Philips FWM372, FWM572 Diagram

Service

Service

Mini System

Service

Service

Service

FWM372/all versions

FWM572/all versions

Service Manual

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by SL0612 Service Audio Printed in The Netherlands Subject to modification.

Version 1.1

TABLE OF CONTENTS

Page

Location of PC Boards................................................1-2

Versions Variation & Package .................................... 1-2

Specifications..............................................................1-3

Measurement Setup ................................................... 1-4

Service Aids, Safety Instruction, etc................ 1-5 to 1-7

Preparations & Controls ................................ 1-8 to 1-10

Maintenance & Troubleshooting............................... 1-11

Setting Procedure & Repair Instructions ....................... 2

Disassembly Instructions & Service positions .............. 3

Block Diagram ............................................................... 4

Wiring Diagram .............................................................. 5

Front Board & Key Board .............................................. 6

ECO6 Tuner Board : Systems Non-Cenelec.............. 7A

Systems Cenelec...................... 7B

ETF7 Tape Board ........................................................... 8

Mains Board ................................................................... 9

Power Board ................................................................ 11

AF9 Board .................................................................... 12

Mechanical Exploded View & Parts List ...................... 13

Revision List ................................................................ 14

CLASS 1

LASER PRODUCT

GB

3141 785 30861

SERVICE TEST PROGRAM

3-1

To star t service test program

6

& AUX

hold

depressed while

plugging in the mains cord

3-1

TUNER

TEST

TUNER

Button pressed?

Y

Display Tuner Version

"ccc"

N

copied to the RAM (see Table1)

N

PRESET

10

11

TUNER

Button pressed?

Y

Service frequencies are

Tuner works nor mally

except:

PROGRAM button

Disconnect

Mains cord ?

Y

Service Mode left

Europe

"EUR"

87.5MHz

1

108MHz

2

531kHz

3

1602kHz

4

558kHz

5

1494kHz

6

153kHz

7

279kHz

8

198kHz

9

98MHz

87.5MHz

N

East Eur. Extended-band

"EAS"

65.81MHz

108MHz

74MHz

87.5MHz

531kHz

1602kHz

558kHz

1494kHz

98MHz

70.01MHz

65.81MHz

Table 1

STANDBY-ON

Button pressed?

Set is in Service PLAY Mode.

In case of failures, error

codes according to table 2

will be displayed.

The Service Play Mode is intended to

detect and identify the failures in the CD Mode.

In this mode the electronics will still function

even when an error is detected so that

repair activities can be carried out.

East Eur.

"EAS"

87.5MHz

87.5MHz

108MHz

531kHz

1602kHz

1700kHz

558kHz

1494kHz

1500kHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

98MHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

USA

"USA"

108MHz

530kHz

560kHz

98MHz

SERVICE

PLAY MODE

Y

Oversea

"OSE"

87.5MHz

108MHz

530/531kHz*

1700/1602kHz*

560/558kHz*

1500/1494kHz*

98/87.5MHz*

87.5MHz

87.5MHz

87.5MHz

87.5/98MHz*

Note: * Depending on the selected grid frequency (9 or 10kHz)

R

By holding the TUNER and

buttons depressed while switching on the Mains supply, one

of the undermentioned features will be activated:

- the tuning grid frequency is toggled between 9kHz and 10kHz for the Oversea (/21) version.

- the extended FM1 (65.81MHz - 74MHz) is toggled on and off for East Eur. (/34) version.

Display shows the

R

OM version *

"S-Vyy"

(Main menu)

N

Error code

E1000

E1001

S refers to Service Mode.

V refers to Version.

yy refers to Software version number of µProcessor.

(Counting up from 01 to 99)

Figure 1

Figure 2

Error Description

Focus Error

Triggered when the focus could not be found within a certain time when starting up the CD

or when the focus is lost for a certain time during play.

Radial Error

Triggered when the radial servo is off-track for a certain time during play.

DISPLAY

TEST

2;

Button pressed?

Y

Display shows all LEDs on

except ECO POWER.

(see Figure 1)

2;

Button pressed?

Y

Display shows

selected LEDs on

(see Figure 2)

9

Button pressed?

Y

ADC

TEST

N

Display shows "ADC1 Value"

N

Display shows "ADC2 Value"

N

Display shows "ADC3 Value"

AUX

Button pressed?

Y

for ADC1

(Input Line - IoSA2)

AUX

Button pressed?

Y

for ADC2

(Input Line - IoSA1)

AUX

Button pressed?

Y

for ADC3

(Input Line - IoAmNTC)

N

N

N

Sledge In Error

E1002

The sledge did not reach its inner position (inner-switch is still close) before approximately

6 Sec. have passed by. Inner-switch or sledge motor problem.

9

Button pressed?

N

Sledge Out Error

E1003

E1005

E1006

E1007

E1008

E1020

E1070

E1071

E1079

The sledge did not come out of its inner position (inner-switch is still open) before approximately

250 mSec. have passed by. Inner-switch or sledge motor problem.

Jump-offtrack error

Triggered in normal play when the jump destination could not be found within a certain time.

When this error occurred, software will try to recover by initiating the jump command again.

If it is recoverable, the disc will continue to play.

Subcode Error

Triggered when a new subcode was missing for a certain time during play.

PLL Error

The Phase Lock Loop could not lock within a certain time.

Turntable Motor Error

Generated when the CD could not reached 75% of speed during startup within a certain time.

Discmotor problem.

Focus Search Error

The focus point has not been found within a certain time.

This happens when the carousel switch is defective and closed all the time, or when the

carousel is blocked when it is located exactly at a disc position.

This happens when the carousel switch is defective and does not closed electrically, or when

the carousel is blocked in between two disc positions. The time-out is approximately 5 Sec.

The drawer could not open or enter the inside position and is opening again. This happen when

the drawer is blocked and cannot go fully inside or when the drawer switch is defective and does

not close.

Table 2

Y

ADC Test is used for checking the

TEST

ADC inputs to the microprocessor.

The display shows an ADC value

between 0 and 255 for an input

signal between 0 and 5V.

Activated with

ET M

TS

ORPEE

6

ACTION

set A

p t

tt

i

a

w nr

e

ll

Various

other Tests

t

eb

ne

o

s

EE

t

eh

t

"PASS" is displayed if the uProcessor read

back the test pattern correctly, otherwise

9

to Exit

EEPROM FORMAT Load default data. Display shows "NEW"

5

"FAIL" will be displayed.

for 1 second.

Caution!

All presets from the customer will be lost!!

ROTARY

ENCODER TEST

LEAVE SERVICE

TESTPROGRAM

Volume Knob

or

Jog Shuttle knob

Disconnect

mains cord

Display shows value for 2 seconds.

Values increases or decreases in steps of 1

until 0 (Min.) or 40 (Max.) is reached.

MORP

.

SET BLOCK DIAGRAM - FWM372

4-1

4-1

SET BLOCK DIAGRAM - FWM572

4-2

4-2

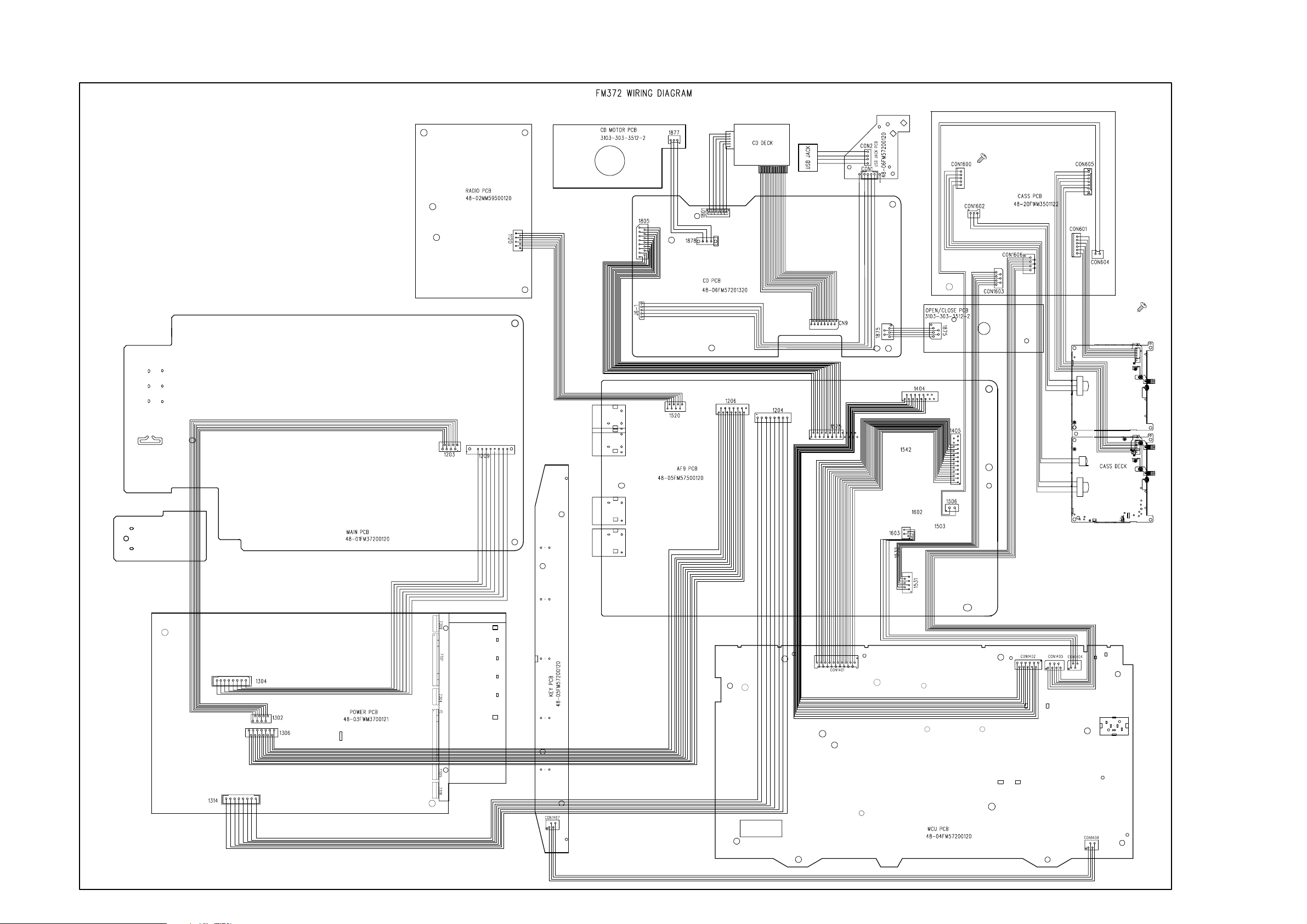

SET WIRING DIAGRAM - FWM372

5-1

5-1

SET WIRING DIAGRAM - FWM572

5-2

5-2

6-4

CIRCUIT DIAGRAM - FRONT & KEY BOARD

6-4

Loading...

Loading...