Philips 220B4LPCS/00, 220B4LPCB/00, 220B4LPCB/27, 220B4LPCB/69, 220B4LPCB/75 Service Manual

22ƎLCD Color Monitor Chassis: Meridian 3

Service

Service

Service

Description Page

Table of Contents.........................................………….1

Revision List………….................................................2

Important Safety Notice…………................................3

1. Monitor Specifications….........................................5

2. LCD Monitor Description….....................................7

3. Operation Instructions….........................................8

3.1General Instructions…………………………….…...8

3.2 Control Buttons…………..…………………….…8

3.3 OSD Menu…………………...................................9

4. Input/output Specification...............................……10

4.1 Input Signal Connector.................................……10

4.2 Resolution & Preset Modes.................................11

4.3 Pixel Defect Policy…………………………………12

4.4 Failure Mode of Panel………………………….....14

5. Block Diagram………………………….................15

5.1 Scaler Board....................................………….....15

5.2 Power Board................................………….........16

6. Schematic Diagram.............................................. 17

6.1 Scaler Board…………………….…………………17

6.2 Power Board.................................................…...22

6.3 Key Board…….……………………………………25

Description

Page

6.4 IR Board…….………………………………………26

6.5 EAR Board…….……………………………………27

6.6 USB Board…….……………………………………28

7. PCB Layout………………………………………...29

7.1 Scaler Board……………………………………..29

7.2 Power Board……………...………………………30

7.3 Key Board…….……………………………………31

7.4 IR Board…………………………………………….31

7.5 EAR Board………………………………………….31

7.6 USB Board………………………………………….32

8. Wiring Diagram………………………………….…..33

9. Scaler Board Overview…………………………....34

10. Mechanical Instructions………………………....35

1 1. Repair Flow Chart…….……………………………38

12. ISP Instructions...…............................................42

13. DDC Instructions….............................................50

14. White Balance, Luminance Adjustment…...........59

15. Monitor Exploded View…....................................61

16. Recommended & Spare Part s List...…................62

17. General Product Specification………….……….64

SAFETY NOTCE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE

CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHE N

SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFOMER FOR THIS UNIT WHEN SERVICING

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Copyright 2012 Philips Consumer Lifestyle Subject to modification ƻK Jul.24,2012

220B4LPCS/00

220B4LPCB/00

220B4LPCB/27

220B4LPCB/69

220B4LPCB/75

!

!

Meridian 3

2

Revision List

Version Release Date Revision History

A00 Jul.24, 2012 Initial release, Draft Version

A01 Aug.03, 2012 Add new model 220B4LPCB/75

A02 Oct.19, 2012 Add new model 220B4LPCB/27

A03 Nov.19, 2012 Add new model 220B4LPCB/00 and 220B4LPCB/69

3

Meridian 3

Important Safety Notice

This electronic user guide is intended for anyone who uses the Philips monitor. Take time to read this user manual

before you use your monitor. It contains important information and notes regarding operating your monitor. The

Philips guarantee applies provided the product is handled properly for its intended use, in accordance with its

operating instructions and upon presentation of the o riginal invoice or cash receipt, indicatin g the date of p urchase,

dealers name and model and production number of the product.

Warnings

Use of controls, adjustments or procedures other than those specified in this document ation may result in exposure

to shock, electrical hazards and/or mechanical hazards. Read and follow these instructions when connecting and

using your computer monitor.

Operation

y Keep the monitor out of direct sunlight and away from stoves or any other heat source.

y Remove any object that could fall into ventilation holes or prevent proper cooling of the monitor’s electronics.

y Do not block the ventilation holes on the cabinet.

y When positioning the monitor , make sure the power plug and outlet are easily accessible.

y If turning off the monitor by detaching the power cable or DC power cord, wait for 6 seconds before attaching

the power cable or DC power cord for normal operation.

y Please use approved power cord provided by Philips all the time. If your power cord is missing, please contact

with your local service center. (Please refer to Customer Care Consumer Information Center)

y • Do not subject the monitor to severe vibration or high impact conditions during operation.

y • Do not knock or drop the monitor during operation or transportation.

Maintenance

y To protect your monitor from possible damage, do not put excessive pressure on the LCD panel. When moving

your monitor, grasp the frame to lift; do not lift the monitor by placing your hand or fingers on the LCD panel.

y Unplug the monitor if you are not going to use it for an extensive period of time.

y Unplug the monitor if you need to clean it with a slightly damp cloth. The screen may be wiped with a dry cloth

when the power is off. However , never use organic sol vent, such as, alcoh ol, or ammonia-ba sed liquids to clean

your monitor.

y To avoid the risk of shock or permanent damage to the set, do not expose the monitor to dust, rain, water, or

excessive moisture environment.

y If your monitor gets wet, wipe it with dry cloth as soon as possible.

y If foreign substance or water gets in your monitor, please turn the power off immediately and disconnect the

power cord. Then, remove the foreign substance or water, and send it to the maintenance center.

y Do not store or use the monitor in locations exposed to heat, direct sunlight or extreme cold.

y In order to maintain the best performance of your monitor and use it for a longer lifetime, please use the monitor

in a location that falls within the following temperature and humidity ranges.

¾ Temperature: 0-40°C 32-95°F

¾ Humidity: 20-80% RH

!

!

Meridian 3

4

y IMPORTANT: Always activate a moving screen saver program when you leave your monitor unattended.

Always activate a periodic screen refresh application if your monitor will display unchanging static content.

Uninterrupted display of still or static images over an extended period may cause “burn in”, also known a s

“after-imaging” or “ghost imaging”, on your screen. “Burn-in”, “after-imaging”, or “ghost imaging” is a

well-known phenomenon in LCD panel technology. In most cases, the “burned in” or “after-imaging” or “ghost

imaging” will disappear gradually over a period of time after the power has bee n switched off.

Warning

Severe” burn-in” or “after-image” or “ghost image” symptoms will not disappear and cannot be repaired. The

damage mentioned above is not covered under your warranty.

Service

y The casing cover should be opened only by qualified service personnel.

y If there is any need for any document for repair or integration, please contact with your local service center.

(Please refer to the chapter of “Consumer Information Center”)

y For transportation information, please refer to “Technical Specifications”.

y Do not leave your monitor in a car/trunk under direct sun light.

Note

Consult a service technician if the monitor does not operate normally, or you are not sure what procedure to take

when the operating instructions given in this manual have been followed.

5

Meridian 3

1. Monitor Specifications

Technical specifications

!

!

Meridian 3

6

Note:

1. EPEAT Gold or Silver is valid only where Philips registers the product. Please visit www.epeat.net

for

registration status in your country.

2.This data is subject to change without notice. Go to www.philips.com/support

to download the latest version

of leaflet.

7

Meridian 3

2. LCD Monitor Description

The LCD monitor will contain a scaler board, a power board, an USB board, an Ear board, an IR board and a key

board. The scaler board houses the flat panel control logic, brightness control logic and DDC.

The power board will provide AC to DC inverter voltage to drive the backlight of panel and the scaler board chips

each voltage.

Monitor Block Diagram

LED Panel

Scaler Board

VGA

DVI-D

LED Drive

Key Board

Video signal, DDC

HOST Computer

AC IN

90 ~ 264 V

Power Board

USB Board

PC USB

Ear Board

IR Board

Audio

Remote

control

!

!

Meridian 3

8

3. Operating Instructions

3.1 General Instructions

Press the power button to turn the monitor on or off.

The other control knobs are located at front panel of

the monitor. By changing these setting, the picture

can be adjusted to your personal preference.

γThe power cord should be connected.

γ Press the power button to turn on the monitor.

The power indicator will light up.

3.2 Control Buttons

Operating the Monitor

Connecting to your PC

Connect to PC

1. Connect the power cord to the back of the monitor

firmly.

2. Turn off your computer and unplug its power cable.

3. Connect the monitor signal cable to the video

connector on the back of your computer.

4. Plug the power cord of your computer and your

monitor into a nearby outlet.

5. Turn on your computer and monitor. If the monitor

displays an image, installation is complete.

9

Meridian 3

3.3 OSD Menu

On-screen Display (OSD) is feature in all Philips LCD

monitors. It allows an end user to adjust screen

performance or select functions of the monitors directly

through an on-screen instruction window. A user

friendly on screen display inter face is shown as below:

Basic and simple instruction on the control keys

In the OSD shown above, users can press źŸ

buttons at the front bezel of the monitor to move the

cursor, and press OK button to confirm the choice or

change.

The OSD tree

Below is an overall view of the structure of the

On-Screen Display. You can use this as a reference

when you want to work your way around the different

adjustments later on.

!

!

Meridian 3

10

4. Input/ Output Specification

4.1 Input Signal Connector

D-sub Connector

Pin No. Signal Name

1 Red

2 Green/ SOG

3 Blue

4 Sense (GND)

5 Cable Detect (GND)

6 Red GND

7 Green GND

8 Blue GND

9 DDC +3.3V or +5V

10 Logic GND

11 Sense (GND)

12 Bi-directional data

13 H/H+V sync

14 V-sync

15 Data clock

DVI Connector

Pin No. Signal Name

1 T.M.D.S. data22 T.M.D.S. data2+

3 T.M.D.S. data2 shield

4 No Connect

5 No Connect

6 DDC clock

7 DDC data

8 No Connect

9 T.M.D.S. data110 T.M.D.S. data1+

1 1 T.M.D.S. data1 shield

12 No Connect

13 No Connect

14 +5V Power

15 Ground (for +5V)

16 Hot plug detect

17 T.M.D.S. data018 T.M.D.S. data0+

19 T.M.D.S. data0 shield

20 No Connect

21 No Connect

22 T.M.D.S clock shield

23 T.M.D.S. clock+

24 T.M.D.S. clock-

11

Meridian 3

4.2 Resolution & Preset Modes

Maximum Resolution

1680 x 1050 at 60 Hz (analog input)

1680 x 1050 at 60 Hz (digital input)

Recommended Resolution

1680 x 1050 at 60 Hz (digital input)

Note:

Please notice that your display works best at native resolution of 1680 x 1050@60Hz. For best display quality,

please follow this resolution recommendation.

Power Management Definition

Power Management Definition

VESA Mode Video H-Sync V-Sync Power Used LED Color

Active ON Yes Yes 19.6 W (typ.) White

Sleep

(Standby)

OFF No No 0.1W (typ.)

White

(Blink)

Switch off OFF - - 0 W (typ.) OFF

Note:

This data is subject to change without notice.

!

!

Meridian 3

12

4.3 Pixel Defect Policy

Philips strives to deliver the highest quality products.

We use some of the industry's most advanced

manufacturing processes and practice stringent quality

control. However, pixel or sub pixel defects on the TFT

Monitor panels used in flat panel monitors are

sometimes unavoidable. No manufacturer can

guarantee that all panels will be free from pixel defects,

but Philips guarantees that any monitor with an

unacceptable number of defects will be repaired or

replaced under warranty. This notice explains the

different types of pixel defects and defines acceptable

defect levels for each type. In order to qualify for repair

or replacement under warranty, the number of pixel

defects on a TFT Monitor panel must exceed these

acceptable levels. For example, no more than

0.0004% of the sub pixels on a monitor may be

defective. Furthermore, Philips sets even higher quality

standards for certain types or combinations of pixel

defects that are more noticeable than others. This

policy is valid worldwide.

Pixels and Sub pixels

A pixel, or picture element, is composed of three sub

pixels in the primary colors of red, green and blue.

Many pixels together form an image. When all sub

pixels of pixel are lit, the three colored sub pixels

together appear as a single white pixel. When all are

dark, the three colored sub pixels together appear as a

signal black pixel. Other combinations of lit and dark

sub appear as single pixels of other colors.

Types of Pixel Defects

Pixel and sub pixel defects appear on the screen in

different ways. There are two categories of pixel

defects and several types of sub pixel defects within

each category.

Bright Dot Defects

Bright dot defects appear as pixels or sub pixels that

are always lit or ‘on’. That is, a Bright dot is a sub-pixel

that stands out on the screen when the monitor

displays a dark pattern. There are three types of bright

dot defects:

One lit red, green or blue sub pixel

Two adjacent lit sub pixels:

- Red + Blue = Purple

- Red + Green = Yellow

- Green + Blue = Cyan (Light Blue)

Three adjacent lit sub pixels (one white pixel)

Note:

A red or blue bright dot must be more than 50 percent

brighter than neighboring dots while a green bright dot

is 30 percent brighter than neighboring dots.

13

Meridian 3

Black Dot Defects

Black dot defects appear as pixels or sub pixels that

are always dark or ‘off’. That is, a dark dot is a

sub-pixel that stands out on the screen when the

monitor displays a light pattern. There are two types of

black dot defects:

Proximity of Pixel Defects

Because pixel and sub pixels defects of the same type

that are near to one another may be more noticeable,

Philips also specifies tolerances for the proximity of

pixel defects.

Pixel Defect Tolerances

In order to qualify for repair or replacement due to pixel

defects during the warranty period, a TFT LCD p anel in

a Philips flat panel monitor must have pixel or sub pixel

defects exceeding the tolerances listed in the followin g

tables.

Bright Dot Defects Acceptable level

1 lit subpixel 3

2 adjacent lit subpixels 1

3 adjacent lit subpixels (one white pixel) 0

Distance between two bright dot defects* >15mm

Total bright dot defects of all types 3

Black Dot Defects Acceptable level

1 dark subpixel 5 or fewer

2 adjacent dark subpixels 2 or fewer

3 adjacent dark subpixels 0

Distance between two black dot defects* >15mm

Total black dot defects of all types 5 or fewer

Total Dot Defects Acceptable level

Total bright or black dot defects of all types 5 or fewer

Note:

1. 1 or 2 adjacent sub pixel defects = 1 dot defect.

2. This monitor is ISO9241-307 compliant. (ISO9241-307: Ergonomic re quirement, analysis and compliance test

methods for electronic visual displays)

!

!

Meridian 3

14

4.4 Failure Mode Of Panel

Failure description

Phenomenon

Vertical block defect

Vertical dim lines

Vertical lines defect

(Always bri

g

ht or dark)

Horizontal block defect

Horizontal dim lines

Horizontal lines defect

(Always bri

g

ht or dark)

Has bri

g

ht or dark pixel

Polarizer has bubbles

Polarizer has bubbles

Foreign material inside

polarizer. It shows liner or

dot shape.

Concentric circle formed

Bottom back light of LCD is

brighter than normal

Back light un-uniformity

Backli

g

ht has foreign material.

Black or white color, liner or

circular type

Quick reference for failure mode of LCD panel

this pa

g

e presents problems that could be made by LCD panel.

It is not necessary to repair circuit board. Simply follow the mechanical

instruction on this manual to eliminate failure by replace LCD panel.

15

Meridian 3

5. Block Diagram

5.1 Scaler Board

!

!

Meridian 3

16

5.2 Power Board

EMI FilterCircuit

Input AC Source

Inrush

Prevention

Rectification

Main

Transforme

r

Switching Circuit

( PWM Control IC

& MOSFET )

Rectification

FeedbackControl

Circuit

B+

Diode Rectifierand Filter Circuit

Output (+5V ) To Main

board /Audio *2

W

Fuse For OLP

Diode Rectifierand Filter Circuit

Output (+16V) To

USB(Option) Circui

t

Diode Rectifie

and Filter Circuit

PWM Control Circuit

CONVERTER LD7750RGR

Driver Circuit

( Full Bridge )

LED Panel

bnormal Protect

Control Circuit

Feedback Control

Circuit

Dimming

Control

Circuit

ON / OFF Control Signal( 16v: on / 0v:off )

Dimming Control Signa

l

(Burst model Signal )

dapter Block Circuit

Converter Block Circuit

17

Meridian 3

6. Schematic

6.1 Scaler Board (715G5428M01000004Q)

Remark: Parts position can be searched by using FIND function in PDF.

BIN0-

GIN0HSIN0

VSIN0

DDCSCL_A

DDCSDA_A

I/O11GND2I/O2

3

I/O3

4

VDD

5

I/O4

6

U102

AZC398-04S

I/O11GND2I/O2

3

I/O3

4

VDD

5

I/O4

6

U103

AZC398-04S

BIN0

DET_VGA

DDCSCL14

R119

0R05 OHM

R107

75R 1/16W 1%

R105

0R05 OHM

C107

5PF 50V

R109

470OHM1/16W

R118 22K1/16W

3

1

2

D101

BAV70

C115

NC/22pF 50V

C109

47NF 16V

1728394105

11

12

13

14

15

17 16

6

CN101

DB15

R120

0R05 OHM

R113

75R 1/16W 1%

C111

47NF 16V

R116 4. 7K1/16W

C104

47NF 16V

R125 100OHM

R126 100OHM

C106 47NF 16V

1 2

ZD101

RLZ5.6B

C108

47NF 16V

R112

100OHM

C101

5PF 50V

R128

2.2K1/16W

R124 0R05 1/ 10W

R123

100OHM

R102 100OHM

ZD102

RLZ5.6B

C110

220N 10V

R111

0R05 OHM

C113

22P 50V

C117

100N 16V

C116

100N 16V

C102

47NF 16V

R115

1K

R103

100OHM

E01E12E2

3

VSS

4

SDA5SCL6WC7VCC

8

U101

M24C02-RMN6TP

FB101

300OHM

R127

2.2K1/16W

R101

100OHM

R114

100OHM

C114

NC/22pF 50V

C103

5PF 50V

R106

100OHM

R110

0R05 OHM

FB102

300OHM

C112

22P 50V

C105

1N 50V

R108

100OHM

R121

100OHM

R122

75R 1/16W 1%

R104

0R05 OHM

R117 4. 7K1/16W

+5V3,4,6

ESD_VGA

ESD_DVI

+5V VGA_5V

VGA_5V

ESD_VGA

VGA_CABLE_DET 4

C136

1N 50V

R/A: 088G 35315F HD HF

V/T: 088G 35315FVCL HF

RIN0

GIN0

BIN0-

BIN0

RIN0

GIN0-

RIN0-

RIN0

BIN0

R0- 4

G0- 4

R0+ 4

G0+ 4

SOG_DET 4

B0- 4

B0+ 4

AHS0 4

AVS0 4

GIN0-

GIN0

RIN0-

DDCSDA_A

DDCSCL_A

VSIN0

DET_VGA

HSIN0

DDCSDA1

VGA_5V

VSIN0

DDCSCL1

HSIN0

R0-

B0-

B0+

G0+

G0-

R0+

DDCSDA1

DDCSCL1

VGA_CABLE_DET

DDCSDA14

EDID_WP3,4

EDID_WP

Input VGA

!

18

Meridian 3

Remark: Parts position can be searched by using FIND function in PDF.

ESD_DVI

DDCSCL2 4

DDCSDA2 4

RX0+ 4

RX0- 4

RX1+ 4

RX2- 4

RX2+ 4

RX1- 4

RXC+ 4

RXC- 4

DVI_CABLE_DET 4

I/O11GND2I/O2

3

I/O3

4

VDD

5

I/O4

6

U132

AZC398-04S

I/O11GND2I/O2

3

I/O3

4

VDD

5

I/O4

6

U134

AZC398-04S

DAT1-

DAT2-

C135

100N 16V

ESD_DVI2

DAT1+

FB132

300OHM

DAT0+

C137

1N 50V

ESD_DVI

DAT0-

DCLK+

DCLK-

I/O11GND2I/O2

3

I/O3

4

VDD

5

I/O4

6

U131

AZC398-04S

DDC_WP

DAT2+

ESD_DVI

R145 10 OH M

C134

100N 16V

C132

100N 16V

R134 100OHM

Q131

NC

R146 10 OH M

R131 10 OH M

R133 100OHM

R136

1K

E01E12E2

3

VSS

4

SDA5SCL6WC7VCC

8

U133

M24C02-RMN6TP

R141 10 OH M

R142 10 OH M

R137 4.7K1/16W

C133

220N 10V

FB131

300OHM

R144 10 OH M

R132

100OHM

R140 10 OH M

3

1

2

D131

BAV70

R138 4.7K1/16W

C131

100N 16V

R143 10 OH M

DAT2-

1

DAT2+

2

2/4shield

3

DAT4-

4

DAT4+

5

DDC SCL

6

DDC SDA

7

VSYNC

8

DAT1-

9

DAT1+

10

1/3shield

11

DAT3-

12

DAT3+

13

+5V

14

SYNC GND

15

HPD

16

DAT0-

17

DAT0+

18

0/5shield

19

DAT5-

20

DAT5+

21

clk shield

22

clk+

23

clk-

24

GND

26

GND

25

GND

27

GND

28

CN102

JACK

SDA_DVI

SCL_DVI

ZD131

RLZ5.6B

R135 1K

1 2

ZD132

RLZ5.6B

R139 22K1/16W

DVI_HPD 4

DET_DVI

EDID_WP 2,4

+5V2,4,6

ESD_DVI2

ESD_DVI

HPD

DVI5V

ESD_DVI

+5V

DVI5V

DVI5V

Input DVI

19

Meridian 3

Remark: Parts position can be searched by using FIND function in PDF.

Adj_BACKLIGHT 6

Audio_MUTE 6

Audio_VOL 6

on_BACKLIGHT 6

PS_EN 6

CABLE_DET

Panel_ON 6

DVI_HPD 3

EDID_W P2,3

DDCSCL12

VGA_CABLE_DE T2

DDCSDA12

DDCSCL23

DDCSDA23

LVB1PPB6

LVB2MPB5

LVB1MPB7

LVB3MPB1

LVB3PPB0

SPI_SI

SPI_CK

LVBCKPPB2

LVBCKMPB3

LVB2PPB4

PB[0..9]

DVI_CABLE_DET3

LTSDA

1234567891011

12

CN464

CONN

LTSCL

Panel_ON

12345

6

CN465

NC/CONN

AHS0

AVS0

B0-

B0+

LED_A

POWER

LVB0PPB8

G0+

CN464,CN465 BOTH LAYOUT

LVB0MPB9

G0-

SOG_DET

EDID_WP

PA[0..9]5

R0-2

R0+2

LED_2

R0+

G0-2

G0+2

B0-2

B0+2

SOG_DET2

R0-

PS_OUTPUT

KEY2

LED_1

PS_DISTANCE

PS_ON

AHS02

AVS02

RX2+3

RX2-3

PA6 LVA1P

DDCSCL1

PA8 LVA0P

PA9 LVA0M

RX1+3

RX1-3

PA2 LVACKP

PA5 LVA2M

PA7 LVA1M

PA3 LVACKM

RX0+3

RX0-3

PA4 LVA2P

PA1 LVA3M

PA0 LVA3P

RXC-3

RXC+3

DDCSDA1

PA6 LVA1P

PA5 LVA2M

PA0 LVA3P

PA4 LVA2P

PA3 LVACKM

PA1 LVA3M

PA7 LVA1M

PA[0..9]

LED_1

PA8 LVA0P

RX0-

LED_2

KEY2

RX2+

VSO

HSO

RX0+

VSO

SPI_SO

RXC+

HSO

DDCSCL2

RX1-

DDCSDA2

R432

NC/100K1/ 16W

C430

NC

Q466

NC/LMBT3904LT1G

RX1+

R431

NC/4. 7K1/16W

piove_powerPIVOT_EN

piovtOC_SW

Q467

NC/LMBT3904LT1G

VCC3.3

VCC3.3

Cathode

1

Anode

2

Emitter2

3

Collector

4

Emitter1

5

OC401

NC

R436

NC/10K

R433

NC/10K

Audio_VOL

R430

NC/620 OHM 1/16W

VCC3.3

R434

NC/22K1/16W

R435

NC/10K

Audio_MUTE

R472NC

R429 NC

C421

1uF 10V

C0402

R419

NC/10K 1/ 16W 5%

R470NC

Q464

LMBT3906LT1G

R403

100K1/16W

R405

10K

R480

NC/0R01 1/10W

C415

4.7UF

C0805

R417

NC/22K 1/ 16W 5%

D464

RLZ5.6B

R471NC

C409

100N 16V

R414 2.2K1/16W

SPI_CE

R464

2.2K1/16W

C411

100N 16V

C424

100N 16V

R402

470R 1/16W 1%

C465

100N 16V

C419

4.7UF

C0805

R469 0R05 OHMC408

4.7UF

C0805

C470

1uF 10V

TP402

R409 7.5K 1/16W

piovtOC_SW

C405

100N 16V

R427

NC

1 2

FB464

300 OHM

C464

NC

C410

1uF 10V

TP401

R479

NC/0R05 1/16W

R468 0R05 OHM

POWER

KEY1

D467

RLZ5.6B

FB407

300 OHM

C426

220N 10V

RSTB

1

DVDD_ZP

2

DGND

3

RX2+4RX2-

5

AVCC

6

RX1+7RX1-

8

AGND

9

RX0+10RX0-

11

AGND

12

RXC+13RXC-

14

AVCC

15

REXT

16

ADC_BIAS

17

PGND

18

BIN1+19BIN1-20SOG1I21GIN1+22GIN1-23RIN1+24RIN1-

25

ADC_VAA18

26

ADC_GNDA

27

ADC_VAA33

28

PD6

29

PB3/ADC3/INTE1

30

P31/TXD31P30/RXD

32

PB2/ADC2/INTE033PB7/DDC_SDA1*34PB6/DDC_SCL1*

35

PA3/PWM5

36

PA4/PWM6*37PA5/PWM7*38PA6/PWM8*39PA7/PWM9*

40

HSYNCI141VSYNCI1

42

PLL_GND

43

GND

44

PLL_DVDD

45

PB5/DDC_SDA0*46PB4/DDC_SCL0*

47

PD548P3549P34

50

DVDD

51

CVDD

52

NC

53

V054V155V256V357V458V559V660V7

61

VCKI

62

NC

63

DGND/CGND

64

PC6

102

NC

101

NC

100NC99NC98NC97NC96NC95NC94NC93NC92NC91

DVDD

90

NC

89

T0M

88

T0P

87

T1M

86

T1P

85

T2M

84

T2P

83

TCLK1M

82

TCLK1P

81

T3M

80

T3P

79

DGND/CGND

78

T4M

77

T4P

76

T5M

75

T5P

74

T6M

73

T6P

72

TCLK2M

71

TCLK2P

70

T7M

69

T7P

68

PA1/PWM367PA2/PWM466PA0/PWM2

65

OSCO

128

OSCI

127

PB0/ADC0

126

PB1/ADC1

125

PC5

124

PC4/PWM1

123

PC3/PWM0

122

PC1*

121

PC0*

120

CVDD_ZP

119

PWMB*

118

PWMA*

117

DVDD

116

CVDD

115

INT_HSO

114

INT_VSO

113

NC

112

NC

111

PC2

110

GND

109

PD4

108

SPI_CLK

107

SPI_SI

106

SPI_SO

105

SPI_CE

104

PC7

103

U401

NT68668AUFG/C

R410

100OHM

R466

3.9K1/16W

R426

10K

C417

100N 16V

C401

100N 16V

R481

56R 1/10W 5%

FB401

300 OHM

C412

4.7UF

C0805

C420

4.7UF

C0805

R482

0R05 1/10W

R407 100OHM

C413

1uF 10V

C0402

CE#1SO2WP#3GND

4

VDD

8

HOLD#

7

SCK

6

SI

5

U402

Pm25LD020C -SCE

R416

30Kohm 1/16W +/ -5%

FB403

NC

Q465

LMBT3906LT1G

C466

100N 16V

C418

100N 16V

D465

RLZ5.6B

R476

1R 1/10W 5%

C406

1uF 10V

R428

NC

R412 10K

C468

NC

D466

RLZ5.6B

C425 22P 50V

R404

220K OHM

R467

3.9K1/16W

TP403

R408 4.7K1/16W

R401 NC

R473

NC/0R05 1/10W

R411 NC

FB405

300 OHM

R475

0R05 OHM

C423 22P 50V

VGA_CABLE_DET

R413 NC

CABLE_DET

FB402

NC

C416

100N 16V

R425 100OHM

C471

1uF 10V

C414

1uF 10V

C0402

R415 100OHM

R406 120 OHM +-1% 1/16W

R478

2.2K1/16W

R465

3.9K1/16W

C403

100N 16V

R474

NC/0R05 1/16W

C467

NC/1N 50V

R418

1M 1/16W

FB406

300 OHM

R477

0R05 OHM

R423

NC

R421

NC/100OHM

DVI_CABLE_DET

C422 100N 16V

C407

100N 16V

1 2

X401

12MHz

C404

100N 16V

C402

1UF 16V

C469

NC

FB404

300 OHM

VCC3.3 6

RX2-

LT-SCL5

VCC1.8 6

LT-SDA5

VCC3.3a 6

VCC3.3

ADC_VAA

AVCC

+5V2,3,6

+5V

ADC_BIAS

DVDD

AVCC

VCC3.3a

VCC3.3a

VCC1.8

ADC_VAA

CVDD

ADC_VAA33

CVDD

VCC3.3a

VCC3.3a

VCC3.3

DVDD

VCC3.3a

AVCC

DVDD

ADC_BIAS

+5V

+5V

ADC_VAA33

DVDD

+5V

VCC3.3

VCC3.3a

VCC3.3a

VCC3.3

+5V

VCC3.3a

VCC3.3

+5V

LVB1PPB6

LVBCKPPB2

LVB2MPB5

LVB3MPB1

LVB0PPB8

LVBCKMPB3

LVB3PPB0

LVB0MPB9

LVB1MPB7

LVB2PPB4

LED_A

LED_G

LTSDA

LTSCL

WP

5V_DET

PA9 LVA0M

PA2 LVACKP

RXC-

Adj_BACKLIGHT

KEY1

PS_EN

PS_DISTANC E

PS_OUTPUT

PS_ON

DVI_HPD

SPI_CE

SPI_SO

SPI_SI

SPI_CK

PB[0..9]5

WP

piove_po wer

LED_G

on_BACKLIGH T

LED_A

Scaler

!

20

Meridian 3

Remark: Parts position can be searched by using FIND function in PDF.

LVB3PPB0

LVB1MPB7

PA[0..9]

PA9 LVA0M

PA2 LVACKP

LVB0MPB9

LVB0PPB8

PA0 LVA3P

PA8 LVA0P

PA6 LVA1P

LVB1PPB6

LVB2PPB4

PA7 LVA1M

PB[0..9]

LVBCKPPB2

PA3 LVACKM

PA5 LVA2M

LVB2MPB5

LVBCKMPB3

PA4 LVA2P

LVB3MPB1

PA1 LVA3M

PA[0..9]4

RXEC-

RXEC+

RXOC-

RXOC+

LT-SDA 4

LT-SCL 4

RXO0- RXO0+

RXO1- RXO1+

RXO2- RXO2+

RXOC- RXOC+

RXO3- RXO3+

RXE0- RXE0+

RXE1- RXE1+

RXE2- RXE2+

RXEC- RXEC+

RXE3- RXE3+

LT-SDA

LT-SCL

LT-SDA LT-SCL

LT-SCL

LT-SDA

C496

100N 16V

1 2

FB495

120OHM

+

C495

100uF/16V

C498

NC

R496220 OHM 1/4W

R497220 OHM 1/4W

C497

NC

123456789

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

CN408

CONN

R/A: 033G804330C H HR

V/T: 033G804330B F

033G801930F CH JS

246

8

1012141618202224262830

1357911131517192123252729

CN409

NC/CONN

VLCD 6

VLCD

LVA0P RXE0+

PB[0..9]4

RXE2-LVA2M

RXO3-LVB3M

RXO1-LVB1M

RXO0-LVB0M

RXE3-LVA3M

LVACKM RXEC-

RXE1-LVA1M

LVB2M RXO2-

RXOC+LVBCKP

LVBCKM RXOC-

RXE0-LVA0M

RXO0+LVB0P

RXE2+LVA2P

RXO1+LVB1P

RXO2+LVB2P

RXEC+LVACKP

RXO3+LVB3P

RXE1+LVA1P

RXE3+LVA3P

Output

21

Meridian 3

Remark: Parts position can be searched by using FIND function in PDF.

R708

100OHM

PS_EN 4

Audio_VOL 4

on_BACKLIGHT 4

Adj_BACKLIGHT 4

Panel_ON4

R709

0R05 OHM

R711 100OHMR701 0R05 OHM

R710

10K

VIN

3

VOUT

2

ADJ(GND)

1

U702

Audio_MUTE 4

TO252

TO-223

TO-252

R706

NC

C712

NC

C703

100N 16V

C710

100N 16V

C701

100N 16V

R702

10K

Q493

LMBT3904LT1G

R705

10K

R491

10K

GND

1

VOUT(heat si nk )

2

VIN

3

4

4

U703

NC/AME8815BEGT180Z

VOUT

2

VIN

3

GND

1

U704

NC

S

1

S

2

S

3

G

4

D

8

D

7

D

6

D

5

Q492

NC/ AO4449 -7A/ - 30V

VIN

3

VOUT

2

GND

1

U701

NC

R704

10K

R492

56K 1/16W

C493

1UF 16V

C491

220N 10V

C492

220N 10V

C705

100N 16V

+

C702

100uF/16V

R703 1K

C704

100N 16V

R495

10K

+

C708

100uF/16V

Q701

LMBT3904LT1G

C706

100N 16V

C709

100N 16V

R493

NC

R707

22K1/16W

+

C711

NC

R494

22K1/16W

Q491

AO3401A

C707

100N 16V

C713

NC

123456789

CN701

CONN

VLCD 5

VCC3.3 4+5V2,3,4

VCC3.3a4

VCC1.8 4

VLCD

+5V

+5V

VCC3.3a

+5V

VCC1.8

+5V

+5V VCC3.3

VCC3.3

VCC3.3

Audio_SD

Mute

Volume

DIM

ON/OFF

Power 1A1D

!

22

Meridian 3

6.2 Power Board (715G5164P01002001M)

Remark: Parts position can be searched by using FIND function in PDF.

PWM1ISEN12ISEN23ISEN34ISEN45GNDA6ISEN87ISEN68ISEN79OVP10ISET11RT

12

ENA

13

ISW

14

ISEN5

15

LDR

16

VREF

17

GNDP

18

VIN

19

SEL

20

COMP

21

SSTCMP

22

NC

23

STATUS

24

IC801

OZ9998AGN

R851

NC

1 2

FB802

BEAD

12345

CN803

NC

R847

NC

R849

NC

+

C813

220uF

Q801

APM1105NUC-TRG

R806

10K 1/10W 5%

Vout

R812

100R 1/10W 5%

C805

0.47uF 16V

R808

NC

R810

1K 1/10W 5%

C807

2U2 16V

JUMP/EMI

R824

36KOHM +-1% 1/10W

ZD801

NC/SK510B

R804 20K 1/10W 1%

R809

100K

C806

0.47UF 50V

C811

100PF 50V

R805

270K +-1% 1/8W

+16V

12345

6

7 8

CN802

CONN

R801

0.3R 1/4W

1 2

FB803

BEAD

IS1

IS3

IS2

IS7

IS6

IS4

C812

100P 50V

R814

10R

IS8

IS5

2

4

L801

33UH

IS1

IS2

IS3

R848

1R 1/1 0W 5%

IS4 IS8IS7IS5 IS6

R850

1R 1/1 0W 5%

R852

1R 1/10W 5%

+

C804

4.7U F 100V

IO1 IO3IO2 IO4

R846

1R 1/10W 5%

C820

0.47U F 50V

C821

0.47U F 50V

1 2

FB801

NC

IO1

IO2

IO3

IO4

ZD802

SR5100

R844

10 OHM 1/4W

R822

1M 1/8W 5%

C815

330NF 1 6V

Vout

Vout

NC/R842

18K 1/10W 1%

R845

100 OHM 1/4W

C814

680P 50V

246

135

NC/CN801

CONN

R802

0.3R 1/4W

R813 10K 1/10W 5%

C801

0.1uF 50V

DIM

ON/OFF

OVP1

OVP1

R807

10R 1/10W 5%

IO2

IO1

IO3

IO4

Vout

CONVERTER

23

Meridian 3

Remark: Parts position can be searched by using FIND function in PDF.

OTP1COMP2CS3GND

4

OUT

5

VCC

6

HV

8

IC901

LD7750RGR

C934

1N 50V

C922

1N 50V

L904

3.5uH

R917

220oHM

3

256

789

10

11

12

4

T901

430uH

R932

100KOHM +-5% 1/8W

123456789

10

NC/CN902

CONN

D902

FR107

C911

0.1uF 50V

D904

1N4148

R910

3.3 OHM 1/4W

C914

NC

C906

1500PF2KV

C924

100N 50V

R923

22 OHM 1/4W

R905

10K 1/4W

1

2

3

D905

MBRF10100CT

F902

T4AL 250V

F903

T4AL 2 50 V

+

NC/C 905A

120uF 450V

IC903

TL431G-A-TA

R924

820 OHM +-5% 1/4W

+

C916

1000UF 1 0V

R908

10K 1/4W

C933

4.7nF 50V

!

R913

100K

R940

1K 1/8W

R914

100K

R907

100K

R906

100K

R927

10KOHM +- 1% 1/8W

373G0174290CP0

R919

0.43 OHM +-5% 2WS

+5V

R930

9.53KOHM +-1% 1/8W

+16V

+5V

L903

1.1uH

L905

1.1uH

Q903

KTD1028

12

3

CN901

SOCKET

2

1

3

4

-

+

BD901

KBJ408G

R962 47 O HM 1/4W

Audio_SD

R936

2K 1/8W 1%

C920

47pF

R920

47 OHM 1/4W

1 2

FB902

BEAD

!

+5V1

R939

1K 1/8W

!

F901

T4AL 25 0 V

C931

100N 50V

HV

C903

470NF

+

C915

470UF 16V

5V/2.5A

16V/2.35A

C932

1N 50V

R943

470OHM +-5% 1/8W

1

2

3

D907

NC/SF F1004G

C907

1NF 2KV

R941

NC

1

2

HS2

HEAT SINK(D905)

1

2

HS3

HEAT SINK(D906)

ZD902

GDZJ24B

+

C913

47uF

C901

1NF 250V

1

2

GND2

GND

C902

1NF 250V

C912

2N2 500V

C921

330PF

C900

2.2NF 250V

R947

470R

R946

470R

S80GL32P6V

C930

100N 50V

NC/R933

20KOHM +-1% 1/8W

C910

2N2 500V

C929

2N2 500V

C935

2N2 500V

1

2

HS1

HEAT SINK

R902

680K 1/4W

12

43

IC902

PS2561DL1-1

DIM

+16V

1

2

GND1

GND

!

ON/OFF

1

2

3

D906

SFF1004G

R935 47 O HM 1/4W

R961 47 O HM 1/4W

12

FB903

BEAD

+

C917

470UF 35V

+

NC/C905

82uF 450V

VOL

R918

47 OHM 1/4W

+

C918

470UF 35V

R916

47 OHM 1/4W

R903

680K 1/4W

12

t

NR901

NTCR

L

1

N

2

CN905

NC/CONN

123456789

1011121314

CN903

CONN

C905

MUTE

1 2

FB901

BEAD

R919 0.43

231B

R926

2K 1/8W 1%

R925

2.2K OHM 1%

0.39

231P

C919

1NF

150u120u

1

2

4

3

NC/L901

30MH

1

2

4

3

L902

30MH

R901

680K 1/4W

R912

10K 1/4W

R911

22 OHM 1/4W

Q901

SMK0870F

!

D903

FR107

Power

!

24

Meridian 3

Remark: Parts position can be searched by using FIND function in PDF.

OUT-R+

SCALER I N R

1234567891011

12

CN602

CONN

SCALER I N L

12345

6

CN603

CONN

OUT-L+

OUT-R-

C611

1UF 16V

C607 1UF 16V

C612

1UF 16V

R61162K

+5V_AUDIO

VOL1

R627 NC/0R05 1/10W

SE

R625

100R 1/10W 5%

R632

10K 1/10W 5%

R619 39R 1/10W 5%

C606 1UF 16V

+5V_AUDIO

OUT-R-

SCALER I N R

C631

220N 25V

SCALER OU T L

12

FB606

120 OHM

R605

10K 1/10W 5%

1 2

FB603 120 OHM

C625

1UF 16V

C614

1UF 16V

C615

220P 50V

Q604

LMBT3904LT1G

1

23

Q603

LMBT3906LT1G

+

C603

220uF16V

R609

10K 1/10W 5%

+5V_AUDIO

R603

10K 1/10W 5%

R620 100K 1/10W 5%

1 2

FB601

BEAD

1 2

FB602 120 OHM

+5V1

Audio_SD

Audio_SD

R

SCALER I N L

+5V_AUDIO

VOL

C608330P 50V

R604

10K 1/10W 5%

C613

10uF 16V

R602

1K 1/10W 5%

SCALER I N L

MUTE-1

R631

10K 1/10W 5%

C630

220N 25V

SE

+OUTL

1

-OUTL

4

/ MUTE

6

+OUTR

24

PGNDL

3

INR

17

INL

8

PGNDL

2

PGNDR

22

PGNDR

23

PVDDL

5

VDC

10

PVDDR

20

VREF

14

-OUTR

21

LINE/EAR

15

/ SHDN

19

Volume

11

VDD

7

GND

18

EarInL

9

EarOutL

12

EarInR

16

EarOutR

13

U601

PAM8007DHR

C617

220P 50V

+

C620 220uF16V

L

1 2

FB607

BEAD

OUT-R+

R624

750 OHM 1/8W

SCALER OU T R

C616

220P 50V

MUTE

+

C601

220uF16V

1 2

FB604 120 OHM

SCALER OUT L

SCALER OUT R

+5V_AUDIO

OUTL

SCALER I N R

R618

100K 1/10W 5%

R626

100R 1/10W 5%

OUTR

R633

10R 1/8W 5%

Q601

LMBT3904LT1G

C622

220N 25V

C610

220N 25V

C621

0.1uF 50V

+5V_AU DI O

R606

470OHM +-5% 1/ 10W

OUT-L+

R621 39R 1/10W 5%

+5V_AUDIO

12354

CN601

PHONE J AC K

1 2

FB605 120 OHM

OUT-L-

+

C619 220uF16V

C605

1UF 16V

R601

10K 1/10W 5%

+5V_AUDIO

R628 NC/0R05 1/10W

C623

1UF 16V

+5V1

C624

10uF 16V

R610

10K 1/10W 5%

OUTL

C609330P 50V

SE-1

R61262K

C618

220P 50V

OUT-L-

MUTE-1

OUTR

VOL1

R607

10K 1/10W 5%

C602

0.1uF 50V

+5V_AUDIO

220B4 LPC

Audio

25

Meridian 3

6.3 Key Board (715G5446K01000004S)

Remark: Parts position can be searched by using FIND function in PDF.

SM_INT#

CIN_07

FFC R/A: 311GF100C06ADH

FFC V/T: 311GF100D06ACJ

FFC CABLE: 089G 76J 6 3

WIRE V/T: 033G8032 6F S HR

CIN_07

CIN_11

CIN_03

V3.3

R003

4.7K1/16W

R005

100OHM

R004

680OHM +-5% 1/10W

C004

100P 50V

MenuBrightness PowerSmartPower

GPIO_00

C003

100N 16V

CIN_01

SmartPowerBrightness

TP6 KEY0.1524

Menu

CIN_05

C001

100N 16V

Differential

C002

100N 16V

SmartImage

GPIO_00

SM_CLK

CIN031CIN072CIN093CIN11

4

VSHILD

5

VBIAS

6

AVSS

7

AVCC

8

DVCC

9

SCLK

10

SDA

11

INT#

12

GPIO0

13

GPIO1

14

CIN00

15

CIN01

16

E-PAD

17

U001

IT7230EFN/BX

12

ZD001

MLVS0603M04

CIN_09

SmartImage

CIN_03

SM_DATA

SM_INT#CIN_05

V3.3

V3.3

AC_SHIELD

VBIAS

Power

R001

10K

AC_SHIELD

CIN_01 CIN_09CIN_11

KEY0.1524

TP3

KEY0.1524

TP2

KEY0.1524

TP5

KEY0.1524

TP1

R002

4.7K1/16W

KEY0.1524

TP4

12345

6

78

CN001

CONN

KEY0.1524

TP7

VBIAS

12

ZD002

MLVS0603M04

SM_CLK CLK

C005

1UF 16V

V3.3

DATASM_DATA

KEY-TOUCHPAD_NONE LED

!

26

Meridian 3

6.4 IR Board (715G5459R01000004S)

Remark: Parts position can be searched by using FIND function in PDF.

IR_RX

PS_OUTPUT

VCC_IN

IR_RX

R/A: 081G 15W 1 EL

V/T: 081G 63W 2 GP

REVERSE: 081G 14 31 EL

FFC R/A: 311GF100C06ADH

FFC V/T: 311GF100D06ACJ

FFC CABLE: 089G 76J 6 3

WIRE V/T: 033G8032 6F S HR

FFC R/A: 311GF100C12ADH

FFC V/T: 311GF100D12ACJ

FFC CABLE: 395G076J12NM01

WIRE V/T: 033G803212F S HR

R313

1K

C311

100N 16V

C318

100N 16V

C316

100N 16V

C312

100N 16V

C317

100N 16V

R312

100K1/16W

LED_VCC

PS_OUTPUT

C315

100N 16V

12345

6

78

CN311

CONN

VCC_KB

R323

10K

I2C_SDA

PS_ON

1 2

ZD312NC/UDZSNP5.6B

123456789

101112

CN312

CONN

PS_DISTANCE

I2C_SCL

SM_INT#

R315

100K1/16W

C314 22UF 16V

R320

100OHM

R316

100 OHM 1/8W

R311

1K

1OUT

1

1IN-

2

1IN+

3

GND

4

2IN+52IN-62OUT7VCC+

8

U311

AS358MTR-E1

R317

33 OHM 1/8W

VDD1GP5/T1CKI/P1A*/OSC1/CLKIN2GP4/AN3/CIN1-/T1G/P1B*/OSC2/CLKOUT3GP3/T1G*/MCLR/VPP

4

GP2/AN2/T0CKI/INT/COUT/CCP1/P1A

5

GP1/AN1/CIN0-/VREF/ICSPCLK

6

GP0/AN0/CIN+/P1B/ICSPDAT

7

VSS

8

U313

PIC12F615-I/SN

C313 22UF 16V

1 2

ZD313NC/UDZSNP5.6B

R319

1K

Q313

AO3401A

C320

100N 16V

R324

10K

R322

10K

C319

100N 16V

Q312

SST2222A

R314

100K1/16W

VOUT1GND2VCC3HAND14HAND2

5

U312

IRM-3638M3S28

R321

1K

12

LED311

A8824B/IR204C-A

12

LED312

LED

1 2

ZD311NC/UDZSNP5.6B

R318

33 OHM 1/8W

Q311

SST2222A

VCC

VCCVCC

VCC_IN

VCC

VCC

VCC

VCC_IN

PS_ON

VCC_KB

LED_White

I2C_SCL

I2C_SDA

PS_ON

PS_OUTPUT

PS_DISTANCE

LED_VCC

PS_DISTANCE

LED_white

SM_INT#

POWER SENSOR_LED

27

Meridian 3

6.5 EAR Board (715G5462T01000004Q)

Remark: Parts position can be searched by using FIND function in PDF.

LOUT+

Headset_R

Earphone_Det

ROUT+

ROUT-

Headset_L

LOUT-

1

2

3

4

6 5

CN683

CONN

GND

123456789

1011

CN681

CONN

12354

CN684

PHON E J AC K

Headset_R

Headset_L

Ear-phone

GND

LOUT+

LOUT-

ROUT+

ROUT-

Earphone_Det

HEADPHONE JACK

!

28

Meridian 3

6.6 USB Board (715G5437T01000004S)

Remark: Parts position can be searched by using FIND function in PDF.

DM4

/OC2

/OC1

DM2

DP2

/OC1

VBUS1A

C763

1N50V

C764

1N50V

UGND

UGND

2A

1A

DP3

1 2

FB738

120R 0.3A

/OC3

3A

4A

VBUS_DET

1B

DM3

C765

1N50V

C766

1N50V

UGNDUGND

2010/1/25

/OC2

12345

67

CN736

CONN

C737

100N 16V

DP0

VBUS0

UGND

123

4

6 5

12

34

CN732

CONN

DM0

UGND

DM4

UGND

DP4

R/A: 088G 3527A2 CL HF

V/T: 088G 352 11VCL

DOUBLE: 088G 350 1VCL HF

R/A: 088G 351 2B XH HF

V/T: 088G 351 4 XH HF

DM / DP Trace

䫷

à

ǂ

˄70

ǂ

EEPROM NC: R818~820 pull low

Disable Downstream 4

SW

1

EN

2

COMP

3

FB

4

GND5FREQ6VIN7BST8Thermal Pad

9

MP1584EN

/OC3

EEPROM mount: R812~814 pull hi

Power Regulator

Disable Downstream 3: R735, R736 pull high 10K

Disable Downstream 4: R737, R738 pull high 10K

UGND

DM / DP Trace width 18 mils

DM / DP

ϕ⾃

:7 mils

U802 Decoupling

ㅓ⫻㎐

IC

DM33

DP4

DP11

DP22

DP1

DM3

DM2

DP44

DP3

DM22

DP2

DM1

DM44

DM11

DM3

DP3

DP33

DM4

Disable Downstream 3

Layout Not e

DM / DP pair t o pair

ϕ⾃

35mil

VBUS2A

VBUS3A

UGND UGND

R745

0R05

/OC4

C770

1N50V

UGND

VBUS4A

/OC4

VBUS4

DM44

DP44

UGND

C771

1N50V

C772

1N50V

UGND

UGND

C773

1N50V

UGND

C595

10uF 25V

UGND

DP0

DM1

UGND

C596

10uF 25V

DP1

R756

10K

C585

10uF 25V

1 2

ZD581

RLZ6.2B

R582

68.1K 1%

FB581

0R05 1/10W

123

4

6 5

1234

CN735

USB CONN

+

C759

100UF 16V

C588

150pF 50V

R581

100K1/16W

R750

10K

R763

15K 1/16W

R746

100K1/16W

C735

100N 16V

1 2

FB737

120OHM

1 2

FB582

120OHM

C736

1uF 10V

R586

12.4K 1%

R751

11.5K +-1% 1/16W

C751

33P 50V

A01A12A2

3

GND

4

SDA5SCL6WP7VCC

8

U731

NC/M24C02-WMN6TP

D731

NC/LL4148

C755

100N 16V

C592

0.1UF50V

C731

4.7UF

1 2

D582

SR34

C586

1N 50V

C738

100N 16V

USBUP_DP

31

USBUP_DM

30

USBDN1_DP

2

USBDN2_DP

4

USBDN3_DP

7

USBDN4_DP

9

USBDN1_DM

1

USBDN2_DM

3

USBDN3_DM

6

USBDN4_DM

8

VBUS_DET

27

PRTPWR1

12

PRTPWR2

16

PRTPWR3

18

PRTPWR4

20

OCS_N[1]

13

OCS_N[2]

17

OCS_N[3]

19

OCS_N[4]

21

RBIAS

35

SDA/SMBDATA/NON_REM1

22

SCL/SMBCLK/CF G_SEL0

24

HS_IND/CFG_SEL1

25

XTAL1/CLKIN

33

XTAL2/CLKIN_EN

32

RESET26LOCAL_PWR/NON _REM0/SUSP_IND28TEST

11

VDD33

23

PLLFILT

34

VDDA33

29

VDDA33/VDD 33PLL

36

VDD33

15

CRFILT

14

VSS(FLAG)

37

VDDA335VDDA33

10

Upst re am

Dow ns tr eam 1

Dow ns tr eam 2

Dow ns tr eam 3

Dow ns tr eam 4

EEPROM/C on f ig

Common

U733 USB2514B-AEZC

1 2

FB734

120OHM

C758

100N 16V

+

C732

100UF 16V

1 2

FB733

120OHM

12

t

F733

PTCR

C587

1N 50V

C745

100N 16V

R736

NC/10K

C744

100N 16V

C589

10uF 25V

12

t

F731

PTCR

C582

100N 16V

ADJ(GND)

1

VOUT

2

VIN

3

4

4

U732

AP1117E33L-13-77

1

4

2

3

L732

90R/400mA

R754

10K

R760

15K 1/16W

R744

NC

L581

22uH

R732

51K 1/16W 5%

R738

NC/10K

R762

15K 1/16W

R758

10K

C752

100N 16V

R752

NC

C584

0.1UF50V

C748

100N 16V

R583

10K 1/10W 5%

C741

NC

C749

100N 16V

R742

NC

1 2

FB735

120OHM

DM0

C753

100N 16V

R759

10K

C591

0.1UF50V

C581

1N 50V

12

X731

24.000MHZ

1 2

FB731

120OHM

R749

10K

C594

0.1UF50V

R737

NC/10K

C743

100N 16V

C760

100N 16V

R584

300K

+

C761

100UF 16V

+

C583

330UF 20% 35V

1 2

FB732

120OHM

C747

4.7UF

+

C590

470uF 10V

+

C756

100UF 16V

12

t

F734

PTCR

R731

1M 1/16W

1 2

D581

SR34

123

4

6 5

1234

CN734

USB CONN

C742

100N 16V

+

C733

100UF 16V

C746

33P 50V

R761

15K 1/16W

123

4

CN581

CONN

123

4

6 5

1234

CN733

USB CONN

C754

4.7UF

C740

100N 16V

DP4

R757

10K

R748

10K

R733

100K1/16W

+

C757

100UF 16V

R585

30K 1/10W 5%

12

t

F732

PTCR

123

4

6 5

1234

CN731

USB CONN

R735

NC/10K

C739

100N 16V

C734

100N 16V

R743

NC

C762

100N 16V

C593

100N 16V

1 2

FB736

120OHM

C750

100N 16V

USB_POWER

UGND

VBUS0

UGND UGND

UGND

U5V

UGND

UGND

1

4

2

3

L733

90R/400mA

VBUS1

UGND

UGND

UGND

UGND

UGND

UGND UGND

UGND

U5V

VBUS4

UGND

1

4

2

3

L734

90R/400mA

USB3.3V

UGND

UGND

VBUS0

UGND

UGND

UGND

VBUS4

UGND

UGND

UGND

UGND

UGND

1

4

2

3

L731

90R/400mA

USB3.3V

VBUS2

UGND

USB3.3V

UGND

UGND

USB3.3V

USB5V

VBUS2

USB3.3V

USB5V

VBUS3

UGND

UGND

UGND

UGND

1

4

2

3

L735

90R/400mA

UGND

UGND

UGND

UGND

USB5V

UGND

VBUS3

UGND

UGND

USB3.3V

UGND

UGND

UGND

UGND

UGND

UGND

UGND

USB5V

VBUS1

UGND

USB5V

USB3.3V

UGNDUGND

UGND

USB2.0_USB 2514

29

Meridian 3

7. PCB Layout

7.1 Scaler Board (715G5428M01000004Q)

Remark: Parts position can be searched by using FIND function in PDF.

!

30

Meridian 3

7.2 Power Board (715G5164P01002001M)

Remark: Parts position can be searched by using FIND function in PDF.

31

Meridian 3

7.3 Key Board (715G5446K01000004S)

Remark: Parts position can be searched by using FIND function in PDF.

7.4 IR Board (715G5459R01000004S)

Remark: Parts position can be searched by using FIND function in PDF.

7.5 EAR Board (715G5462T01000004Q)

Remark: Parts position can be searched by using FIND function in PDF.

!

32

Meridian 3

7.6 USB Board (715G5437T01000004S)

Remark: Parts position can be searched by using FIND function in PDF.

33

Meridian 3

8. Wring Diagram

1

Scaler Board

CN408

Scaler

1

9

2 30

CN102

CN602

CN905

CN802

Power Board

IR Board

CN312

EAR Board

CN684

Key Board

CN001

CN701

CN465

CN101

CN501

Switch

CN311

Panel

Panel

CN903

1

14

1

6

1

12

CN733 CN712

CN734

USB Board

CN702

!

34

Meridian 3

9. Scaler Board Overview

ScalerIC

DC-DC

Flash ROM

FFC Cable

EEPROM

35

Meridian 3

10. Mechanical Instructions

Step 1: Remove STAND ASSY

1. Press the button on the rear cover to remove the

STAND ASSY.

Step 2: Remove the Rear cover

1. Unscrew the four screws on the rear cover ,

2. Use disassembly tool to open all the latches along

the edge of the Rear Cover.

Step 3: Remove the mainframe

1. Tear up the tapes and disconnect cables.

Press here

!

36

Meridian 3

2. Disconnect the pin on power board.

3. Disconnect the COVER_USB one the mainframe.

4. Unscrew the screws to remove the mainframe.

Step 4: Remove the boards.

1. Disconnect the pins to remove the boards.

37

Meridian 3

2.The power board.

3.The main board.

4.The USB board.

!

38

Meridian 3

11. Repair Flow Chart

1. No Power

OK

NG

No power

Check power cable is

tightened?

Check Power “On/Off”

is “On”?

Re-plug the power cable

Replace main board and check connections

Check the LED

indicator is OK?

Check the AC power

Replace the power board and check connections

OK

NG

OK

NG

NG

Turn on the Power “On/Off” switch

Replace key board and check connections

NG

39

Meridian 3

2.

Video (Power LED White)

No Video (Power LED White)

Press the power

button is OK?

Check the FFC cable

or panel

The end

NG

OK

OK

NG

Replace the main board

Replace the power

board and connection

Replace the FFC cable

or panel

NG

The end

Replace the key board

NG

OK

Replace the main

board and connection

OK

!

40

Meridian 3

3. DIM

OK

The end

OK

The end

OK

The end

DIM (image overlap, focus or flicker)

Reset in factory mode

Set to the optimal

frequency, select the

recommended fre

q

uenc

y

Pull out signal cable and

check “Self Test Feature

Check” is ok?

Check the signal cable

and the PC

Readjust the phase and pixel

clock in the user mode

Replace the main board

Replace the panel

NG

NG

NG

OK

NG

NG

OK

The end

OK

NG

41

Meridian 3

4. Color is not optimal

NG

Color is not optimal

Miss color

Color shift

Replace the signal cable

Pull out the signal cable

and check the screen

color display is normal?

The end

Replace the signal cable or PC

Reset the factory mode

In the user mode, set the “color

settings” until customer satisfy

Replace the main board

NG

OK

NG

OK

NG

!

42

Meridian 3

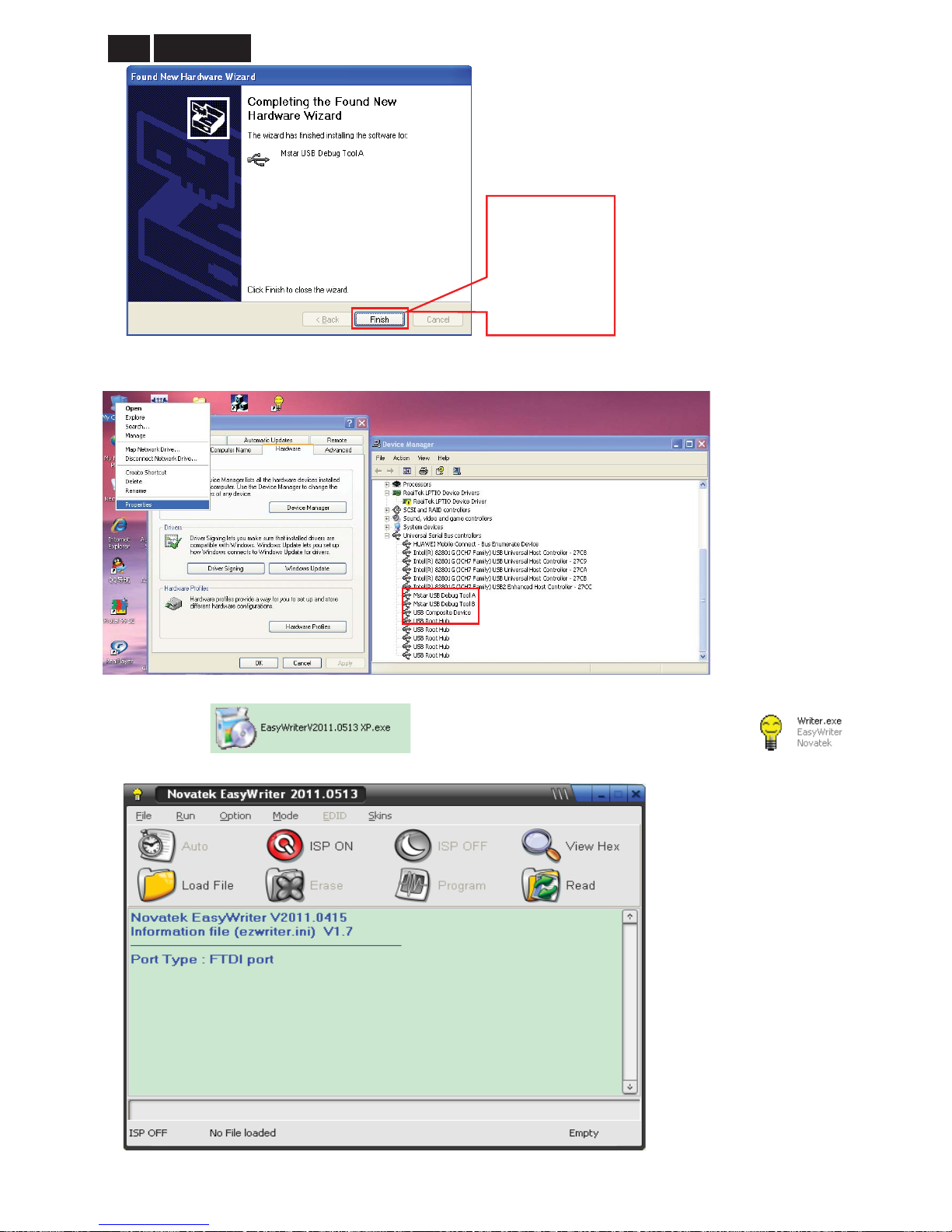

12. ISP Instruction

When do the parts, need the tools as follow:

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98/2000/XP.

3. ISP tool “EasyWriterV2011.0513XP.exe”

4. USB port driver and Installation patch

5. ISP Board (715GT089-B/C) x1

6. USB cablex1, VGA cable x1

7. software

12.1. Connect the ISP board, PC and monitor as follow:

12.2 Install the USB driver.

1. When insert the USB cable to PC USB port, it will pop up a Hardware Wizard to help you install the USB driver if

you use this ISP board first time. You can install it successfully as the below instruction step by step.

Remark: The USB driver files path: D:\FTC100103(Mstar)\FT CUSB.INF

43

Meridian 3

!

44

Meridian 3

After installation the USB serial port driver, please check the usb port. look the properties of “my Computer”.

12.3 Install the ISP tool and run it:

1. Double-click to install ISP program. After installation, double- click

to run the ISP tool.

Click “Finish” to

complete the

USB serial port

driver

installation.

45

Meridian 3

2. Set the parameters to restore the HDCP key if the monitor has DVI or HDMI.

(1) Click the “Option” item.

(2) Tick “FE2P Mode Enable”.

(3) Tick “Enable Auto FE2P Detect”

3. Setup ISP tool. Click “Setup ISP tool” to open the configuration window.

!

46

Meridian 3

4. Configuration for ISP tool. Tick “FTDI”

5. Load the F/W you want to upgrade.

47

Meridian 3

6. Start to program. Click Äuto” to start programming

7. Programming success. There will be the message in the red frame after successful programming.

!

48

Meridian 3

12.4 Check the firmware version:

1. The way to open factory menu.

(1)Connect video source to monitor and AC on.

(2)The way to factory menu: Press “MENU” and “+” keys synchronously (The righ tmost and lef tmost keys in t he

touch keyboard), and DC on. When the screen lights, release the two keys and press “MENU” again to open

factory menu.

“+” key menu key DC key

(3)Select the “Factory” and press the menu key button to open factory menu as below.

(4)Please do ”Auto Color” in factory menu after change main board and upgrade F/W.

2.Do factory reset in user menu. User menu- Setup- Reset- Yes.

(1) Restart the monitor after open factory menu. And then open the user menu.

(2) Factory reset will turn off “Burn in” mode which screen color switches among red, green, blue and black.

Check this F/W version.

49

Meridian 3

12.5 Troubleshooting

1. “CheckSum Comparing Fail!” error.

Method: Tick the “Send MX2060 CMD” at Option item.

2.When can’t upgrade, please retry below several ways to upgrade.

(1) When the tool appears erase error, you can change another version tool to try.

(2) The program must be in the monitor standby state, while the fail communication with monitor might result the

monitor power off. In this situation, you may AC off the monitor for a while and then AC on to retry. Maybe the

defect will be cured.

(3) Change ISP JIG or cable.

(4) Change PC

!

50

Meridian 3

13. DDC Instruction

General

DDC Data Re-programming

In case the main EEPROM with Software DDC which store all factory settings were replaced because a defect

repaired monitor’ the serial numbers have to be re-programmed.

It is advised to re- soldered the main EEPROM with Software DDC from the old board onto the new board if circuit

board have been replaced, in this case the DDC data does not need to be re-pro grammed.

Additional information about DDC (Display Data Channel) may be obtained from Video Electronics Standards

Association (VESA). Extended Display Identification Data (EDID) information may be also obtained from VESA.

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98/2000/XP.

3. LPT port driver “PORT95NT.exe” and EDID tool “VgaSinglePort.exe”

4. EDID Board (715GT034-B) x1,

5. LPT cable (male to male) x1, VGA cable x 1

6. 12V DC power source

7. EDID data

13.1 Connect the ISP board, PC and monitor as follow:

13.2 Install the LPT drive

1. Double click the icon to install the driver.

2. Restart the PC after the LPT driver installation

51

Meridian 3

13.3 Prepare the EDID written

1. Change the EDID files name as below rule.

Anolog EDID WA.dat Digital EDID WD.dat

2. Copy these three files to one folder named as PHILIPS 220B4L which must contains “config.ini” file.

3. Copy PHILIPS 220B4L to DDC folder and put DDC and ISP tool together.

13.4 Run the ISP tool

1. Double-click the icon to open the tool.

!

52

Meridian 3

Tick the “Analog+DVI” and click “Loadfile” to set the parameters.

(1).Tick “Analog”, and “Digital” .

(2).Manufacturer: PHL Product Code: 08BF Model Name: 220BLP

Select the EDID folder. Select correct folder.

53

Meridian 3

2. Load EDID successful, the tool will read the EDID information:

3. Tick the “Only connect VGA” and “Write SN”, and type in the 14 digit S/N and date.

!

54

Meridian 3

4. Click the “Program” to start programming after monitor power on. When the green “PASS” appear, The writing

process are finished.

13.5 Check the S/N

Connect the VGA or DVI source an d power on monitor.

1. Press the “MENU” button to enter the user menu, and then check the SN.

13.6. Troubleshooting.

6.1. Can’t write error.

6.2. Try below few ways to cure can’t write errors!

(1) AC on the monitor and turn on it.(Restart the monitor)

(2)Take apart the monitor and connect the 7pin of EEPROM to GND to diable write protection then write EDID

one by one.

(3)Set the Burn in on last to try again.

55

Meridian 3

220B4LPCS EDID

Analog

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

-----------------------------------------------

00| 00 FF FF FF FF FF FF 00 41 0C BF 08 01 01 01 01

10| 11 16 01 03 6E 2F 1E 78 2A FD A5 A2 56 51 9E 27

20| 0C 50 54 BD 4B 00 B3 00 95 00 95 0F 81 C0 81 80

30| 01 01 01 01 01 01 7C 2E 90 A0 60 1A 1E 40 30 20

40| 36 00 DA 28 11 00 00 1A 00 00 00 FF 00 0A 20 20

50| 20 20 20 20 20 20 20 20 20 20 00 00 00 FD 00 38

60| 4C 1E 53 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70| 00 32 32 30 42 4C 50 0A 20 20 20 20 20 20 00 D7

EDID Structure Version/Revision: 01 03

<-Vendor/Product Identification:->

ID Manufacturer Name: PHL

ID Product Code: 08BF

ID Serial Number: No Use

Week of Manufacture: 17

Year of Manufacture: 2012

<-Basic Display Parameters/Features:->

Video i/p definition: Analog

Max. H. Image Size : 47cm

Max. V. Image Size : 30cm

Display Gamma : 2.2

<-Color Characteristics:->

Rx: 0.636 Gx: 0.318 Bx: 0.154 Wx: 0.312

Ry: 0.339 Gy: 0.618 By: 0.049 Wy: 0.329

<-Established T imings:->

Established Timings 1:BD

720 x 400 @ 70Hz VGA,IBM

640 x 480 @ 60Hz VGA,IBM

640 x 480 @ 67Hz Apple,Mac II

640 x 480 @ 72Hz VESA

!

56

Meridian 3

640 x 480 @ 75Hz VESA

800 x 600 @ 60Hz VESA

Established Timings 2:4B

800 x 600 @ 75Hz VESA

1024 x 768 @ 60Hz VESA

1024 x 768 @ 75Hz VESA

1280 x1024 @ 75Hz VESA

Established Timings 3:00

<-Standa rd T i ming Identification:->

1680 x 1050 @ 60Hz

1440 x 900 @ 60Hz

1440 x 900 @ 75Hz

1280 x 720 @ 60Hz

1280 x 1024 @ 60Hz

<-Detailed Timing Descriptions:->

FC (Monitor Name) : 220BLP

FD (Monitor Limits):

Min. V. rate: 56 Hz

Max. V. rate: 76 Hz

Min. H. rate: 30 KHz

Max. H. rate: 83 KHz

Max. P Clock: 170 MHz

FF (Monitor SN) :

Detailed Timing : 1680x1050 @ 60Hz

Extension Flag : 00

Block0 Checksum : D7

Digital

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

-----------------------------------------------

00| 00 FF FF FF FF FF FF 00 41 0C BF 08 01 01 01 01

10| 11 16 01 03 80 2F 1E 78 2A FD A5 A2 56 51 9E 27

20| 0C 50 54 BD 4B 00 B3 00 95 00 95 0F 81 C0 81 80

30| 01 01 01 01 01 01 7C 2E 90 A0 60 1A 1E 40 30 20

40| 36 00 DA 28 11 00 00 1A 00 00 00 FF 00 0A 20 20

57

Meridian 3

50| 20 20 20 20 20 20 20 20 20 20 00 00 00 FD 00 38

60| 4C 1E 53 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70| 00 32 32 30 42 4C 50 0A 20 20 20 20 20 20 00 C5

EDID Structure Version/Revision: 01 03

<-Vendor/Pro duct Identification:->

ID Manufacturer Name: PHL

ID Product Code: 08BF

ID Serial Number: No Use

Week of Manufacture: 17

Year of Manufacture: 2012

<-Basic Display Parameters/Features:->

Video i/p definition: Digital

Max. H. Image Size : 47cm

Max. V. Image Size : 30cm

Display Gamma : 2.2

<-Color Characteristics:->

Rx: 0.636 Gx: 0.318 Bx: 0.154 Wx: 0.312

Ry: 0.339 Gy: 0.618 By: 0.049 Wy: 0.329

<-Established T imings:->

Established Timings 1:BD

720 x 400 @ 70Hz VGA,IBM

640 x 480 @ 60Hz VGA,IBM

640 x 480 @ 67Hz Apple,Mac II

640 x 480 @ 72Hz VESA

640 x 480 @ 75Hz VESA

800 x 600 @ 60Hz VESA

Established Timings 2:4B

800 x 600 @ 75Hz VESA

1024 x 768 @ 60Hz VESA

1024 x 768 @ 75Hz VESA

1280 x1024 @ 75Hz VESA

Established Timings 3:00

!

58

Meridian 3

<-Standa rd T i ming Identification:->

1680 x 1050 @ 60Hz

1440 x 900 @ 60Hz

1440 x 900 @ 75Hz

1280 x 720 @ 60Hz

1280 x 1024 @ 60Hz

<-Detailed Timing Descriptions:->

FC (Monitor Name) : 220BLP

FD (Monitor Limits):

Min. V. rate: 56 Hz

Max. V. rate: 76 Hz

Min. H. rate: 30 KHz

Max. H. rate: 83 KHz

Max. P Clock: 170 MHz

FF (Monitor SN) :

Detailed Timing : 1680x1050 @ 60Hz

Extension Flag : 00

Block0 Checksum : C5

59

Meridian 3

14. White Balance, Luminance Adjustment

1. Apparatuses and program: analyzer CA-210, PC, tool, FGA adjustment program (Philips LEDFGA.DDCI),

Pattern generator.

2. Equipment installation:

a. Connect analyzer CA-210 to PC by USB connector, inst all drive p rogram CA-SDK Ver4.00 for CA-210 and restart

PC after finish installing

b. Install Port95NT drive program, set PC printer connector mode as ECP mode and reset PC after finish installing.

c. Connect tool as follow:

Note: It’s not necessary to connect Port 2.

3. Adjustment

Preparation before adjustment:

a. Monitor should be warmed up for more than half an hour .

b. Make sure that the tools are connected right and drive programs have been installed OK.

4. Adjustment process:

a. Press the power of CA-210, shut off the lens, press 0-Cal and open the lens after analyzer reset.

b. Open white balance adjustment program, select the right parameter according with the program and click OK.

c. Make sure that the lens of CA-210 aims at the center of the screen, then click START to adjust.

d. After finish adjusting, the adjustment program displays pass, and the START button changes for NEXT, which

means that you can adjust another monitor.

To PC LPT

To BSG-265A or

e

q

uivalent instrument

To PC Port 2

Philips model

!

60

Meridian 3

5. Color Temp confirmation

Connect the signal to the monitor, the monitor displays white-picture, use CA-210 to measure the Color Temp of the

screen center and select the OSD to make sure whether the Color Temps accord with the SPEC.

CIE coordinates 9300K 6500K/sRGB sRGB

x 0.283±0.02 0.313±0.02 0.313±0.02

y 0.297±0.02 0.329±0.02 0.329±0.02

6. How to enter into the factory mode:

1. Connect the video source and power off the monitor.

2. Press

and buttons at the same time, power on the monitor, and then press the menu again; the

picture will appear on the top left corner.

3. Select the “Factory” and press the “MENU” button to enter the factory mode.

61

Meridian 2

15. Monitor Exploded View

!

62

Meridian 3

16. Recommended & Spare Parts List

Note: Take the 220B4LPCS/00 BOM for example, the parts information listed below are for referen ce only, and are

subject to change without notice. Please go to http://cs.tpv.com.cn/hello1.asp

for the latest information

Item Location PCM Codes Description Remark

1

FQ106 A34G2924 VOB1S0101 BEZEL

2

FQ004 KEPCVQP1 KEY BOARD ASSY

3

FQ007 IRPCVQP1 IR BOARD ASSY

4

FQ016 HJPFVQA1 HEAD PHONE JACK BOARD ASSY

5

E750 750GBS220MT9TCN000 LCD LTM220MT09 Y01 FQ SEC

6

FQ002 756GQCCB0PH0320000 SCALER BOARD ASSY(CBPC*)

7

FQ003 PLPCCD454EQEF POWER BOARD ASSY

8

FQ124 A15G1798S01201 MAINFRAME

9

FQ138 A33G1324AMT 1S0100 COVER_USB

10

FQ105 A34G2925AMT 2S0101 REAR_COVER

11

FQ112 A37G0304013 ML STAND ASSY

12

FQ109 A34G2891AMT 1S0100 BASE

13

FQ143 A15G1805101 BKT_BASE

14

FQ006 USBVQP2 USB BOARD ASSY

E08904 089G 17356G553 AUDIO CABLE 1800MM

E08902 089G 728HAA 2G D-SUB CABLE 1800MM

E08903 089G1748CAA AC DVI CABLE 1800

E08901 089G404A18N CX AC POWER CORD 1800 FOR EUROPE C13

ECN802 095G8014 6D 69 HARNESS 6P-6P(CI1406S) 250MM

ECN408 395G179X30NH85 FFC CABLE 30PIN 172 1.0MM

ECN311 S95G176T006H31 FFC CABLE --6 --218 1.0MM

ECN465 S95G176T12NF01 FFC CABLE 12PIN 1.0MM 184MM

U402 100GPNSC008NT1 MCU ASSY(056G2233 11)

U401 056G 562327 IC SCALER NT68668AFG QFP-128

U701 056G 563149 IC G903T63UF 0.6A/3.3V SOT-22 3

U102 056G 662 52 ESD PROTECT AZC398-04S.R7G SOT23-6

U101 056G1133 34 1 EEPROM M24C02-RMN6TP 2KB SO-8

X401 093G 2251B J CRYSTAL 12MHZ NXS12.000AC30F-KAB10

U001 056G 669 45 TOUCH KEY IT7230EFN/BX QFN16

U682 056G 662 15 ESD PROTECT AZ2025-04S SOT23-5L

U312 356G0927070 IR RECEIVER IRM-3638M3S28 38 KHZ

U311 056G 192 25 D-AMP AS358MTR-E1 SOIC-8

U313 056G1125200 MCU PIC12F615-I/SN SOIC-8

U7581 056G 563215 IC DC/DC MP1584EN SOIC8E

U732 056G 585 4A LDO AP1117E33G-13 1A 3.3V SOT-223

U733 056G 659 30 C USB USB2514B-AEZC-TR QFN-36

IC902 056G 139 8

PHOTO-COUPLER PS2561DL1-1 CTR

Q100~200%

IC903 056G 158 10 T DC/DC AS431AZTR-E1 150MA 40V TO-92

IC901 056G 379190 AC/DC CONVERTER LD7750RGR SOP-7

U601 056G 616119 AUDIO P AM8007DHR 3W SOP-24

IC801 056G 700 12 LED DRIVER OZ9998AGN-A1-0-TR SOP-24

Meridian 3

63

Service Kit