Philips 32PF4321/96 Schematic

Published by JH 0664 TV Service Printed in the Netherlands Subject to modification EN 3122 785 16140

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

Al

l rights reserved. No part of this publication may be reproduced, stored in a

retr

ieval system or transmitted, in any form or by any means, electronic,

mechan

ical, photocopying, or otherwise without the prior permission of Philips.

Colour Television Chassis

MQC1.0A

LA

Contents

1. Technical Specifications, Connections, and Chassis Overview

2. Safety Instructions, Warnings, and Notes

3. Directions for Use

4. Mechanical Instructions

5. Service Modes, Faultfinding

6. Block Diagrams

7. Circuit Diagrams, PCB Layouts

Alignments

8.

9. IC data sheet

10. Space Parts list

. Revision List

11

Page

1

3

4

5

8

15

19

53

54

55

56

EN 1

Technical Specifications, Connections, and Chassis Overview

1.

MQC1.OA LA

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

1.3 Chassis Overview

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD (CMO)

Screen size : 32 inches (813.3 mm) diagonal

Resolution : 1366x768

Contrast ratio : 1000:1

Light output (cd/m2) : 550 Cd/m²

Response time (ms) : 12ms

Viewing angle : 85° (L) / 85° (R), 85° (U) / 85° (D)

TV color systems : NTSC

Video playback : NTSC, PAL, SECAM

Supported inputs : 480i

: 576i

: 480p

: 576p

: 1080i

: 720p

1.1.2 Sound

Sound systems : MTS (NTSC), FM-FM

Internal speaker : 10 W x 2 stereo, volume adjustable

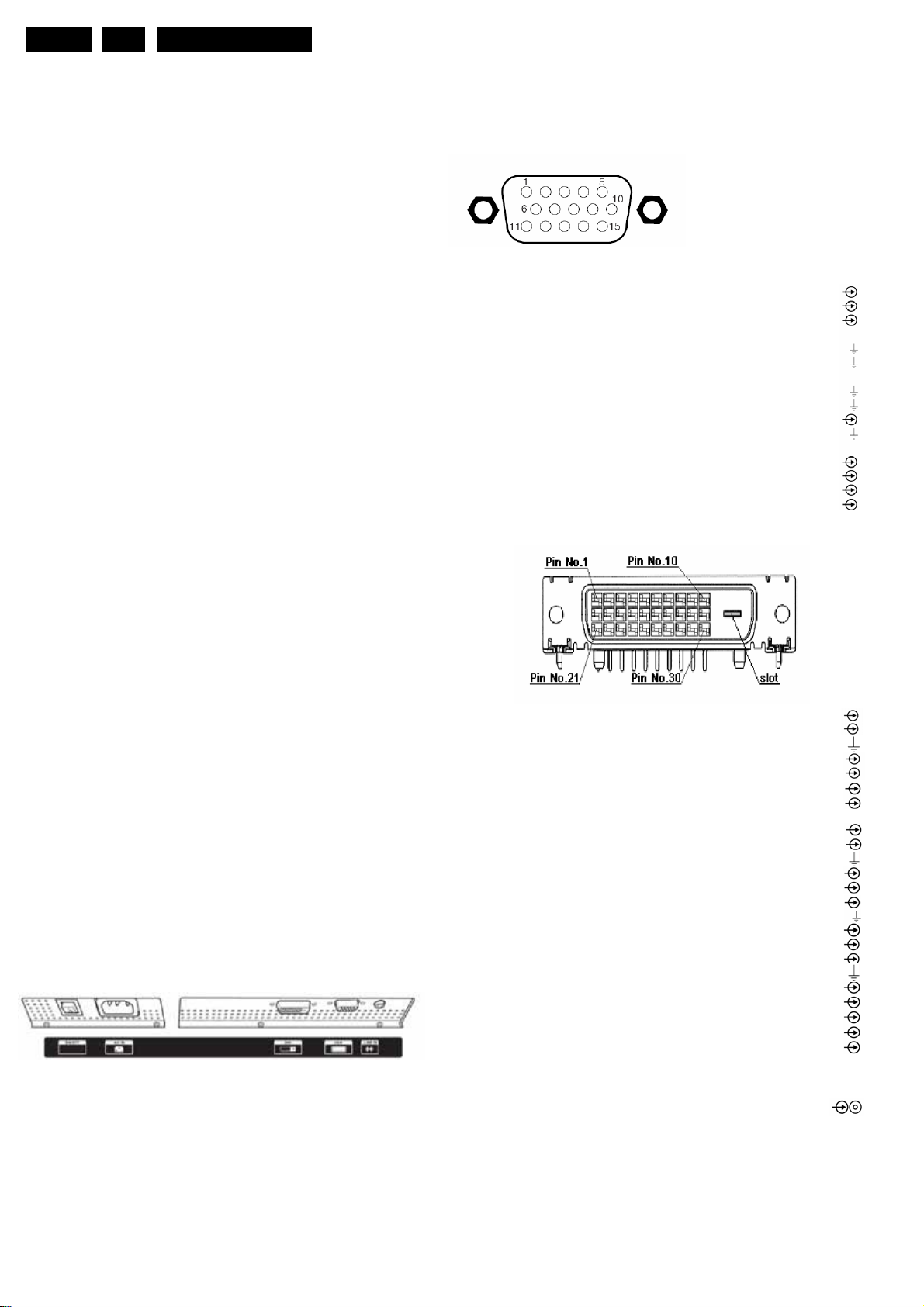

VGA:Video 2fh RGB In

Figure 1-2 VGA Connector

1 - Video Red 0.7 VPP / 75 ohm

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

4 – n.c

5 –Ground Gnd

6 -Ground Red Gnd

7 -Ground

Green Gnd

8 -Ground Blue Gnd

9 - +5V_DC +5V

10 -Gnd Sync Gnd

11 - n.c.

12 - DDC_SDA DDC data

13 - H-sync 0 - 5V

14 - V-sync 0 - 5V

15 - DDC_SCL DDC clock

DVI Digital Video-In

PP / 75 ohm

PP / 75 ohm

DC

1.1.3 Miscellaneous

Power supply:

-AC Power voltage (VAC) : 90-264V

-AC Power frequency (Hz) : 47~63Hz

Ambient conditions:

-Temperature range : 0~35°C

- Maximum humidity : 10%~90%

Power consumption

- Normal operation : 210 W

- Stand-by: < 5 W

Dimensions (WxHxD mm) :617.7*1017.4*210.0

Weight (kg) :20.5Kg

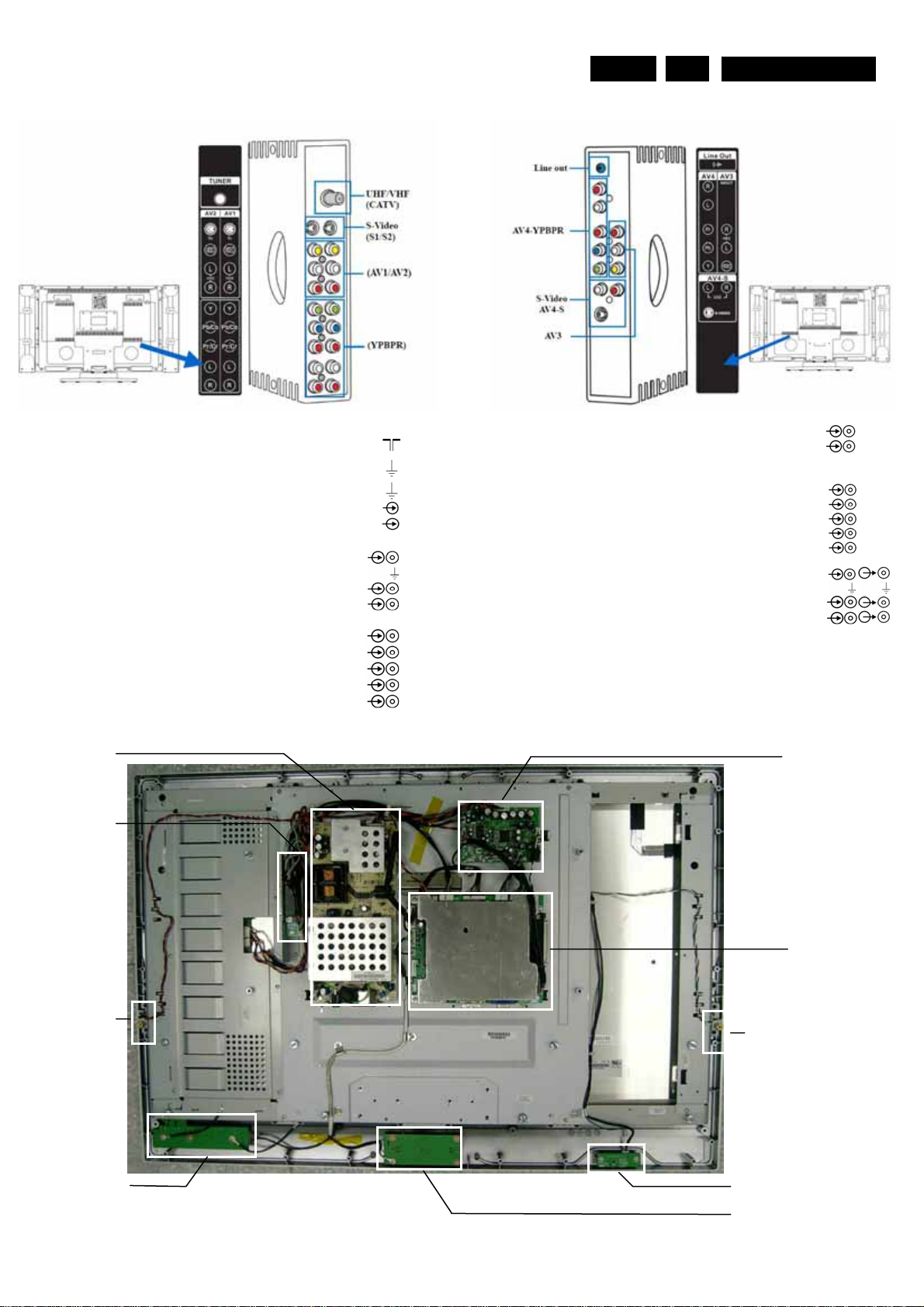

1.2 Connections

1.2.1 Rear I/O Connections

Figure 1-1 back connections

1 TMDS Data 2- Data channel

2 TMDS Data 2+ Data channel

3 TMDS Data 2/4 shield GND

4 TMDS Data 4- Data channel

5 TMDS Data 4+ Data channel

6 DDC Clock DDC Clock

7 DDC Data DDC Data

8 N.C

9 TMDS Data 1- Data channel

10 TMDS Data 1+ Data channel

11 TMDS Data 1/3 shield

12 TMDS Data 3- Data channel

13 TMDS Data 3+ Data channel

14 +5V

15 Ground ( For +5V) GND

16 Hot Plug Detect Hot Plug Detect

17 TMDS Data 0- Data channel

18 TMDS Data 0+ Data channel

19 TMDS Data 0/5 shield GND

20 TMDS Data 5- Data channel

21 TMDS Data 5+ Data Channel

22 TMDS Clock shield Data channel

23 TMDS Clock+ Data channel

24 TMDS Clock Data channel

Audio-In

Gn Stereo R/L Channels 500mVrms/22K ohm

Technical Specifications, Connections, and Chassis Overview

EN 2

1.

MQC1.OA LA

1.2.2 Right I/O Connections

Aerial-In

-F-type 75ohm

AV1-S1/AV2-S2: S-Video 1Fh Y/C-In

1 -Ground Y Gnd

2 -Ground C Gnd

3 -Video Y 1Vpp/75 ohm

4 -Video C 0.3Vpp/75 ohm

AV1/AV2 Video In, Audio In

1 -Audio R 0.5 Vrms/10Kohm

2 -Gnd CVBS Gnd

3 -Video CVBS 1Vpp/75 ohm

4 -Audio L 0.5 Vrms/10Kohm

YPBPR1/YPBPR2

Wh….-Audio L 0.5 Vrms/10Kohm

Rd….-Audio R 0.5 Vrms/10Kohm

Bu Video Pb 0.7 Vpp/75 ohm

Rd Video Pr 0.7 Vpp/75 ohm

Gn Video Y 1Vpp/75 ohm

1.3 Chassis overview

1.2.3 Left I/O Connections

Line-out

1 Audio R 0.5 Vrms/10Kohm

2 Audio L 0.5 Vrms/10Kohm

AV4-YPBPR

AV4-YPBPR

Wh….-Audio R 0.5 Vrms/10Kohm

Rd….-Audio R 0.5 Vrms/10Kohm

Bu Video Pb 0.7 Vpp/75 ohm

Rd Video Pr 0.7 Vpp/75 ohm

Gn Video Y 1Vpp/75 ohm

AV3 Video In/out /Audio in/out

1 -Audio R 0.5 Vrms/10Kohm

2 -Gnd CVBS Gnd

3 -Video CVBS 1Vpp/75 ohm

4 -Audio L 0.5 Vrms/10Kohm

AV4 S-Video In/Audio In

1 -Ground Y Gnd

2 -Ground C Gnd

3 -Video Y 1Vpp/75 ohm

4 -Video C 0.3Vpp/75 ohm

Rd….-Audio R 0.5 Vrms/10Kohm

Wh….-Audio L 0.5 Vrms/10Kohm

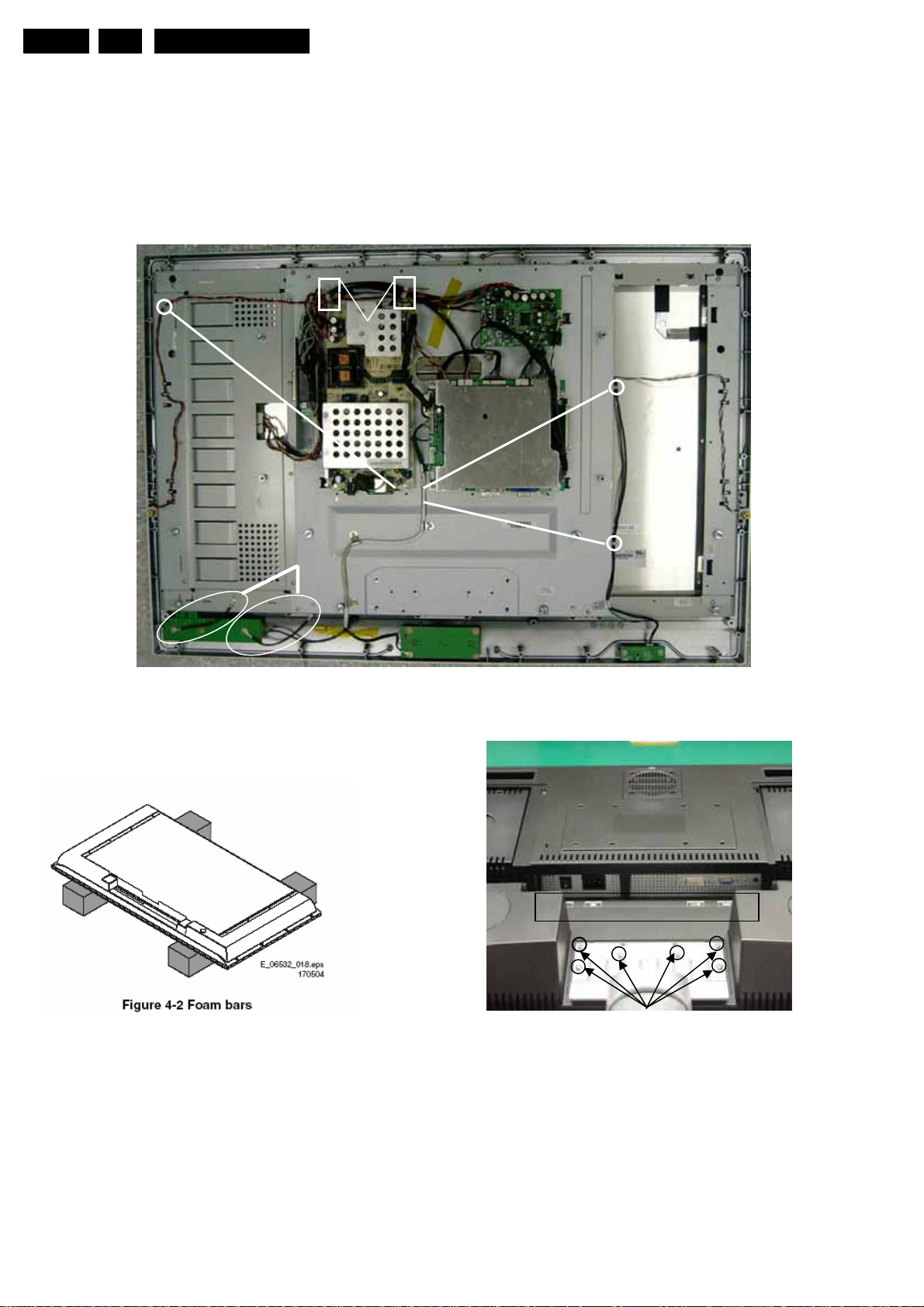

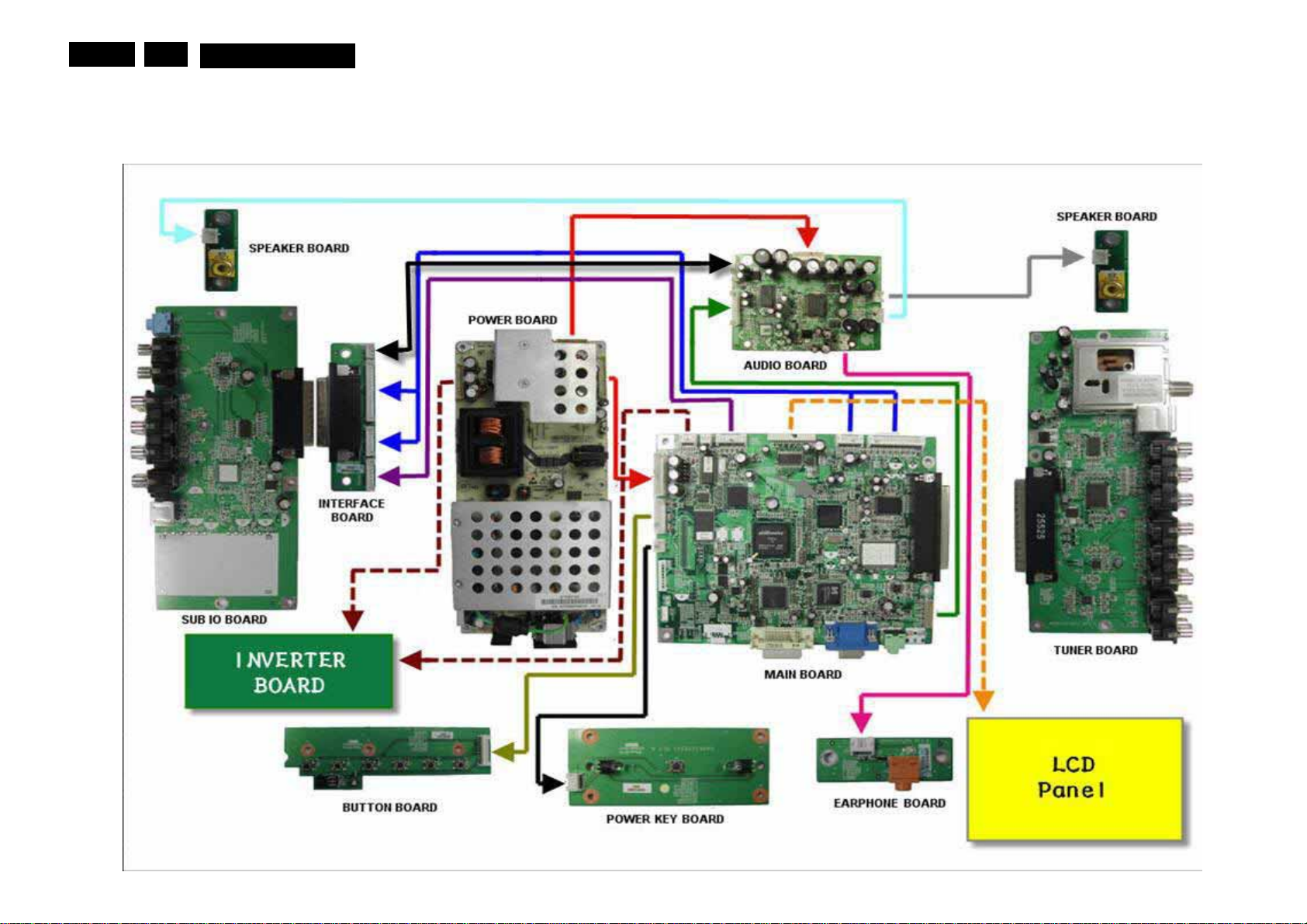

Power Board

Interface Board

Speaker Board

Button Board

Audio Board

Main Board

Speaker Board

Earphone Board

Power Key Board

EN 3

Safety Instructions, Warnings, and Notes

2.

MQC1.OA LA

2. Safety Instructions, Warnings, and Notes

2.1 Safety Instructions

Safety regulations require that during a repair:

• Connect the set to the AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the AC Power lead for external

damage.

• Check the strain relief of the AC Power cord for proper

function.

• Check the electrical DC resistance between the AC Power

plug and the secondary side (only for sets which have a AC

Power isolated power supply):

1. Unplug the AC Power cord and connect a wire

between the two pins of the AC Power plug.

2. Set the AC Power switch to the "on" position (keep the

AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

AC Power plug and the metal shielding of the tuner or

the aerial connection on the set. The reading should be

between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the AC Power plug.

• Check the cabinet for defects, to avoid touching of any

inner parts by the customer.

,

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

). Careless handling

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground ( ), or hot ground ( ), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with ( ) and without ( ) aerial signal. Measure the

voltages in the power supply section both in normal

operation ( ) and in stand-by ( ). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby” and the “double-D symbol”, are trademarks of

Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 Kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

2.3.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device Removal

As is the case with any component that, it is essential when

removing an (LF)BGA, the board, tracks, solder lands, or

surrounding components are not damaged. To remove an

(LF)BGA, the board must be uniformly heated to a temperature

close to the reflow soldering temperature. A uniform

temperature reduces the chance of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has shown to result in

problems during re-soldering.

-9

), or pico-farads (p= x10

-6

-12

),

).

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

To reflow the solder, apply a temperature profile according to

the IC data sheet. So as not to damage neighboring

components, it may be necessary to reduce some

temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

www.atyourservice.ce.philips.com (needs subscription,

URL:

not available for all regions). After login, select “Magazine”,

then go to “Workshop Information”. Here you will find

Information on how to deal with BGA-ICs.

2.3.4 Lead Free Solder

Philips CE is going to produce lead-free sets (PBF) from

1.1.2005 onwards.

Lead-free sets will be indicated by the PHILIPS-lead-free logo

on the Printed Wiring Boards (PWB):

Figure 2-1 Lead-free logo

This sign normally has a diameter of 6 mm, but if there is less

space on a board also 3 mm is possible.

In case of doubt wether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperature

profile,which is coupled to the 12NC. For an overview of these

profiles, visit the website

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repair-helpdesk.

http://www.atyourservice.ce.philips.com/

EN 4 Directions for Use MQC1.OA LA

3.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able

– To reach at least a solder-tip temperature of 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

-380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will rise drastically and flux-fluid will be destroyed. To

avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If not to avoid, clean carefully the

solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

short before it is used (soldered). Otherwise the body of the

IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam)pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection !).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

2.3.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions - reactions that are best avoided. Before reaching

into a powered TV set, it is best to test the high voltage

insulation. It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Mechanical Instructions

EN 5

4.

MQC1.OA LA

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

Service Positions

4.2

4.3 ASSY/PCBA Removal

4.1 Cable Dressing

4.2 Service Positions

4.2.1 Foam Bars

67

68

69

4.2.2 Stands

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. By laying the TV

face down on the (ESD protective) foam bars, a stable situation

is created to perform measurements and alignments.

By placing a mirror under the TV, you can monitor the screen.

70

Figure 4-3 Stands

The stands can be mounted with the back cover removed or

still left on. So, the stand can be used to store products or to do

measurements. It is also very suitable to perform duration tests

without taking much space, without having the risk of overheating

,or the risk of products falling. The stands can be mounted and

removed quick and easy with use of the delivered screws that

can be tightened and loosened manually without the use of tools.

See figure above.

Note: Only use the delivered screws to mount the monitor to

the stands

Mechanical Instructions

4.3 Assy/Panel removal

4.3.1 IO/Sub IO

Warning: Disconnect the AC Power cord before you open the

set.

1. Place the TV set upside down on a table top, using the

foam bars (see part "Foam Bars").

Caution: do not put pressure on the display, but let the

monitor lean on the speakers or the Front cover.

2. Remove M3*12(4 pieces) from IO Box and Sub-IO Box

4.3.2 R&L Speaker/Fan cover/Back cover

1. Remove T3*8 (4 pieces) screws from the Fan cover

2. Remove all T4*12(16 pieces) screws from the Back cover.

3. Than, remove the T4*24(6 pieces) from R/L speaker

4. Lift the back cover from the set. Make sure that wires and

flat foils are not damaged during the back cover removal.

4.3.3 Wall mount

1. Remove T3*5(4 pieces) screws from down of wall mount

2. Remove M3*4(4 pieces) screw from top of wall mount

3. Remove Io Nut(4 pieces) screw from down of wall mount

4. Remove 4-40(2 pieces) screw from right side of wall mount

5. Lift the wall mount from chassis. Make sure wires are not

damaged during the back cover removal.

4.3.11 LCD Panel

7

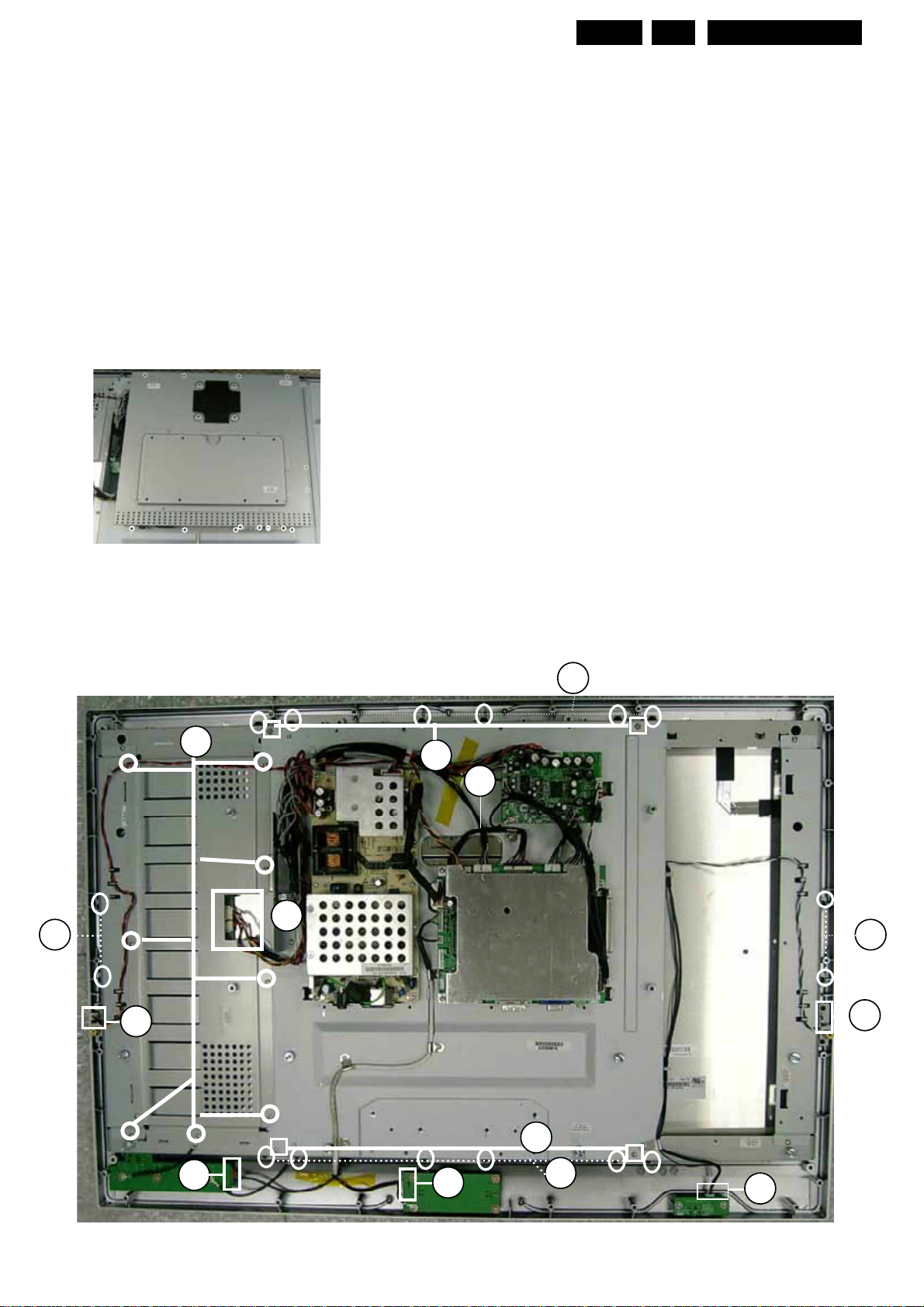

4.3.4 Main Board

1. Disconnect all cable from Base unit

2. Remove the fixation screws

3. Take out Main Board

4.3.5 Audio Board

1. Remove the fixation screws

2. Take out Main Board

4.3.6 Power Board

1. Remove the fixation screws

2. Take out Main Board

4.3.7 Interface Board

1. Remove the fixation screws

2. Take out Main Board

4.3.8 Power-Key Board

1. Remove the fixation screws

2. Take out Main Board

4.3.9 Earphone Board

1. Remove the fixation screws

2. Take out Main Board

4.3.10 Button Board

1. Remove the fixation screws

2. Take out Main Board and Bracket

10

6

11

EN 6

4.

MQC1.OA LA

8

4

9

2

3

11

1

1111

5

EN 7

Mechanical Instructions

4.

MQC1.OA LA

Disassembly

1. Place the TV set down on the foam bars. Place the

bars at the edges of the set, so they will support the

front frame and not only the glass plate!

2. Remove the Earphone cable (1), Button cable (2), Power key cable (3)

Speak L Cable (4), Speaker R cable (5) from all PCBA. Remove

LVDS cable from LCD panel (6)

3. Remove the eight M3*5 screws (7) from Inverter shielding

Lift the shielding and remove inverter cable (8)

4. Remove the two M3*5 screws (9) and two M3*4 screws (10)

Lift the PCB tray from the set. Make sure that wires and

flat foils are not damaged during the PCB tray removal.

5. Remove the sixteen T4*12 screws (11) from front cover

Lift the LCD panel from front cover.

6. Remove the ten M4*10 screws from Chassis-U, Chassis-R

Chassis-D, Chassis-L. Lift the LCD from Chassis.

2. Remove the 5 screws from shielding

3. Remove the 5 screws from shielding

4. Remove the screw from shielding

Assembly

To re-assemble the LCD panel, execute all processes

in reverse order.

Note:

.While re-assemble, make sure that all are placed and

And connected in their original position. See figure

“Cable dressing”

.Pay special attention not to damage the EMC foams at the

SSB shielding. Check that EMC foams are put correctly on

their places.

4.3.12 R,L speaker

Disassembly

1. Remove the four screws from speaker shielding

and lift the shielding

.

4.3.13 IO Assy

Disassembly

1. Remove the three screws form shielding.

2. Remove the eight screws from speaker back cover

and open the mylar then lift the speaker back cover.

2. Remove the 4 screws from shielding

3. Remove the four screws

3. Remove the 2 screws from shielding

4.3.13 Tune r Assy

Disassembly

1. Remove the three screws from shielding

4. Remove the screw from shielding

5 Service mode and Fault Finding

Service mode, Fault Finding

EN 8

5

MQC1.OA LA

Index if this chapter:

5.1Service Modes

5.1Fault Finding

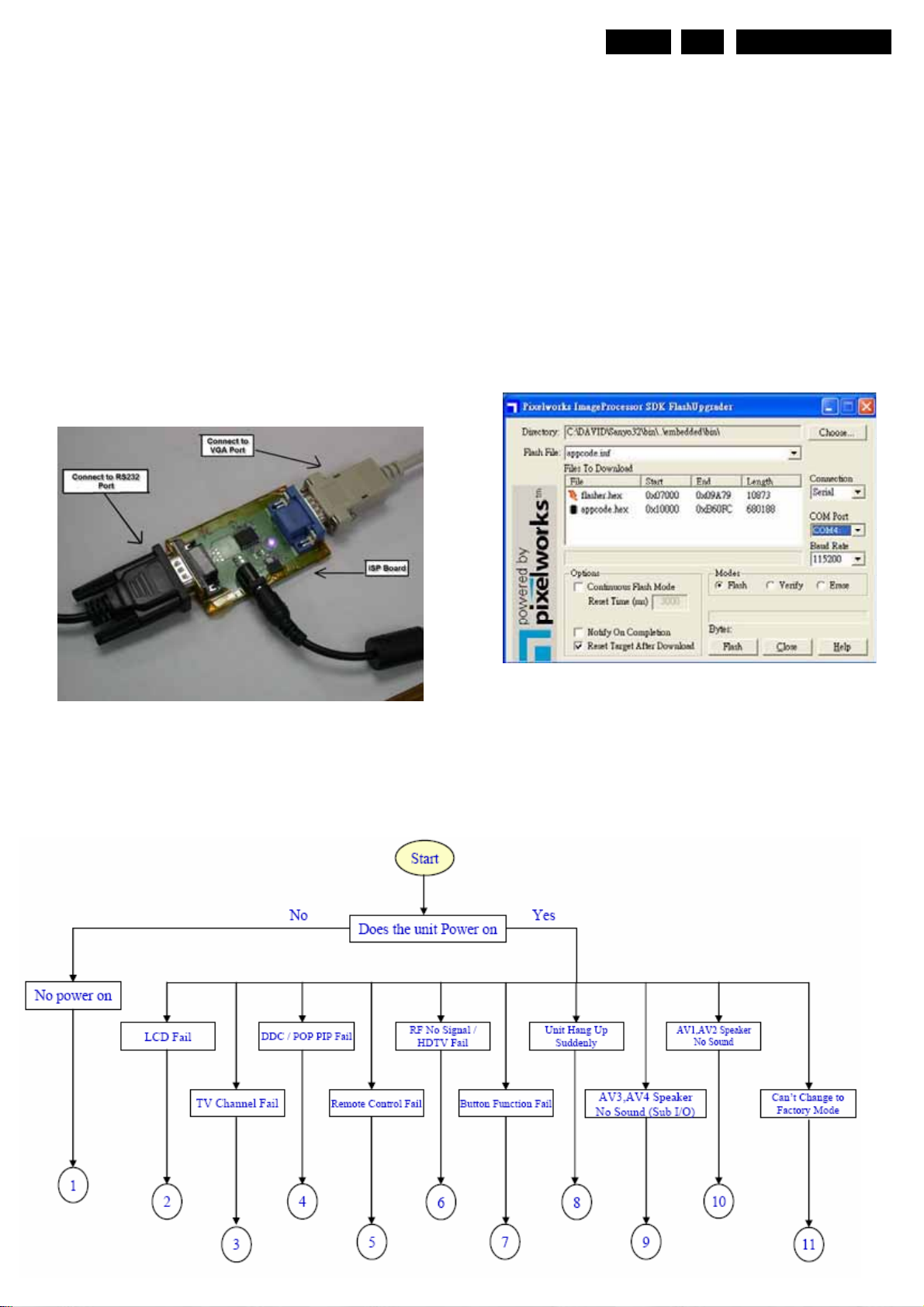

5.1 Service Mode (update BIOS)

Purpose

. To update new version BIOS

Tools

. ISP Board

. RS232 cable

. VGA cable

. Software (Pixlworks)

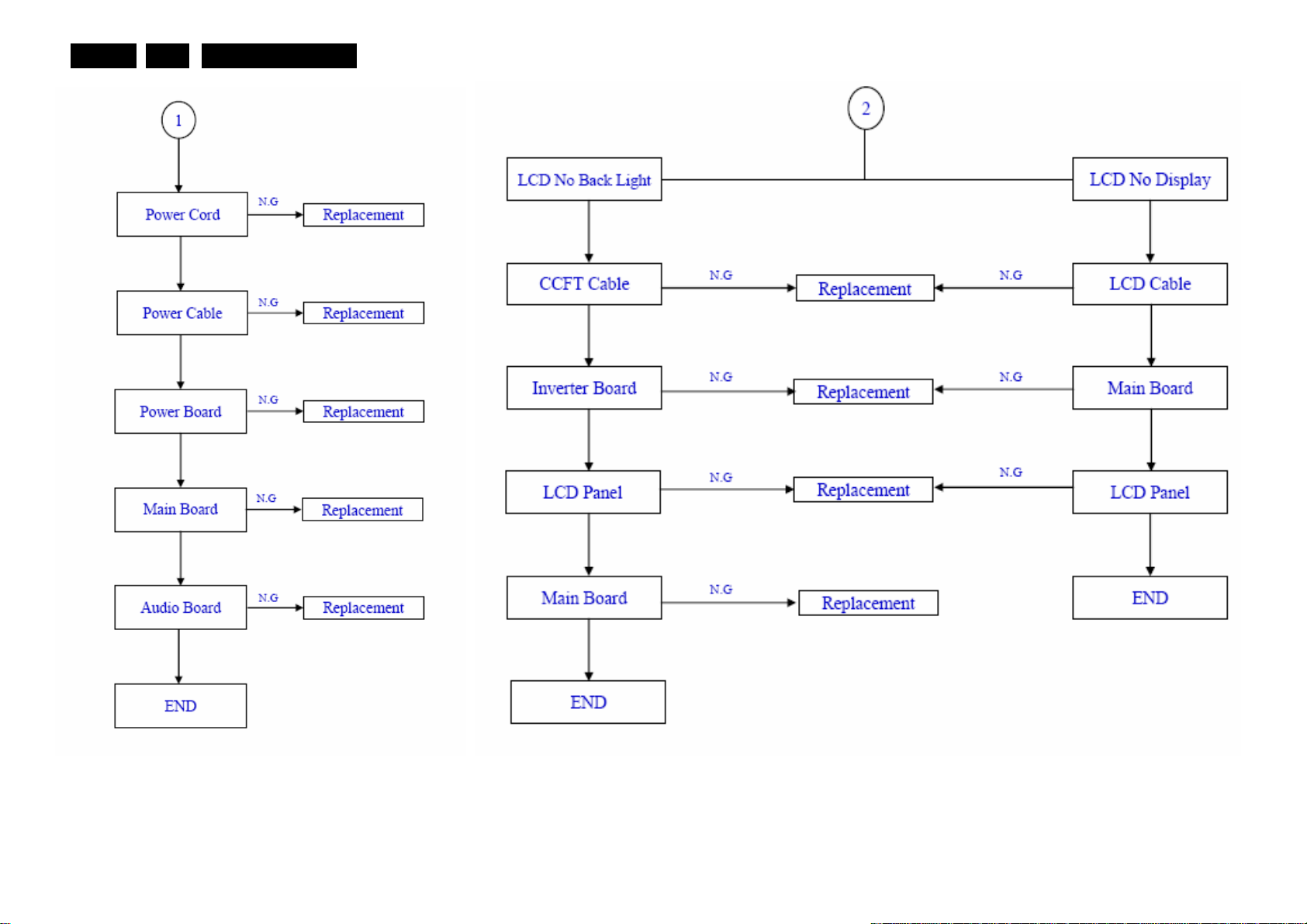

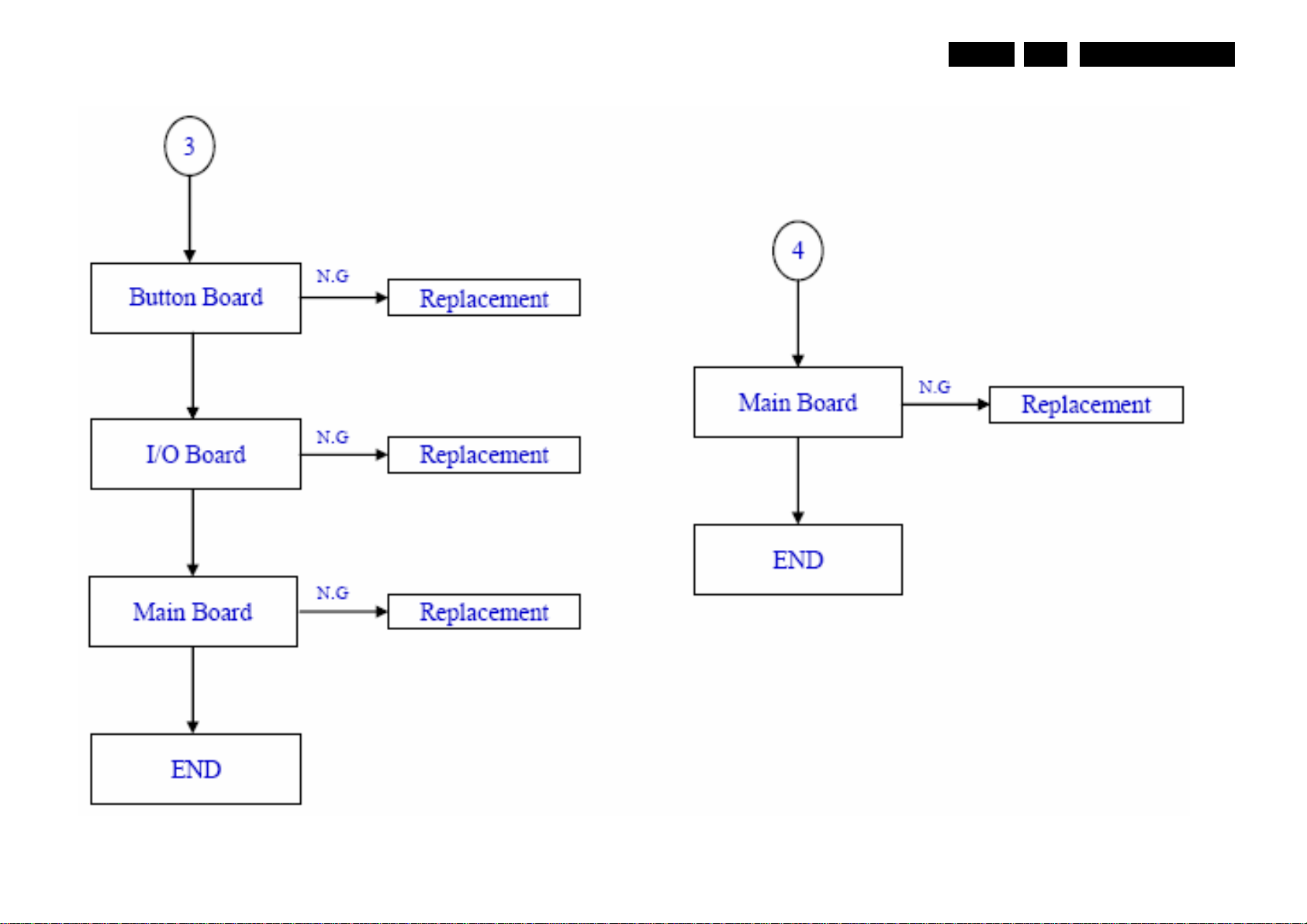

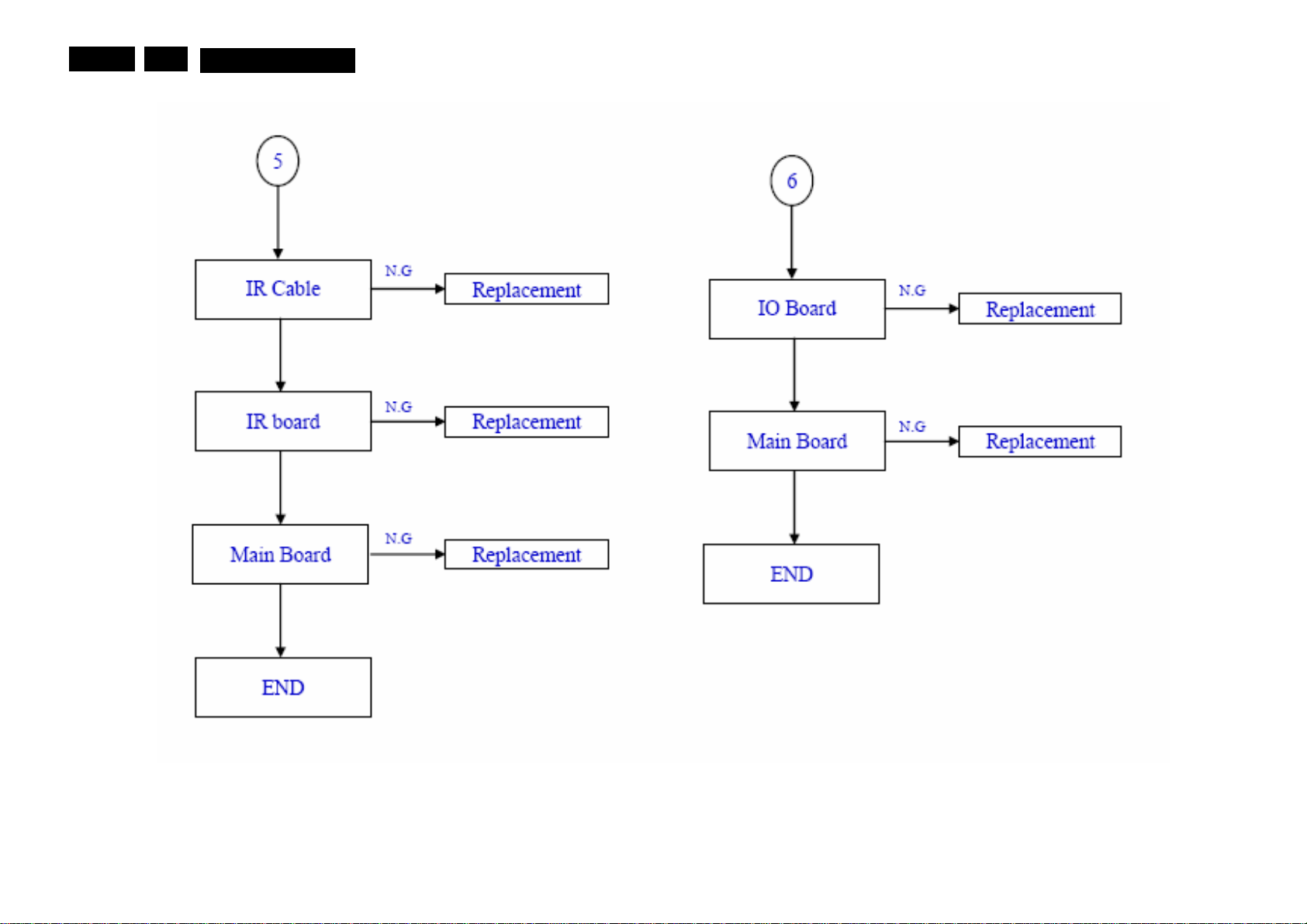

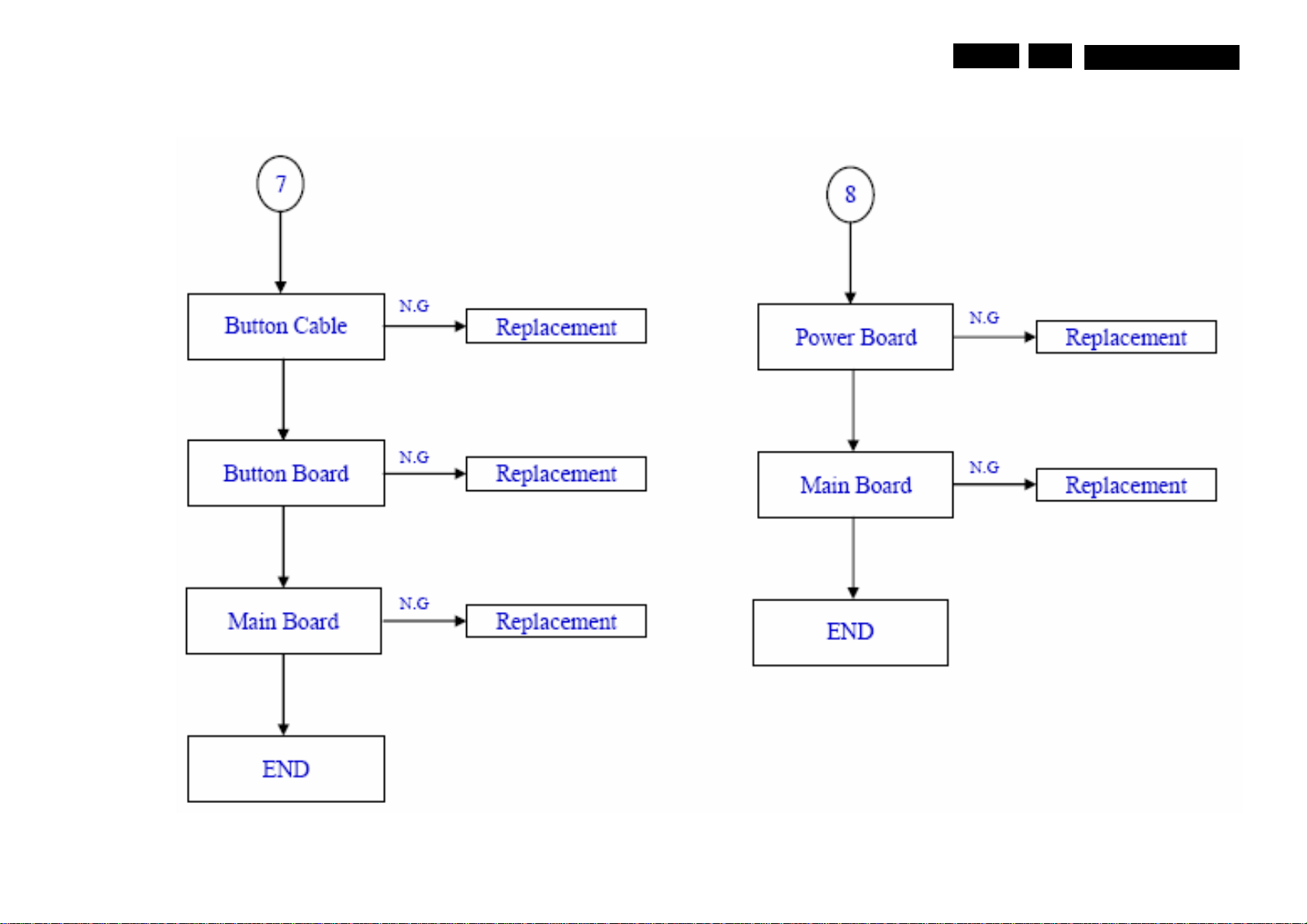

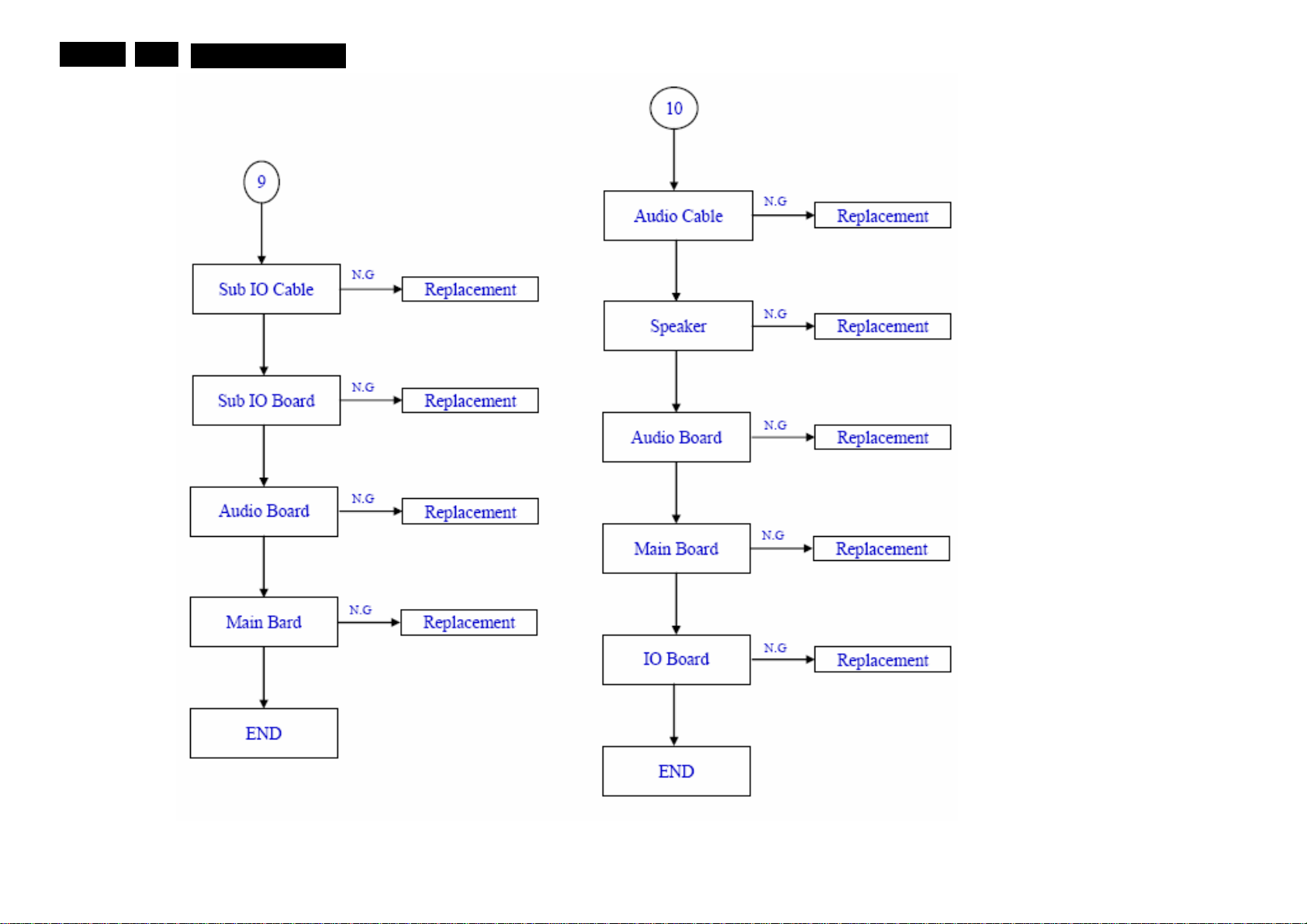

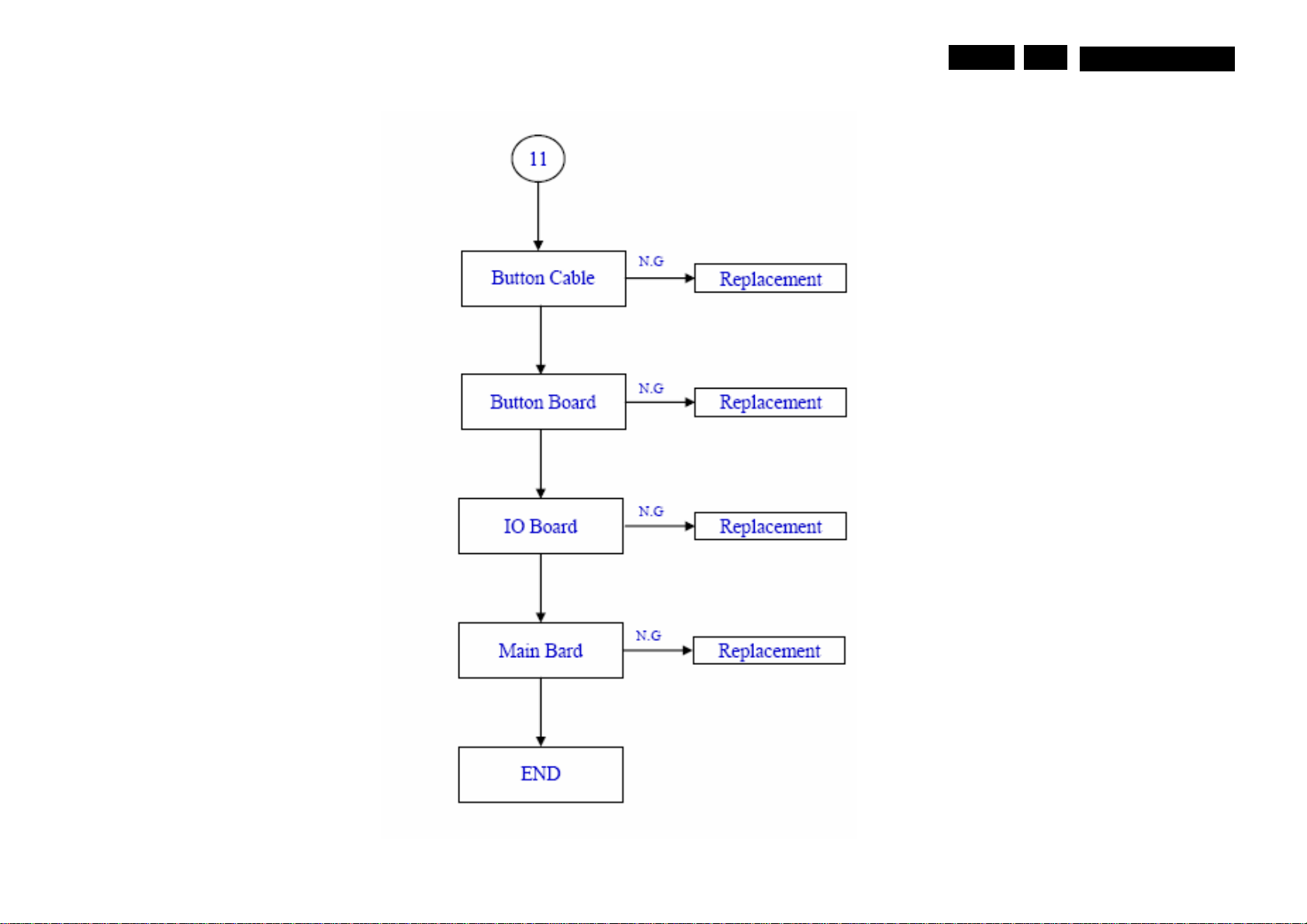

5.2 Fault Finding

Purpose

.To find the fault

How to find fault

Setup

1. Off TV Pow e r

2. Process Pixlworks program

3. Choose appcode.inf

4. Check connection. Should be in serial

5. Check COM Port of R232

6. Check Baud Rate

7. Click Flash

8. Turn on the TV .The program will automatic

9. After few seconds, then screen will showing flash

completed. TV will power on itself

Service mode, Fault Finding

EN 9

5

MQC1.OA LA

Service mode, Fault Finding

EN 10

5

MQC1.OA LA

Service mode, Fault Finding

EN 11

5

MQC1.OA LA

MQC1.OA LA Service mode, Fault Finding 5EN 12

EN 13

5

MQC1.OA LA

Service mode, Fault Finding

Service mode, Fault Finding

EN 14

5

MQC1.OA LA

EN 15

6

MQC1.OA LA

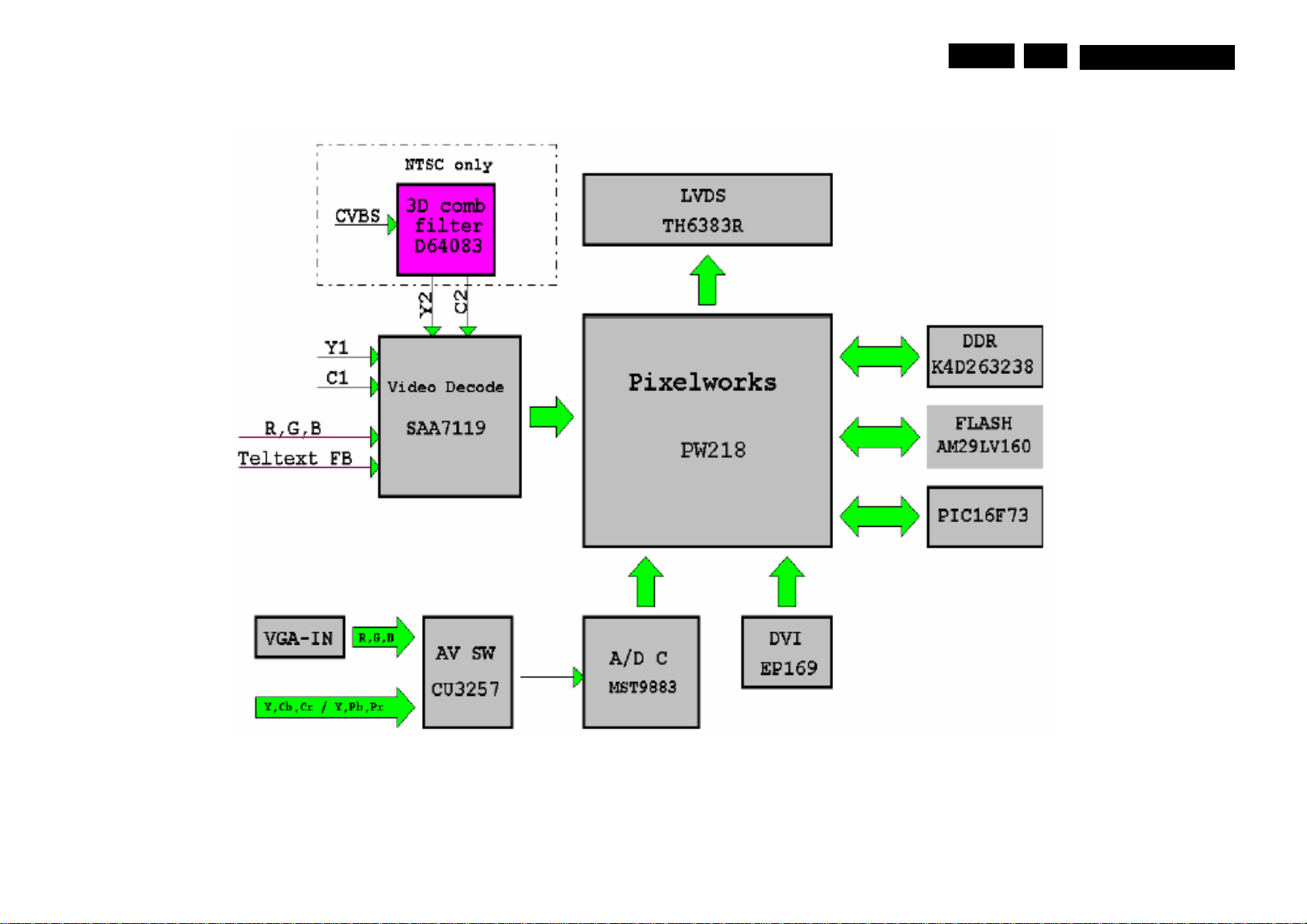

6. Block Diagrams

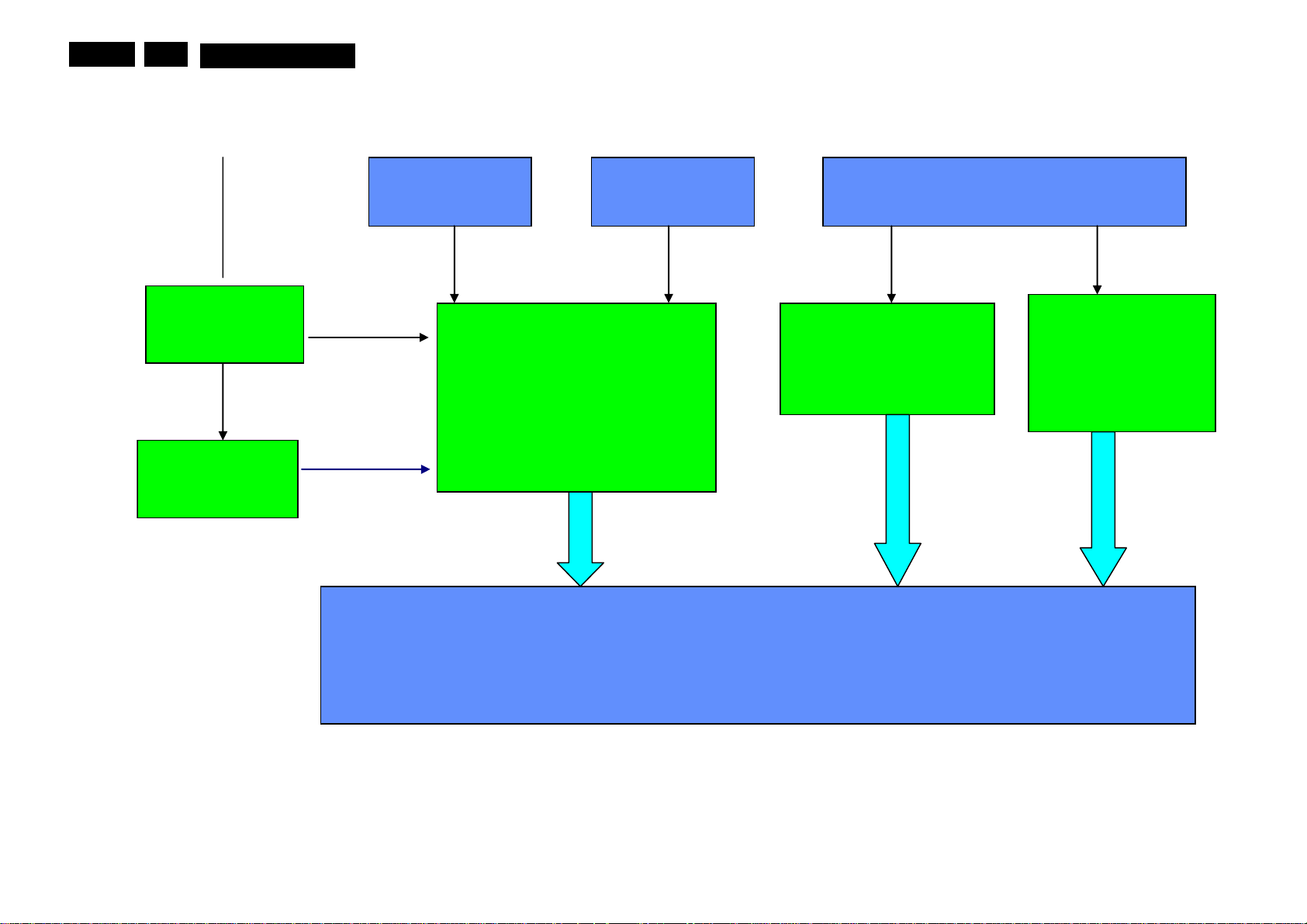

Wiring Diagram

Block Diagrams

Main Board Block diagrams

MQC1.OA LA Block Diagrams 6EN 16

EN 17

Io Board Block diagrams

6

TV

MQC1.OA LA

signal

Block Diagrams

TV Tune r

TMQH6-011A

Audio Decoder

AN5832SA

TV Video

Audio

AV1 /AV2

Video& Audio Video

Video & Audio SW

Video & Audio SW

CVBS & YC

TA1218

TA1218

S1/S2

YUV Video

IO PORT

CU3257

YUV

YUV1/YUV2

SoundVideo

YUV Sound

74HCT4052_0

Loading...

Loading...