Page 1

Owner's manual

Page 2

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

Read all instructions before using this household sewing machine.

DANGER – To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 5 Watt.

WARNING – To reduce the risk of burns, À re, electric

shock, or injury to person:

• This sewing machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the sewing machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if

it has been dropped or damaged, or dropped into water. Return the sewing machine to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep À ngers away from all moving parts. Special care is required around the sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deÁ ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• This sewing machine is provided with double insulation. Use only identical replacement parts.

See instructions for Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

SERVICING OF DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No ground

means is provided on a double-insulated product, nor should a means for grounding be added to the

product. Servicing of a double-insulated product requires extreme care and knowledge of the system and

should be done only by qualiÀ ed service personnel. Replacement parts for a double-insulated product must

be identical to those parts in the product. A double-insulated product is marked with the words ‘DOUBLE

INSULATION’ or ‘DOUBLE INSULATED’.

Page 3

Congratulations!

Congratulations on purchasing your new PFAFF® creative™ 2.0 sewing and embroidery

machine. As a sewing enthusiast, you have acquired a machine that features the very

latest in both design and technology, enabling you to transform all your creative ideas into

reality.

Before you start, please spend some time reading this owner’s manual. You will soon

discover how to maximize the use of your machine. Our authorized PFAFF® dealers will

of course also be pleased to advise you at any time.

Your PFAFF®

experience a totally new dimension of sewing and embroidery.

creative™ 2.0 sewing and embroidery machine will deÀ nitely enable you to

Page 4

Table of contents

4

1

Introduction 1:5

Machine overview ....................................................1:5

Front side ...................................................................... 1:5

Top parts .......................................................................1:5

Rear side .......................................................................1:6

Accessory tray ..............................................................1:6

Parts of the embroidery unit ......................................1:6

Included accessories ....................................................1:7

Presser feet ....................................................................1:8

Stitch overview .........................................................1:9

Alphabets ................................................................1:11

2

Preparations 2:1

Unpacking .................................................................2:1

Connect to the power supply .................................2:1

Pack away after sewing ...........................................2.2

Free arm .....................................................................2:2

Thread cutter.............................................................2:2

Spool pins ..................................................................2:2

Threading the machine............................................2:3

Bobbin winding ........................................................ 2:5

Inserting the bobbin .................................................2:6

IDT (Integrated dual feed) ......................................2:6

Needles ......................................................................2:7

Changing the needle ................................................2:7

Lowering feed dogs .................................................2:8

Changing the presser foot .......................................2.8

USB port ....................................................................2:9

5D™ Embroidery Software ..................................2:10

Buttons .....................................................................2:12

Settings menu .........................................................2:14

3

Sewing 3:1

Sewing mode - overview ............................................3:1

Select a stitch .............................................................3:1

Sewing recommendations .......................................... 3:1

Stitch adjustments .................................................... 3:2

Mirroring ...................................................................3:3

Tie-off options ........................................................... 3:3

Tapering program ....................................................3:4

Speed control ............................................................3:4

Personal stitches ....................................................... 3:5

Sewing techniques ...................................................3:6

Common sewing pop-ups ....................................3:11

Sequencing 4:1

Sequencing - overview................................................4:1

Create a sequence .....................................................4.1

Using the alphabet ...................................................4:2

Manage your sequences .......................................... 4:2

Sewing a sequence ...................................................4:3

5

Embroidery preparations 5:1

Embroidery unit overview .....................................5:1

Embroidery hoop overview .................................... 5:1

Connect the embroidery unit .................................5:2

Remove the embroidery unit .................................. 5:2

To hoop the fabric ....................................................5:3

6

Embroidering 6:1

Embroidery stitch-out view .......................................6:1

Embroidery edit view .................................................6:1

Design information .................................................. 6:1

Embroidery stitch-out .............................................6:2

Load a design ............................................................... 6:2

Load a font ....................................................................6:2

Stitches left in color block ...........................................6:3

Current color ................................................................ 6:3

Orbit to check position................................................6:3

Hoop options................................................................6:4

Basting ...........................................................................6:5

Speed control ................................................................6:5

Thread tension ............................................................. 6:5

Getting started embroidering ....................................6:6

Embroidery edit .......................................................6:7

Design width ................................................................ 6:7

Design height ...............................................................6:7

Rotate ............................................................................6:7

Monochrome ................................................................6:7

Move ..............................................................................6:7

Mirroring ......................................................................6:7

Common embroidery pop-ups ..............................6:8

7

Maintenance 7:1

Changing the light bulbs .........................................7:1

Cleaning the machine ..............................................7:1

Replacing the stitch plate ........................................7:2

Troubleshooting .......................................................7:3

Index ..........................................................................7:5

Page 5

Introduction

Machine overview

1

Introduction

2

3

4

5

6

7

8

9

10

11

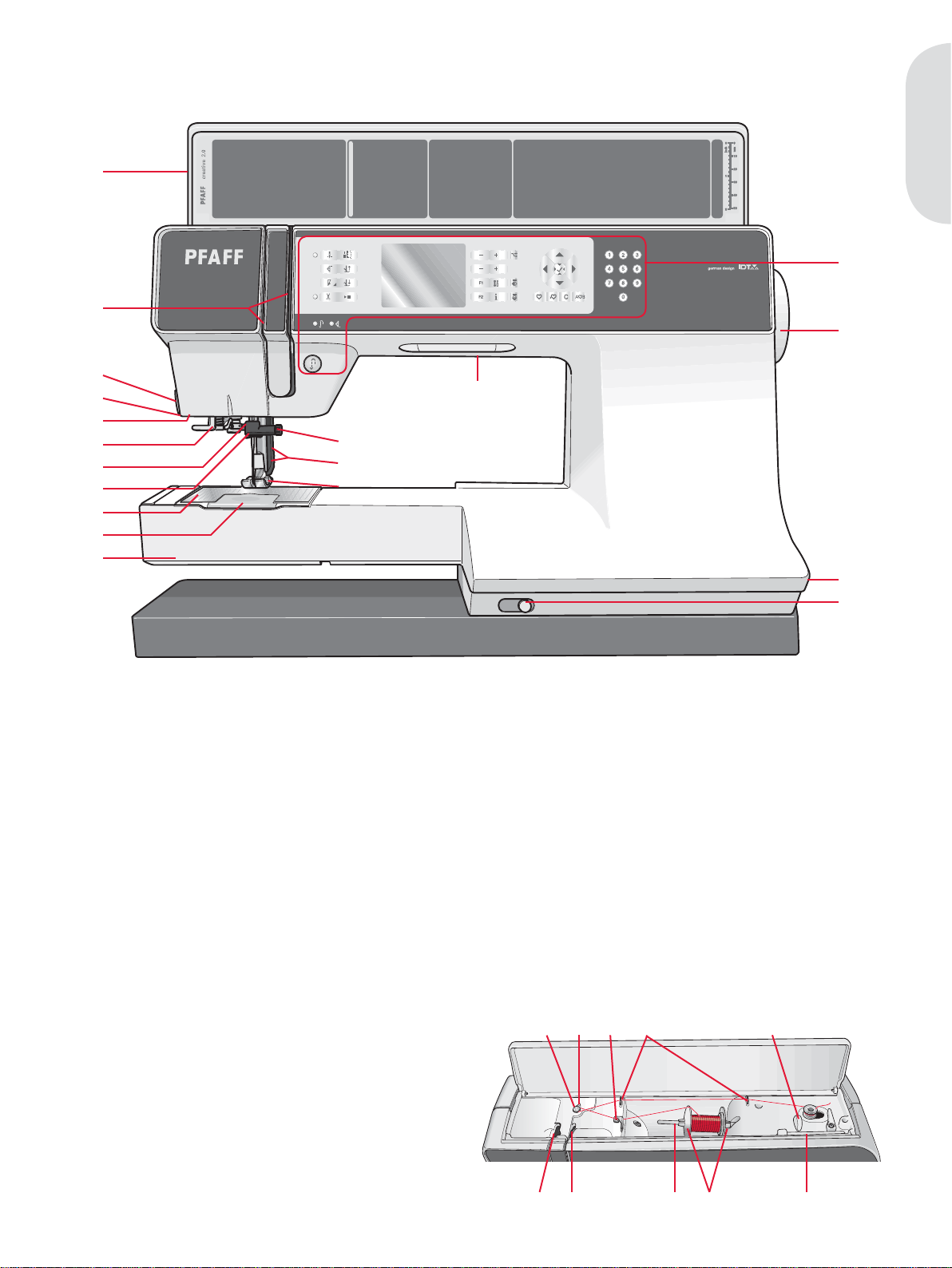

Front side

1. Lid with stitch overview and button ruler

2. Threading slots

3. Thread cutter

4. Sensormatic buttonhole foot socket

5. Light bulbs

6. Built-in needle threader

7. Needle bar

8. Needle thread guide

9. Stitch plate

10. Bobbin cover

11. Free arm

12. Presser foot

13. Presser foot bar and presser foot holder

14. Needle screw

15. Buttons and graphic display

16. Handwheel

17. Main switch, connectors for power cord and

foot control

18. Slide for lowering the feed dogs

14

13

12

creative 2.0

5

Top parts

19. Pre-tension disk for threading and bobbin

winding

20. Bobbin winder thread guide

21. Thread guide

22. Bobbin thread guides

23. Bobbin thread cutter

24. Bobbin winder lever and bobbin spindle

25. Auxiliary spool pin

26. Spool caps

27. Spool pin

28. Thread tension disk

29. Take-up lever

212019 22 23 24

15

16

17

18

272829

26 25

1:5

Page 6

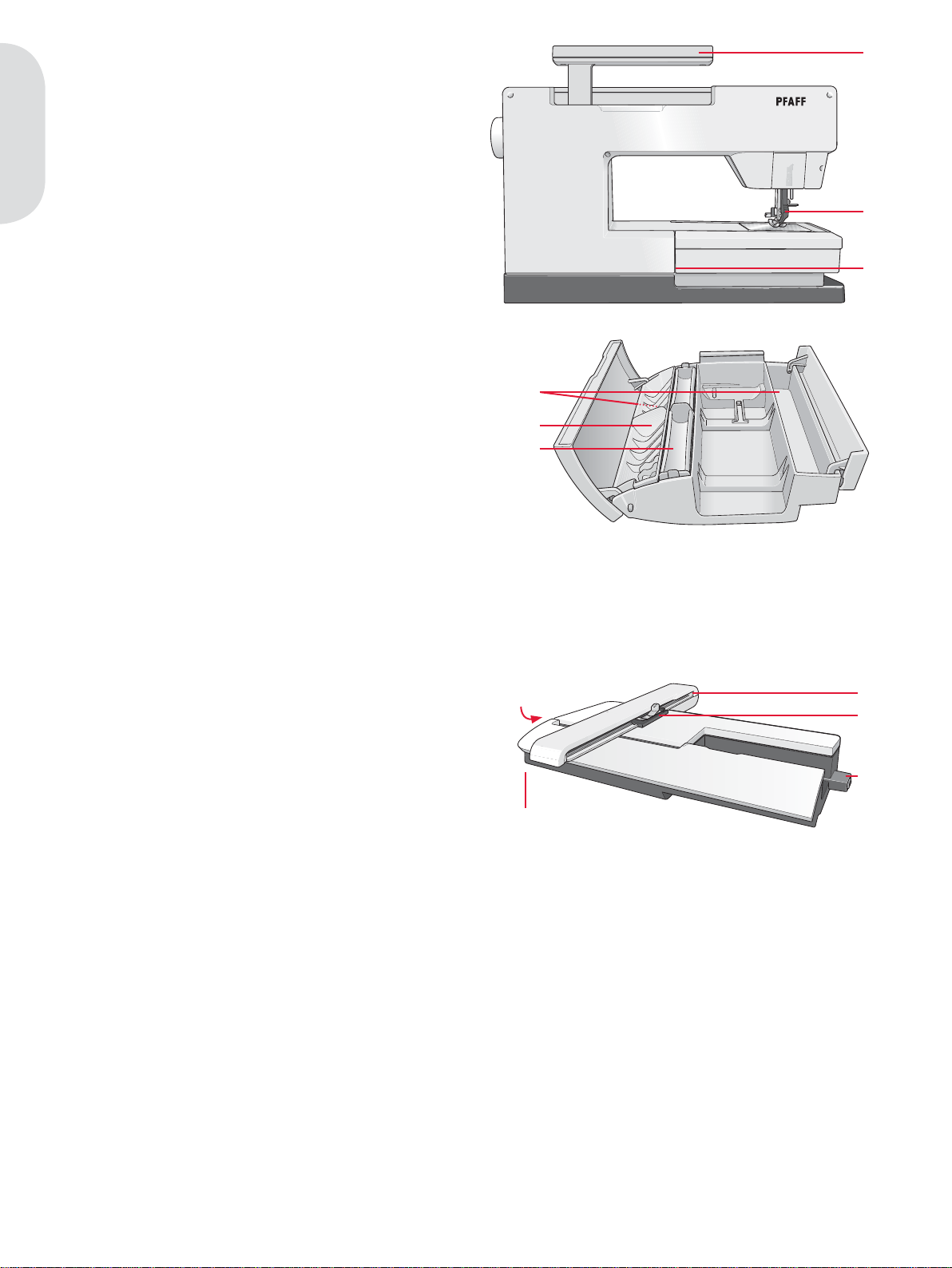

Rear side

30. Handle

31. IDT

32. Embroidery unit connection socket

Introduction

Accessory tray

The accessory tray features special compartments

for presser feet and bobbins, plus space for needles

and other accessories. Store the accessories in the

tray so they are easily accessible.

33. Space for accessories

34. Removable tray for presser feet

35. Removable bobbin holder

30

31

32

33

34

35

Parts of the embroidery unit

(type BE16)

36. Embroidery unit release button

37. Level adjusting feet

38. Embroidery unit socket

39. Embroidery hoop connection assembly

40. Embroidery arm

36

37

40

39

38

1:6

Page 7

Included accessories

41. Thread net

42. Edge guide

43. Felt pad

44. Light bulb remover

45. Screwdriver

46. Seam ripper

47. Brush

48. Spool cap, large

49. Spool cap, medium

50. Spool cap, small

51. USB embroidery stick

52. Multi-purpose tool

53. Bobbins

54. Hoop clips

44

434241

474645

Introduction

Included hoops

55. creative™ 120 SQUARE HOOP (120x120)

56. creative™ ELITE HOOP (260x200)

51

48

49

55 56

50

545352

Included accessories not in picture

• Foot control

• Power cord

• Needles

• CDs with embroidery designs, communication software etc.

• creative™ 2.0 Embroidery collection

1:7

Page 8

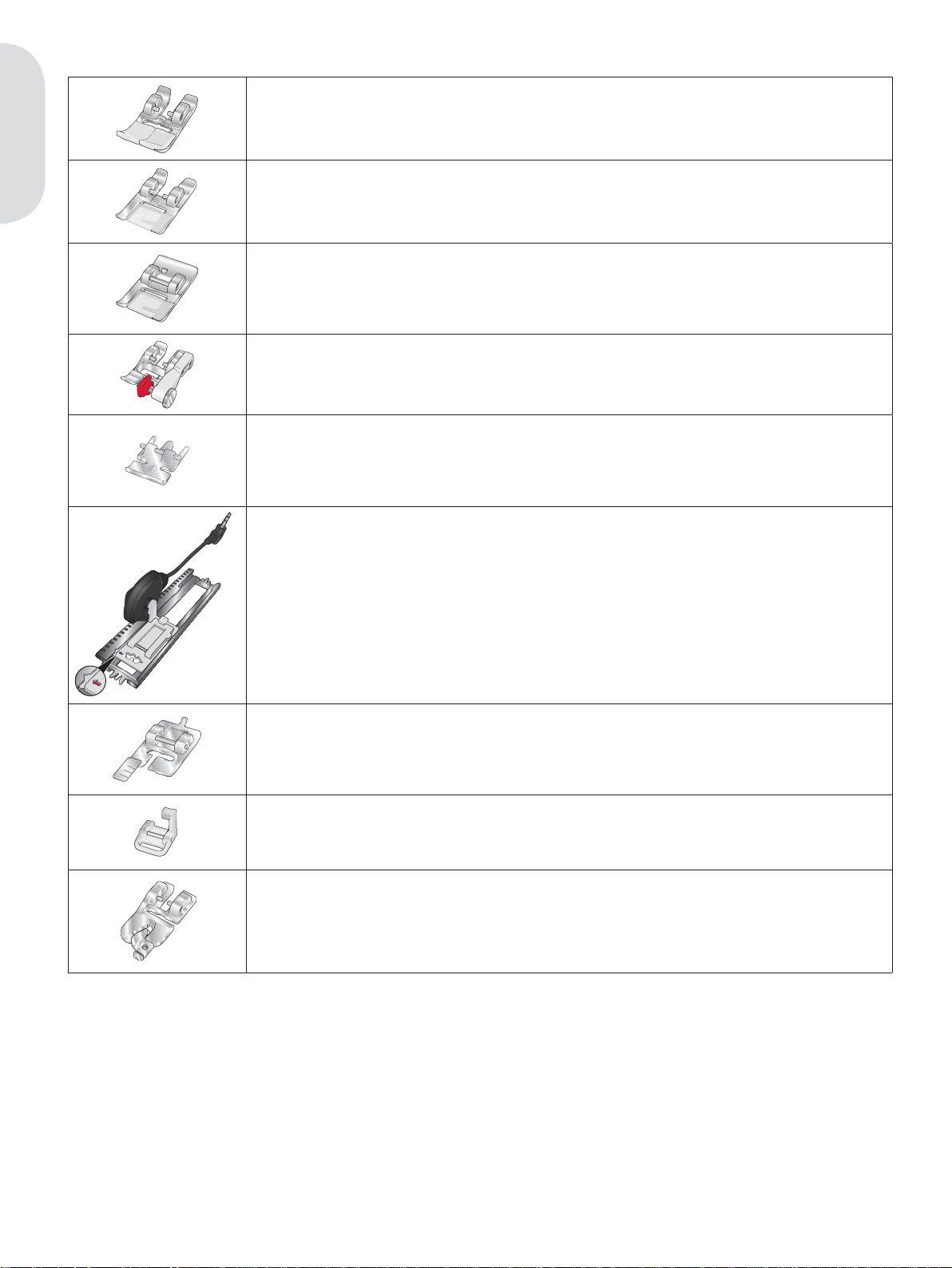

Presser feet

Standard presser foot 0A with IDT (attached on the machine upon delivery)

This foot is used mainly for straight stitching and zigzag stitching with a stitch

length longer than 1.0 mm.

Introduction

Fancy stitch foot 1A with IDT

This foot is used for decorative stitches. The groove on the underside of the foot

is designed to Á ow smoothly over the stitches.

Fancy stitch foot 2A

When sewing decorative stitches or short zigzag stitches and other utility stitches

with less than 1.0mm stitch length, use this foot. The groove on the underside of

the foot is designed to Á ow smoothly over the stitches.

Blindhem foot 3 with IDT

This foot is used for blindhem stitches. The toe on the foot guides the fabric. The

red guide on the foot is designed to ride along the fold of the hem edge.

Zipper foot 4 with IDT

This foot can be snapped on either the right or the left of the needle, making it

easy to sew close to both sides of the zipper teeth. Move the needle position to

the right or left to sew closer to zipper teeth.

Sensormatic buttonhole foot 5A

When connected to the machine, the buttonhole is sewn in a suitable length to

the button size that has been entered into the machine. Used to sew buttonholes

up to 50 mm.

Manual buttonhole foot 5M

This foot is used for sewing manual buttonholes longer than 50 mm. Use the

markings on the foot to position the garment edge. The À nger on the back of the

foot holds cording for corded buttonhole.

Embroidery/Sensormatic free-motion foot 6A

This foot is used for embroidery and sensormatic free-motion sewing. This foot

can also be used for darning.

Rolled hem foot 7 with IDT, 3 mm

This foot is used to sew narrow hems in light to medium weight fabric.

Important: Make sure that the IDT is disengaged when using presser foot 2A, 5A, 5M and 6A.

1:8

Page 9

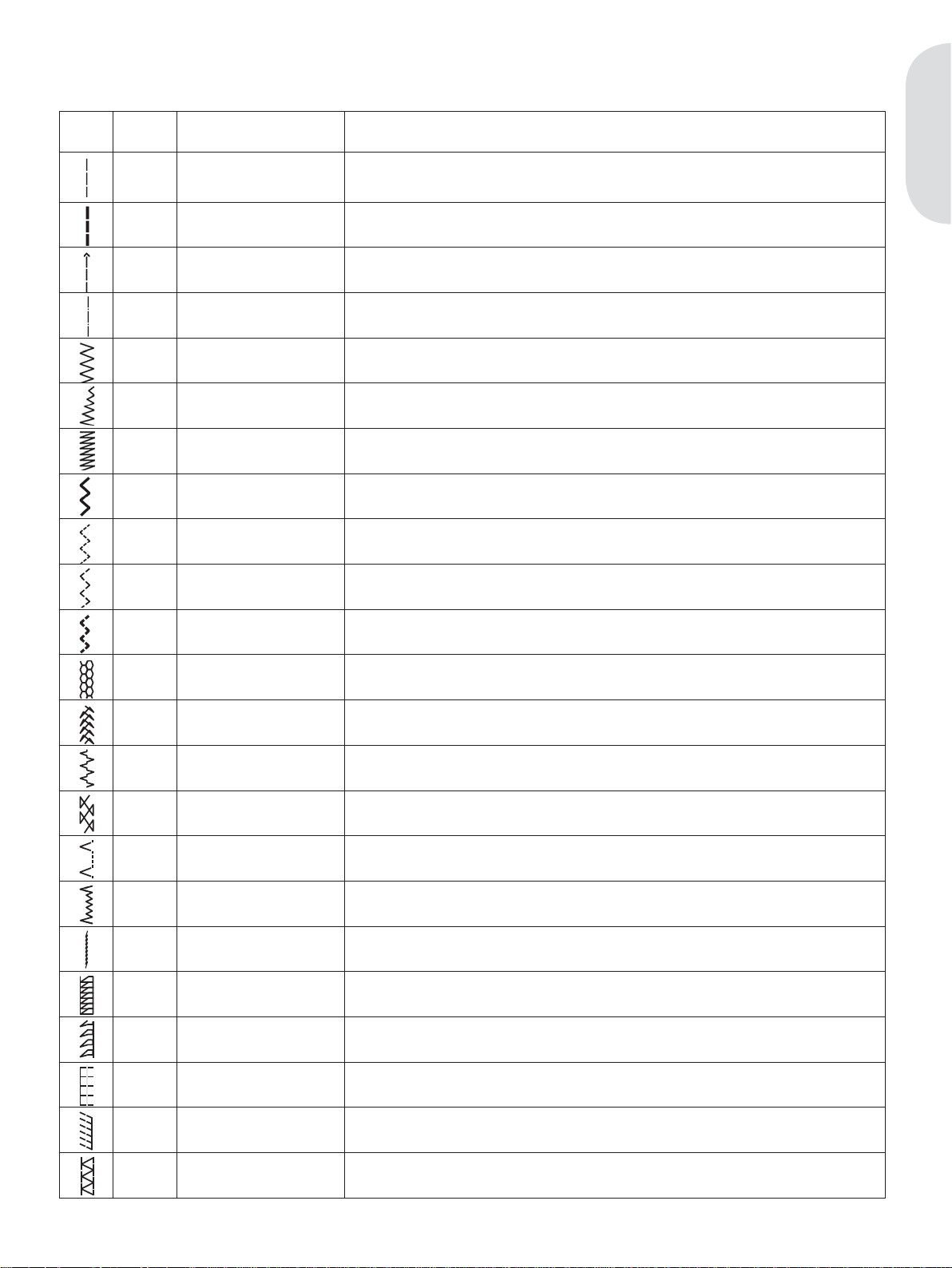

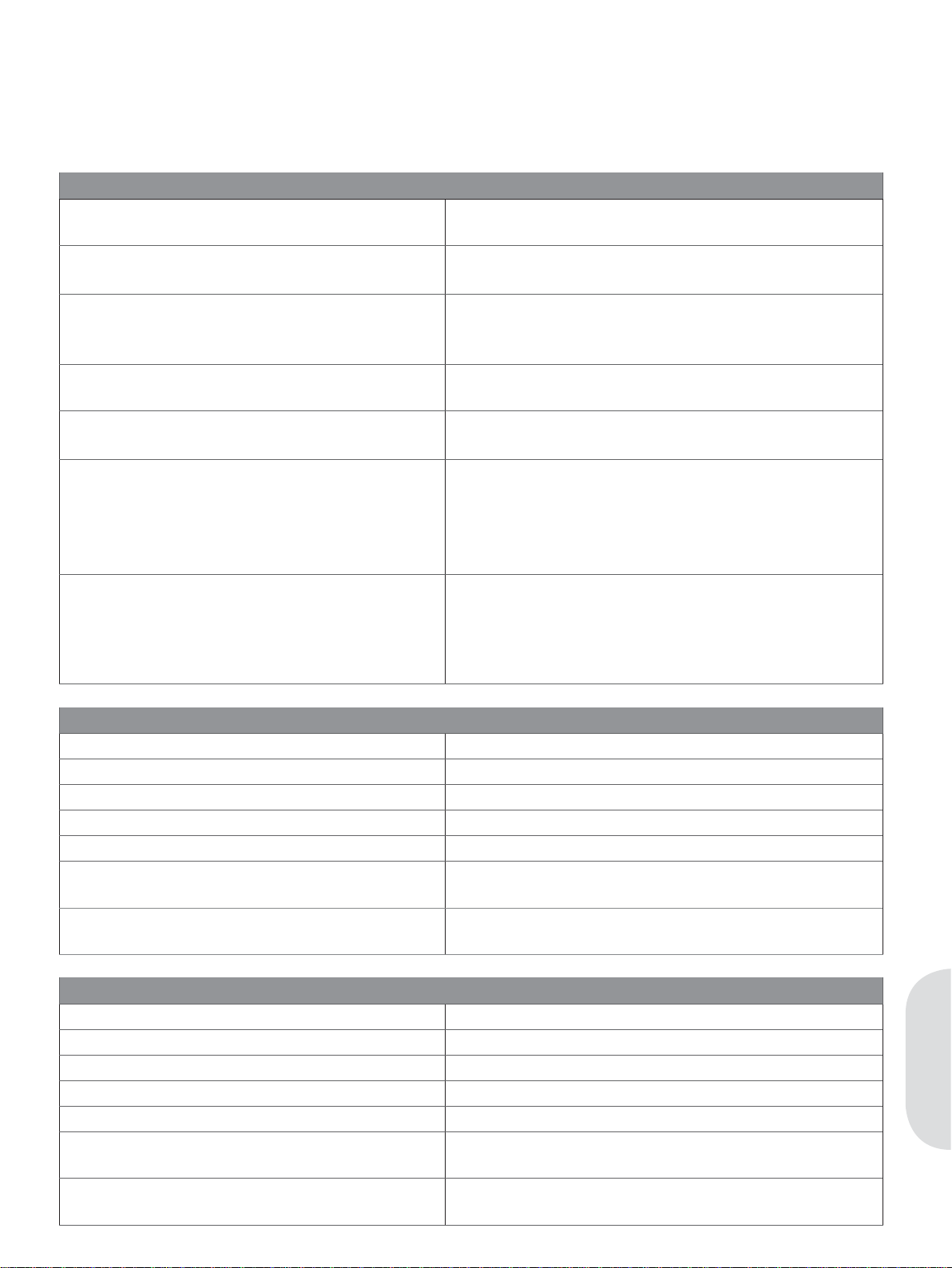

Stitch overview

Utility stitches

Stitch

Stitch

number

Name Description

1 Straight stitch For seaming and topstitching. Select from 37 different needle positions.

2 Stretch triple straight stitch Reinforced seam. Topstitching.

3 Straight stitch reverse Sew continuous reverse.

Introduction

Note: This stitch makes a stronger tie-off than stitch 40.

4 Basting stitch Single stitch used for basting. Touch foot control to sew one stitch. Move fabric manually to desired

5 Zigzag stitch Reinforce seams, clean À nish, stretch sewing, lace insertion.

6 Zigzag stitch Reinforce seams, clean À nish, stretch sewing.

7 Z-zigzag stitch Appliqué, couching, eyelets.

8 Stretch triple zigzag stitch Elastic stitch for decorative hems or topstitching.

9 Three-step zigzag stitch Sewing elastic, darning, patching.

10 Elastic stitch Sewing elastic, darning, patching.

11 Triple stretch stitch Sewing elastic, darning, patching and decorative sewing.

12 Honeycomb stitch Decorative stitch for stretch fabrics and hems. Also used with elastic thread in the bobbin.

13 Bridging stitch Joining fabrics and quilt batting, decorative stitch for quilting, hemstitching.

14 Foundation elastic stitch Joining stitch for undergarments, terry cloth, leather, bulky fabrics where overlapping the seams.

position and touch foot control again. to sew another stitch.

15 Crosshem stitch Elastic decorative hem for stretch fabrics.

16 Blindhem stitch Sewing blindhems on woven fabrics.

17 Elastic blindhem stitch Sewing blindhems on stretch fabrics.

18 Stretch tricot stitch Sewing seams on stretch fabrics.

19 Closed overlock Seam and overcast stretch fabrics in one step.

20 Closed overlock Seam and overcast in one step with reinforced edge.

21 Elastic overcast Seam and overcast stretch fabrics in one step.

22 Overlock Seam and overcast stretch fabrics in one step.

23 Closed overlock Seam and overcast in one step, patch, hem.

1:9

Page 10

Stitch

Stitch

number

Name Description

24 Stretch knit overlock Seam and overcast stretch fabrics in one step.

25 Linen buttonhole Buttonhole for blouses, shirts and linen.

Introduction

26 Standard buttonhole Basic buttonhole for blouses, shirts and jackets. Also for pillowcases.

27 Rounded buttonhole with

pointed tack

28 Rounded buttonhole with

lengthwise tack

29 Eyelet buttonhole with pointed

tack

30 Eyelet buttonhole with

lengthwise tack

31 Rounded buttonhole Buttonhole for light garments or jackets.

32 Stretch buttonhole Buttonhole for stretch fabrics.

33 Button sewing Sew on buttons or tacking.

34 Eyelet Heirloom sewing decorative trim.

35 Programmable darning stitch Darning holes or damaged fabric.

Buttonhole for garments.

Buttonhole for garments.

Tailors buttonhole or decorative buttonhole.

Tailors buttonhole for jackets and trousers.

36 Programmable reinforced

darning stitch

37 Bartack Automatically reinforce seams and pockets.

38 Denim bartack Automatically reinforce seams and pockets decoratively.

39 Decorative bartack Automatically reinforce seams and pockets decoratively.

Quilt stitches

Stitch

40* 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62

Needle art stitches

Stitch

63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85

Stitch

Reinforced darning holes or damaged fabric.

86 87 88

* This stitch makes a more decorative tie-off than stitch 1.

1:10

Page 11

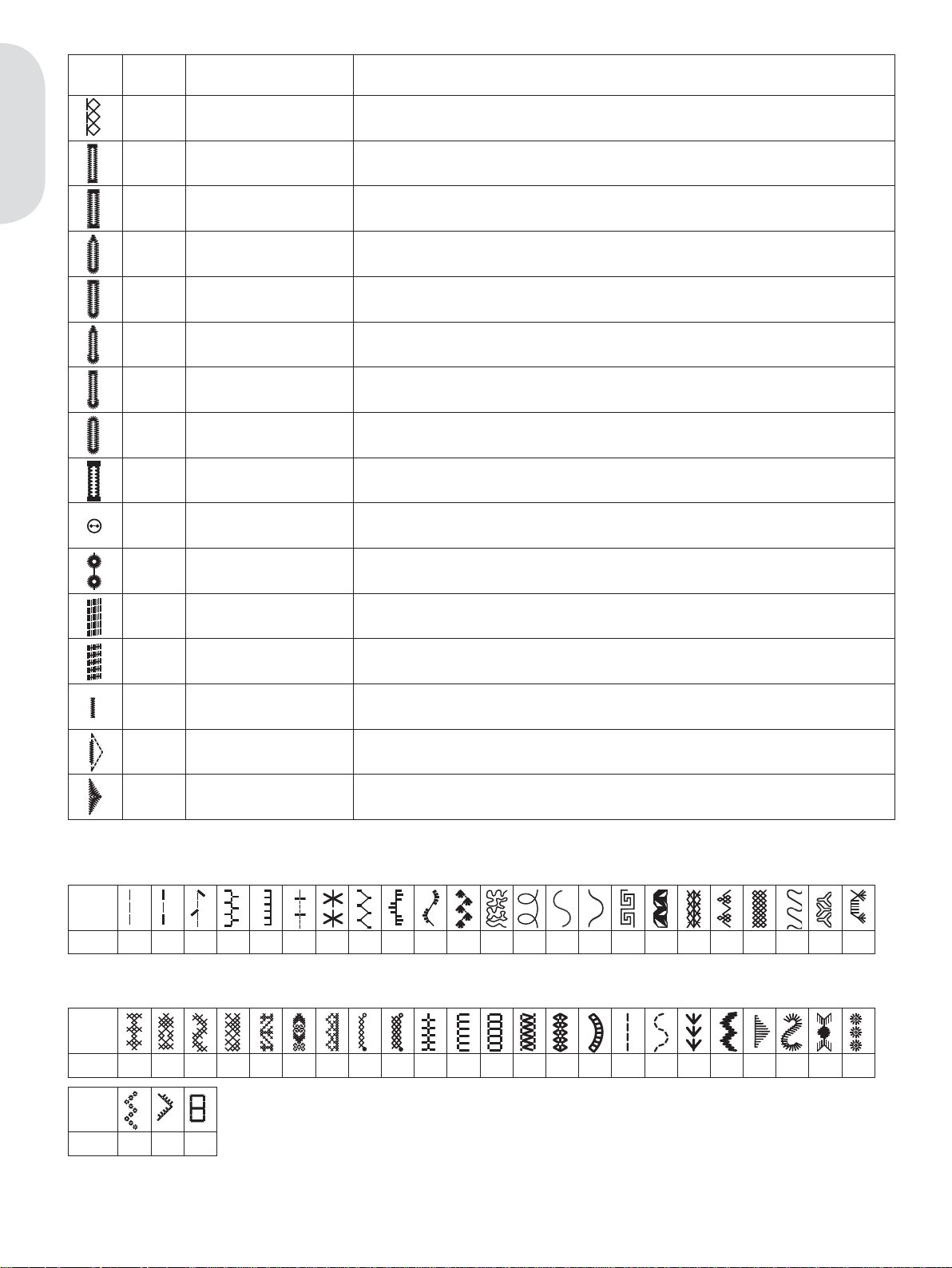

Decorative stitches

Stitch

89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112

Stitch

113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136

Stitch

137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153

Alphabets

Comic

Introduction

Cyrillic

1:11

Page 12

Preparations

Page 13

Preparations

Unpacking

1. Place the box on a steady, Á at surface. Lift

the machine out of the box, remove the outer

packaging and lift off the machine carrying

case.

2. Remove all outer packing material and the

plastic bag.

3. Slide off the accessory tray and remove the

styrofoam inside.

Note: Styrofoam left in the accessory tray while sewing

may affect stitch quality. The styrofoam is for packing

purposes only and should be removed.

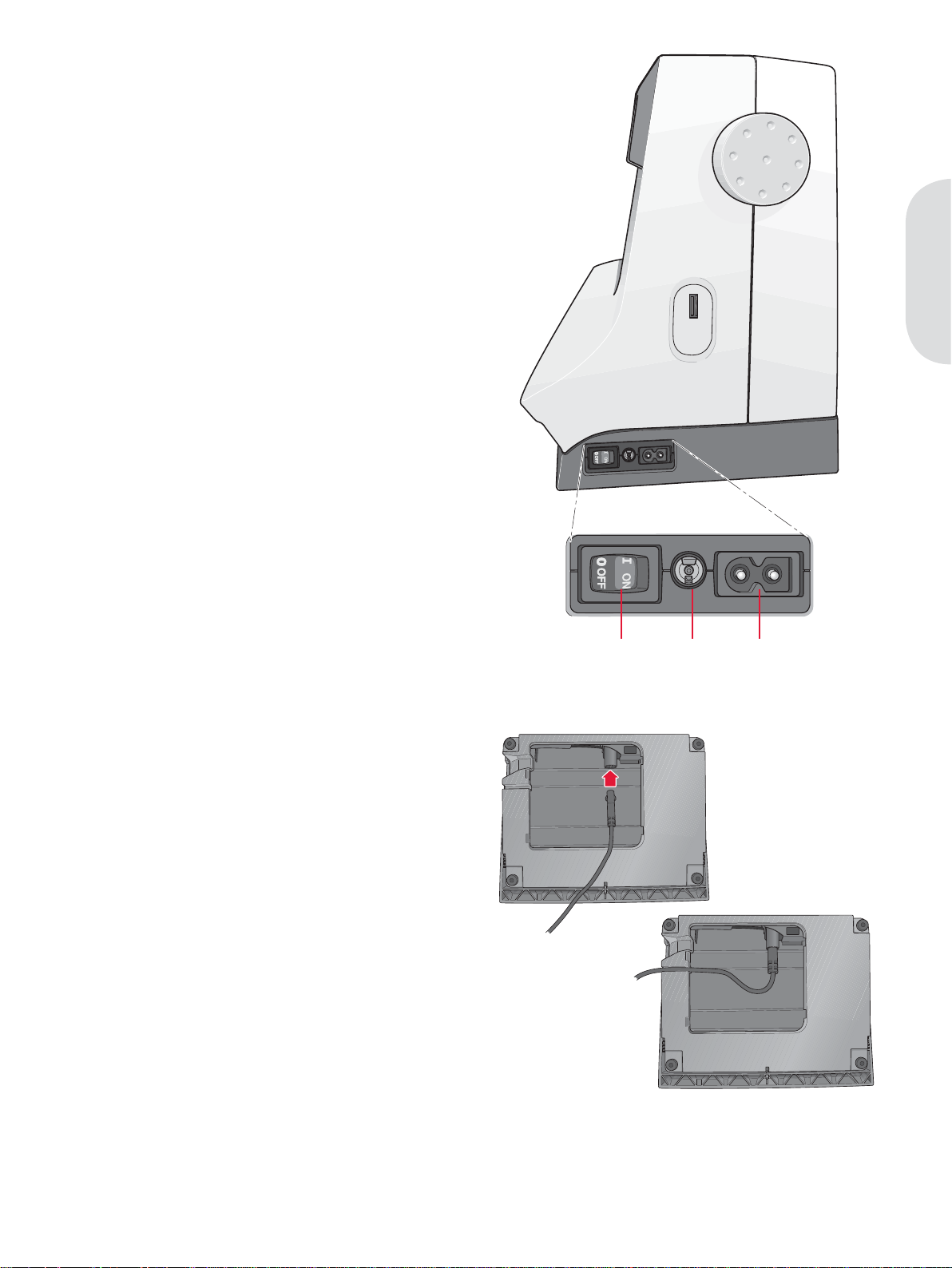

Connect to the power supply

Among the accessories you will À nd the power

cord and the foot control.

Note: Before plugging in the foot control, check to

ensure that it is type ”FR5” (see underside of foot

control).

1. Take out the foot control cord. Turn the foot

control over. Connect the cord to the socket

inside the space of the foot control. Push À rmly

to make sure it is properly connected. Lay the

cord in the slot on the underside of the foot

control.

Note: Connecting the foot control cord to the foot

control is only necessary the very À rst time you are

going to use the machine.

2. Connect the foot control cord to the front

socket on the bottom right side of the machine

(A).

4. Connect the power cord to the rear socket on

the bottom right side of the machine (B). Plug

the cord into the wall socket.

5. Press the ON/OFF switch to ON to turn on

power and light (C).

Preparations

ABC

For the USA and Canada

This sewing machine has a polarized plug (one

blade wider than the other). To reduce the risk

of electric shock, this plug is intended to À t in a

polarized outlet only one way. If the plug does not

À t fully in the outlet, reverse the plug. If it still does

not À t, contact a qualiÀ ed electrician to install the

proper outlet. Do not modify the plug in any way.

2:1

Page 14

Pack away after sewing

1. Switch the main switch off.

2. Unplug the cord from the wall socket and then

from the machine.

3. Unplug the foot control cord from the machine.

Wind the cord around the foot control for easy

storage.

4. Place all accessories in the accessory tray. Slide

the tray on to the machine around the free arm.

5. Place the foot control in the space above the

free arm.

6. Put on the hard cover.

Preparations

Free arm

To use the free arm, slide off the accessory tray.

When attached, a hook keeps the accessory tray

locked to the machine. Remove the tray by sliding

it to the left.

Thread cutter

To use the thread cutter, pull the thread from back

to front as shown (A).

A

Spool pins

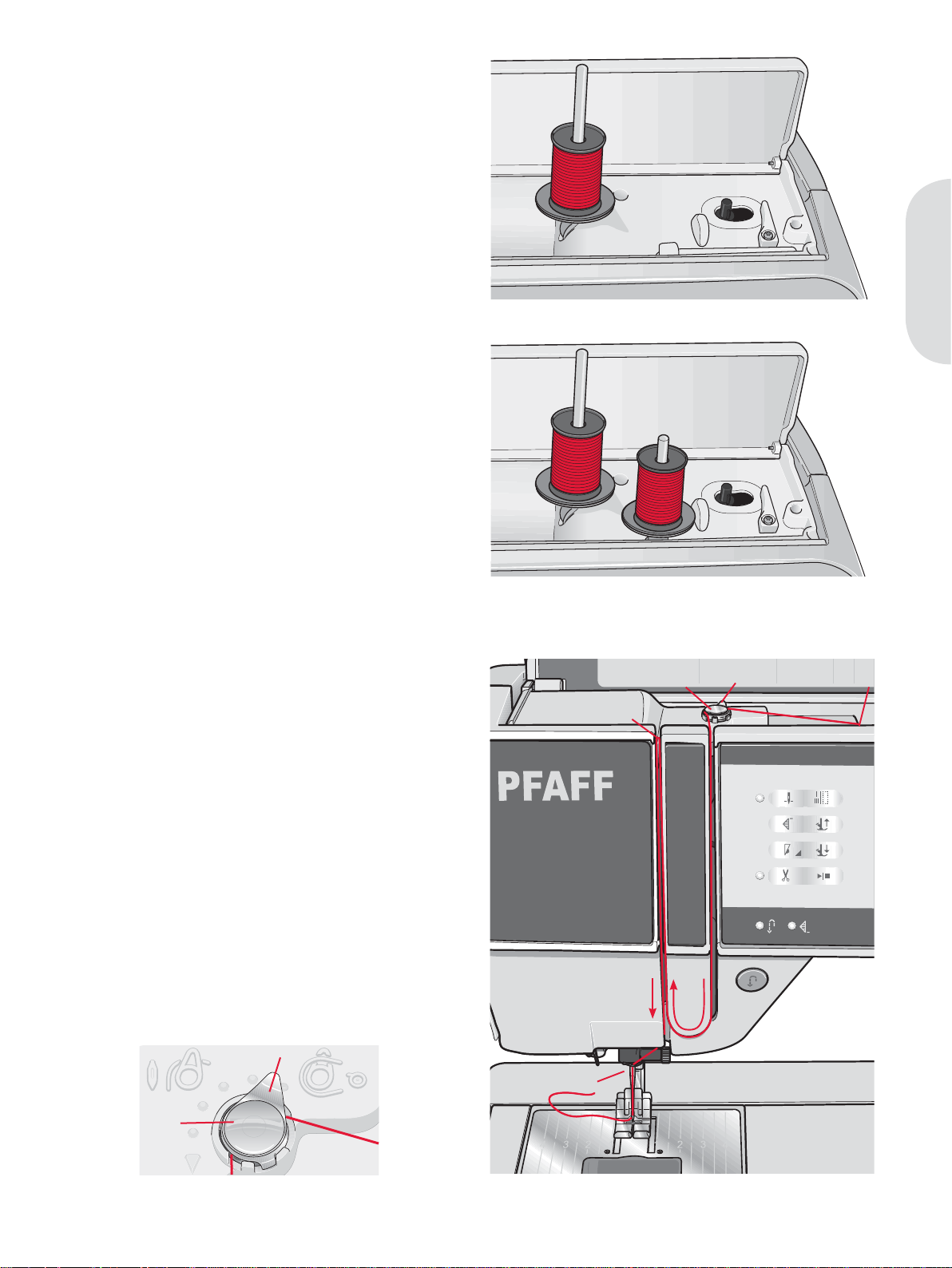

Your machine has two spool pins, a main spool

pin and an auxiliary spool pin. The spool pins

are designed for all types of thread. The main

spool pin is adjustable and can be used both in a

horizontal position (the thread reels off the spool)

and a vertical position (the thread spool rotates).

Use the horizontal position for normal threads and

the vertical position for large spools or specialty

threads.

Horizontal position

Place a spool cap and the thread spool on the spool

pin. Make sure that the thread reels over the top

and slide on a second spool cap.

Use a spool cap slightly larger than the thread

spool. For narrow thread spools, use a smaller

spool cap in front of the spool. For large thread

spools, use a larger spool cap in front of the spool.

The Á at side of the spool cap should be pressed

À rmly against the spool. There should be no space

between the spool cap and the thread spool.

Small spool cap

Large spool cap

2:2

Page 15

A

Vertical position

Raise the spool pin to the vertical position. Slide

on the large spool cap and place a felt pad under

the thread spool. This is to prevent the thread from

reeling off too fast.

Do not place a spool cap on top of the spool pin as

that would prevent the spool from rotating.

Auxiliary spool pin

The auxiliary spool pin is used when winding a

bobbin thread from a second spool of thread or for

a second spool when sewing with a twin needle.

Raise the auxiliary spool pin. Slide on a large spool

cap and place a felt pad under the thread spool.

Preparations

Main spool pin in vertical position

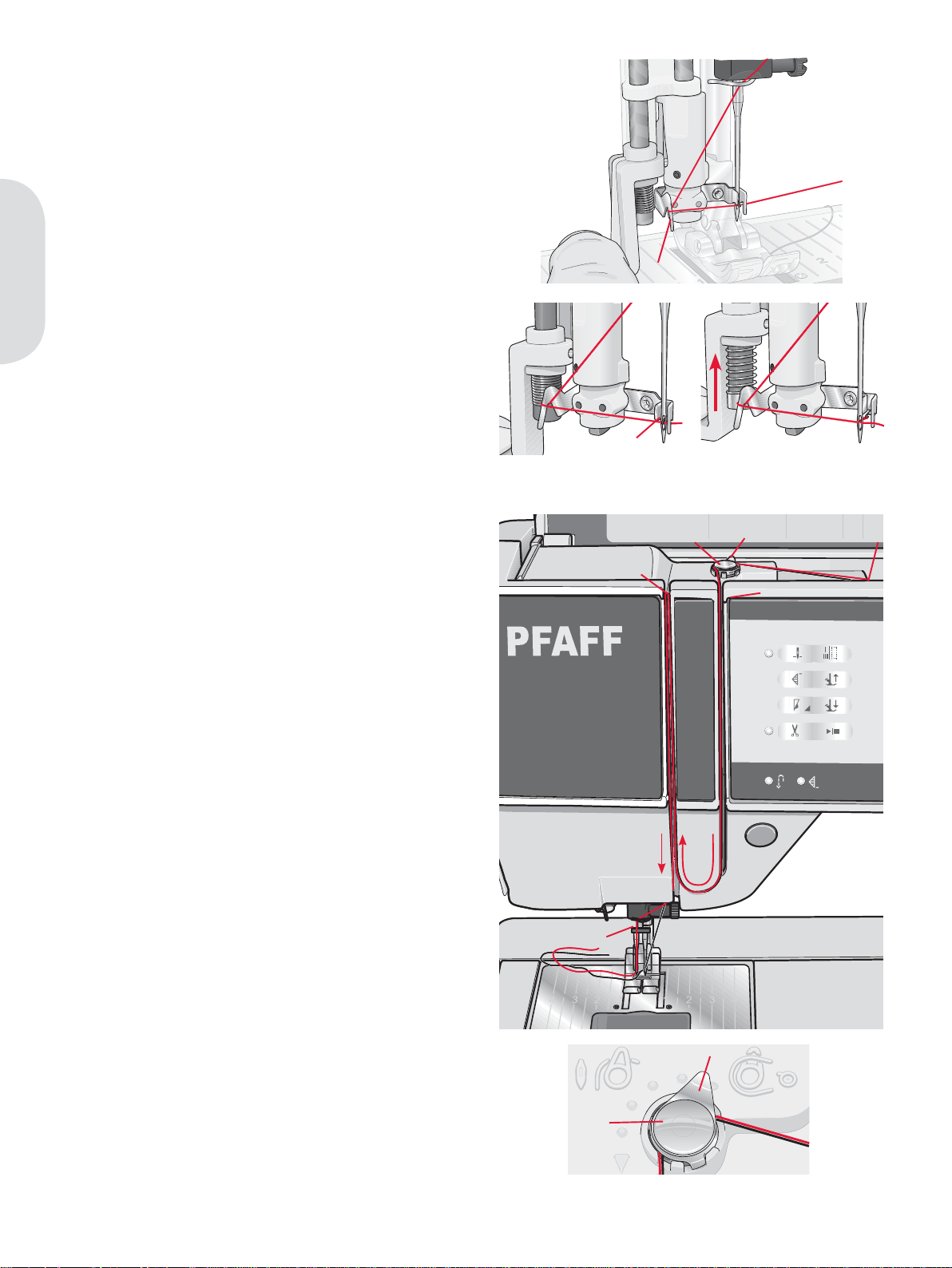

Threading the machine

Make sure that the presser foot is raised and the

needle is in the up position.

1. Place the thread on the spool pin and À t a spool

cap of the right size.

2. Pull the thread into the thread guide (A) from

the front to the back. Pull the thread from the

right underneath the bobbin winder thread

guide (B) on the pre-tension disc (C).

3. Thread down through the right-hand

threading slot and then upwards through the

left-hand threading slot.

4. Bring the thread from the right into the take-up

lever (D) and down in the left-hand threading

slot to the needle thread guide (E).

5. Thread the needle.

Auxiliary spool pin and main spool pin in vertical

position.

PF

D

B

AC

B

E

C

2:3

Page 16

A

Needle threader

The needle threader allows you to thread the

needle automatically. The needle must be in the up

position to use the built-in needle threader. We also

recommend lowering the presser foot.

1. Use the handle to pull the needle threader all

the way down. The threader hook (G) swivels

through the needle eye.

2. Place the thread from the back over the hook

(H) and under the thread hook (G).

3. Let the needle threader gently swing back. The

hook pulls the thread through the needle eye

Preparations

and forms a loop behind the needle. Pull the

thread loop out behind the needle.

Note: The needle threader is designed to be used for size

70-120 needles. You cannot use the needle threader for

size 60 needles or smaller, a wing needle, twin needle or

triple needle. There are also some optional accessories

that require manual threading of the needle.

When threading the needle manually, make sure that the

needle is threaded from front to back. The bobbin cover

can be used as a magnifying glass.

PF

H

G

B

AC

Threading for twin needle

Replace the sewing needle with a twin needle.

Make sure that the presser foot is raised and the

needle is in the up position.

1. Place the thread on the spool pin and À t a

spool cap of the right size. Raise the auxiliary

spool pin. Slide on a large spool cap and a felt

pad. Place the second thread on the spool pin.

2. Pull the threads into the thread guide (A) from

the front to the back. Pull both threads from

the right underneath the bobbin winder thread

guide (B) on the pre-tension disc (C).

3. Thread down through the right-hand

threading slot and then upwards through the

left-hand threading slot. Make sure that you

pass one thread to the left and one thread to

the right sides of the tension disk (D).

4. Bring the threads from the right into the

take-up lever (E) and down in the left-hand

threading slot. Make sure that one thread is

inside the needle thread guide (F) and the

other one outside. Make sure that the threads

do not become twisted together.

5. Thread the needles.

E

D

F

B

2:4

C

Page 17

C C

E

Preparations

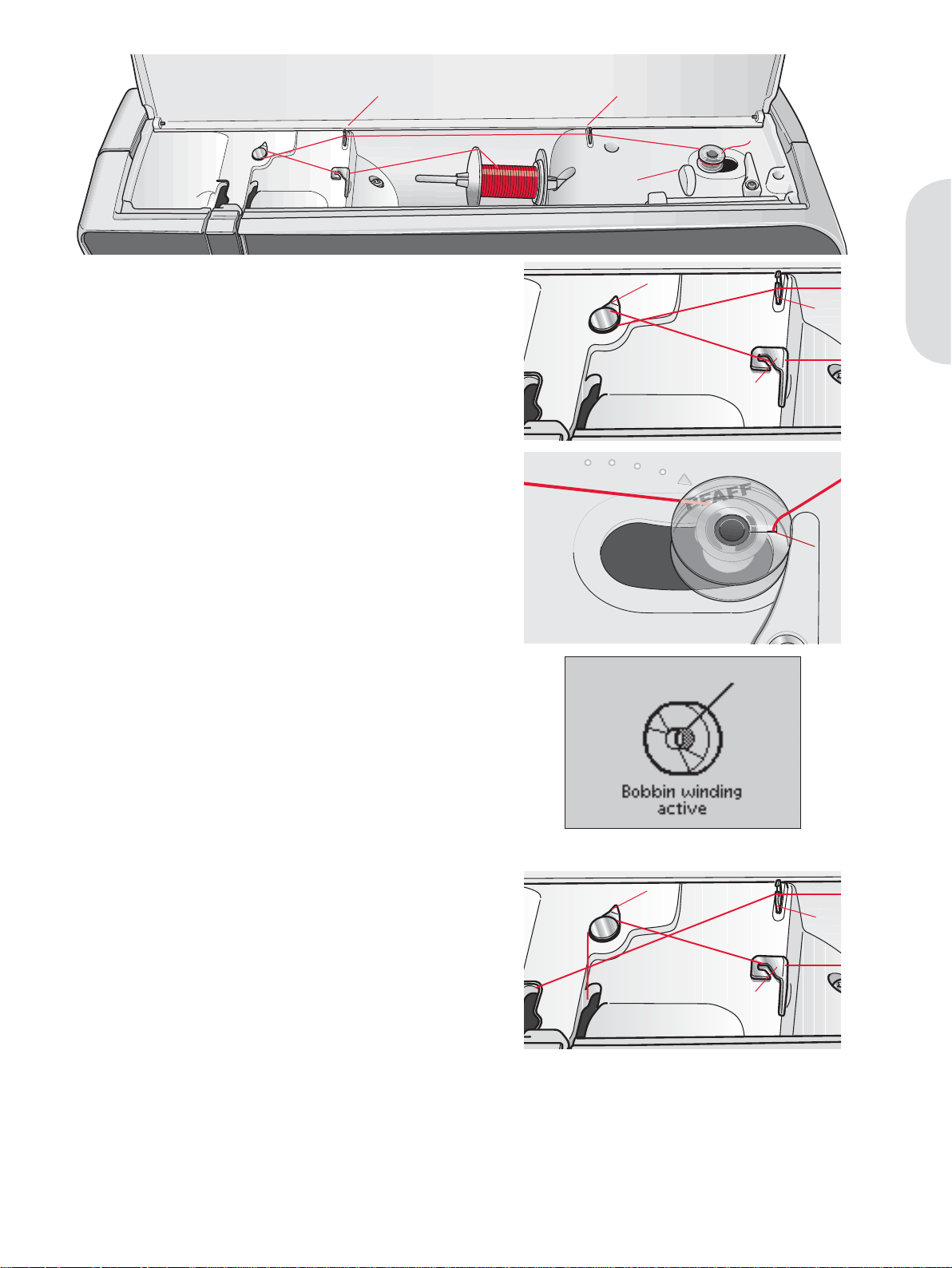

Bobbin winding

Winding from horizontal position

1. Place an empty bobbin on the bobbin spindle,

with the logo facing up. Use only the original

PFAFF® bobbins approved for this model.

2. Place the thread spool on the spool pin in

horizontal position. Slide a spool cap tightly

against the spool.

3. Place the thread into the thread guide (A) from

front to back. Pull the thread counter-clockwise

above the bobbin winder thread guide (B) and

then through the bobbin thread guides (C) at

the rear.

Note: Make sure the thread is pulled securely inside

the pre-tension device for correct thread tension.

4. Thread through the hole in the bobbin (D) from

the inside to the outside.

5. Push the bobbin lever to the right to wind. A

pop-up appears on the screen to inform you

that bobbin winding is active. Press the foot

control to start winding the bobbin.

When the bobbin is full, the bobbin winding

will slow down and stop automatically. The

pop-up closes. Remove the bobbin and cut the

thread using the bobbin thread cutter (E).

B

C

A

D

Winding through the needle

Make sure that the presser foot and the needle are

in the up position. Only wind through the needle if

using a metal presser foot.

Bring the thread up from the needle, under

the presser foot, upward through the left-hand

threading slot and through the bobbin thread

guides (C). Then follow step 4 and 5.

B

C

A

2:5

Page 18

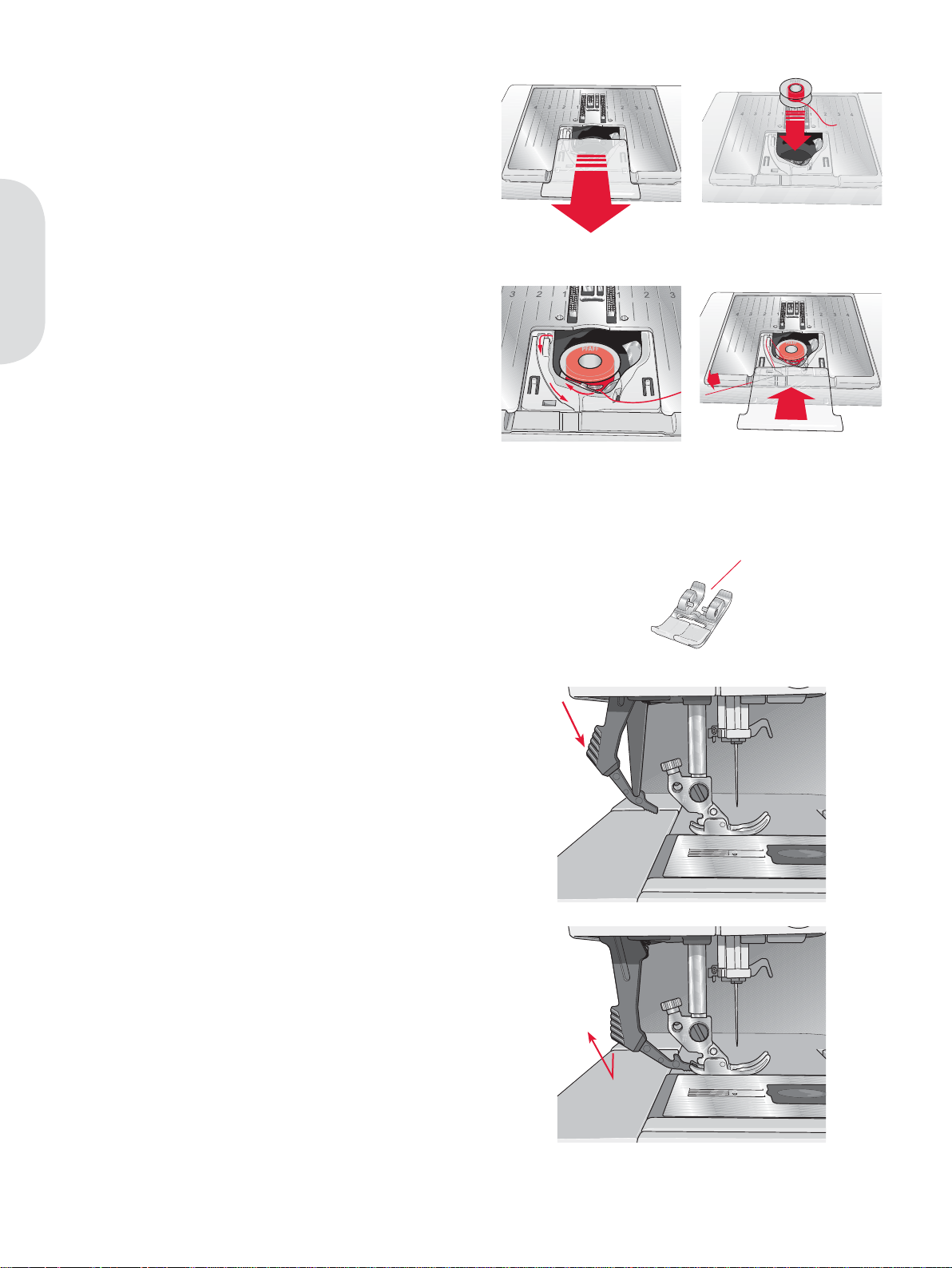

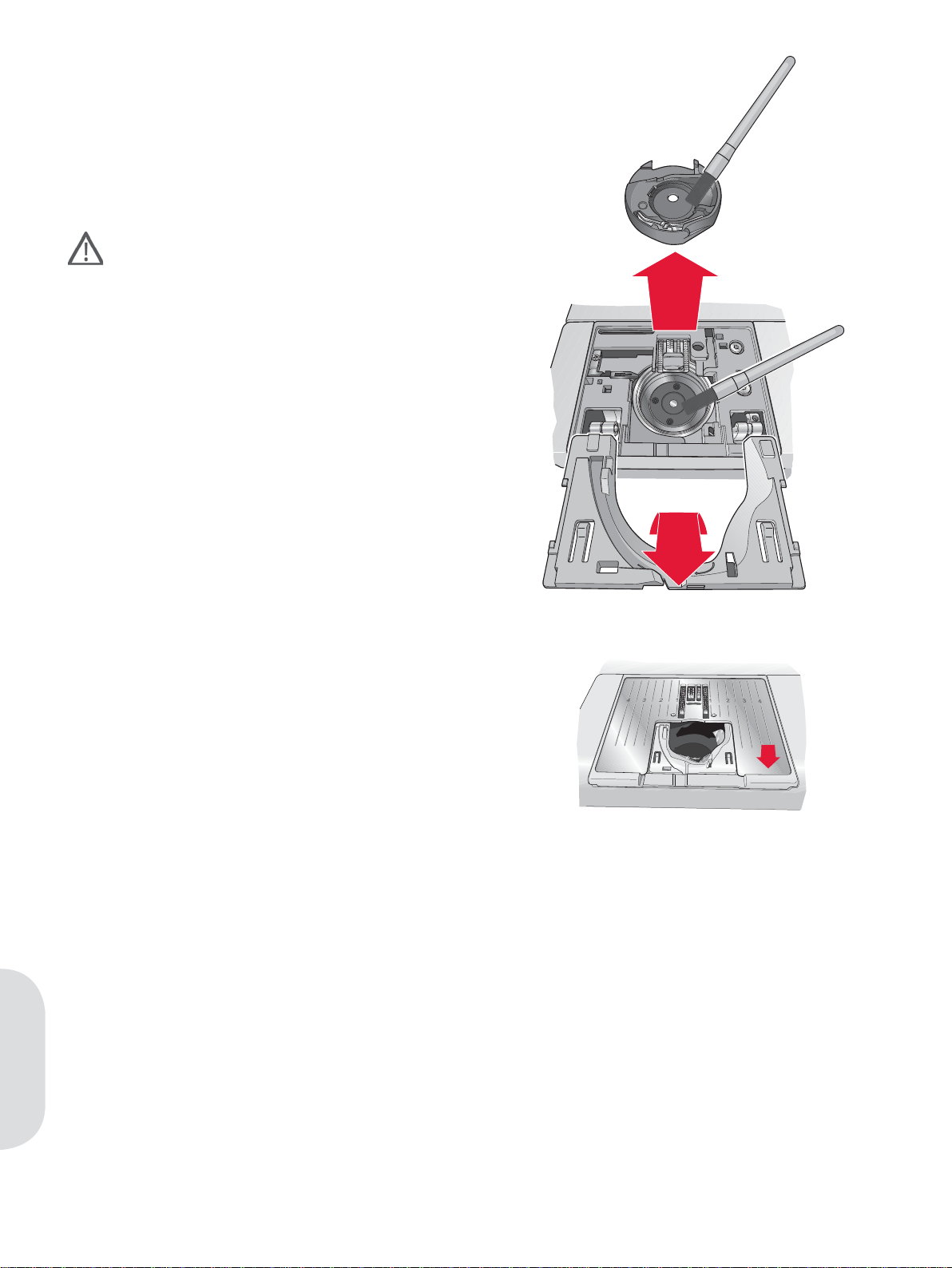

Inserting the bobbin

1. Remove the bobbin cover by sliding it towards

you.

2. Place the bobbin in the bobbin case with the

logo facing up and the thread unreeling from

the left of the bobbin. The bobbin will then

rotate counter-clockwise when you pull out

the thread.

3. Place your À nger on the bobbin to keep it from

turning as you pull the thread À rmly to the

right and then to the left into the tension spring

(A) until it “clicks” into place.

Preparations

4. Continue threading around (B) and to the right

of the thread cutter (C). Replace the cover. Pull

the thread to the left to cut.

IDT (integrated dual feed)

For sewing any fabric precisely, PFAFF® creative™

2.0 sewing and embroidery machine provides

the ideal solution: the integrated dual feed, IDT

system. As on industrial machines, the IDT feeds

the fabric from the top and bottom at the same

time. The material is fed precisely. On light fabrics

such as silk or rayon the dual feed prevents

puckering of the seam. The even feeding action

also ensures perfect matching of checked and

striped fabrics. The IDT keeps all layers of quilt

projects aligned to prevent shifting of the top

layers.

1

B

A

C

2

43

D

Engaging the IDT

Important: For all work with the IDT, use presser feet

with the center back cut-out (D).

Raise the presser foot. Press the IDT down until it

engages.

Disengaging the IDT

Raise the presser foot. Hold the IDT with two

À ngers at the ribbed ankle. Pull the IDT down, then

pull it away from you to release the IDT slowly

upward.

2:6

Page 19

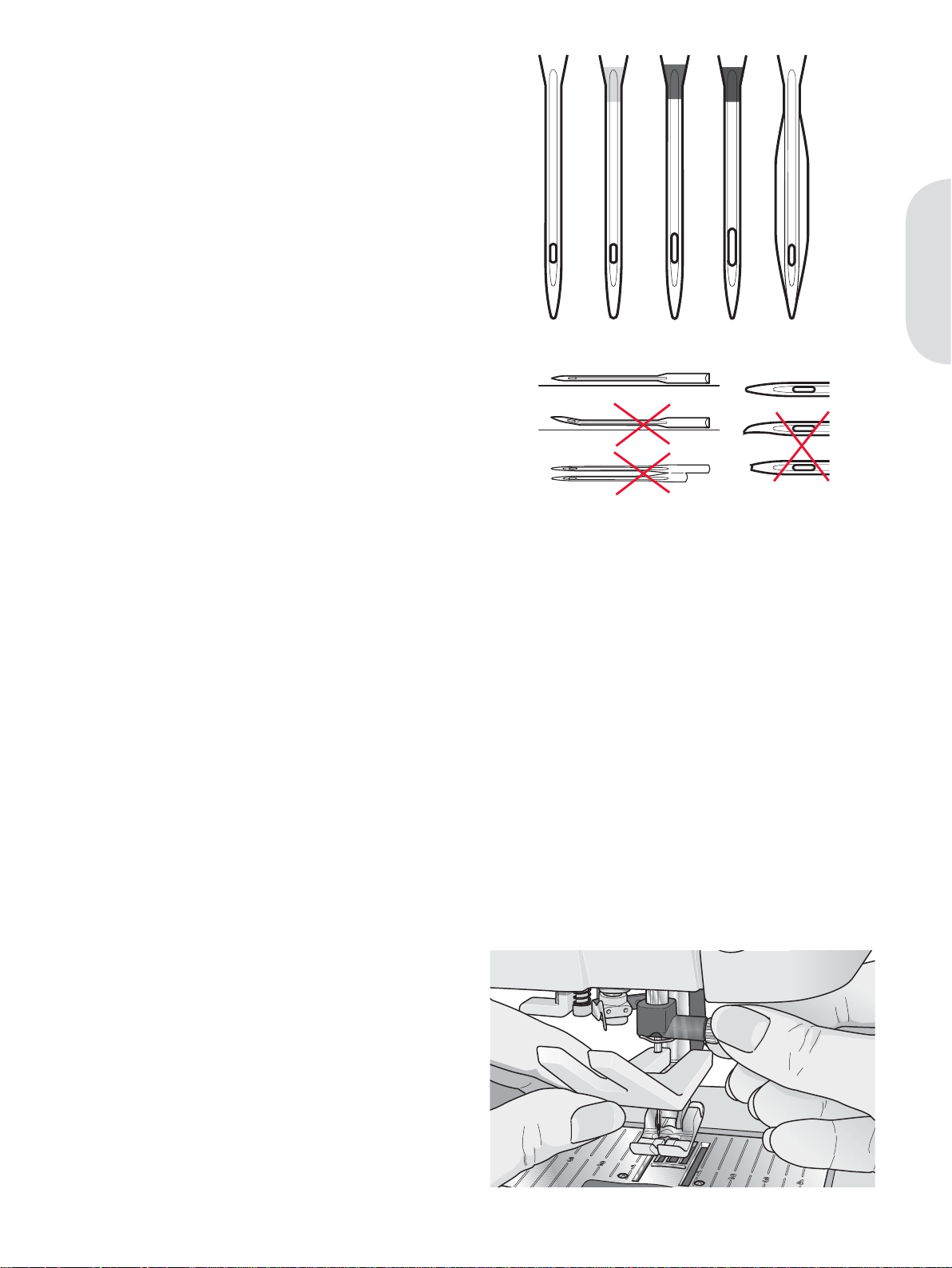

Needles

The sewing machine needle plays an important

role in successful sewing. Use only quality needles.

We recommend needles of system 130/705H.

The needle package included with your machine

contains needles of the most frequently used sizes.

Universal needle (A)

Universal needles have a slightly rounded point

and come in a variety of sizes. For general sewing

in a variety of fabric types and weights.

Stretch needle (B)

Stretch needles have a special scarf to eliminate

skipped stitches when there is a Á ex in the fabric.

For knits, swimwear, Á eece, synthetic suedes and

leathers.

Embroidery needle (C)

Embroidery needles have a special scarf, a slightly

rounded point and a slightly larger eye to avoid

damage to thread and materials. Use with metallic

and other specailty threads for embroidery and

decorative sewing

Denim needle (D)

Denim needles have a sharp point to penetrate

tightly woven fabrics without deÁ ecting the needle.

For canvas, denim, microÀ bers.

Wing needles (E)

The Wing needle has wide wings on the side of

the needle to poke holes in the fabric when sewing

entredeux and other hemstitches on natural À ber

fabrics.

Preparations

ABCDE

F

G

H

Note: Change the needle often. Always use a straight

needle with a sharp point (F).

A damaged needle (G) can cause skipped stitches,

breakage or snapping of the thread. A damaged needle

can also damage the stitch plate.

Do not use asymmetrical twin needles (H), since it may

damage your sewing machine.

Changing the needle

1. Use the hole in the multi-purpose tool to hold

the needle.

2. Loosen the needle screw. Use the screw driver

if necessary.

3. Remove the needle.

4. Insert the new needle, using the multi-purpose

tool. Push the new needle upwards with the

Á at side away from you until it will go no

further.

5. Tighten the needle screw as tight as it will go.

2:7

Page 20

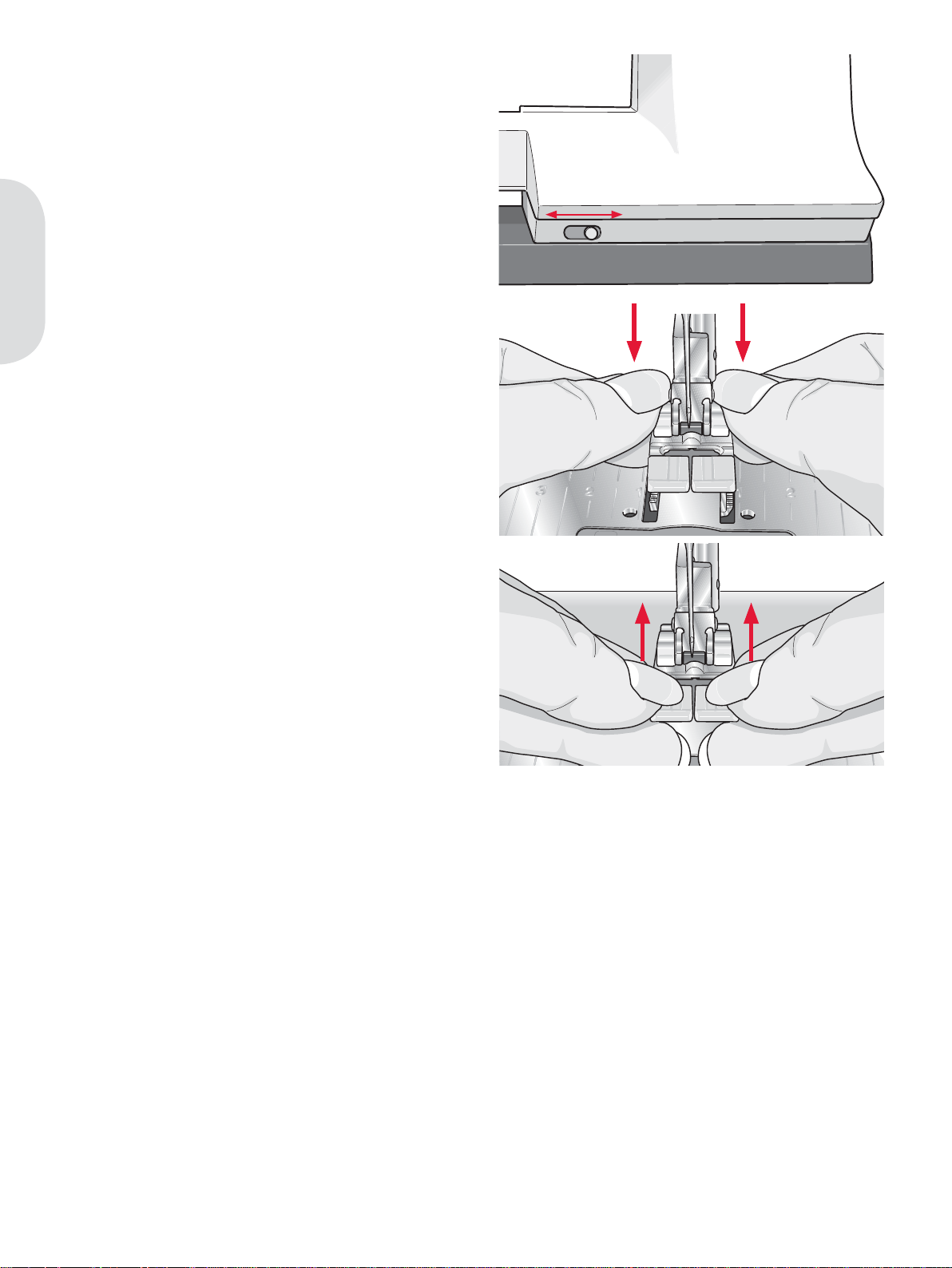

Lowering feed dogs

You can lower the feed dogs by moving the switch

on the front of the sewing machine to the left.

Move the switch to the right if you wish to raise the

feed dogs.

Preparations

Changing the presser foot

Remove presser foot

Press the presser foot downwards until it

disengages from the presser foot holder.

Attach presser foot

Place the presser foot under the presser foot holder,

so that when the presser foot is lowered, the pins of

the foot engage in the presser foot holder.

Note: Check that the presser foot is properly attached by

raising the presser foot lifter.

2:8

Page 21

USB port

Your machine has a USB port to connect your USB

embroidery stick.

USB embroidery stick

Delivered with your machine is a USB embroidery

stick. Use the stick to store designs and embroidery

fonts.

Connect to and remove from USB port

Insert the USB embroidery stick in the port. The

USB plug can only be inserted one way – do not

force it into the port!

To remove, carefully pull the USB embroidery stick

out straight.

Using the USB embroidery stick

A light at the end of the stick indicates that the USB

embroidery stick is plugged in correctly. When

loading from the USB embroidery stick, the light

Á ashes.

Note: Do not remove the USB embroidery stick while

the light is Á ashing, as this can damage the À les on your

USB embroidery stick.

creative 2.0

Preparations

Note: The USB embroidery stick provided

with the machine can be left in the machine

when putting on the hard cover. Make sure

that the cover of the USB stick is turned

downwards.

2:9

Page 22

5D™ Embroidery Software

5D™ QuickFont

Create font À les (.vf3) for your PFAFF® creative™

2.0 embroidery machine from most TrueType® or

OpenType® fonts on your computer.

5D™ Organizer

Find your designs and pictures easily. Browse

them in different sizes and print selected groups

as full worksheets of thumbnail catalogs. Convert

your designs between major embroidery formats,

to pictures or desktop wallpaper for your

Preparations

computer.

Installing your software

If you own other PFAFF® 5D™ Embroidery

System software, you may need to install the 5D™

Embroidery System 9.2 (or higher version) Update

instead of installing the Embroidery Machine

Communication Software. Then add the PFAFF®

creative™ 2.0 from the Machine Manager in 5D™

ConÀ gure, as described in Step 4.

1. Ensure you are logged onto the computer with

a user name that is an administrator on the

computer, then install your software from the

CD provided (attached inside the back cover of

this User’s Guide).

2. Insert your CD. In Windows® 7/Vista, an

AutoPlay message may appear, asking what

you wish to do with the CD. Click the option to

Run Menu.exe. Select your desired language,

and select the ’Install Embroidery Machine

Communication Software’ option from the

menu.

3. Follow the instructions in the Installation

Wizard. When asked to enter your Installation

Code, enter the following number: 8200.

4. In the 5D™ ConÀ gure Wizard under

MyMachines select your machine type:

PFAFF® creative™ 2.0. Under Send 1 or Send 2

select PFAFF® creative™ 2.0, USB Embroidery

Stick.

Note: You can À nd more detailed information about the

installation in the 5D™ Embroidery System Getting

Started Guide, in the folder ’UserGuides’ on the CD.

Your installation CD includes an option to Install

Drivers. However, this is not required for the PFAFF®

creative™ 2.0 embroidery machine.

Register your 5D™ software

After À nishing the software installation, you

can select to register your software by clicking

on Register in the menu. Create an account and

enter your details to receive customized 5D™

newsletters.

Important!

During the registration process you will be given

an option to enter which sewing and embroidery

machine(s) you own. This is NOT a product or

warranty registration. The machine information

entered here is only used to customize 5D™

Software newsletters. For product and warranty

registration, go to the PFAFF® web site at

www.pfaff.com.

To register later, select the Register button in 5D™

ConÀ gure at any time.

How to launch the programs

Shortcuts on the desktop

1. Double-click on the shortcut to the 5D™

Embroidery System program folder. A list of

the programs appears.

2. Double-click on 5D™ Organizer, 5D™

QuickFont or 5D™ ConÀ gure to launch it.

Alternatively use the Start Menu to open modules

under Start, All Programs, 5D™ Embroidery

System.

2:10

Page 23

Viewing and printing PDF Guides

To À nd all the Reference and Sample Guides for

your 5D™ Embroidery System software, go to

Start, All Programs, 5D™ Embroidery System

then choose Reference Guides or Sample Guides.

Choose the relevant folder, then select the desired

PDF Guide. Double-click on the desired name to

launch the relevant .pdf À le if you have Adobe

Acrobat installed on your computer. To install

the Acrobat Reader, insert the 5D™ Embroidery

System CD and select that option from the menu

that appears.

How to update your machine

Be sure to consult the web site at www.pfaff.com

and/or your local authorized PFAFF® dealer

for updates and upgrades for your machine and

Owner’s manual.

Updating instructions

• Go to the PFAFF® web site at www.pfaff.com

and À nd your sewing machine. Here you will

À nd updates available for your machine.

• Download the update software to your USB

embroidery stick, following the instructions on

the web site.

• Make sure that your machine is turned off.

Connect the USB embroidery stick loaded with

the new software version to the USB port on

your machine.

• While pressing and holding the needle up/

down button and the reverse button, turn your

machine on.

• The new software version will install

automatically. When the reverse indicator

starts Á ashing, release the buttons.

• The update procedure can take several

minutes. The graphic display will be blank

while the three indicators are Á ashing in

different combinations.

• When the update is completed the machine

will restart automatically. Check the software

version number in the settings menu.

Note: If the update is not completed successfully the

three indicators will Á ash simultaneously. Turn the

machine off and start the update from the beginning.

If the problem remains contact your authorized

PFAFF® dealer.

Preparations

2:11

Page 24

Preparations

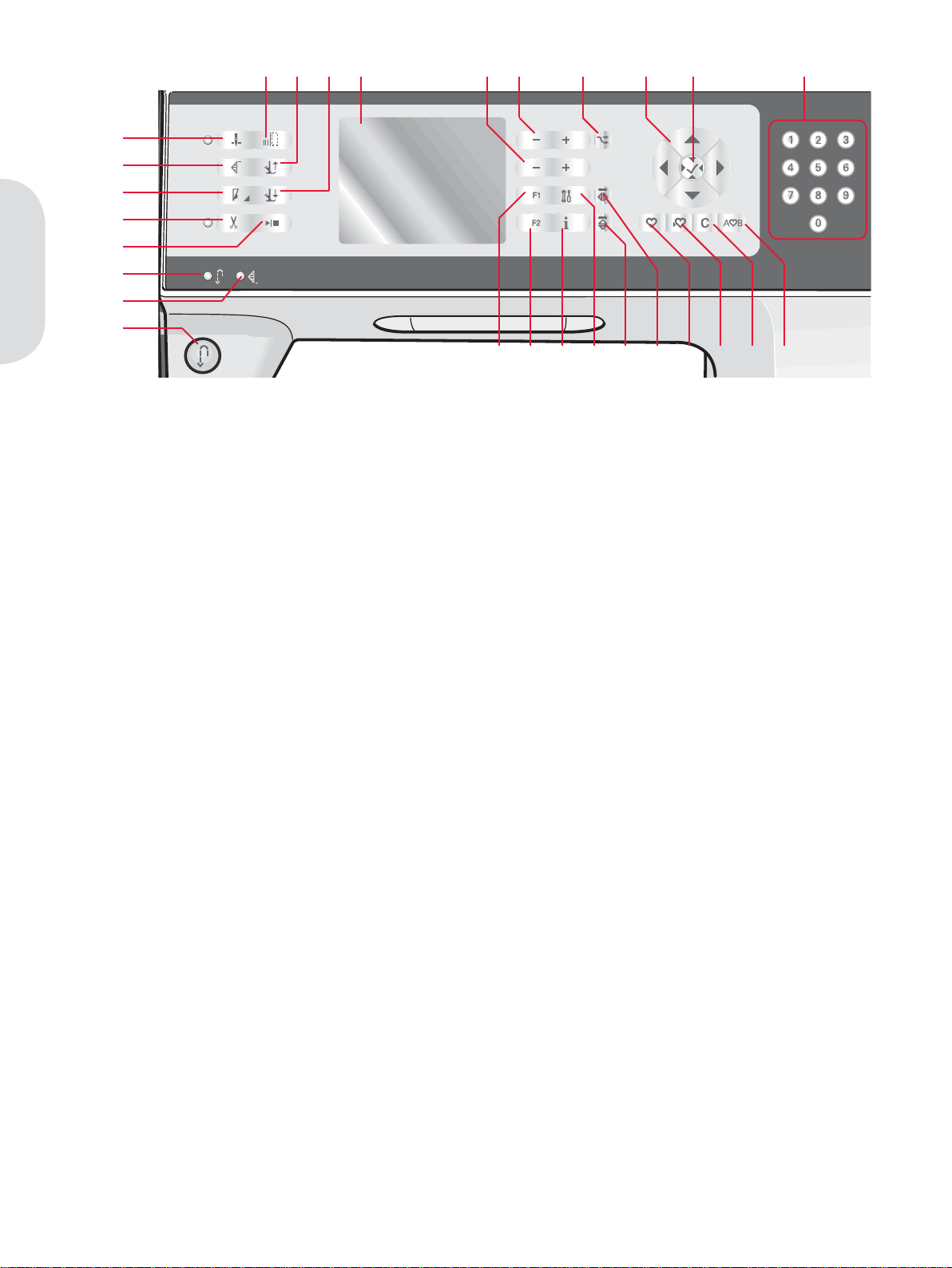

Buttons

10 11 12 14 13 15 16 17 18

1

2

3

4

5

6

7

8

19 20 21 22 23 24 25926 27 28

Needle up/down with indicator (1)

Press this button to move the needle up or down.

The set ting of the needle stop po si tion is changed

at the same time. When needle down is activated,

the indicator is lit, the needle will stop in the down

position and the presser foot will raise to pivot

height.

You can also tap the foot control to raise or lower

the needle.

Stitch restart (2)

When having stopped sewing in the middle of

a stitch, press stitch restart to start sewing at the

beginning of the stitch again without having to

reset any special settings you have made.

If pressing the stitch restart button while sewing,

the stitch will be À nished and the machine will

then stop.

Speed control (3)

Press the speed button to sew at a slower speed.

An icon on the graphic display will indicate how

slow your machine will sew. Long press the speed

button and use the wheel (16) to change the sewing

speed.

Note: You cannot select a higher speed than the default

speed.

Thread snips with indicator (4)

Press the button when you are not sewing and

your sewing machine cuts the top and bobbin

threads and raises the presser foot and the needle.

To cut before the needle moves to the start position

of the next stitch, press the thread snips button

while sewing. The thread snips indicator will be lit.

Start/stop (5)

Press this button to start or stop the machine

without using the foot control. Press the button

once to start and press it again to stop.

Reverse (8) with indicator (6)

For permanent reverse, press the button

before starting to sew. The reverse indicator (6)

will be lit and the machine sews in reverse until

you press the button again to cancel.

If you press the reverse button while sewing, the

machine sews in reverse for as long as you keep the

button pressed. The reverse indicator is lit when

the reverse button is pressed.

Reverse is also used when sewing buttonholes,

programmed tie-off end, darning stitches and

tapering stitches to step between the parts of the

stitch.

Programmed tie-off indicator (7)

The programmed tie-off indicator is lit to indicate

that one or several tie-off options are activated. The

indicator stays lit until the tie-off options are no

longer in use.

Immediate tie-off (9)

Press the tie-off button while sewing and your

machine sews a few tie-off stitches and stops

automatically.

Presser foot up and extra lift toggle (10)

Raises the presser foot and needle to the up

position. Press the button once more and the

presser foot will raise to extra lift.

2:12

Page 25

Presser foot down and pivot toggle (11)

Lower the presser foot completely. Press the button

once more to raise the presser foot to pivot height.

The presser foot is lowered automatically when

you start sewing.

Graphic display (12)

The graphic display lets you view all your

selections and options. Stitches are shown in real

size.

Stitch width or stitch positioning (13)

Increase or decrease the stitch width using the +

and - buttons.

Press the alternatives button (15) to view the stitch

positioning for the selected stitch. Use the + and buttons to change the stitch position.

Stitch length or stitch density (14)

Increase or decrease the stitch length using the +

and - buttons.

Press the alternatives button (15) to view the

density setting for satin stitches. Use the + and

- buttons to change the density for the selected

stitch.

Direct selection (18)

By pressing one of, or a combination of, the 0 to 9

buttons, you select the stitch represented by that

number immediately.

F1 - Function 1 (19)

The F1 button is used to set the tapering program.

It is also used to deactivate repeat for darning

stitches. In sequencing the F1 button is used to

select a character set.

In embroidery mode it is used to check the position

of the design and to rotate the design.

All selections will be shown on the graphic display.

F2 - Function 2 (20)

The F2 button is used to set the tie-off and thread

snips options as well as to deactivate repeat for

buttonholes. In sequencing it is used to select font.

In embroidery mode it is used to select hoop

options and to select monochrome embroidering.

All selections will be shown on the graphic display.

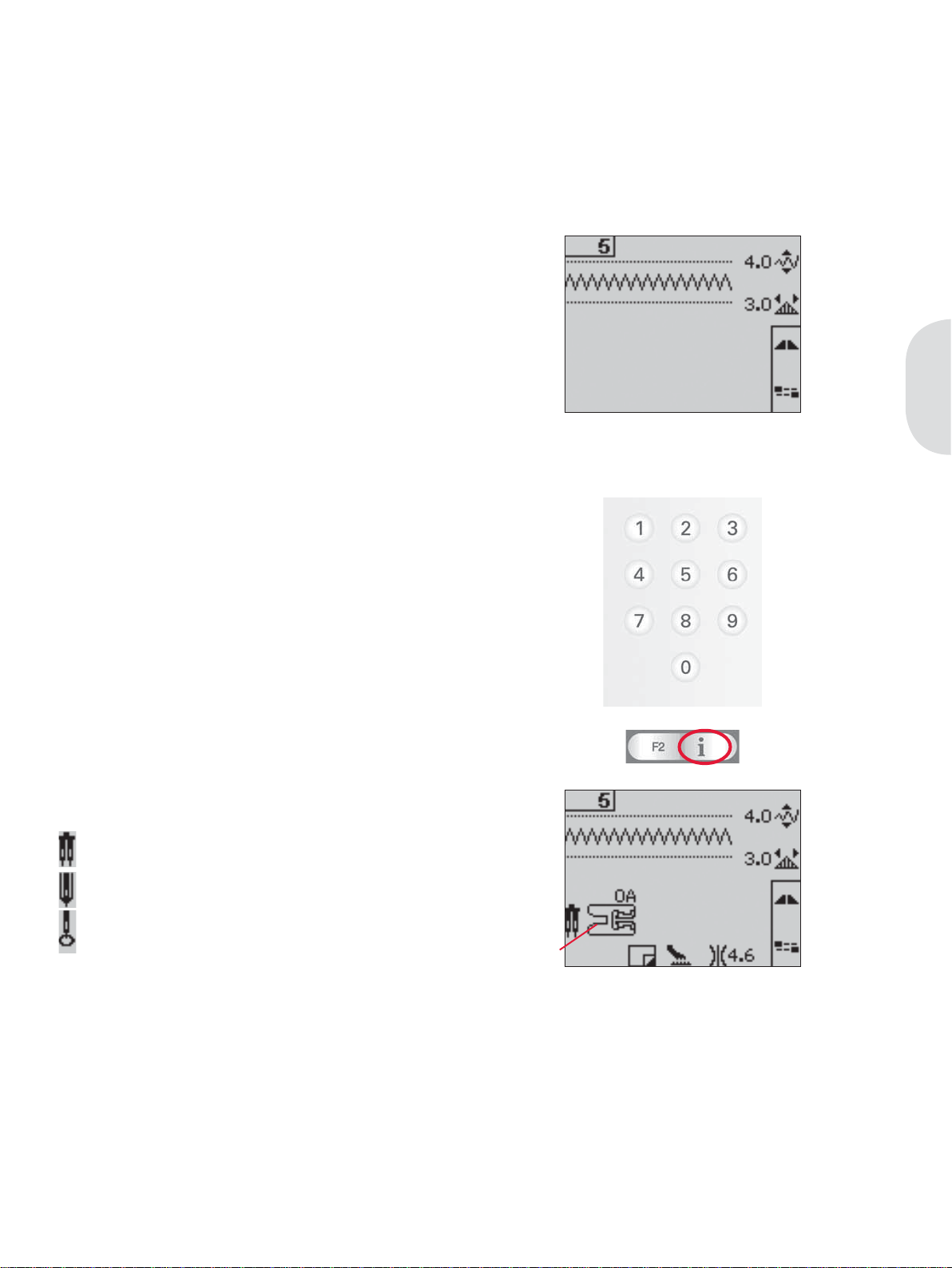

Info button (21)

Press this button to toggle the recommendations

view on and off.

Preparations

Alternatives (15)

When you select a decorative stitch, the width

and length settings will be shown on the graphic

display. By pressing the alternatives button, the

stitch positioning will be shown instead of the

stitch width setting and the density will be shown

instead of the length setting.

In embroidery mode, this button is used to switch

between embroidery edit and embroidery stitchout.

Wheel (16)

Use these buttons to move around the graphic

display. The wheel has up and down arrow

buttons, left and right arrow buttons and the wheel

center icon is a checkmark for OK (17).

The wheel has several functions, for example

stepping between stitches, setting the size of a

buttonhole and moving between options in the

settings menu. In embroidery mode use the wheel

to move the design in the hoop.

OK button (17)

The wheel center icon is a checkmark for OK.

Use the OK button to conÀ rm your selections. In

embroidery mode you can center the design in the

hoop with the OK button.

Settings menu (22)

Press this button to open the menu for machine

settings.

Mirror end to end (23)

For mirroring stitches and sequences end to end.

Mirror side to side (24)

For mirroring stitches and sequences side to side.

Load personal stitch or sequence (25)

Press this button to load a personal stitch or

sequence.

Save personal stitch or sequence (26)

Press this button to save a stitch or sequence to the

machine’s memory.

Clear (27)

For deleting single stitches in a sequence, or

personal stitches and sequences.

Sequencing/Embroidery text editor (28)

Press this button to enter sequencing.

In embroidery mode, press this button to open the

embroidery text editor.

2:13

Page 26

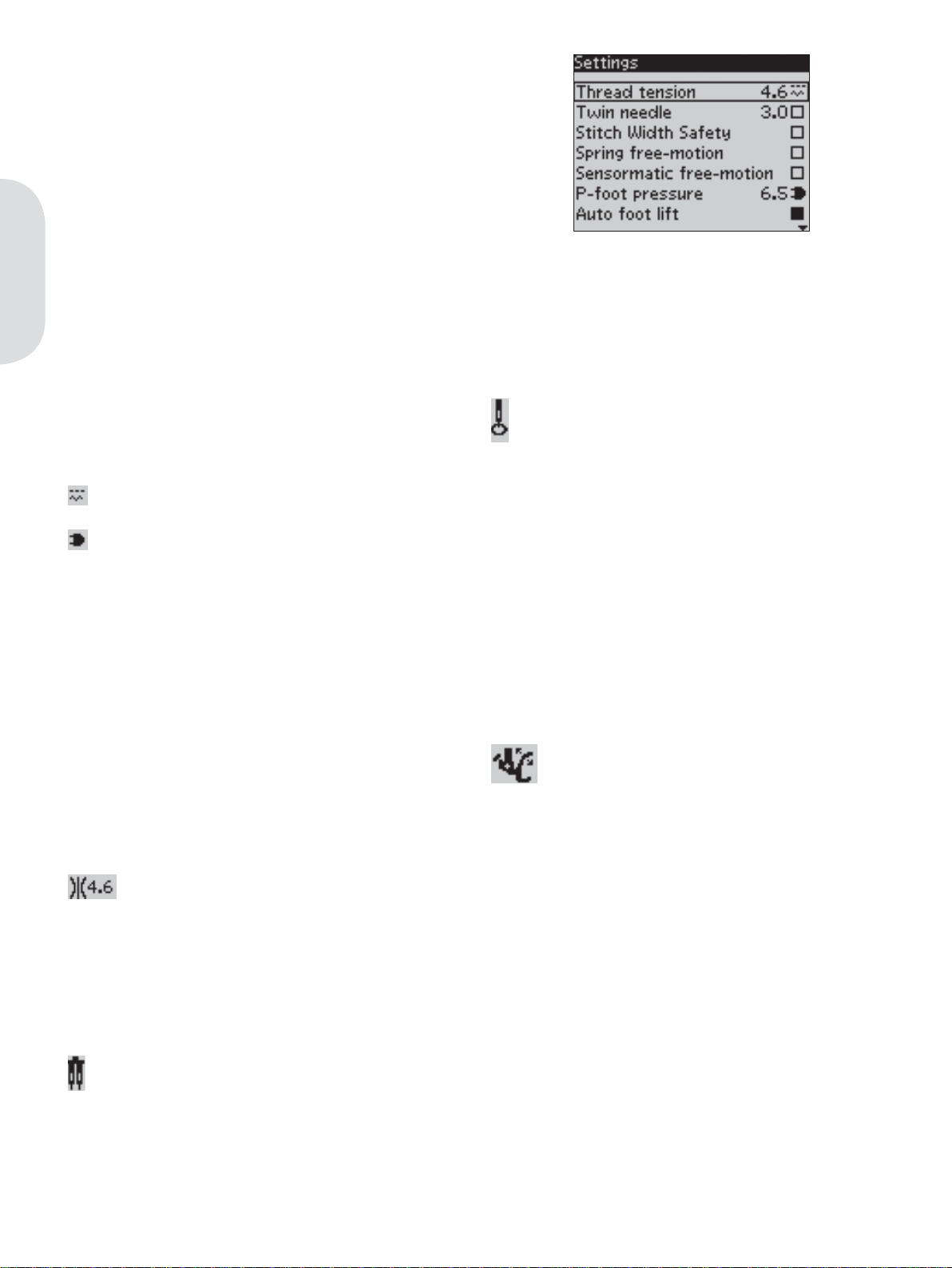

Settings menu

In the settings menu, you can override default

settings and make manual adjustments to the

machine settings, sound settings and screen

settings.

Open the menu by pressing the settings menu

button and select the setting you wish to adjust by

pressing the up and down arrow buttons on the

wheel.

Use the left and right arrow buttons to adjust

the values and activate settings or open a list of

choices by pressing OK. A À lled box means it is

Preparations

activated, an empty box means it is not activated.

Note: If a setting cannot be combined with a previously

selected setting, the outlines of that box will be dashed.

Different settings are available depending on whether

you are in sewing or embroidery mode.

There are two icons which are shown next to some

of the setting alternatives.

This icon shows you that the setting will be

kept until you select another stitch.

This icon shows you that the setting will be

kept until you switch your machine off.

No icon means that this setting is kept until you

deactivate it.

Press the settings menu button again to leave the

settings menu.

Thread tension

Your sewing machine will electronically pre-set a

thread tension for the selected stitch. Depending

on the fabric, batting, thread etc, the tension may

need to be adjusted. Use the left and right arrow

buttons on the wheel to adjust the thread tension.

The changes only affect the selected stitch. The

setting will go back to default when you select

another stitch.

In sewing mode, press the info button to

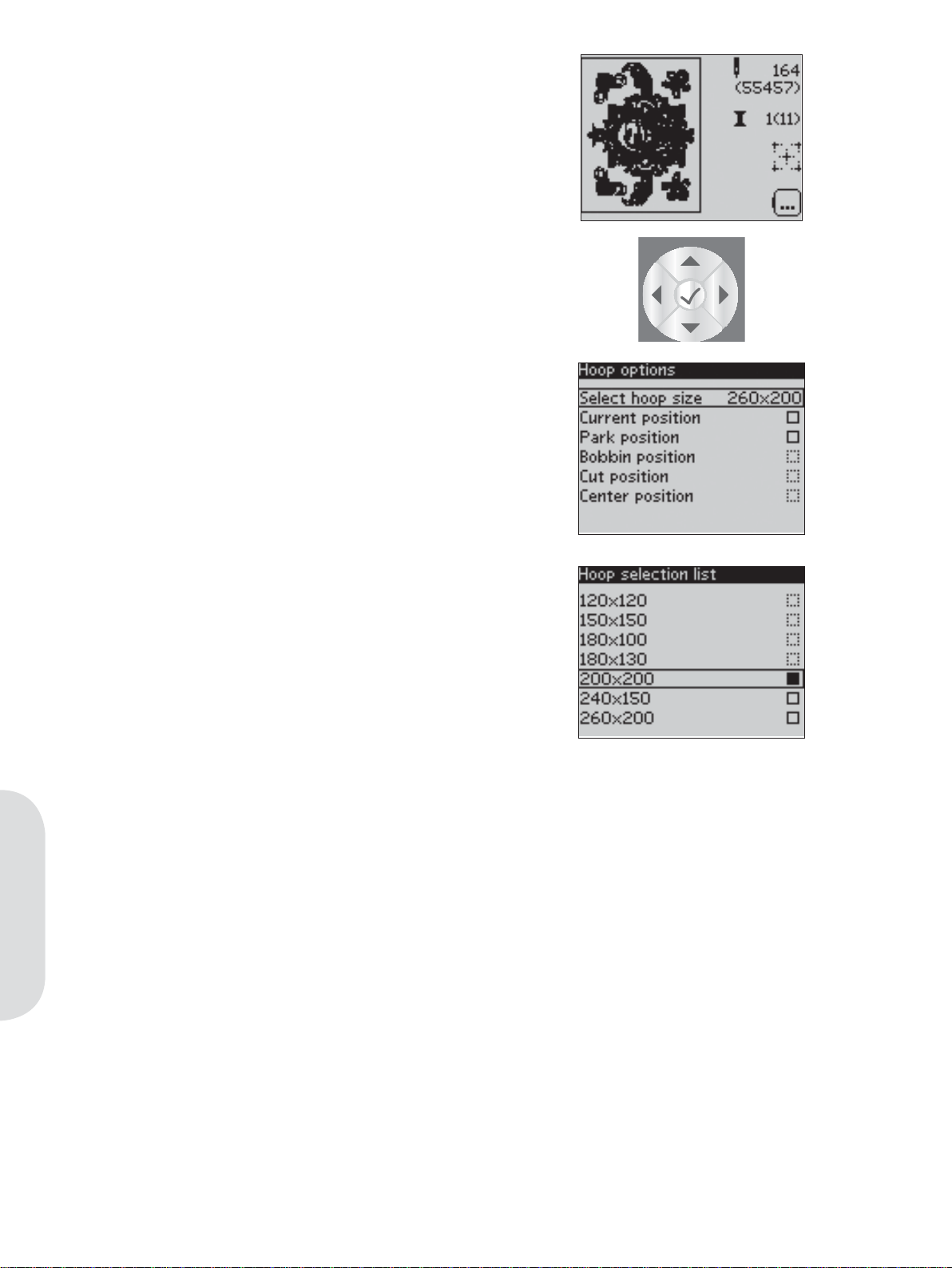

see the current selected thread tension.

Twin needle

Activate the twin needle program and use the left

and right arrow buttons on the wheel to set the

twin needle width. When a twin needle size is

selected, the width of all stitches is limited for that

needle size to prevent needle breakage.

In sewing mode, press the info button. The twin

needle recommendation icon will be shown.

The setting is kept until you deactivate it.

Note: Twin needle and stitch width safety cannot be

used at the same time.

A warning pop-up will be shown if you select a stitch

that is too wide for the set twin needle size.

Stitch width safety

Select this function when using a straight stitch

needle plate or a straight stitch presser foot to lock

the center needle position for all stitches to prevent

damage to the needle, presser foot or stitch plate.

In sewing mode, press the info button. The

stitch width safety icon will be shown.

The setting is kept until you deactivate it.

Note: When turning on the machine with this setting

activated and for every stitch selection that is not a

straight stitch, a pop-up informs you that it is set to

straight stitch.

Twin needle and stitch width safety cannot be used at

the same time.

Spring foot free-motion

Activate to set the machine in spring foot freemotion mode. Lower the feed dogs. A spring foot

will raise and lower with each stitch to hold the

fabric on the stitch plate while the stitch is being

formed.

In sewing mode, press the info button. The

spring foot free-motion icon will be shown

instead of the presser foot recommendation.

The setting is kept until you deactivate it. A popup will inform you that spring foot free-motion is

active when turning on the machine.

Note: Free-motion feet are optional and can be purchased

at your local authorized PFAFF® dealer. Do not use if

sensormatic free-motion is activated, since the needle

might damage the presser foot.

Any spring foot with light grey plastic housing, can also

be used for free-motion embroidery.

2:14

Page 27

Sensormatic free-motion

Activate to set the machine in sensormatic freemotion mode for presser foot 6A. Lower the feed

dogs.

In sewing mode, press the info button. The

sensormatic free-motion icon will be shown

instead of the presser foot recommendation.

The fabric must be moved manually. When sewing

in free-motion at low speed the presser foot will

raise and lower with each stitch to hold the fabric

on the stitch plate while the stitch is being formed.

At higher speed, the presser foot Á oats over the

fabric while sewing.

When turning on the machine, a pop-up informs

you that the sensormatic free-motion is active.

Presser foot pressure (only for sewing)

In most cases, you do not need to adjust the presser

foot pressure. To improve the result when using

specialty techniques, adjust the pressure.

Use the left and right arrow buttons on the wheel to

adjust the pressure. The higher the number, the more

pressure on the fabric. The value can be adjusted

between 0 and 9 in steps of 0.5. Your manual setting

will be cancelled when you turn off the machine.

Note: If you want to change the presser foot pressure

for a sequence, bring the sequence to sewing mode and

change the setting.

Balance (only for sewing)

When sewing on special fabrics or doing a special

technique, the balance may need to be adjusted.

Start by sewing a stitch on a piece of scrap fabric.

Use the left and right arrow buttons to balance the

stitch between -7 and 7. When you sew again, the

balance will be adjusted.

The changes only affect the selected stitch. The

setting will go back to default when you select

another stitch.

Cut jump stitches (only for embroidering)

Your machine features the automatic function

cut jump stitches. This function saves you time

trimming after the embroidery is completed.

Select cut jump stitches in the settings menu. As

you embroider your machine will trim the top

jump stitch thread and pull the thread end to the

underside of the fabric.

Note: Your machine will also cut the thread after you

have changed to a new color. Hold the thread end when

you start embroidering again, so that you can easily

remove the thread end when cut.

Designs marked ”Cut jump stitch trim command” are

programmed for cut jump stitches. Jump stitch trim

commands can be added to any design using the 5D™

Organizer Software, included with your machine. Go to

”File” and select ”Add Trim Commands”.

Preparations

Pivot height

Adjust the height of the presser foot when

the machine is set for free-motion or when in

embroidery mode.

In Sensormatic free-motion mode: Skipped stitches

can occur if your fabric moves up and down with

the needle as you are stitching. Lowering the pivot

height will reduce the space between the presser foot

and the fabric and eliminate the skipped stitches.

Note: Be careful not to reduce the pivot height too much.

The fabric must still move freely under the presser foot.

In Embroidery stitch-out mode: Some

embroideries may build up under the presser foot.

If there is not enough space between the presser

foot and the embroidery, the top thread will form

loops on the underside of the embroidery. Increase

the pivot height in small steps until the embroidery

moves freely under the presser foot.

Automatic presser foot lift (only for sewing)

When selected, the automatic presser foot lift

is activated. The presser foot will raise to pivot

height when stopping with the needle in the down

position. When deselected, the presser foot will

stay lowered even if the machine stops with the

needle in down position.

Stop for cut (only for embroidering)

When starting to embroider the machine stops after

a few stitches asking you to cut the thread end. Use

the OK button to turn on or off this function in the

settings menu.

Note: Stop for cut and cut jump stitches cannot be used

at the same time. Stop for cut is also disabled if you use

the foot control when embroidering.

Language

Use the left and right arrow buttons to change the

language of all text in your machine.

Audible alarm

Turn all alarm sounds of the machine on or off.

Default setting is on.

Contrast

Adjust the contrast of the graphic display by using

the left and right arrow buttons. The value can be

set between -20 to 20 in steps of 1.

Software version

Check the software version for your sewing

machine.

2:15

Page 28

Sewing

Page 29

Sewing

Sewing mode is the À rst view on the graphic display after you turn on the machine. Your selected stitch

will be shown in real size in the stitch À eld. Here you will À nd all the basic information you need to start

sewing. This is also the menu where you adjust the settings of your stitch. Straight stitch is selected by

default.

Sewing mode - overview

1. Selected stitch number

2. Stitch À eld

3. Stitch width/stitch positioning

4. Stitch length/density

5. Tapering program

6. Tie-off options

Select a stitch

By pressing one of the direct selection buttons, you

select that stitch number immediately. Press two

or three digits in quick succession to select a stitch

from 10 and up. If the stitch number does not exist,

you will hear a beep and the À rst entered digit will

be selected as a stitch.

Use the up and down arrow buttons on the wheel

to step between stitches.

1

3

2

4

5

6

Sewing

Sewing recommendations

Press the info button to show sewing

recommendations for the current stitch.

Press the button again to hide the information.

7. Needle recommendation/setting

Set for twin needle

Wing needle recommended

Set for stitch width safety

8. Presser foot recommendation

9. Stabilizer recommended

10. Feed dog/IDT recommendation

11. Thread tension value

Note: All symbols and options will not be shown at the

same time.

7

8

10

119

3:1

Page 30

Stitch adjustments

Your machine will set the best settings for

each selected stitch. You can make your own

adjustments on the selected stitch.

The setting changes only affect the selected stitch.

Your changed settings will be reset to default when

selecting another stitch. The changed settings

are not automatically saved when turning your

machine off.

The set stitch width and the stitch length are shown

next to the icons for each adjustment. When trying

to exceed minimum or maximum settings for

width and length, a warning sound will be heard.

Note: The numbers are highlighted when the setting is

changed.

Sewing

Stitch width (1)

Increase or decrease the stitch width using + and -.

Stitch length (2)

Increase or decrease the stitch length using + and

-. If lengthening a zigzag stitch or a decorative

stitch, the entire stitch will be longer. If lengthening

a satin stitch where the density can be adjusted,

the entire stitch will be longer but the density will

remain the same.

Thread tension (5)

For the best stitch appearance and durability, make

sure the needle thread tension is correctly adjusted,

i.e. for general sewing, the threads evenly meet

between the two fabric layers.

Your sewing machine electronically sets a thread

tension for the selected stitch. Depending on the

fabric, batting, thread etc, the tension may need to

be adjusted. See page 2:14 for instructions on how

to change the setting manually.

If the bobbin thread is visible on the top side of

the fabric, the needle thread tension is too tight.

Reduce the needle thread tension.

If top thread is visible on the underside of the

fabric, the needle thread tension is too loose.

Increase the needle thread tension.

For decorative stitches and buttonholes, the top

thread should be visible on the underside of the

fabric.

Stitch positioning (3)

Press the alternatives button to show the stitch

positioning instead of the stitch width. Use the +

and - buttons to move the stitch to the left or right.

Note: This is only possible when using a stitch that is

narrower than 9 mm. You can decrease the stitch width

to make the stitch narrower if necessary.

Stitch density (4)

Press the alternatives button to show the density

setting instead of the stitch length for satin stitches.

Now the stitch length + and - buttons adjust the

density. The stitch density does not affect the

actual length of the entire stitch.

Note: This is often used with specialty threads and when

a less dense satin stitch is desired. If you have selected a

buttonhole, the graphic display will by default show the

density setting instead of the stitch length setting.

1

2

5

Press the alternatives button to view

stitch positioning and density

3

4

3:2

Page 31

Mirroring

To mirror stitches or sequences side to side, press

the mirror side to side button. To mirror end to

end, press the mirror end to end button.

Tie-off options

The tie-off options let you program tie-offs both

at the beginning (A) and the end (B) of the stitch.

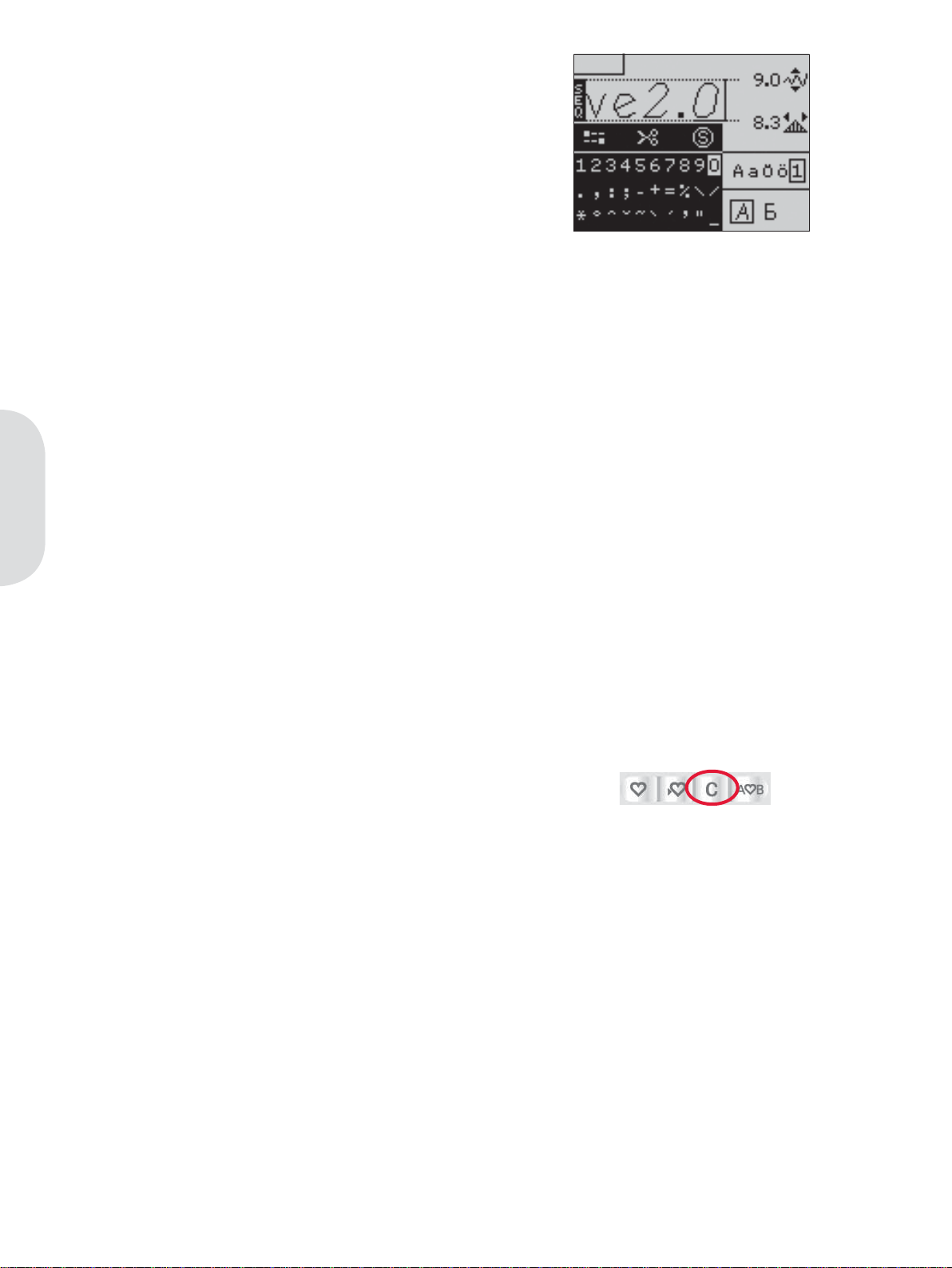

Thread snips (C) can also be used.

1. Press the F2 button to open the tie-off options

view.

2. Use the wheel to step between the options and

press OK to select which functions you want

to use.

3. When you have made your selections, close the

view by pressing the F2 button again. Tie-off

mini icons (D) will be shown on the graphic

display, indicating which tie-off functions are

selected. The selections will remain until you

deselect them.

Note: For immediate tie-off, use the tie-off button, found

on the front of the machine.

Sewing

D

ABC

Sewing with tie-off options selected

1. The tie-off beginning (A) will be performed as

soon as you start to sew.

2. Press the reverse button to activate tie-off end

(B). The programmed tie-off indicator will be

lit. The machine will À nish the stitch and do a

tie-off.

When a thread snip (C) is programmed, the

machine will automatically cut the threads

after performing the tie-off end. The needle

and presser foot will raise.

Note: Stop sewing and press the reverse button

twice to activate reverse sewing. The reverse

indicator will be lit. No tie-off will be performed.

Press the reverse button when sewing in reverse to

activate tie-off end. Both the reverse indicator and

the programmed tie-off indicator will be lit.

To go back to sewing forward, stop sewing in

reverse and press the reverse button. No indicators

will be lit and no tie-off will be performed.

3. To deactivate the tie-off options, use the wheel

to step between the options and press OK for

each one to deselect.

3:3

Page 32

Tapering program

Tapering increases or decreases the width of the

stitch during sewing to create symmetrical or

asymmetrical tapers.

1. Open the tapering program view by pressing

the F1 button.

2. Use the left and right arrow buttons on the

wheel to select beginning or end tapering.

Press OK to turn the setting on or off.

3. Long press OK to open a view with different

angle choices for either beginning or end

tapering. Select the angle you want for your

taper by using the arrow buttons, and press

OK to select.

4. Press the F1 button again to close the tapering

program view. There are mini icons (A) on the

Sewing

graphic display that will show you if beginning

or end tapering are activated.

5. When tapering is activated at both the

beginning and at the end and you start to sew,

the stitch width will start at 0 mm. It becomes

wider until the selected stitch width is reached.

Sew your desired length and press the reverse

button. The width is reduced until the width is

0 mm.

Note: Almost all stitches can be tapered. When you

try to open the tapering program view for a stitch

that cannot be tapered, a warning sound will be

heard.

A

Speed control

1. Long press the speed button to open a popup where you can use the left and right arrow

buttons on the wheel to change the sewing

speed.

Note: You cannot select a higher speed than the

default speed.

2. Press the speed button again to close the popup.

3. Press the info button. An icon on the graphic

display will indicate the speed your machine is

set to sew (B).

4. To deactivate the reduced speed, press the

speed button. Press the button again to sew

with the speed you previously selected.

B

3:4

Page 33

Personal stitches

Save personal stitch

1. Save your personal stitches in your machine

by pressing the save button. This will open

the save personal stitch or sequence menu.

Select the personal stitch option with the arrow

buttons on the wheel and conÀ rm by pressing

OK.

2. Select an empty memory by using the arrow

buttons. ConÀ rm your selection by pressing

OK. If the selected memory is not empty, a

pop-up message will appear asking if you wish

to overwrite the previously saved stitch with

the new one. Select yes or no with the arrow

buttons and press OK.

3. Press the save button again to return to sewing

mode.

Note: Some special stitches, such as buttonholes, cannot

be saved. A pop-up will inform you of this when you try

to save such a stitch.

Sewing

Load personal stitch

1. Load your personal stitches by pressing the

load button. This will open the load personal

stitch or sequence menu. Select the personal

stitch option in the pop-up with the arrow

buttons on the wheel. ConÀ rm by pressing OK.

2. Use the arrow buttons to select the stitch you

want to use and press OK. The stitch will

appear in sewing mode ready to be sewn out.

The number of the loaded stitch will be shown

preÀ xed by a heart.

Delete personal stitch

1. Delete your personal stitches from your

machine when you are in load or save mode.

2. Select the stitch you want to delete and press

the clear button. A pop-up will appear asking

you to verify the deletion. Select yes or no with

the arrow buttons on the wheel and press OK.

3:5

Page 34

Sewing techniques

Three-step zigzag stitch

Stich number 9 can be used to overcast raw edges.

Make sure the needle pierces the fabric on the left

side and overcasts the edge on the right side.

Stitch number 9 can also be used as an elastic stitch

to add elastic to pajamas, skirts and sportswear.

Buttonholes

Sewing

To sew a buttonhole, À rst attach the correct foot.

Make sure that the IDT is disengaged.

Note: Buttonholes up to 50 mm are sewn with the

Sensormatic buttonhole foot. Buttonholes over 50 mm

are sewn manually in four steps with presser foot 5M.

Then select your buttonhole. To ensure good

results, start by sewing a test sample on a scrap

piece of the fabric with the stabilizer you will use.

The direction of the stitches being sewn will be

indicated on the screen by an arrow next to the

buttonhole.

A

Sensormatic buttonhole

When you sew a buttonhole with the sensormatic

buttonhole foot, adjust the slit length so that

it is slightly larger than the size of the button.

1. Snap on the sensormatic buttonhole foot 5A.

2. Plug the cord into the socket (A) found to the

left underside behind the light bulb.

3. Use the ruler on the lid to measure your

button. Set the slit length using the left and

right arrow buttons on the wheel.

4. Make sure that the red arrow lines up with the

marking on the foot (B).

5. Start sewing by pressing the foot control.

6. The arrows on the graphic display will show

when each part of the buttonhole is sewn and

in which direction. The columns will be sewn

in the same direction.

7. The buttonhole will be completed

automatically. You can repeat the buttonhole

as many times as you wish by pressing the foot

control.

B

3:6

Page 35

Manual buttonhole

1. To sew a buttonhole longer than 50 mm, use

presser foot 5M. Make sure that the IDT is

disengaged.

2. The À rst column will be sewn backwards.

Sew the À rst column as long as you want the

buttonhole. The graphic display will show the

part and sewing direction of the buttonhole

that is being sewn.

3. Press the reverse button. The machine sews

the bartack and the second column. When the

columns are aligned, press the reverse button

again to sew the second bartack.

The machine will stop automatically when the

buttonhole is complete.

Note: The repeat icon will be highlighted, showing

you that repeat is activated. You can repeat the

buttonhole as many times as you wish by pressing

the foot control.

4. Press the F2 button to deactivate repeat.

Sewing

Corded buttonhole

Corded buttonholes that are sewn with gimp

threads are more stable, durable and have a

professional appearance. Use pearl cotton or a

regular gimp thread.

1. Place the center of a length of gimp thread over

the metal bar extending from the center back

of the sensormatic buttonhole foot 5A. Pass the

thread ends under the foot and pull up into the

right and left guides on the front of the presser

foot.

2. Snap on the sensormatic buttonhole foot 5A.

Before starting to sew, make sure that the red

arrow lines up with the marking on the foot.

3. After completing the buttonhole, pull the ends

of the gimp thread until the loop of thread is

hidden below the buttonhole bartack.

4. Thread the gimp threads into a needle and pull

them to the wrong side of the garment. Tie the

gimp threads and cut off the excess thread.

3:7

Page 36

Sew on a button

1. To sew on a button, remove the presser foot

and select the button sewing stitch.

2. Lower the feed dogs.

3. Place the button under the presser foot holder.

Use the mirroring function to make sure the

holes in the button are aligned with the swing

of the needle and the width is appropriate

for the actual button. If necessary change the

width between holes with the width + and buttons.

4. You can increase or decrease the number of

stitches that will fasten the button on the fabric

in steps of two, using the left and right arrow

buttons on the wheel.

5. Start to sew. The machine will sew the

Sewing

program for you and then tie-off and stop.

Note: Use the multi-purpose tool to create a thread

shank for your button. You can also use a sew-on

button foot, available as an optional accessory.

Darning

Darning a small hole or a tear before it becomes

larger can save a garment. Choose a lightweight

thread in a color as close to your garment as

possible.

1. Place fabric or stabilizer in position under the

hole or tear in your garment.

2. Select a darning stitch.

3. Start sewing above the hole and over it.

4. Once you have sewn across the hole, press the

reverse button to set the length of the stitch.

Your sewing machine will automatically

complete the stitch.

5. By default, the machine will be set to repeat

the same size darning square, just continue

sewing.

Press the F1 button to deactivate repeat.

Note: The repeat icon (A) will be highlighted,

indicating that repeat is activated.

A

Sewing hems in heavy fabric

When sewing over seams in extra heavy fabric or

a blue jeans hem, the foot can tip as the machine

climbs over the seam. Use the multi-purpose tool to

balance the height of the presser foot as you sew.

One side of the multi-purpose tool is thicker than

the other. Use the side that suits the thickness of

the seam best.

3:8

Page 37

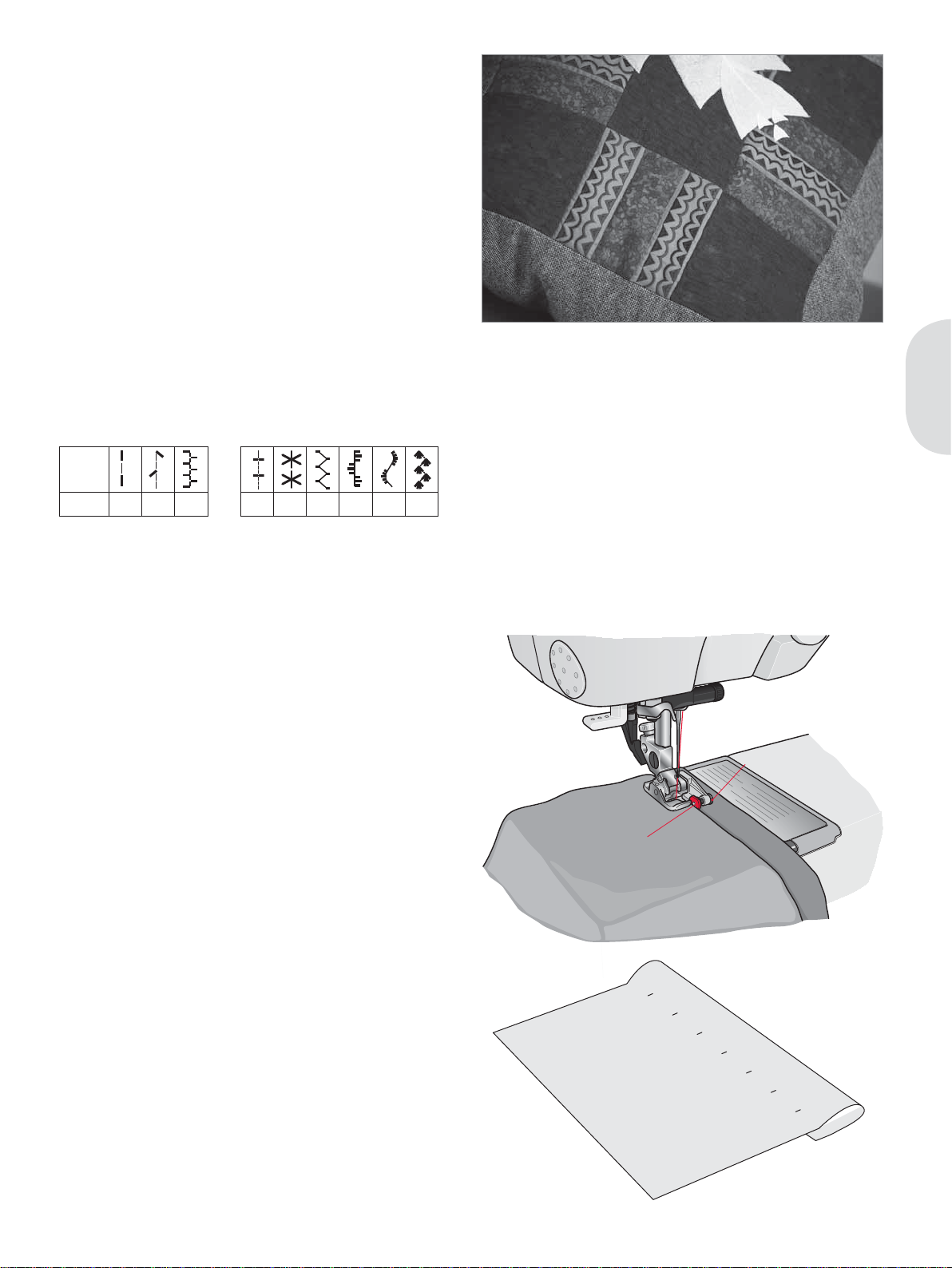

Handlook quilting

A quilt usually consists of three layers, two layers

of fabric with a layer of batting sandwiched

between.

1. Baste the completed quilt top to the batting and

backing.

2. Thread the needle with an invisible

(monoÀ lament) thread. Use contrasting or

matching rayon or cotton thread in the bobbin.

3. Snap on the recommended foot shown in the

sewing recommendations view.

4. Engage the IDT.

5. When you sew the stitch you should only see

your bobbin thread. Increase the needle tension

as needed to produce the desired effect.

Recommended stitches for a handlook quilt

Stitch

41 42 43 45 46 47 48 49 50

Sewing

Blindhem stitch

The blindhem stitch number 16 is used to make

invisible hems on skirts, trousers and home

decorating. Use foot number 3 with IDT.

1. Finish the edge of the hem.

2. Fold and press the hem allowance to the wrong

side.

3. Fold the hem back on itself so approximately

3/8” (1 cm) of the À nished edge extends

beyond the fold. The wrong side of your

project should now be facing up.

4. Place the fabric under the presser foot so that

the fold runs along edge guide A.

5. When the needle swings into the fold it should

catch a small amount of fabric. If the stitches

are visible on the right side, adjust edge guide

A by turning adjusting screw B until the stitch

that catches the hem just barely shows.

B

A

3:9

Page 38

Elastic blindhem stitch

The elastic blind stitch number 17 is especially

suitable for stretchy fabrics, because the zigzag in

the stitch lets the stitch stretch. The hem is À nished

and sewn at the same time. There is no need to

À nish the raw edge À rst on most knits.

Sewing in zippers

There are different ways to sew in zippers. Follow

the directions included with your pattern for best

results.

For all types of zippers it is important to sew close

Sewing

to the teeth of the zipper. The zipper foot 4 can be

snapped to the presser foot bar on the left or right,

depending on how you will insert your zipper.

Then set the stitch position so that it enters close

to the edge of the zipper teeth by using one of the

37 needle positions available for the straight stitch.

If the presser foot is attached on the right side, the

needle must only be moved to the right. If the foot

is attached on the left, the needle must only be

moved to the left.

Rolled hem

Use the rolled hem foot 7 to À nish the edges of

blouses, scarves, or rufÁ es without having to

iron the edges beforehand. Hemming prevents

the edges from fraying and produces a neat and

durable edge À nish.

1. Double-fold the fabric edge (about 1/8” - 2 mm

- per fold).

2. Place the folded fabric edge under the rolled

hem foot and sew a few stitches to secure.

3. Turn the handwheel towards you until the

needle is at its lowest point. Raise the presser

foot and slide the fabric into the scroll of the

foot.

4. Lower the presser foot and while sewing,

guide the fabric edge evenly into the foot.

When roll-hemming, make sure the raw edge

of the fabric butts against the left edge of the

rolled hem foot opening. Ensure the fabric does

not run underneath the right side of the presser

foot.

Note: A narrow zigzag stitch also makes a nice rolled

hem on lighter stretch fabrics such as lingerie nylon.

3:10

Page 39

Common sewing pop-ups

Bobbin empty

When the bobbin is almost empty, the machine

stops automatically and a pop-up appears on the

screen. Replace the empty bobbin with a full one

and press OK on the wheel to conÀ rm.

Mainmotor overload

If you are sewing on very heavy fabric or if the

machine is blocked when sewing, the mainmotor

can get overloaded and the machine will stop

sewing. The pop-up message will close when the

mainmotor and power supply are secure.

Remove thread jam

Clean the area under the stitch plate from thread

and lint. Press OK on the wheel to close the popup.

Sewing

3:11

Page 40

Sequencing

Page 41

Sequencing

The sequencing function on your machine makes it possible to combine stitches and letters into

sequences. You can add up to 40 stitches, letters and commands in the same sequence. Save your own

stitches and sequences on your machine and reload and sew them any time you like.

All stitches in your sewing machine can be used for sequencing except for buttonholes, darning, tapering

stitches, button sewing and bartacks.

Sequencing - overview

1. Current stitch number

2. Stitch À eld

3. Sequence commands

4. Alphabet

5. Stitch width/stitch positioning

6. Stitch length/density

7. Character set (upper case/lower case, normal/

special symbols)

8. Font selection

1

2

3

4

5

6

7

8

Sequencing

Create a sequence

1. Press the sequencing button to enter

sequencing.

2. Press the number of the stitch you wish to use.