Philips MCM-761 Service Manual

Micro System

MCM761/12/61

TABLE OF CONTENTS

Page

Location of PC Boards & Versions Variation ........................1-2

Speci cations .......................................................................1-3

Measurement Setup .............................................................1-4

Service Aids, Safety Instruction, etc ...........................1-5 to 1-7

Connections & Functional Overview.........................1-8 to 1-11

Troubleshooting ......................................................1-12 to 1-13

Disassembly Instructions & Service positions .........................2

Service Test Program ..............................................................3

Set Block Diagram ...................................................................4

Set Wiring Diagram .................................................................5

Display Board .......................................................................... 6

CD Board .................................................................................7

Power Board ............................................................................8

Cassette Board........................................................................9

Main and Top Key Boards ..................................................... 10

Set Mechanical Exploded View & Parts List ..........................11

Revision List ..........................................................................12

©

Copyright 2011 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise without

the prior permission of Philips.

Published by SL 1108 Service Audio Printed in The Netherlands Subject to modification

Version 1.4

CLASS 1

LASER PRODUCT

3141 785 34044

LACATION OF PCBS

¥

¥

¥

¥

1-2

VERSION VARIATIONS:

Type /Versions:

Board in used:

Service policy

DISPLAY BOARD

TOP KEY BOARD

TUNER BOARD

MAIN BOARD

POWER BOARD

CASS BOARD

CD BOARD

Type /Versions:

Features

RDS

VOLTAGE SELECTOR

ECO STANDBY - DARK

* TIPS : C -- Component Lever Repair.

M -- Module Lever Repair

-- Used

Feature diffrence

MCM761

/37

/05 /61

/12

C

C

M

C/M

C/M

C/M

C/M

/37

/05 /61

/12

C

C

M

C

C/M

C

C

/98

MCM761

/98

SPECIFICATIONS

1-3

GENERAL:

Mains voltage : 110-127V/220-240V Switchable

for /98

117V ± 10% for /37

220V ± 10% for /61

230 ± 10% for /05/12

Mains frequency : 50/60Hz

Power consumption : 55W at 1/8 P

rated

< 15W at Standby (Demo mode off)

< 0W at ECO Standby

Clock accuracy : < 4 seconds per day

Dimension centre unit : : 340 x 179 x 252 mm ( L x D x H )

TUNER:

FM

Tuning range : 87.5-108MHz

Grid : 50kHz

100kHz for /37

IF frequency : 10.7MHz ± 25kHz

Aerial input : 75 ohm coaxial

300 ohm click fit for /37

Sensitivity at 26dB S/N : < 22uV

Selectivity at 600kHz bandwidth : > 25dB

Image rejection : > 25dB [> 75dB]

Distortion at RF=1mV, dev. 75kHz : < 3%

-3dB Limiting point : < 23.5dBf

Crosstalk at RF=1mV, dev. 40kHz : > 18dB

MW

Tuning range : 531-1602kHz

530-1700kHz for /98/37

Grid : 9kHz

10kHz for /98/37

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : < 22uV

Selectivity at 18kHz bandwidth : > 18dB

IF rejection : > 45dB

Image rejection : > 28dB

Distortion at RF=50mV, M=80% : < 5%

Input sensitivity

Aux in (at 1kHz) : 500mV at 600 ohm

CD (Audio Disc1) : -6dB track (Trk 35)

USB : -6dB track

Output sensitivity

Headphone output at 32 ohm : 15mW ±2dB (Max. vol.)

CASSETTE RECORDER:

Number of track : 2 tracks (stereo)

Tape speed : 4.76 cm/sec ± 2%

Wow and flutter : < 0.4% DIN

Fast-wind/Rewind time C60 : 130 sec

Bias system : 78kHz ± 10kHz

Rec/Pb frequency response within 8dB : 80Hz - 10kHz

Signal to Noise Ratio (Type I) : > 48dBA

Signal to Noise Ratio (Type II) : > 52dBA

COMPACT DISC:

Measurement done directly at the connector on the board.

Output Resistance : < 100 ohm

Output Voltage (0dB, 1kHz) : 0.5Vrms ± 1dB (unloaded)

Channel Unbalance : < ±1dB

Channel Separation (1kHz) : > 60dB

Frequency Response (±3dB) : 20Hz-20kHz

Signal to Noise Ratio : > 76dBA

MP3-CD Bit Rate : 8-320 kbps

WMA-CD Bit Rate : 64-192kbps

Sampling Frequencies : 8,11.025,12,16,22.05,24,

32,44.1,48kHz

Recording Format : ISO9660 UDF format not

supported

USB:

Measurement done at speaker terminals across 6: load

w/ 500mW output and DSC setting in Jazz Mode.

Frequency response within ± 3dB : 100Hz - 16kHz

Signal/Noise ratio (A-weighted) : > 60dBA

Channel crosstalk at 1kHz : > 35dB

Channel unbalance at 1kHz : ± 3dB

AMPLIFIER:

Output power (6 ohm, 1kHz, 10% THD)

L & R : 2 x 75W RMS

Frequency response within -3dB : 60Hz-16kHz

Bass : 60Hz ± 3 Steps

Treble : 12kHz ± 3 Steps

Incredible Surround : On / Off

[....] Values indicated are for "ECO6 Cenelec Board" only.

e

MEASUREMENT SETUP

Tuner FM

1-4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50:

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50:

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

L

R

SBC429 4822 397 30184

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

-

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette

LF Generator

e.g. PM5110

Fe SBC420 4822 397 30071

DUT

L

R

S/N and distortion met

e.g. Sound Technology ST170

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

SERVICE AIDS

1-5

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure thatyouare

connected with the same potential as the mass

of the set viaawrist wrap with resistance.

Keep components and tools also at this

potential.

WARNING

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

Safety components are marked by the symbol

!

.

ESD

CLASS 1

LASER PRODUCT

Lead free

INSTRUCTIONS ON CD PLAYABILITY

Customer complaint

"CD related problem"

Set remains closed!

check playability

1 - 6

playability

ok ?

Y

Play a CD

for at least 10 minutes

check playability

playability

ok ?

Y

add Info for customer

"SET OK"

N

"fast" lens cleaning

check playability

playability

ok ?

N

For flap loaders (= access to CD drive possible)

cleaning method is recommended

N

Y

Exchange CDM

return set

- For description - see following pages

INSTRUCTIONS ON CD PLAYABILITY

1 - 7

PLAYABILITY CHECK

For sets which are compatible with CD-RW discs

use CD-RW Printed Audio Disc ....................7104 099 96611

TR 3 (Fingerprint)

TR 8 (600µ Black dot) maximum at 01:00

• playback of these two tracks without audible disturbance

playing time for: Fingerprint

Black dot from 00:50 to 01:10

• jump forward/backward (search) within a reasonable time

For all other sets

use CD-DA SBC 444A..................................4822 397 30245

TR 14 (600µ Black dot) maximum at 01:15

TR 19 (Fingerprint)

TR 10 (1000µ wedge)

• playback of all these tracks without audible disturbance

playing time for: 1000µ wedge 10seconds

Fingerprint 10seconds

Black dot from 01:05 to 01:25

• jump forward/backward (search) within a reasonable time

10seconds

LIQUID LENS CLEANING

Before touching the lens it is advised to clean the

surface of the lens by blowing clean air over it.

This to avoid that little particles make scratches on

the lens.

Because the material of the lens is synthetic and coated

with a special anti-reflectivity layer, cleaning must be done

with a non-aggressive cleaning fluid. It is advised to use

“Cleaning Solvent

The actuator is a very precise mechanical component and

may not be damaged in order to guarantee its full function.

Clean the lens gently (don’t press too hard) with a soft and

clean cotton bud moistened with the special lens cleaner.

The direction of cleaning must be in the way as indicated in

the picture below.

CUSTOMER INFORMATION

It is proposed to add an addendum sheet to the set which

informs the customer that the set has been checked

carefully - but no fault was found.

The problem was obviously caused by a scratched, dirty or

copy-protected CD. In case problems remain, the customer

is requested to contact the workshop directly.

The lens cleaning (method ) should be mentioned in the

addendum sheet.

The final wording in national language as well as the printing

is under responsibility of the Regional Service Organizations.

DISMANTLING INSTRUCTIONS

2-1

2-1

Dismantling of the Cover Cassette and Universal Loader

1) Remove the Cover Cassette (pos 1+pos 2) in the direction as

shown in Figure 1.

2) Loosen 4 screws to remove the Cover Top (pos 62) by

sliding it out towards the rear before lifting up.

- 2 screws on the rear

- 1 screw each on the left & right side

3) Loosen 2 screws each to remove the Panel Left (pos 61)

and Panel Right (pos 60). The Panels are removed by

sliding it towards the rear and outwards.

- 1 screw on the rear

- 1 screw on the side

- see Service position A

4) Loosen 4 screws A (see Figure 2) to remove the Bracket

Module Mounting (pos 54) and Universal Loader (pos

58).

- 2 screws each on the left & right side

5) Shake up the Bracket Module Mounting and CD Loader

as shown in Figure 3 till the Cover CD (pos7) fall off.

Figure 1

Detaching the Universal Loader from the Bracket Module Mounting

1) Slide out the Loader Tray fully and remove4 screws B (see

Figure 4) to detach the Universal Loader (pos 58) from

the Bracket Module Mounting (pos 54).

- see Service position B

Figure 4

Detaching the Front Panel assembly from the Bottom/Rear assembly

1) Remove 2 screws C (see Figure 5) from the bottom of the

Cabinet Front .

2) Release the fixation of the Main Board to Bracket Combi

by removing the 1 screw and pulling the Main Board

outwards (see Figure 6).

Figure 2

3) Uncatch 2 catches on the left & right sides of the Cabinet

Front and slides the Front Panel assembly out towards

the front.

- see Service position C

Figure 5

Figure 3

7erugiF

DISMANTLING INSTRUCTIONS

2-2

2-2

Dismantling of the Front Panel assembly

1) The Knob Volume (pos 10) can be remove by pulling it

out in the direction as shown in Figure 7

2) The Knob Bass/Knob Treble (pos 11) can be remove by

pulling it out in the direction as shown in Figure 8.

3) Loosen 4 screws D (see Figure 10) to remove the Shield

Tape Deck and Module Tape Deck (pos 29).

4) Loosen 2 screws E (see Figure 9) to remove the Bracket

Top Support .

Figure 7

5) Loosen 4 screws G (see Figure 9) to remove the Bracket

Main.

6) Loosen 6 screws C4 (see Figure 11) to remove the

Display Board.

7) Loosen 4 screws H (see Figure 11) to remove the Top

Key Board.

Dismantling of the Front Panel assembly

Figure 11

Dismantling of the Rear Panel assembly

1) Loosen 3 screws K and 2 catches C5 (see Figure 12) to

remove the Tuner Board assembly.

2) Loosen 3 screws L (see Figure 12) to free the Main

Board.

3) Loosen 1 screw M (see Figure 12) to free the Mains

Socket Board.

4) Loosen 1 screw N and 2 catches C6 (see Figure 12) to

free the PanelRear (pos 53)by sliding it out towards the

rear.

Note : Tuner Board assembly and Mains Socket Board

can also be remove together with the PanelRear.

Figure 8

Figure 9

Figure 10 Figure 12

DISMANTLING INSTRUCTIONS

2-3

2-3

Repair Hints & Service Positions

1) During repair it is possible to disconnect theTuner Board

and/or CD Module completely unless the fault is sus-

pected to be in that area. This will not affect the

performance of the rest of the set.

Service position A

Service position B

Note: The flex cables are very fragile, care should be taken

not to damage them during repair. After repair, be

very sure that the flex cables are inserted properly

into the flex sockets before encasing, otherwise faults

may occurs.

Service position C

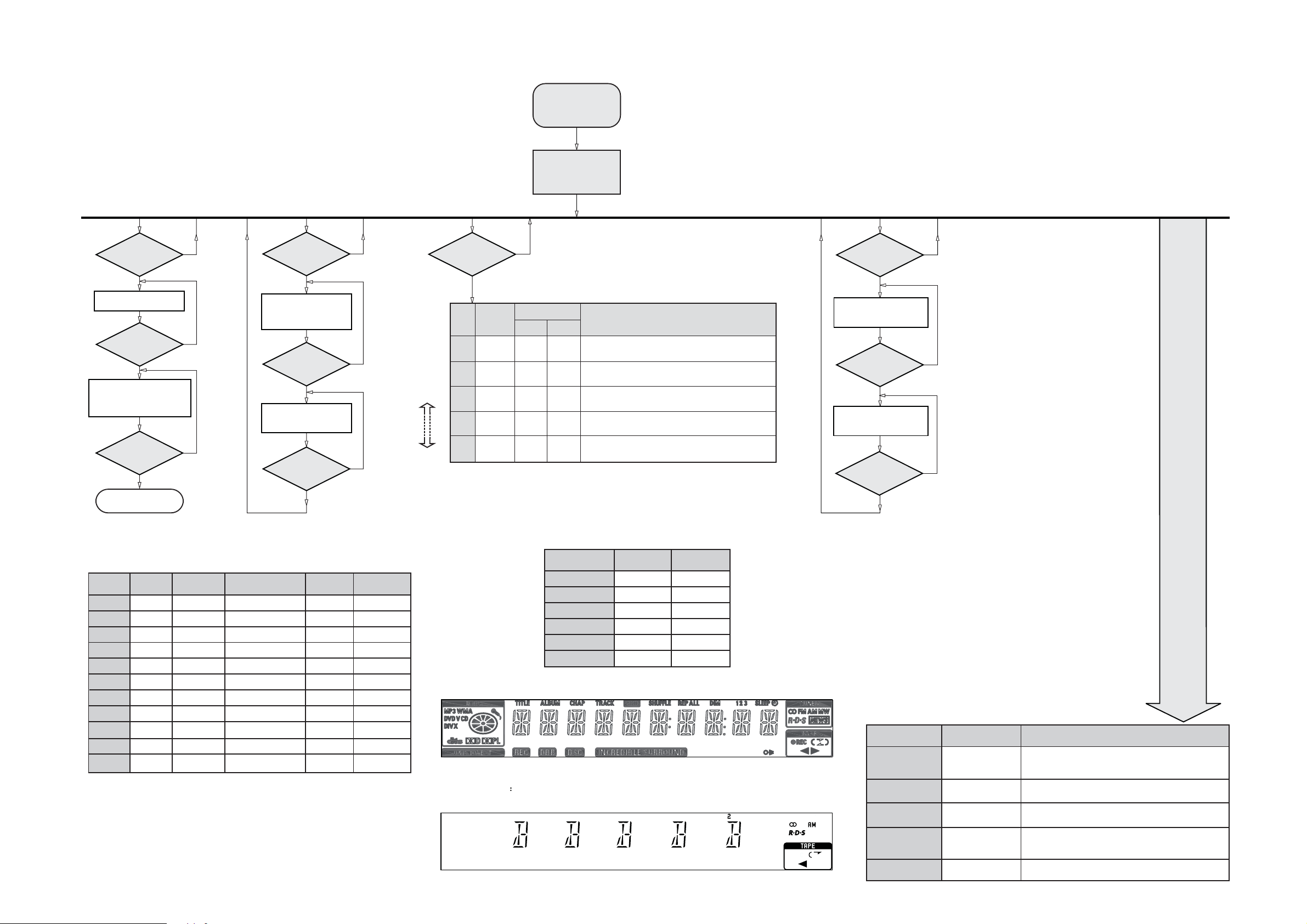

SERVICE TEST PROGRAM

3-1

To start service test program

hold PREVIEW & PLAY

buttons depressed while

plugging in the mains cord

and in standby status.

3-1

TUNER

TEST

TUNER

Button pressed?

Y

Display Tuner Version

"ccc"

TUNER

Button pressed?

Y

Service frequencies are

copied to the RAM (see Table 1)

Tuner works normally except:

PROGRAM button

Disconnect

Mains cord ?

Y

Service Mode left

Display shows the

ROM version

"S-Vyy"

(Main menu)

QUARTZ

TEST

N

N

N

TAPE

Button pressed?

Y

Display shows

32K

Output at (Display Board)

pin 19 of uP = 2048Hz

TAPE

Button pressed?

Y

Display shows

12M

Output at (Display Board)

pin 19 of uP = 2,929.6875Hz

9

Button pressed?

Y

N

CD (on RC)

Button pressed?

Y

Note : Disc should be available on the tray before entering the Service Test Mode.

STEP

DISPLAY

CD USB

N

N

Choose

level

by pressing

on the RC

Q

R

1

2

3

MO-Vnn

BITRATE

TESTING

MP3-CD MODULE

TEST

N

MESSAGE

OKAY

-

-

-

ERROR

-

-

-

ACTION

Indicates the module used.

Version of the MPEG software (nn = Version Number).

Bit rate check

Press

S refers to Service Mode

V refers to Version

yy refers to Software version number of the uProcessor

(counting up from 01 to 99)

9

to exit.

DISPLAY

TEST

DIM or RDS

Button pressed?

Y

Display shows Figure 1

and switch all LEDs on

except ECO LED

(see Table 2 Pattern 1)

DIM or RDS

Button pressed?

Y

Display shows Figure 2

and switch alternate LEDs on

(see Table 2 Pattern 2)

9

Button pressed?

Y

N

N

N

PRESET

1

2

3

4

5

6

7

8

9

10

11

Europe

"EUR"

87.5MHz

108MHz

531kHz

1602kHz

558kHz

1494kHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

98MHz

East Europe

"EAS"

87.5MHz

108MHz

531kHz

1602kHz

558kHz

1494kHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

98MHz

East Eur. Extended-band

"EAS"

65.81MHz

108MHz

74MHz

87.5MHz

531kHz

1602kHz

558kHz

1494kHz

98MHz

70.01MHz

65.81MHz

Table 1

USA

"USA"

87.5MHz

108MHz

530kHz

1700kHz

560kHz

1500kHz

98MHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

Note: * Depending on the selected grid frequency (9 or 10kHz).

By holding the ECO and TUNER buttons depressed while switching on the Mains supply,

one of the undermentioned features will be activated:

- the tuning grid frequency is toggled between 9kHz and 10kHz for the Oversea (/98) version.

- the extended FM1 (65.81MHz - 74MHz) is toggled on and off for East Eur. version.

Oversea

"OSE"

87.5MHz

108MHz

531/530kHz*

1602/1700kHz*

558/560kHz*

1494/1500kHz*

87.5/98MHz*

87.5MHz

87.5MHz

87.5MHz

98/87.5MHz*

LEDs

ECO

CD

TUNER

TAPE

AUX

Volume Rotary

Pattern 1 Pattern 2

Off

On

On

On

On

On

Table 2

Figure 1

Off

On

Off

On

Off

On

Remark Full Display Pattern function is not available for no RDS version.

Figure 2

TEST

EEPROM FORMAT

TEST

DEMO TOGGLE

ROTARY

ENCODER TEST

LEAVE SERVICE

TEST PROGRAM

Activated with

S

to Exit

9

S

B

II

Volume, Treble or Bass

Knob

Disconnect

mains cord

Various

other Tests

ACTION

"PASS" is displayed if the uProcessor read back the test patterns

correctly, otherwise "FAIL" will be displayed.

Load default data. Display shows "NEW" for 1 second.

Caution! All presets from the customer will be lost!!

Pressing this button will toggle between DEMO ON and DEMO

OFF. The DEMO status will scroll once across the Display.

Display shows value for 2 seconds.

Values increases or decreases until Volume Maximum (0dB) or

Volume Minimum (VOL MUTE) is reached.

.MORPEEehtottneseblliwsnrettaptseTTSETMORPEE

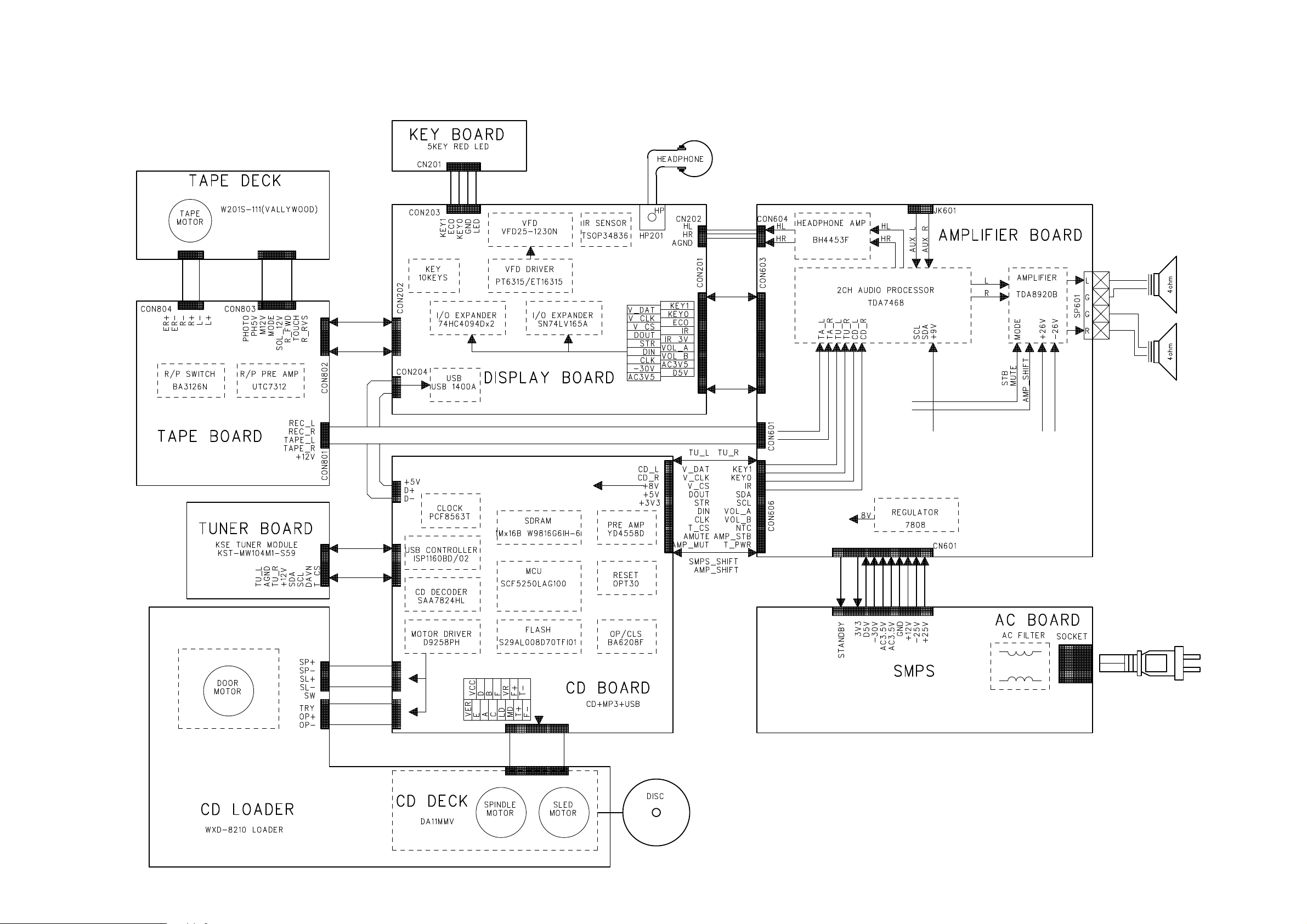

SET BLOCK DIAGRAM

4-1

4-1

Loading...

Loading...