Philips HD7870/81, HD7870/62, HD7870/60, HD7870/61, HD7870/10 Service Manual

...

Senseo Twist

HD7870/80

HD7870/81

Philips Consumer Lifestyle

Service Manual

PRODUCT INFORMATION

• This product meets the requirements regarding

interference suppression on radio and TV.

• After the product has been repaired, it should function

properly and has to meet the safety requirements as

officially laid down at this moment.

TECHNICAL INFORMATION

• Voltage : 220 - 240 V

• Frequency : 50 Hz

• Power consumption : 1450 W

• Standby power : 0.25 W

• Color setting : Chinese Fire

• Weight : 2,05 Kg

• Dimensions H x W x D

- Appliance : 31,5 x 24,9 x 30,8 cm

- F-Box : 36 x 29 x 29,5 cm

• Length of cord : 80 cm

• Contents water reservoir : 930 cc (ml)

ACCESSORIES

• CRP475/01 1-cup pod holder Black

• HD5015/01 2-cup pod holder Black

• CRP862/01 Drip tray cover Black

• CRP872/01 Collector

• CRP864/01 Water container small

• CRP869/01 Water container lid Deep Black

OPTIONAL (accessories)

• CRP865/01 Water container big (incl. bucket, optional

Britta Filter to be purchased separately)

• CRP866/01 Water container lid

(for Water container big)

Published by Philips Consumer Lifestyle Printed in the Netherlands © Copyright reserved Subject to modification

13/02

TECHNICAL INFORMATION

Volume adjustment

The PCB circuit board makes it possible to adjust the

volume output by means of pushing the one-cup and twocup user controls. How to adjust the volume output:

1. Make sure the boiler is lled properly, otherwise

perform ll procedure see DFU for instructions.

2. Switch appliance on and wait until the unit is ready to

brew.

3. Make sure a pod holder is placed, but without a Coffee

POD. (Only adjusting with plain water)

4. Place a cup on the drip tray cover and push the onecup button.

5. When the appliance has nished it is stabilized to

perform the volume adjustment.

6. Empty the cup, pod holder and push again for one cup

setting, measure the volume output with a graduated

beaker. In the table you can nd the requirements for

the minimum / maximum volume output cc/mL values

depending from the country version: (see Technical

speci cations)

7. Unplug the appliance from the mains.

8. Press the 1- and 2 cup button simultaneously and plug

the mains on.

9. When above step succeeded the LED will turn on

continuously.

10. Depending if the volume has to de- or increase you

have to push the one- or two cup button. Every time

you push the 1- or 2 cup button the LED will turn

off for 0.5 second (feedback to user) and the pump

time will be shortened or lengthened for 0.5 seconds

depending which button was pushed.

Pushing 1 cup button pump, time will be shorten

with 0.5 sec is approximately − 3.5 cc/mL (less coffee).

Pushing 2 cup button pump, time will be lengthen

with 0.5 sec is approximately + 3.5 cc/mL (more

coffee).

When the volume has to increase with 10 cc for

example, push the 2 cup button 3 times. The new value

will be stored when you switch the appliance off by

pushing the main switch (LED will turn off).

11. Turn appliance on again and brew one cup, measure the

volume. In case the volume is not within speci cation

repeat steps 6 - 11.

HD7870/80 / HD7870/81

Note:

Changing a newly installed PCBA (by default delivered with

General version settings) into a French or Spanish setting

requires a decrease of the pump time by 2,5 seconds

(or ve pushes of the 1-cup button).

2-12

SCHEMATICS

HD7870/80 / HD7870/81

UI PCBA

On/Off button

1-cup button

2-cup button

Toggle button

On/Off LED

1-cup LED

2-cup LED

Toggle LED

Regular LED

Strong LED

Memory LED

Descale LED

Buzzer

Water level

sensor

Communi

cation

L

N

DISASSEMBLY- AND RE-ASSEMBLY ADVISE

Before you start dismantling! For your

!

safety be sure the plug is disconnected from

the mains! The product is designed for easy

access to the internal components. Make sure

that all accessories like tank, pod holder, drip

tray, spout and collector have been removed.

Pump

NTC

Water

Supply

System

TCO

Boiler

PCBA

Fuse

M

Fuse

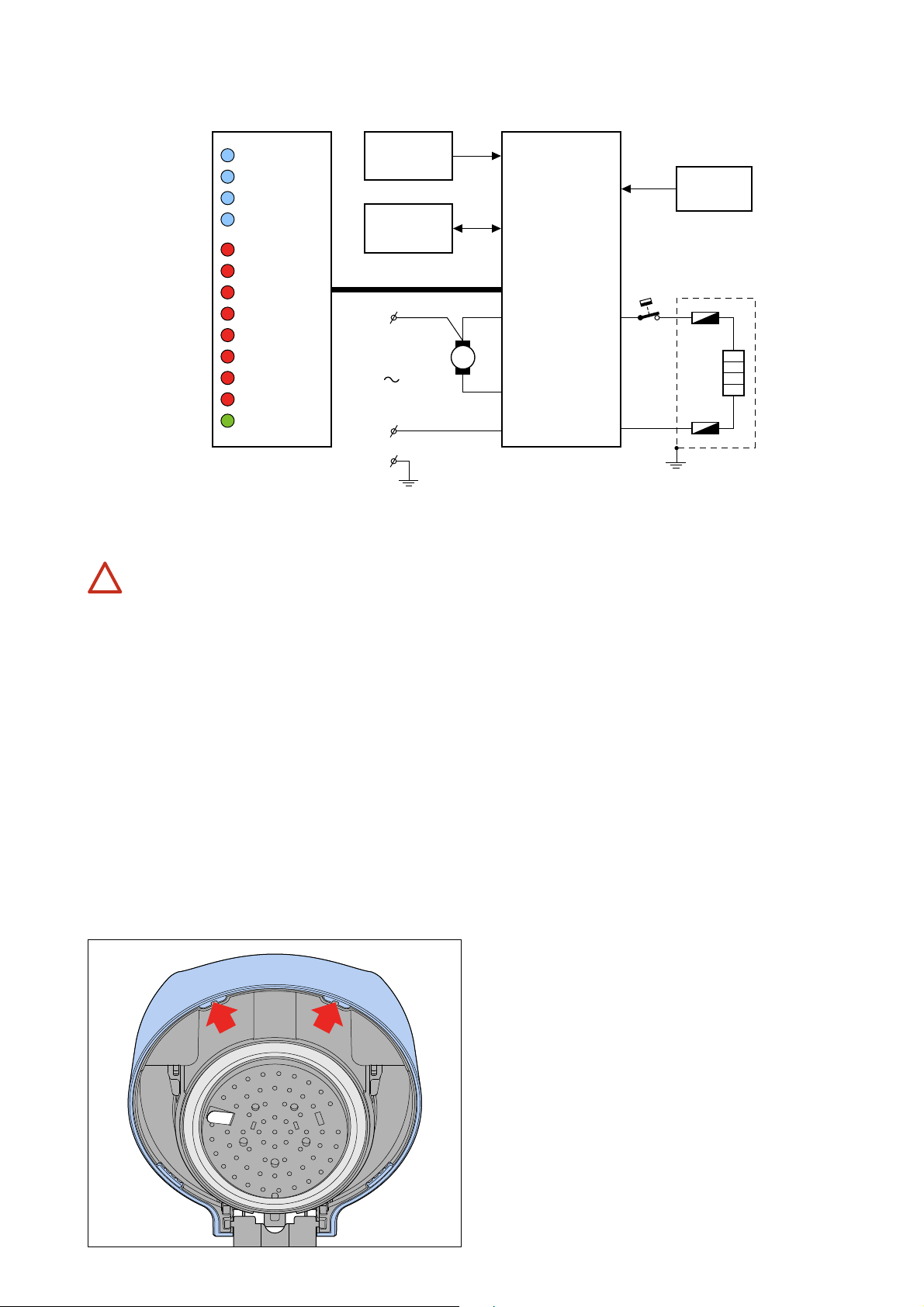

Caution, the hinge spring on the back side of the appliance may

come out when the brewhead lid cover is being removed.

When reinstalling it, mind your ngers as this is a strong spring.

To remove the boiler (24):

Caution the boiler may still be hot!

To remove the back cover (31):

Place the appliance facing its backside. Using a small

screwdriver remove screw cover (28) and unscrew both

screws A. You can now remove the back cover from the

appliance, please be aware that the Water level sensor (32)

is still attached to the back cover.

To remove the brewhead lid cover:

Place a screwdriver on the positions (see picture) and

work your way to the bottm. Please be aware that due

to the construction of the brewhead, the space inside is

limited. There is a chance Hose (a) will come off the pillar

when opening the brewhead (22).

• Remove the back cover.

• Disconnect the Hose (a) to the brewhead.

• Unhook the 3-way valve (27) from its seat on the

bottom of the brewhead.

• Unhook the boiler from the snap hook on the bottom of

the brewhead.

• Disconnect the following leads:

- (x) Boiler +

- (y) Boiler –

- (w) Earth

• Remove Hose (b) from the bottom side of the boiler.

The boiler will not drain as long as the 3-way valve is still

connected to the top. You can now safely remove the

boiler from the appliance.

Note:

Please note, after replacing the boiler the appliance has to be

restored to factory default. The lling procedure (cold ush),

known from the predecessor Senseo’s is no longer available

after the ush before rst use has been executed. When

the “restore to factory default” procedure is not carried out,

a new and empty boiler can be switched on, without having

the protection of the initial ush procedure, causing the

thermal fuses in the heating element to fail. After a boiler

replacement or drained system, carry out the “Boiler reset”

procedure! Then the initial ush procedure can be carried out.

3-12

DISASSEMBLY- AND RE-ASSEMBLY ADVISE

HD7870/80 / HD7870/81

To remove the brewhead assembly:

• Remove the back cover.

• Remove the boiler, or simply lay it aside.

• Use both thumbs to push the brewhead upwards; you

may need to tilt the brewhead forward to remove it

from the appliance.

To remove the PCB assembly (34):

• Remove the back cover

• Remove the boiler

• Remove the brewhead assembly

• Remove the Main PCBA cover (33)

• Disconnect the following leads:

- NTC ( at cable)

- Water level sensor ( at cable)

- (z) UI PCBA ( at cable)

- (s) Live

- (t) Pump

- (u) Neutral

- (v) Earth

• You can now unhook the snap hooks holding the PCBA

in place.

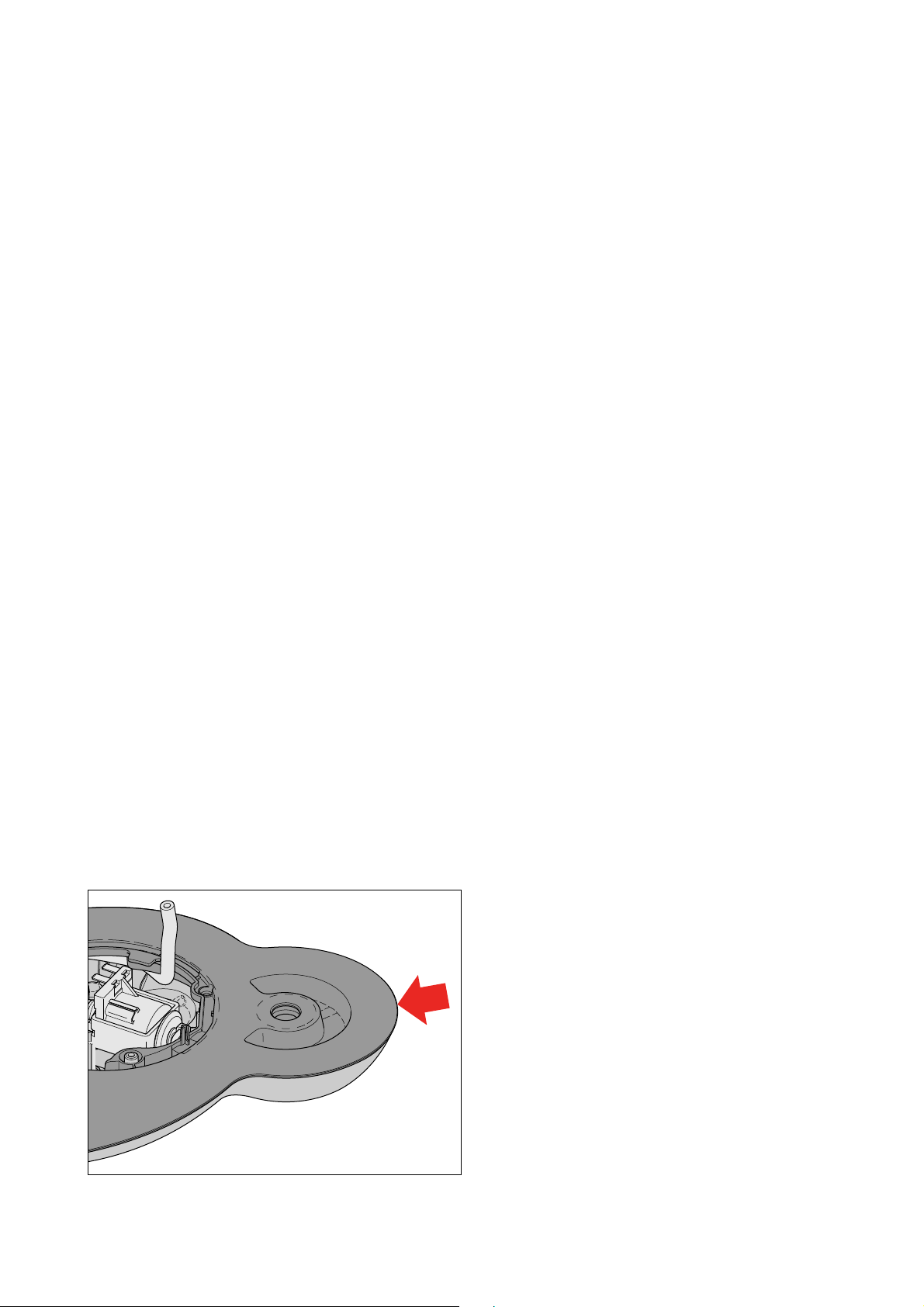

To access components located in the base of

the appliance (UI Panel, Pump, Water container

interface)

Open the Base:

• Remove the back cover

• Remove the boiler

• Remove the brewhead assembly

• Remove the Main PCBA cover (33)

• Remove the PCB assembly

• Unscrew the two screws (B) holding the Front housing

(23) in place. Remove the front housing

• Take the base of the appliance, using a small screw driver

start at the point indicated in the picture. Gently push

it between the tray panel assembly (36) and base plate

(41), the hidden snap should click open.

• Now use the screwdriver to trace around the edge of

the tray panel assembly and base plate until you reach

the position of the drip tray. Repeat the process for the

other side. All snap hooks will come undone.

Please note that the water container interface is still

connected to the tray panel assembly and to the pump on the

base plate

To access the capacitive UI PCBA:

• Remove the back cover

• Remove the boiler

• Remove the brewhead assembly

• Remove the Main PCBA cover (33)

• Remove the PCB assembly

• Unscrew the two screws (B) holding the Front housing

(23) in place. Remove the front housing

• Open the Base

• Turn the Tray panel assembly upside down and open the

clicks of the UI PCBA Cover

• Here you will find:

- UI PCBA (38)

- UI Panel frame

- Light distributor

Descaling

Descaling is an important element in Senseo maintenance.

It should be done at least once every 3 months, up to

6times a Year! This will prolong the life of your appliance

and will guarantee optimal brewing results for a long time.

Use the correct descaling agent. Only citric acid-based

descalers are suitable for descaling the SENSEO

This type of descaler descales the appliance without

damaging it. For the correct amount, see the instructions

in the packaging of the descaler.

We advise you to use the special SENSEO® Descaler

(HD7011 or HD7012). Read the instructions on the

package of the descaling agent. Never use a descaling agent

based on mineral acids such as sulphuric acid, hydrochloric

acid, sulphamic acid and acetic acid (e.g. vinegar). These

descaling agents may damage your SENSEO® coffee

machine. Follow the steps in the section headed “Descale

the appliance” see DFU (Direction for Use manual).

®

machine.

• Undo the two click connections visible on the bottom

side of the appliance.

4-12

Loading...

Loading...