Page 1

00

c©j1

00

Page 2

K

Fold

J

out

this

page

4

Selecting

UtilitySelecting

for

Droppingthemachinefeed

Changing

Changingthesewingfoot

Special

Buttonhole

Sewing

Sewing

Changing

Cleaningandoiling

Trouble

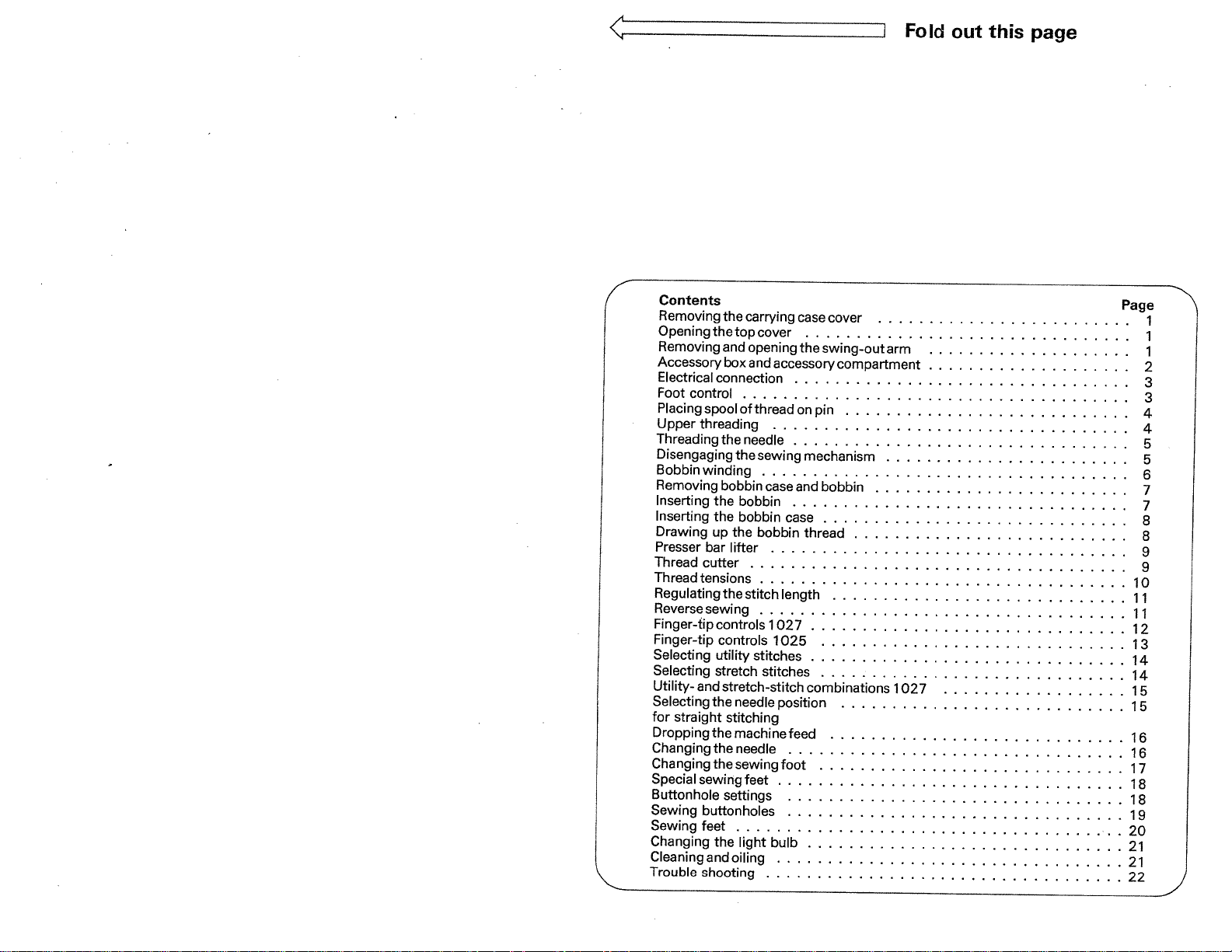

Contents

Removing

Opening

Removing

Accessory

Electrical

Foot

Placing

Upper

Threading

Disengaging

Bobbin

Removing

Inserting

Inserting

Drawing

Presser

Thread

Thread

Regulating

Reverse

Finger-tip

Finger-tip

Selecting

the

control

spool

threading

winding

the

the

up

bar

cutter

tensions

sewing

and

the

straight

the

sewing

buttonholes

feet

the

shooting

the

carrying

top

cover

and

opening

box

and

connection

of

thread

the

needle

sewing

the

bobbin

case

bobbin

bobbin

the

bobbin

lifter

the

stitch

controls

controls

utility

stretch

1027

stitches

stitches

stretch-stitch

needle

stitching

needle

feet

settings

light

bulb

case

the

accessory

on

pin

mechanism

and

case

thread

length

1025

combinations

position

cover

swing-out

compartment

bobbin

.

arm

1027

Page

4

4

5

10

11

11

12

13

14

14

•15

15

16

16

17

18

18

19

20

21

21

22

Page 3

0

c)

Page 4

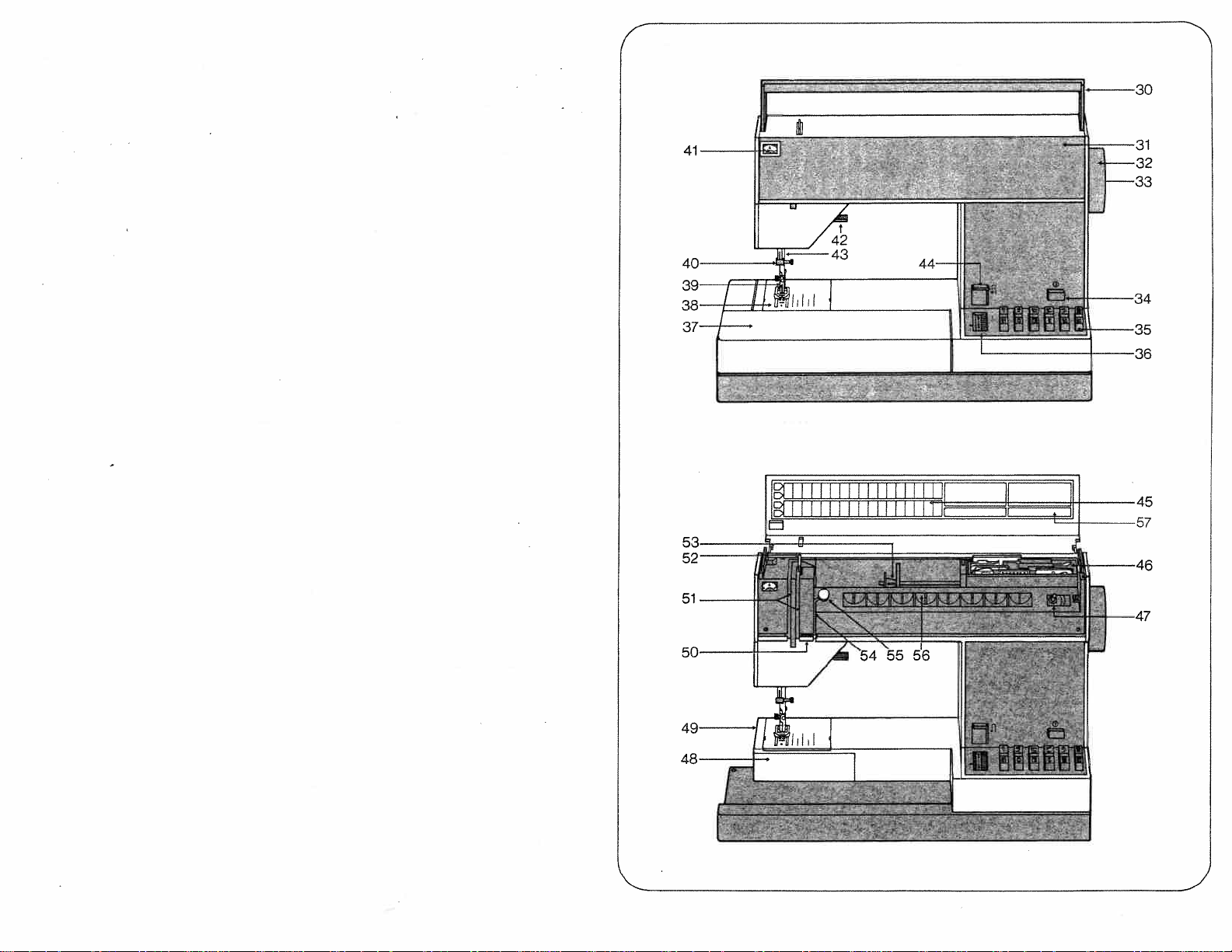

Parts

of

your

sewing

machine

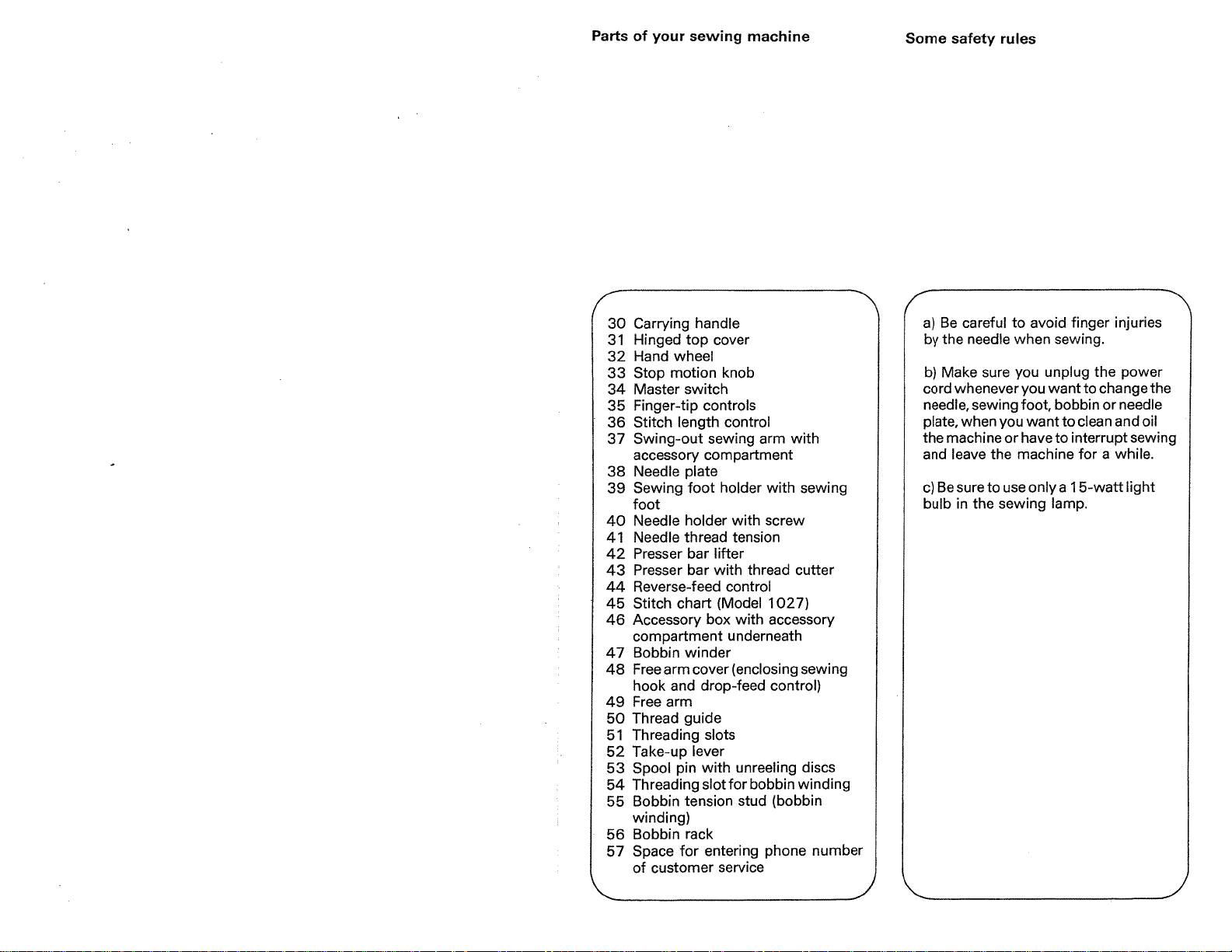

Some

safety

rules

I

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

top

wheel

motion

switch

length

plate

foot

holder

thread

bar

bar

chart

winder

cover

arm

and

arm

guide

lever

pin

tension

rack

for entering

customer

handle

Carrying

Hinged

Hand

Stop

Master

Finger-tip

Stitch

Swing-out

accessory

Needle

Sewing

foot

Needle

Needle

Presser

Presser

Reverse-feed

Stitch

Accessory

compartment

Bobbin

Free

hook

Free

Thread

Threading

Take-up

Spool

Threading

Bobbin

winding)

Bobbin

Space

of

cover

knob

controls

control

sewing

compartment

box

drop-feed

slots

with

slot

holder

with

tension

lifter

thread

with

control

(Model

with

underneath

(enclosing

unreeling

bobbin

for

stud

service

arm

screw

phone

with

with

sewing

cutter

1027)

accessory

sewing

control)

discs

winding

(bobbin

number

Be

carefultoavoid

a)

needle

the

by

Make

b)

whenever

cord

needle,

plate,

the

and

c)

bulb

when

machine

leave

sure

Be

in

sewing

the

sure

the

to

when

you

you

foot,

want

you

or

have

machine

only

use

sewing

finger

sewing.

unplug

want

bobbin

to

to

interrupt

a

15-watt

lamp.

the

to

clean

for

injuries

power

change

or

needle

and

sewing

while.

a

light

the

oil

Page 5

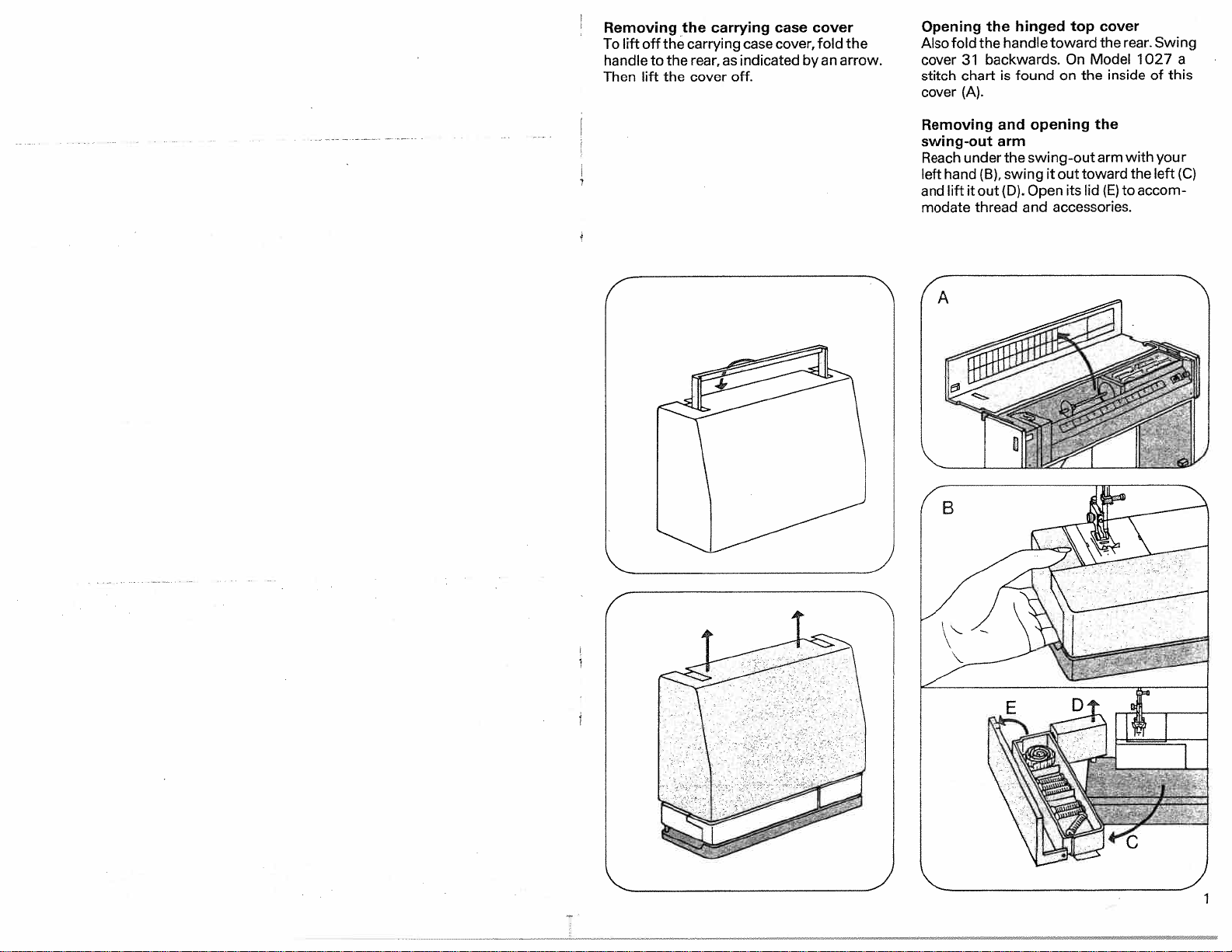

Removing

To

lift

off

the

handletothe

Then

lift

the

the

carrying

carrying

rear,asindicated

cover

case

off.

cover

case

cover, fold

byan

the

arrow.

Opening

Also

fold

cover

stitch

cover

the

the

backwards.

31

chart

(A).

hinged

handle

toward

is

foundonthe

top

On

cover

the

Model

inside

rear.

1027

Swing

this

of

a

4

Removing

swing-out

Reach

under

left

hand

and

lift

it

modate

and

arm

the swing-out

swingitout

(B),

out

(D).

thread

opening

Open

and accessories.

the

arm with

toward the

its

lid

(E)

to

your

left

accom

(C)

4

N

1

Page 6

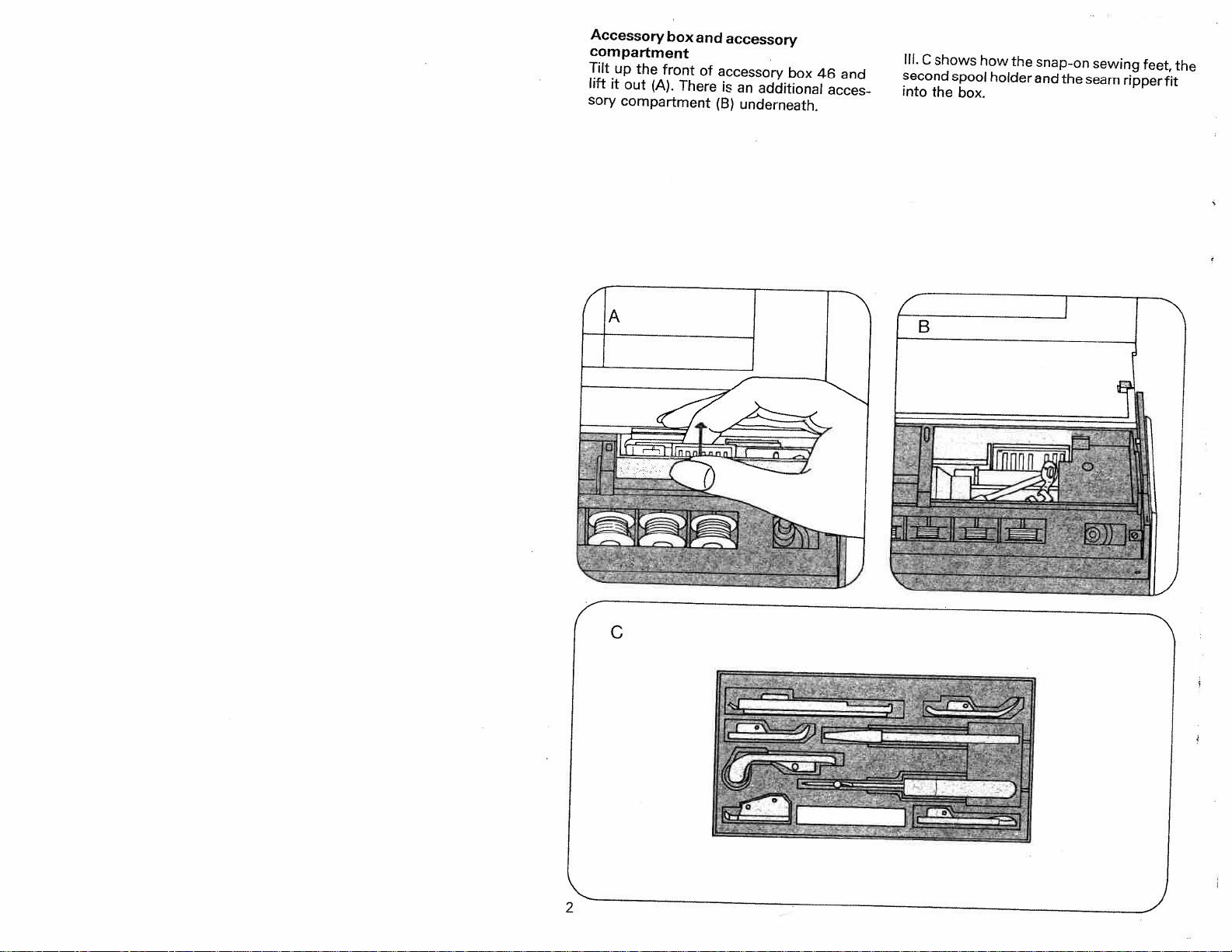

Accessory

compartment

Tilt

up

the

lift

it

out

sory

(A).

compartment

box

front

There

and

of

accessory

(B)

accessory

is

an

additional

underneath.

box

46

and

acces

Ill.

C

second

into

the

shows

spool

box.

how

holder

the

snap-on

and

the

sewing

seam

feet,

ripper

the

fit

I;—

C

.

0

a

2

C

0

Page 7

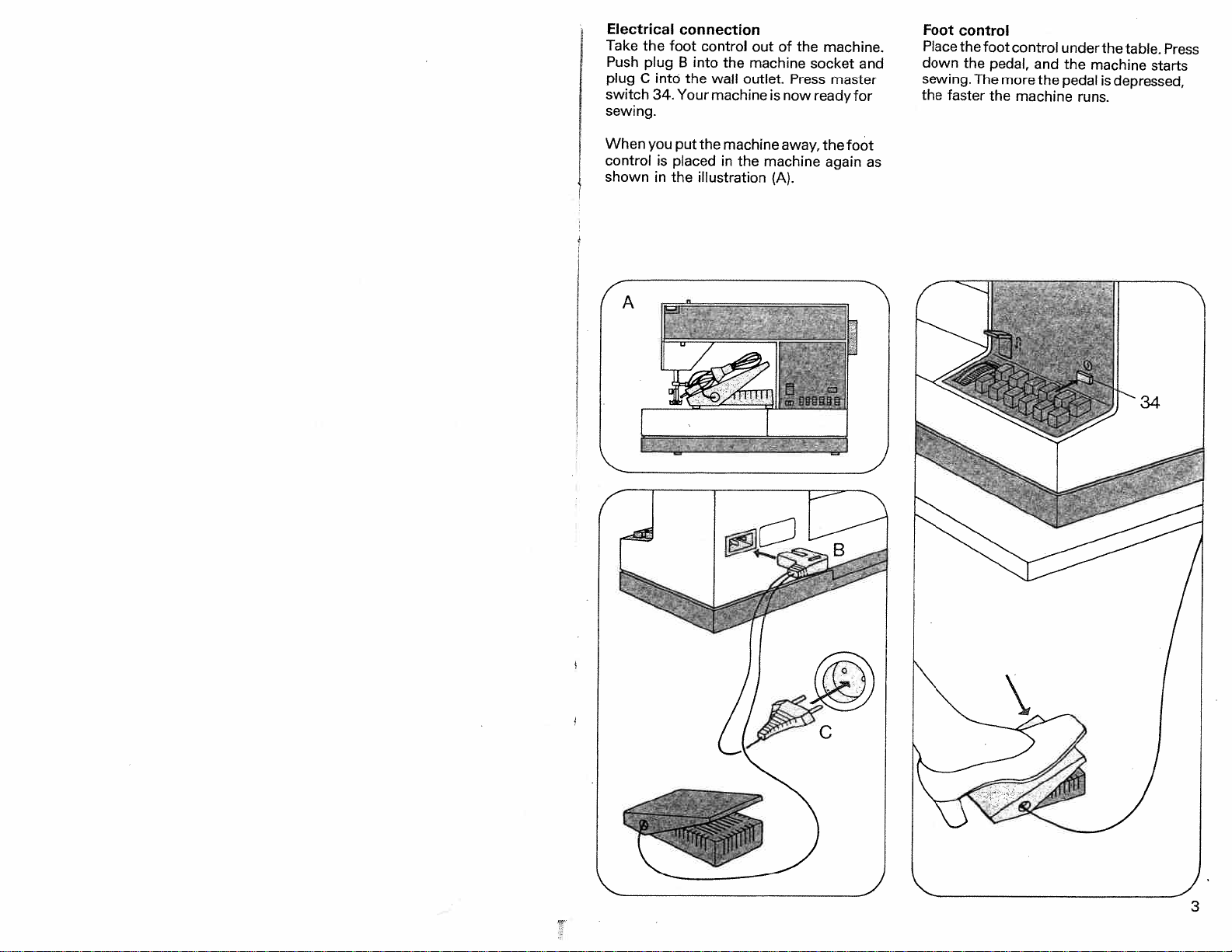

Electrical

Take

the

Push

plug

plugCinto

switch

34.

sewing.

When

you

control

shown

is

in

connection

foot

control

B

into

the

wall

Your

machine

put

the

placed

the

illustration

out

the

machine

outlet.

machine

in

the

of

the

Press

now

is

away,

machine

(A).

machine.

socket

master

readyfor

the

again

foot

and

as

Foot

Place

down

sewing.

the

faster

control

the

foot

the

The

control

pedal,

more

the

and

the

machine

under

the

pedal

runs.

the

table.

machine

is

depressed,

Press

starts

3

Page 8

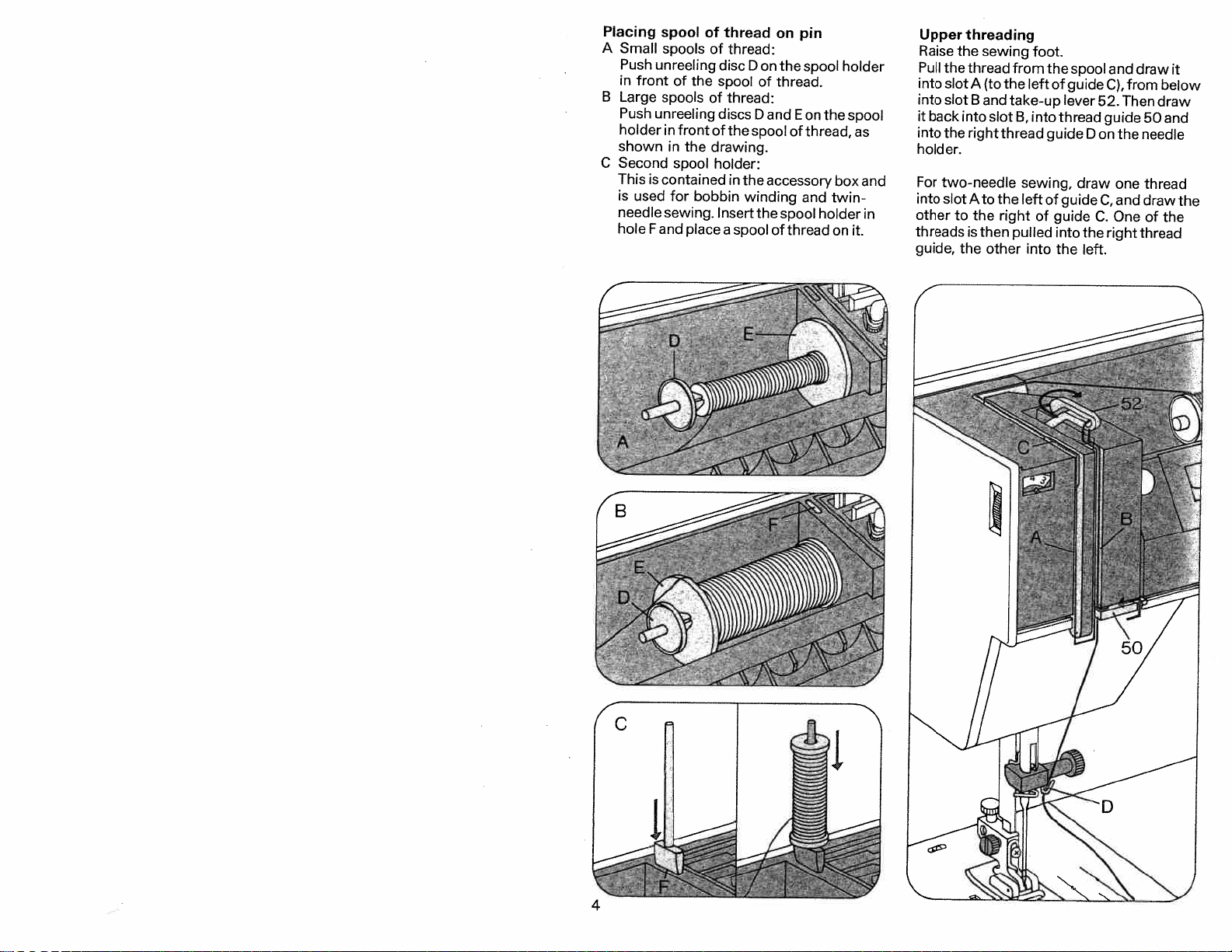

Placing

A

Small

Push

in

B

Large

Push

holder

shown

C

Second

This

is

used

needle

hole

spool

unreeling

front

spools

unreeling

is

contained

F

and

of

spools

of

the

in

front

the

in

spool

for

bobbin

sewing.

placeaspooi

thread

of

thread:

disc

Don

spool

of

thread:

discs

of

the

drawing.

holder:

in

the

winding

Insert

on

the

thread.

of

D

and

spool

accessory

the

spool

of

pin

spool

Eon

thread,

of

and

thread

holder

the

box

twin-

holder

on

spool

as

and

in

it.

Upper

Raise

Pull

the

into

slot

into

slot

it

back

into

the

holder.

For

two-needle

into

slot

other

threads

guide,

threading

the

sewing

thread

A

(to

Band

into

slot

right

Ato

to

the

is

then

the

other

foot.

from

left

the

take-up

B,

into

thread

sewing,

the

leftofguide

right

of

pulled

into

the

of

lever

thread

guide

guide

into

the

spool

guide

Don

draw

the

left.

C),

52.

guide

C,

C.

right

and

the

one

and

One

draw

from

Then

thread

below

draw

and

50

needle

thread

draw

of

the

it

the

4

Page 9

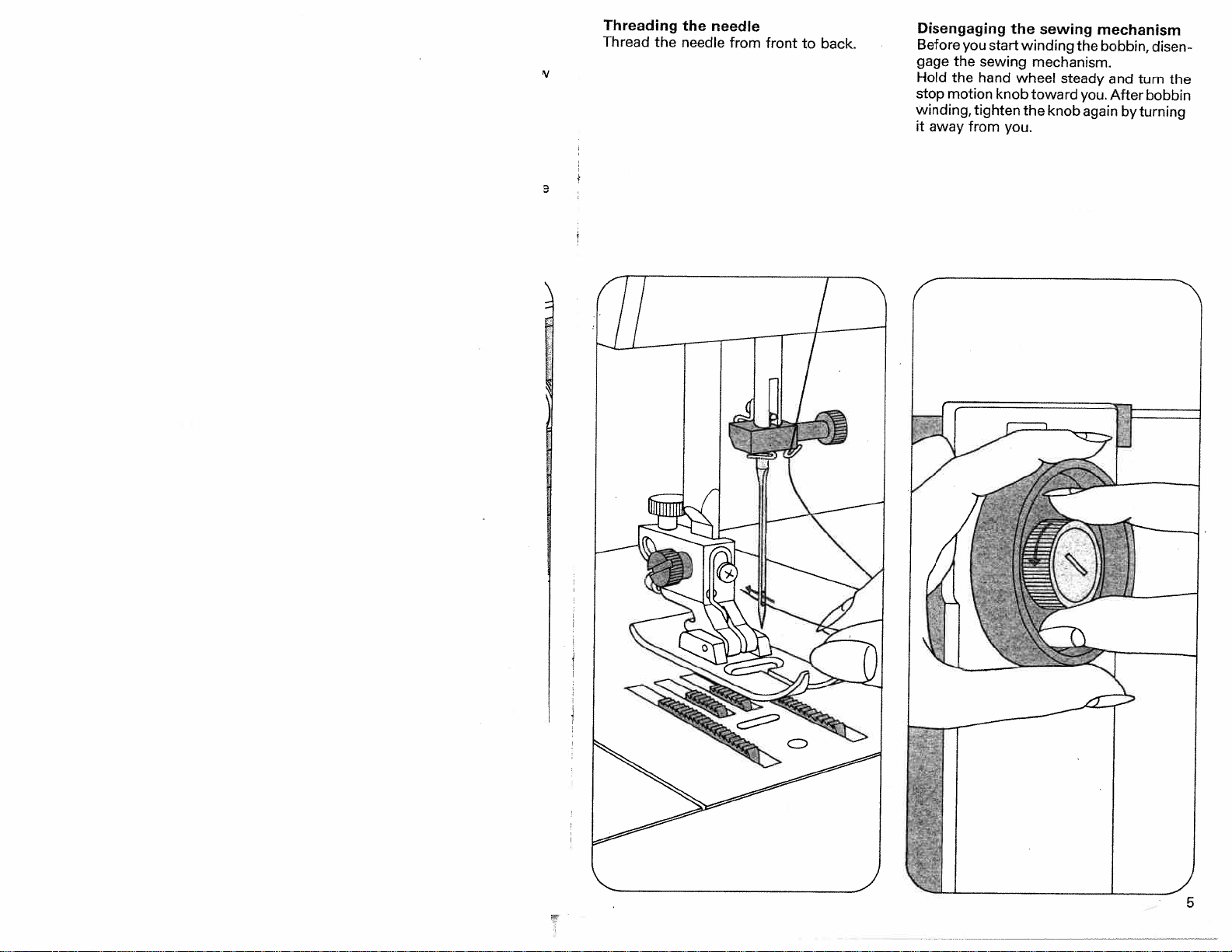

Threading

Thread

V

the

the

needle

needle

from

front

to

back.

Before

gage

Hold

stop

you

the

the

motion

winding,

it

away

Disengaging

start

sewing

hand

tighten

from

the

wheel

knob

you.

sewing

winding

mechanism.

steady

toward

the

knob

mechanism

the

bobbin,

and

you.

After

again

by

disen

turn

bobbin

turning

the

5

Page 10

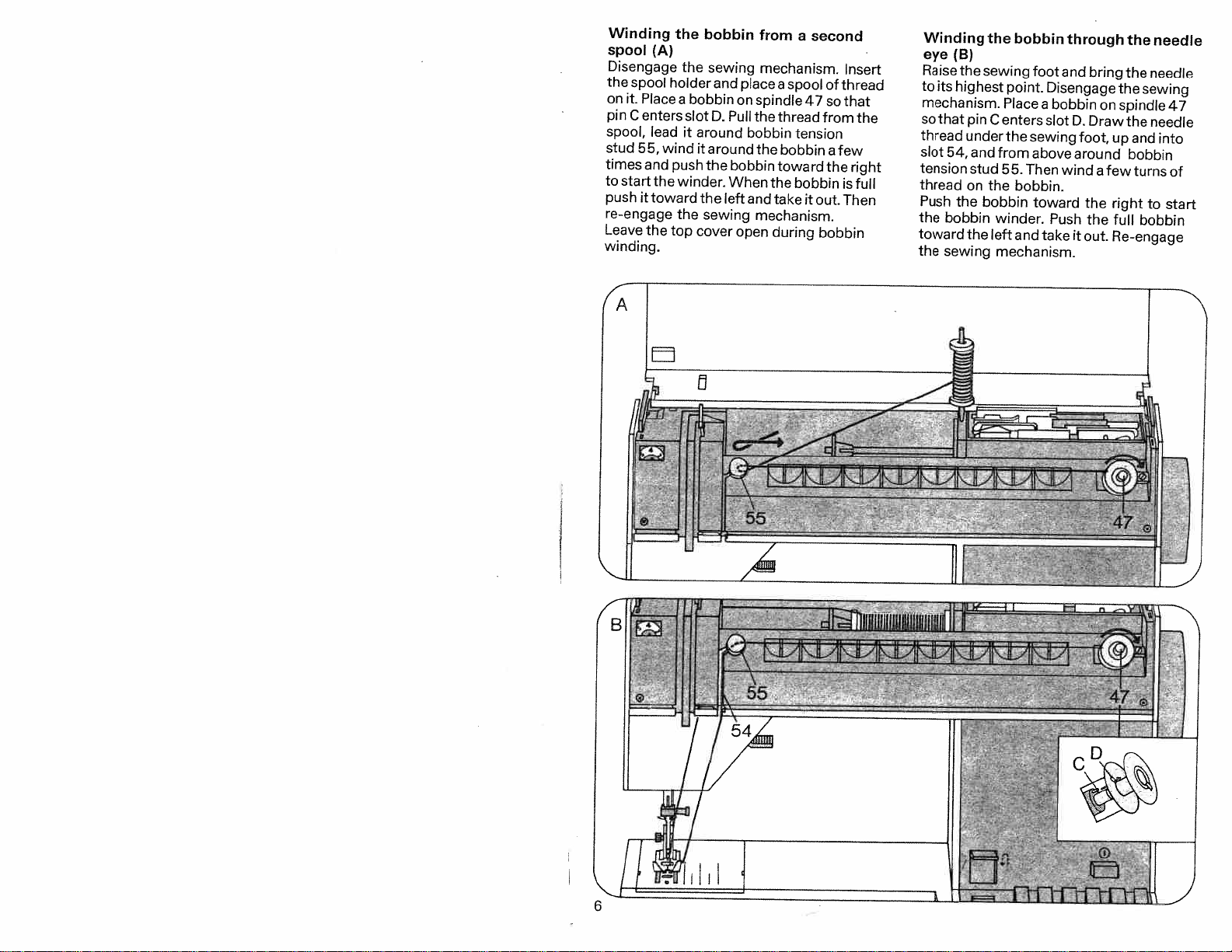

Winding

spool

(A)

Disengage

spool

the

on

it.

Place

Centers

pin

spool,

lead

stud

55,

times

and

to

start

push

it

toward

re-engage

Leave

the

winding.

wind

the

the

the

holder

bobbin

a

slot

it

push

winder.

the

top

bobbin

sewing

and

D.

around

it

around

the

the

left

sewing

cover

from

place

on

spindle

Pull

the

bobbin

the

bobbin

When

and

mechanism.

open

a

second

mechanism.

a

spool

47

thread

tension

bobbin

toward

the

bobbin

take

it

out.

during

bobbin

of

so

from

a

few

the

Insert

thread

that

the

right

is

full

Then

Winding

eye

(B)

Raise

the

to

its

highest

mechanism.

that

so

thread

slot

tension

thread

Push

the

toward

the

pin

under

54,

and

stud

on

the

bobbin

the

sewing

the

bobbin

sewing

point.

Place

Centers

the

sewing

from

55.

Then

the

bobbin.

bobbin

winder.

left

and

mechanism.

through

foot

and

Disengage

a

bobbin

slot

above

wind

toward

Push

take

bring

D.

Draw

foot,

around

a

the

the

it

out.

the

the

the

on

spindle

the

up

and

bobbin

few

turns

right

full

bobbin

Re-engage

needle

needle

sewing

47

needle

into

of

to

start

6

Page 11

Removing

free

Open

lift

then

and

latch

cannot

pulled

fall

out.

out

take

bobbin

arm

the

out

out

cover

bobbin

long

as

the

case

48.

case,

bobbin.

as

you

and

Pull

out

release

The

keep

bobbin

latch

bobbin

latch

the

K

K,

Inserting

the

Insert

so

that

Then

(A>.

the

under

the

the

filled

thread

draw

spring

bobbin

bobbin

unreels

the

into

into

thread

eye

the

toward

into

C.

bobbin

the

slot

case

back

B

and

7

Page 12

Inserting

out

Pull

stud

onto

latch

the

to

case

place.

the

latch

B,

and

make

bobbin

and

K

making

lightly

sureithas

push

sure

press

case

the

slot

against

snapped

bobbin

is

A

up.

the

case

Release

bobbin

into

the

wheel

is

and

up.

hole

back

up

needle

32

Pull

and

Drawing

Hold

hand

movesdownand

lever

needle

left

the

a

you

thread

threads

sewing

thread

little

until

bobbin

the

thread

toward

upagainandthetake-up

bobbin

the

both

lay

under

taut.

the

out

toward

foot.

Turn

needle

of

the

the

8

Page 13

Presser

Lever

42

A=The

remove

toward

take-up

B=The

inserting

The

C

bar

lifter

has

three

sewing foot

the

work,

you

lever

sewing

sewing

footisraised

extra-thick

footislowered

positions:

is

turn

to raise

52.)

raised.

the

the

materials.

(Before

hand

needle

further

for

you

wheel

and

for

sewing.

Thread

The

thread

at

the

sewing

machine

into

the cutter

to

cut

cutter

cutter

backofthe

foot.

Pull

toward

slot

them.

isanoblique

presser

the

work

the

back.

and

pulithem

bar.

out

Draw

slot

located

Raise

of

the

the

threads

downwards

the

9

Page 14

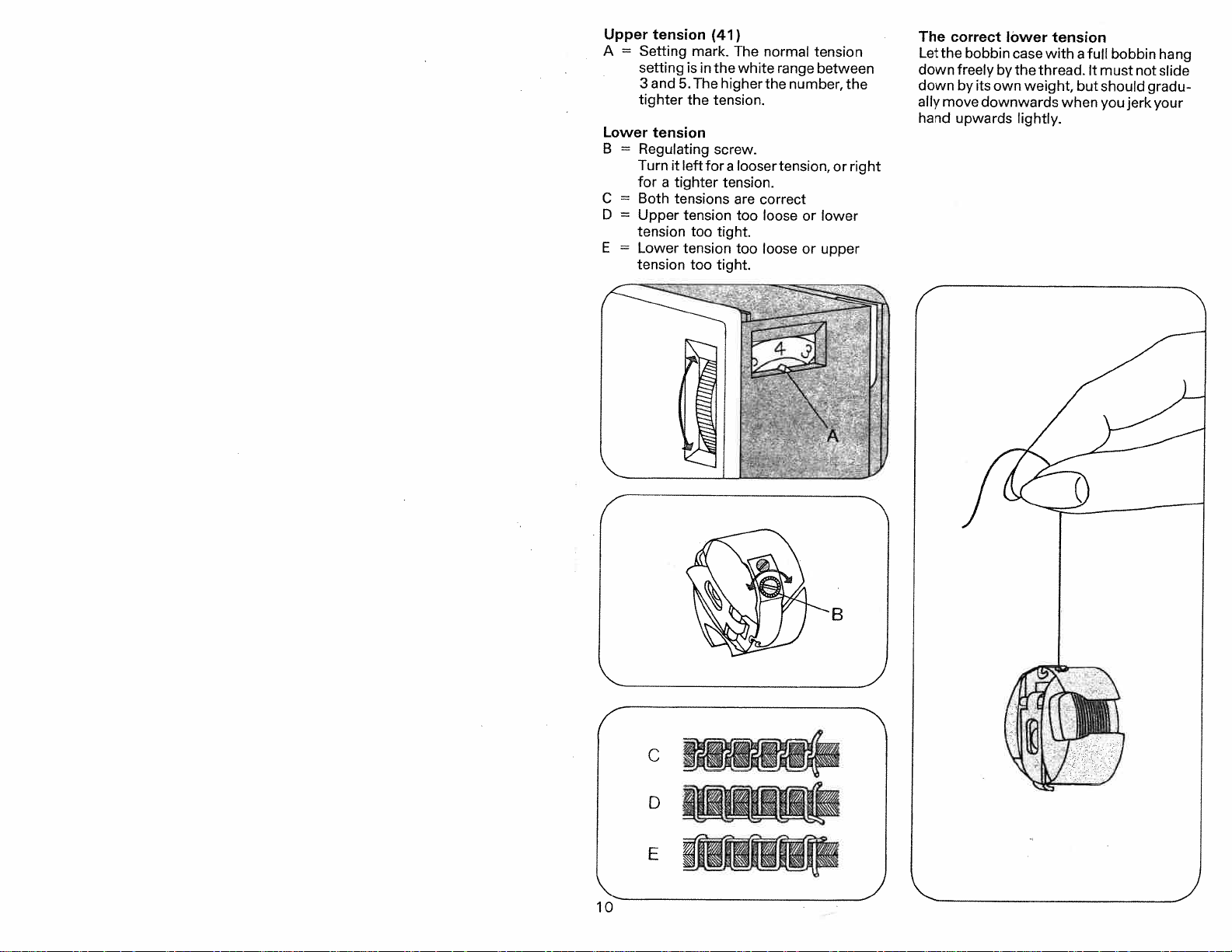

Upper

A

Lower

B

C=Both

D

E

tension

=

Setting

setting

and

3

tighter

tension

=

Regulating

Turn

for

=

Upper

tension

Lower

tension

5.

it

leftfora

a

tighter

tensions

tension

tension

mark.

is

in

The

the

too

too

(41)

The

the

white

higher

tension.

screw.

loosertension,

tension.

are

too

tight.

too

tight.

normal

the

correct

looseorlower

looseorupper

range

number,

tension

between

or

the

right

The

Let

down

down

ally

hand

correct

the

bobbin

freely

by

move

upwards

lower

case

by

the

own

its

weight,

downwards

lightly.

tension

with

thread.

when

a

but

full

It

must

should

you

bobbin

not

jerk

hang

slide

gradu

your

4

4—

10

E

I

Page 15

Regulating

Turn

the

cating

the

mark

A.

Stitch

length

Model

Model

Ill.

control

stitch

B

shows

1025:

1027:

for

symbols

the

control

stitch

range:

0—4

0—6

how

sewing

stitch

so

length

to

on

that

set

stretch

push

length

the

chosen

stitch

the

stitches

buttons).

number

opposite

is

indi

length

(red

Reverse

Push

button

wards.

sewing

button

depressed,

44.

As

long

the

as

you

machine

keep

sews

this

back

11

Page 16

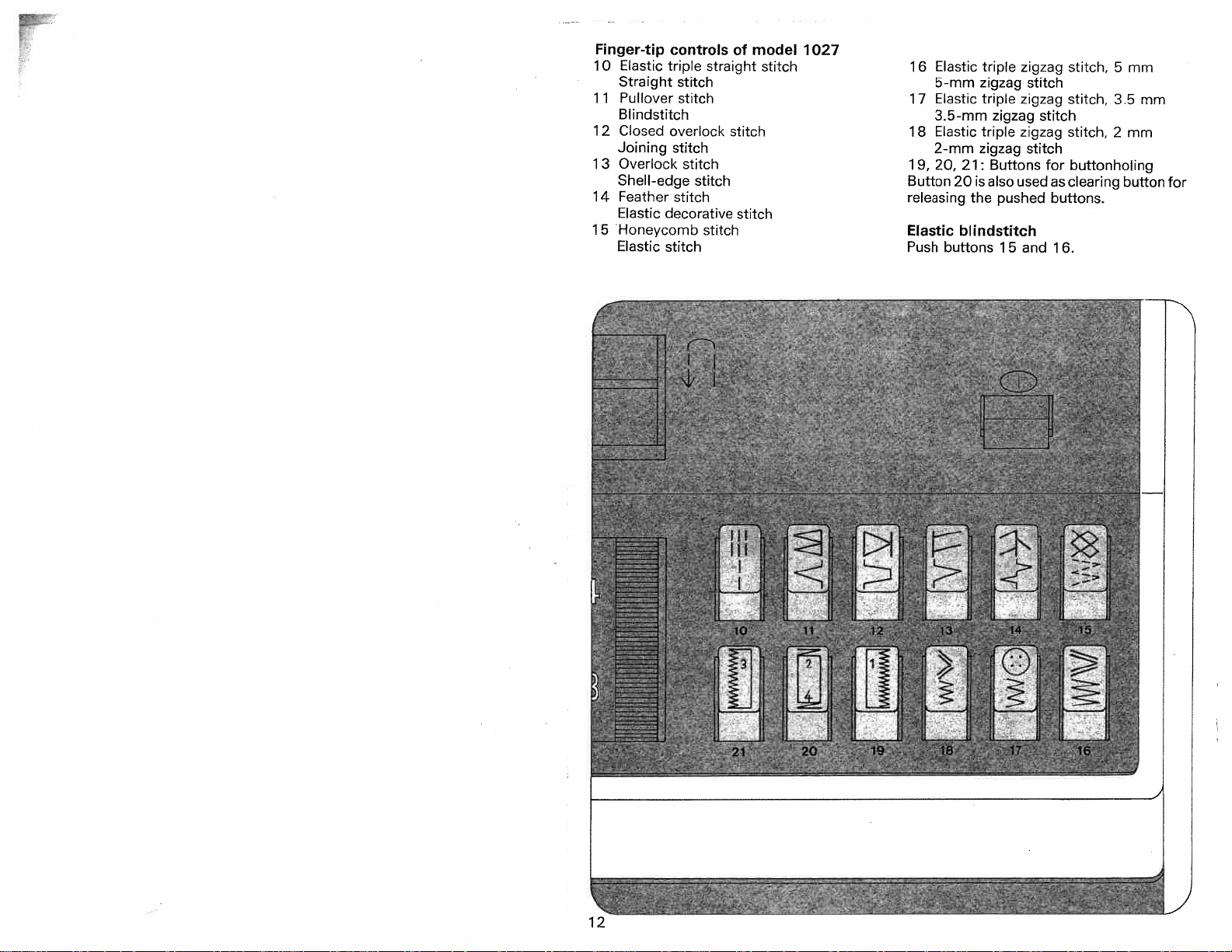

Finger-tip

10

Elastic

Straight

Pullover

11

Blindstitch

12Closed

Joining

13Overlock

Shell-edge

14

Feather

Elastic

15Honeycomb

Elastic

controls

triple

stitch

stitch

overlock

stitch

stitch

decorative

stitch

stitch

stitch

stitch

of

straight

stitch

stitch

model

stitch

1027

Elastic

1

6

5-mm

Elastic

17

3.5-mm

18Elastic

2-mm

19,

20,

21:

Button20is

releasing

Elastic

Push

the

blindstitch

buttons

triple

zigzag

triple

zigzag

triple

zigzag

Buttons

also

pushed

15

zigzag

stitch

zigzag

stitch

zigzag

stitch

used

and

stitch,

stitch,

stitch,2mm

for

buttonholing

as

clearing button

buttons.

16.

5

3.5

mm

mm

for

Page 17

I

Finger-tip

Elastic

10

Straight

Overlock

3

1

Shell-edge

Feather

14

Elastic

Honeycomb

1

5

Elastic

Elastic

1

6

5-mm

Elastic

1

7

3.5-mm

controls

triple

straight

stitch

stitch

stitch

stitch

decorative

stitch

stitch

triple

zigzag

zigzag

triple

zigzag

stitch

zigzag

of

stitch

stitch

model

stitch

stitch,

stitch,

1025

5

3.5

mm

mm

18Elastic

2-mm

19,

20,

Button

releasing

Elastic

Push

20

blindstitch

buttons

21:

the

triple

zigzag

Buttons

is

also

pushed

15

zigzag

stitch

used

and

stitch,

buttonholing

for

clearing

as

buttons.

16.

2

mm

button

for

I

13

Page 18

Selecting

symbols)

(white

the

Push

length

control

desired

or

stitch

1—4onmodel

utility

desired

length

to

stitches

button

the

1025).

and

number

(1

—6

turn

indicating

model

on

the

stitch

the

1027,

Selecting

(red

symbols)

Push

the

control

length

stretch

desired

as

stitches

button

asitwill

far

and

turn

go

the

(red

stitch

symbol).

Page 19

Utility-

model

various

The

the

in

cover.

elastic

select

6,

1

This

1025.

and

1027

chart

For

example,

blindstitch,

a

stitch

stretch-stitch

combinations

stitch

inside

on

the

if

push

stitch

length

can

alsobesewn

you

of

want

buttons

between

combinations,

are

shown

the

hinged

sew

to

1

5

1

and

with

model

top

an

and

Selecting

straight

Left

Central

Right

buttons

4.

needle

needle

needle

11

the

stitching

position:

position:

position

and

needle

1

2.

position

push

push

(model

button

button

1

027):

for

20

1

push

0

L

6

L

ri

J

Page 20

Dropping

Open

free

control

(for

embroidering,

For

sewing,

toward

the

arm

toward

A.

machine

cover

B.

push

48.

The

feed

darning,

the

feed

Push

dog

etc.)

drop-feed

the

is

dropped

drop-feed

control

Changing

Raise

the

loosen

screw

downwards.

1

30/705

shank

facing

up

as

far

as

Twin

needles

1.4mm

stitch

may

sewing.

the

needle

Insert

needle

H

toward

it

will

be

needle

A

with

used

bar.

and

go.

Then

pull

new

a

(with

the

Then

needle

a

for

hold

the

System

the

flat

back)

tighten

zigzag

the

needle

side

and

push

screw

distance

and

needle,

out

its

of

of

utility

it

A.

16

Page 21

Changing

release

To

button

make

sure

sewing

and

hold

A.

foot

the

the

When

stud

under

it

in

sewing

sewing

attaching

B

the

place

enters

sewing

with

foot

foot

push

a

slot

your

the

sewing

Place

C.

foot

holder

left

red

foot

hand.

the

Lower

time

B

fits

for

attaching

to

secure

presser

presser

reposition

in

slot

C.

the

bar.

bar

the

Hole

an

edge

sewing

lifter

sewing

E

and

guide.

foot

42

screw

and

foot

Screw

holder

at

so

Dare

the

that

serves

F

on

same

stud

used

the

17

Page 22

Special

A

Blindstitch

Blindstich

screw

B

Zipper

First

push

zipper

stitching

chain.

Darning

C

Remove

secure

screw

sewing

D.

foot

insert

its

foot

the

H.

foot

guide

its

front

can

along

foot

the

darning

feet

Eisadjusted

pin

rear

into

pin

be

adjusted

the

sewing

foot

into

right

foot

groove

groove

sideways

or left

holder

in

position

by

G.

zipper

turning

then

F,

The

for

and

with

Buttonhole

Push

button

density

length

foot.

Placeitover

taut

As

This

length.

and

you

serves

in

control

Insert

sew,

the

the

the

clamp

arrow

to

settings

1

9

(A).

buttonhole

(B).

Attach

filler

rear

lugofthe

in

front

it

E

moves

determine

Regulate

range

the

cord

as

lug

along

the

the

stitch

of

the

buttonhole

follows

foot,

pull

D.

scale

buttonhole

stitch

(C):

it

F.

Page 23

Sewing

the

Pull

ward

Sew

1

wheel

Push

2

until

tacking

release

Push

3

hole

Raise

4

buttonholes

bottom

far

as

first

torward

button

the

stitches.

the

button

seam

the

the

of

will

it

as

buttonhole

you

20

and

machine

Raise

button.

.

Sew

21

same

the

needle.

buttonhole

go.

seam.

to

raise

keep

has sewn

the

the

second

length

foot

Turn

the

it

depressed

4to6

needle.

as

the

for

hand

needle.

Then

button

first.

bar-

4

5

6

Push

until

tacking

release

Sew

wheel

is

up.

cord

Cut

the

button

the

machine

stitches.

the button.

a

few

tying

toward

Remove

taut

and

buttonhole

20

stitches.

you

the

trim.

and

has

Raise

until

fabric,

keep

sewn

the

the

open.

it

needle.

Turn

take-up

pull

depressed

4to6

Then

the

hand

lever

the

filler

bar-

19

Page 24

Sewing

A

Normal

B

Clear-view

C

Buttonhole

D

Hemmer

I

feet

sewing

foot

foot

foot

foot

A

98-694

563-00

E

Zipper

F

Blindstitch

G

Darning

H

Guide

foot

foot

foot

98-694

20

98-694

D

401-00

Page 25

Changing

Push

the

pull

and

pins slide

its

toward

the

light

it

out. Insert

in

B.

light

bulb

slots

bulb

up,

turnittoward

the

new

C.

Push

bulb so

it

up

and

A

that

turn

it

Cleaning

Tilt

needle

takeitout

the

parts

withasàft

because

to

doisput

way

now and

oiling

and

up

38

Clean

vicinity

Do

maintenance-free.

dropofoil

in

it

plate

(B).

the

brush.

is

a

then.

at

the

of

not

into

the

back

machine

the

sewing

oil

the

the

(A)

feed and

machine

All

you

hook

and

hook

have

race

21

Page 26

Trouble

shooting

use:

rCa

Machine

1.

Needle

Wrong

Needle

Machine

Needle too

Needle

2.

any

For

Thread

Poor-quality or

thread

excessive

Needle

3.

Needle

Needle

Needle

Needle

because

Bobbin

not

needle

bent

threaded

thread

of

the

tension

that

storage.

breaks

pushed

not

bent.

too

bent

work

case

skips

inserted

used.

or

blunt.

for

thin

above

too

knotty

become

has

or

thin

and

strikes

is

pushed

improperly

stitches

correctly.

improperly.

reasons.

thread

too

asfar

thick.

needle

or

inserted.

used.

as

thread

breaks

strong.

up

too

used,

dry

it

will

plate

pulled.

by

or

go.

Remedy:

needleupas

Push

flat

shank

system

Insert

Insert

Check

Select

Thread

par.

See

Regulate

only

Use

new

Insert

will

it

go.

Insert

Needle

See

machine

Let

guide

Only

When

against

side

needle.

new

threading.

needle

Chart.

above.

1

thread

good-quality

needle

needle.

new

and

feed

the

inserting

until

it

far

facing

1

30/705

according

tensions.

and

Thread

the

material

bobbin

the

it

snaps

as

toward

H

to

thread.

push

Chart.

work

lightly.

into

it will

the

needle.

Needle

it

up

alone.

case,

place.

go,

back.

and

far

as

press

its

as

22

Page 27

4

Cause:

4.

Tension

Thread

Bobbin

Kinks

material.

Seam

is

not

outofadjustment.

too

thick,

thread

appear

uniform

knottyorhard.

wound

on

top

and

unevenly.

bottom

of

Remedy:

Check

upper

and lower

Use

first-class

During

thread

bobbin

Thread machine

both

bobbin winding,

in

hand,

tension

tensions.

thread

but

pass

stud.

properly

tensions.

only.

do

through

it

and

not

hold

the

check

Machine

5.

Lint

rows

Feed

control

Machine

6.

Thread

has

accumulated

of

feed

dog

dropped.

is

at

ends

feeds

dog.

left.)

runs

in

hook

irregularly

between

(Reverse-feed

with

difficulty

raceway.

or

notatall

tooth

Remove

Flick

reverse-feed

Remove

oil

into

needle

thread

hook

plate

control to

ends

raceway.

and

and

clean

put

a

out

the

drop

lint.

right.

of

23

Loading...

Loading...