Page 1

User Guide for the

Philips CM200

FEG TEM

cm200 user guide 2009

1

Page 2

THE RULES:

1. If in doubt, CLOSE THE GUN VALVE.

2. Do not touch a control if you don’t know exactly

what it will do.

3. Never force anything beyond finger strength.

4. If in doubt, ask for help.

Contact staff for this instrument:

Katie Levick, Sean Lim, Paul Munroe

cm200 user guide 2009

2

Page 3

Contents

1. IMPORTANT PARTS OF THE PHILIPS CM200 TEM ........... 4

2. CHECK cm200 STATUS ..................................................... 8

3. TURN THE FILAMENT UP ................................................. 9

4. LOAD THE SPECIMEN ..................................................... 10

5. OBTAIN AN IMAGE ........................................................ 12

6. SET THE EUCENTRIC HEIGHT ......................................... 13

7. FOCUS THE IMAGE ......................................................... 13

8. MOVE AROUND THE SPECIMEN ................................... 14

9. CHECK THE MINOR ALIGNMENTS ................................ 15

10. INSERT AN OBJECTIVE APERTURE ................................ 17

11. RECORD AN IMAGE ON PHOTOGRAPHIC FILM ........ 18

12. RECORD A DIGITAL IMAGE ......................................... 19

13. EXCHANGE SPECIMENS ................................................ 20

14. END THE SESSION ........................................................ 21

Appendix a: Using the double tilt holder .............................. 22

Appendix b: Diffraction patterns .......................................... 24

Appendix c: X-ray analysis ................................................... 25

Appendix d: X-ray mapping/line scans ................................. 32

cm200 user guide 2009

3

Page 4

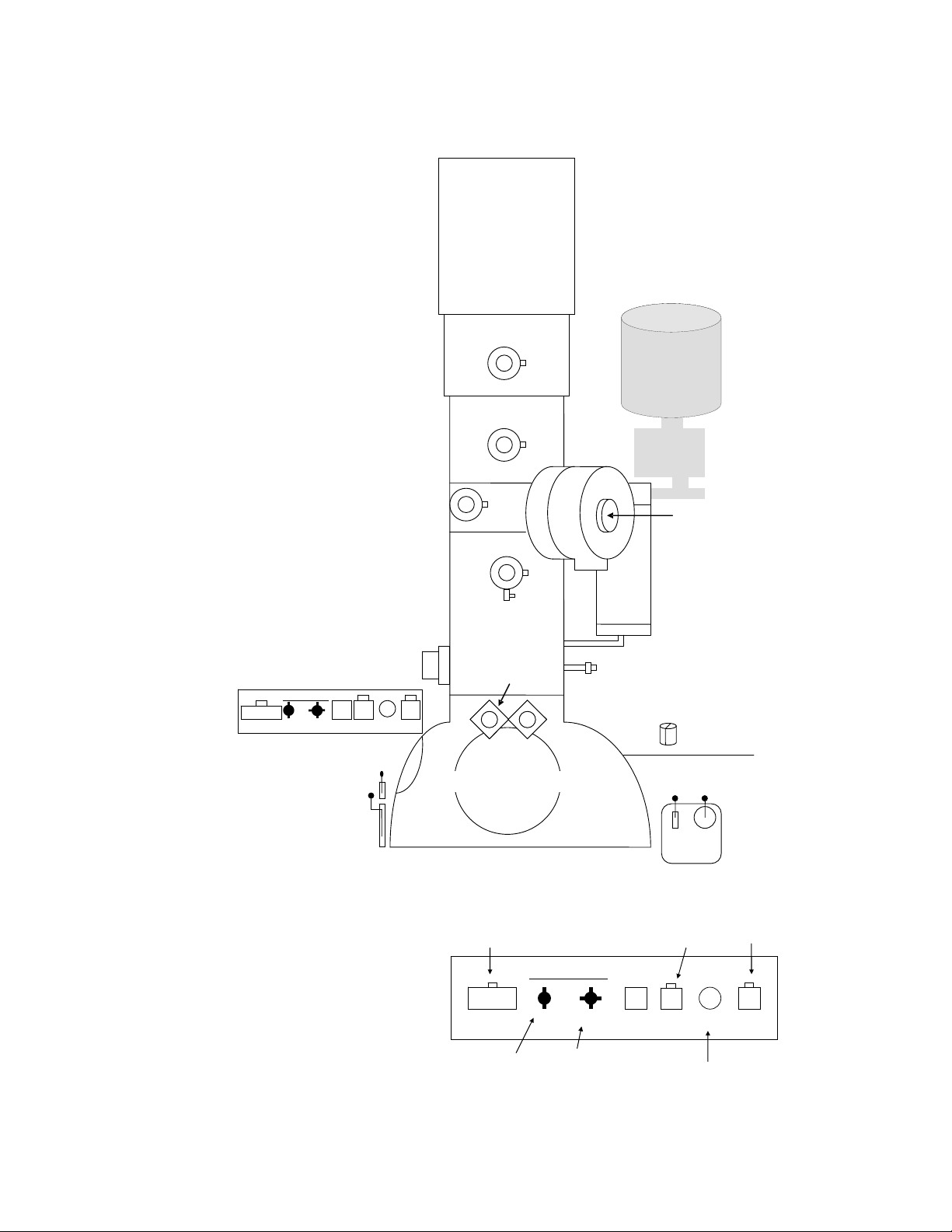

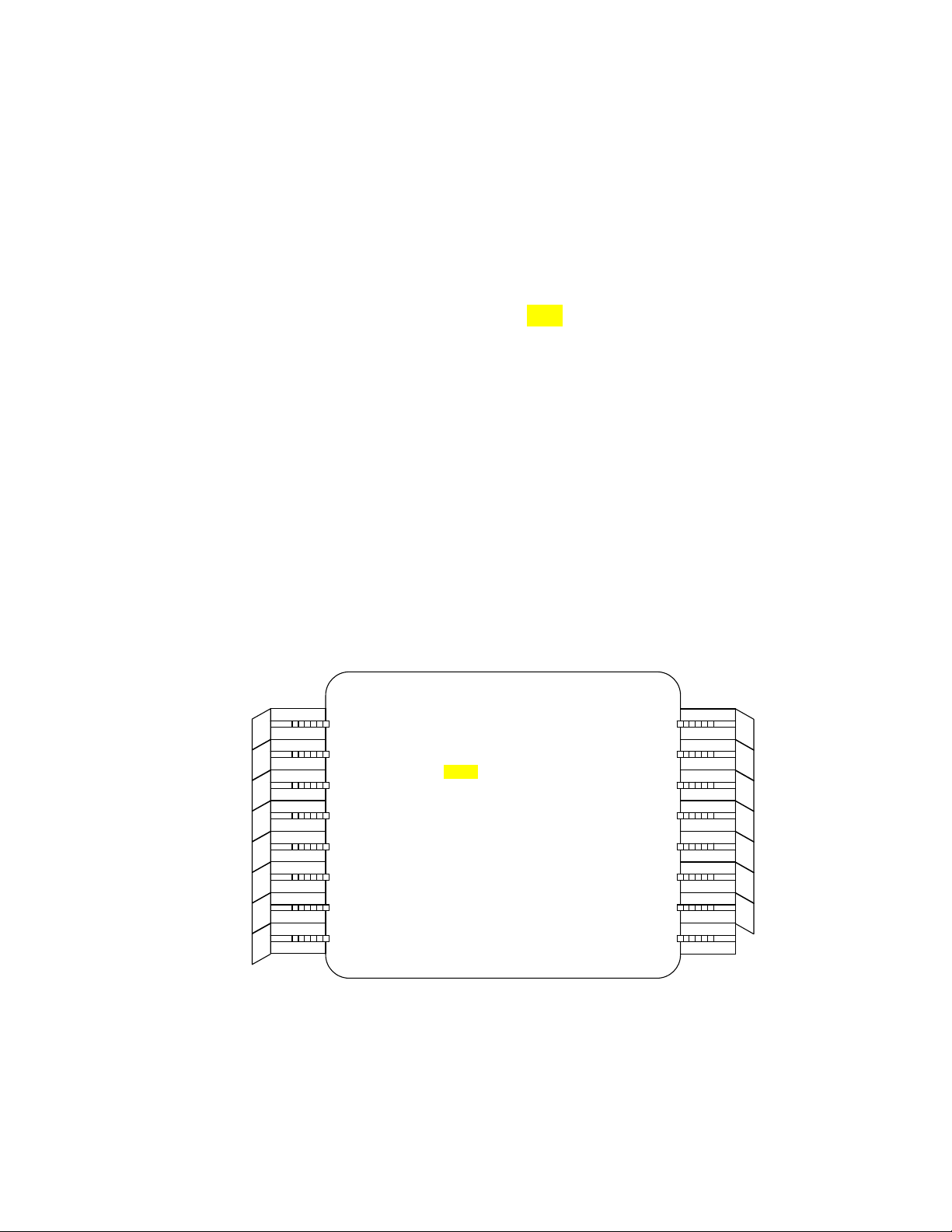

1. IMPORTANT PARTS OF THE PHILIPS CM200 TEM

r

r

r

r

r

r

j

r

Exposure

To the left of the column:

field emission gun (FEG)

condenser aperture 1

condenser aperture 2

Goniomete

RST WBL

Tilt Holder Intensity

side viewing window

focus stage leve

main stage leve

objective aperture

diffraction

aperture

fine

dewar

liquid N

2

for EDS system

specimen

holde

liquid N

container fo

cold finge

focus stage

viewe

gun valv e

control

Close Open

main viewing window

Film camera exposure

button

Goniometer

Goniometer

Exposure RST WBL

check camera

switch is set to CM

Tilt Holder Intensity

α-tilt control β-tilt control

(with floor pedal)

GUNVALVE

Z XY

oystick

intensity fine

adjustment

on/off

intensity

control

2

beam

beam

wobbler

4

cm200 user guide 2009

Page 5

The gun valve:

A

A

k

V

The Philips cm200 TEM uses a field emission gun (FEG) which provides very

high resolution but requires more care than a standard TEM filament. It is very

important that a high vacuum is maintained in the gun chamber at all times.

The gun chamber is sealed off from the rest of the column using the gun valve.

The gun valve must be closed whenever a specimen is being exchanged. If you

have a problem with the operation of the instrument or if you need to leave the

room, please close the gun valve by turning the control knob slowly clockwise

to the closed position.

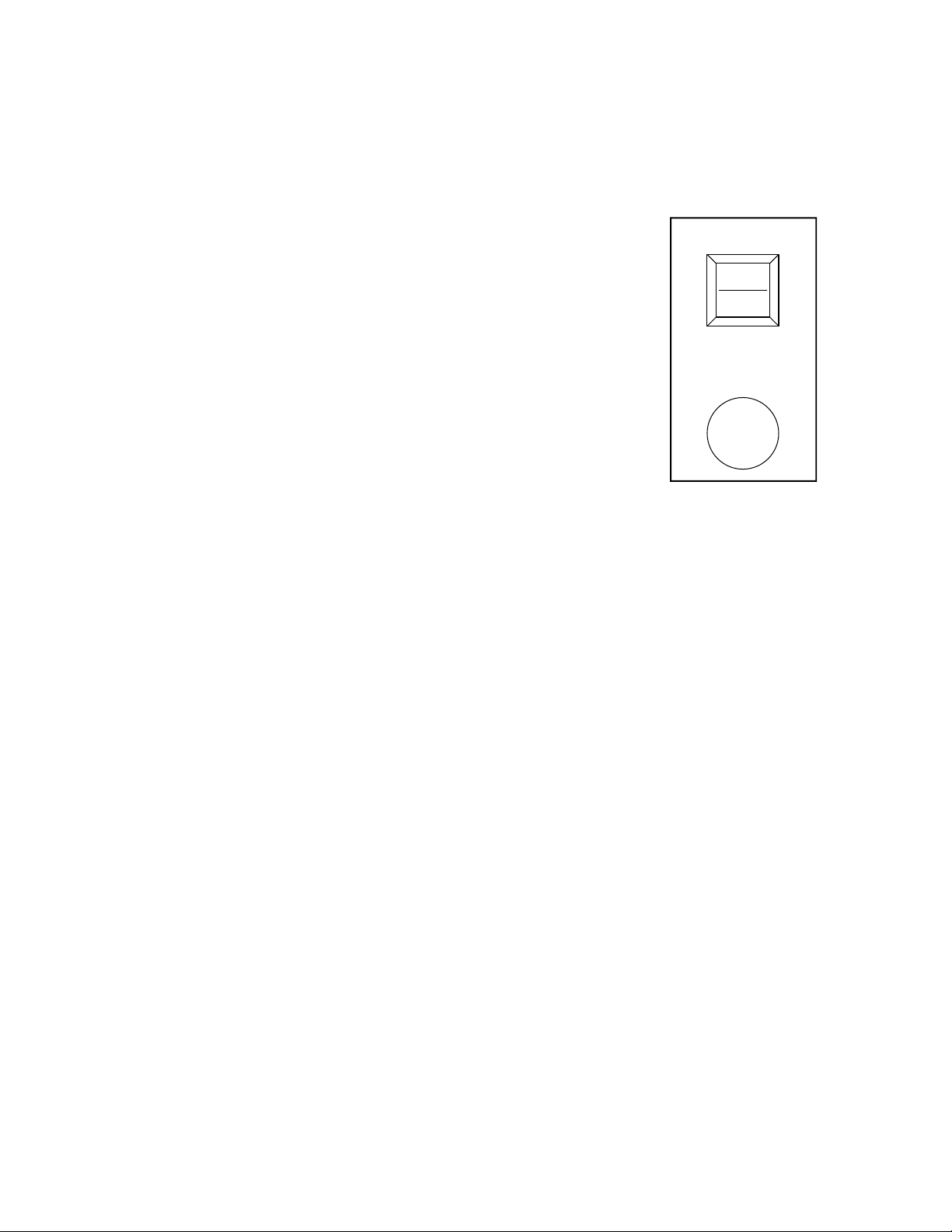

The computer screen:

The cm200 contains many manual controls, such as focus and magnification.

However, many functions are controlled via a computer interface, using the

“softkeys” at the edges of the screen. To select a particular function press the

softkey next to the appropriate function title. To leave a page or function, press

the READY button at the lower right hand side of the screen. In most cases, this

will take you back to the HR-TEM BRIGHT FIELD page.

The functions described here are those required for most users. The other

functions must not be used unless you have received appropriate training.

DO NOT PRESS A SOFTKEY IF YOU DON’T KNOW WHAT IT DOES.

INT ZOOM

INT LIMIT

-

-

-

-

-

-

HR-TEM BRIGHT FIELD

LM

HT

spot 1

focusstep 1

defocus -4.30um

plate auto

meter XXX s

exp no

stoc

X: -141.61 um

Y: -78.72 um

Z: 135.69 um

: 0.00 d

B: 0.00 d

1000x

200k

350nm

E7773

50

MODES

PARAMETERS

UTOCON-1

COMPUSTAGE

RSET DEFOC

MEASURING

VACUUM

TEM CAMERA

HR-TEM BRIGHT FIELD page

¾ This page allows access to most of the functions of the microscope.

¾ The page is made up of three columns. The central column shows the

magnification, spotsize, focus step, film exposure information, film

stock levels, and stage positions.

¾ The right-hand column allows access to other pages in the program

via the softkeys. The most commonly required are COMPUSTAGE,

VACUUM STATUS and MODE SELECTION (MODES).

5

cm200 user guide 2009

Page 6

COMPUSTAGE page

A

A

k

V

¾ The

COMPUSTAGE allows stage position to be monitored and

controlled. Stage positions can be stored and recalled. The central

column on this page contains the same information as on the HRTEM BRIGHT FIELD page.

¾ To store a stage position, select a number in the right-hand column

on the monitor using a softkey (when selected, the number is

highlighted). Press the STORE softkey to save the position.

¾ To return to a saved position, select the appropriate number and

press the RECALL softkey on the right-hand side of the page. The

stage will automatically move to that position.

¾ To clear a saved stage position, select the appropriate number and

press the CLEAR softkey on the left-hand side of the page.

¾ To clear all saved stage positions, press the CLEAR ALL softkey twice

(located on the left-hand side of the page).

¾ The COMPUSTAGE page also contains functions for setting eucentric

height (A-WOBBLER) and for returning the specimen to zero tilt

(RESET AB). The RESET AB softkey must always be pressed before a

specimen is removed.

COMPUSTAGE REGISTER CONTROL

COMPUCTRL

Z DISPL = 0

Z DISPLAY

USER REAL

CLEAR

CLEAR ALL

XY RECALL-

RESET AB

-WOBBLER

LM

HT

spot 1

focusstep

plate auto

meter XXX s

exp no

stoc

X: -141.61 um

Y: -78.72 um

Z: 135.69 um

: 0.00 d

B: 0.00 d

1000x

200k

350nm

-defocus 44.30um

E7773

50

STORE

1

2

3

RECALL

6

cm200 user guide 2009

Page 7

VACUUM STATUS page

A

¾ The

VACUUM STATUS page shows a diagram of the vacuum system.

The status of the vacuum can be read at the top of the screen. Below

the diagram of the vacuum system is a series of pressure readings,

including the IGP (ion getter pump) reading.

P1: 32 P3: 34

P2: 49

¾ Before the gun valve is opened, the IGP reading must be less than 27

and the VACUUM STATUS must be ‘READY’.

MODE SELECTION page

¾ The modes page allows the user to select the TEM mode to be used.

Usually this is HR-TEM. The CONFIGURATION page can be

accessed from this page.

CONFIGURATION page

¾ This page contains information on the state of the microscope

(STANDBY or OPERATE) and on the extraction voltage. As the filament is

turned up, the change in extraction voltage (“Actual”) can be

monitored on this page.

IGP: 5

STANDBY

EXTR LIMIT

CONFIGURATION

FEG CONTROL

State: STANDBY

Time: 0 min

: 4.5 kV

ctual: 2.29 kV

--

DISPLAY

FIL OFF

7

cm200 user guide 2009

Page 8

2. CHECK cm200 STATUS

1. Log in to the EMU Booking System on the PC.

2. Check that the vacuum is OK by confirming that both the UHV and HV

indicators on the far right side of the panel are illuminated. If not, check

with EMU staff.

3. Go to the VACUUM STATUS page (from the HR-TEM page, press the

VACUUM softkey). Check that the vacuum status is READY and that the IGP

is less than 27. If not, check with EMU staff.

4. Return to the HR-TEM page (press READY).

5. Check that the High Tension indicator on the right side of the panel is lit. If

not, check with EMU staff.

6. Fill the liquid nitrogen dewar and place it under the cold finger. You must

wear safety glasses and protective gloves when handling liquid nitrogen.

7. Ensure that condenser aperture 4 and objective aperture 7 are selected and

that the diffraction aperture is out (swing shift to the right).

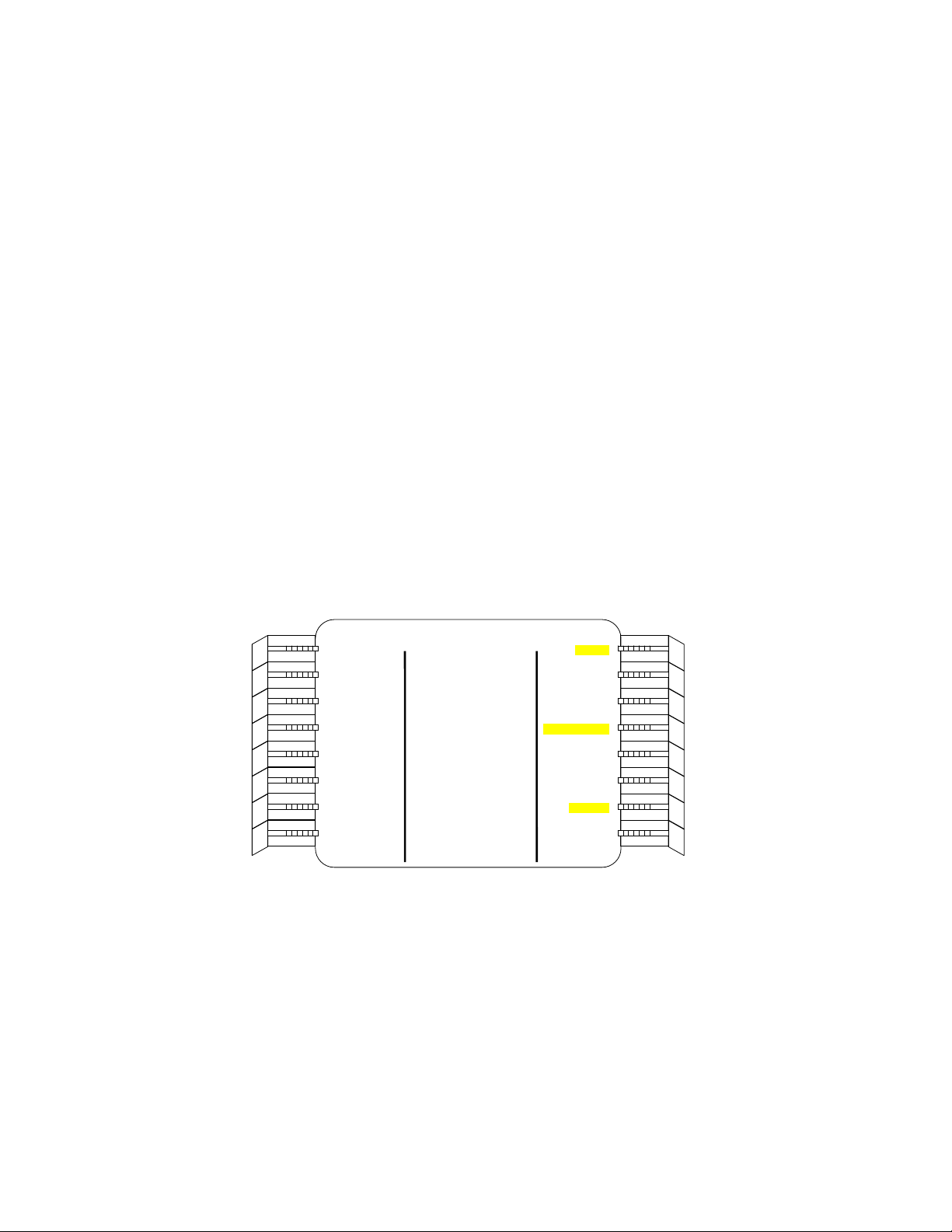

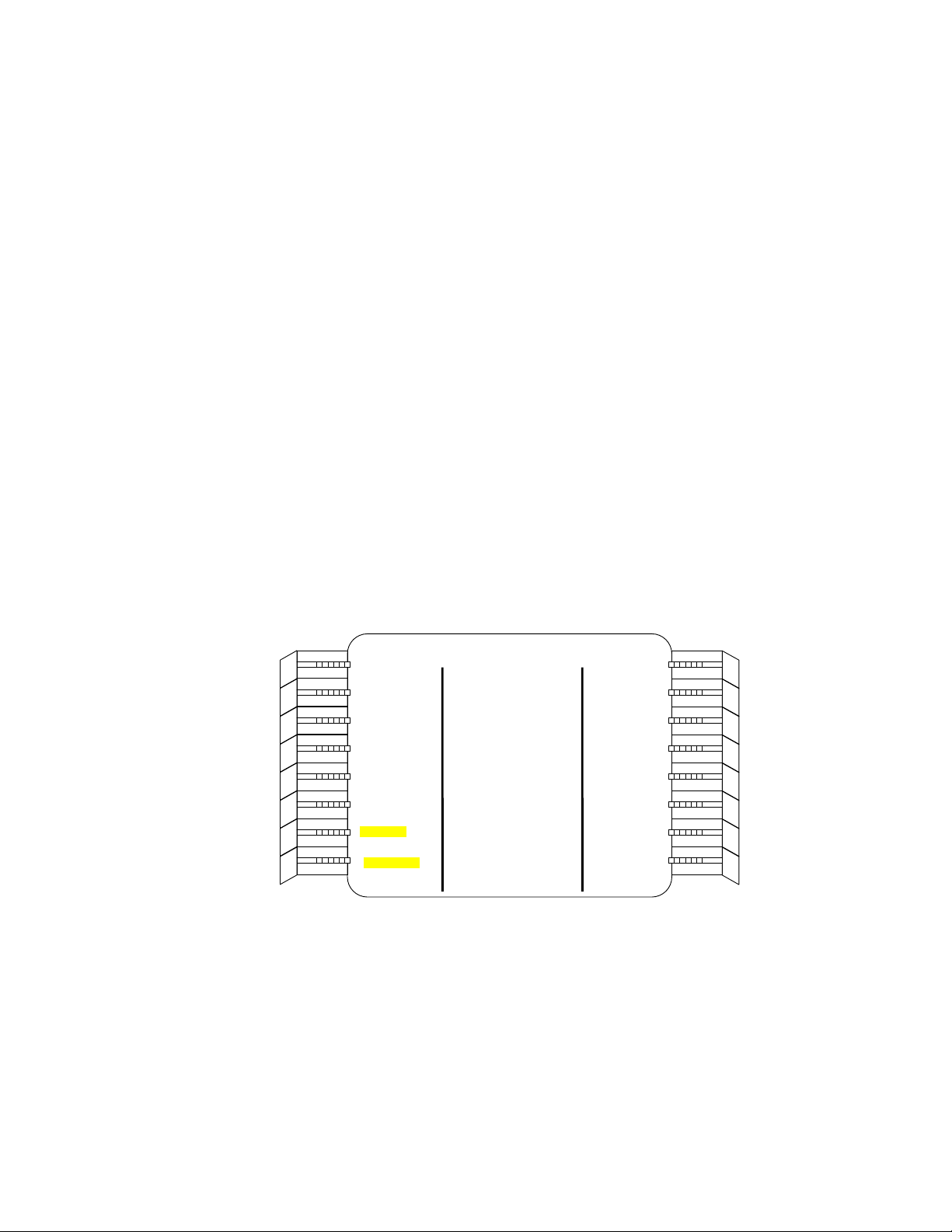

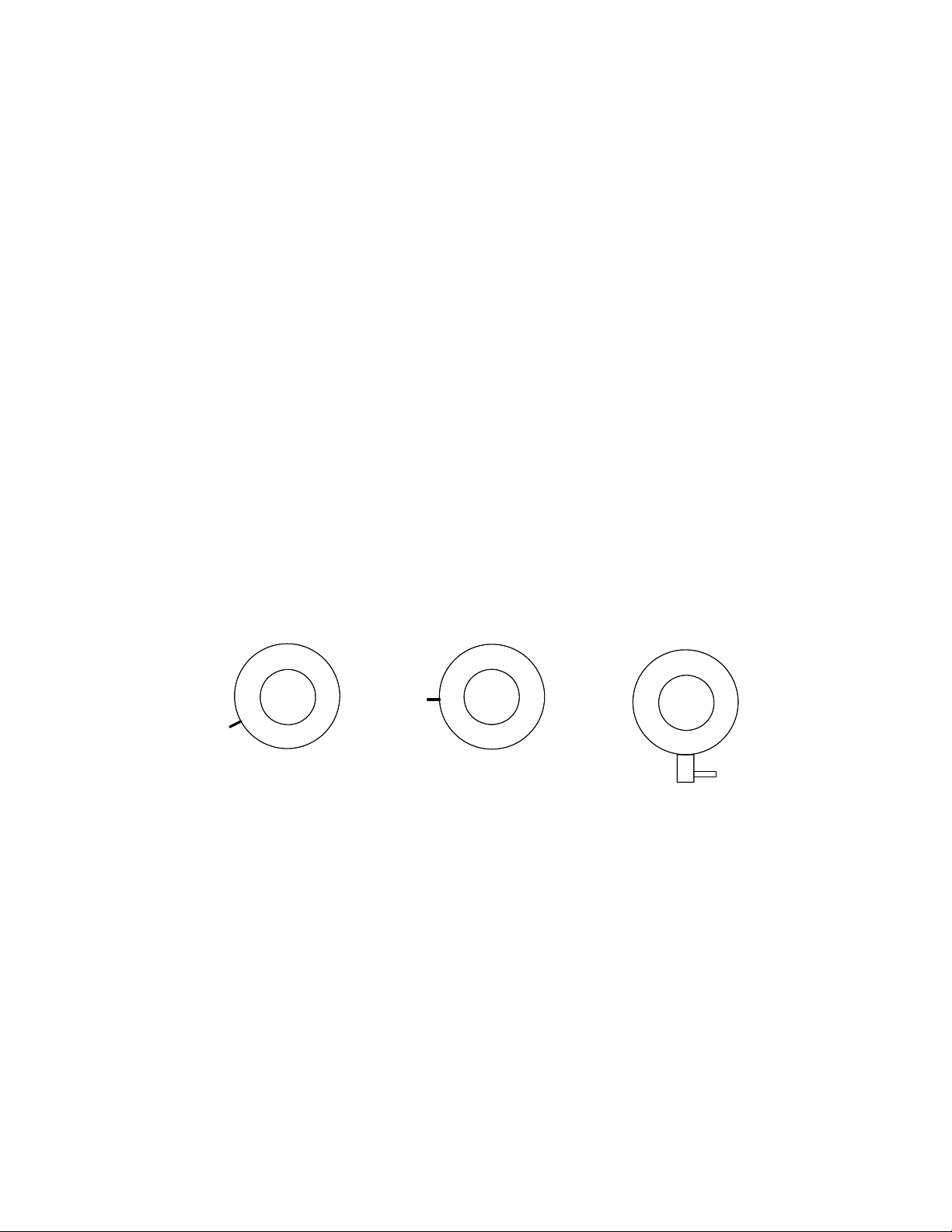

condenser aperture objective aperture diffraction aperture

1

1

7

7

2

2

3

3

4

4

32

32

1

1

6

6

5

5

4

4

cm200 user guide 2009

8

Page 9

3. TURN THE FILAMENT UP

1. Press the MODES softkey and then the CONFIGURATION softkey to go to

the CONFIGURATION page.

2. Turn the filament knob on the right-hand side of the

display screen slowly clockwise (three or four clicks at a

time).

Note: If the voltage is increased too quickly, the kV value

will freeze and you will need to seek assistance from

EMU staff.

Monitor the extraction voltage on the screen. When the

voltage approaches its limit (~4.5 kV), you will hear a

beep. Make sure you reach the maximum possible

voltage by turning the knob a few more clicks. The

voltage will usually reach 4.48 kV.

3. Press the READY button and then the HR-TEM softkey to return to the HRTEM BRIGHT FIELD page.

High tension

On

Off

Filament

3

cm200 user guide 2009

9

Page 10

4. LOAD THE SPECIMEN

There are two specimen holders available:

1) A single-tilt holder for conventional imaging and EDS analysis.

2) A low-background double tilt holder for crystallographic studies and

specialised EDS analysis (see appendix a).

When you begin your cm200 session the single-tilt holder will normally be in

the microscope.

Remove the single-tilt holder:

1. CHECK THAT THE GUN VALVE IS CLOSED. If not, close it by turning the

switch slowly clockwise.

2. Pull the specimen holder out until it cannot

be pulled any further (~8cm).

3. Rotate the holder clockwise as far as it will

go (~120º).

4. Pull the holder gently out of the airlock.

Take care not to knock the specimen holder against the airlock walls as it is

released.

5. Place the specimen holder in the support. Do not touch the brass part of the

specimen holder with your fingers.

6. Lift the specimen securing clamp using the special tool.

7. Load the specimen into the recessed ring, then gently lower the securing

clamp using the special tool.

8. Rotate the specimen holder slightly and gently tap it to ensure that the

specimen stays in place.

1

2

3

Insert the single-tilt holder:

1. CHECK THAT THE GUN VALVE IS CLOSED. If not close it by turning the

switch slowly clockwise.

2. Check the IGP reading by going to the VACUUM STATUS page. The IGP

reading should be less than 27. If not, check with EMU staff.

cm200 user guide 2009

10

Page 11

3. Insert the rod gently into the specimen airlock. Orient the rod so that the

large key peg is at the 11 o’clock position. Push the rod into the airlock until

you feel a stop and the red light on the airlock illuminates (this indicates that

the airlock is being pumped). After the pump has started it is often useful to

gently wiggle the rod, which allows it to be inserted another few

millimetres.

4. Wait until the red light has turned off.

5. Rotate the rod anti-clockwise (~120º) keeping a firm grip on the holder. The

vacuum will ‘grab’ the rod when it gets to the 6 o’clock position.

6. Guide the rod as it enters the airlock. The key peg should slide into the slot

on the airlock. Monitor any change in vacuum by noting the IGP value. (The

IGP value may rise above 27 during rod insertion – it must be 27 before

operation).

cm200 user guide 2009

11

Page 12

5. OBTAIN AN IMAGE

1. Check that the IGP reading is less than 27.

2. Go to the HR-TEM BRIGHT FIELD page (from the VACUUM page, press

READY).

3. Set the magnification to ~500x.

4. Open the gun valve by turning the switch slowly anti-clockwise. The beam

should appear on the viewing screen within a few seconds.

5. If the beam does not appear, check that the high tension indicator is still lit.

¾ If not, close the gun valve by turning the switch slowly clockwise and

check with EMU staff.

¾ If the high tension indicator is lit, check the magnification is ~500x and

that the objective aperture is set to 7.

¾ If you are examining an electro-polished specimen move the specimen

around using the X-Y joystick until you find the hole

6. Centre the beam using the X and Y shift

controls.

7. Spread the beam over the screen by

turning the INTENSITY knob.

8. Locate the area of interest on the

specimen and place it in the centre of

the stage using the X-Y joystick.

Intensity

The INTENSITY knob is

used to spread out &

concentrate the beam (left).

The SHIFT controls are

used to move the beam

around the stage to the

desired position (right).

ShiftYXShift

YX

cm200 user guide 2009

12

Page 13

6. SET THE EUCENTRIC HEIGHT

1. Increase the magnification to 5 -10K.

2. Spread the beam over the screen by turning the INTENSITY knob.

3. Move the beam to the centre of the screen using the X and Y SHIFT controls.

4. Move the specimen (X-Y joystick) so that a recognizable feature is in the

centre of the screen.

5. Go to the COMPUSTAGE page.

6. Press the A-WOBBLER softkey. This causes the specimen to tilt continuously

from +15º to -15º. If the specimen is not at eucentric height the image will

move back and forth on the screen.

7. Adjust the height of the specimen using the Z joystick until the movement of

the image is minimized.

8. Press the A-WOBBLER softkey to stop the specimen tilting.

7. FOCUS THE IMAGE

1. Check that the image is in focus using the FOCUS control. FOCUS STEP

(sensitivity of focus control) can be adjusted using the inner control knob.

¾ Use the small screen (lift by using the rear lever on the left-hand side

of the column) and the binocular microscope on the front of the

column to attain the best focus.

¾ Check that the binoculars are focused by inserting the pointer (right

hand side of the column; turn to insert) and adjust the eyepieces until

the image of the pointer is focused. To remove the pointer pull it out

and turn it to lock.

¾ When focusing, start with a large focus step (5 or 6) and get the best

focus you can before progressively reducing the focus step to achieve

fine focus (focus step 2 or 3).

cm200 user guide 2009

13

Page 14

8. MOVE AROUND THE SPECIMEN

¾ The X-Y joystick controls x-y movement of the specimen. The Z joystick

should be adjusted only when eucentric height is being set.

¾ The stage position can be monitored on the HR-TEM page or the

COMPUSTAGE page. On the COMPUSTAGE page, stage positions can be

stored and recalled (see section 1).

¾ Specimen tilt.

¾ a-tilt is available on both the single and double tilt holder. The

specimen is tilted by turning the TILT knob either clockwise or anticlockwise depending on the desired direction of the tilt. The extent to

which the knob is turned determines the tilt speed.

¾ B-tilt is available only with the double-tilt holder. The direction and

speed of the tilt are controlled by the HOLDER knob. The tilt is

controlled by the foot pedal

¾ Reset the specimen to 0º tilt by pressing RESET AB on the

COMPUSTAGE page.

cm200 user guide 2009

14

Page 15

9. CHECK THE MINOR ALIGNMENTS

The minor alignments should be checked at the start of each session, and may

be adjusted at any time. They should be performed whenever the condenser

aperture is changed.

Condenser aperture alignment

The aim of this alignment is to make the

beam expand and contract

concentrically.

1. Check that the objective aperture is out (position 7).

2. Focus the image.

3. Condense the beam to a fine spot using the intensity knob.

4. Centre the spot on the screen using the X and Y shift knobs.

5. Expand the spot using the INTENSITY knob until it is ~10cm in diameter.

6. Centre the spot on the screen using the condenser aperture drives.

34

5

7. Repeat from step 2 until the beam expands concentrically from the centre of

the screen.

Condenser stigmation alignment

The aim of this alignment is to make the

beam as circular as possible.

1. Check that the objective aperture is

out (position 7).

2. Set the magnification to ~50K.

3. Focus the image.

:

4. Press the STIG button on the right hand side of the console. The LED will

illuminate and the STIGMATOR CONTROL page will be displayed.

5. Select the COND softkey.

: ;

cm200 user guide 2009

15

Page 16

6. Condense the beam to a spot about 3cm in diameter using the INTENSITY

knob.

7. Adjust the beam so that it is as circular as possible using the X and Y

MULTIFUNCTION knobs on the right hand side of the console.

8. Press the STIG button to leave this function.

Pivot point alignment

If the pivot points are aligned, focussing at high magnifications is easier

1. Check that the objective aperture is out (position 7).

2. Set the magnification to ~50K.

3. Focus the image.

4. Condense the beam to a small spot.

5. Press the ALIGN button on the right hand side of the console. The LED will

illuminate and the ALIGNMENT SELECTION page will be displayed.

6. Press the PIVOT POINT X softkey. You should see two spots on the screen.

(If the spots are not visible you may need to reduce the magnification).

7. Use the MULTIFUNCTION X and Y knobs on the right hand side of the

console to make the two spots overlap. (Keep the spots in view by adjusting

the X and Y SHIFT controls, if necessary).

8. Press the PIVOT POINT Y softkey. You should see two spots on the screen.

(If the spots are not visible you may need to reduce the magnification).

9. Use the MULTIFUNCTION X and Y knobs on the right hand side of the

console to make the two spots overlap. (Keep the spots in view by adjusting

the X and Y SHIFT controls, if necessary).

10. Press the ALIGN button to leave this function.

cm200 user guide 2009

16

Page 17

10. INSERT AN OBJECTIVE APERTURE

There are 4 objective apertures available. The largest aperture (1) produces the

least image contrast; the smallest (4) produces the most contrast. Positions 5, 6

and 7 do not have an aperture.

1. Set magnification to 5-10K.

2. Condense the beam to a fine spot using the INTENSITY knob.

3. Press the D button on the right hand side of the console. This will produce a

diffraction pattern on the screen.

4. Turn the objective aperture control counter clockwise to select the desired

aperture.

5. Centre the aperture (the dim circle) over the bright spot using the aperture

alignment knobs. Be careful! The amount of movement required is very

small.

6. Press the D button again to go back to a normal (bright-field) image.

7. Spread the beam over the screen using the INTENSITY knob.

cm200 user guide 2009

17

Page 18

11. RECORD AN IMAGE ON PHOTOGRAPHIC FILM

1. CHECK THAT THE IMAGE SELECTOR SWITCH IS SET TO CM.

2. Align the area of interest on the centre of the screen.

The corners of the negative are marked by the middle

spot of each group of three spots. The data bar

(including the scale bar and exposure number)

occupies the far right of the image, so make sure that

your primary area of interest is not in this region.

3. Check that the image is in focus using the FOCUS

control. FOCUS STEP (sensitivity of focus control) can be adjusted using the

inner control knob.

¾ Use the small screen and the binocular microscope on the front of

the column to attain the best focus.

4. Spread the beam so that it covers the whole screen. The exposure time is set

automatically.

5. Note the exposure number. This number is the number of the next negative

to be used and will appear on the negative when it is developed.

6. Lift the main screen into the vertical position using the front lever on the

left-hand side of the column. The light on the EXPOSURE button on the lefthand side of the column will turn on.

¾ If the EXPOSURE light does not illuminate, check that there is still

film in the camera (stock) and that the exposure time is not too

long. The EXPOSURE light will not illuminate when the rotary

pump is operating – wait until it stops to take your image.

7. Press the exposure button. All of the console lights will turn off and the film

will be exposed.

8. Wait until the console lights turn back on and then lower the screen using

the lever on the left-hand side of the column. The EXPOSURE light will turn

off when the stage is lowered.

cm200 user guide 2009

18

Page 19

12. RECORD A DIGITAL IMAGE

1. CHECK THAT THE IMAGE SELECTOR SWITCH IS SET TO CCD.

2. Align the image in the centre of the screen. The digital camera captures the

area shown on the small screen (lift by using the rear lever on the left-hand

side of the column). The digital image will be rotated by 90º.

3. Check that the image is in focus using the FOCUS control. FOCUS STEP

(sensitivity of focus control) can be adjusted using the inner control knob.

¾ Use the small screen and the binocular microscope on the front of

the column to attain the best focus.

4. Spread the beam so that it covers the whole screen.

5. Start ANALYSIS on the PC by clicking on START>PROGRAMS>AnalySIS>

AnalySIS.

6. Lift the main screen into the vertical position using the front lever on the

left-hand side of the column.

7. Click on the ACQUIRE icon .

¾ This image is ‘live’ and will be refreshed every few seconds.

¾ The camera control icon controls the brightness/contrast.

Adjust the exposure time so that the intensity histogram is

normally centred (usually 1000ms).

8. Click on the

9. Click on the SCALEBAR icon to add a scale bar.

10. Save the image into your folder on the network (m:\images\cm200\your

user name).

11. Lower the stage to continue imaging.

SNAPSHOT icon to capture the image.

cm200 user guide 2009

19

Page 20

13. EXCHANGE SPECIMENS

1. Reduce the magnification to ~500x.

2. Remove the objective aperture by turning the aperture control fully

clockwise so that it is in position 7.

3. CLOSE THE GUN VALVE by turning the control knob slowly clockwise.

4. Ensure that the stage is at 0º tilt by going to the COMPUSTAGE page and

pressing the RESET AB softkey.

5. Pull the specimen holder out until it cannot be pulled any further (~8cm).

6. Rotate the specimen holder ~120º clockwise.

7. Pull the specimen holder gently out of the airlock.

8. Place the specimen holder in the support.

9. Lift the specimen securing clamp using the special tool.

10. Remove the specimen.

11. Insert the new specimen into the holder.

12. Lower the specimen securing clamp using the special tool.

13. Insert the specimen holder into the column as described in section 4.

cm200 user guide 2009

20

Page 21

14. END THE SESSION

1. Remove the specimen as described in section 13.

2. Insert the single tilt specimen holder into the column as described in section

4.

3. Go to the CONFIGURATION page by pressing MODES then

CONFIGURATION.

4. Press the STANDBY softkey to put the microscope into standby mode.

Check that the filament emission automatically reduces to ~2.29kV.

5. Clear any stored stage positions by going to the COMPUSTAGE page and

pressing CLEAR ALL twice.

6. Cover the TEM windows.

7. Exit from any programs that you have been running on the PC.

8. Log out of the EMU booking system.

cm200 user guide 2009

21

Page 22

Appendix a: Using the double tilt holder

The double-tilt holder may be used by advanced users for crystallographic

studies and/or specialised EDS analysis.

If you would like to use the double-tilt holder, contact a member of EMU staff

for training.

1. Close the gun valve and remove the single-tilt holder as described on pX.

2. Rest the double-tilt holder in the clear plastic support.

3. Unscrew and remove the beryllium ring using the tool provided (kept

in a plastic, snap-top tube).

4. Load your specimen into the circular recess in the holder.

5. Gently and carefully screw the beryllium ring into place to secure the

sample, using the tool provided.

AVOID CROSS-THREADING & DO NOT OVER-TIGHTEN THE RING

6. Rotate the specimen holder slightly and gently tap it to ensure that the

specimen remains in place.

7. Check the IGP reading by going to the

Open

VACUUM STATUS page. The reading

should be less than 27.

If not, check with EMU staff

8. Lower the shift on the airlock so that the

Close

circular slot is open.

9. Orient the rod so that the large key peg is at about 11 o’clock. Insert the rod

gently into the specimen airlock until the red light on the airlock illuminates

(this indicates that the airlock is being pumped). After the pump has started

it is often useful to gently wiggle the rod, which allows it to be inserted by

another centimetre or so.

DO NOT INSERT THE ROD FURTHER UNTIL THE RED LIGHT HAS TURNED

OFF.

10. The computer system will automatically sense that a double-tilt holder is

being inserted and will ask you to specify which specimen holder you are

using. On the computer interface, select

PHILIPS DOUBLE TILT and press READY.

Open

Close

cm200 user guide 2009

22

Page 23

11. As instructed on the screen, plug in the double-tilt holder cable to the right

side of the airlock and press READY.

12. Check that the red light is off.

13. Rotate the rod ~120° anti-clockwise 4, keeping a firm grip on the holder.

(The vacuum will ‘grab’ the rod when it gets to about 6 o’clock.)

14. Guide the rod as it enters the airlock. The key peg should slide into the slot on

the airlock. Monitor any change in vacuum by noting the IGP value. (IGP may

rise above 27 during rod insertion – it must be below 27 before operation).

cm200 user guide 2009

23

Page 24

Appendix b: Diffraction patterns

1. Select the required field of view with the sample at the appropriate tilt angle.

2. Insert a selected area diffraction aperture (if required) by turning the swing shift

to the left. Align the aperture over the area of interest.

3. Remove the objective aperture from the beam.

4. Press the D button.

5. Adjust magnification (camera length), focus and intensity to optimise the

pattern.

6. Centre the pattern on the screen with the MULTIFUNCTION X and Y knobs.

7. Record the pattern.

¾ Check that the image selector switch is set to CM.

¾ Select TEM CAMERA.

¾ Adjust MAN TIME to set the exposure time. For most patterns 1-2

seconds is appropriate. (Exposure time is best determined by running a

series of test exposures.)

¾ Note the exposure number.

¾ Lift the main screen.

¾ Press the exposure button.

¾ Wait until the console lights turn back on and then lower the main

screen.

8. Insert and align the objective aperture.

9. Remove the selected area diffraction aperture.

10. Press the D button to leave diffraction mode.

cm200 user guide 2009

24

Page 25

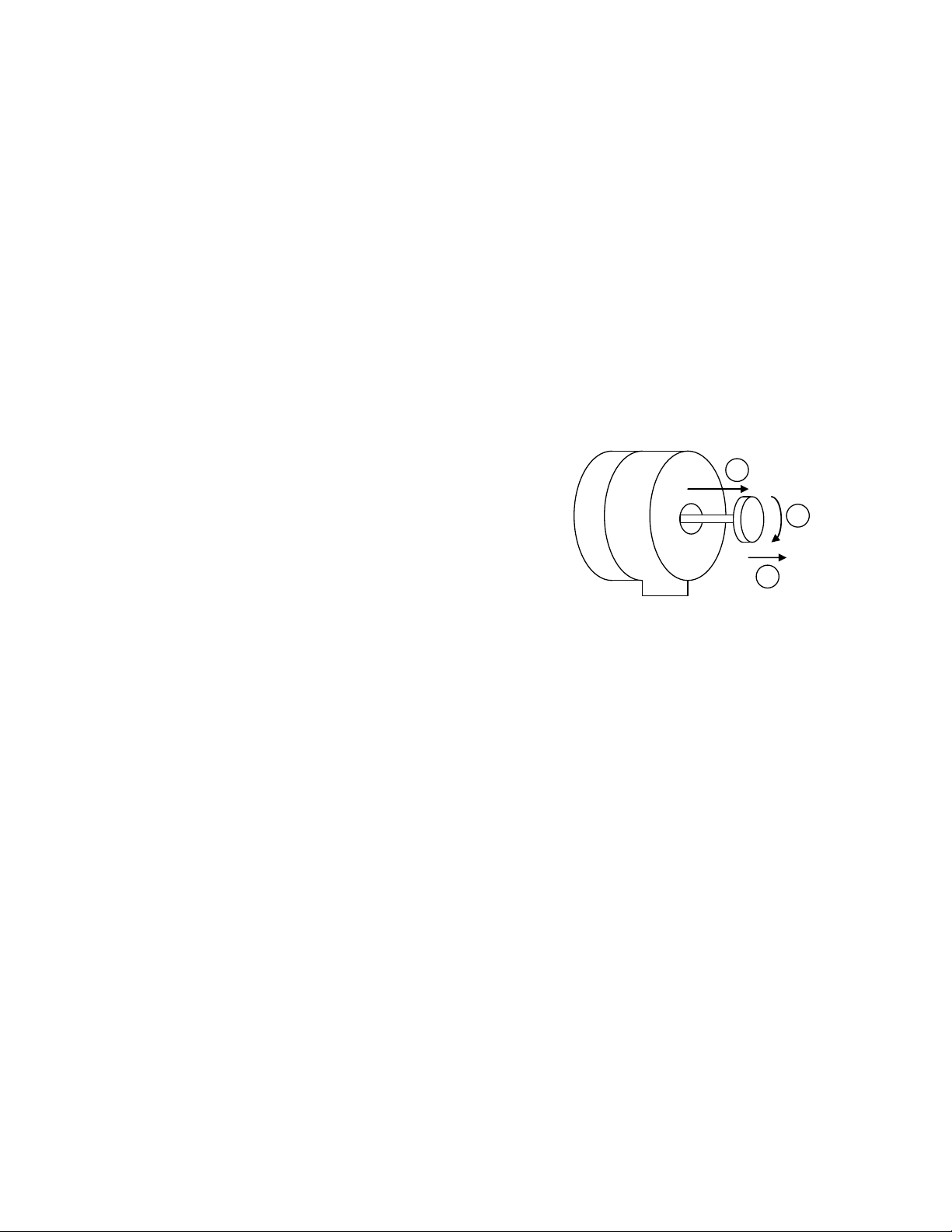

Appendix c: X-ray analysis

SEE EMU STAFF BEFORE ATTEMPTING X-RAY ANALYSIS FOR THE FIRST

TIME.

The Philips CM200 is equipped with an EDAX r-TEM system to perform energydispersive x-ray spectroscopy (EDS). We use a Sapphire Si(Li) EDAX detector

with 30mm2 active area. This is used to acquire and analyse chemical spectra

from the TEM sample. The software programs used to run the analyses operate

in a Windows™ environment and many of the functions of the software are

similar to other Windows-based programs.

These instructions are intended as a basic guide. For advanced software

features, please consult the mDX or iDX Reference Manual available from EMU

staff.

Getting Started

1. Start the EDS software by double-clicking on the mDX icon.

2. Locate the region of interest in the centre of the TEM viewing screen.

3. Remove the objective aperture.

4. Insert condenser aperture 3. Align the aperture (see p.23).

5. Tilt the specimen toward the detector by increasing the α-tilt to

approximately +15°.

6. Reduce the spot size to spot size 4. You may need to adjust the spot size

again later.

7. Position the beam over the area of interest using the

INTENSITY and BEAM SHIFT knobs.

8. Insert the EDS detector by pressing the red ANALYZE button

on the RTEM hardware control box.

RTEM

Analyze

Retracted

EDAX

9. Check the COUNT RATE (bottom left corner of the computer screen). It

should be between approximately 1000 counts per second (cps) and 4000

cps.

¾ If the count rate is much too high, the

detector will retract automatically. The

green RETRACTED button will flash.

Press the RETRACTED button to stop the flashing. Diagnose the cause

of the high count rate (e.g., objective aperture left in or Cu grid in

cm200 user guide 2009

25

Page 26

¾ If the count rate is over 4000cps but the detector does not

automatically retract, try decreasing the spot size to reach 10004000cps.

¾ If the count rate is too low (<~200cps), increase the spot size, re-

position the beam and re-acquire.

Acquiring a Spectrum

1. Click on the clock icon in the top left corner of the mDX menu bar to

start acquiring a spectrum. The icon will turn yellow when activated. The

spectrum will automatically acquire for 100 seconds. To stop acquisition at

any time, click on the clock icon again (it will turn grey).

2. Check the count rate and adjust if necessary.

Modify Spectrum Appearance

1. The scale of the spectrum can be manipulated by holding down the left

mouse button and moving the mouse left, right, up or down. The spectrum

can be expanded or contracted by pressing the appropriate buttons on the

toolbar:

¾ Expand/contract horizontally:

¾ Expand/contract vertically:

¾ Press the house icon

2. Add text to the spectrum by selecting ADD TEXT from the EDIT menu.

Click on the spectrum at the point where the text is to be added and enter

the text in the box that appears. Press ENTER to place the text on the

spectrum. The text can be edited or removed at any time by re-selecting

ADD TEXT from the EDIT menu and then clicking on the text.

3. Add text to the spectrum header by selecting LABEL from the EDIT menu,

enter a label in the box and press OK.

4. Erase a spectrum by pressing the paint-roller icon in the top left corner

of the screen.

cm200 user guide 2009

to restore the full spectrum.

26

Page 27

Savin Spectral Data

s

m

ppr

a

p

e

y

w

o

g

e

g

h

e

m

u

e

e

o

m

-

x

g

d

a

i

p

l

T

t

o

e

n

e

t

u

u

e

n

a

g

c

e

r

K

I

i

C

g

g

o

x

o

a

p

gh

e

A

h

d

a

s

y

o

s

e

t

y

s

M

d

m

a

d

c

a

e

e

f

a

L

i

e

s

m

L

p

m

S

i

s

h

e

M

E

f

O

t

s

e

o

2

0

. Save file

1

. Spectru

2

to your username folder under M:\ > IMAGES > CM200.

files can be saved in .spc, .tif, .csv or .bmp format.

¾ .s

¾ .tiinf and .bmp

¾ .c

Qua

itative Elemental Analysis

he EDS sys

q

ualitative

u

sers should

a

nalysis.

. The seri

1

screen a

the PEA

IDENTIF

screen.

c files can

actice to s

fu

ture.

most ima

sv files sav

e allows th

fil

s

ch as Micr

em we us

r semi-qua

consider u

s of icons i

e used for

IDENTIFI

CATION d

only be o

ve these fil

files save t

ing softwar

a spectru

user to re

soft Excel.

is almost

titative da

sing the mi

n the top ri

nterpretin

ATION ic

ialogue bo

ened by th

es in case

e spectru

programs

trace as

raph the

xclusively

a. For acc

croprobe o

ht corner

the spectr

n to o

on the ri

mDX soft

ou need t

as a pictu. re that can be opened

and y dat

ata in a sp

sed for th

rate quanti

r performin

f the mDX

l data. Sel

en the PE

t side of t

are. It is

manipulat

points. Th

readsheet

acquisitio

tative data

mass spe

ct

K

e

ood

them in

s type of

rogram

of

nalysis,

trometric

2

. Click on

3

. Check th

. Manuall

4

cm2

identify

element

definitel

clicking

box. Thi

associat

incorrec

ELEM bo

element

POS ELE

0 user gui

the AUTO

nd label th

will also a

at each aut

associate

n the ele

will displ

d with that

ly identifie

x and click

identify a

associated

box. Cli

e 2009

button. Thi

e main pe

ppear in th

omatically

with a par

ent (e.g., F

y all of the

element. I

, select th

on the DE

peak by cl

with that

k on a pos

s will auto

ks. The list

SAVED E

identified

ticular ele

K) in the

peak posit

a peak ha

t element i

ETE box to

cking on t

nergy valu

ible eleme

atically

of identifie

EM box.

eak is

ent by

AVED ELE

ons

been

n the SAV

remove it

e peak itse

(keV) will

nt in the P

d

D

rom the lis

lf. The pos

be display

S ELEM b

.

ible

d in the

x to display

7

Page 28

all of the peak locations associated with that element. When you identify an

element, click on ADD to add the element to the SAVED ELEM box.

Adjust the Display Characteristics

1. Element labels can be removed individually from

the spectrum (and SAVED ELEM box) by

highlighting them and clicking on the DELETE

button. Clicking on the DELETE ALL button will

remove all peak labels and will clear the SAVED

ELEM box.Select the ALPHA LINES ONLY box to

remove labels from all peaks except the α peaks.

2. Select ELEM to label peaks by element (e.g., Cu or Sn); SHELL to label peaks

by their electron shell level (e.g., CuK or SnL); or TRANS to label peaks by

their transition type (e.g., CuKa or SnLb).

3. Select EPIC to bring up a periodic table with x-ray energies to assist in peak

identification. Select an element and click on ENERGY TABLE to display

peak energies.

Regions of Interest (ROI)

Energy ranges (regions of interest) representing certain element peaks can be

selected for use in elemental mapping (see p.44). Peaks falling within the

selected ROI will be shaded (default colour is grey).

To remove an ROI label, select the the ROI icon and click on the DELETE

button. Select DELETE ALL to remove all ROI labels at once.

Comparing Two Spectra

1. Click on VIEW on the menu bar and select

COMPARE. A COMPARE SPECTRA window will

appear showing the name of the last spectrum

acquired as Spectrum A.

2. Click on the OVERLAY box.

3. Open a second, saved spectrum by clicking on

OPEN. Select your second spectrum for

comparison (Spectrum B).

4. Click on OK. The two spectra will be overlayed

for comparison.

cm200 user guide 2009

28

Page 29

Opening a Saved Spectrum

1. To open a previously saved spectrum, click on FILE > OPEN, locate your

folder and file and click on OK.

2. A FILE or CURRENT PARAMETERS dialogue box

will appear with a selection of display options. For

most applications, ensure that all the FILE options

are selected. This will display the spectrum in the

same format as it was saved.

3. Select the VIEW option to look at the parameters

stored with the saved spectrum.

4. Click OK to open the spectrum.

Semi-Quantitative Analysis

The mDX program’s QUANTIFY function allows the user to perform semiquantitative elemental analysis of a sample. Proper quantitative analyses can be

conducted but require replicate analyses and the careful preparation and use of

standards in order to assess the accuracy and precision of the results.

Using mDX, first identify the elements to be quantified, subtract the

background, and select the appropriate set of correction parameters. The

following description is generic and should be modified depending on the

nature of the quantification to be performed. Consult the reference manual and

EMU staff for assistance.

1. Click on the QUANT icon in the top right corner of the computer

screen. The QUANTIFY control panel will appear.

2. Click on the button. A Z LIST dialogue box will appear,

listing the elements to be quantified.

3. Select or de-select the elements to be quantified by clicking on them. Click

OK.

4. Click on the button. A BACKGROUND display panel

will appear.

5. Select SET to generate a list of elements identified using the qualitative

analysis in the AUTO field. These elements are used to determine the

background radiation.

cm200 user guide 2009

29

Page 30

6

f

d

C

u

u

x

X

I

t

n

m

a

o

e

)

l

u

r

r

d

m

e

o

n

y

u

c

o

r

d

k

r

.

N

e

L

g

e

m

r

l

c

o

o

h

a

t

o

A

s

c

o

r

e

s

u

e

e

t

T

a

e

t

R

O

d

t

N

H

d

O

a

A

c

s

R

s

x

r

f

p

n

n

d

a

D

c

w

a

3

0

. Click on

SUBTRA

backgro

backgro

the – (subt

T field to

nd. Select

nd to the s

act) button

remove the

UNDO to

pectrum.

in the

estore the

. Click on

7

. Click on

8

open the

which e

intensity

oxide mi

select O

9

. Click on

quantific

QUANT

I

you need

1

0. Click on

applied.

For most

dependi

approxi

denotes

absorpti

the QUAN

the

TYPE cont

cludes oxi

has been

xtures (wh

IDES.

the

ation calcu

FICATION

o define y

the

A correctio

applicatio

on the t

ation calc

bsorption

n correcti

T icon

ol panel.

es from th

easured, E

re the oxy

lation to b

panel. In

ur own co

n factor wi

s, select ei

pe of corre

lations, IN

orrection

n calculati

button to

ormally, t

quantific

EMENTS s

en peak in

butt

used. A K

ost cases,

rection fa

butt

l appear in

ther INTEN

ction requi

TEN denot

alculation

ns with fl

e ELEMEN

tion calcul

hould be s

ensity has

n to select

B FACTO

elect THE

tors/metho

n to select

the QUA

only or T

ed. THIN

s intensity

and FLU

orescence.

S option i

tions. If o

lected. Fo

not been m

he type of

S field ap

.

, see Paul Munroe.

he correcti

TIFICATIO

IN, INTEN

enotes thi

calculatio

RESENCE

selected,

ygen peak

analysis o

easured),

ears in the

on factors

N panel.

and ABS,

s, ABS

enotes

1

1. Click on

1

2. The resu

cm2

you hav

window

~200nm

Save res

0 user gui

the

elected to

will appea

, a-tilt valu

ts will be

lts by clic

e 2009

button to

do an abs

. Enter the

e and the n

isplayed in

ing on the

perform th

rption corr

nominal sp

ominal spe

a QUANT

bu

quantific

ction, an

ecimen thi

cimen den

IFICATION

ton in the

tion calcul

BS CON

kness (typi

ity and cli

RESULTS

ESULTS p

tions. If

ITIONS

cally

k OK.

indow.

nel.

0

Page 31

Ending the EDS Session

1. Remove the EDS detector by pressing the green RETRACTED button on the

RTEM hardware control box to the right of the column.

2. Press the AB RESET softkey on the COMPUSTAGE page to return the

specimen to 0° tilt.

3. Insert and align condenser aperture 4 (see p.15).

4. Exit the mDX program.

5. End the session as described in section 14.

cm200 user guide 2009

31

Page 32

Appendix d: X-ray mapping/line scans

X-ray maps can be made using the iDX software installed on the computer

attached to the CM200. A map is a two-dimensional representation of

elemental distribution in a sample. A map is made by obtaining an STEM

image, transferring the STEM image to the PC, and acquiring spectra across the

selected sample area on a pixel-by-pixel basis.

SEE EMU STAFF BEFORE ATTEMPTING THIS FOR THE FIRST TIME.

Getting Started

1. Check that the image selector switch is set to CM.

2. Obtain a well-focused image on the TEM viewing screen.

3. Tilt the specimen so that an α-tilt of approximately +15° is achieved.

4. Insert and align condenser aperture 3 (see p.15).

5. Align the condenser stigmator (see p.15).

6. Remove the objective aperture.

7. Adjust the magnification to 10,000-20,000x.

8. Condense the beam to a small spot, centre the beam using the X and Y shift

controls, and press the D button to obtain a diffraction pattern.

Obtaining a STEM Image

1. Press the MODES softkey and then press the SCAN BF-DF softkey twice to

view the SCANNING page.

2. Lift the TEM stage and a STEM image should be displayed on the two

monitors on the top of the microscope console. The bright-field image

should be visible on the left monitor, and a dark-field image on the right.

(The magnification may need to be reduced to ~20,000x using the

magnification control.)

3. Ensure that the bright-field image is active. Two LEDs below the screen will

be illuminated when the screen is active. Use the DETECTOR

CONTROL button in the SIGNAL CONTROL area of the STEM

controls to toggle between the screens.

4. Centre the beam.

'

I. Press ALIGN go to the ALIGNMENT SELECTION page.

cm200 user guide 2009

32

Page 33

II. Press the DET ALIGNM softkey

III. Centre the illumination on the bright field image using the X and Y

MULTIFUNCTION controls. The magnification may need to be

reduced in order to see the illumination spot. If magnification is

changed, the DET ALIGNM softkey must be pressed again in order to

activate the X and Y MULTIFUNCTION knobs.

IV. Press ALIGN to exit the ALIGNMENT SELECTION page.

5. Optimise the image.

¾ Adjust the image position, magnification and focus using the

standard TEM controls. The STEM image may be rotated by turning

the MULTIFUNCTION X knob.

¾ Adjust the brightness and contrast of the image using the

BRIGHTNESS and CONTRAST controls on the STEM control panel.

¾ Adjust the SCAN RATE at any time by selecting the appropriate

button: SLOW or FAST.

Collecting the Electron Image

1. Enable external control of the microscope by pressing the EXP 3 button on

the PHOTO SCAN RATE section of the STEM control panel.

2. Open the iDX program.

3. Click on the icon in the toolbar to acquire an electron

image (or select COLLECT > ELECTRON IMAGE). The image will be

refreshed continuously until the icon is pressed again.

4. Adjust image parameters.

I. Click on the icon.

II. Select the matrix size.

III. Enter the magnification.

IV. Display a micron bar by selecting MICRON BAR from the DISPLAY

menu.

V. Adjust the brightness and contrast of the image using the

BRIGHTNESS and CONTRAST controls on the STEM control panel.

cm200 user guide 2009

33

Page 34

Select regions of interest

e

e

c

o

P

p

n

o

O

n

a

i

k

s

8

d

e

e

e

(

a

A

y

O

a

a

n

l

r

n

l

e

y

E

p

A

a

n

s

o

t

O

e

a

t

O

M

s

d

i

w

s

D

t

n

n

t

t

m

p

o

w

e

D

h

e

w

t

O

.

e

D

t

n

h

l

x

k

t

y

e

A

e

a

E

e

L

V

g

3

0

. Insert th

1

hardwar

EDS dete

control b

tor by pres

x.

sing the red ANALYZE button on the RTEM

. Select S

2

acquire.

on the s

again.

3

. Select th

. Click on

4

and labe

also app

5

. Check th

associat

element

display

If a peak

in the S

remove i

6

. Manuall

possible

in the P

display

identify

box.

ECTRUM f

Acquisitio

ectrum to

PEAK ID

the AUTO

l the main

ar in the S

at each aut

d with a p

e.g., FeK) i

ll the peak

has been i

VED ELEM

t from the l

identify a

elements a

S ELEM b

ll the peak

n element,

rom the C

can be sta

lbar. Stop t

NTIFICATI

button. Thi

eaks. The

VED ELE

omatically

rticular ele

n the SAVE

positions a

correctly i

box and cl

ist.

peak by cl

sociated

x. Click on

locations a

click on A

LLECT me

rted manu

he acquisit

N icon

s will auto

list of ident

box.

identified

ment by cli

D ELEM b

sociated

entified, s

ick on the

cking on t

ith that en

a possible

sociated

D to add

u. A spect

lly by clic

on by pres

.

atically id

ified eleme

eak is defi

cking on t

x. This will

ith that ele

lect that e

ELETE bo

e peak itse

rgy value (

element in

ith that ele

he elemen

rum should

ing on the

ing the

entify

nts will

itely

e

ment.

ement

to

lf. The

eV) will b

the POS E

ment. Whe

t to the SA

in to

be

button

button

displayed

EM box to

n you

ED ELEM

. Click on

7

(ROI) pa

previous

.

Click on

range fo

panel. A

the ROI

of the el

the list b

0 user gui

cm2

the bu

el on the r

y saved R

the AUTO

all of the

individua

ist will be

ments liste

selecting

e 2009

ton to ope

ight side of

I by clicki

button. Thi

lements in

l map of ea

cquired. If

d, remove

he elemen

the REGI

the screen

on DELE

s will creat

the PEAK I

ch of the el

you do no

he unwant

and clicki

NS OF IN

Delete an

TE ALL.

a ROI en

ENTIFIC

ements sel

want to m

ed element

ng on DEL

TEREST

rgy

TION

cted in

p all

(s) from

TE.

4

Page 35

Acquiring a map

1. Click on the button to open the X-MAPS PARAMETERS panel.

2. Adjust the resolution of the image/maps by changing the size of the MATRIX

(# data points/pixels) and the DWELL TIME.

¾ Usually a 128 x 100 collection matrix with a 10ms dwell time is

sufficient to obtain at least a preliminary idea of the results.

¾ A 256 x 200 collection matrix with a 10ms dwell time usually takes

~20 minutes, depending on the number of elements to be mapped.

¾ Increasing the dwell time and the matrix size will increase the

resolution, but will also increase the acquisition time.

3. Click on the button to start the acquisition (or select X-RAY MAPS from

the COLLECT menu).

¾ A prompt will ask for a filename. Filenames must be ≤4 characters

long. Enter an appropriate filename and select your folder (under M:

> Images > CM200). Files will be saved as bitmaps; file size depends

on the size of the collection matrix. Click OK.

¾ A prompt box will display the collection parameters you have

chosen. Click on YES to start the map acquisition.

¾ To stop the acquisition at any time, click on the button again (or

select STOP from the COLLECT menu).

¾ The maps are automatically saved when acquisition is complete.

Acquiring a line scan

1. Click on the icon to open the LINE SCAN PARAMETERS panel.

2. Click the icon to activate the line drawing function.

3. Click and drag on the image to draw a line. To redraw the line, click on the

icon again.

4. Adjust the parameters of the line scan.

¾ Select the number of points.

cm200 user guide 2009

35

Page 36

¾ Select the dwell time.

¾ The estimated time for the line scan is displayed in the status bar.

5. Click on the icon to start the acquisition.

¾ A prompt will ask for a file name. Select your folder (under

M:>images>cm200). Files will be saved as .csv files. They may be

imported into MS Excel spreadsheets.

Acquiring further maps/line scans

1. Press the SLOW (or FAST) button on the VIEWING SCAN RATE panel to

return to STEM mode.

2. Adjust the image as required (position, brightness, contrast, magnification,

etc.).

3. Continue as described from Collecting the Electron Image (p.33).

Ending the Mapping Session

1. Remove the detector by pressing the green RETRACTED button on the RTEM

hardware control box to the right of the column.

2. Press the SLOW button on the VIEWING SCAN RATE panel to return to

STEM mode.

3. Lower the viewing screen on the TEM.

4. Press the MODES softkey and press HR-TEM twice to return to the HR-TEM

main page.

5. Go to the COMPUSTAGE page and press the RESET AB softkey to return the

specimen to 0° tilt.

6. Insert and align condenser aperture 4 (see p. 15).

7. Quit the iDX software.

8. Log out of the EMU system and turn off the monitor.

cm200 user guide 2009

36

Loading...

Loading...