Page 1

0

°©fl

UOLIDfl4SUI

©n

5

©Qwcda

>1009

LV©E

S.

ST

Page 2

EJ

Fold

this

page

out

Index

Accessory

Accessory

Basting

Bobbin

Bobbin

Bobbin

Buttonholing

Carrying

Carrying

Cleaning

Electrical

Electronic

Electronic

Finger-tip

Foot

Fuse

Light

Machine

Needle

Needle

Oiling

case

thread

case

handle

control

bulb

position

Presser

Reverse

Safety

Sewing

Sewing

Slot-threading

Special

Spool

Stitch

Stitch

Straight-stitch

Stretch

Top

Thread

Thread

Trouble

bar

sewing

rules

feet

mechanism

sewing

of

length

program

stitches

cover

cutter

tensions

threading

Upper

stitches

Utility

Utility/stretch

Winding

support

Work

box

compartment

connection

bobbin

top

stitch

feed

thread

shooting

thread

speed

buttons

lifter

feet

chart

needle

stitch

monitor

selector

position

combinations

Page

16,

7,

20,

6,

1

6,

1

16,

8,

1

26—29

24,

17

21

22

1

1

1

23

22

2

2

7

1

1

17

22

11

23

1

20

8

8

1

1

3

7

7

2

11

1

1

1

25

3

5

5

9

9

5

4

4

4

3

1

9

0

5

1

3

1

4

6

1

Page 3

L

120

121

122

123

124

125

126

L

107

108

109

110

111

112

113

________

4

‘IIII

1

Øi7i8

1

L

9

119

[1

130

118

__________

<:

115

LI

14

116

i

117—

I

-

I’

}103

105

104

102

101

100

N

1

29

Sewing

spool

holder

(swing-up)

3-ampere

fuse

has

to

be

fitted.

27

28

Bobbin

(swing-out)

Spool

holder

winder

with

thread

unreeling

guide

disc

When

Please

a

note:

13-ampere

plug

is

used

a

1

1

1

1

1

24

26

25

Take-up

Needle

Bobbin

thread

winder

lever

tension

thread

guide

1

1

22

23

Threading

hook

Free

arm

slots

which

coloured

is

red.

119

120

121

Bobbin

Base

Free

arm

plate

winder

cover,

enclosing

sewing

The

must

wire

be

connected

marked

which

is

with

coloured

to

the

the

letter

terminal

brown

L

or

116

117

118

Presser

Reverse-feed

Stitch

program

bar

with

control

chart

thread

cutter

connected

marked

black.

with

to

the

the

letter

terminal

N

or

which

coloured

is

113

114

115

“Sew

Presser

“Basting

slow”

bar

stitch”

lifter

button

button

your

wire

marking

which

plug,

identifying

proceed

is

coloured

as

the

follo’ws:

blue

terminals

must

The

in

be

110

111

112

foot

Needle

Bobbin

“Needle

thread

holder

down

with

indicator

button

set

screw

light

As

correspond

with

the

coloured

Brown:

mains

the

lead

colours

Live

of

this

of

the

appliance

wires

in

may

the

not

108

109

Sewing

Needle

plate

foot

holder

with

sewing

following

Blue:

Neutral

code:

107

1

1

05

06

Finger-tip

Stitch

Detachable

accessory

length

box

and

compartment

coloured

in

accordance

with

the

stitch

work

control

buttons

support

with

The

Valid

IMPORTANT

wires

for

United

in

this

mains

Kingdom

lead

only

are

103

104

Stop

Master

motion

switch

knob

101

102

Hinged

Hand

wheel

top

cover

100

Carrying

handle

light

bulb

in

the

sewing

lamp.

3.

machine

Be

sure

to

for

use

a

while.

only

a

15-watt

when

machine,

interrupt

you

sewing

or

clean

when

and

and

you

oil

leave

have

the

the

to

to

foot,

change

bobbin

fuse,

or

needle

needle,

plate,

sewing

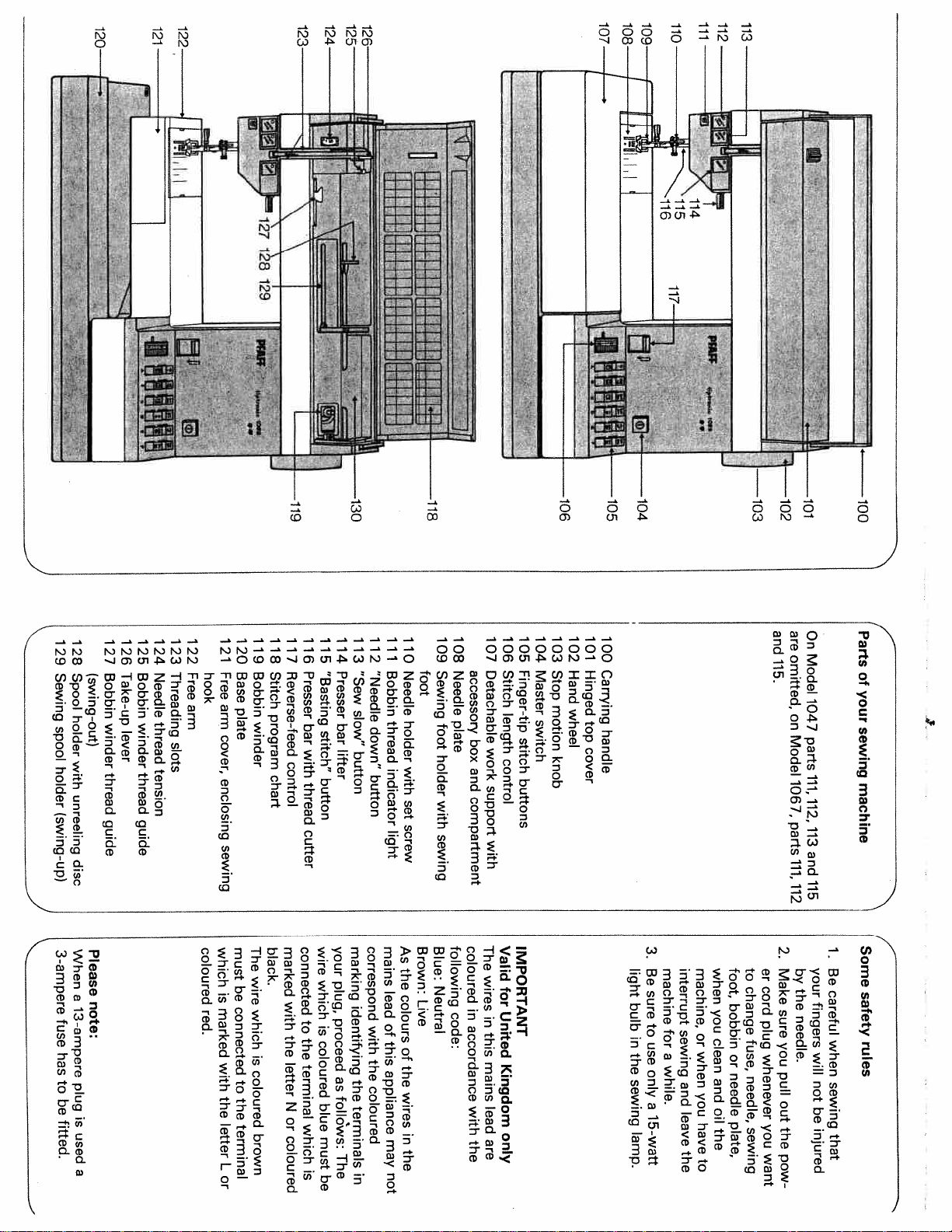

are

and

omitted,

115.

on

Model

1067,

parts

111,

112

2.

by

Make

er

cord

the

sure

needle.

plug

you

whenever

pull

out

you

the

want

pow

On

Model

1047

parts

111,

112,

113

and

115

1.

your

Be

careful

fingers

when

will

not

sewing

be

injured

that

Parts

of

your

sewing

machine

Some

safety

rules

Page 4

I

Removing

lift

off

To

handle

arrow.

Then

to

lift

4

the

the

the

the

carrying

carrying

rear,

cover

case

indicated

as

off.

case

cover

cover,

by

told

an

the

Opening

cover

Swing

stitch

A

of

inside

Removing

support

work

Reach

with

toward

under

your

its

open

removable

a

additional

the

101

program

this

and

left

left

the

lid

(R).

accessory

accessories

hinged

backwards

chart

cover.

opening

detachable

the

hand

(P),

Inside

top

is

swing

(0),

lift

and

the

box

underneath.

cover

(N).

found

the

it

work

with

the

on

detachable

support

work

it

out

(Q).

out

support

space

Then

is

for

4

Page 5

Accessory

compartment

Open

the

take

out

accessory

tional

accessory

shows

Ill.

P

to

0

the

6,

the

box.

Darning

0

Standard

1

Clear-view

2

Hemming

3

box

and

detachable

compartment

how

the

needles

foot

sewing

foot

foot

accessory

work

box

N.

snap-on

the

and

foot

support

There

underneath.

sewing

bobbins

Blindstitch

4

Zipper

5

Buttonhole

6

Electrical

and

is

an

addi

feet

fit

into

foot

foot

foot

1067/1069

Connect

plug

into

O

the

foot

under

socket

master

is

now

foot

The

faster

soon

As

the

needle

“up”

the

into

N

the

control

the

on

S

switch

ready

control.

more

the

as

position.

connection

(see

left

power

the

machine

wall

socket.

(P).

table,

and

the

machine.

button

for

sewing.

The

machine

you

press

machine

the

automatically

runs.

Model

ill.

cord

Place

push

104.

down

1069

and

on

as

socket

Pull

Press

returns

foot

page

follows:

the

the

plug

Then

Your

starts

the

machine

control

3)

and

cord

foot

into

R

press

machine

down

sewing.

pedal,

to

Push

plug

out

control

the

the

stops,

its

of

p

2

Page 6

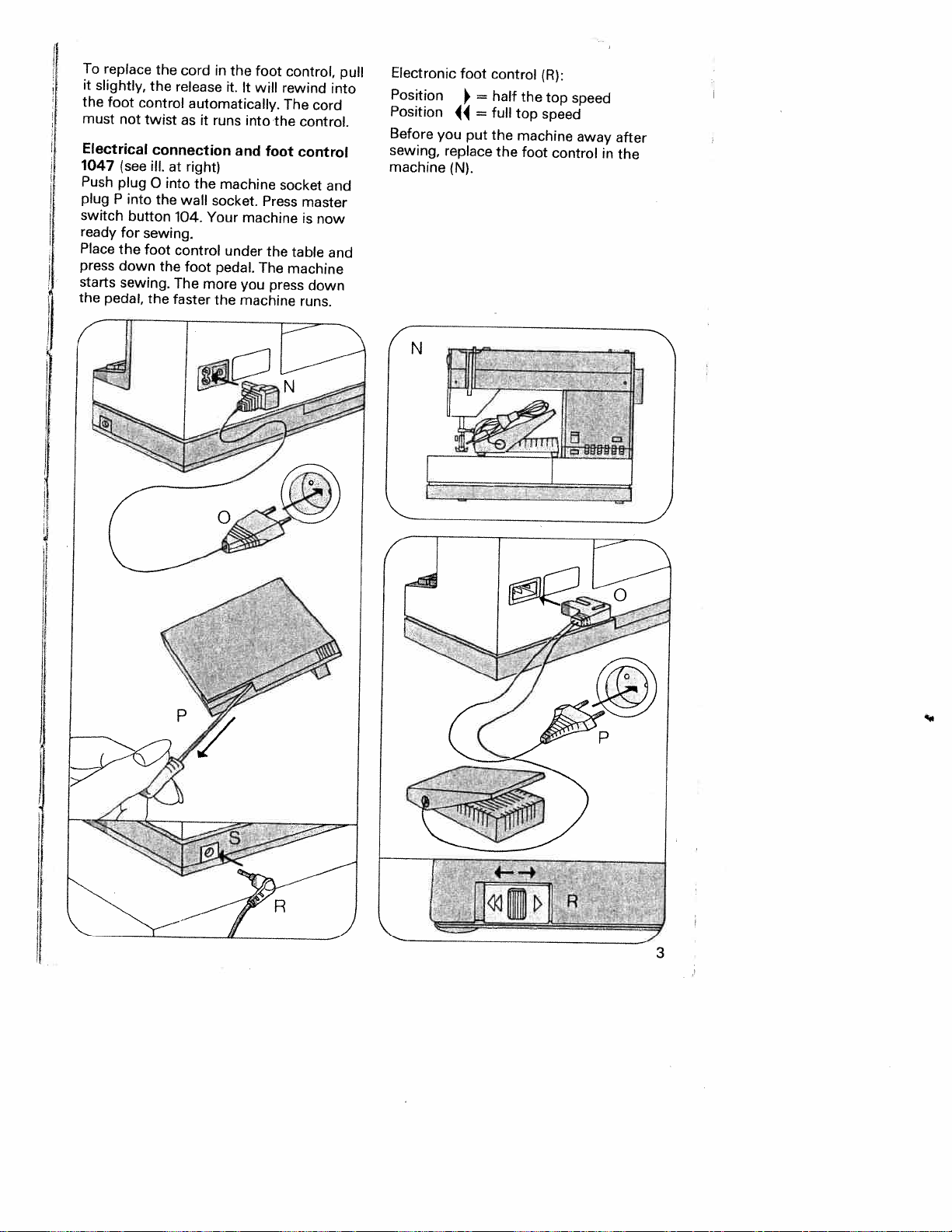

To

replace

it

slightly,

the

foot

must

not

Electrical

1047

(see

Push

plug

plug

P

switch

ready

for

Place

the

press

down

starts

sewing.

the

pedal,

the

the

control

twist

connection

III.

0

into

the

button

sewing.

foot

the

cord

release

automatically.

as

it

at

right)

into

the

wall

104.

control

the

foot

The

more

faster

in

the

it.

runs

machine

socket.

Your

under

pedal.

the

foot

It

will

into

and

foot

Press

machine

the

The

you

machine

control,

rewind

The

the

socket

table

machine

press

cord

control.

control

and

master

is

now

and

down

runs.

pull

into

Electronic

Position

Position

Before

sewing,

machine

N

foot

control

=

half

=

full

44

you

put

the

replace

the

(N).

H1.r

(R):

the

top

top

speed

machine

foot

control

F

speed

away

in

after

the

c.:1

3

Page 7

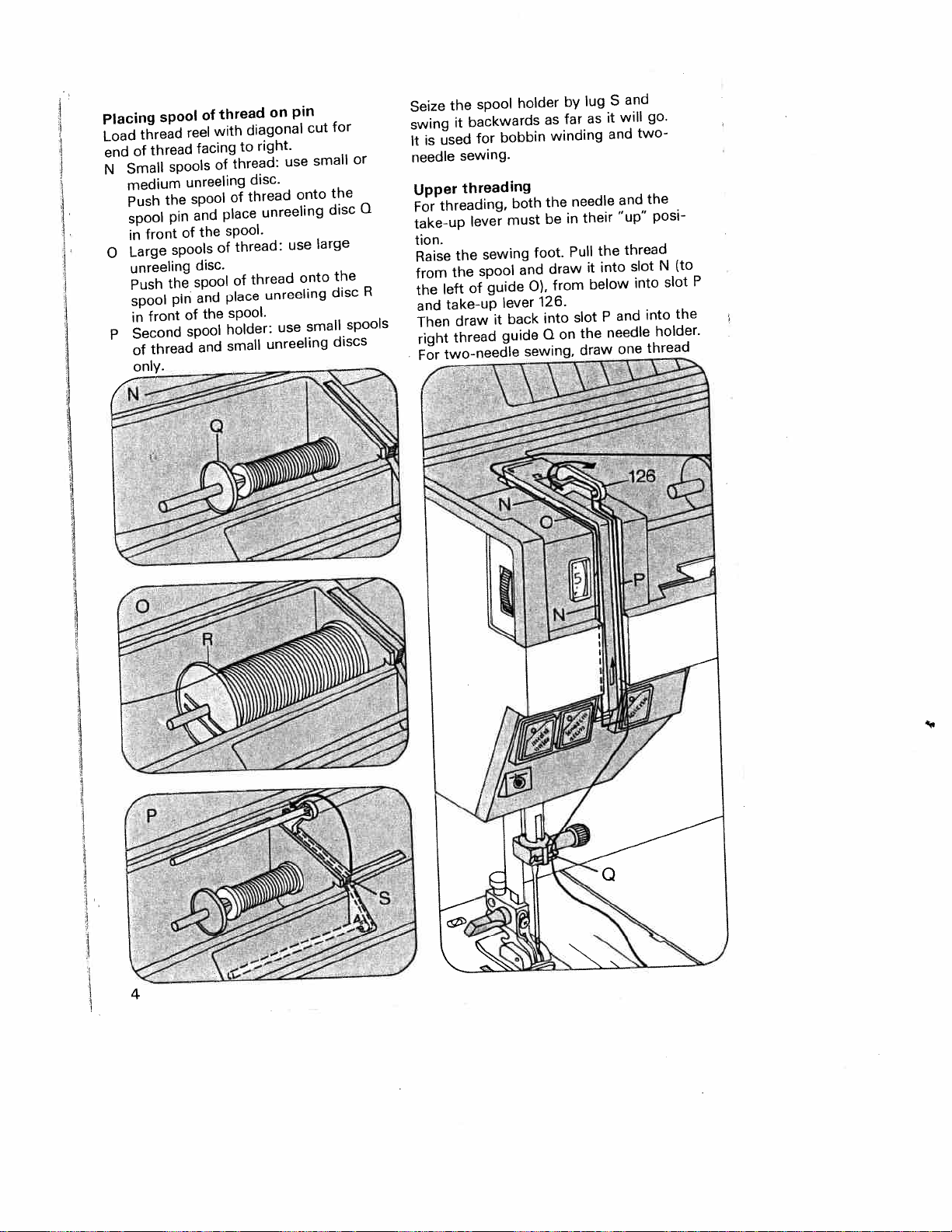

Placing

Load

of

end

Small

N

medium

Push

spool

in

Large

o

unreeling

Push

spool

in

Second

P

of

only.

spool

thread

thread

front

front

thread

reel

spools

unreeling

the

pin

of

spools

the

pin

of

spool

of

facing

spool

and

the

disc.

spool

and

the

and

thread

with

thread:

of

of

place

spool.

thread:

of

of

place

spool.

holder:

small

on

diagonal

right.

to

disc.

thread

unreeling

thread

unreeling

unreeling

use

use

pin

use

cut

onto

onto

small

small

the

disc

large

for

the

disc

spools

discs

Seize

swing

It

or

needle

Upper

Q

R

For

take-up

tion.

Raise

from

the

and

Then

right

For

it

used

is

threading,

the

the

left

take-up

draw

thread

two-needle

backwards

bobbin

for

sewing.

threading

lever

sewing

spool

guide

of

it

guide

both

must

and

lever

back

foot.

0),

126.

sewing,

far

as

winding

the

in

be

Pull

draw

from

into

on

Q

as

needle

their

it

below

slot

the

draw

the

into

will

it

and

and

“up”

thread

and

P

needle

one

two-

slot

into

go.

the

posi

N

slot

into

holder.

thread

(to

P

the

and

S

lug

by

holder

spool

the

4

Page 8

the

into

other

the

threads

the

thread

on

guide

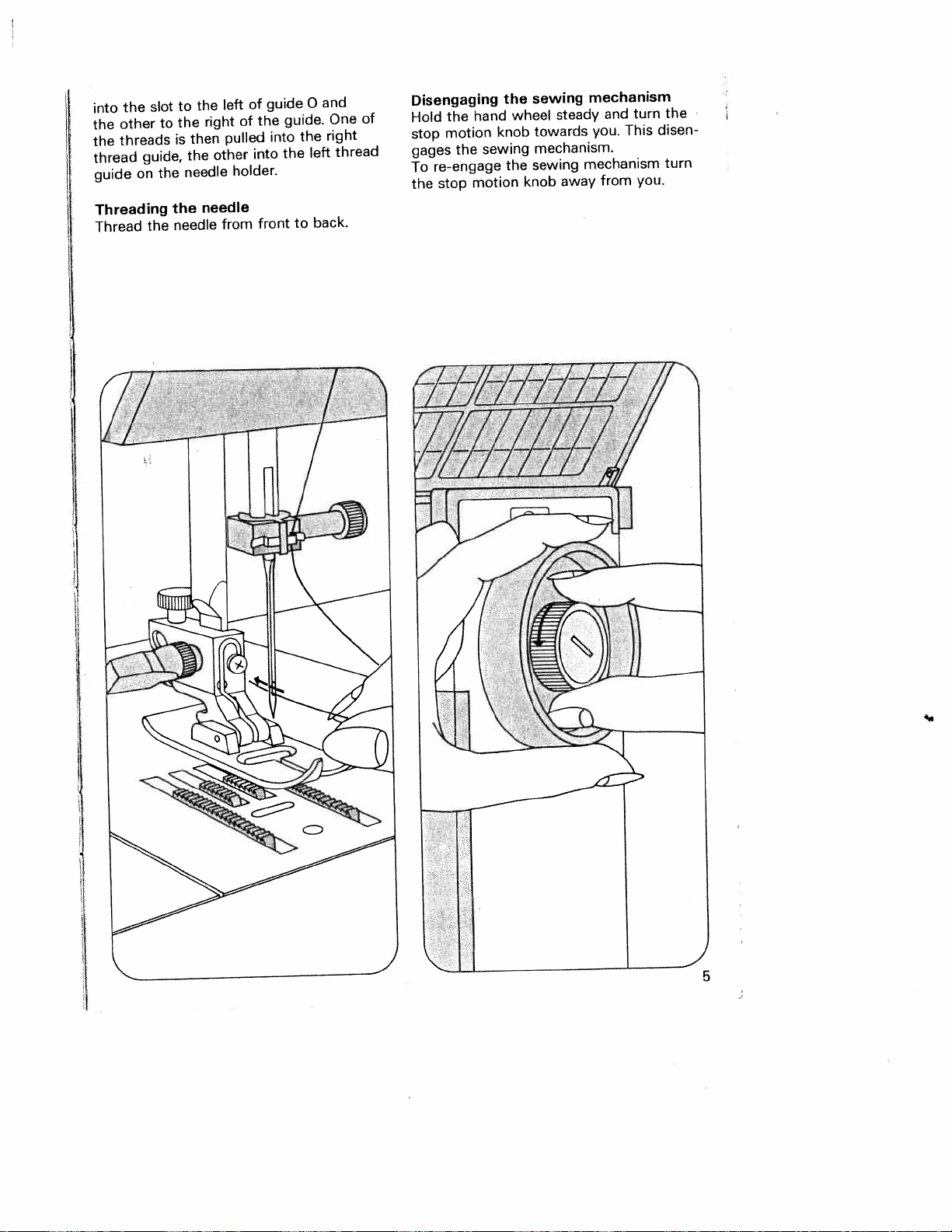

Threading

Thread

slot

to

guide,

the

the

the

to

the

then

is

the

needle

the

needle

left

right

pulled

other

needle

from

of

the

of

into

holder.

front

guide

guide.

into

the

to

the

0

left

back.

and

One

right

thread

of

Disengaging

hand

the

Hold

motion

stop

the

gages

re-engage

To

motion

stop

the

the

wheel

knob

sewing

the

sewing

steady

towards

mechanism.

sewing

away

knob

mechanism

turn

and

This

you.

mechanism

you.

from

the

disen

turn

5

Page 9

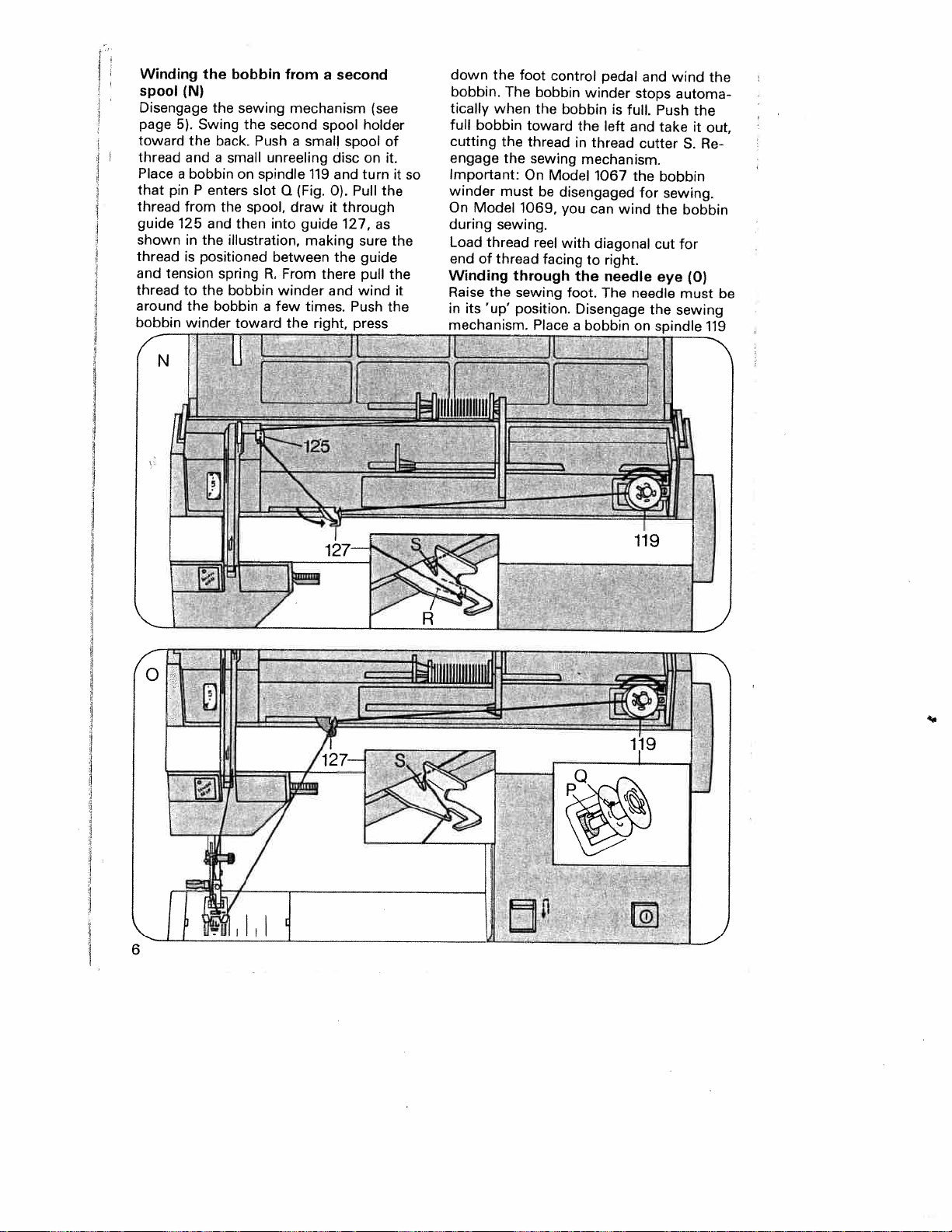

Winding

spool

(N)

Disengage

page

5),

toward

thread

Place

a

that

pinPenters

thread

from

guide

125

shown

thread

tension

and

thread

to

around

bobbin

the

the

and

the

Swing

back.

a

bobbin

small

sewing

the

Push

unreeling

second

fromasecond

bobbinonspindle

slot

0

spool,

the

and

then

into

in

the

illustration,

is

positioned

spring

the

bobbin

the

winder

bobbin

toward

between

From

R.

winder

a

few

mechanism

spool

a

small

disc

and

119

(Fig.

0).

draw

it

guide

making

the

there

and

times.

the_right,

(see

holder

spool

on

turn

Pull

through

127,

as

sure

guide

pull

wind

Push

press

of

it.

the

the

it

the

the

the

down

bobbin.

tically

full

cutting

engage

Important:

so

winder

On

during

Load

end

Winding

it

Raise

in

its

mechanism.

when

bobbin

the

must

Model

sewing.

thread

of

thread

the

‘up’

foot

The

toward

thread

the

sewing

On

1069,

through

sewing

position.

control

bobbin

the

bobbin

Model

be

disengaged

you

reel

with

facing

Place

pedal

winder

is

the

left

in

thread

mechanism.

1067

can

diagonal

right.

to

the

needle

foot.

The

Disengage

bobbin

a

stops

full.

and

the

wind

needle

on

and

Push

take

cutter

bobbin

for

the

cut

eye

the

spindle

wind

automa

the

it

S.

sewing.

bobbin

for

(0)

must

sewing

the

out,

Re

be

119

4

6

Page 10

and

Draw

foot,

pull

the

wind

Push

down

bobbin.

tically

full

bobbin

cutting

engage

turn

the

up

it

the

the

when

it

so

needle

and

thread

around

bobbin

foot

The

toward

the

thread

the

sewing

that

into

to

the

toward

control

bobbin

the

bobbin

pin

P

thread

guide

127.

the

bobbin

bobbin

pedal

winder

is

the

left

in

thread

mechanism.

enters

under

a

the

stops

full.

and

cutter

slot

the

From

winder

few

right,

and

Push

take

Q.

sewing

there

and

times.

press

wind

automa

the

it

S.

Re-

the

out,

Removing

Open

free

then

lift

latch

and

cannot

N

pulled

Inserting

Insert

the

case

so

back

(N).

and

under

out

fall

that

arm

take

out.

the

filled

Then

the

bobbin

the

out

bobbin

the

spring

cover

bobbin

out

as

long

bobbin

thread

draw

case

the

121.

case,

bobbin.

as

into

unreels

the

into

and

Pull

you

the

thread

eye

bobbin

out

latch

release

The

keep

bobbin

toward

into

P.

N,

the

bobbin

latch

the

slot

0

7

Page 11

Inserting

up

Pull

stud

onto

point

must

0

Stud

Close

kept

be

the

the

latch

0

and

free

closed

bobbin

and

P

far

as

upwards.

P

latch

arm

during

push

it

as

Release

must

cover,

case

the

will

be

It

sewing.

bobbin

go.

the

flush.

must

Cutout

latch.

always

case

a

and

Pull

and

left

bobbin

the

the

thread

little

you

up

the

and

depress

taut.

until

again

bobbin

both

lay

back

thread

basting

button.

Turn

the

and

thread

under

can

stitch

the

the

be

the

102

down

is

needle

foot.

1069

operating

the

again

bobbin

thread

toward

up.

hole

the

the

button,

press

the

wheel

moves

lever

the

of

toward

sewing

model

up

Press

and

up

needle

by

Drawing

Hold

N

hand

needle

take-up

out

threads

the

On

drawn

button.

pedal

8

Page 12

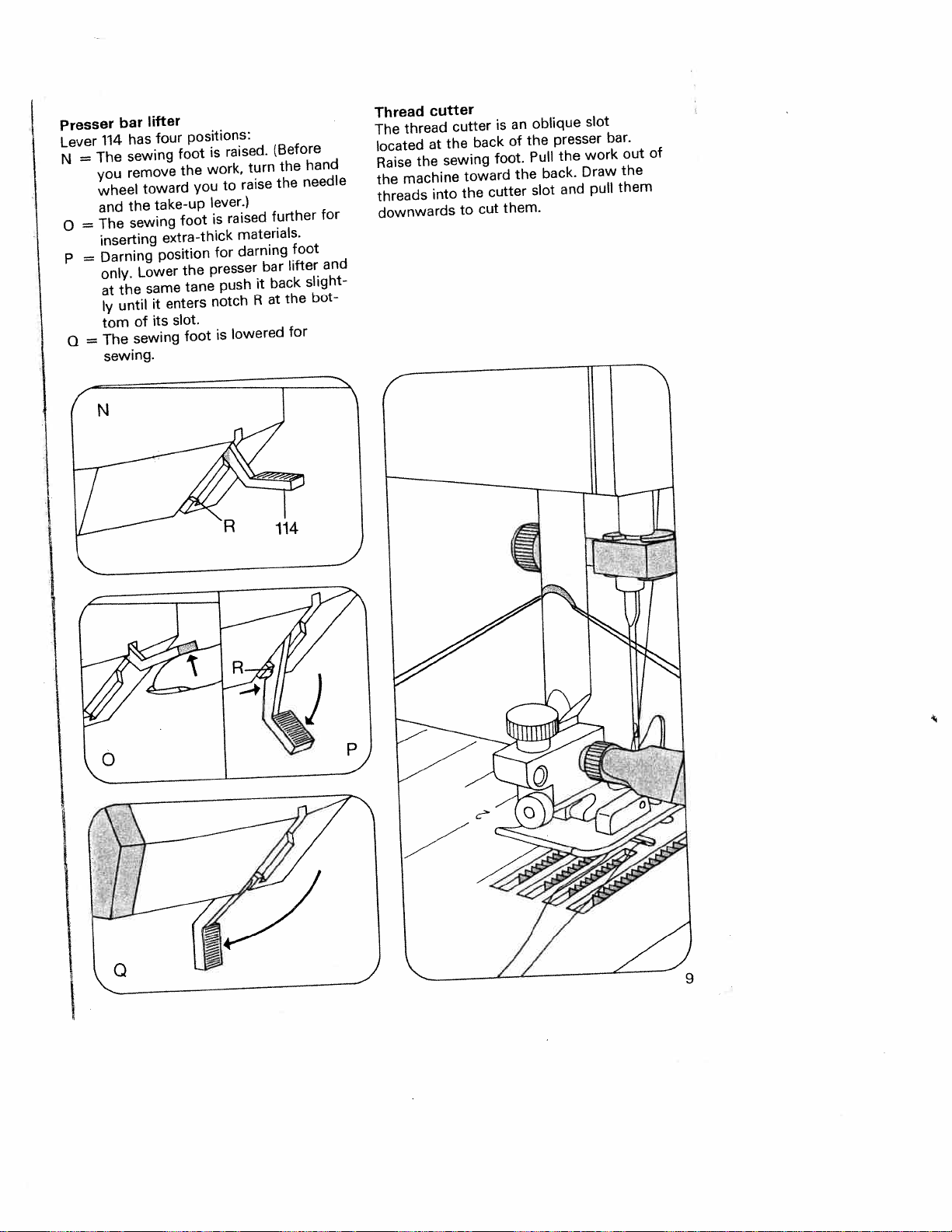

Presser

Lever

=

N

=

o

P

=

Q

bar

has

114

sewing

The

remove

you

wheel

the

and

sewing

The

inserting

Darning

only.

the

at

until

ly

tom

sewing

The

sewing.

lifter

four

toward

take-up

Lower

same

it

its

of

position

positions:

is

foot

work,

the

you

lever.)

is

foot

extra-thick

for

presser

the

tane

notch

enters

slot.

is

foot

raised.

turn

raise

to

raised

materials.

darning

push

lowered

bar

it

R

(Before

the

the

further

foot

lifter

back

the

at

for

hand

needle

for

and

slight

bot

Thread

The

located

Raise

the

cutter

thread

at

the

machine

threads

downwards

cutter

the

sewing

into

back

toward

the

cut

to

is

of

foot.

cutter

them.

an

the

oblique

presser

the

Pull

back.

slot

the

and

slot

work

Draw

pull

bar.

out

the

them

of

9

Page 13

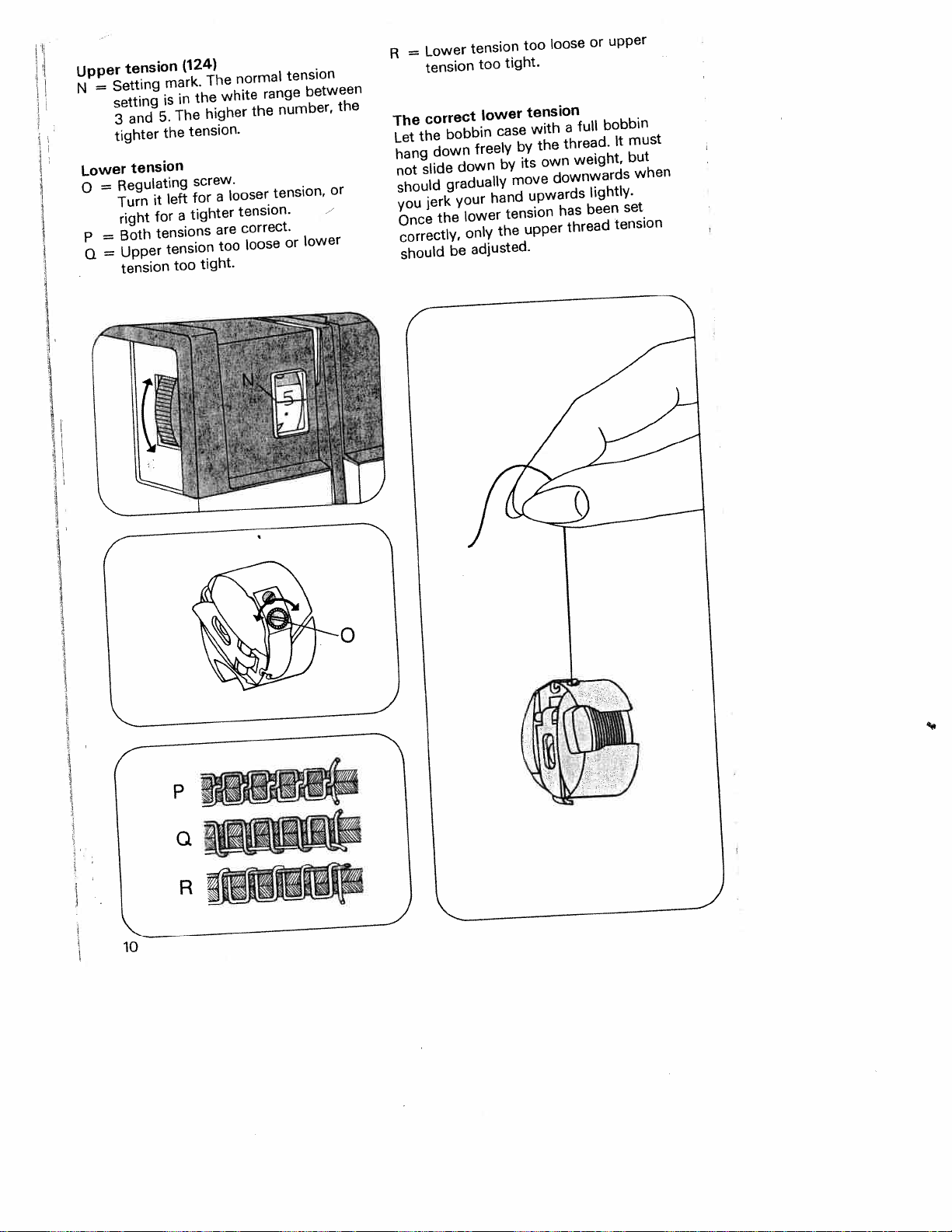

Upper

=

N

Lower

=

0

P

Q

tension

Setting

setting

and

3

tighter

tension

Regulating

Turn

right

Both

=

Upper

=

tension

(124)

mark.

in

is

The

5.

tension.

the

left

it

a

for

tensions

tension

too

The

the

higher

screw.

a

for

tighter

are

tight.

normal

white

looser

too

range

the

tension.

correct.

loose

tension

between

number,

tension,

lower

or

or

the

Lower

=

R

tension

correct

The

the

Let

hang

slide

not

should

jerk

you

Once

correctly,

should

bobbin

down

down

gradually

your

lower

the

only

be

tension

tight.

too

tower

case

freely

by

move

hand

tension

the

adjusted.

too

tension

with

the

by

own

its

upwards

upper

or

loose

bobbin

full

a

thread.

weight,

downwards

lightly.

been

has

thread

upper

must

It

but

when

set

tension

10

RIB

}

Page 14

Regulating

numbers

The

indicate

The

the

the

N.

Fig.0shows

control

stitch

the

stitch

control

stitch

for

symbols

stitch

the

on

stitch

length

stitch

length range

the

that

so

desired

length

how

to

on

stretch

push

sewing

length

length

is

number

set

buttons).

control

millimeters.

in

to

0

opposite

is

stitch

the

stitches

106

mm. Turn

6

indicating

mark

length

(red

Reverse

Press

button

button

backwards.

depressed,

sewing

117.

As

the

long

machine

as

you

keep

sews

this

11

Page 15

Finger-tip

C:

B,

A,

Button

releasing

for

setting

Elastic

D

2-mm

Elastic

E

3.5-mm

Elastic

F

5-mm

Elastic

G

Straight

Pullover

H

Blindstitch

controls

Buttons

is

B

left

the

triple

zigzag

triple

triple

zigzag

triple

also

the

stitch

zigzag

stitch

stitch

buttonholing

for

as

used

pushed

length

zigzag

stitch

zigzag

stitch

zigzag

stitch

straight

clearing

buttons

stitch,

stitch,

stitch,

stitch

(see

2

3.5

5.0

button

and

page

mm

mm

mm

for

14).

Closed

I

Joining

Overlock

K

Shell-edge

Feather

L

Elastic

Honeycomb

M

Elastic

stitch

A

inside

also

is

booklet

this

stitch

possible

overlock

stitch

stitch

stitch

stitch

decorative

stitch

stitch

program

hinged

the

of

reproduced

shows

and

combinations

applications.

stitch

chart

on

together

stitch

top

pages

is

found

cover.

all

This

26

stitches

with

on

to

the

chart

29

and

their

of

12

Page 16

Selecting

(whtte

Push

the

stitch

cating

1

and

6.

All

zigzag,

halved

too.

utility

symbols)

desired

length

the

desired

utility

in

width

stitches

button

control

stitch

and

when button

the

to

stretch

and

number

length

the

turn

between

stitches

is

G

pressed

indi

are

Selecting

(red

symbols)

Push

the

stitch

length

(red

symbol).

stretch

desired

control

stitches

button

as

and turn

far

asitwill

the

go

13

Page 17

Utility-

The

various

in

the

chart

top

cover

together

example,

blindstitch,

stitch

length

and

stretch-stitch

stitch

on

and

with

sewing

if

you

push

between

combinations

the

inside

at

the

want

buttons

combinations

of

end

instructions.

to

the

of

this

sew

an

M

and

1

and

4.

are

shown

hinged

booklet,

For

elastic

F,

select

a

Selecting

straight

Left

Central

Right

7-

needle

needle

needle

the

stitching

position:

position:

position:

needle

push

push

[;J

position

button

push

buttons

for

button

B

G

H

and

I.

14

\

CD

I

I

11iR

LLi

H

[hg

I

Page 18

(

8u

JOd

uado

p884

iajje

6u!ddoia

884

paddoip

•3T0

•0

pJeMo

SABMIV

41.

wie

JOJitIOD

.io

‘6uiMas

asoo

6uiNew

qsnd

alp

JBAOO

N

J9MO}

aqj

88.4

P°oi

ouiqoew

LZL

qsn

aqj

‘8uuapioiqwa

Wie

uawsn1pe

Olp

BOf3

paaj

‘butuiep

paaj-doip

.JOAOD

-doip

!

-seq

joiuoo

ue6e

paau

wai

p

qsnd

pi.

6u6ueq

aS!BU

Otfi

‘of

TflO

apaau

sp

N

dn

N

ti!MJ.

ww

1401!1s-AT

aig

ajpeau

uasooj

H

YoLIoEL

)fUES

ie

Se

sepeeu

eq

Aew

6u!Mas

eq

MOflS

Dupej

1!

se

IfliM

pasn

ajpaeu

uaq

N

U9

spJeMuMop

apaau

pieMc

filM

aipaau

ioj

1JBSUJ

qM)

aq

‘oO

poq

uind

B

aq

6ezfiiz

aq

aq

MOU

mu

(oeq

ueqj

aouejsp

pue

-SAS

ap!s

pue

uajq8j

o

-!fl1

I

I

SL

Page 19

Important

Model

On

always

1067

disengaged

be

the

bobbin

for

winder

sewing.

must

Operating

Model

of

“needle

N

slow”

“sew

“basting

P

controls

1069

down”

button

stitch”

button

with

button

electronic

of

with

indicator

with

indicator

light

indicator

system

light

0

light

Operating

Model

of

slow”

“sew

controls

1067

button

of

with

electronic

indicator

system

light

0.

16

Page 20

4

Basting

Press

green

the

on

fabric

you

machine

fabric

length

then

press

again.

basting

When

your

ing

cator

feed

arm

Electronic

(1067

By

top

halved.

0

again,

the

The

remains

the

indicator

machine

darning

the

under

press

under

of

holding

down

Repeat

you

foot

stitch

lamp

control

cover

and

pressing

speed

lights

the

machine

full

(1069)

basting

feed

the

and

sews

the

stitch

the

stitch.

have

from

button

P

to

121.

top

1069)

the

of

the

At

When

up.

indicator

piercing

the

lamp

foot

release

one

required

the

this

the

goes

the

your

same

speed

same

stitch

(page

(page

sewing

stitch.

sewing

fabric

pedal

foot

operation

finished

pedal

again.

out.

left

speed

“sew

machine

you

light

can

power

at

button.

lights

P

15)

foot.

the

foot

is

in

basting

The

Push

again.

selection

slow”

time

press

be

of

any

up.

and

20).

Each

foot

Move

until

obtained,

position,

this

and

for

press

and

green

the

Close

button,

can

indicator

this

off

goes

varied

the

speed.

The

Drop

screw

Place

time

pedal

the

the

release

each

move

indi

drop-

be

button

and

at

needle

the

the

bast

free

the

light

will.

it

Electronic

(1069)

red

The

monitor

thread

bin

when

out

sewing

Important:

kept

The

(important

Needle

(1069)

After

retained

press

tor

remains

corners

sewing

the

off,

retained

the

The

ing.

continues.

closed.

Pfaff

sewing

the

light

button

the

machine

button

bobbin

lamp

signal

starts

Ill

running

is

full

a

Free

1069

when

positions

the

“up”

its

at

“needle

lights

N

down

turning

and

interrupted.

is

again,

needle

its

“up”

in

stops.

can

thread

of

flash

to

out.

bobbin

cover

arm

special

a

has

re-ordering).

“up”

needle

position.

down”

and

up

fabric

the

in

the

When

indicator

the

be

upwards

position

pressed

moves

monitor

bobbin

when

The

inserted

is

and

always

is

button,

the

fabric)

thread

the

lamp

and

must

121

bobbin

“down”

When

indica

needle

sewing

(for

whenever

press

you

light

and

whenever

during

bob

goes

be

you

goes

is

sew

17

Page 21

Changing

release

To

button

make

sewing

hold

and

N.

sure

foot

the

the

When

stud

under

in

it

sewing

sewing

attaching

0

place

enters

the

with

foot

foot

a

slot

sewing

your

push

sewing

P.

left

Place

foot

the

hand.

red

foot

the

holder

Lower

same

that

screw

guide

serves

the

on

presser

time

stud

Q

and

reposition

0

are

the

secure

to

presser

fits

used

lifter

bar

slot

in

for

darning

the

bar.

114

sewing

the

Hole

P.

attaching

foot.

sewing

and

R

Screw

foot

at

foot

and

an

holder

the

so

edge

S

Page 22

Sewing

o

Darning

1

Standard

2

Clear-view

3

Hemmer

feet

foot

sewing

foot

foot

foot

4

5

6

7

I

Blindstitch

Zipper

Buttonhole

Edge

foot

guide

foot

foot

93-035

960-91

98-69441

98-694401-00

4-0

0

944

5

98-694

98-694563-00

981-00

3

404-00

407-00

J

2422-0

19

Page 23

Special

Blindstitch

N

adjusted

Zipper

0

groove

groove

adjusted

the

Darning

P

Push

hold

in

rests

W

Tighten

right

hole

so

sewing

by

foot.

S.

The

T.

sideways

or

foot.

bracket

it

there.

and

U

against

that

screw

foot.

turning

First

then

left

bears

it

feet

Blindstitch

insert

push

zipper

zipper

Raise

toward

W

Insert

attach

stop.

its

V.

screw

its

foot

stitching

for

chain.

the

the

the

Release

against

Q.

rear

its

front

can

needle

the

pin

foot

screw

guide

pin

be

back

the

of

so

bracket

pin

into

along

bar.

that

X.

R

into

and

foot

the

button

the

(C):

pull

sew,

thin

settings

stitch

of

the

C

upper

range.

Place

it

arrow

determine

to

thread

density

stitch

Attach

(N).

tensionat3

Insert

it

over

and

taut

E

moves

for

length

the

the

clamp

the

sewing

in

the

control

buttonhole

the

in

cord

filler

rear

it

in

along

buttonhole

buttonholes.

button

the

of

lug

front

scale

(Q).

as

F.

Buttonhole

is

Regulate

range

hole

Press

Set

foot.

buttonhole

follows

foot,

the

D.

lug

you

As

serves

This

it

length.

a

Use

20

Page 24

Sewing

Pull

buttonholes

the

bottomofthe

wardasfarasit

1

2

3

Sew

needle

Push

until

tacking

Model

Push

tonhole

first.

first

buttonhole

(on

Model

buttonBand

the

machine

stitches.

1067).

button

seam

Raise

the

will

Then

A.

the

go.

1067)

has

Raise

Sew

same

needle

buttonhole

seam.

it

keep

depressed

sewn

the

needle

release

the

the

second

lengthasthe

(on

Model

Raise

4

to

foot

the

6

(on

button.

but

1067).

for

bar-

4

5

6

Push

until

tacking

Model

Sew

fabric,

Cut

the

button

machine

the

stitches.

1067).

few

a

pull

buttonhole

B

tying

the

and keep

has

Raise

Then

stitches.

filler

it

depressed

sewn4to6bar-

the needle

release

the

button.

Remove

cord

taut

and

open.

(on

the

trim.

B

21

Page 25

Changing

Switch

power

cord

cover

and

Take

the

box

and

face

cover

in

the

machine.

down

with

there.

The

exchanged.

Push

the

and

take

that

its

pins

turn

it

toward

off

edge

insert

light

it

the

the

plug.

swing

and

the

light

bulb

out.

slide

0.

light

machine

Close

up

the

guide

it

into

housing

Push

edge

bulb

up,

Insert

slots

in

Let

the

bulb

out

the

the

guide

can

turn

the

and

pull

the

hinged

carrying

of

the

slot

and

into

lamp

and

now

it

new

Push

P.

lamp

out

top

handle,

accessory

between

cutout

housing

hold

be

toward

bulb

so

it

up

housing

the

it

N

Q

and

resume

the

edge

Cleaning

Tilt

needle

and

take

feed

and

sewing

Clean

the

1069

as

Do

not

maintenance.

no

drop

a

then,

as

its

original

guide.

and

plate

it

out

the

hook

bobbin

instructed

oil

the

of

oil

shown

oiling

108

(0).

parts

with

machine

All

in

the

in

position

up

CTean

in

the

a

soft

thread

on

you

hook

the

and

at

the

the

machine

vicinity

brush.

monitor

page

25.

because

have

to

raceway

illustration

pull

back

of

of

it

do

below.

out

(N>

the

Model

requires

is

put

now

and

22

Page 26

Changing

out

Pull

holder

a

with

Pull

out.

fuse

new

holder,

turning

and

fuses

FF2A

Pfaff

local

fuse

the

power

the

counter-clockwise

N

screwdriver,

out

0

fuse

pushing

the

in

it

can

dealer.

holder

in

it

clockwise

be

plug.

cord

release

holder

of

and

with

obtained

the

quarter

a

a

it

replace

fuse

Turn

quarter

take

and

Insert

N.

the

screwdriver

turn.

your

from

turn

it

a

Some

1.

your

2.

3.

safety

careful

Se

the

by

Make

power

want

sewing

plate,

machine,

the

interrupt

to

machine

the

sure

Be

light

fingers

needle

sure

cord

change

to

foot,

when

to

bulb

rules

when

will

you

plug

bobbin

you

sewing

for

use

the

in

sewing

not

pull

whenever

fuse,

clean

when

or

a

only

sewing

be

out

needle,

or

and

while.

15-watt

a

that

injured

the

needle

and

you

leave

lamp.

you

oil

have

23

Page 27

4

Trouble

Cause:

Machine

1.

Needle

Wrong

Needle

Machine

Needle

Needle

2.

any

For

Thread

Poor-quality

thread

or

excessive

by

Needle

3.

Needle

go.

will

Needle

Needle

Needle

because

Bobbin

shooting

skips

inserted

not

needle

bent

threaded

thin

too

thread

the

of

tension

that

breaks

not

bent.

too

bent

work

case

stitches

used.

blunt.

or

improperly.

for

above

too

knotty

or

has

storage.

pushed

or

thin

strikes

and

pushed

is

improperly

correctly.

thread

breaks

reasons.

strong.

thread

become

as

up

thick.

too

used.

used,

too

as

far

needle

pulled.

or

inserted.

dry

it

plate

Remedy:

needle

Push

shank

flat

Insert

lnsert

Check

Select

Thread

par.

See

Regulate

Used

Insert

it

as

Insert

See

machine

Let

Only

When

it

in

up

side

system

needle.

new

threading.

needle

Chart.

above.

1

thread

good-quality

only

needle

new

go.

will

new

Needle

guide

inserting

for

as

far

as

facing

130/705

according

tensions.

needle.

Thread

and

feed

material

the

the

will

it

as

toward

and

the

bobbin

as

H

work

go.

will

it

needle.

Needle

to

thread.

push

Chart.

lightly.

go,

the

up

it

alone.

case,

its

back.

and

as

push

far

4.

Tension

Thread

24

Seam

Bobbin

Kinks

material.

is

out

too

thread

appear

uniform

not

adjustment.

of

thick,

wound

on

knotty

top

or

unevenly.

bottom

and

hard.

of

Check

Use

During

thread

bobbin

Thread

both

upper

first-class

bobbin

hand,

in

tension

machine

tensions.

and

thread

winding,

but

stud.

properly

lower

pass

tensions.

only.

do

it

and

hold

not

through

check

the

Page 28

Cause:

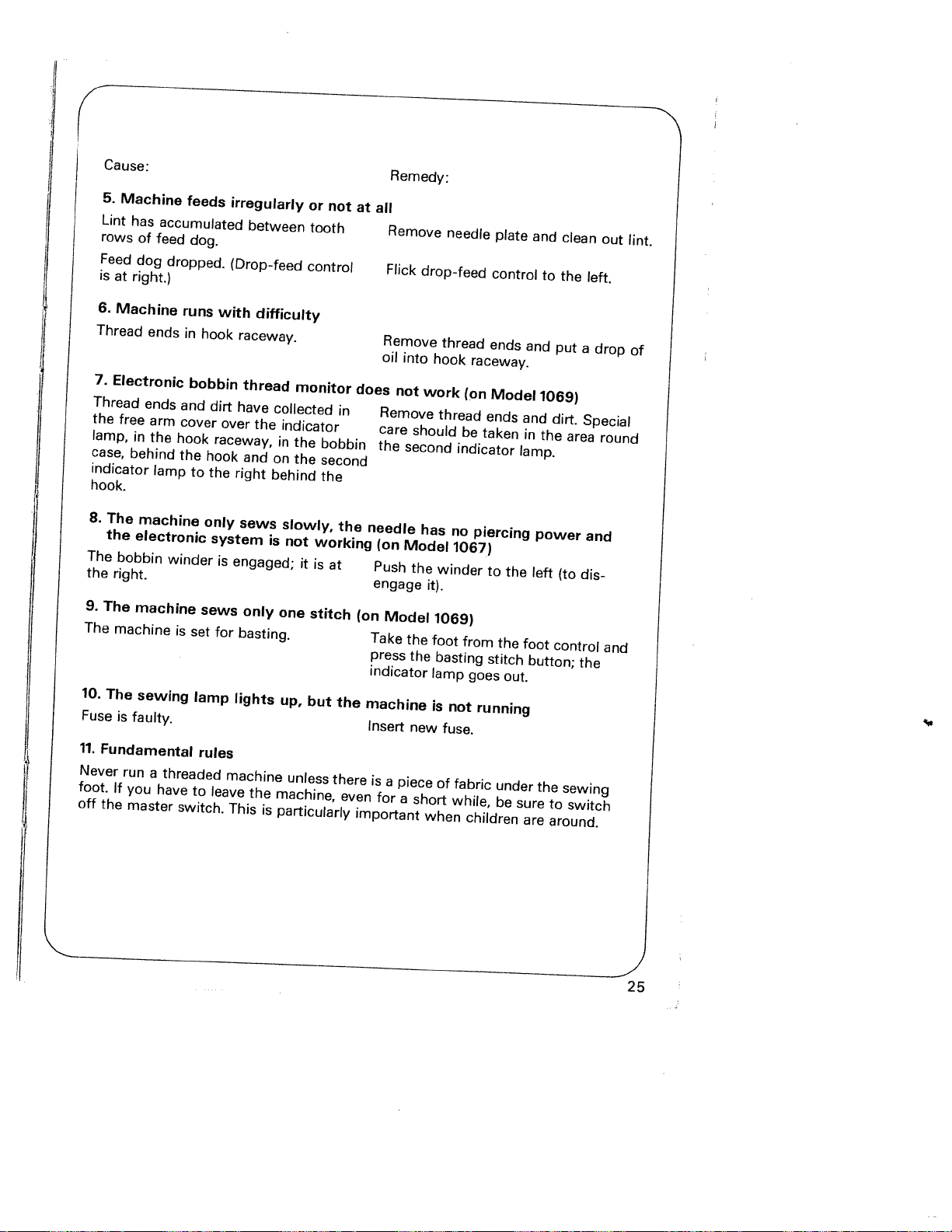

5.

Machine

Lint

rows

Feed

is

at

6.

Machine

Thread

7.

Electronic

Thread

the

free

lamp,

case,

indicator

hook.

8.

The

the

The

bobbin

the

right,

9.

The

The

machine

10.

The

Fuse

is

11.

Fundamental

Never

foot.

If

off

the

has

accumulated

of

feed

dog

right.)

ends

ends

arm

in

the

behind

lamp

machine

electronic

machine

sewing

faulty.

run

a

you

have

master

feeds

dog.

dropped.

runs

in

hook

bobbin

and

cover

hook

the

to

winder

sews

is

set

lamp

rules

threaded

to

switch.

irregularly

(Drop-feed

with

dirt

over

raceway,

hook

the

only

system

is

engaged;

for

lights

machine

leave

This

between

difficulty

raceway.

thread

have

collected

the

and

on

right

behind

sews

is

only

basting.

the

is

or

not

tooth

control

monitor

indicator

in

the

bobbin

the

second

the

slowly,

not

working

it

is

at

one

stitch

up,

but

unless

machine,

particularly

at

does

in

the

(on

the

there

even

important

Remedy:

all

Remove

Flick

Remove

oil

into

not

Remove

care

the

second

needle

(on

Model

Push

engage

Model

Take

press

indicator

machine

Insert

is

a

piece

for

a

drop-feed

hook

work

should

has

the

winder

it).

1069)

the

foot

the

basting

lamp

is

new

of

short

when

needle

thread

(on

thread

be

indicator

no

1067)

from

not

fuse.

fabric

while,

plate

control

ends

raceway.

Model

ends

taken

piercing

to

the

stitch

goes

running

under

be

children

the

out.

and

and

and

in

lamp.

left

foot

button;

sure

are

to

the

put

1069)

dirt.

the

power

(to

control

the

to

around.

clean

left.

a

Special

area

and

dis

the

sewing

switch

Out

drop

round

and

lint.

of

Page 29

Stitch

program

Listedinthis

number,

the

the corresponding

lower

half,

chart

the

chart

are

buttons

the

stitch

stitch

to

program

be

and,

pressed

to

sew

this

seam

pattern.

in

programs

length

marked

control

“stretch”,

toward

For

turn

“stretch”

all

stitch

the

as

far

stitch

as

it

7f.

01

02

03

04

05

01

I

I

I

I

ED

Stitch

Straight

Zigzag

Buttonholes

Elastic

straight

Elastic

zigzag

Ill

I I

G

stitch

triple

stitch

triple

stitch

I

H

I

stitch

02

/

\

/

\

/

\

D D

—-------

,,

—.

-

—--

—

———-

s—.

E

All

stitching

Edge finishing,

sewing,

Just

The

Seams

stretch

Flat,

well

—.---.

F

E

Application

ordinary

satin

push

stitch

exposed

under

elastic

as

sewing

03

E1

ii

Eli

Eli

EJ

I

_j

ABC

sewing

operations.

appliqué

stitching,

the

buttons

density

to

stress.

reinforcing

and

=

=

operations

and

can

be

great

mending

04

F

Ill

‘

II

HE

III

Ii

iii

I

LE

CD

L

GDM

CD

C)

:T

and

work,

inserting

embroidering,

the

buttonhole

regulated,

stress

which

seams,

as

corsetry.

Ill

‘

III

ni

ill

GD

CD

—

C)

D’

6-mm

darning

05

——

•“$,,

rD

lace,

is

—

C)

fancy

button

etc.

finished.

06

--.

———

N

06

Elastic

Elastic

07

stitch

08

Crown

09

Elastic

1026Scallop

stitch

ornamental

stitch

blindstitch

stitch

Inserting

fabrics.

Inserting

or

sewing

An

ornamental

Hemming

For

decorating

patches

patches

ornamental

seam,

elastic

handkerchiefs,

and darning

and darning

seams

on

e.g.

fabrics

with

rips

on

elastic

ripsonelastic

on

elastic

night

gowns.

invisible

for

instance.

materials

fabrics.

stitches.

Page 30

will

stitch

stitch

For

go.

length

programs

07

>

I

.>

I

the

in

19

I

I

j

I

-.-

G

table

20

I

I

K

detail

more

15

II\

l/

II\

fl/

II\

)/

in

16

17

18

•_I

—‘

—

I

i

—I

I

—.-..

—

—

—,

S.-..’

5

_J

-..-

—

—

TT

F

C)

_____

D

C)

described

below.

14

—#

S.$,,

—4”

—I

-S.-’

MT

C)

,.__z.

the

other

desired.

and

09

‘

‘S

-w

F

programs,

their

10

7

‘

‘..

wM

G

all

as

08

—I

‘S

S.-.,

•‘

--

E

select

The

individual

application

11

/\/

\/\

/\/

\/\

/\/

\/\

-,

C)

D

/1/

\I\

/1/

\t\

/1/

\I\

Mi

12

are

13

4’

‘..\

-I

C)

f4io.

1

1

1

1

1

1

17

18

1

2

3

4

5

6

Stitch

Honeycomb

Joint

stitch

Florentine

narrow

Florentine

wide

Houndstooth

Lampshade

wide

Viennese

narrow

Viennese

wide

stitch

stitch,

stitch,

stitch,

stitch,

stitch,

stitch

Application

Sewing

or

A

For

on

covering

durable

decorating

Ornamental

Ornamental

Classical

Ornamental

Ornamental

elastic

seams

ornamental

hems,

seams,

seams,

ornamental

seams,

seams,

threads

terry

on

joining

e.g.

e.g.

e.g.

seam

e.g.

e.g.

on

on

on

on

on

cloth.

seam.

bed

linen.

bed

linen.

table

on

all

napkins.

table

linen.

plain

cloths.

N

fabrics.

1

20

9

Lampshade

narrow

Shell-edge

wide

stitch,

stitch,

Classical

Effective

ornamental

finish

edge

seam

on

on

dainty

plain

fabrics.

fabrics.

27

Page 31

22

21

I

5

D

23

24

25

26

27

\S.-J

L—i

..1

%J

i

%J

i

‘%J

IN

I/I

r-.

I/I

r-.i

/I

T

0•...

,—4.

-‘

-‘

0

o

Dzi-

D

l—.-i

—i

N.J

i..—i

r--J

‘

—4—

I

-,

£FGKR.

o

T

K

G

/i

‘—i

/.-i

\-.J

/-i

‘°

I

_

Ii

Ii

‘—4.

5•

0

28

29130

\\‘

If

/_-.

Ill

\\\

,

•

/_-

lii

\

,_-

I,!

5•

‘-4.

0

z

-I

DlGIM.

ol

i-

-I

ol

Dt

\/\

\/\

\/\

-1

—#

-#

31

32

5_

--

-‘

0

D

Th-

0

34

33

—‘

‘

S.

<

(_

<

‘

[

C

D

/‘iO.

21

22

23

24

25

26

27

28

29

30

31

Stitch

Elastic

edge

Shell-edge

narrow

Closed

stitch,

overlock

wide

Pennant

Closed

stitch,

overlock

narrow

Turkish

Overlock

wide

Peacock

Overlock

narrow

Knurl

stitch

Blindstitch,

stitch

stitch

stitch,

stitch

stitch,

stitch

stitch

wide

Application

Finishing

Ornamental

Covering

fabric

edges

Decorative

Sewing

on

Topstitching

Elastic

assembly

seams

Festive

Dainty

on

ornamental

border

Ornamental

Hemming

edges

that

seams,

folded

with

joining

dainty

patches.

knitted

ornamentation.

seam

heavier

e.g.

fancy

a

seam

lace.

and

fabrics.

seam,

light

on

fabrics

do

edge

not

on

girls

seam.

and

finishing

e.g.

clothing.

with

fray

dresses.

sewing

on

table

invisible

much.

on

borders.

linen.

stitches.

28

Blindstitch,

32

narrow

33

\\

Peak

Mound

stitch

stitch

Hemming

lighgtweight

stitches.

A

dainty

ornamental

handkerchiefs.

Ornamental

seam,

e.g.

seam,

on

fabrics

e.g.

children’s

with

on

invisible

ladies’

napkins.

Page 32

44

45

46

47

/Iio.

38

40

41

42

43

35

-

—

I

F

Stitch

Viennese

narrow

Lampshade

narrow

Pullover

wide

Pullover

medium

Pullover

narrow

Feather

Dutch

Snail

Loom

Diagonal

Trellis

Twig

stitch

Border

Triangular

stitch

stitch

stitch

stitch

.

stitch

36

I

I

I

stitch,

stitch,

stitch,

stitch

stitch

stitch

37

.—‘i

-Jl

.—9l

...-il

—Jl

UCfl

F-.

C)

:,.

stitch,

stitch,

-ll

“Jl

S—il

-J

..-il

Jl

L.JCI)

38

—

C)

:r

39

40

/11

ii

\ll

i%.

/11

di

\h

i

/11

dl

\ll

LJO

101(J)

—

—

C)

C)

:r

:z

Application

Ornamental

Classical

Elastic

jersey

Elastic

polo

Elastic

lightweight

Decorative

Ornamental

Ornamental

Ornamental

Ornamental

Ornamental

Ornamental

Ornamental

pockets.

Ornamental

41

K

/‘

‘

/‘

—

C)

seams,

ornamental seam

edge

finishing

fabrics.

edge

edge

finishing

farbrics.

finishing

shirt

jersey

cover

seam,

seam,

seam,

seam,

seam,

seam,

seam,

seam,

e.g.

i-:

F.

e.g.

e.g.

e.g.

42

4

cf

e.g.

e.g.

ij-

-,

C)

crepe.

seams,

e.g.

e.g.

for

for

for

for

for

for

43

i:-

-,

C)

e.g.

on

seams

seams

seams

e.g.

on

kitchen

for

bath

country-look

plain-look,

airy

hiking

border

children’s

44

45

iIi<

_S<l)o

r

._

.,

C)

KTlKK

table

linen.

on

plain

fabncs.

on

on

on

on

aprons.

textiles.

room

utensils.

modern

ladies’

dresses.

wear.

ornamentations

night

46

-,

dresses.

dresses.

47

x’

I

<

i

-I

dresses.

on

48

Al

I

,,\

A

/\

-1

N

29

Page 33

Special

special

The

obtained

cessory

accessories

accessories

your

from

dealer.

listed

below

are

Part.

intended

No.

for

special

Sewing

sewing

Operation

jobs.

They

can

be

Appliqué

Cording

consisting

Cording

(twin

needle

Cording

needle

(twin

Cording

sewing

Fringe

Straight-stitch

—

foot,

Felling

foot,

Felling

Shirring

Single-needle

Eyeletting

Overlock

foot

set

of:

foot.

foot,

blade

foot

plate

foot

5

with

7

with

—----.--.——.—

4.5

6.5

grooves

1.8-2.5

grooves

1.4-1.8

ea.(

(2

foot

foot

mm

mm

cording

foot

mm

mm

needle

needle

gauge>

gauge>

.

93-035

93-035

93-035

93-035

93-035

98-694

93-035

93-035

93-035

98-620

920-91

950-91

953-91

952-45

943-91

803-00

-

998-91

91

946-45

404-00

5-91

1

—

For

appliqué

For

cording

(Needle

for

fine

needle

size

sewing

For

topstitching

For

sewing

very

and

soft

For

felled

For

shirring

For

single-needle

For

eyeletting

For

finsishing

elastic

fabrics

overcasting

work

size

cording

70>

fringes

fabrics

seams

valances

their

work

80,

and

delicate

(silk

raw

and

for

and

jersey,

cording

or for

edges

simultaneonsly

edges

basting

etc.>

joining

Hemmêr

jlon

foot

foot

mm

2

edge>.

(rolled

PFAFF-HANDELSGESELLSCHAFT

Haushaltnähmaschinen

für

7500

KarIsruhe41

West

m.b.H.

Germany

98-694

98-694

804-00

801-00

For

For

hemming

sewing

edges

plastic

with

materials

Printed

Subject

Nr.

22607

zigzag

in

to

West

Germany

alterations

1182 WI.

engl.

stitches

in

design.

Loading...

Loading...