Page 1

8301

INSTRUCTION MANUAL

This instruction manual applies to machines

from serial number 2 777 829 and software

version 0398/003 onwards.

296-12-18 995/002

Betriebsanleitung engl. 10.11

Page 2

The parts list for the machines can be downloaded free of

charge from the internet address

www.pfaff-industrial.com/pfaff/de/service/downloads.

As an alternative to the internet download the adjustment manual can also be

ordered in book form under part no.296-12-18 995.

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Contents

Contents ..................................................................................Page

1 Safety .................................................................................................................................... 5

1.01 Directives ............................................................................................................................... 5

1.02 General notes on safety ......................................................................................................... 5

1.03 Safety symbols ......................................................................................................................6

1.04 Important notes for the user .................................................................................................. 6

1.05 Operating and technical staff ................................................................................................. 7

1.05.01 Operating staff ....................................................................................................................... 7

1.05.02 Technical staff ........................................................................................................................ 7

1.06 Danger ...................................................................................................................................8

2 Proper use............................................................................................................................. 9

3 Specifi cations ..................................................................................................................... 10

4 Disposal of Machine ...........................................................................................................11

5 Transportation, packing and storage ................................................................................ 12

5.01 Transportation to customer‘s premises ............................................................................... 12

5.02 Transportation inside the customer‘s premises ................................................................... 12

5.03 Disposal of packing materials ..............................................................................................12

5.04 Storage ................................................................................................................................ 12

6 Explanation of symbols ..................................................................................................... 13

7 Controls .............................................................................................................................. 14

7.01 Summary of control elements ............................................................................................. 14

7.02 Main switch ......................................................................................................................... 15

7.03 Pedal .................................................................................................................................... 15

7.04 Setting wheel for roller distance ..........................................................................................16

7.05 Setting wheel for roller pressure.......................................................................................... 16

7.06 Control panel ........................................................................................................................ 17

7.06.01 Symbols on the display ........................................................................................................ 17

7.06.02 Function keys ....................................................................................................................... 18

8 Installation and commissioning ....................................................................................... 19

8.01 Installation ............................................................................................................................ 19

8.01 Adjusting the table-top height .............................................................................................. 19

8.02 Commissioning .................................................................................................................... 20

8.03 Switching the machine on/off .............................................................................................. 20

9 Preparation ......................................................................................................................... 21

9.01 Programme call-up and modifi cation .................................................................................... 21

9.02 Setting roller distance and roller pressure ........................................................................... 21

9.03 Setting the differential transport .......................................................................................... 22

9.04 Additional transport rollers (optional) ................................................................................... 22

9.05 Inserting and removing the SD-memory card ...................................................................... 23

10 Sealing ................................................................................................................................ 24

10.01 Sealing principle .................................................................................................................. 24

10.02 Error messages .................................................................................................................... 25

3

Page 4

Contents

Contents ..................................................................................Page

11 Input .................................................................................................................................... 26

11 .01 Access codes ....................................................................................................................... 26

11 .01.01 Inputting the access code .................................................................................................... 26

11 .01.02 Modifying the access code .................................................................................................. 27

11 .01.03 Assigning access rights ....................................................................................................... 27

11 .02 Example of a parameter input .............................................................................................. 28

11 .03 List of parameters ................................................................................................................ 29

11 .04 Error messages in the display ..............................................................................................33

11 .05 Programme Management .................................................................................................... 34

11 .05.01 Calling up Programme Management ................................................................................... 34

11 .05.02 Copying machine data to the SD card .................................................................................. 35

11 .05.03 Copying data from the SD card to the machine memory .................................................... 36

11 .05.04 Formatting the SD memory card ......................................................................................... 37

11 .06 Internet update of the machine software ............................................................................ 38

11 .06.01 Update with null modem cable ............................................................................................38

11 .06.02 Update with SD-card ............................................................................................................ 39

12 Care and Maintenance ....................................................................................................... 41

12.01 Maintenance intervals .......................................................................................................... 41

12.02 Cleaning the feed rollers ...................................................................................................... 41

12.03 Checking/adjusting the air pressure ..................................................................................... 42

12.04 Cleaning the air fi lter of the air-fi lter/lubricator ..................................................................... 42

12.05 Exchanging the transport rollers .......................................................................................... 43

13 Connection diagram .......................................................................................................... 44

13.01 Pneumatics-switch diagram ................................................................................................. 44

13.02 Circuit diagrams ................................................................................................................... 45

4

Page 5

Safety

1 Safety

.01 Directives

1

This machine is constructed in accordance with the European regulations indicated in the

conformity and manufacturer’s declarations.

In addition to this instruction manual, please also observe all generally accepted, statutory

and other legal requirements, including those of the user’s country, and the applicable

pollution control regulations! The valid regulations of the regional social insurance society for

occupational accidents or other supervisory authorities are to be strictly adhered to!

1.02 General notes on safety

● The machine may only be operated by adequately trained operators and only after these

have read the appropriate Instruction Manual!

● The danger and safety instructions attached to the machine must be followed!

● The machine may only be used for the purpose intended and may not be operated wit-

hout its safety devices. All relevant safety regulations must be adhered to.

● When changing the feed rollers or the hot air nozzle, when leaving the machine unatten-

ded or during maintenance work, the machine must be disconnected from the power

supply by pulling out the plug!

● The daily maintenance work may only be carried out by appropriately trained personnel!

● During repair and maintenance work on pneumatic devices the machine must be discon-

nected from the pneumatic supply system! The only exceptions permitted are during ad-

justment work and function tests carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualifi ed service staff

or appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

Exceptions to this rule are found in the regulations EN 50110.

● Modifi cations and alterations to the machine may only be carried out under observance

of all the relevant safety operations!

● Only spare parts which have been approved by us are to be used for repairs! We draw

special attention to the fact that spare parts and accessories not supplied by us have not

been subjected to testing nor approval by us. Fitting and/or use of any such parts may

cause negative changes to the design characteristics of the machine. We shall not accept

any liability for damage caused by the use of non-original parts.

5

Page 6

Safety

o

o

o

o

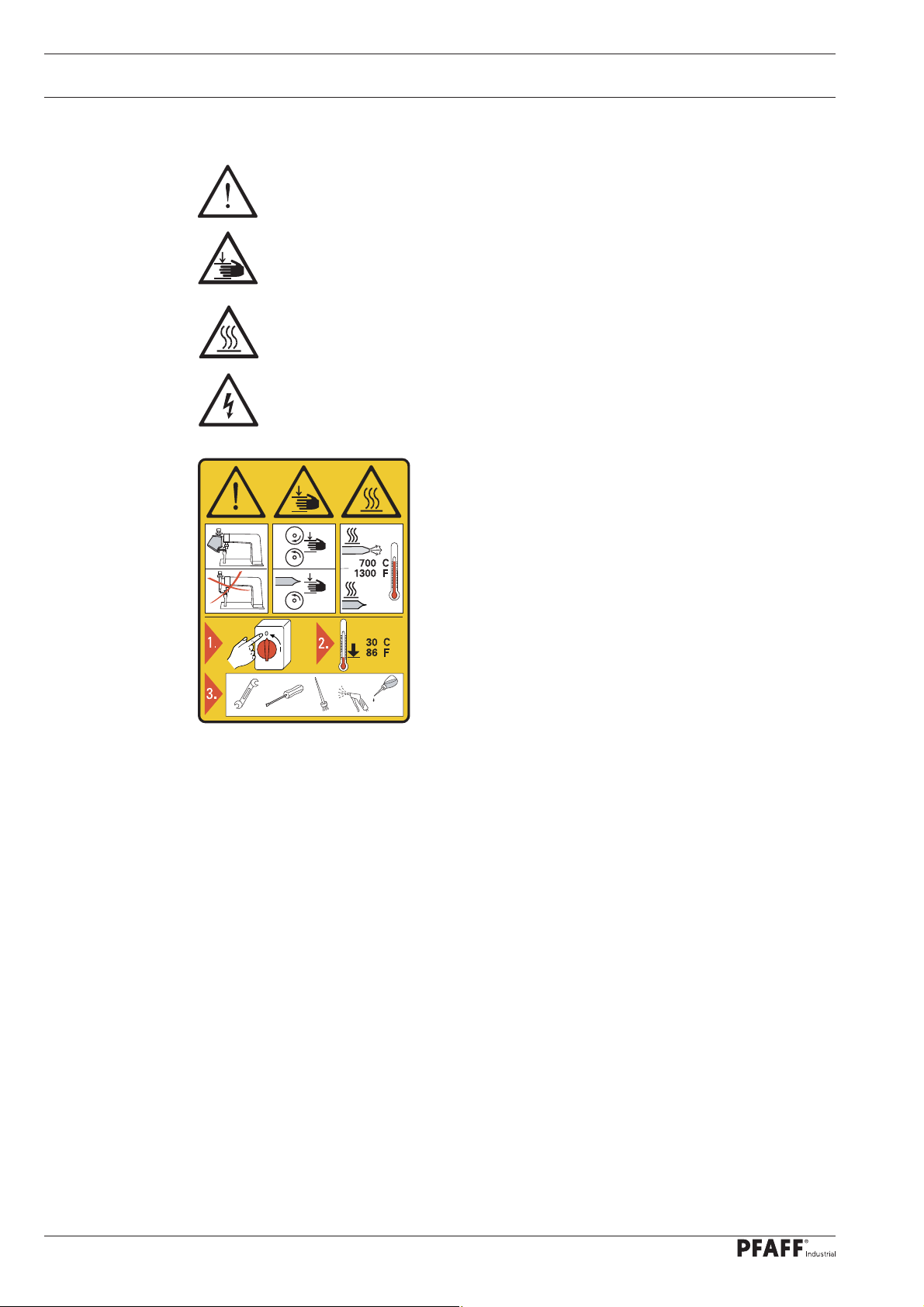

1.03 Safety symbols

Danger!

Special points to observe.

Danger of hands being crushed!

Danger of burns from hot surface!

Danger from electric voltage!

Caution

Do not operate without fi nger guard and safety

devices.

1.04 Important notes for the user

● This instruction manual belongs to the equipment of the machine and must be available

to the operating staff at all times.

● This instruction manual must be read before the machine is operated for the fi rst time.

● Both operating and technical staff must be instructed on the safety devices of the machi-

ne and on safe working methods.

● It is the duty of the user to operate the machine in perfect running order only.

● The user must ensure that none of the safety devices are removed nor put out of wor-

king order.

Turn off the main switch and let the machine cool

down before any setting up, maintenance or cleaning

work!

● The user must ensure that only authorized persons operate and work on the machine.

● The user must make sure there is no high-frequency welding equipment being operated

in direct proximity to the machine that exceeds the EMC limit values according to

EN 60204-31 for the machine.

For further information please refer to your PFAFF agency.

6

Page 7

Safety

1.05 Operating and technical staff

1

.05.01 Operating staff

Operating staff are the persons responsible for setting up, operating and cleaning the machi-

ne and for removing any disturbances in the sewing area.

The operating staff is obliged to observe the following points, and must:

● always observe the notes on safety in this instruction manual!

● avoid using any working methods which adversely affect the safety of the machine!

● avoid wearing loose-fi tting clothing or jewelry such as necklaces or rings!

● also ensure that only authorized persons are allowed near the danger area of the machine!

● immediately report to the user any changes to the machine that may affect its safety!

1.05.02 Technical staff

Technical staff are persons who have been trained in electrical engineering, electronics and

mechanical engineering. They are responsible for lubricating, servicing and repairing the ma-

chine.

The technical staff is obliged to observe the following points, and must:

● always observe the notes on safety in this instruction manual!

● switch off the on/off switch before carrying out any maintenance and repair work on the

machine!

● never work on parts or equipment still connected to the power supply! Exceptions to this

are only permissible according to regulations EN 50110.

● replace all safety covers after maintenance and repair work!

7

Page 8

Safety

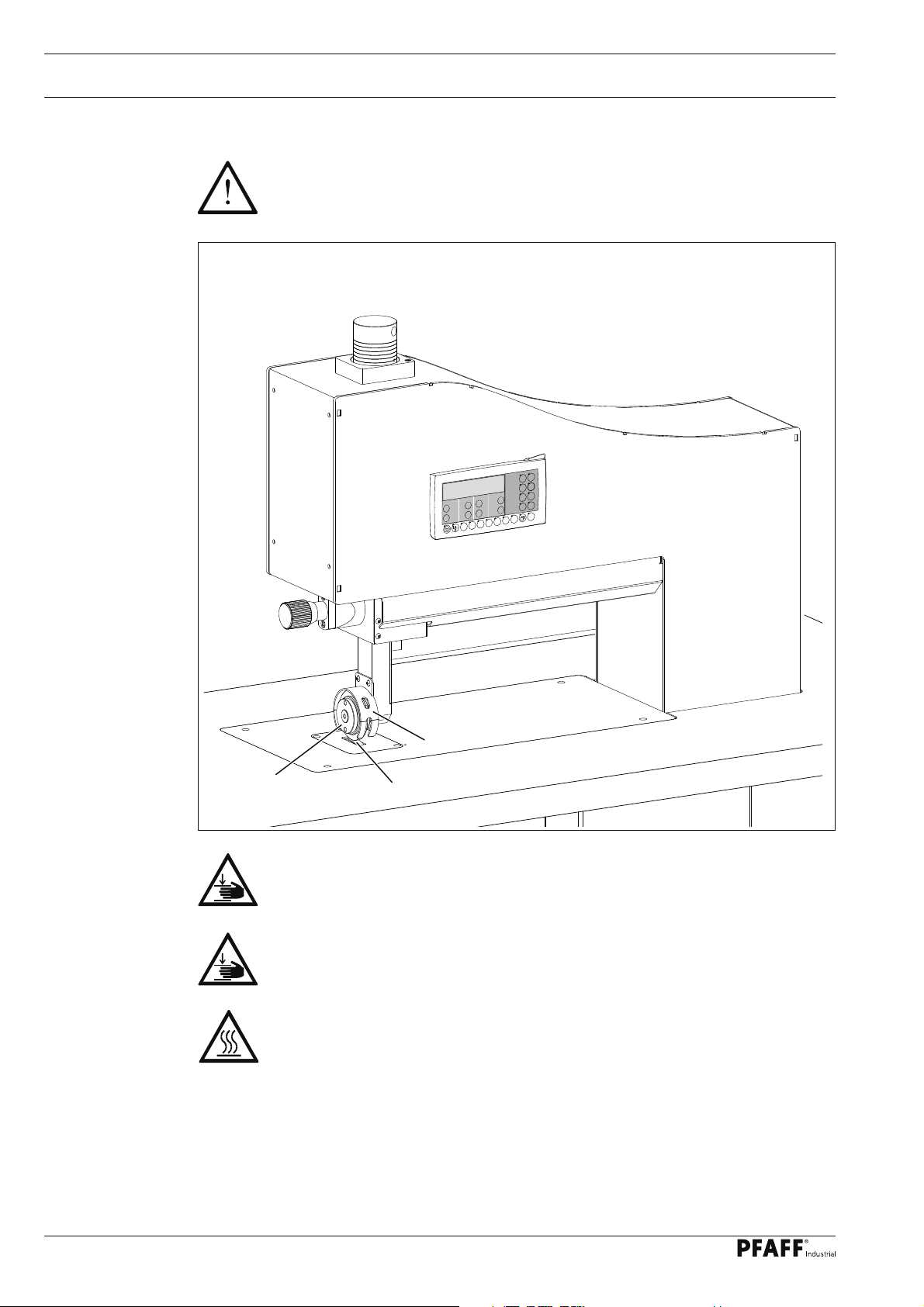

1.06 Danger

When the machine is in operation, a work area of 1 m must be kept free in

front of and behind the machine, so that access to the machine is possible at all

times without diffi culty.

P

TE

F1

P6

P5

P4

P3

P2

P1

Fig. 1 - 01

1

2

Do not operate the machine without fi nger guard 1!

Danger of crushing if the fi ngers are drawn in!

During operation do not place your hands in the area of feed roller 2 and

sonotrode 3! Danger of fi ngers being drawn in and crushed!

During operation do not touch sonotrode 3!

Danger of burns from the heat-generating surface!

3

8

Page 9

Proper use

2 Proper use

The PFAFF 8301 is an ultrasonic welding machine for the continuous welding of thin

thermoplastic materials, e.g. fl eeces, felts, meshed or woven fabrics.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

9

Page 10

Specifi cations

3 Specifi cations▲

Dimensions:

Width: ............................................................................................................ approx. 1200 mm

Depth: ............................................................................................................. approx.. 800 mm

Height: ........................................................................................................... approx. 1310 mm

Passage width: ................................................................................................. approx. 410 mm

Max. through-passage under transport rollers: .............................................................. 20 mm

Connectivity data

Operating voltage: ..................................................................230 V ± 10%, 50/60 Hz, 1-phase

Max. input power: ......................................................................................................... 1000 VA

Mains protection: ................................................................................................................ 16 A

Leakage current: .......................................................................................................... < 5 mA

Performance data:

Sealing pressure: .....................................................................................................100 - 500 N

Sealing power: ........................................................................................................ max. 400 W

Sealing speed: .................................................................................................. 0,1 - 10 m/min*

◆

Noise data

Emission sound level at the workplace: .............................................................LpA < 70 dB(A)

(Noise measurement in acc. with DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO 4871)

Net weight: ........................................................................................................approx. 120 kg

▲

Subject to alterations

* Depending on transport roller diameter; stated max. value for 80 mm roller diameter

■

KpA = 2,5 dB

◆

Due to the use of network fi lters there is a nominal leakage current of < 5 mA.

■

10

Page 11

Disposal of Machine

4 Disposal of Machine

● Proper disposal of the machine is the responsibility of the customer.

● The materials used for the machine are steel, aluminium, brass and various plastic

materials. The electrical equipment comprises plastic materials and copper.

● The machine is to be disposed of according to the locally valid pollution control regula-

tions; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

11

Page 12

Transportation, packing and storage

5 Transportation, packing and storage

5

.01 Transportation to customer‘s premises

The machines are delivered completely packed.

5.02 Transportation inside the customer‘s premises

The manufacturer cannot be made liable for transportation inside the customer‘s premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fi bre. Proper dis-

posal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a fi lm of oil.

12

Page 13

Explanation of symbols

6 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

13

Page 14

Controls

7 Controls

7

.01 Summary of control elements

5

P

TE

F1

P6

P5

P4

P3

P2

4

P1

2

6

7

Fig. 7 - 01

● Main switch 1, see Chapter 7.02

● Control panel 2, see Chapter 7.06

● Pedal 3, see Chapter 7.03

● Setting wheel 4 for roller distance, see Chapter 7.04

1

3

14

● Setting wheel 5 for roller pressure

● Upper transport roller 6

● Sonotrode 7

Page 15

Controls

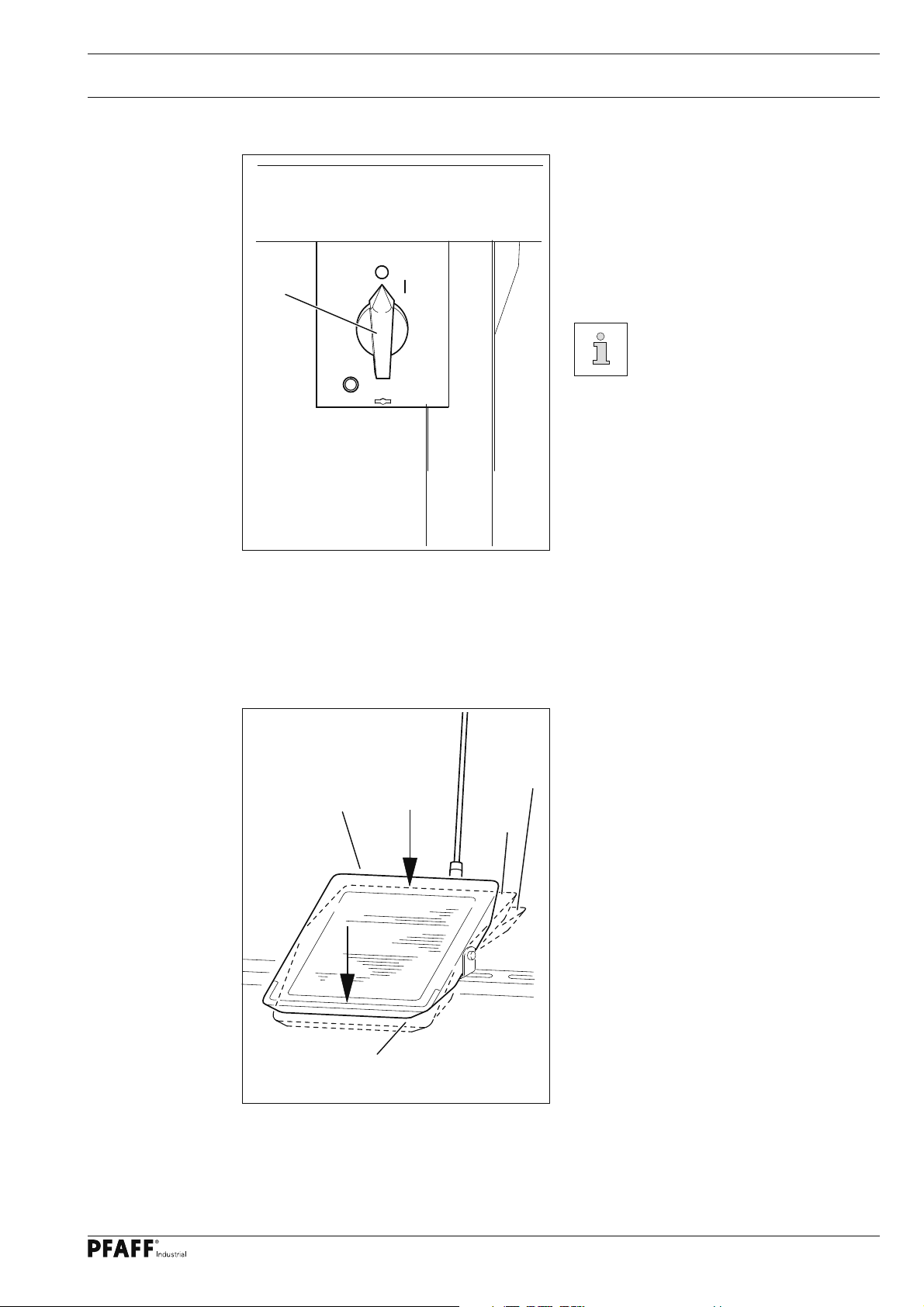

7.02 Main switch

● The machine is switched on or off by

turning main switch 1.

Position "0": Machine is switched off

Position "I": Machine is switched on

1

Fig. 7 - 02

7.03 Pedal

About 30 seconds after the

machine is switched on,

the last basic menu called

up before the machine was

switched off will be displayed.

Foot switch functions

Fig. 7 - 03

0 = Rest position (welding stops)

+2

0

+1

+1 = Transport roller is lowered to welding

position.

+2 = Press and hold treadle:

Welding process begins and runs as

long as the treadle is pressed.

-1 = Lift transport roller

-1

15

Page 16

Controls

7.04 Setting wheel for roller distance

Fig. 7 - 04

● The distance between the upper

transport roller and the sonotrode is

adjusted by turning the setting wheel 1.

Sonotrode 2 and transport

roller 3 must never be in direct

contact!

F1

P6

P5

P4

P3

P2

P1

Danger of machine damage!

Exempted are steel sonotrodes.

1

3

2

7.05 Setting wheel for roller pressure

1

F1

P6

P5

P4

P3

P2

P1

Fig. 7 - 05

● Roller pressure is adjusted by turning the

setting wheel 1.

● The roller pressure is shown on the scale

of the setting wheel.

● This roller pressure value can be input in

the display for each programme, but only

serves for memory purposes.

P

TE

16

Page 17

Controls

7.06 Control panel

The control panel is used to display and access machine functions for set-up and welding, to

enter parameter values and to read error messages and service settings.

1

P

2

P3

Fig. 7 - 05

P2

3

P1

P5

P4

F1

P6

The control panel has the following control and display elements:

● The display screen 1 consists of a two-line, alphanumerical LCD display with 16 symbols

per line and is used to show relevant information and selection parameters.

● The plus-minus keys 2 are used to select or alter the functions and parameters shown on

the display.

● The function keys 3 are used to switch the relevant function on or off. Activated functions

are shown in each case by an illuminated LED.

TE

7.06.01 Symbols on the display

In addition to texts and set values, the following symbols are shown on the display

Current program number

Maximum speed in current seam sector

17

Page 18

Controls

7.06.02 Function keys

The function keys described in the following are used primarily for the

activation/ deactivation of machine functions. If the function is turned on,

the corresponding key LED lights up.

Where a value is to be set for the activated function, this can be done via

the +/- keys 2.

Pressing and holding the +/- keys will initially change the number value shown

above the key slowly. Holding the +/- key longer will speed up the speed at

which the number value changes.

The following description contains the relevant +/- keys as shown here.

Stop

The machine is stopped during the welding process.

Low/lift the transport roller

When activated, the transport rollers are lifted or lowered.

P1

to

P6

F1

TE

P

Programming keys

Programmes 1 - 6 are called up with these keys.

Alternatively, the programmes 0 - 19 can be called up via the left +/- keys.

F1

Transport rollers are blocked (e.g. when replacing the transport rollers).

Scroll

Pressing and holding this key will scroll through the following sub-menus:

Amplitude, Speed, Welding Pressure (only advance registration function), Differential,

Parameters, SD Card.

TE

This key allows toggling between Production mode (LED off) and Input mode (LED on.

P

Here, a test programme can be created.

18

Page 19

Installation and commissioning

8 Installation and commissioning

After the machine has been unpacked, check it for any damages caused during transportation. If there are any damages, please notify the transport company and your

local PFAFF agency.

The machine must only be installed and commissioned by qualifi ed personnel.

All relevant safety regulations must be strictly adhered to!

8.01 Installation

The site where the machine is installed must be provided with suitable connections for the

electric current, see Chapter 3 Specifi cations.

It must also be ensured that the standing surface of the machine site is fi rm and horizontal,

and that suffi cient lighting is provided.

8.01 Adjusting the table-top height

1

Fig. 8 - 01

● Slide the machine off the pallet.

● Loosen screw 1.

2

3

1

● Adjust the table tap to the required working height by increasing or reducing the height

of the stand and then level the table-top horizontally.

To avoid the stand tilting, adjust it evenly on both sides.

● To guarantee that the stand is standing securely, it must be positioned securely on the

ground with all four legs.

● The height can be adjusted with screw 2 ( nut 3).

19

Page 20

Installation and commissioning

8.02 Commissioning

● Thoroughly clean machine as needed.

● Check the machine, particularly the electrical wiring, for any damage.

● Have skilled personnel check if the machine can be operated with the available mains

voltage.

Do not operate the machine if there is any discrepancy.

The machine may only be connected to an earthed socket!

● Connect the machine to the compressed air system. The manometer should display

a pressure of 6 bar. Set this value, if needed (see Section 12.03 "Checking the air

pressure of the maintenance unit").

8.03 Switching the machine on/off

● Turn the main switch in position "I" (see Section 7.02 "Main switch") to turn the machine

on.

20

Page 21

Preparation

9 Preparation

All regulations and notes in this Service Manual must be observed!

Special attention must be paid to the safety regulations!

All setting-up work must only be carried out by personnel with the appropriate

training!

9.01 Programme call-up and modifi cation

● Switch machine on.

Ampl

2 75.0% 2.0

P3

P2

P1

P5

P4

F1

P6

● Call up the programme with the desired welding parameters (0 - 19) via the keys P1 to P6

P1

to

P6

or via the +/- keys on the left.

● The values displayed for Amplitude and Speed can be modifi ed directly via the

corresponding +/- keys as needed.

● Once modifi ed, these values will be saved.

9.02 Setting roller distance and roller pressure

● Switch machine on.

● Call up the menu for inputting the roller pressure.

● Lower the transport rollers and set the roller distance as described in Section 7.04.

P

TE

● Set the roller pressure (see Section 7.05).

The roller pressure show on the scale can be entered on the display via the relevant

+/- keys for each programme, but only serve as a memory aid.

Push Diff

P

2 130 0%

P3

P2

P1

P5

P4

F1

P6

TE

21

Page 22

Preparation

9.03 Setting the differential transport

● Switch machine on.

● Call up the menu for inputting the differential transport.

● A differential transport value can be entered via the corresponding +/- keys for each

programme.

1.0 % means that the upper transport roller will run 1% faster than the sonotrode.

-1.0 % means that the upper transport roller will run 1% slower than the sonotrode.

Push Diff

2 130 1.0%

P3

P2

P1

P5

P4

F1

P6

9.04 Additional transport rollers (optional)

P

TE

22

1

2

Fig. 9 - 04

● The two additional transport rollers 1 can be lifted or lowered as needed via the setting

screws 2.

Page 23

Preparation

9.05 Inserting and removing the SD-memory card

Inserting the SD-memory card

● Open cover 1.

1

● Insert SD-memory card 2 into the card

slot with the label at the front.

P6

Fig. 9 - 05

P

2

● Close cover 1 again.

2 GB

max.

Removing the SD-memory card

● Open cover 1.

F1

TE

● Press the edge of the SD-memory card 2

lightly – the SD-card is ejected.

● Close cover 1 again.

3

By moving slide 3 it is possible to activate (position "LOCK") or deactivate

the write protection function of the SD-memory card. To store, process or

delete data on the SD-memory card, the write protection function must be

deactivated.

23

Page 24

Sealing

10 Sealing

10.01 Sealing principle

The machine may only be operated by properly instructed personnel. The

operating personnel must make sure that only authorised persons are in the

danger zone of the machine.

Due to the vibrations of the sonotrode, the plies of the workpiece are mechanically "ham-

mered" in the seam area. Through the hammering motions of the sonotrode the workpiece

is heated until it becomes viscous and at the same time it is pressed and fed to form the

seam.

In order to achieve optimum sealing results, certain conditions concerning the workpiece

and the machine settings have to be fulfi lled.

The workpiece must be:

- sealable (thermoplast),

-- suitable for processing with the PFAFF 8301 with regard to thickness and properties and

- clean in the seam area.

The basic requirements on the machine are:

- selection of the correct feed roller and setting

- roller pressure

- sealing power

- sealing speed and

- roller gap (distance of the anvil roller to the sonotrode during sealing).

All settings of the sealing machine are always dependent on the type being

sealed and the ambient temperature. As a result of the infl uence of the

individual parameters on each other, optimum settings can only be determined

by means of test sealing operations.

All settings required for the welding process are entered or displayed in the

control panel.

24

Page 25

Sealing

10.02 Error messages

When an error occurs, the text "ERROR" appears on the display together with an error

code and short instructions. In addition the diode in the memory card slot lights up red

(see arrow). An explanation of the error codes can be found in the Chapter 11.04 Error

message explanations.

ERROR: 308

P

RESET

P3

P2

P1

P5

P4

F1

P6

● Correct the error.

● Acknowledge the correction of the error by pressing the corresponding plus - key or by

switching the machine off and on.

● The diode in the memory card slot (see arrow) turns yellow again

TE

25

Page 26

Input

11 Input

11

.01 Access codes

The call-up of each individual parameter level can be blocked by inputting a four digit access

code. The access code can be modifi ed at any time. The access code is set to "8301" ex

works.

11 .01.01 Inputting the access code

An input prompt for the access code is displayed for functions called up in Input mode that

have an access code assigned.

TE

PINCODE:

P

8 3 0 1

P3

P2

P1

P5

P4

F1

P6

● ZuEnter the access code via the corresponding +/- keys.

● Finish your input by pressing the key "TE" (the machine will switch to "Production" mode).

Once the access code has been entered, all protected functions are freely

accessible until the machine is switched off.

TE

26

Page 27

Input

11 .01.02 Modifying the access code

● Call up the menu Parameters in Input mode.

● Call up parameter "811".

● Enter the access code if needed (see Section 11.01.01 "Inputting the access code").

No VAL

811 8301

P3

P2

P1

● Modify the access code via the corresponding +/- keys.

TE

● Finish your input by pressing the key "TE" (the machine will switch to "Production" mode).

Remember the code!

Protected functions cannot be called up without the corresponding code!

In this case request support from the PFAFF service centre.

11 .01.03 Assigning access rights

P

F1

P6

P5

P4

TE

TE

● Call up the menu Parameters in Input mode.

● Call up parameters "801" to "809" (see Section 11.03 "List of parameters").

● Enter the access code if needed (see Section 11.01.01 "Inputting the access code").

No VAL

P

801 OFF

P3

P2

P1

P5

P4

F1

P6

● Allow (ON) or disallow (OFF) access via the corresponding +/- key.

● Finish your input by pressing the key "TE" (the machine will switch to "Production" mode).

TE

27

Page 28

Input

11 .02 Example of a parameter input

TE

● Call up the menu Parameters in Input mode.

● Enter the access code if needed (see Section 11.01.01 "Inputting the access code").

No VAL

P

001 OFF

P3

P2

P1

P5

P4

F1

P6

● Select the desired parameter via the corresponding +/- keys, e.g. 004 key tone ON/OFF.

No VAL

TE

P

004 OFF

TE

P3

P2

P1

P5

P4

F1

P6

TE

● Switch the key tone to ON via the corresponding +/- key.

No VAL

P

004 ON

P3

P2

P1

P5

P4

F1

P6

● Finish the input by pressing TE. (Machine switches to Production mode).

An overview with explanations for all the parameters can be found in Section

11.03 "List of parameters".

TE

28

Page 29

Input

11 .03 List of parameters

Parameter values must only be modifi ed by relevantly trained personnel!

000

100

200

Group

Parameter

Description

Setting

001 Start delay [ms] ON/OFF ON - OFF

10 - 800

002 Reverse after stop [mm] ON - OFF

1 - 15

003 Treadle mode

00

004 Key tome ON - OFF ON

101 Display main processer software version - -

103 Display control panel software version - -

201 Speed max. [1/10 m/min] 1 - 200 200

202 Sonotrode drive

1 = Motor to gear factor.

2 = Number of teeth - motor side

3 = Number of teeth - sonotrode side

4 = Sonotrodes ø [1/10 mm]

2

5 = Acceleration factor [1/10 1/s

]

range

Set value

ON

300

ON

2

8

18

30

1040

2000

203 Anvil wheel drive

1 = Motor to gear factor.

2 = Number of teeth - motor side

3 = Number of teeth - sonotrode side

4 = Sonotrodes ø [1/10 mm]

5 = Acceleration factor [1/10 1/s

204 Torque (motor current)

2

]

1 - 3 2

8

1

1

650

1 = Reduced current

2 = Normal current

3 = Max. current (only for a short time)

29

Page 30

Input

600

Group

Parameter

601

Description

Display inputs

This function allows the checking of the digital

inputs. "IN" denotes the input numbers (1 - 16).

The associated switch state is displayed under

"VAL".

IN VAL

1 (X5 D-SUB Pin 1) IN1, roller down

(ON = Roller down)

2

3 X5 D-SUB Pin 3) Ultrasonic generator

error (ON = Error)

4

5

6

7

8

9

10

11

12

13

14

15

16

Setting

range

Set value

30

602 Display special inputs

This function allows the display of the special

inputs for "Treadle"; "IN" denotes the inputs

(PED). The associated switch state is displayed

under "VAL".

IN VAL

PED Treadle

(Speed control unit -1; 0; +1; +2)

Page 31

Input

600

Group

Parameter

603 Switch outputs

Description

This function allows the switching of the digital

outputs. "OUT" denotes the selected output

(1 - 16). The selected output (S) is set under

"VAL" via the +/- key (+), and also reset (R) via

the +/- key (-). Locks are checked. Unassigned

outputs are not switched.

OUT VAL

1 S/R

2 S/R

3 S/R X13 D-SUB Pin 5) roller up/down

4 S/R

5 S/R

6 S/R X13 D-SUB Pin 8) blower ON

7 S/R X13 D-SUB Pin 9) sonotrode fan

8 S/R

9 S/R

10 S/R

11 S/R

12 S/R

13 S/R

14 S/R

15 S/R

16 S/R

Setting

range

Set value

604 Move step motors

The step motors SM1 (X-axis) and SM2 (Y-axis)

are moved individually via their respective +/-

keys. Locks are not checked.

605 Cold start (RESET)

The controls carry out a cold start (RESET) via

this function; data is re-initialised. Once this

function is selected, the machine must be

switched OFF and ON again.

31

Page 32

Input

800

Group

Parameter

801 Access authorisation group 000 ON - OFF ON

802 Access authorisation group 100 ON - OFF ON

803 Access authorisation group 200 ON - OFF OFF

807 Access authorisation group 600 ON - OFF OFF

808 Access authorisation group 700 ON - OFF OFF

809 Access authorisation group 800 ON - OFF OFF

Description

Function groups can be released (ON) or locked

(OFF) for manipulation. The parameters of a

locked function group can only be modifi ed

after a valid access code has been entered.

Once a valid access code has been entered,

the lock will remain deactivated until the

machine is switched off.

Setting

range

Set value

811

Access code

The access code can be modifi ed via this

parameter. Upon initial delivery of the machine

ex works, the access code is set to "8301".

8301

32

Page 33

Input

11 .04 Error messages in the display

The following error messages are shown in the display of the control panel.

ERROR: 1 Processor error STACK_OVERFLOW

ERROR: 2 Processor error STACK_UNDERFLOW

ERROR: 3 Processor error UNDEF_OPCODE

ERROR: 4 Processor error PROTECTION_FAULT

ERROR: 5 Processor error ILLEGAL_WORD_OPERAND

ERROR: 6 Processor error ILLEGAL_INSTRUCTION

ERROR: 7 Processor error ILLEGAL_BUS_ACCESS

ERROR: 8 Processor error NMI

ERROR: 50 Wrong control panel

ERROR: 51 Incorrect machine class in OTE

ERROR: 52 Wrong software for main drive

ERROR: 101 Mains voltage

ERROR: 102 Power supply overload

ERROR: 103 24 V to low

ERROR: 230 Error ultrasonic generator

ERROR: 308 The lower safety limit switch was not reached when roller was lowered

(unauthorised object in the way or lower limit switch not mounted

correctly)

ERROR: 309 The lower safety limit switch did not open when the roller was lifted

ERROR: 416 SD card reader error

1: No SD card inserted

2: Incorrect SD card (does not match machine)

3: SD card incorrectly inserted

4: SD card is write-protected

5: Data error on SD card

6: Formatting has failed

7: File does not match machine

8: Incorrect fi le size

9: Transfer error

10: File could not be deleted

33

Page 34

Input

11 .05 Programme Management

In Programme Management, confi guration and machine data, and programmes stored in the

machine memory or on the inserted SD card can be deleted or copied.

You can insert commercially available standard SD cards with max. 2 GB capacity into the

control panel. The data is stored in machine-relevant sub-directories. The insertion and

removal of SD cards is described in Section 9.05.

The following data types are stored:

● Confi guration data in fi le KD.

● The programmes 0 - 19 and the machine data in fi le MD.

If the SD card is to be formatted via PC, select the format "FAT16". Alternatively, the SD

memory card can also be formatted using the formatting function on the corresponding

machine, see Section 11.05.05 "Formatting the SD card".

11 .05.01 Calling up Programme Management

TE

● Switch machine on.

● Call up mode "Entry"

● Call up "Programme Management"

P

COPY

P3

P2

P1

P5

P4

F1

P6

The fi rst menu item is displayed when "Programme Management" is called up.

The menu item selection is confi rmed via the "Enter" function; press the right + key to

confi rm. In the context of this example, the machine memory will now be displayed.

Browse through the other menu items by pressing the left +/- key (see also following

sections).

TE

34

The following menu items are available in program management:

● Copying machine data to the SD card

● Copying data from the SD card to the machine memory

● Formatting the SD memory card

Page 35

Input

11 .05.02 Copying machine data to the SD card

TE

● Call up mode "Entry"

● Call up "Programme Management"

P

COPY

P3

P2

P1

P5

P4

F1

P6

● Press and hold the +/- keys until the corresponding menu item is displayed.

● Select the menu item via the "Enter" function, press the right + key to confi rm.

TE

P

COPY ALL

P3

P2

P1

P5

P4

F1

P6

TE

● Select the data to be copied from the machine memory to the SD card by pressing the

corresponding +/- keys:

KD = Confi guration fi les

MD = Machine parameters and programmes 0 - 19

ALL = all fi les

● Start the copy process via the "Enter" function, press the right + key to confi rm.

If the data to be copied already exists, a security prompt will be displayed

before overwriting. The copy process is confi rmed by pressing the right + key.

The copy process can be cancelled by pressing the right - key.

● Other menu items in "Programme Management" are called up by pressing the left +/-

keys.

35

Page 36

Input

11 .05.03 Copying data from the SD card to the machine memory

TE

● Call up mode "Entry"

● Call up "Programme Management"

P

COPY

P3

P2

P1

P5

P4

F1

P6

● Press and hold the +/- keys until the corresponding menu item is displayed.

● Select the menu item via the "Enter" function, press the right + key to confi rm.

TE

P

COPY MD

P3

P2

P1

P5

P4

F1

P6

TE

● Select the data to be copied from the SD card to the machine memory by pressing the

corresponding +/- keys:

KD = Confi guration fi les

MD = Machine parameters and programmes 0 - 19

ALL = all fi les

● Start the copy process via the "Enter" function, press the right + key to confi rm.

If the data to be copied already exists, a security prompt will be displayed

before overwriting. The copy process is confi rmed by pressing the right + key.

The copy process can be cancelled by pressing the right - key.

● Other menu items in "Programme Management" are called up by pressing the left

+/- keys.

36

Page 37

Input

11 .05.04 Formatting the SD memory card

TE

● Call up mode "Entry"

● Call up "Programme Management"

P

FORMAT

P3

P2

P1

P5

P4

F1

P6

● Press and hold the left +/- keys until the corresponding menu item is displayed.

● Start the formatting process via the "Enter" function, press the right + key to confi rm.

Before the start of formatting, a prompt for confi rmation will be displayed. The

formatting process is confi rmed by pressing the right + key. The formatting

process can be cancelled by pressing the right - key.

TE

● Other menu items in "Programme Management" are called up by pressing the left +/-

keys.

37

Page 38

Input

11 .06 Internet update of the machine software

The machine software can be updated with PFAFF fl ash programming. For this purpose

the PFP boot program (from version 3.25 on) and the appropriate control software for

the machine type must be installed on a PC. The transfer of the data to the machine can

be carried out with a null modem cable (part no. 91-291 998-91) or with an SD-card.

The SD-card must be formatted in the FAT16 format and must not exceed a capacity of

2 GBytes.

The PFP boot program and the control software of the machine type can

be downloaded from the PFAFF-homepage using the following path:

www.pfaff-industrial.com/pfaff/de/service/downloads

11 .06.01 Update with null modem cable

● After downloading the PFP tool and the control software, open the PFP program.

● Select the machine type and under control unit P320.

● The software version is displayed under report.

● Switch off the machine.

● Connect the PC (serial interface or appropriate USB-adapter) and the machine control unit

(RS232). To do so disconnect the plug of the control panel.

While the machine software is being updated, no setting up, maintenance or

adjustment work may be carried out on the machine!

38

● Switch on the machine, keeping the boot key 1 pressed.

● Press the "OK" button.

The software update is carried out, the update progress is shown on the bar display of

the PFP boot program.

● During the updating process the machine must not be switched off.

● When the update has been completed, switch off the machine and end the PFP boot

program.

● End the connection between the PC and the machine control unit and reconnect the

control panel to the machine control unit.

Page 39

Input

● Switch on the machine

● A plausibility control is carried out and, if necessary, a cold start.

More information and assi-

stance is at your disposal in the

fi le "PFPHILFE.TXT", which can

be called up from the PFP boot

program by pressing the "help"

button.

1

Fig. 11 - 06

11 .06.02 Update with SD-card

● After downloading the PFP tool and the control software, open the PFP program.

● Select the machine type and under control unit SD-CARD.

● The software version is displayed under report.

● Under programming copy the software to the drive with the SD-card.

39

Page 40

Input

● With the machine switched off insert the SD-card into the control panel.

P

P3

P2

P1

P5

P4

F1

P6

TE

To update the machine software carry out the following steps:

While the machine software is being updated, no setting up, maintenance or

adjustment work may be carried out on the machine!

● Switch on the machine, keeping the boot

key 1 pressed.

● Press the "TE" key.

The software update is carried out. Duri-

ng the updating process the diode in the

memory card slot fl ashes.

● During the updating process the machine

must not be switched off.

1

● When the update has been completed,

switch off the machine and remove the

SD-card.

40

● Switch on the machine

● A plausibility control is carried out and, if

necessary, a cold start.

Fig. 11 - 06

More information and assistance is at your disposal in the fi le "PFPHILFE.TXT",

which can be called up from the PFP boot program by pressing the "help"

button.

Page 41

Care and Maintenance

12 Care and Maintenance

12

.01 Maintenance intervals

Check the air pressure .........................................................................daily, before start-up

Clean the air fi lter of the maintenance unit .........................................................as required

Clean the feed rollers ..........................................................................................as required

During all cleaning work the machine must be disconnected from the power

supply by switching off the main switch or pulling out the plug!

Danger of injury if the machine is started accidentally!

12.02 Cleaning the feed rollers

● When necessary, remove any sealing re-

sidues left on the top and bottom feed

rollers 1 and 2.

2

Fig. 12 - 02

F1

P6

P5

P4

P3

P2

P1

1

41

Page 42

Care and Maintenance

.03 Checking/adjusting the air pressure

12

● Before operating the machine, always

2

check the air pressure on gauge1.

● Gauge 1 must show a pressure of 6 bar.

● If necessary adjust to this reading.

1

Fig. 12 - 03

12

.04 Cleaning the air fi lter of the air-fi lter/lubricator

8

6

4

2

0

10

100

150

50

0

12

200

14

230

16

● To do so, pull knob 2 upwards and turn

it so that the gauge shows a pressure of

6 bar

Fig. 12 - 04

Switch the machine off!

Disconnect the air hose at the

air-fi lter/lubricator.

To drain water bowl:

● Water bowl 1 drains itself automatically

whe the compressed-air hose is discon-

nected from the air-fi lter/lubricator.

1

Cleaning fi lter:

● Unscrew water bowl 1 and take out

fi lter 2.

2

● Clean fi lter 2 with compressed air or iso-

propyl alcohol (part No. 95-665 735-91).

● Screw in fi lter 2 and screw on water

bowl 1.

42

Page 43

Care and Maintenance

12.05 Exchanging the transport rollers

P

TE

F1

P6

P5

P4

P3

P2

P1

1

F1

2

Fig. 12 - 04

● Press F1 to lock the transport rollers.

● Loosen nut 1 and remove with the transport wheel 2.

● Mount the desired transport wheel 2 in reverse sequence.

Do not operate the machine without fi nger guard 1!

Danger of crushing if the fi ngers are drawn in!

3

43

Page 44

Connection diagram

13 Connection diagram

13

.01 Pneumatics-switch diagram

Transport roller up - down (controlled)

44

Page 45

Circuit diagrams

13.02 Circuit diagrams

Reference list for circuit diagrams 95-212 092-95

Q1 Main switch

A1 Control P320

A2 Operating panel BDF S3

A3 Ultrasonic generator

B1 Treadle

M1 Sonotrode drive

M2 Anvil drive

M11 Sonotrode fan

Y1 Roller down

Y2 Seam blower

S1 Limit switch roller down

45

Page 46

Circuit diagrams Version 30.09.11 95-212 092-95 Part 1

PE

N

L1

A3

PE

N

L1

GND

.9

CTS

.8.7.6.5

RTS

GND

+5V

.4.3.2.1

TxD

RxD

+24V

X1A

GND

.9

.8.7.6.5

GND

+5V

+5V

.4.3.2.1

NA

NA

NA

X11B

ULTRASCHALL-GENERATOR

sw

gn

rs

bl

rt

gr

ge

P

625 8 13

625 8 13

4

4

ws

gn

br

TE

F1

P6

P5

P4

P3

Bedienfeld BDF S3

P2

P1

A2

Sollwertgeber

B1

46

L N PE

Q1

Oberteil

A1

Steuerung P320

GND

5V

GND

5V

.9

.8.7.6.5

.4.3.2.1

X4A

.9

.8.7.6.5

.4.3.2.1

X4B

ge

gn

br

ws

ge

gn

br

ws

belegung

RTA Wunsch

.2.1

.3 .4

X21

belegung

RTA Wunsch

.2.1

.4

.3

X20

sw

ws

ge

rt

bl

or

sw

ws

ge

rt

bl

or

RTA

M2

103-H7126-0740

RTA

M1

103-H7126-0740

Ambossantrieb

Sonotrodenantrieb

Page 47

95-212 092-95 Part 2 Version 30.09.11 Circuit diagrams

A3

+24V

+24V

.2 .4.3 .5 .6 .7 .8 .9 .10.11 .12.13.14 .16.15 .17 .19.18 .20 .21 .22.23 .24.25

.1

X13

ULTRASCHALL-GENERATOR

gr

M11

Y2

Y1

Modus Amp/Leistung

rt

Test

25V

DA Wandler

1W

Fehler Amplitudenüberhöhung

.1X1.2 .4.3 .5 .6 .7 .8 .9 .10.11 .12.13.14 .16.15 .17 .19.18 .20 .21 .22.23 .24.25

ge

X20.1

X20.4

bl

X20.3

X20.2

gn

ws

Sonotrodenluefter

br

ws

br gn ge

+24V

Steuerung P320

A1

24V

A16

+

GND

GND

GND

GND

GND

GND

.2 .4.3 .5 .6 .7 .8 .9 .10.11 .12.13.14 .16.15 .17 .19.18 .20 .21 .22.23 .24.25

.1

X5

br

ws

X2.1.2

ws br

X2.1.1

X2.2.1

X2.2.2

S1

47

Page 48

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Telefon: +49 - 6301 3205 - 0

Telefax: +49 - 6301 3205 - 1386

E-mail: info@pfaff-industrial.com

Gedruckt in der BRD / Printed in Germany / Imprimé en la R.F.A. / Impreso en la R.F.A

© PFAFF Industriesysteme und Maschinen AG 2009, PFAFF is the exclusive trademark of VSM Group AB.PFAFF Industriesysteme und Maschinen AG is an authorized licensee of the PFAFF trademark.

Loading...

Loading...