Page 1

Philips Semiconductors Systems Laboratory Hamburg, Germany

d

APPLICATION HINTS Fault-tolerant CAN Transceiver

Application Hints

Fault-tolerant CAN Transceiver

PCA82C252 / TJA1053 / TJA1054 / TJA1054A

Application Hints FTCAN 3_1.PDF

Version 3.1

Date : 23

r

of November 2001

Philips

Semiconductors

Page 2

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

Revision History

Changes Version 1.0 -> 2.0 :

1. Chapter 3, calculation examples for PCA82C252 and TJA1053 added, new aspects

2. Chapter 4, calculation hints for termination resistors added, new aspects

Changes Version 2.0 -> 2.1 :

1. Chapter 6 added

2. Chapter 7 added

3. Chapter 8 added

Changes Version 2.1 -> 2.2 :

1. Chapter 5, clarification that external ESD diodes are optional for further improvements

2. Chapter 8 added, Software design hints ( previous chapter 8 re-numbered to chapter 9 )

3. Chapter 9, FAQ 9.6, No communication at CANH to VCC short circuit

Changes Version 2.2 -> 3.0 :

1. Foreword added

2. Chapter 2 added, Upgrading Note TJA1053 -> TJA1054

3. Chapter 3 added, Mode Control of the TJA1054

4. Chapter 5, formula 11 corrected, calculation example updated

5. Chapter 10, Software design hints dealing with the pin ERR added

Changes Version 3.0 -> 3.1 :

1. Editorial changes

2. Chapter 8, series resistor at pin WAKE, more details

3. Chapter 9 added, series resistor at pins TXD

Foreword

In this document, application related information for the various fault-tolerant transceiver implementations from Philips Semiconductors is collected. The different transceivers are a result of a continuous

improvement of the fault-tolerant and system performance.

The first available product in the mar ket was the PCA82C252, followed by the TJA1053 and lat er on

by the TJA1054. In the mean time even the TJA1054 has become improved with respect to ESD

capabilities. The so-called TJA1054A behaves identical to the TJA1054 but offers a higher ESD

robustness on the bus- related pins. T hus wherever the T JA1054 is m entioned within th is document it

could also be read as TJA1054A, except in case a certain transceiver type is mentioned explicitly.

Application Hints V3.1 Page 2 of 41

Page 3

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

Table of Contents :

1. Comparison PCA82C252 / TJA1053 / TJA1054 / TJA1054A.........................................................6

1.1. System parameters........................................................................................................................6

1.2. Device parameters.........................................................................................................................6

2. Upgrading a TJA1053 Design with the TJA1054...........................................................................7

2.1. Overview........................................................................................................................................7

2.2. Hardware Issues............................................................................................................................7

2.2.1. External Components..............................................................................................................7

2.2.2. Wake-up sensitivity at pin WAKE............................................................................................8

2.2.3. Current consumption...............................................................................................................8

2.2.4. Operating Voltage Range........................................................................................................8

2.3. Software Issues .............................................................................................................................9

2.3.1. Error signalling via pin ERR ....................................................................................................9

2.3.1.1. Software polls pin ERR.....................................................................................................9

2.3.1.2. Software reads pin ERR during CAN interrupt service only.............................................9

2.3.2. VCC Standby / PWON Standby..............................................................................................9

2.3.3. First Battery Connection, behaviour of pin INH.......................................................................9

2.3.4. Goto-Sleep / Wake-up Priority ................................................................................................9

2.3.5. Other issues ..........................................................................................................................10

2.4. Interoperability : Mixed Systems with TJA1053 and TJA1054 ....................................................10

2.4.1. Overview ...............................................................................................................................10

2.4.2. Hardware Interoperability Investigations...............................................................................10

2.4.3. Results of Hardware Interoperability Investigation................................................................11

1.5. Conclusion ...................................................................................................................................11

1.6. Migration Checklist.......................................................................................................................12

3. Mode Control with the TJA1054....................................................................................................13

3.1. Overview......................................................................................................................................13

3.2. Operating Modes .........................................................................................................................14

3.2.1. Normal Mode.........................................................................................................................14

3.2.2. Goto Sleep ............................................................................................................................15

3.2.3. Stby Sleep.............................................................................................................................15

3.2.4. PWON Stby...........................................................................................................................15

3.3. System Wake-up..........................................................................................................................15

3.3.1. Local wake-up .......................................................................................................................15

3.3.2. Remote wake-up ...................................................................................................................15

3.3.3. Mode change.........................................................................................................................15

3.4. State diagrams.............................................................................................................................16

3.4.1. PWON Flag ...........................................................................................................................16

3.4.2. Pin INH..................................................................................................................................16

3.4.3. Wake-up Flag........................................................................................................................16

3.4.4. Pin RXD.................................................................................................................................16

3.4.5. Pin ERR.................................................................................................................................17

4. Vcc Supply and Recommended Bypass Capacitance ...............................................................18

4.1. List of used Abbreviations............................................................................................................18

1.2. Summary......................................................................................................................................19

1.3. Average Supply Current at Absence of Bus Short-Circuit Conditions.........................................20

1.3.1. Maximum dominant supply current (without bus wiring faults) .............................................20

1.3.1.1. Example calculation................................................................................................... .....20

1.3.2. Thermal considerations (without bus wiring faults)...............................................................20

1.3.2.1. Example calculation................................................................................................... .....20

1.4. Average Supply Current at Presence of a Short-Circuit of one Bus Wire ..................................21

1.4.1. Maximum dominant supply current (with CANH shorted to GND)........................................21

1.4.1.1. Example calculation........................................................................................................21

Application Hints V3.1 Page 3 of 41

Page 4

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

1.4.2. Thermal considerations (with CANH shorted to GND)..........................................................21

1.4.2.1. Example calculation................................................................................................... .....21

1.4.3. Vcc extra supply current in single fault condition..................................................................22

1.1.1.1. Example calculation................................................................................................... .....22

1.5. Worst Case Max Vcc Supply at Presence of a Dual Short Circuit...............................................23

1.5.1. Max Vcc supply current in worst case dual fault condition....................................................23

1.5.1.1. Example calculation................................................................................................... .....23

1.5.2. Vcc extra supply current in dual fault condition.....................................................................24

1.1.1.1. Example calculation................................................................................................... .....24

1.6. Calculation of worst-case bypass capacitor.................................................................................24

1.1.1. Example calculation, separate supplied transceiver @ 83,33kBit/s .....................................25

1.1.2. Example calculation, shared supply......................................................................................25

5. Bus Termination and EMC issues ................................................................................................26

5.1. How to dimension the Bus Termination Resistor values, some basic rules................................26

5.1.1. Variable System Size, Optional Nodes .................................................................................26

5.1.1.1. Example calculation, Variable System Size ...................................................................27

5.2. Tolerances of Bus Termination Resistors, EMC Considerations.................................................27

5.3. Output Current and Power Dissipation of Bus Termination Resistors R

5.3.1. Summary...............................................................................................................................28

5.3.2. Average power dissipation, no bus fail ures ..........................................................................28

5.3.2.1. Example calculation, average power dissipation............................................................28

5.3.3. Maximum continuous power dissipation (single bus failure).................................................28

5.3.3.1. Example calculation, maximum continuous power dissipation ......................................28

5.3.4. Maximum peak power dissipation (single bus failure) ..........................................................29

5.3.4.1. Example calculation, maximum peak power dissipation................................................29

....................................28

T

6. ESD Protection...............................................................................................................................30

6.1. Improved ESD capability of TJA1054A........................................................................................30

6.2. Optional external ESD Improvement ...........................................................................................30

7. Series Resistor at Pin BAT............................................................................................................31

8. Series Resistor at Pin WAKE........................................................................................................32

1.1. Parameters defining the range of R

1.2. Calculating the limits of R

...........................................................................................................33

S

...........................................................................................32

S

1.3. Example calculation.....................................................................................................................33

9. Series Resistor at Pin TXD............................................................................................................34

9.1. Parameters defining the range of R

9.2. Calculating the Limits of R

......................................................................................................34

TXD

........................................................................................34

TXD

9.3. Example calculation.....................................................................................................................34

10. Hardware Design Checklist...........................................................................................................35

11. Software Design Hints...................................................................................................................36

11.1. System Sleep Procedure...........................................................................................................36

11.2. Using the ERR output for failure diagnosis................................................................................37

11.2.1. ERR signal at open bus wires.............................................................................................37

11.2.1.1. Behaviour using PCA82C252 / TJA1053 .....................................................................37

11.2.1.2. Behaviour using TJA1054 ............................................................................................38

11.2.2. ERR signal while CANH shorted to GND or CANL shorted to VCC...................................38

11.2.3. ERR signal while other short circuit conditions...................................................................38

11.3. Using ERR for Reading out the PWON Flag.............................................................................39

Application Hints V3.1 Page 4 of 41

Page 5

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

12. Frequently Asked Questions ........................................................................................................40

12.1. The transceiver does not enter the Sleep Mode........................................................................40

12.2. System operates in Single Wire Mode all time..........................................................................40

12.3. System does not wake-up, even if there is bus activity.............................................................40

12.4. Transceiver is damaged when ex terna l tools are con nected ....................................................41

12.5. CAN tool cannot communicate with certain application.............................................................41

12.6. No communication at CANH to VCC short circuit......................................................................41

Application Hints V3.1 Page 5 of 41

Page 6

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

1.

Comparison PCA82C252 / TJA1053 / TJA1054 / TJA1054A

1.1. System parameters

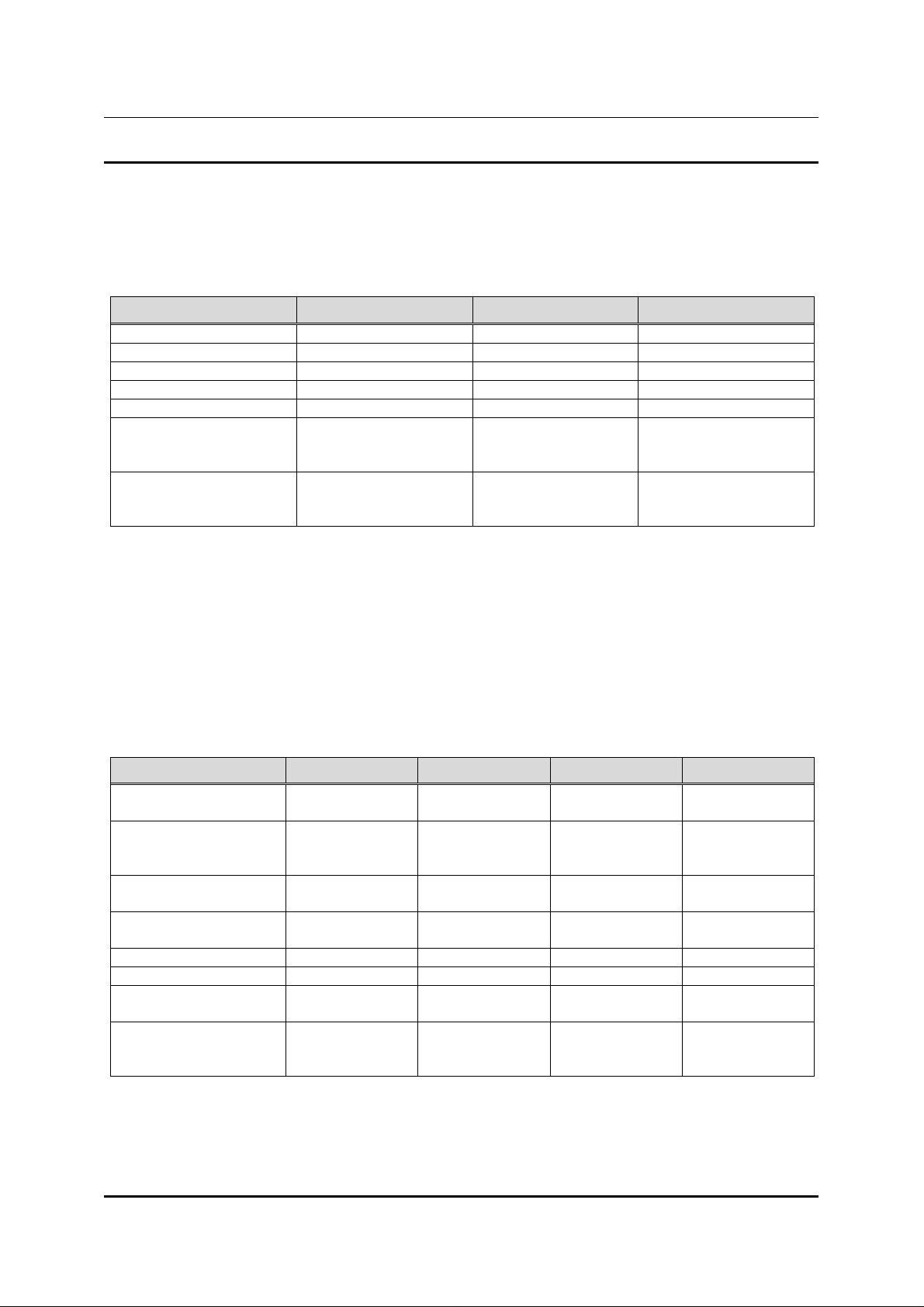

Key PCA82C252 TJA1053 TJA1054

System size 10 – 15 nodes

Speed 20 - <125 kbps

1) 2)

3)

10 – 15 nodes

20 – 125 kbps 40 – 125 kbps

Emission + + ++

Immunity + + ++

TxD dominant monitoring no yes yes

Extended bus failure

no no yes

management

(CANH to Vcc)

Resolved problem of

no yes yes

arbitration across open

failures

1) The limit is give n by the perform ance during C ANH to ground failures , which v ery much depends

on the size and type of cable used.

2) The limit is given by the wake-up capability during CANH to ground failures, which very much

depends on the values of the distri buted t erm inations acros s the n etwork . T heref ore, exact f igures

of system size cannot be given.

3) W ith CANH to VBAT failures the de lay of the dominant edge is increased. The max imum speed

strongly depends on the inductance of the cable used.

2)

> 32 nodes

1.2. Device parameters

Key PCA82C252 TJA1053 TJA1054 TJA1054A

Current consumption in

Normal Mode (I

CC

)

Current consumption in

Standby Modes (I

I

)

CC

BAT

+

Minimum operating

voltage

Prevention of VBAT

reverse current

1)

WAKE sensitivit y negative edge negative edge both edges both edges

Vcc Standby mode yes yes no no

ERR reporting of open

failures

ESD Protection pins

RTH / RTL / CANH /

CANL

1) In case a module looses its battery connection, a reverse power supply of this module via the CAN

bus lines is prevent ed. For the PC A82C252 and t he TJA1053 a n external diode at the battery pin

of the transceiver is required. This diode is required additionally to the control unit’s polarity

protection diode typically implemented at the battery connector of the entire module.

6 mA (rec)

29 mA (dom)

6 mA (rec)

29 mA (dom)

7 mA (rec)

17 mA (dom)

70 uA 70 uA 30 uA 30 uA

6V 6V 5V 5V

no no yes yes

during frame only during frame only during frame and

inter frame space

2kV Human Body

200V Machine M.

2kV Human Body

200V Machine M.

2kV Human Body

200V Machine M.

7 mA (rec)

17 mA (dom)

during frame and

inter frame space

4kV Human Body

300V Machine M.

Application Hints V3.1 Page 6 of 41

Page 7

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

2. Upgrading a TJA1053 Design with the TJA1054

2.1. Overview

The TJA1054 is a fau lt-toleran t CAN trans ceiver suitable for net works including up to 32 nodes and is

the compatible successor of the well-known TJA1053. Compared with the TJA1053, the TJA1054

provides several enhanced features:

•

Extremely reduced electro-magnetic emission (EME)

•

Very good electro-magnetic im munity (EMI)

•

Enhanced bus failure management (short circuits to 5V are tolerated)

•

Improved error signalling

•

Improved behaviour during “Loss of Power” situations

The TJA1054 is designed to be downward com patible to the T JA1053 and can be us ed in m ost of the

existing TJA1053 applicati ons without any changes in hardware and softwar e. Nevertheless, due to

the enhanced functionalit y there are some points to be cons idered if the TJA105 3 is replaced by the

TJA1054.

The following chapters disc uss all hardware and software issues i n detail in order to allo w a smooth

migration from the TJA1053 to the TJA1054.

Special attention is paid to inter operabilit y issues giving the conf idence that both devices can be used

simultaneously within one network. Validation showed that a “step-by-step” introduction of the

TJA1054 into an existing TJA1053 system can be made without risk.

2.2. Hardware Issues

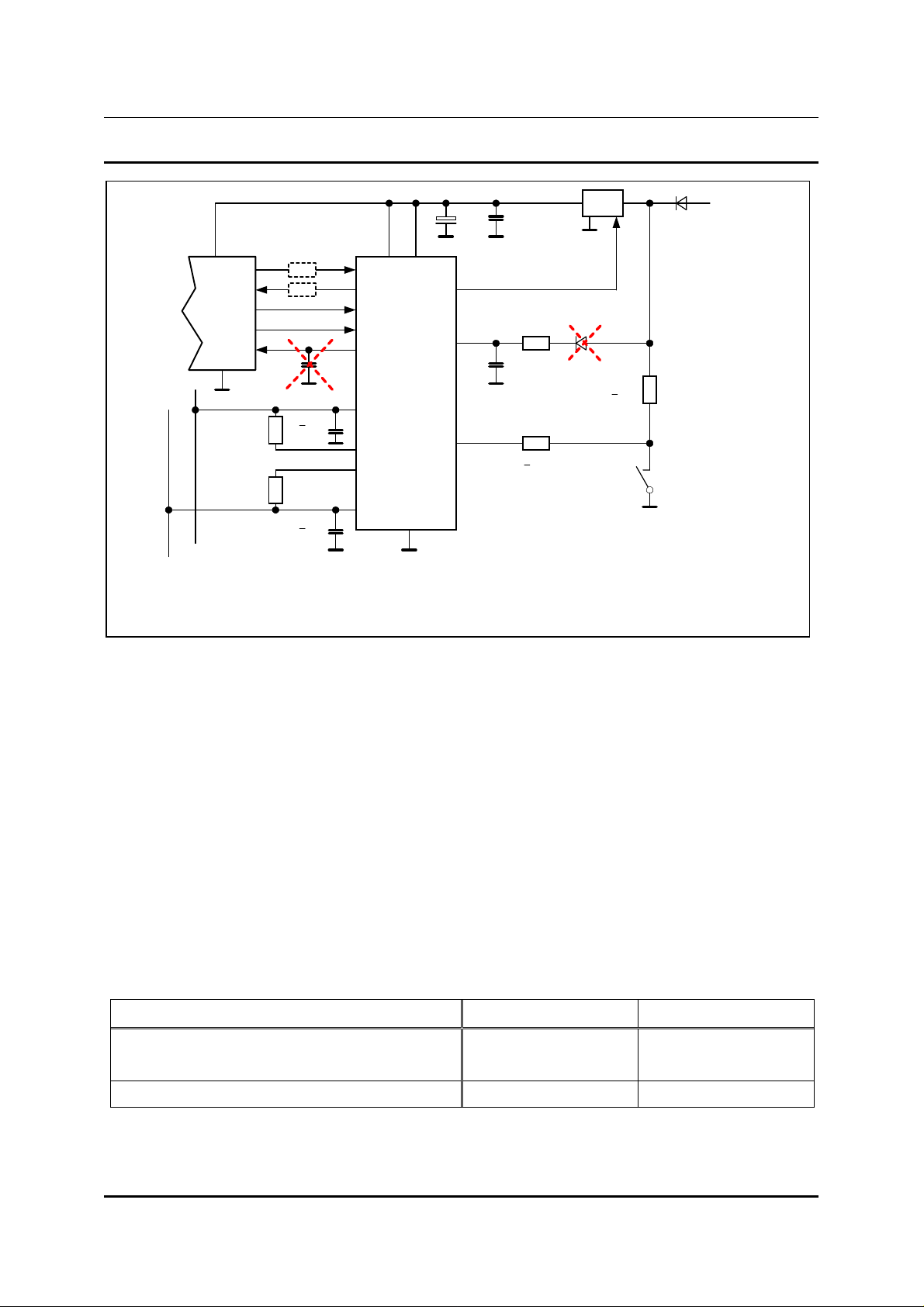

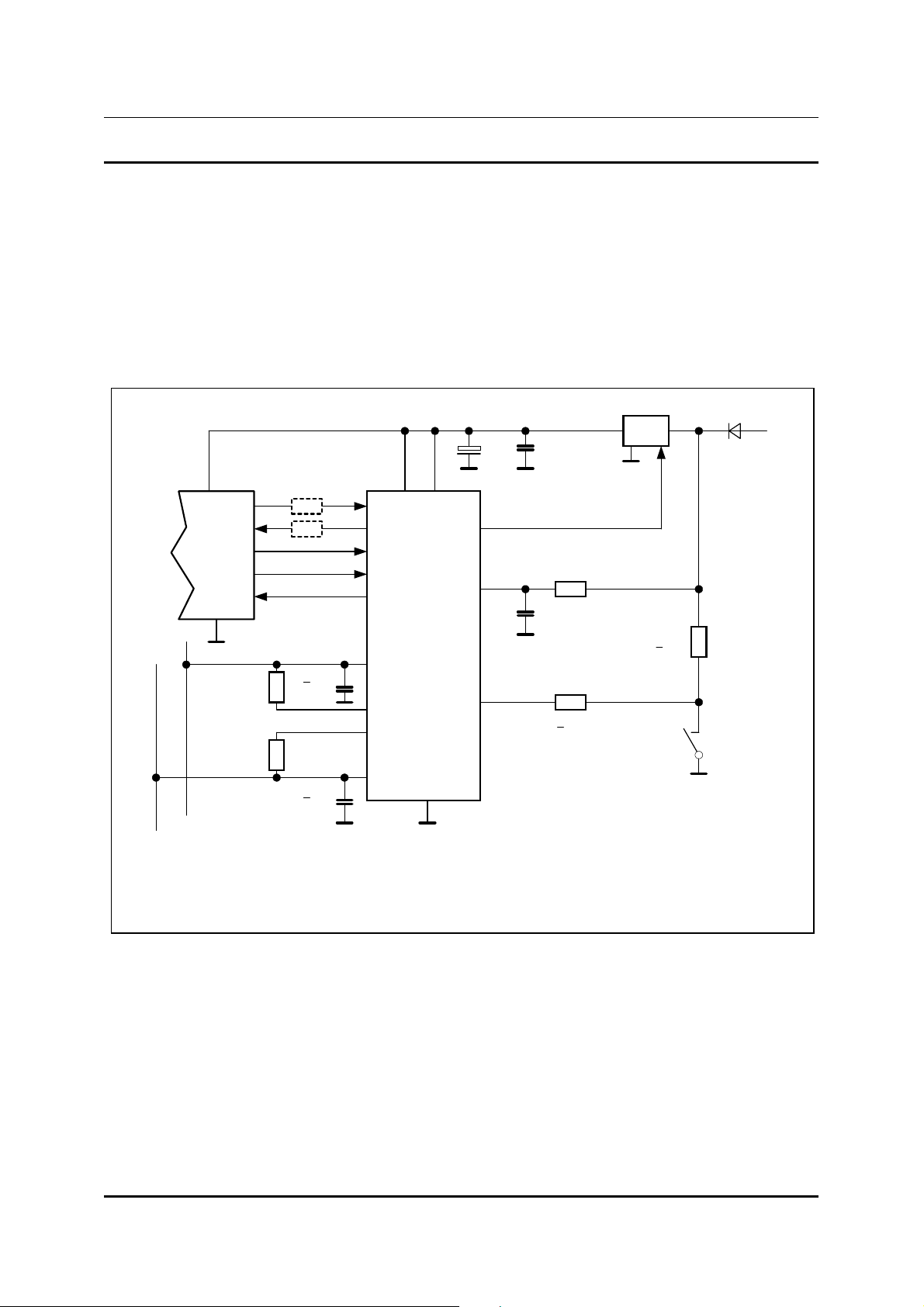

2.2.1. External Components

When the TJA1053 is replaced by a TJA1054, t wo external hardware c omponents ma y be removed

(see also figure 1) :

•

Reverse current protection diode at pin BAT

•

Pulse lengthening capacitor at pin ERR

The extra diode for th e TJA1053 is needed to suppress a rever se power suppl y of the contro l unit if

the battery connection of the e ntire unit was lost. For the TJA1053, a c urrent flow f rom the CANL bus

line backward to the pin BAT of the transceiver was pos sible if the transceiver was not powered. In

some applications, this re verse current was high enough to s upply the m icrocontroller un intentionall y.

The TJA1054 is internally protected against such reverse currents making the diode superfluous.

Reading the pin ERR during the normal CAN interrupt service routine was not possible for the

TJA1053 in case of “ open f ailures ” on t he bus l ines . Here, the so- called “ ack nowledge bi t” of an y valid

CAN message cleared an already detected “open failure” at the pin ERR. Therefore, an external

lengthening capacit or was required for the TJ A1053 in order to keep t he detected failure signa l valid

until the interrupt service routine was executed by the host uC.

The TJA1054 does not require this extr a len gth eni ng c a pacitor since the pin E RR no w i nternally keeps

the failure signal active. ( see also 11.2.1. )

Application Hints V3.1 Page 7 of 41

Page 8

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

100n

**

VCC

TXD TXD

RXD RXD

uC

I/O STB

+

CAN

GND

RTH***

RTL***

CAN

bus

* For further EMC optimization a series resistor could be applied in case the bus timing parameters allow this additional delay

caused by the additional R/C time constant.

** Size of capacitor depends on regulator.

*** Size of termination resistors depends on system size. The overall system termination should be about 100 Ohms per CAN line.

optional *

<150pF

<150pF

ERRI/O

470n

CANH

RTH

RTL

CANL

ENI/O

PCA82C252

V

or

TJA1053

or

TJA1054

GND

CC

INH

V

BAT

WAKE

1k - 2k

10n

> 1k8

5V

<180k

WAKE-UP

BAT

Figure 1 : Typical application circuitry using the TJA1053 and the TJA1054

2.2.2. Wake-up sensitivity at pin WAKE

The wake-up input of the TJ A1054 is s ensitiv e on bo th edg es, whereas the T JA1053 was s ensit ive on

the falling edge only. This has typically no impact on the application since such external wake-up

events are usually pulses including both edges.

Another improvem ent of the TJ A1054 is that wak e-up events have higher pr iority than the goto-sle ep

command. System s using the TJA1053 may lose such a wake-up event. Consequent ly, a TJA1053

node may keep sleeping without starti ng the voltage regu lator although a wake- up request has been

driven to the pin W AKE. The TJ A1054 will now reco gnise any wak e-up event independentl y from the

current command setting of the host CPU.

2.2.3. Current consumption

The total current cons um ption of the TJ A1054 is reduc ed c om pared to t he T JA1053 , es pec iall y durin g

low-power modes. The slightly increased short circuit current of the CANH bus driver within the

TJA1054 is compensated by its reduced normal mode supply current during dominant bus states.

Thus, there is no im pact to the applications power s upply concept. But introduction of the TJA1054

provides a much lower sleep current per control unit now compared with the TJA1053.

Condition TJA1053 TJA1054

Current consumption in Normal Mode, I

CC

Current consumption in Low-power Modes, I

BAT + ICC

6 mA recessive

29mA dominant

7 mA recessive

17mA dominant

70uA 30uA

2.2.4. Operating Voltage Range

In order to increase the system perf ormance during low battery conditions, the T JA1054 now allows

operation down to 5V at the pin BAT, whereas the TJA1053 required at least 6V.

Application Hints V3.1 Page 8 of 41

Page 9

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

2.3. Software Issues

2.3.1. Error signalling via pin ERR

As already mention ed before, the behavi our of the error signa lling at the pin ERR is im proved within

the TJA1054. This al lows removing the ext ernal lengthening capacitor needed for the T JA1053 (see

also 2.1). This new behaviour of the TJA1054 may have an impact on application software if the

TJA1053 was used

2.3.1.1. Software polls pin ERR

Application software polling the pin ERR will see fewer transitions if th e TJA1053 is replaced b y the

TJA1054. Especiall y during “open failures” on th e bus lines , the soft ware load cause d by ERR eve nts

is reduced if the TJA1054 is used.

2.3.1.2.Software reads pin ERR during CAN interrupt service only

Here, the “open failures” are now detected

TJA1053 has signal led no problem. Thus , a s im ple migration to the TJ A105 4 a utomatically im proves a

software driven diagnosis function.

2.3.2. VCC Standby / PWON Standby

The VCC Standby Mode k nown f rom the T JA1053 is replaced b y the so-c alled PWO N Standb y Mode

in the TJA1054 (STB = 1; EN = 0). There is no change in functionality between both transceivers

except for the CANL biasing level. The TJA1053 drives 5V to CANL through pin RTL and the

termination resistor, whi le the TJA1054 now drives 12V to CAN L using the same path. This has no

impact on the overall system performance if both transceivers are m ixed in one network. Software is

not influenced since both transc eivers provide the same status inf ormation to the microcontr oller via

ERR and RXD.

without

external lengthening capacitor. Two scenarios are possible:

and

signalled by the TJA1054 as desired, whereas the

2.3.3. First Battery Connection, behaviour of pin INH

The TJA1053 allows to be s et into Sleep Mode ( INH floating) direc tly after first batter y connection by

driving the goto-sleep com mand to the control pins ST B and EN (“01”) . The TJ A1054 needs t o be set

into Normal Mode bef ore accepting the first go to-sleep command af ter first connectio n of the batter y

supply. After setting Normal Mode both devices behave identical concerning this item.

An internal power-on reset signal within the TJA1054 makes sure that the transceiver is reset

successfully after power- up and the INH output is saf ely set to batter y level. This internal reset si gnal

is cleared whenever the Norm al Mode is entered once. There are no special timing requir ements to

clear the internal reset sig nal thus sof tware just has to se t the Norm al Mode via STB a nd EN fol lowed

by any other control cod e. Within mos t of the existing app lications this is already implem ented inside

of the systems cold-start routines.

2.3.4. Goto-Sleep / Wake-up Priority

The pin INH of the TJ A1053 does ignore wak e-up events in case these wake-up events are present

while the goto-sleep command is continuously driven to t he tr a ns c ei ver vi a pi ns STB and EN ( ST B = 0

/ EN = 1). After the goto-sleep filter tim e ( see dat a shee ts T JA1054/T JA10 54A : “ react ion tim e of goto

sleep command” ) the INH flip-flop is continuously cleared thus setting the pin INH to a floating

condition. Wak e-up events are forwar ded to INH first with releasing the goto- sleep comm and. Thus a

systems voltage regu lator connected to INH will becom e disabled e ven if there is a pend ing wake-up

request. Nevertheless RXD and ERR will signal the wake-up event with a LOW output level

independently from the pending goto-sleep command.

For the TJA1054 this behaviour is improved and no wake-up event is lost with respec t to the pin INH.

Within the TJA1054 the wake-up events ha ve a higher priority than the goto-sl eep command. Thus

any wake-up event will reset IN H to a HIG H out put le vel i ndepen dentl y from the goto-s leep c omm and.

RXD and ERR will reflect the wake-up condition with a LOW output level as known from the TJA1053.

From software point of view it is highl y recommended for both transc eivers monitoring the pi ns RXD

and/or ERR whenever the goto-sleep command was executed in order to detect a wake-up event

Application Hints V3.1 Page 9 of 41

Page 10

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

while the system s hould f all in to s l eep mode. INH might keep HIG H or become HIG H ag ai n c aus e d by

a wake-up event before the supply of the uC was successfully disabled. ( see also 11.1. )

2.3.5. Other issues

Experiences with dif ferent software drivers have sho wn the advantage to implement a kind of CAN

communication m onitoring in software, expecting CAN b us events in certain time fr ames. At least a

reception of mes sages or succ essful transm issions should appear in or der to get conf idence, th at the

CAN bus is still operating properly. This is especially important for recovery from dual bus failure

situations towards single bus failure situations.

Due to the automatic transmit message repetition mechanism of a CAN protocol engine it might

happen that a node r etransm its a message forever in case t here is no ack nowledge rec eived fr om the

bus. This continuously transm itting node might lock the bus system and thus prevents other nodes to

recover from a dual bus failure situation towards a single bus failure situation.

Therefore, whenever there is no response from the CAN bus within a reasonable time, pending

transmission requests should be abor ted in software. This will inc rease the system avai lability during

certain bus failure conditions, which require single wire operation.

2.4. Interoperability : Mixed Systems with TJA1053 and TJA1054

2.4.1. Overview

During developm ent of the TJA1054 special attention was paid to interop erability issues in order to

allow a smooth m igration of existi ng applicatio ns by simple replacement of the T JA1053. Part icularly,

the enhancements of the bus f ai lure management (5V s hor t cir cuits) have been included very car ef ul l y

into the existing circuitry to avoid system hang-ups, if both transceivers are mixed in one system.

The TJA1054 is designed to replace the TJA1053 within running car series production without

interoperability risk.

Interoperability of both devices has been proved in system simulation as well as in hardware

investigation.

The key results of these investigations are :

•

A pure TJA1054 network solves the known weaknesses of a TJA1053 system

( wake-up of big networks with failure HxGND, short circuits to 5V .... )

•

A mixed system of TJA1053 and TJA1054 has at least the same performance as the pure

TJA1053 system; in some aspects the growing presence of T J A1054 no des i n th e n et work even

improves the overall system performance

•

T aking into consi deration the is sues desc ribed in the previous cha pters, m ixed systems of both

transceiver are possible at any ratio without restrictions

2.4.2. Hardware Interoperability Investigations

In order to investigate in teroperability issues of th e transceiver, a network with 25 nodes was set up

and investigated in detail. A typical topology including star points was chosen according to real

automotive applicat ions. This topology inc ludes cable stubs with m ore than 5 meters and more than

55 meters overall cable length.

Worst case scenarios were analysed including weak bus failure conditions, double failures, ground

shifts and power sup ply drops. Esp ecially, oper ating mode c hanges (Norm al Mode / Sta ndby / Sleep)

were performed simultaneously with bus failure situations.

Application Hints V3.1 Page 10 of 41

Page 11

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

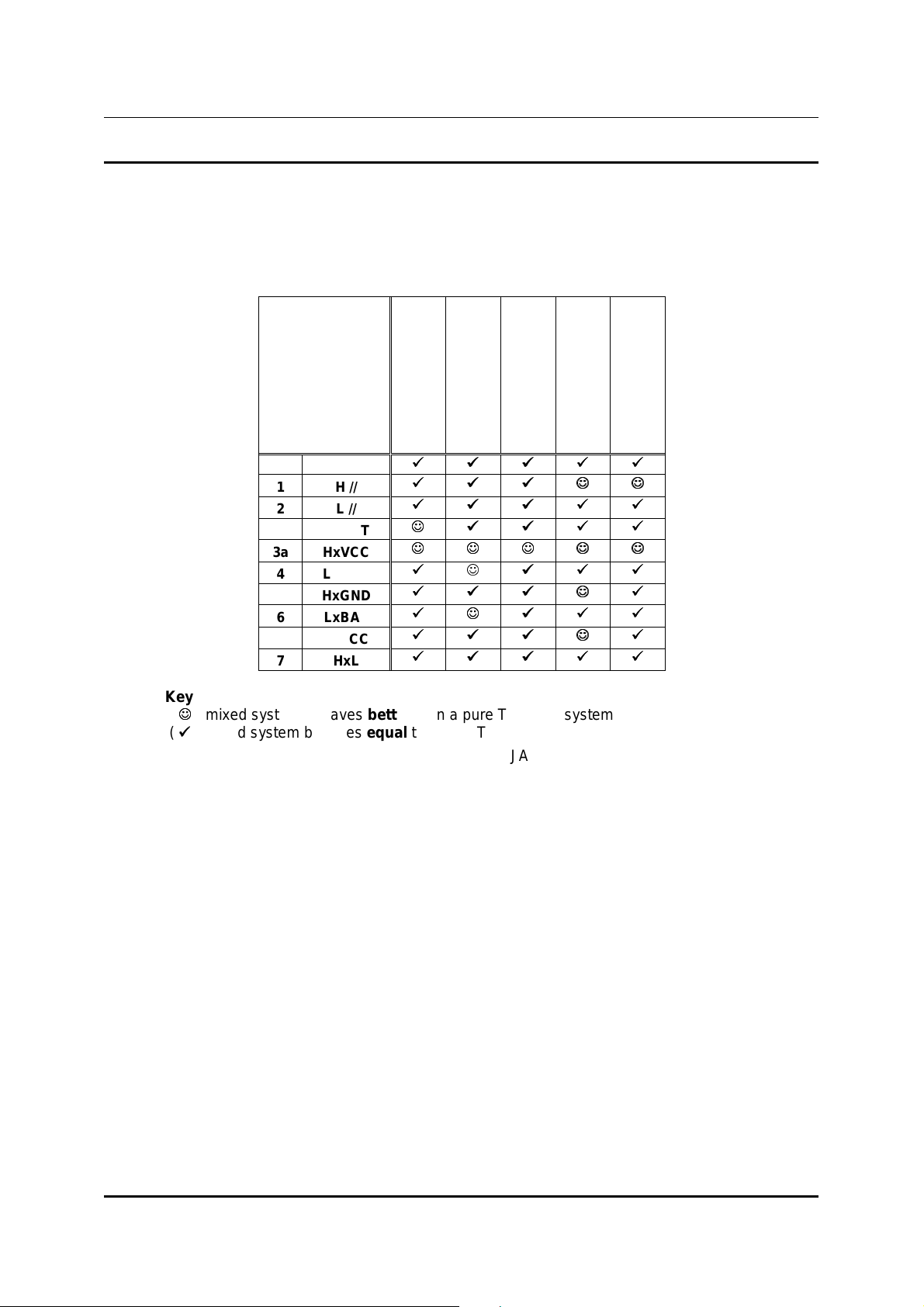

2.4.3. Results of Hardware Interoperability Investigation

The following table gives an overview about the mixed system investigations using the TJA1053

together with the TJA10 54 in different mixing ratios. An assessment is made compar ed with a pure

TJA1053 system with same topology.

Bus Failure

0 none

1 H //

2 L //

3HxBAT

3a HxVCC

4LxGND

5HxGND

6LxBAT

6a LxVCC

7HxL

9

9

9

9

9

9

-

-

-

-

9

9

9

9

9

9

9

9

9

9

Communication with

( incl. resistive failures )

Standard Communication

9

9

9

9

9

9

9

9

-

-

-

9

9

-

-

9

9

9

9

Communication at

9

9

9

9

9

9

9

9

-

-

9

9

9

9

9

9

9

9

9

9

Low Battery Voltages

Ground Shift (+/- 1.5V)

combined with Bus

Mode Changes / Wake-up

9

9

-

-

9

9

9

9

-

-

9

9

-

-

9

9

-

-

9

9

Failure Conditions

9

9

-

-

9

9

9

9

-

-

9

9

9

9

9

9

9

9

9

9

Loss of Termination

Communication with local

Key :

(

-- ) mixed system behaves

(

99 ) mixed system behaves

'

) mixed system behaves

(

than a pure TJA1053 system

better

to a pure TJA1053 system

equal

worse

than a pure TJA1053 system

2.5. Conclusion

Both transceivers, T JA1053 and TJA1054, are in teroperable and can be us ed simultaneously within

the same network. This allows migrating gradually from TJA1053 to TJA1054 in running car mass

production.

Due to new features intr oduc ed wit h the T JA1054, exis ting T JA10 53 a pplicat ions nee d to be r eview ed

according to the comments within this report before replacing the transceiver.

Application Hints V3.1 Page 11 of 41

Page 12

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

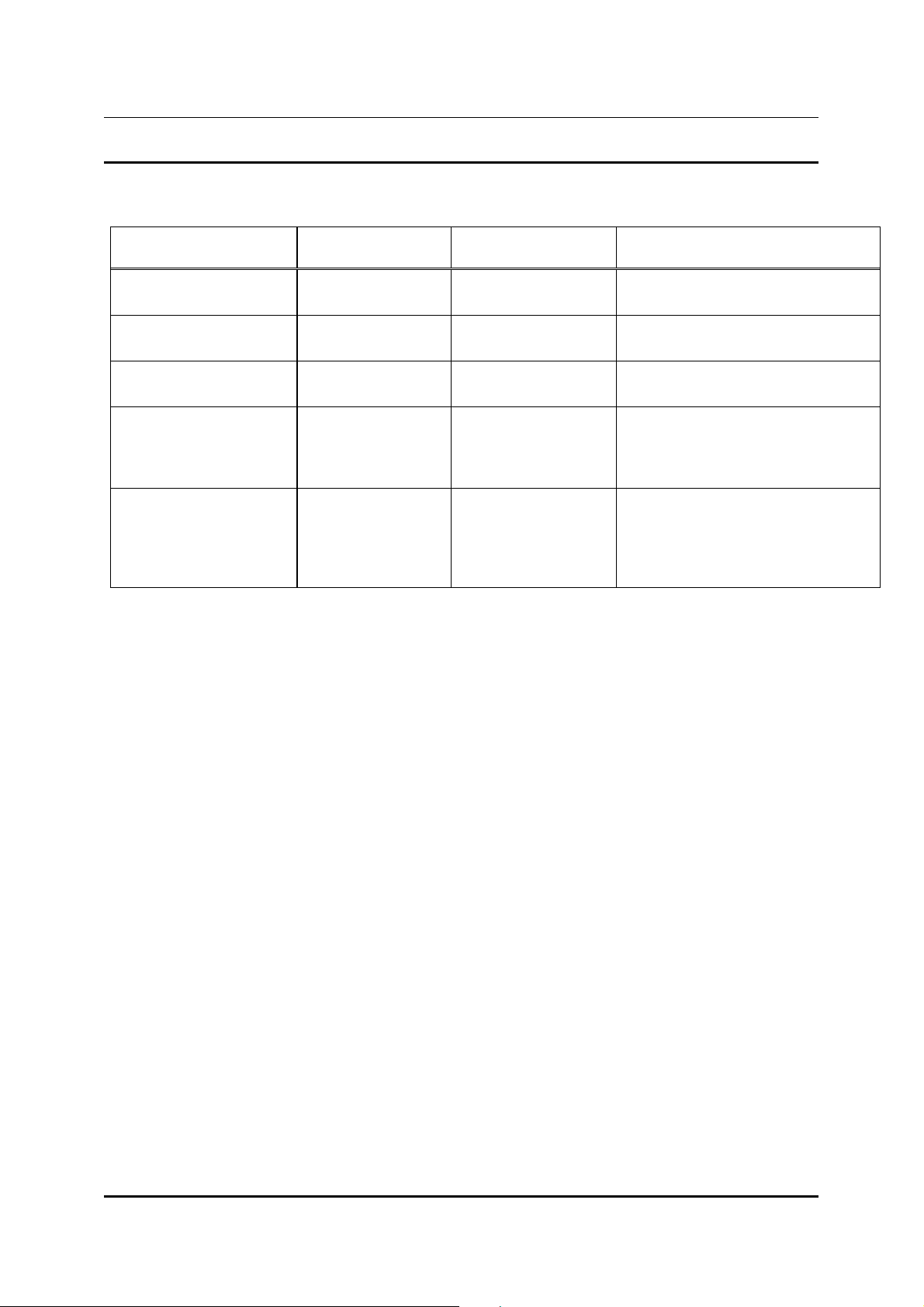

2.6. Migration Checklist

Item TJA1053 TJA1054 Comment

Diode @ pin BAT needed can be removed no reverse power supplying by

TJA1054

Capacitor @ pin ERR depends on

software

Sensitivity of pin WAKE falling edge only both edges check behaviour of system wake-up

Goto-sleep command

after first battery

connection

Goto-sleep command,

priority of wake-up event

always possible possible only after

INH becomes

floating the time

goto-sleep is driven

even if there is a

wake-up coming

can be removed function is integrated into the

TJA1054

via pin WAKE

Internal power-on signal has to be

Normal Mode was

entered once

INH keeps HIGH if

there is a wake-up

coming during gotosleep is driven

cleared by setting the TJA1054 into

Normal Mode after first battery

connection

It is recommended to monitor pin

RXD and/or pin ERR after goto-

sleep in order to detect a wake-up

event during the transition into

Sleep Mode.

Application Hints V3.1 Page 12 of 41

Page 13

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

3. Mode Control with the TJA1054

3.1. Overview

The fault tolerant CA N trans c eiv er T J A1054 provides an integrated functi ona lity controlling an external

voltage regulator in order to design low power CAN bus systems with remote and local wake-up

capabilities. A dedicated INH pin allows disabling the entire power supply of a control unit, thus

reducing the overall system power consumption to a m inimum. The transceiver is the only supplied

component during such a low-power state.

Following figure shows an application example using the TJA1054.

**

VCC

TXD TXD

RXD RXD

uC

I/O STB

+

CAN

GND

RTH***

RTL***

CAN

bus

* For further EMC optimization a series resistor could be applied in case the bus timing parameters allow this additional delay

caused by the additional R/C time constant.

** Size of capacitor depends on regulator.

*** Size of termination resistors depends on system size. The overall system termination should be about 100 Ohms per CAN line.

optional *

ENI/O

ERRI/O

CANH

<150pF

RTH

RTL

CANL

<150pF

V

TJA1054

GND

CC

INH

V

BAT

WAKE

100n

1k - 2k

10n

> 1k8

5V

<180k

WAKE-UP

BAT

Figure 2 : Typical application of the TJA1054

As shown within Figure 2 the transceiver is powered d irectly from the battery s upply via the pin BAT.

This allows disabling the VCC supply entirely during tim e phases, the CAN bus is not required b y the

system. Therefore two control pins STB and EN coming from the host microcontroller are used to

control the actual mode of operation like normal communication or low-power operation.

For wake-up purposes a battery-related WAKE pin is provided.

In addition to bus fail ure information and the CAN receive d bit stream, the pins ERR and RXD are

used to signal wake-up requests towards the application controller.

Application Hints V3.1 Page 13 of 41

Page 14

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

3.2. Operating Modes

The two fail-safe coded pins STB and EN mainly control the power management of the TJA1054.

They are defining directly the actual mode of operation as illustrated within Figure 3.

The following operating modes are implemented:

•

Normal Mode normal transceiver operation

•

Goto Sleep disables the external voltage regulator via INH after a certain time out

•

Stby Sleep similar to Goto Sleep, but INH is not affected

•

PWON Stby similar to Stby Sleep, but allows to read back the PWON flag

indicating a power-on condition

All modes different from Normal Mode are low-power modes reducing the current consumption

significantly.

o

P

CC (stb)

n

r O

e

w

(NSTB = 0

OR

AND

EN = 0)

Power Fail

NSTB = 0

AND

EN = 1

Goto

Sleep

(NSTB = 0

Power Fail

OR

AND

(NSTB = 1

(NSTB = 0

AND

EN = 0)

AND

EN = 1)

(NSTB = 1

(NSTB = 0

EN = 1)

Power ok

Normal

AND

EN = 0)

AND

EN = 1)

AND

(NSTB = 0

OR

Stby

Sleep

(NSTB = 1

AND

EN = 1)

EN = 0)

Power Fail

(NSTB = 1

Power On

AND

NSTB = 1

EN = 0

AND

AND

Pwon

Stby

AND

EN = 0)

Power ok

(NSTB = 1

AND

EN = 1)

AND

Power ok

Fail

VCC > V

CC (stb)

OK

Power Fail

VCC < V

Figure 3 : Operating Modes of the TJA1054

Note, that a change from the power-on condition (STB and EN = “0”) is possible only, if the VCC

supply is present. Whenever VCC fa lls b el o w a c ertai n leve l ( s e e da ta s he et TJA1054: “supp ly voltage

for forced Standby Mode” ) the fail-saf e Stand b y Mode is ent ered automatically (power-fai l).

Depending on the selected mode of operation, the I/O pins provide different information for the

application as described within the next chapters.

3.2.1. Normal Mode

During normal mode the transceiver is used to transmit data to the bus and to receive dat a from the

CAN bus. Here the pin RXD reflects the bus signal and the pin ERR is used to signal bus failure

conditions with an active LOW behaviour.

Application Hints V3.1 Page 14 of 41

Page 15

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

3.2.2. Goto Sleep

Entering Goto Sleep the transce iver immediatel y changes int o low-power o peration, while the pin I NH

is still kept active HIGH. N ow a n intern al wak e- up flip-f lop is output via t he pins RXD and ERR , if VC C

is present. Thus both pin’s signa ls can b e use d to wak e- up the ap plicati on with an ac ti ve low sign al. If

the Goto Sleep state k eeps present for a certain time ( see data sheet TJA1054: “reaction tim e of

goto-sleep command” ) the INH output of the TJA1054 becomes “floating” disabling the externally

connected voltage regulat or. The application can keep within the Got o Sleep state or switch over t o

Stby Sleep mode without any difference in behaviour of the transceiver.

Typically the applicatio n automatically changes towar ds Stby Sleep because the power supply of the

host microcontroller becom es disabled during Got o Sleep and thus the c ontrol pins STB and E N are

falling towards a LOW signal with the decreasing supply of the microcontroller.

3.2.3. Stby Sleep

If the system needs to k eep the external voltage reg ulator active for some r eason during low-power

operation, this m ode c an be en ter ed direc t l y from normal mode. Then the pin INH keeps HIGH all time

and the external voltage regulator stays alive. During this mode RXD and ERR are signalling a

possible wake-up condition as described for the Goto Sleep state.

The internal “sub-modes” Standby and Sleep are distinguished only by the state of the pin INH. In

case of a previous successful Goto Sleep procedure INH is floating during Stby Sleep.

3.2.4. PWON Stby

This mode behaves similar to Stb y Sleep with the diff erence that th e pin ERR allows re ading bac k the

internal PWO N flag. This flag is set whe never the transce iver is powered with battery suppl y the first

time. So the applicat ion can disti nguish between a cold start situat ion caused b y a system sleep or a

cold start due to first battery connection of the device.

3.3. System Wake-up

Once the transceiver is not within Normal Mode there are th e following possibilities to wak e-up the

system:

•

Local wake-up using the local pin WAKE

•

Remote wake-up caused by CAN bus traffic

•

Mode change entering Normal Mode via STB and EN

3.3.1. Local wake-up

A local wake-up can be forced with an edge at t he pin WAKE of the transc eiver. A positive edge as

well as a negative edge r esults in a system wake-up if the signal keeps constant f or a certain time

(see data sheet TJA1054: “required time on pin WAKE for local wake-up”). Thus short spikes are

filtered and do not result in unwanted system wake-up conditions.

As a result of the edge at pin WAKE, the intern al wak e-up flip- flop is s et and outp ut at ER R and RXD .

Additionally the pin INH becomes HIGH again, starting the external voltage regulator.

Note that the pin WAKE provides an inter nal weak pull-up curr ent towar ds batter y in order to pro vide a

defined condition in case of open circuit.

3.3.2. Remote wake-up

Another possibility waking u p the system is traffic on the CAN bus lines. Whenev er the bus becom es

dominant for a certain time within a CAN message (see data sheet TJA1054: “dominant time for

remote wake-up on pin C ANH or CANL” ) the int erna l wak e-up fli p-flop is set and the pin INH activ ates

the external voltage regulator.

3.3.3. Mode change

The connected host m icrocontroller can directly switch the transceiver into Normal Mode by setting

STB and EN High in case the VCC supply is present at the transceiver.

Application Hints V3.1 Page 15 of 41

Page 16

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

3.4. State diagrams

Within this chapter some state diagram s are collec ted showin g the behav iour of the T JA1054 in m ore

detail.

3.4.1. PWON Flag

The PWON flag is set whenever the transceiv er is supplied the f irst time or the batter y voltage drops

below a certain lim it (s ee data sheet T JA1054: “pow er-on f lag vo ltage on pin BAT ”). It is c leared when

entering the Normal Mode.

3.4.2. Pin INH

The pin INH is controlle d b y the Goto S leep s tate a nd the wak e-up events . Ther e is a prior ity of wakeup in order to make sure that any wake-up event keeps the external voltage regulator active

independently of a goto-sleep command.

Note that a successful Goto Sleep is possible only if the Normal Mode was entered once after a

power-on condition. The PWON flag has to be cleared making sure that the system was started

successfully before entering the Sleep Mode the first time.

3.4.3. Wake-up Flag

An internal wak e-up flag is set upon a local or rem ote wake-up event. This flag is cleared whenever

the Normal Mode is en tered via STB and EN. The content of this flag is signalled v ia RXD and ERR

according to the corresponding state diagrams.

n

r O

e

w

o

P

n

r O

e

w

o

P

VBAT

Clear

n

er O

w

o

P

Set

Normal Mode

V

Clear

PWON Flag

(Goto Sleep) > t

No Wake-up Event

< V

BAT

BAT (pof)

NOT

AND

AND

PWON

r (SLEEP)

[ (BUS = dominant) > t

NOT

Change @ NWAKE > t

(STB = 1

AND

Float

Pin INH

Figure 4 : State Diagrams, PWON Flag, pin INH and Wake-up Flag

AND

Normal ]

OR

OR

V

CC

CAN

WAKE

> V

)

CC (stb)

[

Normal

NOT

AND

(BUS = dominant) > t

OR

Change @ NWAKE > t

CAN

WAKE

]

Normal

Set

Wake-up Flag

3.4.4. Pin RXD

During Normal Mode t he p in RXD r ef lects the ac tua l b us signal. Immediately with c h ang ing in to o ne of

the low power modes, the content of the internal Wake-up Flag is reflected at pin RXD if the VCC

supply of the transceiver is present. A wake-up condition is signalled active LOW.

Application Hints V3.1 Page 16 of 41

Page 17

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

3.4.5. Pin ERR

The pin ERR is used to signal bus failure conditions during normal operation with an active LOW

behaviour. As soon as the transceiver is switched into Goto Sleep or Stb y Sleep Mode the inter nal

Wake-up Flag is ref lect ed vi a E RR s imilar to the pi n RX D. A change towards PW ON Stby immediatel y

switches ERR to the in ternal PW ON Flag. A power -on conditio n is signa lled acti ve LOW . Please take

care that the external loading to the pin ERR may cause a delay changing the level from LOW to

HIGH. Typically a uC-por t pin caus es a lo ad of s ome 10pF to th e pin ERR. Due to th e re lativel y weak

pull-up behaviour of the pin ERR, charg in g this wire may need relev ant t ime for fast operat ing s of t ware

( see also 11.3. ).

Bus

Goto Sleep

OR

Stby / Sleep

OR

PWON Stby

Bus

Signal

Wake-up

Flag

Normal

Goto Sleep

OR

Stby / Sleep

Wake-up

Flag

P

ow

er O

n

Power On

Failure

Normal

Goto Sleep

OR

Stby / Sleep

PWON Stby

Normal

PWON Stby

PWON

Flag

Pin RXD

Pin ERR

Figure 5 : State Diagrams, pins RXD and ERR

Application Hints V3.1 Page 17 of 41

Page 18

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4. Vcc Supply and Recommended Bypass Capacitance

4.1. List of used Abbreviations

Table 4-1 : Used abbreviations

Symbol Description

I

cc_dom

I

cc0_dom

I

CANH_dom

I

RTL_dom

I

cc_rec

I

cc_norm_avg

I

cc_sc1_dom

I

CANH_sc1_dom

I

cc_sc1_avg

∆

I

cc_sc1

I

cc_sc2_dom

I

RTL_sc_dom

∆

I

cc_sc2

V

CC

V

CANL_dom

R

T

t

dom_max

∆

V

max

C

BUFF

Supply current at pin VCC while driving a dominant bit

Supply current at pin VCC while driving a dominant bit

Output current of pin C ANH whi le dri ving a dom inant bit with n om inal bus load of 100

Ohms in total

Output current of pin RTL while driving a dominant bit with a certain load

Supply current at pin VCC while driving a recessive bit

Average supply current at pin VCC assuming no bus failure and continuous sending

Supply current at pin VCC driving a dominant bit while CANH is shorted to GND

Output current of pin CANH driving a dominant bit while CANH is shorted to GND

Average supply current at pin VCC assum ing CANH shorted to GND and cont inuous

sending

Supply current change at pin VCC in case a dominant bit is driven while CANH is

shorted to GND

Supply current at pin VCC drivi ng a dom inant bit whi le CANH

to GND

Output current of pin RTL while driving a dominant bit with CANL shorted to GND

Supply current change at pin VCC in case a dom inant bit is driven whil e CANH and

CANL are shorted to GND

Supply voltage at pin VCC

Voltage level on CANL while a dominant bit is driven

Termination resistor connected to pins RTL and RTH

Maximum possible continuous dominant drive time

Maximum allowed voltage change at pin VCC

Required buffer capacitance in case the voltage regulator does not deliver extra

current within t

dom_max

with

a certain load to the pins

without

any load to the pins

and

CANL are shorted

Application Hints V3.1 Page 18 of 41

Page 19

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.2. Summary

In order to properly dimension the Vcc s upply of the fault-tolerant CAN tr ansceivers two parameters

have to be taken into account:

1) the average supply current

2) the peak supply current

The average supply current is needed to calculate the thermal load of the required Vcc voltage

regulator. The peak supply curr ent ma y flow in case of certain bus failur e conditi ons f or a c ertain t ime

and thus has an impact on the power supply buffering.

The Vcc supply of the transceiver is recommended to support the characteristics as follows:

Table 4-2 : Overview of supply currents

Item PCA82C252 TJA1053 TJA1054

Average Vcc supply current without bus failures 44.5 mA 44.5 mA 41 mA

Average Vcc supply current at presence of

single bus failures

Worst case peak Vcc supply current at presence

of single bus failure (for 6 bit times max.)

Worst case peak Vcc supply current at presence

of dual bus failures (for 17 bit times max.)

74.5 mA 74.5 mA 76 mA

139 mA 139 mA 141 mA

140 mA 140 mA 142 mA

The capacitive buff ering needed for the transcei ver depends on the system s power concept and the

regulator characteristic of the used voltage regulator chip.

In case the transceiv er has a

supply current dur ing single bus fail ures is relevant because here th e communic ation medium has to

keep unaffected. T he worst case dual failure situation is not relevant since here the c ommunication

medium is complete ly out of operation and the transceiver does not need to be supplied anymore.

Such systems ar e recommended to pr ovide a bypass capacitanc e of

wiring faults.

regulation time constant is fast enough.

In case the transceiver’s Vcc power supply is

current during the worst case dual failur e situation has to be tak en into account. This is b ecause the

uC has to keep a proper supply even if there is no CAN comm unication pos sible at all. Such s ystems

are recommended to provide a bypass capacitance of

behaviour this capacitan ce may become much smaller if the regulation time constant is fast

enough.

This capacitance can be implemented as a separate component or alternatively through a

corresponding increas e of the capacitance of the b ypass capacitor being locat ed at the Vcc vo ltage

regulator.

In the following, relevant cases are considered in more detail.

Depending on the regulator behaviour this capacitance may become smaller if the

separated

Vcc power suppl y apart from the microcontroller, the peak

shared

47 uF

with its host microcontroller, the peak supply

150uF. Depending on the regulator

in order to support s ingle

Application Hints V3.1 Page 19 of 41

Page 20

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.3. Average Supply Current at Absence of Bus Short-Circuit Conditions

In recessive state the different transceivers are consuming a Vcc supply current as listed in the

corresponding data s heets. In dominant state t he Vcc supply current is calculated by the addition of

the IC-internal supply current ( see data she et TJA105 4: “no lo ad” condit ion) an d the output current a t

pins CANH and RTL.

4.3.1. Maximum dominant supply current (without bus wiring faults)

I

cc_dom

I

RTL_dom

= I

cc0_dom

= (Vcc - V

+ I

CANH_dom

CANL_dom

+ I

) / R

RTL_dom

T

(1)

(2)

4.3.1.1.Example calculation

Maximum dominant supply current without bus wiring faults:

Item from Data Sheet / Assumptions Symbol PCA82C252 TJA1053 TJA1054

Max. Vcc supply current dominant, no load

CANH dominant current

Assumed termination resistor

Assumed CANL dominant voltage

PCA82C252

TJA1053

TJA1054

: I

: I

: I

cc_dom 252

cc_dom 1053

cc_dom 1054

= 35mA + 40 mA + (5V - 1V) / 1k = 79 mA max. (Ex 1.1)

= 35mA + 40 mA + (5V - 1V) / 1k = 79 mA max. (Ex 1.2)

= 27mA + 40 mA + (5V - 1V) / 1k = 71 mA max. (Ex 1.3)

I

cc0_dom

I

CANH_dom

R

T

V

CANL_dom

35 mA 35 mA 27 mA

40 mA 40 mA 40 mA

1 k 1 k 1 k

1 V 1 V 1 V

4.3.2. Thermal considerations (without bus wiring faults)

For thermal consider ations the average sup ply current at pi n Vcc is relevan t considering the tra nsmit

duty cycle. In the f ollowing exam ple a continuousl y transmitting n ode is as sumed. T his might h appen

e.g. if a node starts a transmission while the rest of the network does not respond with an

acknowledge for s ome reason. Typically a m uch lower duty cycle is relevant since a node transm its

messages within certain time slots only, depending on the applications network management.

With an assumed transmit duty cycle of 50% on pin TxD, the maximum average supply current is

I

cc_norm_avg

= 0.5 * (I

cc_rec

+ I

cc_dom

) (3)

4.3.2.1.Example calculation

Thermal considerations without bus wiring faults:

Item Symbol PCA82C252 TJA1053 TJA1054

Vcc supply current recessive, max.

PCA82C252

TJA1053

TJA1054

:I

cc_norm_avg 252

:I

:I

cc_norm_avg 1053

cc_norm_avg 1054

= 0.5 * (10mA + 79mA) =

= 0.5 * (10mA + 79mA) =

= 0.5 * (11mA + 71mA) =

I

cc_rec

10 mA 10 mA 11 mA

44.5 mA max.

44.5 mA max.

41 mA max

. (Ex 3.3)

(Ex 3.1)

(Ex 3.2)

Application Hints V3.1 Page 20 of 41

Page 21

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.4. Average Supply Current at Presence of a Short-Circuit of one Bus Wire

The maximum Vcc supply current occurs with a bus wire s hor t-c irc uit bet wee n CANH and GND. In this

case the CANH outputs a maximum short circuit current in dominant state (see data sheets). For

thermal considerations the average supply current is relevant. For buffering considerations the

maximum dominant supply current is relevant.

4.4.1. Maximum dominant supply current (with CANH shorte d to GND)

I

cc_sc1_dom

= I

cc0_dom

+ I

CANH_ sc1_dom

+ I

RTL_dom

( t < 6 bit times ) (4)

The 6-bit time limitation is caused by a supposed Error Flag to be sent by the CAN Controller.

4.4.1.1.Example calculation

Maximum dominant supply current with CANH shorted to GND:

Item Symbol PCA82C252 TJA1053 TJA1054

CANH dominant current, short circuit I

PCA82C252

TJA1053

TJA1054

: I

: I

: I

cc_sc1_dom 252

cc_sc1_dom 1053

cc_sc1_dom 1054

= 35mA + 100 mA + (5V - 1V) / 1k =

= 35mA + 100 mA + (5V - 1V) / 1k =

= 27mA + 110 mA + (5V - 1V) / 1k =

CANH_sc1_dom

100 mA 100 mA 110 mA

139 mA max.

139 mA max.

141 mA max.

(Ex 4.1)

(Ex 4.2)

(Ex 4.3)

4.4.2. Thermal considerations (with CANH shorted to GND)

For thermal consider ations the average sup ply current at pi n Vcc is relevan t considering the tra nsmit

duty cycle. With a transmit duty cycle of 50% on pin TxD, the maximum average supply current at

CANH to GND short-circuit is:

I

cc_sc1_avg

= 0.5 * (I

cc_rec

+ I

cc_sc1_dom

) (5)

4.4.2.1.Example calculation

Thermal considerations with CANH shorted to GND:

PCA82C252

TJA1053

TJA1054

: I

: I

: I

cc_sc1_avg 252

cc_sc1_avg 1053

cc_sc1_avg 1054

= 0.5 * (10mA + 139mA) =

= 0.5 * (10mA + 139mA) =

= 0.5 * (11mA + 141mA) =

74.5 mA max.

74.5 mA max.

76 mA max.

(Ex 5.1)

(Ex 5.2)

(Ex 5.3)

Application Hints V3.1 Page 21 of 41

Page 22

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.4.3. Vcc extra supply current in single fault condition

Compared to the quiescent current in recessive state the maximum

CANH driver is turned on with CANH shorted t o GND is needed to c alculate the required worst case

Vcc buffer capacitance. This ex tra supply current has to be buffered for up to 6 bit times, depending

on the applications voltage regulator.

extra

supply current when the

I

∆

cc_sc1

= I

cc_sc1_dom

- I

(6)

cc_rec

4.4.3.1.Example calculation

Vcc extra supply current in case of single fault condition.

Item Symbol PCA82C252 TJA1053 TJA1054

Min Vcc supply current, recessive I

1) The minimum quiescent current is estimated since this value is not specified for the PCA82C252 and the TJA1053.

PCA82C252

TJA1053

TJA1054

:

:

: ∆ I

∆

∆

cc_sc1 252

I

cc_sc1 1053

I

cc_sc1 1054

= 139 mA - 3.5 mA =

= 139 mA - 3.5 mA =

= 141 mA - 4 mA =

cc_rec

3,5 mA

135.5 mA max.

135.5 mA max.

137 mA max.

1)

3,5 mA

1)

4 mA

(Ex 6.1)

(Ex 6.2)

(Ex 6.3)

Application Hints V3.1 Page 22 of 41

Page 23

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.5. Worst Case Max Vcc Supply at Presence of a Dual Short Circuit

The worst case m ax. Vcc supply current is flowing in case of a

CAN_H and CAN_L to ground. In this case no communication is possible. Nevertheless the

application suppl y should be able to deliver a proper Vcc f or the microcontroller in order to pre vent

faulty operation.

If there is a

be taken on this dual short circuit cond ition since the transceivers are beha ving fail safe in case of

under voltage conditions and the uC is still powered properly by its own supply.

In case of a

relevant to dimension the required buffer capacitor.

separate

shared

voltage regu lator avai lable supp lying th e transce iver exclus ively,

voltage supply of transceiver and microcontroller this dual fault condition is

dual short-circuit

of the bus lin es

no care

has to

4.5.1. Max Vcc supply current in worst case dual fault condition

I

cc_sc2_dom

I

RTL_sc_dom

The 17-bit time limitation is ca used by the CAN protocol. Due to the dual fault condition with CANH

and CANL shorted to GND the pin RxD of the transcei ver is con tinuo usly clam ped r ecessiv e (CANL t o

GND forces CANH operation; CANH is clamped recessive).

The moment the CAN controller starts a trans m ission, th is dom inant Star t Of Fram e bit is n ot fed b ack

via RxD and thus forces an err or f lag due to t he bit f ailur e cond ition ( TX Error Count er i ncrem ented b y

8). This first bit of the error flag again is not reflected at RxD a nd forces the next err or flag (TX Err or

Counter + 8).

= I

cc0_dom

= Vcc / R

+ I

CANH_sc1_dom

T

+ I

RTL_sc_dom

( t < 17 bit times ) (7)

(8)

Latest after 17 bit tim es, depending on the TX Error Counter Level befor e starting this transm ission,

the CAN controller reaches the Error Passive limit (128) and stops sending dominant bits. Now a

sequence of 25 recessive bits follows (8 Bit Error Delimiter + 3 Bit Intermission + 8 Bit Suspend

Transmission) and the Vcc current becomes reduced to the recessive one.

From now on only single dom inant bits (Start Of Frame) followed b y 25 recessive b its (Passive Error

Flag + Intermission + Suspend Tr ansmission) are output until the CAN controller enters the Bus Off

State.

So, for dimensionin g the Vc c voltag e sourc e in t his worst c ase du al fai lure sc enario, up to 17 b it t imes

might have to be buff ered by a bypass capac itor dependin g on the regulati on capabilities of the used

voltage supply.

4.5.1.1.Example calculation

Max Vcc supply current in worst case dual fault condition:

PCA82C252

TJA1053

TJA1054

: I

: I

: I

cc_sc2_dom 252

cc_sc2_dom 1053

cc_sc2_dom 1054

= 35 mA + 100 mA + 5V / 1k =

= 35 mA + 100 mA + 5V / 1k =

= 27 mA + 110 mA + 5V / 1k =

140 mA max.

140 mA max.

142 mA max.

(Ex 7.1)

(Ex 7.2)

(Ex 7.3)

Application Hints V3.1 Page 23 of 41

Page 24

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.5.2. Vcc extra supply current in dual fault condition

Compared to the quiescent current in recessive state the maximum

CANH driver is turned on in dual short-c ircuit conditio n is needed to calculate t he requir ed worst case

Vcc buffer capacitance. This extra supply current has to be buffered for that time the applications

voltage regulator needs to react.

extra

supply current when the

I

∆

cc_sc2

= I

cc_sc2_dom

- I

(9)

cc_rec

4.5.2.1.Example calculation

Vcc extra supply current in case of dual fault condition.

Item Symbol PCA82C252 TJA1053 TJA1054

Min Vcc supply current, recessive I

1) The minimum quiescent current is estimated since this value is not specified for the PCA82C252 and the TJA1053.

PCA82C252

TJA1053

TJA1054

:

:

: ∆ I

∆

∆

cc_sc2 252

I

cc_sc2 1053

I

cc_sc2 1054

= 140 mA - 3.5 mA =

= 140 mA - 3.5 mA =

= 142 mA - 4 mA =

cc_rec

3,5 mA

136.5 mA max.

136.5 mA max.

138 mA max.

1)

3,5 mA

1)

4 mA

(Ex 9.1)

(Ex 9.2)

(Ex 9.3)

4.6. Calculation of worst-case bypass capacitor

Depending on the power supply concept, the required wo rst-c ase bypass c apacitor c an be ca lculated.

In case of a

single fault condition

the

separate Vcc

supply for the transceiv er only, the extra supp ly current ∆ I

has to be taken with a maximum of 6 dominant bit times.

in case of

cc_sc

If the transceiver and the host microcontroller are supplied from the same regulator (

supply

), the extra supply current ∆ I

in case of the

cc_sc

dual fault condition

has to be taken with a

shared Vcc

maximum of 17 dominant bit times.

C

= ∆ I

BUFF

The capacitor C

BUFF

maximum dominant output drive t

cc_sc

* t

dom_max

/ ∆V

max

is needed if the voltage regulator is

dom_max

during the dual fault condition.

not

able to deliver any extra current with in t he

(10)

Application Hints V3.1 Page 24 of 41

Page 25

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

4.6.1. Example calculation, separate supplied transceiver @ 83,33kBit/s

In case of a separate tr ansceiver supply the bypass c apacitance has to be calculate d based on the

single fault condition with CANH shorted to GND. Here the dual fault is not relevant.

Assumption of 83,33 kBit/s : t

Maximum allowed Vcc voltage drop :

PCA82C252

TJA1053

TJA1054

: C

: C

: C

= 135.5 mA * 72 us / 0.25 V =

BUFF 252

BUFF 1053

BUFF 1054

= 135.5 mA * 72 us / 0.25 V =

= 137 mA * 72 us / 0.25 V =

∆

= 6 * 12 us = 72 us

dom_max

= 0.25V

V

max

39 uF

39 uF

39,5 uF

(Ex 10.1)

(Ex 10.2)

(Ex 10.3)

In this example the bypass capacitance to be reserved for the Vcc supply of the transceiver is

recommended to be 39,5 uF minimum at 83,33 kBit/s. It may become smaller, if the used voltage

regulator is able to deliver an extra current within t

dom_max

.

4.6.2. Example calculation, shared supply

In case of a shared sup ply concept the b ypass capacitance has to be calculate d based on the worst

case dual fault condition in order to keep the uC supply stabile:

Assumption of 83,33 kBit/s : t

Maximum allowed Vcc voltage drop :

PCA82C252

TJA1053

TJA1054

: C

: C

: C

= 136.5 mA * 204 us / 0.25 V =

BUFF 252

BUFF 1053

BUFF 1054

= 136.5 mA * 204 us / 0.25 V =

= 138 mA * 204 us / 0.25 V =

∆

= 17 * 12 us = 204 us

dom_max

V

= 0.25V

max

111.4 uF

111.4 uF

113 uF

(Ex 10.1)

(Ex 10.2)

(Ex 10.3)

In this example the bypass capacitance to be reserved for the Vcc supply of the transceiver is

recommended to be 113 uF minimum at 83,33 kBit/s. It may become smaller, if the used voltage

regulator is able to deliver an extra current within t

dom_max

.

Application Hints V3.1 Page 25 of 41

Page 26

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

5. Bus Termination and EMC issues

5.1. How to dimension the Bus Termination Resistor values, some basic rules

The fault tolerant tr ansc ei vers ar e desi gn ed to deliver optimum system behav iour at a total termination

resistance of 100 Ohms. This means that the CANH line is terminated with 100 O hms as well as th e

CANL line. Because th e termination of this fault tolerant system is distributed all over the network,

each of the transceivers has to del iver only a par t of the total 100 Ohm termination. So depend ing on

the overall system size the single nodes local termination resistors have to be calculated.

Termination resistor s are connected wit hin each control unit to the correspond ing pins RTH and RTL

of the transceivers.

5 node system : 500 Ohms termination at each transceiver,

10 node system : 1000 Ohms termination at each transceiver

Transceiver

RTH RTL

CANH CANL

500 500

CANH

CANL

#1

Transceiver

#2

RTH RTL

CANH CANL

500 500

Transceiver

#3

RTH RTL

CANH CANL

500 500

Transceiver

#4

RTH RTL

CANH CANL

500 500

Transceiver

#5

RTH RTL

CANH CANL

500 500

Figure 6 : Example Network with 5 nodes, 500 Ohms termination at each node

It is not required that each transc eiver in the s ystem has the same term ination resistor value. In total

the termination should resu lt in 100 Ohm s. It is not recom m ended to ter m inate the e ntire system lower

than 100 Ohms since the CAN output drivers are limited to a load of 100 Ohms.

The minimum termination resistor value allowed per transceiver is 500 Ohms due to the driving

capability of the pins RT L and RTH. So within system s with less than 5 trans ceivers it is n ot possible

to achieve the 100 Ohm termination optimum. In prac tice this is typically no problem because such

“small” systems will have less bus cable lengths compared to bigger networks and thus have no

problem with a higher total termination resistances.

It is recommended not to exceed approx im ately 6k Ohm s term ination a t a sing le trans cei ver in or der to

provide a good EMI (Elec tro Magnet ic Im m unity) perf orm ance of the s ystem in case of interru pted bus

wires. Nevertheless up to 16kOhms are specified for the transceivers.

5.1.1. Variable System Size, Optional Nodes

In case of variable system sizes with optional nodes it is recom mended to achie ve a total term ination

resistance close to 100 Ohm s provided b y the s tandard no des wh ich are alwa ys present . T he optio nal

nodes should have the higher term ination resist ances then. D ue to EMI is sues it is rec ommended no t

to exceed approx. 6kOhms for the optional nodes.

Application Hints V3.1 Page 26 of 41

Page 27

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

5.1.1.1.Example calculation, Variable System Size

The entire exam ple system has 15 nodes in total, 5 nodes of this system ar e optional ones and only

implemented if required:

Termination of the 10 standard nodes : 1.2 kOhm per node

Termination of the 5 optional nodes : 3 kOhm per node

Total system termination, standard nodes only : 1.2 kOhm / 10 nodes =

120 Ohms

Total system termination, 15 nodes : (3 kOhm / 5 nodes) parallel to 120 Ohms =

100 Ohms

There is no general rule how to distribute the termination within the network. A rule of thumb is :

“The longer the cable stub, the lower the local termination.”

(...close to 100)

5.2. Tolerances of Bus Termination Resistors, EMC Considerations

The symmetry of the termination resistors within a single node has a major impact to the systems EME

(Electro Magnetic Em iss ion) beha viour . Thus it is im portant t o have well matched terminat ion resis tors

within each control unit. This means that the RTH resistor should have exactly the same value

compared to the RTL resistor within one contro l unit in order to get the same time constant on each

bus wire during signal transitions. Two different control units might have completely different

termination values. ( see also 5.1.1. “Variable system size, optional nodes” ).

The principle to achieve a good EME performance is that the differential signal on the bus wires

eliminates an y emission d ue to com pensation ef fects if both CAN wires are c arrying exactl y the s ame

signal, but with inverse polarities.

Here the transceiver can only provide a perfect s ymmetry for the dominan t transitions b y design. The

recessive transitions ar e mainly driven by the termination r esistors and the network cables itself. So

not only the transceiver’s output drivers have an impact to the EME performance but also the

termination and the cable symmetry.

It is recommended to provid e a ter m ination res istor ac curacy (RTH compar ed to RT L) within th e sam e

node of 1% or lower. Also the bus cable has to be at least a twisted pair cable in order to achiev e a

symmetrical capacitive load for both bus wires resulting in a good EMC performance.

It is obvious that also the layout of printed c irc uit boards has a signif ic ant impact to the EMC beha vi our

if the CAN lines have different capacitive loads due to different wire lengths.

Application Hints V3.1 Page 27 of 41

Page 28

Philips Semiconductors Systems Laboratory Hamburg, Germany

APPLICATION HINTS Fault-tolerant CAN Transceiver

5.3. Output Current and Power Dissipation of Bus Termination Resistors R

T

5.3.1. Summary

The bus terminatio n resistors RT being connected to the fault tolerant tr ansceivers are r ecommended

to withstand the following power dissipations (@ R

PCA82C252 :

TJA1053 :

TJA1054 :

64 mW

64 mW

31,7 mW

> 1000 Ohms):

T

The following chapters are discussing this issue in more detail.

5.3.2. Average power dissipation, no bus failures

In order to dimension t he power dissipation of the term ination resistors connected to pins RTH and

RTL, the average power dissipation between dominant and recessive bits has to be taken into

account. Additionally a worst case ground offset of the certain module has an impact.

CAN frames are ass umed to have a ratio of dominant bi ts in the ran ge of 0.75 worst case bec ause of

stuffing and fixed recessive frame segments. Thus the average power dissipation is calculated as

follows:

P

= 0.75 * (V

avg

cc + VGND

5.3.2.1.Example calculation, average power dissipation

) 2 / R

T

(11)

Assumption : RT = 1000 Ohms

= 0.75 * (5V + 1,5V) 2 / 1000 Ohms =

P

avg

31.7 mW

(Ex 11.1)

5.3.3. Maximum continuous power dissipation (single bus failure)

Because the PCA82C25 2 an d t he T J A105 3 d o no t pr o vi de a f ail ure d etec tor f or CANH short circuits to

Vcc the maximum continuous current flows in case CANH has a short circuit to 8V. This is the

maximum detection threshold for CANH to battery short circuit conditions.