Philips DVP-9000-S Service manual

Service Manual

Service

Service

DVD Player

Service

Service

Service

DVP9000S/00/69

©

Copyright 2004 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by BB0441 Service AV Systems Printed in The Netherlands Subject to modification

Version 1.0

TABLE OF CONTENTS

Page

Location of pc boards & Version variations................1-2

Technical Specifications ............................................. 1-3

Measurement setup ....................................................1-4

Service Aids, Safety Instruction, etc. .........................1-5

Disassembly Instructions & Service positions .............. 2

Diagnostic Software....................................................3-1

Software version & upgrade .................................... 3-13

Set Wiring diagram .....................................................4-1

PSCAN HDMI Board ..................................................... 5

Front Board .................................................................... 6

AV Board........................................................................ 7

Module SD5.2 (S) XSA 4FL DV HDMI .......................... 8

Set Mechanical Exploded view & parts list ................... 9

PSU Board (For Information only) ............................... 10

CLASS 1

LASER PRODUCT

GB

3139 785 30880

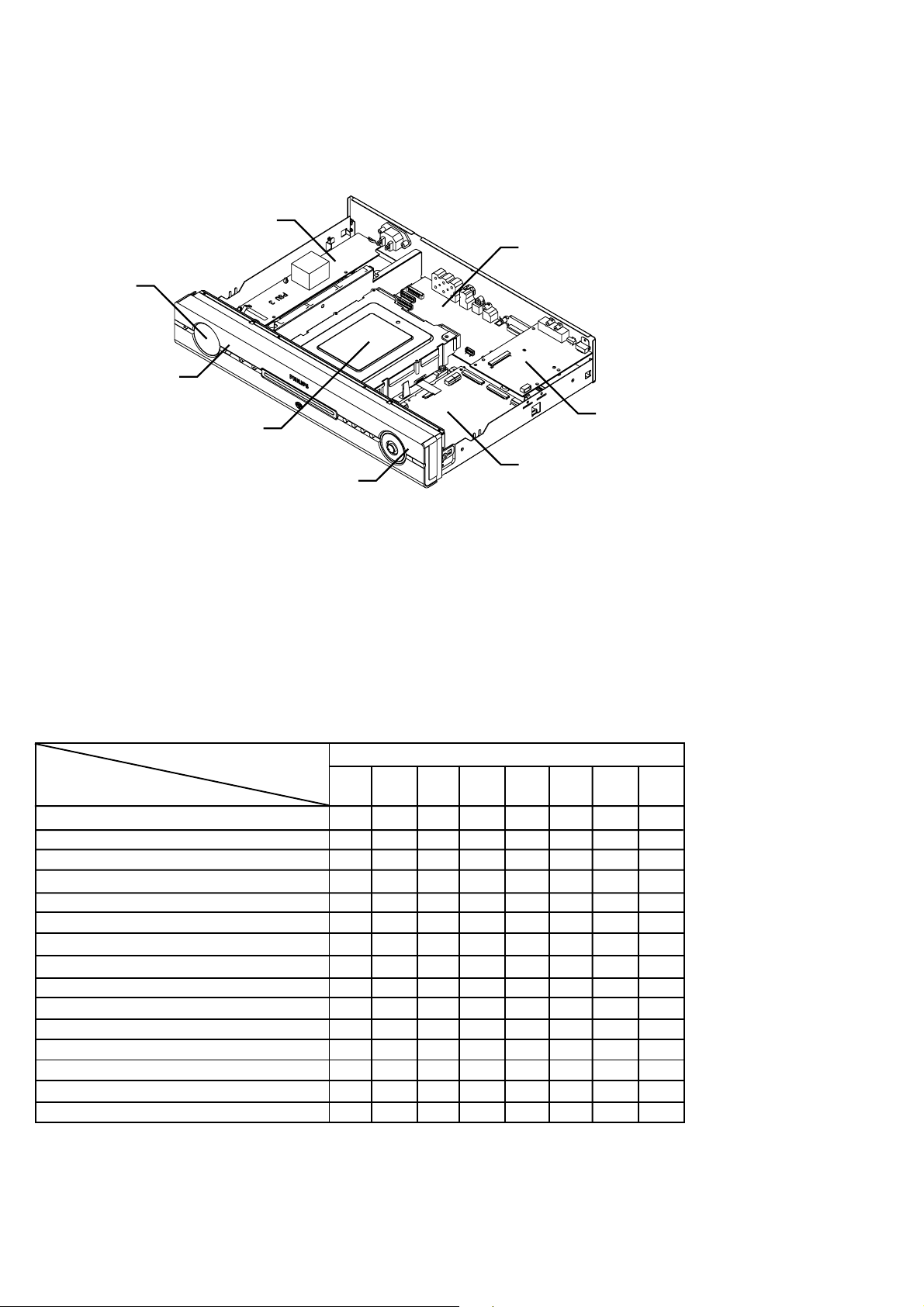

LOCATION OF PC BOARDS

PSU Board

LCM Module

Front Left Board

1-2

AV Board

DVD Loader

Front Right Board

VERSION VARIATIONS:

Type /Versions: DVP9000S

Features &

Board in used:

Aux-In

Digital In

TV-In

Audio Out (2 Channel/6 Channel) x x

Digital Out (Coaxial/Optical) x x

Video Out (Video/S-Video) x x

SCART x

Y/Pb/Pr (YUV) Component Video Output x x

Progressive Scan x x

Voltage Selector

HDMI x x

/00 /69

PScan HDMI Board

SD5.2 (S) XSA 4FL DV HDMI Board

SPECIFICATIONS

1-3

GENERAL:

Mains voltage : 220-240V for /00

110-127V/220-240V for /69

Mains frequency : 50/60Hz

Power consumption : 25W

< 1W at Standby

Dimension centre unit : 435 x 79 x 315mm

AUDIO PERFORMANCE:

Output Voltage : 2.0Vrms

Channel Unbalance (1kHz) : < 0.5dB

Crosstalk (1kHz) : 115dB

Crosstalk (20Hz-20kHz) : 100dB

Freq. Response (20Hz-20kHz) : < 0.2dB

THD (1kHz) : 95dB

THD (20Hz-20kHz) : 90dB

AUDIO FORMAT:

MPEG : Compressed Digital

Dolby Digital : 16, 20, 24 bits

PCM : fs, 44.1, 48, 96 kHz

MP3 (ISO 9660) : 96, 112, 128, 256 kbps & variable

bit rate fs, 32, 44.1, 48 kHz

VIDEO PERFORMANCE:

Video Output

S-Video Output

Component Video Output

1)

Output terminals to be terminated with 75Ω

1)

: 1.0V

1)

Y : 1.0V

C : 0.3V

Y : 1.0V

PbPr : 0.7V

p-p

p-p

p-p

1)

p-p

p-p

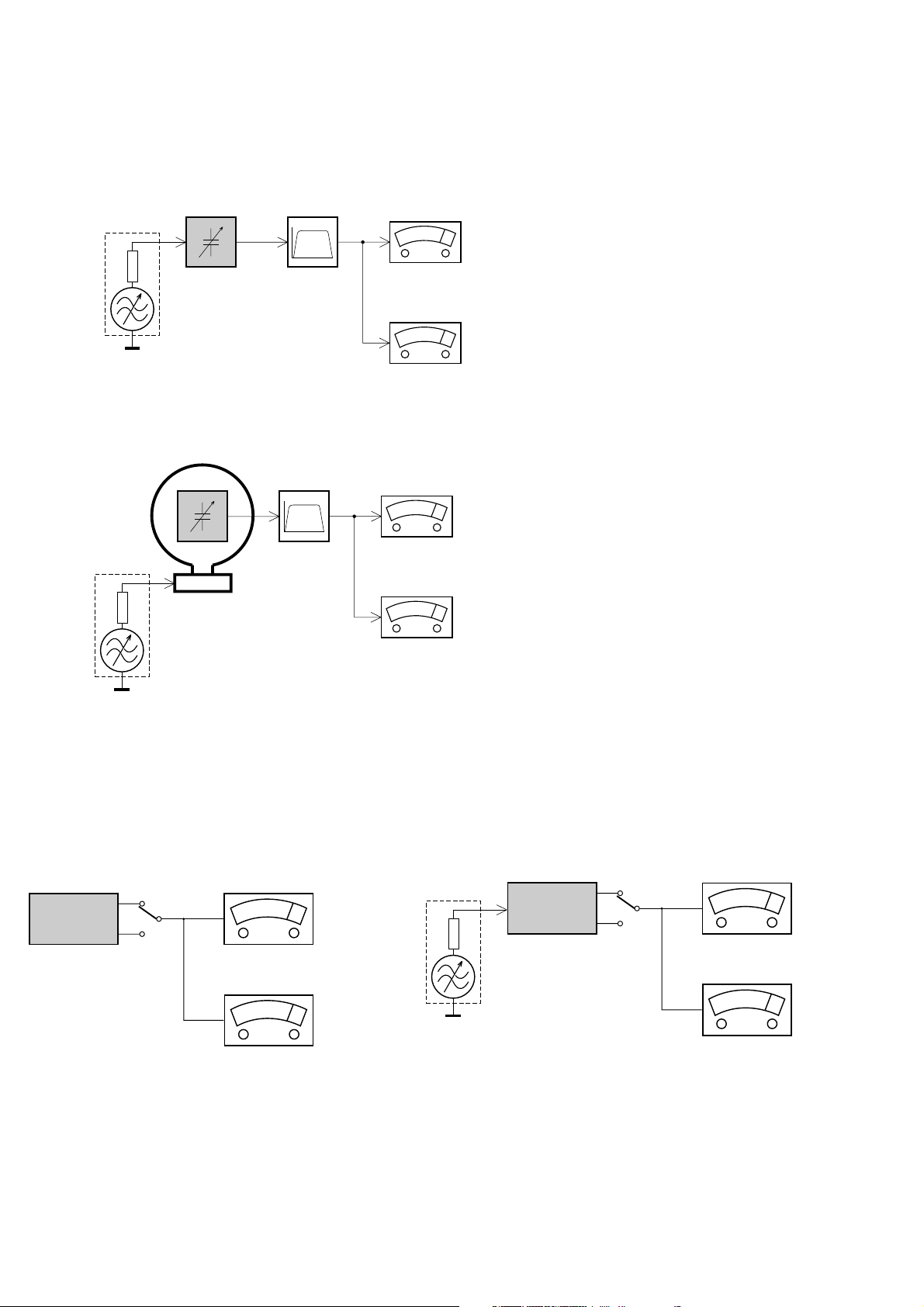

MEASUREMENT SETUP

Tuner FM

1-4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50Ω

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50Ω

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

L

R

SBC429 4822 397 30184

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette

LF Generator

e.g. PM5110

Fe SBC420 4822 397 30071

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................. 4822 395 91019

Torx bit T10 150mm ............................................. 4822 395 50456

Torx driver set T6 - T20 ......................................... 4822 395 50145

Torx driver T10 extended ...................................... 4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ............................ 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz ................. 4822 397 30155

SBC429 Audio Signals disc .................................. 4822 397 30184

Dolby Pro-logic Test Disc ...................................... 4822 395 10216

1-5

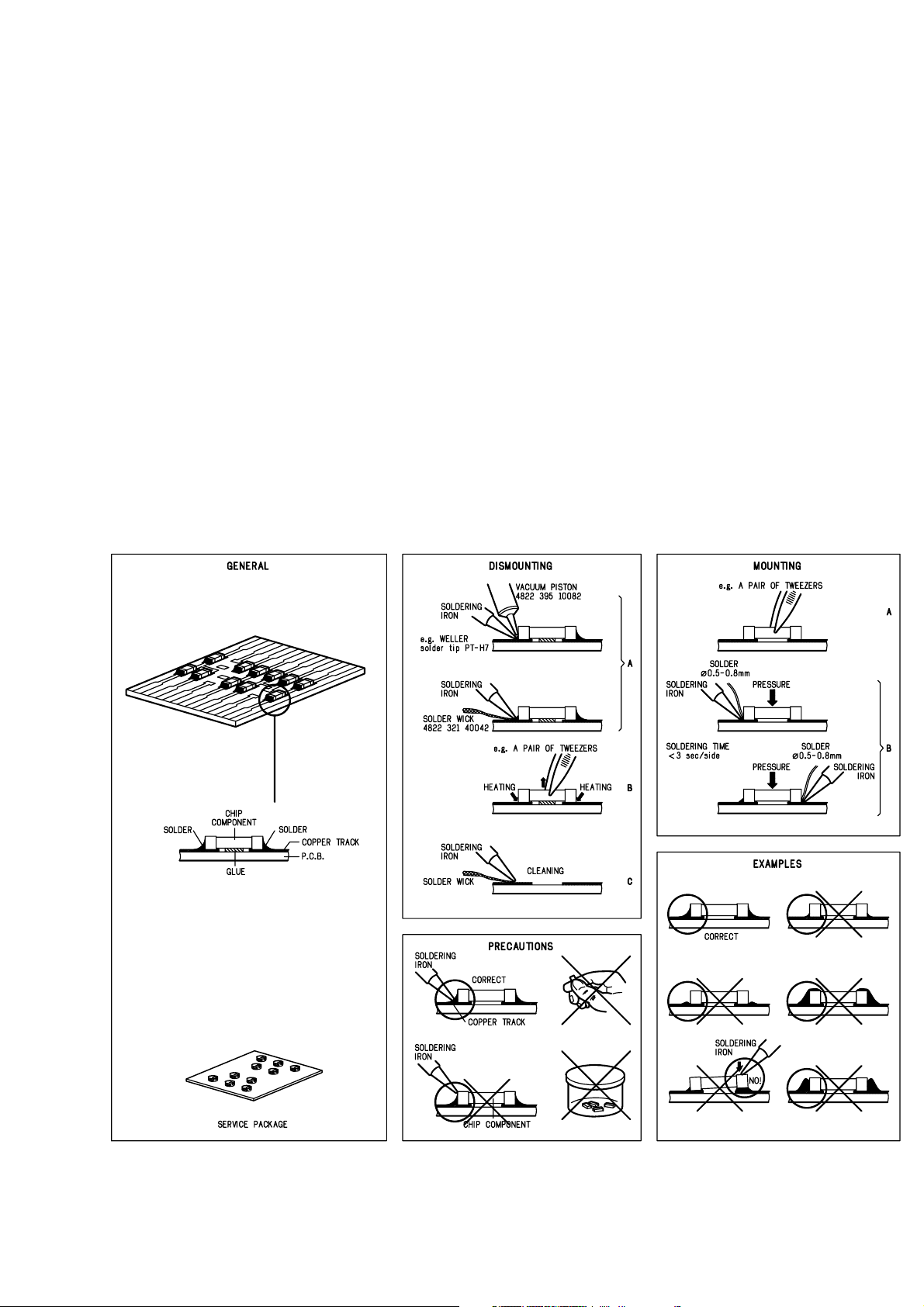

HANDLING CHIP COMPONENTS

1-6

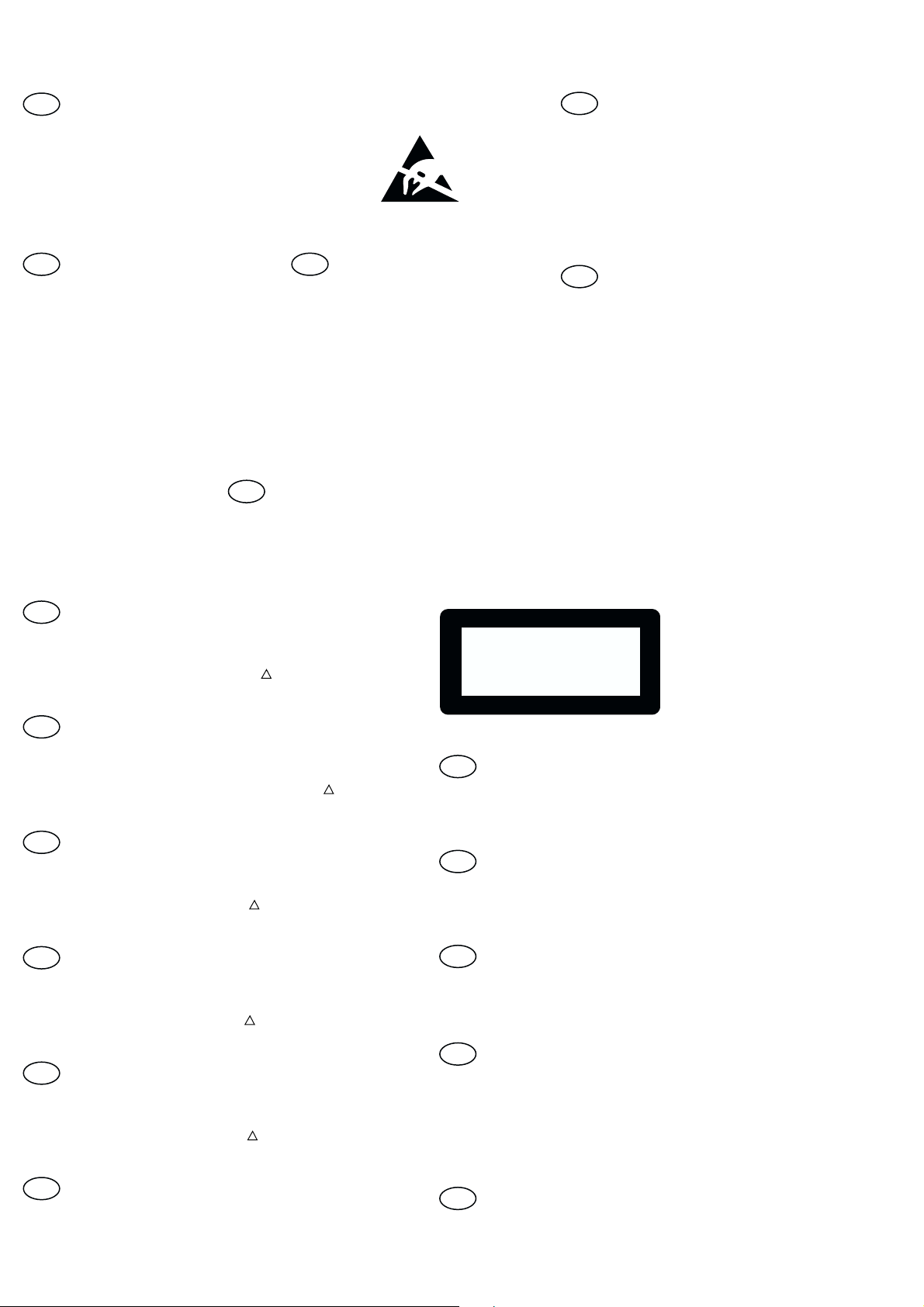

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

F

WARNING

ATTENTION

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, extention cable and earth cable) ...........4822 310 10671

Wristband tester ....................................................................4822 344 13999

ESD

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT:

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

WAARSCHUWING

I

AVVERTIMENTO

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

Safety components are marked by the symbol

!

.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

!

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

CLASS 1

LASER PRODUCT

GB

Invisible laser radiation when open.

Avoid direct exposure to beam.

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

S

Warning !

Varning !

Varoitus !

Advarse !

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground to

assure no shock hazard exist. The leakage current must not exceed

0.5mA.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

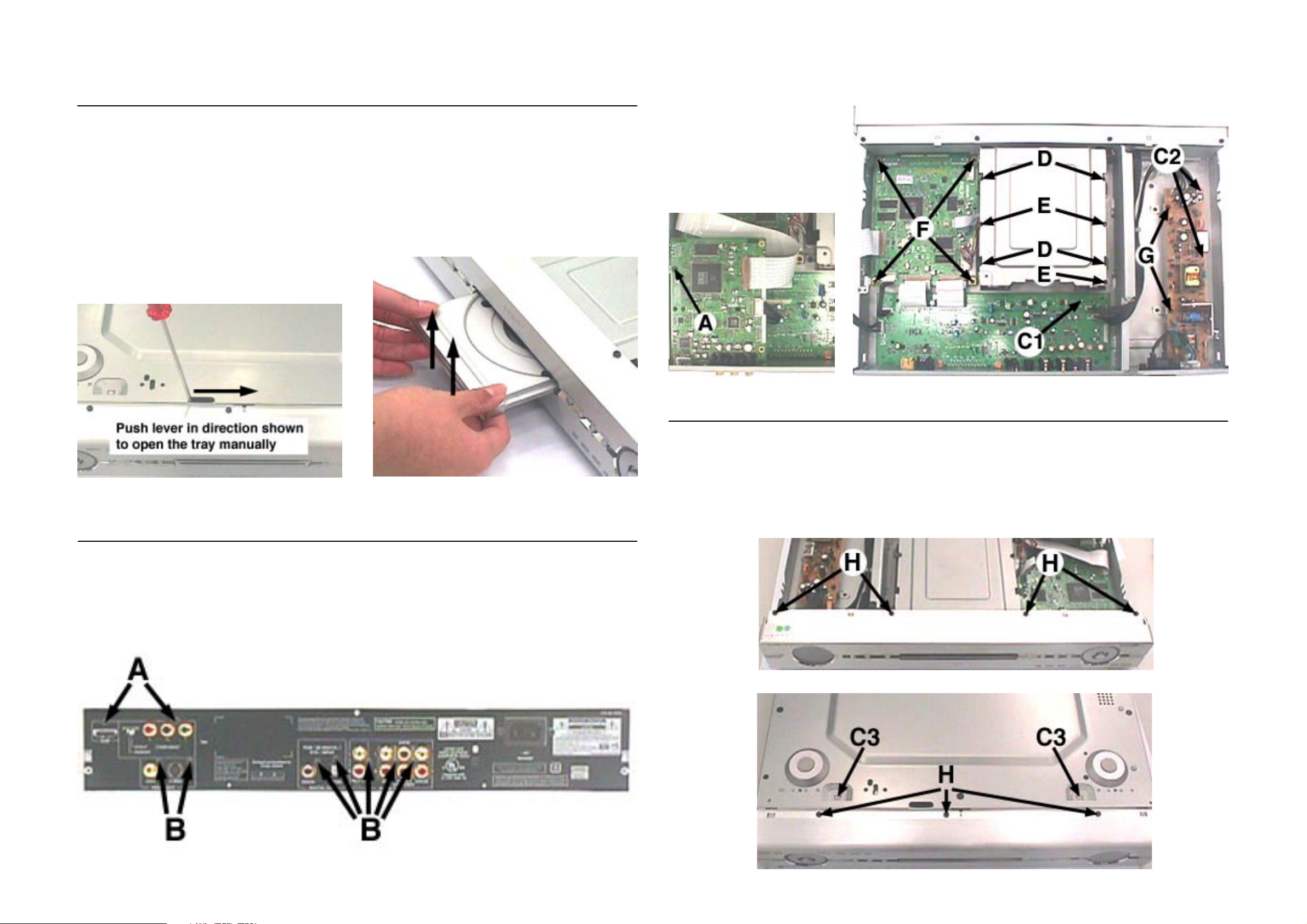

DISMANTLING INSTRUCTIONS

Dismantling of the DVD Loader

2-1 2-1

Figure 5

1) The tray can be manually open by inserting a screw

driver and push the lever in the direction as shown in

Figure 1 to unlock the tray before sliding it out.

2) Slide out the tray and remove the Cover Tray assembly

(pos 113 + pos 115 + pos 117) as shown in Figure 2.

3) Loosen 7 screws to remove the Cover Top (pos 197).

- 2 screw each on the left & right side

- 3 screws on the rear

4) Loosen 4 screws D (see Figure 5) to remove the DVD

Loader (pos 1003-0001).

5) Loosen 3 screws E (see Figure 5) to remove the Plate

Shield (pos 191) from the DVD Loader.

Figure 2Figure 1

Figure 4

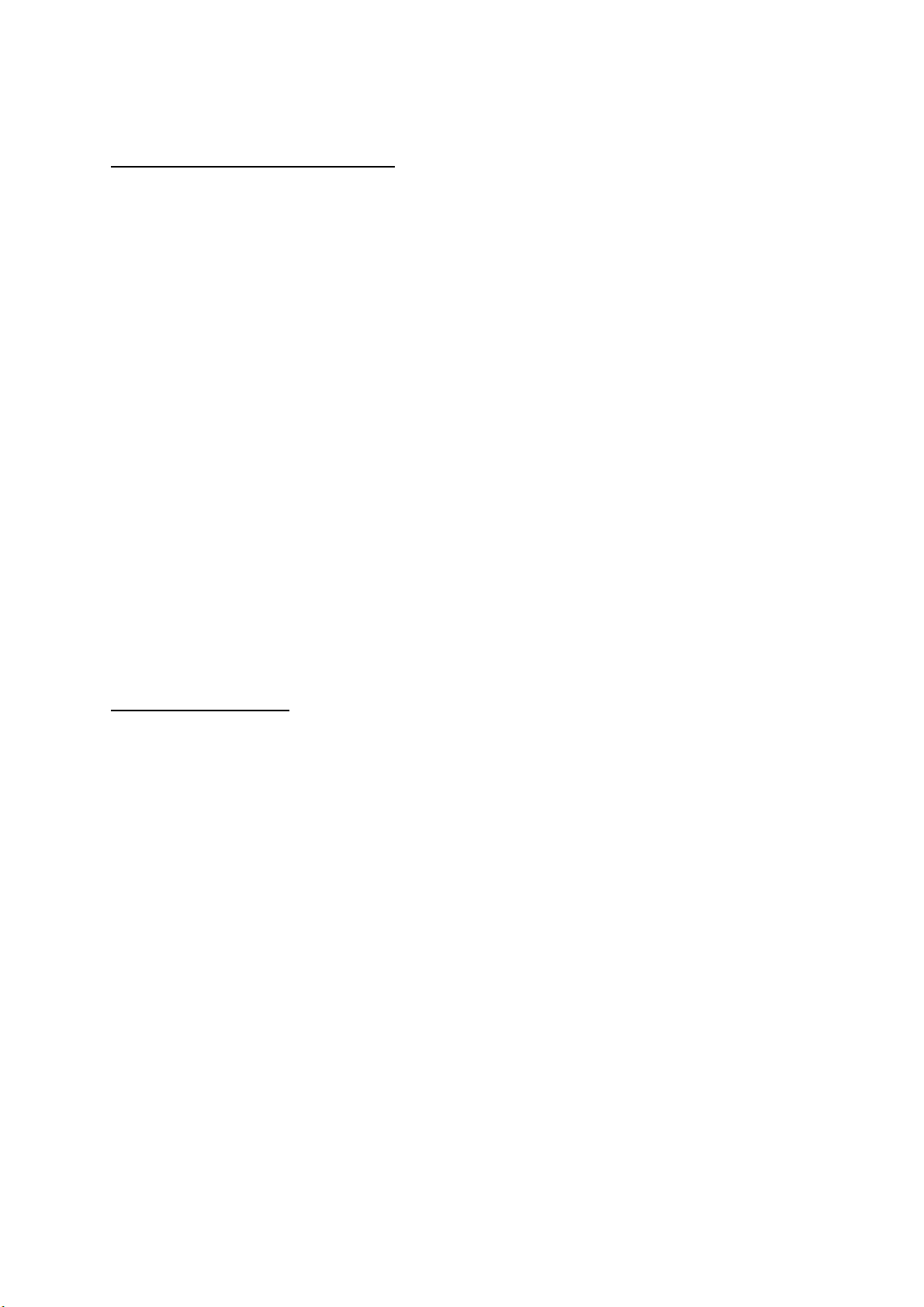

Detaching the Cabinet Front assembly

1) Loosen 7 screws H (see Figure 6 & 7) and uncatch 2

catches C3 (see Figure 7) to detach the Cabinet Front

assembly from the Frame (pos 161) by sliding it out

towards the front.

- see Service position C

Dismantling of the PSCAN HDMI Board, AV Board, PSU Board and SD5.2 (S) XSA 4FL DV HDMI Board

1) Loosen 3 screws A (see Figure 3 & 4) to remove the

PSCAN HDMI Board (pos 1006).

2) Loosen 7 screws B (see Figure 3) and uncatch C1 (see

Figure 5) to remove the AV Board (pos 1002).

3) Loosen 2 screws G and uncatch 2 catches C2 (see

Figure 5) to remove the PSU Board (pos 1004).

4) Loosen 4 screws F (see Figure 5) to remove the SD5.2

(S) XSA 4FL DV HDMI Board (pos 1003-1001).

Figure 6

Figure 7

Figure 3

SERVICE POSITIONS

2-2

2-2

Service position A

PSCAN HDMI Board

Service position B

AV Board Thick Insulation Sheet DVD Loader Thick Insulation Sheet

SD5.2 (S) XSA 4FL DV HDMI Board

Service position C

3-1

Diagnostic Software

1. Definitions and Abbreviations

Definitions

Control PC Automatic test equipment, part of the production control system in the factory, to control the

execution of Diagnostic Nuclei in the DVD player.

Diagnostic Nucleus Part of the Diagnostic Software. Each nucleus contains an atomic and software

independent diagnostic test, testing a functional part of the DVD player hardware on

component level.

Script Part of the Diagnostic Software. Each script contains a sequence of Diagnostic Nuclei to be

executed.

Service PC PC used by a service- or repairman to communicate with the Diagnostic Software in the

DVD player.

Abbreviations

BHDS Basic Hardware Diagnostic Software

BDS Basic Diagnostic Software

FDS Full Diagnostic Software

HSI Hardware Software Interface

OSD On Screen Display

PWB Printed Wire Board

RC Remote Control

ZiVa5 the single-chip DVD backend processor from LSI Logic

SACD Super Audio CD

SD5.2 Standard Design DVD-SACD Module – 5th generation

2. Product Overview

The purpose of the DVD Diagnostic Software is to support the user (factory and service) in diagnosing the DVD player.

The context of the diagnostic software consists of:

- Service PC, a personal computer with a terminal emulation program that emulates a simple ASCII terminal.

The Service PC is connected to the RS232 port of the DVD player and is used for Level 2 / Second Line

diagnostic mode. The Service PC is operated by a service personnel or repairman.

- Local Keyboard, input device of the DVD player hardware, used during power-on and during the execution of

the Player Test Script.

- Test Pin, input device of the DVD player hardware, used during power-on.

- Local Display, output devices of the DVD player hardware, used by the Player Test Script and Dealer Test

Script to output messages and test results.

- Control PC, a computer system in the factory connected to the RS232 port of the DVD player, used during

Level 1 diagnostic mode to communicate with the Diagnostic Software (bi-directional).

- DVD Player Hardware, all the DVD player hardware which is subject to the Diagnostic Software.

The DVD has only one single RS232 port, implying that all interfaces using this port are mutually exclusive.

The Full Diagnostic Software (FDS) is aimed to support service and repair and can present menus and receive

commands via a Service PC.

The Diagnostic Software contains a large number of tiny Diagnostic Nuclei. Each nucleus contains an atomic and

software independent diagnostic test, testing a functional part of the DVD player hardware on component level.

Each Diagnostic Nucleus works directly on the DVD player hardware, no drivers will be used. Each Diagnostic

Nucleus returns a Result indicating if and which error was detected (e.g. faulty SDRAM chip).

It is possible to combine these diagnostic nuclei in a Script to create a high level test like a player test, a script can

be as simple as a sequence of executed Diagnostic Nuclei. The Diagnostic Software contains standard scripts for

dealer and player test. Each script returns a Result indicating if and which error was detected (e.g. faulty module).

3-2

During power-on the Selector (part of the DVD boot sequence) will check the presence of certain triggers (signal

on Test Pin, key combinations on local keyboard). Via the Selector the appropriate diagnostic mode will be activated:

Power-on condition Activate diagnostic mode: Short Description

Name used Name used

in Factory in Service

OPEN & PLAY key (Dealer Script) Dealer test Fully automatic stand-alone test without any user

pressed intervention resulting in one overall result: passed or

not passed.

No SDRAM tests are performed prior to DSW startup.

OPEN & STOP key Level 3 or First Line Automatic test sequence with user intervention and

pressed Player test use of screen/audio test device (i.e. a television set).

(Player Script) The result will be an indication of which board is

faulty.

No SDRAM tests are performed prior to DSW startup.

Test pin active & ‘C’ Level 1 or - Externally (Control PC) controlled test sequence via

character received Module test a simple command line interface. Each command

from RS232 Port in production activates one Diagnostic Nucleus.

line SDRAM tests are performed prior to DSW startup.

Test pin active & ‘M’ Level 2 or Second Line Externally (Service PC) controlled test sequence via

character received Module test a simple menu driven interface. Each menu selection

from RS232 Port for repair activates a Diagnostic Nucleus or a Standard Script.

SDRAM tests are performed prior to DSW startup.

Note: Some players do not have a power-on key, in such cases, the player must be powered-on by connecting

the power-cable.

The Selector, Command Handler and Menu Handler are the heart of the Diagnostic Software and will be referenced

as the Diagnostic Engine in the context of this document. They form a framework in which Diagnostic Nuclei and

standard Scripts can be added via a well-defined software interface. The actual contents of the Menu Handler are part

of the FDS.

3. Product Functions

Dealer diagnostics (For I2C Master Modules only)

The dealer diagnostic mode can be activated by pushing the script activation keys during power-on. The script

activation keys vary depending on the model used.

This test consists of running a predefined script (Dealer Test Script). The script controls the execution of a number

of diagnostic tests. No external input is required during the execution of the script. During the execution a

progress indicator will be displayed on the local display. At the end of the script one message is returned indicating if a failure in the DVD player is detected or not. The message will be displayed on the local display. No external test equipment is required.

DVD Project/Model Dealer Script mode activation key

DVP900 – All series Press and hold OPEN and PLAY key

First Line & Level 3 diagnostics (For I2C Master Modules only)

The First Line & Level 3 diagnostic mode can be activated by pushing the script activation keys during power-on.

The script activation keys vary depending on the model used.

This test consists of running a predefined script (Player Test Script). The script controls the execution of a number

of diagnostic nuclei. The first group of Diagnostic Nuclei in this script will check the local display and the local

keyboard and will output the result on the local display before it continues with the remaining Diagnostic Nuclei of

the script. The Diagnostic Nuclei for the readout of the error log and the Basic Engine will also be part of the

predefined script. During execution of the script input from the local keyboard is required for confirmation of

3-3

certain steps. At the end of the script a message is returned indicating if a failure in one of the modules (Basic

Engine, Digital PWB or Display PWB) is detected or not. The message will be displayed on the local display. The

test will be done with a closed player and requires equipment for testing audio and video (e.g. a television set).

DVD Project/Model Player Script mode activation key

DVP900– All series Press and hold OPEN and STOP key

Level 1 diagnostics

The Level 1 diagnostic mode can be activated by making the test pin active (pull to ‘L’) during power-on and

subsequently, sending a ‘C’ character to the RS232 port. The execution of Diagnostic Nuclei is under external

control via a simple command line interface. There is no standard Level 1 Script embedded in the Diagnostic

software. Each command activates one Diagnostic Nucleus. In case a Diagnostic Nucleus detects a failure it will

try to give an indication via Result which component(s) or connection(s) is (are) failing. Result consists of an error

number and an error string. These will be sent to the Control PC. The error string contains the textual equivalent

of the error number extended with additional detailed error information. The required external test equipment will

be part of the Control PC.

Second Line & Level 2 diagnostics

The Second Line & Level 2 diagnostic mode will be activated by making the test pin active during power-on and

sending a ‘M’ character to the RS232 port. The execution of Diagnostic Nuclei is under external control via the

terminal program on the Service PC with a simple menu driven interface. In case a Diagnostic Nucleus detects a

failure it will try to give an indication via Result of which component(s) or connection(s) is(are) failing. Result

consists of an error number and an error string. These will be sent to the service PC. The error string contains the

textual equivalent of the error number extended with additional detailed error information. The required external

test equipment will be part of the standard repair suite.

4. Functional Requirements

Diagnostic Engine

The diagnostic Engine consists of the following objects:

- Selector (partly implemented in the DVD boot sequence)

- Command Handler

- Menu Handler

The actual contents of the Menu Handler are part of the FDS.

Scripts

Each script controls the execution of Diagnostic Nuclei. There is no direct interaction from the script with the hardware.

A script can be a sequence of Diagnostic Nuclei and can also contain branches and loops. Results of the execution

of a Script are given back to the user. The Scripts will be embedded in the ROM of the DVD player and will be written

in C-code as part of sources of the Diagnostic Software (there is no script interpreter).

The following script objects are defined for the Basic Diagnostic Software:

- Dealer Test Script

- Player Test Script

Diagnostic Nuclei

Each nucleus contains an atomic and independent diagnostic test, testing a functional part of the DVD player hardware

on component level. Each Nucleus returns a result message to its caller. Some tests (e.g. generating a color bar) can

only return an “OK” result. Internal communication will be done via a uniform interface between the diagnostic Engine,

Scripts and the Diagnostic Nuclei.

The diagnostic Engine can only operate if a certain (minimal) set of hardware is functioning properly. To test this set

of hardware, a set of basic diagnostic nuclei is embedded in the DVD player. Each basic diagnostic nucleus will only

test that part of the hardware which is required for execution of the diagnostic Engine, e.g. a RAM test will only test

that part of RAM that is used by the diagnostic engine. After the Diagnostic Engine is operational it is possible to do

a full RAM diagnostic. All basic diagnostic nuclei start with prefix ‘Basic’.

3-4

In the overview each Diagnostic Nucleus consists of a reference number, a reference name and remarks. Reference

number and name are coupled and one of them is enough for unique identification.

Since this document caters to more than one SD module, and not all modules support the same set of test nuclei, a

note is placed in the remarks of each test to indicate whether this applies to a specific module or not. Otherwise it is

assumed that the test is supported by all platforms.

Basic Diagnostic Nuclei

Ref. # Reference Name Remark

1 BasicSpAcc Serial port Access test/initialization

2 CompProcInfo Display processor specific info (LOR register, Chip Revision)

Processor and Peripherals

Ref. # Reference Name Remark

6 PapChksFl Calculate and Verify Checksum FLASH

7a PapUclkAclkCdda External uClock A_CLK in CD-DA mode (SD5.2 only)

7b PapUclkAclkDvd External uClock A_CLK in DVD mode (SD5.2 only)

7c PapUclkAclkDvd96 External uClock A_CLK in DVD (96kHz) mode (SD5.2 only)

8a PapSgsAclkCdda Internal PLL CLK in CD-DA mode

8b PapSgsAclkDvd Internal PLL CLK in DVD mode

8c PapSgsAclkDvd96 Internal PLL CLK in DVD (96kHz) mode

10 PapFlashWrAcc Tests Backend flash write access function

11 PapI2cNvram I2C NVRAM access

12 PapI2cDisp I2C / Sio Bus - Display PWB communications check

13 PapUdeEcho / PapAtapiEcho UDE Echo (SD5.2) / ATAPI bus echo (SD5.12/SD5.31)

14 PapUdePass Enter UDE Pass-through mode (SD5.2 only)

15 PapNvramWrR NVRAM Write Read

62 PapChksSum Show checksums stored in flash

Components

Ref. # Reference Name Remark

16 CompSdramWrR SDRAM Write Read

Audio

Ref. # Reference Name Remark

18a AudioDeemp0On Audio Deemphasization 0 On

18b AudioDeemp0Off Audio Deemphasization 0 Off

18c AudioDeemp1On Audio Deemphasization 1 On

18d AudioDeemp1Off Audio Deemphasization 1 Off

18e AudioDeemp0TristateOn Audio Deemphasization 0 Tristate On

18f AudioDeemp0TristateOff Audio Deemphasization 0 Tristate On

18g AudioDeemp1TristateOn Audio Deemphasization 1 Tristate On

18h AudioDeemp1TristateOff Audio Deemphasization 1 Tristate Off

19a AudioMuteOn Audio Mute On

19b AudioMuteOff Audio Mute Off

20a AudioPinkNoiseOn Audio Pinknoise On

20b AudioPinkNoiseOff Audio Pinknoise (or beep tone) Off

21a AudioSineOn Audio Sine signal On/Off

21b AudioSineBurst Audio Sine signal Burst

Video

Ref. # Reference Name Remark

22a InitProgressiveBoard Initialize Progressive Scan Board

23a VideoColDencOnPAL Colourbar (PAL) DENC On

23b VideoColDencOff Colourbar DENC/Digital Video Off

23c VideoColDencOnNTSC Colourbar (NTSC) DENC On

23d AudioVideoHDMIon Audio Video HDMI On

23e AudioVideoHDMIoff Audio Video HDMI Off

24a VideoProgMPEGon Progressive - Digital Video Colour bar ON (SD5.2 only)

3-5

24b VideoYuvMPEGon Enhanced YUV - Digital Video Colour bar ON

25a VideoScartLo Scart Low (SD5.2 only)

25b VideoScartMi Scart Medium (SD5.2 only)

25c VideoScartHi Scart High (SD5.2 only)

54 VideoScartSwComm Scart Switch communication (SD5.2 only)

55a VideoScartSwDvd Scart Switch Dvd (SD5.2 only)

55b VideoScartSwPass Scart Switch Pass-through (SD5.2 only)

57a VideoScartPinLo PIO-pins used for Scart-switching

57b VideoScartPinMi PIO-pins used for Scart-switching

57c VideoScartPinHi PIO-pins used for Scart-switching

61a VideoColOutRGB Enable Video Output to RGB

61b VideoColOutYUV Enable Video Output to YUV

DisplayPWB (slave processor)

Ref. # Reference Name Remark

26 DispVer Version number (SD5.2 only)

27 DispKeyb Keyboard (SD5.2 only)

28 DispRc Remote Control (SD5.2 only)

29 DispLed LEDs (SD5.2 only)

30a DispDisplay VFT Display test (SD5.2 only)

30b DispLCDisplay LCD display test (SD5.2 only)

30c DispLCDBkLight LCD Backlight test (SD5.2 only)

60 DispP50 P50 loopback test (SD5.2 only)

Log (error logging in NVRAM)

Ref. # Reference Name Remark

31 LogReadErr Read last Errors

32 LogReadBits Read errors Bits

33 LogReset Reset

Miscellaneous

Ref. # Reference Name Remark

34 MiscReadConfig Read Configuration area from NVRAM

35 MiscNvramReset NVRAM Reset

36 MiscNvramMod Modify NVRAM contents

46 MiscApplVer Read version of application software

47a MiscTrayOpenNr Read the number of times the tray opened

47b MiscPowerOnTime Read the total time the player’s power has been on

47c MiscPlayTimeCddaVcd Read the Playtime of CDDA and VCD discs

47d MiscPlayTimeDvd Read the Playtime of DVD discs

Basic Engine

Ref. # Reference Name Remark

37 BeVer Version number

38a BeFocusOn Focus On

38b BeFocusOff Focus Off

39a BeDiscmotorOn Discmotor On

39b BeDiscmotorOff Discmotor Off

40a BeRadialOn Radial control On

40b BeRadialOff Radial control Off

41a BeSledgeIn Sledge Inwards

41b BeSledgeOut Sledge Outwards

42a BeGroovesIn jump Grooves to Inside

42b BeGroovesMid jump Grooves to Middle

42c BeGroovesOut jump Grooves to Outside

43a BeTrayIn Tray In

43b BeTrayOut Tray Out

44 BeReset Reset Basic Engine

58a LaserCdOn CD Laser on

3-6

58b LaserCdOff CD Laser off

58c LaserDvdOn DVD Laser on

58d LaserDvdOff DVD Laser off

Furore IC

Ref. # Reference Name Remark

62 Furore_SdramWrR Furore SDRAM Write Read test (SD5.2 only)

63 Furore_SdramWrRFast Furore SDRAM interconnection test (SD5.2 only)

64 Furore_Id Furore version ID check (SD5.2 only)

83 Furore_Reset Furore reset (SD5.2 only)

84a Furore_High Sets Furore output pins DSD_PCM0-9 to high (SD5.2 only)

84b Furore_Low Sets Furore output pins DSD_PCM0-9 to low (SD5.2 only)

Audio DAC related

Ref. # Reference Name Remark

65 DAC_I2C Resets DAC and check I2C communication with DAC (SD5.2 only)

66a DAC_I2CEnable Enable I2C communication to AV board (SD5.2 only)

66b DAC_I2CDisable Disable I2C communication to AV board (SD5.2 only)

67a DAC_ClockInternal Uses internal clock from monoboard for DAC (256fs) (SD5.2 only)

67b DAC_ClockExternal Uses external clock for DAC (384fs) (SD5.2 only)

68a DAC_AudioPreMuteOn Enable Audio Pre-mute pin (SD5.2 only)

68b DAC_AudioPreMuteOff Disable Audio Pre-mute pin (SD5.2 only)

69a DAC_CenterOn Enable Center on pin (SD5.2 only)

69b DAC_CenterOff Disable Center on pin (SD5.2 only)

79 DAC_Reset Resets DAC (SD5.2 only)

80a DAC_ModeCDDA Sets DAC to CDDA mode (SD5.2 only)

80b DAC_ModeDVD48 Sets DAC to DVD mode (48kHz) (SD5.2 only)

80c DAC_ModeDVD96 Sets DAC to DVD mode (96kHz) (SD5.2 only)

80d DAC_ModeDSD Sets DAC to DSD mode (SD5.2 only)

81a DAC_LowPowerStandbyOn Enable Low Power Standby (SD5.2 only)

81b DAC_LowPowerStandbyOff Disable Low Power Standby (SD5.2 only)

82a DAC_UpsamplingFreq192k Sets Upsampling frequency to 192kHz (SD5.2 only)

82b DAC_UpsamplingFreq96k Sets Upsampling frequency to 96kHz (SD5.2 only)

82c DAC_UpsamplingOn Enable upsampling (SD5.2 only)

82d DAC_UpsamplingOff Disable upsampling (SD5.2 only)

Basic Engine - Special Diagnostics

Ref. # Reference Name Remark

70 BedReadFlashID Read flash memory manufacturer and device ID

71 BedCalcRomChksum Calculate ROM checksum

RS232

Ref. # Reference Name Remark

93a Rs232cI2cCheck RS232 I2C communication check

93b Rs232TxRxCheck RS232 transmit receive check

93c Rs232cCtsRtsCheck RS232 Cts Rts check

93d Rs232cIrPortCheck RS232 port check

93e Rs232cStbyCtrlCheck RS232 standby control check

5. Description of Diagnostic Engine

Selector

During initialization of the Diagnostic Software the Selector will first execute the required Basic Diagnostic Nuclei

(nuclei of which the names start with the word “Basic”) to ensure correct operation. In case one of the basic diagnostics

fails an error code and message will be communicated to the outside world via the RS232. In case all basic diagnostics

are passed successfully, the selector will activate the appropriate diagnostic mode.

3-7

Command Handler

The Command Handler handles all commands from the Control PC. Commands will be received as ASCII strings via

the RS232 port. All commands received is interpreted by the Command Handler and only correct commands result

in the execution of the matching Diagnostic Nucleus. Illegal commands result in an error message to the Control PC.

Menu Handler

The Menu Handler (part of the Full Diagnostic Software) handles all menus and selections to and from the Service PC.

The interface consists of simple text menus with sub-menus. A menu selection results in the execution of the matching

Diagnostic Nucleus. Only valid menu selections will be accepted.

6. Description of Script Objects

Dealer test (for I2C Master Modules Only)

The Dealer Test Script object performs the Dealer test by executing a few Diagnostic Nucleus which do not need any

user intervention and are meaningful on a stand alone DVD player. During the execution of the Dealer test a progress

indicator will be displayed on the local display.

In general the Diagnostic Nuclei with a large test scope (i.e. testing many components at once) will be executed first.

When a Diagnostic Nucleus detects a fault a message indicating that the test is not passed will be displayed on the

local display [ ERROR ] and the Dealer test will terminate. If all Diagnostic Nuclei are passed successfully a message

indicating that the test is passed [ PASS ] will be displayed on the local display and the Dealer test will terminate. The

only way to continue after termination is via a power down of the DVD player.

Player test (for I2C Master Modules Only)

The Player Test Script object performs the Player test by executing all available Diagnostic nuclei which are meaningful

on a DVD player which is connected to audio/video test equipment (e.g. a television set). Some Diagnostic Nuclei

require user intervention.

The first phase will check the following modules:

- Display PWB (communication, display, backlight, LEDs, keyboard, RC, P50)

- Basic Engine (communication, mechanical)

- Digital PWB (all components)

For each module all the available Diagnostic Nuclei which are meaningful for that module will be executed. Some

Diagnostic Nuclei require user intervention. After all tests have been executed an indication will be given on the local

display which module is most likely to be faulty. Also, the error code of the last detected error will be displayed. To

continue, push the PLAY key on the local keyboard, the second phase will be entered automatically. The test of the

module Display PWB consists of the Diagnostic Nuclei PapI2cDisp, DispDisplay, DispLCDisplay, DispLCDBkLight ,

DispLed, DispKeyb and DispRc and can be aborted at any moment by switching the power off.

The second phase is the read out of the error log and error bits from the NVRAM. Only a part of the information will

be displayed on the local display at the time. With the keys: STOP key and OPEN/CLOSE (EJECT) key, it will be

possible to walk through the whole error log and bits in a controlled way. The loop phase can be entered by pushing

the PLAY key on the local keyboard.

The loop phase will check the following modules:

- Display PWB (communication)

- Basic Engine (communication)

- Digital PWB (all components)

For each module all the available Diagnostic Nuclei which are meaningful for that module will be executed. None of

the Diagnostic Nuclei require any user intervention. After all tests have been executed an indication will be given on

the local display which module is most likely to be faulty. Also, the error code of the last detected error will be displayed.

A loop counter on the local display will be incremented and the loop phase will start all over again.

3-8

7. Description of Diagnostic Nucleus Objects

BasicSpAcc

This is a Basic Diagnostic Nucleus required for correct operation of the Diagnostic Software.

Checks and initializes RS232 port and outputs a message that the Diagnostic software has been started.

CompProcInfo

Reads and display processor specific information. This platform specific function allows the user to read certain

registers in the chip at runtime that would be helpful in getting info on the current chip used. For ZiVA5, the LatchedOn-Reset register contents and the Chip Revision register contents are read and displayed.

PapChksFlash

Calculates and verifies the checksum of the backend FLASH or ROM. This includes the entire binary ROM image

checksum.

PapUclkAclkCdda, PapUclkAclkDvd, PapUclkAclkDvd96 (for SD5.2 only)

Diagnostic Nucleus PapUclkAclkCdda switches clock A_CLK from the microclock to 16.93 MHz(CD_DA).

Diagnostic Nucleus PapUclkAclkDvd switches clock A_CLK from the microclock to 18.43 MHz(DVD).

Diagnostic Nucleus PapUclkAclkDvd96 switches clock A_CLK from the microclock to 36.86 MHz(DVD).

Correct operation cannot be detected by the Diagnostic Software but must be checked with external equipment (e.g.

a frequency counter).

Note:

This nucleus will only work if the external clock is available on board.

PapSgsAclkCdda, PapSgsAclkDvd, PapSgsAclkDvd96

Diagnostic Nucleus PapSgsAclkCdda switches the PCM clock to 16.93MHz(CD_DA).

Diagnostic Nucleus PapSgsAclkDvd switches the PCM clock to 18.43 MHz(DVD).

Diagnostic Nucleus PapSgsAclkDvd96 switches the PCM clock to 36.86 MHz(DVD).

Correct operation cannot be detected by the Diagnostic Software but must be checked with external equipment (e.g.

a frequency counter).

PapFlashWrAcc

Reads out the Flash ROM’s Chip Identification Number. This nucleus tests the write access by writing a defined

sequence of data to the FLASH chip, to be able to read the FLASH ID number.

PapI2cNvram

Checks the I2C interface with the NVRAM by reading from an arbitrary address.

PapI2cDisp (for SD5.2 only)

Checks the I2C or SIO bus interface with the slave processor on the display PWB with the echo command.

PapUDEEcho (SD5.2) / PapAtapiEcho (SD5.12/SD5.31)

Checks the UDE / ATAPI interface to the basic engine with an ‘echo’ command. This tests the hardware

communications interface between the loader and the backend processor.

PapUDEPass (for SD5.2 only)

Switches the RS232 port and the UDE port in pass-through mode. The only way to exit this nucleus is via a power off

of the DVD player.

PapNvramWrR

Non destructive pattern test (checker board) of all locations in the NVRAM. This Nucleus can detect stuck at faults and

permanent coupling errors in the NVRAM chip.

VidPortOutAA, VidPortOut55 (for SD5.2 only)

Writes the value 0xAA to the Digital Video Interface port of the ZiVa5 ITU-656 ports.

Writes the value 0x55 to the Digital Video Interface port of the ZiVa5 ITU-656 ports.

3-9

AudioMuteOn, AudioMuteOff

Diagnostic Nucleus AudioMuteOn switches the audio mute on.

Diagnostic Nucleus AudioMuteOff switches the audio mute off.

Correct operation cannot be detected by the Diagnostic Software but must be checked externally.

Note: The audio will be muted by the DAC.

AudioPinkNoiseOn, AudioPinkNoiseOff

Diagnostic Nucleus AudioPinkNoiseOn will generate a pink noise internally on the ZiVa5 chip, which will be passed

to the DAC where it is converted to an analogue audio signal.

Diagnostic AudioPinkNoiseOff will switch off the pink noise generated with AudioPinkNoiseOn.

The signal will also be passed to the digital outputs. For a 6 channel player the signal must be available on all 6 analogue

audio channels.

Correct operation cannot be detected by the Diagnostic Software but must be checked externally.

AudioSineOn, AudioSineBurst

Nucleus AudioSineOn will generate a sine signal of 1 kHz on the analogue output. The sine signal digital data are stored

in the audio buffer in the SDRAM, passed through the audio decoder and without any further processing to the audio

DAC where it is converted to an analogue audio signal.

The signal will also be passed to the digital outputs.

Correct operation cannot be detected by the Diagnostic Software but must be checked externally. The sine signal can

be stopped by pressing the STOP key on the DVD player or by sending a ‘#’ character via hyperterminal.

Nucleus AudioSineBurst will generate a sine signal of 1 kHz on the analogue output that lasts for about four seconds.

The generation of the signal is the same as in AudioSineOn.

Correct operation cannot be detected by the Diagnostic Software but must be checked externally.

Note:

In the player script the test AudioSineOn will be used.

VideoColDencOnPAL, VideoColDencOff, VideoColDencOnNTSC

Diagnostic Nucleus VideoColDencOnPAL enables colour bar (PAL format) in the DENC in the ZiVa5 chip.

Diagnostic Nucleus VideoColDencOff disables colour bar in the DENC and the digital video outputs in the ZiVa5 chip.

Diagnostic Nucleus VideoColDencOnNTSC enables colour bar (NTSC format) in the DENC in the ZiVa5 chip.

The signal must be simultaneously available on the RGB, Y/C and CVBS outputs. The RGB and CVBS signals will be

present on the SCART, while the Y/C signal will only be available on the Y/C connector.

Correct operation cannot be detected by the Diagnostic Software but must be checked externally.

VideoProgMPEGon, VideoYuvMPEGon (for SD5.2 only)

VideoProgMPEGon outputs a colourbar pattern on the TV using the external progressive board connected to the

DVD module.

VideoYuvMPEGon outputs a colourbar pattern on the TV using the external “enhanced-YUV” board connected to

the DVD module.

VideoScartLo, VideoScartMi, VideoScartHi (for SD5.2 only)

VideoScartLo steers pin16 on the SCART connector with the value Low (0 to 2V)

VideoScartMi steers pin16 on the SCART connector with the value Medium (4.5 to 7V)

VideoScartHi steers pin16 on the SCART connector with the value High (9.5 to 12V).

Correct operation cannot be detected by the Diagnostic Software but must be checked externally.

DispVer (for SD5.2 only)

Gets the version number of the slave processor on the Display PWB.

3-10

DispKeyb (for SD5.2 only)

Checks that all keys will be pressed once (arbitrary sequence). Feed back will be given via the local display for each

key that has been pressed.

DispRc (for SD5.2 only)

Displays Header, System and Command code for each received RC code on the local display.. The remote control

test can be left by pressing the PLAY key on the local keyboard.

DispLed (for SD5.2 only)

Lights all local LEDs until the PLAY key on the local keyboard is pressed.

DispDisplay, DispLCDisplay, DispLCDBacklight (for SD5.2 only)

- For VFT-display only: Displays test patterns on the local display until the PLAY key on the local keyboard is pressed.

Test patterns can be walked through by pressing the OPEN/CLOSE (EJECT) key (next pattern) .

- For LCD-display only: Displays test patterns on the local display until the PLAY key on the local keyboard is pressed.

Test patterns can be walked through by pressing the OPEN/CLOSE (EJECT) key (next pattern) .

- For LCD-display only: Sets the backlight intensity to different levels (LOW – DIM – BRIGHT) until the PLAY key

on the local keyboard is pressed. Test patterns can be walked through by pressing the OPEN/CLOSE (EJECT) key

(next pattern) .

LogReadErr

Read error log from NVRAM and output the data as error numbers only.

LogReadBits

Read error bits from NVRAM and output the numbers of the error bits which are set. Each error bit will get a number,

starting from 1 (bit 0 in first byte of error bit area) to N*8 (bit 7 in last byte of error bit area) where N is the number of

bytes in the error bit area.

LogReset

Reset all error log and bits in the NVRAM.

MiscReadConfig

Read configuration area from NVRAM and output as raw data.

MiscNvramReset

Reset the whole NVRAM to zero.

MiscNvramMod

Read/Modify any location in NVRAM.

BeVer

Get version number of the Basic Engine / Loader used.

BeFocusOn, BeFocusOff

Diagnostic Nucleus BeFocusOn puts the laser of the BE into focus (focus loop).

Diagnostic Nucleus BeFocusOff switches the focus loop off.

BeDiscmotorOn, BeDiscmotorOff

Diagnostic Nuclei BeDiscmotorOn switches the disc motor (=spindle motor) on.

Diagnostic Nuclei BeDiscmotorOff switches the disc motor (=spindle motor) off.

BeRadialOn, BeRadialOff

Diagnostic Nuclei BeRadialOn closes the radial loop.

Diagnostic Nuclei BeRadialoff opens the radial loop.

BeSledgeIn, BeSledgeOut

Diagnostic Nuclei BeSledgeIn moves the sledge fully inwards.

Diagnostic Nuclei BeSledgeOut moves the sledge fully outwards.

3-11

BeGroovesIn, BeGroovesMid, BeGroovesOut

Diagnostic Nuclei BeGroovesIn lets the laser spot jump to the inside limit of the disc.

Diagnostic Nuclei BeGroovesMid lets the laser spot jump to the middle of the disc.

Diagnostic Nuclei BeGroovesOut lets the laser spot jump to the outside limit of the disc.

BeTrayIn, BeTrayOut

Diagnostic Nucleus BeTrayIn closes the disc tray.

Diagnostic Nucleus BeTrayOut opens the disc tray.

BeReset

Resets the Basic Engine.

MiscApplVer

Read the version of the application software from a fixed location in the NVRAM.

MiscTrayOpenNr, MiscPowerOnTime, MiscPlayTimeCddaVcd, MiscPlayTimeDvd

MiscTrayOpenNr reads the number of times the tray has opened

MiscPowerOnTime reads the total time the player has been powered on

MiscPlayTimeCddaVcd reads the total playtime of CDDA and VCD discs

MiscPlayTimeDvd reads the total playtime of DVD discs

VideoScartSwComm (for SD5.2 only)

VideoScartSwComm checks the I2C interface with the scart switch on the Audio/Video board.

VideoScartSwDvd, VideoScartSwPass (for SD5.2 only)

VideoScartSwDvd and VideoScartSwPass sets the scart switch IC on the Audio/Video board to give out DVD

signal or pass-through the auxiliary Scart input.

VideoScartPinLo. VideoScartPinMi, VideoScartPinHi

VideoScartPinLo, VideoScartPinMi and VideoScartPinHi are used to toggle the PIO-pins that were used in

DVDv2A to set the level of the Scart-pin 8. These PIO-pins may have a different meaning.

LaserCdOn, LaserCdOff, LaserDvdOn, LaserDvdOff

Diagnostic Nucleus LaserCdOn/LaserDvdOn puts the selected laser on.

Diagnostic Nucleus LaserCdOff/LaserDvdOff switches the laser off.

DispP50 (for SD5.2 only)

DispP50 performs a loop-back test on the P50 communication present on the front panel.

VideoColOutRGB, VideoColOutYUV

VideoColOutRGB and VideoColOutYUV nuclei configures the DENC on the ZiVa5 chip to output either RGB

format or YUV format respectively.

PapChksSum

The PapChksSum nucleus displays the value of the binary image checksum stored in the backend flash.

FURORE_SdramWrR (for SD5.2 only)

Checks the SDRAM memory of the FURORE SDRAM. Checking is done with a data bus test, an address bus test

and finally a device test.

FURORE_SdramWrRFast (for SD5.2 only)

Checks the lower and upper memory portion of the FURORE SDRAM. Checking is done faster compared to

FURORE_SdramWrRLow, FURORE_SdramWrRHigh because the device test is skipped. Checking is done with a

data bus test, and finally an address bus test.

FURORE_Id (for SD5.2 only)

This nucleus gets the revision ID of the FURORE chip.

3-12

DAC_I2C, DAC_I2Cenable, DAC_I2Cdisable (for SD5.2 only)

This nucleus checks the interface between the I2C controller on the ZiVa5 and the external DAC board.

DAC_ClockInternal, DAC_ClockExternal (for SD5.2 only)

These nuclei select the final clock input to the audio DAC.

- Internal clock means the PCM clock from the monoboard is used.

- External clock means the DSD clock on the AV board is used.

DAC_AudioPreMuteOn, DAC_ AudioPreMuteOff (for SD5.2 only)

This nucleus selects Audio Pre-mute on/off.

DAC_CentreOn, DAC_ CentreOff (for SD5.2 only)

This nucleus selects the centre on/off.

BedReadFlashID

Loads a special diagnostic firmware on the front engine which reads the Flash device and manufacturer’s ID .

BedCalcRomChkSum

Loads a special diagnostic firmware on the front engine that calculates the checksum of the front engine ROM.

BedScratchTest

Loads a special diagnostic firmware on the front engine that checks the scratch detector circuit of the front engine.

DAC_Reset

This nucleus resets the DAC board.

DAC_ModeCDDA, DAC_ModeDVD48, DAC_ModeDVD96, DAC_ModeDSD (for SD5.2 only)

- DAC_ModeCDDA switches the DACs into CDDA mode.

- DAC_ModeDVD48 switches the DACs into DVD 48 kHz mode.

- DAC_ModeDVD96 switches the DACs into DVD 96 kHz mode.

- DAC_ModeDSD switches the DACs into DVD DSD mode.

DAC_LowPowerStandbyOn, DAC_LowPowerStandbyOff (for SD5.2 only)

DAC_LowPowerStandbyOn switches the Low power standby mode on, removing power supply to SCART switch IC.

DAC_LowPowerStandbyOff switches the Low power standby mode off, enabling power supply to SCART switch IC.

DAC_UpSamplingFreq192k, DAC_ UpSamplingFreq96k, DAC_UpSamplingOn, DAC_ UpSamplingOff (for

SD5.2 only)

These nuclei select whether upsampling should be activated and at what frequency.

Furore_Reset (for SD5.2 only)

This nucleus resets the Furore IC.

Furore_High, Furore_Low (for SD5.2 only)

These nucleus sets the output lines DSD_PCM0-9 to either high or low.

3-13

Procedure to upgrade software

1) Power up the set.

2) Open tray by press "OPEN/CLOSE" button on the set or press and hold "STOP" button on the RC.

3) Place upgrade disc onto tray and close.

4) The set will response and display shows [READING] follow by [UPGRADING].

Caution: Do not press any buttons or interrupt the mains supply during the upgrading process, otherwise the

set may become defective.

5) The whole process should not take more than 3 minutes.

6) Tray will open indicating that the upgrading process is completed. The set display will continue to show

[UPGRADING].

7) Take out the upgrade disc from the tray and switch off the mains supply.

8) Power up the set again. Tray will close and go to standby automatically.

Note : If the set does not go to standby automatically, give it sufficient time (about 1 minute) to initialize

NVM etc. then press "STANDBY" button to go to standby.

Procedure for check Software version

1) Power up the set.

2) Open tray by press "OPEN/CLOSE" button on the set or press and hold "STOP" button on the RC.

3) Press "DISC MENU" button on the RC.

4) The TV screen will shows:

Copyright(c)

PHILIPS 2002-03

SD5.2-9000S-XX

04Oct2004

17:34

YYYYYYYY

A1160-129

C3091-178

UDE28.0001.07

FE Ver:08

XX = software version number

YYYYYYYY = slash version

Reprogramming of DVD Version Matrix

After repair, the customer setting and region code may be lost. Reprogramming will put the set back in the state

in which it has left the factory, ie. with the default setting and the allowed region code.

Model Region Slash Version

DVP9000S/00 Europe 22201700

DVP9000S/69 AP 32301700

To reprogram do as follows:

1) Power up the set.

2) Press buttons <PLAY> <1> <5> <9> on the RC.

3) The set display shows [ _ _ _ _ _ _ _ _ ].

4) Press now successively the following keys:

<2> <2> <2> <0> <1> <7> <0> <0> - for DVP9000S/00

<3> <2> <3> <0> <1> <7> <0> <0> - for DVP9000S/69

5) Press button <PLAY> again on the RC.

6) Wait for the set to reboot by itself (less than 1 minute) to confirm that the set has been reprogrammed.

Loading...

Loading...