Page 1

MONITOR/DEFIBRILLATOR

HEARTSTART MRx

Service Manual

M3535A

M3536A

Page 2

Page 3

Notice

About This Edition

Edition 4

Printed in the USA

Publication number M3535-90900

The information in this document applies to the

HeartStart MRx product version indicated below. This

information is subject to change without notice.

Philips shall not be liable for errors contained herein or

for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

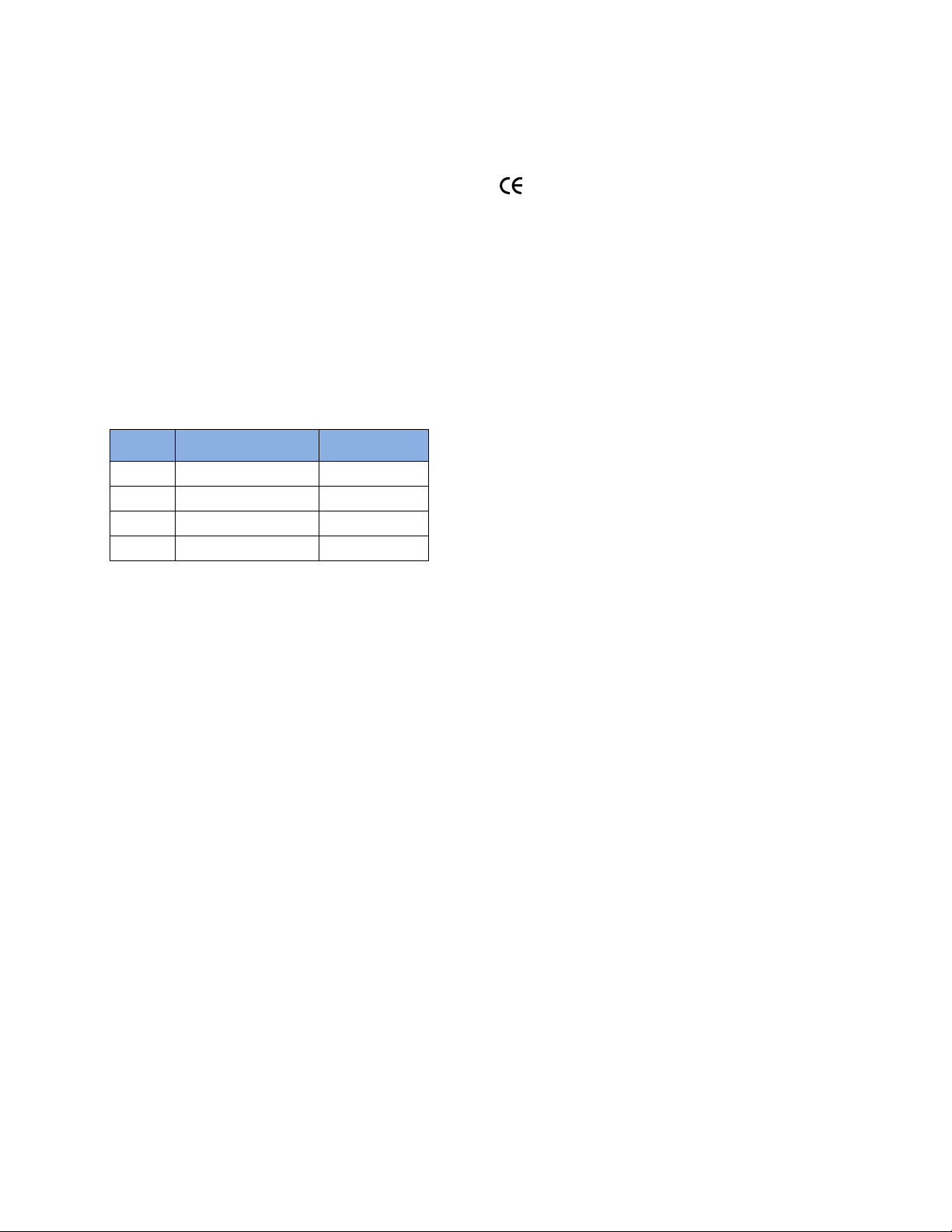

Edition History

Edition Product Version Print Date

1 A.00/A.01 December, 2003

2 A.02 and earlier June, 2004

3 B.03 and earlier November, 2004

4 B.xx and earlier January, 2005

Copyright

Copyright © 2005

Medical Device Directive

The HeartStart MRx complies with the requirements of

the Medical Device Directive 93/42/EEC and carries the

mark accordingly.

0123

Manufacturer

Philips Medical Systems

3000 Minuteman Road

Andover, MA USA 01810-1099

(978) 687-1501

Authorized EU-representative:

Philips Medizin Systeme Böblingen GmbH

Hewlett Packard Str. 2

71034 Böblingen

Germany

Canada EMC:ICES-001

Warning

Radio frequency (RF) interference from nearby

transmitting devices may degrade the performance of the

HeartStart MRx. Electromagnetic compatibility with

surrounding devices should be assessed prior to using the

monitor/defibrillator.

Koninklijke Philips Electronics N.V.

All rights are reserved. Permission is granted to copy and

distribute this document for your organization’s internal

educational use. Reproduction and/or distribution

outside your organization in whole or in part is

prohibited without the prior written consent of the

copyright holder.

SMART Biphasic is a registered trademark of Philips.

FilterLine is a registered trademark of Oridion Medical

Ltd.

Use of supplies or accessories other than those

recommended by Philips may compromise product

performance.

THIS PRODUCT IS NOT INTENDED FOR HOME

USE.

IN THE U.S., FEDERAL LAW RESTRICTS THIS

DEVICE TO SALE ON OR BY THE ORDER

OF A PHYSICIAN.

i

Page 4

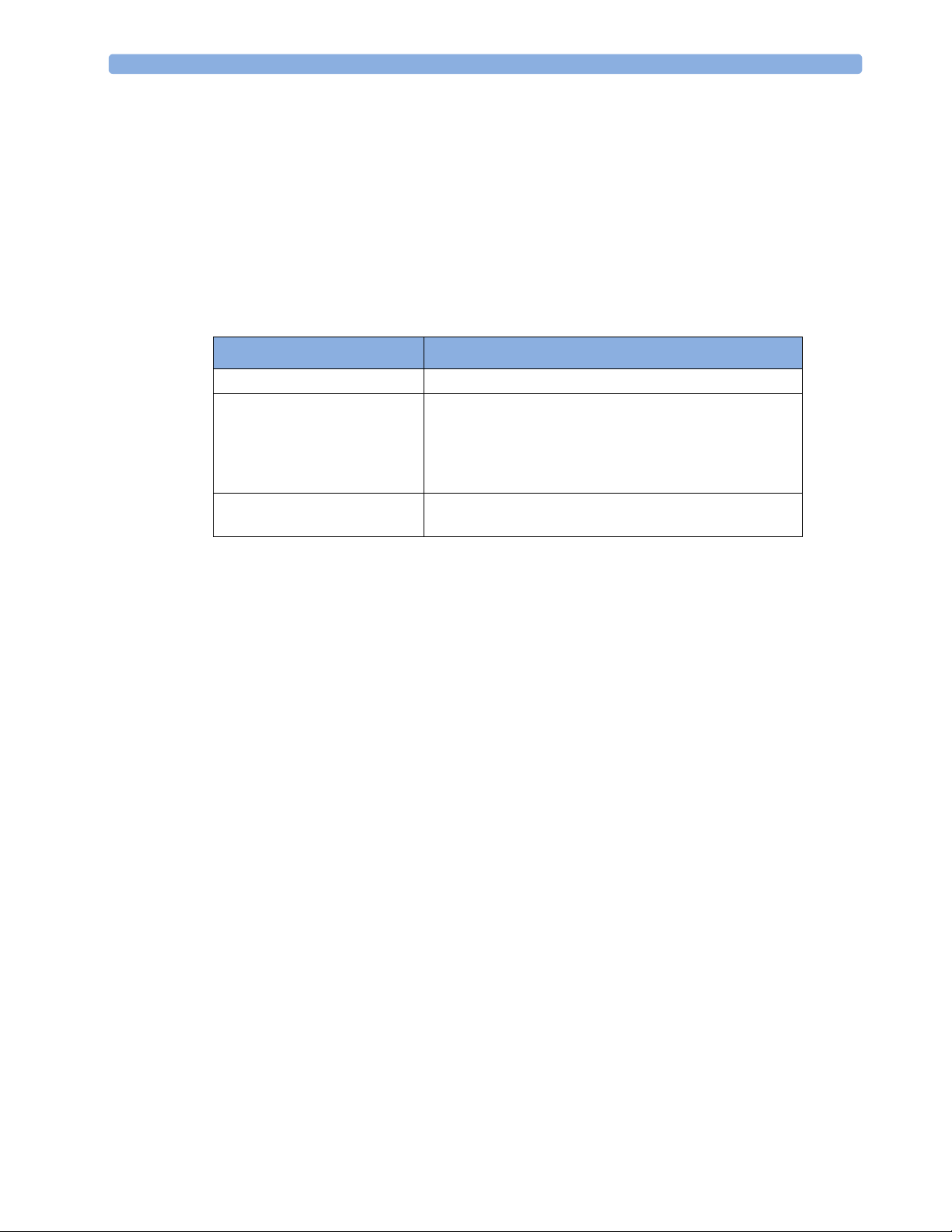

Conventions Used in This Manual

This Service Manual contains the following conventions:

WARNING Warning statements describe conditions or actions that can result in personal injury or loss of life.

CAUTION Caution statements describe conditions or actions that can result in damage to the equipment or loss of

data.

NOTE Notes contain additional information on usage.

TIP Tips provide hands-on insight into servicing this product.

TEXT represents messages that appear on the screen

[Softkey] represents softkey labels that appear on the screen above or below the

button to which they correspond.

On-line viewing only

Hypertext represents hypertext links, which will display as blue; click on

Abbreviations

Name Abbreviation

HeartStart MRx Monitor/Defibrillator monitor/defibrillator

Noninvasive Blood Pressure NBP

End-tidal carbon dioxide

Carbon dioxide CO

Pulse Oximetry

the blue link to go to that destination, then click on

the blue destination to return.

device

EtCO

2

2

SpO

2

ii

Page 5

1Table of Contents

1 Introduction 1

Who Should Use This Manual 1

Overview 1

Features and Capabilities 2

Tour of the Device 3

Right Side 4

Left Side 5

Rear 6

To p 7

General Service Information 8

Installation 8

Display Menus 8

Passwords 8

Upgrades 8

Preventive Maintenance 8

Repair Philosophy 9

Accessing Service Mode 10

Navigating in Service Mode 11

Service Mode Functions 12

Other Resources 16

2 Maintenance 17

Overview 17

Maintenance Tools and Equipment 18

Checking the NBP Module 19

NBP 19

Checking the CO2 Module 23

CO2 23

3 Troubleshooting 33

Overview 33

Troubleshooting Tools and Equipment 34

Obtaining Replacement Parts 34

Ready For Use Indicator 35

Automated Tests 36

Automated Test Summary 36

iii

Page 6

Operational Check 39

Operational Check Report 43

Operational Check Summary 44

Service Mode Tests 44

Troubleshooting Methodology 45

Troubleshooting Flowcharts 47

Troubleshooting Tables 53

Audio Tones 54

Status Log Errors 55

Startup Errors 62

General Problems 63

ECG Monitoring Problems 64

NBP Monitoring Problems 66

SpO2 Monitoring Problems 67

CO2 Monitoring Problems 68

Defibrillation Problems 70

Pacing Problems 73

Printing Problems 74

Display Problems 75

Audio Problems 75

Controls Problems 76

Internal Memory Problems 77

External Data Card Problems 77

4 Repair 79

Overview 79

Who Should Perform Repairs 80

Repair Philosophy 80

Calling for Service 81

Repair Notes 82

Safety Precautions 82

Flex Circuit Connections 82

Flex Circuit Handling 83

Internal Connections 83

Cable and Assembly Placement 83

Device Reassembly 83

Disposal 84

Disposing of Empty Calibration Gas Cylinders 84

Repair Tools and Equipment 85

Key Components 85

iv

Page 7

External Assemblies 86

Accessory Pouches 87

Bedrail Hook Mount 89

Therapy Knob 90

Labels 91

Printer Assembly 93

Paddle Tray 95

Paddle Tray 50 ohm Load Resistor 98

Handle and Cap Plate 100

Opening the case 102

Discharge the Power Supply Capacitors 102

Separate the Case 102

Discharge the Therapy Capacitor 105

Disconnect the Case Halves 106

Internal Assemblies - Front Case 107

Overview of Front Case 108

PCMCIA Hole Plug 109

Speaker and Microphone Assembly 111

Internal Memory Card 113

SpO2 PCA 115

Measurement Module Panel 117

Therapy Switch 119

Fan Assembly 121

Processor PCA 123

Clock Battery 132

Printer Connector PCA 133

Display Assembly 135

Ready For Use Indicator 138

Front Panel Buttons 140

Front Case Assembly 141

Internal Assemblies - Rear Case 144

Overview of Rear Case 145

Therapy Capacitor 146

Power PCA 148

NBP and CO2 Module Tray 152

Therapy PCA 154

Therapy Port 158

NBP Module 160

CO2 Module 162

CO2 Compartment Door 167

Battery Connector PCA 169

Rear Case Assembly 174

Closing the case 176

v

Page 8

5 Performance Verification 179

Overview 179

Required Testing Levels 180

External Repairs/Replacements 180

Printer Replacement 181

Internal Repairs 181

Verification Test Equipment 182

Test and Inspection Matrix 184

Performance Verification Procedures 190

Visual Inspection 191

Service Mode Tests 192

Functional Checks 200

Safety Tests 208

6 Parts and Accessories 211

Overview 211

Parts and Accessories Notes 212

Ordering Replacement Parts 212

Ordering Supplies and Accessories 212

Key Component Tracking 212

Replacement Parts 213

Electrical Assemblies 214

Processor PCA 214

Other Replacement PCAs 215

Other Electrical Assemblies 216

Individual Electrical Parts 216

External Electrical Components 217

Internal Cables 218

Paddles 219

Mechanical Assemblies 220

Replacement Mechanical Assemblies 220

Individual Mechanical Parts 221

Labels 222

Instruction Label Sets 222

Hazardous Shock Warning Label Set 223

Branding Label Set 223

Speaker Label Set 223

Connector Label Set 223

Supplies and Accessories 224

Key Components 229

vi

Page 9

7 Theory of Operation 233

Overview 233

Schematic Diagrams 235

System Level Interconnections 236

Signal and Data Flow 237

ECG Signal Flow 238

Functional Descriptions 239

Processor PCA 239

Therapy PCA 240

Power PCA 240

Battery Connector PCA 240

Power/Batteries 240

Display Assembly 241

Indicators 242

RFU Indicator 242

Front Panel Buttons 242

Therapy Knob 242

Paddle Indicators and Controls 242

Printer Assembly and Printer Connector PCA 243

ECG Monitoring Functions 243

Defibrillation 244

Transcutaneous Pacing 246

Audio 246

Data Storage 247

Clock Backup Battery 247

NBP Module 247

SpO2 PCA 247

CO2 Module 248

vii

Page 10

8 Specifications and Safety 249

Specifications 249

General 249

Defibrillator 249

ECG and Arrhythmia Monitoring 252

Display 254

Battery 254

Thermal Array Printer 255

Noninvasive Pacing 255

SpO2 Pulse Oximetry 256

NBP 256

EtCO2 257

AwRR 258

Calibration Gas for CO2 Measurement System 259

12-Lead ECG 259

Patient Data Storage 259

Environmental (M3535A) 259

Environmental (M3536A) 261

Symbol Definitions 263

Safety Considerations 266

General 266

Defibrillation 268

Battery 268

Electromagnetic Compatibility 270

Reducing Electromagnetic Interference 270

Restrictions for Use 270

Emissions and Immunity 270

Guidance and Manufacturer’s Declaration 271

Waveforms 278

1 Index 283

Page 11

This Service Manual provides the information needed to successfully service the M3535A/M3536A

HeartStart MRx monitor/defibrillator. This manual provides you with information on

troubleshooting, repairing, and performance verification and safety testing of the monitor/defibrillator.

There is also information on the theory of operation, maintenance procedures, and ordering parts and

supplies.

Who Should Use This Manual

The intended users of this manual are technical personnel who have been trained in the safe and proper

servicing of the HeartStart MRx. To assist in training, the Service Training video

(M3535-89300 NTSC, M3535-89310 PAL) is available.

1

1Introduction

Overview

In this chapter, you’ll find general information that you should know before servicing the HeartStart

MRx. Detailed information regarding controls, operation, and capabilities of the device can be found

in the Instructions for Use that was shipped with the product. The Instructions for Use also provides

information on setting up the device and regular maintenance procedures, such as performing

operational checks and battery maintenance. We recommend you review the Instructions for Use before

servicing this device. This Service Manual assumes you are familiar with the controls and with basic

operations.

This chapter is organized into the following sections:

To p ic Pa ge

Features and Capabilities 2

Tour of the Device 3

General Service Information 8

Accessing Service Mode 10

Other Resources 16

1

Page 12

1 Introduction Features and Capabilities

Features and Capabilities

The HeartStart MRx is a lightweight, portable, monitor/defibrillator. It provides four modes of

operation, Monitor, Manual Defib, AED, and Pacer (optional).

In Monitor Mode you can monitor up to four ECG waveforms, acquired through a 3-, 5-, or 10-lead

ECG set or multifunction electrode pads. Optional monitoring of pulse oximetry (SpO

blood pressure (NBP), and carbon dioxide (EtCO

parameters are presented on the display and alarms are available to alert you to changes in the patient’s

condition.

Monitor Mode also provides an optional 12-Lead ECG function, enabling you to preview, acquire,

store, and print 12-lead ECG reports, with or without analysis/interpretation.

Manual Defib Mode offers simple, 3-step defibrillation. You analyze the patient’s ECG and, if

appropriate: 1) select an energy setting, 2) charge, and 3) deliver the shock. Defibrillation may be

performed using paddles or multifunction electrode pads. Manual Defib Mode also allows you to

perform synchronized cardioversion and internal defibrillation.

In AED Mode, the HeartStart MRx analyzes the patient’s ECG and determines whether a shock is

advised. Voice prompts guide you through the 3-step defibrillation process, providing easy-to-follow

instructions and patient information. Voice prompts are reinforced by messages that appear on the

display.

) are also available. Measurements from these

2

), noninvasive

2

Both Manual Defib and AED Mode incorporate the Philips’ low energy SMART Biphasic waveform

for defibrillation.

Optional Pacer Mode offers noninvasive transcutaneous pacing therapy. Pace pulses are delivered

through multifunction electrode pads, using a monophasic waveform.

The HeartStart MRx is powered by rechargeable lithium ion batteries. Available battery power is easily

determined by viewing the convenient battery power indicators located on the device display or by

checking the indicators on the battery itself. Additionally, an external AC or DC power supply may be

applied as a secondary power source and for continual battery charging.

The HeartStart MRx performs Automated Tests on a regular basis. The status of the device’s critical

functions are reported to the Ready For Use (RFU) indicator. Prominently displayed, the RFU

indicator communicates the status of your device, letting you know if it is operating correctly, needs

attention, or is unable to deliver therapy. In addition, performing the specified Operational Check

ensures that the HeartStart MRx is functioning properly.

The HeartStart MRx automatically stores critical event data in its internal memory, such as Event

Summaries and 12-Lead Reports. The HeartStart MRx also enables you to copy data and event

information on an optional external data card for downloading to Philips’ data management solution,

HeartStart Event Review Pro.

The HeartStart MRx is highly configurable to better meet the needs of diverse users. Be sure to

familiarize yourself with the device’s configuration before using the HeartStart MRx.

2

Page 13

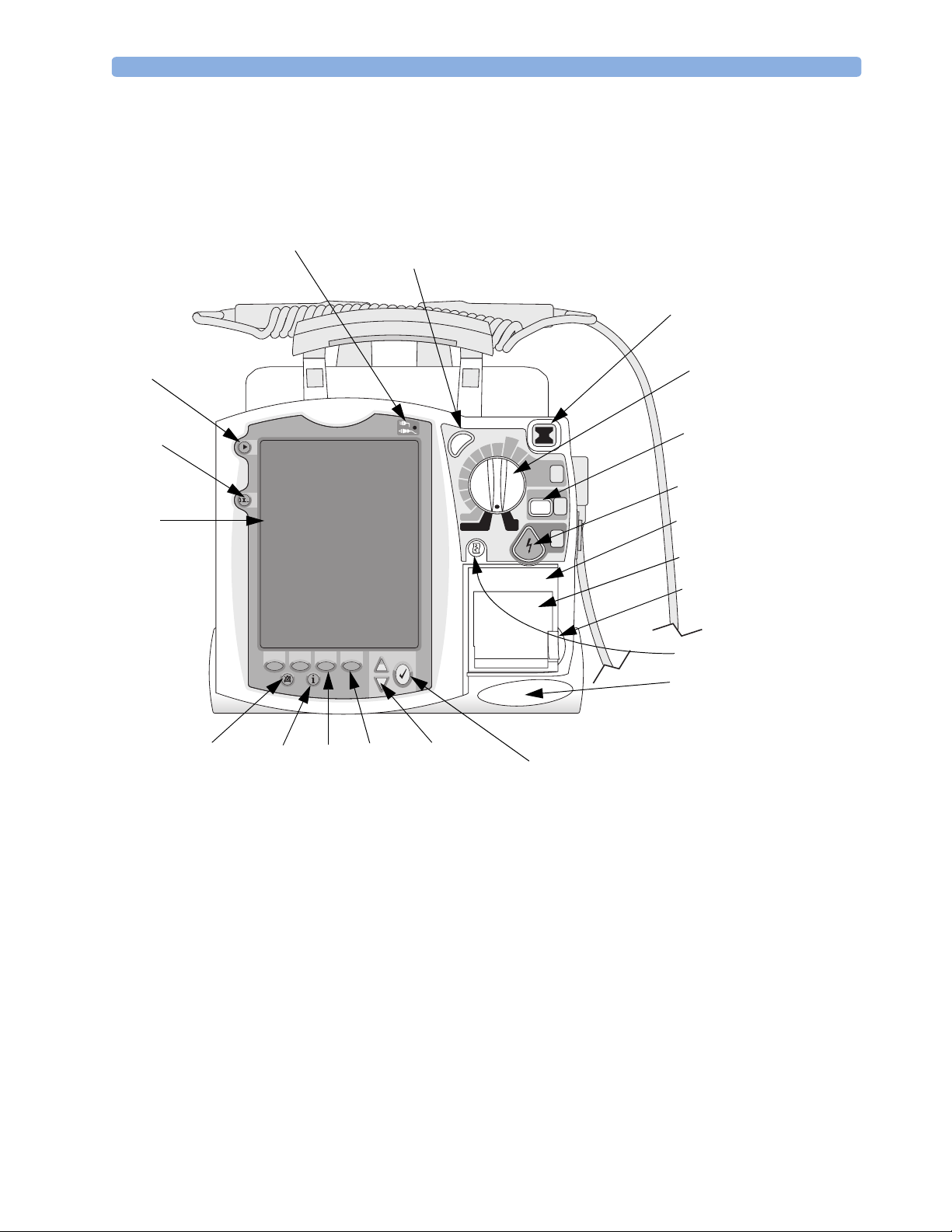

Tour of the Device 1 Introduction

Tour of the Device

This section gives an overview of the outside of the device.

Figure 1 Front view

External Power Indicator

Synchronized Cardioversion

(Sync) button

Ready For Use (RFU)

Indicator

Mark Event

button

Lead Select

button

Display

Alarm Pause button

Event Summary

button

Soft keys (4 total)

c

n

y

S

120

b

b

i

i

100

f

f

e

e

70

D

D

l

l

a

a

50

u

u

n

n

a

a

30

M

M

20

15

1-10

n

O

P

acer

O

ff

M

onitor

Navigation buttons

A

dult

D

ose

150

170

200

S

elect

E

nergy

1

C

harge

O

n

AED

2

S

hock

3

Menu Select button

Therapy Knob

CHARGE button

SHOCK button

Printer

Printer door

Printer door

latch

Print button

Speaker

3

Page 14

1 Introduction Tour of the Device

Right Side

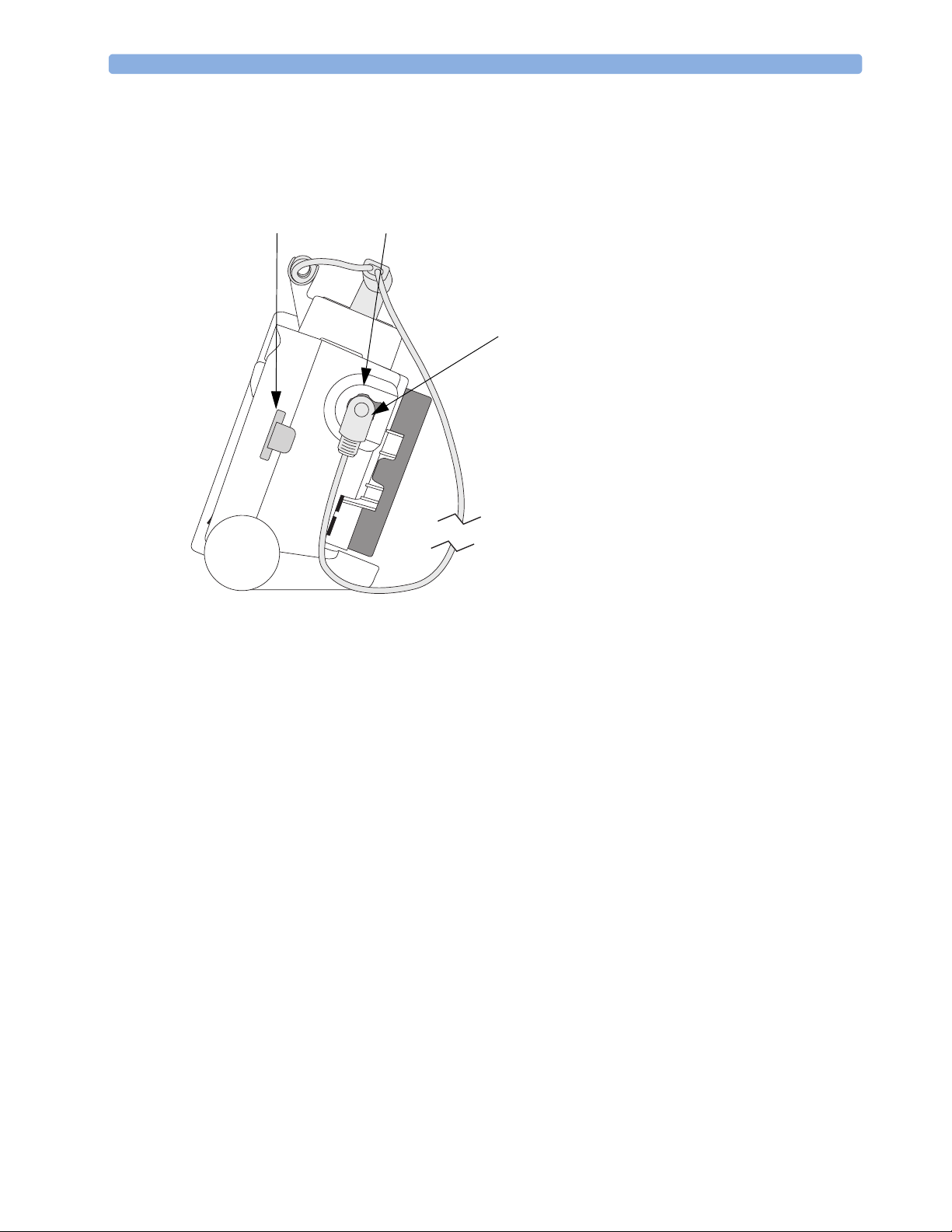

Figure 2 Right side view

Data Card

Therapy port (behind connector)

Therapy connector

4

Page 15

Tour of the Device 1 Introduction

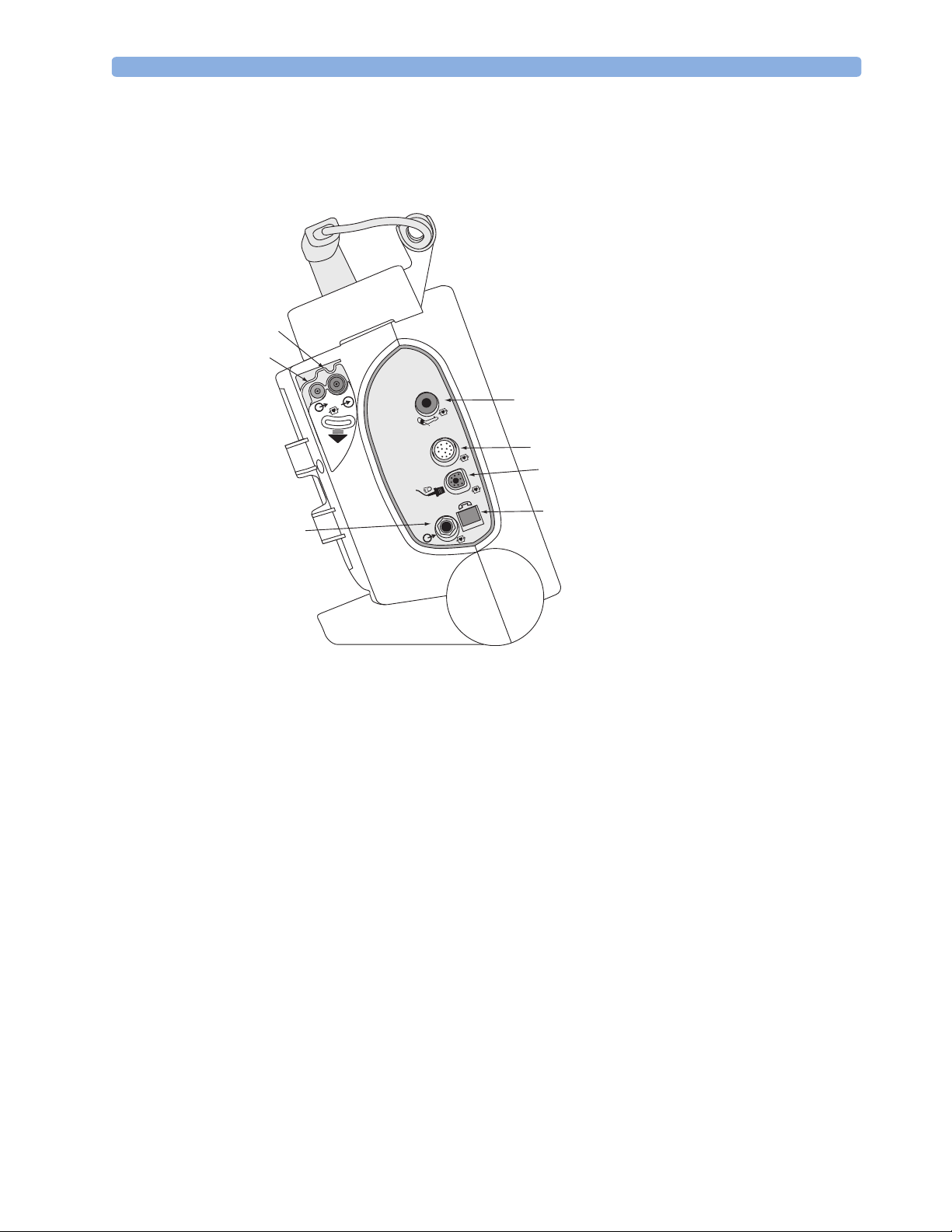

Left Side

Figure 3 Left side view

CO2 Inlet Port

CO2 Outlet Port

ECG Out (Sync)

Jack

2

CO

™

m

a

e

r

t

s

o

r

c

i

M

1

NBP Port

2

ECG Port

ECG

SpO2 Port

RJ11 Telephone

Jack

ECG

5

Page 16

1 Introduction Tour of the Device

t

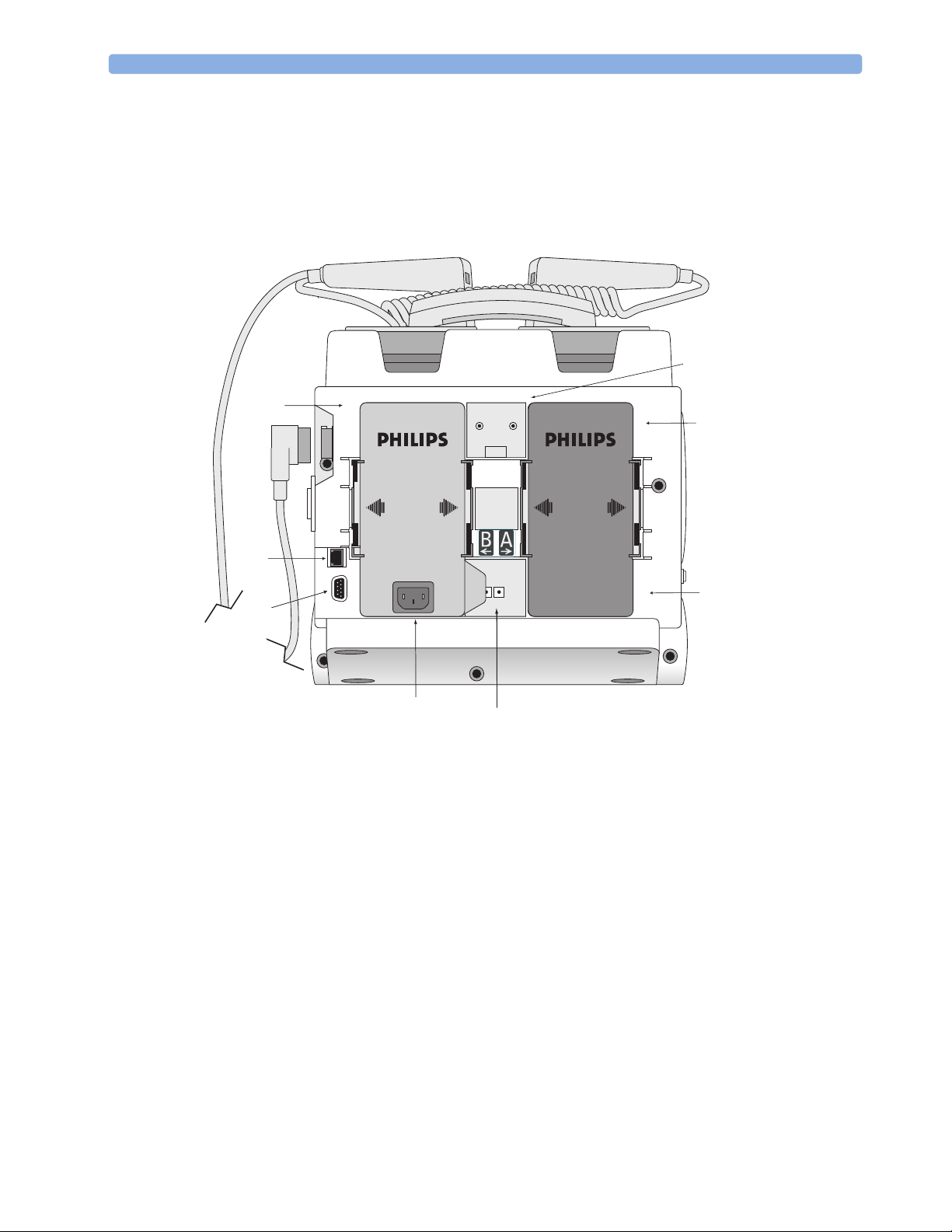

Rear

Figure 4 Rear view

Bed Rail Hook Moun

Battery/AC

Compartment B

Battery

Compartment A

LAN Connection

RS 232 Serial Port

AC Power Module

NOTE The LAN port is for factory use only.

Battery

DC Power Input

6

Page 17

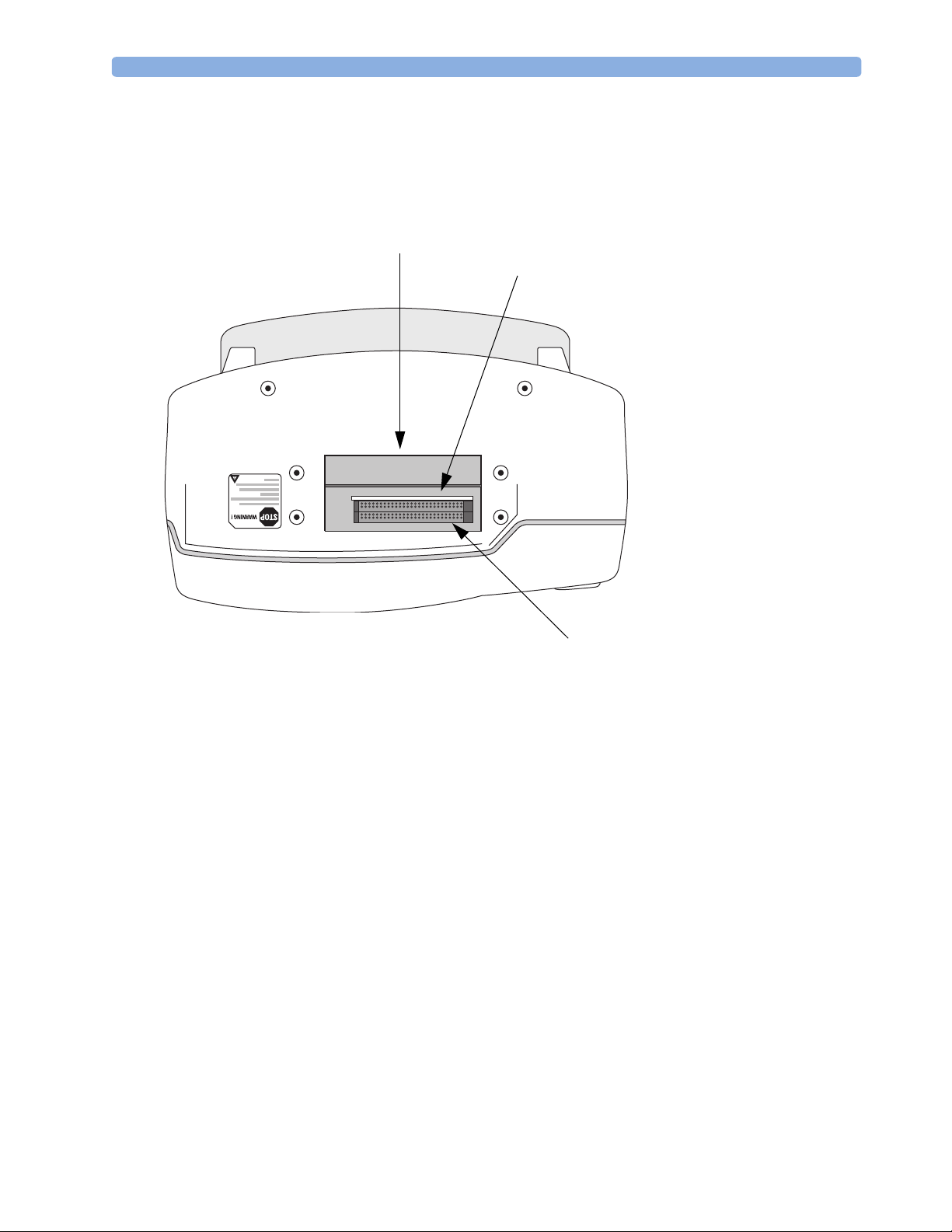

Tour of the Device 1 Introduction

Top

Figure 5 Top view.

Top access panel

PCMCIA card slots

Internal memory card slot

7

Page 18

1 Introduction General Service Information

General Service Information

Keep the following points in mind when servicing this product.

Installation

The HeartStart MRx does not require installation. The Instructions for Use describes the setup required

before placing the device into service, as well as configuration options. All setup activities are designed

to be performed by personnel trained in the proper operation of the product. To obtain a copy of the

Instructions for Use and other MRx documentation go to:

www.medical.philips.com/goto/productdocumentation.

Display Menus

To display a menu, press the Menu Select button. Then use the up or down Navigation

buttons to scroll through the available choices until the desired selection is highlighted. To activate the

selection, press the Menu Select button. Press Exit to close the menu without activating a selection.

Passwords

In order to access different modes within the monitor/defibrillator, a password is required. The

passwords are listed below:

Upgrades

• Service Mode: 27689

• Configuration Mode: 387466

Upgrades are available to add specific functionality to the device after purchase. These upgrades are:

• M3530A SpO

• M3531A NBP

• M3532A CO

• M3533A Pacing

• M3534A 12-Lead

Option B02 - 12-lead acquisition

Option B03 - 12-lead transmission

Option B04 - 75 mm printer

• M4760A Handle and Cap Plate

• M5527A External paddles

• M4765A Hardware Upgrade Option B01 - Version B hardware that supports 12-lead transmission

Consult your sales representative, dealer, or distributor for the latest details.

2

2

Preventive Maintenance

Preventive maintenance and periodic operational checks are intended to be performed by the user.

Both topics are covered in the Maintenance chapter of the Instructions for Use.

The Maintenance chapter of this manual provides procedures for the CO

procedures, which are intended to be performed by qualified service personnel.

8

and NBP calibration

2

Page 19

General Service Information 1 Introduction

Repair Philosophy

Monitor/Defibrillator

The repair philosophy of the HeartStart MRx is subassembly replacement. Examples of subassemblies

are the printer, the Processor Printed Circuit Assembly (PCA), Therapy PCA, and selected connectors

and other items. Repairs that involve replacing components on a PCA are not supported.

CAUTION Individual component replacement should not be attempted. Component level repair is inadvisable

due to the extensive use of surface mount technology and the high parts-density on the circuit boards.

Unauthorized component replacement can impair performance of the HeartStart MRx.

WARNING Remove all power sources (AC, battery, DC) before opening the device. Failure to do so may allow the

device to charge without warning and could result in serious injury or death.

Batteries

The M3538A Lithium Ion battery is rechargeable. The battery periodically requires a calibration. At

the end of the battery’s useful life, it should be discarded and replaced. Refer to the Instructions for Use

for additional information.

For information on ordering replacements, see "Ordering Supplies and Accessories" on page 212.

WARNING Never crush, penetrate or attempt to open lithium ion batteries. Never incinerate lithium ion batteries.

High case temperatures resulting from abuse of the battery could cause physical injury. The electrolyte

is highly flammable. Rupture of the battery pack may cause venting and flame.

CAUTION Due to their high energy density, lithium ion batteries can deliver significant power. Use care when

working with or testing lithium ion batteries. Do not short circuit the terminals.

9

Page 20

1 Introduction Accessing Service Mode

Accessing Service Mode

CAUTION Be sure that the monitor/defibrillator is not connected to a patient when performing any function in

Service Mode.

NOTE Make sure that you insert a battery charged to at least 20% into the device or connect external power

when you are performing functions in Service Mode.

To access Service Mode:

1. Turn the Therapy Knob to Monitor.

2. Press the Menu Select button to display the Main menu.

3. Select Other.

4. From the Other menu select Service.

The message “Leaving Normal Operating Mode. Patient Monitoring is Off. To return to Normal

Operating Mode, press the Exit Softkey.” appears.

5. Press the Menu Select button to acknowledge the message.

You are prompted to enter a password.

6. Enter the password (27689) by scrolling through the list until the desired number is highlighted.

7. Press the Menu Select button to activate each selection.

8. Select Done when you have entered all of the numbers.

10

Page 21

Accessing Service Mode 1 Introduction

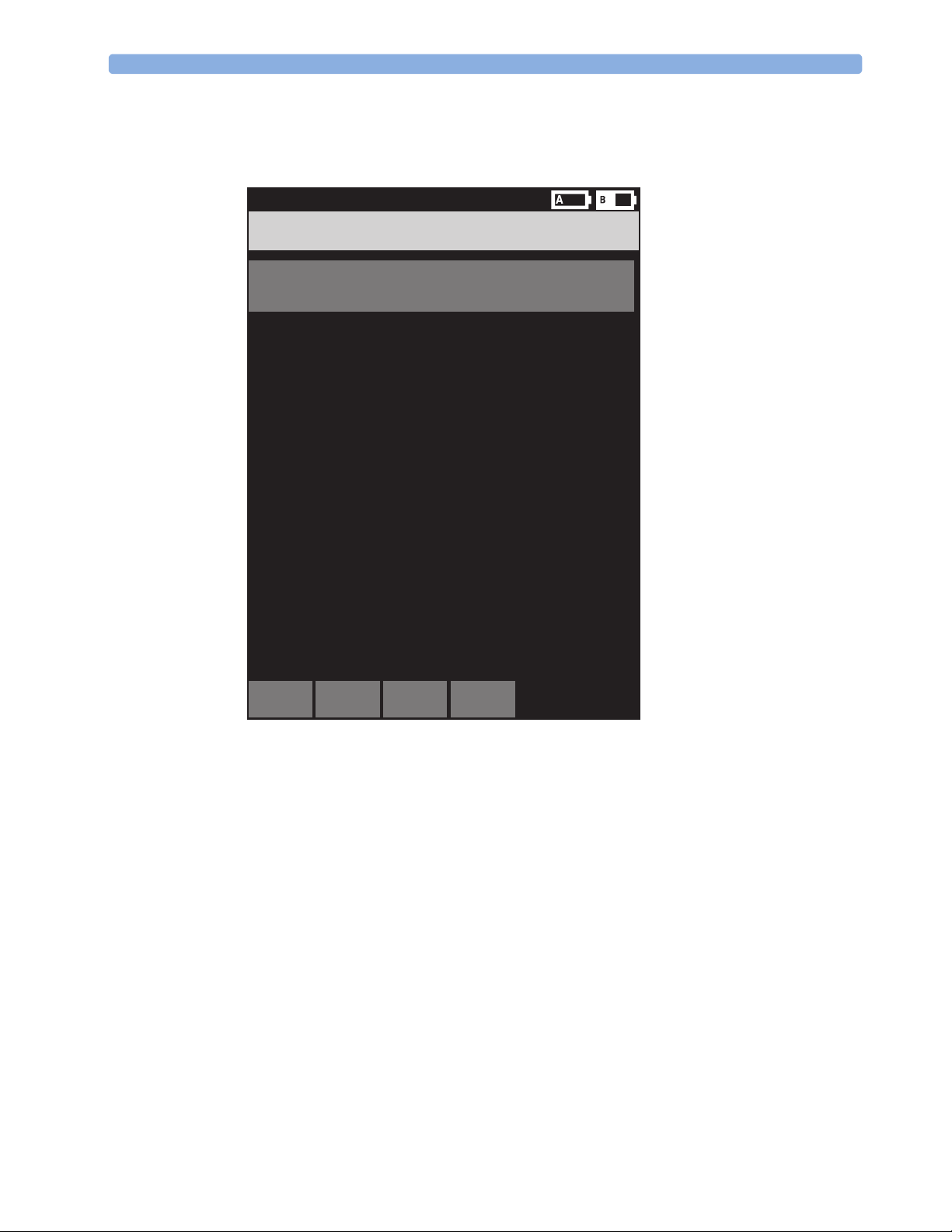

The Service Mode Main menu is displayed, as shown in Figure 6.

Figure 6 Service Mode Main Menu

02 Mar 2003 10:52

Service

Exit

Service

.

MAIN

Service

Operational Check

Status Log

NBP

CO2

Controls

Printer

Device Info

Software Upgrade

Navigating in Service Mode

Service Mode uses the same navigation controls as normal operating mode:

• To select a menu item, use the Navigation buttons to highlight your choice, then select that choice

by pressing the Menu Select button.

• To exit Service Mode and return to clinical mode, press the [Exit Service] soft key.

• To return to the Service Mode Main menu from any service screen press the [Main Service]

soft key.

NOTE The device’s default configuration settings are restored when you return to clinical mode after exiting

Service Mode.

11

Page 22

1 Introduction Accessing Service Mode

Service Mode Functions

You can perform a variety of service related activities from Service Mode, as follows:

• Run an Operational Check - See “Operational Check” on page 39.

• View, print and clear the Status log - See “Status Log Errors” on page 55.

• Perform maintenance on the NBP module - See “Checking the NBP Module” on page 19.

• Perform maintenance on the CO

• Run the Controls test - See “Controls Test” on page 193.

• Run the Printer test - See “Printer Test” on page 194.

• View information about the device, such as model number, serial number, options enabled on the

device, and the device’s language - See “Device Info” on page 13. You also use the Device Info menu

to enter the serial number and to enable options on the device after a Processor PCA repair. See

“Entering the Serial Number and Enabling Options” on page 128 for more information.

NOTE You can print detailed information on board and module levels through the Print Device Info option,

available in normal operating mode. See “Printing the Device Information” on page 16.

• Install software and change the device’s language using the Software Support Tool - See “Software

Support Tool” on page 13.

module - See “Checking the CO2 Module” on page 23.

2

12

Page 23

Accessing Service Mode 1 Introduction

Device Info

To view information about the device:

1. From the Service Mode Main menu, select Device Info.

Figure 7 Device Info Screen

02 Mar 2003 10:52

Service

Model Number: M3536A

Serial Number: US00100320

Options: SpO2, CO2, NBP

Language: American English

.

DEVICE INFO

Main

Service

Software Support Tool

To install software onto the device or to change the device’s language:

1. Be sure an AC power module or battery charged to at least 20% is in place.

2. Insert the Software Support Tool into the data card slot.

3. From the Service Mode Main menu, select Software Upgrade.

4. Select the appropriate product version.

5. Press the [Upgrade] soft key.

The software is installed on the device. This process takes a few minutes. While the software is

being updated, progress messages are displayed and the [Main Service] soft key is disabled.

MENU

13

Page 24

1 Introduction Accessing Service Mode

NOTE

Be careful not to interrupt the software installation process by removing the power source or turning

the device off.

Figure 8 Software Upgrade Screen

02 Mar 2003 10:52

Service SOFTWARE UPGRADE

HeartStart MRx Version B.04.00 Upgrade: American English

.

Main

Service

6. When the software or language installation process is complete, turn the device off and on.

7. Run an Operational Check.

8. Review the Operational Check results to ensure all tests have passed.

See “Operational Check” on page 39.

9. Print the Device Info to ensure the product version or language is correct.

See “Printing the Device Information” on page 16.

Prev

Item

Next

Item Upgrade

14

Page 25

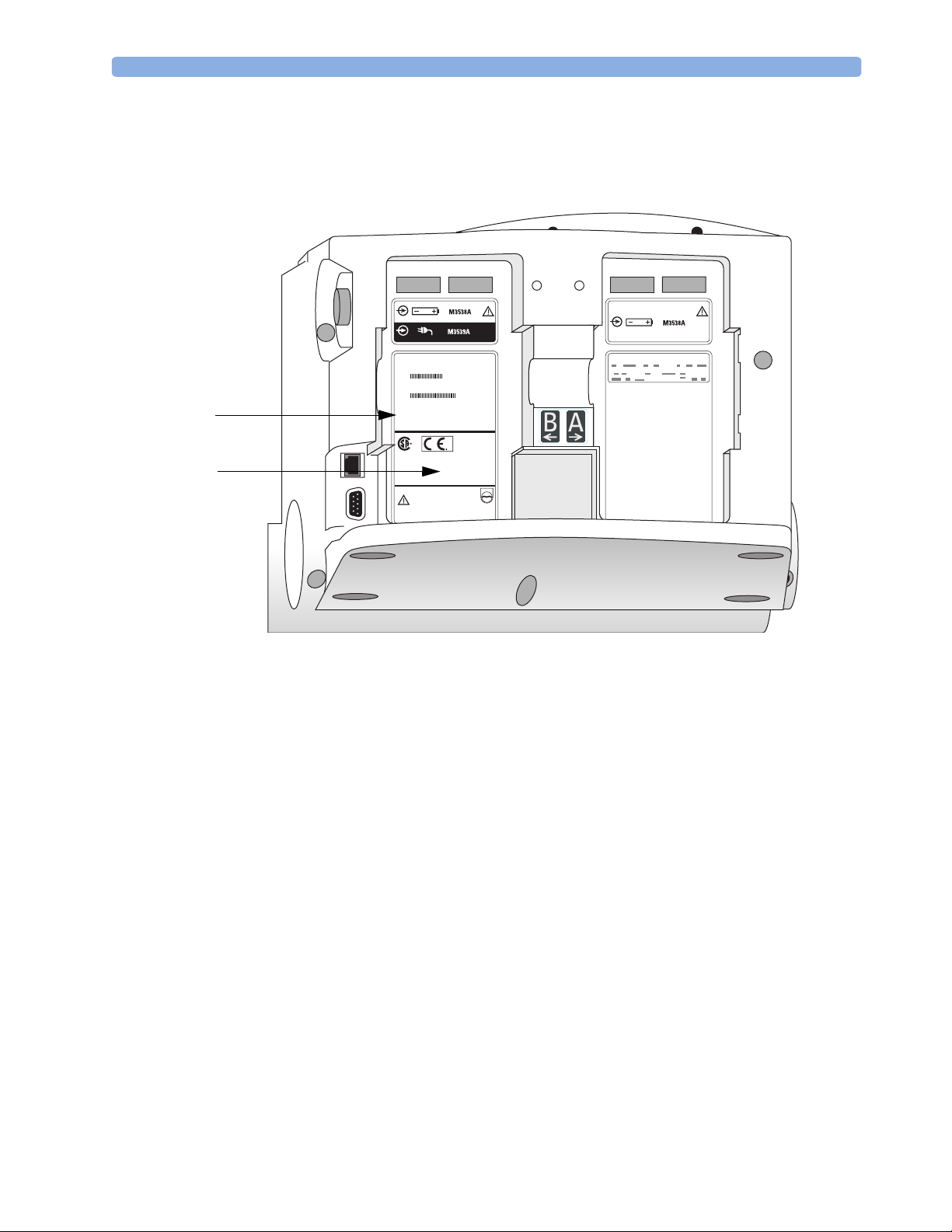

Accessing Service Mode 1 Introduction

10. Affix the appropriate label found in the Software Support Tool kit to battery compartment B, as

show in Figure 9. Additionally, make sure that the customer has the Instructions for Use (found

on the User Documentation CD) that matches the product version.

Figure 9 Rear case labels

Primary label

Product Version

label

B2.04.00

NOTE The label that you apply to the device is in the format Xx.xx. This is functionally equivalent to the X.xx

Product Version that appears on the Device Info and Software Upgrade screens and the printed device

information report. For example, product version B2.04 is functionally equivalent to B.04.

15

Page 26

1 Introduction Other Resources

Printing the Device Information

You can print detailed information on product versions, and board and module levels from the Print

Device Info menu option. This option is available from the Other menu in clinical modes.

To print the device information:

1. Be sure a battery charged to at least 20% is in place, or that external power is connected.

2. Turn the Therapy Knob to Monitor.

3. Press the Menu Select button to access the Main menu.

4. From the Main menu, select Other.

5. From the Other menu, select Print Device Info.

Detailed information about the device is printed.

Other Resources

For additional information on the HeartStart MRx, refer to the following Learning Products:

• HeartStart MRx Instructions for Use (M3535-91900)

• HeartStart MRx Service Training Video (M3535-89300 NTSC, M3535-89310 PAL)

• HeartStart MRx Lithium Ion Battery Characteristics and Care Application Note (M3535-91930)

Other documentation can be found on the Philips website at:

www.medical.philips.com/goto/productdocumentation.

16

Page 27

This chapter describes how to perform routine maintenance on the HeartStart MRx

monitor/defibrillator.

Overview

Most routine maintenance is performed by the user. This includes:

• Performing operational checks

• Replacing paper

• Charging and maintaining the lithium ion battery

•Cleaning

2

2Maintenance

Refer to the Instructions for Use for detailed information on these maintenance procedures.

Service personnel are responsible for the following routine maintenance:

• Yearly calibration (or every 10,000 cycles) of the Noninvasive Blood Pressure (NBP) module

• Yearly calibration (or every 4000 hours) of the End-tidal Carbon Dioxide (EtCO

This chapter provides the following information:

To p ic Pa ge

Maintenance Tools and Equipment 18

Checking the NBP Module 19

Checking the CO

Module 23

2

) module

2

17

Page 28

2Maintenance Maintenance Tools and Equipment

Maintenance Tools and Equipment

You will need the following equipment to perform the yearly calibration procedures:

• Password to access Service Mode (27689)

•NBP

– manometer

– expansion chamber (volume 250 ml +/- 10%) or an NBP cuff can be used

NOTE If you are using an NBP cuff, make sure it is wrapped around a solid object.

•CO

NOTE In addition to the items listed above, the calibration procedures require tubing and connectors typically

found in a biomedical engineering shop.

2

– calibration gases and regulator

cal 1 gas 15210-64010 (5% CO

cal 2 gas 15210-64020 (10% CO

cal gas flow regulator M2267A

– electronic flowmeter, M1026-60144

– Gas calibration equipment

cal tube 13907A

FilterLine set, M1920A

– local barometric pressure rating or reading received from a reliable local source (airport, regional

weather station, or hospital weather station) which is located at the same altitude as the hospital

or EMS service.

– calculator

)

2

)

2

18

Page 29

Checking the NBP Module 2 Maintenance

Checking the NBP Module

NBP

These instructions describe how to test the NBP measurement function. A complete test consists of the

following activities, which are described in detail in this chapter.

NBP Check Page

Setup

Setup

Check the status displays

Test the accuracy

Test for leaks

Tes t t he l i ne a r it y

Calibrate the NBP Measurement

Run an Operational Check

Each of the procedures assumes the monitor/defibrillator, the manometer, and the expansion chamber

are still set up as they were at the end of the previous test.

If all results are as described, the device passes that portion of the test. Return to the Service Mode

Main menu by pressing the [Main Service] soft key.

If there is any failure, begin troubleshooting and repairing the device as needed. See

“Troubleshooting” on page 33.

1 Access the Service Mode Main menu as described in “Accessing Service Mode” on page 10.

2 From the Service Mode Main menu, select NBP.

The NBP Service screen is displayed.

19

20

21

21

22

22

22

19

Page 30

2Maintenance Checking the NBP Module

NOTE

You will hear a high-pitch tone when you access the NBP Service screen - this is normal operation.

Figure 10 NBP Service Screen

02 May 2003 10:52

Service

Cycle Counter: 50,010

Last Calibration: 2 May 2004

Pressure In Cuff: 23 mmHg

.

NBP

Replacement recommended

Calibration recommended

Main

Service

Check the status displays

1. Check the cycle counter.

Check the number of measurement cycles shown on the screen. If the NBP module has executed

more then 50,000 cycles, replacement is recommended. See “NBP Module” on page 160 for

instructions on replacing the NBP module.

Following replacement, run the required Performance Verification and Safety Tests (see “Required

Testing Levels” on page 180).

2. Check the calibration status.

If the screen indicates that calibration is recommended, perform all of the actions described in this

chapter, beginning with "Test the accuracy".

The calibration status is automatically reset at the successful completion of a calibration.

20

Calibrate

Page 31

Checking the NBP Module 2 Maintenance

NBP Safety Timeout

Do not keep the cuff pressurized for more than 3 minutes. The NBP module times out if the pressure

is greater than 5mmHg for 180 seconds. The valve opens and the pressure drops. To reset the module,

exit Service Mode and press the [Start NBP] soft key. The inop “Cuff not deflated” is displayed.

Access the NBP Service screen again to start the calibration.

Test the accuracy

1 Connect the NBP tubing to the NBP port on the monitor/defibrillator, and connect the test

manometer and expansion chamber to the tubing. See Figure 11.

Figure 11 NBP Test Setup

Expansion Chamber

2 Pressurize the expansion chamber to approximately 280 mmHg.

3 When the pressure stabilizes, compare the displayed pressure reading to the pressure indicated by

4 If the difference between the manometer and the displayed pressure is >+ 2mmHg, perform the

Test for leaks

1 Pressurize the expansion chamber to approximately 280 mmHg.

Tu b i n g

To N B P p o r t

1

2

ECG

ECG

Manometer

the manometer.

steps in “Calibrate the NBP Measurement” on page 22.

c

n

y

S

dult

A

e

s

o

D

0

12

150

n

0

10

0

O

17

b

0

i

7

f

0

0

2

e

D

0

5

t

c

e

l

e

S

y

g

r

e

1

n

E

0

4

0

3

e

g

r

a

h

C

0

2

10

-

2

2

r

e

c

a

D

P

E

A

k

c

ho

S

n

O

ff

O

r

nito

o

M

3

2 Watch the displayed pressure for 60 seconds.

3 At the end of this 60 seconds record the pressure drop. Any pressure drop observed should be

<

6 mmHg.

4 If the pressure decreases by more than 6 mmHg, there is a leak. Replace the NBP tubing and cuff

and try the leakage test again. If the pressure still decreases by more than 6 mmHg, begin

troubleshooting and repairing the device as needed.

5 Release the pressure in the cuff before proceeding to the next test to avoid the safety timeout.

21

Page 32

2Maintenance Checking the NBP Module

Test the linearity

1 Pressurize the expansion chamber to increase pressure to approximately 150 mmHg.

2 When the pressure is stabilized, compare the displayed pressure reading to the pressure indicated

by the manometer.

If the difference between the manometer and the displayed pressure is >±2mmHg, perform the

steps in "Calibrate the NBP Measurement". Then repeat this linearity test.

Calibrate the NBP Measurement

NOTE If the error message “Calibration failed. Check that the pressure applied is correct. Please restart

calibration.” appears after entering either calibration point, re-start the calibration.

Pressing the [Calibrate] soft key starts the calibration process. You must complete the calibration

process within three minutes or the NBP module times out and will be out of calibration.

1 Press the [Calibrate] soft key.

The message “Apply 0 mmHg. Select Next when ready” is displayed.

2 Release all of the pressure in the expansion chamber so that the manometer reads 0 mmHg.

3 Press the [Next] soft key.

The message “Apply 250 mmHg. Select Next when ready” is displayed.

4 Increase the pressure so that the manometer reads 250 mmHg.

5 Press the [Next] soft key.

If the calibration is successful, the message “Calibration complete. Please perform the accuracy and

leakage tests to check the results.” is displayed. After several seconds the message clears and the NBP

Service screen is displayed.

Run an Operational Check

You must run an operational check after calibrating the NBP module in order for the calibration status

to get updated. See “Operational Check” on page 39 for instructions.

22

Page 33

Checking the CO2 Module 2 Maintenance

Checking the CO2 Module

CO

2

These instructions describe how to test the CO2 module. The CO2 tests are as follows:

Check Page

CO

2

Setup 23

Check the Status Display 24

Ambient Pressure 25

Leakage Check 26

Pump Check 27

Flow Rate Check 28

Noise Check 28

Calibration Check 29

CO

Calibration 30

2

Run an Operational Check 31

Setup

Each of the tests assumes the device and the test equipment are still set up as they were at the end of the

previous test.

If all results are as described, the device passes that portion of the test. Return to the Service Mode

Main menu by pressing the [Main Service] soft key.

If there is any failure, begin troubleshooting and repairing the device as needed. See

“Troubleshooting” on page 33 for more information.

1 Access the Service Mode Main menu as described in “Accessing Service Mode” on page 10.

2 From the Service Mode Main menu, select CO

The pump starts when you access the CO

.

2

Service screen.

2

23

Page 34

2Maintenance Checking the CO2 Module

The CO2 Service screen is displayed, as shown in Figure 12.

Figure 12 CO

Service Screen

2

02 Mar 2003 10:52

CO2 Sensor Warmup

Service

.

CO2

CO2 Operating Hours: 15,010 hours

Last Calibration: 9 Jun 2002

Ambient Pressure: 756 mmHg

Cell Pressure: 756 mmHg

Replacement recommended

Main

Service

Check the Status Display

1. Check the CO2 Operating Hours.

You are directed to replace the CO

hours is more than 15,000 the message “Replacement recommended” is displayed. See “CO

Module” on page 162 for instructions on replacing the CO

2. Check calibration status.

Displays the date of the last calibration. The CO

4000 hours. If more than one year has passed or the module has operated more than 4000 hours

since the last calibration, the message “Calibration recommended” is displayed. Perform all of the

actions described in this section, beginning with “Ambient Pressure.”

CO2

Ambient Pressure

Leakage Check

Pump Check

Flow Rate Check

Noise Check

Calibration Check

Exit

module after 15,000 hours of operating time. If the number of

2

2

module.

2

module should be calibrated every year or after

2

24

Page 35

Checking the CO2 Module 2 Maintenance

3. Check the ambient and cell pressure.

Obtain a reliable measurement of local barometric pressure (reference value). This is typically

available from a local airport, weather station, or the internet. Be sure the reading is taken at the

same altitude as the monitor/defibrillator is at now. Check that the monitor/defibrillator’s internal

setting of ambient atmospheric pressure (barometric pressure) is within +

reference value. If the ambient pressure is not within +

12 mmHg of the reference value, adjust it

through the Ambient Pressure menu. If the ambient pressure is within +

12 mmHg of the

12 mmHg of the reference

value, proceed with the Leakage check.

Ambient Pressure

This menu enables you to adjust the ambient pressure setting of the monitor/defibrillator.

1 If the ambient pressure is not within + 12 mmHg of the reference value, select Ambient Pressure

from the CO

2 Use the Navigation buttons to enter the barometric pressure reference value.

The displayed ambient pressure is updated to the reference value.

Service menu.

2

25

Page 36

2Maintenance Checking the CO2 Module

Leakage Check

The leakage check consists of two parts:

1 Check of the internal tubing between the pump outlet and the CO

Outlet port on the

2

monitor/defibrillator (device outlet). This test is done by pressurizing the outlet line between the

pump and the outlet port.

2 Check of the internal tubing between the pump inlet and the FilterLine inlet. This test is done by

pulling a vacuum on the inlet line between the inlet fitting and the pump.

These procedures are described in the following sections.

Outlet leakage

To perform Part 1 of the CO2 Leakage check:

1 From the CO

Service menu, select Leakage Check.

2

2 Set up the flowmeter and the MRx.

a. Connect the FilterLine to the monitor/defibrillator CO2 Inlet port.

b. Connect tubing from the flowmeter outlet to the FilterLine.

Figure 13 CO

Outlet Leakage Check Setup

2

1

2

26

3 Follow the instructions on the screen to perform Part 1 of the Leakage check.

4 The reading on the flowmeter should decrease to between 0 and 4 ml/min.

If this reading is correct, proceed to the second part of the leakage test (the Inlet Leakage) by

pressing the [Proceed] soft key.

If this reading is incorrect (>4 ml/min. flow) it indicates a leak in the line between the pump outlet

and the CO

Outlet port. Begin troubleshooting and repairing the device as needed. See

2

“Troubleshooting” on page 33.

Page 37

Checking the CO2 Module 2 Maintenance

Inlet leakage

To perform Part 2 of the CO2 Leakage check:

1 Set up the flowmeter and the MRx.

a. Leave the FilterLine connected to the monitor/defibrillator CO

Inlet port.

2

b. Disconnect the FilterLine from the flowmeter outlet.

c. Connect the tubing from the flowmeter inlet to the monitor/defibrillator CO

Outlet port.

2

Figure 14 CO2 Inlet Leakage Check Setup

1

2

2 Follow the instructions on the screen to perform Part 2 of the Leakage check.

3 The reading on the flowmeter should decrease to between 0 and 4 ml/min.

If this reading is incorrect (>4 ml/min. flow) it indicates a leak in the line between the FilterLine

inlet and the pump inlet. Begin troubleshooting and repairing the device as needed. See

“Troubleshooting” on page 33.

Pump Check

This test checks the ‘strength’ of the pump by occluding the inlet and measuring how deep a vacuum

the pump can pull.

NOTE It is important these tests be conducted in this order. For example, if you perform the Pump check and

there’s a leak you haven’t found because you didn’t perform the leak tests, it may appear that the device

has a faulty pump when in fact it’s a loose tubing connection.

1 From the CO

2 Follow the instructions on the screen to perform the Pump check.

3 The difference between the cell pressure displayed and the ambient pressure should be more than

120 mmHg.

If the pressure reading is correct (difference >120 mmHg), the device passes the pump test.

If the pressure reading is incorrect, it indicates the pump is defective (regardless of the number of

hours it has run) and the CO

Service menu, select Pump Check.

2

module must be replaced. See “CO2 Module” on page 162.

2

27

Page 38

2Maintenance Checking the CO2 Module

Flow Rate Check

1 From the CO

2 Follow the instructions on the screen to perform the Flow Rate check.

NOTE Be sure there are no kinks, pinches, or obstructions in any of the tubing - this can create a restriction

that will diminish the flow rate and cause a false failure of this test.

3 If the flow rate is within the tolerance limit (50 ml/min ±7.5 ml/min), the test passes.

If the flow rate is not within the tolerance limit, proceed to Step 4 to calibrate the flow rate.

4 Use the Navigation buttons to increase and decrease the flow until it is as close as possible to 50 ml

per minute as indicated on the flowmeter gauge.

5 When you are satisfied that the flow is set as close as possible to 50 ml, press the [Store Flow]

soft key to confirm the setting. If the adjusted flow is not stored within 60 seconds of the

adjustment, the old flow setting is restored.

Service menu, select Flow Rate Check.

2

NOTE If the flow cannot be adjusted to within tolerance, the CO

Module” on page 162.

Noise Check

This test looks for noise on the CO2 signal due to deterioration of the IR source.

1 From the CO

2 Set up the calibration gas as shown in Figure 15.

a. Connect the 5% calibration gas to the CO2 Inlet port.

b. Turn on the gas.

Figure 15 CO

M2267A

15210-64020

10%

15210-64010

5%

Service menu, select Noise Check.

2

Noise and Calibration Check Setup

2

M1920A

module must be replaced. See “CO2

2

1

2

28

13907A

End open to atmosphere

3 Follow the instructions on the screen to perform the Noise check.

4 Wait until the displayed CO

value is stable. Check the noise index reading.

2

Page 39

Checking the CO2 Module 2 Maintenance

5

If the noise index exceeds 3 mmHg, the CO2 module must be replaced. See “CO2 Module” on

page 162.

Calibration Check

This tests the accuracy of the CO2 measurement and, if needed, adjusts the measurement to meet

specifications.

1 The monitor/defibrillator must be operating for at least 20 minutes prior to starting this test with

the FilterLine connected to the CO

2 From the CO

3 The CO

5% Calibration Check

Set up the calibration gas as shown in Figure 15.

4

Service menu, select Calibration Check.

2

Calibration screen is displayed,

2

a. Connect the 5% calibration gas to the CO2 Inlet port.

b. Turn on the gas.

Inlet port.

2

5 Wait until the displayed CO

6 Calculate the expected CO

value is stable.

2

reading, which depends on both the gas concentration you are using

2

(typically 5.0%) and the ambient pressure. Calculate as follows:

[concentration of cal gas] X [ambient pressure] = expected CO2 value

For example:

[0.05] X [736 mmHg] = 36.8 mmHg

7 Calculate the allowable tolerance, which is ±5% of the expected reading. Calculate as follows:

[±0.05] X [expected CO

value]] = ±[tolerance] mmHg

2

example:

[±0.05] X [36.8 mmHg] = ±1.8 mmHg

In this example, the reading displayed with 5% cal gas must be 36.8 mmHg ±1.8 mmHg, or

between 35.0 mmHg and 38.6 mmHg.

8 Compare the displayed CO

value to the allowable range of values.

2

If the displayed value falls within the allowable range, proceed to the 10% Calibration Check

section below.

If the displayed value does not fall within the allowable range, the CO

needs to be calibrated. Perform the steps under “CO

Calibration” on page 30, then begin again at

2

measurement module

2

step 1.

29

Page 40

2Maintenance Checking the CO2 Module

10% Calibration Check

Disconnect the 5% gas (and regulator, if needed) and connect the 10% gas.

1

2 Turn on the gas.

3 Wait until the displayed CO

4 Calculate the expected CO

value is stable.

2

reading, which depends on both the gas concentration you are using

2

(typically 10.0%) and the ambient pressure. Calculate as follows:

[concentration of cal gas] X [ambient pressure] = expected CO2 value

example:

[0.10] X [736 mmHg] = 73.6 mmHg

5 Calculate the allowable tolerance, which is ±7% of the expected reading. Calculate as follows:

[±0.07] X [expected CO

value]]= ±[tolerance] mmHg

2

example:

[±0.07] X [73.6 mmHg] = ±5.2 mmHg

In this example, the reading displayed with 10% cal gas must be 73.6 mmHg ±5.2 mmHg, or

between 68.4 mmHg and 78.8 mmHg.

6 Compare the displayed CO

7 Return to the CO

CO2 Calibration

If you haven’t already done so, perform the following three steps before proceeding with the calibration.

1 The monitor/defibrillator must be operating and a FilterLine connected to the CO

2 From the CO

3 The CO

value to the allowable range of values.

2

If the displayed value falls within the allowable range, the device has passed its accuracy test.

If the displayed value does not fall within the allowable range, the CO

needs to be calibrated. Perform the steps under “CO

Calibration” on page 30, then begin again at

2

measurement module

2

step 1.

Service screen by pressing the [Done] soft key.

2

Inlet port for

2

at least 20 minutes prior to starting this test.

Service menu, select Calibration Check and press the Menu Select button.

2

Calibration screen is displayed. Wait until the display indicates the autozero is finished

2

before proceeding.

30

Page 41

Checking the CO2 Module 2 Maintenance

Calibration

Connect the 5% calibration gas (and regulator, if needed) to the CO2 Inlet port. Turn on the gas.

4

5 Wait until the displayed CO

6 Press the [Calibrate] soft key.

7 The screen prompts you for the value of cal gas being used. Acceptable values are from 4% to 6%.

value is stable.

2

The recommended value is 5%, which is the default.

8 Using the Navigation buttons, set the correct cal gas value, then press the Menu Select button.

9 When you have selected the correct cal gas value, the monitor/defibrillator begins an auto

calibration sequence, and the screen displays the message "CO

calibration in progress". Do not

2

remove the gas until the monitor/defibrillator is finished as indicated by the screen prompts.

Calibration Verification

If it is not already connected, connect the 5% calibration gas (and regulator, if needed) to the CO2

10

Inlet port. Turn on the gas.

11 Wait until the displayed CO

12 Check the displayed CO

value is stable.

2

value against the expected value calculated earlier. The displayed value

2

should match the expected value within the tolerance calculated earlier.

13 Disconnect the 5% gas and connect the 10% gas.

14 Wait until the displayed CO

15 Check the displayed CO

value is stable.

2

value against the expected value calculated earlier. The displayed value

2

should match the expected value within the tolerance calculated earlier.

If both the 5% and 10% values are correct, the device has been successfully calibrated.

If either value is not within tolerance, repeat the calibration beginning at step 1. If the device fails

the Calibration Verification a second time, replace the CO

page 162.

Run an Operational Check

You must run an operational check after calibrating the CO2 module in order for the calibration status

to get updated. See “Operational Check” on page 39 for instructions.

module. See “CO2 Module” on

2

31

Page 42

Page 43

This chapter describes how to troubleshoot the HeartStart MRx monitor/defibrillator.

Overview

Here are the topics covered in this chapter:

To p ic Pa ge

Troubleshooting Tools and Equipment 34

Obtaining Replacement Parts 34

Ready For Use Indicator 35

Automated Tests 36

Operational Check 39

Service Mode Tests 44

Troubleshooting Methodology 45

Troubleshooting Flowcharts 47

Troubleshooting Tables 53

3

3Troubleshooting

33

Page 44

3 Troubleshooting Troubleshooting Tools and Equipment

Troubleshooting Tools and Equipment

You need the following tools and equipment:

• Defibrillator Discharge Tool (M2475-69573) — Used to discharge the defibrillator capacitor.

• 50 ohm defibrillator test load, grey plug connector (M3725A)

• 50 ohm defibrillator test load, white barrel connector (M1781A)

Obtaining Replacement Parts

See “Parts and Accessories” on page 211 for details on replacement parts.

34

Page 45

Ready For Use Indicator 3 Troubleshooting

Ready For Use Indicator

The Ready For Use (RFU) indicator, located on the upper right corner of the device, reports the status

of critical functions of the device as determined by the Automated tests. These Automated tests run

periodically while the device is turned off (but has a power source) and check the following critical

functions of the device:

• defibrillation and cardioversion

•pacing

• pads/paddles ECG

• 3-lead/5-lead/12-lead ECG

• battery

The RFU indicator also reports failures in critical functions detected at run time, during an

Operational Check, and during Service Mode tests. Always check the RFU indicator when

troubleshooting the device.

Automated test failures of non-critical components (such as the NBP, SpO

modules) are not reflected in the RFU indicator, but are reported through inops when the device is

turned on.

The RFU indicator displays the status of the device using the following definitions.

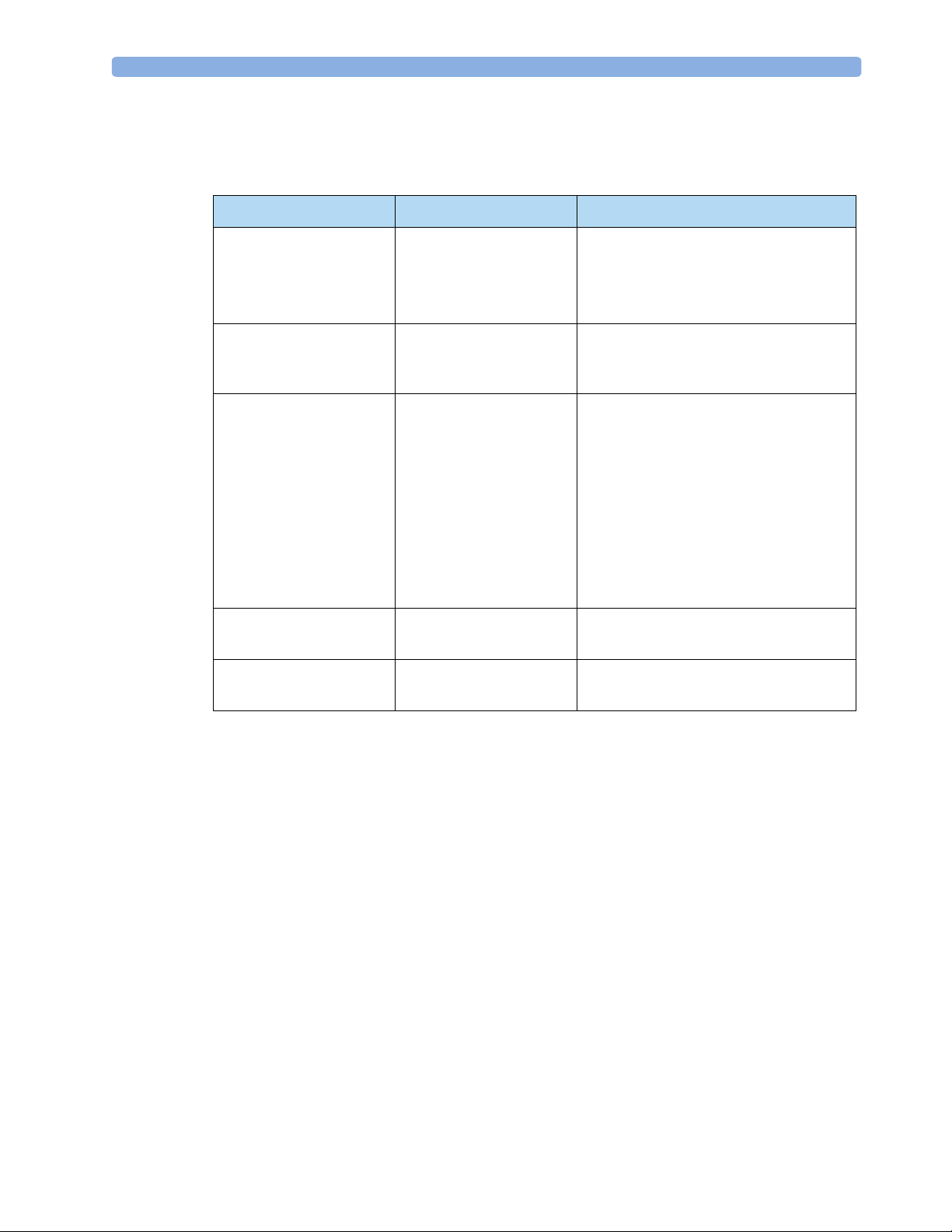

Table 1 RFU Indicator Status

RFU Status Meaning Required Action

Blinking black hourglass Shock, pacing, and ECG functions are

ready for use and sufficient battery power

is available.

Blinking red “X” with or

without a periodic chirp

Solid red “X” and a

periodic chirp

Solid red “X” without a

periodic chirp

Low battery or no battery. The device

can be used but run time is limited.

Chirping indicates the battery is not

being charged. No chirping indicates the

battery is being charged.

A failure has been detected that prevents

the delivery of a shock, pacing, or ECG

acquisition.

No power, or device failure (cannot turn

on).

None

Charge the battery as soon as possible and/or

replace the battery with a charged battery.

Charging may be done in the HeartStart MRx

by connecting to AC/DC power, or in a

Philips-approved battery support system.

Turn the Therapy Knob to Monitor. A message

describing the failure is displayed. Begin

troubleshooting, as described in

“Troubleshooting Methodology” on page 45.

Note: The device displays the message for the

first critical failure that is detected. To see

additional failures (if any) run an Operational

Check and check the status log.

Insert a charged battery or connect to AC/DC

power. Begin troubleshooting, as described in

“Troubleshooting Methodology” on page 45.

, CO2, and printer

2

NOTE The RFU indicator briefly displays a solid red “X” when initially turning on the device, switching

between clinical and non-clinical operating modes, and at the start of any Automated test.

35

Page 46

3 Troubleshooting Automated Tests

Automated Tests

The HeartStart MRx performs many maintenance activities independently, including three tests that

run automatically at regularly scheduled intervals while the device is off to assess operational

performance and alert you if a problem exists. Results of tests associated with critical functionality of

the device are reported through the Ready For Use indicator and the Automated Test Summary report.

Results are also reported through inop statements on the display when the HeartStart MRx is turned

on. Table 2 provides a brief explanation of the tests and lists the frequency with which each test is

performed.

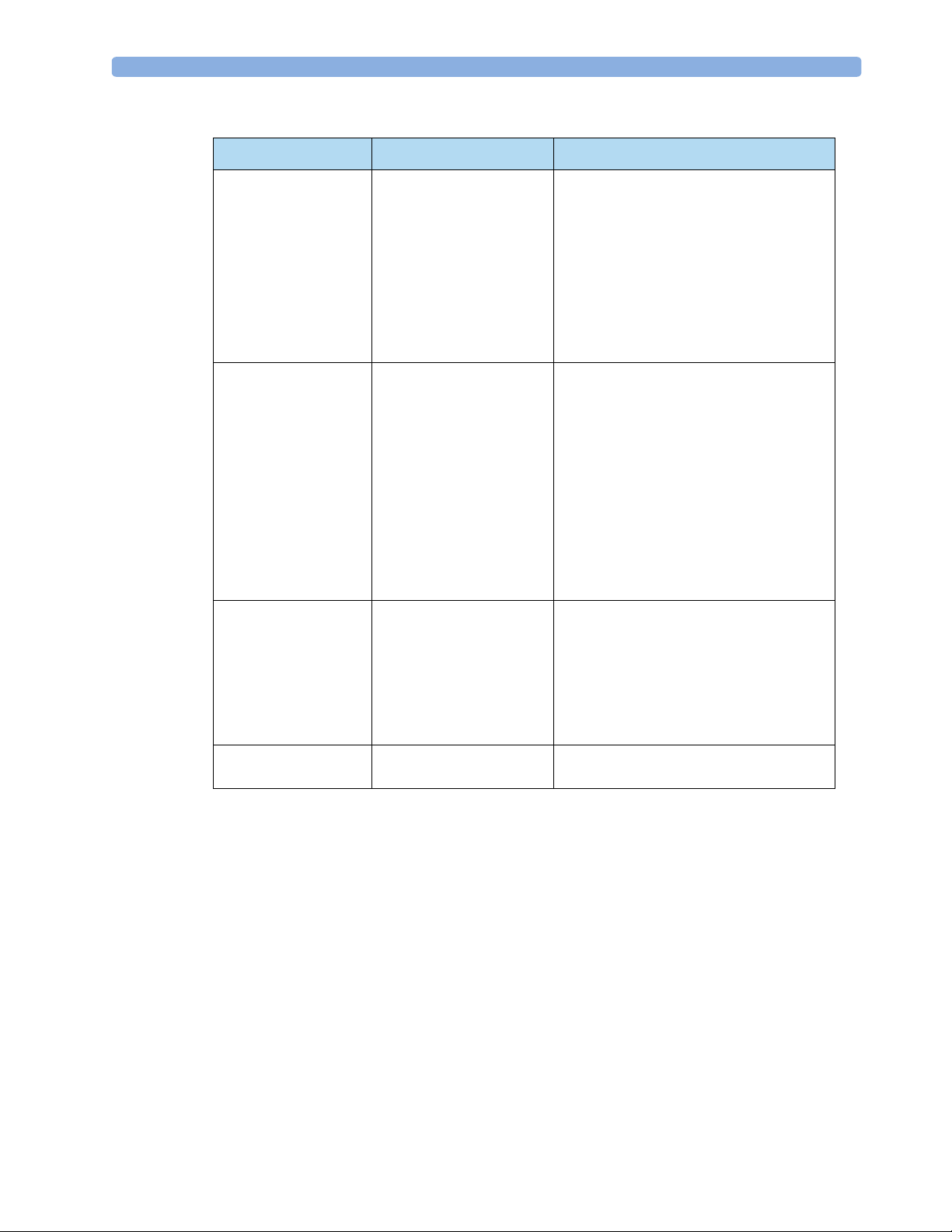

Table 2 Automatic Self-Tests

Tes t Ty p e /Freq u en c y Description

Hourly Tests batteries, internal power supplies, and internal memory.

Daily, between 11:00 PM and

1:00 AM

Weekly (Sunday between 11:00

PM and 1:00 AM)

Tests batteries, internal power supplies, internal memory,

internal clock battery, defibrillation, pacing, ECG, SpO

EtCO

, NBP, and printer. The defibrillation test includes low

2

energy internal discharges. If a 3-, 5-, or 10-lead ECG cable is

attached, the cable is tested as well.

Performs a Daily Test plus delivers a high energy internal

discharge to exercise the entire defibrillation circuitry.

,

2

NOTE Automated tests do not test the therapy cables, paddles, buttons, audio, or the display. An ECG cable is

tested if connected at the time of the test.

Automated Test Summary

An Automated Test Summary (ATS), showing the results of recent tests, may be viewed or printed as

evidence that the HeartStart MRx is tested regularly. To run the ATS:

1 Turn the Therapy Knob to Monitor.

2 Press the Menu Select button.

3 Using the Navigation buttons, select Other and press the Menu Select button.

4 Select Operational Check and press the Menu Select button.

The message “Leaving Normal Operating Mode” appears to let you know that you are exiting from

clinical functionality of the device.

5 Using the Navigation buttons, select Auto Test Summary and press the Menu Select button.

The Automated Test Summary is displayed.

6 Press the [Print] soft key to print the report.

36

Page 47

Automated Tests 3 Troubleshooting

The report shows the results of the most recent hourly test, the daily tests that have run since the last

weekly test, and the last 53 weekly tests. Test results are reported, as described in Table 3.

Figure 16 Automated Test Summary Screen

02 Mar 2003 10:52

Automated Test Summary

1 02 Mar 03 10:45 Hourly Pass

2 02 Mar 03 2:00 Daily Fail/NC

2 02 Mar 03 2:00 Daily Fail/NC

3 01 Mar 03 2:00 Daily Pass

4 28 Feb 03 2:00 Daily Pass

5 27 Feb 03 2:00 Daily Pass

6 26 Feb 03 2:00 Daily Pass

7 25 Feb 03 2:00 Daily Pass

8 24 Feb 03 2:00 Weekly Pass

9 17 Feb 03 2:00 Weekly Pass

10 10 Feb 03 2:00 Weekly Pass

11 03 Feb 03 2:00 Weekly Pass

12 27 Jan 03 2:00 Weekly Pass

13 20 Jan 03 2:00 Weekly Pass

14 13 Jan 03 2:00 Weekly Pass

15 06 Jan 03 2:00 Weekly Pass

16 30 Dec 02 2:00 Weekly Pass

17 23 Dec 02 2:00 Weekly Pass

18 16 Dec 02 2:00 Weekly Pass

19 09 Dec 02 2:00 Weekly Pass

20 02 Dec 02 2:00 Weekly Pass

21 25 Nov 02 2:00 Weekly Pass

22 18 Nov 02 2:00 Weekly Pass

23 11 Nov 02 2:00 Weekly Pass

24 04 Nov 02 2:00 Weekly Pass

25 28 Oct 02 2:00 Weekly Pass

26 21 Oct 02 2:00 Weekly Pass

27 14 Oct 02 2:00 Weekly Pass

28 07 Oct 02 2:00 Weekly Pass

29 30 Sep 02 2:00 Weekly Pass

30 23 Sep 02 2:00 Weekly Pass

31 16 Sep 02 2:00 Weekly Pass

32 09 Sep 02 2:00 Weekly Pass

33 02 Sep 02 2:00 Weekly Pass

34 26 Aug 02 2:00 Weekly Pass

35 19 Aug 02 2:00 Weekly Pass

36 12 Aug 02 2:00 Weekly Pass

37 05 Aug 02 2:00 Weekly Pass

38 29 Jul 02 2:00 Weekly Pass

39 22 Jul 02 2:00 Weekly Pass

40 15 Jul 02 2:00 Weekly Pass

41 08 Jul 02 2:00 Weekly Pass

42 01 Jul 02 2:00 Weekly Pass

43 24 Jun 02 2:00 Weekly Pass

44 17 Jun 02 2:00 Weekly Pass

45 10 Jun 02 2:00 Weekly Pass

46 03 Jun 02 2:00 Weekly Pass

47 27 May 02 2:00 Weekly Pass

48 20 May 02 2:00 Weekly Pass

49 13 May 02 2:00 Weekly Pass

50 06 May 02 2:00 Weekly Pass

51 29 Apr 02 2:00 Weekly Pass

52 22 Apr 02 2:00 Weekly Pass

53 15 Apr 02 2:00 Weekly Pass

54 08 Apr 02 2:00 Weekly Pass

55 01 Apr 02 2:00 Weekly Pass

56 25 Mar 02 2:00 Weekly Pass

57 18 Mar 02 2:00 Weekly Pass

58 11 Mar 02 2:00 Weekly Pass

59 04 Mar 02 2:00 Weekly Pass

30 25 Feb 02 2:00 Weekly Pass

Exit

Summary Print

37

Page 48

3 Troubleshooting Automated Tests

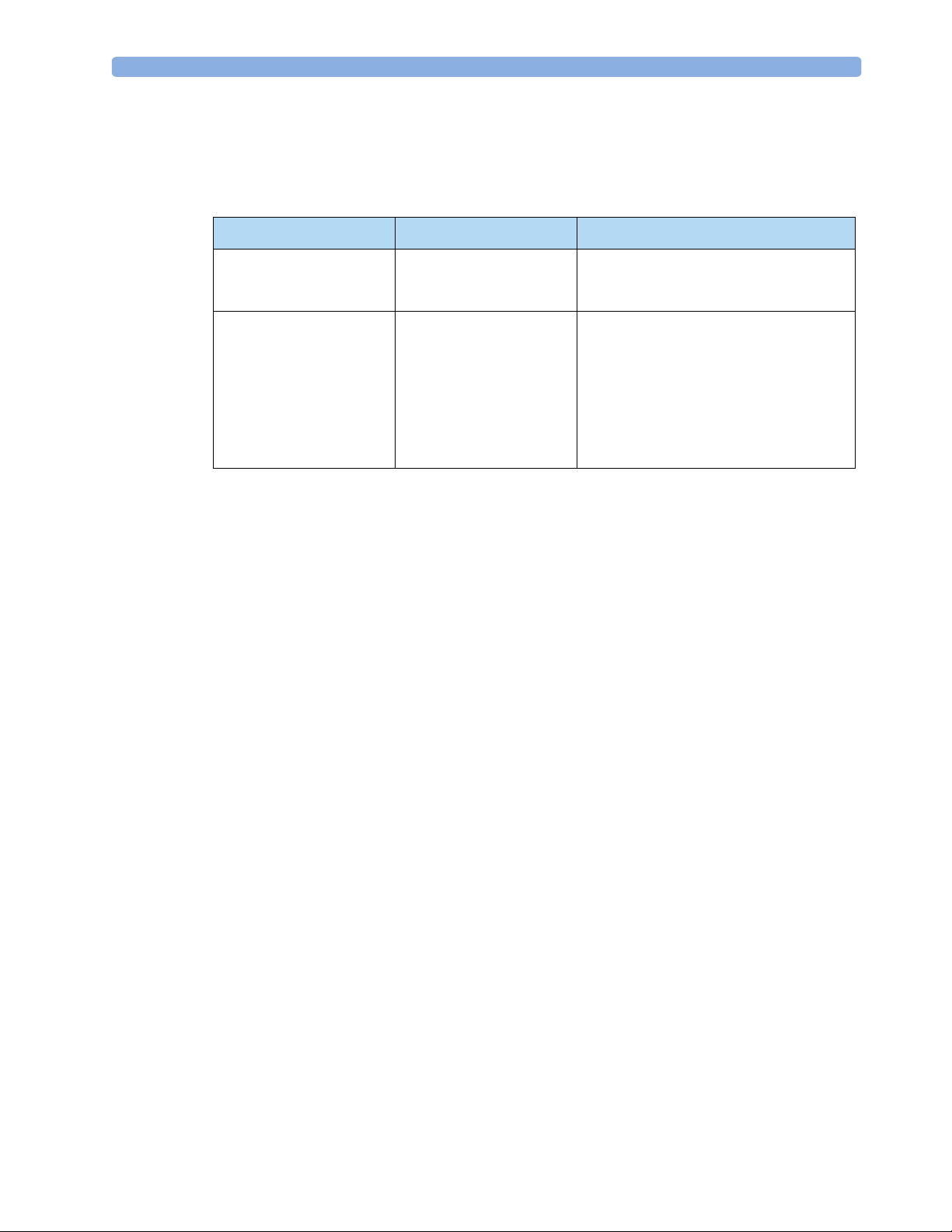

Tab l e 3 ATS R e s u lt s

Result RFU

Definition Required Action

Indicator

Pass Hourglass All tests passed None

Fail/C Solid Red “X”

accompanied

by a chirp

Fail/NC Hourglass A non-critical failure was detected. Non-

Fail/BF Blinking “X” The battery is not charged to the

A critical failure was detected. Critical

failures impact life-saving functionality,

including defibrillation, pacing, and

ECG acquisition.

critical failures do not impact life-saving

functionality.

minimum level (20%), there is no battery

present, or a battery failure was detected.

Respond to the RFU indicator as described

in “Troubleshooting Flowcharts” on

page 47.

Press the [Exit Summary] soft key. An

inop statement indicating the failure is

displayed.You can also note the time of the

failed test, then check the Status log for

failures logged at approximately the time of

the test. Refer to the Troubleshooting

Tables in this chapter for the action to take.

The message will continue to display in all

modes until the problem is corrected.

(Refer to the Instructions for Use for a

complete set of user prompts and

messages,)

Charge the battery as soon as possible and/

or replace the battery with a charged

battery. Charging may be done in the

HeartStart MRx by connecting to AC/DC

power, or in a

support system.

Philips-approved battery

38

Page 49

Operational Check 3 Troubleshooting

Operational Check

Operational Checks should be performed at regular intervals to supplement the hourly, daily, and

weekly Automated Tests executed by the MRx. Automated Tests provide adequate assurance that the

device is in a functional state of readiness. Operational Checks supplement the Automated Tests by

verifying therapy cables, the ECG cable, paddles, audio, and display functionality, along with

replicating the Weekly test. Operational Checks also notify you if the battery, NBP module, or CO

module need calibration.

At completion of the Operational Check, the message “Operational Check Passed” is displayed if all of

the tests pass. If any test fails the message “Non-Critical Failure”, “Critical Failure”, or “Battery

Failure” is displayed, depending upon the severity of the failed functionality. You must fix the problem

and successfully run the Operational Check to clear the failure.

Keep in mind the following points about the Operational Check:

• The Operational Check runs the Defib test on battery power to reflect optimal operating conditions

for defibrillation. The device automatically disconnects AC/DC power.

• Perform the Defib Test for each type of patient Therapy cable used on the device (multifunction

defib pads, external or internal paddles). At the conclusion of the Defib Test, you can attach another

Therapy cable and repeat the test.

2

• The message “In Progress” is displayed as each test is run. The test result (pass or fail) is displayed at

the completion of each test. (See Table 4 on page 41 for a full explanation of each test.)

• Use the test results to troubleshoot and repair the device.

• Clear the Status log after all errors have been addressed and the Operational Check passes. See

“Status Log Errors” on page 55 for more information.

To run the Operational Check:

1 Insert a battery charged to at least 20%.

2 Attach a Pads or Paddles therapy cable.

3 Attach an ECG cable.

4 Turn the Therapy Knob to Monitor.

5 Press the Menu Select button.

6 Using the Navigation buttons, select Other and press the Menu Select button.

NOTE You can run Operational Check from the Other menu in Monitor Mode or from the Service Mode

Main menu - the Operational Check is the same in both modes. When you exit the Operational Check

from Service Mode, you are returned to Monitor Mode.

7 Select Operational Check and press the Menu Select button.

8 Select Run Operational Check and press the Menu Select button.

“Leaving Normal Operating Mode. Patient Monitoring is Off. To return to Normal Operating

Mode, press the Exit Softkey.” appears.

9 Press the Menu Select button to acknowledge the message.

10 Carefully read and respond to the Operational Check prompts for each test. Screen prompts are

accompanied by an audio prompt to alert you of a message that should be acknowledged before

proceeding with the rest of the Operational Check.

39

Page 50

3 Troubleshooting Operational Check

When a response is required, use the Navigation buttons to select your answer and the Menu Select

button to confirm your choice. Table 4 shows the tests, in the order in which they are performed,

explains the prompts that may appear, and describes the actions you should take (if any).

NOTE Options that are not on the device do not appear on the screen or printed report.

Figure 17 Operational Check Screen

02 Mar 2003 10:52

Operational Check

Model Number: M3535A

Serial Number: US00108360

Last Operational Check: 01 Mar 2003 9:35 Pass

Display Test: Pass

General System Test: Pass

Audio Test: Pass

Leads ECG Test: Pass/ECG Cable

Pads/Paddles ECG Test: Pass/Pads

Pacer Test: Pass

Defib Test: Pass/External Paddles

Pass/Internal Paddles

Pass/Pads

Battery Compartment A Test: Pass/Cal Recommended

Battery Compartment B Test: Pass

SpO2 Test: In Progress

NBP Test:

CO2 Test:

Printer Test:

In Progress

Exit

Op Check

WARNING Be sure to safely discharge internal and external paddles tested during the Operational Check, as

described in Table 4.

40

Page 51

Operational Check 3 Troubleshooting

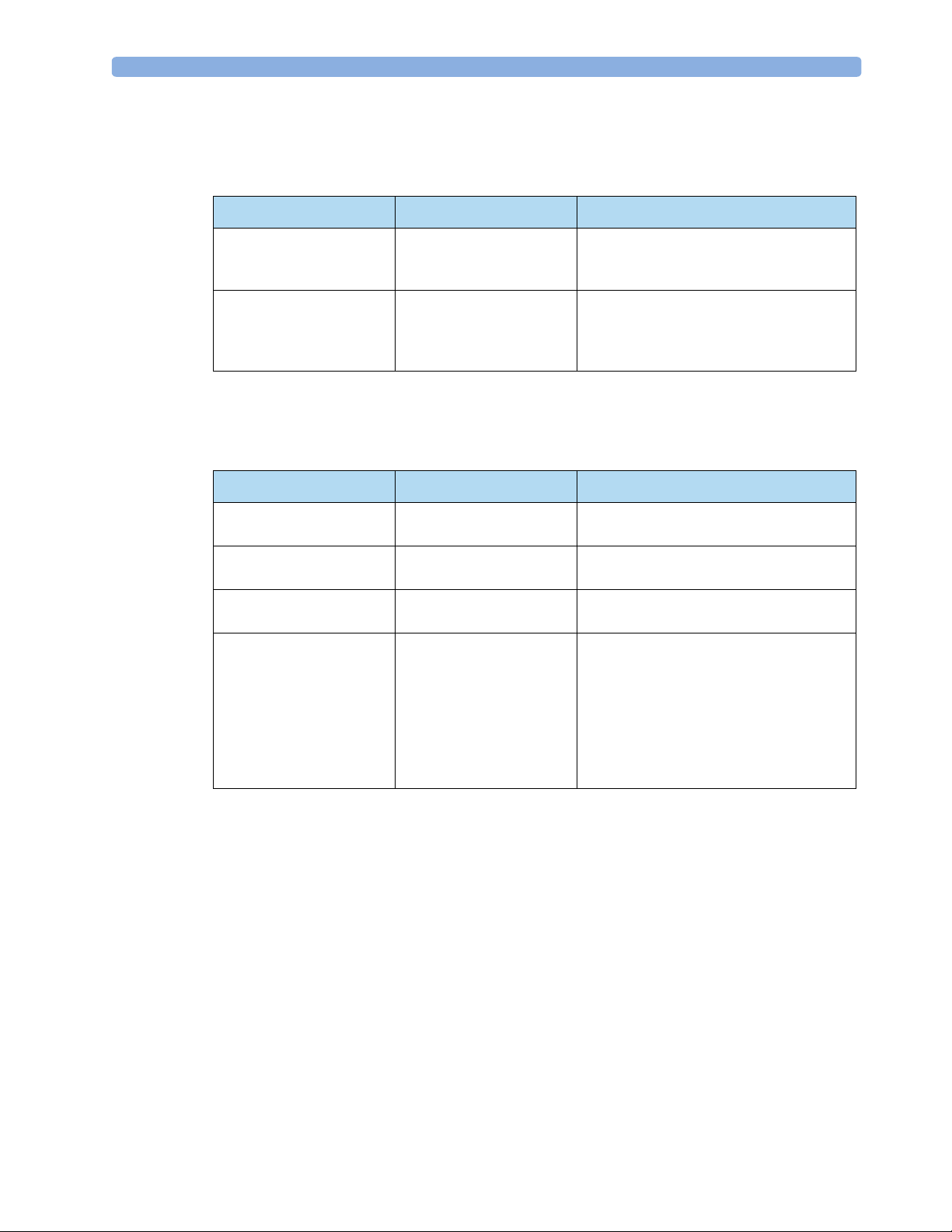

Table 4 Operational Check Tests

Te s t Description Prompts Action

Display A test pattern is displayed; the

display is filled with black, then

white, then red from top to

bottom, then green from left to

right.

General System Tests internal clock battery,

power supply, and internal

memory card.

Audio The voice prompt,

Delivered

Leads ECG Tests leads ECG acquisition

and, if attached, the ECG cable.

The recommended practice is

to run the test with the ECG

cable attached.

Pads/Paddles ECG Checks ECG acquisition

through pad/paddles.

is annunciated.

No Shock

Did you see the test pattern

correctly?

None. None.

Did You Hear, “No Shock

Delivered?”

•

Connect ECG Cable, Cable

Connected

or Test Without

Cable

• Detach Leads, if the ECG

cable is connected to a patient

or the leads are shorted

together.

•

Disconnect ECG Cable, if the

test fails with the cable

connected.

Remove Paddles from Holders

Place Paddles in Holders

Use the navigation buttons to

respond Yes or No. Then press

the Menu Select button.

Use the navigation buttons to

respond Yes or No. Then press

the Menu Select button.

• Connect an ECG cable and

select “Cable Connected” or

“Test Without Cable”.

• Make sure the leads are not

attached to a patient, a

simulator, or touching each

other.

• Disconnect the ECG cable.

Note: If testing paddles, make

sure that they are secured in

their pockets. If the PCI LEDs

light, adjust the paddles in the

pockets. If the LEDs continue to

light, clean the paddle electrode

surfaces.

Remove the paddles from the

holders.

Place the paddles in the holders.

Pacer

(only runs if the option

is present)

Tests pacing functionality and

delivers a paced pulse into a 50

ohm test load.

Connect Pads/Paddles Cable,

Connect Therapy Cable

• Connect Pads Cable, if the

Pads cable is not detected.

• Attach Test Load, if a test load

is not detected.

Attach the Pads or Paddles cable

typically used.

• Connect the Pads cable to the

MRx, if prompted.

• Connect the test load to the

Pads cable, if prompted.

41

Page 52

3 Troubleshooting Operational Check

Table 4 Operational Check Tests (Continued)

Te s t Description Prompts Action

Defib Tests defibrillation circuitry and

delivers a shock through:

• pads, into a test load,

and/or

• external paddles, into the

MRx,

and/or

• internal paddles, into a load.

Depending on the cable

connected, as follows:

• If the Pads cable is attached,

you are prompted to,

Verify

Test Load is Attached and

Press the Charge Button

• If external paddles are

attached, you are prompted to,

.

Verify Paddles are in Holders

and Press the Charge Button

• If internal paddles are

attached, you are prompted to,

Respond to the prompt, as

follows:

• Check the test load is

attached and press the

Charge button.

• Make sure the paddles are

seated in their pockets and

press the Charge button.

.

• Apply the paddles to the load

and press the Charge button.

Apply Paddles to Load and

Press the Charge Button

• If no cable is attached, you are

prompted to,

.

Cable

Once charged the Shock button

lights and you are prompted to,

Connect Therapy

.

• Connect a Therapy cable.

Press the Shock button.

Press Shock or Press Shock

buttons on paddles

After the test completes using one

Therapy cable, you are prompted

to,

Run defib test again with a

different therapy cable? Yes/No

Battery A

Battery B

SpO

2

NBP Checks to see if the NBP

CO

2

Printer Runs a printer self test. None. None.

Checks the capacity and

calibration status of the

batteries in Compartments A

and B.

Checks the internal SpO2 PCA.

The SpO

module is functioning;

determines if it is due for

calibration.

Checks to see if the CO

module is functioning;

determines if it is due for

calibration.

cable is not tested.

2

2

Cal Recommended, if battery

calibration is required.

None. None.

None. None.

None. None.

.

Use the Navigation and Menu

Select buttons to respond.

Change the cable and select

to repeat the test for another

cable. You should repeat the test

for each cable used. Select

once all cables have been tested.

If prompted, calibrate the

battery. See the Instructions for

Use for details.

Yes,

No,

42

Page 53

Operational Check 3 Troubleshooting

Operational Check Report

The Operational Check takes only a short time to complete. When it is done, a report is printed, as

shown in Figure 18. The first part of the report lists test results. The second part lists checks to be

performed by the user.

Figure 18 Operational Check Report

Operational Check Report

Model Number: M3535A

Serial Number: USD00123456

Options: 12-Lead NBP SpO2 EtCO2 Pacer

Ver.: B.03.00

Current Operational Check:

DD Mon YYYY HH:MM:SS

Last Operational Check:

DD Mon YYYY HH: MM:SS: Pass/Fail

Qty/Check List:

___ Defibrillator Inspection ___ CO2 FilterLine

___ Cables/Connectors

___ Paddles/Pads

___ Monitoring Electrodes

___ Charged Batteries

___ AC/DC Power & Cord

___ Printer Paper

___ Data Card

___ SpO2 Sensor

___ NBP Cuffs & Tubing

Current Test Results:

Display Test: Pass

General System Test: Pass

Audio Test: Pass

Leads ECG Test: Pass/ECG Cable

Pads/Paddles ECG Test: Pass/Pads

Pacer Test: Pass

Defib Test: Pass/External Paddles

Battery Compartment A Test: Pass

Battery Compartment B Test: Pass

SpO2 Test: Pass

NBP Test: Pass

CO2 Test: Pass

Printer Test: Pass

Comments:

Inspected by:______________________

Press the [Print] soft key when the Operational Check is complete to print an additional copy of the

report.

43

Page 54

3 Troubleshooting Service Mode Tests

Operational Check Summary

The Operational Check summary lists the results from the last 60 operational checks.

To view the Operational Check summary:

1 Turn the Therapy Knob to Monitor (or Exit Service Mode, if applicable).

2 Press the Menu Select button.

3 Using the Navigation buttons, select Other and press the Menu Select button.

4 Select Operational Check and press the Menu Select button.

5 Select Op Check Summary and press the Menu Select button.

The message “Leaving Normal Operating Mode. Patient Monitoring is Off. To return to Normal

Operating Mode, press the Exit Softkey.” appears. The Operational Check Summary screen is

displayed.

6 Press the [Print] soft key to print the report.

Service Mode Tests

These tests include manual interaction on tests such as the display and controls. These tests help you to

isolate any problems with the device. See “Service Mode Tests” on page 192 for more information on

Service Mode tests.

44

Page 55

Troubleshooting Methodology 3 Troubleshooting

Troubleshooting Methodology

We recommend using the methodology described on the following pages to isolate and repair problems

with the HeartStart MRx.

1. Decontaminate the device using local decontamination procedures.

Refer to the Instructions for Use.

2. Check the Ready for Use (RFU) indicator.

See “Ready For Use Indicator” on page 35.

3. Perform a visual inspection.

Thoroughly examine the device and its cables and accessories. Refer to “Visual Inspection” on

page 191.

If no further troubleshooting is needed, proceed to Step 13 to repair the device. Otherwise,

continue with Step 4.

4. Turn on the device.

Failures and messages appear on the display when you turn on the monitor/defibrillator.

Continue with Step 5.

5. Check the status log.

The Status log includes entries for all errors logged during normal operating mode, Automated

tests, Service Mode tests, and Operational Checks. The error indicates the most likely module or

PCA that failed. (See "Status Log Errors" on page 55 for more information.)

Continue with Step 6.

6. Run the Operational Check.

The Operational Check tests the functionality of all PCAs and modules present on the device. For

example, if the HeartStart MRx is equipped with the Noninvasive Blood Pressure measurement,

the Operational Check performs a self-test on that module, and includes the results both on the

screen and on the printed report. The Operational Check results indicate the area of the device that

is experiencing problems. Use this information to troubleshoot and repair the device. See

“Operational Check” on page 39 for detailed instructions.

Continue with Step 7.

7. Check the Status log and the Automated Test summary.

Any errors that occur during the Operational Check are written to the Status log. Use these

messages to isolate the problem. The Automated Test summary lists the results of past hourly, daily,

and weekly tests and provides you with information on the device’s history.

If no further troubleshooting is needed, proceed to Step 13 to repair the device. Otherwise,

continue with Step 8.

45

Page 56

3 Troubleshooting Troubleshooting Methodology

8. Use the Troubleshooting tables to identify the problem.

Use the Troubleshooting tables to find information on messages and common troubleshooting

issues.

If no further troubleshooting is needed, proceed to Step 13 to repair the device. Otherwise,

continue with Step 9.

9. Interview the user. Gather the external components.

If possible, talk directly with the user who reported the problem. Identify what they were doing

when the problem occurred, and exactly what happened. What was on the display? Were any

sounds noticed? Were there operational problems?