Page 1

L

.—

c-I)

--

C)

D

I

I

/

‘.

Page 2

Fold

i

out

this

page

Some

rules

safety

Contents

Removing

Openng

Removing

Accessory

Electrical

Placing

Upper

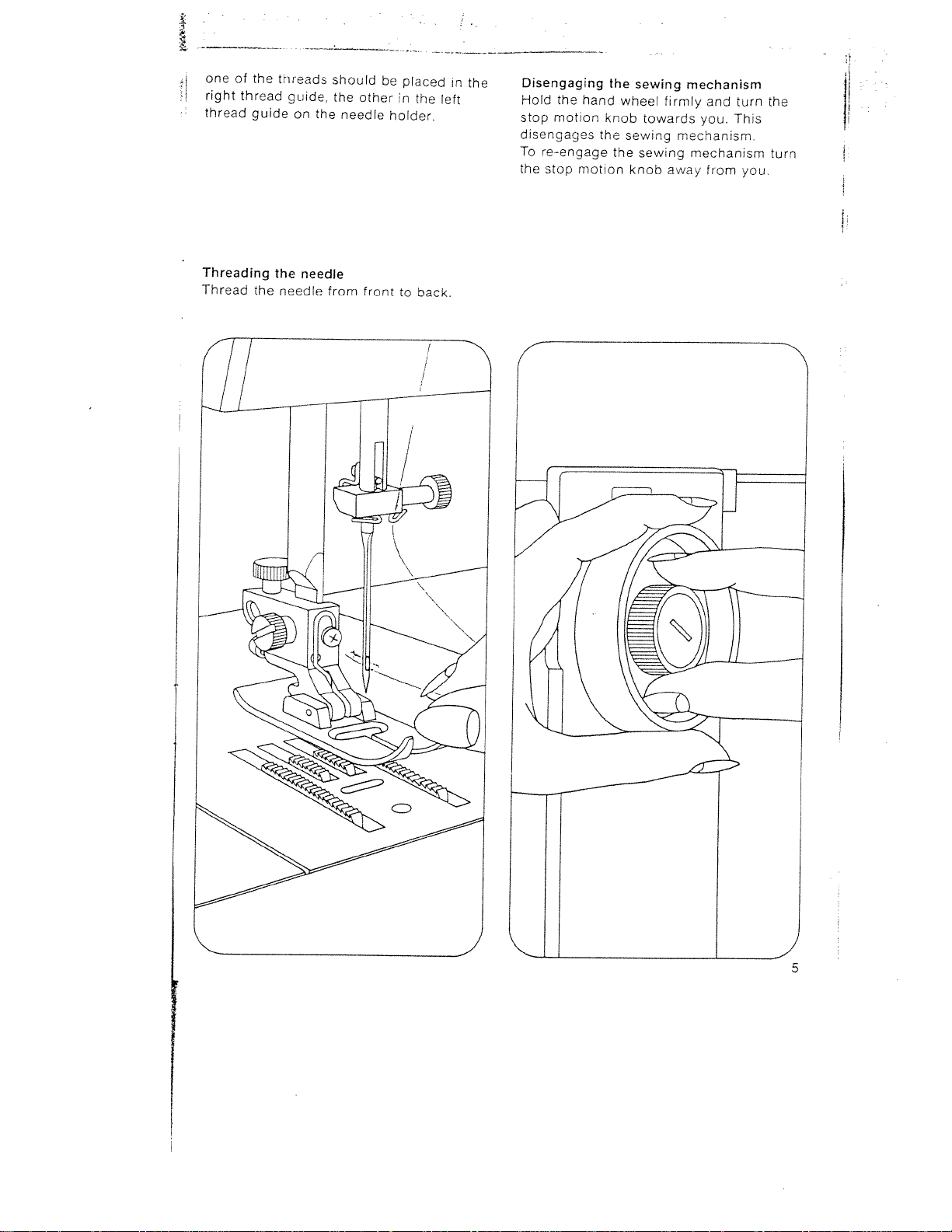

Threading

Disengaging

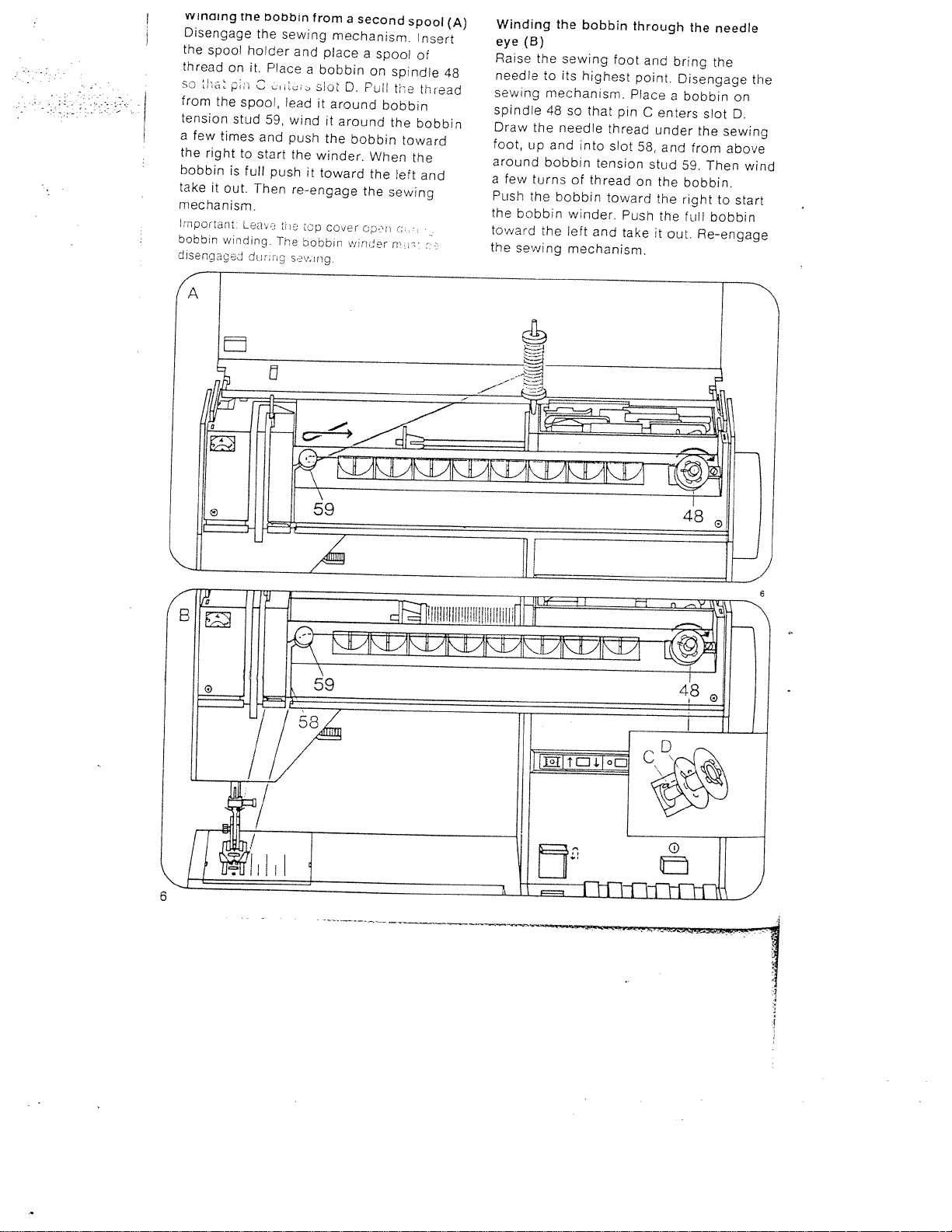

Winding

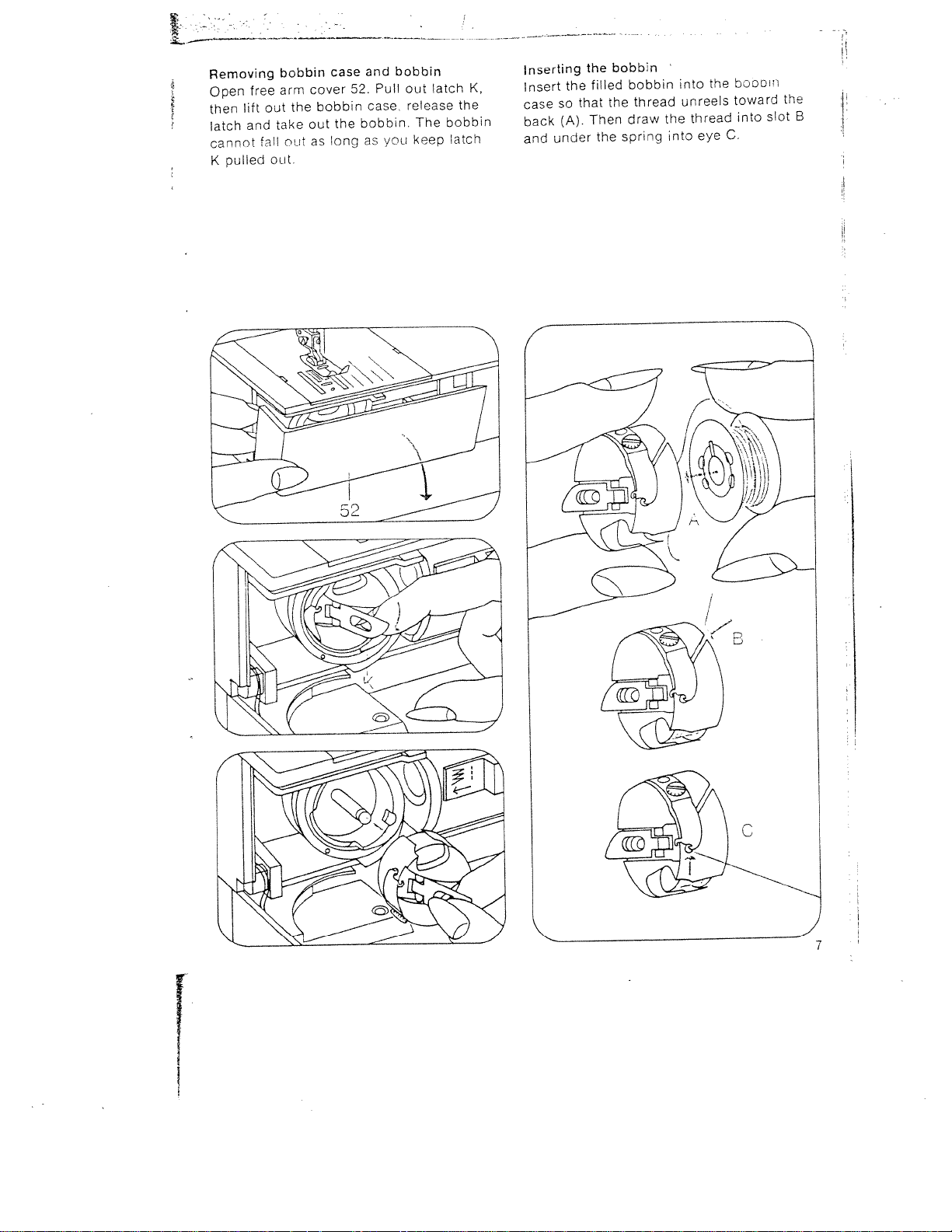

Removing

iflsertng

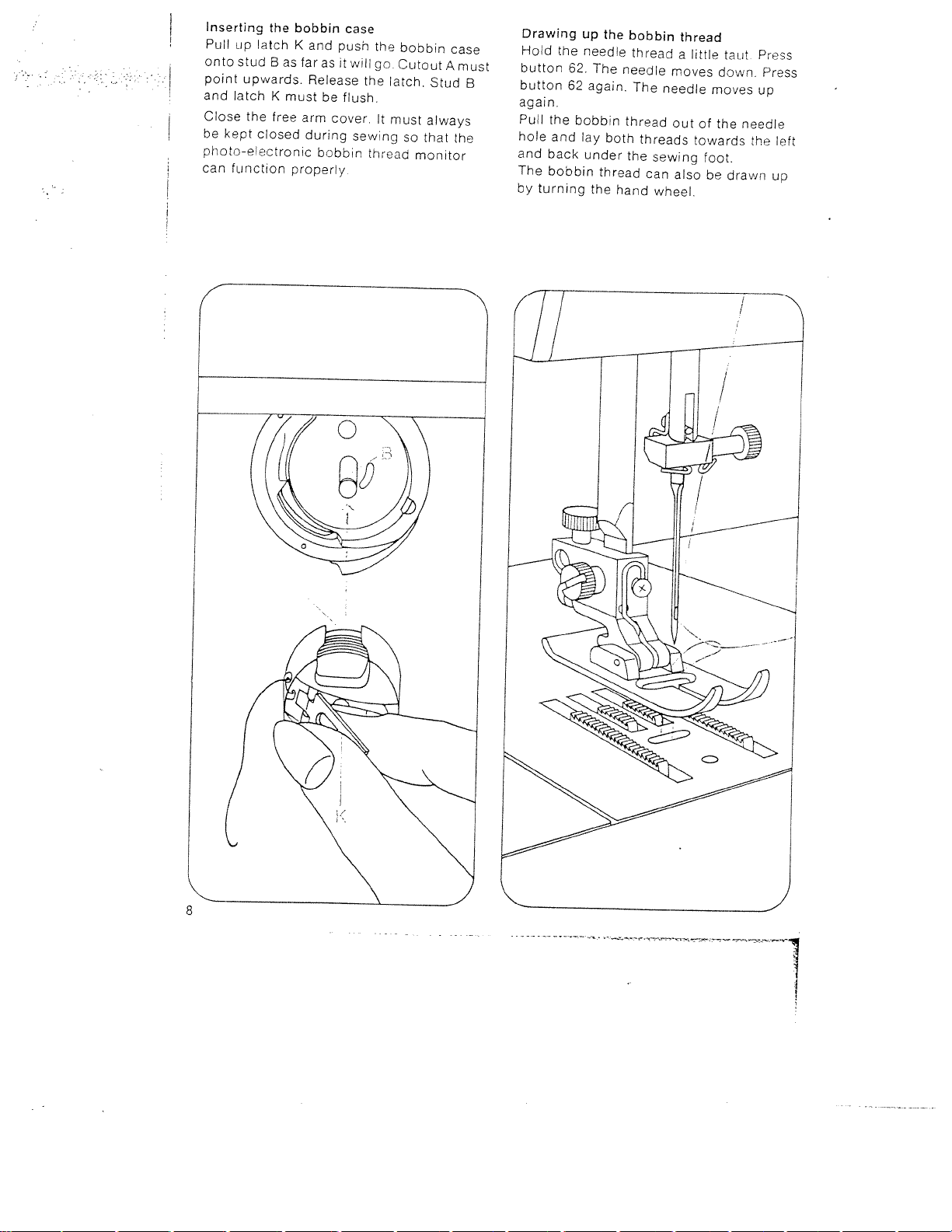

Inserting

Drawing

Presser

Thread

Thread

Regulating

Reverse

Finger-tip

Selecting

Selecting

UtilitySelecting

Dropping

Changing

Biectronic

Needle

Basting

Electronic

Changing

Sewing

Speciai

Sewing

Changing

Cleaning

Changing

Troebie

the

the

hinged

and

box

connection

spool

threading

he

the

the

bobbin

bobbin

the

bobbin

the

bobbin

up

the

bar

lifter

cutter

tension

the

sewing

controls

utility

stretch

and

stretch-stitch

the

the

the

bobbin

positioner

top

the

feet

sov;ng

buttonholes

the

and

the

shooting

carrying

opening

and

of

thread

needle

sewing

case

bobbin

stitch

stitches

stitches

needle

machine

needle

thread

speed

sewing

toot

light

oiling

fuse

case

top

the

accessory

and

on

and

case

thread

length

position

feed

selector

feet

bulb

cover

cover

swIng-out

compartment

control

foot

pin

mechanism

bobbin

combinations

straight

for

monitor

arm

stitching

Page

16,17

16,

16.

16,

20.21

24,

22

22

23

25

17

18

19

20

13

14

14

15

15

17

17

10

11

12

13

the

to

bobbin

clean

interrupt

to

your

sewing.

power

change

for

bulb

or

or

a

in

injuring

avoid

the

on

sure

sewing

plate,

machine

and

use

lamp.

to

needle

you

or

leave

a

unplug

you

when

have

or

the

15-watt

when

have

foot,

you

machine

light

careful

Be

a)

1

2

3

4

4

5

5

6

7

7

8

8

9

9

ii

fingers

Make

b)

cord

the

needle

the

oil

sewing

while.

Only

c)

the

whenever

needle,

sewing

Page 3

Parts

your

of

sewing

machine

Carrying

30

Hinged

31

Hand

32

33

Stop

34

Master

Finger-tip

35

36

Stitch

37

Swing-out

accessory

38

Needle

Sewing

39

sewing

40

Needle

41

Needle

42

Presser

43

Presser

44

Reverse-teed

45

Stitch

46

Space

of

47

Accessory

compartment

48

Bobbin

49

Top

Basting

50

51

Foot

Free

52

enclosing

53

Free

54

Thread

Threading

55

Take-

56

57

Spool

58

Threading

Bobbin

59

(bobbin

60

Bobbin

61

Bobbin

62

Needle

(“up

wheel

motion

switch

length

plate

foot

foot

holder

thread

chart

for

customer

winder

speed

stitch

control

arm

arm

guide

up

pin

tension

winding)

rack

thread

positioner

and

handle

top

cover

knob

controls

control

sewing

compartment

holder

bar

lifter

bar

with

control

entering

service

box

underneath

regulator

button

cover,

sewing

SlOtS

lever

with

slot

down

arm

with

with

screw

tension

thread

phone

with

hook

unreeling

bobbin

for

stud

monitor

posihoning)

with

cutter

numbei

accessory

discs

winding

Page 4

6U!Aowe

eq

eq

o

0j

eq

o

ejpu

ai

ie

6u

bUi/HJE3

ss

eSD

eseD

‘eAOD

paipui

AO

Aq

JAOD

[

epiSUi

pe6uq

81

°A

JAO3

dO

IRM

AOD

PUH

(v)

J8L

Si

6uiuad

pjot

L4

u

3q

fl

P14D

1DiS

ULJ

8L4

iJ

JeAOD

p

6uowaH

pu

JepUn

qDEe

puq

()

pu

eL

()

H

no

POWWODDE

UiMS

H

(c)

5uiudo

nO

eqj

WJU

nO-buiMS

S

uedQ

pJEMo

p

no-6u!MS

HHM

9I

L4

()

O

SiJOSSODD

uije

JflOA

)

j

I

N

4

I

Page 5

CD

—

C

—

a

CD’<

C

U;-

oo

—

®

0

a

3

CD

0

Co0.DO

—

8

p.

t

-‘

®n

a

CD

Cd)

0

o

—‘

an

00

S<%<

CDO

OCt

Cd)

‘-<

E°’

o-i

CD

DC)

V

-CD

z

a

0

CDCQ

Cd)

0

t

a

0

CD

t3tn

CD®

a

‘0

—0

C/C

OD

o

0

a

_D)

a

Dv)

00

0-CD—a

—

0-a®

a

0

x

0(0

-L

Page 6

[.

Electrical

Take

the

the

from

of

out

sewing

For

place

and

Itisalso

in

the

it

hand.

by

connection

foot

right,

it.

it

possible

machine

turn

under

control

Fig.

the

during

C,

foot

the

to

keep

and

foot

Outofthe

and

pull

control

table.

the

sewing

control

machine

the

round

foot

and

lead

control

operate

plug

Push

B

machine

pedal,

soon

replace

slightly

the

into

34.

down

sewing.

into

plug

switch

Your

Press

starts

the

As

automatically

To

it

rewind

Push

A

the

A

the

as the

the

and

the

control

into

red

the

returns

then

the

wall

indicator

is

now

foot

The

faster

machine

lead

control

back

machine

socket.

ready

control.

more

the

to

in

the

release

automatically.

into

Press

lamp

for

The

press

you

machine

stops

its

‘up’

foot

it

and

the

socket

master

lights

sewing.

machine

down

runs.

needle

the

position.

control

will

it

machine.

and

up.

pull

I

3

Page 7

6010519

oods

V

jjsW$

509

9

a6s

p509

cods

sipj

pus

Si

psaip

iepjop

psaJp

puooa

I

iepjop

ui

Sloods

ui

sioods

iepjop

55

cods

pesn

epeeu-uitvft

i!

uc

app

jo

p

6u!IeeJUfl

iuoij

jo

p

6uijeeiun

UI

UMOpS

pauiciuoa

io

6

uiMaS

d

OSip

snsip

iuois

UI

ui

puc

psaip;

uo

:pceip

epj

:psaJpi

Q

o

8P1

:Jepop

ep

uiqqoq

uc

cods

api

iiesui

ecoid

u!d

pus

s

ap

jo

3

5uiMsJp

buipuiM

ap;

cods

uo

cods

jo

A.iossaocc

pus

cods

cods

psaip

api

jo

xoq

JOd

dn

IVd

Olu!

cui

JOd

OIUI

iadd

J8A8j

85189

aq

iois

MOIeq

ueqj

peeiq

iOjS

01

JOLflO

OL4

v

01W

weip

powqi

V

buipeapi

isnw

ci)

1!

epin5

01

eq

5uipsaiqj

pioq

eq

u

6uities

pueiq

woj

api

9

lOIS

NDEq

epinb

pg

uo

elpecu-oMi

uei

eq

q6u

,to

api

iOOJ

Ul

pue

OIUI

eLfi

buiMes

jo

ap

o

pus

!Pi

epsn5

lOIS

epaeu

dn,,

cods

epinO

dn-eu

9

oiu

e{peeu

MEJp

epin6

2

N81

aLg

pue

uoiisod

11

MEip

pus

(

wo

99

JeAeJ

iq5u

W04

eq

q6iJ

j9P1011

peeiq

cue

o

pue

Apejiw;g

eq

p

Page 8

euO

B451J

i0

PE9JL1

eLfl

peoJq

epinb

spueu

epn5

uo

pnoqs

oq

aq

J9L4O

ei

eipau

peDod

ui

Ui

eq

aj

apo

e

PICH

dos

0±

dois

5ui6e6uesi

eq

puq

uodow

se5e6uesp

et

6E5ue-eJ

uoiow

qou

a

i-i

uMes

qou>j

6uiMes

Awi

spto

buiMes

,wE

puo

noA

wo

wsiuElpaw

wrn

Gq

sa

wsiuELDew

wsuqDw

un

noA

pCen

6U!peJq

jpaeu

ajpu

wo

iuo

o

DEq

C

Page 9

wincirng

Disengage

the

spool

thread

s.

from

the

tension

a

few

times

the

right

bobbin

take

it

Out.

mechanism.

-npcrtan:.

bobbin

winninq

disenq

on

;.

stud

is

me

holder

it.

spool,

to

full

Then

Leu-

bobbin

the

Place

C

59,

and

start

push

sewing

.

lead

wind

push

the

reengage

t

The

ng

and

a

.

it

boobin

from

mechanism.

place

bobbin

it

around

it

around

the

winder.

toward

cc,r

a

second

a

D.

bobbin

the

ui

w’der

spool

on

P

When

the

spindle

te

bobbin

the

toward

left

sewing

r

spool

Insert

of

tniead

bobbin

the

and

48

(A)

Winding

eye

Raise

need1e

sewing

spindle

Draw

foot,

around

fe’

1v

a

Push

the

bobbin

toward

the

sewing

(8)

the

to

mechanism.

48

the

and

up

bobbin

turns

the

the

the

bobbin

sewing

its

highest

so

that

needle

into

of

thread

bobbin

winder.

left

and

mechanism.

foot

pin

thread

slot

tension

toward

through

point.

Place

58,

on

Push

take

and

C

enters

under

and

stud

the

the

the

it

the

bring

Disengage

bobbin

a

the

from

59.

bobbin.

right

full

Re-engage

Out.

needle

the

slot

Then

to

bobbin

the

on

D.

sewing

above

wind

start

6

Page 10

Removing

free

Open

lift

then

and

latch

cannnt

pulled

K

fall

out

out.

bobbin

arm

the

take

cit

cover

bobbin

out

as

case

the

long

and

52.

case,

bobbin.

as

Pull

y’i

bobbin

out

release

The

keeo

latch

the

bobbin

latch

the

the

that

filled

Then

the

bobbin

bobbin

the

draw

spring

thread

the

into

into

unreels

thread

eye

the

b000L

toward

into

C.

slot

the

B

Inserting

K,

Insert

case

back

and

so

(A).

under

Page 11

Inserting

Pull

onto

point

and

Close

be

up

stud

latch

kept

the

latch

B

upwards.

the

closed

photo-electronic

can

function

K

free

as

must

bobbin

K

and

far

as

Release

be

arm

during

bobbin

properly.

case

push

it

will

flush.

cover.

the

go.

the

sewing

thread

It

bobbin

Cutout

latch.

must

so

Stud

always

that

monitor

A

case

must

the

Drawing

Hold

button

B

button

again.

Pull

hole

and

The

by

the

the

and

back

bobbin

turning

up

needle

62.

62

bobbin

lay

under

the

The

again.

thread

the

both

hand

bobbin

thread

needle

The

thread

threads

the

needle

sewing

can

wheel.

thread

a

little

moves

out

also

down.

moves

the

of

towards

foot.

be

tauL

drawn

Press

Press

up

needle

the

left

up

8

-—-

Page 12

ress

ress

D

left

up

Presser

Lever

=

A

=

B

=

C

bar

42

has

sewing

The

sewng

The

inserting

sewing

Toe

sewing.

lifter

three

foot

foot

extra-thick

foot

positions:

raised.

is

raised

is

o,;red

is

further

materials.

for

for

Thread

thread

The

located

the

Raise

machine

the

thre-ids

downwards

cutter

at

sewing

into

cutter

the

back

toward

the

cut

to

is

foot.

cutter

them.

of

an

the

oblique

the

Pull

back.

slot

presser

the

and

slot

work

Draw

pull

bar.

out

the

znern

of

)

9

Page 13

Upper

tension

=

•

•

I

Setting

A

setting

3

and5.The

tighter

Lower

tension

=

Regulating

B

Turn

right

=

Both

o

D=Upper

tension

E=Lower

tension

mark.

is

the

it

left

for

a

tensions

tension

too

tension

too

(41)

The

in

the

white

higher

tension.

screw.

foralooser

tighter

are

too

fight.

too

tight.

normal

the

tension.

correct.

loose

loose

range

number,

tension,

or

or

tension

between

lower

upper

correct

The

the

Let

hang

the

or

slide

not

should gradually

jerk

you

bobbin

down

down

your

lower

freely

hand

case

by

tension

by

its

move

upwards

with

the

own

downwards

full

a

thread.

weight,

bobbin

lightly.

must

It

but

when

10

N

j

4

•1

Page 14

V.

V.;

V

V

-

0

C])

-n

0

U)

-:

ci

-o

0

—.

CD

:3

(D

(DO

U)

O

CD

c0—

w

U)3OU)00

—

U)

Z

0

cUCD

0)

0C0

CD

0

0U)CD

‘H

CD

0

U)

(DO

ci

0

00

0

U)

—

0(0

OD

U)

0

0

:3

cr

cic(D

0

U)

0

0

—U)

3uD

ci>

U)

U)

Page 15

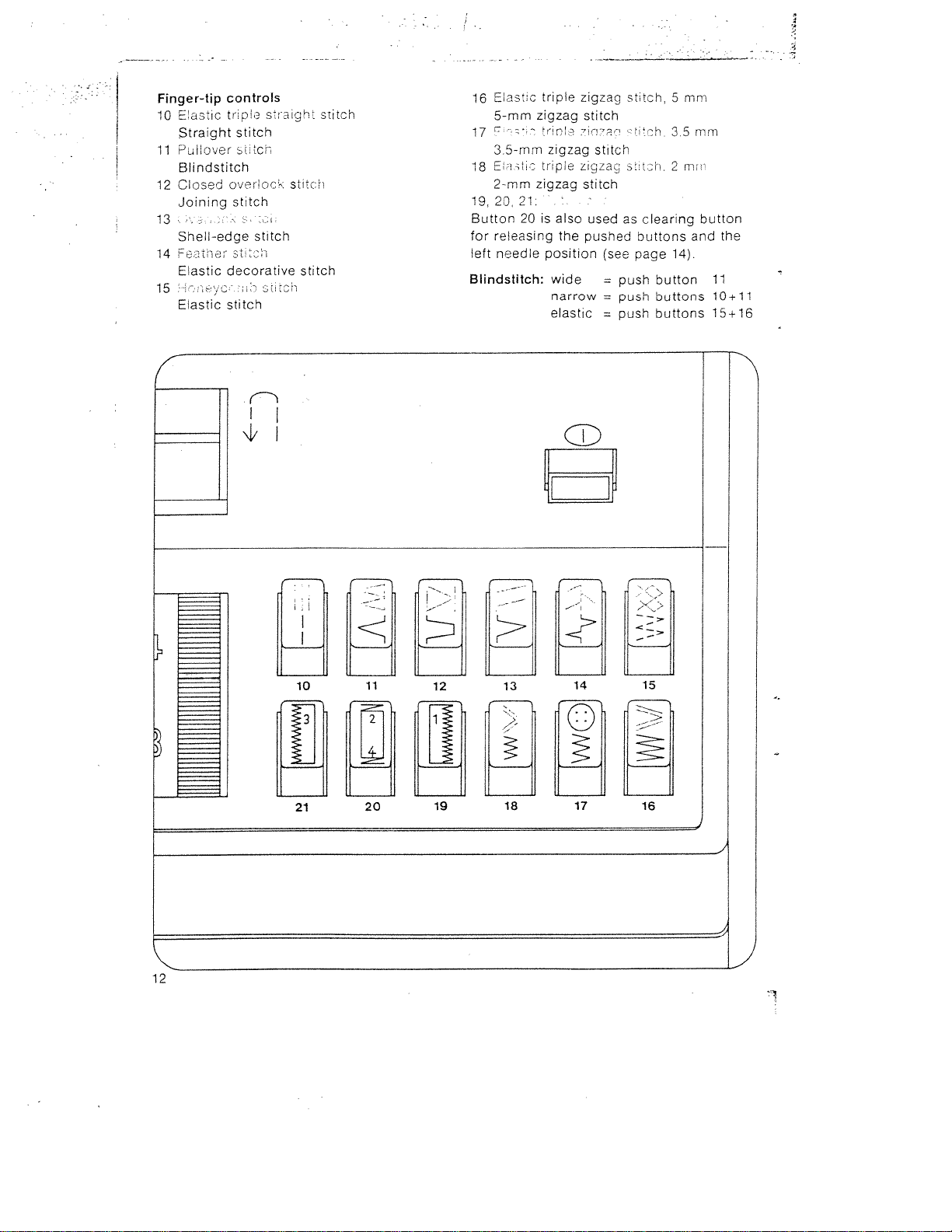

Finger-tip

Easic

10

Straight

11

Pu

Blindstitch

12

C.osed

Joining

13

Shell-edge

eone:

14

Elastic

15’

Elastic

lover

controls

S

trpD

stitch

.oo

‘c

cv

stitch

stitch

decorative

stitch

stl:c”

stitch

st’tch

Elost’c

16

5-mm

17

3.5-mm

18

2-mm

19,

20.

Button

releasing

for

left

needle

Blindstitch:

21.

20

triple

zigzag

r

n

zigzag

triple

zigzag

is

also

position

wide

narrow

elastc

the

zigzag

stitch

‘m

stitch

zrozac;

stitch

used

pushed

(see

=

=

sttch.

rh

-,:‘rr

as clearing

buttons

page

button

push

buttons

push

push

buttons

5

3.5

2

14)

mm

m

and

mm

button

the

11

10+11

15+

16

12

Page 16

—

0-

-o-—cn

((3

C-)

(I)

ci

0

—

T

0)

-‘

(0—

(J)<N

-o

0)

—

D

cc

CD

Ci)

.

CO

ci3

0

ciE

-cD

ci

0)

2-

—

(0

ci—.

(0

0:

C).

C)

U)

0)

C)

-

0)

0

2

0

ci

0.

¶2

C)

C)

ci

U)

—

D

‘o

Zr

O

DC)

CO

,

0-

(0

03

CO

(0

C)

U)

00.

Q)0

(0(0

ci

-o

C

0.

C)

ci

CO

C)

00)

0-

ci

C)

0(0

¶2.

C).

(1)

C)

CO

C).

C)

Zr

Dci

¶20

ci

)U

(ft

CO

C

-

0

(C)

0))

Page 17

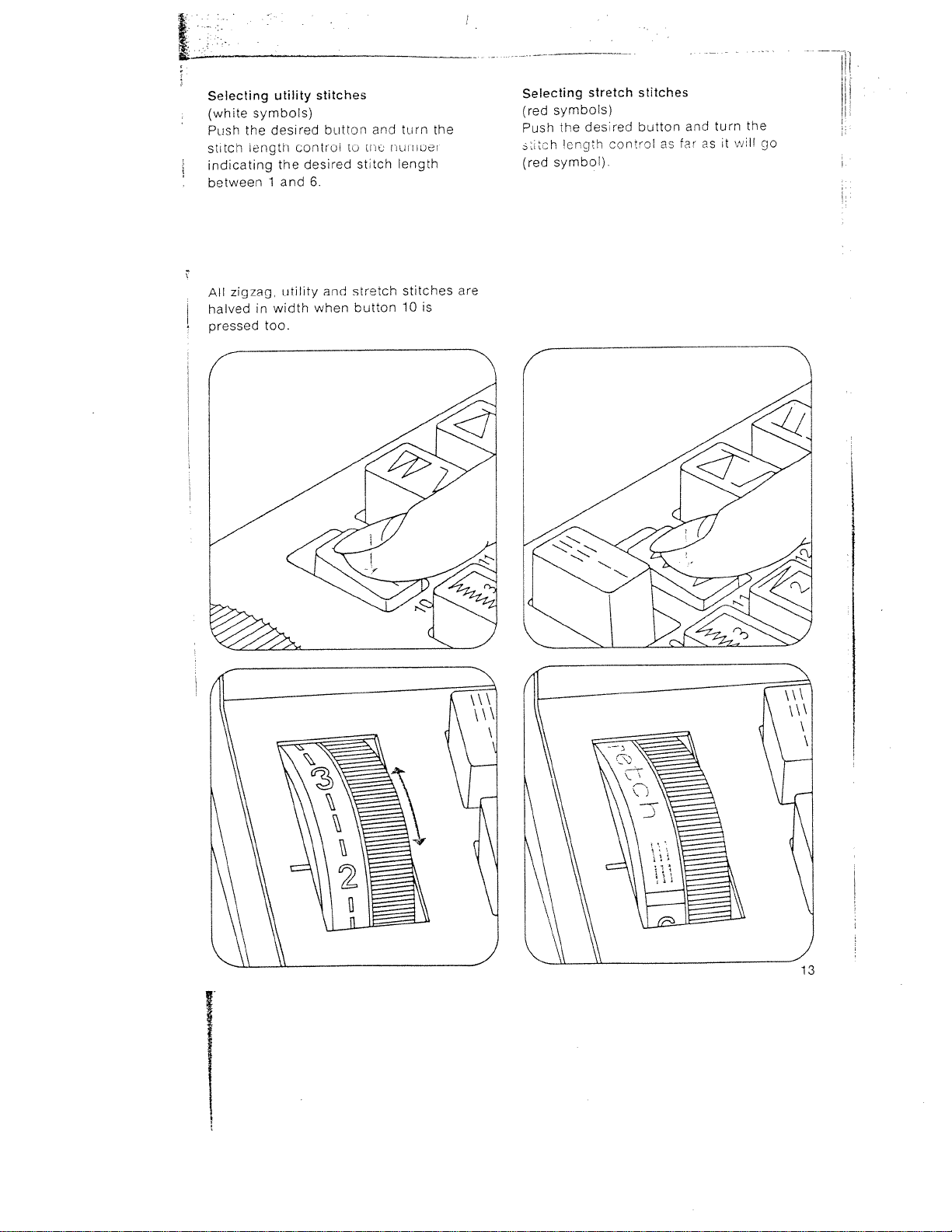

Utility-and

The

various

shown

hinged

want

to

buttons

between

in

top

sew

15

1

the

and

and

stretch-stitch

stitch

combinations

chart

on

cover.

For

an

elastic

16,

select

4.

combinations

the

inside

example,

blindstitch,

a

stitch length

are

of

the

if

you

push

Selecting

stitching

Left

Central

Right

and

needle

needle

12.

the

needle

needle

position:

position:

position:

position

push

push

push

button

buttons

for

button

straight

20

10

11

4

14

L

4

LL

11

LZ

)

12

1

Page 18

5-00

CL

a-

-n

y

5-

Z

(0

CD

Q

CD

3

C)_.

CD

S

C)3CDDC

CD

CD

cC

0

CD

D

—

5-CD

Ct)

CD

CD

(9

CD

CO

5-

2CD

-‘

CD

-o

CD

CL

5-

Q(Q

5-

CD

(0

3:

D

(00Zr

CD

(j)CD

CD

Zr

H

-

CD

CD

CD

<

CD

CD

-L

Zr

CD

CD

C)CDCDCD

0

5-o

-ZrD-CD

CD

3

Zr

C)

(0(t)

C’)

C-)

QCD

CL

3

-.

‘

0

Zr

5-

CD

CD

CL

DCt)CDCDCD

CD

5

-D

.3

CD

CD

-D

Zr

CD

CD

CL

5-CD

CL

C)0CD

ci

CL5-

CD

CL

CD

o

C)

o

CD(0CD

-D

—.0

(/

CD

0

CD

—D

C)CDcii

crCCD

Z)CDCD

I

r

CD

C)

C)Zr

cV-.-

CD CD

CD

CD

CD

CD

‘2.

Zr

NCL=CD-

ZrCDj5-CD

—

o2

ZrCDCD

Zr

CD

CD

95-

CDCD

CDCD

CD

CD

CD

CDCD

ci2

0

CD

>

CD

5CD

0)

Page 19

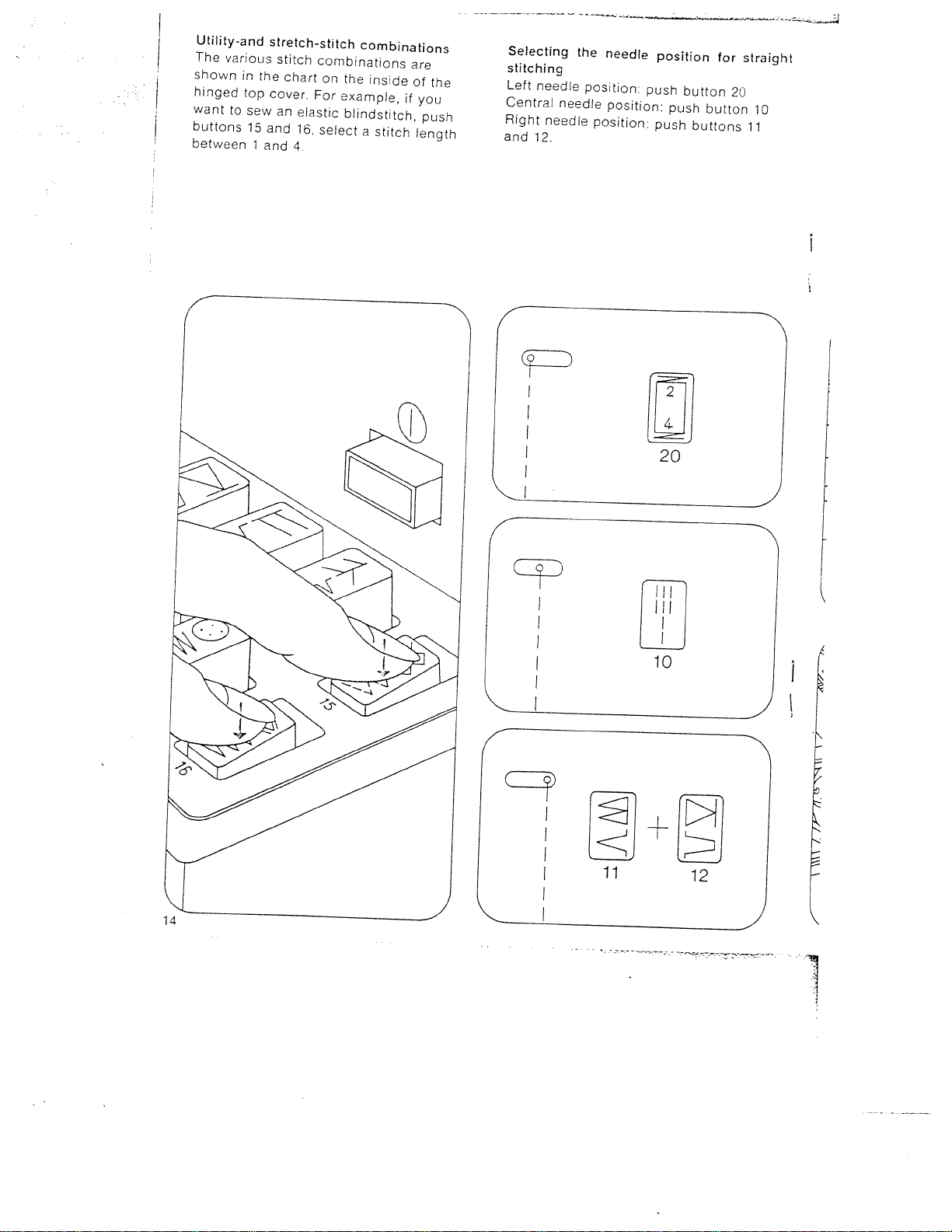

Important

The

bobbin

gaged

during

winder

sewing.

must

always

he

disen

Electronic

61

Bobbin

62

Needle

(‘up

50

Basting

lamp

49

Top

34

Master

and

A

speed

controls

thread

positioner

down”

stitch

regulator

switch

monitor

button

positioning)

wth

nd

c’

16

Page 20

4

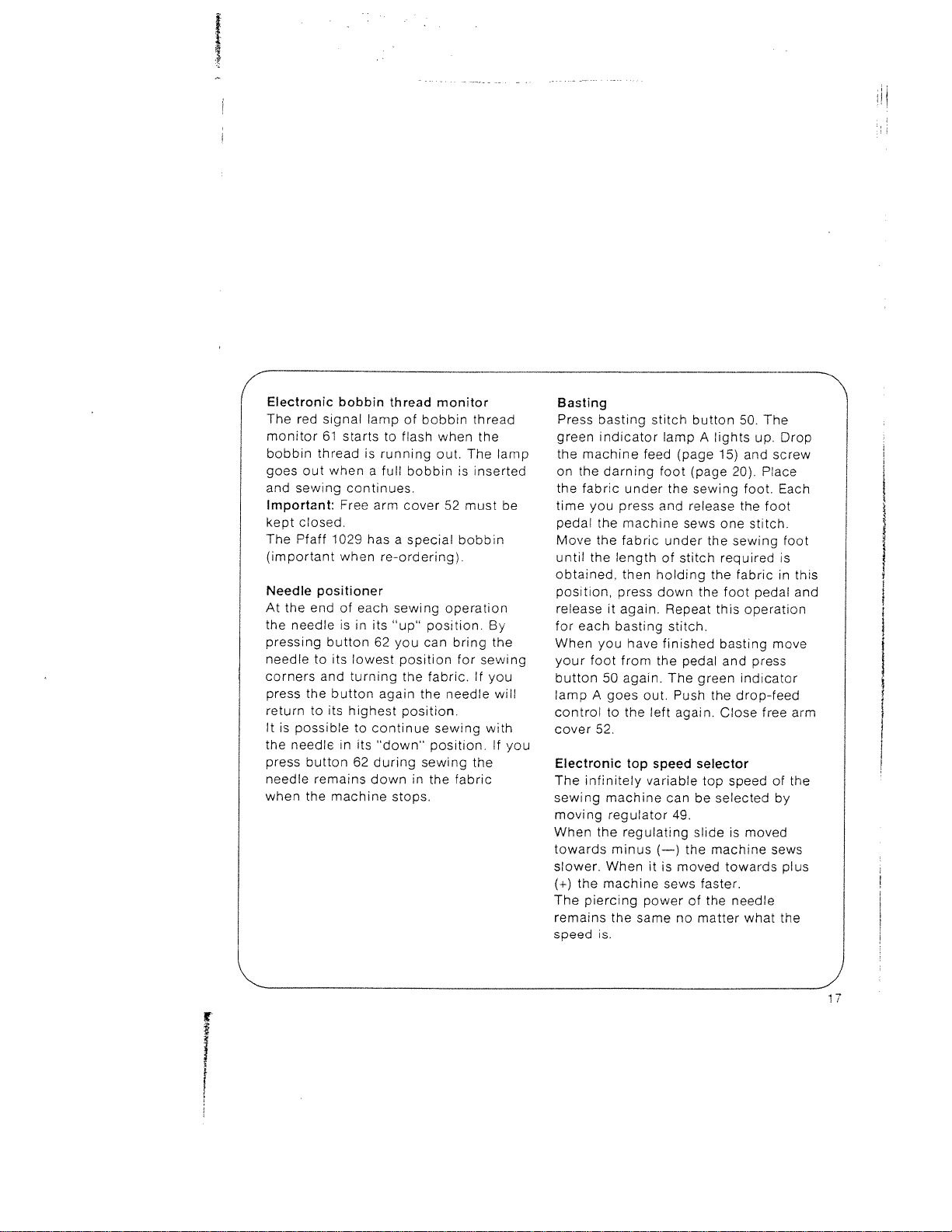

Electronic

The

red

monitor

bobbin

goes

and

sewing

Important:

kept

The

Pfaff

(important

Needle

At

the end

the

needleisin

pressing button

needle

corners

press

return

It

is

possible

the

needle

press

needle

when the

signal

61

thread

out

closed.

positioner

to

and

the

to

button

remains

bobbin

starts

when

continues.

Free

1029

when

of

its

lowest

turning

button

its

highest

to

in

its

62

machine

thread

lamp

of

to

flash

is

running

a

full

bobbin

arm

cover

has

a

special

re-ordering).

each

sewing

its

‘up’

62

you

position

the

again

position.

continue

“down”

during sewing

in

down

stops.

monitor

bobbin

when

out.

52

operation

position.

can

fabric.

the

sewing

position.

the

The lamp

is

must

bobbin

bring

for

needle

fabric

thread

the

inserted

By

the

sewing

If

you

will

with

If

the

be

you

Basting

Press

basting

green

indicator

the

machine

the

fabric

you

the

each

foot

darning

the

the

it

you

50

to

52.

on

the

time

pedal

Move

until

obtained,

position,

release

for

When

your

button

lampAgoes

control

cover

Electronic

The

infinitely

sewing

moving

When

towards

slower.

(+)

The

remains

speed

machine

regulator

the regulating

minus

When

the

machine

piercing

the

is.

under

press

machine

fabric

length

then

press

again.

basting

have

from

again.

the

top

same

stitch

lamp

feed

(page

foot

the sewing

and

under

of

stitch

holding

down

Repeat

stitch.

finished

the

The

out.

Push

left

again.

speed

variable

can

49.

(—)

it

is

moved

sews faster.

power

no

button

(page

release

sews

pedal

selector

be

slide

the

of

A

lights

the

the

the

this

green

the

top

selected

machine

the

matter

15)

one

required

foot

basting

and

Close

50.

The

up.

and

screw

20).

Place

foot.

Each

the

foot

stitch.

sewing

fabricinthis

pedal

operation

move

press

indicator

drop-feed

free

speed

of

by

is

moved

sews

towards

needle

what

Drop

foot

is

and

arm

the

plus

the

Page 21

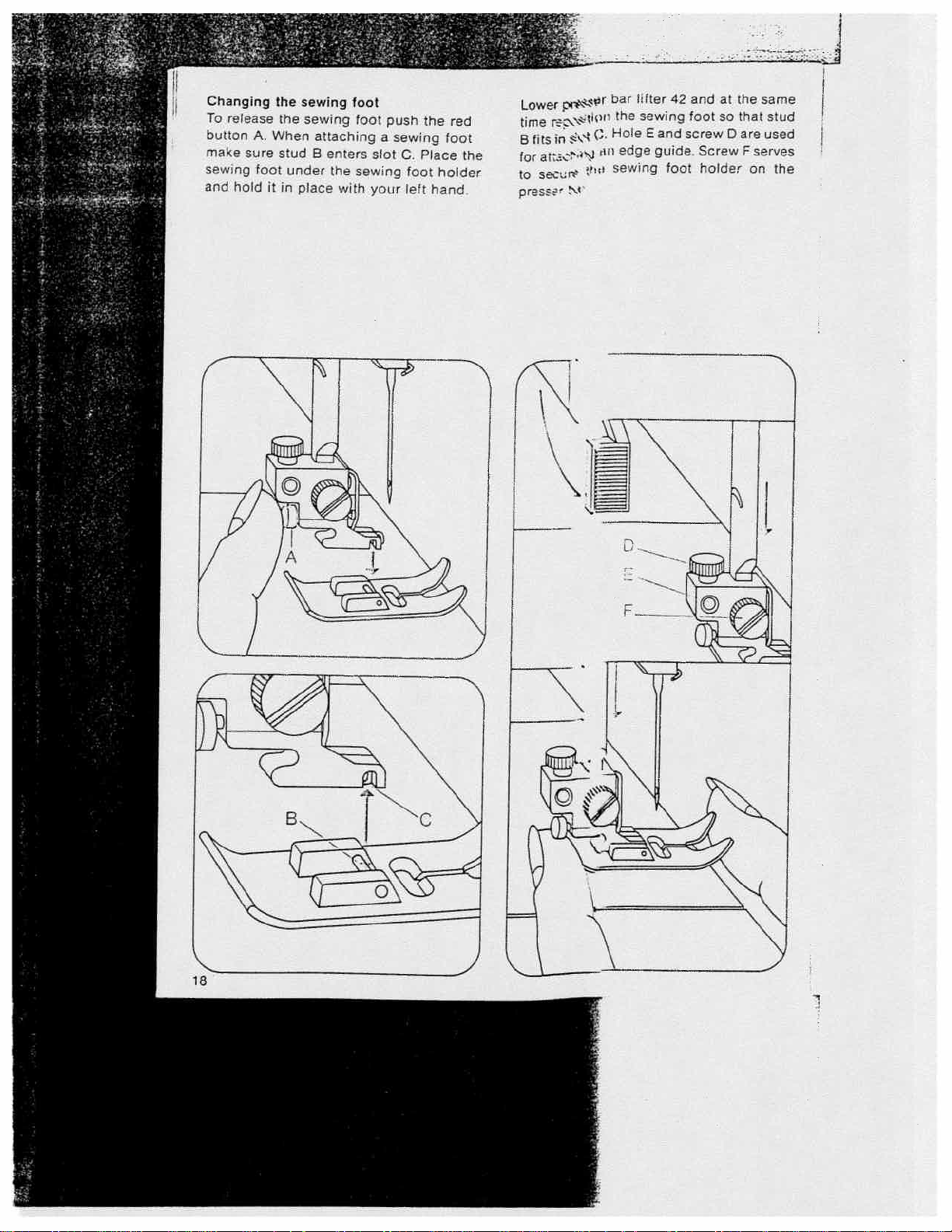

1

J81

at.fl

O

UO

6UM

pu

po

eflS

OO

eqi

U8M

B

pnS

jepufl

u

6U!M

5uM8S

qM

1OO

OO

6U

0S

6UN

noA

snd

6U!M

OO

8

p8)

O0

JPl

0

ew

JO

q

6uMS

3

ao

PU

ep

6

e5P

2

OO

pU

oO

os

0

MaJS

efl

Ma°S

)8pt°

eq

pnS

a

pesfl

s8Mes

UO

Page 22

C)OJ

C

IoJoz

CD

3

E5

(1)

.

CD

-

0

‘

00

‘—0

0-—--

9o

g

0

0

IGm

-

0

zy0

CD

CD

C

CD

0

o

0-.—

o

(0

P1

\—,

/

VL)

/

/

4

4

Page 23

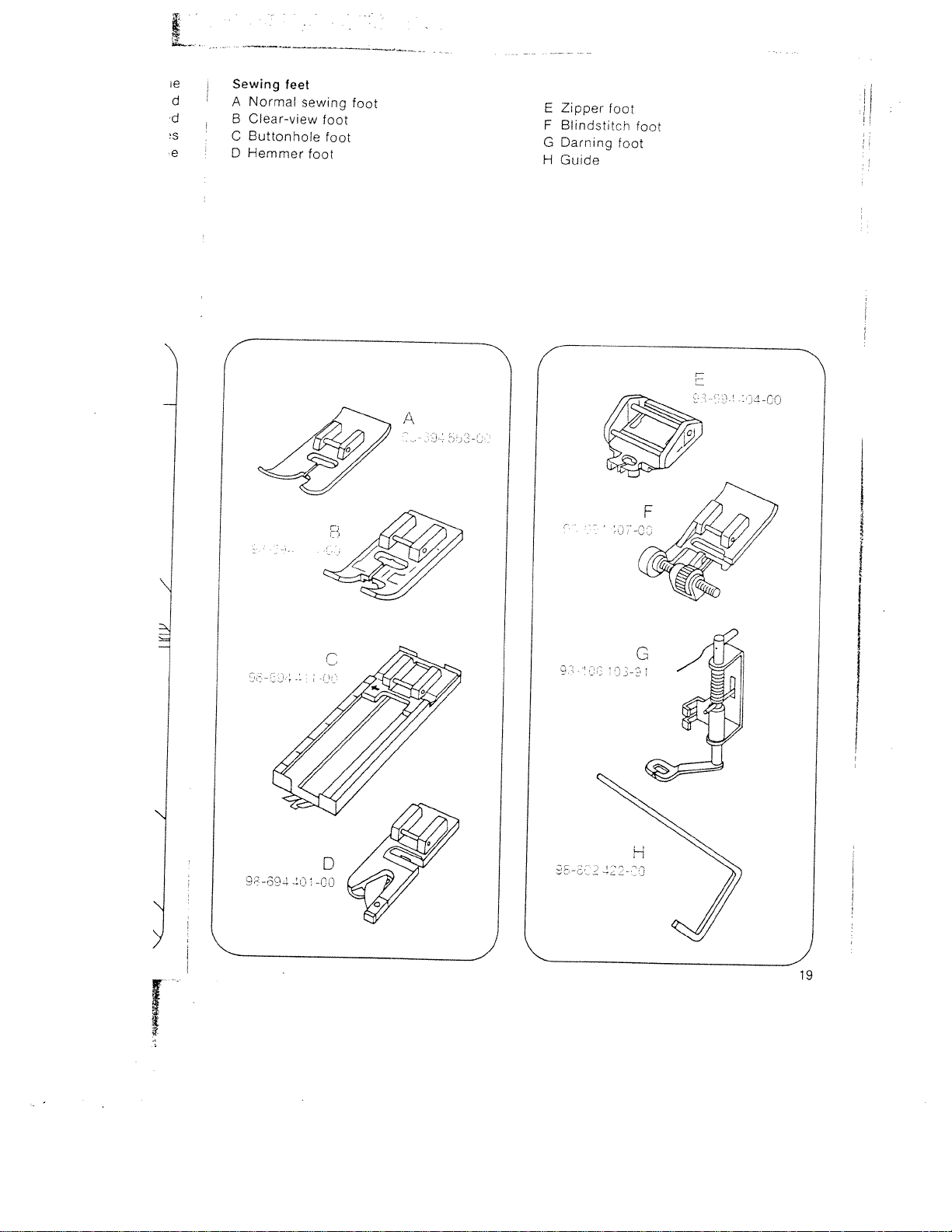

Speciat

A

Blindstitch

Blindstitch

turning

B

Zipper

First

Then

The

sideways

left

Darning

C

Remove

secure

screw

sewing

insert

push

zipper

zipper

H.

foot

the

screw

for

chain.

foot

the

darning

feet

foot

guide

its

its

foot

stitching

sewing

D.

rear

front

can

E

pin

pin

foot

foot

is

adjusted

be

alonq

into

into

adjusted

holder

in

position

groove

groove

the

by

rh:

and

F,

6.

with

The

applications

described

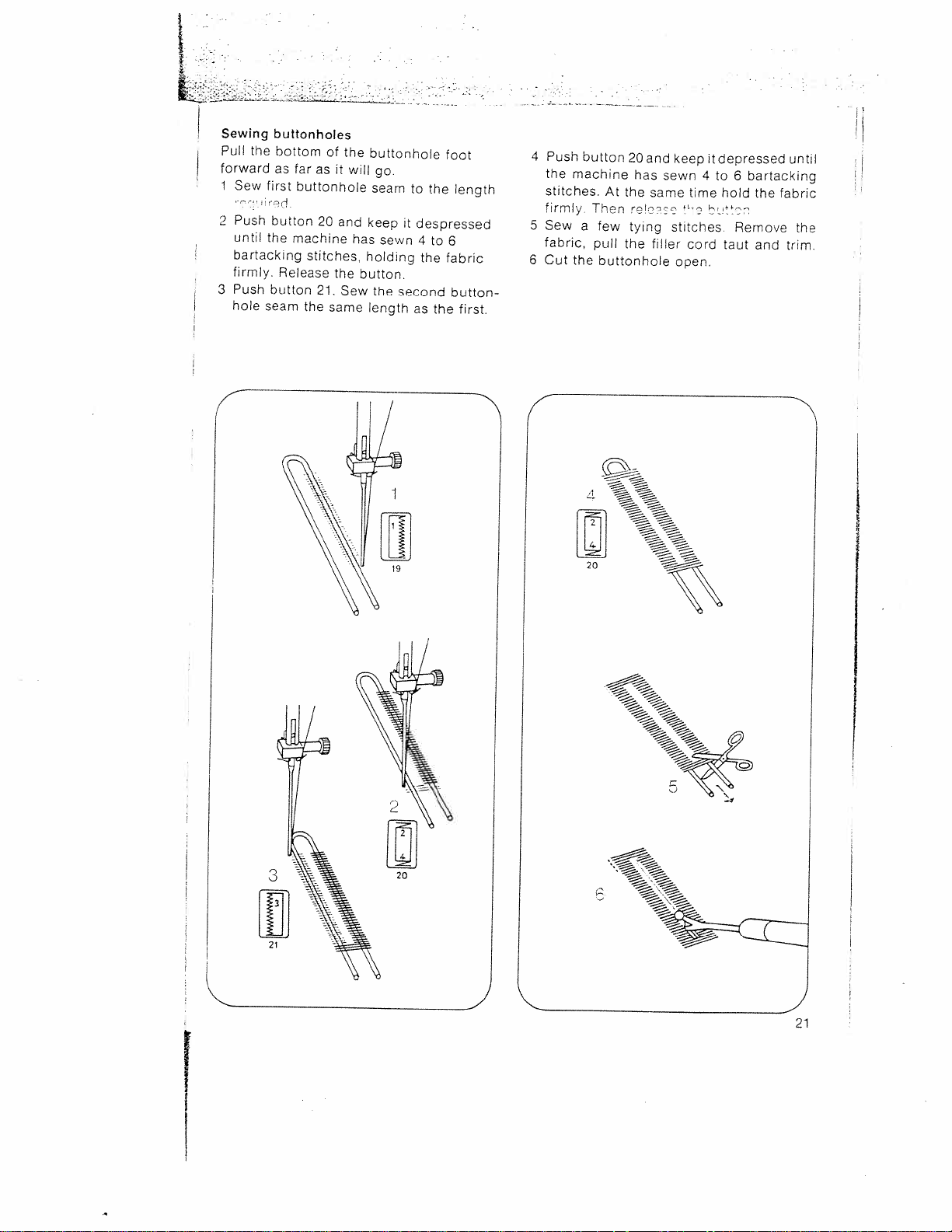

Buttonhole

Push

density

stitch

buttonhole

foov;s

the

foot,

lug

D.

As

you

This

serves

length.

button

in

length

(C:

pull

sew,

in

our

settings

19

the

control

foot.

Place

it

arrow

to

of

Sewing

(A).

buttonhole

Insert

c

taut

and

E

determine

these

Regulate

(B).

Attach

the

.

me

clamp

moves

the

sewing

hints

range

filler

rear

along

buttonhole

the

it

feet

booklet.

stitch

of

the

the

cord

lug

in

front

scale

are

as

of

F.

20

1

Page 24

JCJ)

Cct

H.

=

CD

03

CD

o

CD

cr

c:

0

C

:3-

0

Co

0

0

-

—

Co

:3

(0

ci

0)

Co

C1.

6:-

(00)

-‘

0

3

—

8

6:

C

-

(D

-6:

-0)

0)

g

C)

•:3

0

o

DZ

3

D

-

6:

ç

HY3O

CD

CD

6:D

<

=

C

o

Co

CU

0)

(1)

D

cc1

‘)

:3V

r

0=

0

C3

0(0

3

:3-

30)Co

6:0

0C

o.o6:

0C0

)

)

:3-”

6:

]D

CD

CD

CD

°

—

0)

C

—

0)3

E.

3D

o

-o

--

-

I/___

r\)

Page 25

‘4

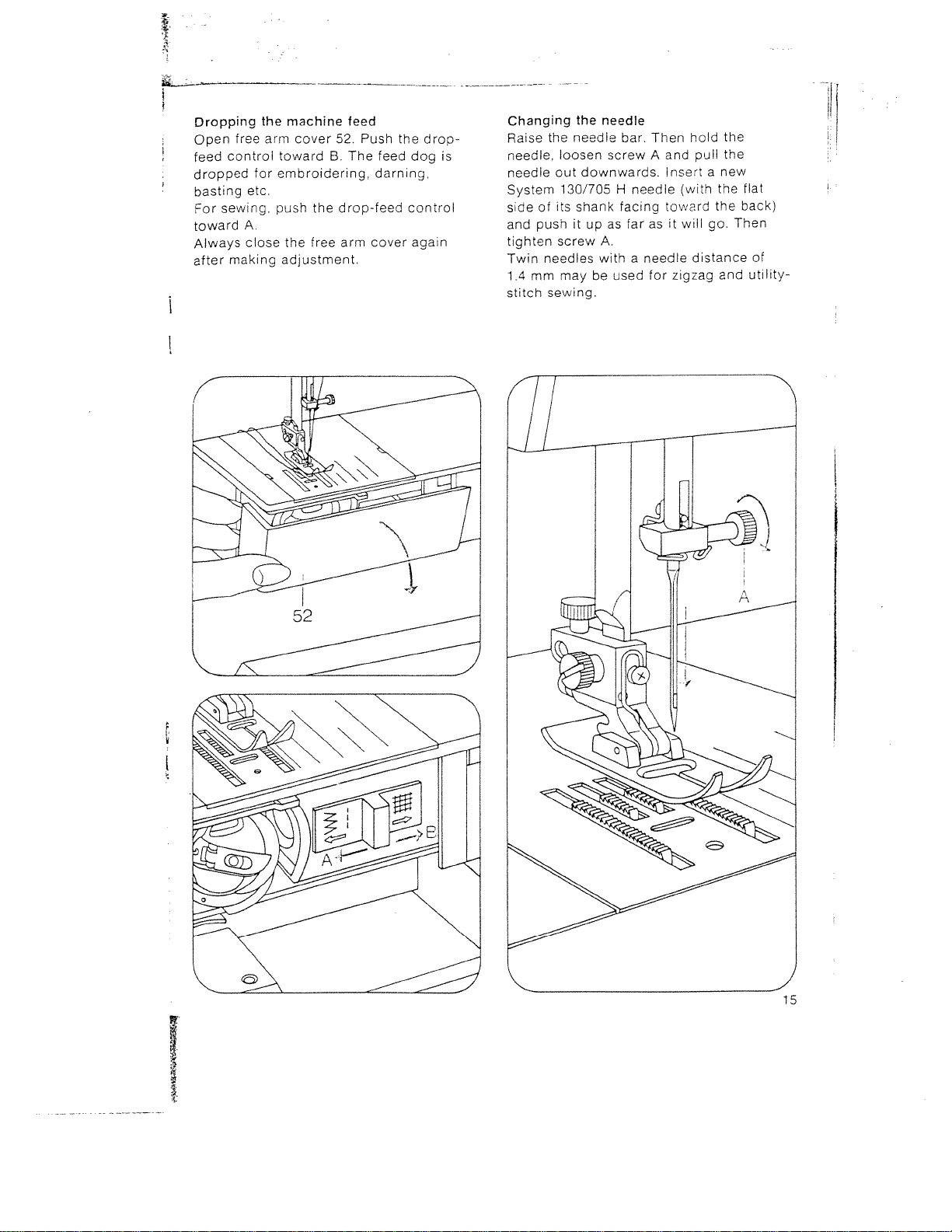

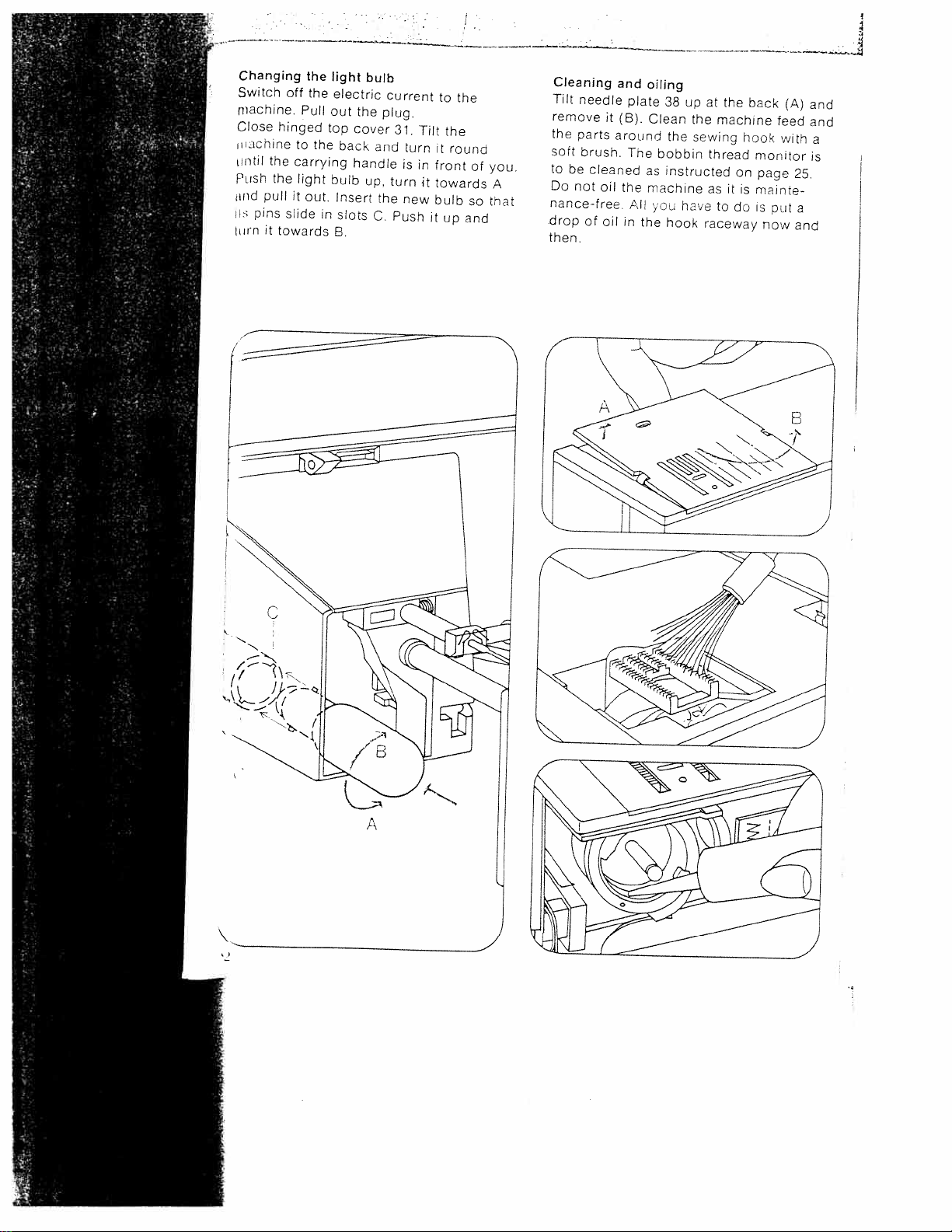

Changing

Switch

machine.

Close

unchine

the

Otil

push

pull

md

pins

is

it

in

off

hinged

carrying

the

it

slide

towards

Pull

to

light

out.

the

the

the

light

electric

out

top

bulb

in

back

Insert

slots

B.

bulb

the

cover

handle

up,

C.

current

plug.

and

the

31

turn

Push

turn

is

new

Tilt

in

it

to

the

it

round

front

towards

bulb

it

up

the

of

so

and

you.

A

that

Cleaning

Tilt

needle

remove

the

parts

soft

brush.

to

be

cleaned

Do

not

nance-free.

drop

of

then.

it

oil

oil

and

plate

(B).

around

The

the

AH

in

oiling

Clean

bobbin

as

machine

ou

the

38

up

the

the

sewing

instructed

hae

hook

at

the

machine

thread

as

it

to

do

raceway

on

is

back

hook

monitor

page

mainte

s

now

put

(A)

feed

with

and

and

a

is

25.

a

and

Page 26

the

plug

from

holderAat

to

the

fuseBout

new

FF2A

fuses

dealer.

fuse

left

fuse

socket.

the

with

of

and

are

backofthe

coin

a

holder

replace

obtainable

and

take

it

A.

the

at

your

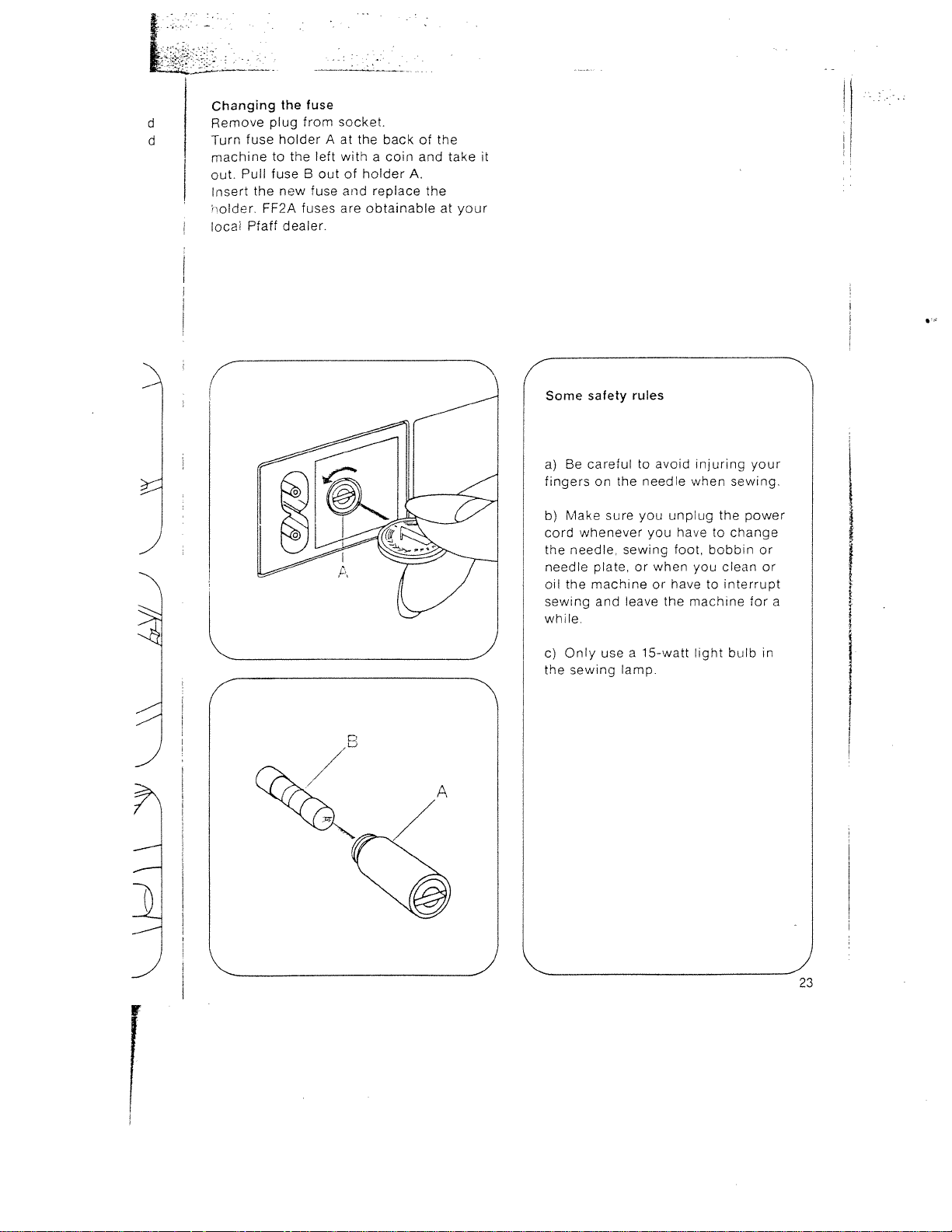

Changing

d

d

Remove

Turn

machine

out.

insert

‘older.

local

fuse

Pull

the

Pfaff

4

4

Some

Be

a)

fingers

Make

b)

cord

the

needie

the

oil

sewing

while.

Only

c)

the

safety

careful

on

the

sure

whenever

needle,

plate,orwhen

machine

and

use

sewing

rules

to

needle

you

sewing

leave

15-watt

a

lamp.

injuring

avoid

when

unplug

you

have

foot,

you

or

havetointerrupt

the

machine

light

sewing.

the power

change

to

bobbin

clean cr

bulb

your

for

N

or

a

in

I.

)

23

Page 27

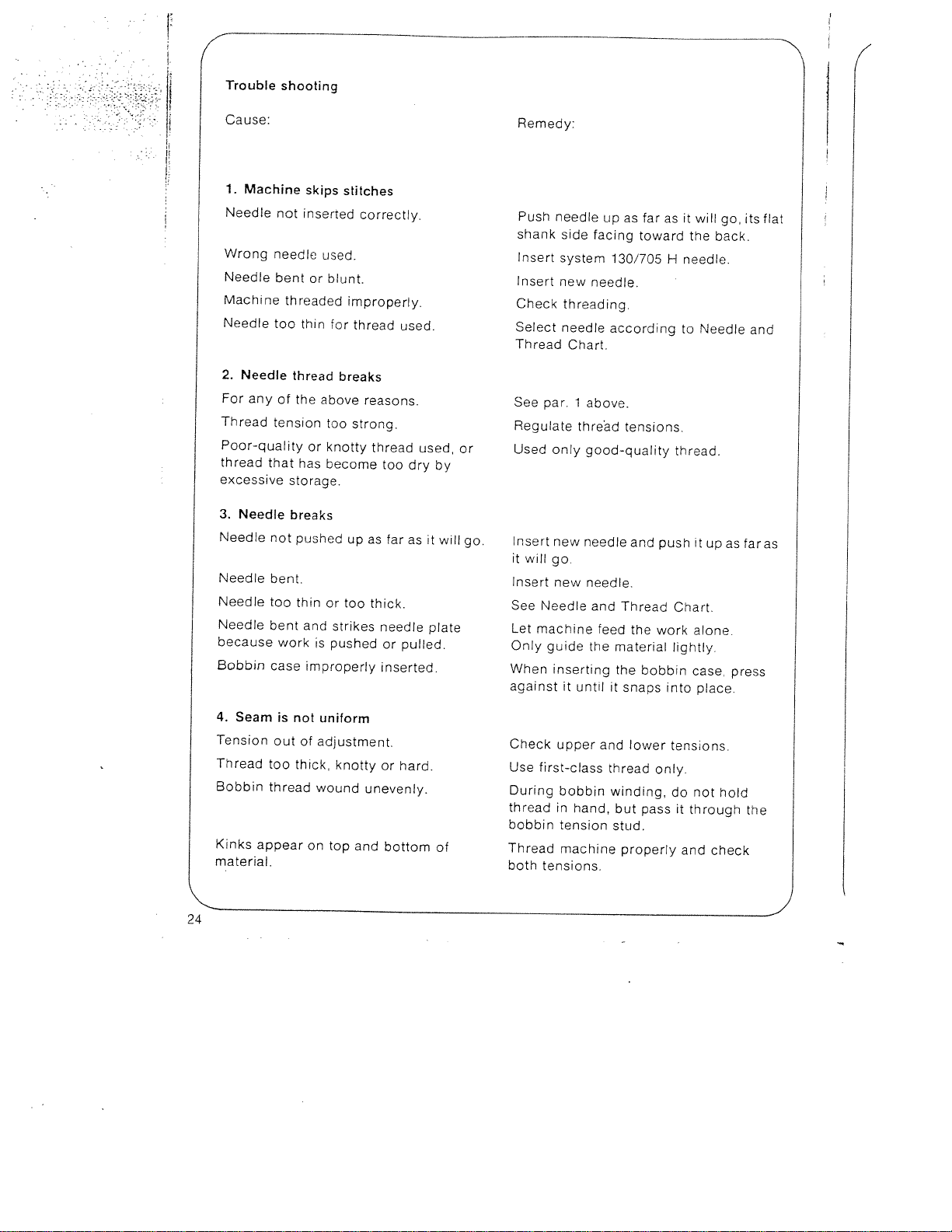

Trouble

6

shooting

Cause:

Machine

1.

Needle

Wrong

Needle

Machine

Needle

2.

Needle

For

any

Thread

Poor-quality

thread

excessive

3.

Needle

Needle

Needle

Needle

Needle

because

Bobbin

not

needle

bent

threaded

too

of

tension

that

not

bent.

too

bent

work

case

skips

rserted

or

thin

thread

the

or

has

storage.

breaks

pushed

thin

and

is

improperly

used.

blunt.

for

breaks

above

too

knotty

become

or

strikes

pushed

stitches

correctly.

improperly.

thread

reasons.

strong.

thread

too

up

as

thick.

too

needle

or

inserted.

used.

far

used,

dry

asitwill

plate

pulled.

by

Remedy:

Push

needle

shank

side

Insert

system

Insert

new

Check

threading.

Select

Thread

See

Regulate

Used

Insert

it

Insert

See

Let

Only

When

against

needle

or

go.

will

nachine

par.

only

new

go.

new

Needle

guide

inserting

it

Chart.

1

up

facing

130/705

needle.

according

above.

thred

good-quality

needle

needle.

and

Thread

feed

the

material

the

until

it

as

farasit

toward

tensions

and

the

bobbin

snaps

H

push

work

into

will

the

needle.

to

thread.

it

Chart

alone.

lightly.

case,

place.

go,

back.

Needle

up

as

press

its

far

flat

and

as

24

4.

Seam

Tension

Thread

Bobbin

Kinks

material.

is

Out

too

thread

appear

not

of

adjustment.

thick,

wound

on

uniform

knotty

top

or

unevenly.

and

hard.

bottom

Check

upper

and

lower

tensions.

Use

first-class

During

tnread

bobbin

of

Thread

both

bobbin

in

tension

machine

tensions.

hand,

thread

winding,

but

stud.

properly

pass

only.

do

it

and

not

through

check

hold

the

Page 28

4

Cause:

Machine

5.

has

Lint

rows

Feed

right.)

at

Machine

6.

Thread

Electronic

7.

Thread

free

the

lamp,

case,

indicator

hook.

The

8.

system

bobbin

The

right.

accumulated

feed

of

dropped.

dog

ends

ends

arm

the

n

behind

lamp

machine

feeds

runs

hook

is

winder

dog.

hook

in

bobbin

and

cover

the

to

not

irregularly

between

(Drop-feed

difficulty

with

raceway.

thread

have

dirt

over

raceway,

hook

and

right

the

sews

only

functioning

is

engaged:

the

on

slowly,

not

or

tooth

control

monitor

collected

indicator

the

in

the

behind

it

at

bobbin

second

the

the

is

at

all

is

does

in

needle

the

Remedy:

Remove

Flick

Remove

into

not

Remove

care

the

has

Move

drop-feed

hook

function

should

second

no

the

needle

thread

raceway.

thread

indicator

piercing

winder

be

plate

control

ends

ends

taken

power

to

and

and

and

in

lamp.

the

and

to

put

the

left

clean

the

dirt.

the

out

left.

drop

a

Special

area

electronic

(switch

lint.

of

round

off)

oil

9.

The

10.

Fuse

The

machine

The

is

machine

sewing

faulty.

stitch

one

only

sews

press

foot

control

from

foot

machine

Take

button

Insert

is

50.

not

ne’N

running

fuse.

basting.

for

is

set

the

and

up

lights

lamp

and

25

r

Page 29

C

m

C:

cU)I

Q

oI

):

cuD

•

Tr

DD

3CJ)

CD

C

cm

CD

1

CD

CI)

J1D

CD

CD

Page 30

LJ

JL

CO

Cl)

C

CC

D

U)

H

-D

C

D

C)

ro

(0

7

Page 31

Contents

Page

Topstitching

Blindstitching

Buttonholes

Button

sewing

Inserting

Completely

Zip

resembling

Zip

closure

Darning

Applique

clearvew

z

ps:

work

foot.

in

with

the

concealed

a

seam

ladies

and

edge

slacks

cording

zip

guide

closure

can

3

4

5

6

7

8/9

io

1 1

be

done

with

the

Page 32

__________________________________

I

V

L

l

/

/

/

/

/

/

/

/

_t

/

/

/

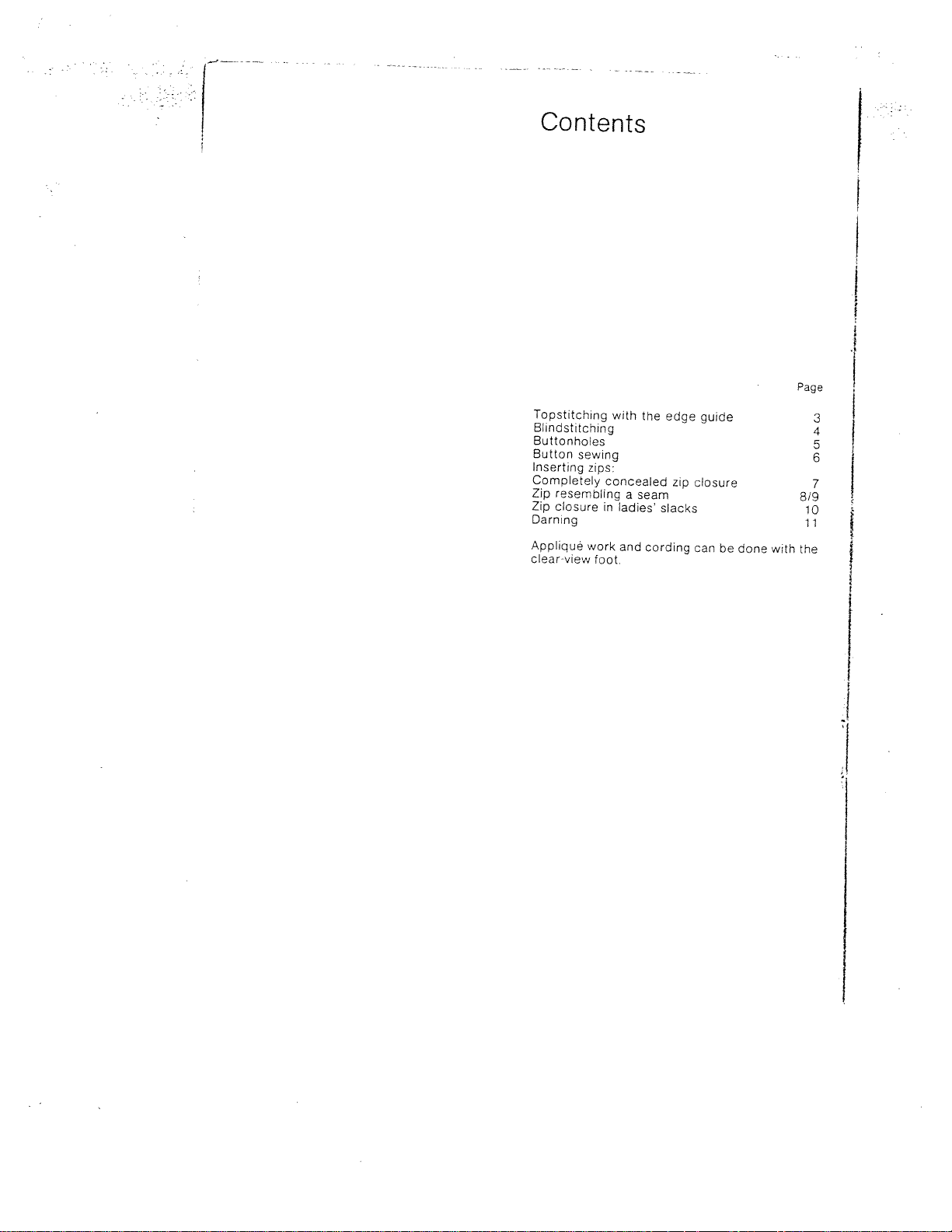

Topstitching

edge

Preparing

Sewing

i

Fitting

secure

guide

stitching

(Fig.

to

parallel

follows

parallel

preceding

seam

Push

With

sew

the

edge

it

can

1).

the

parallel

to

an

lines

thus

guide

the

foot:

edge

in

position

be

margin

edge

the

edge

line

made

machine:

OrdInary

can

guide:

guide

adjusted

for

guide

lines

edge.

(Fig.

of

stitches

of

stitches

looks

be

A

through

with

various

of

The

2)

with

sewing

used

screw

to

the

applications

attached,

stitches

guide

or

when

runs

(Fig.

neat and

the

foot

with

hole

C.

desired

it

or

either

making

along

3).

accurate.

or

nearly

B

The

is

easy

stitch

to

the

The

clear

and

Topstitching

/

-

-

-

-

J

-

-

-

- -

-

2

3

This

attached.

needle

bobbin

is

and

done

Use

ordinary

with

6-mm

with

buttonhole

the

sewing

long

fancy

clear-view

thread

thread

in

stitches

foot

the

in

the

3

Page 33

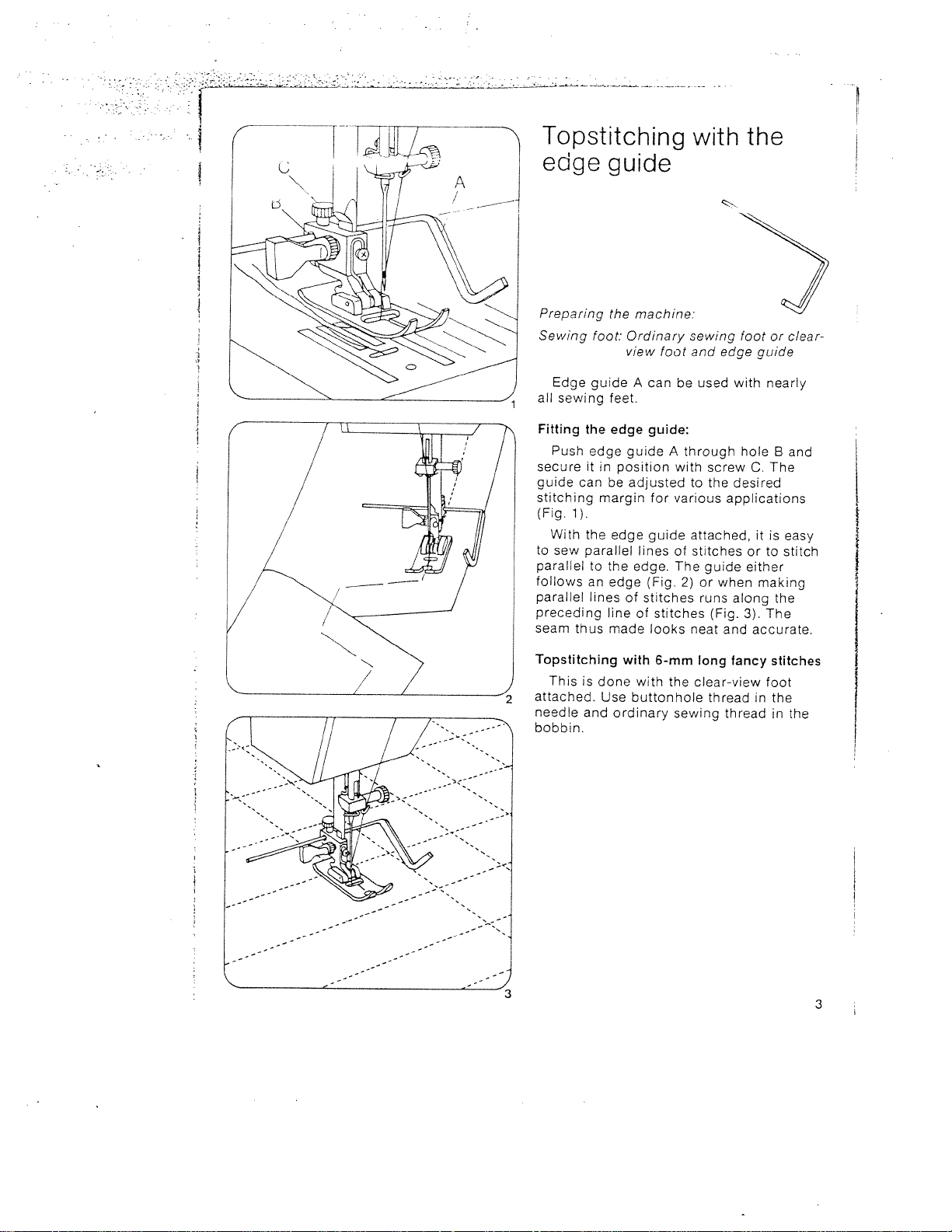

Blindstitching

of

Preparing

Sewing

Tension:

Thread:

8/indstitch:

Stitch length:

Needle:

How

to

Place

blindstitch

outer

material

blindstitch

Turn

adjusting

left

the

to

thread

one

descending

If

press

you

blindstitch

guideEaccordingly.

Sew

a

material

Elastic

Prepare

B/indstitch:

machine:

the

Blinds

foot:

Ease

Ordinary

wide,

narrow,

3-4

Size

adjust

the

the

folded

foot

so

is

foot.

screw

until

the

in

the

on

the

buttons

becomes

trial

seam

first.

blindstitching

the

machine

wide,

narrow,

needle

button

70

needle

hem

that

against

needle

material

left

10

narrower.

on

buttons

foot

fitch

thread

sewing

11

buttons

or

80

position

under

the

fold

guide

move

D

to

catches

when

side

(Figs.2and

and

lithe

pieceofscrap

a

as

described

15

buttons

tension

thread

10

and

the

the

of

of

the

E

guide

only

Adjust

above:

and

16

15,16and

11

E

3).

1

1

I

18

-j

is

The

elastic

-j

-j

suitable

overedged

be

operation

along

the

to

the

correct

for

stretch

if

edge

you

blindstitch

fabrics.

and

sewn

let

the

(Fig.

position

specially

downinone

zigzag

4).

Adjust

described

as

The

hem

stitch

the

can

run

needle

above.

-J

EJj

4

Page 34

•

:,

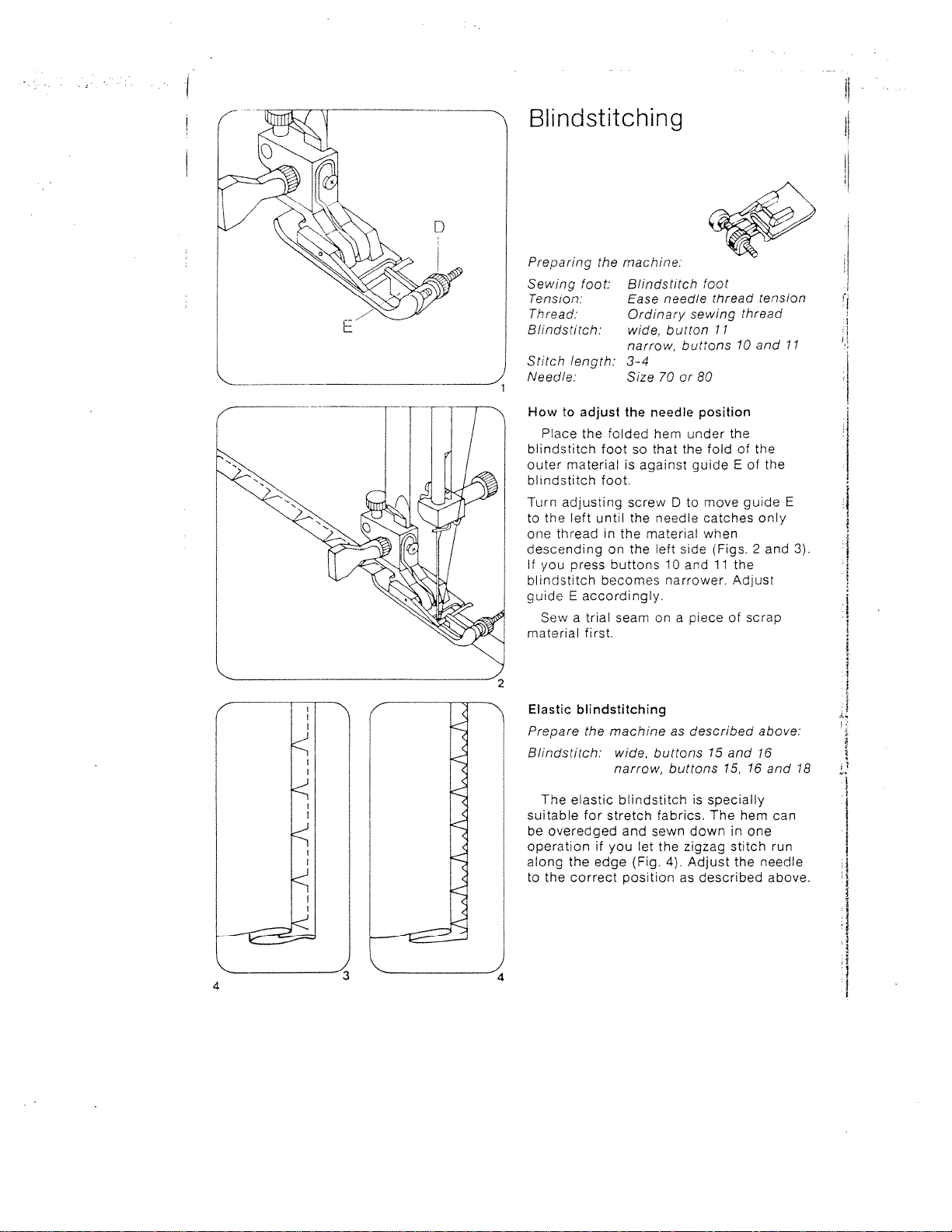

Buttonholes

machine:

Preparing

Sewing

Tension:

Thread:

Stitch

Stitch

Needle:

the

foot:

length:

type:

Buttonhole

Ease

Fine

thread

Buttonhole

Button

Size

needle

machine

19

70—80

foot

thread

embroidery

range

tension

We

distinguish

without

and

thread

prominent,

a

stretching

over

clamped

to

against

on

tion

size.

When

make

same

and

material

is

filler

thread

As

shown

lug

Use

scale

determine

Pull

slide

needle

information

machine.

and

the

scale

on

the

As

you

you

4to6

Sew

the

length,

a

few

Please

Sewatrial

filler

the

used

and

prevents

out

of

in

Fig.

under

led

C,

in

lug

F

on

the buttonhole

out

sewing

needle.

F

(Fig.

scale,

arrow

sew,

have

bartacking

second

make

tying

consult

on

buttonhole

first.

between

thread.

buttonhole

stretch

on

shape.

1

the

D.

the

far

as

foot.

Read

and

2)

depending

sewn

buttonhole

4

to

stitches.

the

adjusting

buttonholes

When

fabrics

buttonhole

the

fillerthread

the

sewing

the

left

of

will

it

as

Place

the

addupto

moves

E

the

length

stitches.

bartacking

6

instruction

and

on

a

filler

a

more

is

the

foot

slide

length.

Lower

go.

button

the

length

one

on

the

along

required

seam

book

operating

scrap

use

placed

is

and

given

gradua

button

scale

in

the

stitches

for

piece

with

of

F.

the

of

5

Page 35

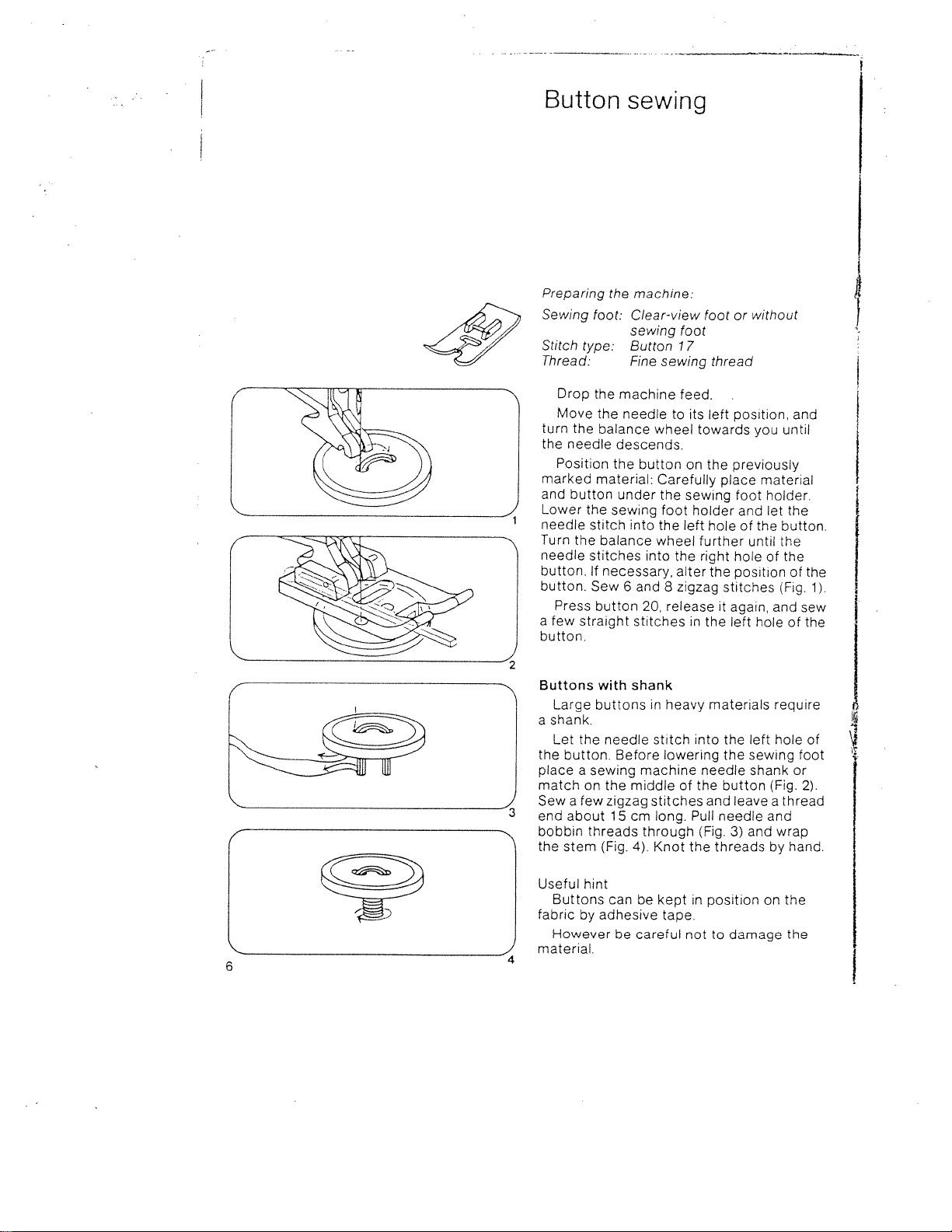

Button

sewing

Preparing

Sewing

Stitch

Thread:

Drop

Move

turn

the

the

needle

Position

marked

and

button

Lower

needle

Turn

the

needle

button.

button.

Press

few

a

button.

Buttons

Large

shank.

a

Let

the

button.

place

match

Sew

a

end

about

bobbin

the

stem

foot:

type:

the

the

balance

material:

the

stitch

balance

stitches

If

necessary,

Sew

button

straight

with

buttons

needle

the

sewing

a

on

the

few

zigzag

threads

(Fig.

the

machine:

Clear-view

sewing

Button

Fine

sewing

machine

needle

wheel

descends.

the

button

Carefully

under

into

and

6

stitches

shank

Before

machine

middle

through

4).

the

foot

the

wheel

into

8

20,

in

stitch

lowering

stitches

Knot

release

heavy

sewing

15cmlong.

foot

1

7

feed.

to

its

towards

on

sewing

holder

left

further

the

alter

zigzag

in

into

of

the

Pull

(Fig.3)and

the

foot

thread

left

the

place

hole

right

the

stitches

it

again,

left

the

materials

the

the

needle

button

and

needle

threads

without

or

position,

previously

foot

holeofthe

position

leave

you

and

of

the

until

hole

left

sewing

shank

until

material

holder.

let

button.

the

(Fig.

and

require

hole

(Fig.

thread

a

and

wrap

by

and

the

of

sew

of

foot

or

2).

hand.

the

1)

the

of

Useful

hint

Buttons

fabric

However

material.

6

4

by

can

adhesive

be

careful

keptinposition

be

tape.

not

to

damage

on

the

the

Page 36

Inserting

zips

Preparing

Sewing

Stitch

Stitch

Thread:

How

to

Insert

groove

pin

enters

positioned

middle,

involved

Completely

Baste

foot

to

the

open

run

along

of

the

foot(Fig.

of

the

needle

foot

and

zipper

then

sew

Sew

margin.

leave

the

the

zipper

Lower

end.

the

foot:

length:

type:

fit

the

the

and

F

groove

to

depending

(Fig.

in

zip

the

left

zip

the

zip

at

down

close

foot

again,

across

the

other

Shortly

needle

foot

the

zipper

machine:

Zipper

2—3

Button

Ordinary

zipper

rear

pin

push

the

right,

1).

concealed

by

hand

far

as

under

right

2).Sew

the

required

in

the

the

continue

the

side

before

down

and

foot

foot

10

sewing

foot

zipper

of

the

shoeupuntil

This

G.

to

the

on

zip

first.

it

as

the

foot

guiding

about

material,

zip

(Fig.

end.

of

the

the

in

open

again

zipper

the

sewing

closure

Push

will

so

edge

width.

3).

the

zip

end

the

the

and

thread

foot

foot

left

go.

that

on

half

Leave

raise

Lower

seam

at

of

material,

zip

(Fig.

sew

D

in

rear

the

front

can

or

in

the

operation

the

zipper

Place

its

teeth

the

sole

the

length

the

the

zipper

the

and

the

same

the

seam

raise

4).

to

the

be

Useful

We

sewers

seam

hint

recommend

use

an

is

straight

edge

and

that

guide

neat.

less

to

experienced

ensure

the

7

Page 37

_

______

_

___________

_____

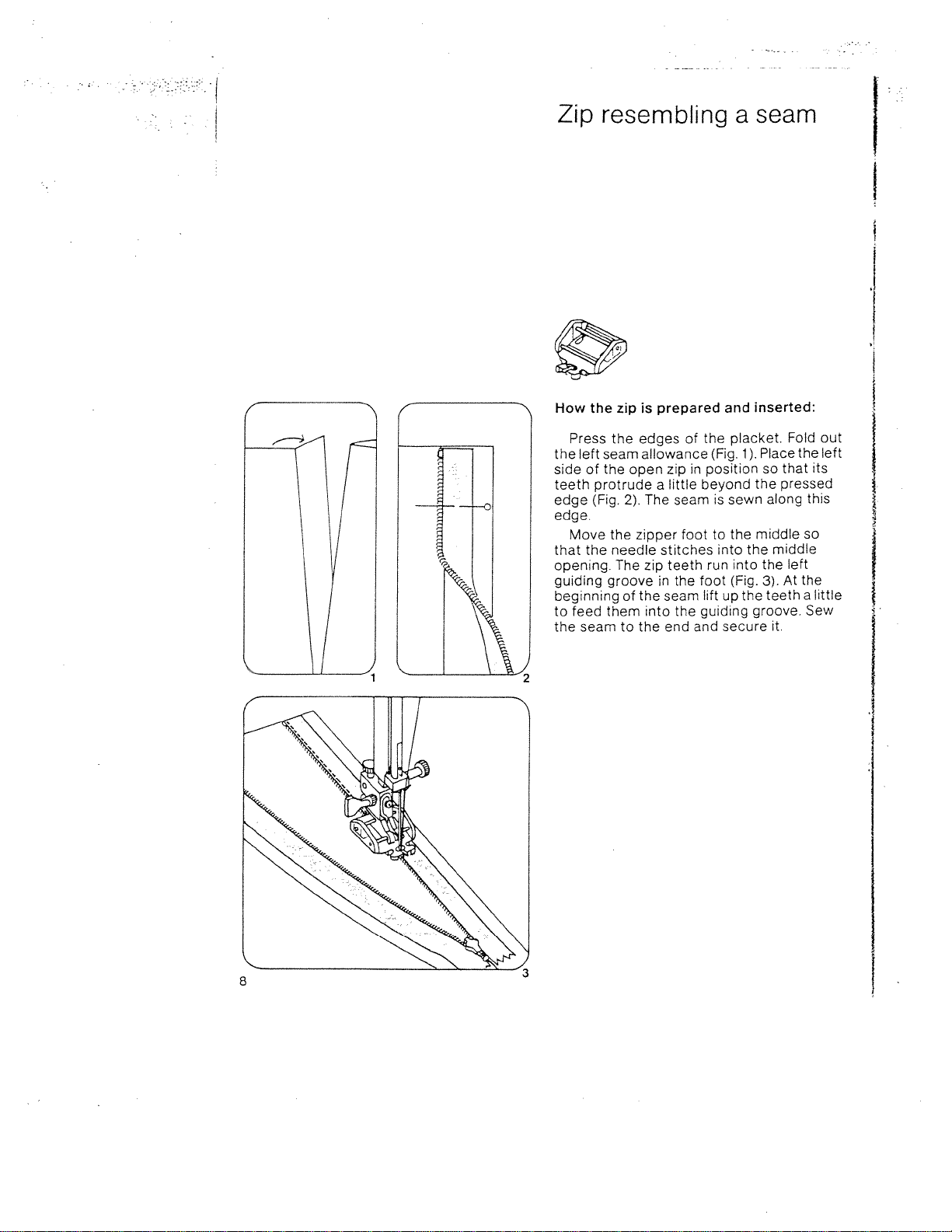

Zip

resembling

a

seam

D

inserted:

How

the

zipisprepared

Press

the

the

left

sideofthe

teeth

(Fig.

—

edge

edge.

Move

that

the

opening.

guiding

beginningofthe

to

feed

the

seamtothe

edges

seam

allowance

zip

open

protrudealittle

The

zip

into

seam

stitches

teeth

seam

the

end

2).

the zipper

needle

The

grooveinthe

them

and

placket.

of

the

(Fig.

position

in

beyond

is

sewn

foottothe

into

into

run

foot

(Fig.

liftupthe

guiding

secure

and

Place

1).

so

the

middle

the

the

3).

groove.

that

pressed

along

middle

At

teeth

it.

Fold

the

left

this

so

the

a

Sew

out

left

its

little

8oL

\

Page 38

beginning

Remove

allowance

the

to

teeth

in

the

sew

Now

teeth

7).

(Fg.

of

pin,

the

wth

fabric,asshowninFig.

run

now

(Fig.

foot

down

along

run

Pin

zi

Close

at

seam

the

into

6).

the

the

other

turn

(Fig.

Out

zip

tape,

the

Finish

zip

guiding

side

right

tape

of

4).

the

and

guiding

sewing

letting

edge

zip

Open

right

pin

5.

to

The

the

of

material

zip.

seam

atter

the

zip

groove

zip.

the

the

zip

foot

9

Page 39

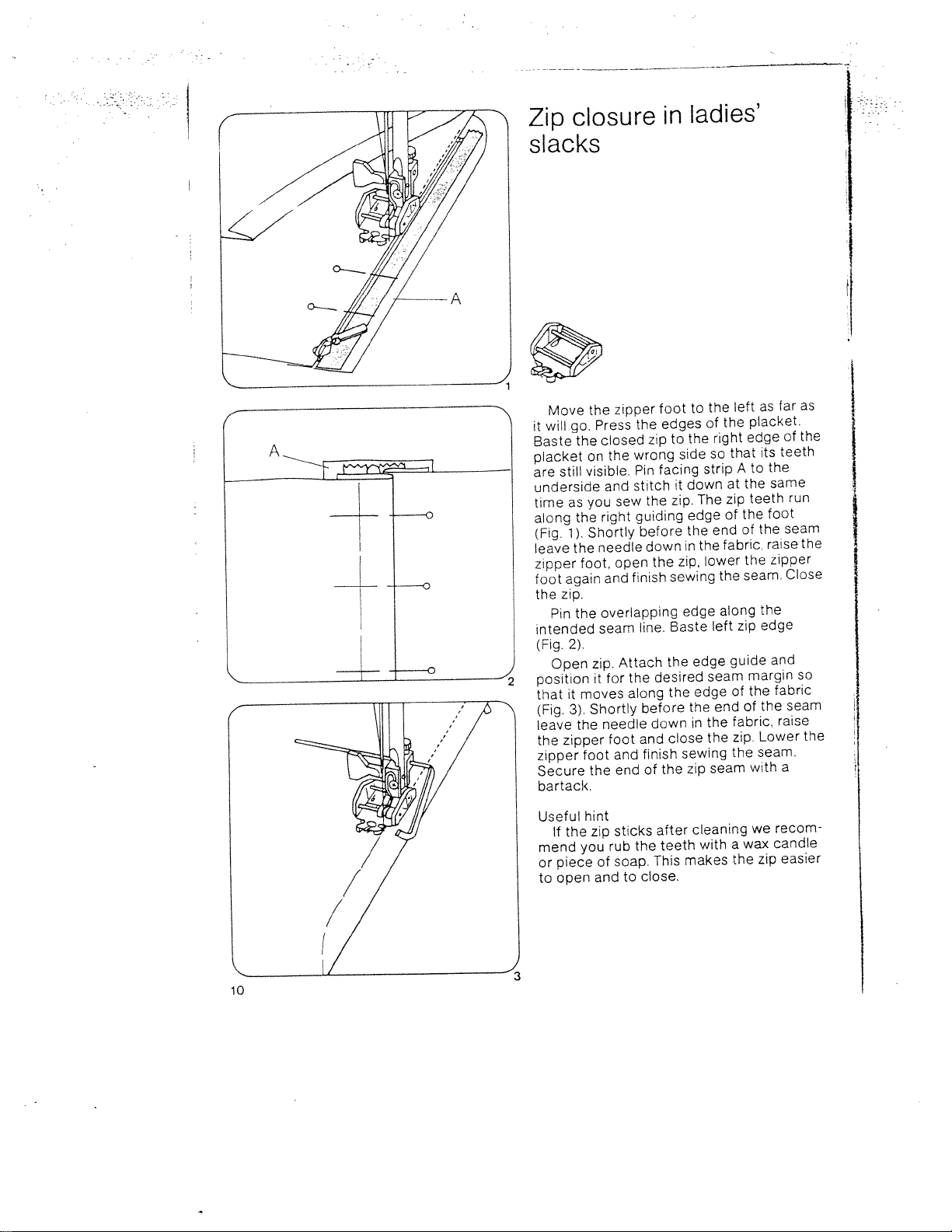

ladies’

Zip

closure

in

slacks

D

far

as

as

left

the

to

foot

zipper

the

4

—0

Move

will

it

go.

the

Baste

placket

still

are

underside

as

time

the

along

1).

(Fig.

the

leave

zipper

again

foot

zip.

the

Pin

the

intended

2).

(Fig.

Open

position

it

that

3).

(Fig.

the

leave

the

zipper

zipper

Secure

bartack.

Press

closed

the

on

visible.

and

sew

you

right

Shortly

needle

open

foot,

and

overlapping

seam

zip.

for

it

moves

Shortly

needle

foot

and

foot

end

the

the

wrong

Pin

stitch

guiding

before

finish

line.

Attach

the

along

before

and

finish

edges

zip

facing

the

down

the

desired

down

of

to

side

it

zip.

zip.

sewing

Baste

the

the

close

the

of

the

strip

down

The

edge

the

the

in

lower

edge

edge

seam

edge

the

the

in

the

sewing

zip

the

right

so

zip

of

end

fabric,

the

along

left

end

seam

that

A

the

at

the

o

the

seam.

zip

guide

of

of

fabric,

zip.

the

placket.

edge

its

the

to

same

teeth

foot

the

raise

zipper

the

edge

and

margin

fabric

the

the

Lower

seam.

with

of

teeth

run

seam

Close

seam

raise

a

the

the

so

the

hint

Useful

If

the

mend

piece

or

open

to

10

you

zip

of

and

sticks

rub

soap.

to

the

close.

after

teeth

This

cleaning

with

makes

a

the

we

wax

zip

recom

candle

easier

Page 40

H—

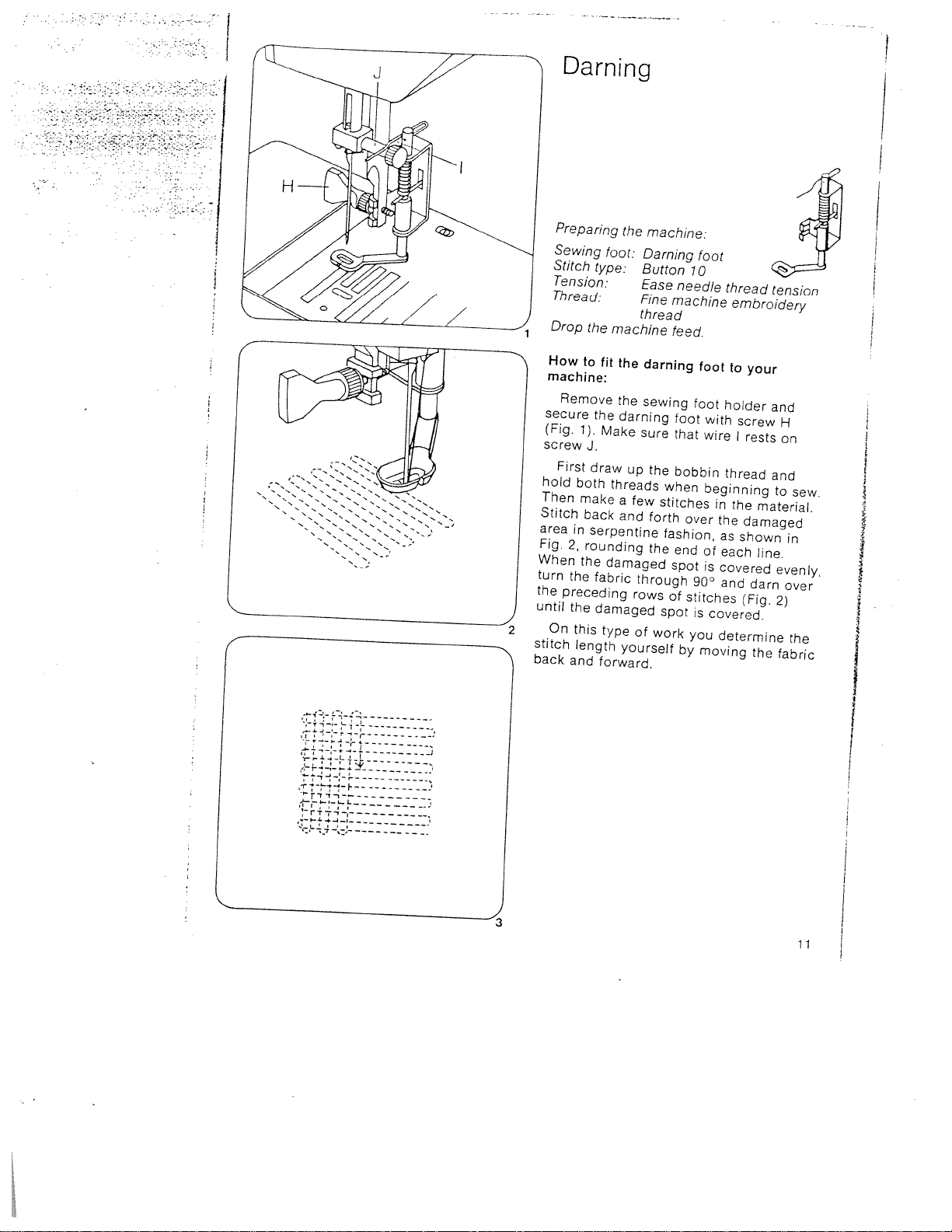

Darning

Preparing

Sewing

Stitch

Tension:

0

//

Thread:

Drop

How

machine:

Remove

secure

(Fig.

screw

First

hold

both

Then

Stitch

area

in

Fig.

2,

When

turn

the

the

preceding

until

On

stitch

back

the

this

length

and

)

2

foot:

type:

the

machine

to

fit

the

1>.

Make

J.

draw

threads

make

back

serpentine

rounding

the

damaged

fabric

damaged

type

forward.

the

g1ot

Ease

Fine

thread

the

darning

the

sewing

darning

sure

up

a

few

and

through

rows

of

yourself

machine:

needle

machine

feed.

foot

that

the

bobbin

when

stitches

forth

over

fashion,

the

end

spot

of

spot

work

by

foot

foot

with

wire

beginning

of

is

9O

stitches

is

covered.

you

moving

thread

embroidery

to

your

holder

screw

I

rests

thread

in

the

the

damaged

as

shown

each

covered

and

darn

(Fig.

determine

tension

and

H

on

and

to

material.

line.

evenly,

2)

the

fabric

sew.

in

over

the

11

Loading...

Loading...