PHILIPS L04.6U AA Service Manual

Color Television Chassis

L04.6U

AA

F_15760_000.eps

171105

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety and Maintenance Instructions, Warnings, and

Notes 4

3. Directions for Use 5

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 8

6. Block Diagrams, Testpoint Overviews, and

Waveforms

Wiring Diagram 17

Block Diagram Supply and Deflection 18

Testpoint Overview Mono Carrier 19

Block Diagram Video 20

Testpoint Overview CRT Panel 21

Block Diagram Audio/Control 22

ATSC Block Diagram 23

I2C and Supply Voltage Overview 24

7. Circuit Diagrams and PWB Layouts Diagram PWB

Mono Carrier: Power Supply (A1) 25 37-42

Mono Carrier: Diversity Table for [A1] 26 37-42

Mono Carrier: Deflection (A2) 27 37-42

Mono Carrier: Diversity Table for [A2] 28 37-42

Mono Carrier: Tuner IF (A3) 29 37-42

Mono Carrier: Hercules (A4) 30 37-42

Mono Carrier: Features & Connectivity (A5) 31 37-42

Mono Carrier: Class D - Audio Amplifier (A6) 32 37-42

Mono Carrier: Audio Amplifier (A7) 33 37-42

Mono Carrier: Rear I/O Cinch (A8) 34 37-42

Mono Carrier: Front Control (A9) 35 37-42

Mono Carrier: DVD PSU (optional) (A10) 36 37-42

CRT Panel (B1) 43 45-45

CRT Panel: Eco Scavem (B2) 44 45-45

Side AV + Headphone Panel (D) 46 47-47

Top Control Panel (E) 48 48-48

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Front Interface Panel (For PV02 Styling) (J) 49 49-49

Main Switch Panel (For SL5 Styling) (M) 50 51-51

8. Alignments 53

9. Circuit Descriptions, List of Abbreviations, and IC

Data Sheets 59

Abbreviation List 62

IC Data Sheets 63

10. Spare Parts List 64

11. Revision List 69

Published by WS 0571 TV Service Printed in the Netherlands Subject to modification EN 3122 785 15760

EN 2 L04.6U AA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : CRT, DV, RF

Screen size : 27”, 4:3

Tuning system : PLL

TV Color systems : ATSC (QAM, 8VSB)

IF picture carrier : 45.75 MHz

Video playback : NTSC

1.1.2 Sound

Sound systems : BTSC

Maximum power (W

):2 x 5

RMS

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

) : 90 - 140

AC

- Mains frequency (Hz) : 60

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 90% R.H.

Power consumption (values are indicative)

- Normal operation (W) : ≈ 120

- Stand-by (W) : < 1

1.1.4 Mechanical Styling

Model Number Styling Name

27PT9015D/37 SL5

27MT5005D/37 PV02

27MT6005D/37 SL3

32PT7005D/37 SL3

32PT9005D/37 PV02

In above table the link is shown between the model number and

the (internal) Philips styling number. In this manual, sometimes

a refernce is made to this styling number. For a mechanical

drawing of the model, please check the quarterly published

Product Survey.

: 32”, 4:3

:NTSC

1.2 Connections

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, Ye= Yellow.

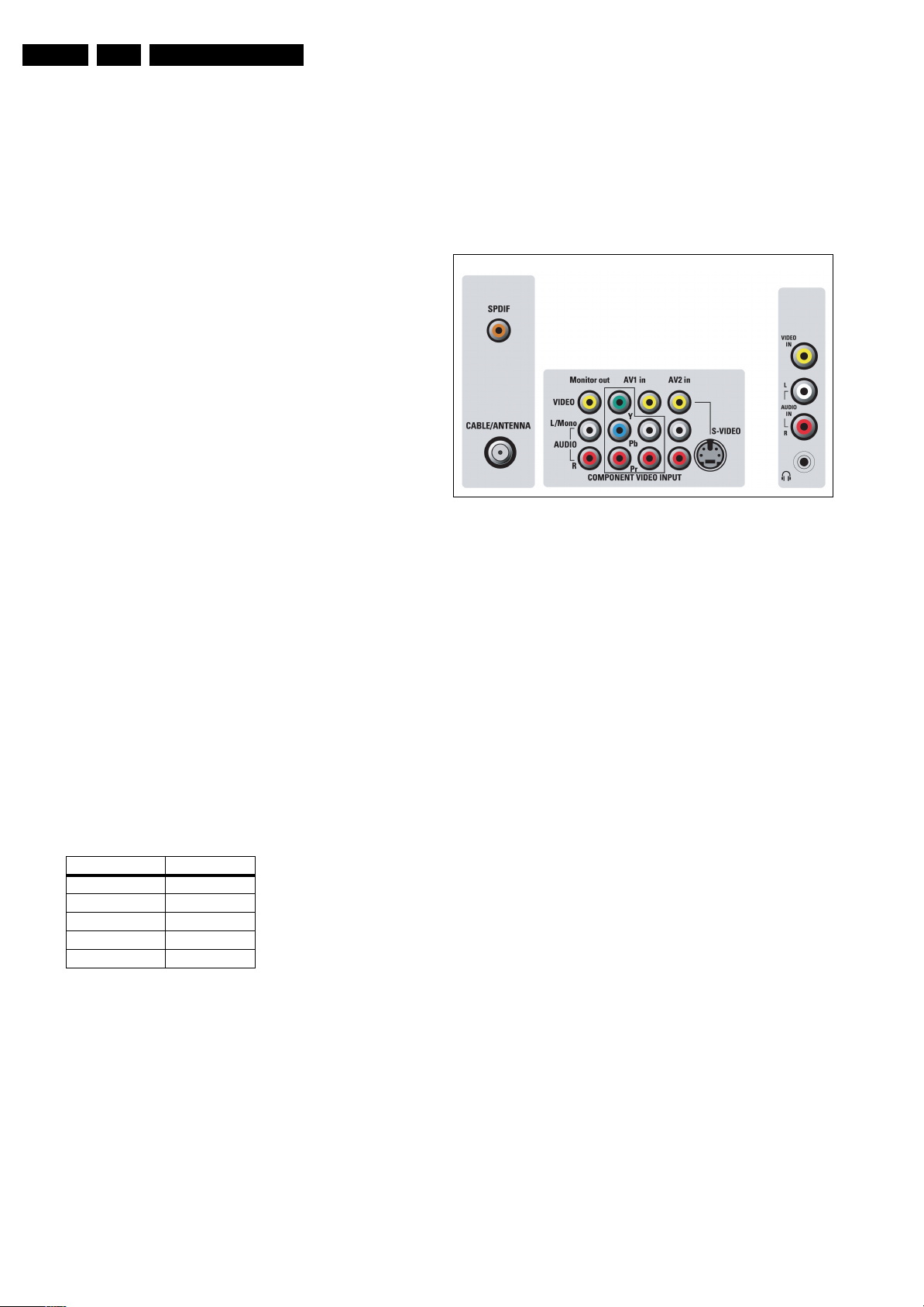

Rear I/O

Rear I/O

Figure 1-1 Connections overview

1.2.1 Rear Connections

Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

Cable/Antenna - In

- - F-type (US) Coax, 75 ohm D

Monitor Out - Cinch: Video CVBS - Out, Audio - Out

Ye - Video CVBS 1 V

PP

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

AV1 - Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

PP

Rd - Video Pr 0.7 V

AV1 - Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

PP

Rd - Audio R 0.5 V

AV2 - Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

PP

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

AV2 - SVHS (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

PP

4 - Video C 0.3 V

/ 75 ohm kq

PP

/ 75 ohm kq

/10 kohm kq

RMS

/ 10 kohm kq

RMS

/ 75 ohm jq

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm j

P / 75 ohm j

PP

Side I/O

F_15760_003.eps

111105

1.2.2 Side Connections

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Bk - Head phone 32 - 600 ohm / 10 mW ot

Technical Specifications, Connections, and Chassis Overview

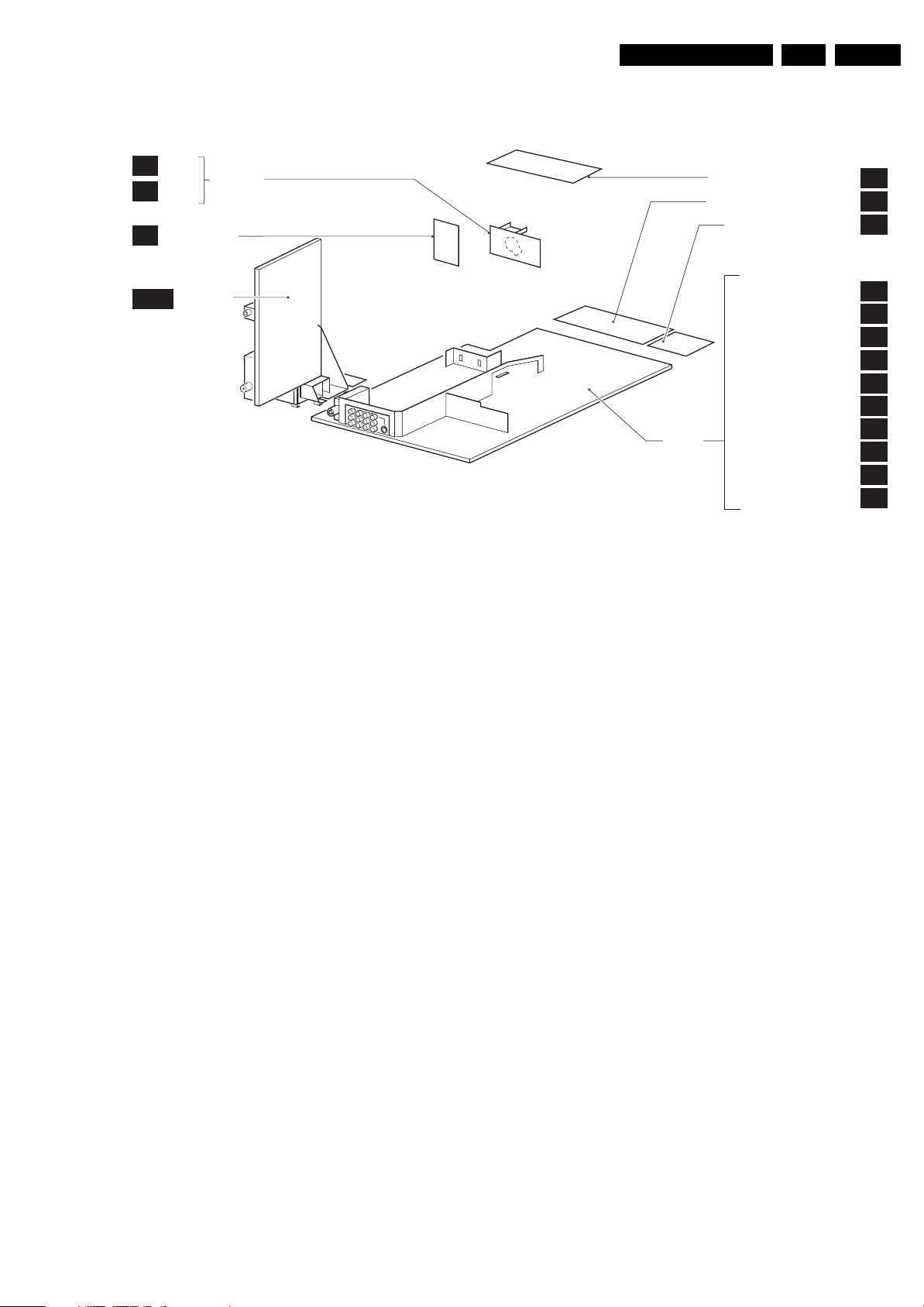

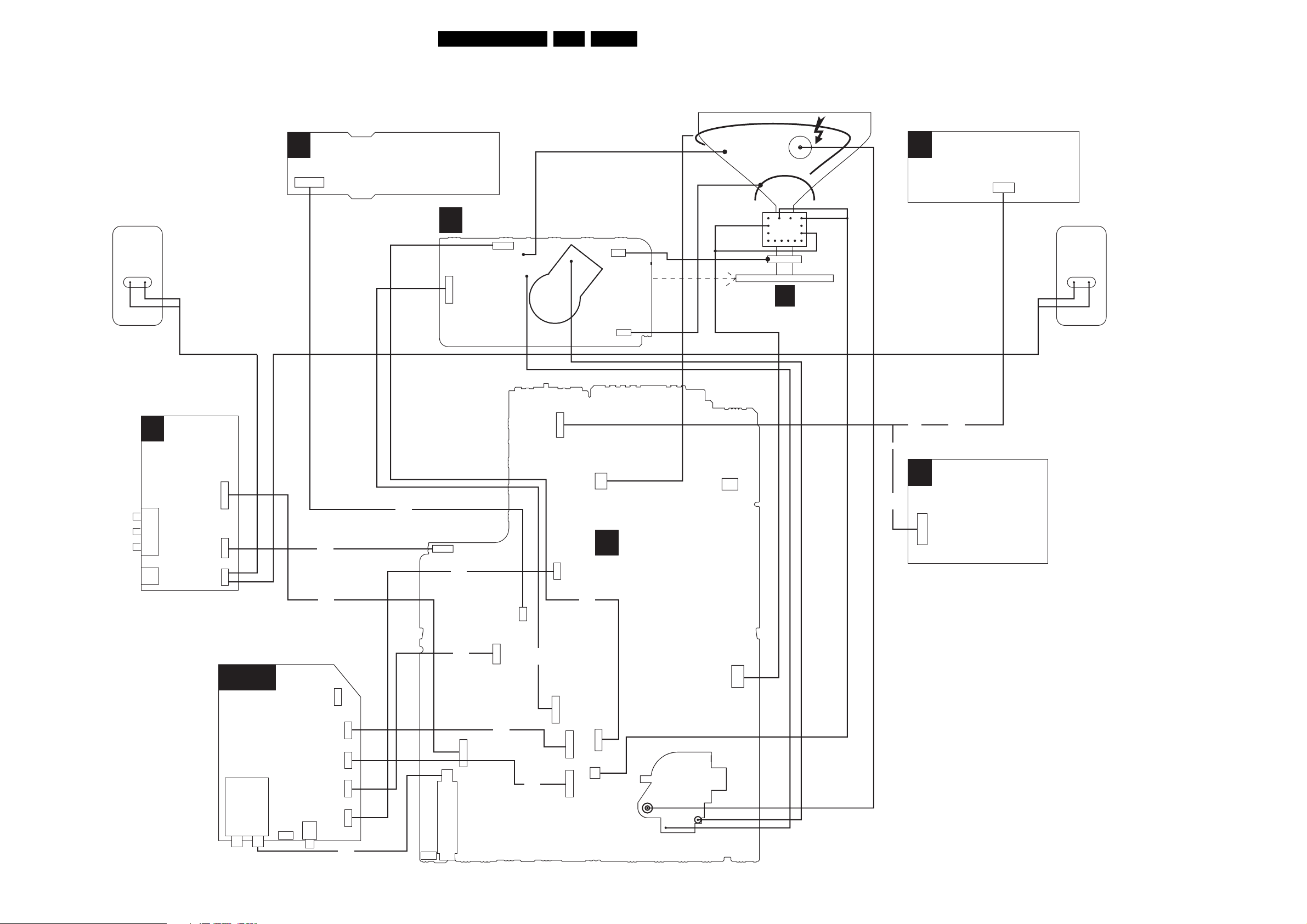

1.3 Chassis Overview

B1

CRT

ECO

B2

SCAVEM

SIDE AV PANEL +

D

HEADPHONE

CRT PANEL

TOP CONTROL PANEL (OPTIONAL)

MAINS SWITCH PANEL (OPTIONAL)

FRONT INTERFACE PANEL

(OPTIONAL)

EN 3L04.6U AA 1.

E

M

J

ATSC

ATSC PANEL

Figure 1-2 PWB location

MONO

CARRIER

POWER SUPPLY

LINE DEFLECTION

TUNER IF

HERCULES

FEATURES & CONNECTIVITIES

CLASS D AUDIO AMPLIFIER

AUDIO AMPLIFIER

REAR I/O CINCH

FRONT CONTROL

DVD POWER SUPPLY

F_15760_008.eps

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

171105

EN 4 L04.6U AA2.

Safety and Maintenance Instructions, Warnings, and Notes

2. Safety and Maintenance Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require that during a repair:

• Due to the chassis concept, a very large part of the circuitry

(incl. deflection) is 'hot'. Therefore, connect the set to the

mains via an isolation transformer.

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, you must return

the set in its original condition. Pay, in particular, attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current is flowing. In particular this is

valid for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the mains cord for external

damage.

• Check the strain relief of the mains cord for proper function,

to prevent the cord from touching the CRT, hot

components, or heat sinks.

• Check the electrical DC resistance between the mains plug

and the secondary side (only for sets that have an isolated

power supply). Do this as follows:

1. Unplug the mains cord and connect a wire between the

two pins of the mains plug.

2. Turn on the main power switch (keep the mains cord

unplugged!).

3. Measure the resistance value between the pins of the

mains plug and the metal shielding of the tuner or the

aerial connection of the set. The reading should be

between 4.5 MΩ and 12 MΩ.

4. Switch the TV 'off' and remove the wire between the

two pins of the mains plug.

• Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

1. Perform the 'general repair instruction' noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

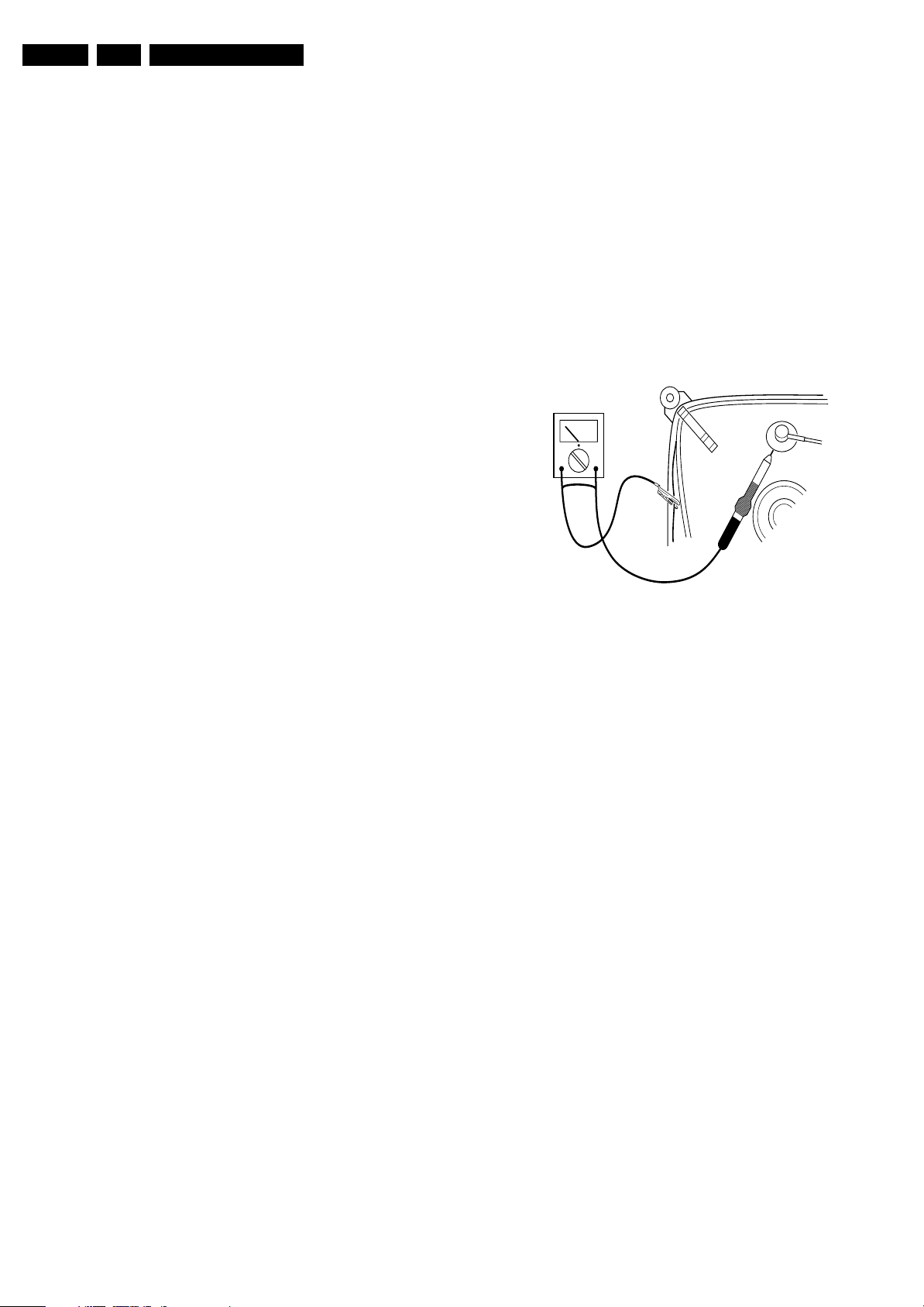

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in Fig. 2-1, to

discharge the picture tube. Use a high voltage probe and a

multi-meter (position V_dc). Discharge until the meter

reading is 0 V (after approx. 30 s).

V

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this potential. Available ESD

protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and ground cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Together with the deflection unit and any multi-pole unit,

flat square picture tubes form an integrated unit. The

deflection and the multi-pole units are set optimally at the

factory. We do not recommend adjusting this unit during

repair.

• Be careful during measurements in the high voltage

section and on the picture tube.

• Never replace modules or other components while the unit

is 'on’.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.4 Notes

E_06532_007.eps

250304

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry.

• The voltages and waveforms shown in the diagrams are

indicative. Measure them in the Service Default Mode (see

chapter 5) with a color bar signal and stereo sound (L: 3

kHz, R: 1 kHz unless stated otherwise) and picture carrier

at 475.25 MHz for PAL, or 61.25 MHz for NTSC (channel

3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in standby (F). These values are

indicated by means of the appropriate symbols.

• The picture tube panel has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

2.4.2 Schematic Notes

• All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are expressed in micro-farads (µ= x

10^-6), nano-farads (n= x 10^-9), or pico-farads (p= x 10^-

12).

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

2.4.3 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

Directions for Use

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

EN 5L04.6U AA 3.

P

b

Figure 2-3 Lead-free logo

Figure 2-2 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

E_06532_024.eps

230205

2.4.4 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

EN 6 L04.6U AA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Set Disassembly

4.2 Service Position

4.3 Assy/Panel Removal

4.4 Set Re-assembly

Notes:

• Figures below can deviate slightly from the actual situation,

due to different set executions.

4.1 Set Disassembly

Warning: Be sure to disconnect the AC power from the set

before opening it.

4.1.1 Rear Cover

1. Remove all fixation screws of the rear cover (do not forget

the screws that hold the rear connection panel).

2. Pull the rear cover backwards to remove it.

4.2 Service Position

Before placing the Mono Carrier in its service position, remove

the Front Interface assy/panel (see paragraph “Front Interface

Assy/Panel removal”) and the Side AV assy/panel (see

paragraph “Side AV Assy/Panel removal”).

2. Release the two fixation clamps (at the mid left and mid

right side of the bracket), and remove the bracket from the

bottom tray, by pulling it backwards [2].

3. Turn the chassis tray 90 degrees counter clockwise.

4. Move the panel bracket somewhat to the left and flip it 90

degrees [3], with the components towards the CRT.

5. Turn the panel bracket with the rear I/O toward the CRT.

6. Place the hook of the tray in the fixation hole of the cabinet

bottom [4] and secure it.

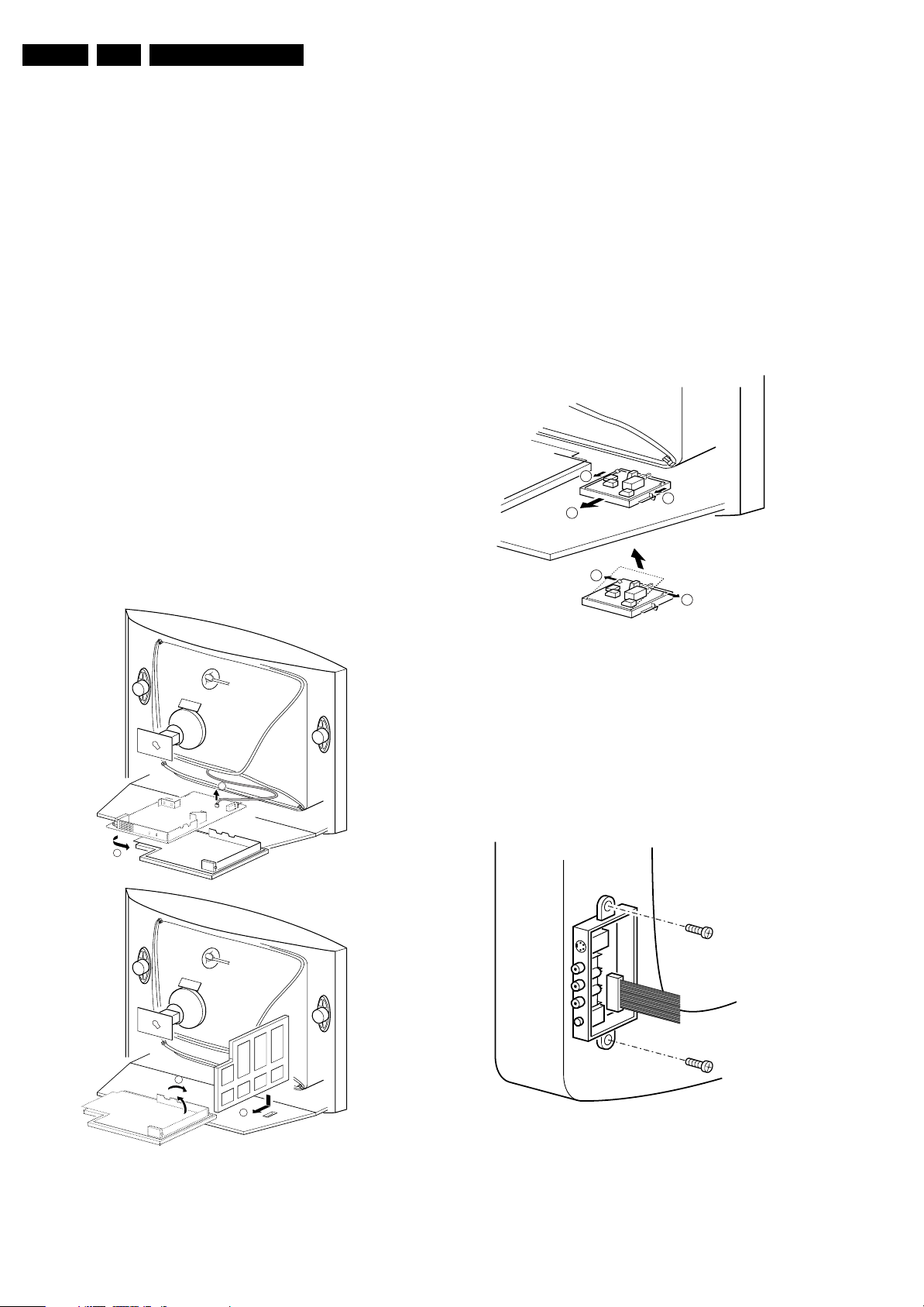

4.3 Assy/Panel Removal

4.3.1 Front Interface Assy/Panel Removal

1

2

3

1

3

E_14480_049.eps

110204

Figure 4-2 Front interface assy/panel removal

1. Remove the complete module from the bottom plate, by

pulling the two fixation clamps upward [1], while sliding the

module away from the CRT [2].

Note: these clamps are difficult to access.

2. Release the two fixation clamps [3] at the side of the

bracket, and lift the panel out of the bracket (it hinges at

one side).

1

4.3.2 Side AV Assy/Panel Removal

2

A

3

4

E_14480_050.eps

170204

B

Figure 4-1 Service position Mono Carrier

1. Disconnect the degaussing coil [1].

E_14480_048.eps

110204

Figure 4-3 Side AV assy/panel removal

1. Remove the two fixation screws, and remove the complete

Side AV assembly.

2. Release the two fixation clamps, and lift the panel out of the

bracket.

4.3.3 ATSC Module/Panel Removal

Mechanical Instructions

EN 7L04.6U AA 4.

3

1

2

Figure 4-4 ATSC bracket

1. Disconnect all cables that lead to the module.

2. Unlock the clip [1] at the left side of the bracket and pull out

the ATSC module [2].

3. Release the fixation clips that hold the panel [3] and take

out the panel (it hinges at the bottom).

4.4 Set Re-assembly

To re-assemble the whole set, do all processes in reverse

order.

Note: before you mount the rear cover, perform the following

checks:

• Check whether the AC power cord is mounted correctly in

its guiding brackets.

• Check whether all cables are replaced in their original

position

3

F_15760_009.eps

151105

EN 8 L04.6U AA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 ComPair

5.4 Error Codes

5.5 The Blinking LED Procedure

5.6 Protections

5.7 Fault Finding and Repair Tips

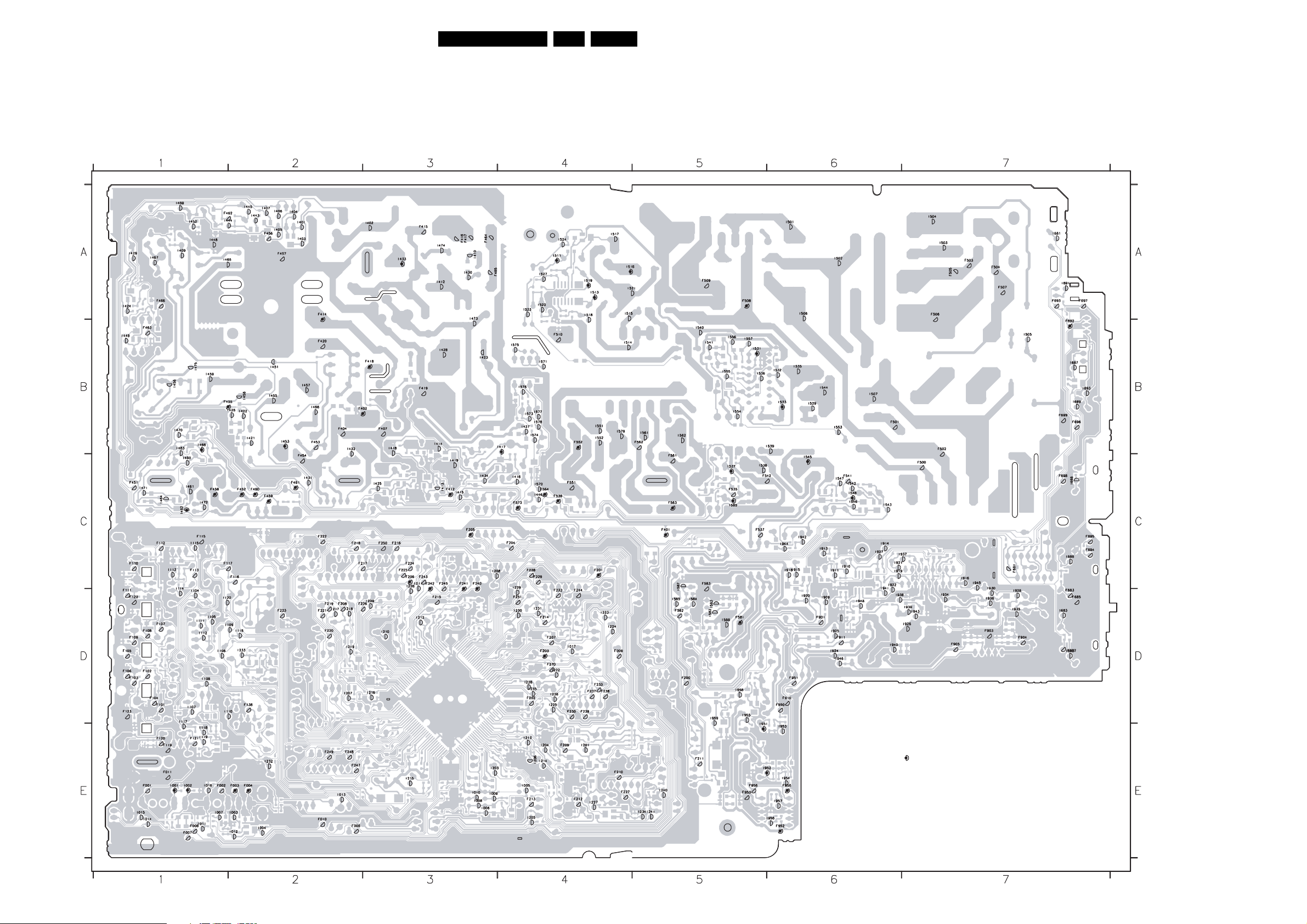

5.1 Test Points

This chassis is equipped with test points in the service printing.

In the schematics test points are identified with a rectangle box

around Fxxx or Ixxx. These test points are specifically

mentioned in the “Test Point Overview” as “half moons” with a

dot in the center.

Perform measurements under the following conditions:

• Television set in Service Default Alignment Mode.

• Video input: Color bar signal.

• Audio input: 3 kHz left channel, 1 kHz right channel.

5.2 Service Modes

Service Default mode (SDM) and Service Alignment Mode

(SAM) offers several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between the call center and the customer.

This chassis also offers the option of using ComPair, a

hardware interface between a computer and the TV chassis. It

offers the abilities of structured troubleshooting, error code

reading, and software version readout for all chassis.

Minimum requirements for ComPair: a Pentium processor, a

Windows OS, and a CD-ROM drive (see also paragraph

"ComPair").

– Auto switch "off" (when no video signal was received

for 10 minutes).

– Skip/blank of non-favorite pre-sets.

– Smart modes.

– Auto store of personal presets.

– Auto user menu time-out.

How to Enter

To enter SDM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU button

(do not allow the display to time out between entries while

keying the sequence).

• Short jumper wires 9252 and 9275 on the family board (see

Fig. 8-1) and apply AC power. Then press the power button

(remove the short after start-up).

Caution: Entering SDM by shorting wires 9252 and 9275

will override the +8V-protection. Do this only for a short

period. When doing this, the service-technician must know

exactly what he is doing, as it could damage the television

set.

• Or via ComPair.

After entering SDM, the following screen is visible, with SDM in

the upper right corner of the screen to indicate that the

television is in Service Default Mode.

00058 L6AUS1 0.4 SDM

ERR 0 0 0 0 0

OP 000 129 000 032 248 136 000

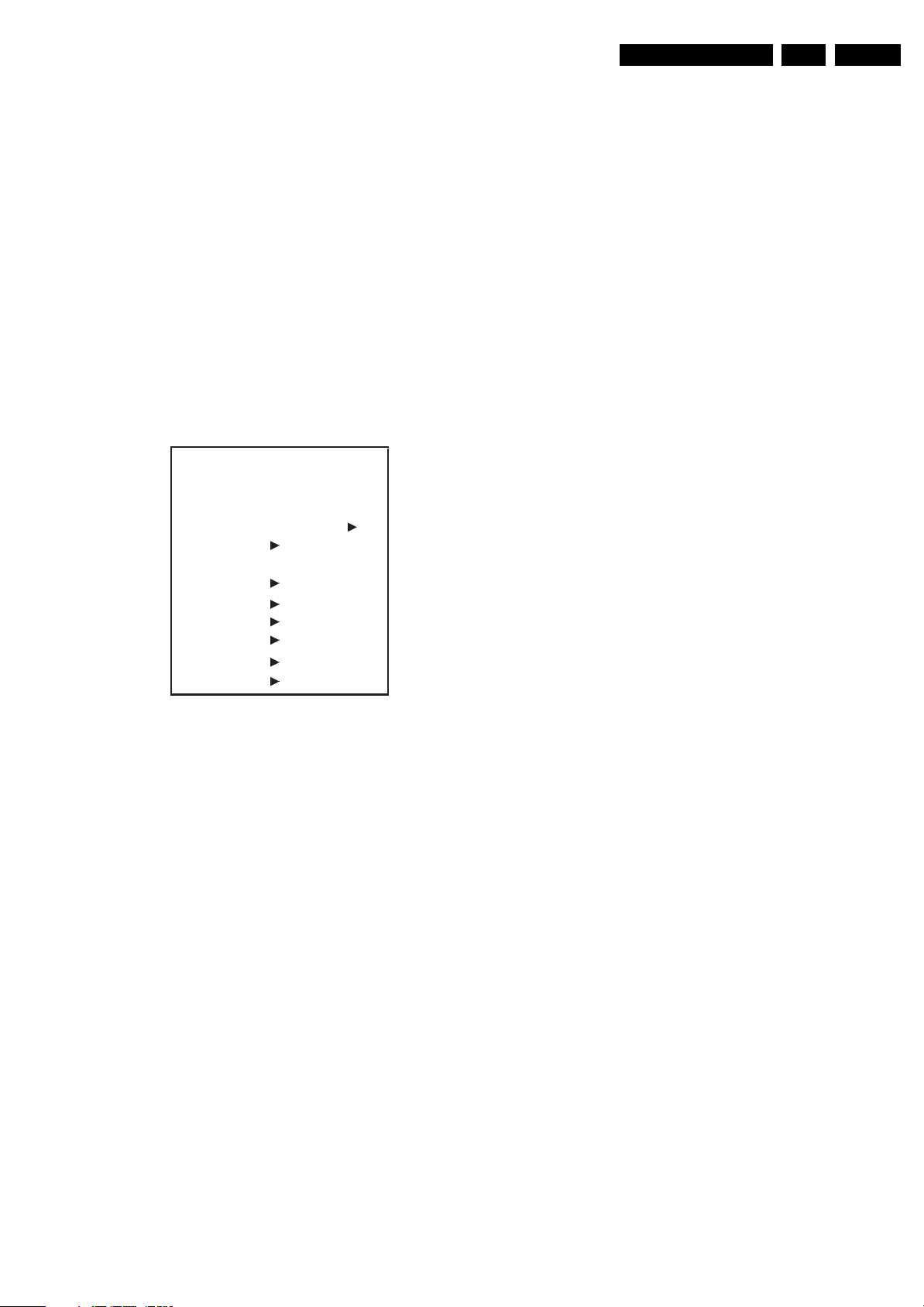

5.2.1 Service Default Mode (SDM)

Purpose

• To create a predefined setting for measurements to be

made.

• To override software protections.

• To start the blinking LED procedure.

Specifications

Table 5-1 SDM default settings

Region Freq. (MHz)

Europe, AP-PAL/Multi 475.25 PAL B/G

NAFTA, AP-NTSC, LATAM 61.25 (ch. 3) NTSC M

• Tuning frequency 61.25 MHz for NTSC: The TV shall tune

to physical channel 3 only if channel 3 is an analog channel

or if there is no channel 3 installed in the channel map. If

there is a digital channel installed in channel 3, then the

frequency to which the set will tune, would be as specified

in the channel map and could be different from the one

corresponding to the physical channel 3.

• All picture settings at 50% (brightness, color, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

– Picture mute (blue mute or black mute).

– Automatic volume levelling (AVL).

Default

system

F_15760_004.eps

111105

Figure 5-1 SDM menu

How to Navigate

Use one of the following methods:

• When you press the MENU button on the remote control,

the set will switch on the normal user menu in the SDM

mode.

• On the TV, press and hold the VOLUME DOWN and press

the CHANNEL DOWN for a few seconds, to switch from

SDM to SAM and reverse.

How to Exit

Switch the set to STANDBY by pressing the POWER button on

the remote control transmitter or the television set.

If you turn the television set off by removing the AC power (i.e.,

unplugging the television) without using the POWER button,

the television set will remain in SDM when AC power is reapplied, and the error buffer is not cleared.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To change option settings.

• To display / clear the error code buffer.

• To perform alignments.

Service Modes, Error Codes, and Fault Finding

EN 9L04.6U AA 5.

Specifications

• Operation hours counter (maximum five digits displayed).

• Software version, Error codes, and Option settings display.

• Error buffer clearing.

• Option settings.

• AKB switching.

• Software alignments (Tuner, White Tone, Geometry &

Audio).

• NVM Editor.

• ComPair Mode switching.

How to Enter

To enter SAM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “062596" directly followed by the OSD/

STATUS button (do not allow the display to time out

between entries while keying the sequence).

• Or via ComPair.

After entering SAM, the following screen is visible, with SAM in

the upper right corner of the screen to indicate that the

television is in Service Alignment Mode.

00058 L6AUS1 0.4 SAM

ERR 0 0 0 0 0

OP 000 129 000 032 248 136 000

. Clear Clear ?

. Options

. AKB On

. Tuner

. White Tone

. Geometry

. Audio

. NVM Editor

. ComPair off

F_15760_005.eps

111105

Figure 5-2 SAM menu

Menu explanation

1. LLLLL. This represents the run timer. The run timer counts

normal operation hours, but does not count standby hours.

2. AAABCD-X.Y. This is the software identification of the

main microprocessor:

– A= the project name (L4.6 ATSC= L6A).

– B= the region: E= Europe, A= Asia Pacific, U= NAFTA,

L= LATAM.

– C= the software diversity:

• Europe: T= 1 page TXT, F= Full TXT, V= Voice

control.

• LATAM and NAFTA: N= Stereo non-dBx, S=

Stereo dBx.

• Asian Pacific: T= TXT, N= non-TXT, C= NTSC.

• ALL regions: M= mono, D= DVD, Q= Mk2.

– D= the language cluster number.

– X= the main software version number (updated with a

major change that is incompatible with previous

versions).

– Y= the sub software version number (updated with a

minor change that is compatible with previous

versions).

3. SAM. Indication of the Service Alignment Mode.

4. Error Buffer. Shows all errors detected since the last time

the buffer was erased. Five errors possible.

5. Option Bytes. Used to set the option bytes. See “Options”

in the Alignments section for a detailed description. Seven

codes are possible.

6. Clear. Erases the contents of the error buffer. Select the

CLEAR menu item and press the MENU RIGHT key. The

content of the error buffer is cleared.

7. Options. Used to set the option bits. See “Options” in the

Alignments section for a detailed description.

8. AKB. Used to disable (Off) or enable (On) the “black

current loop” (AKB= Auto Kine Bias).

9. Tuner. Used to align the tuner. See “Tuner” in the

Alignments section for a detailed description.

10. White Tone. Used to align the white tone. See “White

Tone” in the Alignments section for a detailed description.

11. Geometry. Used to align the geometry settings of the

television. See “Geometry” in the Alignments section for a

detailed description.

12. Audio. No audio alignment is necessary for this television

set.

13. NVM Editor. Can be used to change the NVM data in the

television set. See table “NVM data” further on.

14. ComPaIr. Can be used to switch on the television to In

System Programming (ISP) mode, for software uploading

via ComPair.

Caution: When this mode is selected without ComPair

connected, the TV will be blocked. Remove the AC power

to reset the TV.

How to Navigate

• In SAM, select menu items with the MENU UP/DOWN keys

on the remote control transmitter. The selected item will be

highlighted. When not all menu items fit on the screen, use

the MENU UP/DOWN keys to display the next / previous

menu items.

• With the MENU LEFT/RIGHT keys, it is possible to:

– Activate the selected menu item.

– Change the value of the selected menu item.

– Activate the selected submenu.

• In SAM, when you press the MENU button twice, the set

will switch to the normal user menus (with the SAM mode

still active in the background). To return to the SAM menu

press the MENU or STATUS/EXIT button.

• When you press the MENU key in while in a submenu, you

will return to the previous menu.

How to Store SAM Settings

To store the settings changed in SAM mode, leave the top level

SAM menu by using the POWER button on the remote control

transmitter or the television set.

How to Exit

Switch the set to STANDBY by pressing the POWER button on

the remote control transmitter or the television set.

If you turn the television set “off” by removing the AC power

(i.e., unplugging the television) without using the POWER

button, the television set will remain in SAM when AC power is

re-applied, and the error buffer is not cleared.

5.2.3 Customer Service Mode (CSM)

Purpose

The Customer Service Mode shows error codes and

information on the TV’s operation settings. The call center can

instruct the customer (by telephone) to enter CSM in order to

identify the status of the set. This helps the call center to

diagnose problems and failures in the TV set before making a

service call.

The CSM is a read-only mode; therefore, modifications are not

possible in this mode.

How to Enter

To enter CSM, press the following key sequence on the remote

control transmitter: “123654” (do not allow the display to time

out between entries while keying the sequence).

Upon entering the Customer Service Mode, the following

screen will appear:

EN 10 L04.6U AA5.

Service Modes, Error Codes, and Fault Finding

1 00058 L6AUS1 0.4 CSM

2 CODES 0 0 0 0 0

3 OP 000 129 000 032 248 136 000

4

5 P3C-1

6

7 NTSC

8 Stereo

9 CO 50 CL 50 BR 50 HU 0

0 AVL Off BS 50

F_15760_006.eps

181105

Figure 5-3 CSM menu

Menu Explanation

1. Indication of the decimal value of the operation hours

counter, Software identification of the main microprocessor

(see "Service Default or Alignment Mode" for an

explanation), and the service mode (CSM= Customer

Service Mode).

2. Displays the last five errors detected in the error code

buffer.

3. Displays the option bytes.

4. Displays the type number version of the set.

5. Reserved item for P3C call centers (AKBS stands for

Advanced Knowledge Base System).

6. Indicates the television is receiving an "IDENT" signal on

the selected source. If no "IDENT" signal is detected, the

display will read "NOT TUNED"

7. Displays the detected Color system (e.g. PAL/NTSC).

8. Displays the detected Audio (e.g. stereo/mono).

9. Displays the picture setting information.

10. Displays the sound setting information.

How to Exit

To exit CSM, use one of the following methods:

• Press the MENU, STATUS/EXIT, or POWER button on the

remote control transmitter.

• Press the POWER button on the television set.

1 HRM SW Ver: 01.03a CSM

2 CODES of HRM

3 OP 000 129 000 032 248 136 000

4

5 P3C-1

6

7 ATSC

8 Stereo

9 CO 50 CL 50 BR 50 HU 0

0 AVL Off BS 50

F_15760_002.eps

101105

Figure 5-4 DCSM menu

Menu Explanation

1. Indication of the digital software version.

2. Displays the error codes related to the ATSC module.

3. Displays the option bytes.

4. Displays the type number version of the set.

5. Reserved item for P3C call centers (AKBS stands for

Advanced Knowledge Base System).

6. Indicates the television is receiving an "IDENT" signal on

the selected source. If no "IDENT" signal is detected, the

display will read "NOT TUNED"

7. Displays the detected Color system (e.g. PAL/NTSC).

8. Displays the detected Audio (e.g. stereo/mono).

9. Displays the picture setting information.

10. Displays the sound setting information.

How to Exit

To exit DCSM, use one of the following methods:

• Press the MENU, STATUS/EXIT, or POWER button on the

remote control transmitter.

• Press the POWER button on the television set.

5.3 ComPair

5.3.1 Introduction

5.2.4 Digital Customer Service Mode (DCSM)

Purpose

The Digital Customer Service Mode shows error codes and

information on the TV’s operation settings in “digital” mode.

The call center can instruct the customer (by telephone) to

enter CSM in order to identify the status of the set. This helps

the call center to diagnose problems and failures in the TV set

before making a service call.

The DCSM is a read-only mode; therefore, modifications are

not possible in this mode.

How to enter

To enter DCSM, press the following key sequence (with the

TV in “digital” mode) on the remote control transmitter:

“123654” (do not allow the display to time out between entries

while keying the sequence).

Upon entering the Digital Customer Service Mode, the

following screen will appear:

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the European DST (service remote control),

which allows faster and more accurate diagnostics. ComPair

has three big advantages:

• ComPair helps you to quickly get an understanding on how

to repair the chassis in a short time by guiding you

systematically through the repair procedures.

• ComPair allows very detailed diagnostics (on I

is therefore capable of accurately indicating problem areas.

You do not have to know anything about I

yourself because ComPair takes care of this.

• ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

the Force/SearchMan electronic manual of the defective

chassis, schematics and PWBs are only a mouse click

away.

5.3.2 Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

(or RS-232) cable.

2

C level) and

2

C commands

Service Modes, Error Codes, and Fault Finding

EN 11L04.6U AA 5.

For this chassis, the ComPair interface box and the TV

communicate via a bi-directional service cable via the service

connector(s).

The ComPair fault finding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in two ways:

• Automatically (by communicating with the television):

ComPair can automatically read out the contents of the

entire error buffer. Diagnosis is done on I

ComPair can access the I

ComPair can send and receive I

2

C/UART bus of the television.

2

C/UART commands to

the microcontroller of the television. In this way, it is

possible for ComPair to communicate (read and write) to

devices on the I

2

C/UART buses of the TV-set.

• Manually (by asking questions to you): Automatic

diagnosis is only possible if the microcontroller of the

television is working correctly and only to a certain extent.

When this is not the case, ComPair will guide you through

the fault finding tree by asking you questions (e.g. Does the

screen give a picture? Click on the correct answer: YES /

NO) and showing you examples (e.g. Measure test-point I7

and click on the correct oscillogram you see on the

oscilloscope). You can answer by clicking on a link (e.g.

text or a waveform picture) that will bring you to the next

step in the fault finding process.

By a combination of automatic diagnostics and an interactive

question / answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

5.3.3 How to Connect

This is described in the chassis fault finding database in

ComPair.

TO

UART SERVICE

CONNECTOR

TO

I2C SERVICE

CONNECTOR

2

C/UART level.

– ERROR: 0 0 0 0 0: No errors detected

– ERROR: 6 0 0 0 0: Error code 6 is the last and only

detected error

– ERROR: 9 6 0 0 0: Error code 6 was detected first and

error code 9 is the last detected (newest) error

• Via the blinking LED procedure (when you have no

picture). See “The Blinking LED Procedure”.

•Via ComPair.

5.4.2 How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

• By using the CLEAR command in the SAM menu:

– To enter SAM, press the following key sequence on the

remote control transmitter: “062596” directly followed

by the OSD/STATUS button (do not allow the display

to time out between entries while keying the

sequence).

– Make sure the menu item CLEAR is highlighted. Use

the MENU UP/DOWN buttons, if necessary.

– Press the MENU RIGHT button to clear the error

buffer. The text on the right side of the “CLEAR” line will

change from “CLEAR?” to “CLEARED”

• If the contents of the error buffer have not changed for 50

hours, the error buffer resets automatically.

Note: If you exit SAM by disconnecting the AC power from the

television set, the error buffer is not reset.

5.4.3 Error Codes

In case of non-intermittent faults, write down the errors present

in the error buffer and clear the error buffer before you begin

the repair. This ensures that old error codes are no longer

present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

and not the actual cause of the problem (for example, a fault in

the protection detection circuitry can also lead to a protection).

PC VCR I2CPower

9V DC

E_06532_021.eps

180804

Figure 5-5 ComPair interface connection

5.3.4 How to Order

ComPair order codes (US):

• ComPair Software: ST4191.

• ComPair Interface Box: 4822 727 21631.

• AC Adapter: T405-ND.

• ComPair Quick Start Guide: ST4190.

• ComPair interface extension cable: 3139 131 03791.

• ComPair UART interface cable: 3122 785 90630.

Note: If you encounter any problems, contact your local

support desk.

5.4 Error Codes

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is displayed at the left side and all other errors shift one

position to the right.

5.4.1 How To Read The Error Buffer

You can read the error buffer in 3 ways:

• On screen via the SAM (if you have a picture). Examples:

EN 12 L04.6U AA5.

Service Modes, Error Codes, and Fault Finding

Table 5-2 Error code overview

Error Device Error description Check item Diagram

0 Not applicable No Error

1 Not applicable X-Ray/Over-voltage protection (US only) 2411, 2412, 2413, 6404, 6411,

6412

2 Not applicable High beam (BCI) protection 3404, 7405 A2

3 Not applicable Vertical guard protection 3466, 7451, 7452, 7453, 7454 A2

4 Tuner I

2

C error while communicating with 2nd tuner 1000, 5010, (PIP Module) F2

5 Not applicable +5v protection 7604, 7605 A5

2

6I

C bus General I2C error 7200, 3207, 3214 A4

7 Not applicable Power down (over current) protection - -

8 Not applicable EW protection (only for sets with EW circuitry) - -

2

9 24C16 I

10 Tuner I

C error while communicating with the EEPROM 7601, 3604, 3605 A5

2

C error while communicating with the PLL tuner 1000, 5001 A3

11 TDA6107/A Black current loop instability protection 7330, 3351, CRT B1

2

12 SDA9488X I

13 Not applicable I

14 DVD Loader I

15 TDA9178T/N1 I

16 TDA9887 I

17 ATSC module I

18 ATSC module I

C error while communicating with the PIP processor 7242 (PIP Module) F1

2

C error while communicating with the Voice Ctrl processor - -

2

C error while communicating with the DVD Interface module DVD Interface module DVD Loader

2

C error while communicating with the LTI module 7610 H

2

C error while communicating with the PIP Demodulator 7201 F2

2

C error while communicating with the IBO module - ATSC

2

C error while communicating with other I2C IBO module - ATSC

A2

Note: For all error codes the following applies: error codes are

only valid when the module or device they refer to is used in the

TV set.

5.5 The Blinking LED Procedure

Using this procedure, you can make the contents of the error

buffer visible via the front LED. This is especially useful when

there is no picture.

When the SDM is entered, the front LED will blink the contents

of the error-buffer:

• When all the error-codes are displayed, the sequence

finishes with a LED blink of 1.5 seconds,

• The sequence starts again.

Example of error buffer: 12 9 6 0 0

After entering SDM, the following occurs:

• 1 long blink of 5 seconds to start the sequence,

• 12 short blinks followed by a pause of 1.5 seconds,

• 9 short blinks followed by a pause of 1.5 seconds,

• 6 short blinks followed by a pause of 1.5 seconds,

• 1 long blink of 1.5 seconds to finish the sequence,

• The sequence starts again at 12 short blinks.

5.6 Protections

If a fault situation is detected, an error code will be generated;

and, if necessary, the television set will go into protection

mode. Blinking of the red LED at a frequency of 3 Hz indicates

the protection mode. In some error cases, the microprocessor

does not put the set in protection mode. The error codes of the

error buffer and the blinking LED procedure can be read via the

Service Default Menu (SDM), or via ComPair.

To get a quick diagnosis the chassis has three service modes

implemented:

• The (Digital) Customer Service Mode ((D)CSM).

• The Service Default Mode (SDM).

• The Service Alignment Mode (SAM).

For a detailed mode description, see the relevant sections.

5.7 Fault Finding and Repair Tips

Notes:

• It is assumed that the components are mounted correctly

with correct values and no bad solder joints.

• Before any fault finding actions, check if the correct options

are set.

5.7.1 NVM Editor

In some cases, it can be handy if one directly can change the

NVM contents. This can be done with the “NVM Editor” in SAM

mode. In the next table, some default NVM values are given.

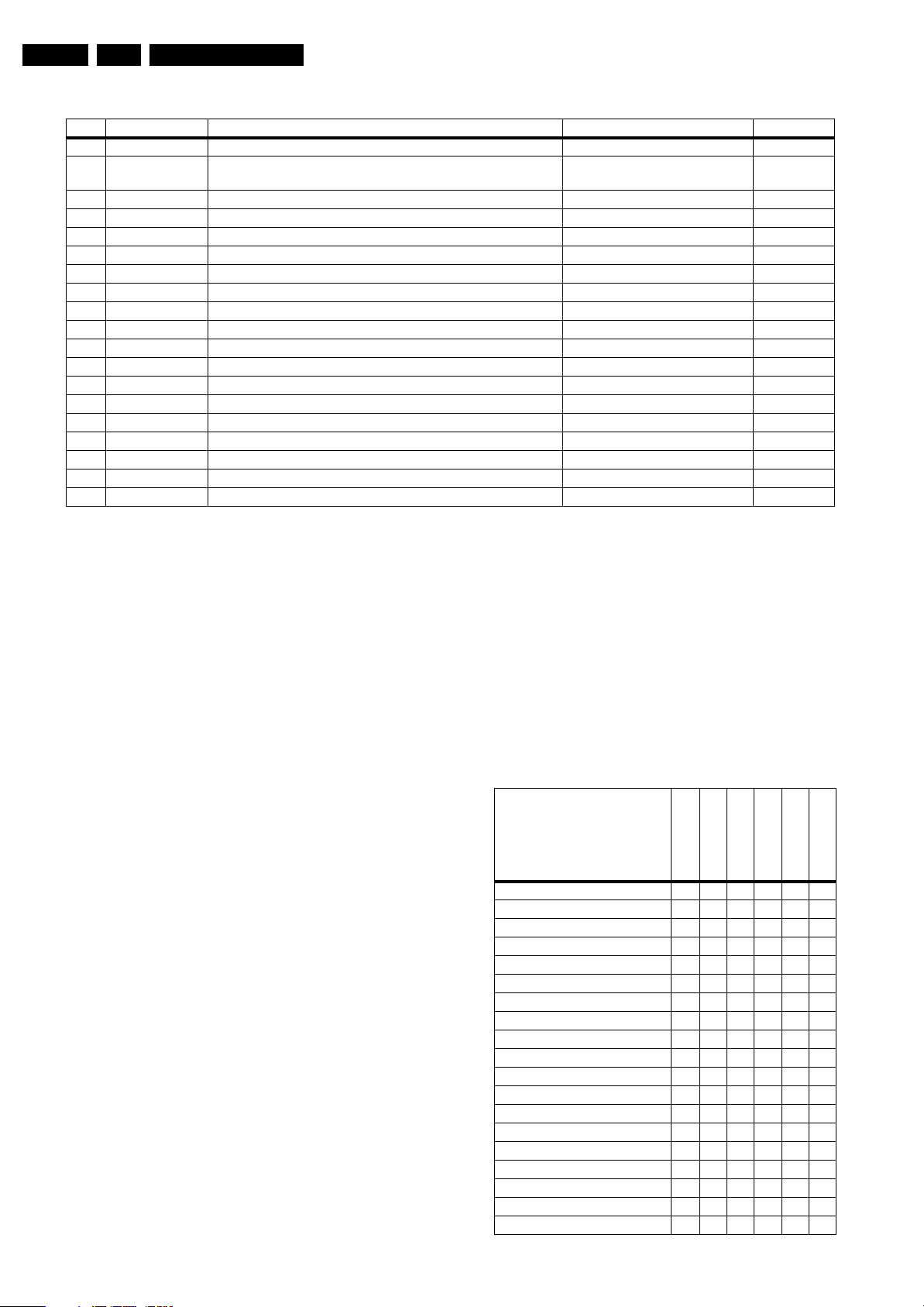

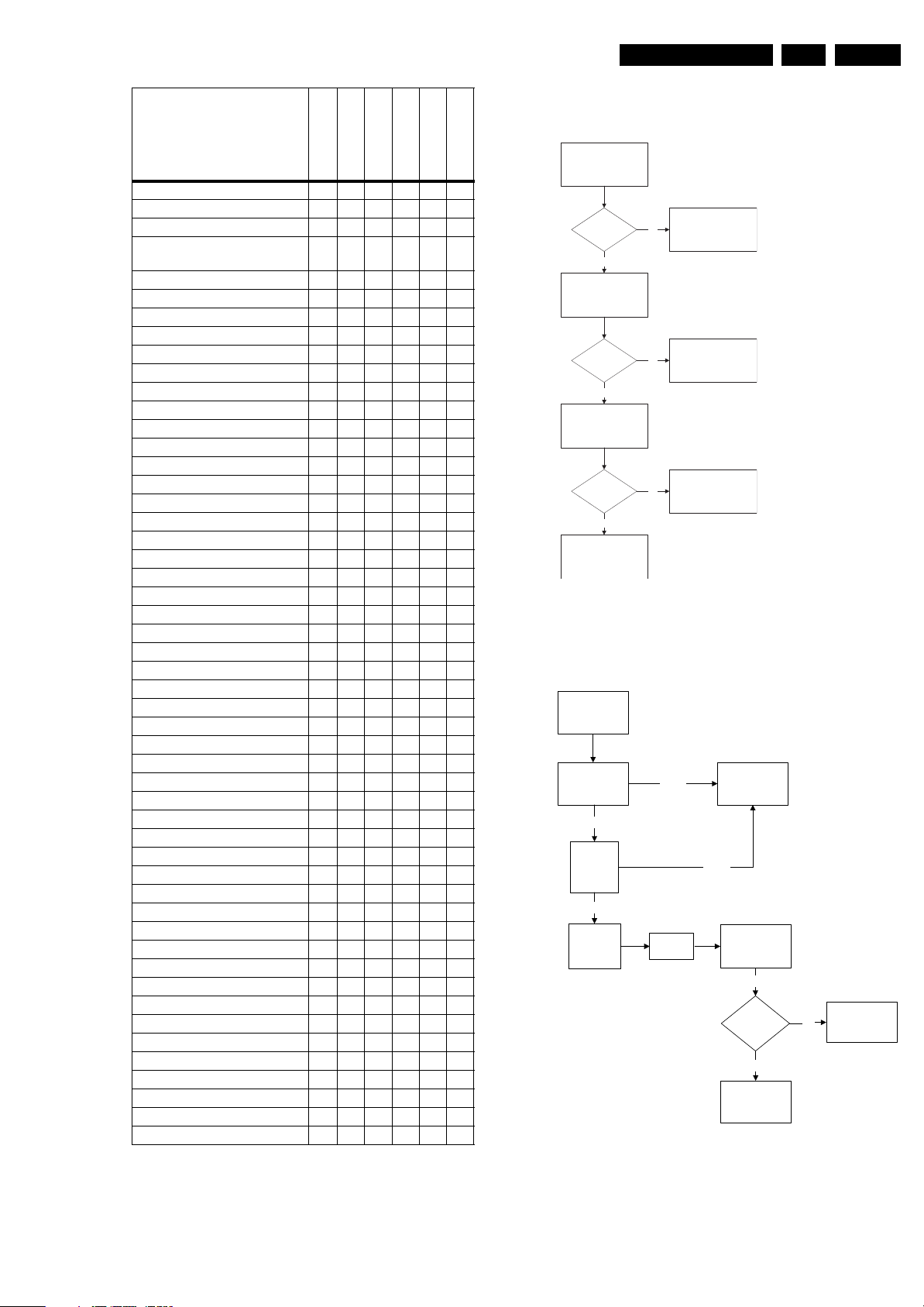

Table 5-3 Default NVM values

Bit

Addr. (DEC)

EW (EW width) 19 37 45 45 37 37

PW (EW parabola width) 20 10 20 20 10 10

HS (Horizontal shift) 21 26 43 43 26 26

HP (Horizontal Parallelogram) 22 31 33 33 31 31

HB (Horizontal Bow) 23 31 31 31 31 31

UCP(EW Upper Corner Parab.) 24 30 41 41 30 30

LCP(EW Lower Corner Parab.) 25 40 51 51 40 40

TC (EW Trapezium) 26 26 20 20 26 26

VS (Vertical Slope) 273731313737

VA (Vertical Amplitude) 28 30 31 31 30 30

SC (S-Correction) 29 35 30 30 25 25

VSH (Vertical Shift) 30 26 33 33 26 26

VX (Vertical Zoom) 312525252525

VSL (Vertical scroll) 323232323232

EHTC (Vertical linearity) 33 32 32 32 32 32

BLOR (Black Level Offset Red) 34 36 36 36 36 36

BLOG (Black Level Offset Grn) 35 31 31 31 31 31

AGC (AGC Take over) 36 255 255 255 255 255

OIF (IF-PLL Offset) 373838383838

27MT5005D/37

27MT6005D/37

27PT9015D/37

32PT7005D/37

32PT9005D/37

Service Modes, Error Codes, and Fault Finding

EN 13L04.6U AA 5.

Bit

Addr. (DEC)

27MT5005D/37

27MT6005D/37

27PT9015D/37

32PT7005D/37

32PT9005D/37

-Empty- 3822222

H60 (60 Hz Horizontal Shift) 3999999

PWL (Peak White Limit) 40 10 10 10 10 10

Phase 1 time constant, Video

41 15 15 15 15 15

Coring, Ratio & White Stretch

60 Hz Vertical amplitude 42 48 48 48 48 48

YD & CL 43 87 88 88 89 89

RGB amplitude full TXT mode 46 8 8888

NVM Table Version 601818181818

Option Table Version 61 18 18 18 18 18

NVM_CVI_BLOR 62 25 25 25 25 25

NVM_CVI_BLOG 6333333

TXT Brightness 64 40 40 40 40 40

V60 offset (60Hz Vert. Ampl.) 66 254 254 254 254 254

FOAB, CHSE 13933333

SPR, WS 14000000

VMA, SVM 141 50 52 52 50 50

NVM_SOC_SMD 14233333

NVM_CCC_Preset_Gain_Red 143 31 31 31 31 31

NVM_CCC_Preset_Gain_Grn 144 31 31 31 31 31

NVM_CCC_Preset_Gain_Blue 145 31 31 31 31 31

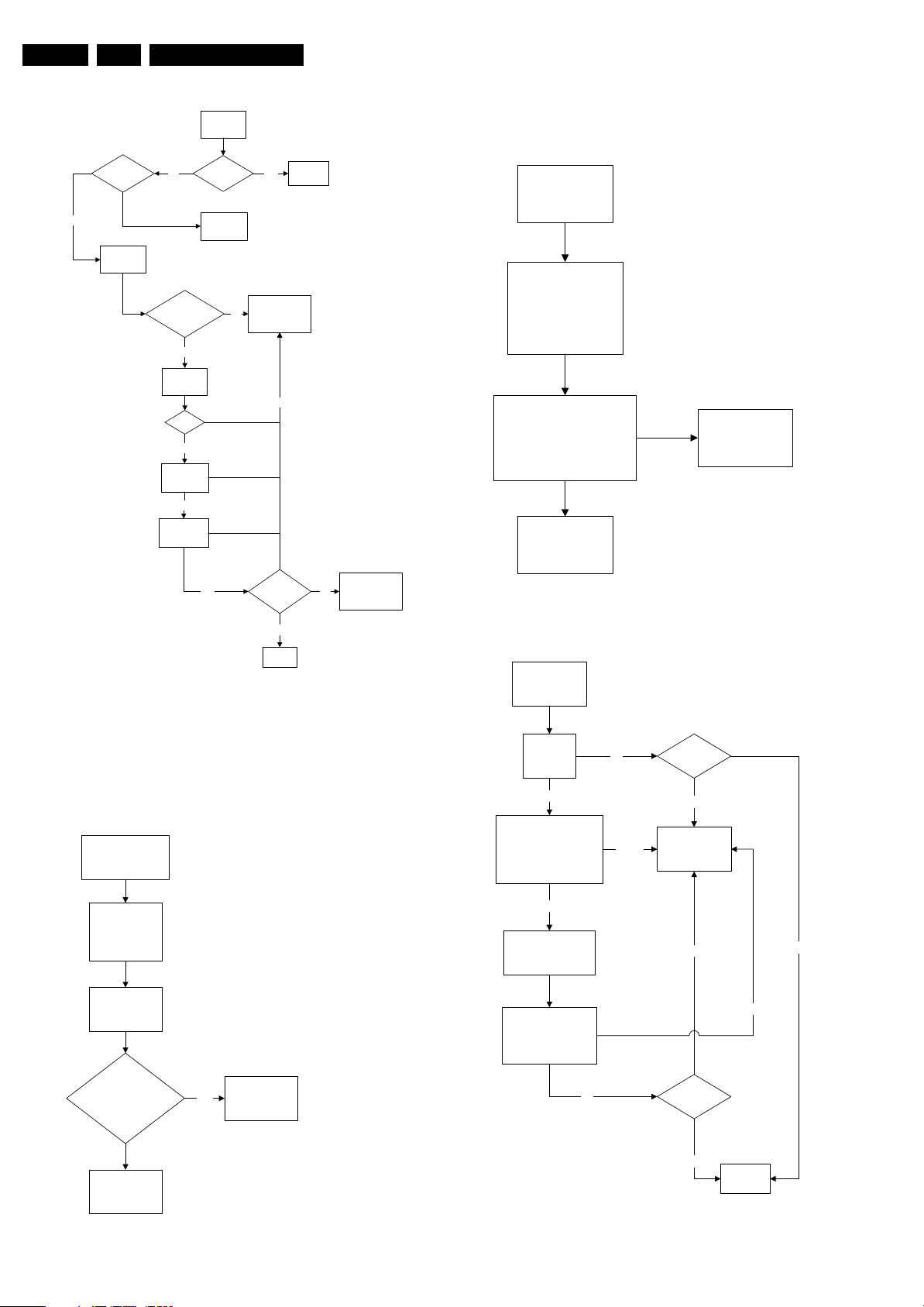

5.7.2 ATSC Module

ATSC Module check

Check 10 V supply

from Main Chassis

Check Auxillary

OK?

Yes

Check UART Signal

(P1206)

OK?

Yes

Check Video &

Audio signal o/p

from ATSC Module

OK?

Yes

Check wiring and

connections of ATSC

Module

No

No

No

Power Supply

Check Hercules

UART o/p

Replace ATSC

Module

F_15760_010.eps

161105

Figure 5-6 Fault finding tree “ATSC Module check”

5.7.3 Power Supply

NVM_FMWS 14933333

NVM_ASD_SC1_THR 150 16 16 16 16 16

NVM_CRYSTALALIGN 208 63 63 63 63 63

Last Brightness(VID PP others) 264 50 50 50 50 50

Last Color (VID PP others) 265 40 40 40 40 40

Last Contrast (VID PP others) 266 85 85 85 85 85

Last Sharpness(VID PP others) 267 60 60 60 60 60

Last Hue (VID PP others) 268 48 48 48 48 48

Last Col.Temp.(VID PP others)26944444

White-D Cool Red 29400000

White-D Cool Green 29511111

White-D Cool Blue 29677777

White-D Normal Red 297 32 32 32 32 32

White-D Normal Green 298 27 27 27 27 27

White-D Normal Blue 299 26 26 26 26 26

White-D Warm Red 30000000

White-D Warm Green 301 251 251 251 251 251

White-D Warm Blue 302 239 239 239 239 239

Last Volume 343 24 24 24 24 24

Last Balance 344 50 50 50 50 50

Last Treble (AUD PP others) 345 50 50 50 50 50

Last Bass (AUD PP others) 346 50 50 50 50 50

Set Not Working

Check Power

Supply Mains

Switch

Not Ok

Check fusible

resistor 3510 &

circuit before it

Check IC7511 &

IC7531

Ok

Set able to

start-up

Ye s

End

No

Bridge Rectifier

circuit 6500

Ok

Check DC

voltage at

2505/2507

Ok

Check

fusible

resistor 3532

Not Ok

Check

7512

Figure 5-7 Fault finding tree “Set not working”

Check other

fusible resistor

and capacitor in

the circuit

E_14480_057.eps

190204

EN 14 L04.6U AA5.

Service Modes, Error Codes, and Fault Finding

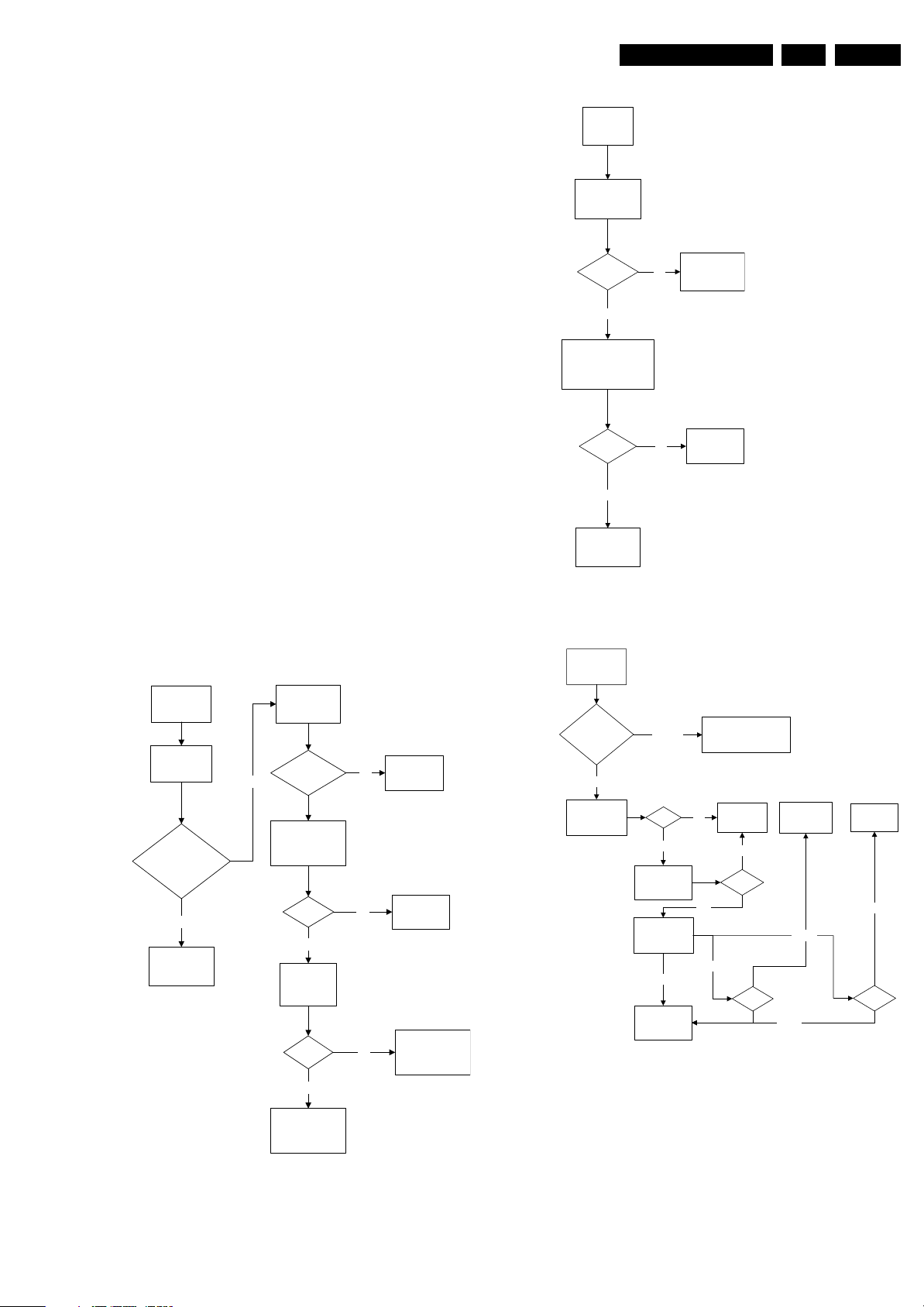

Set Does Not Start Up

Set Unable

to Start

Software

loaded?

Yes

Check

voltage

across 2552

No

Is Vbatt

approximately

140V

Yes

Check

voltage 2562

&2563

16V

Yes

Check 3V

across 2535

Yes

Check 6V

across 2535

Fuse Blown?

Load

Software

Yes

No

Yes

Check Power

Supply circuit

No

Set able to

Start

Yes

End

Change

Fuse

No

Check Line

Transistor 7405

E_14480_058.eps

Figure 5-8 Fault finding tree “Set does not start up”

170204

One Thin Horizontal Line

Quick check:

• Set in protection mode.

• LED blinking with error “2”.

One Horizontal

Thin Line

LED Blinking

Check all connection

and peripheral at

Deflection Circuit

in place

Check transistor

(7451, 7523, 7543) at

Replace transistor

Vertical Deflection Circuitry

Check Vertical

Deflection Circuit

E_14480_060.eps

170204

Figure 5-10 Fault finding tree “One thin horizontal line”

Blank Screen

Blank Screen

5.7.4 Deflection

One Thin Vertical Line

Quick check:

• Set in protection mode.

• LED blinking with error “3”.

One Thin Vertical Line

LED Blinking

Check all

connection and

peripheral at

Deflection Circuit in

place

Check

Line Transistor

7405

Is VBE between

200mV to 30mV & V

approximately 500mV

Replace transistor

Check Vg2

(fine tune)

Not Ok

Check Beam Current Limit

(voltage is 1.8V-2V when

brightness and contrast is

set to the maximum

Ok

Check heater voltage

(measure pin 9&10

at the CRT socket)

Check video supply

(2457) is approximately

180V

Yes

Check Horizontal

Deflection

Circuitry

E_14480_059.eps

170204

CB

Ok

Not Ok

Ok

Picture

appears?

Picture not appearing

Check deflection

circuit

Picture not appearing

Picture

appears?

Ok

Not Ok

End

E_14480_061.eps

Ok

170204

Figure 5-9 Fault finding tree “One thin vertical line”

Figure 5-11 Fault finding tree “Blank screen”

Service Modes, Error Codes, and Fault Finding

EN 15L04.6U AA 5.

5.7.5 Source Selection

Set is not able to go into AV or any missing AV is encountered

E.g. AV1 is available but not able to enter to AV1: Check if the

option setting is correct.

Set is able to go to AV, but no Audio is heard.

1. Check that continuity of signal is there from the SCART/

Cinch input to the input of the Hercules.

2. If continuity is there and still no audio, check that option

settings are correct.

3. If logic setting is correct and still no audio, proceed to Audio

Decoder/Processor troubleshooting section.

Set is able to go into AV but no Video is available:

1. Check continuity from AV input to Hercules depending on

the input.

2. If continuity is available and yet no video, proceed to Video

Processor troubleshooting section.

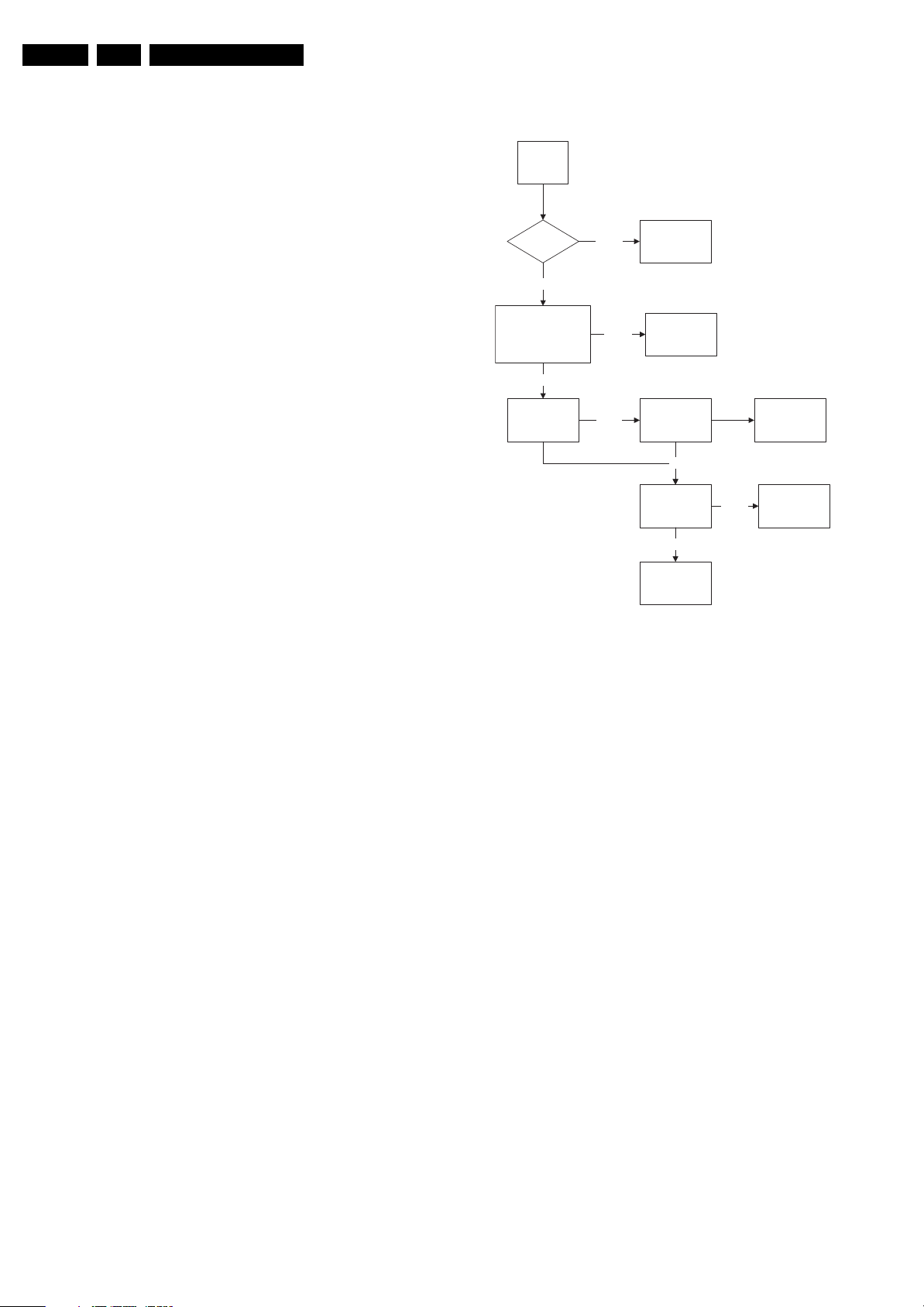

5.7.6 Tuner and IF

No Picture

1. Check that the Option settings are correct.

2. If correct, check that supply voltages are there.

3. If supply voltages are present, check whether picture is

present in AV.

4. If picture is present in AV, check with the scope the Tuner

IF output signal by manual storage to a known channel.

5. If IF output is present, Tuner is working fine. If no IF output,

I2C data lines may be open, check continuity of I2C lines.

If I2C lines are ok, Tuner may be defect, replaced Tuner.

6. If Tuner IF is present and yet still no picture in RF mode, go

to Video Processing troubleshooting section.

No Picture, No Sound

Yes

Check tuning

supply voltage,

pin 9 of tuner

>30V & <35V

Check supply

voltage, pin 7 of

tuner

5V

Yes

Check Tuner

pin 4 & 5

I2C Bus

Ok

Yes

No

No

No

No Picture,

No Sound,

Raster Ok

Check AGC

Voltage, pin 1

of tuner

AGC voltage

changes with

different signal

strength

No

Check AGC

circuit section

Check

Supply

V

T

Section

Check Power

Supply

Check other

functional area

Picture Ok, No Sound

Picture Ok,

No Sound

Check IF output of

tuner, pin 11

CVBS

present?

Ye s

Check SAW filter output

(pin 4&5)

EU/AP/CH (QSS)- 1001

NA/LA/AP INT - 1002

Output Ok?

Ye s

Check other

functional area

No

No

Refer to fig.

"Power Supply:

Set not working"

Replace SAW

filter

E_14480_063.eps

170204

Figure 5-13 Fault finding tree “Picture ok, no sound”

Unable To Perform Tuning

Unable to

perform tuning

Enter SDM

check optionbyte 1

Correct

Check if tuner

Supply Voltage

pin 7

Incorrect

5V

Yes

Check Tuner

Supply Voltage

Check I2C at pin

4 & 5 and tuner

Ok

Check other

functional area

Enter SDM and change

to the appropriate byte

Check Power

No

Supply

No

33V

Yes

Not Ok

Check I2C

circuit

Not Ok

I2C

Not Ok

Replace

Tuner

Not Ok

Tuner

E_14480_064.eps

Figure 5-14 Fault finding tree “Unable to perform tuning”

170204

Replace Tuner

E_14480_062.eps

Figure 5-12 Fault finding tree “No picture, no sound”

170204

EN 16 L04.6U AA5.

Service Modes, Error Codes, and Fault Finding

5.7.7 Controller

Below are some guidelines for troubleshooting of the Micro

Controller function. Normally Micro Controller should be

checked when there is a problem of startup.

1. Check that both +3.3 V_dc and +1.8 V_dc are present.

2. Check that crystal oscillator is working.

3. Check that Power Good signal is at “high” logic, normal

operation.

4. Check that Hercules is not in standby mode. Pin 15 of

Hercules should be 0 V_dc.

5. Make sure H-drive pulse is there. This can be checked at

resistor R3239. If H-drive does not exist, remove resistor

R3239 to check if there is loading.

Note: When the set shuts down after a few second after power

“on”, the main cause is that Vg2 not aligned properly, try

adjusting Vg2 during the few seconds of power “on”.

5.7.8 Video Processing

No Picture

When “no picture in RF”, first check if the microprocessor is

functioning ok in section “Controller”. If that is ok, follow the

next steps.

When “no picture in AV”, first check if the video source

selection is functioning ok in section “Source Selection”. If that

is ok, follow the next steps.

1. Check that normal operating conditions are met.

2. Check that there is video signal at pin 81. If no video,

demodulator part of the Hercules is faulty, replace with new

Hercules.

3. If video signal is available at pin 81, check pin 56, 57, and

58 for the RGB signal.

4. If signal is not available, try checking the BRIGHTNESS

and/or CONTRAST control, and make sure it is not at zero.

5. If still with the correct settings and no video is available,

proceed to the CRT/RGB amplifier diagram.

For sets with Scavem, and Scavem does not work, follow steps

below:

1. Check Scavem coil connector (position is 1361) if

connected; if not, connect it.

2. If connected, check NVM “bit storage” byte 1 bit 7; if it is not

“1”, set it to “1”.

3. If it is “1”, then check the data of the NVM addresses as in

table “Default NVM values“ (addresses 140, 141, and 142).

If the data is not correct, then set these addresses to the

table values.

4. If it still not works, track Scavem output from pin64 of

Hercules to CRT panel.

5.7.9 Audio Processing

No Sound

Picture Ok,

No Sound

Tuner IF Ok Check Tuner/IFNot Ok

Ok

Check AUDOUTLSL &

AUDOUTLSR pin at

UOCIII

Ok

Check Audio

Amplifier

Not Ok

Not Ok

Check UOCIII IC

Check Audio

Power Supply

Ok

Check Audio

Amplifier Circuit

and loud speaker

Ok

Check NVM

Not Ok

Figure 5-15 Fault finding tree “No sound”

No RF Audio for QSS/Inter-Carrier Stereo Sets.

1. Check pin 99 and 100 for SIF signal (for QSS) or pin 104

and 105 for video with SIF (for Inter-Carrier)

2. If signal is not present, check for the QSS/FMI bit settings.

Check also the NVM data.

3. If signals are present and still no audio, check the audio

supply voltage +8V are present.

4. If still no audio signal at Hercules output, Hercules is faulty.

No AV Audio.

1. Check troubleshooting methods in section “Source

Selection”.

2. Check the output of the Hercules to see if there is signal

available. If no, check the normal operating condition and

also the NVM data.

3. If still no audio signal at Hercules output, Hercules is faulty.

Note: If there is audio signal at Hercules output and no audio

at loudspeaker, proceed to Audio Amplifier troubleshooting

methods.

Check Power

Supply

Replace Audio

Amplifier

E_14480_065.eps

201005

5.7.10 Audio Amplifier

No RF as well as AV Audio at the Loudspeaker:

1. Check that the normal operation condition of the amplifier

is met.

2. If normal operation conditions are met, check the continuity

from Hercules output to input of the amplifier.

3. If continuity is there and still no audio, check speaker wire

connections. If still no audio, amplifier IC might be faulty.

Block Diagrams, Testpoint Overviews, and Waveforms

6. Block Diagrams, Testpoint Overviews, and Waveforms

Wiring Diagram

TOP CONTROL PANEL

E

(ONLY FOR PV02 STYLING)

1010

3P

CRT PANEL

B

RIGHT

SPEAKER

1331

7P

5P

1351

1332

1352

CRT

SOCKET

17L04.6U AA 6.

DEGAUSSING COIL

1361

3P

AQUADAG

CRT

FRAME

ROTATION

COIL

SCAVEM

COIL

EHT

CRT

MAIN SWITCH PANEL

M

(ONLY FOR SL5 STYLING)

1693

6P

LEFT

SPEAKER

B

CRT PANEL

1381

3P

CVBS (YELLOW)

LEFT (WHITE)

RIGHT (RED)

HEADPHONE

SIDE

D

A/V PANEL +

HEADPHONE

1252

7P

1254

5P

1278

4P

ATSC

TUNER

ATSC

PANEL

P701

3P

SPDIF

8280

8207

P703

4P

P1212

P1219

P1206

P1582

8000

1693

6P

1504

2P

1505

2P

OR

OR

J

8341

FRONT INTERFACE

PANEL

(ONLY FOR PV02 STYLING)

8010

MONO

5P

1280

8582

1682

1206

8206

5P

5P

4P

4P

1005

COMPAIR

CONNECTOR

1207

7P

TUNER

3P

7P

8212

1582

4P

3P

8204

1204

7P

1212

1219

8219

A

CARRIER

8401

1404

2P

H

1401

5P

5P

1451

2P

5P

LOT

8157

1693

6P

F_15760_033.eps

161105

Block Diagrams, Testpoint Overviews, and Waveforms

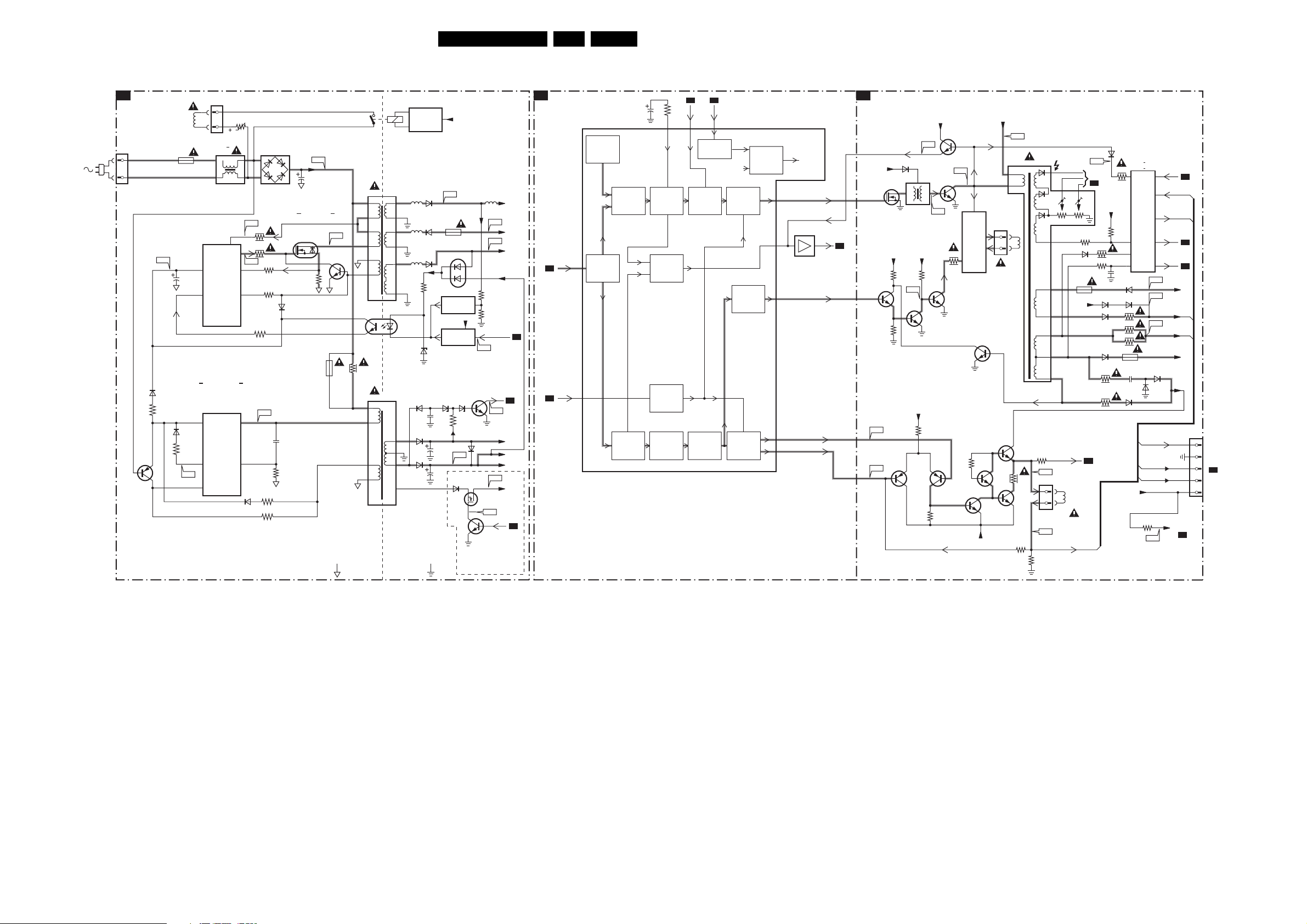

Block Diagram Supply and Deflection

SUPPLY AND DEFLECTION

POWER SUPPLY

A1

1505

Degaussing

1500

I511

6512

3519

7532

T4E

2511

6533

3530

Coil

I531

7511

TEA1506T

2

Vcc

CONTROL

6

CTRL

STANDBY

SUPPLY

7531

TEA1623

3

Vcc

CONTROL

6

REG

11

AUX

1504

2

1

5500 :

5501

DRAIN

IC

IC

DRIVER

SENSE

DEMAG

DRAIN

SOURCE

3507

t

6500

AC

I513

3513

14

3514

11

I519

3532

9

3517

7

3518

I533

14

2534

12

3538

6532

3534

3531

F508

2505

DC

MAIN

SUPPLY

3516

I516

D

S

7514

7512

G

6511

1503

42

1

3

5520

9

8

4

5

3

2

35321532

1A

4

5

1

2

HOT GROUND COLD GROUND

17

18

13

14

10

11

4

1

7515

TCET1103

2

3

5531

10

9

8

6

7541

ENERGIZING

CIRCUIT

(optional)

5551 5552

5562

5561

6564

6535

6536

6551

6563

6562

3571

6573

2564

2535

2536

V_DG

F552

1543

6571

7571

REFERENCE

CIRCUIT

+3V3

7573

STANDBY

CIRCUIT

6565 6566

3565

F536

6537

G

7536

7561

6576

DS

I573

7535

For IDTV only

Vbatt

F563

-Vaudio

F561

+Vaudio

+6VA

3575

3576

Stdby_Con

POWER-DOWN

A4

F564

+3V

+6VA

+6VA

+6V

F537

Vaux

I548

B

A4

2x

A4

DEFLECTION

HERCULES

A4

INTF_Y GREEN_IN

A5

EHTinfo

A2

56

97

7200-H

(SYNC)

VIDEO

IDENT

MAIN

SYNC

SEPARATOR

EHTo

18L04.6U AA 6.

DETECTOR

VERTICAL

SEPARATOR

PHI 1

SYNC

3232

2240

HORIZONTAL

OSC.

SAND-

CASTLE

GENERATOR

X-RAY

PROTECTION

VERTICAL

DIVIDER

112

A2 A2

EHTinfo

113 116

VERTICAL

GUARD

DETECTOR

PHI 2

DETECTOR

VERTICAL

SAW-

THOOTH

Vguard

HORIZONTAL

OUTPUT

E/W

+

GEOMETRY

VERTICAL

OUTPUT

+

GEOMETRY

R.G.B.

BLANKING

LINE + FRAME DEFLECTION

A2

LINE

+

E/W

CORR.

7452

7411

3465

-12V

7454

Vbatt

1404

1

2

7451

7453

3

1

F402

HOR.

DEFL.

COIL

3461

3466

5450

3474

3471

F458

1451

1

2

F459

EHT

FOCUS VG2

10

6

5

7

8

9

Vguard

VER.

DEFL.

COIL

FRAME_FB

1454

3442

6481

Vbatt

A4

I433

TO

CRT

B1

+Vbatt

3481

3410

6483 6484

6453

6456

3457

3455

6401

3411

3451

2403

6452

3458

3484

3485

1452

2456

6459

Vbatt

7401 : 7403

7480 : 7483

Frame_FB

EHTb

EHTb

+

EHTinfo

+

EHTinfo

BCL

PROC.

F452

F453

F455

6454

6455

EHTb

Filament

VideoSupply

3401

F401

F_15760_034.eps

POWER-DOWN

A1

A4

BCL

A4

-12V

VideoSupply

Filament

+9V

VT_SUPPLY

A4

161105

1401

5

4

3

2

1

TO 1351

B1

CRT

+6VA

LINE

7408

F412

TO RGB

PROC.

7207

HDRIVE

HD

SANDCASTLE

A5

EW_DRIVE

62

63

108

-9V

7404

+8V

7410

3498

HD

6486

5402

E/W

+8V

3420 3440

I417

7484

7405

BU4508DX

F418

7406

3497

F414

OUTPUT

CIRCUIT

FRAME

+9V

106

107

VDRA

VDRB

F460

F461

3462

7455 7456

3463

Block Diagrams, Testpoint Overviews, and Waveforms

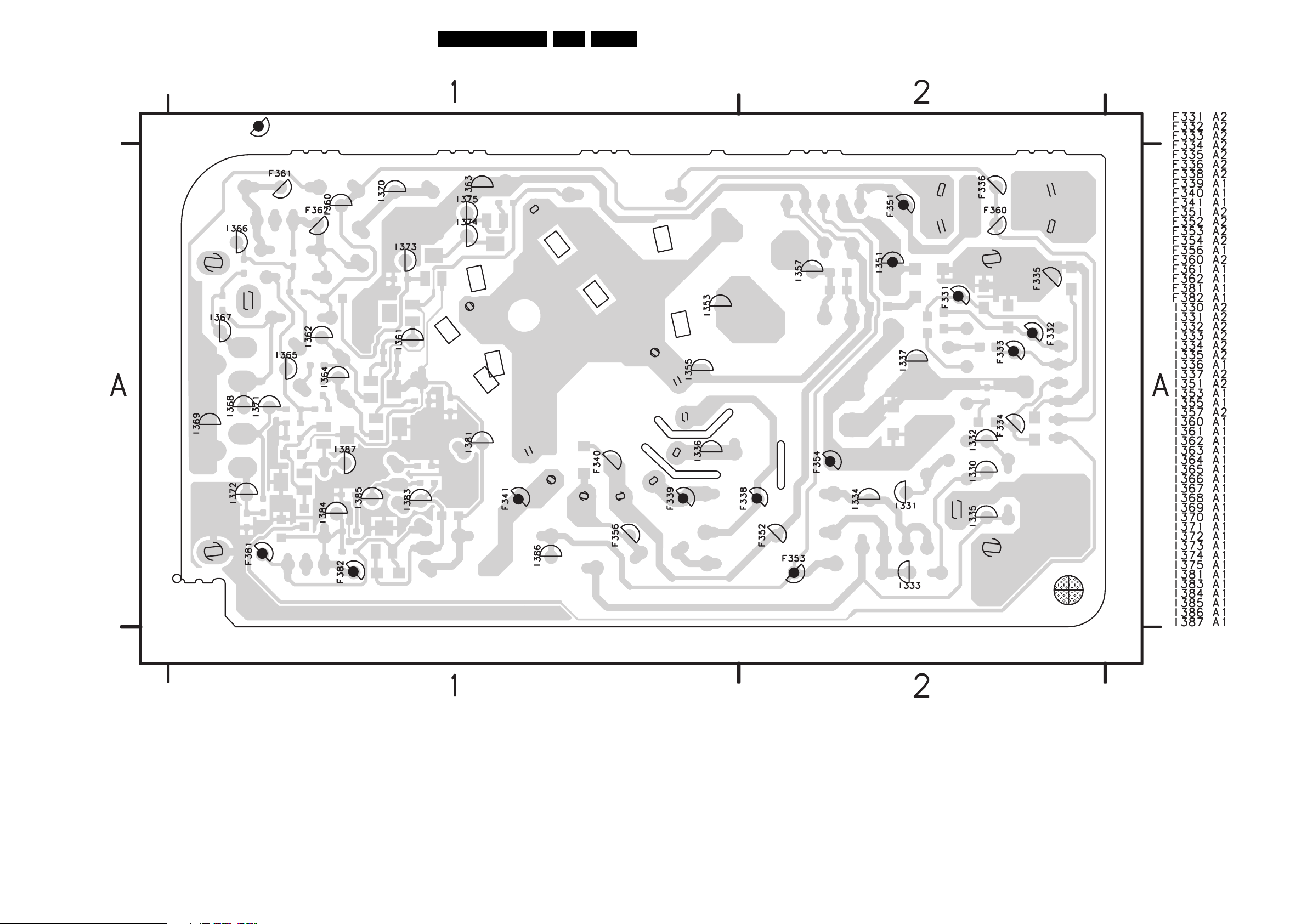

Testpoint Overview Mono Carrier

F001 E1

F010 E2

F002 E1

F011 E1

F003 E2

F101 D1

F004 E2

F102 D1

F005 E1

F103 D1

F006 E2

F104 D1

F007 E1

F105 D1

F008 E1

F106 D1

F009 D4

F107 D1

3139 123 5673.4

F108 D1

F109 D1

F110 C1

F111 D1

F112 C1

F113 C1

F115 C1

F116 C2

F117 C1

F119 E1

F120 E1

F121 E1

F122 D1

F123 D1

F138 D2

F200 D5

F201 C4

F202 D4

F203 D4

F204 C4

F205 C3

F206 C3

F207 D4

F208 D2

F209 E4

F210 E4

F211 E5

F212 E4

F213 E4

F214 D4

F215 D3

F216 C3

F217 C2

F218 C2

F219 D2

F220 D2

F221 D2

F222 C2

F223 D2

F224 C3

F225 C3

F226 D2

F227 E4

F228 C4

F229 C4

F230 D4

F232 D4

F233 D4

F237 D4

F238 D4

F239 D4

F240 C3

F241 C3

F242 C3

F243 C3

F244 D4

F245 C3

F247 E2

F248 E2

F249 E2

F250 C3

F251 D4

F270 D4

F401 C5

F402 B2

F404 B2

F407 B3

F412 C3

F414 A2

F415 A3

F416 A3

F417 A3

F418 B3

F419 B3

F420 B2

F451 C1

F452 C2

F453 B2

F454 C2

F455 B1

F456 A2

F457 A2

F458 C1

F459 C2

F460 C2

F461 C2

F462 A1

F463 B1

F464 A3

F465 A3

F466 A1

F500 C7

F501 B6

F502 B7

F503 A7

F504 A7

F505 A7

F506 A7

F507 A7

F508 A5

F509 A5

F510 B4

F535 C5

F536 C4

F537 C5

F541 C6

F542 C5

F551 C4

F552 B4

F561 C5

F562 B5

F563 C5

F564 C4

F573 C4

F581 D5

F582 D5

F583 C5

19L04.6U AA 6.

F682 D7

F683 D7

F685 D7

F691 C7

F692 B7

F693 A7

F694 C7

F695 C7

F696 B7

F697 A7

F698 C7

F699 B7

F901 D6

F903 D7

F904 D7

F905 D7

F910 D6

F911 D6

F950 D6

F951 D6

F952 E6

F953 E5

F955 E6

F956 E5

I001 E1

I002 E1

I003 E2

I004 E2

I005 E4

I006 E3

I007 E1

I008 E3

I009 E3

I010 E3

I011 E1

I012 E2

I013 E2

I014 E1

I015 E1

I016 E1

I017 D4

I104 D1

I105 D1

I106 D1

I107 D1

I108 D1

I109 D2

I110 D1

I111 D1

I112 D1

I113 C1

I114 D1

I115 C1

I116 D2

I117 D1

I118 E1

I119 E1

I120 D1

I201 E4

I203 E3

I204 E4

I205 E4

I206 E4

I207 D2

I208 C3

I209 D3

I210 D3

I211 C3

I212 D3

I213 E4

I214 E4

I215 E3

I216 D3

I217 D2

I218 D2

I219 D2

I222 D4

I223 D4

I224 D4

I225 D4

I226 C3

I227 E4

I228 D4

I229 C4

I230 D4

I231 D4

I232 E2

I233 D2

I234 E5

I235 D4

SERVICE TESTPOINT

I236 D4

I240 E5

I241 E5

I401 A2

I402 A3

I403 A2

I404 A2

I405 A2

I406 A2

I407 A2

I409 A1

I410 A3

I412 A3

I413 C3

I414 B3

I415 C3

I416 C4

I417 B4

I418 B3

I419 C3

I421 B2

I422 B2

I423 B3

I424 A1

I425 C3

I426 B2

I427 B4

I428 B3

I429 A1

I430 A3

I431 C2

I432 B2

I433 A3

I434 C3

I443 A2

I444 A1

I445 A2

I446 C4

I448 A1

I449 B1

I451 B2

I452 A1

I453 B2

I455 B2

I456 B1

I457 B2

I458 B2

I459 B1

I460 C1

I461 C1

I462 C1

I463 B1

I464 C1

I465 A1

F_15760_043.eps

I466 B2

I467 A1

I468 B1

I469 A1

I470 B1

I471 C1

I472 C1

I473 A3

I474 A3

151105

I475 B1

I501 A6

I502 A6

I503 A7

I504 A7

I505 B7

I506 A6

I507 B6

I511 A4

I513 A4

I514 B4

I515 A4

I516 A4

I517 A4

I518 A4

I519 A4

I520 A4

I521 A4

I523 A4

I524 A4

I527 A4

I529 B6

I531 B5

I532 B6

I533 B6

I535 B6

I536 B5

I537 C5

I538 C5

I539 B6

I540 B5

I541 B5

I542 C6

I543 C6

I544 B6

I545 C6

I546 C6

I547 C6

I548 C6

I551 B4

I552 B4

I553 B6

I554 B5

I555 B5

I556 B5

I557 B5

I561 B5

I562 B5

I565 C5

I571 B4

I572 C4

I573 B4

I574 B4

I575 B4

I576 B4

I577 B4

I578 B4

I579 B4

I582 D5

I583 D5

I584 D5

I585 D5

I587 C5

I588 D5

I681 A7

I682 D7

I683 D7

I686 C7

I687 B7

I688 C7

I689 B7

I691 A7

I693 B7

I909 D6

I910 C6

I911 C6

I913 C6

I914 C6

I915 C6

I916 C7

I918 C6

I919 C6

I920 D6

I921 C6

I922 C6

I924 D6

I925 D6

I926 D7

I927 C6

I928 D7

I930 C7

I934 D7

I935 D7

I936 D7

I937 C7

I938 D6

I939 D7

I940 D6

I941 C6

I942 C6

I943 D7

I944 C6

I945 C7

I946 D6

I948 D6

I951 E5

I952 E5

I953 E6

I954 E6

I955 D5

I956 E6

I957 E6

I958 D5

I959 D5

Block Diagrams, Testpoint Overviews, and Waveforms

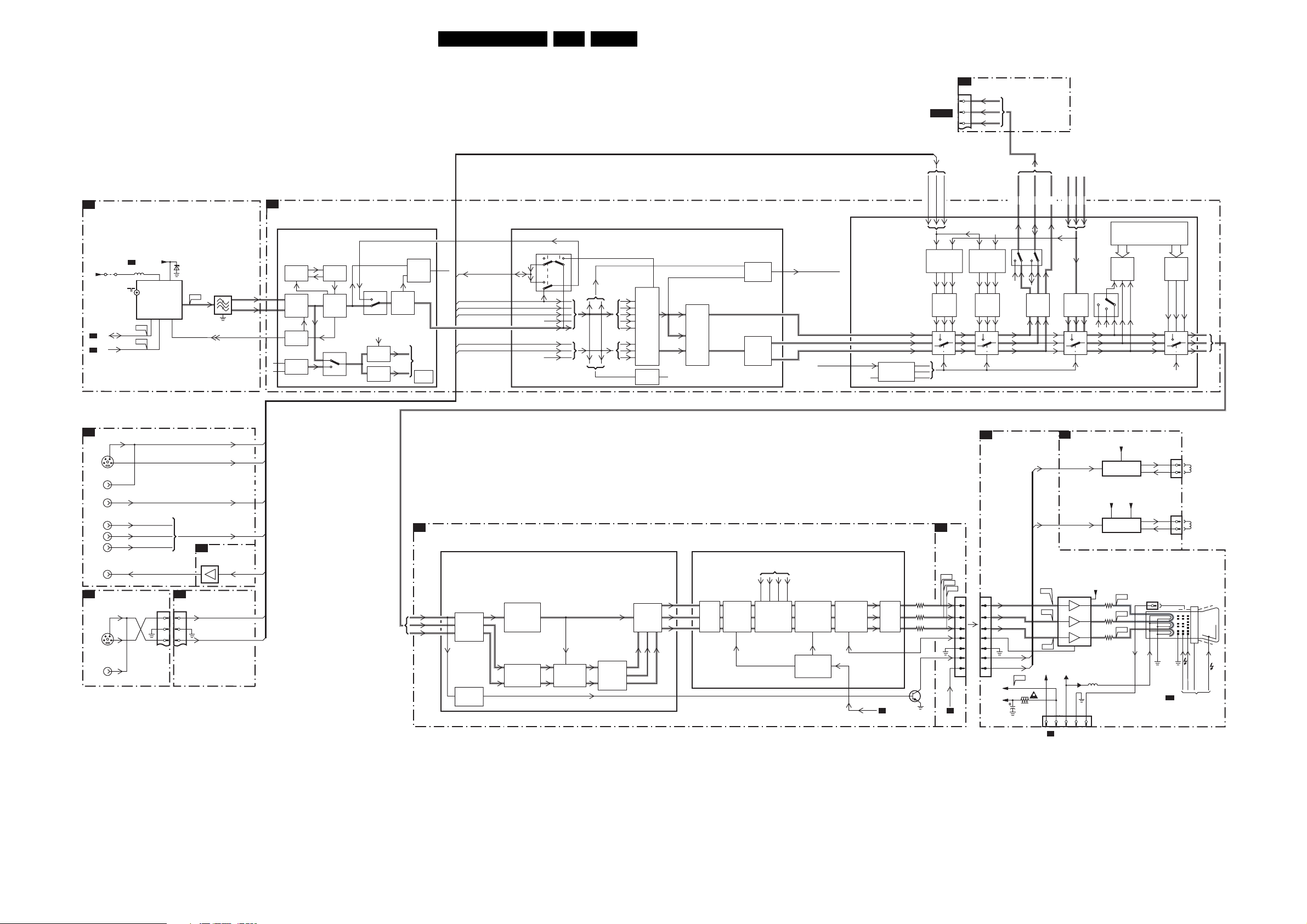

Block Diagram Video

VIDEO

20L04.6U AA 6.

FEATURES & CONNECTIVITIES

A5

1212

TO P1212

ATS C

ATSC PANEL

1

2

3

TUNER IF

A3

+5V

A4

A4

REAR I/O CINCH

A8

SVHS

YUV INPUT

MONITOR

OUTPUT

SIDE AV

D

SVHS

VIDEO

IN

SDA

SCL

154

AV2

V

AV1

V

Y

U

V

V

154

HERCULES

A4

7200-A (IF)

VT_SUPPLY

A2

50019002

1000 6, 7 9

TV

I002

I001

32

SC1_GREEN_IN

SC1_BLUE_IN

SC1_RED_IN

Y

32

C

VT

TUNER

IF

AGC

4

5

1

SC2_Y/CVBS_IN

SC2_CHROMA_IN

SC1_CVBS_IN

SC2_CVBS_OUT

A5

1207

1252

7

6

5

6001

BZX79-C33

F004

11

CONNECTION

7

6

5

1002

A5

7606

7607

SW_SC2_CVBS

SIDE_CHROMA_IN

SIDE_Y/CVBS_IN

VIF_1

VIF_2

RF_AGC

86

SOUND

TRAP

FM/QSS

AM

SWITCH

TO

AUDIO

PAR T

See block

diagram

AUDIO

A4

HERCULES

Y

Pr

Pb

PHASE

DISC

24

VIDEO

25

IF

31

TUNER IF

AGC

29

AUDIO IF

30

QSS/AM

VCO

VIDEO

DEMOD

PLL

PLL

SOUND

MIXER

AM

SOUND

DET.

SW_SC2_CVBS

N.C.

SC1_CVBS_IN

SC2_Y/CVBS_IN

SIDE_Y/CVBS_IN

SC2_CHROMA_IN

SIDE_CHROMA_IN

7200-D (YUV PROCESSING)

PEAKING

SCAVEM

PROC.

7200-B (CVBS I/O + FILTERS + COLOUR DECODING)

81

74

71

78

CVBS1

70

77

WHITE/BLACK

STRETCH

GAMMA COR.

TINT CONTROL

SKINTONE

OUTPUT

SWITCH

CVBS/Y

INPUT

SWITCH

VIDEO

IDENT

RGB

ADDER

R_Y

G_Y

MATRIXSATURATION

B_Y

COMB

FILTER

&TRAP

SWITCH

C

64

CHROMA/CVBS

7200-E (RGB PROCESSING + CATHODE CALIBRATION)

R

CLAMP

G

+

MUTE

B

BLUE

STRETCH

&

CONTRAST

PAL, NTSC

SECAM

DECODER

FROM µP PART

R_OSD

G_OSD

OSD

INSERTION

YintYint

Uint

Vint

B_OSD

FBL

INTF_CVBS_OUT65

BRIGHTNESS

+

PEAK WHITE

LIM.

BEAM

CURRENT

LIM.

SC1_FBL

N.C.

N.C.

7200-C

INSSW352

CATHODE

CALIBRATION

46

(RGB/YPrPb/YUV

INPUT SWITCHING)

Yint

Uint

Vint

LOGIC

YUV

RGB

DVD

3226

42

3227

43

3228

44

45

SELECTION

OUTPUT

STAGE

BCL

A2 A4

SC1_GREEN_IN

SC1_BLUE_IN

51

SELECTION

A5

BOUT

GOUT

ROUT

IBLACK

SVM

7308

SC1_RED_IN

49

50

YPrPb2/

YPrPb3

DVD

TO

DVD

F240

F241

INTF_U-OUT58INTF_Pb/BLUE_IN

INTF_V-OUT

53

RGB2/

RGB3

SELECTION

RGB

TO

DVD

B1

13311204

RGB

CRT PANEL

B

1

G

2

R

3

4

5

6

7

+200V

+200VA

DVD

F242

1

2

3

4

5

6

7

ROT

BC_INFO

SVM

ROT

V14

2351

DVD

YUV

3351

1351

55

54

TO

B2

ROT

SVM

V13

7330

3

V11

1

2

V12

VSVM

Filament

1351

123 45

TO 1401

A2

DEFLECTION

INTF_Y/GREE_IN

59

57

YUV

TO

DVD

YUV

ECO SCAVEM

+200VA

5

5352

EHTb

DIGITAL SIGNAL PROC.

- 4:3 LINEAR/NON-LINEAR SCALING

- DOUBLE WINDOW PROC.

ADC

FILAMENT

ROTATION

OUTPUT

FILAMENT

VSVM

SCAVEM

OUTPUT

V16

3332

7

B

V15

3334

9

G

V14

3336

8

R

1332

11

B

6

G

8

R

10 9 5 7 1

DAC

DINT

1381

1

ROTATION

COIL

2

(OPTIONAL)

1361

1

SCAVEM

COIL

2

(OPTIONAL)

AQUADAG

DEFLECTION

FOCUS

VG2

A2

FROM DEFLECTION

F_15760_035.eps

Y

Pr

Pb

CRT

25kV

EHT

161105

INTF_Pr/RED_IN

INTF_Y_OUT

Block Diagrams, Testpoint Overviews, and Waveforms

Testpoint Overview CRT Panel

SERVICE TEST POINT

21L04.6U AA 6.

3139 123 5674.3

F_15760_039.eps

151105

Loading...

Loading...