Page 1

PFAFF

tiptronic

6270

Instruction

book

Page 2

For

easier

please

understanding

unfold

this

page

of

when

this

reading

instruction

it.

I

book

;afety

r

he

plug

ie

wires

3

the

ith

the

ie

wire

d

with

e

wire

rked

t

off

mains

fective

ly

3

A

I

the

fuse

plug

must

electrical

e

also

the

United

leads

with

Blue:

Brown:

colours

colour

which

the

which

with

mains

spare

cover

observe

rules

Kingdom

must

three

in

the

Neutral

Live

of

the

coding

is

coloured

letter

N

is

coloured

the

letter

plugs

leads

fuses

must

never

suppliers

be

the

definitely

pins.

mains

wires

of

or

coloured

L

or

are

definitely

must

must

be

be

used

or

the

general

only

not

lead

are

in

the

the

terminals

blue

brown

coloured

be

replaced

used

marked

without

PFAFF

safety

be

coloured

mains

must

black.

must

red.

not

to

as

approved

3

A

fuse

agencies.

notes

connected

according

lead

in

your

be

connected

be

connected

be

used,

complete.

or

with

cover.

on

page

to

the

of

this

appliance

plug,

proceed

to

but

disposed

by

ASTA

the

corresponding

Spare

fuse

2.

safety-lead

to

the

following

the

terminal

to

the

terminal

according

covers

terminal

may

not

as

follows:

which

which

of

immediately.

to

BS

colour

are

available

code:

correspond

is

mar

is

1362

code.

I

nor

to

Page 3

___________

10

-

—11

[

PFAFF

J7

-

I

-

1;

I

I

PFAF:

ptronc6

27

O

--

-

-

-----

35

34

:.

jr

.-

—

4

-

-

—

33

—j

Page 4

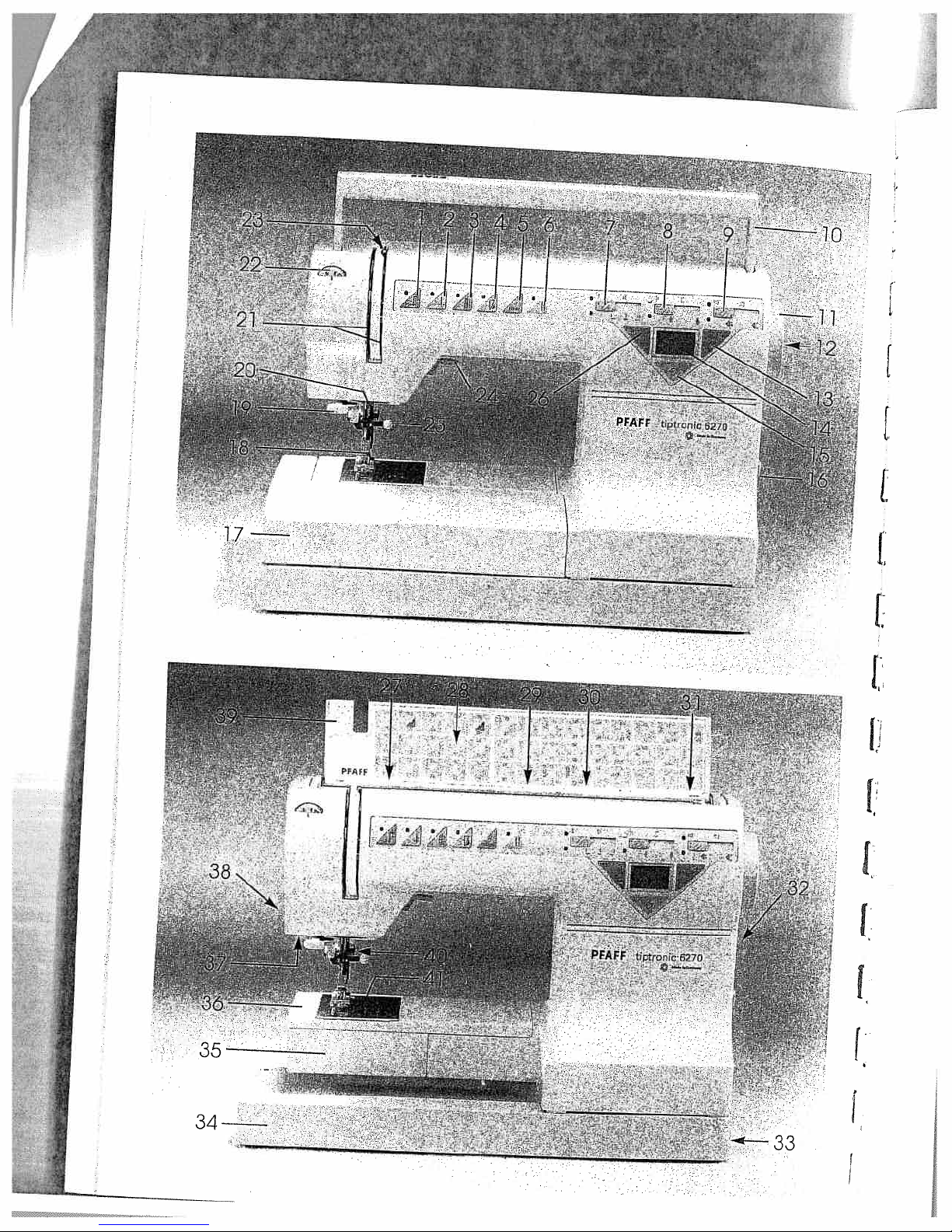

Parts

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(1

4)

(15)Clear

(16)

(1

7)

(18>Sewing

(1

9)

Thread

(20)

(21)

Threading

(22>

Needle

(23>

Take-up

(24)

Presser

(25)

Needle

(26)

Program

(27)

Thread

(28)

Program

(29)

Spool

(30)

Second

(31)

Bobbin

Connection

(32)

Connection

(33)

(34)

Base

(35)

Hook

(36)

Free

(37)

Sewing

(38)

Thread

(39)

Top

(40)

Dual

(41)

Needle

of

Key

for

Key

for

Key

for

Key

for

Clear

key

Twin

needle

Stitch

width

Stitch

length

Balance

Carrying

Handwheel

Handwheel

Program

Liquid

crystal

key

Master

Accessory

Needle

threader

guides

thread

bar

holder

guide

holder

spare

winder

plate

cover

arm

lamp

trimmer

cover

Feed/IDT

plate

the

sewing

“reverse

“needle

“buttonhole/tacking/Single

“slow

slide

handle

keyfor

“beginning

switch

box

foot

slot

lever

lifter

key

table

socket

socket

sewing”

“pattern

indicator

slide

slide

key/pattern

release

display

holder

tension

with

for

tens

for

bobbin

with

spool

system

sewing”

up/down

start”

key/needle

key/buttonhole

length

disk

unitdigits

pattern”

of

with

sewing

set

screw

digits

winding

unwinding

holder

“lead

cord”

“foot

controller”

(top

feed)

position”

disk

machine

pattern”

positions

length/stitch

foot

density

I

I

Page 5

IMPORTANT

For

the

United

When

you

Read

all

instructions

D/LF%IGER

1.

The

sewing

from

the

2.

Always

3.

Do

not

4.

Do

not

in

or

drop

l!ARI\IING

1.

Do

not

or

near

2.

Use

this

recommended

3.

Never

operate

has

been

dealer

or

4.

Never

operate

F

5.

6.

7.

8.

9.

1

0.

11.

1

2.

1

3.

4.

1

1

5.

1

6.

1

7.

Please

sewing

Never

Do

Do

red.

To

Never

Do

Keep

Always

Do

Do

Switch

threading

Always

making

Hold

also

machine

drop

not

use

not

operate

disconnect,

operate

not

unplug

fingers

use

not

use

not

pull

the

unplug

any

plug

observe

States

use

an

machine

electric

unplug

reach

place

into

allow

to

children.

sewing

dropped

service

the

or

insert

out-of-doors.

turn

on

by

away

the

proper

bent

or

push

sewing

needle,

sewing

other

when

rewinding

the

only

electric

before

To

outlet

sewing

for

a

or

store

water

be

machine

by

the

this

sewing

or

center

sewing

and

where

all

a

soft

pulling

from

or

blunt

fabric

machine

changing

user

general

SAFETY

appliance,

using

reduce

should

immediately

machine

sewing

a

sewing

or

other

To

reduce

used

as

only

manufacturer

machine

damaged,

for

examination,

machine

foot

control

any

object

aerosol

controls

surface

on

cord.

all

moving

needle

needles.

while

off

needle,

machine

servicing

into

safety

basic

this

the

risk

never

before

machine

machine

liquid.

the

a

toy.

Close

for

its

or

free

into

(spray>

to

off

such

To

parts.

plate.

The

Use

stitching.

(“0”>

when

threading

from

adjustments

cord

reel.

notes

sewing

of

electric

be

left

after

that

risk

of

intended

as

contained

if

it

has

dropped

with

any

from

any

opening.

products

(O”)

as

a

unplug,

Special

wrong

needles

It

the

electric

Do

on

INSTRUCTIONS

safety

machine.

unattended

using

replacing

has

fallen

where

burns,

attention

a

damaged

into

repair,

air

the

are

position,

bed

or

grasp

plate

recommended

may

making

bobbin,

mentioned

not

page

2.

precautions

shock

and

bulb.

it

can

fire,

is

use

as

in

water.

electrical

openings

accumulation

being

then

couch

the

care

can

deflect

any

outlet

allow

should

when

before

cleaning.

Replace

into

water.

fall

or

electric

necessary

described

this

manual.

cord

Return

or

mechanical

blocked.

used

remove

where

plug,

not

is

required

cause

the

needle,

adjustments

or

changing

when

removing

in

the

plug

to

always

plugged

bulb

Unplug

be

pulled

shock,

when

in

this

or

plug,

the

appliance

Keep

of

lint

dust

or

where

plug

the

air

the

cord.

around

the

needle

by

the

manufacturer

causing

in

the

presser

instruction

whip

when

be

in.

Always

with

same

immediately.

into

a

or

injury

this

sewing

manual.

if

it

is

not

adjustment

ventilation

and

oxygen

from

outlet

openings

the

sewing

to

it

needle

foot

covers,

manual.

rewinding.

adhered

unplug

type

tub

or

to

persons:

machine

Use

working

to

the

nearest

openings

loose

is

being

may

break

only.

to

break.

area,

etc.

lubricating,

to

as

this

rated

sink

only

attachments

properly,

cloth.

administe

be

blocked.

machine

such

or

follows:

appliance

1

5

watts.

Do

not

is

used

authorized

of

needle.

as

when

the

place

by

if

it

SAVE

This

sewing

machine

is

designed

and

manufactured

THESE

for

HOUSEHOLD

INSTRUCTIONS

use

only.

1

Page 6

Notes

on

safety

1

11.

1

8.

9.

0.

2.

Notes

nes

IEC

3.

4.

5.

6.

7.

To

open

inside

repair.

of

Be

The

supply

+1—10

+1-4

on

in

accordance

60

335-2-28

1.

The

user

with

ment

observe

2.

When

during

replacing

ries,

always

from

the

plug.

The

maximum

sewing

The

tension

adjusted

The

machine

accordance

specification

Do

not

the

machine.

Do

not

—

there

—

its

function

—

it

is

wet

can

occur

brought

Do

not

this

than

is

wrongly

liability

pull

by

appliance

socket

If

pose

it

any

avoid

the

the

Repairs

our

qualified

sure

to

machine

with

%

%.

safety

must

regard

to

of

the

needle

the

sewing

leaving

maintenance

mechanical

disconnect

mains

lamp

is

of

by

a

must

with

plate.

insert

any

use

the

is

visible

is

e.g.

with

when

into

a

the

mains

its

cord.

that

for

operated,

for

any

the

risk

machine.

machine

are

service

use

only

is

designed

a

nominal

and

a

rated

for

household

with

exercise

the

up

and

area

the

machine

by

pulling

permissible

1

5

watts.

the

drive

PFAFF

mechanic.

be

operated

the

indications

objects

sewing

damage

disturbed

condensation

a

cold

warm

room.

plug

is

used

for

which

we

damage

of

electric

There

which

solely

the

staff.

original

voltage

frequency

EN

60

335-2-28

adequate

sewing

and

down

must

while,

unattended,

work

or

parts

or

the

out

wattage

belt

must

into

openings

machine

machine

out

of

another

it

is

intended

cannot

caused.

shock,

are

no

parts

the

user

responsibility

PFAFF

for

a

mains

of

caution

move

constantly

sewing.

when

accesso

machine

the

mains

for

only

in

on

if:

which

is

the

pur

or

accept

do

not

can

parts.

of

machi

the

be

the

on

if

and

Environment

The

Ambient

Humidity

Storage

The

interference;

near

broadcasting

This

nic-mechanical

supervised

subjected

static

chemicals

For

be

firm

Care

Always

which

ped.

Cleaning

Housing

To

clean

lint-free

soft

cloth

Please

Do

not

ducts

the

housing.

1

3.

When

outer

controlled

85

°C.

therefore

damage.

recommended

temperature

temperature:

machine

electronic

sewing

to:

electricity,

or

ventilation

operated

and

horizontal.

of

the

protect

may

be

and

the

cloth.

with

note!

use

any

such

as

used

components

foot

Constant

not

20

%

to

is

suppressed

however,

devices

transmitters

machine

device.

use

in

the

dust

heat-radiating

liquids.

purposes

on

an

machine

the

machine

caused

display

housing,

To

remove

alcohol.

insecticides

petrol

or

properly,

of

control

use

permitted

environment

1

0

80

°C

%

—25

it

should

such

etc.

is

a

high-quality

It

is

home.

dampness,

the

open

surface

by

it

being

use

only

any

or

liquid

the

temperature

a

non-electronically

can

reach

at

a

low

speed

in

order

to

is:

to

40

°C

°C

+60

to

and

as

immune

not

be

radios,

°C

electro

a

machine

It

should

direct

objects,

machine

for

not

sunlight

corrosive

must

which

from

damage

hit

or

drop-

a

clean,

stubborn

chemical

chemicals

dry,

dirt

pro

to

up

to

is

avoid

to

operated

TVs,

PCs,

be

only

is

both

soft,

use

clean

of

the

a

2

Page 7

Modern,

—

Computerized

Congratulations!

You

have

that

offers

Your

new

material

through

ft

features

technology,

just

sewing

If

you

the

instruction

wrong.

After

the

things

make

If

you

no

problem!

in

thick

the

as

uncomplicated

machine.

now

all,

this

the

full

use

have

any

uncomplicated

bought

unique

sewing

its

stride

and

very

and

take

book,

is

the

machine

of

further

high-quality

a

advantages.

machine

and

thin

latest

this

instruction

time

enough

nothing

only

them.

for

as

way

can

questions,

sewing

can

take

will

sew

you.

in

design

book

your

PFAFF

to

study

can

to

learn

do,

and

—

product

any

and

go

all

to

that

is

is

Your

PFAFF

with

any

So

now

you

many

your

fashion

dealer

help

you

can

enjoyable

ideas.

or

advice

get

will

started!

hours

be

you

at

of

your

need.

We

service

wish

creating

3

Page 8

i&

Index

Accessories

Accessory

Adjusting

Alphabet

Appliqués

Appliquefoot

Applying

Automatic

Balance

Balance

Bartack

Basting

Bias

tape

Blind

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Borders

Braces

Buttonhole

Buttonholes

Buttonhole,

Buttonhole

Buttonhole,

Buttonhole/tacking/single

Carrycase

Changing

Changing

Changing

Cleaning

Clear

key

Closed

Closed

Combined

Cording

Couching

Cross

Cross

Darning

Darning

Darning

Darning

Decorative

Detachable

Dual

4

overlock

overlock

hem

stitch

tears

with

with

Feed

slide

patches

darning

slide

stitch

binder

stitch

case

thread,

thread

winding

winding

balance

fully

with

programmable

a

sewing

the

needle

the

needle

and

oiling

borders

foot

foot

stitch

zigzag

straight

stitches

work

compartment

support

and

needles

keys

key

raising

tension

through

automatic

gimp

foot

stitch

stitch

stitch

stitch

thread

plate

with

the

the

needle

pattern

edge

thread

,

81—101

1

19—21

85,

64—67’

114

73—75

74,

1

29,

30

03—il

37—40

54+74

11

23,

89

66

65

67

65

36

16

28

31

124

1

24

36

60

61

85

11

3

63

87

75

75

8

Page

92

ioi

75

40

37

54

51

53

23

27

24

22

86

1

90

2

9

8

Page 9

Index

Elastic

Electrical

Electronics

Embroidery

Embroiderytechniques

J

Explanation

Eyelet

embroidery

Eyelets

Fagoting

Fancy

elastic

Faults

Felling

foot

Foot

control

Free

arm

Fringe

foot

Function

Gathering

Gathering

Handwheel

Hemstitching

Hem

with

Honeycomb

Inserting

Inserting

Knit-edge

Lacework

Large-area

Leather

Left

Lightbulb

Light

Linen

Lowering

Maintenance

Master

Monograms

Needle

Needle

Needle

Needle

Needle

embroidery

needle

knit

embroidery

switch

chart

positions

thread

threader

up/down

stitch

connection

stitch

for

stitch

stitch

keys

with

with

release

the

twin

stitch

the

bobbin

zippers

foot

embroidery

position

mending

the

feed

and

tension

programs

sewing

elastic

straight

disk

needle

stitch

dog

sewing

position

recommendations

threads

stitch

faults

table

1

33—45

81—101

98,

36,

95—97

76,

111

38,

125

32

121—126

1

91

118,119

38

68

26

36

6,

11

77

79

87

88

68

63

93

7

Page

50

99

56

62

62

1

26

1

09

1

18

37

71

70

1

9

69

sg

24

59

1

10

7

3

7

5

Page 10

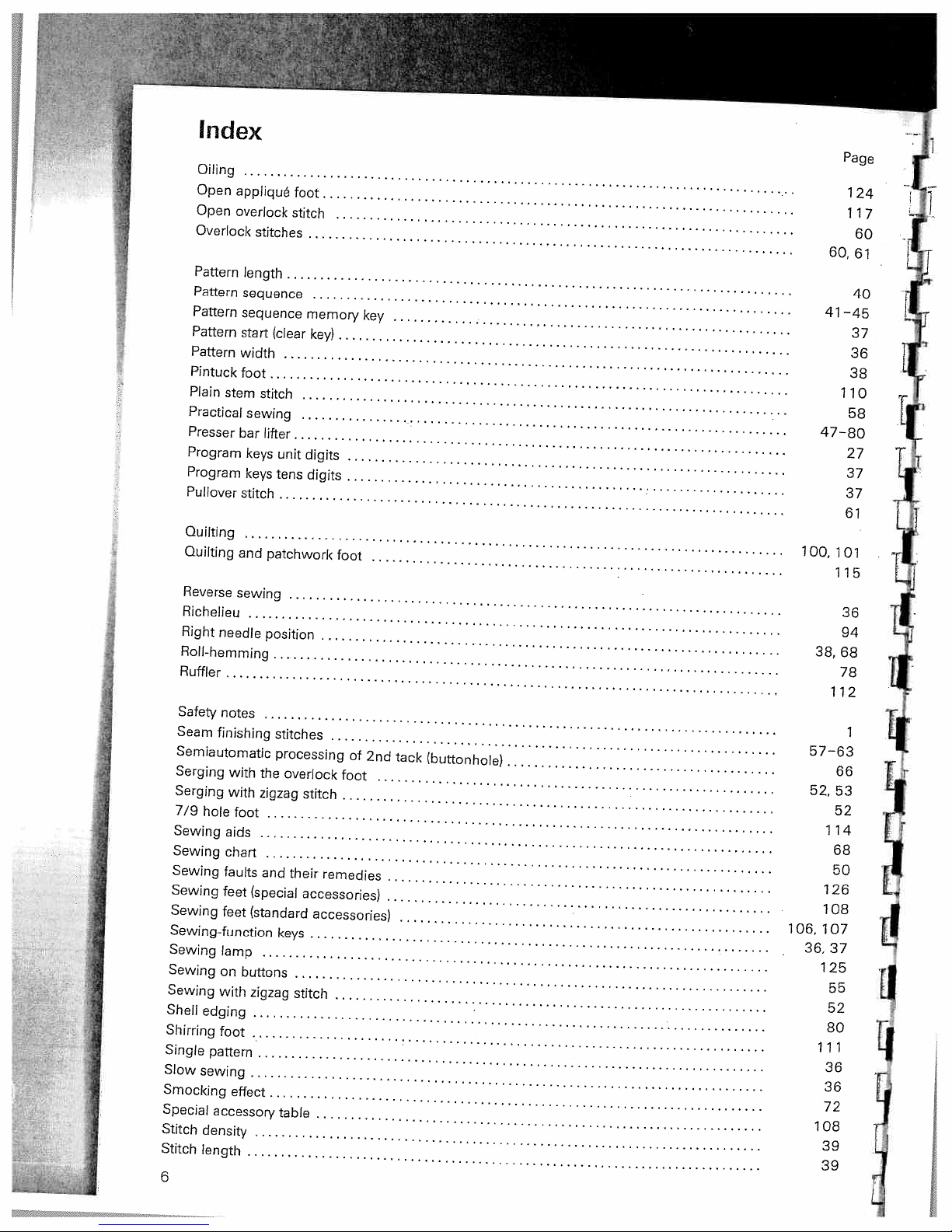

index

Oiling

Open

appliqué

Open

overlook

Overlock

Pattern

Pattern

Pattern

Pattern

Pattern

Pintuck

Plain

stem

Practical

Presser

Program

Program

Pullover

Quilting

Quilting

Reverse

Richelieu

Right

Roll-hemming

Ruffler

Safety

Seam

Semiautomatic

Serging

Serging

7/9

Sewing

Sewing

Sewing

Sewing

Sewing

Sewing-function

Sewing

Sewing

Sewing

Shell

Shirring

Single

Slow

Smocking

Special

Stitch

Stitch

6

needle

notes

finishing

with

with

hole

aids

chart

faults

feet

feet

lamp

on

with

edging

foot

pattern

sewing

effect

accessory

density

length

sewing

foot

stitches

length

sequence

sequence

start

(clear

width

foot

stitch

sewing

bar

lifter

keys

unit

keys

tens

stitch

and

patchwork

position

stitches

processing

the

zigzag

and

(special

(standard

keys

buttons

zigzag

table

foot

stitch

memory

key)

digits

digits

overlook

stitch

their

remedies

accessories)

accessories)

stitch

.

foot

foot

Page

124

117

60

60,

61

40

41

47-80

100,

38,

57—63

52.

126

108

36,

1

111

36

72

108

39

39

112

114

68

50

37

25

55

52

80

36

—45

110

101

11

36

94

68

78

66

53

52

27

37

37

61

I

38

58

ci

37

36

I

5

ii

ti

key

of

2nd

tack

(buttonhole)

106,107

I

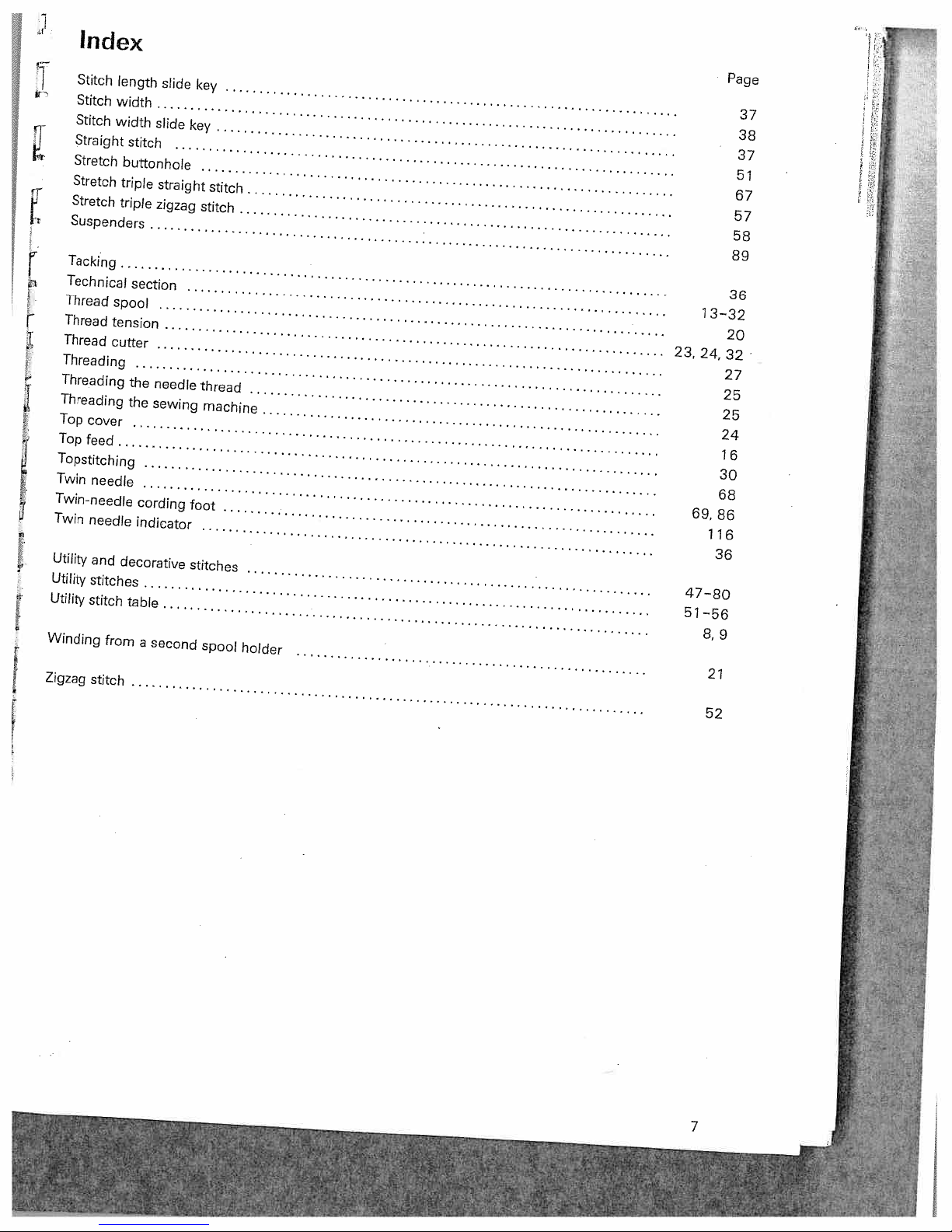

Page 11

Index

Fi’

I

r

r

-

I

Zigzag

Stitch

Stitch

Stitch

Straight

Stretch

Stretch

Stretch

Suspenders

Tacking

Technical

Thread

Thread

Thread

Threading

Threading

Threading

Top

cover

Top

feed

Topstitching

Twin

needle

Twin-needle

Twin

needle

Utility

and

Utility

stitches

Utility

stitch

Winding

stitch

length

width

width

stitch

buttonhole

triple

triple

section

spool

tension

cutter

the

the

indicator

decorative

table

from

slide

slide

straight

zigzag

needle

sewing

cording

a

second

key

key

stitch

stitch

thread

machine

foot

stitches

spool

holder

23,

69,

47—80

51

1

3—32

24,

11

36

—56

8,

21

Page

37

38

37

51

67

57

58

89

36

20

32

27

25

25

24

16

30

68

86

6

9

52

7

Page 12

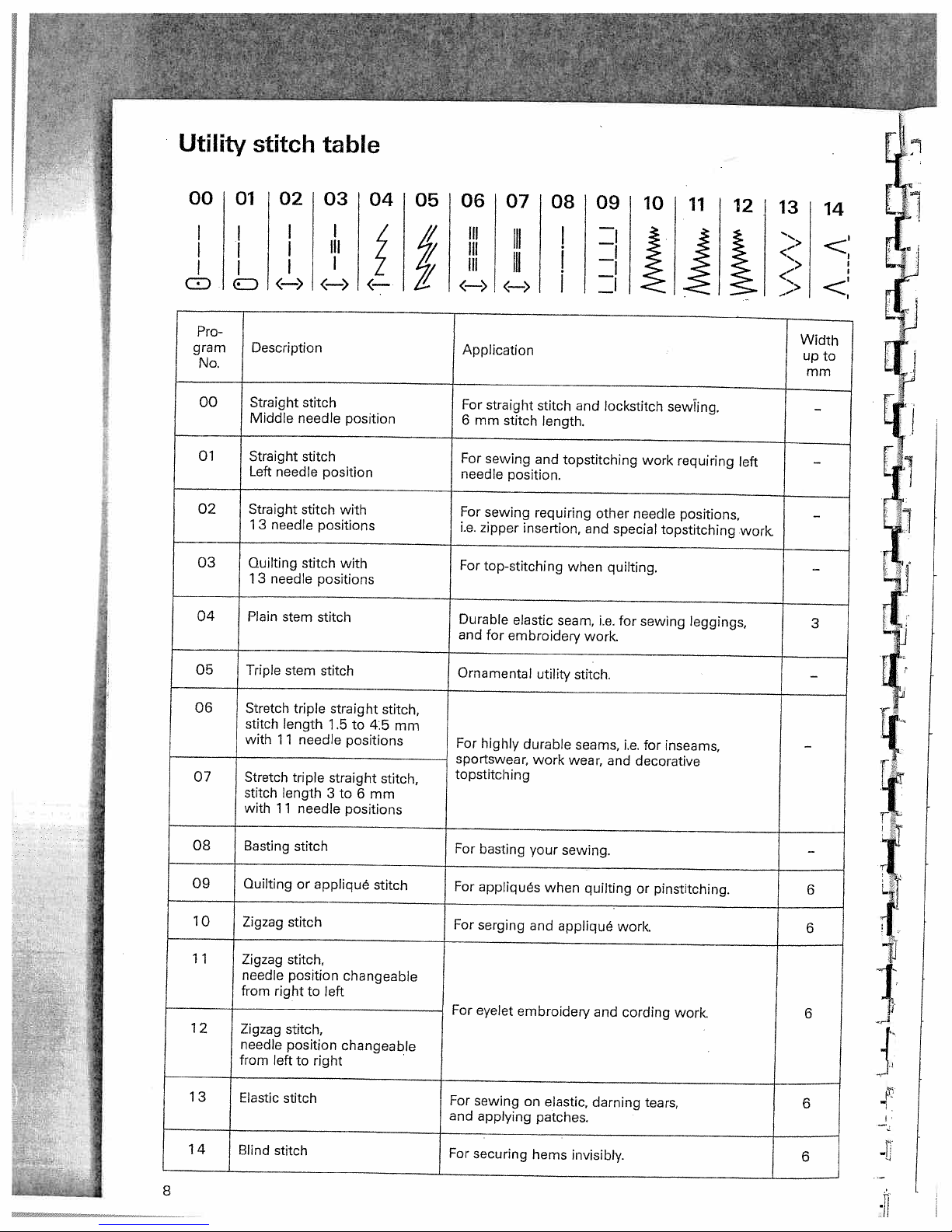

Utility

stitch

table

000102l03

‘

I

I

I

I

J

Pro

gram

No.

00

01

02

03

04

i

El)

I

Description

Straight

Middle

Straight

Left

Straight

1

Quilting

1

Plain

GD

I

3

3

I

needle

needle

needle

stem

I

<—>

stitch

needle

stitch

position

stitch

positions

stitch

positions

stitch

1

III

I

position

with

with

05O6l07lO8I09

‘

,,,

Application

For

6

For

needle

For

i.e.

For

Durable

and

IA

III

I

III

ill

I

<—>

straight

mm

stitch

sewing

position.

sewing

zipper

top-stitching

elastic

for

embroidery

I

i

I

I

I

stitch

length.

topstitching

and

requiring

insertion,

seam,

I

I

and

and

when

work.

:‘

I

lockstitch

other

needle

special

quilting.

i.e.

for

10

sewling.

work

topstitching

sewing

requiring

positions,

leggings,

left

work.

13!

—>

>

Width

up

mm

—

—

3

14

to

—

—

05

06

07

08

09

1

1

1

2

1

3

Triple

stem

stitch

Stretch

stitch

with

Stretch

stitch

with

Basting

Quilting

Zigzag

0

1

Zigzag

needle

from

Zigzag

needle

from

Elastic

length

1

1

triple

length

1

1

stitch

stitch,

position

right

stitch,

position

left

stitch

triple

needle

needle

stitch

appliqué

or

to

right

to

straight

to

1

.5

positions

straight

to

3

6

positions

changeable

left

changeable

stitch,

45

stitch,

mm

stitch

mm

Ornamental

For

highly

sportswear,

topstitching

For

basting

For

appliqués

For

serging

For

eyelet

For

sewing

and

applying

utility

durable

work

wear,

your

sewing.

when

and

appliqué

embroidery

on

elastic,

patches.

stitch.

seams,

quilting

and

darning

i.e.

and

work

cording

for

inseams,

decorative

or

pinstitching.

work

tears,

—

—

I

—

6

6

6

6

1

4

Blind

stitch

8

For

securing

hems

invisibly.

6

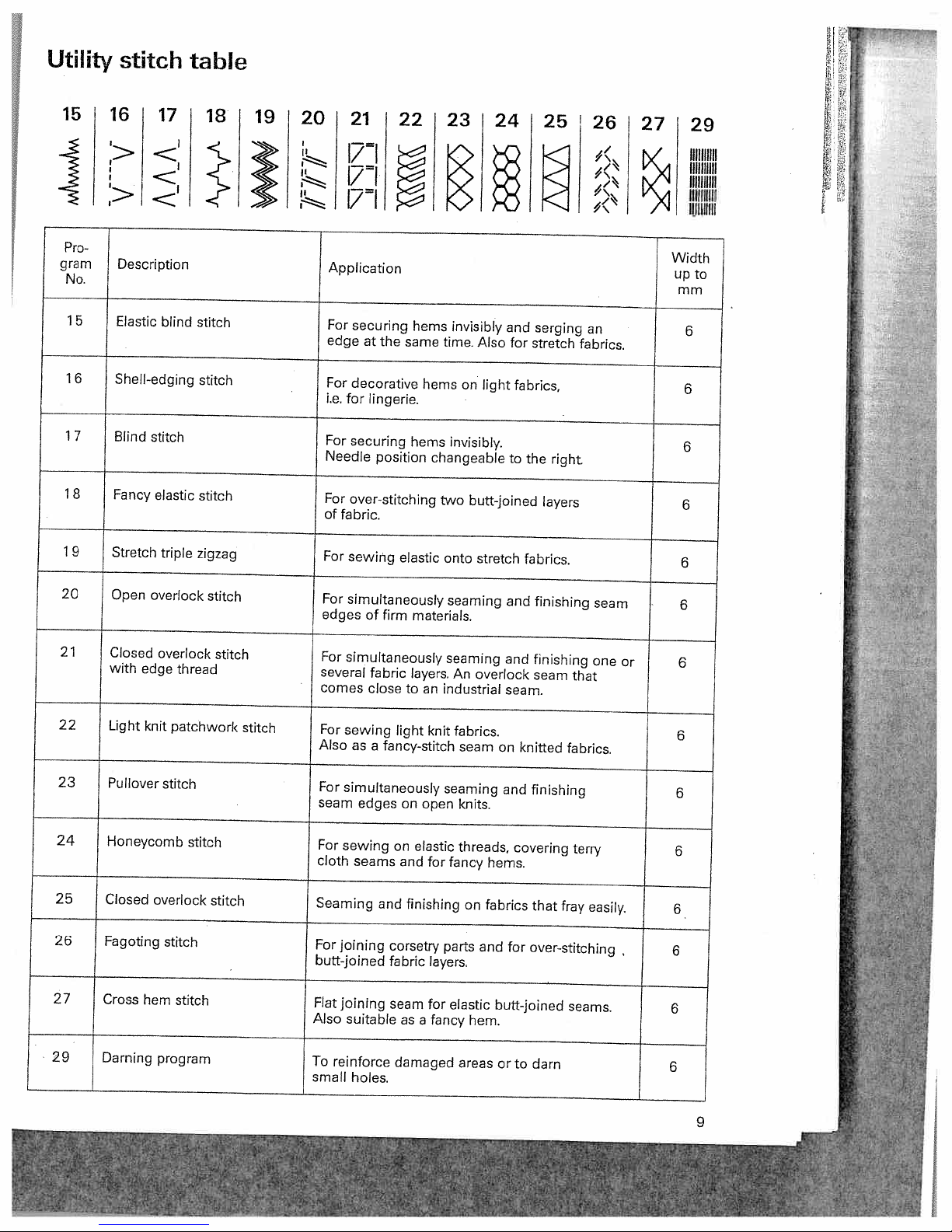

Page 13

Utility

stitch

table

ii

Pro-

gram

No.

1

5

1

6

1

7

1

8

1

9

16

17

:>

I

<‘i

:>

Description

Elastic

blind

Shell-edging

Blind

stitch

Fancy

elastic

Stretch

triple

18

ii

I(

stitch

stitch

stitch

zigzag

19

I

II

I

20

Application

For

edge

For

i.e.

For

Needle

For

of

For

21

22

I

17=1

I

171

=i

i

I

securing

at

the

decorative

for

lingerie.

securing

position

over-stitching

fabric.

sewing

elastic

hems

same

hems

hems

changeable

23

invisibly

time.

on

invisibly.

two

butt-joined

onto

24

Also

light

stretch

and

for

fabrics,

to

the

fabrics.

25

serging

stretch

right

ayers

I

26

an

fabrics.

27

I

29

IllIflilli

HhIIll

1111111111

I

11111111

I!

Width

up

to

mm

6

6

6

6

6

26

27

24

25

20

21

22

23

Open

overlock

Closed

with

Light

Pullover

Honeycomb

Closed

Fagoting

Cross

overlook

edge

knit

overlock

hem

thread

patchwork

stitch

stitch

stitch

stitch

stitch

stitch

stitch

stitch

For

simultaneously

edges

For

simultaneously

several

comes

For

sewing

Also

as

For

simultaneously

seam

edges

For

sewing

cloth

seams

Seaming

For

joining

butt-joined

Flat

joining

Also

suitable

of

firm

fabric

close

light

fancy-stitch

a

on

on

and

and

corsetry

fabric

seam

as

materials.

layers.

an

industrial

to

knit

open

elastic

for

finishing

layers.

for

fancy

a

seaming

seaming

An

overlook

fabrics.

seam

seaming

knits.

threads,

fancy

on

parts

and

elastic

hem.

and

and

seam.

on

knitted

and

covering

hems.

fabrics

for

butt-joined

finishing

finishing

seam

finishing

that

over-stitching

that

fabrics.

terry

fray

seams.

seam

one

easily.

6

or

6

r

I

r

6

6

6

6

,

6

6

29

Darning

program

To

small

reinforce

holes.

damaged

areas

or

darn

to

6

9

Page 14

rn

co

0

0

C)

cJ,

r..

P.

C)

-I

0

C’s,

_____________

_____________

CA)%Z%,J

C)

00

i;t

ILEL.

C;,

C1

c2

Co

c*5

01

C)

C.1

pp

%J

co

(0

€(*

i511L51’

rY

J

6j

01

0

1111

“i’I”IIIIIIIIlIII

(.1

Co

iiiiiiiiiiiII1Ill

C;1

CD

C)

(7!

k)

tII’jI’

4

[

c—4

J

.-

!

cji

01

-*

(‘3

—-L

—

-

——4-

“m’I”31’ol’h’m

-

0)

III

11111111

hII1(tl,fttIIIIIljIIP’

C)

(A)

0)

11111

Is,.)

,-

‘lItliii.

.“lII”J

CD

-

—

o

..1I1IllhI1,_.411111111

“IIItIIII”IIIIIIlIi’,

0)

II1IIIIH*—

0)

a.

‘idllflllfIIIIIi’u”

‘IjIIIjIIIIr’IIIIfI,fl;r

0)

=

=

=

=

1=

=

=

=

“IIIII”lIIIl”

.IqIIIIIIIrI9IIIIlII.

1

-

F1

p1:

ic

r

Page 15

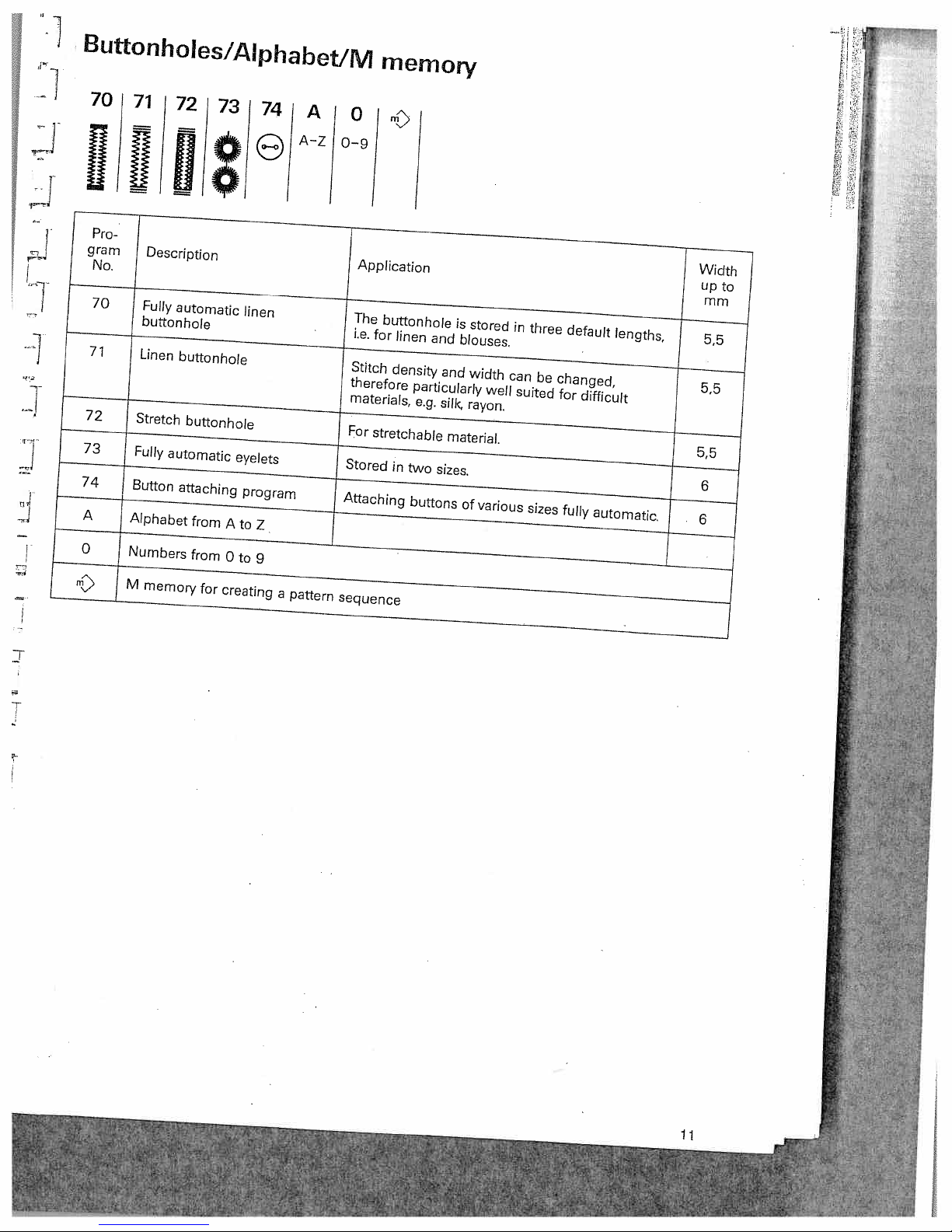

Buttonholes/iUphabetlM

70

71

72

73

74

A

memory

0

H

Pro-

gram

No.

70

71

72

73

74

A

0

m

Description

Fully

buttonhole

Linen

Stretch

Fully

Button

Alphabet

Numbers

M

memory

fl8t9

automatic

buttonhole

buttonhole

automatic

attaching

from

from

for

linen

eyelets

program

A

to

0

to

creating

Application

The

buttonhole

i.e.

for

linen

Stitch

density

therefore

materials,

For

stretchable

Stored

in

two

Attaching

Z

9

a

pattern

sequence

is

and

blouses.

and

particularly

e.g.

silk,

material.

sizes.

buttons

of

stored

width

well

rayon.

various

in

can

suited

three

be

sizes

default

changed,

for

difficult

fully

automatic.

lengths,

Width

up

mm

5,5

5,5

5,5

6

6

to

4

I

Yêc

11

Page 16

V.

--

•V.)

.•

•

Page 17

section

Tech,ijcat

C’,

CD

z

:,-

—

crz

0,

CD

(00

Co

0

0C

()

Page 18

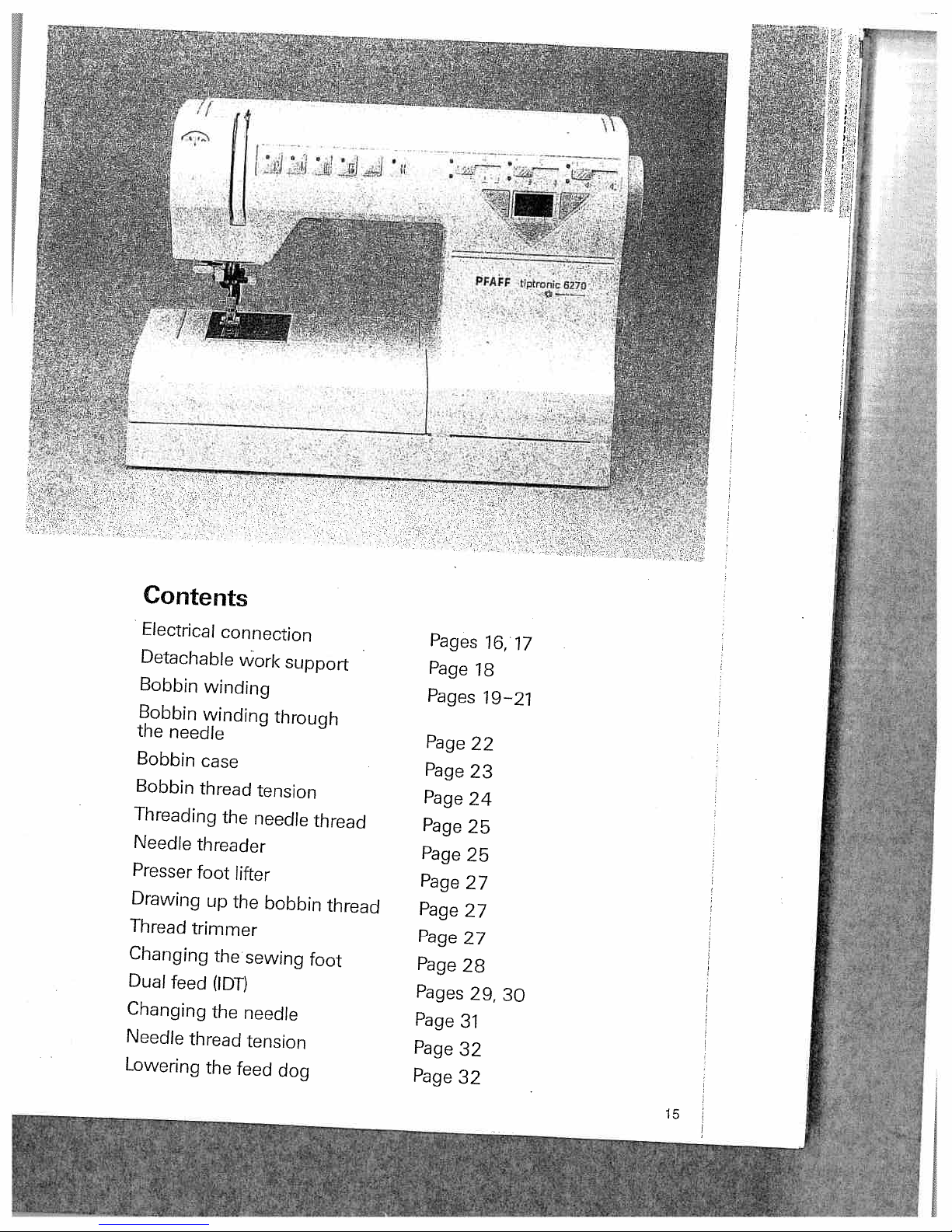

Contents

tJ

i

Ji

:i

zr

PIAFF

d

3

bptronc

6270

I

—

—

Electrical

Detachable

Bobbin

Bobbin

the

needle

Bobbin

Bobbin

Threading

Needle

Presser

Drawing

Thread

Changing

Dual

feed

Changing

Needle

Lowering

connection

winding

winding

case

thread

the

threader

foot

up

the

trimmer

the

(IDT)

the

thread

the

work

tension

needle

lifter

bobbin

sewing

needle

tension

feed

Support

through

thread

foot

dog

thread

Pages

Page

Pages

Page

Page

Page

Page

Page

Page

Page

Page

Page

Pages

Page

Page

Page

18

22

23

24

25

25

27

27

27

28

29,

31

32

32

16,17

19—21

30

15

Page 19

4

I

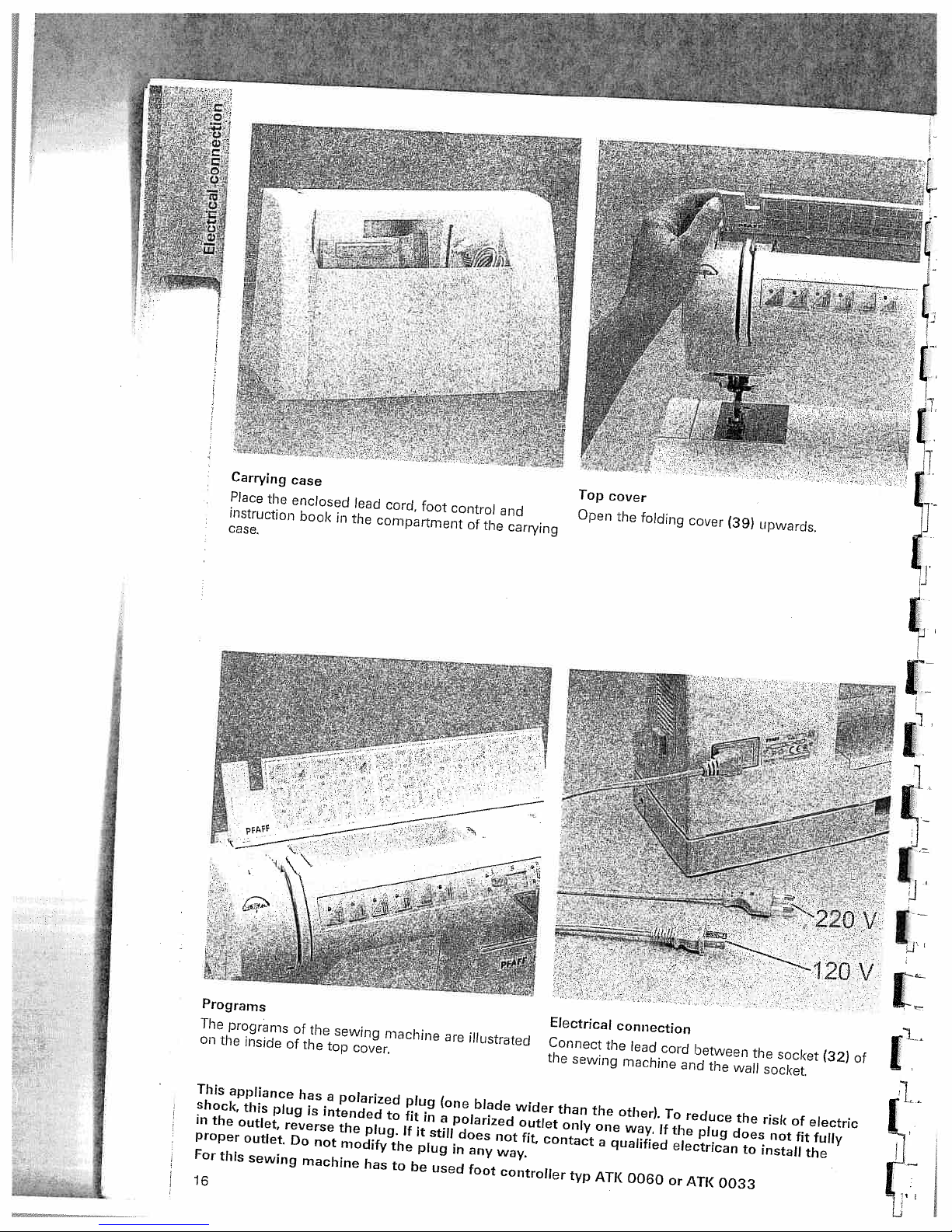

Carrying

Place

the

instruction

case.

case

enclosed

book

lead

in

the

cord,

foot

compartment

control

of

the

and

carrying

Top

Open

cover

the

folding

cover

(39)

upwards.

(frJI

Programs

The

programs

on

the

inside

This

appliance

shock,

in

proper

For

16

the

this

outlet

outlet

this

plug

sewing

of

the

of

the

has

is

reverse

Do

not

machine

sewing

top

cover.

a

polarized

intended

the

modify

plug.

has

machine

plug

to

fit

If

it

the

plug

to

be

in

still

used

are

(one

a

polarized

does

in

illustrated

blade

wider

not

any

way.

foot

controller

outlet

fit,

Electrical

Connect

the

sewing

than

only

contact

typ

connection

the

the

one

a

qualified

ATK

lead

machine

other).

way.

0060

cord

and

To

reduce

If

the

electrican

or

ATIK

—

between

the

plug

0033

wall

the

does

to

the

socket.

risk

not

install

-220

socket

of

fit

the

120

(32)

electric

fully

V

V

of

Page 20

J

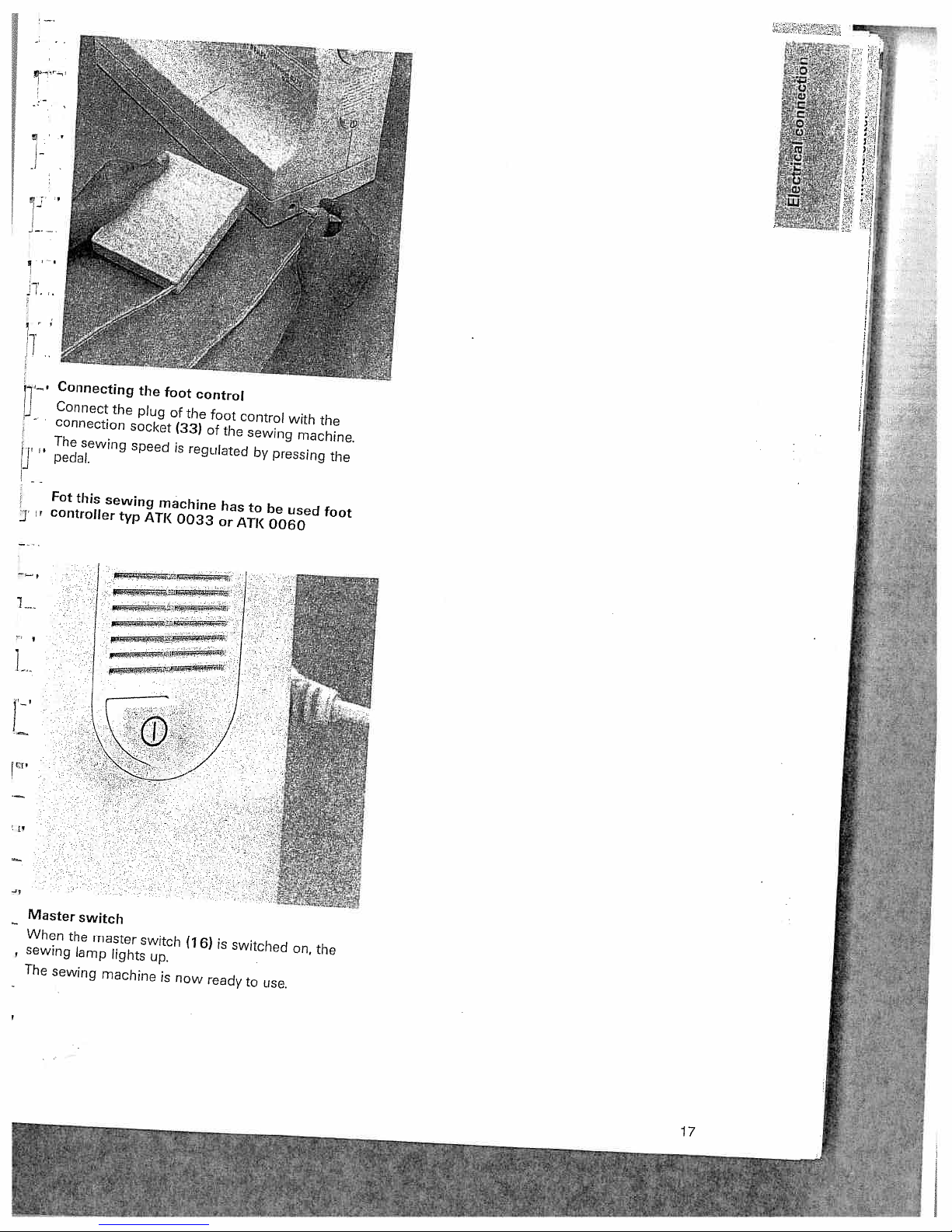

Connecting

Connect

connection

The

sewing

pedal.

Fot

this

controller

the

socket

speed

sewing

typ

the

plug

ATK

foot

of

the

(33)

is

regulated

machine

0033

control

foot

of

the

has

or

control

sewing

by

to

ATI(

with

pressing

be

used

0060

the

machine.

the

foot

Master

When

sewing

The

switch

the

lamp

sewing

master

lights

machine

switch

up.

is

(1

now

6)

ready

is

switched

on,

the

to

use.

17

Page 21

.

‘7

0.

0.-C

c

0..

r

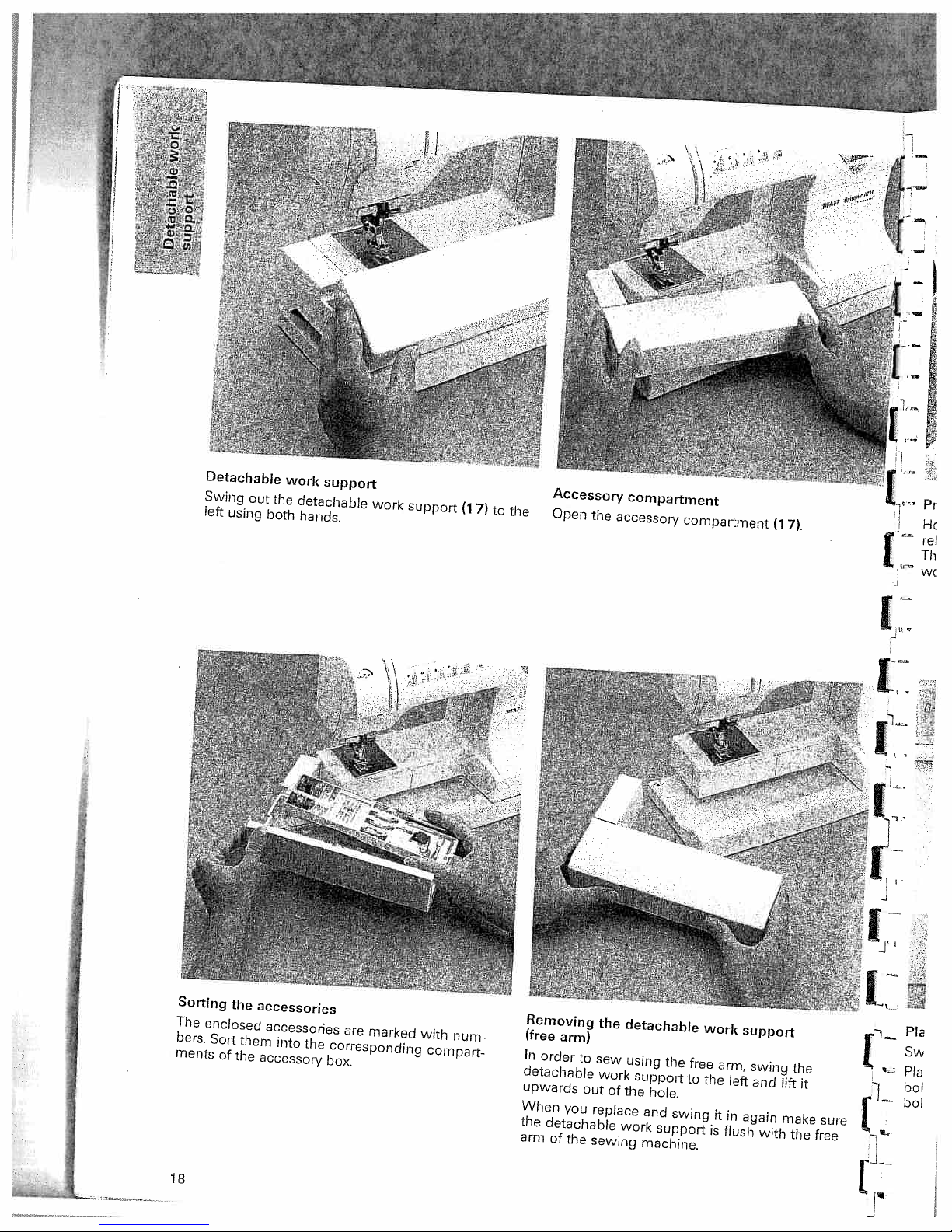

Detachable

Swing

out

left

using

work

the

both

support

detachable

hands.

work

V

support

Accessory

(1

7)

to

the

Open

the

accessory

compartment

compartment

Pr

(1

7).

Hr

rel

Th

wc

U

Sorting

The

bers.

ments

18

the

enclosed

Sort

them

of

the

accessories

accessories

into

the

accessory

L

are

marked

corresponding

box.

with

compart

num

Removing

(free

arm)

In

order

detachable

upwards

When

the

detachable

arm

of

you

the

to

out

sewing

the

sew

work

of

replace

work

detachable

using

the

support

the

hole.

and

support

machine.

free

to

swing

work

arm,

the

it

is

left

in

flush

support

swing

and

again

with

the

lift

make

the

—

Pla

Sw

—

it

sure

free

Pla

bol

bol

-j*

Page 22

.‘

—

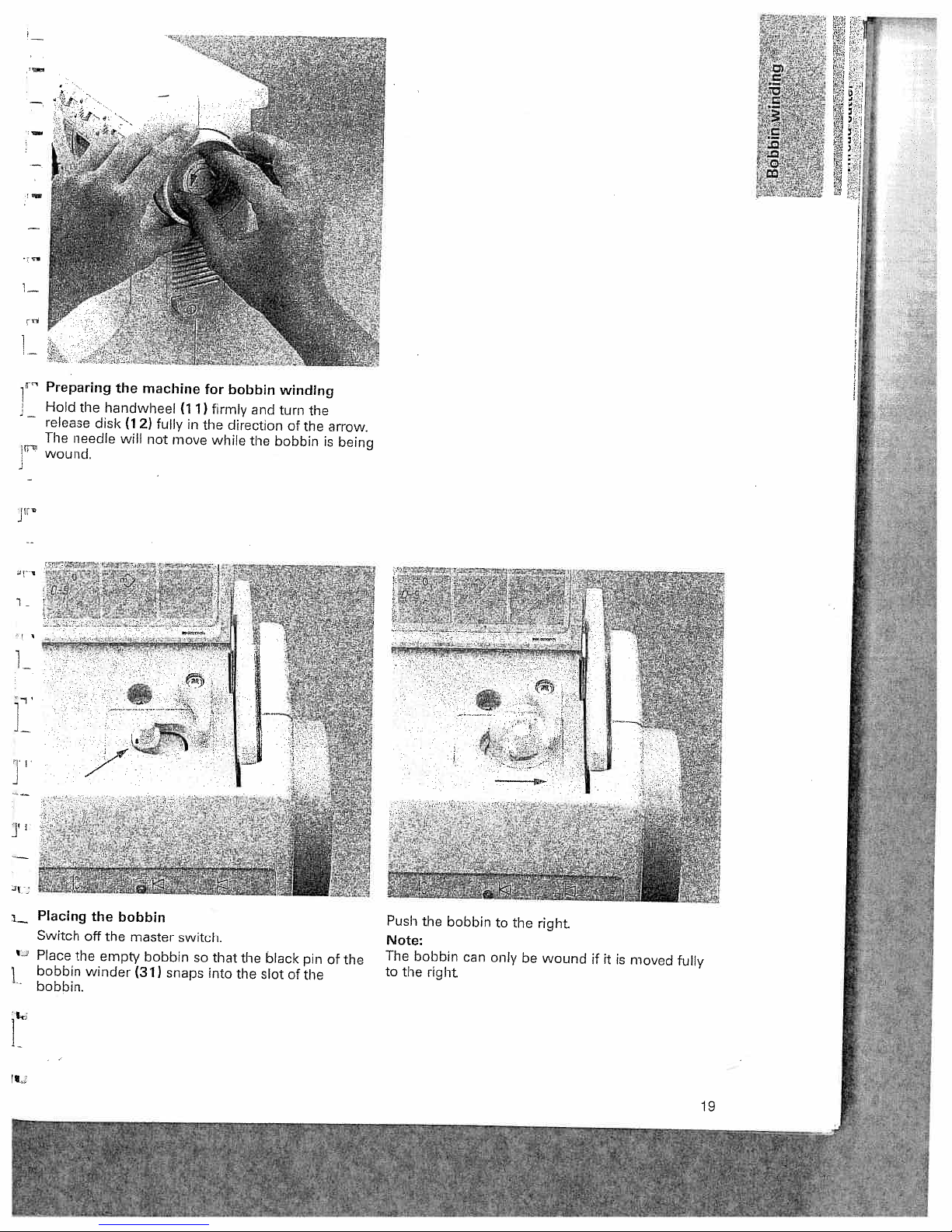

Preparing

Hold

the

release

The

needle

wound.

the

handwheel

disk

(1

will

machine

fully

2)

not

(11)

in

move

for

firmly

the

while

bobbin

and

direction

the

winding

turn

of

bobbin

the

the

arrow.

is

being

C)

•

0•

£0

Placing

Switch

‘

Place

bobbin

I

bobbin.

the

off

the

winder

bobbin

the

empty

master

bobbin

(31)

switch.

snaps

so

that

into

the

the

black

slot

pin

of

the

Push

the

bobbin

Note:

The

the

of

bobbin

to

the

right

can

to

only

the

be

right

wound

if

it

is

moved

fully

19

Page 23

fr

A

11

;

.

PFAFF

i...

-

-i

.

,,-,,

.,

‘4

.

----—

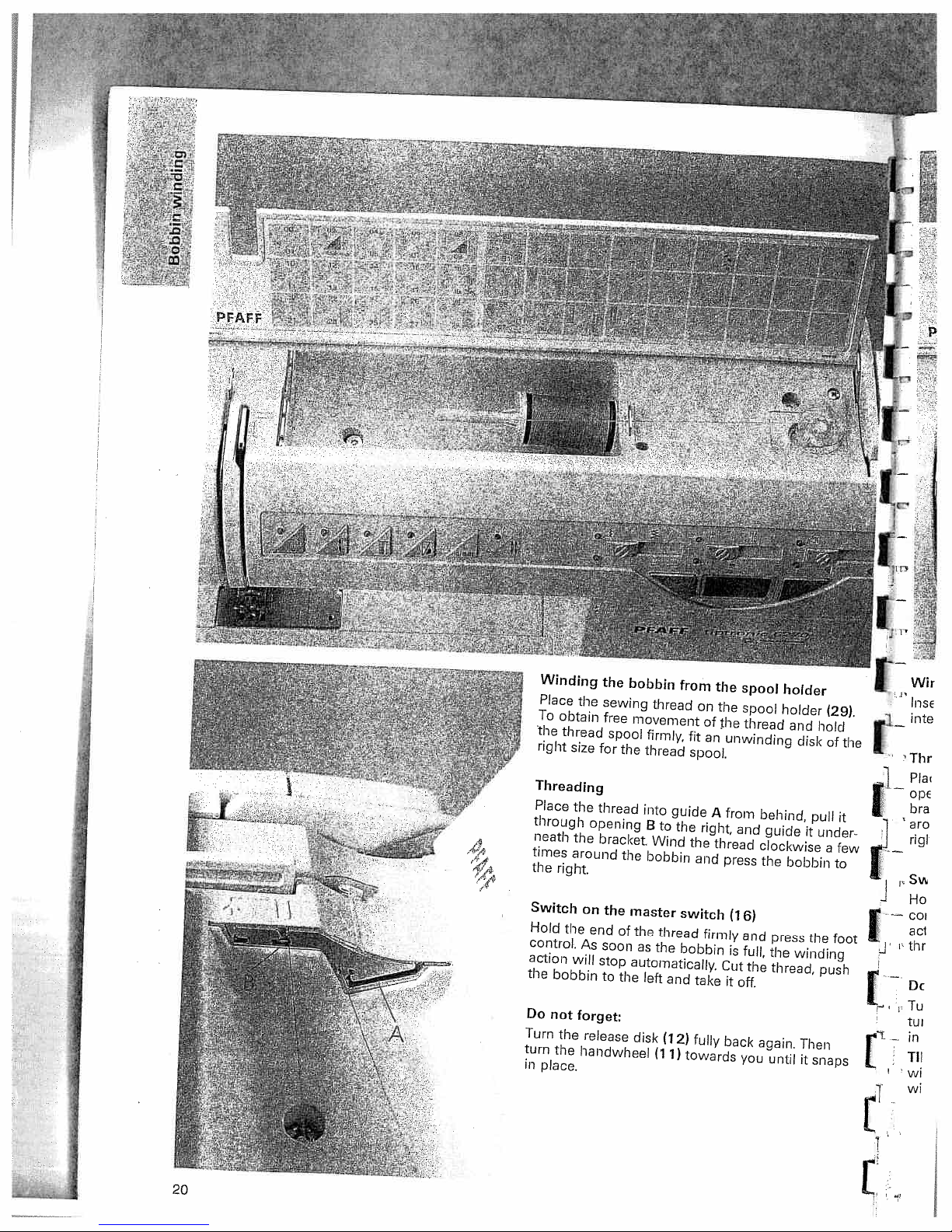

Winding

Place

To

the

right

Threading

Place

through

neatl

times

the

obtain

thread

size

the

the

around

right.

the

for

thread

opening

bracket.

the

bobbin

sewing

free

spool

the

the

from

thread

movement

firmly,

thread

into

guide

B

to

the

Wind

bobbin

on

of

fit

an

spool.

right,

the

and

the

spool

the

spool

the

thread

unwinding

A

from

and

thread

press

holder

holder

and

disk

behind,

guide

clockwise

the

bobbin

pull

it

(29).

hold

of

under

a

few

to

it

the

Ew

r

ns€

I

‘

inte

‘Thr

Pla

op€

bra

1

aro

rigi

20

Switch

Hold

control.

action

the

bobbin

Do

not

Turn

turn

in

place.

the

will

forget;

the

the

on

the

end

of

As

soon

stop

to

the

release

handwheel

master

the

as

thread

the

switch

bobbin

automatically.

left

and

take

disk

(12)

fully

(11)

towards

firmly

Cut

it

back

i

Ho

(1

6)

and

press

the

is

full,

the

the

thread,

foot

winding

push

off.

co’

aol

i

thr

Dc

Tu

tu

in

Til

wi

W

.1

you

again.

until

Then

it

snaps

Page 24

-

[-;;

r’

PFAFF

-c

C)

:J

j

L

r

JJ

Jr

1

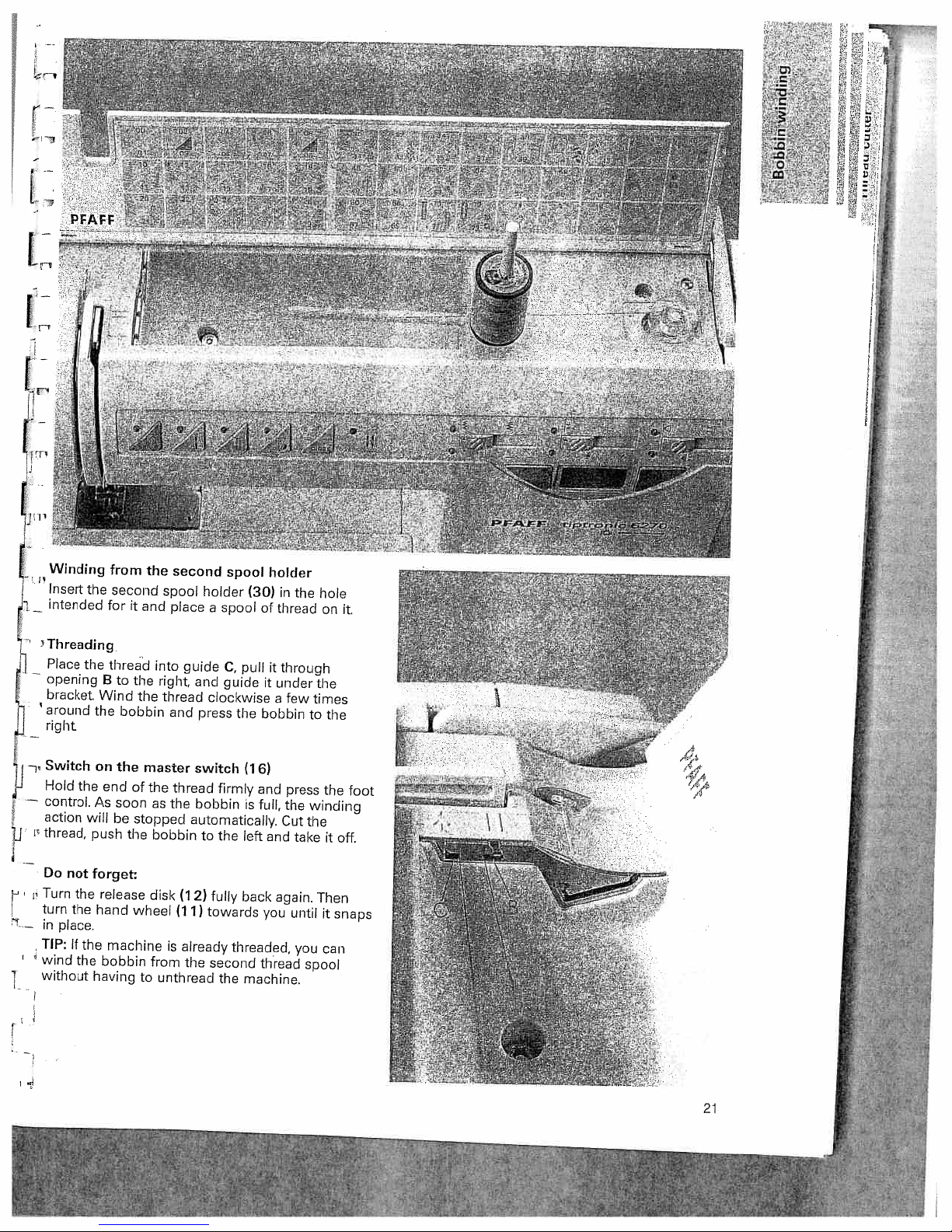

Winding

Insert

intended

Threading

Place

opening

bracket

around

right.

-

Switch

Hold

control.

action

thread,

11.

from

the

second

for

the

thread

S

to

Wind

the

bobbin

on

the

the

end

As

soon

will

he

push

the

it

and

the

the

master

of

the

as

stopped

the

bobbin

-

second

spool

place

into

guide

right,

thread

and

thread

the

automatically.

holder

spool

a

C,

and

guide

clockwise

press

switch

firmly

bobbin

to

the

spool

pull

the

(1

left

(30)

is

holder

in

of

thread

it

through

under

it

a

bobbin

6)

and

full,

Cut

and

the

few

press

the

take

hole

on

the

times

the

to

the

winding

the

it

off.

it.

foot

:

•

4.

-,

1.’

J

Do

not

forget:

Turn

the

the

place.

If

the

release

hand

the

bobbin

having

turn

—

in

TIP:

wind

without

wheel

machine

to

disk

(12)

(11)

already

is

from

unthread

the

fully

towards

threaded,

second

the

back

again.

you

thread

machine.

Then

until

you

spool

it

can

snaps

21

Page 25

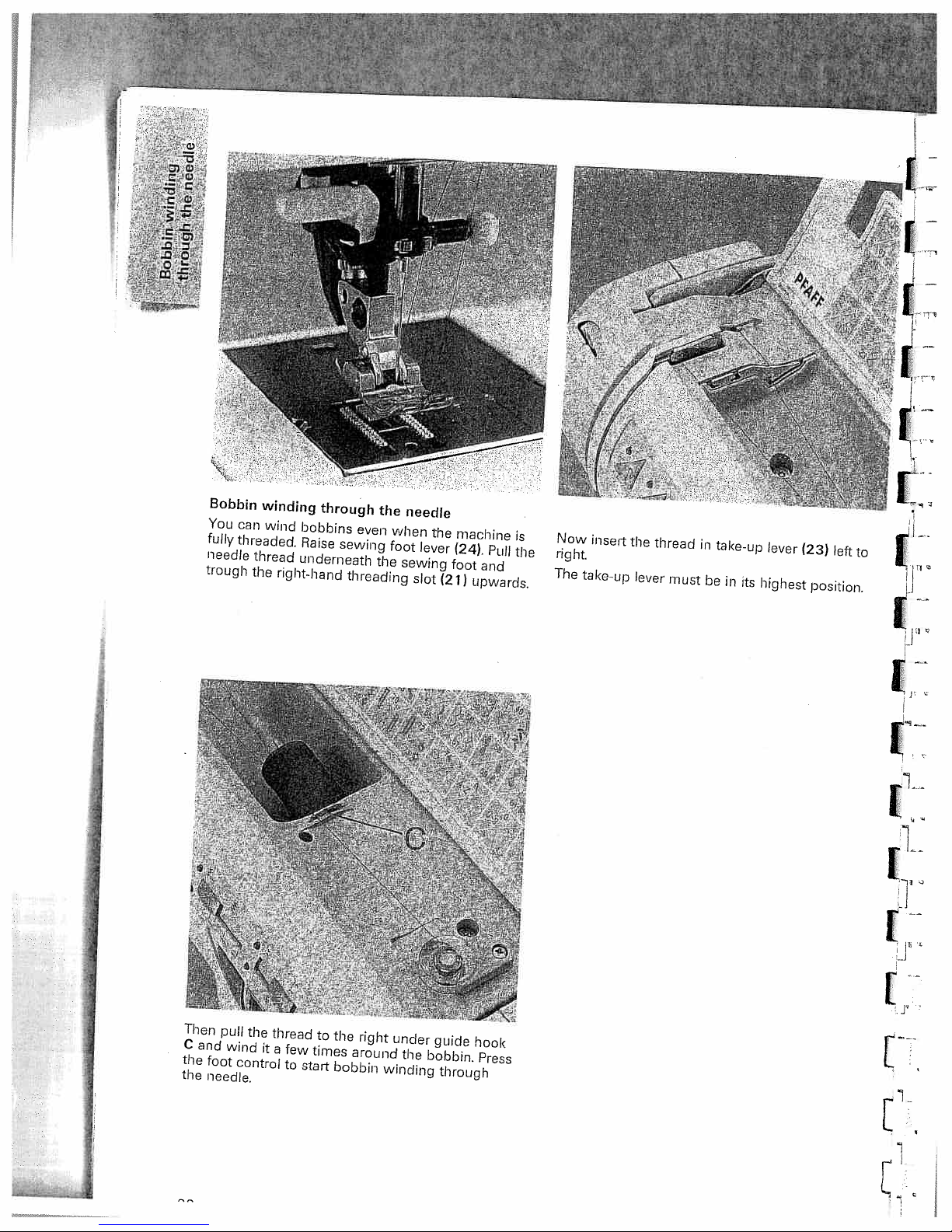

Bobbin

You

fully

needle

trough

winding

can

wind

threaded.

thread

the

through

bobbins

Raise

underneath

right-hand

even

sewing

threadng

the

the

needle

when

foot

sewing

slot

the

lever

machine

(24).

foot

(21)

Pull

and

upwards.

is

the

Now

right.

The

insert

take-up

the

lever

thread

must

in

take-up

be

lever

(23)

left

to

in

its

highest

position.

r

t

Then

pull

the

thread

C

and

wind

the

foot

the

needle.

it

control

to

a

few

times

to

start

the

around

bobbin

right

under

the

winding

guide

bobbin.

through

hook

Press

Page 26

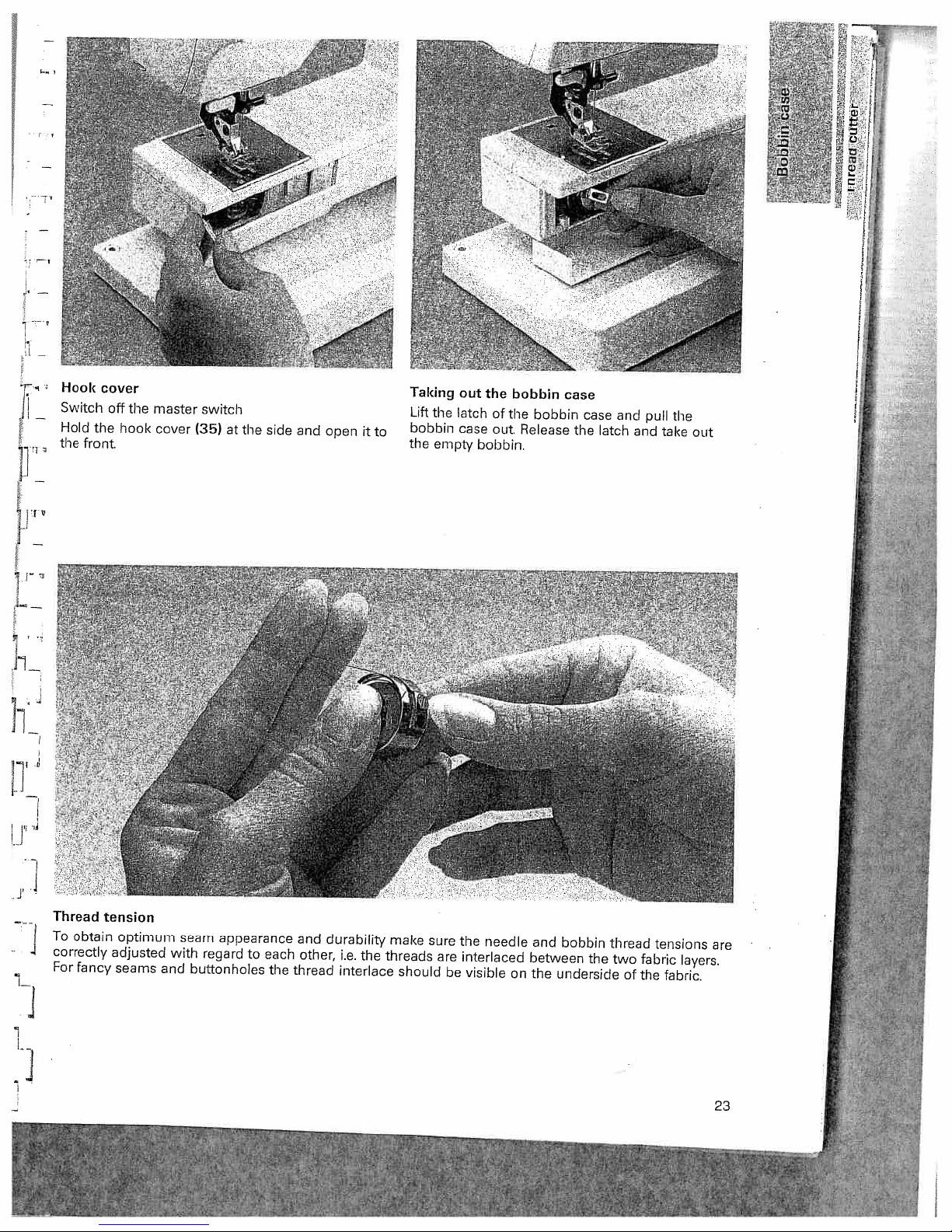

Hook

Switch

Hold

the

front.

cover

the

off

the

hook

master

cover

switch

(35)

Taking

Lift

at

the

side

and

open

bobbin

i

to

the

the

empty

out

latch

case

the

of

the

out

bobbin.

bobbin

bobbin

Release

case

the

case

latch

and

and

pull

take

the

out

I

LII

Thread

To

correctly

For

obtain

fancy

tension

optimum

adjusted

seams

seam

with

and

appearance

regard

buttonholes

each

the

and

other,

thread

to

durability

i.e.

the

interlace

make

threads

should

sure

are

the

interlaced

be

visible

needle

on

and

bobbin

between

the

underside

the

thread

two

of

tensions

fabric

the

are

layers.

fabric.

23

Page 27

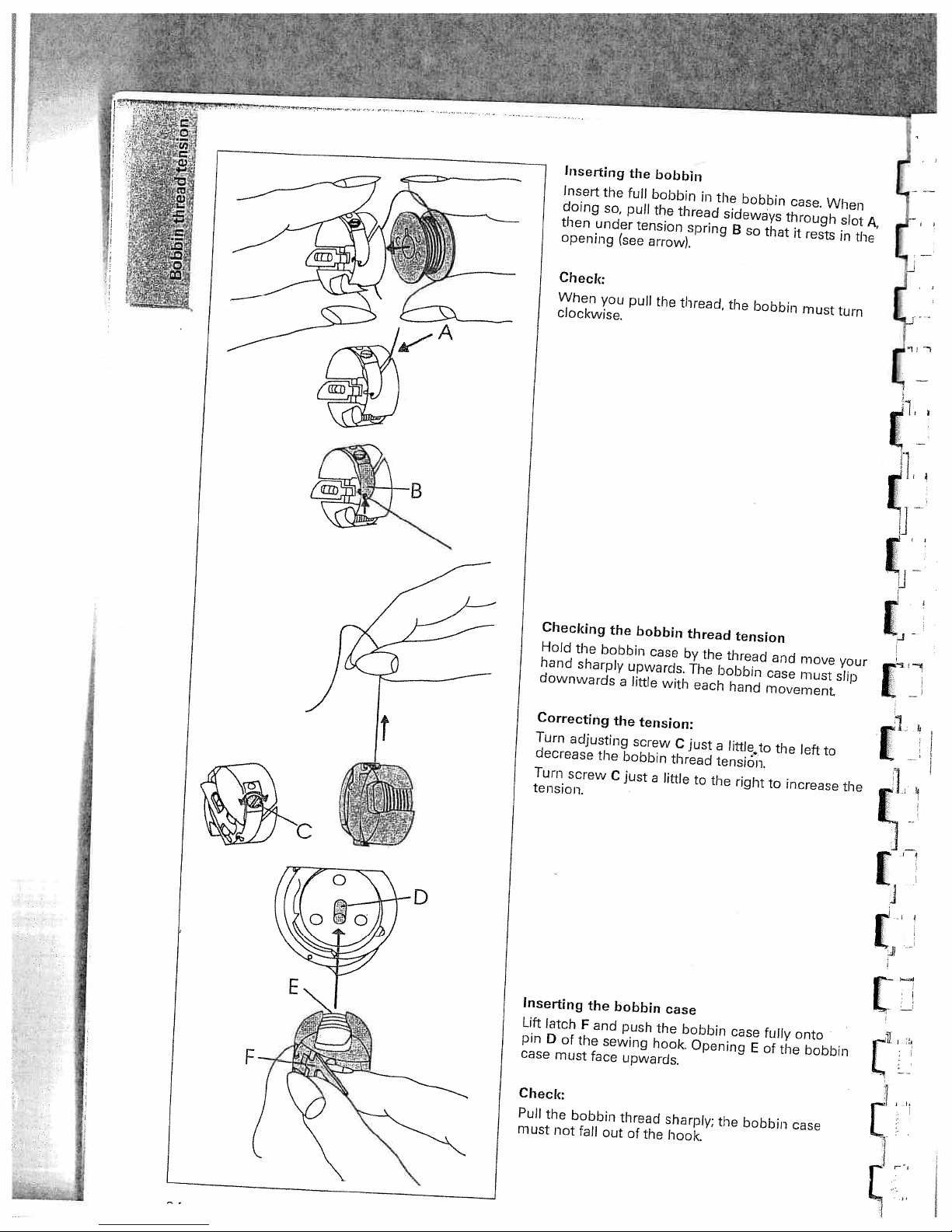

Inserting

Insert

the

doing

so,

then

under

opening

Check:

When

you

clockwise.

the

full

pull

(see

pull

bobbin

bobbin

the

tension

arrow).

the

in

thread

spring

thread,

the

bobbin

sideways

B

so

the

that

bobbin

case.

through

it

rests

must

When

slot

in

turn

A,

the

I

ti:

Checking

Hold

hand

downwards

Correcting

Turn

decrease

Turn

tension.

Inserting

Lift

latch

pin

D

case

must

the

sharply

adjusting

screw

the

F

of

the

bobbin

the

and

sewing

face

the

upwards,

a

little

the

screw

bobbin

C

just

bobbin

push

upwards.

bobbin

case

with

tension:

a

little

the

hook

by

C

thread

case

bobbin

thread

the

The

bobbin

each

just

a

tension,

to

the

Opening

tension

thread

hand

littleto

right

case

and

case

movement.

the

to

increase

fully

E

of

the

move

must

left

onto

bobbin

your

slip

[I

to

the

[E

I

Check:

Pull

must

the

not

bobbin

fall

out

thread

of

the

sharply;

hook.

the

bobbin

case

Page 28

17

PFAFF

1

20:

22

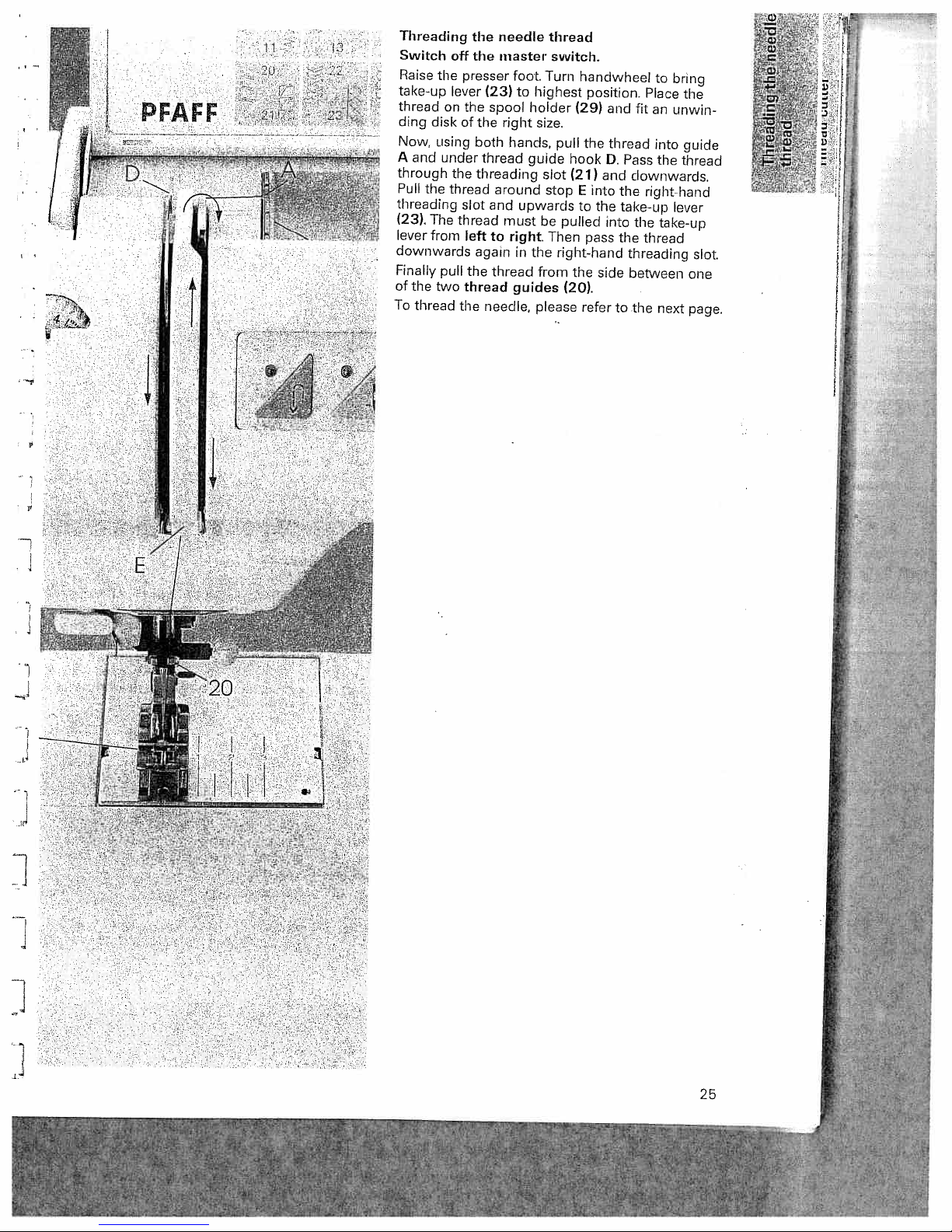

Threading

Switch

Raise

the

take-up

thread

on

ding

disk

Now,

using

A

and

under

through

Pull

the

threading

(23).

The

lever

from

downwards

Finally

pull

of

the

two

To

thread

the

the

off

presser

lever

the

of

the

thread

slot

thread

left

the

thread

the

needle

master

foot

to

(23)

spool

the

right

both

hands,

thread

threading

around

and

must

to

right.

again

in

thread

guides

needle,

thread

switch.

Turn

highest

holder

size.

guide

slot

stop

upwards

be

Then

the

from

please

handwheel

position.

(29)

pull

the

hook

(21)

and

E

into

the

to

pulled

pass

right-hand

the

side

(20).

refer

and

fit

thread

D.

Pass

downwards,

the

take-up

into

the

the

threading

between

to

the

to

bring

Place

the

an

unwin

into

guide

the

thread

right-hand

lever

take-up

thread

one

next

page.

slot.

‘::.

25

Page 29

•

‘•

+‘-•

1

‘V

Needle

In

order

quicker

Lower

stitch

Place

taut

turn

goes

the

hook

Turn

the

thread

upwards.

through

threader

to

the

the

to

bring

the

Move

it

towards

through

from

threader

carefully,

You

the

make

PFAFF

sewing

needle

the

the

can

needle

threading

foot

the

needle

thread

threader

the

needle

the

underside.

towards

and

now

eye.

needle

needle

allow

pull

(see

under

(1

eye.

of

threader

next

to

its

9)

fully

so

that

the

the

the

the

needle

page).

highest

hook

downwards

the

Place

rear,

releasing

threader

end

the

of

is

0

small

the

easier

provided.

Take

one

position.

and

hold

hook

thread

the

to

move

thread

and

it

and

R

into

ii

26

Page 30

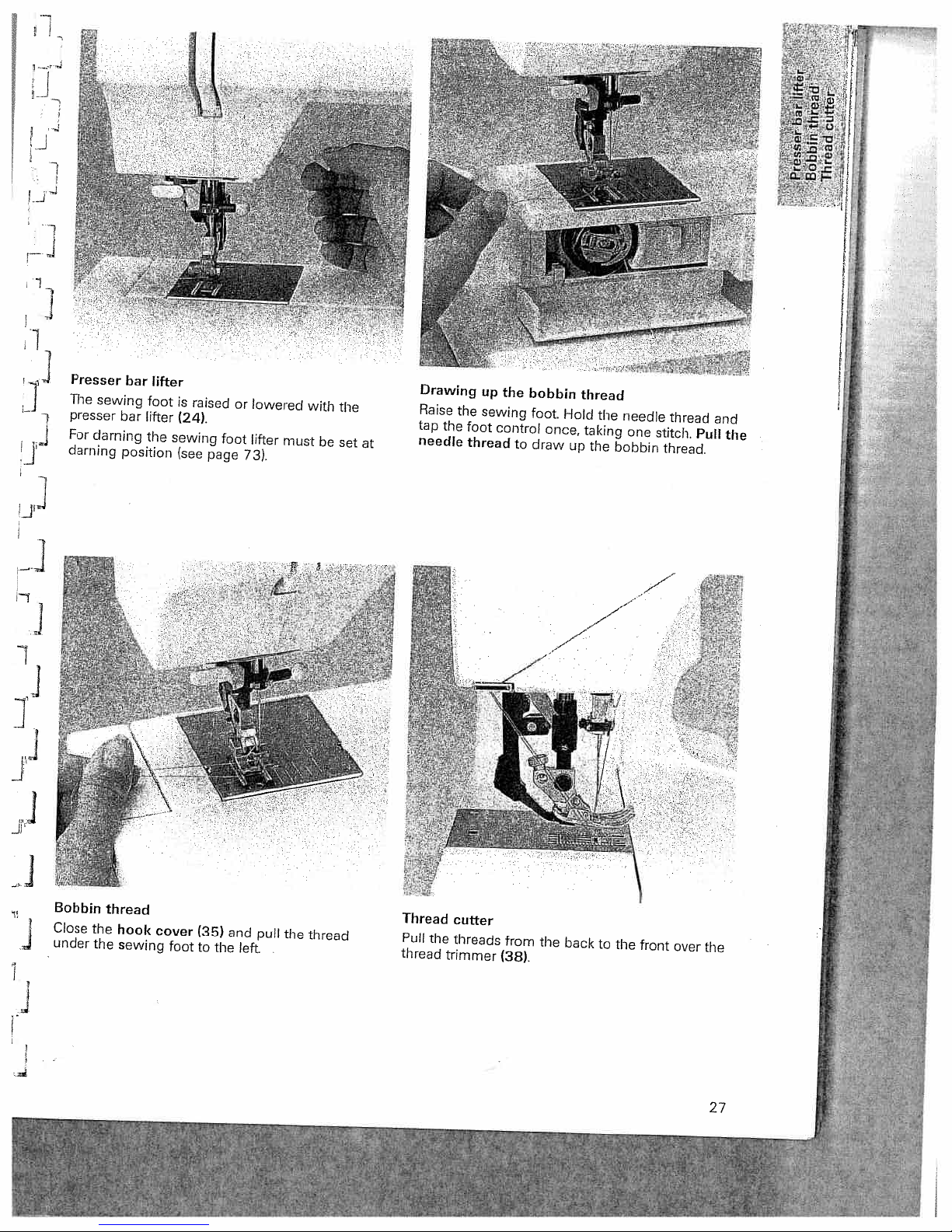

Presser

The

sewing

presser

For

darning

darning

bar

lifter

foot

bar

lifter

the

position

is

raised

(24).

sewing

(see

foot

page

or

lowered

lifter

73).

must

with

be

the

set

Drawing

Raise

tap

at

needle

the

the

foot

thread

up

the

sewing

control

to

bobbin

foot

once,

draw

thread

Hold

up

the

taking

the

needle

one

bobbin

thread

stitch.

thread.

Pull

and

the

I

Z

\

\

Bobbin

Close

under

J

the

the

thread

hook

sewing

cover

foot

(35)

to

the

and

—

left.

pull

the

thread

Thread

Pull

thread

the

trimmer

cutter

threads

from

(38).

the

back

to

the

front

over

the

27

Page 31

S..

--

--

Li:

-

_..-x..

Removing

Turn

off

Set

the

foot

Press

and

downwards

that

it

disengages

In

the

case

backwards

the

the

needle

the

of

and

sewing

master

at

sewing

at

the

press

foot

switch

its

highest

foot

the

back

from

the

buttonhole

it

upwards.

point

upwards

at

the

sewing

foot

Raise

same

foot

5,

at

push

the

the

time

holder

front

the

sewing

so

8)

(1

strip

Attaching

Place

(18)

so

lowered,

foot

holder,

The

Dual

the

sewing

that

the

Feed

the

when

pins

sewing

foot

the

of

must

foot

under

presser

the

foot

be

disengaged

the

sewing

bar

engage

lifter

(see

in

foot

(24)is

the

page

holder

sewing

30).

Li

L

L4

1:1.

J

Check:

Please

check

that

the

attached

‘)Q

by

raising

sewing

the

presser

foot

bar

is

properly

lifter.

Ei

[11

ri

Page 32

-

-

—

.1

The

built-in

For

sewing

solution:

industrial

the

top

fed

accurately.

silk

and

seam

pucker.

perfect

next

(see

dual

difficult

built-in

sewing

and

bottom

rayon

The

matching

page).

fabric

Dual

machines,

On

fabrics

even

of

materials

Feed.

at

the

light

or

the

feeding

checked

feed

same

difficult

dual

(IDT

PFAFF

The

feeds

it

fabric

action

and

system)

offers

sSrne

the

time.

fabrics

feed

striped

as

fabric

The

also

the

on

fabric

such

prevents

ensures

fabrics

ideal

from

is

as

29

Page 33

C

1

C

Engaging

Raise

the

(40>

so

sewing

that

the

it

Dual

snaps

foot

Feed

Now

in

place.

push

the

Dual

Feed

Disengaging

Hold

the

places.

out

also

to

the

the

Pull

illustration

Dual

the

rear,

the

Feed

Dual

and

Dual

with

let

on

Feed

it

page

Feed

two

move

(40)

fingers

down

slowly

29).

at

the

a

little

upwards

marked

and

(see

jiL

I

Important!

For

all

sewing

jobs

with

I

I

30

the

Dual

Feed,

only

use

sewing

feet

that

are

cutout

at

the

back

(0.

1,

3,

4).

Page 34

11

p

I

I

JA

Changing

Switch

To

remove:

needle

screw

To

insert:

to

the

rear.

needle,

needle

off

at

its

(25)

The

pushing

and

the

master

Lower

highest

and

Lower

tighten

needle

pull

flat

the

it

up

switch

the

point.

the

side

the

sewing

needle

A

of

sewing

as

far

set

Now

the

foot

as

screw

foot

looserj

out

needle

it

will

and

(25)

and

set

the

the

insert

go.

firmly.

set

must

Hold

downwards.

face

the

the

I

F

I

.

31

Page 35

M’

F

Setting

Set

tension

The

embroidering

and

the

required

normal

3.

the

(22)

1

needle

using

setting

and

thread

amount

mark

for

sewing

buttonhole

on

A.

tension

the

needle

is

sewing

4

to

5.

thread

For

between

I

[.

2

ii

Lowering

For

certain

has

to

(35)

feed

dog

32

and

be

dropped.

meve

is

the

feed

sewing

slide

lowered.

-,

work,

To

dog

C

do

fully

i.e.

this,

darning,

open

to

the

the

the

right

\

feed

hook

Now

r

S..

dog

cover

the

Page 36

I

If

I

I

iii

/1

1

:1

Electron.

Sewj

Patter,tCtions

Pages

‘3to4

5

mflhinatjo

2

/

I.

I

/

L

I

I

I

I

/

I

Page 37

/1

,

—

Contents

Sewing

Slide

Stitch

Stitch

buttonhole

stitch

function

keys/Program

width/Needle

width!

length!

density

Balance/Pattern

Pattern

sequence

keys

keys

length

positions

Page

Page

Page

Page

Page

Pages

36

37

38

35

40

41

to

45

35

4

4

;f

Page 38

Sewing

function

keys

Backward

When

pressing

amp

lights

wards.

To

again.

If

the

sew

case

Needle

With

needle

when

Buttonhole/Tacking/Single

This

1.

In

buttonhole

2.

If

the

sewn

•

or

•

3.

If

the

immediately

a

fancy

continue

key

is

backwards

the

green

stop

this

key

is

to

the

foot

key

has

programs

key

is

automatically

the

pattern.

key

is

stitch.

sewing

the

up

and

pressed

until

lamp

(2)

you

be

in

control

three

71/72

length

pressed

pressed

in

a

key

backward

the

machine

forward

while

the

does

can

determine

the

fabric

is

released.

functions.

you

yourself

before

at

the

while

utility

stitch

(1)

sewing,

sewing,

key

is

not

or

can

and

sewing

beginning

sewing,

sewing

will

press

the

released.

light

up.

whether

in

the

up-position

Pattern

determine

save

start,

a

and

at

the

key

sew

machine

In

the

(3)

the

it

of

the

tack

end

the

back

the

this

a

tack

is

green

key

seam

sewn

of

will

is

Slow

When

reduced.

Clear

key

With

this

ning

of

In

the

case

the

programmed

Twin-needle

In

some

case

you

width

is

possible

sewing

this

key

(5)

key

a

program

of

programs

must

reduced

to

sew

(4)

is

pressed

it

is

possible

which

buttonhole

length

key

(6)

the

not

use

and

the

with

the

red

a

the

has

and

can

lamp

twin

lamp

twin

to

be

sewing

return

already

darning

deleted.

lights

needle.

goes

needle.

speed

to

the

been

programs

up.

If

the

out,

In

it

is

is

begin

started.

this

stitch

Sti

foi

W

or

F

T

36

C:

Page 39

Slide

time

Any

adjusts

Stitch

Stitch

means

Stitch

this

With

stitch

or

for

determining

Balance

With

this

the

or

keys/program

program

a

new

width

this

to

and

the

slide

slide

itself

width

of

length

slide

key

density.

the

slide

slide

key

pattern

length.

keys

corresponding

key

needle

position

key.

key

slide

can

you

case

of

In

buttonhole

key

(9)

can

you

selected

is

(7)

(8)

determine

program

determine

default

are

length.

machine

the

setting.

determined

length

stitch

this

the

key

balance

70

±

Program

toggle

With

program

the

goes

same

pattern

selection

key

switch

jumping

for

sequence.

can

be

tens

the

carried

digits

you

“+“

10programs

alphabet,

toggle

With

out

(26)

can

the

in

browse

numbers

switch

reverse

at

through

a

time.

“-“

order.

and

the

The

the

by

unit

“+“

After

toggle

reverse

74,

also

is

pattern,

the

on

digits

you

74

73

possible

or

memory

alpha-numeric

display

the

Program

±

toggle

With

from

ber

from

again

is

pattern

and

number

continuing

switches

selected

to

item

ni)

With

another.

Patten

this

character

memory.

short

for

a

key

switch

00

to

00.

‘+/—“

group

sequence

key

shown

When

time.

for

74.

With

in

with

it

(alphabet

the

saving

(0

select

the

switch

order

etc.

numbers)

symbol

to

9)

a

pattern

selection

starting

With

toggle

to

switch

from

key

(1

saved

are

m

(1

you

from

5)

or

lights

3)

num

starts

select

inside

one

special

in

a

00

a

the

up

37

Page 40

I

1

—-—

Setting

Any

adjusts

or

The

in

10,

When

(7)

stitch

mm.

—

time

pattern

stitch

the

top

the

lights

or

the

a

new

itself

width.

or

line

upper

up,

you

pattern

stitch

program

to

a

pattern

on

lamp

can

width

width/pattern

specific

width

the

left,

i.e.

of

the

infinitely

within

is

selected

default

shown

is

3.0

stitch

adjust

a

value

mm

range

width

the

in

for

width

the

from

machine

for

the

the

display

program

slide

desired

0

to

stitch

key

6

1

-

If

the

recalled

the

program

digits,

default

by

thus

setting

pressing

keys

for

reselecting

had

the

both

been

“+1—”

the

altered,

toggle

unit

digits

pattern.

it

can

switches

and

tens

be

of

[1j

rFj

Adjusting

When

(7)

has

ons.

07.

When

‘1-”

is

that

change

38

the

This

selecting

shown

the

the

the

bottom

lit

up,

is

possible

needle

needle

needle

you

in

is

light

can

one

the

in

position

of

set

in

programs

of

these

upper

center

position.

the

stitch

up

to

programs

display

position.

1

3

02,

line.

width

needle

03,

the

This

Now

slide

positi

06

symbol

means

you

and

can

key

The

display

i.e.

i.e.

the

shows

the

needle

i.e.

needle

to

L6

moves

to

the

3J

moves

the

2,5

02

left

2,5

02

three

right

6

positions

positions

iii

—_i

I’

11

Cl

Page 41

7

-ii

Setting

Any

timeanew

adjusts

length or

the

When

lights

(8>

stitch

length

stitch

length,

upper

lineofthe

In

program

12,1

(8,

the

stitch

itselftoa

buttonhole

upper

up,

you

withinarange

6,0

70

6

mm)

length/buttonhole

programisselected

specific

default

length.

lampofthe

can

stitch length slide

infinitely

from 0.5to6

this

mm

in

case,

displayincenter

three

different

buttonhole

canbeadjusted

value

adjust

position.

with

is

length

the

for

the

shown

slide

machine

stitch

the

desired

mm.

in

the

lengths

key

key

The

(8).

If

the

default

setting

recalledbypressing

the

program

digits,

thus

keys

reselecting

for

has

the

both

the

been

“+/—“

unit

pattern.

altered,itcan

switches

toggle

digits

and

tens

be

of

Setting

Any

time

adjusts

stitch

the

new programisselected

a

itselftoa

density

specific

default

value

the

machine

for

density.

stitch

adjust

from

length

0.2

case,

the

to

desired

1

is

position.

When

lights

(8)

stitch

The

in

the

the

density

stitch

upper

upper

lampofthe

up,

you

withinarange

density,

lineofthe

can

infinitely

0.30

mminthis.

displayincenter

the

slide

mm.

shown

stitch

key

If

the default

setting

has

recalledbypressing the

the

digits,

program

thus

for both

keys

reselecting

been

“+1—”

the

altered,

toggle

unit

digits

pattern.

it

can

switches

and

tens

be

of

39

Page 42

ci

j

Setting

Appearance

depend

wool

you

to

the

tiptronic

called

default

lamp

of

can

alter

The

balance

line

on

The

more

shorter

of

the

pattern

,.-

the

on

is

fed

reach

balance

setting

the

the

the

the

are

balance

and

the

in

a

optimum

is

balance

balance

setting

right

slide

the

are

size

of

material

different

provided

to

change

of

the

balance

slide

within

is

shown

key

backwards

set

less

.

—i-.

‘-

an

embroidery

it

is

embroidered

way

as

embroidery

with

a

the

backwards

is

key

(9)

a

range

in

is

pushed

stitches,

densely.

.

silk.

In

pattern

correction

0.

When

has

lit

from

the

upper

to

the

i.e.

the

pattern

on

order

quality

system

feed.

the

up,

you

—7

display

left

the

stitches

—

i.e.

for

The

upper

+7

to

——‘.——

The

more

longer

of

the

Any

time

adjusts

balance.

If

the

recalled

the

program

digits,

the

are

the

pattern

a

new

itself

default

by

pressing

thus

reselecting

-4——.-—--—--_—,

slide

backwards

are

set

program

to

a

specific

setting

keys

for

key

has

the

both

is

more

“+1—”

the

pushed

stitches,

densely.

is

selected

default

been

unit

pattern.

to

i.e.

value

altered,

toggle

digits

I

the

right

the

the

machine

for

it

can

switches

and

tens

the

stitches

c.

the

be

of

I

Setting

Any

adjusts

pattern

When

has

for

The

display

40

time

the

lit

up,

fancy

selected

line

the

a

new

itself

length.

lower

you

stitches.

on

pattern

program

to

a

lamp

can

pattern

the

length

specific

of

adjust

length

right

is

selected

default

the

the

is

value

balance

desired

shown

the

machine

for

slide

pattern

in

the

the

key

top

(9)

length

If

the

recalled

the

program

digits,

default

by

thus

setting

pressing