Philips PCF8535 Datasheet

INTEGRATED CIRCUITS

DATA SH EET

PCF8535

65 × 133 pixel matrix driver

Objective specification

File under Integrated Circuits, IC12

1999 Aug 24

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 ORDERING INFORMATION

5 BLOCK DIAGRAM

5.1 Block diagram functions

5.1.1 Oscillator

5.1.2 Power-on reset

5.1.3 I2C-bus controller

5.1.4 Input filters

5.1.5 Display data RAM

5.1.6 Timing generator

5.1.7 Address counter

5.1.8 Display address counter

6 PINNING

6.1 Pin functions

6.1.1 R0 to R64

6.1.2 C0 to C132

6.1.3 V

6.1.4 V

6.1.5 V

6.1.6 V

6.1.7 V

and V

SS1

to V

DD1

LCDOUT

LCDIN

LCDSENSE

SS2

DD3

6.1.8 SDA

6.1.9 SDAOUT

6.1.10 SCL

6.1.11 SA0 and SA1

6.1.12 OSC

6.1.13 RES

6.1.14 T1, T2, T3, T4 and T5

7 FUNCTIONAL DESCRIPTION

7.1 Reset

7.2 Power-down

7.3 LCD voltage selector

7.4 Oscillator

7.5 Timing

7.6 Column driver outputs

7.7 Row driver outputs

7.8 Drive waveforms

7.9 Set multiplex rate

7.10 Bias system

7.10.1 Set bias system

7.11 Temperature measurement

7.11.1 Temperature read back

7.12 Temperature compensation

7.12.1 Temperature coefficients

7.13 V

OP

7.13.1 Set VOP value

7.14 Voltage multiplier control

7.14.1 S[1:0]

7.15 Addressing

7.15.1 Input addressing

7.15.2 Output addressing

7.16 Instruction set

7.16.1 RAM read/write command page

7.16.2 Function and RAM command page

7.16.3 Display setting command page

7.16.4 HV-gen command page

7.16.5 Special feature command page

7.16.6 Instruction set

7.17 I2C-bus interface

7.17.1 Characteristics of the I2C-bus

7.17.2 I2C-bus protocol

8 LIMITING VALUES (PROVISIONAL)

9 HANDLING

10 DC CHARACTERISTICS

11 AC CHARACTERISTICS

12 RESET TIMING

13 APPLICATION INFORMATION

14 BONDING PAD LOCATIONS

15 DEVICE PROTECTION DIAGRAM

16 TRAY INFORMATION

17 DEFINITIONS

18 LIFE SUPPORT APPLICATIONS

19 PURCHASE OF PHILIPS I2C COMPONENTS

20 BARE DIE DISCLAIMER

1999 Aug 24 2

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

1 FEATURES

• Single-chip LCD controller/driver

• 65 row, 133 column outputs

• Display data RAM 65 × 133 bits

• 133 icons (last row is used for icons)

• Fast mode I2C-bus interface (400 kbits/s)

• Software selectable multiplex rates:

1:17,1:26,1:34,1:49and1:65

• On-chip:

– Generation of intermediate LCD bias voltages

– Oscillator requires no external components

(external clock also possible)

– Generation of V

LCD

.

• CMOS compatible inputs

• Software selectable bias configuration

• Logic supply voltage range V

• Supply voltage range for high voltage part V

V

DD3

to V

SS2

and V

4.5 to 5.5 V

SS3

• Display supply voltage range V

DD1

LCD

to V

to VSS:

4.5 to 5.5 V

SS1

DD2

and

– Mux rate 1 : 65: 8 to 16 V.

• Low power consumption, suitable for battery operated

systems

• Internal Power-on reset and/or external reset

• Temperature read back available

• Manufactured in N-well silicon gate CMOS process.

2 APPLICATIONS

• Automotive information systems

• Telecommunication systems

• Point-of-sale terminals

• Instrumentation.

3 GENERAL DESCRIPTION

The PCF8535 is a low power CMOS LCD row/column

driver, designed to drive dot matrix graphic displays at

multiplex rates of 1 : 17, 1 : 26, 1 : 34, 1 : 49 and 1 : 65.

Furthermore, it can drive up to 133 icons. All necessary

functions for the display are provided in a single chip,

including on-chip generation of LCD bias voltages,

resulting in a minimum of external components and low

power consumption. The PCF8535 is compatible with

most microcontrollers and communicates via an industry

standard two-line bidirectional I2C-bus serial interface.

All inputs are CMOS compatible.

4 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

PCF8535U − chip with bumps in tray −

1999 Aug 24 3

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

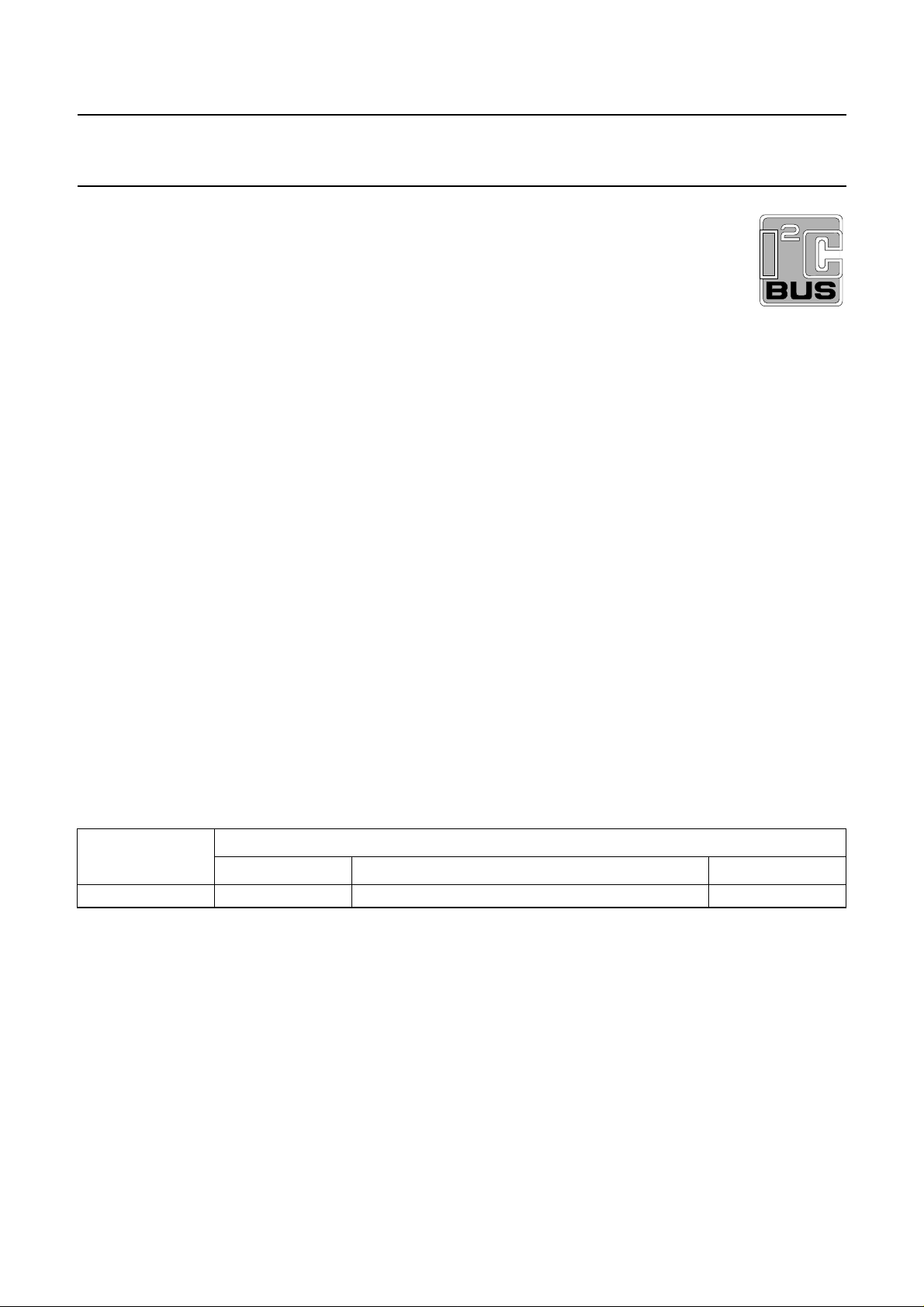

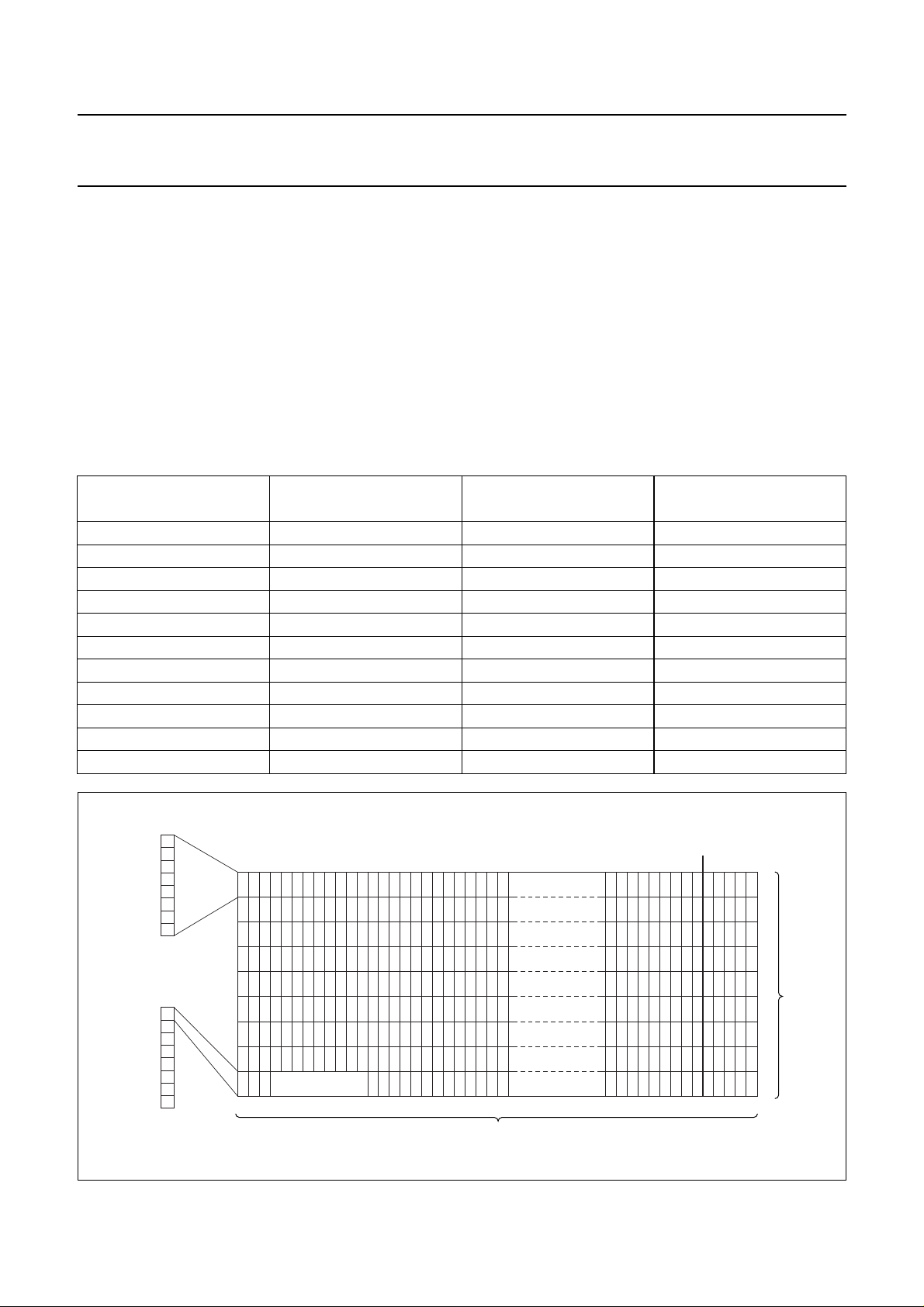

5 BLOCK DIAGRAM

handbook, full pagewidth

V

V

T4, T5

T1, T2, T3

V

LCDIN

V

LCDSENSE

V

LCDOUT

SDAOUT

SS1

SS2

SCL

SDA

BIAS

VOLTAGE

GENERATOR

V

LCD

GENERATOR

INPUT

FILTERS

R0 to R64

65

ROW

DRIVERS

PCF8535

C0 to C132

133

COLUMN

DRIVERS

DATA LATCHES

MATRIX

LATCHES

DISPLAY DATA RAM

MATRIX DATA

RAM

I2C-BUS

CONTROL

V

DD1

POWER-ON RESET

COMMAND

DECODER

V

DD2

INTERNAL

RESET

OSCILLATOR

TIMING

GENERATOR

DISPLAY

ADDRESS

COUNTER

ADDRESS

COUNTER

V

DD3

RES

OSC

SA0

SA1

Fig.1 Block diagram.

1999 Aug 24 4

MGS669

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

5.1 Block diagram functions

5.1.1 OSCILLATOR The on-chip oscillator provides the display clock for the

system; it requires no externalcomponents. Alternatively,

an external display clock may be provided via the OSC

input. The OSC input must be connected to V

DD1

or V

SS1

when not in use. During power-down additional current

saving can be made if the external clock is disabled.

5.1.2 POWER-ON RESET The on-chip Power-on reset initializes the chip after

power-on or power failure.

2

5.1.3 I

C-BUS CONTROLLER

The I2C-bus controller detects the I2C-bus protocol, slave

address, commands and display data bytes. It performs

the conversion of the data input (serial-to-parallel).

The PCF8535 acts as an I2C-bus slave and therefore

cannot initiate bus communication.

5.1.4 INPUT FILTERS Input filters are provided to enhance noise immunity in

electrically adverse environments; RC low-pass filters are

provided on the SDA, SCL and RES lines.

5.1.5 D

ISPLAY DATA RAM

The PCF8535 contains a 65 × 133 bit static RAM which

storesthe display data. The RAM is dividedinto9 banks of

133 bytes. The last bank is used for icon data and is only

one bit deep. During RAM access, data is transferred to

the RAM via the I2C-bus interface. There is a direct

correspondence between the X address and the column

output number.

5.1.6 TIMING GENERATOR The timing generator produces the various signals

required to drive the internal circuitry. Internal chip

operation is not disturbed by operations on the data bus.

5.1.7 ADDRESS COUNTER TheAddressCounter(AC)sendsaddressestotheDisplay

Data RAM (DDRAM) for writing.

5.1.8 DISPLAY ADDRESS COUNTER The display is generated by continuously shifting rows of

RAM data to the dot matrix LCD via the column outputs.

The display status (all dots on or off, normal or inverse

video) is set via the I2C-bus.

1999 Aug 24 5

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

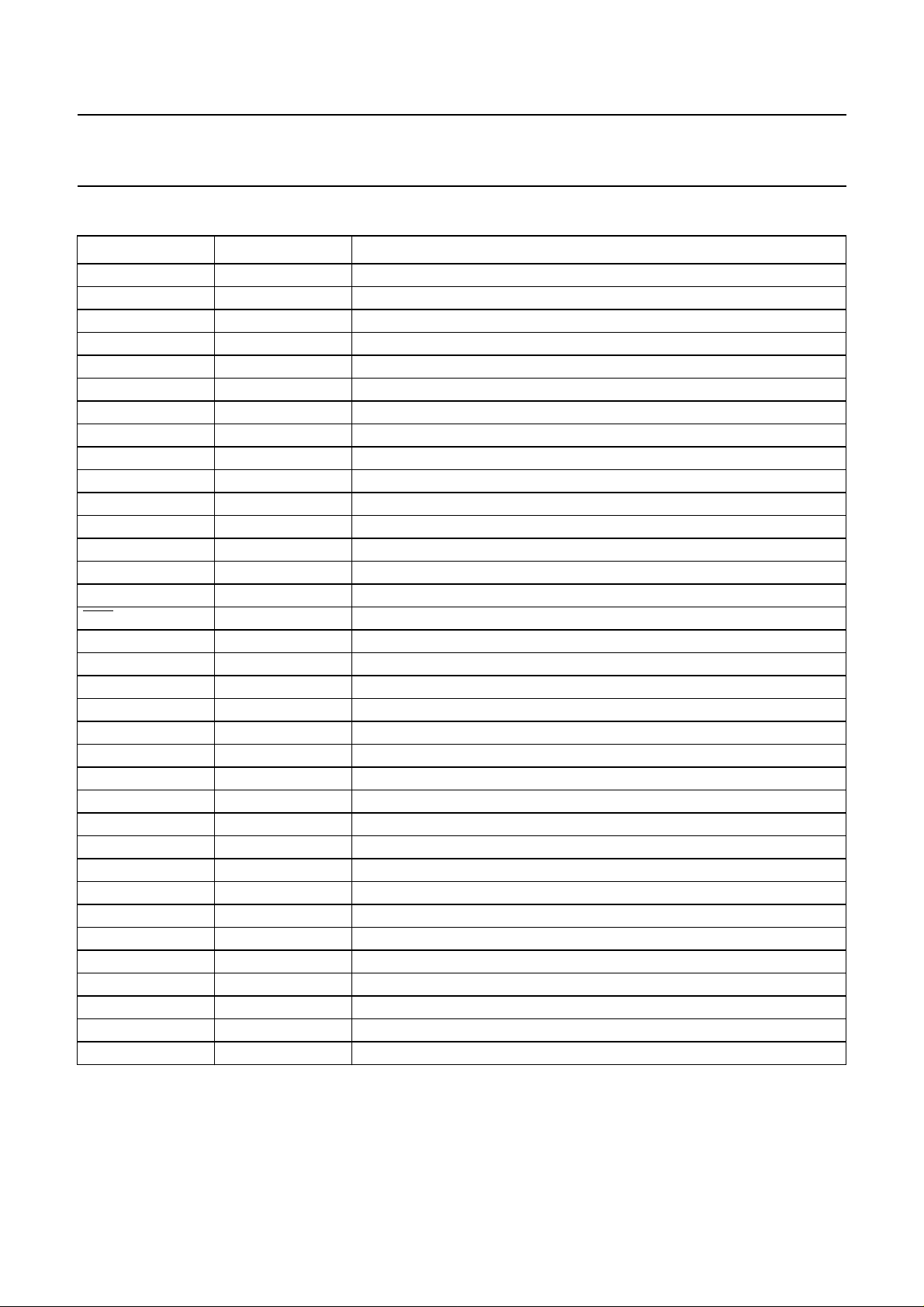

6 PINNING

SYMBOL PAD DESCRIPTION

1 dummy pad

2 bump/alignment mark 1

R0 to R15 3 to 18 LCD row driver outputs

C0 to C132 19 to 151 LCD column driver outputs

R47 to R33 152 to 166 LCD row driver outputs

167 bump/alignment mark 2

168 dummy pad

R48 to R64 169 to 185 LCD row driver outputs; R64 is icon row

186 bump/alignment mark 3

187 to 189 dummy pad

OSC 190 oscillator

V

LCDIN

V

LCDOUT

V

LCDSENSE

RES 207 external reset input (active LOW)

T3 208 test output 3

T2 209 test output 2

T1 210 test output 1

V

DD2

V

DD3

V

DD1

SDA 230 and 231 I2C-bus serial data inputs

SDAOUT 232 I2C-bus serial data output

SA1 233 I2C-bus slave address input

SA0 234 I2C-bus slave address input

V

SS2

V

SS1

T5 251 test input 5

T4 252 test input 4

SCL 254 and 255 I2C-bus serial clock inputs

R32 to R16 257 to 273 LCD row driver outputs

191 to 196 LCD supply voltage

197 to 203 voltage multiplier output

204 voltage multiplier regulation input (V

205 and 206 dummy pad

211 to 218 supply voltage 2

219 to 222 supply voltage 3

223 to 228 supply voltage 1

229 dummy pad

235 to 242 ground 2

243 to 250 ground 1

253 dummy pad

256 bump/alignment mark 4

LCD

)

6.1 Pin functions

6.1.1 R0 TO R64

These pads output the display row signals.

1999 Aug 24 6

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

6.1.2 C0 TO C132

These pads output the display column signals.

6.1.3 V

V

and V

SS1

6.1.4 V

V

is the logic supply. V

DD1

multiplier. For split power suppliesV

AND V

SS1

SS2

DD1

SS2

must be connected together.

TO V

DD3

and V

DD2

are for the voltage

DD3

and V

DD2

DD3

must be

connectedtogether.If only one supply voltage is available,

all three supplies must be connected together.

6.1.5 V

If, in the application, an external V

LCDOUT

is used, V

LCD

LCDOUT

must be left open-circuit; otherwise (if the internal voltage

multiplier is enabled) the chip may be damaged. V

should not be driven when V

is below its minimum

DD1

LCDOUT

allowed value otherwise a low impedance path between

V

LCDOUT

6.1.6 V

This is the V

If the internal V

V

LCDIN

driven when V

otherwisea low impedance path between V

and V

LCDIN

will exist.

SS1

supply for when an external V

LCD

generator is used, then V

LCD

must be connected together. V

is below its minimum allowed value,

DD1

should not be

LCDIN

LCDIN

is used.

LCD

LCDOUT

andV

and

SS1

will exist.

and the Indium Tin Oxide (ITO) track resistance. It is

possible that during the acknowledge cycle the PCF8535

will not be able to create a valid logic 0 level. By splitting

the SDA input from the SDAOUT output the device could

be used in a mode that ignores the acknowledge bit.

In COG applications where the acknowledge cycle is

required or where read back is required, it is necessary to

minimizethetrackresistancefromtheSDAOUT pad to the

system SDA line to guarantee a valid LOW level.

6.1.10 SCL

2

C-bus serial clock input.

I

6.1.11 SA0 AND SA1

Least significant bits of the I2C-bus slave address.

Table 1 Slave address; see note 1

SA1 AND SA0 MODE SLAVE ADDRESS

0 and 0 write 78H

read 79H

0 and 1 write 7AH

read 7BH

1 and 0 write 7CH

read 7DH

1 and 1 write 7EH

read 7FH

6.1.7 V

LCDSENSE

This is the input to the internal voltage multiplier regulator.

It must be connected to V

LCDOUT

when the internal voltage

generator is used otherwise it may be left open-circuit.

V

LCDSENCE

should not be driven when V

is below its

DD1

minimum allowed value, otherwise a low impedance path

between V

LCDSENCE

and V

will exist.

SS1

6.1.8 SDA I2C-bus serial data input.

6.1.9 SDAOUT SDAOUT is the serial data acknowledge for the I2C-bus.

By connecting SDAOUT to SDA externally, the SDA line

becomes fully I2C-bus compatible. Having the

acknowledge output separated from the serial data line is

advantageous in Chip-On-Glass (COG) applications.

In COG applications where the track resistance from the

SDAOUT pad to the system SDA line can be significant, a

potential divider is generated by the bus pull-up resistor

1999 Aug 24 7

Note

1. The slave address is a concatination of the following

bits {01111, SA1, SA0 and R/W}.

6.1.12 OSC

If the on-chip oscillator is used this input must be

connected to V

DD1

or V

SS1

.

6.1.13 RES

External reset pad: when this pad is LOW the chip will be

reset; see Section 7.1. If an external reset is not required,

this pad must be tied to V

. Timing for the RES pad is

DD1

given in Chapter 12.

6.1.14 T1, T2, T3, T4 AND T5

In applications T4 and T5 must be connected to VSS.

T1, T2 and T3 are to be left open-circuit.

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

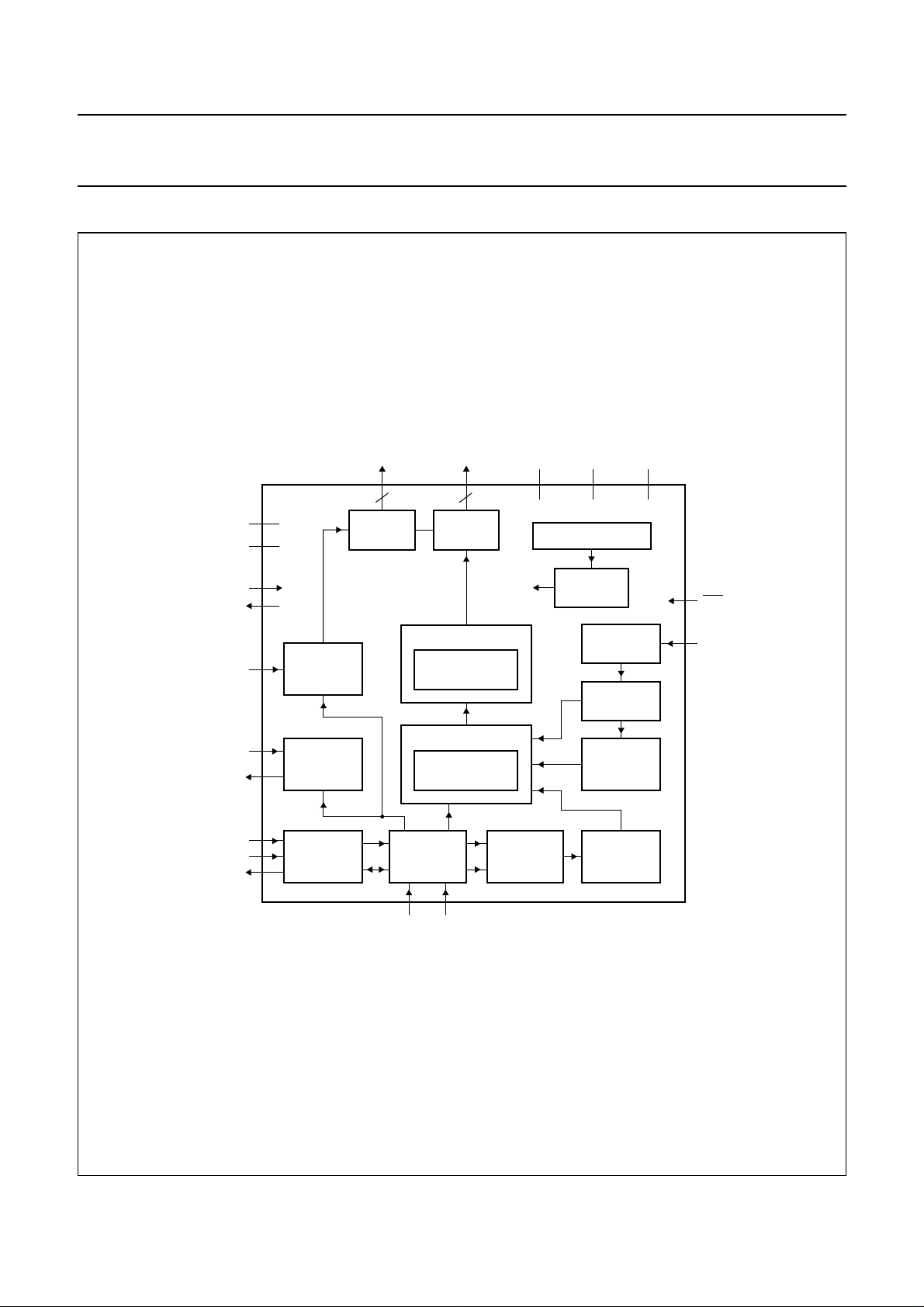

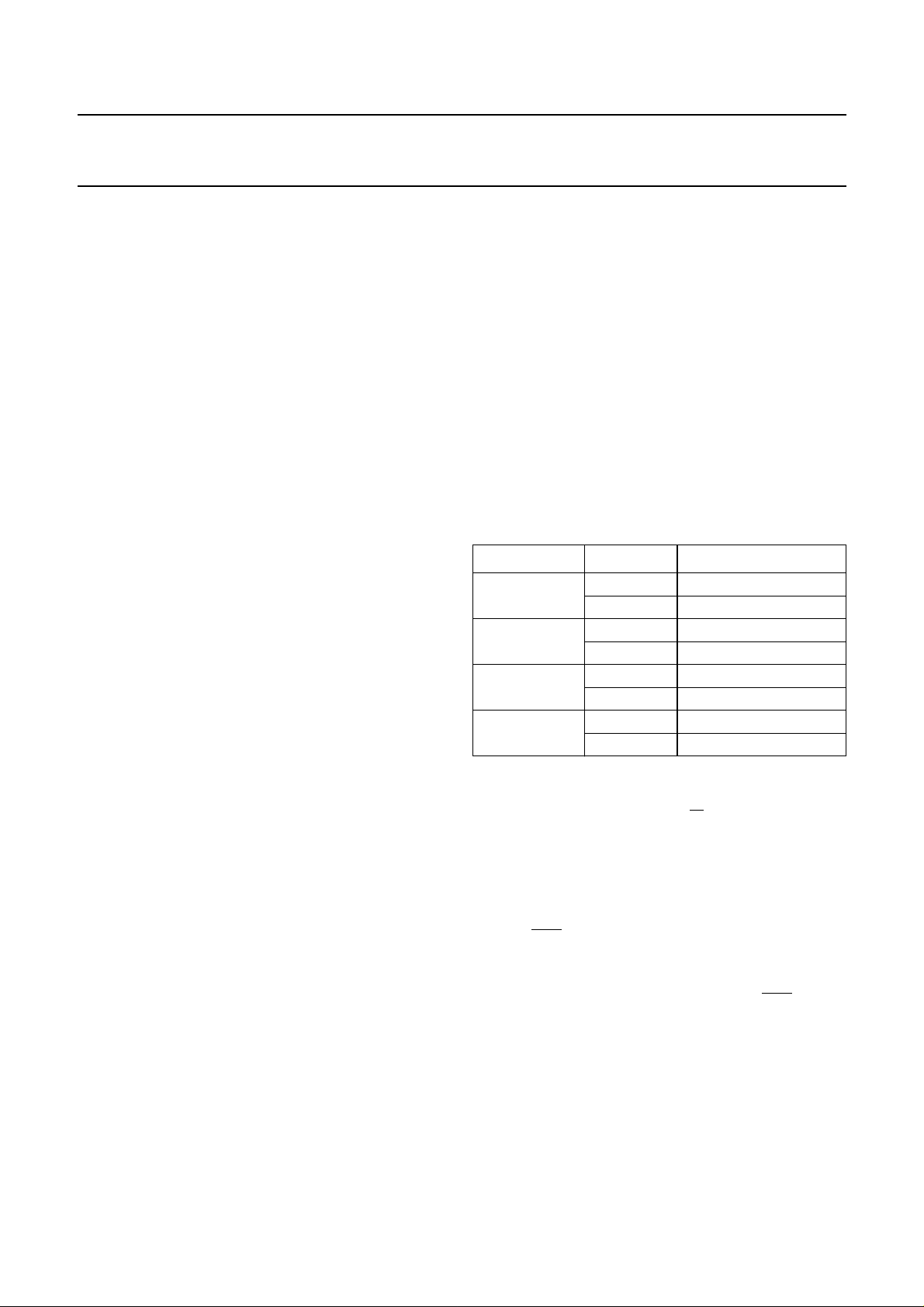

7 FUNCTIONAL DESCRIPTION

The PCF8535 is a low power LCD driver designed to interface with microprocessors/microcontrollers and a wide variety

of LCDs.

The host microprocessor/microcontroller and the PCF8535 are both connected to the I2C-bus. The SDA and SCL lines

must be connected to the positive power supply via pull-up resistors. The internal oscillator requires no external

components. The appropriate intermediate biasing voltage for the multiplexed LCD waveforms are generated on-chip.

The only other connections required to complete the system are to the power supplies (VDD,VSSand V

capacitors for decoupling V

LCD

and VDD.

) and suitable

LCD

handbook, full pagewidth

V

to V

DD1

V

DD(I2C)

V

SS1, VSS2

DD3

RES

SA0

SA1

SCL

SDA

V

LCD

DD2

DD1,VDD3

V

V

HOST

MICROPROCESSOR/

R

R

pu

pu

MICROCONTROLLER

V

SS

SS1VSS2

V

PCF8535

133 column drivers

65 row drivers

LCD PANEL

MGS670

Fig.2 Typical system configuration.

1999 Aug 24 8

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.1 Reset

The PCF8535 has two reset modes; internal Power-on

reset or external reset. Reset initiated from either the RES

pad or the internal Power-on reset block will initialize the

chip to the following starting condition:

• Power-down mode (PD = 1)

• Horizontal addressing (V = 0); no mirror X or Y

(MX = 0 and MY = 0)

• Display blank (D = 0 andE=0)

• Address counter X[6:0] = 0, Y[2:0] = 0 and XM0=0

• Bias system BS[2:0] = 0

• Multiplex rate M[2:0] = 0 (Mux rate1:17)

• Temperature control mode TC[2:0] = 0

• HV-gen control, HVE = 0 the HV generator is switched

off, PRS = 0 and S[1:0] = 00

• V

LCDOUT

is equal to 0 V

• RAM data is unchanged (Note: RAM data is undefined

after power-up)

• All row and column outputs are set to VSS (display off)

• TRS and BRS are set to zero

• Direct mode is disabled (DM = 0)

• Internal oscillator is selected, but not running (EC = 0)

• Bias current set to low current mode (IB = 0).

7.3 LCD voltage selector

The practical value for VOP is determined by equating

V

with defined LCD threshold voltage (Vth), typically

off(rms)

when the LCD exhibits approximately 10% contrast.

7.4 Oscillator

The internal logic operation and the multi-level drive

signals of the PCF8535 are clocked by the built-in RC

oscillator. No external components are required.

7.5 Timing

ThetimingofthePCF8535organizestheinternaldataflow

of the device. The timing also generates the LCD frame

frequency which is derived from the clock frequency

generated in the internal clock generator.

7.6 Column driver outputs

The LCD drive section includes 133 column outputs

(C0 to C132) which should be connected directly to the

LCD. The column output signals are generated in

accordance with the multiplexed row signals and with the

data in the display latch. When less than 133 columns are

required the unused column outputs should be left

open-circuit.

7.7 Row driver outputs

7.2 Power-down

During power-down all static currents are switched off (no

internal oscillator, no timing and no LCD segment drive

system) and all LCD outputs are internally connected to

VSS. The serial bus function remains active.

The LCD drive section includes 65 row outputs

(R0 to R64) which should be connected directly to the

LCD. The row output signals are generated in accordance

with the selected LCD drive mode. If lower Mux rates or

less than 65 rows are required, the unused outputs should

be left open-circuit.

1999 Aug 24 9

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

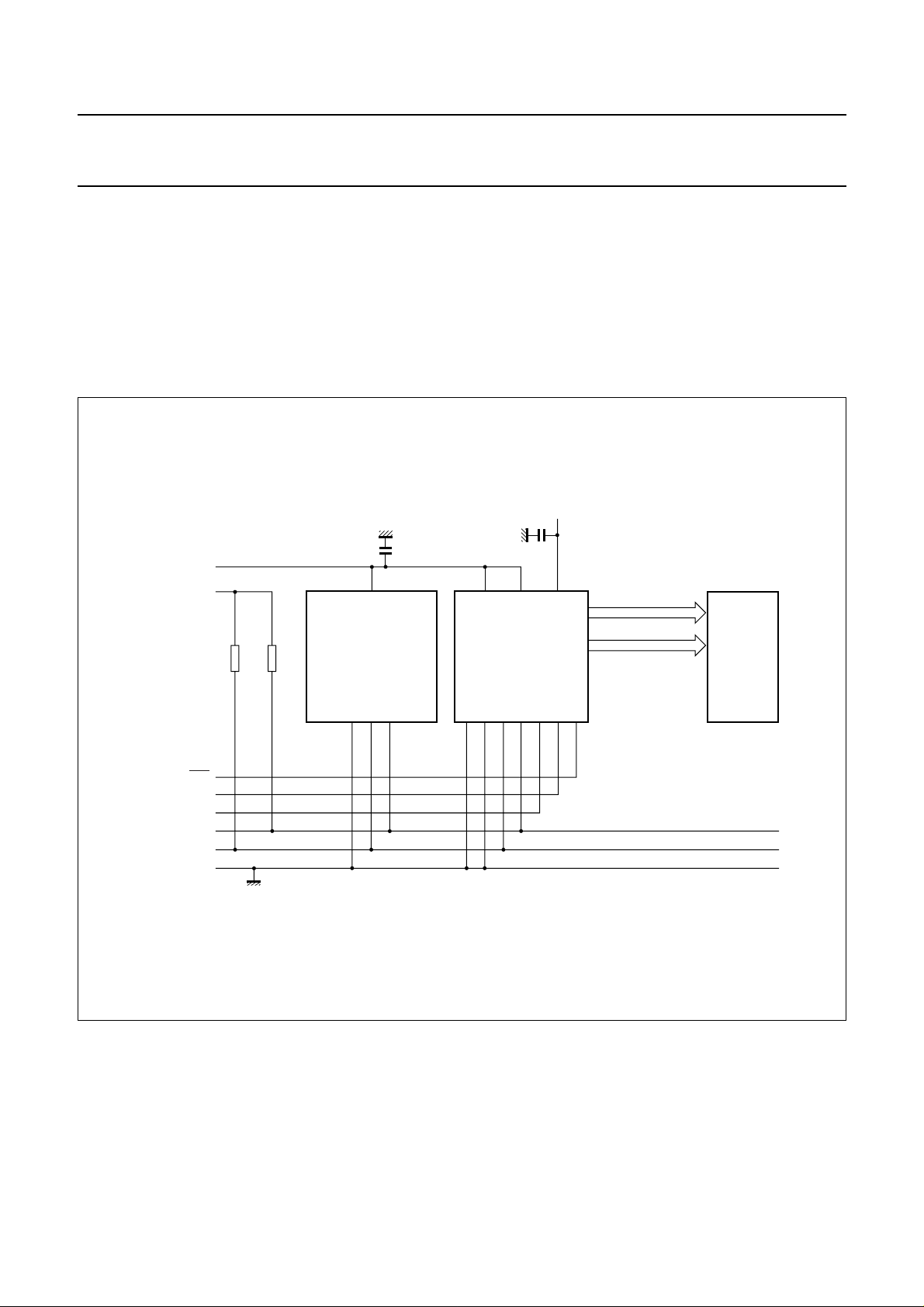

7.8 Drive waveforms

ROW 0

R0 (t)

ROW 1

R1 (t)

COL 0

C0 (t)

COL 1

C1 (t)

V

LCD

V3 − V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

− V

SS

SS

frame n frame n + 1

V

state1

V

state2

(t)

(t)

V

− V

LCD

V

V

V

(t) = C1(t) − R0(t).

state1

V

(t) = C1(t) − R1(t).

state2

state1

state2

(t)

(t)

0 V

V3 − V

V

LCD

V3 − V

V

LCD

0 V

V3 − V

2

SS

− V

SS

SS

− V

2

SS

012345678... ... 64 01234567 8... ... 64

Fig.3 Typical LCD driver waveforms.

1999 Aug 24 10

V4 − V

0 V

VSS − V

V4 − V

V

− V

SS

V4 − V

0 V

VSS − V

V4 − V

V

− V

SS

MGS671

5

5

LCD

LCD

5

5

LCD

LCD

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.9 Set multiplex rate

The PCF8535 can be used to drive displays of varying sizes. The multiplex mode selected controls which rows are used.

In all cases, the last row is always driven and is intended for icons. If Top Row Swap (TRS) is at logic 1 then the icon row

will be output on pad R48. M[2:0] selects the multiplex rate (see Table 2).

Table 2 Multiplex rates

M[2] M[1] M[0] MULTIPLEX RATE ACTIVE ROWS

0 0 0 1 : 17 R0 to R15 and R64

0 0 1 1 : 26 R0 to R24 and R64

0 1 0 1 : 34 R0 to R32 and R64

0 1 1 1 : 49 R0 to R47 and R64

1 0 0 1:65 R0toR64

101 − 111 do not use −

7.10 Bias system

7.10.1 SET BIAS SYSTEM

The bias voltage levels are set in the ratio of R − R − nR − R − R. Differentmultiplex rates require differentfactors n. This

is programmed by BS[2:0]. For optimum bias values, n can be calculated from:

n Mux rate 3–=

Changing the bias system from the optimum will have a consequence on the contrast and viewing angle. One reason to

come away from the optimum would be to reduce the required V

. A compromise between contrast and VOP must be

OP

found for any particular application.

Table 3 Programming the required bias system

BS[2] BS[1] BS[0] n BIAS MODE TYPICAL MUX RATES

00071/

00161/

01051/

01141/

10031/

10121/

11011/

1110

11

10

9

8

7

6

5

1

/

4

1 : 100

1:80

1:65

1:49

1:33

1:26

1:17

1:9

1999 Aug 24 11

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

Table 4 Example of LCD bias voltage for1/7bias, n = 3

1

SYMBOL BIAS VOLTAGE FOR

V1 V

V2

V3

V4

V5

V6 V

6

/7× V

5

/7× V

2

/7× V

1

/7× V

LCD

SS

/7BIAS

LCD

LCD

LCD

LCD

7.11 Temperature measurement

7.11.1 T

EMPERATURE READ BACK

The PCF8535 has an in-built temperature sensor.

For power saving, the sensor should only be enabled

when a measurement is required. It will not operate in

power-down mode. The temperature read back requires a

clock to operate. Normally the internal clock is used but, if

the device is operating from an external clock, then this

must be present for the measurement to work. V

V

mustalso be applied. A measurement is initialized by

DD3

DD2

and

setting the SM bit. Once started the SM bit will be

automatically cleared. An internal oscillator will be

initialized and allowed to warm-up for approximately

2 frame periods. After this the measurement starts and

lasts for a maximum of 2 frame periods.

Temperature data is returned via a status register. During

the measurement the register will contain zero. Once the

measurement is completed the register will be updated

with the current temperature (non zero value). Because

the I2C-bus interface is asynchronous to the temperature

measurement, read back prior to the end of the

measurement is not guaranteed. If this mode is required

the register should be read twice to validate the data.

For calibrating the temperature read-out a measurement

must be taken at a defined temperature. The offset

between the ideal read-out and the actual result has to be

stored into a non-volatile register (e.g. EEPROM);

Offset TR

where TR

meas

TR

–=

ideal

meas

is the actual temperature read-out of the

(2)

PCF8535.

The calibrated temperature read-out can be calculated for

each measurement as follows:

TR

cal

TR

meas

Offset+=

(3)

The accuracy after the calibration is ±6.7% (plus ±1 lsb) of

the difference between the current temperature and the

calibration temperature. For this reason a calibration at or

near the most sensitive temperature for the display is

recommended.

E.g. for a calibration at 25 °C with the current temperature

at −20 °C, the absolute error may be calculated as:

Absolute error = 0.067 × (25 °C −−20 °C)

= ±3 °C+±1 lsb = ±4.17 °C.

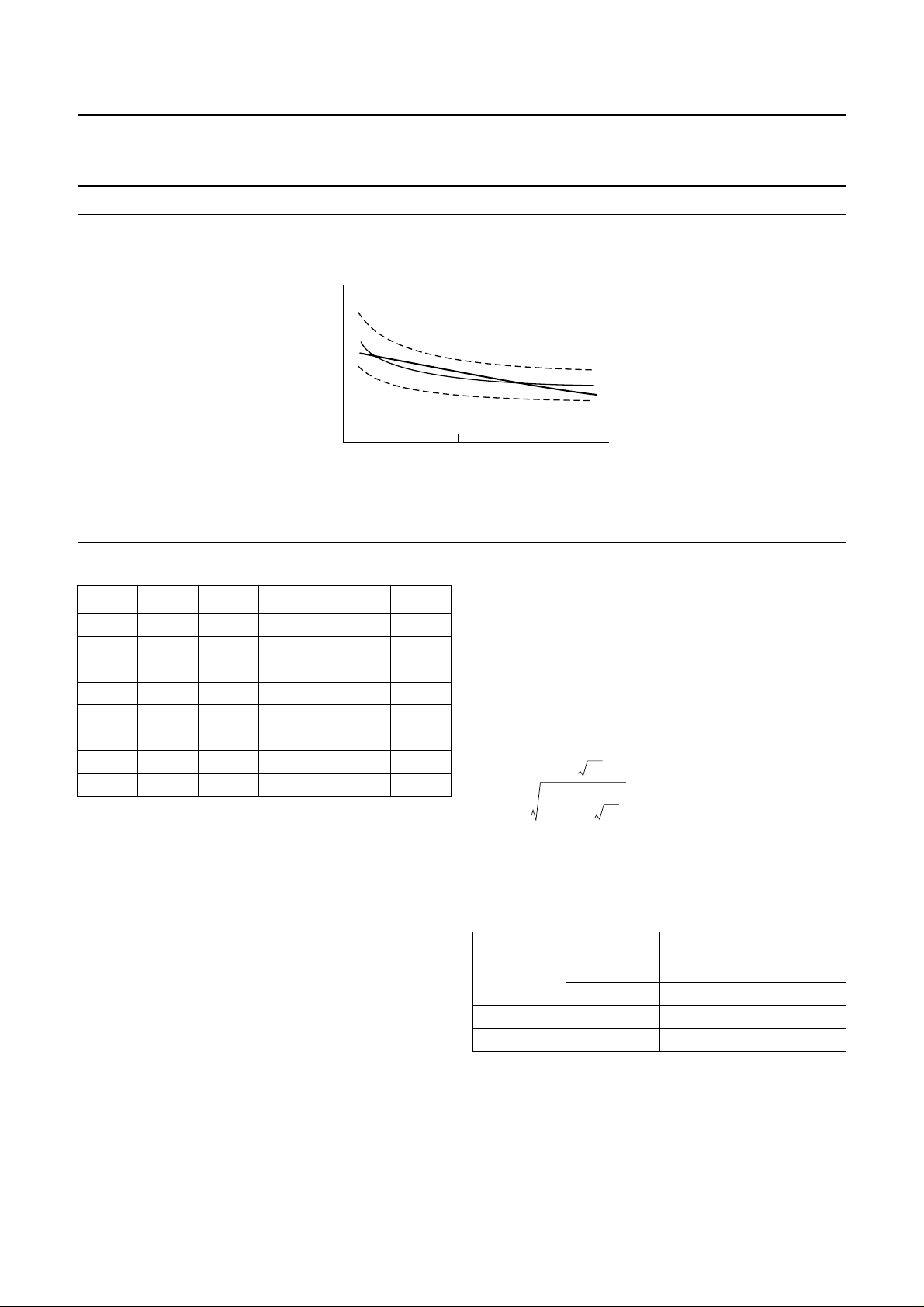

7.12 Temperature compensation

7.12.1 TEMPERATURE COEFFICIENTS Due to the temperature dependency of the liquid crystals

viscosity the LCD controlling voltage,V must be increased

at lower temperatures to maintain optimum contrast.

Figure 4 shows V

as a function of temperature for a

LCD

typical high multiplex rate liquid.

Inthe PCF8535 the temperature coefficient of V

LCD

canbe

selected from 8 values by setting bits TC[2:0],

see Table 5.

The ideal temperature read-out can be calculated as

follows;

TR

128 T 27 °C–()

ideal

×+=

-- c

(1)

1

where T is the on-chip temperature in °C and c is the

conversion constant; c = 1.17 °C/lsb.

Toimprove the accuracy of the temperature measurement

a calibration is recommended during the assembly of the

final product.

1999 Aug 24 12

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, halfpage

V

LCD

Fig.4 V

as function of liquid crystal temperature (typical values).

LCD

Table 5 Selectable temperature coefficients

TC[2] TC[1] TC[0] TC VALUE UNIT

000 0 1/°C

001−0.44 × 10

010−1.10 × 10

011−1.45 × 10

100−1.91 × 10

101−2.15 × 10

110−2.32 × 10

111−2.74 × 10

7.13 V

7.13.1 SET V

OP

OP

VALUE

−3

−3

−3

−3

−3

−3

−3

1/°C

1/°C

1/°C

1/°C

1/°C

1/°C

1/°C

The voltage at the reference temperature can be

calculated as: [V

V

LCD

Tcut()

The operating voltage, V

(T=T

LCD

aVOPb×+()=

)]

cut

, can be set by software.

OP

(4)

The generated voltage is dependent on the temperature,

programmed Temperature Coefficient (TC) and the

programmed voltage at the reference temperature (T

V

LCD

aVOPb×+()1TT

The values for T

, a and b are given in Table 6.

cut

–()TC×()+()×=

cut

cut

):

(5)

The maximumvoltagethatcan be generated is dependent

on the voltage V

and the display load current.

DD2

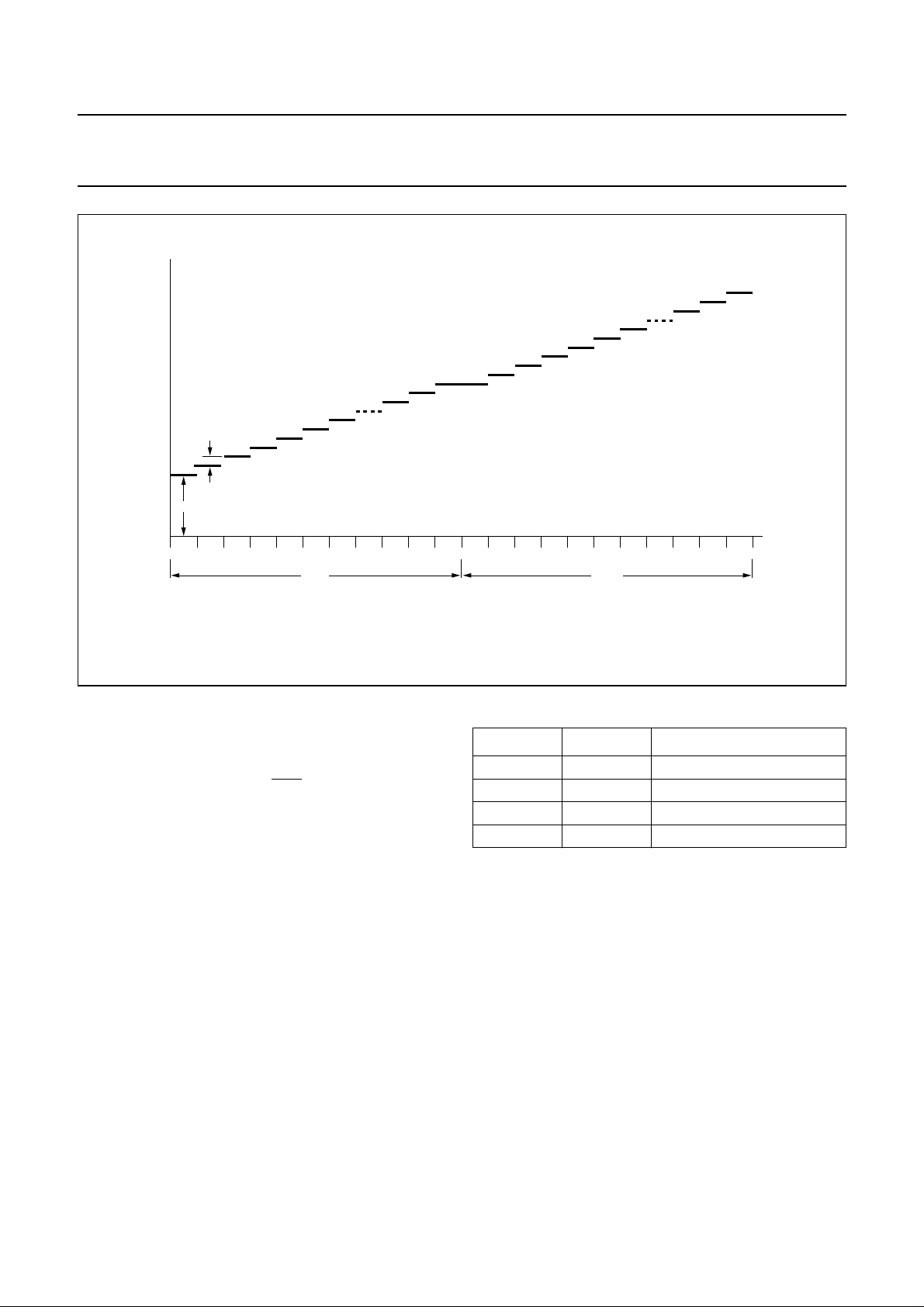

Two overlapping VOP ranges are selectable via the

command page “Hv-gen control”, see Fig.5.

MGS473

0 °C

T

The low range offers programming from 4.5 to 10.215 V,

with the high range from 10.215 to 15.93 V at the cut point

temperature, T

. Care must be taken, when using

cut

temperature coefficients, that the programmed voltage

does not exceed the maximum allowed V

LCD

voltage,

see Chapter 10.

Fora particular liquid, the optimumV

canbe calculated

LCD

for a given multiplex rate. For a Mux rate of 1 : 65, the

optimum operating voltage of the liquid can be calculated

as:

V

LCD

where V

165+

---------------------------------------

×

–

21

is the threshold voltage of the liquid crystal

th

----------

1

65

V

× 6.85 Vth×==

th

material used.

Table 6 Values for parameters of the HV generator

programming

SYMBOL BITS VALUE UNIT

a PRS = 0 4.5 V

PRS = 1 10.215 V b 0.045 V T

cut

27 °C

(6)

1999 Aug 24 13

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, full pagewidth

V

LCD

b

a

00 01 02

VOP[6:0] programming (00H to 7FH, programming range LOWand HIGH).

03 04 05 06 . . . 5F 6F 7F 00 01 02 03 04 05 06 . . . 5F 6F 7F

LOW HIGH

Fig.5 VOP programming of PCF8535.

7.14 Voltage multiplier control

7.14.1 S[1:0] The PCF8535 incorporates a software configurable

voltage multiplier. After reset (RES) the voltage multiplier

is set to 2 × V

. Other voltage multiplier factors are set

DD2

via the HV-gen command page. Before switching on the

charge pump, the charge pump has to be pre-charged

using the following sequence.

A starting state of HVE = 0, DOF = 0, PD = 1 and DM = 0

is assumed. A small delay between steps is indicated.

The recommended wait period is 20 µs per 100 nF of

capacitance on V

LCD1

.

1. Set DM = 1 and PD = 0

2. Delay

3. Set the multiplication factor to 2 by setting S[1:0] = 00

4. Set the required VOP and PRS.

5. Set HVE = 1 to switch-on the charge pump with a

multiplication factor of 2

6. Delay

7. Increase the number of stages, one at a time, with a

delay between each until the required level is

achieved.

MGS472

Table 7 HV generator multiplication factor

S[1] S[0] MULTIPLICATION FACTOR

00 2× V

01 3× V

10 4× V

11 5× V

DD2

DD2

DD2

DD2

1999 Aug 24 14

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15 Addressing

Addressing of the RAM can be split into two parts; input

addressing and output addressing. Input addressing is

concerned with writing data into the RAM. Output

addressing is almost entirely automatic and taken care of

by the device, however, it is possible to affect the output

mode.

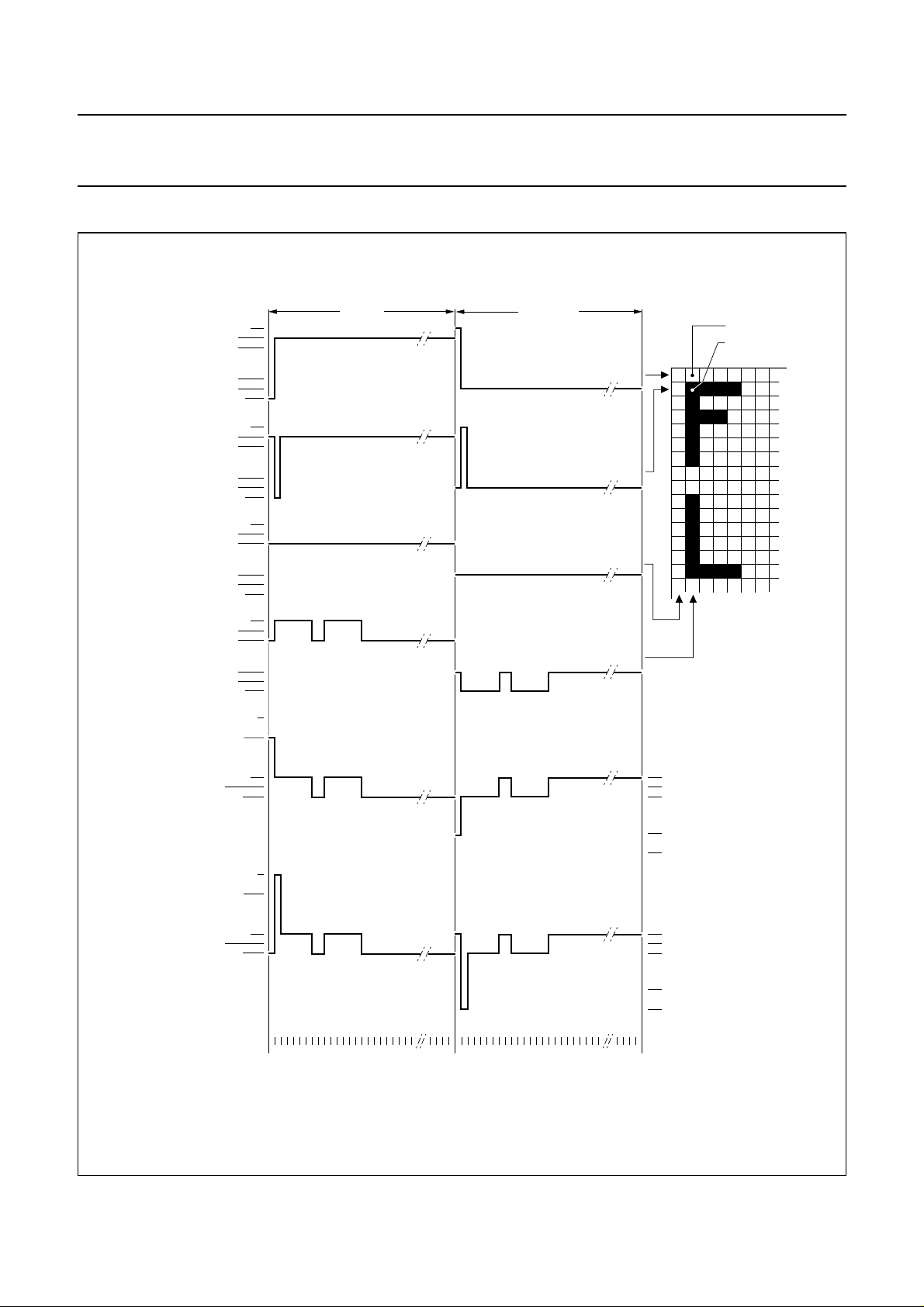

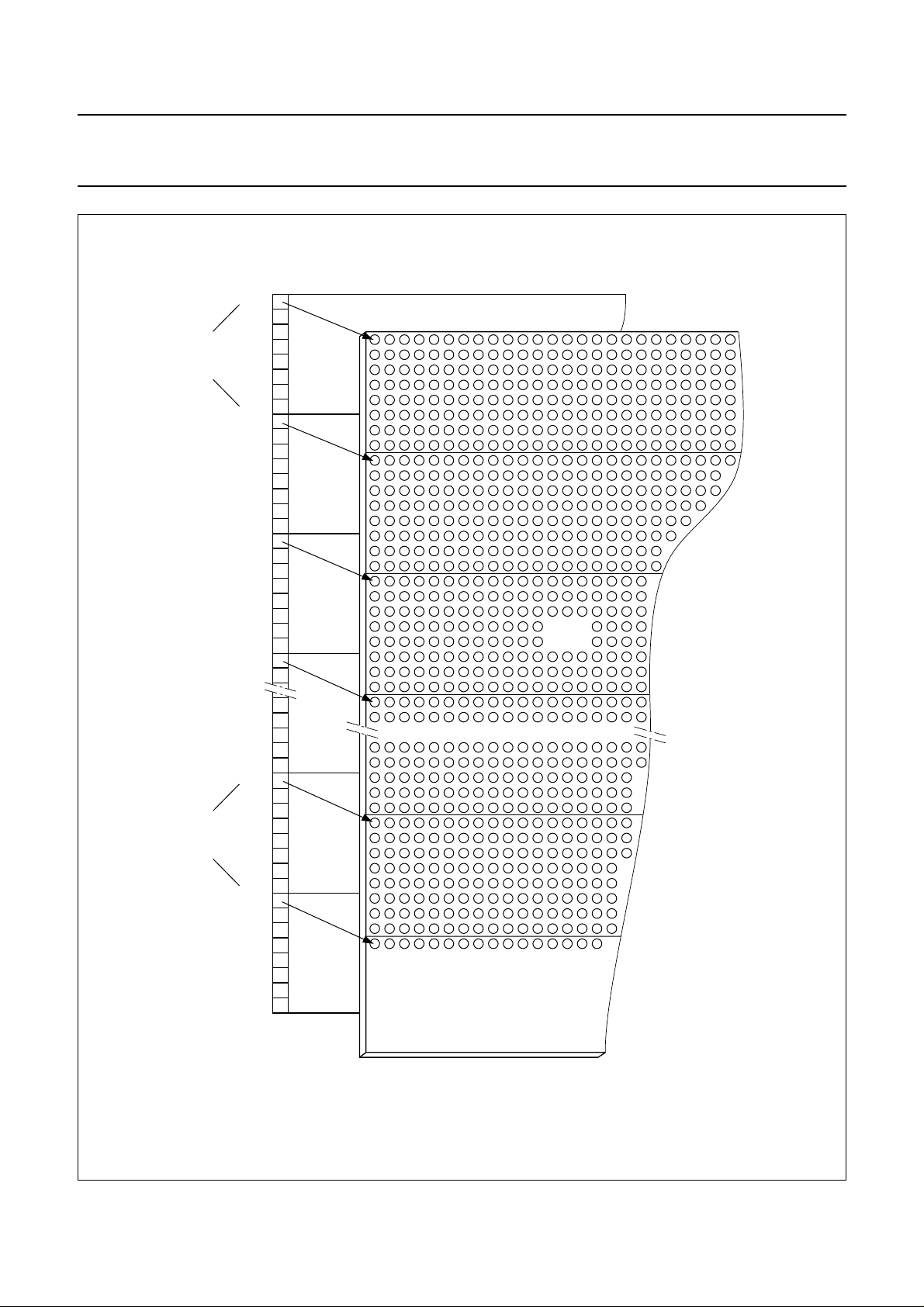

7.15.1 INPUT ADDRESSING

Data is down loaded byte wise into the RAM matrix of the

PCF8535 as indicated in Figs 6 to 10.

Table 8 Effect of X-RAM page pointer

X ADDRESS POINTER

X-RAM PAGE POINTER

XM

0

0 0 C0 C132 1 0 C1 C131 2 0 C2 C130

:::: 125 0 C125 C7 126 0 C126 C6 127 0 C127 C5

0 1 C128 C4 1 1 C129 C3

::::

4 1 C132 C0

The display RAM has a matrix of 65 × 133 bits.

The columns are addressed by a combination of the

X address pointer and the X-RAM page pointer, whilst the

rows addressed in groups of 8 by the Y address pointer.

The X address pointer has a range of 0 to 127 (7FH).

Its range can be extended by the X-RAM page pointer,

XM0. The Y address pointer has a range of 0 to 8 (08H).

The PCF8535 is limited to 133 columns by 65 rows,

addressing the RAM outside of this area is not allowed.

ADDRESSED COLUMN

MX = 0

ADDRESSED COLUMN

MX = 1

Banks 1 to 7 use

the entire byte

handbook, full pagewidth

MSB

LSB

Bank 8 is only

1 bit deep and

uses the MSB

MSB

LSB

01234

icon data

56789

101112131415161718192021222324

Fig.6 RAM format, input addressing.

1999 Aug 24 15

.. .. .. ..

X address

XM0 = 1XM0 = 0

0

1

2

3

4

5

Y address

6

7

8

119

123

120

121

122

124

125

126

127

01234

MGS673

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

Data byte in location

X = 0, Y = 0, MX0 = 0

(MX = 0, MY = 0)

MSB

LSB

bank 0

top of LCD

R0

bank 1

R8

bank 2

R16

LCD

bank 3

R24

MSB

Data byte in location

Y = 7, X = 0, MX0 = 0

(MX = 0, MY = 0)

LSB

bank 7

bank 8

Fig.7 DDRAM to display mapping.

1999 Aug 24 16

R56

R64

MGS674

Loading...

Loading...