Page 1

creative™

4874

coverlock

Instruction manual

Page 2

Page 3

This houshold sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this household sewing machine.

DANGER - To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine

from the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 12 V, 5 Watt.

WARNING - To reduce the risk of burns, fi re,

electric shock, or injury to persons:

• This sewing machine is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the sewing machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorised

dealer or service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the

Sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep fi ngers away from all moving parts. Special care is required around the Sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may defl ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Hold plug when rewinding into cord reel. Do not allow plug to whip when rewinding.

Keep fi ngers away from moving parts, especially the area near the blades.

•

SAVE THESE INSTRUCTIONS

For the USA and Canada

This sewing machine has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this plug

is intended to fi t in a polarized outlet only one way. If the plug does not fi t fully in the outlet, reverse the plug. If it still

does not fi t, contact a qualifi ed electrician to install the proper outlet. Do not modify the plug in any way.

1-3

Page 4

Table of contents

Technical part

Safety Instructions 1-3

1

How to use this instruction manual 1-6

Parts of creative 4874 1-10

Summary of stitch programs for the creative 4874 1-13

Technical section, general

Machine cover 2-2

2

Electrical connection 2-2

Connect the foot control 2-2

Power switch 2-2

Swivel table 2-3

Trim catcher 2-3

Front cover 2-3

Detachable thread stand 2-4

Thread stand 2-4

Thread guide slide 2-4

Foam pads/Cone holders 2-5

Thread run-off disc 2-5

Spool net 2-5

Detachable thread guide 2-5

Hand wheel 2-6

Presser foot lift 2-6

Presser foot 2-7

Changing the presser foot 2-7

Needle position 2-8

Changing a needle 2-9

Threading (stitch programs 01-20) 2-10 - 2-17

Thread guides 2-10

Threading the needle(s) 2-18 - 2-19

Important note on threading 2-20

Changing spools with the machine threaded 2-20

Needle threader 2-21

Summary of threading paths and

threading sequences 2-22

Speed control 2-25

Presser foot pressure 2-25

Thread cutter 2-26

Check spring for edging the thread chain 2-26

Disengage the upper knife 2-27

Engage the upper knife 2-27

Stitch fi nger 2-28

Attach converter 2-29

Disengage the upper looper 2-30

Remove knife guard 2-31

Set seam width 2-32

Setting the stitch length 2-33

Differential feed 2-34

Electronic functions

Set language 3-2

3

LCD Display 3-2

Button functions 3-4

Save 3-5

Recalling the memory 3-5

Selecting a memory 3-5

Notes on the saving to memory 3-6

Deleting all memories 3-6

Changing settings for tension, stitch length and

differential feed directly without saving 3-7

Error 3-7

Cover stitch

Switching the machine to cover stitch

4

(progs. 01, 02, 03) 4-2

Threading the cover-stitch looper 4-4

Threading the needle(s) 4-6

Summary of threading paths and their threading

sequences 4-7

Important notes on sewing with the cover stitch 4-7

Sewing table 4-7

Starting to sew 4-8

Preparing the project 4-8

Stopping sewing 4-8

Ruler 4-9

Stitch formation 4-10

Top Cover Stitch

Sewing program sticker 5-2

5

Detachable thread guide for top/deco cover 5-2

Detachable thread stand 5-2

Stitch program selection 5-3

Top/deco switch lever 5-3

Accessories 5-5

Top cover hook 5-5

Top cover round thread guide 5-6

Top cover triangle thread guide 5-6

Threading the cover-stitch looper 5-7

1-4

Page 5

Threading the needle(s) 5-9

Top cover thread tension, blue 5-10

Threading the top cover thread 5-10

Summary of threading paths and their threading

sequences 5-11

Starting to sew 5-12

Important notes on sewing with the

top cover stitch 5-12

Sewing table 5-12

Preparing your project 5-12

Stopping sewing 5-13

Stitch formation 5-14

Deco Cover

Sewing for stitch 6-2

6

Detachable thread stand 6-2

Detachable thread guide for top/deco cover 6-2

Top/deco switch lever 6-3

Stitch program selection 6-3

Accessories 6-6

Decorative thread guide 6-6

Threading the cover-stitch looper 6-7

Threading the needle(s) 6-9

Deco-cover thread tension dials, blue and yellow 6-10

Threading the deco cover threads 6-10

Summary of threading paths and their threading

sequences 6-11

Important notes on sewing with the

Deco Cover Stitch 6-13

Sewing table 6-13

Preparing your project 6-13

Starting to sew 6-14

Stopping sewing 6-14

Stitch formation 6-16

Technnical Part

Care of the machine

Removing the needle plate 9-2

9

Placing the needle plate 9-2

Oiling the machine 9-2

Cleaning of the machine 9-2

Cleaning rubber feet 9-3

Replacing the upper knife 9-3

Secure the upper knife for heavier fabric 9-3

Changing the light bulb 9-4

What happens if...? 9-5

Thread Tension

Correct thread tension 7-2

7

Correcting stitch formation 7-3 - 7-22

Thread table for 2-, 3-, and 4-thread overlock seams 7-23

Accessories

Standard accessories 8-2

8

Special accessories 8-5

1-5

Page 6

Simple,

up-to-date sewing

Congratulations! You have bought a high-quality product that provides unique

advantages. Your new creative™ 4874 can take any fabric in its stride and will sew

through thick and thin for you.

Your PFAFF® coverlock™ features the very latest in design and technology, and it is just as

easy to use as this instruction manual is to follow.

If you now take a bit of time to study the instruction manual, nothing can go wrong. It is

certainly time well spent, since it is the only way to fi nd out just what your machine can

do, and make full use of all its features.

If you have any further questions, just ask your PFAFF dealer. He is happy to be of service

with any help or advice.

So now let’s get started! We wish you many enjoyable hours creating your very own

fashion ideas!

How to use this instruction manual

To make it as easy as possible to use your creative 4874, we have given this instruction

manual a clear structure. The various chapters cover the following topics:

1. Technical part – This chapter contains pages that describe the individual parts of the

machine, as well as the table of contents and a program summary.

2. Technical section, general – This chapter contains information on all the basic

mechanical functions of your creative 4874. You will also fi nd additional information

in chapters 5 and 7.

3. Electronic functions – This chapter contains information about all the electronic

functions of the machine.

4. Cover stitch – In this chapter, we explain the basic functioning of your creative 4874,

using the coverstitch as an example.

5. Top cover stitch – In this chapter, we describe the basic functioning of your creative

4874 with reference to top cover stitching.

6. Deco cover – In this chapter, we are going to describe the basic functioning of your

creative 4874 using the example of the deco cover stitch.

7. Thread tension – This chapter includes information on correct thread tensions for

all the stitches you can create with your creative 4874. We also provide you with a

number of hints on selecting the correct thread.

8. Accessories – This chapter includes a list of all standard and special presser feet

available for use with your creative 4874.

9. Care of the machine – This chapter includes all the information you need for care and

maintenance of your creative 4874 and suggestions for solving certain problems.

1-6

Page 7

Technical Part

This chapter contains pages that describe the individual parts of the machine and a

program summary.

Note: Some fabrics have a lot of excess dye which can cause discoloration on other fabric

but also on your sewing machine. This discoloring may be very diffi cult or impossible to

remove.

Fleece and denim fabric in especially red and blue often contain a lot of excess dye.

If you suspect that your fabric/ready-to-wear garment contains a lot of excess dye, always

pre-wash it before sewing/embroidering to avoid the discoloring.

Technnical Part

1-7

Page 8

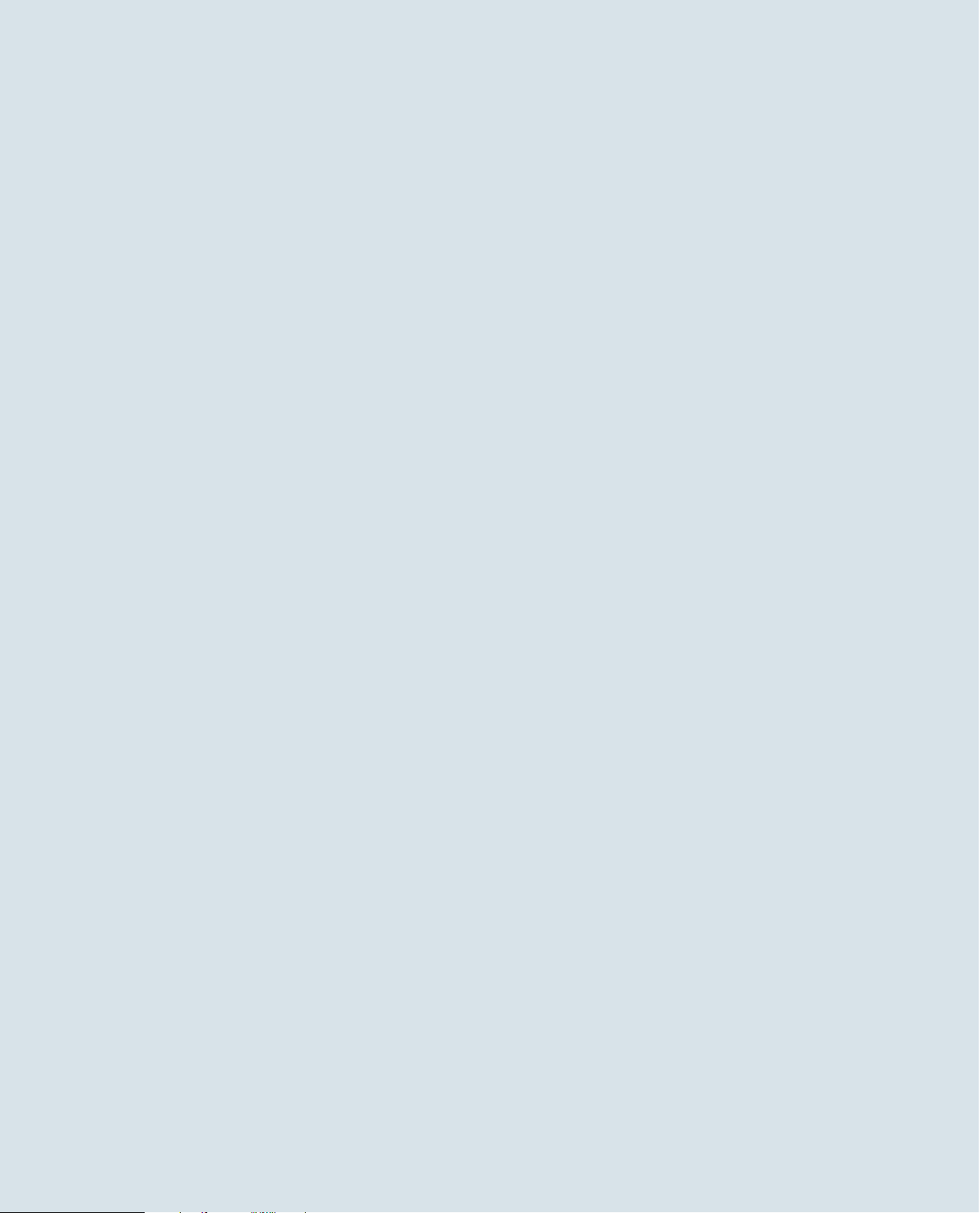

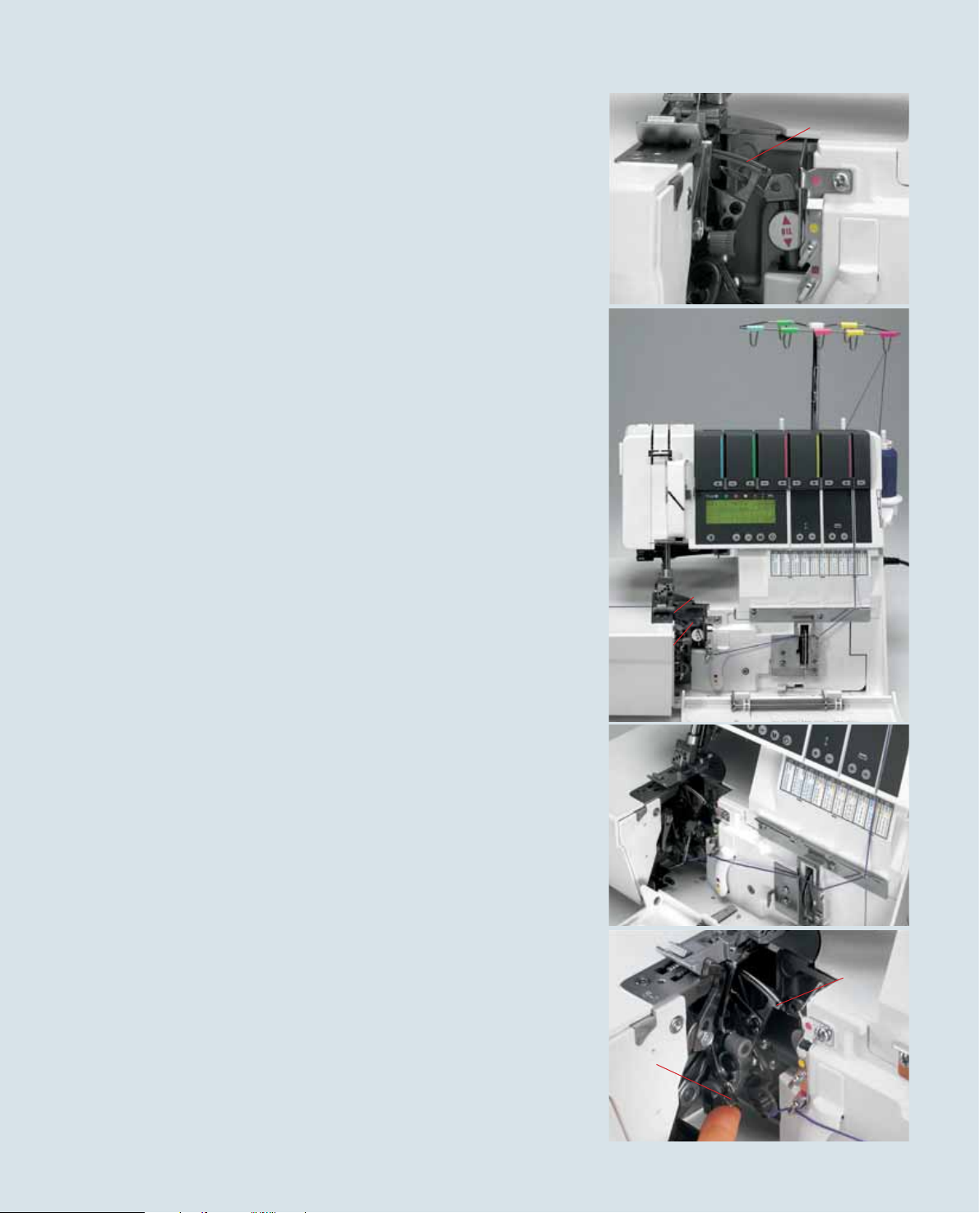

Parts of creative 4874

1 Needle thread tension

2 Needle thread tension

3 Carrying handle

4 Thread tension / upper

looper

5 Thread tension / lower

looper

6 Thread tension/ double

chain-stitch and coverstitch looper

7 Tension buttons + / –

8 Speed control

9 LCD Display

10 Tension release button

11 Stitch program selection

buttons + / –

12 Memory button M

13 Memory selection

button P

14 Stitch length adjustment

buttons + / –

15 Differential feed

adjustment buttons + / –

16 Front cover

17 Knife guard

18 Upper looper

disconnection lever

19 Needle plate

20 Standard presser foot

21 Swivel table

22 Seam width adjustment

knob

23 Viewer for seam width

24 Needle holder

25 Top/deco sewing

program sticker

26 Adjustment knob for

presser foot pressure

27 Detachable thread stand

28 Thread guide slide -

Top / deco cover

29 Color coded thread

guides -Top / deco cover

28

27

23

22

21

29

26

24

2

1

3

4

5

6

7

8

9

25

10

11 12 13 14 15

20

19

16

18

17

1-8

Page 9

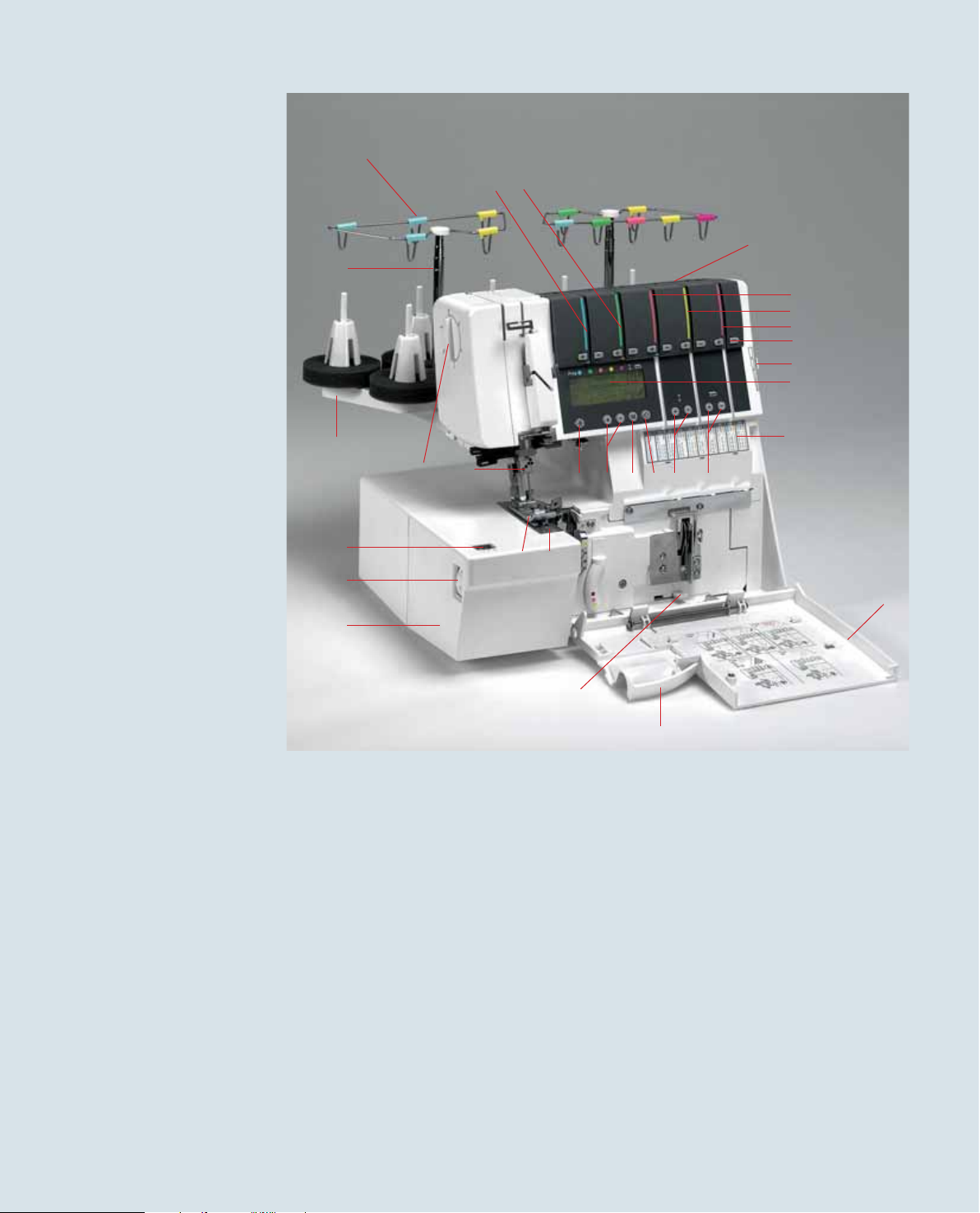

30 Upper looper

31 Lower looper

32 Stitch fi nger

33 Double chainstitch and

cover-stitch looper

34 Threading aid for

double chainstitch and

cover-stitch looper

35 Movable upper knife

36 Fixed lower knife

37 Check spring for edging

the thread chain

38 Needle plate

disconnection lever

39 Knob for lowering the

upper knife

40 Tweezers

41 Converter

42 Allen key

39

40

41

38

Technnical Part

42

30

31

32

33

36

35

34

37

1-9

Page 10

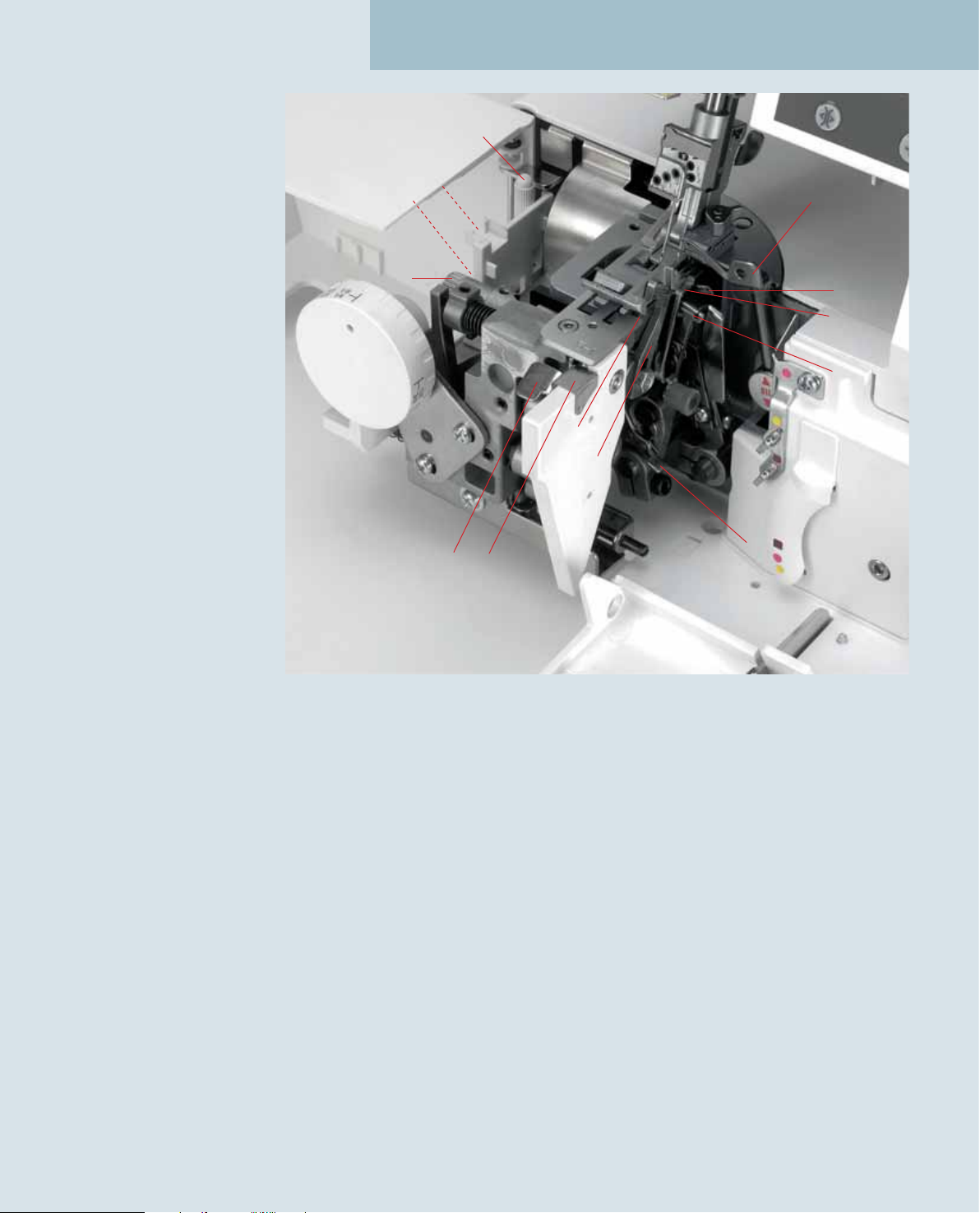

43 Color coded telescoping

thread guides

44 Telescoping thread

guide slide

45 Thread tensions top/

deco cover

46 Rear thread guides top/

deco cover

47 Thread cutter

48 Slots for detachable

thread stand

49 Thread stand

50 Spool pin

51 Cone thread holder

52 Foam pads

53 Power cable socket

54 Foot control socket

55 Power switch

56 Hand wheel

57 Presser foot lifter

58 Rear thread guides

58

57

56

50

49

43

44

45

46

47

48

55

54

51

52

53

1-10

Page 11

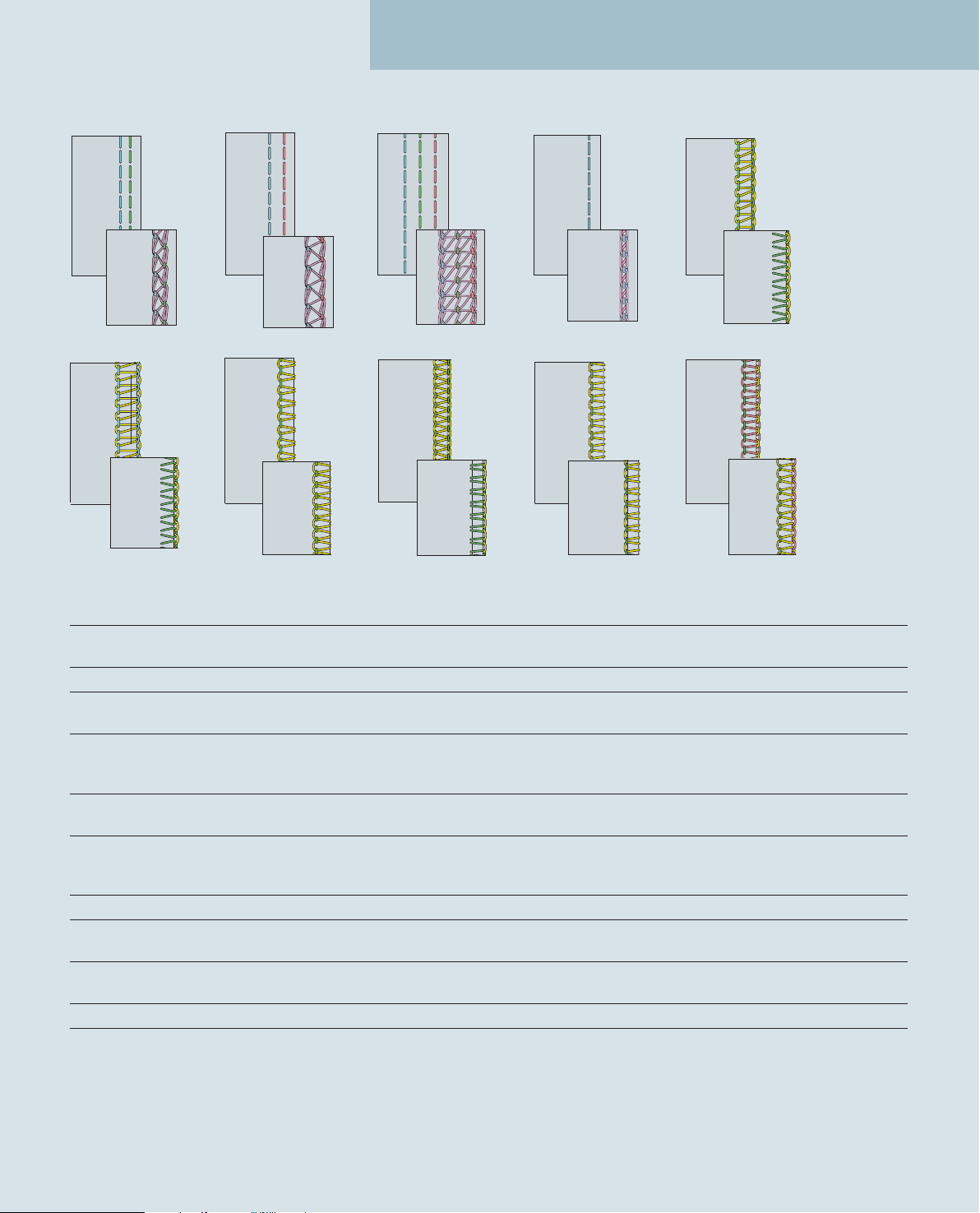

Summary of stitch programs for the creative 4874

Technnical Part

Program 01

Program 06

Program No. Description Use

01 2-needle cover hem, narrow For hemming stretch fabrics and piping, for decorative

02 2-needle cover hem, wide For hemming stretch fabrics and for decorative effects.

03 3-needle cover hem For hemming highly stretch fabric and for decorative

04 Chainstitch For sewing together extremely durable fabrics such as

05 2-thread fl atlock, narrow As fl atlock seam for sewing stretchy fabrics together

06 2-thread fl atlock, wide As fl atlock seam for sewing stretchy fabrics together

07 2-thread serging, narrow For overedging light fabrics.

08 2-thread fl at hem For overedging very fi ne fabrics and as decorative edge

09 2-thread fold. rolled hem For overedging very fi ne fabrics and as decorative edge

10 3-thread overedge seam, narrow For edging light, easily fraying fabrics.

Program 02

Program 03

Program 08Program 07

Program 04

effects.

effects.

upholstery covers and denim, both without overedge.

May also be used for decorative effects.

with decorative effect, or for overedging light fabrics.

with decorative effect, or for overedging medium

fabrics.

fi nish.

fi nish.

Program 05

Program 10Program 09

1-11

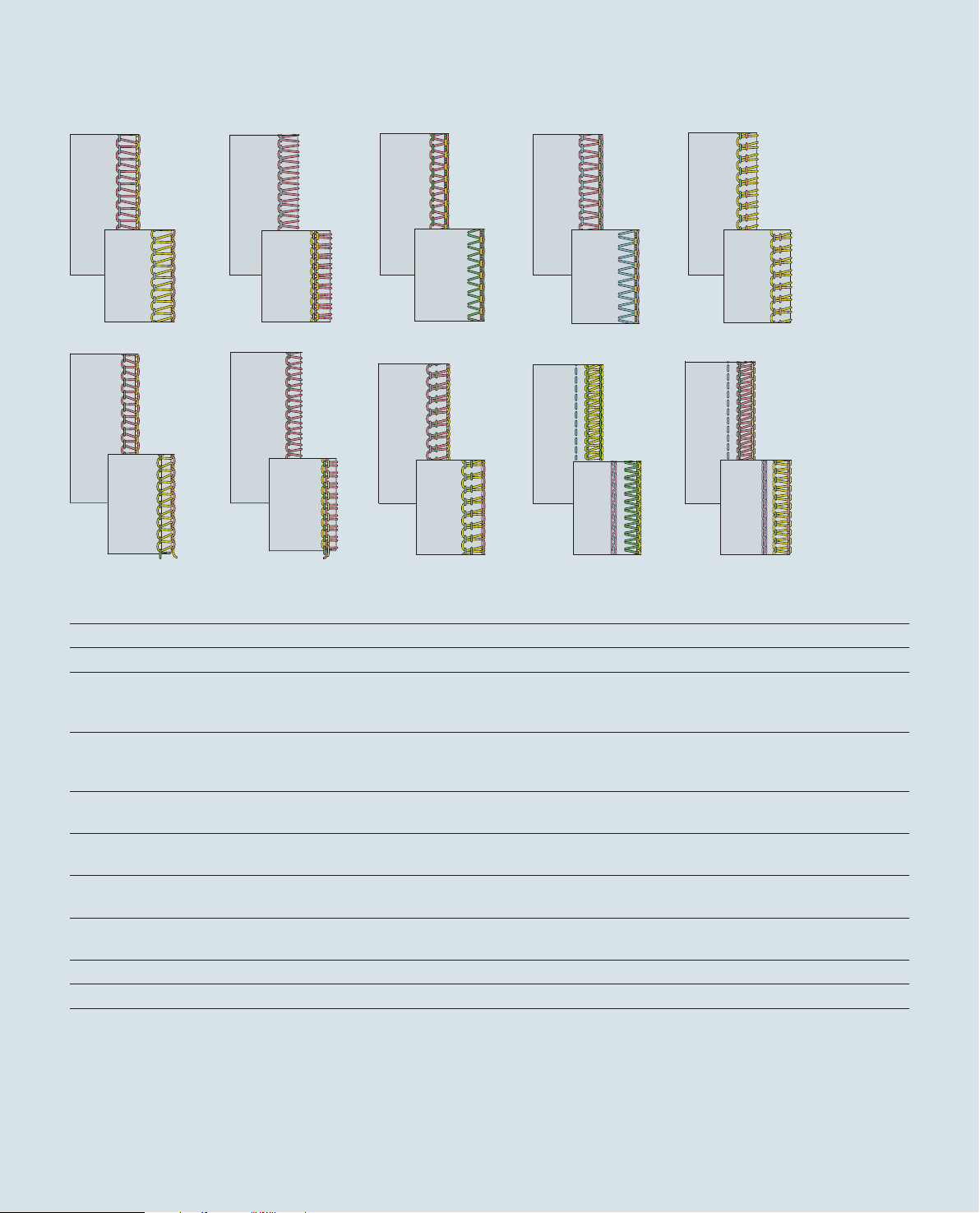

Page 12

Program 11

Program 12

Program 13

Program 14

Program 15

Program 16

Program No. Description Use

11 3-thread overedge seam, wide For overedging medium to heavy, easily fraying fabrics.

12 3-thread serging, wide For overedging heavy fabrics not prone to fraying

13 3-thread fl atlock, narrow As fl atlock seam for sewing stretchy fabrics together with

14 3-thread fl atlock, wide As fl atlock seam for sewing stretchy fabrics together with

15 2-needle, 3-thread overedge

16 3-thread fl at hem For overedging light to medium fabrics and as decorative

17 3-thread fold. rolled hem For overedging light to medium fabrics and as decorative

18 4-thread overedge seam For sewing together all fabrics with overedge,

19 4-thread safety stitch, wide For sewing together heavy fabrics with overedge.

20 5-thread safety stitch, wide For sewing together heavy fabrics with overedge.

Program 17

seam

Program 19Program 18

decorative effect and as decorative edge fi nish. Also for

overedging medium weight fabrics.

decorative effect and as decorative edge fi nish. Also for

overedging medium weight fabrics.

For sewing together and overedging light, highly

stretchy fabrics.

edge fi nish.

edge fi nish.

particularly stretch fabrics.

Program 20

1-12

Page 13

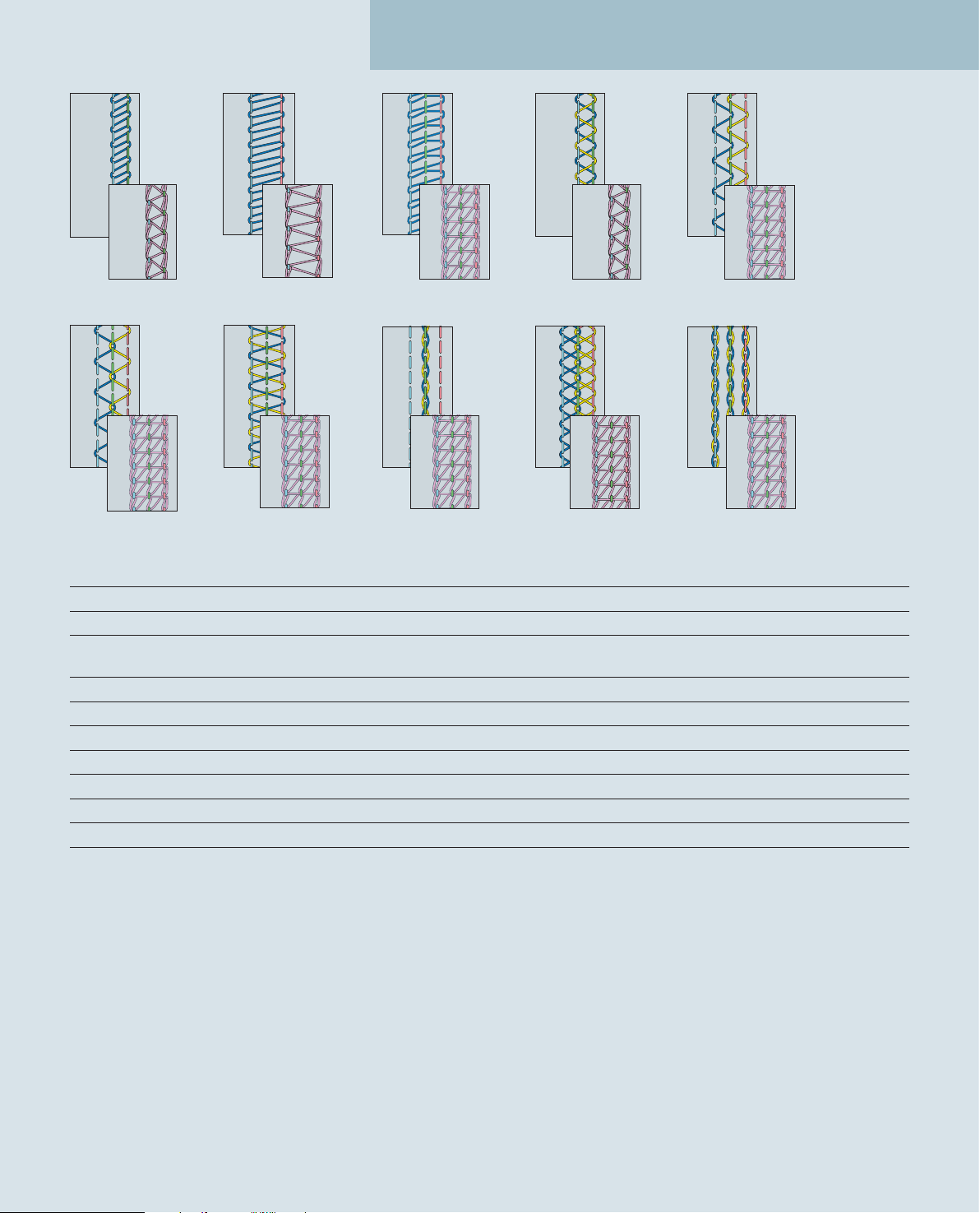

Technnical Part

Program 21

Program 26

Program No. Description Use

21 2-needle Top-cover, narrow For hemming stretch fabric and for decorative effects.

22 2-needle Top-cover, wide For hemming stretch fabric and for decorative effects.

23 3-needle Top-cover For hemming highly stretch fabric and for decorative

24 5-thread Deco-cover For decorative effects and for sewing stretch fabric.

25 6-thread Deco-cover For decorative effects and for sewing stretch fabric.

26 6-thread Deco-cover For decorative effects and for sewing stretch fabric.

27 6-thread Deco-cover For decorative effects and for sewing stretch fabric.

28 6-thread Deco-cover For decorative effects and for sewing stretch fabric.

29 8-thread Deco-cover For decorative effects and for sewing stretch fabric.

30 10-thread Deco-cover For decorative effects and for sewing stretch fabric.

Program 22

Program 27

Program 28

Program 24Program 23

Program 29

effects.

Program 25

Program 30

1-13

Page 14

1-14

Page 15

Technical section, general

This chapter contains information on all the basic mechanical functions of your creative

4874. You will also fi nd additional information in chapters 5 and 7.

Technical section, general

2-1

Page 16

Machine cover

The machine cover protects your

machine from dust and dirt. When

you have fi nished sewing, push the thread

guides (28 and 44) down. The thread

stand (49) must be pushed as far as it will

go towards close to the machine; you can

take the thread cones off fi rst, but this is

not essential. Now you can pull the 4874

cover over the machine. The operator’s

manual and accessories can be placed in

the pockets.

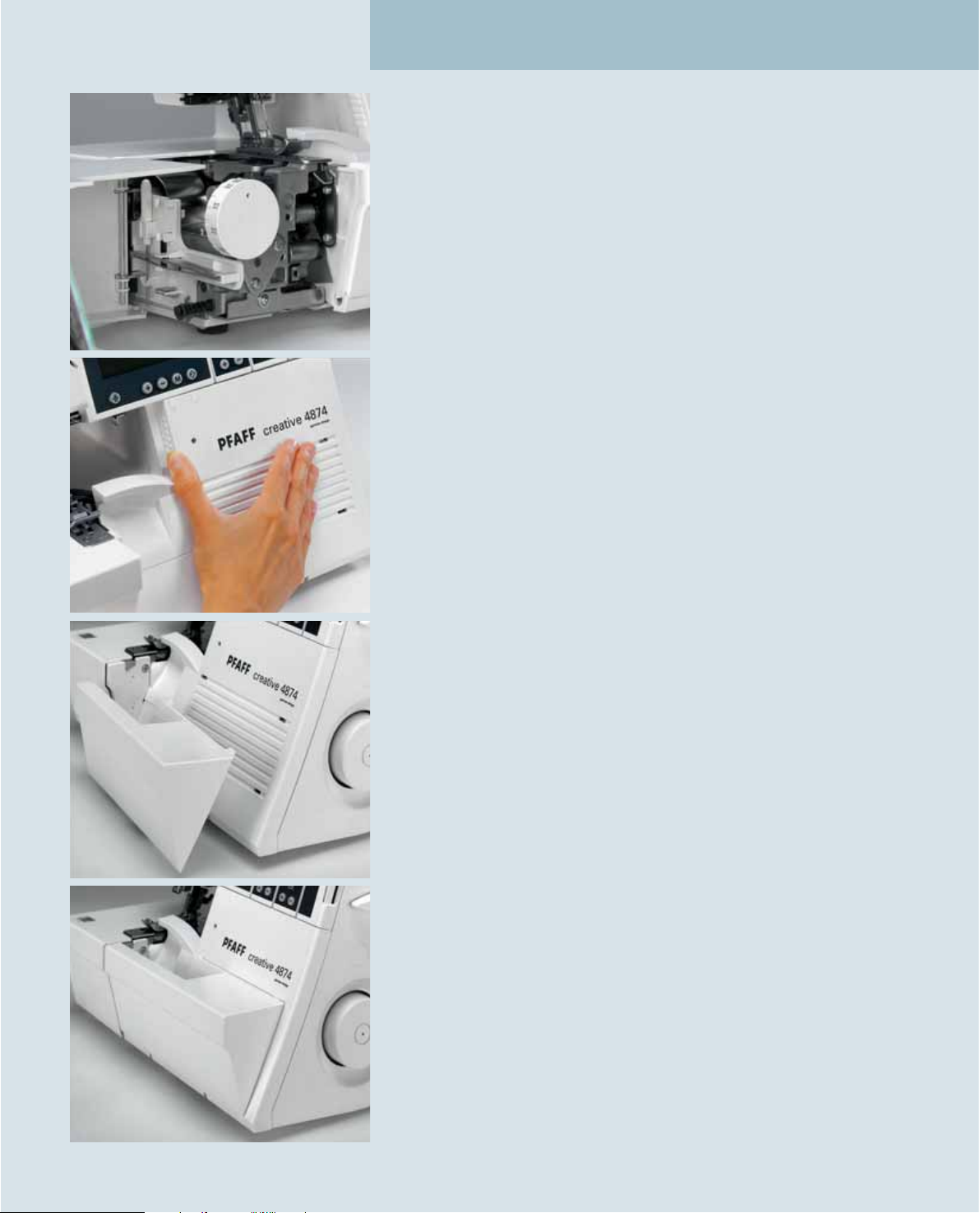

Electrical connection

Plug the power cable into socket (53) on

the machine, and the power supply.

120 V

Connect the foot control

Insert the foot control plug in the socket

(54) on the machine.

The foot control YC-485 has to be used for

this sewing machine.

Power switch

When the power switch (55) is turned on,

the sewing light and the LCD display will

light up (9).

The machine is now ready for use.

220 V

2-2

Page 17

Technical section, general

Swivel table

Push the swivel table (21) to the left. The

converter, the tweezers and the allen key

are located behind the swivel table.

Front cover

Push the front cover (16) to the right as

far as it will go and swing it down. The

top/deco cover sewing program sticker

is behind the front cover. The 5 most

important stitch types and their threading

paths are illustrated in color on the inside

of the front cover.

Note: As soon as either the

swivel table (21) or the front

cover (16) is opened, the

power supply to the machine

is cut off for safety reasons,

so that you cannot continue

sewing.

Note: As soon as either the

front cover (16) or the swivel

table (21) is opened, the power

supply to the machine is cut

off for safety reasons, so that

you cannot continue sewing.

Trim catcher

Insert the upper catches of the trim catcher

in the upper slots in the front cover (16).

Press the bottom part of the catcher until

the lower catches engage in the lower slots

of the front cover.

Perform these steps in reverse order to

remove the trim catcher.

2-3

Page 18

Note: The detachable thread

stand is required for stitch

programs 21 – 30.

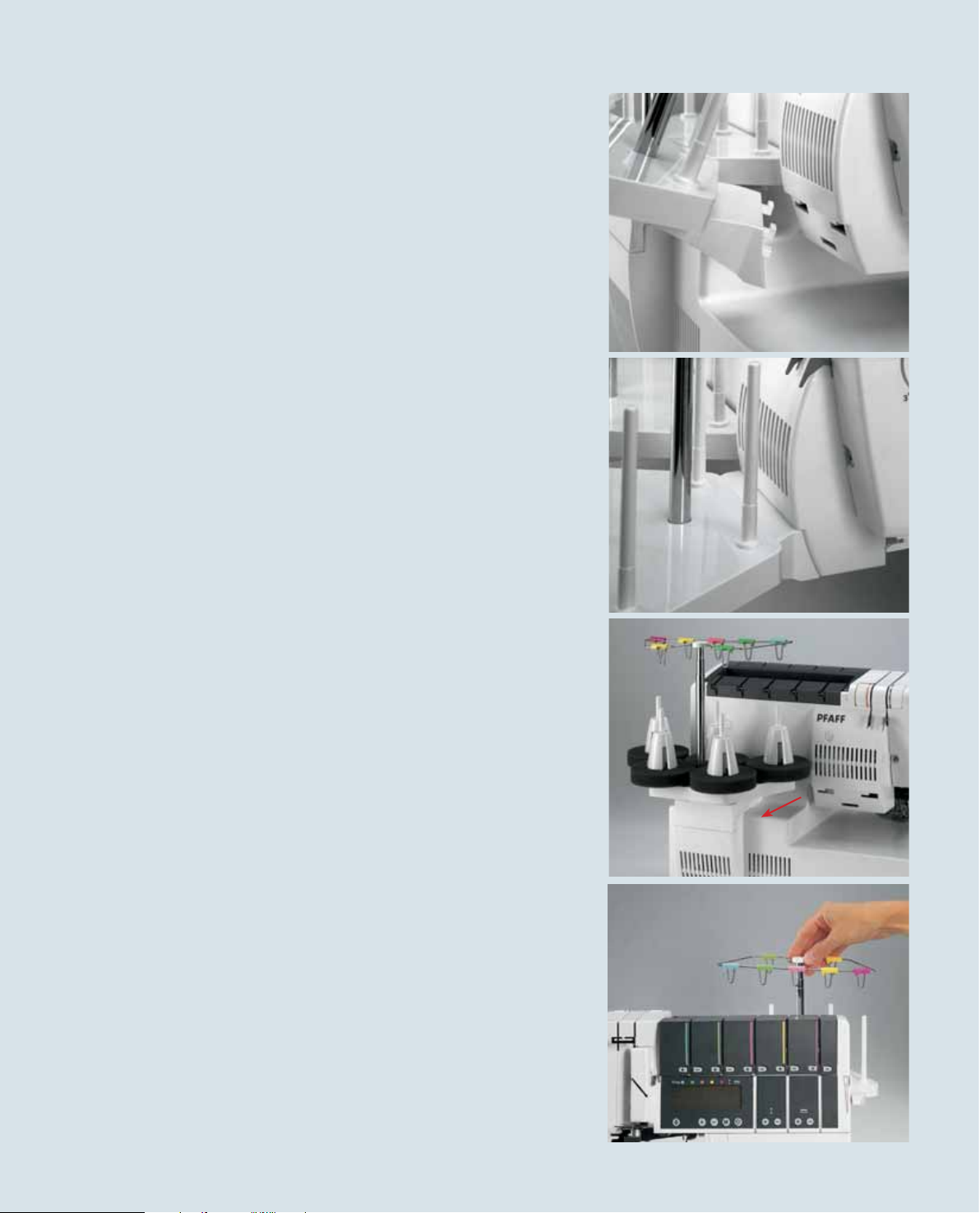

Detachable thread stand

Insert the top catches of the detachable

thread stand (27) into the top slots on the

rear cover and press the bottom portion of

the stand against the cover.

Push the detachable thread stand to the

right as far as it will go.

Place one foam pad (52) and one cone

holder (51) on each of the spool pins (50).

To remove, push the thread stand to the

left and pull up.

Thread stand

Before placing the spools, you must slide

the thread stand (49) back as far as it will

go.

Place one foam pads (52) and one thread

cone holder (51) on each of the spool pins

(50).

Thread guide slide

Pull the thread guide (28 and 44) up as far

as it will go.

To assure optimum thread feed, the two

top slide sections must be rotated slowly

until you hear their locking pommels click

into place.

2-4

Page 19

Technical section, general

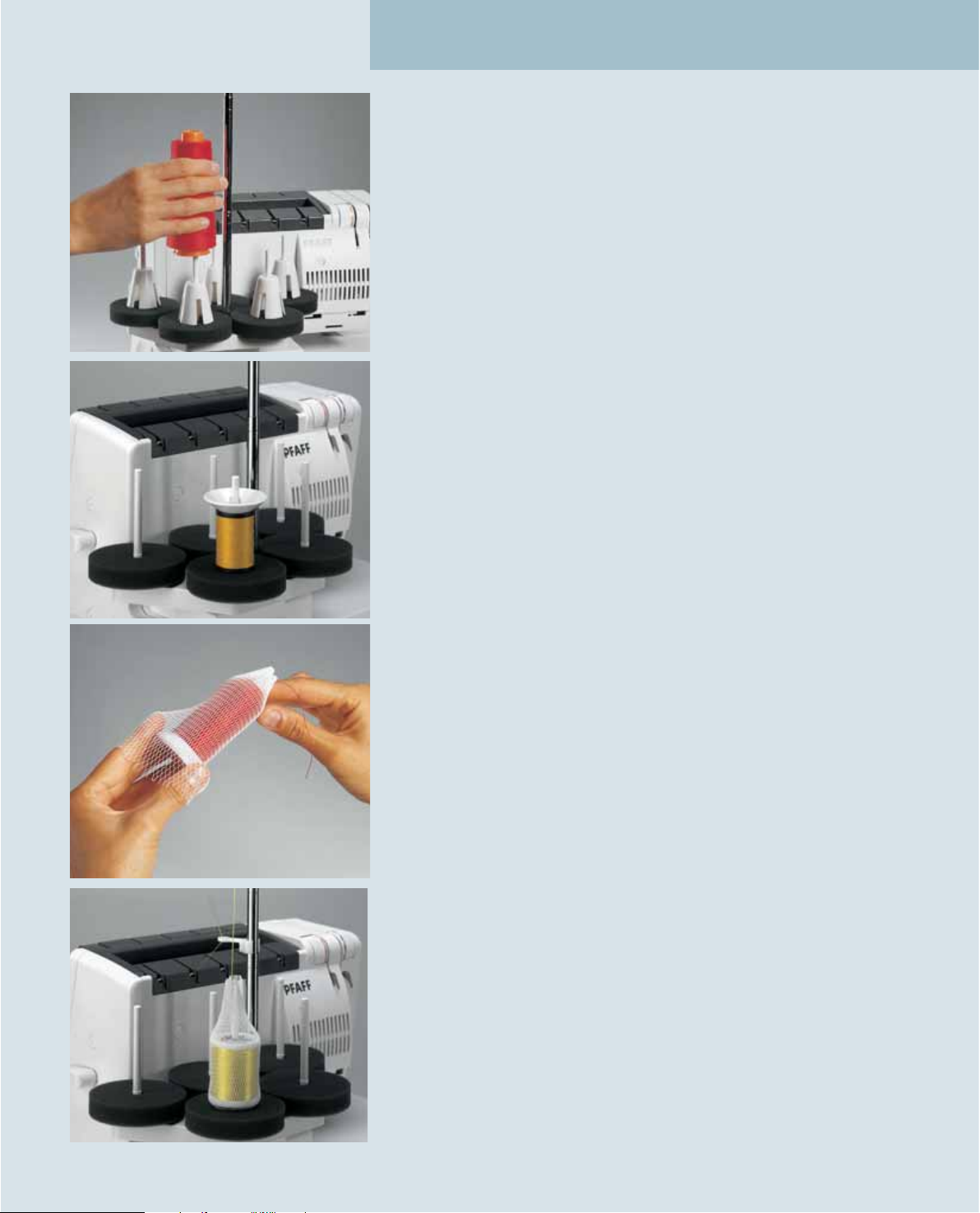

Foam pads/Cone holders

If you are using large cones (5,000 – 10,000

mm), the foam pads (52) and the cone

holders (51) will be helpful to you.

With synthetic threads, the foam pads

catch threads that have slipped down and

help to advance the thread fl awlessly.

Cone holders serve to ensure that large

cones are well positioned.

Thread run-off disc

The thread run-off disc in the accessory

box is used for smaller spools. Use the

foam pads (52) and place the spool on the

pin (50). Attach the thread run-off disc as

shown in the illustration.

Spool net

The spool net in the accessory box should

be pulled over the reel from below. Use

for synthetic threads or decorative threads

that can easily unwind from the spool.

After you have done this, you can place the

spool on the foam pad.

Detachable thread guide

For sewing with decorative thread, use the

detachable thread guide in the accessory

box. Place it on the thread guide (44) and

thread as shown in the illustration. Use the

spool net and the foam pad.

2-5

Page 20

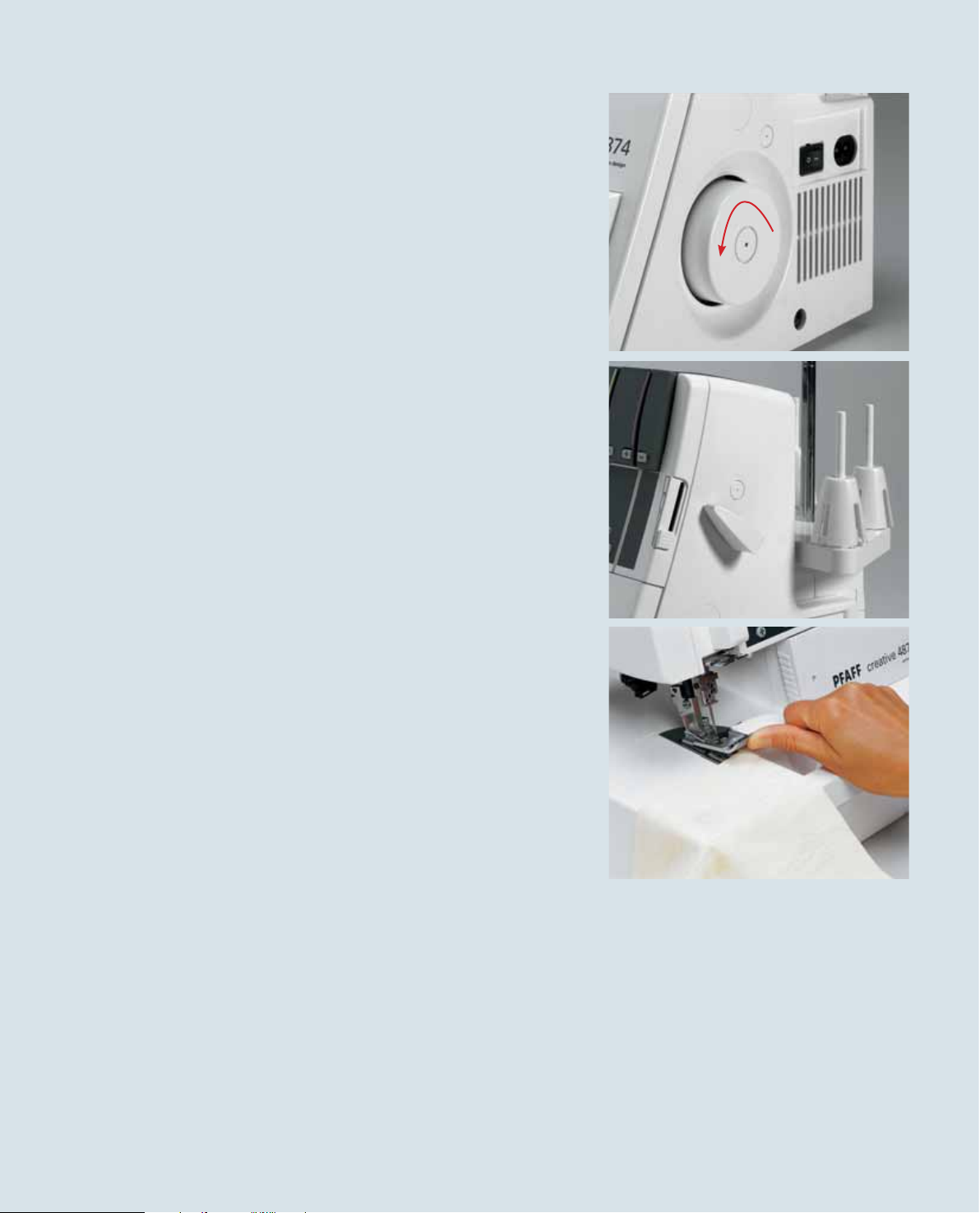

Hand wheel

When turning the hand wheel (56) by

hand, e.g. to raise the needle(s) to their

highest position, always turn toward you.

Presser foot lift

Use the presser foot lifter (57) to raise or

lower the presser foot. If you push the

lifter one step up, you will be able to raise

the presser foot to its maximum height of

6.5 mm for particularly thick fabrics.

Note: Once a thread chain has

been formed, the presser foot

no longer needs to be raised as

long as you are working with

the same thread and the same

presser foot. You can simply lift

the front of the presser foot

gently with your thumb. Slide

the fabric under the raised

part of the presser foot. When

the foot control is activated,

the fabric will then be gripped

and advanced by the feed dog

automatically.

2-6

Page 21

Technical section, general

20

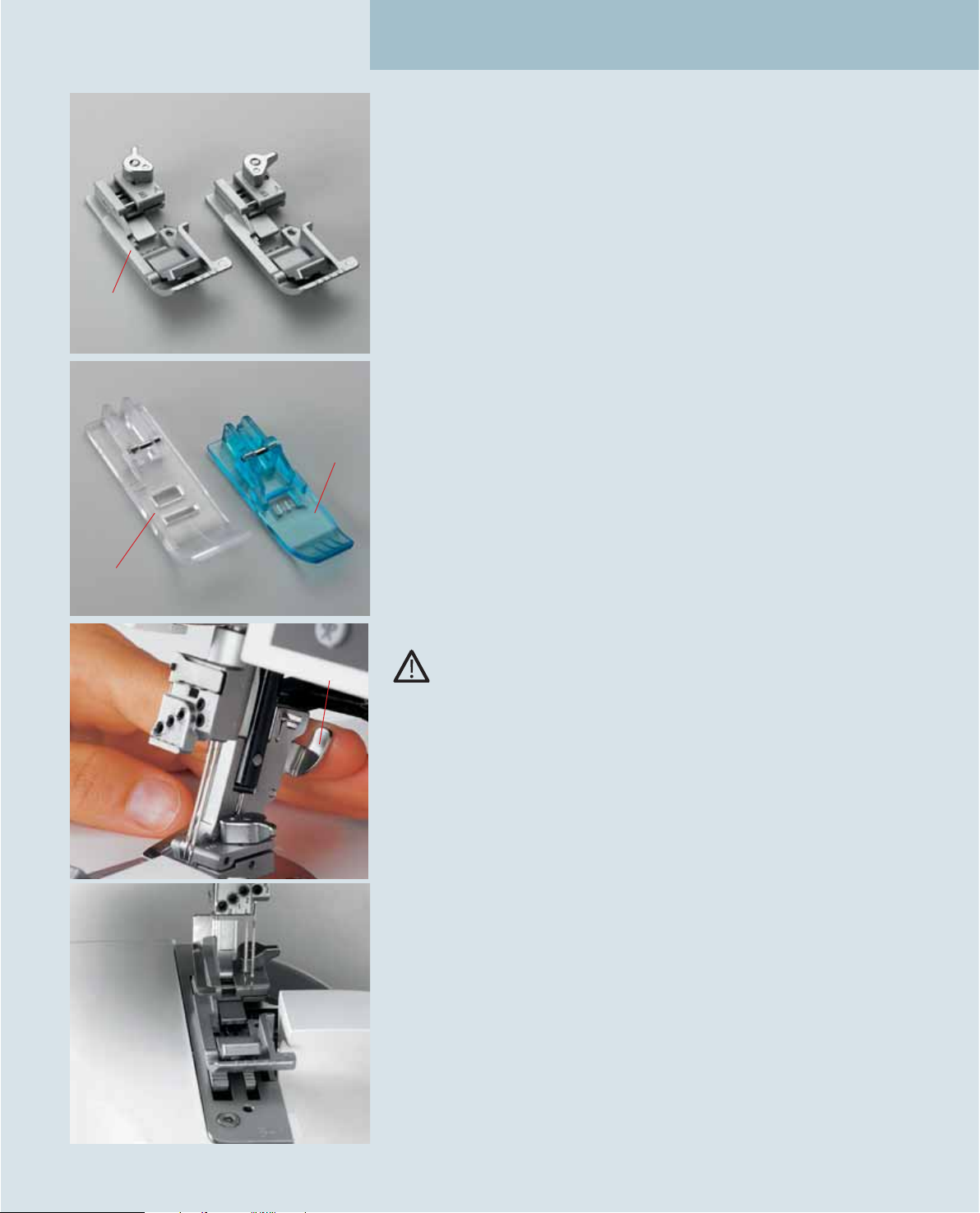

Presser foot

The standard presser foot has two

different positions:

Note: The position of the

presser foot, “A” or “B”,

appears in the LCD display (9)

(see page 3-2).

Position “A” - for sewing cover stitch

(progs. 1, 2, 3), double chainstitch (prog.

4), the 4-thread safety seam (prog. 19) and

the 5-thread safety seam (prog. 20).

Position “B” - for sewing programs 05 – 18.

To choose these positions, simply move the

selection lever.

For cover stitch (progs. 1, 2, 3) and double

chainstitch (prog. 4), clearview foot F from

the accessory box can also be used.

Note: The foot you need to

use will be shown in the LCD

display (9) (see page 3-2).

For top cover (progs. 21, 22, 23) and deco

R

cover (progs. 24 – 30), use clearview foot R

from the accessories box.

F

Changing the presser foot

A

Turn off the power switch

To remove: Raise the needle(s) to its/their

highest position. Lift up the presser foot

and press lever A on the back of the

presser foot holder. The presser foot is

released automatically and you can pull it

out to the left.

To insert: Place the presser foot below

the presser foot holder so that when the

presser foot lifter is lowered, the pin on

the foot is directly beneath the presser

foot holder. Lower the presser foot and if

necessary press lever A, the presser foot

will now click back into place.

Check: Lift the presser foot

to confi rm that it is correctly

attached.

2-7

Page 22

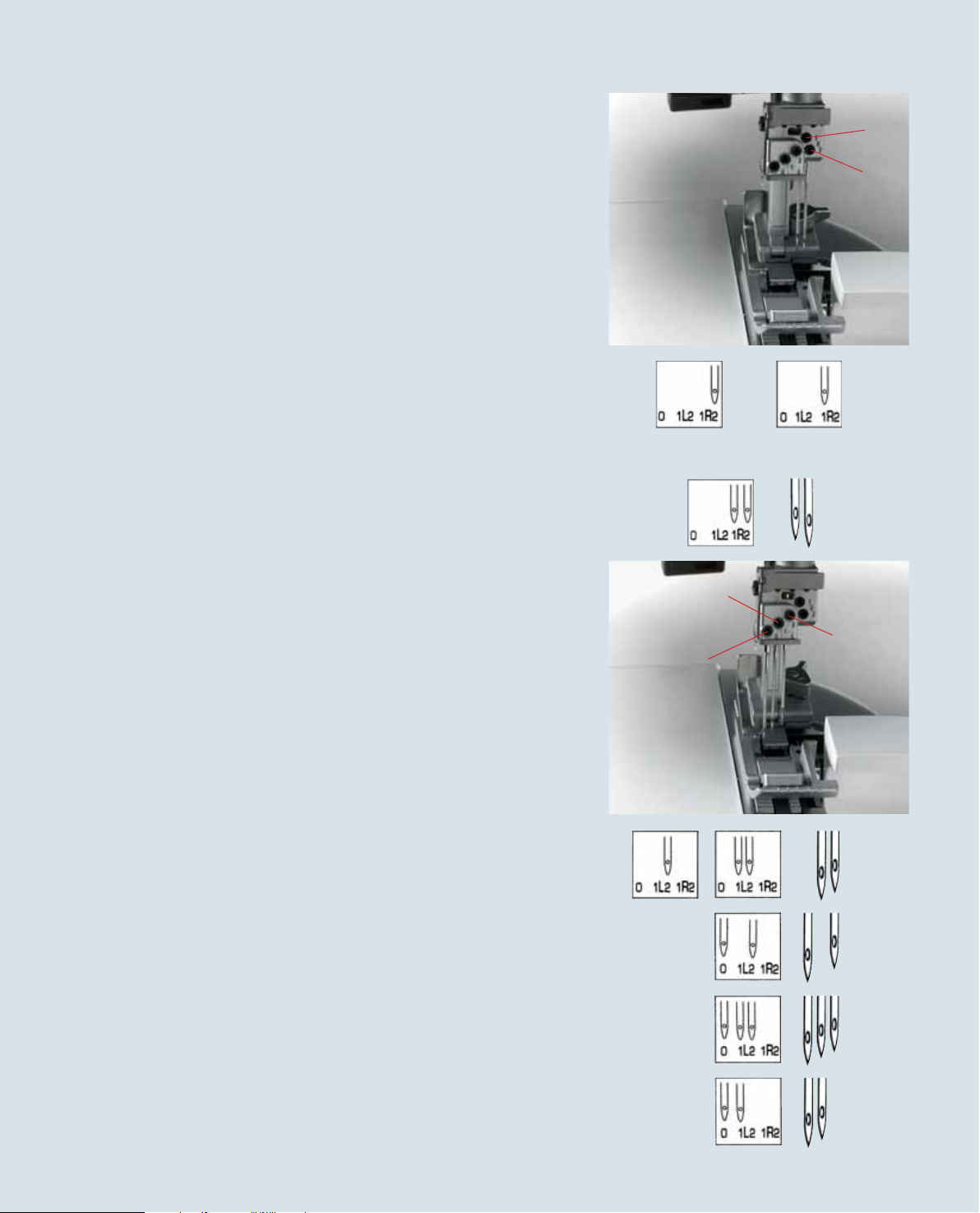

Needle position

The 4874 offers a choice of 5 needle

positions. You can sew with as many as

3 needles simultaneously. The needle

positions are L0, L1, L2, R1 and R2. A

retaining screw is provided above each

needle.

R1

R2

Note: If the needles are

inserted at R2 and R1, the left

needle is slightly higher than

the right.

In this operator’s manual and in the LCD

display (9) (see page 3-2), the different

needle positions are shown in a schematic

diagram. See the examples at top and

bottom. Insert the needle(s) as shown in

the LCD display (9) (see page 3-2).

L1

L2

L0

If the needles are inserted at L1 and L2, the

left needle is slightly lower than the right.

If the needles are inserted at L0 and L2, the

left needle is also lower than the right.

If the needles are inserted at L0, L1 and L2,

the left needle is at the lowest point.

2-8

Page 23

Technical section, general

Changing a needle

Turn off at the power switch

To remove: Lower the presser foot and

raise the needle(s) to its/their highest

position. Take the needle changing tool

out of the accessory box and push it up

over the needle as far as it will go. Loosen

(but do not remove) the needle’s retaining

screw with the allen key and pull the

needle out from below.

To insert: Insert the needle in hole A of the

B

A

needle changing tool so that the fl at side

K of the needle is opposite face B of the

tool. Insert the needle as far as it will go

into the needle holder (you may have to

push a little harder by hand) and tighten

the retaining screw. Remove the needle

changing tool.

K

The 4874 uses system EL X 705 overlock

needles, Cat. No. 2002.

2-9

Page 24

Threading (stitch programs 01-20)

Thread guides

Slide the thread stand (49) backwards and

pull the thread guide (44) up as far as it

will go.

Place the spools on the spool pins (50). For

notes on the spool net, the thread run-off

disc, the foam pads and the cone holders,

please see page 2-5. Thread the threads

from the back to the front through the

thread guides (43) as indicated by the color

codes.

Lift the carrying handle (3). Thread the

threads underneath the carrying handle

into the rear thread guides (58). To do this,

pull the thread down with both hands

until it slips under the thread guide. Pass

the thread between the tension discs and

pull it down so that it is between the

tension discs. Fold the carrying handle

forwards.

Note: The thread tensions for

threading are shown in the

LCD display (9) (see page 3-5).

The sticker behind the front

cover is also provided to make

threading easier.

Thread single threads in order from 1 to 5.

The open thread guides make threading

easy. To ease the task further, use the

tweezers located behind the swivel table.

Remove the trim catcher and open the

front cover.

5 1

4

2

3

2-10

Page 25

Technical section, general

Threading

30

1

2

3

Upper looper (red)

Turn the hand wheel towards you until

the upper looper (30) reaches its highest

position.

Thread the threads in order from 1 to 9.

Some of the thread guides are marked

with a red dot.

9

8

4

7

6

5

Thread the thread in thread guides 1 to

8

9

8

7. Pass the thread over the top of guide 8

from above and pull it down and to the

left until it slips into the guide.

From the front, pass the thread through

the eye 9 of the upper looper. Pull about

10 cm (5”) of thread through the hook and

place it facing to the left under the presser

foot.

7

6

5

2-11

Page 26

Threading

Lower Looper (yellow)

Turn the hand wheel towards you until the

lower looper (31) is as far to the right as

possible.

31

Thread the thread in order from 1 to 10.

Some of the thread guides are marked

with a yellow dot.

Thread the thread in thread guides 1 to 6.

Pass the thread under the latch 7 and into

thread guide 8.

1

2

3

4

10

5

9

8

7

6

Note: The lever will return to

its original position as soon as

you start to sew.

2-12

8

5

7

6

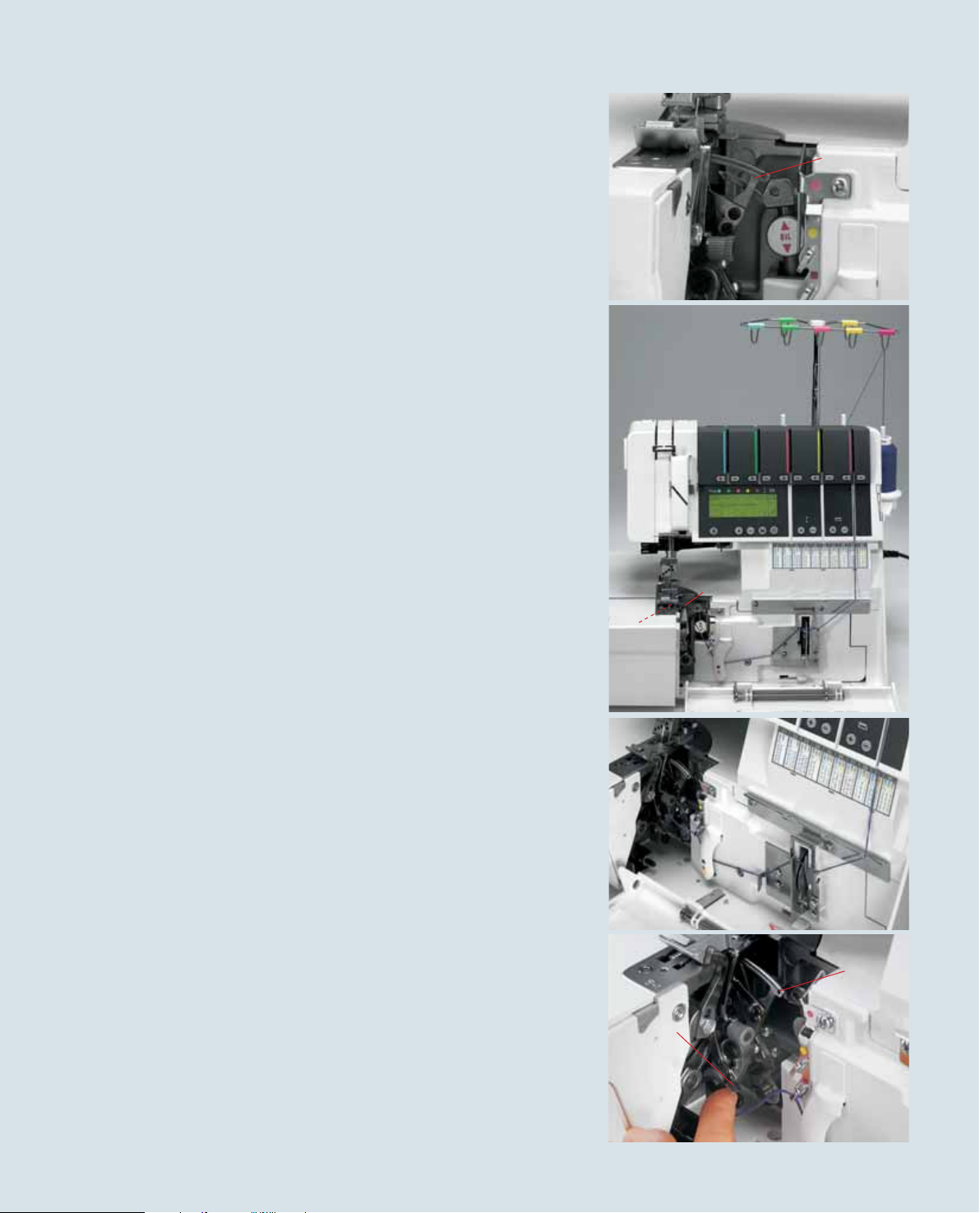

Press lever A down and hook the thread

into guide B from left to right. The

illustration right shows how to do this.

B

A

Page 27

Technical section, general

Pass the thread forwards through eye C (=

Threading point 10) of the lower looper.

Pull about 10 cm (5”) of thread through

the hook and place it to the left under the

presser foot.

2-13

Page 28

Threading

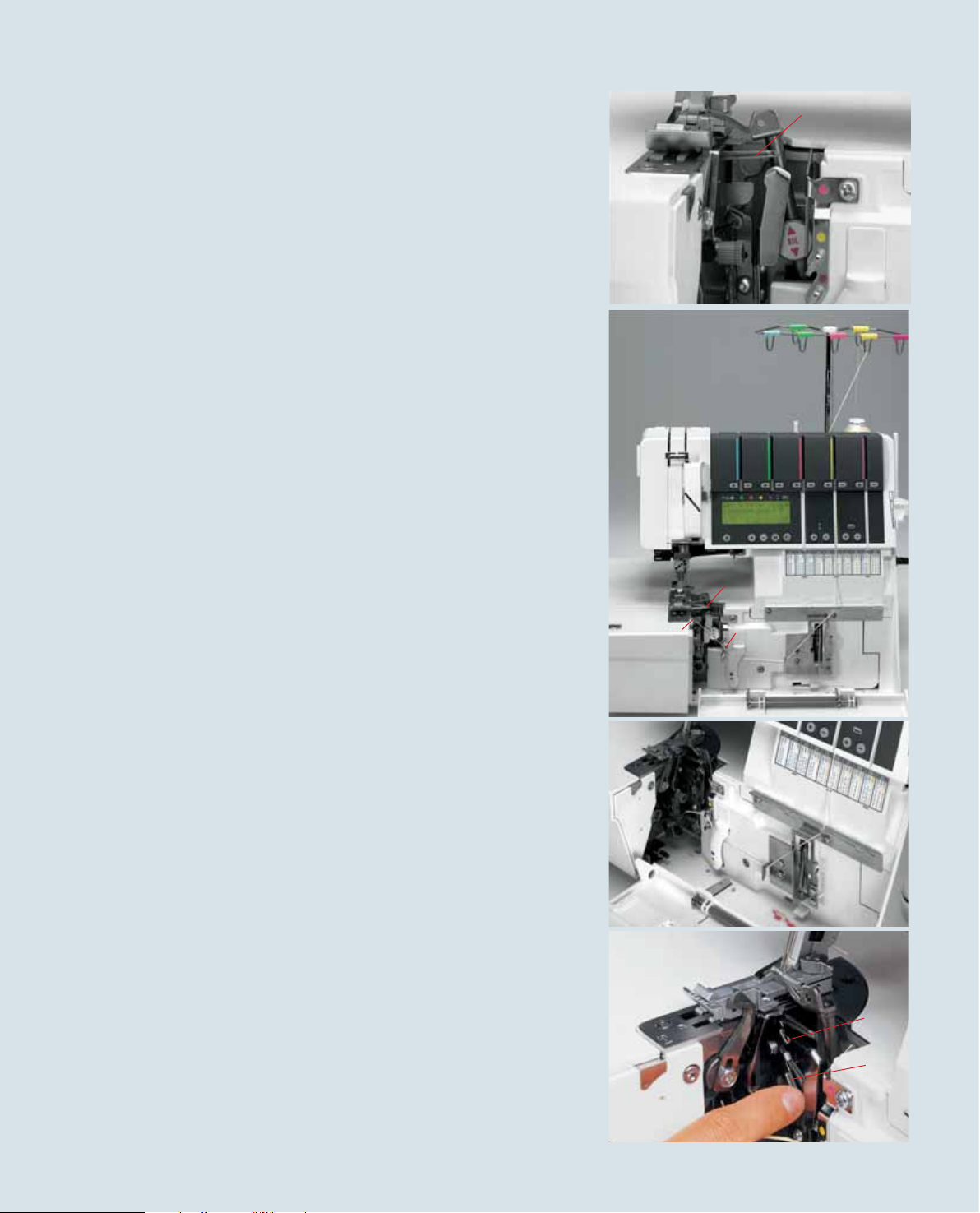

Double chainstitch and cover stitch looper

for progs. 04, 19 and 20 (purple)

Turn the hand wheel towards you until the

double chainstitch and cover stitch looper

(33) is as far to the right as possible.

Thread the thread in order from 1 to 12.

Some of the thread guides are marked

with a purple square.

33

1

2

3

Note: In the case of thread

guides 6 and 7, the thread is

simply placed on top of them,

not threaded through.

Note: The lever will return to

its original position as soon as

you start to sew.

Thread the thread in the guides from 1 to

8. Pull the thread under latch 9 and into

thread guide 10.

Press lever A up and hook the thread into

slot B. The illustration right shows how to

do this.

12

11

10

6

7

8

9

4

5

10

7

6

9

8

5

4

B

A

2-14

Page 29

Technical section, general

From the front, pass the thread through

eye C (- threading point 12) of the double

chain stitch and cover stitch looper.

Pull about 10 cm (5”) of thread through

the looper and place it to the left under

the presser foot.

2-15

Page 30

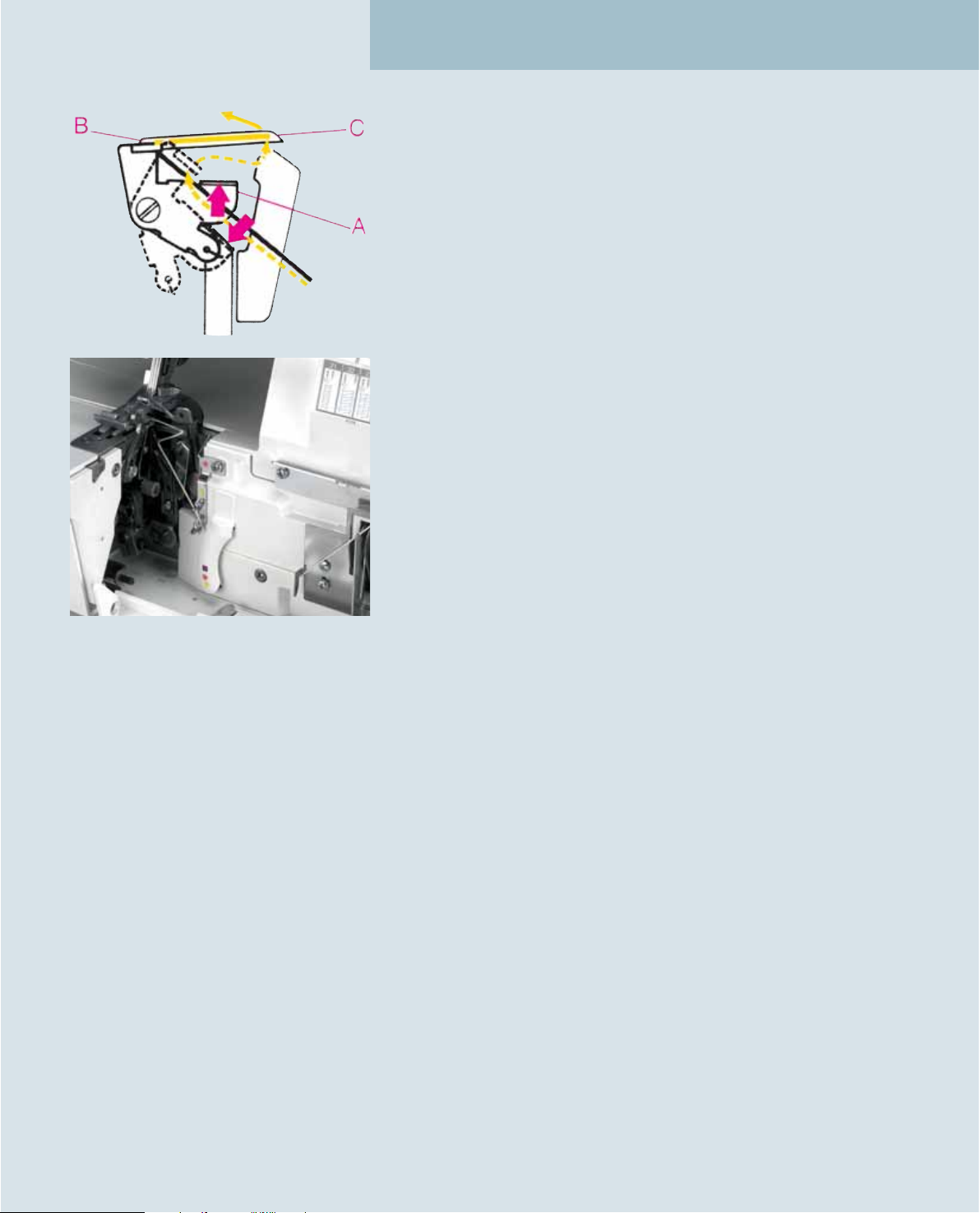

Exception:

Threading double chain stitch and

coverstitch looper for coverstitch (progs.

01, 02, 03) top/deco stitches (progs. 21-30)

(purple)

Turn the hand wheel towards you until the

double chainstitch or coverstitch looper

(33) is as far to the right as possible.

Thread the threads in order from 1 to 10.

Thread guide 8 is marked with a purple

square

33

1

2

3

Note: In the case of thread

guides 6 and 7, the thread is

simply placed on top of them,

not threaded through.

Note: The lever will return to

its original position as soon as

you start to sew.

Thread the threads in the guides from 1

to 8. (Caution: The thread does not pass

under the latch.)

Press lever A up and hook the thread into

slot B. The illustration right shows how to

do this.

10

4

6

7

9

8

5

8

7

6

4

5

B

A

2-16

Page 31

Technical section, general

From the front, pass the thread through

eye C (- threading point 10) of the double

chain stitch and cover stitch looper.

Pull about 10 cm (5”) of thread through

the hook and place it to the left under the

presser foot.

2-17

Page 32

Threading the needle(s)

Thread the thread in order from 1 to 8.

1

2

The thread must pass through the lower

slot in thread guide 5. To thread needles

more easily, use the needle threader in the

accessories box (see page 2-21).

Pull the thread about 10 cm (5”) through

the eye of the needle and place it facing

to the left under the presser foot (if

necessary, press the tension release button

(10), see page 3-4).

5

3

4

6

7

8

5

4

7

2-18

8

If you sew with the needle(s) L0, L1, or L2

you have to use the thread guide A.

A

Page 33

Technical section, general

Exception:

1

2

5

3

Threading needle L2 when sewing the

5-thread safety seam (prog. 20), the 4thread safety seam (prog. 19) and double

chainstitch (prog. 04)

Thread the thread in order from 1 to 9.

Note: To thread the double

chainstitch (prog. 04) you have

to thread the green tension

(see page 2-22).

4

6

7

8

9

The thread must pass through the upper

slot in thread guide 5.

5

4

7

Pull the thread about 10 cm (5”) through

the eye of the needle and place it facing

to the left under the presser foot (if

necessary, press the tension release button

(10), see page 3-4).

8

9

2-19

Page 34

Note: Even when the looper

threads break, you must

remove the threads from the

eye of the needle, rethread

the looper threads, and then

rethread the needles.

Important note on threading

Always thread the needles last, so the

needle thread pass over the looper thread

as shown in Fig. 2 and not under it as in

Fig. 1. Otherwise the thread may break or

stitches may be formed incorrectly.

Changing spools with the machine

threaded

Cut the spool threads close to the spool

and position new spools. Tie the thread

that is still in the machine to the threads

on the new spools and unthread the

needles. Press the tension release button

(10) (see page 3-4) and pull the needle

threads until the knots have advanced

through the last thread guide before the

needles. Cut the knots off and thread the

thread through the eye of the needle. You

can pull the looper threads all the way

through the looper eyes and place them to

the left under the presser foot.

2-20

Page 35

Technical section, general

Needle threader

Turn off at the power switch

Raise the needle(s) to its/their highest

position and lower the presser foot. Place

the thread running from right to left in

notch A of the needle threader (the needle

threader is included in the accessory box).

One of the two triangles must be pointing

A

upwards.

Place the needle threader against the front

groove of the needle. Move down as far

as the eye of the needle and press the

threader gently against the needle. This

causes a small metal pin to pass through

the eye and the needle is threaded

automatically.

Now you can use the needle threader to

pull the thread loop through to the rear.

Note: If you press too hard, the

small metal pin will bend and

you will no longer be able to

use the threader to thread the

needle.

2-21

Page 36

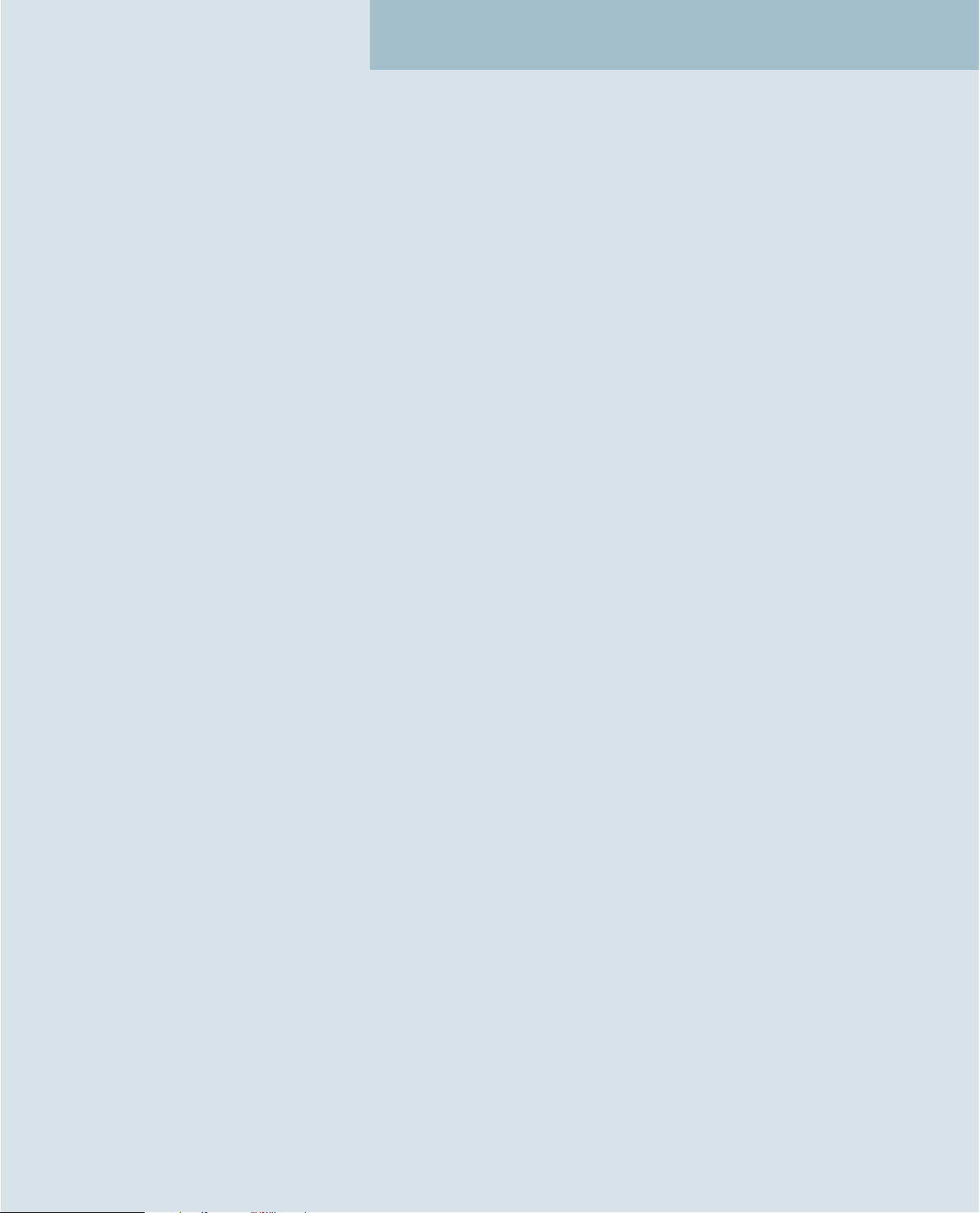

Summary of threading paths and threading sequences

Stitch program 01:

2-needle cover hem, narrow

Stitch program 02:

2-needle cover hem, wide

Stitch program 03:

3-needle cover hem

Stitch program 04:

Chainstitch

2-22

Page 37

Stitch program 05:

2-thread fl atlock, narrow

Stitch program 07:

2-thread serging, narrow

Stitch program 08:

2-thread fl at hem

Stitch program 09:

2-thread fold. rolled hem

Stitch program 06:

2-thread fl atlock, wide

Technical section, general

Stitch program 10:

3-thread overedge seam, narrow

Stitch program 13:

3-thread fl atlock, narrow

Stitch program 16:

3-thread fl at hem

Stitch program 17:

3-thread fold. rolled hem

Stitch program 11:

3-thread overedge seam, wide

Stitch program 12:

3-thread serging, wide

Stitch program 14:

3-thread fl atlock, wide

2-23

Page 38

Stitch program 15:

2-needle, 3-thread overedge seam

Stitch program 18:

4-thread overedge seam

Stitch program 19:

4-thread safety stitch, wide

Stitch program 20:

5-thread safety stitch, wide

2-24

Page 39

Technical section, general

Speed control

With the speedcontrol slider (8), you can

set the maximum speed to any value from

700 rpm to 1500 rpm.

If you select programs 21 – 30, the

maximum speed is reduced to 400 rpm.

Presser foot pressure

The preset presser foot pressure on the

machine is suitable for medium fabrics. For

most fabrics, the presser foot pressure does

not need to be altered.

If you intend to work with lighter or

heavier fabrics, however, it may be

necessary to reset the pressure. In this

case, you can choose from six positions;

make your selection with the presser foot

pressure adjustment knob (26).

The standard setting is “N”.

Note: Lower the presser foot

before turning the presser foot

pressure adjustment knob. This

makes the knob easier to turn.

2-25

Page 40

Thread cutter

At the end of a seam, sew a thread chain

of 15 to 20 cm (7”-10”) and pull the thread

chain from back to front over the thread

cutter (47).

This will cut off the thread chain.

Check spring for edging the thread chain

Use the check spring for edging the thread

chain (37) to edge the thread chain at the

start of the seam.

To do this, sew a thread chain at least 10

cm long before you begin the seam. Raise

the presser foot and pull the thread chain

carefully away from the stitch fi nger (32).

Draw the thread chain forwards and secure

it under the spring.

Note: This technique cannot

be used for the 5-thread safety

seam, the 4-thread safety

seam, the double chain stitch,

the rolled hem, or for sewing

in the fabric (progs. 01-03,

21-30).

Place the fabric just in front of the

needle(s). If necessary, fi rst cut about 3

cm along the cutting line with a pair of

scissors. Lower the presser foot and start

sewing. The thread chain will be drawn

inside the seam automatically.

2-26

Page 41

Technical section, general

Disengage the upper knife

Turn off the power switch

Remove the trim catcher and open the

front cover and the swivel table. Raise the

upper knife (35) to its highest position by

turning the hand wheel. Now push the

knob for lowering the upper knife (39) as

far as it will go to the right.

Turn the knob towards you until the upper

knife is seated in its lowest position. The

upper knife is now disengaged.

Engage the upper knife

Push the knob for lowering the upper

knife (39) to the right and swing the knife

back until it clicks back into its working

position. Close the front cover and the

swivel table and reattach the trim catcher.

Note: The position of the

upper knife will be shown in

the LCD display (9) (see page

3-2).

2-27

Page 42

Stitch fi nger

For Standard Overlock Seams:

For sewing all standard overlock seams (ex.

progs. 01-04 and 21-30) the stitch fi nger

(32) remains in its engaged position.

For rolled hems

Remove the trim catcher and open the

front cover. Pull knob A of the stitch fi nger

(32) to the right and swing it down into its

disengaged position.

32

A

Note: The position of the stitch

fi nger will be shown in the

LCD display (9) (see page 3-2).

You can sew all rolled hems with this

setting. This setting is also used for

sewing coverstitches, double chain

stitch, top cover and deco cover

(progs. 01-04 and 21-30).

2-28

Page 43

41

Technical section, general

Attach converter

Turn off the power switch

The converter (41) must be attached for all

2-thread seams (except program 04) and

the 2-needle, 3-thread overedge seam.

Open the swivel table and take out the

converter.

30

Move the upper looper (30) beside and

to the right of the needle by turning the

hand wheel.

Secure the tip of the converter in the

eye of the upper looper and push the

converter onto the upper looper base.

To remove the converter, fi rst release its tip

from the eye of the upper looper. Now you

can pull the converter up and out.

Note: The LCD display (9) will

show whether the converter

should be attached (see page

3-2).

2-29

Page 44

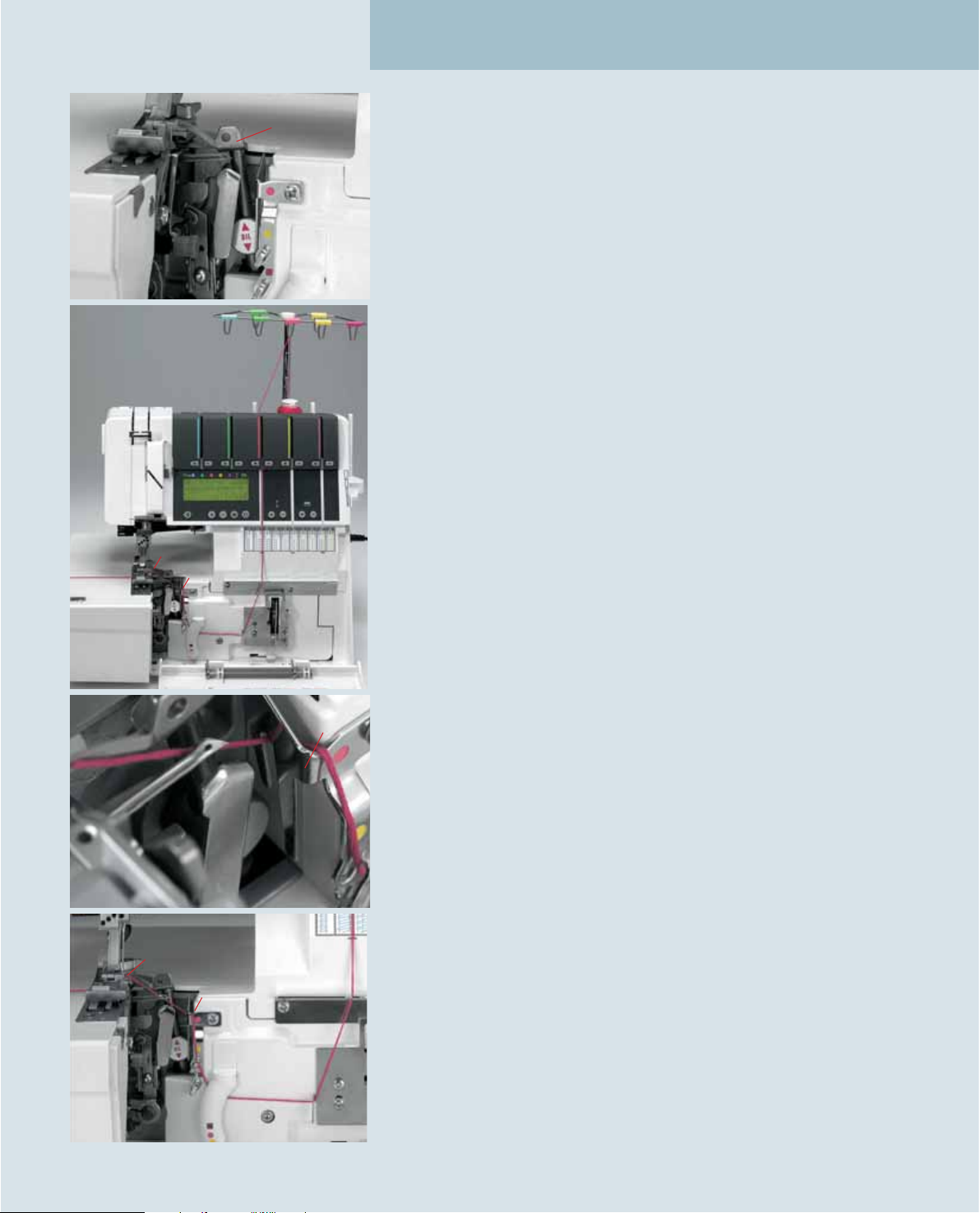

Disengage the upper looper

You can disengage the upper looper (30)

with the upper looper disconnection lever

(18). Remove the trim catcher and open

the front cover. Turn the hand wheel to

bring the looper to its lowest position.

30

Note: The LCD display (9)

will show whether the upper

looper should be attached (see

page 3-2).

Press the upper looper disconnection lever

(18) down and push it to the left. Turn the

hand wheel to ensure that the looper is

indeed disengaged.

To engage the upper looper, push the

upper looper disconnection lever (18) into

its position to the right. Turn the hand

wheel until the looper engages with an

audible click and moves upwards again.

Close the front cover and attach the trim

catcher.

2-30

Page 45

Technical section, general

Remove knife guard

Remove the trim catcher and open the

front cover. Pull the knife guard (17) up

and off.

To insert, place the knife guard under latch

A and push down into the front cover

guides.

A

Note: The sewing table

(accessory) is attached in the

same way.

A

2-31

Page 46

Set seam width

Turn the seam width adjustment knob (22)

to select any seam width value from 3.5

to 6.0 mm; it will also be displayed in the

viewing window (23). (Double chain stitch

is sewn with a gap of 6.5 to 9 mm.)

Figure A: If loops are protruding from the

edge of your seam, turn the seam width

selection knob upwards to shift the upper

knife (35) to the right.

Figure B: If your seam puckers at the

edge, turn the seam width selection knob

downwards to shift the upper knife (35) to

the left.

Note: The seam width settings

3,5 mm and 6,0 mm are only

relevant for the needle R1. This

set-value is reduced by 2,0 mm

when using the needle R2, i.e.

you have a seam width which

is completely adjustable from

1,5 mm to 4,0 mm.

A

B

1,5 mm

4,0 mm

2-32

3,5 mm

6,0 mm

Page 47

Technical section, general

Setting the stitch length

The stitch length is selected automatically

by the creative 4874. However, it can be

changed and stored at any time using

stitch length adjustment buttons (14) (see

page 3-4).

2-33

Page 48

Note: The effect of the

differential feed also depends

on the stitch length selected

and the type of fabric being

used.

Differential feed

The differential feed consists of two feed

dogs arranged one behind the other.

Both feed dogs (A + B) move the fabric.

The movement of the front feed dog (A)

can be regulated using the differential

feed adjustment buttons (15). The setting

range is from 0.5 to 2. This setting

regulates the amount of material being

fed by the front feed dog.

The creative 4874 selects the differential

feed automatically, but it can be changed

at any time using the setting buttons (15)

and can be stored (see page 3-4).

The default setting is 1; with this setting,

the movement of the front feed dog (A)

is synchronized with that of the rear feed

dog (B), which means that the front feed

dog advances the same quantity of fabric

as the rear feed dog.

B

A

If you set the differential feed to 0.5 the

front feed dog moves at half the speed

of the rear feed dog. This means that the

front feed dog feeds only half as much

fabric as the rear feed dog. This stretches

the fabric.

This way, when you are working with very

fi ne fabrics such as silk and taffeta you can

prevent puckering of the seam. The seam

will remain fl at (A).

But you can also use it to achieve

fashionable effects such as the “lettuce

edge” with a rolled edge (B).

A

B

2-34

Page 49

A

Technical section, general

If you set the differential feed to 2.0 the

front feed dog moves at twice the speed

of the rear feed dog. This means that the

front feed dog moves twice as much fabric

as the rear feed dog. This gathers the

fabric.

In this way, you can prevent the seam

from stretching when you work with knits

such as jersey or cable knits. The seam will

remain fl at (A).

However, you can also use it to achieve

fashionable effects such as the gathered

effect with very fi ne fabrics (B).

B

The following table includes notes on setting the differential feed. Always test your

setting fi rst on a piece of scrap fabric.

Type of fabric / effect Differential feed setting

gather

<2> <1,5>

Very light fabrics: silk, satin, poplin, taffeta, linings.

Normal fabrics: light and medium-heavy cottons, fi ne cords, thermal-

wear

Light knitwear: jerseys, polo fabrics, cut-pile pullovers, tricot, fi ne

knitwear and gathered fabrics.

Heavy knitwear: sweatshirt fl eece, heavy gathered fabrics, heavy

knitwear

Stretch “lettuce edge” effect: medium and light knitwear, jerseys,

knitwear, ruffl ed sleeve and collar edges, skirt hems, dense stitch

lengths.

Gathering: ruffl ing light fabrics and lace, seam allowances for curves,

arches on blouses, shirts, round pockets, fl aps, stretching or gentle

ruffl ing of sleeves, sleeve widths for cuffs or gathered fabrics.

•

•

••

normal

<1>

••

•

stretch

<0,5>

•

2-35

Page 50

2-36

Page 51

Electronic functions

This chapter contains information about all the electronic functions of the machine.

Electronic functions

3-1

Page 52

Set language

You can select any of the following

languages:

Czech, Danish, German, English, Spanish,

French, Italian, Dutch, Polish, and

Portuguese. Hold down the program

selection buttons +/– (11) simultaneously as

you switch the machine on. Use program

selection button + (11) to select the

language you want. Press the memory

button M (12) once to store the language

you have selected.

Now the description will be displayed in

your chosen language.

11 12

123

5

LCD Display

1. Stitch program number

2. Stitch designation (Main menu)

3. Stitch length in mm

4. Differential feed setting

5. Needle position

6. Position of the swivelling stitch fi nger

7. Position of the upper looper

6789

Stitch fi nger engaged.

Stitch fi nger disengaged.

Upper looper engaged

Upper looper disengaged

4

10

11

8. Position of the sewing table

with sewing table

with knife guard

9. Position of the upper knife

Upper knife engaged

10. Setting for the standard presser foot:

A or B – as well as F appears in the

11. Seam width in mm

Upper knife disengaged

display, you can also use clearview foot

F from the accessory box.

3-2

Converter engaged

Page 53

If you have selected stitch programs 21-30,

R appears in the display. Use clearview foot

R.

If you have selected stitch programs 24

–30 and you press the program selection

button + beside the R, one of these two

symbols will appear:

<> The two arrows pointing away from

each other indicate that a thick thread

can be used for the deco cover (45) thread

tensions.

>< The two arrows pointing towards each

other indicate that a thin yarn can be used

for the deco cover (45) thread tensions.

Electronic functions

3-3

Page 54

10 11 12 13

Button functions

7 Tension buttons +/–: To increase or

decrease the tension settings.

10

Tension release button: If you press

the tension release button, all thread

tension discs are opened automatically.

Keep the button pressed down and

you can remove the threads by pulling

gently.

11 Stitch program selection buttons +/–:

Use these buttons to select the program

you want. There are 30 programs to

choose from. If you keep the buttons

pressed down for a moment longer, the

display scrolls through the programs

automatically. The program that was

last used always appears when the

machine is fi rst switched on.

12 Memory button M: Use this button to

store changed settings for stitch length,

differential feed and thread tensions.

13 Memory selection button P: Press this

button to open the program memory

and memories A, B and C.This button

will always return you to the main

menu.

7

1514

14 Stitch length setting buttons +/-: If

you press one of these buttons, the

program memory opens. Use the +/- to

adjust the stitch length. If you press the

memory selection button P repeatedly,

you will be returned to the main

menu and the changed setting will

be cancelled. If no changes are made

within 10 seconds, the display switches

back to the main menu automatically.

15

Differential feed setting buttons +/-:

If you press one of these buttons, the

program memory opens. Use the +/- to

adjust the differential feed. If you

press the memory selection button P

repeatedly, you will be returned to the

main menu and the changed setting

will be cancelled. If no changes are

made within 10 seconds, the display

switches back to the main menu

automatically.

3-4

Page 55

Save

Recalling the memory

Use the program selection buttons +/– to

recall the program you want. If you press

the memory selection button P once, the

program memory will open. The settings

for the thread tensions, stitch length and

differential feed are displayed next to the

program number. Tension settings marked

with two asterisks ** are not available

for that program and do not have to be

threaded. If no changes are made within

10 seconds, the display switches back to

the main menu automatically.

Electronic functions

Note: The top/deco cover (45)

thread tension settings are not

displayed and are therefore

also not set automatically.

These settings can be found

on the top/deco cover stitch

program sticker, and must be

set manually. The top/deco

cover stitch program sticker is

behind the front cover.

Selecting a memory

Call the program you want using the

program selection button +/ –. You can

choose from three memories (A, B and C)

for each program. To access them, press

the memory selection button P repeatedly

until the memory you want appears. In our

example, we have selected memory A for

stitch program 21.

3-5

Page 56

Save

The settings for automatic thread tensions,

stitch length, and differential feed can be

changed and stored. To do this, use the

appropriate buttons +/– to change the

previous setting. In our example we have

changed the stitch length setting from 2.5

to 3.0.

Note: If you press memory

selection button P repeatedly,

you will be returned to the

main menu.

By pressing memory button M you activate

memory A, which is indicated by the

fl ashing letter A. To store the changed

setting, press the memory button M again

– the fl ashing will stop and the setting will

be stored.

If the memory button M is not pressed

within 10 seconds, the letter will stop

fl ashing and the changed setting will not

be stored in the memory.

Notes on the saving to memory

If you do not select a memory to receive

the settings you want to save, the changed

settings will be stored in a vacant memory

automatically when you press memory

button M.

If all memories already contain settings,

the changed settings will not be accepted.

You cannot delete individual memories,

but you can overwrite them.

Deleting all memories

Switch the machine off. Press the program

selection buttons +/– and the memory

button M together. Hold the buttons down

and switch the machine on. After about 10

seconds, the last stitch program used on

the 4874 will appear in the display, and the

contents of all memories will be deleted.

3-6

Page 57

Changing settings for tension, stitch

length and differential feed directly

without saving

If you want to change tension settings in

the middle of a sewing project, but don’t

want to save these values, press one of

the tension buttons + /-. To change the

stitch length or the differential feed value,

press the corresponding +/- buttons. The

program memory will open. Now you can

change any setting with the corresponding

+/- buttons. If you press memory selection

button P repeatedly you will be returned

to the main menu, the changed setting

will not be saved. If no changes are made

within 10 seconds, the display switches

back to the main menu automatically.

Electronic functions

Error

If a stepping motor for controlling thread

tension should fail, the following message

appears in the display:

ERROR. Error 1 means: stepping motor

number 1 for the blue needle thread

tension is no functioning. If the Error

message is still displayed after you have

switched the machine off and on again,

you should take your machine to a service

center.

3-7

Page 58

3-8

Page 59

Cover stitch

In this chapter, we explain the basic functioning of your creative 4874, using the

coverstitch as an example.

Cover stitch

4-1

Page 60

Note: Always set up your

creative 4874 as shown in the

display fi rst. Then open the

program memory (see page

3-5) before threading the

machine.

Cover stitch

Switching the machine to cover stitch

(progs. 01, 02, 03)

Use the program selection buttons +/- (11)

to select one of the cover-stitches. In our

example, we have selected program 03,

3-needle cover hem.

3.0 1.0

The stitch length and the differential feed

are set automatically, but can be altered

and stored individually (see page 3-4).

0

1

L 21R2

With the needle changing tool, insert

needles L 0, 1 and 2 as far as they will go

into the needle holder (make sure they

are inserted all the way with your fi ngers).

Tighten the associated retaining screw and

remove the needle changing tool.

Pull knob A of the swivelling stitch fi nger

(32) to the right and swing it down into its

disengaged position.

A

4-2

Page 61

Turn the hand wheel to bring the upper

looper to its lowest position. Press the

lever to disengage the upper looper (18)

down and push it to the left. Turn the

hand wheel to ensure that the looper is

disengaged.

Remove the knife guard and push the

sewing table (accessory) down between

the two front cover guides.

Cover stitch

Raise the upper knife (35) to its highest

position by turning the hand wheel. Now

push the knob for lowering the upper

knife (39) as far as it will go to the right.

Turn the knob towards you until the upper

knife is seated in its lowest position. The

upper knife is now disengaged.

3,5

Turn the seam width selection knob (22) to

set the seam width to 3.5 mm.

4-3

Page 62

A F

Set the standard presser foot heel to A

or insert the clearview foot F from the

accessory box.

When you press the memory selection

button P once, the program memory

opens. The thread tension settings appear

beside the program number in the display.

First thread the purple thread tension for

the cover-stitch looper, followed by the

blue, green and red thread tensions for the

needles.

You can also refer to the threading

diagram behind the front cover.

Threading the cover-stitch looper

Turn the hand wheel towards you until the

cover-stitch looper (33) is as far to the right

as possible.

33

4-4

Thread the thread in order from 1 to 10.

Thread guide 8 is marked with a purple

square

1

2

3

10

7

9

8

4

6

5

Page 63

Cover stitch

Thread the thread in the guides from 1 to

8. (Make sure: The thread does not pass

under the latch)

8

7

6

4

5

Press lever A up and hook the thread into

slot B. The illustration below shows how to

do this.

Note: In the case of thread

guides 6 and 7, the thread is

simply placed on top of them,

not threaded through.

Note: The lever will return to

its original position as soon as

you start to sew.

B

A

From the front, pass the thread through

eye C (- threading point 10) of the double

chain stitch or cover stitch looper.

Pull about 10 cm (5”) of thread through

the looper and place it to the left under

the presser foot.

4-5

Page 64

Threading the needle(s)

Thread the threads in order from 1 to 9.

1

2

The thread must pass through the lower

slot in thread guide 5.

To thread needles more easily, use the

needle threader in the accessory box.

5

3

4

6

7

8

9

5

4

4-6

Pull the thread about 10 cm (5”) through

the eye of the needle and place it to the

left under the presser foot (if necessary,

press the tension release button (10), see

page 3-4).

7

8

9

Page 65

Summary of threading paths and their threading sequences

Stitch program 01:

2-needle cover hem, narrow

Stitch program 02:

2-needle cover hem, wide

Cover stitch

Stitch program 03:

3-needle cover hem

Important notes on sewing with

the cover stitch

Sewing table

The sewing table is marked with various

measurements. The fi gures at the top are

centimeters, those at the bottom represent

inches.

4-7

Page 66

Note: The hem guide H2

may be ordered as an extra

accessory. It makes hemming

child’s play without the need

to iron the hem before you

sew.

Preparing the project

When hemming, it is helpful to iron the

hem beforehand. Depending on the

hemdepth, add 0.5 cm (1/4”) to the hem.

For example, if you want a 2 cm hem, iron

up 2.5 cm(1” hem iron up 1 1/4”).

Starting to sew

Lift up the presser foot and position the

fabric under the presser foot so that the

needles pierce the fabric on the fi rst stitch.

The raw edge must be along the two on

the ruler of the sewing table.

Keep the threads moderately taut and

start sewing slowly. As soon as the fi rst

few stitches have been formed, you can

increase the sewing speed.

Note: In most cases, the

differential feed will need to

be adjusted. Sew a test seam

fi rst.

Stopping sewing

1. If you are sewing to the edge of the

project:

Grasp the threads at the end of the

seam and sew slowly off the project.

As you do so, pull the threads gently

backwards.

2. If you are sewing a continuous hem

(around a project):

Sew 4–5 stitches over the previous

stitches. On the last stitch, turn the

hand wheel towards you slowly until

the needles reach their lowest position.

4-8

Page 67

Now turn the hand wheel back until

the needles are in their highest

position. At the same time, loosen the

needle threads slightly with one fi nger.

Raise the presser foot. Grasp the

threads at the end of the seam and

press the tension release button to pull

the project out. Cut the threads off.

Pull the needle threads through to the

wrong side of the fabric and tie off.

Cover stitch

Edge guide

A

Slide the edge guide from the accessory

box left to right into guide A of the presser

foot holder. You can adjust the ruler as you

wish by sliding it in the guide.

The edge guide is used for sewing seams

at a constant distance from the edge of a

project. It can also be used programs 21-30.

To return your creative 4874 to normal

sewing:

Open the front cover and take off the

sewing table. Push the upper looper lever

to the right so that the upper looper is

engaged. Return the stitch fi nger to its

upright and engage the movable knife.

Replace the knife guard onto the front

cover, and close the cover.

4-9

Page 68

Stitch formation

3-needle cover hem, program 03

If all the thread tensions are set correctly,

the needle threads (blue, green and red)

are almost invisible on the underside of the

fabric. The looper thread (purple) lies slack

between them.

The needle threads (blue, green and red)

are too loose and form small loops on the

underside of the fabric.

Choose a higher setting for the blue, green

and red thread tensions.

The needle threads (blue, green and red)

are too tight and the fabric is puckering.

Set a lower value for the blue, green and

red thread tensions.

4-10

Page 69

Cover stitch

2-needle cover hem, narrow and wide,

programs 01, 02

If all the thread tensions are set correctly,

the needle threads (blue and green) are

almost invisible on the underside of the

fabric. The looper thread (purple) lies slack

between them.

The right needle thread (green) is too

loose.

Adjust the green thread tension to a

higher setting.

4-11

Page 70

4-12

Page 71

Top Cover Stitch

In this chapter, we describe the basic functioning of your creative 4874 with reference to

top cover stitching.

Top Cover Stitch

5-1

Page 72

Top Cover Stitch

Switching the machine to top cover

operation (progs. 21, 22, 23).

Detachable thread stand

For top cover sewing you need to use the

detachable thread stand. Insert the top

catches of the thread stand (27) into the

top slots on the rear cover and press the

bottom portion of the stand against the

cover. Push the detachable thread stand to

the right as far as it will go. Place one foam

pad (52) on each spool pin (50).

To remove, push the thread stand to the

left and pull upwards.

Detachable thread guide for top/deco

cover

Pull the thread guide up as far as it will go

and twist it until the locking pommels click

into place. Place the detachable thread

guide from the accessories box on top of

the fi rst thread guide slide.

Sewing program sticker

The top/deco sewing program sticker

(25) is located behind the front cover and

includes the following information:

1. Row: Stitch program number

2. Row: Needle position

3. Row: Tension setting in blue.

(Remember, the blue thread tension

must be changed manually.)

4. Row: Stitch formation with needle

stitch lines in grey

5-2

1

2

3

4

Page 73

Top Cover Stitch

Top/deco switch lever

Choose a stitch program and move the top/

deco switch lever A to the correct position:

Right for top cover, programs 21, 22 and

23.

A

Left for deco cover, programs 24 – 30.

For our example, we have chosen program

23.

Stitch program selection

Switch the machine on and select one of

the top cover programs with the program

selection buttons +/- (11). The stitch length

and differential feed will be adjusted

and the sewing speed will be slowed

automatically. For our example, we have

selected program 23, 3-needle, 4-thread

top cover.

If you hear an alarm when you make your

stitch program selection, this means that

the top/deco switch lever (A) is in the

wrong position.

Note: If the top/deco switch

lever is not in the correct

position, the machine will not

run in programs 21 – 30 and an

alarm will sound.

Note: Always set up your

creative 4874 as shown in the

display fi rst. Then open the

program memory (see page

3-5) before threading the

machine.

3.0 1.0

The stitch length and the differential feed

are set automatically, but can be altered

and stored individually (see page 3-4).

0

L 21R2

1

With the needle changing tool, insert

needles L 0, 1 and 2 as far as they will go

into the needle holder (make sure the

needles are inserted all the way with your

fi ngers). Tighten the associated retaining

screw and remove the needle changing

tool.

5-3

Page 74

Pull knob A of the stitch fi nger (32) to

the right and swing it down into its

disengaged position.

Turn the hand wheel to bring the upper

looper to its lowest position. Press the

upper looper disconnection lever (18)

down and push it to the left. Turn the

hand wheel to ensure that the upper

looper is disengaged.

A

Remove the knife guard and push the

sewing table (accessory) down between

the two front cover guides.

Raise the upper knife (32) to its highest

position by turning the hand wheel. Now

push the knob for lowering the upper

knife (39) as far as it will go to the right.

Turn the knob towards you until the upper

knife is in its lowest position. The upper

knife is now disengaged.

5-4

Page 75

3,5

Turn the seam width adjustment knob (22)

to set the seam width to 3.5 mm.

R

Use clearview foot R from the accessory

box.

Top Cover Stitch

Accessories

The following accessories are provided for

the top cover:

1

2

3

1. Top cover hook

2. Top cover round thread guide

3. Top cover triangle thread guide

Top cover hook

Insert the top cover hook into the top slot

(blue) of the holder.

To do this, loosen but do not remove the

screw on the side with the allen key.

Note: You must attach presser

foot R and lower it.

5-5

Page 76

Insert the top cover hook and tighten the

screw.

To remove the top cover hook, loosen the

screw with the allen key.

Place the screwdriver between the top

cover hook and the holder. Press the tip of

the screwdriver gently forwards. The top

cover hook will pop out of the holder.

Top cover round thread guide

Loosen screws R1 and R2. Insert the Top

cover round thread guide into the holder

and tighten the screws, R2 fi rst and then

R1.

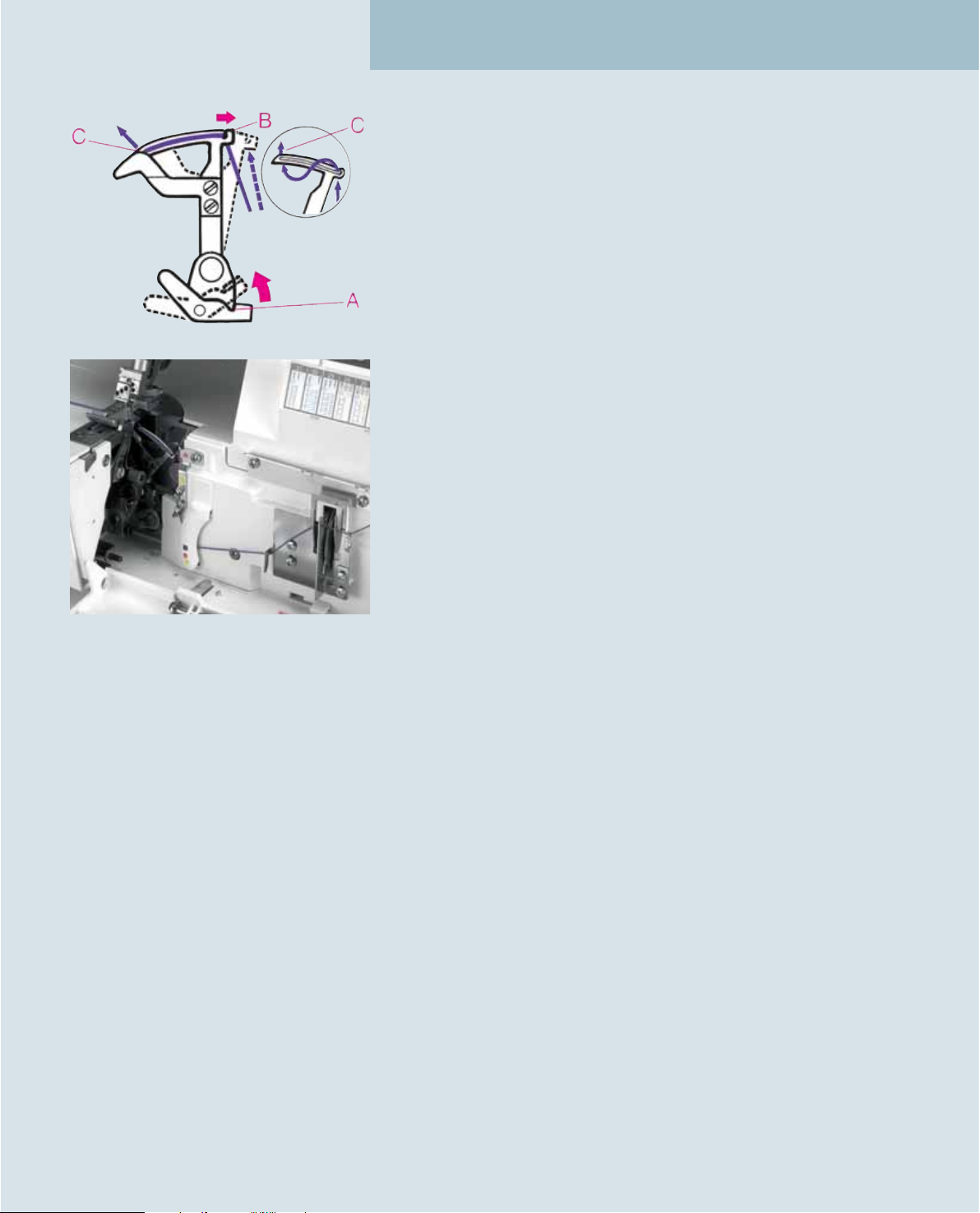

Top cover triangle thread guide

The triangle thread guide device has a

wide slot A and black handle B.

B

C

A

5-6

Page 77

Top Cover Stitch

When attaching the thread guide, make

sure that the holder for the top/deco

switch lever is fully seated in slot A. Now

push the thread guide device back as far as

it will go until you hear it click into place.

To remove it, press handle B down against

C (the part where the triangle thread

guide is attached). Pull it gently towards

you and out of the holder.

B

C

33

When you press the memory selection

button P once, the program memory

opens. The thread tension values appear

beside the program number in the display.

First thread the purple thread tension for

the cover-stitch looper, followed by the

blue, green and red thread tensions for the

needles.

You can also refer to the threading

diagram behind the front cover. Finally,

you must thread the blue top cover thread.

Threading the cover-stitch looper

Turn the hand wheel towards you until the

cover-stitch looper (33) is as far to the right

as possible.

5-7

Page 78

Thread the threads in order from 1 to 10.

Thread guide 8 is marked with a purple

square

1

2

3

Note: In the case of thread

guides 6 and 7, the thread is

simply placed on top of them,

not threaded through.

Note: The lever will return to

its original position as soon as

you start to sew.

Thread the thread in the guides from 1 to

8. (Make sure: The thread does not pass

under the latch)

Press lever A up and hook the thread into

slot B. The illustration below shows how to

do this.

10

9

7

4

6

5

8

8

7

6

4

5

B

A

5-8

From the front, pass the thread through

eye C (- threading point 10) of the double

chain stitch and cover stitch looper.

Page 79

Top Cover Stitch

Pull about 10 cm (5”) of thread through

the looper and place it to the left under

the presser foot.

Threading the needle(s)

Thread the thread in order from 1 to 9.

1

2

5

3

4

6

7

8

9

The thread must pass through the lower

5

4

7

8

slot in thread guide 5. To thread needles

more easily, use the needle threader in the

accessory box.

Pull the thread about 10 cm (5”) through

the eye of the needle and place it to the

left under the presser foot (if necessary,

press the tension release button (10), see

page 3-4).

9

5-9

Page 80

Top cover thread tension, blue

Set the top cover thread tension, blue (45)

as indicated on the stitch program sticker.

To do this, turn the thread tension dial

by hand until the corresponding setting

appears directly above line A.

Threading the top cover thread

Place the spool on the front left spool pin

of the detachable thread stand. Thread the

corresponding thread guide from the back

forwards.

A

With both hands, pull the thread between

the tension discs and place it under the

rear thread guide (46).

Now feed the thread into the hole in the

detachable thread guide.

5-10

Page 81

Top Cover Stitch

1

Thread the thread in order 1 to 4 and place

the thread to the left over the presser foot.

Some thread guides are marked in blue.

2

3

4

Summary of threading paths and their

threading sequences

Stitch program 21

2-needle Top cover, narrow

Stitch program 22

2-needle Top cover, wide

Stitch program 23

3-needle, Top cover

5-11

Page 82

Important notes on sewing with

the top cover stitch

Sewing table

The sewing table is marked with various

measurement units. The fi gures at the

top are centimeters, those at the bottom

represent inches.

Preparing your project

If you are going to use top cover stitches

for decorative effects, you can mark the

outlines on the right side of the fabric with

textile pen or chalk, and sew along these

lines.

Test your textile pen with your fabric.

Note: Test sew the cover stitch

fi rst, without adding the top

cover thread. When the stitch

is tested, continue sewing also

with the top cover thread.

If you intend to use top cover stitches

for hemming, it is helpful to iron a hem

beforehand. Depending on the hemdepth,

add 0.5 cm (1/4”) to the hem. For example,

if you want a 2 cm hem, iron up 2.5 cm (1”

hem, iron up 1 1/4”).

Starting to sew

Lift up the presser foot and position the

fabric under the presser foot so that the

needles pierce the fabric on the fi rst stitch.

The top cover thread must be in front of the

needles in order to be picked up on the very

fi rst stitch. The raw edge must be along the

two of the sewing table. Keep the threads

moderately taut and start sewing slowly.

As soon as the fi rst few stitches have been

formed, the top cover thread can be cut

short at the start of the seam and you can

increase the sewing speed.

5-12

Page 83

Stopping sewing

1. If you are sewing to the edge of the

project:

Grasp the threads at the end of the

seam and sew slowly off the project.

As you do so, pull the threads gently

backwards.

2. If you are sewing a continuous hem

(around a project):

Sew 4–5 stitches over the previous

stitches. On the last stitch, turn the

hand wheel towards you slowly until

the needles reach their lowest position.

Top Cover Stitch

Now turn the hand wheel back until

the needles are in their highest

position. At the same time, loosen the

needle threads slightly with one fi nger.

Raise the presser foot. Grasp the threads at

the end of the seam and press the tension

release button to pull the work piece out.

Cut the threads off. Pull the top cover

threads through to the wrong side of the

fabric and tie off.

5-13

Page 84

Stitch formation

Since the top cover-stitch consists of a

combination of the cover-stitch with top

cover thread, we offer suggestions about

adjustment options that predominantly

refer to the cover-stitch.

3-needle Top cover, stitch program 23

If all the thread tensions are set correctly,

the needle threads (blue, green and red)

are almost invisible on the underside of the

fabric. The looper thread (purple) lies slack

between them.