Philips M3921A, M3922A, M3923A, M3924A, M3926A User manual

...

*

Philips A1 and A3 Patient Monitors

A1 Models: M3921A

M3922A

M3923A

M3924A

A3 Models: M3926A

M3927A

M3928A

M3929A

Service Guide

*M3921-9000C

Part Number M3921-9000C

Printed in the U.S.A. February 2002

First Edition

About this Manual

Proprietary Information

This document contains proprietary information, which is protected by copyright. All Rights

Reserved. Reproduction, adaptation, or translation without prior written permission is

prohibited, except as allowed under the copyright laws.

Philips Medical Systems

3000 Minuteman Road

Andover, MA 01810-1085

(978) 687-1501

Publication number

M3921-9000C

Printed in USA

Warranty

The information contained in this document is subject to change without notice.

Philips Medical Systems makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties or merchantability and fitness for Philips

Medical Systems shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Copyright

Printing History

Copyright © 2002 Philips Electronics North America Corporation

New editions of this document incorporate all material updated since the previous edition.

Update packages may be issued between editions and contain replacement and additional

pages to be merged by a revision date at the bottom of the page. Pages that are rearranged due

to changes on a previous page are not considered revised.

The documentation printing date and part number indicate its current edition. The printing

date changes when a new edition is printed. (Minor corrections and updates that are

incorporated at reprint do not cause the date to change.) The document part number changes

when extensive technical changes are incorporated.

This edition, M3921-9000C combines both A1 and A3 Service Guides into one book.

There is no M3921-9000B book.

First Edition............................................................... February 2002

ii

Philips Software License Terms

ATTENTION: USE OF THE SOFTWARE IS SUBJECT TO THE PHILIPS SOFTWARE LICENSE

TERMS SET FORTH BELOW. USING THE SOFTWARE INDICATES YOUR

ACCEPTANCE OF THESE LICENSE TERMS. IF YOU DO NOT ACCEPT THESE

LICENSE TERMS, YOU MAY RETURN THE SOFTWARE FOR A FULL REFUND. IF

THE SOFTWARE IS BUNDLED WITH ANOTHER PRODUCT, YOU MAY RETURN

THE ENTIRE UNUSED PRODUCT FOR A FULL REFUND.

PHILIPS SOFTWARE LICENSE TERMS

The following License Terms govern your use of the accompanying Software unless you have

a separate signed agreement with Philips Medical Systems.

License Grant. Philips Medical Systems grants you a license to Use one copy of the

Software. "Use" means storing, loading, installing, executing or displaying the Software. You

may not modify the Software or disable any licensing or control features of the Software. If

the Software is licensed for "concurrent use", you may not allow more than the maximum

number of authorized users to Use the Software concurrently.

About this Manual

Ownership. The Software is owned and copyrighted by Philips or its third party suppliers.

Your license confers no title to, or ownership in, the Software and is not a sale of any rights in

the Software. Philips’ third party suppliers may protect their rights in the event of any

violation of these License Terms.

Copies and Adaptations. You may only make copies or adaptations of the Software for

archival purposes or when copying or adaptation is an essential step in the authorized Use of

the Software. You must reproduce all copyright notices in the original Software on all copies

or adaptations. You may not copy the Software onto any public network.

No Disassembly or Decryption. You may not disassemble or decompile the Software unless

Philips prior written consent is obtained. In some jurisdictions, Philips consent may not be

required for limited disassembly or decompilation. Upon request, you will provide Philips

with reasonably detailed information regarding any disassembly or decompilation. You may

not decrypt the Software unless decryption is a necessary part of the operation of the

Software.

Transfer. Your license will automatically terminate upon any transfer of the Software. Upon

transfer, you must deliver the Software, including any copies and related documentation, to

the transferee. The transferee must accept these License Terms as a condition to the transfer.

Termination. Philips Medical Systems may terminate your license upon notice for failure to

comply with any of these License Terms. Upon termination, you must immediately destroy

the Software, together with all copies, adaptations and merged portions in any form.

Export Requirements. You may not export or re-export the Software or any copy or

adaptation in violation of any applicable laws or regulations.

U.S. Government Restricted Rights. The Software and any accompanying documentation

have been developed entirely at private expense. They are delivered and licensed as

iii

About this Manual

"commercial computer software" as defined in DFARS 252.227-7013 (Oct. 1988), DFARS

252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun. 1995), as a "commercial item" as

defined in FAR 2.101(a), or as "Restricted computer software" as defined in FAR 52.227-19

(Jun. 1987)(or any equivalent agency regulation or contract clause), whichever is applicable.

You have only those rights provided for such Software and any accompanying documentation

by the applicable FAR or DFARS clause or the Philips standard software agreement for the

product involved.

iv

Text Conventions

The following conventions for Notes, Cautions, and Warnings are used in this manual.

NOTE

A Note calls attention to an important point in the text.

A Caution calls attention to a condition or possible situation that could damage or destroy the

product or the user’s work.

A Warning calls attention to a condition or possible situation that could cause injury to

the user and/or patient.

About this Manual

Caution

WarningWarning

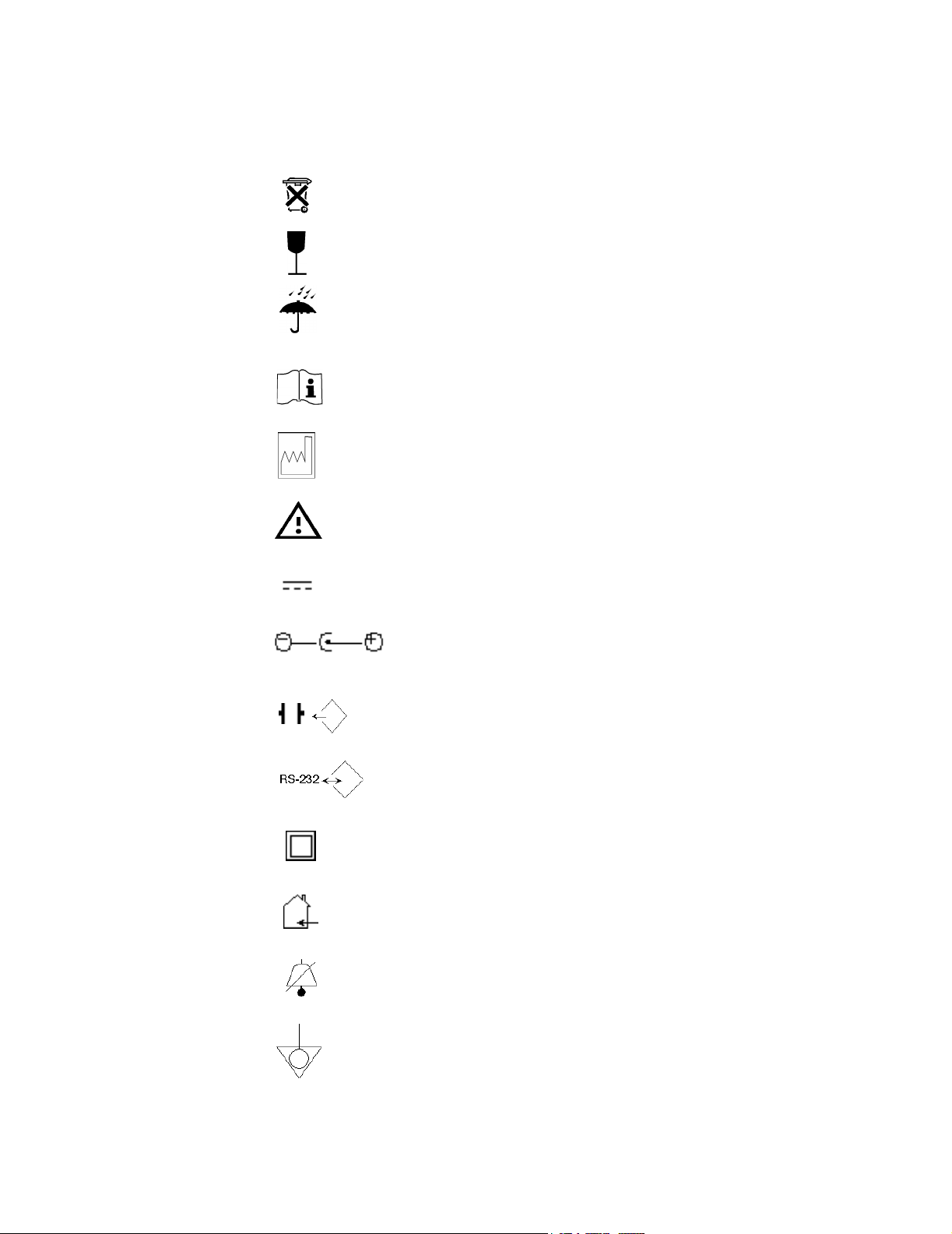

Explanation of Symbols

Symbols on products and packaging mean the following:

Battery Gauge icon

Defibrillator-proof type CF equipment

On/Standby button.

Alarm Limits icon.

Adjust Screen Contrast to display (monochrome) or invert the video to (color).

Adjust Heart Rate Tone volume.

Initiate NiBP measurement

v

About this Manual

T

Temperature

NiBP

ECG

SpO

2

SpO

2

Located on recorder. Produces a 20 Second Snapshot

Located on recorder. Produces a Continuous Print

Signal (ECG) Input

Signal (ECG) Output

Data input/output

Alternating Current

Direct Current

Temperature

Humidity

Altitude or atmospheric pressure

vi

About this Manual

Contains parts that may not be put into normal waste disposal but must be recycled or

dealt wi disposed as chemical waste

Fragile, handle with care

Keep dry

Consult instructions for use

Date of manufacture

Refer to User’s Guide

DC Lines

DC Input

Defib Sync.

RS-232 I/O

Class II Equipment

Power supply if for indoor use only

Silence Alarm

Equipotential Ground

vii

About this Manual

Recorder’s front-panel charging LED

Recorder’s front-panel communication LED

Ground Wire

viii

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Patient Monitor Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction to External Recorder (M3925A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Periodic Safety And Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Environmental Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Performance Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Test And Inspection Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Equipment Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power-On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware and Software Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SpO

2

Operation with an ECG Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation with a Respiration Simulator (A3 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Verification of Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation with a Temperature Simulator (A1 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation with a Temperature Simulator (A3 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial Interface Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Printer Verification (For A1 Optional Printer M3925A) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ground Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4. Power-up Defaults Menu And Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power-up Defaults Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

System A/D Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

NIBP Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Restoring Factory Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Contents ix

5. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

How To Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Who Should Perform Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Replacement Level Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Obtaining Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Generating an Error Log Printout (A1 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Serviceable Hardware Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Other Error Codes (All Monitors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Buttons/Wheels (All Monitors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Display/Audible Tones (All Monitors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operational Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6. Disassembly Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

How To Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Disassembly Procedures (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Closed Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Separation of Front and Rear Case Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Front Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rear Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Main PCB Disassembly Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Disassembly Procedures (A3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Closed Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Separation of Front and Rear Case Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Front Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Rear Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7. Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Small Parts Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Top Level Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Front Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Rear Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Main PCB Assembly (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Power Supply, Cables, and Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Exchange Unit Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8. Packing For Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Repacking In Original Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Repacking In A Different Carton. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

x Contents

9. RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Nurse Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10. Training Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Levels of Involvement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Preventative Maintenance Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Phone Support or Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Training Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Essential Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Optional Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Support Strategies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Unit exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Bench repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Theory of Operation and System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

System Overview - A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Block Diagram - A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Block Diagram - A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

System Overview - A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Block Diagram - A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Block Diagram - A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Monitor Applications and Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Reference Documents and Other Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Index

Contents xi

xii Contents

Manual Overview

1

Introduction

This manual contains information for servicing the A1 and A3 patient

monitors, subsequently referred to as the monitor throughout this manual.

Only where there are differences in service procedures for the two monitor

types is each monitor referred to specifically as A1 and A3. Only qualified

service personnel should service this product. Before servicing the monitor,

read the User Guide carefully for a thorough understanding of operation.

Introduction 1

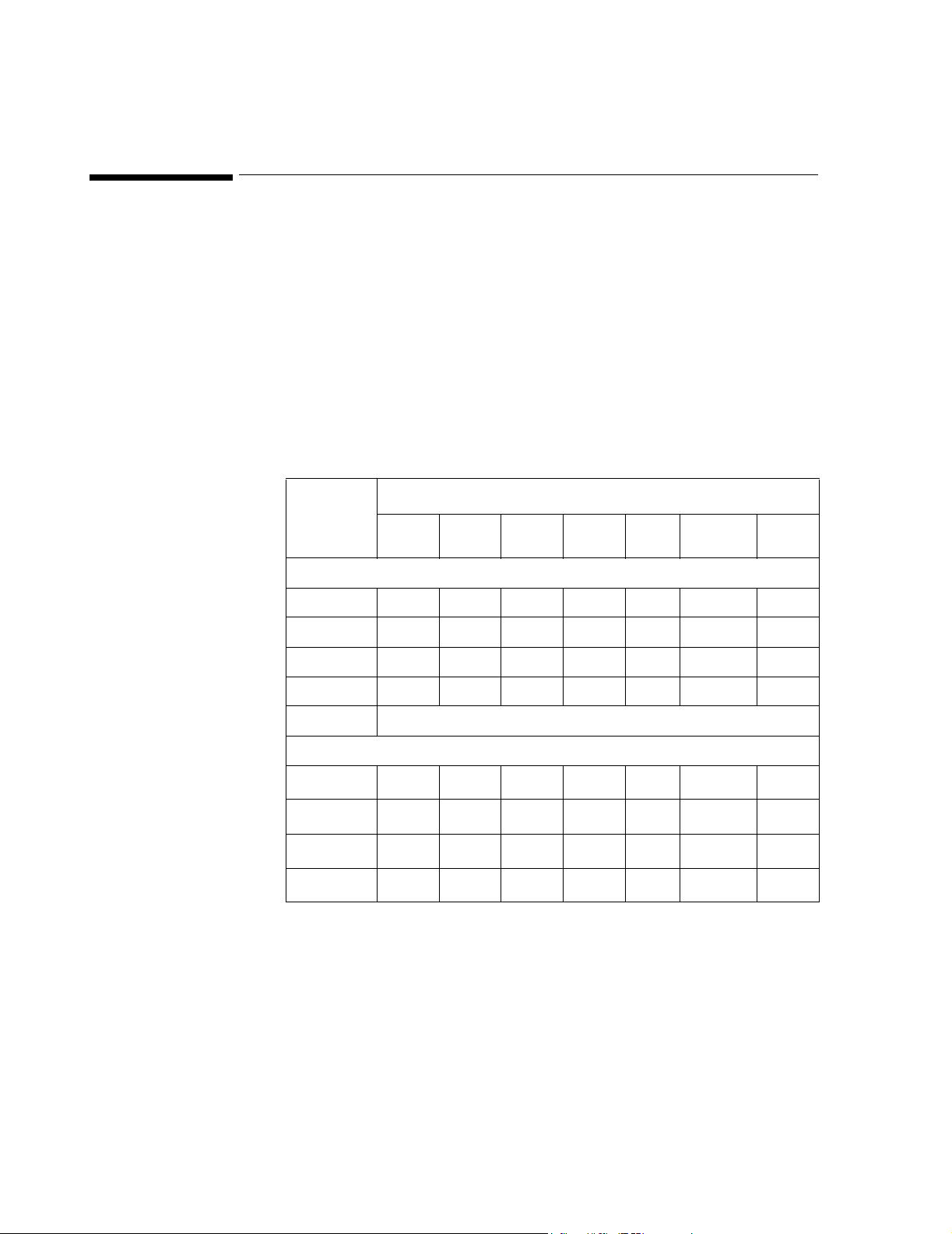

Patient Monitor Description

Patient Monitor Description

The purpose and function of the patient monitor is to monitor: ECG; heart

rate; noninvasive blood pressure (systolic, diastolic, and mean arterial

pressures); functional arterial oxygen saturation; respiration rate (A3 only);

and temperature for adult and pediatric patients in all hospital areas and

hospital-type facilities. It can be used during hospital transport and in mobile,

land-based environments, such as ambulances.

The physical and operational characteristics of the monitor are described in

the User Guide.

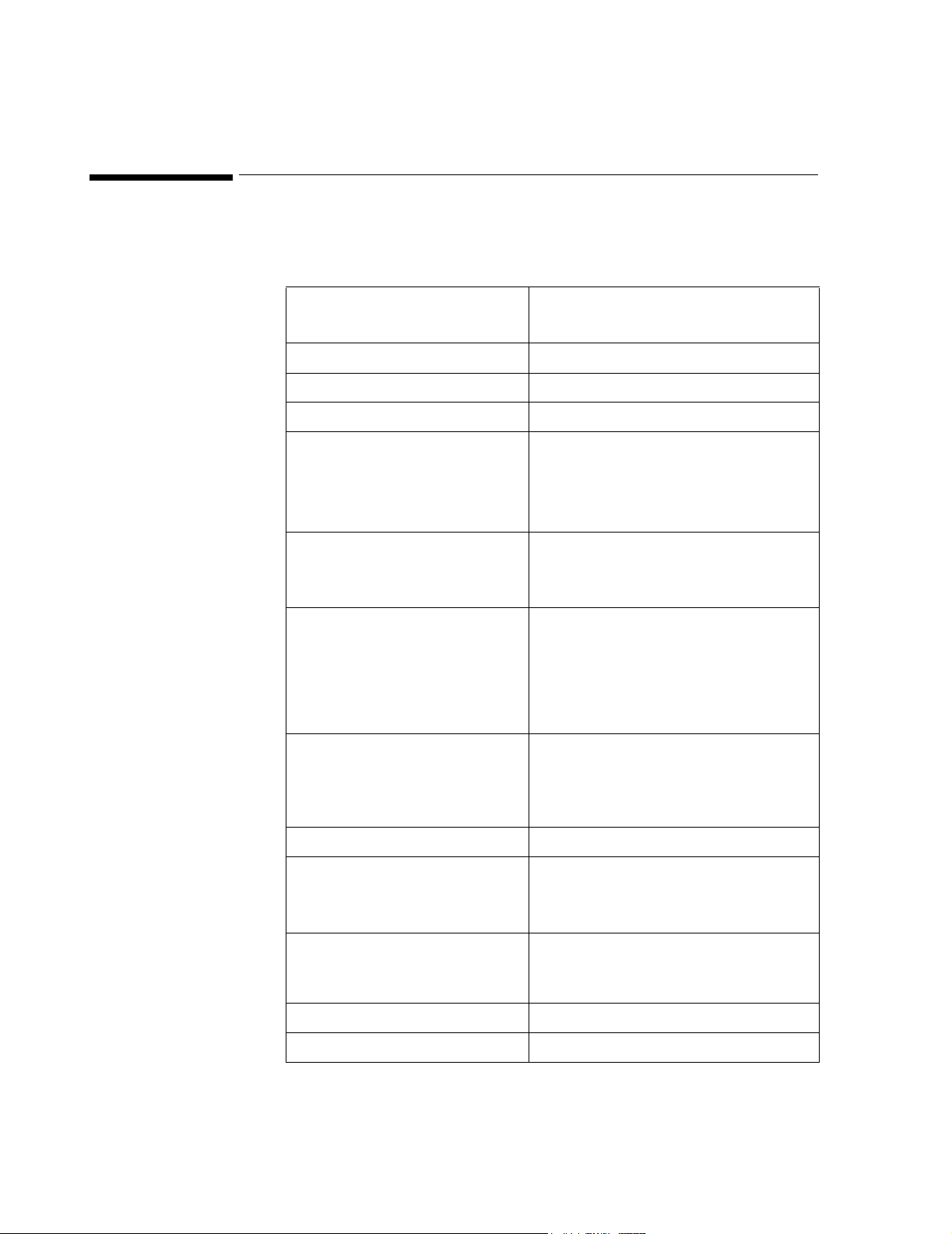

The measurement parameters and features for each model are indicated

below.

Model

NIBP SpO

M3921A Yes Yes No No No No Mono

M3922A Yes Yes Yes No No No Mono

M3923A Yes Yes No Yes No No Mono

M3924A Yes Yes Yes Yes No No Mono

M3925A Optional Standalone Recorder for A1

M3926A Yes Yes Yes Yes Yes

M3927A Yes Yes Yes Yes Yes

M3928A Yes Yes Yes Yes Yes

M3929A Yes Yes Yes Yes Yes

Measurement Parameters and Features

Temp ECG Resp Integral

2

A1 Monitor

A3 Monitor

Recorder

No

Yes

No

Yes

Color/

Mono

Mono

Mono

Color

Color

2 Introduction

Introduction to External Recorder (M3925A)

The recorder is an optional, standalone printer designed for use with the A1

patient monitor. The recorder communicates with the monitor using a nullmodem cable connected between each device’s RS-232 connector.

The recorder contains an internal battery, which, when fully charged, will

operate the recorder for 3 hours (typical, at 25°C, producing fifteen 20-second

printouts per hour). The recorder can be connected to AC power using an

external power supply. The recorder uses the same type of power supply as

the A1 monitor, the PS-120V or PS-240V.

The recorder does not have an On/Off switch. The recorder can sense when it

has an established communication link with the monitor. At that time, the

green LINKED indicator on the front panel lights, indicating that the recorder

is ready for operation. See the recorder’s User Guide for more information

regarding its operation.

Introduction to External Recorder (M3925A)

Related Documents

To perform test and troubleshooting procedures and to understand the

principles of operation and circuit analysis sections of this manual, you must

know how to operate the monitor. Refer to the User Guide to understand the

various sensors, ECG lead, blood pressure cuffs, and temperature probes that

work with the monitor. Refer also to the user guide and individual directions

for use that accompany these accessories.

Introduction 3

Related Documents

4 Introduction

Routine Maintenance

Cleaning

Warning Do not immerse the monitor or its accessories in liquid or

clean with caustic or abrasive cleaners. Do not spray or

pour any liquid on the monitor or its accessories.

To clean the monitor, dampen a cloth with a commercial, nonabrasive cleaner

and wipe the exterior surfaces lightly. Do not allow any liquids to come in

contact with the power connector or switches. Do not allow any liquids to

penetrate connectors or openings in the instrument. For cables, sensors and

cuffs, follow the cleaning instructions in the directions for use that accompany

these accessories.

2

Periodic Safety And Functional Checks

The monitor requires cleaning, battery maintenance and NiBP performance

and verification check every two years. The following performance

verification tests may be used following repair or during routine maintenance

(if required by your local institution).

1. Inspect the exterior of the monitor for damage.

2. Inspect labels for legibility. If the labels are not legible, contact Philips’

Response Center or your local Philips representative.

3. Verify that the NiBP performs properly as described in “Verification of

Pneumatic System” on page 21.

Battery

If the monitor has not been used for a long period of time, the battery will

need charging. To charge the battery, connect the monitor to an AC outlet, or

external DC supply in the case of the A3, as described in “Battery Charge” on

page 13 or the “Setup and Use” chapter of the User Guide.

Note Storing the monitor for a long period without charging the battery

can degrade the battery capacity. A complete battery recharge

requires 8 hours.

Chapter 2 - Routine Maintenance 5

Environmental Protection

The battery can be recharged while the monitor is in use, in

which case, the battery requires 14 hours to be recharged.

The battery can require a full discharge/charge cycle to restore

normal capacity.

If the monitor operates1 for less than one hour on battery power before the

low battery alarm occurs, the battery should be conditioned.

If the same symptom persists even after the battery is conditioned and

indicating a full charge, the battery should be replaced.

Refer to Chapter 6, “Disassembly Guide”.

Environmental Protection

Follow local governing ordinances and recycling plans regarding disposal or

recycling batteries and other device components.

1. See “Battery Performance Test” on page 14 for typical battery operating times

and conditions.

6 Chapter 2 - Routine Maintenance

Introduction

3

Performance Verification

This section discusses the tests used to verify performance following repairs

or during routine maintenance. All tests can be performed without removing

the covers of the monitor.

If the monitor fails to perform as specified in any test, repairs must correct the

problem before the monitor is returned to the user.

Performance Verification 7

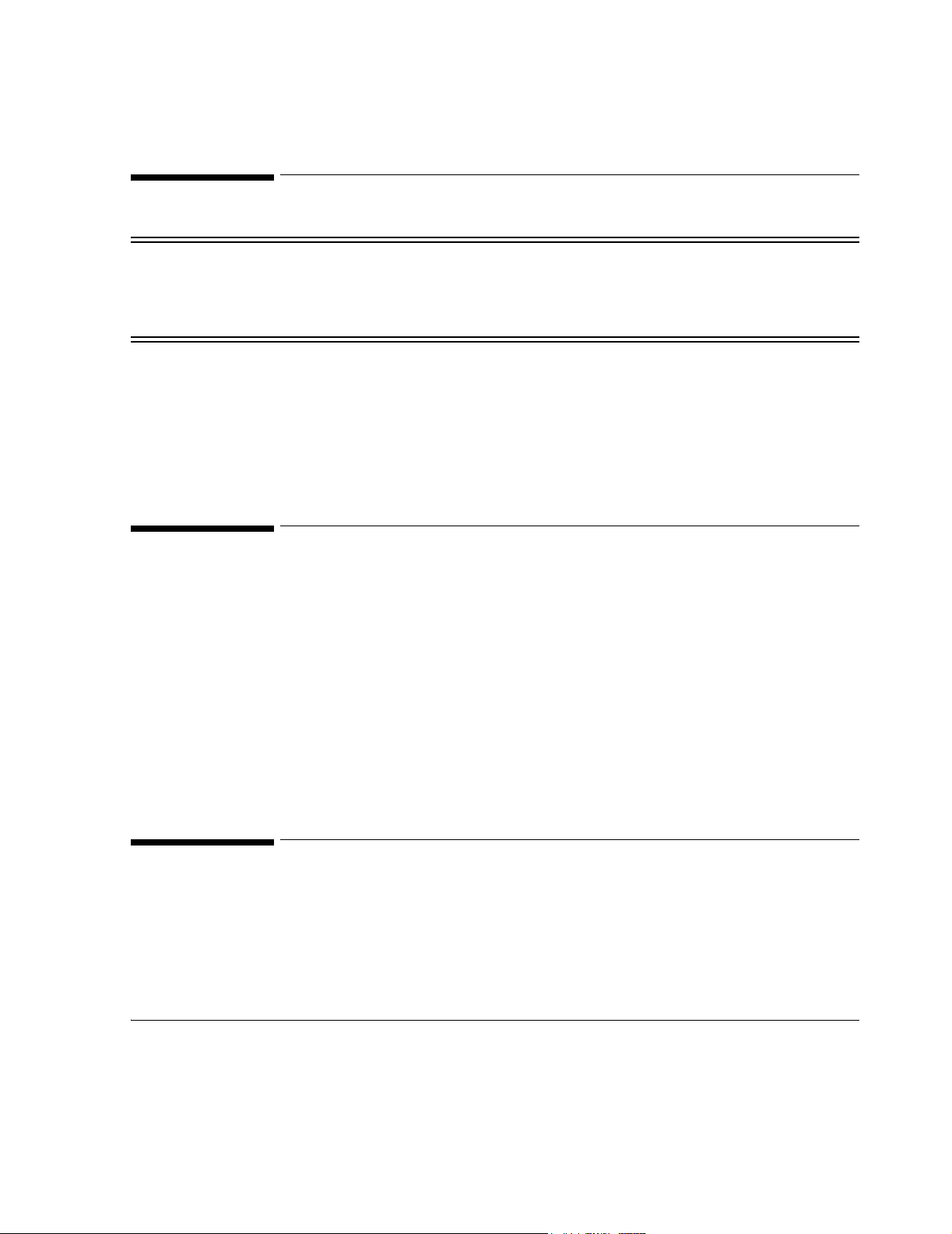

Test And Inspection Matrix

Test And Inspection Matrix

The following test map shows which tests are required in which situations.

Table 1 Test Map

Service Event (When

Performing…)

Installation Visual and Power On Tests

Repairs

A. Unit Exchange Visual and Power On Tests

B. Unit Opened Power On Test

C. NBP Pump replaced Power On Test

D. SpO

E. Front End Connectors replaced Power On Test

Module replaced Power On Test

2

Test Blocks Required (…Complete

these Tests)

Basic Pneumatic Leakage Test (BPL)

Ground Integrity Test

Leakage Current Test

NBP Tests:

Pneumatic Leakage and Inflation Rate

BPL Test

Tests:

SpO

2

Dynamic Operating Range and

LED Excitation

BPL Test

Performance test for the parameter that had

the connector replaced.

F. Power Supply replaced (A3 only) Power On, BPL, and Safety tests

G. Component level repair on any

PC board

H. Main PC board replaced Power On Test

All software upgrades Power On

Preventative maintenance Power On and NBP Performance Tests

8 Performance Verification

Power On Test

All Performance Tests

All Safety Tests

All Performance tests except Battery

Charge Test and Battery Performance Test

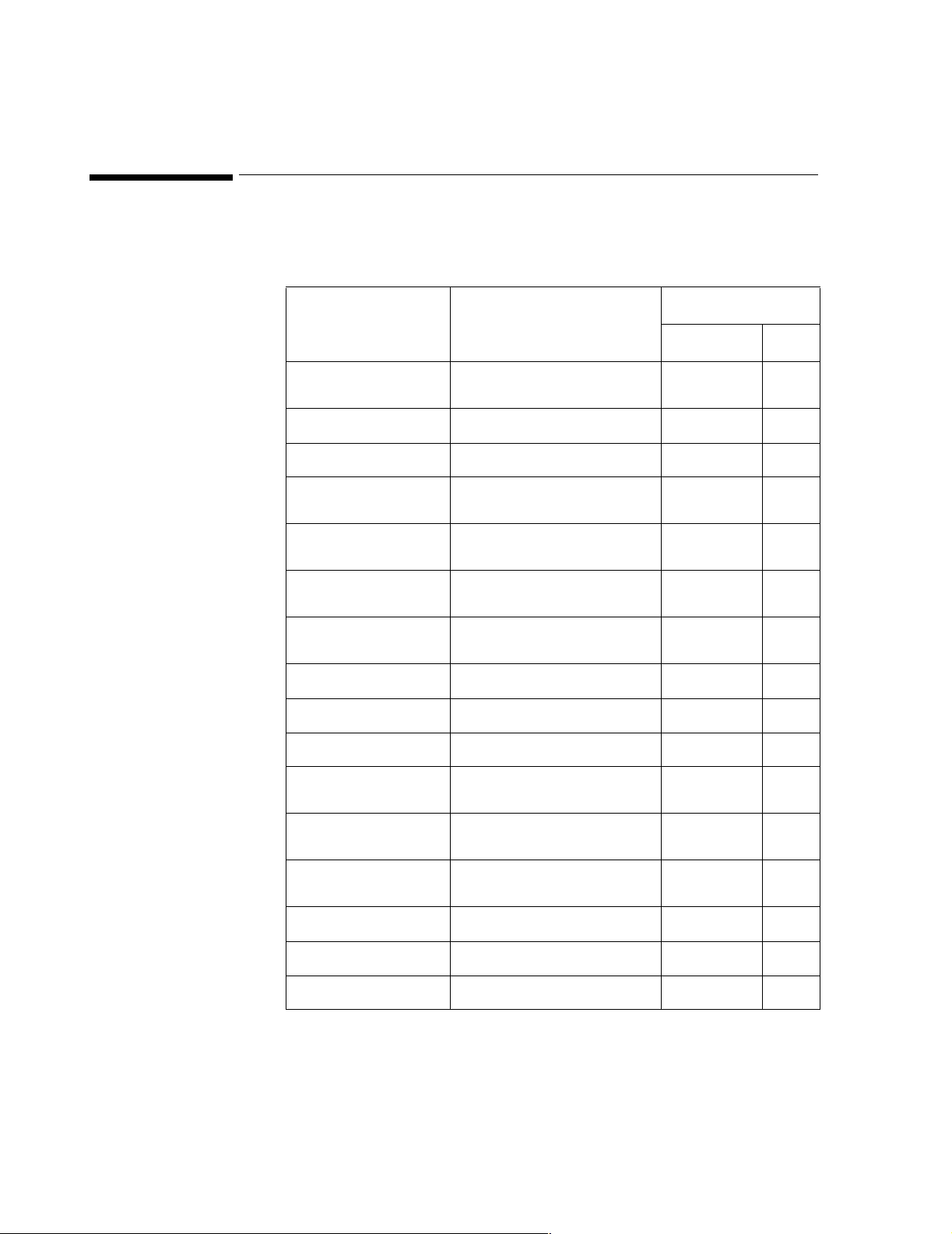

Table 2 Test and Inspection Reporting

Test And Inspection Matrix

1

Test

Visual: Inspect exterior

of monitor for damage

Power-On Self-Test Displays Normal Monitoring

Basic Pneumatic

Leakage Test (NBP

test)

NiBP Accuracy Test 250 mmHg; ±5 mmHg

NiBP Leakage Test After 1 Minute at 250 mmHg,

NiBP Inflation Rate

Test

NiBP Overpressure

Test

Expected Results

No Visual Damage V:P or V:F

Screen Configuration and emits

tones

After 1 minute at approximately

250 mmHg, pressure drops no

more than 6 mmHg.

pressure drops no more than

6 mmHg

Monitor Reports NiBP = 280

mmHg in <6 seconds

Overpressure Deflation is

activated at a value between

280 mmHg to 330 mmHg

What to Record

PO:P or PO:F

BPL: Px6

Where x6 =Pressure

Drop in mmHg

PN:P/X1…X4 (or X5

PN:F/X1…X4 (or X5

Record Pressure in

mmHg = X1

Record Pressure

Drop in mmHg = X2

Record Time to

280 mmHg in

Seconds = X3

Record value in

mmHg at which

Overpressure

Deflation occurs =X4

2

3

)

3

)

NiBP Deflation Rate

Test (A3 only)

Safety Performance

Tests

Monitor reports NiBP >10

mmHg and <190 mmHg

All Safety Performance Tests

are in range of Table 5 to

Table 12

Record value in

mmHg on monitor at

1 min = X5

S:P or S:F

1. Details of the tests are included later in this chapter.

2. When authorized Philips Medical Systems personnel service the instrument. The results are reported back to Philips. The collected data form a

database to be used in product development. It is not necessary for hospital personnel to report these results.

3. In the case of the NiBP Deflation Rate Test, applicable to the A3 only.

Performance Verification 9

Equipment Needed

Equipment Needed

The following table lists the equipment required for performance verification.

Table 3 Required Test Equipment

Required For

Equipment Description A1 A3

Digital multimeter

(DMM)

Sensor extension cable M4787A

Finger clip sensor M4789A

Oxisensor® II adhesive

sensor

ECG cable M3913A M3923A and

ECG electrodes Standard M3923A and

ECG leads M3914A (IEC) or M3915A

NiBP tubing M3918A

NiBP cuff 40401C

Pulse oximeter tester Nellcor Puritan Bennett SRC-2

ECG simulator Dynatech Nevada medSim

Fluke Model 87 or equivalent

D-25

(AAMI)

300 or equivalent

··

··

··

··

M3924A only

M3924A only

M3923A and

M3924A only

··

··

··

··

·

·

·

NiBP simulator Bio-Tek BP Pump or

equivalent

Temperature simulator medSim 300 or equivalent M3922A and

Respiration simulator medSim 300 or equivalent

Safety analyzer Bio-Tek 601 Pro or equivalent

Stopwatch Manual or electronic

10 Performance Verification

··

·

M3924A only

-·

··

··

Performance Tests

Battery Charge

Performance Tests

The battery charge and battery performance test should be performed before

monitor repairs whenever the battery is suspected as being a source of the

problems. All other tests can be used following repairs or during routine

maintenance (if required by your local institution). Before performing the

battery performance test, ensure that the battery is fully charged. (See

“Battery Charge” below).

This section is written using factory-set power-up defaults. If your institution

has pre configured custom defaults, those values display.

To fully charge the battery:

1. Connect the monitor to an AC power source using the proper power cord. For

the A1, use the PS-120V or PS-240V external power supply and power cord.

2. • For the A1, verify that the EXTERNAL POWER indicator is

lit.

• For the A3, verify that the

BATTERY CHARGING/AC SOURCE

indicator is lit.

3. Charge the battery for at least 8 hours.

The battery can require a complete discharge/charge cycle to restore its normal

capacity, depending on its previous usage.

4. To check for a full charge, perform the procedure described in “Battery

Performance Test” on page 12.

Performance Verification 11

Battery Performance Test

Battery Performance Test

The the A1 and A3 mono monitors are specified to typically operate on

battery power for a minimum of 4 hours, at 25°C, with no printing, and one

NiBP measurement every 15 minutes. The A3 color monitor is specified to

typically operate on battery power for a minimum of 3 hours, at 25°C, with no

printing, and one NiBP measurement every 15 minutes. Before performing

this test, ensure that the battery is fully charged (see “Battery Charge”).

1. Connect the Nellcor Puritan Bennett SRC-2 pulse oximeter tester to the monitor

via the M4787A sensor cable.

2. Connect the NiBP simulator to the monitor via the M3918A tubing.

3. Set the SRC-2 switches as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

4. Set the NiBP simulator to simulate a pressure setting of 120/80 mmHg and heart

rate of 80 bpm.

5. Ensure that the monitor is not connected to AC power.

6. With the monitor turned off, press the ON/STANDBY button and verify

that the battery icon appears at the bottom of the display after the power-on selftest is completed. The boxes in the battery icon should all be filled, indicating

that the battery is charged.

7. Verify that the monitor is responding to the SpO

audible alarm is sounding. Use the wheel to select the SpO

permanently silence the SpO

8. Use the wheel to select the NiBP Menu and set the Automatic Measurement

Interval to 15 minutes. Exit the menu and press the front panel NiBP button

to manually start the first NiBP measurement. Subsequent NiBP

measurements are taken automatically every 15 minutes.

audible alarm.

2

simulator signal and that the

2

Menu and

2

12 Performance Verification

Power-On Self-Test

Power-On Self-Test

9. The A1 and A3 mono monitors must operate for at least 4 hours before they

automatically power down due to low battery condition. The A3 color monitor

must operate for at least 3 hours before the monitor automatically powers down

due to low battery condition.

10. Verify that the low battery alarm occurs 15-30 minutes before the battery fully

discharges.

11. Allow the monitor to operate until it automatically powers down due to low

battery condition. Verify that the audible alarm sounds when the monitor

automatically shuts down. Press the Alarm Silence button to terminate this

audible alarm.

12. If monitor passes this test, immediately recharge the battery. (See “Battery

Charge” on page 11).

1. Connect the monitor to an AC power source. For the A1, use the PS-120V or

PS-240V power supply and power cord. For the A3, use the proper power cord

supplied.

2. • For the A1, verify that the EXTERNAL POWER indicator is

lit.

• For the A3, verify that the

BATTERY CHARGING/AC SOURCE

indicator is lit.

3. Do not connect any input cables to the monitor.

4. Observe the monitor front panel. With the monitor off, press the ON/

STANDBY button . The monitor must perform the following sequence:

a. The A1 emits a beep.

The A3 emits three consecutively higher pitched beeps.

b. A few seconds later, the display backlight illuminates, but the display is

blank.

c. The version numbers of the boot and operational software display in the

lower left corner of the display.

d. A beep signals the end of the power-on self-test. Power-on self-test takes

approximately 10 seconds to complete.

e. Upon successful completion of the power-on self-test, the display is in

normal monitoring screen configuration. No vital-sign numeric values or

waveforms are displayed.

Performance Verification 13

Hardware and Software Tests

Hardware and Software Tests

Hardware and software testing includes the following tests applicable to the

indicated models in the series:

SpO2 Testing A1, A3 - all models

Operation with an ECG Simulator A1 - M3923A, M3924A

Operation with a Respiration Simulator A3 - all models

Verification of Pneumatic System A1, A3 - all models

Operation with a Temperature Simulator A1 - M3922A, M3924A

Test Applies to Model(s)

A3 - all models

A3 - all models

SpO

Testing

2

Alarms and Alarm

Silence

General Operation A1, A3 - all models

SpO2 testing includes the following tests:

n Alarms and Alarm Silence

n Heart Rate Tone Volume Control

n Dynamic Operating Range

n LED Excitation Test

1. Connect the SRC-2 pulse oximeter tester to the M4787A sensor cable and

connect the cable to the monitor.

2. Set SRC-2 as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

3. Press the ON/STANDBY button to turn the monitor on.

4. After the normal power-up sequence, verify that the SpO

14 Performance Verification

% display initially

2

Hardware and Software Tests

indicates zero or is blank. The pulse bar can occasionally indicate a step change

as the monitor is in the pulse search mode.

5. Move the modulation switch on the SRC-2 to LOW.

6. Verify the following monitor reaction:

a. The pulse bar begins to track the artificial pulse signal from the SRC-2.

b. Initially, zero is displayed in the SpO

frame, or it is blank.

2

c. After about 10 to 20 seconds, the monitor displays saturation and heart rate

as specified by the tester. Verify that the values are within the following

tolerances:

Oxygen Saturation Range 79% to 83%

Heart Rate Range 35 to 41 bpm

d. The audible alarm sounds and both the SpO2% and HEART RATE displays

flash, indicating both parameters have violated the default alarm limits.

e. The heart rate tone is heard. For this test, the user should set the heart rate

tone source to SpO

7. Press the ALARM SILENCE button on the front panel of the monitor.

The audible alarm is temporarily silenced.

8. Verify the following:

a. The audible alarm remains silenced.

b. The slashed bell icon appears in each numeric frame on the display.

c. The SpO

% and HEART RATE displays continue flashing.

2

from the Heart Rate Menu.

2

d. The heart rate tone remains audible.

e. The audible alarm returns in approximately 60 seconds.

Heart Rate Tone

Volume Control

1. Connect the SRC-2 pulse oximeter tester to the M4787A sensor cable and

connect the cable to the monitor.

2. Set SRC-2 as follows:

POSITION

SWITCH

A1 A3

RATE 38 38

LIGHT LOW LOW

MODULATION LOW OFF

RCAL/MODE RCAL 63/LOCAL RCAL 63/LOCAL

Performance Verification 15

Hardware and Software Tests

3. Power on the monitor and verify that the SpO2 and heart rate values are

correctly displayed.

4. Press the ALARM SILENCE button on the front panel of the monitor

to temporarily silence the audible alarm.

5. Verify that the heart rate tone source, found in the Heart Rate Menu, is set to

SpO

.

2

6. Press the Heart Rate Tone VOLUME button on the front panel of the

monitor. Within 3 seconds of having pressed the button, rotate the wheel

clockwise and verify that the beeping heart rate tone sound level increases.

7. Rotate the wheel counterclockwise and verify that the beeping heart rate tone

decreases until it is no longer audible. Rotate the wheel clockwise to return the

beep volume to a comfortable level.

3 seconds after the last button-press or rotation of the wheel, function of the

wheel reverts to moving the highlight on the display screen.

Dynamic Operating

Range

The following test sequence verifies proper monitor operation over a range of

input signals.

1. Connect the pulse oximeter tester to the monitor and turn the monitor on.

2. Place the SRC-2 pulse oximeter tester in the RCAL 63/LOCAL mode.

3. Set the SRC-2 as indicated in below. Verify that the monitor readings are within

the indicated tolerances. Allow the monitor several seconds to stabilize the

readings.

Table 4 SRC 2 Settings and Monitor Indications

SRC-2 Settings Monitor Indications

RATE LIGHT MODULATION SpO2 Pulse Rate

38 HIGH2 LOW

112 HIGH1 HIGH

201 LOW LOW

201 LOW HIGH 79-83* 195-207*

An * indicates values that produce an alarm. Press the ALARM SILENCE

button to temporarily silence the audible alarm.

For the pulse rate setting of 201 bpm, the pulse rate tolerance of 195 to 207 bpm

is greater than the ±3 bpm accuracy specification of the monitor, due to the

performance characteristics of the SRC-2 tester.

79-83* 35-41*

79-83* 109-115

79-83* 195-207*

4. Turn the monitor off.

LED Excitation Test

16 Performance Verification

This procedure uses normal system components to test circuit operation. A

Hardware and Software Tests

Nellcor Puritan Bennett Oxisensor II adhesive sensor, model D-25, is used to

examine LED intensity control. The red LED is used to verify intensity

modulation caused by the LED intensity control circuit.

1. Connect a M4787A sensor extension cable to the monitor.

2. Connect a D-25 sensor to the sensor extension cable.

3. Press the ON/STANDBY button to turn the monitor on.

4. Leave the sensor open with the LED and photo detector visible.

5. After the monitor completes its normal power-up sequence, verify that the

sensor LED is brightly lit.

6. Slowly move the sensor LED in proximity to the photo detector element of the

sensor. Verify, as the LED approaches the optical sensor, that the LED intensity

decreases.

7. Open the sensor and notice that the LED intensity increases.

8. Repeat step 6 and the intensity again decreases. This variation is an indication

that the micro-processor is in proper control of LED intensity.

9. Turn the monitor off.

Operation with an ECG Simulator

1. With the monitor off, connect the ECG leads to the appropriate jacks on the

ECG tester.

2. Connect the leads to the ECG cable.

3. Connect the cable to the ECG input port on the monitor.

4. Set the ECG simulator as follows:

Heart rate: 30 bpm

Amplitude: 1 millivolt

Lead select: II

Wave Type: Normal sinus rhythm

Patient Type: Adult mode

Note

The accuracy of the monitor’s ECG measurements is ±5 bpm. In

the procedure below, add the tolerance of the simulator to the

acceptable range of readings.

5. Press On/Standby button to turn monitor on.

Performance Verification 17

Hardware and Software Tests

6. After normal power-up sequence, verify the following monitor reactions:

a. After at least five heartbeats, the monitor displays a heart rate of 30 ±5 bpm.

b. The audible alarm sounds and the

indicating heart rate is below the default lower alarm limit.

7. Press the ALARM SILENCE button. Verify that the audible alarm is

silenced.

8. Increase the heart rate setting on the ECG simulator to 240 bpm.

9. After at least five heartbeats, verify that the monitor displays a heart rate of 240

±5 bpm.

10. Verify that the audible alarm sounds and the

indicating that the heart rate is above the default upper alarm limit.

11. Press ALARM SILENCE button to silence alarm.

12. Decrease the heart rate setting on ECG simulator to 120 bpm.

13. After at least five heartbeats, verify that the monitor displays a heart rate of 120

±5 bpm.

14. Disconnect the LL lead from ECG simulator.

15. Verify that the

displayed in

sounds.

16. Reconnect the LL lead to ECG simulator. Verify that the

message no longer appears and audible alarm is silenced.

17. Repeat steps 14 through 16 for LA and RA leads.

18. Turn the monitor off.

Leads Off alarm message appears, three dashes are

HEART RATE display, and the low priority audible alarm

HEART RATE display flashes,

HEART RATE display flashes,

Leads Off alarm

Operation with a Respiration Simulator (A3 only)

1. With the monitor off, connect the ECG leads to the appropriate jacks on the

respiration simulator.

2. Connect the ECG leads to the ECG cable.

3. Connect the cable to the ECG input port on the monitor.

Note

The accuracy of A3 measurements is ±3 breaths per minute. In

the procedure below, add the tolerance of the simulator to the

acceptable range of readings.

4. Set the simulator for a respiration rate of 120 breaths per minute.

5. Press the ON/STANDBY button to turn the monitor on.

18 Performance Verification

Loading...

Loading...