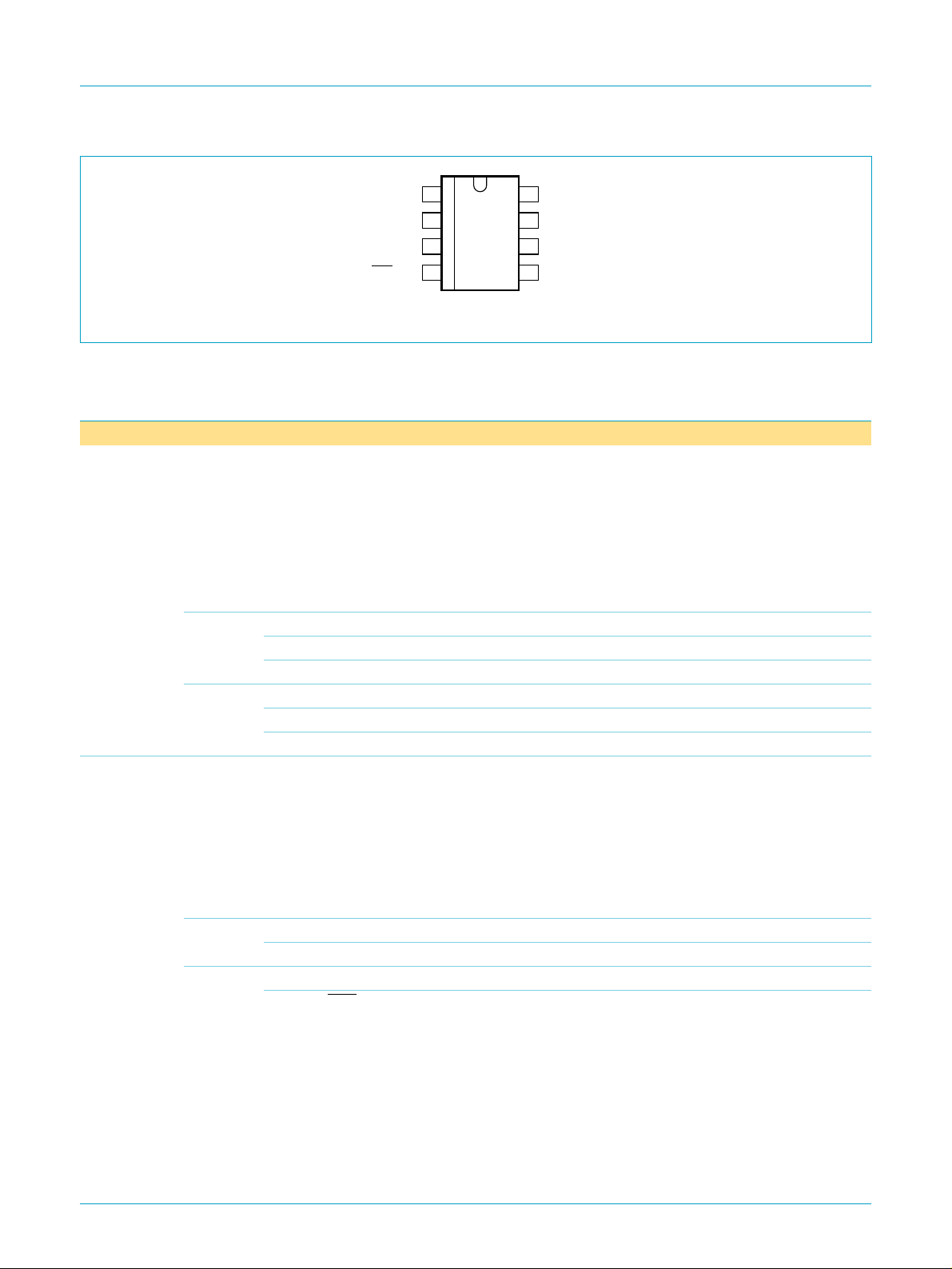

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

1 kB 3 V Flash with 128-byte RAM

Rev. 04 — 21 November 2003 Product data

1. General description

The P89LPC901/902/903 are single-chip microcontrollers in low-cost 8-pin packages,

based on a highperformance processorarchitecture that executesinstructions in two

to four clocks, six times the rate of standard 80C51 devices. Many system-level

functions have been incorporated into the P89LPC901/902/903 in order to reduce

component count, board space, and system cost.

2. Features

2.1 Principal features

■ 1 kB byte-erasable Flash code memory organized into 256-byte sectors and

16-byte pages. Single-byte erasing allows any byte(s) to be used as non-volatile

data storage.

■ 128-byte RAM data memory.

■ Two 16-bit counter/timers. (P89LPC901 Timer 0 may be configured to toggle a

port output upon timer overflow or to become a PWM output.)

■ 23-bit system timer that can also be used as a Real-Time clock.

■ Two analog comparators (P89LPC902 and P89LPC903, single analog

comparator on P89LPC901).

■ Enhanced UART with fractional baudrate generator, break detect, framing error

detection, automatic address detection and versatile interrupt capabilities

(P89LPC903).

■ High-accuracy internal RC oscillator option allows operation without external

oscillator components. The RC oscillator option is selectable and fine tunable.

■ 2.4 V to 3.6 V VDDoperating range with 5 V tolerant I/O pins (may be pulled up or

driven to 5.5 V). Industry-standard pinout with VDD, VSS, and reset at locations 1,

8, and 4.

■ Up to six I/O pins when using internal oscillator and reset options.

■ 8-pin SO-8 package.

2.2 Additional features

■ A high performance 80C51 CPU provides instruction cycle times of 167 ns to

333 ns for all instructions except multiply and divide when executing at 12 MHz.

This is six times the performance of the standard 80C51 running at the same

clock frequency. A lower clock frequency for the same performance results in

power savings and reduced EMI.

■ In-Application Programming (IAP-Lite) and byte erase allows code memory to be

used for non-volatile data storage.

Philips Semiconductors

■ Serial Flash In-Circuit Programming (ICP) allows simple production coding with

■ Watchdog timer with separate on-chip oscillator, requiring no external

■ Low voltage reset (Brownout detect) allows a graceful system shutdown when

■ Idle and two different Power-downreduced power modes. Improved wake-up from

■ Active-LOWreset. On-chippower-on reset allows operation without external reset

■ Configurable on-chip oscillator with frequency range options selected by user

■ Watchdog timer with separate on-chip oscillator, requiring no external

■ Programmable port output configuration options: quasi-bidirectional, open drain,

■ Port ‘input pattern match’ detect. Port 0may generate aninterrupt when thevalue

■ LED drive capability (20 mA) on all port pins. A maximum limit is specified for the

■ Controlled slew rate port outputs to reduce EMI. Outputs have approximately

■ Only power and ground connections are required to operate the

■ Four interrupt priority levels.

■ Two (P89LPC901), three (P89LPC903), or five (P89LPC902) keypad interrupt

■ Second data pointer.

■ Schmitt trigger port inputs.

■ Emulation support.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

commercial EPROMprogrammers.Flash security bits prevent reading of sensitive

application programs.

components. The watchdog prescaler is selectable from 8 values.

power fails. May optionally be configured as an interrupt.

Power-down mode (a low interrupt input starts execution). Typical Power-down

current is 1 µA (total Power-down with voltage comparators disabled).

components. A reset counter and reset glitch suppression circuitry prevent

spurious and incomplete resets. A software reset function is also available.

programmed Flash configuration bits. Oscillatoroptions support frequencies from

20 kHz to the maximum operating frequency of 12 MHz (P89LPC901).

components. The watchdog prescaler is selectable from 8 values.

push-pull, input-only.

of the pins match or do not match a programmable pattern.

entire chip.

10 ns minimum ramp times.

P89LPC901/902/903 when internal reset option is selected.

inputs.

9397 750 12293

Product data Rev. 04 — 21 November 2003 2 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

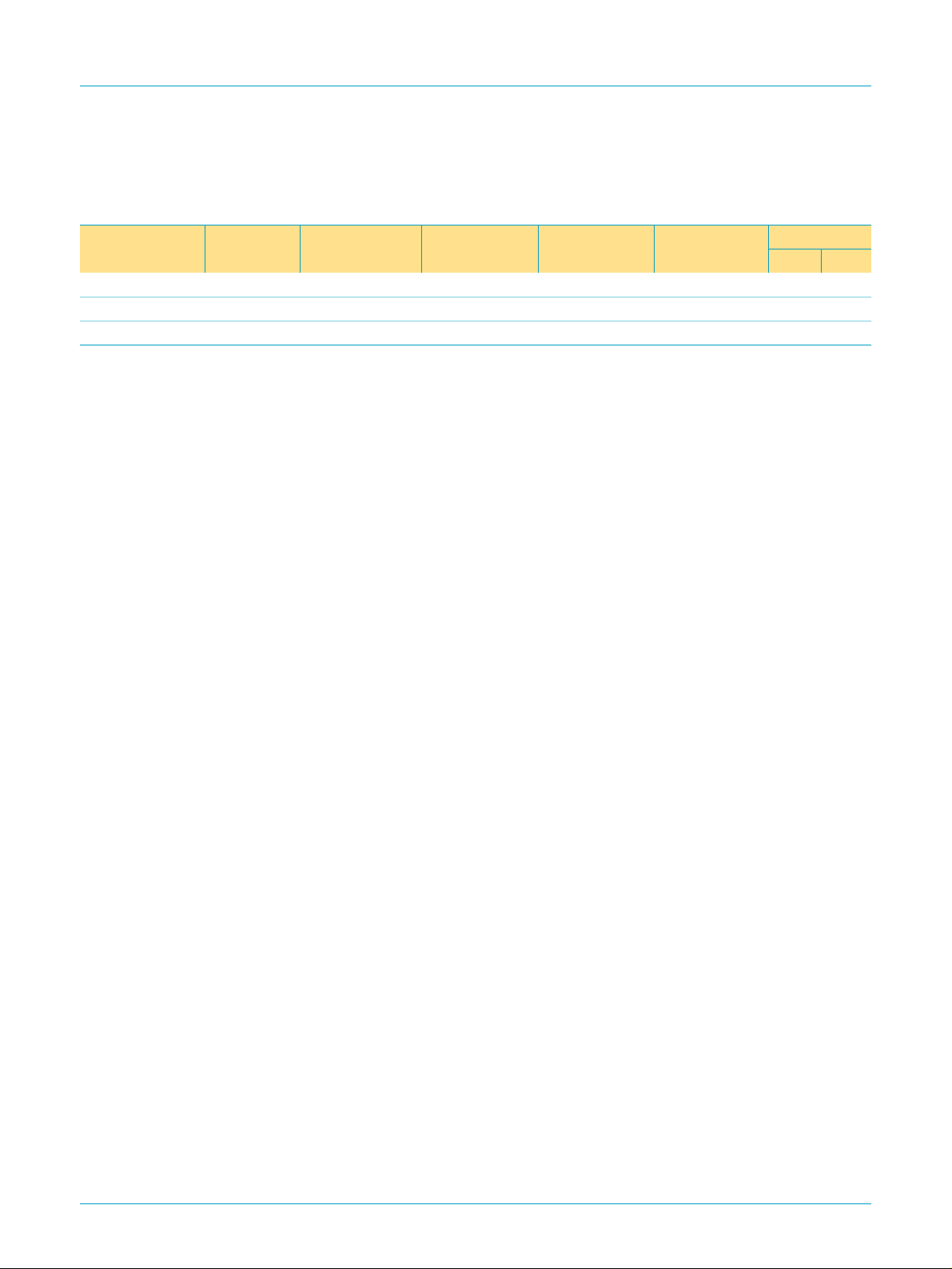

3. Ordering information

Table 1: Ordering information

Type number Package

P89LPC901FD SO8 plastic small outline package; 8 leads;

P89LPC902FD

P89LPC903FD

P89LPC901FN DIP8 plastic dual in-line package; 8 leads (300 mil) SOT97-1

P89LPC902FN

3.1 Ordering options

Table 2: Part options

Type number Temperature range Frequency

P89LPC901xx −40 °Cto+85°C 0 to 12 MHz

P89LPC902xx Internal RC or watchdog

P89LPC903xx Internal RC or watchdog

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Name Description Version

SOT96-1

body width 7.5 mm

9397 750 12293

Product data Rev. 04 — 21 November 2003 3 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

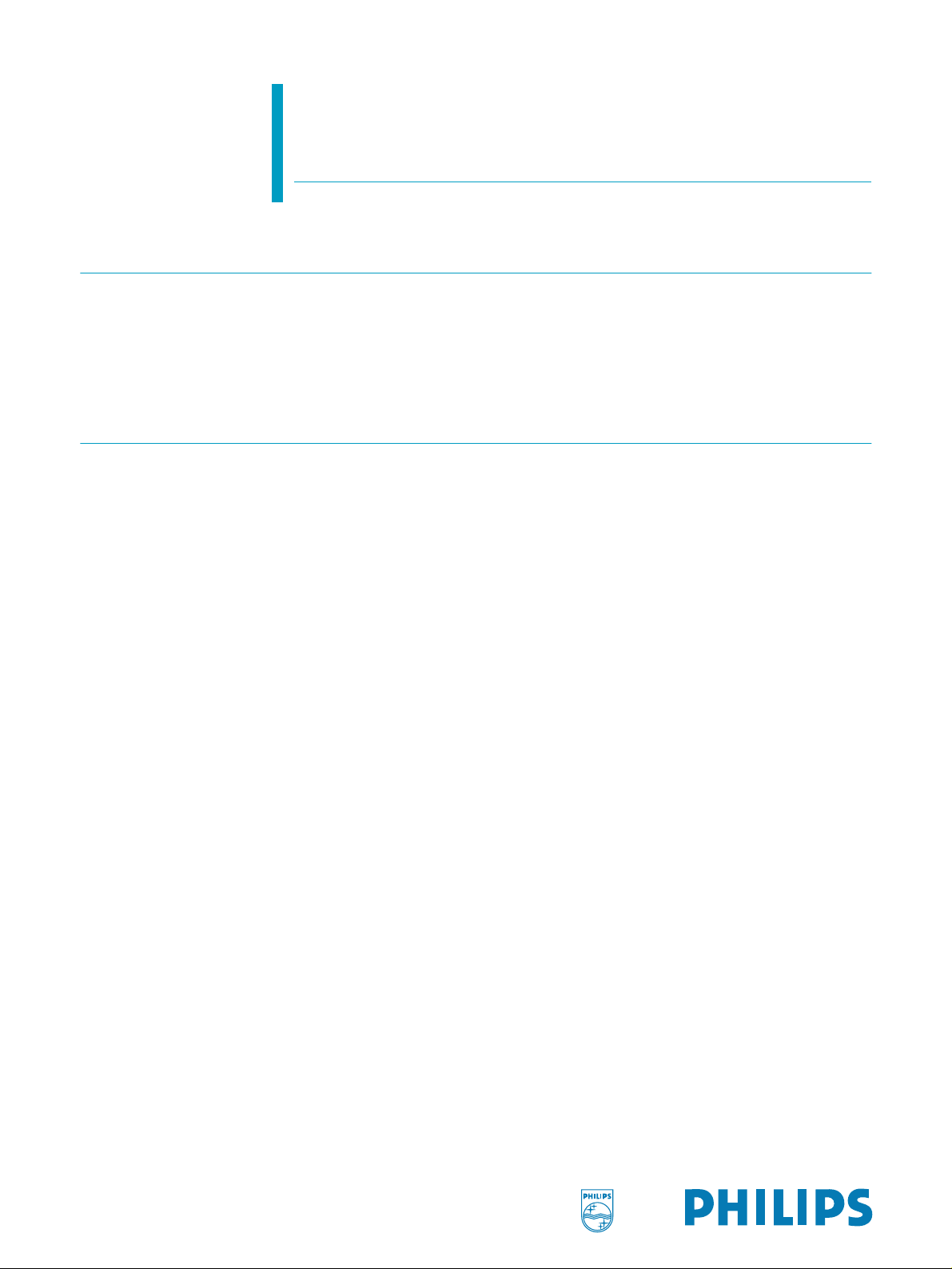

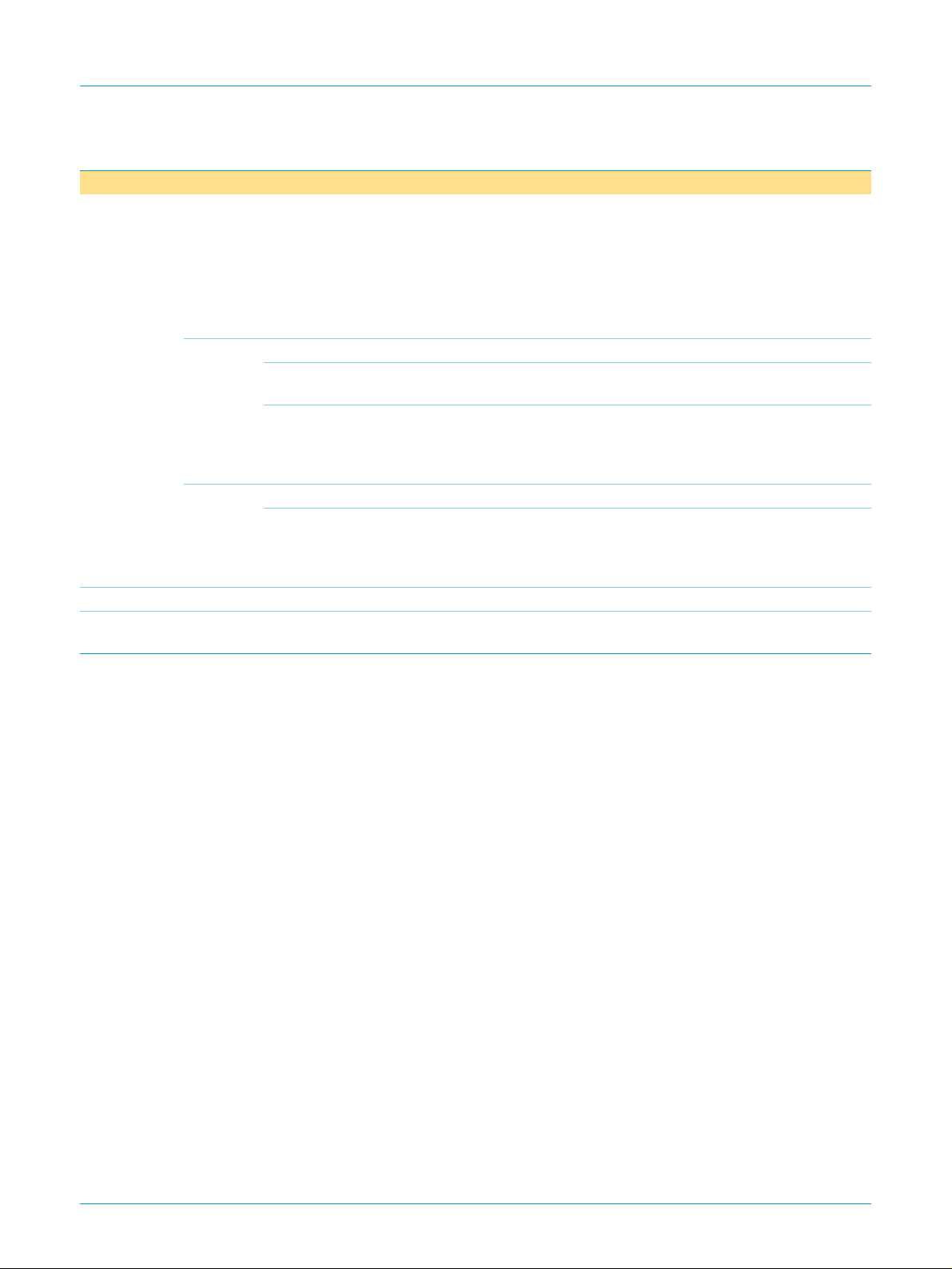

4. Block diagram

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

CRYSTAL

OR

RESONATOR

P89LPC901

1 kB

CODE FLASH

128-BYTE

DATA RAM

PORT 3

CONFIGURABLE I/Os

PORT 1

CONFIGURABLE I/Os

PORT 0

CONFIGURABLE I/Os

KEYPAD

INTERRUPT

WATCHDOG TIMER

AND OSCILLATOR

PROGRAMMABLE

OSCILLATOR DIVIDER

CONFIGURABLE

OSCILLATOR

HIGH PERFORMANCE

ACCELERATED 2-CLOCK 80C51 CPU

INTERNAL BUS

CPU

CLOCK

ON-CHIP

RC

OSCILLATOR

TIMER 0

TIMER 1

REAL-TIME CLOCK/

SYSTEM TIMER

ANALOG

COMPARATOR

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

002aaa444

Fig 1. P89LPC901 block diagram.

9397 750 12293

Product data Rev. 04 — 21 November 2003 4 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

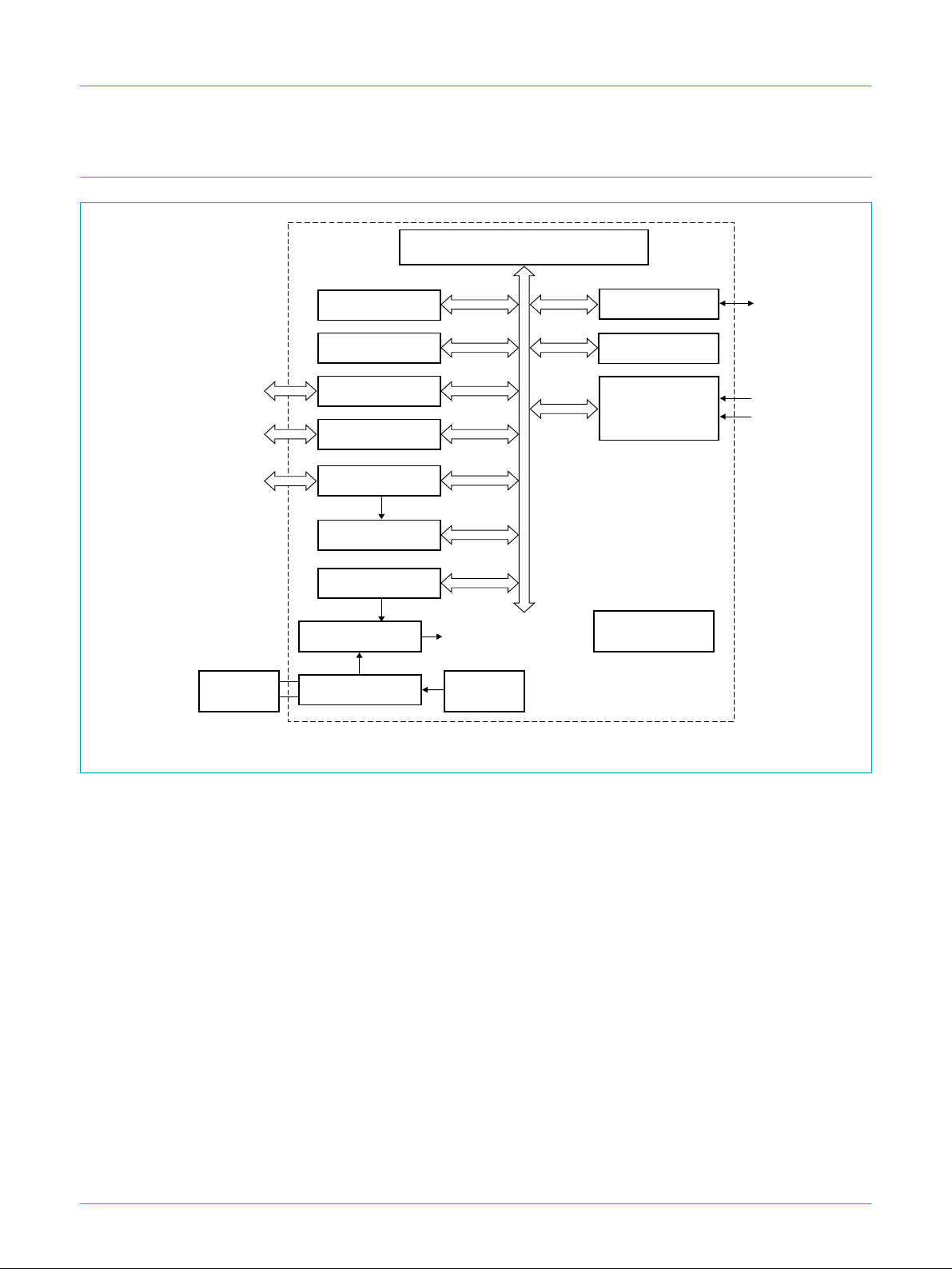

P89LPC902

CODE FLASH

128-BYTE

DATA RAM

PORT 1

PORT 0

CONFIGURABLE I/Os

KEYPAD

INTERRUPT

WATCHDOG TIMER

AND OSCILLATOR

PROGRAMMABLE

OSCILLATOR DIVIDER

ON-CHIP

OSCILLATOR

1 kB

INPUT

RC

HIGH PERFORMANCE

ACCELERATED 2-CLOCK 80C51 CPU

INTERNAL

BUS

CPU

CLOCK

TIMER 0

TIMER 1

REAL-TIME CLOCK/

SYSTEM TIMER

ANALOG

COMPARATORS

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

002aaa445

Fig 2. P89LPC902 block diagram.

9397 750 12293

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Product data Rev. 04 — 21 November 2003 5 of 55

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

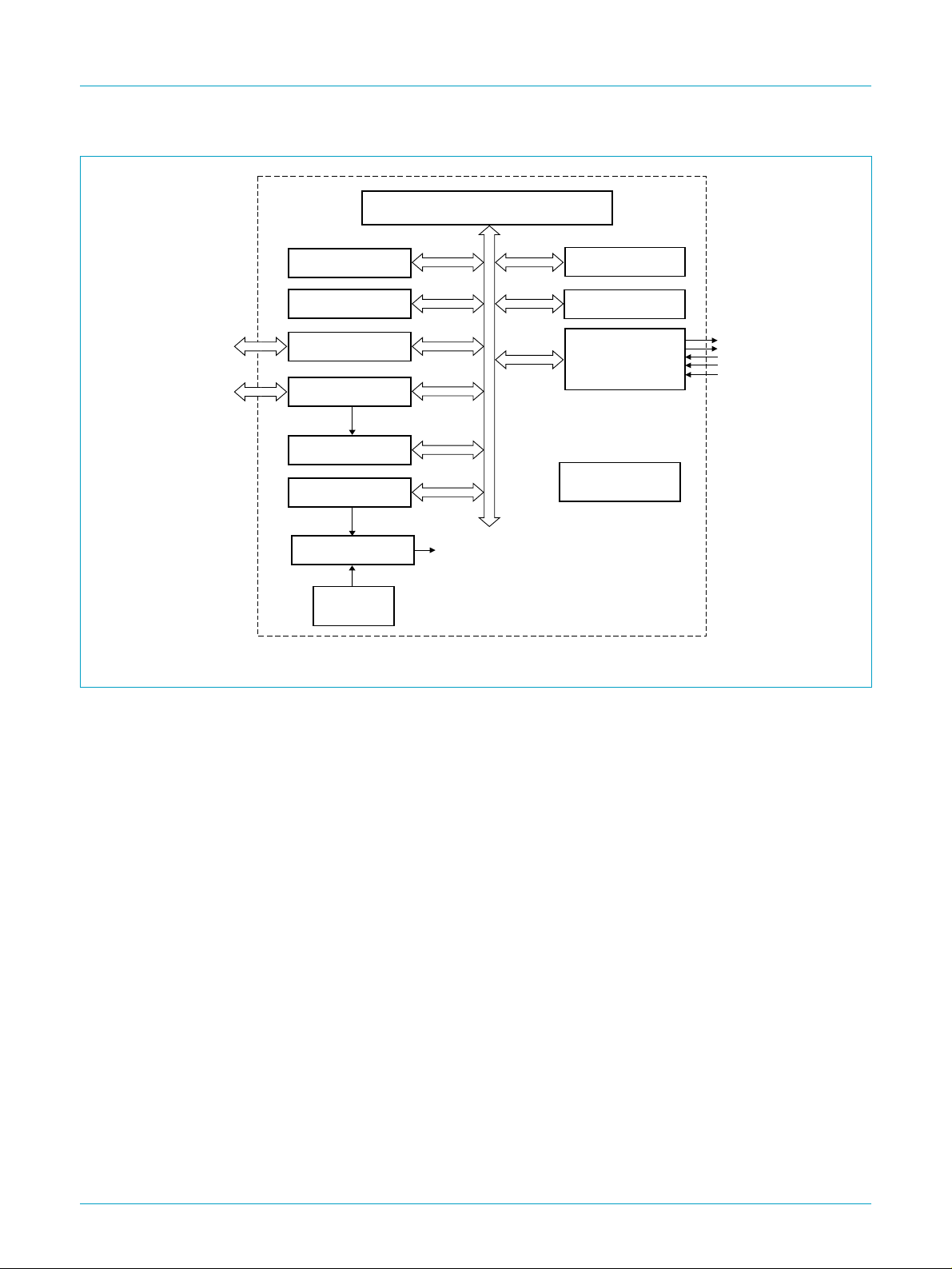

P89LPC903

1 kB

CODE FLASH

128-BYTE

DATA RAM

PORT 1

INPUT

PORT 0

CONFIGURABLE I/Os

KEYPAD

INTERRUPT

WATCHDOG TIMER

AND OSCILLATOR

PROGRAMMABLE

OSCILLATOR DIVIDER

ON-CHIP

RC

OSCILLATOR

HIGH PERFORMANCE

ACCELERATED 2-CLOCK 80C51 CPU

INTERNAL

BUS

CPU

CLOCK

UART

TIMER 0

TIMER 1

REAL-TIME CLOCK/

SYSTEM TIMER

ANALOG

COMPARATORS

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

002aaa446

Fig 3. P89LPC903 block diagram.

9397 750 12293

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Product data Rev. 04 — 21 November 2003 6 of 55

Philips Semiconductors

5. Pinning information

5.1 Pinning

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

handbook, halfpage

Fig 4. P89LPC901 pinning (SO8).

handbook, halfpage

CLKOUT/XTAL2/P3.0

Fig 5. P89LPC901 pinning (DIP8).

handbook, halfpage

V

DD

XTAL1/P3.1

CLKOUT/XTAL2/P3.0

RST/P1.5

V

DD

XTAL1/P3.1

RST/P1.5

V

DD

P0.2/CIN2A/KBI2

P0.0/CMP2/KBI0

RST/P1.5

1

2

3

4

1

2

3

4

1

2

3

4

P89LPC901FD

002aaa438

P89LPC901FN

002aaa469

P89LPC902FD

002aaa439

V

8

SS

P0.4/CIN1A/KBI4

7

P0.5/CMPREF/KBI5

6

P1.2/T0

5

V

8

SS

P0.4/CIN1A/KBI4

7

P0.5/CMPREF/KBI5

6

P1.2/T0

5

V

8

SS

7

P0.4/CIN1A/KBI4

6

P0.5/CMPREF/KBI5

5

P0.6/CMP1/KBI6

Fig 6. P89LPC902 pinning (SO8).

handbook, halfpage

P0.2/CIN2A/KBI2

P0.0/CMP2/KBI0

V

DD

RST/P1.5

1

2

3

4

P89LPC902FN

002aaa470

V

8

SS

7

P0.4/CIN1A/KBI4

6

P0.5/CMPREF/KBI5

P0.6/CMP1/KBI6

5

Fig 7. P89LPC902 pinning (DIP8).

9397 750 12293

Product data Rev. 04 — 21 November 2003 7 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

handbook, halfpage

P0.2/CIN2A/KBI2

V

DD

P1.1/RxD

RST/P1.5

1

2

3

4

P89LPC903FD

002aaa440

V

8

SS

P0.4/CIN1A/KBI4

7

P0.5/CMPREF/KBI5

6

P1.0/TxD

5

Fig 8. P89LPC903 pinning (SO8).

5.2 Pin description

Table 3: P89LPC901 pin description

Symbol Pin Type Description

P0.0 - P0.6 6, 7 I/O Port 0: Port 0 isan I/O port with a user-configurable output type. During reset Port 0

latches are configured in the input only mode with the internal pull-up disabled. The

operation of Port 0 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 8.12.1 “Port

configurations” and Table 13 “DC electrical characteristics” for details.

The Keypad Interrupt feature operates with Port 0 pins.

All pins have Schmitt triggered inputs.

Port 0 also provides various special functions as described below:

7 I/O P0.4 — Port 0 bit 4.

I CIN1A — Comparator 1 positive input.

I KBI4 — Keyboard input 4.

6 I/O P0.5 — Port 0 bit 5.

I CMPREF — Comparator reference (negative) input.

I KBI5 — Keyboard input 5.

P1.0 - P1.5 4, 5 Port 1: Port 1 is an I/O port with a user-configurable output type. During resetPort 1

latches are configured in the input only mode with the internal pull-up disabled. The

operation of the configurable Port 1 pins as inputs and outputs depends upon the

port configuration selected. Each of the configurable port pins are programmed

independently. Refer to Section 8.12.1 “Port configurations” and Table 13 “DC

electrical characteristics” for details. P1.5 is input only.

All pins have Schmitt triggered inputs.

Port 1 also provides various special functions as described below:

5 I/O P1.2 — Port 1 bit 2.

O T0 — Timer/counter 0 external count input or overflow output.

4IP1.5 — Port 1 bit 5 (input only).

I

RST — External Reset input during Power-on or if selected via UCFG1. When

functioning as a reset input aLOW on this pin resetsthe microcontroller, causing I/O

ports and peripherals to take on their default states, and the processor begins

execution at address 0. Also used during a power-on sequence to force In-System

Programming mode.

9397 750 12293

Product data Rev. 04 — 21 November 2003 8 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Table 3: P89LPC901 pin description

Symbol Pin Type Description

P3.0 - P3.1 2, 3 I/O Port 3: Port 3 is an I/O port with a user-configurableoutput types. During reset Port 3

3 I/O P3.0 — Port 3 bit 0.

O XTAL2 — Output from the oscillator amplifier (when a crystal oscillator option is

O CLKOUT — CPU clock divided by 2 when enabled via SFR bit(ENCLK -TRIM.6). It

2 I/O P3.1 — Port 3 bit 1.

I XTAL1 — Input to the oscillator circuit and internal clock generator circuits (when

V

SS

V

DD

8IGround: 0 V reference.

1IPower Supply: This is the power supply voltage for normal operation as well as Idle

…continued

latches are configured in the input only mode with the internal pull-up disabled. The

operation of port 3 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 8.12.1 “Port

configurations” and Table 13 “DC electrical characteristics” for details.

All pins have Schmitt triggered inputs.

Port 3 also provides various special functions as described below:

selected via the FLASH configuration).

can be used if the CPU clock is the internal RC oscillator, Watchdog oscillator or

external clock input, except when XTAL1/XTAL2 are used to generate clock source

for the real time clock/system timer.

selected via the FLASH configuration).It can be a port pin if internal RC oscillator or

Watchdog oscillator is used as the CPU clock source,and if XTAL1/XTAL2 are not

used to generate the clock for the real time clock/system timer.

and Power-down modes.

9397 750 12293

Product data Rev. 04 — 21 November 2003 9 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Table 4: P89LPC902 pin description

Symbol Pin Type Description

P0.0 - P0.6 2, 3, 5, 6,7I/O Port 0: Port 0 is an I/O port with a user-configurable output type. During reset Port 0

latches are configured in the input only mode with the internal pull-up disabled. The

operation of Port 0 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 8.12.1 “Port

configurations” and Table 13 “DC electrical characteristics” for details.

The Keypad Interrupt feature operates with Port 0 pins.

All pins have Schmitt triggered inputs.

Port 0 also provides various special functions as described below:

3 I/O P0.0 — Port 0 bit 0.

I CMP2 — Comparator 2 output.

I KBI0 — Keyboard input 0.

2 I/O P0.2 — Port 0 bit 2.

I CIN2A — Comparator 2 positive input.

I KBI2 — Keyboard input 2.

7 I/O P0.4 — Port 0 bit 4.

I CIN1A — Comparator 1 positive input.

I KBI4 — Keyboard input 4.

6 I/O P0.5 — Port 0 bit 5.

I CMPREF — Comparator reference (negative) input.

I KBI5 — Keyboard input 5.

5 I/O P0.6 — Port 0 bit 6.

O CMP1 — Comparator 1 output.

I KBI6 — Keyboard input 6.

P1.0 - P1.5 4 Port 1: Port 1 is an I/O port with a user-configurable output type. During reset Port 1

latches are configured in the input only mode with the internal pull-up disabled. The

operation of the configurable Port 1 pins as inputs and outputs depends upon the

port configuration selected. Each of the configurable port pins are programmed

independently. Refer to Section 8.12.1 “Port configurations” and Table 13 “DC

electrical characteristics” for details. P1.5 is input only.

All pins have Schmitt triggered inputs.

Port 1 also provides various special functions as described below:

4IP1.5 — Port 1 bit 5 (input only).

I

V

SS

V

DD

8IGround: 0 V reference.

1IPower Supply: This is the power supply voltage for normal operation as well as Idle

RST — External Reset input during Power-on or if selected via UCFG1. When

functioning as a reset input a LOW on this pin resets the microcontroller, causing I/O

ports and peripherals to take on their default states, and the processor begins

execution at address 0. Also used during a power-on sequence to force In-System

Programming mode.

and Power-down modes.

9397 750 12293

Product data Rev. 04 — 21 November 2003 10 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Table 5: P89LPC903 pin description

Symbol Pin Type Description

P0.0 - P0.6 2, 6, 7 I/O Port 0: Port 0 is an I/O port with a user-configurable output type. During reset Port 0

latches are configured in the input only mode with the internal pull-up disabled. The

operation of Port 0 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 8.12.1 “Port

configurations” and Table 13 “DC electrical characteristics” for details.

The Keypad Interrupt feature operates with Port 0 pins.

All pins have Schmitt triggered inputs.

Port 0 also provides various special functions as described below:

2 I/O P0.2 — Port 0 bit 2.

I CIN2A — Comparator 2 positive input.

I KBI2 — Keyboard input 2.

7 I/O P0.4 — Port 0 bit 4.

I CIN1A — Comparator 1 positive input.

I KBI4 — Keyboard input 4.

6 I/O P0.5 — Port 0 bit 5.

I CMPREF — Comparator reference (negative) input.

I KBI5 — Keyboard input 5.

P1.0 - P1.5 3, 4, 5 Port 1: Port 1 is an I/O port with a user-configurable output type. During reset Port 1

latches are configured in the input only mode with the internal pull-up disabled. The

operation of the configurable Port 1 pins as inputs and outputs depends upon the

port configuration selected. Each of the configurable port pins are programmed

independently. Refer to Section 8.12.1 “Port configurations” and Table 13 “DC

electrical characteristics” for details. P1.5 is input only.

All pins have Schmitt triggered inputs.

Port 1 also provides various special functions as described below:

5 I/O P1.0 — Port 1 bit 0.

O TxD — Serial port transmitter data.

3 I/O P1.1 — Port 1 bit 1.

I RxD — Serial port receiver data.

4IP1.5 — Port 1 bit 5 (input only).

I

V

SS

V

DD

8IGround: 0 V reference.

1IPower Supply: This is the power supply voltage for normal operation as well as Idle

RST — External Reset input during Power-on or if selected via UCFG1. When

functioning as a reset input a LOW on this pin resets the microcontroller, causing I/O

ports and peripherals to take on their default states, and the processor begins

execution at address 0. Also used during a power-on sequence to force In-System

Programming mode.

and Power-down modes.

9397 750 12293

Product data Rev. 04 — 21 November 2003 11 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

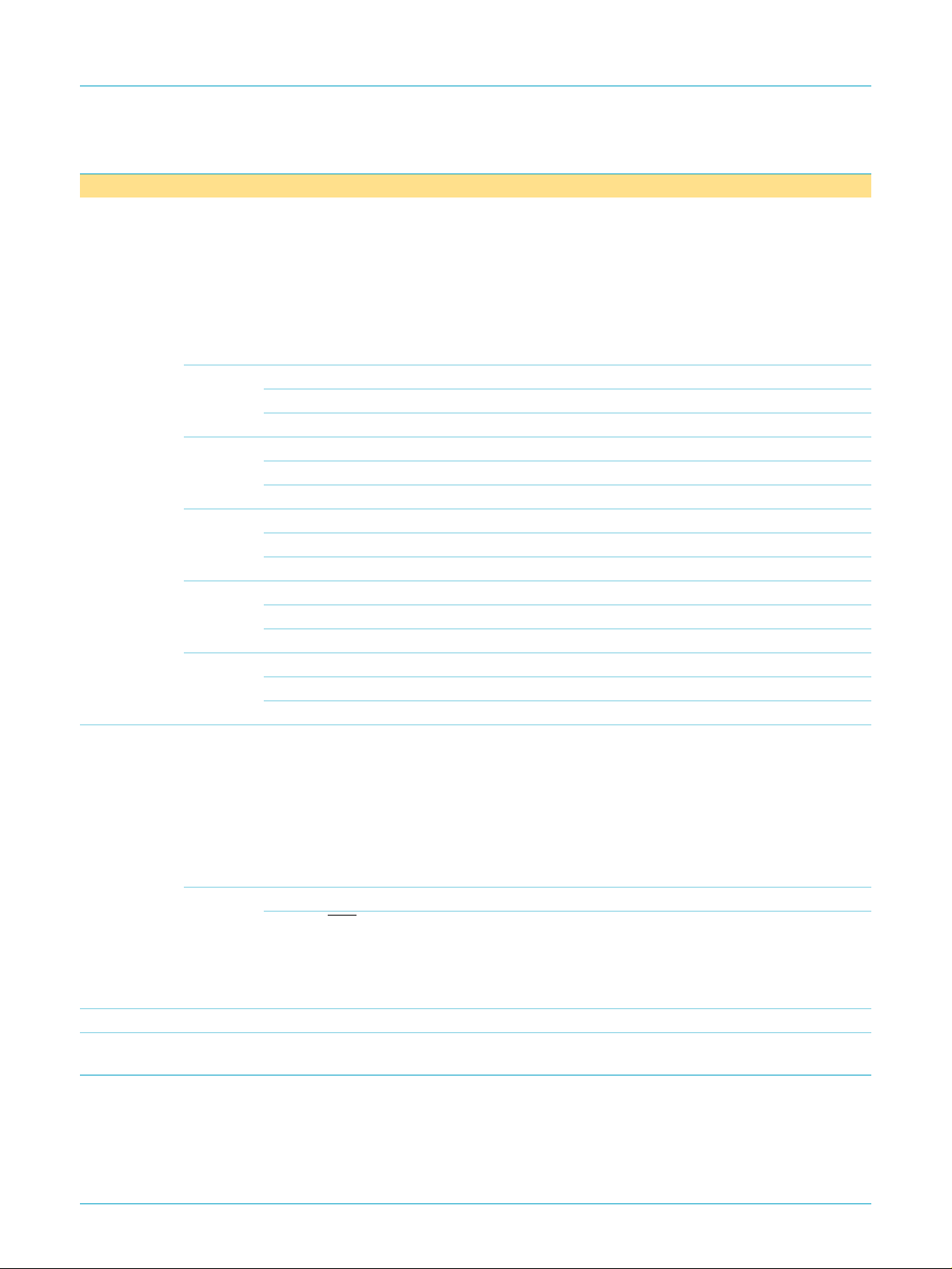

6. Logic symbols

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

V

DDVSS

KBI4

KBI5

CLKOUT

Fig 9. P89LPC901 logic symbol.

KBI4

KBI5

KBI6

KBI2

KBI0

Fig 10. P89LPC902 logic symbol.

CIN1A

CMPREF

XTAL2

XTAL1

CIN1A

CMPREF

CMP1

CIN2A

CMP2

PORT 0

PORT 0

PORT 3

VDDV

P89LPC901

002aaa441

SS

P89LPC902

002aaa442

PORT 1

PORT 1

RST

RST

T0

VDDV

SS

KBI4

KBI5

KBI2

CIN1A

CMPREF

CIN2A

PORT 0

PORT 1

RST

RxD

TxD

P89LPC903

002aaa443

Fig 11. P89LPC903 logic symbol.

9397 750 12293

Product data Rev. 04 — 21 November 2003 12 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Table 6 highlights the differences between these three devices. For a complete list of

device features, please see Section 2 “Features” on page 1.

Table 6: Product comparison overview

Type number External

crystal pins

P89LPC901xx X X X - - - P89LPC902xx - - - X X - P89LPC903xx - - - X - X X

CLKOUT output T0 PWM output CMP2 input CMP1 and

CMP2 outputs

UART

TxD Rxd

9397 750 12293

Product data Rev. 04 — 21 November 2003 13 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

7. Special function registers

Remark: Special Function Registers (SFRs) accesses are restricted in the following

ways:

• User must not attempt to access any SFR locations not defined.

• Accesses to any defined SFR locations must be strictly for the functions for the

SFRs.

• SFR bits labeled ‘-’, ‘0’ or ‘1’ can only be written and read as follows:

– ‘-’ Unless otherwise specified, must be written with ‘0’, but can return any value

when read (even if it was written with ‘0’). It is a reserved bit and may be used in

future derivatives.

– ‘0’ must be written with ‘0’, and will return a ‘0’ when read.

– ‘1’ must be written with ‘1’, and will return a ‘1’ when read.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

9397 750 12293

Product data Rev. 04 — 21 November 2003 14 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 15 of 55

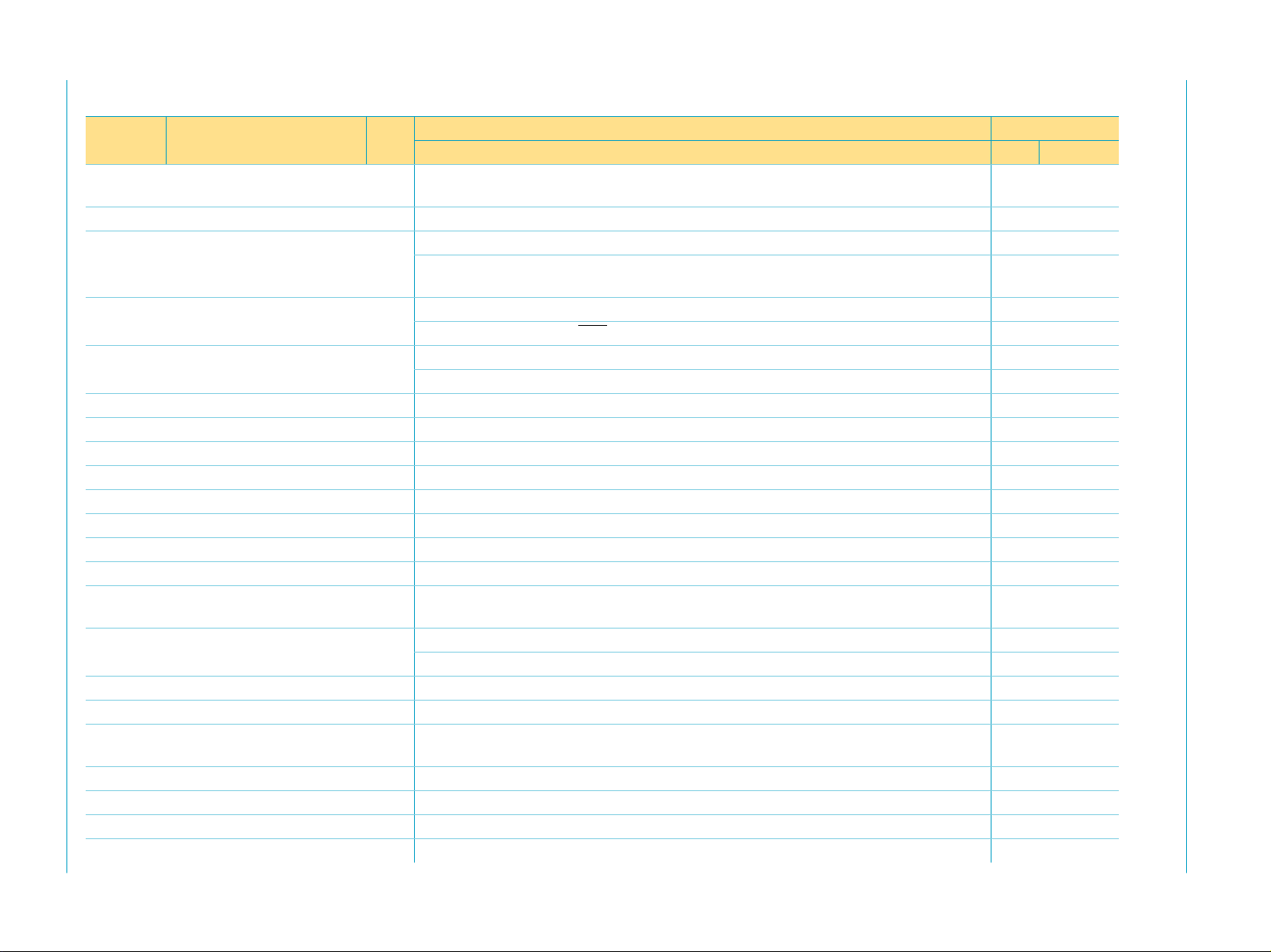

Table 7: P89LPC901 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

ACC* Accumulator E0H 00 00000000

AUXR1 Auxiliary function register A2H CLKLP - - ENT0 SRST 0 - DPS 00

B* B register F0H 00 00000000

CMP1 Comparator 1 control register ACH - - CE1 - CN1 - CO1 CMF1 00

DIVM CPU clock divide-by-M

DPTR Data pointer (2 bytes)

DPH Data pointer HIGH 83H 00 00000000

DPL Data pointer LOW 82H 00 00000000

FMADRH Program Flash address HIGH E7H 00 00000000

FMADRL Program Flash address LOW E6H 00 00000000

FMCON Program Flash Control

FMDATA Program Flash data E5H 00 00000000

IEN0* Interrupt enable 0 A8H EA EWDRT EBO - ET1 - ET0 - 00 00000000

IEN1* Interrupt enable 1 E8H -----ECEKBI - 00

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

IP0* Interrupt priority 0 B8H - PWDRT PBO - PT1 - PT0 - 00

IP0H Interrupt priority 0 HIGH B7H - PWDRTHPBOH - PT1H - PT0H - 00

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

addr.

Bit address E7 E6 E5 E4 E3 E2 E1 E0

Bit address F7 F6 F5 F4 F3 F2 F1 F0

95H 00 00000000

control

E4H BUSY - - - HVA HVE SV OI 70 01110000

(Read)

Program Flash Control

(Write)

Bit address EF EE ED EC EB EA E9 E8

Bit address BF BE BD BC BB BA B9 B8

MSB LSB Hex Binary

FMCMD.7FMCMD.6FMCMD.5FMCMD.4FMCMD.3FMCMD.2FMCMD.1FMCMD.

Bit functions and addresses Reset value

[1]

[1]

0

[1]

[1]

[1]

Philips Semiconductors

000000x0

xx000000

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

00x00000

x0000000

x0000000

Bit address FF FE FD FC FB FA F9 F8

IP1* Interrupt priority 1 F8H -----PCPKBI - 00

IP1H Interrupt priority 1 HIGH F7H -----PCHPKBIH - 00

KBCON Keypad control register 94H ------PATN

KBIF 00

_SEL

[1]

[1]

[1]

00x00000

00x00000

xxxxxx00

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 16 of 55

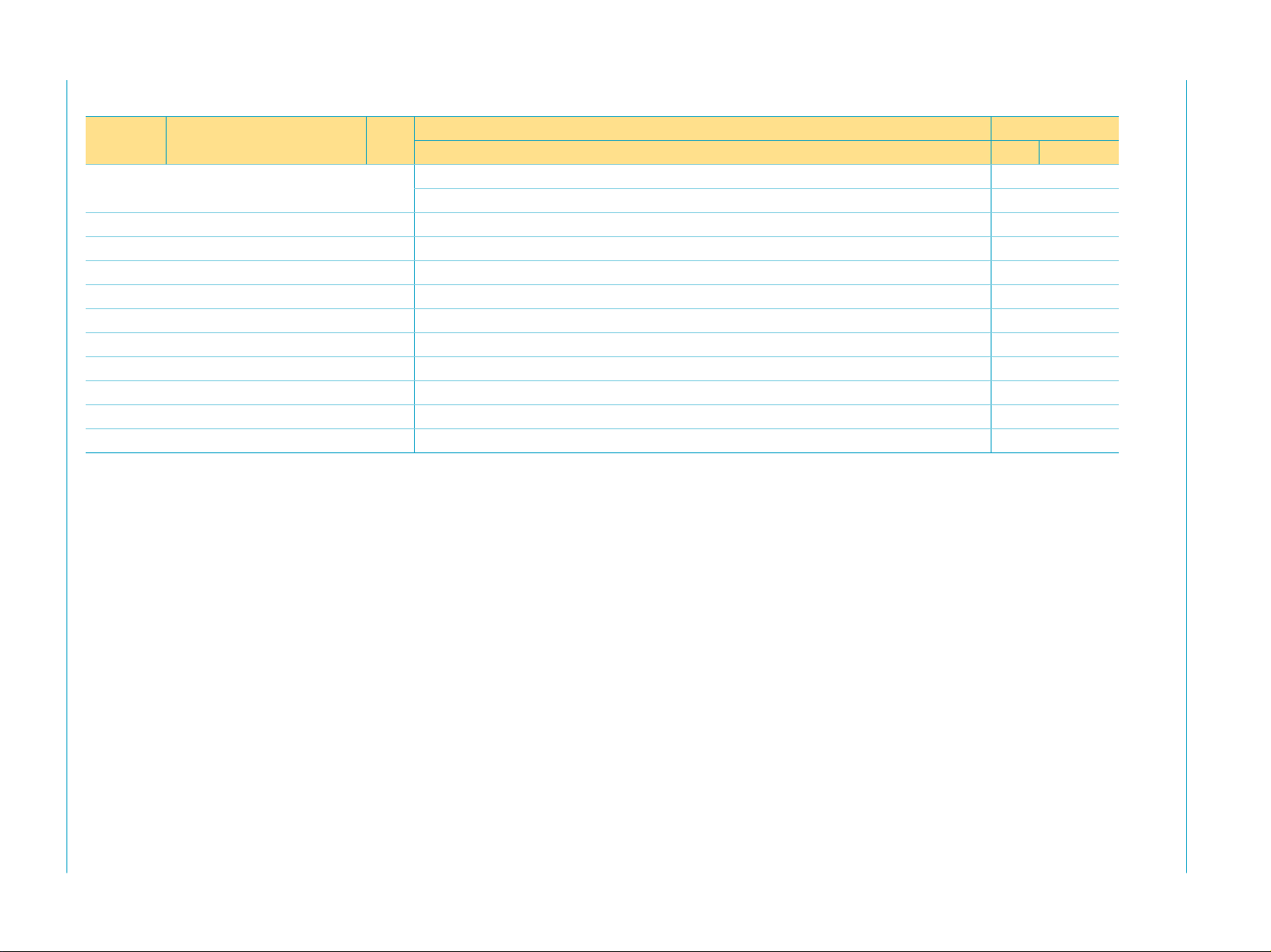

Table 7: P89LPC901 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

KBMASK Keypad interrupt mask

KBPATN Keypad pattern register 93H FF 11111111

P0* Port 0 80H - - CMPREF

P1* Port 1 90H - -

P3*Port3 B0H------XTAL1XTAL2

P0M1 Port 0 output mode 1 84H - - (P0M1.5) (P0M1.4) ----FF11111111

P0M2 Port 0 output mode 2 85H - - (P0M2.5) (P0M2.4) ----0000000000

P1M1 Port 1 output mode 1 91H - - (P1M1.5) - - (P1M1.2) - - FF

P1M2 Port 1 output mode 2 92H - - (P1M2.5) - - (P1M2.2) - - 00

P3M1 Port 3 output mode 1 B1H ------(P3M1.1) (P3M1.0) 03

P3M2 Port 3 output mode 2 B2H ------(P3M2.1) (P3M2.0) 00

PCON Power control register 87H - - BOPD BOI GF1 GF0 PMOD1 PMOD0 00 00000000

PCONA Power control register A B5H RTCPD VCPD - - 00

PCONB reserved for Power Control

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

PSW* Program status word D0H CY AC F0 RS1 RS0 OV F1 P 00 00000000

PT0AD Port 0 digital input disable F6H - - PT0AD.5 PT0AD.4 ----00xx00000x

RSTSRC Reset source register DFH - - BOF POF - R_WD R_SF R_EX

RTCCON Real-time clock control D1H RTCF RTCS1 RTCS0 - - - ERTC RTCEN 60

RTCH Real-time clock register HIGH D2H 00

RTCL Real-time clock register LOW D3H 00

SP Stack pointer 81H 07 00000111

TAMOD Timer 0 auxiliary mode 8FH -------T0M2 00 xxx0xxx0

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

…continued

addr.

86H 00 00000000

register

Bit address 87 86 85 84 83 82 81 80

Bit address 97 96 95 94 93 92 91 90

Bit address B7 B6 B5 B4 B3 B2 B1 B0

B6H--------00

Register B

Bit address D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB Hex Binary

Bit functions and addresses Reset value

[1]

[1]

[1]

[3]

[6]

/KB5

CIN1A

/KB4

----

RST - - T0 - -

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[6]

[6]

11111111

00000000

xxxxxx11

xxxxxx00

00000000

xxxxxxxx

011xxx00

00000000

00000000

Philips Semiconductors

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 17 of 55

Table 7: P89LPC901 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

TCON* Timer 0 and 1 control 88H TF1 TR1 TF0 TR0 ----0000000000

TH0 Timer 0 HIGH 8CH 00 00000000

TH1 Timer 1 HIGH 8DH 00 00000000

TL0 Timer 0 LOW 8AH 00 00000000

TL1 Timer 1 LOW 8BH 00 00000000

TMOD Timer 0 and 1 mode 89H - - T1M1 T1M0 - - T0M1 T0M0 00 00000000

TRIM Internal oscillator trim register 96H - - TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

WDCON Watchdog control register A7H PRE2 PRE1 PRE0 - - WDRUN WDTOF WDCLK

WDL Watchdog load C1H FF 11111111

WFEED1 Watchdog feed 1 C2H

WFEED2 Watchdog feed 2 C3H

[1] All ports are in input only (high impedance) state after power-up.

[2] BRGR1 and BRGR0 must only be written if BRGEN in BRGCON SFR is ‘0’. If any are written while BRGEN = 1, the result is unpredictable.

[3] The RSTSRC register reflects the cause of the P89LPC901/902/903 reset. Upon a power-up reset, all reset source flags are cleared except POF and BOF; the power-on reset

[4] After reset, the value is 111001x1, i.e., PRE2-PRE0 are all ‘1’, WDRUN = 1 and WDCLK = 1. WDTOFbit is ‘1’ after Watchdogreset and is ‘0’ after power-on reset. Other resets will

[5] On power-on reset, the TRIM SFR is initialized with a factory preprogrammed value. Other resets will not cause initialization of the TRIM register.

[6] The only reset source that affects these SFRs is power-on reset.

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

…continued

Bit functions and addresses Reset value

addr.

Bit address 8F 8E 8D 8C 8B 8A 89 88

Unimplemented bits in SFRs (labeled ’-’) are X (unknown) at all times. Unless otherwise specified, ones should not be written to these bits since they may be used for other

purposes in future derivatives. The reset values shown for these bits are ‘0’s although they are unknown when read.

value is xx110000.

not affect WDTOF.

MSB LSB Hex Binary

[5] [6]

[4] [6]

Philips Semiconductors

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 18 of 55

Table 8: P89LPC902 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

ACC* Accumulator E0H 00 00000000

AUXR1 Auxiliary function register A2H ----SRST 0 - DPS 00

B* B register F0H 00 00000000

CMP1 Comparator 1 control register ACH - - CE1 - CN1 OE1 CO1 CMF1 00

CMP2 Comparator 2 control register ADH - - CE2 - CN2 OE2 CO2 CMF2 00

DIVM CPU clock divide-by-M

DPTR Data pointer (2 bytes)

DPH Data pointer HIGH 83H 00 00000000

DPL Data pointer LOW 82H 00 00000000

FMADRH Program Flash address HIGH E7H 00 00000000

FMADRL Program Flash address LOW E6H 00 00000000

FMCON Program Flash Control

FMDATA Program Flash data E5H 00 00000000

IEN0* Interrupt enable 0 A8H EA EWDRT EBO - ET1 - ET0 - 00 00000000

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

IEN1* Interrupt enable 1 E8H -----ECEKBI - 00

IP0* Interrupt priority 0 B8H - PWDRT PBO - PT1 - PT0 - 00

IP0H Interrupt priority 0 HIGH B7H - PWDRTHPBOH - PT1H - PT0H - 00

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

addr.

Bit address E7 E6 E5 E4 E3 E2 E1 E0

Bit address F7 F6 F5 F4 F3 F2 F1 F0

95H 00 00000000

control

E4H BUSY - - - HVA HVE SV OI 70 01110000

(Read)

Program Flash Control

(Write)

Bit address EF EE ED EC EB EA E9 E8

Bit address BF BE BD BC BB BA B9 B8

MSB LSB Hex Binary

FMCMD.7FMCMD.6FMCMD.5FMCMD.4FMCMD.3FMCMD.2FMCMD.1FMCMD.

Bit functions and addresses Reset value

[1]

[1]

[1]

0

[1]

[1]

[1]

Philips Semiconductors

000000x0

xx000000

xx000000

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

00x00000

x0000000

x0000000

Bit address FF FE FD FC FB FA F9 F8

IP1* Interrupt priority 1 F8H -----PCPKBI - 00

IP1H Interrupt priority 1 HIGH F7H -----PCHPKBIH - 00

[1]

[1]

00x00000

00x00000

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 19 of 55

Table 8: P89LPC902 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

KBCON Keypad control register 94H ------PATN

KBMASK Keypad interrupt mask

KBPATN Keypad pattern register 93H FF 11111111

P0* Port 0 80H - CMP1

P1* Port 1 90H - -

P0M1 Port 0 output mode 1 84H - (P0M1.6) (P0M1.5) (P0M1.4) - (P0M1.2) - (P0M1.0) FF 11111111

P0M2 Port 0 output mode 2 85H - (P0M2.6) (P0M2.5) (P0M2.4) - (P0M2.2) - (P0M2.0) 00 00000000

P1M1 Port 1 output mode 1 91H - - (P1M1.5) -----FF

P1M2 Port 1 output mode 2 92H - - (P1M2.5) -----00

PCON Power control register 87H - - BOPD BOI GF1 GF0 PMOD1 PMOD0 00 00000000

PCONA Power control register A B5H RTCPD VCPD - - 00

PCONB reserved for Power Control

PSW* Program status word D0H CY AC F0 RS1 RS0 OV F1 P 00 00000000

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

PT0AD Port 0 digital input disable F6H - - PT0AD.5 PT0AD.4 - PT0AD.2 - - 00 xx00000x

RSTSRC Reset source register DFH - - BOF POF - R_WD R_SF R_EX

RTCCON Real-time clock control D1H RTCF RTCS1 RTCS0 - - - ERTC RTCEN 60

RTCH Real-time clock register HIGH D2H 00

RTCL Real-time clock register LOW D3H 00

SP Stack pointer 81H 07 00000111

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

…continued

addr.

86H 00 00000000

register

Bit address 87 86 85 84 83 82 81 80

Bit address 97 96 95 94 93 92 91 90

Bit address B7 B6 B5 B4 B3 B2 B1 B0

B6H--------00

Register B

Bit address D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB Hex Binary

/KB6

Bit functions and addresses Reset value

KBIF 00

_SEL

CMPREF

/KB5

CIN1A

/KB4

- KB2 - KB0

RST-----

[1]

[1]

[1]

[1]

[1]

[1]

[3]

[1]

[6]

[6]

[6]

xxxxxx00

11111111

00000000

00000000

xxxxxxxx

011xxx00

00000000

00000000

Philips Semiconductors

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 20 of 55

Table 8: P89LPC902 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

TCON* Timer 0 and 1 control 88H TF1 TR1 TF0 TR0 ----0000000000

TH0 Timer 0 HIGH 8CH 00 00000000

TH1 Timer 1 HIGH 8DH 00 00000000

TL0 Timer 0 LOW 8AH 00 00000000

TL1 Timer 1 LOW 8BH 00 00000000

TMOD Timer 0 and 1 mode 89H - - T1M1 T1M0 - - T0M1 T0M0 00 00000000

TRIM Internal oscillator trim register 96H - - TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

WDCON Watchdog control register A7H PRE2 PRE1 PRE0 - - WDRUN WDTOF WDCLK

WDL Watchdog load C1H FF 11111111

WFEED1 Watchdog feed 1 C2H

WFEED2 Watchdog feed 2 C3H

[1] All ports are in input only (high impedance) state after power-up.

[2] BRGR1 and BRGR0 must only be written if BRGEN in BRGCON SFR is ‘0’. If any are written while BRGEN = 1, the result is unpredictable.

[3] The RSTSRC register reflects the cause of the P89LPC901/902/903 reset. Upon a power-up reset, all reset source flags are cleared except POF and BOF; the power-on reset

[4] After reset, the value is 111001x1, i.e., PRE2-PRE0 are all ‘1’, WDRUN = 1 and WDCLK = 1. WDTOFbit is ‘1’ after Watchdogreset and is ‘0’ after power-on reset. Other resets will

[5] On power-on reset, the TRIM SFR is initialized with a factory preprogrammed value. Other resets will not cause initialization of the TRIM register.

[6] The only reset source that affects these SFRs is power-on reset.

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

…continued

Bit functions and addresses Reset value

addr.

Bit address 8F 8E 8D 8C 8B 8A 89 88

Unimplemented bits in SFRs (labeled ’-’) are X (unknown) at all times. Unless otherwise specified, ones should not be written to these bits since they may be used for other

purposes in future derivatives. The reset values shown for these bits are ‘0’s although they are unknown when read.

value is xx110000.

not affect WDTOF.

MSB LSB Hex Binary

[5] [6]

[4] [6]

Philips Semiconductors

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 21 of 55

Table 9: P89LPC903 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

ACC* Accumulator E0H 00 00000000

AUXR1 Auxiliary function register A2H - EBRR - - SRST 0 - DPS 00

B* B register F0H 00 00000000

BRGR0

BRGR1

BRGCON Baud rate generator control BDH ------SBRGS BRGEN 00

CMP1 Comparator 1 control register ACH - - CE1 - CN1 - CO1 CMF1 00

CMP2 Comparator 2 control register ADH - - CE2 - CN2 - CO2 CMF2 00

DIVM CPU clock divide-by-M

DPTR Data pointer (2 bytes)

DPH Data pointer HIGH 83H 00 00000000

DPL Data pointer LOW 82H 00 00000000

FMADRH Program Flash address HIGH E7H 00 00000000

FMADRL Program Flash address LOW E6H 00 00000000

FMCON Program Flash Control

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

FMDATA Program Flash data E5H 00 00000000

IEN0* Interrupt enable 0 A8H EA EWDRT EBO ES/ESR ET1 - ET0 - 00 00000000

IEN1* Interrupt enable 1 E8H - EST - - - EC EKBI - 00

IP0* Interrupt priority 0 B8H - PWDRT PBO PS/PSR PT1 - PT0 - 00

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

[2]

Baud rate generator rate

LOW

[2]

Baud rate generator rate

HIGH

control

(Read)

Program Flash Control

(Write)

addr.

Bit address E7 E6 E5 E4 E3 E2 E1 E0

Bit address F7 F6 F5 F4 F3 F2 F1 F0

BEH 00 00000000

BFH 00 00000000

95H 00 00000000

E4H BUSY - - - HVA HVE SV OI 70 01110000

Bit address EF EE ED EC EB EA E9 E8

Bit address BF BE BD BC BB BA B9 B8

MSB LSB Hex Binary

FMCMD.7FMCMD.6FMCMD.5FMCMD.4FMCMD.3FMCMD.2FMCMD.1FMCMD.

Bit functions and addresses Reset value

[1]

[6]

[1]

[1]

0

[1]

[1]

Philips Semiconductors

000000x0

xxxxxx00

xx000000

xx000000

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

00x00000

x0000000

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 22 of 55

Table 9: P89LPC903 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

IP0H Interrupt priority 0 HIGH B7H - PWDRTHPBOH PSH

IP1* Interrupt priority 1 F8H - PST - - - PC PKBI - 00

IP1H Interrupt priority 1 HIGH F7H - PSTH - - - PCH PKBIH - 00

KBCON Keypad control register 94H ------PATN

KBMASK Keypad interrupt mask

KBPATN Keypad pattern register 93H FF 11111111

P0* Port 0 80H - - CMPREF

P1* Port 1 90H - P0M1 Port 0 output mode 1 84H - - (P0M1.5) (P0M1.4) - (P0M1.2) - - FF 11111111

P0M2 Port 0 output mode 2 85H - - (P0M2.5) (P0M2.4) - (P0M2.2) - - 00 00000000

P1M1 Port 1 output mode 1 91H - - (P1M1.5) - - - (P1M1.1) (P1M1.0) FF

P1M2 Port 1 output mode 2 92H - - (P1M2.5) - - - (P1M2.1) (P1M2.0) 00

PCON Power control register 87H SMOD1 SMOD0 BOPD BOI GF1 GF0 PMOD1 PMOD0 00 00000000

PCONA Power control register A B5H RTCPD VCPD - SPD 00

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

PCONB reserved for Power Control

PSW* Program status word D0H CY AC F0 RS1 RS0 OV F1 P 00 00000000

PT0AD Port 0 digital input disable F6H - - PT0AD.5 PT0AD.4 - PT0AD.2 - - 00 xx00000x

RSTSRC Reset source register DFH - - BOF POF R_BK R_WD R_SF R_EX

RTCCON Real-time clock control D1H RTCF RTCS1 RTCS0 - - - ERTC RTCEN 60

RTCH Real-time clock register HIGH D2H 00

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

…continued

addr.

Bit address FF FE FD FC FB FA F9 F8

86H 00 00000000

register

Bit address 87 86 85 84 83 82 81 80

Bit address 97 96 95 94 93 92 91 90

B6H--------00

Register B

Bit address D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB Hex Binary

Bit functions and addresses Reset value

PT1H - PT0H - 00

/PSRH

KBIF 00

_SEL

[1]

/KB5

CIN1A

/KB4

- KB2 - -

RST - - - RxD TxD

[3]

[6]

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[6]

x0000000

00x00000

00x00000

xxxxxx00

11111111

00000000

00000000

xxxxxxxx

011xxx00

00000000

Philips Semiconductors

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 12293

Product data Rev. 04 — 21 November 2003 23 of 55

Table 9: P89LPC903 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

RTCL Real-time clock register LOW D3H 00

SADDR Serial port address register A9H 00 00000000

SADEN Serial port address enable B9H 00 00000000

SBUF Serial port data buffer register 99H xx xxxxxxxx

SCON* Serial port control 98H SM0/FE SM1 SM2 REN TB8 RB8 TI RI 00 00000000

SSTAT Serial port extended status

SP Stack pointer 81H 07 00000111

TCON* Timer 0 and 1 control 88H TF1 TR1 TF0 TR0 ----0000000000

TH0 Timer 0 HIGH 8CH 00 00000000

TH1 Timer 1 HIGH 8DH 00 00000000

TL0 Timer 0 LOW 8AH 00 00000000

TL1 Timer 1 LOW 8BH 00 00000000

TMOD Timer 0 and 1 mode 89H - - T1M1 T1M0 - - T0M1 T0M0 00 00000000

TRIM Internal oscillator trim register 96H - - TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

WDCON Watchdog control register A7H PRE2 PRE1 PRE0 - - WDRUN WDTOF WDCLK

WDL Watchdog load C1H FF 11111111

WFEED1 Watchdog feed 1 C2H

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

WFEED2 Watchdog feed 2 C3H

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

…continued

addr.

Bit address 9F 9E 9D 9C 9B 9A 99 98

BAH DBMOD INTLO CIDIS DBISEL FE BR OE STINT 00 00000000

register

Bit address 8F 8E 8D 8C 8B 8A 89 88

MSB LSB Hex Binary

Bit functions and addresses Reset value

[6]

[5] [6]

[4] [6]

Philips Semiconductors

00000000

8-bit microcontrollers with two-clock 80C51 core

P89LPC901/902/903

[1] All ports are in input only (high impedance) state after power-up.

[2] BRGR1 and BRGR0 must only be written if BRGEN in BRGCON SFR is ‘0’. If any are written while BRGEN = 1, the result is unpredictable.

Unimplemented bits in SFRs (labeled ’-’) are X (unknown) at all times. Unless otherwise specified, ones should not be written to these bits since they may be used for other

purposes in future derivatives. The reset values shown for these bits are ‘0’s although they are unknown when read.

[3] The RSTSRC register reflects the cause of the P89LPC901/902/903 reset. Upon a power-up reset, all reset source flags are cleared except POF and BOF; the power-on reset

value is xx110000.

[4] After reset, the value is 111001x1, i.e., PRE2-PRE0 are all ‘1’, WDRUN = 1 and WDCLK = 1. WDTOFbit is ‘1’ after Watchdogreset and is ‘0’ after power-on reset. Other resets will

not affect WDTOF.

[5] On power-on reset, the TRIM SFR is initialized with a factory preprogrammed value. Other resets will not cause initialization of the TRIM register.

[6] The only reset source that affects these SFRs is power-on reset.

Philips Semiconductors

8. Functional description

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Remark: Please refer to the

functional description.

8.1 Enhanced CPU

The P89LPC901/902/903 uses an enhanced 80C51 CPU which runs at 6 times the

speed of standard 80C51 devices. A machine cycle consists of two CPU clock cycles,

and most instructions execute in one or two machine cycles.

8.2 Clocks

8.2.1 Clock definitions

The P89LPC901/902/903 device has several internal clocks as defined below:

OSCCLK — Input to the DIVM clock divider. OSCCLK is selected from one of the

clock sources (see Figures 12, 13, and 14) and can also be optionally divided to a

slower frequency (see Section 8.7 “CPU CLOCK (CCLK) modification: DIVM

register”).

Note: f

CCLK — CPU clock; output of the clock divider. There are two CCLK cycles per

machine cycle, and most instructions are executed in one to two machine cycles (two

or four CCLK cycles).

RCCLK — The internal 7.373 MHz RC oscillator output.

PCLK — Clock for the various peripheral devices and is CCLK/2

is defined as the OSCCLK frequency.

OSC

P89LPC901/902/903 User’s Manual

for a more detailed

8.2.2 CPU clock (OSCCLK)

The P89LPC901/902/903 provides several user-selectable oscillator options in

generating the CPU clock. This allows optimization for a range of needs from high

precision to lowest possible cost. These options are configured when the FLASH is

programmed and include an on-chip Watchdog oscillator and an on-chip RC

oscillator.

The P89LPC901, in addition, includes an option for an oscillator using an external

crystal or an external clock source. The crystal oscillator can be optimized for low,

medium, or high frequency crystals covering a range from 20 kHz to 12 MHz.

8.2.3 Low speed oscillator option (P89LPC901)

This option supports an external crystal in the range of 20 kHz to 100 kHz. Ceramic

resonators are also supported in this configuration.

8.2.4 Medium speed oscillator option (P89LPC901)

This option supports an external crystal in the range of 100 kHz to 4 MHz. Ceramic

resonators are also supported in this configuration.

9397 750 12293

Product data Rev. 04 — 21 November 2003 24 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

8.2.5 High speed oscillator option (P89LPC901)

This option supports an external crystal in the range of 4 MHz to 12 MHz. Ceramic

resonators are also supported in this configuration. If CCLK is 8 MHz or slower, the

CLKLP SFR bit (AUXR1.7) can be set to ‘1’ to reduce power consumption. On reset,

CLKLP is ‘0’ allowing highest performance access. This bit can then be set in

software if CCLK is running at 8 MHz or slower.

8.2.6 Clock output (P89LPC901)

The P89LPC901 supports a user selectable clock output function on the

XTAL2/CLKOUTpin when crystal oscillator is not being used. This condition occurs if

another clock source has been selected (on-chip RC oscillator, Watchdog oscillator,

external clock input on X1) and if the Real-Time clock is not using the crystal

oscillator as its clock source. This allows external devices to synchronize to the

P89LPC901. This output is enabled by the ENCLK bit in the TRIM register. The

frequency of this clock output is1⁄2that of the CCLK. If the clock output is not needed

in Idle mode, it may be turned off prior to entering Idle, saving additional power.

8.3 On-chip RC oscillator option

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

The P89LPC901/902/903 has a 6-bit TRIM register that can be used to tune the

frequency of the RC oscillator. During reset, the TRIM value is initialized to a factory

pre-programmed value to adjust the oscillator frequency to 7.373 MHz, ±2.5%.

End-user applications can write to the Trim register to adjust the on-chip RC oscillator

to other frequencies. If CCLK is 8 MHz or slower, the CLKLP SFR bit (AUXR1.7) can

be set to ‘1’ to reduce power consumption. On reset, CLKLP is ‘0’ allowing highest

performance access. This bit can then be set in software if CCLK is running at 8 MHz

or slower.

8.4 Watchdog oscillator option

The Watchdog has a separate oscillator which has a frequency of 400 kHz. This

oscillator can be used to save power when a high clock frequency is not needed.

8.5 External clock input option (P89LPC901)

In this configuration, the processor clock is derived from an external source driving

the XTAL1/P3.1 pin. The rate may be from 0 Hz up to 12 MHz. The XTAL2/P3.0 pin

may be used as a standard port pin or a clock output.

9397 750 12293

Product data Rev. 04 — 21 November 2003 25 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

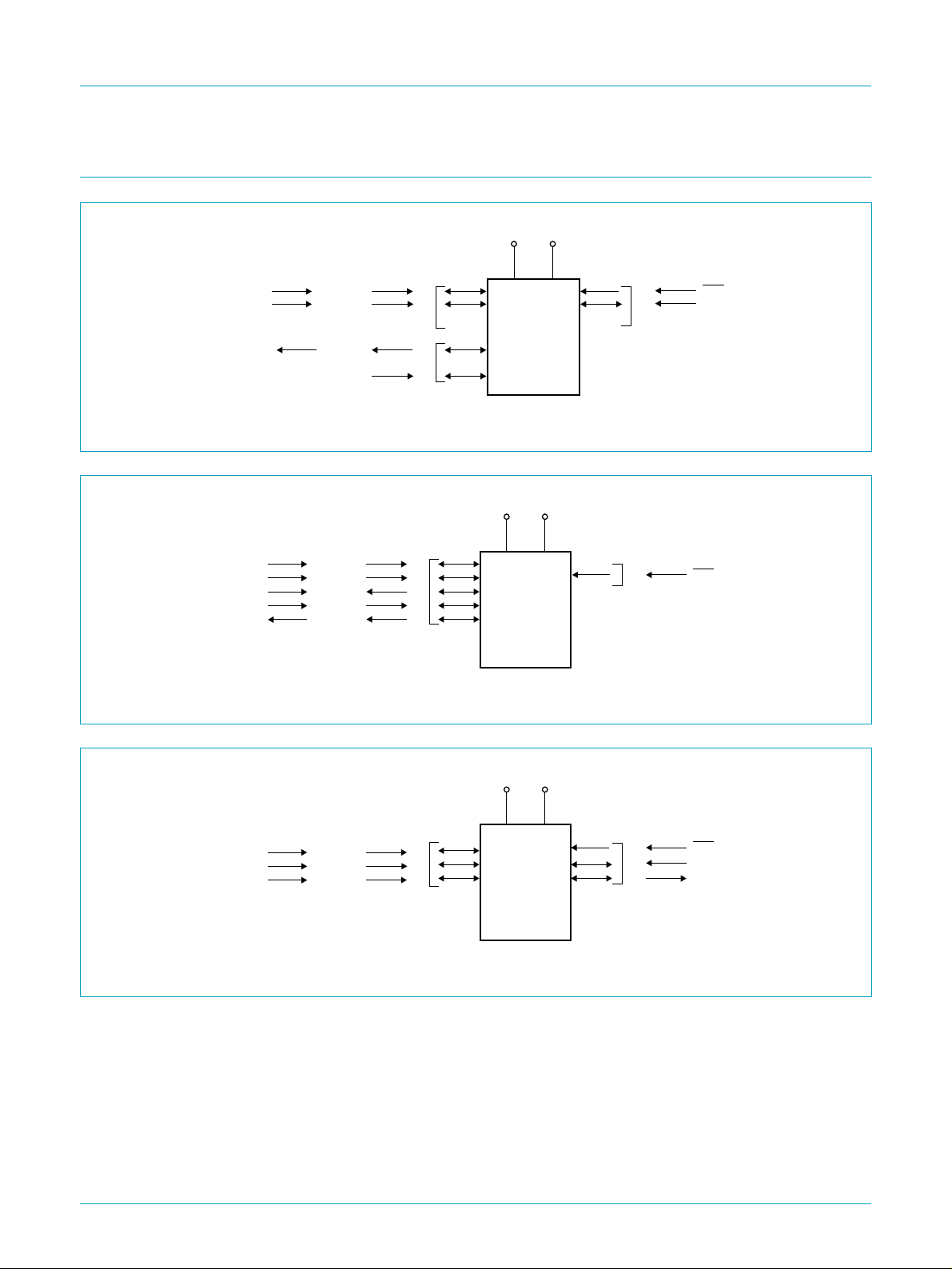

XTAL1

XTAL2

High freq.

Med. freq.

Low freq.

RC

OSCILLATOR

(7.3728 MHz)

WATCHDOG

OSCILLATOR

(400 kHz)

DIVM

CCLKOSCCLK

Fig 12. Block diagram of oscillator control (P89LPC901).

RC

OSCILLATOR

(7.3728 MHz)

WATCHDOG

OSCILLATOR

(400 kHz)

DIVM

CCLKOSCCLK

¸

2

PCLK

¸

2

PCLK

TIMERS 0 & 1

RTC

CPU

WDT

TIMERS 0 & 1

002aaa447

RTC

CPU

WDT

Fig 13. Block diagram of oscillator control (P89LPC902).

RC

OSCILLATOR

(7.3728 MHz)

WATCHDOG

OSCILLATOR

(400 kHz)

BAUD RATE

GENERATOR

DIVM

CCLKOSCCLK

UART

Fig 14. Block diagram of oscillator control (P89LPC903).

002aaa448

RTC

CPU

¸

2

WDT

PCLK

TIMERS 0 & 1

002aaa449

9397 750 12293

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Product data Rev. 04 — 21 November 2003 26 of 55

Philips Semiconductors

8.6 CPU CLock (CCLK) wake-up delay

The P89LPC901/902/903 has an internal wake-up timer that delays the clock until it

stabilizes depending to the clock source used. If the clock source is any of the three

crystal selections (P89LPC901) the delay is 992 OSCCLK cycles plus 60 to 100 µs.

8.7 CPU CLOCK (CCLK) modification: DIVM register

The OSCCLK frequency can be divided down up to 510 times by configuring a

dividing register, DIVM, to generate CCLK. This feature makes it possible to

temporarily run the CPU at a lower rate, reducing power consumption. By dividing the

clock, the CPU can retain the ability to respond to events that would not exit Idle

mode by executing its normal program at a lower rate. This can also allow bypassing

the oscillator start-up time in cases where Power-down mode would otherwise be

used. The value of DIVM may be changed by the program at any time without

interrupting code execution.

8.8 Low power select

The P89LPC901 is designed to run at 12 MHz (CCLK) maximum. However, if CCLK

is 8 MHz or slower,the CLKLP SFR bit (AUXR1.7) can be set to ‘1’ to lower the power

consumption further. On any reset, CLKLP is ‘0’ allowing highest performance

access. This bit can then be set in software if CCLK is running at 8 MHz or slower.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

8.9 Memory organization

The various P89LPC901/902/903 memory spaces are as follows:

• DATA

128 bytes of internal data memory space (00h:7Fh) accessed via direct or indirect

addressing, using instruction other than MOVX and MOVC. All or part of the Stack

may be in this area.

• SFR

Special Function Registers. Selected CPU registers and peripheral control and

status registers, accessible only via direct addressing.

• CODE

64 kB of Code memory space, accessed as part of program execution and via the

MOVC instruction. The P89LPC901/902/903 has 1 kB of on-chip Code memory.

8.10 Data RAM arrangement

The 128 bytes of on-chip RAM is organized as follows:

Table 10: On-chip data memory usages

Type Data RAM Size (Bytes)

DATA Memory that can be addressed directly and indirectly 128

8.11 Interrupts

The P89LPC901/902/903 uses a four priority level interrupt structure. This allows

great flexibility in controlling the handling of the many interrupt sources.

9397 750 12293

Product data Rev. 04 — 21 November 2003 27 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

The P89LPC901 supports 6 interrupt sources: timers 0 and 1, brownout detect,

Watchdog/real-time clock, keyboard, and the comparator.

The P89LPC902 supports 6 interrupt sources: timers 0 and 1, brownout detect,

Watchdog/real-time clock, keyboard, and comparators 1 and 2.

The P89LPC903 supports 9 interrupt sources: timers 0 and 1, serial port Tx, serial

port Rx, combined serial port Rx/Tx, brownout detect, Watchdog/real-time clock,

keyboard, and comparators 1 and 2.

Each interrupt source can be individually enabled or disabled by setting or clearing a

bit in the interrupt enable registers IEN0 or IEN1. The IEN0 register also contains a

global disable bit, EA, which disables all interrupts.

Each interrupt source can be individually programmed to one of four priority levels by

setting or clearing bits in the interrupt priority registers IP0, IP0H, IP1, and IP1H. An

interrupt service routine in progress can be interrupted by a higher priority interrupt,

but not by another interrupt of the same or lower priority. The highest priority interrupt

service cannot be interrupted by any other interrupt source. If two requests of

different priority levels are pending at the start of an instruction, the request of higher

priority level is serviced.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

If requests of the same priority level are pending at the start of an instruction, an

internal polling sequence determines which request is serviced. This is called the

arbitration ranking. Note that the arbitration ranking is only used to resolve pending

requests of the same priority level.

8.11.1 External interrupt inputs

The P89LPC901/902/903 has a Keypad Interrupt function. This can be used as an

external interrupt input.

If enabled when the P89LPC901/902/903 is put into Power-down or Idle mode, the

interrupt will cause the processor to wake-up and resume operation. Refer to Section

8.14 “Power reduction modes” for details.

9397 750 12293

Product data Rev. 04 — 21 November 2003 28 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

RTCF

ERTC

(RTCCON.1)

WDOVF

BOPD

EBO

KBIF

EKBI

EWDRT

CMF

EC

EA (IE0.7)

TF1

ET1

TF0

ET0

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

WAKE-UP

(IF IN POWER-DOWN)

INTERRUPT

TO CPU

002aaa450

Fig 15. Interrupt sources, interrupt enables, and power-down wake-up sources (P89LPC901).

BOPD

EBO

RTCF

ERTC

(RTCCON.1)

WDOVF

KBIF

EKBI

EWDRT

CMF

EC

EA (IE0.7)

TF1

ET1

TF0

ET0

WAKE-UP

(IF IN POWER-DOWN)

002aaa451

Fig 16. Interrupt sources, interrupt enables, and power-down wake-up sources (P89LPC902).

INTERRUPT

TO CPU

9397 750 12293

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Product data Rev. 04 — 21 November 2003 29 of 55

Philips Semiconductors

RTCF

ERTC

(RTCCON.1)

WDOVF

BOPD

EBO

KBIF

EKBI

EWDRT

CMF

EC

EA (IE0.7)

TF1

ET1

TI & RI/RI

ES/ESR

EST

TF0

ET0

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

WAKE-UP

(IF IN POWER-DOWN)

TI

INTERRUPT

TO CPU

002aaa452

Fig 17. Interrupt sources, interrupt enables, and power-down wake-up sources (P89LPC903).

8.12 I/O ports

The P89LPC901 has between 3 and 6 I/O pins: P0.4, P0.5, P1.2, P1.5, P3.0, and

P3.1 The exact number of I/O pins available depends on the clock and reset options

chosen, as shown in Table 11.

Table 11: Number of I/O pins available

Clock source Reset option Number of I/O pins

(8-pin package)

On-chip oscillator or Watchdog oscillator No external reset (except during power-up) 6

External

External clock input No external reset (except during power-up) 5

External

Low/medium/high speed oscillator

(external crystal or resonator)

No external reset (except during power-up) 4

External

The P89LPC902 and P89LPC903 devices have either 5 or 6 I/O pins depending on

the reset pin option chosen.

8.12.1 Port configurations

All but one I/O port pin on the P89LPC901/902/903 may be configured by software to

one of four types on a bit-by-bit basis. These are: quasi-bidirectional (standard 80C51

port outputs), push-pull, open drain, and input-only. Two configuration registers for

each port select the output type for each port pin.

RST pin supported 5

RST pin supported 4

RST pin supported 3

P1.5 (RST) can only be an input and cannot be configured.

9397 750 12293

Product data Rev. 04 — 21 November 2003 30 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

8.12.2 Quasi-bidirectional output configuration

Quasi-bidirectional output type can be used as both an input and output without the

need to reconfigure the port. This is possible because when the port outputs a logic

HIGH, it is weakly driven, allowing an external device to pull the pin LOW. When the

pin is driven LOW, it is driven strongly and able to sink a fairly large current. These

features are somewhat similar to an open-drain output except that there are three

pull-up transistors in the quasi-bidirectional output that serve different purposes.

The P89LPC901/902/903 is a 3 V device, however, the pins are 5 V-tolerant (except

for XTAL1 and XTAL2). In quasi-bidirectional mode, if a user applies 5 V on the pin,

there will be a current flowing from the pin to VDD, causing extra power consumption.

Therefore, applying 5 V in quasi-bidirectional mode is discouraged.

A quasi-bidirectional port pin has a Schmitt-triggered input that also has a glitch

suppression circuit.

8.12.3 Open-drain output configuration

The open-drain output configuration turns off all pull-ups and only drives the

pull-down transistor of the port driver when the port latch contains a logic ‘0’. To be

used as a logic output, a port configured in this manner must have an external

pull-up, typically a resistor tied to VDD.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

An open-drain port pin has a Schmitt-triggered input that also has a glitch

suppression circuit.

8.12.4 Input-only configuration

The input-only port configuration has no output drivers. It is a Schmitt-triggered input

that also has a glitch suppression circuit.

8.12.5 Push-pull output configuration

The push-pull output configuration has the same pull-down structure as both the

open-drain and the quasi-bidirectional output modes, but provides a continuous

strong pull-up when the port latch contains a logic ‘1’. The push-pull mode may be

used when more source current is needed from a port output. A push-pull port pin

has a Schmitt-triggered input that also has a glitch suppression circuit.

8.12.6 Port 0 analog functions

The P89LPC901/902/903 incorporates an Analog Comparator. In order to give the

best analog function performance and to minimize power consumption, pins that are

being used for analog functions must have the digital outputs and digital inputs

disabled.

Digital outputs are disabled by putting the port output into the Input-Only (high

impedance) mode as described in Section 8.12.4 “Input-only configuration”.

Digital inputs on Port 0 may be disabled through the use of the PT0AD register. On

any reset, the PT0AD bits default to ‘0’s to enable digital functions.

9397 750 12293

Product data Rev. 04 — 21 November 2003 31 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

8.12.7 Additional port features

After power-up, all pins are in Input-Only mode. Please note that this is different

from the LPC76x series of devices.

• After power-up all I/O pins, except P1.5, may be configured by software.

• Pin P1.5 is input only.

Every output on the P89LPC901/902/903 has been designed to sink typical LED

drive current. However, there is a maximum total output current for all ports which

must not be exceeded. Please refer to Table 13 “DC electrical characteristics” for

detailed specifications.

All ports pins that can function as an output have slew rate controlled outputs to limit

noise generated by quickly switching output signals. The slew rate is factory-set to

approximately 10 ns rise and fall times.

8.13 Power monitoring functions

The P89LPC901/902/903 incorporates power monitoring functions designed to

preventincorrect operation during initial power-up and power loss or reduction during

operation. This is accomplished with two hardware functions: Power-on Detect and

Brownout detect.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

8.13.1 Brownout detection

The Brownout detect function determines if the power supply voltage drops below a

certain level. The default operation is for a Brownout detection to cause a processor

reset, however, it may alternatively be configured to generate an interrupt.

Brownout detection may be enabled or disabled in software.

If Brownout detection is enabled, the operating voltagerangefor VDDis 2.7 V to 3.6 V,

and the brownout condition occurs when VDD falls below the brownout trip voltage,

VBO (see Table 13 “DC electrical characteristics”), and is negated when VDD rises

above VBO. If brownout detection is disabled, the operating voltage range for VDD is

2.4 V to 3.6 V. If the P89LPC901/902/903 device is to operate with a power supply

that can be below 2.7 V, BOE should be left in the unprogrammed state so that the

device can operate at 2.4 V, otherwise continuous brownout reset may prevent the

device from operating.

For correct activation of Brownout detect, the VDD rise and fall times must be

observed. Please see Table 13 “DC electrical characteristics” for specifications.

8.13.2 Power-on detection

The Power-onDetect has a function similar to the Brownout detect, but is designed to

work as power comes up initially, before the power supply voltage reaches a level

where Brownout detect can work. The POF flag in the RSTSRC register is set to

indicate an initial power-up condition. The POF flag will remain set until cleared by

software.

8.14 Power reduction modes

The P89LPC901/902/903 supports three different power reduction modes. These

modes are Idle mode, Power-down mode, and total Power-down mode.

9397 750 12293

Product data Rev. 04 — 21 November 2003 32 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

8.14.1 Idle mode

Idle mode leaves peripherals running in order to allow them to activate the processor

when an interrupt is generated. Any enabled interrupt source or reset may terminate

Idle mode.

8.14.2 Power-down mode

The Power-down mode stops the oscillator in order to minimize power consumption.

The P89LPC901/902/903 exits Power-downmode via any reset, or certain interrupts.

In Power-down mode, the power supply voltage may be reduced to the RAM

keep-alive voltage V

Power-down mode was entered. SFR contents are not guaranteed after VDD has

been lowered to V

via reset in this case. VDD must be raised to within the operating range before the

Power-down mode is exited.

Some chip functions continue to operate and draw power during Power-down mode,

increasing the total power used during Power-down.These include: Brownout detect,

Watchdog Timer, Comparators (note that Comparators can be powered-down

separately), and Real-Time Clock (RTC)/System Timer. The internal RC oscillator is

disabled unless both the RC oscillator has been selected as the system clock and the

RTC is enabled.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

. This retains the RAM contents at the point where

RAM

, therefore it is highly recommended to wake up the processor

RAM

8.14.3 Total Power-down mode

This is the same as Power-down mode except that the brownout detection circuitry

and the voltage comparators are also disabled to conserve additional power. The

internal RC oscillator is disabled unless both the RC oscillator has been selected as

the system clock and the RTC is enabled. If the internal RC oscillator is used to clock

the RTC during Power-down, there will be high power consumption. Please use an

external low frequency clock to achieve low power with the Real-Time Clock running

during Power-down.

8.15 Reset

The P1.5/RST pin can function as either an active-LOW reset input or as a digital

input, P1.5. The RPE (Reset Pin Enable) bit in UCFG1, when set to ‘1’, enables the

external reset input function on P1.5. When cleared, P1.5 may be used as an input

pin.

Remark: During a power-up sequence, the RPE selection is overridden and this pin

will always function as a reset input. An external circuit connected to this pin

should not hold this pin LOW during a power-on sequence as this will keep the

device in reset. After power-up this input will function either as an external reset

input or as a digital input as defined by the RPE bit. Only a power-up reset will

temporarily override the selection defined by RPE bit. Other sources of reset will not

override the RPE bit.

Remark: During a power cycle, VDDmust fallbelowV

(see Table13 “DC electrical

POR

characteristics”) before power is reapplied, in order to ensure a power-on reset.

9397 750 12293

Product data Rev. 04 — 21 November 2003 33 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

Reset can be triggered from the following sources:

• External reset pin (during power-up or if user configured via UCFG1)

• Power-on detect

• Brownout detect

• Watchdog Timer

• Software reset

• UART break character detect reset (P80LPC903).

For every reset source, there is a flag in the Reset Register, RSTSRC. The user can

read this register to determine the most recent reset source. These flag bits can be

cleared in software by writing a ‘0’ to the corresponding bit. More than one flag bit

may be set:

• During a power-on reset, both POF and BOF are set but the other flag bits are

• For any other reset, previously set flag bits that have not been cleared will remain

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

cleared.

set.

8.16 Timers/counters 0 and 1

The P89LPC901/902/903 has two general purpose timers which are similar to the

standard 80C51 Timer 0 and Timer 1. These timers have four operating modes

(modes 0, 1, 2, and 3). Modes 0, 1, and 2 are the same for both Timers. Mode 3 is

different.

8.16.1 Mode 0

Putting either Timer into Mode 0 makes it look like an 8048 Timer, which is an 8-bit

Counter with a divide-by-32 prescaler. In this mode, the Timer register is configured

as a 13-bit register. Mode 0 operation is the same for Timer 0 and Timer 1.

8.16.2 Mode 1

Mode 1 is the same as Mode 0, except that all 16 bits of the timer register are used.

8.16.3 Mode 2

Mode 2 configures the Timer register as an 8-bit Counter with automatic reload.

Mode 2 operation is the same for Timer 0 and Timer 1.

8.16.4 Mode 3

When Timer 1 is in Mode 3 it is stopped. Timer 0 in Mode 3 forms two separate 8-bit

counters and is provided for applications that require an extra 8-bit timer. When

Timer 1 is in Mode 3 it can still be used by the serial port as a baud rate generator.

8.16.5 Mode 6 (P89LPC901)

In this mode, the corresponding timer can be changed to a PWM with a full period of

256 timer clocks.

9397 750 12293

Product data Rev. 04 — 21 November 2003 34 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

8.16.6 Timer overflow toggle output (P89LPC901)

Timers 0 and 1 can be configured to automatically toggle a port output whenever a

timer overflow occurs. The same device pins that are used for the T0 and T1 count

inputs are also used for the timer toggle outputs. The port outputs will be a logic 1

prior to the first timer overflow when this mode is turned on.

8.17 Real-Time clock/system timer

The P89LPC901/902/903 has a simple Real-Time clock that allows a user to continue

running an accurate timer while the rest of the device is powered-down. The

Real-Time clock can be a wake-up or an interrupt source. The Real-Time clock is a

23-bit down counter comprised of a 7-bit prescaler and a 16-bit loadable down

counter. When it reaches all ‘0’s, the counter will be reloaded again and the RTCF

flag will be set. The clock source for this counter can be either the CPU clock (CCLK)

or the XTAL oscillator, provided that the XTAL oscillator is not being used as the CPU

clock. If the XTAL oscillator is used as the CPU clock, then the RTC will use CCLK as

its clock source. Only power-on reset will reset the Real-Time clock and its

associated SFRs to the default state.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

8.18 UART (P89LPC903)

The P89LPC903 has an enhanced UART that is compatible with the conventional

80C51 UART except that Timer 2 overflow cannot be used as a baud rate source.

The P89LPC903 does include an independent Baud Rate Generator. The baud rate

can be selected from the oscillator (divided by a constant), Timer 1 overflow, or the

independent Baud Rate Generator. In addition to the baud rate generation,

enhancements over the standard 80C51 UART include Framing Error detection,

automatic address recognition, selectable double buffering and several interrupt

options. The UART can be operated in 4 modes: shift register, 8-bit UART, 9-bit

UART, and CPU clock/32 or CPU clock/16.

8.18.1 Mode 0

Serial data enters and exits through RxD. TxD outputs the shift clock. 8 bits are

transmitted or received, LSB first. The baud rate is fixed at1⁄16 of the CPU clock

frequency.

8.18.2 Mode 1

10 bits are transmitted (through TxD) or received (through RxD): a start bit

(logical ‘0’), 8 data bits (LSB first), and a stop bit (logical ‘1’). When data is received,

the stop bit is stored in RB8 in Special Function Register SCON. The baud rate is

variable and is determined by the Timer 1 overflow rate or the Baud Rate Generator

(described in Section 8.18.5 “Baud rate generator and selection”).

8.18.3 Mode 2

11 bits are transmitted (through TxD) or received (through RxD): start bit (logical ‘0’),

8 data bits (LSB first), a programmable 9th data bit, and a stop bit (logical ‘1’). When

data is transmitted, the 9thdata bit (TB8 in SCON) can be assigned the value of ‘0’ or

‘1’. Or, for example, the parity bit (P, in the PSW) could be moved into TB8. When

data is received, the 9th data bit goes into RB8 in Special Function Register SCON,

while the stop bit is not saved. The baud rate is programmable to either1⁄16 or1⁄32 of

the CPU clock frequency, as determined by the SMOD1 bit in PCON.

9397 750 12293

Product data Rev. 04 — 21 November 2003 35 of 55

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Philips Semiconductors

8.18.4 Mode 3

11 bits are transmitted (through TxD) or received (through RxD): a start bit

(logical ‘0’), 8 data bits (LSB first), a programmable 9th data bit, and a stop bit

(logical ‘1’). In fact, Mode 3 is the same as Mode 2 in all respects except baud rate.

The baud rate in Mode 3 is variable and is determined by the Timer 1 overflow rate or

the Baud Rate Generator (described in section Section 8.18.5 “Baud rate generator

and selection”).

8.18.5 Baud rate generator and selection

The P89LPC903 enhanced UART has an independent Baud Rate Generator. The

baud rate is determined by a baud-rate preprogrammed into the BRGR1 and BRGR0

SFRs which together form a 16-bit baud rate divisor value that works in a similar

manner as Timer 1. If the baud rate generator is used, Timer 1 can be used for other

timing functions.

The UART can use either Timer 1 or the baud rate generator output (see Figure 18).

Note that Timer T1 is further divided by 2 if the SMOD1 bit (PCON.7) is cleared. The

independent Baud Rate Generator uses CCLK.

P89LPC901/902/903

8-bit microcontrollers with two-clock 80C51 core

Timer 1 Overflow

(PCLK-based)

Baud Rate Generator

(CCLK-based)

Fig 18. Baud rate sources for UART (Modes 1, 3).

8.18.6 Framing error

Framing error is reported in the status register (SSTAT). In addition, if SMOD0

(PCON.6) is ‘1’, framing errors can be made available in SCON.7, respectively. If

SMOD0 is ‘0’, SCON.7 is SM0. It is recommended that SM0 and SM1 (SCON.7:6)

are set up when SMOD0 is ‘0’.

8.18.7 Break detect

Break detect is reported in the status register (SSTAT). A break is detected when

11 consecutive bits are sensed LOW. The break detect can be used to reset the

device.

8.18.8 Double buffering

The UART has a transmit double buffer that allows buffering of the next character to

be written to SBUF while the first character is being transmitted. Double buffering

allows transmission of a string of characters with only one stop bit between any two