Page 1

Owner’s Manual

Page 2

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including

the following:

Read all instructions before using this household sewing machine. Keep the instructions at a

suitable place close to the machine. Make sure to hand them over if the machine is given to a third

party.

DANGER –

•Asewingmachineshouldneverbeleftunattendedwhenpluggedin.Alwaysunplugthissewing

machine from the electric outlet immediately after using and before cleaning, removing covers,

relamping, lubricating or when making any other user servicing adjustments mentioned in the

instruction manual.

WARNING –

TO REDUCE THE RISK OF ELECTRIC SHOCK:

TO REDUCE THE RISK OF BURNS, FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSON:

•Thissewingmachineisnotintendedforusebypersons(includingchildren)withreduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the sewing machine by a person

responsible for their safety.

•Childrenshouldbesupervisedtoensurethattheydonotplaywiththesewingmachine.

•Usethissewingmachineonlyforitsintendeduseasdescribedinthismanual.Useonly

attachments recommended by the manufacturer as contained in this manual.

•Neveroperatethissewingmachineifithasadamagedcordorplug,ifitisnotworkingproperly,

if it has been dropped or damaged, or dropped into water. Return the sewing machine to the

nearest authorized dealer or service center for examination, repair, electrical or mechanical

adjustment.

•Neveroperatethesewingmachinewithanyairopeningsblocked.Keepventilationopeningsof

the sewing machine and foot control free from the accumulation of lint, dust, and loose cloth.

•Keepngersawayfromallmovingparts.Specialcareisrequiredaroundthesewingmachine

needle.

•Alwaysusetheproperneedleplate.Thewrongplatecancausetheneedletobreak.

•Donotusebentneedles.

•Donotpullorpushfabricwhilestitching.Itmaydeecttheneedlecausingittobreak.

•Wearsafetyglasses.

•Switchthesewingmachineoff(“0”)whenmakinganyadjustmentintheneedlearea,suchas

threading needle, changing needle, threading bobbin, or changing presser foot, etc.

•Neverdroporinsertanyobjectintoanyopening.

•Donotuseoutdoors.

•Donotoperatewhereaerosol(spray)productsarebeingusedorwhereoxygenisbeing

administrated.

•Todisconnect,turnallcontrolstotheoff(“0”)position,thenremoveplugfromoutlet.

•Donotunplugbypullingoncord.Tounplug,grasptheplug,notthecord.

•Thenoiselevelundernormaloperatingconditionsislessthan75dB(A).

•Thefootcontrolisusedtooperatethemachine.Avoidplacingotherobjectsonthefootcontrol.

•Thissewingmachineisprovidedwithdoubleinsulation.Useonlyidenticalreplacementparts.

SeeinstructionsforServicingofDouble-InsulatedAppliances.

SAVE THESE INSTRUCTIONS

Page 3

SERVICING OF DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No

ground means is provided on a double-insulated product, nor should a means for grounding

beaddedtotheproduct.Servicingofadouble-insulatedproductrequiresextremecareand

knowledgeofthesystemandshouldbedoneonlybyqualiedservicepersonnel.Replacement

partsforadouble-insulatedproductmustbeidenticaltothosepartsintheproduct.Adoubleinsulatedproductismarkedwiththewords‘DOUBLEINSULATION’or‘DOUBLEINSULATED’.

Page 4

Congratulations!

Congratulations on purchasing your new PFAFF®

creative™ 4.5 sewing and embroidery machine.

As a sewing enthusiast, you have acquired one

of the most advanced and comprehensive sewing

and embroidery machines in the world; it will

enable you to transform all your creative ideas into

reality using the most highly tuned technology and

features.

Before you start, please spend some time reading

this owner’s manual. You will soon discover how to

maximize the use of your machine. Our authorized

PFAFF

®

dealers will of course also be pleased to

advise you at any time.

Your PFAFF

®

creative™ 4.5 sewing and embroidery

machine will denitely enable you to experience a

totally new dimension of sewing and embroidery.

Page 5

TABLE OF CONTENTS

1

Introduction 1:7

Machine overview 1:8

Front side ...................................................................... 1:8

Rear side ....................................................................... 1:9

Top parts ....................................................................... 1:9

Accessory tray .............................................................. 1:9

Included accessories 1:10

Presser feet .................................................................. 1:10

Stitch overview 1:12

Utility stitches ............................................................ 1:12

Decorative stitches .................................................... 1:15

Alphabets .................................................................... 1:21

2

Preparations 2:1

Unpacking 2:2

Connecting the foot control cord 2:2

Connect the power cord

and foot control 2:2

Pack away after sewing 2:3

LED lights 2:3

Free arm 2:3

Thread cutter 2:3

Electronic knee-lift 2:3

Spool pins 2:4

Threading the machine 2:5

Needle threader ........................................................... 2:5

Thread sensor 2:6

Bobbin winding 2:7

Inserting the bobbin 2:8

IDT™ system (Integrated Dual Feed) 2:9

Attaching the Dynamic spring foot 6D 2:9

Changing the presser foot 2:10

Needles 2:10

Changing the needle 2:11

USB ports 2:11

USB embroidery stick ............................................... 2:11

Complimentary software (PC) 2:12

How to update your machine 2:12

Buttons and indicators 2:13

3

PFAFF® creative™ Color Touch Screen 3:1

Start view 3:2

Main parts 3:2

Task bar ......................................................................... 3:2

Option bar ..................................................................... 3:3

Common icons 3:3

Selection menu 3:4

Selection menu - overview ......................................... 3:4

Embroidery edit 3:6

Embroidery stitch-out 3:7

Settings menu 3:8

Machine settings .......................................................... 3:8

Screen settings ............................................................ 3:11

Sound settings ............................................................ 3:11

Info menu 3:12

Quick help 3:12

4

Sewing mode 4:1

Sewing mode - overview 4:2

Select a stitch 4:3

Sewing recommendations 4:3

Machine settings 4:3

Raise and lower the presser foot 4:3

Stitch settings 4:4

Stitch width .................................................................. 4:4

Stitch positioning ......................................................... 4:4

Stitch length .................................................................. 4:4

Stitch density ................................................................ 4:5

Mirroring ...................................................................... 4:5

Balance .......................................................................... 4:5

Buttonhole slit length .................................................. 4:6

Button stitch repetition ............................................... 4:6

Adjust thread tension ................................................. 4:7

Free-motion options 4:8

Sequence start position 4:9

Save options 4:9

Option bar 4:11

Speed control .............................................................. 4:11

Tie-off options ............................................................ 4:11

Sewing programs ....................................................... 4:12

Sequencing ................................................................. 4:13

Stitch Creator™ feature ............................................ 4:13

Sewing techniques 4:14

Sewing in zippers ...................................................... 4:14

Sewing hems in heavy fabric ................................... 4:14

Three-step zigzag stitch ............................................ 4:15

Blindhem stitch .......................................................... 4:15

Buttonholes ................................................................. 4:16

Sew on a button ......................................................... 4:18

Darning ....................................................................... 4:18

Special sewing techniques 4:21

Four direction sewing ............................................... 4:21

Stacking stitches ......................................................... 4:22

Ribbon stitches ........................................................... 4:22

Common sewing pop-ups 4:23

5

Sequencing 5:1

Sequencing - overview 5:2

Open and exit sequencing 5:3

Create a sequence 5:3

Sequence commands ................................................... 5:4

Page 6

Horizontal preview ..................................................... 5:5

Directional stitches ...................................................... 5:5

Zoom to all ................................................................... 5:6

Loading and sewing a sequence 5:6

Saving a sequence 5:7

Important sequencing information 5:8

Common sequencing pop-ups 5:8

6

Stitch Creator™ feature 6:1

Stitch Creator™ feature - overview 6:2

Open and exit Stitch Creator™ feature .................... 6:3

Denition of a stitch point ........................................ 6:3

Start creating - add a stitch or stitch point ............... 6:3

Select stitches/stitch points ....................................... 6:3

Multi-select ................................................................... 6:4

Delete selected stitch point ........................................ 6:4

Duplicate selected stitch point ................................... 6:4

Insert a new stitch point ............................................. 6:4

Zoom ............................................................................. 6:4

Mirroring side to side ................................................. 6:5

Mirroring end to end .................................................. 6:5

Triple stitch ................................................................... 6:5

Touch functions 6:6

Position of the marked stitch point 6:6

Loading and sewing a stitch 6:7

Saving a stitch 6:7

Common Stitch Creator™ feature pop-ups 6:8

Important Stitch Creator™ feature information 6:8

7

Embroidery mode – preparations 7:1

Embroidery unit overview 7:2

Embroidery hoop overview 7:3

Built-in designs 7:3

Embroidery collection 7:3

Connect the embroidery unit 7:3

Remove the embroidery unit 7:4

Attaching the Dynamic spring foot 6D 7:4

Slide on the hoop 7:5

To hoop the fabric 7:5

Getting started embroidering 7:6

8

Embroidery mode – edit 8:1

Embroidery edit - overview 8:2

Load a design 8:3

Load a font 8:3

Load a stitch 8:4

Zoom Options 8:4

Select design(s) 8:5

Stitch-out order 8:6

Adjustments 8:6

Group ............................................................................ 8:6

Delete ............................................................................. 8:6

Duplicate ....................................................................... 8:6

Mirroring ...................................................................... 8:6

Move design into hoop ............................................... 8:6

Undo .............................................................................. 8:6

Redo ............................................................................... 8:6

Touch functions 8:7

Move .............................................................................. 8:7

Rotate ............................................................................ 8:7

Scale ............................................................................... 8:7

Pan ................................................................................. 8:7

Option bar 8:8

Save to Personal designs ............................................ 8:8

More options ................................................................ 8:9

Select hoop .................................................................... 8:9

Thread color edit ....................................................... 8:10

Basic Shape Creator™ feature ................................. 8:11

Embroidery stitch editor .......................................... 8:18

Embroidery text editor ............................................. 8:21

Embroidery edit pop-ups 8:23

9

Embroidery mode – stitch-out 9:1

Embroidery stitch-out - overview 9:2

Embroidery information 9:2

Crosshair 9:3

Color list 9:3

Zoom options 9:3

Current stitch 9:3

Go to stitch 9:3

Basting 9:4

Thread tension 9:4

Option bar 9:5

More options ................................................................ 9:5

Hoop position .............................................................. 9:6

Speed control ................................................................ 9:6

Precise positioning ...................................................... 9:7

Common Embroidery stitch-out pop-ups 9:11

10

Files & Folders 10:1

Files & Folders - overview 10:2

File formats 10:3

Browse Files & Folders 10:3

Load a le 10:5

Open a folder 10:5

Organize 10:6

Common Files & Folders pop-ups 10:7

11

Maintenance 11:1

Cleaning the machine 11:2

Non-original parts and accessories 11:2

Troubleshooting 11:3

Index 11:5

Page 7

1

Introduction

Page 8

1

17

11

12 13 14 15 16

10

18

2

3

4

5

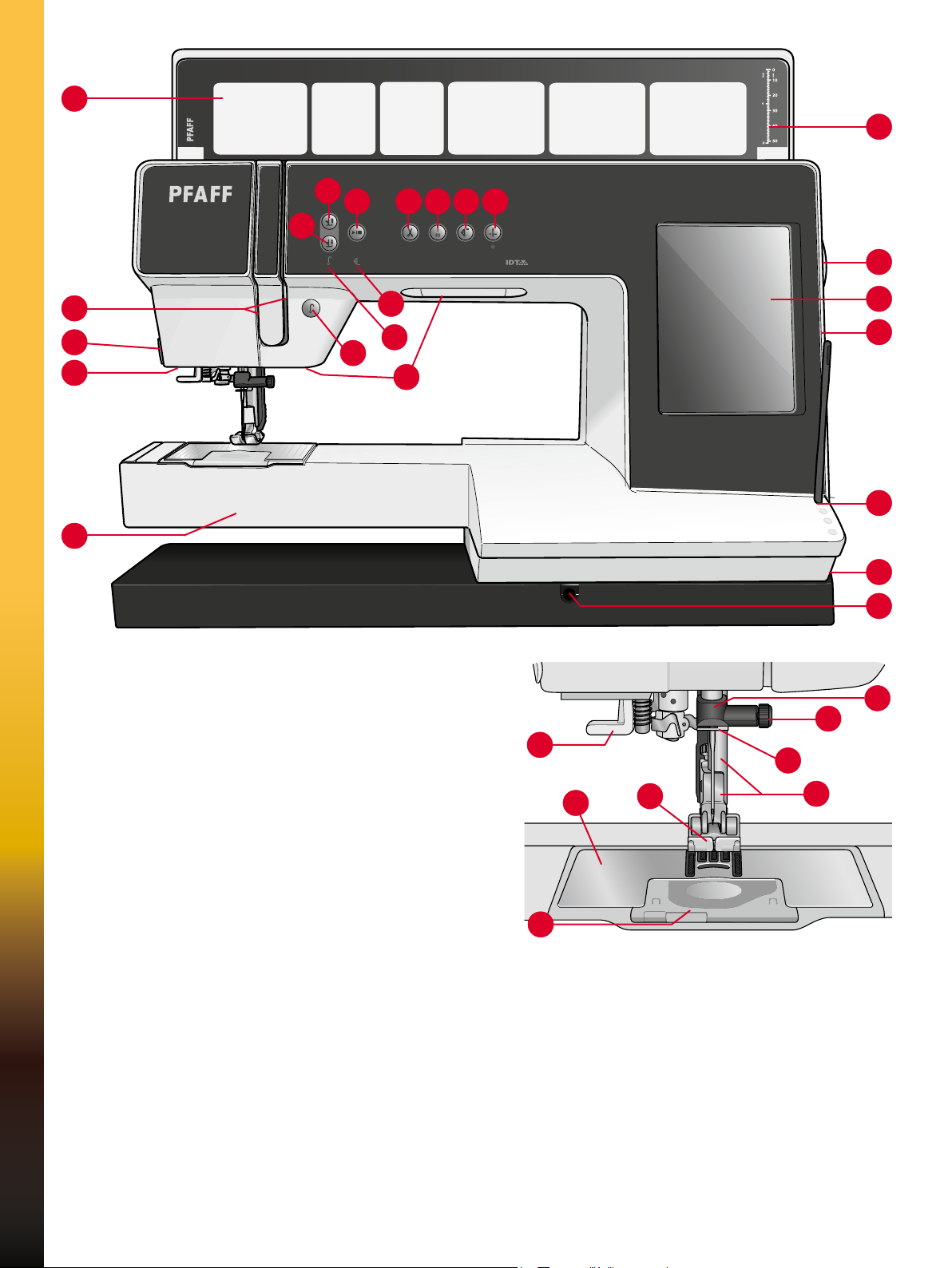

Machine overview

Front side

1. Lid with stitch categories

2. Threading slots

3. Thread cutter

9

8

19

20

7

6

21

22

23

31

30

24

26

27

29

28

4. Sensormatic buttonhole

foot socket

5. Free arm

6. LED lights

7. Reverse

8. Reverse indicator

9. Action indicator

10. Presser foot down and pivot

toggle

11. Presser foot up and extra lift

toggle

12. Start/stop

13. Thread snips

14. Immediate tie-off

15. Stitch restart

Introduction

1:8

25

16. Needle up/down

17. Button ruler

18. Handwheel

®

19. PFAFF

creative™ Color

Touch Screen

20. Built-in USB ports

21. Stylus holder

22. Main switch, connectors for

power cord and foot control

23. Connection for knee-lift

Needle area

24. Built-in needle threader

25. Bobbin cover

26. Needle plate

27. Presser foot

28. Presser foot bar and presser

foot holder

29. Needle thread guide

30. Needle screw

31. Needle bar

Page 9

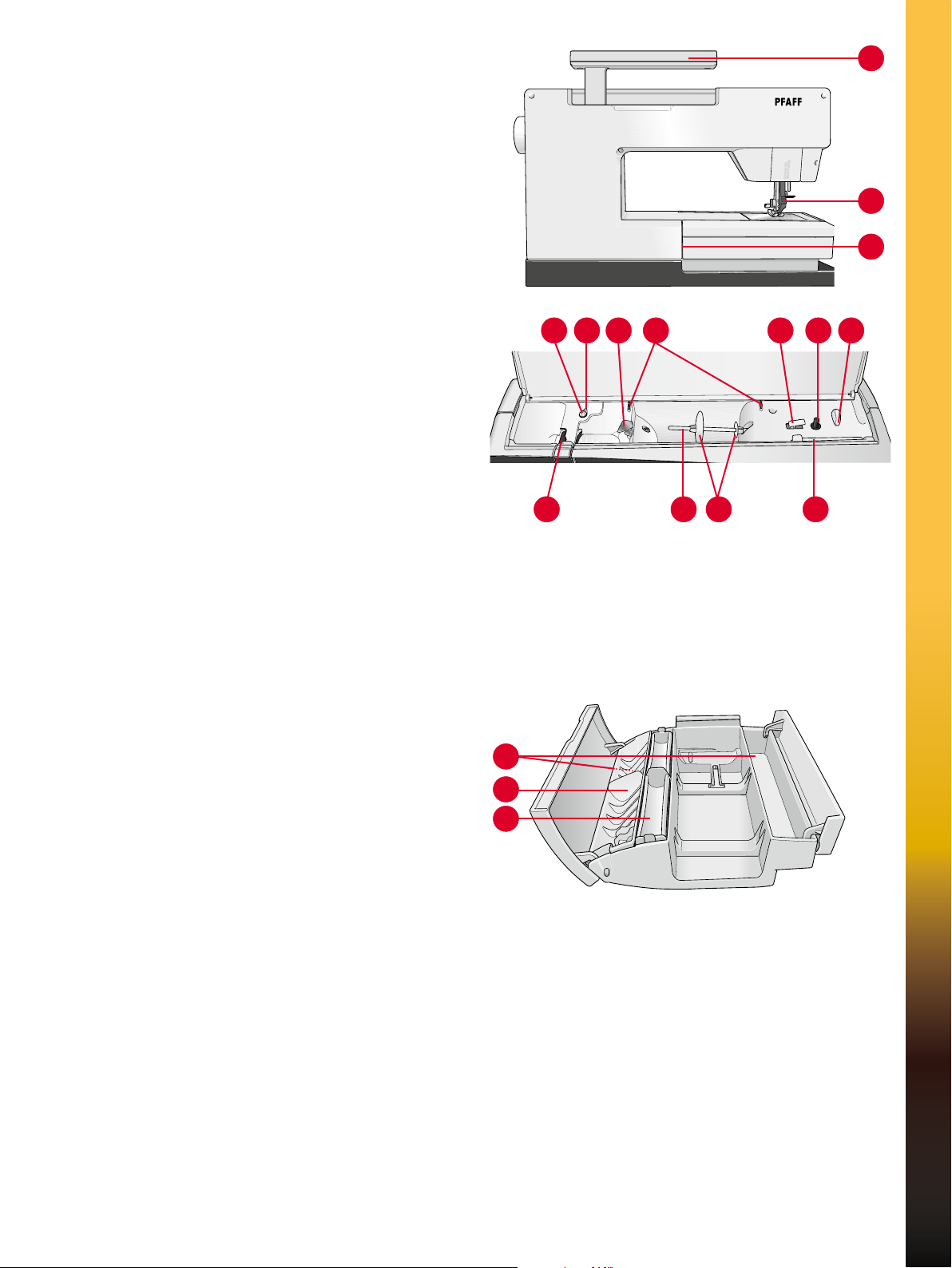

Rear side

32. Handle

33. IDT™ system

34. Embroidery unit connection socket

Top parts

35. Thread guide for needle thread and for bobbin

winding

36. Bobbin winder thread guide and pre-tension

device

37. Thread guide

38. Bobbin thread guides

39. Bobbin winder lever

40. Bobbin spindle

41. Bobbin thread cutter

32

33

34

35 36 37 38 39 40 41

42434445

42. Auxiliary spool pin

43. Spool caps

44. Spool pin

45. Take-up lever

Accessory tray

The accessory tray features special compartments

for presser feet and bobbins, plus space for needles

and other accessories. Store the accessories in the

tray so they are easily accessible.

46. Space for accessories

47. Removable tray for presser feet

48. Removable bobbin holder

46

47

48

1:9

Introduction

Page 10

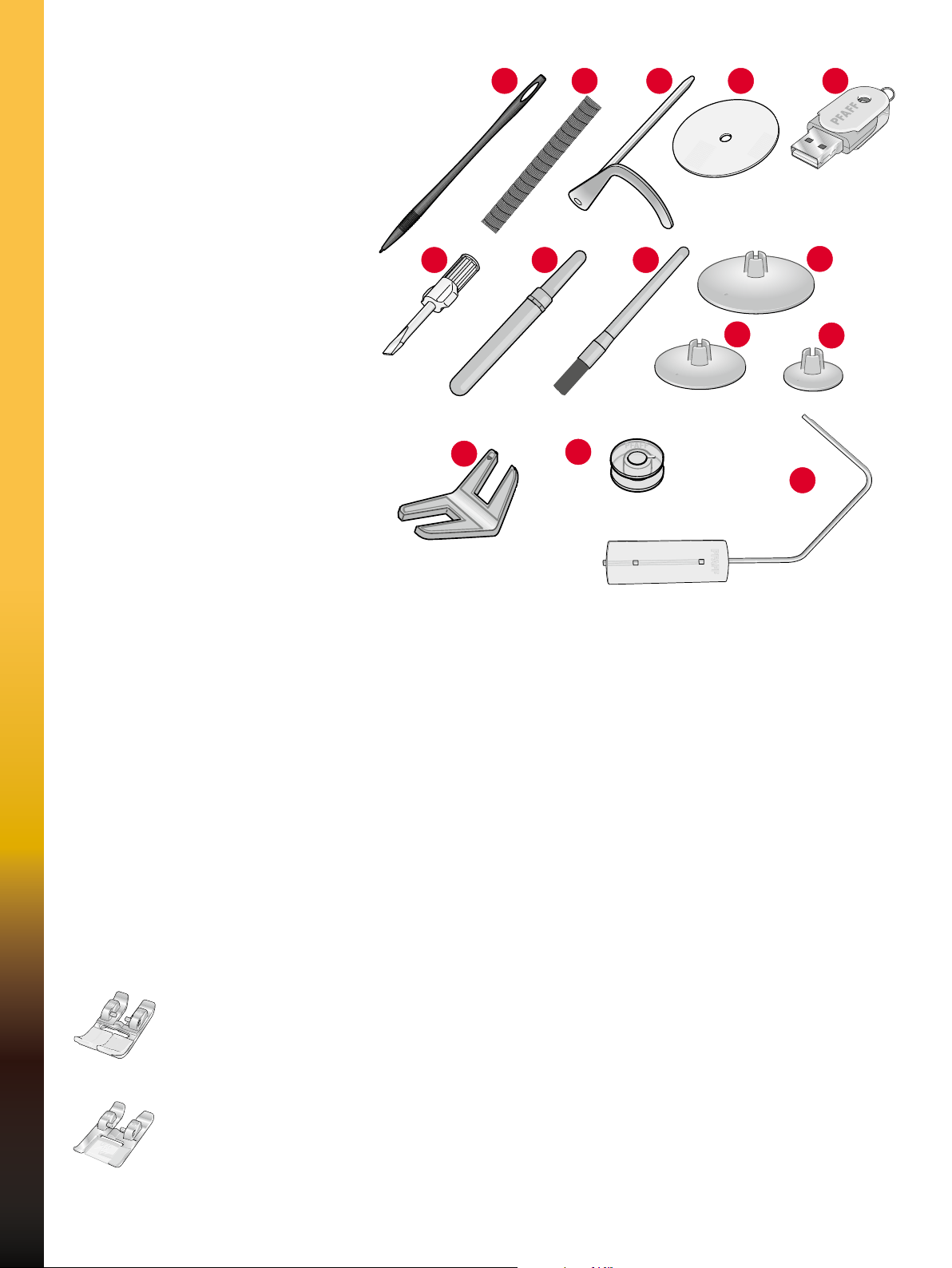

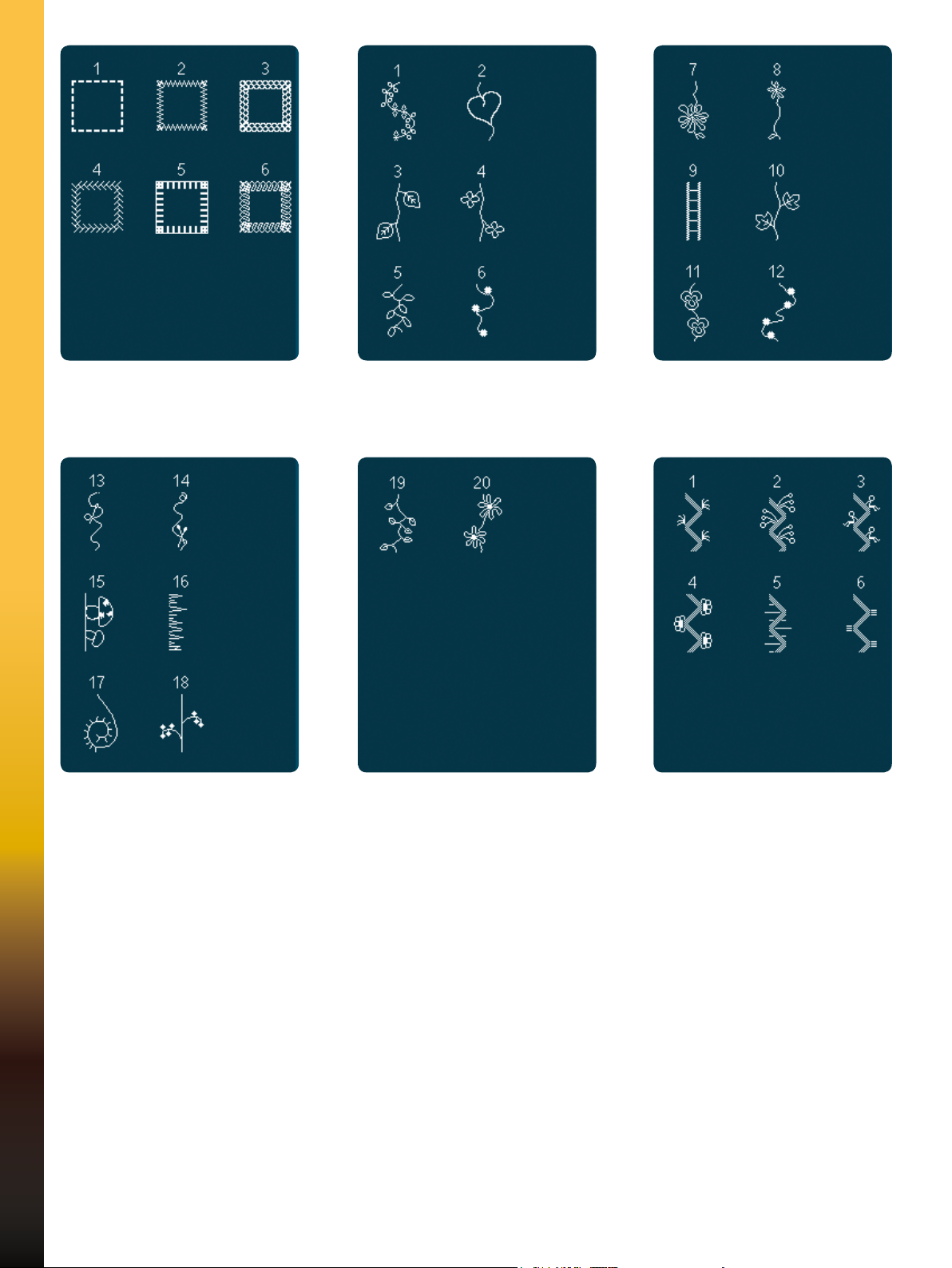

Included accessories

Accessories

55. Stylus

56. Thread net (2)

57. Edge guide

58. Felt pad (2)

59. USB Embroidery stick

55 56 57 58 59

60. Screwdriver

61. Seam ripper

62. Brush

63. Spool cap, large (2)

64. Spool cap, medium

65. Spool cap, small

66. Multi-purpose tool

67. Bobbins (10)

68. Knee-lift

Included accessories not in picture

• Complimentary software (PC) to download

• Foot control

60 61 62

66

67

64

63

65

68

• Power cord

• USB cord (P/N:412 62 59-04)

• Needles

• Microber cloth

• creative™ 4.5 Embroidery collection

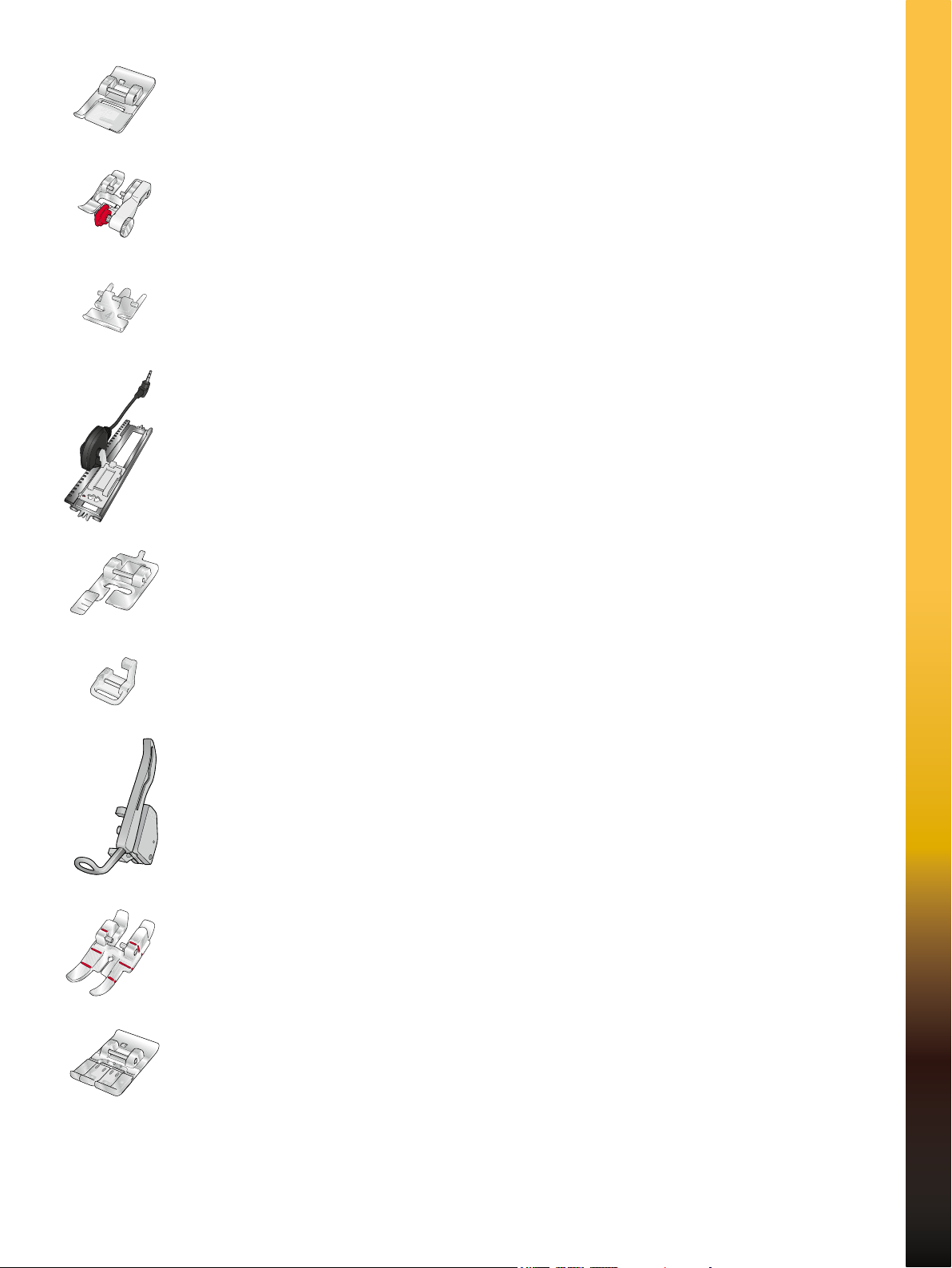

Presser feet

0A - Standard presser foot with IDT™ system

(attached on the machine upon delivery)

This foot is used mainly for straight stitching and zigzag stitching with a stitch length

longer than 1.0mm.

1A - Fancy stitch foot with IDT™ system

This foot is used for decorative stitches. The groove on the underside of the foot is

designed to ow smoothly over the stitches.

Introduction

1:10

Page 11

2A - Fancy stitch foot

When sewing decorative stitches or short zigzag stitches and other utility stitches with less

than 1.0mm stitch length, use this foot. The groove on the underside of the foot is designed

to ow smoothly over the stitches.

3 - Blindhem foot with IDT™ system

This foot is used for blindhem stitches. The toe on the foot guides the fabric. The red guide

on the foot is designed to ride along the fold of the hem edge.

4 - Zipper foot with IDT™ system

This foot can be snapped on either the right or the left of the needle, making it easy to sew

close to both sides of the zipper teeth. Move needle position to right or left to sew closer to

zipper teeth.

5A - Sensormatic buttonhole foot

When connected to the machine, the buttonhole is sewn in a suitable length to the button

size that has been entered into the machine.

5M - Manual buttonhole foot

This foot is used for sewing manual buttonholes. Use the markings on the foot to position

the garment edge. The nger on the back of the foot holds cording for corded buttonhole.

6A - Embroidery/Sensormatic free-motion foot

This foot is used for embroidery and free-motion sewing. This foot can also be used for

darning.

6D - Dynamic spring foot

This foot is always recommended for embroidery. It is also used for free-motion sewing,

quilting and embroidering on especially thick or spongy fabric. When using the Dynamic

spring foot for free-motion, select Dynamic spring foot free-motion setting in the Freemotion options window in sewing mode.

1/4” quilting foot with IDT™ system

This foot is perfect for piecing and patchwork, especially when used in conjunction

with the straight stitch needle plate. The distance from the needle to the outer edge of

the right toe is 1/4” (6mm). The distance from the needle to the inner edge of the

right toe is 1/8” (3mm).

8 - Maxi-stitch foot

This foot is used for side-motion stitches.

Important: Make sure that the IDT™ system is disengaged when using presser foot 2A, 5A, 5M, 6A, 6D and 8.

Introduction

1:11

Page 12

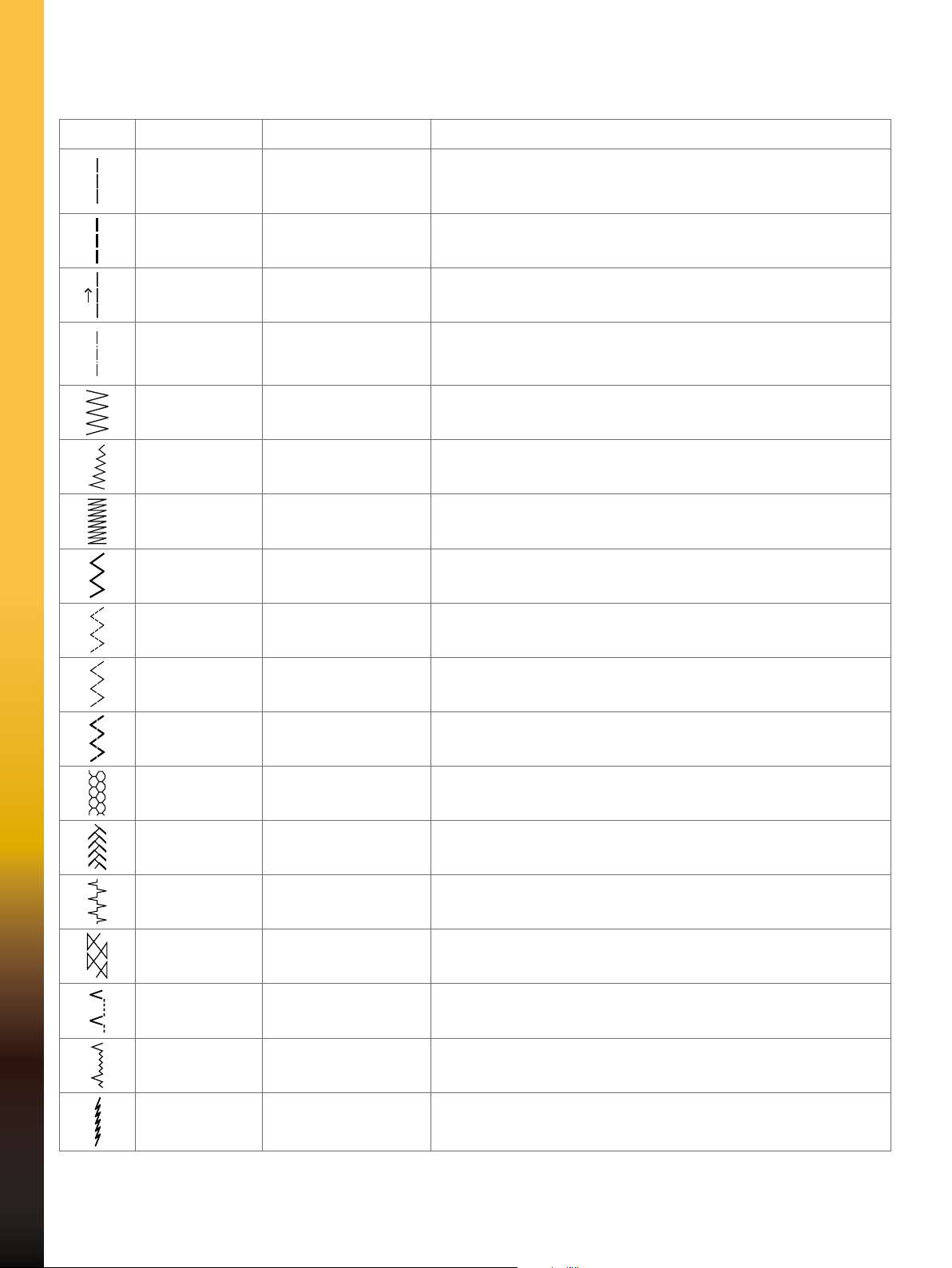

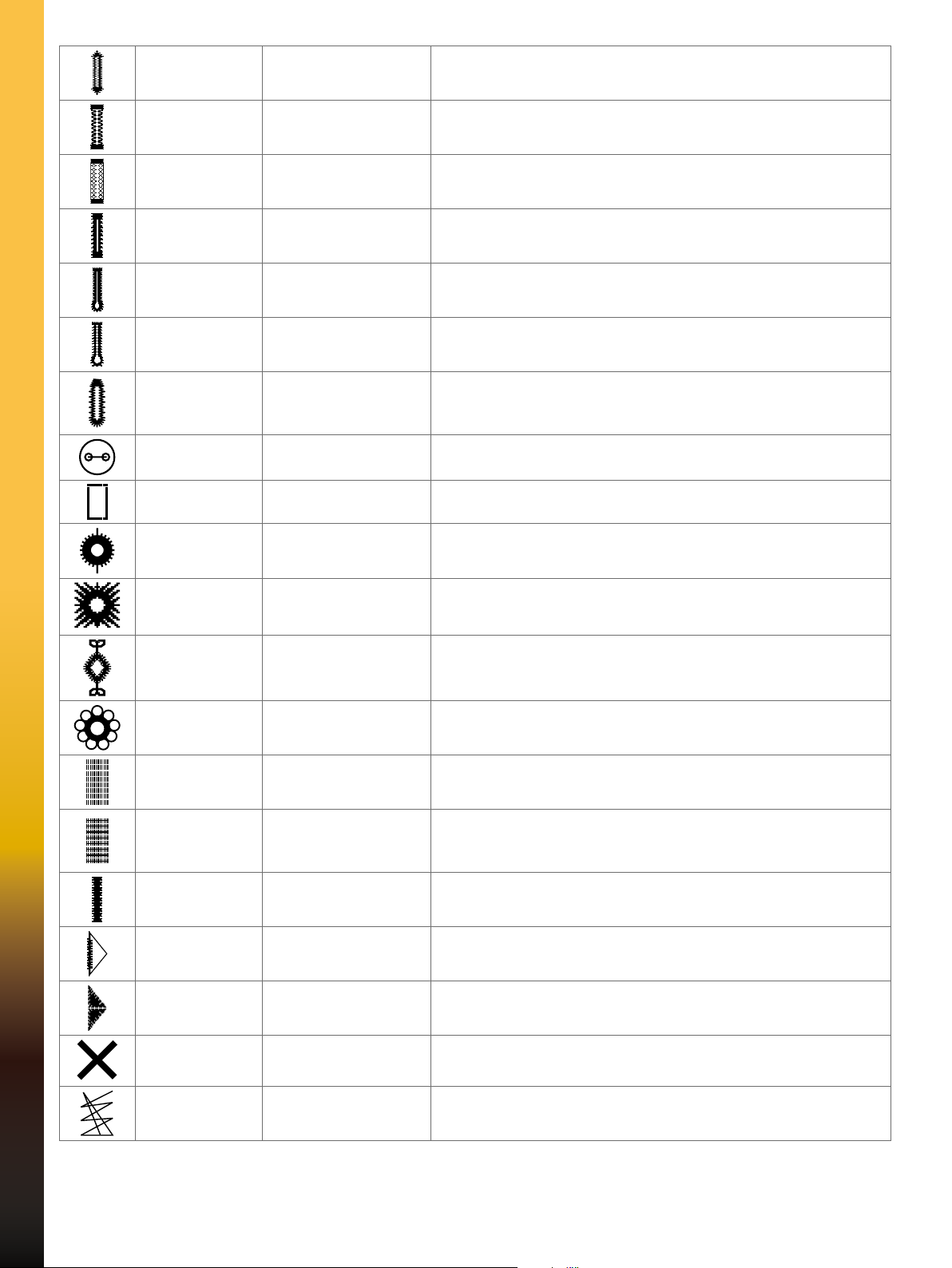

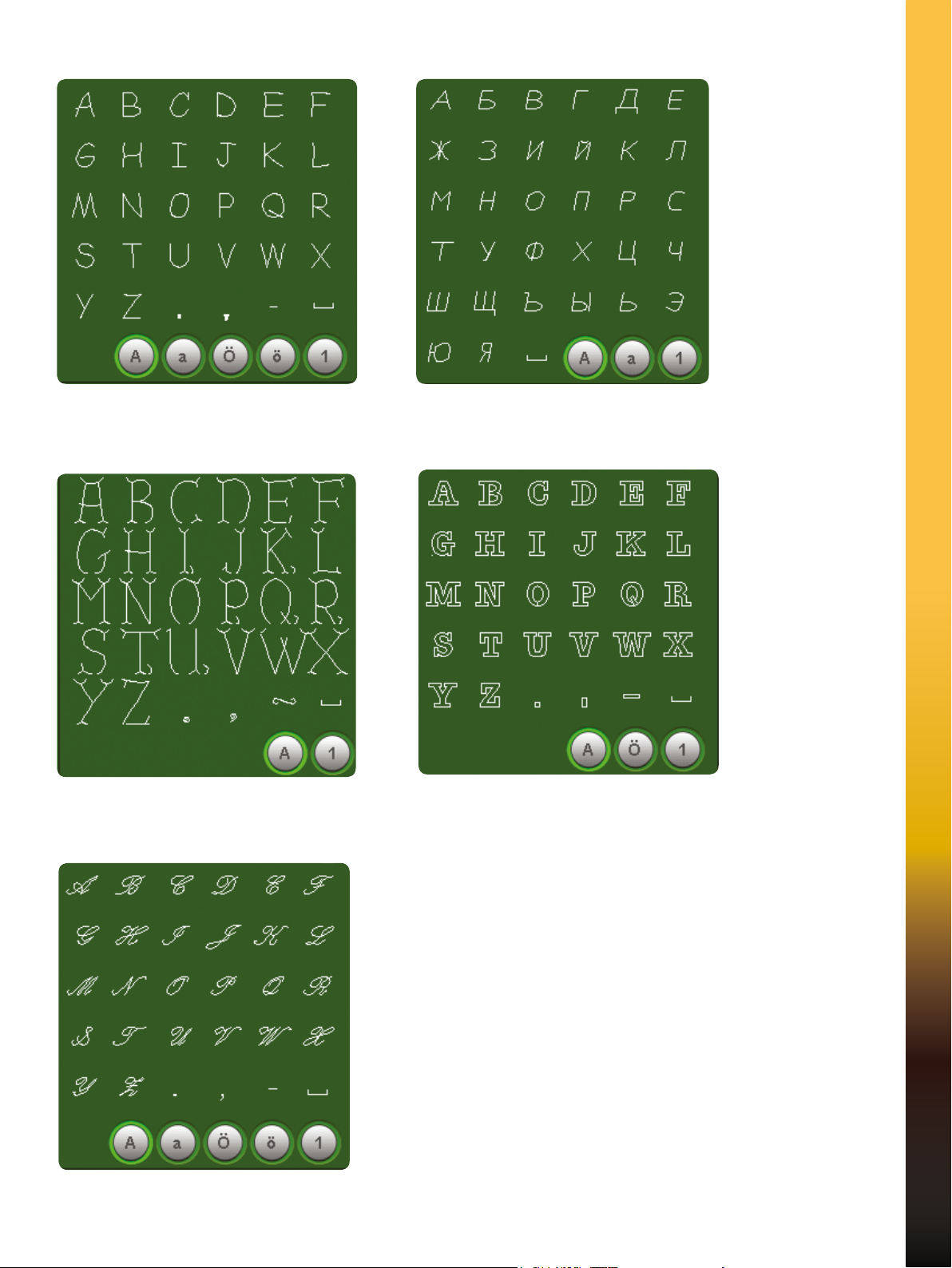

Stitch overview

Utility stitches

Stitch Stitch number Name Description

1.1.1 Straight stitch For seaming and topstitching. Select from 37 different needle

positions.

Note: This stitch makes a stronger tie-off than stitch 2.1.1.

1.1.2 Stretch triple straight

stitch

1.1.3 Straight stitch reverse Sew continuous reverse with strong tie-off.

1.1.4 Basting stitch Single stitch used for basting. Touch foot control to sew one stitch.

1.1.5 Zigzag stitch Reinforce seams, clean nish, stretch sewing, lace insertion.

1.1.6 Zigzag stitch, right or

left needle position

1.1.7 Z-zigzag stitch Applique, couching, eyelets.

1.1.8 Stretch triple zigzag

stitch

1.1.9 Three-step zigzag

stitch

1.1.10 Elastic stitch Sewing elastic, darning, patching.

Reinforced seam. Topstitching.

Move fabric manually to desired position and touch foot control

again to sew another stitch.

Reinforce seams, clean nish, stretch sewing.

Elastic stitch for decorative hems or topstitching.

Sewing elastic, darning, patching.

1.1.11 Triple stretch stitch Sewing elastic, darning, patching and decorative sewing.

1.1.12 Honeycomb stitch Decorative stitch for stretch fabrics and hems. Also used with elastic

thread in the bobbin.

1.1.13 Bridging stitch Joining fabrics and quilt batting, decorative stitch for quilting,

hemstitching.

1.1.14 Foundation elastic

stitch

1.1.15 Crosshem stitch Elastic decorative hem for stretch fabrics.

1.1.16 Blindhem stitch Sewing blindhems on woven fabrics.

1.1.17 Elastic blindhem stitch Sewing blindhems on stretch fabrics.

1.1.18 Stretch tricot stitch Sewing seams on stretch fabrics.

Joining stitch for undergarments, terry cloth, leather, bulky fabrics

where overlapping the seams.

Introduction

1:12

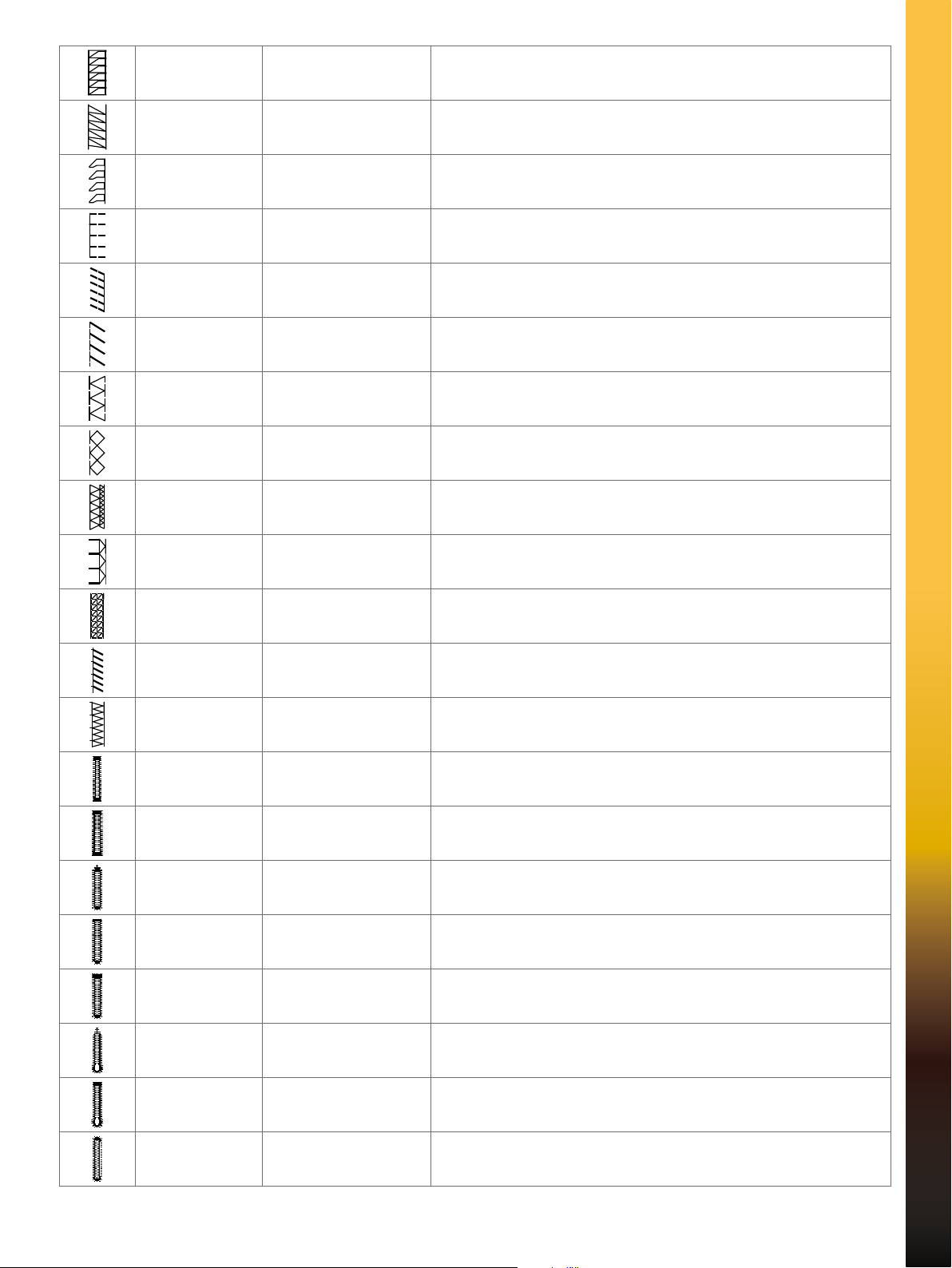

Page 13

1.2.1 Closed overlock Seam and overcast stretch fabrics in one step.

1.2.2 Closed overlock Seam and overcast in one step.

1.2.3 Closed overlock Seam and overcast in one step with reinforced edge.

1.2.4 Elastic overcast Seam and overcast stretch fabrics in one step.

1.2.5 Standard overcast Seam and overcast stretch fabrics in one step with reinforced edge.

1.2.6 Overlock Seam and overcast stretch fabrics in one step.

1.2.7 Closed overlock Seam and overcast in one step, patch, hem.

1.2.8 Stretch knit overlock Seam and overcast stretch fabrics in one step.

1.2.9 Reinforced overlock Seam and overcast stretch fabrics in one step and reinforce.

1.2.10 Finished edge overlock Seam and overcast stretch fabrics in one step with reinforced edge.

1.2.11 Mock cover hem Create the look of a serger cover hem for stretch fabrics.

1.2.12 Open overlock

blindhem

1.2.13 Closed overlock

blindhem

1.3.1 Linen buttonhole Buttonhole for blouses, shirts and linen.

1.3.2 Standard buttonhole Basic buttonhole for blouses, shirts and jackets. Also for pillowcases.

1.3.3 Rounded buttonhole

with pointed tack

1.3.4 Rounded buttonhole

with lengthwise tack

1.3.5 Rounded buttonhole

with crosswise tack

Create decorative overlock blindhem for woven fabrics.

Create decorative overlock blindhem for stretch fabrics.

Buttonhole for garments.

Buttonhole for garments.

Buttonhole for garments.

1.3.6 Eyelet buttonhole with

pointed tack

1.3.7 Eyelet buttonhole with

lengthwise tack

1.3.8 Rounded buttonhole Buttonhole for light garments or jackets.

Tailors buttonhole or decorative buttonhole.

Tailors buttonhole for jackets and trousers.

Introduction

1:13

Page 14

1.3.9 Decorative buttonhole

with triangle tack

1.3.10 Stretch buttonhole Buttonhole for stretch fabrics.

1.3.11 Cross stitch buttonhole Decorative buttonhole.

1.3.12 Decorative buttonhole Decorative buttonhole.

Decorative buttonhole.

1.3.13 Professional eyelet

buttonhole

1.3.14 Decorative eyelet

buttonhole

1.3.15 Heirloom round

buttonhole with

pointed tack

1.3.16 Button sewing Sew on buttons or tacking.

1.3.17 Bound buttonhole Foundation stitch for bound buttonhole.

1.4.1 Eyelet Heirloom sewing decorative trim.

1.4.2 Decorative eyelet Heirloom sewing decorative trim.

1.4.3 Decorative eyelet Heirloom sewing decorative trim.

1.4.4 Decorative eyelet Heirloom sewing decorative trim.

Professional tailors buttonhole for jackets and trousers.

Decorative buttonhole for jackets.

Decorative heirloom buttonhole.

Introduction

1:14

1.5.1 Programmable darning

stitch

1.5.2 Programmable

reinforced darning

stitch

1.5.3 Bartack Automatically reinforce seams and pockets.

1.5.4 Denim bartack Automatically reinforce seams and pockets decoratively.

1.5.5 Decorative bartack Automatically reinforce seams and pockets decoratively.

1.5.6 Cross bartack Automatically reinforce seams and pockets.

1.5.7 Decorative tack Automatically decorative topper for seams and pockets.

Darning holes or damaged fabric.

Reinforced darning holes or damaged fabric.

Page 15

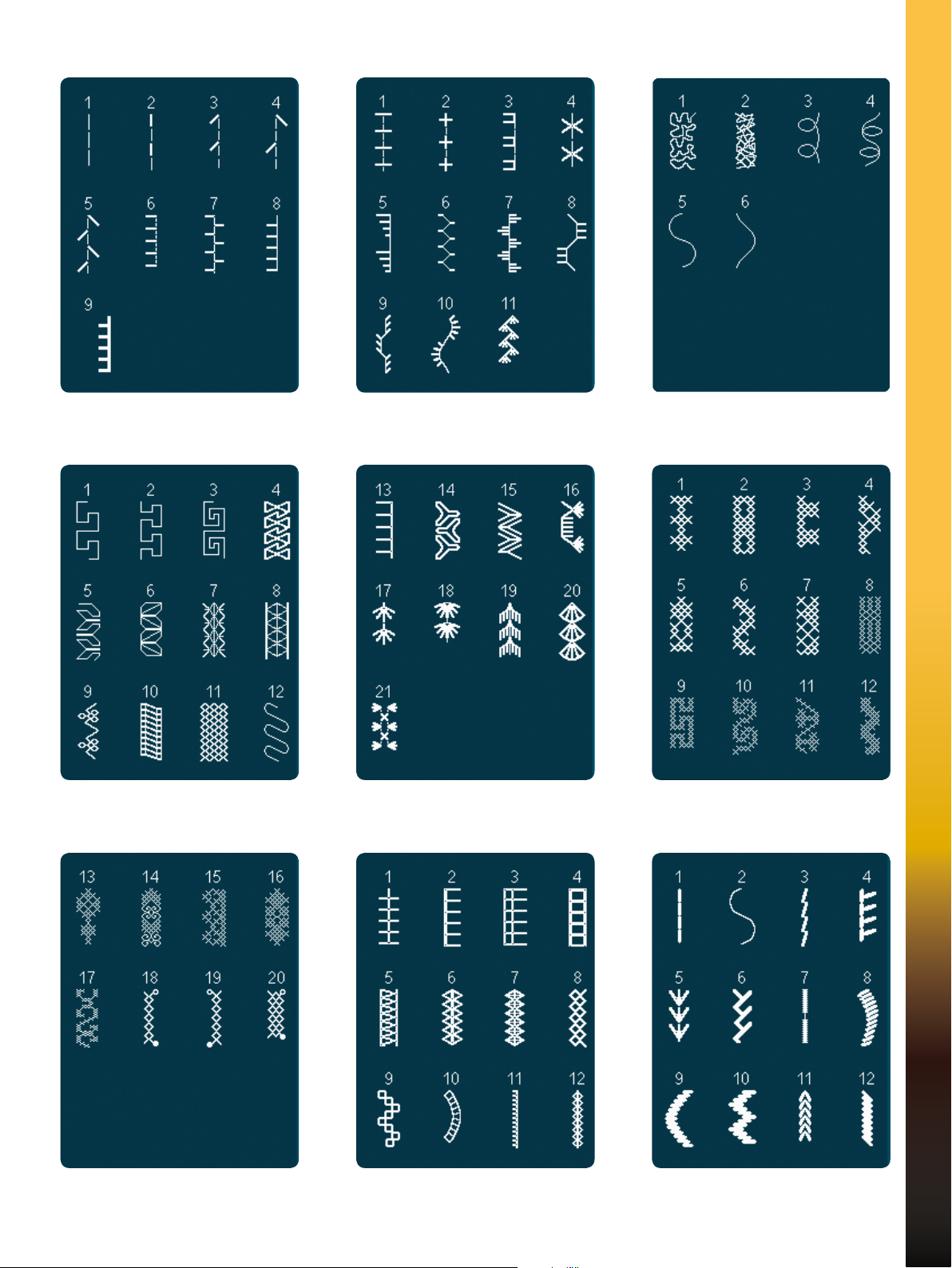

Decorative stitches

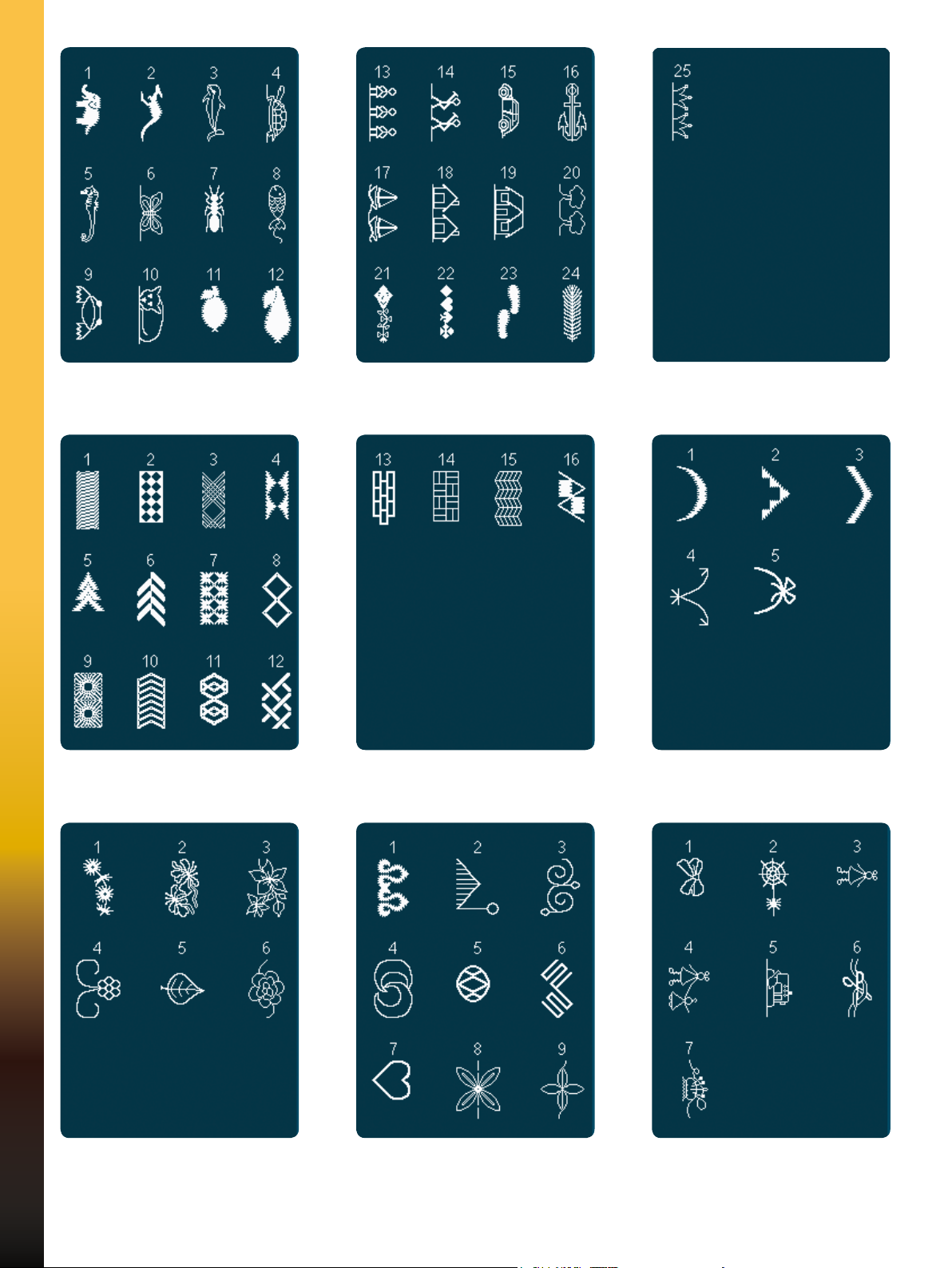

2.1 Quilt stitches Handlook stitches

2.4 Quilt stitches Crazy patch stitches

2.2 Quilt stitches Antique quilt stitches

2.4 Quilt stitches Crazy patch stitches

2.3 Quilt stitches Stippling stitches

3.1 Needle art stitches Cross stitches

3.1 Needle art stitches Cross stitches

3.2 Needle art stitches Hemstitches

Introduction

3.3 Needle art stitches -

Antique hand embroidery stitches

1:15

Page 16

3.3 Needle art stitches -

Antique hand embroidery stitches

3.3 Needle art stitches -

Antique hand embroidery stitches

3.4 Needle art stitches Smocking stitches

4.1 Decorative stitches Scallop edges

4.2 Decorative stitches Satin stitches

Introduction

1:16

4.1 Decorative stitches Scallop edges

4.3 Decorative stitches -

Leaves and owers

4.2 Decorative stitches Satin stitches

4.3 Decorative stitches -

Leaves and owers

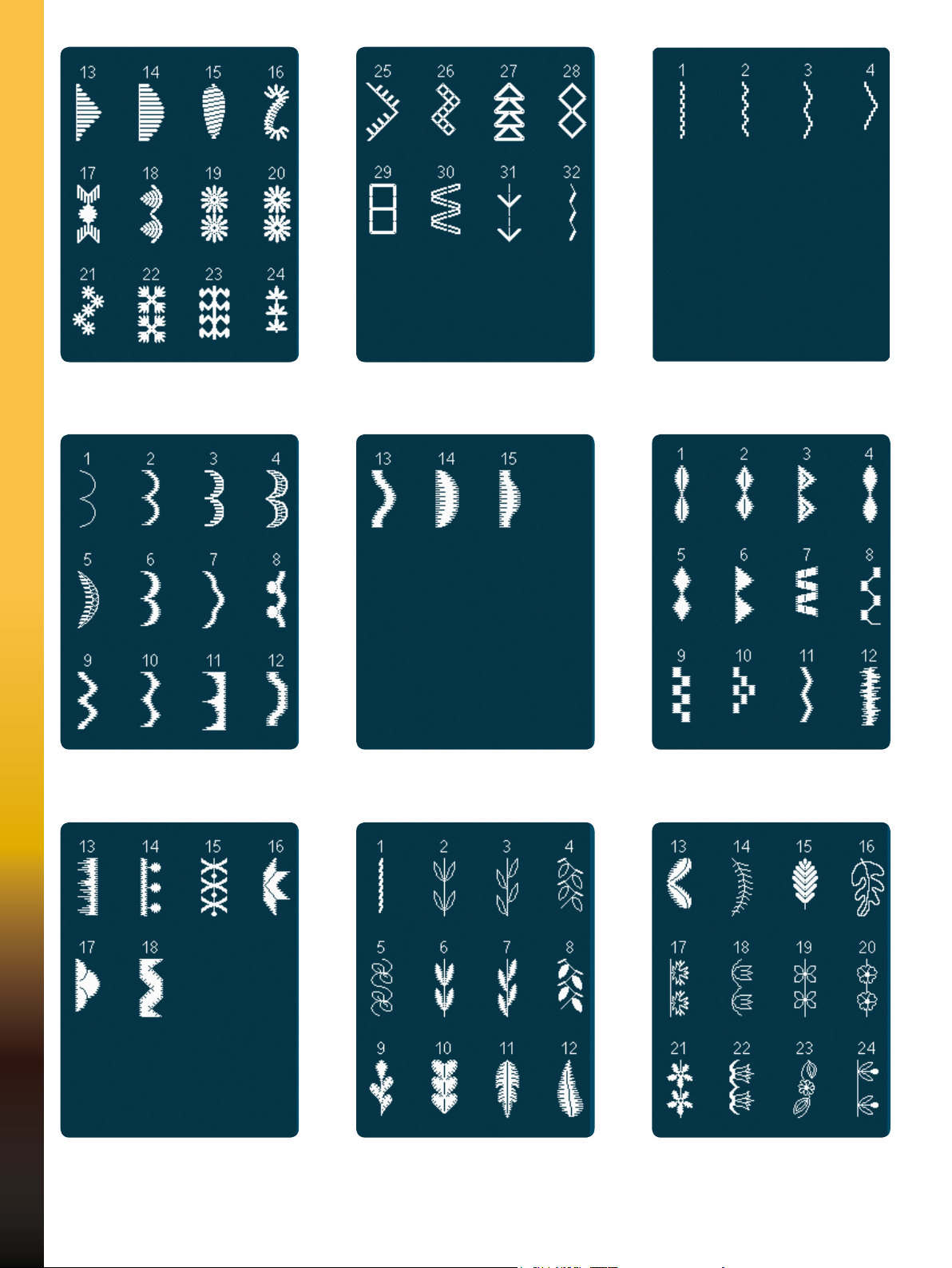

Page 17

4.3 Decorative stitches -

Leaves and owers

4.4 Decorative stitches Art stitches

4.4 Decorative stitches Art stitches

4.4 Decorative stitches Art stitches

4.5 Decorative stitches Ornamental stitches

4.5 Decorative stitches Ornamental stitches

4.6 Decorative stitches Bows and hearts

4.5 Decorative stitches Ornamental stitches

Introduction

4.6 Decorative stitches Bows and hearts

1:17

Page 18

4.7 Decorative stitches Fun stitches

4.7 Decorative stitches Fun stitches

4.7 Decorative stitches Fun stitches

4.8 Decorative stitches - Borders 4.8 Decorative stitches - Borders

5.2 Maxi stitches -

Leaves and owers

5.3 Maxi stitches Art stitches

Introduction

1:18

5.1 Maxi stitches -

Scallop and satin stitches

5.4 Maxi stitches Fun stitches

Page 19

5.5 Maxi stitches -

Stippling stitches

5.6 Monogram 5.6 Monogram

5.6 Monogram 5.6 Monogram

6.1 Sewing techniques -

Optional feet stitches

6.1 Sewing techniques -

Optional feet stitches

6.1 Sewing techniques -

Optional feet stitches

Introduction

6.2 Sewing techniques -

Handlook quilt stitches

1:19

Page 20

6.3 Sewing techniques -

Four direction stitches

6.4 Sewing techniques Stacking stitches

6.4 Sewing techniques Stacking stitches

6.4 Sewing techniques -

Stacking stitches

Introduction

1:20

6.4 Sewing techniques Stacking stitches

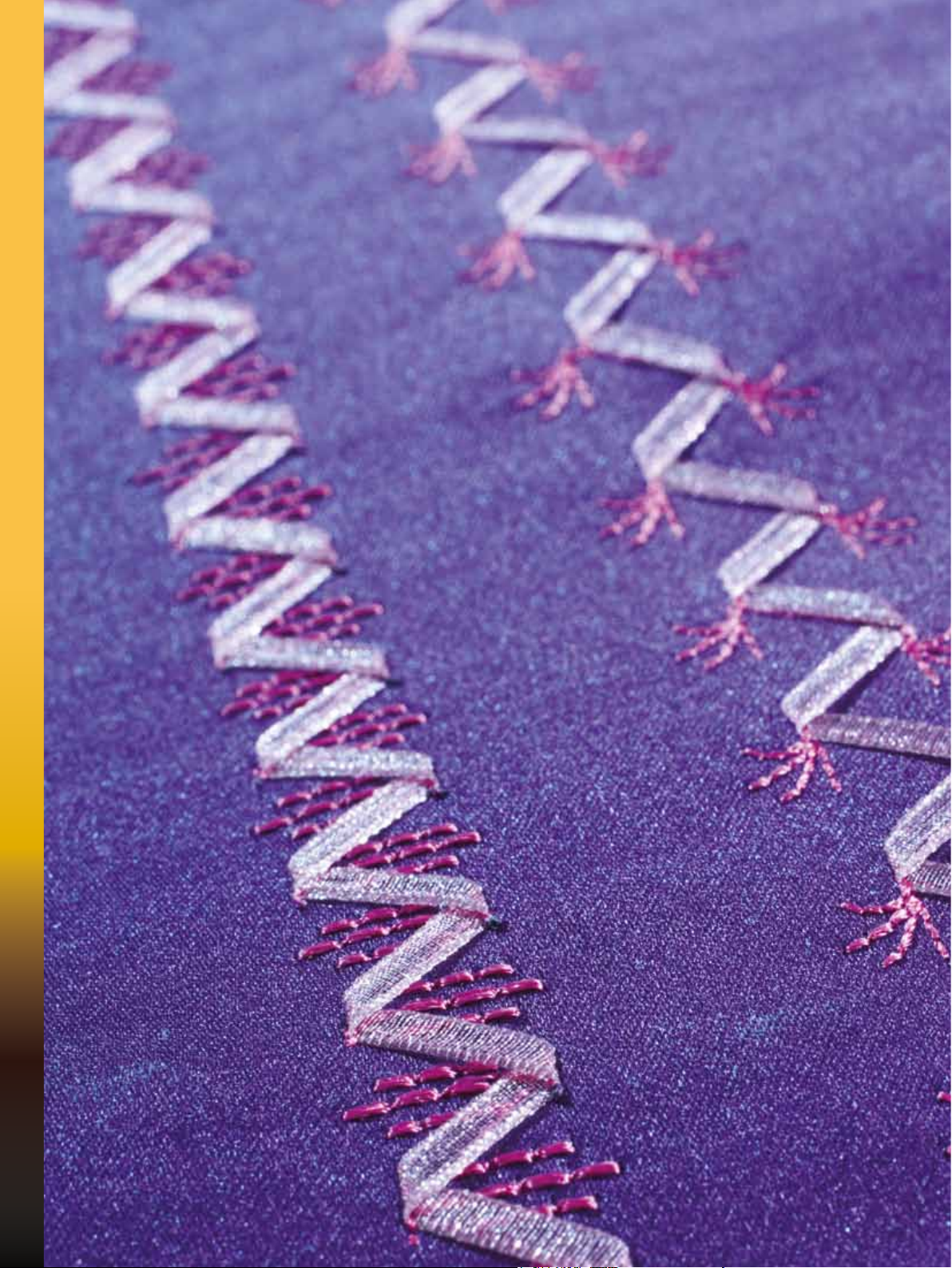

6.5 Sewing techniques Ribbon stitches

Page 21

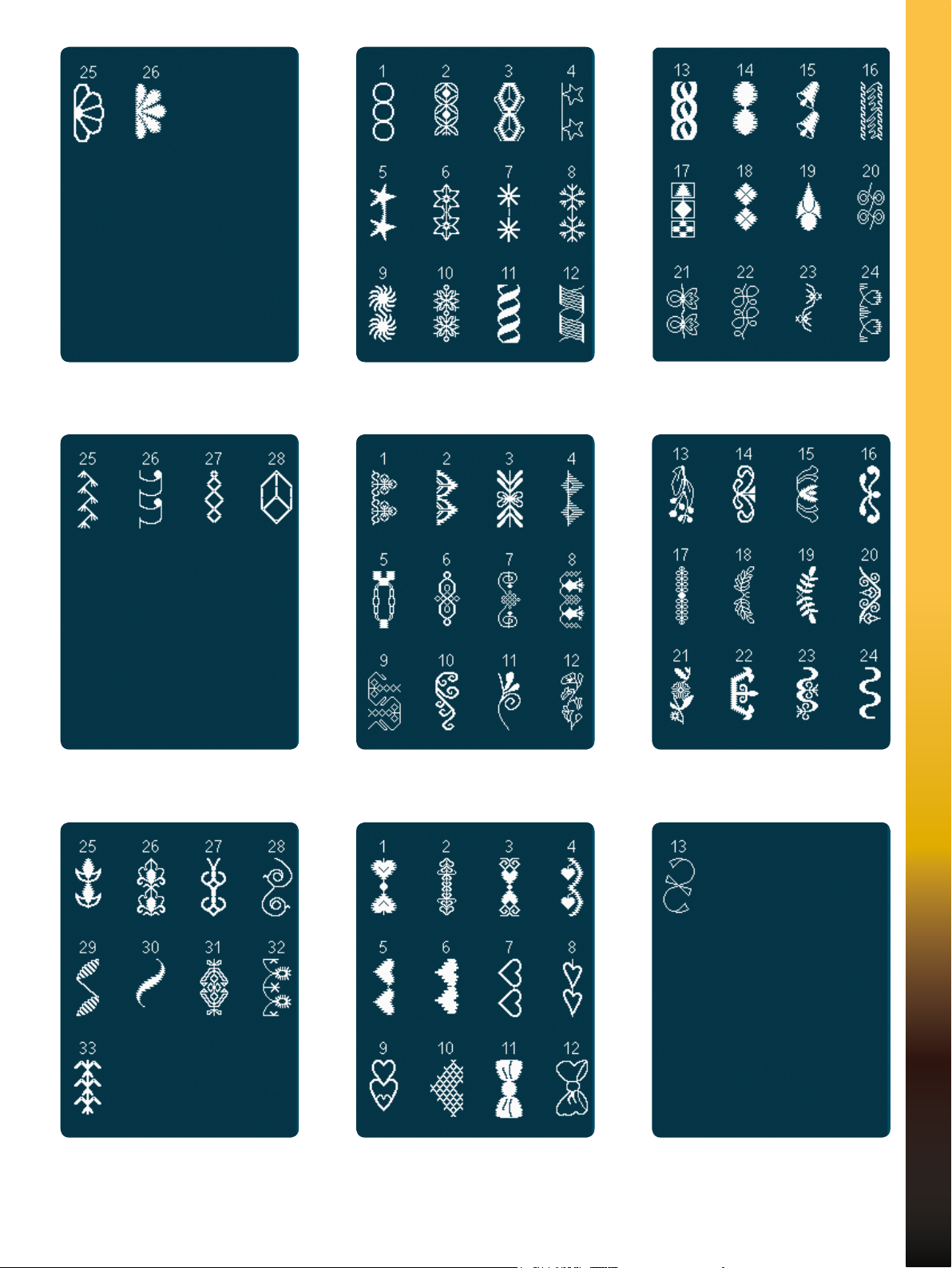

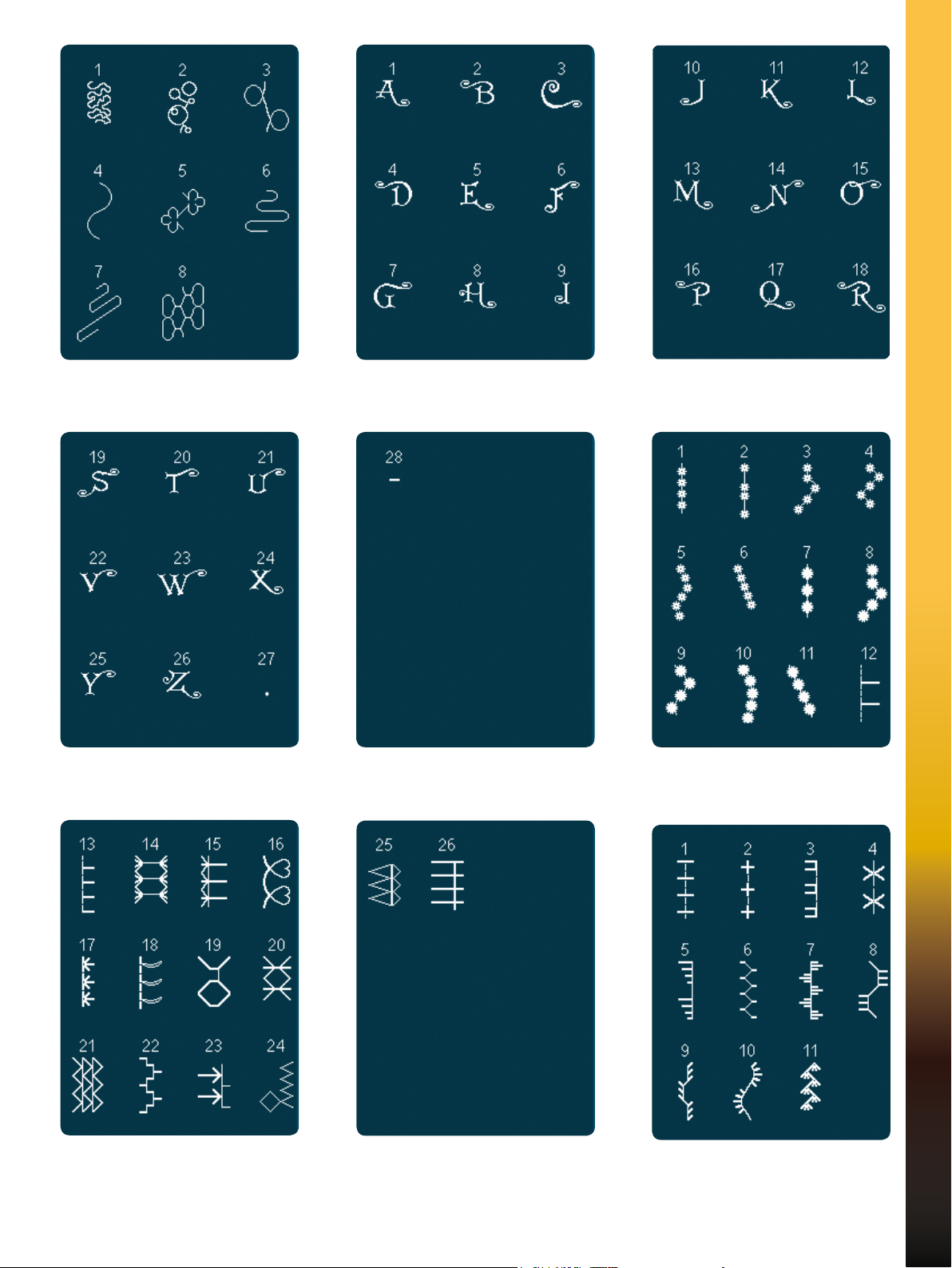

Alphabets

Comic

Grand

Cyrillic

Outline

Script

Introduction

1:21

Page 22

Introduction

1:22

Page 23

2

Preparations

Page 24

Unpacking

1. Place the box on a steady, at surface. Lift the machine out of the box and remove the outer packaging

and lift off the machine carrying case.

2. Remove all other packing material and the plastic bag.

3. Slide off the accessory tray and remove the styrofoam inside.

Note: Styrofoam left in the accessory tray while sewing may affect stitch quality. The styrofoam is for packing

purposes only and should be removed.

™

Note: Your creative

temperature. Extreme hot and cold temperatures can affect the sewn result.

Some fabrics have a lot of excess dye which can cause discoloration on other fabric but also on your sewing machine.

This discoloring may be very difcult or impossible to remove. Fleece and denim fabric, especially red and blue, often

contain a lot of excess dye. If you suspect that your fabric/ready-to-wear garment contains a lot of excess dye, always

pre-wash it before sewing to avoid the discoloring.

4.5 sewing and embroidery machine is adjusted to provide the best stitch result at normal room

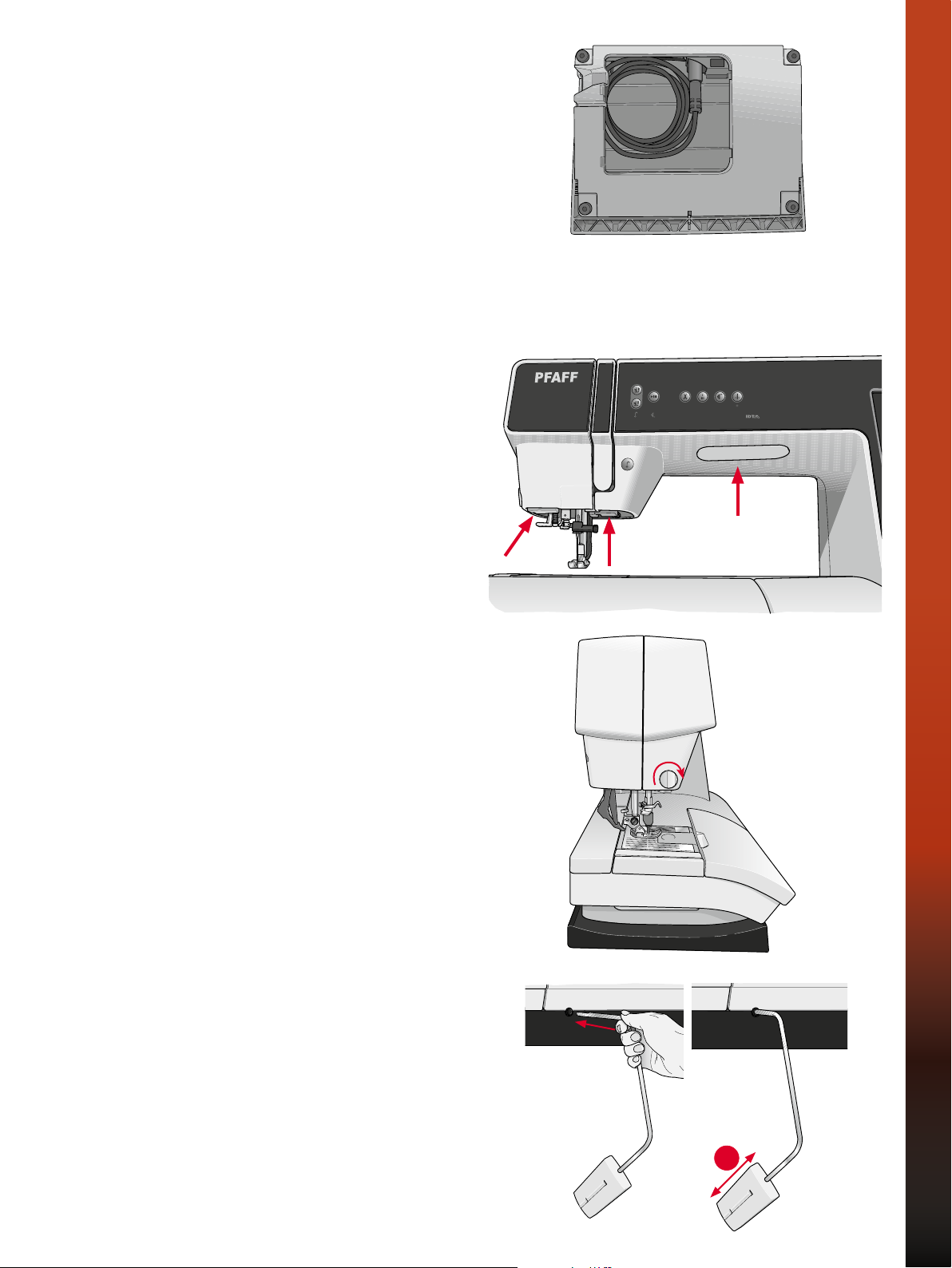

Connecting the foot control cord

Among the accessories you will nd the foot control

cord. Connecting the foot control cord to the foot

control is only neccessary the very rst time you are

going to use the machine.

1. Take out the foot control cord. Turn the foot

control over. Connect the cord to the socket

inside the open space on the underside of the foot

control as shown.

2. Push rmly to make sure it is properly connected.

3. Pull the cord into the slot to the left of the socket

to ensure that the foot control will rest evenly on

the oor.

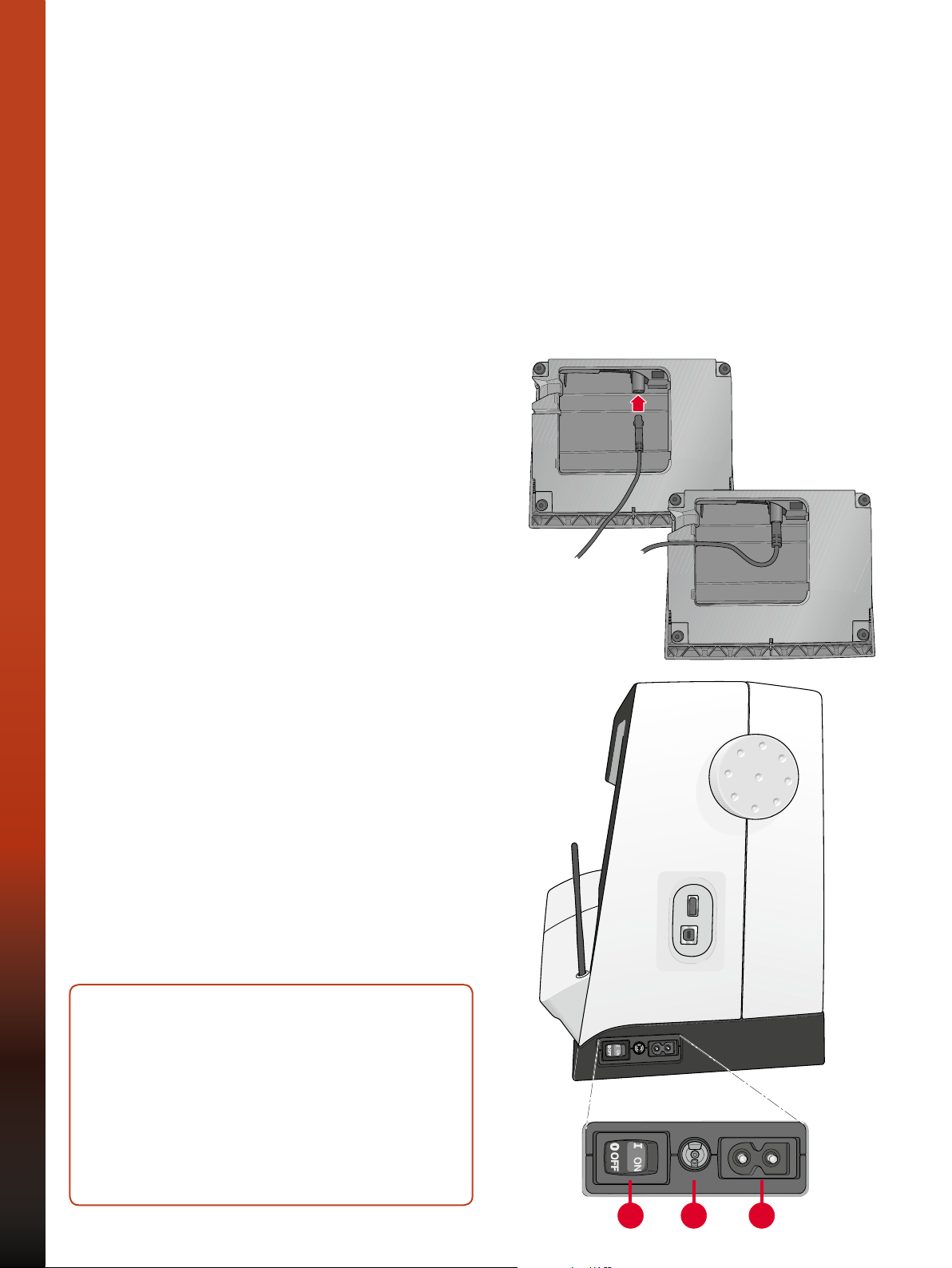

Connect the power cord

and foot control

Note: Before plugging in the foot control, check to ensure

that it is type “FR5” (see underside of foot control).

1. Connect the foot control cord to the front socket

on the bottom right side of the machine (A).

2. Connect the power cord to the rear socket on the

bottom right side of the machine (B). Plug the

cord into a wall socket.

3. Press the ON/OFF switch to ON to turn on

power and light (C).

For the USA and Canada

This sewing machine has a polarized plug (one

blade wider than the other). To reduce the risk

of electric shock, this plug is intended to t in a

polarized outlet only one way. If the plug does

not t fully in the outlet, reverse the plug. If it

still does not t, contact a qualied electrician to

install the proper outlet. Do not modify the plug

in any way.

Preparations

2:2

C A B

Page 25

Pack away after sewing

1. Turn the main switch (C) off.

2. Unplug the cord from the wall socket and then

from the machine (B).

3. Unplug the foot control cord from the machine

(A). Wind the foot control cord and place inside

the open area on the underside of the foot

control.

4. Place all accessories in the accessory tray. Slide

the tray on to the machine around the free arm.

5. Place the foot control in the space above the free

arm.

6. Put on the hard cover.

LED lights

Your machine has LED lights which distribute the

light evenly over the sewing area and eliminates

shadows.

Free arm

To use the free arm, slide off the accessory tray.

When attached, a hook keeps the accessory tray

locked to the machine. Remove the tray by sliding it

to the left.

Thread cutter

To use the thread cutter, pull the thread from back

to front as shown.

Electronic knee-lift

Your machine comes with an electronic knee-lift for

regulating the presser foot height.

Insert the knee-lift in the provided hole on the

machine. The at side must face upwards. Adjust

the rectangular bar on the knee-lift until it is

positioned at a comfortable height for you (C).

If you press the knee-lift to the right, the presser

foot will raise. You can now guide the fabric with

both hands.

To remove the knee-lift, just pull it straight out of

the hole.

Preparations

C

2:3

Page 26

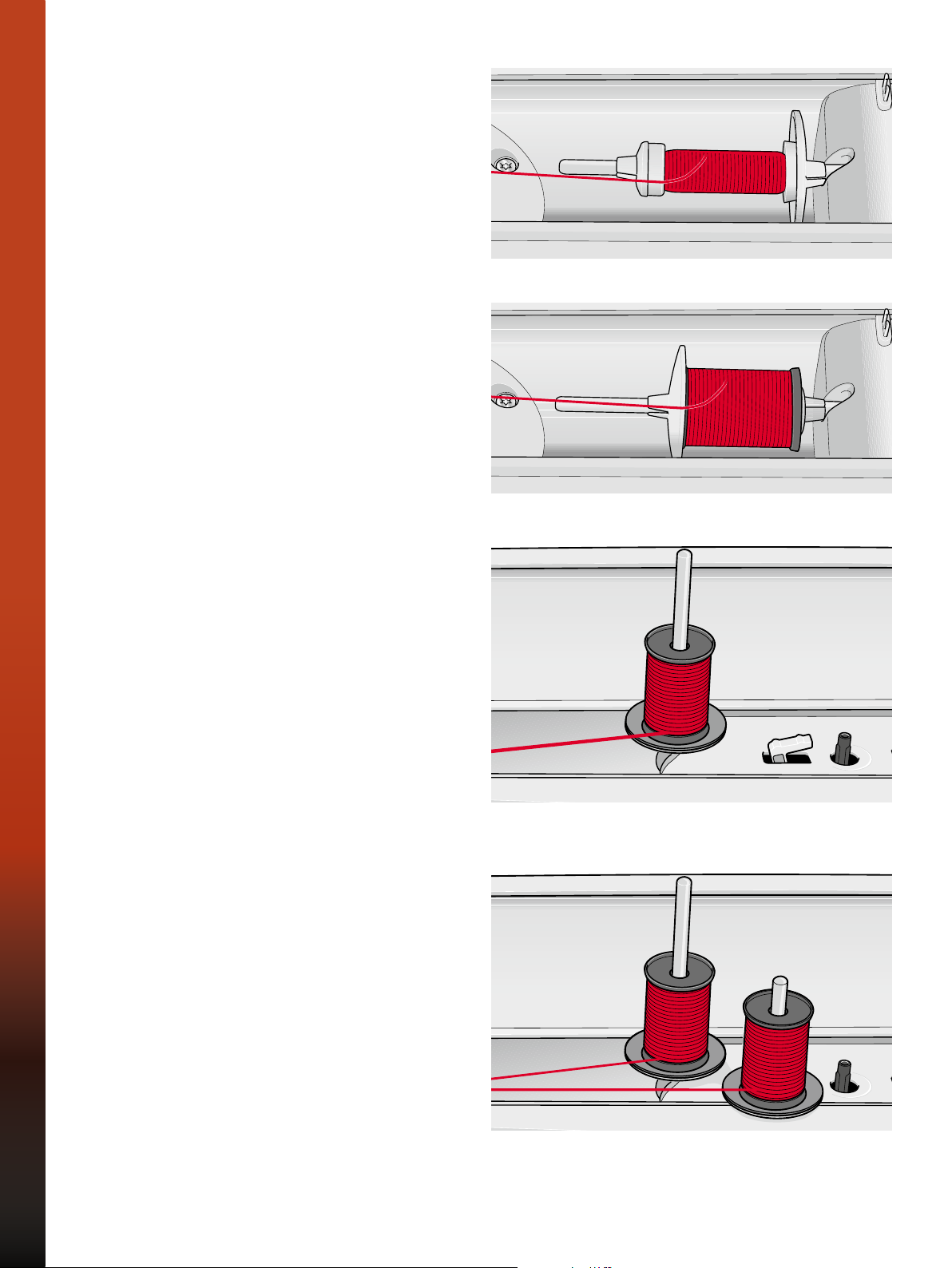

Spool pins

Your machine has two spool pins, a main spool

pin and an auxiliary spool pin. The spool pins

are designed for all types of thread. The main

spool pin is adjustable and can be used both in a

horizontal position (the thread reels off the spool)

and a vertical position (the thread spool rotates).

Use the horizontal position for normal threads and

the vertical position for large spools or specialty

threads.

Horizontal position

Place a spool cap and the thread spool on the spool

pin. Make sure that the thread reels off the spool

counter clock-wise and slide on a second spool cap.

Note: Not all thread spools are manufactured in the same

way. If you experience problems with the thread, turn it

in the opposite way or use the vertical position.

Use a spool cap slightly larger than the thread

spool. For narrow thread spools, use a smaller spool

cap in front of the spool. For large thread spools,

use a larger spool cap in front of the spool.

Small spool cap

Large spool cap

The at side of the spool cap should be pressed

rmly against the spool. There should be no space

between the spool cap and the thread spool.

Vertical position

Raise the spool pin to the vertical position. Slide

on the large spool cap and place a felt pad under

the thread spool. This is to prevent the thread from

reeling off too fast.

Do not place a spool cap on top of the spool pin as

that would prevent the spool from rotating.

Auxiliary spool pin

The auxiliary spool pin is used when winding a

bobbin thread from a second spool of thread or for a

second spool when sewing with a twin needle.

Main spool pin in vertical position

Raise the auxiliary spool pin. Slide on a large spool

cap and place a felt pad under the thread spool.

Preparations

2:4

Auxiliary spool pin and main spool pin in vertical

position.

Page 27

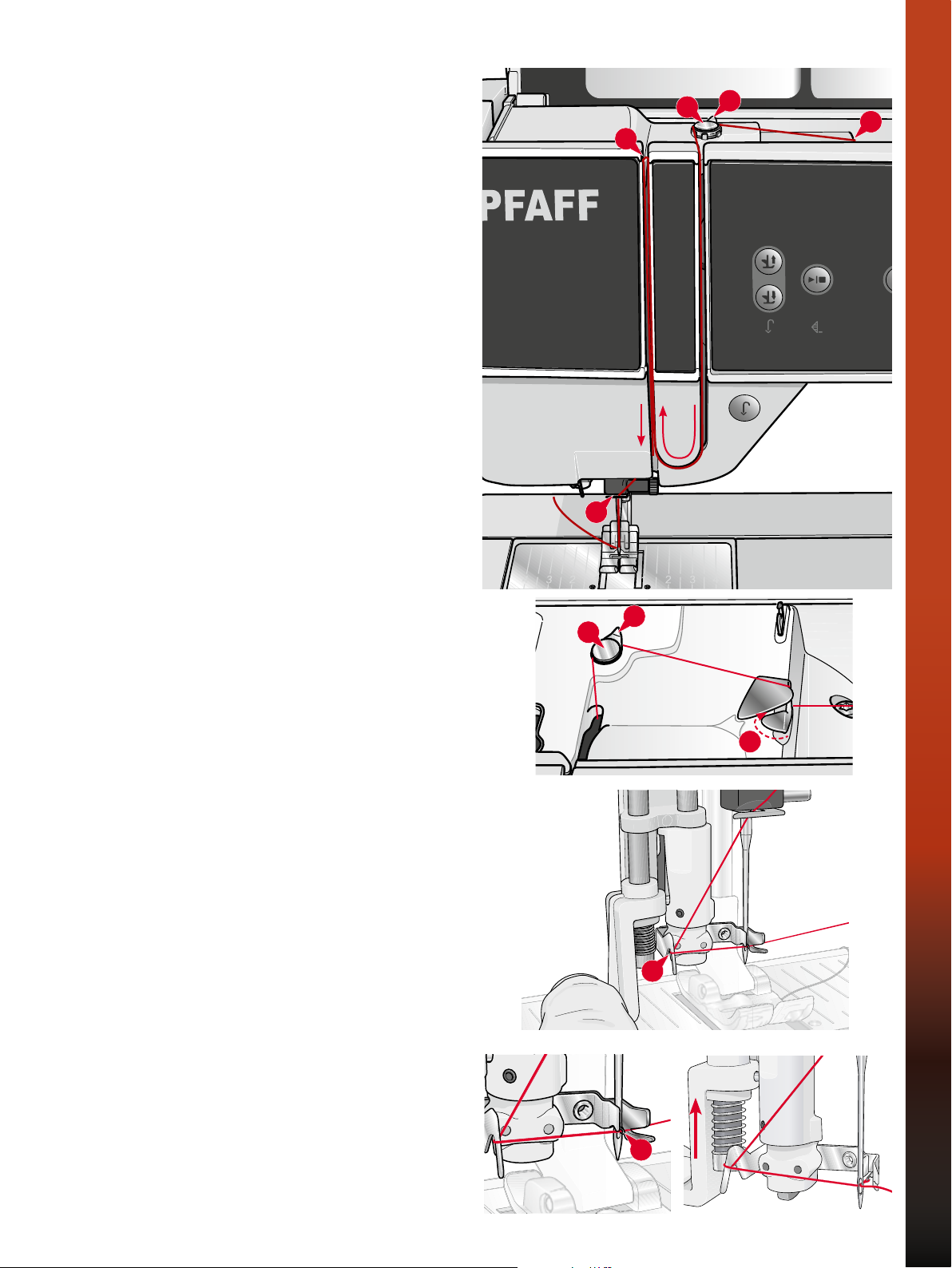

Threading the machine

Make sure that the presser foot is raised and the

needle is in the up position.

1. Place the thread on the spool pin and t a spool

cap of the right size.

Note: Hold thread with both hands to prevent it from

slacking while threading. This ensures that the thread

will be positioned properly in the threading path.

2. Pull the thread into the thread guide by pulling

it from the front to the back (A). Make sure the

thread clicks into place. Then pull the thread

underneath the bobbin winder thread guide (B)

on the pre-tension disc (C).

3. Thread down through the right-hand threading

slot and then upwards through the left-hand

threading slot.

4. Bring the thread from the right into the take-up

lever (D) and down in the left-hand threading

slot to the needle thread guide (E).

B

C

D

A

5. Thread the needle.

Needle threader

The needle threader allows you to thread the

needle automatically. The needle must be in the up

position to use the built-in needle threader. We also

recommend lowering the presser foot.

1. Use the handle to pull the needle threader all

the way down. The threader hook (G) swivels

through the needle eye.

2. Place the thread from the back over the hook (F)

and under the thread hook (G).

3. Let the needle threader gently swing back. The

hook pulls the thread through the needle eye

and forms a loop behind the needle. Pull the

thread loop out behind the needle.

E

B

C

A

F

Note: The needle threader is designed to be used for size

70-120 needles. You cannot use the needle threader for

size 60 needles or smaller, the wing needle, twin needle or

triple needle. There are also some optional accessories that

require manual threading of the needle.

When threading the needle manually make sure that the

needle is threaded from front to back. The bobbin cover

can be used as a magnifying glass.

Preparations

G

2:5

Page 28

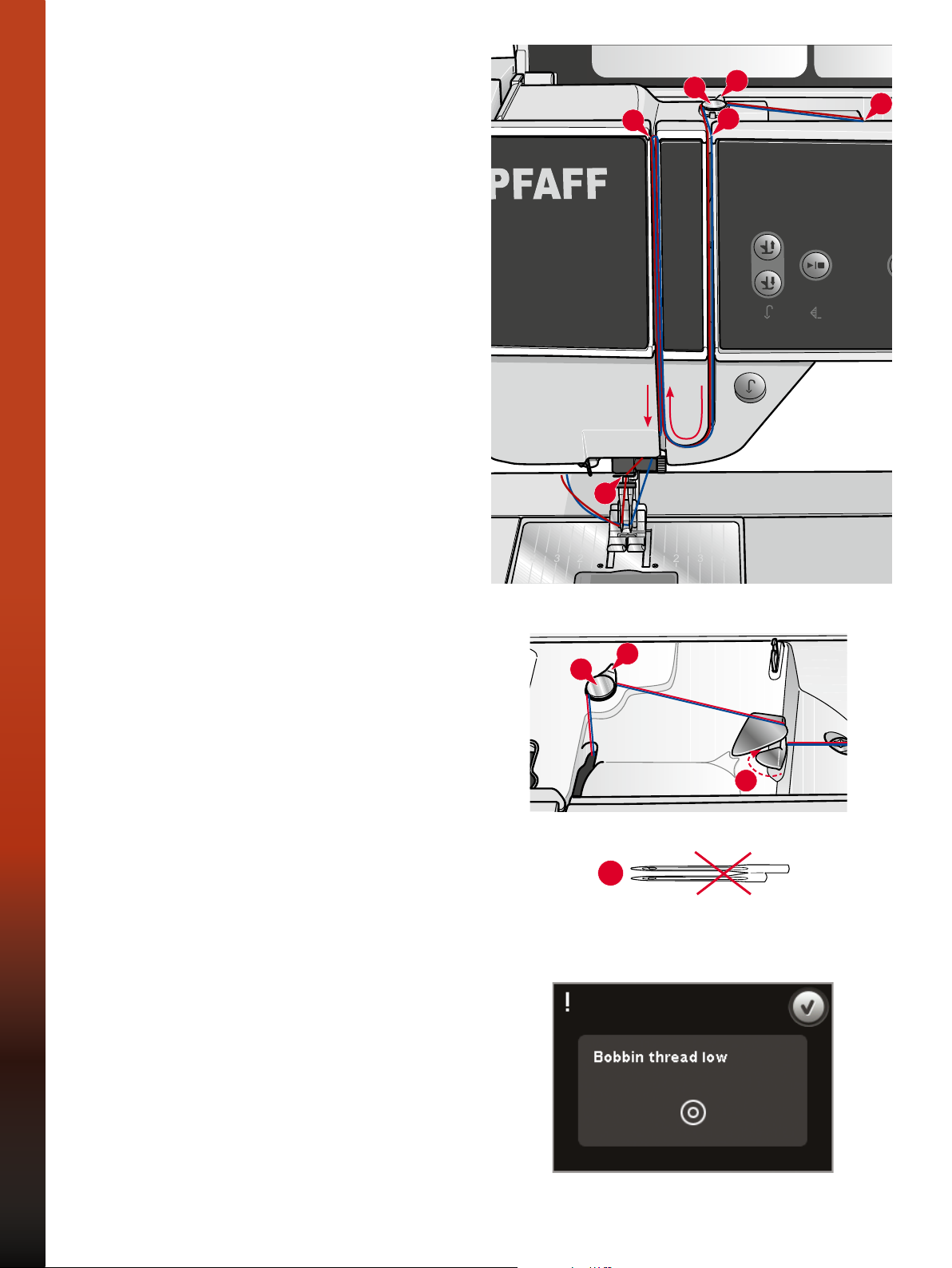

Threading for twin needle

Replace the sewing needle with a twin needle. Make

sure that the presser foot is raised and the needle is

in the up position.

1. Place the thread on the spool pin and t a spool

cap of the right size. Raise the auxiliary spool

pin. Slide on a large spool cap and a felt pad.

Place the second thread on the spool pin.

Note: Hold threads with both hands to prevent them from

slacking while threading. This ensures that the threads

will be positioned properly in the threading path.

2. Pull the threads into the thread guide by pulling

them from the front to the back (A). Make

sure the threads click into place. Then pull the

threads underneath the bobbin winder thread

guide (B) on the pre-tension disc (C).

3. Thread down through the right-hand threading

slot and then upwards through the left-hand

threading slot. Make sure that you pass one

thread to the left and one thread to the right

sides of the tension disk (F).

B

C

D

E

F

A

4. Bring the threads from the right into the take-up

lever (D) and down in the left-hand threading

slot. Make sure that one thread is inside the

needle thread guide (E) and the other one

outside. Make sure that the threads do not

become twisted together.

5. Thread the needles.

Note: Activate twin needle and select the correct twin

needle width in Settings menu. This will limit the width

of all stitches for that needle size to prevent damage to

presser foot and needle.

Note: The weight and irregular surface of specialty

threads such as metallic increases the amount of friction

on the thread. By reducing the tension, the risk of needle

breakage is prevented.

Note: Do not use asymmetrical twin needles (G), since it

may damage your sewing machine.

Thread sensor

If the needle thread breaks or bobbin thread is

running low, the machine stops and a pop-up

appears on the screen. If needle thread breaks:

Re-thread the machine and touch OK in the pop-up.

If bobbin thread is running low: You can continue

sewing without closing the pop-up before the

bobbin thread runs out completly. This gives you

an opportunity to plan where to stop sewing and

change the bobbin. When the bobbin is replaced

with a full one, touch OK in the pop-up.

B

C

A

G

Preparations

2:6

Page 29

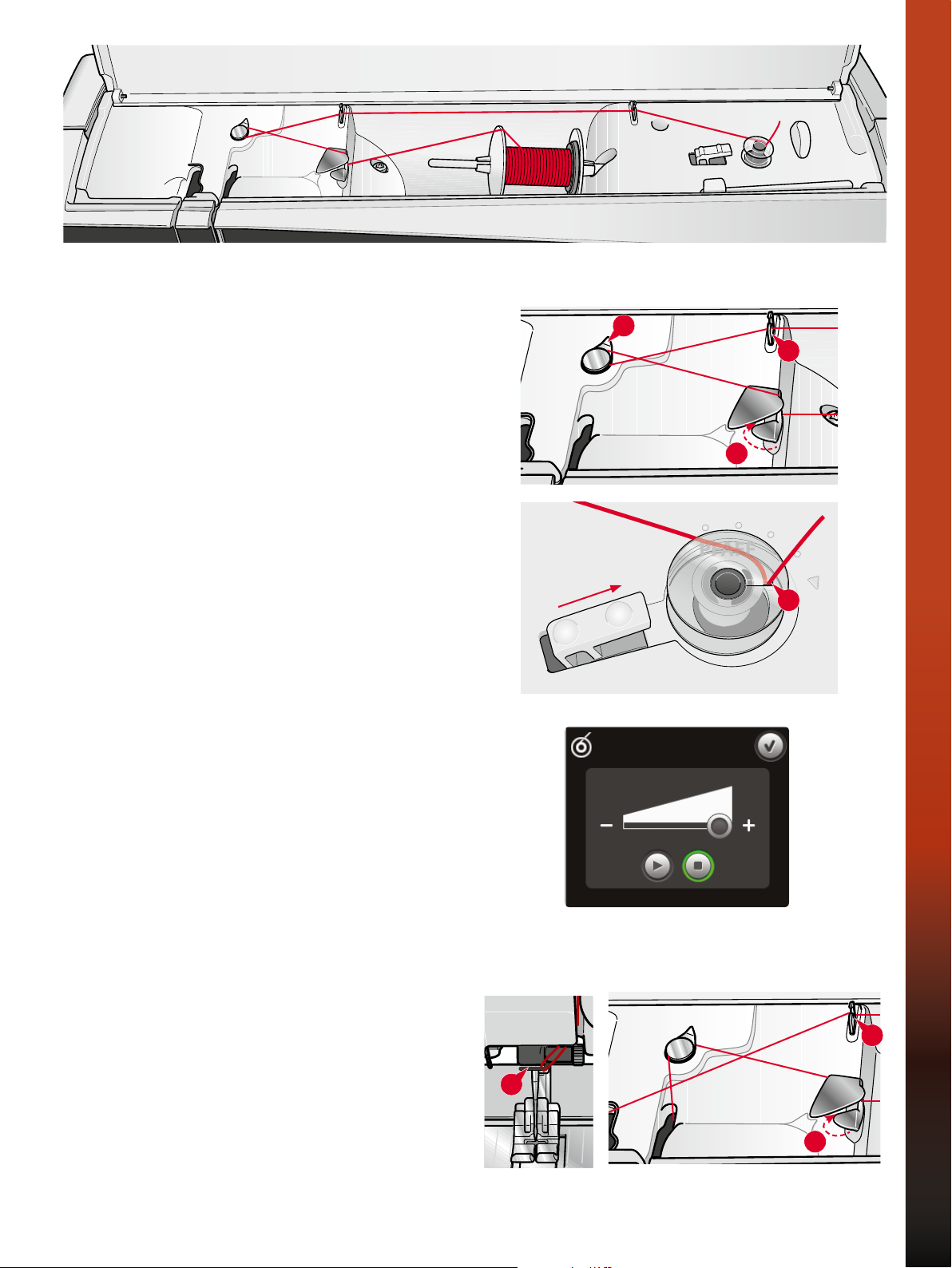

Bobbin winding

Winding from horizontal position

1. Place an empty bobbin on the bobbin spindle,

with the logo facing up. Use only the original

PFAFF

2. Place the thread spool on the spool pin in

horizontal position. Slide a spool cap tightly

against the spool.

3. Place the thread into the thread guide (A) from

front to back. Pull the thread counter-clockwise

above the bobbin winder thread guide (B) and

then through the bobbin thread guides (C) at

the rear.

Note: Make sure the thread is pulled securely inside

the pre-tension device for correct thread tension.

4. Thread through the slot in the bobbin (D) from

the inside to the outside.

5. Push the bobbin winder lever towards the

bobbin to wind. A pop-up appears on the

screen. To adjust winding speed, use the slider

in the pop-up. Stop and start bobbin winding

with the icons in the pop-up. Hold the end of

the thread rmly when starting to wind.

®

bobbins approved for this model.

B

C

A

D

When the bobbin is full, the bobbin winder

lever will switch back and the winding will

stop automatically. The pop-up closes. Remove

the bobbin and cut the thread using the bobbin

thread cutter. Cut the free thread end close to

the bobbin.

Winding while threaded

Make sure that the presser foot and the needle

are in the up position. To prevent the needle from

bending, pull the thread out of the needle.

Bring the thread up from the needle thread guide

(E), upward through the left-hand threading slot

and through the bobbin thread guides (C). Then

follow step 4 and 5 above.

C

E

Preparations

A

2:7

Page 30

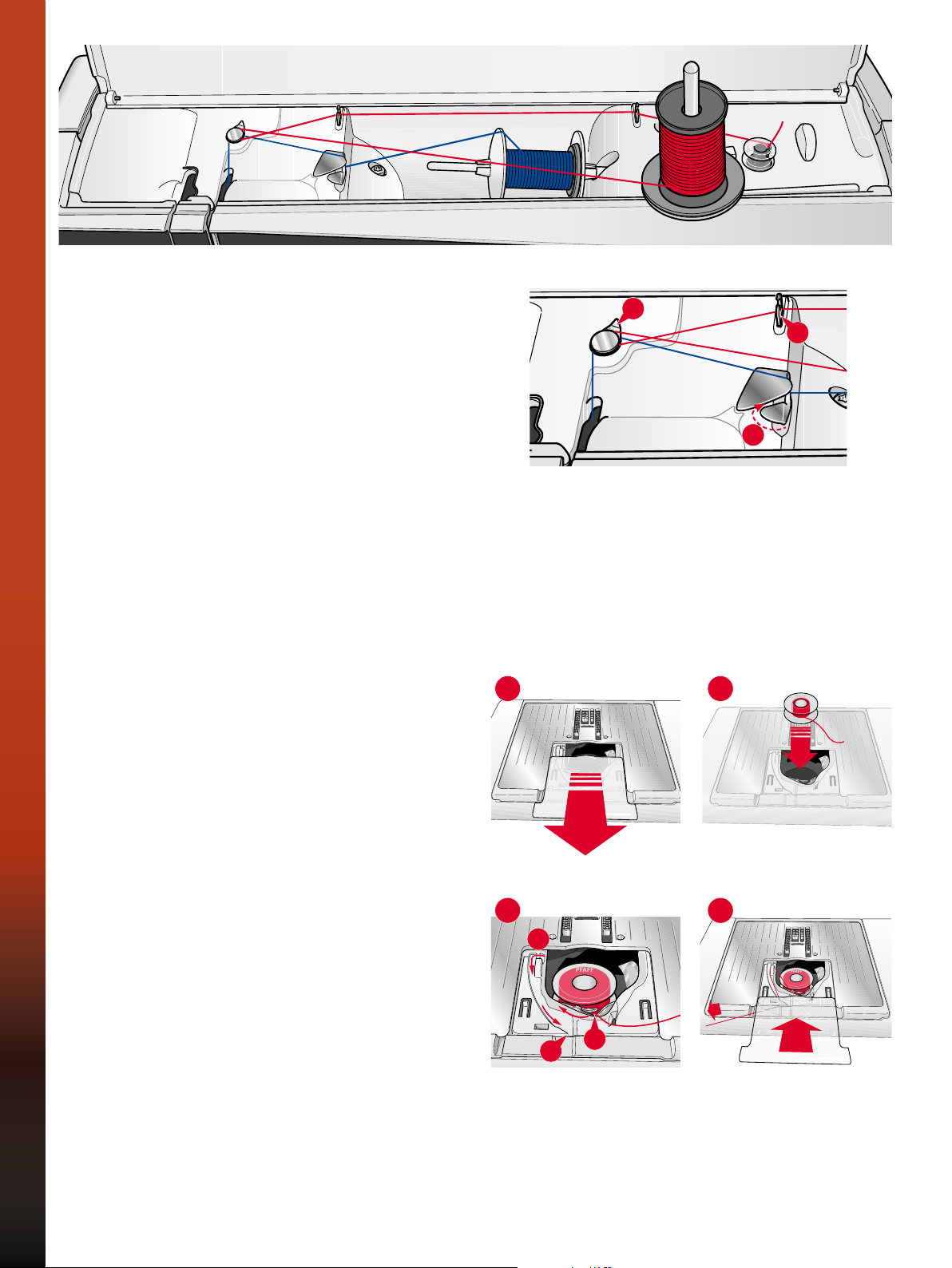

Winding while embroidering or sewing

Swing the auxiliary spool pin up. Place an

appropriate spool cap, felt pad and thread spool on

the spool pin.

The needle thread (blue) is placed into the thread

guide (A) and underneath the bobbin winder thread

guide (B). Pull the bobbin thread (red) counterclockwise above the bobbin winder thread guide

(B) and through the bobbin thread guides (C). Then

follow step 4 and 5 on the previous page.

B

C

A

Inserting the bobbin

1. Remove the bobbin cover by sliding it towards

you.

2. Place the bobbin in the bobbin case with the

logotype facing up and the thread unreeling

from the left of the bobbin. The bobbin will then

rotate counter-clockwise when you pull out the

thread.

3. Place your nger on the bobbin to keep it from

turning as you pull the thread rmly to the

right and then to the left into the tension spring

(A) until it “clicks” into place.

4. Continue threading around (B) and to the right

of the thread cutter (C). Replace the cover. Pull

the thread to the left to cut.

1

3

B

A

C

2

4

Preparations

2:8

Page 31

IDT™ system (Integrated Dual Feed)

For sewing any fabric precisely PFAFF® creative™

4.5 sewing and embroidery machine provides

the ideal solution: the integrated dual feed, IDT™

system. As on industrial machines, the IDT™ system

feeds the fabric from the top and bottom at the

same time. The material is fed precisely, eliminating

puckering on seams in light weight fabrics such as

silk and rayon. The dual feed action of the IDT™

system prevents layers from shifting while sewing,

keeping quilt layers aligned and ensuring a more

perfect match when sewing plaid or striped fabrics.

Engaging the IDT™ system

Important: For all work with the IDT™ system use

presser feet with the center back cut-out.

Raise the presser foot. Press the IDT™ system down

until it engages.

Disengaging the IDT™ system

Raise the presser foot. Hold the IDT™ system with

two ngers at the ribbed ankle. Pull the IDT™

system down, then pull it away from you to release

the IDT™ system slowly upward.

Attaching the Dynamic spring foot 6D

1. Disengage the IDT™ system (A). Remove the

standard presser foot (B). Carefully loosen the

screw (C) until the cross-hole (D) is accessible.

2. Hold the foot in front of the needle. Turn the

hand wheel to lower the needle into the hole of

the foot and through the needle plate.

3. Turn the foot behind the needle screw (E) and

squeeze the foot to insert the pin of the foot into

the cross-hole (D) of the presser foot holder.

4. Push the foot into the hole as far as it will go

while tightening the screw (C).

1

C

A

D

2

3

4

B

E

To remove the embroidery foot loosen the screw

(C), squeeze the embroidery foot together and pull

it out to the right. Tighten the screw.

C

Preparations

2:9

Page 32

Changing the presser foot

Remove presser foot

Press the presser foot downwards until it disengages

from the presser foot holder.

Attach presser foot

Line up the pins on the foot with the gap underneath

the presser foot holder. Press upwards until the foot

snaps into place.

You can also use the presser foot up/down buttons to

raise or lower the presser foot holder. Place the presser

foot under the presser foot holder, so that the pins

of the foot snap onto the presser foot holder when

lowered.

Needles

The sewing machine needle plays an important role

in successful sewing. Use only quality needles. We

recommend needles of system 130/705H. The needle

package included with your machine contains needles

of the most frequently used sizes.

Universal needle (A)

Universal needles have a slightly rounded point and

come in a variety of sizes. For general sewing in a

variety of fabric types and weights.

Stretch needle (B)

Stretch needles have a special scarf to eliminate

skipped stitches when there is a ex in the fabric. For

knits, swimwear, eece, synthetic suedes and leathers.

Embroidery needle (C)

Embroidery needles have a special scarf, a slightly

rounded point and a slightly larger eye to avoid

damage to thread and materials. Use with metallic and

other specailty threads for embroidery and decorative

sewing

Denim needle (D)

Denim needles have a sharp point to penetrate tightly

woven fabrics without deecting the needle. For

canvas, denim, microbers.

Wing needles (E)

The Wing needle has wide wings on the side of

the needle to poke holes in the fabric when sewing

entredeux and other hemstitches on natural ber

fabrics.

Preparations

2:10

A B C D E

F

G

H

Note: Change the needle often. Always use a straight

needle with a sharp point (F).

A damaged needle (G) can cause skipped stitches,

breakage or snapping of thread. A damaged needle can

also damage the needle plate.

Do not use asymmetrical twin needles (H), since it

may damage your sewing machine.

Page 33

Changing the needle

1. Use the hole in the multi-purpose tool to hold

the needle.

2. Loosen the needle screw.

3. Remove the needle.

4. Insert the new needle, using the multi-purpose

tool. Push the new needle upwards with the at

side away from you until it will go no further.

5. Tighten the needle screw as tight as it will go.

USB ports

Your machine has two USB ports – one to connect

the sewing machine to your computer, and one to

connect either your USB embroidery stick, optional

USB hub or optional mouse.

USB embroidery stick

Delivered with your machine is a USB embroidery

stick. Use the stick to store designs and other les,

or to move les between the computer and sewing

machine.

Connect to and remove from USB port

Insert the USB embroidery stick or other devices in

the upper port. The USB plugs can only be inserted

one way – do not force them into the ports!

The USB PC cable packed with your machine

(P/N:412 62 59-04) plugs in to the lower port. No

other cable should be used in this port. Connect the

other end of the cable to your PC.

Note: Install the complimentary software before

connecting the machine to your PC (see next page).

To remove, carefully pull the USB embroidery stick

or the plug of the USB cable out straight.

Using the USB embroidery stick

When loading from or saving to the USB

embroidery stick an hourglass appears on the

screen.

Note: Do not remove the USB embroidery stick when the

hourglass is shown on the screen or while Files & Folders

is open. Removing the stick at that time can damage the

les on your USB embroidery stick.

Note: The USB embroidery stick provided

with the machine can be left in the machine

when putting on the hard cover. Make sure

that the cover of the USB stick is turned

downwards.

Preparations

2:11

Page 34

Complimentary software (PC)

A PC software package is available for your PFAFF

creative™ 4.5 sewing and embroidery machine. It

adds the following features:

• Communication module allows you to connect

the machine to your computer. Required to

use the Send To features in any Embroidery

software system module.

• QuickFont program to create unlimited number

of embroidery fonts from most TrueType® and

OpenType® fonts on your computer.

• Plug-in for your Windows Explorer to handle

embroidery designs: viewing designs as

thumbnail images, reading different embroidery

le formats, add trim commands and more.

This software should be installed before the

machine is connected to your computer for the

rst time. Go to PFAFF

and look for support and download the software.

During installation you will be asked for an

Installation Code. Enter number:

®

website at www.pfaff.com

®

8200

More information and detailed installation

instructions are available on the download page.

How to update your machine

Be sure to consult the web site at www.pfaff.

com and/or your local authorized PFAFF® dealer

for updates and upgrades for your machine and

Owner’s manual.

You can update your machine using the USB

embroidery stick or the USB cable packed with your

machine (P/N:412 62 59-04).

Updating instructions

®

• Go to the PFAFF

nd information about available updates.

• Follow the update wizard to prepare your USB

embroidery stick for the update.

• To start your machine in update mode, press

and hold the reverse button (A) while turning

on your machine. Keep the reverse button

pressed until update mode is visible on the

®

PFAFF

creative™ Color Touch Screen. Follow

the instructions to update.

web site at www.pfaff.com to

A

Preparations

2:12

Page 35

D

F

E

B C

A

Buttons and indicators

J

G H I

Reverse button (A)

For permanent reverse, press the button once before

starting to sew. The reverse indicator (B) will be lit

and the machine sews in reverse until you press

the button again to cancel. If you press the reverse

button while sewing, the machine sews in reverse

for as long as you keep the button pressed. The

reverse indicator is lit when the reverse button is

pressed.

Reverse is also used when sewing buttonholes,

programmed tie-off end, darning stitches and

tapering stitches to step between the parts of the

stitch.

Reverse indicator (B)

The reverse indicator will be lit when pressing the

reverse button to sew in reverse. It is also lit while

sewing permanent reverse.

Action indicator (C)

The action indicator is lit to indicate that an action

is to be done, for example performing tapering. The

icon stays lit until the action is done.

Presser foot down and pivot toggle (E)

Lower the presser foot completely. Press the button

once more to raise the presser foot to pivot height.

The presser foot is lowered automatically when you

start sewing.

Start/stop (F)

Press this button to start or stop the machine

without using the foot control. Press the button once

to start and press it again to stop.

Thread snips (G)

Press to cut both needle and bobbin thread

immediately.

If pressing this button while sewing, the threads

will be cut before the needle moves to the start

position of the next stitch. Your machine ties off

the thread, cuts the needle and bobbin threads and

raises the presser foot and the needle.

The thread snips function can be programmed, see

chapter 4.

Note: Threads are cut automatically when buttonholes

are sewn with the Sensormatic buttonhole foot.

Presser foot up and extra lift toggle (D)

Raises the presser foot and needle to the up

position.

Press the button once more and the presser foot will

raise to extra lift. The feed dogs will be lowered to

make it easier to get thick fabric under the presser

foot.

The presser foot will not raise after thread snips if

Automatic presser foot lift has been deactivated in the

Settings menu.

Thread snips performed by the machine can be cancelled

in the Settings menu.

In embroidery mode the threads are cut and the presser

foot raised. The upper thread is only cut automatically at

the color change. When the design is nished both needle

and bobbin threads are cut automatically.

2:13

Preparations

Page 36

D

J

F

E

G H I

B

A

C

Immediate tie-off (H)

Press immediate tie-off while sewing and your

machine sews a few tie-off stitches and stops

automatically.

By touching the tie-off button once more while the

action indicator is lit, the function can be turned off.

The tie-off function can be programmed, see chapter 4.

Stitch restart (I)

When having stopped sewing in the middle of a

stitch, press restart to start sewing at the beginning

of the stitch again without having to reset any

special settings you have made.

If pressing the stitch restart button while sewing,

the stitch will be nished and the machine will then

stop.

You can also use stitch restart to go back to the

beginning of an embroidery.

Needle up/down (J)

Press this button to move the needle up or down.

The setting of the needle stop position is changed at

the same time. When needle down is activated, the

icon is lit, the needle will stop in the down position

and the presser foot will raise to pivot height.

You can also tap the foot control to raise or lower

the needle.

Preparations

2:14

Page 37

3

PFAFF® creative™

Color Touch Screen

Page 38

PFAFF® creative™ Color Touch Screen

Your machine features the PFAFF® creative™ Color Touch Screen. This technology provides great resolution and

color.

The screen is very easy to work with - just touch it with your stylus or your nger tip to make your choices. The task

bar at the bottom of the screen includes the main functions and help.

Every mode has its own color scheme, to make it easier to navigate and use the machine.

Start view

When your machine is turned on, a welcome screen is shown and then the machine opens sewing mode. If

the embroidery unit is attached the machine automatically opens embroidery mode.

Main parts

The task bar (A) is used for selecting and activating

the main functions.

The colored vertical bar on the right side of the

screen is called the option bar (B). It has different

options depending on which mode is active.

Task bar (A)

The look of the task bar will change depending

on whether sewing mode or embroidery mode is

active. Change mode by touching the corresponding

icon (1 or 2). The icon for the active mode is

highlighted. The task bar is always located at the

bottom of the screen.

B

1. Embroidery mode icon

2. Sewing mode icon

3. Selection menu

4. Settings menu

5. Info menu

6. Quick help

In embroidery mode

7. Embroidery stitch-out icon

The task bar in embroidery mode has an additional

icon (7) above the embroidery icon. This is the

Embroidery stitch-out icon. Touch it to toggle to

Embroidery stitch-out mode.

Return to Embroidery edit by touching the

embroidery mode icon (1).

Color Touch Screen

™

A

1 65432

Main functions in task bar

7

Task bar in Embroidery edit mode

1

creative

®

PFAFF

Task bar in Embroidery stitch-out mode

3:2

Page 39

Option bar (B)

The option bar contains different options in sewing

mode, Embroidery edit and Embroidery stitchout. Read more about the options for each mode in

chapters 4, 7 and 8.

Common icons

There are some icons and functions that are

frequently used on the screen. The most common

are described below.

B

Option bar in

sewing mode

B

Option bar in

embroidery edit

D E

Scroll arrows (C)

Touch the arrows to scroll between available

stitches.

OK (D) and cancel (E)

The OK (D) and cancel (E) icons are used to conrm

your settings and selections. They are also used to

close full screen windows.

To abort an actual process, touch cancel. To

continue, touch OK.

Long touch (F)

Some icons have increased functions, marked

with an arrow at the lower right corner. To access

these functions, touch and hold the icon for a few

seconds.

Touch functions (G)

The touch functions will be used to make

adjustments. There are up to four functions to use;

move (H), rotate (I), scale (J) and pan (K).

When a function is selected, you can make

adjustments by touching the arrows in the wheel, or

by touching and dragging your stylus on the screen.

The appearance of the wheel will change depending

on which function is selected.

F

Touch functions in

embroidery edit

H I

C

G

PFAFF

®

creative

™

Color Touch Screen

J K

3:3

Page 40

Selection menu

The selection menu contains a selection bar at the

bottom with icons for stitches, fonts, designs and

Files & Folders. Read more about Files & Folders in

chapter 10.

Select one of the icons in the selection bar to access

the menus. When a stitch, font or design is selected,

the selection menu will close automatically. To

return to previous view, close by touching cancel.

Selection menu - overview

1. Selection bar

a) Stitches

b) Fonts

c) Designs

d) Files & Folders

2. Stitch categories

a) Utility stitches

2a 2b 2c 2d 2e 2f 2g

2

3

4

b) Quilt stitches

c) Needle art stitches

d) Decorative stitches

e) Maxi stitches

f) Sewing techniques

g) Personal menu

3. Stitch subcategories

4. Stitches

5. Scroll arrows

6. Clear personal menu (only visible if personal

menu is selected)

Selecting a stitch

To select a stitch, rst select a category at the

top (2). For each category, there are one or more

subcategories (3). For each subcategory a list of

stitches is shown (4). Use the scroll arrows (5) to go

to the next page in the subcategory. Select a stitch

by touching it.

5

1a 1b 1c 1d

1

Color Touch Screen

™

creative

®

PFAFF

6

3:4

Page 41

Personal menu

To nd your personal saved stitches, open personal

menu (2g). Each subcategory in the personal menu

has 16 positions to save your own stitches or

sequences. Scroll through the stitches in the selected

subcategory using the scroll arrows. Select a stitch

by touching it.

If you want to delete one stitch, rst touch the delete

icon (6), and then touch the stitch. The positon will

be emptied. To abort the deletion before selecting a

stitch, deselect the delete icon.

A long touch of the delete icon (6) will empty the

whole subcategory selected.

Note: All stitches in the subcategory will be deleted, even

though they are not visible on the screen.

2g

6

Selecting a font

Stitch fonts are indicated with a lighter background

and embroidery fonts have a darker background.

Select a font by touching it. Use the scroll bar to see

additional fonts.

A selected stitch font opens in sequencing. A

selected embroidery font opens in the embroidery

text editor.

Note: Embroidery fonts are only visible if the embroidery

mode is active and neither sequencing nor Stitch Creator

is active.

PFAFF

®

creative

™

Color Touch Screen

3:5

Page 42

Selecting a design

Your machine has four tabs with designs: Personal

designs, machine designs, mini designs and quilt

designs. Read more about the different design tabs

in chapter 8.

Touch a tab to display the contents. Select an

embroidery design by touching it. Use the scroll bar

to browse through additional designs.

When a design is selected, the machine will

automatically switch to embroidery mode and the

design will be loaded into Embroidery edit.

Embroidery edit

In Embroidery edit you can scale, change colors,

position and rotation of your designs. You can also

combine designs, save, restore and delete designs.

You can edit your designs with or without the

embroidery unit attached.

Read more about Embroidery edit in chapter 8.

Color Touch Screen

™

creative

®

PFAFF

3:6

Page 43

Embroidery stitch-out

To embroider your design, change from

Embroidery edit to Embroidery stitch-out by

touching the Embroidery stitch-out icon on the

task bar.

In Embroidery stitch-out you nd functions

that are useful when embroidering.

Read more about Embroidery stitch-out in

chapter 9.

3:7

PFAFF

®

creative

™

Color Touch Screen

Page 44

Settings menu

In the Settings menu, you can change default

settings and make manual adjustments to the

machine settings (A), screen settings (B) and sound

settings (C).

Touch the icons to activate a function or open a list

of choices. The settings are saved even after turning

off the machine with one exception: changes made

to Options for feed dogs will not be saved when the

machine is switched off. The setting will revert back

to the default which is auto. See page 3:10 for more

information.

Use Quick help to receive instant information about

the settings. Touch the Quick help icon (D) and then

the setting you want information about. Read more

about Quick Help on page 3:13.

Machine settings (A)

Language

Touch the icon to view the available languages. Select

your desired language from the list by touching it.

Owner’s name

Touch the icon to get a pop-up where you can enter

your name.

Thread manufacturer

Touch to select preferred thread manufacturer. You

can select between Gütermann Sulky and RobisonAnton. Color codes from the selected manufacturer

will be used when changing colors in a design, or

creating a new design from stitches or fonts in your

machine.

Note: Changing thread manufacturer setting will not

automatically convert the colors in existing designs to the

selected thread manufacturer.

Twin needle

Touch the icon to open a list for twin needle width

selections. When a twin needle size is selected, the

width of all stitches is limited for that needle size to

prevent needle breakage. The setting is kept until

you deselect the twin needle width.

When a twin needle size is selected, a pop-up is

shown when turning on your machine. Another

warning pop-up is shown when selecting a stitch

Color Touch Screen

™

that is too wide for the set twin needle size. The

stitch width of those stitches is automatically

adjusted to t the twin needle. Deselect twin needle

creative

to go back to normal sewing.

®

A B C D

PFAFF

Pop-up for twin needle selection.

3:8

Page 45

Stitch width safety

Select this function when using a straight stitch

presser foot to lock the needle in center position for

all stitches, preventing damage to the needle and/or

presser foot.

When turning on the machine with this setting

activated and for every stitch selection that is not

a straight stitch, a pop-up informs you that it is set

to straight stitch. Deselect stitch width safety to go

back to normal sewing.

Note: Twin needle and stitch width safety cannot be used

at the same time.

Cut jump stitches

Your machine features the automatic function

Cut jump stitches. This function saves you time

trimming after the embroidery is completed. When

Cut jump stitches is selected your machine will trim

the top jump stitch thread and pull the thread end

to the underside of the fabric as you embroider.

Note: Your machine will also cut the thread after you

have changed to a new color. Hold the thread end when

you start embroidering again, so that you can easily

remove the thread end when cut.

Designs marked with this symbol are

programmed for Cut jump stitches. Trim

commands to cut jump stitches can be added

to any design using the software package

downloaded via the PFAFF

®

website (see page

2:12).

Automatic thread snips

When selected, the automatic thread snips is

activated. The threads are cut automatically and

the presser foot raises at color changes or when

an embroidery is nished. When deselected, no

automatic thread snips will be performed.

Timer

Displays the total sewing and embroidery time of

your machine. Touch the icon to reset the timer.

Automatic presser foot lift

When selected, the automatic presser foot lift is

activated. The presser foot will raise to pivot height

for example when stopping with the needle in the

down position. When deselected, the presser foot

will stay lowered even if the machine stops with the

needle in down position.

Options for feed dogs

Touch to open a pop-up with three options.

The default setting is auto (recommended).

Changes to the default setting are not retained once

the machine has been turned off. Your machine

automatically raises or lowers the feed dogs,

depending on the stitch/technique selected.

For example, the feed dogs lower automatically in

free-motion or embroidery modes, when the button

sewing stitch is selected or when using the Presser

foot extra lift. When a new stitch/technique is

selected, the feed dogs come up automatically when

you start sewing.

Select up to set the feed dogs to remain raised for all

sewing.

Select down to set the feed dogs to remain lowered

for all sewing.

AutoSave current state

When AutoSave current state is selected, the

machine will save current state periodically

while embroidering and also when you stop

embroidering.

The information about the embroidery will be saved

even after switching the machine off.

PFAFF

®

creative

™

Color Touch Screen

Note: If AutoSave current state is selected it can take longer

to go from Embroidery edit to Embroidery stitch-out.

3:9

Page 46

Thread tension compensation

If you nd that the thread tension needs to

be increased or decreased for most stitches or

embroideries, you can change the general setting

for embroidering and/or sewing. You may need to

adjust the thread tension controls if you regularly

sew or embroider on special fabric or use specialty

threads.

Touch Thread tension compensation. Adjust the

slider bars to generally increase or decrease the

thread tension for all stitches and/or embroidery.

Default setting is normal.

Once you have increased or decreased the value in

the Settings menu, the thread tension control icon

will change to green.

Note: Contact you authorized PFAFF® dealer if you

experience thread tension problems that cannot be helped

with the Thread tension compensation.

Dynamic spring foot 6D for embroidery

”Dynamic spring foot 6D for embroidery” function

is selected by default. When embroidering, using

the Dynamic spring foot 6D, make sure that the

”Dynamic spring foot 6D for embroidery” is

selected.

When another type of foot is used, e.g. presser

foot 6A, deactivate Dynamic Spring foot 6D for

embroidery in the Settings menu.

Once you have increased or decreased the

value in the Settings menu, the thread

tension control icon will change to green.

Presser foot pressure

In most cases, you do not need to adjust the presser

foot pressure. Specialty techniques may require

an adjustment. The higher the number the more

pressure on the fabric.

Presser foot height embroidery

Adjust the height of the presser foot in Embroidery

stitch-out mode. Use the + and - icons to either raise

or lower the height of the presser foot.

Some embroideries may build up under the presser

foot. If there is not enough space between the

presser foot and the embroidery, the top thread will

form loops on the underside of the embroidery.

Increase the presser foot height in small steps until

Color Touch Screen

™

the embroidery moves freely under the presser foot.

Note: Because the Dynamic spring foot 6D measures the

fabric thickness, the option to adjust presser foot height in

creative

embroidery is only available if Dynamic spring foot 6D

®

for embroidery is deselected.

Presser foot pressure

Presser foot height

embroidery

PFAFF

3:10

Page 47

Screen settings (B)

Lock screen

If needed, you can easily lock the screen while

sewing or embroidering.

When activated, the screen is locked everytime it is

inactive for ten seconds. The screen will be locked

until you unlock it by touching OK.

Screen saver

When activated, the creative™ 4.5 start up screen

will be displayed as a screen saver ten minutes after

the last touch. Touch the screen or press any button

to exit the screen saver.

Calibrate

When touching the icons on the screen, the screen

might need a calibration to adjust to your touch.

Touch the calibrate icon to open a special view for

®

PFAFF

creative™ Color Touch Screen calibration.

Follow the instructions on the screen to calibrate.

Sound settings (C)

You can change the sound settings on your machine

for different situations. First select from the list

which sound event you want to change. Then, select

the sound you want to play by checking one of the

boxes. You will be able to hear the sound when

you check the box. Each event can have a different

sound.

Audio repeat

When active, the signal for some warning or

attention pop-ups is repeated in intervals until it is

cancelled.

B

PFAFF

®

creative

Volume

You can change the volume using the slider.

™

Color Touch Screen

C

3:11

Page 48

Info menu

Use the info system to easily get help topics and

information. The Info menu is a built-in shortened

version of the Owner’s manual.

When you touch the info menu icon on the task bar,

you have four options to select from - category (A),

index (B), personal info (C) and text (D).

Browse through the topics using your stylus.

The left arrow at the top of the screen opens the

previous page. The right arrow takes you back to

the current page.

Category (A)

Category shows the help topics divided into

categories following the structure of the Owner’s

manual.

Index (B)

Index shows the help topics in alphabetical order.

Personal info (C)

Personal info contains the owner’s name, machine’s

software information and serial number.

Text (D)

You can open and read text and HTML-les on your

machine. The text view shows these text les which

are opened from Files & Folders (see chapter 10).

Note: The text icon is not active if no text or HTML le

has previously been opened from Files & Folders.

Quick help (E)

Your machine has a built-in Quick help, which gives

you instant information about everything you see

on the screen. Touch the Quick help icon on the

lower right corner of the screen (E). It starts ashing

indicating that Quick help is active. Touch the icon

or the part of the screen you want information

about. A pop-up gives a short explanation. Touch

OK to close the pop-up and exit Quick help.

A B C D E

When a USB mouse is connected, it is even easier to

use the built-in Quick help. Place the cursor over the

Color Touch Screen

icon and right click on the mouse and Quick help

™

will pop-up instantly.

creative

®

PFAFF

3:12

E

Page 49

4

Sewing mode

Page 50

Sewing mode

In sewing mode you can select stitches, adjust and sew them. Use Stitch Creator™ feature and sequencing

to create your own stitches and sequences. The selected stitch is shown in actual size in the stitch eld.

Recommendations and machine settings are shown at the top of the screen.

Sewing mode - overview

1. Sewing recommendations

2. Machine settings

3. Stitch selection area

1

2

3

4. Arrows for scrolling through stitch

categories

5. Selected stitch number

6. Stitch eld

7. Mirroring side to side

8. Mirroring end to end

9. Sequence start position

10. Stitch width

11. Width/position toggle

12. Stitch length

13. Stitch density

14. Thread tension

15. Save options

16. Free-motion options

17. Balance

18. Zoom to all

19. Speed control

5

6

7 8

4

19

15

17

10

9

11

16

18

12 13 14

20

21

22

23

20. Tie-off options

21. Sewing programs

22. Sequencing

23. Stitch Creator™ feature

24. Selection menu

25. Repeat buttonhole

26. Stitch positioning

27. Buttonhole slit length

28. Button stitch repetition

29. Quick help

Note: All symbols and options will not be shown at

the same time.

Quick help (29)

Use Quick help to receive instant information

about any icon or part of the screen. Touch the

Quick help icon (29) and then the icon or the

part of the screen you want information about.

Sewing mode

4:2

2625 27

24

29

28

Page 51

Select a stitch

To select a stitch, touch the actual stitch in the stitch

selection area (3). You can scroll through the list of

stitches by touching the arrows at the right of the

stitch selection area (4). The number of the actual

subcategory is shown between the arrows (A).

You can also select a stitch from the selection menu

(24), see page 3:4.

Sewing recommendations (1)

Your machine automatically gives you

recommendations for the selected stitch.

1a) Presser foot recommendation

2b 2c 2d 2e

1a 1b 1c 2a

3

4

1b) IDT™ system recommended

1c) Stabilizer recommended

Machine settings (2)

Some machine settings are indicated with a symbol

when activated in the settings menu.

2a) Set for twin needle

2b) Set for stitch width safety

2c) Set for dynamic spring foot free-motion

2d) Set for spring foot free-motion

2e) Set for sensormatic free-motion

Raise and lower the presser foot

Your machine features the automatic presser foot

up and extra lift button and the presser foot down

and pivot button.

To lower the presser foot, place the fabric under the

presser foot and press the presser foot down button

(A) or step on the foot control. To raise the presser

foot, press the presser foot up button (B) or press

the thread snips button (C) to cut needle and bobbin

thread and raise the foot. When the needle stops in

the down position, the presser foot raises to pivot

height.

A

24

B

A

C