Page 1

__

0

C,)

C

C)

oR

0

0

Page 2

Do’s

and

Don’ts

1

2.

3.

4.

5.

Always

running.

is

it

When

pulling

not

Do

may

The

maximum

When

machine

the

beware

changing

the

place

burn

using

plug

out.

your

without

the

of

needle,

the

of

out

anything

permissible

sewing

thread

up-an&down

the

socket.

wall

the

foot

the

on

power

machine

for

sewing

for

few

a

movement

foot,

control,

sewing

the

for

the

minutes.

of

the

otherwise

lamp

time,

first

Wipe

the

bobbin

needle

the

bulb

place

away

and

any

or

machine

is

15

piece

a

oil

any

do

other

watts.

which

not

will

of

turn

parts,

start

waste

may

attention

your

always

inadvertently,

under

fabric

appeared.

have

from

disconnect

the

or

the

the

the

control

sewing

machine

machine

or

foot

motor

and

while

by

run

1

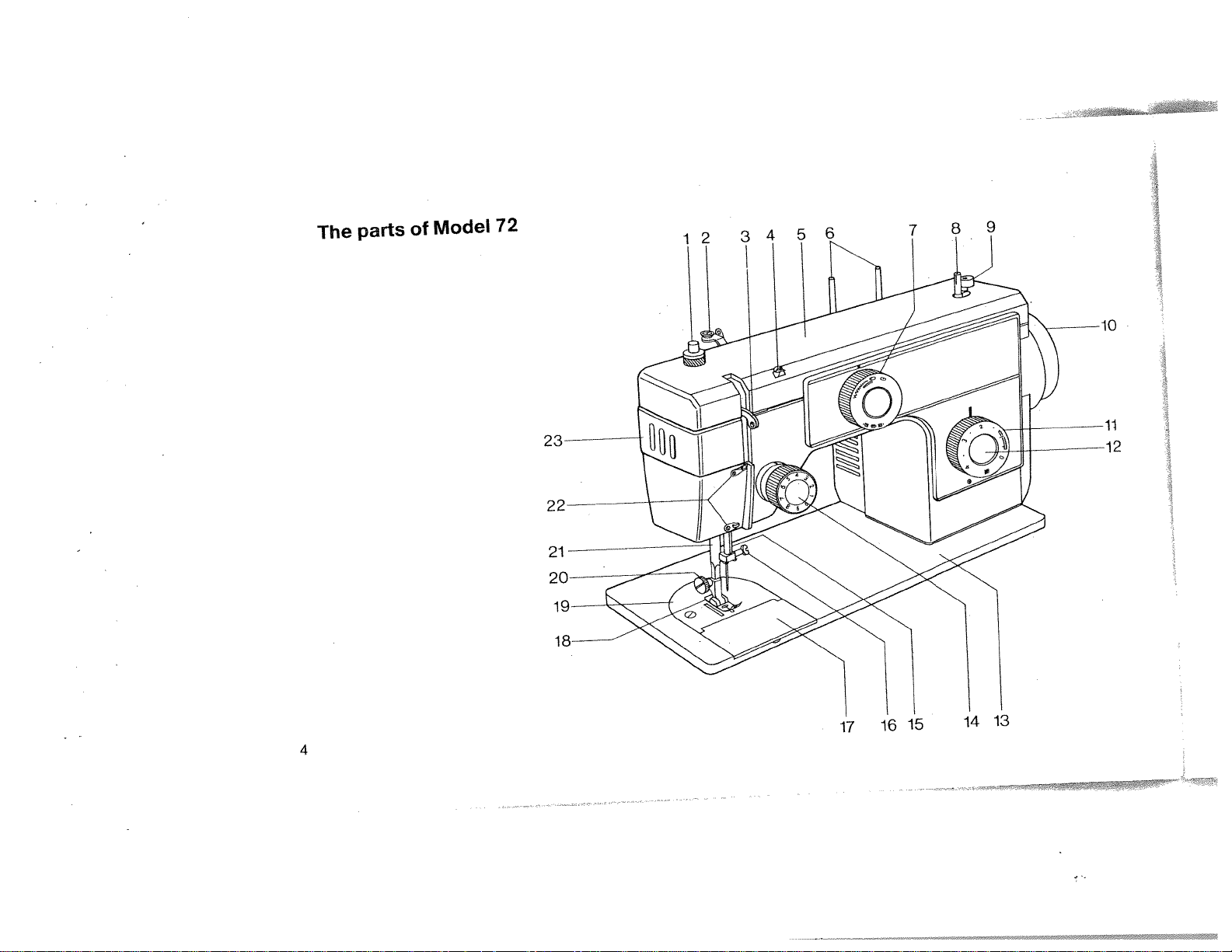

Page 3

Contents

4—

Model

of

parts

The

Model

of

parts

The

Model

parts

usethefoot

sewing

needles,

of

stitch

stitch

stitch

length

to

with

begin

to

turn

to

finish

to

of

workplate,

lamp

the

selector,

selector,

selector,

the

the

the

and

and

the

wind

the

the

the

up

straight

The

Detachable

Howto

The

Table

Inserting

The

The

The

Colourcodeselector

Stitch

Regulating

Regulating

Dropping

Removing

Removing

Winding

How

Threading

Threading

Drawing

Sewing

How

How

2

How

72.

75

77

control

threads

needle

Model

Model

Model

selector

feed

inserting

bobbin

correctly

bobbin

sewing

corners

sewing

and

threadtensions

sewing

inserting

case

needle

bobbin

stitch

Models

and

72

75

77

reversing

foot

the

the

thread

thread

75

fabrics

pressure

bobbin

bobbin

77

and

button

(Patch-O-Matic)

bobbin,

and

case

and

bobbin,

case

Model

Models

72

75

and

77

6—

8—

10

11

1

12

13

14

14

15

15

5

7

9

1

16

17

18

18

19

20

21

22

23

24

25

26

26

27

27

Page 4

Applications

Sewing

Sewing

Tricot

Triple,

Feather

tubular

with

zigzag

straight

stitch,

Overlock

Sewing

Sewing

Sewing

buttonholes

on

in

Hemming

Sewing

Sewing

blind

blind

Embroidery

Cleaning

Cleaning

to

How

belt

Drive

and

Faults

stitch,

zip

the

the

oil

tension

the

for

—

twin

a

stitch,

stretch

Model

buttons

fasteners

hems,

hems,

shuttle

feed

machine

the

how

free

shaped

needle

Models

Models

Model

Models

dog

remedy

to

arm

articles

stitch,

77

75

race

of

75

and

72

75

them

Models

on

77

and

Models

77

and

75

Models

75

77

and

75

and

77

and

77.

28

77

3

Page 5

CD

-4

C’,

-4

CD

a.

0

0

Page 6

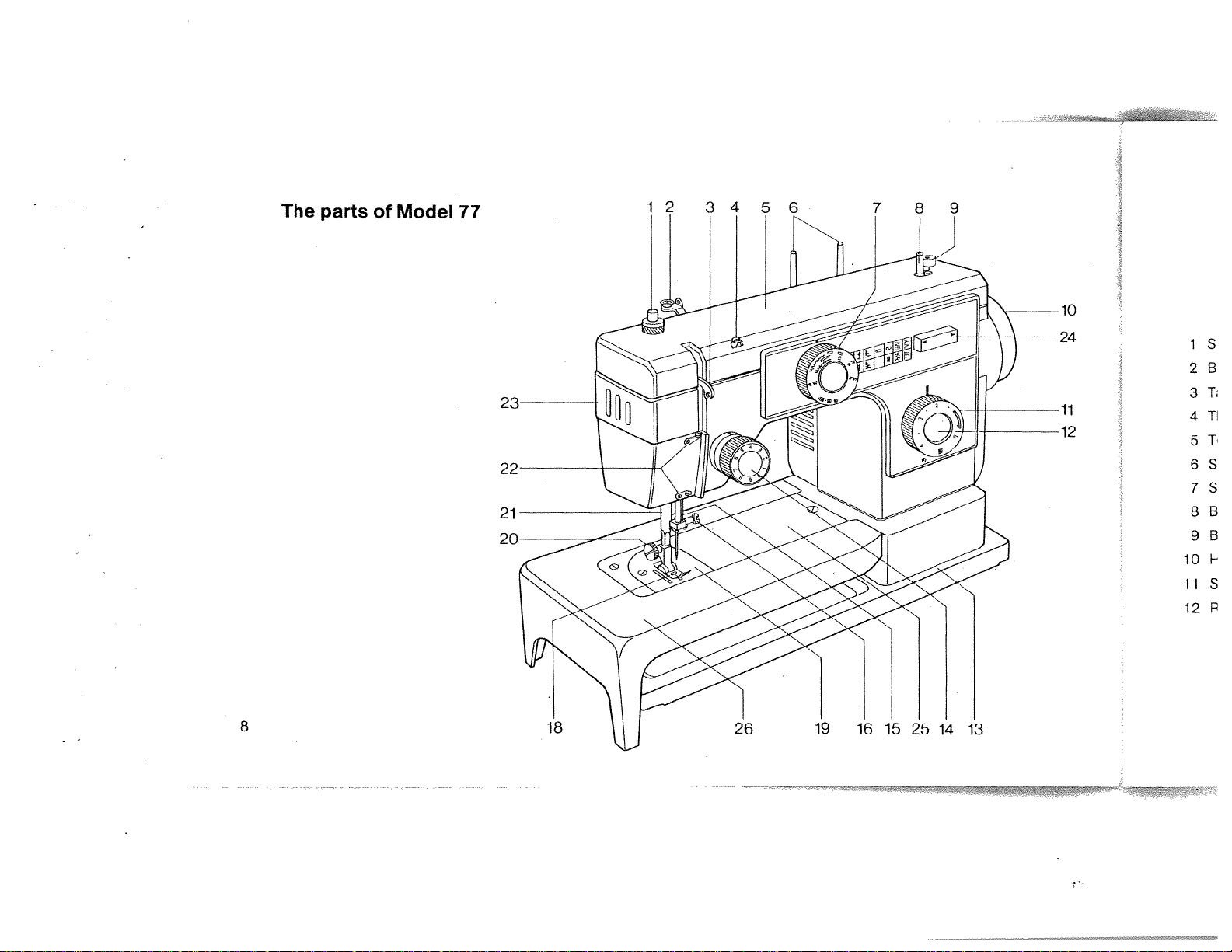

1

2

3

4

5

6

7

8

9

10

11

12

Sewing

Bobbin

Take-up

Thread

Top

cover

Spool

pins

Stitch

selector

Bobbin

Bobbin

Hand

wheel

Stitch

length

Reversing

foot

winder

lever

guide

winder

winder

button

pressure

tension

spindle

stop

selector

regulator

(Patch-O-Matic)

13

14

15

16

17

18

19

20

21

22

23

Bedplate

Needle

Needle

Needle

Bedplate

Sewing

Needle

Sewing

Presser

Thread

Face

plate

thread

bar

holder

cover

toot

plate

foot

bar

guides

tension

with

fixing

fixing

screw

screw

5

Page 7

-l

(D

C’,

0

0a.CD

(Il

-‘

£‘3

()

-

C))

0)

0)

-

C

S

_L

0)

Page 8

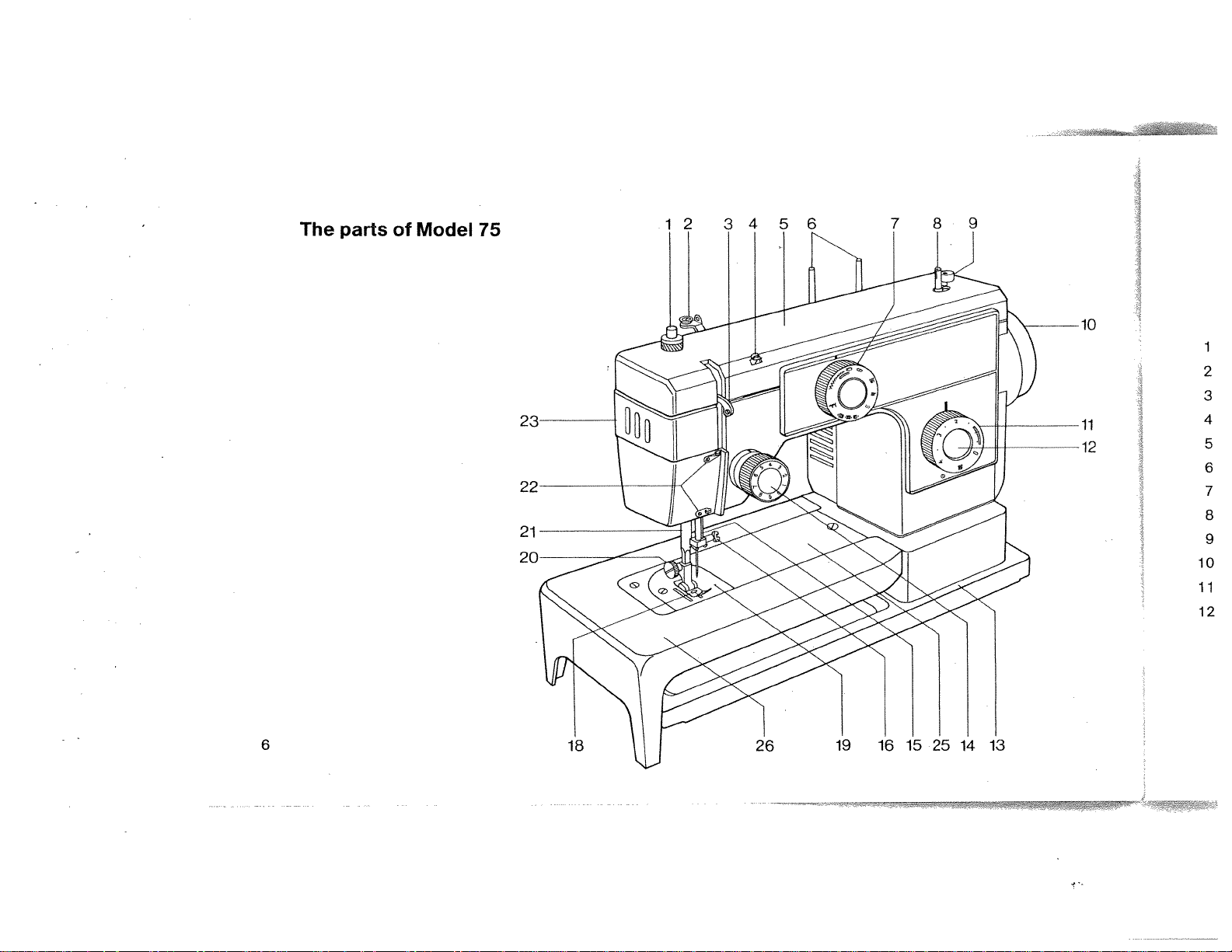

1

2

3

4

5

6

7

8

9

10

11

12

Sewing

Bobbin

Take-up

Thread

cover

Top

Spool

Stitch

Bobbin

Bobbin

Hand

Stitch

Reversing

foot

winder

lever

guide

pins

selector

winder

winder

wheel

length

pressure

tension

spindle

stop

selector

button

regulator

(Patch-O-Matic)

13

14

15

16

18

19

20

21

22

23

25

26

Bedplate

Needle

Needle

Needle

Sewing

Needle

Sewing

Presser

Thread

plate

Face

arm

Free

Detachable

thread

bar

holder

foot

plate

foot

bar

guides

tension

fixing

with

screw

fixing

workplate

screw

7

Page 9

-l

m

0

(I,

0

0

0.

m

-.1

Page 10

10

11

1

1

2

3

4

5

6

7

8

9

2

Sewing

Bobbin

Take-up

Thread

cover

Top

Spool

Stitch

Bobbin

Bobbin

wheel

Hand

Stitch

Reversing

foot

winder

lever

guide

pins

selector

winder

winder

length

button

pressure

tension

spindle

stop

selector

regulator

(Patch-O-Matic)

13

14

15

16

18

19

20

21

22

23

24

25

26

Bedplate

Needle

Needle

Needle

Sewing

Needle

Sewing

Presser

Thread

plate

Face

Colour

Free

arm

Detachable

thread

bar

holder

foot

plate

foot

bar

guides

code

tension

fixing

with

screw

fixing

selector

workplate

screw

9

Page 11

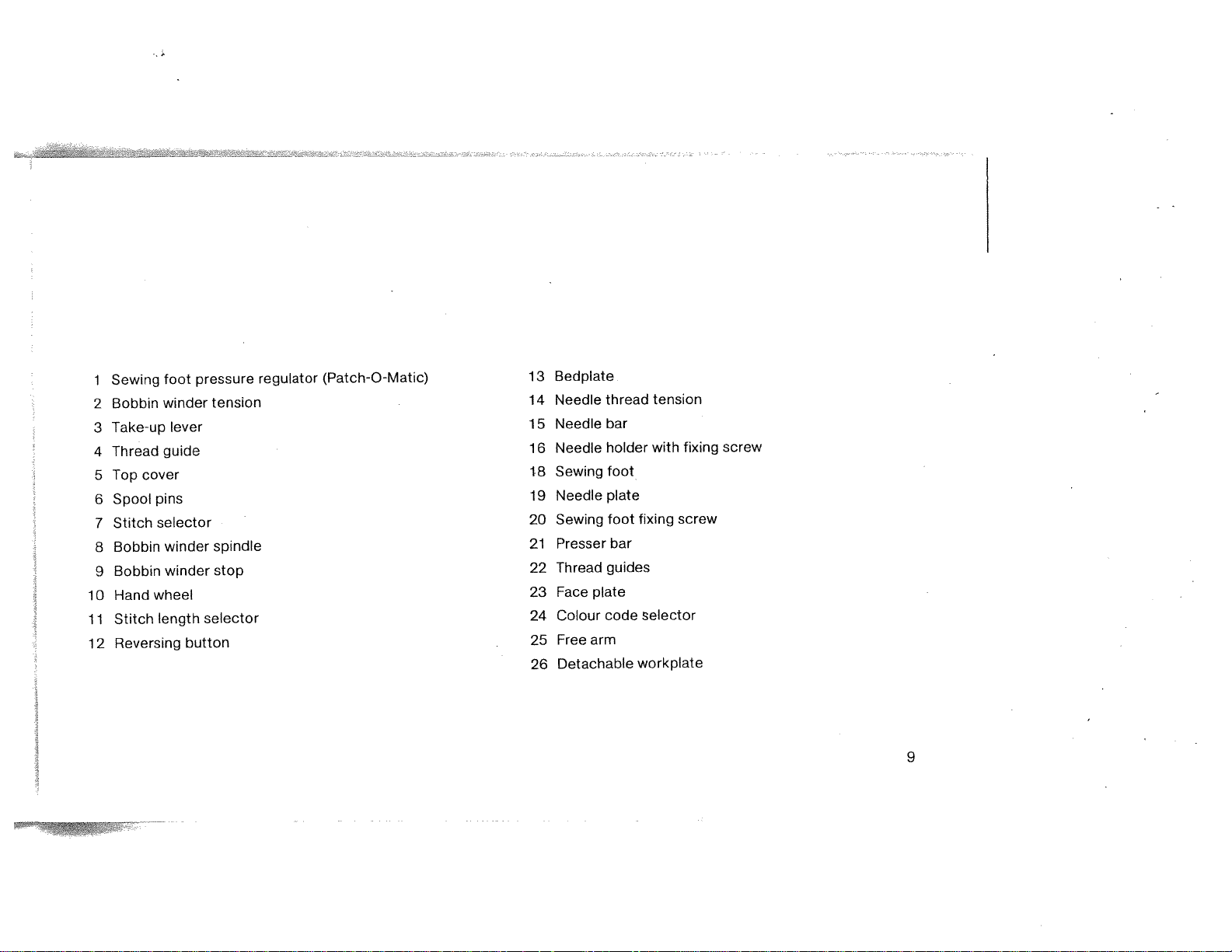

Detachable

The

detachable

sewing

Removing

Lift

operations.

the

end

workplate,

workplate

of

the

V

increases

workplate

Models

near

to

the

sewing

the

75

lug

and

area

and

for

pull

77

ordinary

it

F

P

T

away.

-I

*

10

Fitting

Push

until

Note:

the

its

lug

The

tubular

workplate

snaps

detachable

articles.

into

over

the

workplate

the

notch

free

arm

in

the

is

removed

of

arm.

the

sewing

to

allow

machine

sewing

*

of

*

Page 12

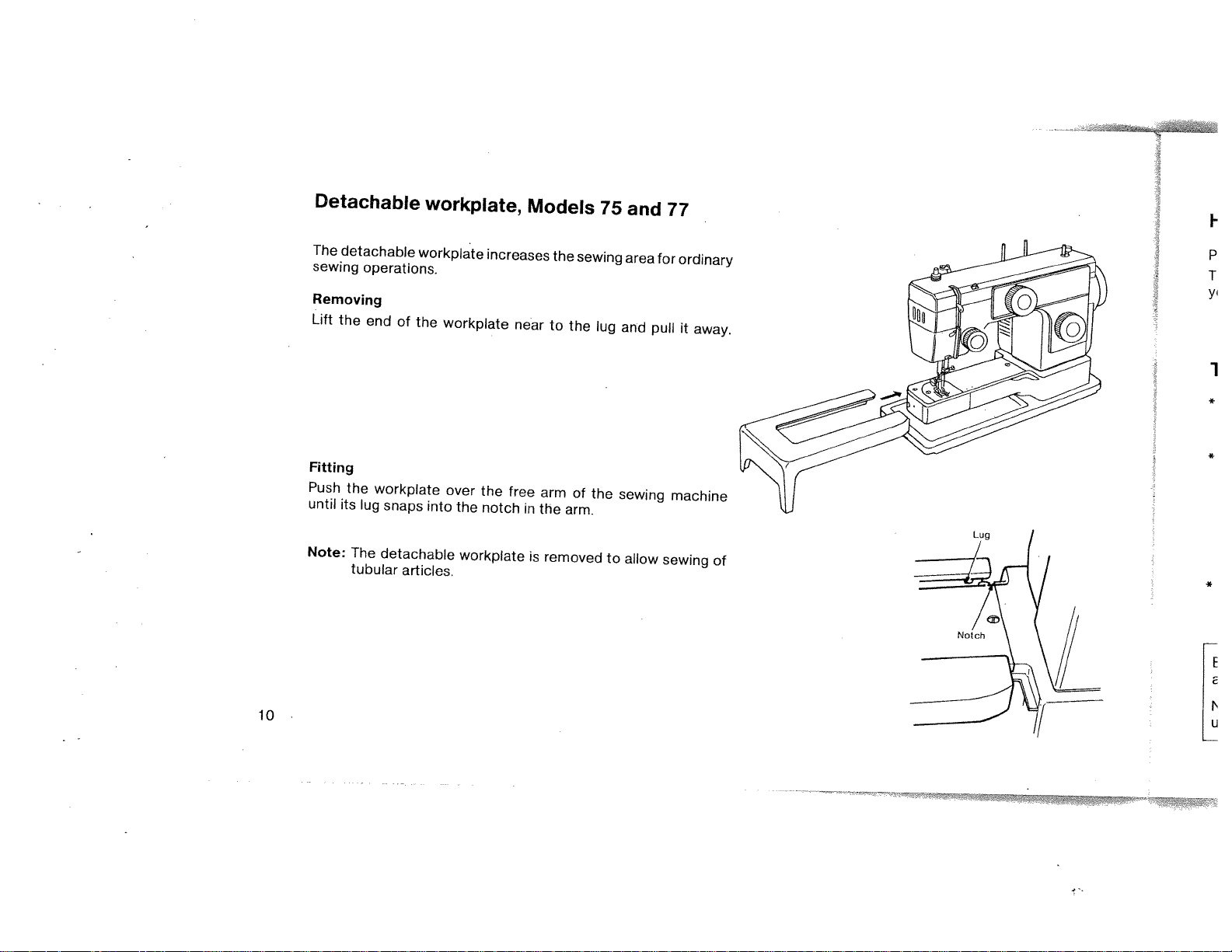

How

to

use

the

foot

control

the

Place

Turn

the

press

you

The

sewing

*

Switch

The

sewlight

*

Changing

Bulb

Type

Bulb

Type

*

Bulb

Use

15-watt

a

Before

always

Never

unintentionally,

leaving

remove

place

control

hand

the

the

(A):

(B):

in

wheel

pedal

lamp

switch

bulb

bulb.

the

the

anything

or

position

a

towards

faster

the

is

found

remove

To

replace

To

To

remove

To replace

machine,

mains

on

the

control

the

where

changing

plug.

foot

you

machine

the

on

the

—

Turn

—

Turn

—

Push

—

Push

Caution!

or

motor

can

you

press

and

control,

sews.

back

of

counter-clockwise

clockwise

and

twist

and

twist

parts

otherwise

may

reach

it

easily

the

pedal

plate.

face

counter-clockwise

clockwise

or doing

burn

any

the

out.

with

down.

other

machine

your

The

work

will

foot.

harder

on

start

[JO

it,

(A)L__-

1

(B)

11

Page 13

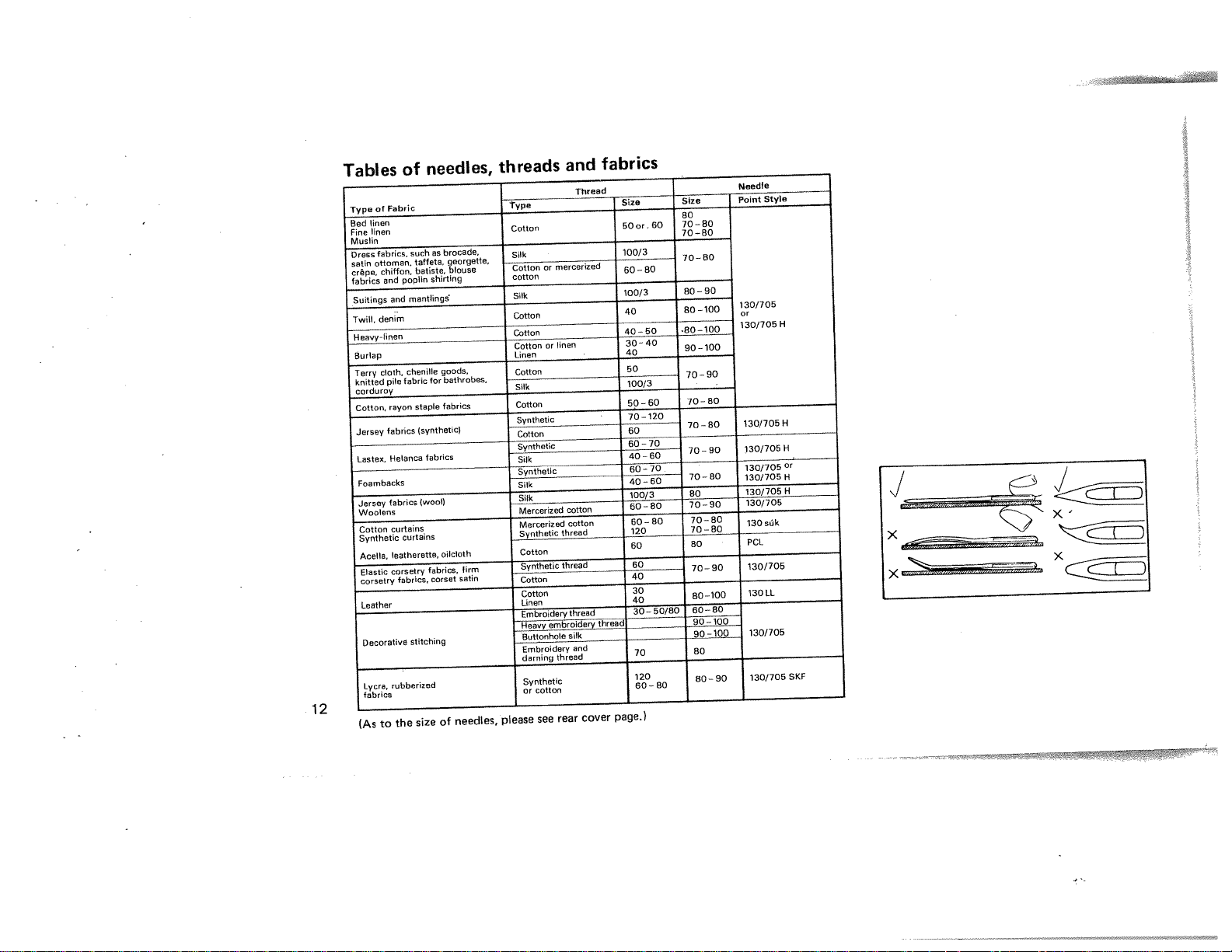

Tables

of

needles,

threads

and

fabrics

xj

12

(As

pagei

cover

rear

see

please

needles

of

size

the

to

Page 14

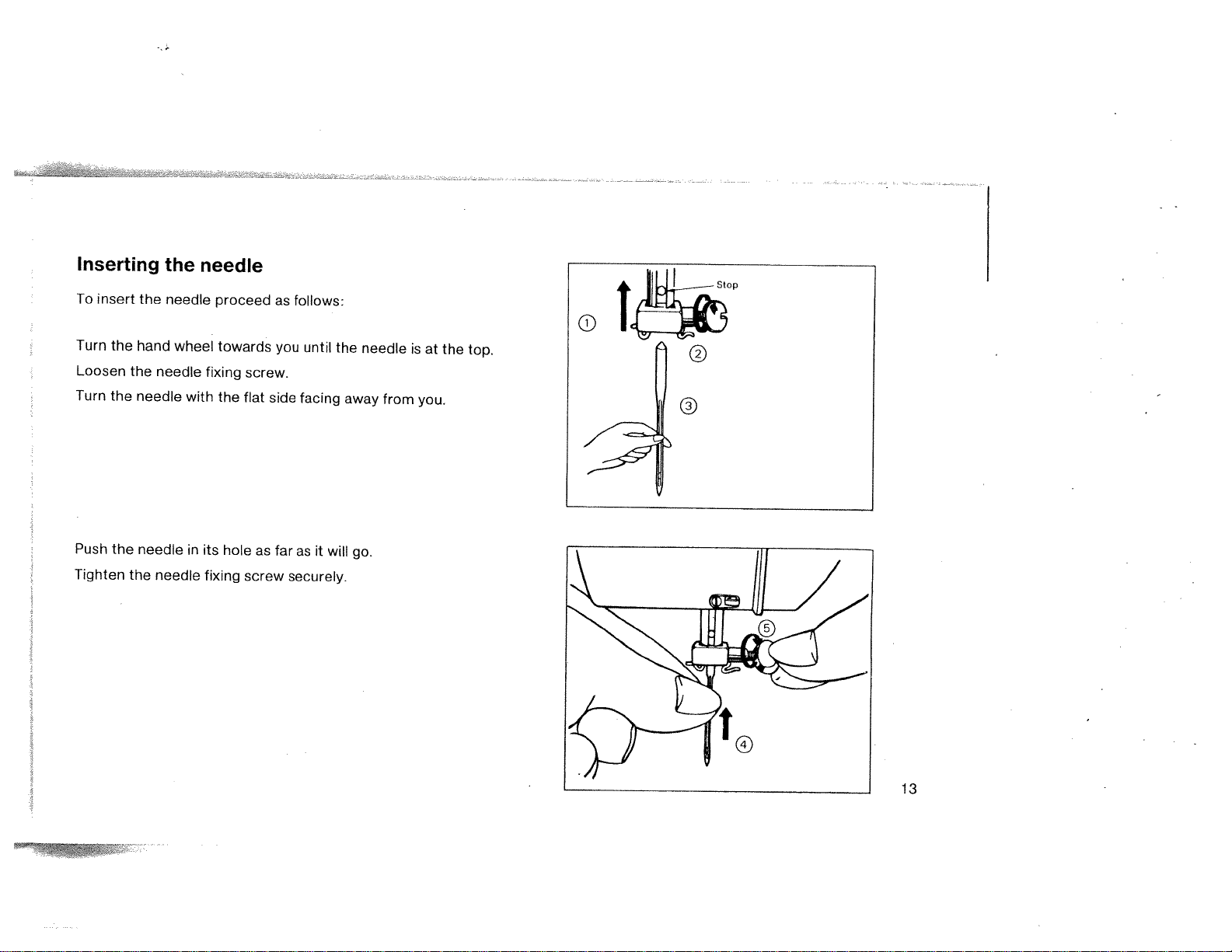

Inserting

To

insert

Turn

the

Loosen

Turn

the

Push

the

Tighten

the

the

hand

the

needle

needle

the

needle

wheel

needle

needle

needle

fixing

with

in

its

fixing

proceed

towards

screw.

the

flat

hole

screw

as

as

you

side

far

securely.

follows:

until

facing

asitwill

the

away

needle

go.

from

is

at

you.

the

o

top.

13

Page 15

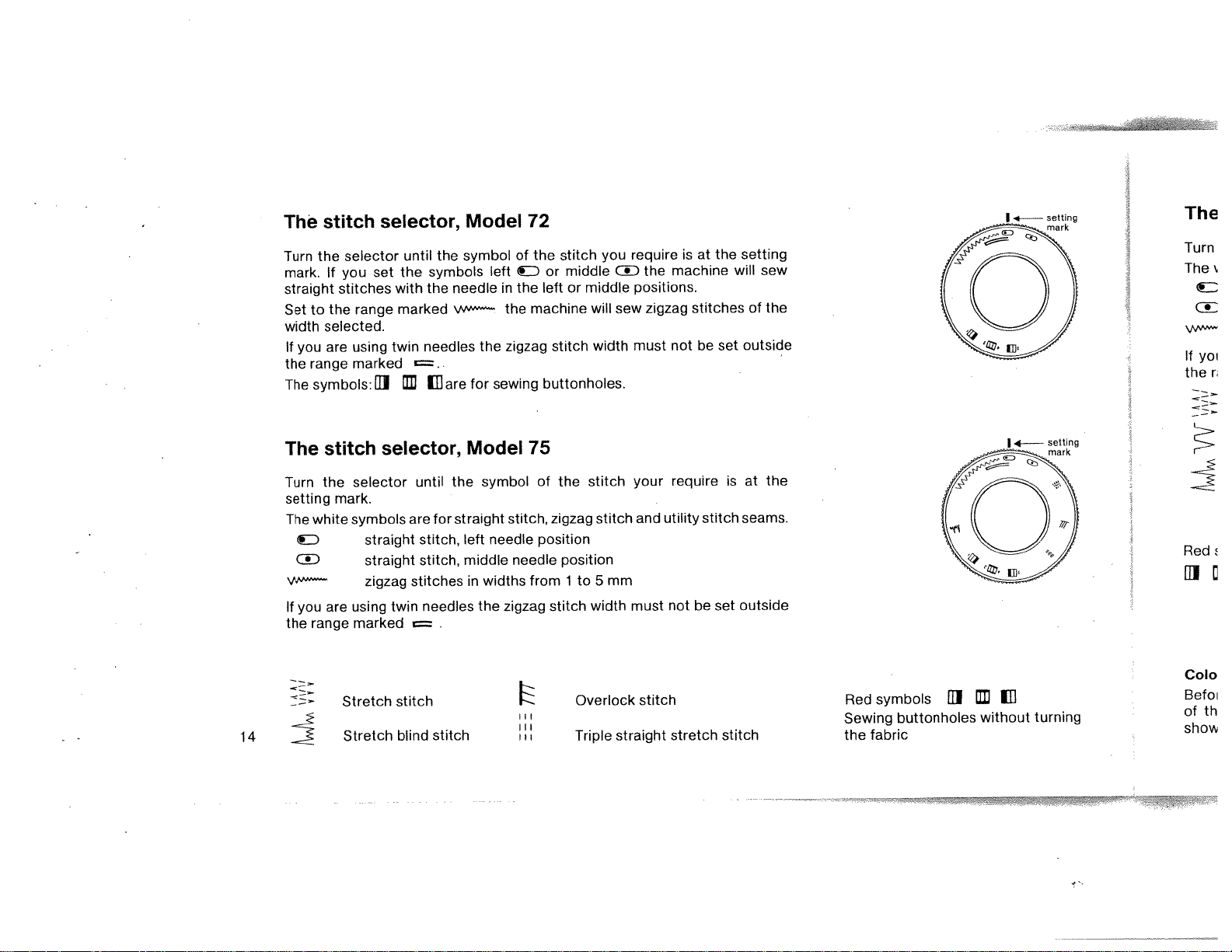

stitch

The

the

Turn

mark.

If

straight

Settothe

selected.

width

are

If

you

range marked

the

The

symbols:

selector

you

stitches

range

using

selector,

until

the

set

with

marked

twin

UI

the

symbols

needle

the

w—

needles

..

are

LU

Model

symbol

left

the

sewing

for

of

D

in

the

the

zigzag

72

stitch

the

middle

or

leftormiddle

machine

stitch

buttonholes.

you

will

width

require

D

positions.

sew

must

the

zigzag

at

the

is

machine

stitches

notbeset

setting

will

of

outside

sew

the

The

Turn

The’.

If

yoi

the

r

14

The

Turn

setting

The

W

you

If

the

stitch

the

white

are

range

selector

mark.

symbols

using

marked

Stretch

Stretch

selector,

straight

straight

zigzag

twin

stitch

blind

until

are

for

stitch,

stitch,

stitches

needles

stitch

Model

the

straight

left

middle

in

the

symbol

stitch,

needle

needle

widths

zigzag

75

of

zigzag

position

from

stitch

the

stitch

position

1

to

width

Overlock

Triple

stitch

mm

5

your

and

must

stitch

straight

require

utility

not

stretch

stitch

be

set

stitch

is

seams.

outside

at

the

Red

Cob

Red

Sewing

the

fabric

symbols

buttonholes

UI

LU

without

turning

Befoi

of

show

th

Page 16

The

Turn

The

W’

If

you

the

stitch

the

white

are

range

selector

symbols

straight

straight

zigzag

using

marked

selector,

untH

the

are

for

stitch,

stitch,

stitches

twin

needles

Model

symbol

straight

left

needle

middle

widths

in

the

77

of

the

stitch,

needle

from

zigzag

stitch

zigzag

position

position

1

stitch

you

require

stitch

to

5

mm

width

and

must

isatthe

utility

not

setting

stitch.

be

set

mark.

outside

Red

111

Colour

Before

of

the

shows

symbols

III

code

you

stitch

the

Stretch

Fancy

Stretch

Sewing

selector

begin

symbol

colour

stitch

stitch

blind

buttonholes

sew,

to

you

range

set.

stitch

set

have

the

selected.

without

lever

turning

of

this

The

the

control

arrow

fabric

to

on

the

the

colour

lever

The

III

\AANv/w

blue

Triple

Triple

Feather

Overlock

Fancy

symbols

straight

zigzag

stretch

White

are

stitch

stitch

and

for

super-utility-stitch

stretch

stretch

stitch

red

range

DcD:

Blue

range

stitch

stitch,

fTh

t

from

seams

1

to

5

mm

15

Page 17

Stitch

To

change

Turn

setting

the

number,

the

length

the

selector

mark

A.

the

length

The

shorter

selector

of

the

so

that

numbers

the

and

stitches

the

number

indicate

stitch.

reversing

proceed

for

the

as

the

stitch

button

follows:

required

lengths

stitch

in

mm.

length

The

is

lower

Re

o

0.5

1

2

3

at

4

16

Sewing

To

sew

the

machine

button

*

Reverse

backwards*:

backwards,

has

the

machine

sewing

made

very

is

push

will

the

sew

useful

the

reversing

number

forwards

as

of

means

a

button

stitches

again:

fully

you

of

strengthening

need.

in

and

When

or

hold

you

securing

it

there

let

go

a

until

of

the

seam.

Stitch

lengths

Corr

tant

thet

res

illust

Rem

u

Page 18

Regulating

the

thread

tensions

increase

needle

tension

or

thread

Correct

tant

the

result.

regulation

for

obtaining

tensions

The

illustrations.

Remarks:*The

the

is

material,

is

not

tensions

correct

fabric

the

needle

tension

of

durable

correct,

are

used.

best

*The

thread

regulated

ly

r’eedle

the

regulated

tension

tension

thread

correct

thread

thread

and

untidy

It

is

tension

by

tension.

tidy

setting

best

on

normal

is

altering

tensions

seams.

seams

as

shown

to

try

a

piece

the

is

impor-

If

will

depends

out

of

one

the

be

in

the

which

waste

of

on

If

the

bobbin

line

on

the

the

needle

loose.

decrease

needle

thread

tension

If

the

needle

material,

the

setatnumber

does,

it

is

tension

as

thread

underside

thread

runs

of

tension

fF

thread

needle

perhaps

shown

4

or

in

runs

thread

lower

necessary

B.

in

the

in

this

a

straight

material,

is

a

straight

tension

fault

to

(A)

too

or

(B)

is

should

increase

If

this

the

sion,

decrease

thread

in

line

set

too

not

you

fault

needle

you

A.

on

the

tight.

normally

the

cannot

by

may

the

tension

top

If

bobbin

remove

increasing

thread

have

bobbin

as

shown

side

of

the

latter

occur.

thread

ten

the

to

is

it

If

17

Page 19

Regulating

the

sewing

foot

pressure

(Patch-O-Matic)

Rer

release the

To

This

causes

The

materialisnow

foot.

For

sewing

littletoprovide

a

you

are

If

farther

the

sewing thick

down

material.

Dropping

Embroidering

disengaged.

drops

the feed

The

length

starts

feed

selectorto“0”orbeyond

foot

free

materials

light

or

normal

pressure,

to

of

sewing

heavy

are

the

function

sewing

the

regulator

thinorlight

the

increase the

to

the

feed

darning

and

Thisisdonebysetting

and

allows

its

pijsh

pressure

push

foot

materials

best

carried

the

again as

it.

to

regulatorBdown

pressure

of

stitch

spring

any

pressure

materialtobe

its

ring

highest

from

push

the

moved

A

downwards.

the

required.

the

sewing

with

out

length

soon

position.

sewing

just

regulai.or

foot

the

feed mechanism

selector

freely

under

you

as

on

at

turn

A

HU

the

the

,which

needle.

stitch

i.

2.

3.

18

Page 20

Removing

and

inserting

the

bobbin

case

and

bobbin,

Model

72

case

open

out

3

with

the

the

bobbin

bobbin

cannot

inside.

drop

Release

out.

the

19

lifting

until

bobbin

As

above

2

long

lever.

the

as

order.

take-up

case

you

latch

hold

leverisat

pull

and

bobbin

the

the

the

top.

bobbin

case

latch

1

fall

Lift

the

the

you

the

out.

1.

2.

3.

Lift

Turn

Open

latch

To

the

the

the

and

insert

sewing

hand

bedplate

the

again

foot

wheel

bobbin

just

raising

by

towards

cover.

will

reverse

Page 21

Removing

1.

Raise

lever

2.

Open

and

sewing

the

isatthe

arm cover.

the

inserting

foot

top.

the

and

bobbin

turn

the

case

hand

and

wheel

bobbin,

towards

Models

you

75

until

and

the

77

take-up

Win

Hold

with

Place

under

Threa

and

Push

stop

Now

away

Tighb

I

y

p

I

20

3.

Lift

the

Release

case

To

insert

bobbin

latch

the

open

again

latch

case

the

just

latch

and

bobbin

reverse

the

and

bobbin

cannot

the

pull

above

the

will

drop

bobbin

out.

fall

out.

order.

case

As

out

long

with

as

you

the

bobbin

hold

the

inside.

bobbin

3

Page 22

Winding

Hold

the

with

your

Place

a

under

the

Thread

and

Push

stop

Now

away

Tighten

the

place

both

fits

let

from

the

hand

right

reel

disc

the

spindle

into

the

the

wheel

of

bobbin

bobbin

the

machine

the

locking

bobbin

hand

thread

winder

of

bobbin.

stop

firmly

(turn

through

and

and

screw

on

tension

on

winder

bobbin

run

cut

with

towards

pin

1.

one

towards

until

the

on

the

your

you).

Pass

2.

of

spindle

the

thread.

hand

left

the

its

3.

the

bobbin

wheel

hand

thread

holes

back

and

from

stops,

again.

undo

through

that

so

then

the

the

the

push

locking

the

inside

bobbin

eyelet

outwards

the

screw

and

winder

spindle

21

Page 23

I

cr-i

0

0D

a-CD

DciøZ-

CQDO_

—

9

D

CDDQ

D0-

CD

0

<D)

—

D

CDCD

C,

0

-I

m

CD

0

cCOD

a

D

,-

0

CD

.

CD0O

D

-.oCJ)

DC)CDcD.g

-

CD

DO

0

D

D

0

0

D

0

f

-

I

CD

oo

CD

—

Cr)

CD

—

cr

0

°CD

—.

D

CO

0

D

a

C)

CD

D

o

00

D)

ZTD

000

*

:r

D0

D

CD

*

—

CD_.D)-Q

*

D

CDD

P-

39.

CD

HD

0

Cl)

DD)

D)C

CD

DD

—

—

D

=

a

3

c

—

ocr

-

0

*0

a-

S

3

—

-

D

a

—

3

0

<

CD

-+CD

D

CD

a

CDO°

0

-

.

D)

O

0

<

CD

4

.4

Page 24

Threading

bobbin

the

Hold

the

Hold

shown

as

filled

the

bobbin

in

bobbin

the

betwen

the

bobbin

case

drawing

inside.

in

the

your

left

and

case

thumb

hand

place

and

forefinger

the

Pull

edge

of

your

of

thread

the

right

bobbin

into

hand

the

case.

and

slot

pull

in

the

off

a

few

Now

spring

inches

pull

and

the

of

into

thread.

thread

the

under

thread

the

eyelet.

tension

Inserting

*

When

(see

the

inserting

page

bobbin

19

and

the

case

bobbin

20).

case

machine

the

in

make

properly

place

into

snaps

latch

the

sure

on

centre

the

pin

23

Page 25

Threading

Move

the

take-up

towards

Lift

the

Pass

your

discs

under

Pass

through

end

Thread

through

you.

the

sewing

machine

the

thread

right

3,

and

the

the

thread

of

the

needle

the

thread

as

hand

then

tension

needle

eye.

the

lever

foot

follows:

through

and

upwards.

guide

from

guides

bar.

from

8

needle

to

raising

by

guides

pass

the

and

right

5

the

its

and

front

thread

top

1

thread

When

thread

to

left

6

and

and

position

the

presser

and

from

you

check

through

through

pull

2.

by

Hold

the

do

spring

about

turning

bar

the

right

so,

the

take-up

guide

six

the

lifter,

reel

between

thread

on

its

7

inches

of

lever

at

hand

and

thread

own.

the

of

wheel

thread

with

tension

passes

4,

then

bottom

thread

Dra

(

(

I

24

Holdtl

your

slowly

moves

take-u

l(

Page 26

Drawing

the

Hold

left

your

slowly

take-up

towards

moves

end

hand.

down

lever

up

of

the

Turn

then

is

the

you

at

bobbin

needle

the

until

up

highest

its

thread

hand

again

the

wheel

needle

and

point.

thread

with

the

the

Pull

bobbin

through

needle

thread

the

needle

thread

will

now

hole

slowly.

come

loop.

in

a

The

up

Pull

under

the

about

the

back.

four

sewing

inches

foot

of

and

each

through

thread

to

25

Page 27

Sewing

Sewing

Stitch

Colour

Stitch

with

foot:.......

selector:.....

code

selector:.

length

selector:.

straight

stitch

zigzag

€D

.

white/red

.

ito

Zigzag

foot

tD

or

(Model

4

77)

Stop

then

Turn

Lowe

foot

Hov

Indicationsinthe

selector

How

Place

Hold

wheel

the

fabric

26

only

to

begin

the

material

thread

the

towards

material to

and

press

different

applytoModel

sewing

under

the

ends

loosely

your

with

you

begin sewing.

the

pedal to

operations

77.

sewing

with

your

right

Let

start

concerning

foot.

left

hand so

the

sewing

machine.

the

hand

that

foot

and

the

the

down

colour

turn

needle

the

onto

code

hand

enters

the

Hoid

At

th

secur

Stop

and

Cut

LeavE

t

Page 28

How

Stop

then

Turn

Lower

the

lift

the

to

the

fabric

the

turn

machine

sewing

about

sewing

corners

the

at

foot.

the

and

foot

corner

needle.

continue

so

that

sewing.

the

needle

is

down

material,

in

the

How

the

At

securing

Stop

pull

and

the

Cut

Leave

to

the

about

finish

end

stitches.

machine

the

thread

the

of

material

using

five

inches

sewing

seam,

that

so

out

the

of

press

the

from

cutter

thread

the

take-up

back.

the

let

hanging

reversing

lever

the

into

is

from

button

at

presser

the

the

in

top.

bar,

needle

order

the

Lift

orapair

eye.

to

presser

of

sew

scissors.

few

a

foot

27

Page 29

Applications

for

the

free

arm

of

Models

75

and

77

Sewin

free

The

such

as

28

Here

are

a

few

examples

/

/

your

machine.

of

arm

free

the

of

help

the

with

do

can

you

work

of

kind

the

of

Page 30

Sewing

tubular-shaped

articles

on

Models

75

and

77

use:

tubular

Place

the

the

begin

the

with

darning

How

or

to

sewing

The

sleeves,

as

such

e

trousers

particularly

is

arm

free

suitable

or

for

socks.

the

free

sewing

sew,

to

material

your

articles

article

arm,

foot

hands.

(

over

lower

and

guiding

lightly

gQ

0

29

Page 31

30

Sewing

Pretty

needles

Sewing

Stitch

Stitch

Colour

the

Set

stitch

Insert

side

(flat

Place

machine

The

thread,

passed

thread

needle

Note:

with

coloured

different-coloured

and

toot

selector

length

code

stitch

selector,

twin

the

away

reels

two

except

between

guides

eyes.

Before

in

ded

corner

the

of

out

twin

The

Needles

left.

used

be

twin

a

patterns

selector:.

selector:

width

not

but

needle

from

thread

of

is

threaded

that

separate

either

at

starting

accessories

the

twin

with

fabric

needle

for

can

.

.

between

higher

exactly

in

you).

on

threads

the

side

sew

to

needles

or

for

with

straight

needle

be

threads.

zigzag

range:

0.5

white!red

.

blue

0

than

the

the

in

discs,

needle

of

place

over

they

this

their

stitch

made

foot

(for

1

to

use

2

and

2

same

the

spool

same

are

separately

the

the

have

you

be

will

machine

shank

at

by

0

stretch

length

normal

stretch

range

in

or

a

pins.

way

divided

bar

two

spool

twisted

in

needle

sewing

2

to

needle

way

as

and

round

take

to

has

the

stitch

“4”)

may

a

as

with

the

at

through

through

pins.

the

broken.

or

shank

its

middle

position

with

on

,

break.

single

a

tension,

the

felts

To

needles

can

two

the

one

single

the

two

provi

turn

the

on

only

middle

+

Tric

This

parts

r

Stil

Co

L

a

Page 32

.4-’

Tricot

This

parts.

Sewing

Stitch

Colour

Stitch

stitch

zigzag

is

foot

selector

code

length

very

selector:.

selector:.

stitch,

suitable

Models

for

zigzag

.

white/red

.

0.3

darning

foot

to

4

75

tears.

and

It

can

77

also

—

Note:

Use

hollow

be

used

the

blue-marked

clearance,

Set

for

reinforcing

the

machine

No.

as

needle

130/705

stretch

described

in

the

H-S.

materials

at

accessories

This

will

the

prevent

and

left

sewing

and

or

stitch

begin

a

needle

on

fabric

to

sew.

with

skipping.

31

Page 33

Triple,

straight

stretch

stitch,

Models

75

and

77

Fe

32

If

you

seams

Triple

Sewing

Stitch

Colour

Stitch

wishtosew

need

that

straight

foot

selector

selector:.

code

selector:.

length

stretch

great

stretch

fabrics,

strength,

stitch

zigzag

blue

.

4

.

thisisthe

crutch

e.g.

foot

right

seams

stitch

or

pocket

to

use

seams.

Note:

Use

needle

prevent

avoid

to

Triple

Sewing

Stitch

Colour

Stitch

the

thread

zigzag

foot

selector

selector:.

code

selector:.

length

blue-marked

hollow

with

skipping.

stitch

breaking.

stretch

stitch

.

.

needle

clearance,

is

It

zigzag

blue

4

in

No.

also

foot

the

1301705

very

suitable

accessories

H-S.

This

for

or

Thi

r

L

a

will

Page 34

I

/-&-

I

f

/j

suitable

for

Feather

stitch

This

Sewing

Stitch

Colour

Stitch

and

stitch,

is

foot-

selector

code

length

sewing

for

suitable

selector:

selector:

Model

for

stretch

fancy

-

.

fabrics.

77

effects

zigzag

blue

4

foot

ccessories

H-S.

O5

This

a

or

will

or

33

Page 35

11111

Iii

1111111!

111111

With

edge

Sewing

Stitch

Colour

Stitch

Place

edge.

Lower

Guide

Sew

this

finish.

selector

length

the

the

the

a

on

Overlock

seam

foot

code

fabric

sewing

material

piece

possible

is

it

selector:.

selector:,

under

foot

lightly

waste

of

the

and

stitch,

to

zigzag

blue

.

4

.

sewing

begin

shown

as

fabric

Models

provide

foot

footsothat

sewing.

right.

check

to

raw

the

75

edges,

the

stitch

77

and

especially

stitches

setting.

are

on

easily

made

fraying

over

the

fabrics,

with

good-looking

a

and

lasting

34

The

fabric

overlock

edge

stitches

when

are

descending

plaäed

on

correctly

right.

the

when

the

needle

just

misses

the

Page 36

ewing

buttonhole

e

iy

turning

buttonholes

mechanism

of

the

material.

fitted

in

this

machine

makes

it

possible

sew

to

buttonholes

inashort

time

without

Sewing

Stitch

Colour

Stitch

xchange

&k

the

find

out

=

for

fabrics

foot

selector

code

length

the

location

the

thick

selector:.

selector:.

ordinary

and

most

sewing

length

suitable

buttonhole

LU’-U1

white/red

O3

to

1

,1

foot

with

of

the

buttonhole

stitch

length

foot

(red

the

-,42

sector)

transparent

on

it

is

best

thin

for

fabrics

the

to

foot

fabric

sew

for

using

sample

a

sewing

pencil

a

buttonhole

buttonholes.

or

tailors

inapieceof

chalk.

buttonhole

waste

foot

fabric.

35

Page 37

Sewing

the

Set

the

Set

the

Set

needle

the

the

Set

To

secure

the

Cut

prominent

Please

buttonholes

selector

stitch

selector

selector

point

at

seledor

seam,

the

buttonhole

buttonholes,

before

note:

B

(continued)

B.

the

the

top.

at

If

you

machine

need

E

with

more

enough,

long

is

seam

the

until

slowly

sew

and

1”

III

“

at

needle

the

“4

“3

2’

111

right

the

until

sew

and

“

at

at

stitches

five

about

sew

and

until

seam

long

is

as

then

point

left

C.

one,

then

stop

at

is

the

as

machine

the

stop

D.

E.

point

is

a

not

few

the

at

stitches.

to

damage

needle

the

must

end

be

tacks.

at

needle

the

at

ripper,

to

until

c

taking

another

and

sew

care

symbol

stitches

five

about

sew

and

2”

“4

at

zigzag

can

a

for

seam

be

moved

set

open

the

the

carefully

use

stitch

stitch

filler

a

selector

selector

using

thread.

36

Page 38

ewing

Sewing

stitch

Stitch

colour

Stitch

the

•

hand

e

five

w

the

t

ease

on

foot

selector

width

code

length

stitch

wheel.

six

or

stitch

note:

buttons

selector:.

selector:.

selector

stitches

selector

move

the

.

a

at

slowly.

at

needle

sewing

button

W’

€D

depending

white/red

width

stitch

and

the

to

sew

top

on

foot

holes

that

three

before

button

in

allows

four

or

setting

the

securing

the

needle

stitch

Exchange

sewing

Place

crosswise

under

Set

slowly

hole.

Lower

enter

to

stitches.

selector

foot.

a

the

the

towards

the

the

button

to

needle.

stitch

button

the

the

to

ordinary

the

selector

you.

right

right

on

sewing

sewing

hole

the

Make

width.

sewing

material

direction

at

sure

foot

in

the

€D”

the

onto

button

foot

so

and

needle

that

and

the

with

the

button.

when

its

turn

enters

the

left

you

holes

the

button

are

hole

hand

the

turn

is

left

button

sewing

foot

37

Page 39

Sewing

Stitch

Colour

Stitch

Move

Loosen

Now

the

Set

right

the

sew

hole.

Sewing

foot

selector

code

length

needle

screw

the

the

on

needle

Tighten

selector:.

selector:.

the

to

on

right

the

at

the

the

half

top

screw

in

top

zip

zip

zip

D

white/red

1to4

.

and

foot

the

of

again,

on

fasteners

foot

or

D

on

screw

set

and

zip.

loosen

the

the

sewing

toot

zip

the

the

zip

foot

screw

foot.

foot.

so

and

Now

that

move

sew

the

on

needle

the

the

can

sewing

left

half

enter

foot

of

the

to

into

the

zip.

the

left

left

so

hole.

that

Tighten

needle

the

the

screw

can

enter

r

[

again.

the

38

Page 40

lemming

old

ake

md

ake

mf

the

over

out

sew

sure

hemmer

the

the

the

workpiece

hem.

that

fabric

edge

During

fabric

the

sufficiently

by

and

draw

sewing,

does

that

so

about

fold

not

the

hemmer

‘Ia”

hem

the

the

move

workpiece

and

fabric

place

into

to

under

the

the

edge

it

hemmer

left

the

runs

under

a

right

little

half

freely

Sewing

Stitch

Colour

Stitch

the

foot

and

foot.

by

allow

the

of

through

selector

length

foot

.

code

selector:

selector:.

Secure

the

pullingonthe

run

to

it

foot.

the

into

The

notch

.

folded

threads.

the

fabric

of

the

hemmer

c.D

.

whitelred

.

2to4

hemmer

must

foot.

edge

with

Lower

be

foot.

fed

the

a

into

few

sewing

stitches.

the

foot

scroll

39

Page 41

Sewing

Stitch

Stitch

Attachment

Place

width

Fold

the

Place

against

Lower

the

guide.

Fold

the

the

(No.

fabric

the

the

the

fabric

Sewing

foot:

selector:

length

fabric

1).

over

workpiece

hemmer

presser

selector:

with

apart.

No.

1

again

guide.

foot

The

the

so

under

and

blind

zigzag

stitch

2

blind

wrong

that

the

sew,

hem

to

the

(No.

hems,

foot

width

4

stitch

side

lowerfold

sewing

making

3)is

Model

3

hemmer

up

foot

sure

now

No.

to

5

and

protrudes

so

the

finished.

2

mm

fold

that

72

the

the

double

by

hem

about

double

folded

over

Turn

needle

Loosen

hem

Tighten

A

5mm

folded

edge

No.3

is

to

(5/32”)

the

guide

in

the

the

C

plate

the

the

required

edge

runs

hand

surface.

sewing

between

sewing

middle

(No.2).

is

along

wheel

of

up

foot

the

foot

the

until

Lower

fixing

screw

fixing

two

the

the

screw

and

screw

prongs

feed

sewing

the

of

dog

in

order

sewing

and

the

is

foot.

foot.

make

sewing

below

to

sure

place

foot.

the

the

guide

I

i

40

B

Page 42

Sewing

blind

hems,

Models

75

and

77

Sewing

Stitch

Colour

Stitch

Attachment

Place

(No.

width

the

Fold

Place

against

Lower

guide.

the

the

Fold

foot

selector

code

length

the

fabric

the

the

the

fabric

selector:.

selector:.

with

fabric

1).

over

workpiece

hemmer

sewing

apart.

No.

1

again

guide.

foot

the

so

under

and

The

zigzag

white!red

to

2

blind

wrong

that

the

sew,

hem

4

stitch

the

sewing

making

(No.

foot

side

lower

3)

hemmer

up

fold

foot

sure

now

is

No.2

and

protrudes

so

the

finished.

the

fold

byabout

the

that

double-folded

Turn

needle

Loosen

hem

Tighten

A

over

hem

5mm

double-folded

edge

No.3

is

to

the

plate

guide

the

in

the

(5/32)

C

hand

the

between

the

middle

required

edge

runs

surface.

sewing

sewing

(No.

is

along

wheel

foot

the

foot

of

2).

up

Lower

the

until

fixing

screw

fixing

two

the

the

screw

and

screw

prongs

feed

sewing

the

of

dog

order

in

sewing

and

the

is

foot.

foot.

make

sewing

to

B

below

place

sure

foot.

the

the

guide

A

hem

gude

41

Page 43

Embroidery

Remove

Stitch

Colour

Stitch

While

(Set

*The

sewing

selector’.....

code

length

are

you

needle

the

required

foot

selector:

selector:.

sewing

the

thread

embroidery

stitch

white/red

.

pattern

tension

pattern

width

move

a

can

the

little

be

to

5

3

embroidery

looser

marked

so

on

that

the

hoop

fabric

Place

selector

hoop

slowly

the

the

firmly

and

bobbin

with

fabric

at”

pencil

a

with

do

not

thread

in

an

Lowerthe

“.

both

allow

is

or

tailor’s

embroidery

sewing

hands.

fingers

your

pulled

not

chalk.

hoop.

foot.

to

through

get

Set

Hold

the

near

to

stitch

the

embroidery

the

to

the

needle.

top

length

side).

42

Page 44

Cleaning

the

shuttle

race

machine

This

means

However,

follows:

as

Move

the

cover

or the

both

Turn

ring.

Carefully

shuttle

replace

To

very

Even

make

will

be

it

should

needle

arm

catches

remove

with

race

the

slight

both.parts

equipped

is

seldom

it

bar

cover

a

parts

damage

unusable.

necesseary

necessary

be

to

and

outwards

shuttle

the

brush.

soft

just

with

top

its

take

reverse

the

to

a

out

and

and

shuttle

clean

to

check

to

position.

bobbin

the

take

clean

above

the

shuttle

race

the

Open

out

the

or

cleaner,

shuttle

the

race,

the

case.

shuttle

the

inside

procedure.

shuttle

which

race.

proceed

bedplate

race

of

race

the

can

shuttle

bobbin

shuttle

bobbin

race

case

ring

43

Page 45

Cleaning

In

order

of

dust

and

Remove

Clean

the

Replace

Note:

After

cleaning,

of

sewing

shown

in

above.

to

make

thread

the

needle

feed

the

needle

machine

the

the

feed

sure

waste

with

dog

apply

oil

illustration

plate

plate.

one

to

dog

there

as

as

a

brush

or

the

on

often

shown

two

holes

the

are

drops

no

as

as

right

in

shown

as

disturbances

possible.

the

illustrations

on

the

in

right.

operation

the

on

left.

of

the

machine

it

is

important

to

clean

the

feed

dog

44

Page 46

How

The

drops

If

the

holes

After

to

oil

holes

of

machine

and

oiling

oil

the

are

a

non-resinous

should

run

the

not

do

machine

marked

not

machine

forget

with

sewing

run

fast

to

sew

arrows

machine

well

with

first

after

all

in

the

being

covers

waste

on

illustrations

oil.

If

the

out

on

fabric

machine

of

use

for

about

in

below.

is

for

a

one

order

Before

in

constant

long

minute.

to

soak

oiling,

period,

Before

up

use,

apply

any

they

this

using

excess

should

should

a

few

the

be

be

drops

machine

oil.

wiped

done

Of

paraffin

clean.

every

again

Apply

two

(kerosine)

oil

it

in

or

the

one

three

usual

two

or

days.

to

the

oil

way.

Model

72,

75,

77

Model

Model

72,

72

75,

77

45

Page 47

Drive

If

the

motor

Todothis:

Unscrew

Loosen

Push

the

then

tighten

belt

and

the

motor

tension

no

longer

take

fixing

bracket

the

off

screw

screw

drives

the

belt

of

the

downwards

again.

properly

cover

motor

or

bracket

to

a

the

drive

(see

position

belt

ill,

in

has

below).

which

just

you

can

been

renewed,

push

the

belt

the

inwards

drive

belt

by

tension

about

c

5mm

has

to

be

(3/16”)

adjusted.

(see

ill.),

46

Caution:

never

adjust

the

belt

too

tight

or

you

may

damage

the

motor

or

the

machine!

Page 48

Faults

and

how

to

remedy

them:

Needle

Thread

Something

Thread

Thread

Needle

Needle

Bobbin

Bobbin

Needle

Needle

Needle

Needle

Needle

Fabric

too

You

are

not

properly

tension

is

is

too

check

not

properly

plate,

thread

thread

not

properly

bent

or

worn

bent

not

properly

heavyortoo

pulling

too

wrong

heavy

spring

shuttle

entangled

not

blunt

on

threaded

tight

with

for

is

inserted

or

under

fitted

fitted

the

the

needle

broken

sewing

tension

hard

fabric

needle

because

on

needle

foot

damaged

of

spring

Cause:

incorrectly

bobbin

on

bar

wound

case

bobbin

Needle

Bobbin

Stitches

Needle

thread

thread

are

breaks

breaks

left

breaks

Thread

Loosen

Replace

Change

Have

Insert

Replace

Wind

Thread

out

Fit

needle

Replace

Replace

Replace

Fit

needle

Use

Do

not

properly

tension

a

new

needle

bobbin

bobbin

needle

pull

needle

properly

properly

of

spring

properly

correctly

correctly

correct

Remedy:

fitted

size

47

Page 49

Faults

Thread

Needle

properly

not

Thread

Thread

Tension

Sewing

NeedleBobbin

Machine

and

Dust

Wrong

Drive

tension

thread

size

check

too

foot

and

thread

oil

belt

and

not

needs

thread

used,

tension

not

not

wound

suited

spring

tight

pressure

bobbin

unevenly

oiling

has

how

properly

properly

thread

shuttle

in

too

not

too

now

fabric

to

working

wound

tight

to

regulated

threaded

strong

of

clogged

remedy

Cause:

and/or

properly

quality

poor

machine

them

bobbin

Machine

thread

Shrinking

does

Thread

or

Irregular

not

forms

puckering

stitches

freely

run

loops

Read

Thread

See

Have

of

Read

Read

Use

Re-wind

and

“Fabrics,

the

makes

Read

Read

Clean

Loosen

instructions

machine

spring

seam

instructions

instructions

quahty

top

bobbin

instructions

instructions

machine

tension

properly

threads,

replaced

threads

noise

a

carefully

of

regulating

for

regulating

for

for

on

on

drive

Remedy:

and/or

thread

regulating

how

to

to

how

and

belt

sizes

oil

clean

re-oil

needle-

wind

and

needle-

sewing

shuttle

with

and

bobbin

needles

and

foot

top

bobbin

thread

bobbin

pressure

race

quality

thread

correctly

thread

oil

tension

tensions

48

Page 50

in

sad

in

ure

oil

thread

correctly

thread

tension

tensions

U.K.

10

11

12

13

14

15

16

17

18

Size

of

needles

Germany

W.

3

4

5

6

7

8

9

40

45

50

55

58/60

62

65

70

75

80

85

90

95

100

105

110/115

—__029

U.S.A.

019

019

022

022

025

027

030

032

034

036

038

040

040

040

U.K.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

W.

Germany

130/140

150/160

170

1801190

200

230

250

280

300

350

380

400

120

125

—

U.S.A.

046

048

051

054

067

073

080

090

100

—

120

—

140

156

156

172

Loading...

Loading...