of which can be

bypassed,alsothe boost factor of the equalizer canbeset.

Thecorner frequencies ofthe equalizer and noisefilter are

equal and can be programmed to a 7-bit resolution.

The RF output signals RFP and RFN can be DC coupled

to a decoder with a differential input pair (as with Philips

Iguana decoders). The common mode output voltage can

be set externally at pin RFREF.

The signals for differential phase detection are tapped

from the inputs A to D at the RF amplifier G1stages.

DC cancellation for the A to D and RFSUM signal paths

can be set independently or simultaneously.

2003 Sep 03 9

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

a

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2003 Sep 03 10

ndbook, full pagewidth

RFREF

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

RFSUMP

RFSUMN

OPUREF

RF

inputs

38

39

RFP

RFN

outputs

servo

radial

outputs

RF

40

30

S1

29

S2

TZA1038HW

MCE468

RF

RF

DPD-A

OFFSL

DPD-B

DPD-C

OFFSR

DPD-D

RFSUM

SW-A

SW-B

SW-C

SW-D

RF

OFFSS

G

3

EQUALIZER

NOISE

FILTER

TZA1038HW

G

2

DPD-A

DPD-D

DPD-C

DPD-B

central aperture signal

DPD

FILTER

DOC

1

2

12

G

8

A

9

B

10

C

11

D

1

G

1

G

1

G

1

Fig.3 RF data and DPD processing.

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

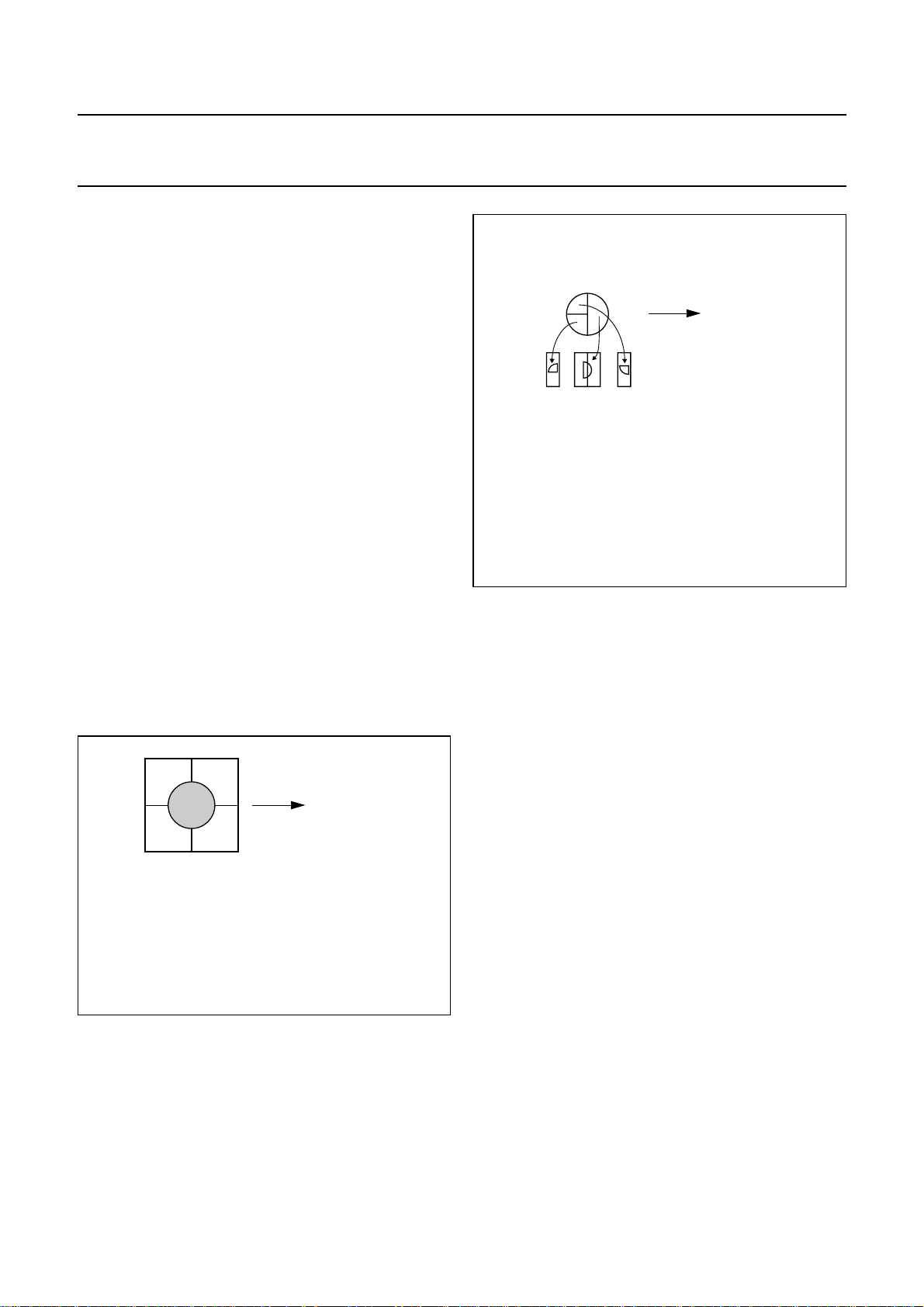

7.2 Servo signal processing

The photodiode configurations and naming conventions

are shown in Figs 4 and 5.

7.2.1 SERVO SIGNAL PATH SET-UP

A block diagram of theservo signal path is shown in Fig.6.

In general, the servo signal path comprises:

• Avoltage-to-currentconverterwith programmable offset

voltage source V

• A 4-bit DAC for each of the six channels to compensate

for offset per channel

• A variable gain stage to adapt the signal level to the

specific pick-up and disc properties

• Low-pass filtering and output stage for the photodiode

current signals

• Error output stage in the radial data path for fast track

counting.

Servo output signals OA to OD, S1 and S2 are unipolar

current signals which represent the low-pass filtered

photodiode signals. In DPD radial tracking, the S1 and S2

signalsaretheequivalentofthe satellite signals commonly

found in traditional CD systems.

The servo output signals OA to OD, S1 and S2 are set to

3-state if bit RFonly = 1 (register 13, bit 11).

handbook, halfpage

Data=A+B+C+D

Push-pull = (A + B) − (C + D)

Focus = (A + C) − (B + D)

DPD2 = phase (A + B, C + D)

DPD4 = phase (A,D) + phase (C,B)

that is common to all inputs

LFOFFS

BA

CD

left

tangential direction

right

MGW553

TZA1038HW

handbook, halfpage

Data=A+B+C+D

Push-pull = A − D

Focus = C − B

DPD2 = phase (A, D)

DPD4 not applicable

Fig.5 Foucault diode configuration.

7.2.2 F

OCUS SERVO

Focus information is reflected in the four outputs

OA to OD. Gain and offset can be programmed.

For optical pick-ups where only channels B and C are

used for focus, channels A and D can be switched off

(bit Focus_mode = 0).

For initial alignment, a copy of the output currents can be

made available on pin OCENTRAL.

7.2.3 RADIAL SERVO

Radial information can be obtained from the two output

signals S1 and S2, and the gain and offset can be

programmed. The TZA1038HW provides differential

phase detection, push-pull and three-beam push-pull for

radial tracking. The signal FTC is made available for fast

track counting and is primarily the voltage error signal

derived from signals S1 or S2.

left

tangential direction

right

DCBA

MGW554

Fig.4 Astigmatic diode configuration.

2003 Sep 03 11

Thepolarityofthe radial loop can be reversed via theserial

control bus (RAD_pol).

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

a

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2003 Sep 03 12

ndbook, full pagewidth

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

RF

inputs

DPD

8

A

9

B

10

C

11

D

3

E

4

F

V

/

C

OFFSA

V

/

C

OFFSB

V

/

C

OFFSC

V

/

C

OFFSD

V

/

R

OFFSE

V

/

R

OFFSF

26k

I

14k

30k

I

14k

30k

I

14k

30k

I

14k

15k

I

15k

I

MUX

2−α

G

G

G

G

α

LFC

LFC

LFC

LFC

G

G

LFR

LFR

MUX

SWAP

CA

FTC

25

FTC

27

FTCREF

30

S1

servo

radial

S2

OA

OB

OC

OD

outputs

servo

focus

outputs

29

36

35

34

33

OPUREF

V

LFOFFS

12

LF

OFFS

TZA1038HW

F

OFFS

OCENTRAL

28

MCE469

OCENTRAL

TZA1038HW

Fig.6 Servo signal path.

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

7.2.4 DIFFERENTIAL PHASE DETECTION

The TZA1038HW provides differential phase detection to

support DVD in various ways:

• DPD2withfour channels programmed to be activegives

DPD as required in the standard specification

• Two of the four channels can be excluded from the DPD

for pick-ups with analternative photodiode arrangement

• An increase in performance, dedicated for DVD+RW,

can be obtained by using the DPD4 method. Then two

truly separated phase detectors are active. After the

phase detection of the two input pairs the result is

summed.

InputsignalsforDPD are taken from input pins A to D after

thefirst gain stage G1(seeFig.3). Pre-emphasis is applied

by means of a programmable lead/lag filter. Additionally, a

programmable low-pass filter is available to improve the

signal quality under noisy signal conditions at lower

speeds. For further signal improvements the DPD pulse

stretcher can be programmed to higher values at lower

speeds.

The DPD signal is low-pass filtered by two internal

capacitors. The signal is then fed to pins S1 and S2, or

directedviathe drop-out concealment circuit to theoutputs

(see Section 7.5).

7.2.4.1 Drop-out concealment

A special function is built in for compatibility with drop-out

detection strategies, based on level detection in the

S1 and S2 signals. When using DPD in a fundamental

way, there is no representation of mirror level information

from the light pen.

When the drop-out concealment function is enabled

(bit DOCEN = 1), a portion of the Central Aperture (CA)

signal is added to S1 and S2. Also, when the CA signal

drops below the DOC threshold, the DPD signal is

gradually attenuated.

The DPD detection cannot work properly when the input

signal becomes very small. The output of the DPD may

then show a significant offset. The DOC may not conceal

this offset completely because:

• DOC is gradually controlled from the CA signal

• The CA signal may not become 0 during disc-defect.

For details see Section 7.5.5.2

7.2.4.2 Push-pull and three-beam push-pull

The TZA1038HW can also provide radial information by

means of push-pull signals (from the photodiodeinputs) or

TZA1038HW

in a three-spot optical system with Three-Beam Push-Pull

(TBPP). The built-in multiplexer gives a flexible method of

dealing with many detector arrangements. For push-pull,

the input signals are taken from channels A to D. There is

also a command that switches off channels B and C,

leaving channels A and D for push-pull

(bits RT_mode[2:0]).

ForTBPP, the input signal is takenfromchannels E and F,

irrespective of bit RFSUM setting.

7.2.4.3 Enhanced push-pull (dynamic offset

compensation for beam landing)

Thisoptioncancels offsets due to beam landing.Afactor α

canbe programmed to re-balancethe signal gain between

channels S1 and S2. In a simplified form this can be

described as:

S1 = A

S2 = A

Factor α can be programmed in a range from 0.6 to 1.35,

with 1.0 as the balanced condition (bits α[3:0]).

7.2.4.4 Offset compensation

A provision is made to compensate electrical offset from a

light pen. The offset voltage from the light pen can be

positiveornegative.In general, the offset between any two

channels is smaller than the absolute offsets. As negative

input signals cannot be handled by the TZA1038HW

internal servo channels, a two-step approach is adopted:

• A coarse DAC, common to all the input channels, adds

an offset that shifts the input signals in positive direction

until all inputs are ≥0. The DAC used (LF

2-bit resolution (bits LF

• A fine setting per channel is provided to cancel the

remainder of the offset between the channels. This is

achieved by DACs subtracting the DC component from

thesignalsandbringingtheinputs to approximately zero

offset (within ≈ 1 mV). The DACs (registers 11 to 13)

have a 4-bit resolution.

The range of both DACs can be increased by a factor of

three to compensate for higher offset values by means of

control parameter bit SERVOOS.

With a switched-off laser, the result of the offset

cancellation can be observed at each corresponding

output pin, OA to OD, S1 and S2, or via a built-in

multiplexer to pin OCENTRAL (central channels only).

See registers 11 to 13 for DAC and multiplexer control.

×α×input left

LFR

× (2 −α)×input right.

LFR

OFF

[1:0]).

OFFS

) has a

2003 Sep 03 13

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

7.2.5 AUTOMATIC DUAL LASER SUPPLY

The TZA1038HW can control the output power of two

lasers; it has an Automatic Laser Power Control (ALPC)

that stabilizes the laser output power and compensates

the effects of temperature and ageing of the laser.

ALPC automatically detects if there is a P-type or N-type

monitor diode in use in either of the laser circuits. The

regulation loop formed by the ALPC, the laser, the monitor

diode and the associated adjustment resistor will settle at

themonitorinputvoltage. The monitor input voltage can be

programmed to HIGH (≈ 180 mV) or LOW (≈ 150 mV),

according to frequently-used pre-adjustments of the light

pen. This set point can be set independently for both

ALPCs. Bandwidth limitation and smooth switch-on

behaviour is realized using an internal capacitor.

A protection circuit is included to prevent laser damage

dueto dips in laser supplyvoltage V

dip occurs, the output can saturate and restrict the

required laser current. Without the protection circuit, the

ALPC would try to maximize the output power with

destructive results for the laser when the supply voltage

recovers. The protection circuit monitors the supply

voltage and shuts off the laser when the voltage drops

belowasafe value. The ALPC recovers automaticallyafter

the dip has passed.

Only one laser can be activated at the same time.

An internal break-before-make circuit ensures safe

start-up for the laser when a toggle situation between the

two lasers is detected. When both lasers are programmed

on, neither laser will be activated.

7.2.6 POWER-ON RESET AND GENERAL POWER ON

When the supply voltage is switched on, bit PWRON is

reset by the Power-On Reset (POR) signal. This

concludes in a STANDBY mode at power up. POR is

intended to prevent the lasers being damaged due to

randomsettings.Allotherfunctionsmay be switched when

power is on. The TZA1038HW becomes active when

bit PWRON = 1.

.If a supply voltage

DDL

TZA1038HW

7.2.7 COMPATIBILITY WITH TZA1033HL/V1

7.2.7.1 Software compatibility

The TZA1038HW is highly software compatible with the

TZA1033HL/V1. Provided that some conditions are met,

the software of the TZA1038HW can be used as a

successor with just minor modifications. This compatibility

is achieved with the implementation of the TZA1038HW

mode control bit (bit K2_Mode). When bit K2_Mode = 0,

the TZA1038HW will act as a TZA1033HL/V1. When

bit K2_Mode = 1, the TZA1038HW will act as a

TZA1033HL/K2 and the new functions will be available

(but require a software update).

Other conditions or restrictions are:

• Registerbits of the TZA1038HW whichwere not defined

areprogrammedto a logic 0. Registers 9, 10, 14 and 15

may be left undefined

• The G4stage high gain setting of the TZA1033HL/V1 is

not available in the TZA1038HW; if this value was set to

logic 0, there will be no difference

• Whenbit K2_Mode = 0the RF bandwidth will be fixed to

theminimumvalueof10 MHz(typical);bit K2_Mode = 1

toselect a higher bandwidth; the bandwidthisnow lower

than using a TZA1033HL/V1.

7.2.7.2 Hardware compatibility

Thepackageis changed from LQFP64 for theTZA1033HL

to LQFP48 for the TZA1038HW.

The hardware differences are:

• Input pins STB, HEADER and LAND of the TZA1033HL

are not present

• Input pins CD of TZA1033HL/V1 are not used;

TZA1038HW has RFSUM inputs instead; the RFSUM

inputs of TZA1038HW may be connected to ground

when not used.

2003 Sep 03 14

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

7.2.8 INTERFACE TO THE SYSTEM CONTROLLER

Programming the registers of TZA1038HW is done via a

serial bus (see Fig.7). The circuitry is formed by a serial

input shift register and a number of registers that store the

data. The registers can always be programmed,

irrespective of STANDBY mode.

If required, the bus lines can be connected in parallel with

an I2C-bus. The protocol needs no switching of the data

line during SICL = HIGH. This means that other I2C-bus

devices will not recognise any START or STOP

commands. Control words addressed to TZA1038HW

handbook, full pagewidth

SICL

SIDA

TZA1038HW

should go uniquely with the SILD signal. When

SILD = HIGH, the TZA1038HW will not respond to any

signal on SIDA or SICL.

During a transmission, the serial data is first stored in an

input shift register. At the rising edge of SILD, the content

of the input register is copied into the addressed register.

This is also the moment the programmed information

becomes effective.

The input pins have CMOS compatible thresholdlevels for

both 3.3 and 5 V supplies.

A3D0 D1 D2 D3 D4 D5 D7 D8 D9 D10D6 D11 A0 A1 A2 D0 D1 D2 D3 A2A1D4 A3

t

load(H)

SILD

MGW496

Fig.7 Two word transmission.

7.3 Control registers

The TZA1038HW is controlled by serial registers. To keep programming fast and efficient, the control bits are sent in

16-bit words. Four bits of the word are used for the address and for each address there are 12 data bits.

Table 1 Overview of control parameters

SYMBOL PARAMETER VALUES REGISTER BITS

Data path

G

) gain of first RF amplifier stage

1(A1

0, 6 and 12 dB (1×, 2× and 4×) 3 11 and 10

(or linear amplification)

) gain of second RF amplifier

G

2(A2

6, 12, 18 and 24 dB (2×, 4×, 8× and 16×) 3 9 and 8

stage (or linear amplification)

G

) gain of third RF amplifier

3(A3

0 to 13 dB in steps of 0.8 dB (1× to 4×)37to4

stage (or linear amplification)

GRFSUM

(A

RFSUM

)

gain of RFSUM input stage (or

linear amplification)

BWRF bandwidth limitation in

−6, 0, 6, 12 and 18 dB

0 7 to 5

(0.5×,1×,2×,4×and 8×)

= 12 to 145 MHz 14 6 to 0

f

0(RF)

RF path

2003 Sep 03 15

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

SYMBOL PARAMETER VALUES REGISTER BITS

RF

OFFSL

RF

OFFSR

RF

OFFSS

Servo radial path

LF

OFFS

R

LFR

R

LFPP

R

OFFSE

R

OFFSF

α dynamic radial offset

I

(FS)(DPD),

I

(FS)(DPD)(DOC)

I

REFRAD(CM)

f

start_DPD

DC offset compensation in left

RF input path

DC offset compensation in

right RF input path

DC offset compensation in

RFSUM path

DC offset compensation for

LF path (common for all servo

inputs)

CD satellite path input

transresistance

DVD push-pull signal

transresistance

DC offset compensation for

radial servo path (input E)

DC offset compensation for

radial servo path (input F)

compensation factor

full scale DPD current, fixed

value based on bandgap

voltage across external

resistor

internally generated common

mode DC reference current in

DPD mode

start frequency lead/lag filter

of DPD block

RFSUM = 0; full range depends on

411to6

G1setting:

G

= 0 dB: 0 to 450 mV in 7.1 mV steps

1

G

= 6 dB: 0 to 225 mV in 3.6 mV steps

1

G

= 12 dB: 0 to 120 mV in 1.9 mV steps

1

RFSUM = 0; full range depends on

4 5 to 0

G1setting:

= 0 dB: 0 to 450 mV in 7.1 mV steps

G

1

G

= 6 dB: 0 to 225 mV in 3.6 mV steps

1

G

= 12 dB: 0 to 120 mV in 1.9 mV steps

1

RFSUM = 1; full range depends on

4or5 5to0

GRFSUM setting:

GRFSUM = −6 dB; 0 to 1700 mV

GRFSUM = 0 dB; 0 to 850 mV

GRFSUM = 6 dB; 0 to 425 mV

GRFSUM = 12 dB; 0 to 210 mV

GRFSUM = 18 dB; 0 to 105 mV

SERVOOS = 0:

V

=0,5,10or15mV

LFOFFS

11 11 and 10

SERVOOS = 1:

V

= 0, 15, 30 or 45 mV

LFOFFS

15 kΩ fixed −−

30 kΩ fixed −−

SERVOOS = 0: V

SERVOOS = 1: V

SERVOOS = 0: V

SERVOOS = 1: V

ROFFSE

ROFFSE

ROFFSF

ROFFSF

= 0 to 20 mV 11 7 to 4

= 0 to 60 mV

=0to20mV 11 3to0

=0to60mV

α = 0.6 to 1.35 in 15 steps of 0.05 6 3 to 0

DOCEN = 0: fixed value = 20 µA15

DOCEN = 1: fixed value = 6.6 µA

3.5 µA fixed −−

f

start_DPD

= 1, 5 or 10 MHz

7 1 and 0

(TZA1033HL/V1 compatible)

f

start_DPD

= 1, 5, 10, 18 or 24 MHz 15 5 to 3

2003 Sep 03 16

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

SYMBOL PARAMETER VALUES REGISTER BITS

G

LFR(ALFR

R

FTC

Servo focus path

R

LFC

C

OFFSA

C

OFFSB

C

OFFSC

C

OFFSD

G

LFC(ALFC

β focus offset compensation β =0to

F

OFFSEN

) lowfrequency gain, radialpath

output stage (or linear

amplification)

gain of fast track count output 680 kΩ±20% fixed for ±2 V (p-p) −−

LF path input transresistance 14 kΩ fixed −−

DC offset compensation for

central servo path A

DC offset compensation for

central servo path B

DC offset compensation for

central servo path C

DC offset compensation for

central servo path D

) low frequency gain, central

path output stage (or linear

amplification)

full range offset compensation

for focus

−15 to +9 dB in steps of 3 dB

611to8

(0.18× to 2.8×)

SERVOOS = 0: 0 to 20 mV 12 7 to 4

SERVOOS = 1: 0 to 60 mV

SERVOOS = 0: 0 to 20 mV 12 3 to 0

SERVOOS = 1: 0 to 60 mV

SERVOOS = 0: 0 to 20 mV 13 7 to 4

SERVOOS = 1: 0 to 60 mV

SERVOOS = 0: 0 to 20 mV 13 3 to 0

SERVOOS = 1: 0 to 60 mV

−15 to +9 dB in steps of 3 dB

6 7 to 4

(0.18× to 2.8×)

31

⁄

32

DAC enabled: I

DAC disabled: I

= 400 nA (fixed) 2 10

FOFFS

=0nA

FOFFS

2 4 to 0

7.3.1 REGISTER 0: POWER CONTROL

Table 2 Register address 0H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 −−−−

BIT76543210

SYMBOL

GRF

SUM2

GRF

SUM1

GRF

SUM0

DVD_ MILVL CD_MILVL DVD_ LDON CD_LDON PWRON

Table 3 Description of register bits (address 0H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0000 = address 0H

11 to 8 − not used

7 to 5 GRFSUM[2:0] Gain of RFSUM input stage.

000 = −6dB

001 = 0 dB

010 = 6 dB

011=12dB

100=18dB

4 DVD_MILVL DVD monitor input level. 0 = 150 mV; 1 = 180 mV.

2003 Sep 03 17

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

BIT SYMBOL FUNCTION

3 CD_MILVL CD monitor input level. 0 = 150 mV; 1 = 180 mV.

2 DVD_LDON DVD laser on. 0 = laser off; 1 = laser on.

1 CD_LDON CD laser on. 0 = laser off; 1 = laser on.

0 PWRON Power on. 0 = STANDBY mode; 1 = power on.

7.3.2 REGISTER 1: SERVO AND RF MODES

Table 4 Register address 1H

BIT 15 14 13 12 11 10 9 8

SYMBOL

BIT76543210

SYMBOL

Table 5 Description of register bits (address 1H)

AD3 AD2 AD1 AD0 DPD_DCC −−RAD_pol

−−DOCEN Focus_

mode

RT_mode2 RT_mode1 RT_mode0 RFSUM

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0001 = address 1H

11 DPD_DCC RF offset DAC for DPD signal control. 0 = DAC controlled by register 4,

bits RF

10 and 9 − not used

8 RAD_pol Radial polarity switch. 0 = inverse; 1 = normal (default).

7 and 6 − not used

5 DOCEN Drop-out concealment enable. 0 = disable; 1 = enable.

4 Focus_mode Focus mode. 0 = two-channel focus (channels B and C only); 1 = four-channel

focus.

3 to 1 RT_mode[2:0] Radial tracking mode.

000 = DPD2; DPD = phase (A,D)

001 = push-pull; channels A,D only

100 = DPD2; DPD = phase (A + C, B + D)

101 = push-pull; four channels

110 = DPD4; DPD = phase (A,D) + phase (C,B)

X11 = TBPP channels E and F

0 RFSUM RF channel selection. 0 = diode inputs selected; 1 = RFSUM input selected.

[5:0]; 1 = DAC controlled by register 5, bits RF

OFFSL

OFFSS

[5:0].

2003 Sep 03 18

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

7.3.3 REGISTER 2: FOCUS OFFSET DAC

Table 6 Register address 2H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 K2_Mode F

OFFSEN

BIT76543210

SYMBOL

β2 β1 β0 −−−−−

Table 7 Description of register bits (address 2H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0010 = address 2H

11 K2_Mode K2 mode. 0 = disable; 1 = enable.

10 F

OFFSEN

Focus offset enable. 0 = enable; 1 = disable.

9to5 β[4:0] Focus offset compensation. 00000 to 11111: β =0toβ=

4to0 − not used

β4 β3

31

⁄32.

7.3.4 R

EGISTER 3: RF PATH GAIN

Table 8 Register address 3H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 G

1G

1

0G

1

1G

2

0

2

BIT76543210

SYMBOL

3G

3

2G

3

1G

3

0 −−−−

3

G

Table 9 Description of register bits (address 3H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0011 = address 3H

11 and 10 G

[1:0] First RF amplifier stage gain.

1

00 = 0 dB

01 = 6 dB

10 = 12 dB

11 = not used

9 and 8 G

[1:0] Second RF amplifier stage gain.

2

00 = 6 dB

01 = 12 dB

10 = 18 dB

11 = 24 dB

7to4 G

[3:0] Third RF amplifier stage gain. 0000 to 1111: 0 to 13 dB in 0.8 dB steps.

3

3to0 − not used

2003 Sep 03 19

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

7.3.5 REGISTER 4: RF LEFT AND RIGHT, OR SUM OFFSET COMPENSATION

Table 10 Register address 4H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 RF

BIT76543210

SYMBOL

RF

OFFSL

1RF

OFFSL

0RF

OFFSR

RF

OFFSS

5/

RF

5

RF

OFFSR

OFFSS

4/

RF

4

RF

Table 11 Description of register bits (address 4H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0100 = address 4H

11 to 6 RF

[5:0] Left channel RF offset compensation definition.

OFFSL

bit RFSUM = 0: left RF channel offset compensation value

bit RFSUM = 1: not used

5to0 RF

[5:0] Right channel RF offset compensation definition.

OFFSR

bit RFSUM = 0: right RF channel offset compensation value (symbol is RF

bit RFSUM = 1 and bit DPD_DCC = 1: not used

bit RFSUM = 1 and bit DPD_DCC = 0: the decoder controls DPD and RFSUM

channels automatically, in parallel and with same values (symbol is RF

OFFSL

OFFSR

OFFSS

5RF

3/

3

RF

RF

OFFSL

OFFSR

OFFSS

4RF

2/

2

RF

RF

OFFSL

OFFSR

OFFSS

3RF

1/

1

RF

RF

OFFSS

OFFSL

OFFSR

OFFSS

OFFSR

).

2

0/

0

)

7.3.6 R

EGISTER 5: RF SUM OFFSET COMPENSATION

Table 12 Register address 5H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 −−−−

BIT76543210

SYMBOL

−−RF

OFFSS

5RF

OFFSS

4RF

OFFSS

3RF

OFFSS

2RF

OFFSS

1RF

OFFSS

Table 13 Description of register bits (address 5H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0101 = address 5H

11 to 6 − not used

5to0 RF

[5:0] RF offset compensation definition.

OFFSS

bit RFSUM = 0: not used

bit RFSUM = 1 and bit DPD_DCC = 0: not used

bit RFSUM = 1 and bit DPD_DCC = 1: the decoder controls RFSUM channels;

the DPD channels can be set independently from the microprocessor.

0

2003 Sep 03 20

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

7.3.7 REGISTER 6: SERVO GAIN AND DYNAMIC RADIAL OFFSET COMPENSATION FACTOR

Table 14 Register address 6H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 G

BIT76543210

SYMBOL

3G

G

LFC

2G

LFC

1G

LFC

0 α3 α2 α1 α0

LFC

Table 15 Description of register bits (address 6H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 0110 = address 6H

11 to 8 G

[3:0] Low frequency gain, radial path output stage. 0000 to 1000: −15 to +9 dB

LFR

in 3 dB steps.

7to4 G

[3:0] Low frequency gain, central path output stage. 0000 to 1000: −15 to +9 dB

LFC

in 3 dB steps.

3to0 α[3:0] Dynamic radial offset compensation factor. 0000 to 1111: 0.60 to 1.35

in 0.05 steps; 1000 = balanced value (default).

3G

LFR

2G

LFR

1G

LFR

LFR

0

7.3.8 R

EGISTER 7: SERVO PATH GAIN AND BANDWIDTH AND RF PATH BANDWIDTH AND PRE-EMPHASIS

Definitions in register 7 are intendedmainly for software compatibility with the TZA1033HL/V1. Newfeatures that require

morebit-space to program aremovedto registers 14 and 15. Only DPDstretchremains programmed in register 7.Some

parameters are slightly modified.

Table 16 Register address 7H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 DPDLPF1 DPDLPF0 DPD_

stretch2

DPD_

stretch1

BIT76543210

SYMBOL

DPD_

stretch0

DPD_

testmode

DVDALAS_

mode

EQ

2EQ

RF

1EQ

RF

RF

0f

start_DPD

1f

start_DPD

0

Table 17 Description of register bits (address 7H)

FUNCTION

BIT SYMBOL

K2_Mode = 0 K2_Mode = 1

15 to 12 AD[3:0] 0111 = address 7H 0111 = address 7H

11 and 10 DPDLPF[1:0] DPD low-pass filter. not applicable

0X : B

1X : B

= 50 MHz (equivalent to TZA1023)

−3dB

= 10 MHz

−3dB

2003 Sep 03 21

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

BIT SYMBOL

K2_Mode = 0 K2_Mode = 1

9 to 7 DPD_stretch [2:0] DPD pulse stretcher (t

). DPD pulse stretcher (tP).

P

000 = 1.9 ns 000 = 30 ns

001 = 3.8 ns (equivalent to TZA1023) 001 = 15 ns

010 = 7.5 ns 010 = 7.5 ns

011 = 15 ns 011 = 3.8 ns

100 = 30 ns 100 = 1.9 ns

101 = not used 101 = 1.2 ns

6 DPD_ testmode For factory test purposes only. For factory test

5 DVDALAS_ mode DVDALAS mode bit. 0 = disables control of

bits 11 to 6 and creates behaviour equivalent to

TZA1023; 1 = enables DPD low-pass filter and time

stretcher equivalent to TZA1033HL/V1.

4to2 EQ

1 and 0 f

[2:0] RF channel low-pass filter (BRF). 001 = 10 MHz not applicable

RF

start_DPD

[1:0] Start frequency lead/lag filter, DPD block. not applicable

00 = 1 MHz

01 = 5 MHz

10 = 10 MHz

11 = not used

FUNCTION

purposes only.

not applicable

7.3.9 REGISTER 8: RF CHANNEL SELECTION

Table 18 Register address 8H

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 −−−−

BIT76543210

SYMBOL

SW-D

mute

SW-D

inv

SW-C

mute

SW-C

inv

SW-B

mute

SW-B

inv

SW-A

mute

SW-A

inv

Table 19 Description of register bits (address 8H)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 1000 = address 8H.

11 to 8 − not used

7SW-D

6SW-D

5SW-C

4SW-C

3SW-B

mute

inv

mute

inv

mute

0 = pass D signal; 1 = mute D signal.

0 = pass D signal with no inversion; 1 = pass D signal with inversion.

0 = pass C signal; 1 = mute C signal.

0 = pass C signal with no inversion; 1 = pass C signal with inversion.

0 = pass B signal; 1 = mute B signal.

2003 Sep 03 22

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

BIT SYMBOL FUNCTION

2SW-B

1SW-A

0SW-A

inv

mute

inv

7.3.10 REGISTER 11: RADIAL SERVO OFFSET CANCELLATION

Table 20 Register address BH

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 LF

BIT76543210

SYMBOL

R

OFFSE

3R

OFFSE

Table 21 Description of register bits (address BH)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 1011 = address BH

11 and 10 LF

[1:0] DC offset compensation for LF path (V

OFFS

9 SERVOOS Servo offset scale (DACs R

8 FTCHBW FTC bandwidth. 0 = 600 kHz (approximately); 1 = 1.2 MHz (approximately.)

7to4 R

3to0 R

[3:0] Programmable DC offset compensation for radial servo path (E input).

OFFSE

[3:0] Programmable DC offset compensation for radial servo path (F input).

OFFSF

0 = pass B signal with no inversion; 1 = pass B signal with inversion.

0 = pass A signal; 1 = mute A signal.

0 = pass A signal with no inversion; 1 = pass A signal with inversion.

2R

OFFSE

1R

OFFSE

OFFS

0R

OFFSF

1LF

3R

LFOFFS

0 SERVOOS FTCHBW

OFFS

2R

OFFSF

). Common for all servo inputs:

SERVOOS = 0 SERVOOS = 1

00 = 0 mV 00 = 0 mV

01 = 5 mV 01 = 15 mV

10 = 10 mV 10 = 30 mV

11 = 15 mV 11 = 45 mV

OFFSx

, C

OFFSx

and LF

). 0 = normal range;

OFFS

1 = triple range.

SERVOOS = 0: 0 to 20 mV; bit SERVOOS = 1: 0 to 60 mV.

SERVOOS = 0: 0 to 20 mV; bit SERVOOS = 1: 0 to 60 mV.

1R

OFFSF

OFFSF

0

7.3.11 REGISTER 12: CENTRAL SERVO OFFSET CANCELLATION INPUTS A AND B

Table 22 Register address CH

BIT 15 14 13 12 D11 D10 D9 D8

SYMBOL

AD3 AD2 AD1 AD0 TSTDPDRF TSTSRV2 TSTSRV1 TSTSRV0

BIT D7 D6 D5 D4 D3 D2 D1 D0

SYMBOL

C

OFFSA

3C

OFFSA

2C

OFFSA

1C

OFFSA

0C

OFFSB

3C

OFFSB

2C

OFFSB

1C

2003 Sep 03 23

OFFSB

0

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

Table 23 Description of register bits (address CH)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 1100 = address CH

11 TSTDPDRF DPD RF test bit. With this bit the DPD filter performance is checked. 0 = normal

operation; 1 = RF signal filtered by the DPD block is connected to the RFoutput.

10 to 8 TSTSRV[2:0] Test matrix for servo signals to pin OCENTRAL.

000 = normal operation

001 = filter DAC current for test purposes

011 = CA (sum A to D)

100 = channel A

101 = channel B

110 = channel C

111 = channel D

7to4 C

3to0 C

[3:0] Central servo input A offset cancellation. Bit SERVOOS = 0: 0 to 20 mV;

OFFSA

bit SERVOOS = 1: 0 to 60 mV.

[3:0] Central servo input B offset cancellation. Bit SERVOOS = 0: 0 to 20 mV;

OFFSB

bit SERVOOS = 1: 0 to 60 mV.

7.3.12 REGISTER 13: CENTRAL SERVO OFFSET CANCELLATION INPUTS C AND D

Table 24 Register address DH

BIT 15 14 13 12 11 10 9 8

SYMBOL

AD3 AD2 AD1 AD0 RFonly −−−

BIT76543210

SYMBOL

C

OFFSC

3C

OFFSC

2C

OFFSC

1C

OFFSC

0C

OFFSC

3C

OFFSC

2C

OFFSC

1C

OFFSC

0

Table 25 Description of register bits (address DH)

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 1101 = address DH

11 RFonly Operation mode. 0 = normal operation; 1 = RF only mode (servo outputs

OA to OD, S1 and S2 are 3-state).

10 to 8 − not used

7to4 C

[3:0] Central servo input C offset cancellation. Bit SERVOOS = 0: 0 to 20 mV;

OFFSC

bit SERVOOS = 1: 0 to 60 mV.

3to0 C

[3:0] Central servo input D offset cancellation. Bit SERVOOS = 0: 0 to 20 mV;

OFFSD

bit SERVOOS = 1: 0 to 60 mV.

2003 Sep 03 24

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

7.3.13 REGISTER 14: RF FILTER SETTINGS

Table 26 Register address EH

BIT 15 14 13 12 11 10 9 8

SYMBOL

BIT76543210

SYMBOL

Table 27 Description of register bits (address EH); bit K2_Mode = 1

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 1110 = address EH

11 and 10 − not used

9 RFNFEN Noise filter enable. 0 = disable; 1 = enable.

8 RFEQEN Equalizer enable. 0 = disable; 1 = enable.

7 RFKEQ Boost factor. 0 = boost factor low; 1 = boost factor high.

6 to 0 BWRF[6:0] Bandwidth limitation in RF path. 000 0000 to 111 1111: f

AD3 AD2 AD1 AD0 −−RFNFEN RFEQEN

RFKEQ BWRF6 BWRF5 BWRF4 BWRF3 BWRF2 BWRF1 BWRF0

= 12 to 145 MHz.

0(RF)

7.3.14 R

Table 28 Register address FH

SYMBOL

SYMBOL

EGISTER 15: DPD FILTER SETTINGS

BIT 15 14 13 12 11 10 9 8

AD3 AD2 AD1 AD0 −−−−

BIT76543210

−−DPD_LL2 DPD_LL1 DPD_LL0 DPD_LPF2 DPD_LPF1 DPD_LPF0

2003 Sep 03 25

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

Table 29 Description of register bits (address FH); bit K2_Mode = 1

BIT SYMBOL FUNCTION

15 to 12 AD[3:0] 1111 = address FH

11 to 6 − not used

5 to 3 DPD_LL[2:0] DPD lead/lag filter start frequency (f

000 = 1 MHz

001 = 5 MHz

010 = 10 MHz

011 = 18 MHz

100 = 24 MHz

2 to 0 DPD_LPF[2:0] DPD low-pass filter (f

000 = 10 MHz

001 = 50 MHz

010 = 100 MHz

011 = 180 MHz

111 = 240 MHz

−3dB

).

start

TZA1038HW

).

7.4 Internal digital control, serial bus and external digital input signal relationships

The settings of all internal switches, DACs and modes of

operationcanbeprogrammed via the serial bus. There are

also a few external digital signals which influence the

programmed settings.

7.4.1 STANDBY MODE

Toensurea safe start-up, the TZA1038HWhasan internal

Power-on reset that resets on bit PWRON. During

STANDBY mode, most circuits, including laser supplies,

are switched off.

bit CD_LDON = 1 if CD laser is on and POWERON

bit DVD_LDON = 1 if DVD laser is on and POWERON.

7.4.2 RF ONLY MODE

The servo outputs can be disabled for easy interfacing in

systems where two front-end signal processors are used.

This mode will set the outputs OA to OD, S1 and S2 to

3-state. The RF data path remains active.

7.5 Signal descriptions

The variables A1to A3, A

RFSUM, ALFC

linear equivalents of G1to G3, GRFSUM, G

and A

LFR

LFC

, are the

and G

7.5.1 DATA PATH SIGNALS THROUGH PINS A TO D

With bit RFSUM = 0:

(DVD

A2×1/4×[SW-A {(A − OPUREF) × A1− RF

+ SW-B {(B − OPUREF) × A1− RF

+ SW-C {(C − OPUREF) × A1− RF

+ SW-D {(D − OPUREF) × A1− RF

RFP = RFREF + 0.5 × A3× (DVD

RFN = RFREF − 0.5 × A3× (DVD

RFP

− DVD

RFN

)=

OFFSL

OFFSR

OFFSR

RFP

RFP

}

}

}]

− DVD

− DVD

OFFSL

RFN

RFN

Thus:

RF

=

dif

ABCD+++

× A2× A1×

A

3

-----------------------------------

4

OPUREF RF

––

OFFS

.

LFR

}

)

)

2003 Sep 03 26

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

Switches SW-A to SW-D can be programmed 1, −1or0

(respectively pass, invert or not pass the signal) for each

channel. In this way the data can be read by any

combination of diode inputs.

The first gain stage also carries the signals for DPD

tracking. Therefore this stage will also be active when

RFSUM input and DPD is selected. The DC offset

cancellation is also active in this situation but left and right

channels are controlled from a single DAC. Also in this

situation, the A to D and RFSUM inputs are used

simultaneously.

Control of the DC offset DACs can be chosen to be from

the same register or from two independent registers

(registers 4 and 5).

7.5.2 DATA SIGNAL PATH THROUGH INPUT PINS RFSUMP

AND RFSUMN

With bit RFSUM = 1:

(DVD

A

RFSUM

RFP = RFREF + 0.5 × A3× (DVD

RFN = RFREF − 0.5 × A3× (DVD

Thus:

RF

7.5.3 HF FILTERING

The differential HF signal from the G3stage is sent to a

filter section that consists of an equalizer and a noise filter,

whicharecontrolledbybits BWRF,RFKEQ,RFEQENand

RFNFEN. The equalizer has a transfer function H

which is modelled after a target transfer function H

H

e

This represents a third-order equi-ripple phase filter with a

good delay response. The boost factor k is programmable

via the serial bus control bit RFKEQ. The corner

frequency ω

parameter bit BWRF. The equalizer is switched on with

control bit RFEQEN.

The noise filter has a transfer function H2(s) which is

modelledafterathird-order Butterworth low-pass filter with

target transfer function H

RFP

− DVD

RFN

)=

× [RFSUMP − RFSUMN − RF

dif=ARFSUM

s()

× [RFSUMP − RFSUMN − RF

2

s

×

1k+

------------------------------------------------------1

--------------- -

ω

0RF

2

s

0RF

=2πf

---------------

ω

0RF

α

×++

2

is programmable via control

0RF

n

2

s

------------

ω

0RF

(s):

OFFSS

− DVD

RFP

− DVD

RFP

1

×=

-------------------------------

×+

1 τ

s

------------

ω

0RF

]

RFN

RFN

OFFSS

)

)

]

(s)

1

(s):

e

TZA1038HW

s()

H

n

-------------------------------------------- 1

The corner frequency ω

1

2

s

++

---------------

ω

0RF

s

------------

2

ω

0RF

0RF

filter. The noise filter is switched on with bit RFNFEN.

7.5.4 FOCUS SIGNALS

Focus servo signals:

OA = × A

+ β×F

OB = × A

+(1−β)×F

OC = × A

+ β×F

OD = × A

+(1−β)×F

1

------------ R

LFC

OFFS

1

------------ R

LFC

1

------------ R

LFC

OFFS

1

------------ R

LFC

× (A − OPUREF + LF

LFC

× (B − OPUREF + LF

LFC

OFFS

× (C − OPUREF + LF

LFC

× (D − OPUREF + LF

LFC

OFFS

The parameter β can be programmed via the serial bus.

The focus offset DAC can be switched on with the control

bit F

OFFSEN

.

7.5.5 RADIAL SIGNALS

7.5.5.1 DPD signals (DVD-ROM mode) with no

drop-out concealment

DPD tracking can be activated with bits RT_mode[2:0] of

register 1. Input signals are taken from the diode inputs

A to D, through the input stage G1 and the DC offset

cancellationDAC. When bit RFSUM = 0, theinputstage is

also used for the RF signal. When bit RFSUM = 1, the

setting for G1and DC offset controlcan be independent of

the setting for the data signal which goes through RFSUM.

S1

DPD=I(FS)(DPD)

S2

= −I

DPD

∆ t

is the time difference between the two input signals,

-----T

P

(FS)(DPD)

∆ t

× +I

-----T

P

∆ t

× +I

-----T

P

relative to the period time T

is the full scale range.

1

×=

---------------------s

1

+

------------

ω

0RF

is equal tothat of the equalizer

− C

OFFS

OFFS

OFFS

OFFS

REFRAD

REFRAD

of the input signal. I

P

− C

− C

− C

(FS)(DPD)

OFFSA

OFFSB

OFFSC

OFFSD

)

)

)

)

2003 Sep 03 27

Philips Semiconductors Product specification

High speed advanced analog DVD signal

processor and laser supply

The bandwidth of the DPD signal is limited by the 100 kHz

phase detector integration filters and the bandwidth of the

output stages (100 kHz for S1 and S2).

The input signals used for DPD depend on the

programmed radial tracking mode (bits RT_mode[2:0]):

DPD

DPD

Range of is from −0.5 to + 0.5.

∆ t

-----T

P

= DPD2: (A,D) or DPD2: (A + C,B+D)

mode

= DPD4: 0.5[ (A,D) + (C,B)]

mode

∆ t

-----T

P

> 0 if A,C phase leads with respect to D,B phase.

FTC = (S1 − S2) × (R

∆t

-----T

P

FTC

∆ t

-----T

P

+ FTCREF)

ForS1 and S2bit RAD_polis assumed to be set to logic 1.

Otherwise the signals appearing at S1 and S2 will be

swapped.

7.5.5.2 DPD signals (DVD-ROM mode) with

drop-out concealment

With bit DOCEN = 1, drop-out concealment is activated

and the S1 and S2 outputs change:

• Thecommonmodelevel (I

REFRAD

the CA signal

• The scaling changes.

At low signal levels (SUM < DOC

∆ t

of is reduced smoothly.

-----T

P

S1

S2

DPD

DPD

=C×I

= −C × I

(FS)(DPD)(DOC)

(FS)(DPD)(DOC)

∆ t

× + 0.25 × CA.

-----T

P

∆ t

× + 0.25 × CA.

-----T

Where:

• I

(FS)(DPD)(DOC)

is the full scale range

• C = concealment multiplier, C = 0 to 1 when CA is

0 to DOC

threshold

• CA=OA+OB+OC+OD

• DOC

is typically 3 µA.

threshold

∆ t

-----T

P

∆ t

-----T

P

)isnowdetermined by

), the contribution

threshold

P

TZA1038HW

ForS1 and S2bit RAD_polis assumed to be set to logic 1.

Otherwise the signals appearing at S1 and S2 will be

swapped.

The DPD detection can not work properly when the input

signal becomes very small. The output of the DPD may

then show a significant offset. The DOC may not conceal

this offset completely because:

• DOC is gradually controlled from the CA signal

• The CA signal may not become 0 during disc-defect.

7.5.5.3 Three-beam push-pull (CD mode)

When the three-beam system is used, the radial signals

S1 and S2 can be composed from inputs E and F.

E OPUREF– LF

S1

PP

S2

PP

FTC = (S1 − S2) × R

A

×=

-----------------------------------------------------------------------------------------

LFR

F OPUREF– LF

×=

A

----------------------------------------------------------------------------------------

LFR

FTC

to 600 kHz).

ForS1 and S2bit RAD_polis assumed to be set to logic 1.

Otherwise the signals appearing at S1 and S2 will be

swapped.

7.5.5.4 Enhanced push-pull

Top hold push-pull method is supported but only in

conjunction with a compatible decoder. The peak hold

function is executed in the decoder, by measuring the

mirror levels of the gap-zones in each header. The

TZA1038HW will compensatefor offset errors in two ways:

• The DC offset from the pick-up can be compensated by

means of a DAC (C

OFFSx

• The dynamic offsets can be compensated by means of

the multiplier ratio α.

The correction values must be calculated in the decoder

and programmed via the serial bus. The method is called

the enhanced push-pull method.

ForS1 and S2bit RAD_polis assumed to be set to logic 1.

Otherwise the signals appearing at S1 and S2 will be

swapped.

++

OFFSROFFSE

R

LFR

–+

OFFSROFFSF

R

LFR

+ FTCREF (bandwidth limited

) in each channel

2003 Sep 03 28

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

S1

S2

PP

PP

A

LFR

A

LFR

××=

α

------------------------------------------------------------------------------------------------------------------------------------------------------

2 α–()

-------------------------------------------------------------------------------------------------------------------------------------------------------

C D 2 OPUREF 2 LF

××=

OFFS

R

LFPP

A B 2 OPUREF 2 LF

or:

S1

S2

PP

PP

A OPUREF– LF

A

LFR

A

LFR

α

××=

---------------------------------------------------------------------------------------- -

D OPUREF– LF

2 α–()

××=

-----------------------------------------------------------------------------------------

R

LFPP

–+

OFFSCOFFSA

–+

OFFSCOFFSD

R

LFPP

The signals from the B and C channels can be switched off, depending on the photodiode configuration

(bit RT_mode[2:0]).

C

OFFSCOFFSCCOFFSD

R

LFPP

–()–×+×–+

OFFSACOFFSB

–()–×+×–+

2003 Sep 03 29

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

8 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOLS PARAMETER CONDITIONS MIN. MAX. UNIT

V

DD

T

amb

V

esd

Note

1. ESD behaviour is tested in accordance with JEDEC II standard:

HBM is equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

MM is equivalent to discharging a 200 pF capacitor through a 0.75 µH series inductor.

9 THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

supply voltage − 5.5 V

ambient temperature −40 +85 °C

electrostatic discharge

voltage

thermal resistance from

Human Body Model (HBM); note 1 − 2000 V

Machine Model (MM); note 1 − 200 V

in free air 27 K/W

junction to ambient

10 CHARACTERISTICS

V

=5V;V

DDA

f

= 50 MHz; R

0(RF)

10 kΩ to V

SS

DDD3

= 3.3 V; V

= 12.1 kΩ (pin REXT); RF output max. load on pins RFP and RFN is Z

ext

DDD5

=5V; V

; unless otherwise specified.

RFREF

= 1.2 V; T

=25°C; RF inputs A to D are referred to pin OPUREF;

amb

: 5 pF parallel with

O(max)

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

T

amb

ambient

−40 − +85 °C

temperature

Supplies

V

DDA1,VDDA2

V

DDA3

V

DDD3

, V

,

analog supply

voltage

DDA4

3 V digital supply

4.5 5.0 5.5 V

2.7 3.3 5.5 V

voltage

V

DDD5

5 V digital supply

4.5 5.0 5.5 V

voltage

V

I(logic)

logic input

note 1 2.7 3.3 5.5 V

compatibility

V

POR

Power-on reset

3.3 3.5 3.7 V

voltage

I

DD

supply current without laser supply − 98 120 mA

STANDBY mode −−1mA

2003 Sep 03 30

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

RF data path, input: pins A to D and OPUREF

V

i(OPUREF)

input voltage on

pin OPUREF

V

i(RF)(FS)

input voltage on

pins A to D for

full-scale at output

V

DC component of

I(DC)

input voltage

V

RFOFFSL

V

RFOFFSR

,

DC offset

compensation

voltage

,

∆V

∆V

RFOFFSL

RFOFFSR

DC offset

compensation

voltage resolution

I

I(bias)

input bias current

on pins A to D

Z

i

input impedance of

pins A to D

A

RF(min)

A

RF(max)

TC

gain

minimum gain G1=0dB, G2= 6 dB,

maximum gain G1=12dB,

gain temperature

coefficient

∆G

1

first RF amplifier

stage gain step size

∆G

2

secondRF amplifier

stage gain step size

RF data path, input: pins RFSUMP and RFSUMN

V

I(DC)

V

I(SUM)(dif)

DC input voltage with respect to V

differential input

voltage

I

I(bias)

Z

I

input bias current − 5 −µA

input impedance note 4 50 − 600 kΩ

note 2 1.5 0.5V

referred to V

OPUREF

DDA

V

− 2V

DDA

G1=0dB −−600 mV

G

=6dB −−300 mV

1

=12dB −−150 mV

G

1

1.8 0.5V

DDA

V

DDA

− 1.4 V

G1= 0 dB 350 450 550 mV

G

= 6 dB 175 225 275 mV

1

G

= 12 dB 90 120 160 mV

1

G1=0dB − 7.1 − mV

G

=6dB − 3.6 − mV

1

=12dB − 1.9 − mV

G

1

−−5µA

100 −−kΩ

468dB

G3= 0 dB; note 3

48 49 52 dB

G2=24dB,

G3= 13 dB; note 3

−−0.025 − dB/°C

567dB

567dB

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

SS

1.3 − V

= −6dB −−1800 mV

=0dB −−1400 mV

=6dB −−700 mV

=12dB −−350 mV

=18dB −−175 mV

− 1.0 V

DDA

2003 Sep 03 31

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

RFOFFSS

∆V

RFOFFSS

A

RFSUM(min)

A

RFSUM(max)

TC

gain

∆G

RFSUM

RF data path, filter and output

V

n(o)(dif)(rms)

V

OO(ref)

DC offset

compensation

voltage

DC offset

compensation

voltage resolution

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

G

RFSUM

= −6dB − 1700 − mV

=0dB − 850 − mV

=6dB − 425 − mV

=12dB − 210 − mV

=18dB − 105 − mV

= −6dB − 27 − mV

=0dB − 13.5 − mV

=6dB − 6.7 − mV

=12dB − 3.4 − mV

=18dB − 1.7 − mV

minimum gain notes 3 and 5 −8 −6 −4dB

maximum gain notes 3 and 5 29 31 33 dB

gain temperature

−−0.02 − dB/°C

coefficient

RFSUM amplifier

5 6 7.5 dB

stage gain step size

differential

RF output noise

voltage (RMS

value)

diode input:

BWRF = 127;

f = 0 to 500 MHz;

RFNFEN = 1; note 6

A=12+24+6dB;

− 7-mV

RFEQEN = 0

A=12+6+6dB;

− 6 − mV

RFEQEN = 0

A=12+6+6dB;

− 9 − mV

RFEQEN = 1;

RFKEQ = 0

A=12+6+6dB;

− 11 − mV

RFEQEN = 1;

RFKEQ = 1

SUM input:

BWRF = 127;

f = 0 to 500 MHz;

RFNFEN = 1; note 6

A=12+6+6dB;

− 12 − mV

RFEQEN = 0

DC output offset

voltagewithrespect

to V

RFREF

V

I(RF)

DVD

V

V

=0V;

= 0; note 7

OFFS

= 1.2 V −−60 mV

RFREF

= 0.8 to 2.1 V −−100 mV

RFREF

2003 Sep 03 32

Philips Semiconductors Product specification

High speed advanced analog DVD signal

TZA1038HW

processor and laser supply

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

o(dif)(p-p)

V

O(RF)(DC)

V

i(RFREF)(CM)

R

o

∆G

3

||h

|−|he|| equalizer amplitude

1

||h

|−|hn|| noise filter

1

B

RF(−3dB)

f

0(RF)

∆f

0(RF)

t

d(RF)

t

st(G3)

α equalizer parameter see Section 7.5.3 1.125 1.25 1.375

τ equalizer parameter see Section 7.5.3 1.18 1.31 1.44

differential output

voltage on

pins RFP and RFN

(peak-to-peak

value)

DC output voltage

on pins RFP and

RFN

input reference

voltagefor common

mode output on

pin RFREF

output impedance

on pins RFP and

RFN

third RF amplifier

stage gain step size

error

amplitude error

−3 dB bandwidth of

RFP and RFN

signal path

noise filter and

equalizer corner

frequency

noise filter and

equalizer corner

frequency step size

flatness delay in

RF data path

amplifier G3 gain

change settling time

−−1.4 V

0.35 − V

− 1.9 V

DDA

0.8 1.2 2.1 V

− 100 −Ω

note 8 − 0.85 1.3 dB

flatness between

−−1.5 dB

f0and 100 kHz

flatness between

−−1.5 dB

f0and 100 kHz

RFEQEN = 0;

200 300 − MHz

RFNFEN = 0

BWRF = 0 8 12.0 14.5 MHz